Patents

Literature

81results about How to "Avoid Longitudinal Cracks" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

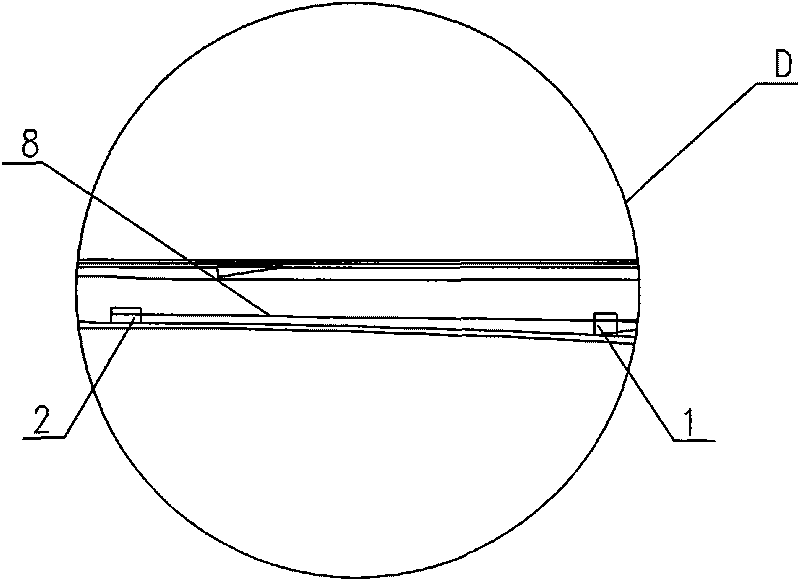

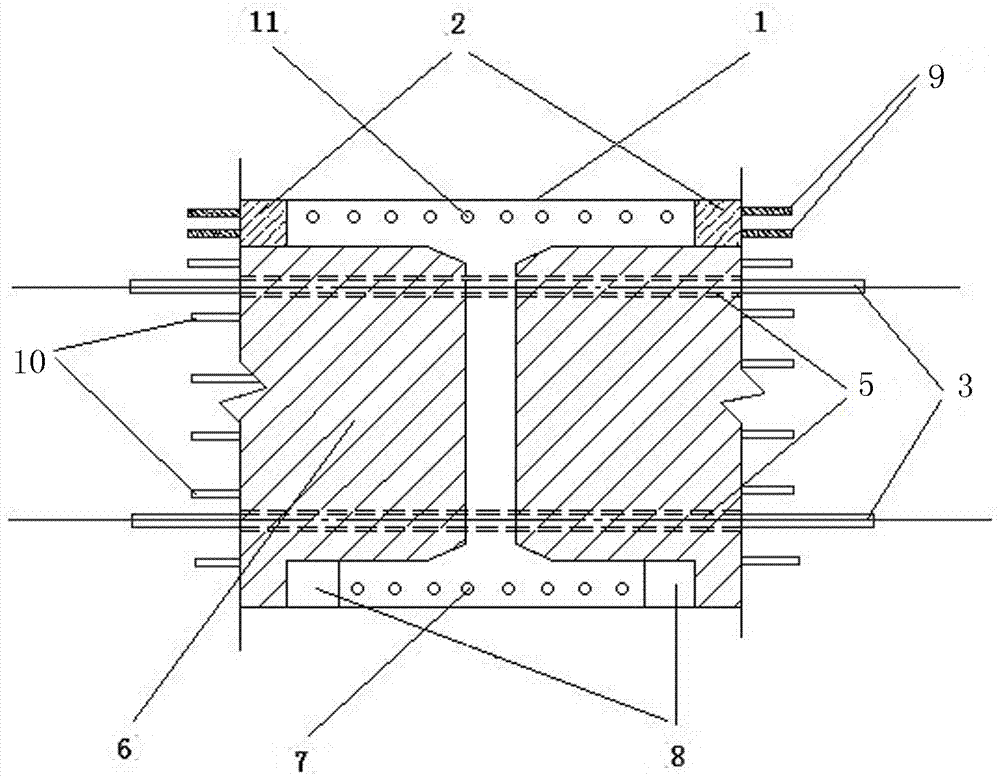

Slab continuous casting chamfer crystallizer narrow-face copper plate capable of effectively controlling longitudinal cracks of corners

