Plate-blank crystallizer hydraulic vibration device

A hydraulic vibration and crystallizer technology, applied in key equipment fields, can solve the problems of inability to adjust amplitude, frequency and waveform online, low vibration accuracy, and low bearing capacity of digital hydraulic cylinder method, achieving light weight and improving the quality of cast slabs , compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

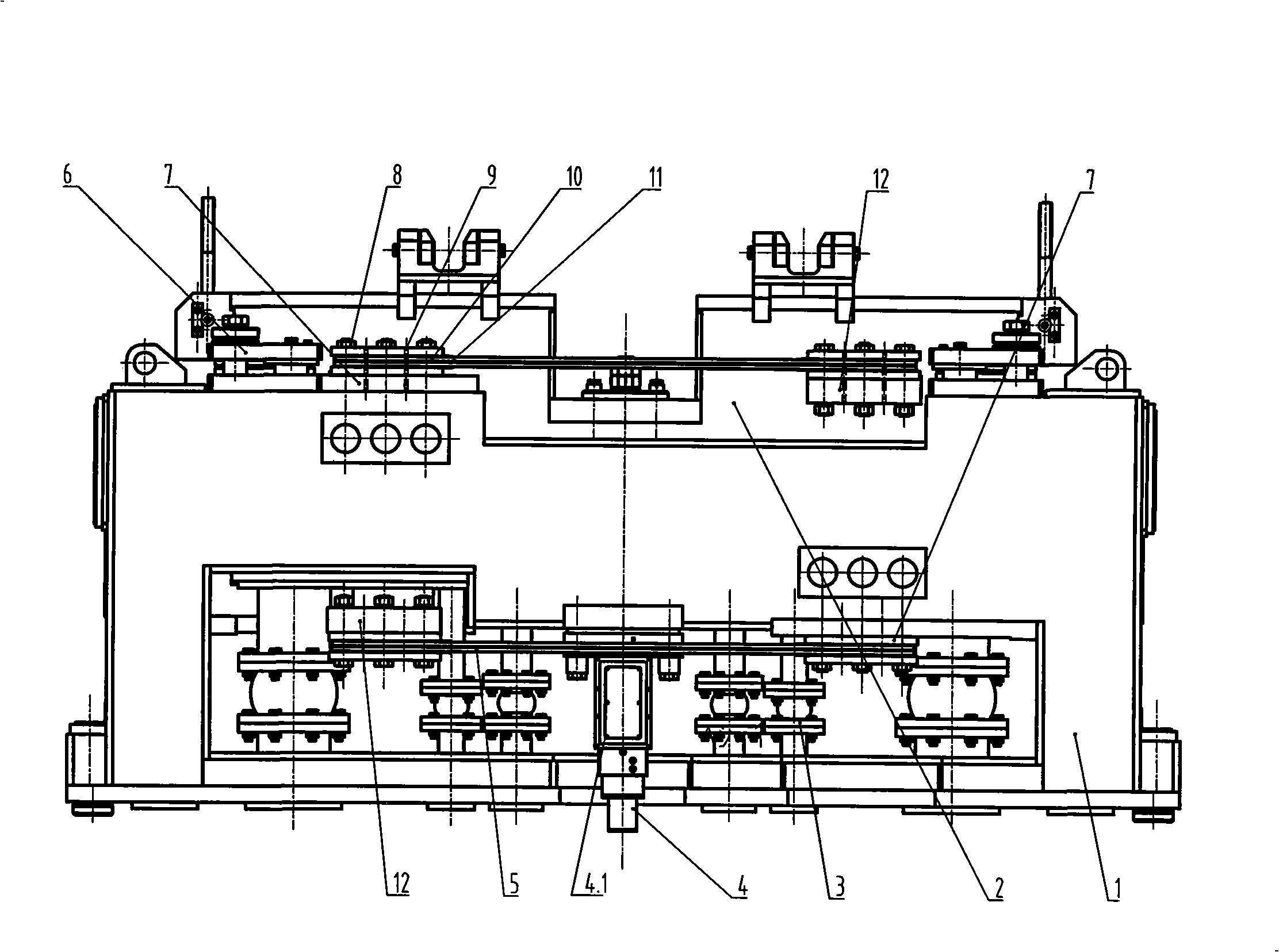

[0027] exist figure 1 Explanation of each label in: fixed frame 1, vibration frame 2, crystallizer water distribution device 3, vibration generating device 4, hydraulic servo cylinder 4.1, vibration guiding device 5, limit device 6, frame support 7, bolt 8, pin 9 , leaf spring 10, spacer plate 11, installation positioning device 12.

