Patents

Literature

94results about How to "Avoid steel breakout accidents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

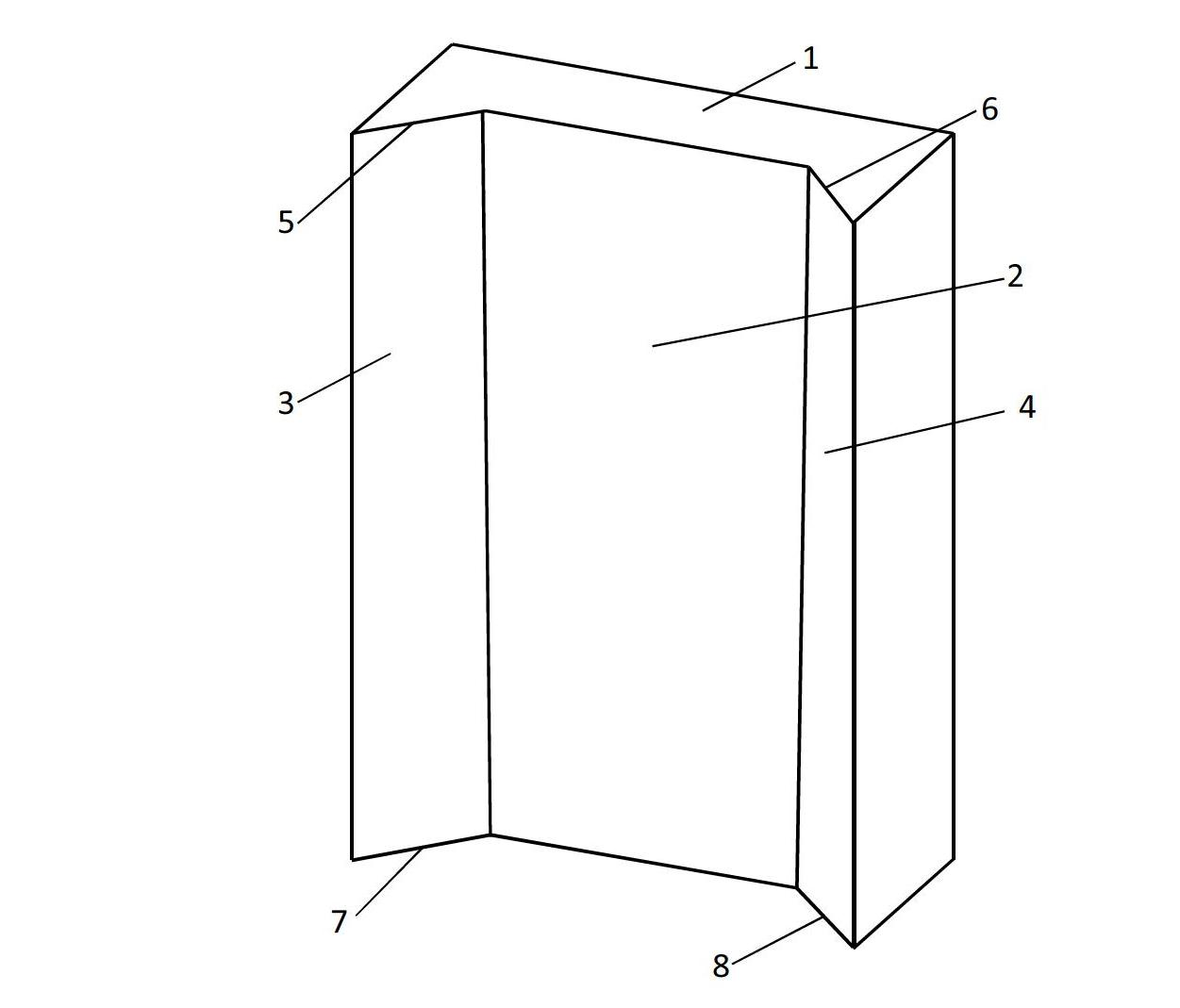

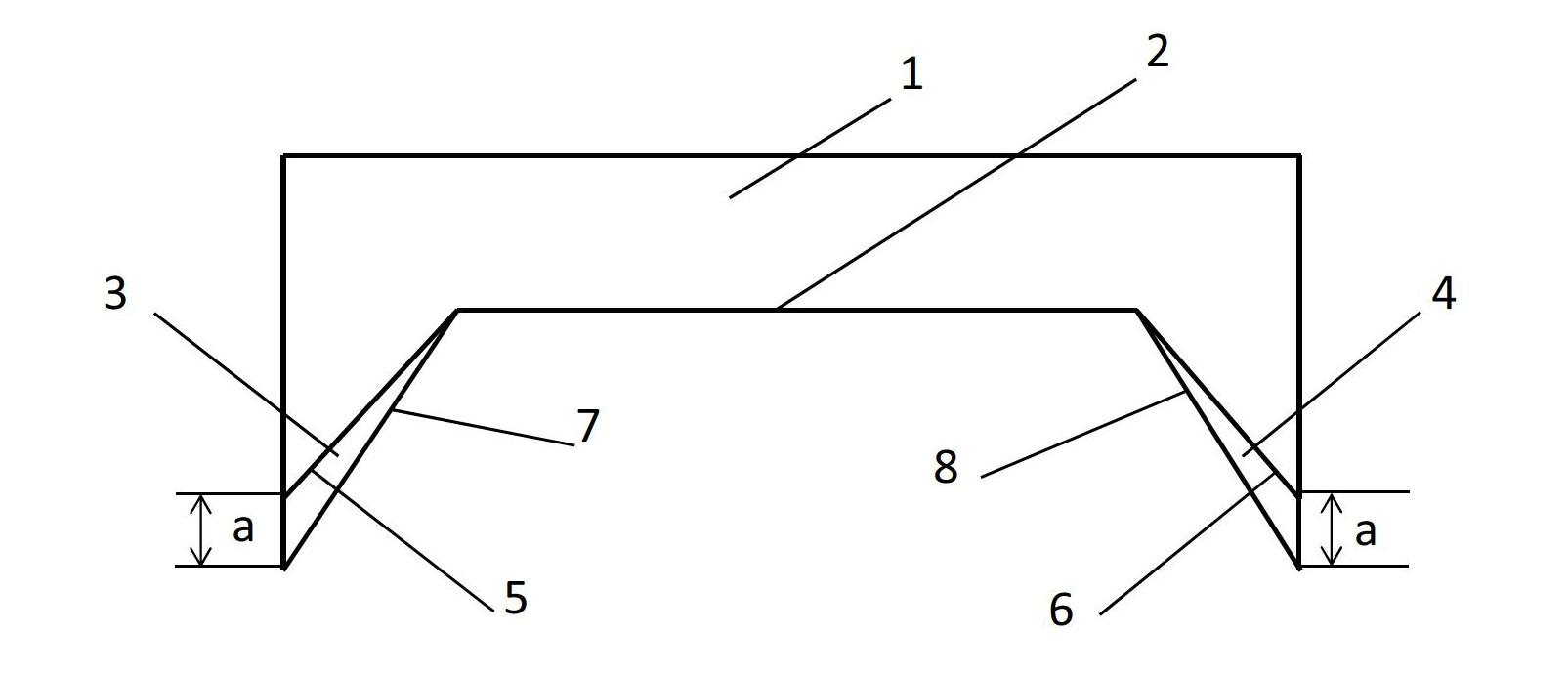

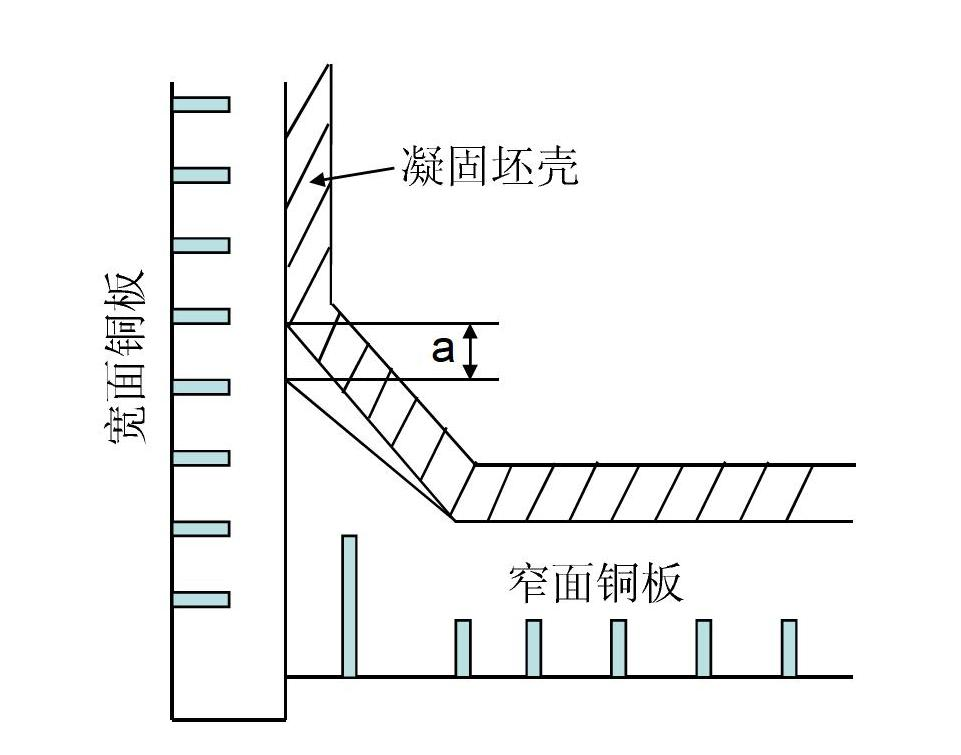

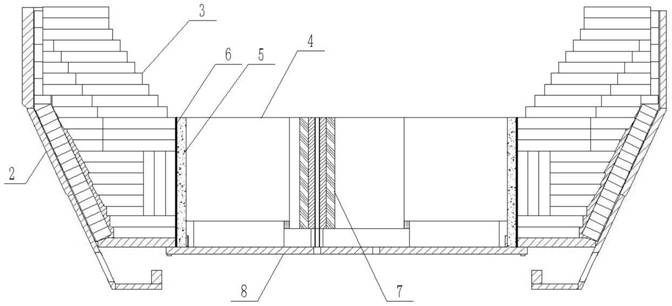

Slab continuous casting chamfer crystallizer narrow-face copper plate capable of effectively controlling longitudinal cracks of corners