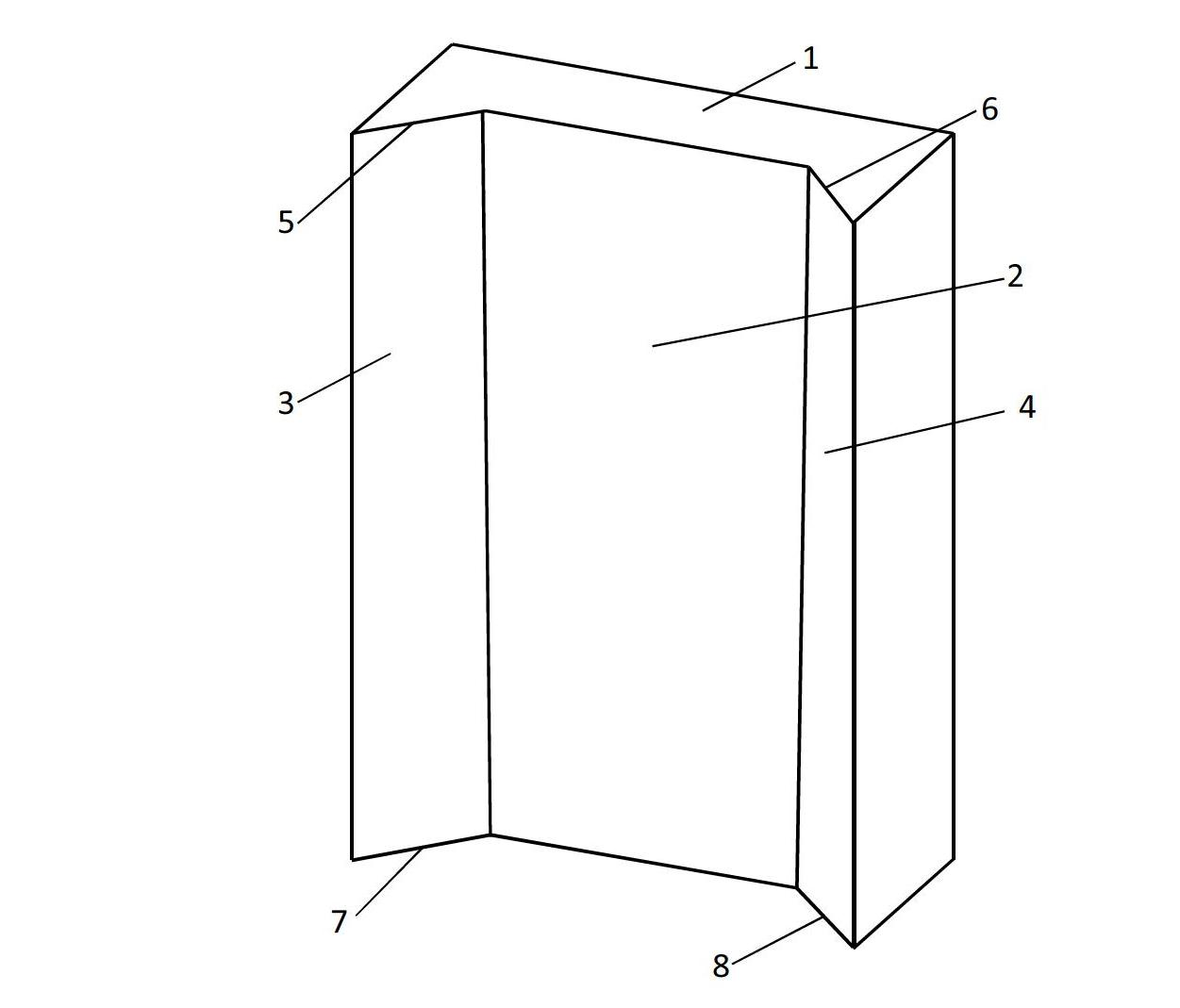

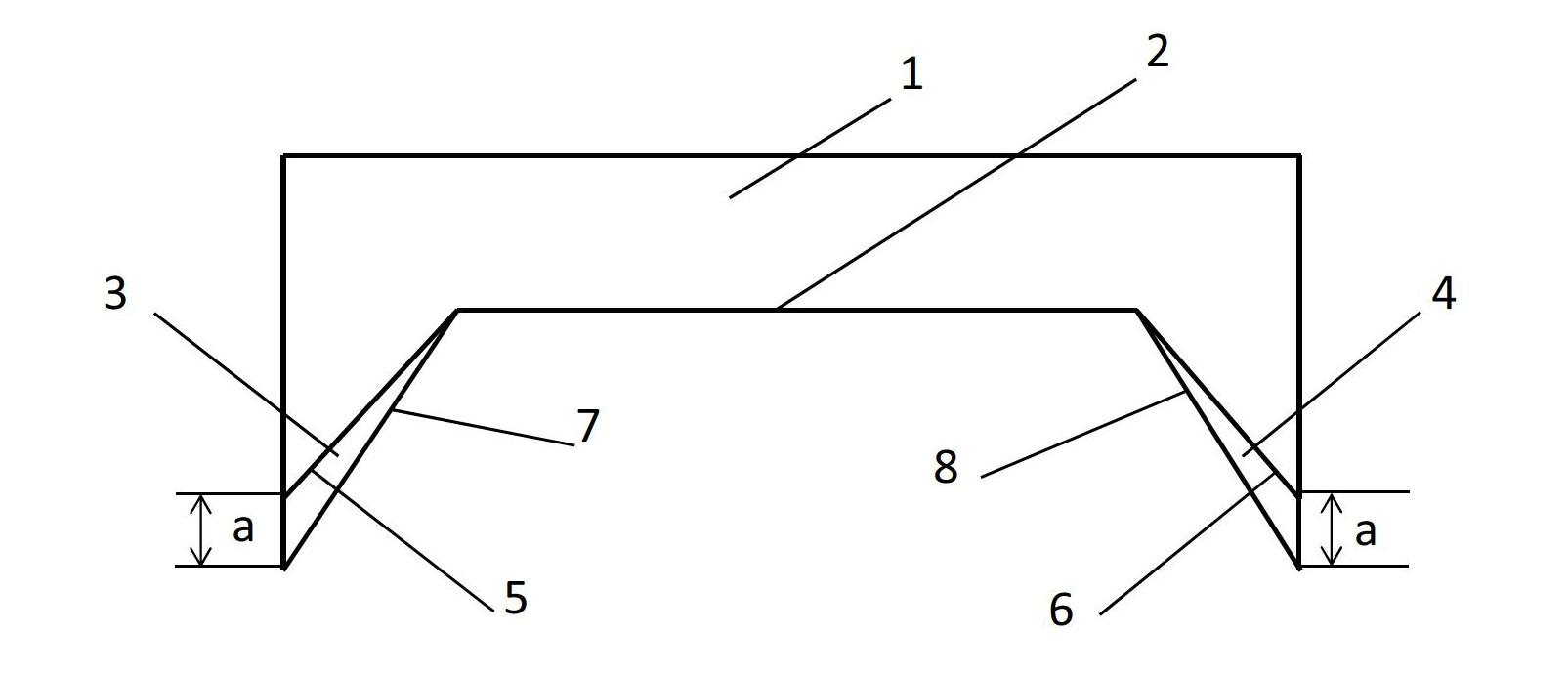

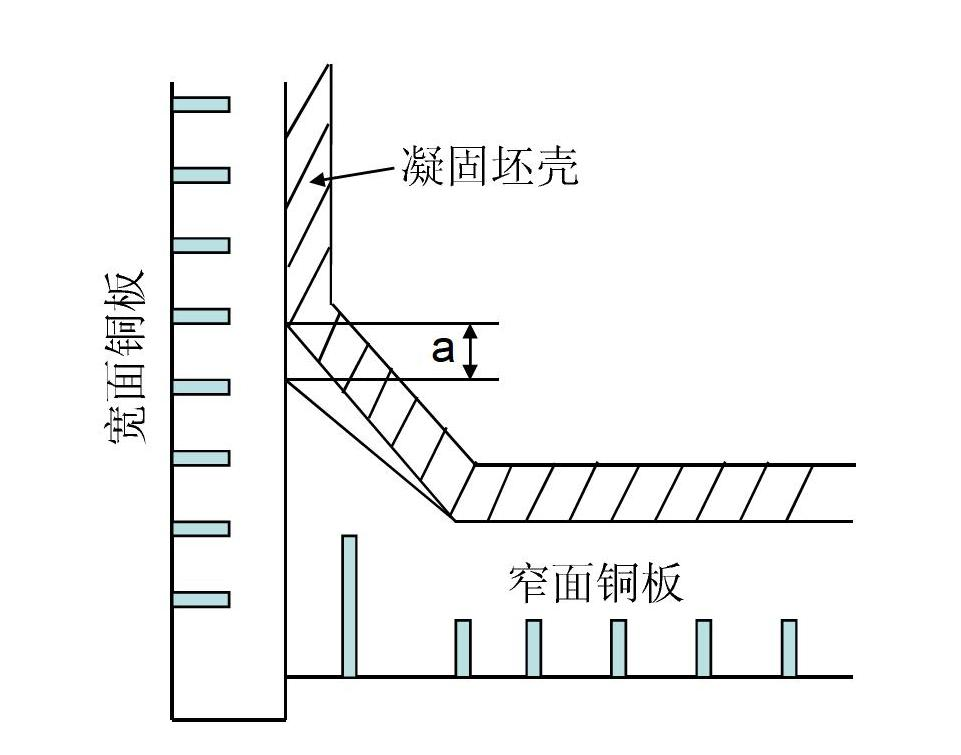

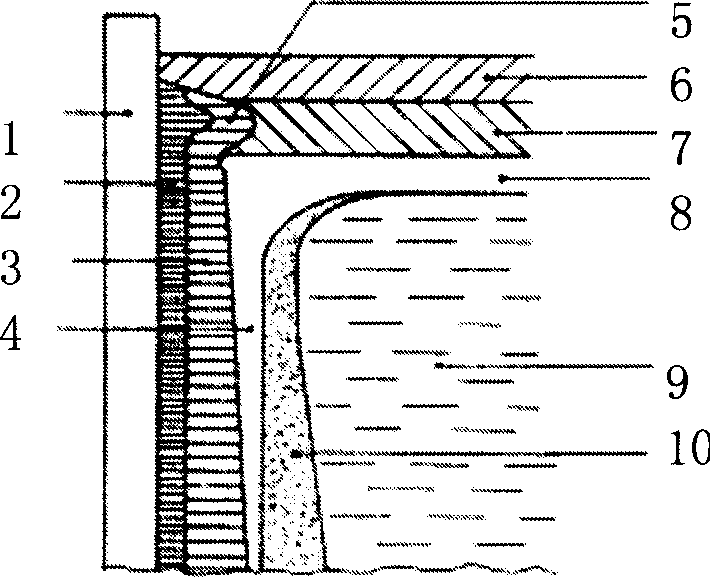

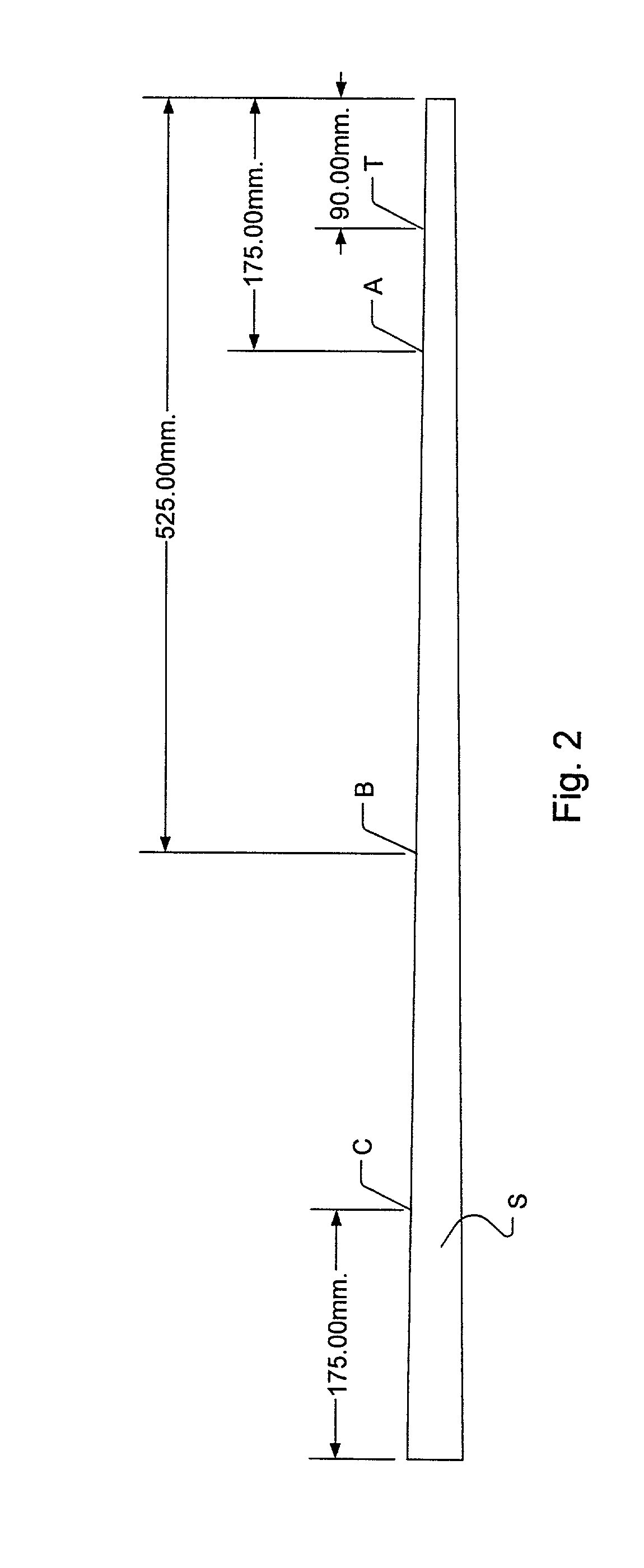

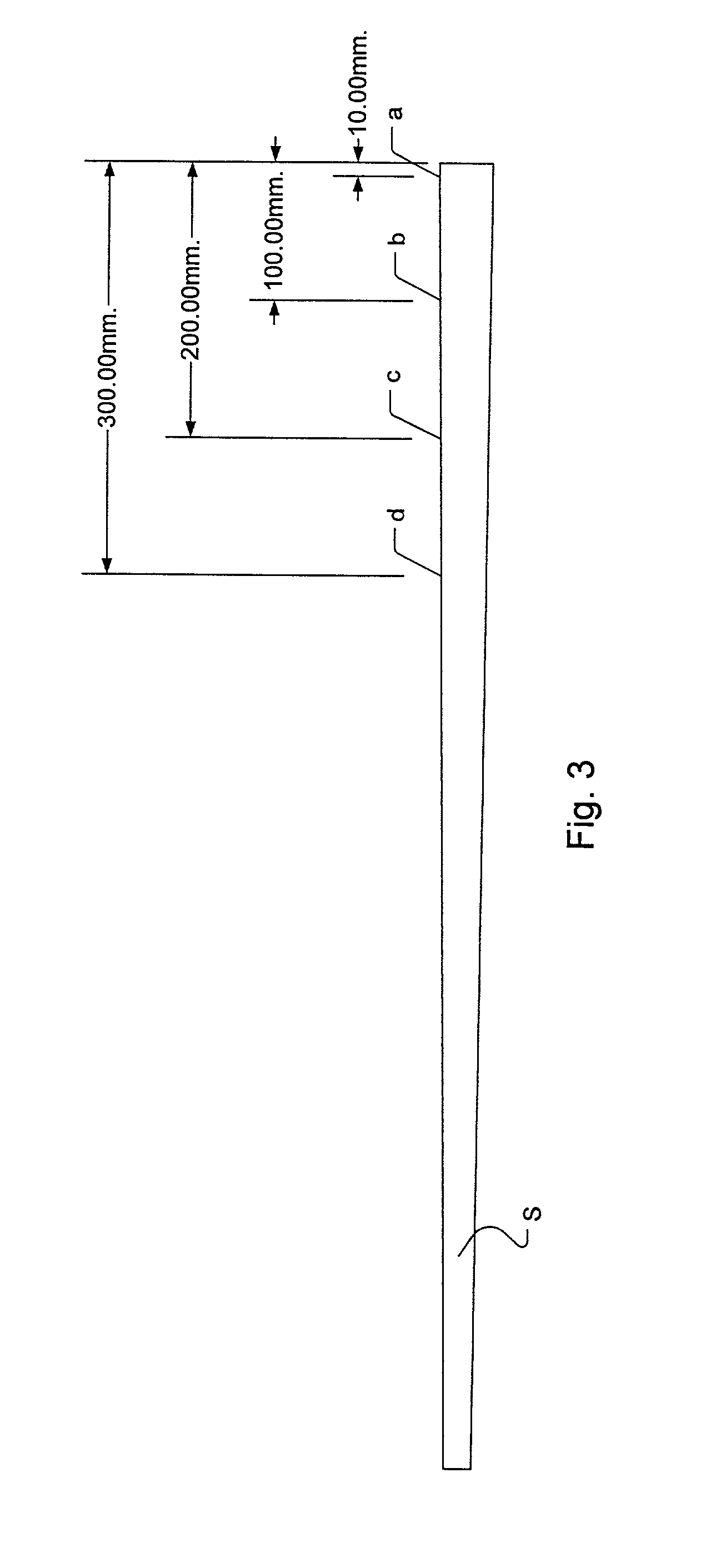

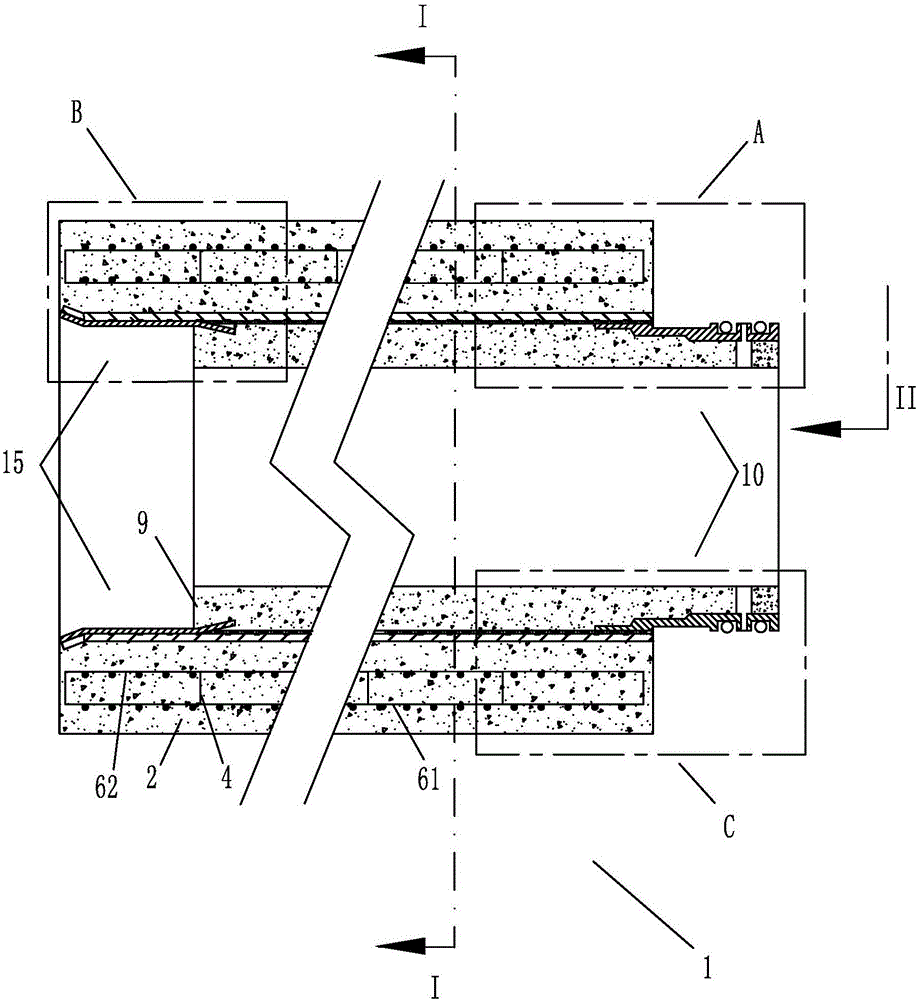

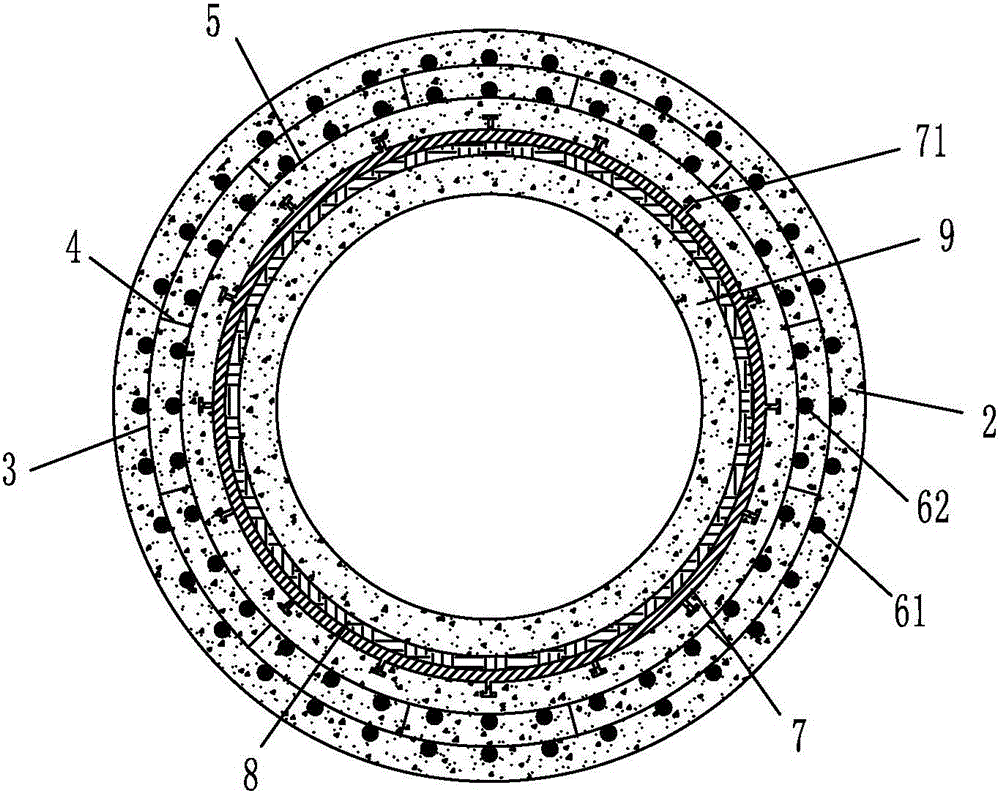

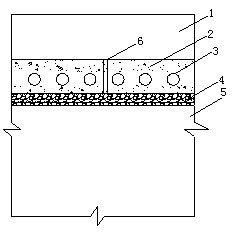

Disclosed is a slab continuous casting chamfer crystallizer narrow-face copper plate capable of effectively controlling longitudinal cracks of corners. The working faces of a narrow-face chamfer copper plate (1), which contact with molten steel, comprise a chamfer surface (3), a chamfer surface (4), a plane portion (2) between the two chamfer surfaces, width portions (5 and 6) of the chamfer surfaces (3 and 4) at the positions of the upper opening of a crystallizer and width portions (7 and 8) of the chamfer surfaces (3 and 4) at the positions of the lower opening of the crystallizer. The narrow-face copper plate is characterized in that the sizes of the width portions (7and 8) of the chamfer surfaces at the positions of the lower opening are larger than those of the corresponding width portions (5 and 6) at the positions of the upper opening respectively, so that tapers are formed on the chamfer surfaces (3 and 4) from the width portions (5 and 6) of the chamfer surfaces (3 and 4) at the positions of the upper opening of the crystallizer to the width portions (7 and 8) of the chamfer surfaces (3 and 4) at the positions of the lower opening of the crystallizer, under the condition of different shrinkage masses of solidified shells of the inner width face and the narrow face of the crystallizer, air gaps formed on the chamfer faces due to large shrinkage mass of width faces are eliminated by means of the taper compensation on the chamfer faces, and the longitudinal cracks of the corners and the bleed-out accidents caused by the longitudinal cracks are avoided.

Owner:SHOUGANG CORPORATION

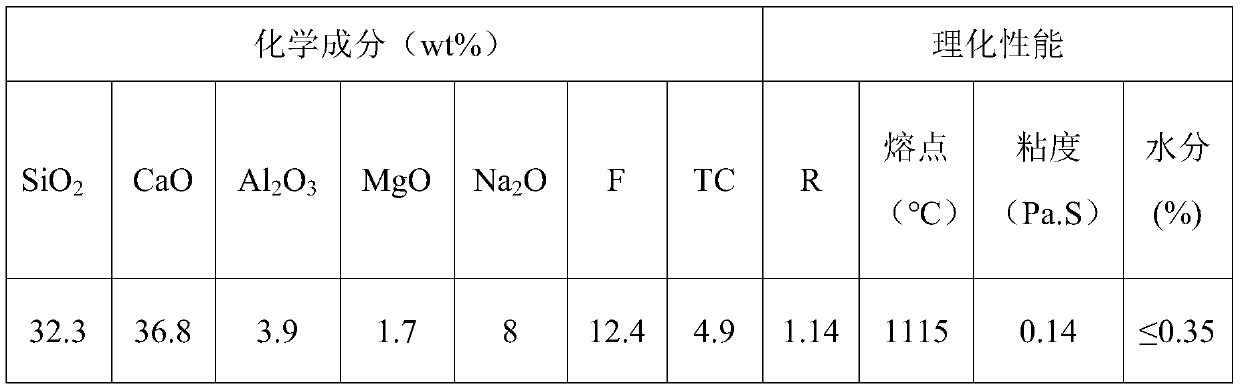

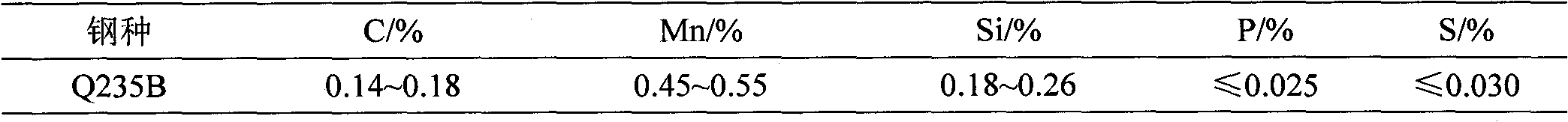

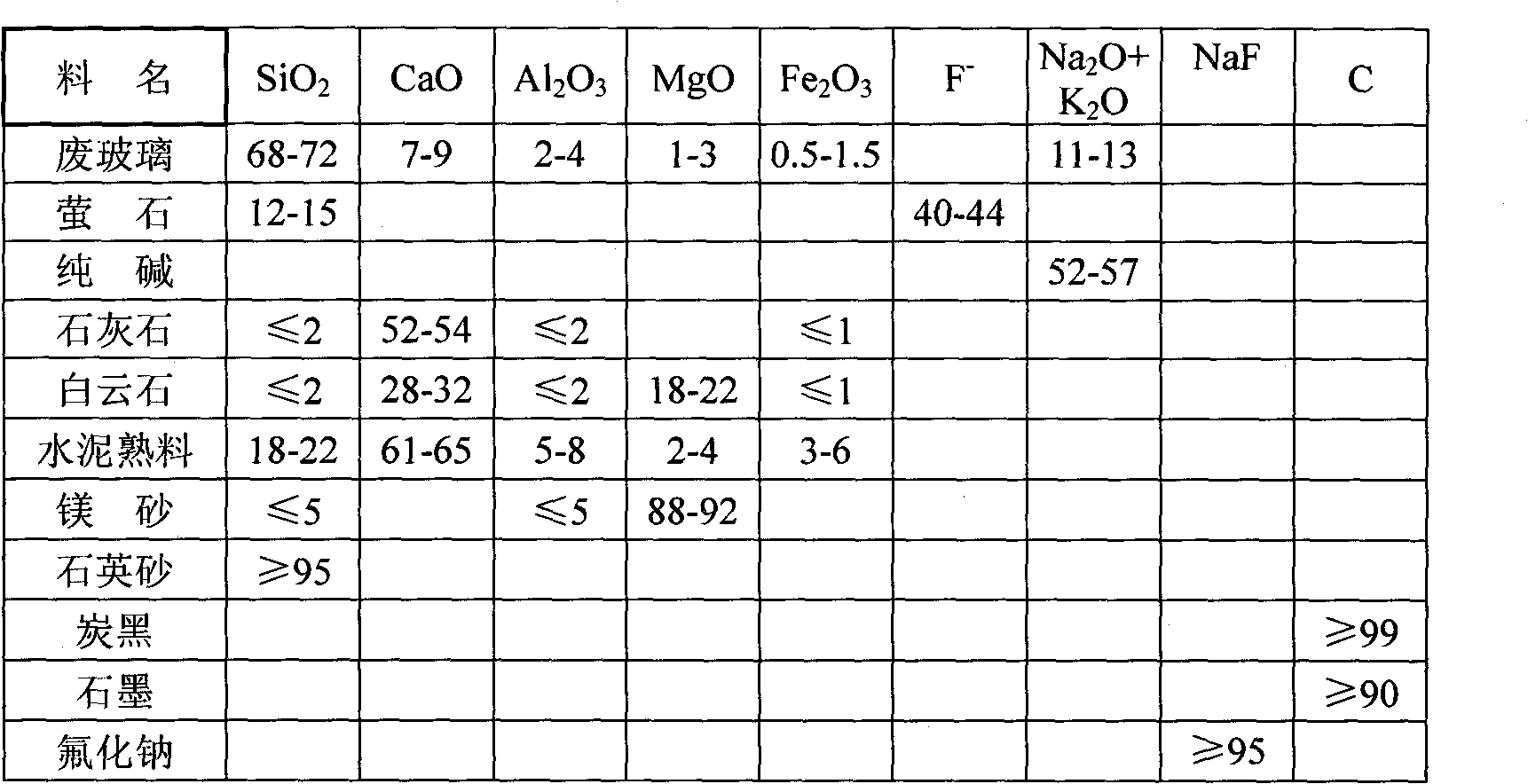

Low-carbon steel protecting slag for continuous casting of sheet billet and preparing method thereof

InactiveCN1927502ALower crystallization temperatureImprove melting uniformityProcess efficiency improvementChemical compositionSlag

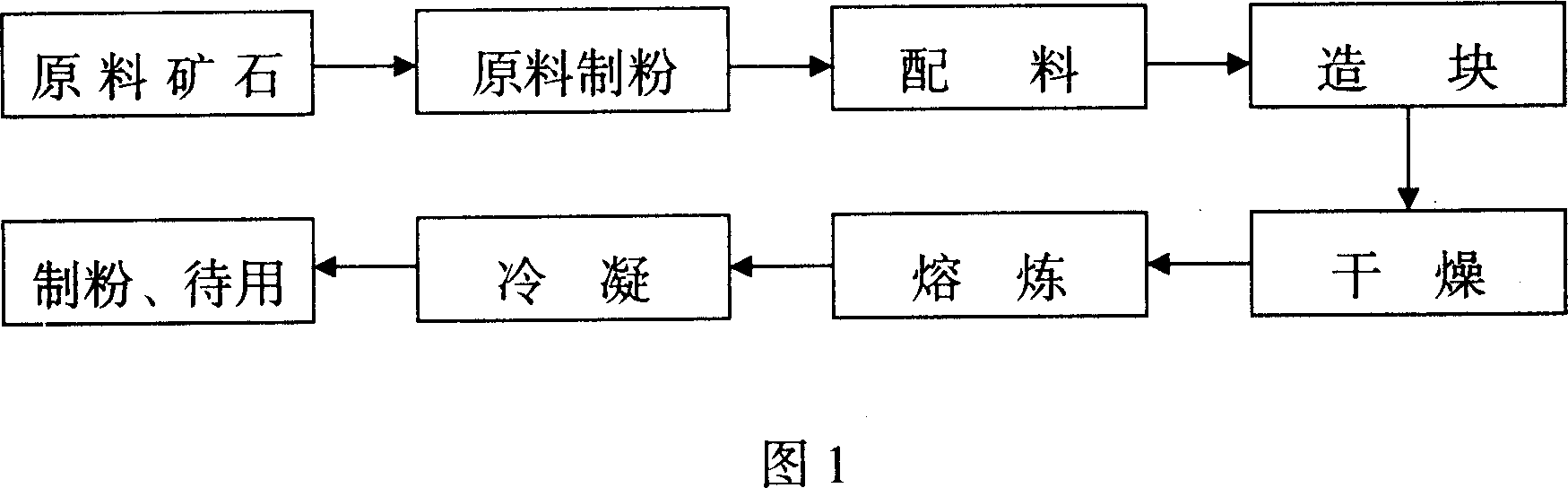

The invention relates to a method for preparing low-carbon steel protective slag used to casting sheet blank. Wherein, it is characterized in that: the chemical component mass percentages of said protective slag are SiO2 at 28-32, CaO at 29-33, Al2O3 at 3-5, MgO at 1-3, Fe2O3<=3, F at 7-9, Na2O+K2O at 9-12, Li2O<=2.0, C at 7-9, and adhesive at 1-3; said protective slag is alkali one whose alkali R is higher then 1 and R=CaO / SiO2. The invention can realize low crystallize temperature, high solidify temperature and high crystallize ratio, to meet the casting demand of FTSC sheet blank.

Owner:HEBEI IRON AND STEEL

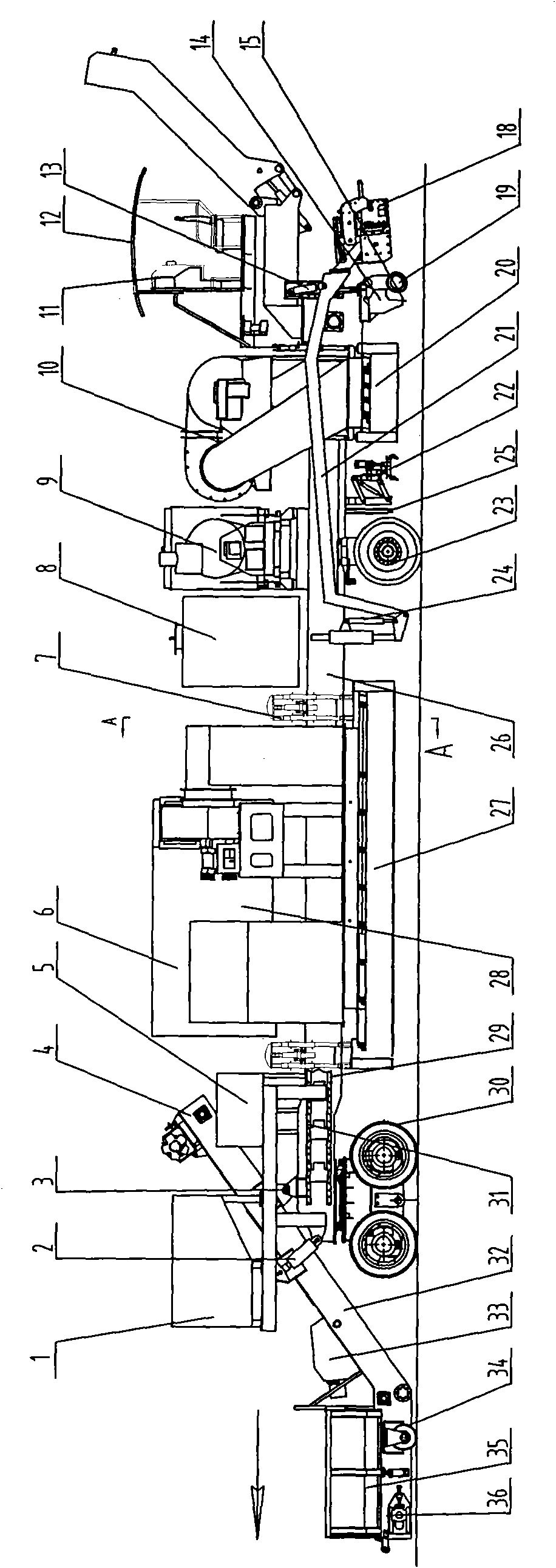

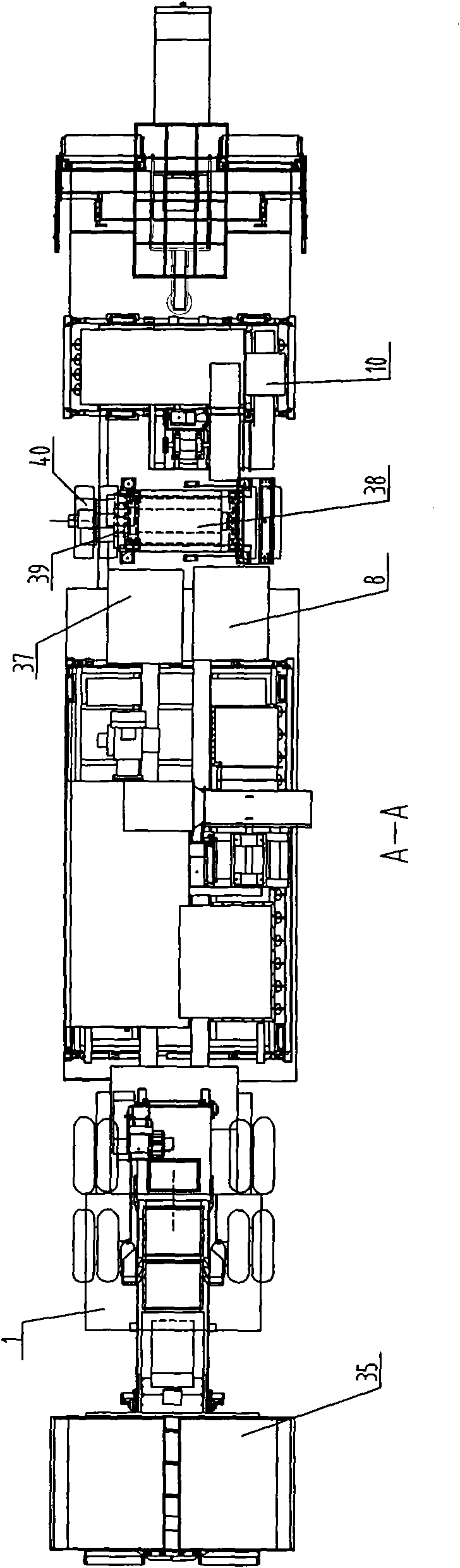

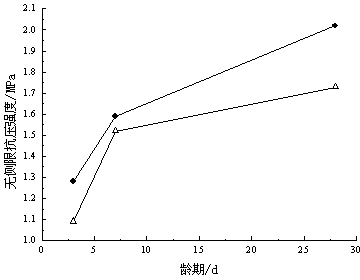

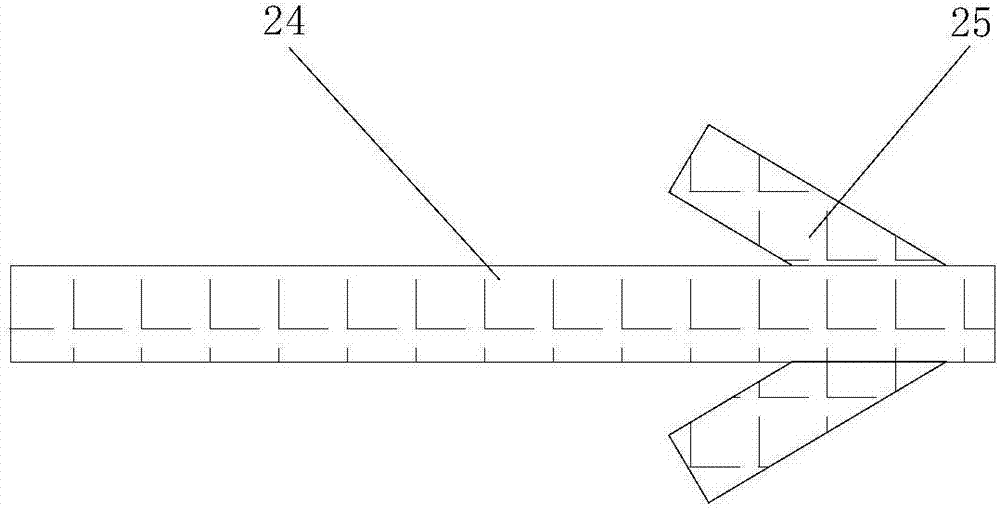

Hot in-place recycling ultrathin overlaying machine of bituminous pavement and construction method thereof

InactiveCN102011362ARestoration of slip resistanceGood lookingIn situ pavingsRoads maintainenceTraffic noiseScreed

The invention provides a hot in-place recycling ultrathin overlaying machine of a bituminous pavement and a construction method thereof. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement comprises an automobile chassis, an integral power device, an electric control system, a diesel tank, a receiving and transporting device, a material transfer hopper, a horizontal transporting device, a heating device, a hydraulic system, a recycling agent spraying system, a harrowing device, a distributing spiral device, a paving screed device, a cab, and an electric control operating floor, wherein the automobile chassis is a special automobile chassis. The hot in-place recycling ultrathin overlaying machine of the bituminous pavement finishes the continuous overlay repair work of the pavement through a series of processes such as receiving the materials, feeding the materials quantitatively, transporting the materials horizontally, spraying the recycling agent, harrowing, heating, distributing and paving the materials, ironing, and grinding and the like, and has the advantage of carrying out one-time maintenance on the defects such as loose, shallow vertical and horizontal cracks, track, slight crack, bituminous aging, pavement seepage and the like of a functional layer of the pavement. By adopting the invention, the antiskid resistance of the pavement is restored, the profile of the pavement is corrected, the appearance and the evenness of the pavement are improved, the pavement strength of the pavement is increased, the traffic noise is reduced, and the service life of the pavement is prolonged.

