Patents

Literature

86results about How to "Improve vertical accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

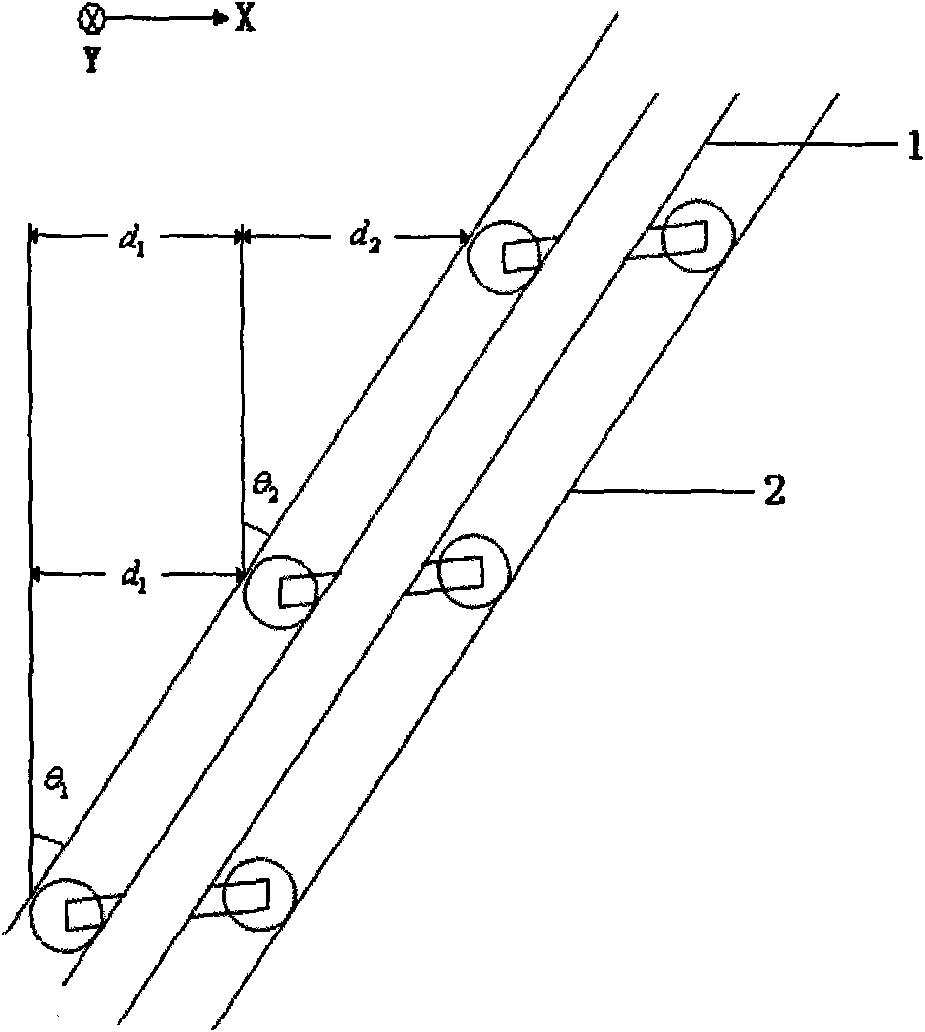

Method and apparatus for accurate aircraft and vehicle tracking

InactiveUS7132982B2Improve vertical accuracyGood HDOPDirection finders using radio wavesBeacon systemsFlight vehicleMultilateration

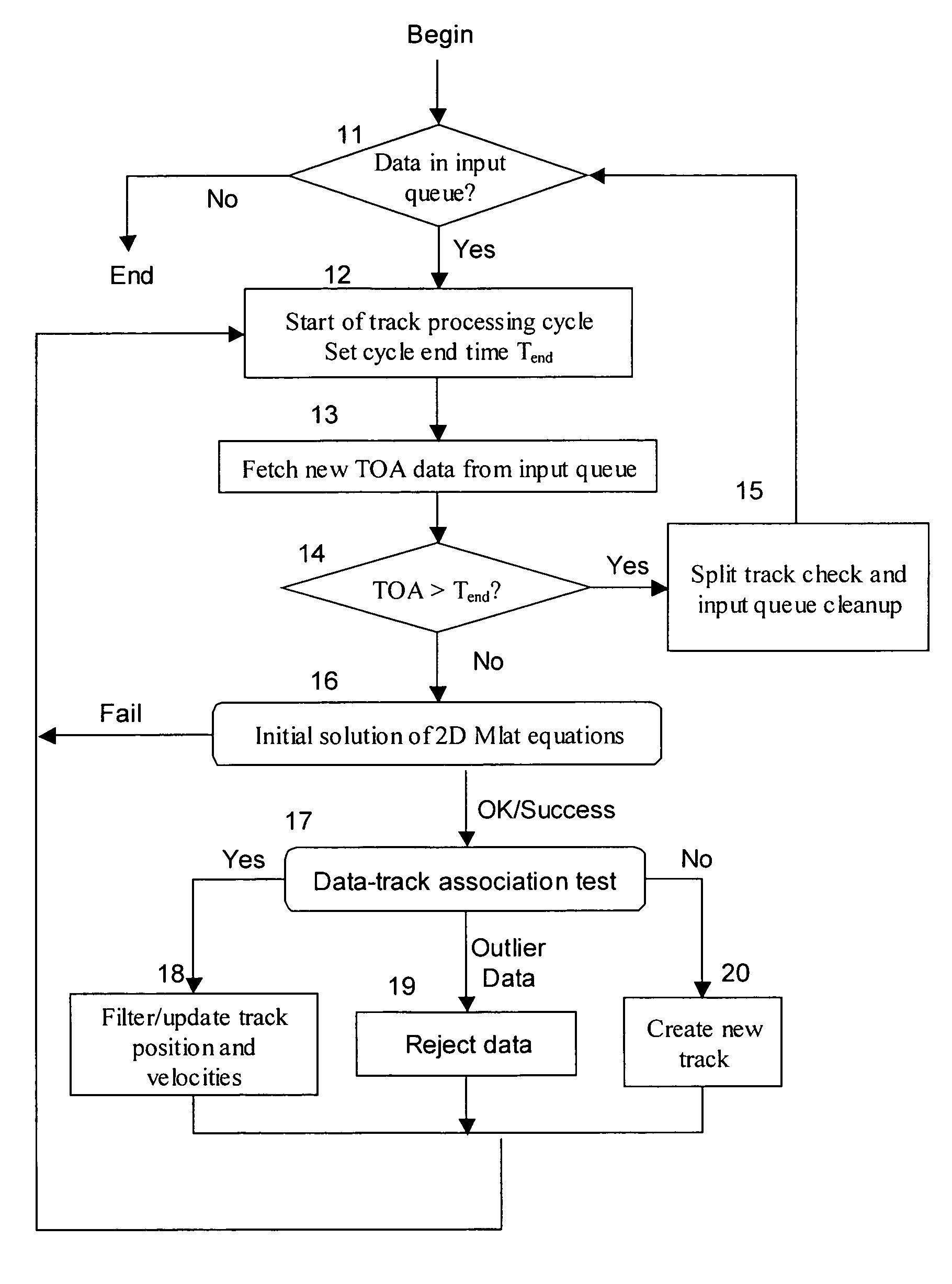

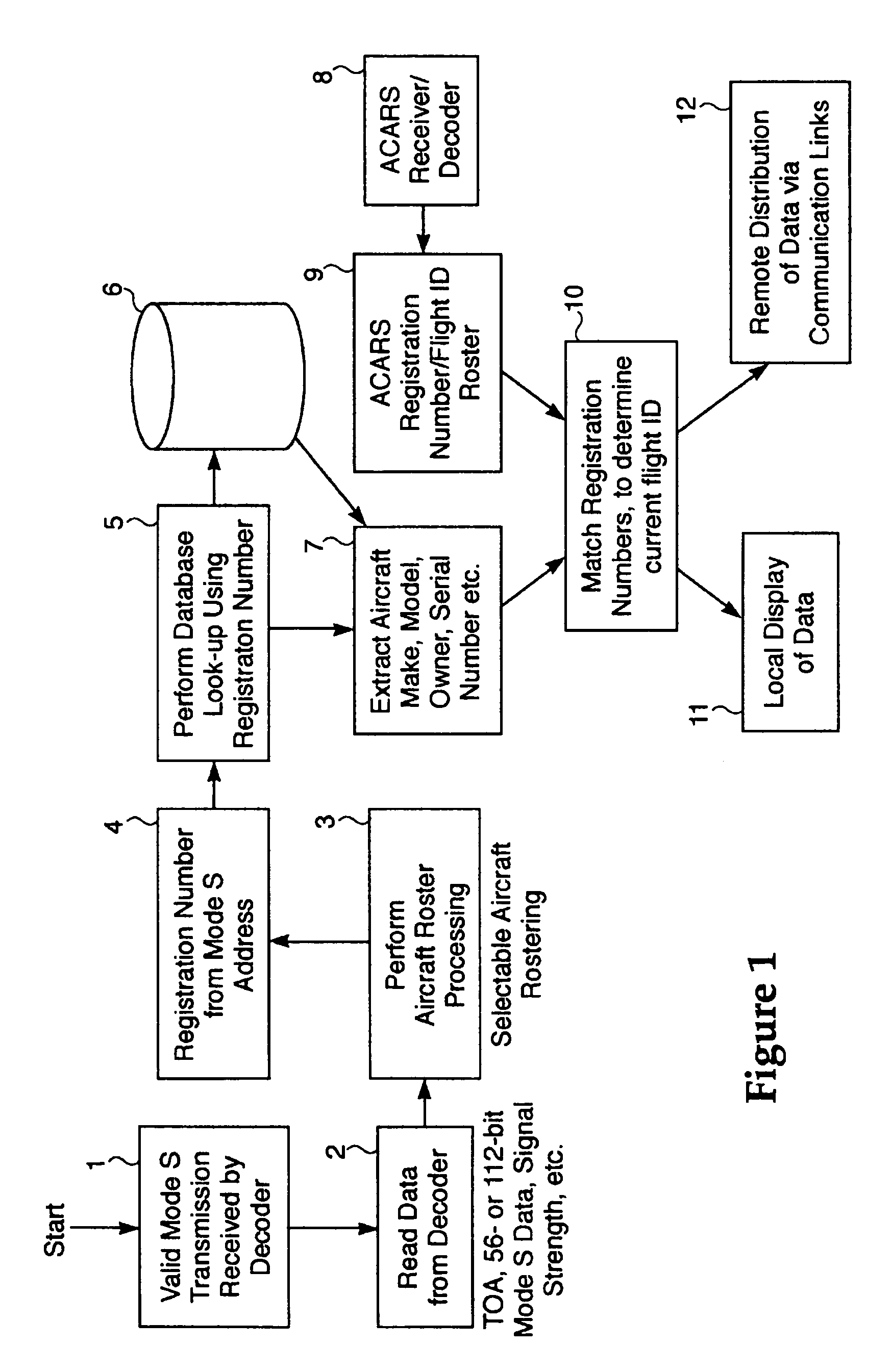

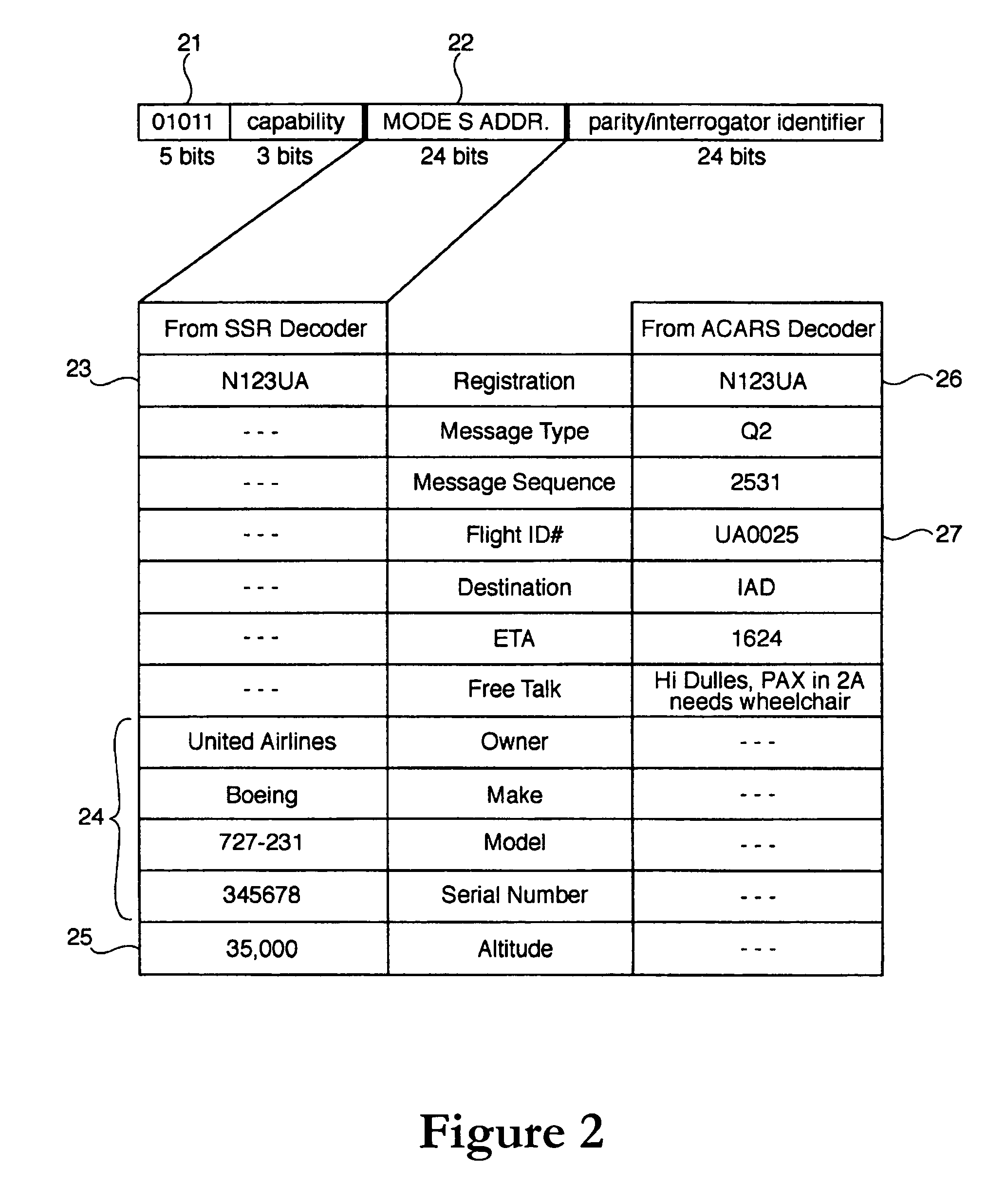

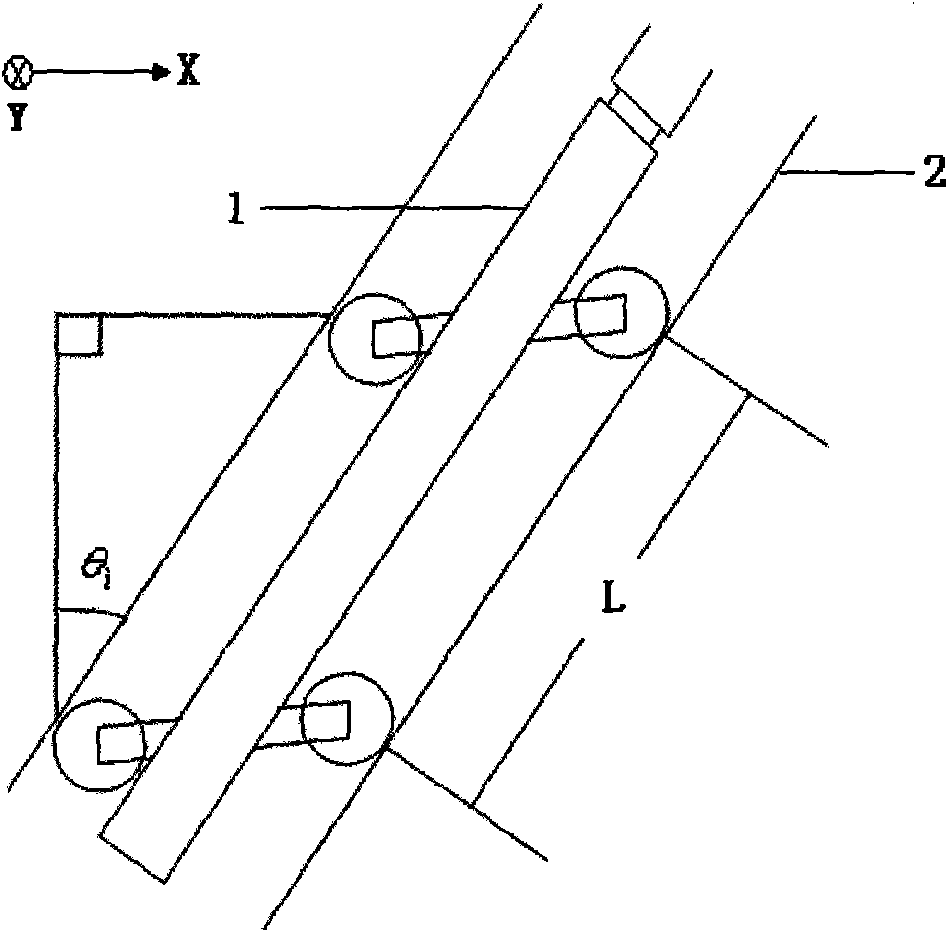

A direct multilateration target tracking system is provided with the TOA time stamp as an input. A technique of tracking targets with varying receiver combinations is provided. Methods of correlating and combining Mode A, Mode C, and Mode S messages to enhance target tracking in a passive surveillance system are provided. A direct multilateration target tracking system is provided by TOA tracking and smoothing. A technique for selecting best receiver combination and / or solution of multilateration equations from a multitude of combinations and / or solutions is provided. A technique for correcting pseudorange values with atmospheric conditions is provided. A technique for improving height determination for regions of poor VDOP in a 3D multilateration system is provided.