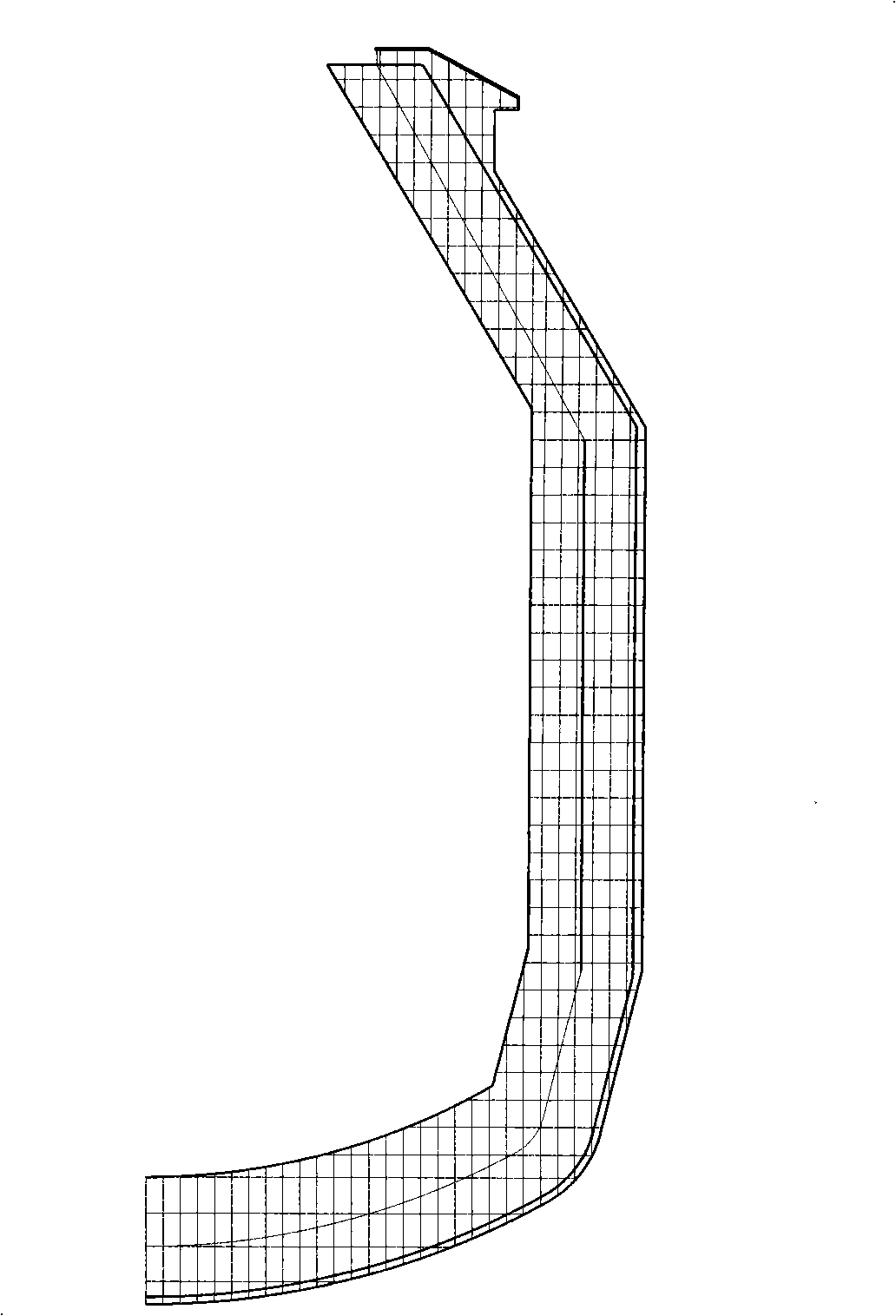

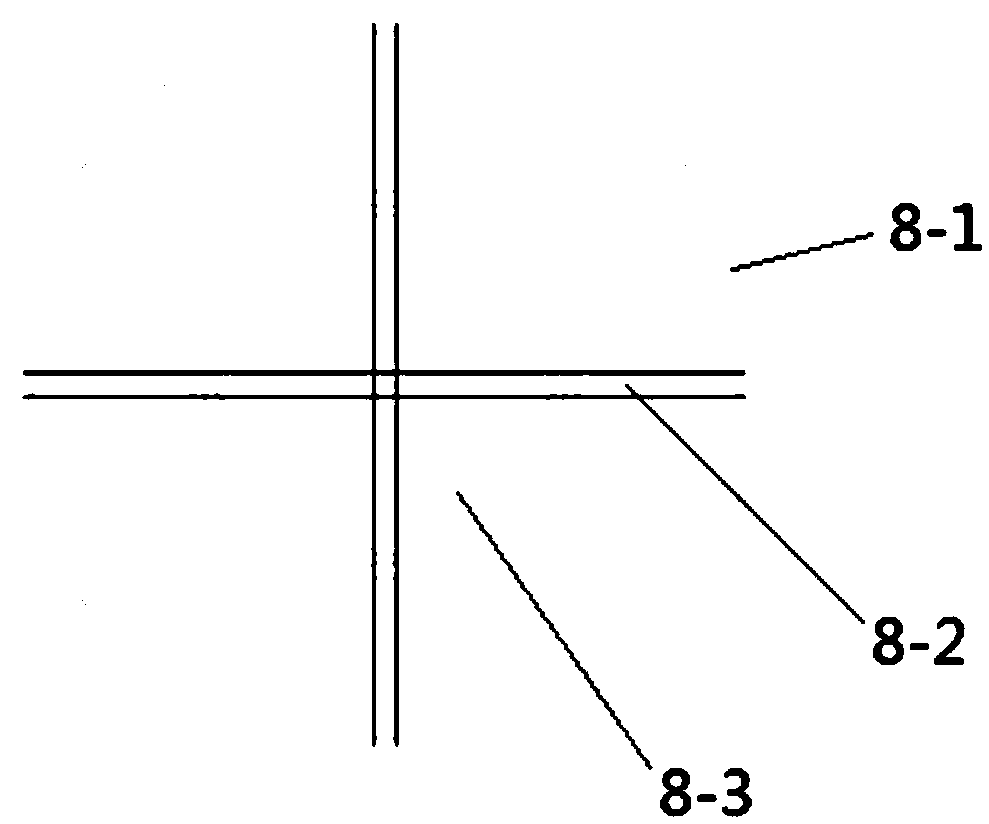

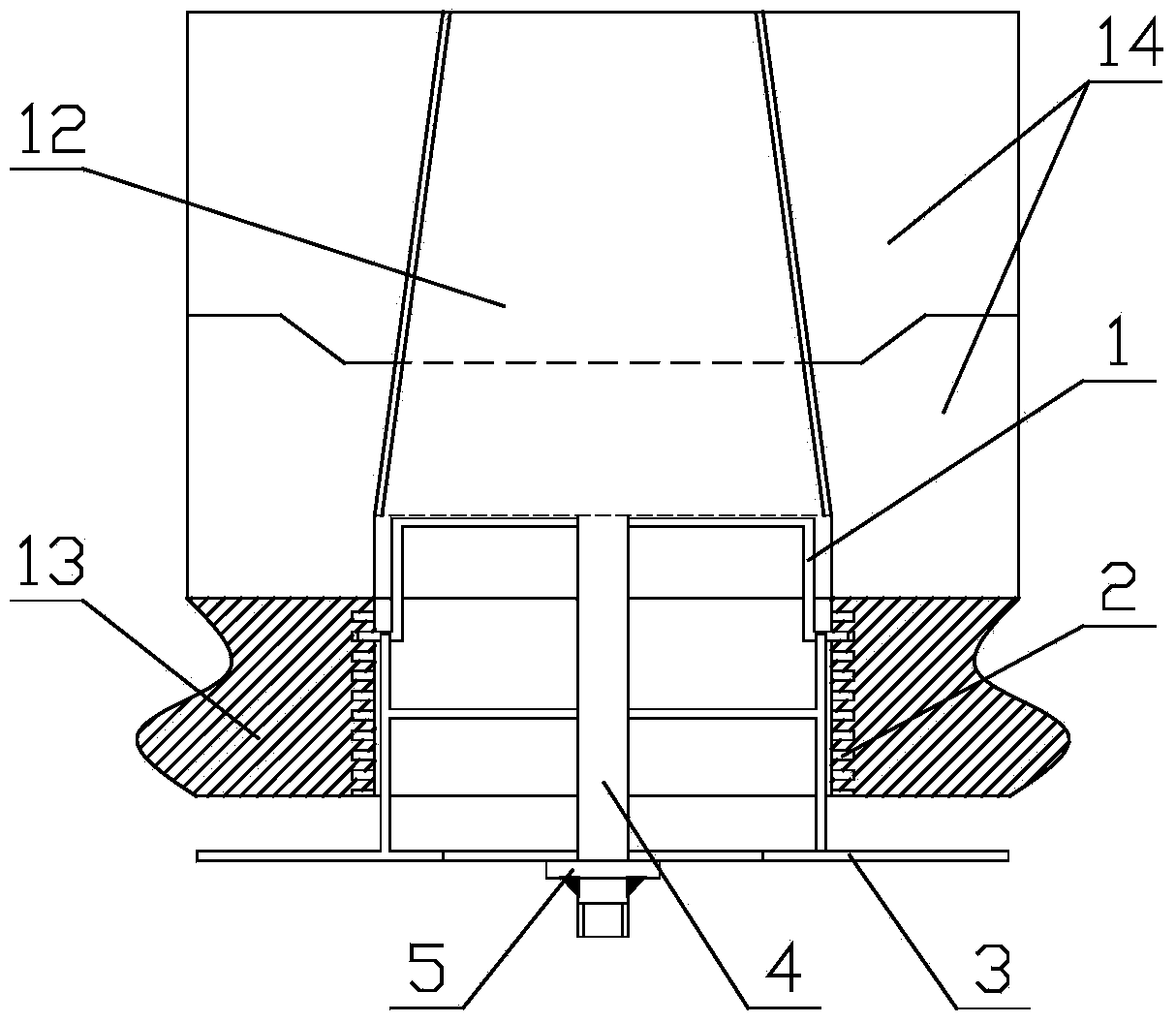

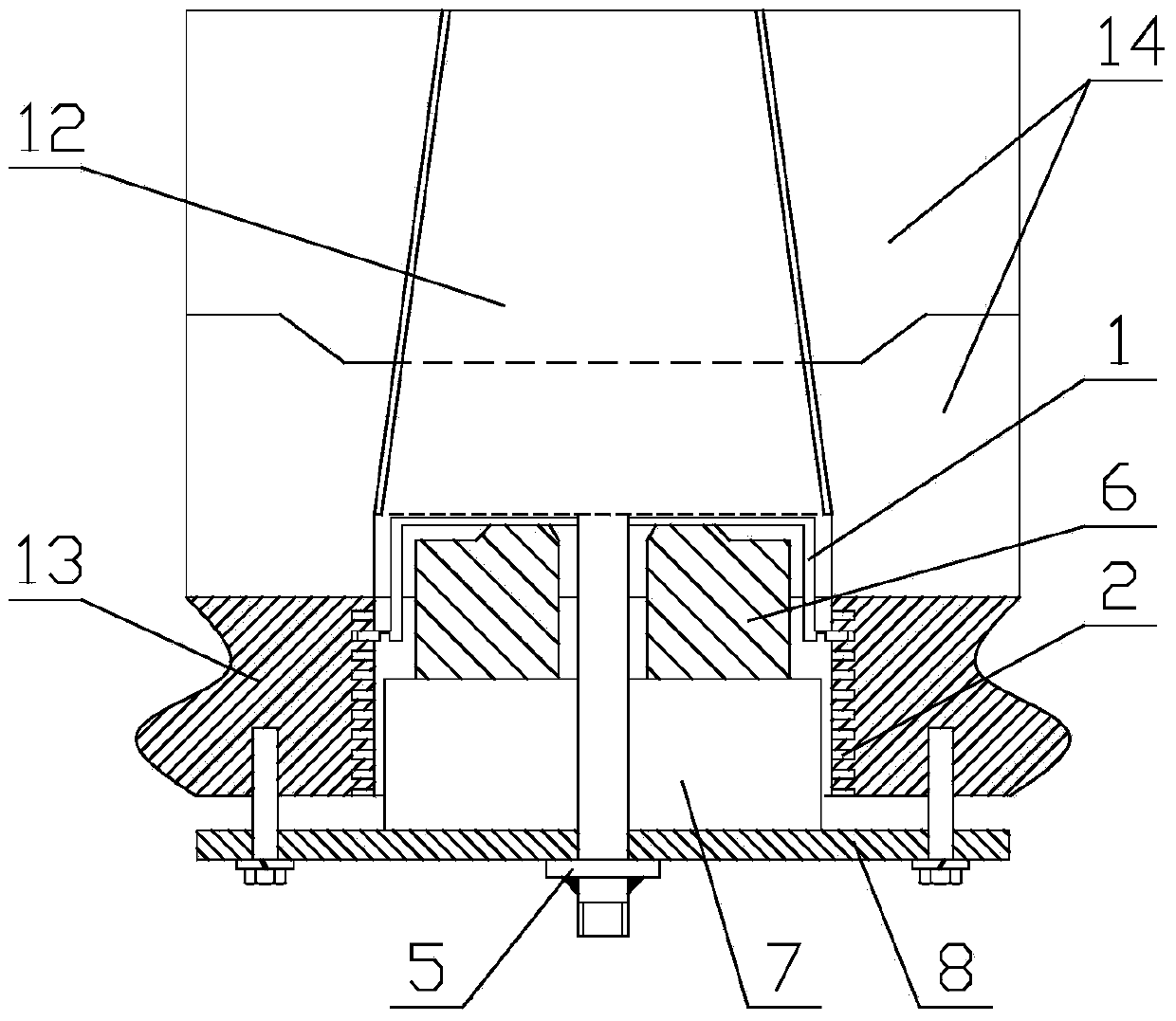

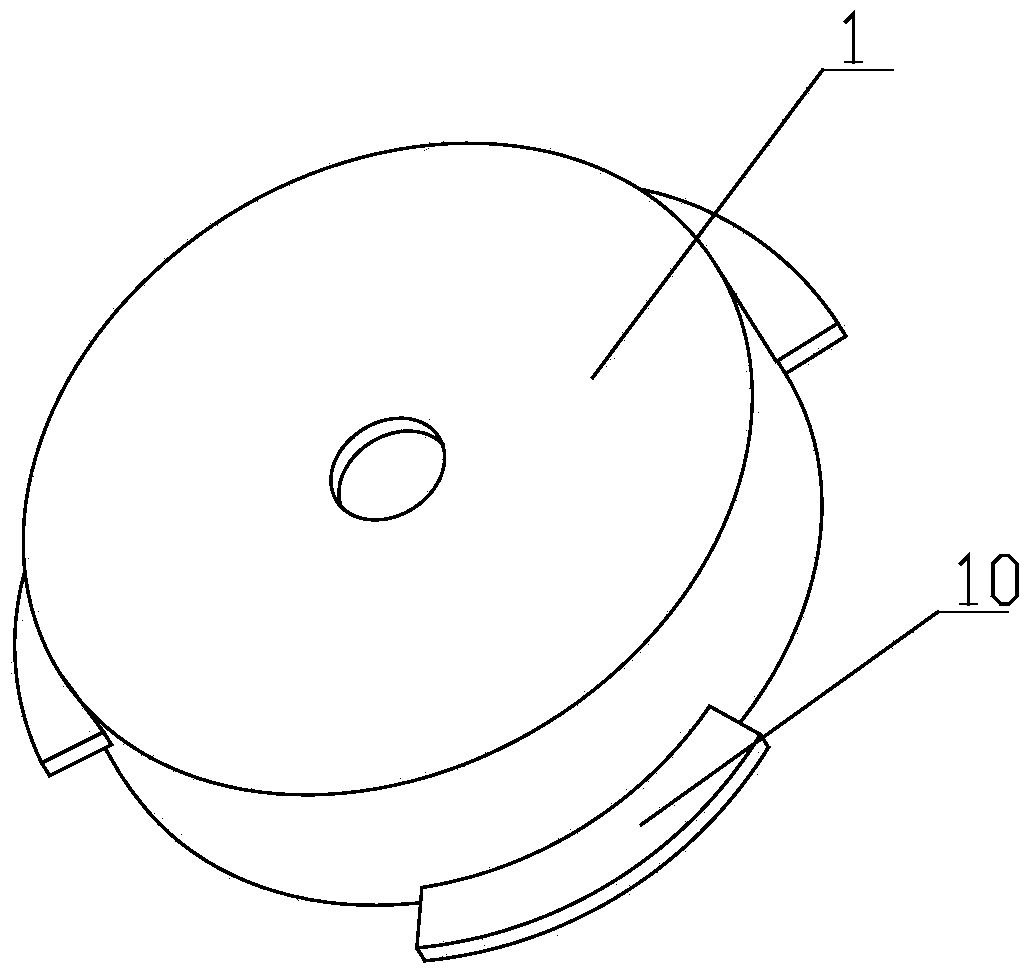

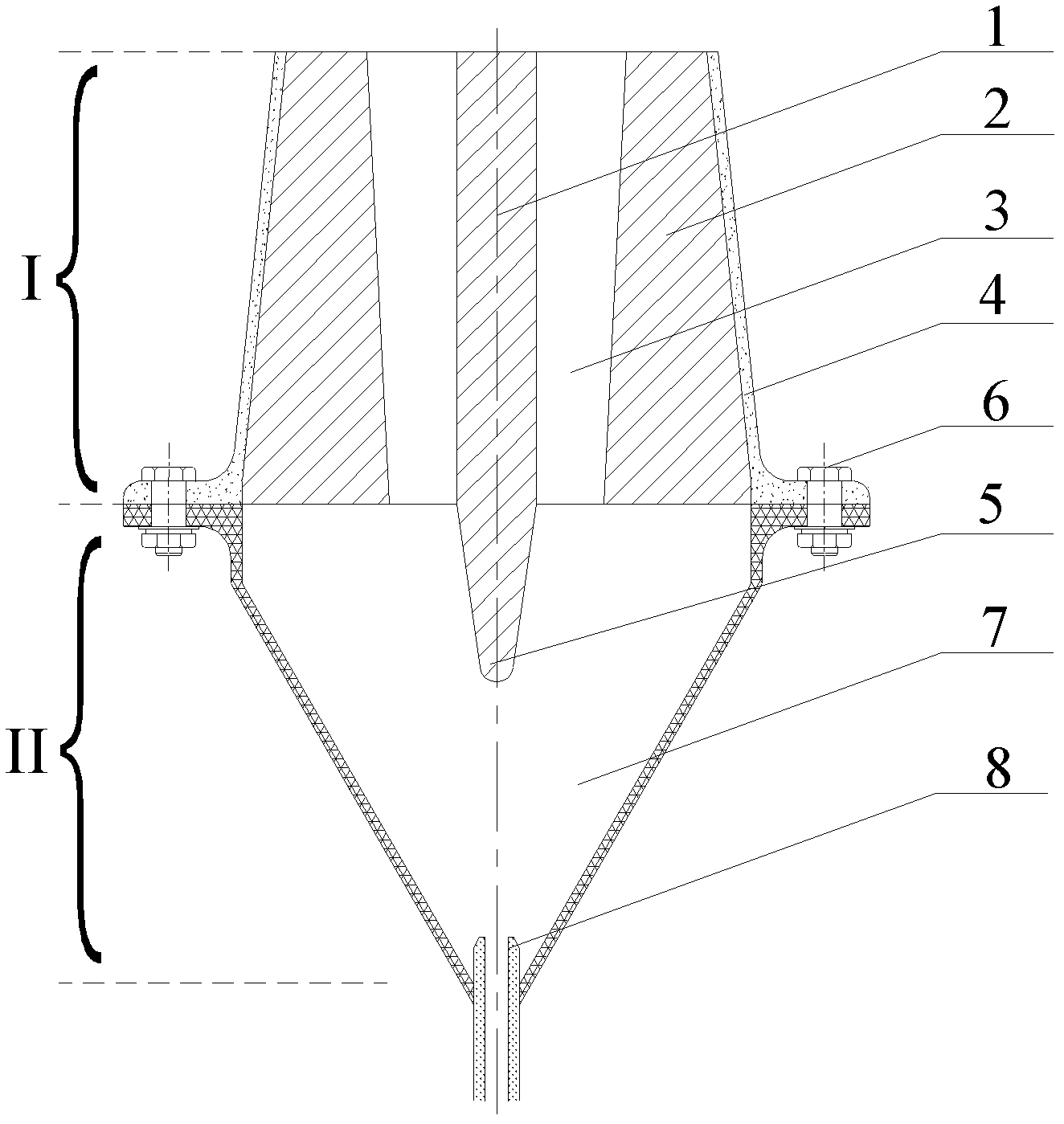

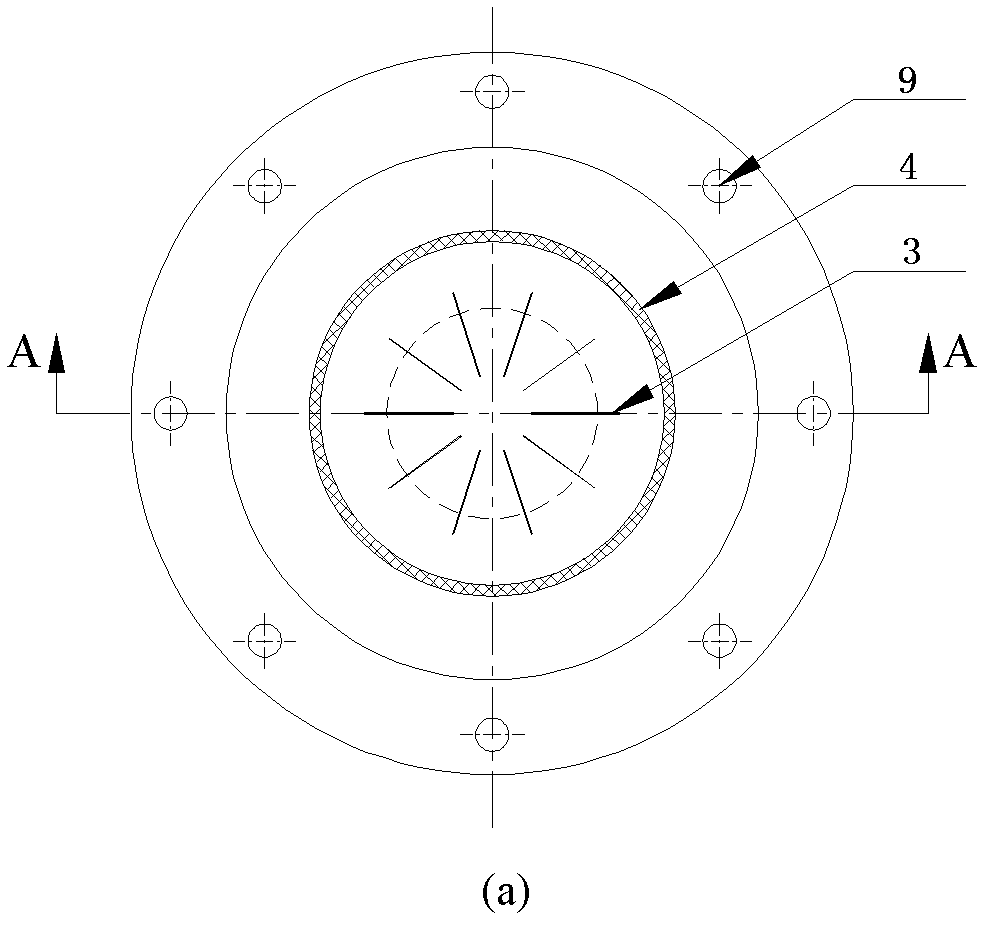

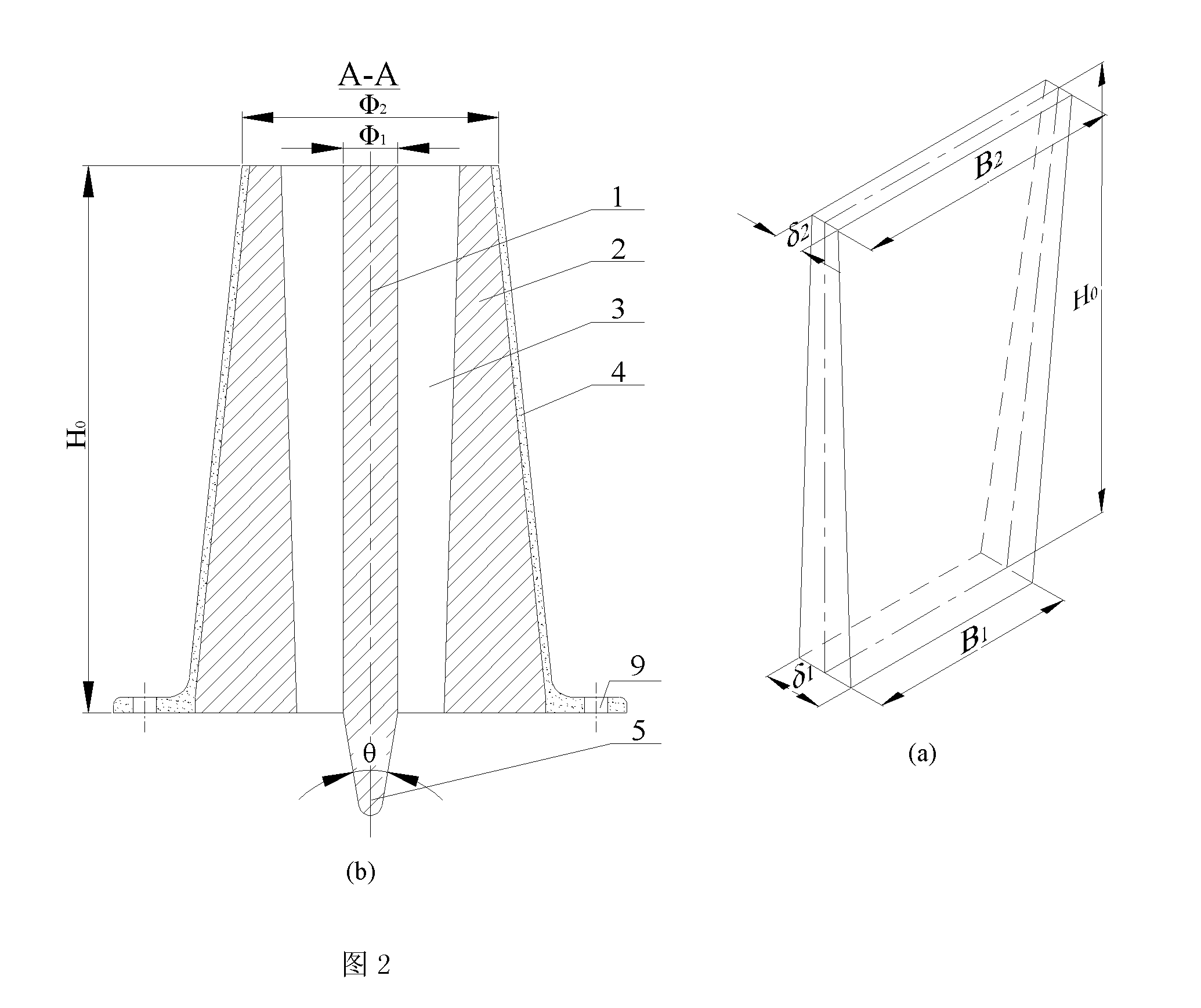

Disclosed is a slab continuous casting chamfer crystallizer narrow-face copper plate capable of effectively controlling longitudinal cracks of corners. The working faces of a narrow-face chamfer copper plate (1), which contact with molten steel, comprise a chamfer surface (3), a chamfer surface (4), a plane portion (2) between the two chamfer surfaces, width portions (5 and 6) of the chamfer surfaces (3 and 4) at the positions of the upper opening of a crystallizer and width portions (7 and 8) of the chamfer surfaces (3 and 4) at the positions of the lower opening of the crystallizer. The narrow-face copper plate is characterized in that the sizes of the width portions (7and 8) of the chamfer surfaces at the positions of the lower opening are larger than those of the corresponding width portions (5 and 6) at the positions of the upper opening respectively, so that tapers are formed on the chamfer surfaces (3 and 4) from the width portions (5 and 6) of the chamfer surfaces (3 and 4) at the positions of the upper opening of the crystallizer to the width portions (7 and 8) of the chamfer surfaces (3 and 4) at the positions of the lower opening of the crystallizer, under the condition of different shrinkage masses of solidified shells of the inner width face and the narrow face of the crystallizer, air gaps formed on the chamfer faces due to large shrinkage mass of width faces are eliminated by means of the taper compensation on the chamfer faces, and the longitudinal cracks of the corners and the bleed-out accidents caused by the longitudinal cracks are avoided.

