Patents

Literature

86results about How to "Improved melt stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Resin composition and multi-layer structures

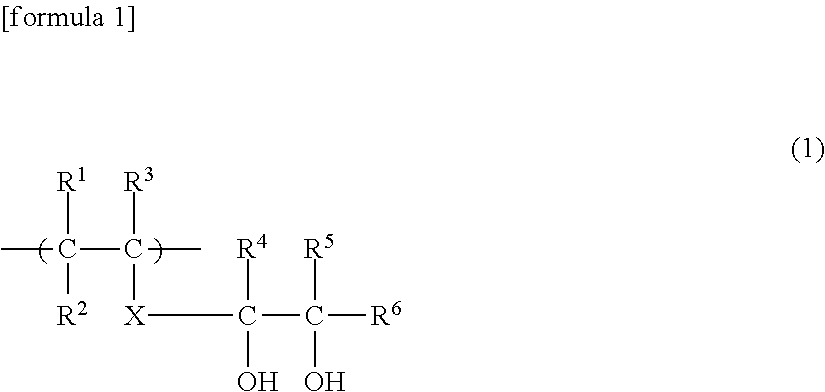

ActiveUS20050147778A1Improved melt stabilityInhibit deteriorationNon-fibrous pulp additionSynthetic resin layered productsStructural unitEthylene

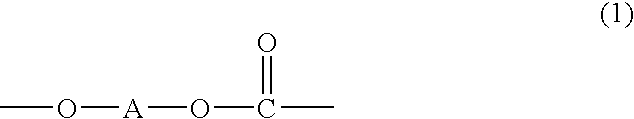

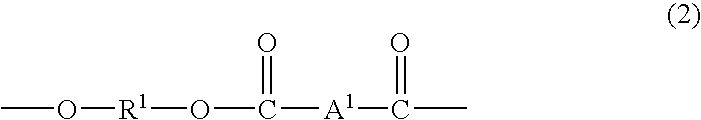

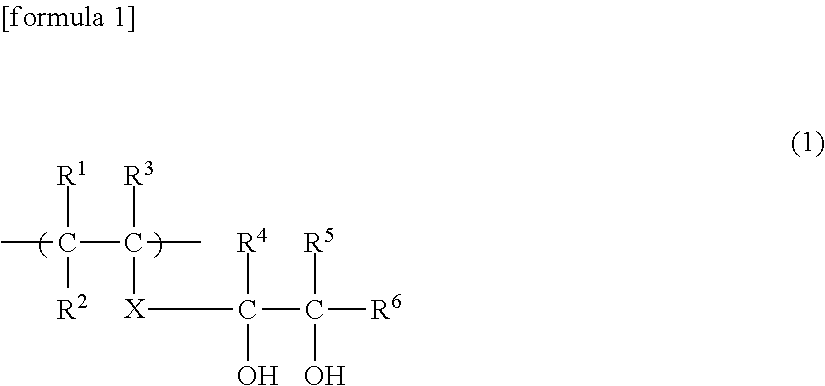

Provided is a resin composition comprising 1-99% by weight of a modified ethylene-vinyl alcohol copolymer (C) having an ethylene content of 5-55 mol %, which contains a specific structural unit (I) in an amount of 0.3-40 mol % and can be obtained by reacting an ethylene-vinyl alcohol copolymer (A) with a monofunctional epoxy compound (B) having a molecular weight of not more than 500, and 1-99% by weight of a thermoplastic resin (T1) other than (C). Moreover, a multilayer structure in which the resin composition and a thermoplastic resin (T2) are laminated is also provided. Thus, a resin composition superior in barrier properties, transparency, stretchability, flexibility, flexing resistance and interlayer adhesiveness and various kinds of molded articles made thereof are provided.

