Patents

Literature

481results about How to "Improve friction performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

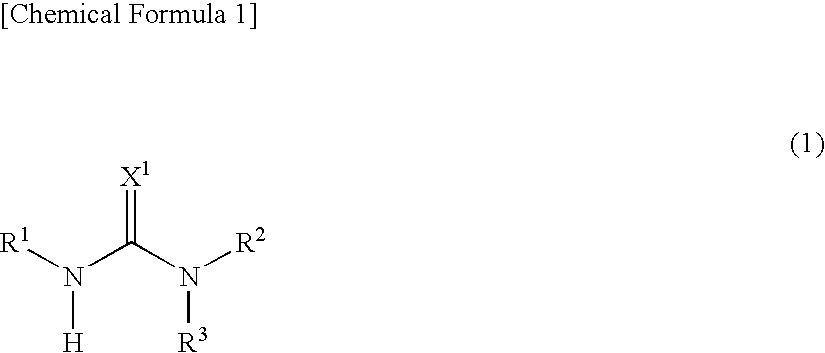

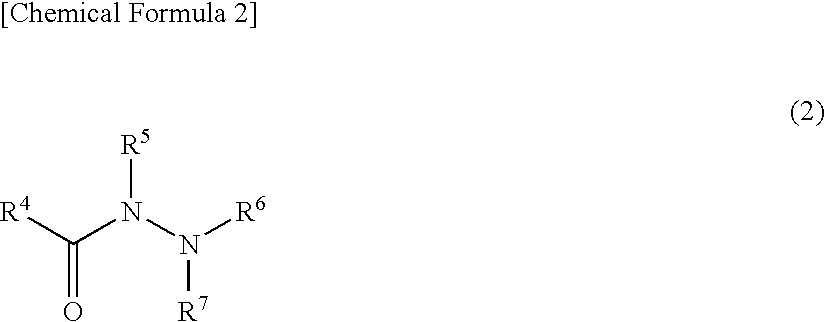

Lubricating oil composition

ActiveUS20080248981A1Improve the level ofLow viscosity propertiesTin organic compoundsLiquid carbonaceous fuelsChemical compositionViscosity index

The lubricating oil composition of the invention comprises a lubricating base oil with a urea adduct value of no greater than 4% by mass and a viscosity index of 100 or higher, an ashless friction modifier at 0.01-10% by mass and a phosphorus-containing anti-wear agent at 0.01-0.2% by mass as phosphorus, based on the total amount of the composition.

Owner:JX NIPPON OIL & ENERGY CORP

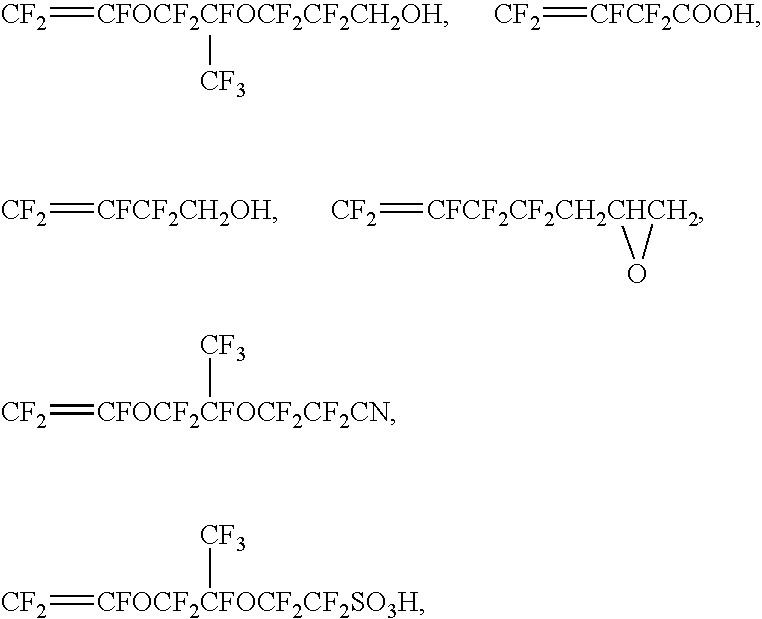

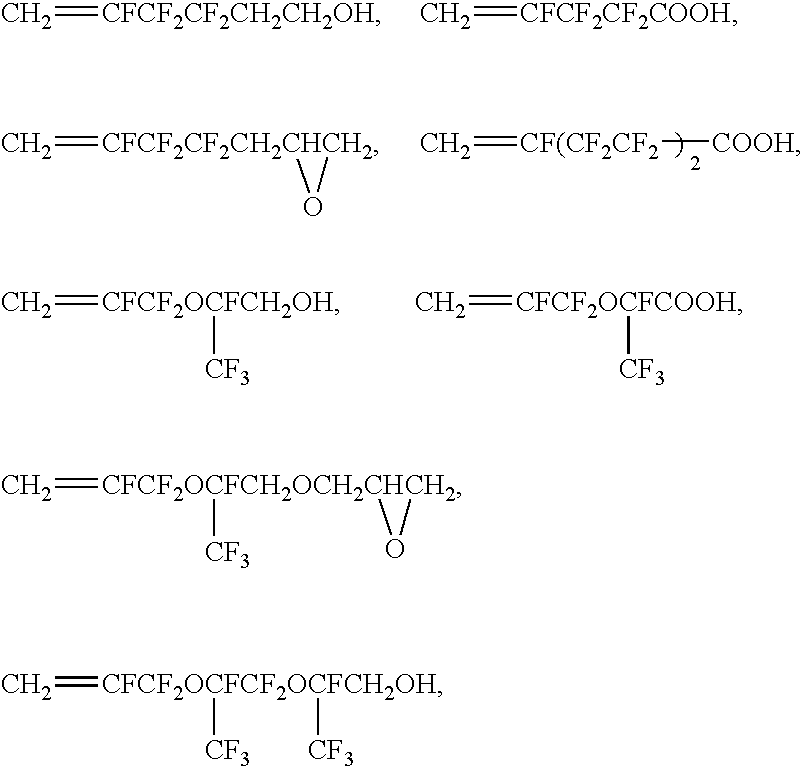

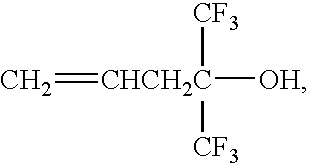

Structural member of fluorine-containing polymer having adhesive property at high temperature and sliding material produced by using same

InactiveUS6726994B1Easy to useImprove friction performanceSynthetic resin layered productsBearing componentsUltimate tensile strengthAdhesive materials

The structural member of the present invention comprises (A) a layer which comprises a fluorine-containing polymer and does not contain an adhesive material other than the fluorine-containing polymer substantially and (B) a substrate, in which the layer (A) is adhered directly to the substrate (B) without interposing a binder therebetween and a longitudinal shear strength between the layer (A) comprising a fluorine-containing polymer and the substrate (B) is not less than 0.98 N / mm<2 >at 150° C. The structural member comprising a fluorine-containing polymer and a substrate adhered to each other, particularly the structural member having improved adhesive strength at high temperature and the sliding material produced by using the structural member are provided.

Owner:DAIKIN IND LTD

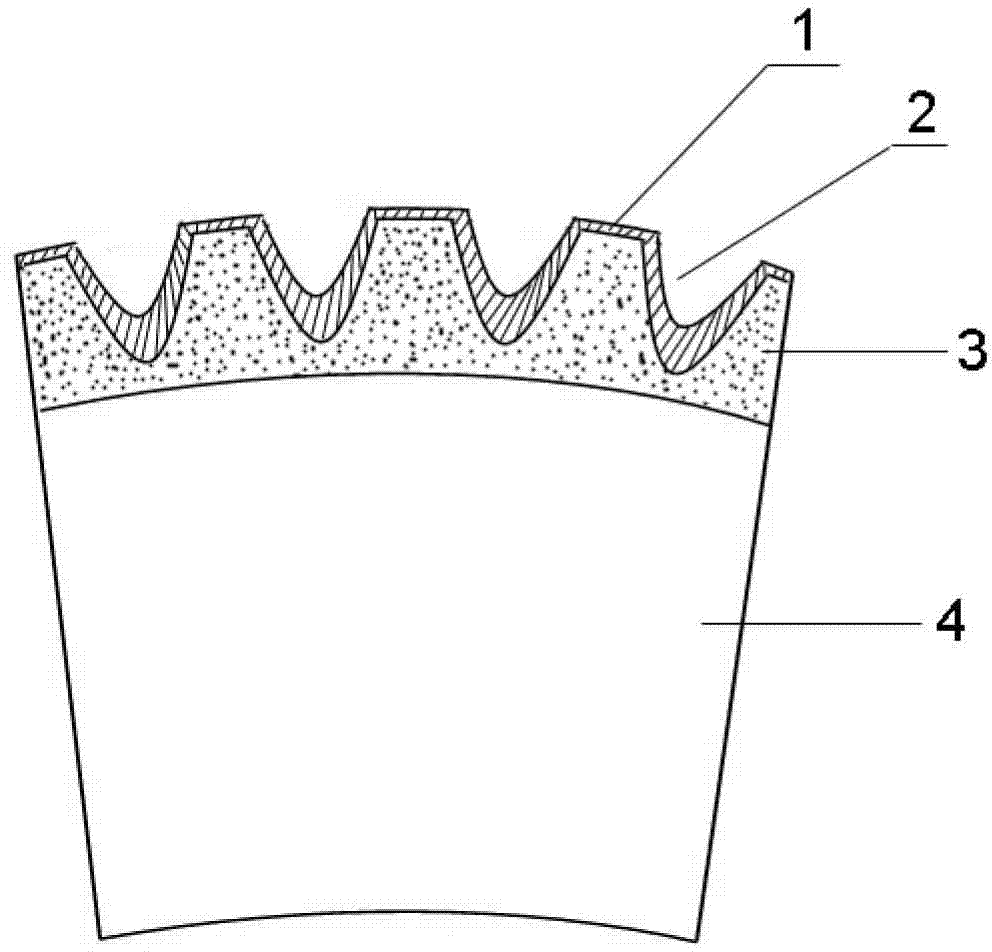

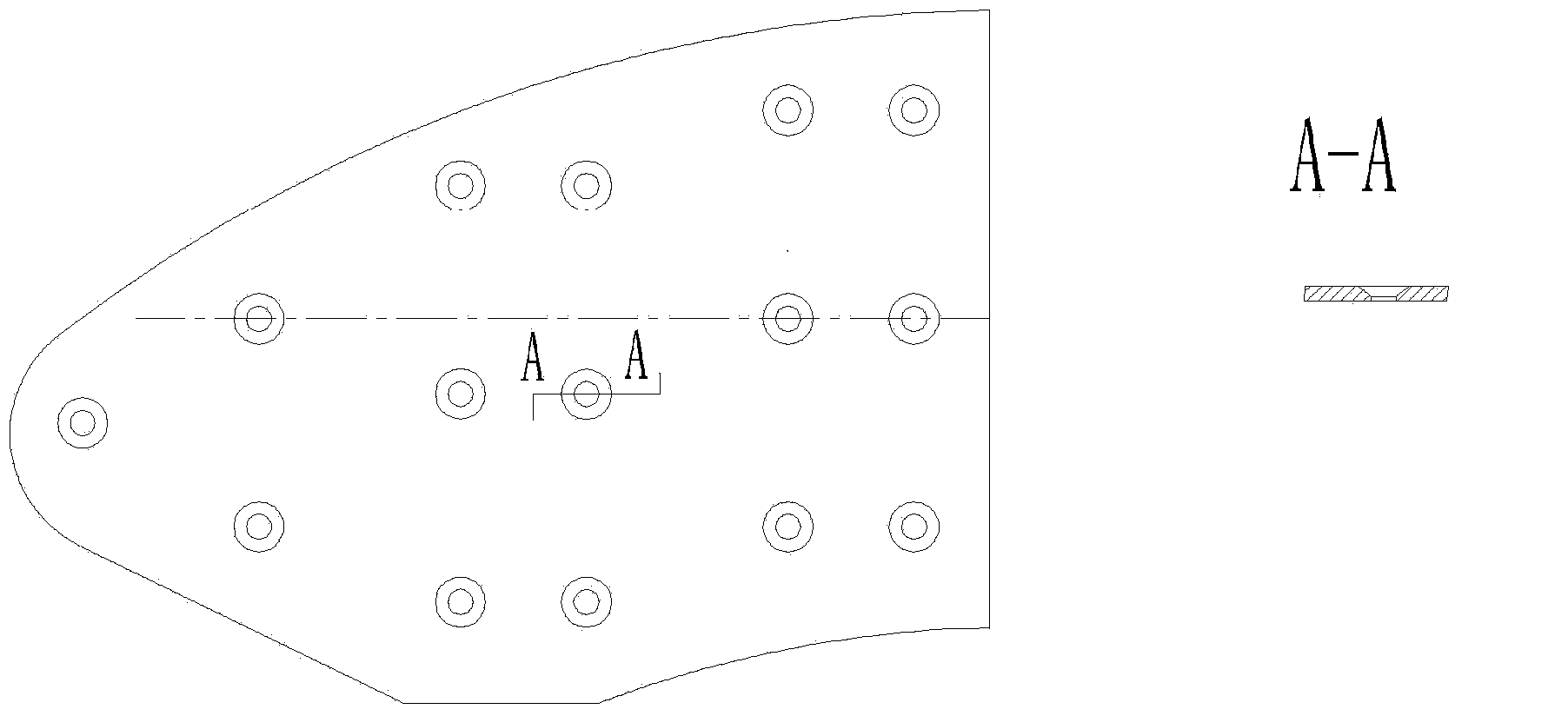

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

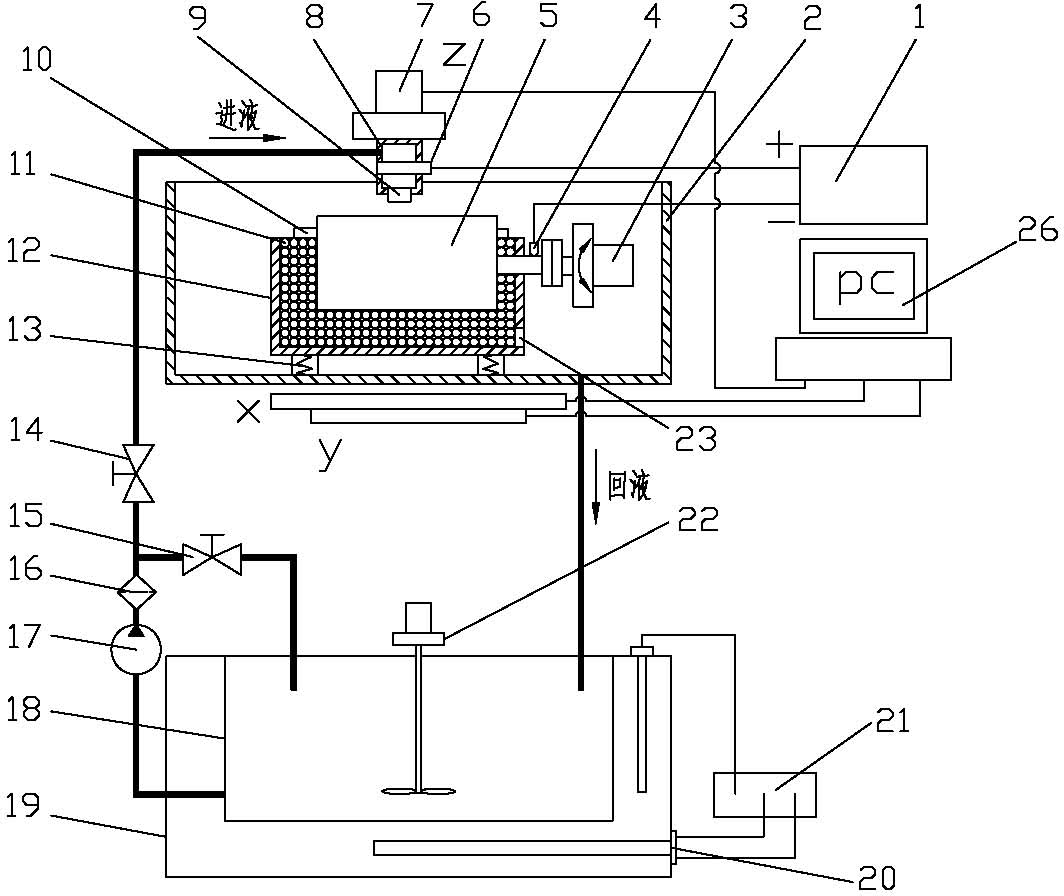

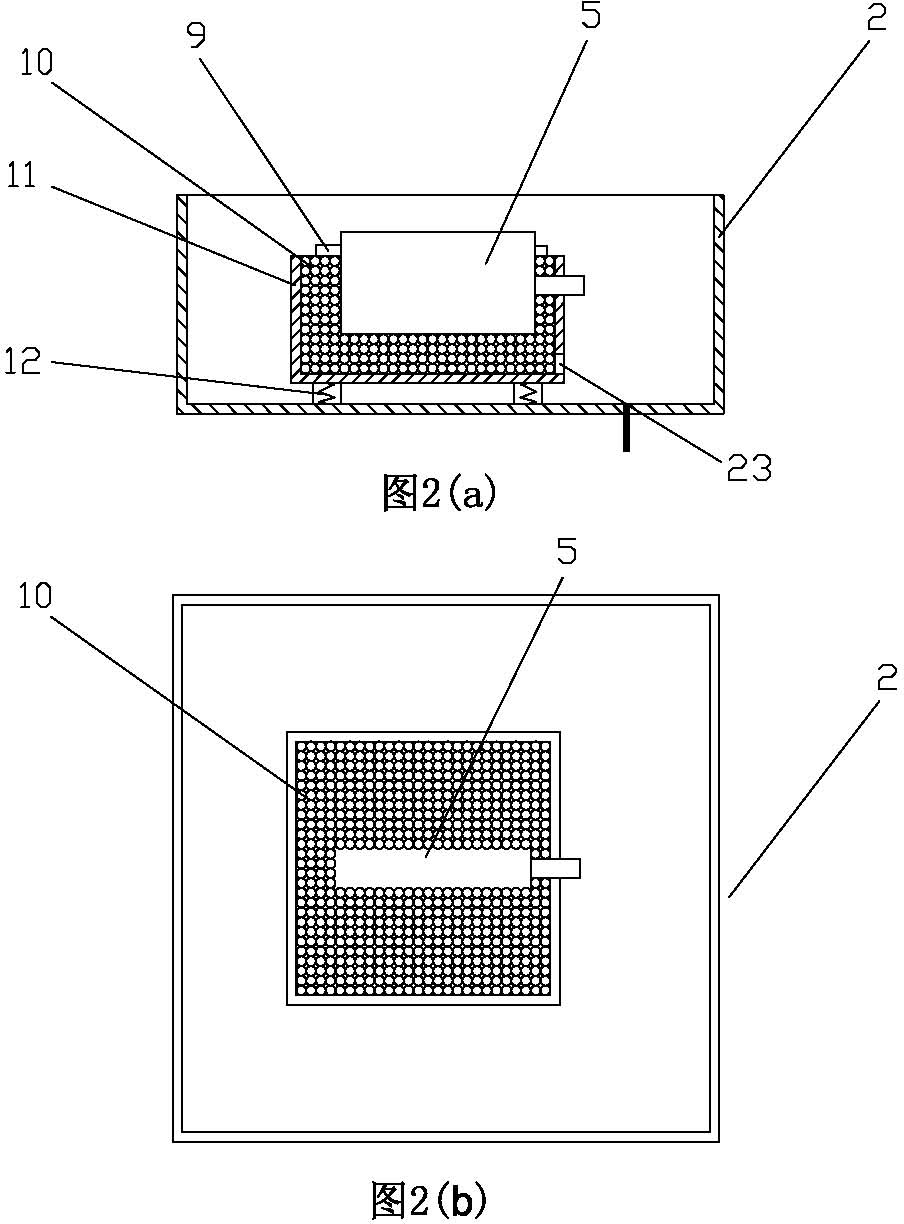

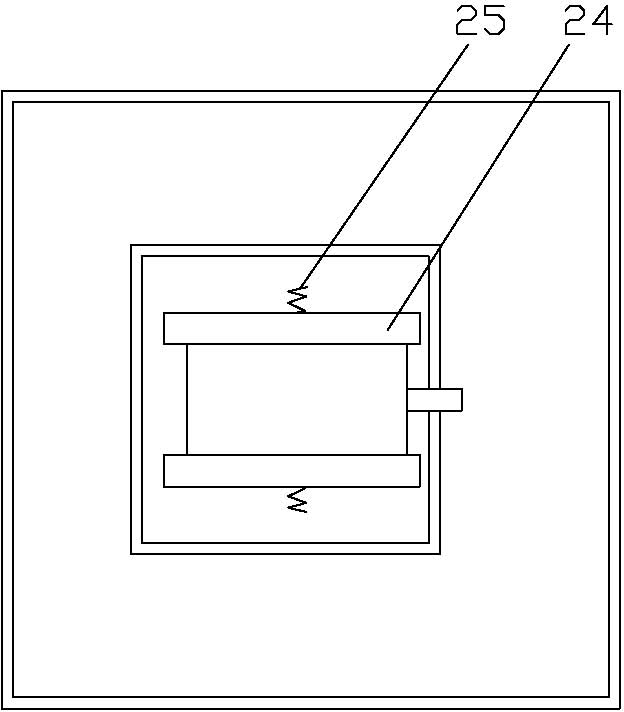

Method and device for processing revolving parts by high-speed jet injection electroforming

InactiveCN101994137AReduce thicknessOvercome timeElectroforming processesTemperature controlControl system

The invention provides a method and device for processing revolving parts by high-speed jet injection electroforming. The method is characterized in that an electroforming core mould is partially buried in an electroforming groove which is filled with hard particles or is in direct contact with a plated negative pole surface through a friction piece, so that the defects of accumulated tumors, burrs and the like on a deposition surface can be effectively removed by the friction of the hard particles or the friction piece on an electroforming layer; and a computer is used for controlling a jet nozzle to scan along with a certain track and cooperates with the rotary motion of the electroforming core mould at the same time, so that the exposed electroforming core mould surface is subjected to selective scanning electroforming so as to pile up the required parts layer by layer. The device of the invention mainly comprises a table movement mechanism, a negative pole rotation drive device, a control system, a temperature control device, an electroforming liquid circulating filter system and the like. The method and device for processing the revolving parts by high-speed jet injection electroforming of the invention are adopted, thus not only effectively removing the defects of hard spots, air holes, accumulated tumors and the like on the electroforming layer surface and manufacturing the electroforming layer with compact and even texture at higher deposition speed, but also abandoning the complicated negative pole female die of the traditional electroforming and rapidly and efficiently forming the revolving parts with different shapes and wall thicknesses by one step.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