Owner:SHOUGANG CORPORATION

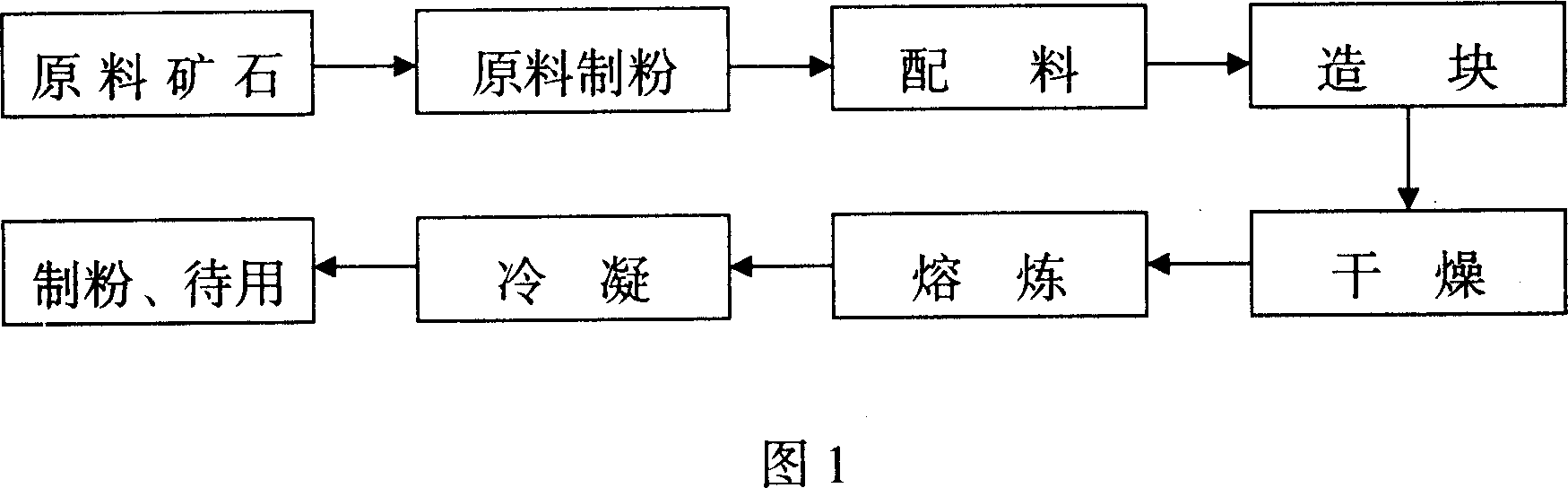

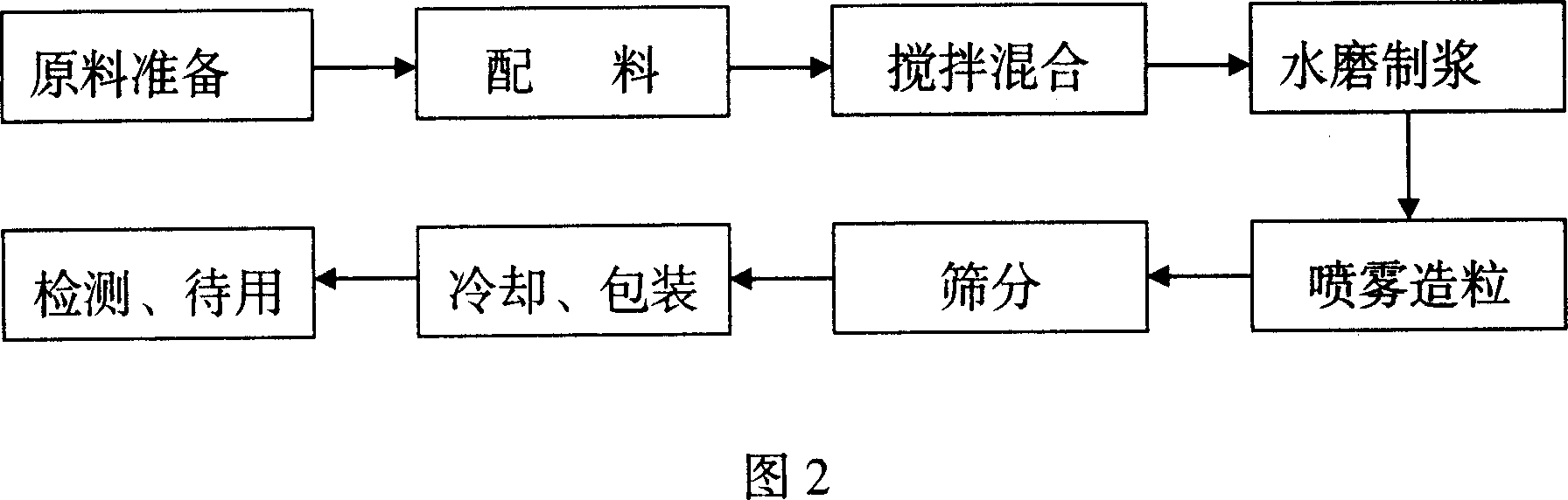

Low-carbon steel protecting slag for continuous casting of sheet billet and preparing method thereof

InactiveCN1927502ALower crystallization temperatureImprove melting uniformityProcess efficiency improvementChemical compositionSlag

The invention relates to a method for preparing low-carbon steel protective slag used to casting sheet blank. Wherein, it is characterized in that: the chemical component mass percentages of said protective slag are SiO2 at 28-32, CaO at 29-33, Al2O3 at 3-5, MgO at 1-3, Fe2O3<=3, F at 7-9, Na2O+K2O at 9-12, Li2O<=2.0, C at 7-9, and adhesive at 1-3; said protective slag is alkali one whose alkali R is higher then 1 and R=CaO / SiO2. The invention can realize low crystallize temperature, high solidify temperature and high crystallize ratio, to meet the casting demand of FTSC sheet blank.

Owner:HEBEI IRON AND STEEL

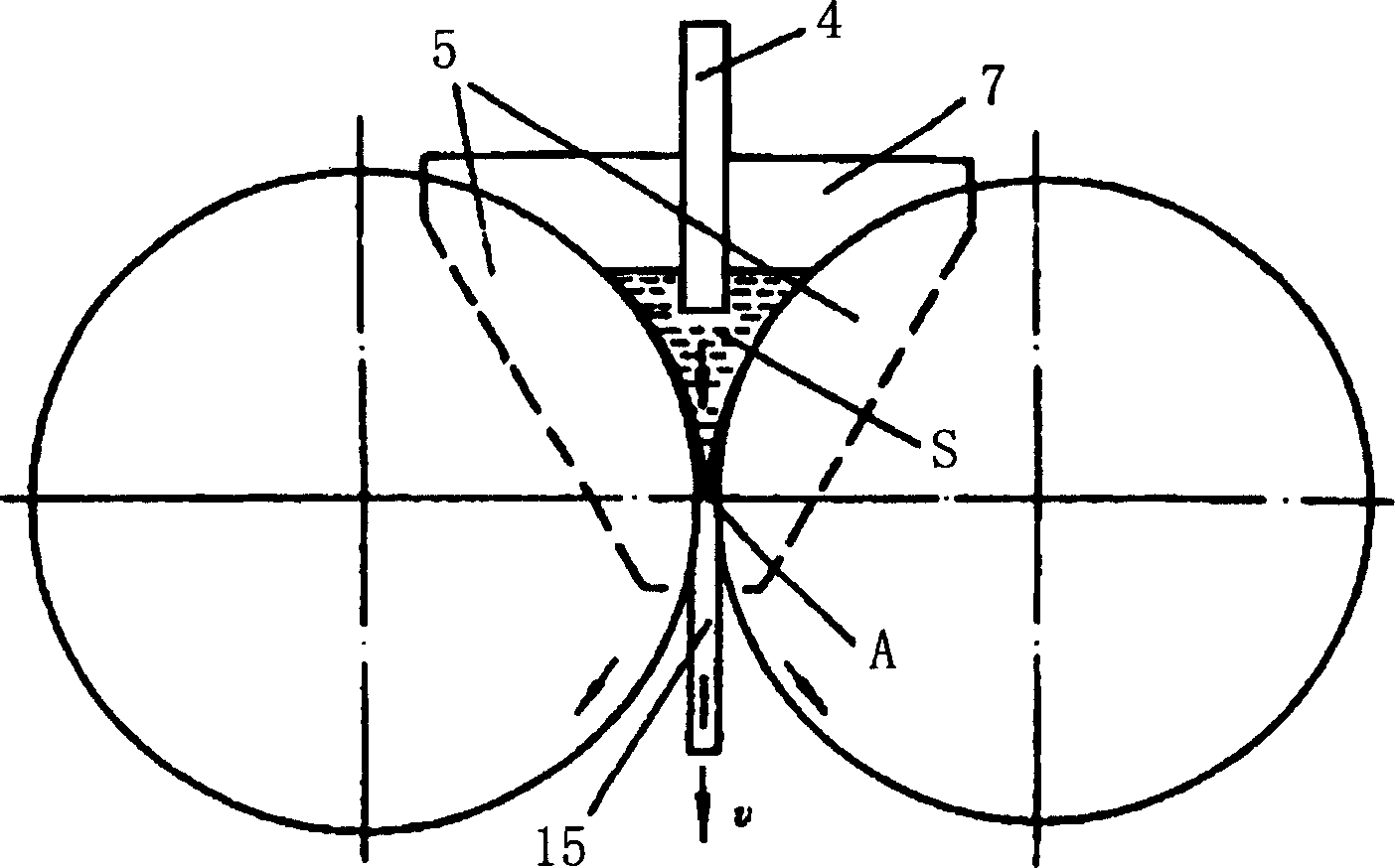

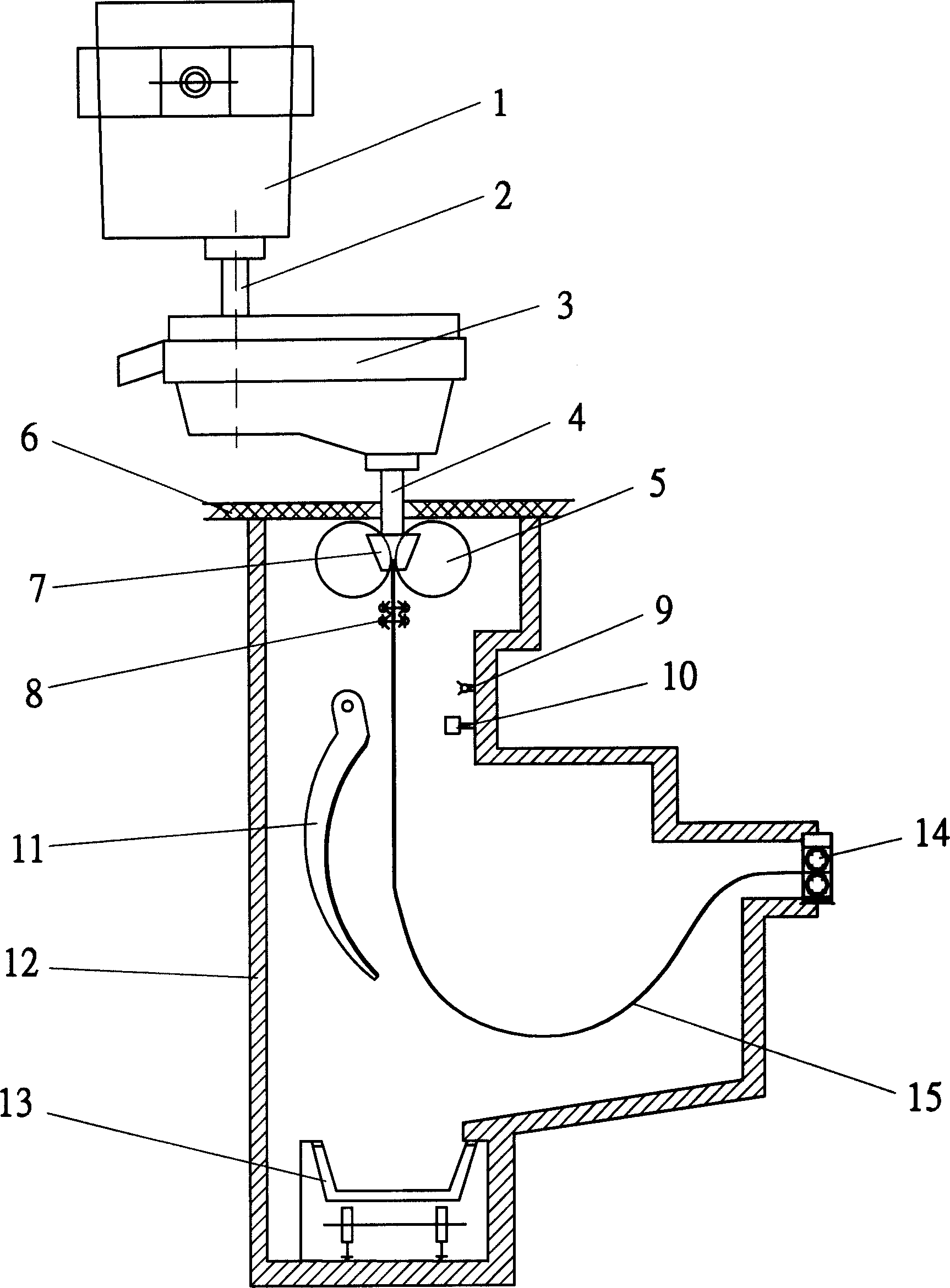

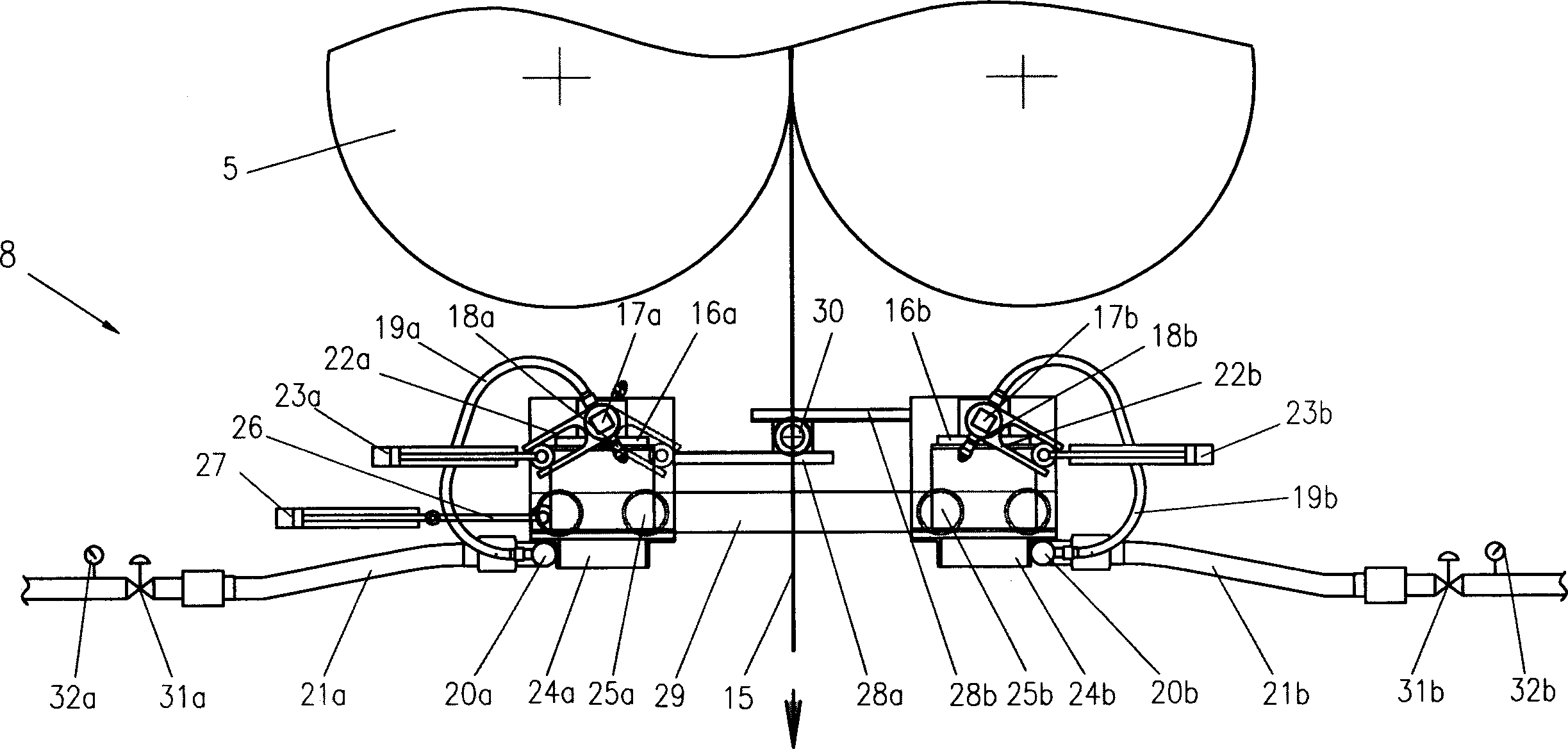

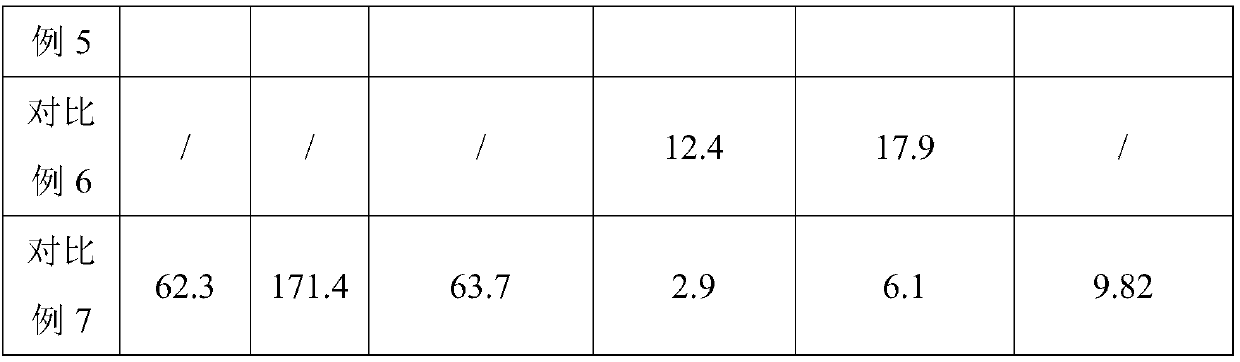

Thin-belt continuous casting method and apparatus

InactiveCN1472019AFlexible process controlEasy to operateMetal rolling arrangementsProduction rateMolten bath

A conticasting technology for thin steel band includes such steps as filling molten steel in the molten bath formed by crystallizing rollers, cooling and slight rolling by crystallizing rollers, blowing gas onto both surfaces of cast band for forced cooling, hot rolling, controlled cooling and winding. Its apparatus is composed of two blowing mechanisms, connecting-rod driver unit and synchronizing unit. Its advantages are high quality of product and high productivity.

Owner:BAOSHAN IRON & STEEL CO LTD

Continuous casting method for steel billets

The invention relates to a continuous casting method for steel billets. The continuous casting method for the steel billets comprises the following steps. Crystallizer casting powder is added to a crystallizer, molten steel in a plurality of tundishes is injected into the crystallizer in sequence, and a continuous casting billet is pulled and rectified, wherein the molten steel in the tundishes is injected into the crystallizer under the condition that the pulling speed of the continuous casting fillet is larger than 0.8m / min. In the process of tundish changing and stopping injecting the molten steel into the crystallizer, the pulling speed of continuous casting is lowered to zero. After 2-5 seconds passes, pulling and rectifying are restarted with the pulling speed of 0.3-0.4m / min, and circulation is performed 2-4 times in such a way. Thus, the continuous casting billet is pulled to a tundish changing position, the crystallizer is taken out from large slag crust produced at the tundish changing position, and small slag crust is mashed so as to be converged in the middle of the crystallizer. The molten steel is continuously injected into the crystallizer after the tundishes are changed, and a steel liquid face of the crystallizer is stirred. With the adoption of the continuous casting method for the steel billets, new and old steel molten can be well welded at a weld line when the tundishes are changed, and steel leakage accidents due to poor welding of the new steel molten and the old steel molten when the tundishes are changed are completely eradicated.