Owner:SRA INTERNATIONAL

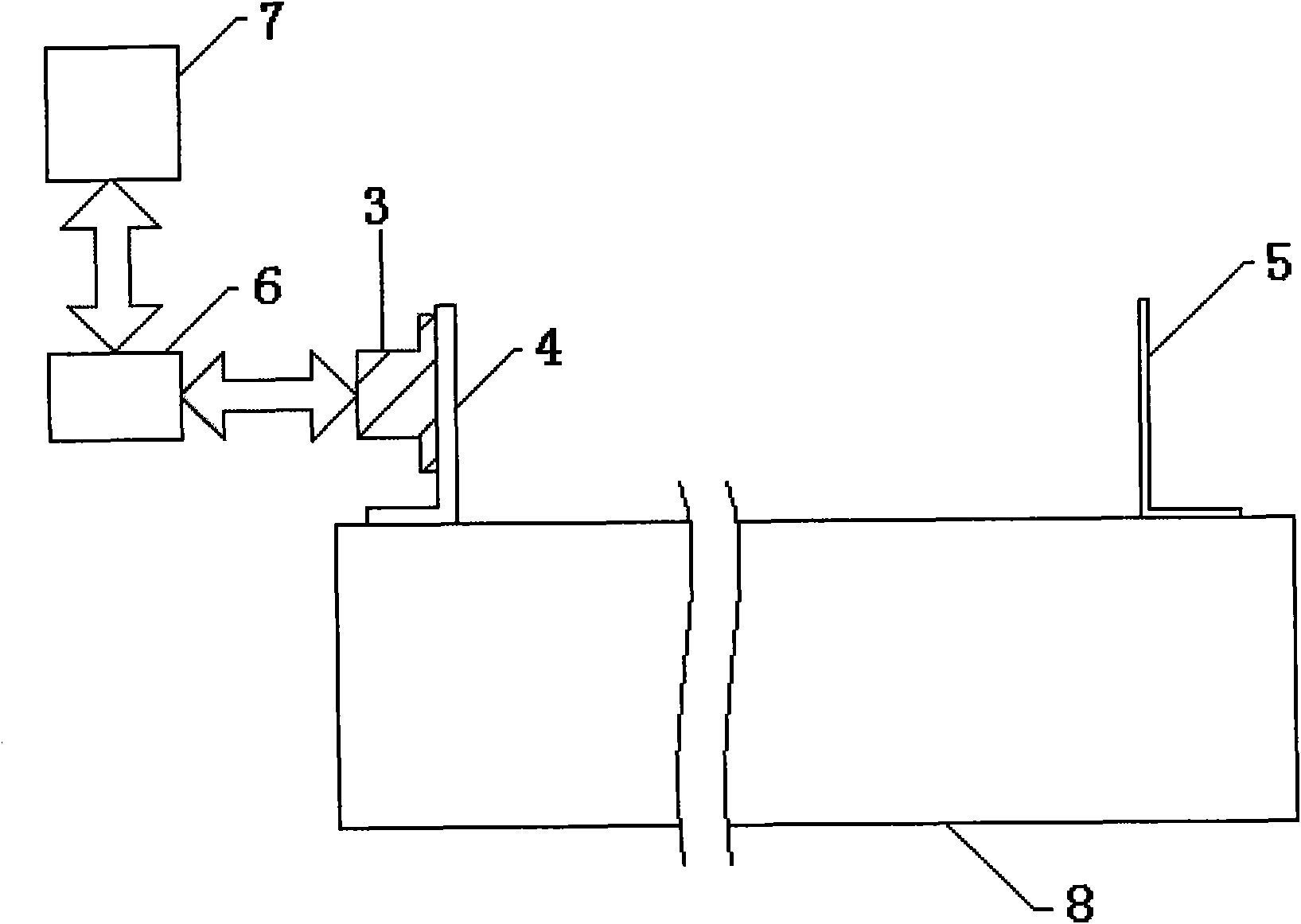

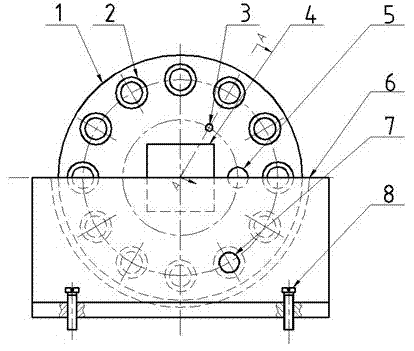

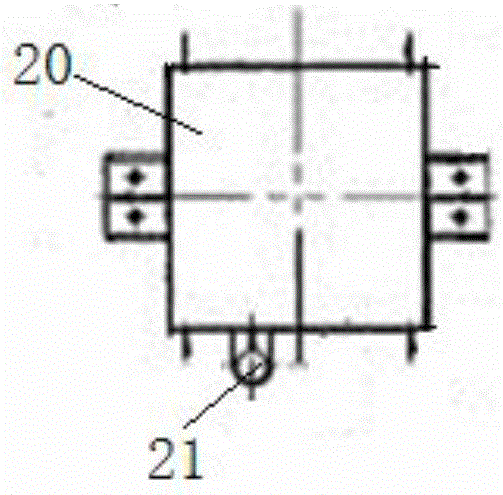

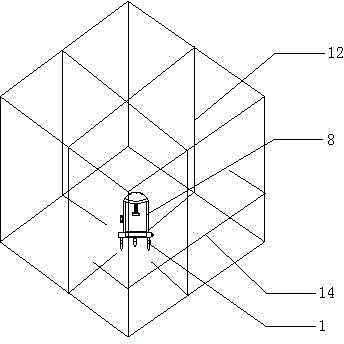

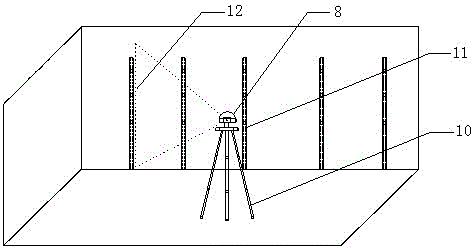

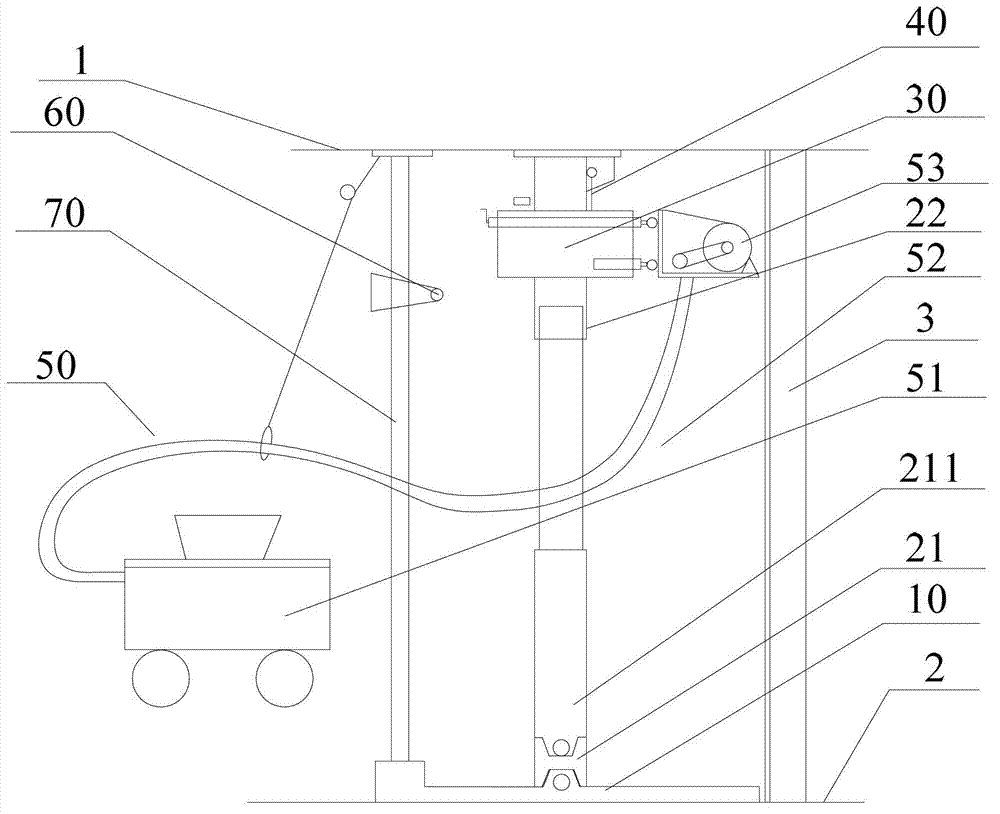

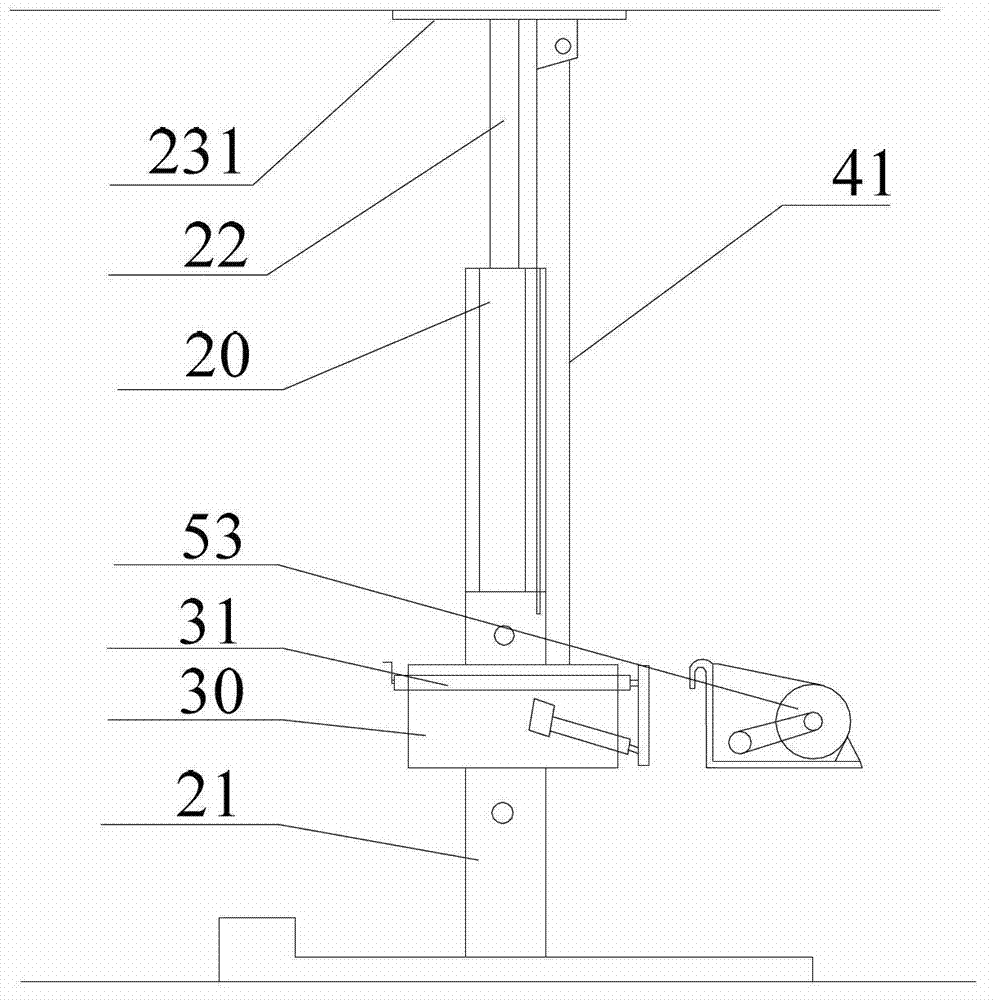

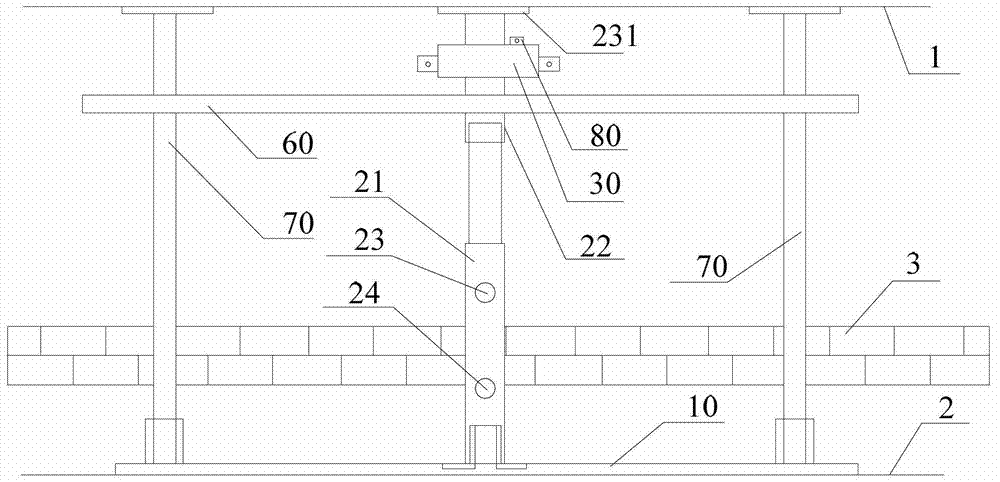

System for measuring and monitoring perpendicularity of lattice column in building engineering in real time

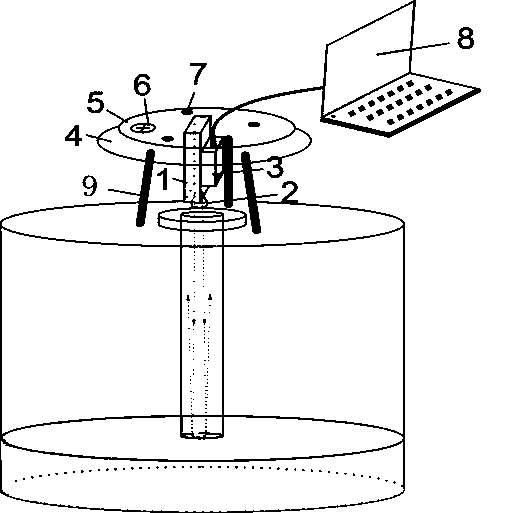

ActiveCN101619967AFully automatedImprove vertical accuracyUsing optical meansMeasurement deviceOutput device

The invention relates to a system for measuring and monitoring the perpendicularity of a lattice column in building engineering in real time. The laser positioning measurement device is used for measuring data and can be accurately positioned on a measured object by a laser; and the data output device is connected with the laser positioning measurement device by a data line, receives the measured data transmitted by the laser positioning measurement device in real time, and carries out relevant calculation on the data to be used as monitoring reference data. The system for measuring and monitoring the perpendicularity of the lattice column in the building engineering in real time has high working efficiency, precision and performance, realizes monitoring automation and is not only suitable for measuring the perpendicularity and monitoring the perpendicular precision of the steel lattice column, but also suitable for measuring absolute inclined angles of various objects with (without) reference installation surfaces.

Owner:SHANGHAI CONSTRUCTION GROUP

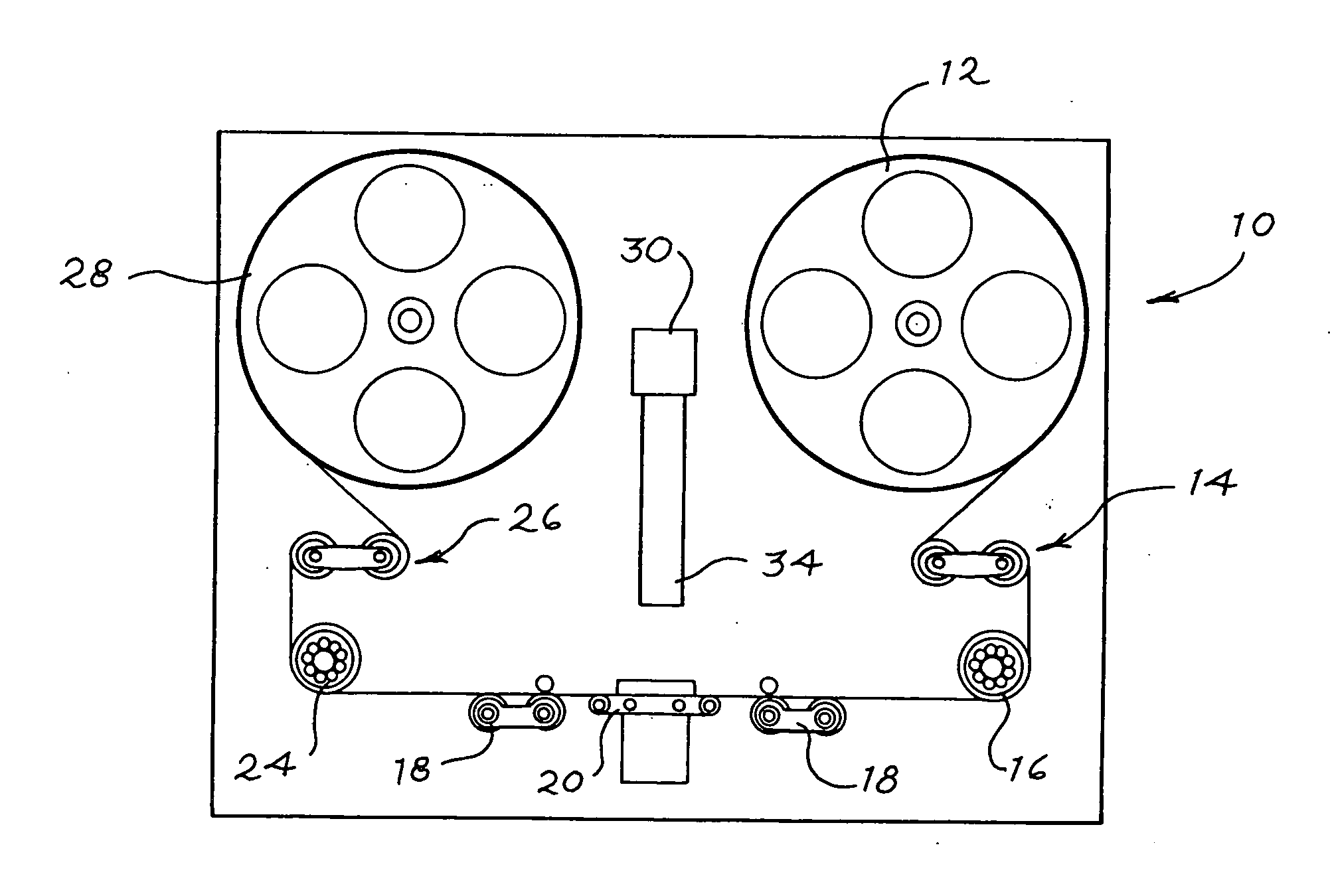

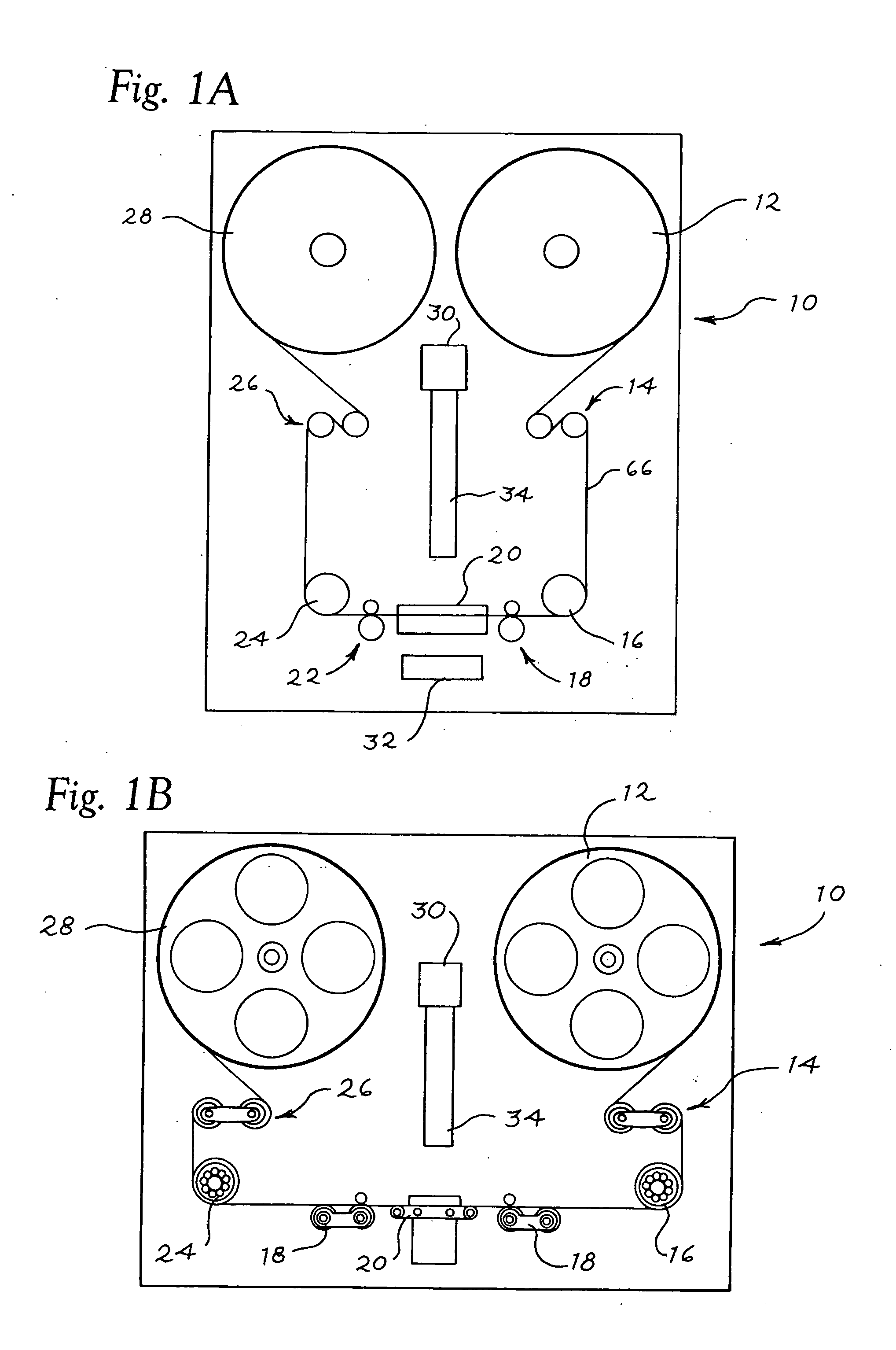

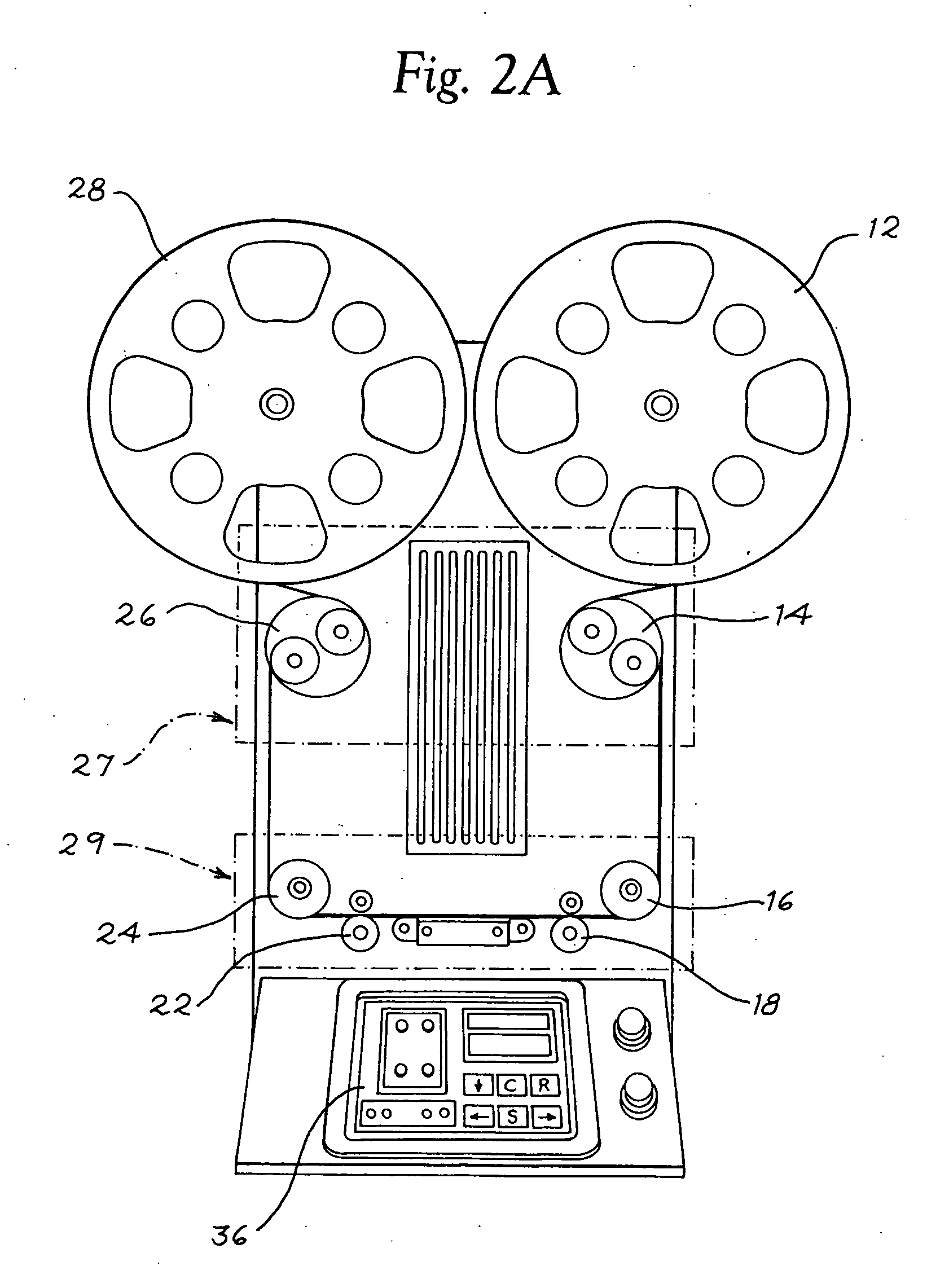

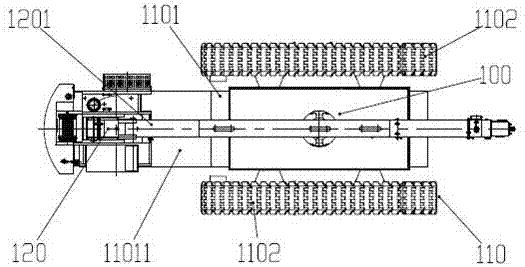

Method and apparatus for continuous motion film scanning

ActiveUS20130076890A1Facilitates high resolution digital duplicationSignificant informationTelevision system detailsTelevision system scanning detailsFilm-outDigital image

A continuous film scanning system for high resolution digital archival and duplication of motion picture film on a frame by frame basis. Film is driven through the film scanning system through the use of rollers and maintained at a consistent tension throughout the scanning process. Optical interrogation of the perforations associated with each film frame is used to trigger digital image capture. The continuous film scanning system is particularly well adapted to safely handle imperfect or damaged film stock.