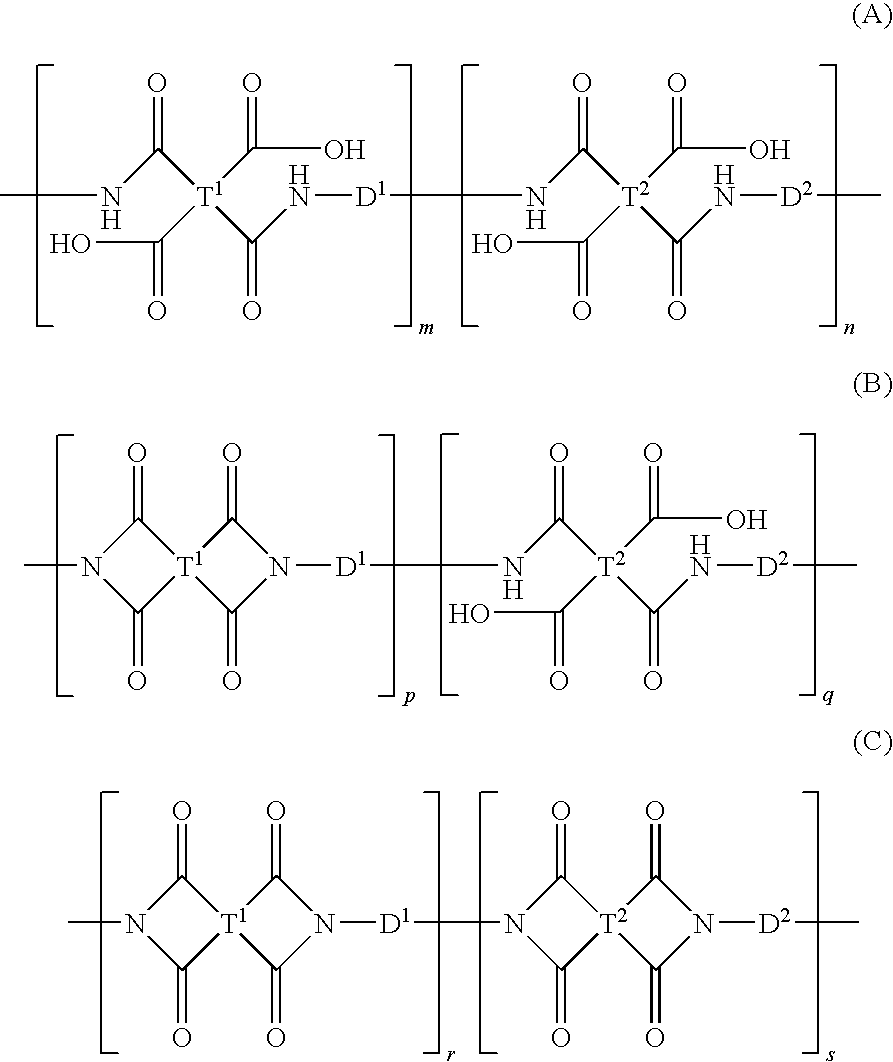

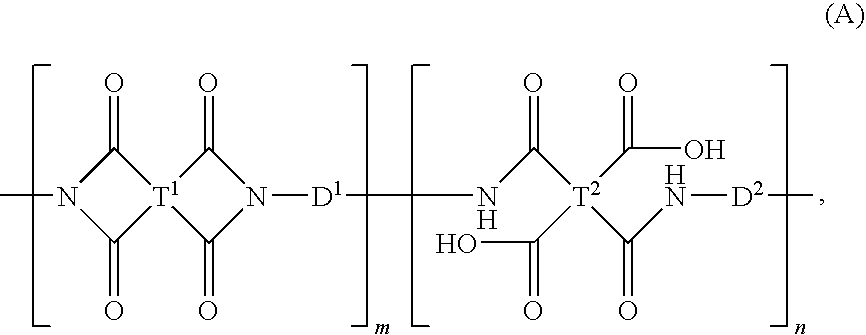

Liquid crystal alignment solution

ActiveUS20100243955A1Increase contrastLow residual direct currentLiquid crystal compositionsThin material handlingCrystallographyPolyamide

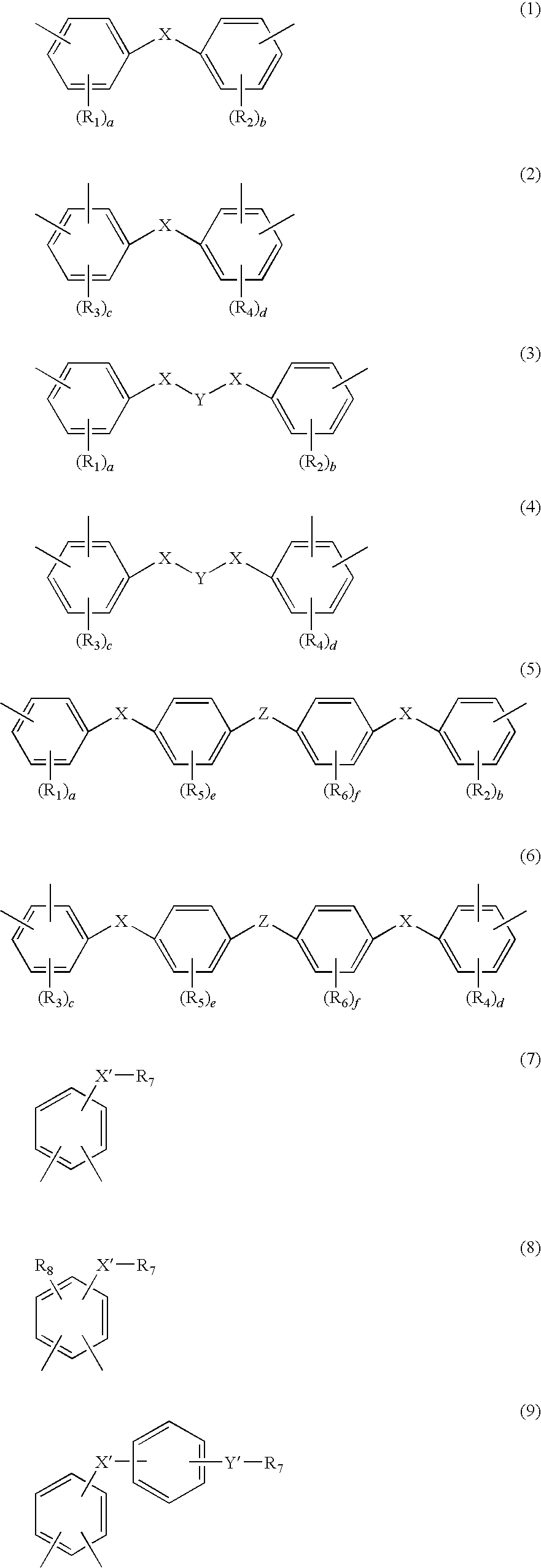

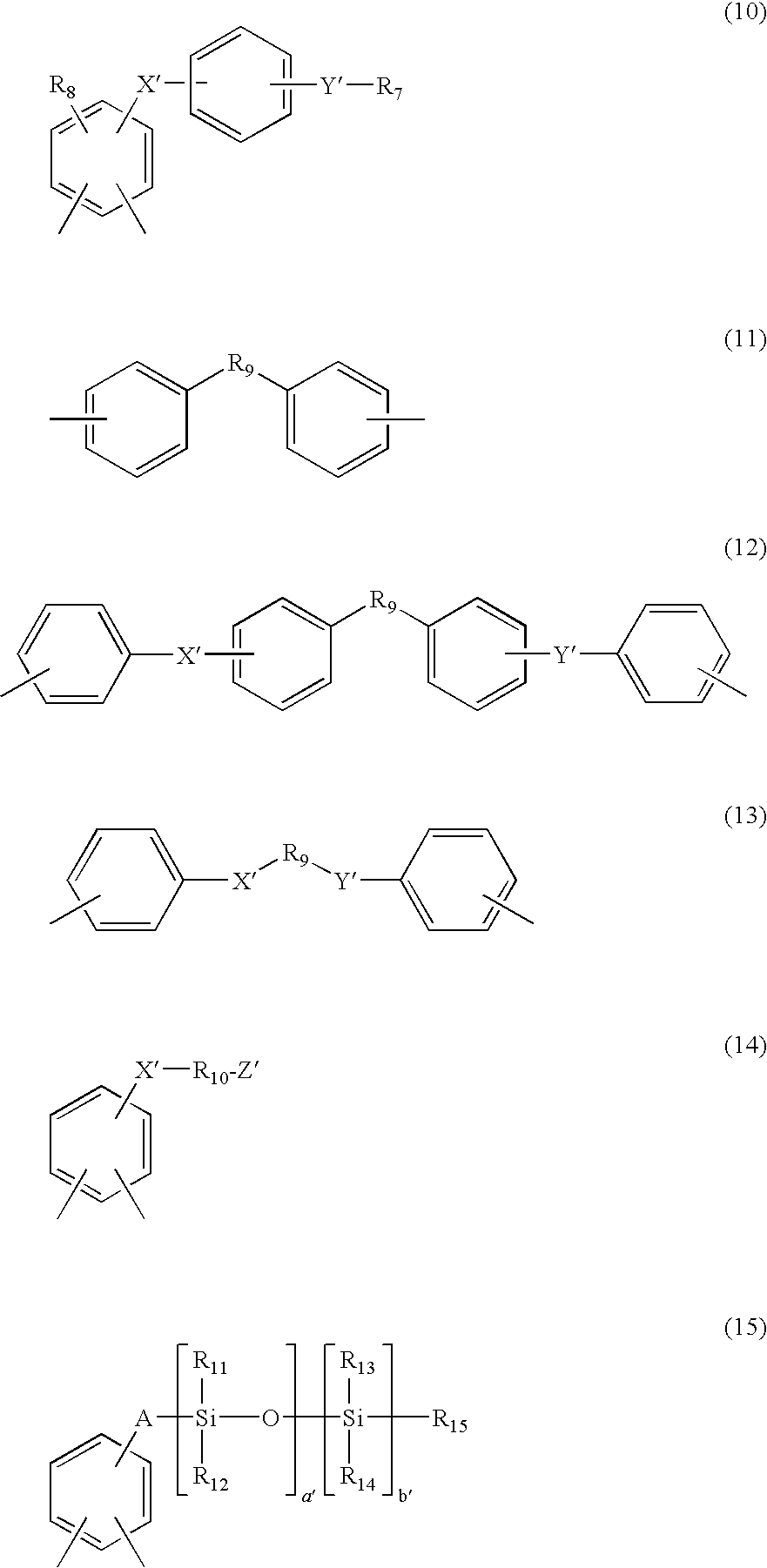

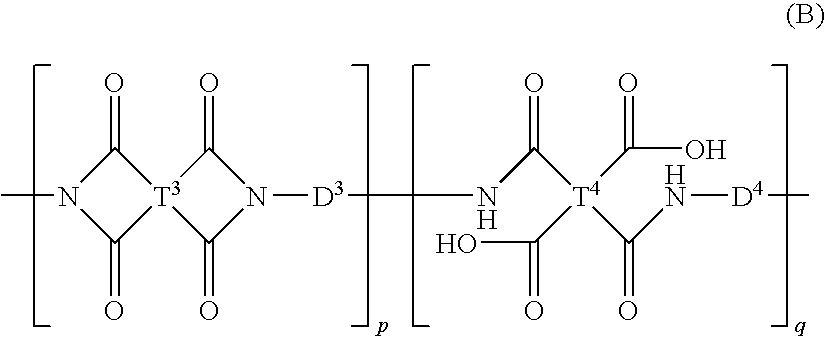

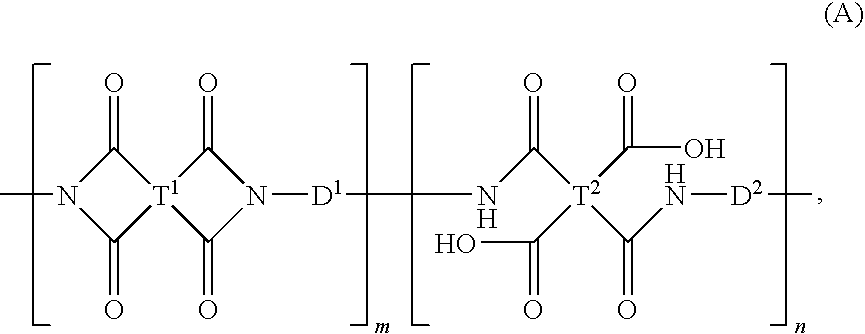

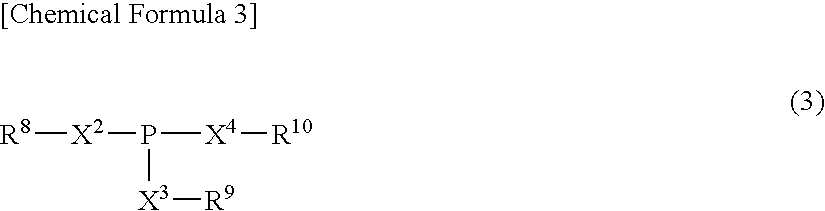

A liquid crystal alignment solution is provided. The liquid crystal alignment solution includes at least one polymer selected from the group consisting of a polyamide acid-polyamide acid polymer represented by formula (A), a polyimide-polyamide acid polymer represented by formula (B) and a polyimide-polyimide polymer represented by formula (C),in which T1 and T2 are each independently a tetravalent organic group; m<n; p<q; r<s; and at least one of D1 and D2 is selected from the group consisting of formulae (1) to (15).

