Patents

Literature

376results about How to "High guiding precision" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

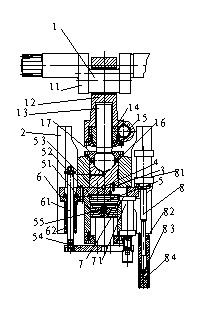

Four-degree-of-freedom servo manipulator

InactiveCN103802095AReduce volumeControl DimensionsProgramme-controlled manipulatorDegrees of freedomEngineering

The invention relates to industrial automation equipment, in particular to an automated manipulator. A four-degree-of-freedom servo manipulator comprises a lifting arm, a rotary arm, a telescopic boom, a torsional arm, a base and a gripper, wherein the lifting arm is fixedly connected to the base, and fixed on the ground; the gripper is fixedly connected to the output end of the torsional arm; the fixing plate of the telescopic boom is fixedly connected to a rotary cover plate; one end of the telescopic boom is fixedly connected to a vertical flange plate, and the torsional arm is fixedly connected to the vertical flange plate. The four-degree-of-freedom servo manipulator provided by the invention is applicable to machine manufacturing processes and achieves material transportation and transmission, the frictional resistance is small, the running is stable, the accuracy is high, the service life is long, the four-degree-of-freedom servo manipulator provided by the invention can be used for picking up workpieces, through the compact structure distribution of the four-degree-of-freedom servo manipulator, the external dimension can be effectively controlled, and a maximal running space can be obtained.

Owner:东莞智得电子制品有限公司

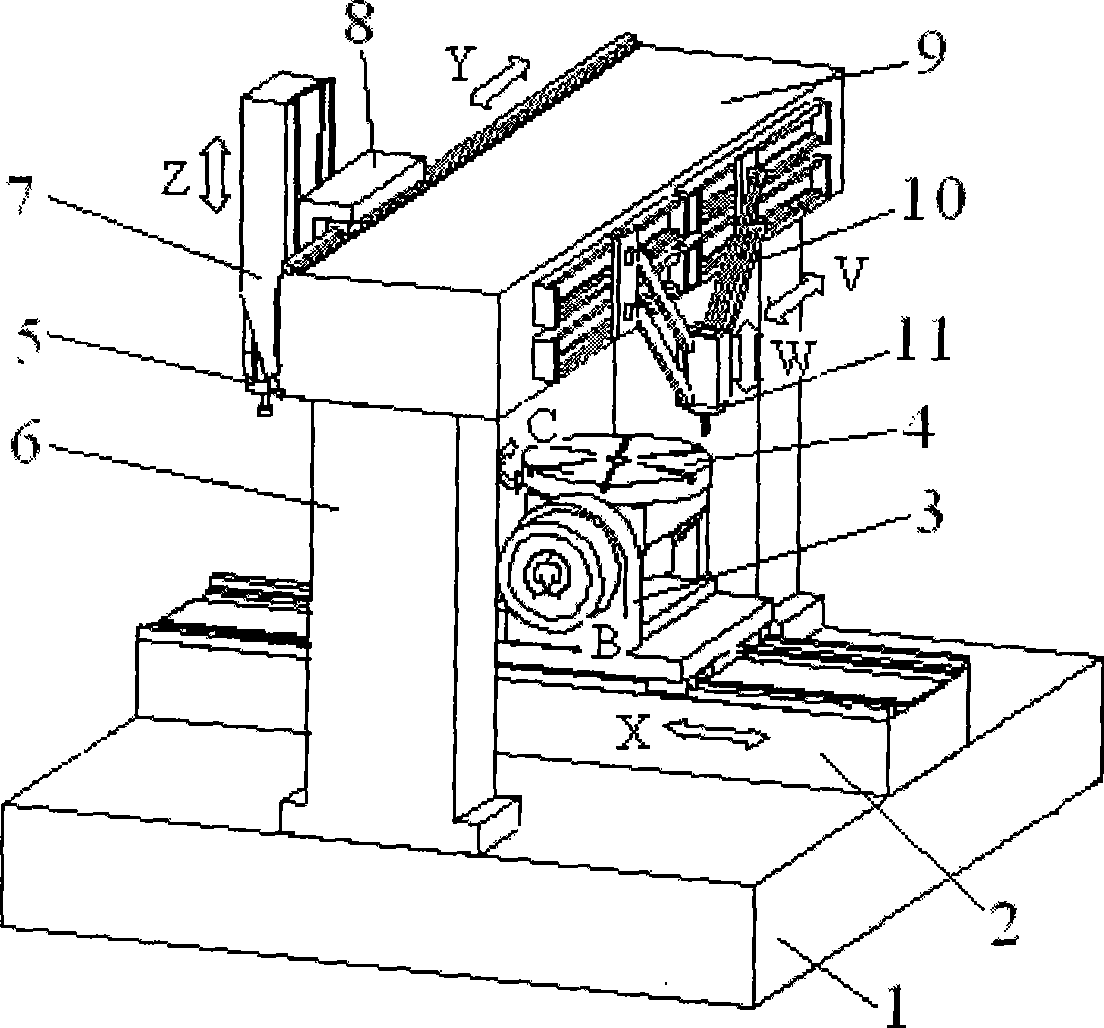

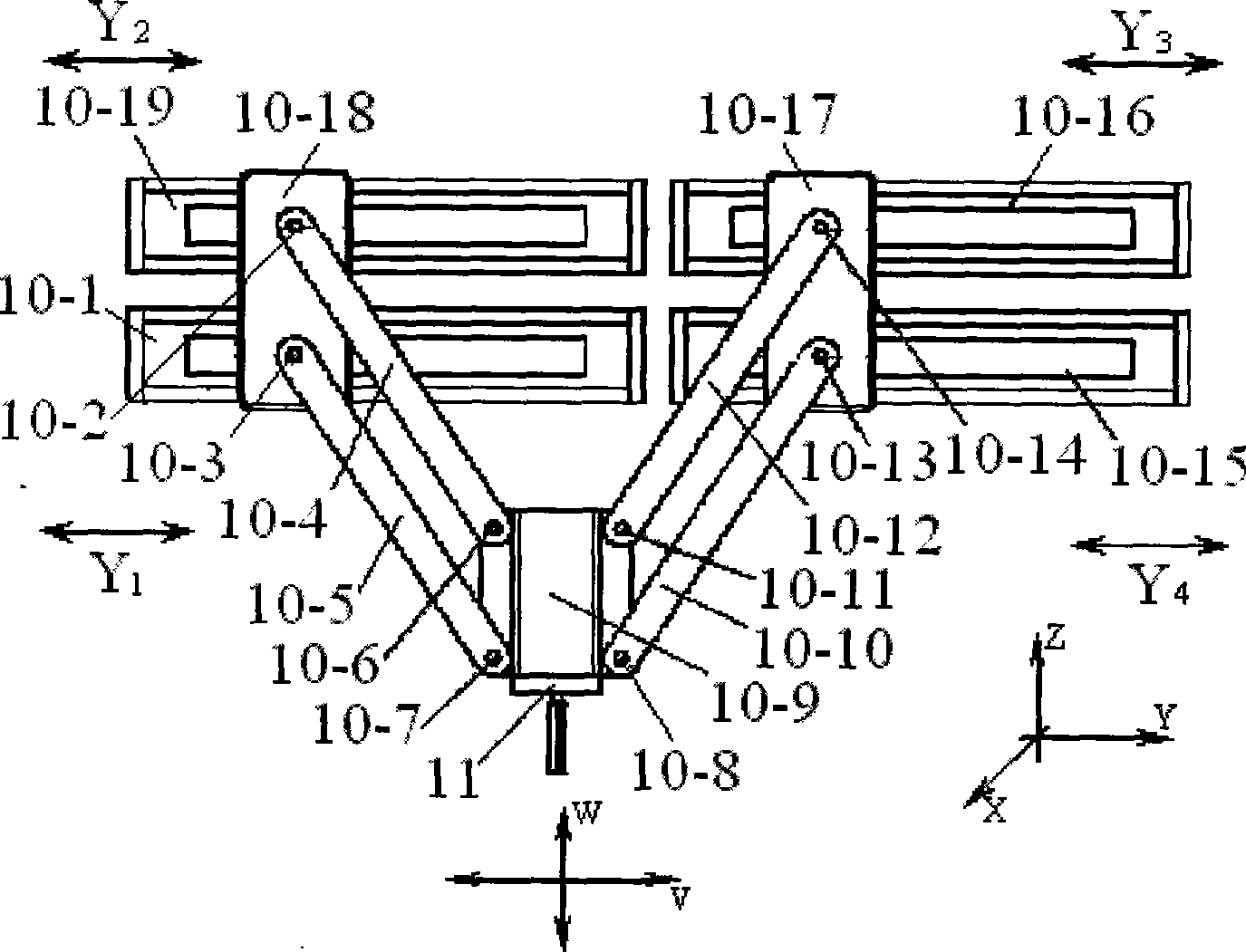

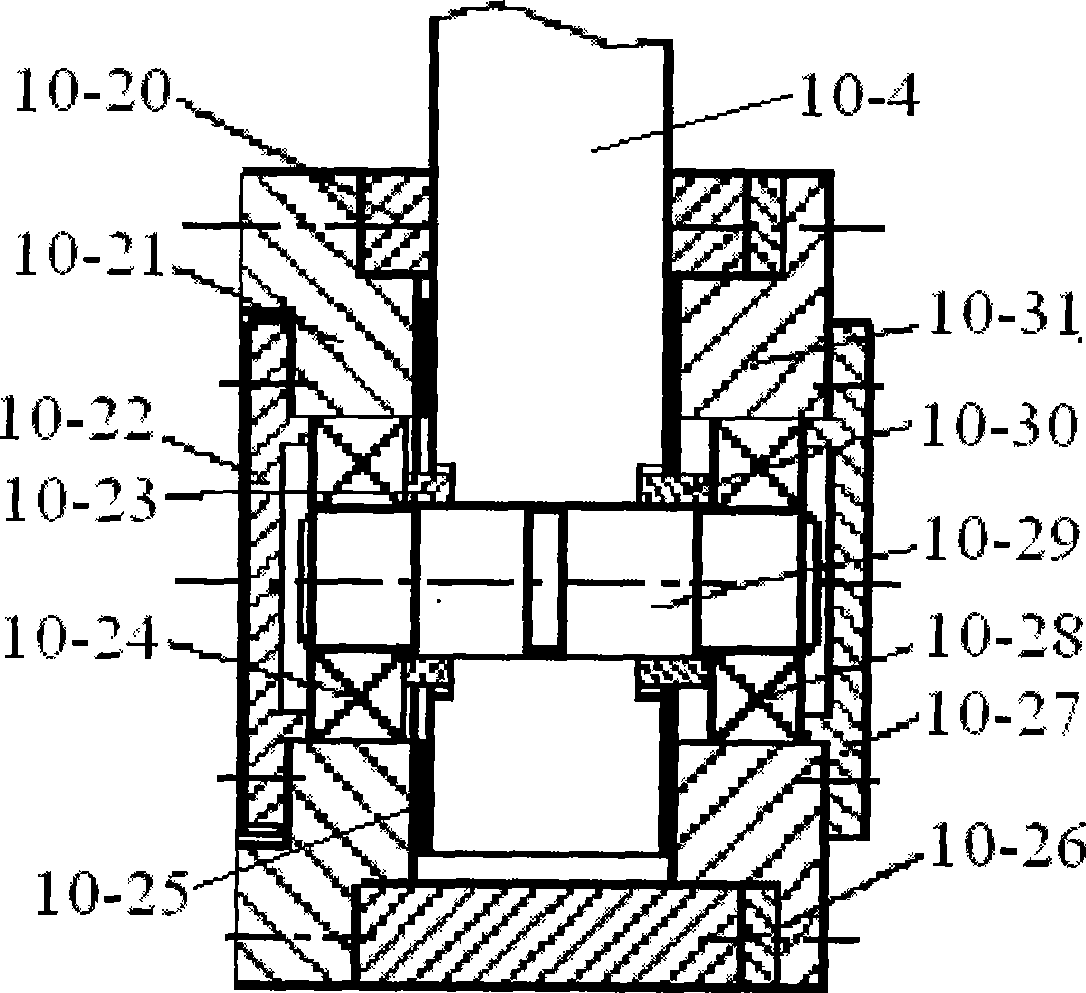

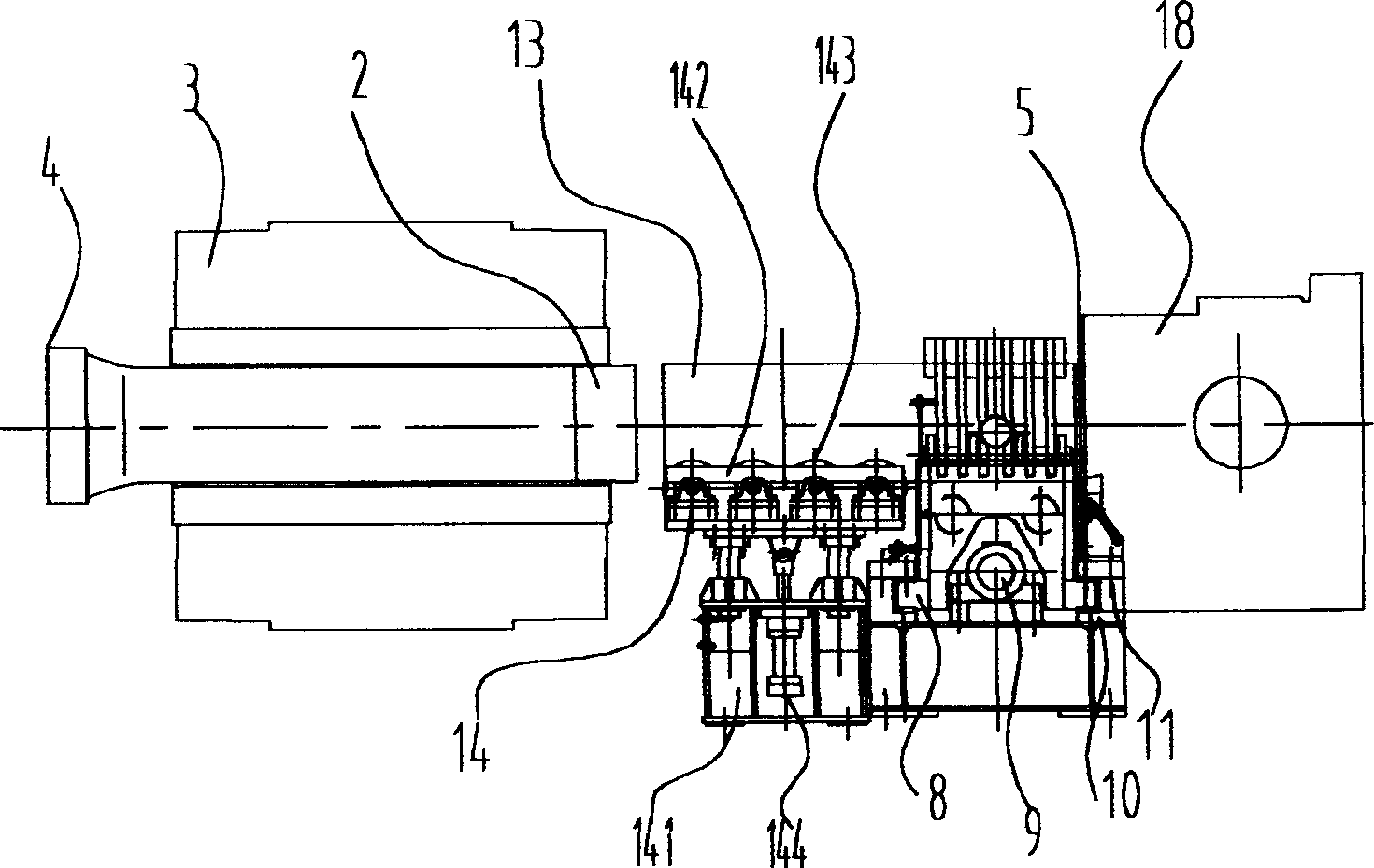

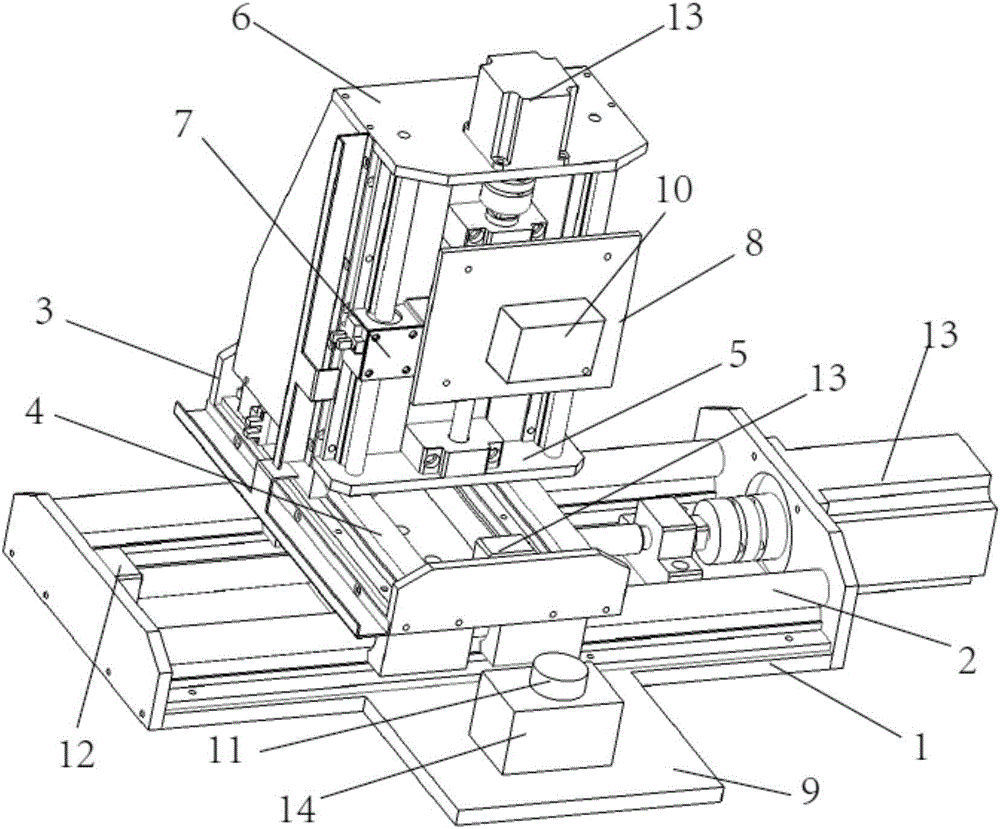

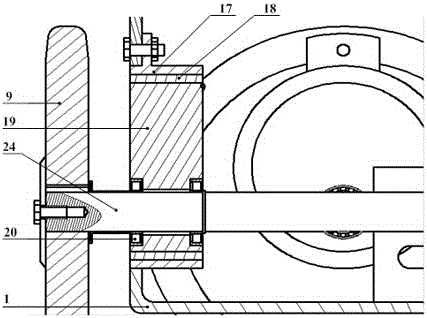

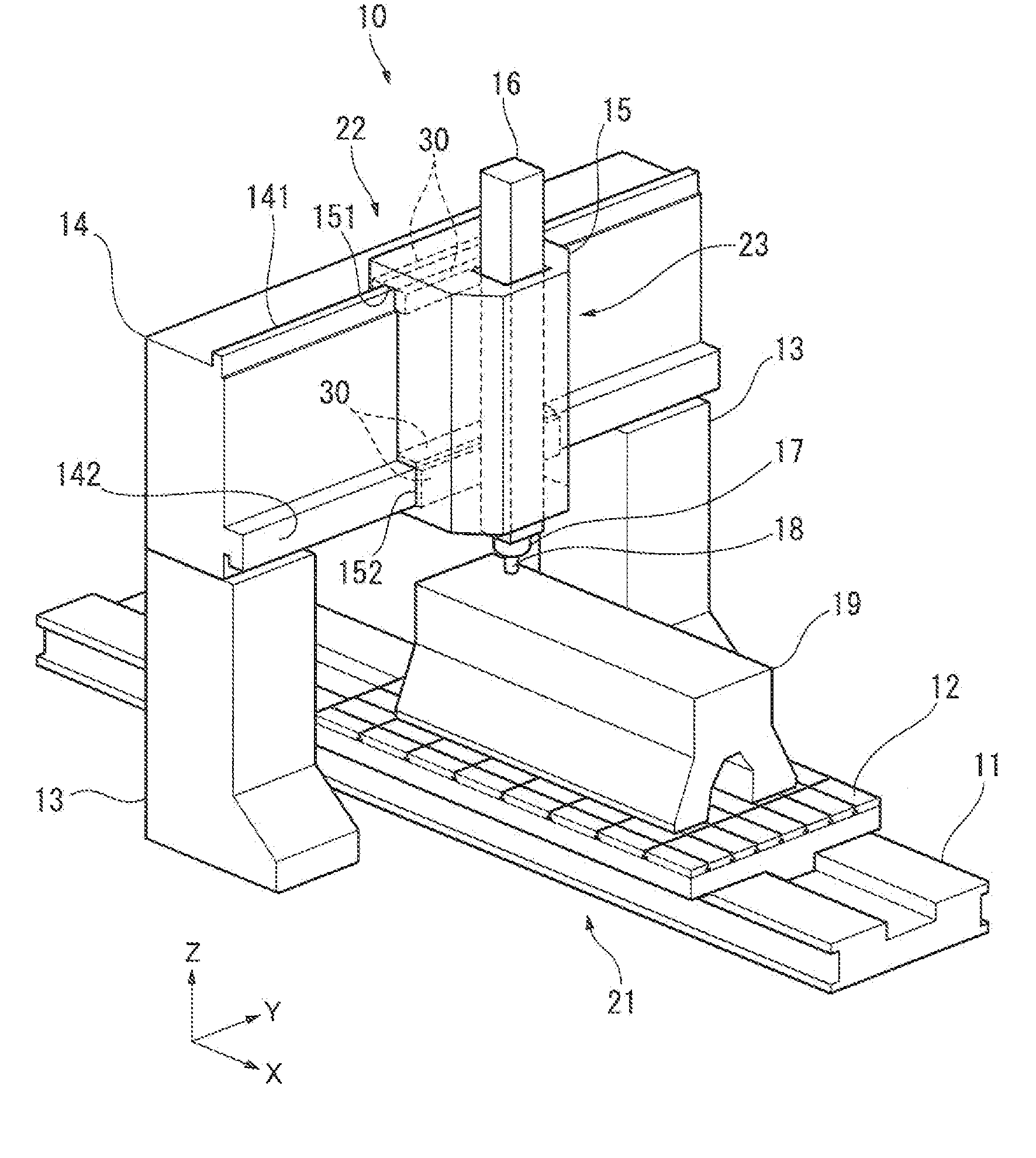

Composite machining center with hot displacement constraint skid revolving joint portion macro/micro drive

InactiveCN101480734AImprove torsion resistanceImprove processing efficiencyMilling machinesActuatorThermal displacement

The invention discloses a macro-micro dual-drive combined machining center which has a skid and rotation joint portion with thermal walking constraint, comprising a lathe body, upright posts, beams, X-axis parts, swing B-axis parts, rotation C-axis parts, a two-axes paralleling mechanism, a milling electro-spindle, Y-axis parts, Z-axis parts and a lapping-polishing electro-spindle, wherein the two-axes paralleling mechanism realizes the movement of a virtual W axis and a virtual V axis by adopting dual drive, a micro-drive actuator deforming guide way is adopted between a macro-micro dual-drive macro-motion table and a macro-micro dual-drive micro-drive table, the X-axis parts, the Y-axis parts and the two-axes paralleling mechanism movement pairs adopt combined slide seats which are combined by a cast iron working slide seat, a thermal walking constraint joint portion and a granite bearing slide seat, and the B-axis, the rotation C-axis and the two-axes paralleling mechanism rotation pairs adopt skid and rotation joint portion mechanisms. The combined machining center has a combined machining function that the five axes of X, B, C, V and W are interlinked so as to mill the complex moulding surfaces of hard parts at high speed and the five axes of X, B, C, Y and Z are interlinked so as to lap and polish the complex moulding surfaces of hard parts with high accuracy.

