Patents

Literature

147 results about "Sinusoidal vibration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Focusing and levelling device with expandable measuring range and focusing and levelling method

ActiveCN102033438AExpand the measurable rangeReduce complexityPhotomechanical exposure apparatusMicrolithography exposure apparatusPhotovoltaic detectorsLight energy

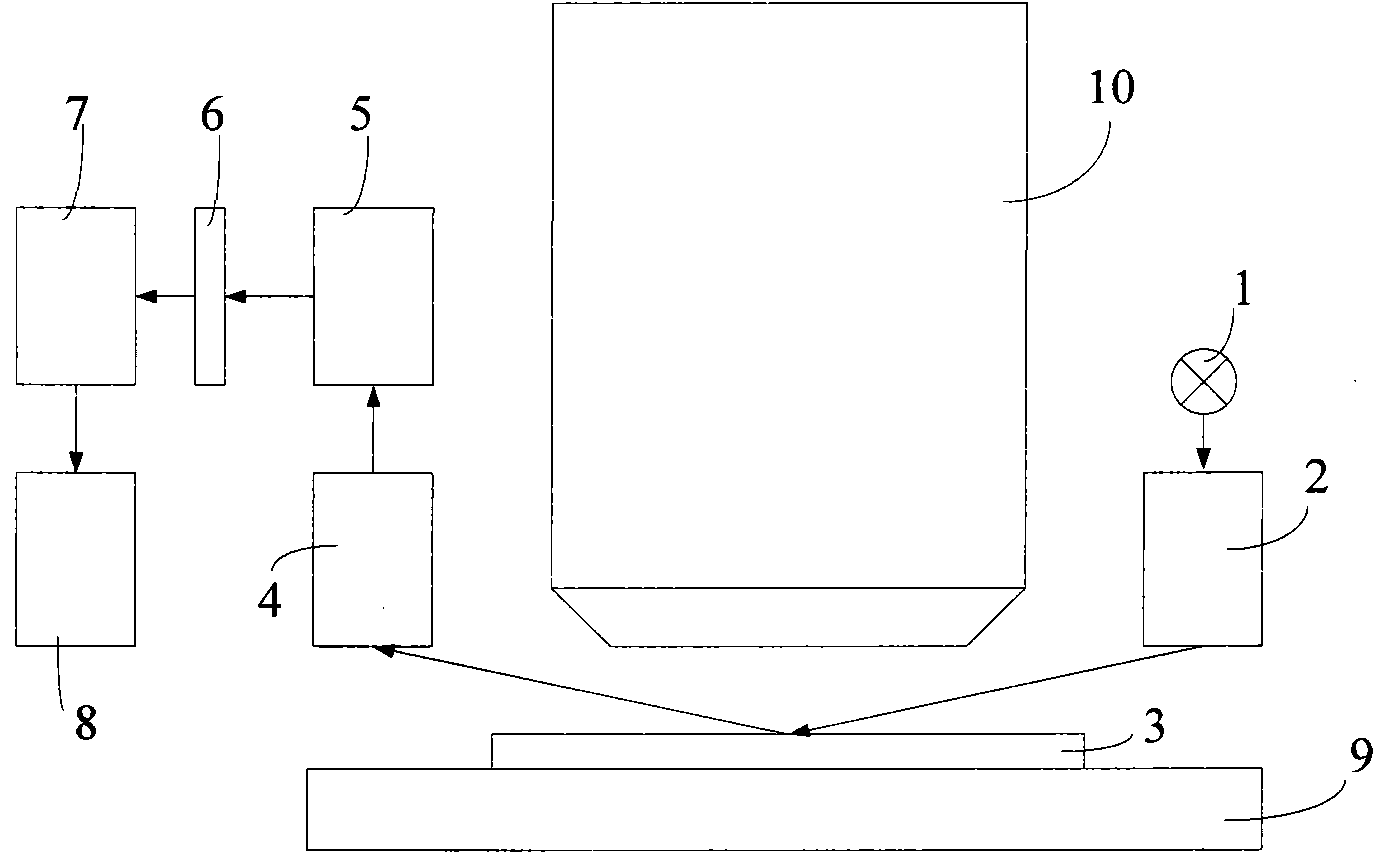

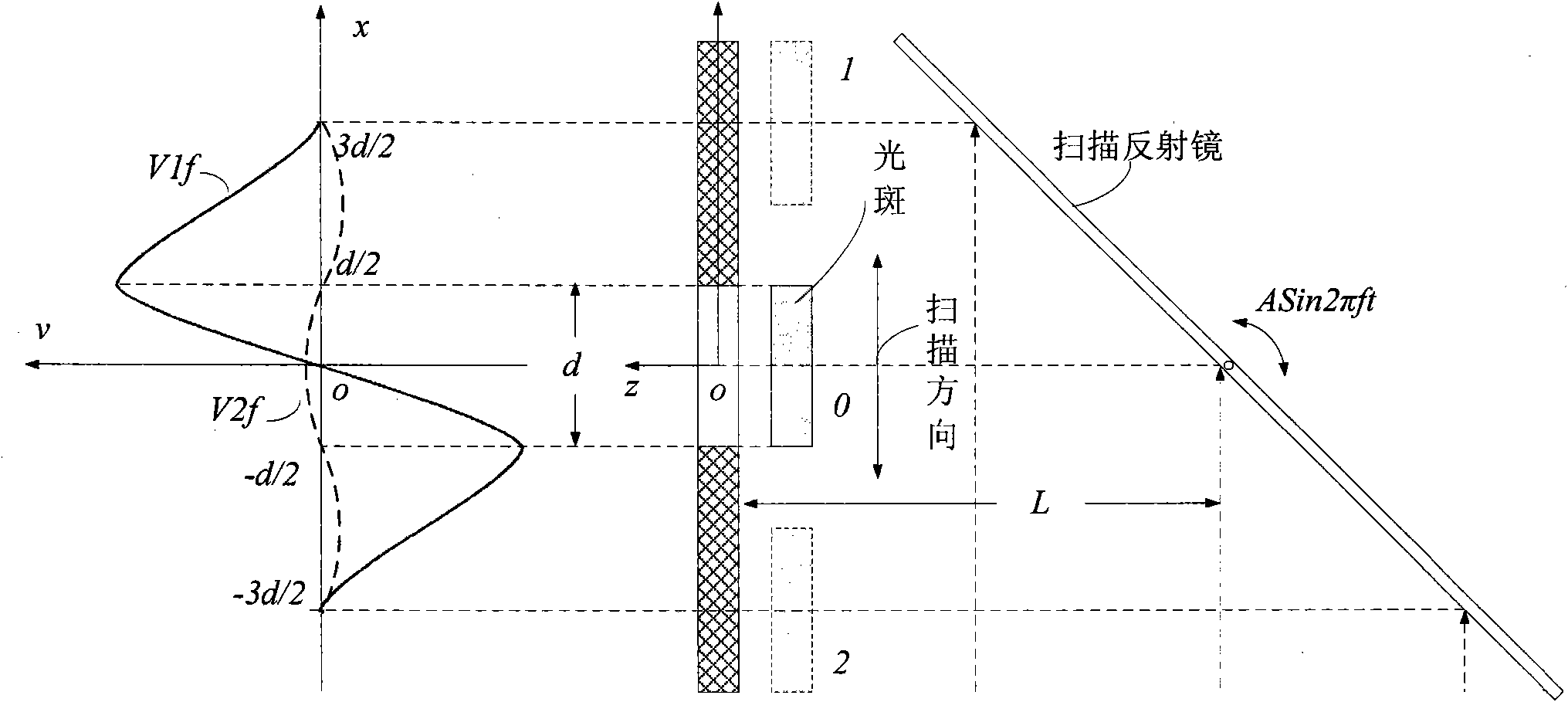

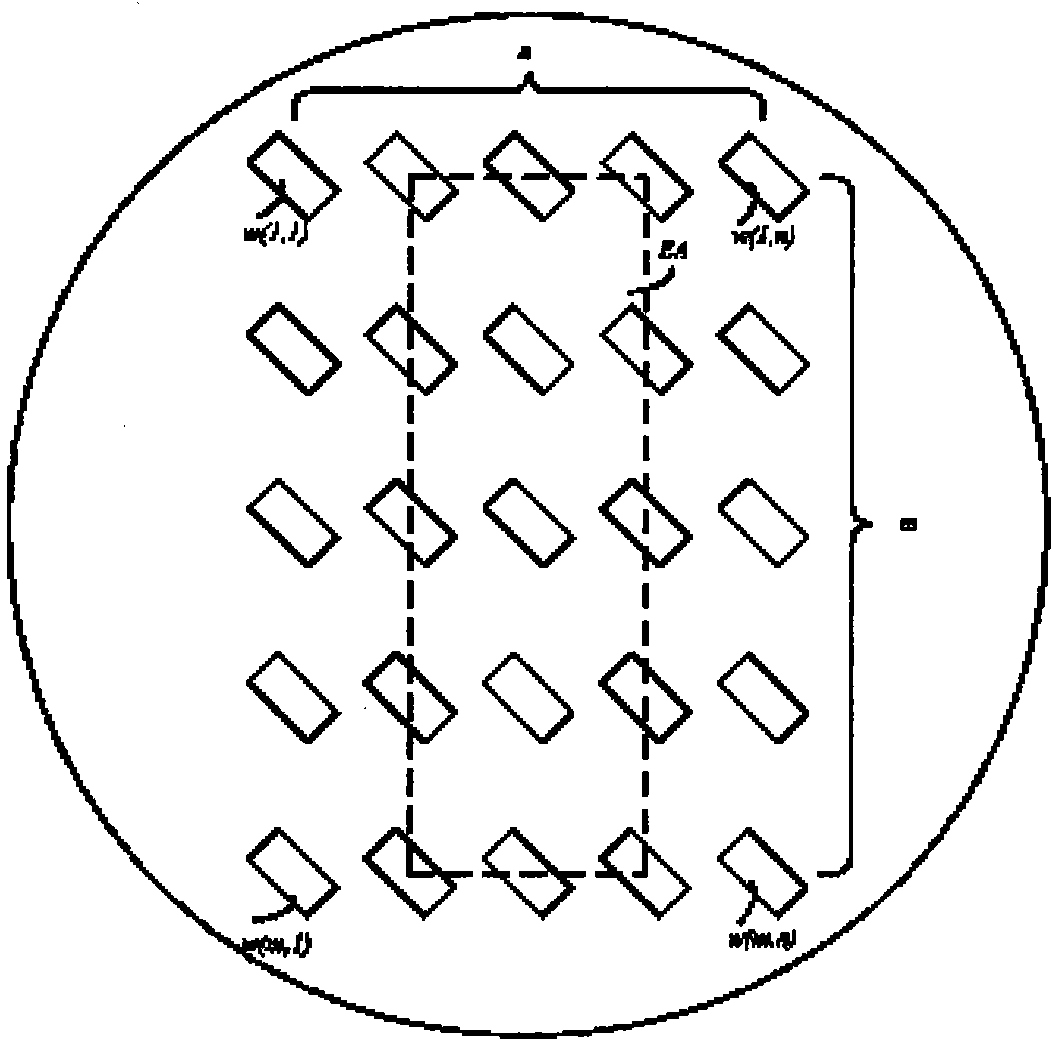

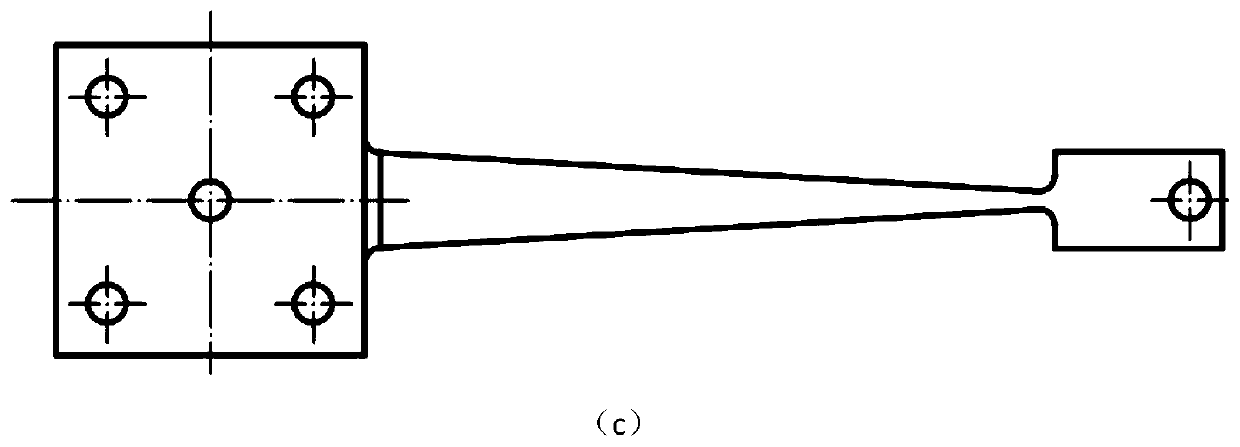

The invention relates to a focusing and levelling device with an expandable measuring range, which comprises a light source, an optical projection unit, an optical receiving unit, an optical modulation unit, a receiving silt surface, a photoelectric detector and a control unit, wherein the optical projection unit receives light emitted by the light source and irradiates the light to the surface of a measured silicon wafer to form a measuring light spot matrix W; the optical receiving unit receives the light reflected by the measured silicon wafer; the optical modulation unit is provided with a scanning reflector which makes sinusoidal vibration during levelling measurement; a silt matrix S of silts corresponding to each light spot on the silicon wafer is formed on the receiving silt surface, and the light spots reflected by the scanning reflector are imaged on the receiving silt surface; the photoelectric detector converts a light energy signal passing through the silts into an electrical signal; the control unit analyzes the electrical signal outputted by the photoelectric detector; and an expanding silt positioned on the edge of the silt matrix is also formed on the receiving silt surface and is used for expanding the measuring range of the focusing and levelling device. The invention also discloses a focusing and levelling method using the device.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

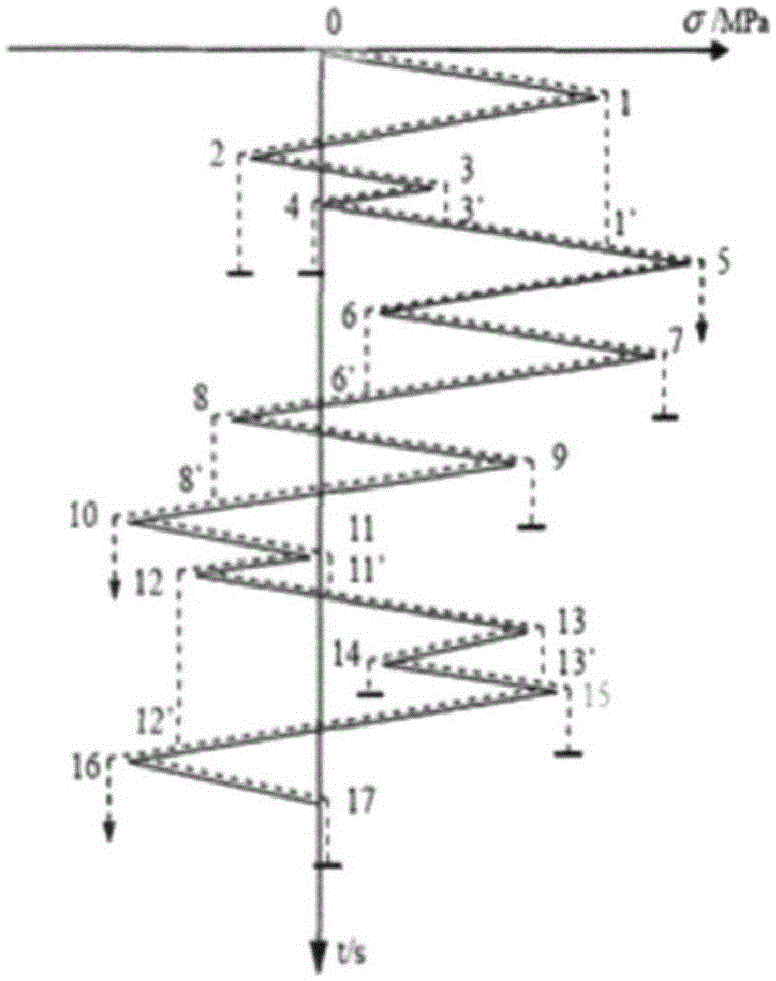

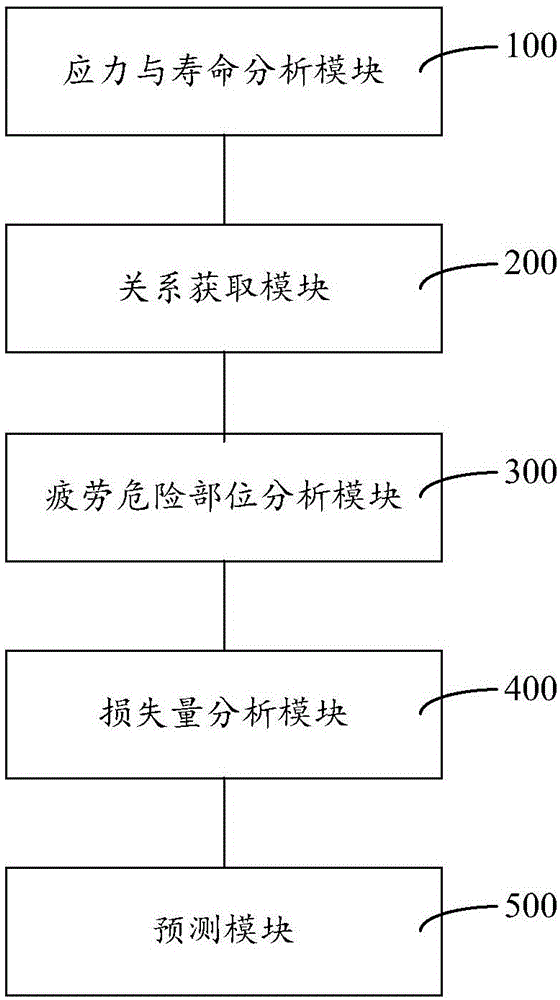

Method and system for predicting random vibration life of PCB solder point

ActiveCN105022860AAccurate acquisitionEasy to operateSpecial data processing applicationsTime responseData acquisition

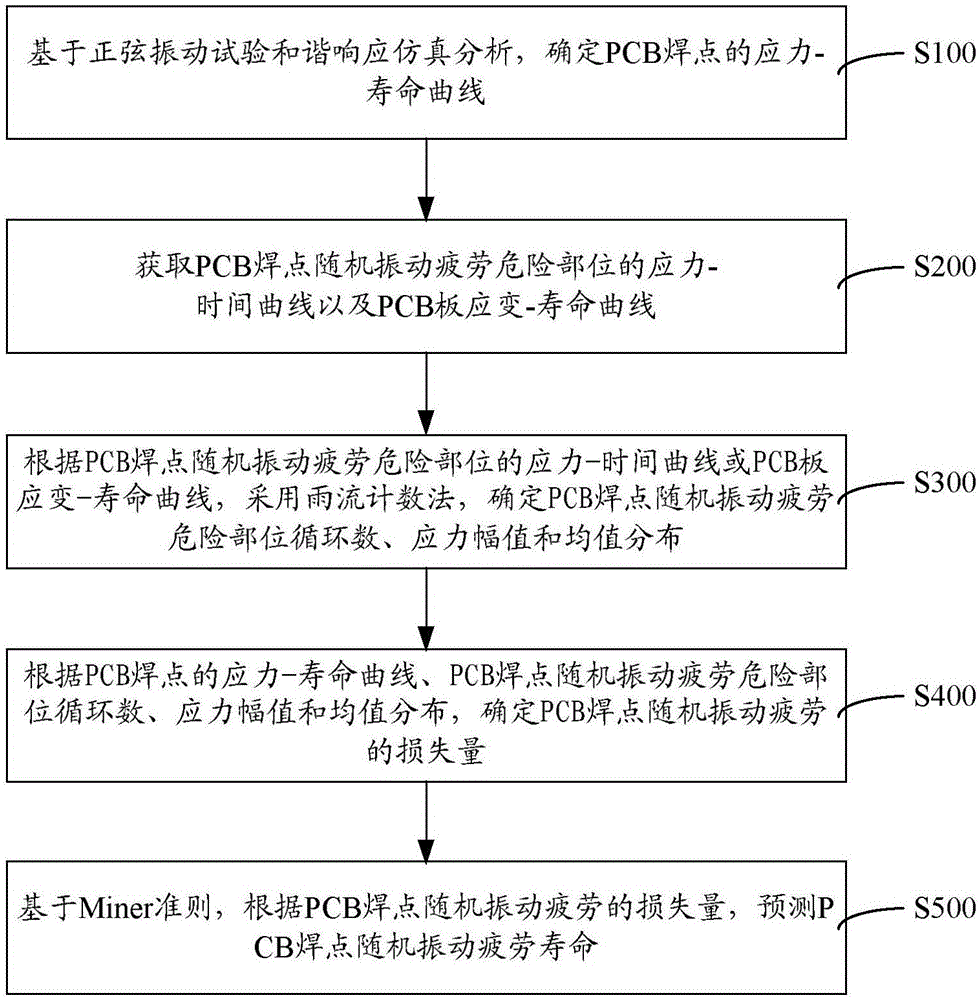

The invention provides a method and a system for predicting random vibration life of a PCB solder point. Based on a sinusoidal vibration test and harmonic response simulation analysis, a stress-life curve of the PCB solder point is determined; According to a stress-time curve of a random vibration fatigue dangerous part of the PCB solder point or a strain-life curve of a PCB, the cycle number, stress amplitude and mean distribution of the random vibration fatigue dangerous part of the PCB solder point are determined with a rain-flow counting method; the random vibration fatigue loss of the PCB solder point is determined; and finally based on a Miner rule, according to the random vibration fatigue loss of the PCB solder point, the random vibration life of the PCB solder point is predicted. The whole process is based on precise data processing, the operability is strong, and a stress and time response signal is subjected to cycle number statistics and sorting with the rain-flow counting method, so that the data acquisition accuracy in the process for predicting the random vibration life of the PCB solder point is ensured.