Owner:PANGANG GRP PANZHIHUA STEEL & VANADIUM

Temperature sensor detection method based on measurement precision

InactiveCN103471743AAvoid false positives and false negativesPrevention of steel breakout accidentsThermometer testing/calibrationAccuracy and precisionMeasurement precision

The invention discloses a temperature sensor detection method based on measurement precision. The temperature sensor detection method comprises the following steps of putting a standard temperature sensor and a temperature sensor under detection in the same temperature environment; acquiring a first instant temperature measured by the standard temperature sensor and a second instant temperature measured by the temperature sensor under detection; and comparing the first instant temperature and the second instant temperature to determine whether the temperature sensor under detection is qualified or not. Using the temperature sensor detection method, a user can perform fine detection on the performance of temperature sensors and find out unqualified temperature sensors through the detection, so that when qualified temperature sensors are applied to a steel breakout forecast system, false alarms and failed reports are prevented as much as possible, and accidents of steel breakout are effectively prevented.

Owner:JING FENG GRP

Convertor lining thickness online testing method and device thereof

ActiveCN101514896ASimple processImprove measurement accuracyThermometer detailsThermometers using electric/magnetic elementsMeasurement pointFinite element software

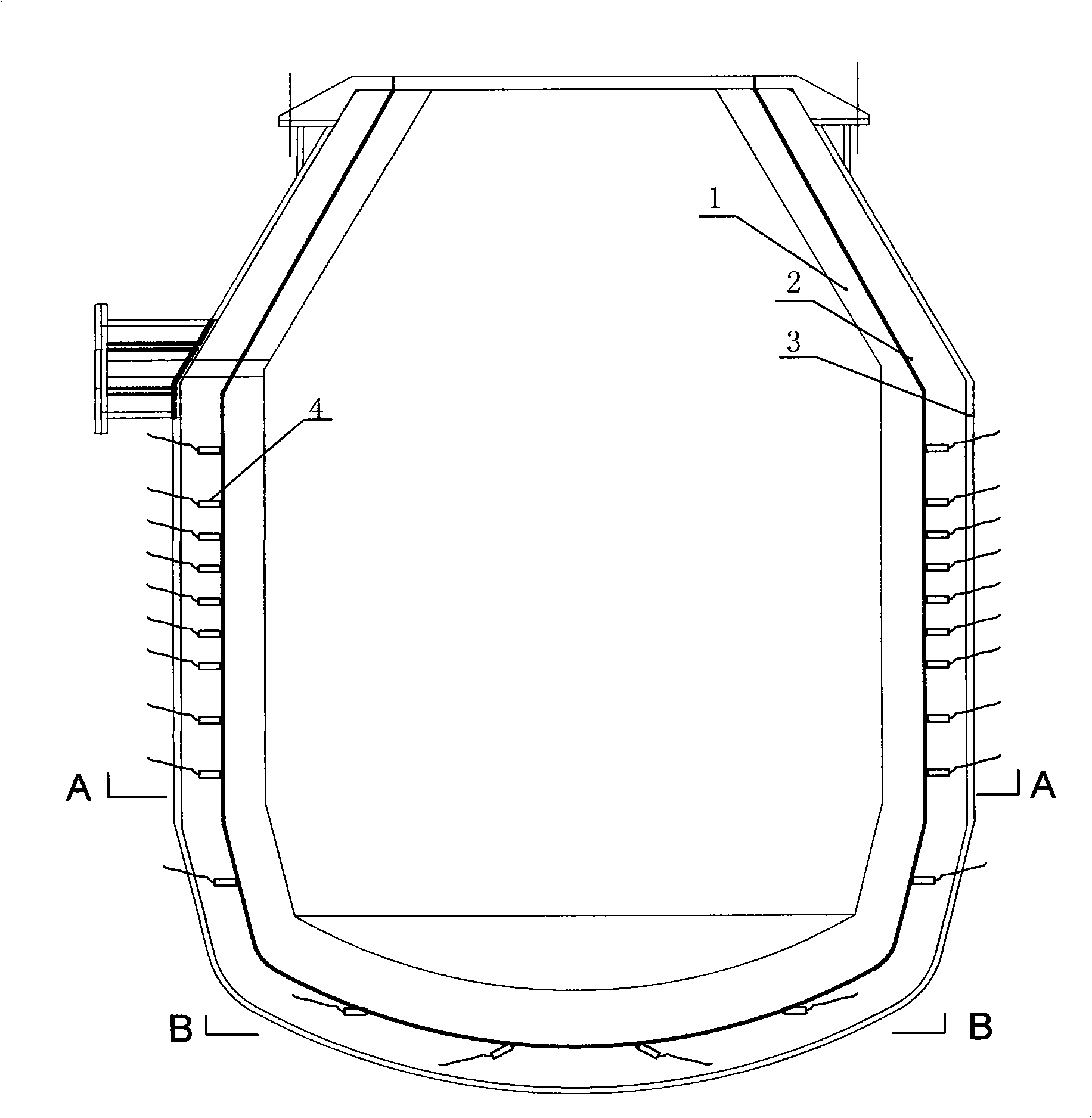

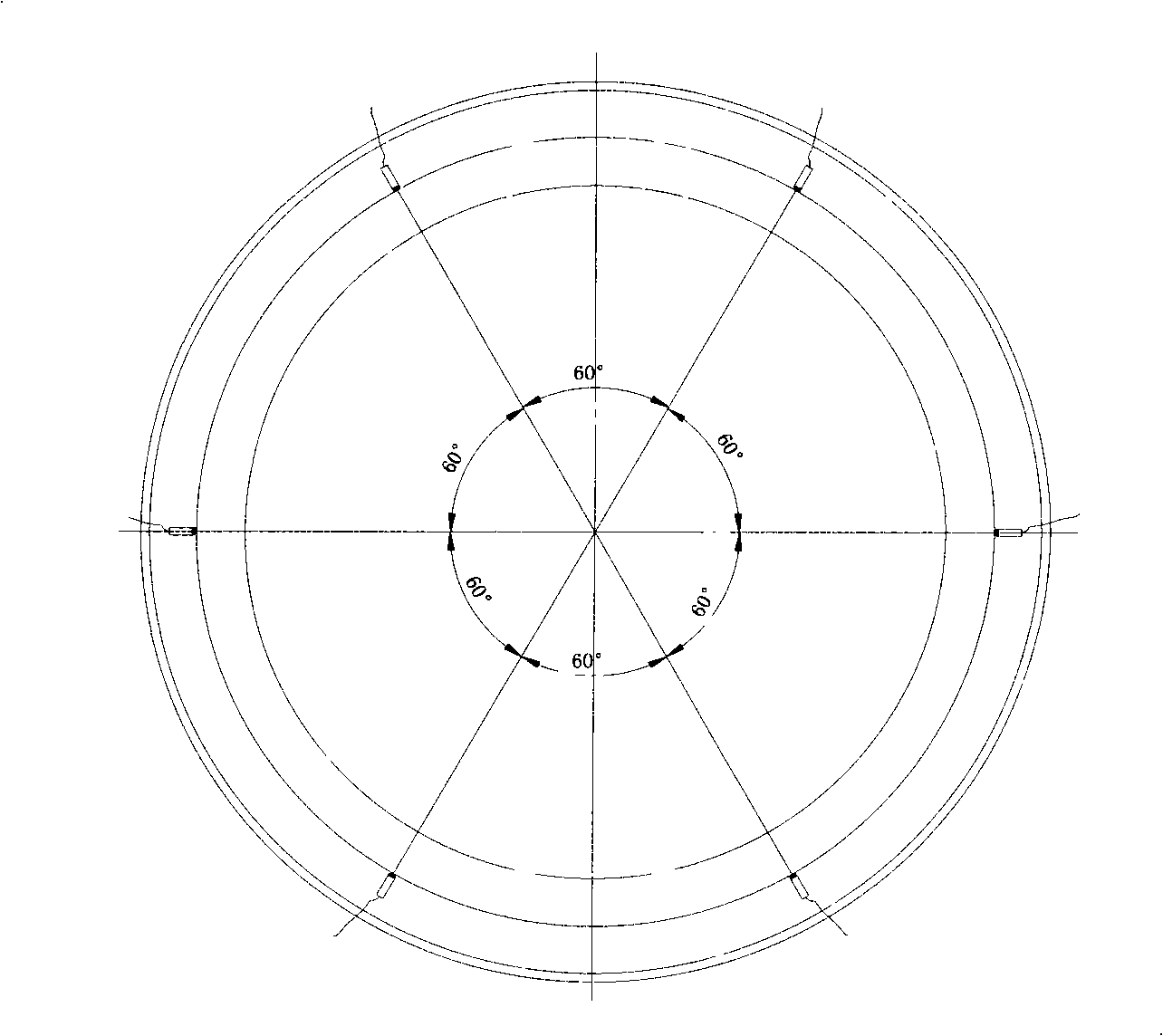

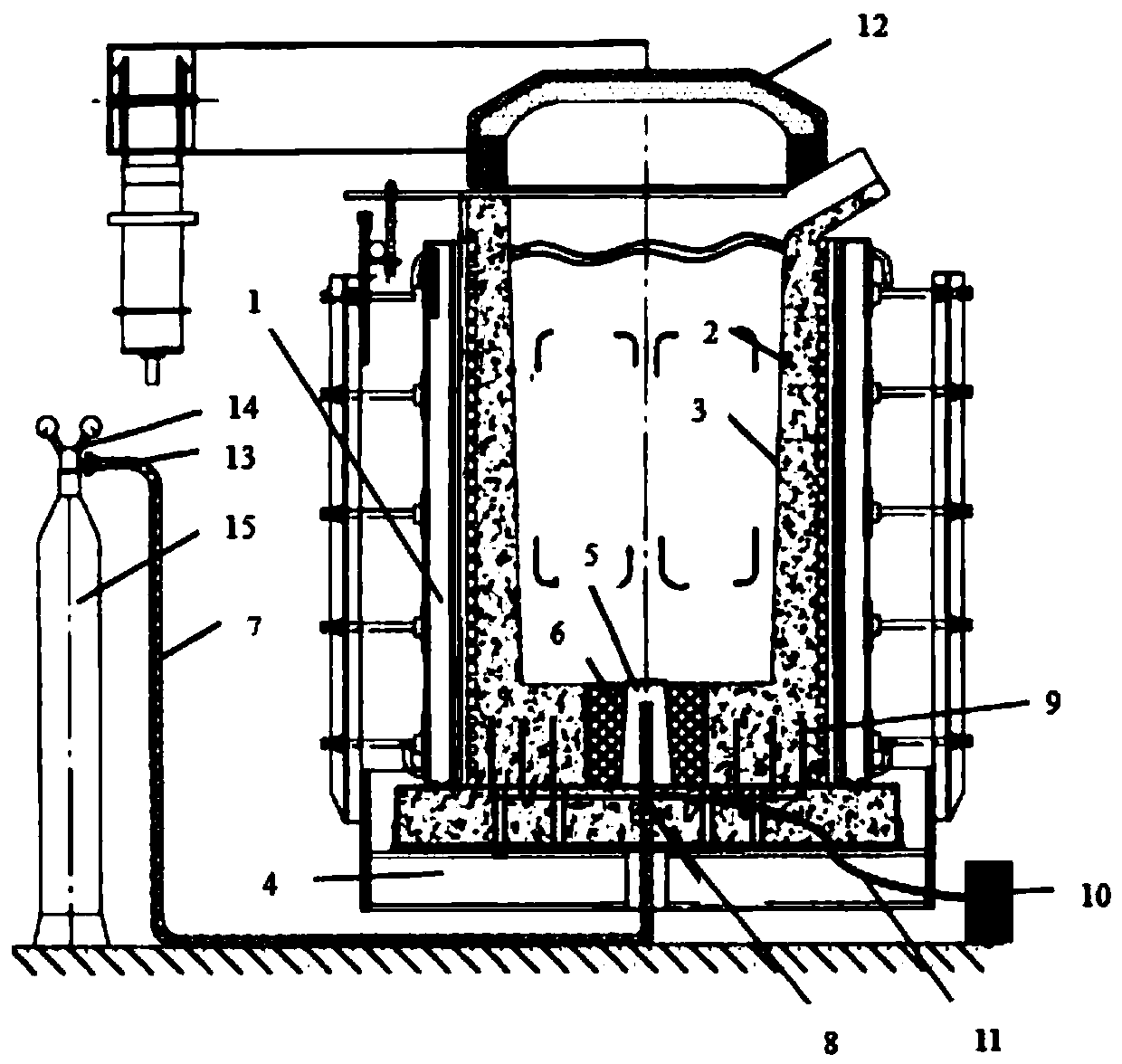

The invention discloses a converter lining thickness online testing method and a device thereof. The testing method comprises the following steps: (1) establishing a converter value module by finite element software to perform a steady-state calculation on converter lining temperature and thickness so as to determine distribution of temperature in a converter lining, setting measuring points in a converter body, and obtaining a converter lining temperature-thickness reference table; (2) according to the determined measuring points in step 1, burying thermocouple temperature measuring devices in a lining permanent layer of the converter and the bottom of the converter body; (3) according to data acquired in step 2, combining the converter lining temperature-thickness reference table obtained in step 1 to backward calculate the converter lining thickness; and (4) determining whether to perform repair treatment on the converter lining or not according to the lining thickness obtained in step 3. The device adopted by the invention comprises the converter body (1), and the thermocouple temperature measuring device is arranged in the lining permanent layer (2) of the converter body (1). The method and the device have simple working procedures and high measuring accuracy, and can effectively improve the campaign length of the converter.

Owner:HUATIAN ENG & TECH CORP MCC

Method for preventing crystallizer of continuous casting machine from sticking breakout

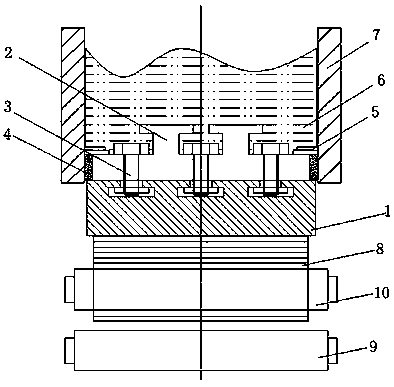

A method for preventing a crystallizer of a continuous casting machine from sticking breakout belongs to the technical field of continuous casting methods. Temperature sensors are mounted on four cooling water outlet pipes of the crystallizer, temperature variation values collected by the temperature sensors are input into a recording and analyzing device, and the recoding and analyzing device is used for predicting a danger level of sticking breakout according to water temperature variation conditions of the cooling water outlet pipes and prejudging whether billet shells cracks or not and whether a sticking breakout danger exists or not by judging transient variation of water temperature of the crystallizer, so that a casting speed of the continuous casting machine can be lowered timely, and breakout accidents can be avoided. A prediction method of the method is reasonable in design, convenience in mounting, utilization and maintenance is achieved, costs on purchasing, utilization and maintenance of equipment are low, and applicability to utilization in various iron and steel enterprises is achieved. The method for preventing the crystallizer of the continuous casting machine from sticking breakout has the advantages that the problem of sticking breakout of the crystallizer of the continuous casting machine bothering the iron and steel enterprises for a long time is solved, a worldwide advanced level in the same industry is reached, and obvious economic benefits are provided.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Continuous casting method for steel billets

The invention relates to a continuous casting method for steel billets, which comprises the following steps of: injecting molten steel in a plurality of tundishes into a crystallizer in turn, performing continuous casting, and adding crystallizer slag powder into the crystallizer, wherein for each tundish, the addition amount of the crystallizer slag powder ensures that three layers of crystallizer slag powder, namely a raw slag layer, a sintering slag layer and a liquid slag layer, are formed in the crystallizer in turn from top to bottom in a first time period; and the addition amount of the crystallizer slag powder ensures that the sintering slag layer and the liquid slag layer are formed in the crystallizer in turn from top to bottom, or only the liquid slag layer is formed in a second time period, and the thickness of the sintering slag layer is less than 5mm. The continuous casting method for the steel billets can ensure that cold steel is not crystallized on the surface of the molten steel in the crystallizer, and new molten steel and old molten steel are well welded on a weld line when the tundishes are changed, and effectively avoids steel leakage accidents.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Continuous casting machine and method for exchanging heat of a tundish in continuous casting production of the continuous casting machine

The invention discloses a continuous casting machine and a method for exchanging heat of tundish in continuous casting production of the continuous casting machine. The continuous casting machine comprises a steel ladle, a steel ladle rotary table, a steel ladle water gap, a tundish, a tundish water gap, a crystallizer and a guide section, and further comprises a connector, wherein the connector is placed in the crystallizer while exchanging heat of the tundish in continuous casting production; the connector comprises a cylindrical barrel body, a cold material rack supporting base and a cold material rack; the cold material rack supporting base is fixedly arranged on the bottom of the cylindrical barrel body; the cold material rack is fixedly arranged on the cold material rack supporting base in the cylindrical barrel body; the axial center line of the cold material rack is superposed with that of the cylindrical barrel body; and a space between the cylindrical barrel body and the coldmaterial rack is used for placing a short cold material. The method comprises inserting the connector into the crystallizer while exchanging heat of the tundish. According to the continuous casting machine and the method for exchanging heat of the tundish in continuous casting production of the continuous casting machine disclosed by the invention, thickness of a blank shell can be increased, bleed-out can be effectively prevented in the process of exchanging heat of the tundish, and success of exchanging heat of the tundish is guaranteed.

Owner:SHANDONG IRON & STEEL CO LTD

Continuous casting mold flux for high-carbon cutting mold steel

The invention provides continuous casting mold flux for high-carbon cutting mold steel. The continuous casting mold flux comprises the following chemical components in percentage by weight: 28.0-29.0% of CaO, 2-5% of MgO, 31.0-33.0% of SiO2, 4-5% of Al2O3, 8.0-9.0% of Na2O, 9-10% of F, 1.5-2.5% of LiO2, 2.0-2.8% of elemental carbon F.c and the balance of ash content I.L; and the alkalinity R of the mold flux is 0.80-0.95%. The continuous casting mold flux has the beneficial effects that by adjusting the components of the mold flux affecting production characteristics of the cutting mold steel and particularly by adjusting the contents of the flux, F, LiO2 and elemental carbon, the melting point of the mold flux is lowered so as to achieve stable dynamic balance between the melting speed and the inflow speed of the mold flux during the continuous casting process, thus improving the fluidity and crystallization speed of the mold flux during the casting process of the cutting mold steel, lowering the melting speed of the mold flux, realizing stable continuous casting production of the cutting mold steel, ensuring lubricating property of an initial shell of a plate blank in a crystallizer, preventing adhesion or bleed-out accidents caused by slag breakage, and realizing stable and smooth production of the high-carbon cutting mold steel.

Owner:BAOSHAN IRON & STEEL CO LTD

Method of mounting and fixing purging plug brick on outer upper portion of ladle

The invention relates to a method for mounting and fixing a purging plug brick on outer upper portion of a ladle. The method includes the steps of firstly, fixing a spiral slideway on the inner side of a reference ring of the purging plug brick, fixing a bolt at the bottom of the purging plug brick, sleeving a screwing slider on the outer side of the bolt, and inserting the top end of an automatic torque wrench to the screwing slider; secondly, starting the power of the automatic torque wrench, and allowing rotation torque to drive the screwing slider to be screwed into the purging plug brick along the spiral slideway; thirdly, demounting a nut and the automatic torque wrench, embedding a support brick with ash into a groove of the screwing slider, mounting support iron, a cover plate and the nut, and tightening the nut and the bolt to fix the cover plate and the support iron. The method has the advantages that due to the fact that mounting is performed through the automatic torque wrench, accurate mounting of the purging plug brick is achieved, the purging plug brick defects such as air channels, eccentricity, position difference, large seam and twin brick raising during purging plug brick mounting are overcome, the purging plug brick can be replaced conveniently, and ladle leakage accidents caused by purging plug brick mounting mistakes are avoided.