Owner:XIAN UNIV OF TECH

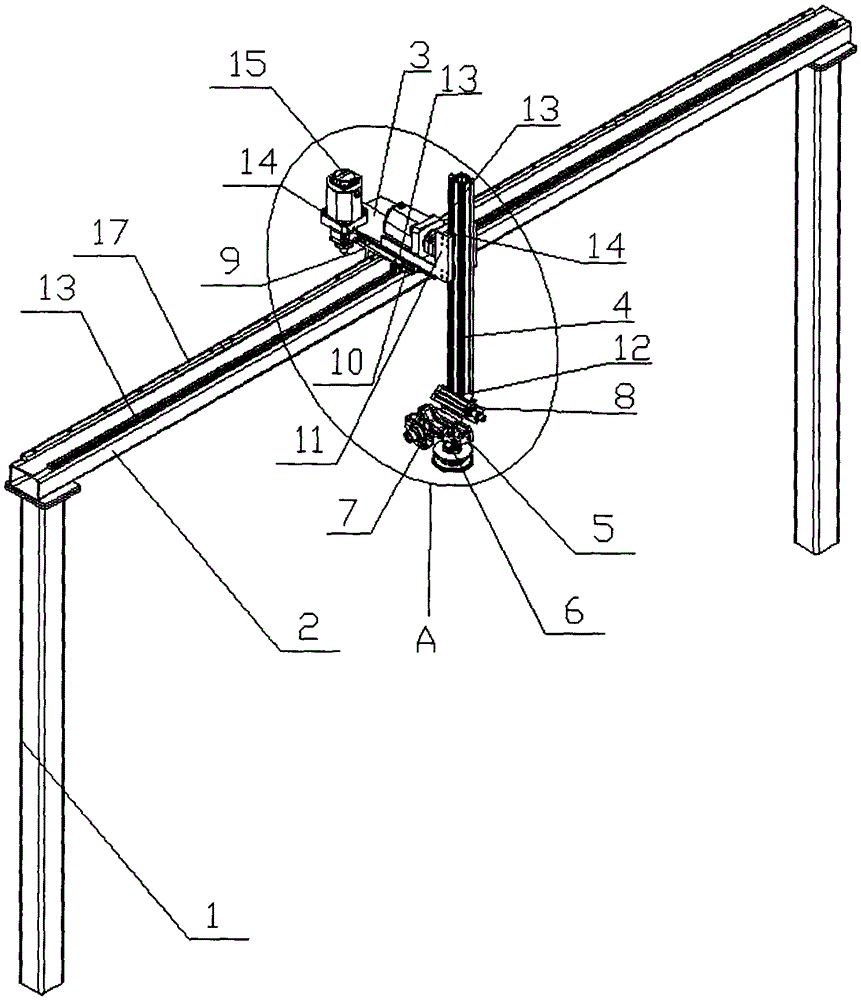

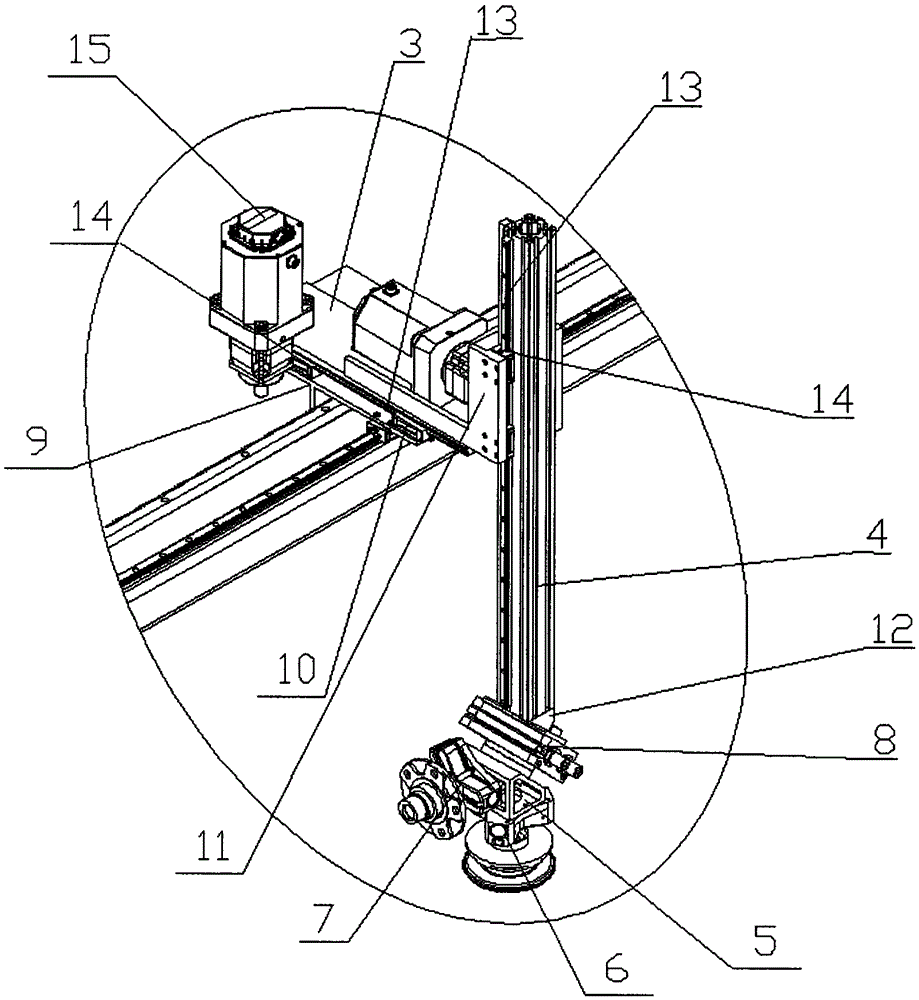

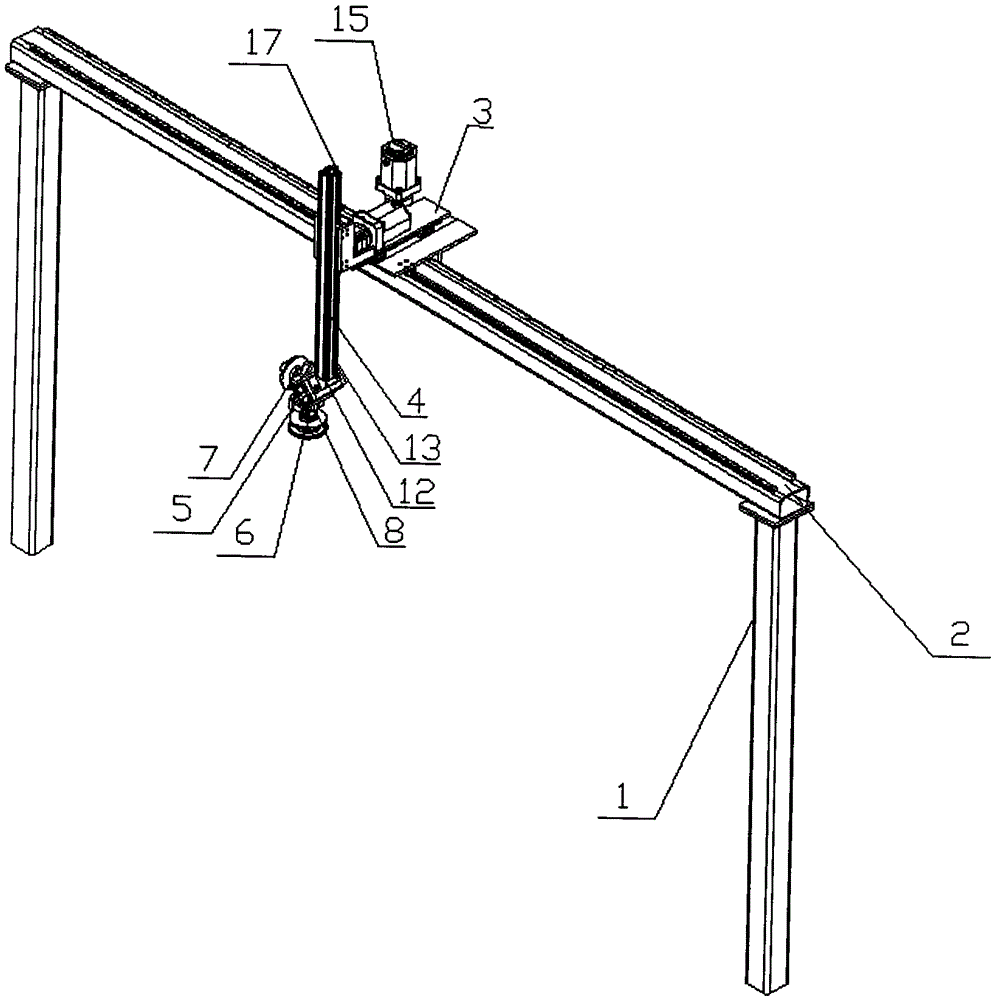

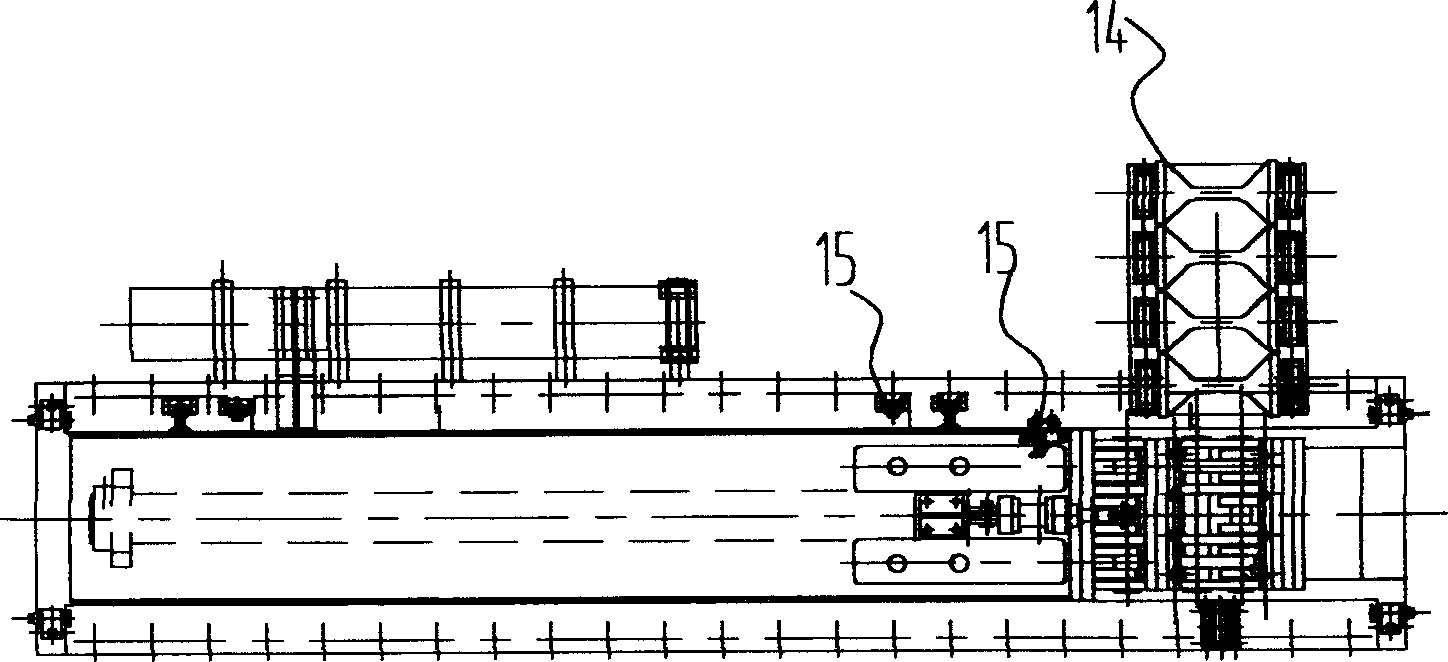

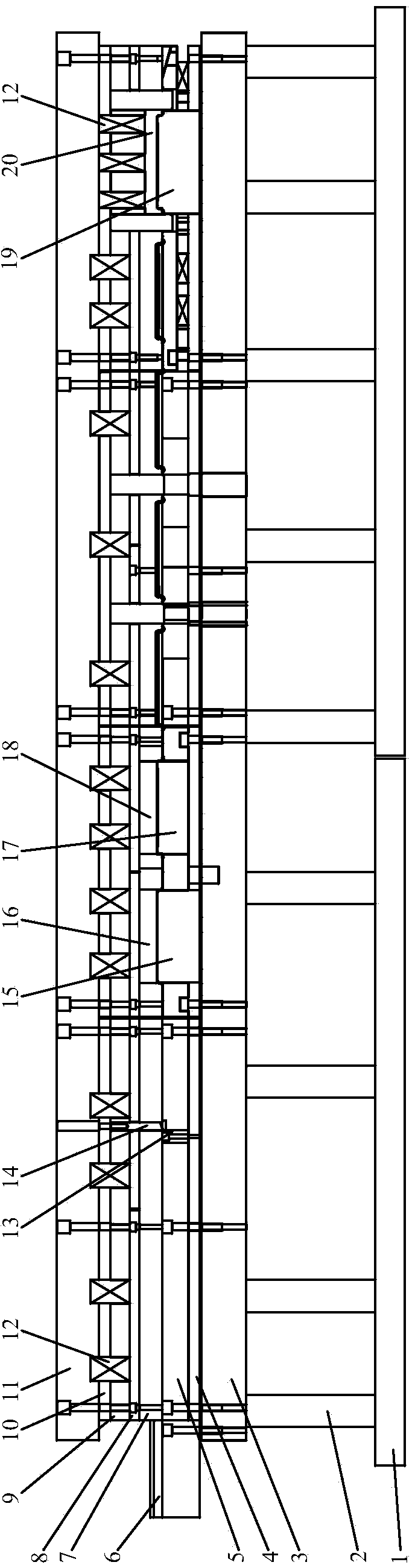

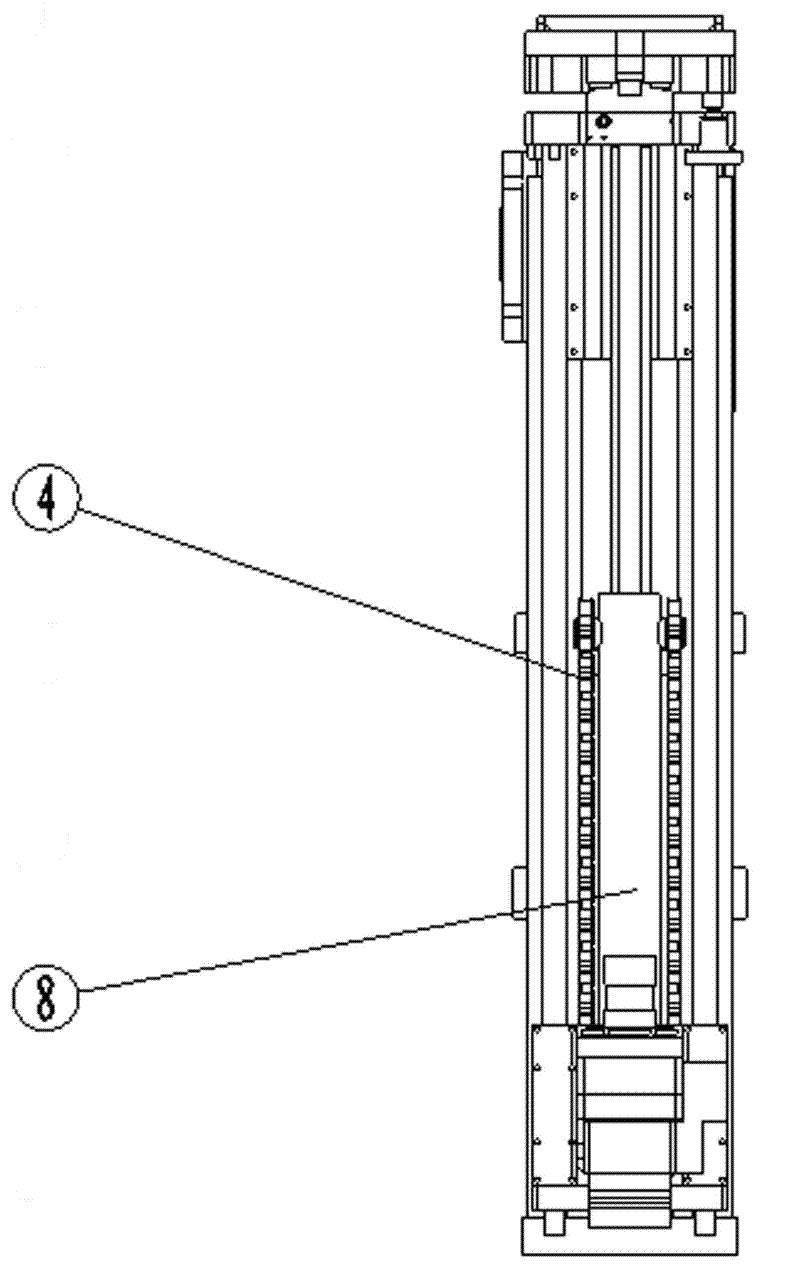

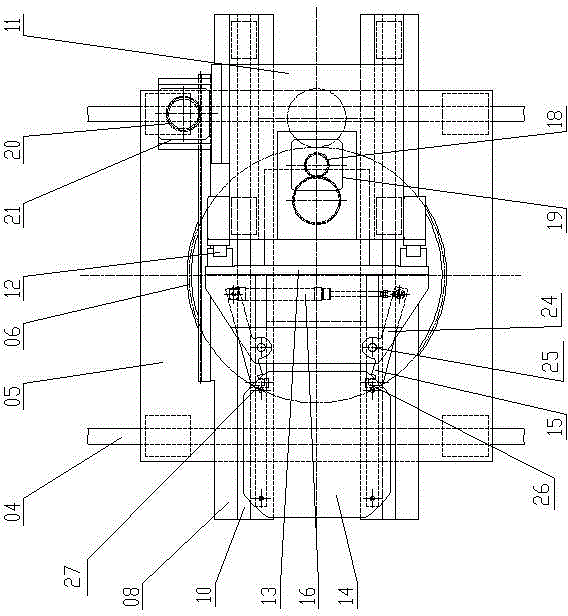

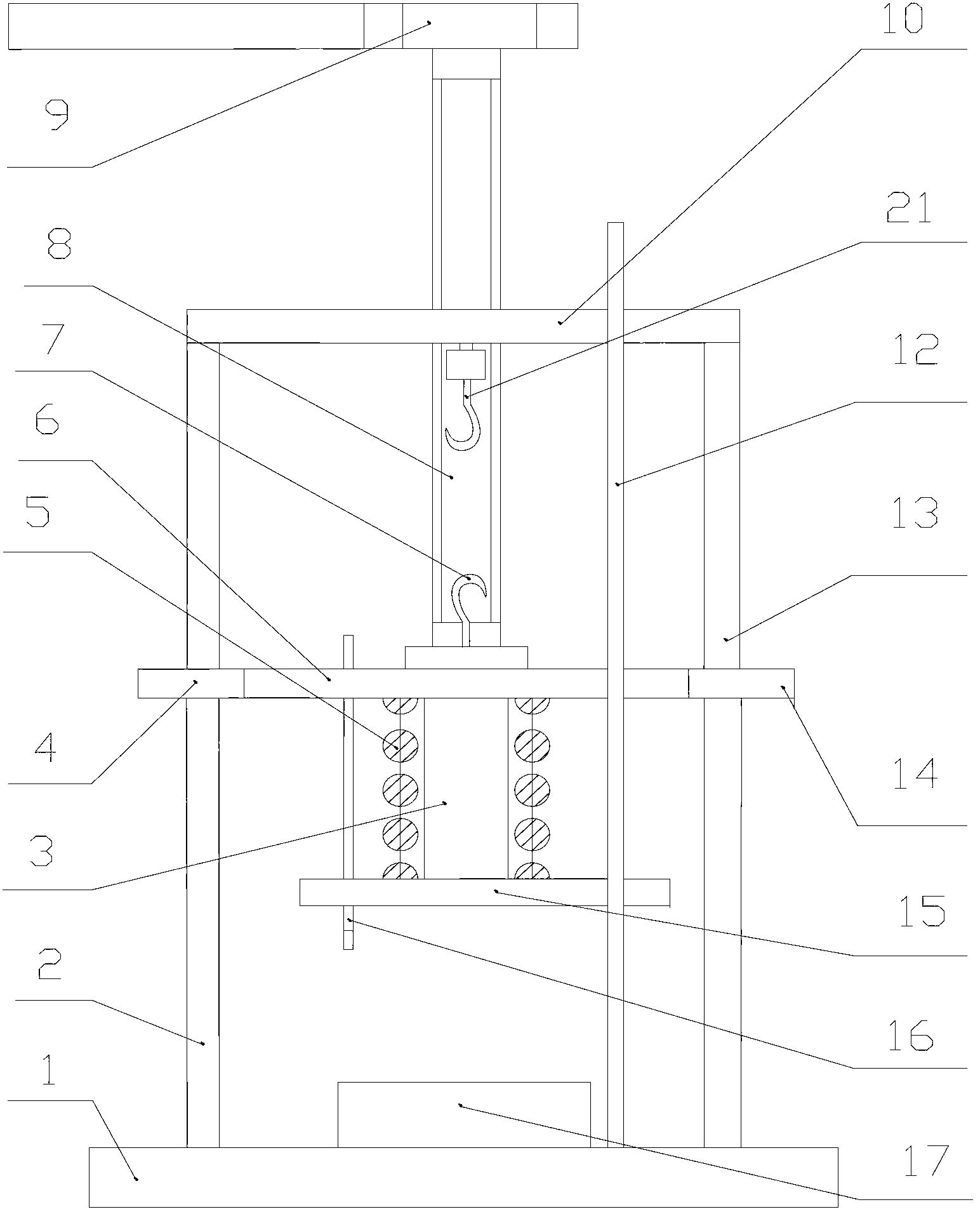

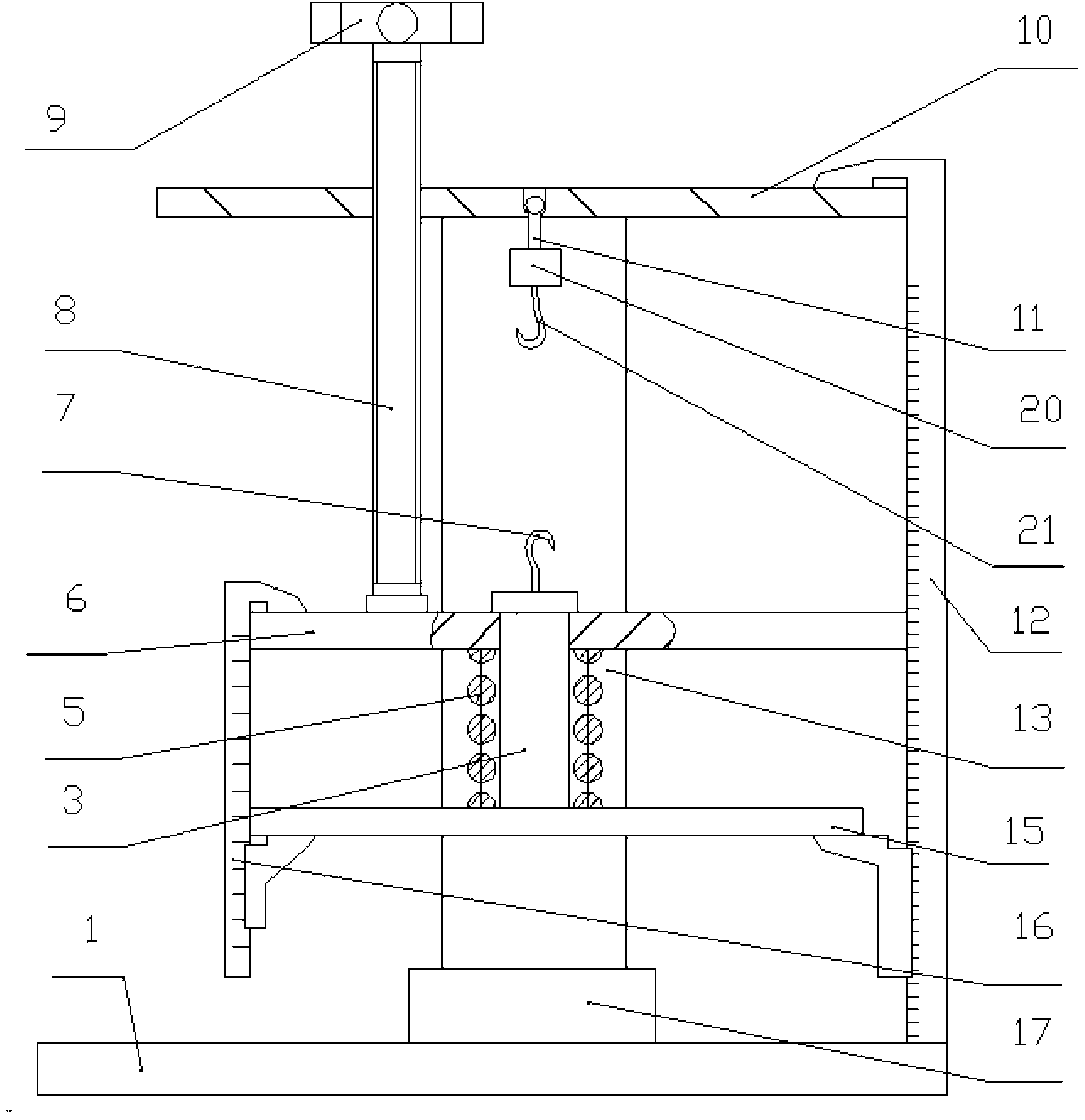

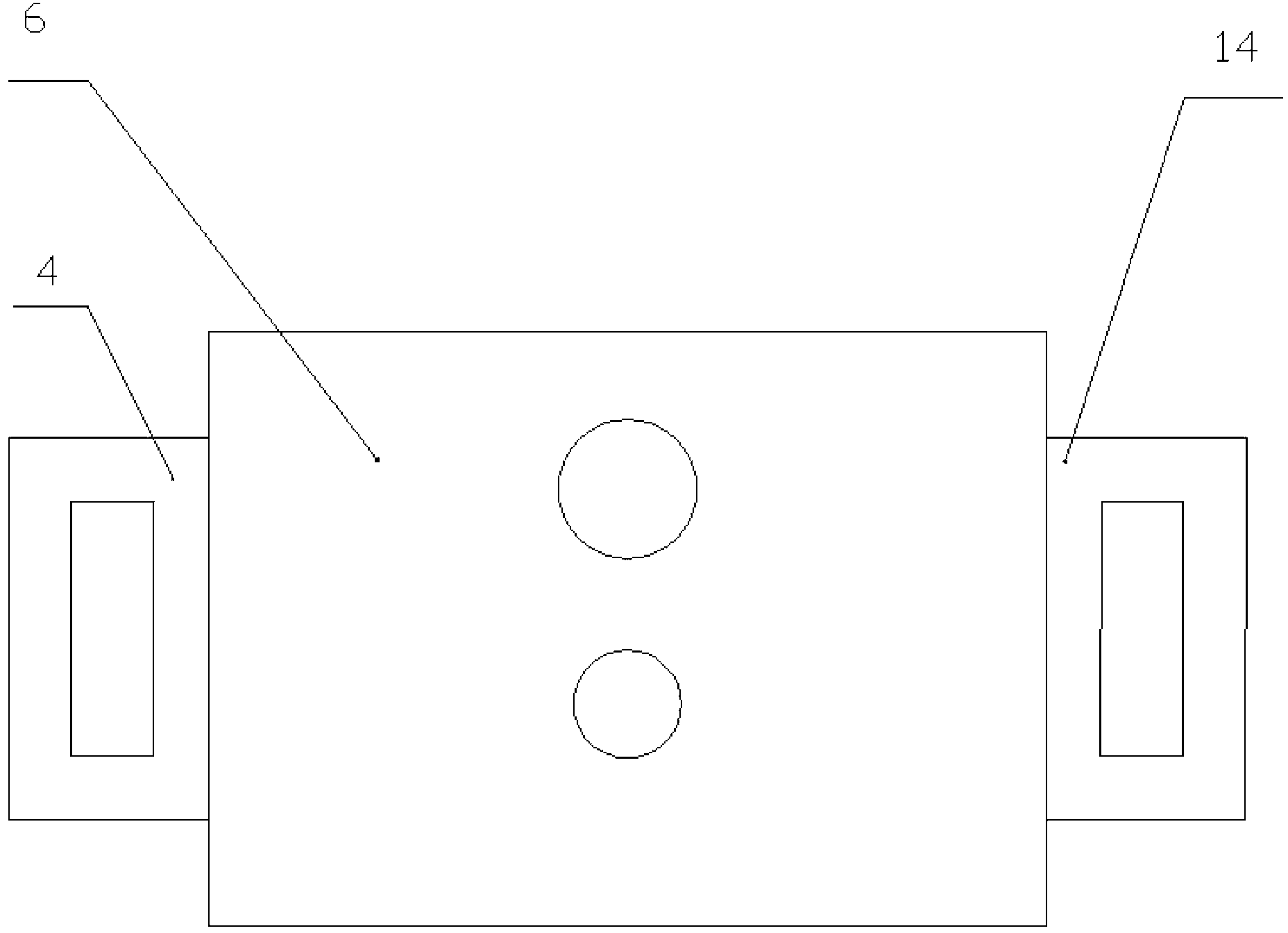

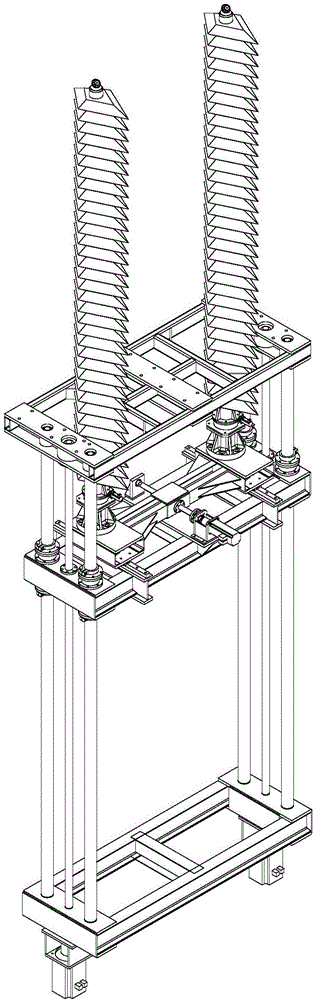

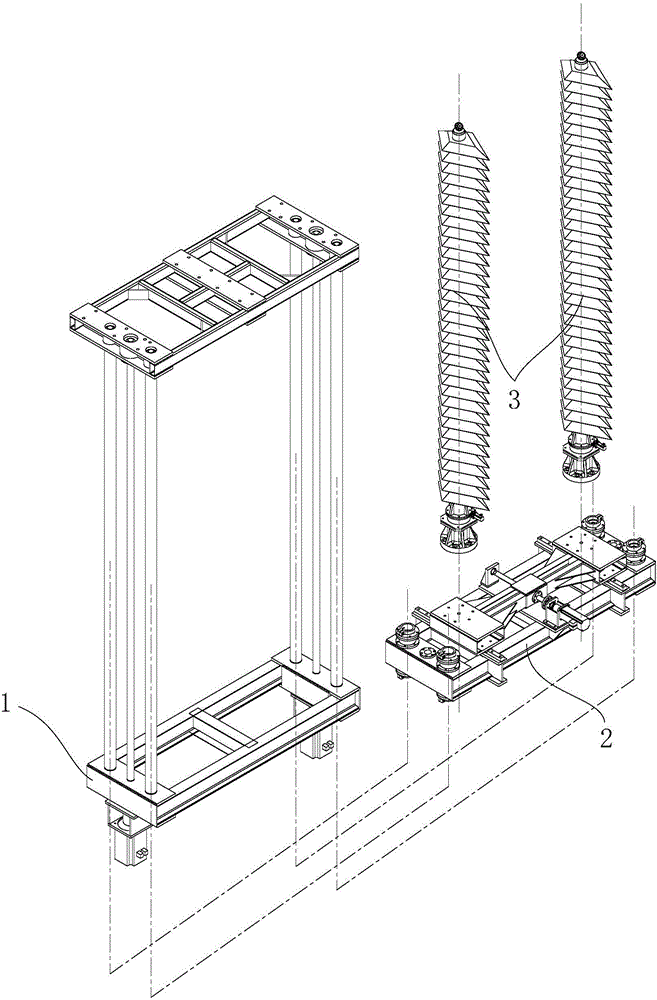

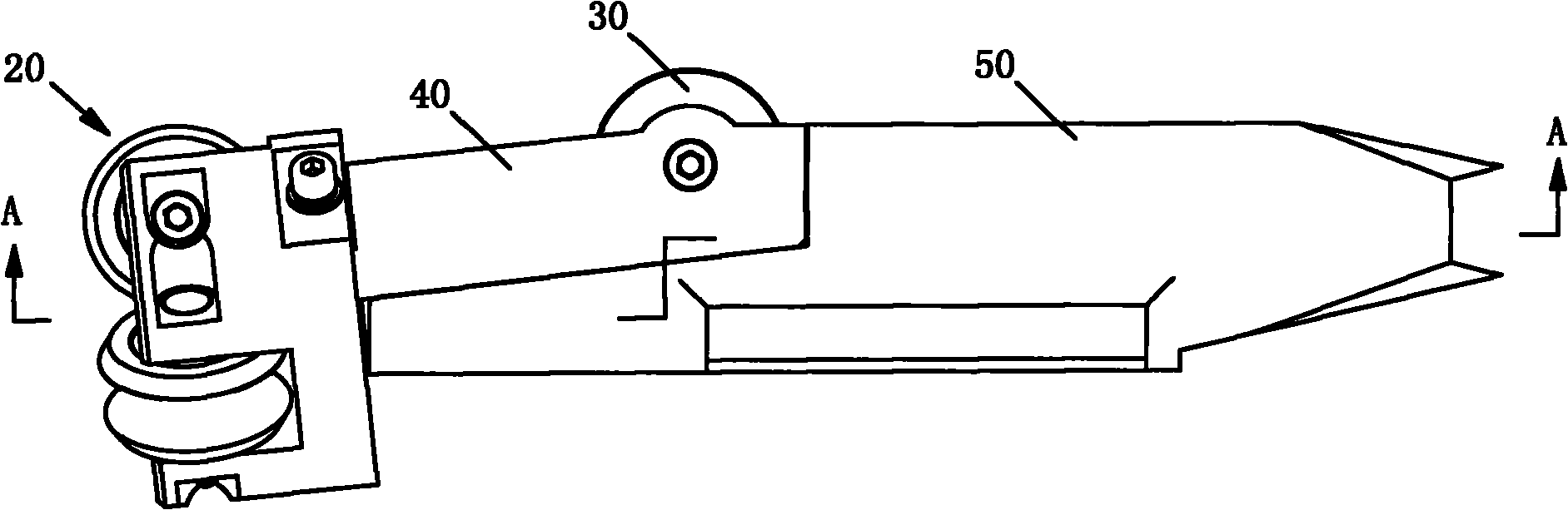

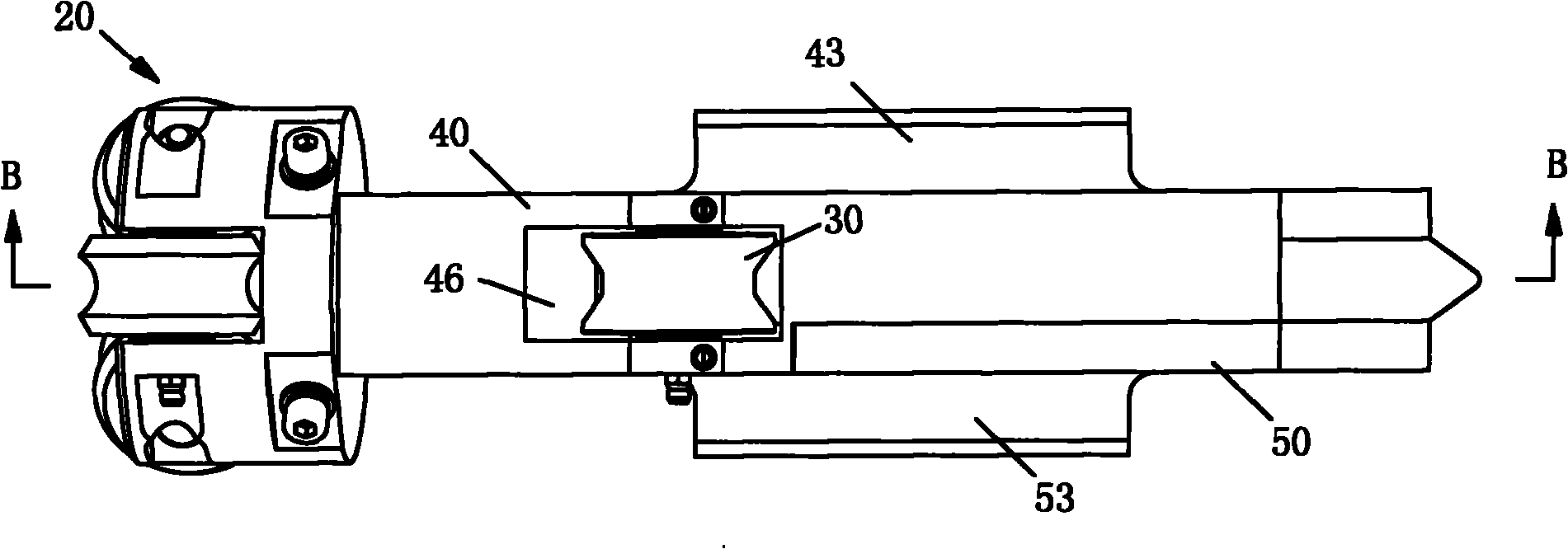

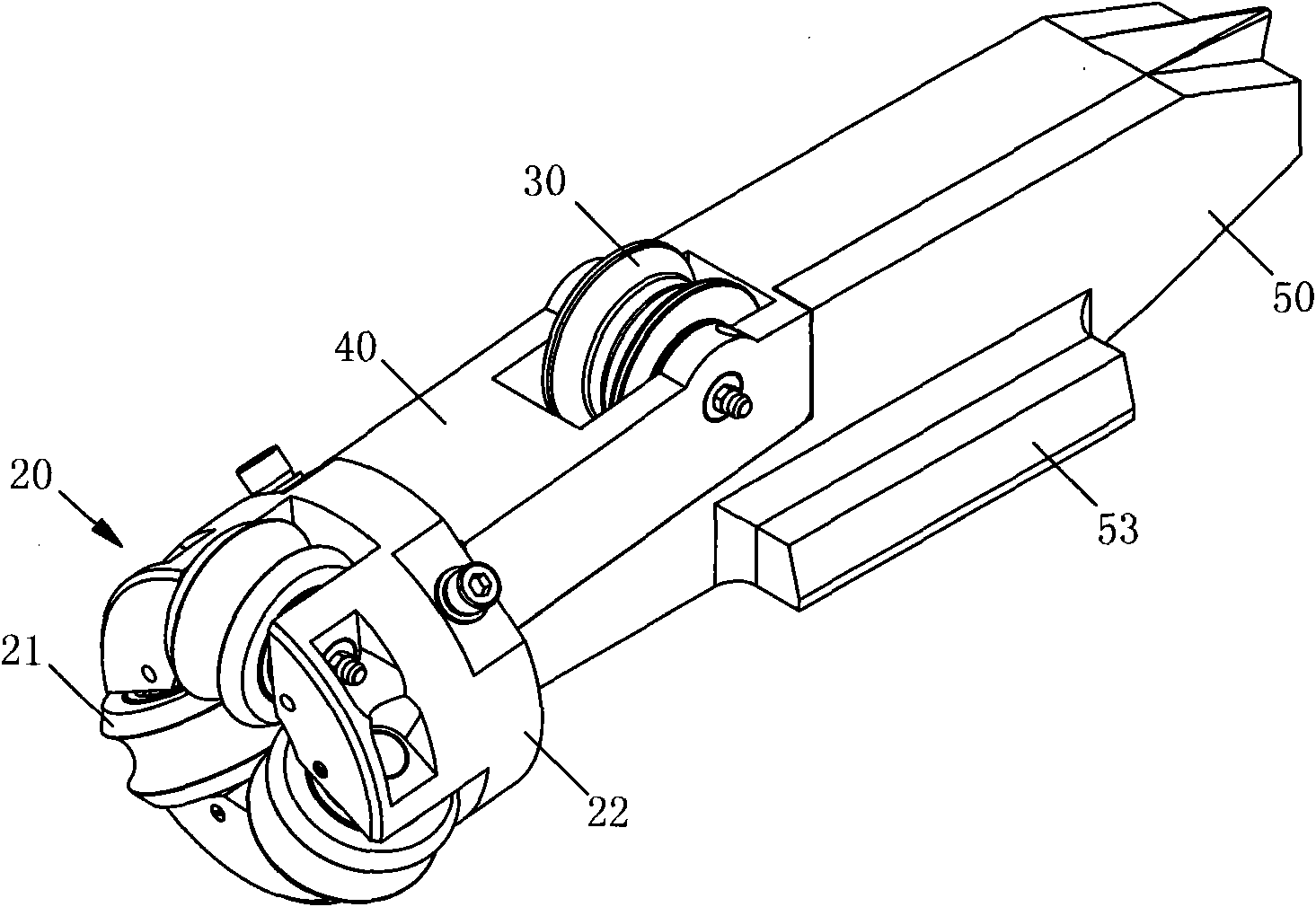

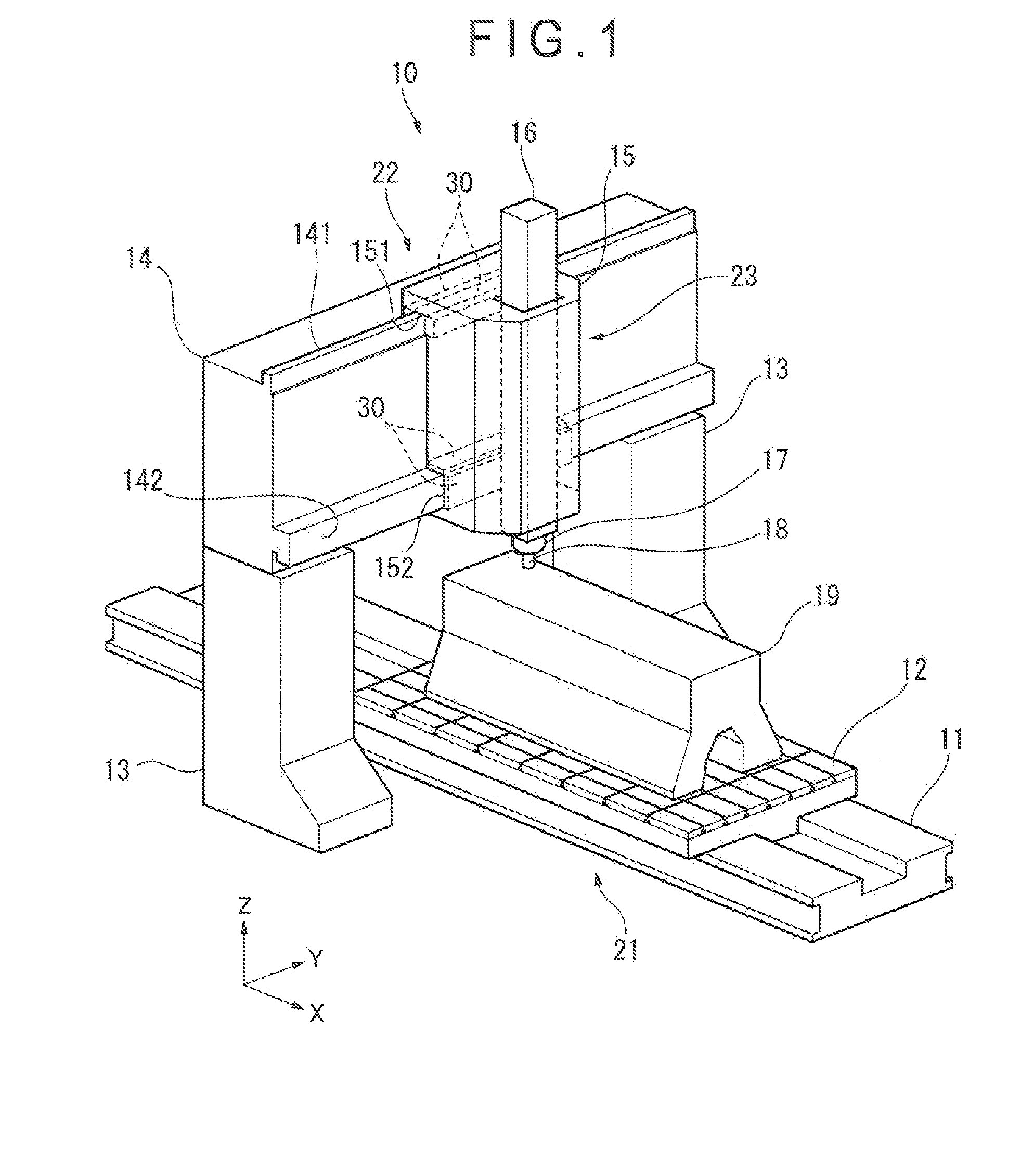

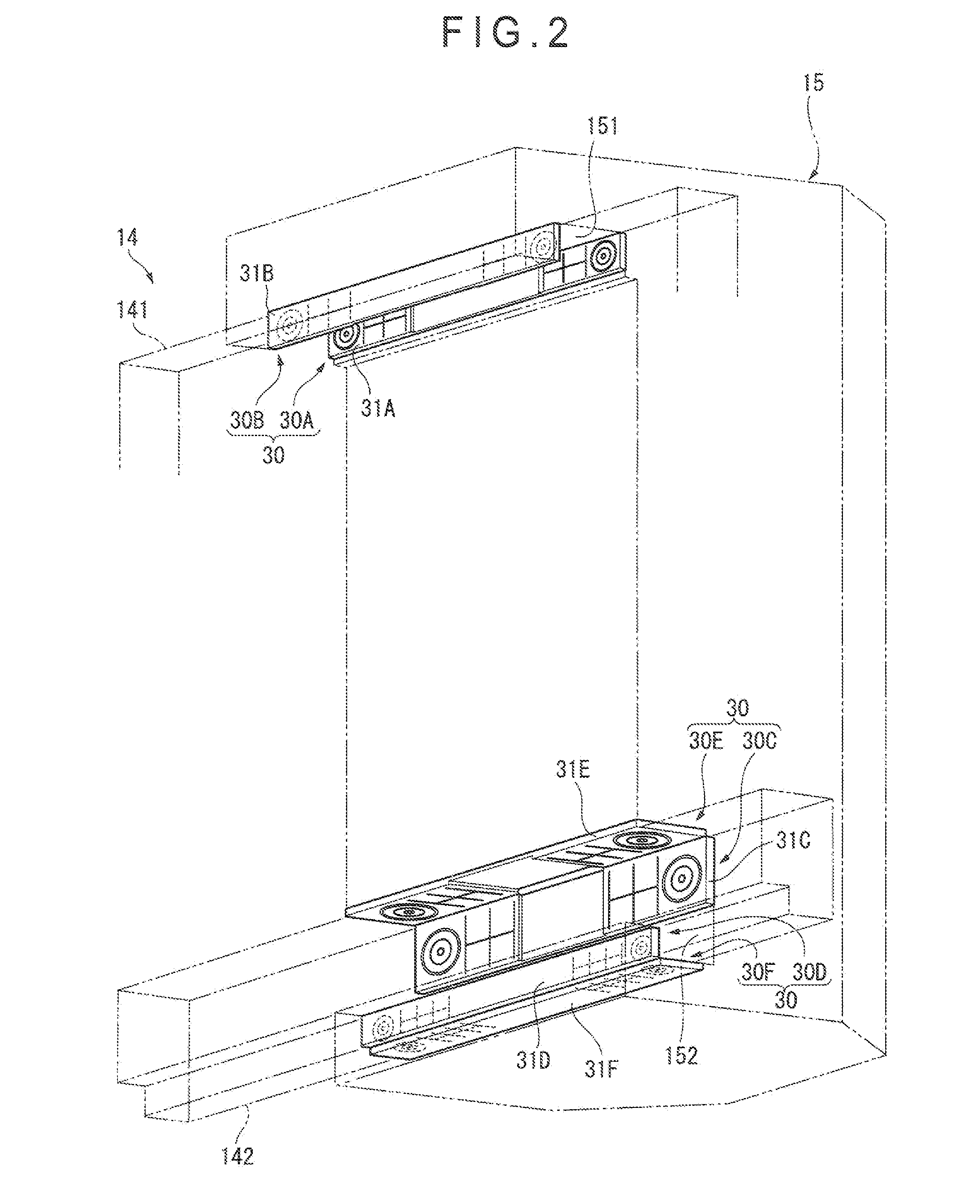

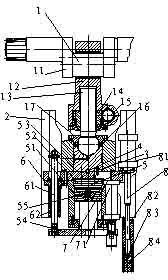

High-speed truss manipulator

InactiveCN105522573ASmall footprintHigh guiding precisionProgramme-controlled manipulatorVibration amplitudeEngineering

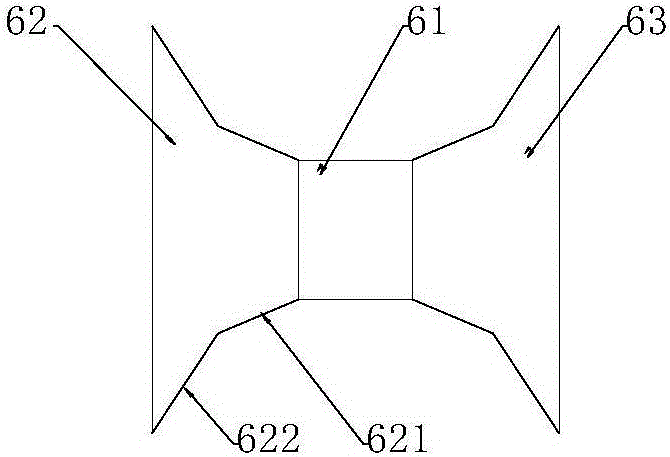

The invention discloses a high-speed truss manipulator. A first sliding block is arranged on an X-direction track on a supporting frame in a sliding mode; a Y-direction track is arranged on a second sliding block fixed to the first sliding block in a linearly reciprocated sliding mode; a Z-direction track is arranged on a third sliding block fixed to the Y-direction track in a longitudinally and linearly reciprocated sliding mode; a mechanical clamping jaw installation support is rotationally positioned at the lower end of the Z-direction track; an included angle of 135 degrees is formed between the axial direction of a rotary shaft of the mechanical clamping jaw installation support and the Z direction; first and second mechanical clamping jaws are symmetrically distributed