Owner:FIFTH ELECTRONICS RES INST OF MINIST OF IND & INFORMATION TECH

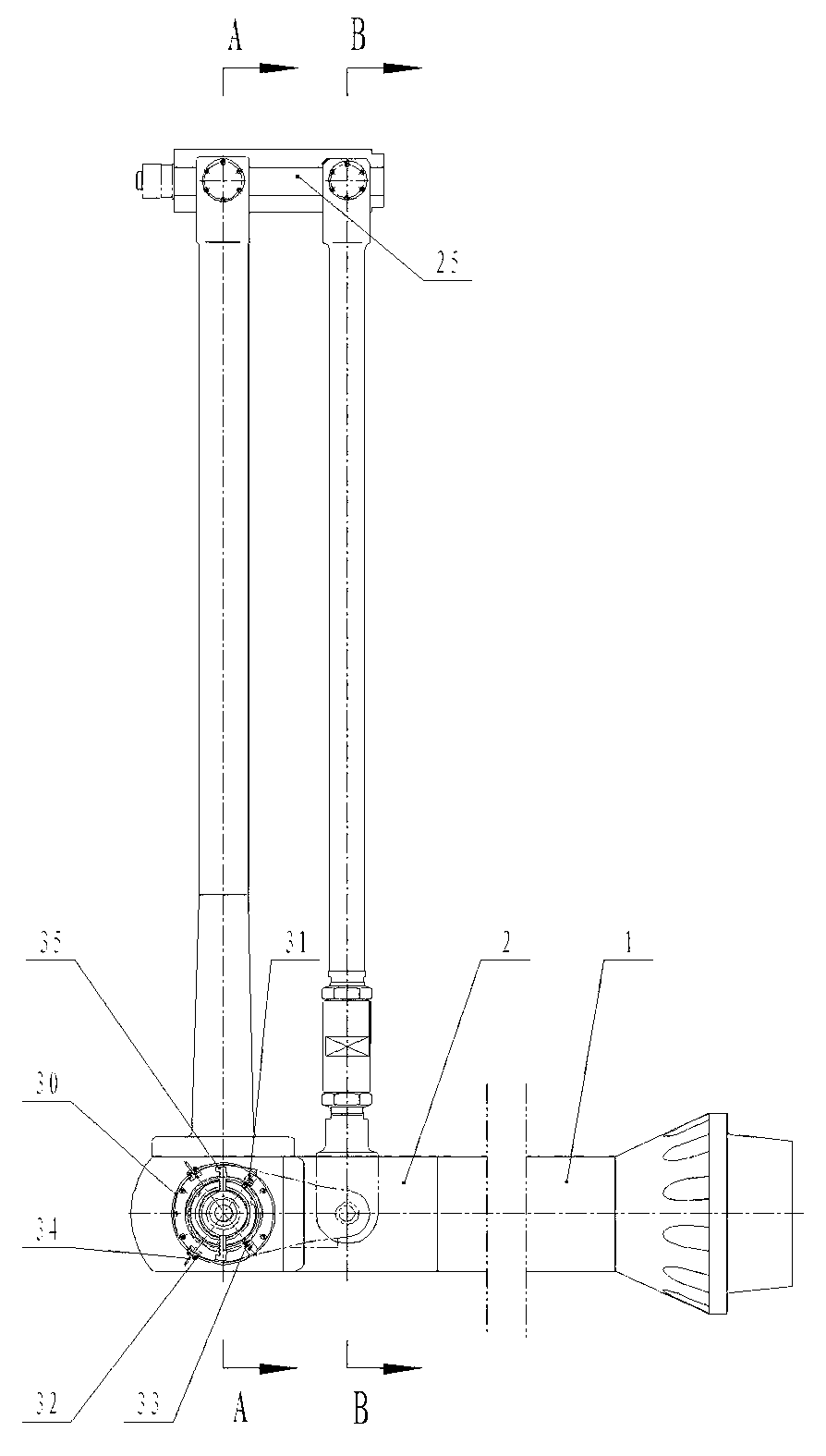

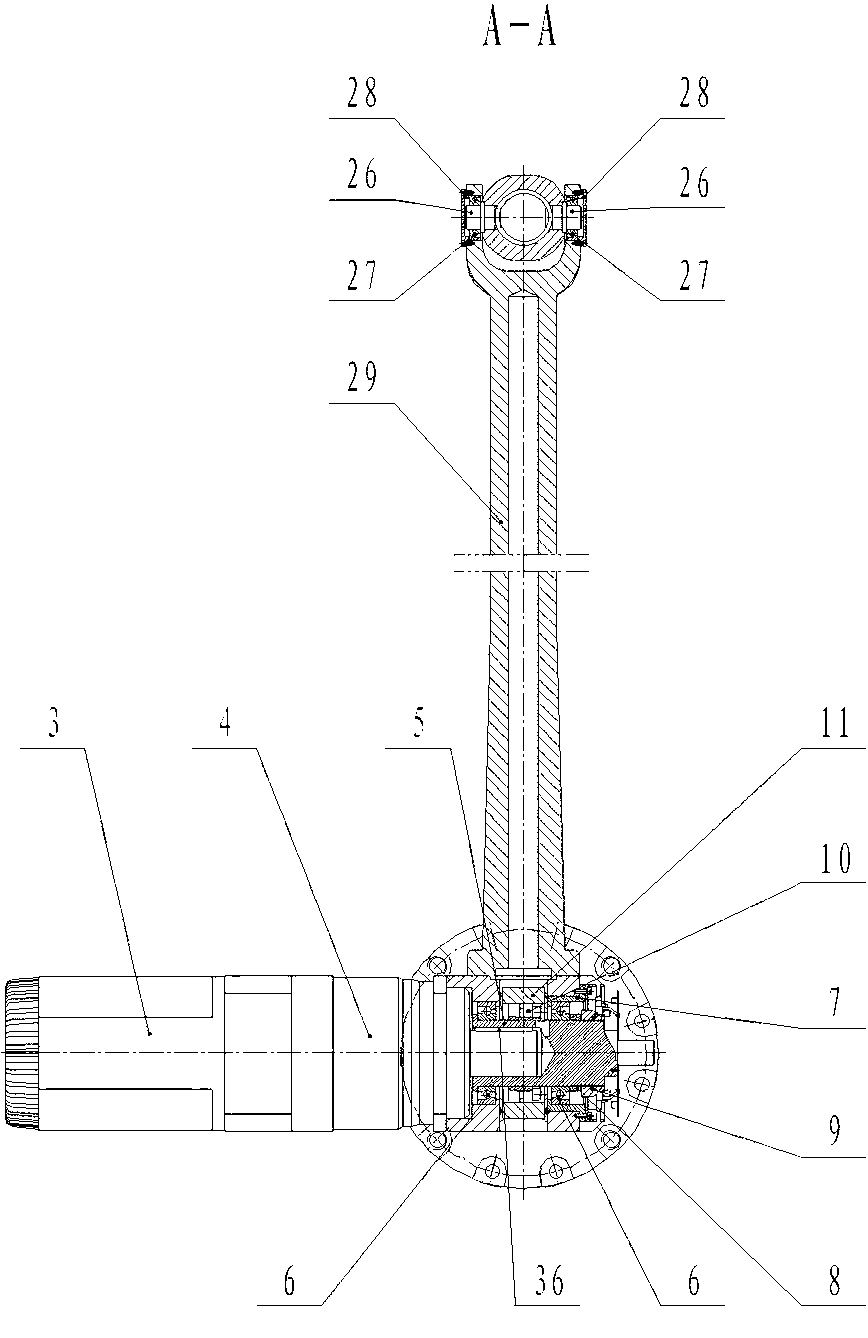

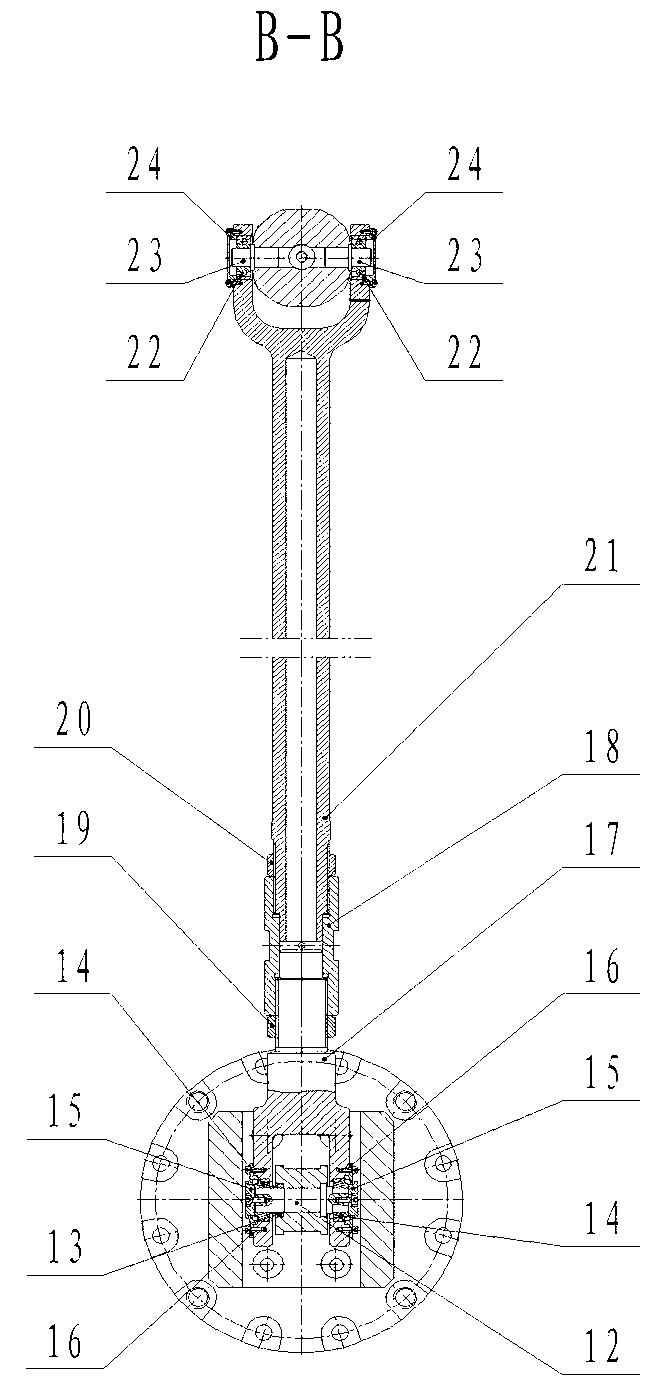

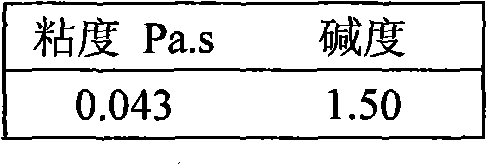

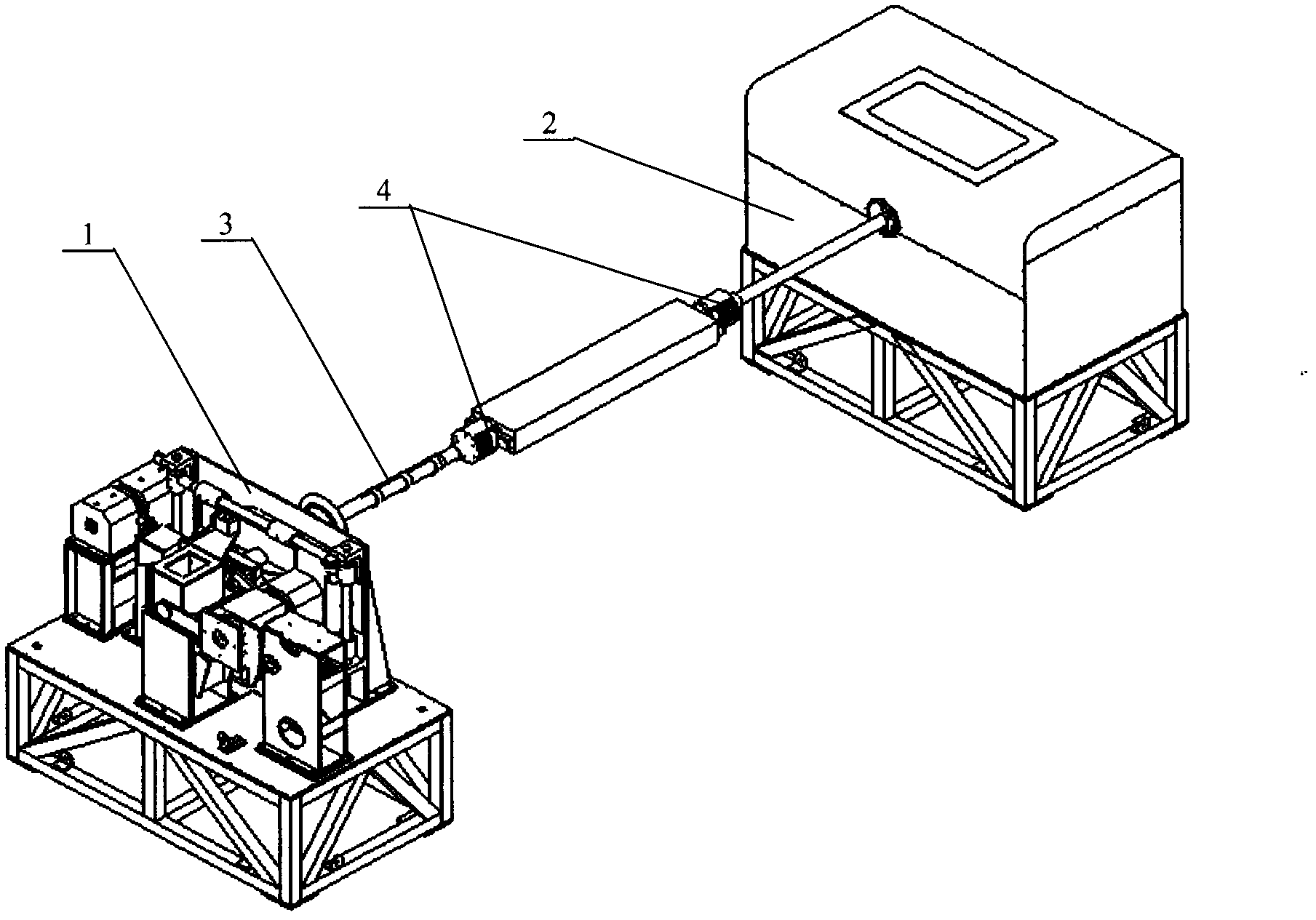

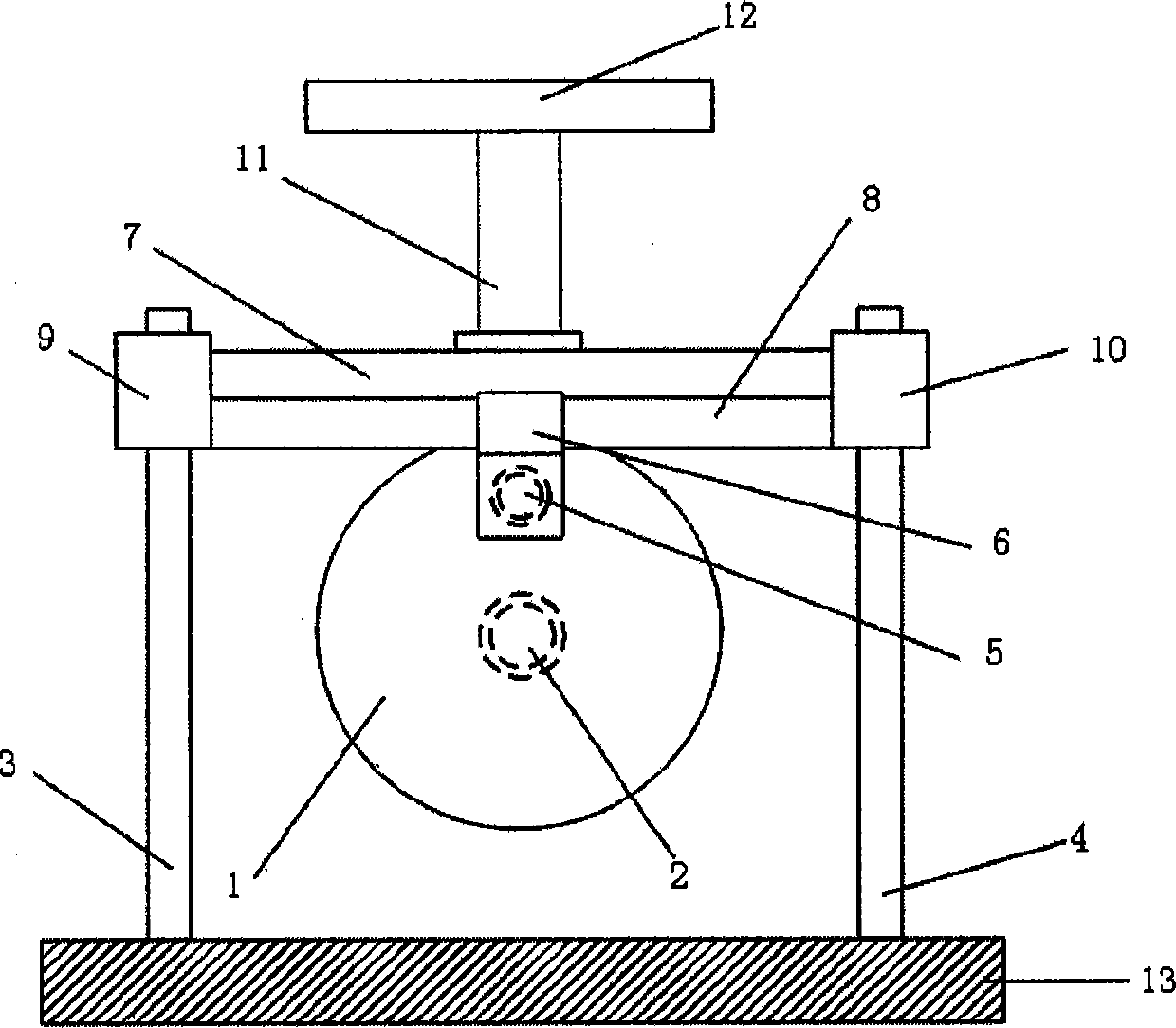

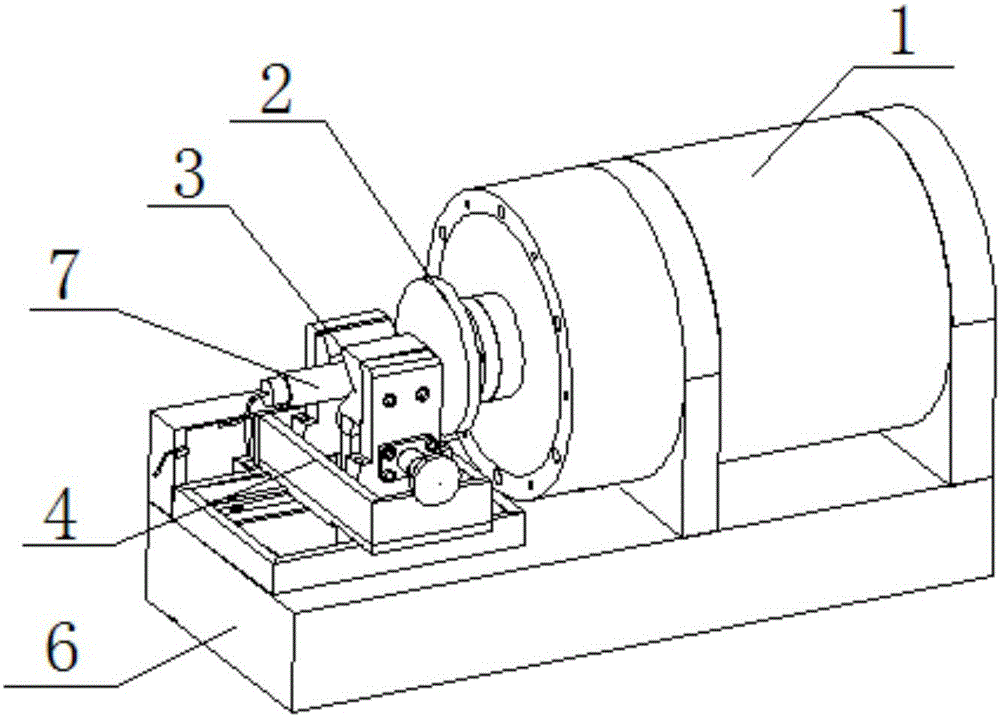

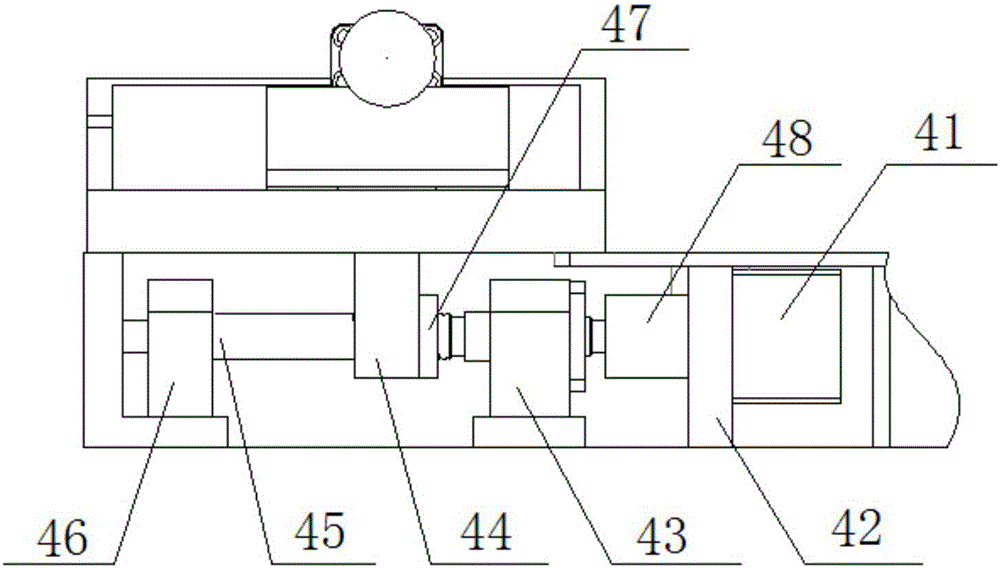

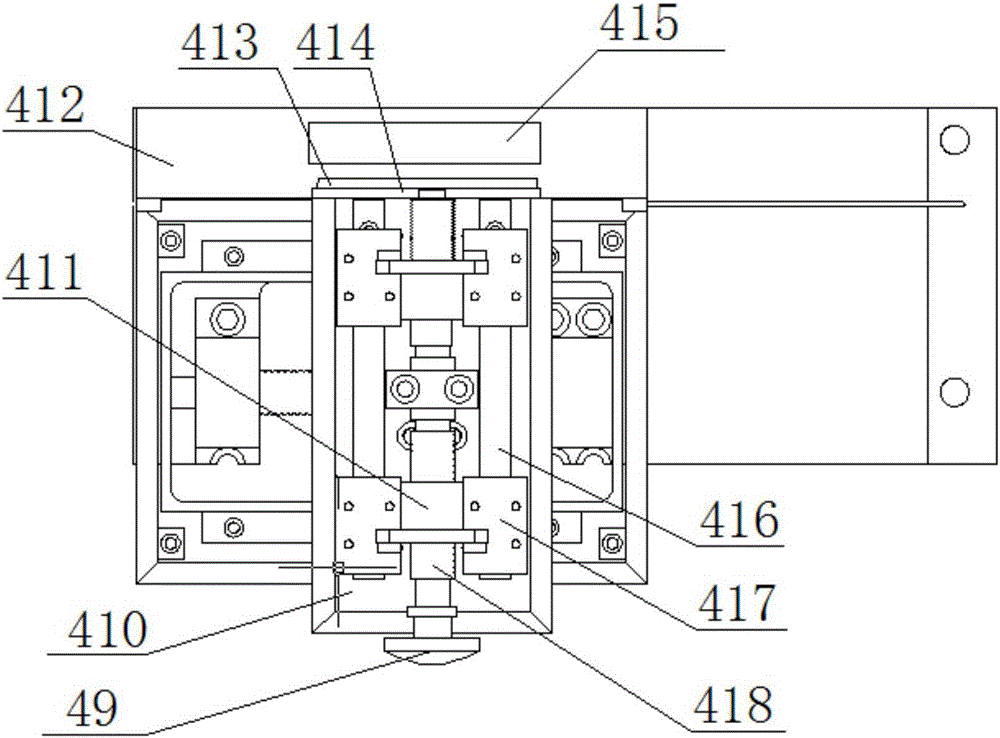

Device for wind tunnel dynamic derivative pitch vibration test

InactiveCN102998082ARealize measurementResolve interferenceAerodynamic testingEngineeringSinusoidal vibration

The invention provides a device for wind tunnel dynamic derivative pitch vibration test. The device comprises a support mechanism, a parallel-double-crank mechanism and a limit detection module, the support mechanism is a base body for mounting of the device, the parallel-double-crank mechanism realizes and transfers pitch sinusoidal vibration motion, and the limit detection module provides alarm for excess of mechanism rotational stroke. After vibration frequency and amplitude are set and a specific vibration curve is outputted by a servo motor, an aircraft model is driven to perform pitch vibration through the parallel-double-crank mechanism mounted on the support mechanism, and in the process, the limit detection module provides limit and protection for the mechanisms.

Owner:MIANYANG WEIBO ELECTRONICS

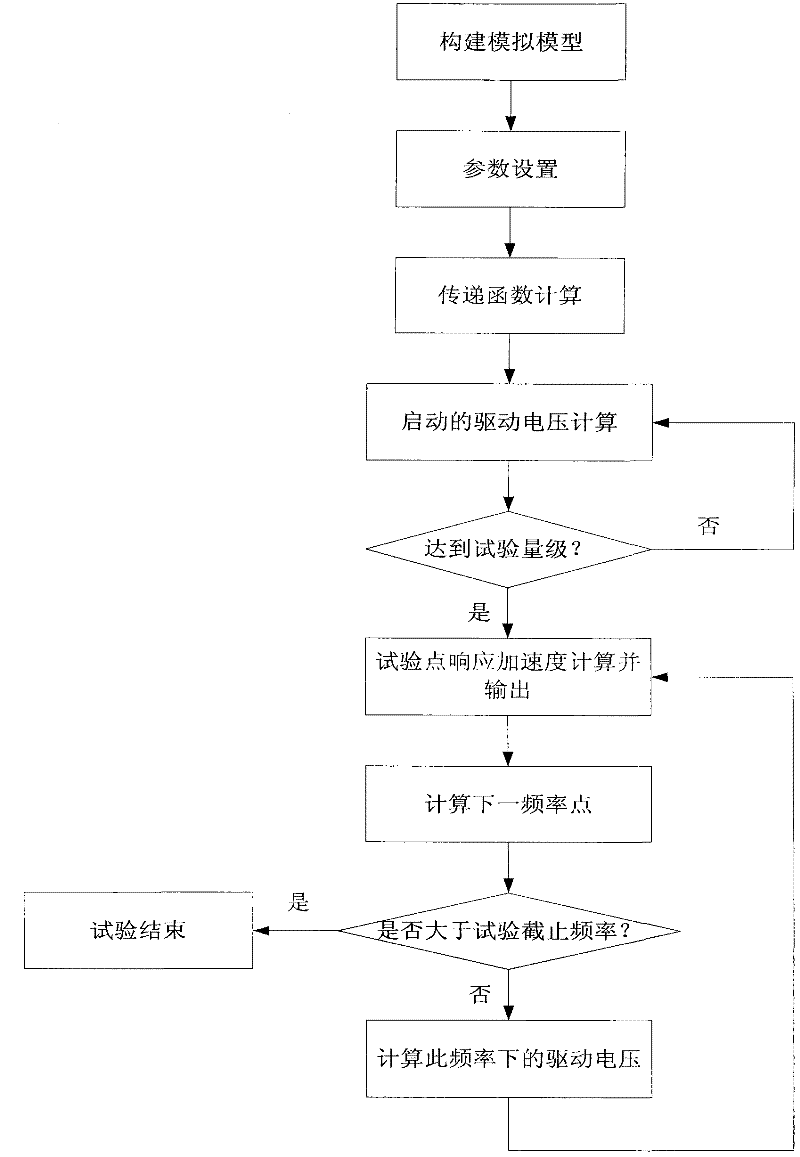

Virtual sinusoidal vibration testing method for spacecrafts

ActiveCN102567575AIncrease authenticityHigh precisionSpecial data processing applicationsControl systemSimulation

The invention discloses a virtual sinusoidal vibration testing method for spacecrafts, which comprises a simulation model building step, a parameter setting step for virtual sinusoidal vibration testing, a transfer function computing step, a testing driving signal generating step and a virtual sinusoidal vibration testing step. By the virtual sinusoidal vibration testing method, all key links of real vibration testing of the spacecrafts are taken into consideration sufficiently, transfer functions of a vibration platform testing control system and a plurality of forming systems are integrated, and reality and accuracy of the conventional open-loop numerical method are evidently improved by the closed-loop computing method.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

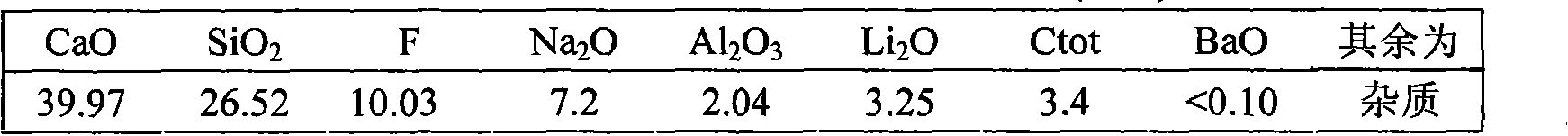

Method for preventing peritectic steel continuous casting blank from generating cracks

The invention discloses a method for preventing a peritectic steel continuous casting blank from generating cracks, which comprises a step of continuously casting by using a continuous casting machine. The method is characterized in that: in the continuous casting process, protective slag of which the alkalinity is 1.3 to 1.5 and the viscosity is 0.03 to 0.07Pa.s at 1,300 DEG C; a crystallizer adopts sinusoidal vibration, and has the vibration frequency of 150 to 198min<-1> and the vibration amplitude of 5.0 to 8.0mm; and the water volume of the crystallizer is reduced by 5 to 10 percent. The method effectively solves the problem of cracks on the surface of the peritectic steel continuous casting blank, improves the quality of the casting blank, and reduces casting blank clearing quantity and waste quantity.

