Patents

Literature

70 results about "Thermal decay" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal Decay Time Log, also known as Thermal Decay Time, is a log record that captures the rate of thermal neutrons in a formation after it is bombarded with a burst of 14 Mev neutrons. In a tool, an electronically operated neutron generator is present that produces the neutron pulses which spread...

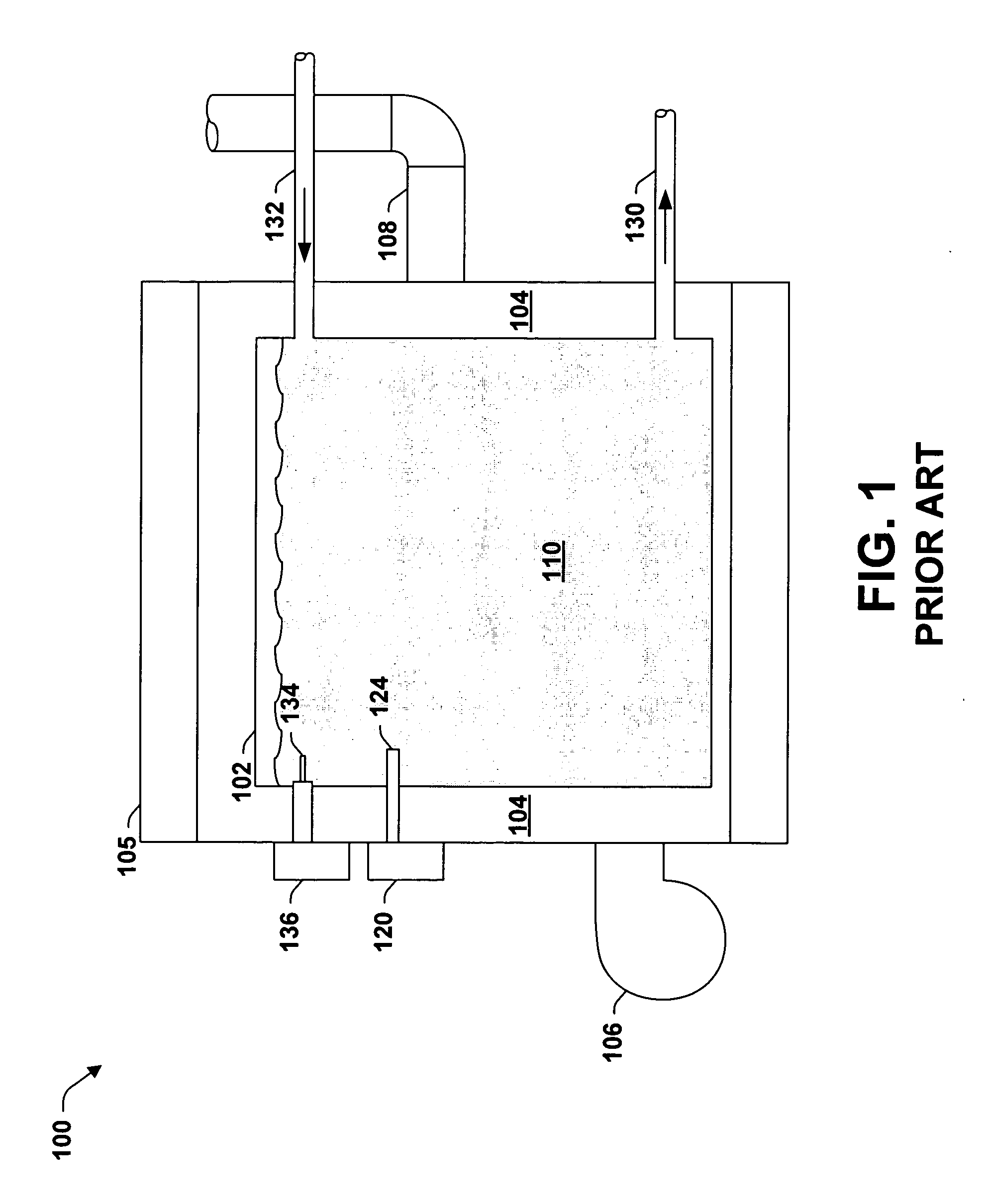

Threshold calorimeter/shelf life monitor

InactiveUS7275863B1Thermometer detailsThermometers using mean/integrated valuesCapacitanceThermal decay

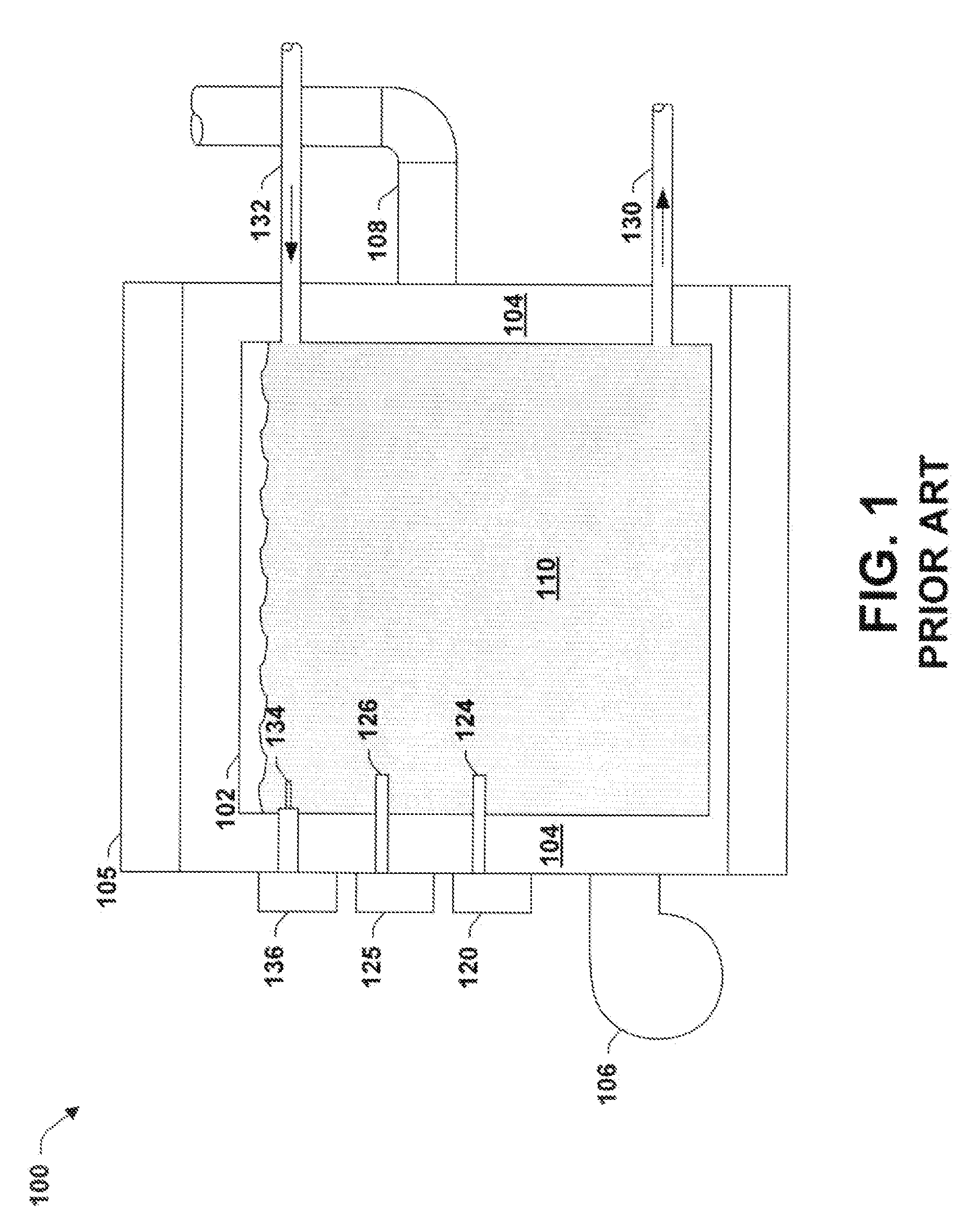

Threshold calorimeter / shelf life monitors having a thermally moderating housing containing a liquid solution and one or more low melting point solids all having properties correlated relative to one another and calibrated to closely match a thermal decay profile (time-temperature profile) of a perishable product being monitored and indicate, by a change in color, electrical capacitance and / or impedance, transmitted RF signals, or combination thereof, the cumulative thermal history of the product while in transit or storage and whether its time-temperature profile has been violated to a detrimental extent or if a significant amount of shelf life has been consumed.

Owner:TIME TEMPERATURE INTEGRATION

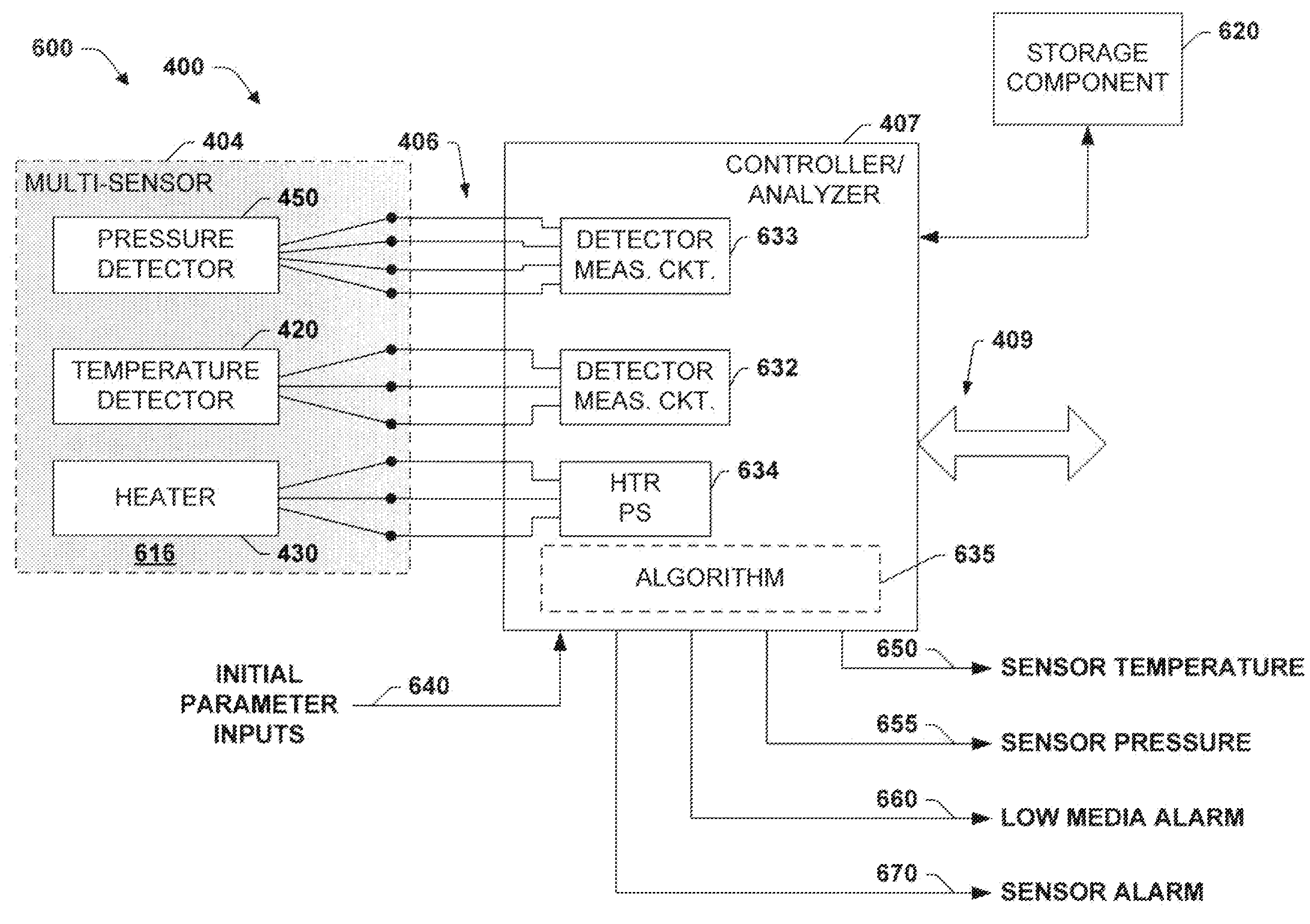

Integrated multi-sensor component

InactiveUS20100280788A1Eliminate needThermometer detailsMechanical apparatusTemperature responseThermal decay

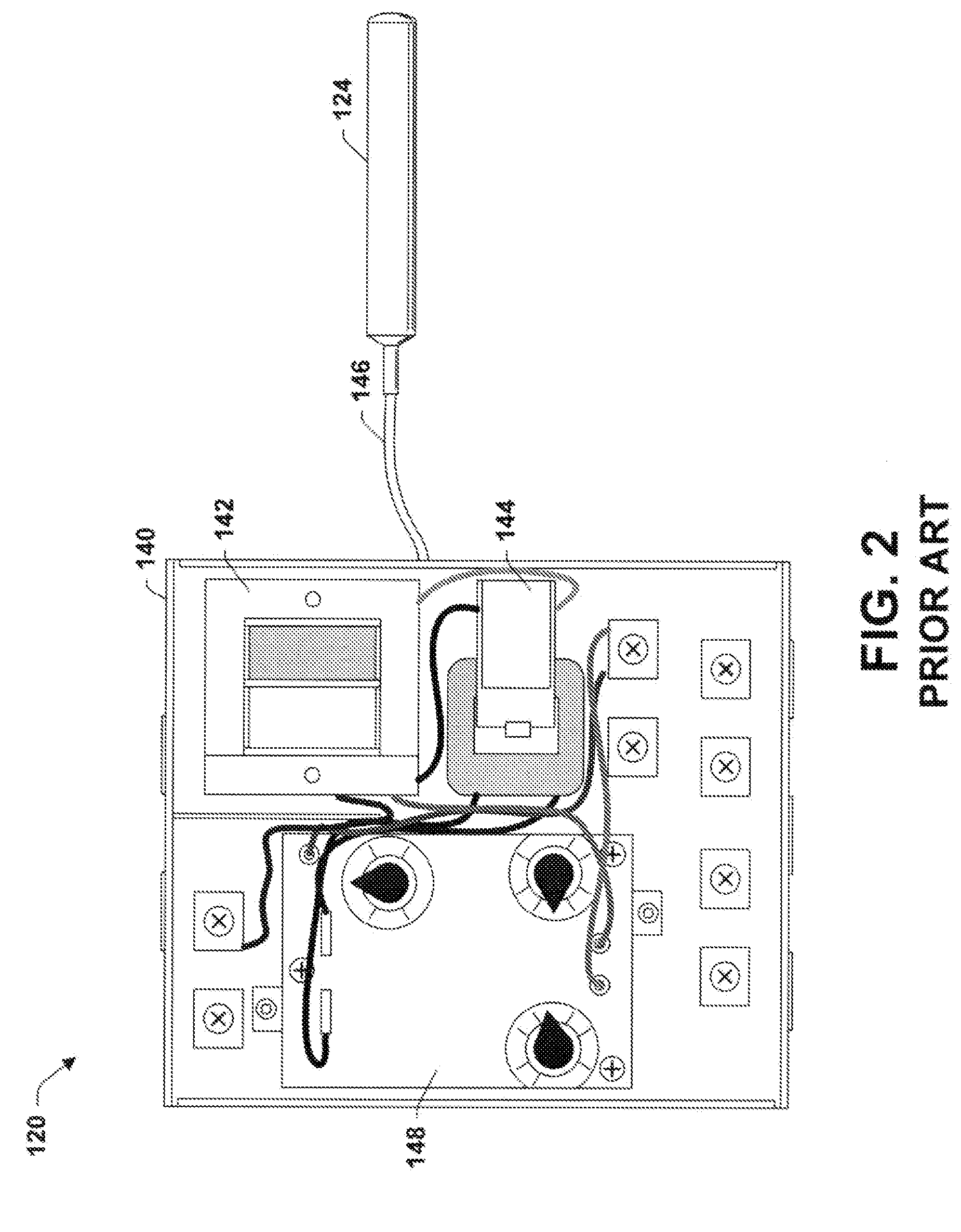

A system and method is presented for a multi-sensor component for an HVAC system. The multi-sensor component comprises a sensor assembly, having a temperature detector for measuring a temperature of an object or medium, a presence detector to detect the presence of the object or medium against the sensor, and a pressure detector for measuring a pressure of the medium. The temperature, presence and pressure detectors may also be affixed within a single sensor housing. In a heating mode the multi-sensor component is heated by a heater, and in a cooling mode the multi-sensor component cools toward a temperature of the object or medium, and the temperature detector provides temperature data indicative of a temperature response comprising one of a temperature change, a rate of change and a time constant of a thermal decay rate of the multi-sensor component and the presence of the object or medium.

Owner:R W BECKETT

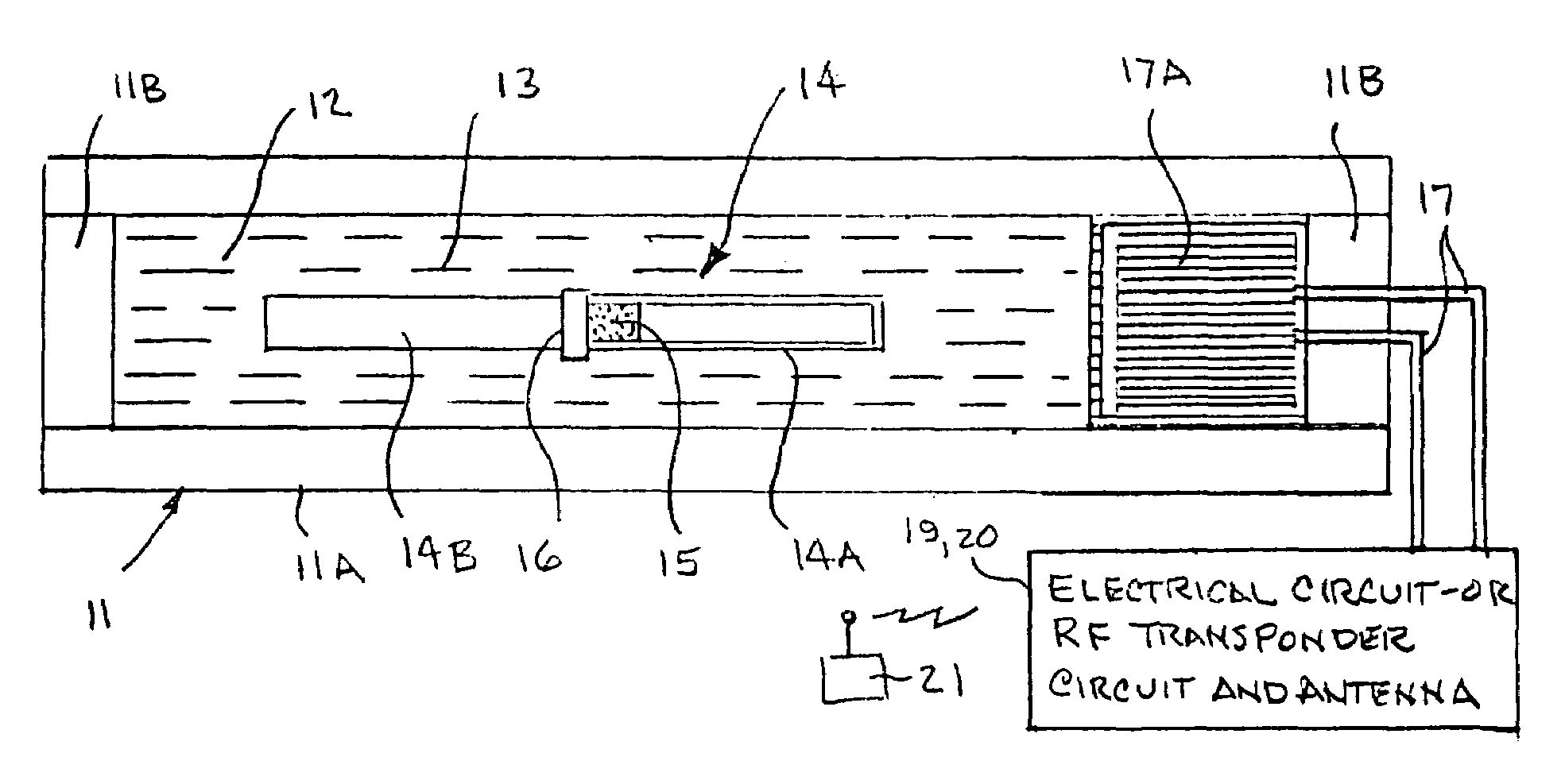

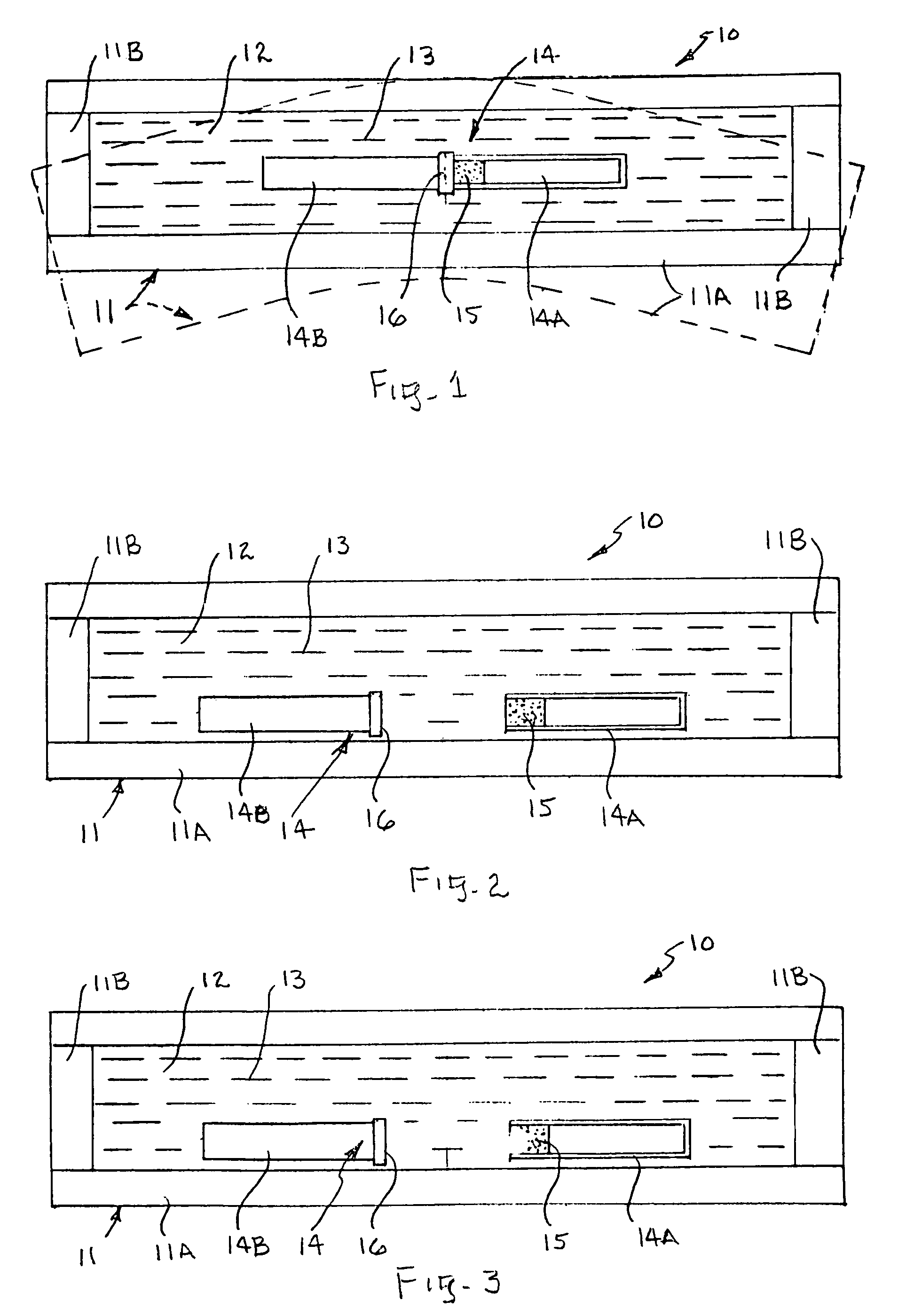

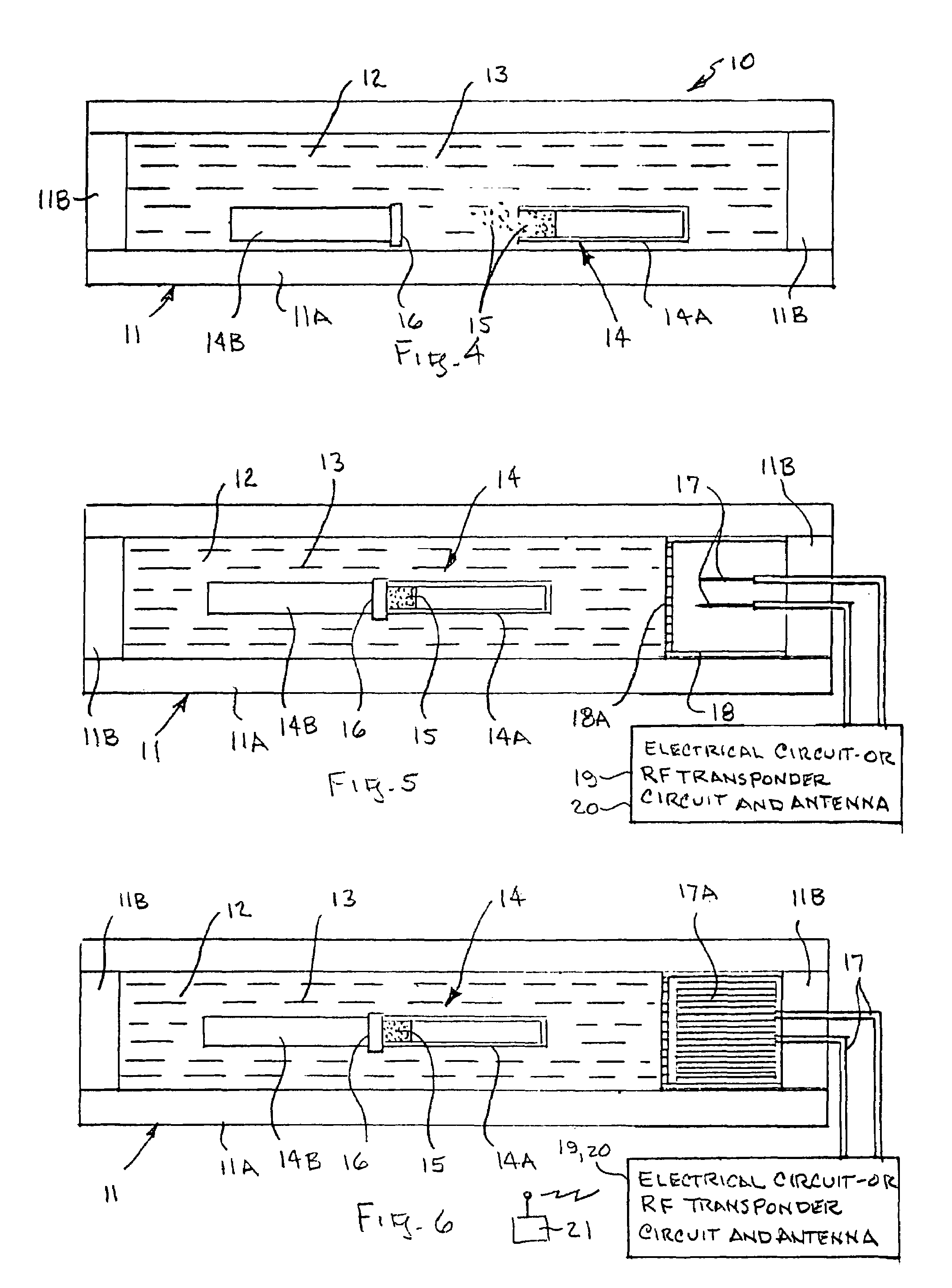

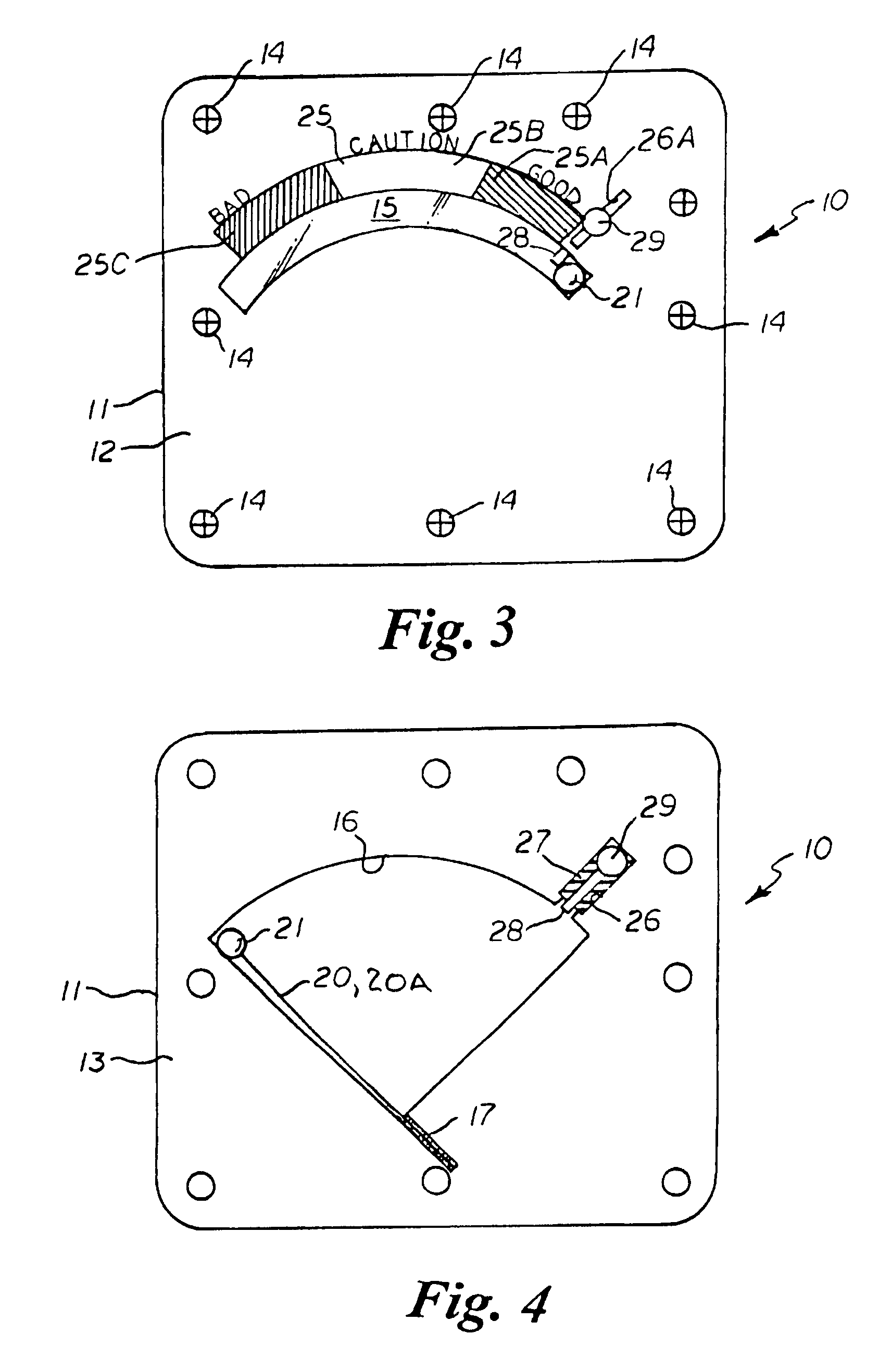

Remote indicating cumulative thermal exposure monitor and system for reading same