Owner:ANGANG STEEL CO LTD

Hot repairing method of steel ladle air brick

ActiveCN101844224AEasy to operateExtended service lifeMelt-holding vesselsRepair materialHeat energy

The invention relates to a hot repairing method of a steel ladle air brick, comprising the following steps: under the condition that the air brick is depressed, adopting a repairing material to carry out hot repairing on the depressed air brick, utilizing the self heat energy of a steel ladle to sinter the repairing material quickly, and utilizing the dispersed air permeability of the sintered repairing material to guarantee the effect of air permeability. The hot repairing method has the advantages of being simple and convenient in operation, effectively prolonging the service life of the air brick and argon-blowing turning up rate, simultaneously effectively avoiding the occurrence of the bleed-out accidents of the steel ladle, reducing the production delay and equipment loss due to the accidents and also reducing the cost.

Owner:ANGANG STEEL CO LTD

Ladle bottom argon blowing air brick for smelting high-purity high manganese steel

The invention discloses ladle bottom argon blowing air brick for smelting high-purity high manganese steel. The air brick is prepared from the following materials: forsterite sand, fused magnesia, corundum, sodium silicate, sodium permanganate, an explosion-proof admixture, a polycarboxylate dispersion water reducing agent and water. Uniformly-distributed tiny pores can be formed in the air brickdisclosed by the invention, and the permeation volume is 1.5 times or more than 1.5 times of the permeation volumes of slit and diffuse air bricks; argon is permeated in molten steel through the plurality of pores, so that the purification rate of the molten steel is obviously increased, and the contents of oxygen and hydrogen in the molten steel are reduced; the problems that a small number of straight thick holes are caused by slag-clearing iron oxygen burning, the argon intensively passes through the molten steel and quickly escapes from the liquid level and the like are solved; the purification rate of the molten steel is obviously increased.

Owner:广西长城机械股份有限公司

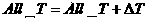

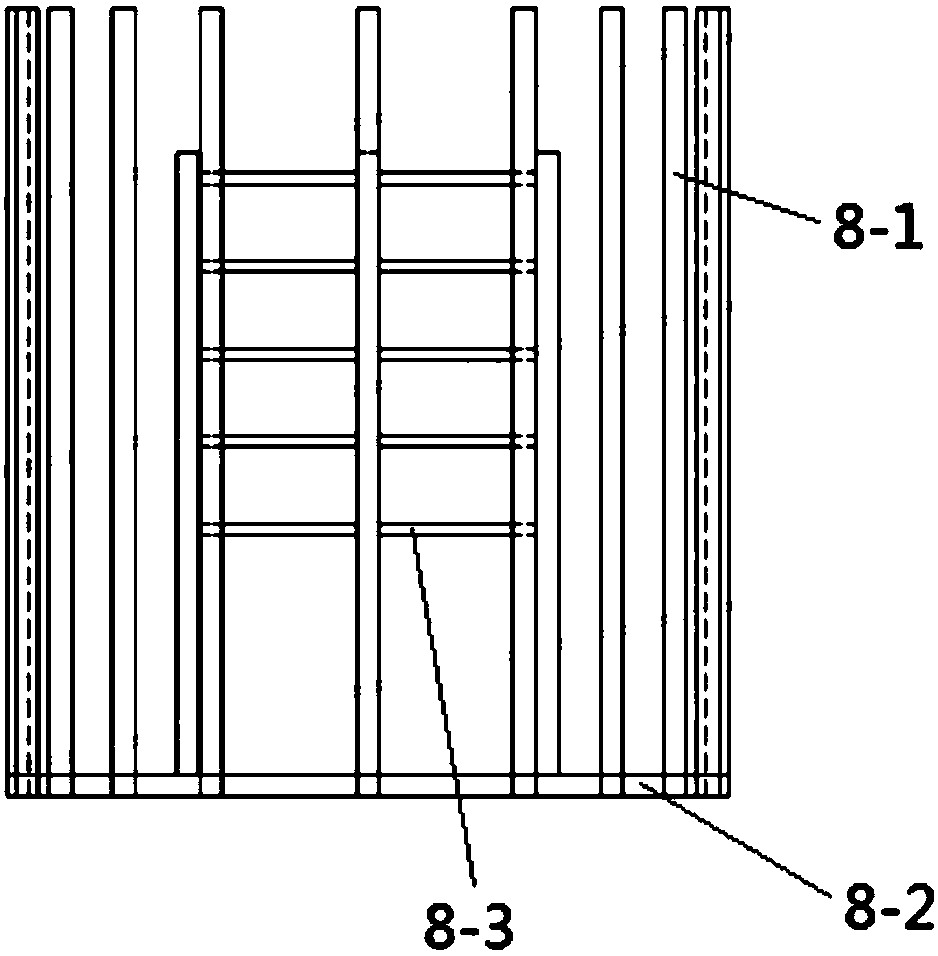

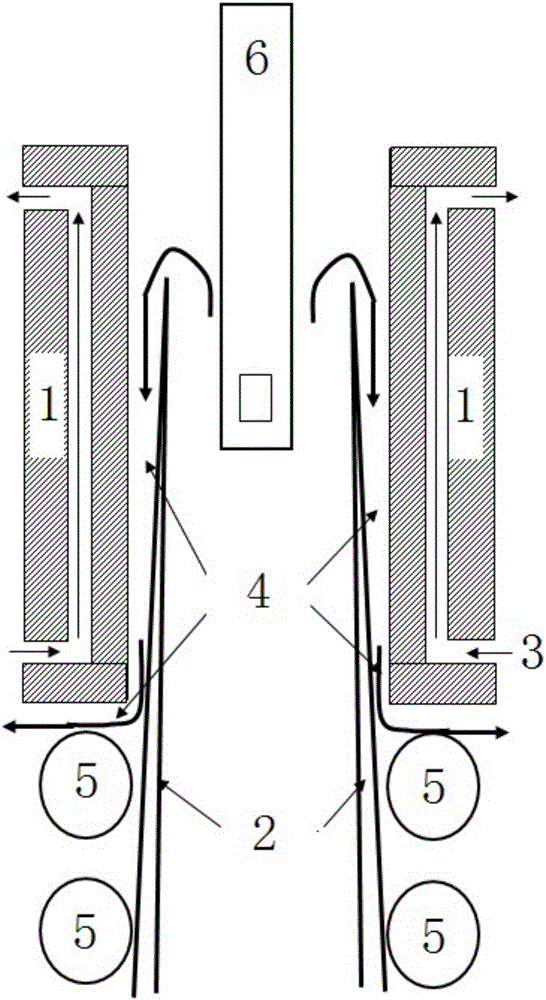

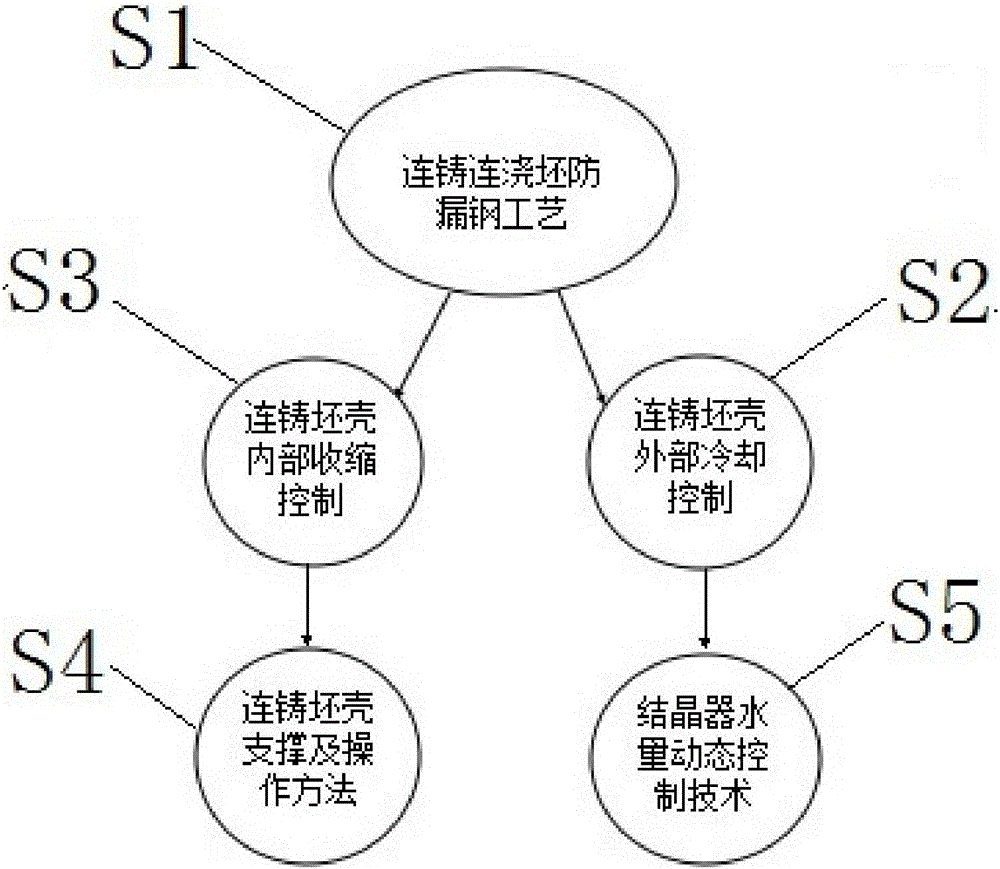

Method and device for preventing steel leakage of continuous casting and continuous pouring blank

ActiveCN106475541AAvoid steel breakout accidentsService life is not affectedAcute angleMaterials science

The invention discloses a method and device for preventing steel leakage of a continuous casting and continuous pouring blank. The method includes the following steps that the water amount of a crystallizer is adjusted to control cooling of the exterior of a continuous casting blank shell. When the pouring pulling speed is lower than the preset value and cutoff of the crystallizer happens, a supporting block is inserted in the crystallizer, and the interior of the blank shell is supported to control contraction of the interior of the continuous casting blank shell. The device is the supporting block and comprises a handle, a cross beam and supporting legs. The handle is installed on the cross beam and is perpendicular to the cross beam. The supporting legs are arranged at the two tail ends of the cross beam correspondingly. The length of the cross beam is matched with the width of the blank shell. The supporting legs and the cross beam are in piece shapes, and the included angles between the supporting legs and the cross beam are acute angles. According to the method and device for preventing steel leakage of the continuous casting and continuous pouring blank, steel leakage accidents happening due to serious contraction of the blank shell can be effectively prevented, and the purpose of stable and smooth production is achieved.

Owner:BAOSHAN IRON & STEEL CO LTD

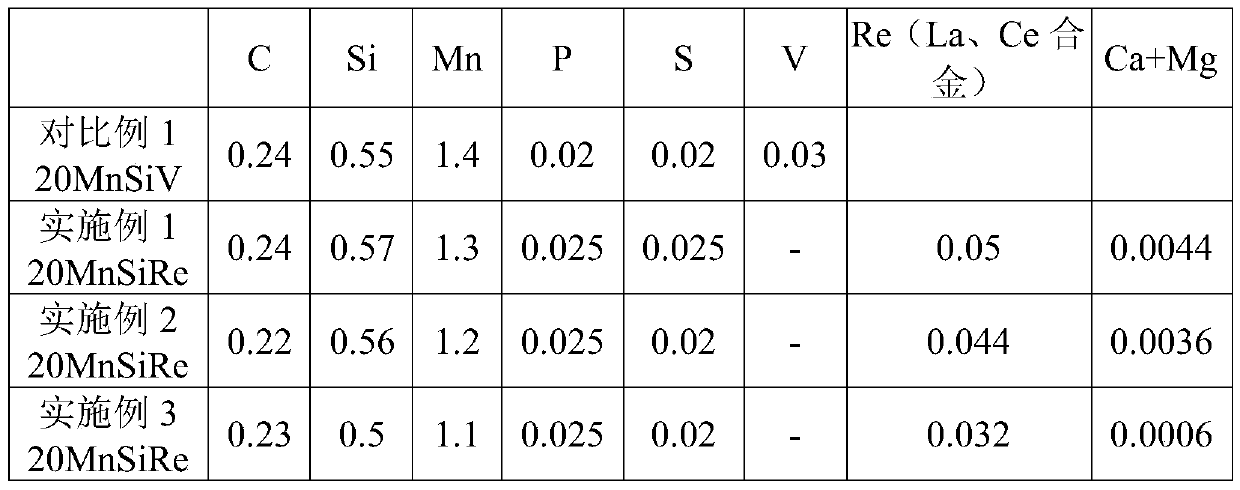

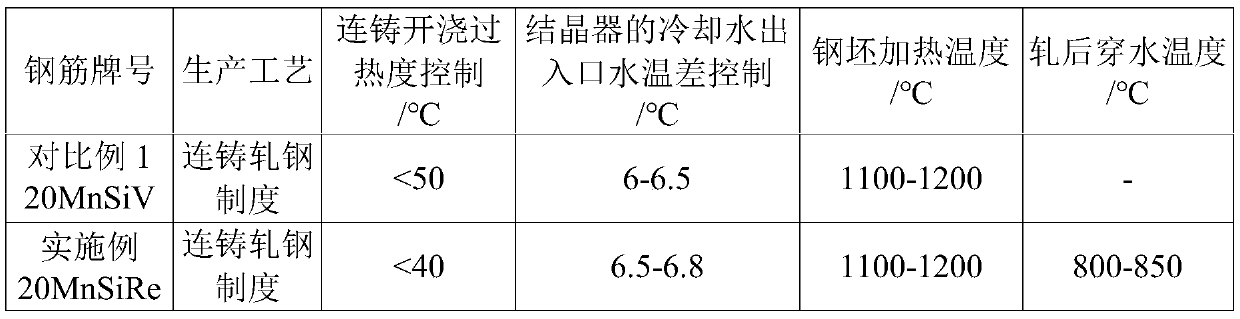

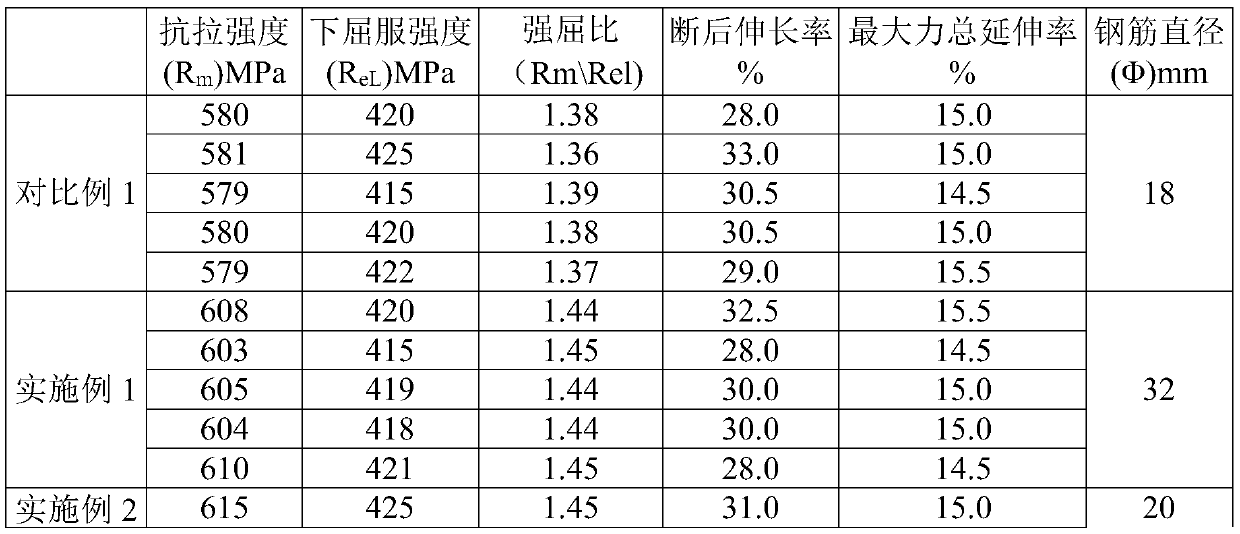

Rare earth microalloyed high-strength construction steel bar and production method thereof

The invention discloses a rare earth microalloyed high-strength construction steel bar and a production method thereof, and belongs to the technical field of steel for construction structures. The novel high-strength construction steel bar is provided, rare earth alloy cored wires are developed according to the variety of the rare earth microalloyed high-strength steel bar, qualified steel bars meeting the national standard requirements are obtained in high-strength steel bar production, and the problem that in the prior art, expensive elements such as V are often used, and consequently the cost is high is solved. The construction steel bar is prepared from the chemical compositions in percentage by weight: 0.20%-0.25% of C, 0.40%-0.80% of Si, 1.1%-1.60% of Mn, greater than 0.025% of Re, less than 0.045% of P, less than 0.045% of S, and the balance of Fe and inevitable impurities, wherein the mass percentage of O, Ca and Mg meets the formula of O / S<0 2, and Re / (Ca+Mg) is controlled between 10-100. The cost is lowered while the construction steel bar meets the national standard requirements.

Owner:CENT IRON & STEEL RES INST +2

Pillar slot type anti-blocking ladle bottom blowing powder spraying device

InactiveCN102274958AAvoid Dusting RequirementsReduce kinetic energy lossMelt-holding vesselsBrickRefractory

The invention relates to a frustum slit type anti-blocking ladle bottom-blown powder injection device, and belongs to the technical field of steel refining. A frustum slit type powder injection component is filled with refractory material, and four frustum-shaped slits are symmetrically distributed in the refractory material. The frustum slit type anti-blocking ladle bottom-blown powder injectiondevice realizes high-efficiency, continuous and stable injection, has high injection rate and low pulsing probability, can obviously improve uniform powder air flow delivery rate in slits, and is stable in injection, low in abrasion of air bricks, safe and reliable.