Owner:KURARAY CO LTD

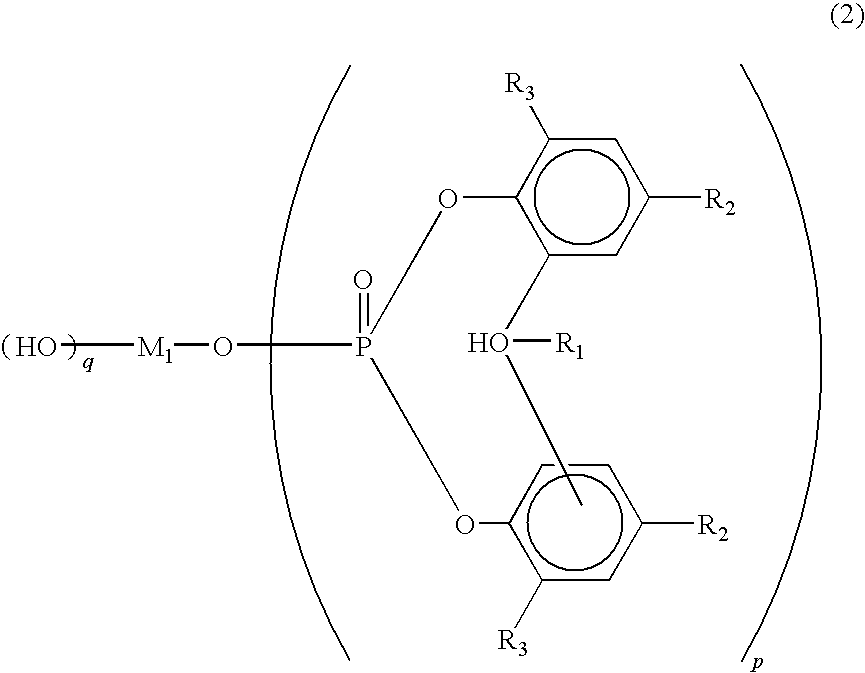

Polylactic acid composition

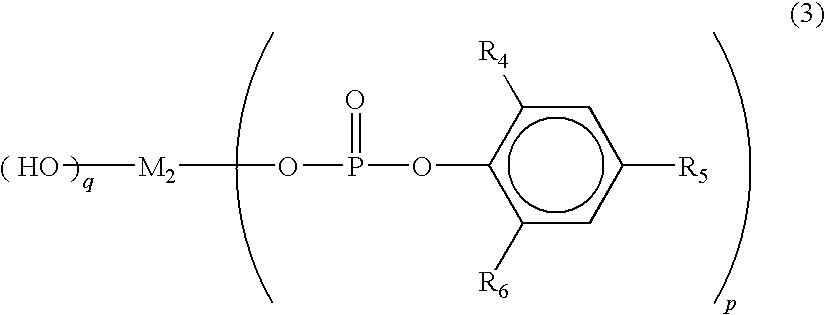

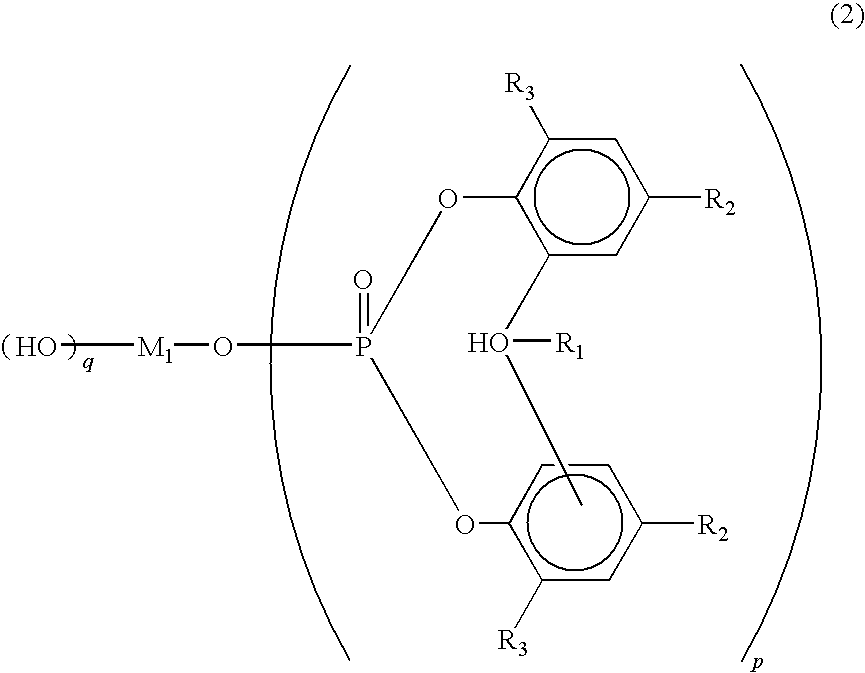

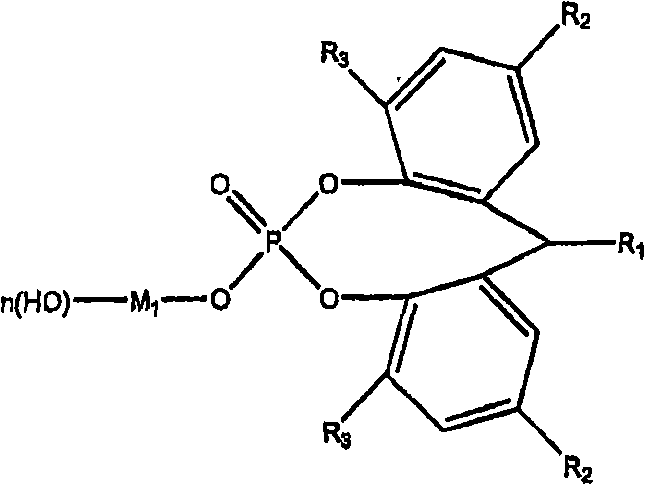

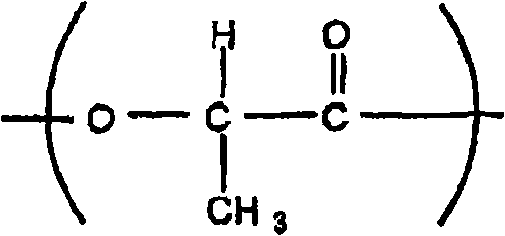

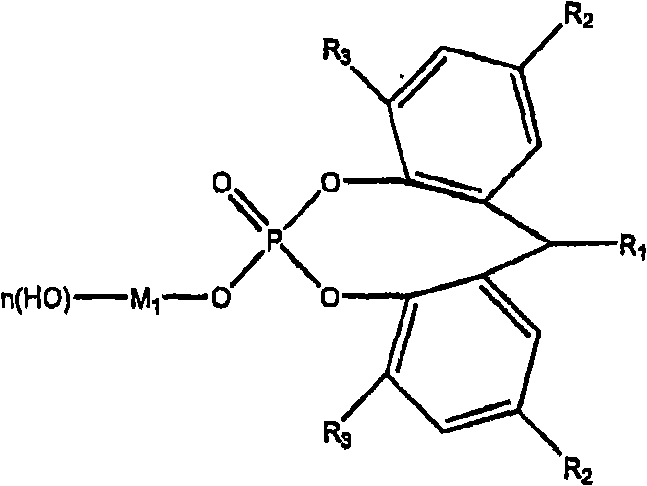

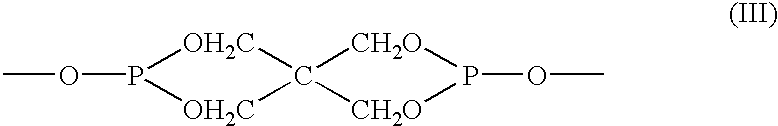

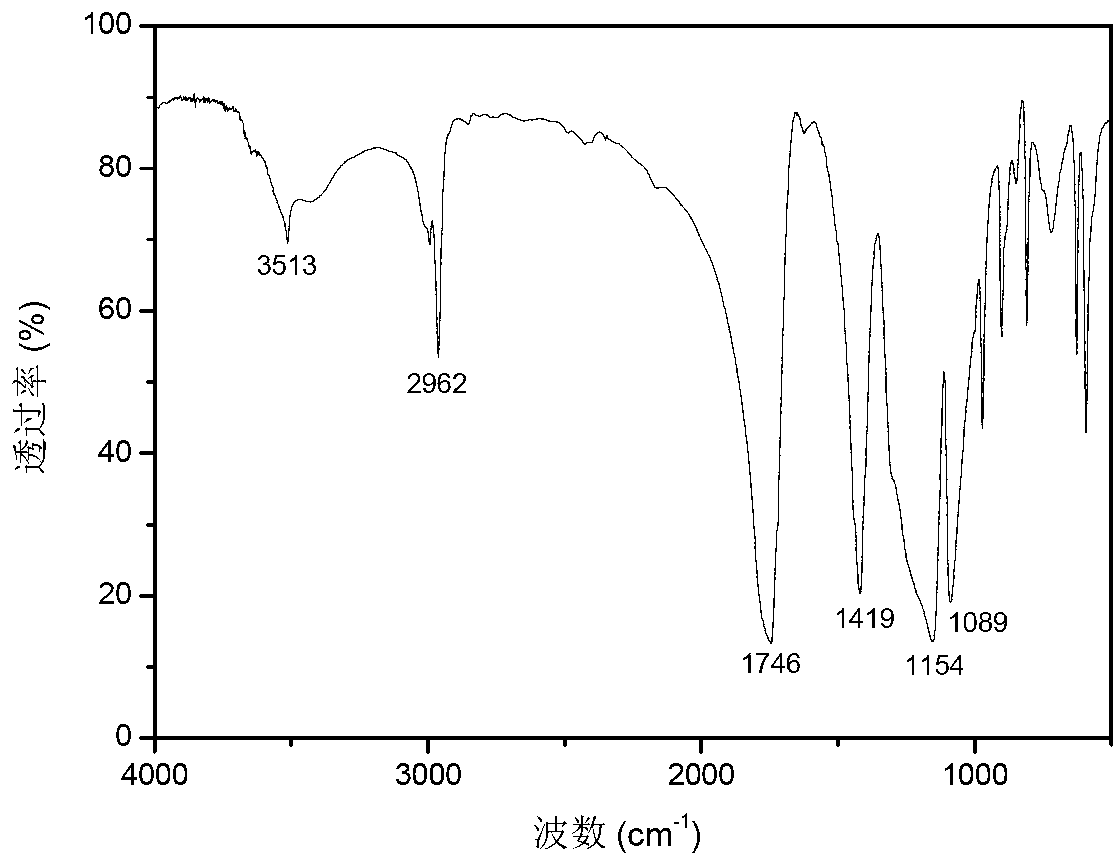

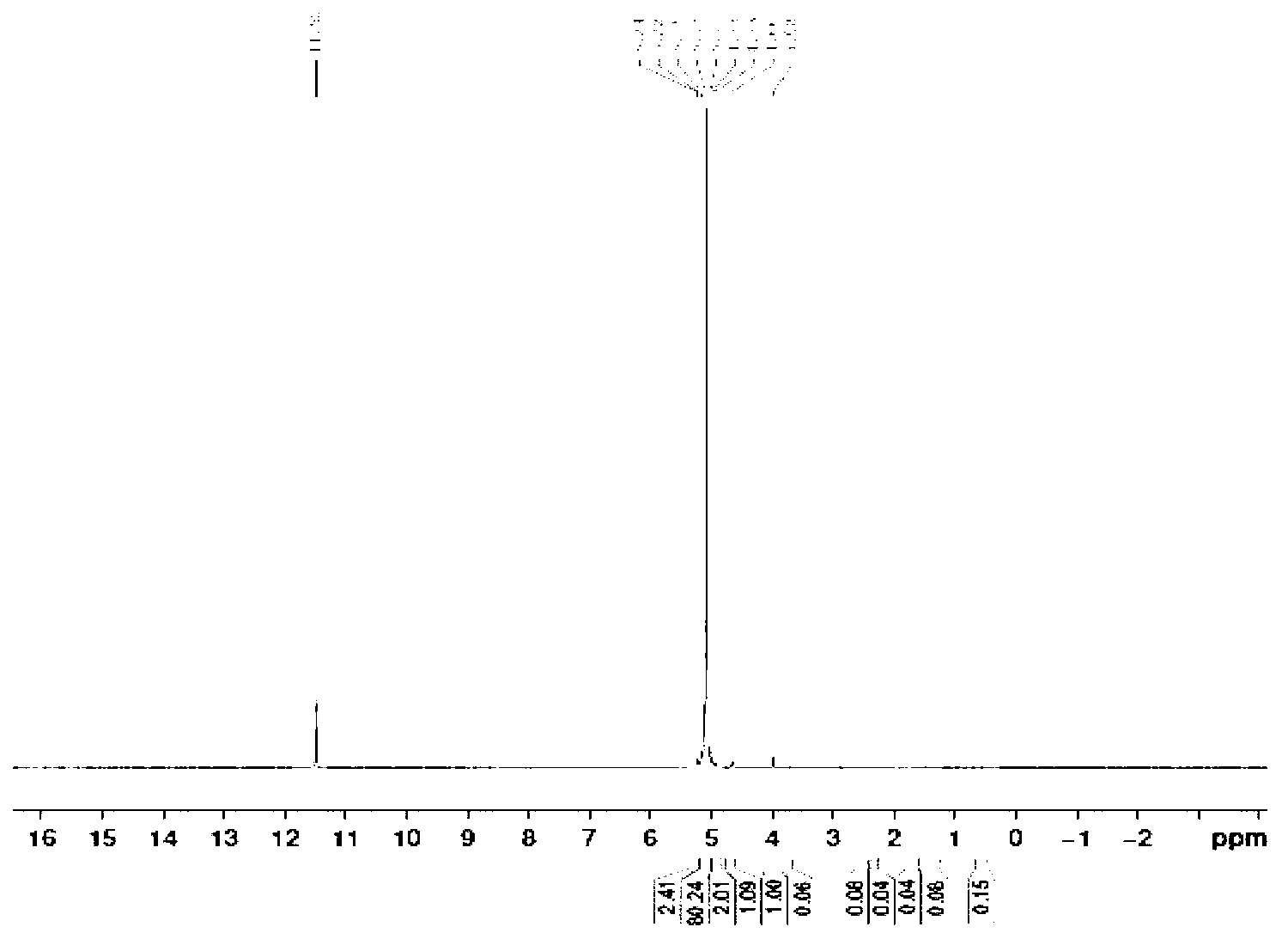

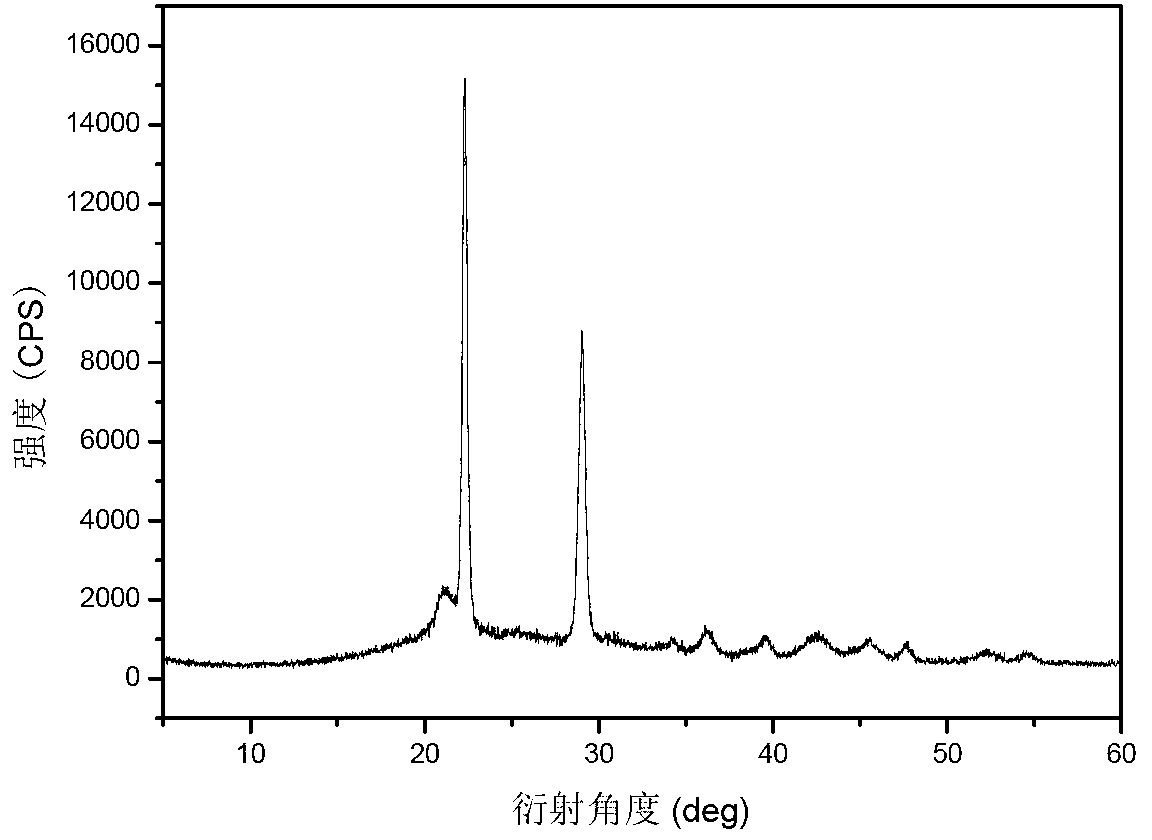

InactiveUS20100093888A1High crystallinityImprove heat stabilityPlastic/resin/waxes insulatorsGroup 5/15 element organic compoundsPhosphoric Acid EstersPolymer science

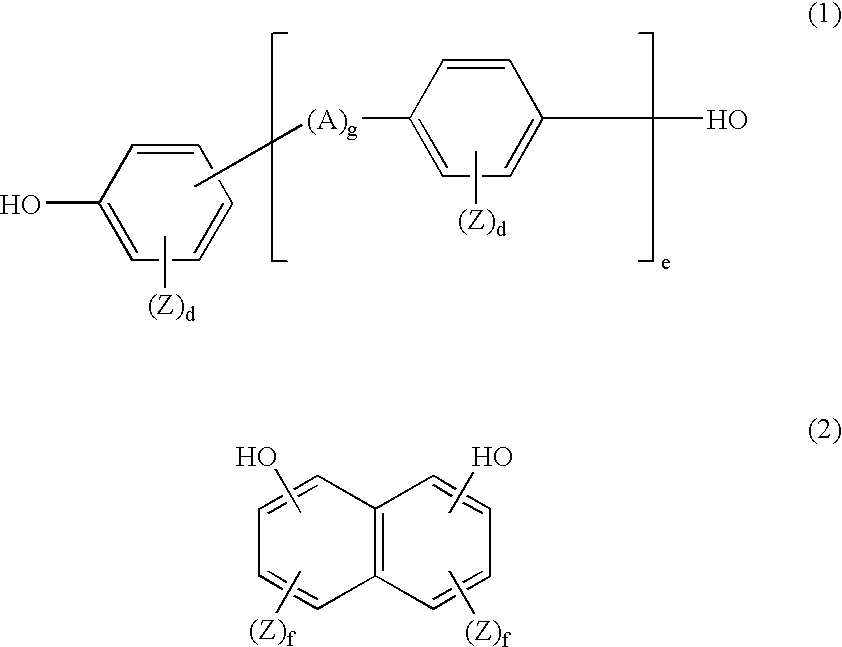

It is an object of the present invention to provide a polylactic acid composition having excellent crystallinity, wet heat stability and melt stability. It is another object of the present invention to provide a molded article which is obtained from the polylactic acid composition and excellent in appearance and color. The present invention is a composition and molded article thereof which comprises a polylactic acid (component A), a carbodiimide compound (component B) and a phosphoric acid ester metal salt (component C).

Owner:TEIJIN LTD +1

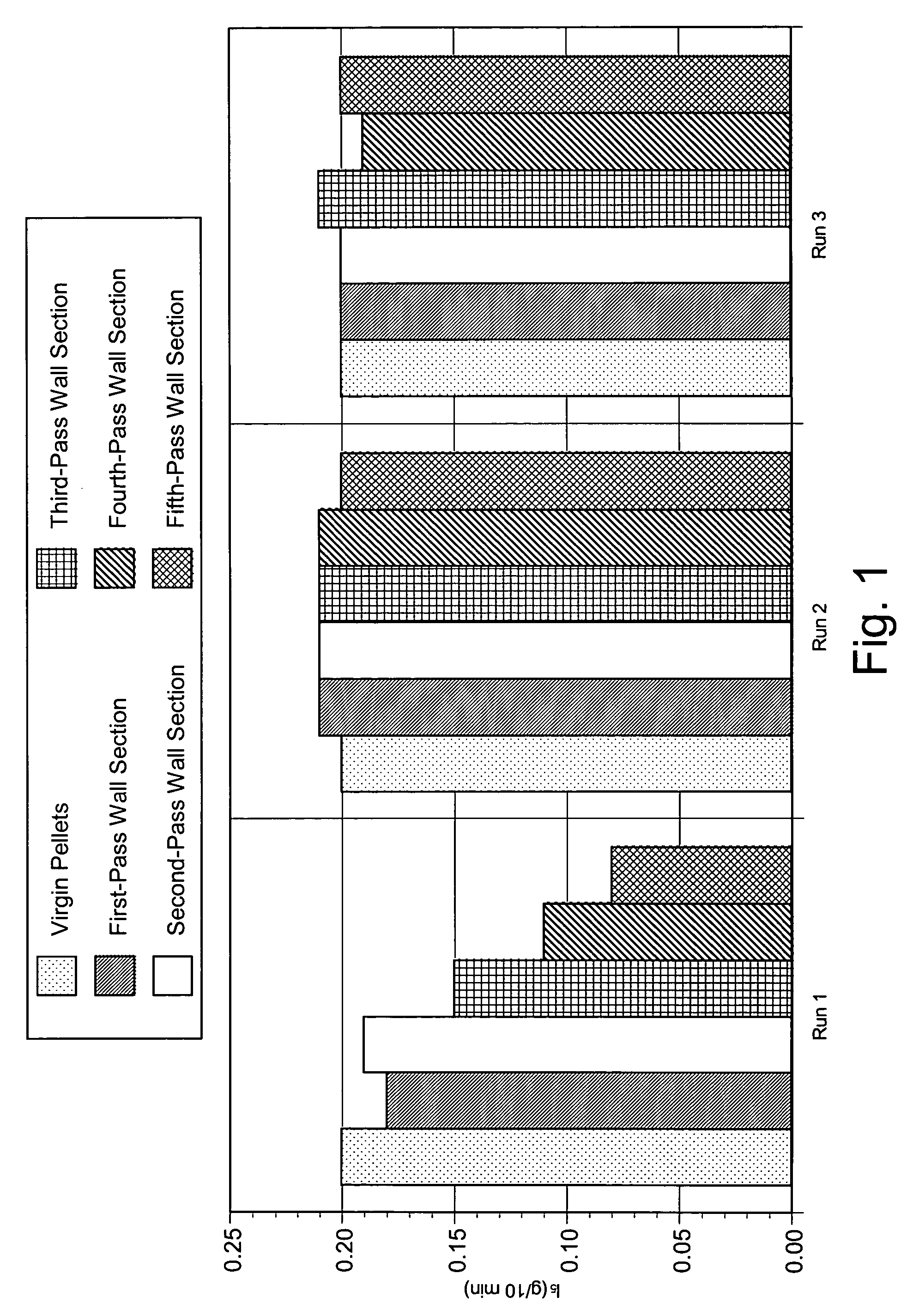

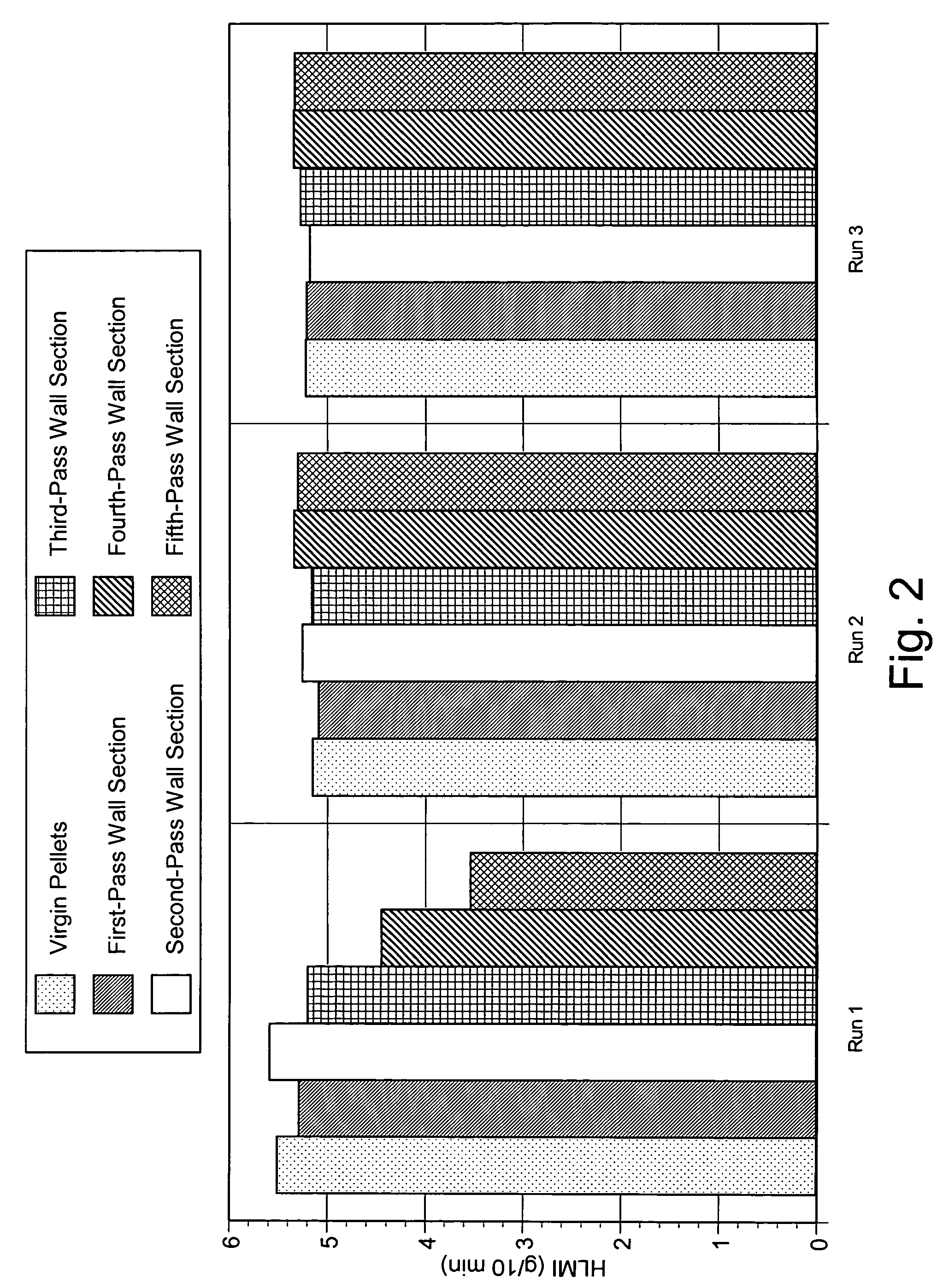

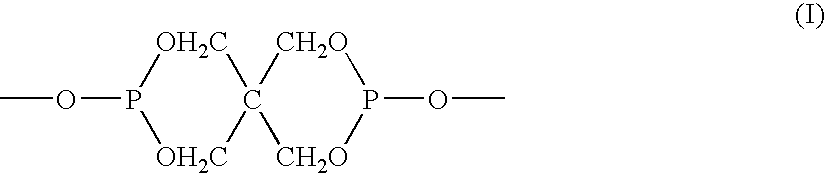

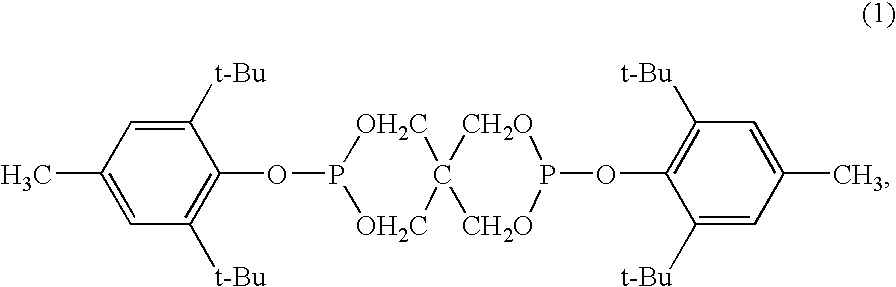

Phosphite additives in polyolefins

ActiveUS20050113494A1Improve color and stabilityImproved melt stabilityAluminium compoundsPolyolefinPolymer chemistry

The whiteness and stability after processing of a polyolefin have been found to be improved upon the addition of a combination of at least one high activity phosphite and at least one hydrolytically stable phosphite.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Phosphite additives in polyolefins

The whiteness and stability after processing of a polyolefin have been found to be improved upon the addition of a combination of at least one high activity phosphite and at least one hydrolytically stable phosphite.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP

Resin composition, method for producing the same and molded article

Owner:TEIJIN LTD +1

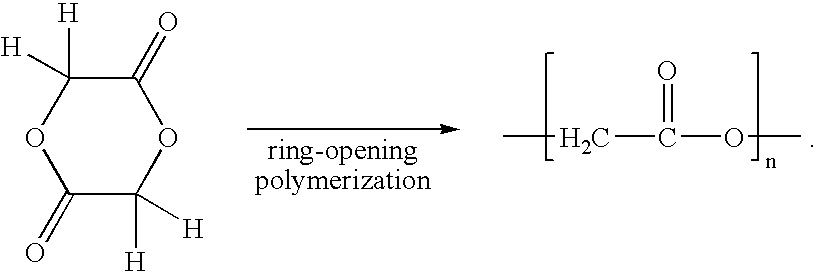

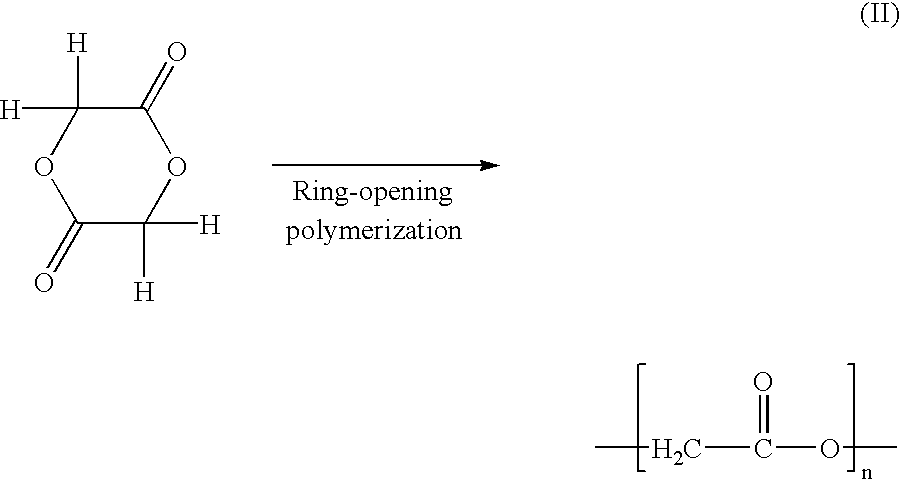

Polyhydroxycarboxylic acid and its production process

Polyhydroxycarhoxylic acids are provided, which are controlled in terms of the rate of biodegradability, and give molded or otherwise formed articles that are of uniform quality with neither premature strength drop nor premature deterioration of retention of outside shape, and their production process is provided as well. The poly-hydroxycarboxylic acids are obtained by ring-opening polymerization of cyclic esters. The polyhydroxy-carboxylic acids have a weight-average molecular weight (Mw) in the range of 10,000 to 1,000,000, a molecular weight distribution in the range of 1.0 to 2.5 as represented by the weight-average molecular weight-to-number-average molecular weight ratio (Mw / Mn) and a yellowness index (YI) of 40 or less, and have a precisely controlled rate of biodegradability.