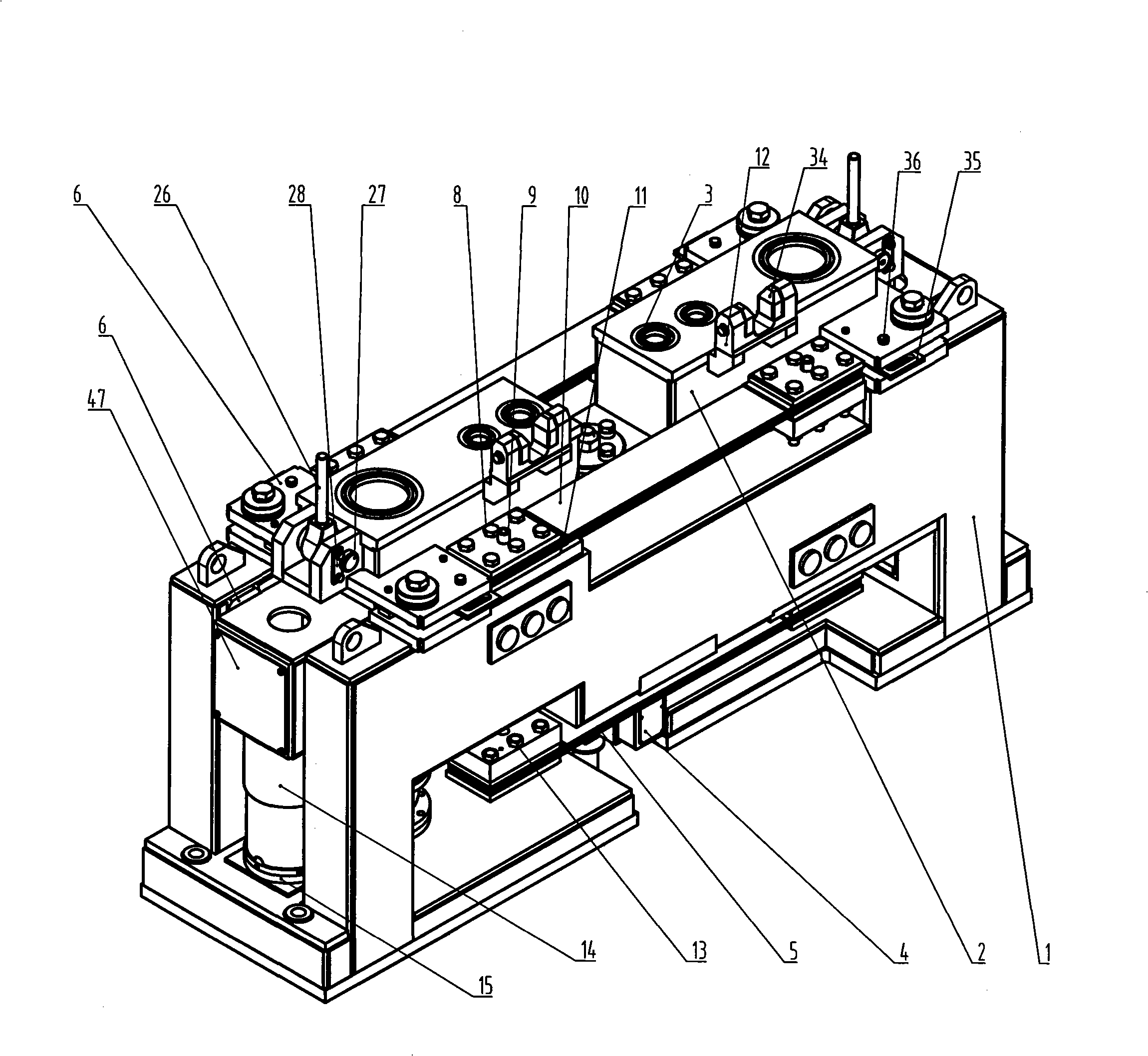

[0028] exist figure 2 Explanation of each label in: fixed position bolt 13, vibration mass buffer device 14, positioning wedge 34, fixed pressure plate 35, pressure plate bolt 36, cover plate 47.