Owner:NORTHEASTERN UNIV

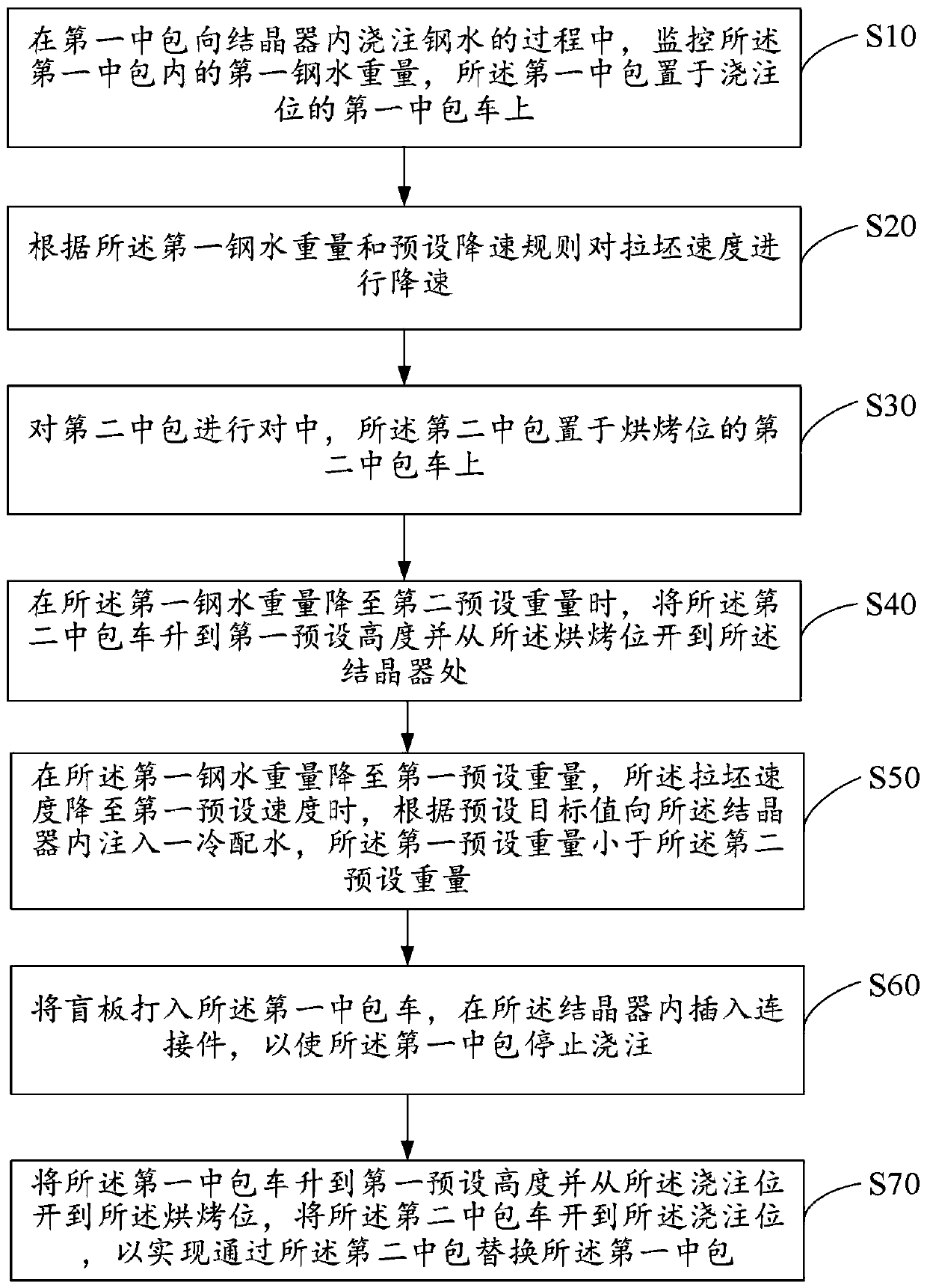

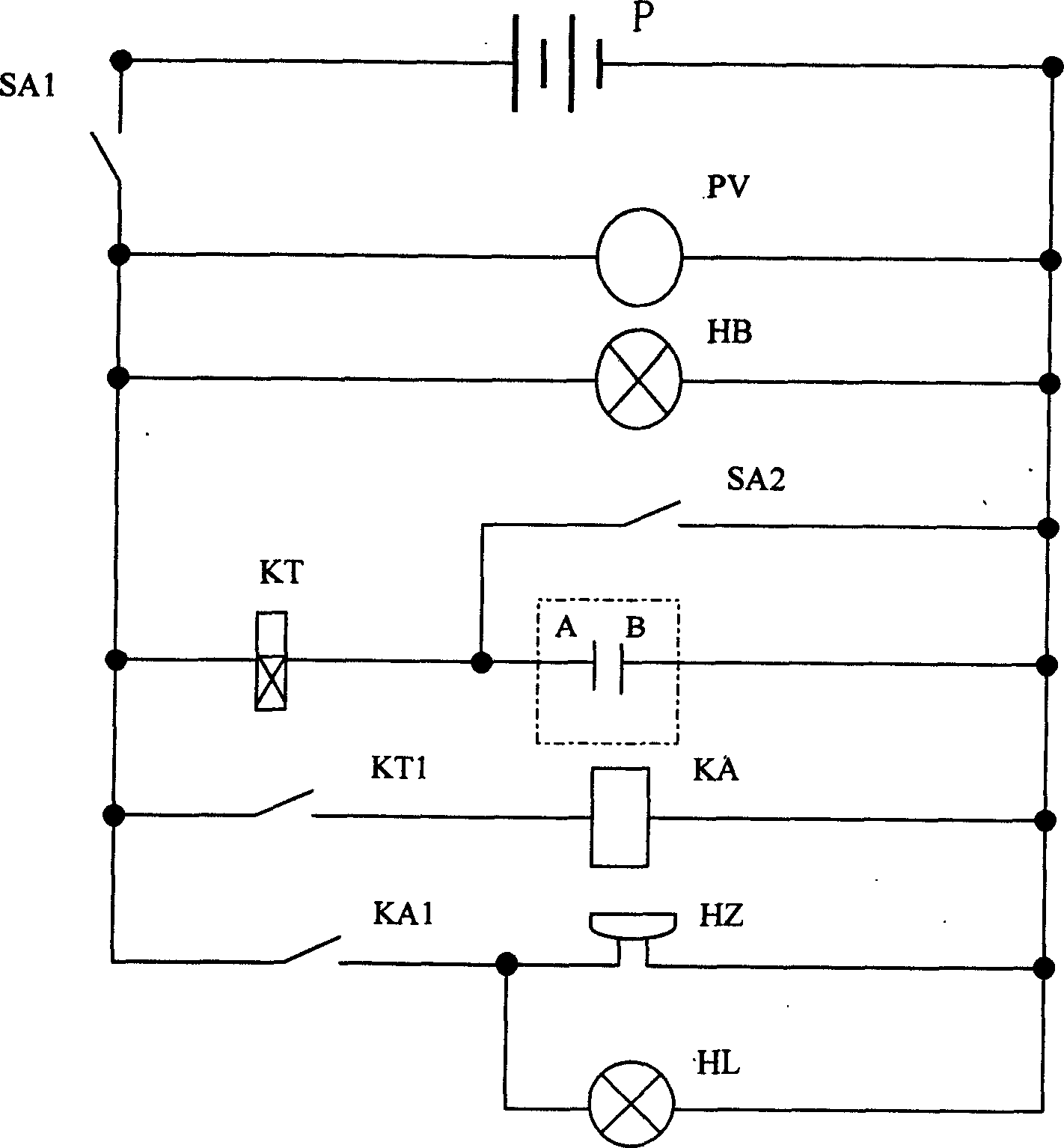

Method for quickly replacing tundish of peritectic steel steel grade

ActiveCN111112565AImprove efficiencyIncrease success rateMelt-holding vesselsTundishManufacturing engineering

The invention relates to the technical field of continuous casting processes, in particular to a method for quickly replacing tundish of peritectic steel steel grade. The method for quickly replacingthe tundish of the peritectic steel steel grade comprises the following steps that in a process of pouring molten steel into a mold in the first tundish, the weight of the first molten steel in the first tundish is monitored; the casting speed is reduced according to the weight of the first molten steel and a preset speed reducing rule; the second tundish is centered; a cold water distribution isinjected into the mold when the weight of the first molten steel is reduced to a first preset weight and the casting speed is reduced to a first preset speed; a blind plate is driven into a first tundish car, a connecting part is inserted into the mold, so that the first tundish stops pouring; the first tundish car is driven to a baking position from a pouring position, and a second tundish car isdriven to the pouring position, so that the first tundish is replaced with the second tundish, the tundish quick change efficiency is improved through the second tundish centering and the casting speed controlling process, the cold water distribution is injected into the mold according to the preset target value, a blank shell shrinkage is effectively controlled, and leakage steel accidents are avoided.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Gravity flow ventilating fast compensation material for sublimation ladle air brick

The invention relates to automatic flow venting rapid mending material for the refined ladle venting brick. The invention is characterized in that the material consists of the ingredients according to the weight proportion as follows: Al2O3 of 80 to 95, wedding agent of 3 to 15, detonation suppression of 0.1 to 0.5 and preservative agent of 1 to 5. The invention has the advantages of rapid sintering, good venting, no seeping steel, long service life and easy operation.

Owner:鞍山盛晨耐火材料有限公司

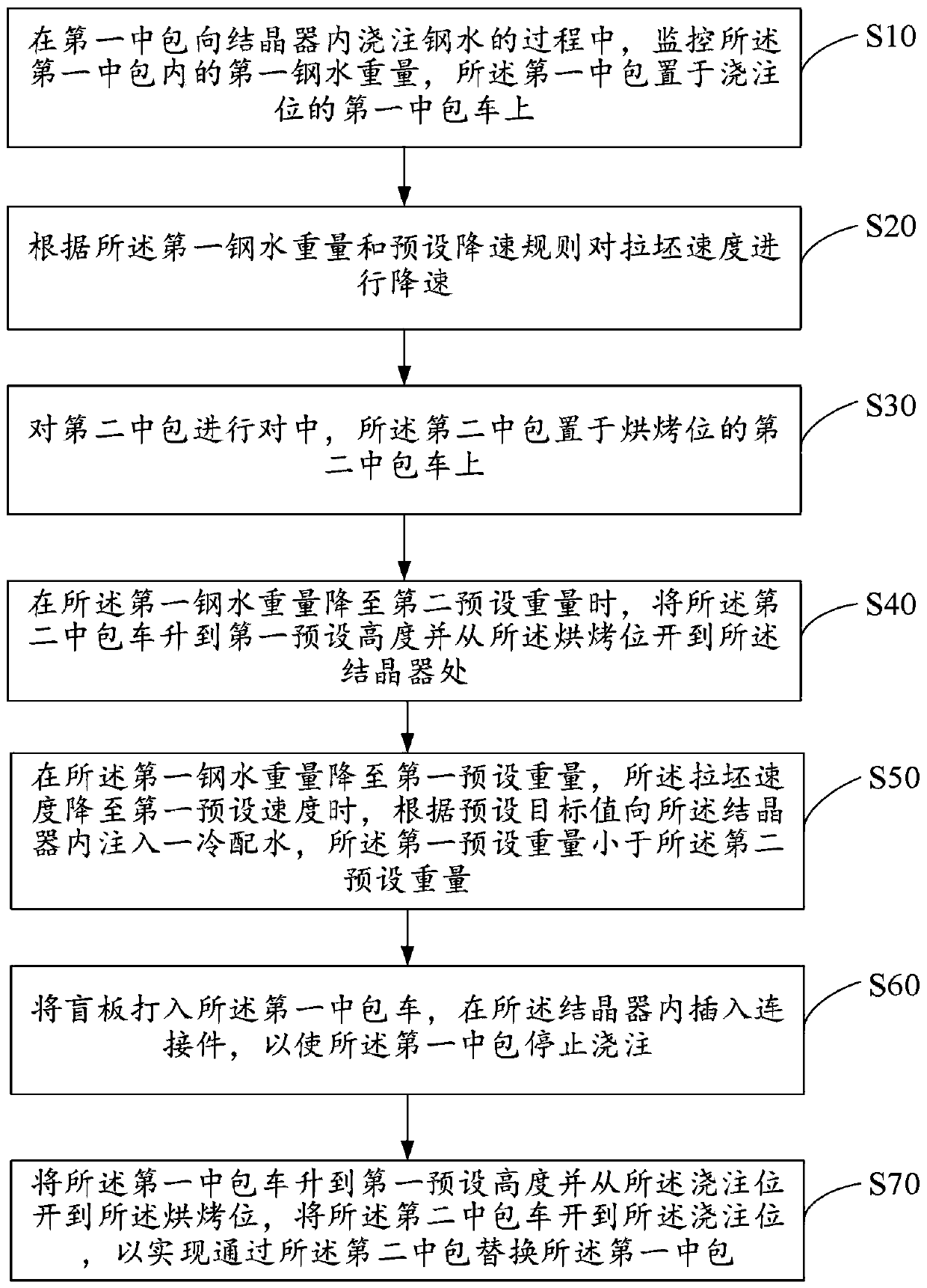

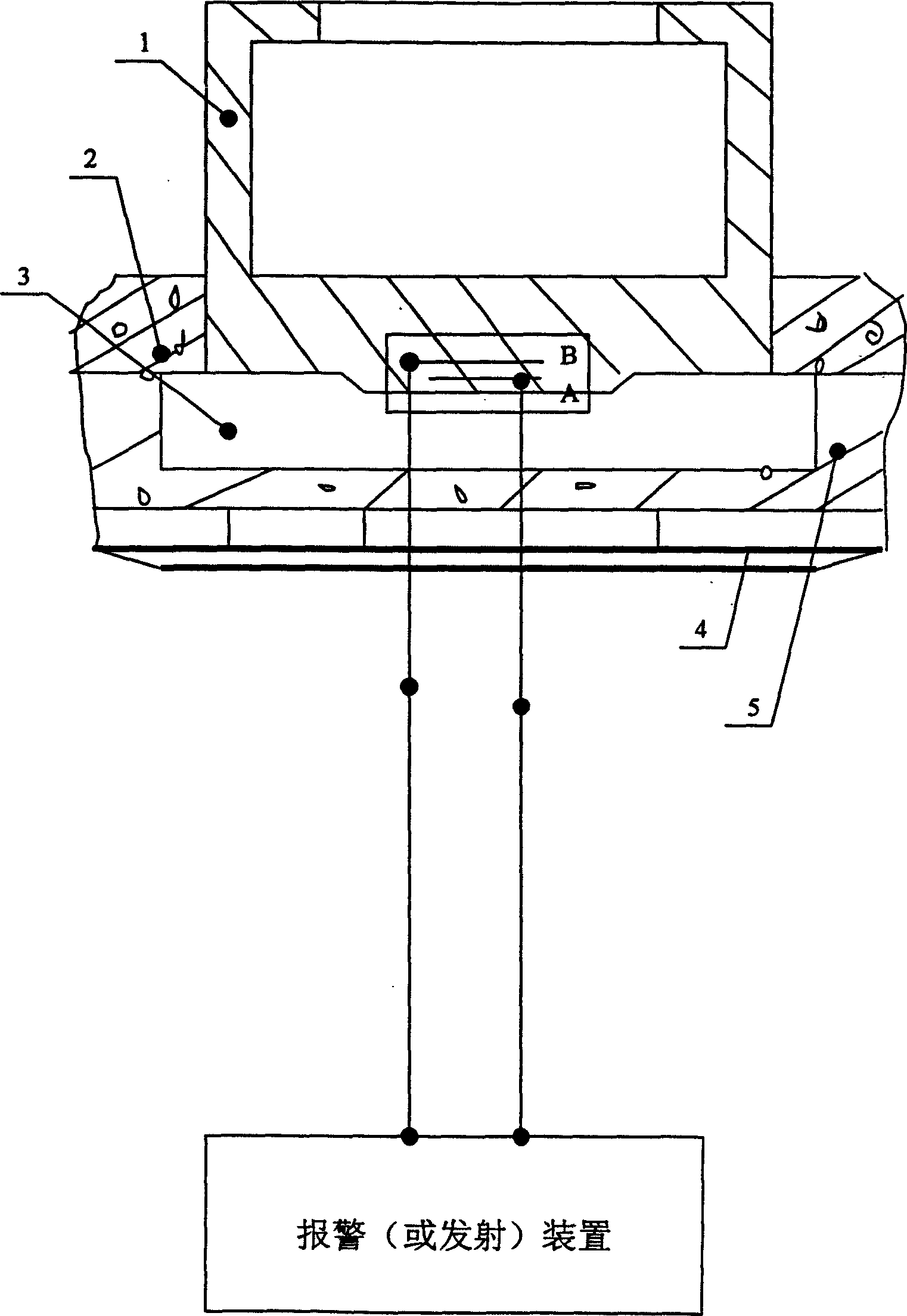

Warning device for preventing middle package from bleeding-out

InactiveCN1541787AExtended service lifeSimple structureCasting parameters measurement/indication devicesRefractoryMolten steel

The alarm for preventing pouring basket from leaking steel consists of two parts including molten steel conducting element and warning device. Two pieces of molten steel conducting elements are set inside the refractory lining in the shock area of pouring basket working layer and connected via wires to outer warning device or emitter. The present invention has the advantages of simple structure, accurate alarming, etc. and may be used in preventing steel leakage accident.

Owner:NORTHEASTERN UNIV

Joint filler for converter tuyere brick replacing

InactiveCN1827789AGood self-flowing heatHigh bonding strengthManufacturing convertersFilling materialsTuyere

The invention relates the fireproof material, especially the joint filling material used to change revolving furnace tuyere brick. The material comprises 60-80% good magnesia, 20-40% anchoring agent and 0.2-6% addition agent. The invention has good self liquidity. The material is heated, and flows into the gap between tuyere brick and furnace bottom. The material has good intensity, oxidation resistance, and durability.

Owner:BAOSHAN IRON & STEEL CO LTD

Permeable dry stamp mass for furnace bottom of intermediate frequency furnace

The invention discloses a permeable dry stamp mass for the furnace bottom of an intermediate frequency furnace. The permeable dry stamp mass is a uniform mixture of 89 percent by weight of refractory aggregate and 11 percent by weight of additive. The permeable dry stamp mass disclosed by the invention is stamped in an area with a diameter being 300-400mm and with an air brick as the center at a top of the air brick, wherein a stamping thickness is 100-250mm; and the whole furnace bottom can be stamped according to the size of the furnace body and a stamping thickness is 100-250mm. Compared with the prior art, a permeable stamp mass is stamped at the top of the air brick, so that the air brick is prevented from directly bearing the corrosion of liquid steel and the service life of the air brick is prolonged. The permeable dry stamp mass disclosed by the invention has the advantages of stable permeable performance, no blockage of an electric furnace subjected to stamping, easy operation, safe smelting and freeness of breakout accidents.