Owner:ANSHAN SENYUAN ROAD & BRIDGE

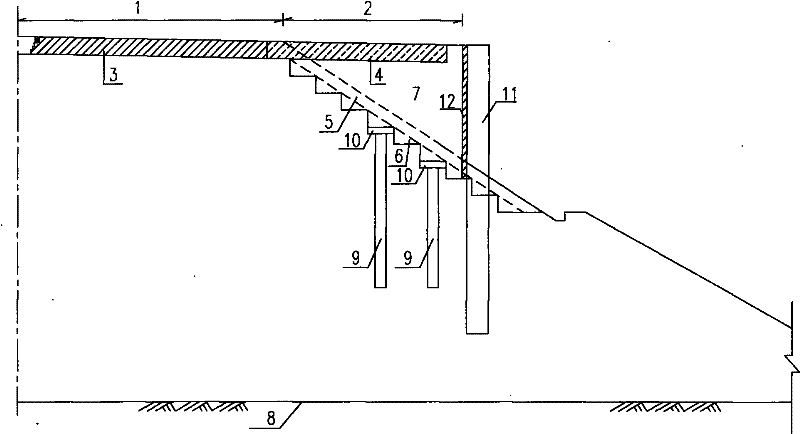

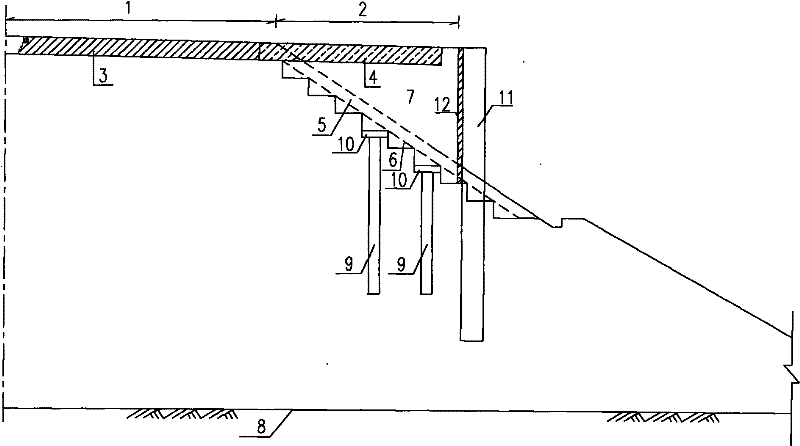

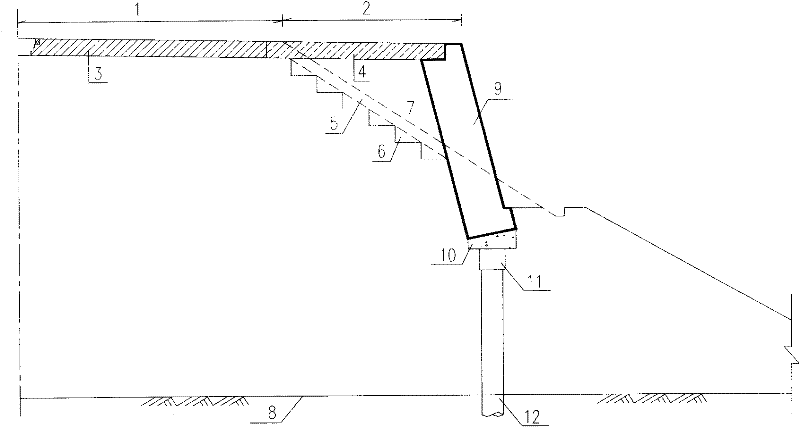

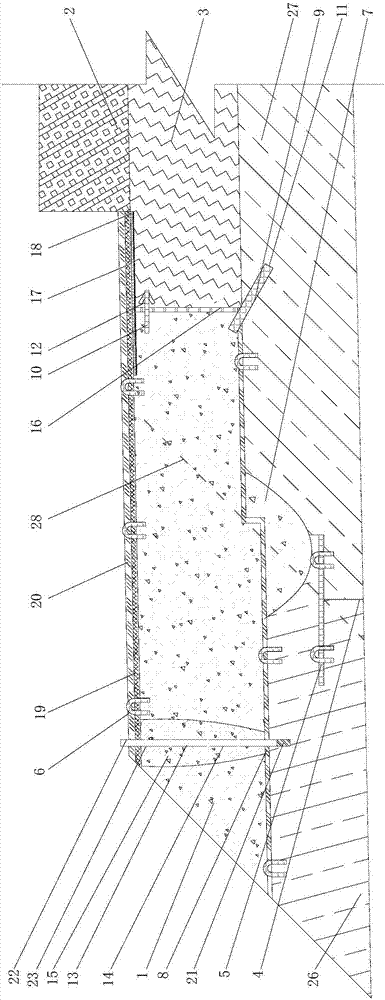

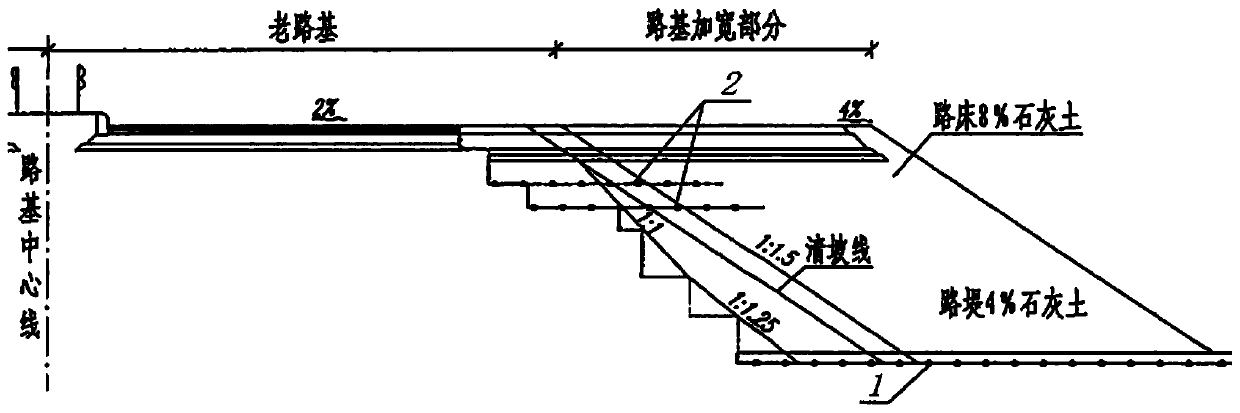

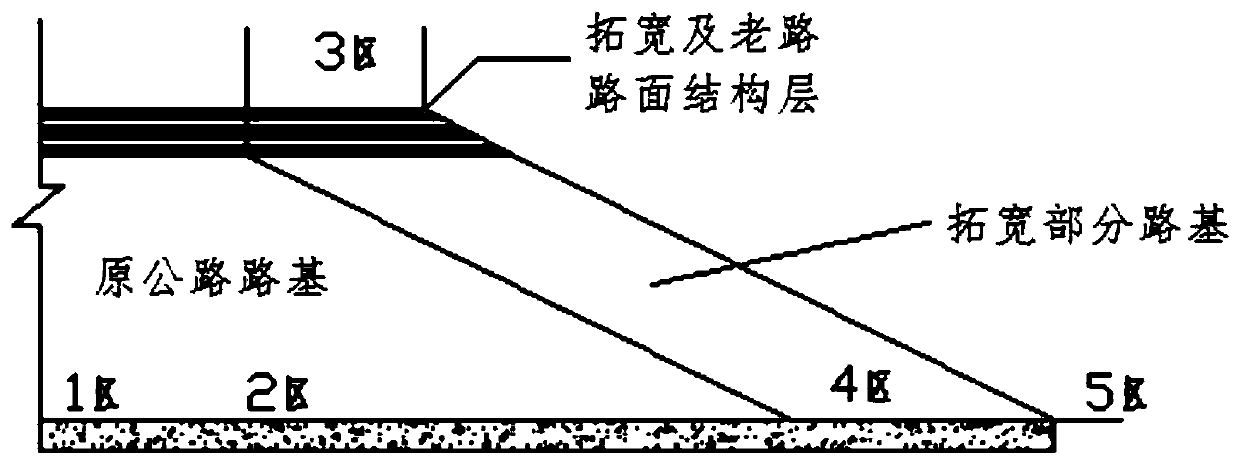

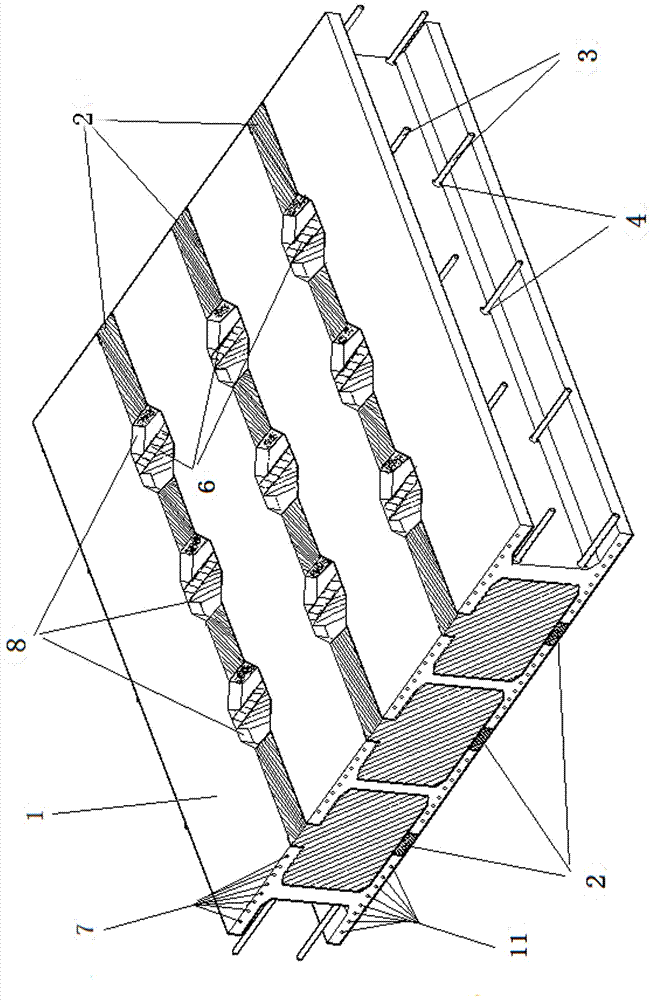

Method for splicing highfill roadbed by adopting pile-sheet retaining wall

ActiveCN102352590AReduce disturbanceReduce land occupationArtificial islandsRoadwaysReinforced concreteEngineering

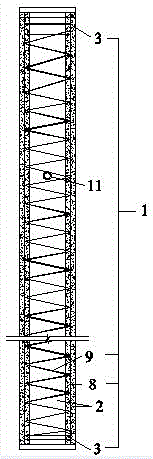

The invention discloses a method for splicing a highfill roadbed by adopting a pile-sheet retaining wall, comprising the following steps of: forming an operation platform by using an old roadbed (1), a cutting slope (5) and an excavation step (6); longitudinally constructing an excavation filling pile (11); hoisting the cutting slope (5) and the excavation step (6) layer by layer from bottom to top during construction; installing a reinforced concrete soil retaining plate (12) so that the reinforced concrete soil blocking plate (12) is in overlap joint with the excavation filling pile (11); constructing an excavation C10-C12 element concrete pile (9) and a C20 reinforced concrete pile follower (10) step by step; and filling and compacting filler (7) layer by layer to realize seamless overlap joint of an old road surface (3) and a new road surface (4). The method has the advantages of no increase of occupied land, simple and convenient construction machines, short construction period, low cost and simplicity in maintaining traffic moving, thereby being extremely suitable for road sections widened by using highfill.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

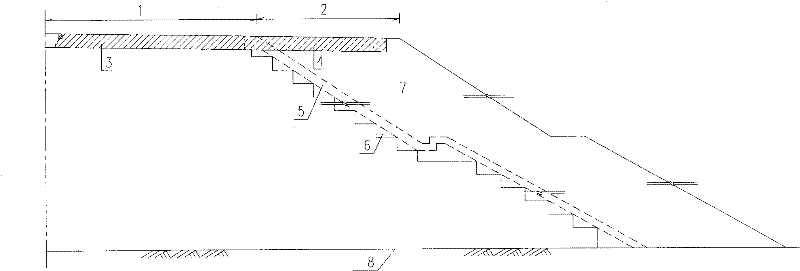

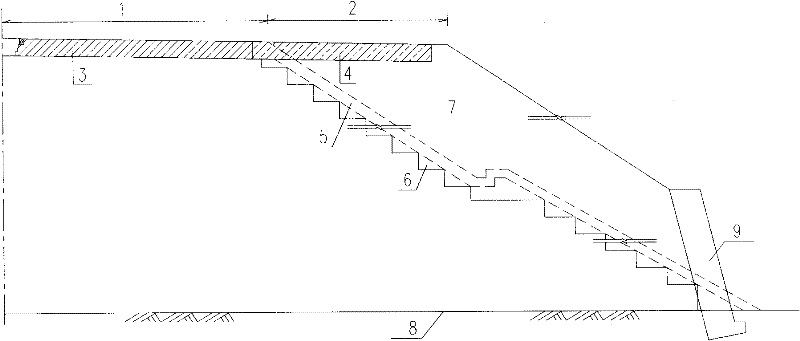

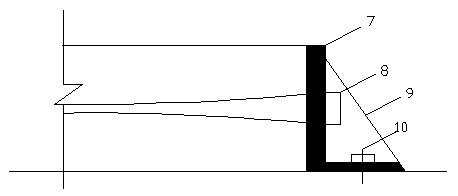

High fill subgrade connection method

The invention discloses a high fill road section connection method, comprising the steps of: conducting bored pile (12) construction vertically at a side slope of an old subgrade (1), connecting multiple bored piles (12) into a vertically continuous bearing platform by means of a reinforced concrete supporting beam (11), the top surface of which is paved with a hardcore bed (10), and carrying out retaining wall (9) construction on the hardcore bed, when the retaining wall strength reaches over 75% of a designed strength level, performing cut slope (5) and step (6) excavation construction to the old subgrade slope, implementing filler (7) filling layer by layer and layering compaction, and finally paving newly connected wide pavement (4). The method of the invention restrains lateral deformations of a new subgrade (2) by means of various supporting and retaining structures, and opposes vertical deformations caused by various loads through a foundation reinforcing structure formed by the bored piles (12) and the reinforced concrete supporting beam (11), thus reaching the purposes of a stable overall structure and usage requirement satisfiable deformations.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD

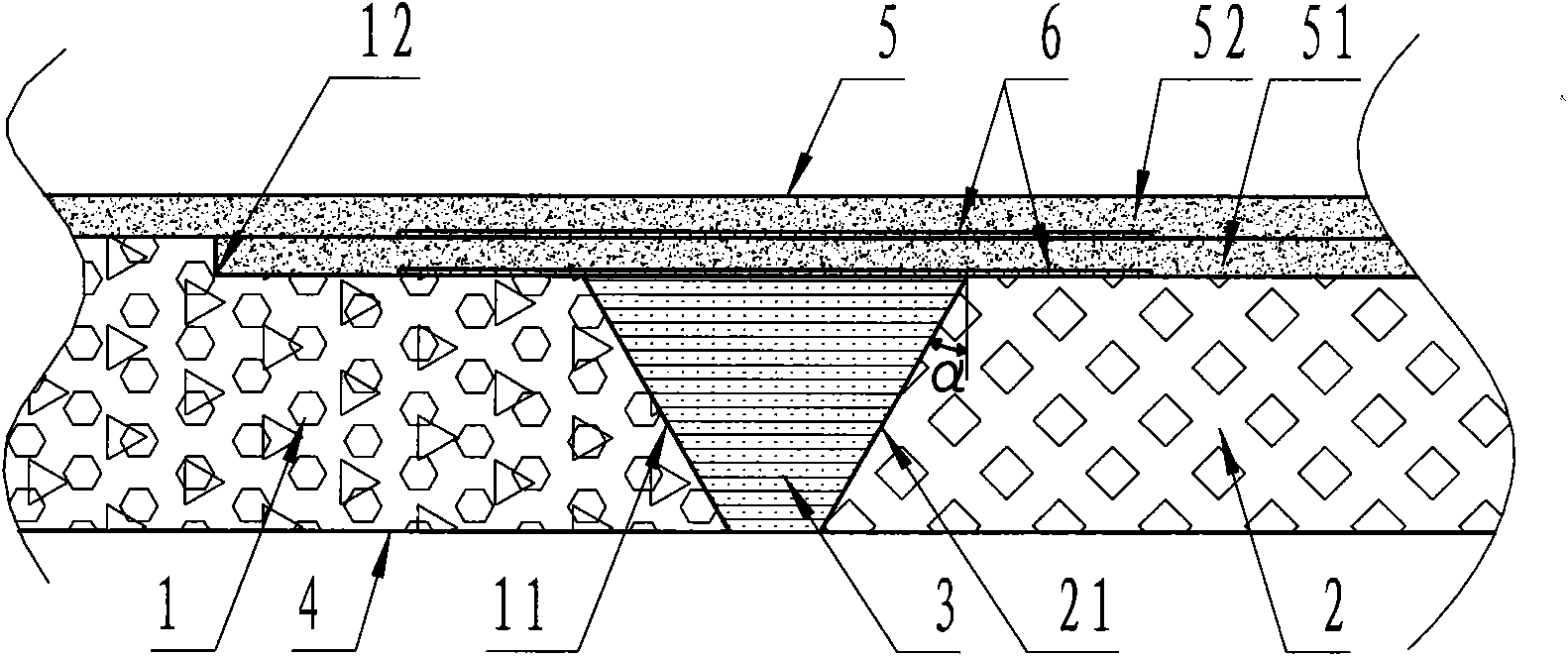

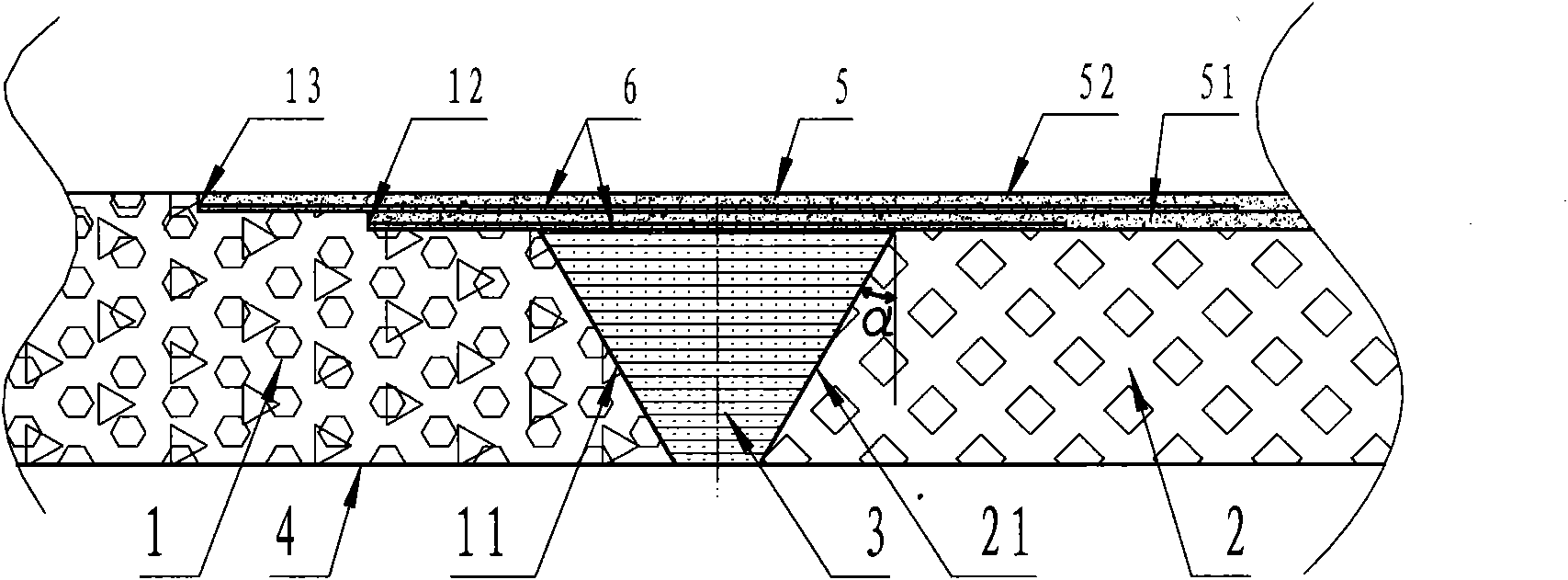

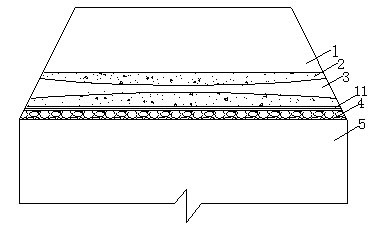

Stress absorption band and construction method thereof

ActiveCN101591882AStrong compression resistanceAvoid Longitudinal CracksPaving detailsCrushed stoneEngineering

The invention discloses a stress absorption band and a construction method thereof. The stress absorption band (3) is arranged at the joint part of a new road (2) and an old road (1), namely from the top surface of a roadbed to the underside of a newly paved oil surface, the stress absorption band (3) is arranged into an inverse trapezoid or an inverse triangular groove, and the groove is filled with asphalt macadam or modified asphalt macadam. The invention also discloses the construction method for the stress absorption band. The stress absorption band (3) is arranged at the joint part of the new road and the old road, can absorb and reduce stress, and prevent road surface diseases caused by the stress at the joint part of the new road and the old road.

Owner:XINGTAI ROAD & BRIDGE CONSTR GENERAL

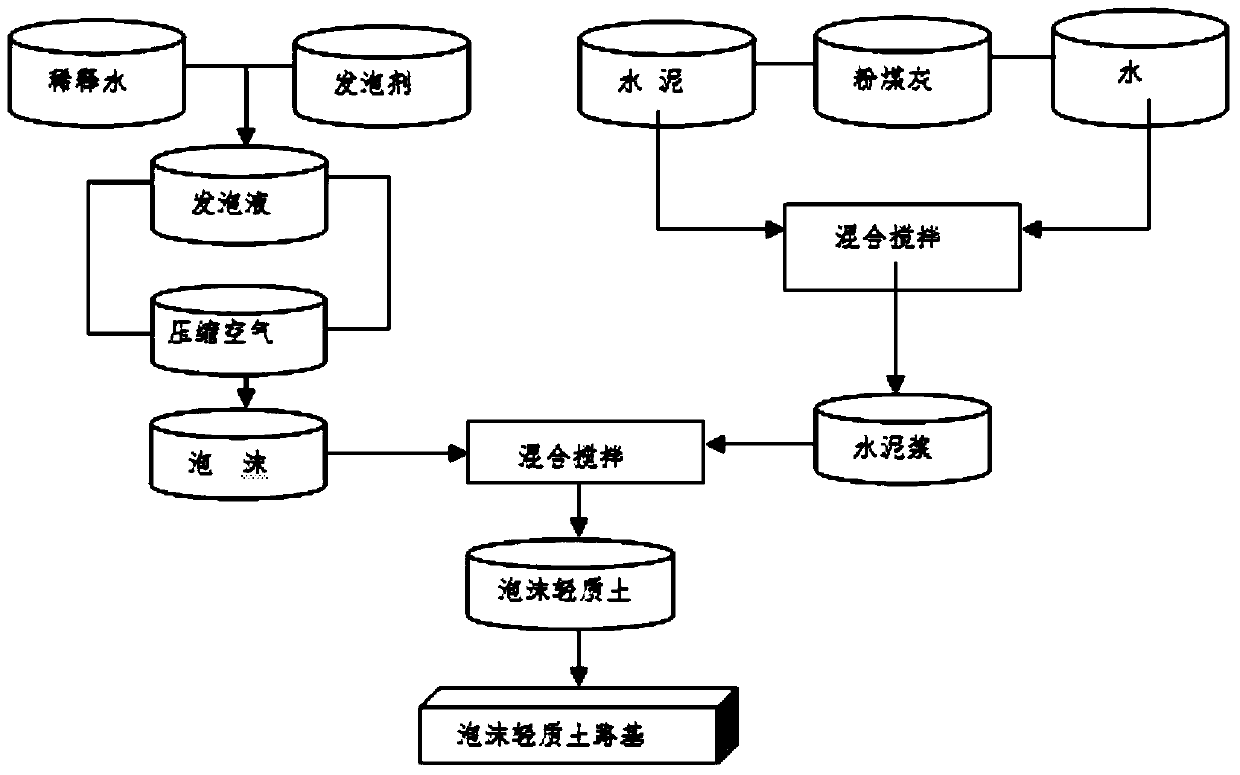

Foamed light soil construction method

The invention discloses a foamed light soil construction method. After the construction of a reinforced concrete protection wall and a soil subgrade is completed, foamed light soil is poured on the soil subgrade, and a galvanized wire mesh, a cushion layer and a reinforced concrete pavement are adopted on the foamed light soil so as to form a pavement structure; the foamed light soil is prepared through the steps of preparing a foaming agent into foams by using a physical method, then adding the foams into slurry prepared from cement, aggregates, admixtures, additives and water through a foamed light soil automation machine, mixing and stirring the obtained mixture through the foamed light soil automation machine, then conveying the obtained object by a guide pipe, and carrying out pouring molding and maintenance on the obtained object so as to obtain microporous light soil. The method disclosed by the invention greatly improves the construction quality of the foamed light soil, and effectively guarantees the molding standard of the foamed light soil.

