Patents

Literature

64results about How to "High in boron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production of modified phenolic resin with high boron content

Production of modified phenolic resin of high-boron content is carried out by reacting boric acid with carbolic acid to generate boric acid ester by two-step method, reacting boric acid ester with paraformaldehyde to obtain final product. It is simple, controllable and quantitative, has higher boron content, excellent thermal, mechanical, friction and anti-corrosive performances. It can be used for high-temperature brake friction material, anti-corrosive materials and special thermal-insulating material.

Owner:TONGJI UNIV

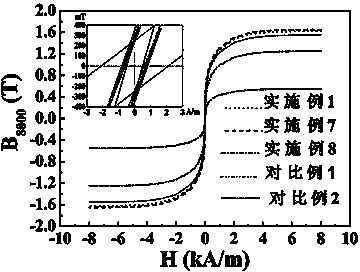

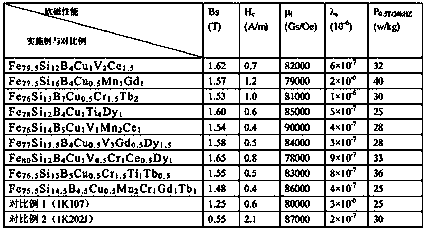

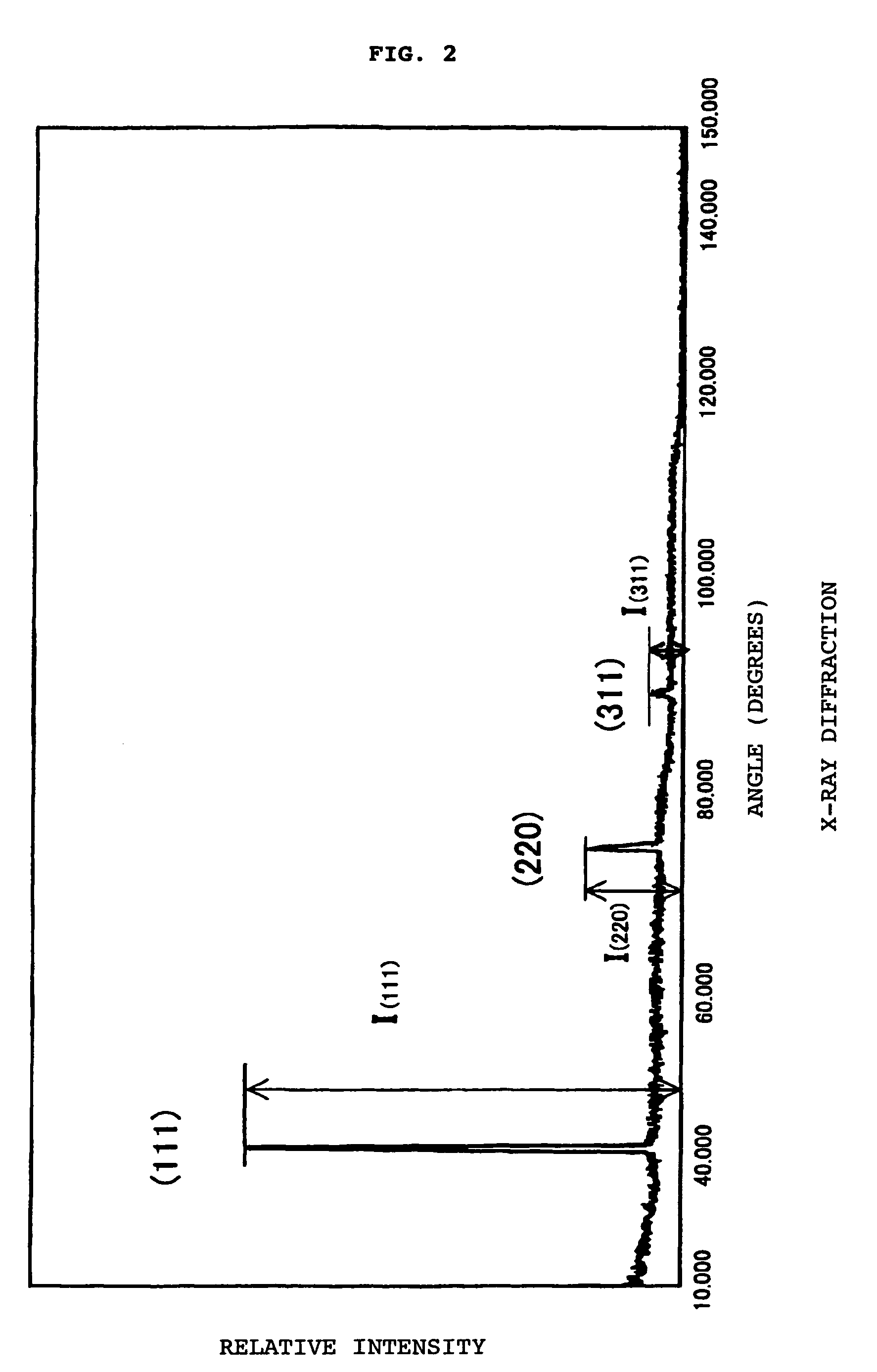

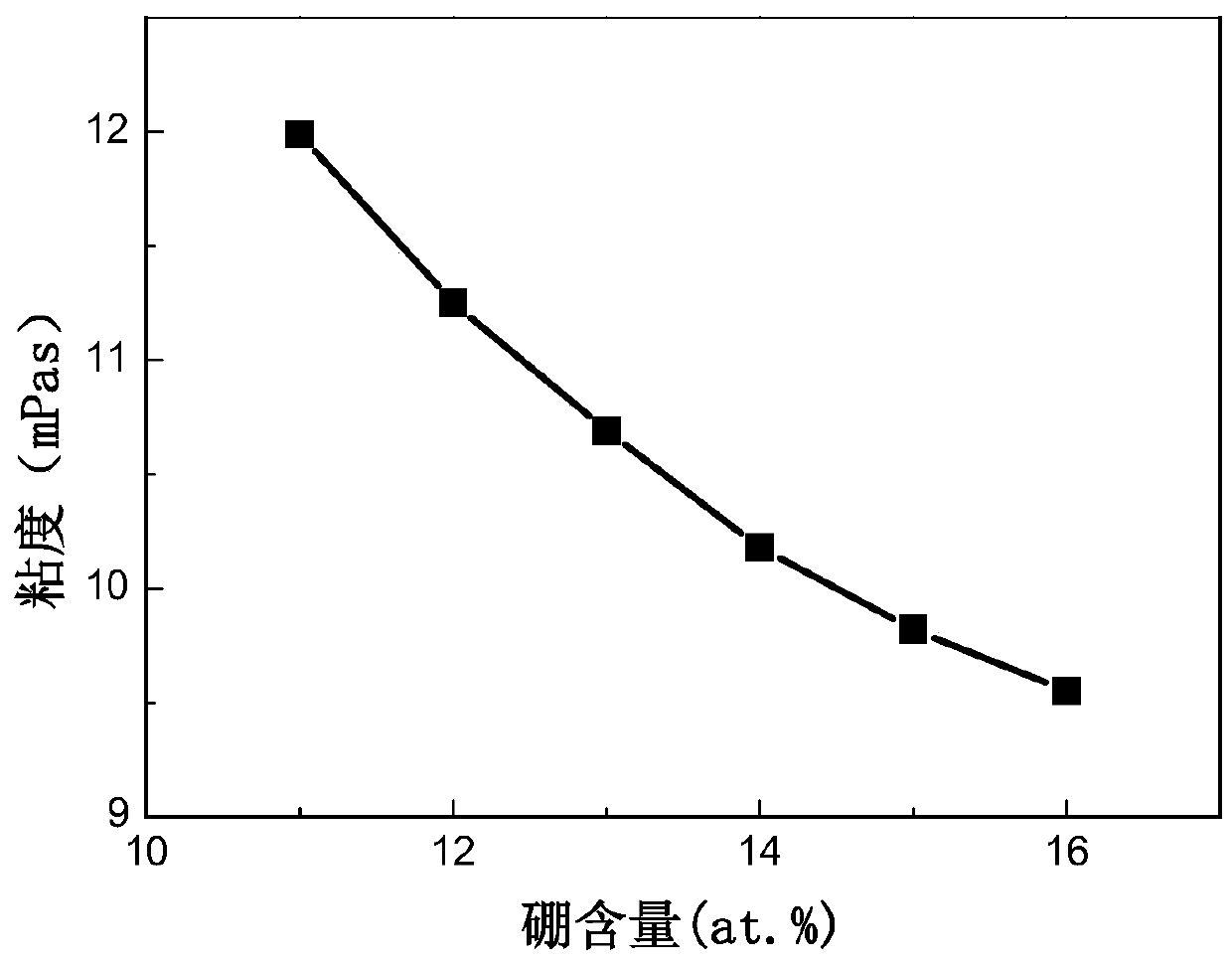

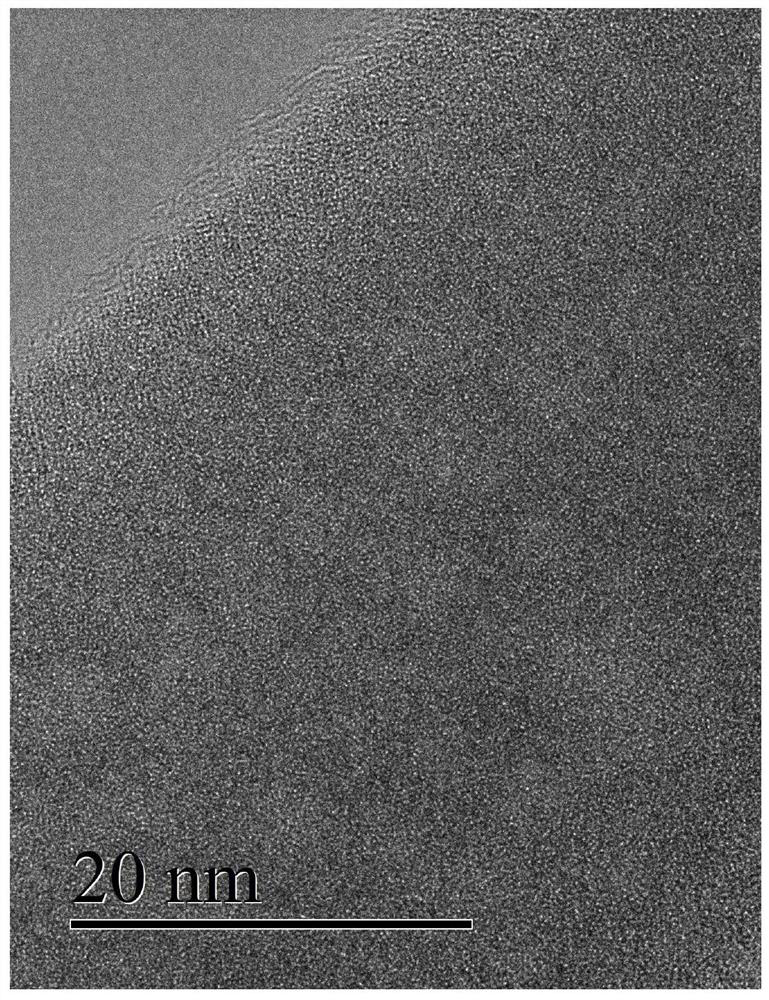

Iron-based nano-crystalline soft magnetic alloy and method for manufacturing same

InactiveCN103489555AHigh saturation magnetic inductionIncrease Fe contentMagnetic materialsElectronic componentCobalt

