Package structure for LED

A technology of light-emitting diodes and packaging structures, applied in the direction of electrical components, electrical solid devices, circuits, etc., to achieve the effects of increasing life cycle, easy implementation, and less heat attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Preferred embodiments of the present invention are described in detail below. However, those of ordinary skill in the art will recognize the many inventive concepts provided by the present invention, which can be implemented with the widest variation. In addition, the specific embodiments described herein are for illustration only and are not intended to limit the scope of the present invention. scope of protection.

[0041] The preferred embodiment described in the present invention is the packaging structure of LEDs, but the present invention can also be applied to the packaging structures of other different components.

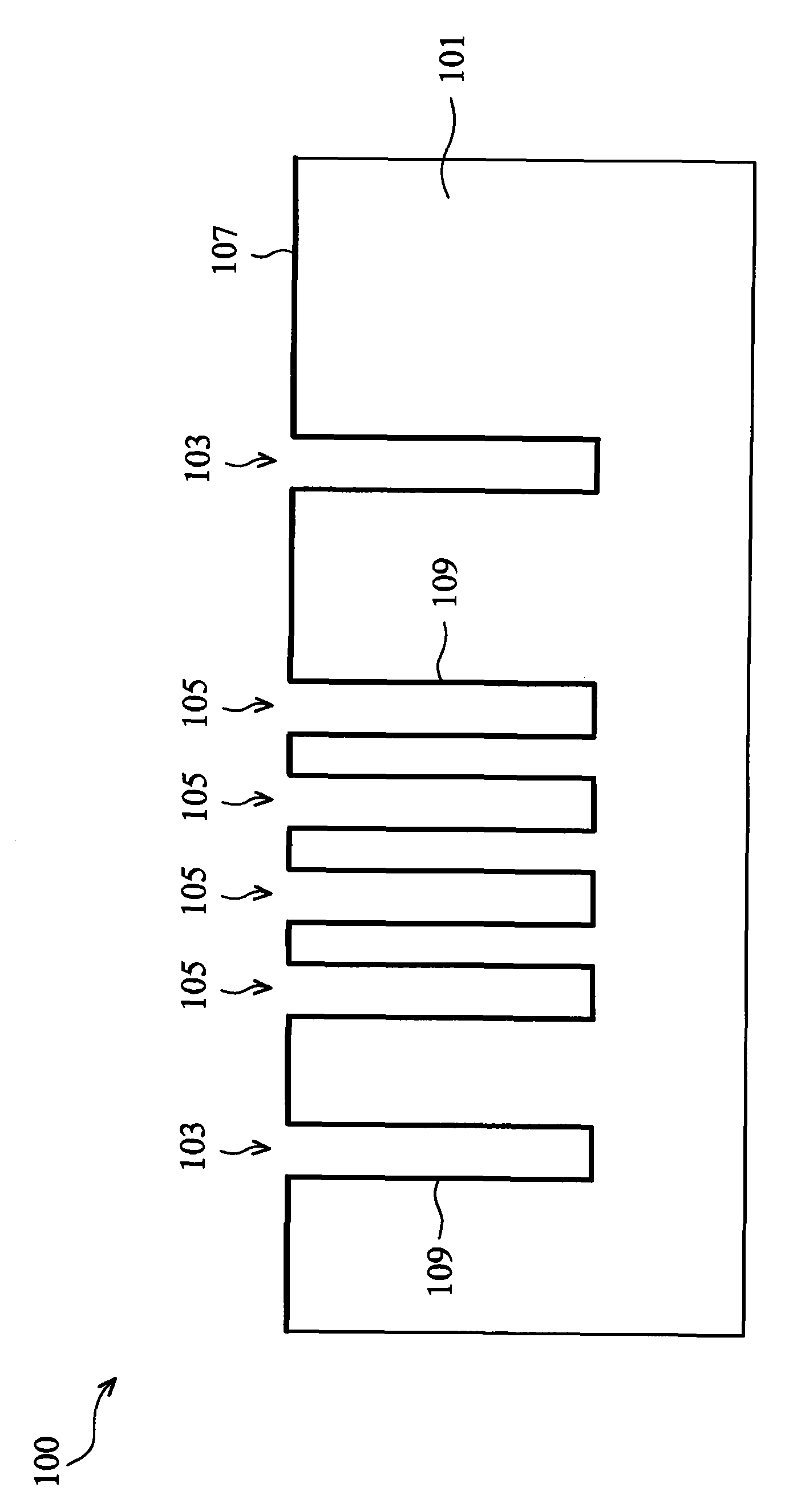