Owner:THE FIRST ENG CO LTD OF CTCE GRP

Method for designing long span concrete beam bridge

InactiveCN101709570AAvoid crackingPrecise dynamic beam distribution designBridge erection/assemblyBridge strengtheningConcrete beamsPre stress

The invention discloses a method for designing a long span concrete beam bridge, which adopts the principle of monitoring the construction of a diagonal cable bridge and comprises the following design steps: (1) carrying out construction monitoring on a variety of elements affecting the stress and the displacement of the long span concrete beam bridge and obtaining parameter values of the elements; (2) carrying out parameter identification on the obtained parameter values; (3) utilizing parameters passing the identification for carrying out structure re-analysis calculation and pre-stress dynamic adjustment design on the beam bridge; and (4) using actual overload for verifying the dynamic adjustment design. The principle of monitoring the construction of the diagonal cable bridge is introduced in the method, thereby ensuring the construction quality of the bridge, ensuring the safety of the construction process, leading the internal force, the linearity and the like of a finished bridge structure to be in line with specification and design requirements, solving the phenomena of multiple cracks with the width exceeding the limit, non-convergent excessive deflection of midspan and the like after the operation of the existing long span concrete beam bridge, ensuring the bearing capacity of the beam bridge, reducing the imposition of prestressed standby beams, ensuring the normal use and the safety of the bridge and reducing the investment in maintenance capital.

Owner:GUANGDONG PROVINCE COMM PLANNING & DESIGN INST

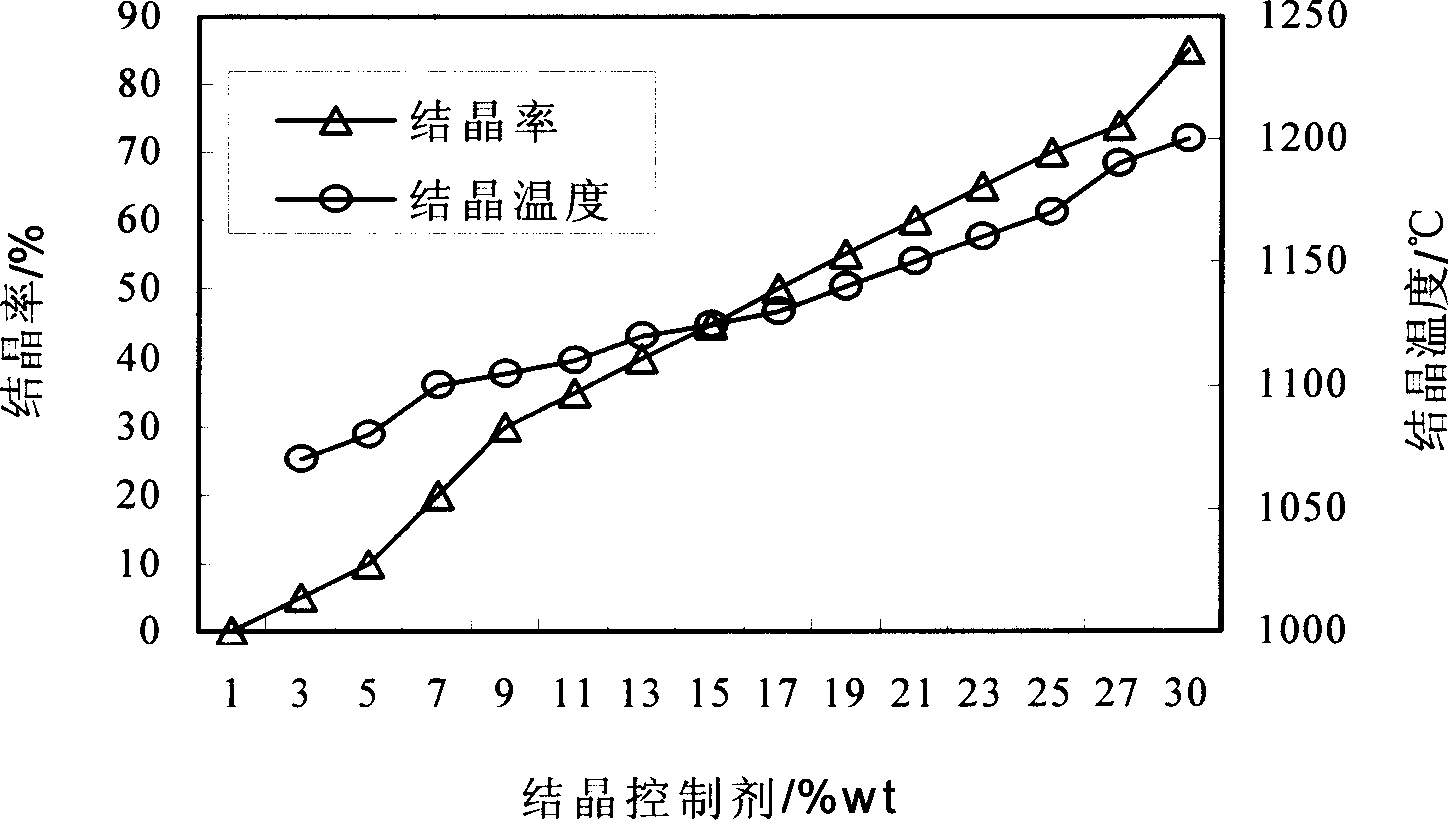

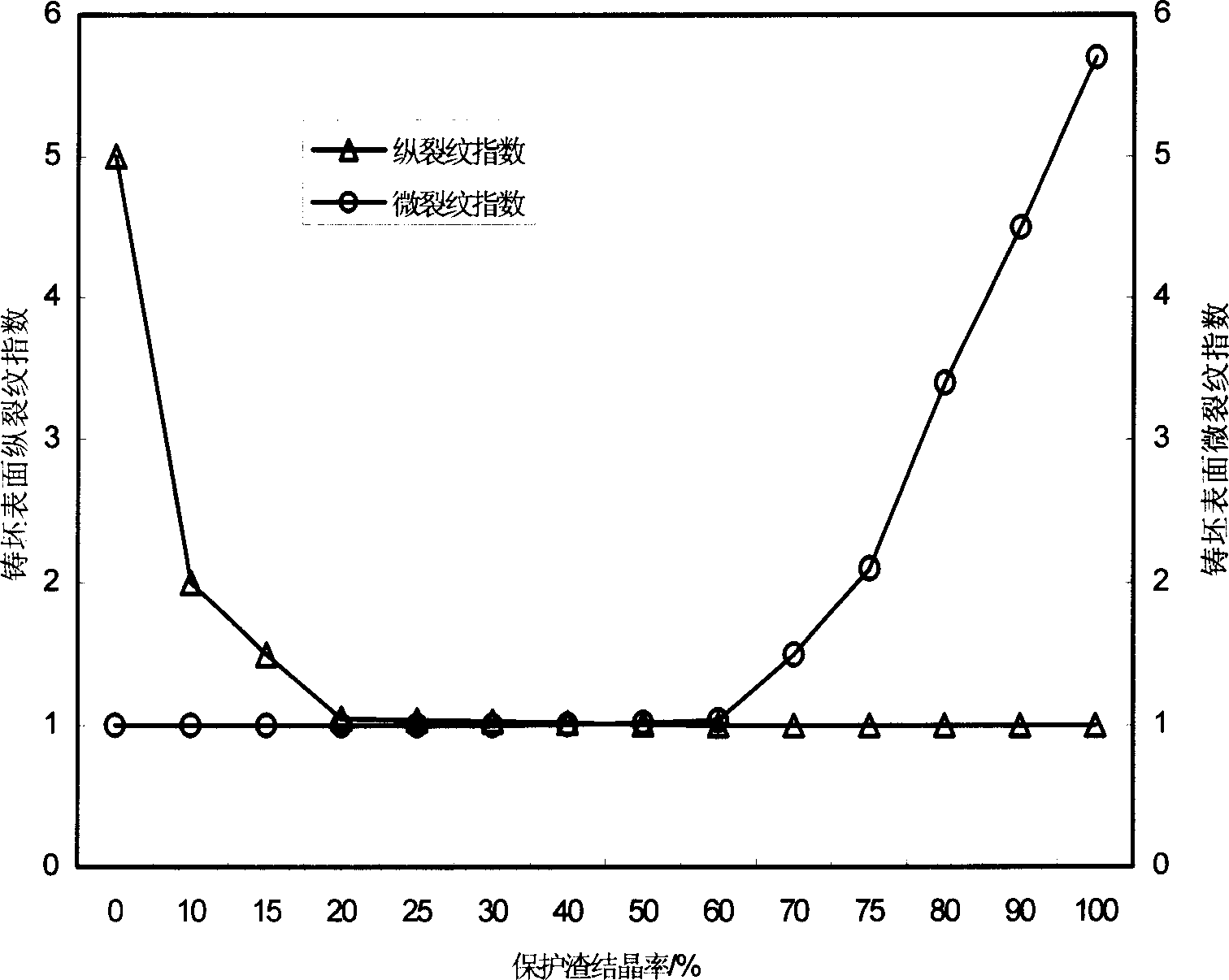

Protective slag for continuous casting medium thick plate of low alloy high strength steel

The protecting slag for continuously cast medium and thick plate of low alloy high strength steel consists of carbon black 0.5-2.0 wt%, graphite 4-10 wt%, Na2O 4-12 wt%, F- 1-7 wt%, Al2O3 2-7 wt%, Fe2O3 1-3 wt%, crystallization controlling agent 7-20 wt%, Li2O 0-2 wt%, except CaO and SiO2, where the weight ratio CaO / SiO2 is 0.90-1.05. The crystallization controlling agent in the protecting slag is component capable of promoting the crystal separation of the molten protecting slag during condensation without deteriorating the lubricant characteristic seriously. The protecting slag of the present invention used in protecting continuously cast medium and thick plate of low alloy high strength steel, can raise the plate product quality and has no influence on the normal delivery of cast blank.

Owner:LIAONING TIANHE TECH

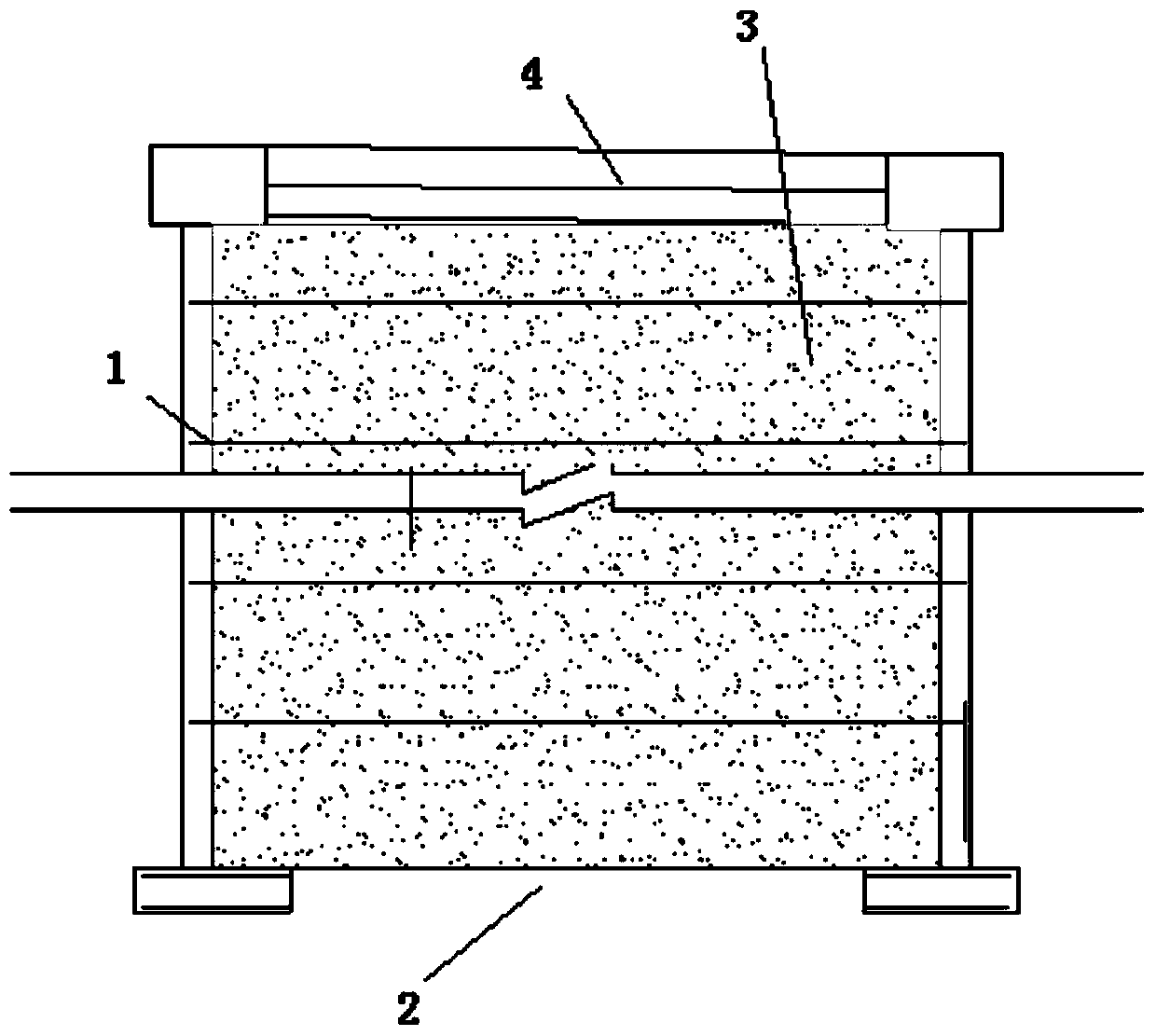

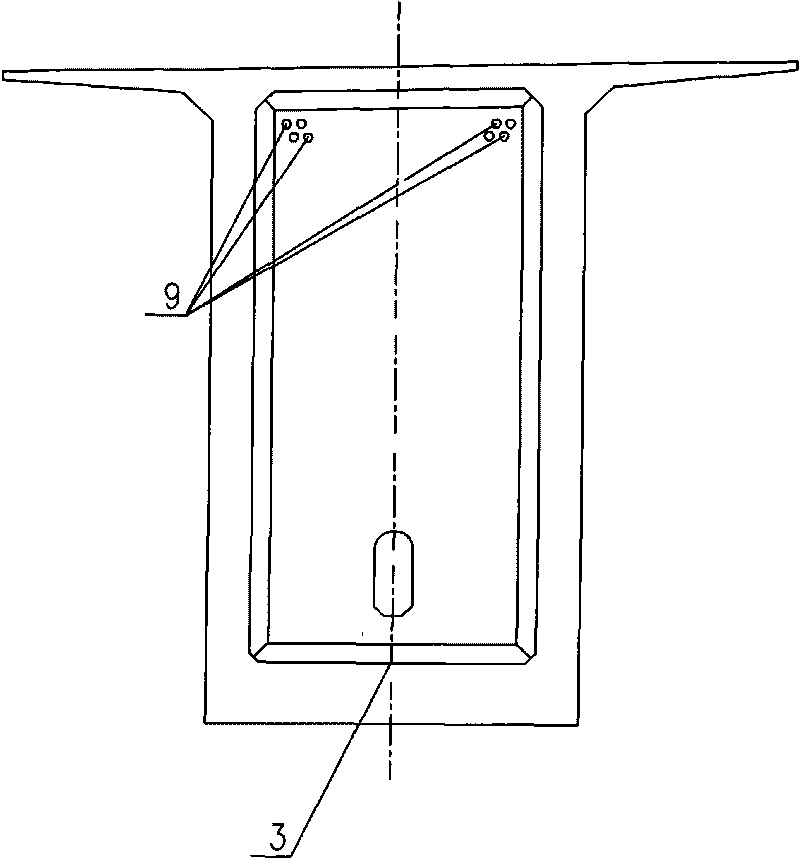

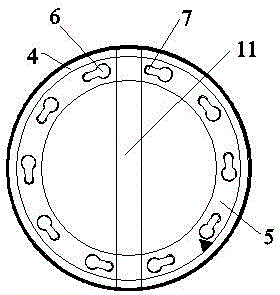

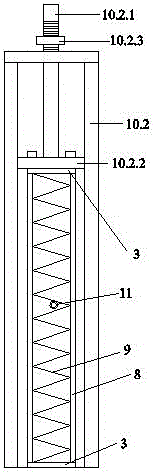

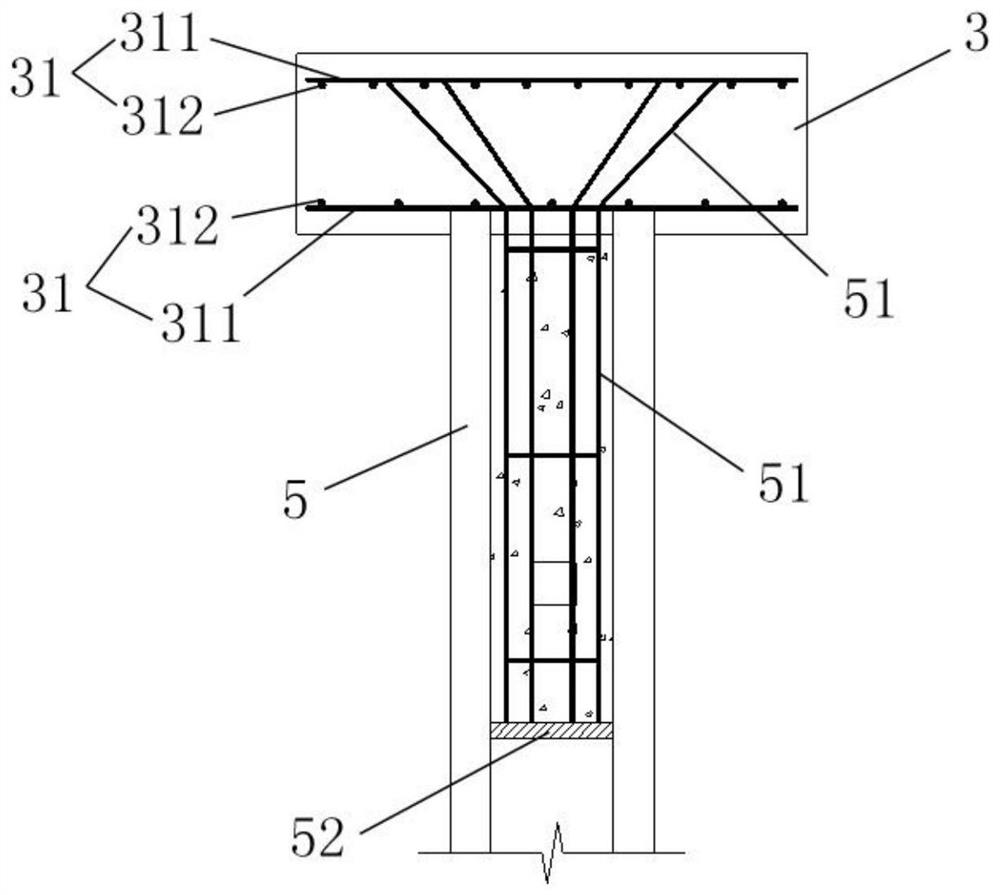

Prestressed concrete pole as well as mold and manufacturing method thereof

InactiveCN106626045AEvenly distributedNo loss of prestressDischarging arrangementShaping reinforcementsCrack resistanceSheet steel

The invention provides a prestressed concrete pole which comprises a reinforcement skeleton and concrete and is characterized in that the reinforcement skeleton is composed of two end plates at the two end respectively; each end plate is composed of a steel plate ring and an anchoring disc; stretching screw holes which are uniformly distributed on the circumference of each anchoring disc are formed in each anchoring disc; prestressed main reinforcement holes are formed beside the corresponding stretching screw holes are formed in each anchoring disc, communicate with the corresponding stretching screw holes and are internally provided with corresponding prestressed main reinforcements longitudinally; a spiral reinforcement is welded on each prestressed main reinforcement in a surrounding manner; a steel tube is pre-buried in the reinforcement skeleton transversely; and concrete is poured in the reinforcement skeleton. The prestressed concrete pole has the beneficial effects that after the prestressed concrete pole stretches, prestress is uniformly distributed without loss, and a longitudinal crack generated due to prestress eccentricity is prevented; through actual measurement, the crack resistance check coefficient is 2.0, the bearing capacity check moment is 75Kn.m, the deflection is 18mm, and the crack resistance check coefficient, the bearing capacity check moment and the deflection are all superior to the national standard; and in addition, the structure of the prestressed concrete pole can realize simultaneous multi-segment stretching.