Owner:DAXIN MATERIALS

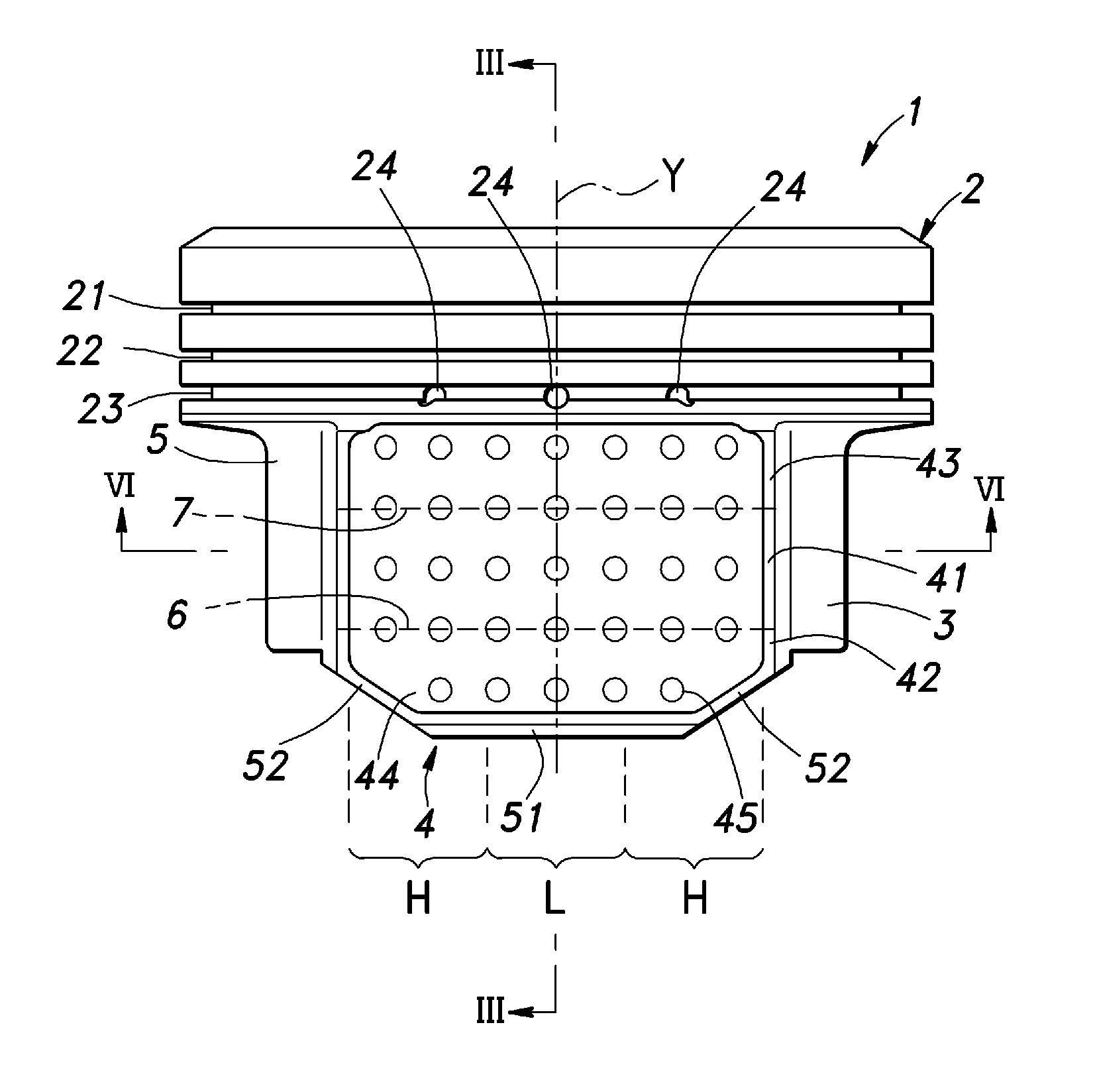

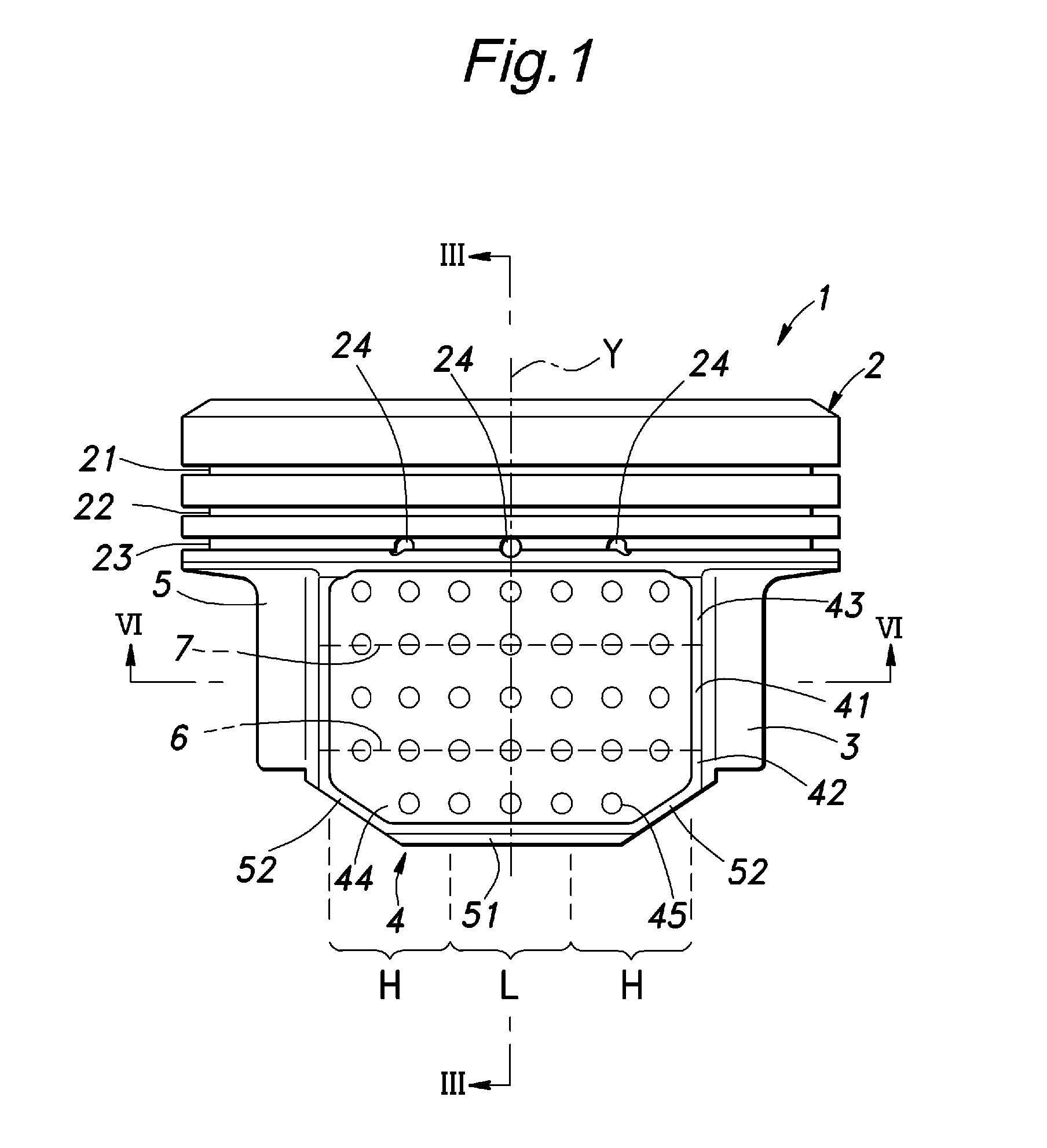

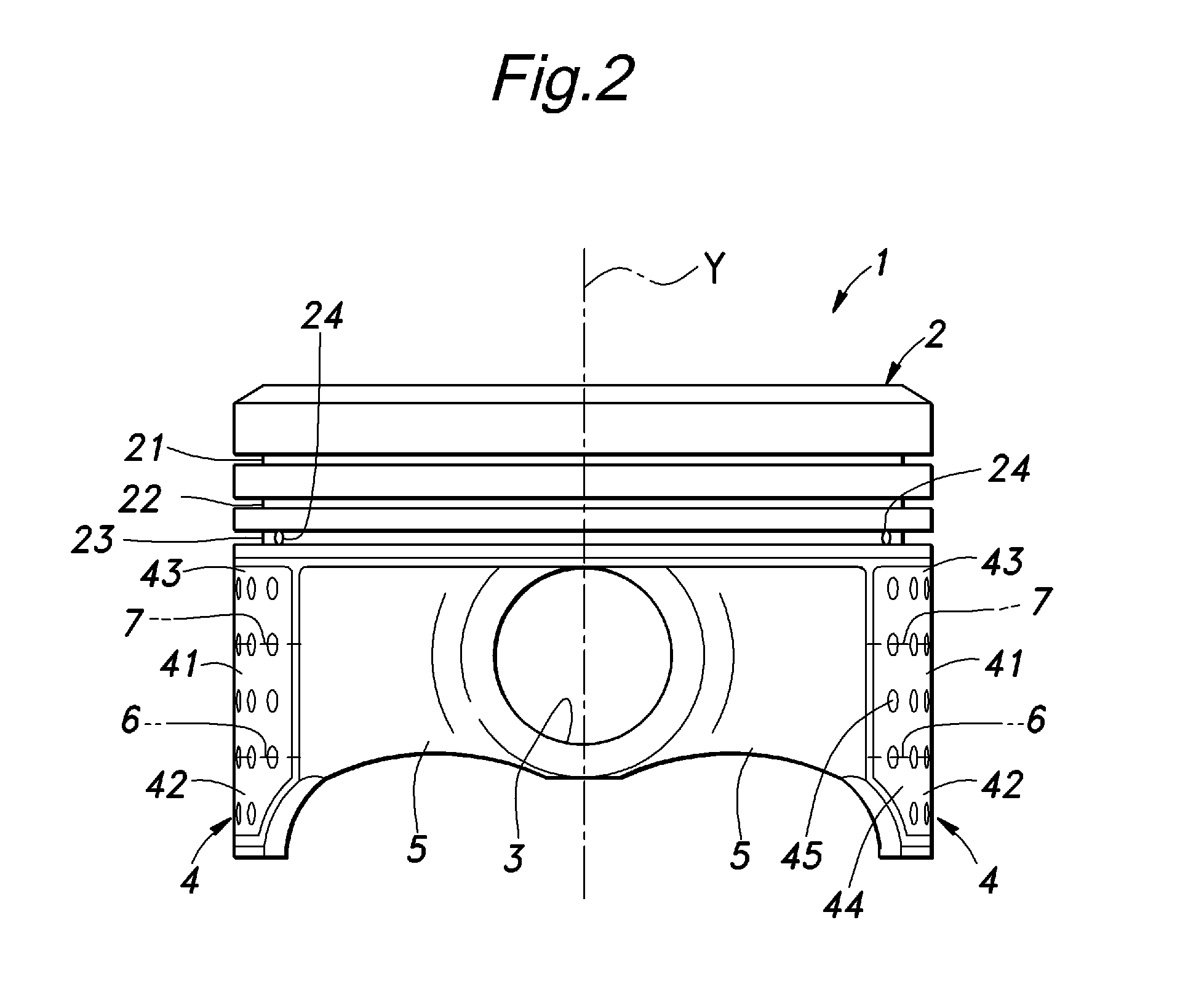

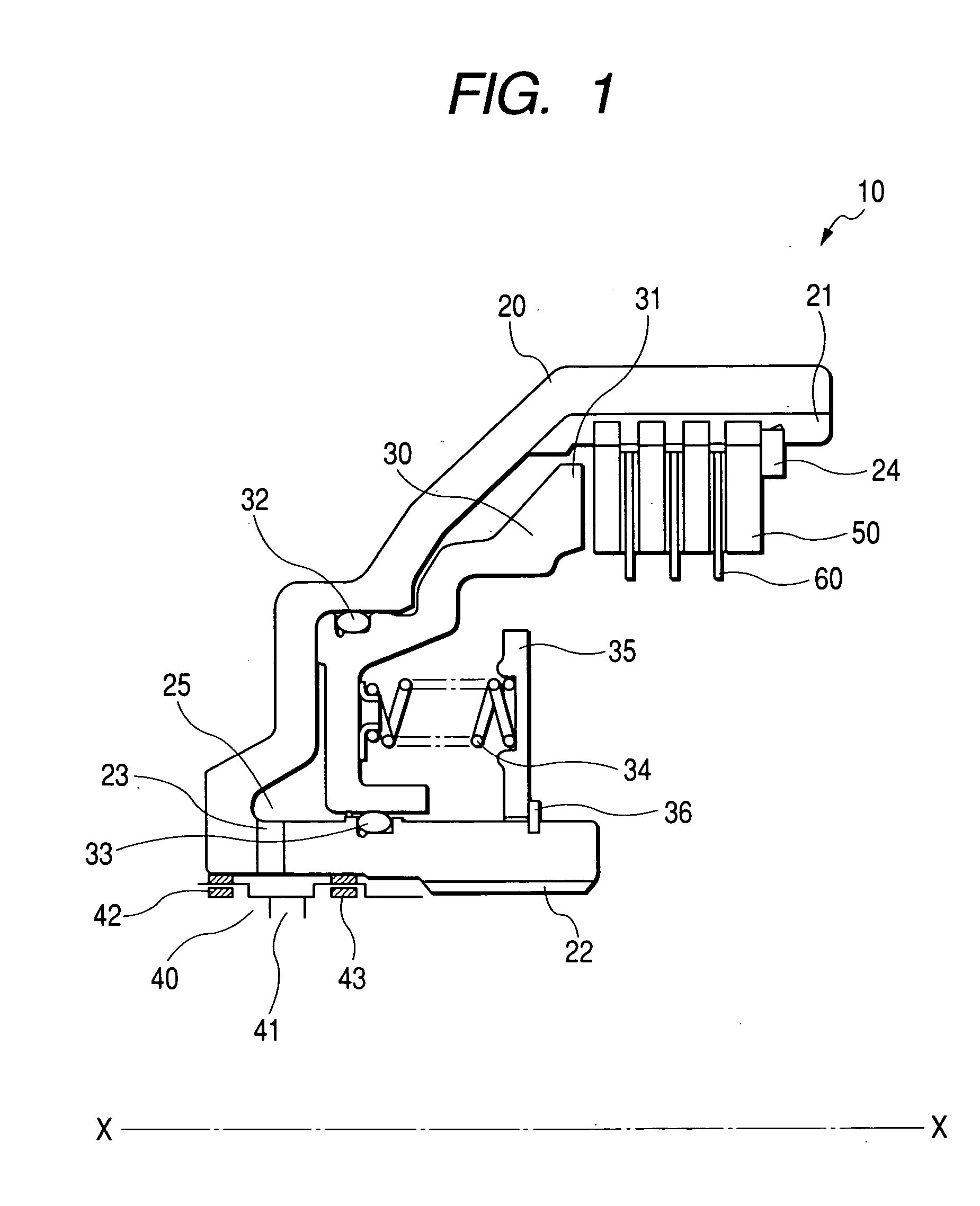

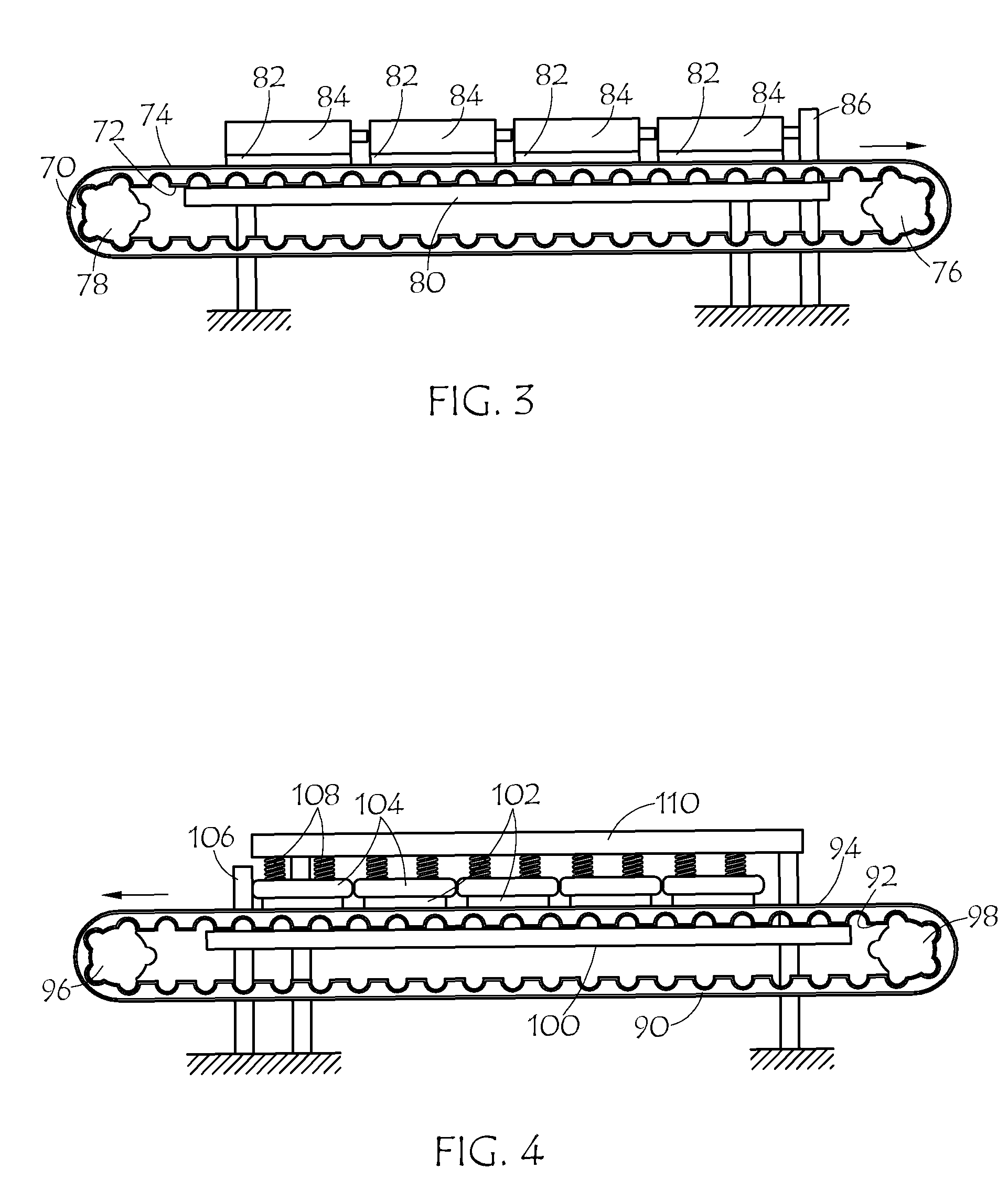

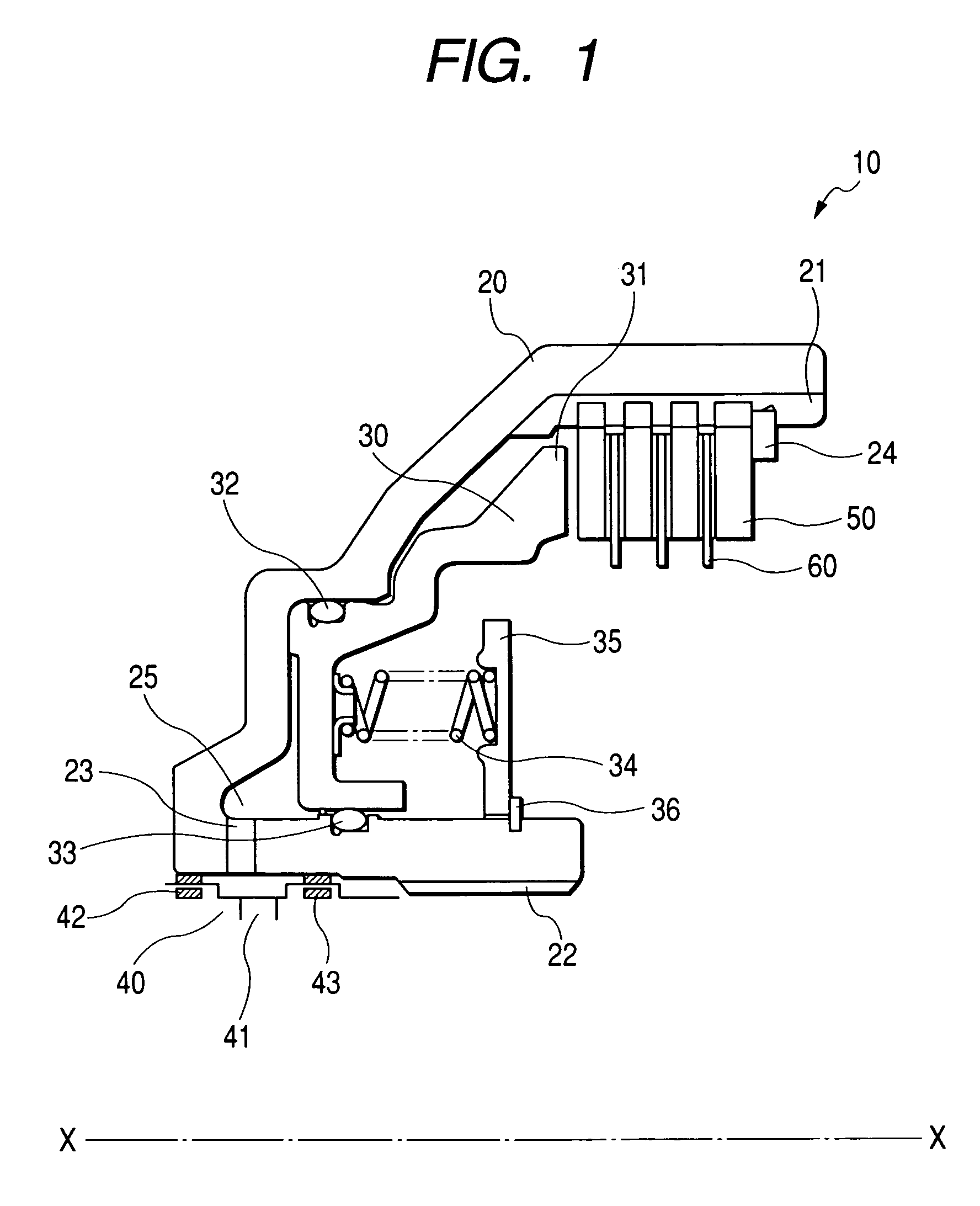

Piston for an internal combustion engine

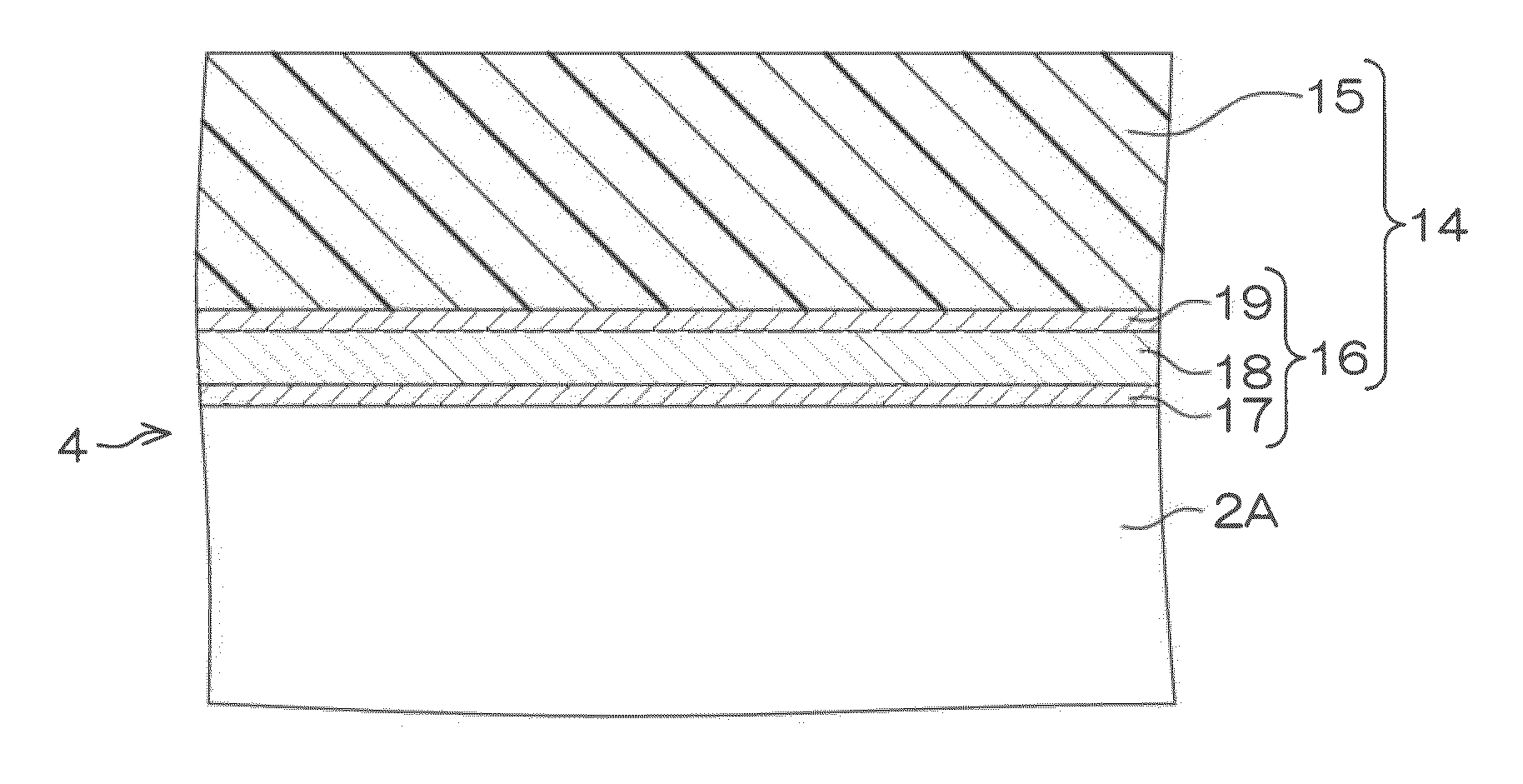

ActiveUS20110139114A1Improve friction performanceSufficient amountPlungersMachines/enginesResin coatingEngineering

To provide a piston for an internal combustion engine including a skirt which causes a relatively small frictional resistance and can maintain a favorable frictional property over an extended period of time. In a piston for an internal combustion engine having a skirt 4 on whose sliding surface a resin coating layer is deposited, the skirt 4 comprises a thin walled portion 51 located in a circumferentially middle part thereof and a pair of thick walled portions 52 provided on either lateral side of the thin walled portion 51. The resin coating layer 44 at least in the part thereof deposited on the thick walled portions 52 is formed with a plurality of dimples 45. The skirt may comprise a skirt main body 41 extending axially at a fixed distance from the central axial line of the piston in an axially middle part thereof, and a first reduced diameter portion 42 depending from the lower end of the skirt main body and having a progressively smaller diameter toward a lower end thereof. The dimples 45 may be arranged along a first boundary 6 between the skirt main body and first reduced diameter portion.

Owner:HONDA MOTOR CO LTD

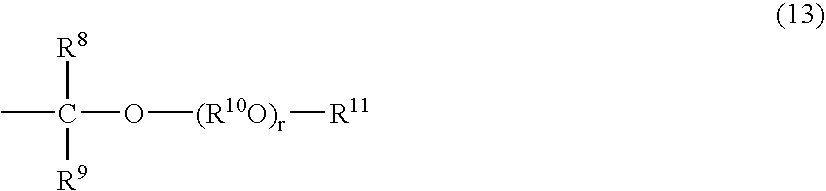

Refrigerating machine oil compositions

ActiveUS20070155635A1Maintaining thermal/oxidation stabilityLong operationBase-materialsAlcoholPolyol

The first refrigerating machine oil composition of the invention comprises a predetermined base oil, and at least one ester additive selected from esters of a monobasic fatty acid having 12 or more carbon atoms and a monohydric alcohol having 1-24 carbon atoms, and an ester of a chain-like dibasic acid and a monohydric alcohol. The second refrigerating machine oil composition of the invention comprises a predetermined base oil, and at least one oxygen-containing compound selected from the following (A1)-(A6). The third refrigerating machine oil composition of the invention comprises a predetermined base oil, and at least one oxygen-containing compound selected from the following (A1), (A2), (A4), (A7) and (A8). (A1) Alkylene oxide adduct of a polyhydric alcohol having 3-6 hydroxyl groups (A2) Polyalkylene glycol (A3) Trihydric alcohol having 3-20 carbon atoms apart from (A1) (A4) Dihydric alcohol having 2-20 carbon atoms apart from (A2) (A5) Hydrocarbyl ether of (A1)-(A4) (A6) Hydrocarbyl ester of (A1)-(A4) (A7) Hydrocarbyl ether of (A1), (A2) or (A4) (A7) Hydrocarbyl ester of (A1), (A2) or (A4)

Owner:NIPPON OIL CORP

Production of modified phenolic resin with high boron content

Production of modified phenolic resin of high-boron content is carried out by reacting boric acid with carbolic acid to generate boric acid ester by two-step method, reacting boric acid ester with paraformaldehyde to obtain final product. It is simple, controllable and quantitative, has higher boron content, excellent thermal, mechanical, friction and anti-corrosive performances. It can be used for high-temperature brake friction material, anti-corrosive materials and special thermal-insulating material.