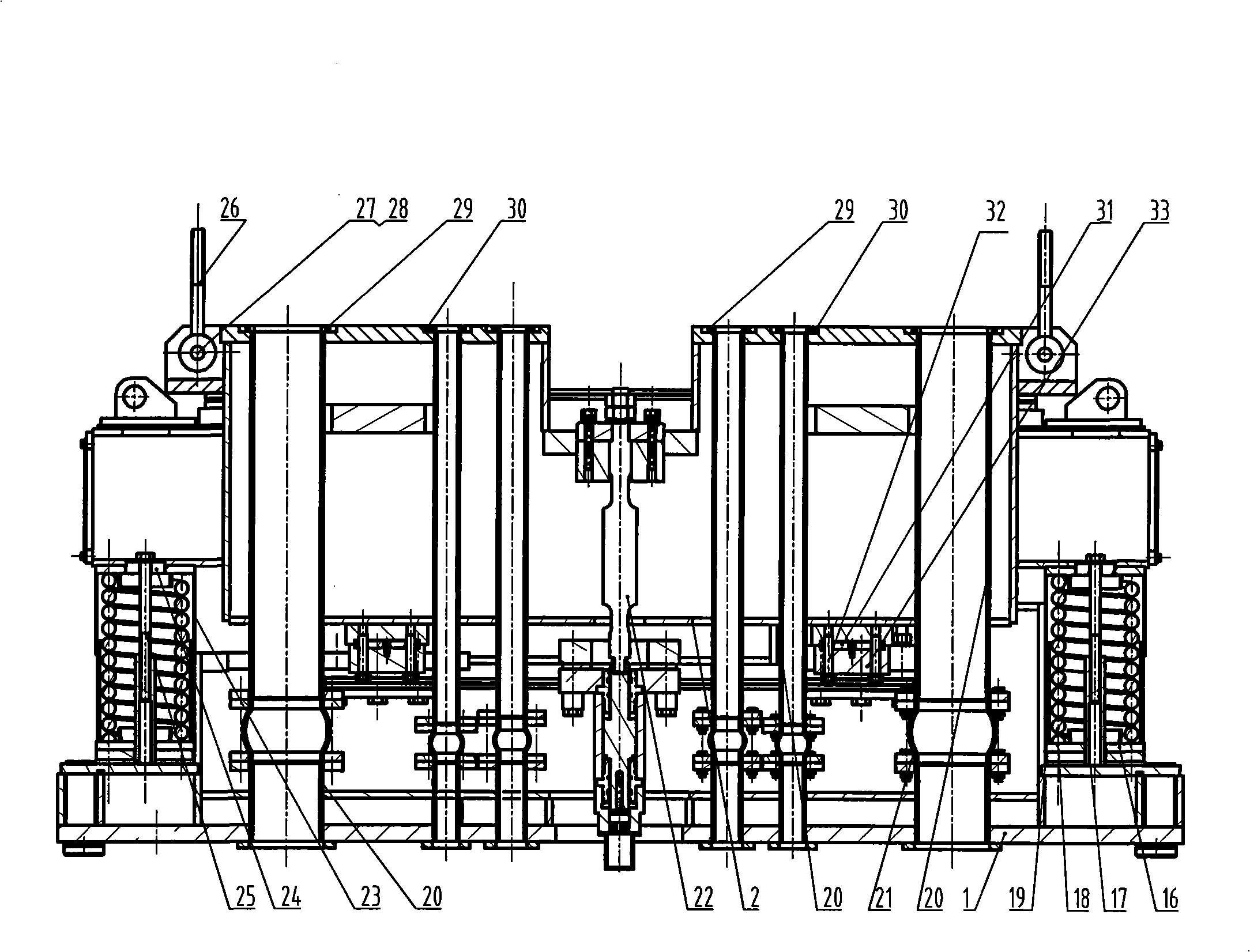

[0029] exist image 3 Description of each label in: Adjusting gasket 15, lower circular plate 16, casing 17, coil spring 18, protective cover 19, water pipe 20, expansion compensator 21, connecting rod 22, protective cover 23, upper circular plate 24, adjustment Position bolt 25, eyebolt 26, pin shaft 27, clamping plate 28, sealing rubber ring 29, water receiving panel 30, key plate 31, key plate screw 32, connecting plate 33.

[0030] exist Fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com