Owner:KUREHA KAGAKU KOGYO KK

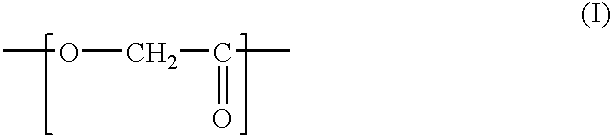

Crystalline polyglycolic acid, polyglycolic acid composition and production process thereof

InactiveUS20030125508A1Improved melt processabilityImproved melt stabilityOrganic chemistryBottlesVitrificationCrystallization temperature

Crystalline polyglycolic acid wherein a difference between the melting point Tm and the crystallization temperature Tc2 is not lower than 35° C., and a difference between the crystallization temperature Tc1 and the glass transition temperature Tg is not lower than 40° C. A production process of polyglycolic acid modified in crystallinity, comprising applying heat history to crystalline polyglycolic acid at a temperature of not lower than (the melting point Tm of the crystalline polyglycolic acid+38° C.). A polyglycolic acid composition comprising crystalline polyglycolic acid and a heat stabilizer, wherein a difference (T2-T1) between the temperature T2 at 3%-weight loss on heating of the polyglycolic acid composition and the temperature T1 at 3%-weight loss on heating of the crystalline polyglycolic acid is not lower than 5° C.

Owner:KUREHA KAGAKU KOGYO KK

Continuous preparation method of polyhydroxy acid with high molecular weight

The invention relates to a continuous preparation method of polyhydroxy acid with high molecular weight and belongs to the technical field of environmentally-friendly high molecular materials. A one-segment / multi-segment temperature controllable screw reactor is used, organic / inorganic lewis acid is used as a catalyst, certain temperature, catalyst dose and screw rotation speed are controlled, a cyclic ester monomer and the catalyst are continuously subjected to polymerization, and a product is fast obtained by means of continuous discharge. The chromaticity of the polyhydroxy acid is regulated and the stability of the polyhydroxy acid is improved by directly adding an antioxidant and a blocking agent at the middle-rear segment of the reactor. The prepared polyhydroxy acid has the advantages of high molecular weight and low chromatic value.

Owner:CHANGZHOU UNIV

Impact modified carbonate polymer composition having improved resistance to degradation and improved thermal stability

InactiveUS7393896B2Allow flexibilityLower surfactant levelSpecial tyresCoatingsPolyesterPolymer science

An aromatic carbonate polymer composition having improved thermal stability consisting of an aromatic carbonate polymer such as a polycarbonate or polycarbonate / polyester blend and an impact modifier which is free of alkali materials which catalytically degrade a polycarbonate. Also an impact modifier which is preferably of a shell-core structure prepared by the emulsion polymerization process and has a pH of about 3 to about 8. A preferred emulsifier is an alkyl sulfonate having an alkyl group of C6-C18 carbons.

Owner:SABIC GLOBAL TECH BV

Glass composition and optical member and optical instrument using the same

A glass composition satisfying the following conditions (A) to (L), the conditions are: (A) a content ratio of TeO2 is in a range from 50 to 95 mol %; (B) a content ratio of B2O3 is in a range from 1 to 33 mol %; (C) a content ratio of ZnO is in a range from 1 to 37 mol %; (D) a content ratio of Bi2O3 is in a range from 1 to 18 mol %; (E) a content ratio of P2O5 is in a range from 0 to 15 mol %; (F) a content ratio of R2O (where R represents at least one element selected from the group consisting of Li, Na, and K) is in a range from 0 to 13 mol %; (G) a content ratio of MO (where M represents at least one element selected from the group consisting of Mg, Ca, Sr, and Ba) is in a range from 0 to 13 mol %; (H) a content ratio of TiO2 is in a range from 0 to 13 mol %; (I) a content ratio of Nb2O5 is in a range from 0 to 10 mol %; (J) a content ratio of Ta2O5 is in a range from 0 to 13 mol %; (K) a content ratio of L2O3 (where L represents at least one element selected from the group consisting of yttrium and lanthanoids) is in a range from 0 to 11 mol %; and (L) a content ratio of a total amount of P2O5, R2O, MO, TiO2, Nb2O5, Ta2O5, and L2O3 described in (E) to (K), respectively, is in a range from 0 to 15 mol %.

Owner:NIKON CORP

Flame-retardant aromatic polycarbonate resin composition

InactiveUS20050256227A1Improved melt stabilityAvoid serious impactSpecial tyresDrageesOrganic sulfonic acidFluoropolymer

A flame retardant aromatic polycarbonate resin composition comprising 100 parts by weight of an aromatic polycarbonate (A), 0.01 to 0.5 part by weight of branched metal oxide particles (branched metal oxide aggregates and / or branched metal oxide agglomerates) (B), 0.0001 to 0.2 part by weight of an alkali metal salt (C) of an organic sulfonic acid, and 0.01 to 0.5 part by weight of a fluoropolymer (D), the branched metal oxide particles (B) being dispersed in a mixture of components (A), (C) and (D), wherein at least 70% of the branched metal oxide particles (B) have a diameter within the range of from 10 to 200 nm.

Owner:ASAHI KASEI KK

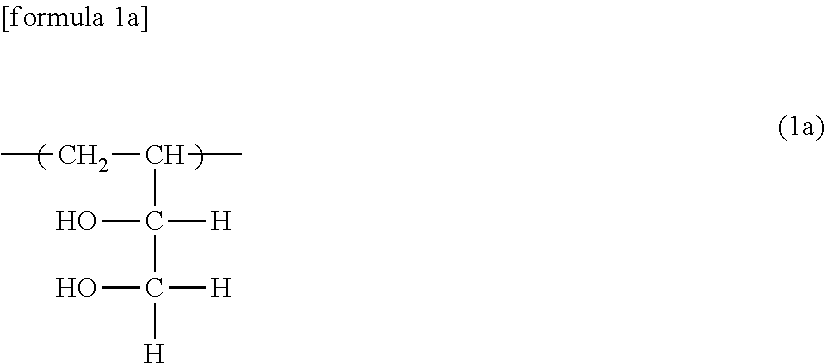

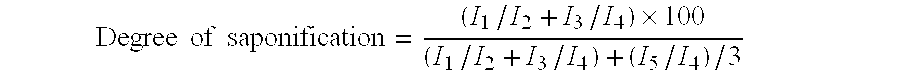

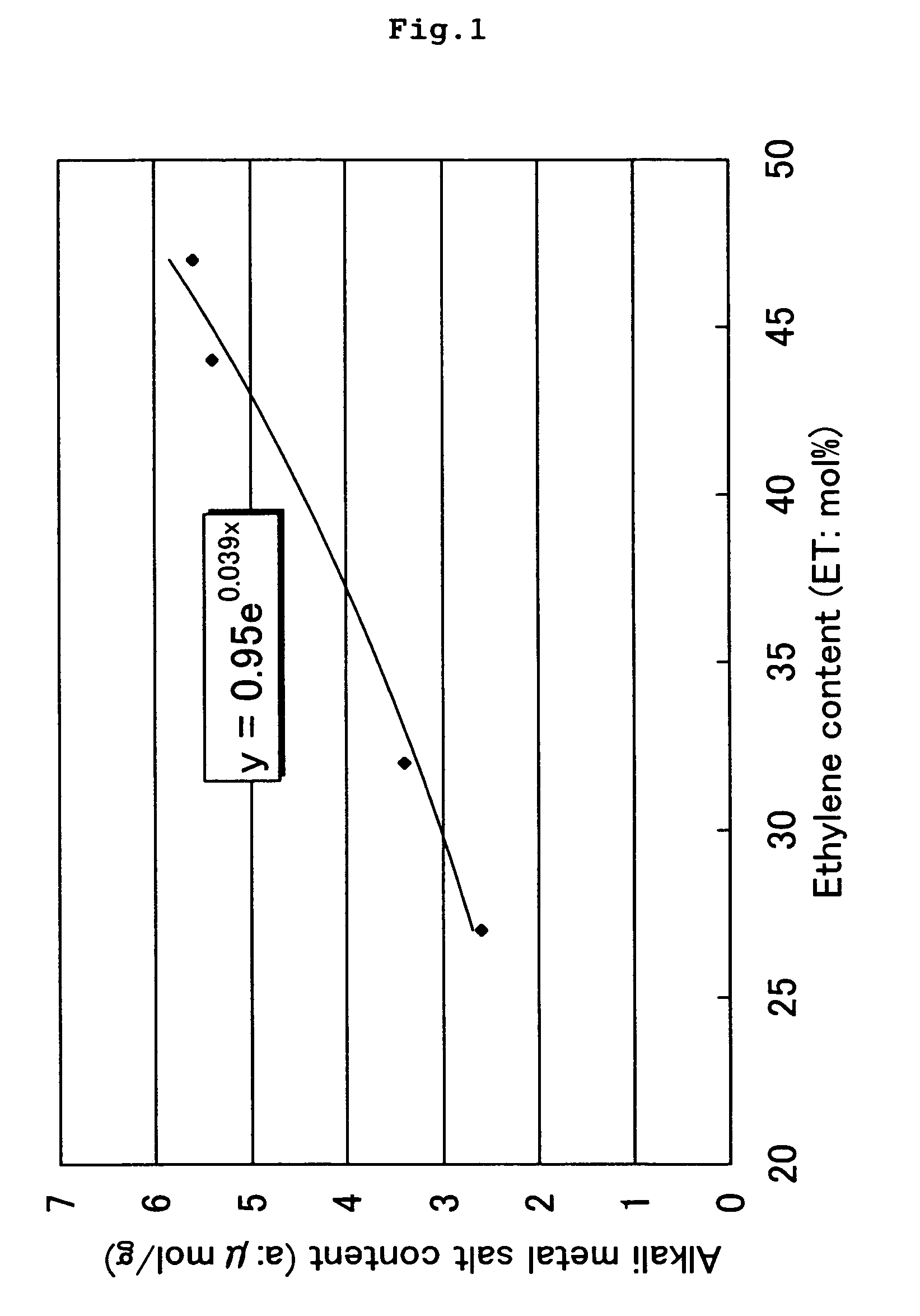

Saponified ethylene-vinyl ester copolymer resin composition and multilayer structure using the composition

ActiveUS20130065001A1Improve impactReduce the amount requiredBottlesSynthetic resin layered productsAlkaline earth metalVinyl ester

Disclosed is an EVOH resin composition which exhibits coloration resistance and thermal resistance even at high temperature, and which has excellent adhesiveness to a thermoplastic resin composition. Such EVOH resin composition can provide a multilayer structure having excellent appearance. The EVOH resin composition comprises (A) an EVOH resin, (B) an alkaline earth metal, (C) an alkali metal, and (D) a carboxylic acid having from 2 to 4 carbon atoms, wherein the contents of the components (B), (C) and (D) are adjusted to the specific range.

Owner:MITSUBISHI CHEM CORP

Smelting process of high-niobium high-temperature alloy large-size ingot and high-niobium high-temperature alloy large-size ingot

ActiveCN111876649AIncrease temperatureFully uniform temperatureIncreasing energy efficiencySmelting processNiobium

The invention discloses a smelting process of a high-niobium high-temperature alloy large-size ingot and the high-niobium high-temperature alloy large-size ingot. The problems that metallurgical defects of black spots and white spots are formed by anabatic segregation due to expansion of diameter or weight of the high-niobium high-temperature alloy large-size ingot, steel ingots are exploded due to large heat stress and the weight of the steel ingots cannot be increased due to the tonnage restriction of vacuum induction melting equipment are solved. The smelting process comprises the steps that that vacuum induction melting is carried out, a plurality of vacuum induction ingots with the same component are prepared, then electroslag electrodes with the same number are prepared, exchanging electroslag remelting is carried out, then prepared electroslag ingots are used for preparing consumable electrodes, and then the consumable electrodes are used as initial raw materials to perform multiple vacuum consumable remelting. By adopting the smelting process, the high-niobium high-temperature 706 alloy large-size ingot with the ingot weight of more than 15 tons and the diameter of more than 800mm can be prepared, the formation of the metallurgical defects of the black spots and the white spots is restrained to the utmost extent, the element segregation degree is reduced, and the steelingots are effectively prevented from being exploded.

Owner:BEIJING CISRI GAONA TECH +1

Poly(arylene sulfide) and production process thereof

InactiveUS7655748B2High whitenessExcellent melt formabilityNatural resin processMolten stateShear rate

A poly(arylene sulfide) having properties that a melt viscosity is 1 to 3,000 Pa·s as measured under conditions of a temperature of 310° C. and a shear rate of 1,216 sec−1, a pH is 7.0 to 12.0 as measured in a mixed solvent of water / acetone (volume ratio=2 / 1), a crystallization temperature is at most 220° C. as measured in the course of lowing the temperature of the polymer at a rate of 10° C. / min from a molten state, and a whiteness degree is at least 70 as measured in the form of a melt molded or formed product, and a production process thereof.

