Foamed light soil construction method

A foam lightweight soil and construction method technology, applied in roads, roads, buildings, etc., can solve problems such as non-environmental protection, unsafety, uneconomical filling, etc., to control post-construction settlement, reduce base stress, and optimize Effect of soft foundation treatment and abutment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

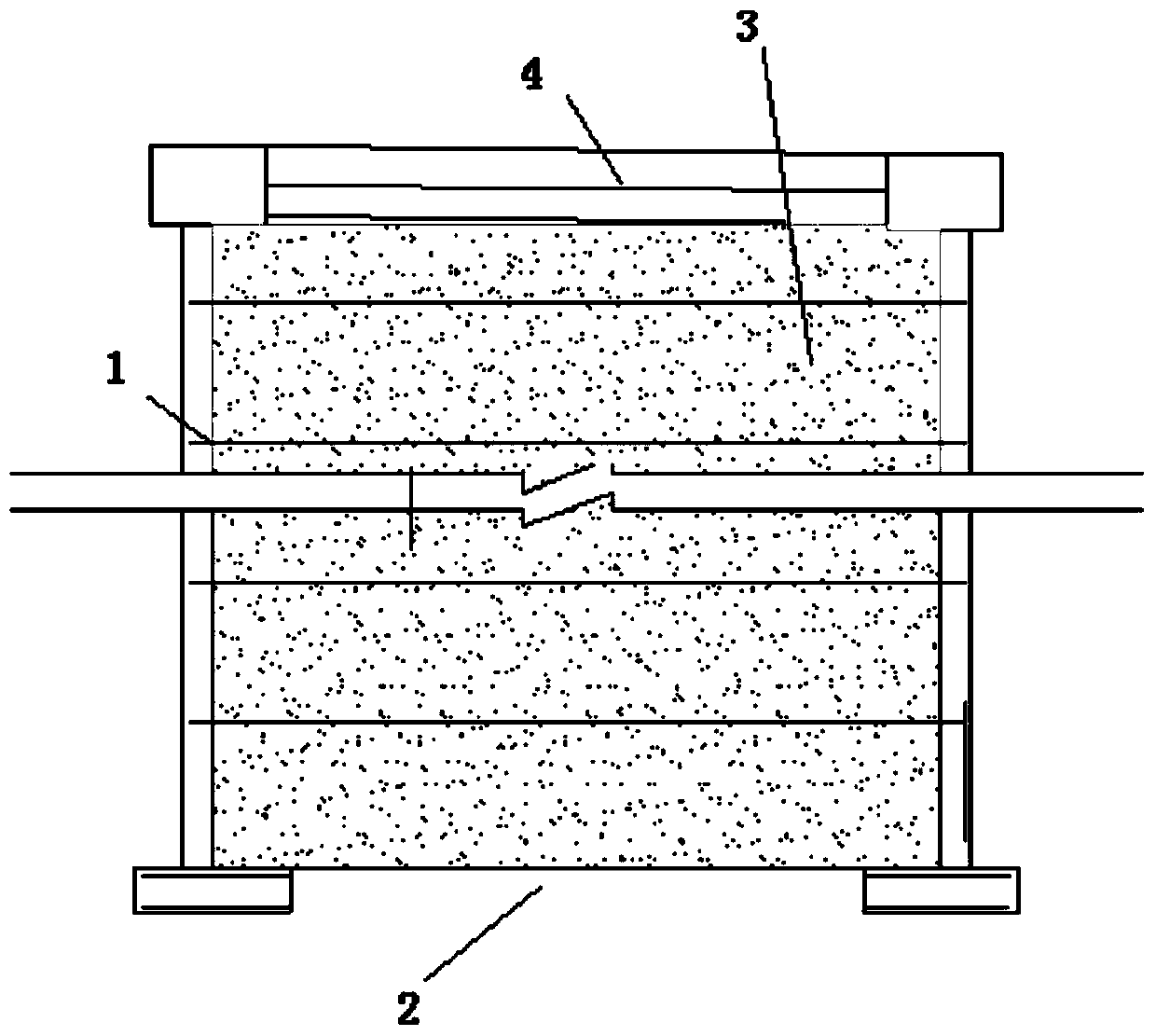

[0026] see figure 1 , the construction method of foam light soil, according to the following steps:

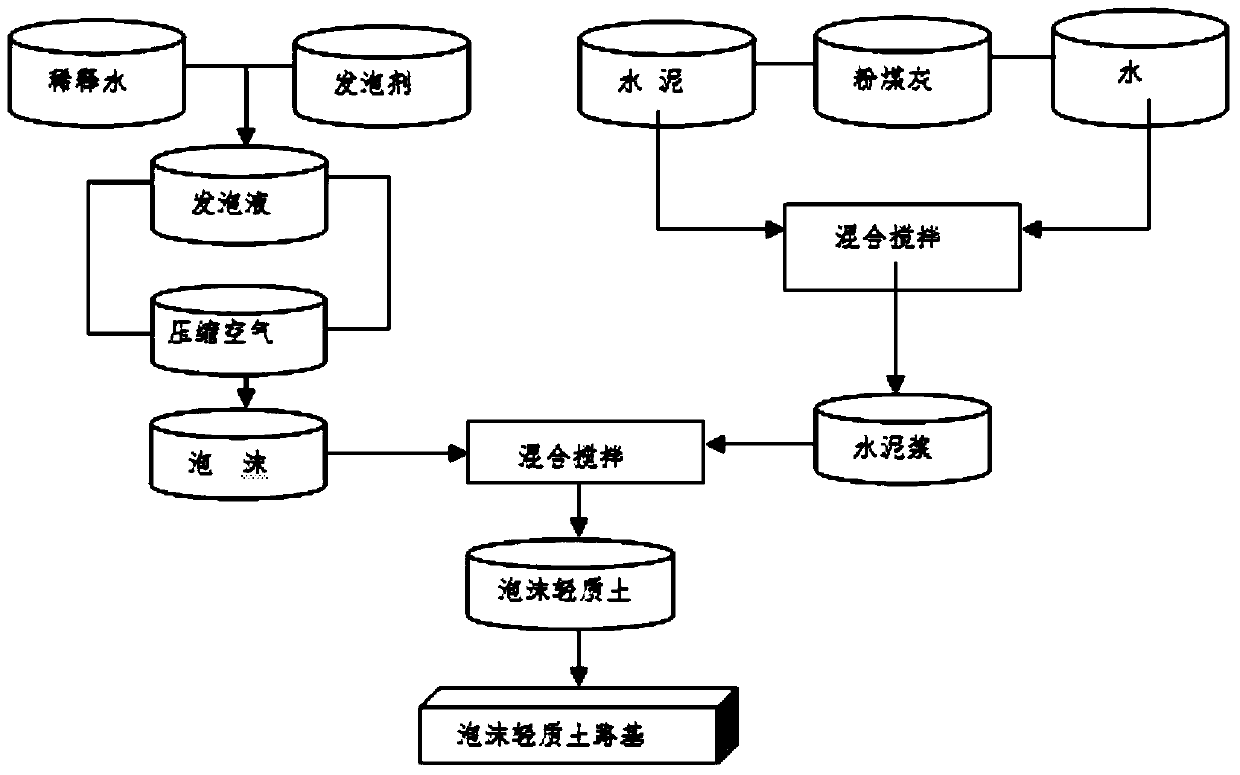

[0027] a. After completing the construction of the reinforced concrete protective wall 1 and the soil subgrade 2 in advance, pour the prepared foam lightweight soil 3 on the inner side of the reinforced concrete protective wall 1 and the soil base 2. The technical index of the foam lightweight soil 3 should meet: 600kg / m3≥Rfw≥560kg / m3, qc≥0.8Mpa (Rfw is the construction wet density, qc is the compressive strength at 28d age, foam light soil 3 is to prepare the foam agent into foam by physical method, and the foam dilution ratio is 1:50;

[0028] b. Add the foam to the slurry made of cement, aggregate, admixture, admixture and water through the foam light soil automatic machinery, and mix and stir through the foam light soil automatic machinery, and the foam light soil mix ratio For cement: foaming agent: water=400:50:200;

[0029] c. Conveying through the conduit, using te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com