on the two sides of the rotary shaft of the mechanical clamping jaw installation support; an included angle of 90 degrees is formed between the axial directions of the first and second mechanical clamping jaws; first, second and third drive devices are used for driving the first sliding block, the Y-direction track and the Z-direction track to move respectively; a rotary drive device is used for driving the mechanical clamping jaw installation support to rotate. The manipulator can operate stably at high speed, the vibration amplitude is small after movement is finished, the speed is high as two manipulators operate alternately, and the occupied space is small.

Owner:SUZHOU KAILINJIE ROBOT CO LTD

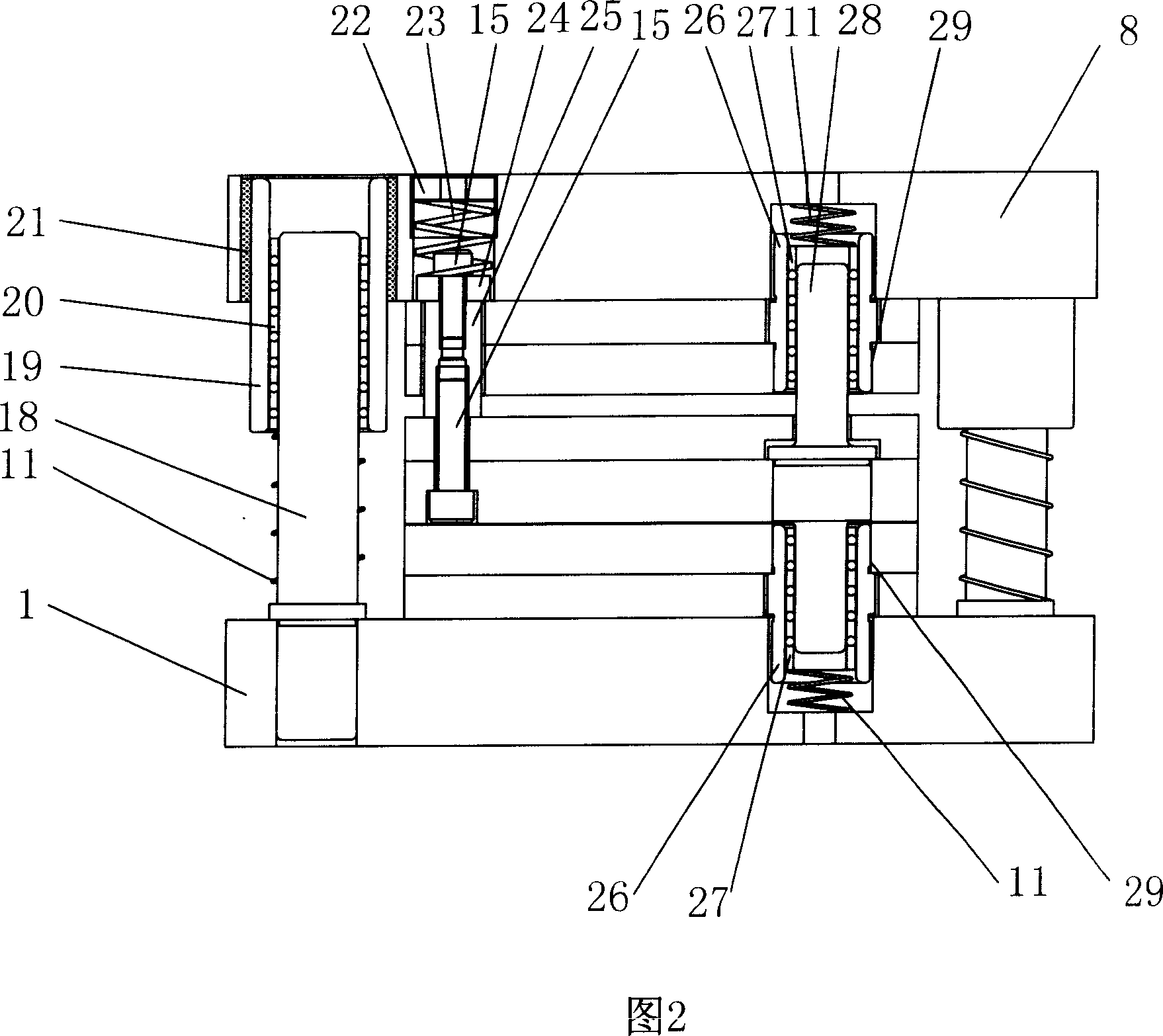

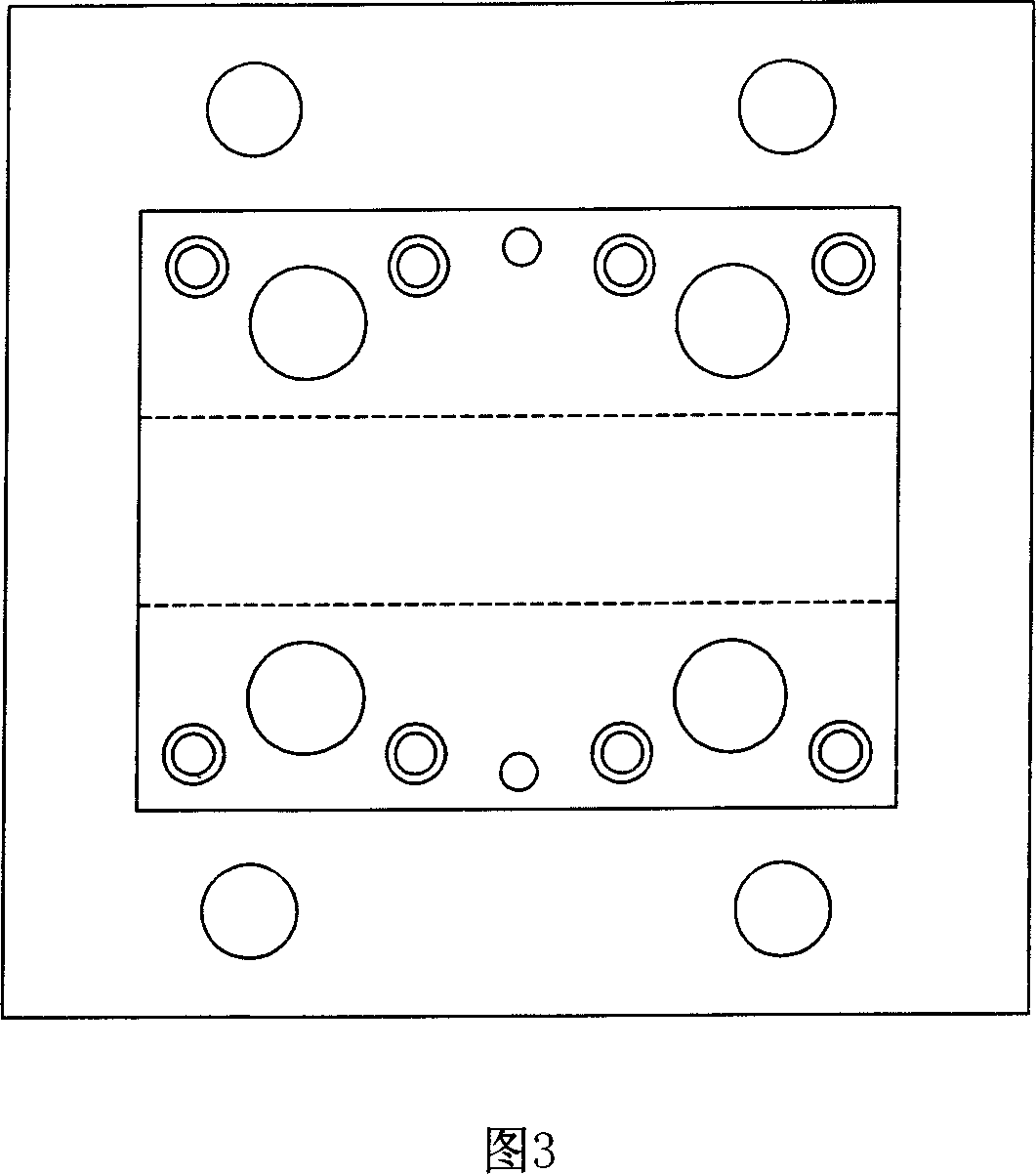

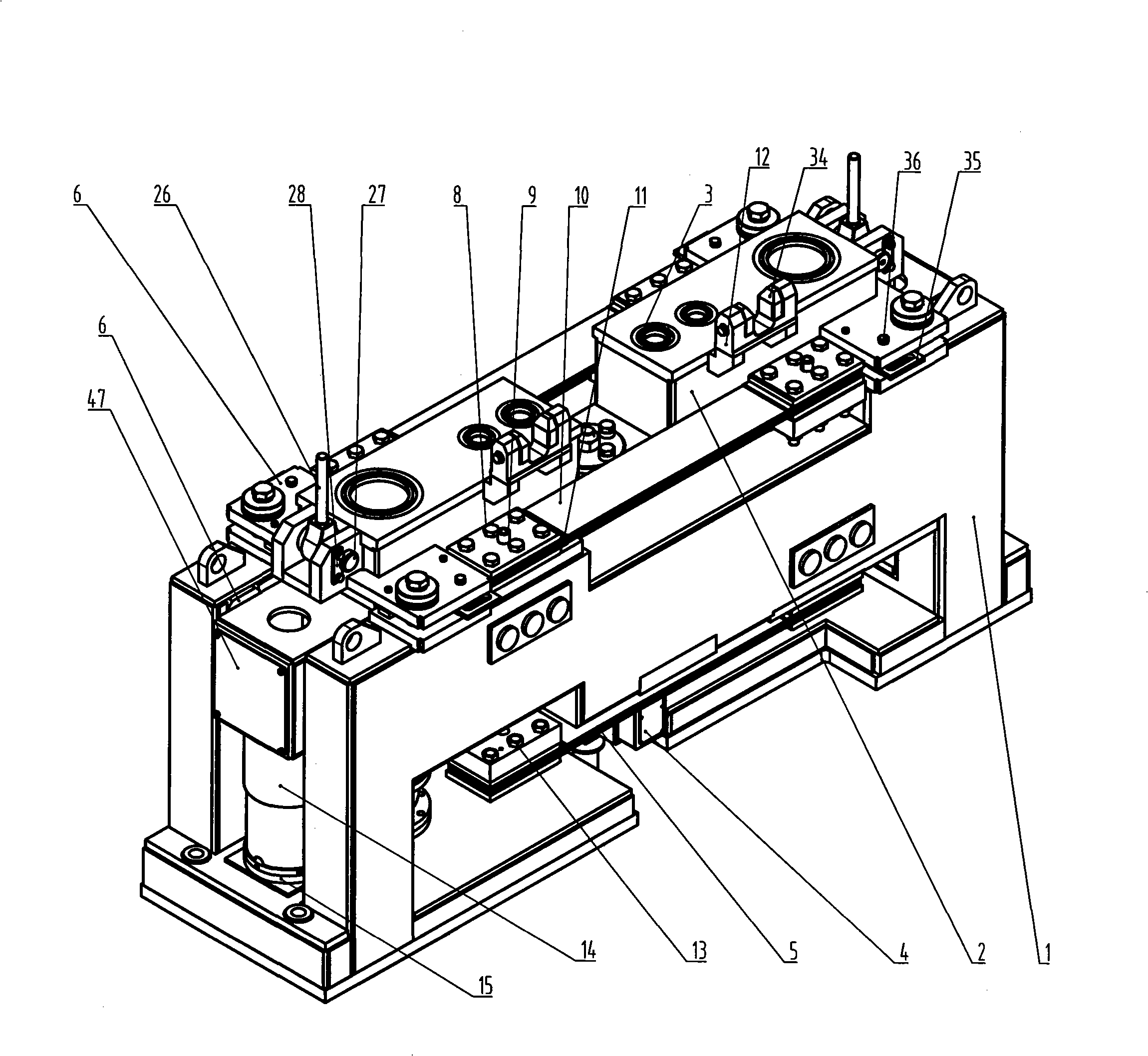

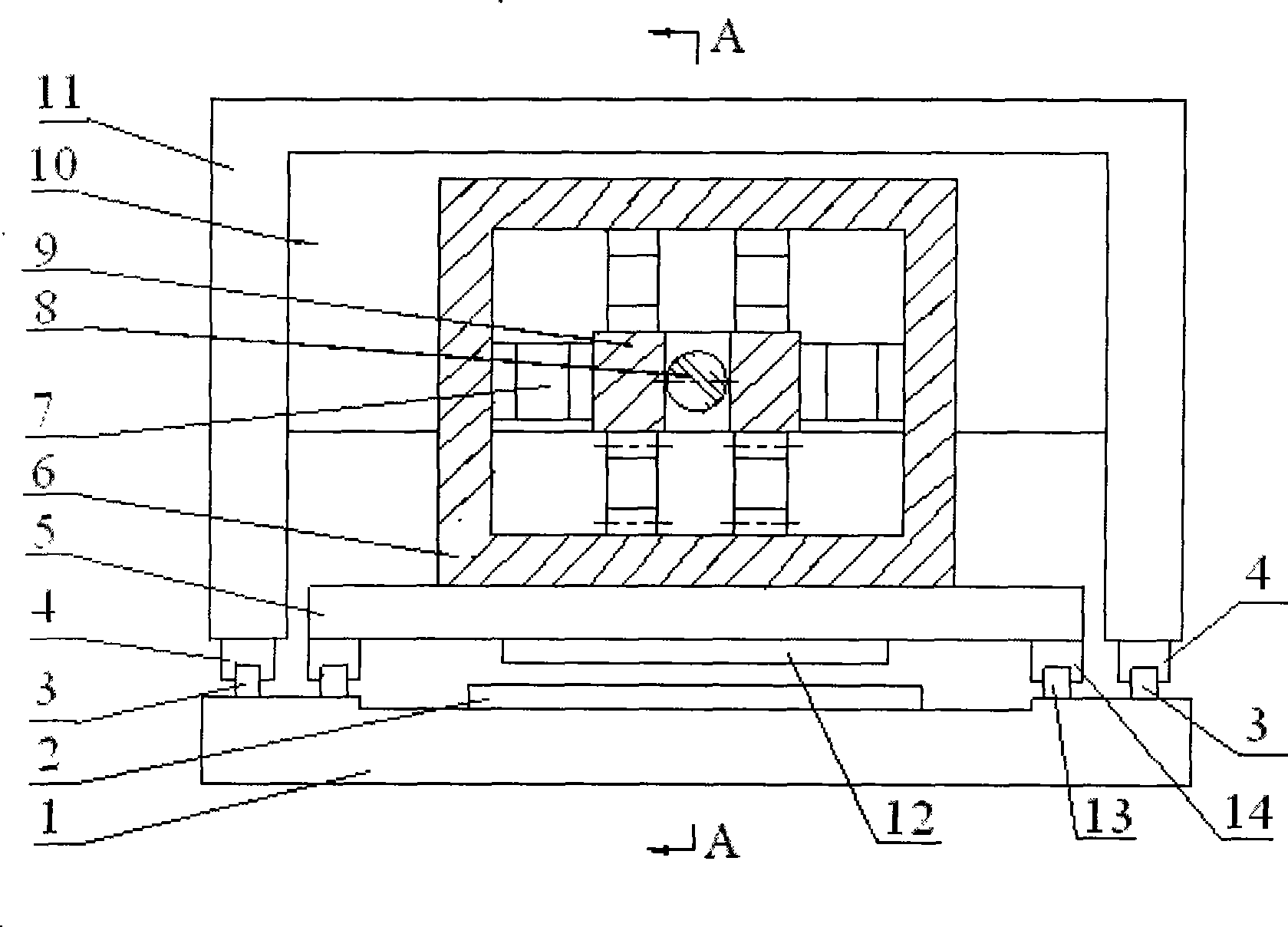

Precise multifunctional incremental pressing die and its making process

InactiveCN1931469AEasy maintenance, adjustment and replacementSimple structureShaping toolsDying backMechanical engineering

The precise multifunctional incremental pressing die includes a lower die, an upper die, an internal guiding mechanism and an outer guiding mechanism. The upper die includes an upper die seat, a convex die back plate, an unloading back plate, and an unloading plate. The lower die includes a lower die seat, a concave back plate and a concave die plate. The outer guiding mechanism includes a large guide pin, a large ball sleeve, a large guide sleeve and a spring. The internal guiding mechanism includes a small guide pin, a small ball sleeve, a small guide sleeve and a spring. The making process features that the unloading plate and the concave die plate are fastened together.