InactiveUS7604398B1Inexpensive and convenient and effective regulatory toolReduce responsibilityThermometer detailsThermometers using mean/integrated valuesThermal decayTransition temperature

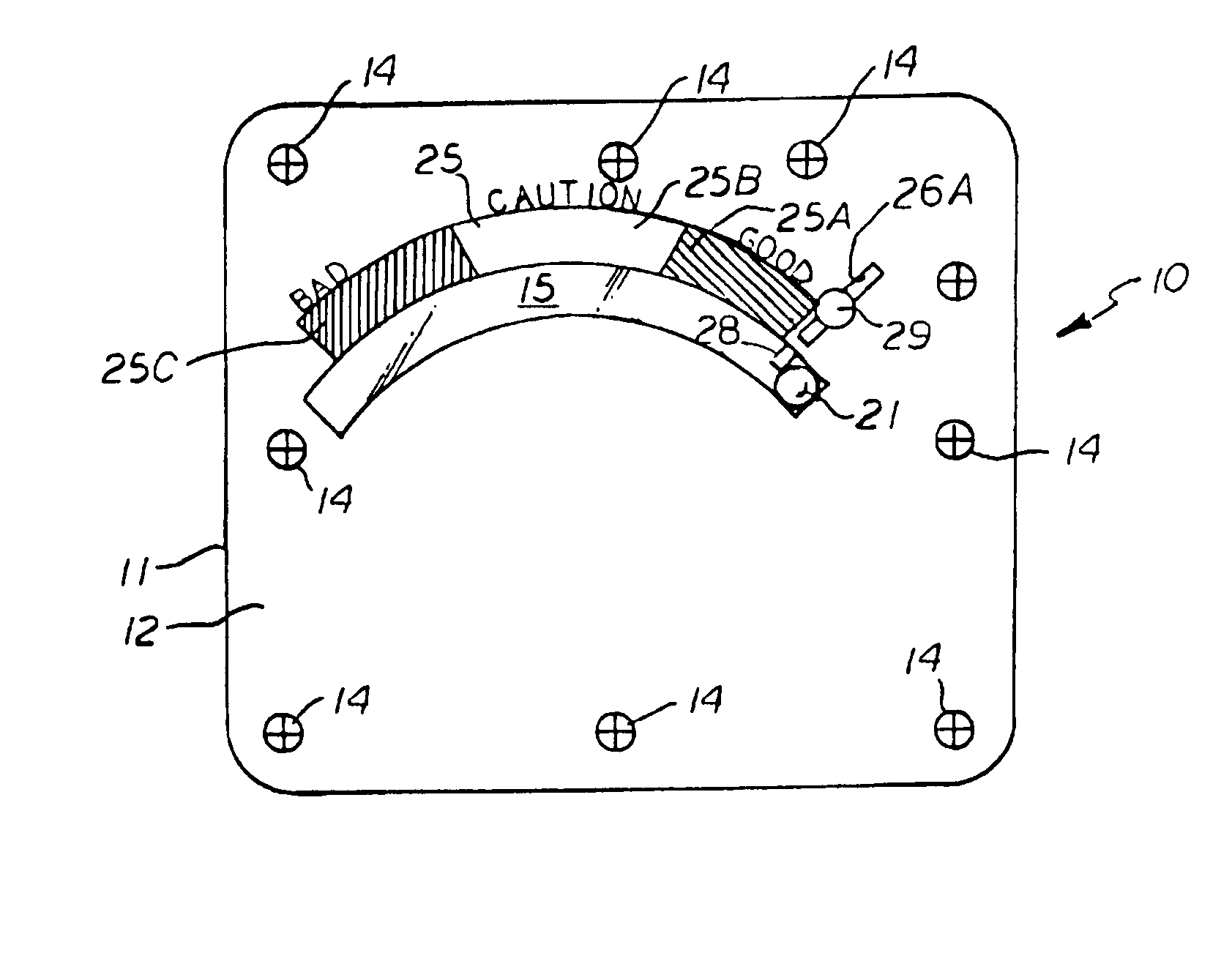

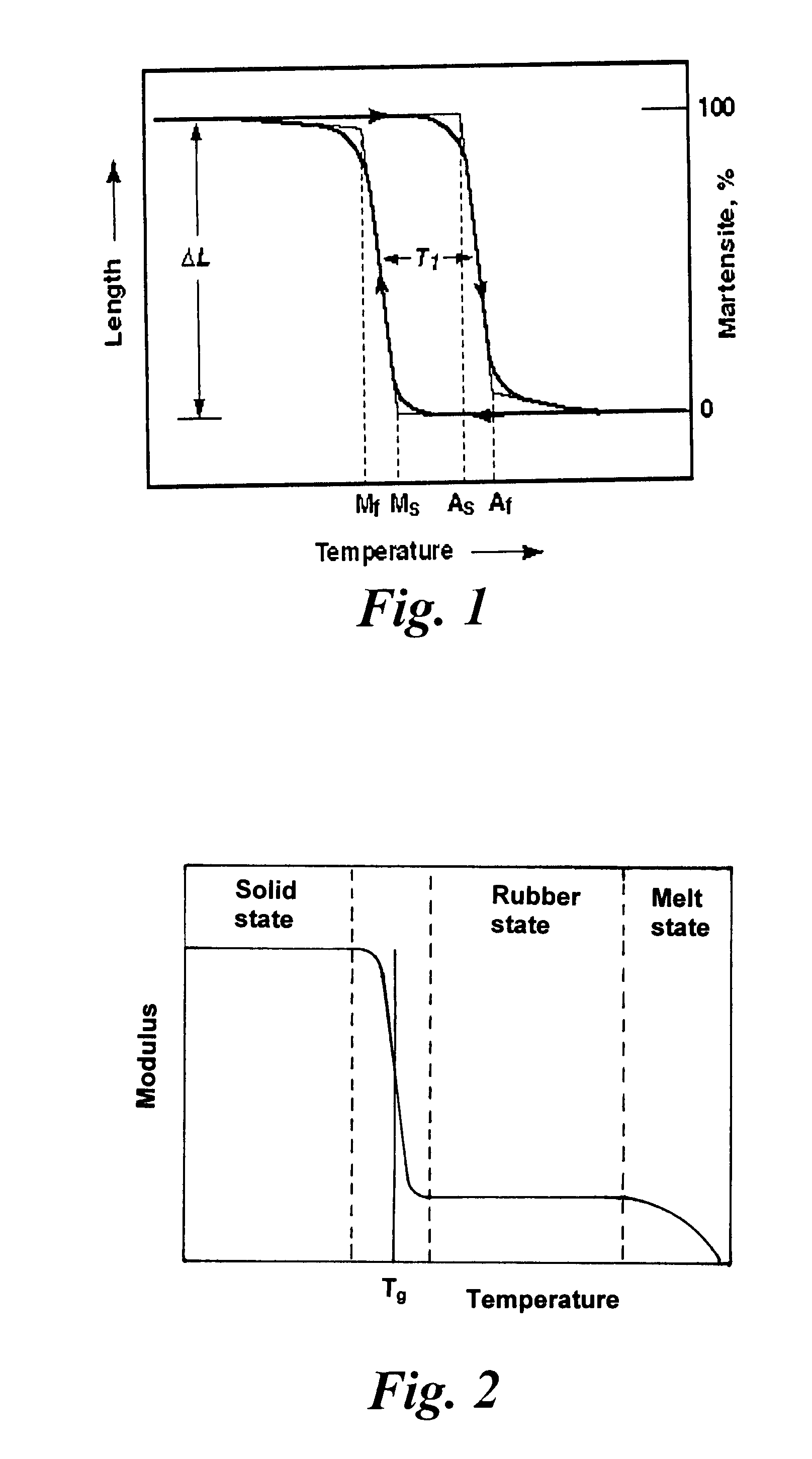

Cumulative thermal exposures monitors and remote indicating cumulative thermal exposure monitors and system for reading the same are disclosed. The monitors have a thermally insulative housing with a cavity and a thermally-responsive member therein formed of shape memory material, which may be provided with a coating or sheath of insulative or shape memory polymer material, that gradually changes from a first shape to a second shape over a prescribed temperature range wherein the thermal capacity and insulative properties of the housing, cavity, and shape memory material transition temperature range are correlated relative to one another and calibrated to closely match a thermal decay profile (time-temperature profile) of the product being monitored. In remote indicating embodiments, the data can be retrieved remotely via RF transponder technology without directly viewing the monitor device.

Owner:AKERS JEFFREY W +2

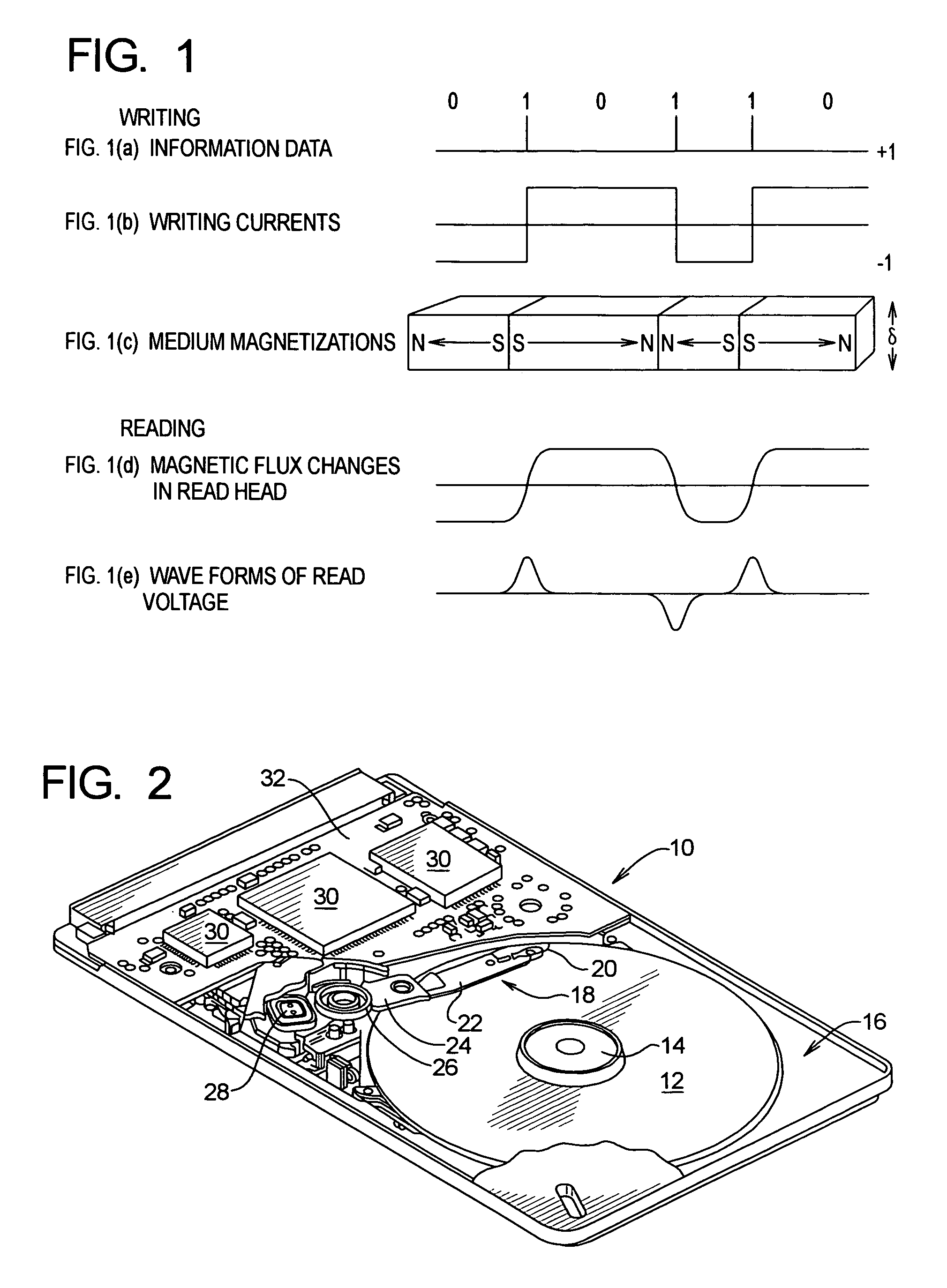

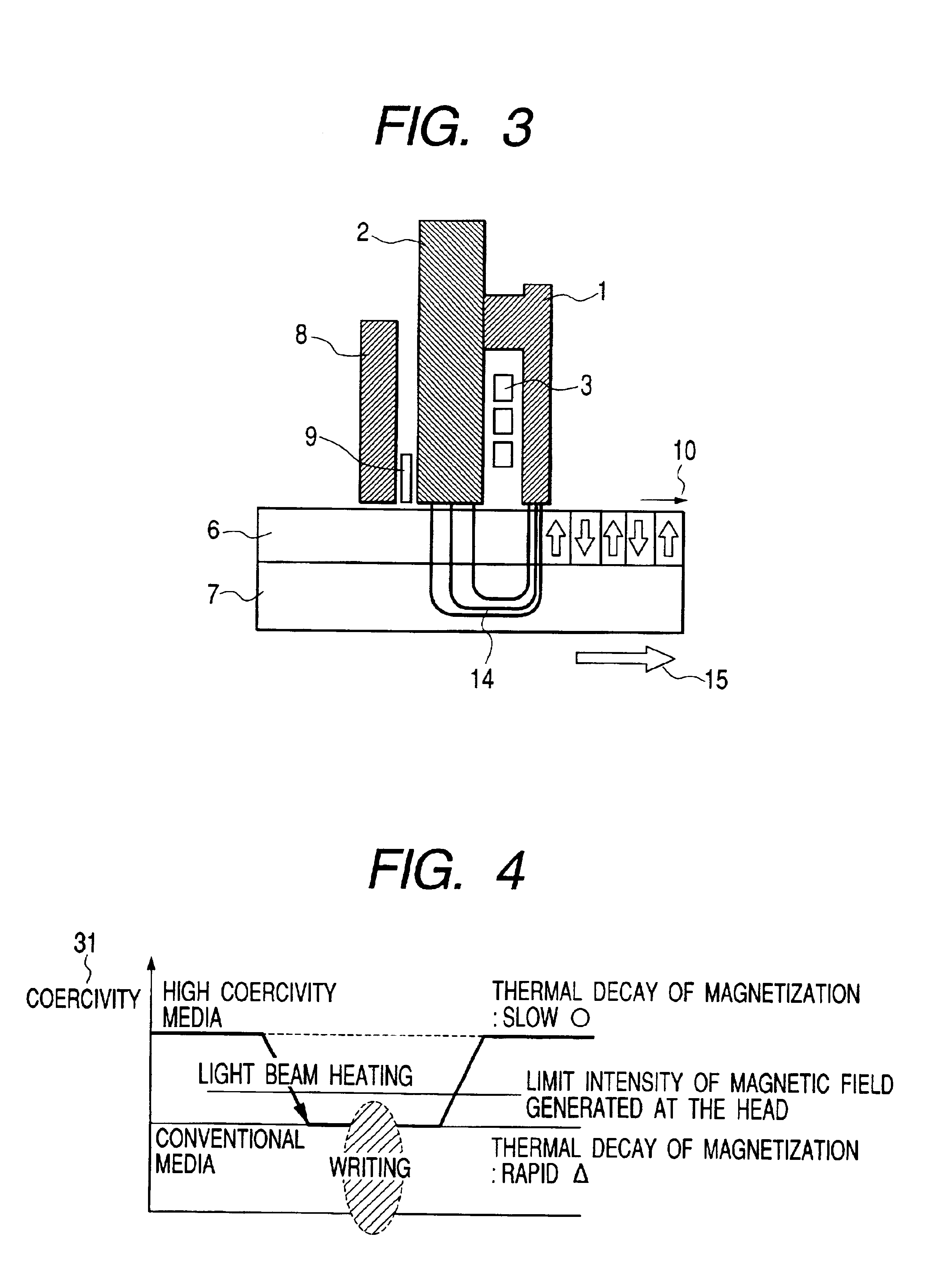

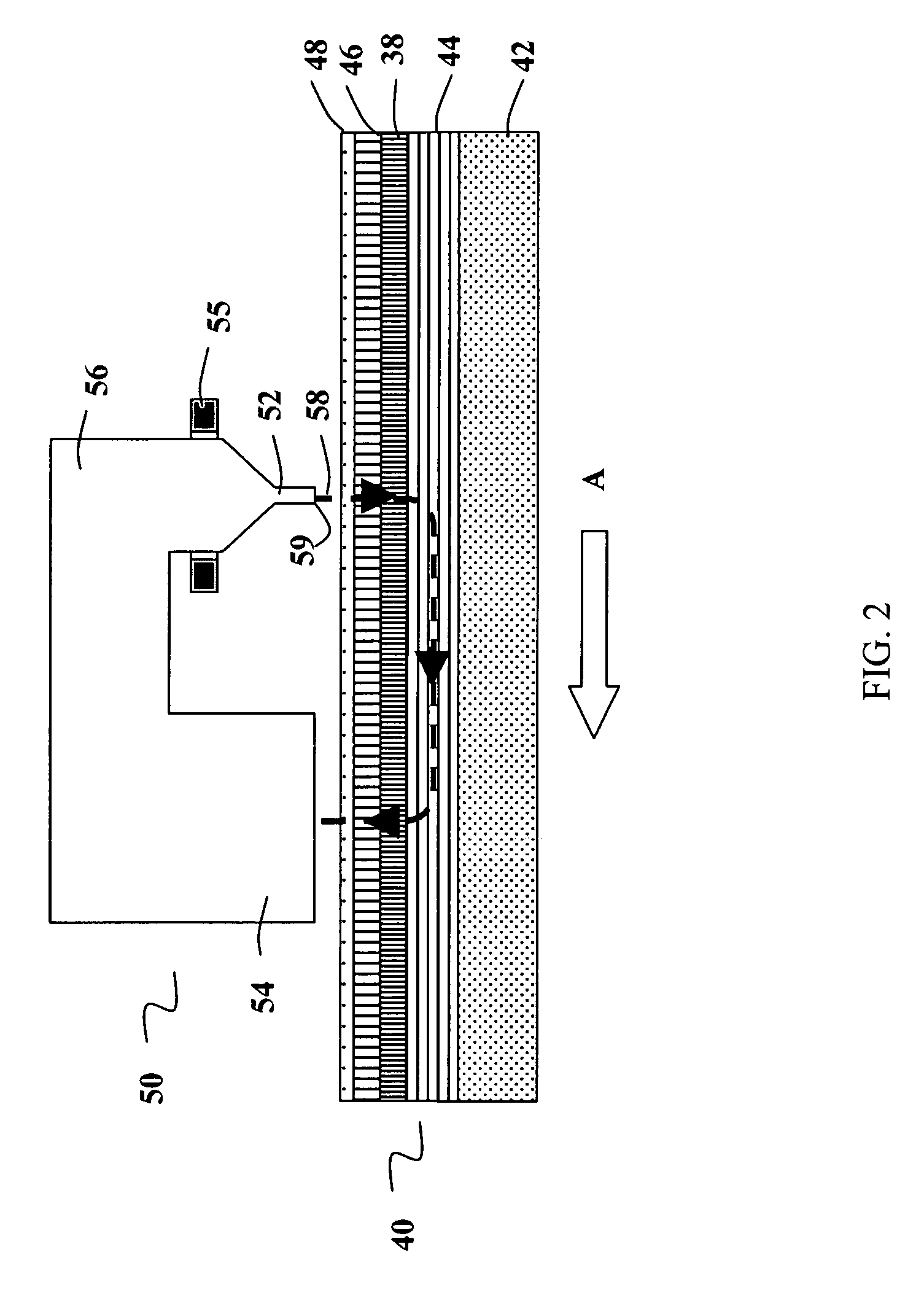

Magnetic recording media for thermo-magnetic printing, magnetic recording method utilizing thereof and magnetic disk recording apparatus

InactiveUS20050163962A1Easy to integrateThin and smallMagnetic materials for record carriersRecord information storageLow noiseRare-earth element

A perpendicular magnetic recording medium for thermo-magnetic printing has an ultra-high recording density and is resistant to thermal decay of magnetization. An intermediate layer of the medium is provided between a first recording layer using a low-noise Co alloy ferromagnetic substance and a second recording layer using a ferrimagnetic substance (e.g., a rare-earth element-transition metal compound) having a compensation temperature below an operation ambient temperature. A magnetic field is applied thereto to form a magnetization pattern on the first recording layer. It is then heated-up to be printed onto the second recording layer, which has a higher coercivity at the ambient temperature, and a recording field is suitably set to form a magnetization pattern only on the first recording layer. The magnetization pattern is printed from the first recording layer to the second recording layer.

Owner:HITACHI LTD

Package structure for LED

ActiveCN101577304AExtend the life cycleDissipates quickly and effectivelySolid-state devicesSemiconductor devicesThermal energyThermal decay

The invention relates to a package structure for LED and manufacturing method thereof. In a preferred embodiment of the package structure for LED, a plurality of thermal vias are located through the packaging substrate to effectively transfer heat away from the LED, and are preferably formed along with conductive vias that extend through the packaging substrate. The thermal vias are preferably in the shape of circles or rectangular, and may either be solid or else may encircle and enclose a portion of the packaging substrate. Advantage of the preferred embodiment is that heat generated by the LED can be radiated rapidly and effectively by the package structure, less thermal decay is generated, and thereby life circle of the LED in increased.

