Organic friction material containing no copper or asbestos and product

A friction material and asbestos-free technology, applied in friction linings, mechanical equipment, gear transmission mechanisms, etc., can solve problems such as threats to river and marine organisms, unstable friction coefficients, driving accidents, etc., and achieve good braking stability, Long service life and pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

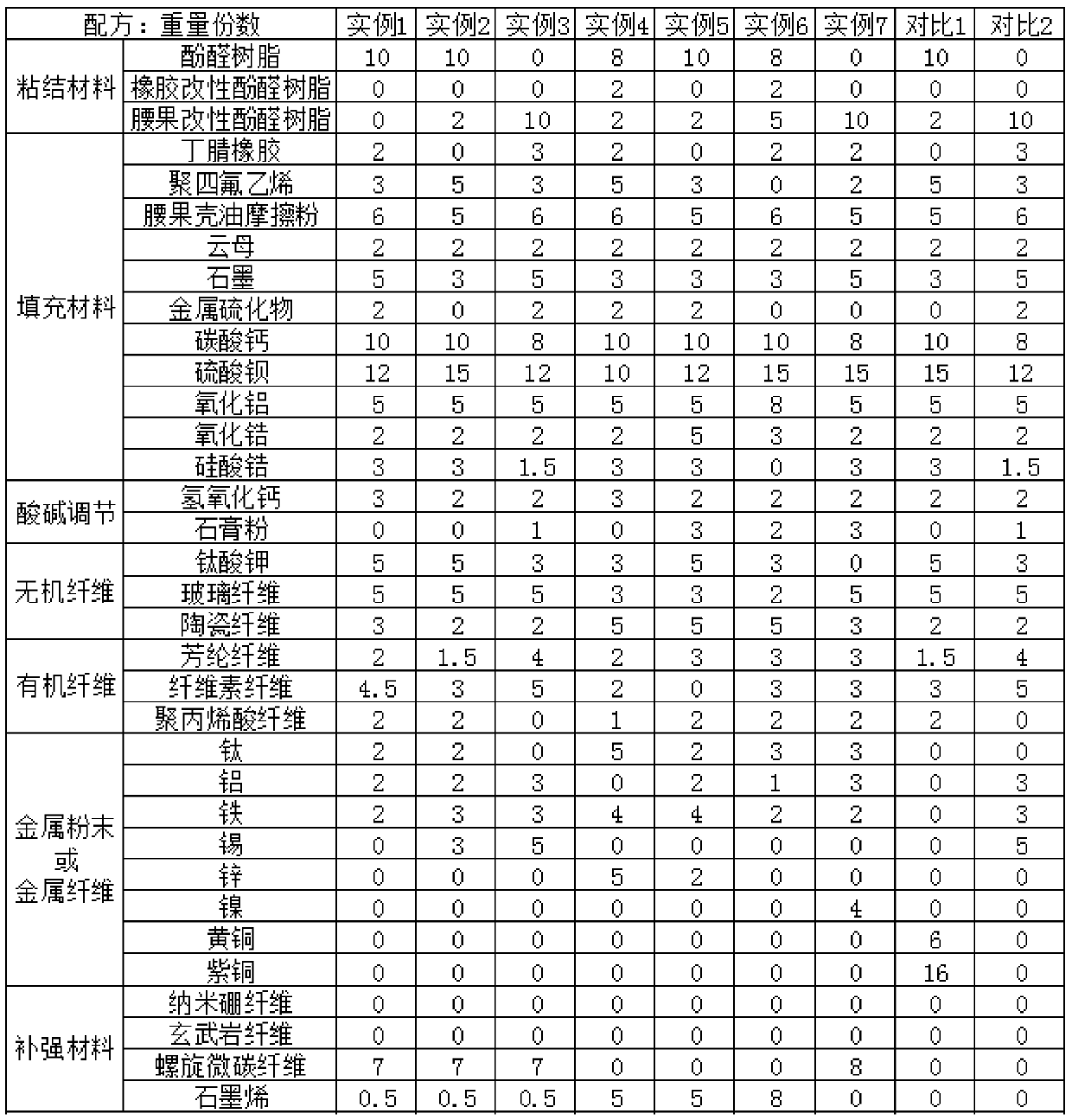

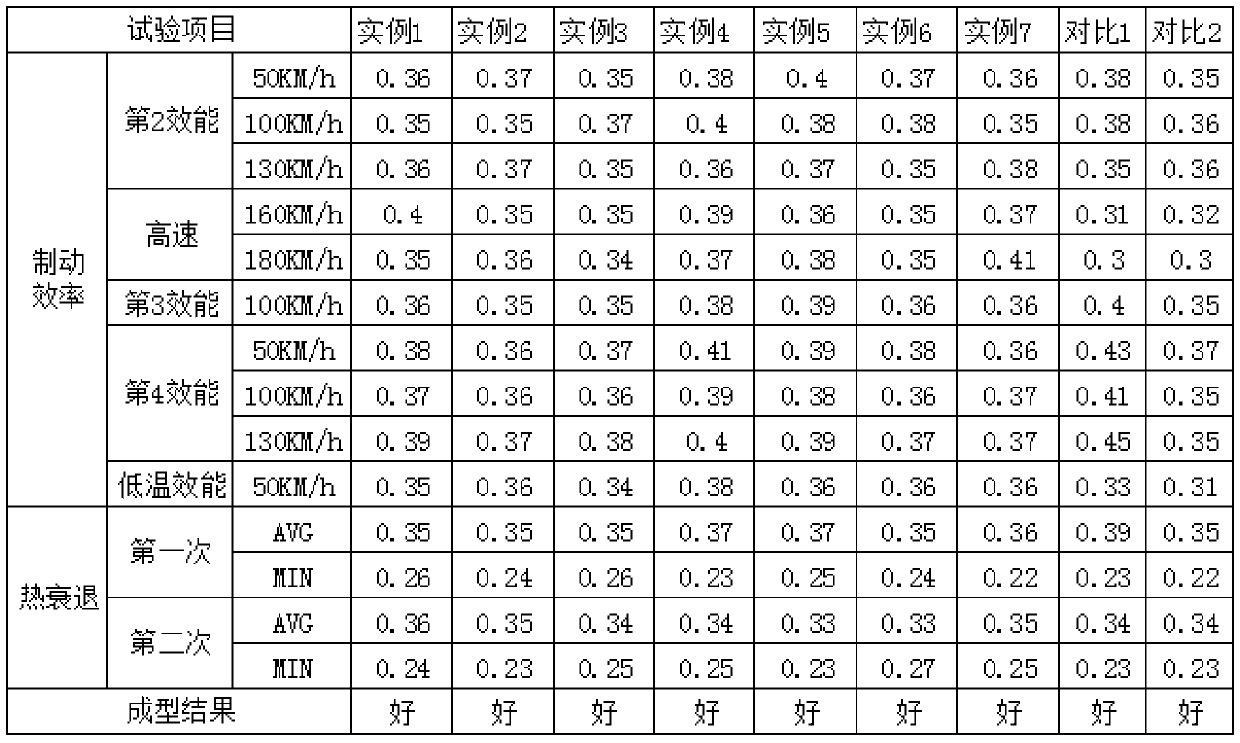