Owner:GELIPU ELECTRONICS SHENZHEN CITY

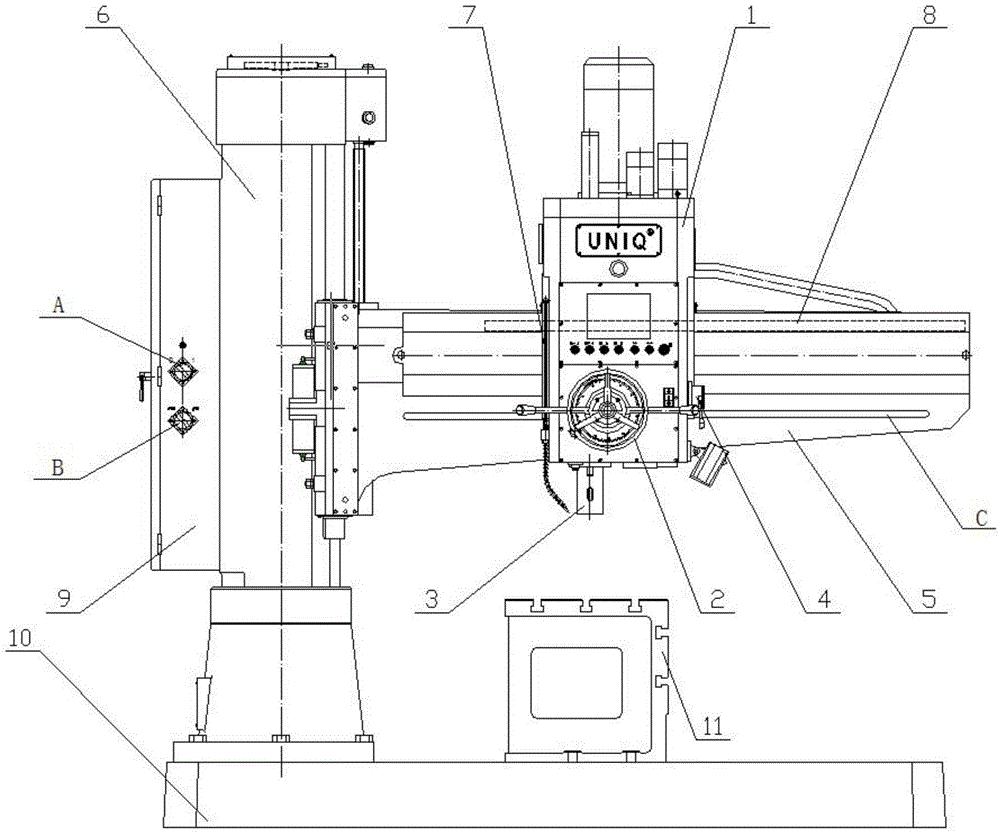

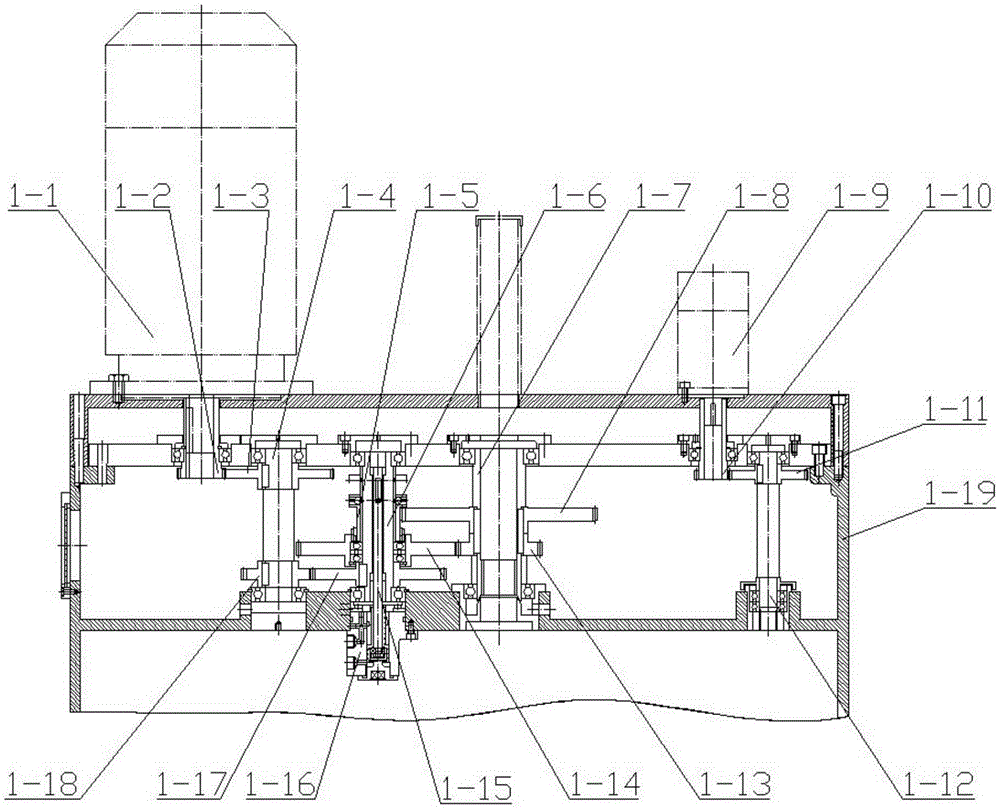

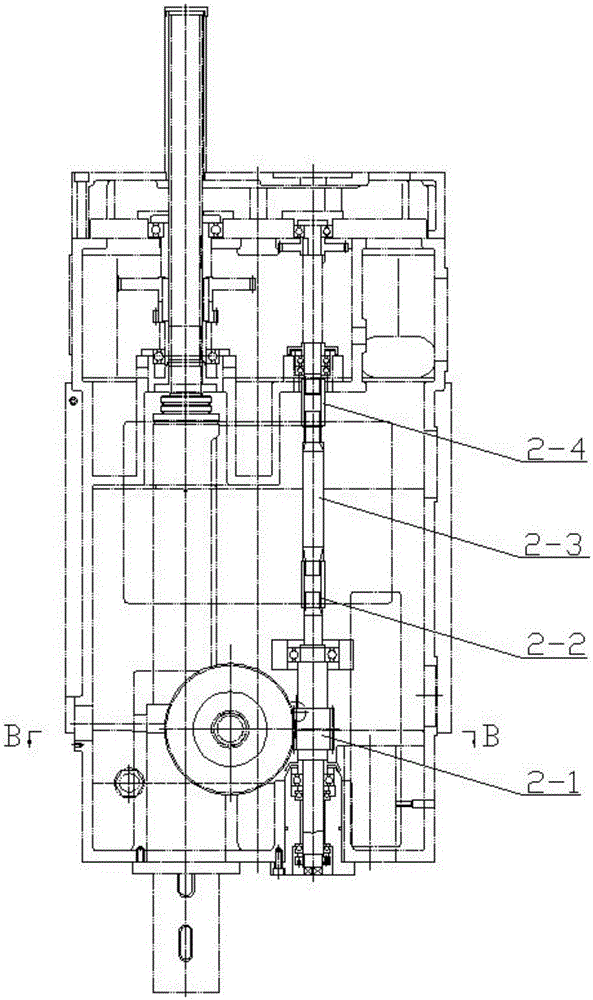

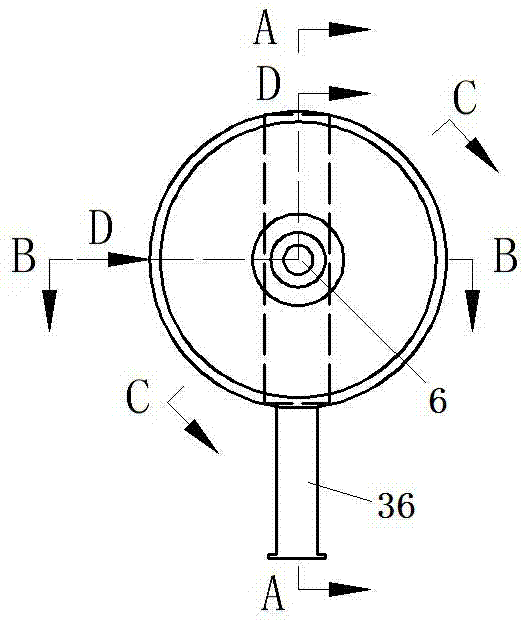

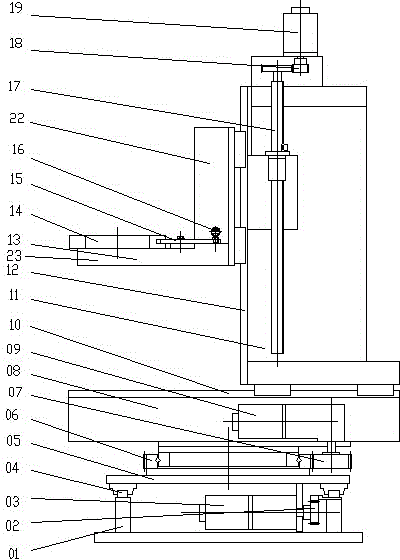

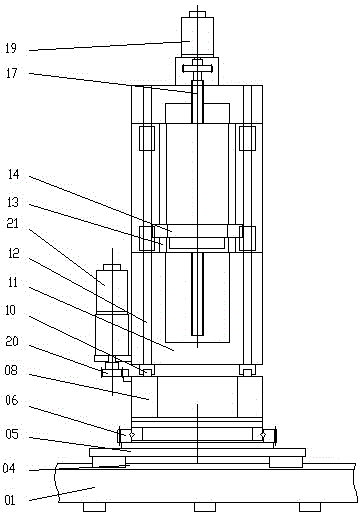

Numerical display type radial drilling machine

ActiveCN105252035AHigh guiding precisionEasy to fixMeasurement/indication equipmentsFeeding apparatusGraphicsBalancing machine

The invention provides a numerical display type radial drilling machine, comprising a spindle speed regulating and spindle feeding speed regulating system, a spindle feeding mechanism, a spindle and balance mechanism, a spindle positive / negative rotation and variable-speed control mechanism, a rocker arm and clamping mechanism, an upright and rocker arm lifting mechanism, a hydraulic and cooling system, a testing system, a numerical display control system and the like; the upright and rocker arm lifting mechanism is mounted on a base; the rocker arm and clamping mechanism is mounted on the upright and rocker arm lifting mechanism; the numerical display control system is mounted on the upright and rocker arm lifting mechanism; the spindle speed regulating and spindle feeding speed regulating system is mounted on the rocker arm and clamping mechanism; the spindle feeding mechanism, the spindle and balance mechanism, the spindle positive / negative rotation and variable-speed control mechanism, and the hydraulic and cooling system are mounted on the spindle speed regulating and spindle feeding speed regulating system. According to the numerical display type radial drilling machine, stepless speed changing of a spindle can be realized without shutdown; graphic and numerical display can be realized at working positions; a die wall clamping device of a guide rail and a spindle limiting structure are sensitive and reliable; in short, the numerical display type radial drilling machine is applicable to machining industries.

Owner:SHENYANG JINGHONG NUMERICAL CONTROL EQUIP CO LTD

Portable double-coil electromagnetic riveting device

The invention relates to a portable double-coil electromagnetic riveting device which comprises a rear gun barrel and a front gun barrel. The front gun barrel slides relative to the rear gun barrel in a reciprocating mode through a damping system. A primary coil is fixedly connected into the front end of the front gun barrel. A sliding secondary coil is arranged at the front end of the front gun barrel in a sleeving mode and located beside the primary coil. The front end face of the primary coil is fixedly connected with a riveting die through an amplifier. The rear end face of the primary coil is fixedly connected with an intermediate spindle penetrating through the primary coil. The intermediate spindle slides relative to the rear gun barrel and the front gun barrel in a reciprocating mode through an elastic limit mechanism and a guide mechanism. The primary coil and the secondary coil are electrically connected. According to the double-coil self-excitation principle, currents with uniform wave forms are loaded to the coils at the same time, so that the riveting energy is increased, and the energy utilization rate is improved. Through a buffering spring, recoil energy is stored in the elastic potential energy of the buffering spring, and a one-way damper consumes energy to reduce vibration sense in the rebounding process.

Owner:FUZHOU UNIV

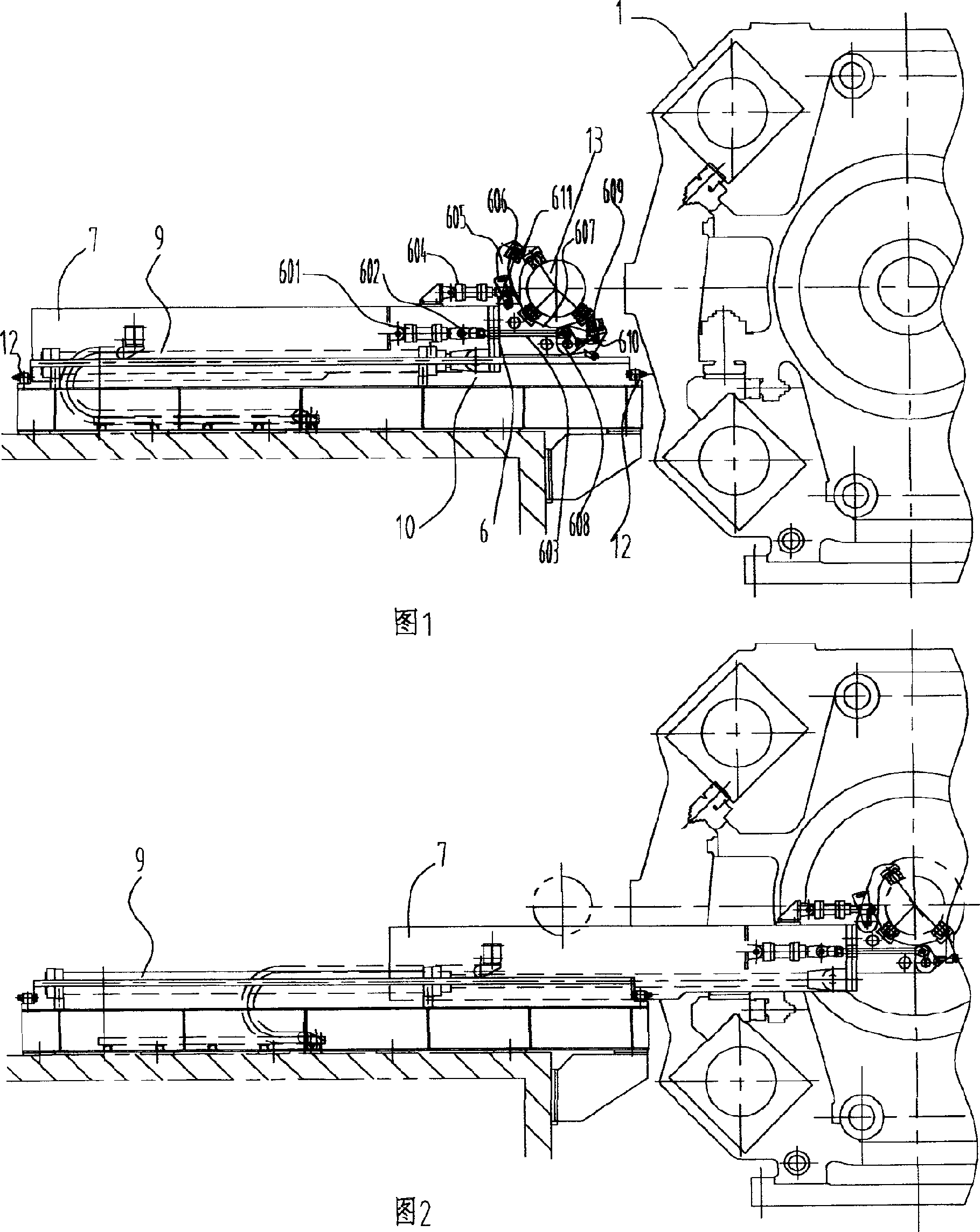

Short path aluminium extrusion machine front feeding system and its gripping pliers type adaptive ingot supply device

A front feeding system for short-stroke squeezer of aluminium part and its clamp-type adaptive ingot supplying system has squeezer with fixed pressing block, clamp-type adaptive ingot supplying system consisting of manipulator, master arm and slide block, master arm cylinder, slide guider and pressing plate, pressing rod, the hydraulic control units for lateral cylinder and pressing rod and ingot supplying unit, and electric control unit.

Owner:TAIYUAN HEAVY IND

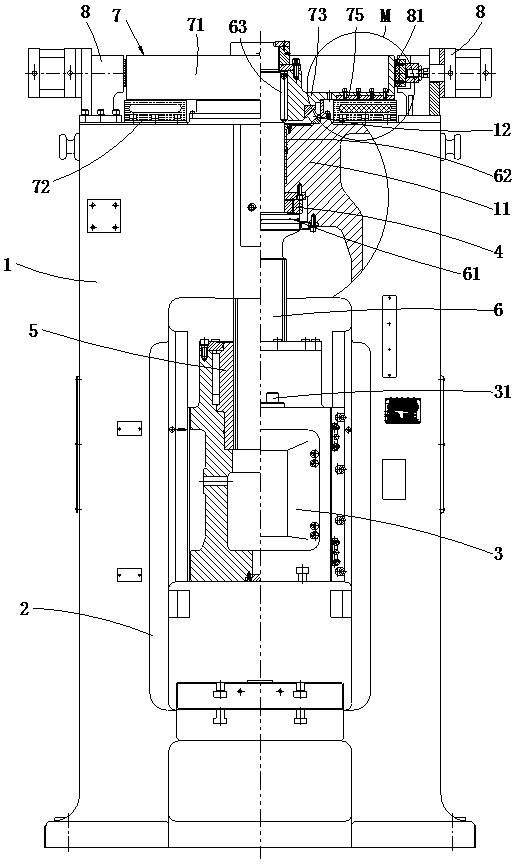

Overload protecting electric screw press

InactiveCN101554640ABig hit energyEliminate energyForging/hammering/pressing machinesForging press drivesLoad resistanceEngineering

An overload protecting electric screw press comprises a body, a platform arranged above the body, a special driving motor vertically disposed and installed at the cross beam of the body, a small driving gear directly mounted on the output shaft of the special driving motor, a friction slipping big flywheel driven by the small driving gear through the joggled transmission, a screw fixed at the flywheel through a pin, a nut driven by the screw, a slide block fixed together with the nut, and an external brake shoe brake installed at the platform for braking the flywheel. The invention has simple structure, a few components, short transmission chain, high mechanical strength, easy manufacturing, convenient maintenance, low cost, simple operation, low loss of components, anti-waving by buffering, good coaxiality, stable running, high beating force and deformation energy, high forming accuracy, strong unbalance loading resistance ability, overload protecting property, safety and reliability, long service life, energy saving and wide application range. The electric screw press can be widely used in forging forming industry.