Owner:KUREHA KAGAKU KOGYO KK

Blow molded container and method for producing the same

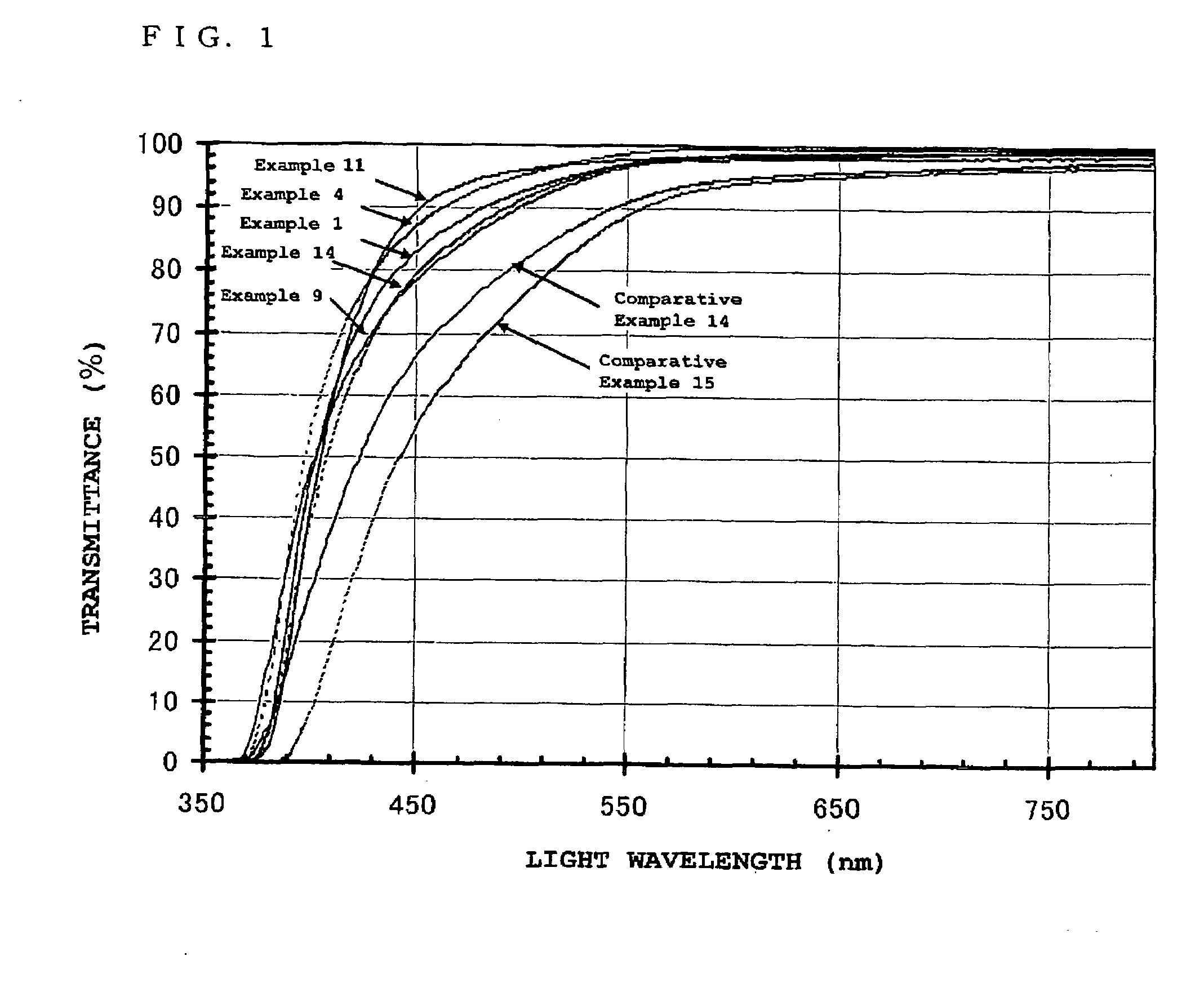

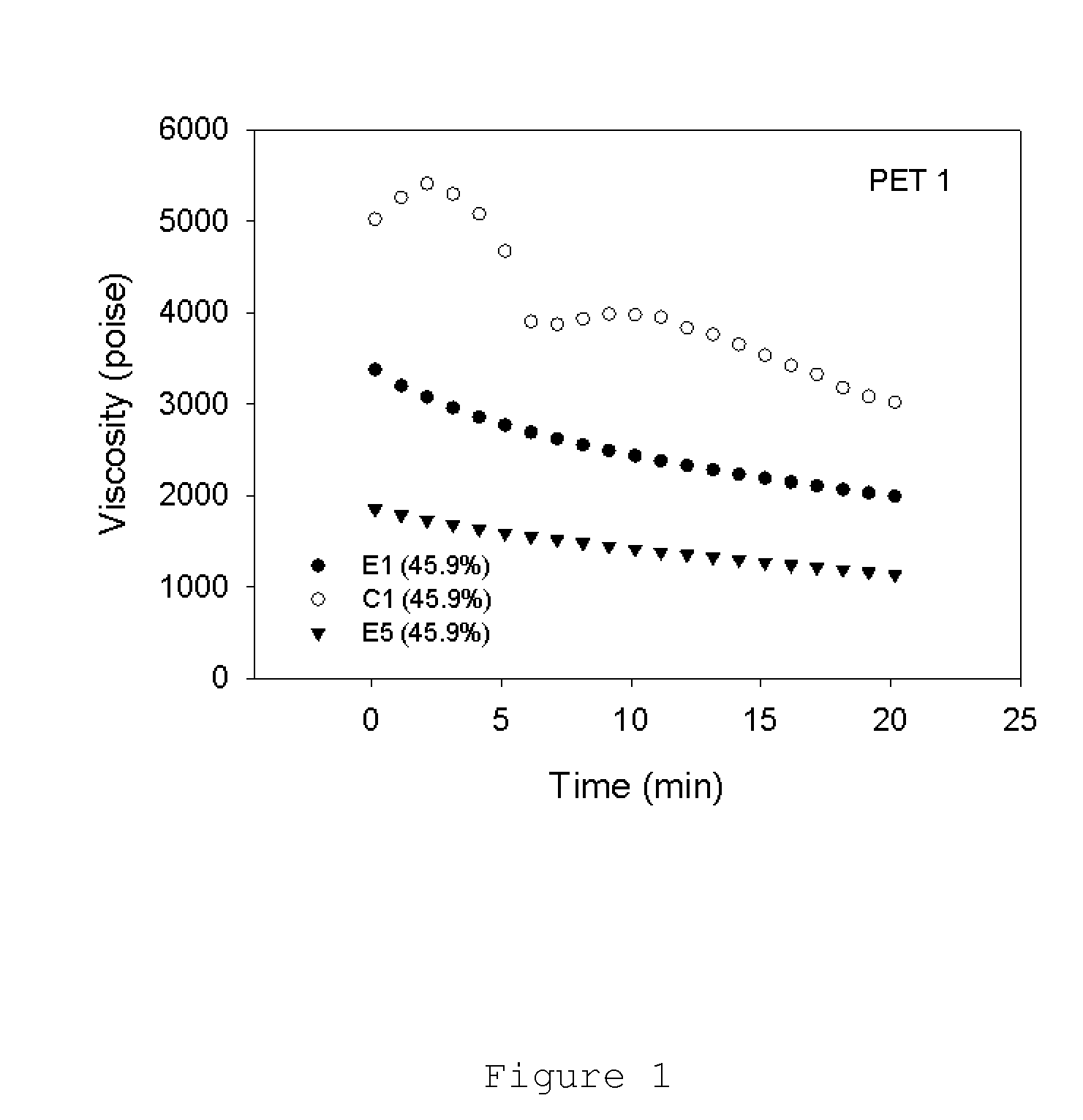

ActiveUS20050038163A1Improve interlayer adhesionImproved melt stabilityEnvelopes/bags making machineryBottlesAcetic acidBlow molding

For providing a blow molded container comprising an EVOH resin composition which generates less sourness and which is superior in interlayer adhesiveness and providing an environmentally friendly production process in which no carboxylic acid such as acetic acid is released during the production and molding of the EVOH resin composition, disclosed is a method comprising blow molding an ethylene-vinyl alcohol copolymer resin composition obtained by contacting an ethylene-vinyl alcohol copolymer with an aqueous solution containing both carbon dioxide gas and at least one additive selected from the group consisting of an alkali metal salt (A) and a boron compound (B) and then drying the copolymer until the water content is reduced to 1% by weight or less.

Owner:KURARAY CO LTD

Polyacetal resin composition

A polyacetal resin composition comprises a polyacetal resin, and at least one carboxylic acid hydrazide selected from a saturated or unsaturated long-chain aliphatic carboxylic acid hydrazide, a saturated or unsaturated alicyclic carboxylic acid hydrazide, a dimer acid or trimer acid hydrazide, and an oxycarboxylic acid hydrazide corresponding to each of these hydrazides. The proportion of the carboxylic acid hydrazide may be about 0.001 to 20 parts by weight relative to 100 parts by weight of the polyacetal resin. The polyacetal resin composition may further comprise at least one member selected from an antioxidant, a heat stabilizer, a processing stabilizer, a weather (light)-resistant stabilizer, an impact resistance improver, a slip-improving agent, a coloring agent, and a filler. With the use of such a resin composition, stability of a polyacetal resin is improved, and formaldehyde emission is inhibited.

Owner:POLYPLASTICS CO LTD

Polyester blends

ActiveUS20100249293A1Good melt stabilityGood melt viscosityOrganic dyesDyeing processPolymer chemistryFiber

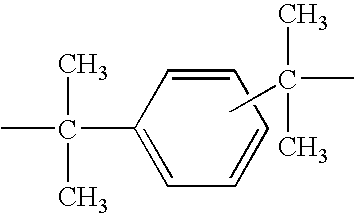

Polyester blends comprising (1) polyesters prepared from terephthalic acid, 100 to 5 mol % of 2,2,4,4-tetramethyl-1,3-cyclobutanediol, and 0 to 95 mol % 1,4-cyclohexanedimethanol and (b) polyesters prepared from terephthalic acid and alkylene glycol. The blends may also contain an impact modifier and a phosphorous stabilizer. These blends can have a combination of thermal stability and toughness—making the materials useful in engineering molding plastics, packaging, films, and fibers.

Owner:EASTMAN CHEM CO

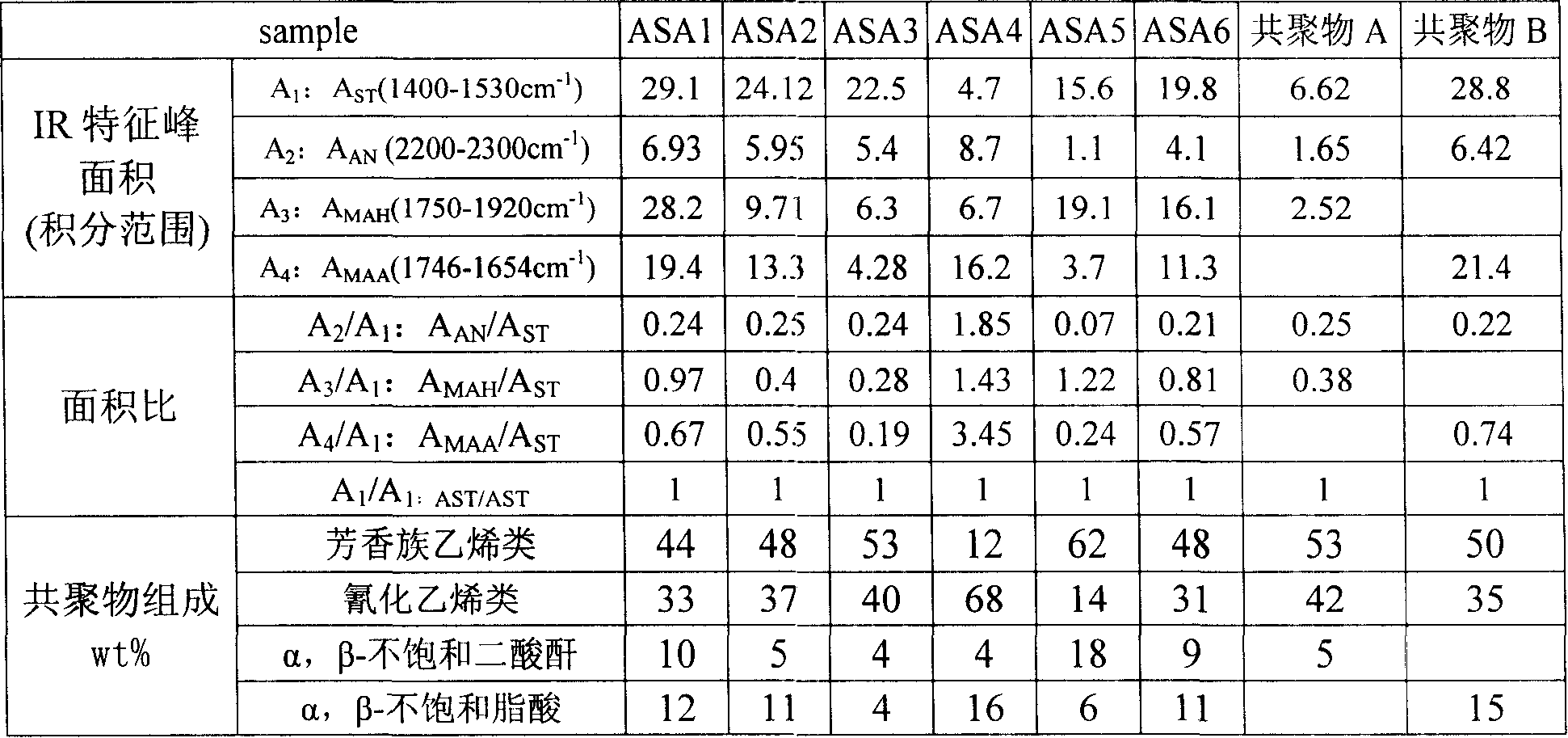

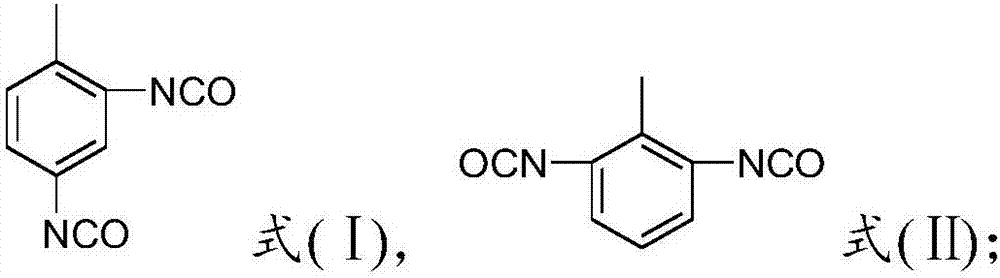

Compatibilizer used for ABS composition and ABS composition having the same

The invention relates to a copolymer compatilizer applied in the composite ABS and a composite composed of the compatilizer, ABS and thermoplastic resin. The copolymer compatilizer is a tetrabasic random copolymer, and which is polymerized by the aromatic series vinyl monomer, the cyaniding vinyl monomer, the Alpha, Beta-unsaturated dicarboxylic anhydride monomer and the Alpha, Beta -unsaturated fatty acid monomer and the polymerized, and through the mass polymerization, Solution Polymerization or emulsion polymerization. When the random copolymer is as a compatilizer applied in the composite comprised of ABS and polyamide, polyimide, polycarbonate, polyester, biodegradable polyesters, polyformaldehyde, polymethyl methacrylate or fibrin, the resistance of the composite, stability of the melt and process ability can be greatly improved.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