Owner:ANGANG STEEL CO LTD

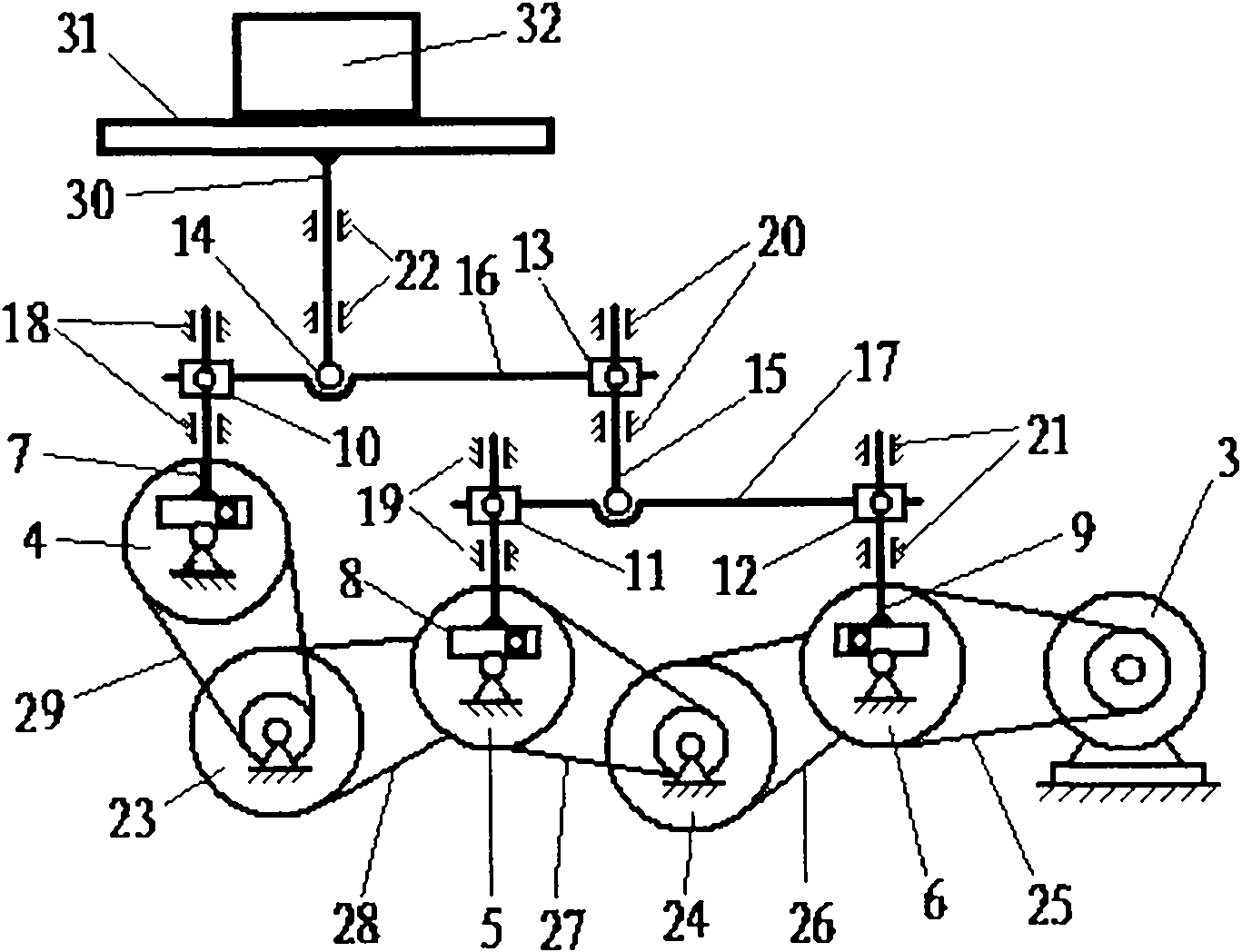

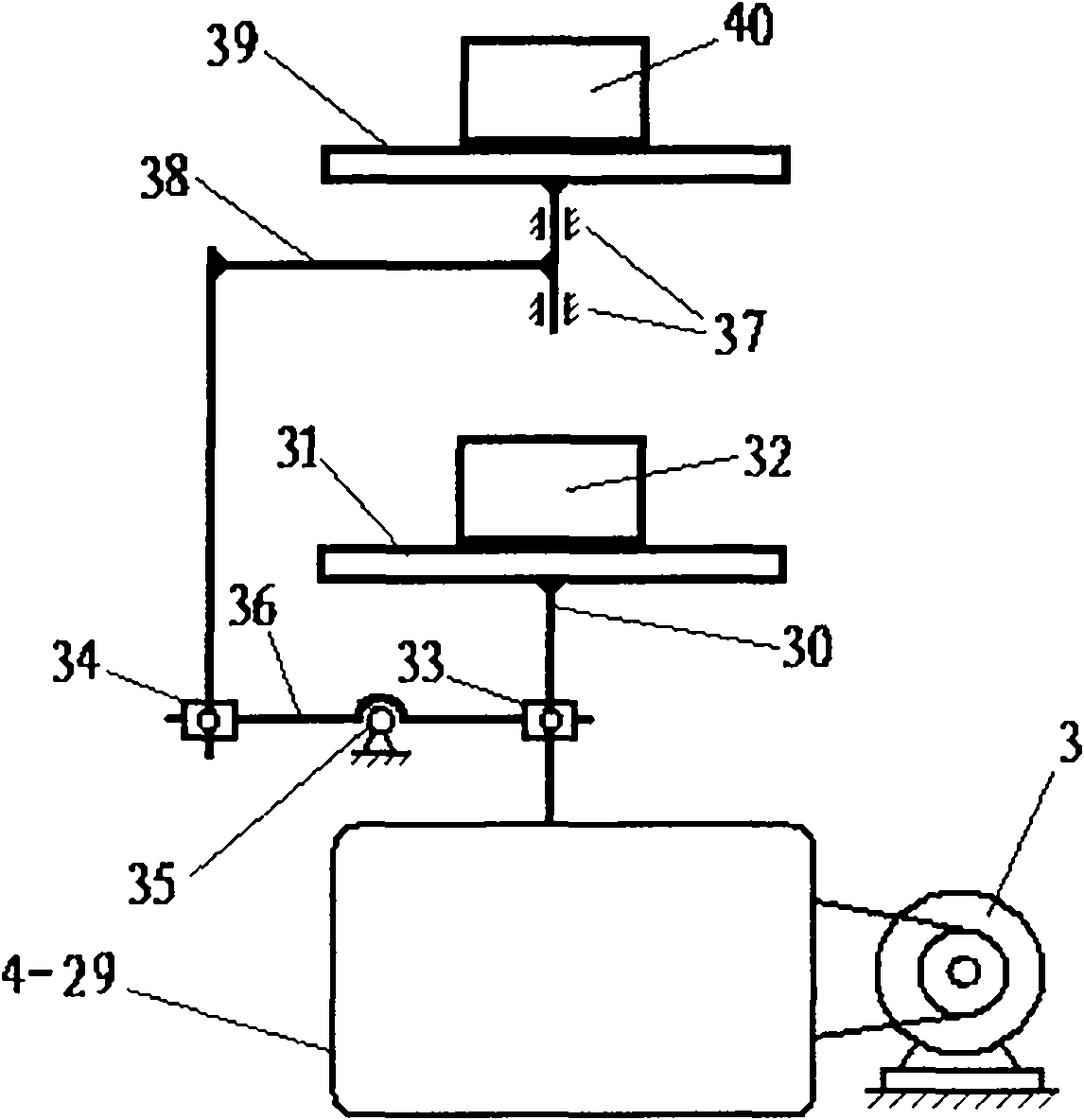

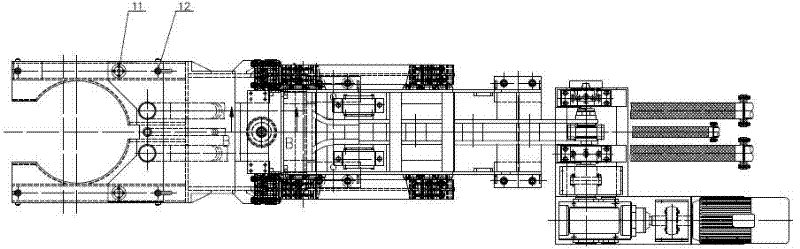

Decoupled three-degree-of-freedom forced vibration system for bridge section model

InactiveCN102607800ALarge amplitudeImprove real-time performanceAerodynamic testingSupporting systemThree degrees of freedom

The invention provides a decoupled three-degree-of-freedom forced vibration system for a bridge section model. The system comprises an outer vibration system, an inner vibration system, a model support system and a detection system, wherein the outer vibration system and the inner vibration system are symmetrically arranged on the two sides of a wind tunnel; the model support system is connected with the outer vibration system and the inner vibration system respectively, and is also connected with the detection system; the detection system is connected with the bridge section model through an inner model connecting plate and an outer model connecting plate; and the outer vibration system and the inner vibration system synchronously vibrate under the drive of a servo motor to realize the synchronous three-degree-of-freedom sinusoidal vibration of the bridge section model. By the system, the transverse motion, vertical motion and torsional motion of the model in a section are realized, and are combined into totally seven kinds of motion with higher amplitude, and each kind of motion is independent simple harmonic motion with adjustable frequency, amplitude and phase. The system has the advantages of capability of acquiring three components of force of the bridge section model in real time, and data accuracy.

Owner:HARBIN INST OF TECH

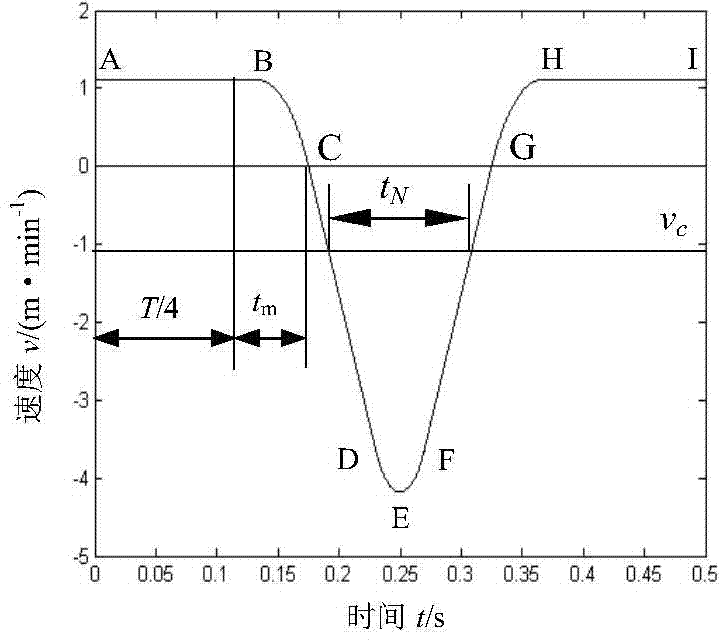

Non-sinusoidal vibration method for continuous casting crystallizer

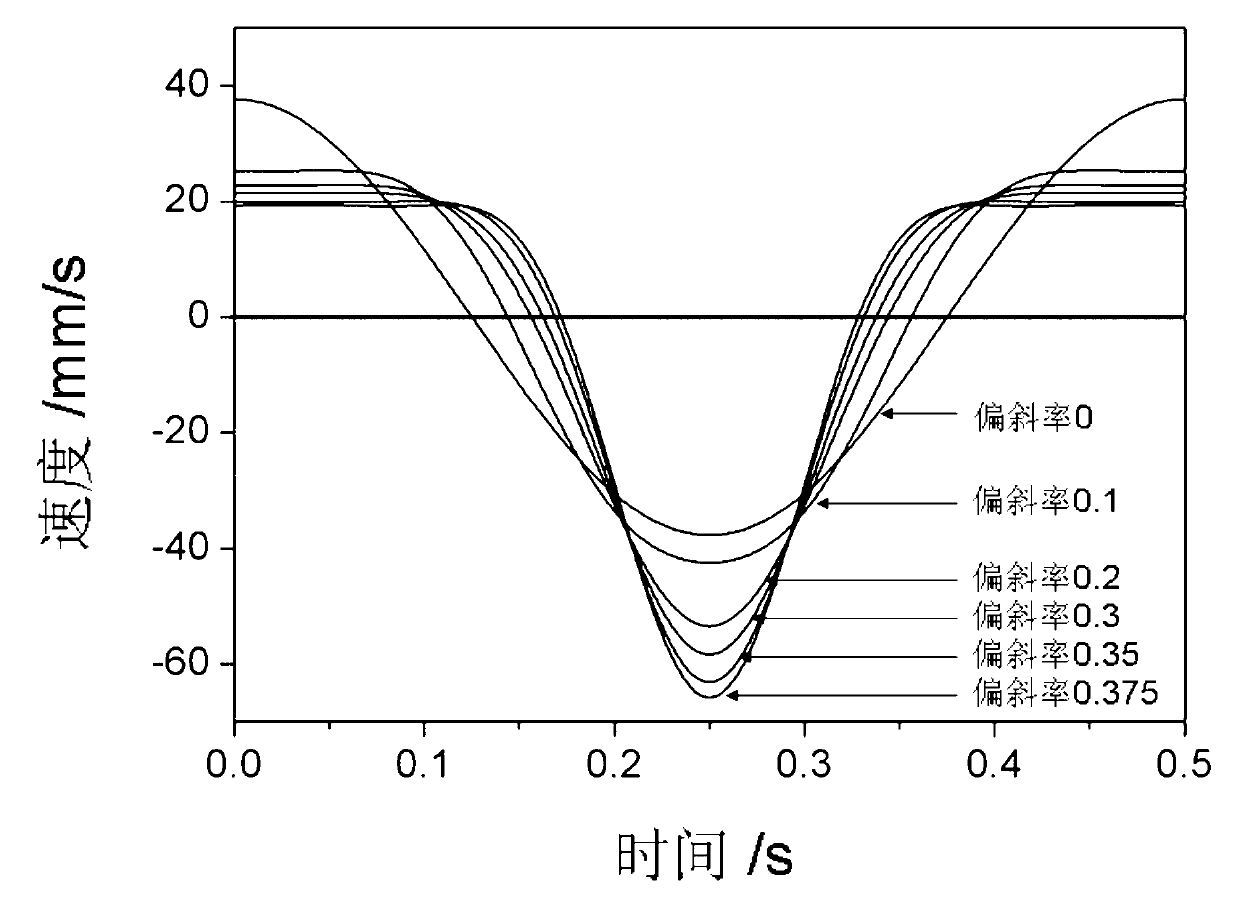

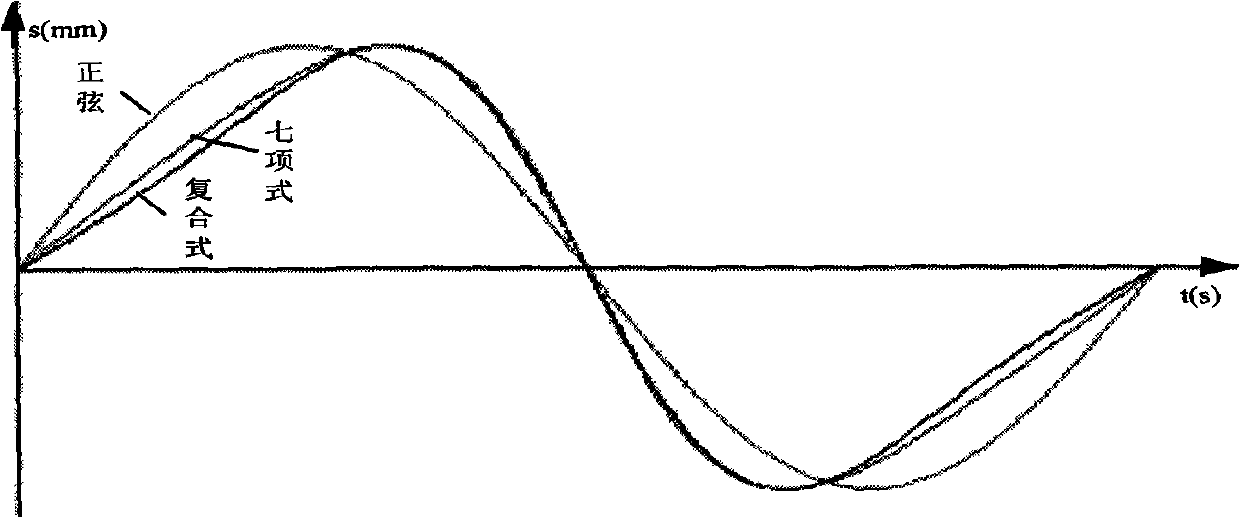

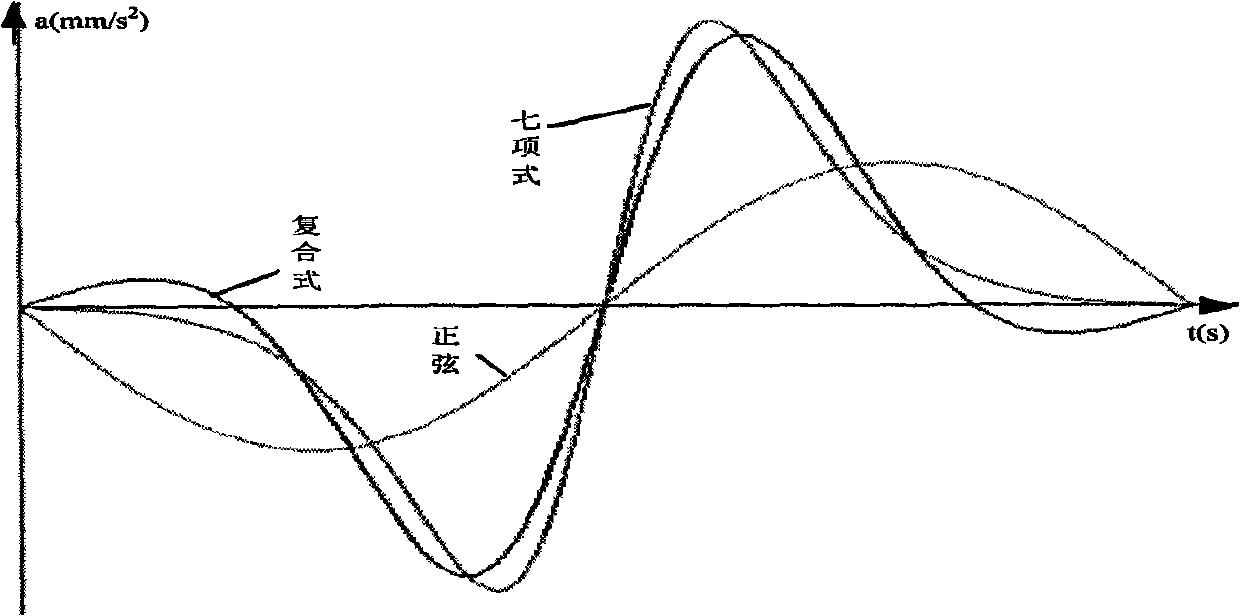

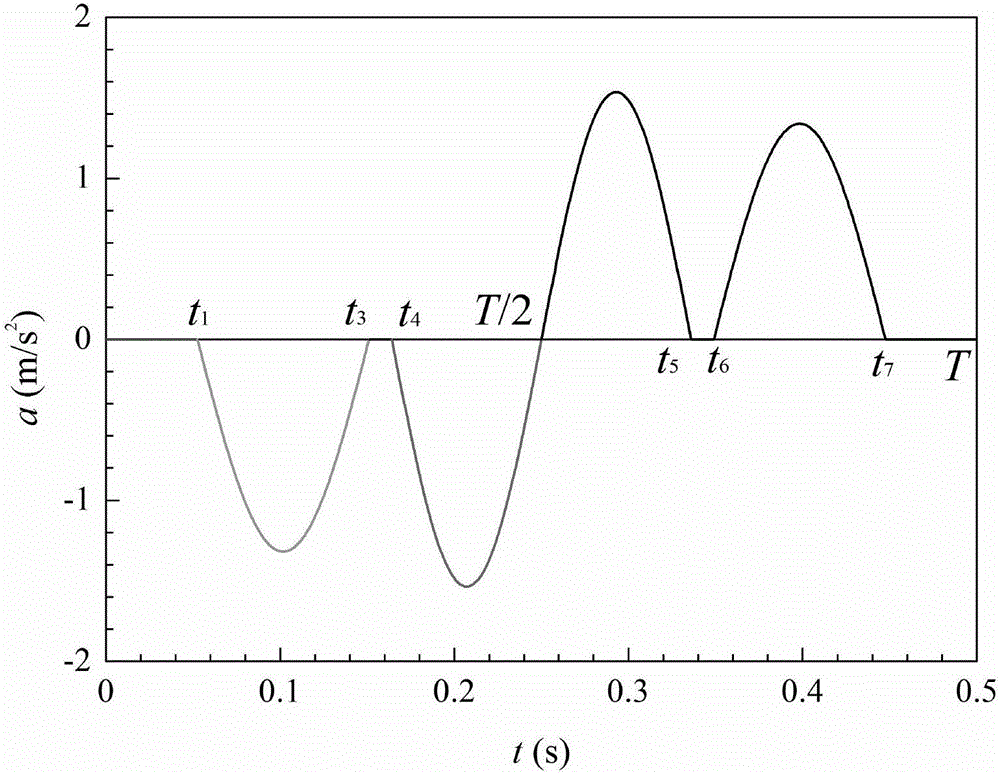

InactiveCN103752783AGood waveform dynamicsConstant accelerationSinusoidal vibrationMaterials science

The invention discloses a non-sinusoidal vibration method for a continuous casting crystallizer. According to the technical scheme, the non-sinusoidal vibration method for the continuous casting crystallizer comprises controlling a driving device of the continuous casting crystallizer to enable the continuous casting crystallizer to perform non-sinusoidal vibration according to speed waveforms which are confirmed according to following functions in every vibration period with the driving of the driving device; enabling the vibrating process of every vibration period to be formed by seven sections; enabling the crystallizer to move according to a given vibrating method due to control of the driving device of the crystallizer and achieving the non-sinusoidal vibration. The non-sinusoidal vibration method for the continuous casting crystallizer has the advantages of being smooth and continuous in displacement and speed waveform, having no mutation in accelerated speed, not generating rigid and flexible impact and having good waveform dynamic characteristics and enabling the largest accelerated speed of the movement of the crystallizer to be served as a quantity which is reflected in the waveforms, enabling the quantity to be allowed setting according to actual conditions and to be invariant, increasing waveform deflection rate, enabling non-sinusoidal vibration of the crystallizer to be enhanced but the accelerated speed of the vibration of the crystallizer to be kept constant and guaranteeing movement smoothness of the crystallizer.

Owner:YANSHAN UNIV

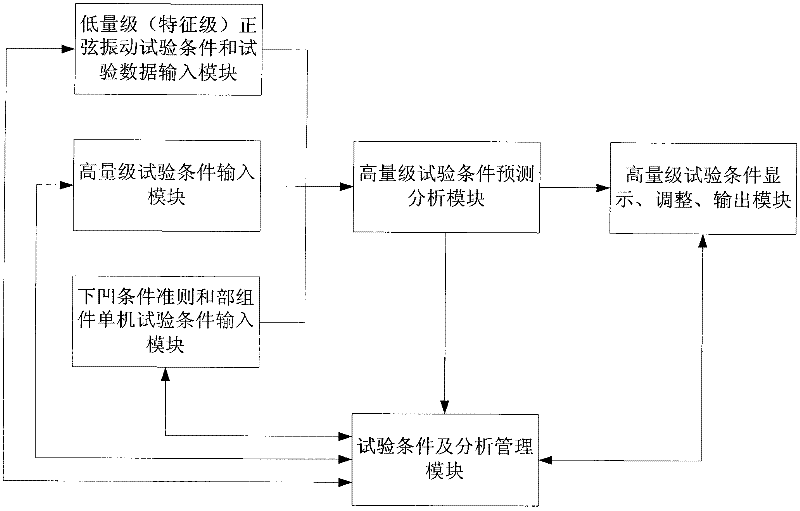

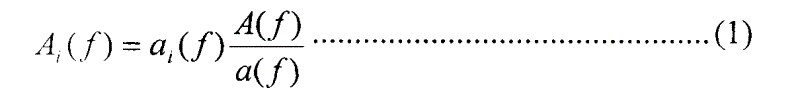

Forecasting system for high-magnitude test condition of sinusoidal vibration test for spacecraft

The invention discloses a forecasting system for a high-magnitude test condition of a sinusoidal vibration test for spacecrafts; the forecasting system comprises the following six modules: (1) a low-magnitude (feature-level) sinusoidal vibration test condition and test data input module; (2) a high-magnitude test condition input module; (3) a sunk condition criterion, part and component one-machine test condition input module; (4) a high-magnitude test condition forecasting and analyzing module; (5) a high-magnitude test condition displaying and adjusting output module; and (6) a test condition and analysis management module. The forecasting system provided by the invention can be directly applied to the vibration test of the spacecrafts and can be used for forecasting the high-magnitude test condition in combination of a low-magnitude (feature-level) sinusoidal vibration test condition and test data according to a given sunk condition criterion and a part and component one-machine test condition. The forecasting system is convenient for condition design and improves the effectiveness of tests and efficiency.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

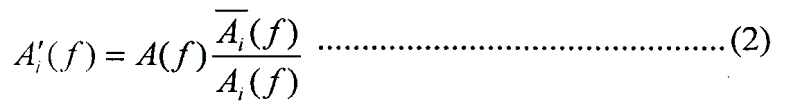

Multi-frequency synthesized vibration test device

The invention discloses a multi-frequency synthesized vibration test device. The multi-frequency synthesized vibration test device comprises a system controller, a motor, a speed adjusting device and a vibration platform, wherein the vibration of the vibration platform at least comprises the vibration of two frequency components; the vibration of each frequency component is generated by an eccentric rotation mechanism with different rotating speeds; multiple vibration is synthesized through a mechanical lever in a pair combination mode; the vibration of each frequency component represents one section of frequency range in a transportation vibration environment; when the rotating speed of the motor is adjusted, each vibration frequency component performs synchronous variable frequency scanning in the frequency section represented by each vibration frequency component; a vibration device can perform fixed frequency and variable frequency tests on samples; the simulation degree of the vibration device on the transportation vibration environment is similar to that of a random vibration test; the vibration device is the optimized combination of two schemes of sinusoidal vibration and random vibration; and after two vibration platforms with complementary phase positions are provided, the influence of the test device on the ambient environment is reduced.

Owner:SHANGHAI UNIV

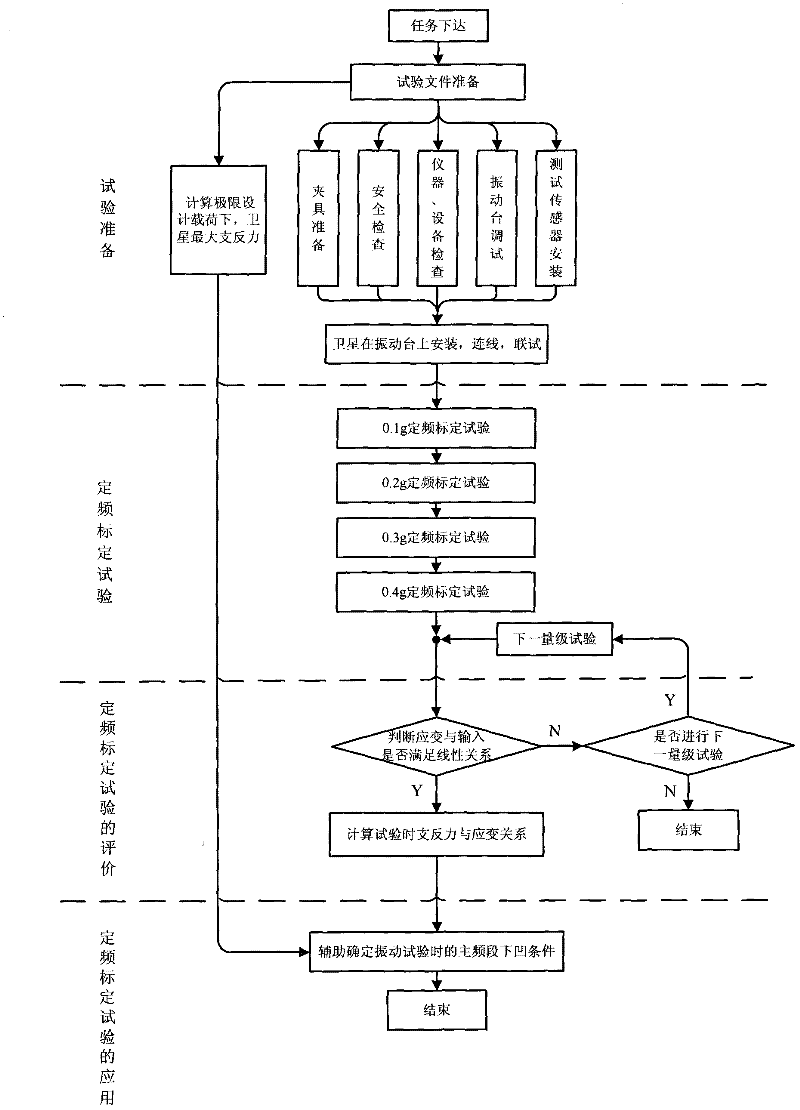

Fixed frequency calibration test method of spacecraft vibration

ActiveCN102494859ASolve the load \"over\"Solve problems such as \"owing\"Vibration testingEngineeringCalibration test

The invention provides a fixed frequency calibration test method of spacecraft vibration. The method comprises the following steps that: a corresponding relation between a support reaction force per unit length and a strain of a spacecraft root is determined, wherein the support reaction force per unit length is generated by the spacecraft during a sinusoidal vibration test, and an auxiliary basis is provided for determination on a concave downward condition of a main frequency range during the sinusoidal vibration test of the spacecraft; more particularly, at an off-resonance range of the spacecraft, by using a lowest working frequency that is allowed by a vibrating table and is normally from 2 to 5 Hz, sinusoidal excitation with a fixed frequency is carried out on the spacecraft under a certain order. After test evaluation is completed, the test method can be applied to vibrating tests of various spacecrafts, so that rationality and effectiveness of the test can be determined. According to the invention, problems that are common in the vibrating test process of a spacecraft can be solved, wherein the problems include a problem of overloading or underloading; and beneficial effects are as follows: the test is reasonable and reliable; the method can be realized simply; and the adaptability is strong and the like.