Owner:REFLEX TECH

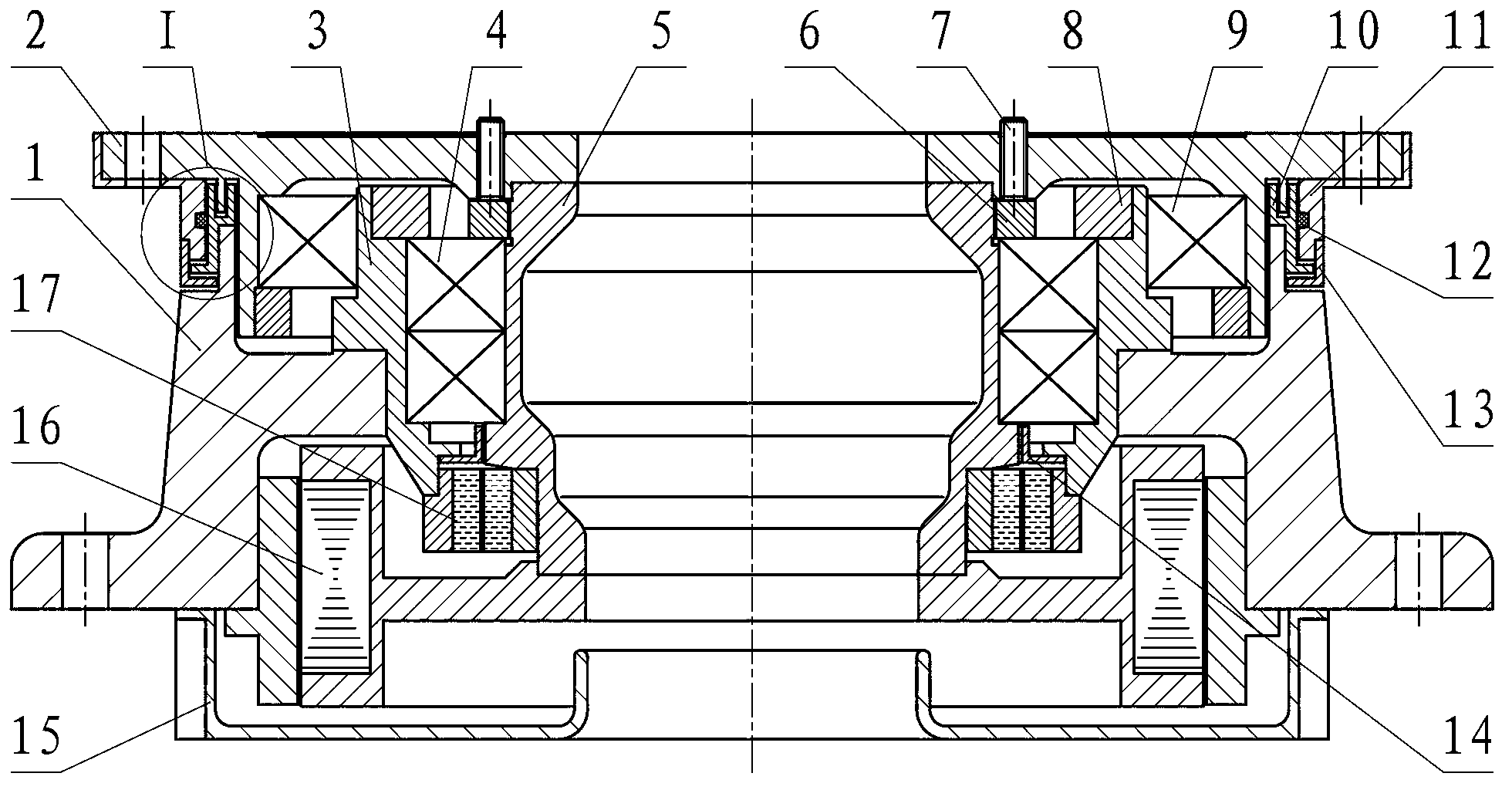

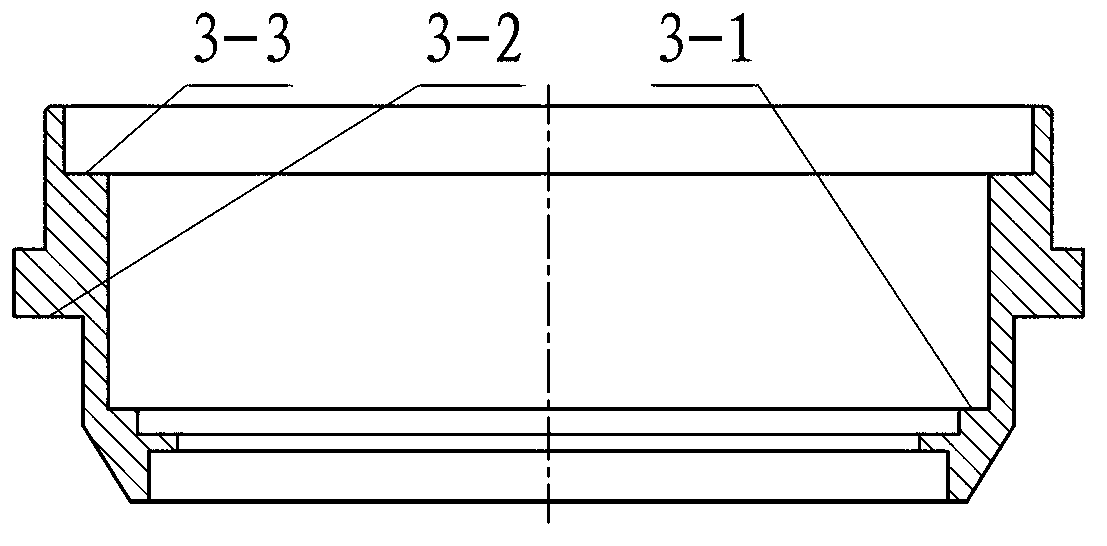

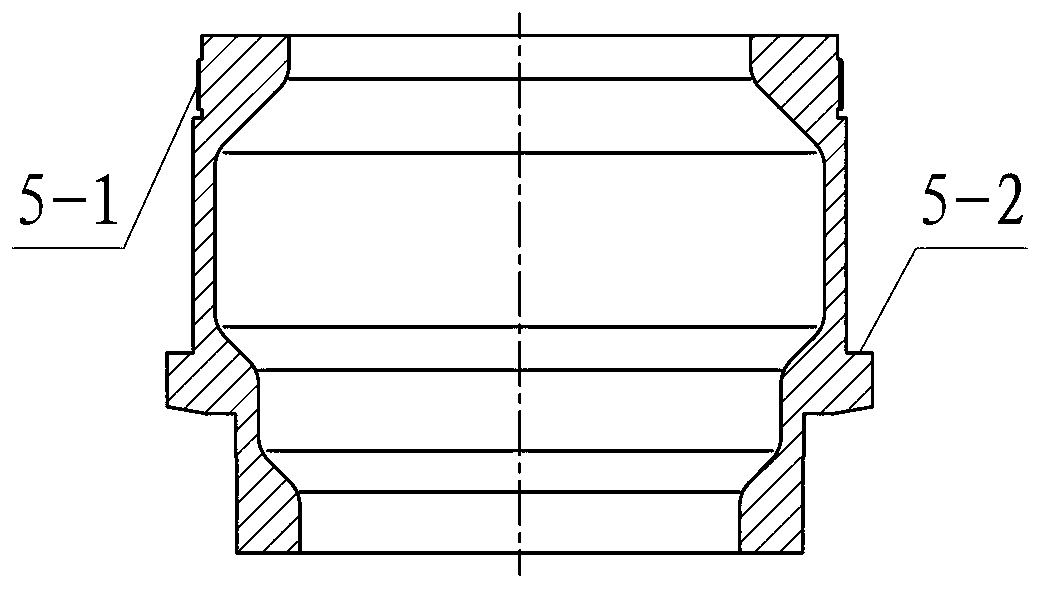

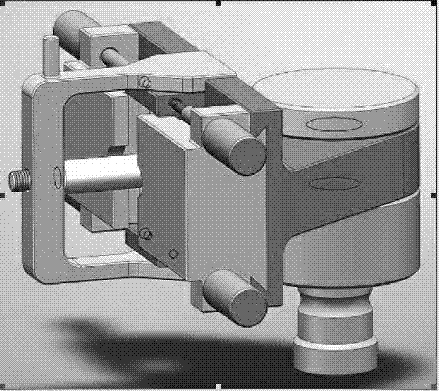

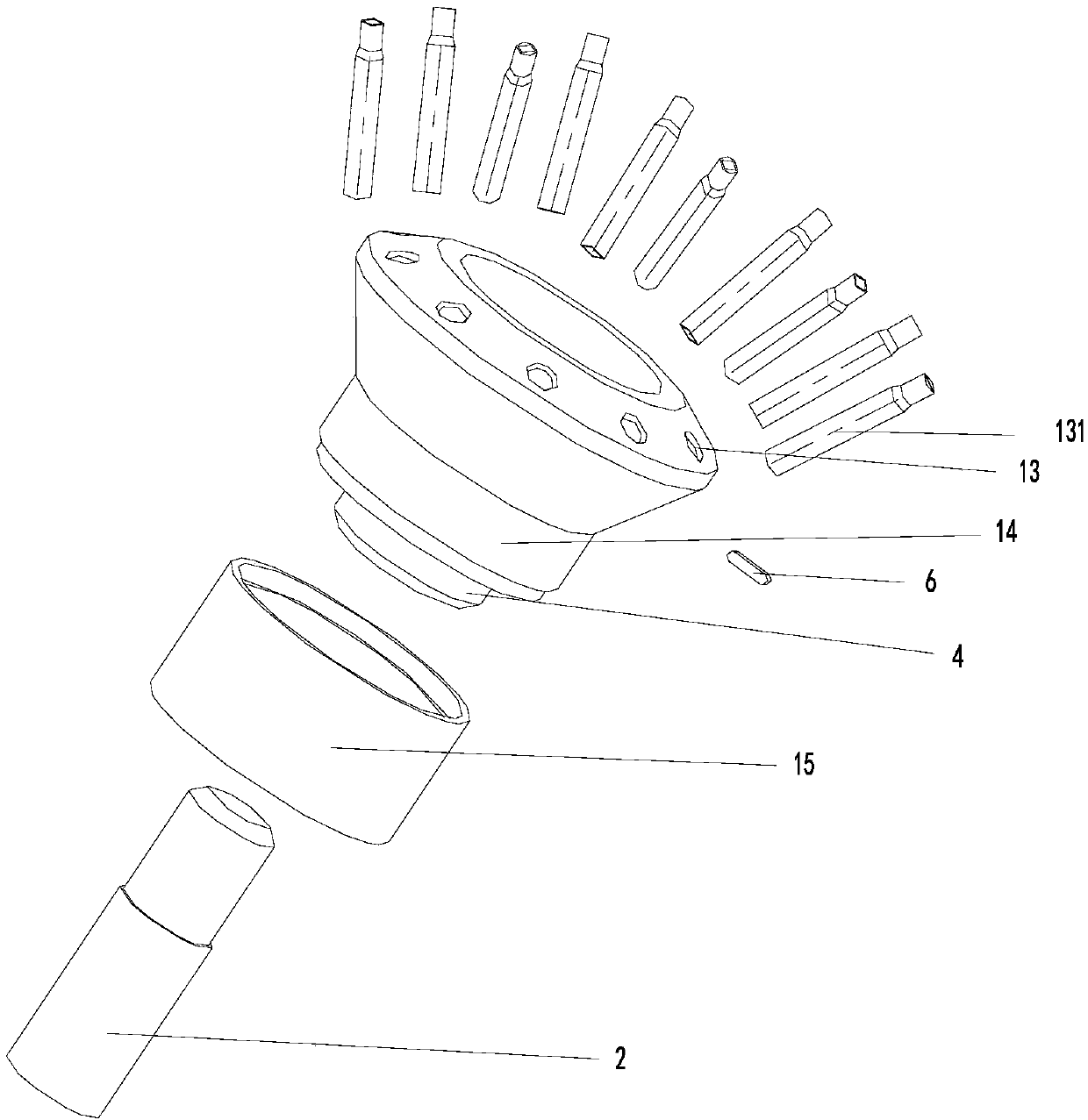

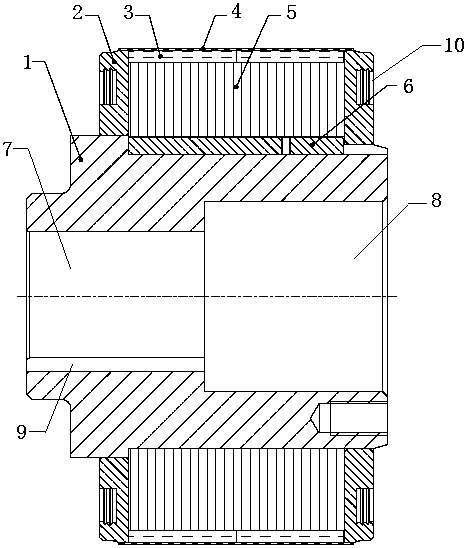

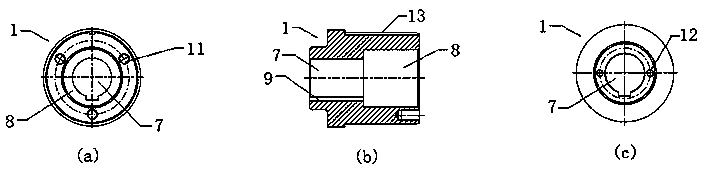

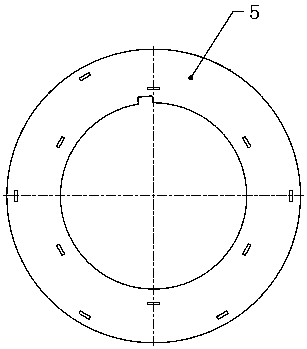

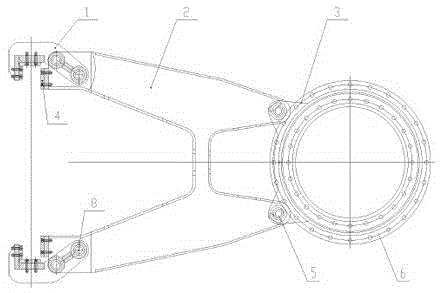

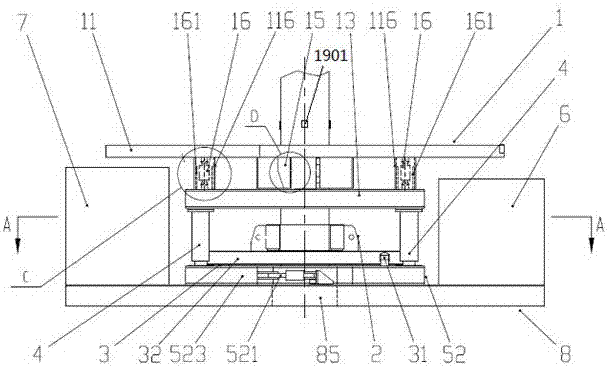

Azimuth device applicable to vehicular photoelectric turntable

ActiveCN103294066AAchieving a modular designImprove maintainabilityPosition/direction controlBiaxial loadMaintainability

The invention discloses an azimuth device applicable to a vehicular photoelectric turntable. The azimuth device comprises a revolving shaft system, an azimuth shell, a rotary transformer and a torque motor. The revolving shaft system comprises an azimuth dead shaft, an azimuth moving shaft, an azimuth rotating adaptor disc and two groups of bearings, the azimuth dead shaft is connected with the azimuth moving shaft and the azimuth rotating adaptor disc respectively via a first bearing and a second bearing, the first bearing bears biaxial loads, the second bearing is larger in diameter and bears radial and tipping loads, and thereby the rotating disc type revolving shaft system borne by the internal and external bearings is formed. The revolving shaft system as well as the rotary transformer and the torque motor are respectively positioned on an upper side and a lower side of an annular transverse plate in the middle of the azimuth shell and are independent to one another. Furthermore, a comprehensive labyrinth felt collar sealing structure is adopted. The azimuth device has the advantages of simple structure, low height, light weight, good maintainability, excellent expansibility, strong environmental suitability and the like, mechanical characteristics and capabilities of resisting shock, vibration and large-angle inclination of the photoelectric turntable are effectively improved, and tracking precision of photoelectric tracking equipment is guaranteed.

Owner:西安应用光学研究所

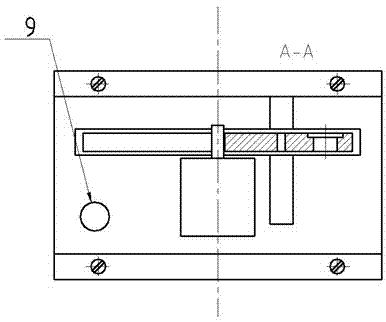

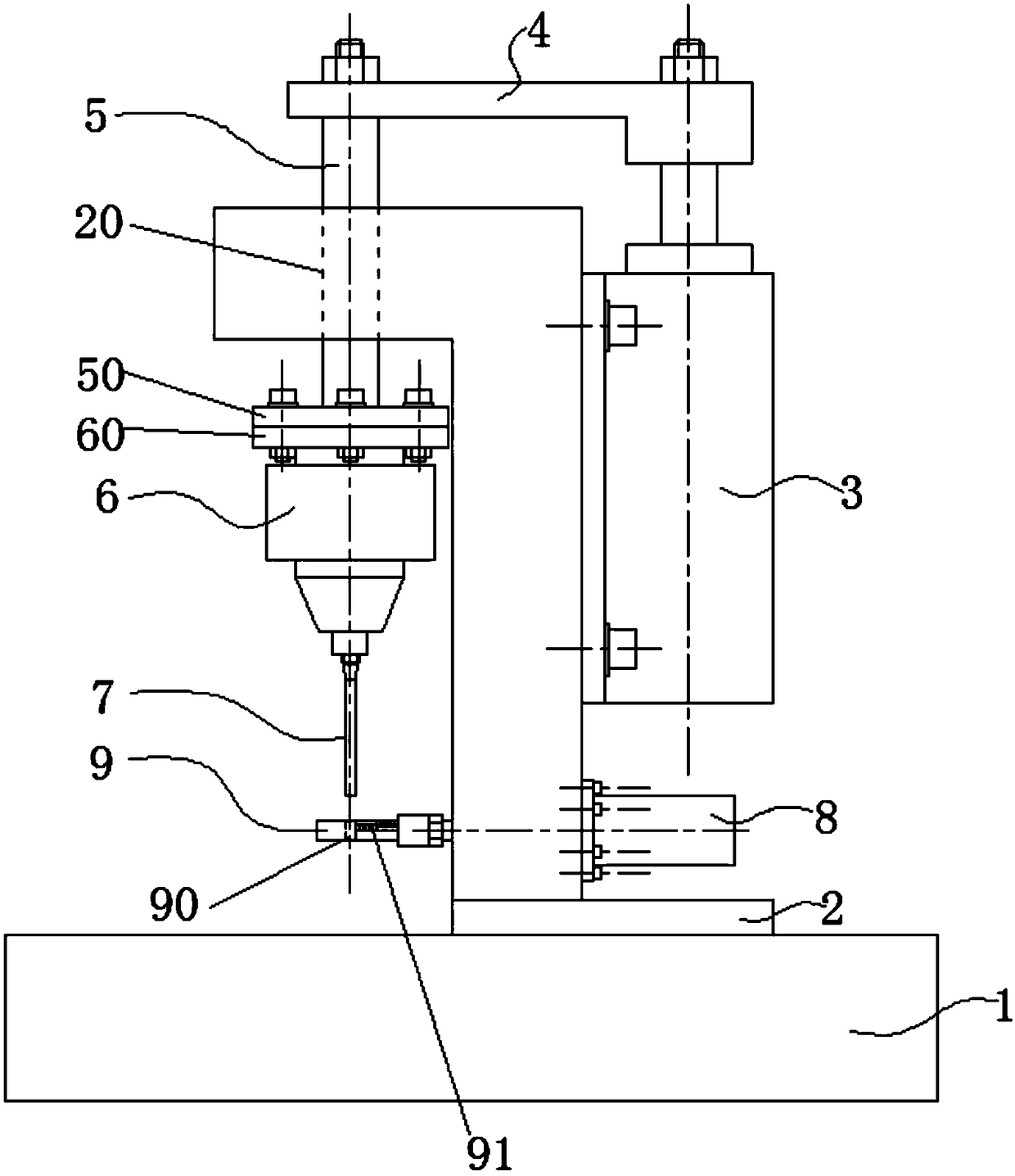

Microcontroller-based terahertz time-domain spectroscopy automatic sample testing device

InactiveCN102305767AImprove measurement efficiencyImprove vertical accuracyColor/spectral properties measurementsOpto electronicPower circuits

The invention discloses a microcontroller-based terahertz time-domain spectroscopy automatic sample testing device. The device comprises a terahertz sample testing device and a control system, wherein the terahertz sample testing device comprises a sample disk, a sample pool, a positioning hole, a stepping motor, a photoelectronic device, a testing platform, a terahertz testing hole, a leveling nut, a level instrument, a pressure spring fixation device, a pressure spring, a metal dome, a sample pool inner hole and a sample pool outer hole; and the control system comprises a microcontroller, a power supply circuit, a keypress circuit, a voice circuit, an alarm circuit, a liquid crystal display circuit, a light-emitting diode (LED) indicator circuit, a stepping motor driving circuit and a photoelectric positioning circuit. The reliability and a human engineering principle are fully considered, the experimental error is furthest reduced, the misoperation probability is reduced, and the experimental efficiency is improved.