Owner:TONGJI UNIV

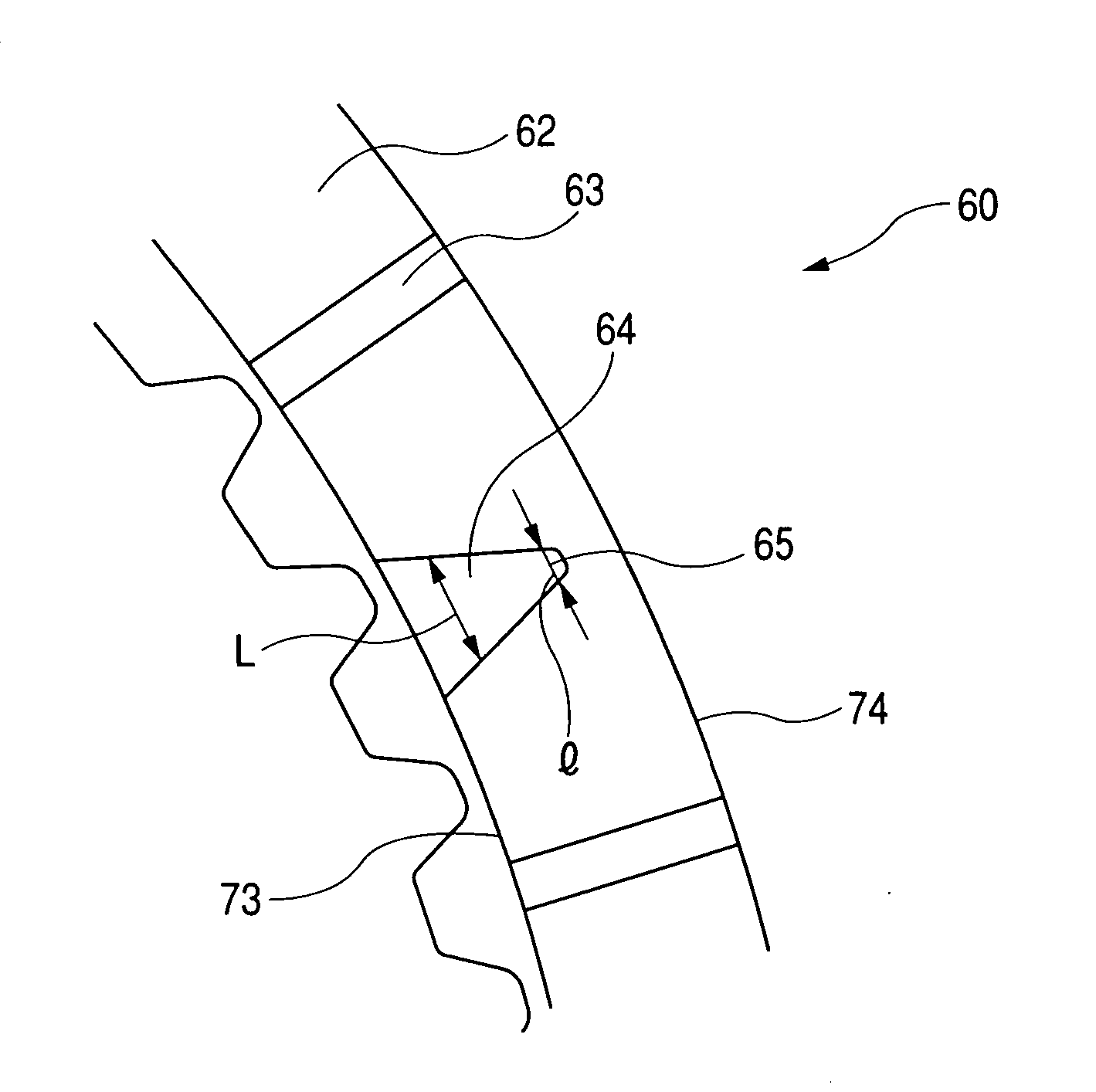

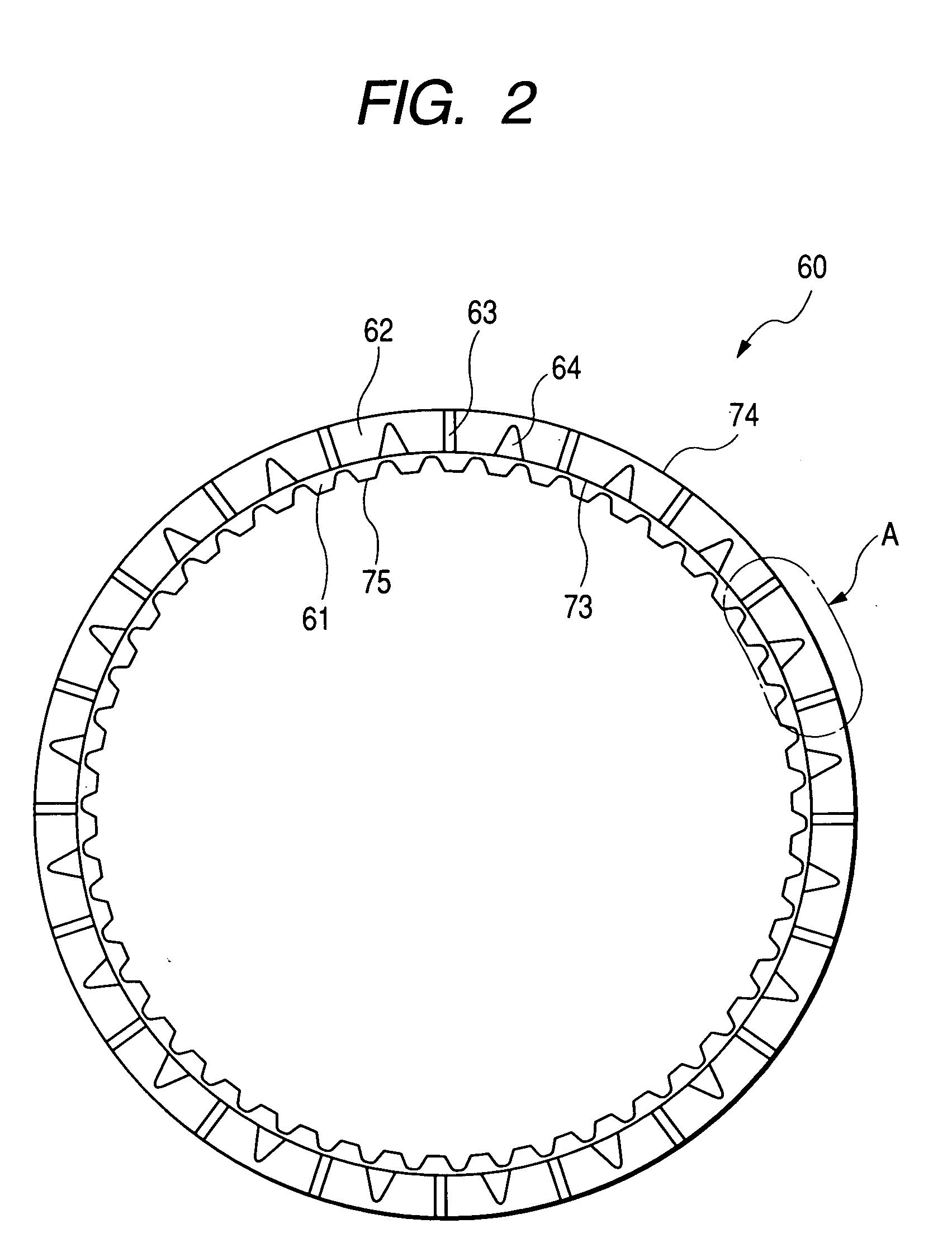

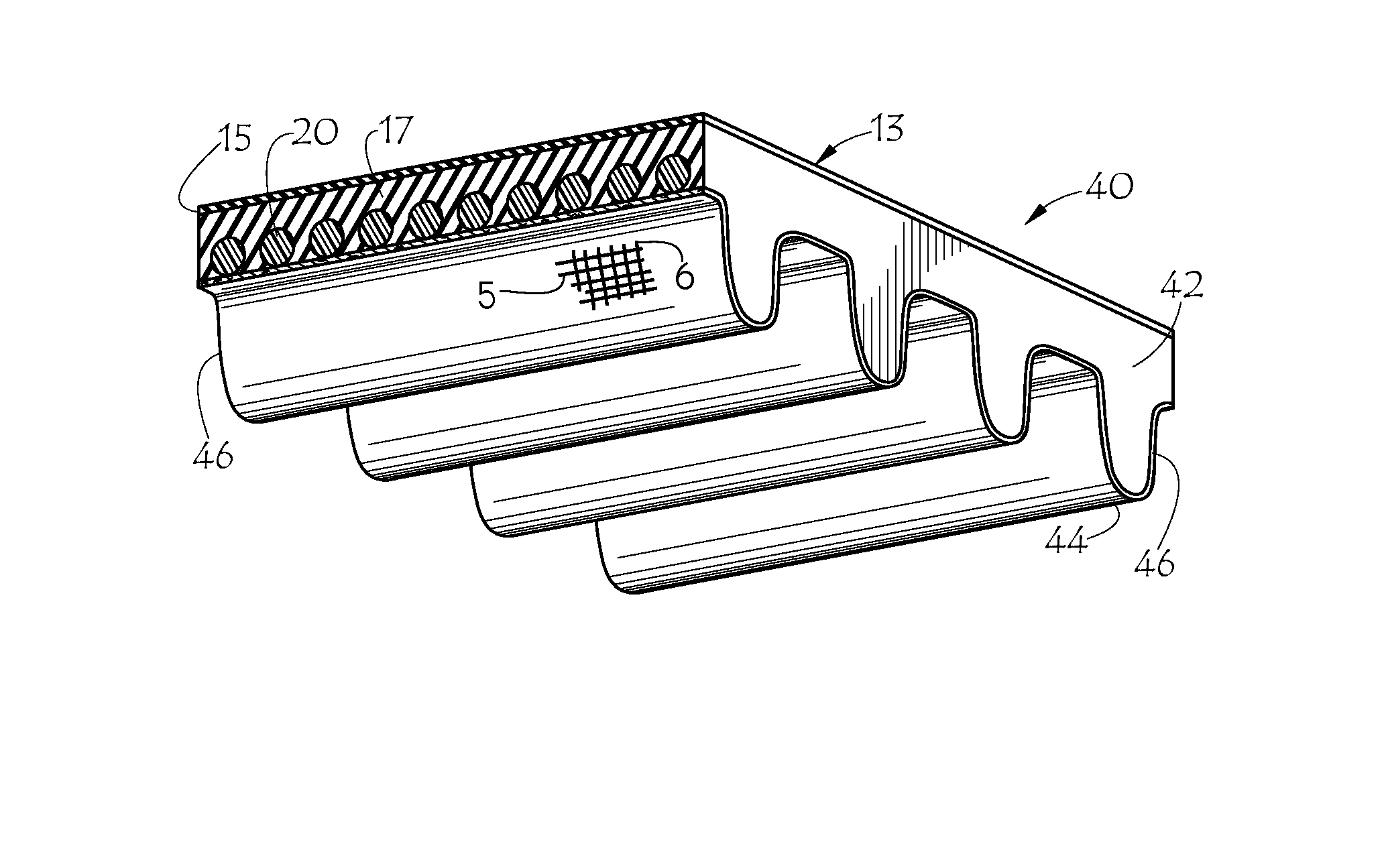

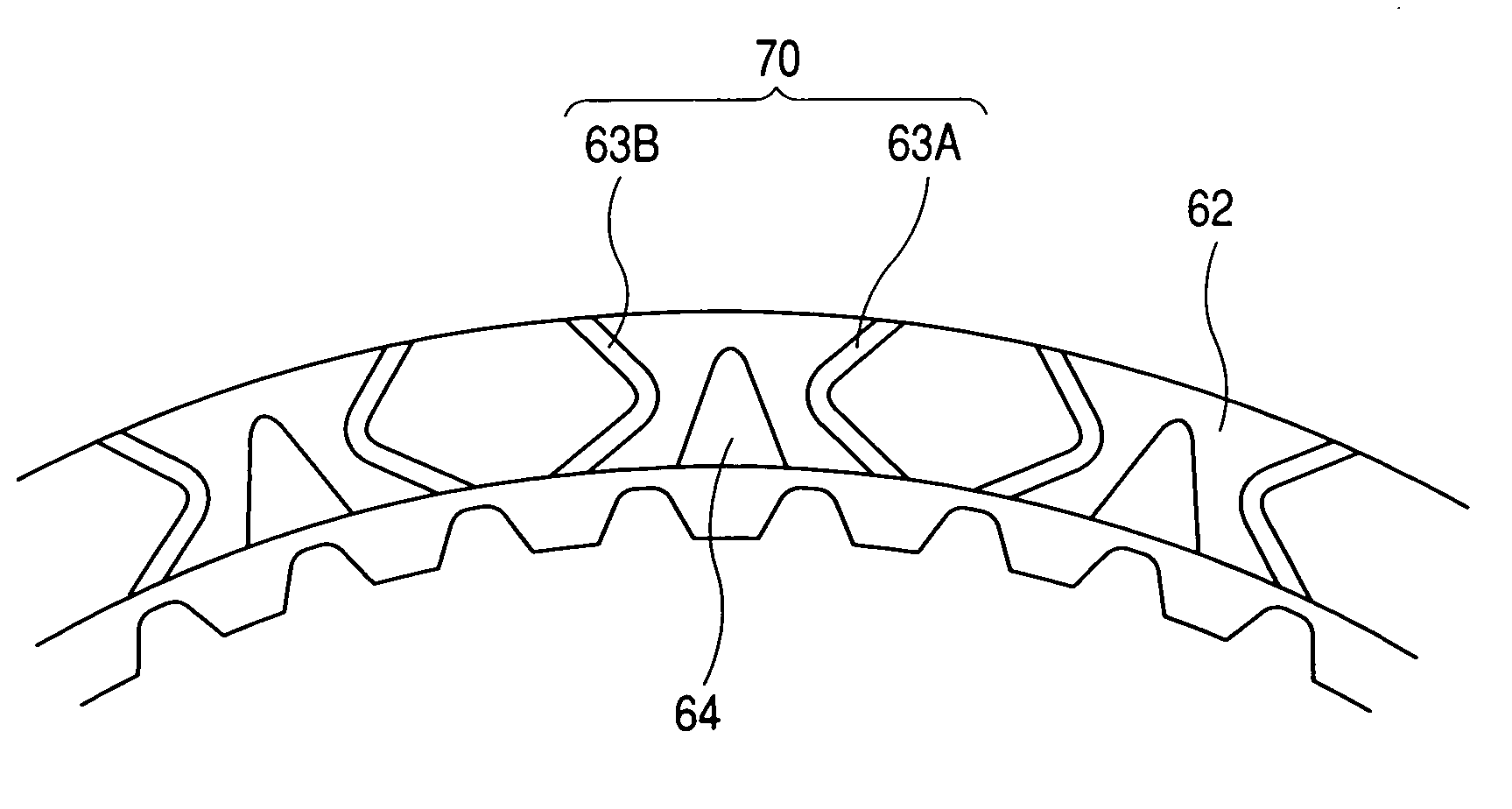

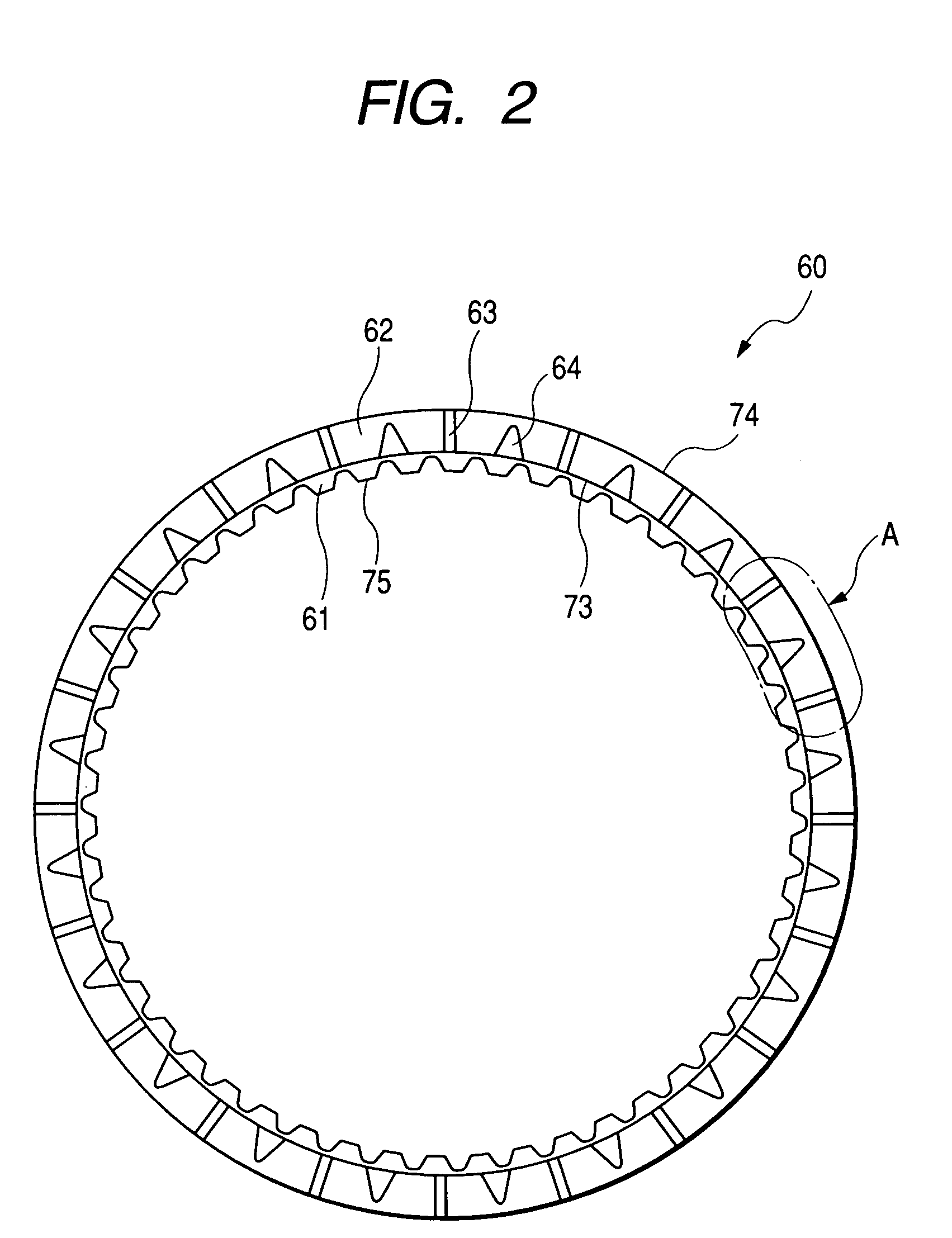

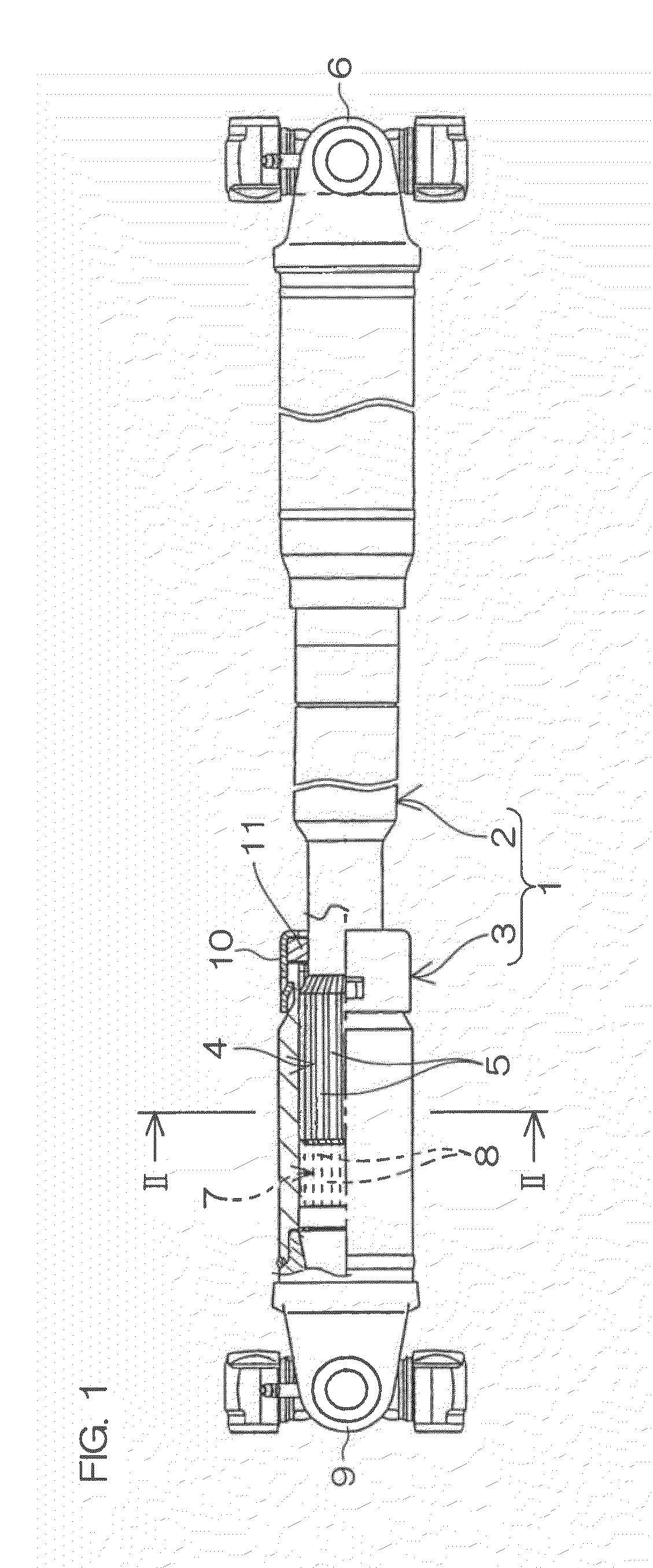

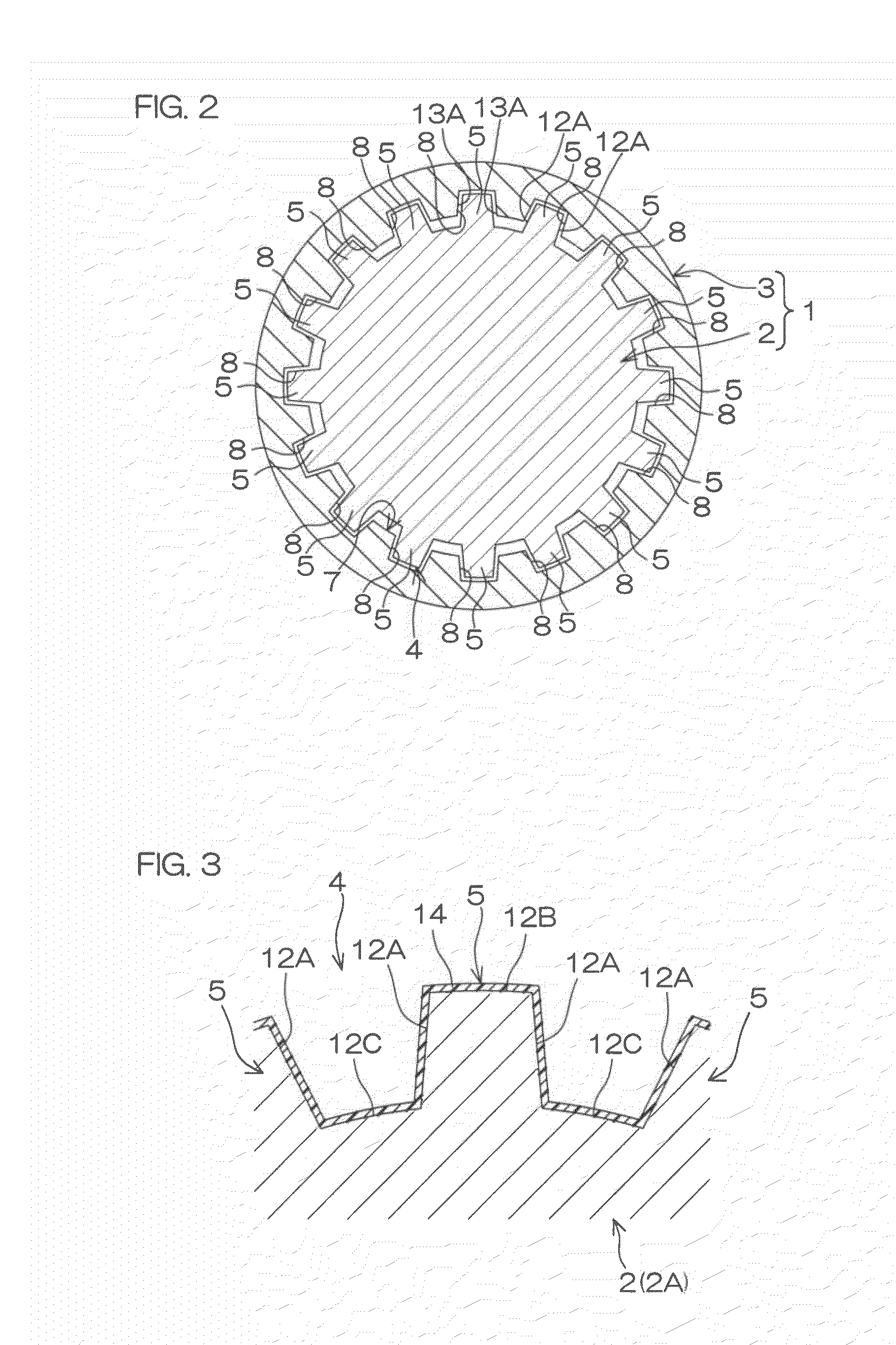

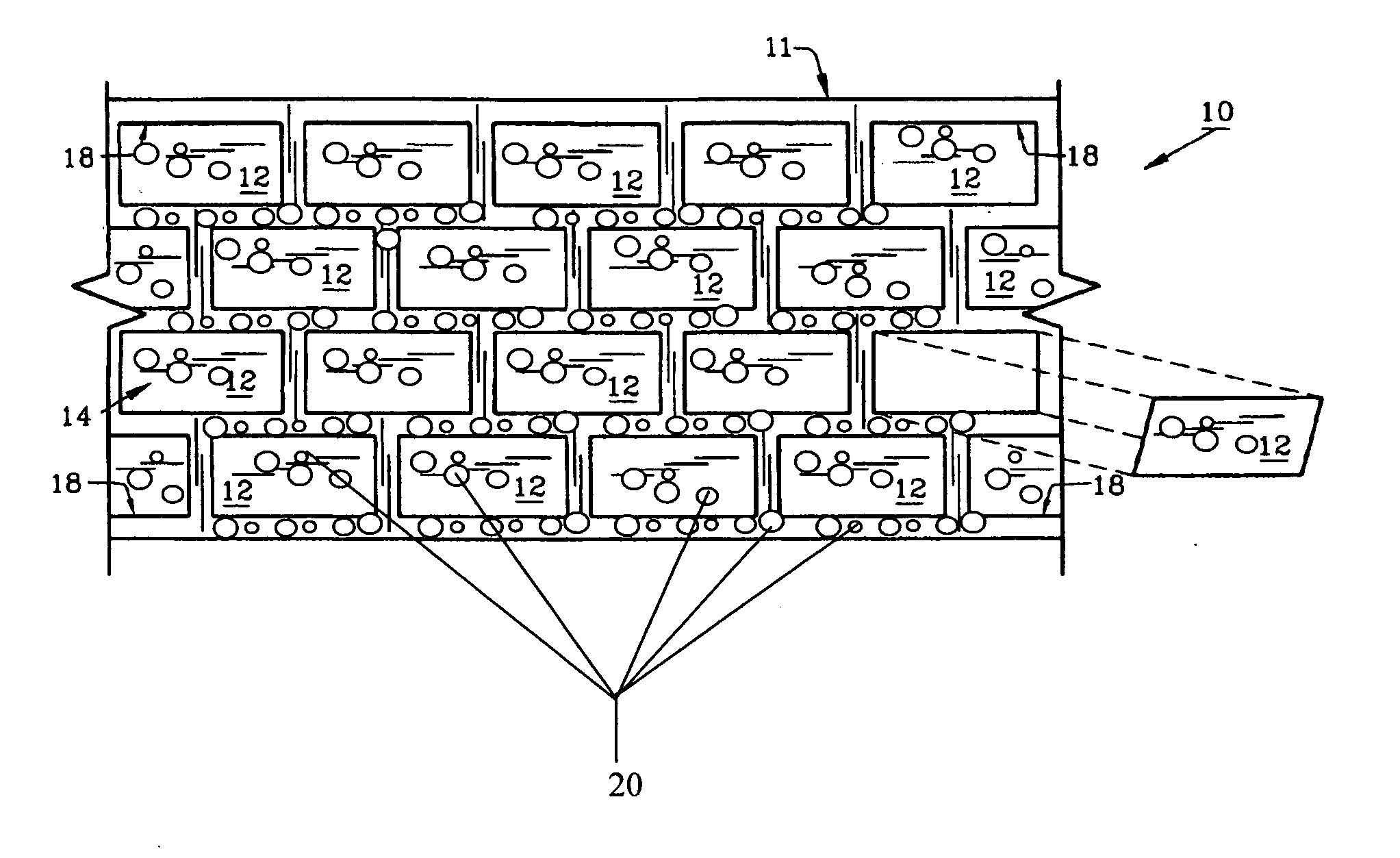

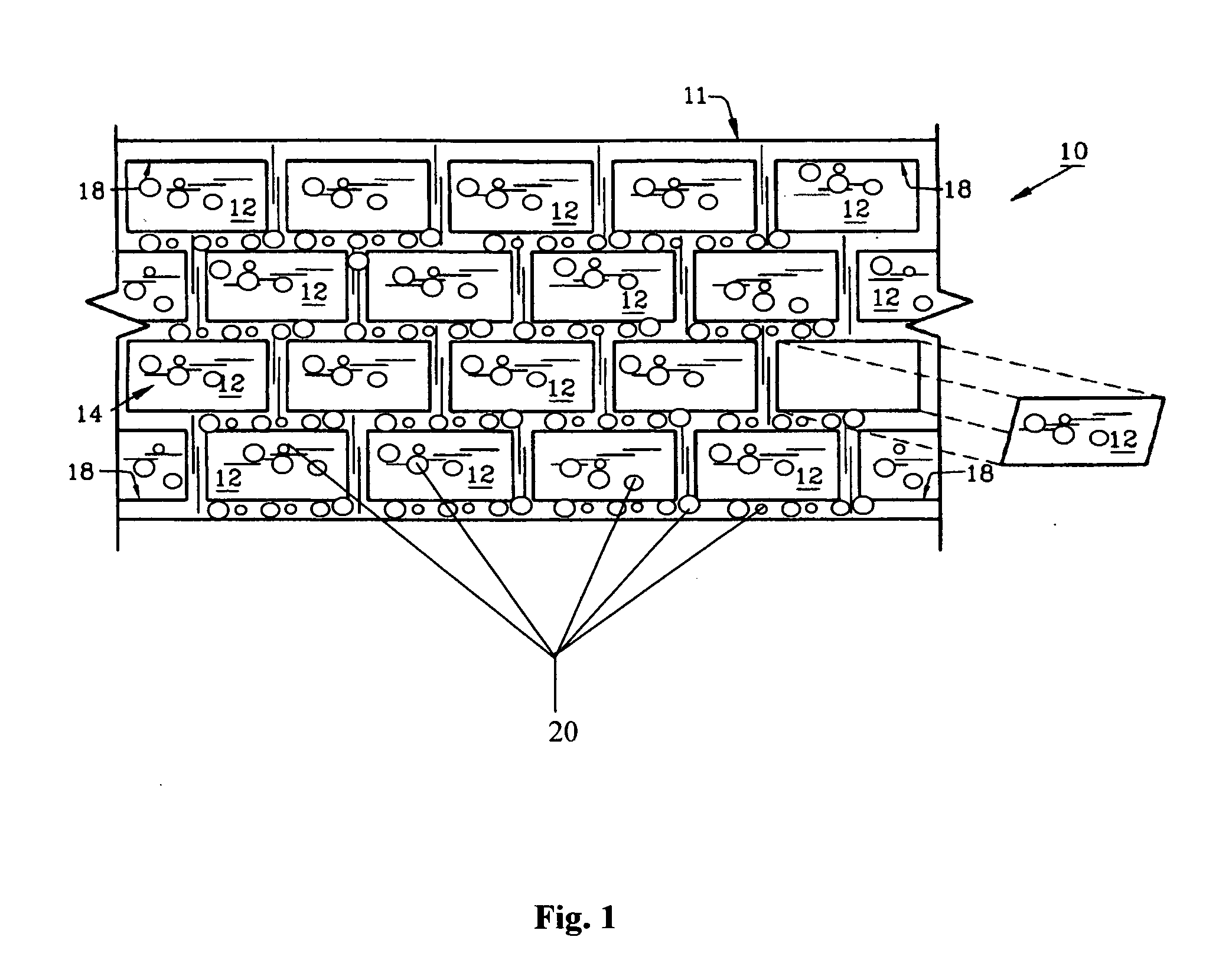

Friction plate for wet type multiplate clutch

ActiveUS20050109576A1Reduce drag torqueImprove friction performanceFluid actuated clutchesFriction clutchesEngineeringClutch

A friction plate for a wet type multiplate clutch has a substantially ring-shaped core plate and a friction member attached to the core plate. The friction member has a surface which includes a passage formed on a surface of the friction member, the passage extending from an inner peripheral edge of the friction member to an outer peripheral edge of the friction member, and a groove having an opened end which opens to the inner peripheral edge of the friction member and a closed end which is closed at a middle of the surface of the friction member. A width of the groove decreases towards a direction to the outer peripheral edge from the inner peripheral edge of the friction member.

Owner:NSK WARNER

Carbon ceramic braking pad for high-speed train and preparation method of carbon ceramic braking pad

ActiveCN103511525ALess impact on friction and wear propertiesHigh and stable coefficient of frictionFriction liningFiberCeramic composite

The invention relates to a carbon ceramic braking pad for a high-speed train and a preparation method of the carbon ceramic braking pad. The carbon ceramic braking pad is made of carbon ceramic composite material; the carbon ceramic composite material comprises the following components in percentage by mass: 16-30 percent of carbon fibers, 20-36 percent of pyrolytic carbon, 28-46 percent of silicon carbide, 6-12 percent of molybdenum disilicide and 2-6 percent of simple substance silicon; the density of the