Owner:SHANGHAI SATELLITE ENG INST

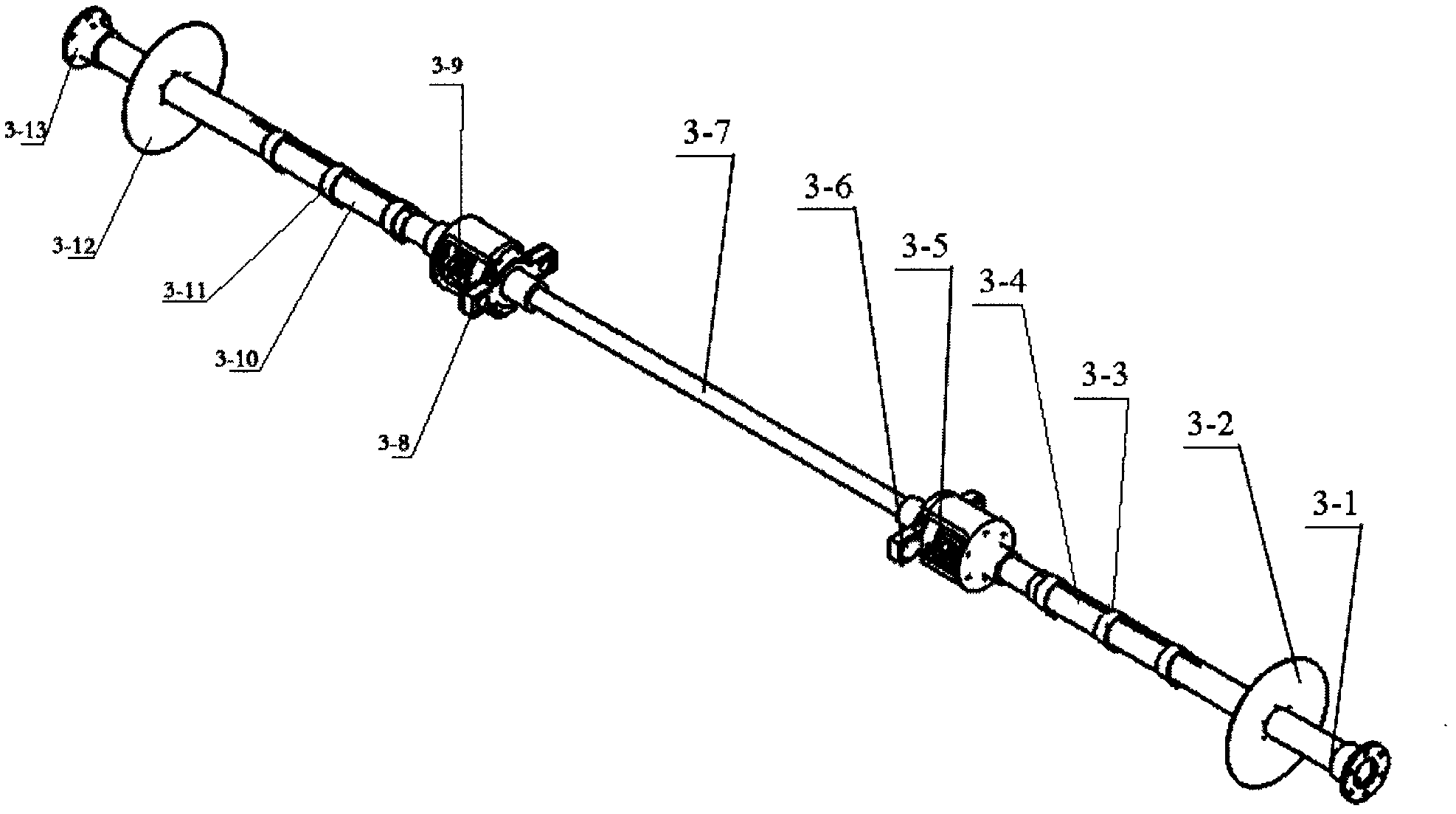

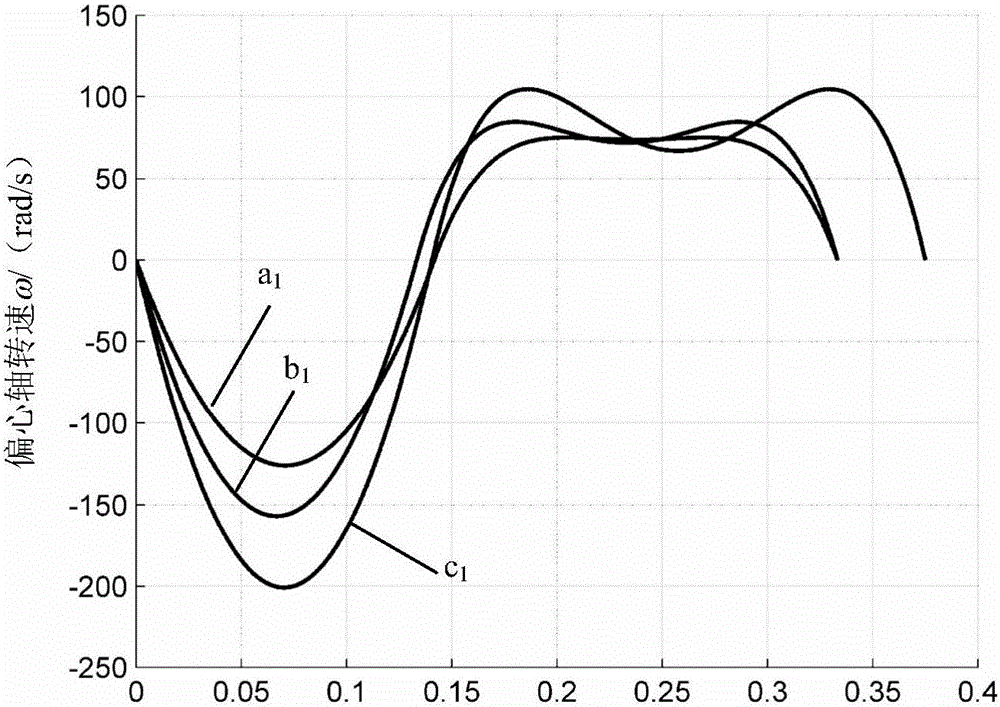

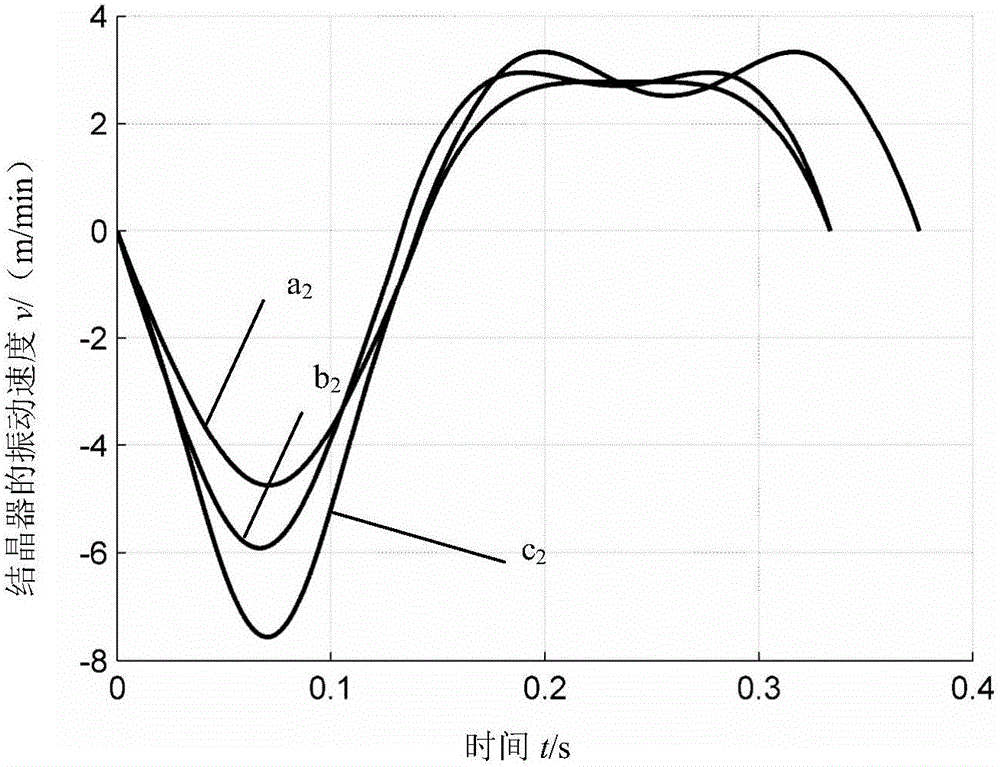

Method for stimulating continuous casting crystallizer to perform non-sinusoidal vibration by swing type eccentric shaft

The invention discloses a method for stimulating a continuous casting crystallizer to perform non-sinusoidal vibration by a swing type eccentric shaft, and is suitable for vibration devices under the swinging operation mode of eccentric shafts. The method comprises the following steps: the amplitude of the crystallizer, the frequency of the crystallizer, and the waveform deviating rate of the crystallizer are independent variables; the speed of the ascending section of the crystallizer, and the speed of the descending section of the crystallizer are respectively represented by two functions; the function curves of the ascending section and the descending section are smoothly connected and meet the requirement that the ascending displacement is equal to the descending displacement. Through the adoption of the method, the acceleration curve of waveforms is continuous, and the dynamics performance is good; no impact is generated during operation; the vibration parameters, such as the amplitude, the frequency and the waveforms, as the original parameters of the waveforms, can be directly adjusted, so that on-line automatic control is convenient.

Owner:蚌埠景图智能科技有限公司

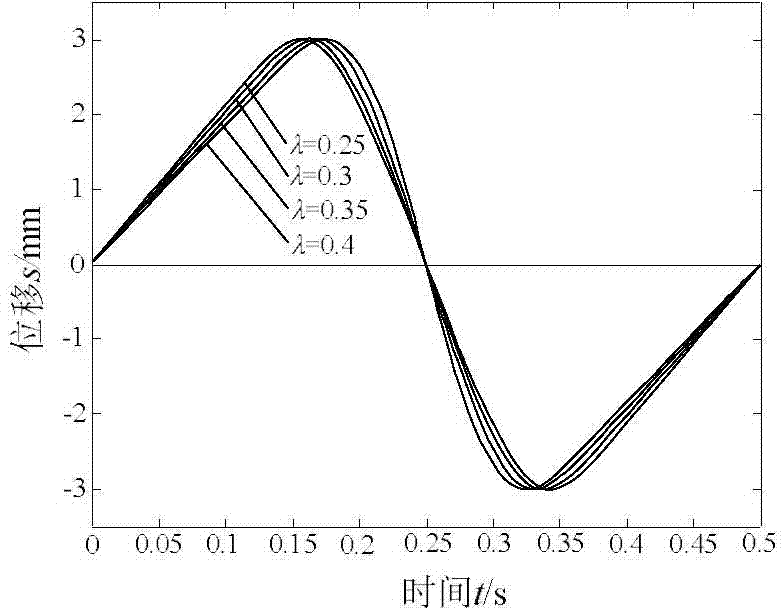

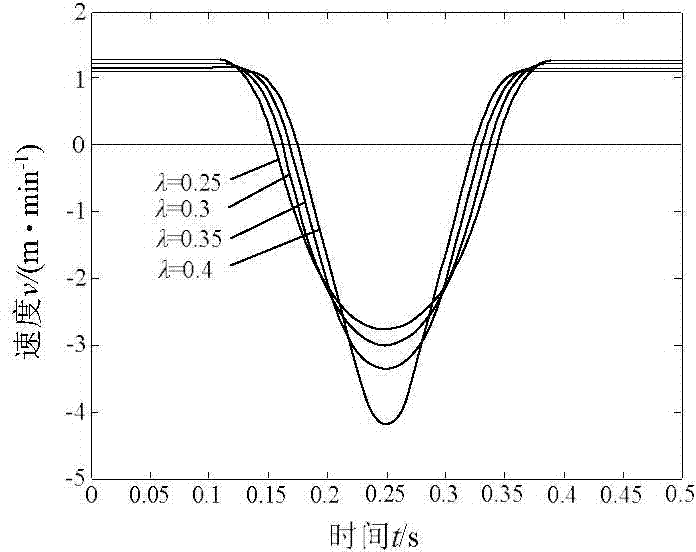

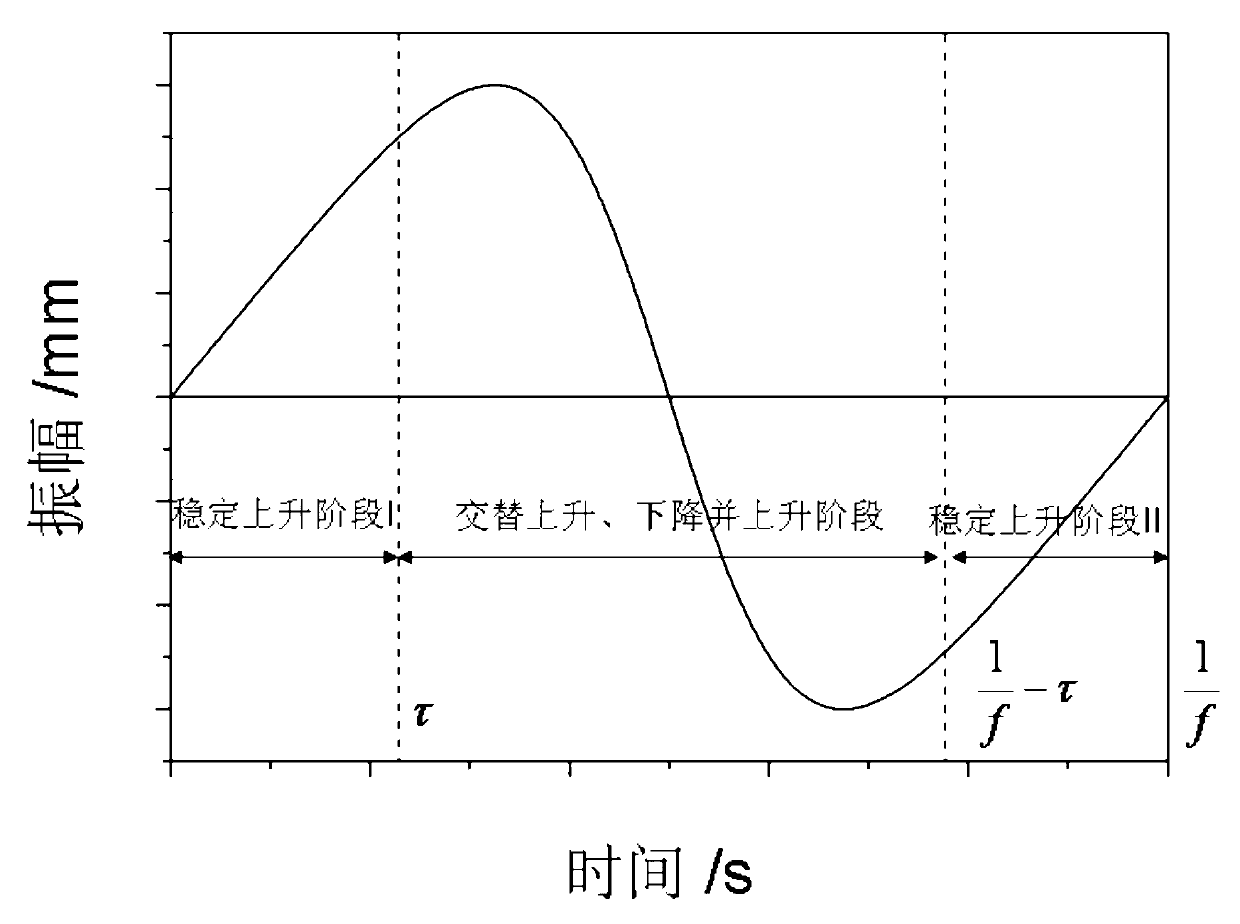

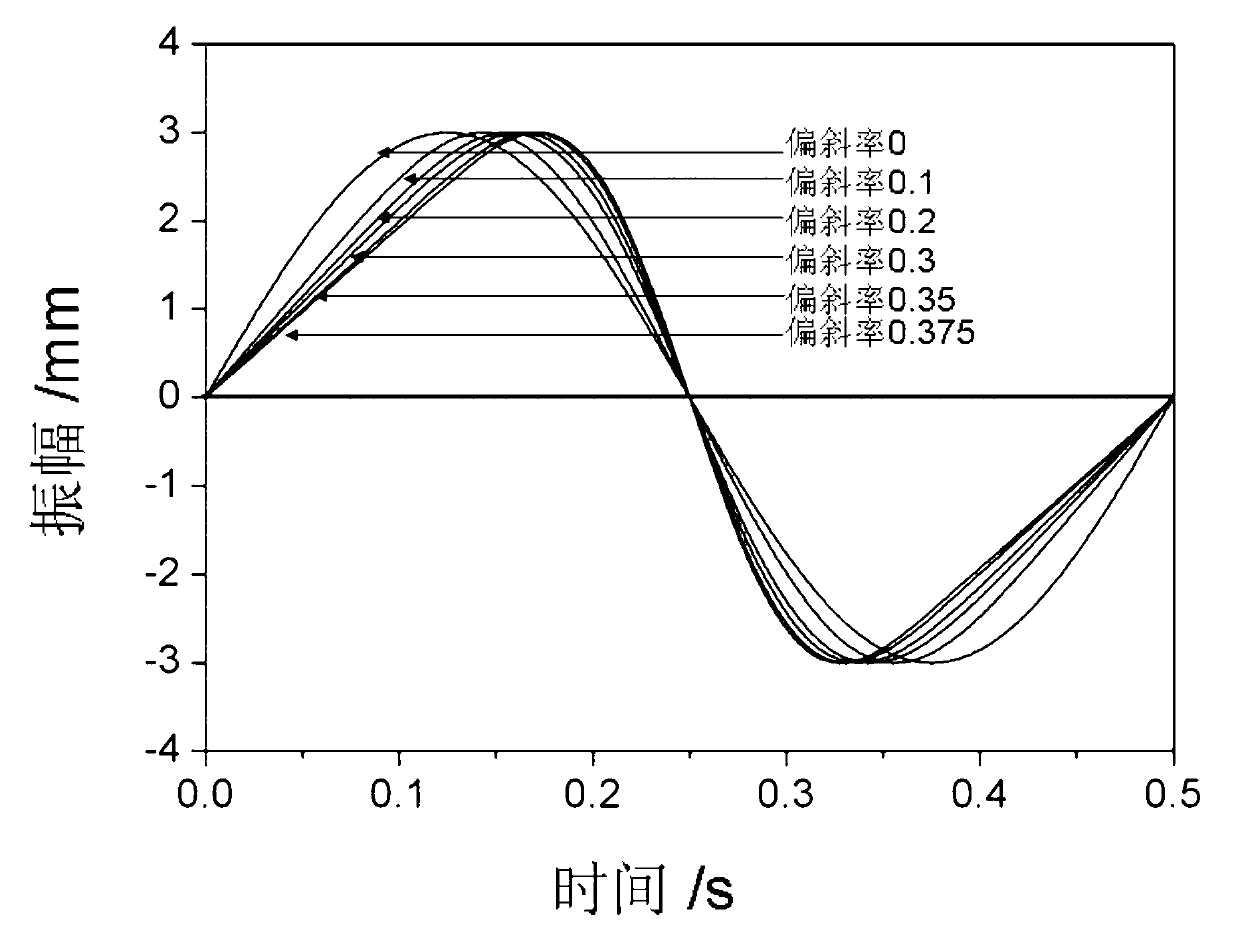

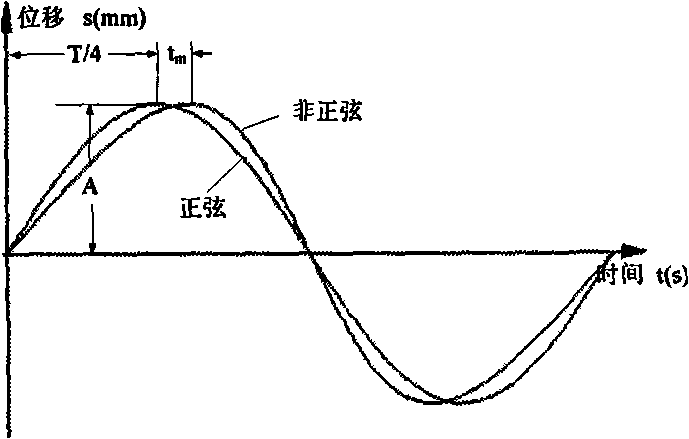

Waveform adjustable non-sinusoidal vibration method of continuous casting crystallizer

The invention discloses a waveform adjustable non-sinusoidal vibration method of a continuous casting crystallizer, which belongs to the technical field of continuous casting. The method is characterized in that a drive device for controlling the continuous casting crystallizer drives the continuous casting crystallizer, in every vibration period, to conduct non-sinusoidal vibration according to a track determined by the following vibration displacement procedure function: a formula (1) is as described in the specification, wherein S(t) is the displacement of the non-sinusoidal vibration; h is the stroke of the non-sinusoidal vibration; omega is angular velocity of the non-sinusoidal vibration, t is time of the non-sinusoidal vibration, ai is a technology constant correlated to the sinusoidal vibration and is not correlated to the stroke h and the angular velocity omega; and i is a term number. According to the method, when the track determined by the vibration displacement procedure function in a quadrinomial can ensure that the waveform does not distort when the rate of deflection is 0-37.5%; and the velocity, accelerated velocity and accelerated velocity change of the non-sinusoidal vibration of the crystallizer are all monotonous and continuous, so that the impact on equipment due to flutter in the course of operating is avoided, and the operation of the equipment is more stable and reliable.

Owner:WISDRI ENG & RES INC LTD

Non-sinusoidal waveform generator used for mold oscillation

ActiveCN101537477AImprove surface qualityReduce frictionMechanical oscillations controlVibration controlComputer module

The invention discloses a non-sinusoidal waveform generator used for mold oscillation, comprising a signal input module, a waveform generation module and a waveform output module, wherein the signal input module is used for inputting the amplitude, the frequency and the deviating rate of the non-sinusoidal waveform; the waveform generation module is used for receiving the amplitude, the frequency and the deviating rate of the signal input module to generate corresponding waveform; and the waveform output module is used for outputting the waveform generated by the waveform generation module to an oscillation controller. The waveform generation module executes the following function: s is equal to Ah x*(-delta)<m-1>Sin(m omega t). The non-sinusoidal oscillation waveform generated by the waveform generator can greatly improve the non-sinusoidal deviating rate, and avoid oscillation during the motion process of the equipment so as to lead the equipment to run smoothly; and the non-sinusoidal oscillation waveform can further greatly improve the negative slip time and the effective control range of the negative slip rate, minimize the friction force between the molten steel and the casting mold, reduce oscillation marks on the surface of casting blank and improve the surface quality of the casting blank.

Owner:CISDI ENG CO LTD

Multi-dimensional sinusoidal vibration control method and control apparatus

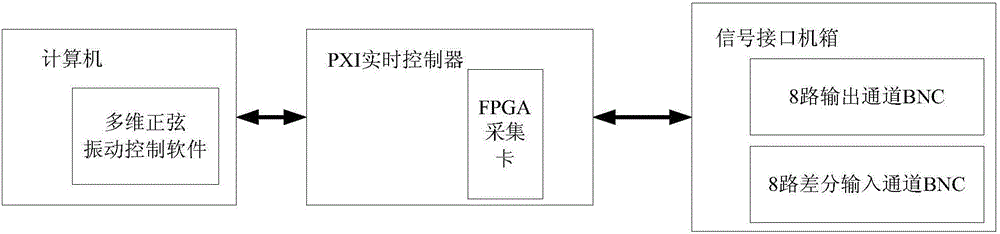

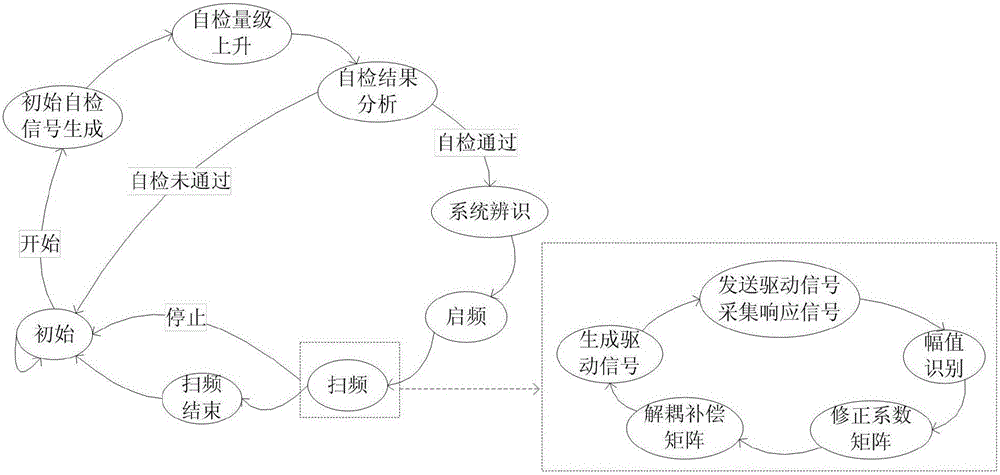

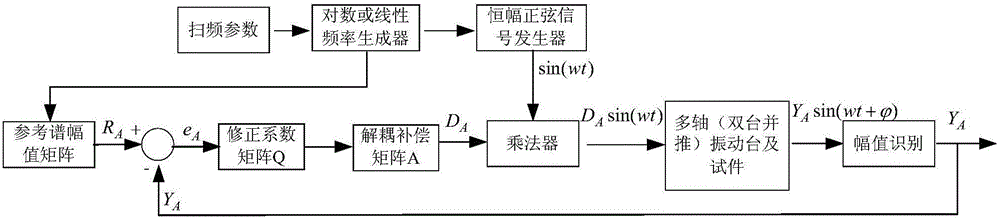

InactiveCN105068571ASatisfied with the test resultsFew modulesMechanical oscillations controlData acquisitionSystem identification

The invention discloses a multi-dimensional sinusoidal vibration control method and control apparatus. The apparatus comprises an upper computer, a PXI real-time controller, a data acquisition card, an acceleration sensor and a displacement sensor. The method includes the steps of system parameter setting, system self detection, system identification, sinusoidal vibration frequency starting, sinusoidal frequency sweeping, and test completing and stopping after frequency sweeping, thereby realizing control on the control apparatus. According to the invention, the control is stable; the apparatus has good sinusoidal vibration control capability from one dimension to six dimensions and is suitable for the multi-dimensional sinusoidal vibration control or sinusoidal test. In addition, different initial phases can be set for different control dimensions to form the sinusoidal vibration or motion under several kinds of combination modes. Meanwhile, an amplitude identification technology based on combination of an FFT and a filter, a semi-sinusoidal-window stable frequency starting technology, a multi-dimensional driving amplitude on-line updating method, and an acceleration and displacement mixed control method are used for obtaining a satisfying testing effect. Moreover, the apparatus has advantages of simple system, less modules, easy installation, and convenient maintenance.