Owner:青岛宏达锻压机械有限公司

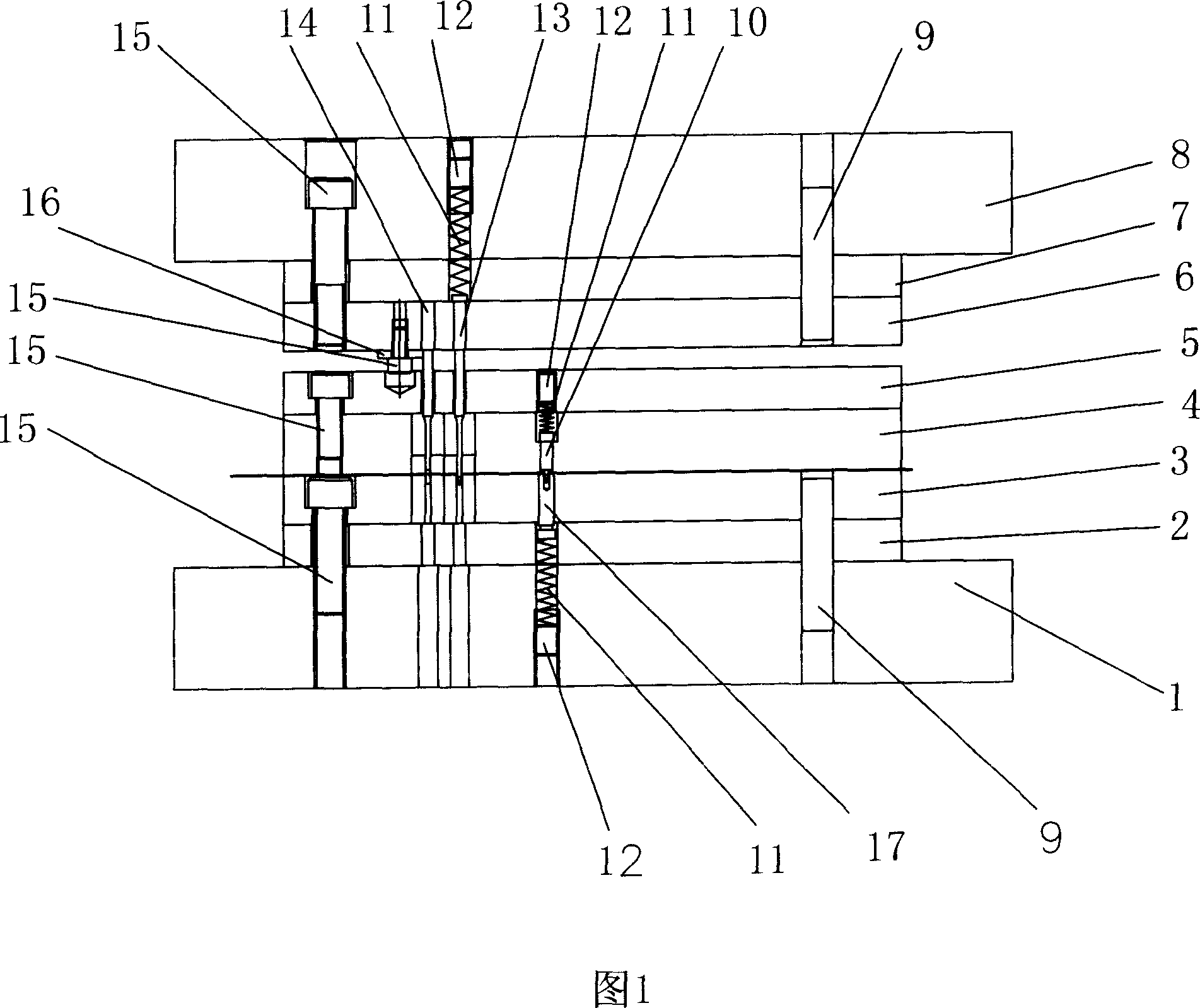

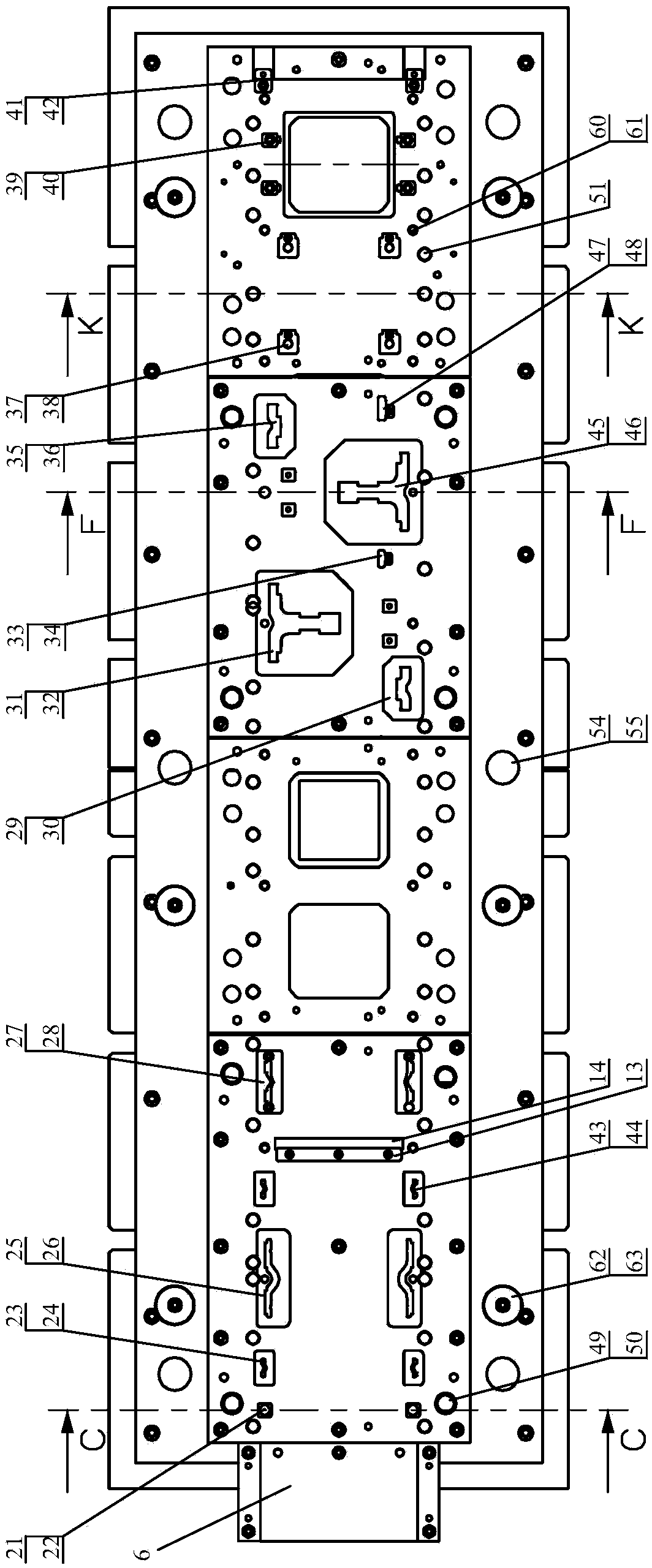

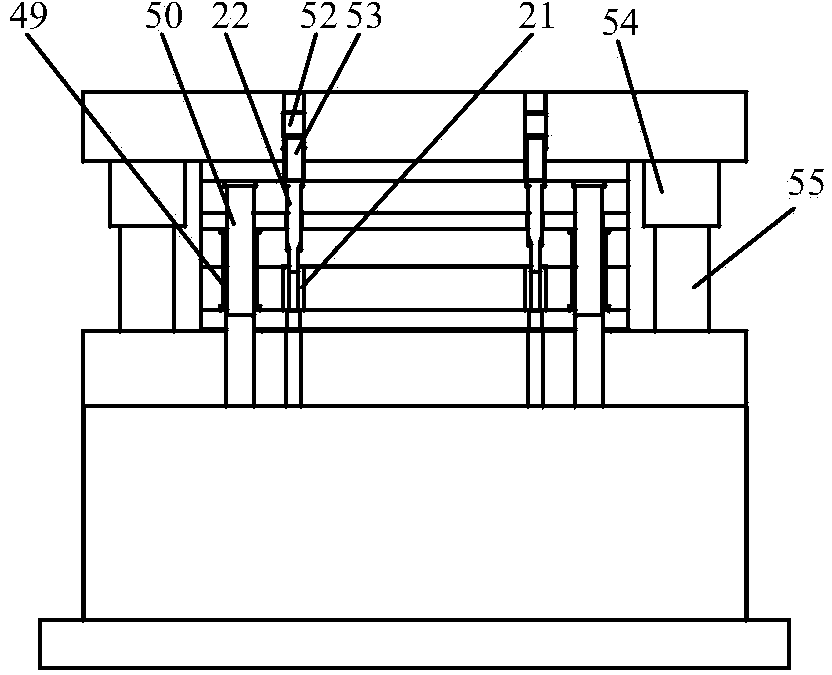

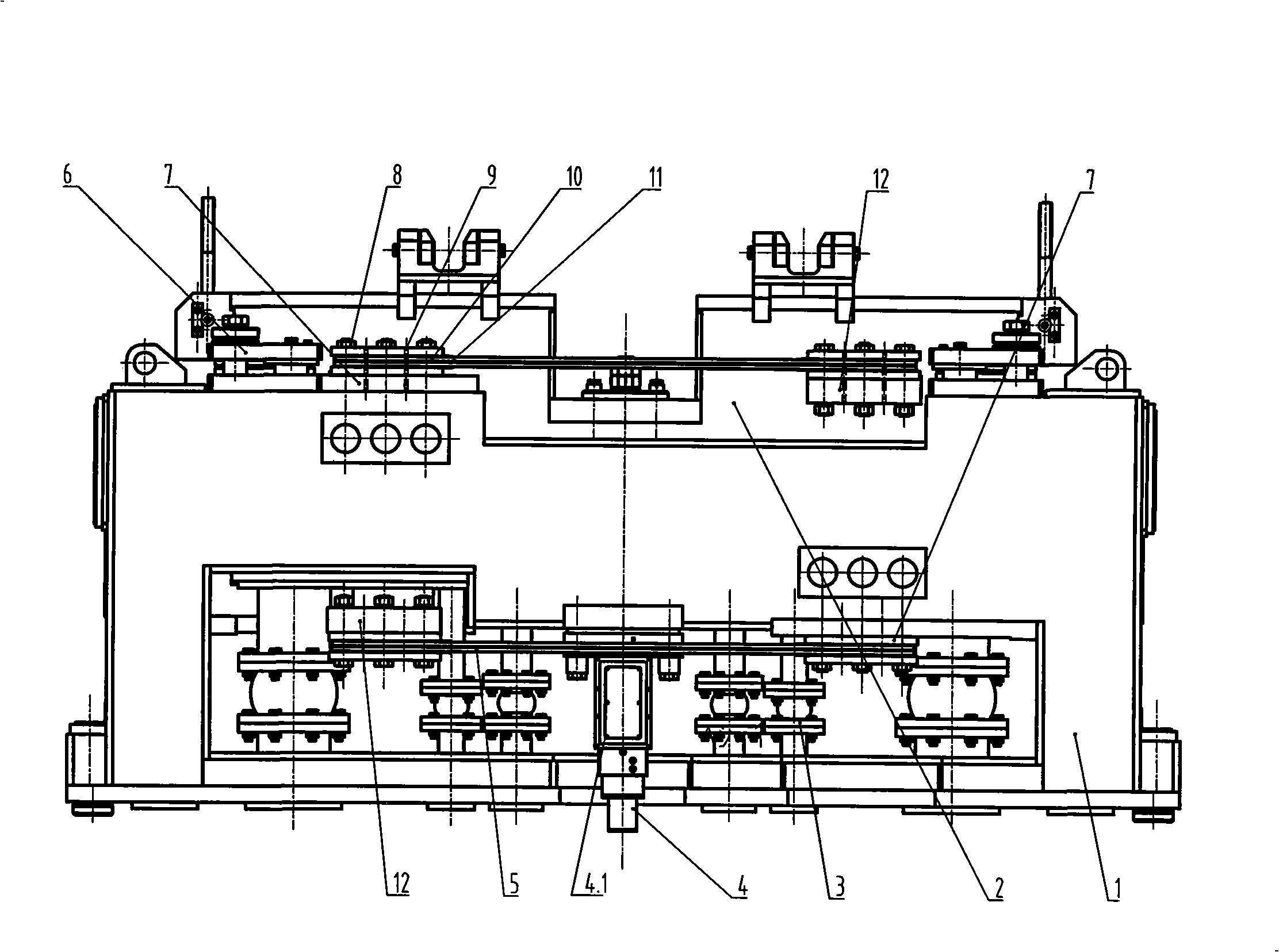

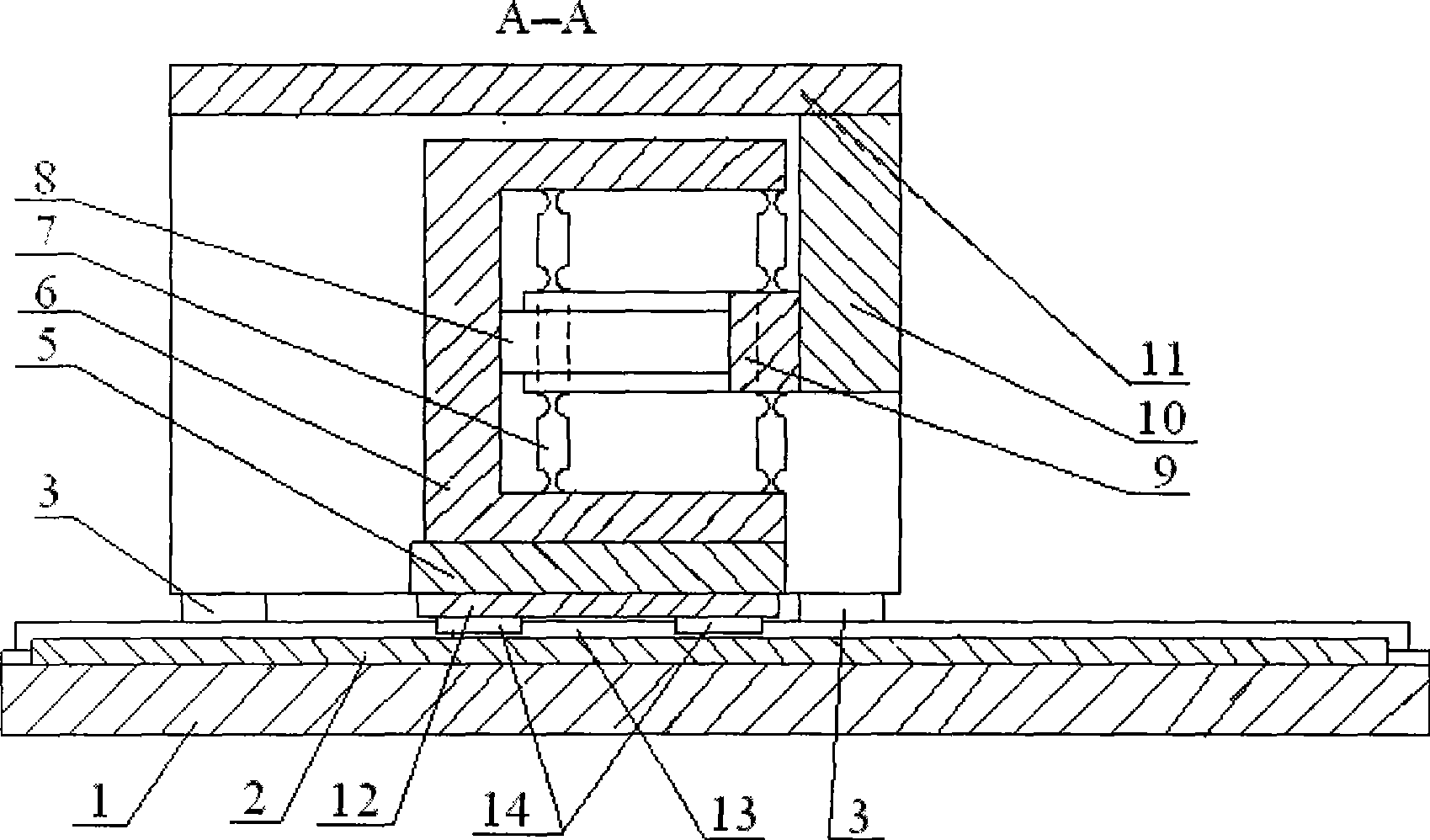

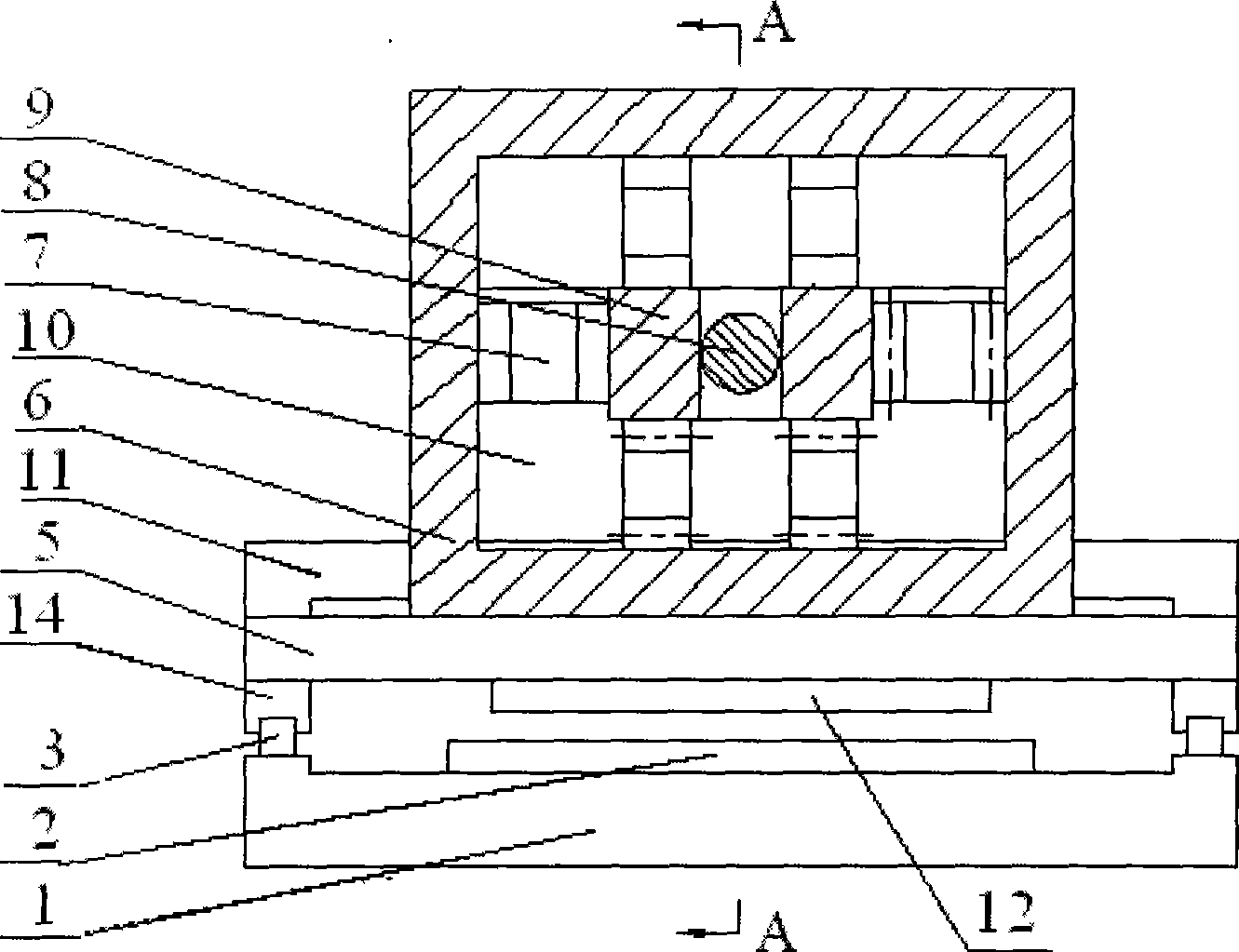

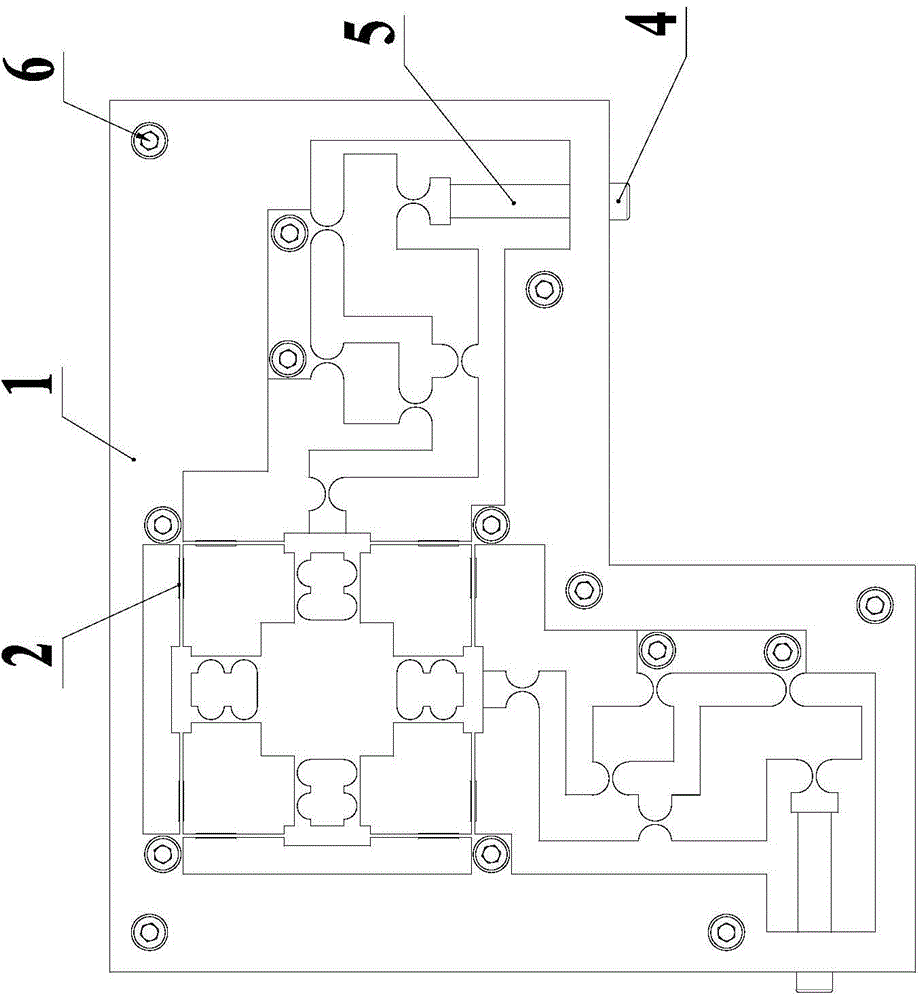

Suspension supporting base multi-station progressive die

ActiveCN103962452ACompact structureHigh guiding precisionShaping toolsPerforating toolsPunchingEngineering

The invention relates to a suspension supporting base multi-station progressive die which comprises an upper die assembly, a lower die assembly, an unloading plate, an unloading plate base plate and a mis-feeding detection device. The upper die assembly is sequentially provided with a corresponding male die in the feeding direction, the lower die assembly is sequentially provided with a female die embedding sleeve matched with the male die of the upper die assembly, corresponding positions on the unloading plate and on the unloading plate base plate are provided with a through hole capable of penetrating through the male die of the upper die assembly, the unloading plate is disposed on the unloading plate base plate, and the unloading plate base plate is arranged on the upper die assembly through an unloading spring. By means of the progressive die, suspension supporting bases are produced in a continuous drawing progressive die mode. The mechanism is compact in structure, high in guide precision, stable in unloading and precise in pitch fixing, and feeding and discharging are convenient to achieve. A quick replacement structure is adopted to a punching male die, and maintenance and replacement time of the die is effectively shortened. After being tried, the mechanism is good in use effect and can meet requirements for high efficiency and high precision of stamping production.

Owner:LIUZHOU VOCATIONAL & TECHN COLLEGE

Parallelism inspection tool for ball screw and guiding rail at gantry machining center

InactiveCN102768003AEasy to detectHigh guiding precisionAngles/taper measurementsBall screwEngineering

The invention relates to a parallelism inspection tool for a ball screw and a guiding rail at a gantry machining center. The innovative point is that the tool includes a bridge plate arranged on the guide rail, and a mounting board fixed in the middle of the bridge plate, wherein a guiding limit component used for guiding the bridge plate in the guiding rail extending direction is arranged on the bridge plate; a screw rod-above bus measurement mechanism and a screw rod-side bus measurement mechanism both used for detecting the offset of a screw rod are mounted on the mounting board simultaneously. The tool has the advantages as follows: under the guiding of the guiding limit component, the bridge plate moves in the guiding rail extending direction, so that the screw rod-above bus measurement mechanism and the screw rod-side bus measurement mechanism can move in the guiding rail extending direction simultaneously, and dial indicators in the screw rod-above bus measurement mechanism and the screw rod-side bus measurement mechanism detect bounce amount when the measurement mechanisms pass by the surface of the screw rod, as a result, the parallelism of the screw rod and the guiding rail can be judged, and the detection is quick and convenient.

Owner:南通京鼎机械科技有限公司

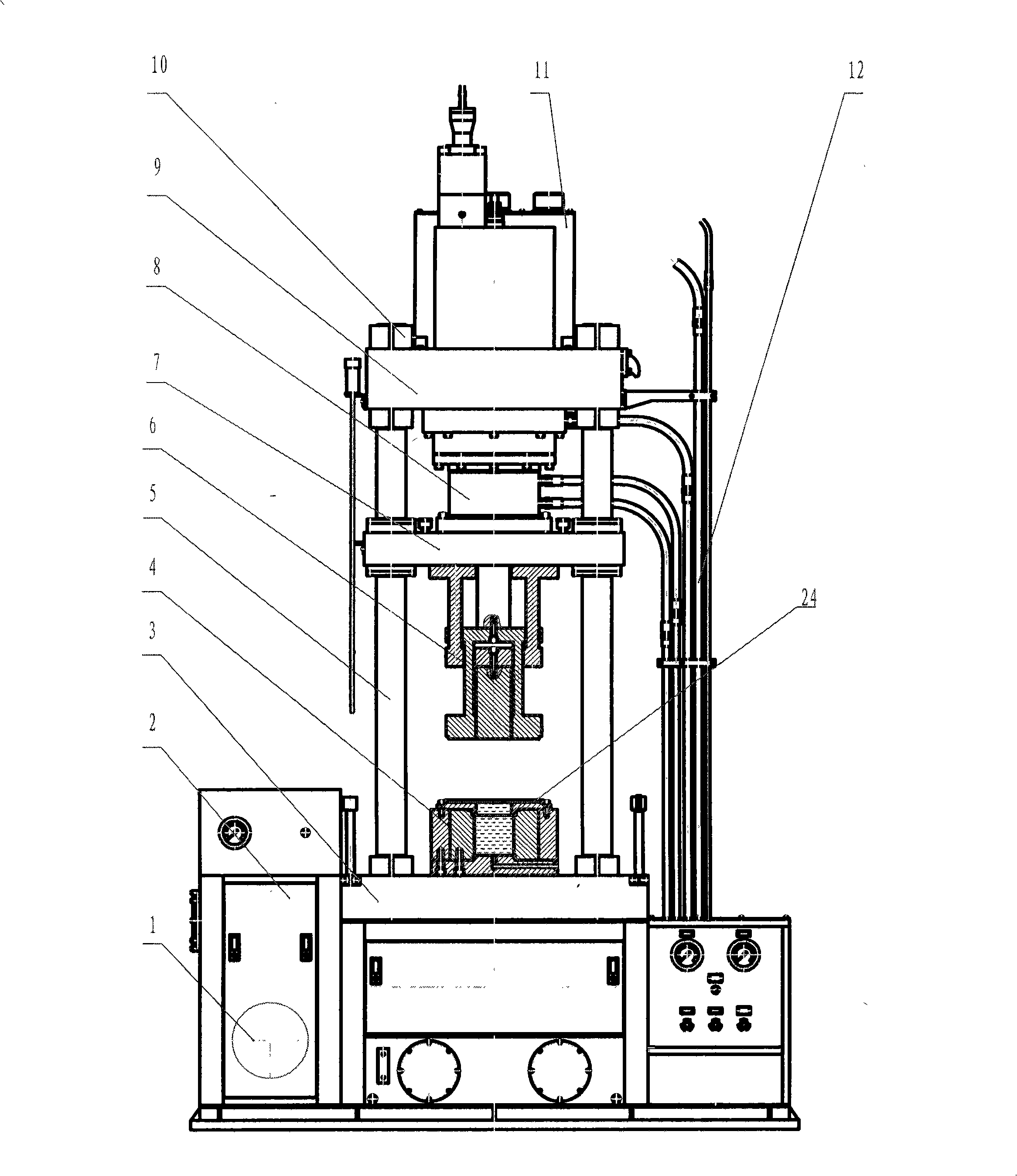

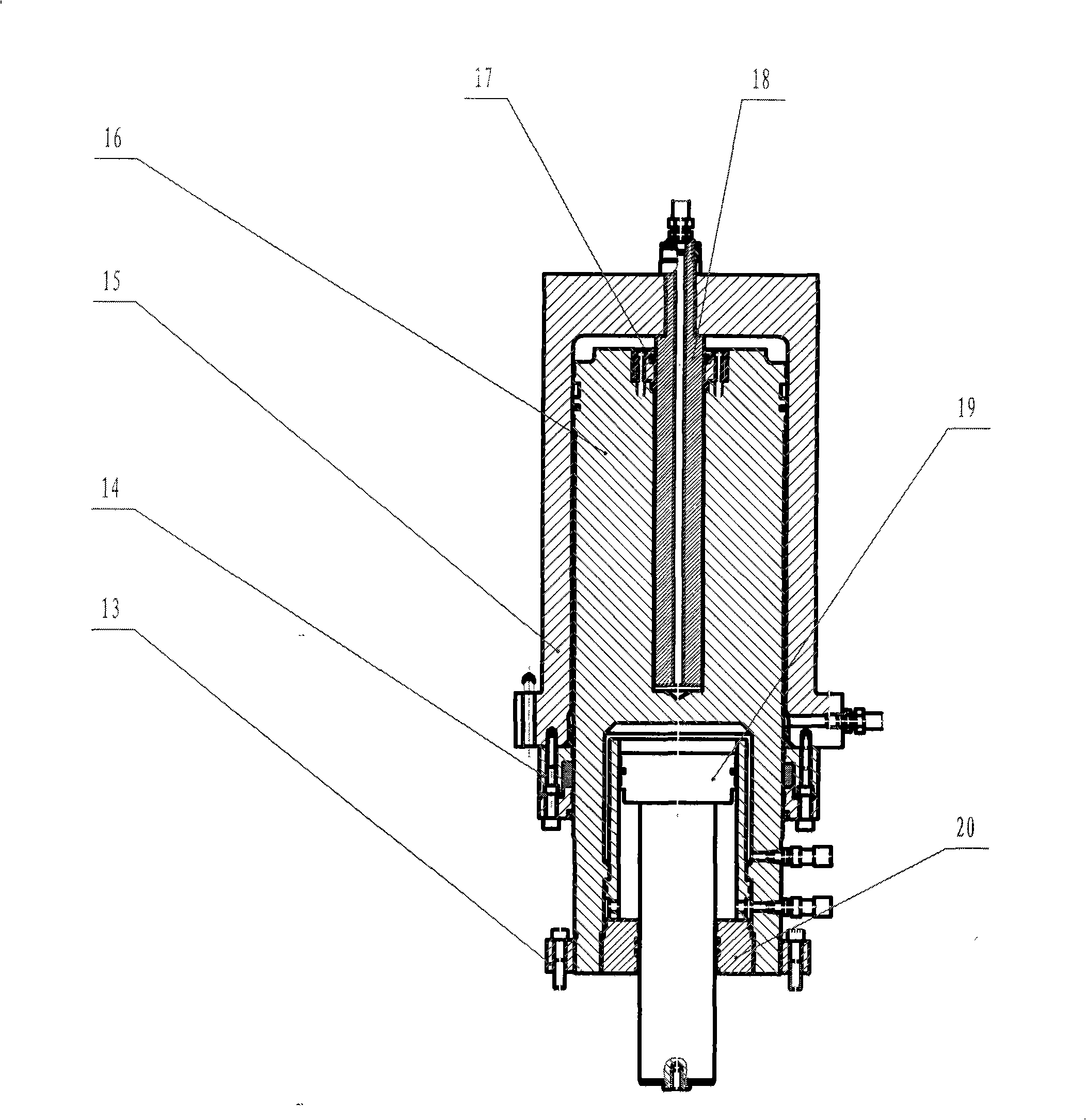

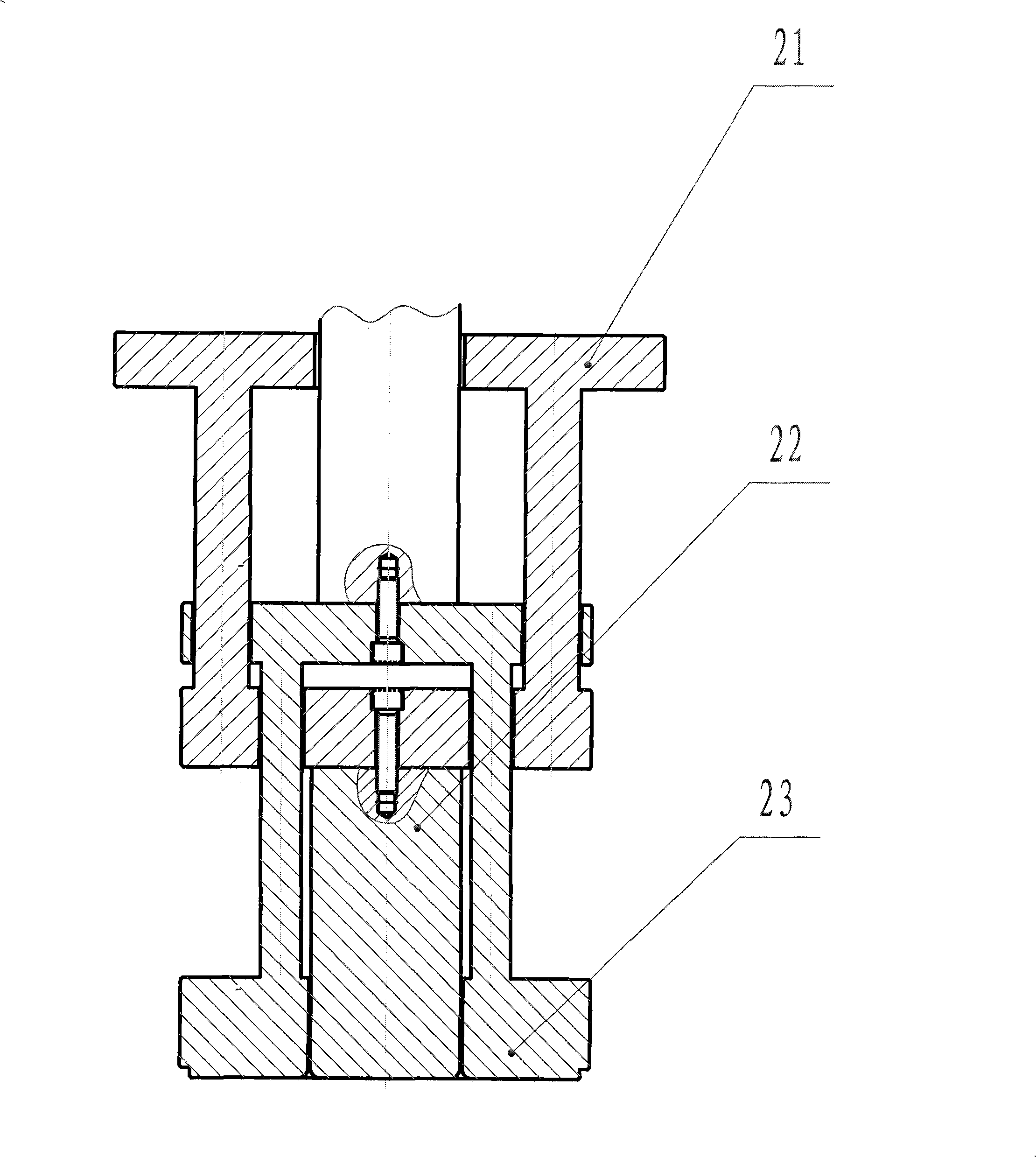

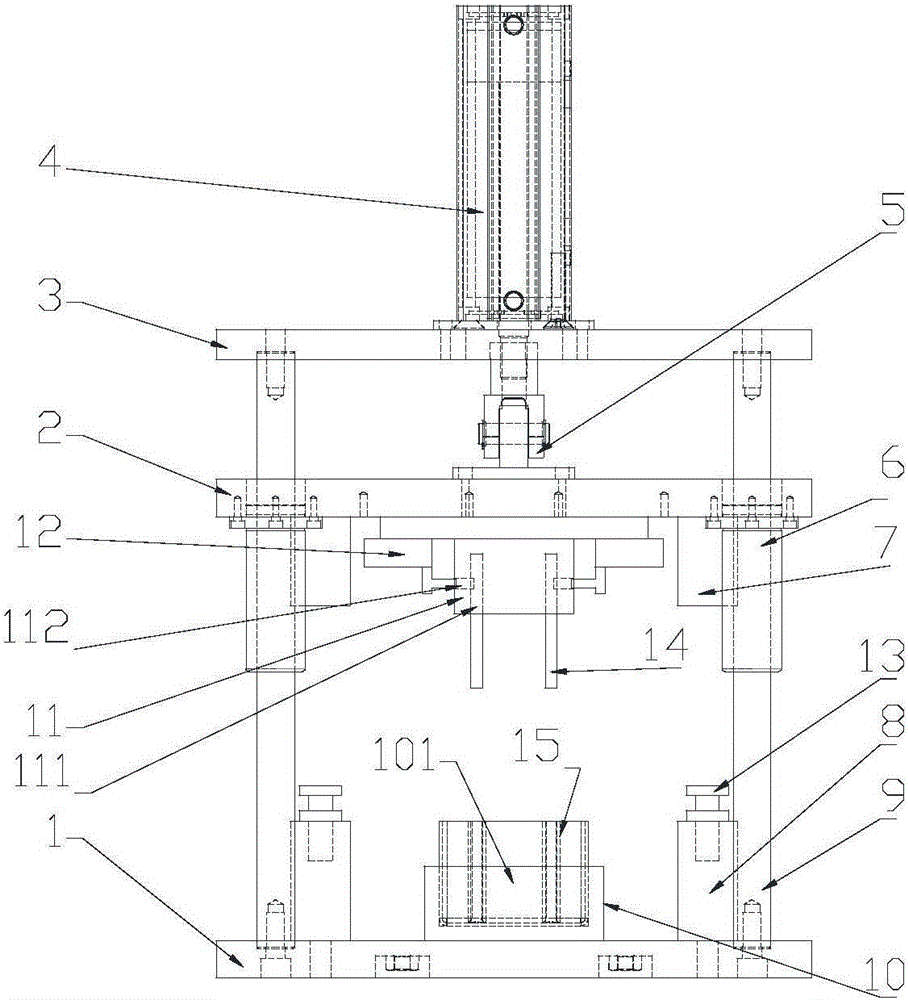

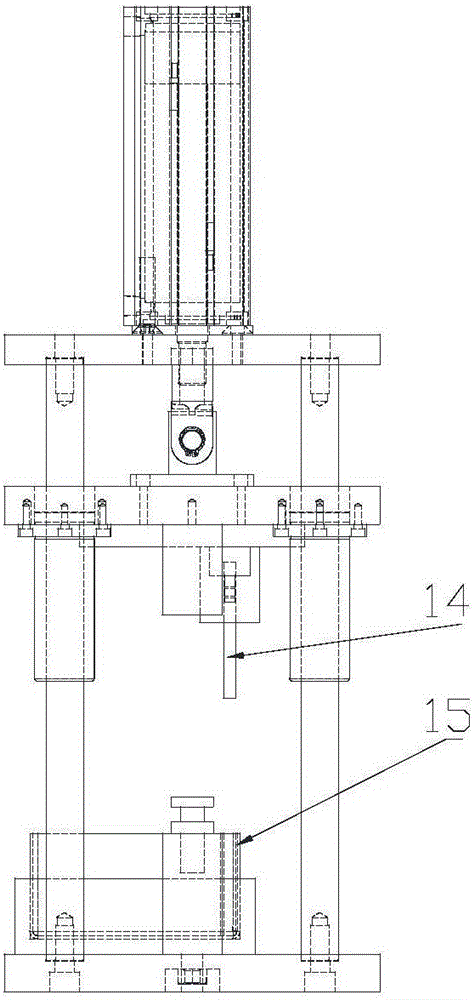

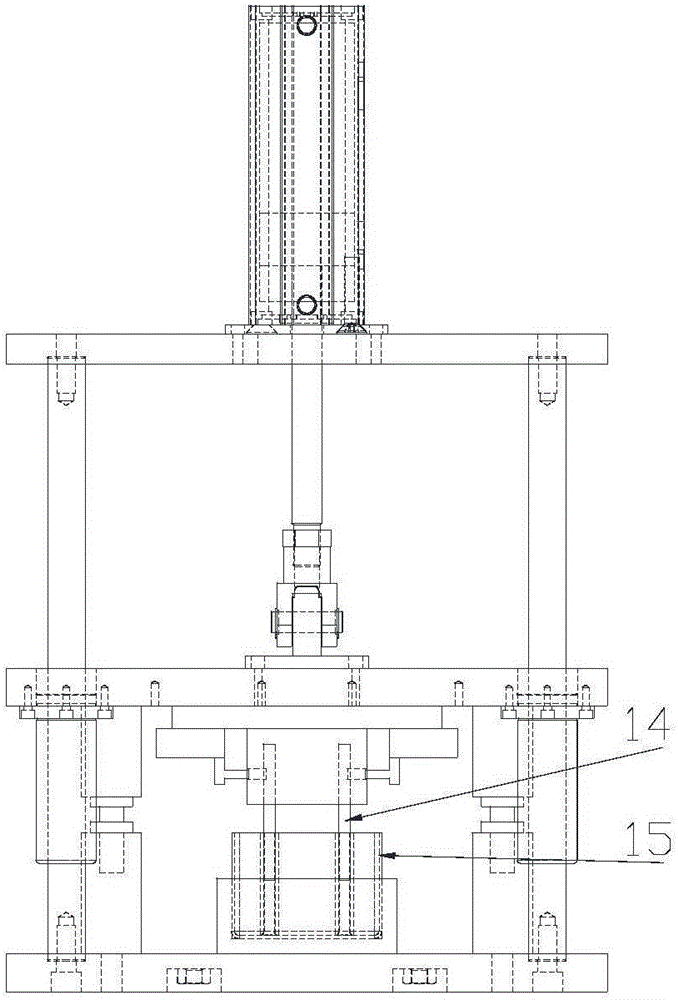

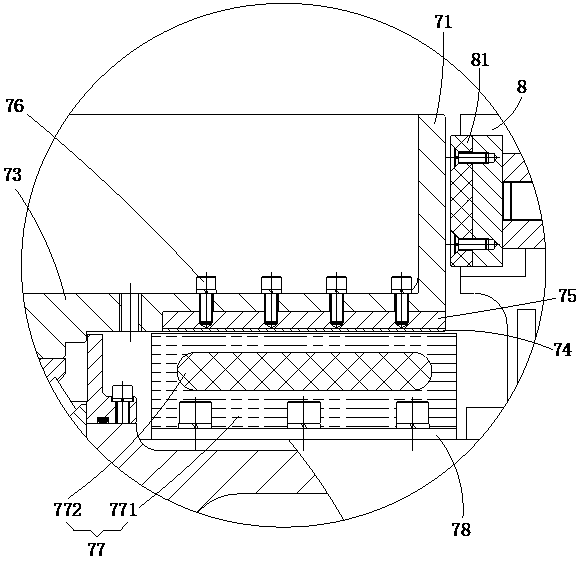

Plate liquid-filling shaping hydraulic machine

ActiveCN101298087AQuality improvementImprove mechanical propertiesMeasurement devicesPower control systemMaster cylinder

The invention discloses a sheet hydraulic-forming hydraulic press which is characterized by essentially comprising an underbeam, an upright post arranged on the underbeam, a top beam arranged on the upright post, a stretching beam connected on the upright post in a sliding manner, a compound master cylinder arranged on the top beam, a coaxial link deep-drawing and blank holding device arranged bellow the stretching beam, a liquid chamber arranged on the underbeam, a support oil tank which comprises a hydraulic power control system, a supercharger, etc. The underbeam, the upright post and the top beam are connected together by upright post nuts to form a rigid body; the compound master cylinder is essentially composed of a cylinder body fixed on the top beam, a master cylinder piston arranged in the cylinder body, a quick rod bush arranged on the master cylinder piston, a quick rod arranged in the rod bush, an embedded bank holding cylinder piston arranged in a master cylinder piston and flanges arranged at the mouth of the cylinder body; the master cylinder piston is connected with the stretching beam by the flanges; the embedded bank holding cylinder piston is connected with the coaxial link deep-drawing and blank-holding device which is essentially composed of a drawing slide, a blank holding slide which is coaxially connected to the drawing slide and is connected with the embedded bank holding cylinder piston and a male die which is fixed on the drawing slide. Compared with the prior art, the hydraulic press of the invention has the advantages of possessing dies with universality, reducing die cost and shortening production cycle.