carbon ceramic composite material is 1.8-2.4g / cm<3>; the carbon fibers are uniformly distributed in the carbon ceramic composite material in a three-dimensional network structure. According to the invention, after the high-temperature heat treatment is performed on a carbon fiber felt with the density of 0.20-0.65g / cm<3>, the pyrolytic carbon is generated in the carbon fiber felt through the thermal-gradient chemical vapor deposition carburizing treatment, then the catalytic graphitization treatment, non-immersion type melting infiltration and assembly are performed, so that the carbon ceramic braking pad for the high-speed train is obtained.The carbon ceramic braking pad is simple in preparation technology, moderate in friction coefficient, good in abrasion performance, stable in braking and strong in environmental suitability and can meet braking requirements of the high-speed train with the speed of 200Km / h.

Owner:HUNAN SHIXIN NEW MATERIALS CO LTD

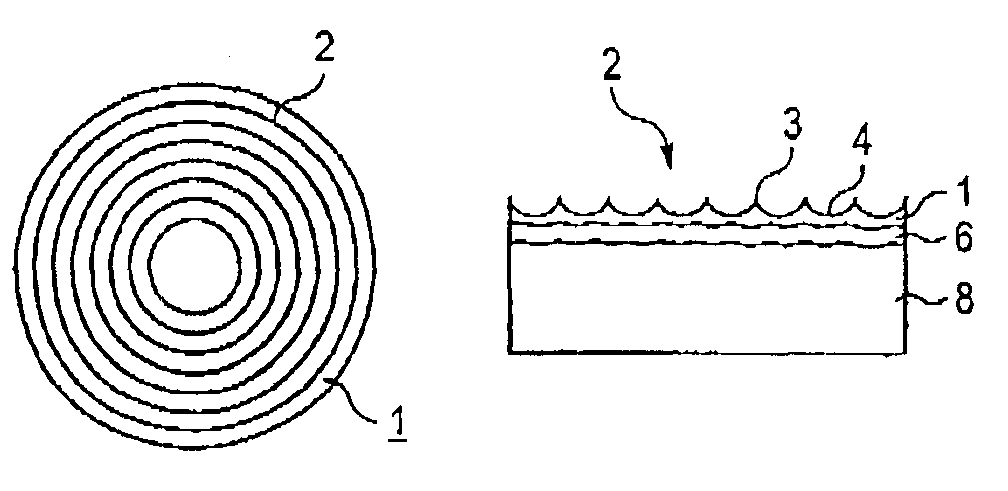

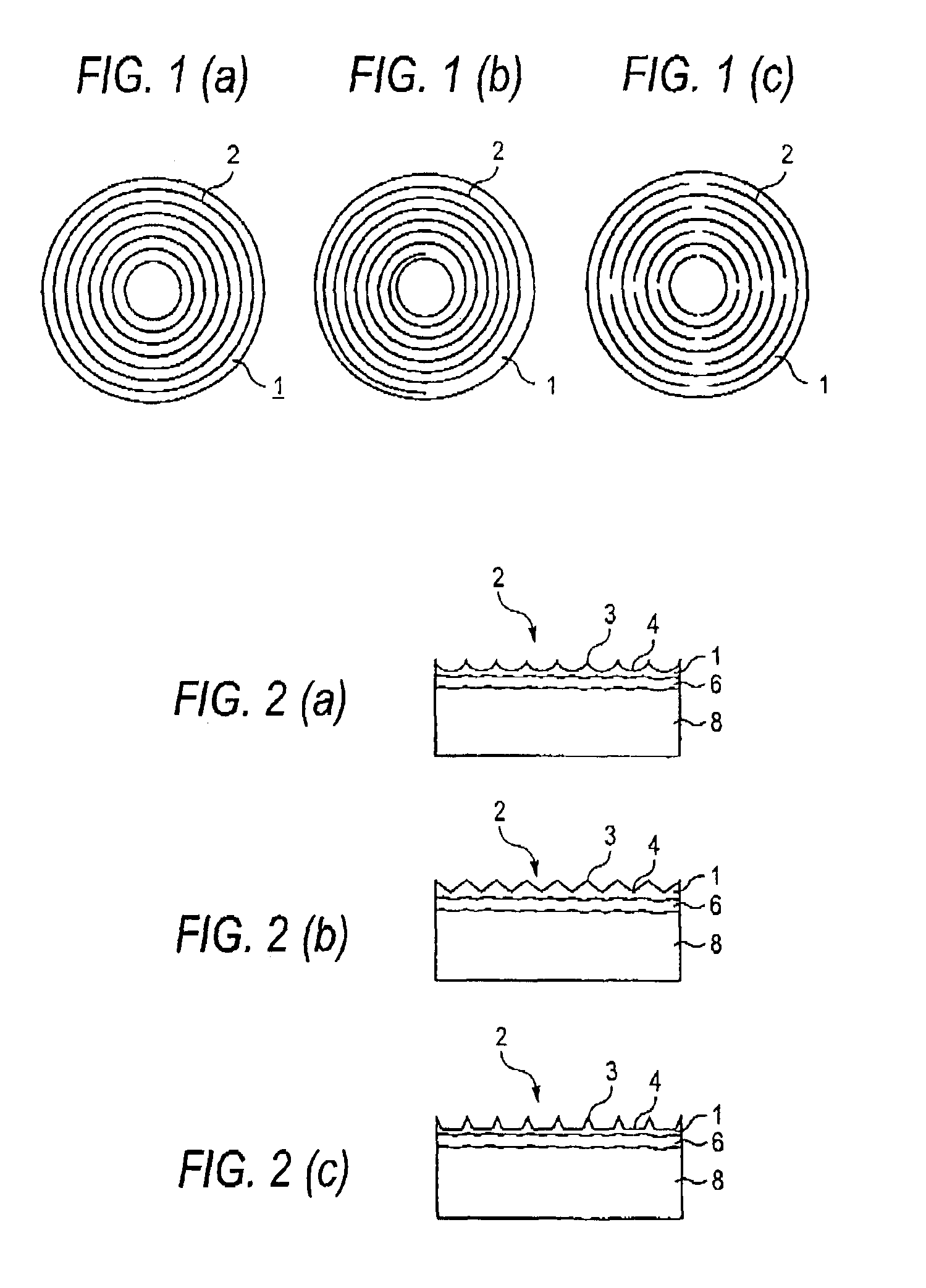

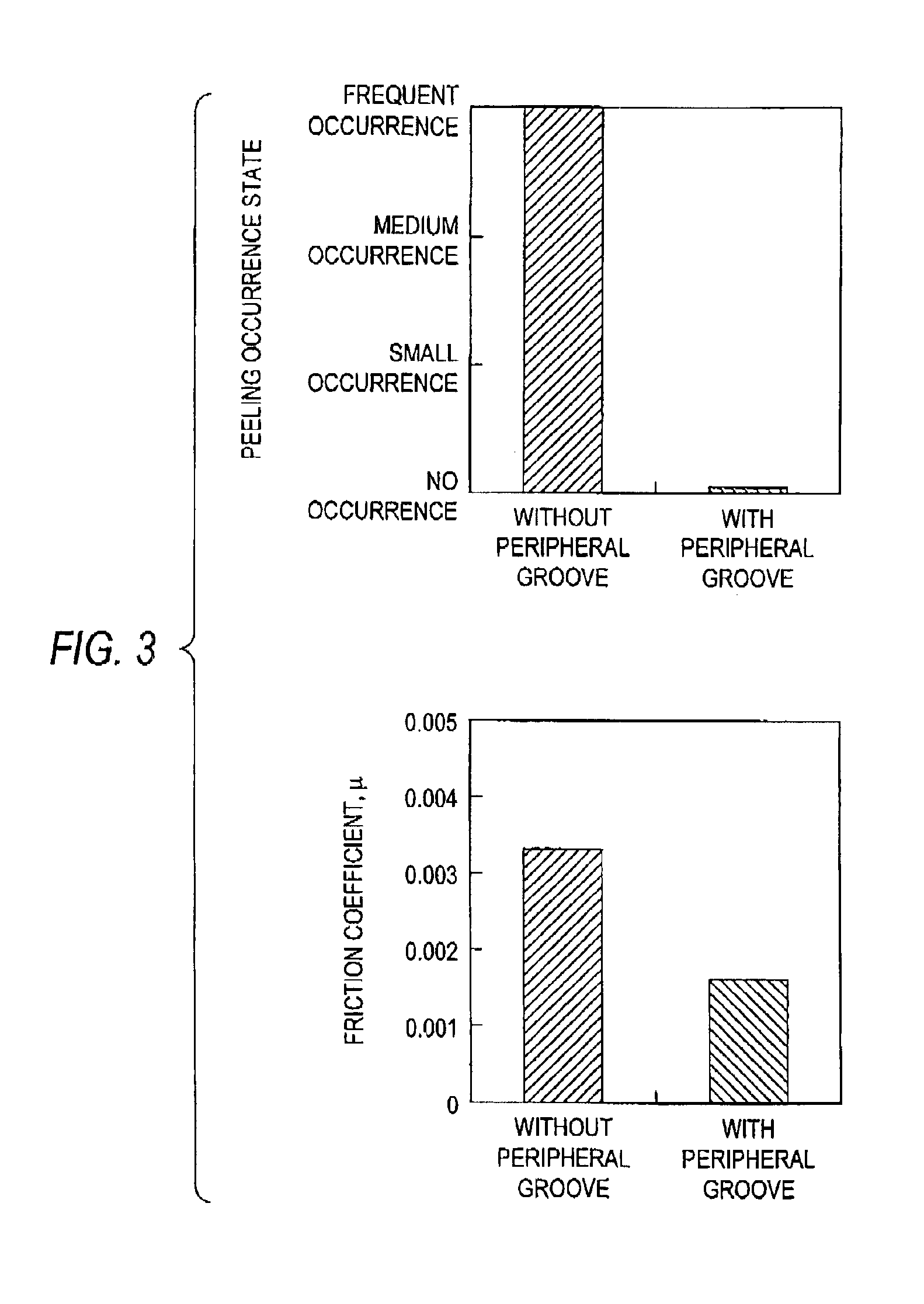

Sliding material

InactiveUS6921205B2Improve friction performanceImprove wear resistanceReflex reflectorsSliding contact bearingsWear resistanceBoundary lubrication

A slide member which is excellent in the initial running-in property and can provide an excellent sliding property even under a strict sliding condition and, in particular, a slide member with a solid lubrication coating film which is excellent not only in the friction property but also in the wear resistance under the fluid lubrication, boundary lubrication and dry lubrication conditions. The slide member includes a solid lubrication coating film on a flat-plate-shaped base member, characterized in that, in the surface of the slide member, there are formed a plurality of concentrical grooves extending in the peripheral direction of the slide member surface, and, between the mutually adjoining ones of the grooves, there are formed ridge portions respectively.

