3D printing supplies easy in secondary shaping

A technology of 3D printing and consumables, applied in the field of 3D printing materials, can solve the problems of reduction and low temperature profile, and achieve the effect of improving layer adhesion, reducing delamination, excellent impact strength and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

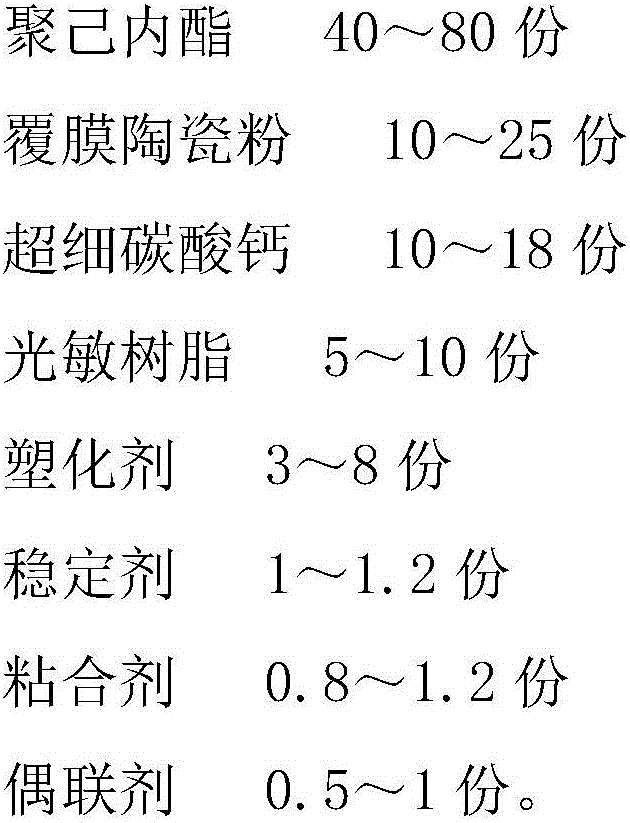

[0025] This embodiment discloses a 3D printing consumable that is easy to secondary plasticity, including the following raw materials in parts by weight,

[0026] Polycaprolactone 40 parts

[0027] 10 parts of coated ceramic powder

[0028] 14 parts superfine calcium carbonate

[0029] Photosensitive resin 5 parts

[0030] 3 parts plasticizer

[0031] Stabilizer 1 part

[0032] Adhesive 0.8 parts

[0033] 0.5 parts of coupling agent.

[0034] Among them, the fineness of ultrafine calcium carbonate is 1.2-5.6um;

[0035] Photosensitive resin: one of polyurethane acrylate, epoxy acrylate, and unsaturated polyester resin;

[0036] Plasticizer: one of dioctyl phthalate, dibutyl phthalate, di-sec-octyl phthalate, and diisodecyl phthalate;

[0037] Adhesive: one of polyurethane, polyacrylate, polyvinyl alcohol.

Embodiment 2

[0039] This embodiment discloses a 3D printing consumable that is easy to secondary plasticity, including the following raw materials in parts by weight,

[0040] Polycaprolactone 60 parts

[0041] 18 parts of coated ceramic powder

[0042] 10 parts superfine calcium carbonate

[0043] 7 parts of photosensitive resin

[0044] Plasticizer 6 parts

[0045] Stabilizer 1.1 parts

[0046] Adhesive 1.0 parts

[0047] 0.8 parts of coupling agent.

[0048] Among them, the fineness of ultrafine calcium carbonate is 1.2-5.6um;

[0049] Photosensitive resin: one of polyurethane acrylate, epoxy acrylate, and unsaturated polyester resin;

[0050] Plasticizer: one of dioctyl phthalate, dibutyl phthalate, di-sec-octyl phthalate, and diisodecyl phthalate;

[0051] Adhesive: one of polyurethane, polyacrylate, polyvinyl alcohol.

Embodiment 3

[0053] This embodiment discloses a 3D printing consumable that is easy to secondary plasticity, including the following raw materials in parts by weight,

[0054] Polycaprolactone 80 parts

[0055] 25 parts of coated ceramic powder

[0056] Superfine calcium carbonate 18 parts

[0057] Photosensitive resin 10 parts

[0058] Plasticizer 8 parts

[0059] Stabilizer 1.2 parts

[0060] Adhesive 1.2 parts

[0061] 1 part of coupling agent.

[0062] Among them, the fineness of ultrafine calcium carbonate is 1.2-5.6um;

[0063] Photosensitive resin: one of polyurethane acrylate, epoxy acrylate, and unsaturated polyester resin;

[0064] Plasticizer: one of dioctyl phthalate, dibutyl phthalate, di-sec-octyl phthalate, and diisodecyl phthalate;

[0065] Adhesive: one of polyurethane, polyacrylate, polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com