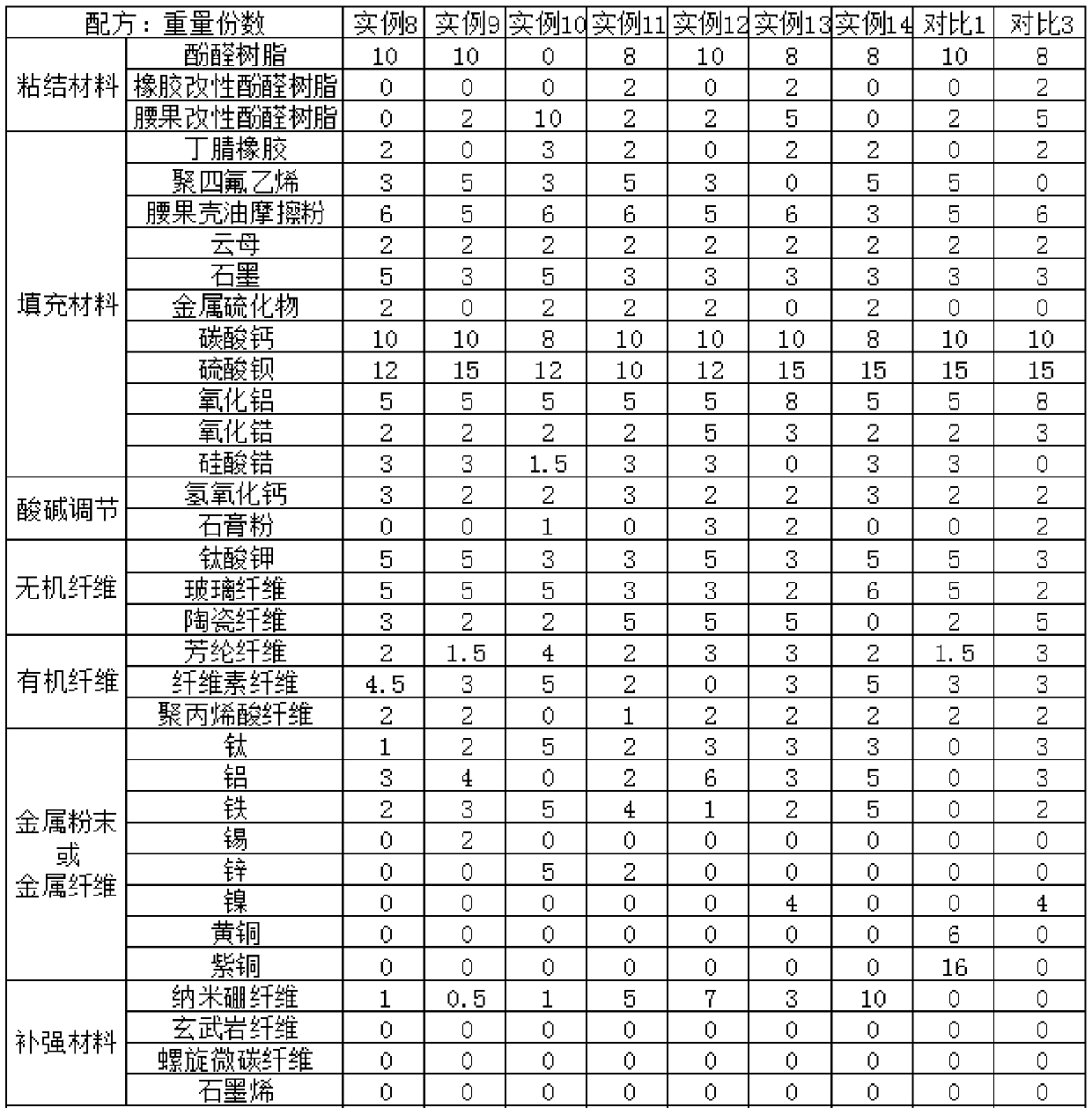

[0017] The invention provides an asbestos-free organic friction product, which includes a base material, an adhesive layer and a friction layer made of copper-free and asbestos-free organic friction materials. The copper-free and asbestos-free organic friction materials are characterized in that That is, the friction material is composed of the following components in parts by weight: 10-15 parts of bonding material, 45-55 parts of non-copper filler, 3-5 parts of acid-base adjustment material, 5-10 parts of organic fiber, 8 parts of inorganic fiber ~13 parts, non-copper metal fiber or non-copper metal powder 6~15 parts, reinforcing material 0.5~10 parts.

[0018] Wherein, the bonding material is phenolic resin or modified phenolic resin, and the modified phenolic resin is preferably cashew nut shell oil modified phenolic resin or rubber modified phenolic resin. The main component of cashew nut shell oil is phenolic compounds containing unsaturated long chains, which can partia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com