Owner:EPISTAR CORP

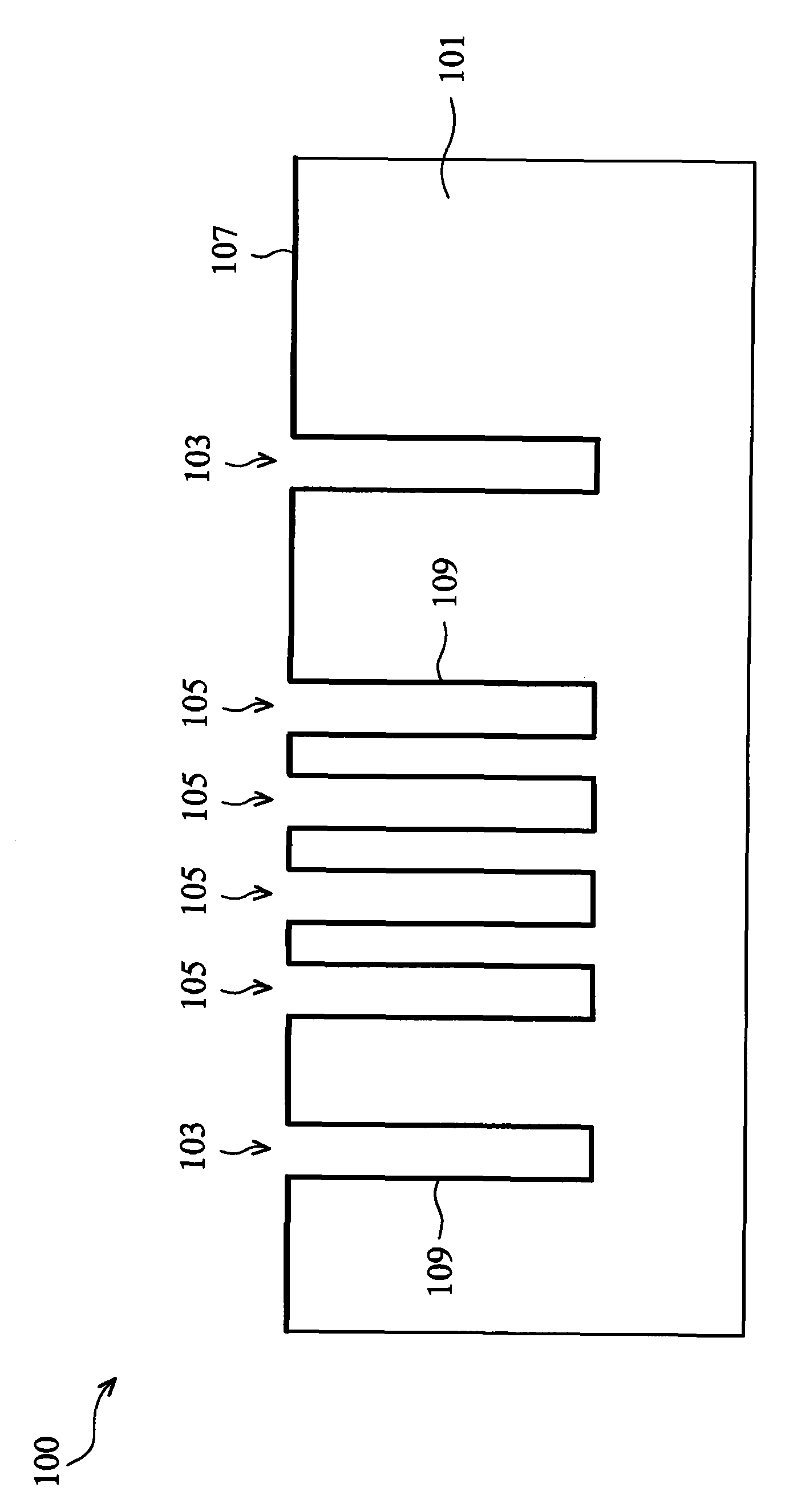

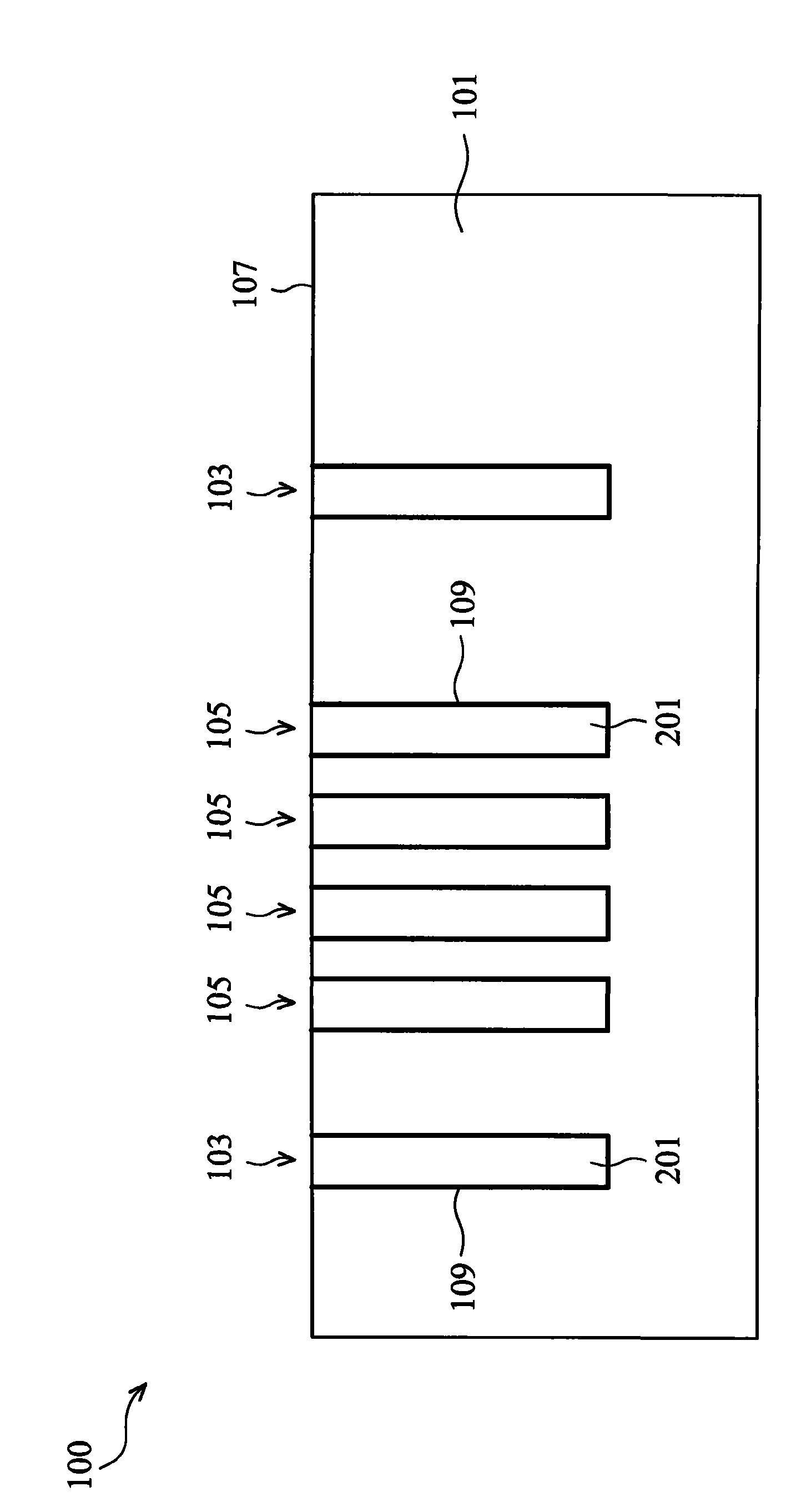

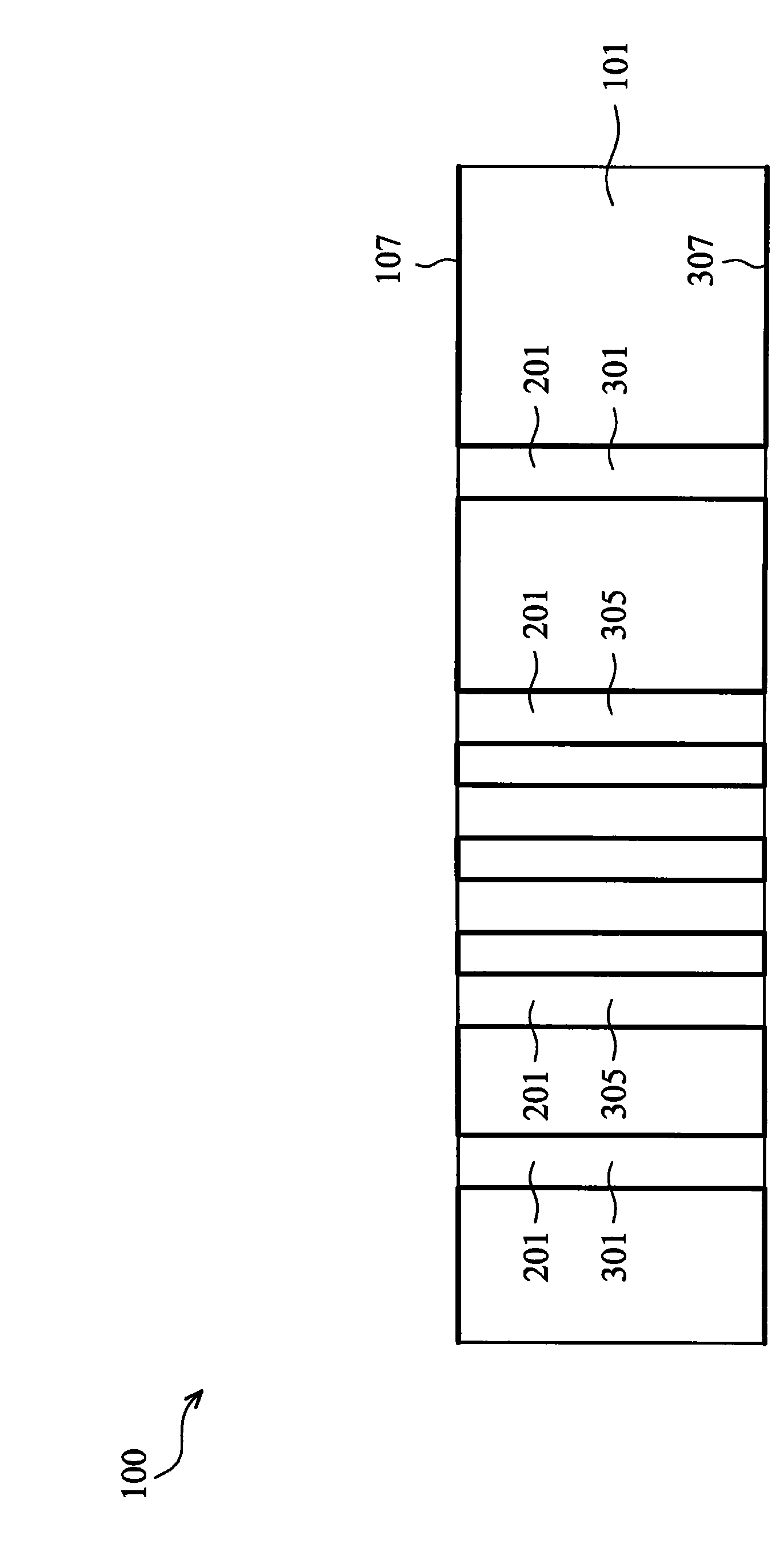

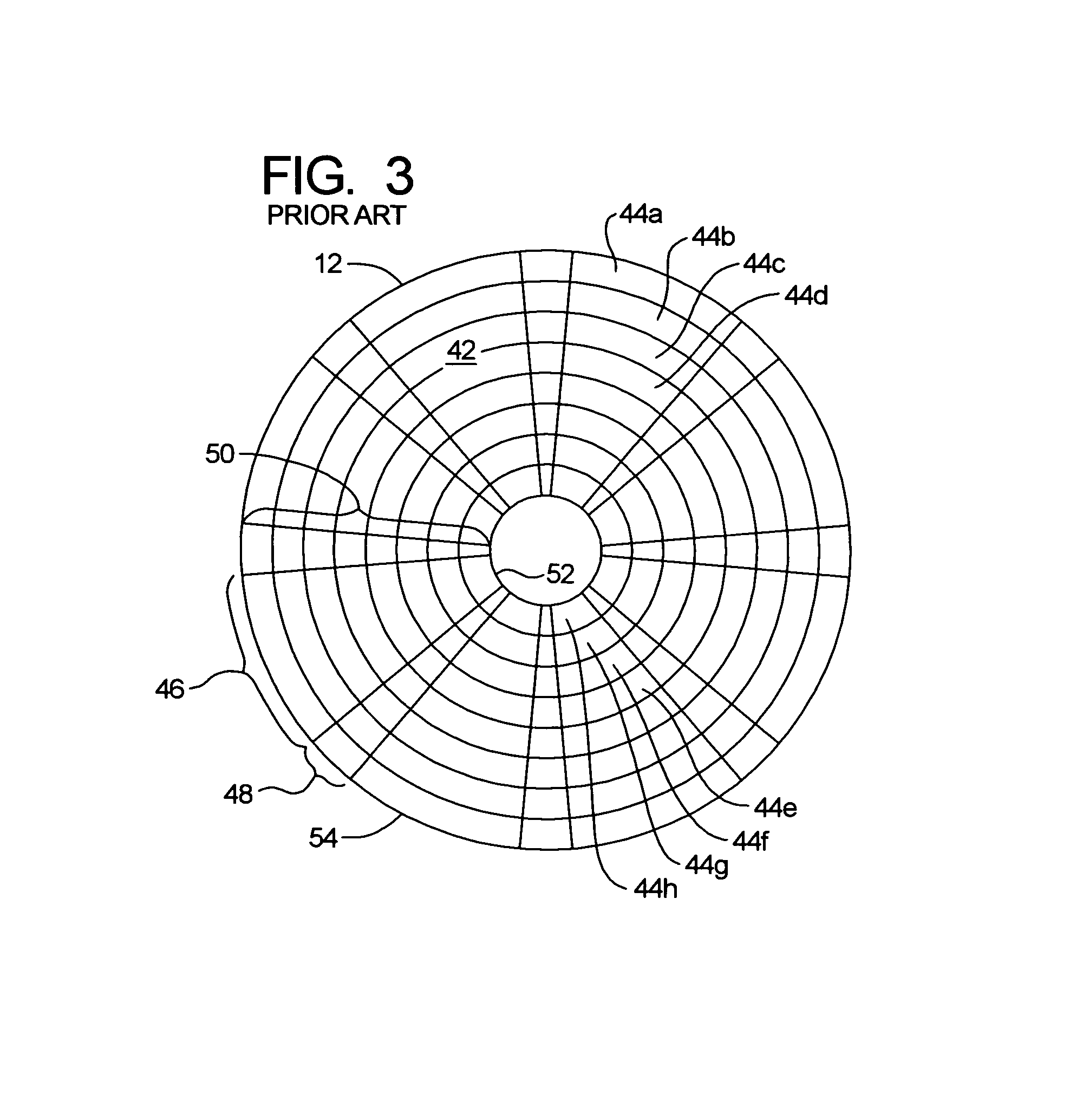

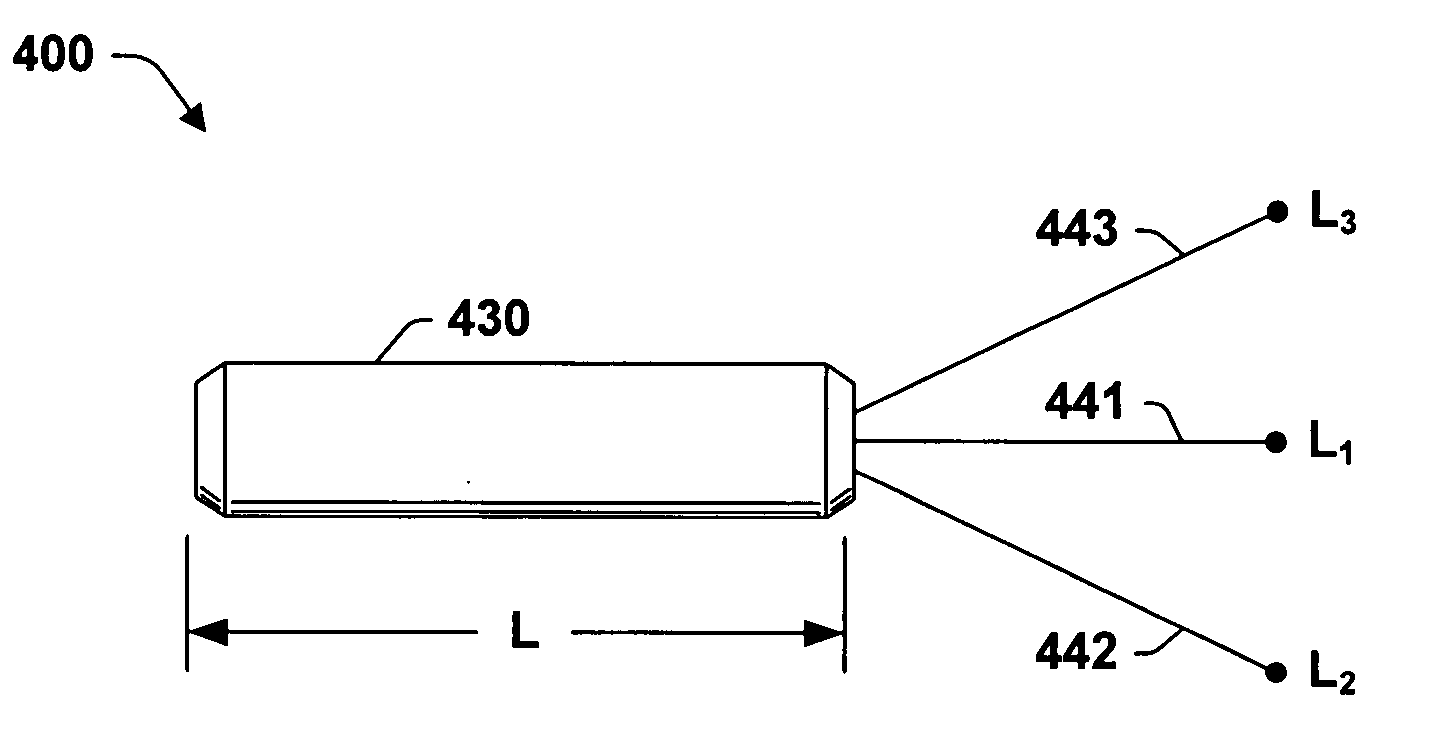

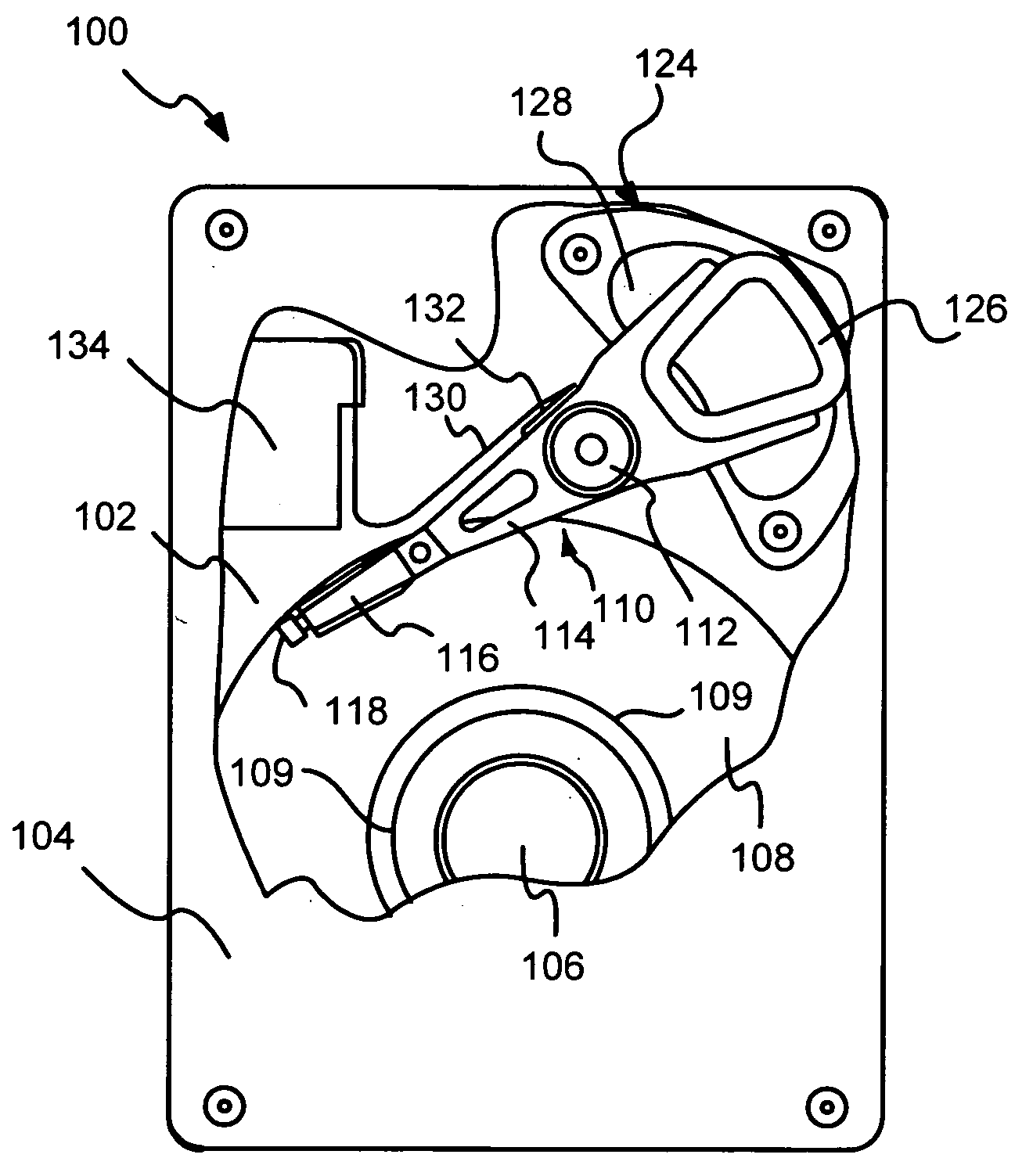

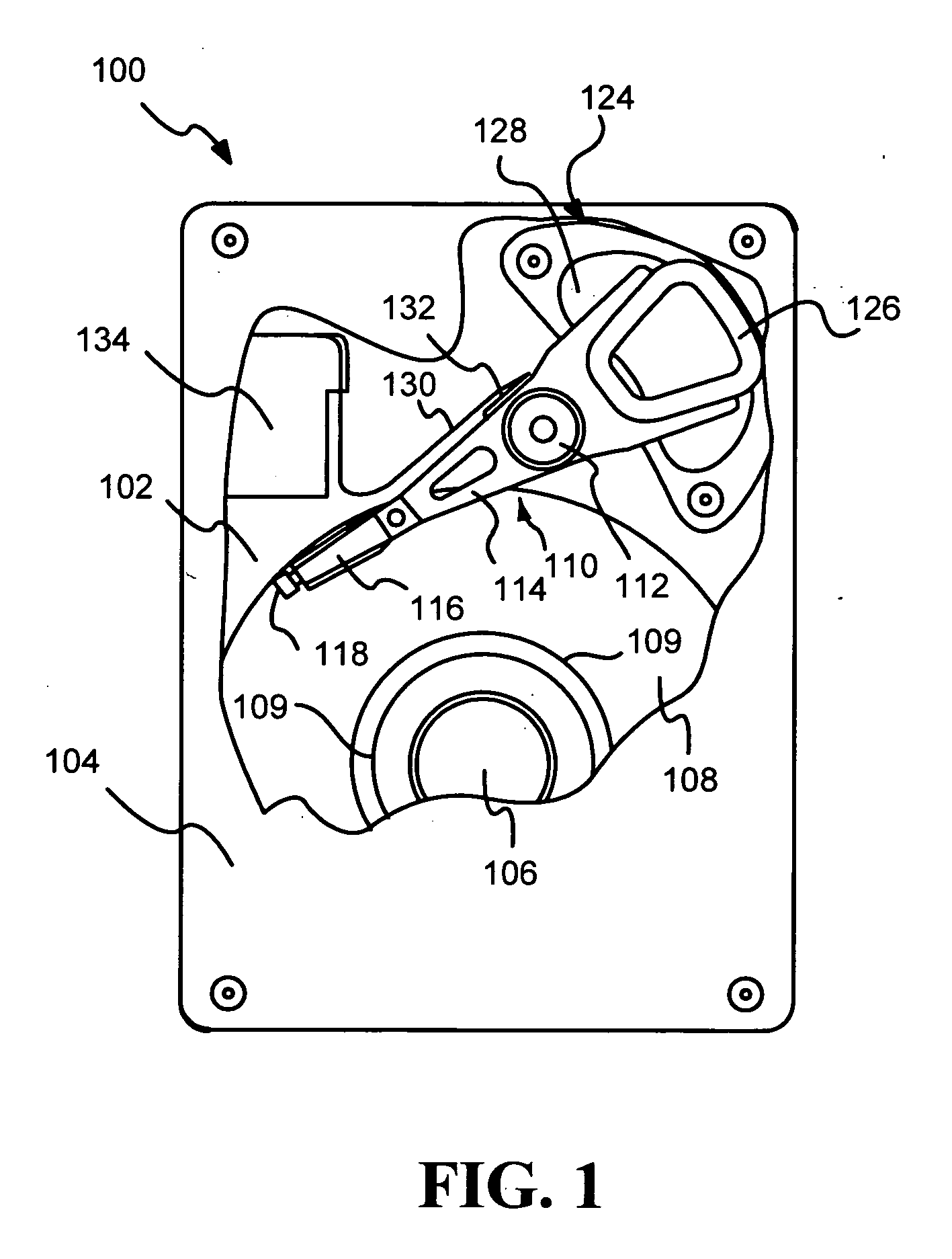

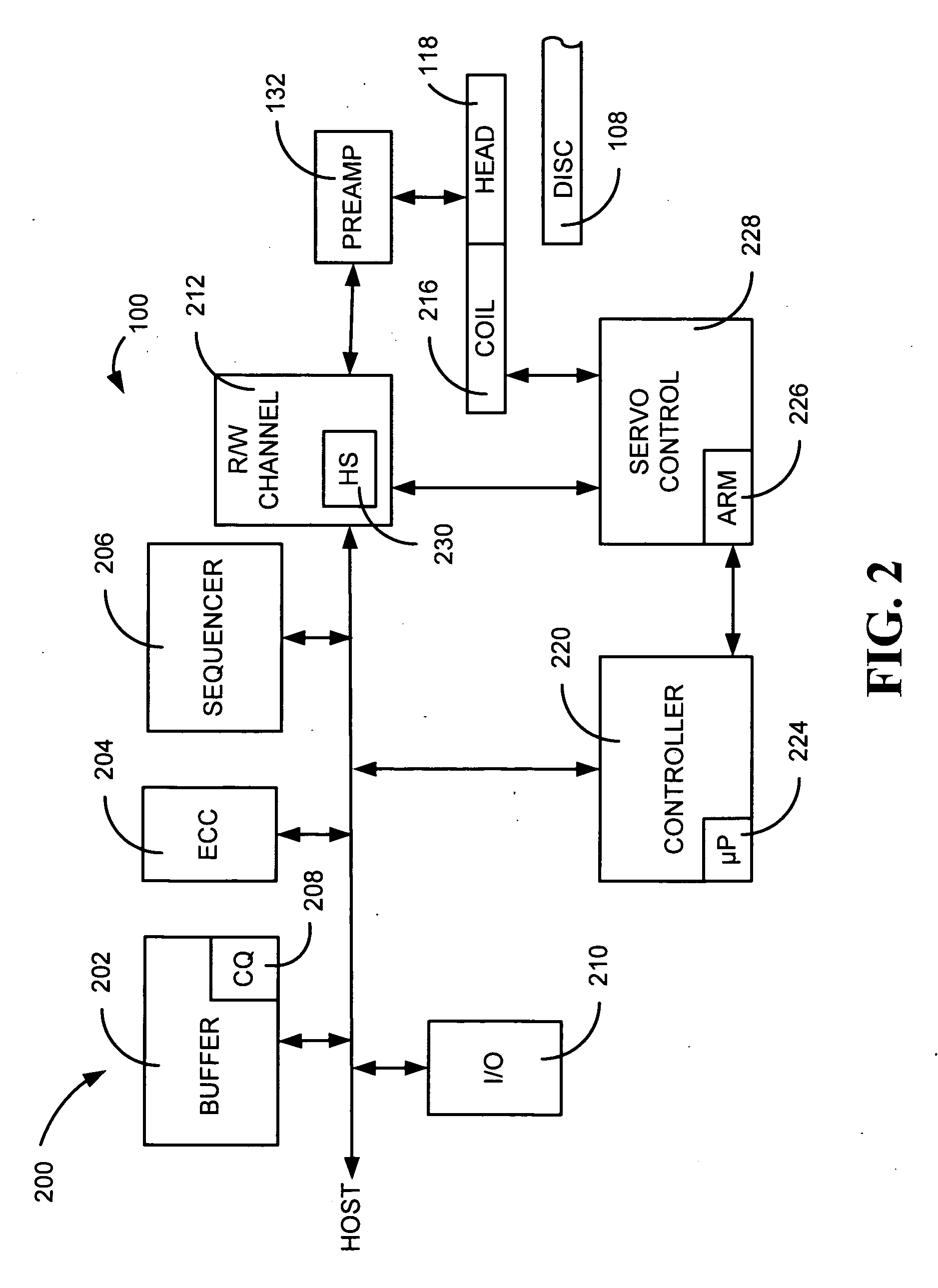

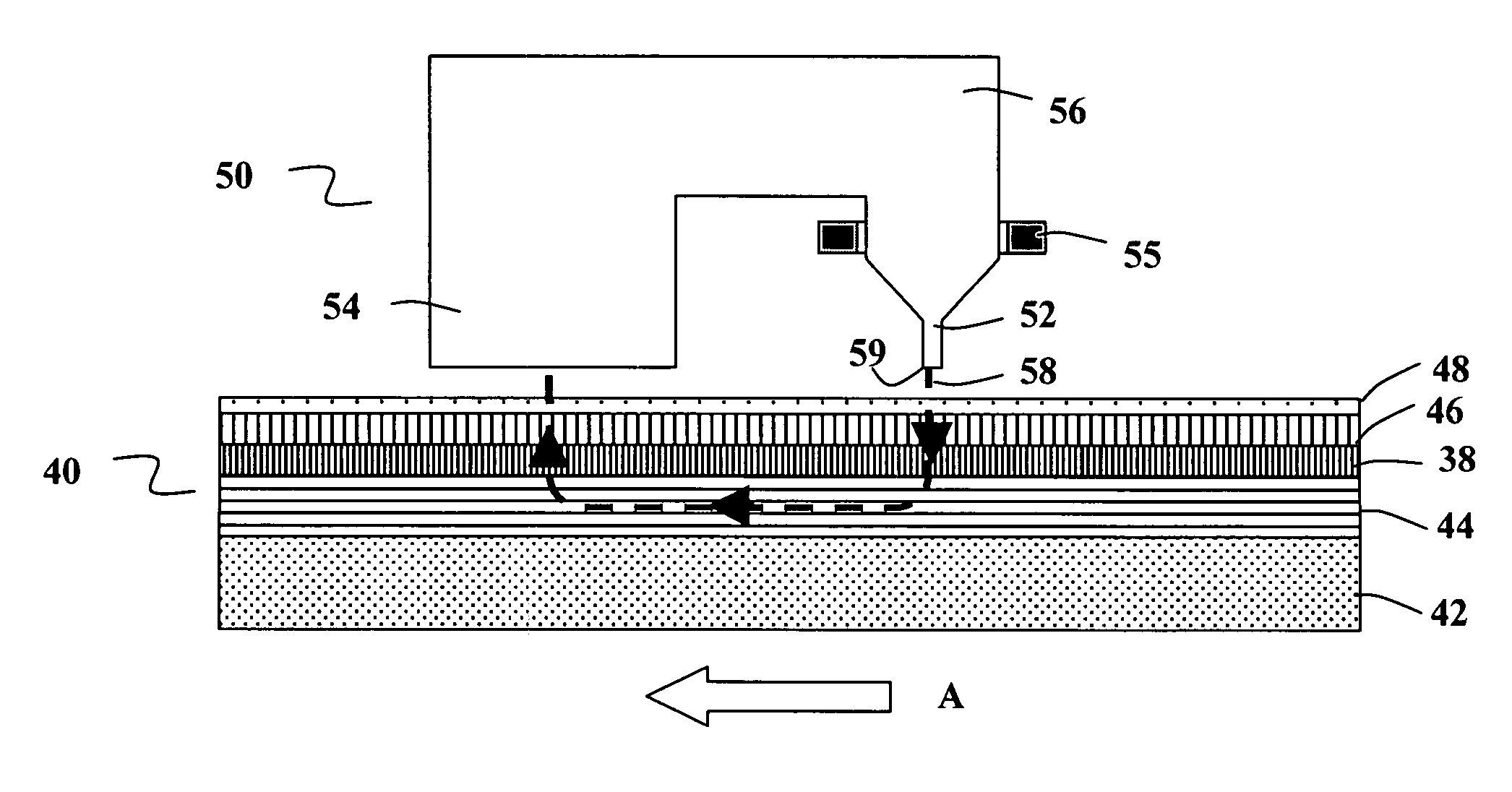

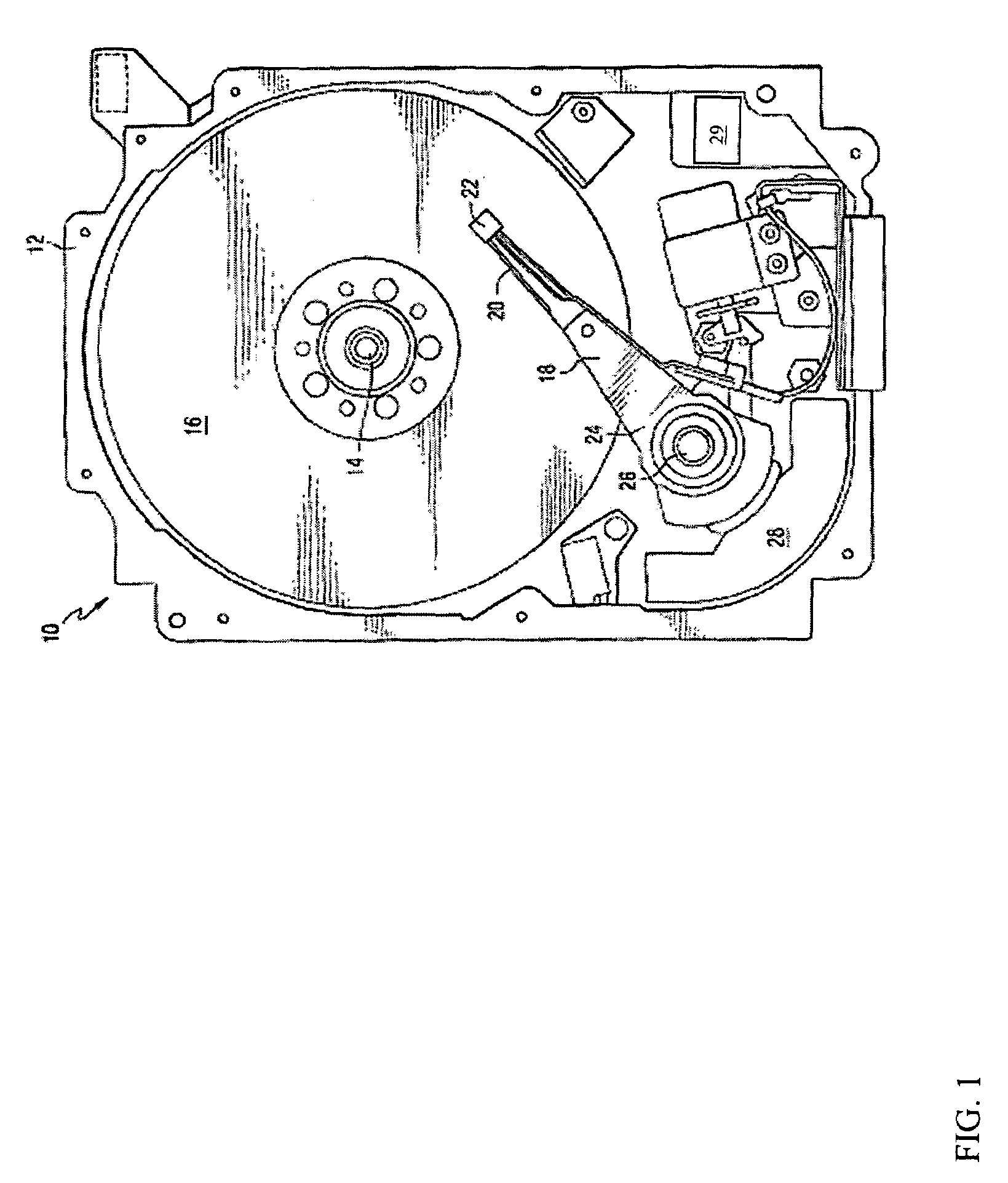

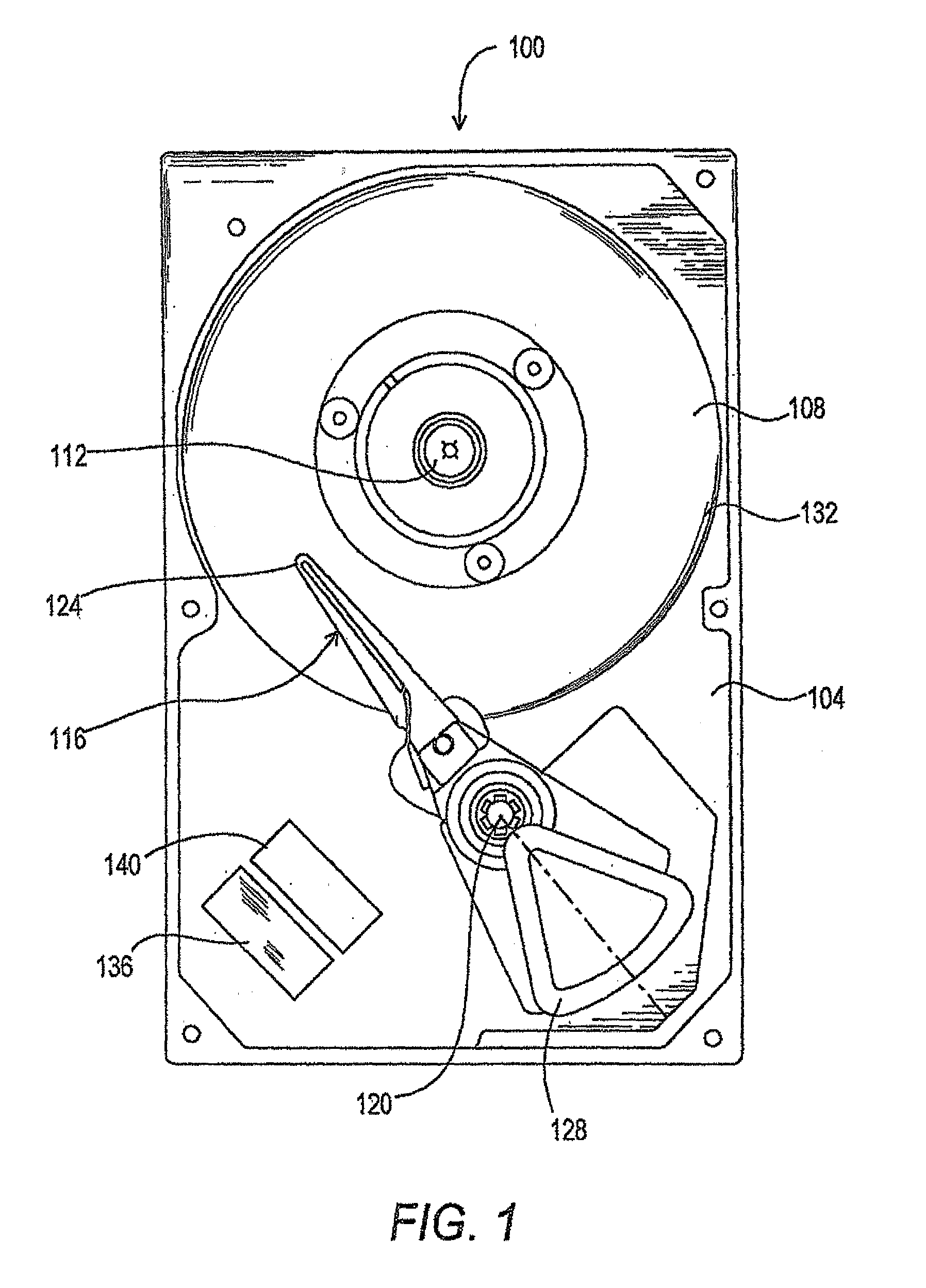

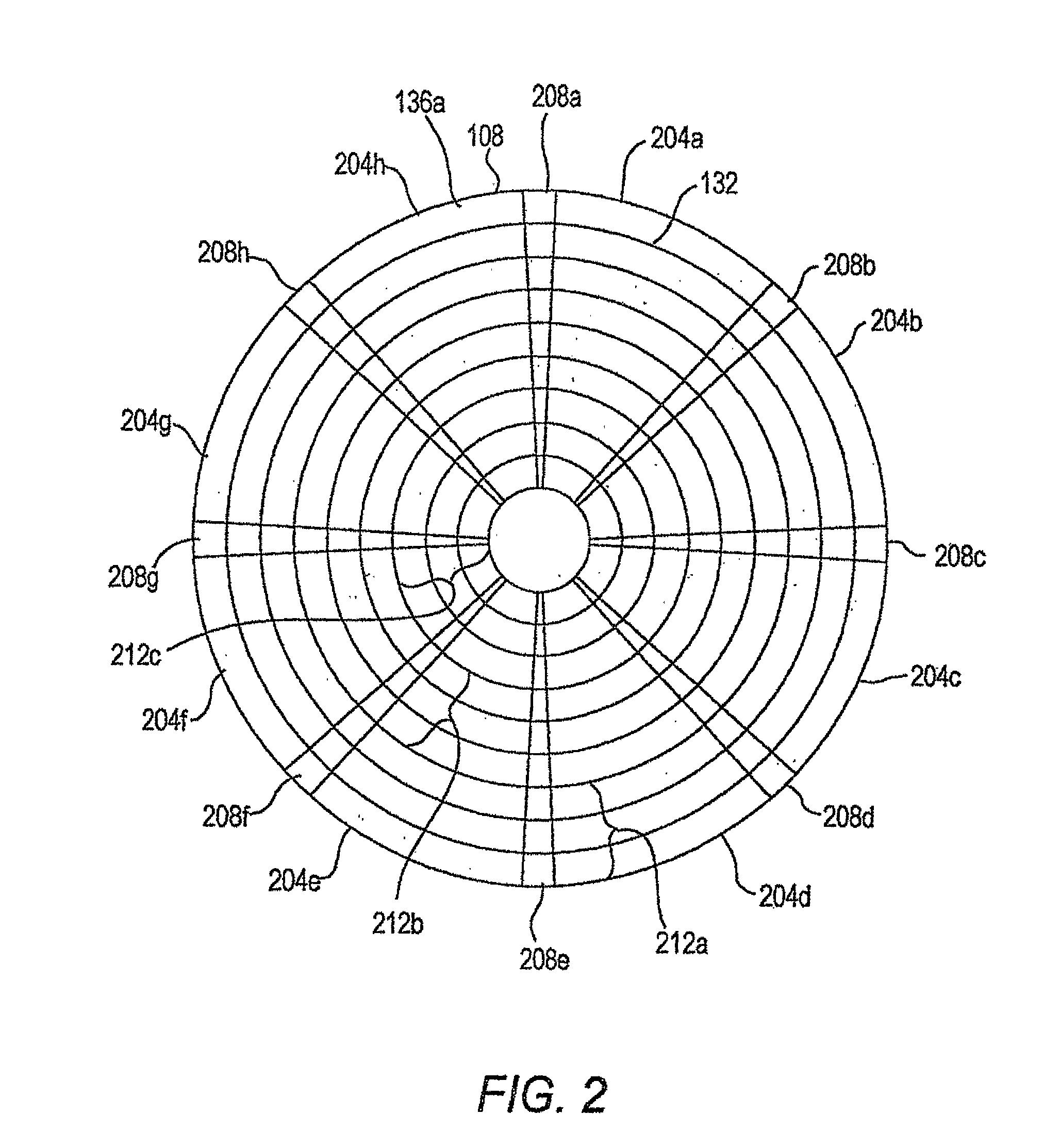

Method and apparatus for media thermal decay measurement in a disk drive

A method and apparatus is provided for measuring a media thermal decay rate for a disk in a disk drive. In one embodiment, reference patterns are written in a plurality of reference sectors on a test track of a disk surface. A thermal decay measurement duration is predetermined. After at least two decades of time longer than the predetermined thermal decay measurement duration have passed since writing the reference patterns in the plurality of reference sectors, sector-under-test patterns are written in a plurality of sectors-under-test, wherein the sectors-under-test and the reference sectors are written in data sectors and alternate with one another about at least a portion of the test track. The mean square error is measured and averaged for the reference sectors, and the mean square error is measured and averaged for the sectors under test. The averaged mean square error for the reference sectors and the averaged mean square error for the sectors-under-test are used to calculate the media thermal decay rate. In another embodiment, information associated with the amplitude of the readback signal is used instead of, or in addition to, the mean square error of the readback signal to calculate the media thermal decay rate.

