Low-carbon steel protecting slag for continuous casting of sheet billet and preparing method thereof

A thin slab continuous casting and mold slag technology is applied in the field of mold slag and preparation, low carbon steel mold slag for thin slab continuous casting and its preparation. problems, to achieve the effect of good slab surface quality, good melting uniformity and reasonable heat flux density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Selection of raw materials: waste glass, fluorite, limestone, magnesia, lithium carbonate, quartz sand, super carbon black, high carbon graphite, sodium fluoride, soda ash, sodium carboxymethyl cellulose.

[0025] Above-mentioned raw material chemical composition weight percentage is: SiO 2 28, CaO 29, Al 2 o 3 5, MgO3, Fe 2 o 3 3, F 9, Na 2 O+K 2 O 10, Li 2 O2, C9, CMC2.

[0026] Preparation:

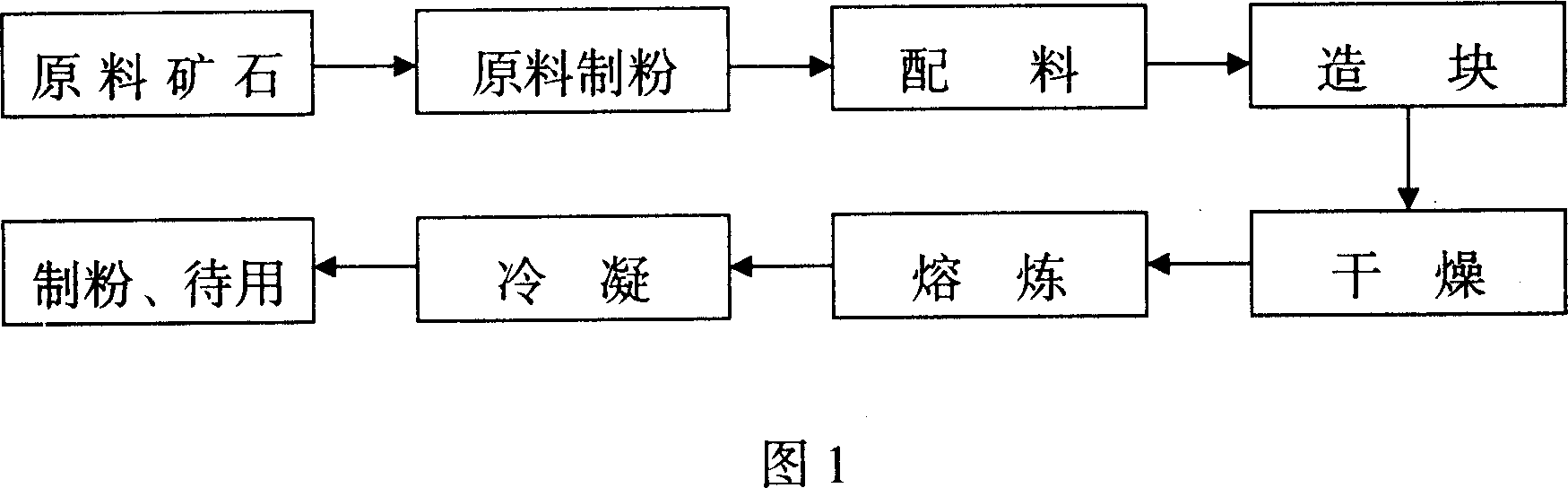

[0027]1. Production of pre-melted materials: crush limestone, waste glass and fluorite among the above raw materials into 0.1-1mm particles, then mix with soda ash and sodium fluoride powdered raw materials, agglomerate, dry, melt in the furnace, and then After condensation and crushing, it is ready for use. When the premelt is out of the furnace, it should be forced to cool by flushing the slag with a large water flow to obtain a premelt in the vitreous phase.