Owner:CHINA JILIANG UNIV

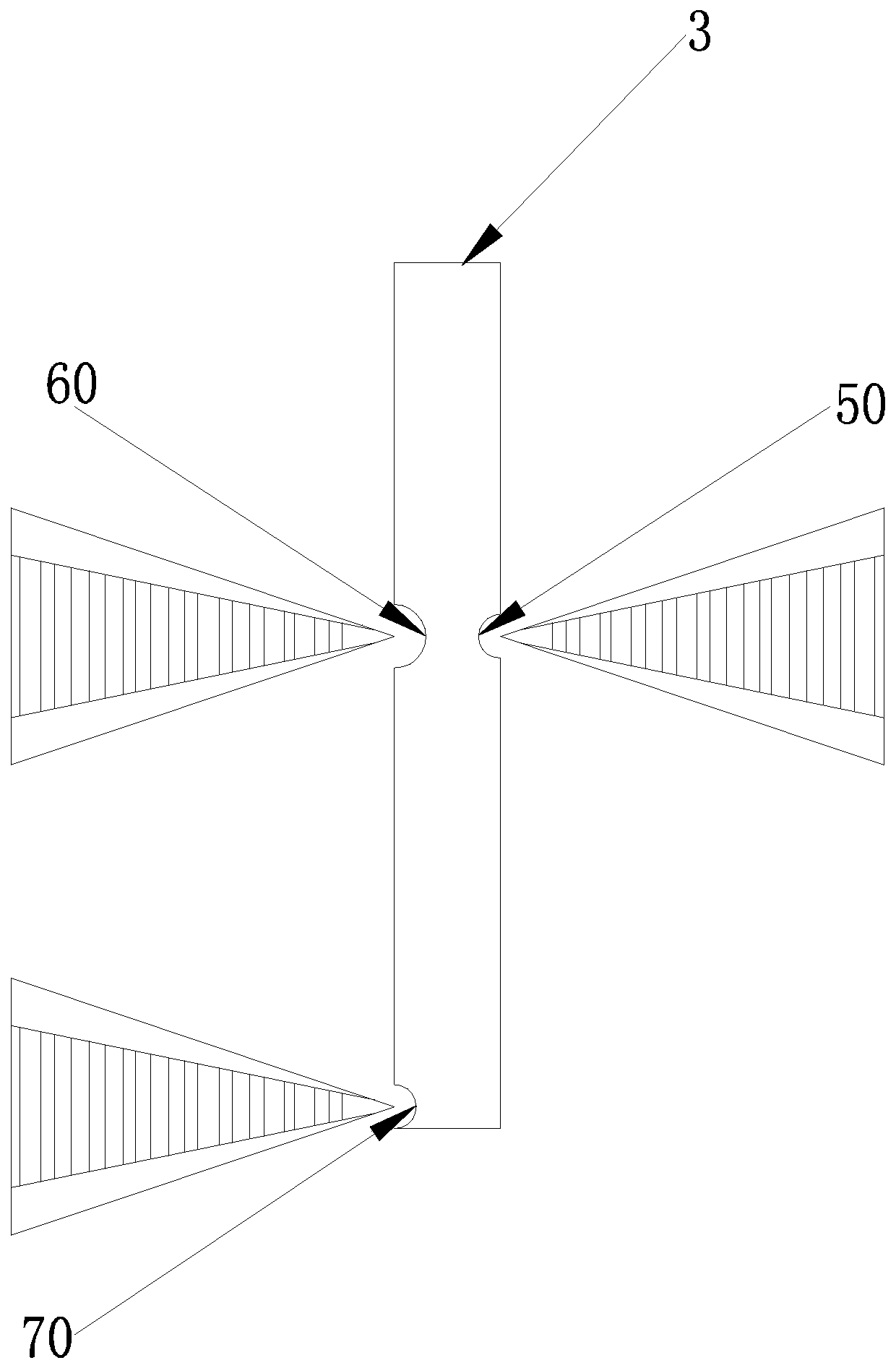

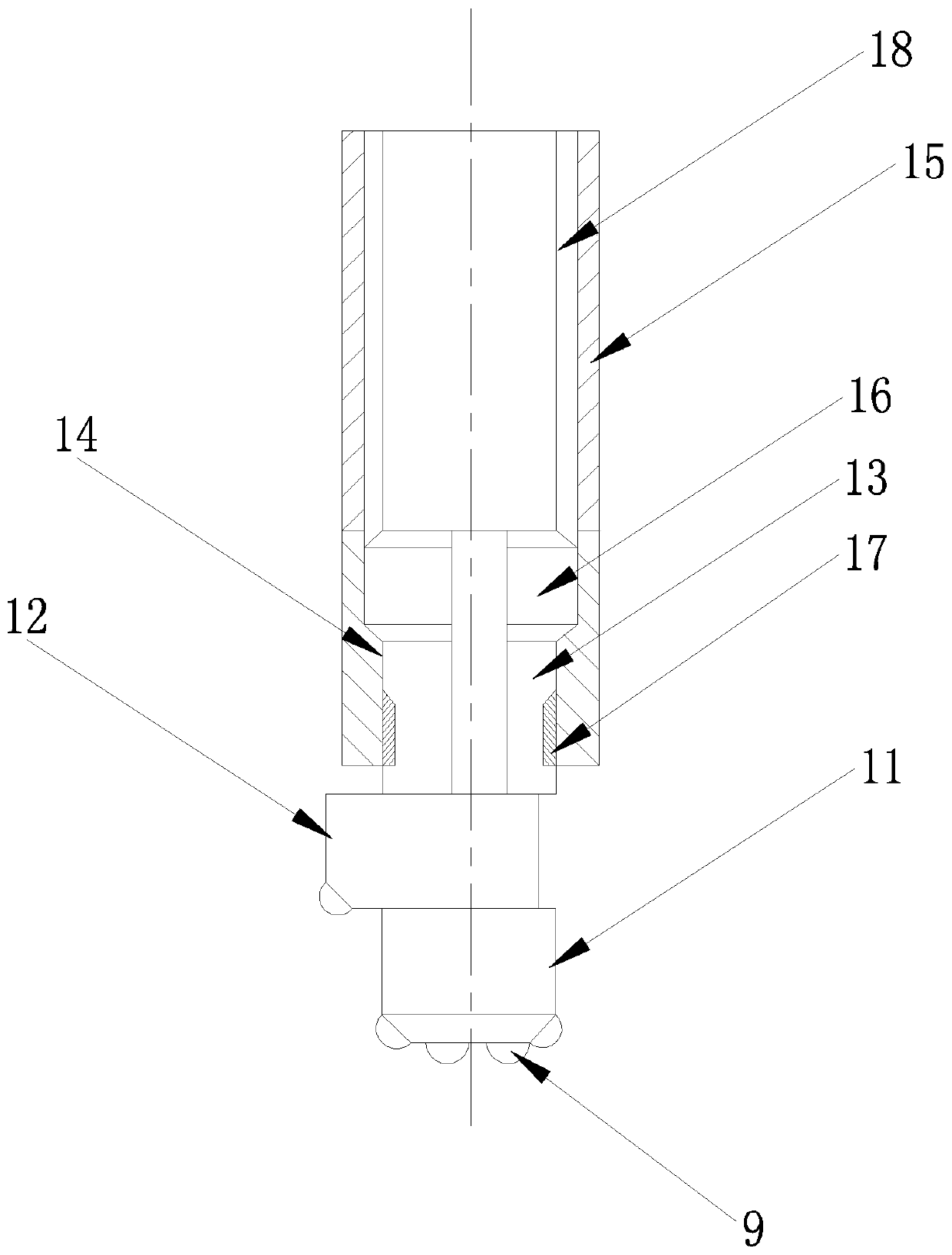

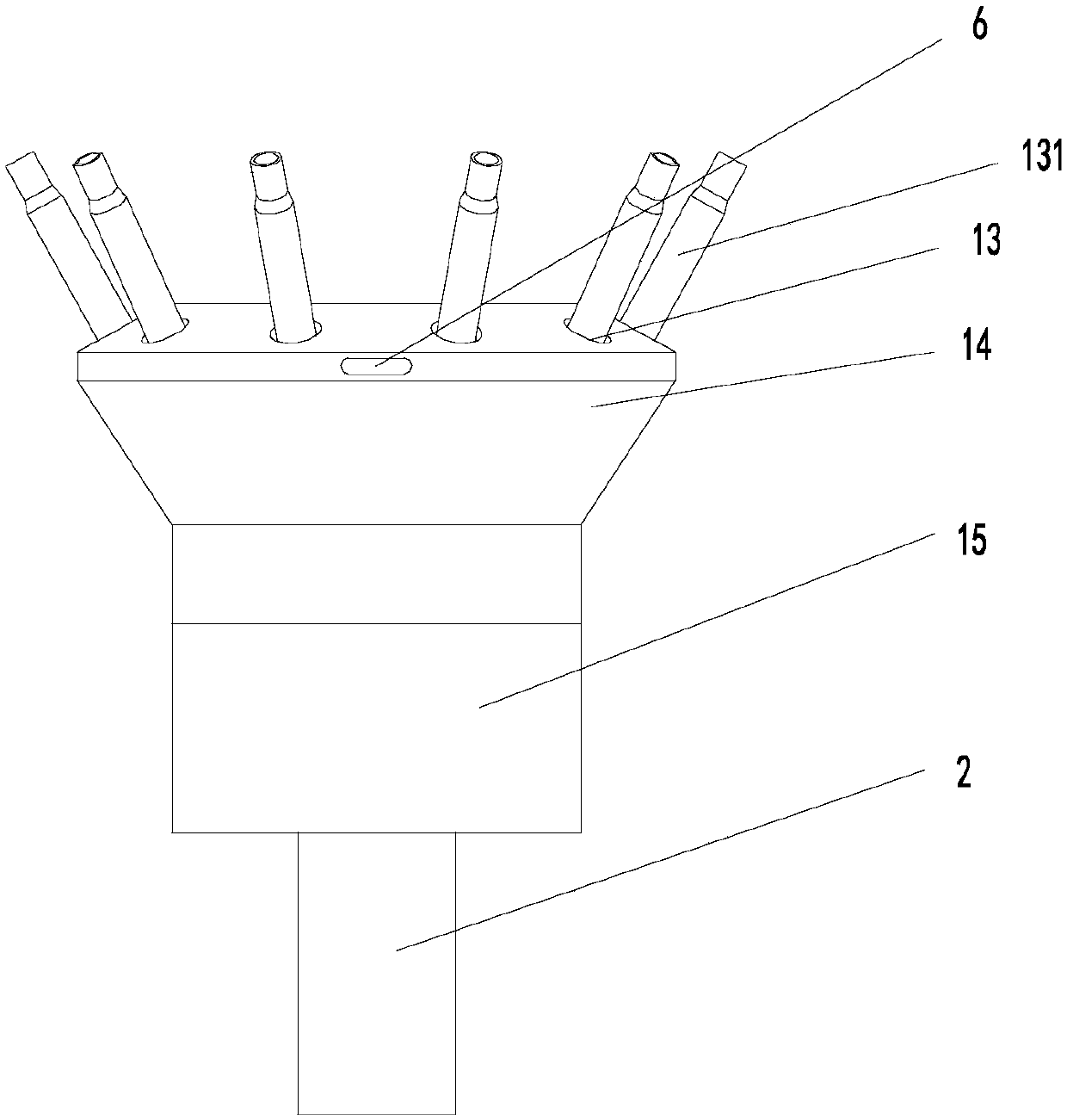

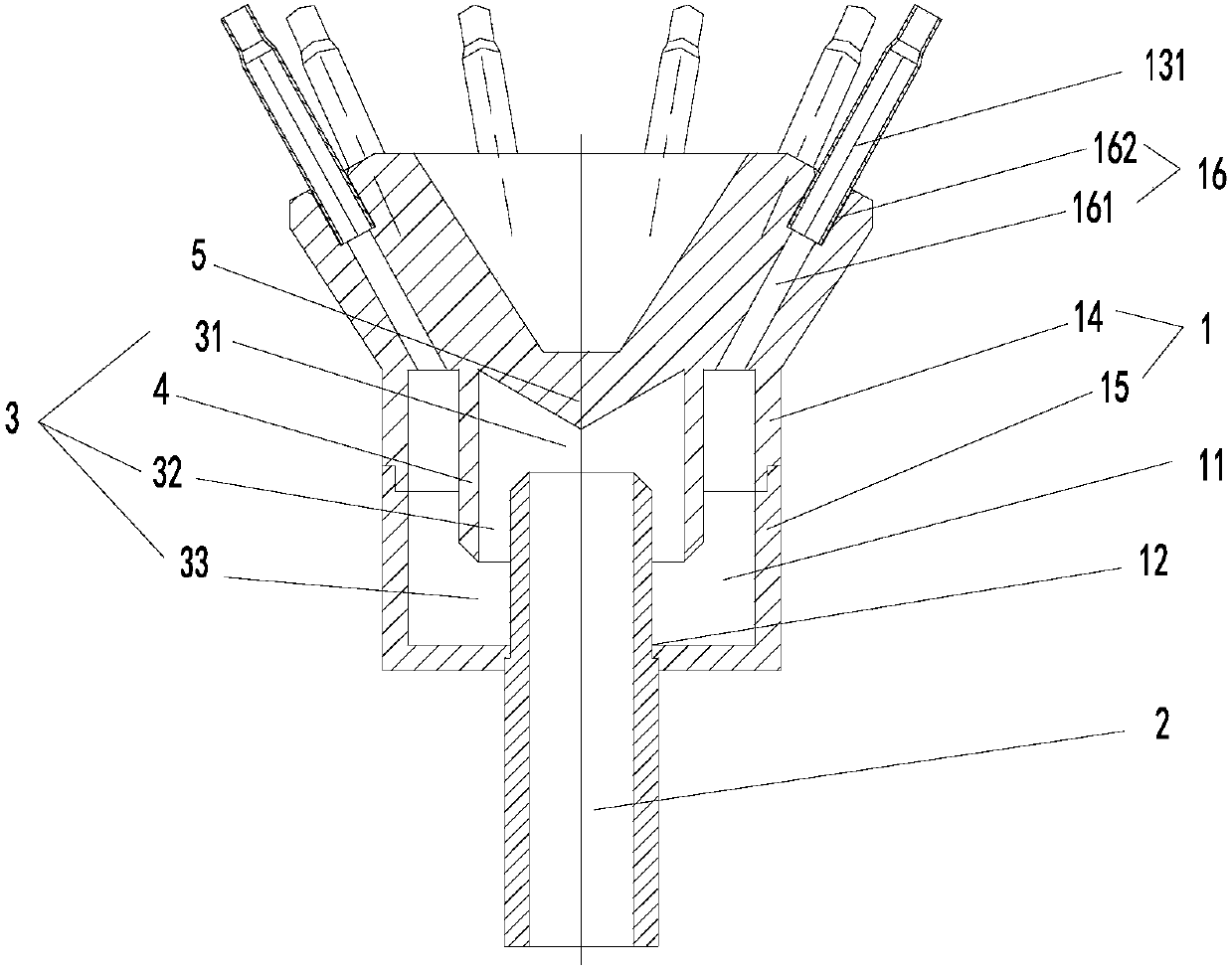

High-pressure jet grouting pile hole leading construction integrated device and construction method thereof

PendingCN111577136ASimple structureHigh pile strengthDirectional drillingBorehole drivesPipeUltimate tensile strength

The invention relates to a high-pressure jet grouting pile hole leading construction integrated device and a construction method thereof. The high-pressure jet grouting pile hole leading constructionintegrated device comprises a jet grouting drilling machine, a high-pressure jet grouting drill rod and a triple pipe, wherein the triple pipe is fixedly arranged at the bottom of the high-pressure jet grouting drill rod, and a down-the-hole hammer is fixedly arranged at the bottom of the triple pipe; and the triple pipe comprises a grout outlet ejector, an inner air outlet ejector and an outer air outlet ejector which are sequentially arranged from inside to outside. The high-pressure jet grouting pile hole leading construction integrated device is simple in structure, convenient to use and practical, the construction technology of combining the triple pipe and the down-the-hole hammer is adopted for the environment of a complex geological layer, and by optimizing construction technical parameters, an obtained pile body is high in strength and good in construction quality. Compared with a traditional high-pressure jet grouting pile construction method, the input mechanical materials are few, the cost is low, construction is safe, and construction is rapid.

Owner:浙江岩科建设有限公司

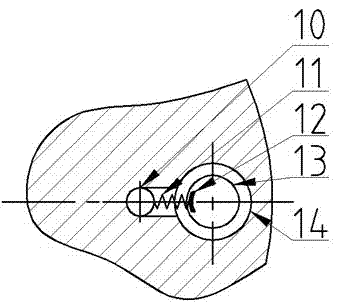

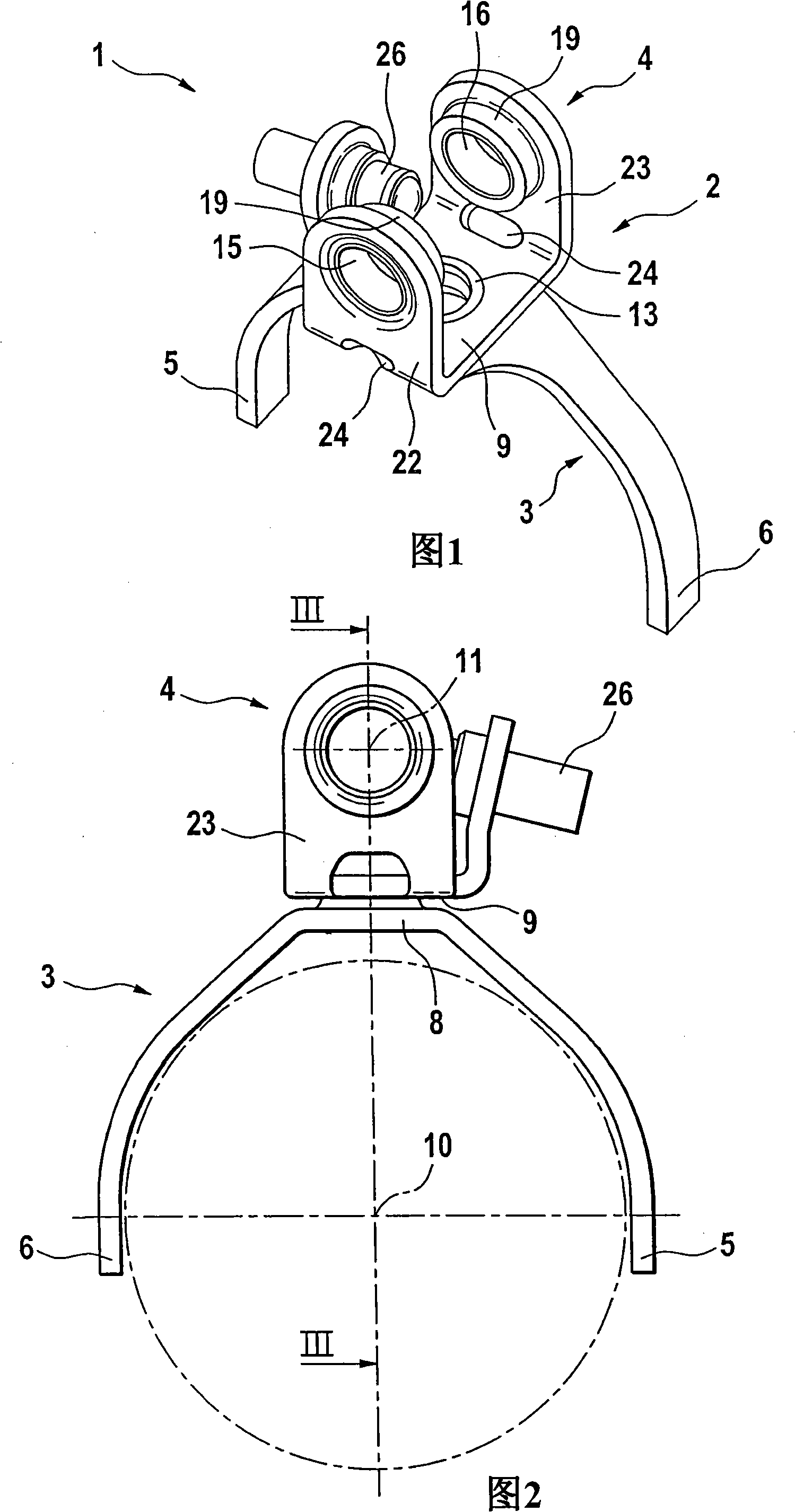

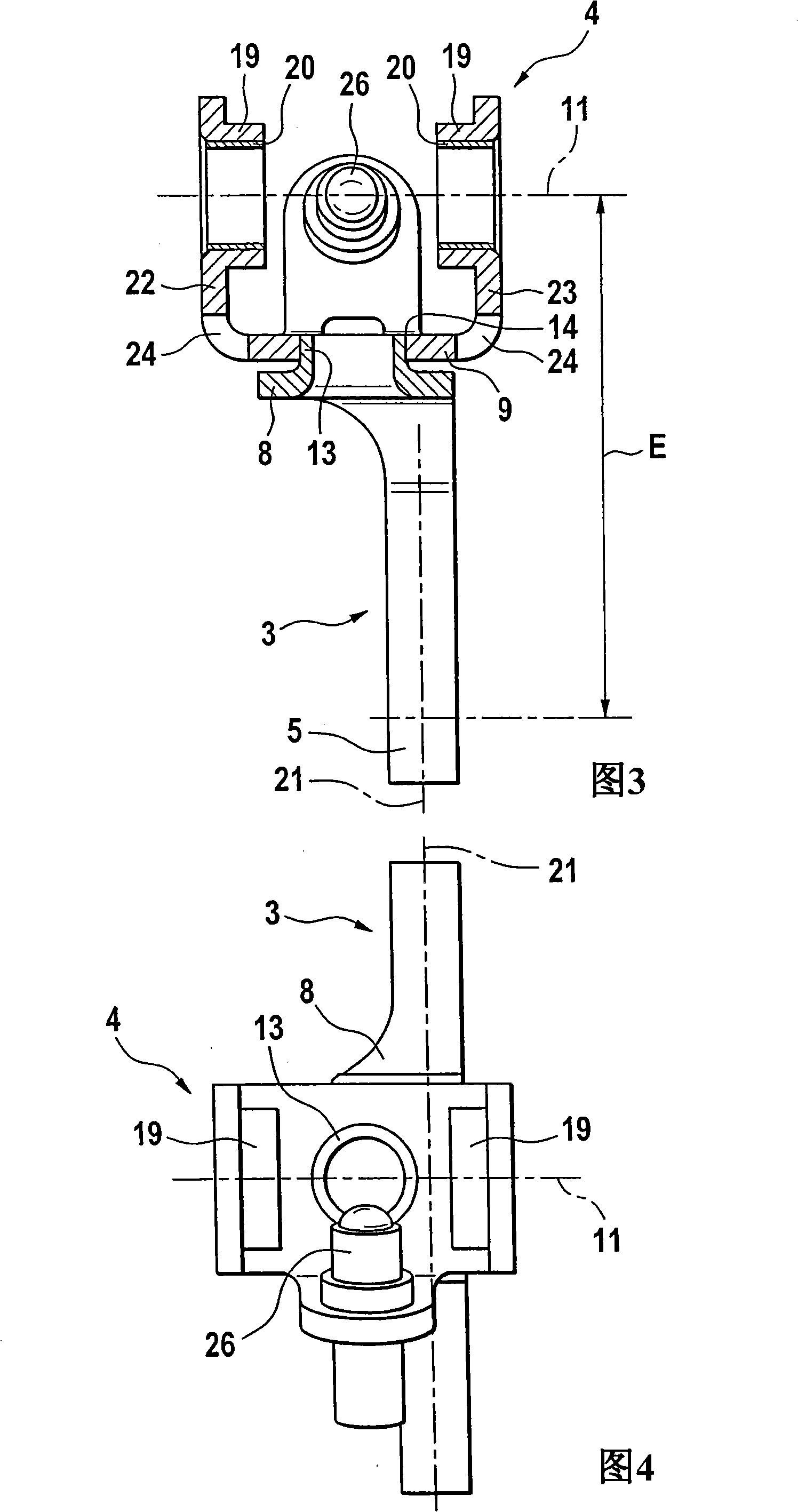

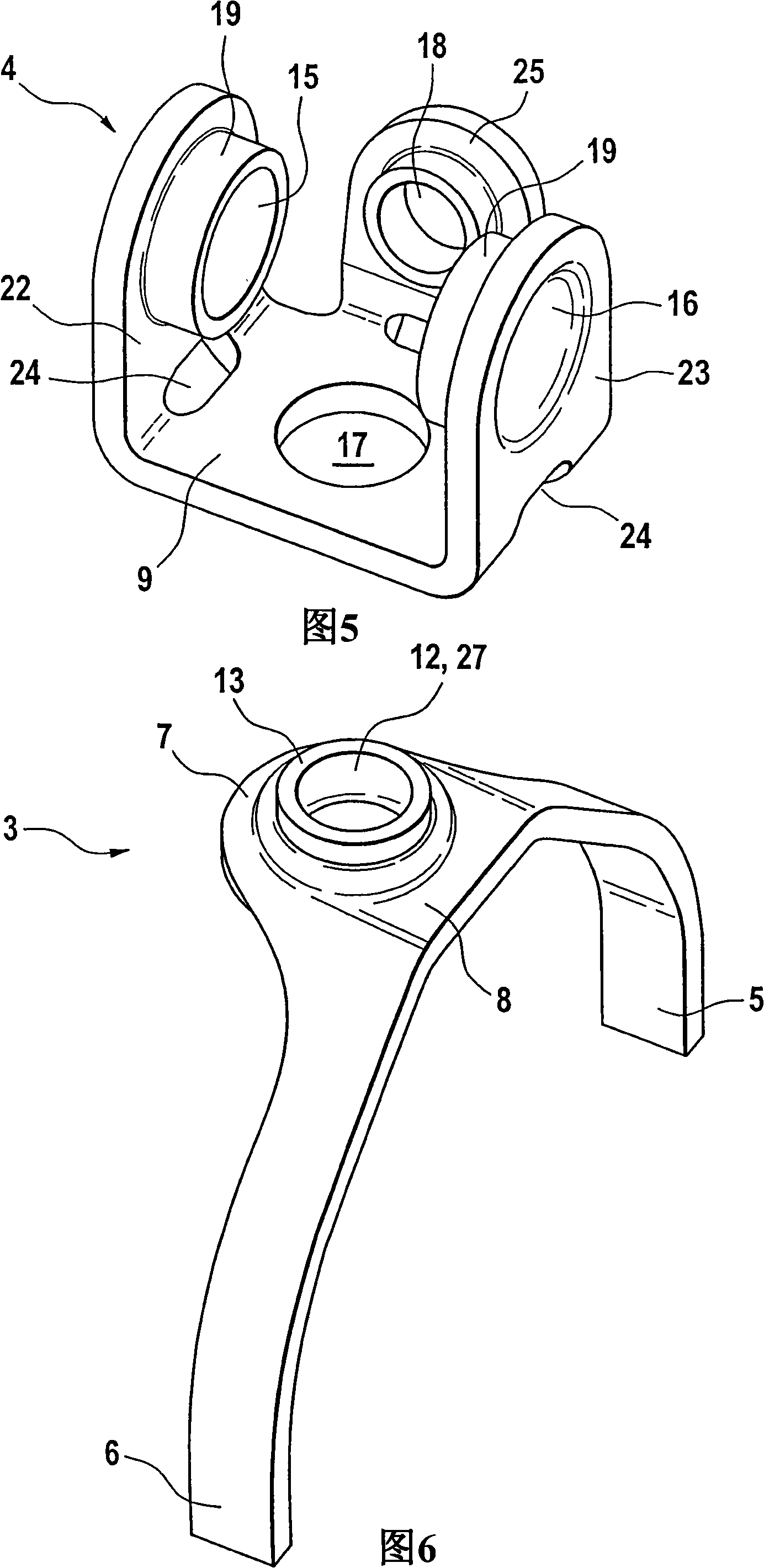

Shift arrangement having a shift fork

InactiveCN101346570AImprove vertical accuracyCorrection of bending errorsControlled membersGearing controlElectrical and Electronics engineeringGear drive

Owner:SCHAEFFLER TECH AG & CO KG

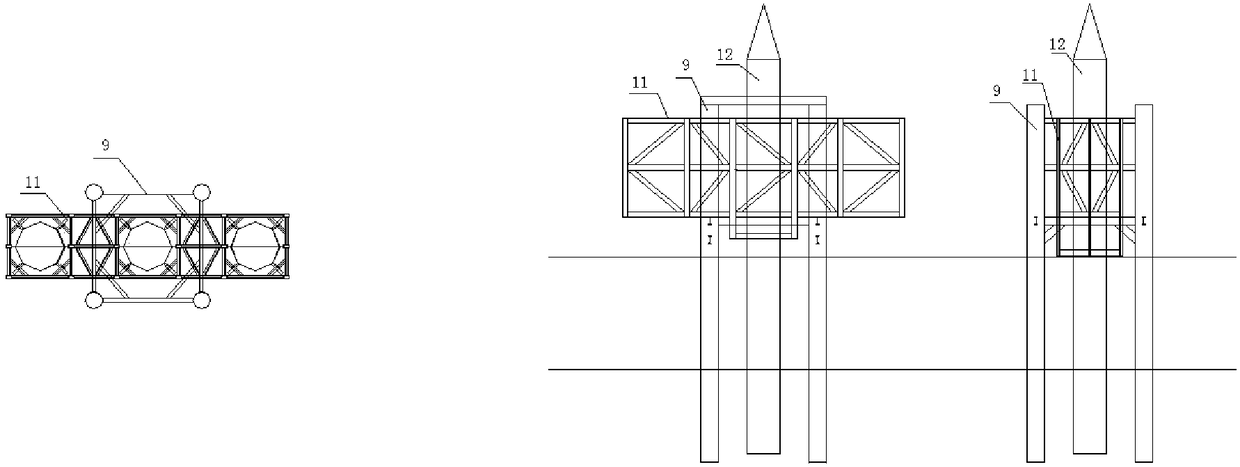

Large-diameter steel pile casing and three-frame type guide frame driving construction method

ActiveCN108193680AHigh positioning accuracyImprove vertical accuracyBulkheads/pilesCastingSelf weight

The invention discloses a large-diameter steel pile casing and three-frame type guide frame driving construction method. The method comprises the following steps that four auxiliary piles are driven in for placing a three-frame type guide frame, and connected through I-shaped steel; the three-frame type guide frame is placed to an auxiliary positioning steel pipe pile platform, and coordinates andperpendicularity are adjusted; steel pile castings sink due to the self weight; the steel pile castings on the two sides of the guide frame continue to be driven and are positioned, inserted and driven in the same ways as the first steel pile casting; locking connection between the guide frame and the auxiliary steel pipe piles and parallel connection of upper ports between the steel pipe piles are cut away, the guide frame is lifted up and rotated by 90 degrees and then placed down, and steel pile castings on the two sides in the longitudinal direction are driven in the same way; the guide frame is lifted and opened, and the auxiliary steel pipe piles are dismantled; two pieces of I45b type steel are welded to the top port of a middle guide port of the guide frame to be used as a bearingbeam, the middle guide port is placed down to the driven steel pile casting, the driven steel pile casting is used as a positioning base pile, and other steel pile castings are driven. The large-diameter steel pile casing and three-frame type guide frame driving construction method has the advantage of improving steel pile casting driving precision.

