Guide pipe for steel stand column guide insertion construction

A technology of guide pipe and steel column, applied in the field of one column and one pile, can solve the problem that the verticality of construction can only reach 1/300, and achieve the effect of simple structure, high guiding precision and high vertical precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the drawings and embodiments.

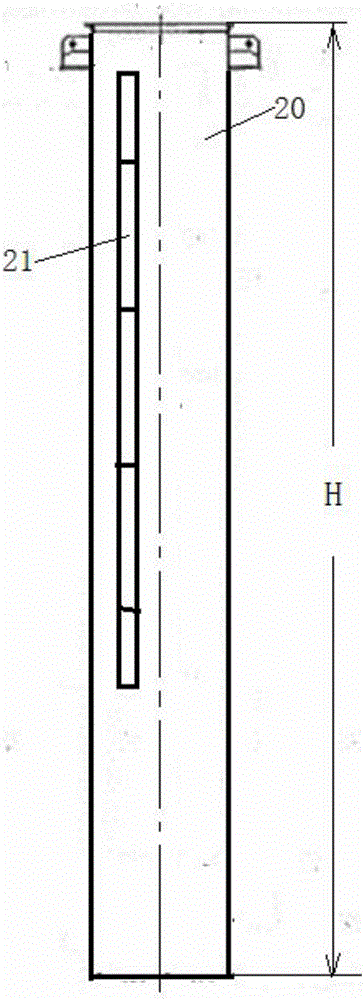

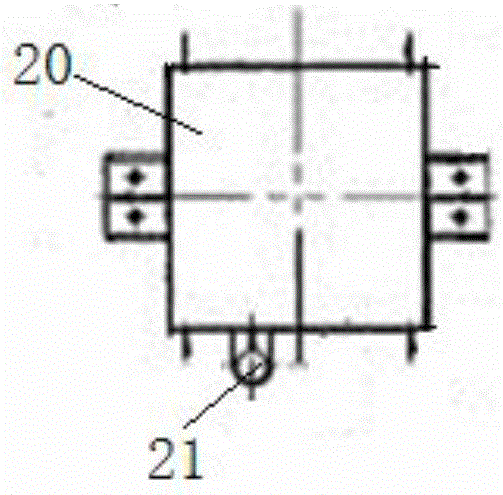

[0020] Such as figure 1 As shown in 2, the guide pipe used for the guide insertion construction of the steel column of the present invention is made of a square steel pipe 20, the height H of the square steel pipe 20 is 3000-20000mm, the cross-sectional inner diameter of the square steel pipe 20 is 500-2000mm, and the square steel pipe 20 is A buoy verticality measuring device 21 is provided on one side.

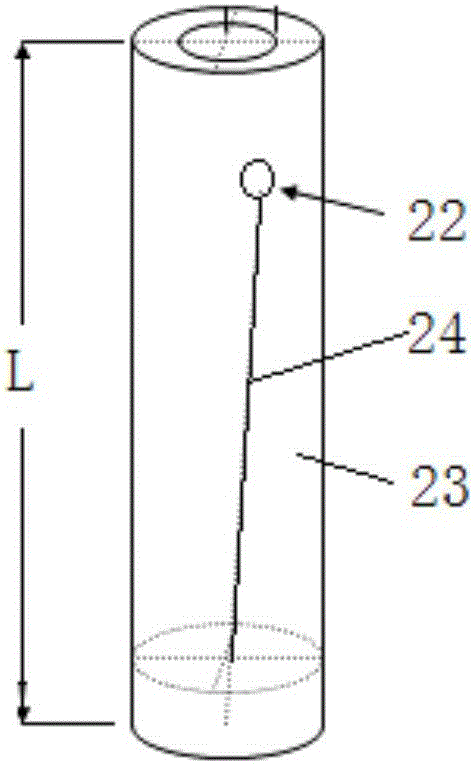

[0021] Such as image 3 , As shown in 4, the buoy verticality measuring device 21 includes a water pipe 23 and a floating ball 22. The length of the water pipe 23 is L=6m, the inner diameter is Φ24mm, the lower end of the water pipe 23 is closed, the floating ball 22 is placed in the liquid in the water pipe 23, and is connected to the center of the lower end of the water pipe 23 by a rope 24. The measurement accuracy of the buoy verticality measuring device 21 is 1 / 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com