Owner:TAIHO INDUSTRIES CO LTD

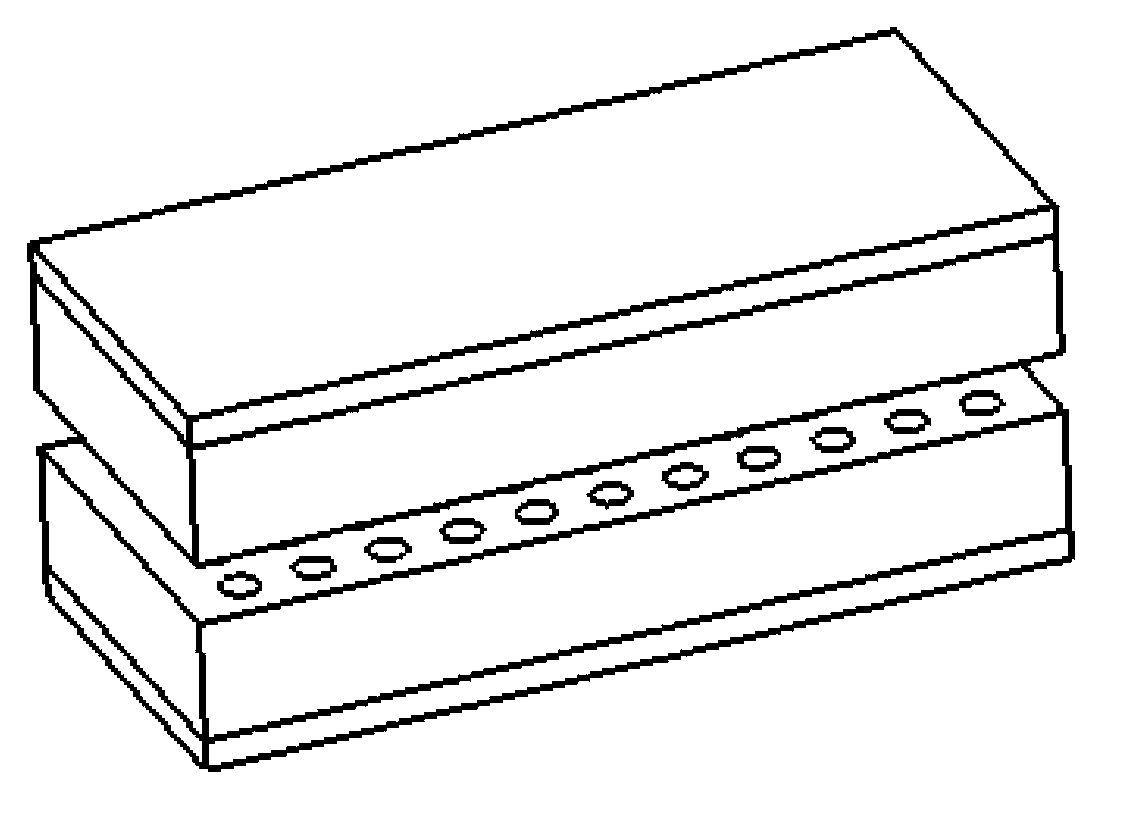

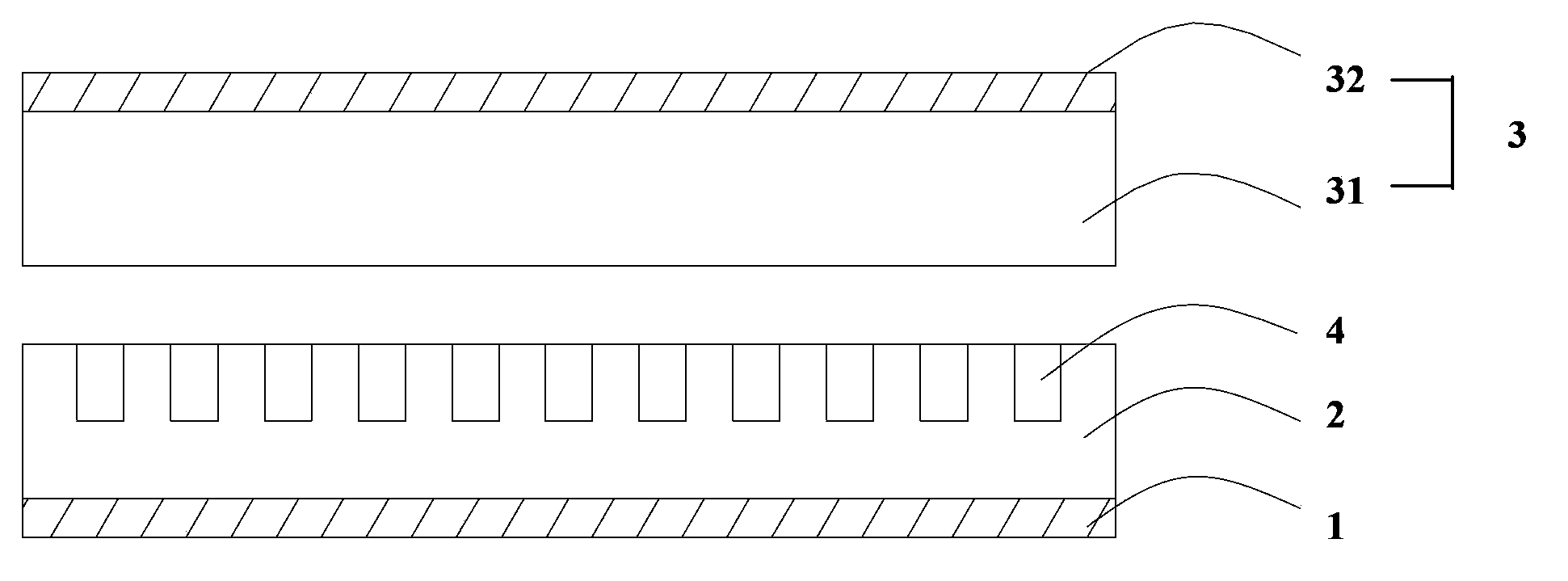

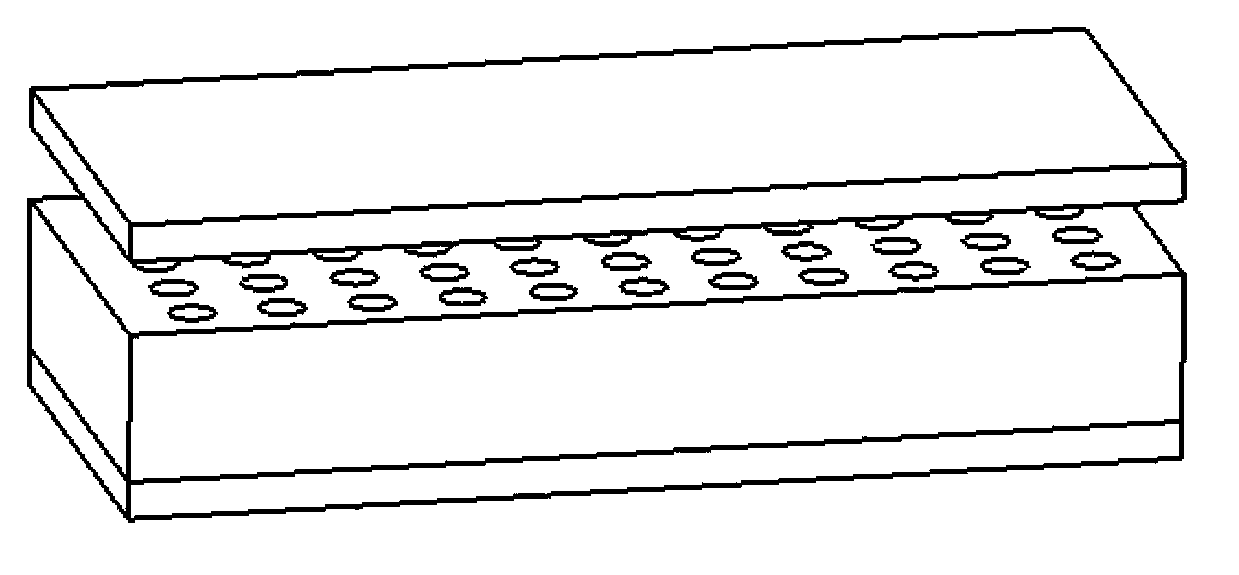

High-power nanometer friction generator and manufacturing method thereof

ActiveCN103856096AIncrease energy outputImprove friction performanceFriction generatorsFriction effectHigh energy

The invention provides a high-power nanometer friction generator and a manufacturing method thereof. The high-power nanometer friction generator comprises a first electrode layer, a macromolecule polymer layer and a friction electrode layer which are sequentially overlaid; the surface, opposite to the friction electrode layer, of the macromolecule polymer layer is provided with a plurality of nanometer holes; the first electrode layer and the friction electrode layer are voltage and current output electrodes of the friction generator. Polyvinylidene fluoride provided with the nanometer holes serves as the macromolecule polymer layer for friction, the friction effect is good, voltage and current output is high, and high-energy output of the friction generator is achieved.

Owner:NEWNAGY TANGSHAN

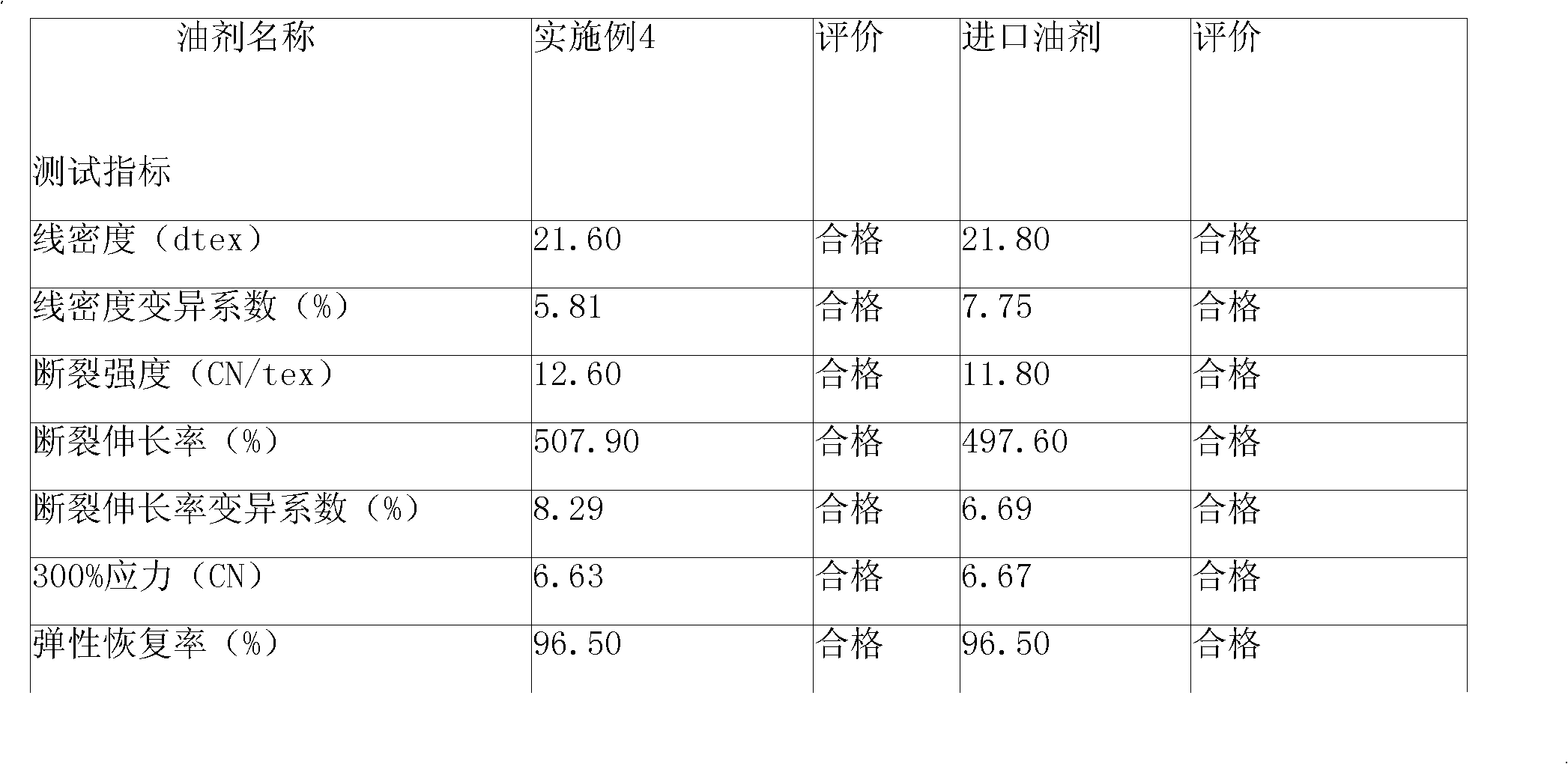

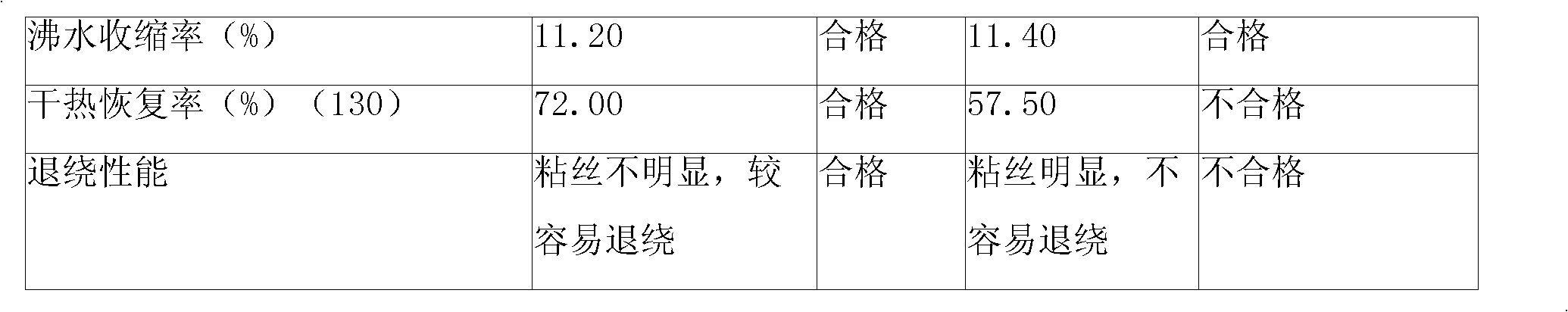

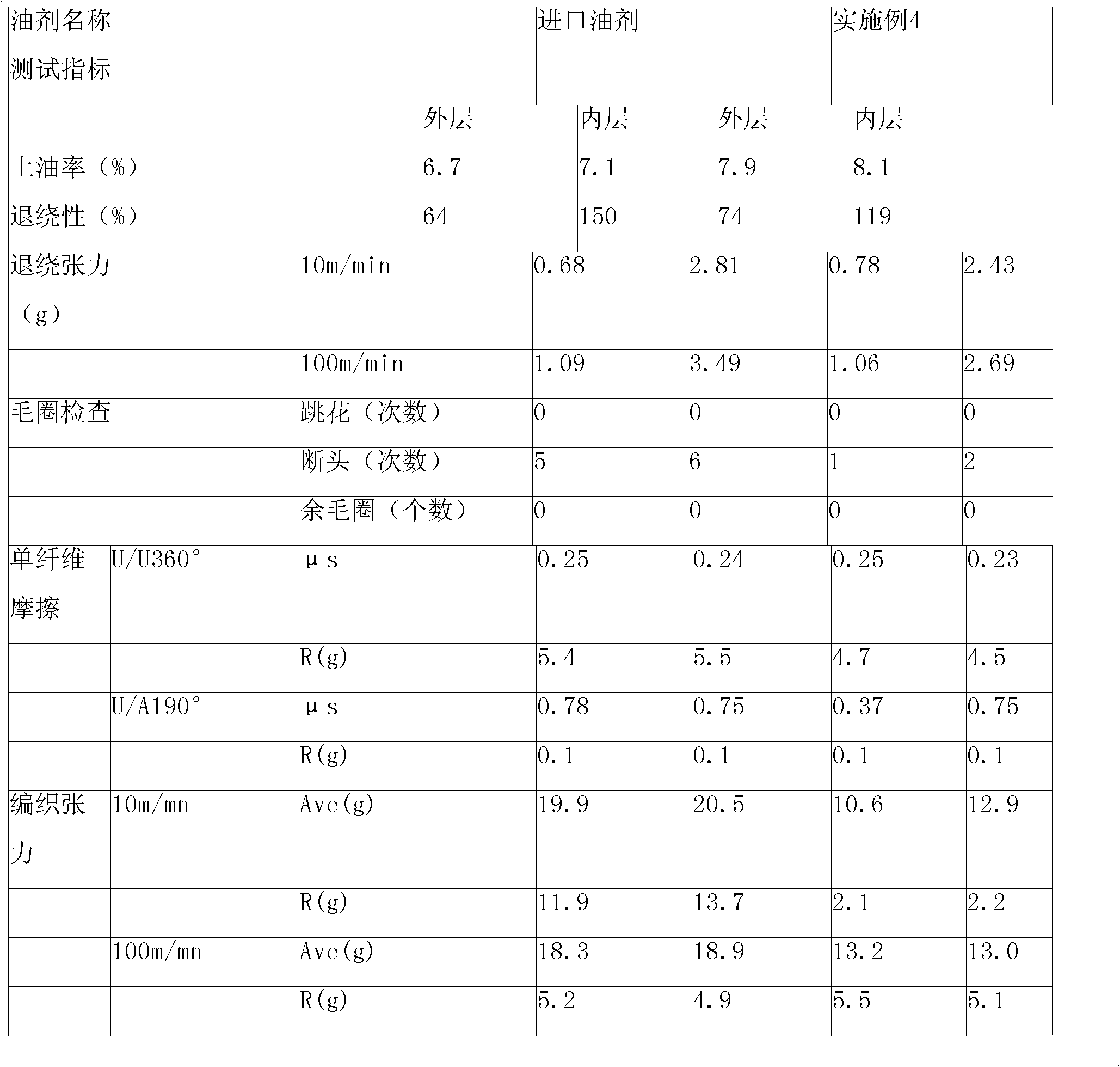

Polyurethane fiber dry spinning oil agent and preparation method thereof

The invention discloses a polyurethane fiber dry spinning oil agent, which comprises 30 to 80 weight percent of dimethyl silicon oil, 10 to 50 weight percent of mineral oil, 1 to 7.5 weight percent of high-carbon isomeric fatty alcohol or acid, 1 to 5 weight percent of dispersed component, 0.1 to 1.5 weight percent of stearate and 2 to 20 weight percent of antistatic component. The dispersed component is a mixture of an organic silicon surfactant and acrylic acid-maleic acid copolymer, and the weight ratio of the organic silicon surfactant to the crylic acid-maleic acid copolymer is 1:0.5-2; and the antistatic component is a mixture of polyether silicon oil and nonionic isomeric alcohol polyethenoxy ether, and the weight ratio of the polyether silicon oil to the nonionic isomeric alcohol polyethenoxy ether is 1:0.5-2. The polyurethane fiber dry spinning oil agent has excellent smoothness, softness, antistatic property, stable performance and excellent anti-adherent performance; polyurethane fiber treated by the oil agent has good unreeling property and forming property; and in the subsequent processing flow, polyurethane filaments are easy to unreel, not drop edge and has few broken filaments.