Owner:CCCC SHEC FIRST HIGHWAY ENG +2

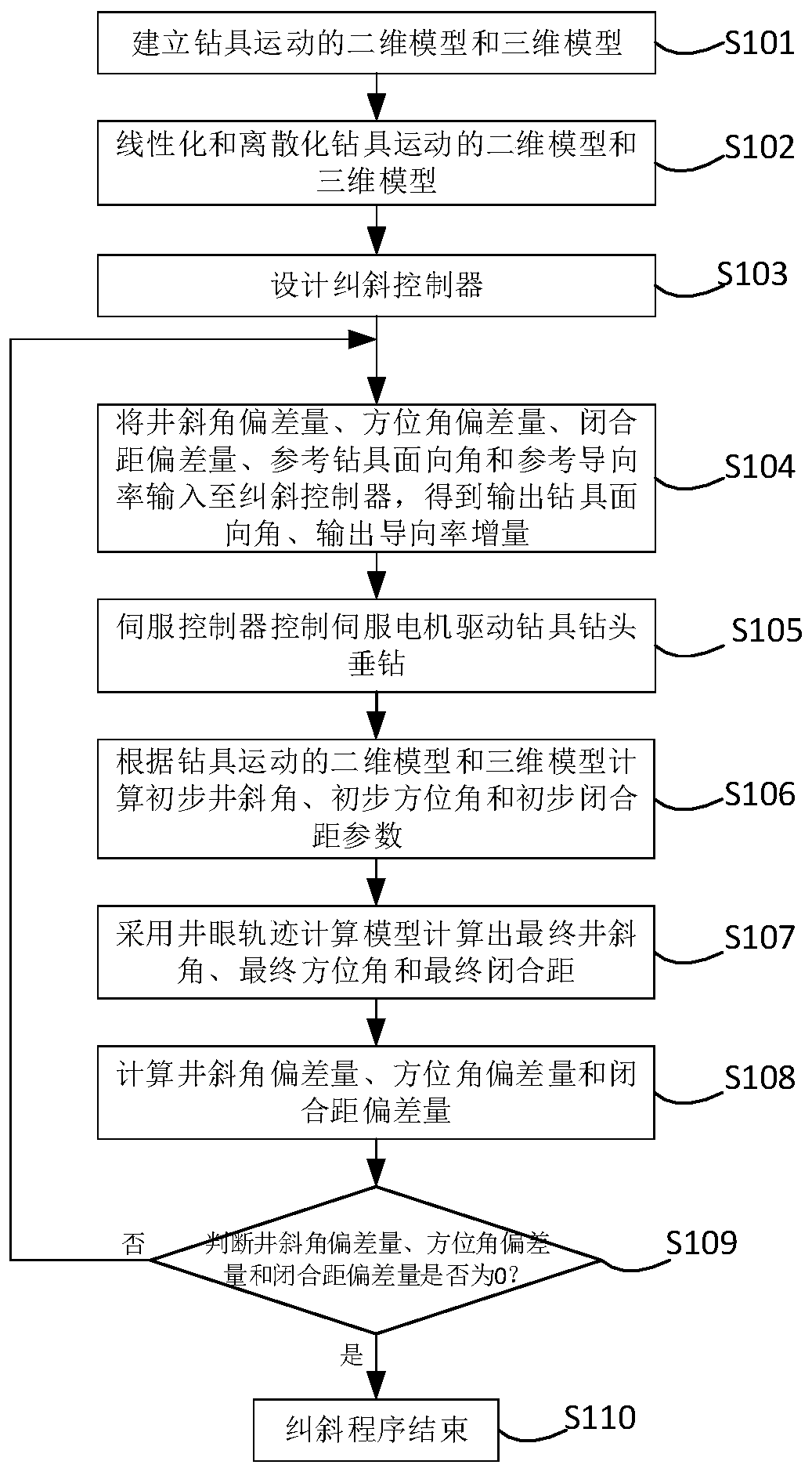

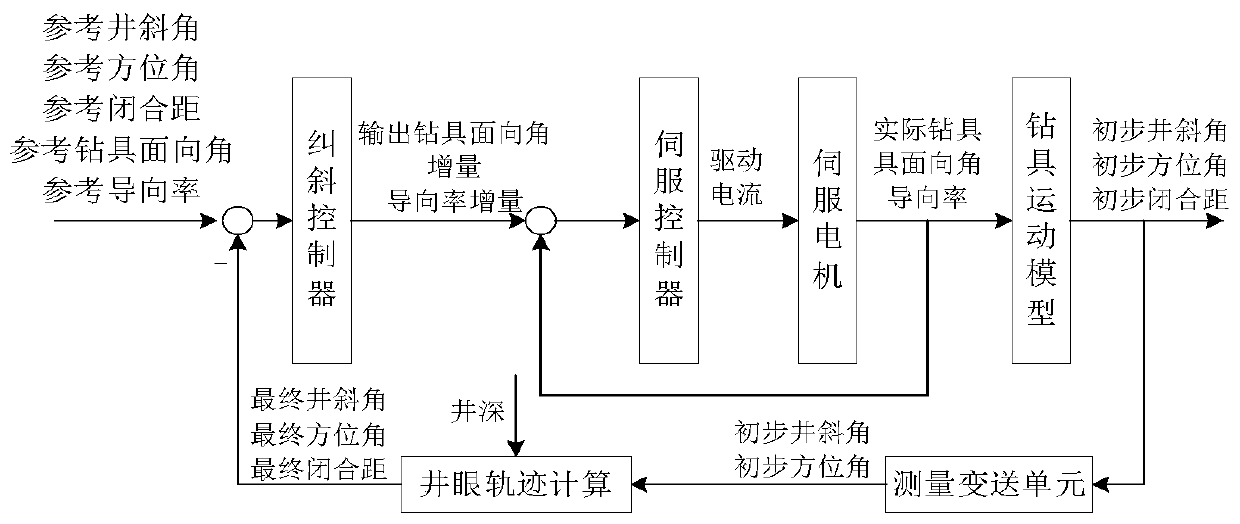

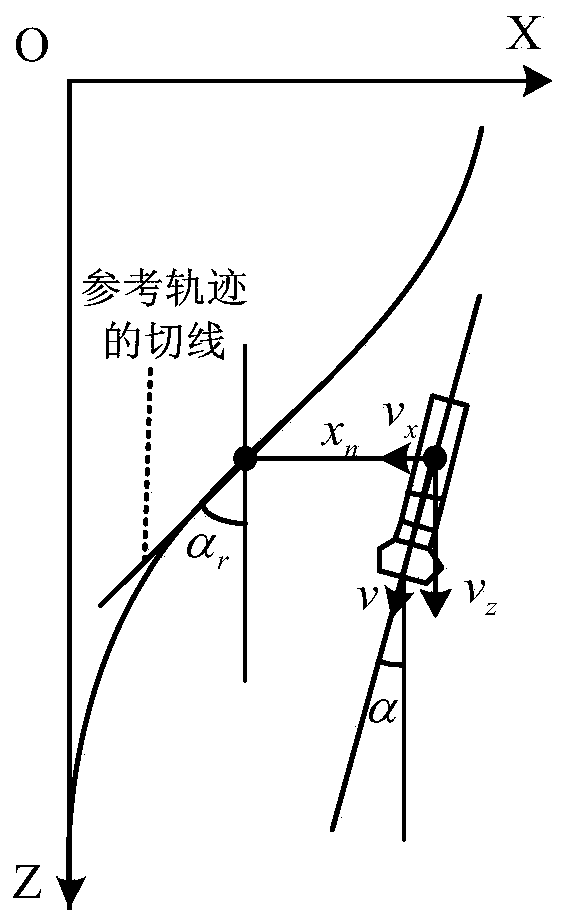

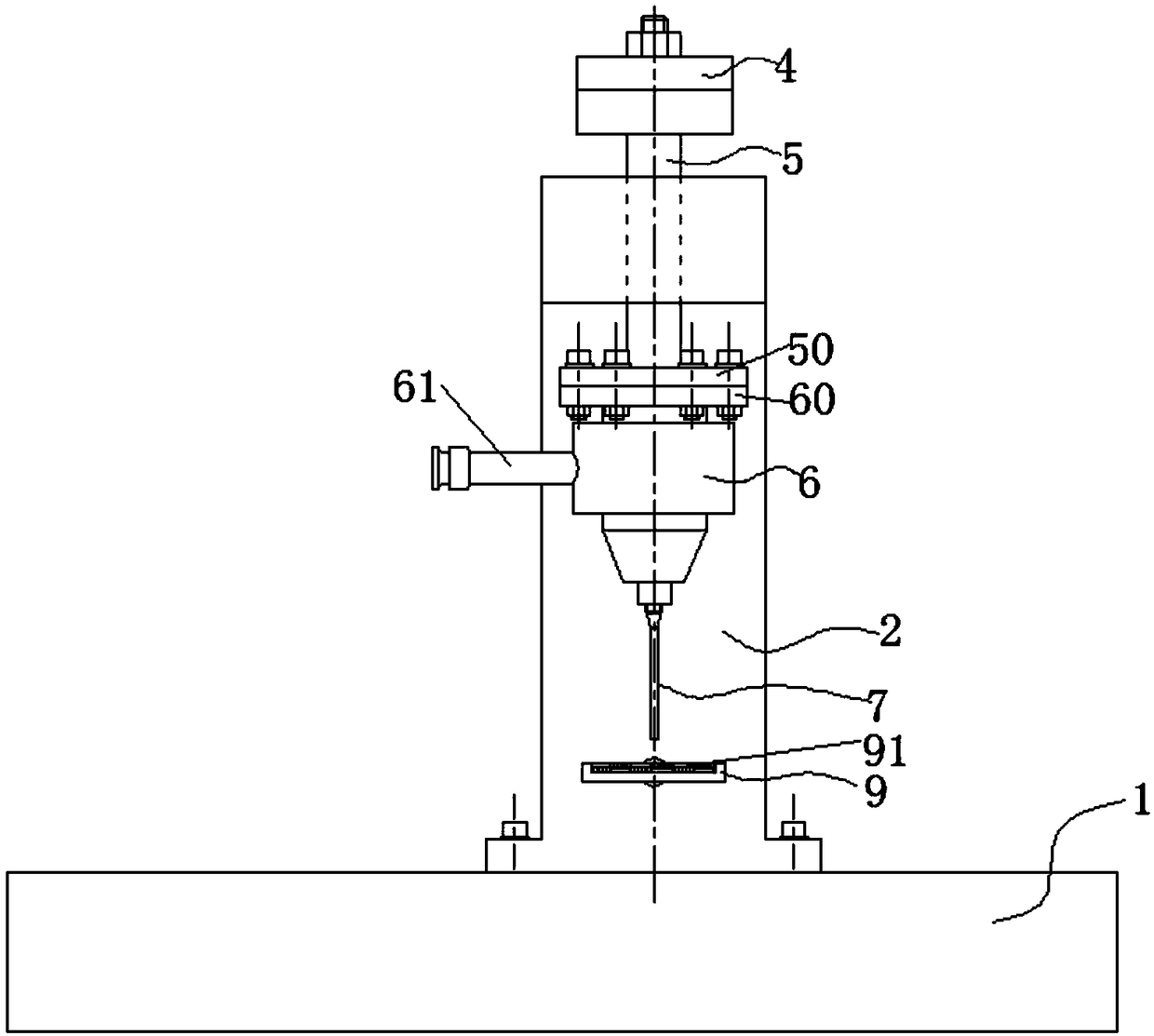

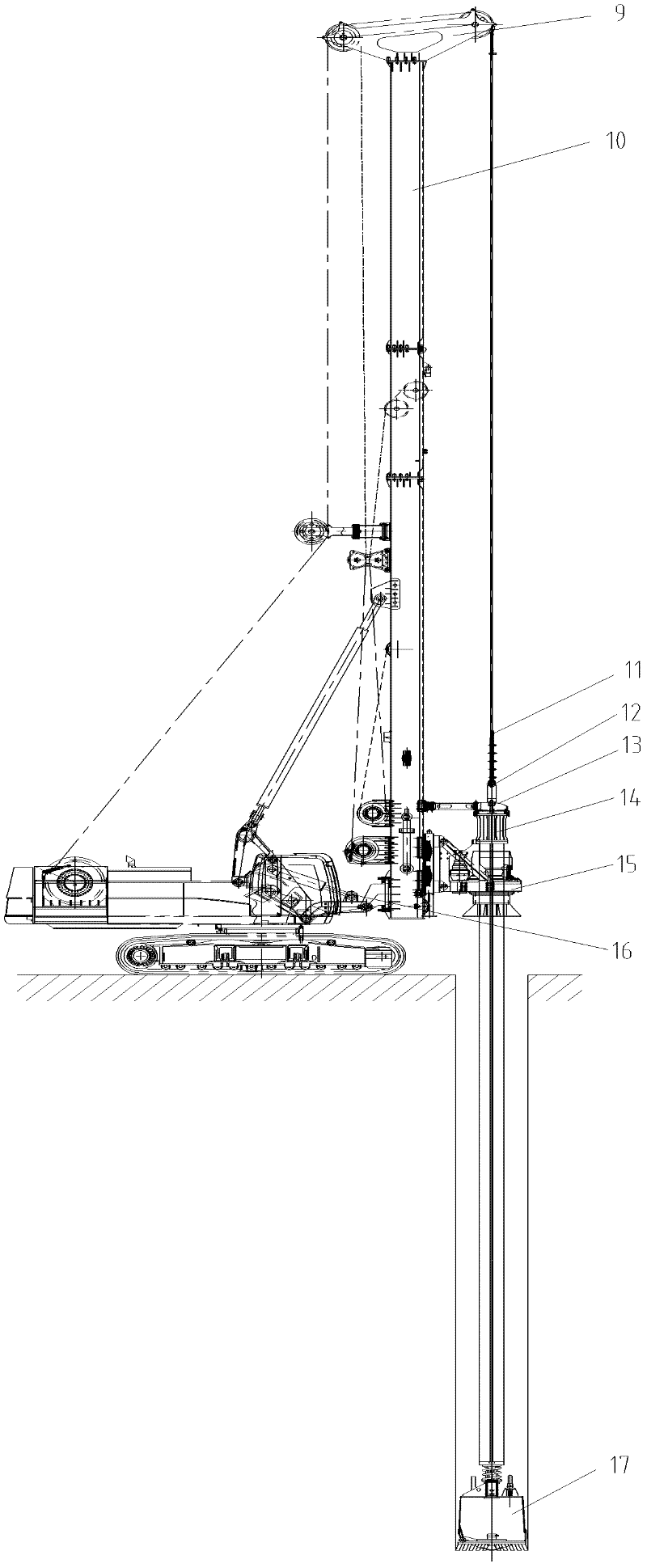

Vertical drilling process deviation correction control method based on automatic guiding drilling tool

ActiveCN110513043AImprove vertical accuracySolving Discrete Optimal Control ProblemsDirectional drillingSpecial data processing applicationsThree dimensional modelLinearization

The invention provides a vertical drilling process deviation correction control method based on an automatic guiding drilling tool. The vertical drilling process deviation correction control method includes the following steps that first, a two-dimensional model and a three-dimensional model of the drilling tool movement are established; then, linearizing and discretizing of the models are conducted, and a deviation correction controller is designed; the hole deviation angle deviation amount, the azimuth deviation amount, the closure distance deviation amount, a reference drilling tool facingangle and the reference guiding rate are input to the deviation correction controller; a servo drive module drives a bit to drill vertically; an initial hole deviation angle, azimuth angle, and closure distance are calculated; a final hole deviation angle, azimuth angle, and closure distance are calculated; the deviation amount of the hole deviation angle, the azimuth angle, and the closure distance is calculated; and the deviation amount is fed back to the deviation correction controller to form closed-loop control. According to the technical scheme, the vertical drilling process deviation correction control method has the beneficial effects that in the case of lack of an existing vertical drilling deviation correction control concept, two-dimensional and three-dimensional modeling of thedrilling tool movement is carried out, the deviation correction controller is designed, and the vertical accuracy of a vertical drilling trajectory and engineering applicability of a deviation correction control system can be improved.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

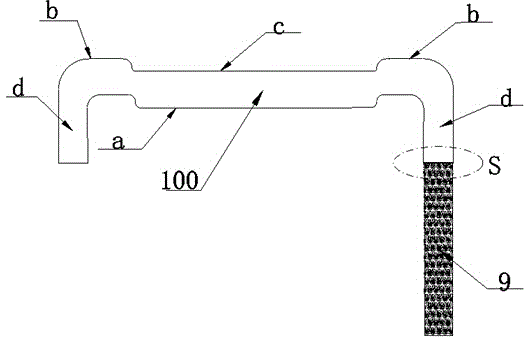

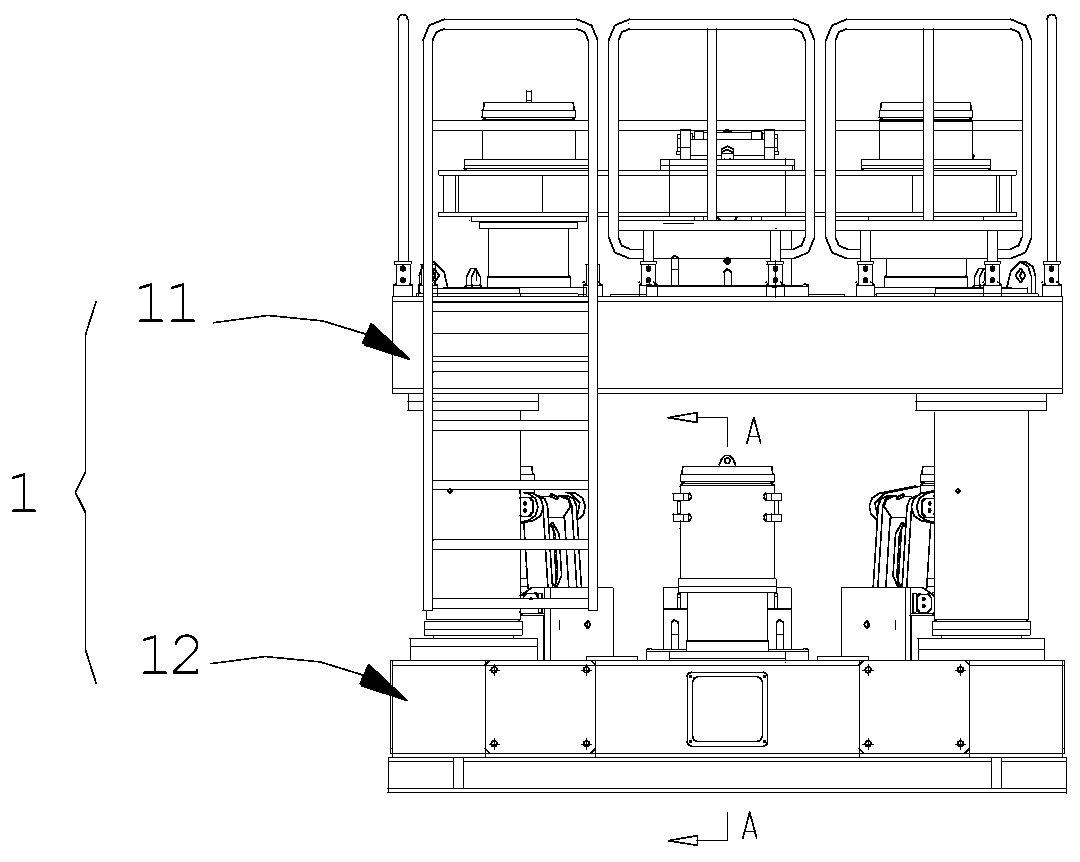

Low-dose injection drug production line fil anti-dripping device

A low-dose injection drug production line fil anti-dripping device including workbench, Support, cylinder 1, Plates, filling rods, Filling head, filling needle, Cylinder 2 and plugs, A low end of thatbracket is connected with the work table, As that air cylinder is connecte with the back of the bracket, An upper end of that piston rod of the air cylinder 1 is connecte with one end of the pressureplate, and locked by a nut, An upper end of that fil rod is connected with the other end of the pressure plate, and locked by a nut, A low end of that filling rod is connecte with the filling head, The filling needle is connected with the lower end of the filling head, the cylinder 2 is connected with the lower end of the back surface of the support, the piston rod of the cylinder 2 passes through the support, the liquid receiving plate is connected with the end of the piston rod of the cylinder 2, and the liquid receiving plate is provided with a cylindrical hole and a water-absorbing sponge, so as to prevent the residual liquid medicine on the outer wall of the filling needle from falling on the outer wall of the small-dose medicine bottle.

Owner:WUHU KANGQI PHARMA

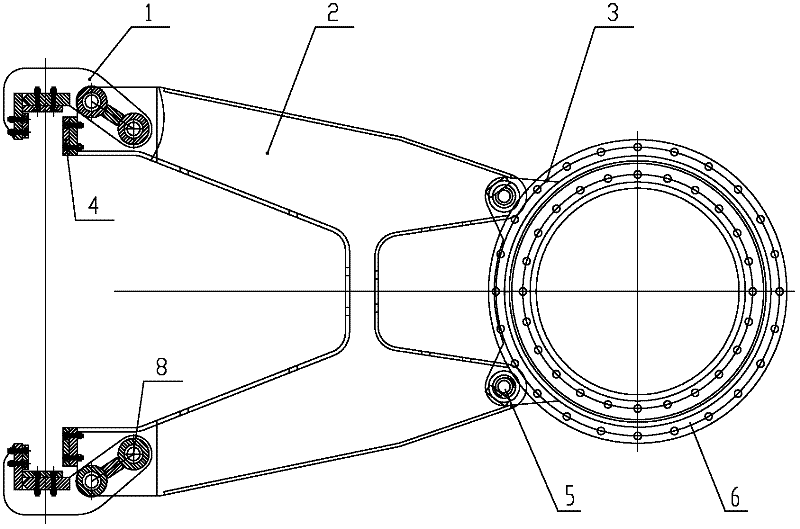

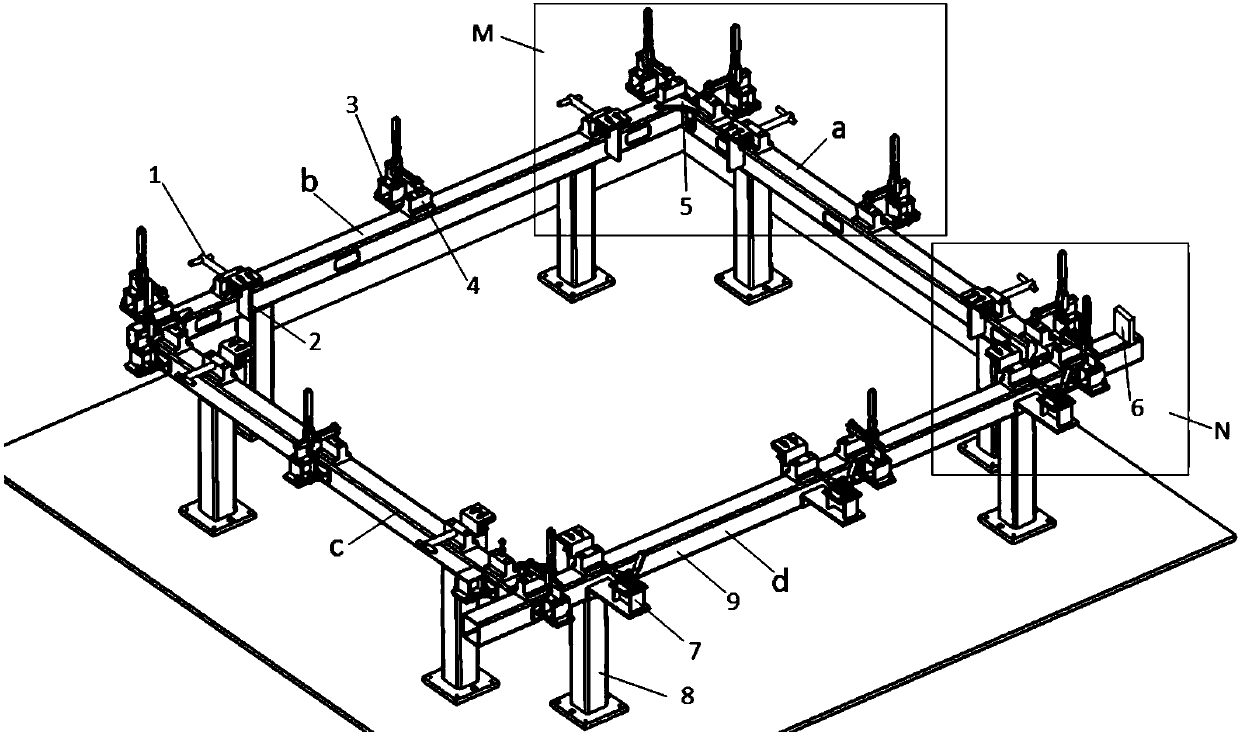

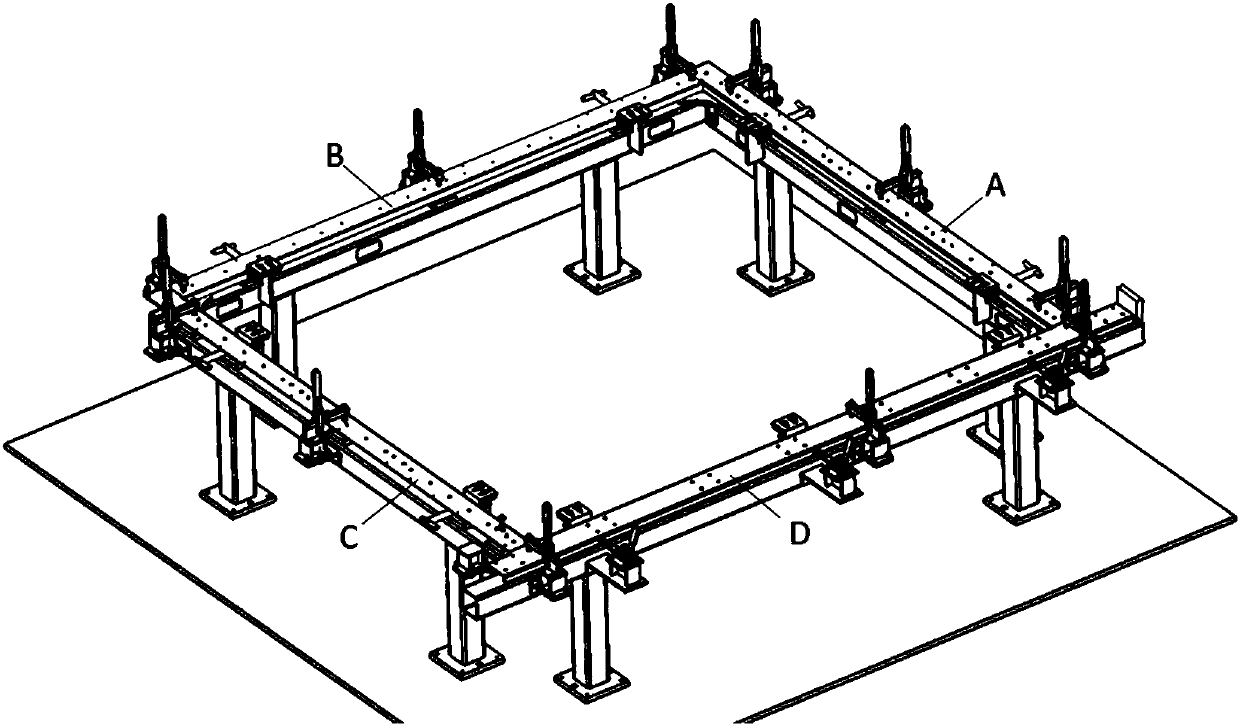

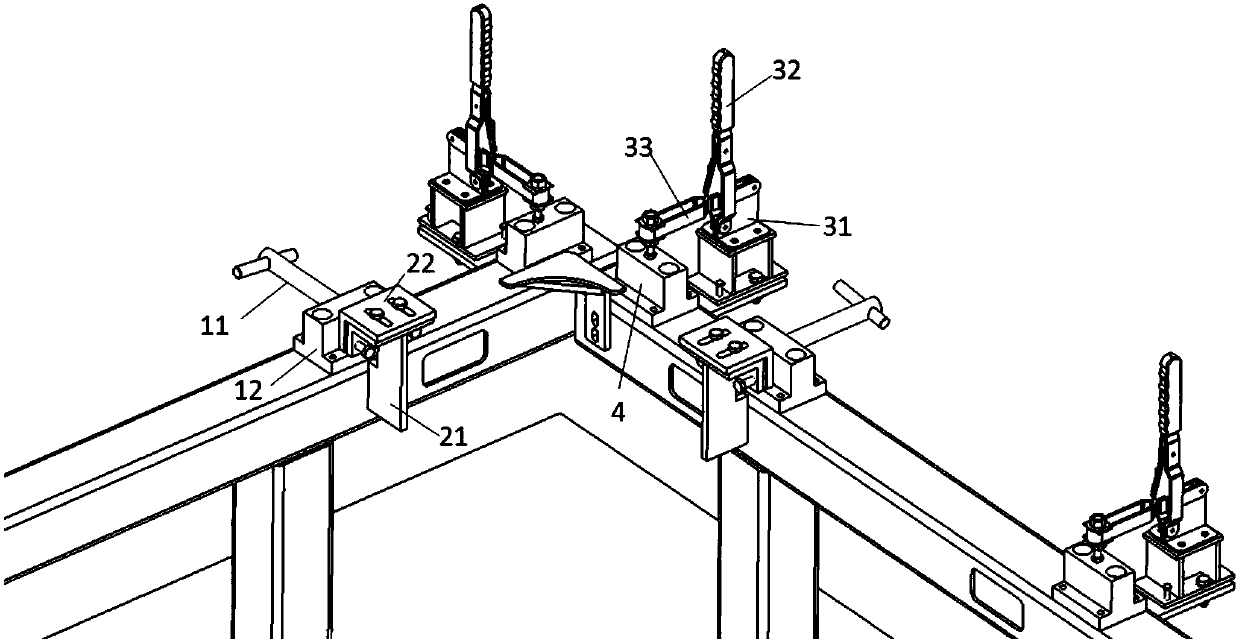

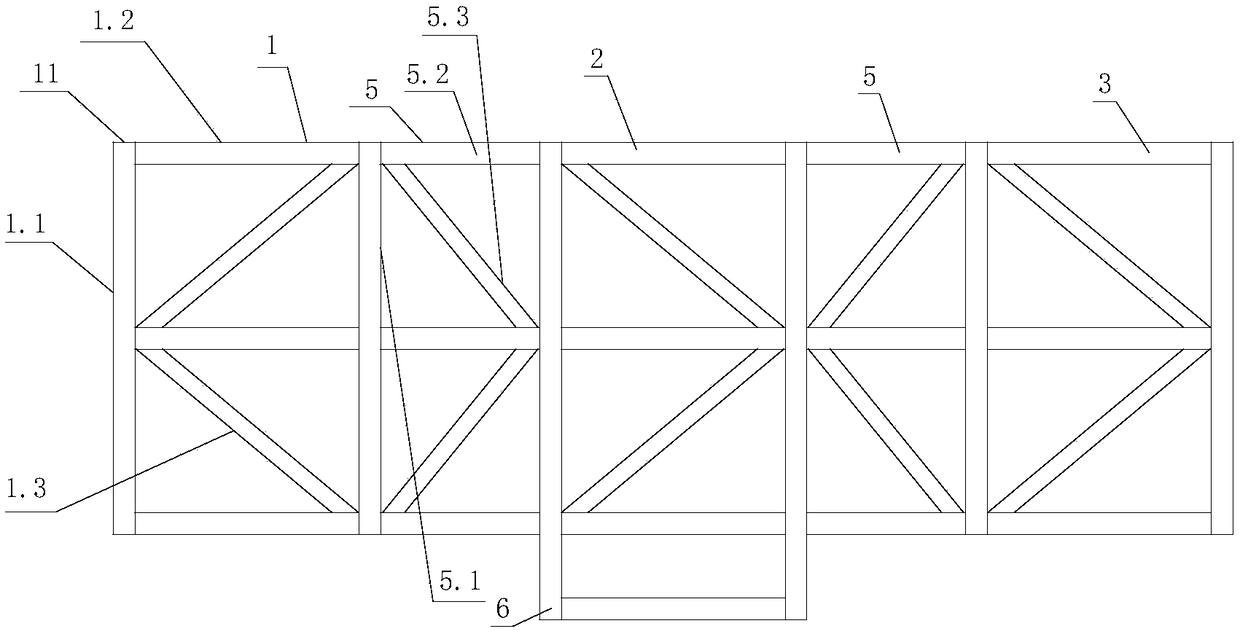

Detachable follow-up frame and installation process thereof

Owner:CHTC JOVE HEAVY IND

Supporting article for preventing sand from subsiding

InactiveCN1508362AReduce usage timeImprove economyExcavationsBulkheads/pilesSheet pileUltimate tensile strength