Owner:MAXTOR

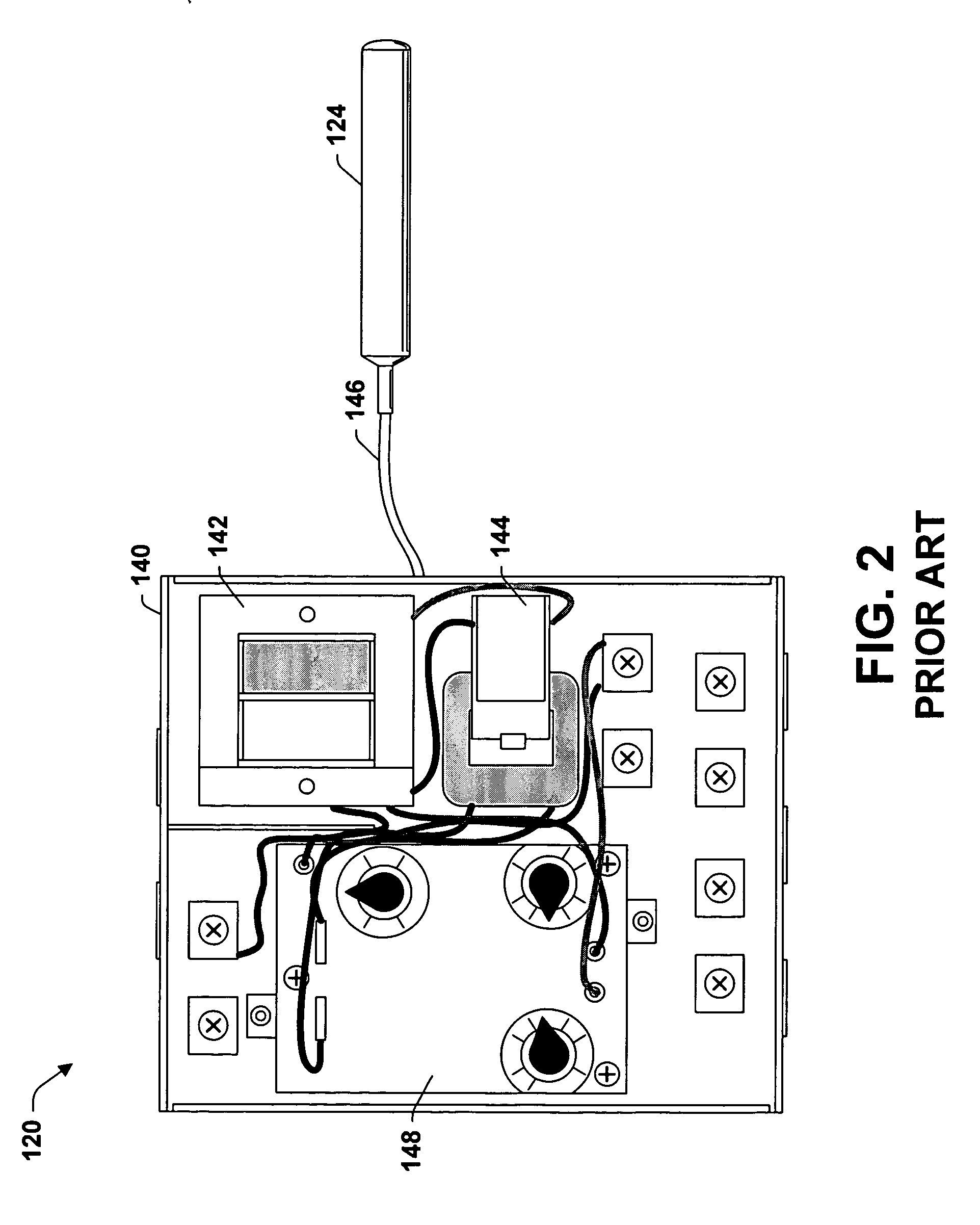

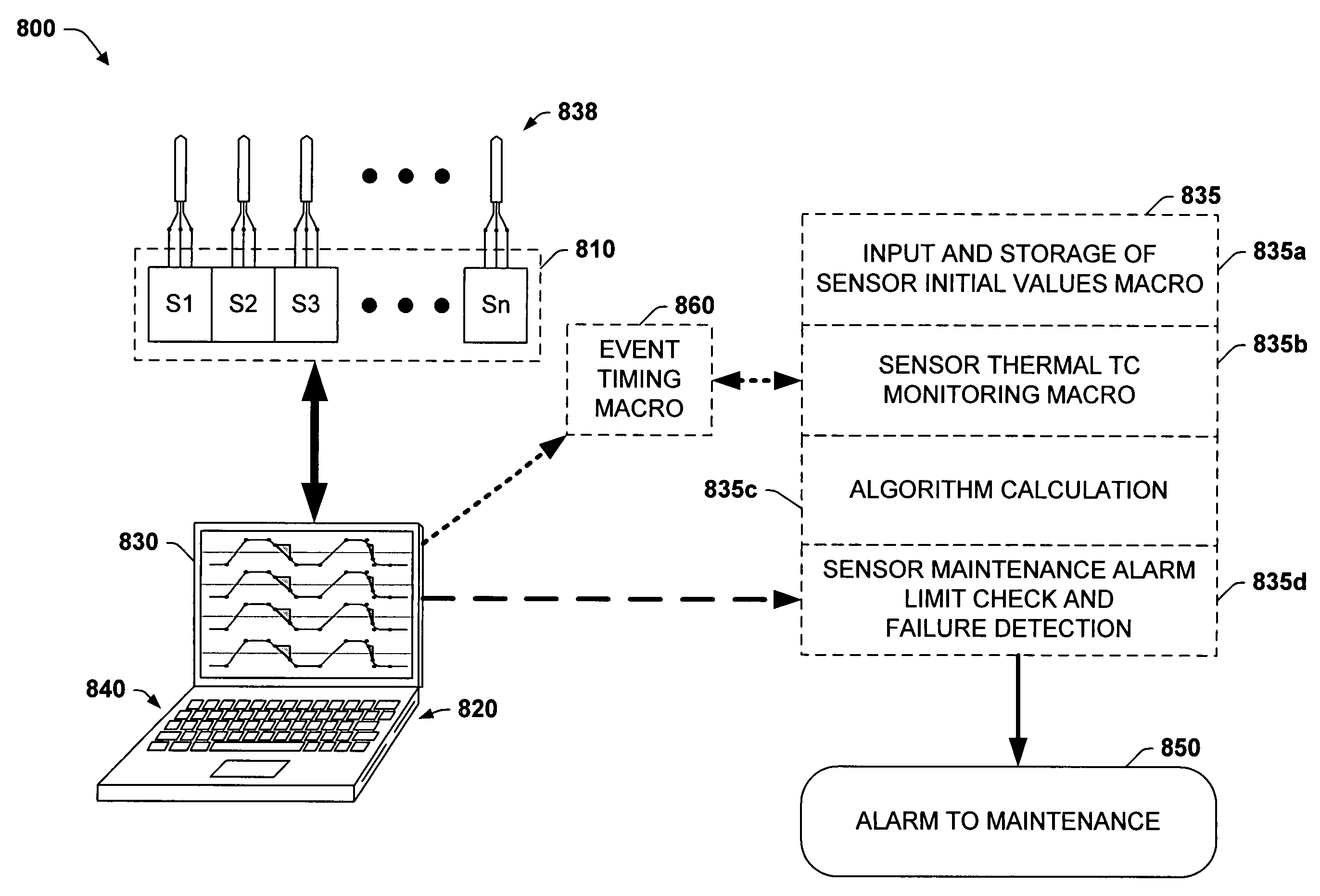

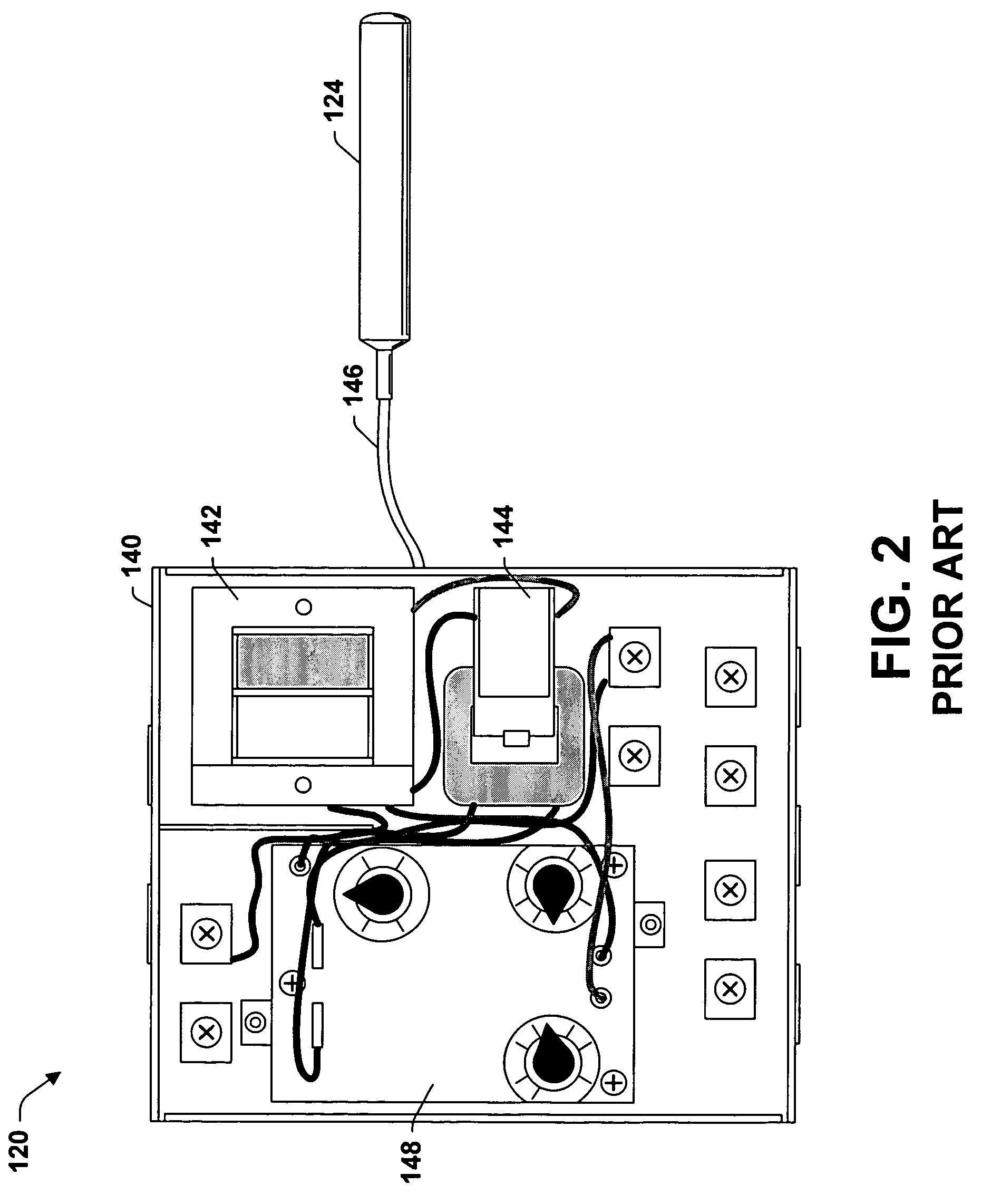

Fail safe HVAC temperature and medium presence sensor

ActiveUS20070000908A1Eliminate needMechanical apparatusSpace heating and ventilation safety systemsThermal decayEngineering

A system and method is presented for a fail-safe sensor for an HVAC system. The sensor comprises a temperature detector operable to measure a temperature of a component or a medium present at the sensor, a PTC heater operable to heat the sensor to a self-regulating temperature, the heater comprising a resistive element having an electrical impedance which increases with increasing temperature in accordance with a positive temperature coefficient characteristic, and a sensor housing comprising the PTC heater and the temperature detector provided within a single housing. An algorithm is provided for HVAC systems, wherein the sensor is heated to the self-regulating temperature by the PTC heater and is then measured by the temperature detector to confirm that the temperature detector is operating properly. Further, the sensor may be allowed to cool to a temperature of the surrounding medium or the component for sensing the temperature thereof. Thereafter, by calculating the time constant of the thermal decay rate of the sensor, the presence or absence of the component or medium surrounding the sensor may be determined in a fail-safe manner by an analyzer, for example.

Owner:R W BECKETT

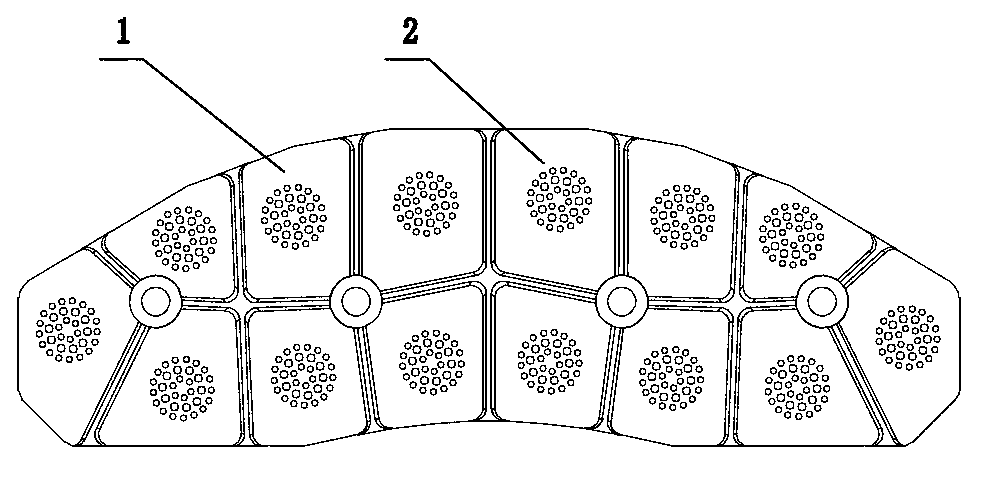

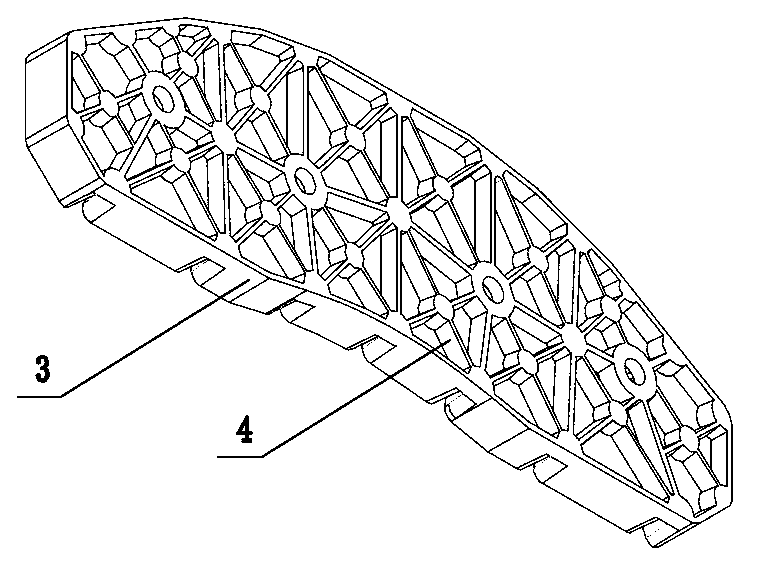

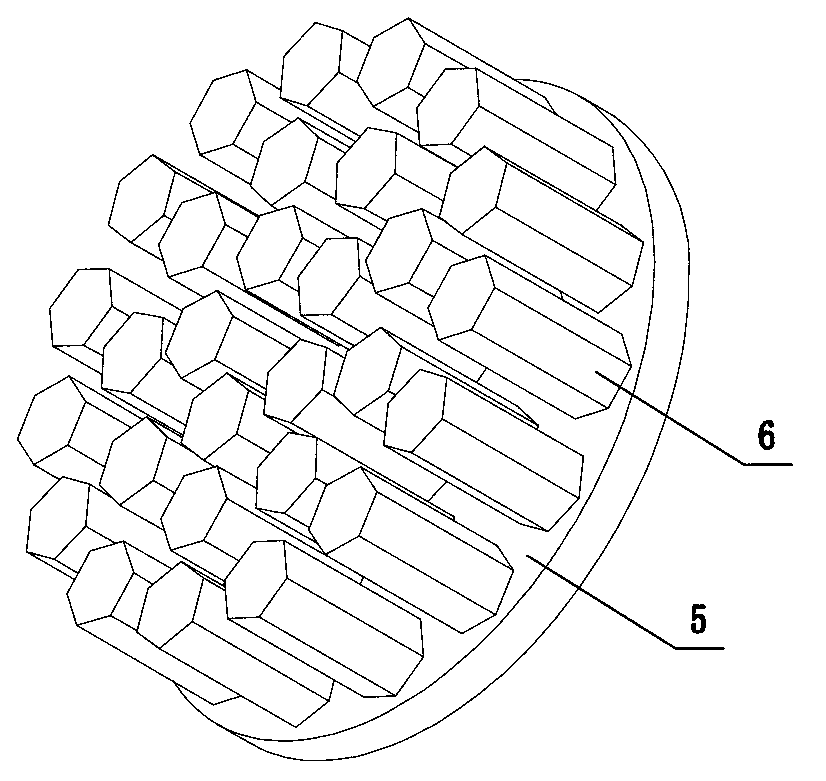

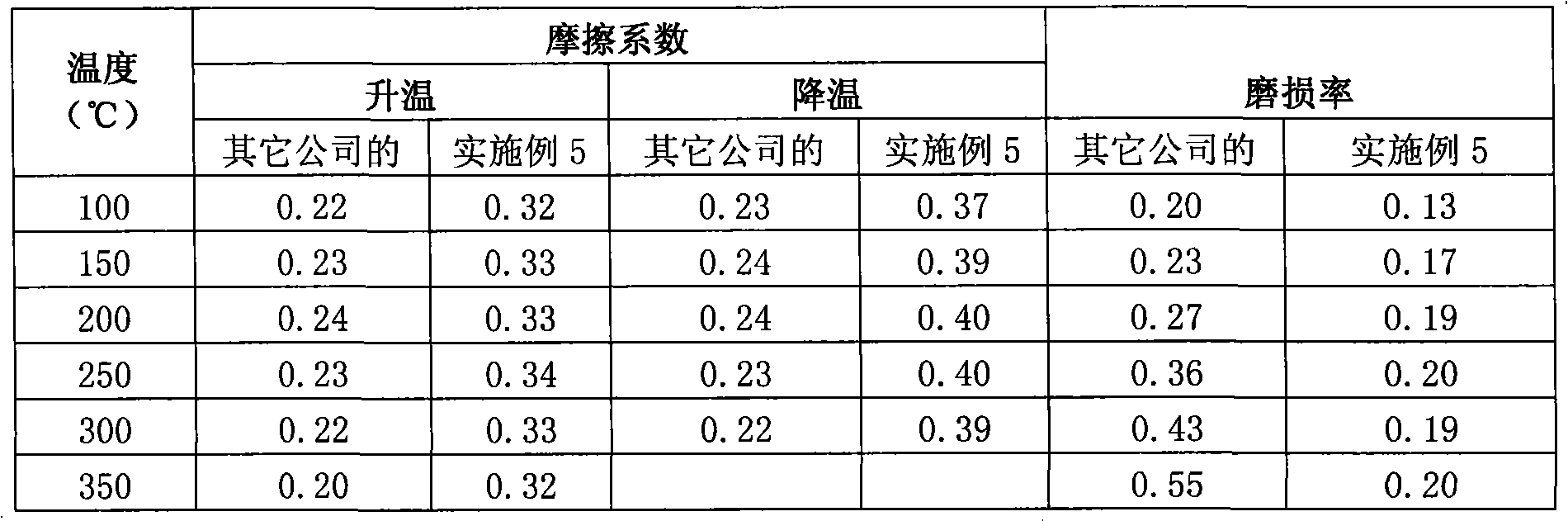

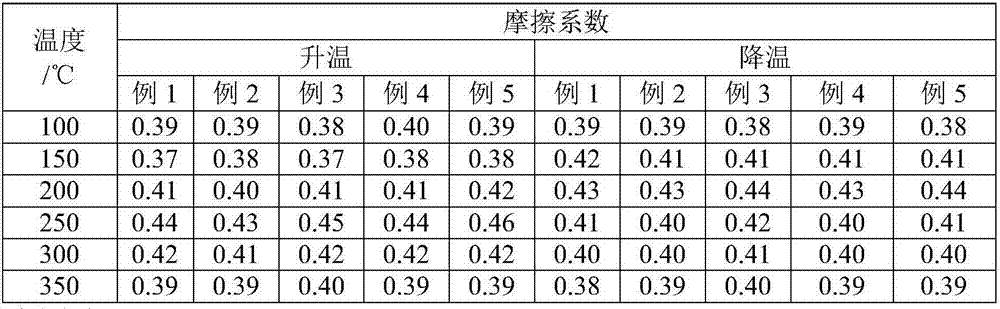

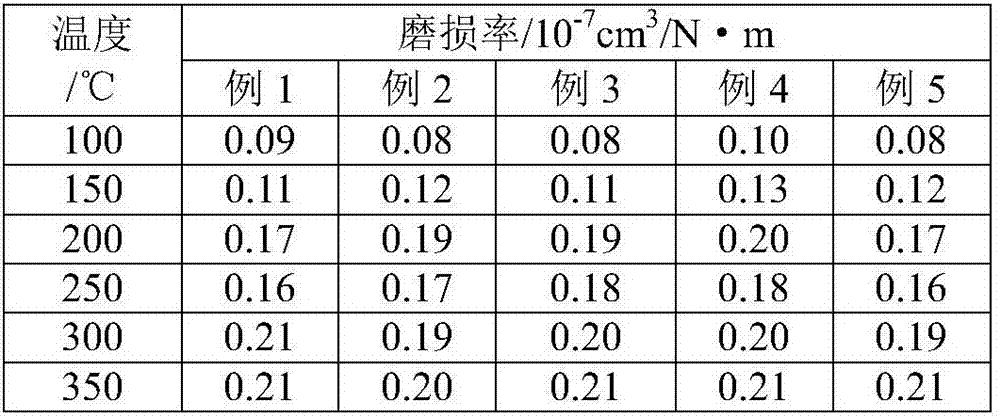

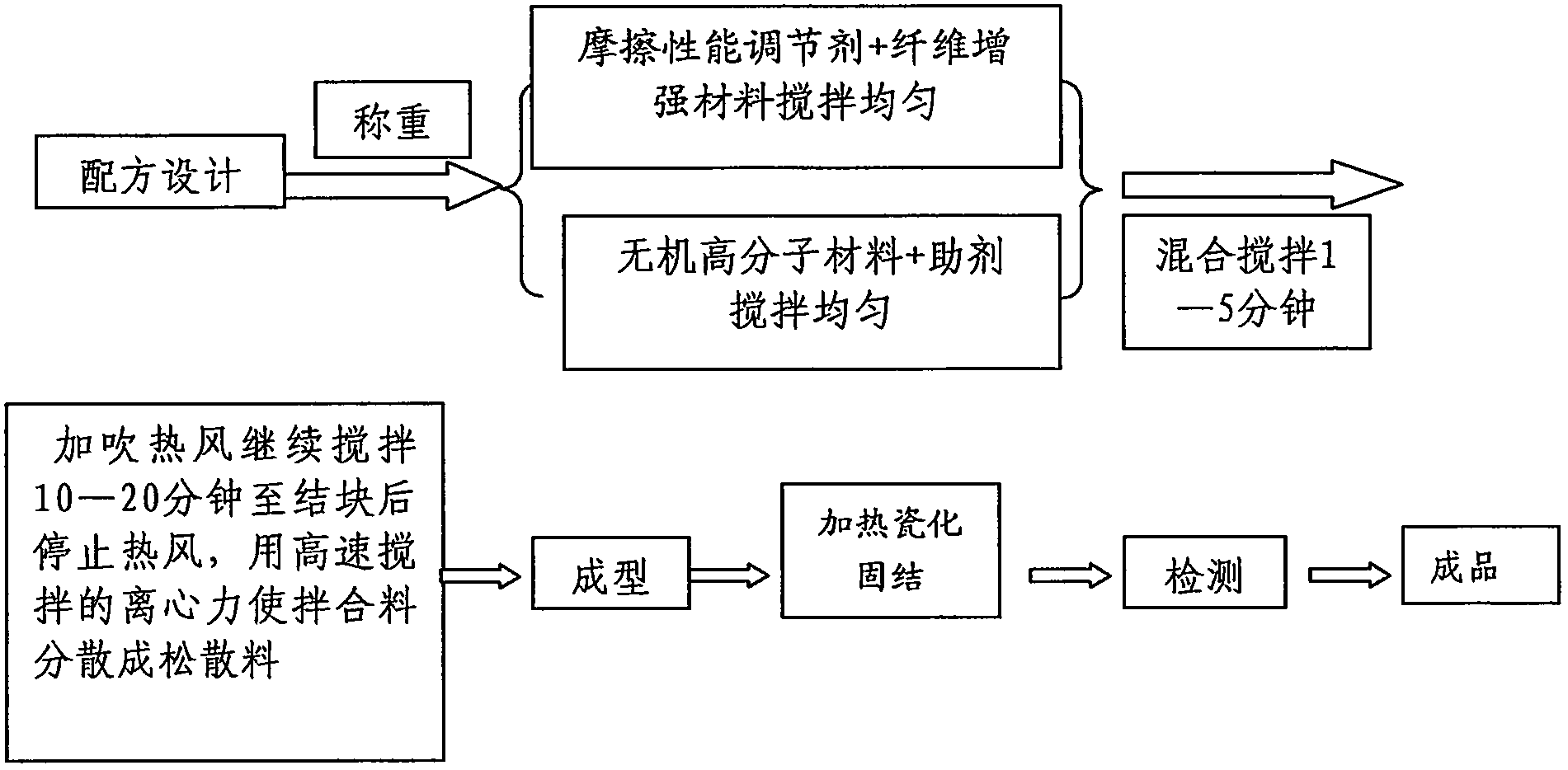

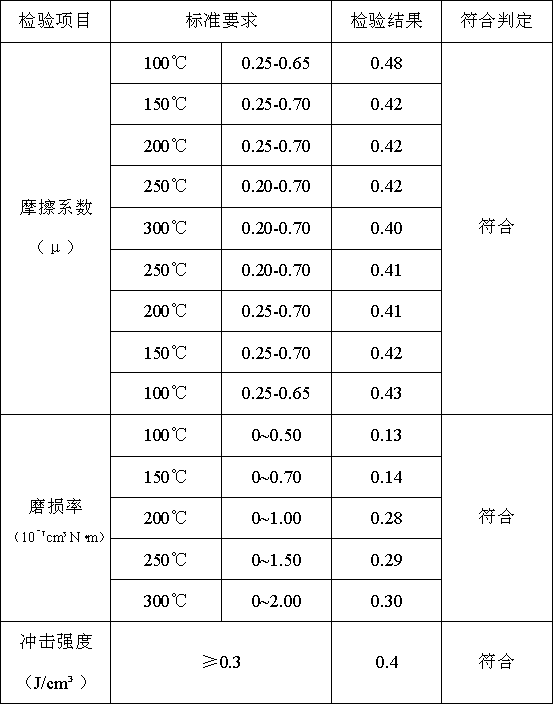

Ceramic/metal composite material brake lining for high-speed train and preparation method of ceramic/metal composite material brake lining

ActiveCN103075445AReduce movementConvenient engineering preparationBraking membersFriction liningThermal decaySlurry

The invention provides a ceramic / metal composite material brake lining for a high-speed train and a preparation method of the ceramic / metal composite material brake lining, and belongs to the technical field of high-speed brake. The existing high-speed train brake lining has the defects that the thermal stability is poor, the friction factor is low, the abrasion rate is high, the thermal decay resistance is poor, and the service life is short. The ceramic / metal composite material brake lining comprises friction blocks, a base plate and a heat radiation fin, wherein the friction blocks are made of ceramic block reinforced metal composite materials, the gap width among the friction blocks is 3 to 8mm, the ceramic block is obtained through sintering ceramic posts of a certain rule and connected ceramic biscuits of ceramic substrates connected with the ceramic posts, and the connected ceramic biscuits can be formed in modes of slurry filling, gel mold filling, molding pressing, isostatic pressing and the like. The preparation method provided by the invention comprises the following steps including ceramic block sintering, surface treatment, brake lining casting, precise processing and heat treatment. The ceramic / metal composite material brake lining has the characteristics that the thermal stability is good, the friction factor is high, the abrasion rate is low, the thermal decay resistance is good, the service life is long, and the like, and the effective braking can be realized on 380km / h high-speed trains.