Owner:常德定海管桩有限公司

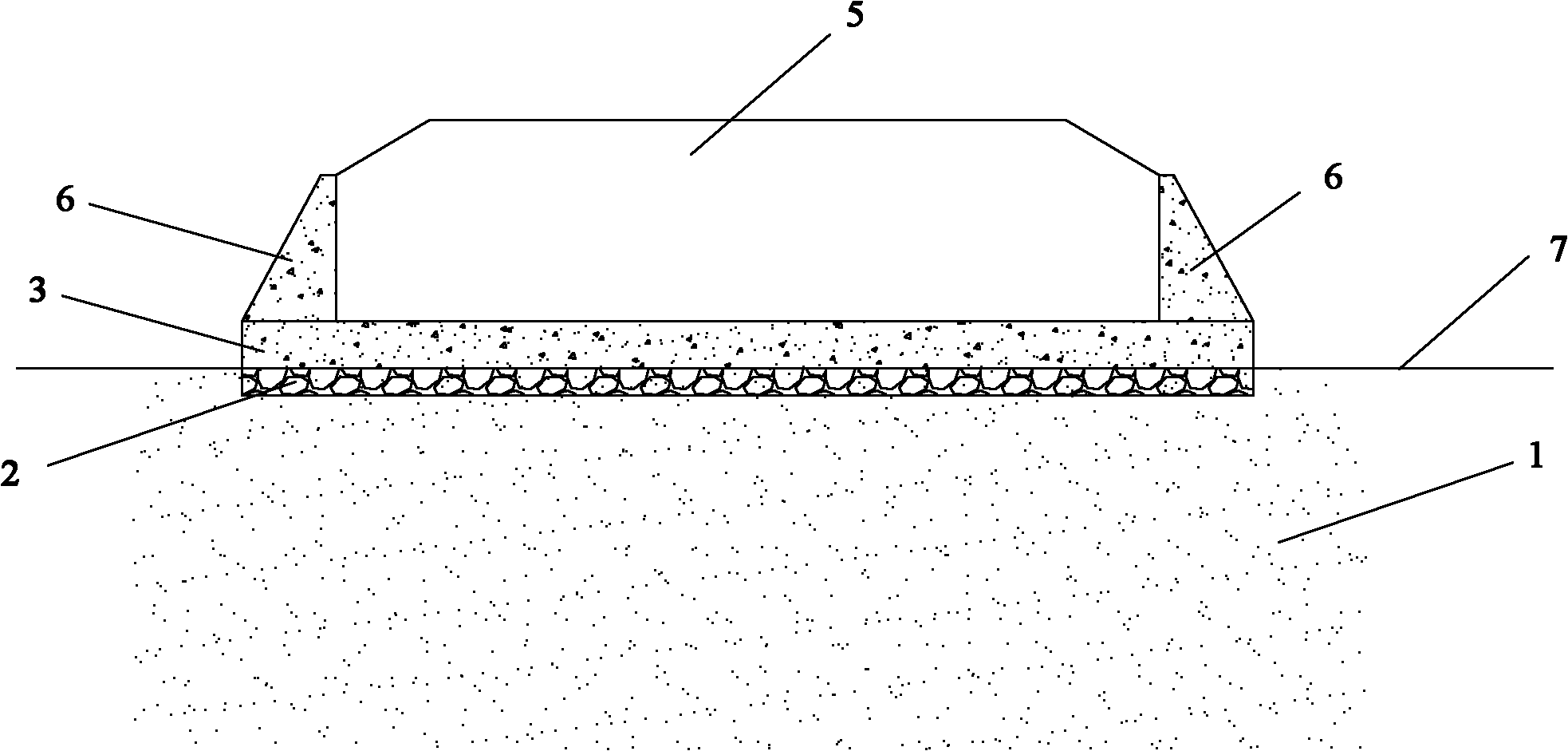

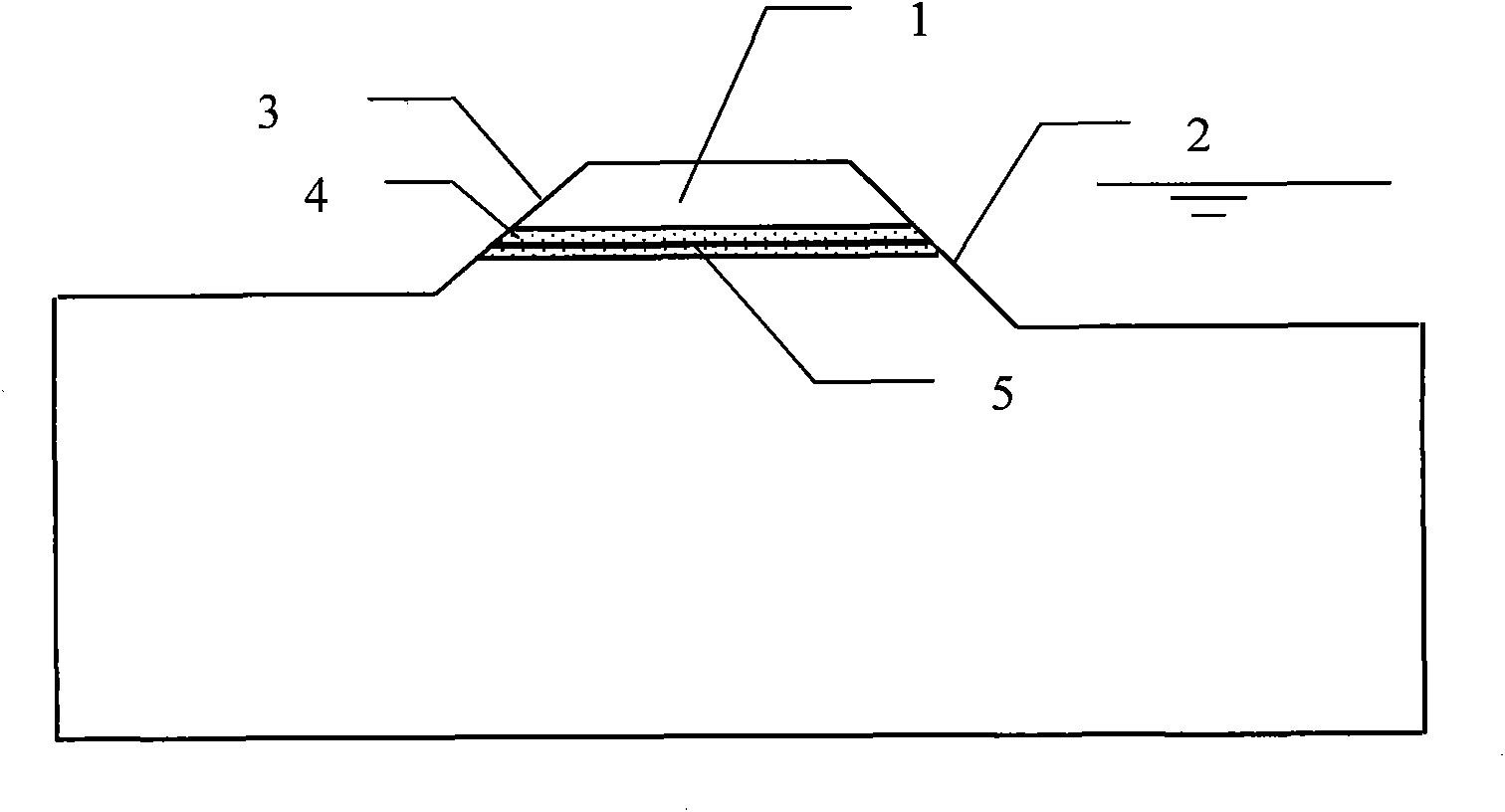

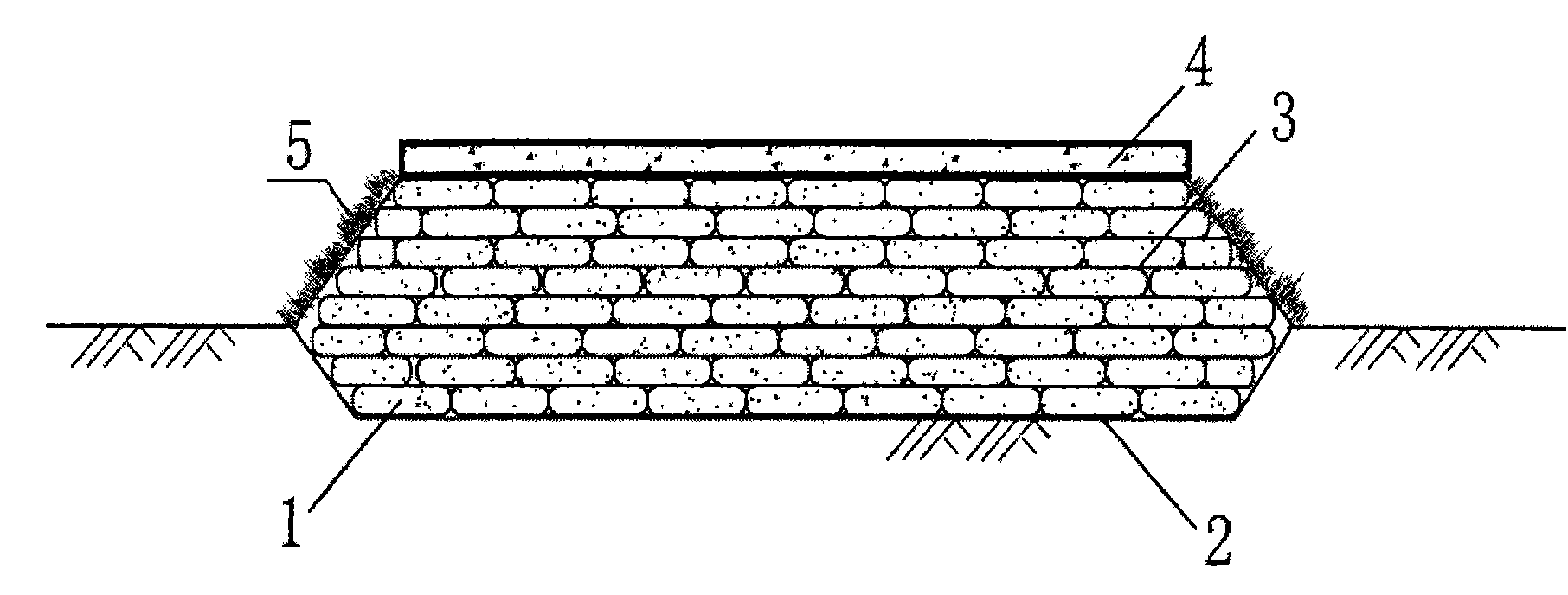

Plate supporting type embankment technology for post-construction settlement controlling of deep soft soil foundation on high-grade highway

The invention discloses a plate supporting type embankment structure for post-construction settlement controlling of a deep soft soil foundation on a high-grade highway. A reinforced concrete plate is arranged as a hard shell layer between the soft soil foundation and embankment earth filling, the thickness of the concrete plate ranges from 300 mm to 1000 mm, the concrete plate can be located above the earth surface or be partly embedded into the foundation or be fully embedded into the foundation, a cushion layer can be arranged at the bottom of the concrete plate, the slope ratio of the embankment earth filling is smaller than 1:1.5, the slope surface is wrapped by geotextile, a low retaining walls can be arranged on each of two sides of the concrete plate, the two sides of the concrete plate are close to the edges of the embankment, the bottom of each low retaining wall is fixed with the concrete plate, and overall deformation is achieved. By means of the plate supporting type embankment structure for the post-construction settlement controlling of the deep soft soil foundation on the high-grade highway, differential settlement of the embankment edges and the embankment center is eliminated, longitudinal cracks of the foundation are avoided, an embankment side slope can not lose stability and not be damaged, and compensation earth volume of the embankment earth filling is decreased. Compared with drainage concretion methods, by means of the plate supporting type embankment structure, post-construction settlement is effectively reduced. Compared with composite foundation methods, the plate supporting type embankment structure is low in cost. According to the plate supporting type embankment structure for the post-construction settlement controlling of the deep soft soil foundation on the high-grade highway, construction time is short, construction time of the earth filling is merely considered, and the plate supporting type embankment structure is particularly applicable to ordinary road sections on the deep soft soil foundation.

Owner:HOHAI UNIV

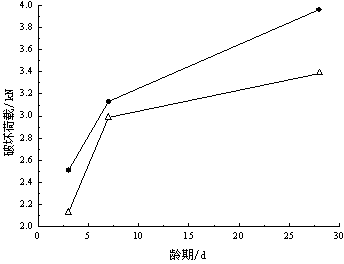

Compound stabilizing method for silty soil in Yellow River flooded areas

The invention discloses a compound stabilizing method for silty soil in Yellow River flooded areas and belongs to the technical field of road construction materials and road building. The method can be realized through reasonable mix proportion of a sodium methyl silicate aqueous solution, polyacrylamide, pulverized coal, lime and silty soil. According to the method, not only can the cost be lowered, but also the non-laterally confined compressive strength and anti-penetrability performance of the silty soil can be improved. In addition, the method also has the advantages that the functions of resisting capillary water and preventing rise of the capillary water can be achieved, and the stability property of the water can be enhanced so as to prevent the damage of roadbed and road surfaces; and the maintenance cost can be lowered, the road service life can be prolonged, and the like.

Owner:HENAN UNIVERSITY +2

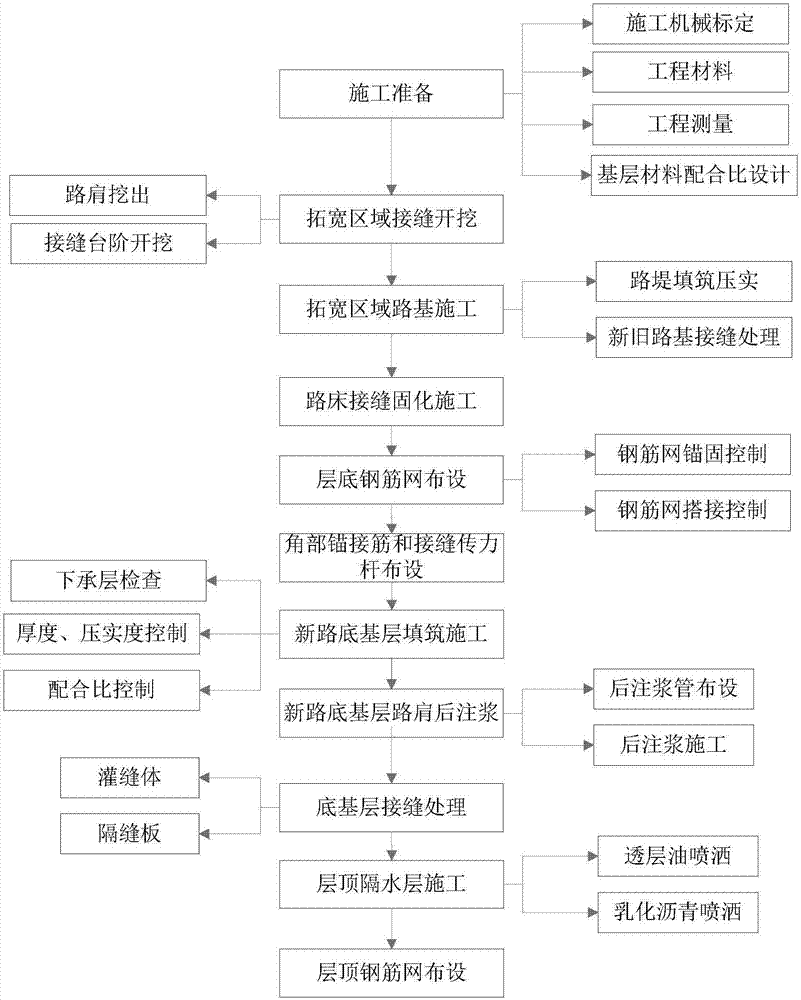

Construction method for widening and ribbing heavy-thickness sub-base of cold-plateau highway

The invention relates to a construction method for widening and ribbing a heavy-thickness sub-base of a cold-plateau highway. Firstly milling is conducted on an old road base and an old road sub-base, then roadbed padding at the seam of an old road roadbed and a new road roadbed is solidified to form a roadbed seam hardened zone; then a layer of bed base reinforcing mesh is laid along the top surfaces of the old road roadbed and the new road roadbed, and a corner-part anchor-connection rib and a seam dowel bar are implanted to the vertical seam of a new road sub-base and the old road sub-base; then paving, laminating and maintaining construction of the new road sub-base are conducted; and after the new road sub-base forms strength, seam seam-body-pouring construction and seam-board-separating construction are sequentially conducted, post-grouting is conducted on the new road sub-base of a road shoulder part through a post-grouting pipe to form a base slurry-solidifying zone, and finally construction of a roof water-resisting layer and roof reinforcing mesh is conducted. According to the construction method for widening and ribbing the heavy-thickness sub-base of the cold-plateau highway, not only can the differential deformation at the seam of the new road base and the old road base be controlled, but also the heavy-thickness sub-base can be prevented from generating cracking disease, and the problem that the degree of compaction on the road shoulder part is not sufficient can further be solved.

Owner:西安市市政建设(集团)有限公司

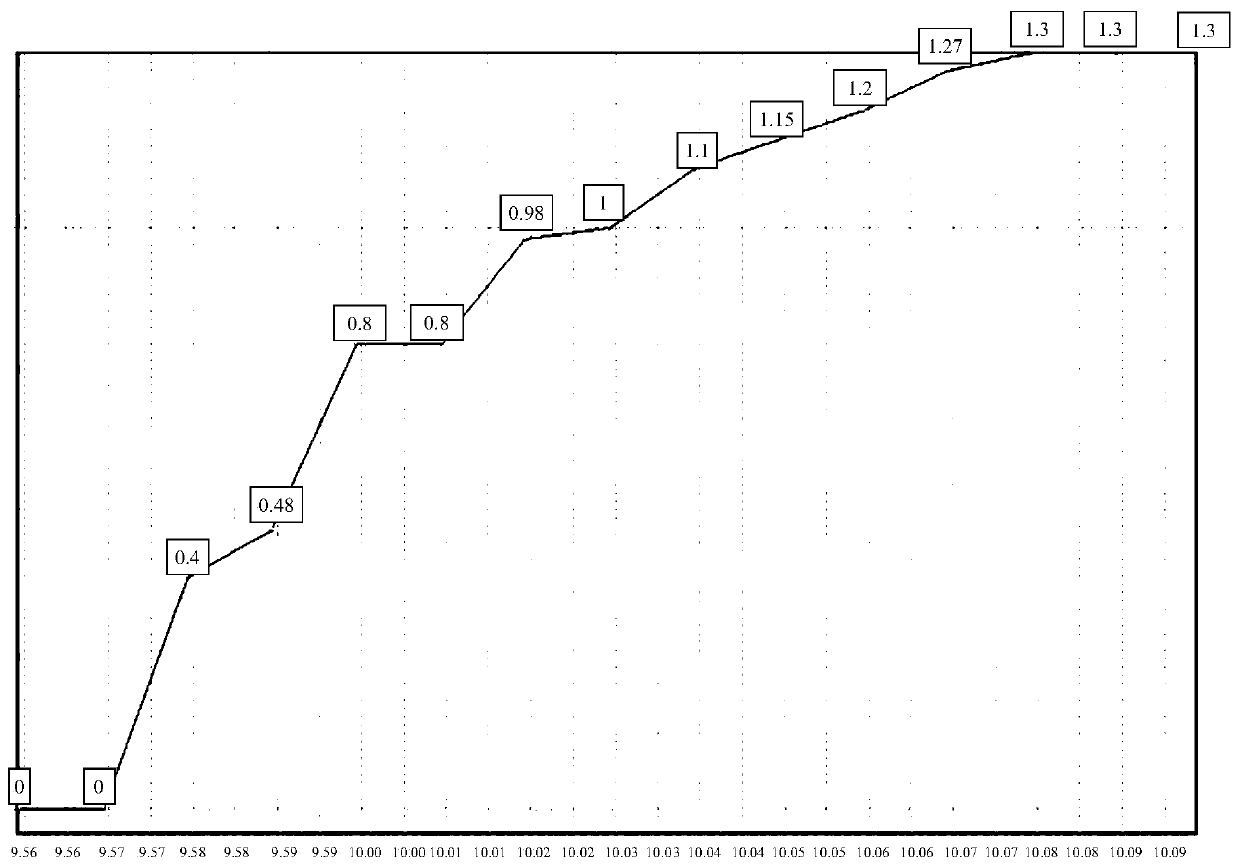

Casting method capable of reducing longitudinal cracks in surfaces of wide and thick plate continuous casting billets

The invention provides a casting method capable of reducing longitudinal cracks in the surfaces of wide and thick plate continuous casting billets. System research and control are carried out on multiple aspects that the superheat degree of molten steel is controlled before casting of a continuous casting machine, novel casting slag special for wide and thick plates is researched and developed, acasting pulling rate curve of the continuous casting machine is developed, a submersed nozzle low-position casting manner of the continuous casting machine is researched and developed in a self-service manner, and the emergence time is reasonably and accurately controlled, stress concentration is reduced, the protecting slag film grain homogenization is improved, billet shells in a crystallizer have enough setting time, the quality of the wide and thick plate continuous casting machine cast casting billets is improved, and the percent of pass of the casting billets under the non-steady condition of the longitudinal cracks of the casting billets is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Prevention of split crack of carbon in intermediate carbon and alloy structural steel ingot by adding titanium and process for producing same

The invention discloses a titanium-adding technology in medium carbon and structural alloy steel slab to prevent diastema. The aim of the invention is to provide a process to use titanium as a substitute for aluminium in terminal deoxidization, ingoting and annealing process to prevent diastema The gross mass comprises 0.03%-0.06% of terminal deoxidization agent titanium and 0.02%-0.04% of terminal deoxidization agent aluminium. Ingoting and annealing process: no need to move forward to annealing process pit or hood for annealing process after more than 6-10 times the time when melted iron is injected into mould, demoulding and when steel slab surface temperature decreases to the temperature bellow 100 Deg. C warehousing-in after qualification test. Without demoulding and annealing in pit or hood just after congealing of milted iron, this invention prevents diastema of medium carbon and structural alloy steel slab, so it reduces intensity of labor, cancels pit or hood installation, more importantly it reduces diastema substantially and shortens period of production. This invention not only decreases capital loss but also guarantees quality.

