Coated tool

a technology of titanium diboride and coating tool, which is applied in the direction of superimposed coating process, chemical vapor deposition coating, milling equipment, etc., can solve the problem of avoiding the large step change in residual stresses in the hard material coating at the boundary to the titanium diboride layer, and achieves the effect of improving the adhesion of the fine-grained titanium diboride layer and the operation of the coated tool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

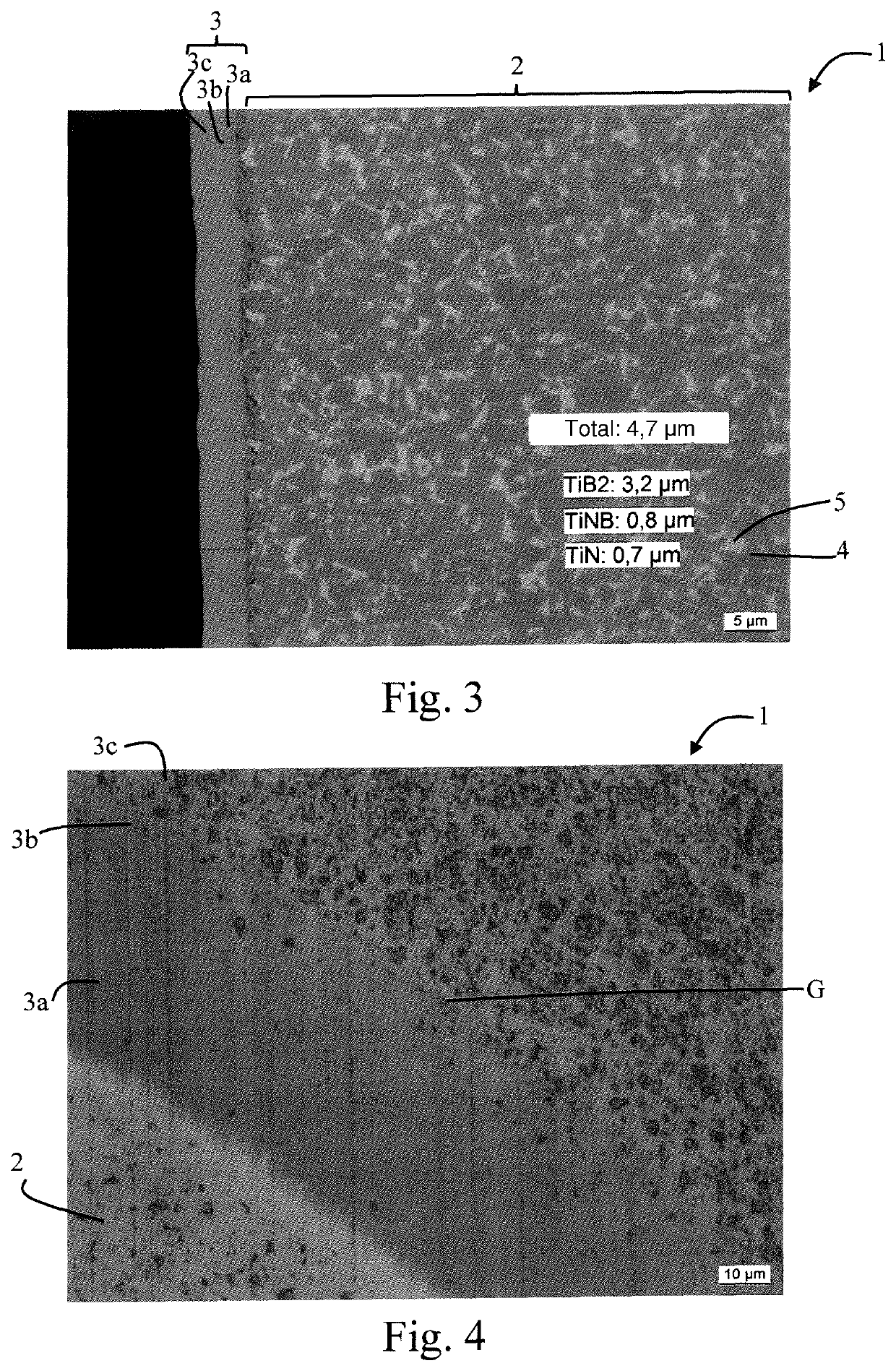

[0044]In order to produce a coated tool 1, an exchangeable cutting insert for the cutting machining of titanium alloys was coated with the hard material coating 3 according to the invention, as described in more detail with the aid of FIG. 3 and FIG. 4. The cutting insert serving as substrate 2 consisted of a commercial cemented hard material produced by the applicant and having a composition of 10% by weight of cobalt, 1.5% by weight of ruthenium, tungsten carbide as balance and an average grain size of the tungsten carbide grains in the range 1.3-2.5 μm.

[0045]A titanium nitride layer 3a having a layer thickness of 0.7 μm was firstly deposited on this substrate 2.

[0046]On top of this titanium nitride layer 3a, an approximately 0.8 μm thick titanium boronitride transition layer 3b having a boron content which increased in steps with increasing distance from the titanium nitride layer 3a was subsequently deposited at about 880° C. The boron content in the titanium boronitride transit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com