Owner:GENERAL ENG RES INST CHINA ACAD OF ENG PHYSICS

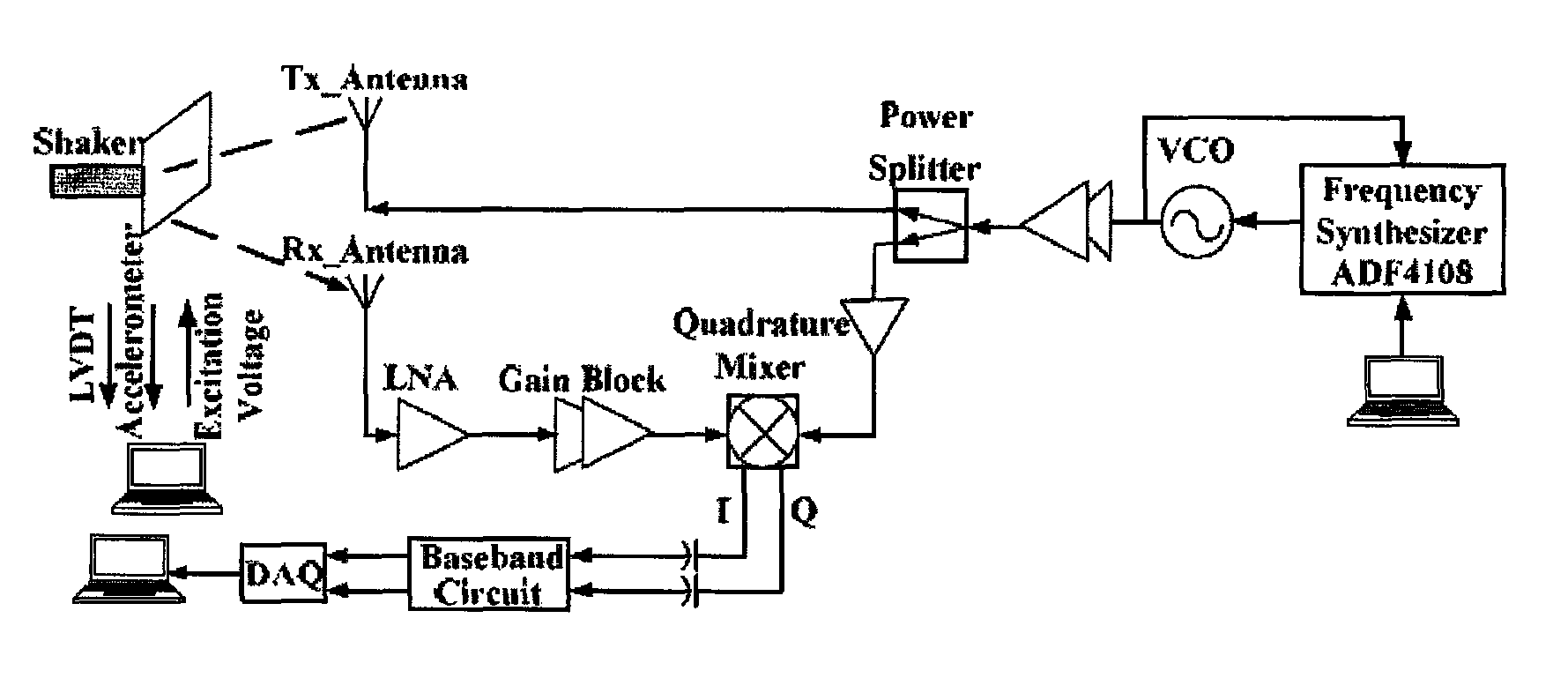

Wavelength division sensing RF vibrometer for accurate measurement of complex vibrations

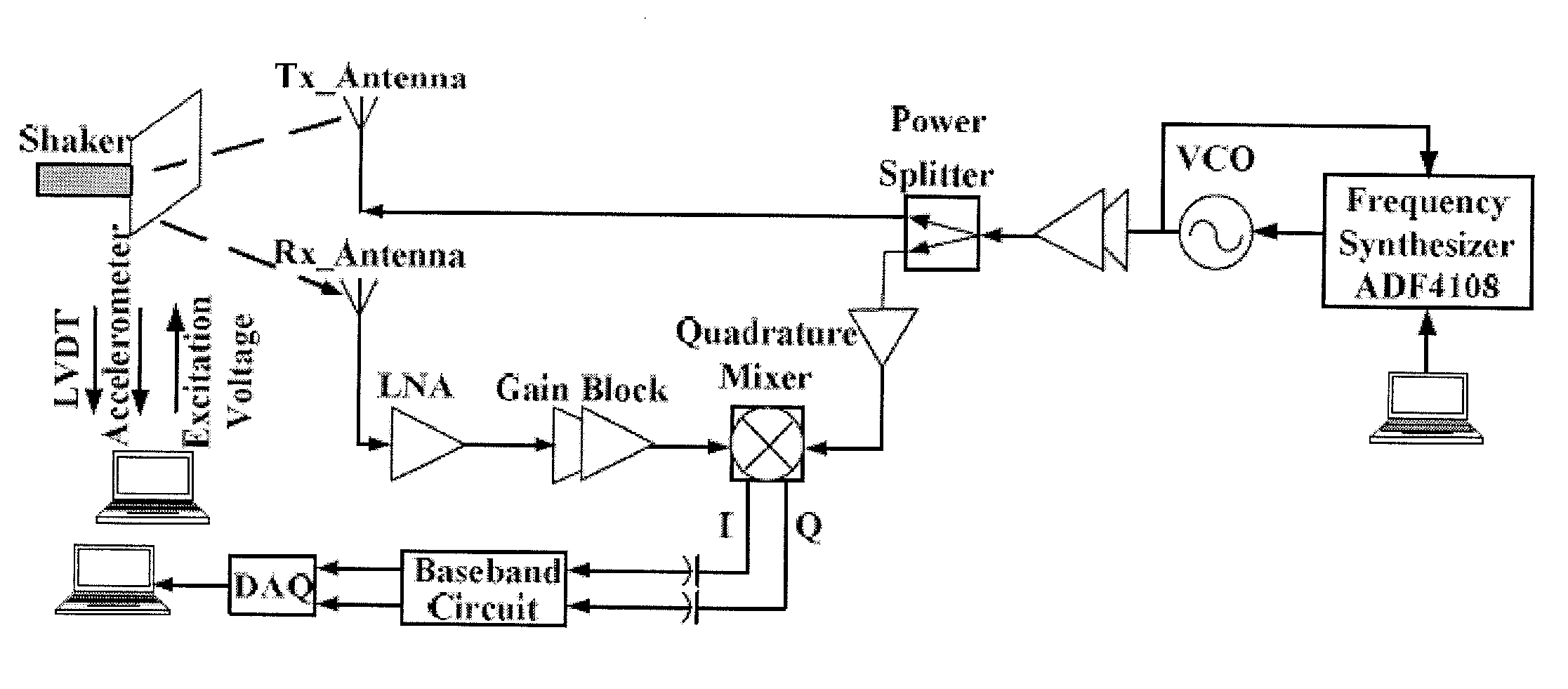

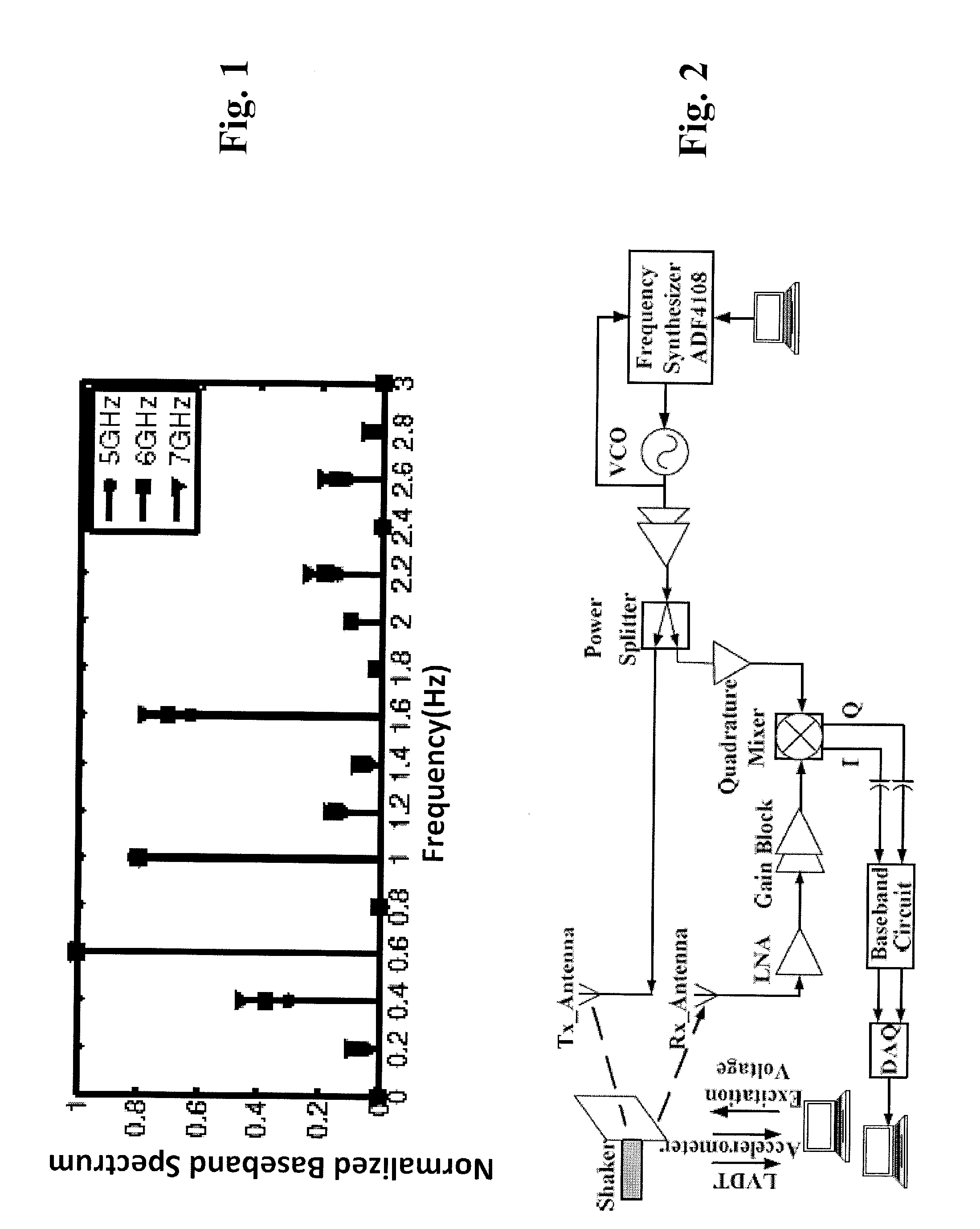

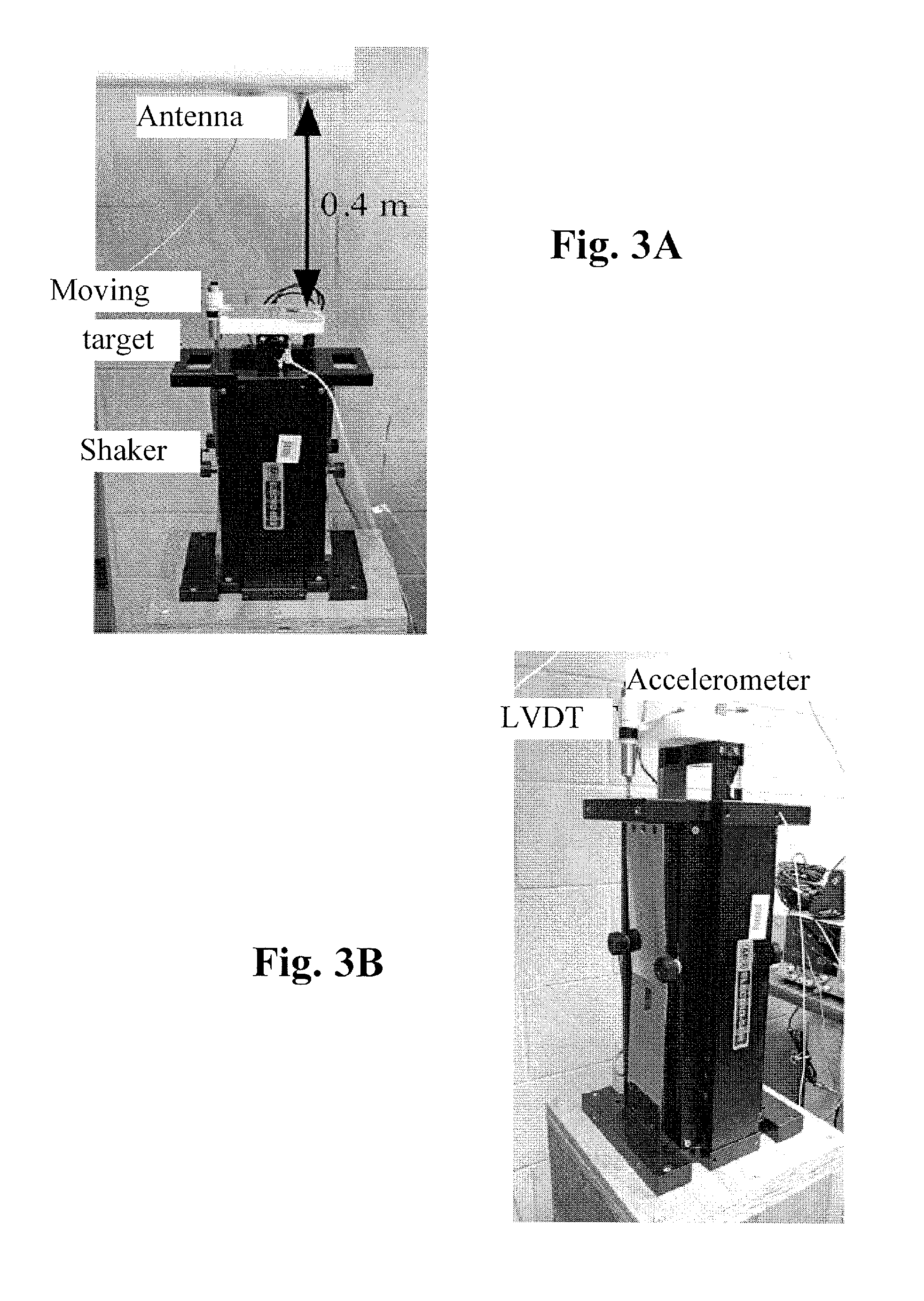

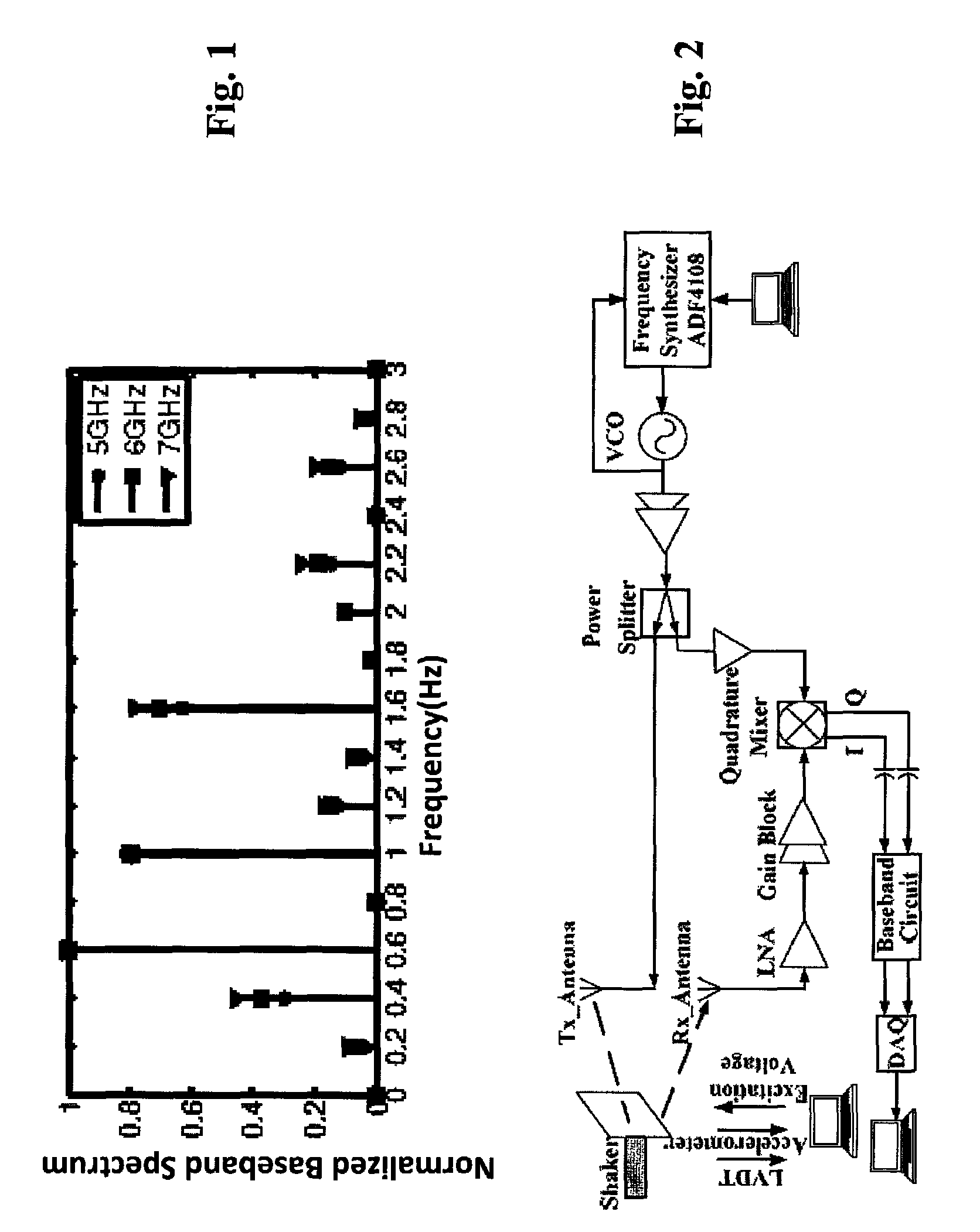

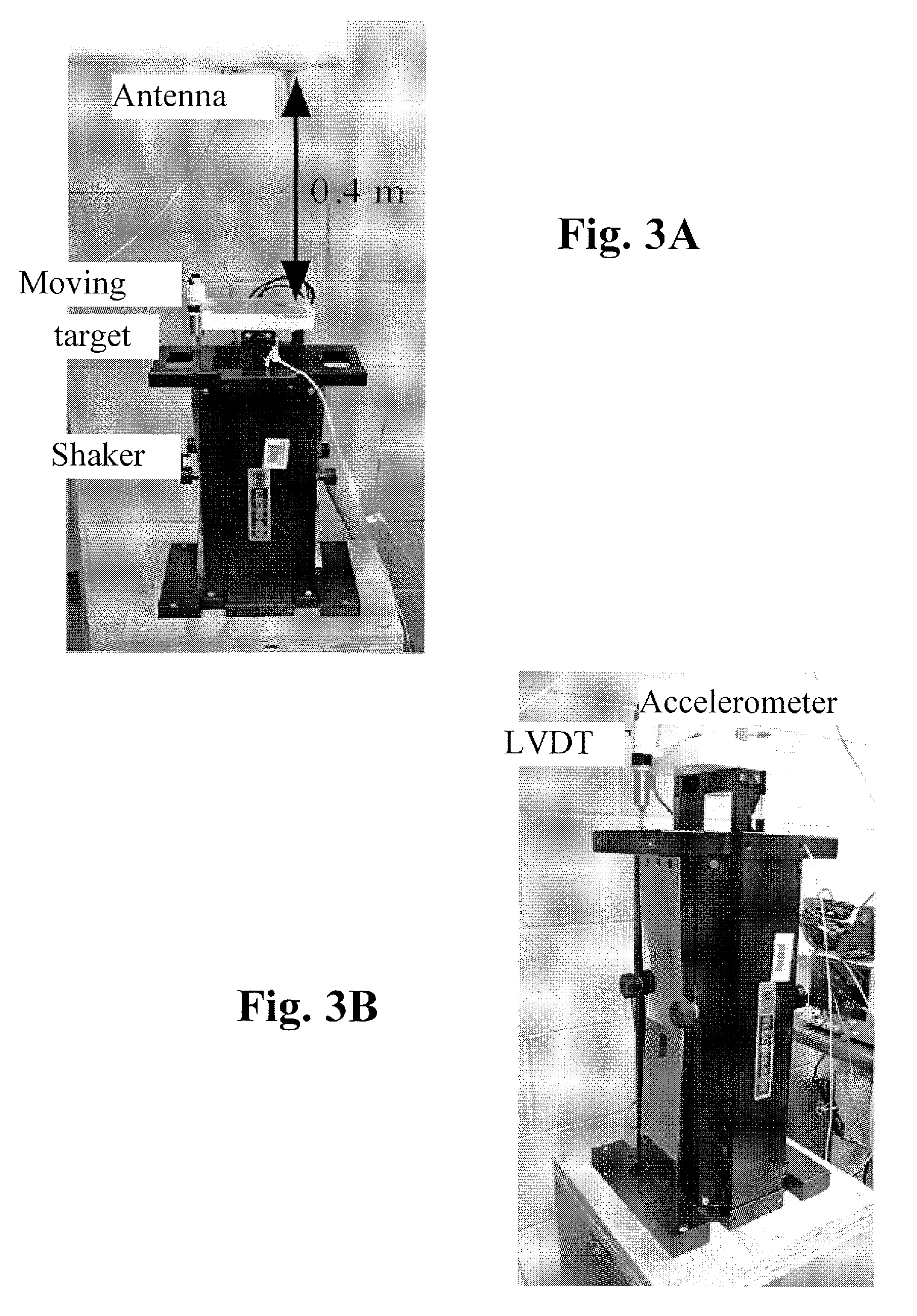

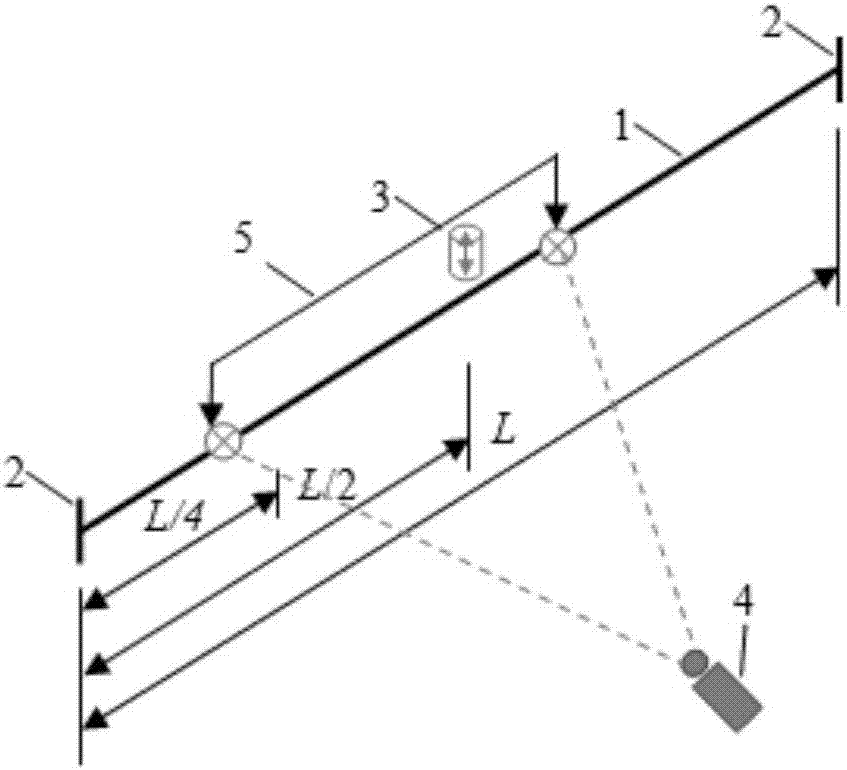

ActiveUS20130139597A1Reduced sampling rate requirementsImprove accuracyVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVisibilityHarmonic

Embodiments of the present invention provide a method for non-contact detection techniques of mechanical vibrations utilizing a radio frequency system incorporating multiple carrier wavelengths. The new detection method measures multiple harmonic pairs at a carrier frequency and improves the detection accuracy and reliability by first inspecting the Bessel function coefficient of each harmonic and then determining the harmonic amplitude. The original mechanical vibration can then be reconstructed. Embodiments can be used to realize sensing of complex non-sinusoidal vibrations using a wavelength division sensing technique and allow non-contact detection through walls, smoke, fog or other low visibility environments with the advantage of longer range detection and easy integration at a low cost.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

