Production of modified phenolic resin with high boron content

A technology of phenolic resin and boron modification, applied in the field of materials, to achieve the effect of simple and easy preparation method and excellent thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

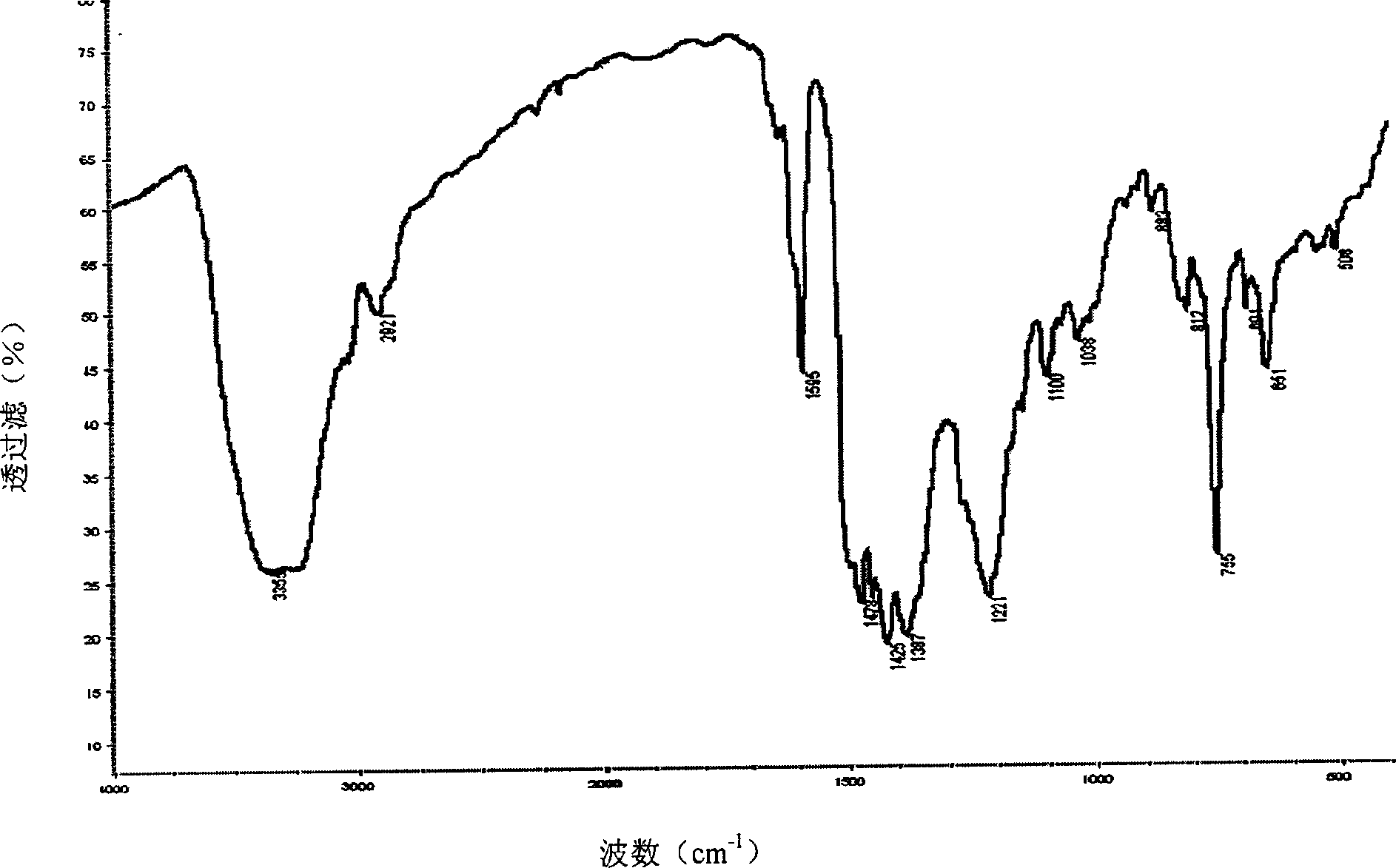

Image

Examples

Embodiment 1

[0019] Step (1): According to the molar ratio of boric acid / phenol=1 / 3, 28.2g of phenol and 40ml of toluene solution were added into a four-necked flask equipped with a condenser, a thermometer, an electric stirrer and a thermocouple. Raise the temperature to 90°C, then add 6.2g of boric acid, and at the same time use 0.1mol / L NaOH solution to adjust the pH value of the solution in the four-necked flask. When the pH is between 6 and 8, make the solution react at a temperature range of 90°C , and vacuum dehydration at the same time, the reaction time is 3 hours, and the vacuum degree is 0.1-1KPa; when the liquid is clear and slightly orange, and no water is produced after long-term pumping, stop pumping.

[0020] Step (2) Add 10.2 g of paraformaldehyde with a molecular weight of 450, make it react at 100° C. while stirring, and dehydrate under reduced pressure. As the dehydration proceeds, the liquid in the reaction bottle gradually becomes viscous. After 3-4 hours of reaction,...

Embodiment 2

[0023] Embodiment 2: the mol ratio of the boric acid / phenol of embodiment 1 step (1) is changed into 1 / 2 by 1 / 3, by the mol ratio of boric acid / phenol=1 / 2, the phenol of 18.8g and 30ml ethanol solution Add it to a four-necked flask equipped with a condenser, a thermometer, an electric stirrer and a thermocouple. Raise the temperature to 60°C, then add 6.2g of boric acid, and at the same time adjust the pH value of the solution in the four-necked flask with 0.1mol / L potassium hydroxide solution. The reaction time is 6 hours, and the vacuum degree is 0.1-1KPa. When the liquid is clear and slightly orange, and when there is no water after long-term pumping, stop pumping.

[0024] Step (2) Add 10.2 g of paraformaldehyde with a molecular weight of 200, make it react at 80° C. while stirring, and dehydrate under reduced pressure. As the dehydration proceeds, the liquid in the reaction bottle gradually becomes viscous. After 5-6 hours of reaction, when it is yellow-green, stop the r...

Embodiment 3

[0025] Embodiment 3: the mol ratio of the boric acid / phenol of embodiment 1 step (1) is changed into 2 / 1 by 1 / 3, by the mol ratio of boric acid / phenol=2 / 1, the phenol of 9.4g and 20ml tetrahydrofuran solution Add it to a four-necked flask equipped with a condenser, a thermometer, an electric stirrer and a thermocouple. Raise the temperature to 90°C, then add 12.4g of boric acid, and at the same time use 0.1mol / L calcium carbonate solution to adjust the pH value of the solution in the four-necked flask. Reaction, vacuum decompression and dehydration at the same time, the reaction time is 4 hours, the vacuum degree is 0.1 ~ 1KPa; when the liquid is clear and slightly orange, and when there is no water after long-term pumping, stop pumping;

[0026] Step (2) Add 10.2 g of paraformaldehyde with a molecular weight of 200, make it react at 80° C. while stirring, and dehydrate under reduced pressure. As the dehydration proceeds, the liquid in the reaction bottle gradually becomes vi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com