Convertor lining thickness online testing method and device thereof

A converter furnace lining and detection method technology, which is applied in the field of converter lining thickness, can solve problems such as affecting the accuracy of measurement values, low measurement accuracy, affecting measurement results, etc., and achieves simple and clear process, high measurement accuracy and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A method for online detection of converter lining thickness, the method comprising the following steps:

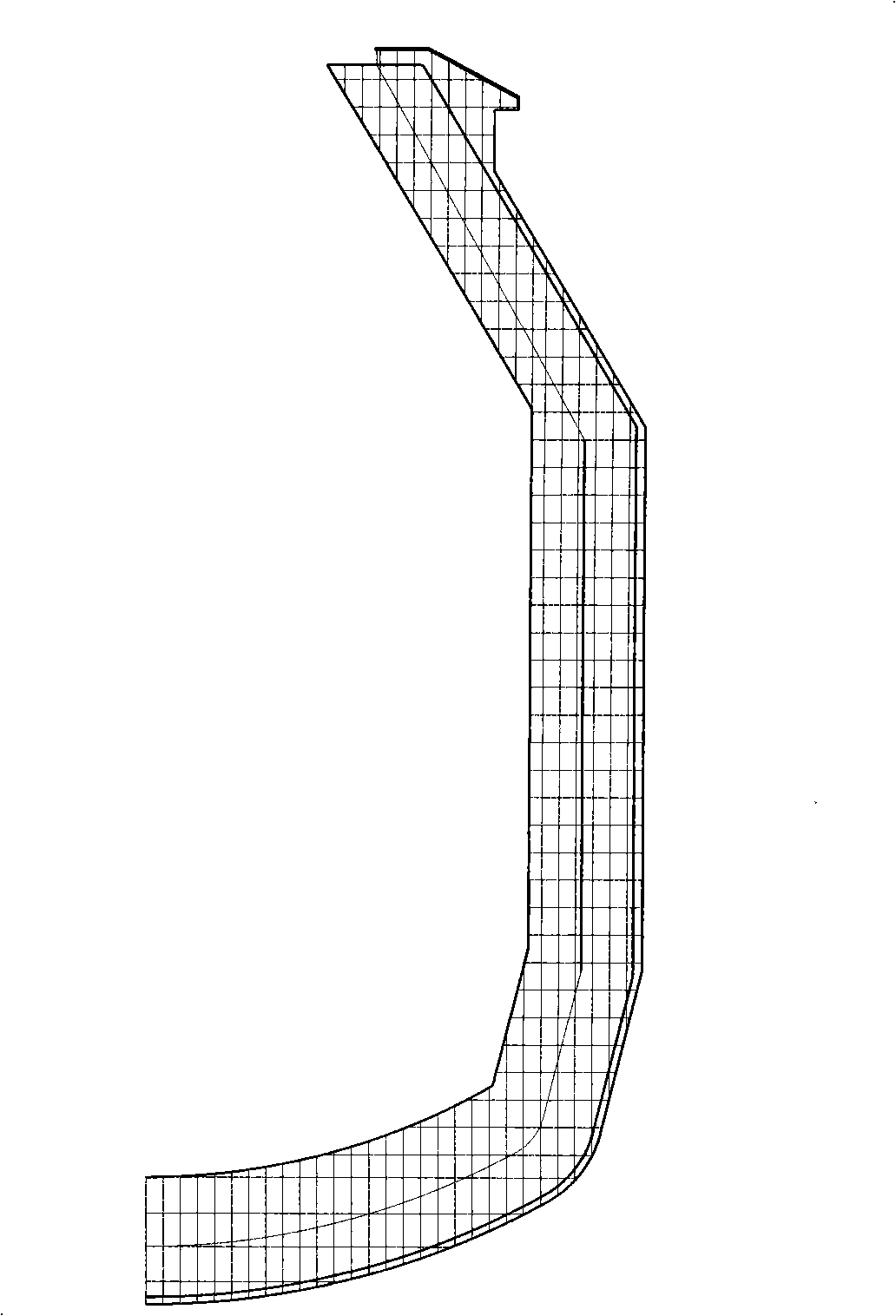

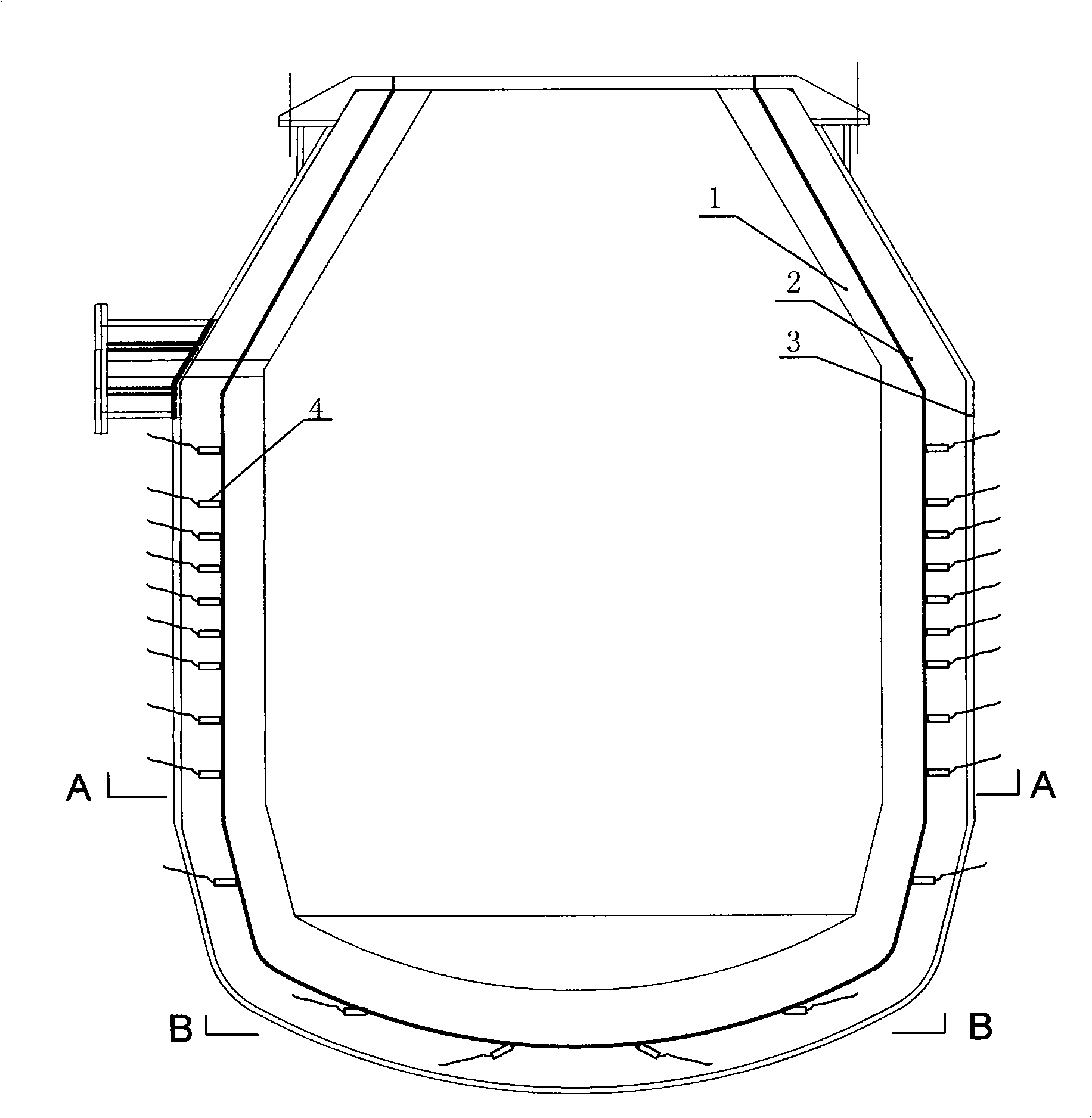

[0030] ① Use finite element software to establish a numerical model of the converter, conduct steady-state calculations for the converter lining temperature and lining thickness, determine the temperature distribution in the furnace lining, set the temperature measurement points in the furnace body, and obtain the lining temperature-thickness reference table;