Owner:FOSHAN CONSTANT HYDRAULIC MACHINERY

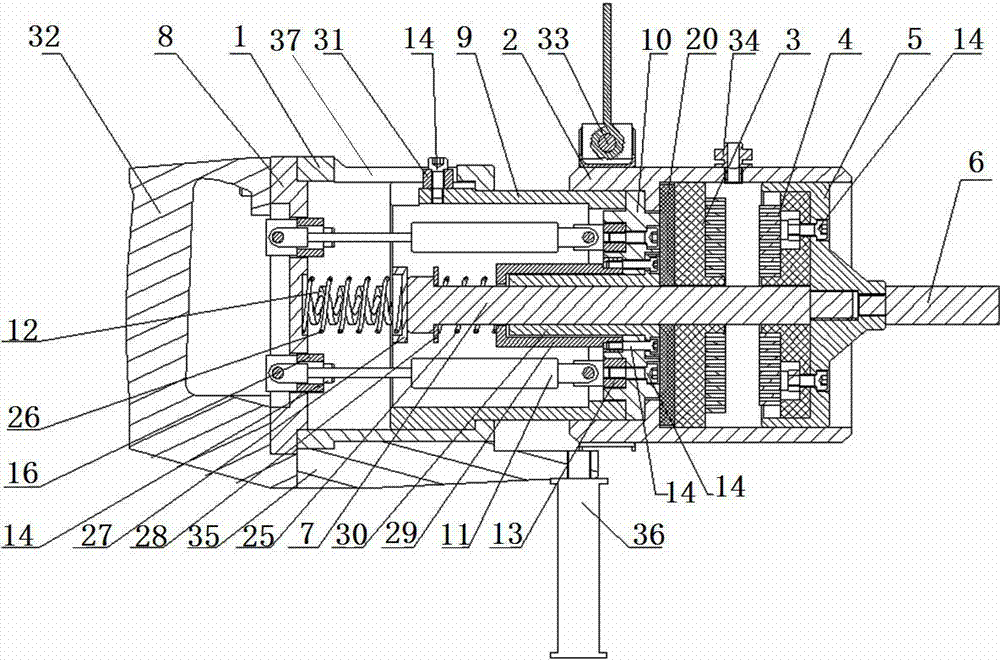

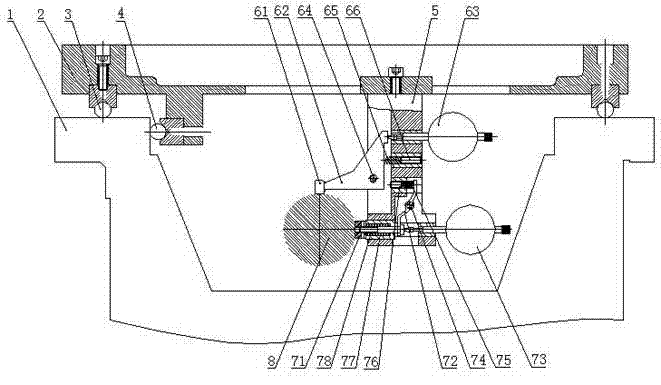

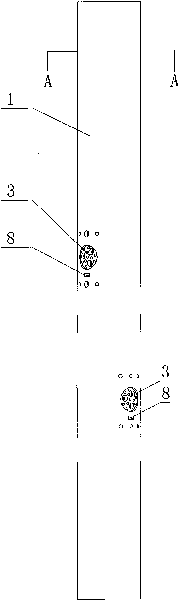

Hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter

The invention belongs to the technical field of the jumbolter, in particular to a hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter. The hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter solves the problem of the traditional jumbolter. The slide block assembly of the hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter comprises two groups of guideposts of a cylindrical structure; a short feeding cylinder is arranged in the slide block assembly; two long feeding cylinders are arranged on the outer side of the slide block assembly; the back of a frame assembly is provided with a dovetail-groove structure in sliding fit with the dovetail-shaped guide rail of a sleeve; the front side of the frame assembly is connected with the guidepost I by a slide block guide block and forms sliding fit with the guidepost I; and a guide connecting plate is connected with the guidepost II and forms sliding fit with the guidepost II. According to the hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter, the reliability of the jumbolter performance can be effectively improved, the anchoring and drilling efficiency is greatly improved, and the hydraulic-driving two-level feeding cylinder-oriented symmetrically-arranged jumbolter can be used for a smaller size space, has a better adaptability and is coal mine underground supporting equipment with high degree of automation and high reliability.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

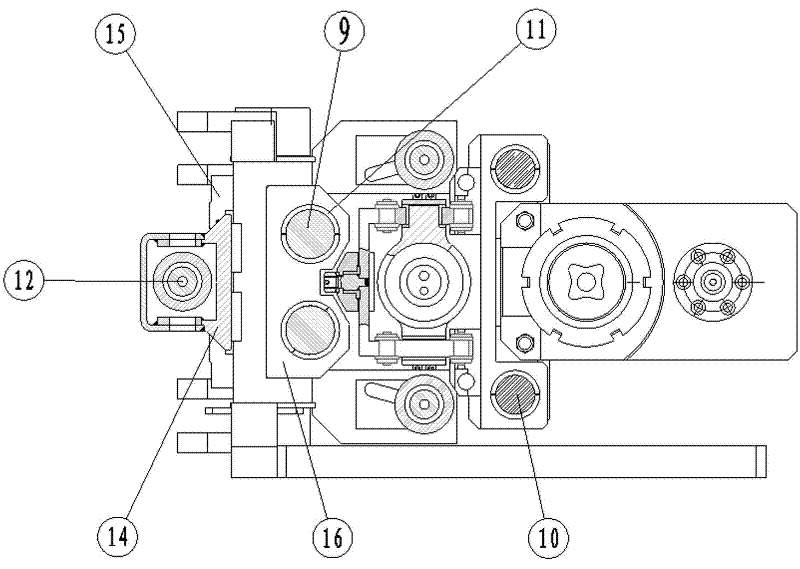

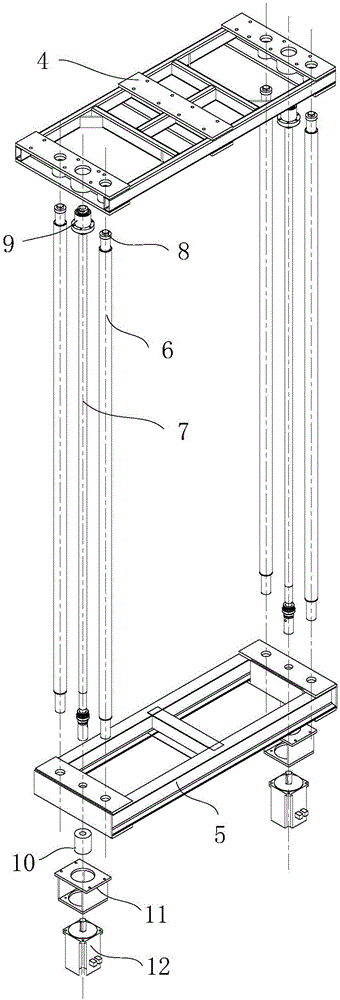

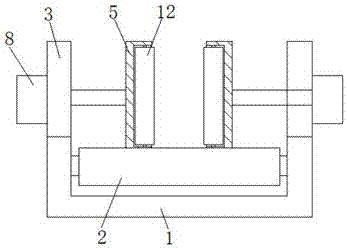

Automatic calibration equipment for light intensity of DLP (Digital Light Processing) printing equipment projector and calibration method

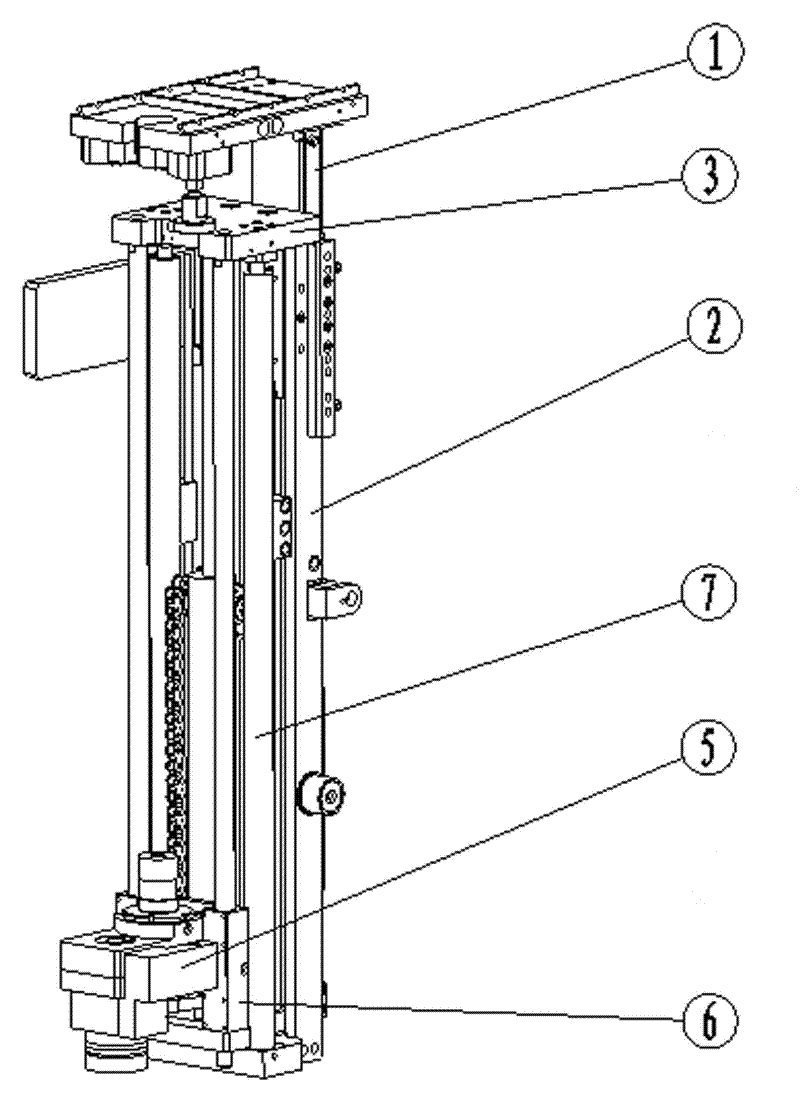

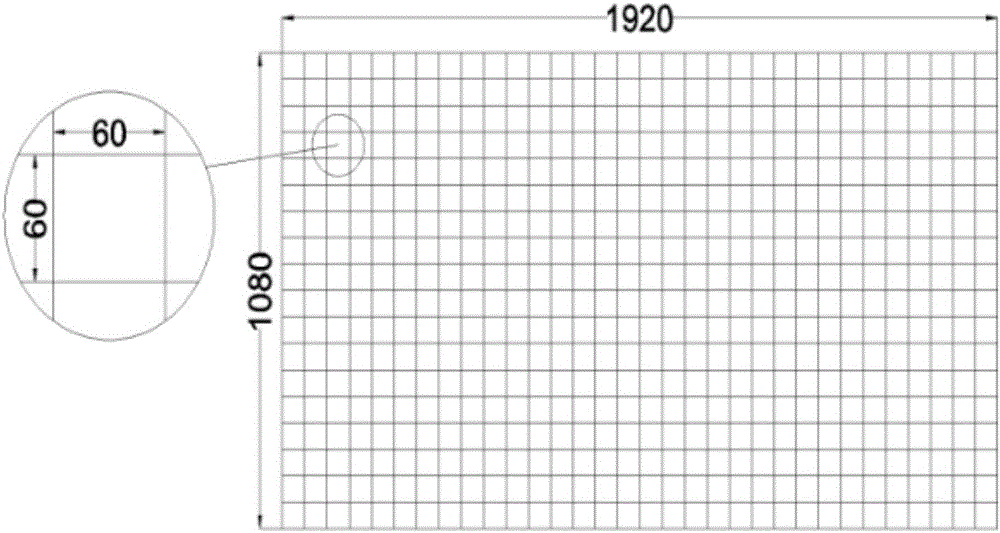

ActiveCN106273487AHigh guiding precisionImprove stabilityAdditive manufacturing apparatusGray levelEngineering

The invention discloses automatic calibration equipment for the light intensity of a DLP (Digital Light Processing) printing equipment projector. The automatic calibration equipment comprises a base; the base is provided with a first cylindrical linear guide rail which moves along the X-axis direction, a first sliding platform, a second cylindrical linear guide rail which moves along the Y-axis direction, a second sliding platform, a mounting platform, a third cylindrical linear guide rail which moves along the Z-axis direction and a third sliding platform in sequence from bottom to top; an extending platform is arranged at a side edge of the base in front of the third sliding platform; the third sliding platform and the extending platform are provided with a projector and a light intensity sensor respectively; the projector and the light intensity sensor are connected with a system control board; a calibration method comprises the following steps: step (1) focusing and adjusting; step (2) determining calibration reference light intensity; step (3) collecting compensation mask gray level numerical value of the projector; step (4) generating a compensation mask; step (5) carrying out calibration. The automatic calibration equipment provided by the invention is reasonable in design, compact in structure, convenient to operate and good in stability and can effectively obtain the light intensity of the projector.

Owner:SUZHOU BC TECH

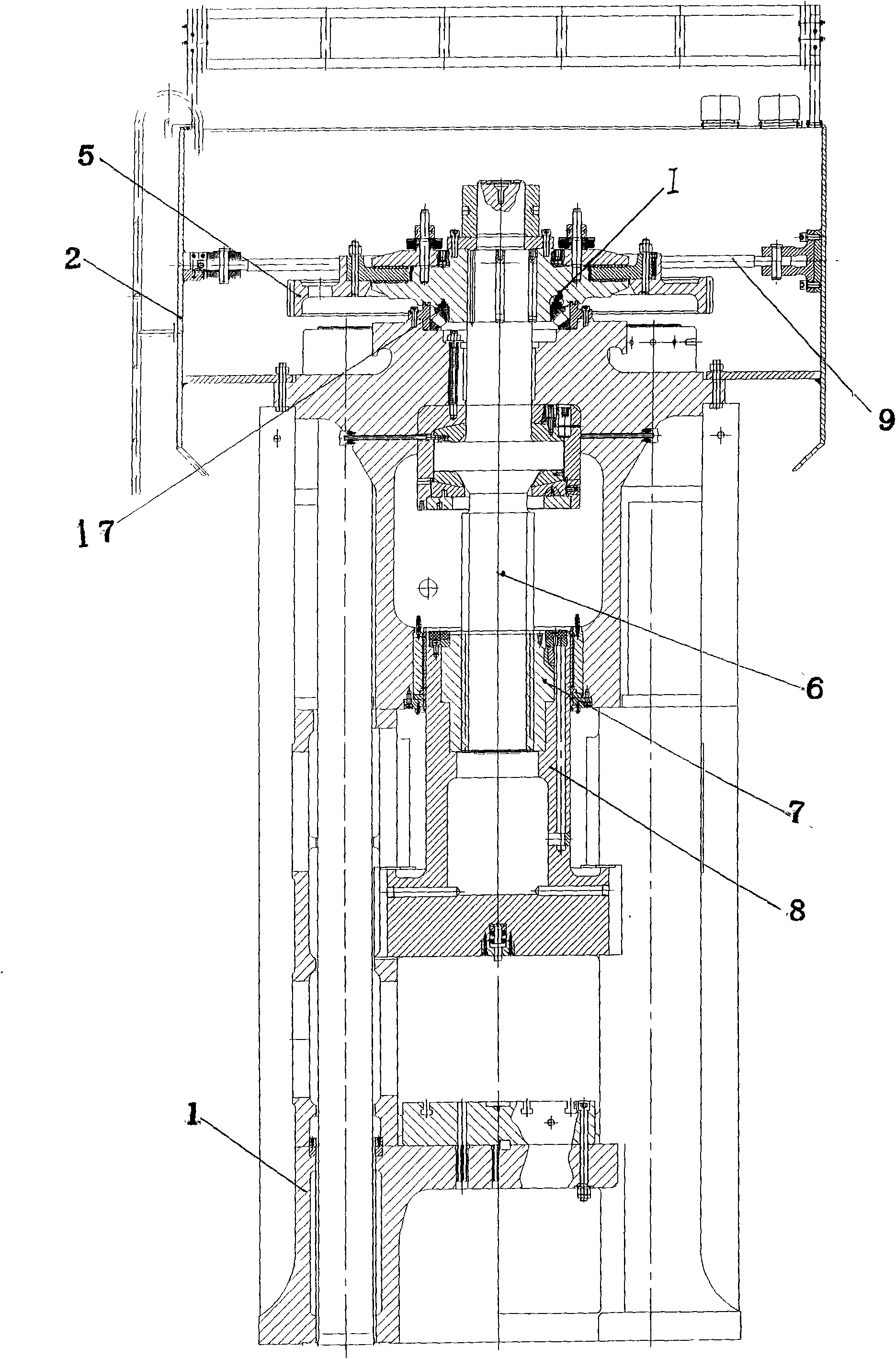

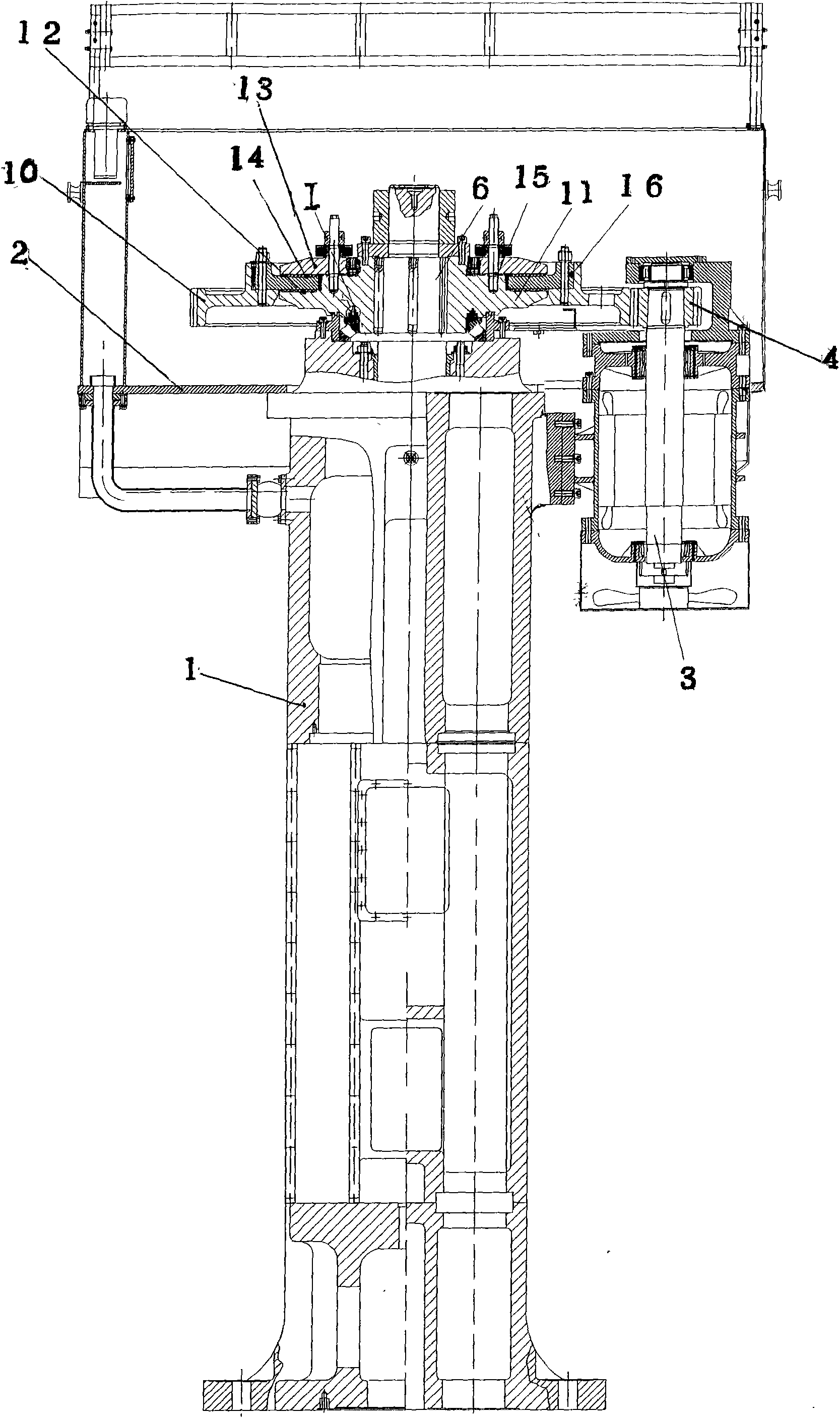

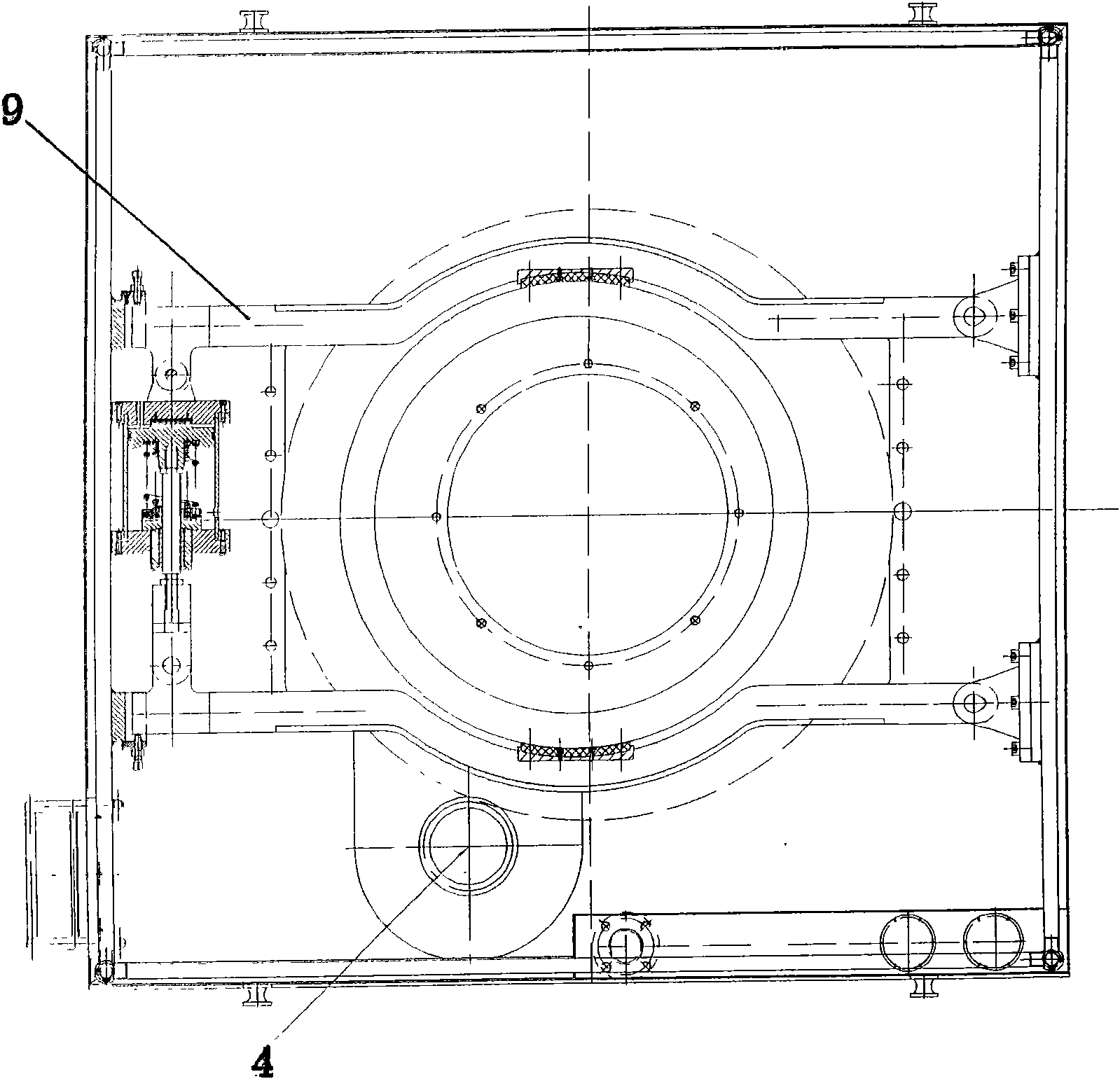

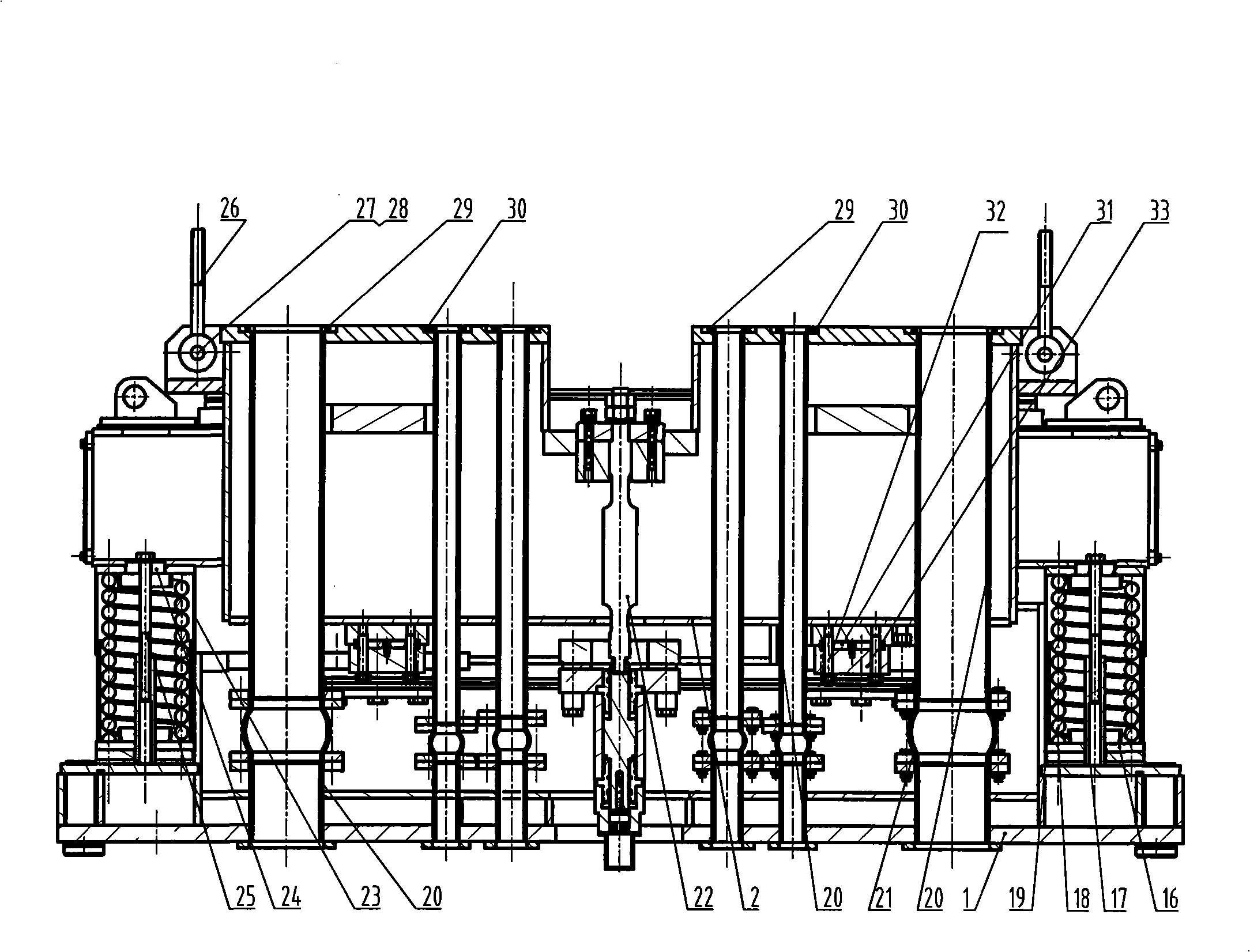

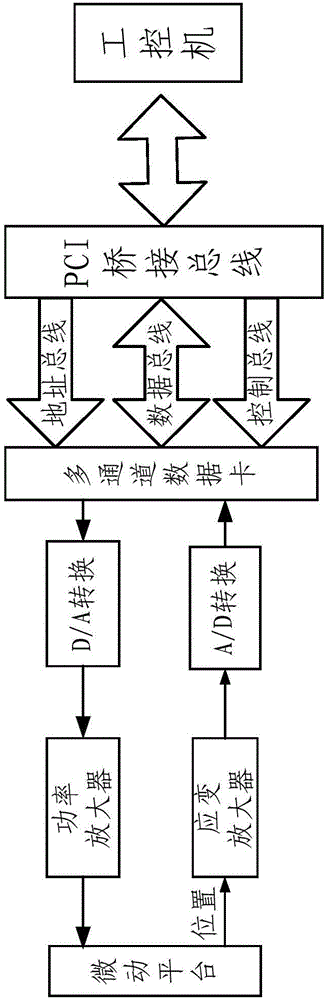

Plate-blank crystallizer hydraulic vibration device

A hydraulic vibration device of a slab crystallizer comprises two identical hydraulic vibration units and a hydraulic servocontrol system; the two hydraulic vibration units are fixed on the two sides of the crystallizer; the vibration guide device of each hydraulic vibration unit is a plate spring-type guide device; plate springs are mounted on the two sides as well as the upper and the lower positions of a vibration frame; the hydraulic servo cylinder of a vibration generation device is arranged on a fixed frame; and the piston rod of the hydraulic servo cylinder is connected with the vibration frame through a connecting rod. The hydraulic vibration device is characterized in that one end of each plate spring is connected with the fixed frame; the other end of each plate spring of the piston rod of the hydraulic servo cylinder that passes the middle part is connected with the vibration frame; a pair of plate springs on the left and the right, and the connecting position of the vibration frame and the fixed frame are arranged in a staggered manner; a pair of plate spring on the upper side and the lower side, and the connecting position of the vibration frame and the fixed frame are arranged in a staggered manner. The hydraulic vibration device can realize a nonsinusoidal vibration curve of the crystallizer, and has the advantages of small volume, light weight, high strength, stable performance in service, enhanced overall rigidity, high kinematic accuracy, long service life, etc.; furthermore, the hydraulic vibration device can meet the requirement for the vibration frequency of the continuous casting technology.