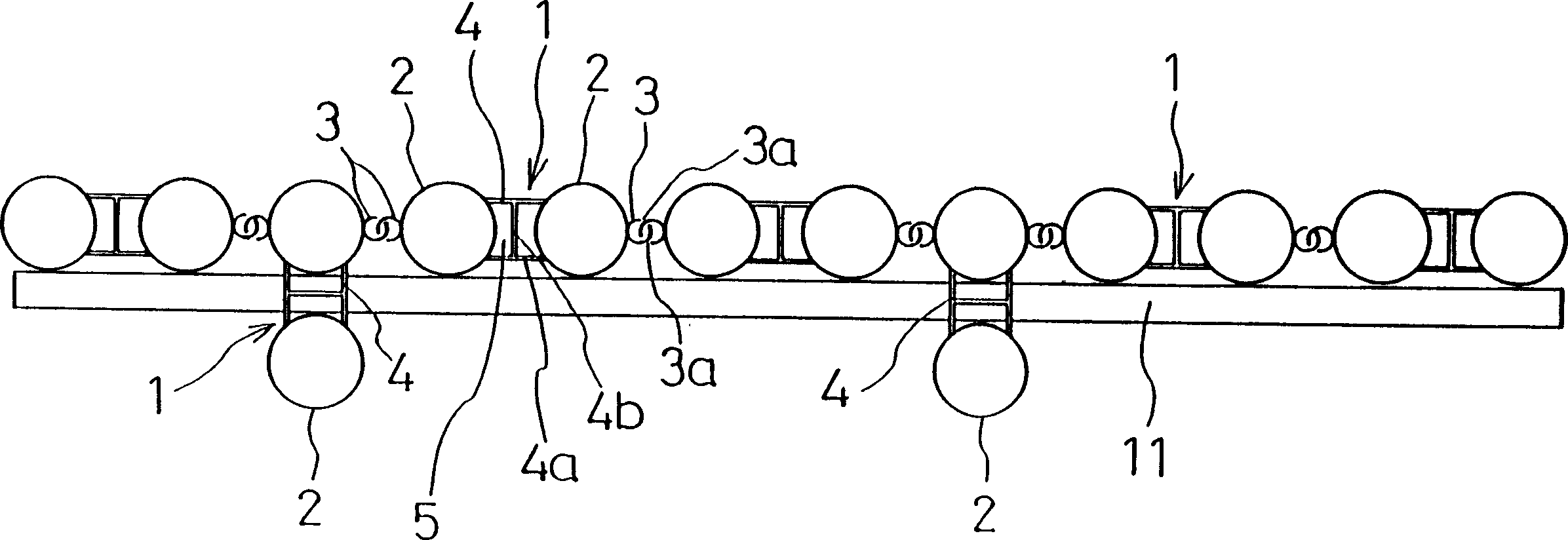

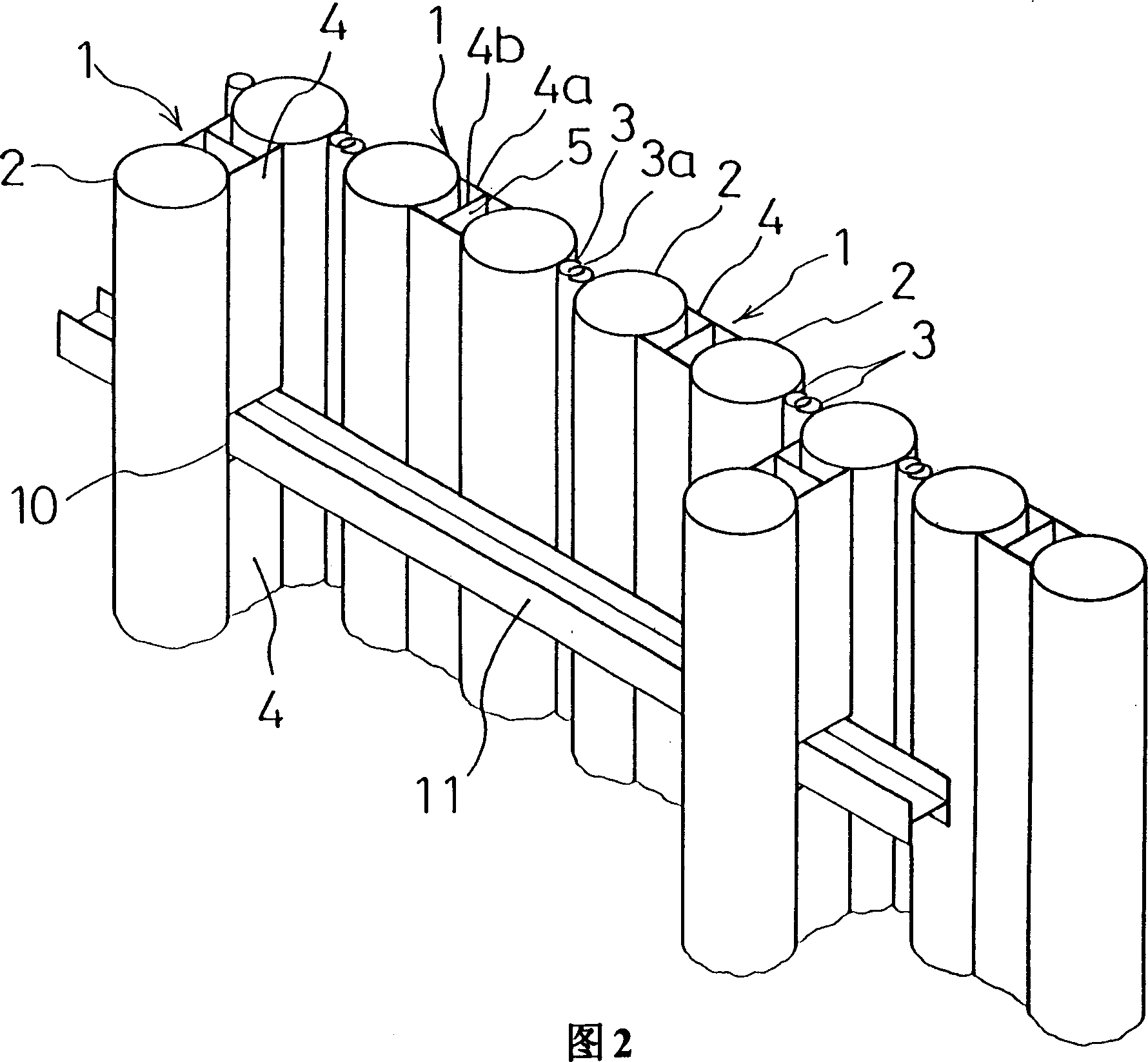

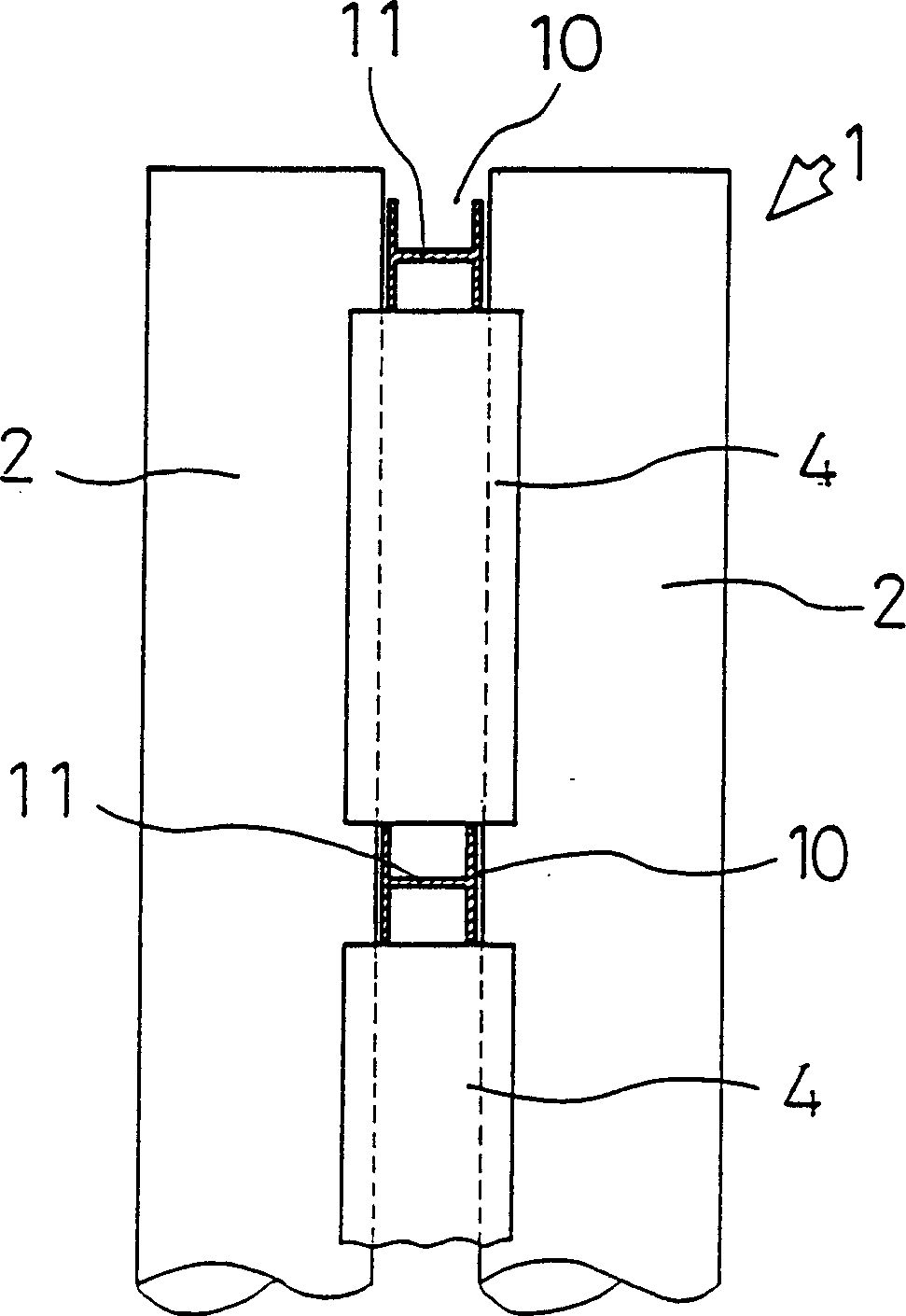

Retaining supporting is provided to reduce water pollution caused by coffering work and to increase economical effects, by achieving a coffering effect by a closed space. In retaining supporting, a steel pipe sheet-pile(1) is used as a supporting unit member. In the steel pipe sheet-pile, steel pipes(2) arranged parallel are integrally interconnected by an H-steel connection member(4) the edges of which are combined to the peripheral surface of each steel pipe and a connection part(3) is arranged to the steel pipe. The supporting unit members are horizontally connected by mutually combining the connection parts, to form a retaining wall. Supporting unit members vertically arranged are interposed at suitable intervals to make the connection members and steel pipes arranged in the rear of the retaining wall.

Owner:DATA TOO +2

Laser water level gauge based on laser distance measurement

InactiveCN103542912AImprove vertical accuracyAccurate measurementMachines/enginesLevel indicatorsObservational errorMeasuring instrument

The invention relates to the photoelectric technology field, in particular to a laser water level gauge based on laser distance measurement. The laser water level gauge comprises a laser distance measuring instrument, an adjustable beam contracting system, a high-precision light sensing CCD, an upper tray, a lower tray, a cross-shaped level gauge, a screw, a data processing system and a supporting frame. The laser distance measuring instrument is fixedly arranged on the lower tray. The adjustable beam contracting system is located at a laser emitting opening front end of the laser distance measuring instrument. The high-precision light sensing CCD is fixed on the right side of the laser distance measuring instrument and the output end of the high-precision light sensing CCD is connected with the data processing system. The cross-shaped level gauge is fixed on the surface of the upper tray. One end of the supporting frame is fixed on the lower surface of the lower tray. The upper tray and the lower tray are connected through the screw. By means of the laser water level gauge based on laser distance measurement, the vertical precision of an incoming laser beam and a measured liquid level is high and meanwhile, the measurement errors are reduced and the height of the measuring liquid level can be efficiently and accurately measured. The laser water level gauge based on the laser distance measurement has the advantages of being simple in structure, reasonable in arrangement, low in manufacturing cost and the like.

Owner:太仓海关综合技术服务中心

Right-side front door frame assembling and welding tool and installing and adjusting method thereof

PendingCN107649815AEffectively fixedSmall sizeWelding/cutting auxillary devicesAuxillary welding devicesPass rateEngineering

The invention discloses a right-side front door frame assembling and welding tool and an installing and adjusting method thereof, and is applied to the field of carbon steel welding. The right-side front door frame assembling and welding tool comprises a threaded jacking clamp, a limiting block, a down pressing quick clamp, a cushion block, a reinforcing plate gasket, a jacking quick clamp, a stand column and a cross beam. The installing and adjusting method is characterized in that components are installed, leveled and installed as a criterion. The method mainly solves the problems that the current right-side front door frame assembly is welded by manual assembly, the size of the assembly is determined by means of measurement of a measuring tape, the size of the assembly is not stable, the manual assembling speed is low, the production efficiency is low, no tool clamp is used to fix, and welding deformation is easily generated after welding. The ingenious design and effective installation and adjustment of the welding tool are realized so that the inner width, the inner height and the diagonal dimension of the right front door frame in the production process are controlled, the welding deformation is reduced, the size deviation is low, the product percent of pass is high and stable, and the production efficiency of the aluminum alloy container body is improved.

Owner:LIAONING ZHONGWANG SPECIAL VEHICLE MFG

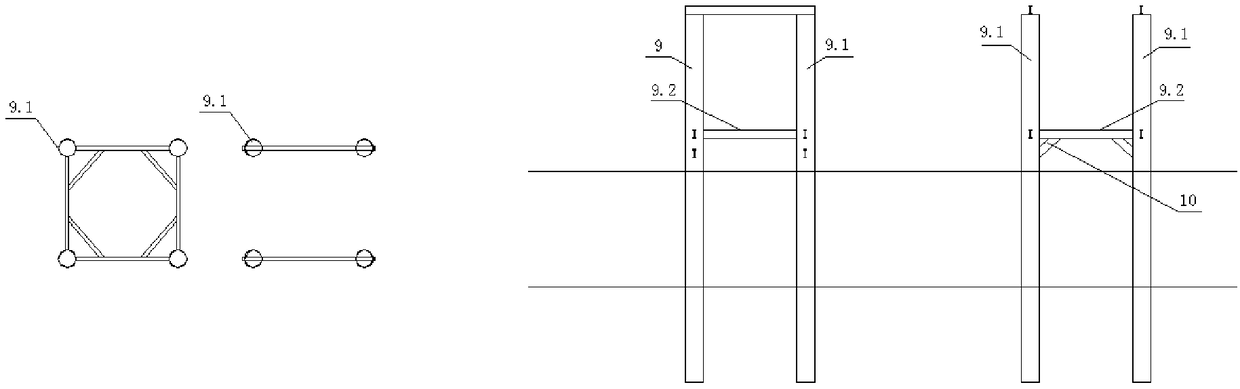

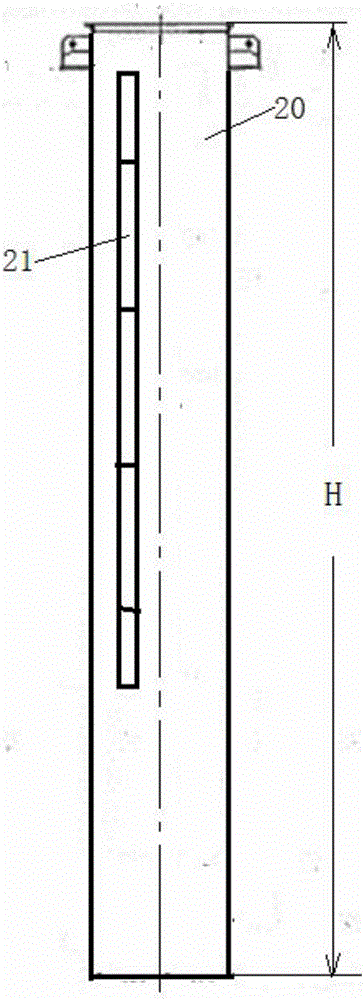

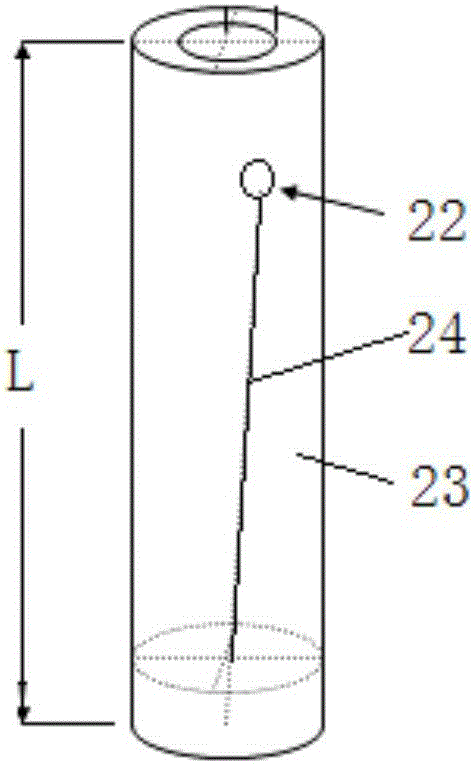

Guide pipe for steel stand column guide insertion construction

ActiveCN106436743AHigh guiding precisionImprove vertical accuracyStrutsFoundation engineeringArchitectural engineeringBuoy

The invention relates to a guide pipe for steel stand column guide insertion construction. The guide pipe is manufactured by a square steel pipe; the height H of the square steel pipe is 3000-20000 mm; the section inner diameter of the square steel pipe is 500-2000 mm; and a buoy perpendicularity measuring device is arranged on one side of the square steel pipe. The buoy perpendicularity measuring device includes a water pipe and a floating ball; the length L of the water pipe is 6 m; the inner diameter is phi 24 mm; the lower end of the water pipe is closed; and the floating ball is positioned in liquid in the water pipe, and is connected to the center of the lower end of the water pipe through a rope. The measuring precision of the buoy perpendicularity measuring device is 1 / 700-1 / 1000. The guide pipe is used for a steel stand column guide insertion process, can guarantee high precision of one-column one-pole perpendicularity of at least above 1 / 600, and reduces later engineering problems caused by vertical deviations of steel stand columns.

Owner:上海开普天岩土科技集团有限公司 +1

Special profiles for three-dimensional printer

The invention discloses special profiles for a three-dimensional printer. By the adoption of the special profiles for the three-dimensional printer, a Z-axis movement structure of an existing three-dimensional printer can be replaced. The structure is formed by arranging the special lifting platform profile, the special box profile and the special sliding block profiles in a matched mode. The lifting platform profile and the box profile are structurally oppositely arranged. A sliding gap between the lifting platform profile and the box profile are supported through the sliding block profiles fixed in lug grooves in the outer side of a lifting platform, so that the function of a vertical sliding track of the lifting platform in the three-dimensional printer is achieved, the vertical (Z-axis) walking precision of the lifting platform relative to the X axis and the Y axis is higher, printed workpieces are stacked in the vertical direction regularly and identically, and the mechanical strength reaches the mechanical strength index of materials; the three-dimensional printer made of the special profiles for the three-dimensional printer is good in integrity, simple in mechanical structure, suitable for large-scale manufacturing, low in cost, capable of saving resources and reducing energy consumption, stable and reliable in operation precision and can reach the maintenance-free level.