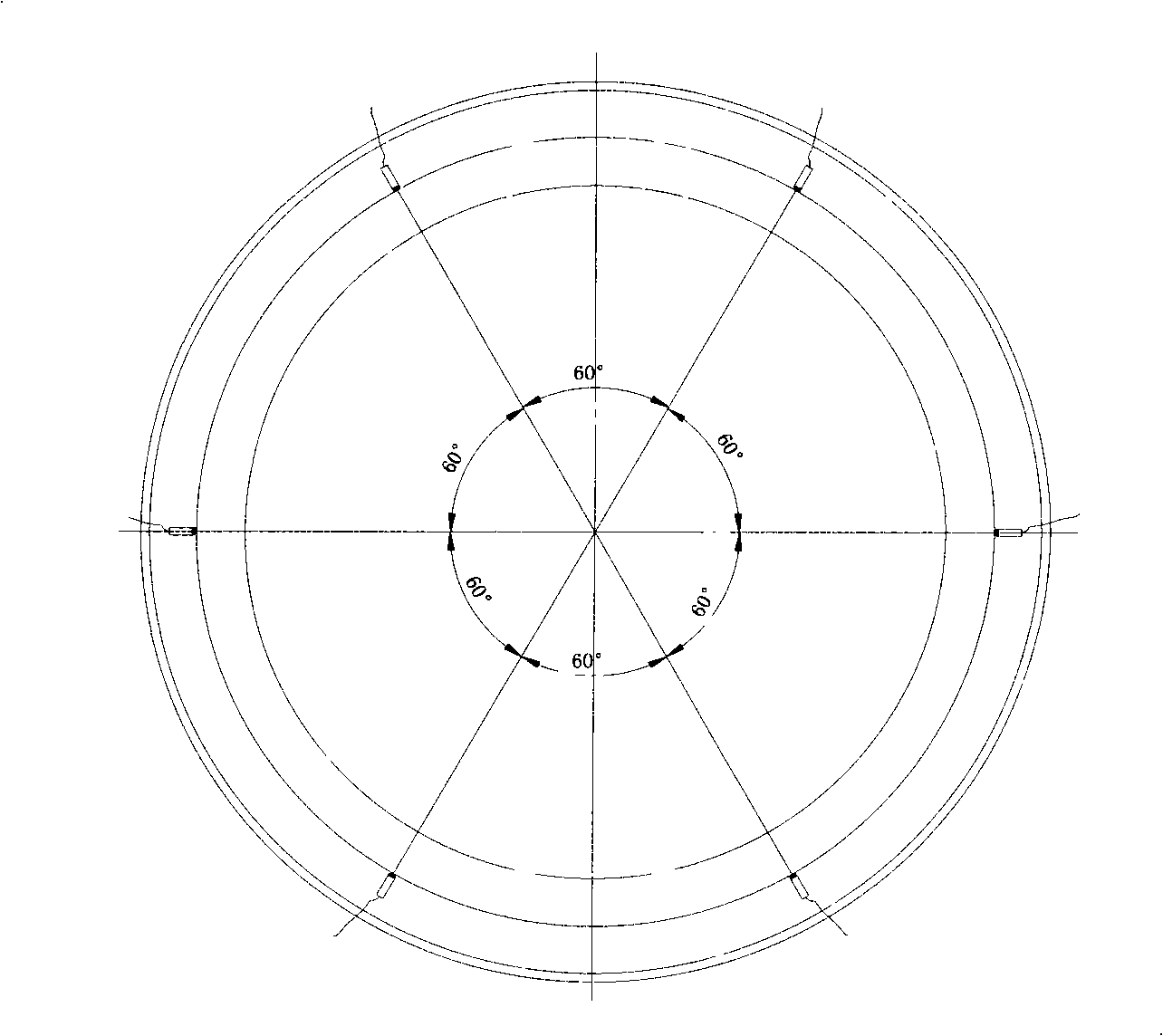

[0031] ②According to the measurement points determined in step ①, a thermocouple temperature measuring device is buried in the permanent layer of the converter lining and the bottom of the converter body, and the online continuous temperature measurement of the furnace lining is carried out;

[0032] ③According to the data obtained in step ②, combined with the furnace lining temperature-thickness reference table obtained in step ①, reversely calculate the thickness of the furnace lining;

[0033] ④ Determine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com