Shift arrangement having a shift fork

A technology of shifting forks and forks, applied in the direction of components with teeth, control/adjustment systems, mechanical control devices, etc., can solve problems such as weight increase, and achieve the effect of correcting bending errors and improving vertical accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

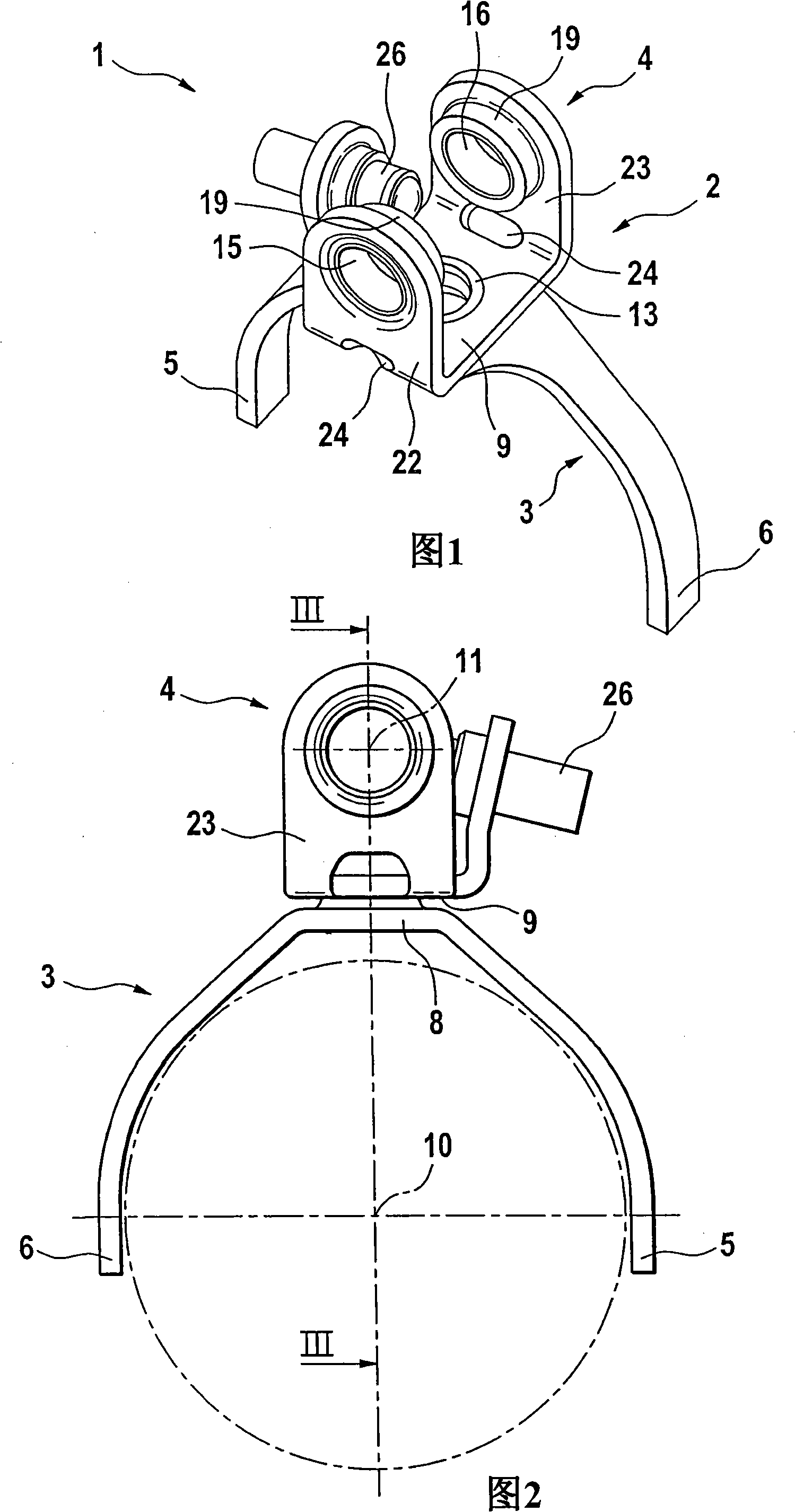

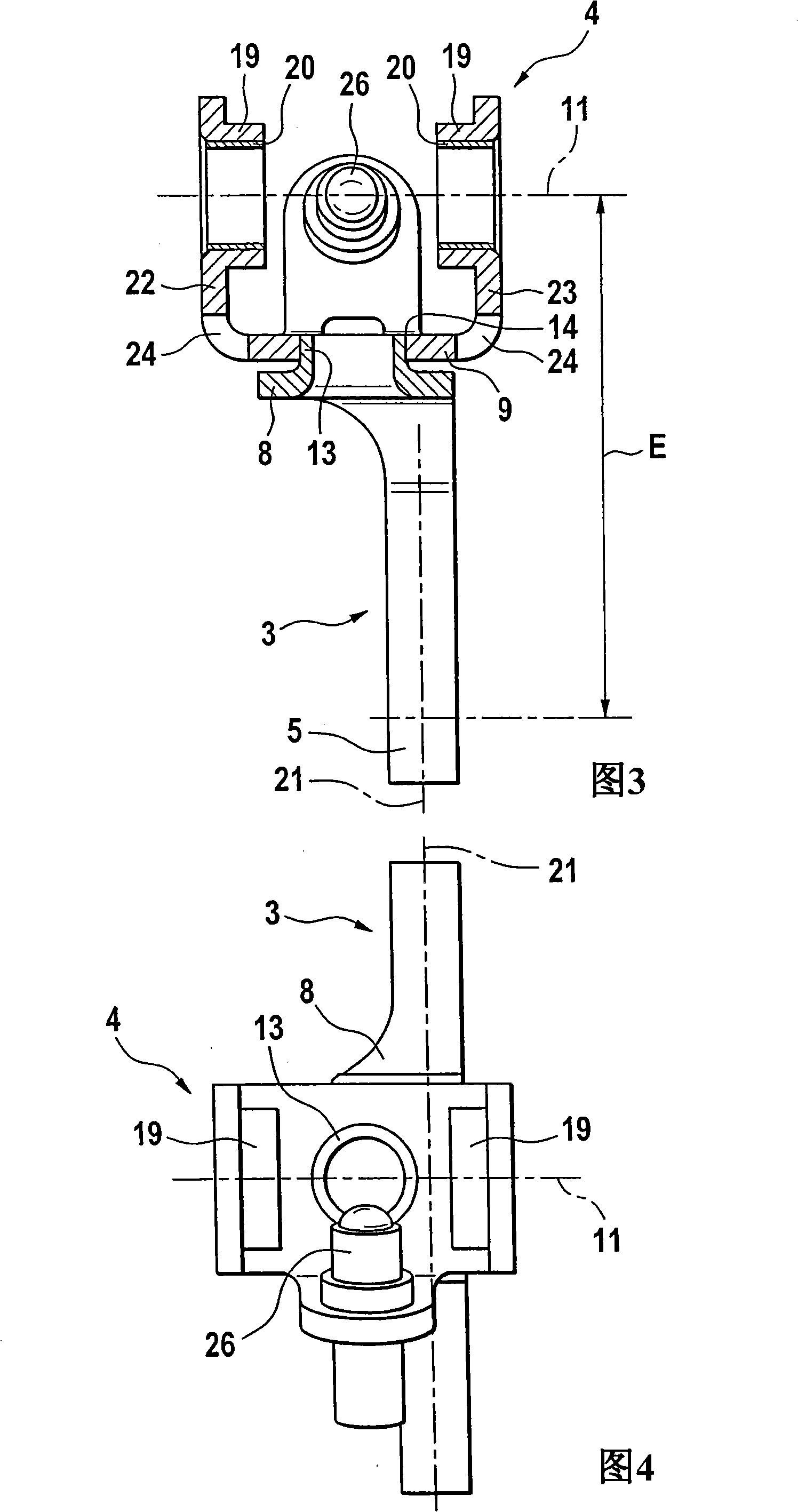

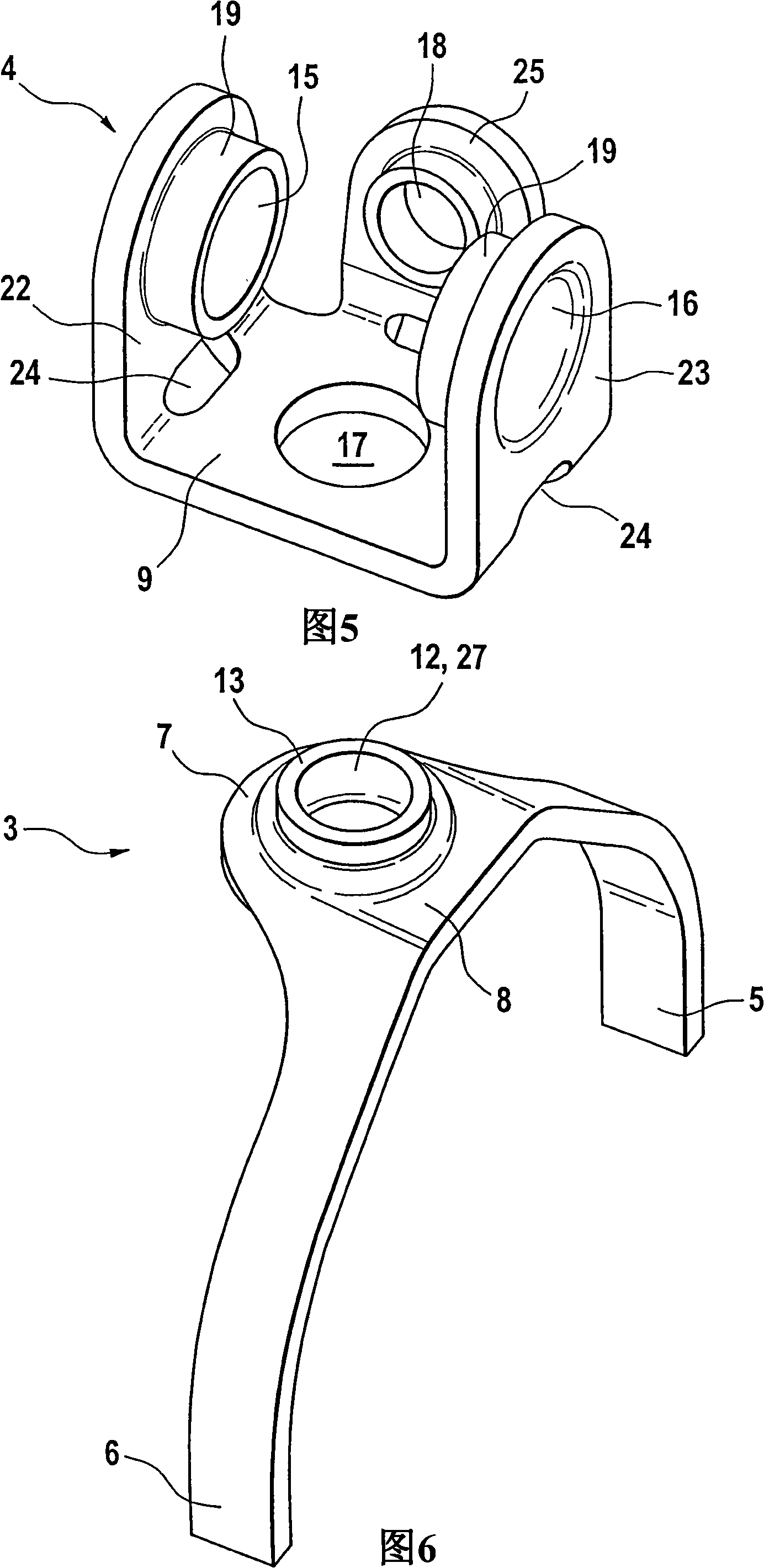

[0024] The exemplary embodiment of the shifting system 1 according to FIGS. 1 to 4 has a shifting fork 2 with a shifting fork base body 3 and a guide 4 , and a shifting link (not shown) along the shifting The link axis 11 is oriented. The selector fork base body 3 is a fork-shaped sheet metal profiled part with fork heads 5 and 6 which enclose sliding sleeves (not shown or shown only in outline), the sliding sleeves The axis of rotation is denoted by reference numeral 10 .

[0025] The shift fork base body 3 ( FIG. 6 ) is shaped in such a way that it has a central region 8 between the fork heads 5 and 6 on the face 7 facing away from the sliding sleeve, the central region 8 with its shape engaging the base 9 of the guide 4 . In the central region 8 , the shift fork base body 3 has a shift fork recess 12 , which is formed as a penetration point 27 , so that a circumferential edge 13 terminates the shift fork on the face 7 facing away from the sliding sleeve. Substrate 3.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com