Owner:浙江天乐新材料科技有限公司

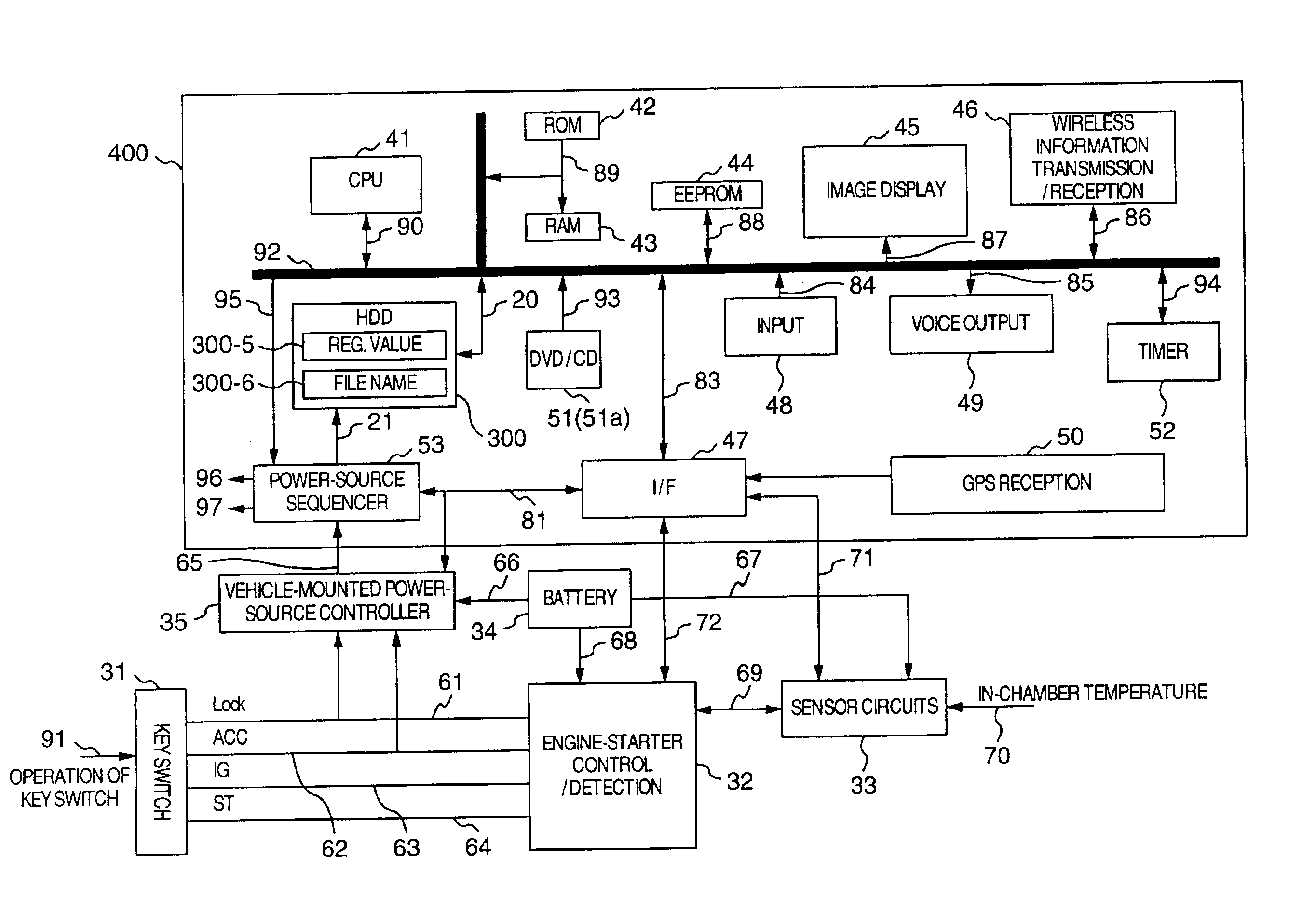

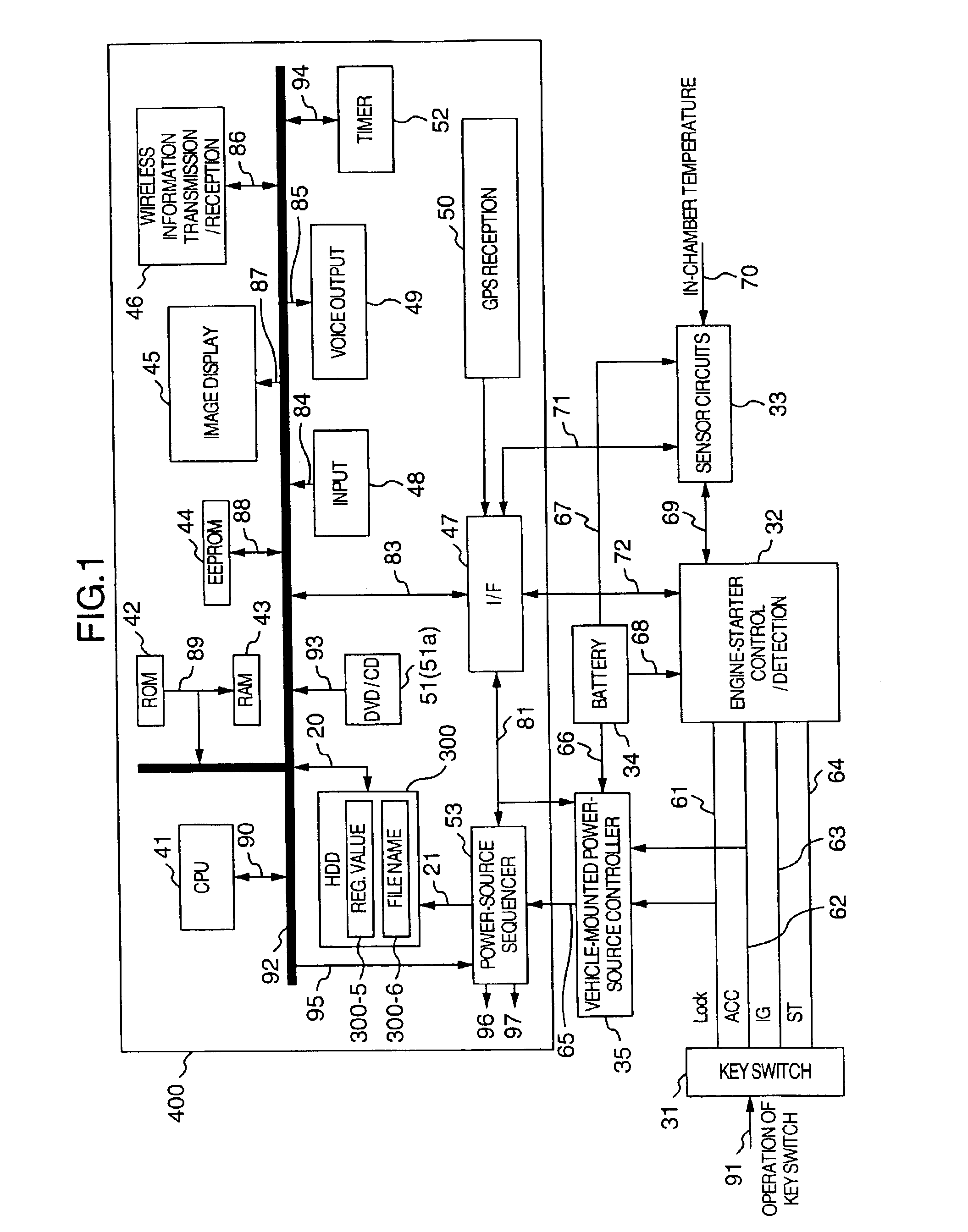

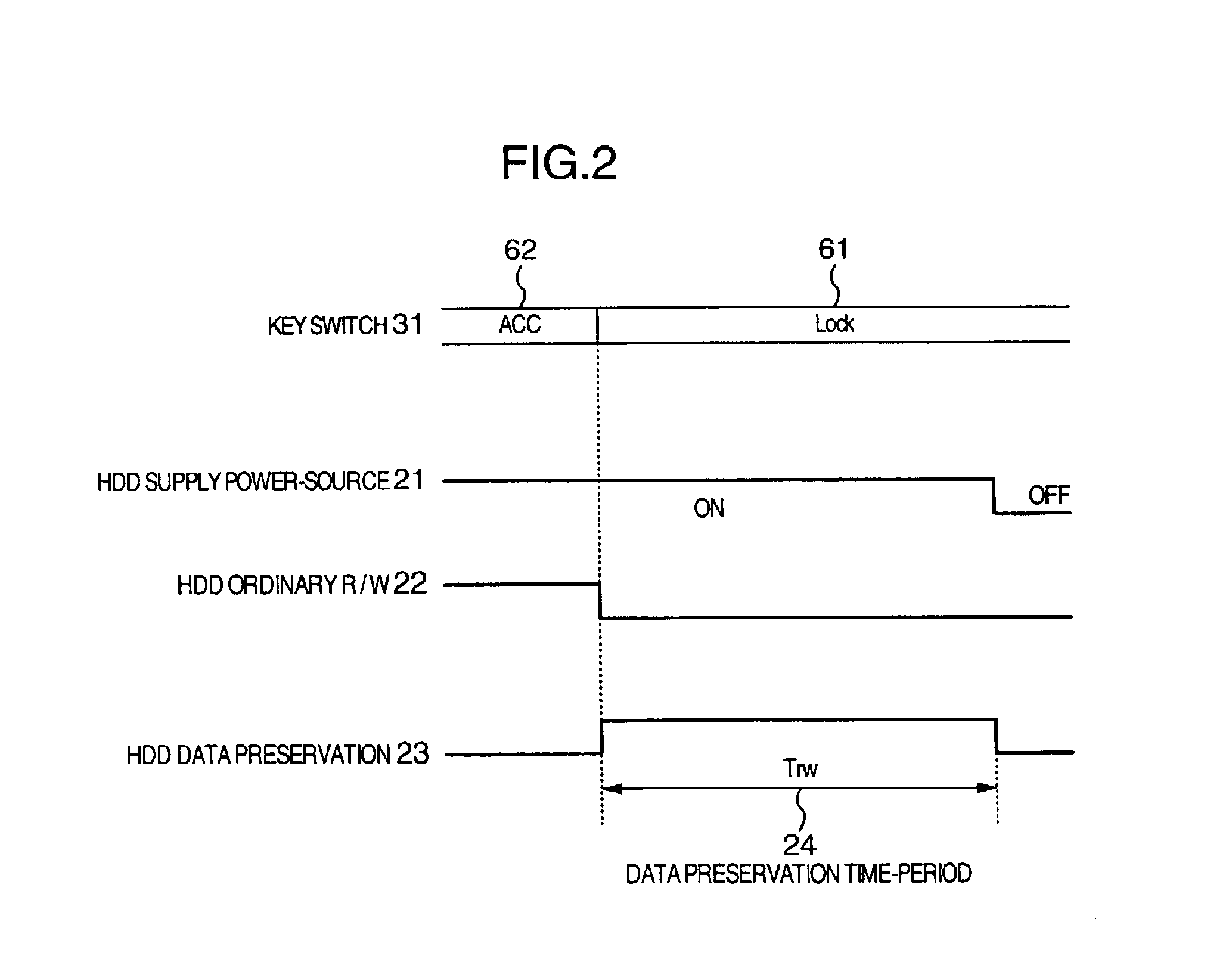

Vehicle-mounted information processing apparatus having magnetic disk device

InactiveUS6862505B2High data reliabilityIncrease opportunitiesTelevision system detailsInstruments for road network navigationInformation processingThermal decay

A vehicle-mounted information processing apparatus such as a car-navigation system detects that a key switch of the vehicle has been set up at a Lock position (i.e., the engine is stopped). After that, the apparatus performs data reproduction of data files in an order from the oldest, then re-recording the reproduced data files with no change added thereto. Here, the above-described data files, which are stored within a magnetic disk device built in the apparatus, have been not updated for a constant time-period. This re-recording prevents a data loss caused by a thermal decay in the case where the magnetic disk device is mounted inside the vehicle that is likely to have existed under a high-temperature environment for a long time-period.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD +1

Copper-free friction material composition for brake pads

InactiveUS20140357758A1Promote environmental protectionSatisfactory high-temperature and thermal decay resistant performanceFriction liningActuatorsPotassiumThermal decay

A copper-free friction material composition for brake pads consists of the following components by weight parts: 0.43 parts of aramid fiber, 1.9 parts of tyre powder, 6 parts of heavy magnesia, 2.55 parts of calcined petroleum coke, 8 parts of ceramic fiber, 6.5 parts of phenolic resin, 14 parts of aluminium silicate fiber, 22 parts of potassium hexatitanate crystal whisker, 25 parts of barite powder, 5 parts of granular graphite, 2 parts of antimony sulfide, 2.8 parts of friction powder of cashew nut oil, 0.9 part of boron nitride, 5 parts of flake aluminum powder, and 0.6 parts of tantalum carbide. The friction material of the present invention is environment-friendly material and contains little heavy metals; hence the friction material is highly environment friendly. And trials show that it has satisfactory high temperature and thermal decay resistant performance, long service life, good abrasion resistance and stable friction coefficient. With the friction material of the present invention used, the brake pad of vehicles is sensitive and stable during braking, produces no screech, is comfortable and has no damage on coupling plate.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

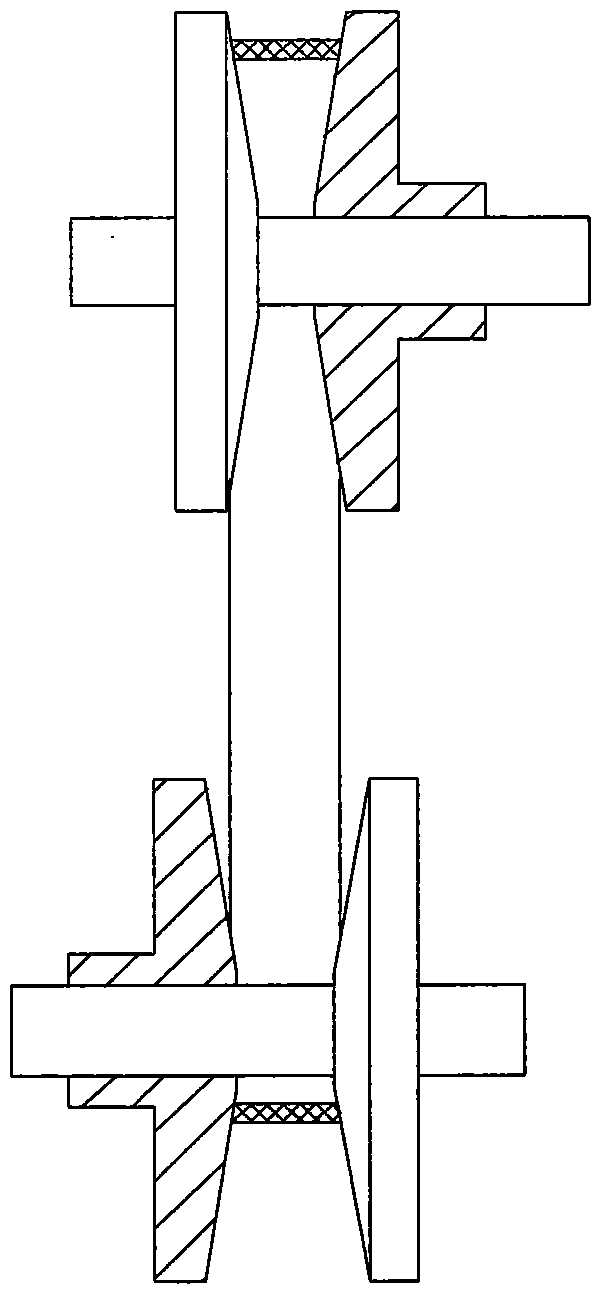

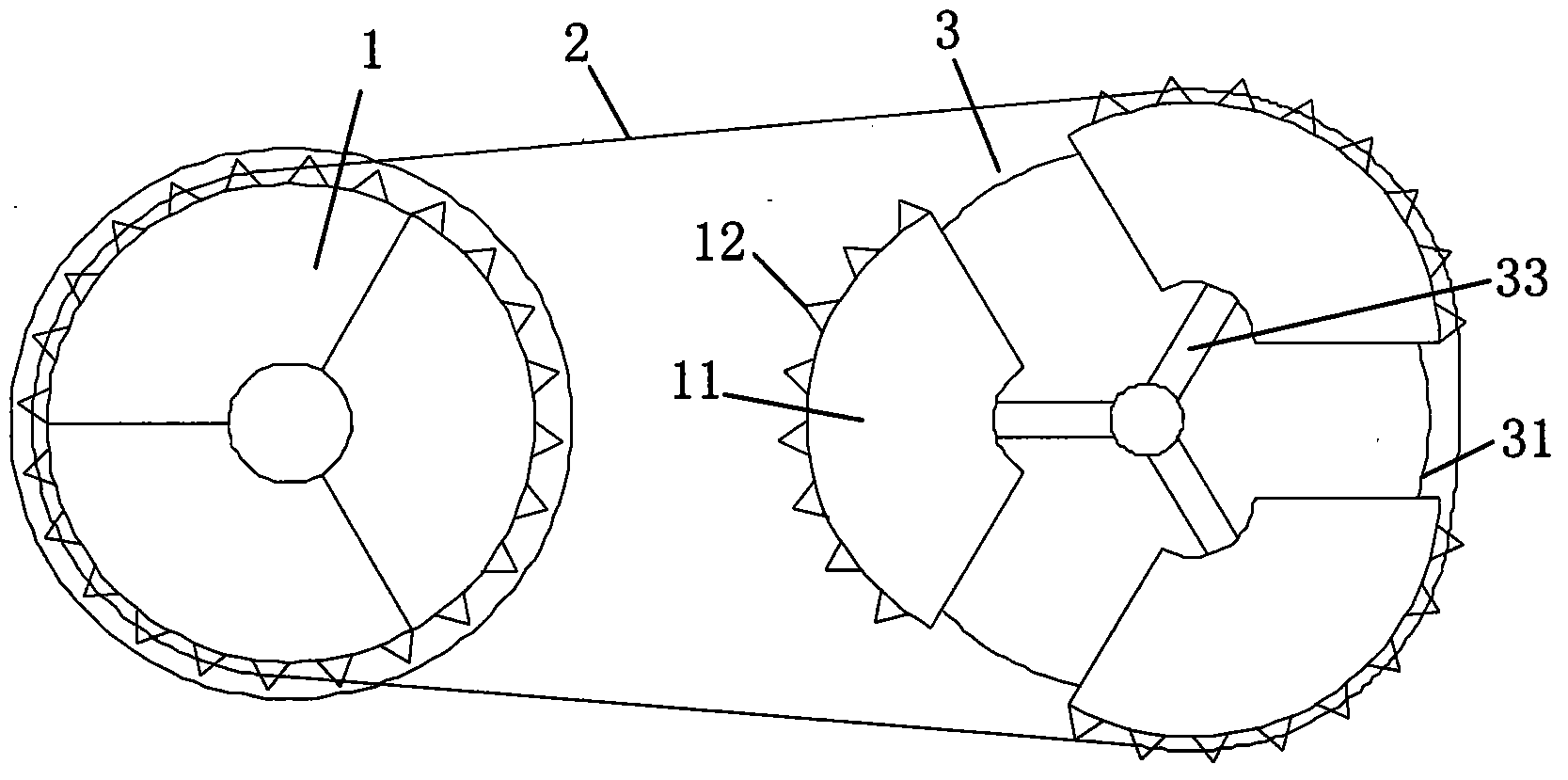

Variable-speed transmission mechanism for relay transmission of variable-diameter gears

ActiveCN104343914ASimple structureExcellent size and weightGearingPortable liftingDrive wheelTorque transmission

The invention discloses a variable-speed transmission mechanism for relay transmission of variable-diameter gears. The variable-speed transmission mechanism comprises two variable-diameter relay transmission gears, variable-diameter adjusting mechanisms, a power input shaft and a power output shaft, wherein the two variable-diameter relay transmission gears are connected with each other through a transmission gear group; the variable-diameter adjusting mechanisms are respectively arranged on the two variable-diameter relay transmission gears; the power input shaft is connected with one variable-diameter adjusting mechanism, and the power output shaft is connected with the other variable-diameter adjusting mechanism. Based on the basic principle of infinitely variable speed, through unique and novel design concept, variable transmission ratio of a main driven wheel is realized by utilizing a clack body combined type variable-diameter wheel body, effective variable-diameter control is realized through the variable-diameter adjusting mechanisms, and power transmission is realized through engagement of gear belts and gears; the variable-speed transmission mechanism is simpler in structure, superior in weight volume and lower in production and manufacturing costs; moreover, the variable-speed transmission mechanism is firmer in structure, the bearing load and torque transmission capacity are greatly improved, and the problems in the prior art that thermal decay exists and larger torques cannot be transmitted through friction transmission speed are solved, so that the variable-speed transmission mechanism can be widely applied to large-displacement automobiles.

Owner:谢瑞成

Corrosion resistant low noise semi-metallic brake pad

ActiveCN101555916AImprove heat resistanceGood instantaneous high temperature resistanceFriction liningLow noiseFiber

A corrosion resistant low noise semi-metallic brake pad comprises the following components according to weight percentages: 2-4% of nitrile rubber buna, 3-5% of tyre powder, 3-5% of expandable graphite, 9-13% of phenolic resin, 10-15% of stainless steel chopped fibre, 4-7% of red copper fibre, 2-3% of cashew nut oil friction powder, 3-5% of graphite particle, 7-10% of superfine ferric oxide powder, 3-5% of diatomite, 7-12% of acicular wollastonite fibre, 10-15% of barite, 3-5% of chromite, 4-8% of sepiolite fibre, 0.2-0.5% of zinc stearate, 2-3% of zirconite, 3-5% of boron nitride and 2-3% of supramoly; the brake pad has the characteristics of corrosion resistant performance, high frictional coefficient, satisfactory high temperature and thermal decay resistant performance, long service life, and the like. After the brake pad is used, the car brake is sensitive, the braking is stable and brake noise is low, and the brake drum or brake disc has no damage in long-term use.

Owner:摩擦一号制动科技(仙桃)有限公司

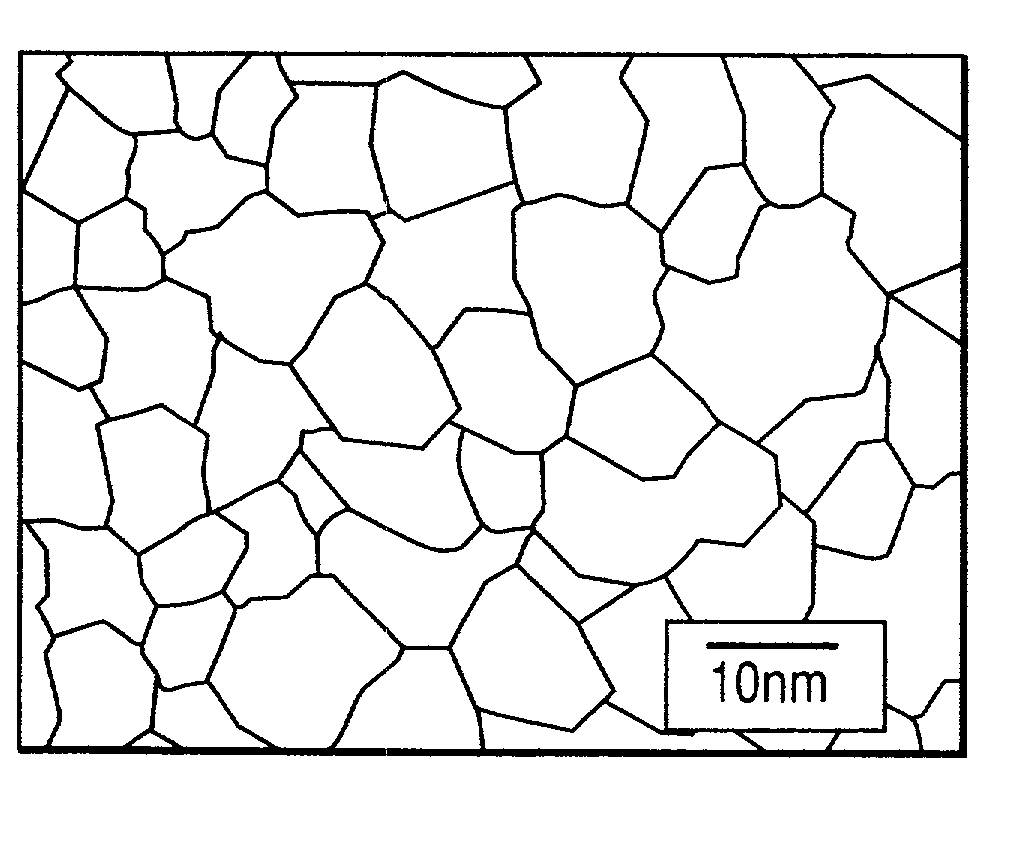

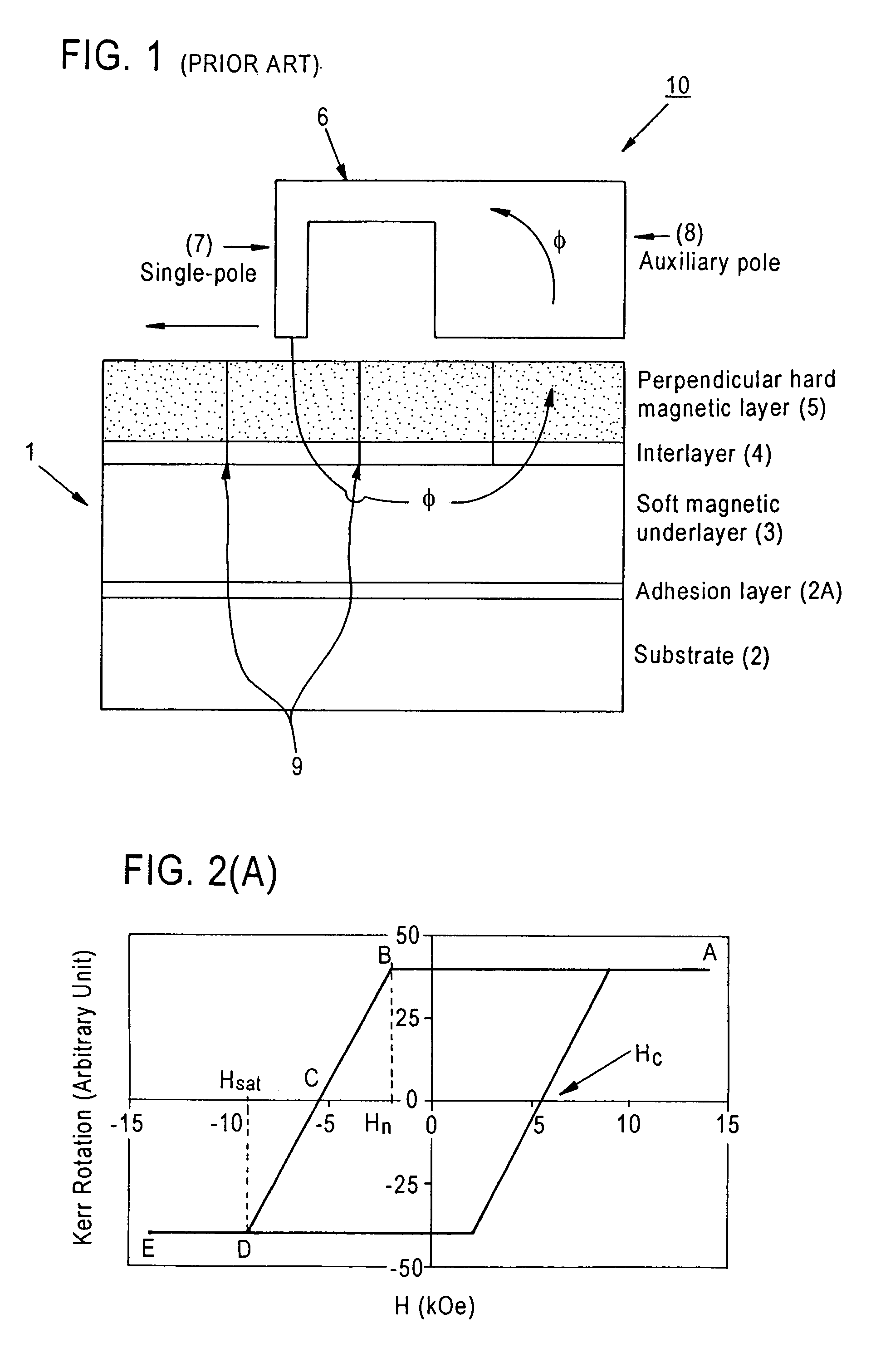

Magnetic recording medium and its manufacturing method and magnetic recording system using such a magnetic recording medium