Owner:CONTINUOUS CASTING TECH ENG OF CHINA

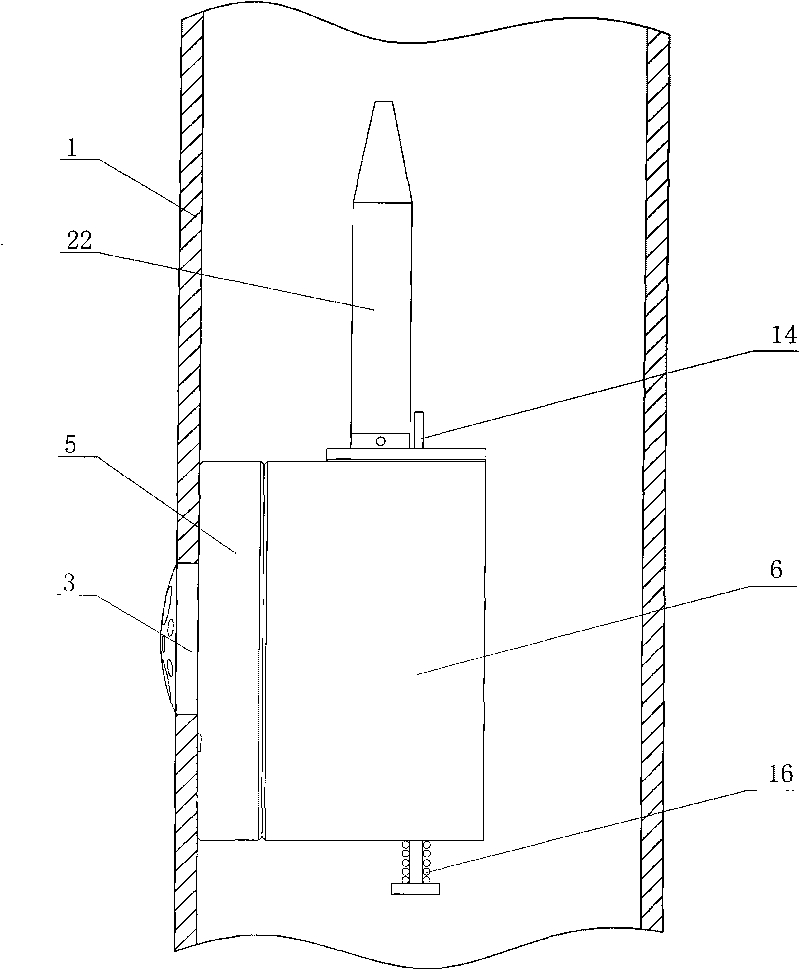

Diaphragm gas meter vertical shaft mounting device

ActiveCN105729095AAvoid deformationThe overall structure is simple and reliableMetal working apparatusHydraulic cylinderEngineering

Owner:CHONGQING RUILIBI GAS EQUIP

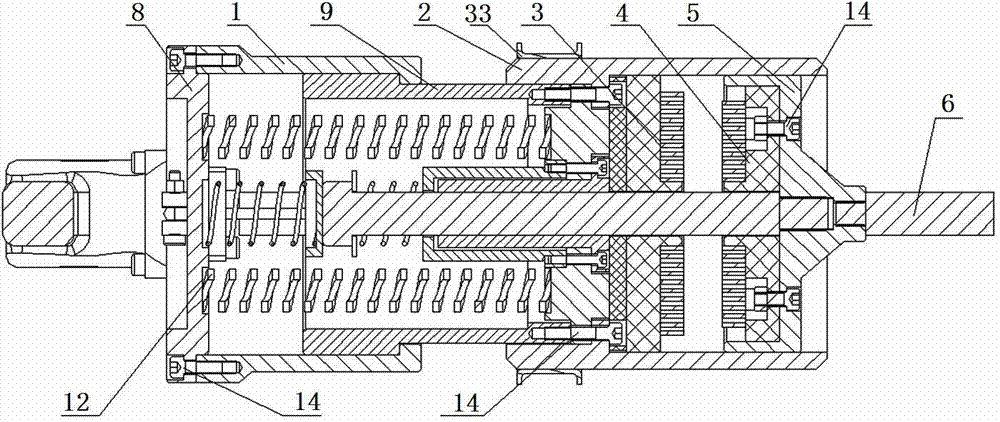

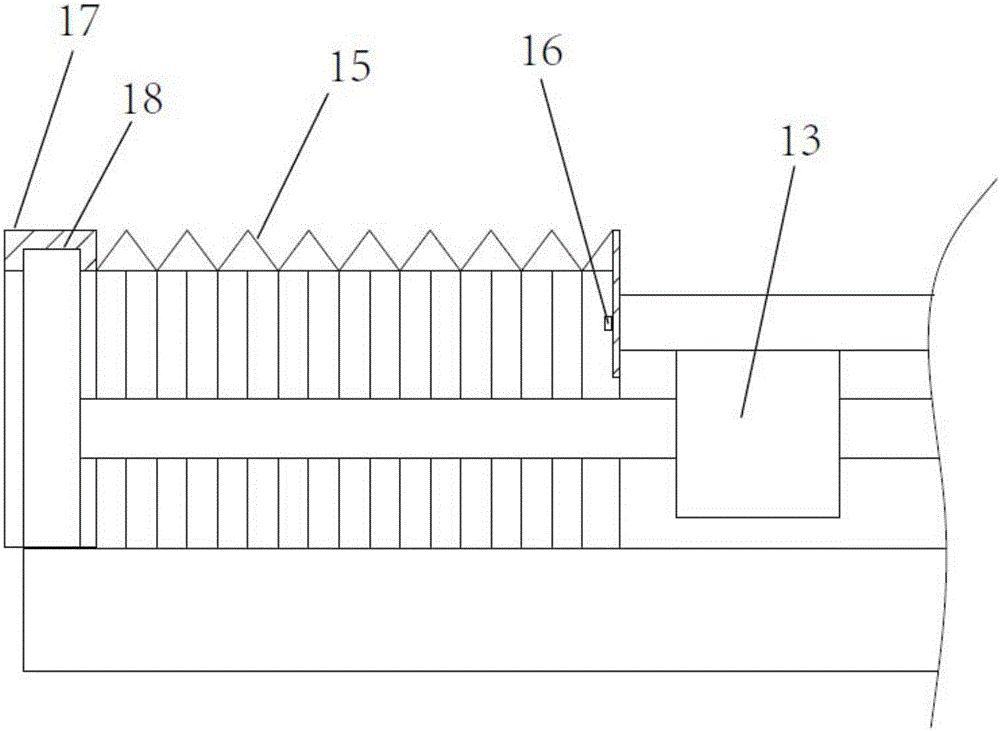

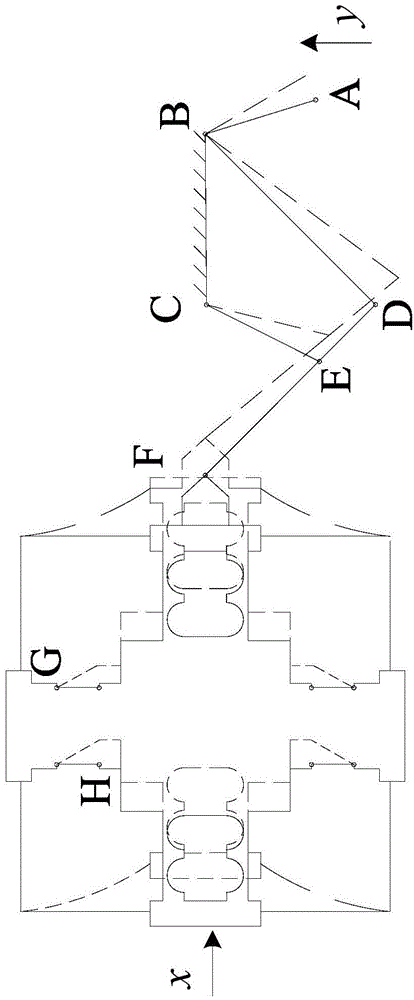

Macro/micro drive accurate feeding system with parallel series guiding rail joint portion

InactiveCN101474758AHigh movement precisionHigh guiding precisionFeeding apparatusNumerical controlPiezoelectric actuators

The present invention discloses a macro micro-drive precise feed system which is provided with a parallel connection slide way combination part. The macro micro-drive precise feed system comprises a slide carriage, a primary electrode of linear electric motor, a secondary electrode of linear electric motor, a macro-motion slide platform and a hollow actuator deformation slide way supporting component which is provided with an opening at one edge, wherein the slide carriage, the primary electrode, the second electrode, the macro-motion slide platform and the hollow actuator deformation slide way supporting component are installed in turn from the lower part to the upper part. A macro-motion slide platform motion guide way is installed between the slide carriage and the macro-motion slide platform in parallel. An actuator deformation flexible hinge assembly and a piezoelectric actuator are installed in the actuator deformation slide way supporting component. The actuator deformation slide way supporting component is fixedly connected with one end of an actuator deformation slide way micro motion block. The other end of actuator deformation slide way micro motion block extends out from the opening of actuator deformation slide way supporting component and is fixedly connected with a connector which is fixedly connected with a micro motion slide platform. The macro micro-drive precise feed system of the invention has the characteristics of high feed precision, high guiding precision, strong bearing capacity and excellent force applying state of actuator. The invention can be used for the middle-large scale multi-axis synchronous precise and ultra-precise numerical control machine tool, and can also be used for other precise digital control machine.

Owner:XIAN UNIV OF TECH

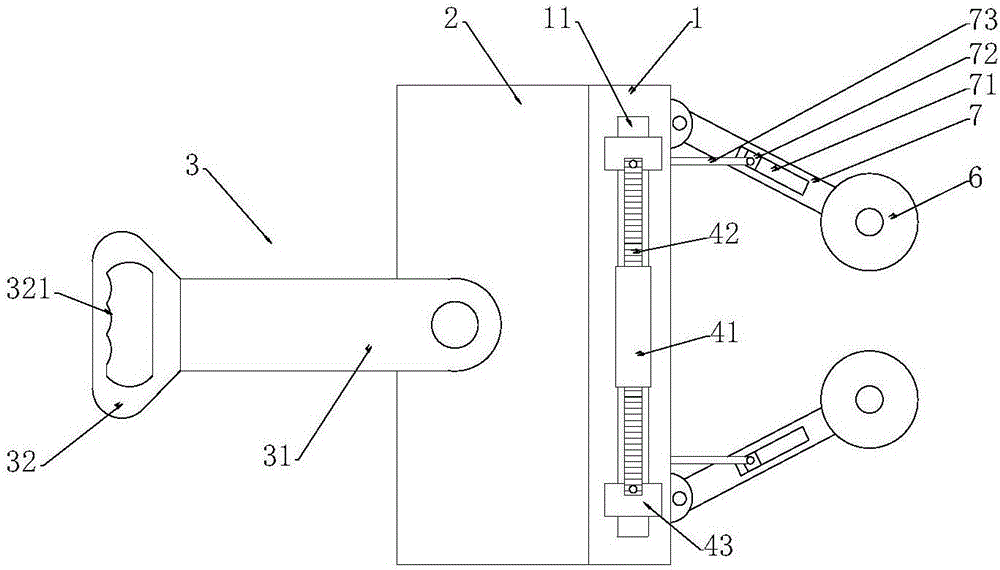

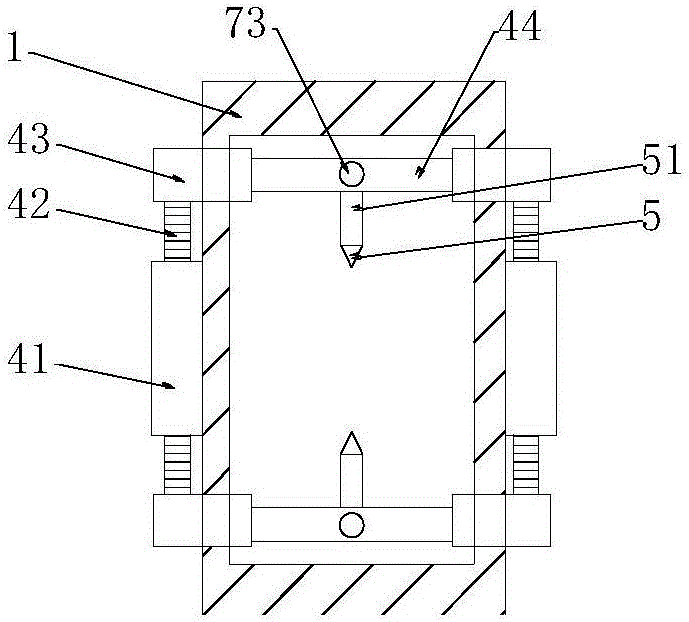

Manual cable stripping tool

InactiveCN107181209AControl feedAvoid damageApparatus for removing/armouring cablesEngineeringMechanical engineering

The invention discloses a manual cable stripping tool including a cutting part, a connecting part and an operating part that are successively connected, cutting knife feeding mechanisms are symmetrically arranged at the left and right sides of the cutting part, the cutting knife feeding mechanisms include screw rod sleeves, screw rods, first slide blocks, and bar-shaped blocks, the two screw rods are respectively connected with the upper and lower ends of each screw rod sleeve, the screw rods are connected with the first slide blocks, the cutting part is provided with a first slide groove matched with the first slide blocks, the first slide blocks are slidably clamped with the first slide groove, the two sides of the cutting part are provided with the bar-shaped blocks that are connected between the corresponding two first slide blocks in the vertical direction, knife rests are fixed at the center positions of the inner side surfaces of the bar-shaped blocks and are provided with cutters. The manual cable stripping tool can effectively complete the cable skin stripping work, is easy to control the feed, and avoids damage to the cable cores of the cutters.

Owner:CHONGQING SANXIA CABLE GRP

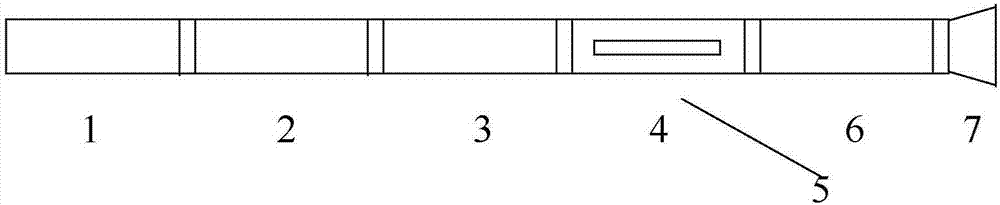

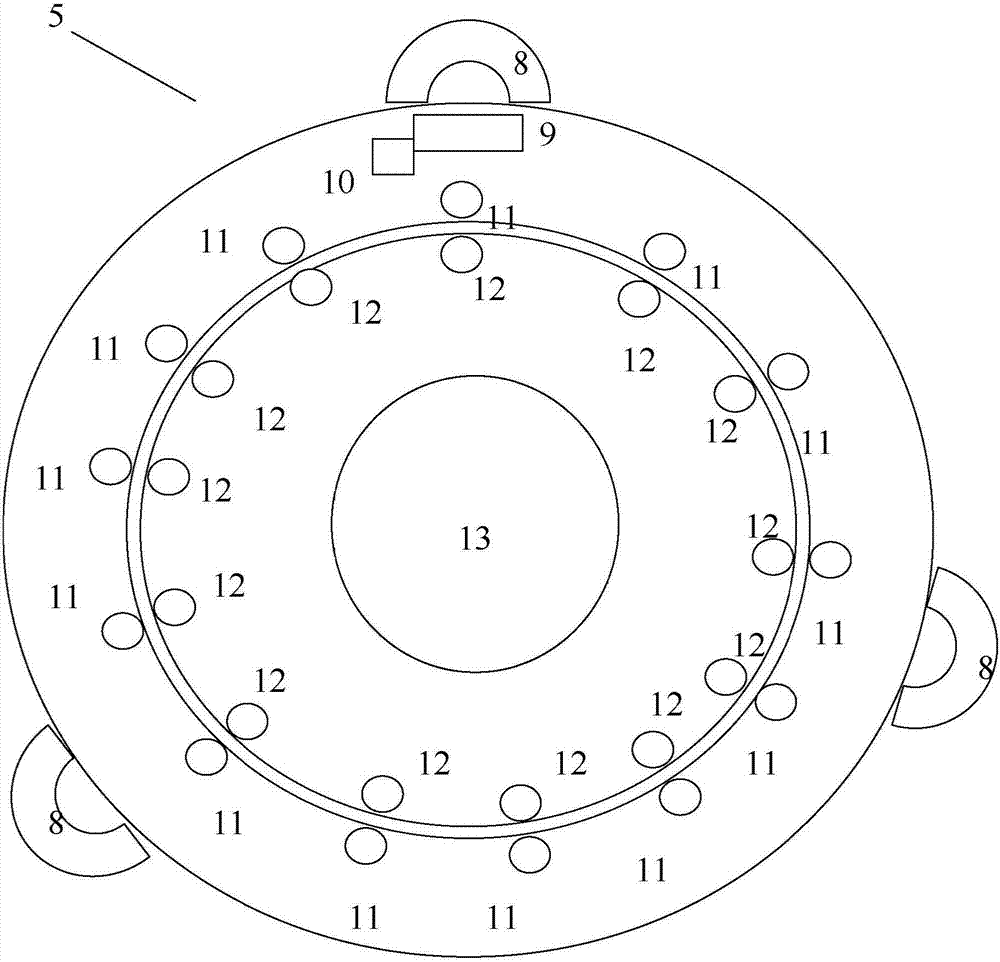

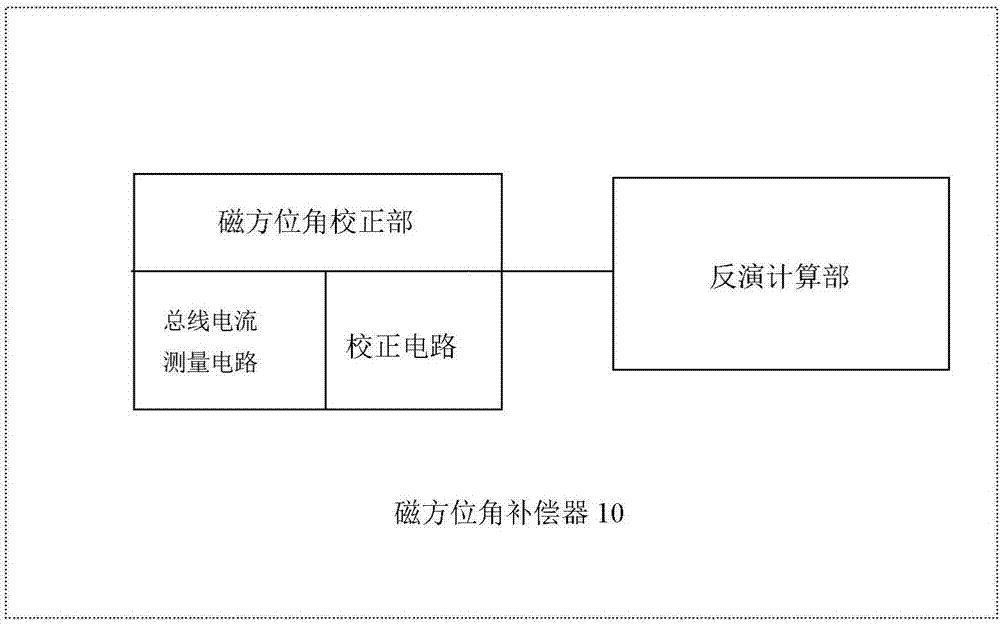

Well drilling orientating sensor

InactiveCN106988727AReduce difficultyEliminate disturbanceSurveyConstructionsControl systemWell drilling

A well drilling orientating sensor can achieve the high anti-interference capacity, the high precision and high guiding operation efficiency and is installed in a measurement and control system connected with a drilling-following measurement tool through an inserted shaft. The well drilling orientating sensor comprises an orientating sensor body, a magnetic orientation angular compensator and an inductive coil.

Owner:青岛智腾科技有限公司

Numerical control electric screw press driven by disk type linear motor

The invention relates to a numerical control electric screw press driven by a disk type linear motor. The numerical control electric screw press comprises a press body provided with a beam. A press body guide track, a sliding block hammer, a thrust bearing, a copper nut and a main screw are arranged on the press body. The press body guide track is fixed on the press body, the sliding block hammer is arranged on the lower portion of the beam and can slide on the press body guide track, the thrust bearing is fixed on the bottom of the beam, the copper nut is fixed on the sliding block hammer, one end of the main screw and the copper nut form a screw pair to drive the sliding block hammer to move linearly, and the disk type linear motor is arranged on top of the beam. The disk type linear motor comprises a flywheel rotor and a stator assembly. The stator assembly is fixed on the top of the beam and arranged at the bottom of the flywheel rotor, and the other end of the main screw is fixed at the rotary axis position of the flywheel rotor. A brake is arranged on the lateral side of the outer circumference of the flywheel rotor and brakes rotation of the main screw by braking the flywheel rotor. The numerical control electric screw press has the advantages of being convenient to maintain, low in energy consumption, small in noise, precise in control, high in safety performance and the like.

Owner:HUBEI FUSHENG FORGING MACHINE

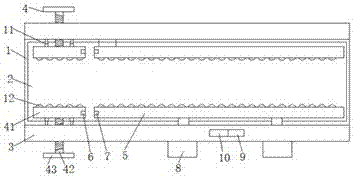

Forklift truck type carrying trolley of flexible manufacturing system

InactiveCN104692063AHigh guiding precisionGood motion stabilityMechanical conveyorsAutomatic processingEngineering

The invention discloses a forklift truck type carrying trolley of a flexible manufacturing system, and relates to the technical field of relevant automatic processing equipment. The forklift truck type carrying trolley comprises an X-direction guide rail bracket, wherein an X-direction linear guide rail is arranged on the X-direction guide rail bracket; an X-direction sliding seat is mounted on a sliding block of the X-direction linear guide rail; an X-direction driving gear is mounted below the X-direction sliding seat and drives the X-direction sliding seat through a gear rack to do transverse motion on the X-direction guide rail bracket. The carrying trolley has the advantages of high guide precision, high moving steadiness and simple and compact structure.