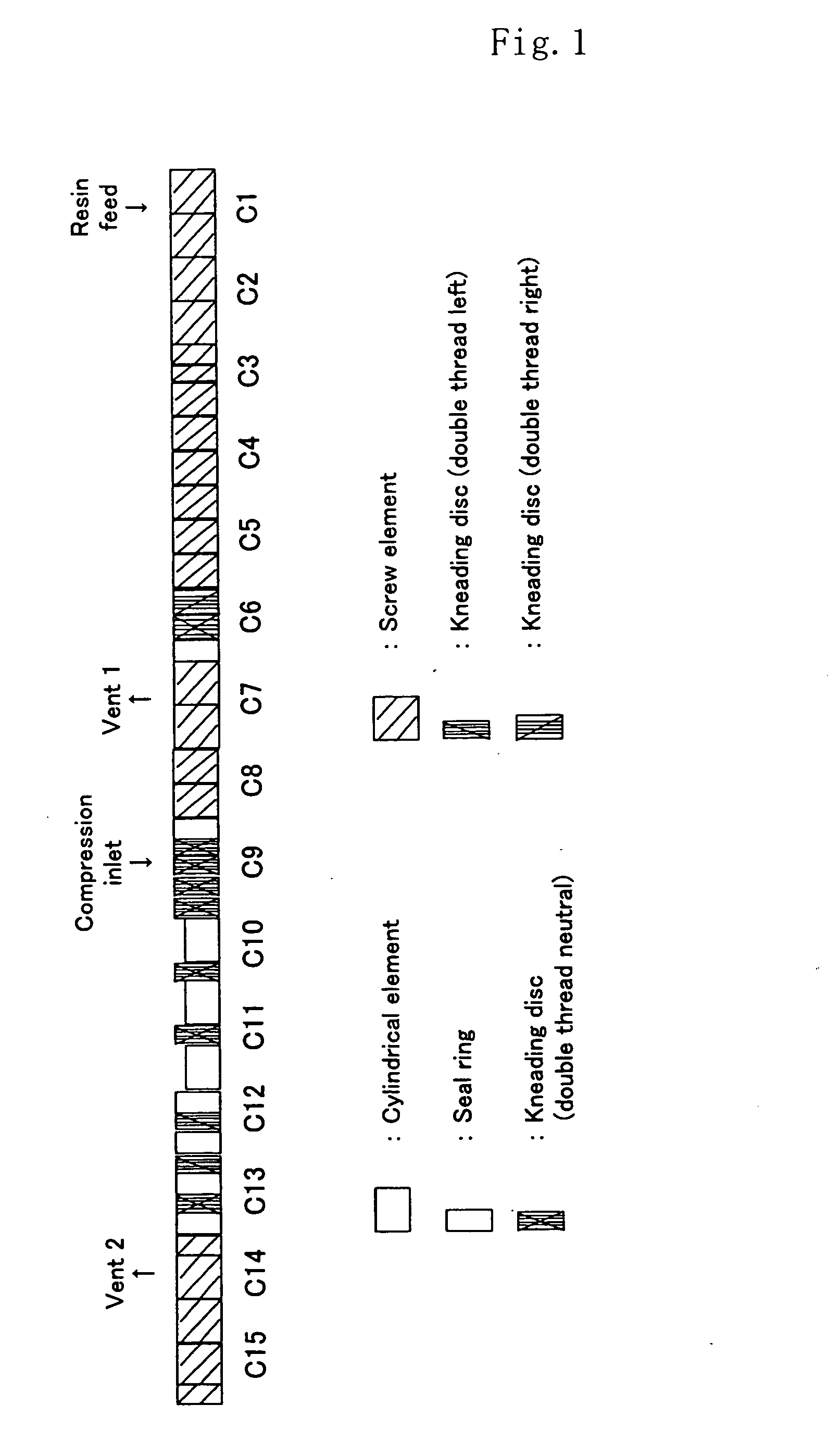

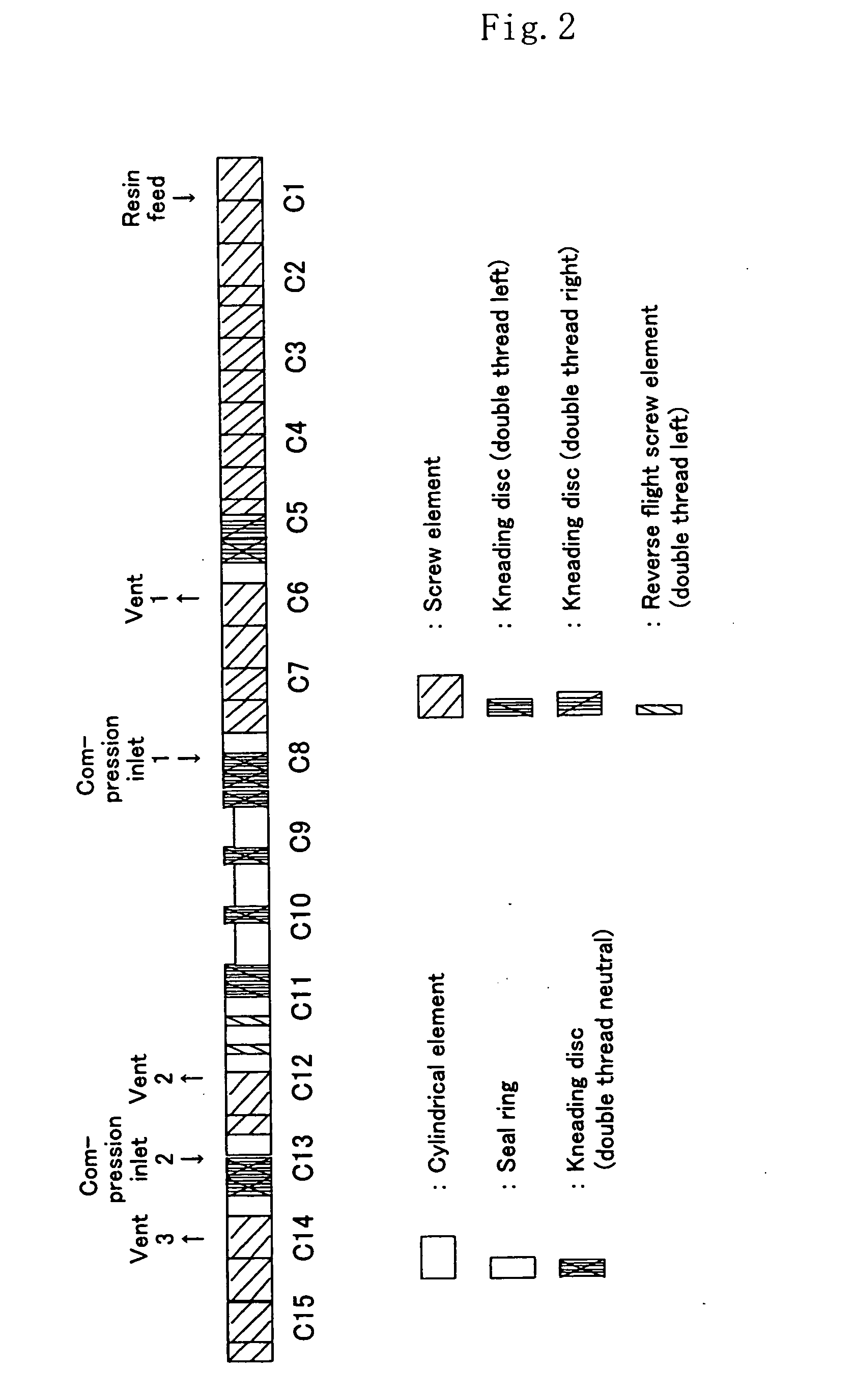

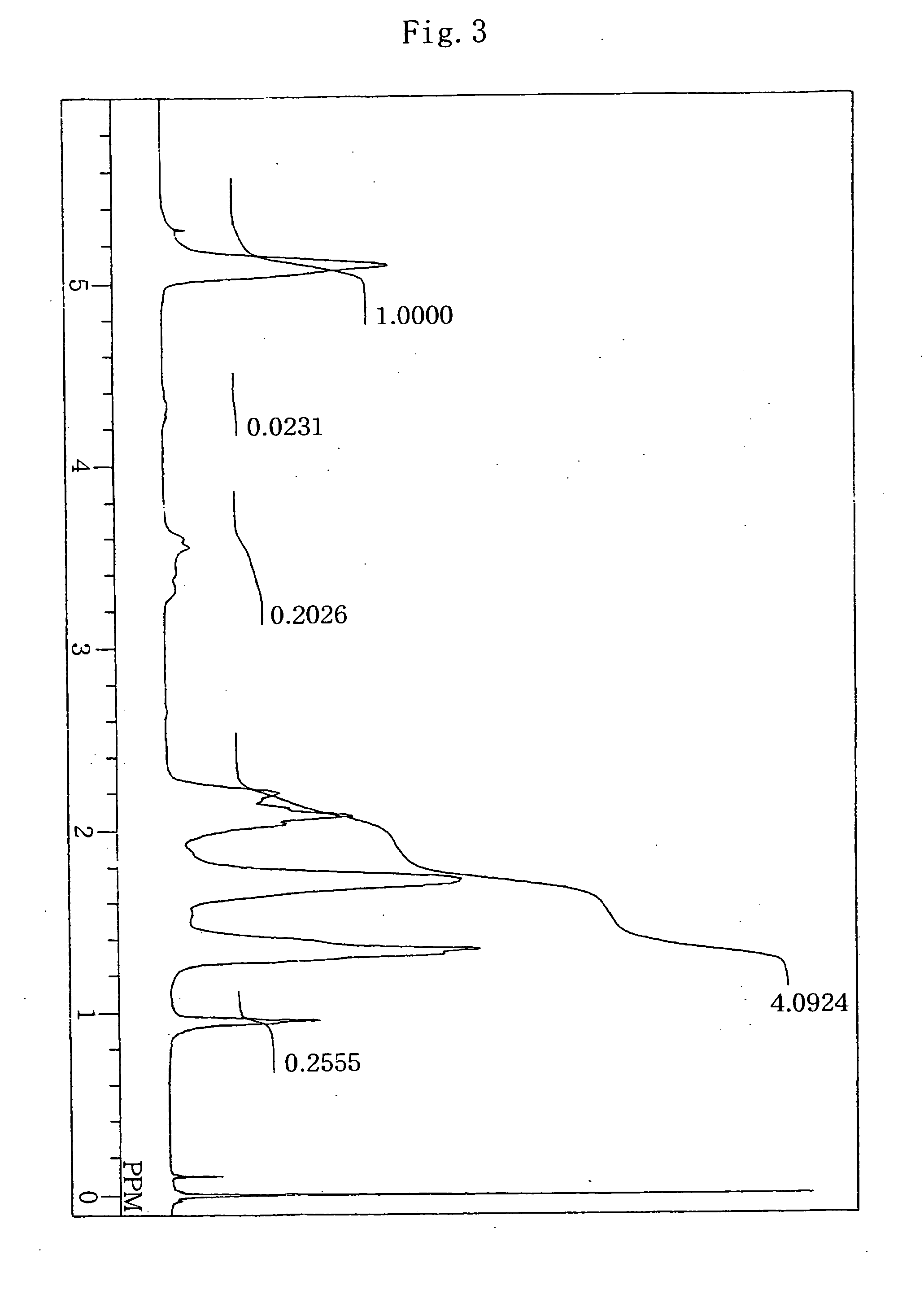

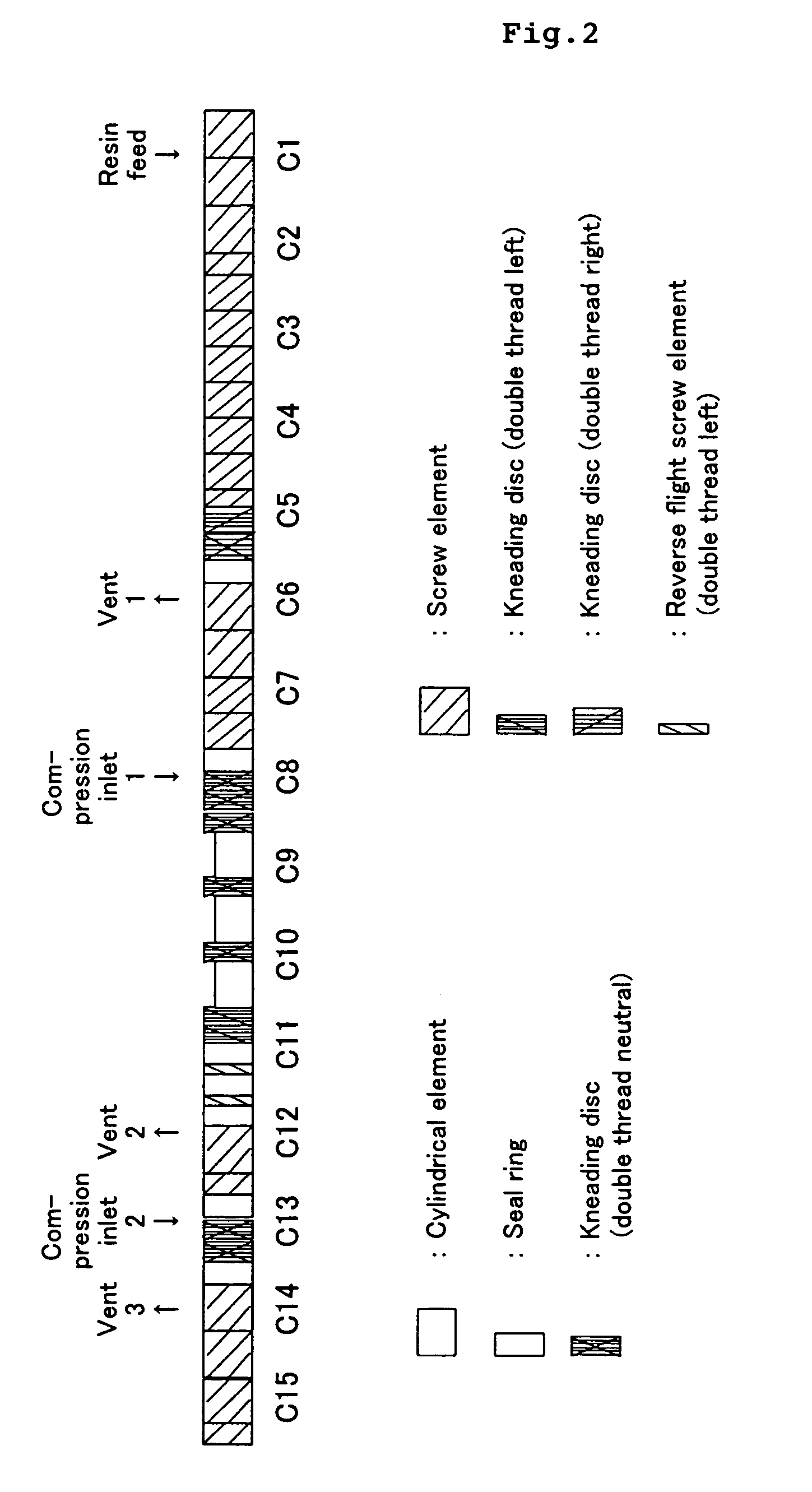

Resin composition and method for producing the same

ActiveUS7473735B2Improved melt stabilityImprove workabilityRecord information storageMagnetic recordingAcetic acidCarboxylic acid

The present invention provides a resin composition which comprises EVOH and a thermoplastic resin other than EVOH and which generates less odor and therefore is suitable for food packaging applications. The invention also provides an environmentally friendly method for producing a resin composition, without releasing any carboxylic acid such as acetic acid to the peripheral environment. A resin composition containing less carboxylate group is obtained by contacting an ethylene-vinyl alcohol copolymer resin with an aqueous solution containing both carbon dioxide gas and at least one additive selected from the group consisting of an alkali metal salt (A) and a boron compound (B) and then melt kneading with a thermoplastic resin (G) other than EVOH.

Owner:KURARAY CO LTD

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Biodegradable material and biodegradable mulching film

The invention provides a biodegradable material and a biodegradable mulching film. The biodegradable material is prepared from, by weight, 50-90 parts of polylactic acid, 5-50 parts of a polyester plasticity agent and 0.5-15 parts of a cross-linking agent. The polyester plasticity agent is prepared from diprotic acid, dihydric alcohol and trihydric alcohol in a copolymerization manner. The biodegradable material comprises the polyester plasticity agent which is prepared from the diprotic acid, the dihydric alcohol and the trihydric alcohol in the copolymerization manner and the cross-linking agent, the polyester plasticity agent interacts with the cross-linking agent, and the prepared biodegradable mulching film has biodegradability as well as high strength and ductility; and melt stability is good. An experiment result shows that compared with the prior art, the biodegradable mulching film has high strength and ductility; after the biodegradable mulching film is used for 70 days, the basic mechanical property of the biodegradable mulching film can still be 50% or above; and the biodegradable mulching film is decomposed into environmental-friendly micromolecules within 3-6 months.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