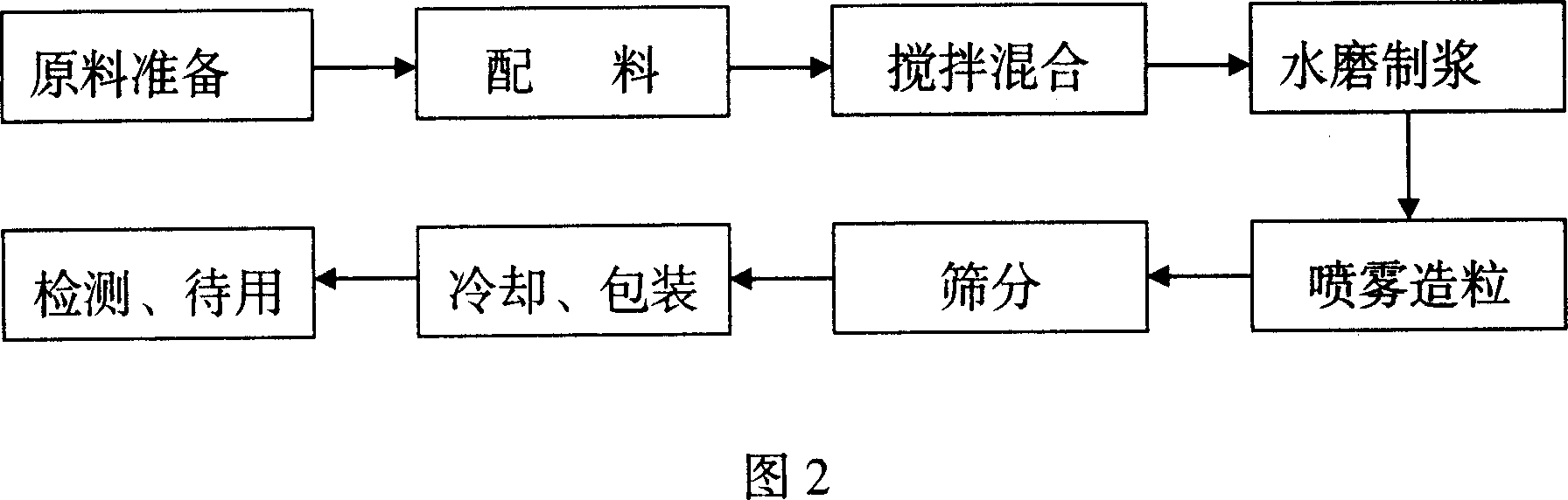

[0028] 2. Production of finished mold powder: Take the above premelt and add carbonaceous material and so...

Embodiment 2

[0030] Selection of raw materials: waste glass, fluorite, limestone, quartz sand, dolomite, magnesia, lithium carbonate, super carbon black, high carbon graphite, soda ash, sodium fluoride powder, cement clinker, sodium wood sulfonate, carboxymethyl Sodium cellulose.

[0031] Above-mentioned raw material chemical composition weight percentage is: SiO 2 31.6, CaO 32.9, Al 2 o 3 4.5, MgO 2.8, Fe 2 o 3 0.7, F7, Na 2 O+K 2 O 9, Li 2 O 1.9, C 8.5, CMC 0.6, sulfonate 0.5.

[0032] Preparation:

[0033] 1. Production of pre-melted materials: crush limestone, quartz sand, waste glass, dolomite, magnesia and fluorite among the above raw materials into 0.1-1mm particles, then mix with soda ash and sodium fluoride powder raw materials to form agglomerates , dried, melted in the furnace, and then condensed and crushed for later use. When the premelt is out of the furnace, the slag is flushed with a large water flow and forced to cool to obtain a premelt in the vitreous phase....

Embodiment 3

[0036] Selection of raw materials: waste glass, fluorite, limestone, magnesia, super carbon black, high carbon graphite, soda ash, cement clinker, sodium carboxymethyl cellulose.

[0037] Above-mentioned raw material chemical composition weight percentage is: SiO 2 32, CaO 33, Al 2 o 3 3, MgO 1, Fe 2 o 3 1.5, F 8.8, Na 2 O+K 2 O 12, C 7, CMC 1.7.

[0038] Preparation:

[0039] 1. Production of pre-melted materials: crush limestone, magnesia, waste glass and fluorite among the above raw materials into 0.1-1mm particles, then mix with soda ash, make agglomerates, dry, melt in the furnace, and then condense and crush Backup. When the premelt is out of the furnace, it should be forced to cool by flushing the slag with a large water flow to obtain a premelt in the vitreous phase.

[0040] 2. Production of finished mold powder: Take the above premelt and add carbonaceous materials, cement clinker, and sodium carboxymethyl cellulose according to the ratio. The carbonaceou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com