Owner:ZHEJIANG DALONG ALLOY STEEL

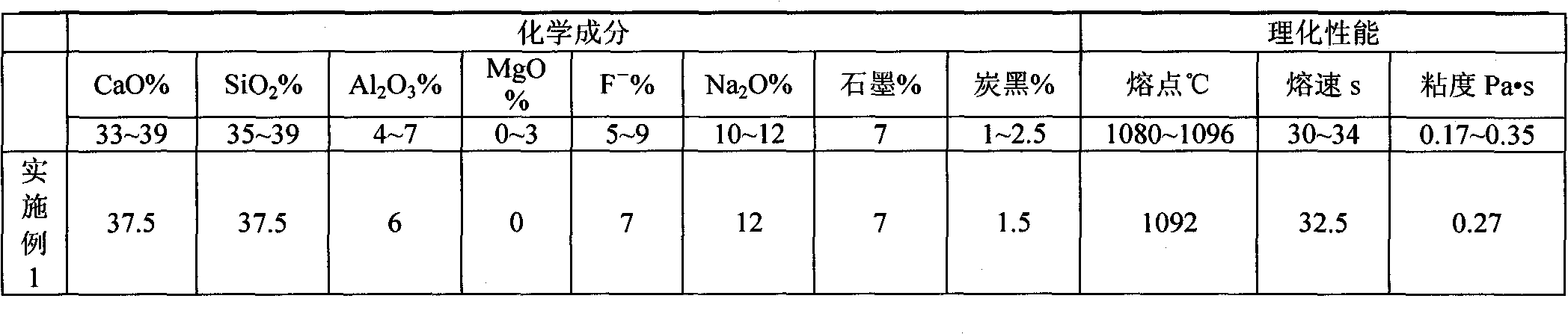

Medium carbon steel casting powder for H-section steel continuous casting

InactiveCN102990025ALower melting temperatureViscosity, proper melting speed properSteelmakingTwo step

The invention relates to medium carbon steel casting powder for H-section steel continuous casting, belonging to the technical field of steelmaking and continuous casting. The medium carbon steel casting powder comprises the following components in percentage by weight: 33-39 percent of CaO, 35-39 percent of SiO2, 4-7 percent of Al2O3, 0-3 percent of MgO, 5-9 percent of F<->, 10-12 percent of Na2O, and balance of composite carbon which comprises 7 percent of graphite and 1-2.5 percent of carbon black, wherein the CaO and the SiO2 are used as base materials; and the Na2O, the MgO, the Al2O3 and the F<-> are used as flux. A preparation process comprises two steps, i.e. the step of producing pre-molten materials and the step of producing finished product casting powder. The prepared casting powder has physical properties that the melting point is 1080-1096DEG C, the viscosity at 1300DEG C is 0.17-0.35Pa.s and the melting speed is 30-40s. The thickness of the molten flux layer of the casting powder is 10-13mm. According to the requirement of carbon steel on the casting powder during production of an H-section steel continuous casting machine, the flux film control goals of lower melting temperature, lower viscosity, proper melting speed and higher thermal resistance are realized, and the situation that the surface of a casting blank is longitudinally cracked because the temperature gradient of the cross section of the casting blank is too large is avoided. The medium carbon steel casting powder has a better using effect than the using effect of domestic and foreign similar products, and can fully meet the process requirement on the carbon steel during H-section steel continuous casting.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

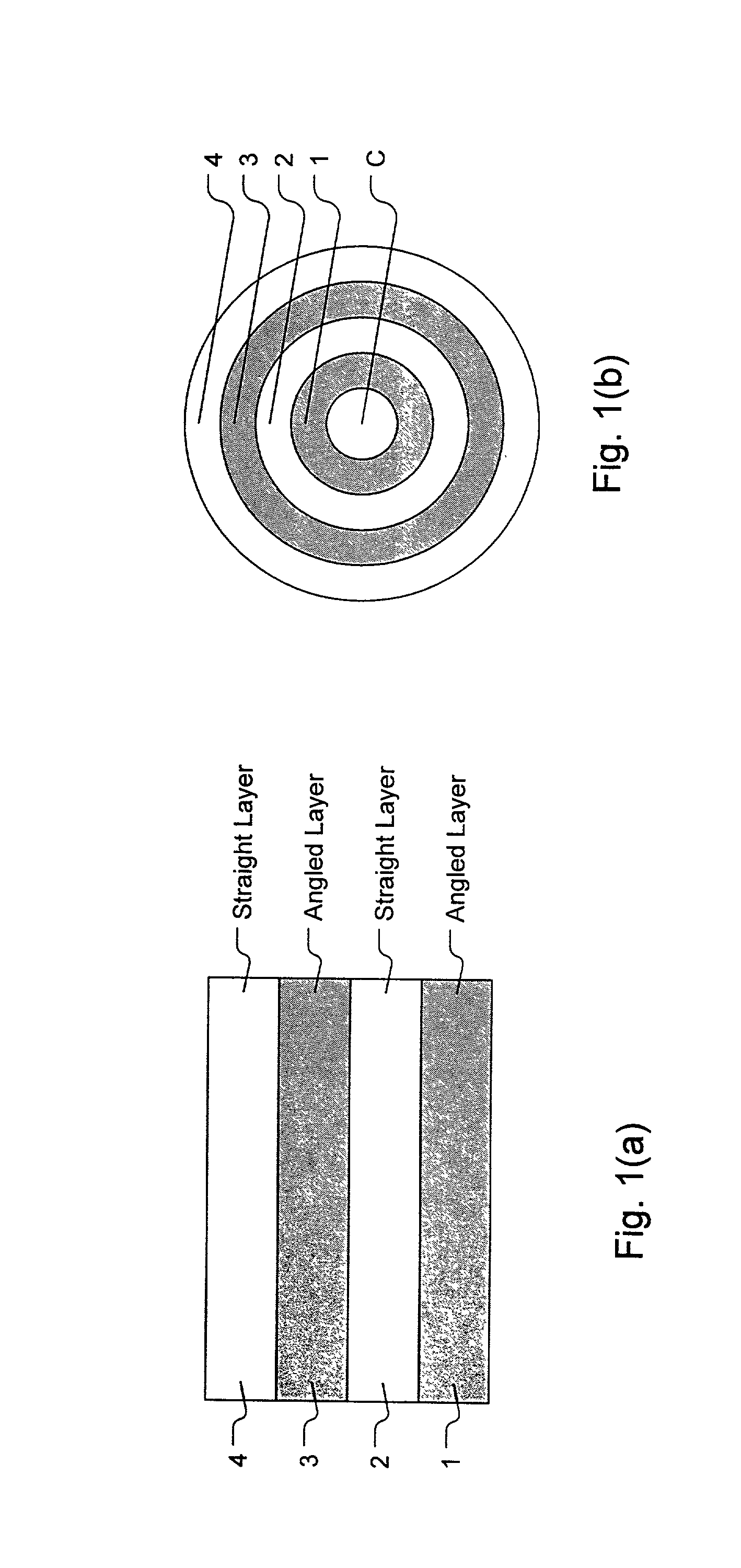

Shaft for light-weight golf clubs

A golf club shaft is 35-50 percent lighter than a conventional shaft while maintaining the outer diameter and structural characteristics of conventional shafts. The shaft has at least four layers of fiber reinforced material. The fiber reinforced layers are from innermost to outermost: a first angled layer; a first straight layer; a second angled layer; and a second straight layer. The angled layers are formed by bonding together two materials, each with fibers aligned in different directions. The second angled layer maintains the proper strength and rigidity of the shaft while keeping the shaft as light weight as possible. Aligning the second layer's fibers at an angle of 35-75 degrees with respect to the longitudinal direction of the shaft ensures proper weight and strength characteristics of the shaft. The resulting shaft is light-weight and exhibits the flexural rigidity, flexural strength, torsional rigidity, torsional strength, and crushing strength of conventional shafts.

Owner:MITSUBISHI RAYON CO LTD

Pressure steel pipe reinforcement composite concrete pipe, manufactured pipe and manufacturing method

InactiveCN106287001AOvercome Longitudinal Crack PhenomenonSimple structureEngine sealsShaping reinforcementsVertical vibrationEngineering

The invention discloses a pressure steel pipe reinforcement composite concrete pipe, a manufactured pipe and a manufacturing method. A pipe body consists of a concrete outer pipe, a rubber pipe, a steel pipe and a concrete inner pipe arranged in sequence from outside to inside; the manufactured pipe is to insert an insertion port part of one pipe into a bearing port part of the other pipe and to uniformly coat polysulfur sealing paste in the joined place. The manufacturing method comprises manufacturing of a bearing port steel ring and an insertion port steel ring, manufacturing of a steel pipe, derusting and polishing of the steel pipe, leakage point detecting, bonding of the rubber pipe, manufacturing of a reinforcement skeleton cage, installing of an inner mold, installing of the steel pipe and the reinforcement skeleton cage on a chassis, sleeving of an outer mold, inserting of concrete into the mold, vertical vibration molding, port leveling, removing of the inner and outer molds, coating of corrosion resisting paint on the surfaces of the bearing port steel ring and the insertion port steel ring, coating of polyurethane on the end surface, finishing and inspecting, marking and curing, and carrying out inspection. The product can effectively overcome the longitudinal crack phenomenon on the inner and outer walls of the pipe due to higher internal and external pressure on the pipe.

Owner:TIANJIN HAILONG PIPE IND

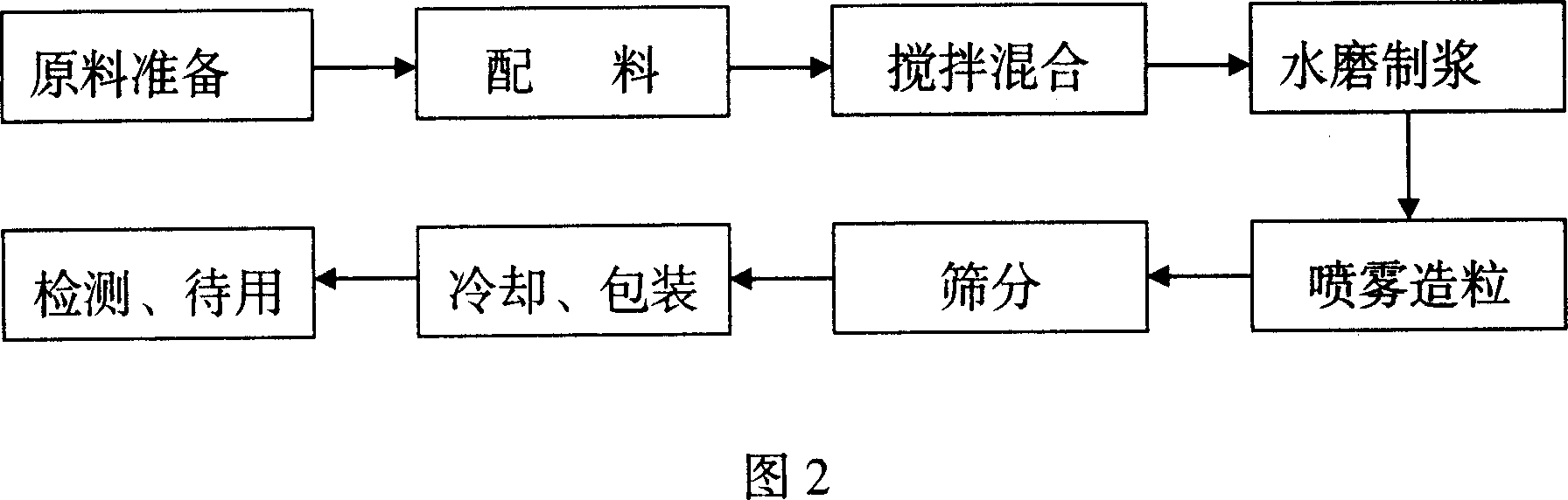

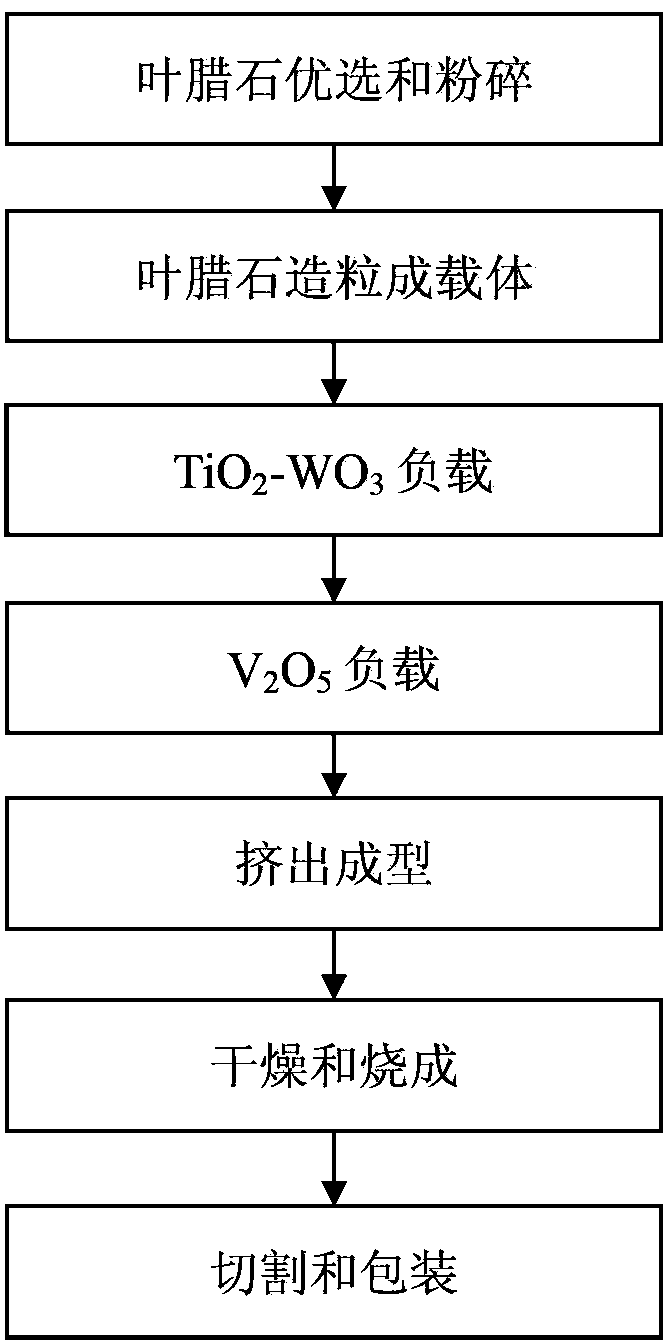

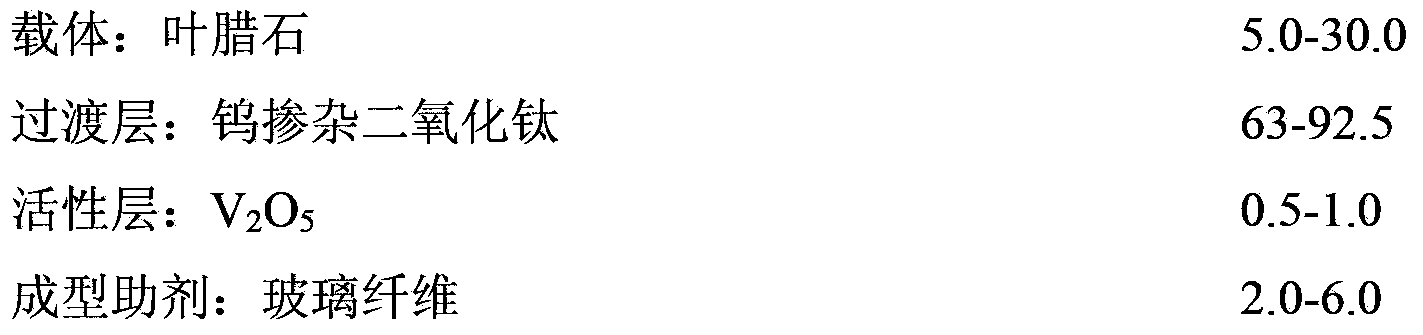

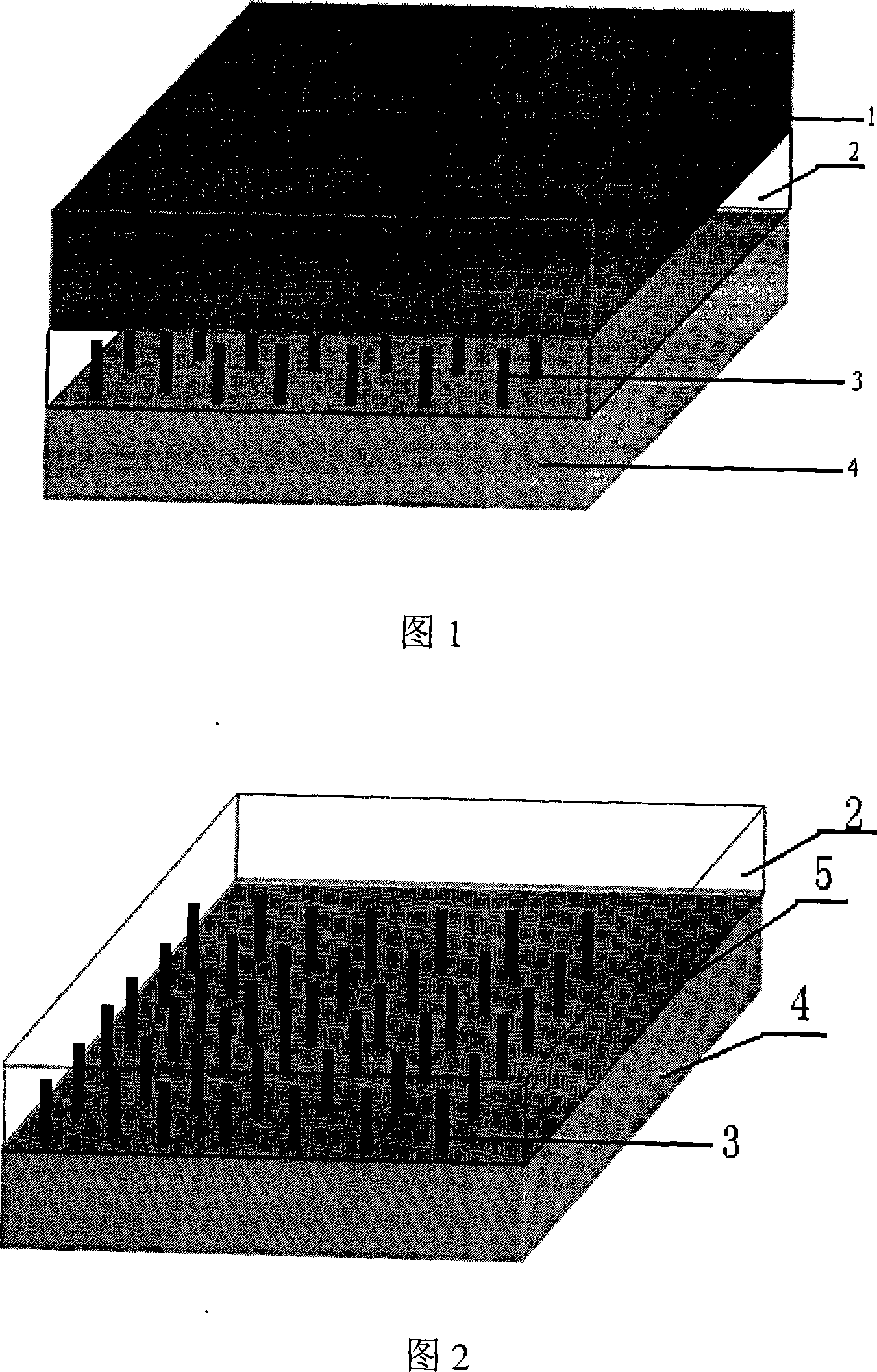

Production process of SCR (selective catalytic reduction) catalyst with pyrophyllite as carrier

ActiveCN103372425AAvoid negative effectsLow costDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPyrophylliteNitric oxide

The invention discloses a production process of a honeycombed SCR (selective catalytic reduction) catalyst with pyrophyllite as a carrier, belonging to the fields of nitric oxide after-treatment and purification and environment-friendly catalytic materials. The catalyst has three layers of microstructures, wherein pyrophyllite forms a carrier layer; tungsten-doped titanium dioxide (TiO2-WO3) forms a transition layer; and vanadium pentoxide (V2O5) forms an active layer. The catalyst has the beneficial effects that the negative effects of trace elements Na and K in pyrophyllite on the activity of the honeycombed SCR catalyst can be avoided by the design of the three layers of microstructures; pyrophyllite has the characteristics of low moisture expansion and high heat stability; as the carrier, pyrophyllite is favorable for improving the yield in the catalyst drying process and is favorable for improving the mechanical strength of the catalyst, and the cost of the catalyst can be also reduced by reasonably adding pyrophyllite; and the catalyst has high lateral and longitudinal mechanical strength, has denitration efficiency of more than 89% at a temperature of 270-500 DEG C, and has denitration efficiency of more than 94% at a temperature of 330-430 DEG C.

Owner:福建帕特纳环境产品有限公司

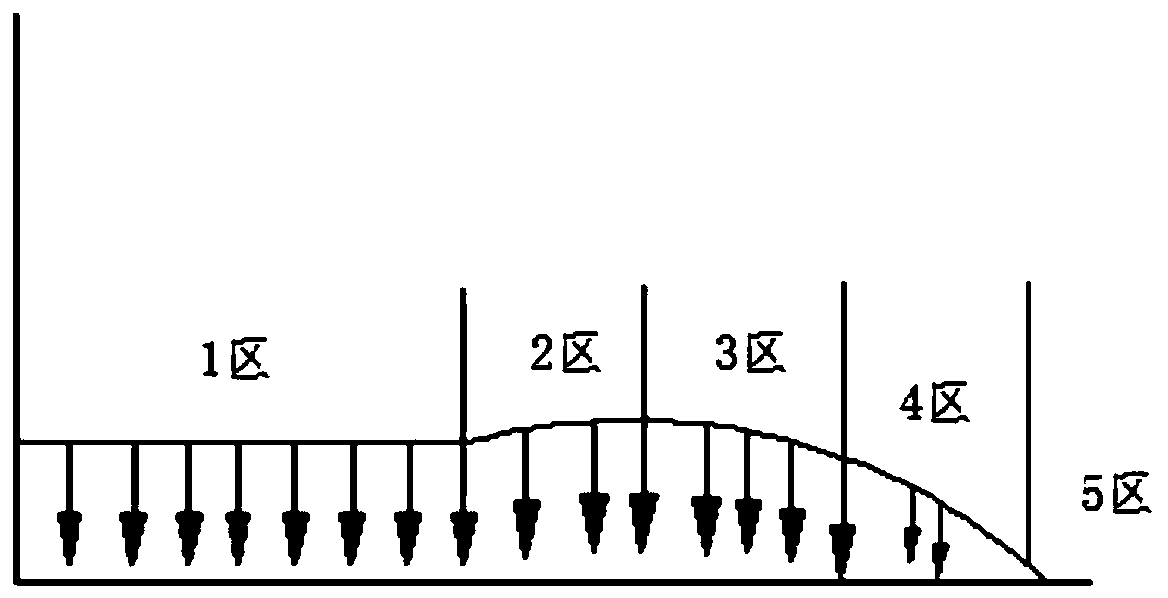

Roadbed splicing construction method in expressway reconstruction and extension

InactiveCN111485463AImprove bindingAvoid uneven settlementRoadwaysObservation pointArchitectural engineering

The invention discloses a roadbed splicing construction method in expressway reconstruction and extension. The method comprises the following steps: 1, removing surface soil of a roadbed substrate tobe widened, and rolling the substrate after the surface soil is removed before filling; 2, laying geocells on the base, and manually scattering gravels in the geocells; 3, performing slope cutting onthe to-be-widened side of the old roadbed, excavating steps at the slope part from top to bottom, and after the steps are excavated, and laying steel-plastic grids at the roadbed along the step surfaces; and 4, performing layered filling on the roadbed to be widened, and arranging settlement observation points and horizontal displacement observation points in the roadbed filling process. With application of the roadbed splicing method, the new roadbed and the old roadbed are well connected, longitudinal cracks caused by differential settlement of the new roadbed and the old roadbed are avoided, and thus the construction quality of highway reconstruction and extension engineering projects is guaranteed, and the highway construction level of China can be improved.

Owner:CHINA RAILWAY 23RD BUREAU GRP THIRD ENG CO LTD

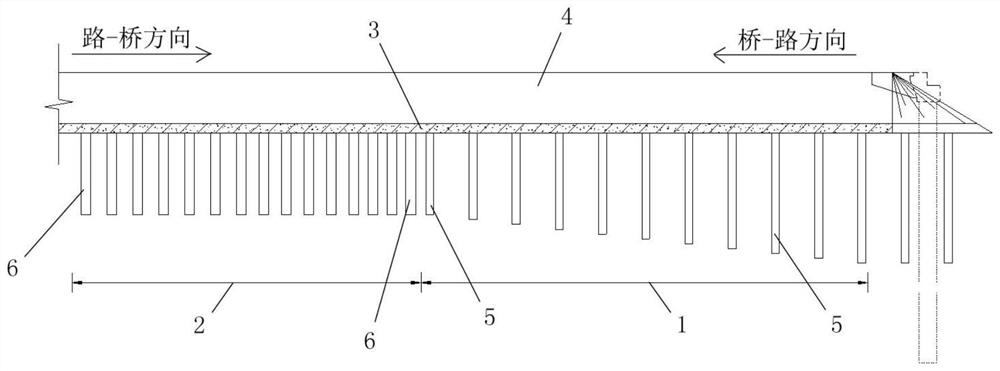

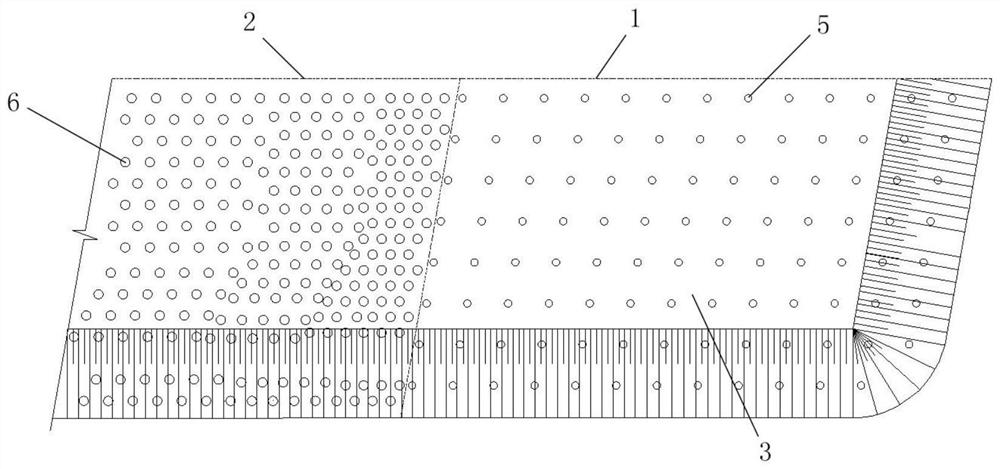

Long and short pile plate structure for controlling differential settlement of highway transition section and construction method of long and short pile-plate structure

PendingCN112211052AControl uneven settlementShorten the construction periodRoadwaysBulkheads/pilesPre stressArchitectural engineering

The invention discloses a long and short pile plate structure for controlling differential settlement of a highway transition section and a construction method thereof.The long and short pile plate structure comprises a transition section and a common section, reinforced concrete slabs are arranged on the transition section and the common section, and a plurality of prestressed pipe piles are arranged in the transition section and located below the reinforced concrete slabs; a plurality of cement mixing piles are arranged in a common road section below the reinforced concrete slab, the prestressed pipe piles and the cement mixing piles are directly and rigidly connected with the reinforced concrete slab, the lengths of the prestressed pipe piles are gradually decreased in the bridge road direction, and the pile intervals of the cement mixing piles are gradually decreased in the road bridge direction. The long and short pile plate structure and the construction method are good in reinforcing effect, reliable in technology, economical and reasonable, and uniform transition of longitudinal rigidity of the highway bridgehead transition section in the soft soil area can be achieved.