Owner:辽宁重彩立体打印机有限公司

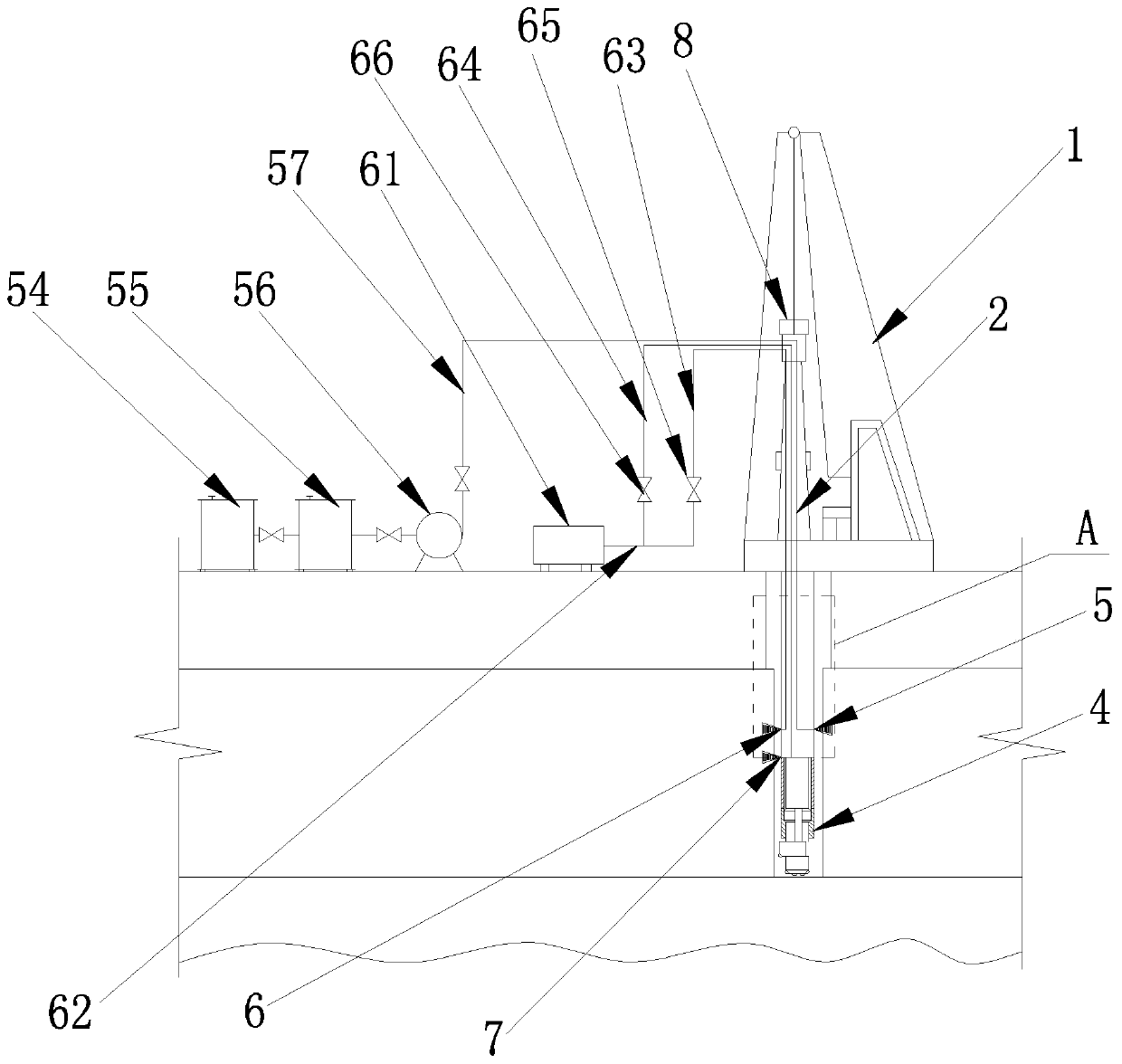

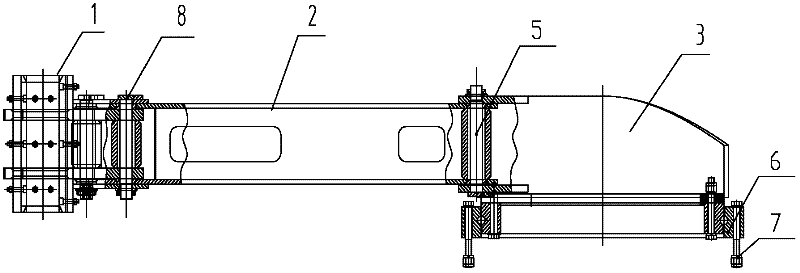

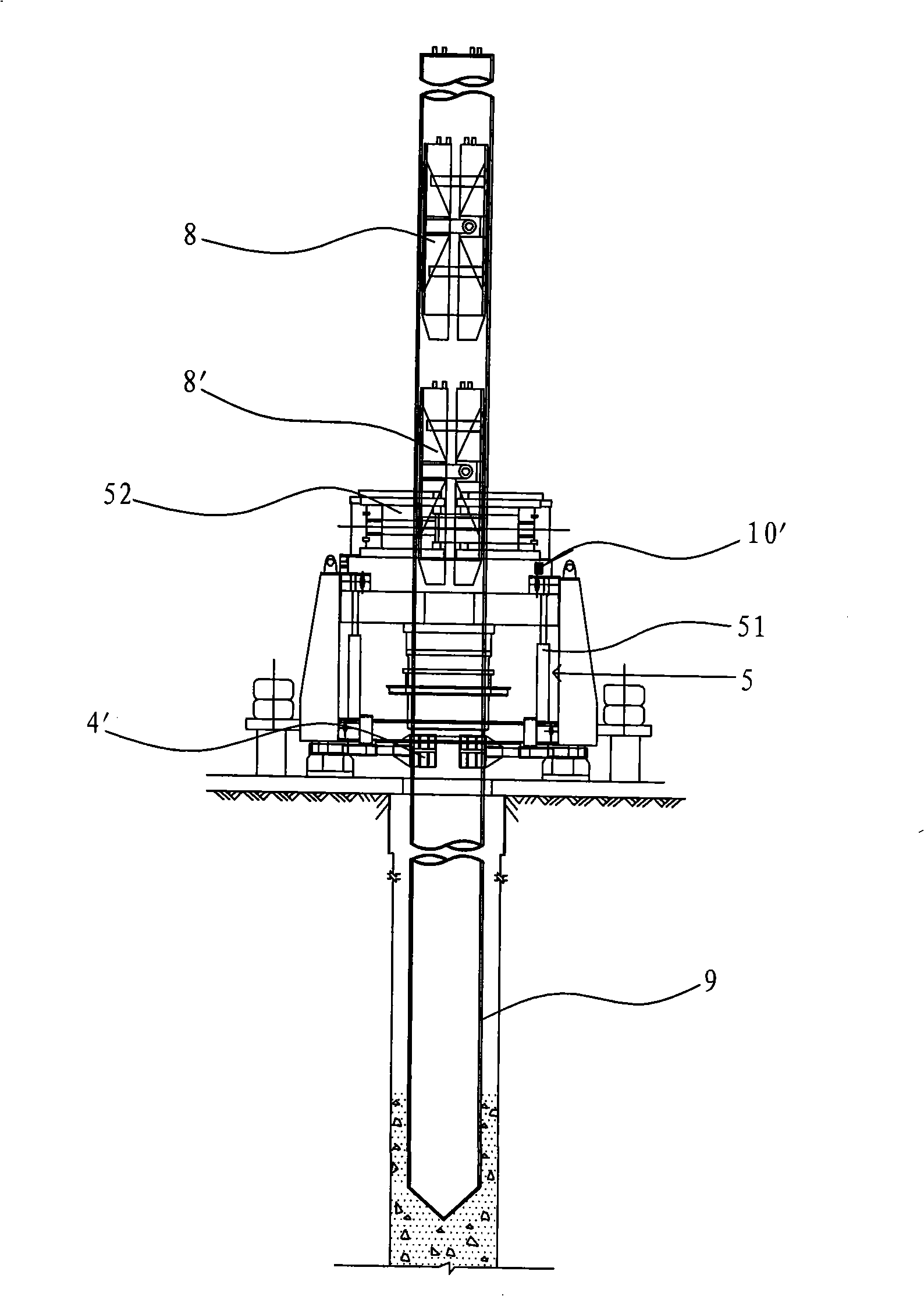

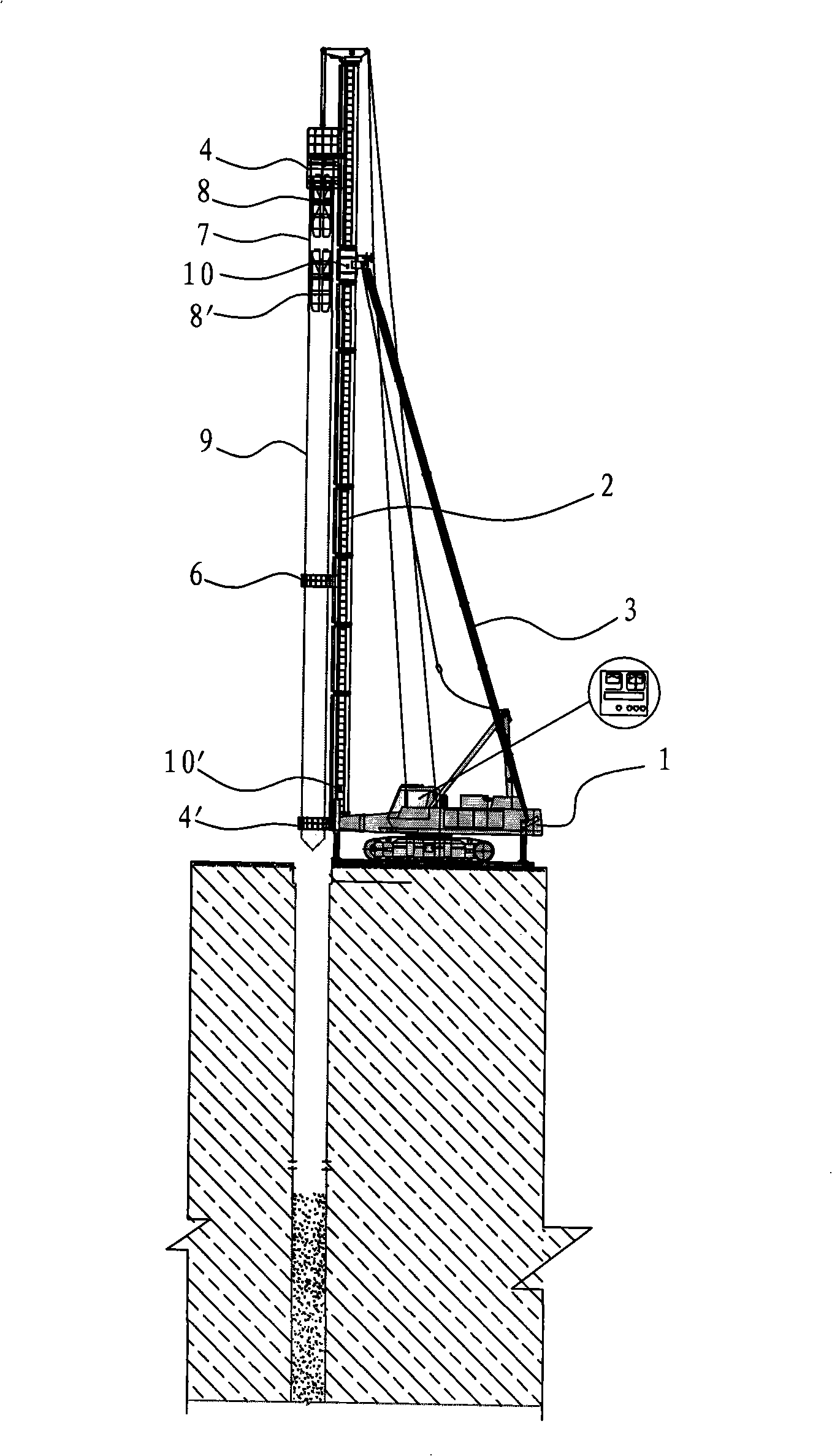

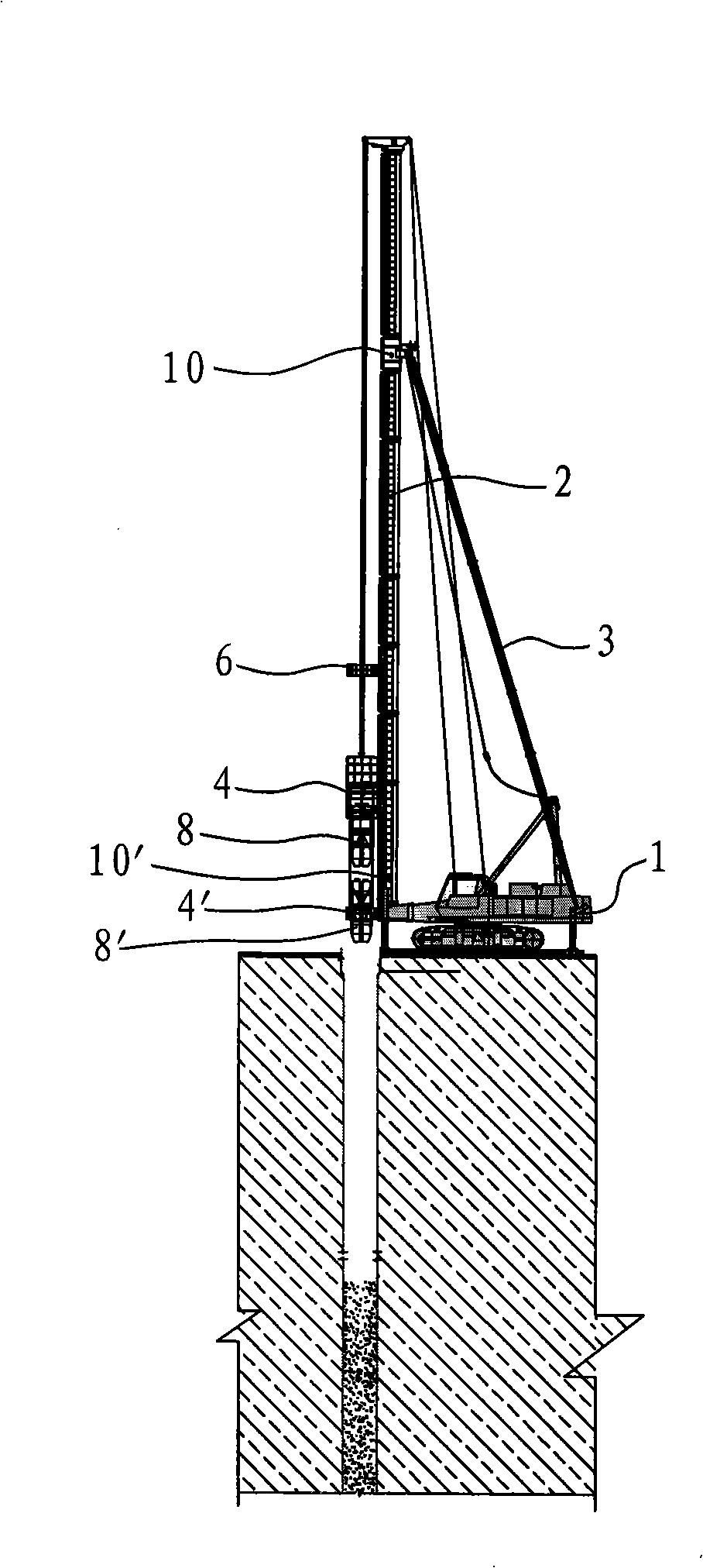

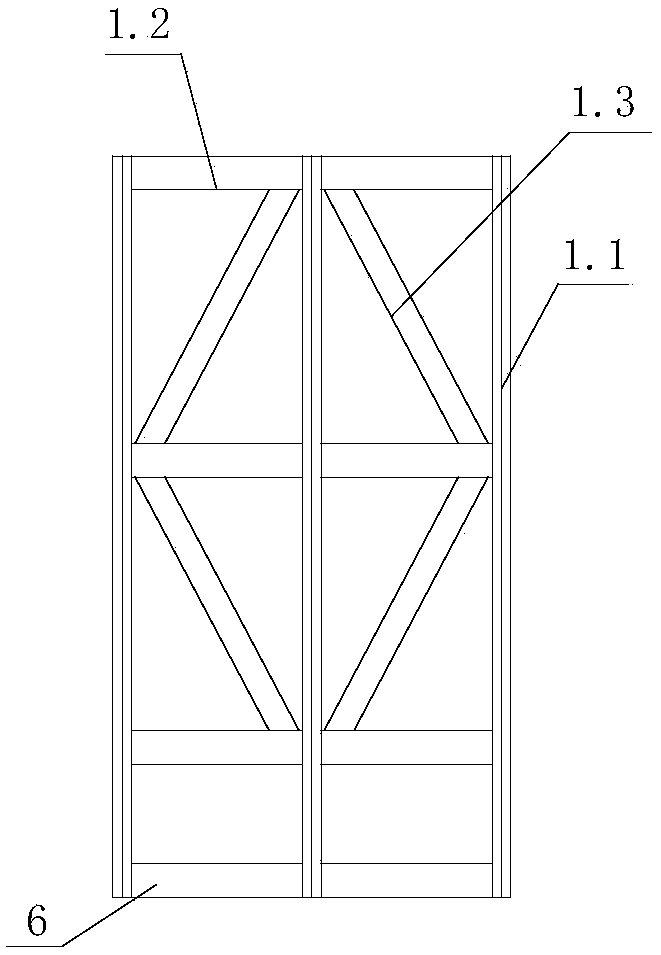

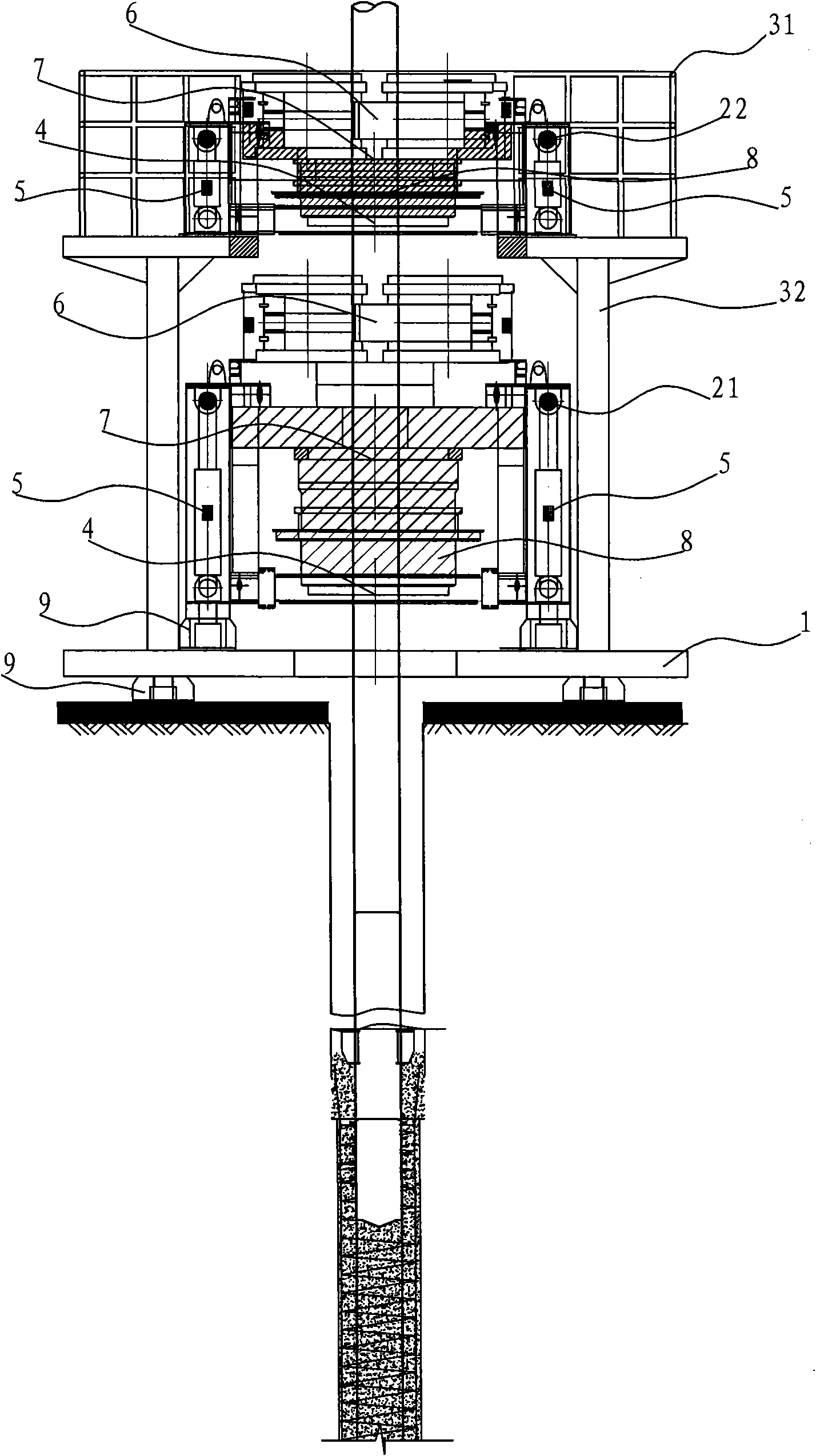

Hydraulic insert machine and connecting method of foundation pile and steel tube by employing hydraulic insert machine

ActiveCN101333810AImprove vertical accuracyHigh technology contentBulkheads/pilesMachineSteel columns

The invention relates to a hydraulic inserting machine and the connecting method of a foundation pile and a steel pipe based on the hydraulic inserting machine which is composed of a base body, a frame body, a telescopic dynamic rod, a hydraulic positioner, a hydraulic coupler, a movable coupler, a vertical adjustment and calibration device and a vertical collimator. The hydraulic inserting machine has high vertical accuracy on the steel pipe insertion and controls the accuracy ranging from 1 / 500 to 1 / 1000L; compared with the general top-down construction, the construction period is reduced by 60%-70%; the energy is saved by 40%; the cost investment is saved by 20%-30%; the connecting method of the foundation and the steel pipe has high vertical accuracy on the steel pipe insertion and controls the accuracy ranging from 1 / 500 to 1 / 1000L; the hydraulic inserting machine has the advantages of rapidness, accuracy, convenience, saving cost and energy, safety and environmental protection.

Owner:ZHEJIANG DINGYE FOUND ENG

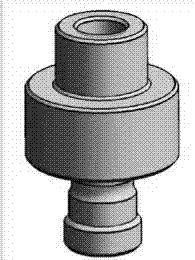

Fixing device for testing pulling-out force of device chip

ActiveCN103115868AAchieve vertical pullSimple structureUsing mechanical meansMaterial analysisEngineeringElectrical and Electronics engineering

The invention discloses a fixing device for testing the pulling-out force of a device chip; the device comprises a base; a rotary holder is sheathed into the base; the device also comprises a fastening screw which is used for fixing the rotary holder along the vertical direction; the rotary holder is assembled with a clamp device and a bracket; and a chip bonding device passes through a hole in the bracket and is fixed on the bracket. The fixing device is simple in structure, convenient to install, high in vertical accuracy, high in reliability and test accuracy, low in manufacturing cost and good in market prospect.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

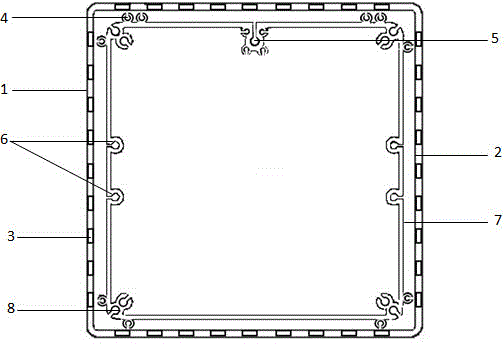

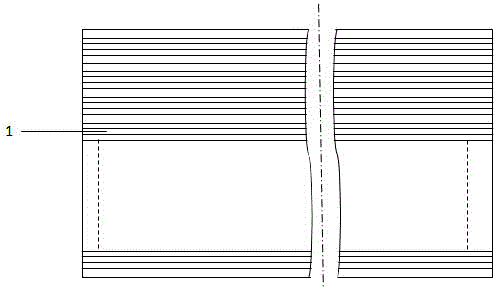

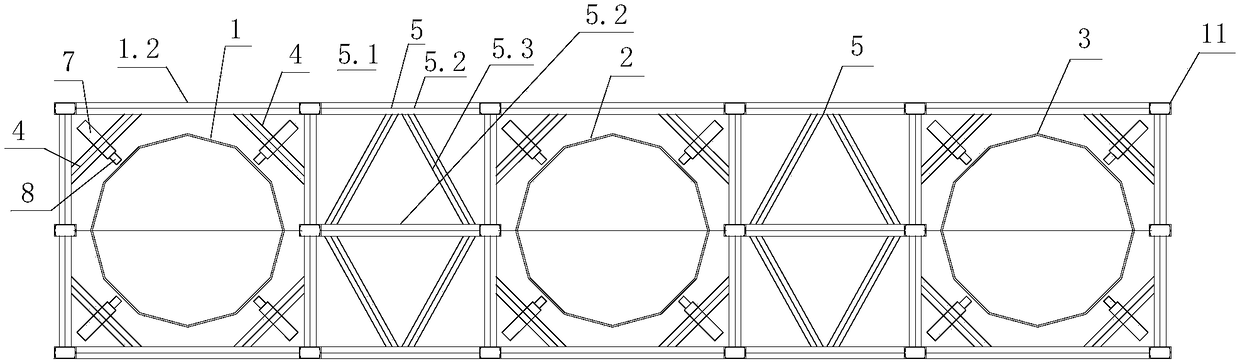

Die frame

InactiveCN104963503AHigh compressive strengthImprove carrying capacityForming/stuttering elementsClassical mechanicsStructural engineering

The invention relates to the field of construction dies and discloses a die frame. A flexible edge (4) is located between a large smooth edge (2) and a small smooth edge (3), the distance between the large smooth edge (2) and a bottom edge is equal to the distance between the small smooth edge (3) and the bottom edge and is larger than the distance between the flexible edge (4) and the bottom edge, and a row of bolt holes (7) are further formed between the flexible edge (4) and the bottom edge (1). One crush resistance corner (6) is located at the joint of the large smooth edge (2) and the flexible edge (4), and the other crush resistance corner (6) is located at the joint of the small smooth edge (3) and the flexible edge (4). A notch (5) is located among the end of the frame, the large smooth edge (2) and the bottom edge (1), one side of the notch (5) is parallel to the bottom edge (1), and the other side of the notch (5) is perpendicular to the bottom edge (1). The die frame is simple in structure, the crush resistance bearing capability is high, the perpendicular precision is high, and slurry leakage is effectively avoided.

Owner:王春雷

Liquid separator and air conditioner

PendingCN107741108AReduced vertical accuracyImprove vertical accuracyMechanical apparatusFluid circulation arrangementVapor–liquid separatorEvaporation

The invention provides a liquid separator and an air conditioner. The liquid separator comprises a liquid separating body, a containing cavity is formed inside the liquid separating body, and the liquid separating body is provided with a liquid inlet and at least one liquid outlet, wherein the liquid inlet and the liquid outlets communicate with the containing cavity. According to the liquid separator and the air conditioner, the containing cavity is arranged inside the liquid separator, when a liquid inlet tube cannot be perpendicularly welded to the lower end face of the liquid separator, itcan be guaranteed that liquid can be evenly distributed to each liquid outlet by means of being far away from liquid level leveling, and the vertical accuracy of the liquid inlet tube can be reduced;a liquid separating protrusion is arranged inside, so that fluid resistance can be effectively reduced, and the power loss can be reduced; and a leveling instrument device is utilized for further improving the vertical accuracy of the liquid separator in the installing process, liquid separating uniformity is further guaranteed, the problems such as excessively non-uniform heat, evaporator frosting, incomplete evaporation and ineffective heat exchange area utilization of the air conditioner which uses the liquid separator can be solved, and the stability and reliability of a unit are improved.

Owner:GREE ELECTRIC APPLIANCES INC

Permanent magnet synchronous motor rotor component and manufacturing method thereof

PendingCN107863830ASimple structureSimple processing technologyMagnetic circuit rotating partsMechanical energy handlingFiberCarbon fibers

The invention discloses a permanent magnet synchronous motor rotor component and a manufacturing method thereof. The permanent magnet synchronous motor rotor component comprises a rotating shaft, a balance ring, a magnetic steel, a carbon fiber sleeve, a rotor core and a flat key, a first U-shaped groove is formed in the outer circle surface of the rotating shaft, the flat key is arranged in the first U-shaped groove, the rotor core is arranged on the outer surface of the rotating shaft in a sleeved manner and in interference fit with the rotating shaft, the balance ring is arranged at the endof the rotating shaft in a sleeved manner and in interference fit with the rotating shaft and the rotor core, the magnetic steel is pasted on the outer surface of the rotor core, the carbon fiber sleeve is arranged on the outer surfaces of the magnetic steel and the balance ring in a sleeved manner, a first cylindrical shaft hole and a second cylindrical shaft hole are mutually communicated and formed in the rotating shaft, and the first cylindrical shaft hole is larger than the second cylindrical shaft hole. The component is simple in structure, convenient to assemble, disassemble and maintain, high in qualification rate, small in size and less in consuming material and not easy to break and generates less heat in operation.