Owner:邯郸市鑫福冶金科技有限公司

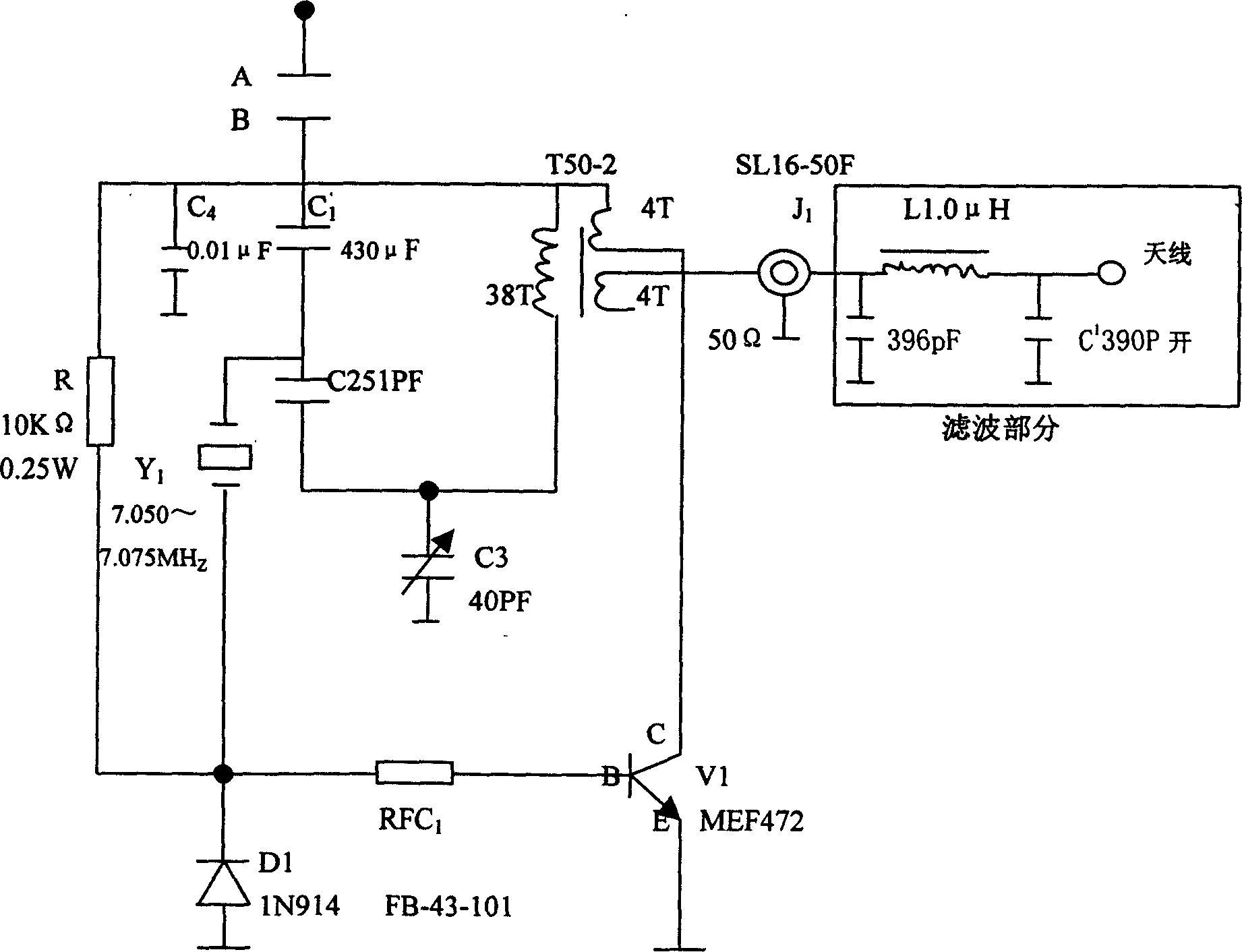

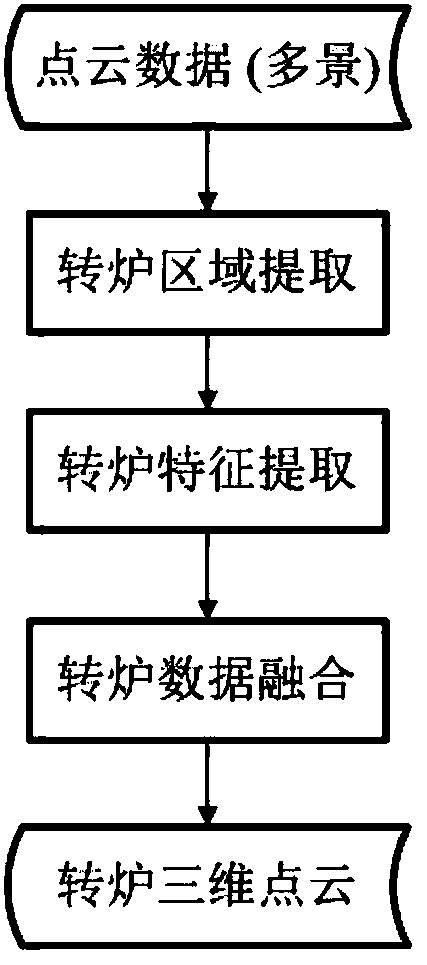

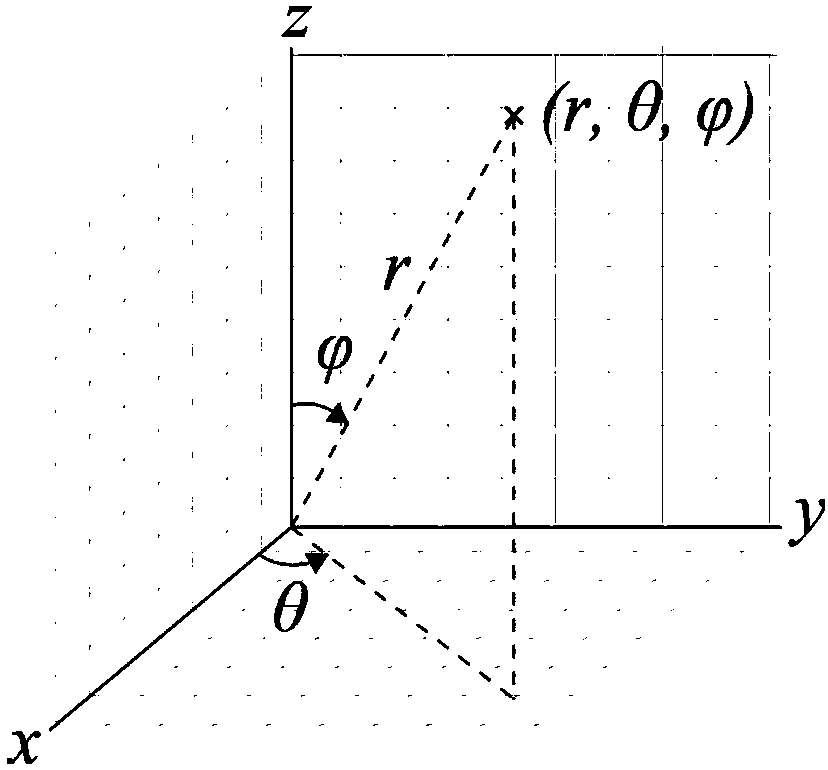

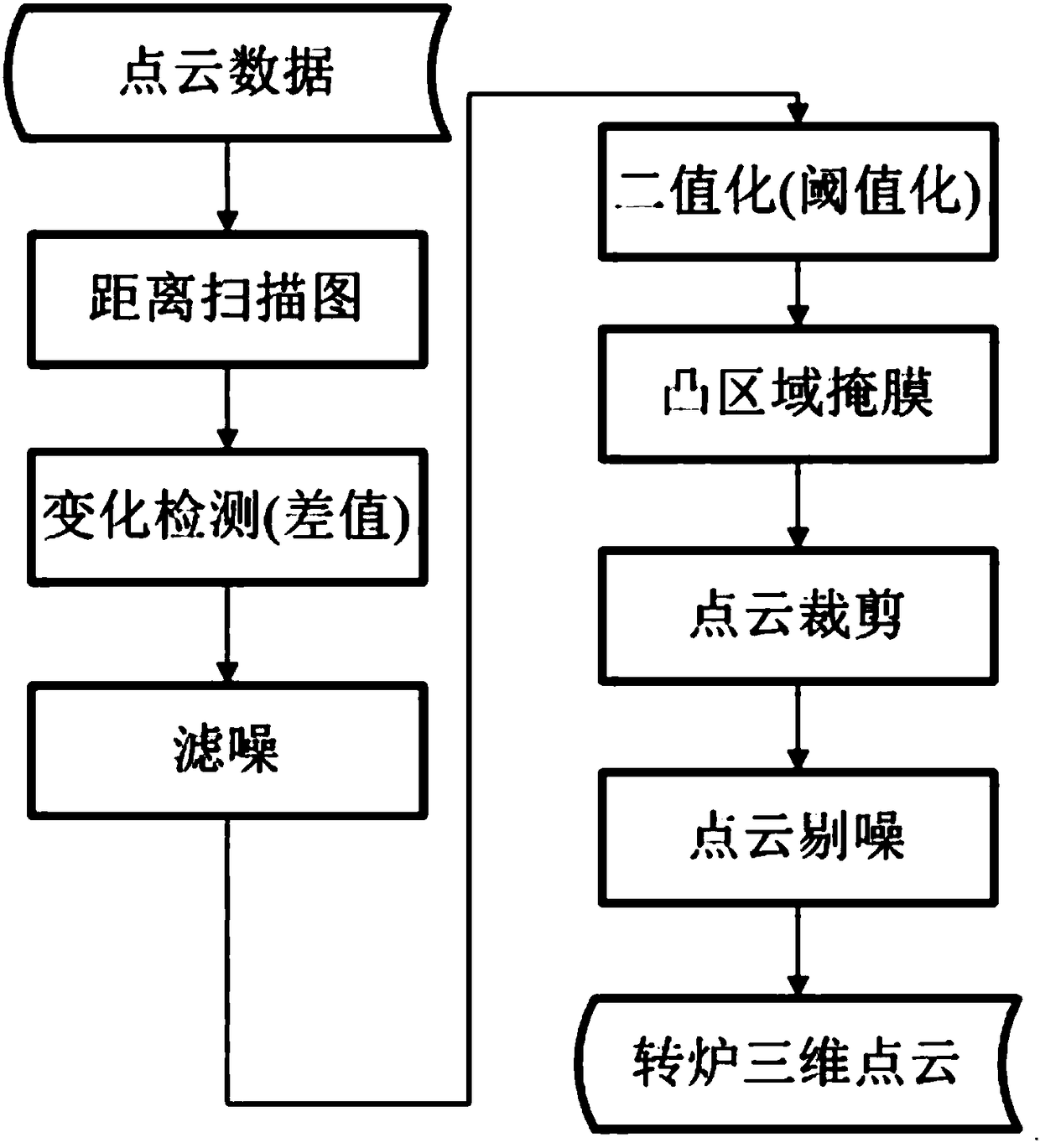

Three-dimensional laser point cloud automatic fusion algorithm for converter in steel furnace

ActiveCN108257222AEnsure safe productionReasonable guide to repairImage data processingFeature extractionPoint cloud

The invention relates to a three-dimensional laser point cloud automatic fusion algorithm for converter in a steel furnace. The algorithm comprises converter area data extraction, converter feature extraction and converter data fusion. The invention has the advantages that: the furnace lining of the steel furnace can be monitored in real time. The erosion condition of the furnace lining of the converter can be automatically detected under the condition of not being shut down. The occurrence of steel leakage accidents of the converter can be prevented. The safety production of the steel furnaceis guaranteed; the furnace lining repair can be reasonably guided. The waste of the furnace charge can be reduced and the service life of the furnace lining is prolonged.

Owner:HANGZHOU ZHONGKE TIANWEI TECH

Tombarthite core-spun yarn for continuous casting

InactiveCN1481953AAvoid performance degradationHigh utilization rate of rare earthProduction rateYarn

The coated RE wire for continuous casting includes outer casing and wire core coated inside the casing, the outer casing is of steel and the wire core of rare earth material. It may be used in continuous casting to prevent crystallizer protecting dregs from performance degradation, ensure the quality and output of steel product, lower steel production cost and reduce bleedout accidents.

Owner:曾宪刚

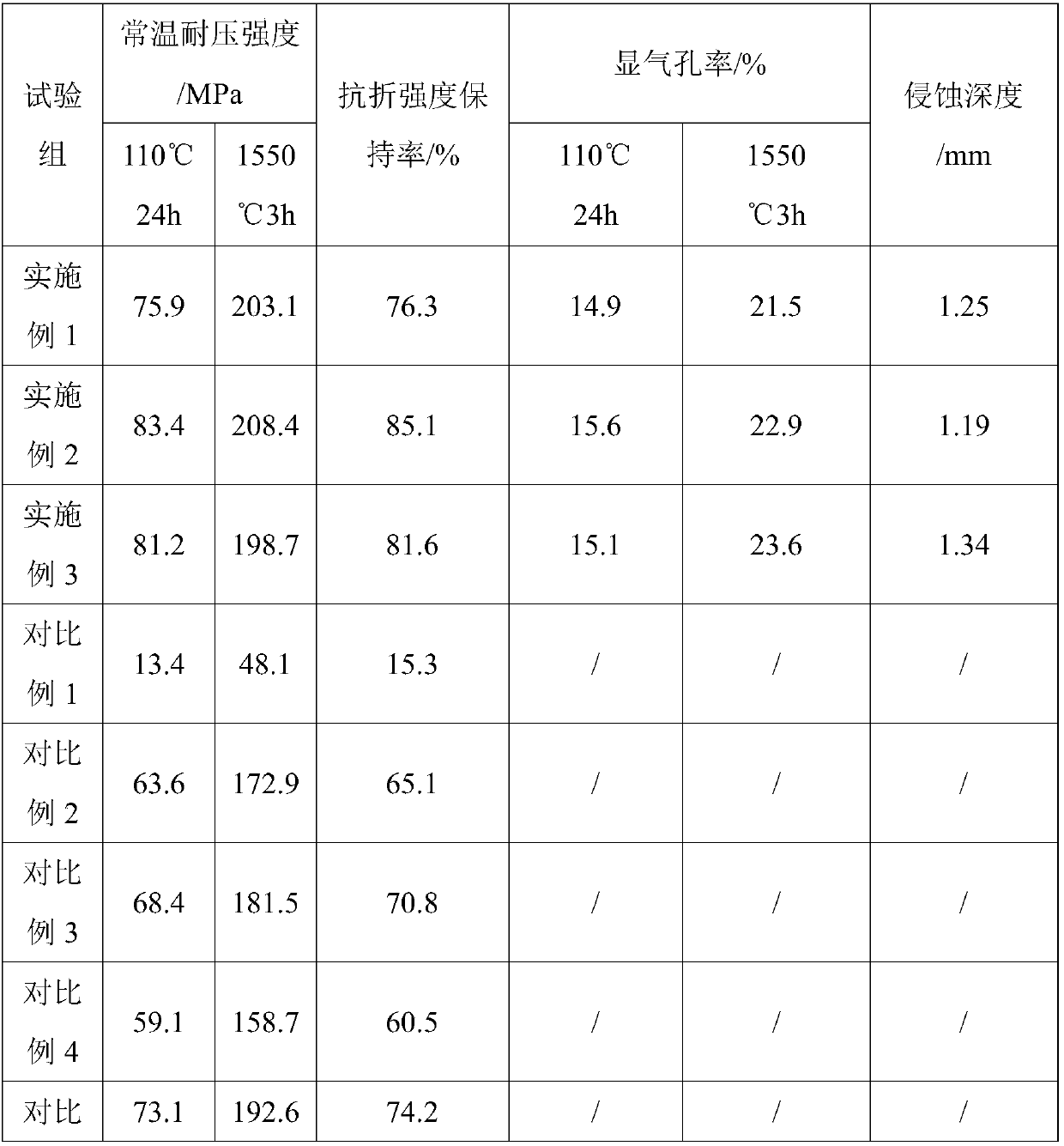

Vacuum induction furnace crucible repair method

InactiveCN109974456AExtended service lifeAvoid steel breakout accidentsLinings repairCrucibleGranularity

The invention relates to a vacuum induction furnace crucible repair method, and belongs to the technical field of vacuum induction furnace crucible preparation. The vacuum induction furnace crucible repair method comprises the concrete steps of firstly carrying out crack analysis, and then carrying out crack cleaning; then uniformly applying sodium silicate onto cracks under the cold state of a crucible; during the preparation of a repair material, matching magnesia with different granularity according to the proportion, and uniformly stirring through a sodium silicate cold-binder; and finallykneading the prepared magnesia into a spherical shape, uniformly pasting onto the repair part, and leveling, wherein the diameter of the spherical shape is 1.2 to 1.3 times of the crack depth. The vacuum induction furnace crucible repair method has the advantages that the service life of the crucible can be prolonged, and the occurrence of a steel leakage accident during smelting is avoided.

Owner:SHOUGANG CORPORATION

Technique control method for preventing CSP continuous casting machine from cast-on breakout

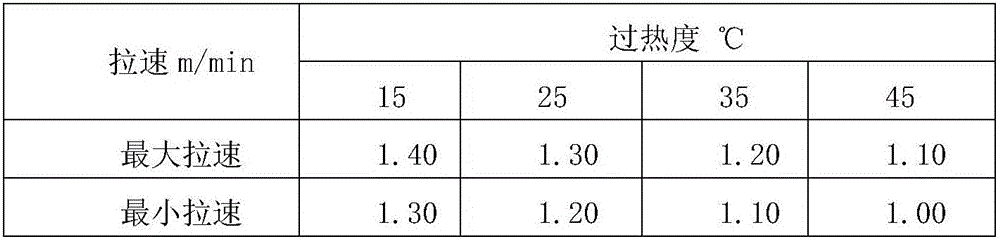

The invention discloses a technique control method for preventing a CSP continuous casting machine from cast-on breakout. The technique control method for preventing the CSP continuous casting machinefrom the cast-on breakout comprises steps of controlling the chemical composition and superheat degree of the continuous casting tundish liquid steel, sealing the seepage-proof steel of a continuouscasting cast-on dummy bar head sealing kit, adding special protective slags for the cast-on, and controlling the cast-on time of the continuous casting machine. The chemical composition of the continuous casting tundish steel liquid is set to comprises less than or equal to 0.06wt% of the low-carbon steel series C, and more than or equal to 0.17wt% of the medium carbon steel series C, the gas N isless than or equal to 50 ppm, and superheat degree of the liquid steel is controlled to be 15-40 DEG C. The technique control method for preventing the CSP continuous casting machine from the cast-onbreakout can effectively prevent cast-on breakout accidents of a thin slab-billet continuous casting machine, thereby improving the product quality and realizing the production of high-quality defect-free continuous casting billets.

