Ceramic based friction material and preparation method thereof

A friction material and ceramic-based technology, applied in the field of friction material preparation, can solve problems such as unstable performance, difficult industrialization, complex process, etc., and achieve improved performance, improved reliability, and large specific surface area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] Below in conjunction with the present invention is further described:

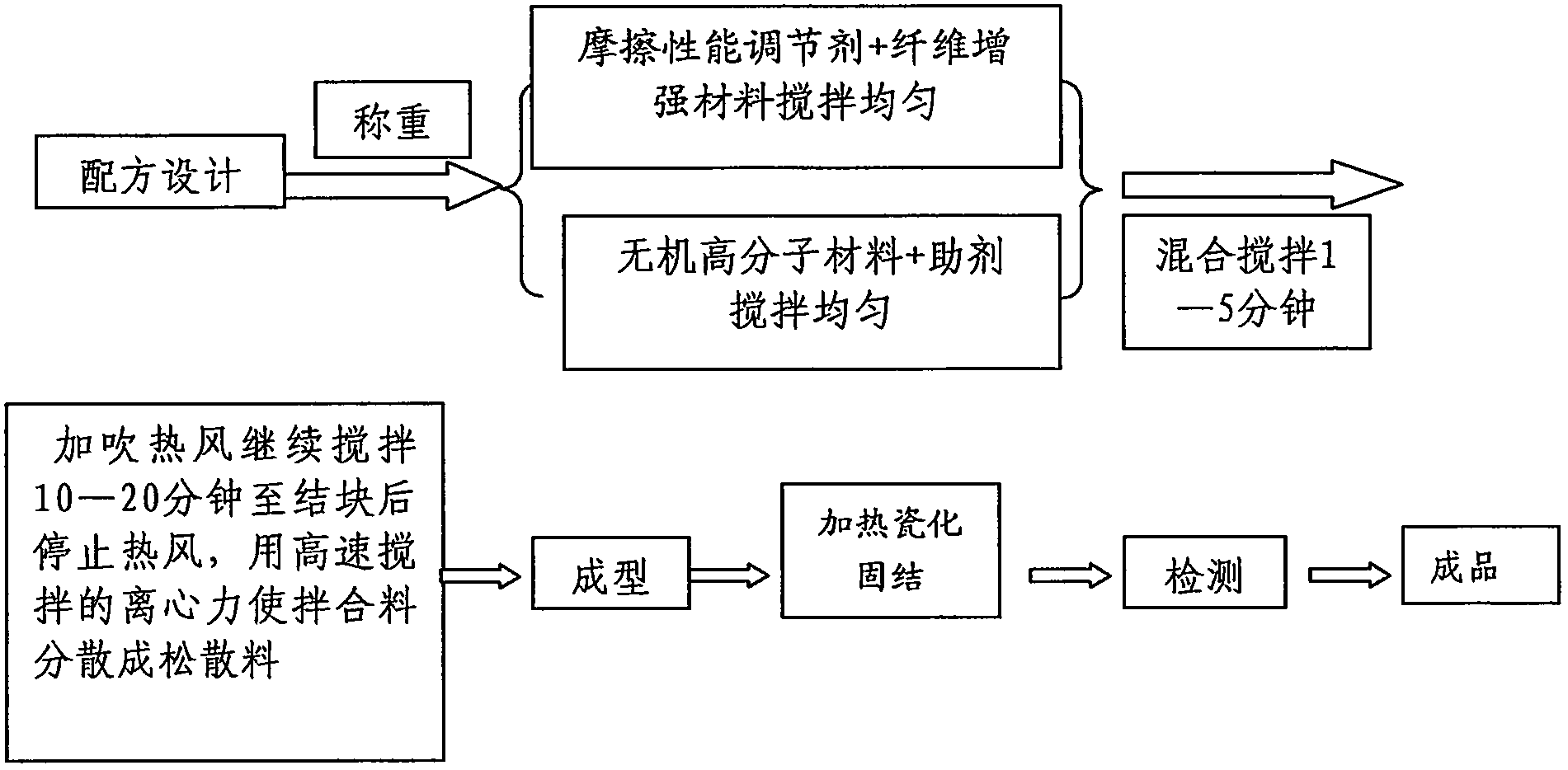

[0066] The preparation method of the ceramic-based friction material provided by the present invention realizes the molding of the friction material through the following steps, specifically as follows:

[0067] a. Design the formula of the product according to the product standard;

[0068] b. Weigh the designed formula according to the proportion;

[0069] c. Stir the inorganic polymer material, reinforcing fiber, friction modifier and others in the formula evenly; when the friction modifier is used in conjunction with the inorganic polymer material, first treat the acidic components on the surface of the friction modifier , wherein the friction modifier is iron oxide (iron red and iron black), copper powder, silicon carbide, corundum, graphite, molybdenum disulfide, iron sulfide, titanium dioxide, barite, cryolite, etc.

[0070] d. Stir the inorganic polymer materials and additives in the formu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com