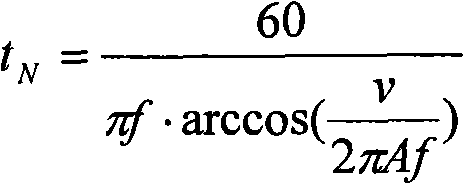

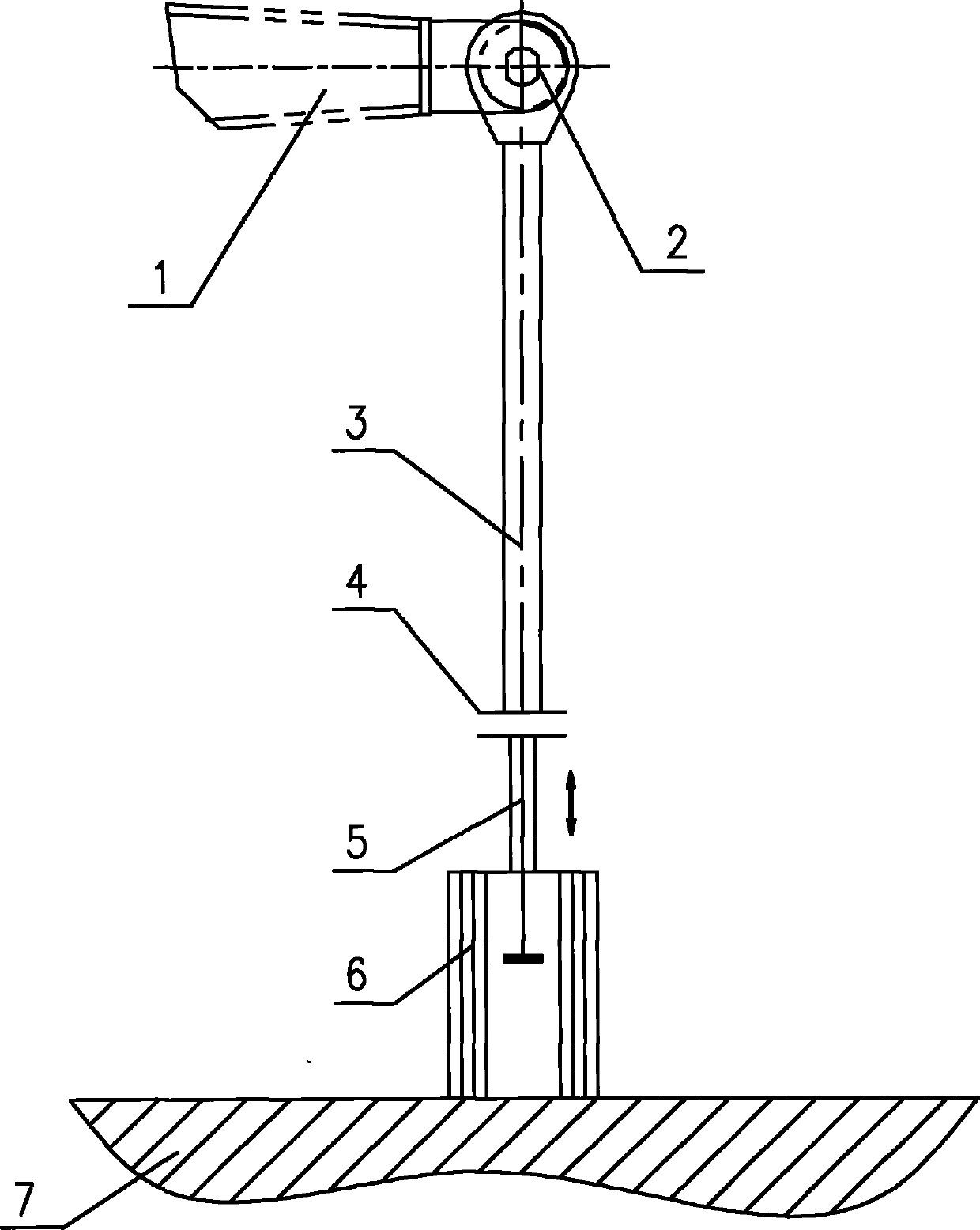

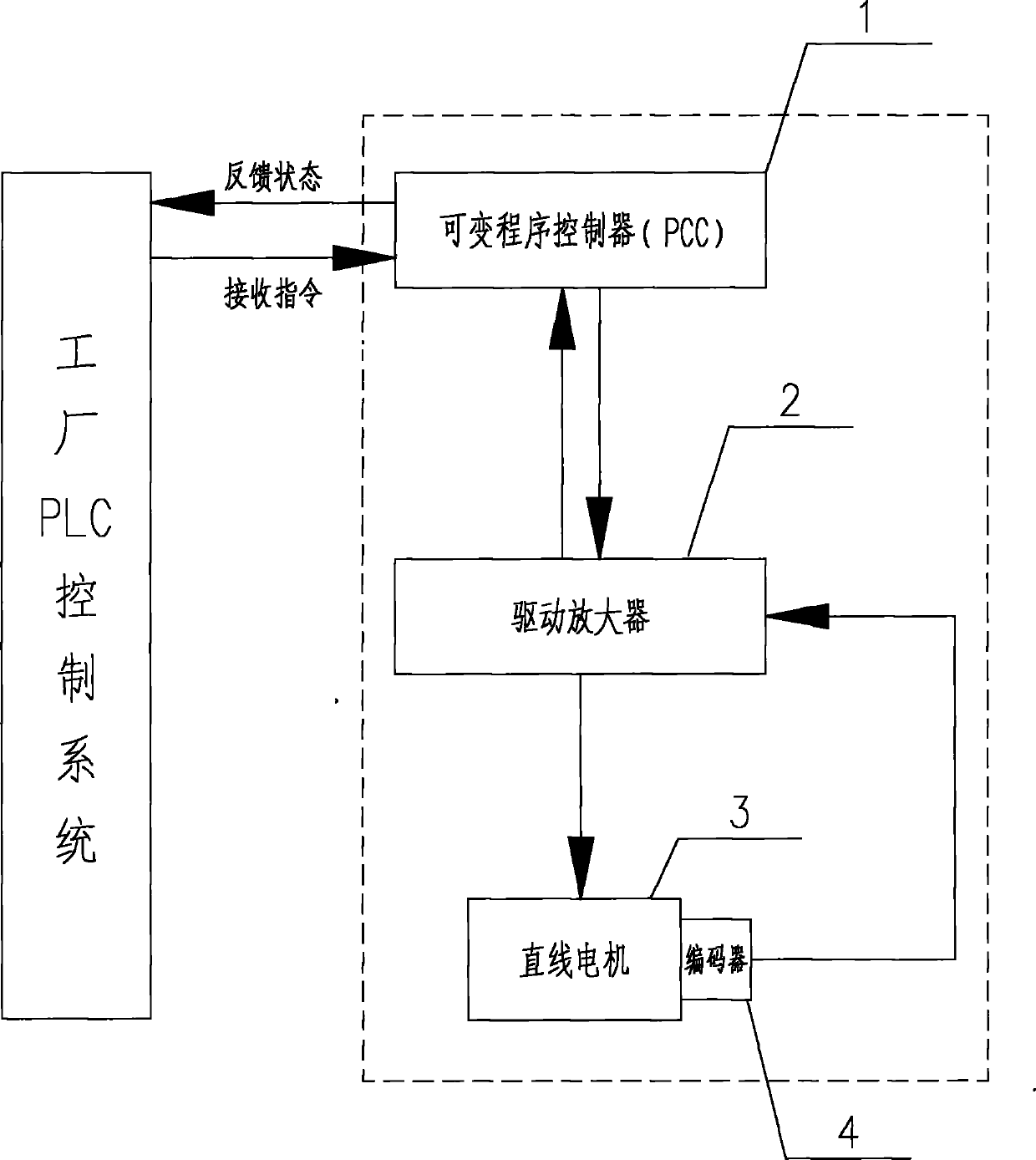

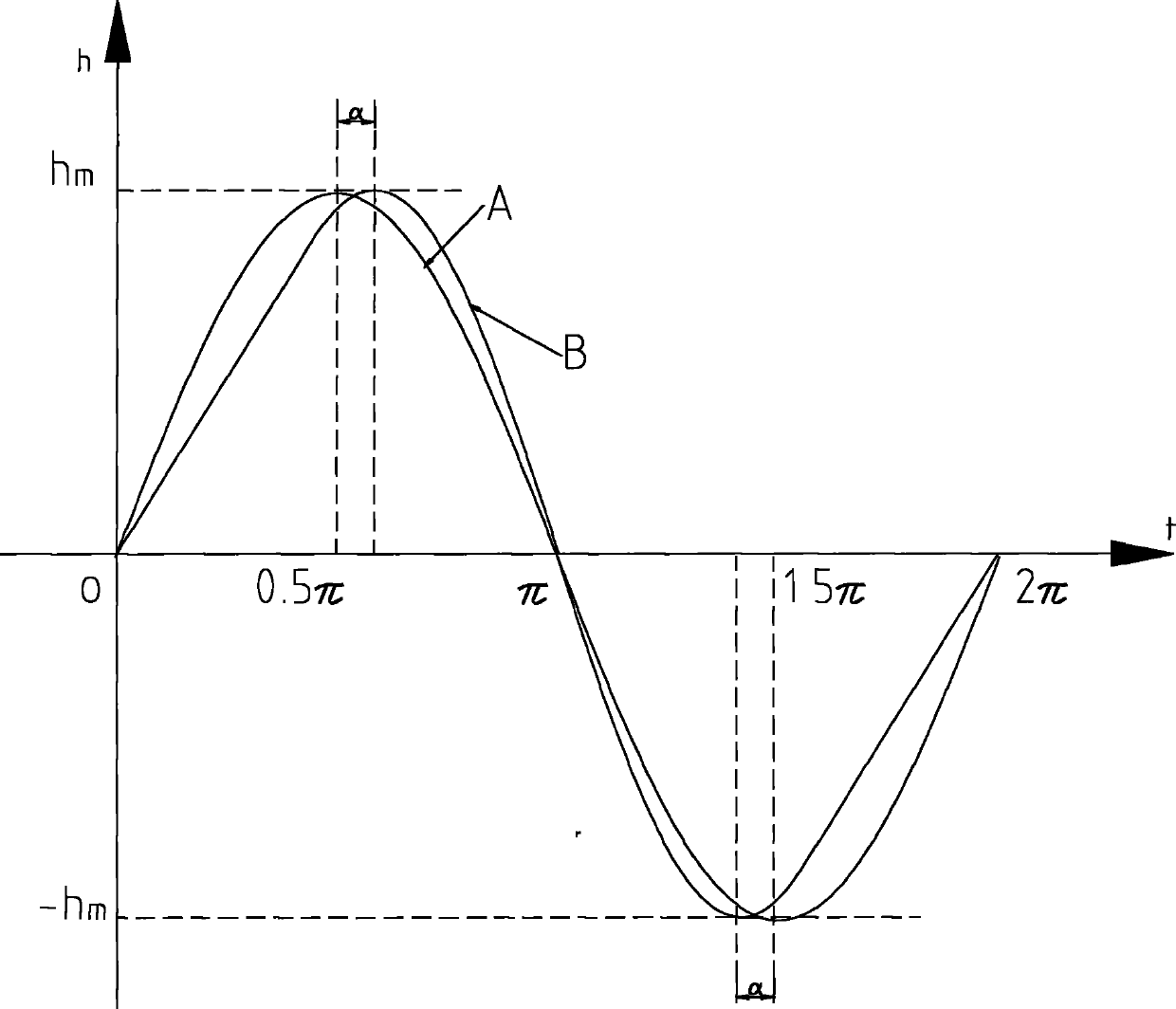

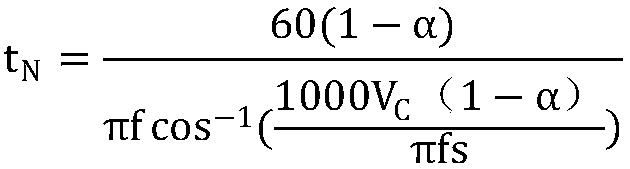

Direct-drive crystallizer vibration generating device and non-sinusoidal vibration method

The invention discloses a direct-drive crystallizer vibration generating device which comprises a vibration platform, wherein the vibration platform is connected with a connecting rod; the connecting rod is connected with a linear motor; the linear motor drives the connecting rod to drive the vibration platform to move; the linear motor is connected with a control component; and the control component controls the moving mode of the linear motor. The invention also discloses a non-sinusoidal vibration method realized by the device. The vibration formula is shown in the specification, wherein Tis the vibration period, tA is the rising half period, tC is the falling period, f is frequency, t is time, h is amplitude, and alpha is the deviation rate. According to the invention, a transmission system is simplified and has a compact structure, and other mechanical structures of the existing traditional mechanical type crystallizer vibration device do not need to be changed; the motor is directly driven to operate up and down, and the service life is prolonged; and the entire structure has the advantages of large bearing capacity, strong impact resistance, high reliability and the like.

Owner:上海重矿连铸技术工程有限公司

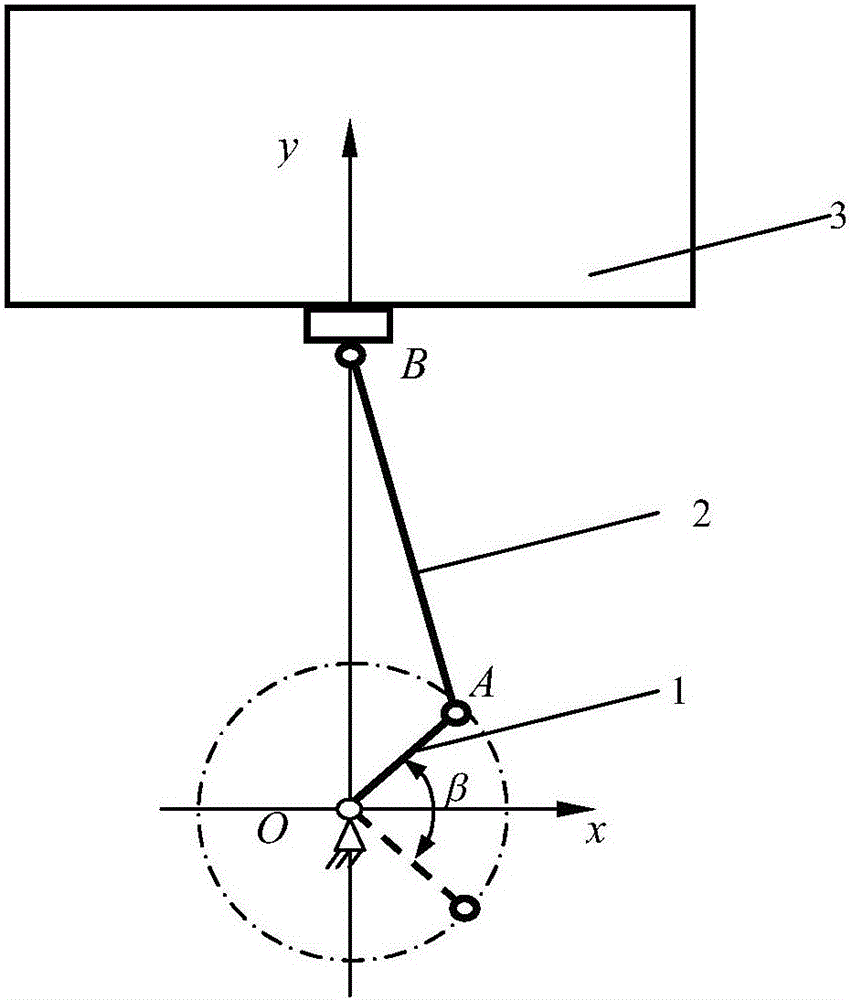

High-precision high-acceleration low-frequency sinusoidal vibration system

InactiveCN104180820AAvoid many problems with experimentationEasy to testMeasurement devicesVibration amplitudeHigh acceleration

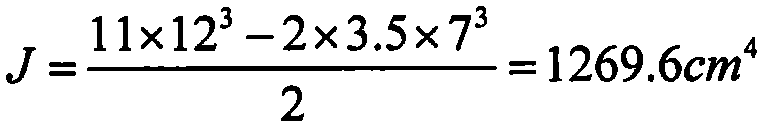

The invention relates to a high-precision high-acceleration low-frequency sinusoidal vibration system which comprises a rotating motor, a crank disc, a crankshaft, a horizontal rolling guide rail, a vertical rolling linear bearing, an upright post, a worktable, a balance weight and a position sensor, wherein a left guide post and a right guide post are arranged on a base; a left linear bearing and a right linear bearing are respectively arranged on the left guide post and the right guide post and can move up and down on the guide posts; two ends of a transverse beam are respectively connected with the left linear bearing and the right linear bearing; the horizontal rolling guide rail is fixedly connected to the transverse beam; a horizontal guide rail slide block can move from left to right on the horizontal rolling guide rail; and the upright post and the worktable are arranged on the transverse beam. According to the mechanical system, high-precision and high-acceleration low-frequency sinusoidal vibration can be realized, the defects of a centrifuge test are overcome, the flexibility of research trial is improved, the problems that a low-frequency section of the conventional vibration table is low in vibration amplitude and vibration frequency precision, the testing requirements of a high-precision inertia type instrument cannot be met and the like are solved, and a high-order error item coefficient of the inertia type instrument is tested.

Owner:HARBIN INST OF TECH

Device used for dynamic and static calibration of eddy current sensor

ActiveCN106403794AImprove calibration efficiencyUsing electrical meansReciprocating motionCurrent sensor

The invention provides a device used for dynamic and static calibration of an eddy current sensor. The device comprises a pedestal, wherein a vibrating stand module and a clamp for clamping a sensor to be calibrated, a motion executing module of the clamp and a grating ruler assembly are arranged on the pedestal; a sensing disc and a standard acceleration sensor are installed on a working tableboard of the vibrating stand module, and the sensing disc is arranged between the working tableboard and the clamp; the motion executing module consists of a position-adjusting driving assembly which drives the clamp to move along the radial direction of the sensing disc, and a calibration driving assembly which drives the clamp to move along the axial direction of the sensing disc; when static calibration is carried out, the vibrating stand module is in a non-operating state, the calibration driving assembly drives the clamp to do lineal reciprocating motion to be close to or away from the sensing disc, and the grating ruler assembly obtains actual displacement of a calibrated sensor at each test point; and when dynamic calibration is carried out, the calibration driving assembly is in a non-operating state, and the vibrating stand module drives the sensing disc to generate sinusoidal vibration. The device provided by the invention has the advantages of wide calibration frequency range.

Owner:ZHEJIANG UNIV

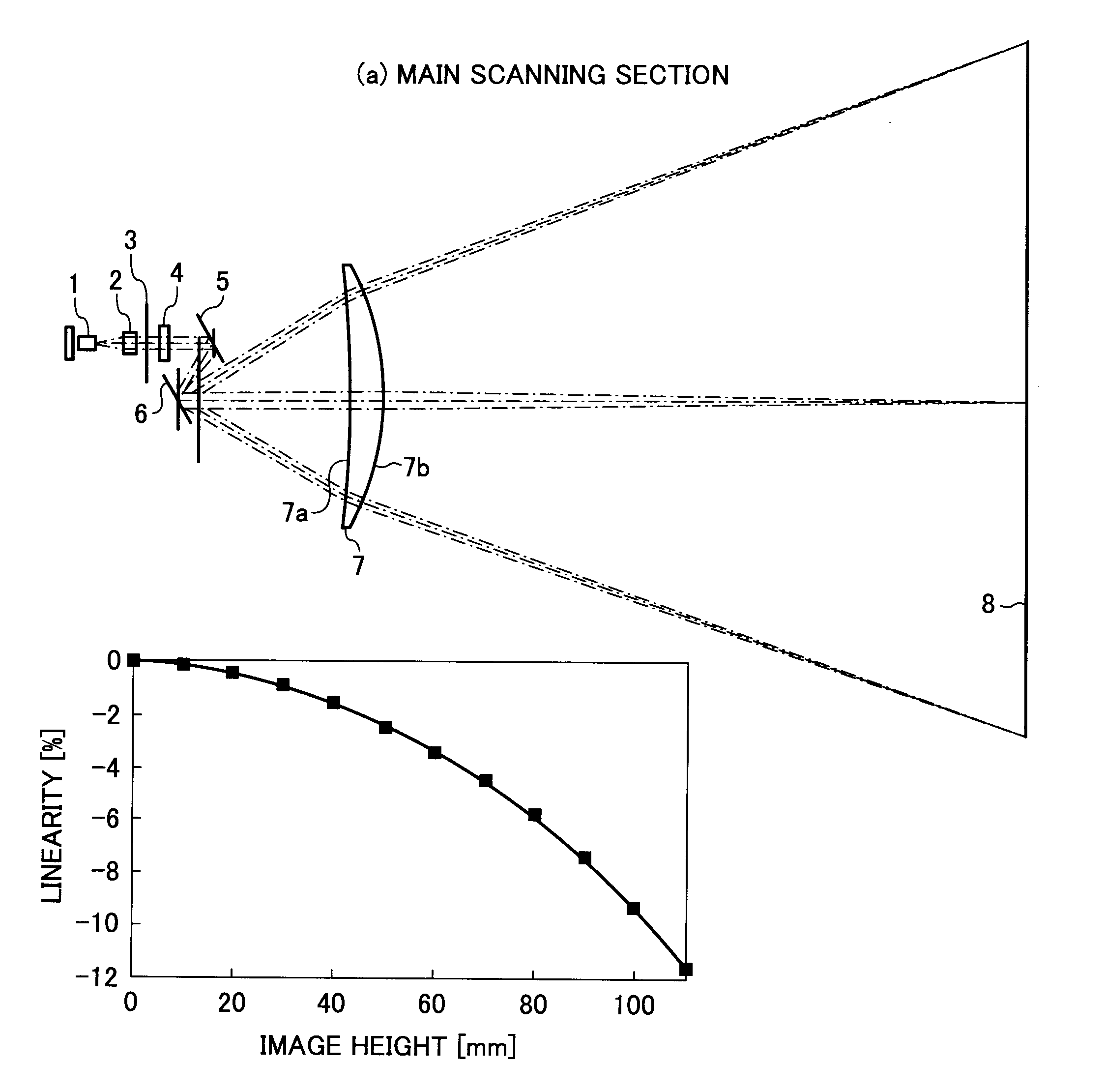

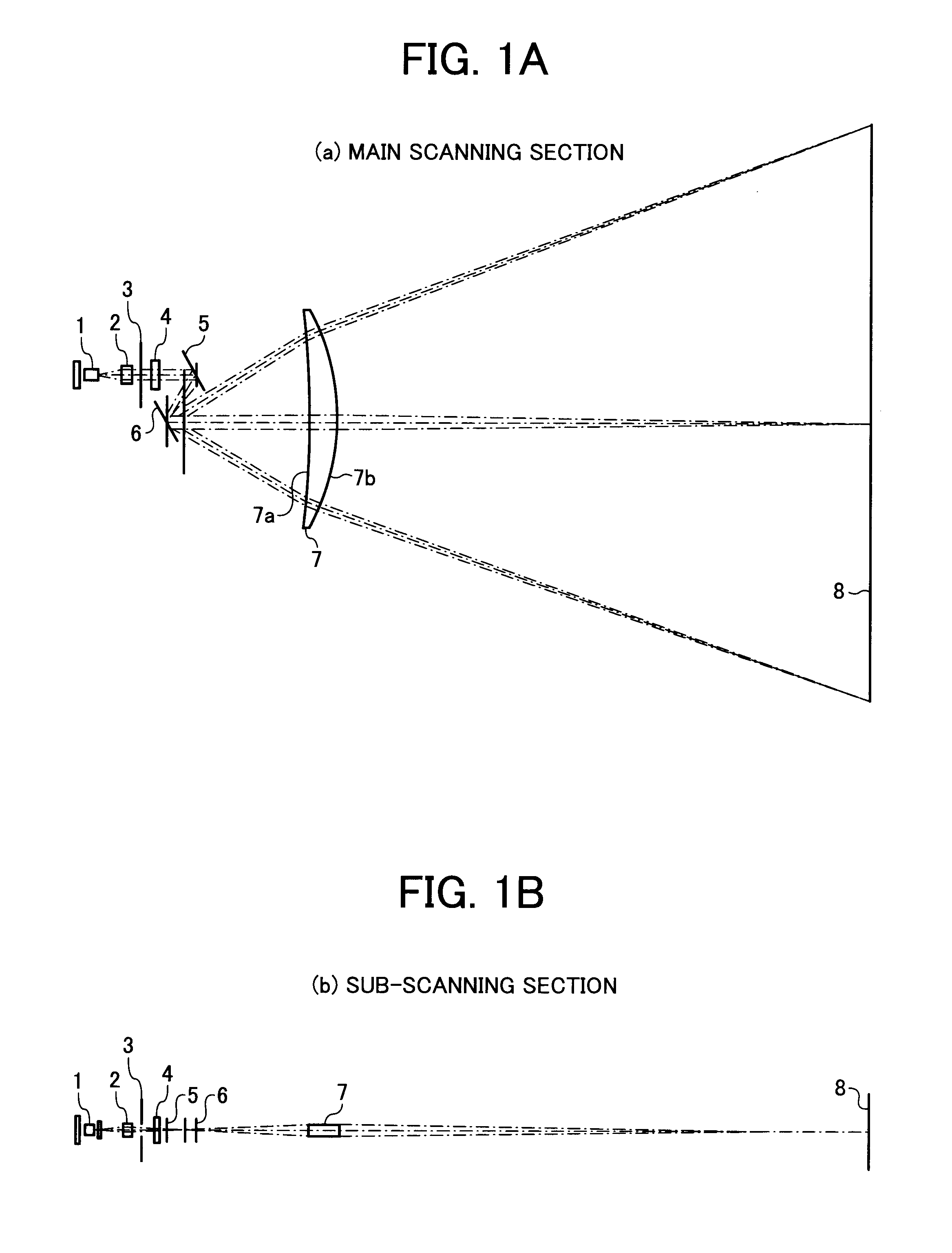

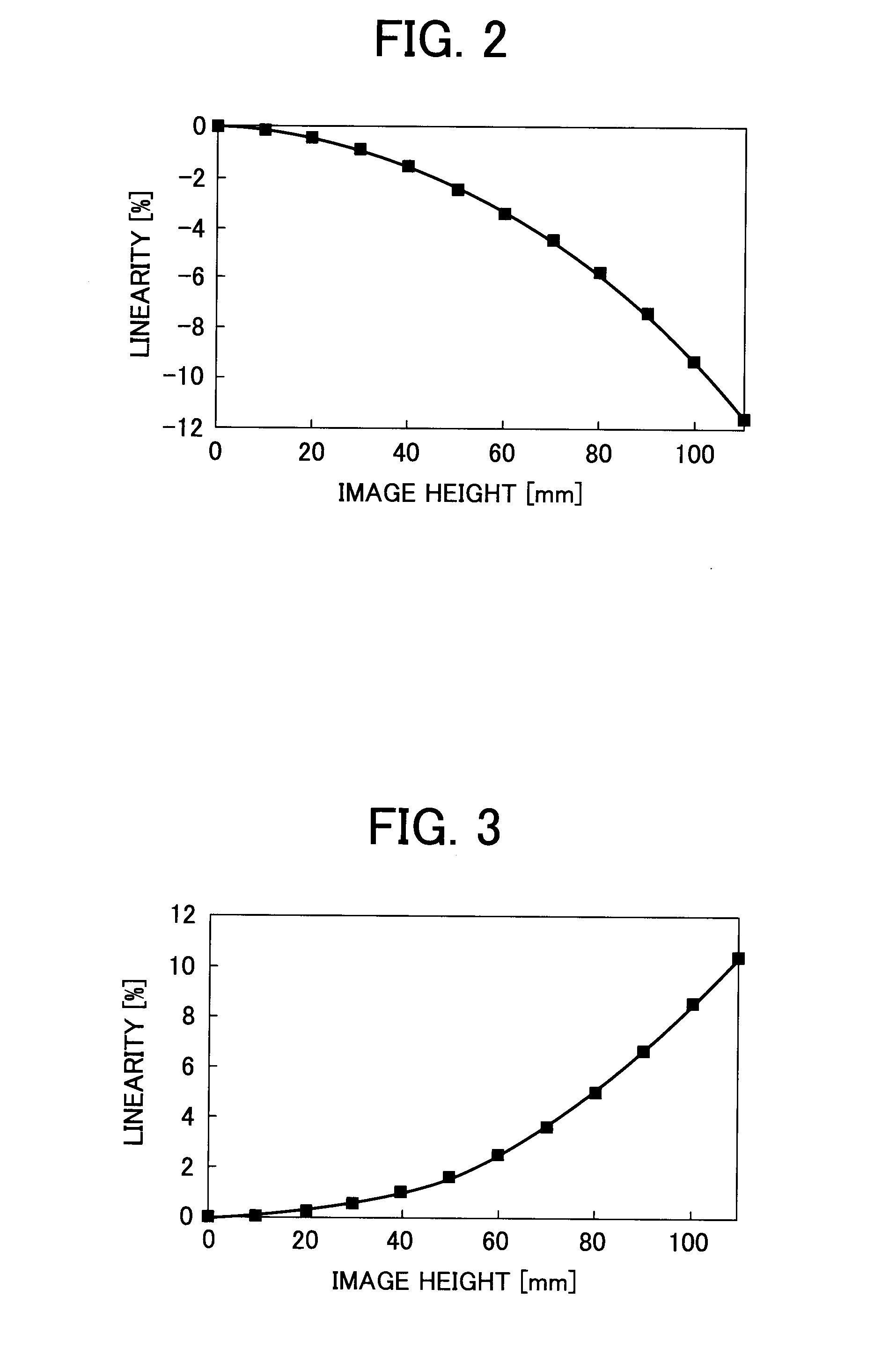

Optical scanning apparatus and image forming apparatus

An optical scanning apparatus includes a light source, a light source driving unit that turns on the light source according to image information, a deflector that deflects and scans a light beam emitted from the light source according to sinusoidal vibration, and a scanning / imaging optical system that guides the light beam from the deflector to a scanned surface. The scanning / imaging optical system satisfies two conditions, i.e., (1) provided that the deflector moves in such a manner that an angular velocity is constant, linearity is made larger at a most peripheral image height than at a central image height within a range of an effective writing width, and (2) when a deflection angle of the deflector has a sinusoidal characteristic, the linearity is made smaller at the most peripheral image height than at the central image height within the range of the effective writing width.