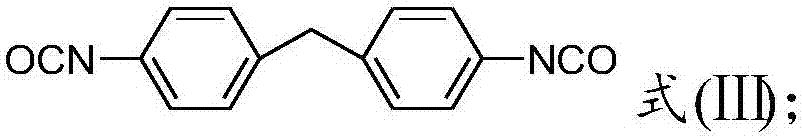

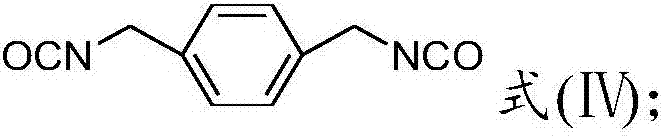

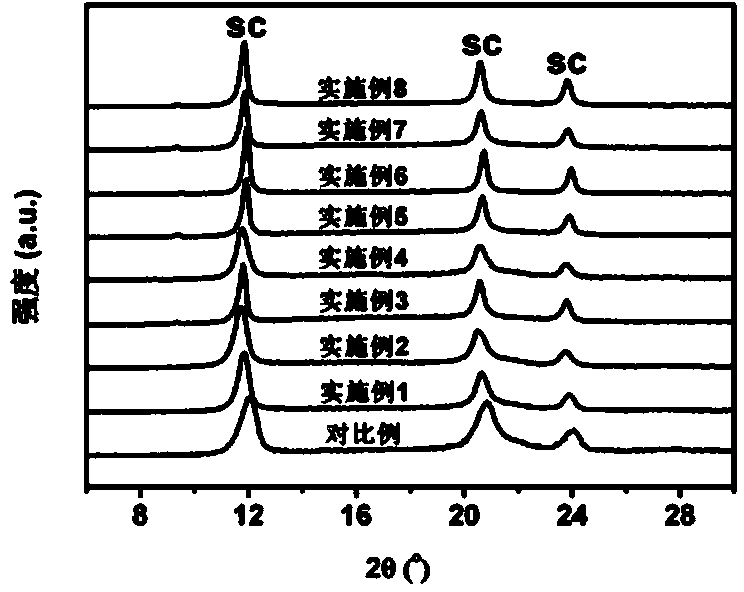

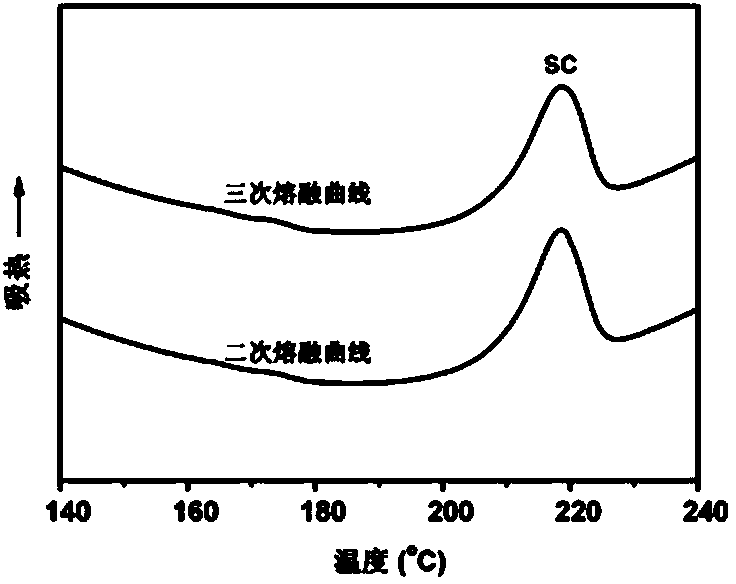

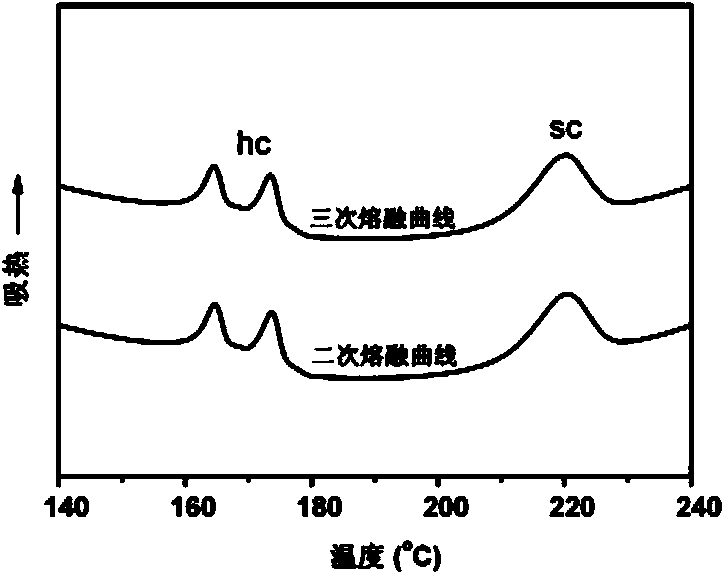

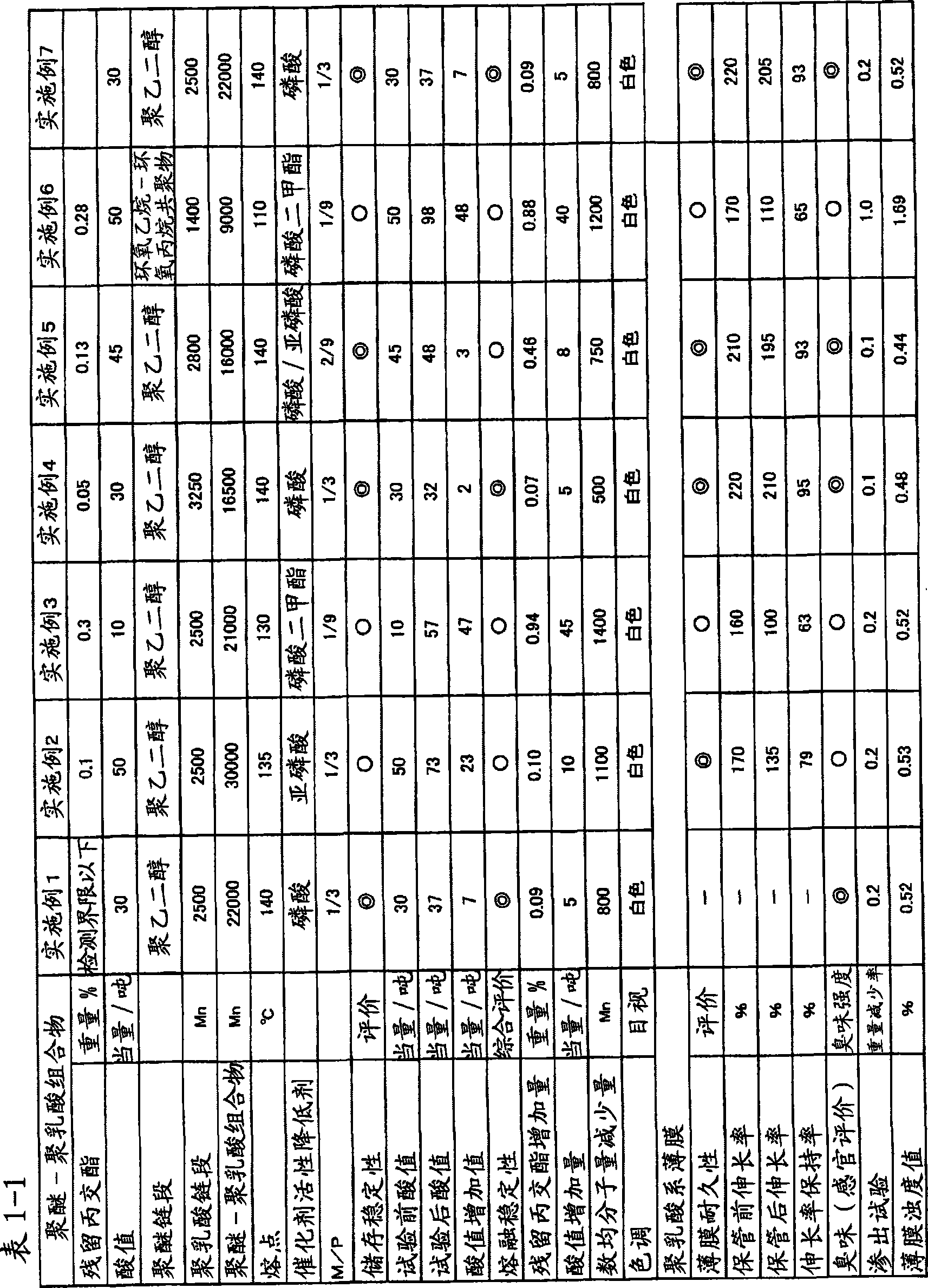

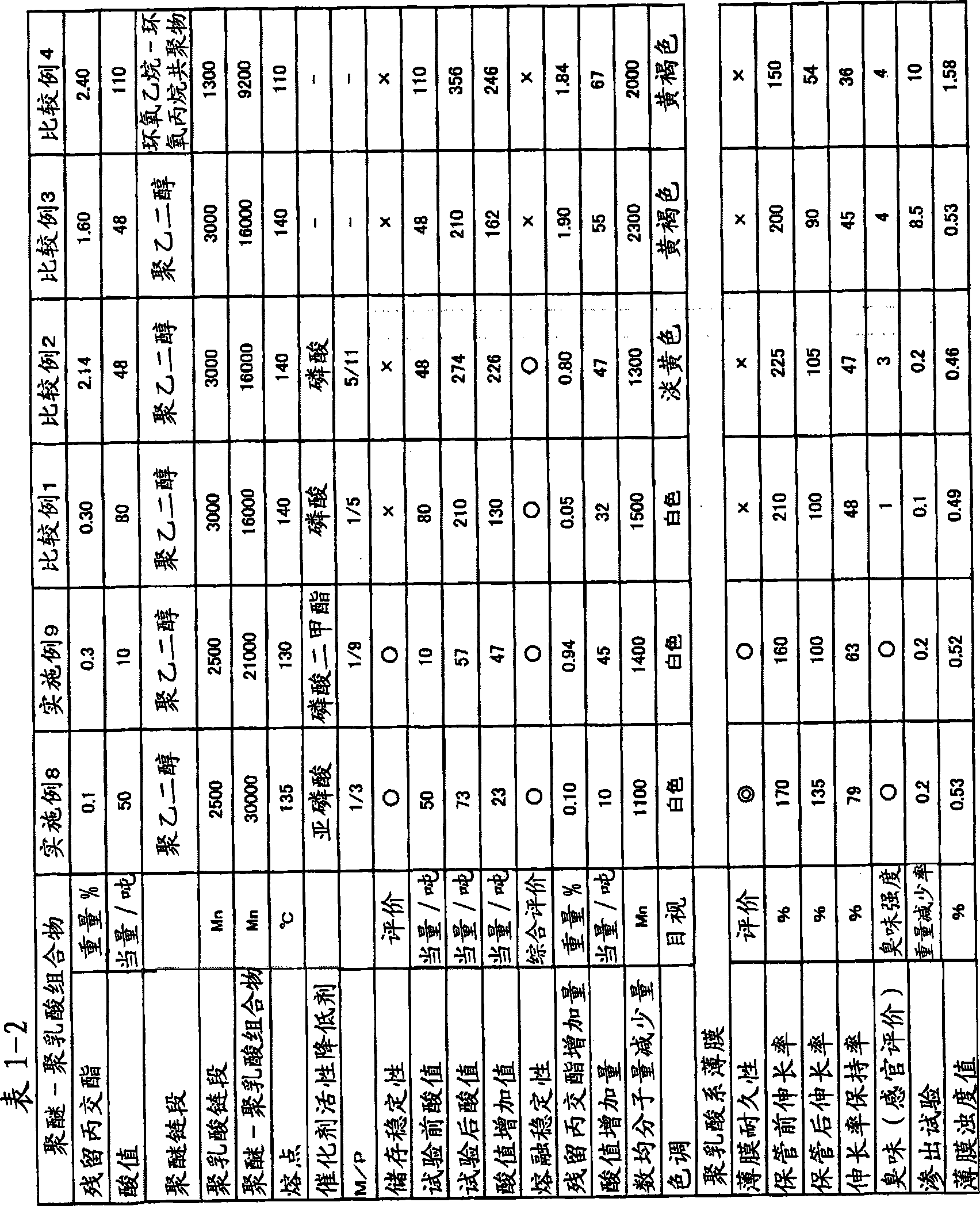

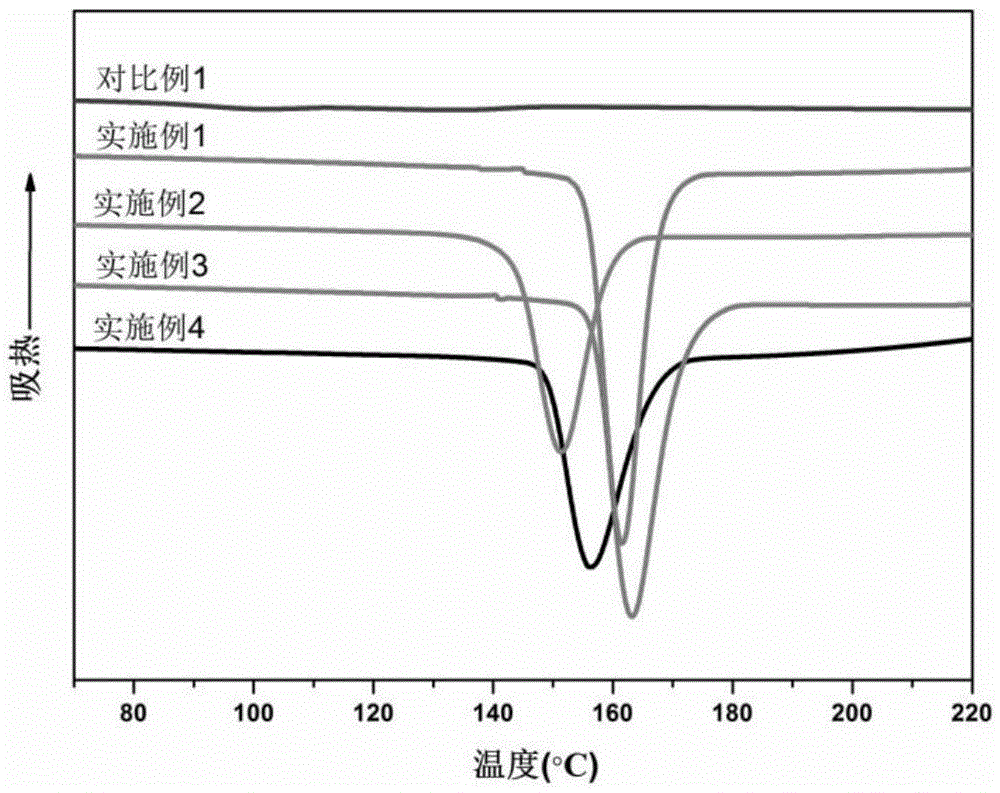

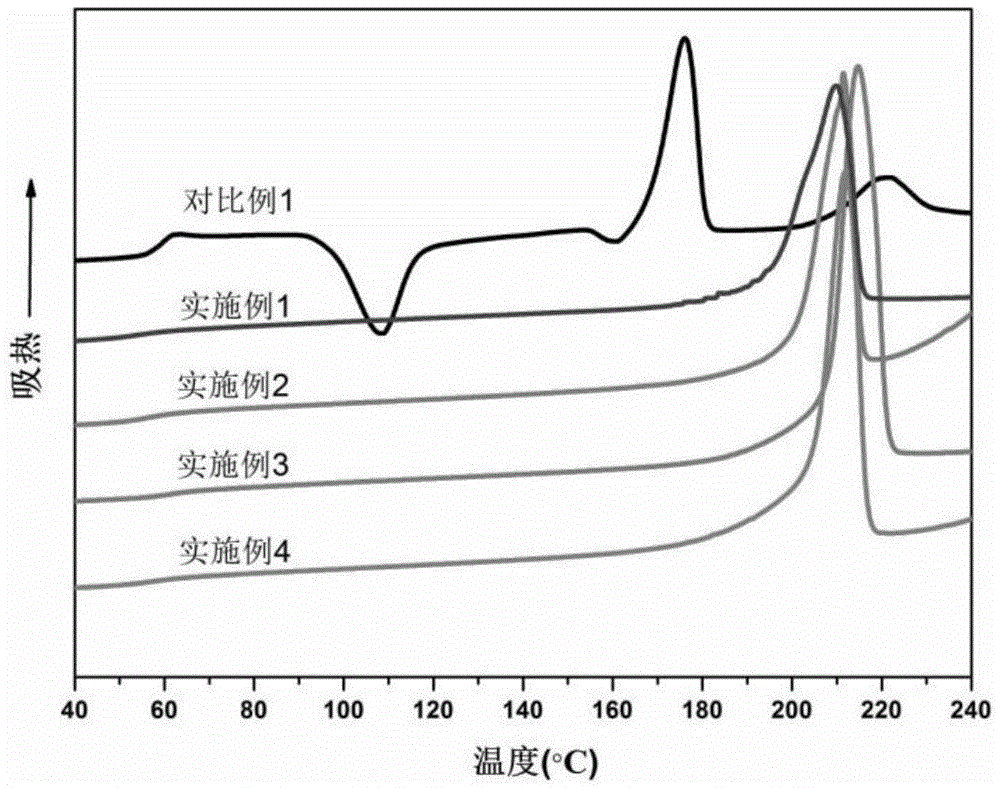

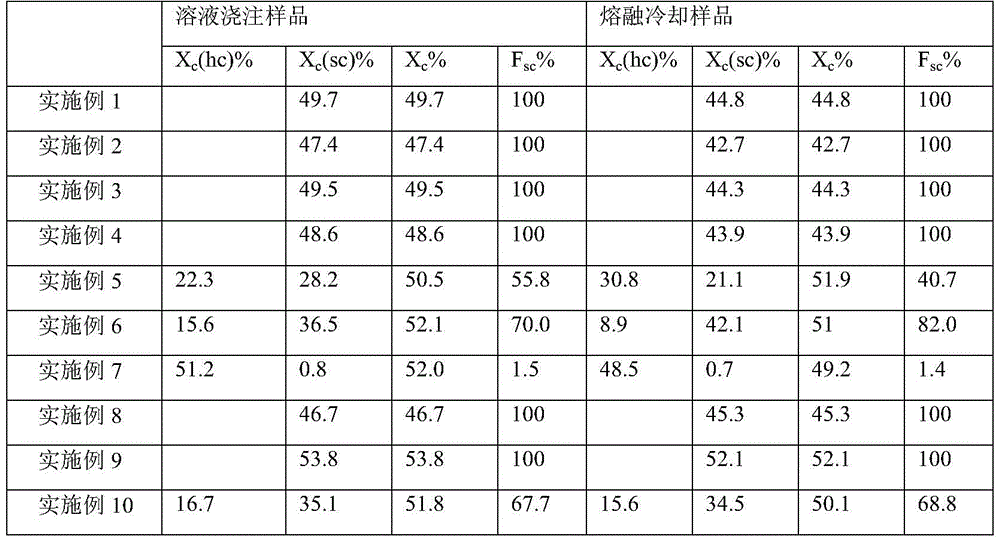

Method for preparing high molecular weight vertical structure composite polylactic acid with melt stability characteristics

The invention discloses a method for preparing a high molecular weight vertical structure composite polylactic acid with melt stability characteristics. The method comprises the following steps: firstly, carrying out drying treatment on L-polylactide and dextral polylactic acid in vacuum, and then mixing an initiator which can be completely dissolved into absolute ethyl alcohol with a cross-linking agent, and then adding a mixture to a fusion mixer; melting and blending under the conditions that the temperature is 170-200 DEG C and the rotating speed is 20-120 rpm (revolutions per minute) for 2-15 minutes. The prepared high molecular weight vertical structure composite polylactic acid not only has excellent melt stability, but also has strong recrystallization ability, and can ensure that the vertical structure composite polylactic acid crystal with high purity and high content is reformed in a molten product, so as to provide excellent heat resistance and weather fastness to the product. The possibility is also provided for preparation of a PLA product with high performance by virtue of a melt processing technology. Meanwhile, the preparation method provided by the invention is simple in process, high in efficiency, and easy for realization of large-scale industrial production.