Owner:CENT SOUTH UNIV +1

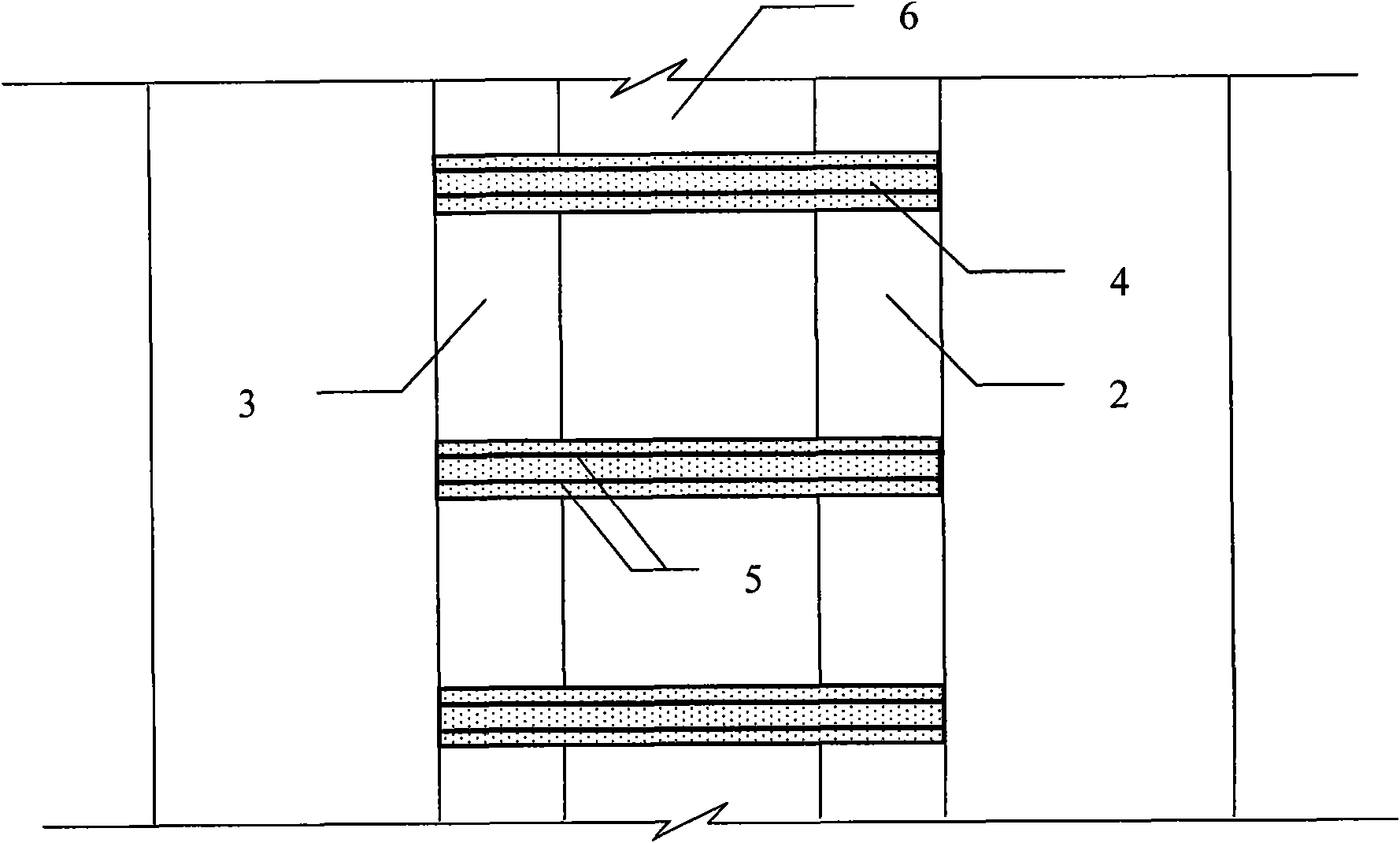

Method for treating corbel with longitudinal crack in riverine highway

InactiveCN101634129AAvoid Longitudinal CracksCut reflex spreadPaving detailsHorizontal forcePull force

The invention relates to a method for treating a corbel with a longitudinal crack in a riverine highway, overcoming the defect that the prior art comprising the prior radical treating effects of excavation, back filling, grid laying, grouting, impermeable wall setting and the like can not fundamentally inhibit the destruction function of transverse pulling force to beds. The invention adopts the corbel as a reinforced concrete member, the corbel is longitudinally laid perpendicular to the highway below the face of the highway, and the development and the extension of the longitudinal crack can be effectively prevented by utilizing the favorable tensile property of steel bars. Namely, the corbel has the function of strengthening the tensile capability of embankment foundation soil bodies or fillers, the placement direction of the steel bars inside the corbel is vertical to the direction of the crack, the steel bars can completely bear transverse horizontal force borne by the beds because of favorable tensile property, the longitudinal cracking of the beds is prevented, and the reflection and the diffusion of the longitudinal crack of the beds towards the face of the highway are thoroughly cut off. For the service life of the highway, the steel bars are wrapt by a concrete material, and the durability of the steel bars can be effectively ensured.

Owner:YANGZHOU UNIV

Method for avoiding crack formation of medium-high carbon steel during hybrid welding

ActiveCN105710542AAvoid Longitudinal CracksQuality improvementWelding apparatusPower flowHigh carbon

The invention provides a method for avoiding crack formation of medium-high carbon steel during hybrid welding. The method comprises the steps that a vacuum chamber and a casting blank are preheated till the temperature of the casting blank reaches 290-310 DEG C; the welding speed of a hybrid welding gun is set to be 7.9-8.2 m / s, and the welding current is set to be 340-360 ma; a short edge is welded on the portion below a pre-welded weld joint at the end of the casting blank in parallel before welding; after the two ends and one edge part are welded, the other edge part is welded to be closed after 1.9-2.1 hours, and a long edge is welded to the lower portion of the other edge part in parallel; and a composite plate blank continues to be placed in a closed welding machine room for 12-15 hours after welding is finished. By the adoption of the method, longitudinal cracks generated in the vacuum hybrid welding process of the medium-high carbon steel are effectively avoided, so that the treatment workload is reduced, the production cost is reduced, and the quality of a composite steel plate is greatly improved.

Owner:ANGANG STEEL CO LTD

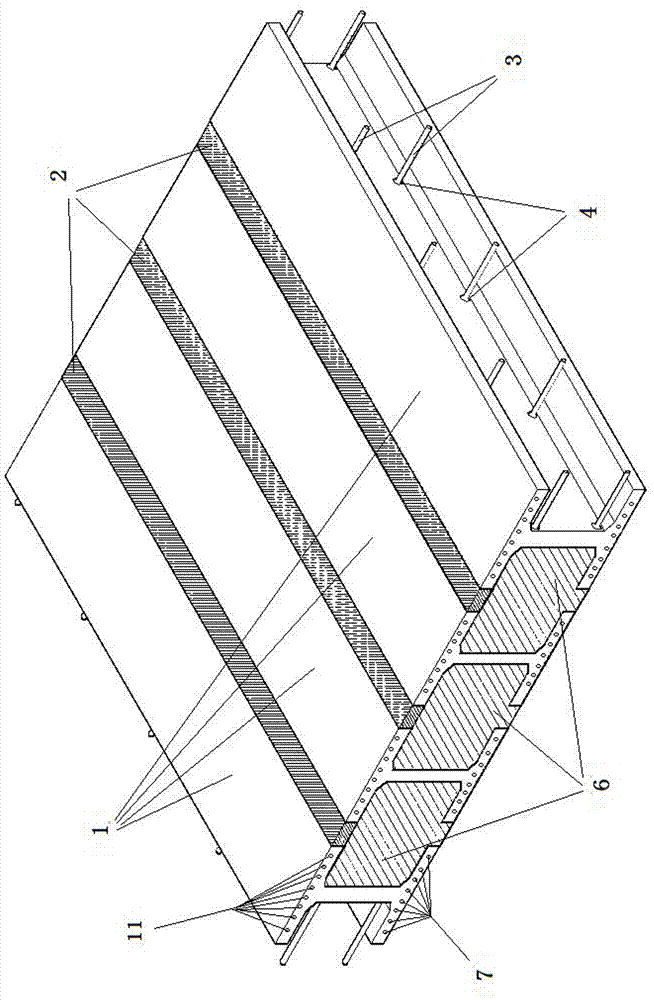

Transverse pre-stress I-shaped box girder structure

PendingCN107142829AAct as uneven loadIncrease stiffnessBridge structural detailsBridge materialsShaped beamPre stress

A transverse pre-stress I-shaped box girder structure is composed of a plurality of I-shaped beams (1) arranged in the longitudinal direction; wet joint concrete (2) is added between every two I-shaped beam top plates, and a plurality of concrete transverse partition plates (6) are arranged in each I-shaped beam; transverse reserved hole channels (5) are formed in the positions, provided with the concrete transverse partition plates, of each I-shaped beam, and transverse pre-stress ribs (3) are arranged in the reserved hole channels; the joint of every two I-shaped beam bottom plates is also provided with wet joint concrete (2); pouring reserved holes (8) are formed in the positions, corresponding to the connection positions of the concrete transverse partition plates, of the I-shaped beam bottom plates. The device is reasonable in structure, the transverse pre-stress ribs and the longitudinal pre-stress ribs form a pre-stress network framework, the overall rigidity of a bridge structure is improved, the overall stability and durability of the bridge structure are greatly improved, and the maintenance cost is reduced. Construction is convenient, the I-shaped beams can be prefabricated in a factory, and then a small amount of cast-in-place can be conducted on site, so that the quality is easy to control, transportation is convenient, and the construction cost is reduced.

Owner:内蒙古综合交通科学研究院有限责任公司

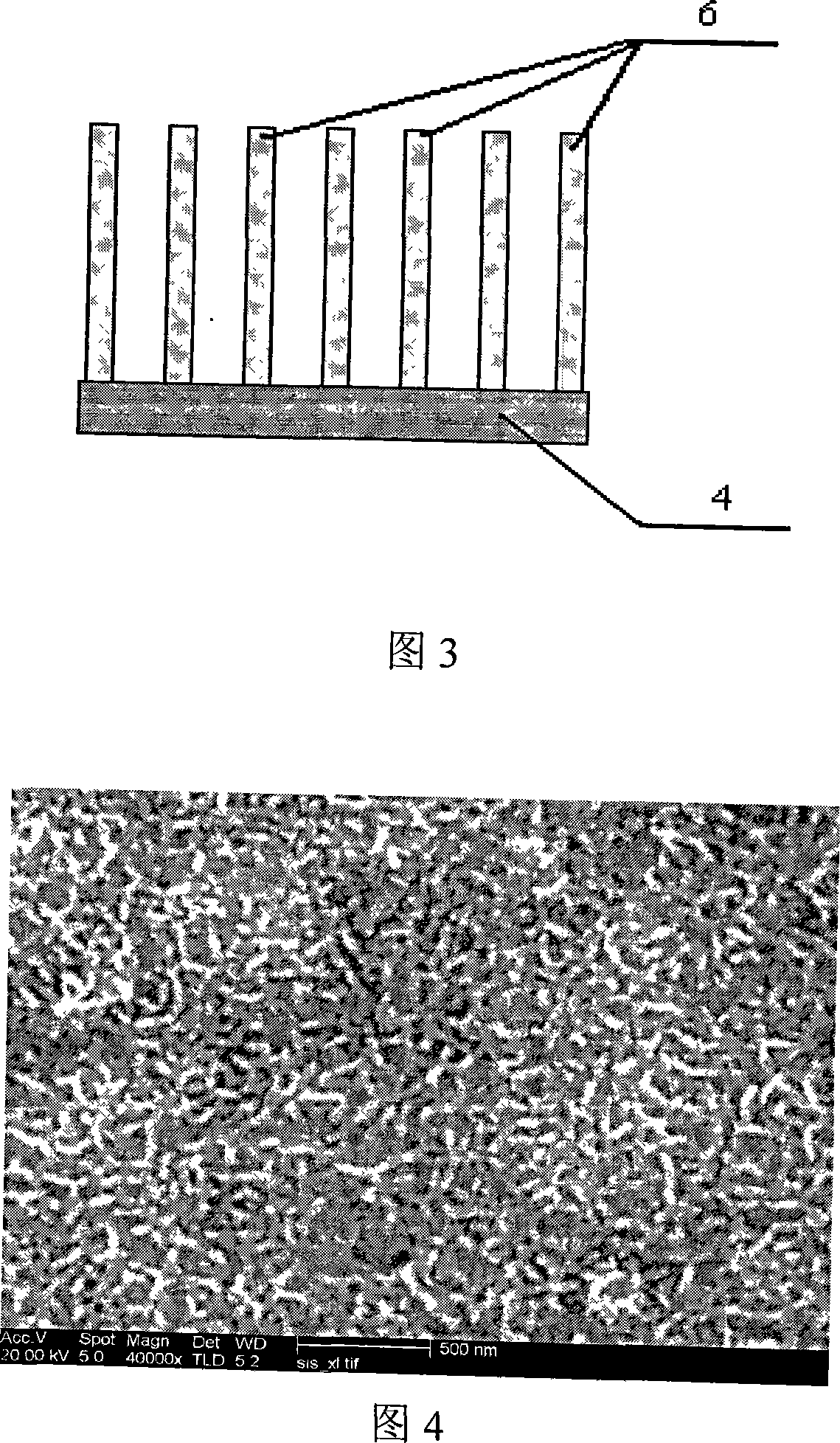

Thermal-barrier coating and method for making same

InactiveCN101200126AImprove shear resistanceEven by forceMetal layered productsYttria-stabilized zirconiaNanometre

A thermal barrier coating and the preparation method of the thermal barrier coating relate to a coating and the preparation of the coating, in which the issues that the relative sliding and falling of the material interface parallel to the direction of the high temperature nickel-based alloy and the vertical cracking of the thermal barrier coating perpendicular to the direction of high temperature nickel-based alloy in high temperature and in the prior art are resolved. The thermal barrier coating is composed of an external ceramic layer (1) and an internal combined layer (5), wherein the internal combined layer (5) is composed of a high temperature nickel-based alloy layer (4) and a bonding layer (2) linked with the external surface of the high temperature nickel-based alloy layer (4). The bonding layer (2) is composed of a nickel nano-wire (3) and yttria stabilized zirconia. According to the preparation, the nickel nano-wire connected to the high temperature nickel-based alloy layer is obtained through the electro-deposition on the outer surface of the high temperature nickel-based alloy layer. And then the sol of yttria stabilized zirconia is sprayed, and the bonding layer (2) is obtained after the calcinations. Afterwards the ceramic layer (1) is prepared on the bonding layer (2), so that the thermal barrier coating is obtained. In the invention, the horizontal and vertical directions of the thermal barrier coating are closely integrated.

Owner:严格集团股份有限公司

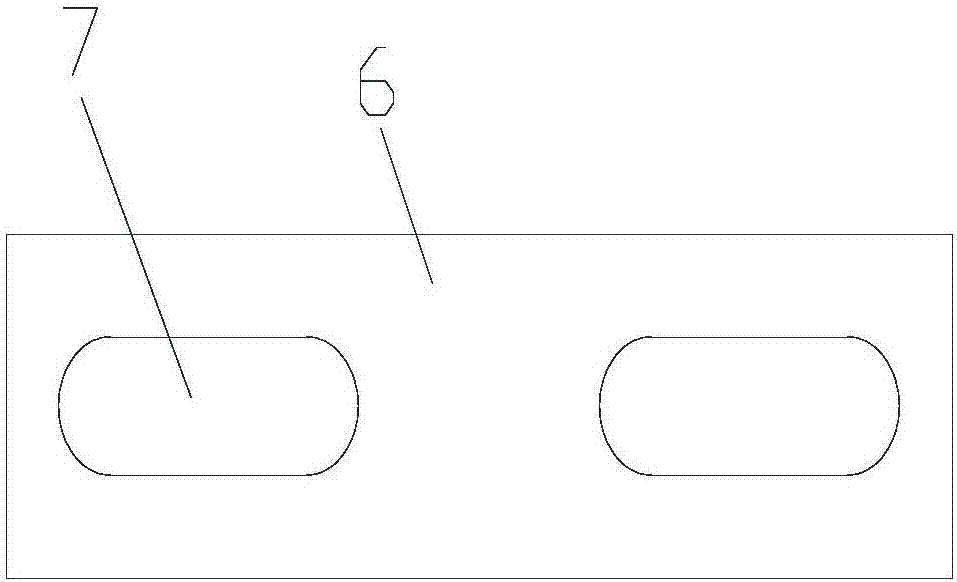

Soilbag roadbed and method

A soilbag roadbed and a method. The soilbag roadbed comprises soilbags, a roadbed substrate, a soilbag roadbed, a pavement and a surface protection. Soilbags are staggered vertically and horizontally and stacked up layer by layer from the roadbed substrate to be tightly combined with asphalt, concrete or broken stone paved on the pavement. The invention is simple, practical, thrift and economical and has substantial social and economic benefits.

Owner:刘斯宏 +1

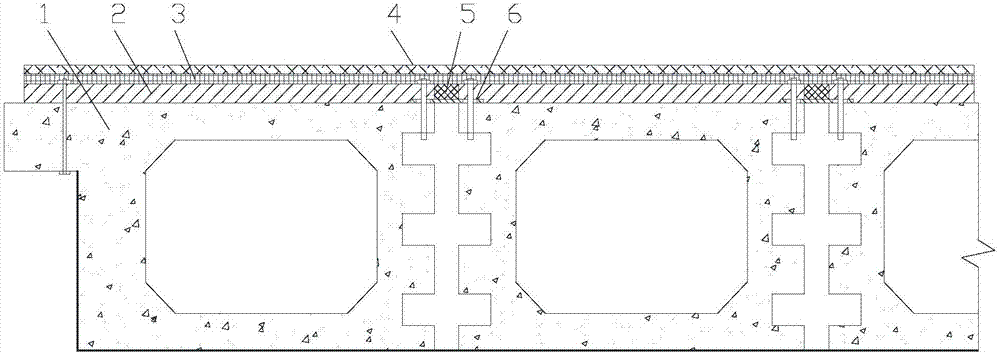

Concrete hollow slab bridge with horizontal reinforced bridge deck pavement layer

ActiveCN106988203AAvoid Longitudinal CracksImprove structural strengthBridge structural detailsSingle plateBridge deck

The invention discloses a concrete hollow slab bridge with a horizontal reinforced bridge deck pavement layer. The concrete hollow slab bridge comprises bridge deck beams and a horizontal reinforced pavement layer, wherein the bridge deck beams are composed of multiple hollow slab beams arranged in parallel, and the horizontal reinforced pavement layer is arranged on the top surfaces of the bridge deck beams. The horizontal reinforced pavement layer comprises a plurality of steel plates laid on the hollow slab beams in a one-to-one correspondence mode, a sliding layer supported by the steel plates and an asphalt layer laid on the sliding layer. The steel plates and the corresponding bridge deck beams are fixed to each other, and lateral load is transmitted through connecting parts between two adjacent steel plates. According to the concrete hollow slab bridge, the strength of the integral structure is high, the bearing capacity of the bridge beam is high, single plate stress can be avoided through reinforcement of horizontal steel beams, the service life of the bridge beam is prolonged, the structure is simple, the construction quality of a project is easy to guarantee, and the stress performance is good.

