Carbon fiber resin-based friction material and preparation method thereof

A carbon fiber resin-based, friction material technology, applied in the field of materials, can solve the problems of complicated production process of friction materials, low comprehensive performance of brake pads, unstable friction coefficient, etc., to improve chemical resistance, good mechanical properties, The effect of small compression set

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

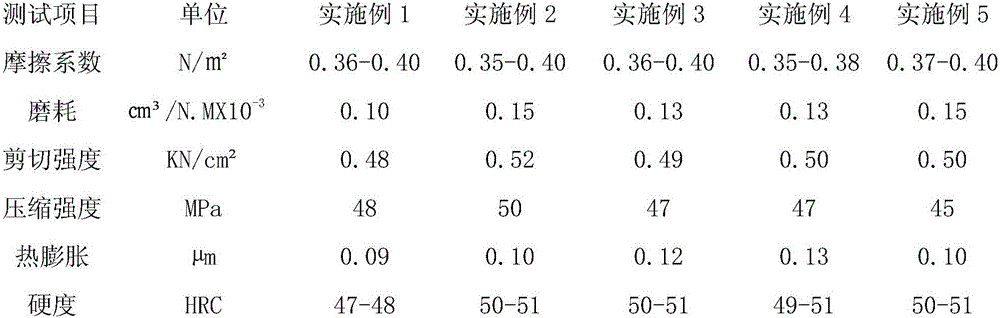

Examples

Embodiment Construction

[0020] The following examples can help those skilled in the art to understand the present invention more comprehensively, but cannot limit the present invention in any way.

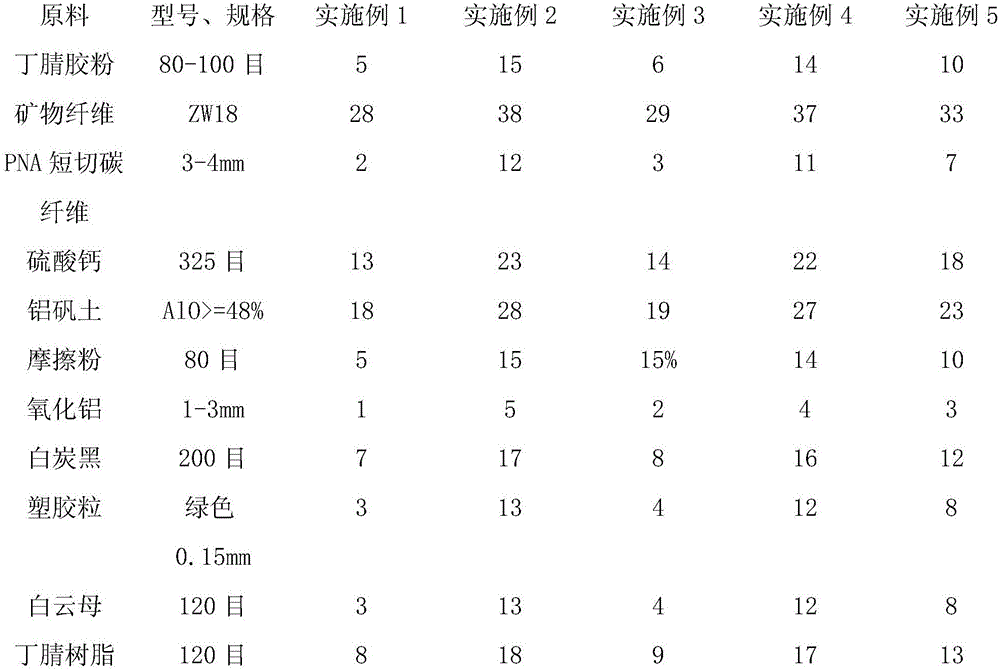

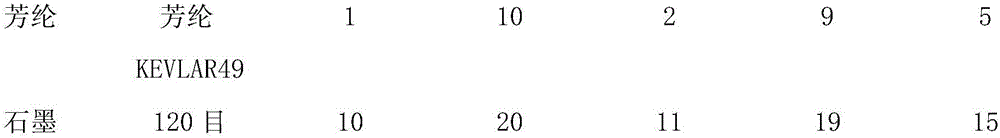

[0021] Provide the formula of embodiment 1-5 raw material below, list as table 1:

[0022] Table 1 The raw materials, contents and specifications of friction materials in Examples 1-5 (unit: gram)

[0023]

[0024]

[0025] The friction materials of Examples 1-5 are made according to the following methods

[0026] A carbon fiber resin-based friction material, mainly made of nitrile rubber powder, mineral fiber, carbon fiber, calcium sulfate, bauxite, friction powder, aluminum oxide, white carbon black, plastic particles, muscovite, resin, aramid fiber and graphite The specific content of each raw material is shown in Table 1.

[0027] The preparation method of the carbon fiber resin-based friction material comprises the following steps:

[0028] 1) Weighing of raw materials: picking the raw mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com