Owner:TSD (BEIJING) MEDICAL TECH CO LTD

Polyether-polylactic acid composition and polylactic acid film containing same

Disclosed is a polyether-polylactic acid composition which is excellent in storage stability and melt stability while having a good hue. Specifically disclosed is a polyether-polylactic acid composition which is a compound containing a polyether and a polylactic acid content. This polyether-polylactic acid composition is characterized by having a residual lactide amount of not more than 0.3% by weight and an acid number of not more than 50 equivalent weight / t.

Owner:TORAY IND INC

Thermoplastic composition containing polycarbonate-polyester and nanoclay

InactiveUS20070161738A1High impact strengthImproved melt stabilityPigmenting treatmentPolyesterCarboxylic acid

A thermoplastic composition comprising a resinous blend of (A) aromatic polycarbonate and (B) polyester, (C) nanoclay and (D) carboxylic acid is disclosed. The composition features improved melt stability and impact strength over corresponding compositions that contain no acid. The nanoclay is present in an amount of 0.1 to 30 percent relative to the weight of the resinous blend, and the acid is present in an amount of 1 to 20 percent relative to the weight of the nanoclay. The average thickness of the clay particles is about 1 to 100 nm, and their average lengths and average widths, independently one of the other are 50 to 700 nm.

Owner:BAYER MATERIALSCIENCE AG

Large-size high-niobium high-temperature 706 alloy ingot and smelting process thereof

ActiveCN111876651AIncrease temperatureFully uniform temperatureIncreasing energy efficiencyVacuum induction meltingSmelting process

The invention discloses a large-size high-niobium high-temperature 706 alloy ingot and a smelting process thereof. The problems that the serious melting loss of Al and Ti elements is prone to occurring to an existing smelting process and metallurgical defects of black spots and white spots are prone to occurring to the prepared high-niobium high-temperature 706 alloy ingot are solved. The smeltingprocess comprises the steps that vacuum induction melting is carried out, a plurality of vacuum induction ingots with the same component are prepared, then electroslag electrodes with the same numberare prepared, (CaF2-CaO-Al2O3-TiO2) quaternary slag is used for exchanging electroslag remelting, then prepared electroslag ingots are used for preparing consumable electrodes, and then the consumable electrodes are used as initial raw materials to perform twice vacuum consumable remelting. By adopting the smelting process, the high-niobium high-temperature 706 alloy large-size ingot with the ingot weight of more than 15 tons and the diameter of more than 800mm can be prepared, the formation of the metallurgical defects of the black spots and the white spots is restrained to the utmost extent, and the melting loss rate of the Al and Ti elements is reduced.

Owner:BEIJING CISRI GAONA TECH +1

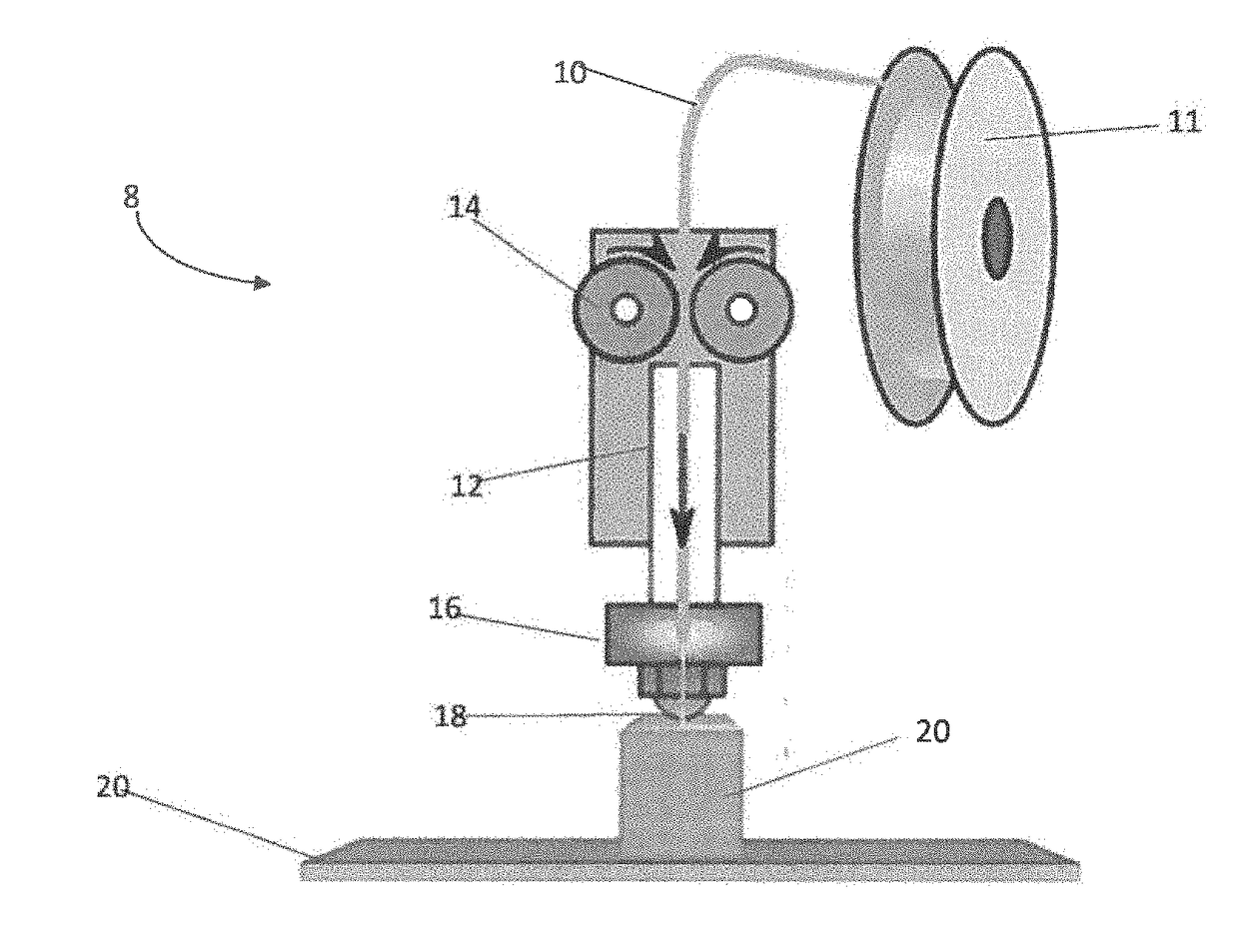

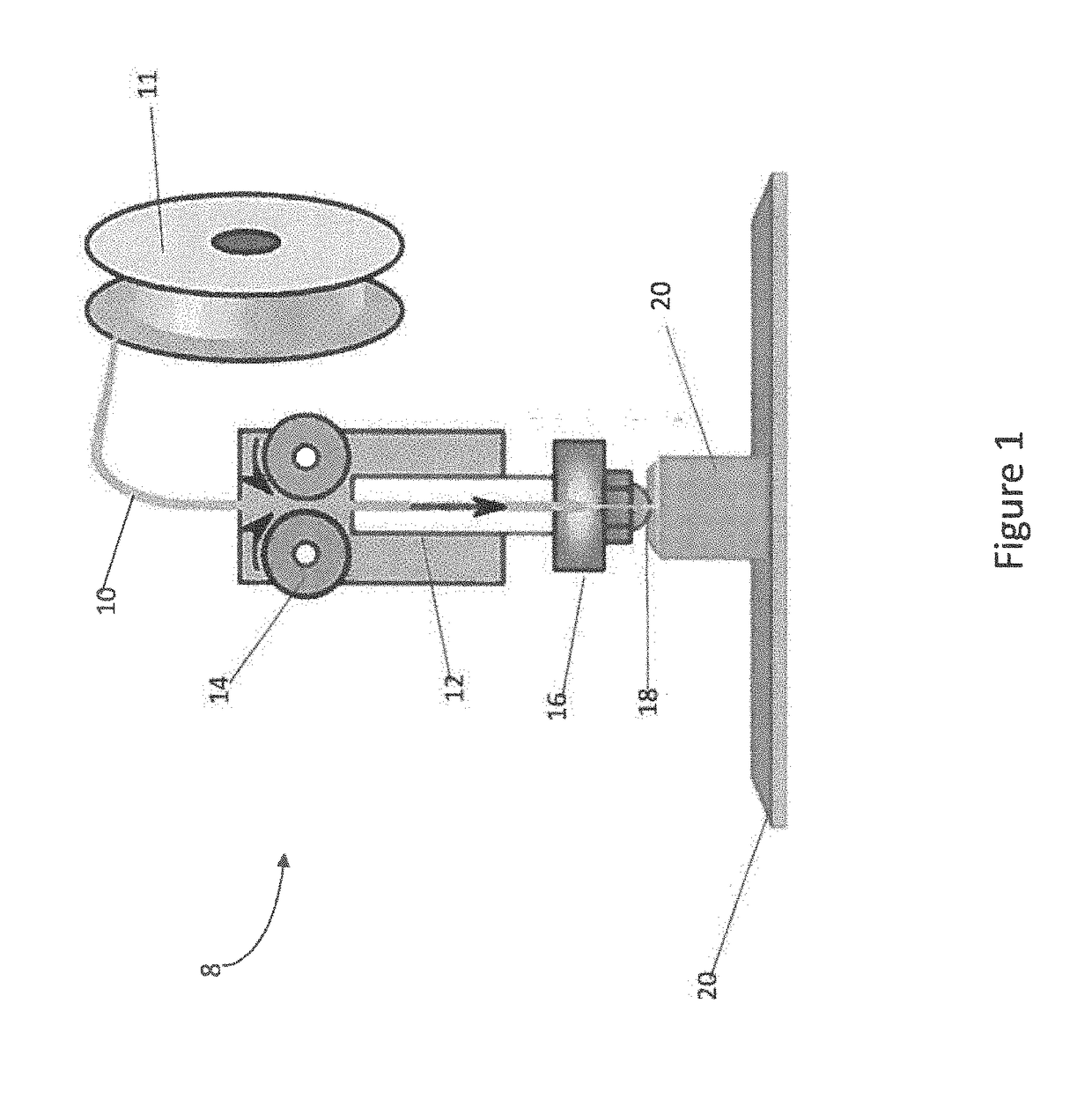

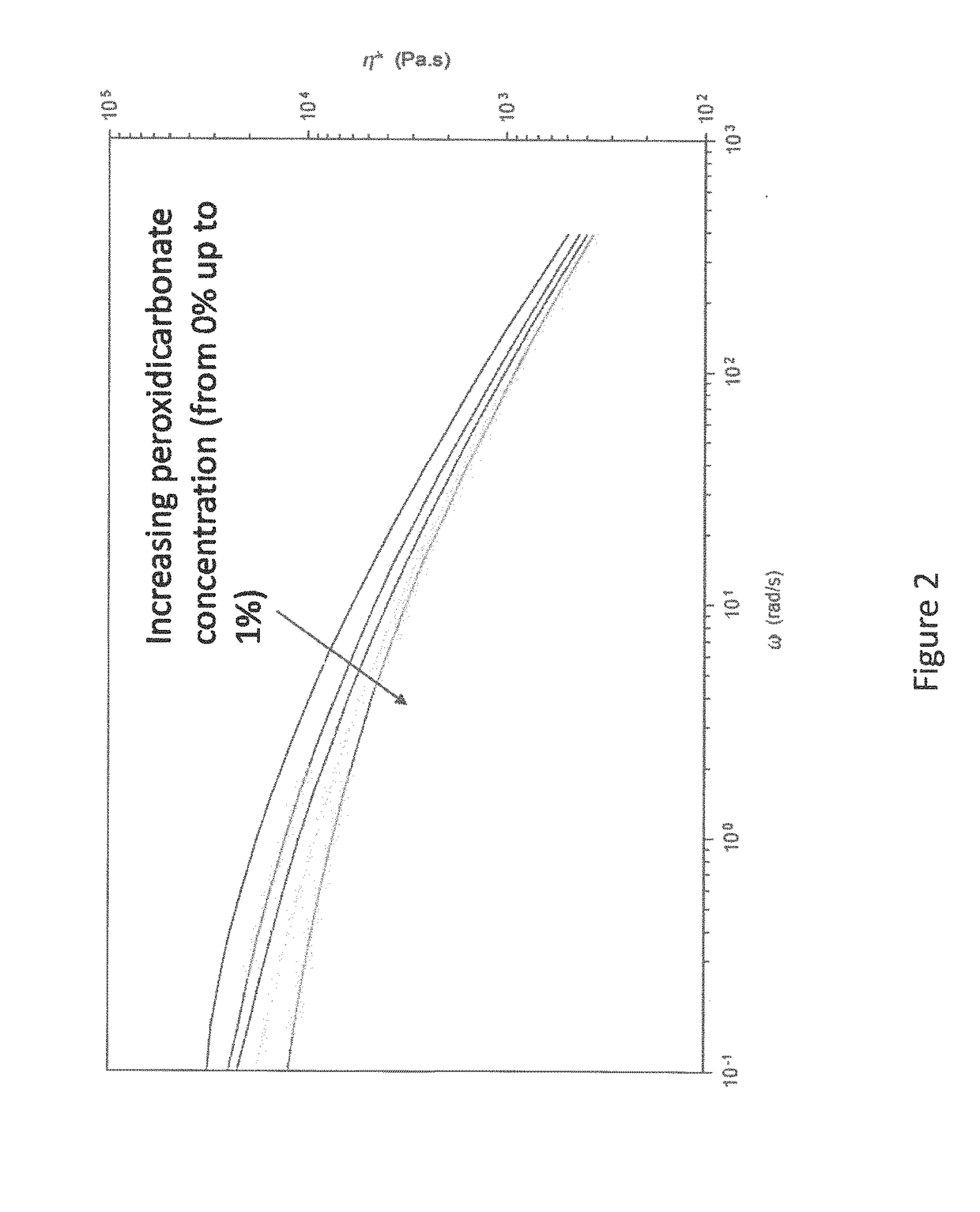

Polypropylene for additive manufacturing (3d printing)

ActiveUS20180056584A1Sufficient melt strengthImprove melt strengthAdditive manufacturing with liquids3D object support structuresPolypropyleneEngineering

A process and printer systems for printing a three-dimensional object are disclosed. The processes may include providing a non-crosslinked peroxydicarbonate-branched polypropylene filament, flake, pellet, or powder adapted for one of a fused deposition modeling (Arburg Plastic Freeforming) printer or a fused filament fabrication printer; and printing the non-crosslinked peroxydicarbonate-branched polypropylene with fused deposition modeling (Arburg Plastic Freeforming) printer or a fused filament fabrication printer to form a three-dimensional article. The printer systems may include one or more print heads for printing a polymer provided in filament, powder, flake, or pellet form to form a three-dimensional article; and one or more feed systems for providing a non-crosslinked peroxydicarbonate-branched polypropylene to a respective print head.