Owner:四川普什宁江机床有限公司

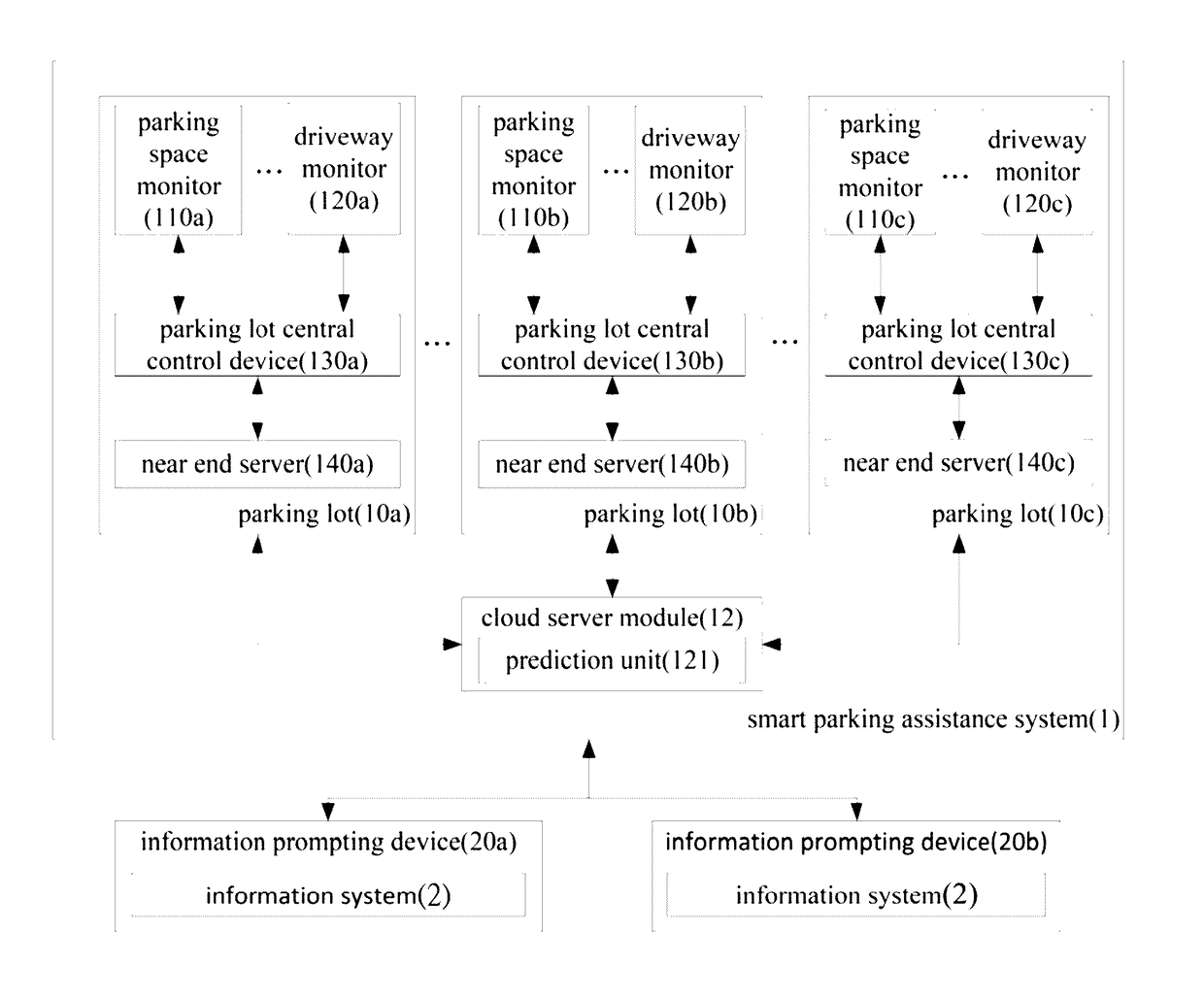

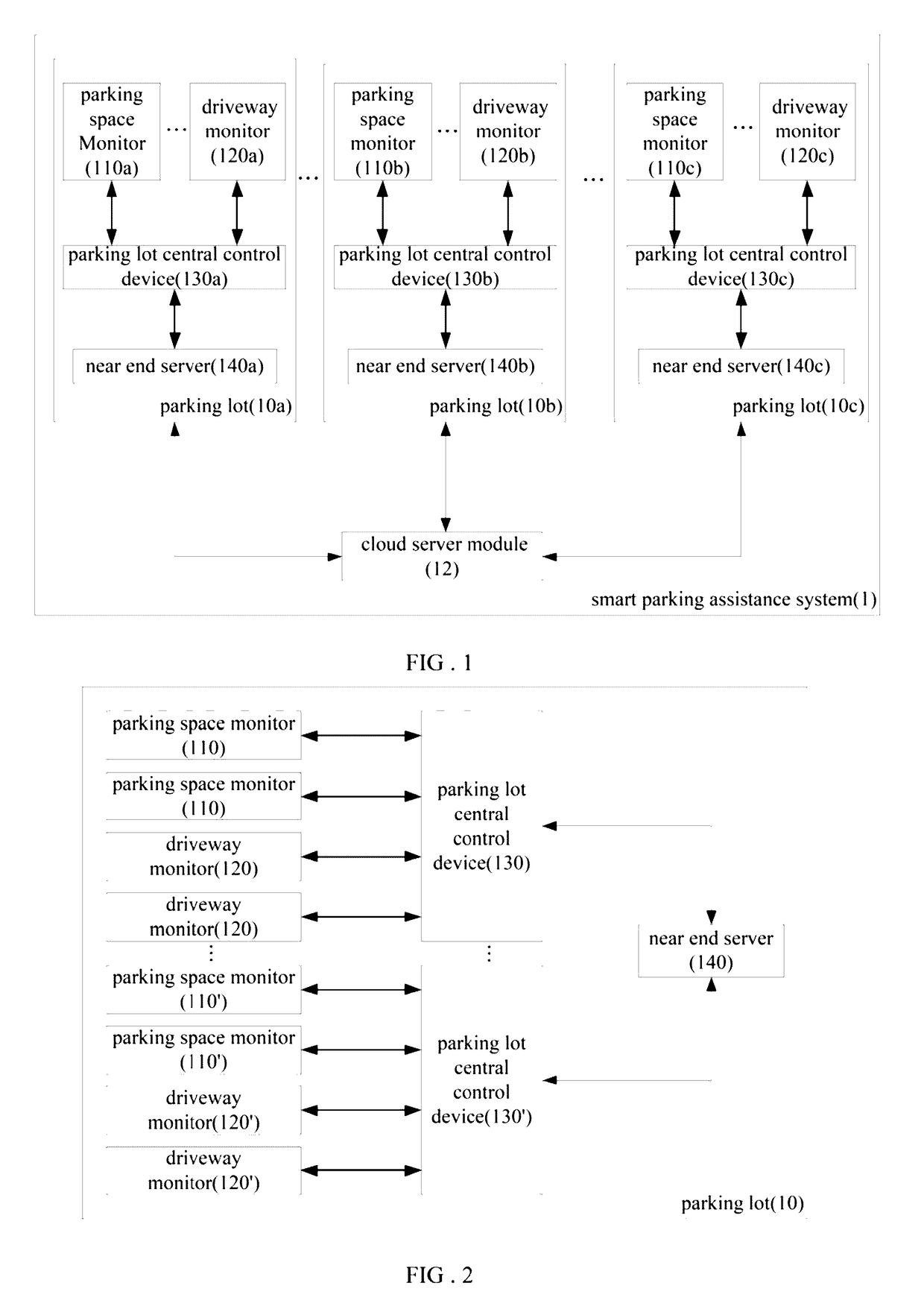

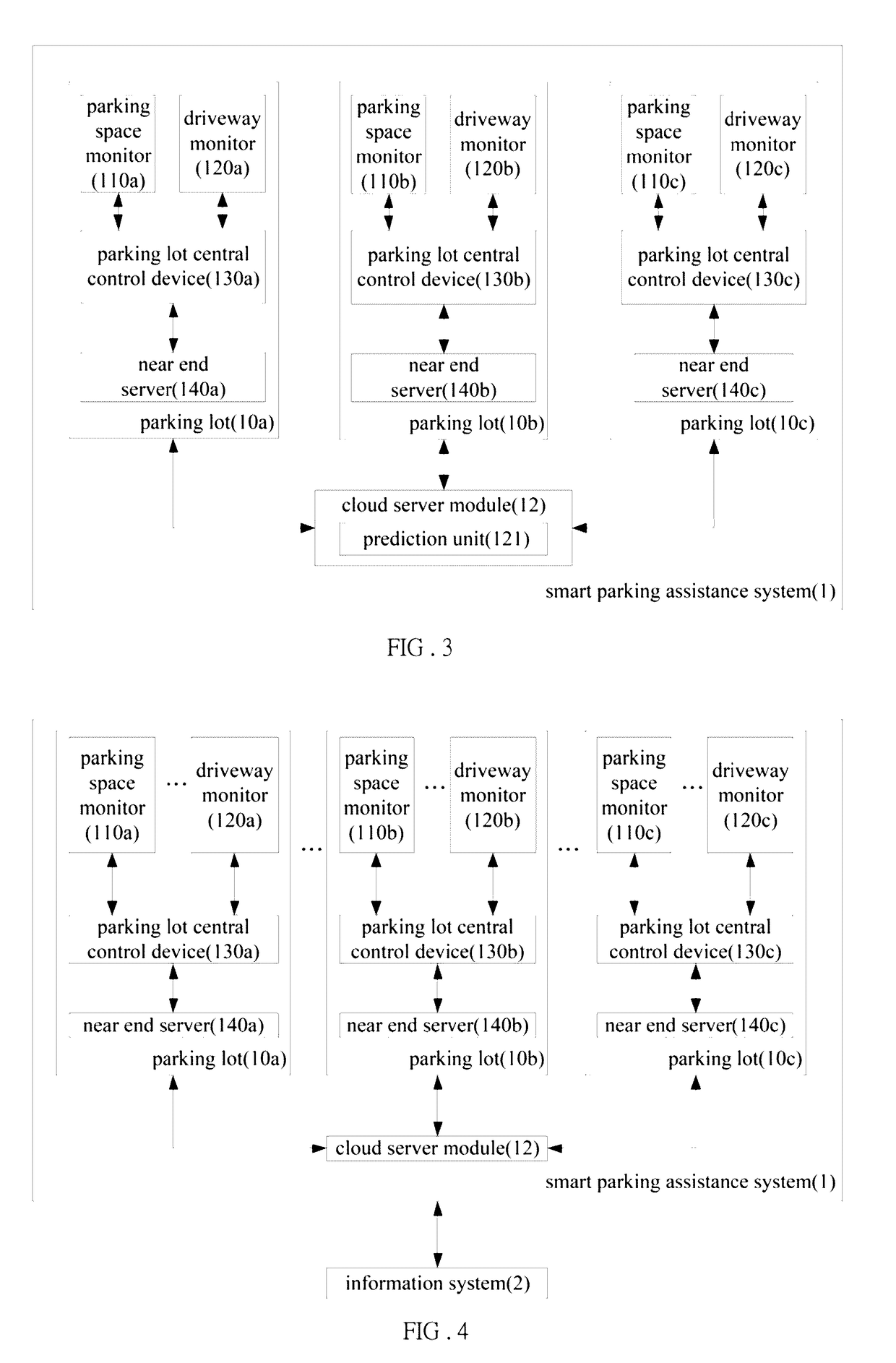

Innovated smart parking assistance system and information system

ActiveUS9666073B1Improve accuracyAvoid runningTransportation facility accessControl with pedestrian guidance indicatorParking areaParking space

An innovated SMART Parking System, PRIN System and an Information System are provided. The PRIN System is able to manage multiple parking lots without range limitation, and deeply monitor the individual parking space status and also driveway status at each parking lot upon the control devices deployed. By the bi-directional communication, the control devices are able to be managed and changed the control methodology for dynamic parking service support. Besides, the Information System can provide the real-time parking service information for either remote or local access to assist the quick parking without spending too much driving and searching time for parking. Therefore, the PRIN System and Information System facilitates the problem solving of traffic jam and difficult parking within the city effectively, and significantly reduce the social cost, vehicle emission and carbon monoxide to improve the air we breathe and city environment we care.

Owner:PAKING TECH INC

Manual spring tension and compression testing machine

InactiveCN103292969AReduce usageLow manufacturing and maintenance costsElasticity measurementElectronic componentCalipers

The invention discloses a manual spring tension and compression testing machine which aims to solve the problems that spring elasticity coefficients are detected by special equipment mostly made of electronic components currently and the special equipment is not applicable to field operation and the like. The manual spring tension and compression testing machine comprises a frame, a measuring mechanism, a transmission mechanism and a tension and compression clamp mechanism. The measuring mechanism comprises a wide-range vernier caliper (12), a small-range vernier caliper (16) and a spring (5). The spring (5) is sleeved on an upper pressing plate guide rod (3), the upper end of the spring (5) is fixed with a middle crossbeam (6), the lower end of the spring (5) is fixed with an upper spring pressing plate (15) of the tension and compression clamp mechanism, an upper measuring jaw of the small-range vernier caliper (16) is fixed with the middle crossbeam (6), a lower measuring jaw of the small-range vernier caliper (16) is fixed with the lower surface of the upper spring pressing plate (15), an upper measuring jaw of the wide-range vernier caliper (12) is fixed with the upper surface of an upper crossbeam (10), and a lower measuring jaw of the wide-range vernier caliper (12) is fixed with the lower surface of the upper spring pressing plate (15).

Owner:JILIN UNIV

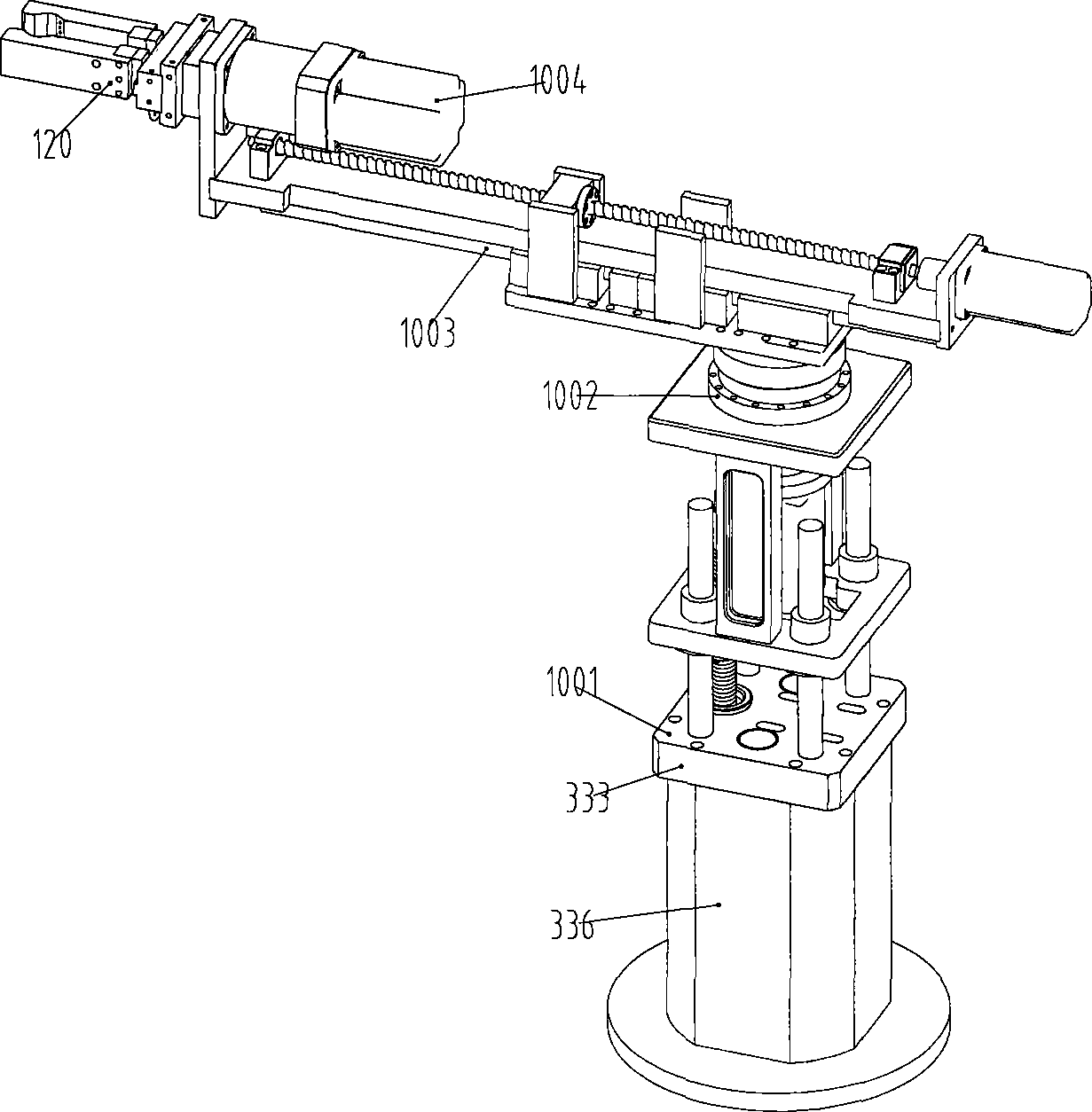

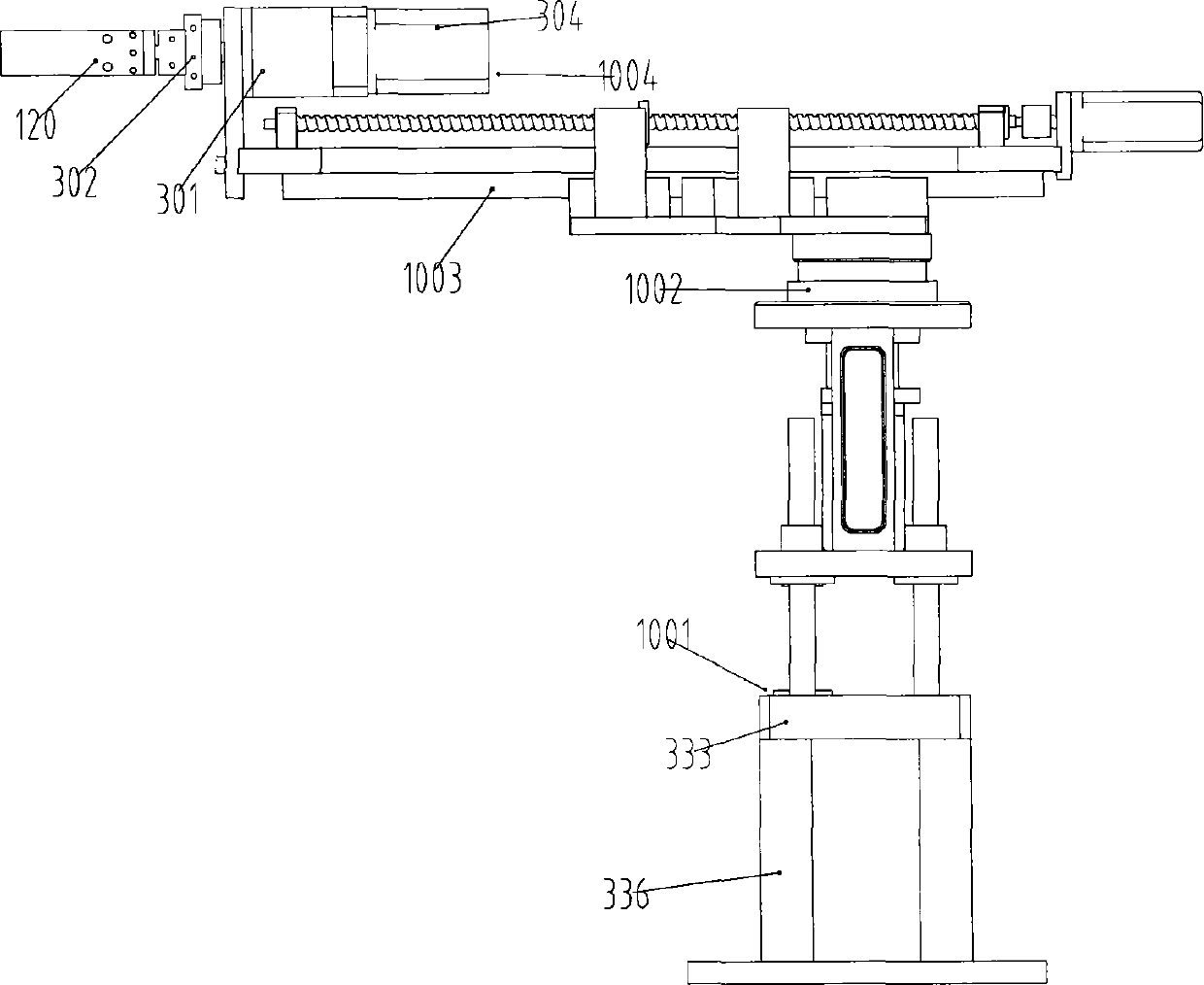

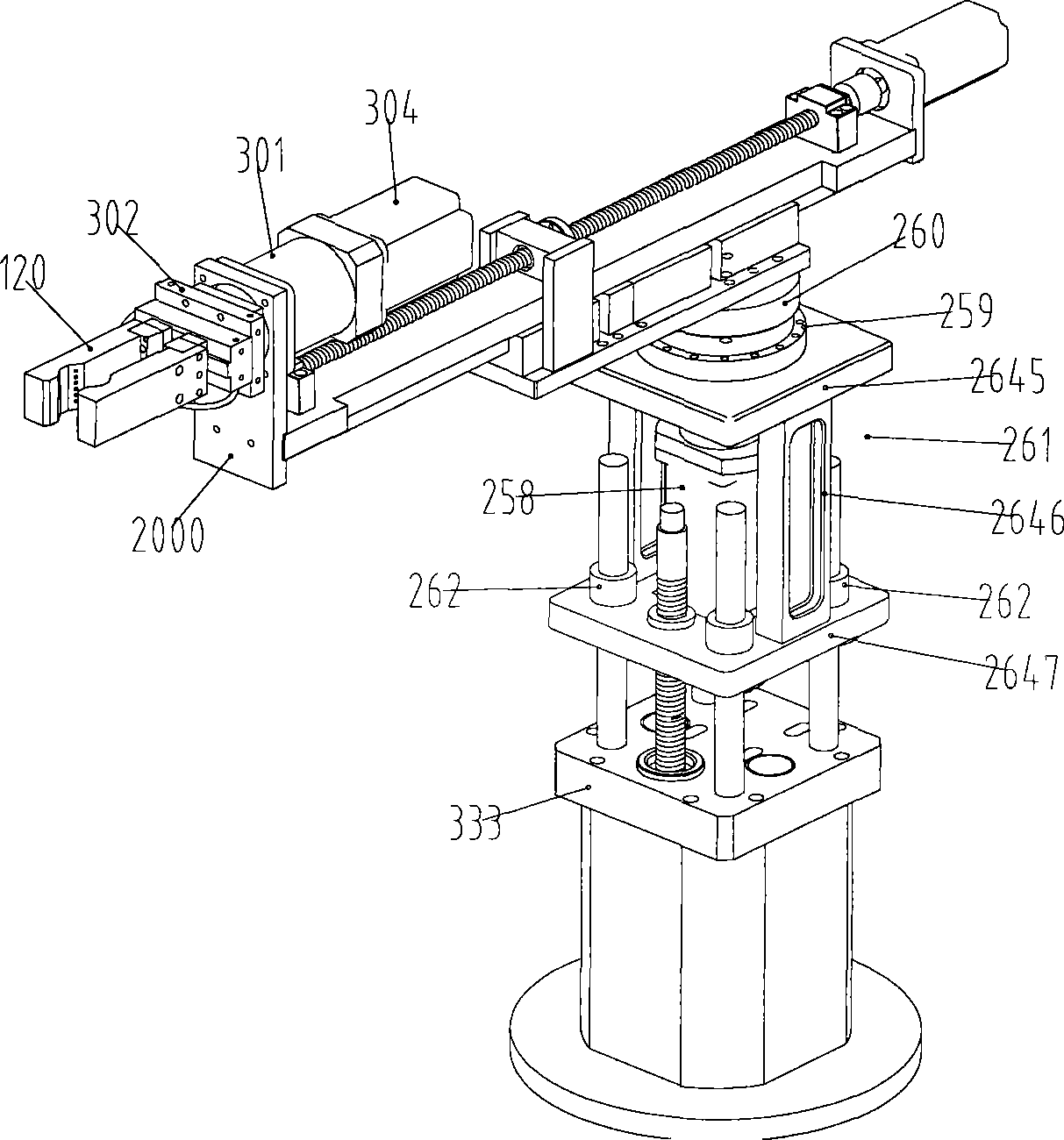

Support unit of two-support and one-lifting target support rotary table

The invention relates to a support unit of a two-support and one-lifting target support rotary table. The support unit mainly consists of a vertical driving guide assembly, a horizontal driving guide assembly, and a support rod and wave absorbing material sleeve cylinder assembly. The support unit is characterized in that the support function of the two-support and one-lifting target support rotary table is mainly realized, and the high-precision movement of the support unit along two directions is realized, namely the vertical movement along the direction of a revolving shaft of the target support rotary table, and the horizontal movement along the radial direction of the target support rotary table; the high-precision movement and positioning along the vertical direction can be realized by the matching of two servo driving motors, two groups of high-precision ball screws and four groups of high-precision guide columns, and the high-precision movement and positioning along the horizontal direction can be realized by the matching of one servo driving motor, one group of high-precision ball screw and two linear guide rails; a support rod is connected with a to-be-tested target through a ball hinge movement pair. The support unit has the advantages that the movement is flexible, the stability is high, the contact area is small, and the like; the support unit is matched with a traction unit, so that the building height and pitch attitude of the to-be-tested target can be adjusted.

Owner:BEIHANG UNIV

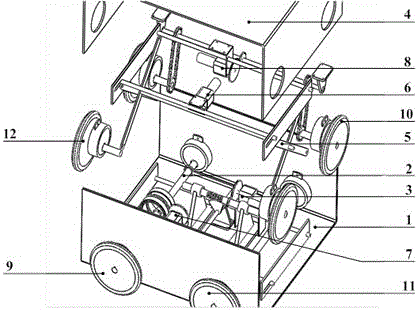

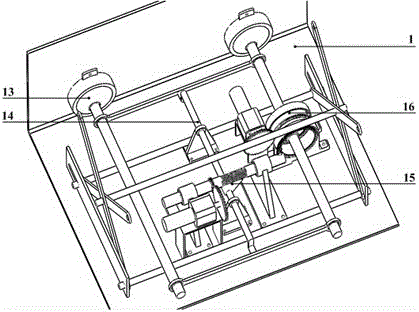

Variable-structure mobile robot capable of making orthogonal bidirectional movement and control method of variable-structure mobile robot

ActiveCN106003039AEnhanced mobilityIncrease flexibilityProgramme-controlled manipulatorDrive wheelEngineering

The invention discloses a variable-structure mobile robot capable of making orthogonal bidirectional movement and a control method of the variable-structure mobile robot. The variable-structure mobile robot capable of making orthogonal bidirectional movement comprises a chassis, a separation type variable-position driving mechanism, a variable-position motor, an integral variable-position driving mechanism, a variable-position electric push rod, a driving wheel motor A, a driving wheel motor B, a driving wheel A, a driving wheel B, a follower wheel A, a follower wheel B, a control device and a guiding sensor. The separation type variable-position driving mechanism is installed on the chassis, and the position, relative to the chassis, of the axis of the driving wheel A is changed while the position of the driving wheel motor A is kept unchanged. The integral variable-position driving mechanism is installed on a top cover, and the position, relative to the chassis, of the axis of the driving wheel B is changed by changing the height of the top cover. The axis of the driving wheel A is orthogonal with the driving wheel B, and the lowest position of the axis of the driving wheel A is the same as that of the driving wheel B. Orthogonal bidirectional movement of the mobile robot is achieved by changing the driving wheels making contact with the ground, the movement direction can be freely switched between orthogonal directions in the same plane, and the movement maneuverability and flexibility of the mobile robot are enhanced.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Core fixing type pinch roll guide

InactiveCN101786108AAvoid large vibrationAvoid stacking, etc.Guiding/positioning/aligning arrangementsEngineeringMechanical engineering

The invention relates to a pinch roll guide for guiding rolled pieces into a laying head. A guide groove for the rolled pieces to pass through is arranged in the guide and is communicated with the inlet and the outlet of the guide; a tail guide roll set is arranged at the tail of the guide and comprises a plurality of branched guide rolls; annular grooves are formed along the circumferential directions of the branched guide rolls; the groove surfaces of the annular grooves on each of the branched guide rolls enclose a full circle for the rolled pieces to pass through; the branched guide rolls are fixed on guide roll seats; and the guide roll shafts of the branched guide rolls are rigidly matched with the guide roll seats. The technical scheme shows that the guide roll shafts of the branched guide rolls are rigidly matched with the guide roll seats for fixing the branched guide rolls, thus the closeness of the full circle can be kept all the time, and the elastic change can not occur. The rigid matching can achieve the purpose of forcibly fixing cores of the rolled pieces, has high guide precision, good rigidity and small vibration, avoids impact, surface scratches and scuffing caused by off tracking generated when the rolled pieces enter the full circle, and simultaneously avoids large amplitude vibration of the guide, or distortion and stacking of the rolled pieces and other phenomena.

Owner:HEFEI BAISHENG SCI & TECH

Guide mechanism of machine tool and machine tool

ActiveUS20160115993A1Improve damping performanceReduce frictionLinear bearingsShaftsHydrostatic pressureEngineering

A guide mechanism for a machine tool includes a movement member and a guide member in a form of first and second rails the movement member and the guide member relatively movable to each other. A hydrostatic pressure guide mechanism and a sliding guide mechanism are formed between the movement member and the first and second rails. The hydrostatic pressure guide mechanism includes a static pressure chamber, a seal portion sealing a periphery of the static pressure chamber, and a supply passage configured to supply a lubricating oil into the static pressure chamber.

Owner:TOSHIBA MASCH CO LTD

Upper sliding block pressing mechanism of powder forming machine

The invention relates to an upper sliding block pressing mechanism of a powder forming machine. The upper sliding block pressing mechanism comprises an upper sliding block ball head screw adjusting mechanism, a hydraulic cushion pressure display mechanism, a protective demoulding mechanism, a synchronous pressing and final pressurizing mechanism and a powder pressing and shifting mechanism. The invention provides the upper sliding block pressing mechanism of the powder forming machine, which has the advantages of reliability in forming products, and stable operation.

Owner:YANGZHOU HAILI PRECISION MACHINERY MFG

Feeding device capable of being prevented from mechanical damage

ActiveCN107214260AAvoid wear and tearSave adjustment timeMetal-working feeding devicesPositioning devicesEngineeringMaterial supply

The invention discloses a feeding device capable of being prevented from mechanical damage. The feeding device comprises a material supplying platform. Conveying rollers are arranged on one side of the material supplying platform at equal intervals. Guide side plates vertically mounted on the material supplying platform are arranged on the two sides of the conveying rollers. A manual adjusting device is arranged at one end of the material supplying platform and comprises two manual adjusting guide plates, two lead screws and two adjusting handles. Two automatic adjusting guide plates are parallelly arranged on one side of the manual adjusting device. Infrared emitters are arranged on the sides, close to the automatic adjusting guide plate, of the manual adjusting guide plates. Infrared receivers are arranged on the sides, close to the manual adjusting guide plates, of the automatic adjusting guide plates. The structure is simple, a worker only needs to set and adjust the distance between the manual adjusting guide plates according to the width of a steel plate, the feeding device can complete the rest of guide position automatically, the adjusting time is saved, abrasion of the guide side plates is avoided, guide precision is high, and the working efficiency is improved.

Owner:JIANGSU BINXIN STEEL GRP

Piezoelectric micro-platform capable of amplifying based on flexible hinge

ActiveCN104925738AReduce volumeNo mechanical frictionTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesEngineeringHinge point

The invention discloses a piezoelectric micro-platform capable of amplifying based on a flexible hinge. The piezoelectric micro-platform comprises a frame and a carrier platform, wherein a micro-driver and an amplifying mechanism are arranged on the frame; the amplifying mechanism is a double-rocker mechanism; an extension section is arranged on one end, which is far away from a connecting rod, of a driving rocker of the double-rocker mechanism, and a free end of the extension section of the driving rocker supports the micro-driver; the driving rocker and the extension section thereof form an amplifying lever with a hinge point of the driving rocker and the frame as a pivot; an extension section is arranged on one end of the connecting rod, which is far away from the driving rocker; the carrier platform is connected to a decoupling mechanism, the decoupling mechanism is formed by at least one pair of decoupling units, and the two decoupling units are symmetrical around the center of the carrier platform; each decoupling unit is formed by a connecting arm and a pair of flexible arms, one end of each flexible arm is hinged to the frame, the other end of each flexible arm is hinged to the connecting arm, and the other end of the connecting arm is hinged to the carrier platform; the extension section of the connecting rod is hinged to any one decoupling unit. The piezoelectric micro-platform has the advantage that the driving displacement of the micro-driver can be amplified.

Owner:NINGBO UNIV

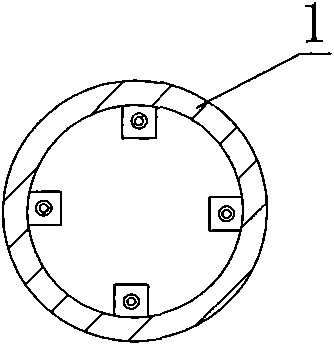

Rotary steerable system and rotary steerable executor for drilling

InactiveCN101705787ATo achieve the guiding purposeIncrease the point of actionDirectional drillingHydraulic cylinderAutomatic control

The invention discloses a rotary steerable system and a rotary steerable executor for drilling, which are used for solving the problems that the numbers of hydraulic cylinders and pistons are limited and the steering is not easy to control in the conventional rotary steerable tool. The rotary steerable system of the invention comprises at least three rotary steerable executors fixedly arranged ina drill collar (1); and the at least three rotary steerable executors are distributed in the circumferential direction from the top to bottom. The rotary steerable executor of invention comprises a hydraulic executing module, a lead wire seal module, and an electromagnetic valve module used for controlling a fluid to enter and exit a piston cavity (27); the lead wire seal module is fixed on a sealing cover (19) and comprises a connecting plug (24); and a lead wire is connected with the electromagnetic valve module through the connecting plug (24) in a sealing mode. The rotary steerable systemand the rotary steerable executor for drilling can perform all-around continuous precise automatic control on a wellbore trajectory safely and reliably, and has no influence on accuracy indexing caused by mud property.

Owner:北京中联博韬科技咨询有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com