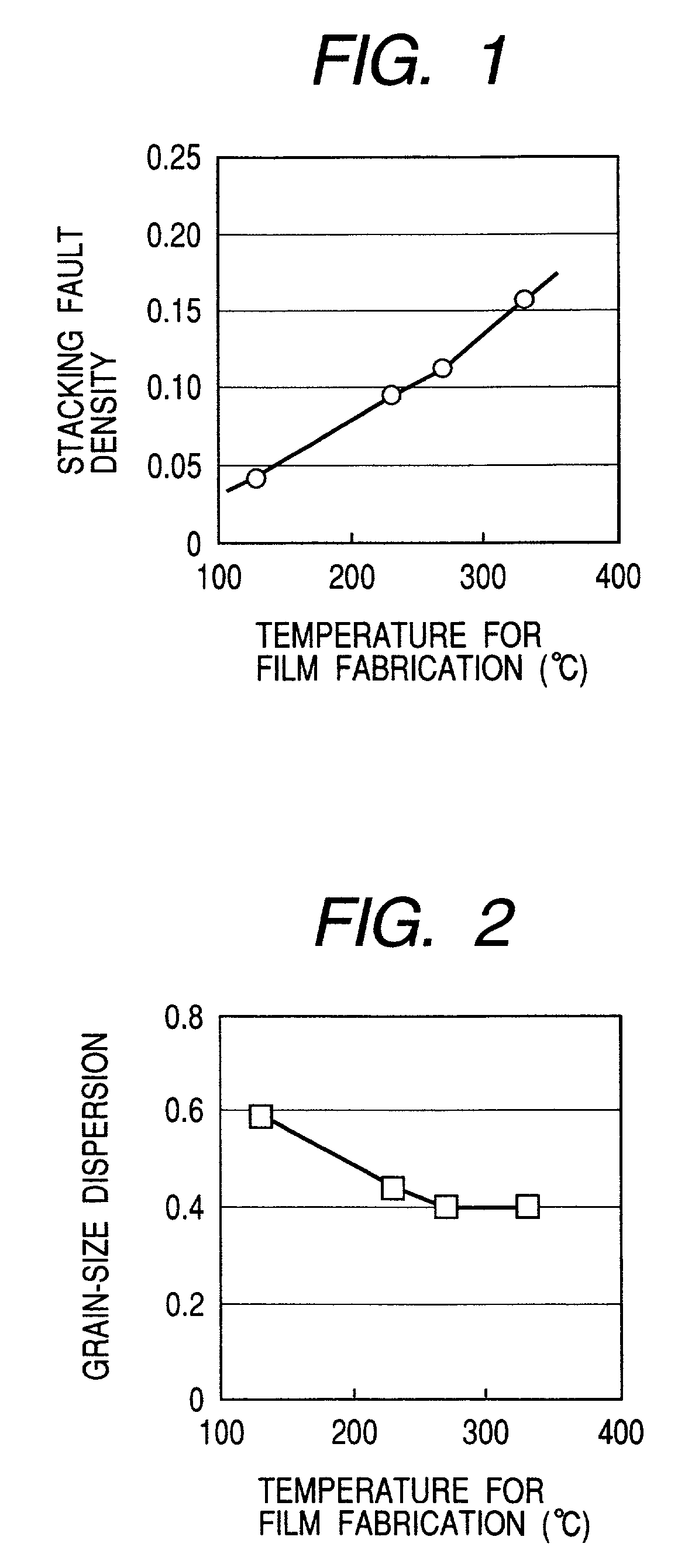

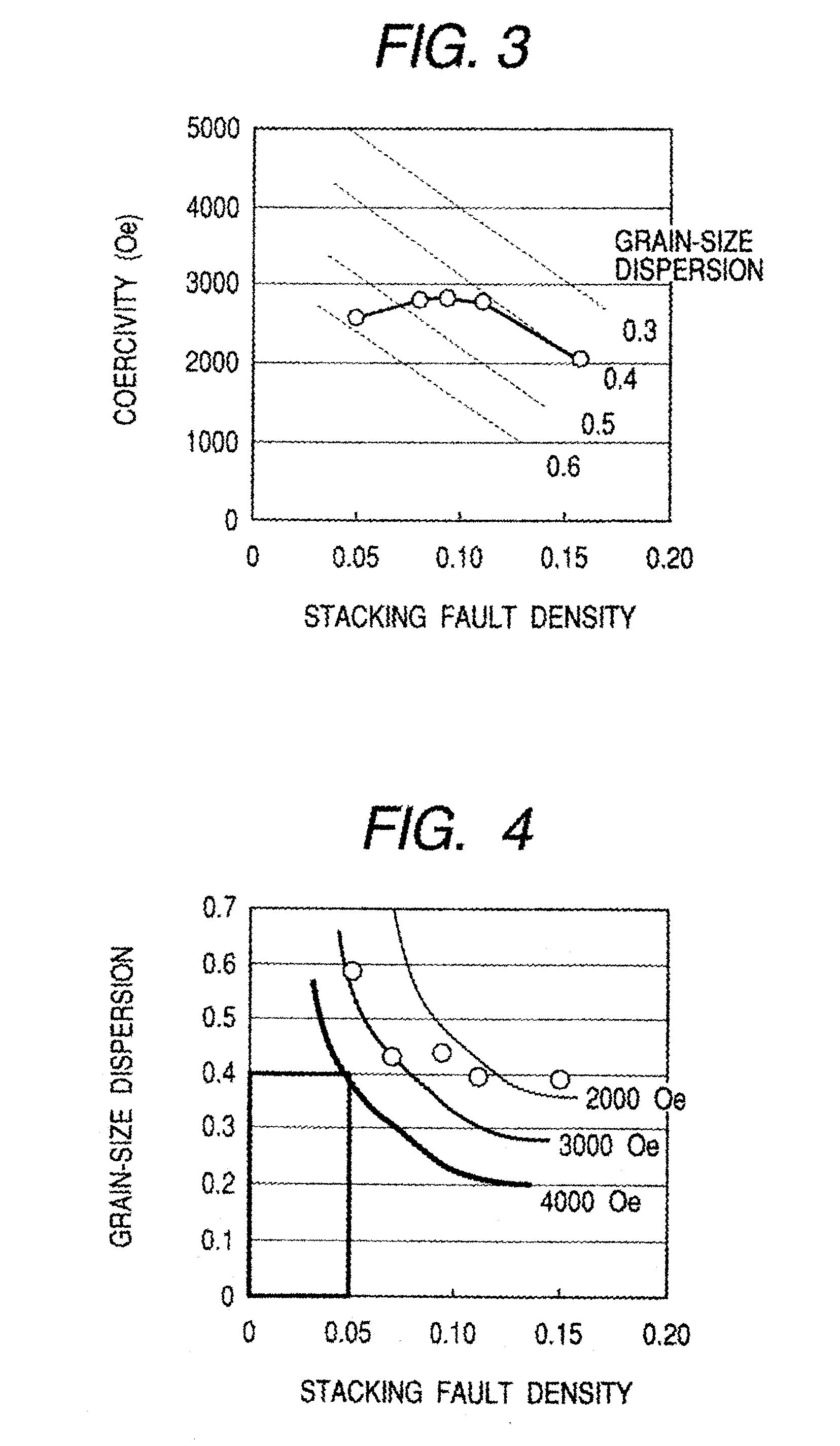

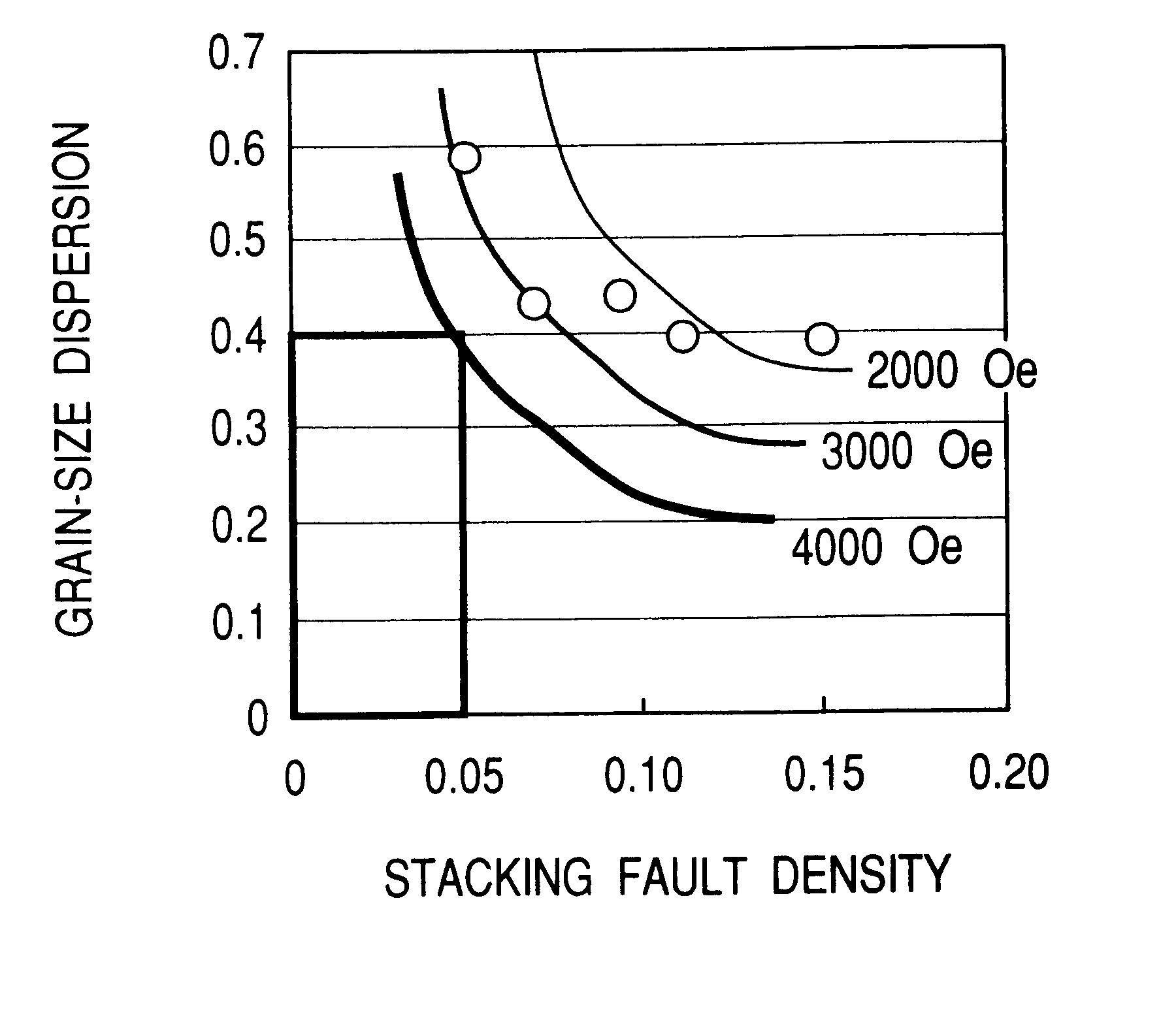

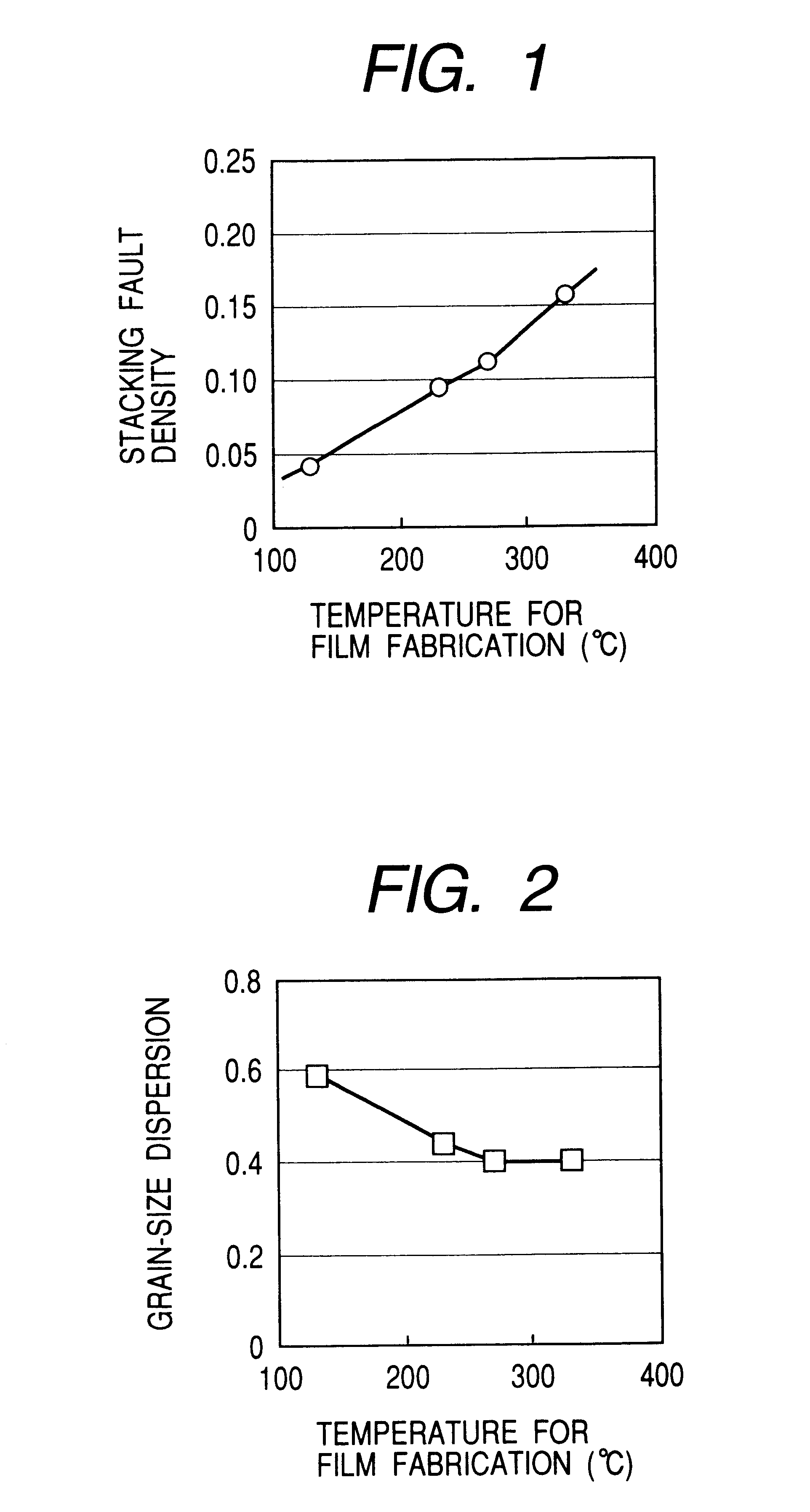

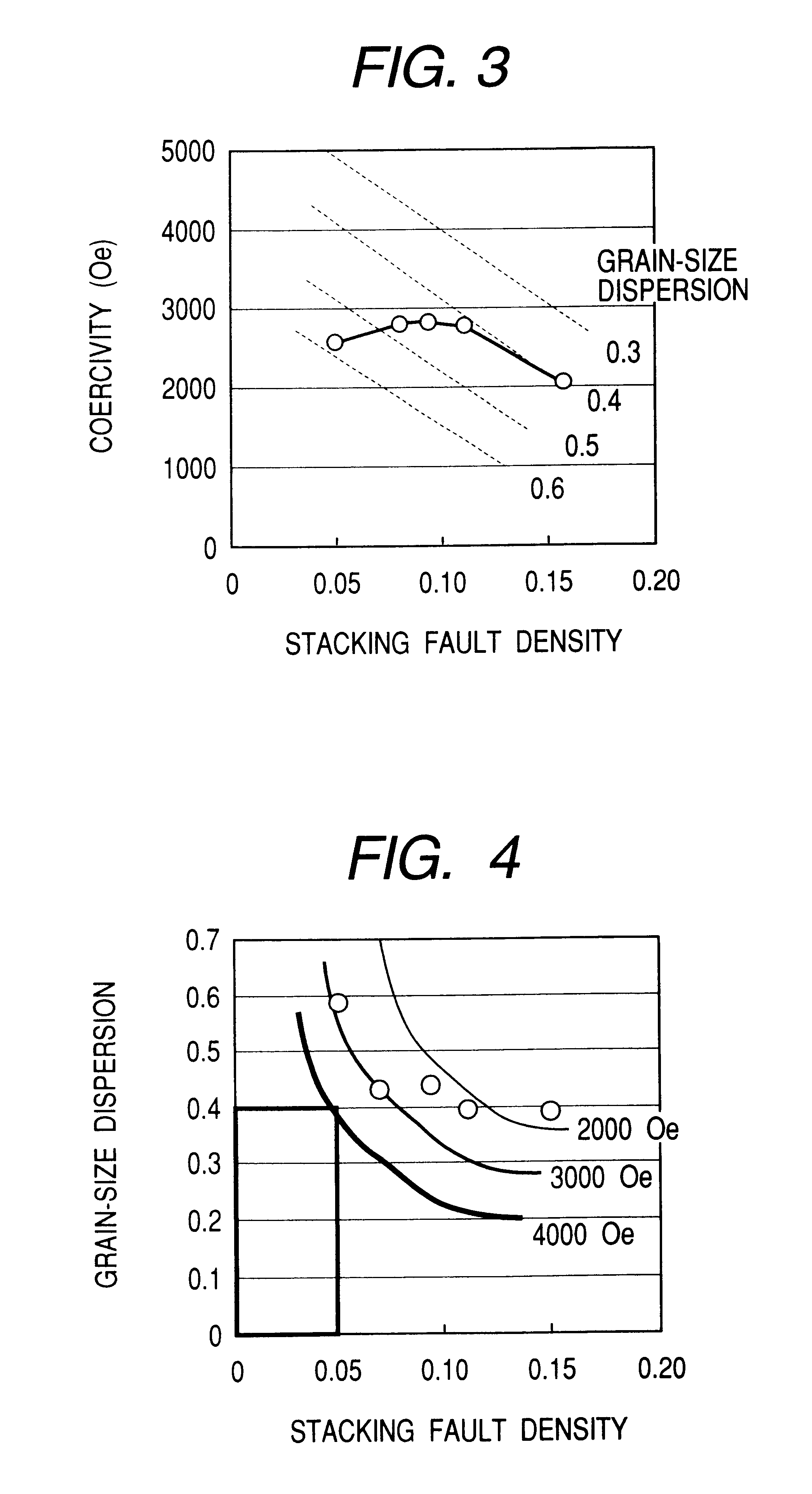

InactiveUS20030099866A1Improve thermal stabilityAddressing Insufficient ControlRecord information storageGlass/slag layered productsHigh densityStacking fault

Disclosed herein are a magnetic recording medium having a high coercive force and being capable of high-density writing / reading, a magnetic recording apparatus equipped with said magnetic recording medium, and a process for producing said magnetic recording medium. The magnetic recording medium is composed of a substrate, a soft magnetic layer, a non-magnetic intermediate layer, a magnetic layer, a protective layer, and a lubricating layer. The magnetic layer is characterized by the product of the stacking fault density and the dispersion of particle diameters which is no larger than 0.02. The stacking fault density should preferably be no larger than 0.05, and the dispersion of particle diameters should preferably be no larger than 0.4. The magnetic recording medium has a coercive force larger than 4000 Oe, is highly stable to thermal decay, and has a recording density in excess of 50 Gbit / in2.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Method and device for compensating for thermal decay in a magnetic storage device

InactiveUS20080165443A1Record information storageRecording/reproducing/erasing methodsMagnetic storageThermal decay

The present disclosure is directed to systems and methods of compensating for thermal decay of a magnetic data storage medium. In a particular embodiment, the method includes reading a calibration track on a magnetic data storage medium to obtain a first measurement of a track characteristic. The method also includes overwriting the calibration track with a first specific data pattern and reading the calibration track to obtain a second measurement of the track characteristic. The method also includes determining whether a thermal decay rate of the calibration track is acceptable based on the first measurement and the second measurement.

Owner:SEAGATE TECH LLC

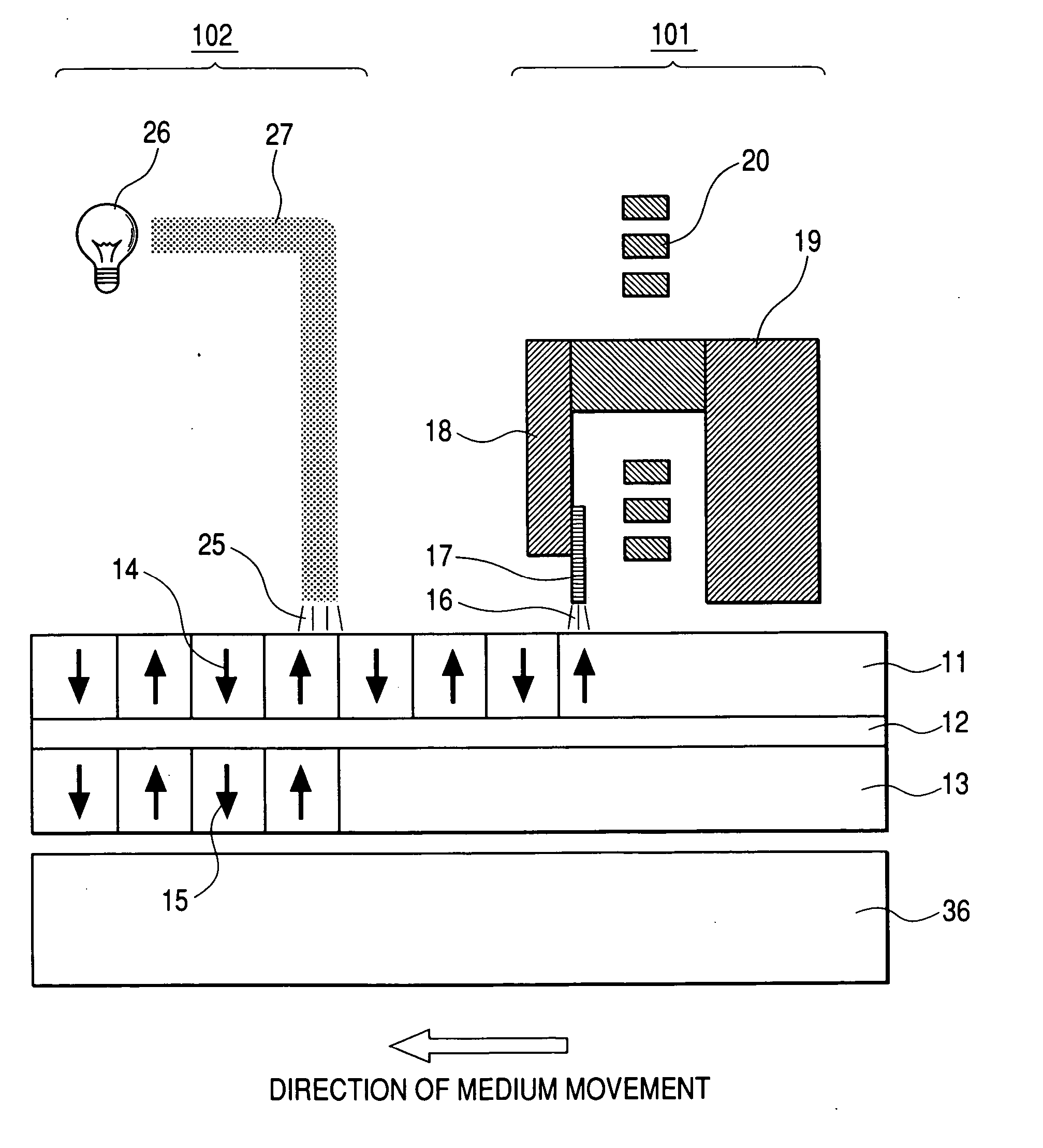

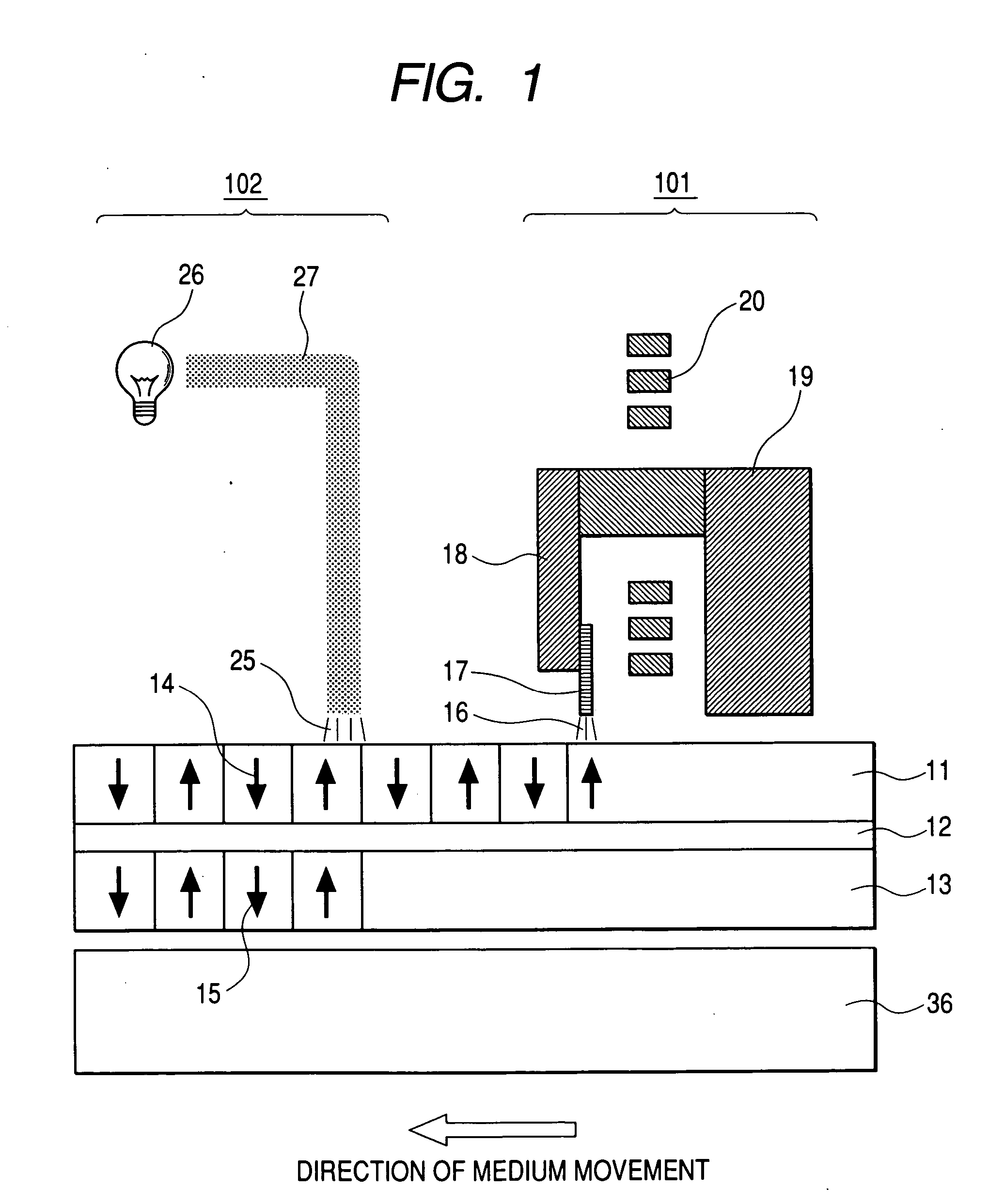

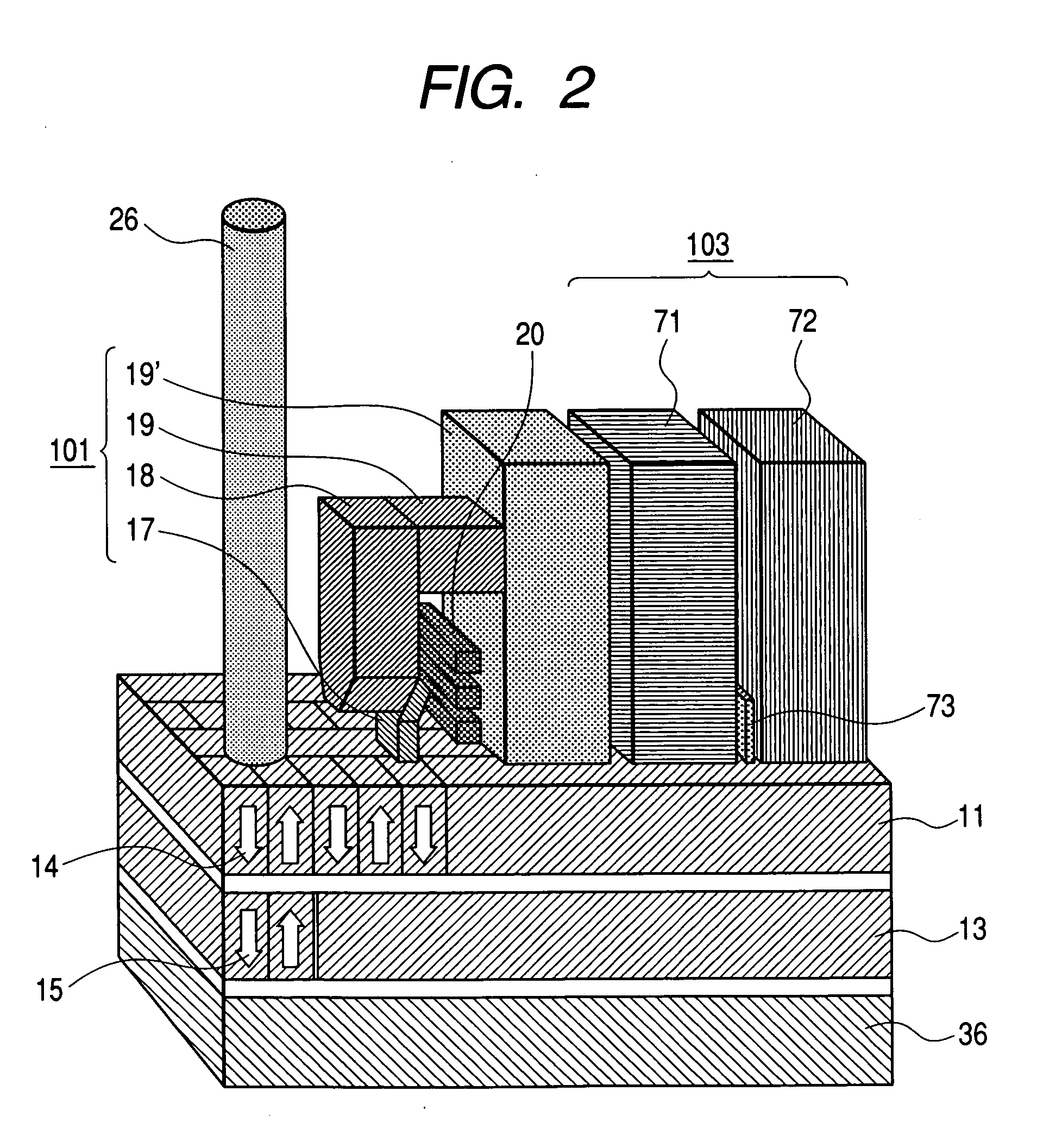

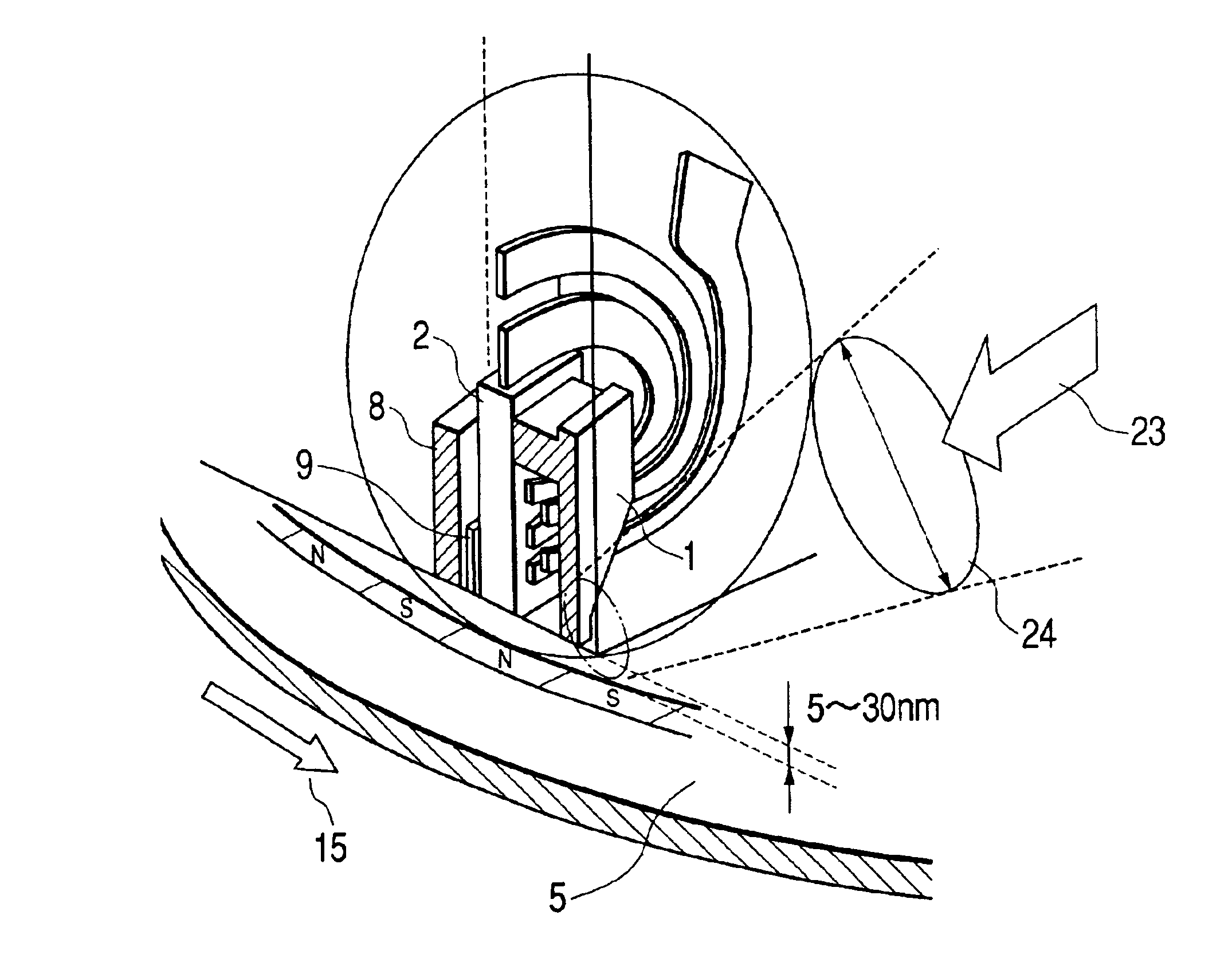

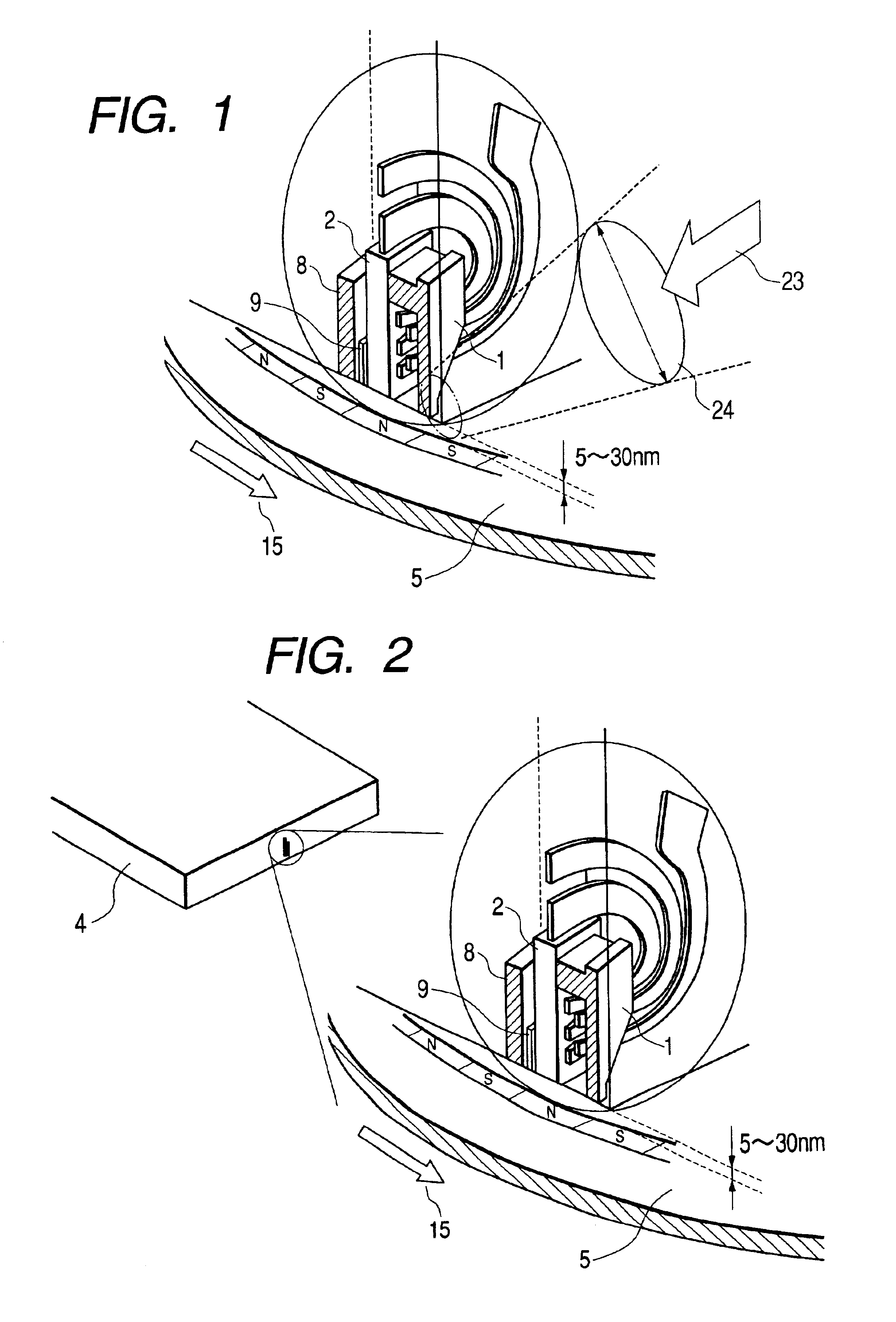

Apparatus and method for recording information

ActiveUS6952380B2Reduce magnetizationImprove reliabilityRecording by magnetic meansRecord information storageRoom temperatureThermal decay

A vertical magnetic recording apparatus is provided which can diminish thermal decay of magnetization to ensure a high reliability of the life of recorded information and which can stably effect the write of magnetic information. Light assist is performed by obliquely applying light to a gap between a main pole of a vertical recording head and a medium. The light is radiated from the head side of the apparatus with respect to the medium. Utilizing the present invention, the thermal decay of magnetization at room temperature is diminished, the life of the recorded information is increased, and the storage reliability of the disk is increased.