Owner:LUMMUS NOVOLEN TECH

Nano particle grafted stereoblock polylactic acid, preparation method and application of nano particle grafted stereoblock polylactic acid

Owner:SICHUAN UNIV

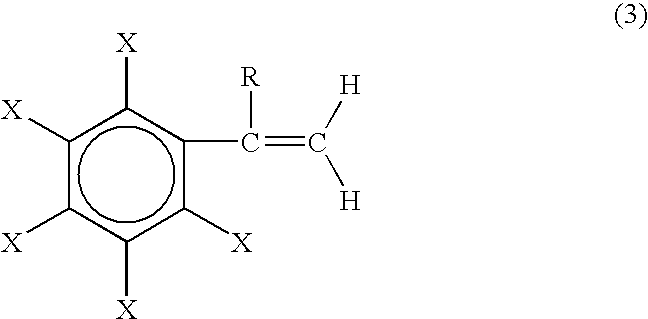

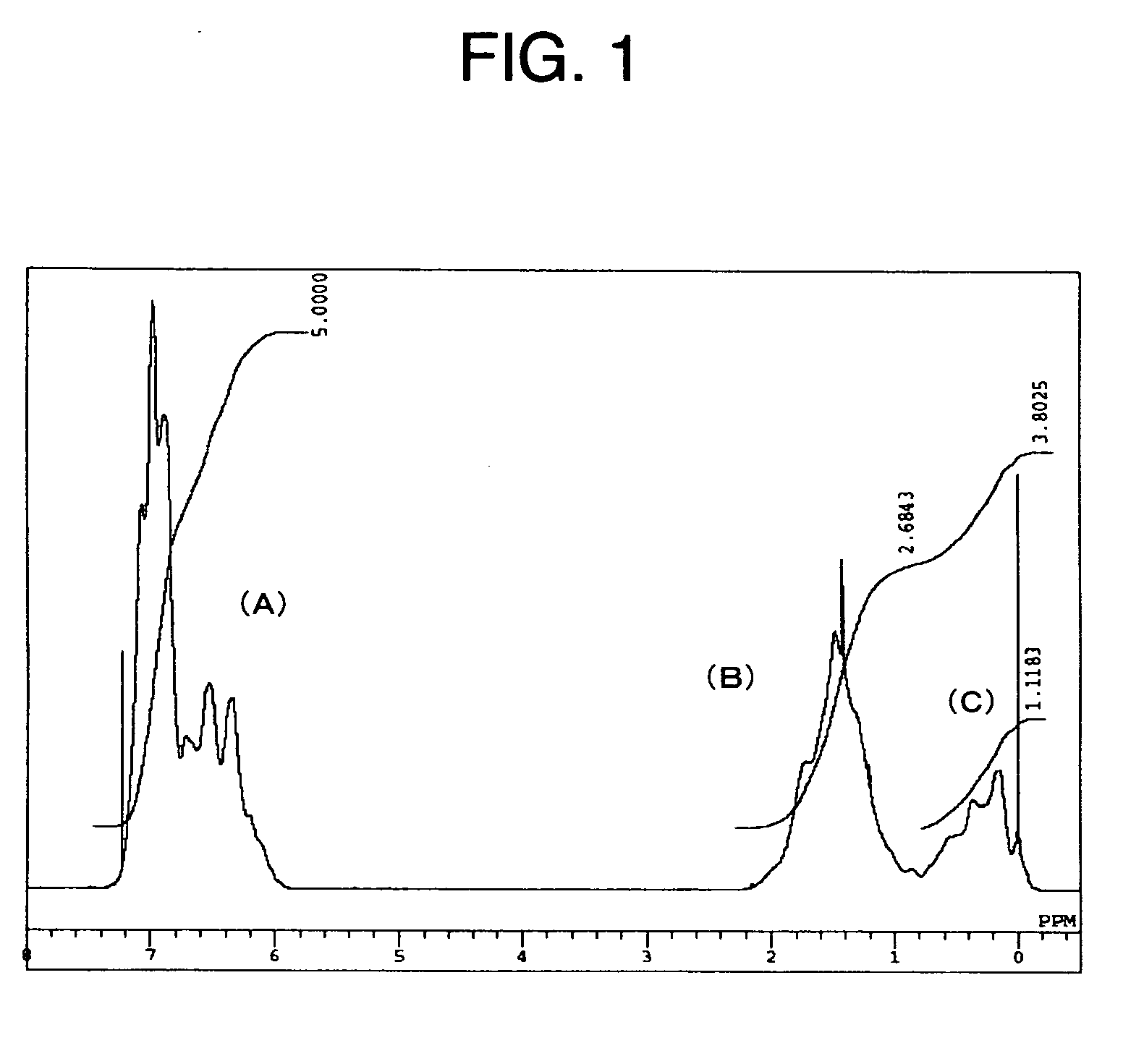

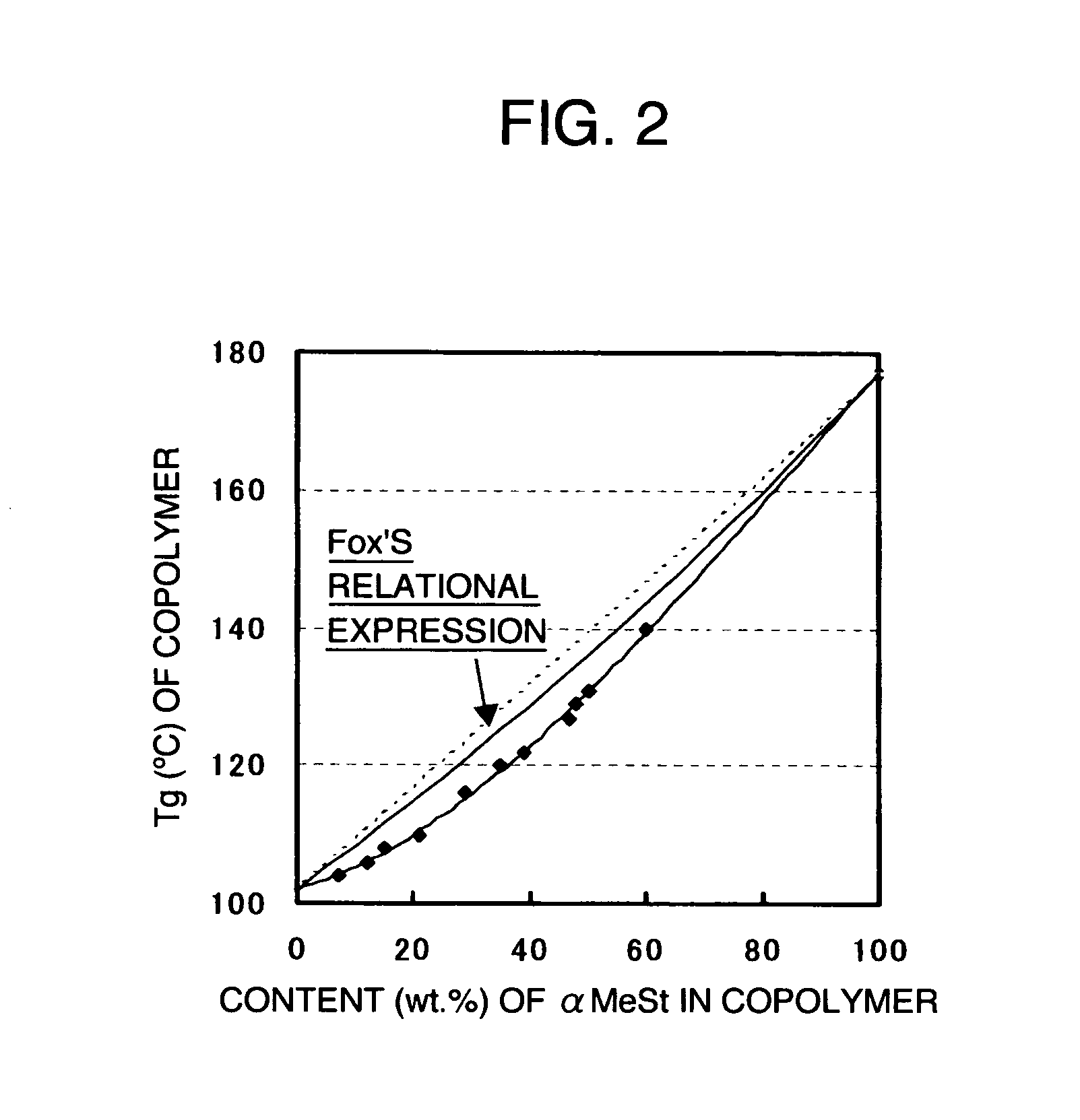

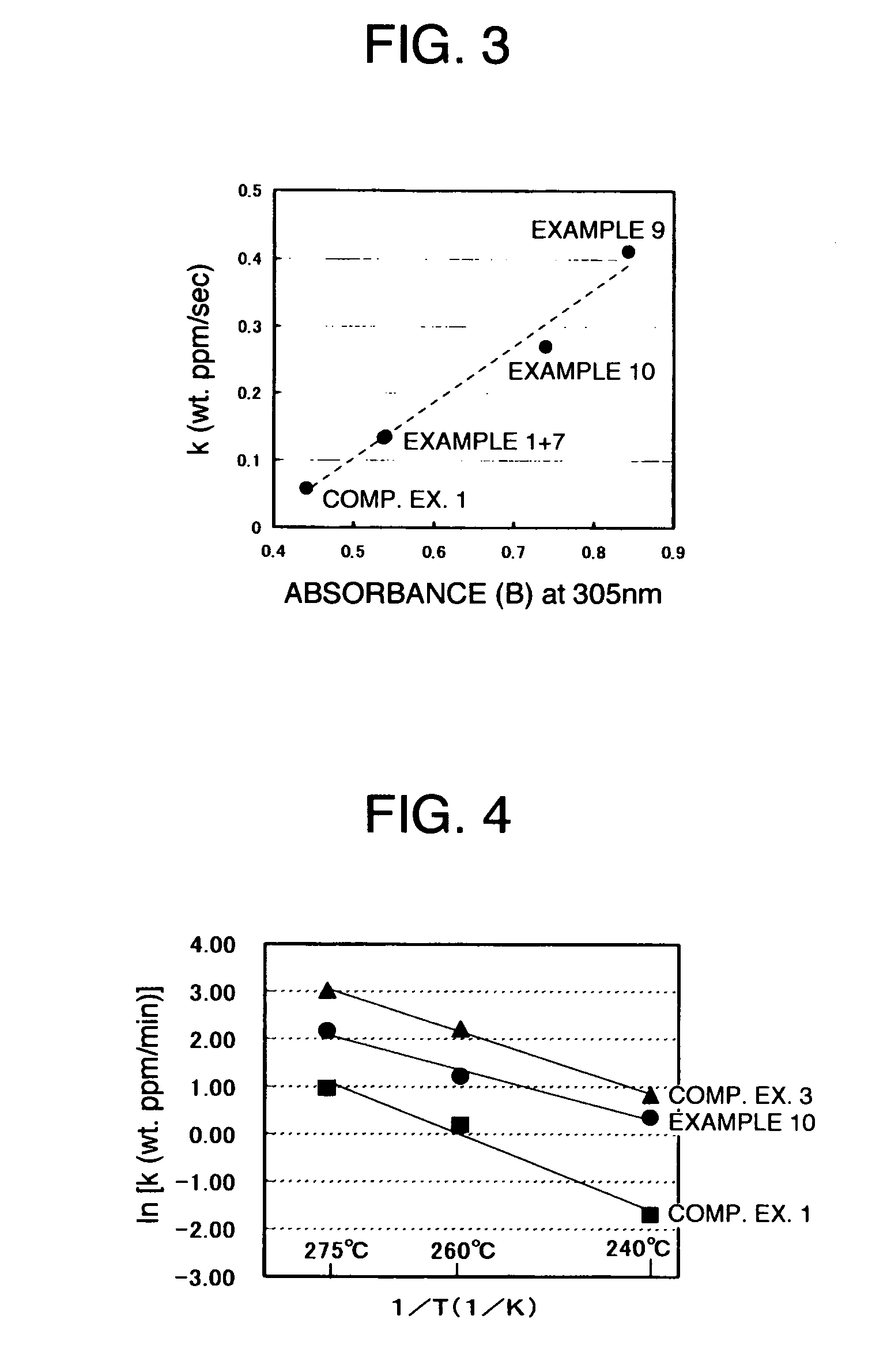

Syrene copolymer and process for producing the same

InactiveUS20070083024A1Improve heat resistanceGood weather resistancePolymer scienceLiving polymerization

A styrene resin excellent in heat resistance, weatherability, melt stability, and suitability for recycling. It is a styrene copolymer obtained by living polymerization (Mw / Mn=1.6-4.0) which comprises isopropenylaromatic units (A) contained in an amount of 5 to 95 wt. % and vinylaromatic units, and has a glass transition temperature (Tg) which satisfies a specific relationship defined by the content of isopropenylaromatic units (A) in the copolymer.

Owner:ASAHI KASEI CHEM CORP

Polyacetal resin composition

ActiveUS7638565B2Upgrading of quality and moldabilityInhibit the amount of formaldehyde emissionSpecial tyresChemical/physical processesAntioxidantCarboxylic acid

Owner:POLYPLASTICS CO LTD

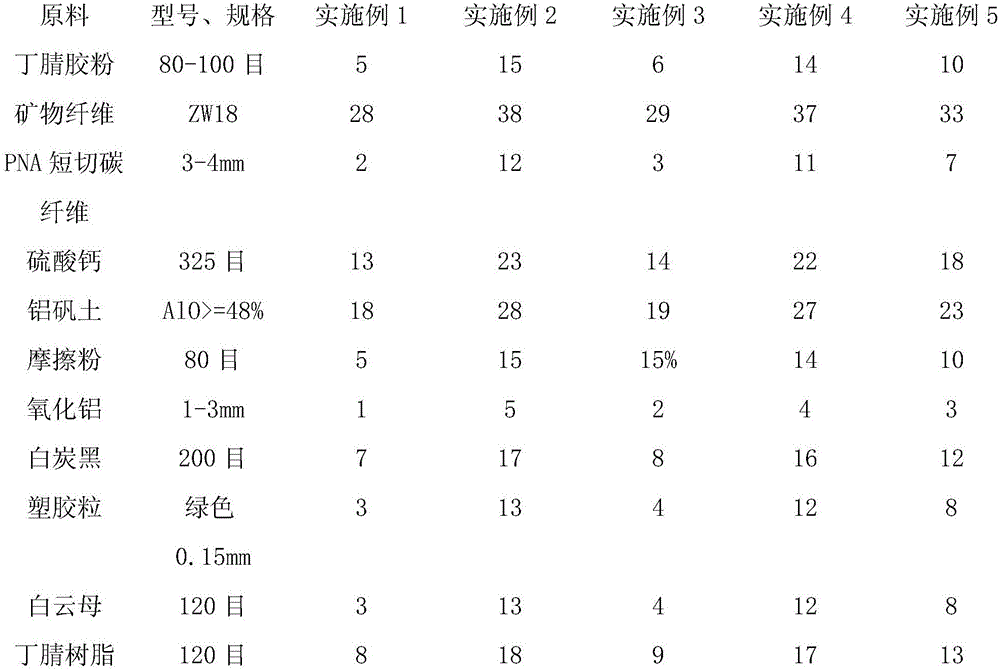

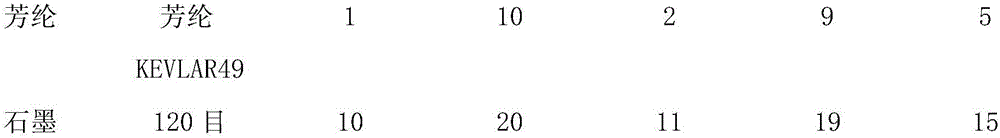

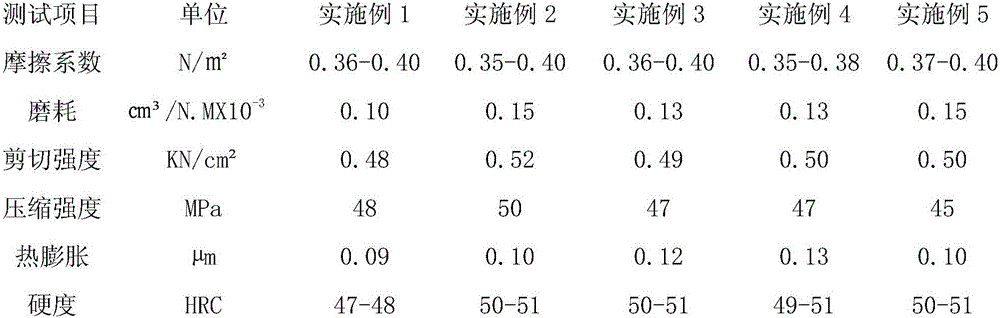

Carbon fiber resin-based friction material and preparation method thereof

InactiveCN106246774AStable coefficient of frictionStrong flexibilityOther chemical processesDomestic articlesCarbon blackAluminium

The invention discloses a carbon fiber resin-based friction material and a preparation method thereof. The raw materials include nitrile rubber powder, mineral fiber, carbon fiber, calcium sulfate, bauxite, friction powder, aluminum oxide, white carbon black, plastic particles, white clouds resin, aramid and graphite. The manufacturing method steps are: weighing of raw materials, processing of carbon fibers, mixing of raw materials, drying of raw materials, pressing of raw materials and solidification of friction materials. The invention uses less material, is low in cost and has a long service life; at the same time, the carbon fiber is subjected to simple ultrasonic surface treatment to make it have better friction and wear performance; the invention is a brake pad with excellent performance and is worthy of vigorous promotion.

Owner:广西驰胜农业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com