Owner:RICOH KK

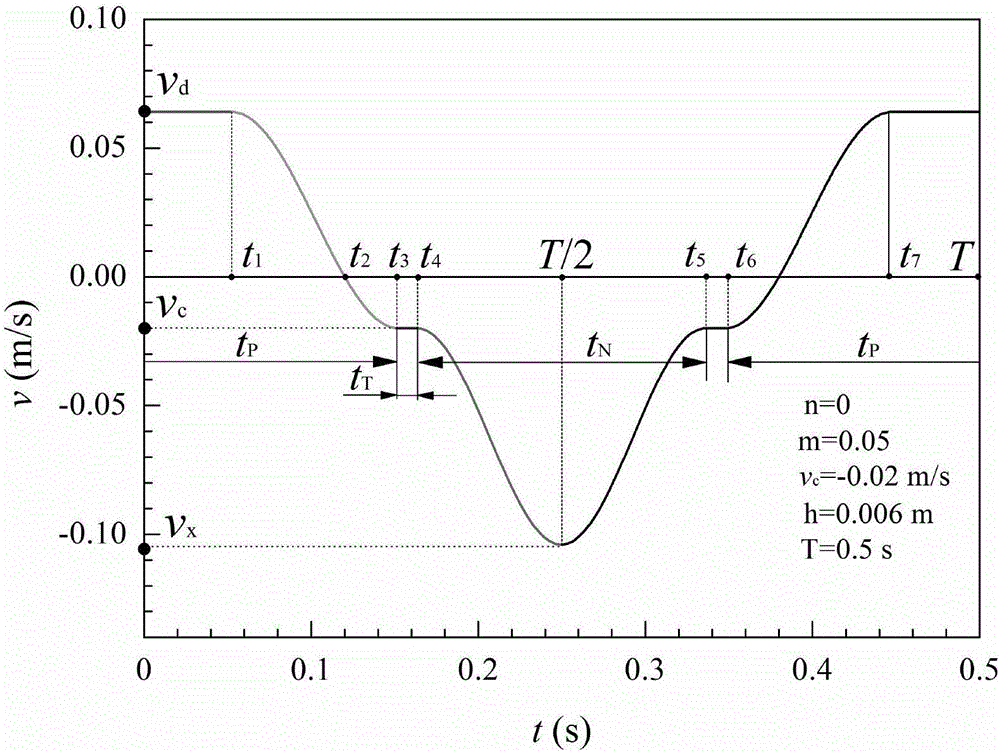

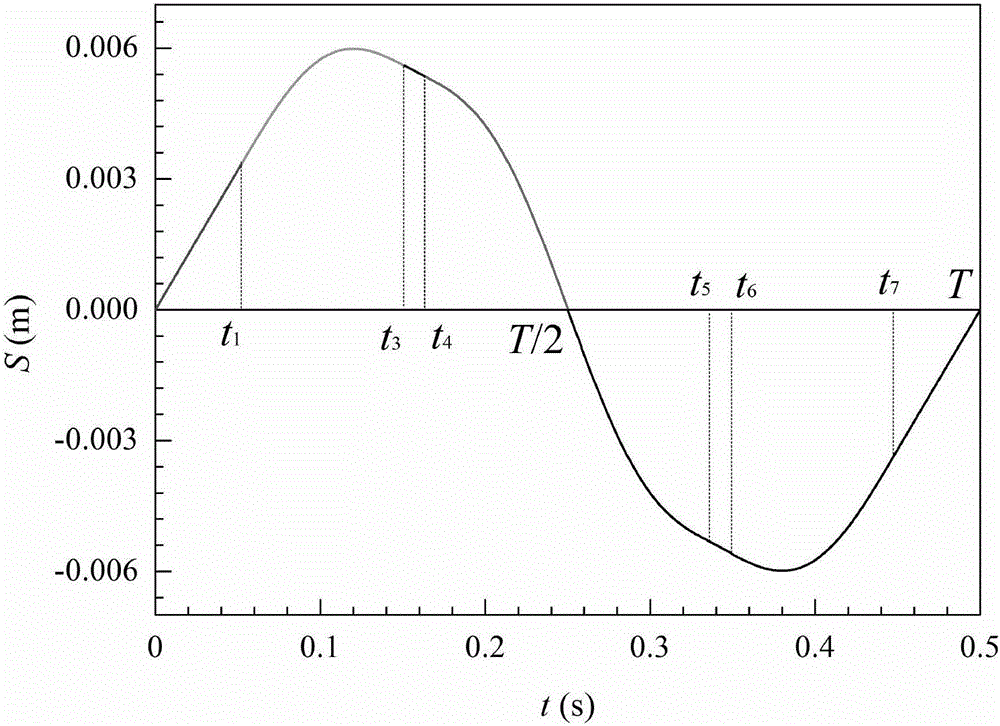

Non-sinusoidal vibration method of continuous casting mold

The invention provides a non-sinusoidal vibration method of a continuous casting mold. The non-sinusoidal vibration method includes steps of controlling a driving device of the continuous casting mold so that the continuous casting mold vibrates non-sinusoidally in line with eight-stage speed determined as the following eight-stage speed function in each vibration cycle; introducing a new vibration control variable, namely the constant-speed duration factor m, increasing the control means for the waveforms to facilitate the vibration control according to the actual conditions. The casting speed and vibration waveform can be combined for different billet speed, and different vibration schemes can be designed; the consumption of casting powder can be increased, continuous casting lubrication is facilitated, and friction, cracks and binding are reduced. Therefore, the vibration speed of the crystallizer is equal to the extension of the casting speed, and the uniform outward heat transfer of the continuous casting and stable growth of the initial base are facilitated.

Owner:NORTHEASTERN UNIV

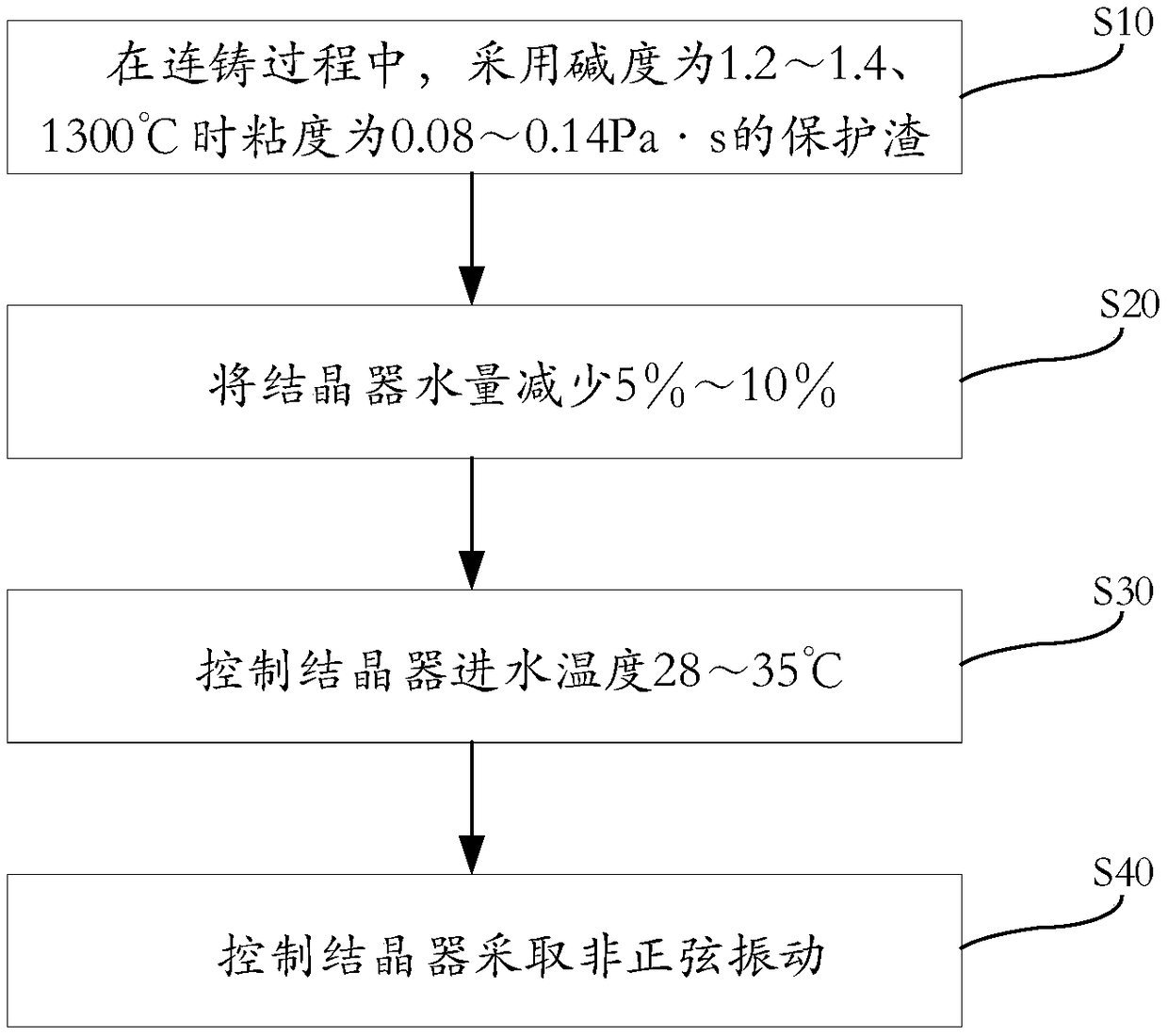

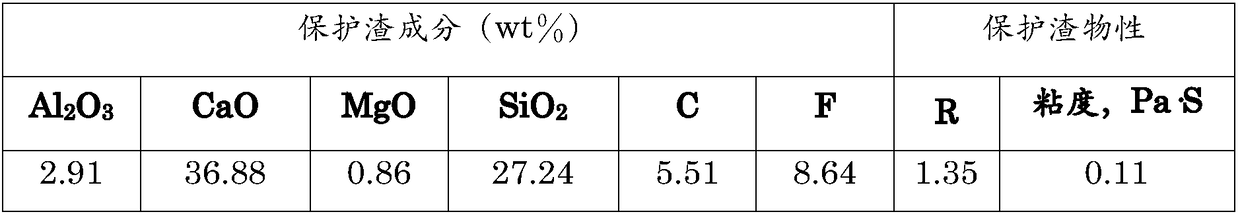

Method for preventing longitudinal cracks on surface of sub-peritectic steel casting blank

The invention relates to the technical field of continuous casting, in particular to a method for preventing longitudinal cracks on the surface of a sub-peritectic steel casting blank. The method comprises the following steps of: in a continuous casting process, adopting casting powder, the viscosity of which is 0.08-0.14 Pa.s when the alkalinity of the casting powder is 1.2-1.4 and the temperature of the casting powder is 1300 DEG C; reducing the water quantity of a crystallizer by 5%-10%; and controlling the water inlet temperature of the crystallizer to be 28-35 DEG C, wherein the crystallizer is in non-sinusoidal vibration. According to the method for preventing the longitudinal cracks on the surface of the sub-peritectic steel casting blank provided by the embodiment of the invention,the cracks are prevented from occurring on the surface of the sub-peritectic steel casting blank by adopting the casting powder, the viscosity of which is 0.08-0.14 Pa.s when the alkalinity of the casting powder is 1.2-1.4 and the temperature of the casting powder is 1300 DEG C, reducing the water quantity of the crystallizer by 5%-10% and controlling the water inlet temperature of the crystallizer to be 28-35 DEG C. As the lubrication effect of the casting powder is reduced after the alkalinity of the casting powder is increased, the non-sinusoidal vibration and the high-vibration frequencyand small amplitude vibration mode are adopted to reduce the negative slip time and improve the lubrication, and the longitudinal cracks on the surface of the sub-peritectic steel casting blank can beeffectively prevented.

Owner:BEIJING SHOUGANG CO LTD

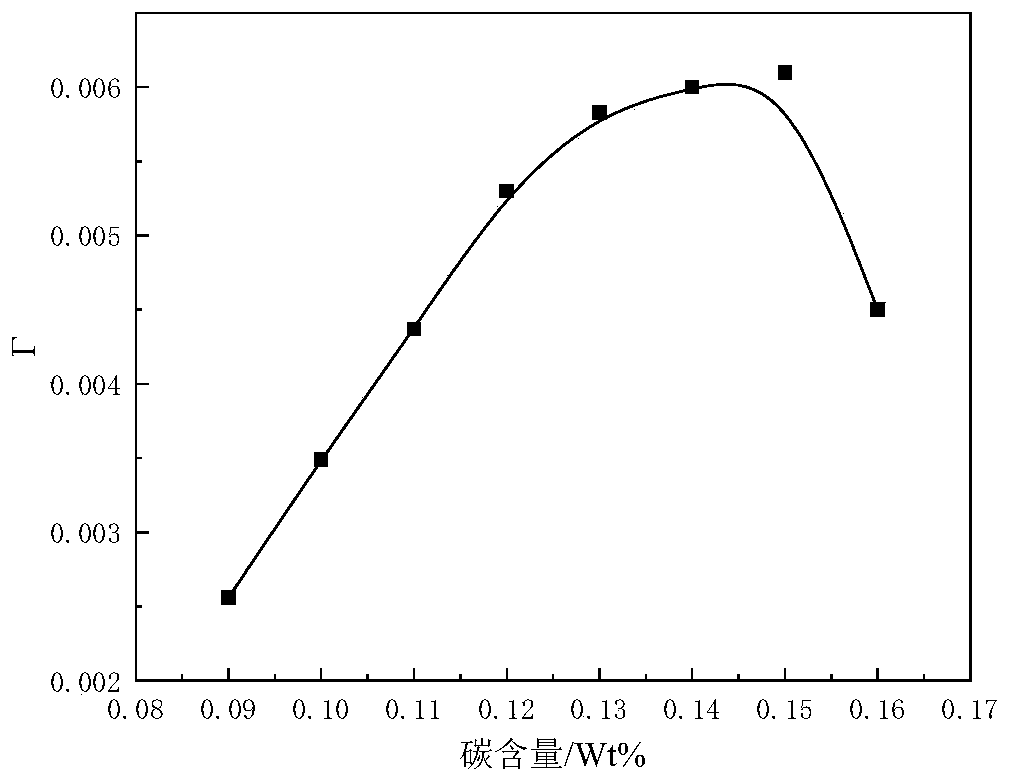

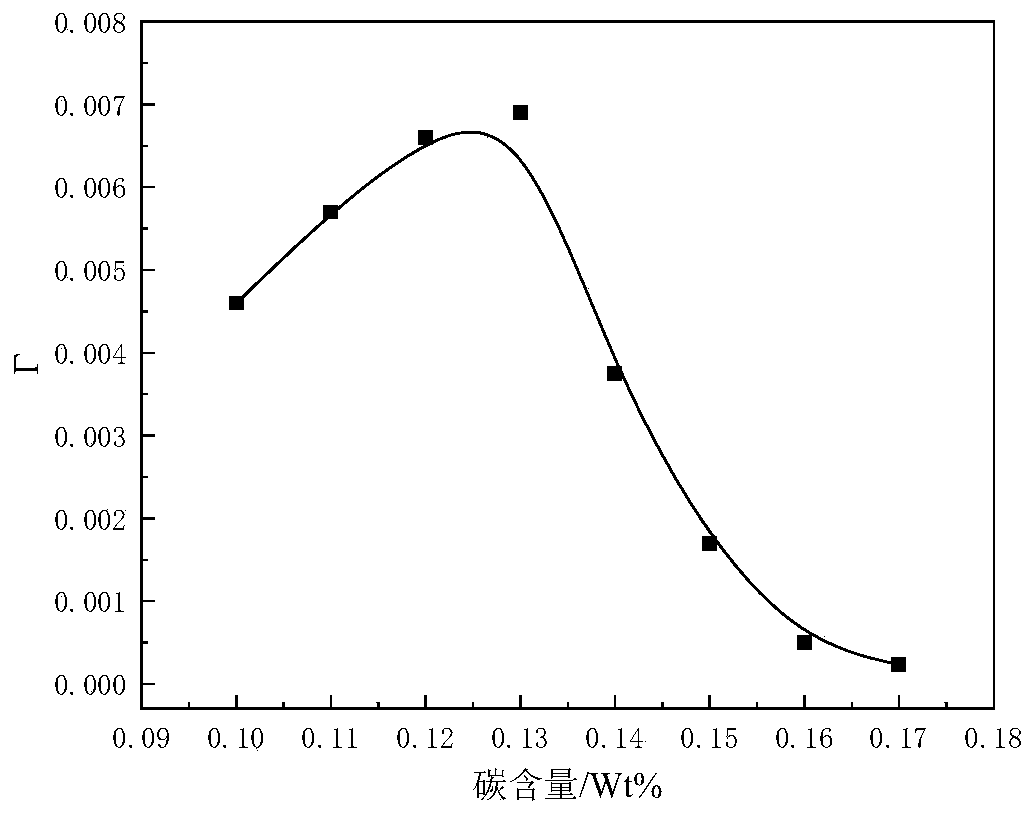

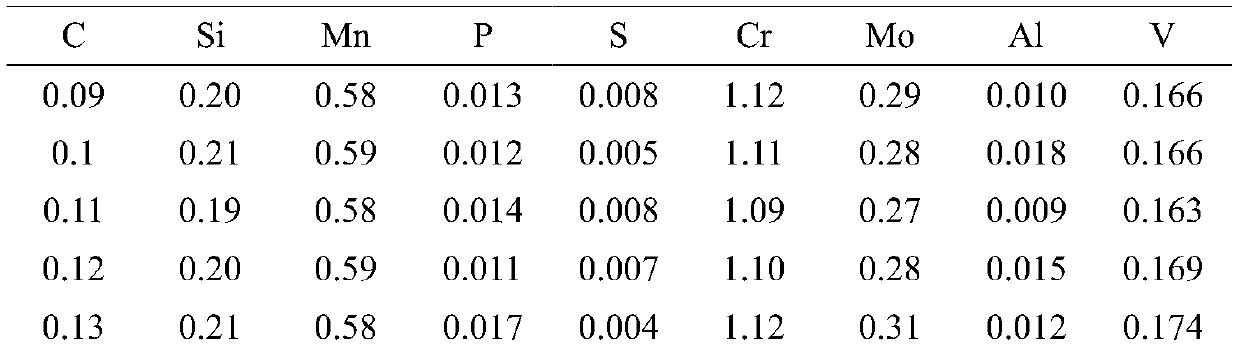

Method for controlling fine cracks on surface of sub-peritectic steel bar

The invention relates to a method for controlling fine cracks on the surface of a sub-peritectic steel bar. The method is characterized in that the relation between a peritectic reaction body shrinkage rare (Gamma) and the carbon content of molten steel at a brittleness temperature zone (LIT-ZDT) is calculated and analyzed through a phase diagram, the carbon content with the shrinkage rate of a peritectic reaction body being less than 0.004 is preferentially selected to be the component control range during smelting of sub-peritectic steel, and the content of sulfur in the molten steel is controlled to be less than 0.005%; the superheat degree of the molten steel during continuous casting is controlled to be 15-25 DEG C through strict refining temperature control; in the case of continuouscasting protective slag, the protective slag which is high in alkalinity, high in viscosity, high in melting temperature, high in melting speed and high in crystallization rate is adopted; the continuous casting pulling speed control is determined according to the peritectic reaction intensity, wherein the pulling speed is less than or equal to 0.002 / Gamma(m / min); a weak cooling mode is adoptedfor cooling and secondary cooling of a crystallizer; the conicity of the crystallizer is controlled to be 1.15-1.25% / m; and the vibration of the crystallizer adopts a non-sinusoidal vibration mode. According to the method, the fine cracks on the surface of the sub-peritectic steel bar can be successfully controlled, the quality and percent of pass of the surface of the sub-peritectic steel bar areremarkably improved, and the production cost is reduced.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for eliminating irregular vibration marks of high-carbon steel billet surface

The invention relates to a method for eliminating irregular vibration marks of a high-carbon steel billet surface. Under the premise that original continuous casting process parameters are not changed, physical and chemical parameters of casting powder are reasonably and accurately selected, the quaternary alkalinity of crystallizer casting powder, namely R{w(CaO)+w(MgO)} / {w(SiO2)+w(Al2O3)}, is 0.64-0.70; the melting temperature Tm (DEG C) of the casting powder and the lowest liquidus temperature T1(DEG C) of casting steel types meet a relationship that Tm is equal to or larger than T1-450, and equal to or smaller than T1-420; the viscosity eta (Pa.s. 1300DEG C) of the casting powder and the casting speed v (m / min) meet the relationship of eta= 0.4 / v + 0.02; and besides, the sinusoidal vibration parameters of a crystallizer are reasonably and accurately set, the vibration frequency f (times / min) and the casting speed v (m / min) of the crystallizer meet the relationship of f=-16v<2>+23v+220, and the amplitude s (mm) and the casting speed v (m / min) of the crystallizer meet the relationship of S=-0.8v<2>+2v+3.8.Through the adoption of the production method disclosed by the invention, the consumption quantity of the high-carbon steel casting powder can be stably and reasonably controlled, the lubricating effect between casting blank and the crystallizer is guaranteed, the irregular marks of the high-carbon steel billet surface are eliminated, the surface quality of the casting blank is stably controlled, and the quality of finished products is improved.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Wavelength division sensing RF vibrometer for accurate measurement of complex vibrations

ActiveUS9200945B2Accurate measurementLong rangeVibration measurement in solidsAnalysing solids using sonic/ultrasonic/infrasonic wavesVisibilityHarmonic

Owner:UNIV OF FLORIDA RES FOUNDATION INC

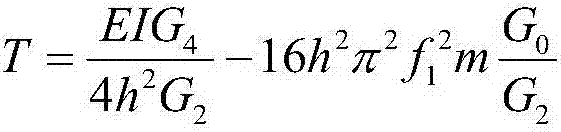

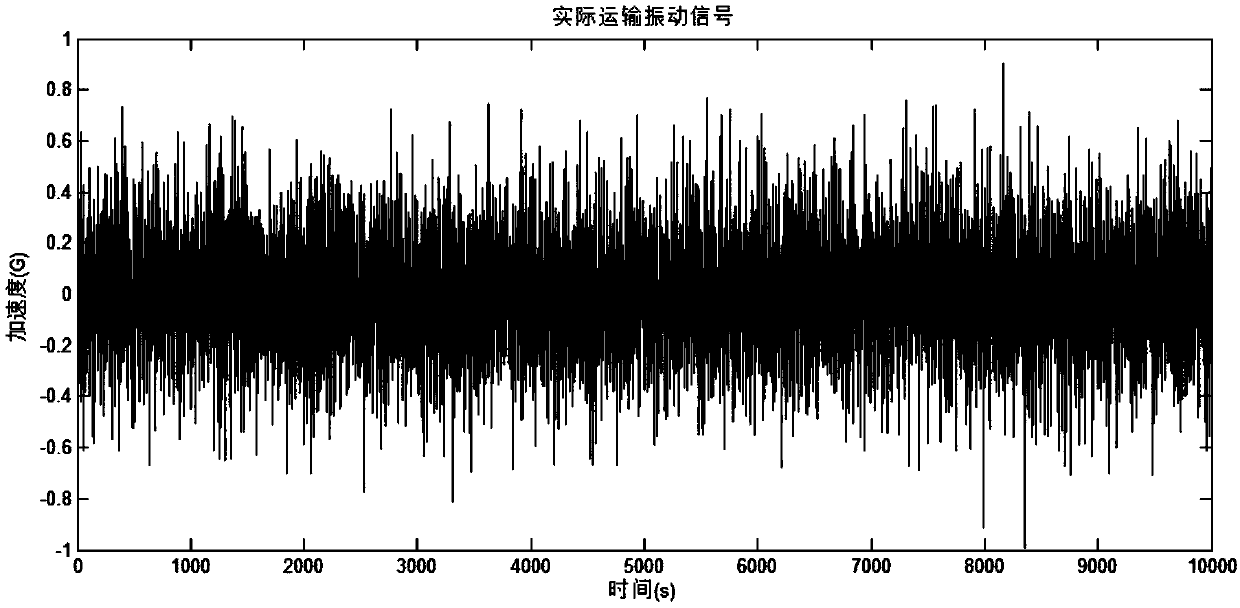

Vibration method stay cable force measuring method by employing sinusoidal vibration exciter and video instrument with introduction of vibration displacement

The invention provides a vibration method stay cable force measuring method by employing a sinusoidal vibration exciter and a video instrument with the introduction of vibration displacement, and belongs to the technical field of civil engineering. The method includes: firstly, estimating the fundamental frequency range of the cable, installing the vibration exciter at the position of half of thelength of the cable, enabling the vibration exciter to perform frequency sweeping excitation in the estimated fundamental frequency range, recording the exciting frequency at the moment as the cable self-vibration frequency f1 when resonance occurs to the cable, observing and recording the vibration displacement [phi]i of a certain section of the cable at a certain instant by employing the video instrument, and finally calculating the cable force by employing a vibration mode cable force recognition model. According to the method, a value calculating method is proposed by employing a certain self-vibration frequency f of the cable and several vibration mode components of corresponding vibration modes, and the pulling force of the stay cable can be recognized in the condition of unknown boundary conditions.