Owner:HITACHI LTD

Magnetic recording medium and its manufacturing method and magnetic recording system using such a magnetic recording medium

InactiveUS6709768B2Improve thermal stabilityRecording medium is economically advantageousRecord information storageGlass/slag layered productsHigh densityStacking fault

A magnetic recording medium having a high coercive force and being capable of high-density writing / reading has a substrate, a soft magnetic layer, a non-magnetic intermediate layer, a magnetic layer, a protective layer, and a lubricating layer. The magnetic layer is characterized by stacking fault density and dispersion of particle diameters. The stacking fault density should preferably be no larger than 0.05, and the dispersion of particle diameters should preferably be no larger than 0.4. The magnetic recording medium has a coercive force larger than 4000 Oe, is highly stable to thermal decay, and has a recording density in excess of 50 Gbit / in<2>.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

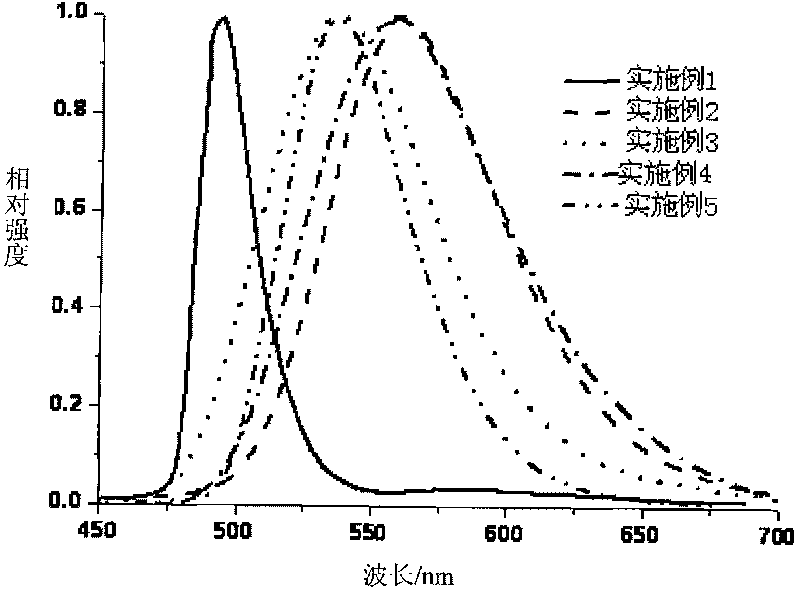

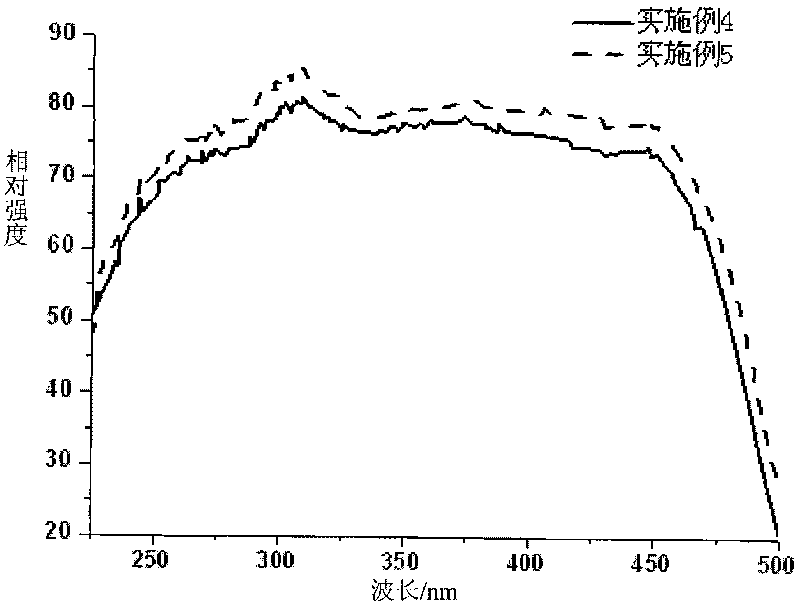

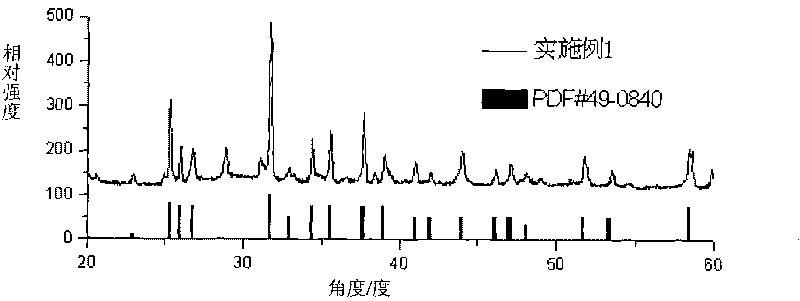

Synthetic rare earth doped nitric oxide fluorescent powder and preparation method thereof

InactiveCN101760190AEasy to operateProcess window widthLuminescent compositionsThermal decayDisplay device

The invention relates to synthetic rare earth doped nitric oxide fluorescent powder and a preparation method thereof, which is characterized in that the general chemical formula of the rare earth doped nitric oxide fluorescent powder is A1-xByOzN2 / 3+4 / 3y-2 / 3z : xRe, wherein A is one or the combination of two or more of Ca ion, Sr ion and Ba ion and comes from the oxide, carbonate or nitrate whichcontains A element; B is one or the combination of Si ion and A1 ion, at least contains Si ion and comes from the nitride which contains B element; Re is one or the combination of two or more of Eu ion, Ce ion, Dy ion and Mn ion and comes from the oxide, nitrate or acetate which contains Re element; and the relations of X is more than or equal to 0 and less than 1.0, Y is more than or equal to 1.0 and less than or equal to 2.0 and Z is more than 0 and less than or equal to 2.0 are satisfied. The luminescent material is of stable physical and chemical properties, strong thermal decay resistance and high quantum efficiency, is suitable for excitation of wavelength at 300nm-600nm and is widely applicable in LED lighting and display devices. The fluorescent powder is synthesized through two-step synthesis by taking cheap compounds as the materials and the fluorescent powder synthesized through the method under normal pressure is of pure phase.

Owner:IRICO

Thermal decay resistant composite fiber reinforced type brake pad

InactiveCN107489717AImprove thermal stabilityStrong resistance to heat decayOther chemical processesFriction liningFiberFrictional coefficient

The invention belongs to the technical field of brake pads and particularly discloses a thermal decay resistant composite fiber reinforced type brake pad. The thermal decay resistant composite fiber reinforced type brake pad is prepared from the components of, by weight, 7-23 parts of phenolic resin, 5-15 parts of reinforced composite fibers, 3-17 parts of mineral fibers, 2-8 parts of glass fibers, 3-8 parts of montmorillonite nano-powder, 0.3-0.9 part of 2,4,6-tris(dimethylaminomethyl)phenol, 5-15 parts of barium sulfate, 3-12 parts of butyronitrile powder, 4-11 parts of coke powder, 5-15 parts of frictional powder, 5-15 parts of graphite, 5-15 parts of tire powder, 3-7 parts of carbon black, 4-10 parts of nano fluorite powder, 2-7 parts of sepiolite, 3-9 parts of nano silicon dioxide aerogel powder, 2-6 parts of ground calcium carbonate and 5-15 parts of silane coupling agents. The metal-free brake pad is high in thermal stability, thermal decomposition resistant capacity and thermal decay resistant capacity, stable in frictional coefficient, high in abrasion resistant performance and low in brake noise.

Owner:杭州西湖摩擦材料有限公司

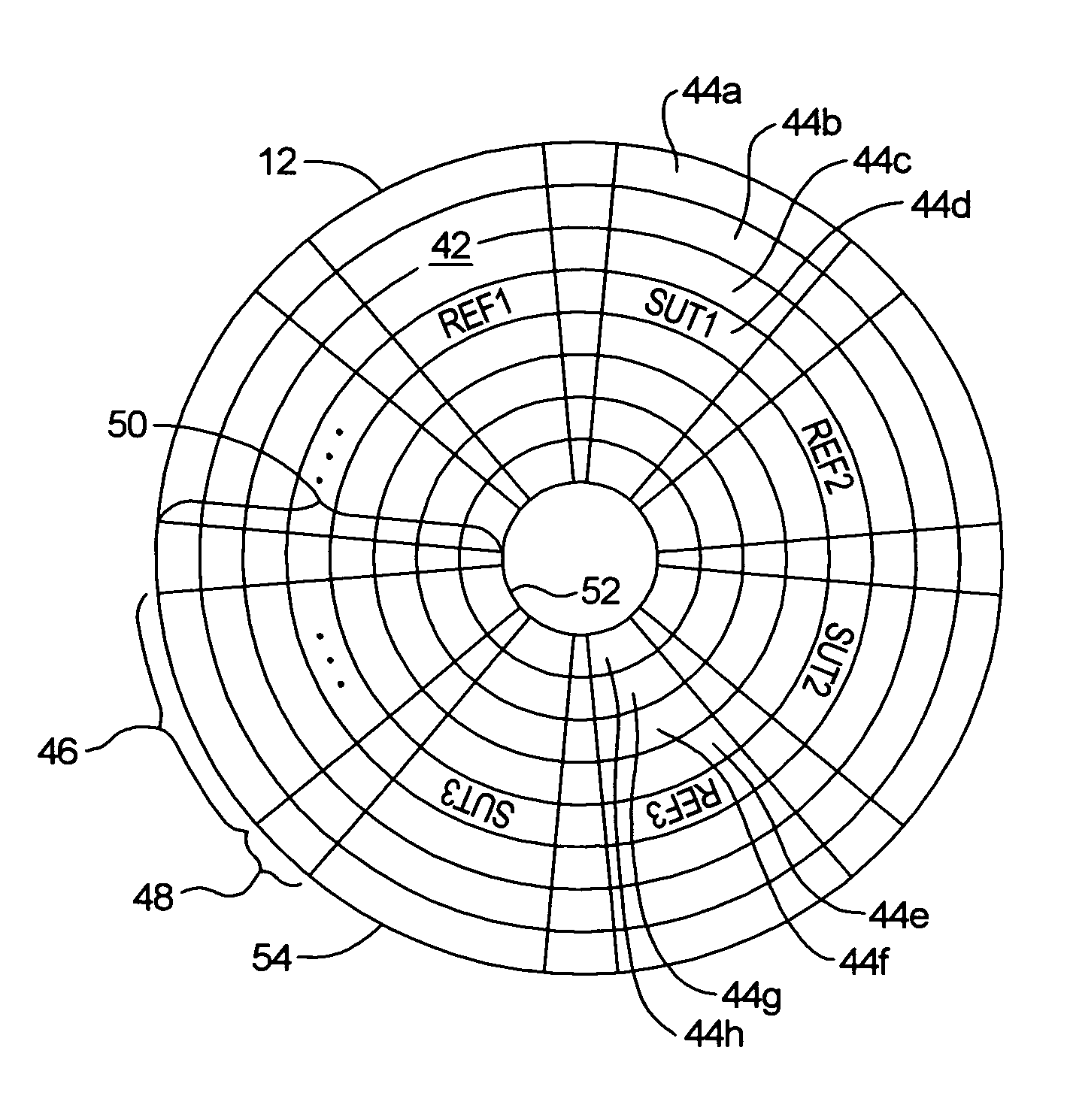

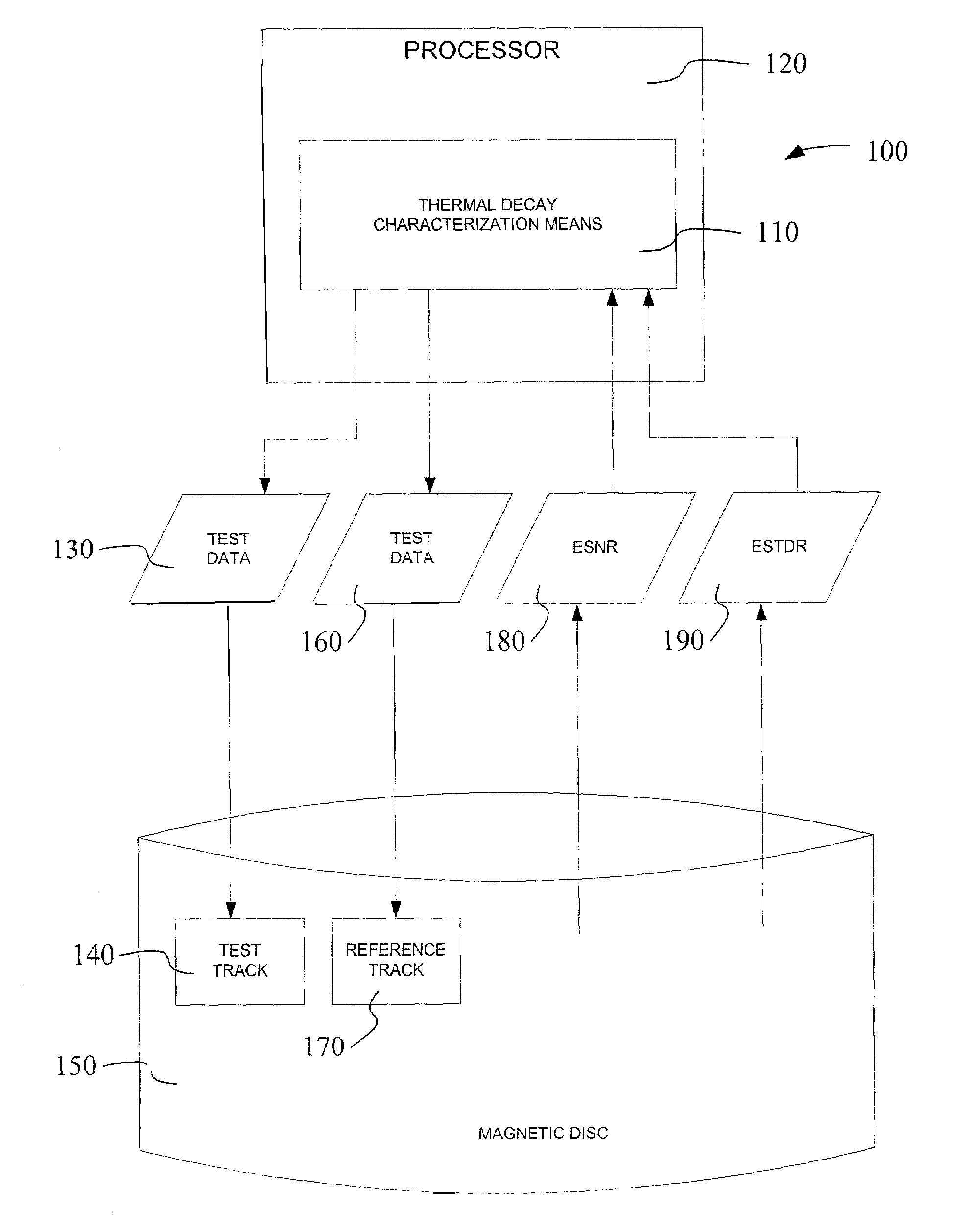

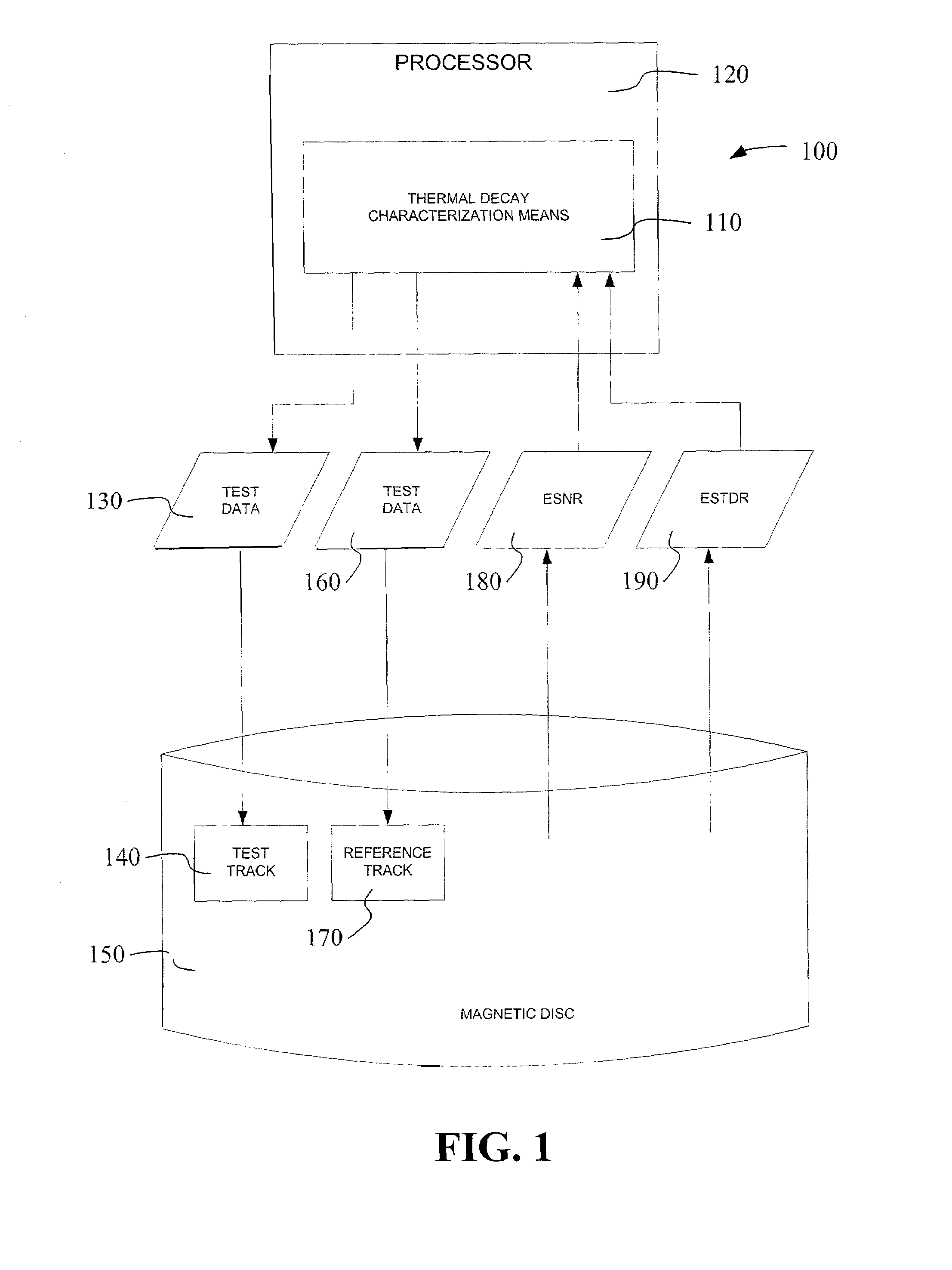

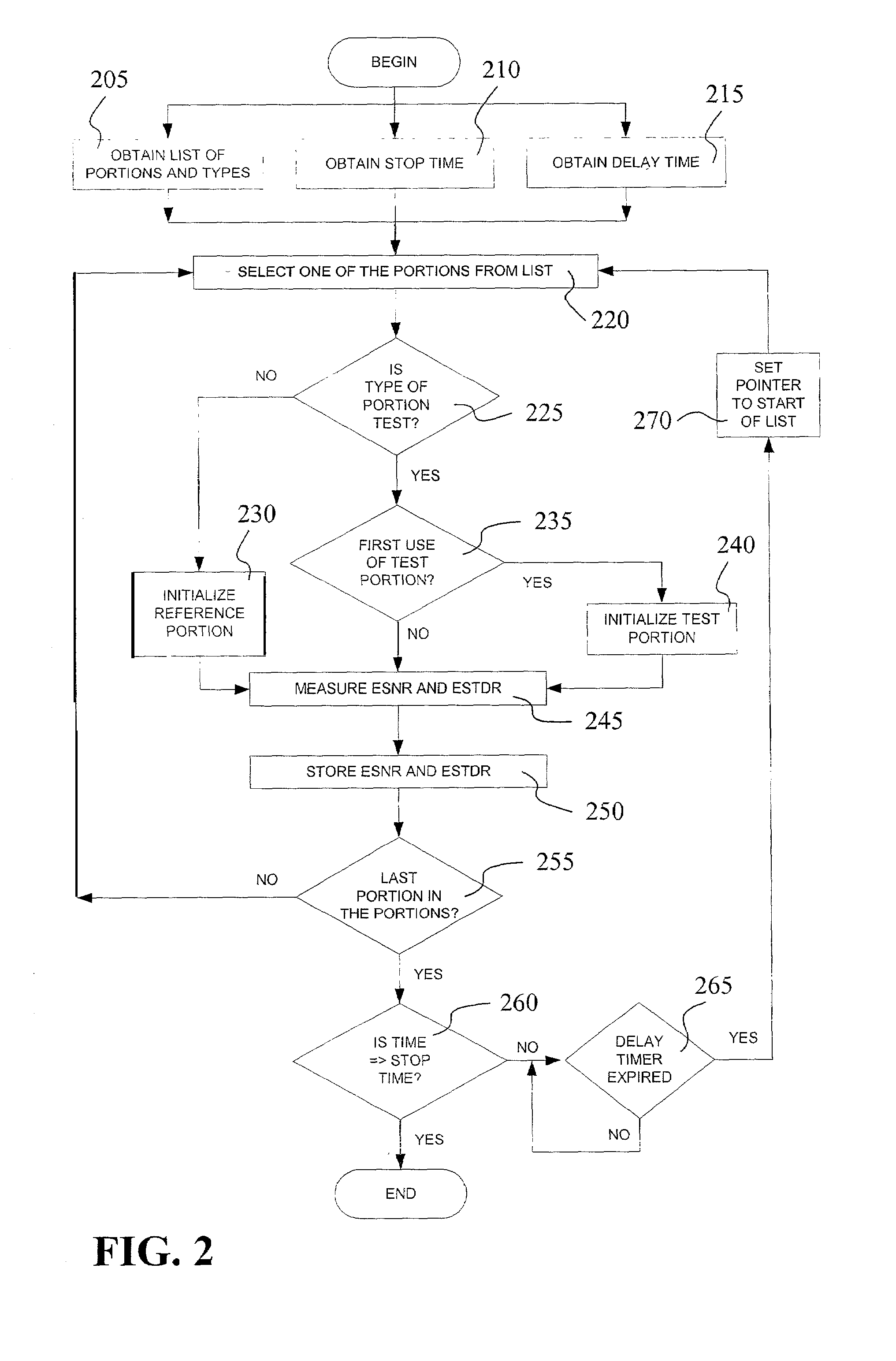

Systems, apparatus, and methods to determine thermal decay characterization from an equalized signal-to-noise ratio of a magnetic disc drive device

InactiveUS7209304B2Disc-shaped record carriersNoise figure or signal-to-noise ratio measurementTime domainMass storage

The thermal decay of data written to a magnetic mass storage medium is determined by measuring and analyzing the time-domain equalized-signal-to-noise ratio (ESNR) and equalized signal-to-total-distortion noise ratio (ESTDR) of written data. In some embodiments, a test track and a reference track are initialized from data. Subsequently, the reference track is re-initialized from the test data, and the time-domain ESNR and / or ESTDR measurements are made of the test track and the reference track, at predetermined time intervals. Later, the time-domain ESNR and ESTDR measurements are analyzed to determine the thermal decay of the data written. In another embodiment of the present invention, the ESNR and / or ESTDR measurements includes reading the data through a non-return-to-zero bus in phases, in which the phases are selected in sequence.

Owner:SEAGATE TECH LLC

Fail safe HVAC temperature and medium presence sensor

ActiveUS7473868B2Eliminate needTemperature control without auxillary powerMechanical apparatusThermal decayEngineering

A system and method is presented for a fail-safe sensor for an HVAC system. The sensor comprises a temperature detector operable to measure a temperature of a component or a medium present at the sensor, a PTC heater operable to heat the sensor to a self-regulating temperature, the heater comprising a resistive element having an electrical impedance which increases with increasing temperature in accordance with a positive temperature coefficient characteristic, and a sensor housing comprising the PTC heater and the temperature detector provided within a single housing. An algorithm is provided for HVAC systems, wherein the sensor is heated to the self-regulating temperature by the PTC heater and is then measured by the temperature detector to confirm that the temperature detector is operating properly. Further, the sensor may be allowed to cool to a temperature of the surrounding medium or the component for sensing the temperature thereof. Thereafter, by calculating the time constant of the thermal decay rate of the sensor, the presence or absence of the component or medium surrounding the sensor may be determined in a fail-safe manner by an analyzer, for example.

Owner:R W BECKETT

Ceramic based friction material and preparation method thereof

The invention discloses a ceramic based friction material and a preparation method thereof. The ceramic based friction material has improved mechanical properties, fracture mechanical properties, thermal shock stability, stable chemical properties, excellent friction performance and wide field of use, and is composed of the following raw materials: an inorganic macromolecular polymeric binder, a reinforcing material, a friction performance conditioning agent and other materials. With the advantages of high temperature resistance, high pressure resistance and impact resistance, good anti-thermal decay performance, unique function, environmental protection and energy saving, light weight, no harm to a dual equivalent, long service life and strong environmental adaptability, the high performance friction material has a service life increased by over 2 times than that of existing products.

Owner:黄曦

Composite magnetic recording structure having a metamagnetic layer with field induced transition to ferromagnetic state

ActiveUS7465502B2Softening of coercivityHigh thermostability ratioDifferent record carrier formsRecord information storageWrite bitMagnetization

A magnetic recording medium having a composite magnetic recording structure comprising the combination of a hard magnetic layer and a metamagnetic layer that possesses a field induced metamagnetic transition characteristic at ambient operating temperature. Under an applied external magnetic field, the metamagnetic layer transitions from an antiferromagnetic state to a ferromagnetic state, and the magnetic field induces magnetization of the metamagnetic layer. The hard magnetic recording layer is magnetically exchange coupled to the magnetized metamagnetic layer. This results in the softening of the coercivity of the overall magnetic recording structure and reduction of the required switching field during data recording. Upon removal of the applied magnetic field, the metamagnetic layer experiences transition back to an antiferromagnetic state and the coercivity of the hard magnetic layer is restored. This restoration allows the written bit to be stored at a high thermostability ratio and thus, preventing magnetization thermal decay of the data bit.

Owner:SEAGATE TECH LLC

Friction material and production method thereof

To improve wear resistance of friction materials and guarantee thermal decay stability of the friction materials, the invention provides a friction material and a production method thereof. Technical key points of the method comprises: (1) mixing, which comprises a first step of preparing materials consisting of 8 to 18 wt% of a phenolic resin, 1 to 10 wt% of vermiculite powder, 3 to 10 wt% of cryolite, 1 to 10 wt% of anglesite, 10 to 25 wt% of composite fibers, 3 to 10 wt% of cellulosic fiber, 1 to 5 wt% of brown aluminum oxide, 1 to 10 wt% of alumina, 3 to 15 wt% of light calcium carbonate , 1 to 5 wt% of zinc stearate, 2 to 25 wt% of barite powder, 1 to 5 wt% of carbon black, 3 to 15 wt% of cashew nut shell oil friction powder, 3 to 15 wt% of glass fibers and 10 to 30 wt% of a friction increasing material and a second step of adding the above-mentioned materials into a blender mixer and uniformly stirring the materials to obtain a mixture; (2) hot press molding, which is a step of subjecting the mixture to hot press molding at a temperature of 150 to 155 DEG C under a pressure of 250 kg / cm<2> by using a die; and (3) sulfuration, which is carried out on a product obtained after hot press molding so as to obtain the friction material, wherein sulfuration temperature is 150 to 155 DEG C and sulfuration time is 4 to 6 h.