Owner:CHONGQING TECH & BUSINESS INST

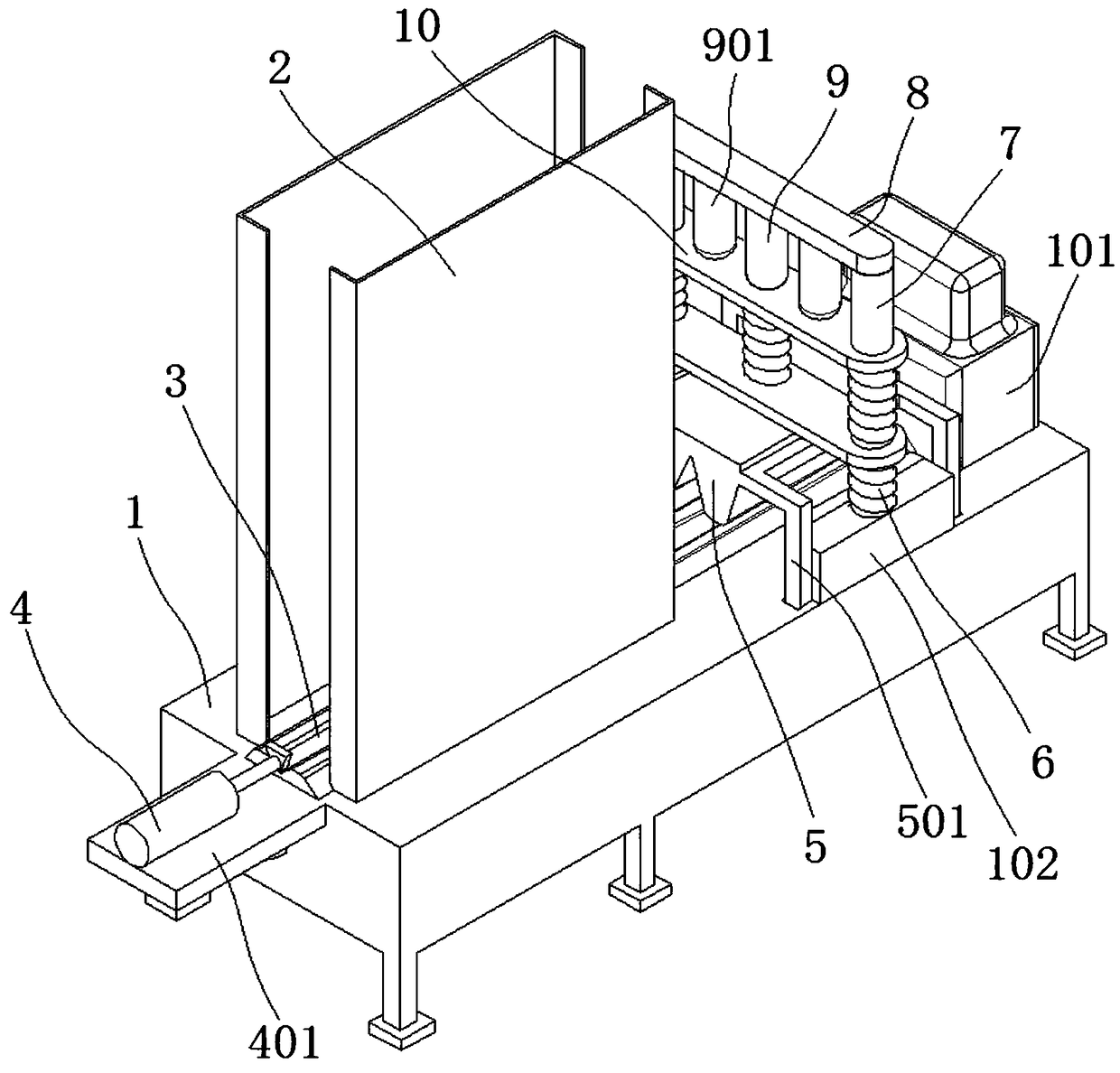

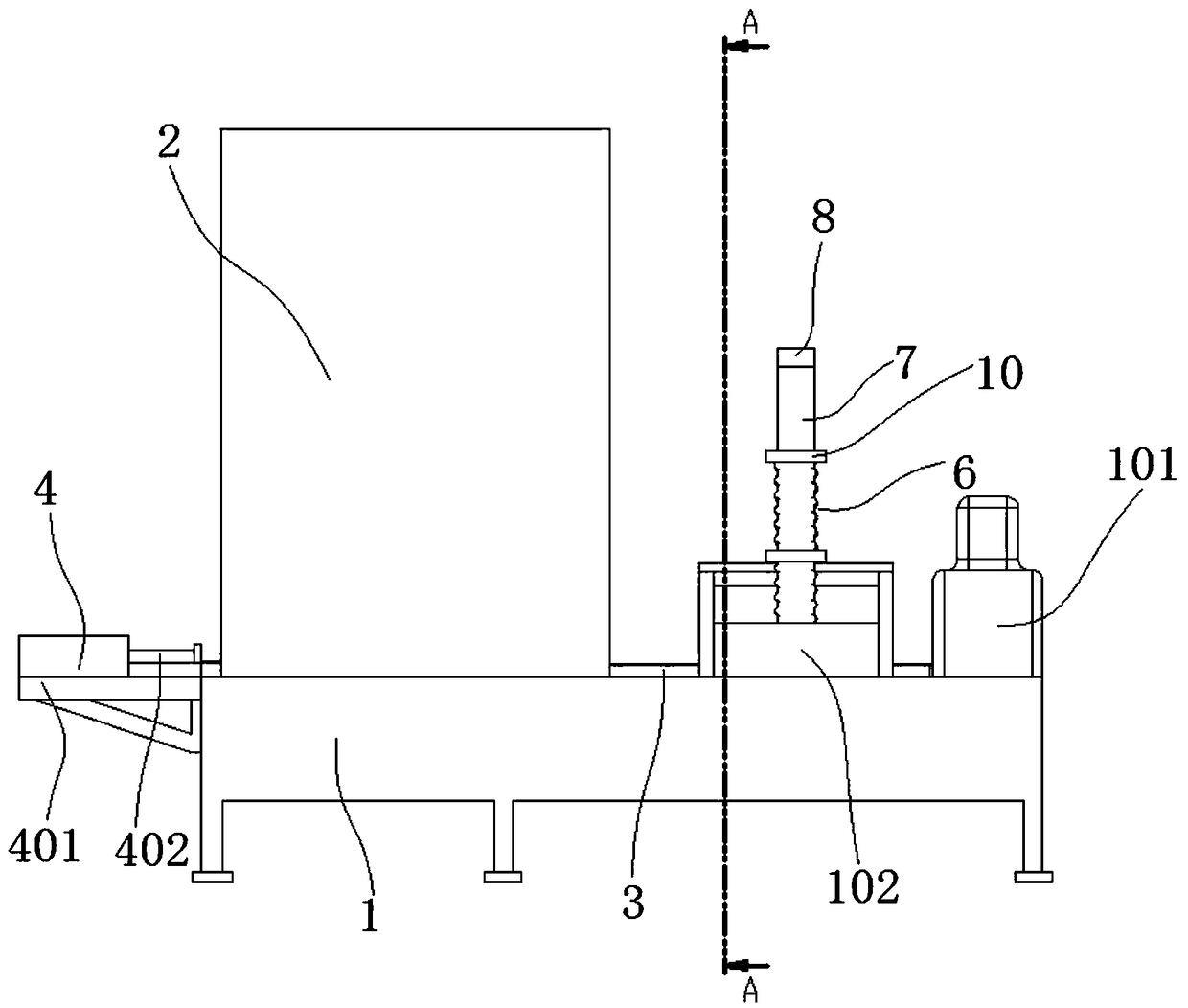

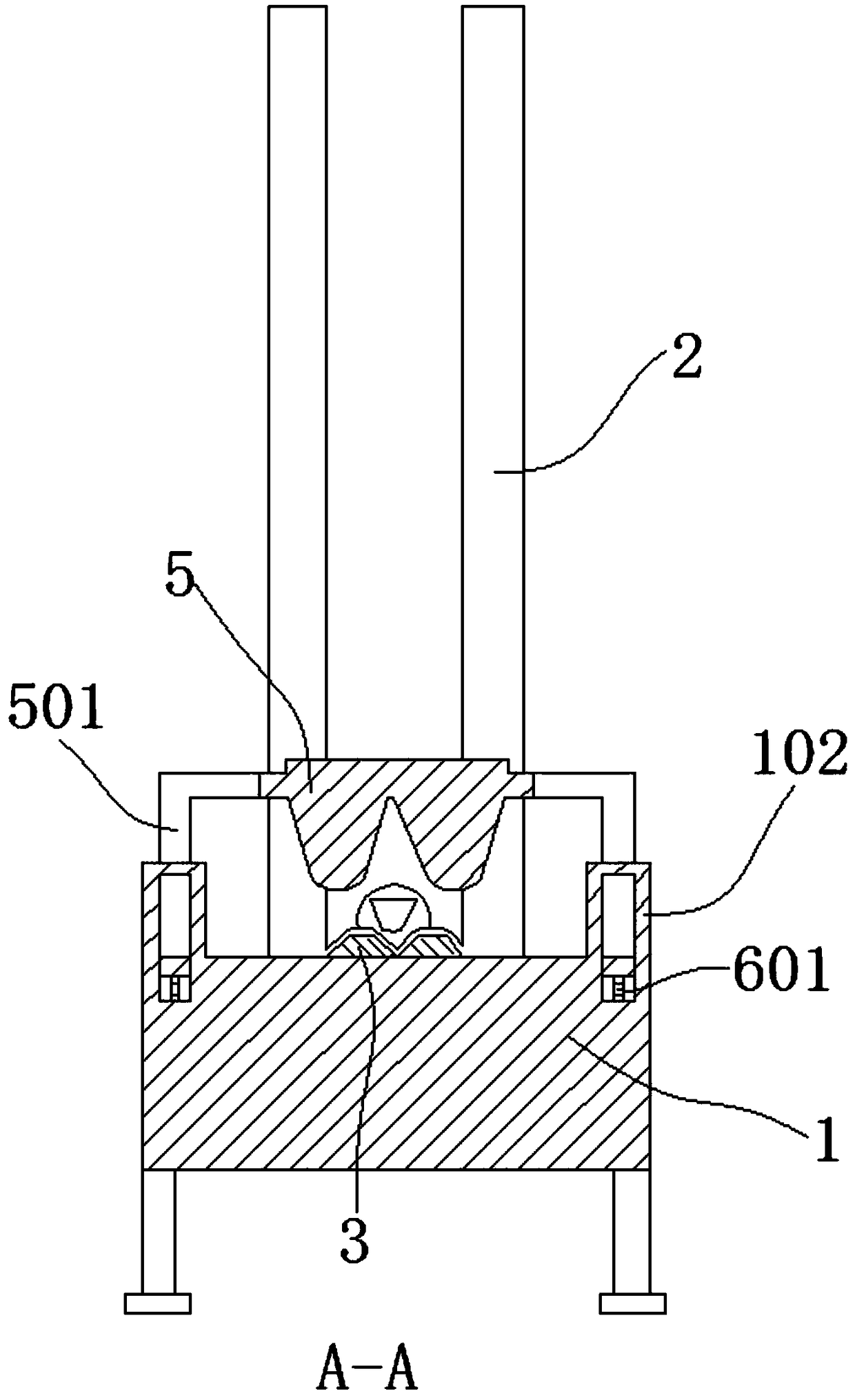

A purple copper tube automatic feeding and clamping device for air conditioning

InactiveCN108890354AAvoid Longitudinal CracksReduce the chance of leaksPositioning apparatusMetal-working holdersHydraulic cylinderEngineering

The invention discloses a purple copper tube automatic feeding clamping device for air conditioning, which relates to the technical field of purple copper tube processing. Including workbenches; A guide bar is fixed on the workbench, and a fixing block is fixed on a pair of sides of the workbench; A surface of that work table is fixedly provided with a storage cylinder and an air cylinder; A pressblock is slidably arranged on the workbench; The two fixing blocks are fixedly provided with a guide column, the end of the guide column is fixed with a cross beam, and two pressure plates are sleeved on the guide column. Two first springs are arranged between the two pressure plates; A first hydraulic cylinder and two second hydraulic cylinders are fixed on the cross beam. As that material to beproces is put into the storage cylinder, By pushing the material to feed through the push rod and pressing the workpiece to be processed through the pressing block, the working efficiency is improved, the clamping positioning precision is clamped, the production cost is reduced, the damage to the purple copper pipe in the process of processing is reduced, the longitudinal cracks in the process ofprocessing the purple copper pipe are effectively avoided, the leakage probability is reduced, and the environmental pollution is reduced when the purple copper pipe is used.

Owner:芜湖辉林奥远自动化科技有限公司

Formula and production process of low-carbon casting powder of titanium-containing stainless steel

The invention belongs to the technical field of metallurgical auxiliary materials, and particularly relates to a formula and production process of low-carbon casting powder of titanium-containing stainless steel. The production process comprises the following steps: S1, raw material preparation: sequentially weighing the following raw materials in parts by weight: 15-19 parts of 330 carbon black, 8-12 parts of medium carbon graphite, 9-13 parts of amorphous graphite, 5-9 parts of a binder, 11-15 parts of industrial sodium carbonate, 7-11 parts of wollastonite, 15-19 parts of perovskite, 3-7 parts of blast furnace slag, 2-6 parts of fluorite, 12-16 parts of cryolite, 24-28 parts of sodium fluoride and 12-16 parts of organic water for later use; and S2, grinding treatment: performing grinding treatment on the 330 carbon black, the medium carbon graphite, the amorphous graphite, the binder, the industrial sodium carbonate, the wollastonite, the perovskite, the blast furnace slag, the fluorite, the cryolite and the sodium fluoride in the step S1. The surface of the prepared casting powder is rougher, and longitudinal cracks can be effectively prevented from appearing on the surface of a slab.

Owner:张家口汇德冶金材料有限公司

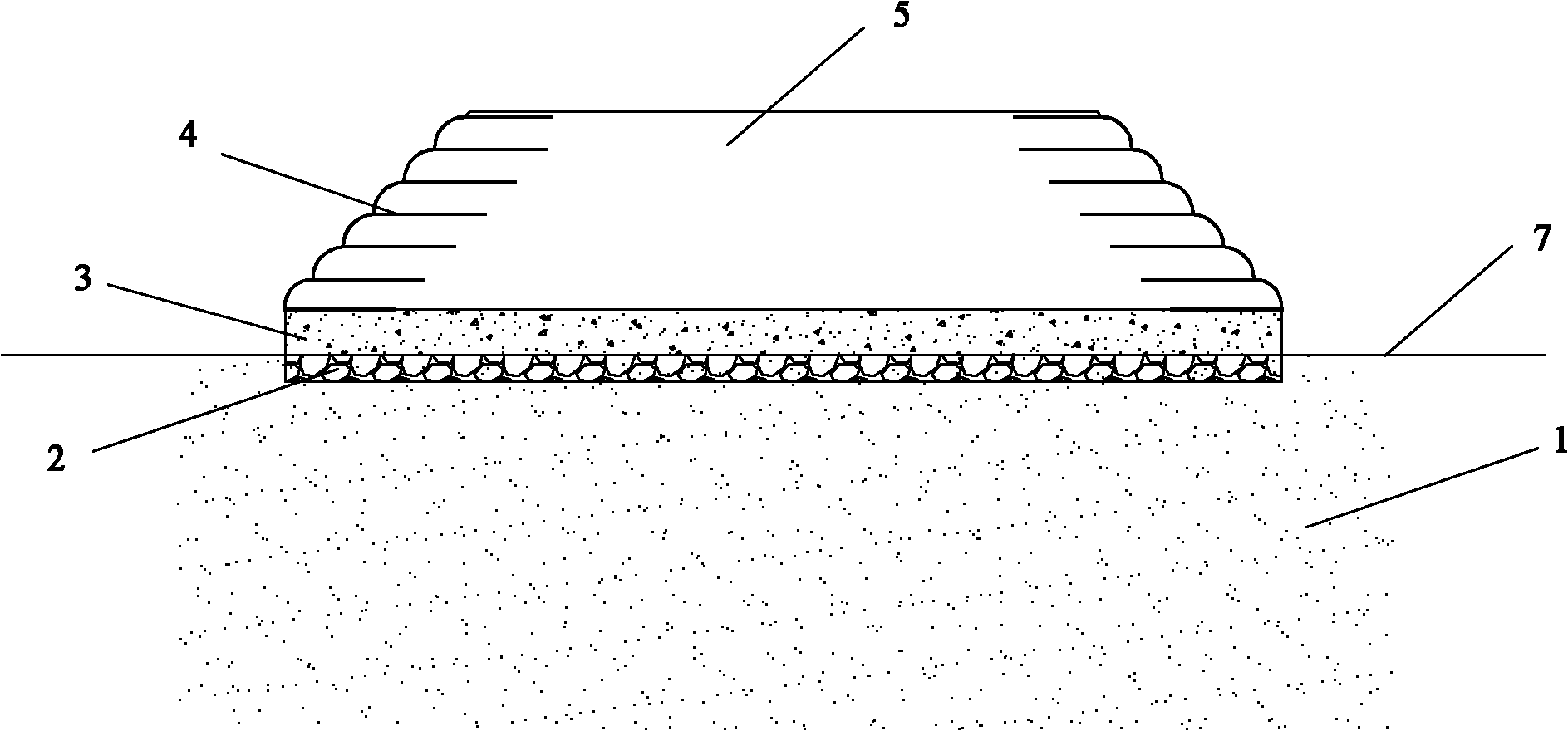

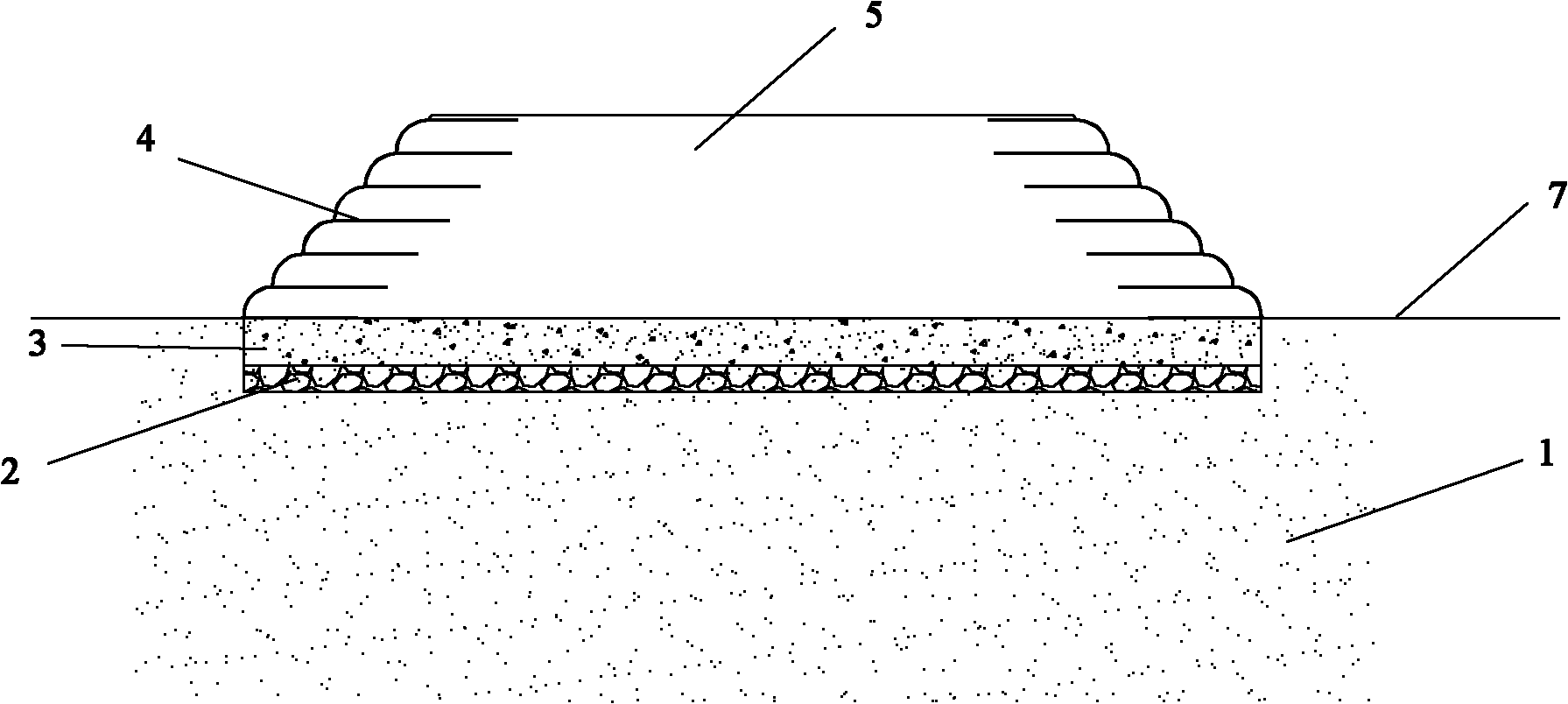

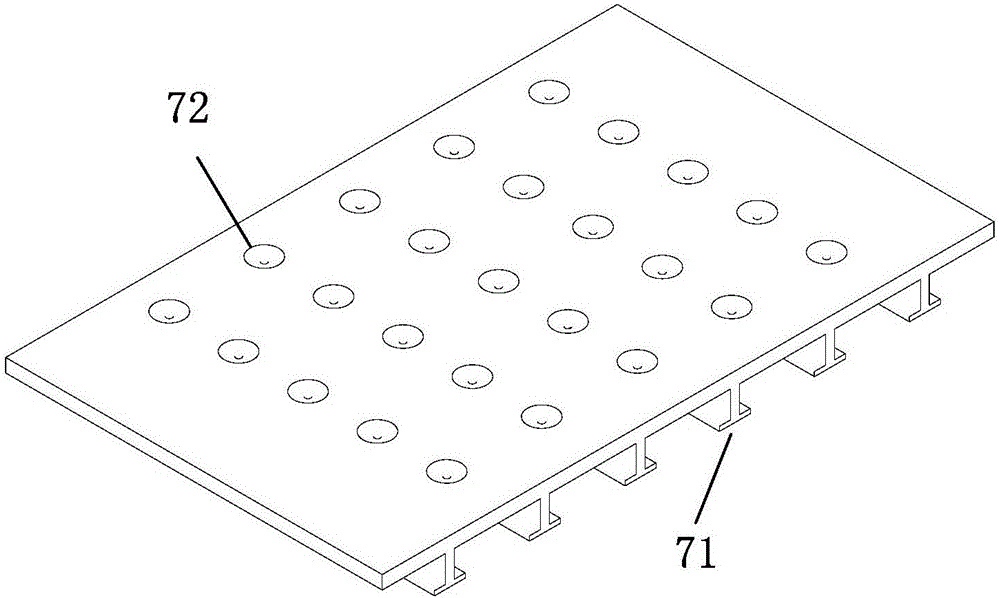

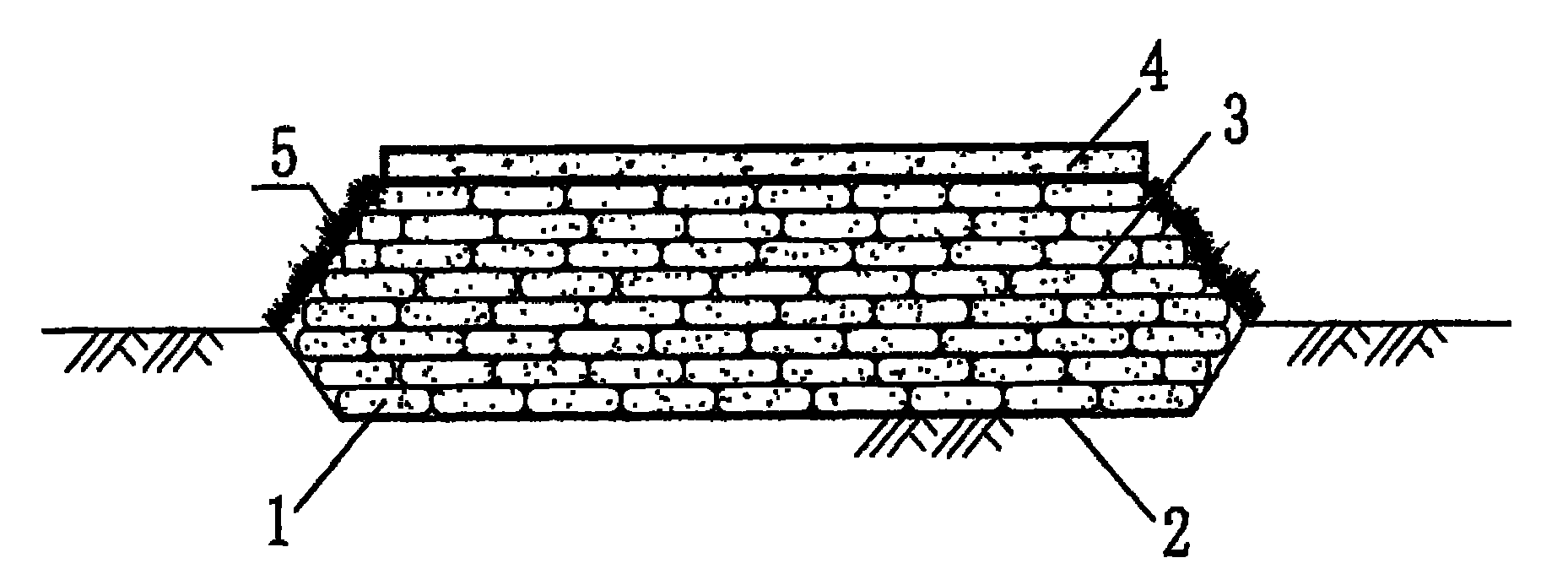

Technology for settlement control of hollow rigid plate after construction of deep soft soil foundation of high-level embankment

InactiveCN102605699ASink evenlyAvoid Longitudinal CracksRoadwaysArchitectural engineeringCrushed stone

The invention discloses a technology for settlement control of a hollow rigid plate after construction of a deep soft soil foundation of a high-level road embankment. The technology comprises the following steps: flattening a roadbed, and filling a broken stone hardcore; mounting a template on the spot; blending and conveying concrete; spreading and vibrating the concrete; setting a joint; finishing a surface; maintaining the concrete and jointing; and filling a road embankment. The template is a template with holes, and the holes are linearly arranged on the template. The direction of the holes at two sides is perpendicular to the road driving direction and is parallel to the road cross-section direction. The diameter of each of the holes is gradually changed, and the diameter of each of the holes in the center of the road embankment is smaller than the edge of the road embankment by 30-50%. Two layers of horizontal steel bars and longitudinal steel bars are distributed at the bottom of a hollow concrete plate, so that the non-uniform settlement of the center and the edges of the road embankment can be effectively reduced.

Owner:HOHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com