Owner:HANDAN IRON & STEEL GROUP +1

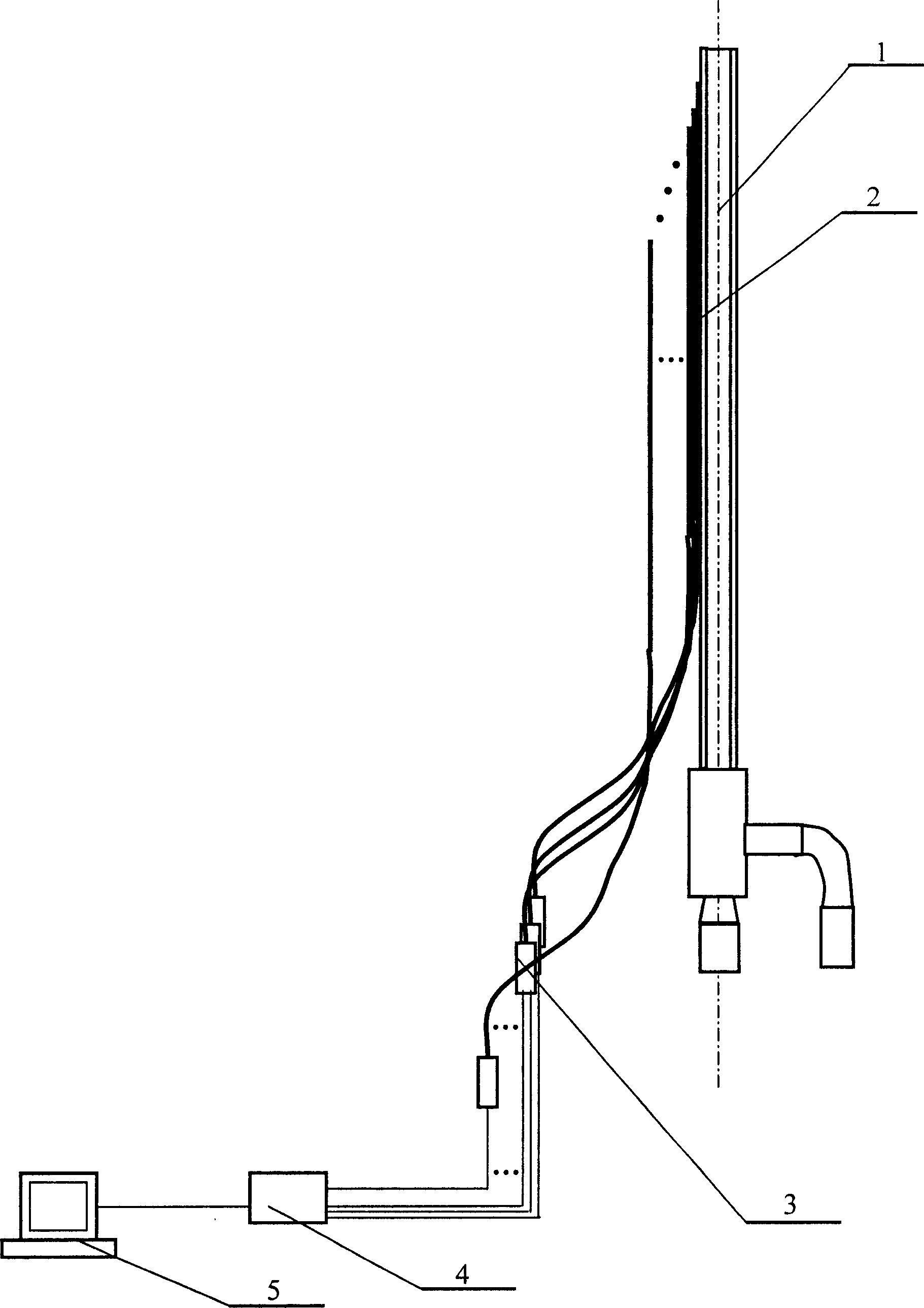

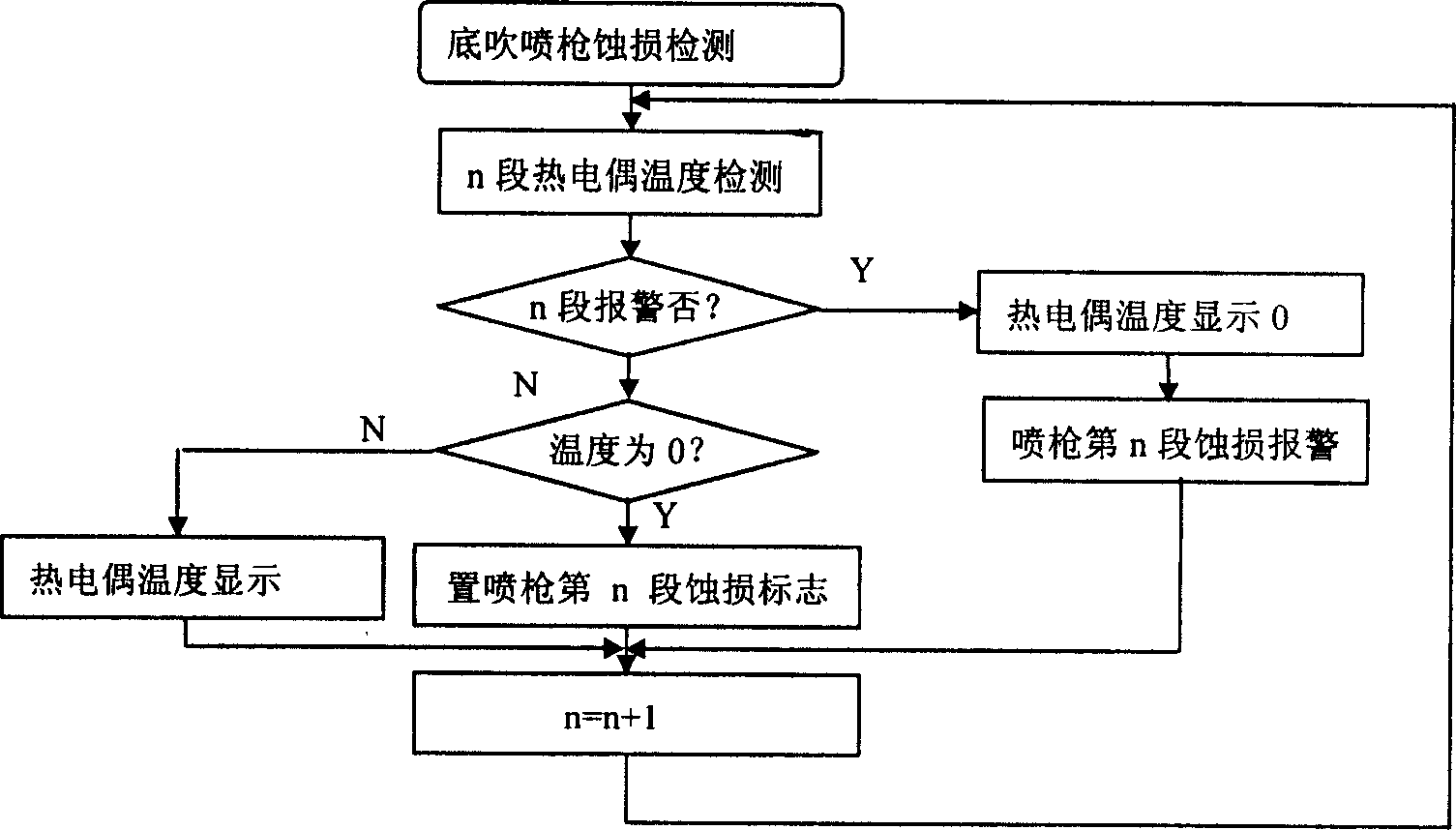

Detection device of corrosion of induction furnace bottom aeration element

InactiveCN1719172AExtended service lifeSteel breakout accidentCrucible furnacesComputerized systemTransducer

The present invention relates to induction furnace bottom-blowing gas-supplying element corrosion damage detection equipment. Sid equipment includes the following components of corrosion damage detection probe, connector plug, transducer and computer processing system. Said invention also provides the connection mode of all the above-mentioned components and the application range of said detection equipment.

Owner:NORTHEASTERN UNIV

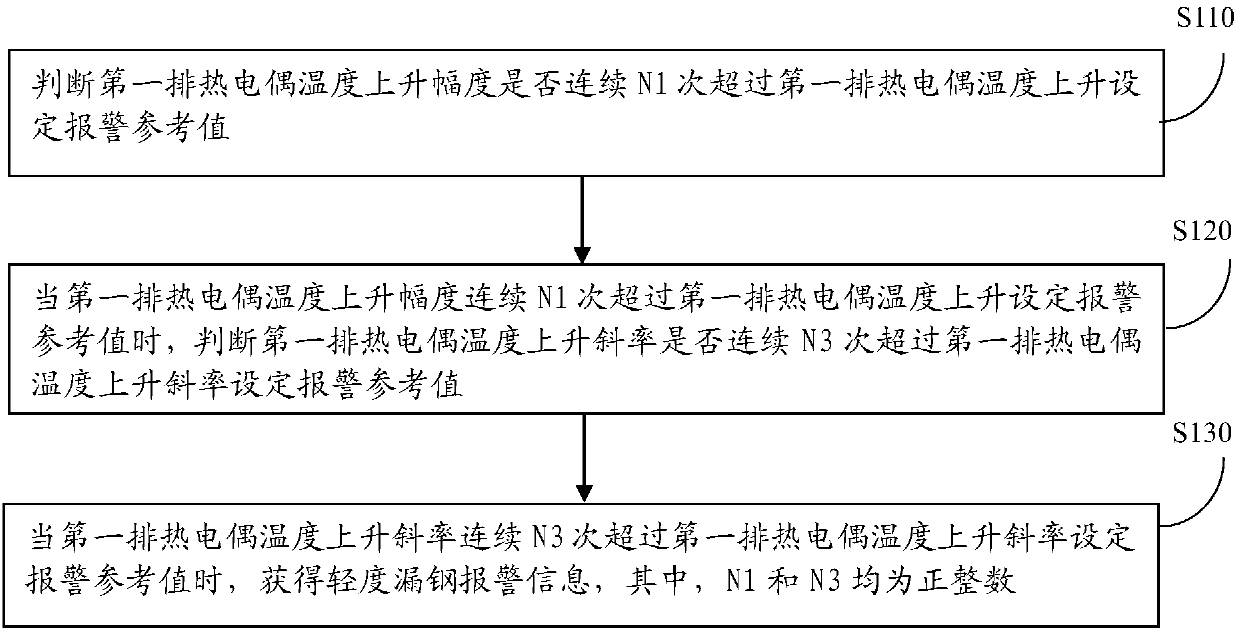

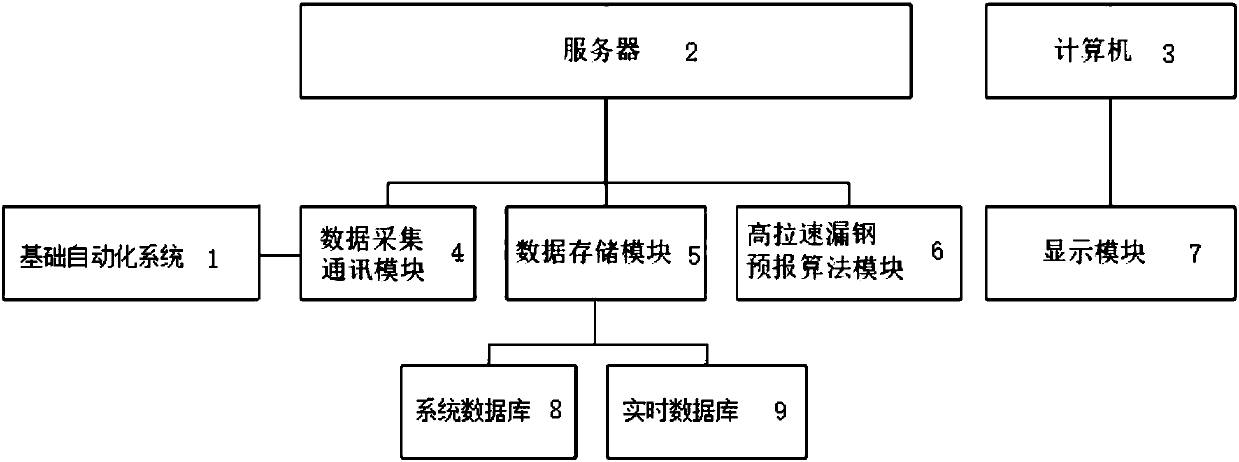

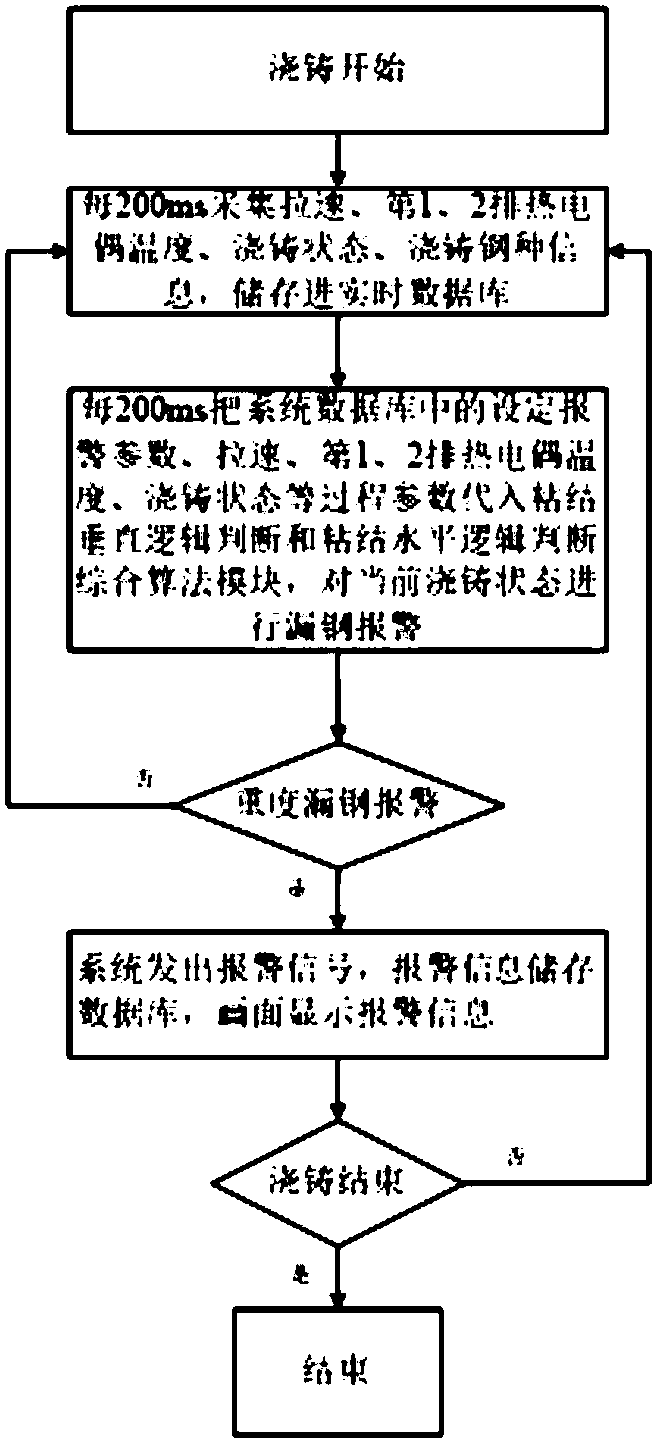

Breakout warning method

The invention provides a breakout warning method applicable to large slab continuous casters. The breakout warning method comprises: judging whether the rise amplitude of a first row of thermocouplesexceeds a set warning reference value of temperature rise for the first row of thermocouples continuously N1 times, and judging whether rise slope of the first row of thermocouples exceeds a set warning reference value of temperature rise slope for the first row of thermocouples continuously N3 times; if the rise slope of the first row of thermocouples exceeds the set warning reference value of temperature rise slope for the first row of thermocouples continuously N3 times, acquiring light breakout warning information, wherein both N1 and N3 are positive integers. The technical problem is solved that since a breakout warning system of the prior art has long warning judging cycle and provides delayed warnings, breakout accidents still occur and the production requirement for high drawing speed is not met.

Owner:BEIJING SHOUGANG AUTOMATION INFORMATION TECH

Production process of high manganese and aluminous steel continuous casting billet

ActiveCN106521082AGuaranteed smooth productionAvoid steel breakout accidentsProcess efficiency improvementElectric furnaceSlagManganese

The invention relates to a production process of a high manganese and aluminous steel continuous casting billet. The production process of the high manganese and aluminous steel continuous casting billet comprises an electric furnace steel making process, a refining process and a continuous casting billet casting process, and comprises the following concrete steps of during electric furnace steel making, controlling the tapping temperature and the contents of C and P, and adding manganese and aluminous; during refining, deoxidizing slag surfaces, vacuum degassing after adjusting the contents of Mn and Al, feeding ferrite calcium wires before tapping, and controlling the tapping temperature; during continuous casting billet casting, controlling the casting speed and the withdrawing speed for ensuring constant-speed production; and during the whole process of casting, carrying out argon shield, and after casting, feeding the steel billet into a slow cooling pit for slow cooling. According to the production process of the high manganese and aluminous steel continuous casting billet provided by the invention, through controlling the tapping time, adjusting the aluminum content during the refining process, and controlling the casting speed during the billet-drawing process, continuous casting billet finished steel meeting the requirements of components and performances can be produced, the occurrence of a bleed-out accident can be prevented, and the smooth production of the high manganese and aluminous steel continuous casting billet is ensured.

Owner:ANSTEEL CAST STEEL CO LTD

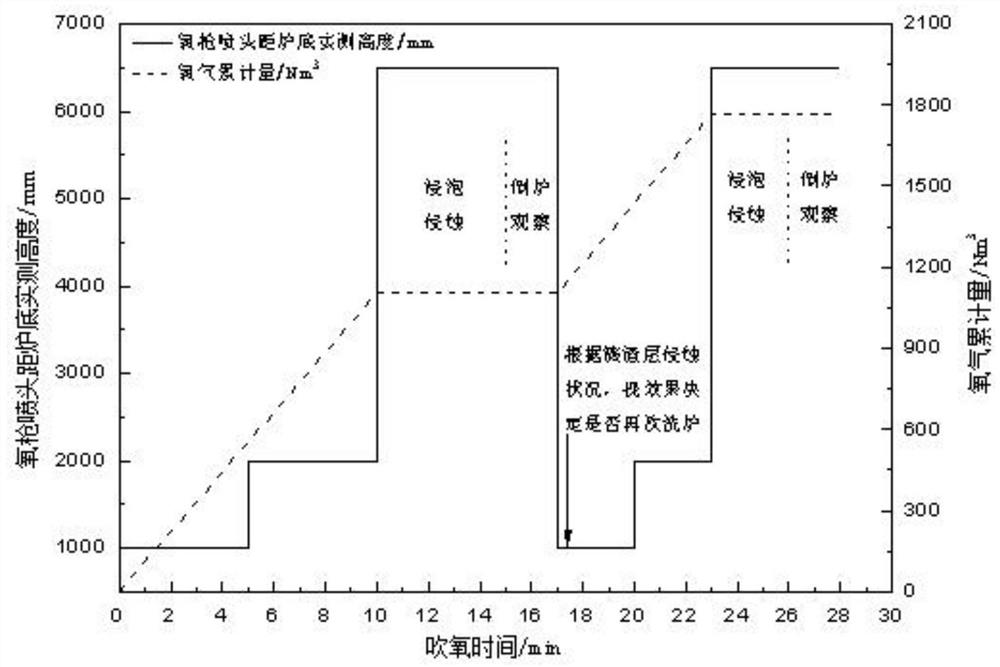

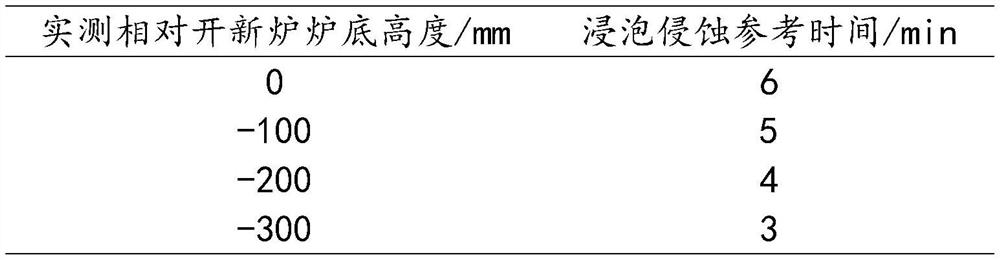

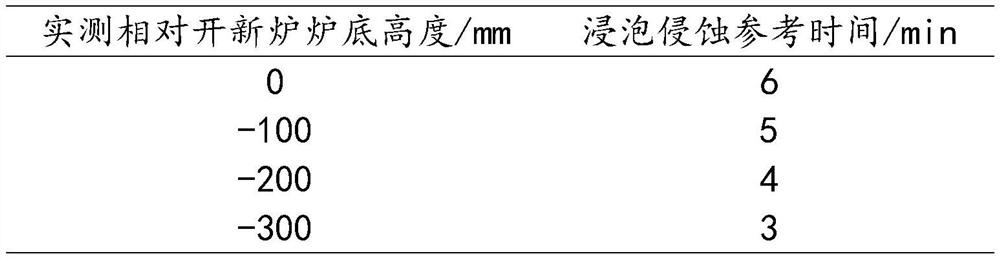

Method for efficiently removing slag splashing layer at joint of bottom and body of converter with movable bottom

ActiveCN112725559AEfficient removalAvoid steel breakout accidentsManufacturing convertersThermodynamicsSlag

The invention discloses a method for efficiently removing a slag splashing layer at a joint of a bottom and a body of a converter with a movable bottom. The method for efficiently removing the slag splashing layer at the joint of the bottom and the body of the converter with the movable bottom comprises the steps of carrying out preparation work before shutdown, carrying out shutdown operation, carrying out oxygen blowing operation in the converter, carrying out soaking erosion on the slag splashing layer at the joint of the bottom and the body, and carrying out inspection and confirmation on the slag splashing layer at the joint of the bottom and the body. According to the method for efficiently removing the slag splashing layer at the joint of the bottom and the body of the converter with the movable bottom, the slag splashing layer can be effectively removed, the gun position, the oxygen supply intensity and the soaking erosion time of an oxygen gun are reasonably controlled according to the actual values of the thickness of a working layer of a lining and the height of the bottom which are actually measured before shutdown, and the steel leakage accident is avoided while the slag splashing layer of the bottom and the body is completely removed; and the method has the advantages of being short in time, stable in operation and high in safety coefficient, the converter washing operation time can be controlled within 30 minutes, and the working efficiency is high.

Owner:安徽长江钢铁股份有限公司

Converter with replaceable furnace bottom and construction method for primary masonry

PendingCN113651601ANot easy to damageAvoid damageManufacturing convertersArchitectural engineeringStructural engineering

The invention discloses a converter with a replaceable furnace bottom and a construction method for primary masonry. The converter comprises a converter bottom shell and a converter body shell which are detachable, a converter body refractory material is built on the inner side of the converter body shell, a converter bottom refractory material is built on the converter bottom shell, the converter bottom shell is connected to the converter body shell, an annular gap is formed between the converter body refractory material and the converter bottom refractory material, an isolating layer is pasted on the vertical surface, on one side of the annular gap, of the converter body refractory material, the annular gap is filled with a special ramming joint material when the converter is constructed for the first time, and the isolating layer isolates adhesion and combination between the converter body refractory material and the ramming joint material. Therefore, when the converter bottom is subjected to hot replacement, the refractory material of the converter body and the ramming material are very easy to separate and easy to disassemble and clean, the construction efficiency of the converter bottom hot replacement is improved, the joint material is filled and tamped in multiple layers, the construction quality is ensured, the erosion speed of molten steel to the joint material is slowed down, and the service life of the converter during primary masonry is greatly prolonged.

Owner:JINAN LUDONG REFRACTORY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com