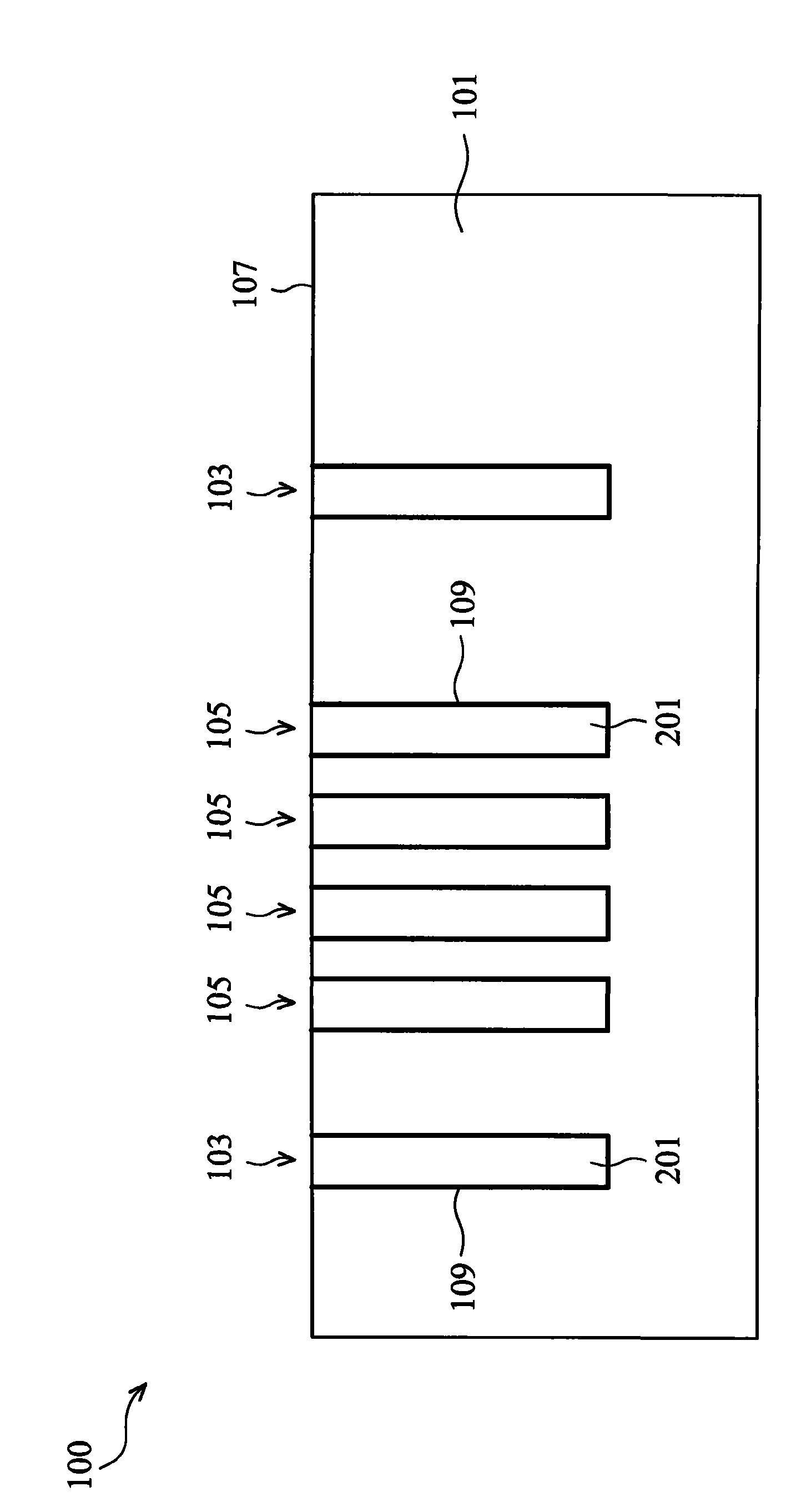

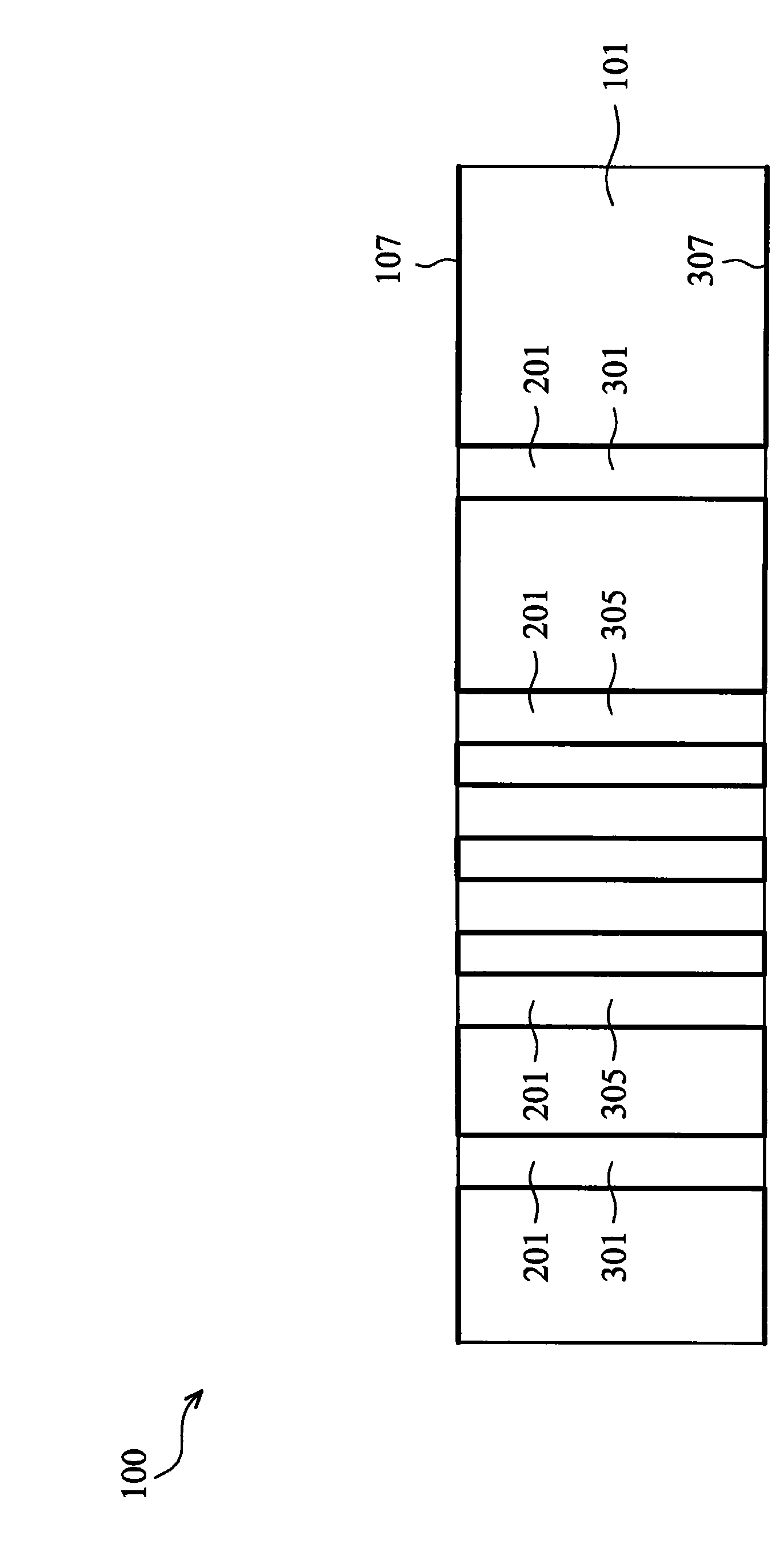

[0042] See figure 1 , which shows a cross-sectional view of a package structure 100 including a substrate 101 and contact openings 103 and thermal openings 105 formed in the substrate 101 . The substrate 101 may include bulk silicon, a doped or undoped substrate, or an active layer of a silicon-on-insulator (SOI) substrate. Generally, a silicon-o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com