Owner:哈尔滨开博科技有限公司

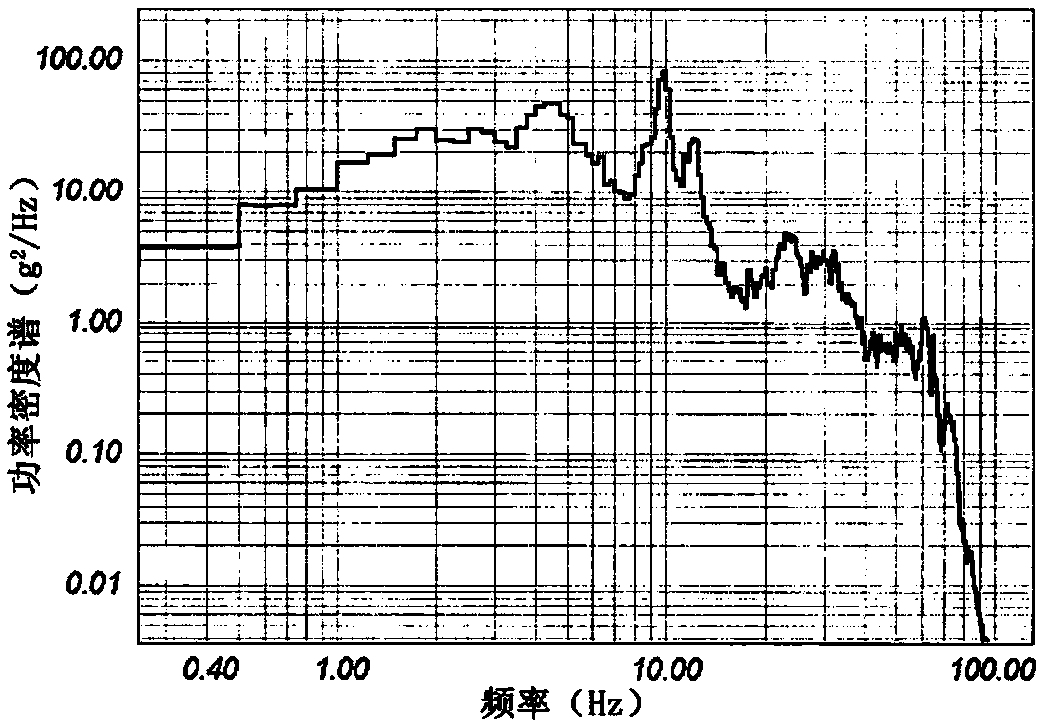

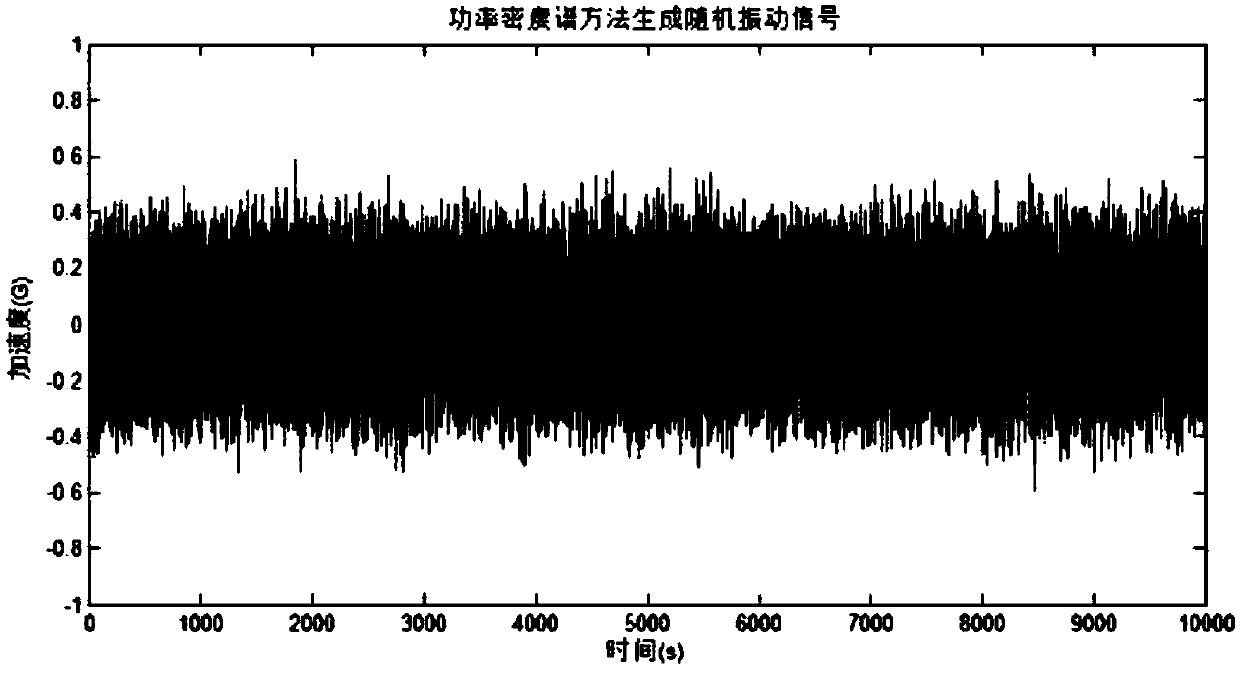

Non-stationary vibration signal generating method used in acceleration test

ActiveCN107727345AUnaltered durationNot subject to change in vibration magnitudeVibration testingVibration accelerationDecomposition

The invention relates to a non-stationary vibration signal generating method used in an acceleration test. The non-stationary vibration signal generating method comprises the steps of: classifying anddecomposing original vibration acceleration signals into Gaussian vibration signals and sinusoidal vibration signals, and synthesizing the Gaussian vibration signals and sinusoidal vibration signalsinto a new non-Gaussian vibration signal. The non-stationary vibration signal generating method restores the non-Gaussian vibration characteristics and intrinsic acceleration transient of random vibration during the road transportation process. Through separating an acceleration transient signal independently during the decomposition process of the original vibration signals, the newly generated accelerating signal can be used in the vibration acceleration test. The non-stationary vibration signal generating method ensures that the duration and vibration magnitude of the transient accelerationsignal are not subject to change during the compression process of vibration testing time.

Owner:HEFEI GENERAL MACHINERY RES INST

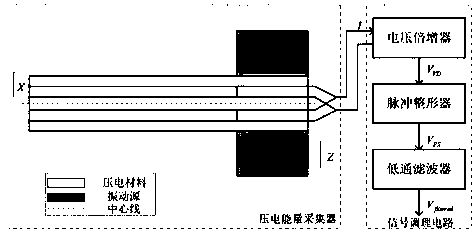

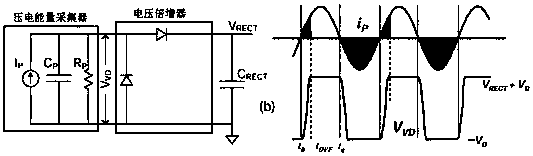

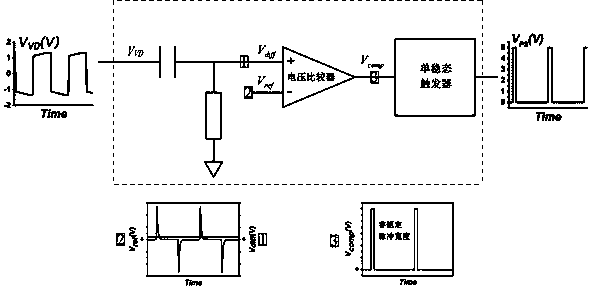

Novel vibration frequency sensor system based on voltage multiplier

PendingCN108955863ASimple structureReduce use costSubsonic/sonic/ultrasonic wave measurementUsing electrical meansElectricitySignal conditioning circuits

The invention provides a novel vibration frequency sensor system based on a voltage multiplier. The novel vibration frequency sensor system consists of a piezoelectric energy harvester and a signal conditioning circuit, wherein sinusoidal vibration is directly detected by means of the piezoelectric energy harvester, and the vibration is converted into a corresponding output voltage; the signal conditioning circuit is constructed by means of the voltage multiplier, a pulse shaper and a low-pass filter; and the output voltage of the piezoelectric energy harvester is processed by means of the signal conditioning circuit to obtain an output voltage signal reflecting the magnitude of the vibration frequency. The novel vibration frequency sensor can realize direct measurement of the sinusoidal vibration frequency, simplifies the structure of the vibration sensor system, and reduces the usage cost.

Owner:天津大学(青岛)海洋工程研究院有限公司

Crystallizer vibrating device

InactiveCN102652987AReliable sinusoidal vibrationThe transmission scheme is simple and reliableEngineeringSinusoidal vibration

The invention discloses a crystallizer vibrating device comprising a driving device and a vibration frame, wherein the driving device comprises a motor, a speed reducer, a coupler, an eccentric shaft, an eccentric sleeve and a pull rod; the eccentric shaft is driven by the motor through the speed reducer; the eccentric sleeve is sleeved outside the eccentric shaft; one end of the pull rod is connected with the eccentric sleeve while the other end is connected with a connecting rod; the middle part of the connecting rod is connected with a connecting rod bearing seat which is fixed on a fixing frame; and one end of an elastic steel plate is connected with the end of the connecting rod while the other end is connected with the vibration frame. By adopting the crystallizer vibrating device disclosed by the invention, the amplitude and vibration frequency of a crystallizer can be easily adjusted to ensure that reliable sinusoidal vibration is provided for the crystallizer.

Owner:WISDRI ENG & RES INC LTD

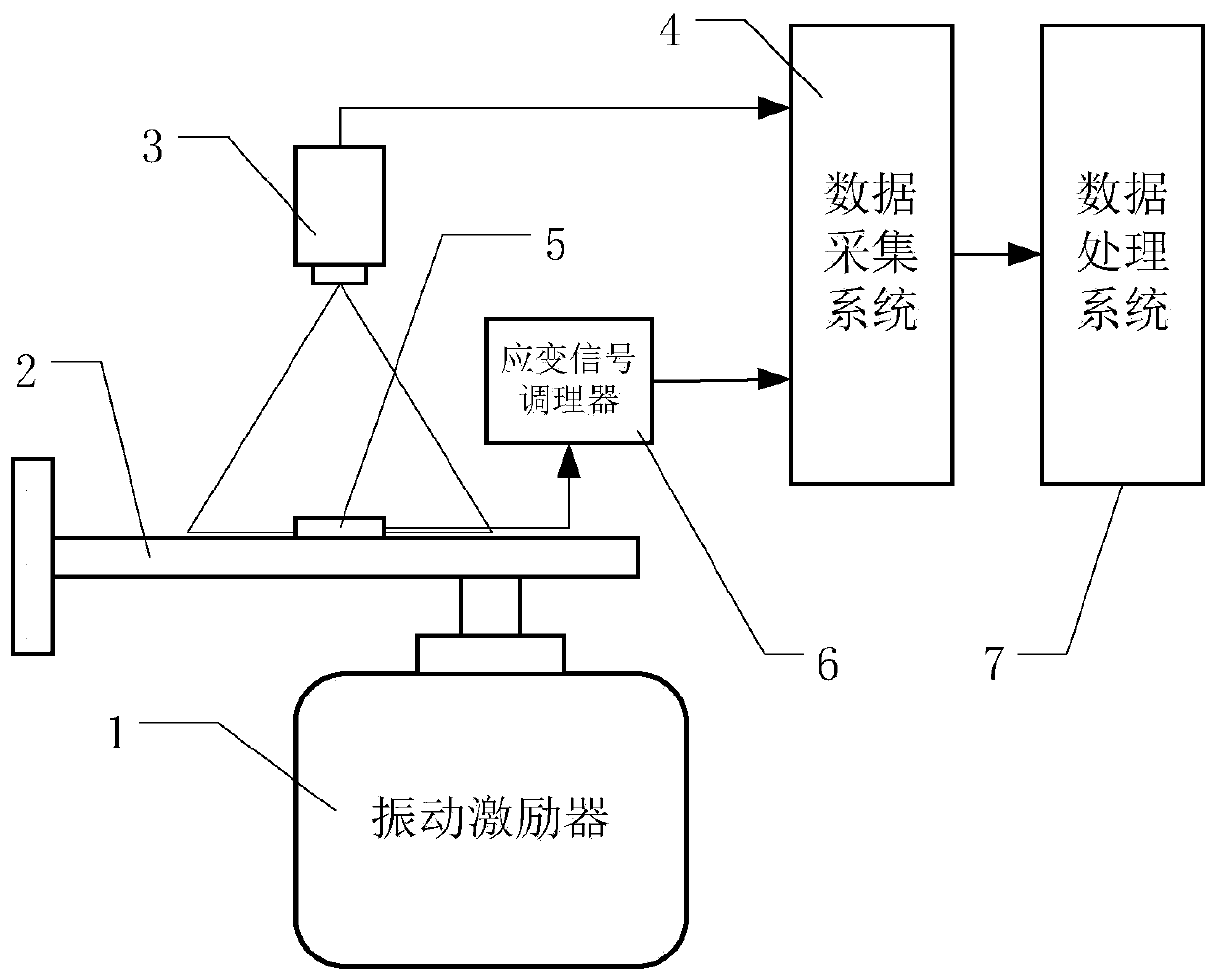

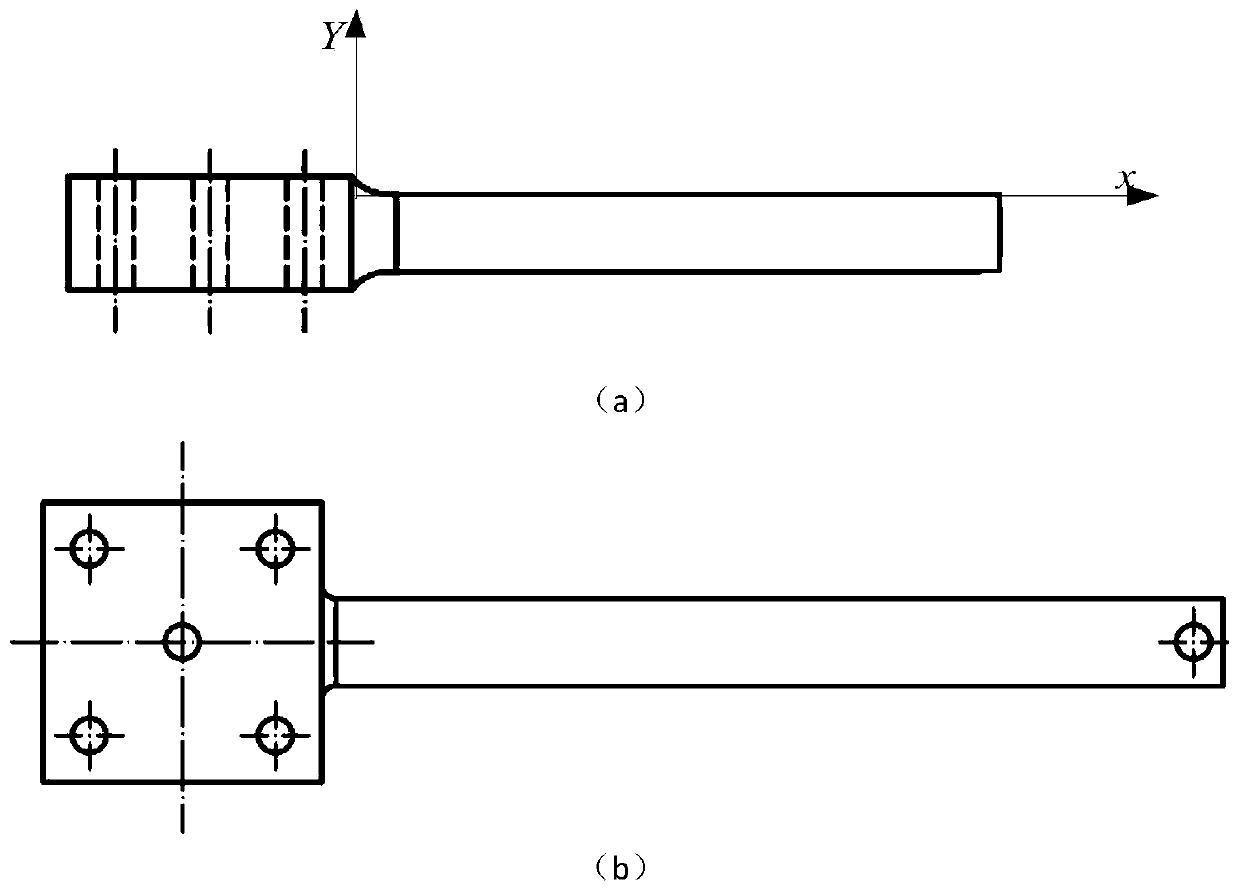

Strain gauge dynamic calibration method and device based on non-contact scanning measurement

The invention discloses a strain gauge dynamic calibration method and device based on non-contact scanning measurement, and belongs to the field of metering test. The implementation method comprises the steps that the output of a controller of a vibration exciter is adjusted to reach a required vibration frequency, and the output of the power amplifier of the vibration exciter is adjusted to reacha required amplitude; a cantilever beam is kept in a sinusoidal vibration state with the stable frequency through the vibration exciter; N measuring points at equal intervals are selected on the surface of the cantilever beam in the axial direction of the beam, and deflection measurement is performed on the surface of the cantilever beam in a forced vibration state; the peak deflection curve of the surface of the cantilever beam is fit according to the obtained deflection state of each measurement point; the peak deflection curve is converted into a strain peak curve; and a calibrated straingauge is installed in the calibration area of the cantilever beam, and the output value of the calibrated strain gauge is compared with a standard strain value, thereby achieving the dynamic strain calibration. The invention further discloses a strain gauge dynamic calibration device based on non-contact scanning measurement. The structure is simple, and the operation is easy.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

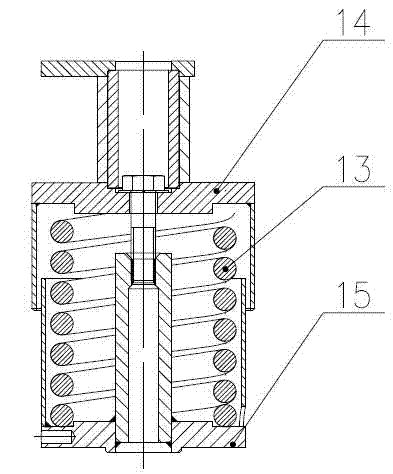

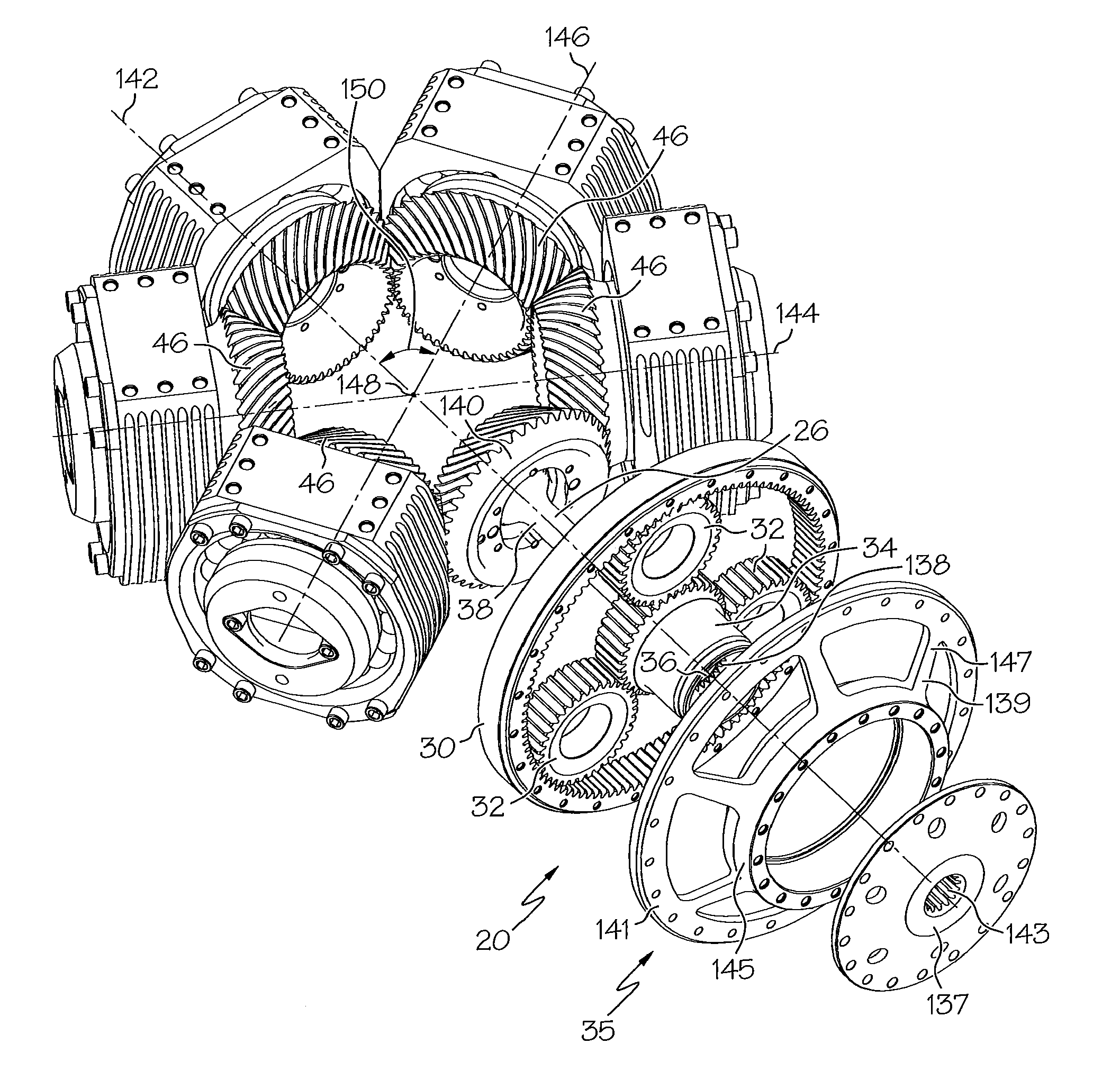

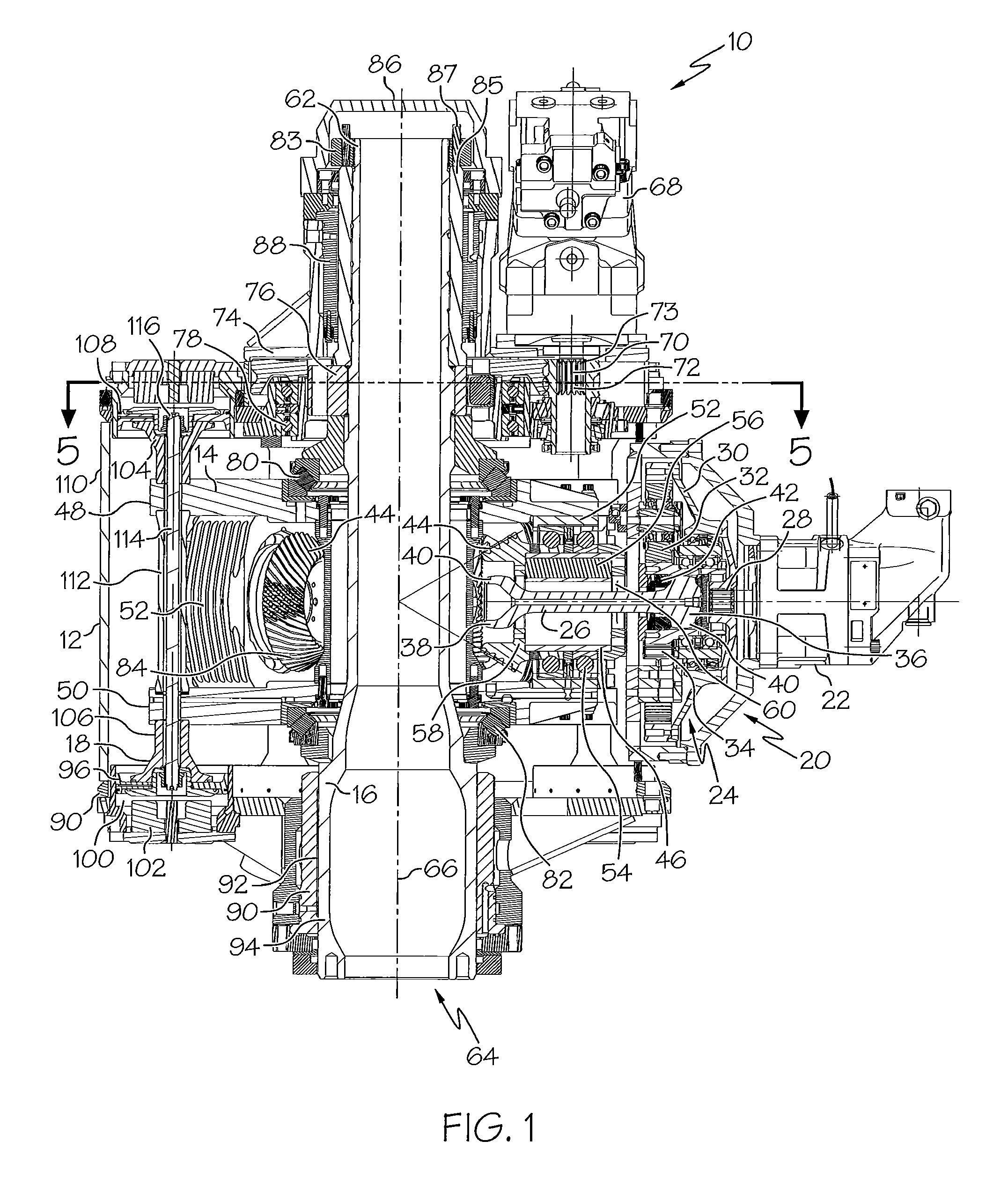

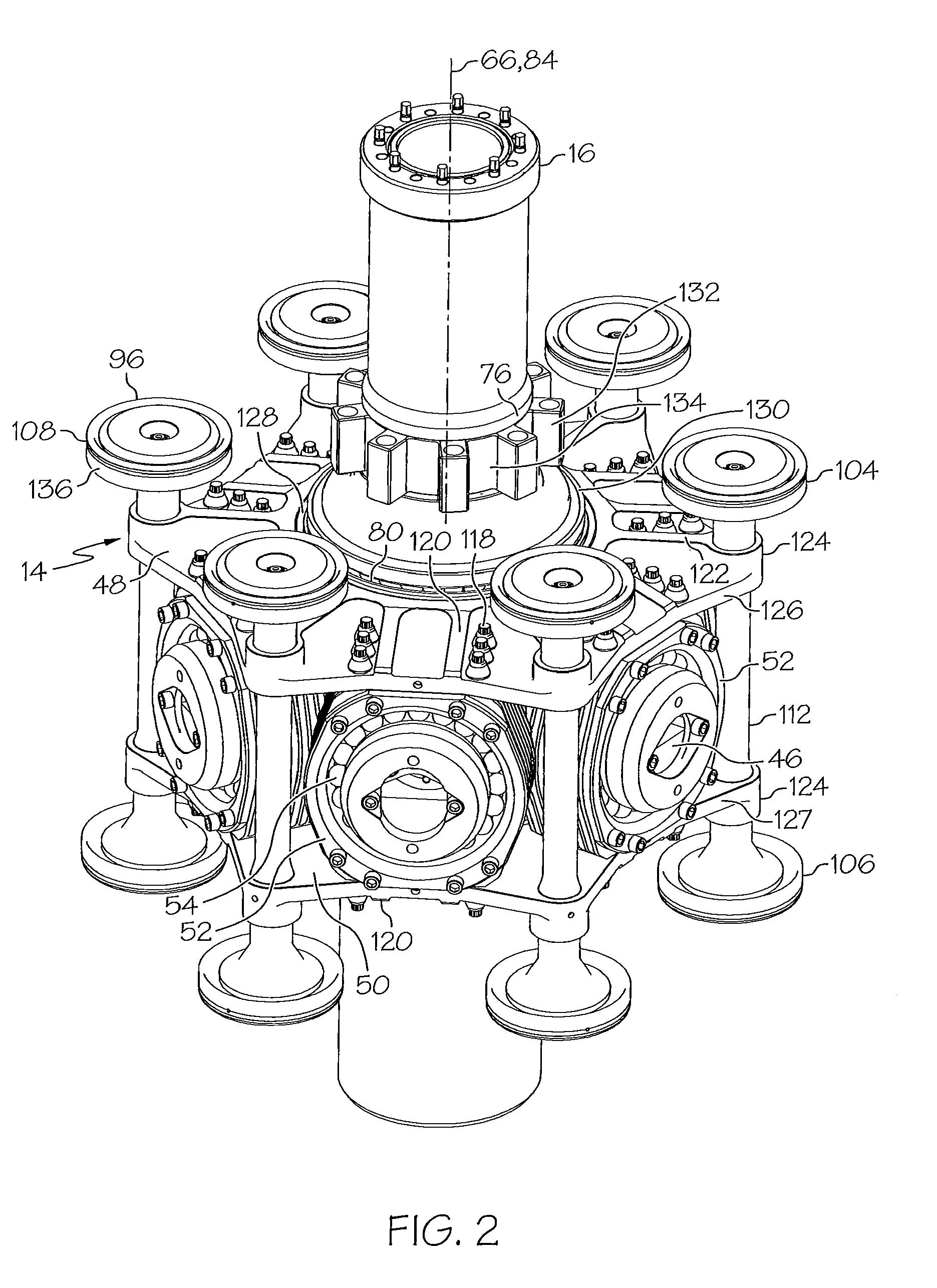

Sonic drill head

A sonic drill head comprising an outer housing, an isolation system, a sine generator and a spindle. The sine generator generates a linear sinusoidal vibration force through the rotation of a plurality of eccentric masses. The sine generator is configured to translate the linear sinusoidal force to the spindle in a direction corresponding to the spindle's axis of rotation. The sine generator supports the spindle within the housing such that the spindle is free to rotate about the spindle axis. The spindle is generally a hollow tube section thereby allowing the passage of drilling fluid, mud, cuttings, and / or tooling. The isolation system generally reduces the transfer of the vibration force generated by the sine generator to the outer housing, yet is able to transfer an applied thrust force from the outer housing to the sine generator.

Owner:LAYNE CHRISTENSEN COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com