Owner:SHIYAN JIUPENG FRICTION MATERIAL

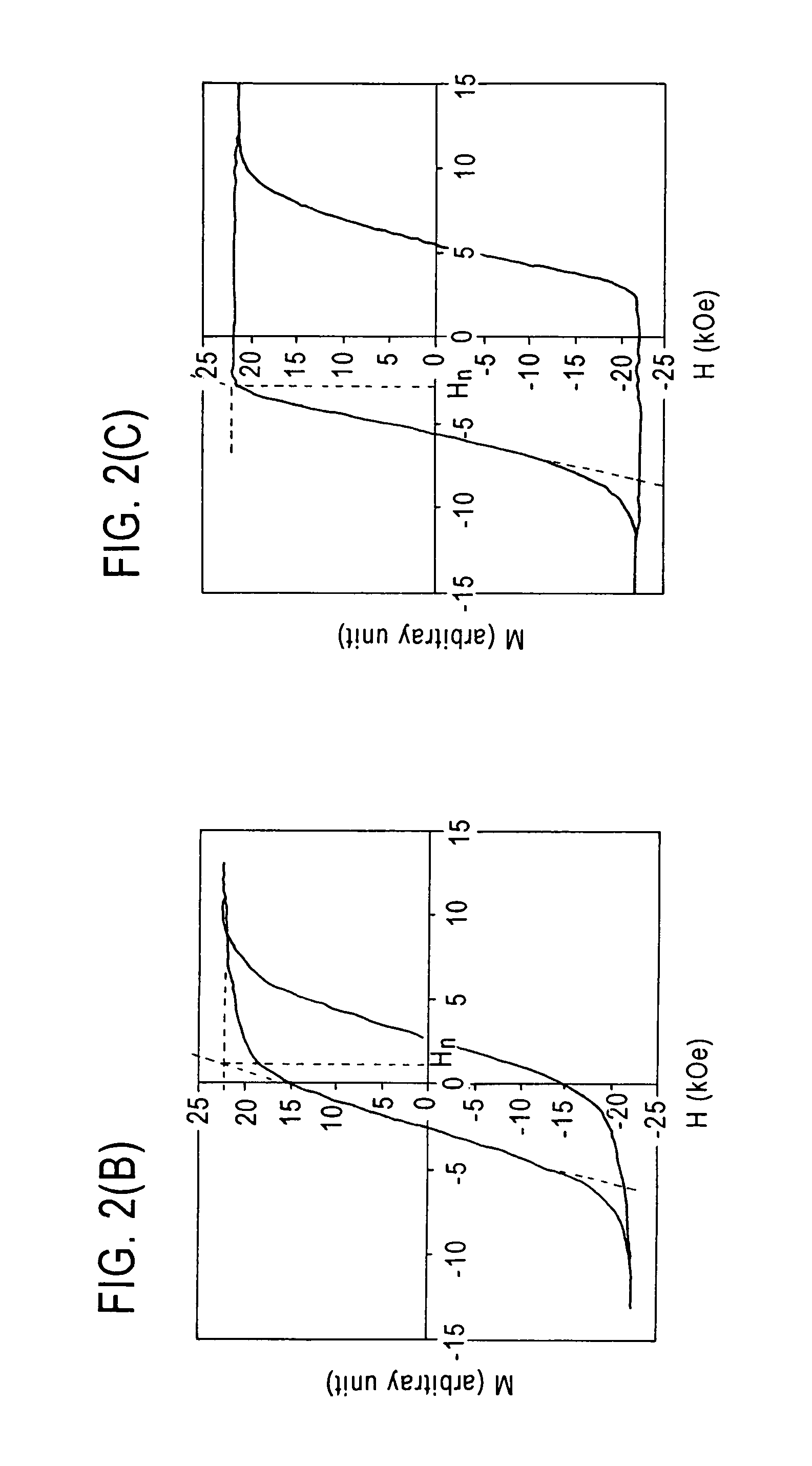

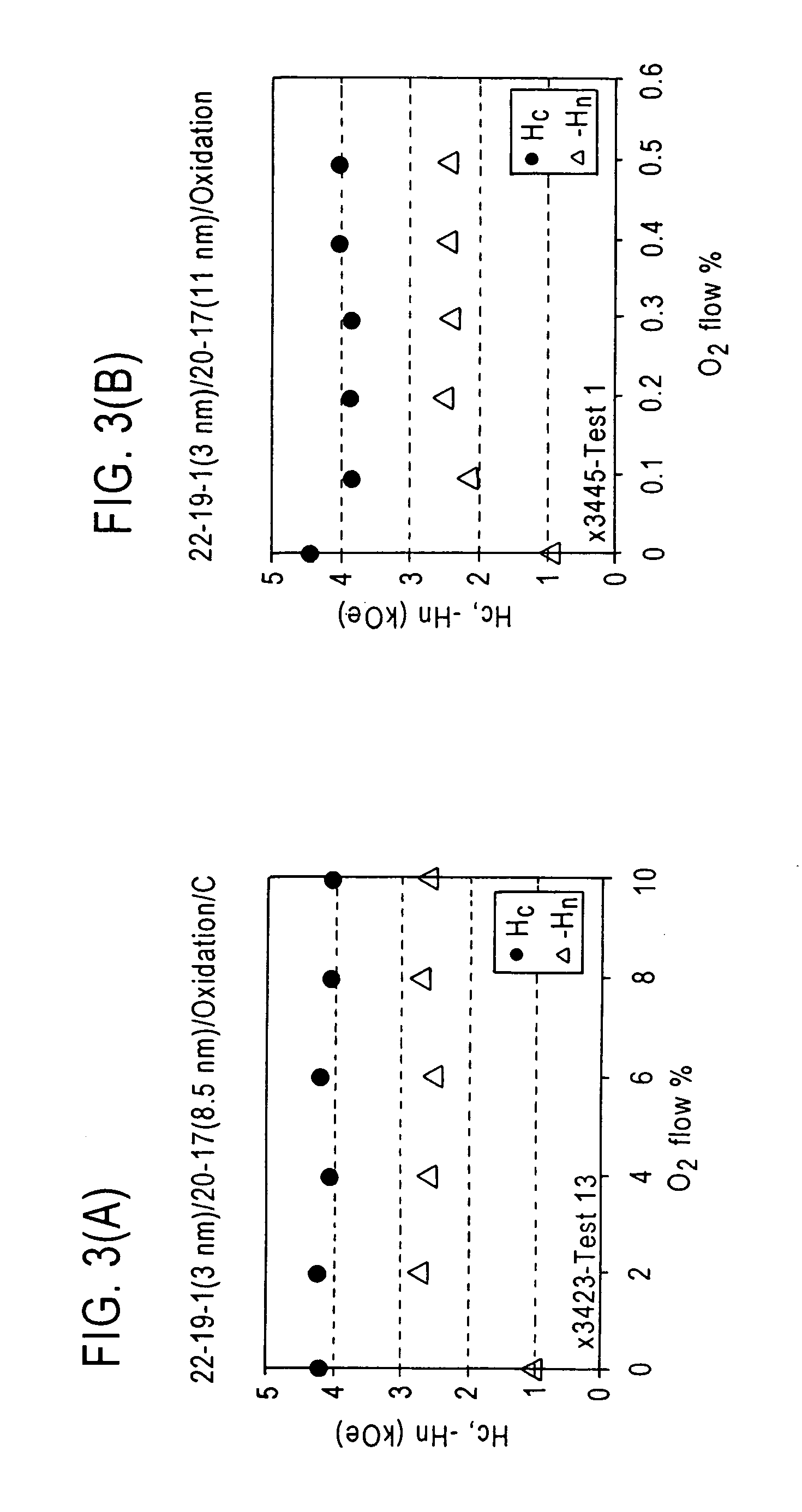

In-situ post-deposition oxidation treatment for improved magnetic recording media

InactiveUS7081268B2Easy to manufactureEasy to optimizeProtective coatings for layersRecord information storageThermal decayRecording layer

A method of manufacturing a magnetic recording medium comprises sequential steps of:(a) providing an apparatus for manufacturing the medium;(b) supplying the apparatus with a substrate for the medium;(c) forming a magnetic recording layer on the substrate in a first portion of the apparatus;(d) treating the magnetic recording layer with oxygen gas in a second portion of the apparatus at a sub-atmospheric pressure and for an interval sufficient to provide the resultant medium with at least one of the following, relative to a similar medium manufactured by a similar method but wherein the oxygen treatment of step (d) is not performed:(i) a more negative nucleation field (Hn);(ii) increased remanent squareness (Sr);(iii) increased signal-to-medium noise ratio (SMNR);(iv) narrower switching field distribution (SFD); and(v) decreased thermal decay rate; and(e) forming a protective overcoat layer on the oxygen-treated magnetic recording layer in a third portion of the apparatus.

Owner:PIONEER CORP +1

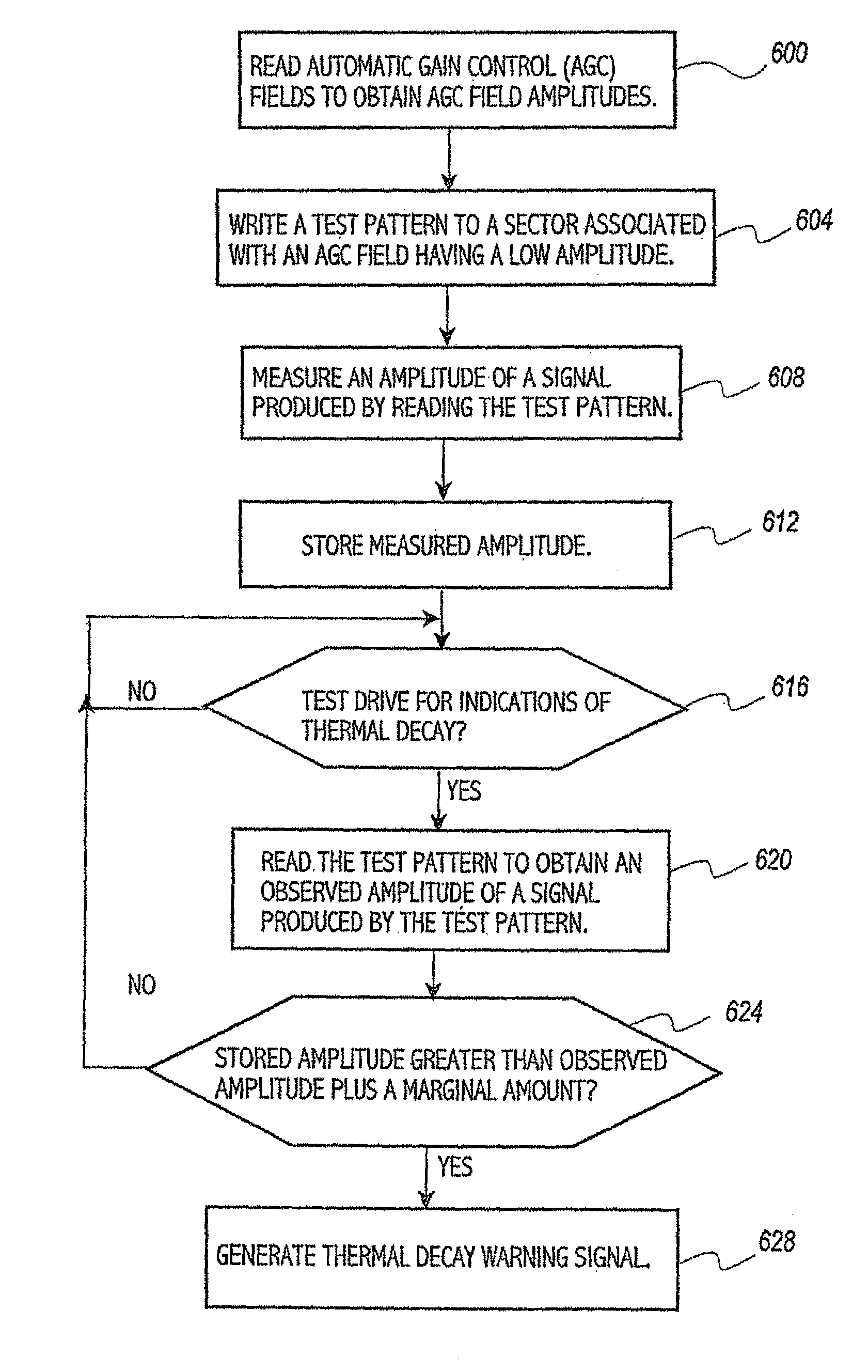

Method and apparatus for providing an early warning of thermal decay in magnetic storage devices

InactiveUS7738206B1Avoid lostRecord information storageCarrier monitoringThermodynamicsMagnetic storage

A method and apparatus for providing an early warning of thermal decay in magnetic storage media are provided. In accordance with an embodiment of the present invention, a test pattern that is particularly susceptible to thermal decay is written to a disk. The test pattern is then read, and the amplitude of the signal produced by the test pattern is stored. When testing for thermal decay is desired, the test pattern is again read, and the amplitude of the signal produced in the channel is compared to the stored amplitude. If the later amplitude is less than the stored amplitude by at least a predetermined amount, a thermal decay warning signal is generated. In accordance with another embodiment of the present invention, a test pattern is written to a portion of a disk that has been identified as being particularly susceptible to thermal decay. The amplitude produced by the test pattern is then stored so that it can later be compared to an observed amplitude when testing for thermal decay. The present invention allows remedial measures to ensure the integrity of data to be taken before data loss due to thermal decay can occur.

Owner:SEAGATE TECH LLC

Airplane middle placement deceleration method and device thereof

The invention relates to an airplane braking field, when braking, the brake feet falls on the X-axis on the ground and rubs against the ground, so as to generate ground braking force, and eliminating deflection moment, thus eliminating the phenomena of deviating, sdieslipping and tailing. The wheels are in a driven state, keeping guiding and making the airplane have good directional stability. The descending height of the brake feet is controlled by load sensing pressure limiting valve to keep balancing the airplane. It radically eliminates the deflection moment caused by unequal two-side braking forces. In addition, the wheels is in a driven rolling state and still has guiding force and adhesive force, to make the airplane have good directional stability, able to prevent sideslipping and tailing, enhancing braking efficacy of the airplane, shortening braking distance and reducing tyre wear. It can also enhance thermal decay resistance, simplifies original braking system and has extremely high social and economic benefits.

Owner:李战

Preparation method of friction material of yaw brake pad

ActiveCN103555273AHigh heat decay stabilityStrong water resistanceOther chemical processesFriction liningPotassiumThermal decay

Owner:贵州新安航空机械有限责任公司

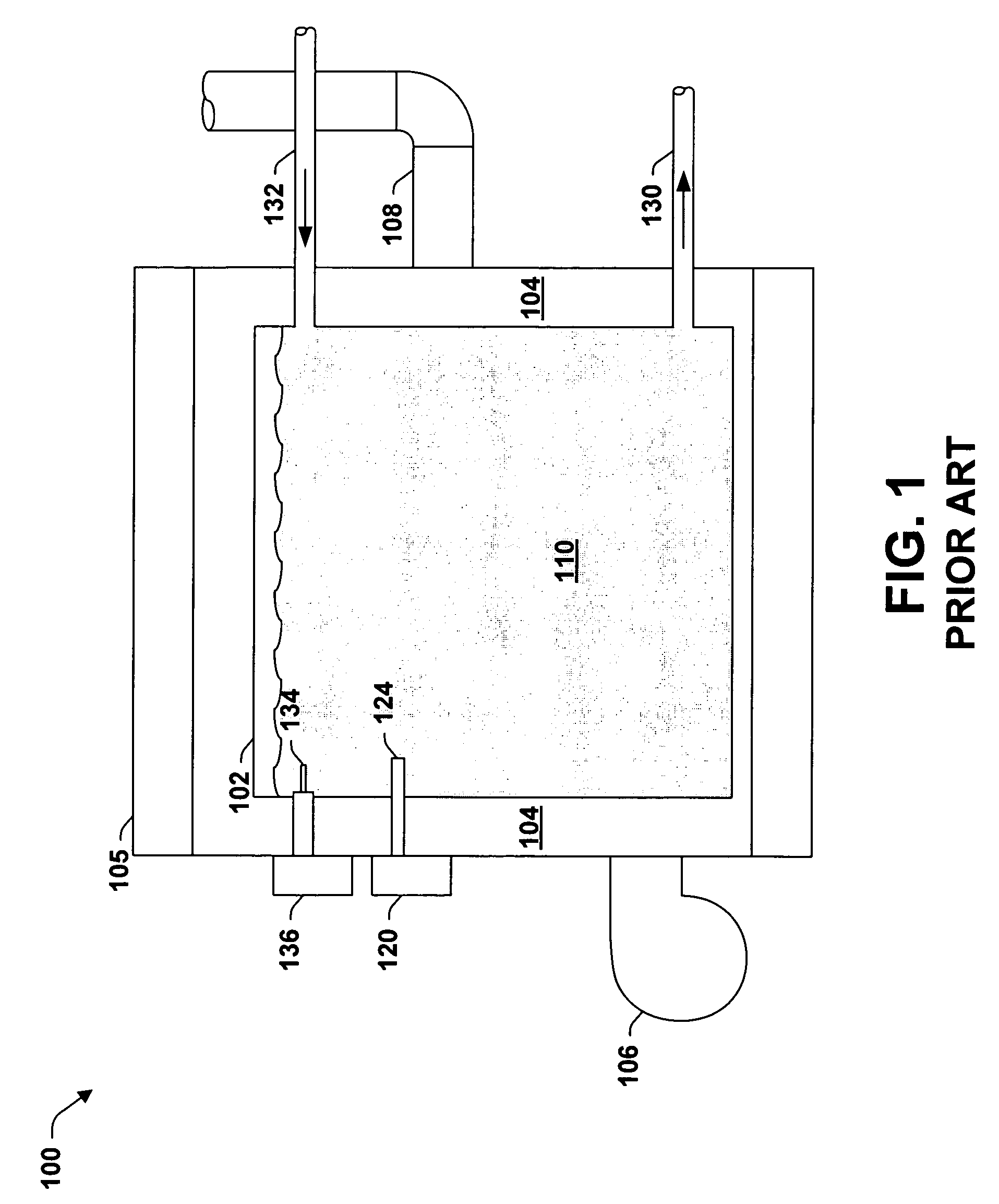

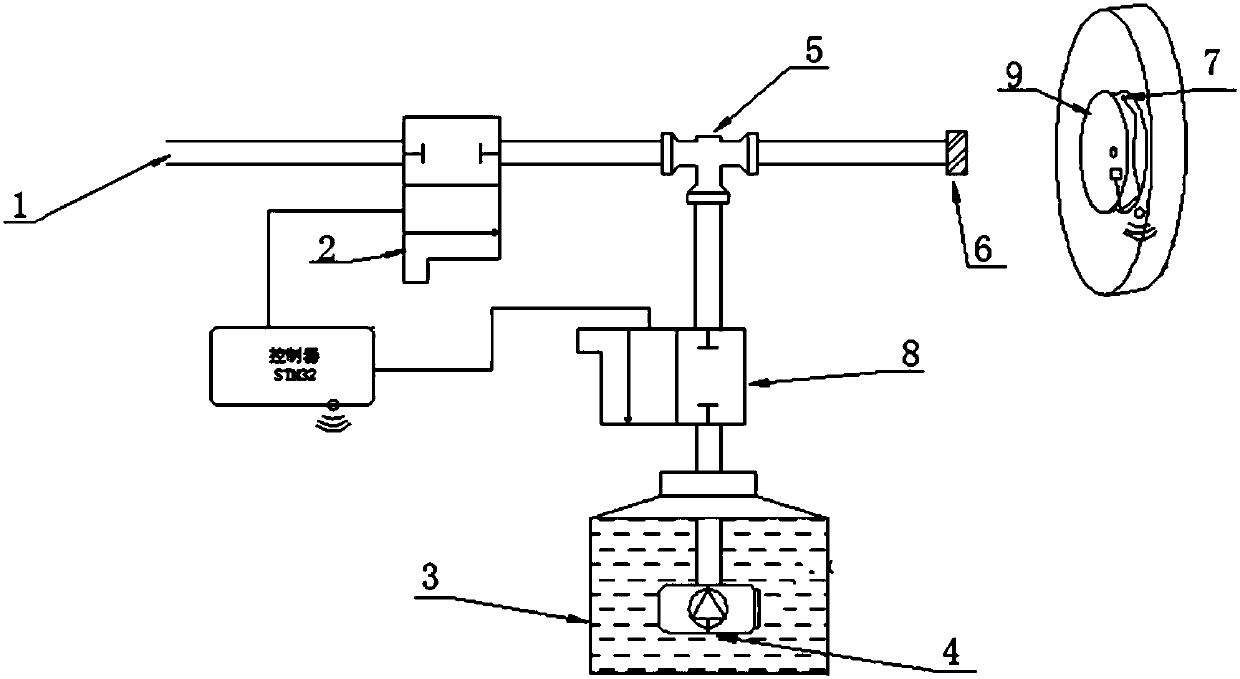

Micro-liquid cooling device and method for automobile brake thermal decay

The invention provides a micro-liquid cooling device and method for automobile brake thermal decay. Braking is unlikely to fail, the temperature is reduced stably, and energy consumption is low. The cooling device comprises a high-pressure gas connecting pipe, a gas circuit switching valve, a tee joint, a nozzle, a water way switching valve, a water pump, a water tank, a controller and a temperature measurement element. The gas circuit switching valve is arranged on the high-pressure gas connecting pipe, the output end of the high-pressure gas connecting pipe communicates with one end of the tee joint, the second end of the tee joint communicates with the nozzle, the third end of the tee joint communicates with the water pump through the water way switching valve, and the water pump communicates with the water tank. Both the gas circuit switching valve and the water way switching valve are connected with the controller, the temperature measurement element is used for acquiring a temperature signal of a brake and sending the temperature signal to the controller, and the controller controls the on-off states of the gas circuit switching valve and the water way switching valve according to the received temperature signal. Firstly, the temperature critical threshold value of the brake is calculated, and when the acquired temperature signal reaches the temperature critical thresholdvalue, the cooling device is started to cool the brake.

Owner:CHANGAN UNIV

Copper-free friction material composition for brake pads

InactiveUS8962711B2Promote environmental protectionSatisfactory high-temperature and thermal decay resistant performanceSolid ballsFriction liningAluminum silicateThermal decay

A copper-flee friction material composition for brake pads consists of: 0.43 parts of aramid fiber, 1.9 parts of tire powder, 6 parts of heavy magnesia, 2.55 parts of calcined petroleum coke, 8 parts of ceramic fiber, 6.5 parts of phenolic resin, 14 parts of aluminum silicate fiber, 22 parts of potassium hexatitanate crystal whisker, 25 parts of barite powder, 5 parts of granular graphite, 2 parts of antimony sulfide, 2.8 parts of friction powder of cashew nut oil, 0.9 part of boron nitride, 5 parts of flake aluminum powder, and 0.6 parts of tantalum carbide. Trials show that it has satisfactory high temperature and thermal decay resistant performance, long service life, good abrasion resistance and stable friction coefficient. With the friction material of the present invention used, the brake pad of vehicles is sensitive and stable during braking, produces no screech, is comfortable and has no damage on coupling plate.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

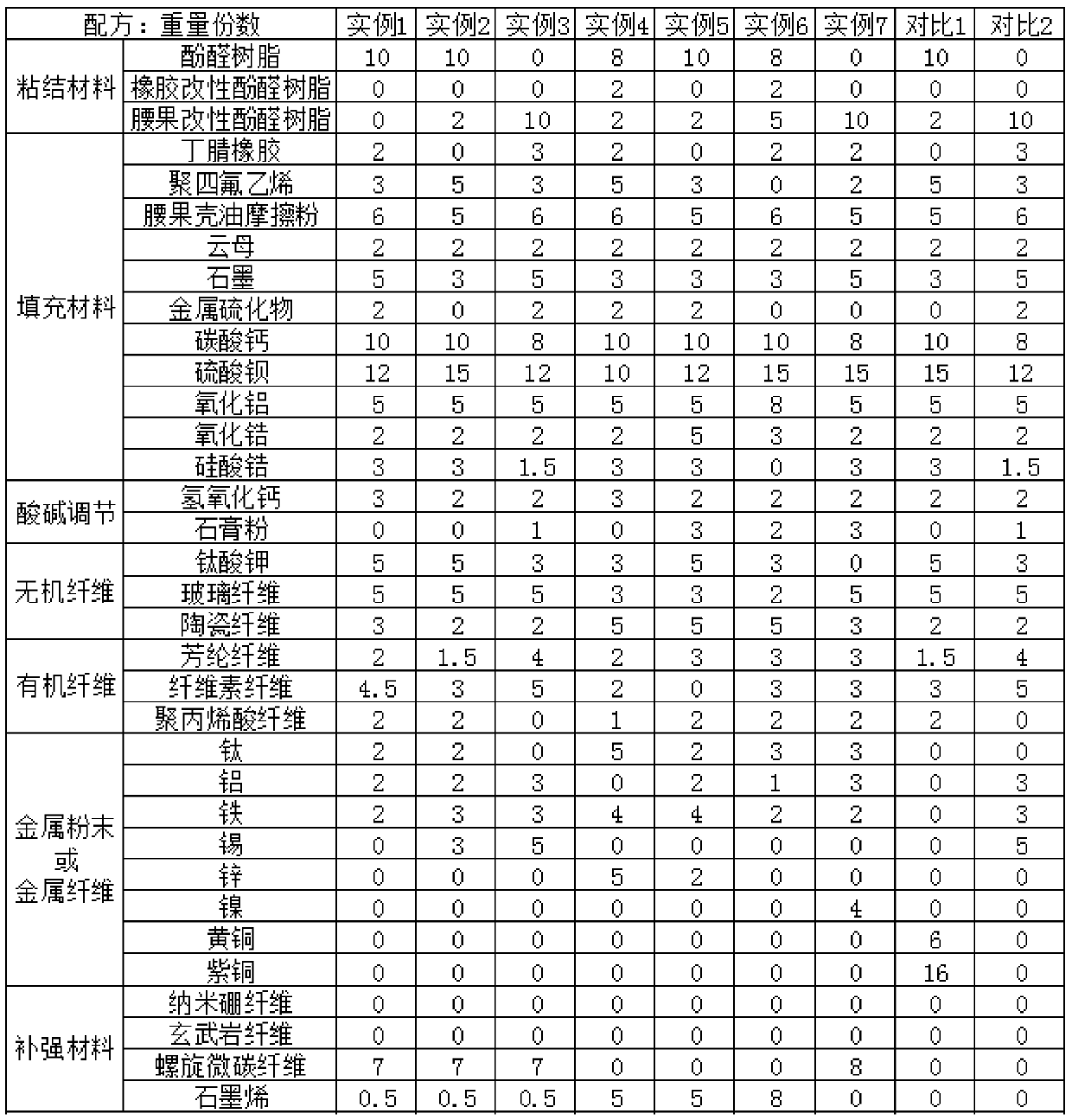

Organic friction material containing no copper or asbestos and product

ActiveCN110273953AStable coefficient of frictionReduce pollutionOther chemical processesFriction liningFiberThermal decay

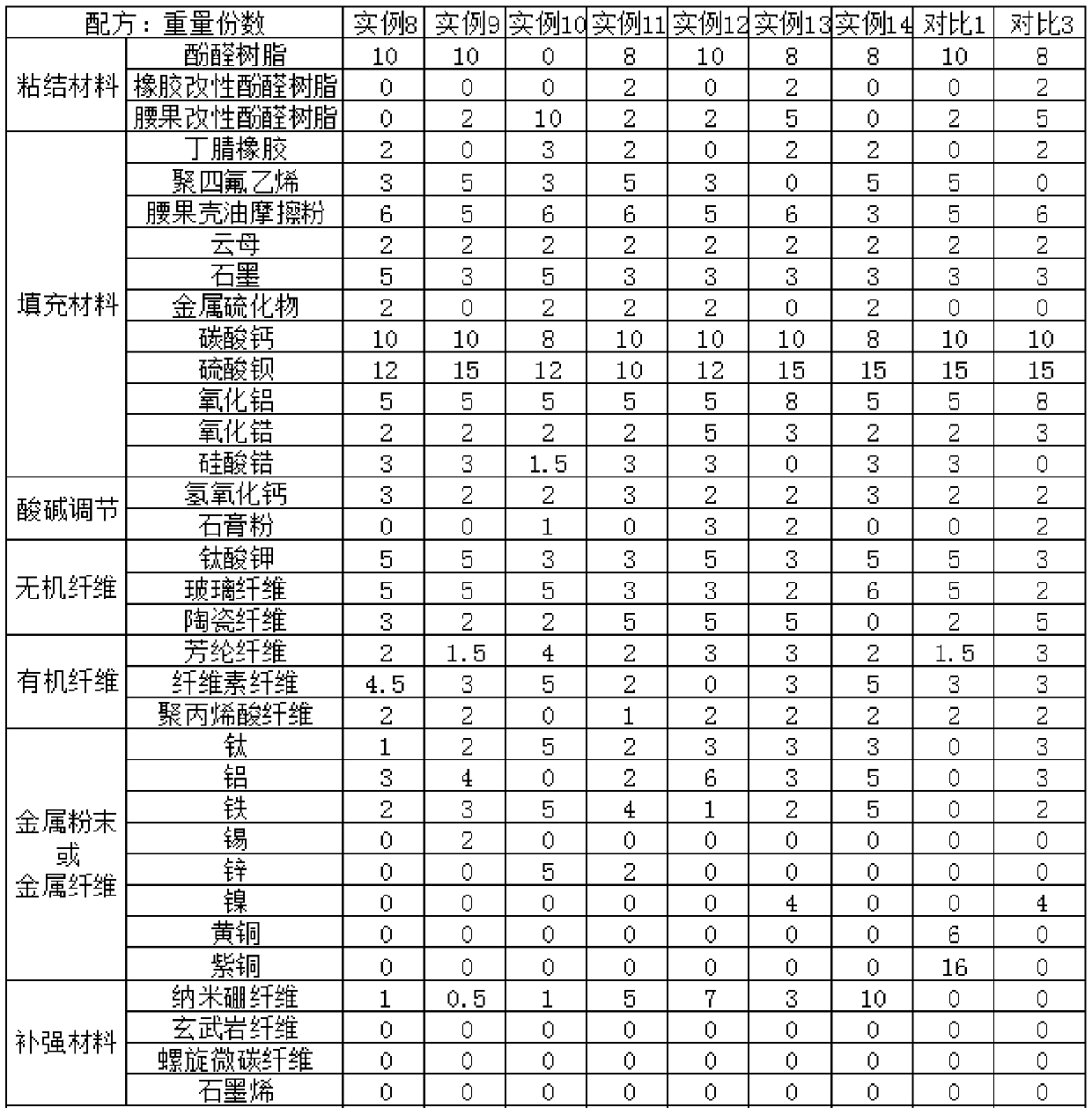

The invention relates to an organic friction material containing no copper or asbestos. The material comprises the following components including, by weight, 10-15 parts of a binding material, 45-55 parts of non-copper packing, 3-5 parts of an acid-base adjusting material, 5-10 parts of organic fiber, 8-13 parts of inorganic fiber, 6-15 parts of non-copper metal fiber or non-copper metal powder and 0.5-10 parts of a reinforced material. According to the organic friction material provided by the invention, the reinforced material is added on the basis of the binding material, the organic fiber and the inorganic fiber, it is guaranteed that the friction coefficient of the friction material is stable, the braking stability is better than that in the prior art particularly under low-temperature and high-temperature working conditions, the friction material is stable and comfortable, and meanwhile, the organic friction material is resistant to thermal decay and long in service life.

Owner:晋江市凯燕新材料研究院股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com