Owner:BEIJING GUANGHUA TEXTILE GRP +2

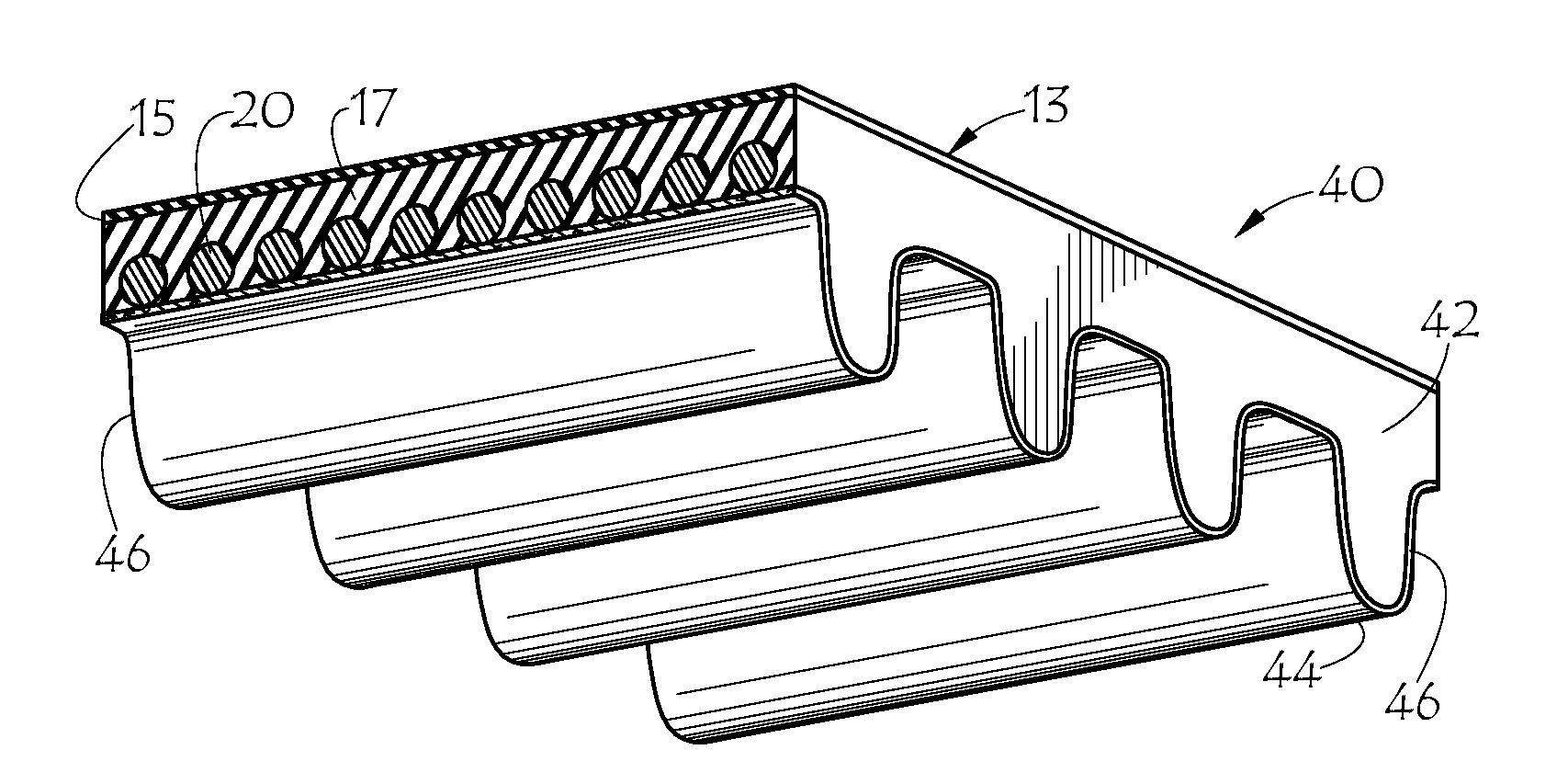

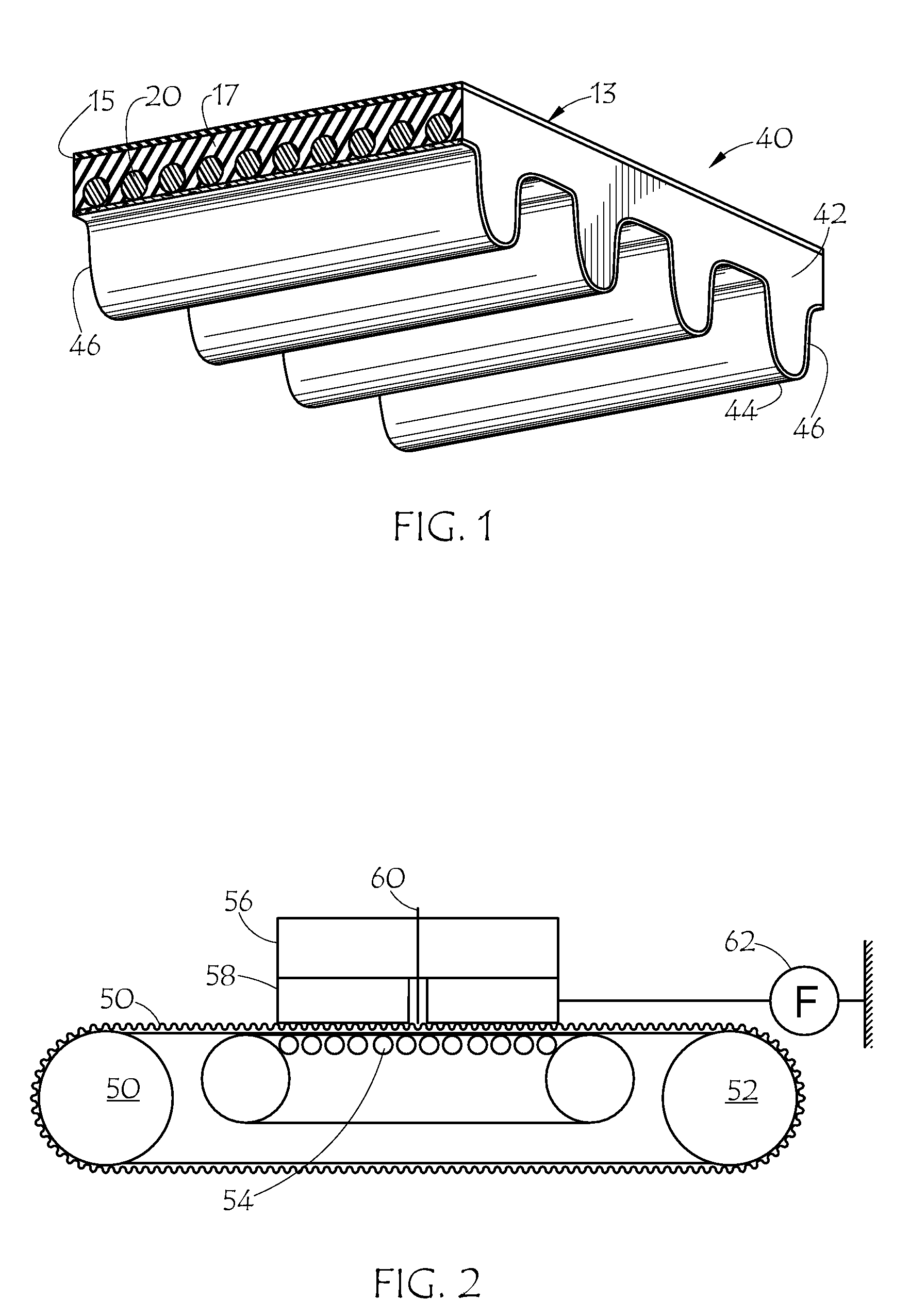

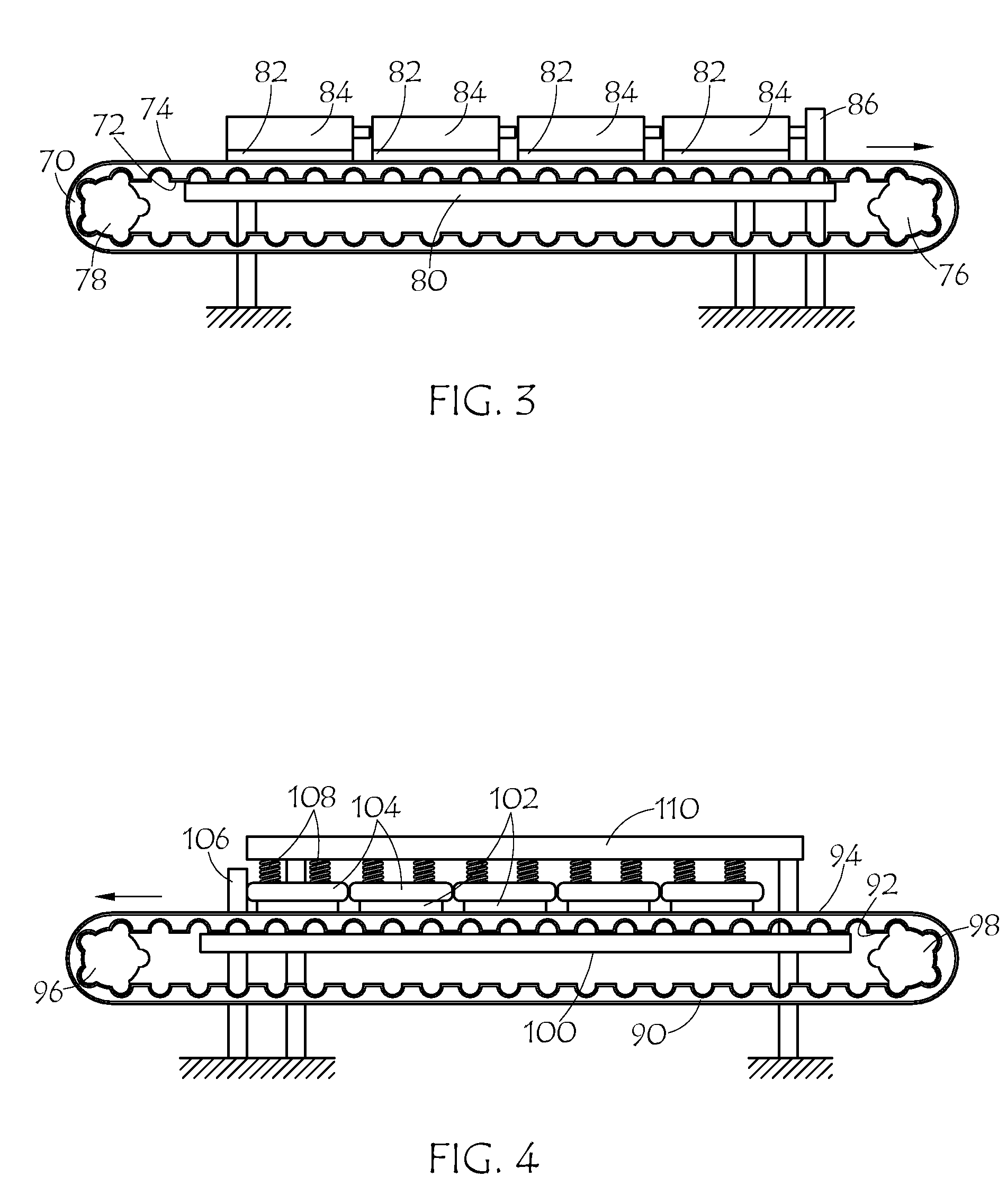

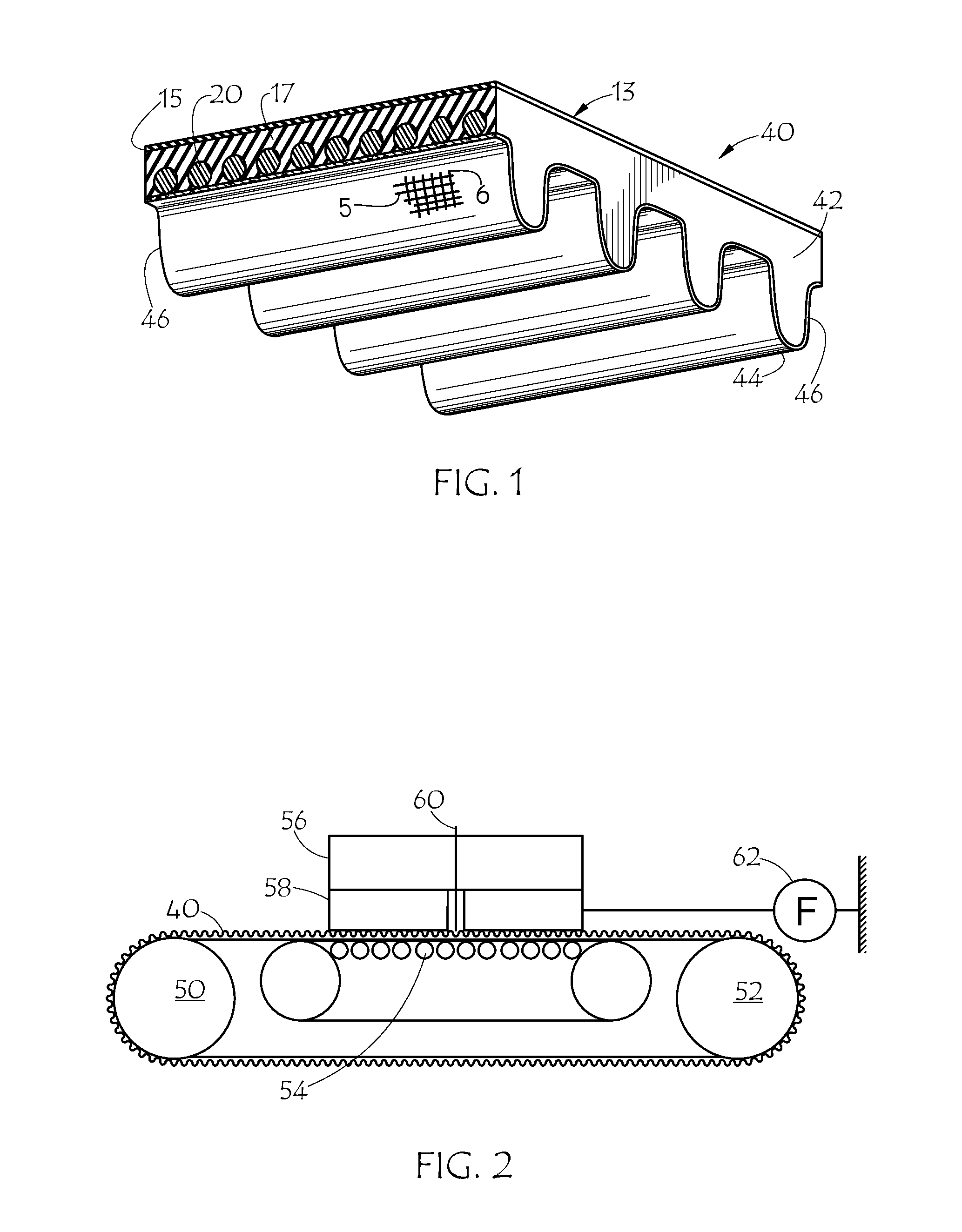

Belt with Wear-Resistant Anti-Static Fabric

ActiveUS20100197435A1Improve wear resistanceAdvantageous frictional propertyConveyorsV-beltsSynthetic polymerWear resistant

The invention is directed to a drive belt such as a transport or synchronous or power transmission belt with an elastomeric belt body having a drive side and a back side, a tensile member embedded in the belt body, and an anti-static, wear-resistant, covering fabric on at least one of the drive and back side. The anti-static fabric includes a nonconductive natural or synthetic polymeric fiber and a conductive fiber. The conductive fiber is a synthetic polymeric fiber with a conductive metallic coating. The metallic coating may be silver.

Owner:THE GATES CORP

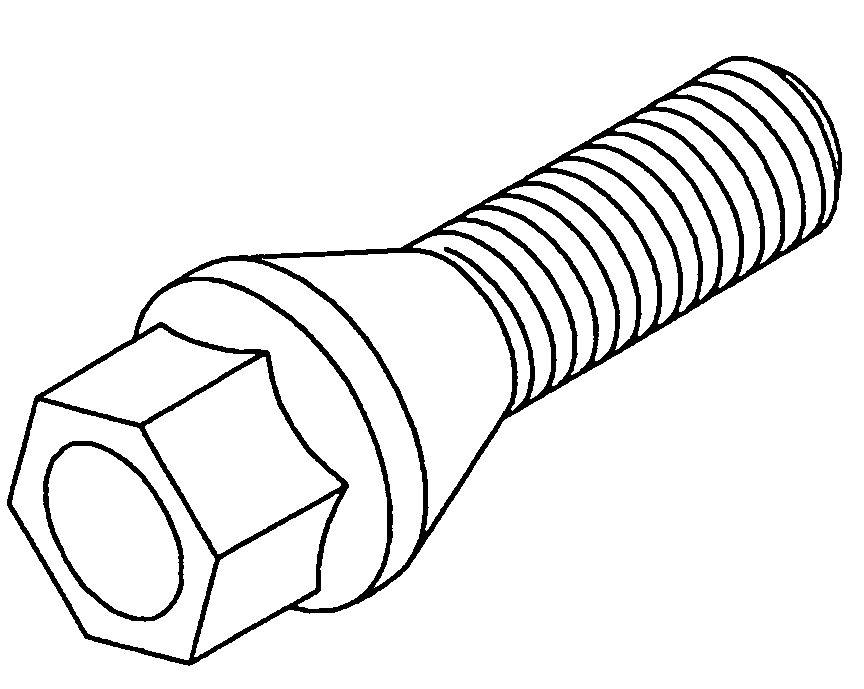

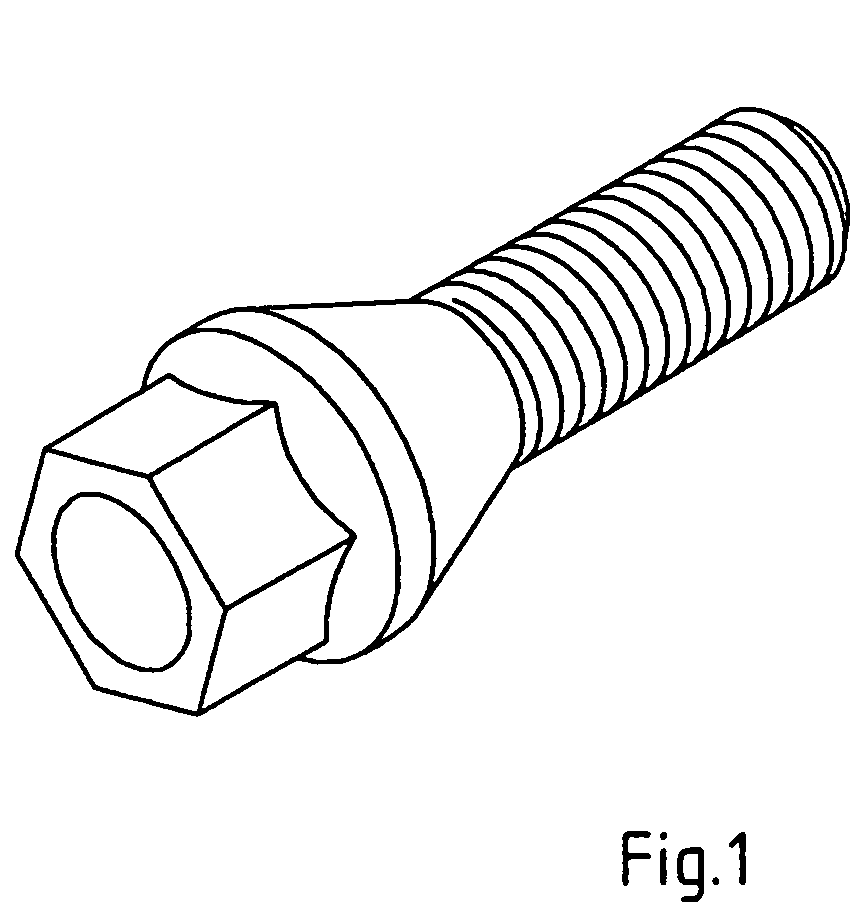

Corrosion resistant article and method of production thereof

InactiveUS7160630B2Highly resistant to chemical attackImprove friction performanceWashersRecord information storagePhosphateZinc

The disclosure relates to a corrosion resistant article comprising a metal body and a protective coating applied on at least one surface of said metal body, said protective coating comprising: (a) a zinc layer comprising metallic zinc; (b) a silicate layer comprising at least one silicate; and (c) a lubricant layer comprising at least one lubricant such as, for example, polyethylene wax. In particular, the disclosure relates to a corrosion resistant bolt and / or nut having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable. The article has an excellent coefficient of friction, temperature resistance and anti-corrosion properties.

Owner:ELISHA HLDG LLC

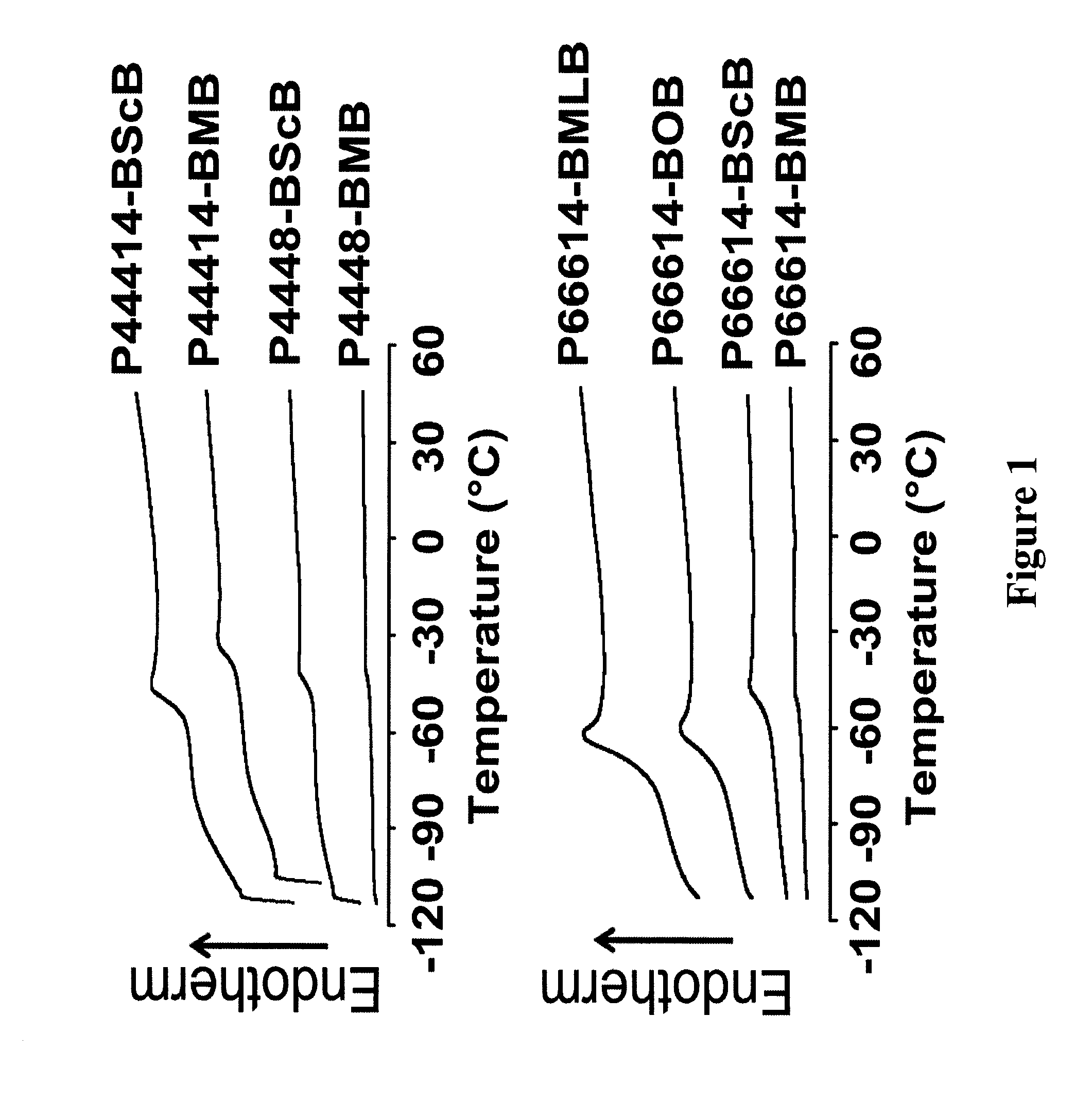

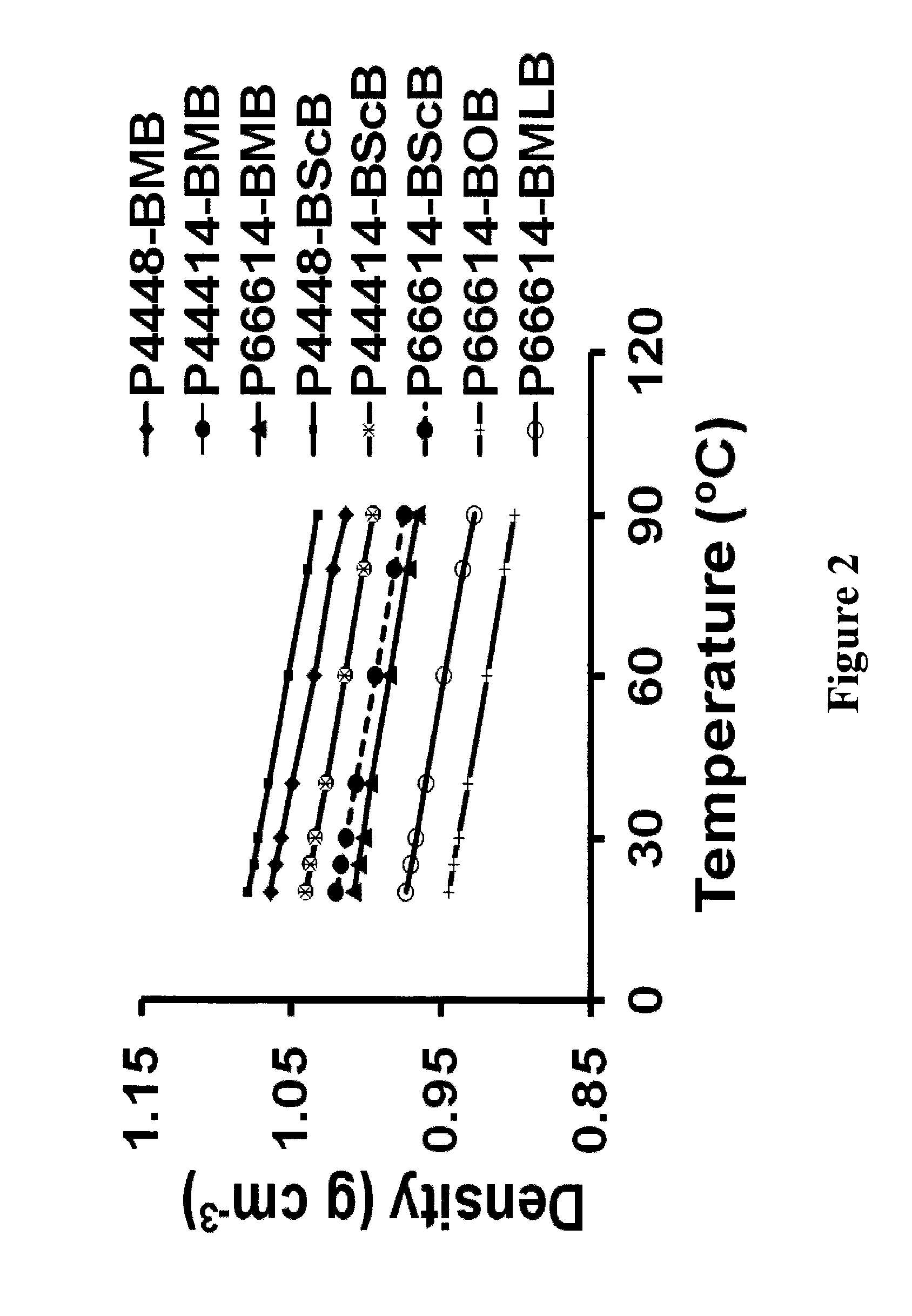

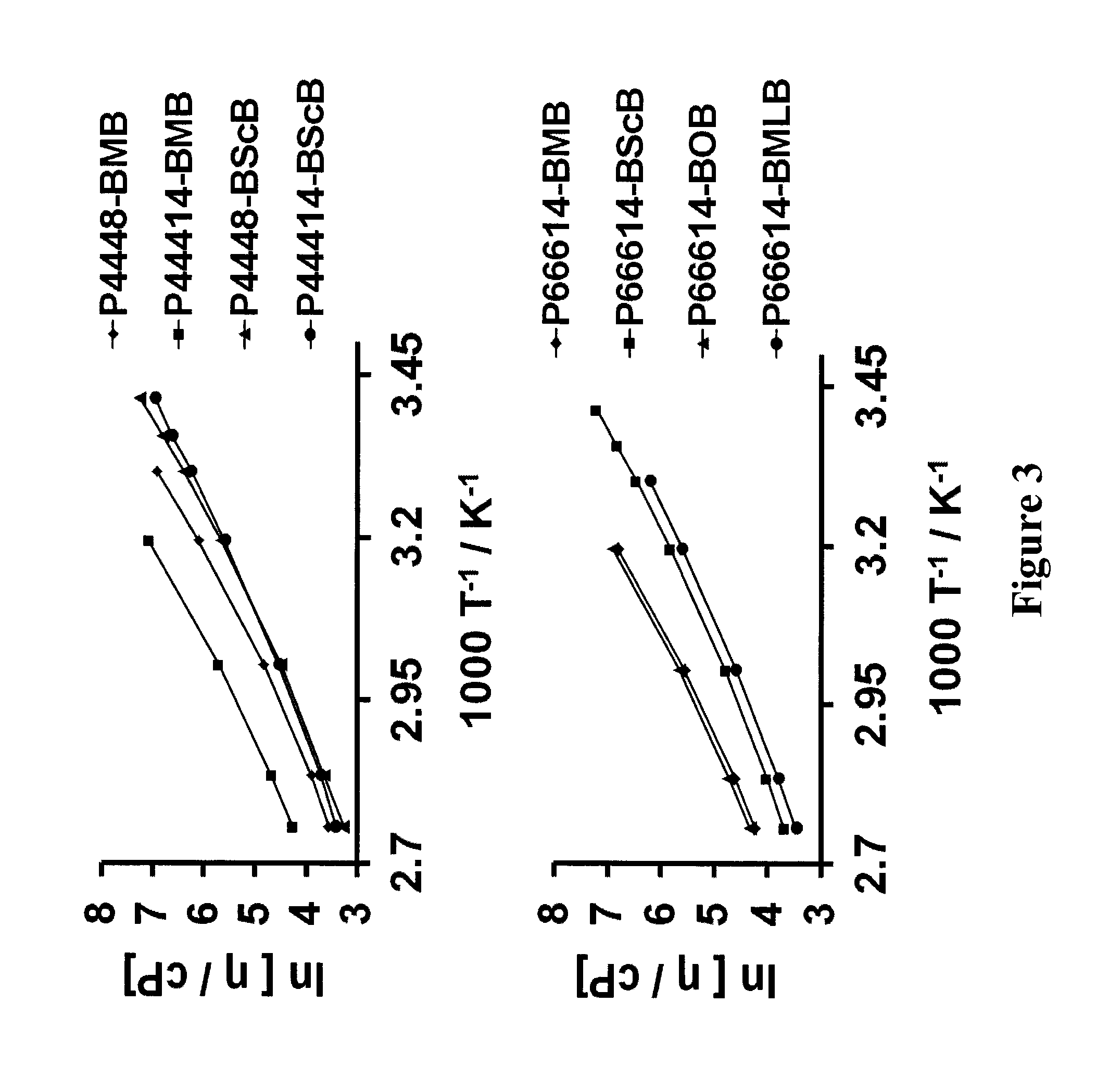

Ionic-liquid-based lubricants and lubrication additives comprising ions

Anti-wear and friction-reducing lubricants and additives to lubricants for both ferrous and non-ferrous materials with / without DLC (diamond-like-coatings) or graphene-based coatings, which are halogen free boron based ionic liquids comprising a combination of an anion chosen from a mandelato borate anion, a salicylato borate anion, an oxalato borate anion, a malonato borate anion, a succinato borate anion, a glutarato borate anion and an adipato borate anion, with at least one cation selected from a tetraalkylphosphonium cation, a choline cation, an imidazolium cation and a pyrrolidinium cation, wherein said at least one cation has at least one alkyl group substituent with the general formula CnH2n+1, wherein 1≦n≦80. Advantages of the invention include that it provides halogen free ionic liquids for lubrication and that sensitivity for hydrolysis is reduced.