Owner:NINGBO PHASE MOTION CONTROL

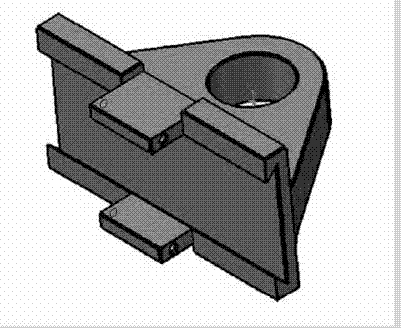

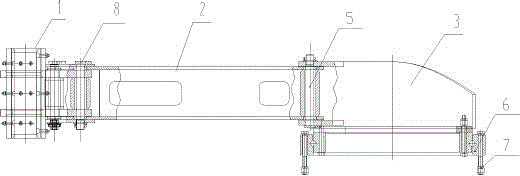

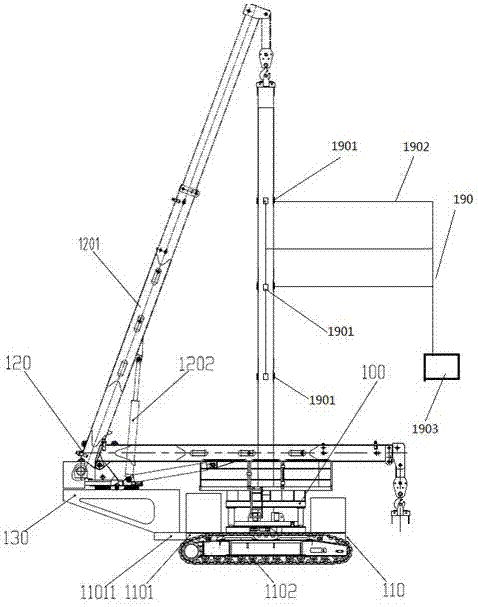

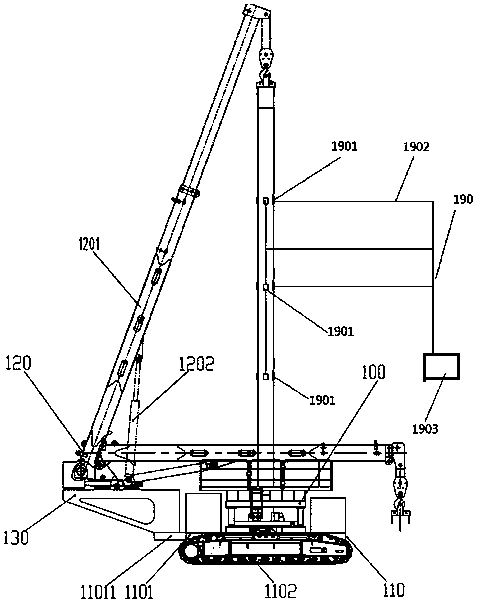

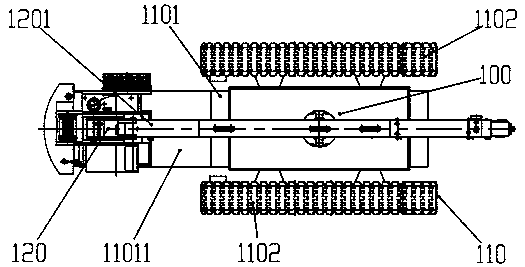

Disassembly and assembly type follow-up frame and installing technology thereof

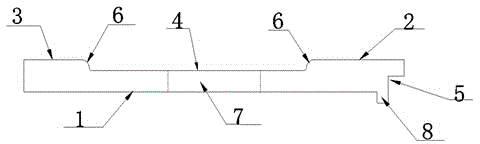

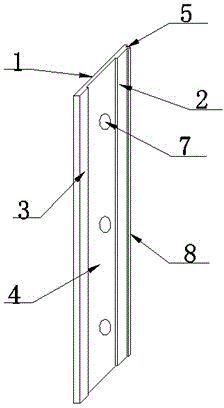

InactiveCN105422015AGuaranteed to work verticallyAvoid it happening againDerricks/mastsEngineeringSlide plate

The invention discloses a disassembly and assembly type follow-up frame and an installing technology thereof. The disassembly and assembly type follow-up frame comprises two slide lugs (1), a supporting frame (2), a supporting tray (3), a rotating support (6) and a nylon slide plate (4). One end of the supporting frame (2) is connected with the supporting tray (3) through a first pin shaft (5). The other end of the supporting frame (2) is connected with the slide lugs (1) through second pin shafts (8). By means of the disassembly and assembly type follow-up frame and the installing technology thereof, vertical accuracy of hole forming of a rotary drilling rig is improved, hole shift and abandoned holes are reduced, hole drilling cost is saved, and the construction progress is guaranteed. The current situation that a follow-up frame cannot be conveniently installed on a large machine type rotary drilling rig is avoided.

Owner:QINGDAO WEIYE FORGING & STAMPING MACHINERY CO LTD

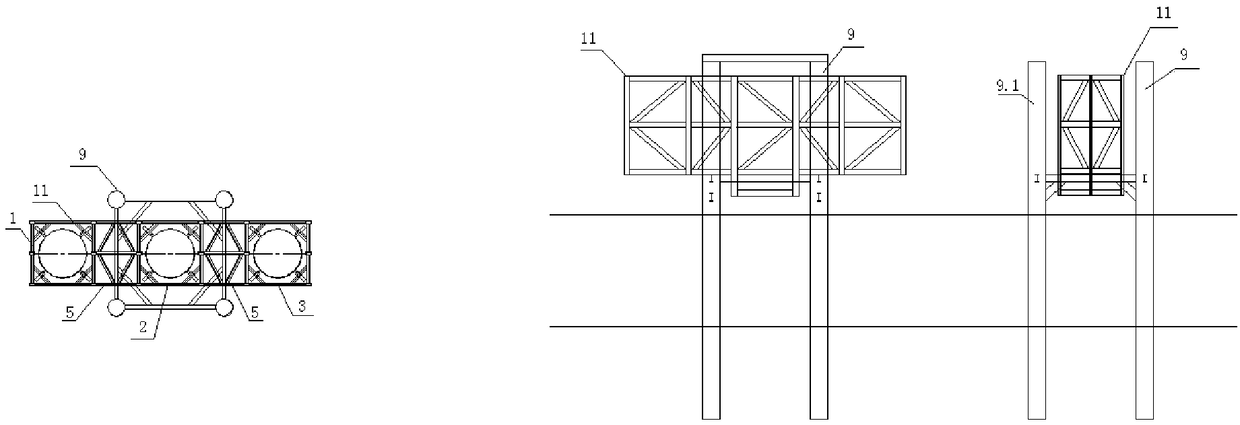

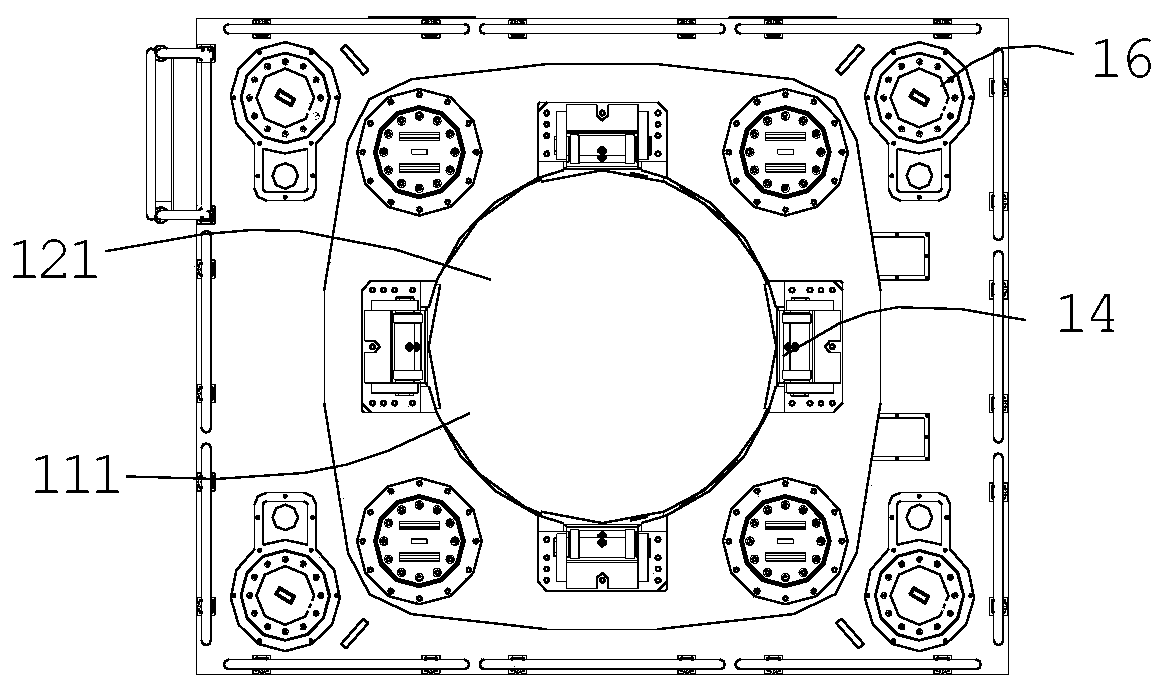

Large-diameter steel protection cylinder three-frame guide frame and auxiliary positioning platform device

PendingCN108104124AImprove the accuracy of punchingShorten the construction periodBulkheads/pilesEngineering

The invention discloses a large-diameter steel protection cylinder three-frame guide frame and auxiliary positioning platform device. The device comprises an auxiliary positioning platform and a three-frame guide frame; the three-frame guide frame is provided with three guide frames and two connecting structures; the three guide frames are connected through the two connecting structures to form awhole; the connecting structures comprise connecting structure vertical rods, connecting structure cross bars and connecting structure inclined supports; the two ends of the connecting structure inclined supports are respectively connected to the middle parts of two adjacent connecting structure cross bars; the other ends of the two connecting structure inclined supports with the same top points are respectively connected to the top points of the two connecting structure vertical rods arranged at intervals; the auxiliary positioning platform comprises auxiliary piles and a guide frame mountingplatform; four auxiliary piles are provided, and are connected through I-shaped steel to form a whole; and the four auxiliary piles are connected through the I-shaped steels to form an auxiliary pileupper-layer structure and an auxiliary pile lower-layer structure. The device has the advantage of greatly improving the plane positions and the verticality precision of steel protection cylinders.

Owner:CCCC SHEC FIRST HIGHWAY ENG

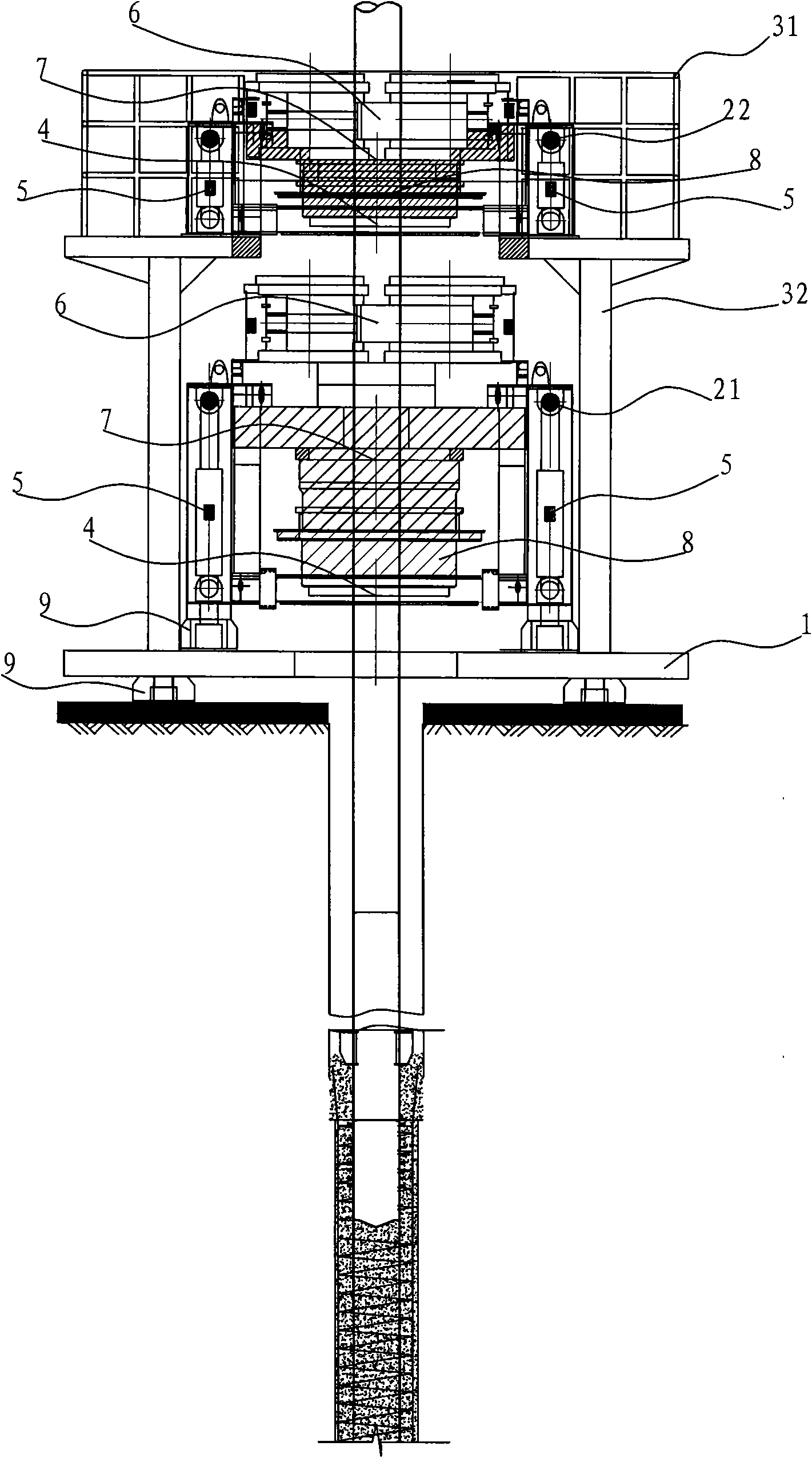

Hydraulic vertical insertion machine and method for connecting foundation pile and steel pipe column

InactiveCN101886398AControl floatGuaranteed verticalityFoundation engineeringBuilding material handlingEngineeringEnergy conservation

The invention relates to a hydraulic vertical insertion machine. The hydraulic vertical insertion machine comprises a seat body and a first hydraulic vertical insertion device arranged on the seat body, and is characterized in that the seat body is provided with a platform on which a second hydraulic vertical insertion device is arranged; the first hydraulic vertical insertion device and the second hydraulic vertical insertion device are sequentially arranged along the axial direction of the seat body; the first hydraulic vertical insertion device is arranged below the second hydraulic vertical insertion device; and the first hydraulic vertical insertion device and the second hydraulic vertical insertion device can independently or synchronously rotate 360 degrees to regulate the verticality of a steel pipe column. The hydraulic vertical insertion machine can effectively control the up-floating of the steel pipe column and ensure the vertical precision of inserting the steel pipe column. Compared with the conventional reversed construction method, the invention has the advantages of short construction period, saved energy resources and saved cost investment. The invention discloses the hydraulic vertical insertion machine and a method for connecting a foundation pile and a steel pipe column.

Owner:王薇

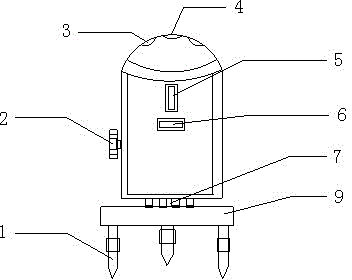

Laser level gauge and application of laser level gauge in installation of bridge stand

InactiveCN105823467ASimple structureEasy to carrySurveying instrumentsIncline measurementLaser transmitterCircular disc

The invention relates to a laser level gauge. The laser level gauge comprises a pedestal and a cylindrical shell, and is characterized in that the pedestal is a disc, three telescopic supporting legs (1) are arranged at the bottom of the disc; a circular arch top cover is arranged at the upper part of the cylindrical shell, a level meter (4) is arranged at the top of the circular arch top cover, a spin button is arranged at the central part of the circular arch top cover; four laser emitters (15) are arranged in the cylindrical shell, and a laser vertical line emission window and a laser horizontal line emission window are arranged on each laser emitter at corresponding circumference of the cylindrical shell. The laser level gauge has the advantages of simple structure, and convenient carrying and usage, is suitable for various work environment, and can effectively increase the installation precision of the bridge stand; the horizontal and vertical installation precision of the bridge stand is increased from known + / -10 mm / 5m to + / -1mm / 5m, the rate of reaching the standard for installation precision is 100%, work efficiency is increased, installation construction time of the bridge stand is saved by about 15%, and the engineering cost is reduced.

Owner:MCC5 GROUP CORP SHANGHAI

Building numerical control rendering motor machine

InactiveCN102758519AImprove flatnessImprove vertical accuracyBuilding material handlingEngineeringMechanical engineering

The invention discloses a building numerical control rendering motor machine. The building numerical control rendering motor machine comprises a transverse rail, a vertical rail, a power lifting device, a mortar supplying device, an upper transverse rail and a plurality of transverse rail supporting rods, wherein the transverse rail can be fixedly arranged on the ground and is parallel to the wall body; the vertical rail comprises a telescopic supporting rod, a driving device for driving the supporting rod to expand and contract, wherein the fixed end of the supporting rod is paved on the transverse rail, and the telescopic end of the supporting rod is driven to linearly move up and down through the driving device; the power lifting device comprises a lifting frame and an electric hoist, wherein the lifting frame can slip along the surface of the supporting rod, and the electric hoist is used for driving the lifting frame to move; the mortar supplying device comprises a motor compressor, a mortar conveying pipe and a mortar roller, wherein the mortar roller is connected with the lifting frame and provided with a mortar outlet; the upper transverse rail is arranged parallel to the transverse rail and connected with the vertical rail for supporting the vertical rail; and the plurality of transverse rail supporting rods are fixed at intervals between the ground and a ceiling for fixing the upper transverse rail. According to the building numerical control rendering motor machine, mechanical rendering is adopted to replace manual rendering, thus the problem of conventional rendering technology that a plurality of workers are required and the efficiency is low can be solved.

Owner:深圳鲁师祖机器人有限公司

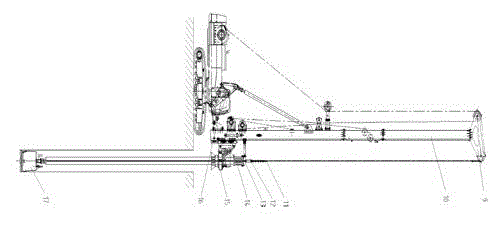

Assembling and disassembling type follow-up frame and installation technology thereof

InactiveCN106812482AReduce riskReduce usageDrilling rodsDrilling casingsSlide platePetroleum engineering

The invention discloses a detachable follower frame and an installation process thereof. The detachable follower frame includes two sliding ears (1), a support frame (2), a support plate (3), a slewing support (6) and a nylon slide plate (4), and the support frame (2) One end is connected to the support plate (3) by a first pin shaft (5), and the other end of the support frame (2) is connected to the sliding ear (1) by a second pin shaft (8). The invention improves the vertical precision of the hole formed by the rotary drilling rig, reduces the generation of partial holes and waste holes, saves the drilling cost, and ensures the construction progress. Solve the current situation that it is inconvenient to install the follower frame on the large-scale rotary drilling rig.

Owner:周子童

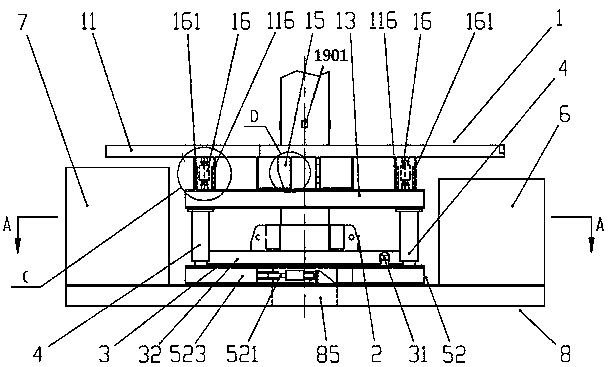

Construction method of pile planting machine

The invention discloses a construction method of a pile planting machine. The construction method comprises the following steps of 1) preparing construction; 2) leveling the ground, and finishing precast hole drilling, excavation and stirring; 3) arranging a plurality of strain gauges on a precast pile body at a certain interval, and selecting a clamping wedged block and a cushion block accordingto the diameter of a precast pile; 4) performing centering adjustment on a clamping mechanism, and debugging the levelness of a working platform; 5) performing adjustment on a fine adjustment mechanism in longitudinal and transverse directions; 6) starting a hoisting mechanism, and hoisting the precast pile to the upper side of the precast hole; 7) manipulating an upper part clamping oil cylinderto enable the clamping wedged block to clamp the pile body and a lower part clamping mechanism to enable a clamping ring to clamp the pile body; and 8) manipulating a vertical jacking oil cylinder toenable the upper part stand to press the precast pile after moving downward, and thus planting the precast pile in the prebored hole. The construction method provided by the invention effectively improves the pile planting accuracy of the precast pile, facilitates up and down butt joint of the precast pile bodies, lowers the construction cost and improves the operation safety of an operator.

Owner:SHANGHAI GUANGDA FOUND ENG

Novel steel stand column embedding device and construction method

InactiveCN110043047AImprove vertical accuracyHigh precisionStrutsFoundation engineeringArchitectural engineering

The invention relates to a novel steel stand column embedding device and a construction method. The steel stand column embedding device comprises an adjusting assembly, a clamping assembly and a powersystem for driving the adjusting assembly to adjust the inclination angle of a steel stand column relative to the vertical direction, wherein the clamping assembly comprises a first clamping unit anda second clamping unit, the second clamping unit is connected to the adjusting assembly, and the first clamping unit and the second clamping unit are matched with each other, clamp the steel stand column correspondingly and each comprise clamping jaws and a supporting platform, the clamping jaws are correspondingly arranged on the supporting platforms, each clamping jaw is provided with a first contact portion extending in the vertical direction and a second contact portion inclined relative to the first contact portion, and each supporting platform is provided with a slideway. The upper supporting platform can move up and down through guide columns. According to the steel stand column embedding device and the steel stand column embedding construction method, the construction efficiency and the construction precision are improved.

Owner:上海工程机械厂有限公司

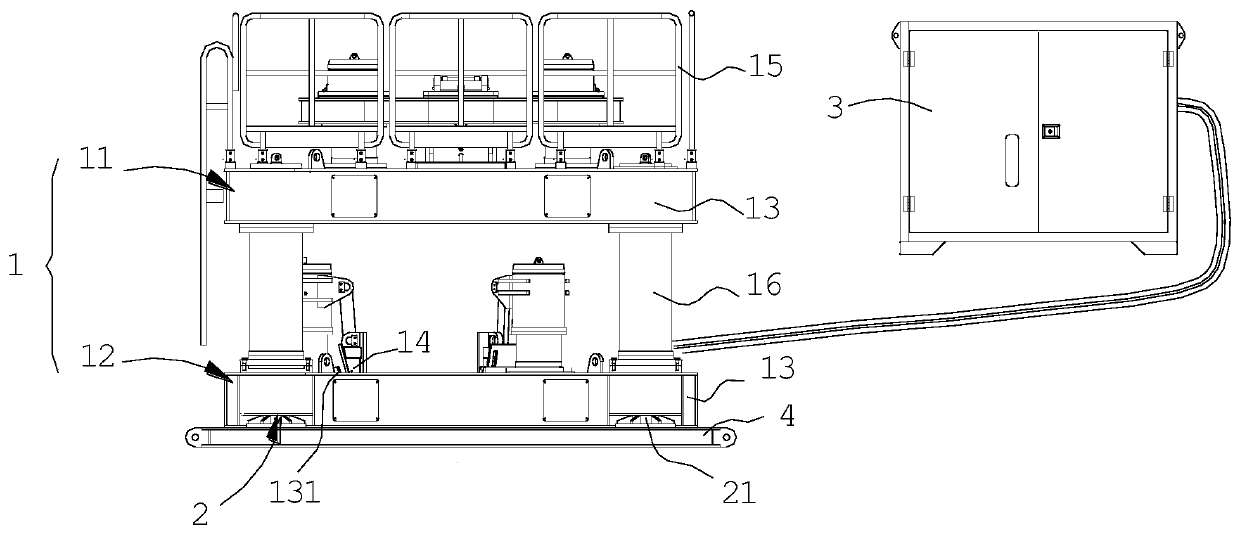

Pile planting machine with monitoring function

ActiveCN107869139APress evenlyRealize the purpose of pressurized pile plantingBulkheads/pilesButt jointMonitoring system

A pile planting machine with a monitoring function comprises a walking mechanism, a hoisting mechanism, a support frame, a clamping mechanism and a pile body monitoring system; the clamping mechanismis fixedly installed on the walking mechanism; the clamping mechanism comprises an upper rack comprising a working platform, a plurality of clamping wedge blocks, a clamping ring, an upper underframeand four groups of upper clamping cylinders, a lower clamping mechanism comprising a lower clamping cylinder, an arc ring and two lower clamping arm supports arranged symmetrically, a slewing mechanism, a fine-tuning mechanism comprising horizontal and vertical fine-tuning cylinders, and four groups of vertical jacking cylinders; and the pile monitoring system comprises a plurality of strain gauges, wire harnesses and monitoring meters, and can be used for monitoring the whole process that planted pile bodies are driven into prefabricated holes. According to the pile planting machine providedby the invention, the pile planting accuracy of precast piles is improved effectively, the pile planting machine facilitates butt joint of the precast pile bodies up and down; and the construction cost is reduced, and the operation safety of operators is improved.

Owner:SHANGHAI GUANGDA FOUND ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com