Owner:ANTZUTKIN OLEG N +2

Corrosion resistant article and method of production thereof

InactiveUS20060228575A1Highly resistant to chemical attackImprove friction performanceWashersRecord information storagePhosphateTemperature resistance

The disclosure relates to a corrosion resistant article comprising a metal body and a protective coating applied on at least one surface of said metal body, said protective coating comprising: (a) a zinc layer comprising metallic zinc; (b) a silicate layer comprising at least one silicate; and (c) a lubricant layer comprising at least one lubricant such as, for example, polyethylene wax. In particular, the disclosure relates to a corrosion resistant bolt and / or nut having a protective coating for use in motor vehicles. The protective coating is substantially free of chromates and phosphates and, hence, environmentally acceptable. The article has an excellent coefficient of friction, temperature resistance and anti-corrosion properties.

Owner:ELISHA HLDG LLC

Belt with wear-resistant anti-static fabric

ActiveUS8192316B2Improve wear resistanceAdversely affecting other performance characteristicsConveyorsV-beltsMetal coatingFiber

The invention is directed to a drive belt such as a transport or synchronous or power transmission belt with an elastomeric belt body having a drive side and a back side, a tensile member embedded in the belt body, and an anti-static, wear-resistant, covering fabric on at least one of the drive and back side. The anti-static fabric includes a nonconductive natural or synthetic polymeric fiber and a conductive fiber. The conductive fiber is a synthetic polymeric fiber with a conductive metallic coating. The metallic coating may be silver.

Owner:THE GATES CORP

Mobile phone curved glass panel and forming method thereof

ActiveCN104023099AFit tightlyComfortable fitGlass reforming apparatusTelephone set constructionsEngineeringGraphite

The invention discloses a mobile phone curved glass panel and a manufacturing method of the mobile phone curved glass panel. A curved glass panel body is formed by bending a mobile phone panel body toward the same side in an arc shape with the center line of the mobile phone panel body in the X-axis direction or the Y-axis direction as a center, or bending the periphery of the mobile phone panel body toward the same side in an arc shape with the center point of the mobile phone panel as the center, or the mobile phone curved glass panel comprises a main panel and curved panels. The curved panels are formed by bending one or more side edges of the main panel. The multiple curved panels are bent toward the same side relative to the main panel. The forming method includes the three steps of manufacturing a planar glass panel, manufacturing a graphite die and forming the curved glass panel. The good lubricating performance of graphite is used, through exerting certain pressure for deformation, heat deformation is achieved at the temperature below a glass softening point, the manufactured product is high in precision, the designing requirements of a 3D mobile phone glass panel are met, large-scale industrial production can be achieved, production cost can be reduced, and the requirement for personalized and fashionable mobile phones can be met for people.

Owner:LENS TECH

Asbestos-free clutch facing used in vehicle and manufacture method therefor

InactiveCN101033786AImprove performanceHigh strengthFriction liningHeat treatedTemperature and pressure

The invention discloses a kind of none asbestos clutch facing used in cars and its production technology. The recipe of the component is that: E-glass fiber 30~50%, fragrance fiber 1~4%, polyacrylonitrile fiber 0.6~1.2%, the oil of cashew shell friction-type mix 3~6%, oil coke blacking 3~5%, particle graphite 5~8%, zinc oxide 0.2~1%, calcium sulfate 5~15%, heavy calcium carbonate 10~20%, flour acrylonitrile butadiene rubber 15~25%, anti-aging protective TMQ 0.2~0.5%, curing accelerator MBTS 0.2~0.5%, the oil of cashew shell resin modified 6~12%. Banburying mix the component told above in proportions at the proper temperature then make up pellicle by smelting and at last rolls in with the E-glass fiber then forms different ordinance blanks by winding. The blanks confect by heat pressing at the proper temperature and pressure then make into production by grinding and drilling holes. It has the merits like that: high strength, good ductility and stabilize coefficient of friction and so on.

Owner:福建冠良汽车配件工业有限公司

Liquid crystal alignment solution

ActiveUS20090194737A1High voltage holding ratioLow currentLiquid crystal compositionsThin material handlingDiaminePolyamide

A liquid crystal alignment solution is provided. The liquid crystal alignment solution includes a first polyimide-polyamide acid and a second polyimide-polyamide acid. The first polyimide-polyamide acid is represented by formula (A),and the second polyimide-polyamide acid is represented by formula (B),in which T1, T2, T3 and T4 are each independently a tetravalent residue of a tetracarboxylic acid dianhydride; D1, D2, D3 and D4 are each independently a divalent residue of a diamine; and m, n, p and q are each independently an positive integer,wherein m / (m+n)≦0.5 and p / (p+q)≧0.5.

Owner:DAXIN MATERIALS

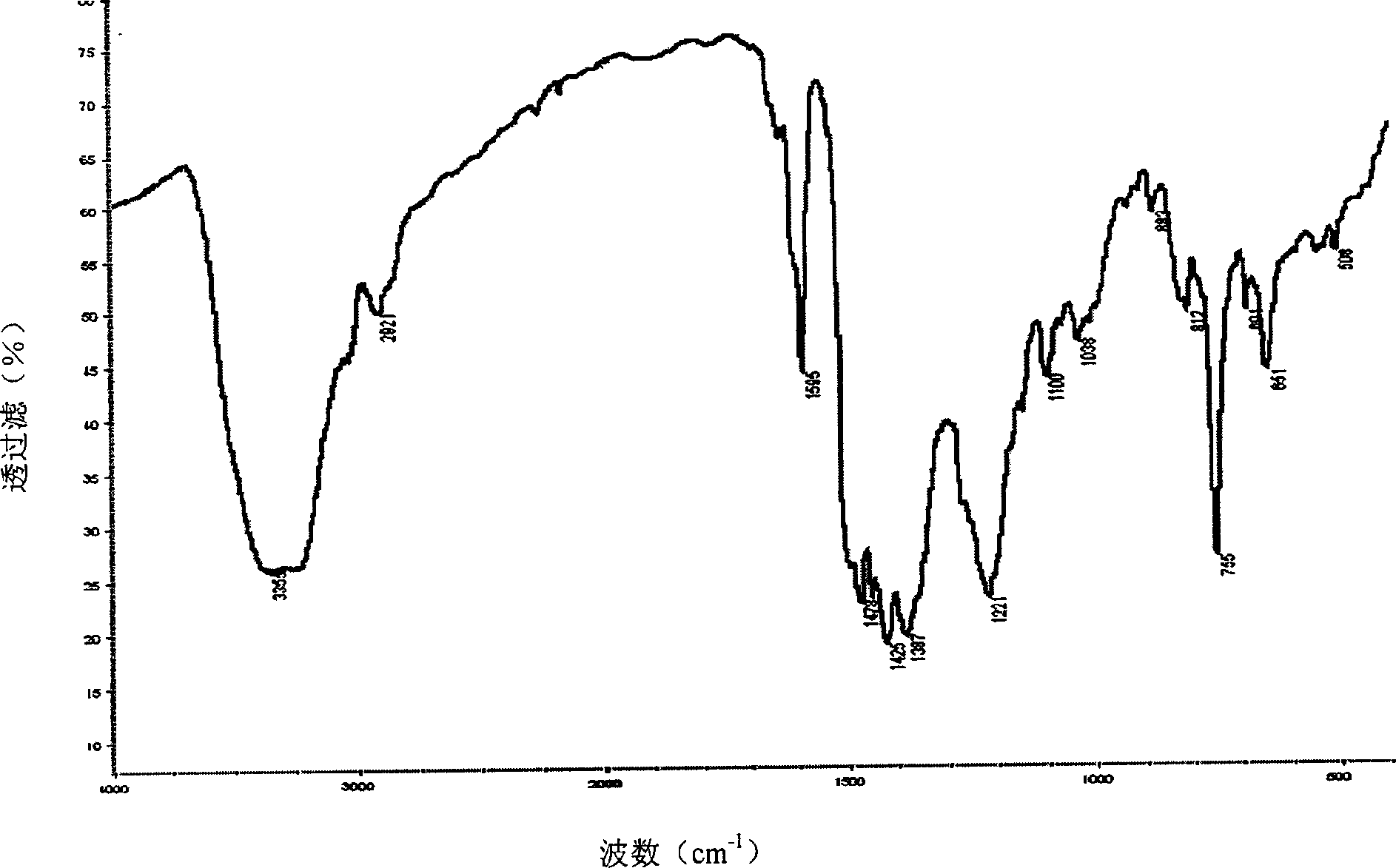

Prepn. process of nano SiO2/boron bakelite resin nano composite material

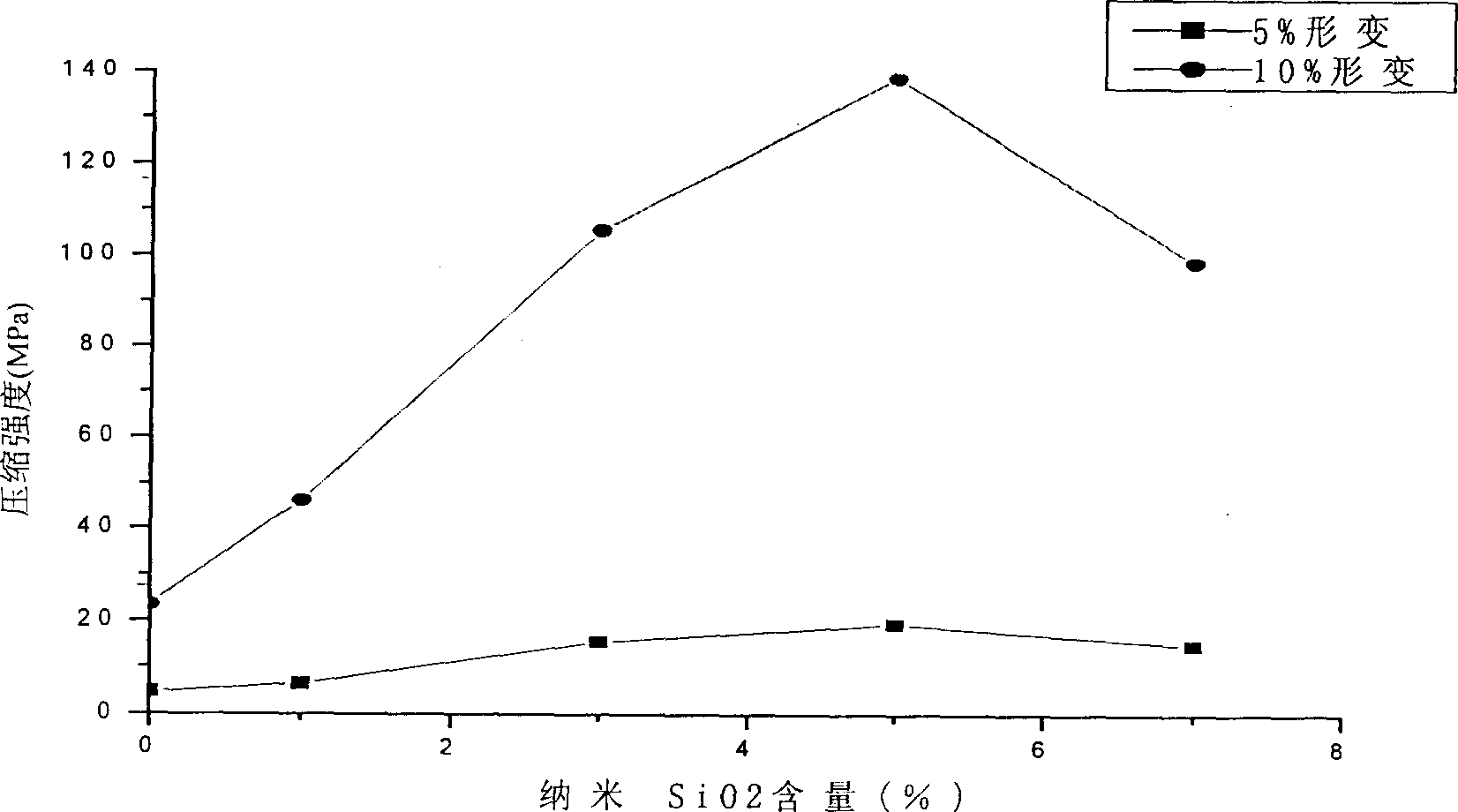

InactiveCN1834151AImprove heat resistanceImproves ablation resistanceFireproof paintsNano compositesResin matrix

This invention is attributed to the technology of nano-composite materials and specifically relates to a method to prepare nano-sized silicon dioxide / boron phenolic resin nano-composite materials. In this method, solution blending and ultrasonic wave-aided dispersion are combined so as to ensure nano-sized dispersion of the nano-particles in composite materials. The nano-sized silicon dioxide is surface treated so as form good interfaces with boron phenolic resin matrix and to adequately take advantages of nano-sized silicon dioxide and boron phenolic resin. This invention aims at preparing boron phenolic resin nano-composites with different nano-sized silicon dioxide content by reasonable technique control. The rigidity, wear resistance and thermo-chemical stability of nano-sized silicon dioxide and good mechanical properties, thermo resistance and ablation resistance of boron-modified phenolic resin are utilized, and therefore the prepared nano-sized silicon dioxide / boron phenolic resin nano-composite materials can be widely used in high-temperature abrasion materials, ablation resistant materials, special structural materials and thermo resistant materials.

Owner:TONGJI UNIV

Ceramic/metallic double continuous phase composite material brake pad and preparation method thereof

The invention relates to the field of friction materials for braking of high-speed trains, in particular to a ceramic / metallic double continuous phase composite material brake pad and a preparation method thereof. The brake pad comprises the following components in percentage by weight: 15 to 40 percent of foam silicon carbide ceramics, 10 to 30 percent of friction element and 75 to 30 percent ofmetal. The method comprises the following steps of: preparing the silicon carbide foam ceramics having a three-dimensional network structure by employing a technology combining polymer pyrolysis withcontrollable infiltration reaction sintering; selecting a proper friction element and filling in mesh holes of the foam ceramics; and injecting melt copper alloy into a framework of the foam ceramicsby utilizing an extrusion casting method to obtain the ceramic / metallic double continuous phase composite material brake pad. The composite material brake pad can be paired with a 28CrMoV forged steel brake disc, has the characteristics of proper and stable friction coefficient, low wear rate, high heat resistance, high thermal or mechanical damage resistance, good process performance, low manufacturing cost, long service life and the like, completely meets the brake requirement of a high-speed train at a speed of 200 to 300km / h, and has good competitive advantage on the brake requirement of a high-speed train at the speed of 350km / h.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Modified phenol formaldehyde resin and preparation method thereof

ActiveCN102757618AImprove toughnessHigh strengthAldehyde/ketone condensation polymer adhesivesToughnessPhenol formaldehyde resin

The invention discloses a modified phenol formaldehyde resin and a preparation method thereof, relating to the field of phenol formaldehyde resins. The preparation method comprises the following steps: reacting 100 parts of phenol, 10-200 parts of lignin and 1-20 parts of acidic catalyst at 80-200 DEG C for 2-8 hours to form a reaction liquid; regulating the temperature of the reaction liquid to 60-110 DEG C, adding 50-200 parts of formaldehyde and 2-20 parts of composite catalyst, and reacting for 1-5 hours to form a sticky matter; washing the sticky matter in 60-70 DEG C water 2-5 times, and dehydrating to obtain a lignin phenol formaldehyde resin; and pulverizing the lignin phenol formaldehyde resin to 200 meshes, and evenly mixing with 2-20 parts of powder nitrile-butadiene rubber to obtain the modified phenol formaldehyde resin. The free phenol content of the modified phenol formaldehyde resin is 2-5%, the thermal decomposition temperature is 400-490 DEG C, the toughness and strength are high, and the friction material prepared from the modified phenol formaldehyde resin has high adhesive property and frictional property.

Owner:HUANGSHI JINZHAOYANG POWDER MATERIALS

Manganese phosphating liquor, preparation and use thereof

InactiveCN101328583AImprove adhesionImprove corrosion resistanceMetallic material coating processesCalcium hydroxidePhosphoric acid

The invention provides a manganese phosphating solution, a preparation method thereof and an application. The compositions in percentage by mass of the manganese phosphating solution are: 5.0 to 15.0 percent of phosphoric acid, 5.0 to 20.0 percent of manganese biphosphate, 1.0 to 18.0 percent of nitric acid, 0.1 to 3.0 percent of calcium hydroxide, 0.2 to 5.0 percent of zinc oxide, 1.0 to 5.0 percent of tartaric acid and the balance being water. Water, phosphoric acid, pasty zinc oxide, nitric acid and phosphoric acid mixture, calcium hydroxide and tartaric acid are added in a reaction kettle in turn, and are stirred continuously so as to prepare the phosphating solution. The manganese phosphating solution is used in surface treatment of oil well pipe coupling. The manganese phosphating solution can be formed into a compact black crystallized phosphating film on metal surface, thereby effectively improving the abrasion resistance, thread gluing-proof property and seizure resistance of metal surface and increasing the performance of oil well pipe coupling to 4 to 10 times; moreover, the manganese phosphating solution, the preparation method thereof and the application ensure simplified operation and convenient maintenance, and can be effectively used in practical industrialized production.

Owner:BAOSHAN IRON & STEEL CO LTD

Friction plate for wet type multiplate clutch

ActiveUS7172062B2Improve friction performanceReduce the drag torqueFluid actuated clutchesFriction clutchesEngineeringClutch

A friction plate for a wet type multiplate clutch has a substantially ring-shaped core plate and a friction member attached to the core plate. The friction member has a surface which includes a passage formed on a surface of the friction member, the passage extending from an inner peripheral edge of the friction member to an outer peripheral edge of the friction member, and a groove having an opened end which opens to the inner peripheral edge of the friction member and a closed end which is closed at a middle of the surface of the friction member. A width of the groove decreases towards a direction to the outer peripheral edge from the inner peripheral edge of the friction member.

Owner:NSK WARNER

Lubricating oil composition

ActiveUS7867957B2Good effectMaintain good propertiesTin organic compoundsLiquid carbonaceous fuelsChemical compositionViscosity index

The lubricating oil composition of the invention comprises a lubricating base oil with a urea adduct value of no greater than 4% by mass and a viscosity index of 100 or higher, an ashless friction modifier at 0.01-10% by mass and a phosphorus-containing anti-wear agent at 0.01-0.2% by mass as phosphorus, based on the total amount of the composition.

Owner:JX NIPPON OIL & ENERGY CORP

Brake pad and preparation method thereof

ActiveCN106378453AGuaranteed mechanical propertiesHigh bonding strengthAdditive manufacturing apparatusIncreasing energy efficiencyWear resistantUltimate tensile strength

The invention provides a preparation method of a brake pad. The preparation method comprises the step of carrying out 3D printing on the surface attached with a metal layer, of a steel backing, by virtue of a raw material powder of the brake pad to obtain the brake pad, wherein the components of the metal layer are the same as metal components in the raw material components of the brake pad. According to the preparation method provided by the invention, a high-power electron beam enables the components in the material of the brake pad to be adequately reacted during a 3D printing process, so that the obtained brake pad has high mechanical performance and functional performance; and moreover, the steel backing with the surface attached with the metal layer having the components the same as the metal components in the raw materials of the brake pad is adopted, the metal layer is molten to form a thin molten bath under the scanning of the high-power electron beam during the 3D printing process, and adequate metallurgical bonding is carried out between the molten bath and the raw material powder of the brake pad, so that a wear-resistant layer in the brake pad and the steel backing have a high bonding strength. In addition, the power of the electron beam scans on the raw material powder of the surface of the steel backing during the 3D printing process, without influence on the organizational structure of the interior of the steel backing, thus the own mechanical performance of the steel backing is ensured.

Owner:SEED TECH CORP LTD

Sliding member

InactiveUS20100210488A1Prolong lifeImprove adhesionYielding couplingLinear bearingsInter layerEngineering

Owner:JTEKT CORP +1

Preformed thermoplastic pavement marking and method utilizing large aggregate for improved long term skid resistance and reduced tire tracking

ActiveUS20110123770A1Labor savingShorten the timeTraffic signalsTextiles and paperThermoplasticEngineering

The present disclosure describes a preformed or in some cases a hot applied thermoplastic marking composition comprising a planar top surface portion and a planar bottom surface portion that are coplanar to each other, wherein said bottom surface portion is directly applied to a substrate via application of heat or pressure or both heat and pressure and wherein said top surface portion comprises an intermix that exits throughout said thermoplastic composition and includes large grit size aggregate in the range of about 8 to about 20 mesh or grit size, thereby reducing or eliminating tire tracking while also improving long-term skid resistance.

Owner:ENNIS FLINT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com