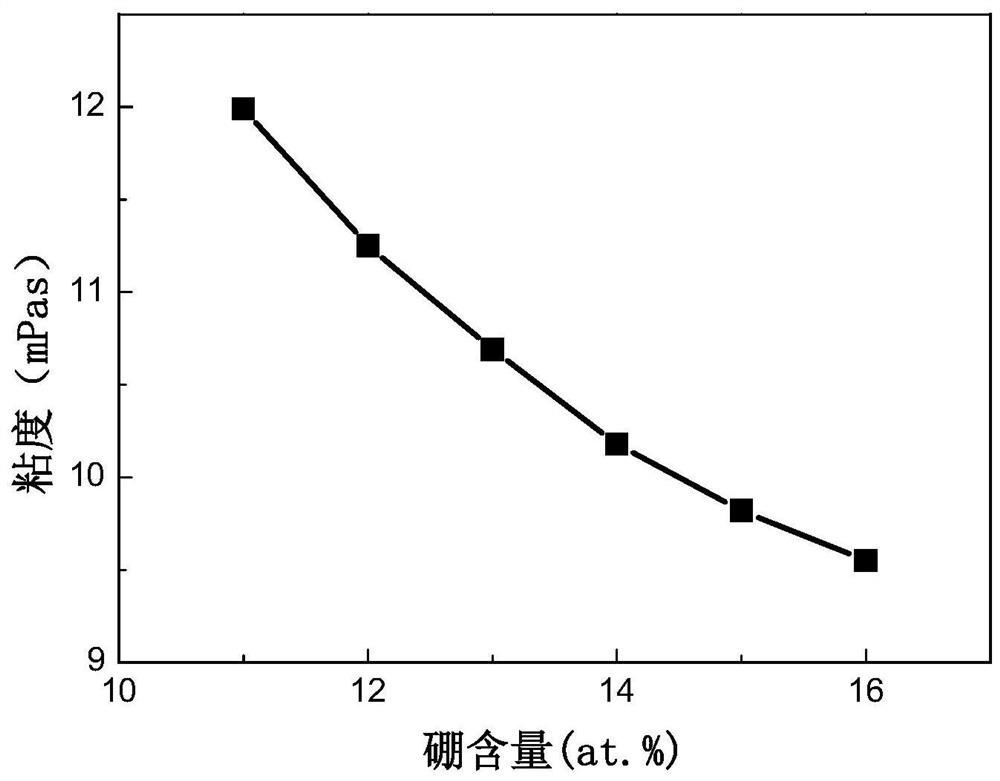

The invention provides iron-based nano-crystalline soft magnetic alloy, and belongs to the technical field of soft magnetic alloy. The iron-based nano-crystalline soft magnetic alloy is characterized in that a chemical formula of the iron-based nano-crystalline soft magnetic alloy is FeSiB<c>Cu<d>T<e>RE<f>, and the T represents at least one of Ti, V, Mn, Cr, Mo, Nb, Zr and W, and the RE represents one or two of La, Y, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho and Er; the a, the b, the c, the d, the e and the f represent atomic percentages of corresponding components, the b ranges from 12 to 16, the c ranges from 4 to 7, the d ranges from 0.5 to 1, the e ranges from 1 to 4, the f ranges from 0.5 to 2, and the a meets an equation of (100-b-c-d-e-f-g). The iron-based nano-crystalline soft magnetic alloy has the advantages that a saturated magnetostriction coefficient of the iron-based nano-crystalline soft magnetic alloy is close to zero, and the iron-based nano-crystalline soft magnetic alloy is high in magnetic permeability and saturated magnetic induction intensity, and can replace cobalt-based amorphous alloy to be applied to the field of manufacture for magnetic cores of precision electronic components.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Smelting method for stably increasing content of boron in boron-containing steel

The invention relates to a smelting method for stably increasing the content of boron in boron-containing steel. The smelting method is characterized in that high-carbon ferromanganese, high-carbon ferrochromium and iron-core aluminum are subjected to the deoxidation alloying in the steel tapping process of a converter, and a whole-course bottom argon blowing and wash heat technology is adopted for reducing oxygen content and nitrogen content in the steel; after steel tapping is completed, molten steel is lifted to an argon station, and the molten steel is converted to an LF (Ladle Furnace) after ferroaluminium is added for adjusting the activity of oxygen in the steel to a required control range; and submerged arc operation, soft argon blowing control, a deep deoxidation technology and a titanium alloy technology are adopted for refining in the LF, then boron alloying is carried out, and later the long-time soft argon blowing is carried out, thus the recovery rate of boron in the steel reaches 82%-86%, the problems of low and instable recovery rate of boron are solved, the fluctuation quantity between the furnaces is less than 0.0005%, the ideal control level is achieved, the dependence of boron alloying on vacuum refining is eliminated, and the requirement of subsequent process for the quality of the boron-containing steel is ensured.

Owner:WUKUN STEEL

Production method of high-concentration potassium chloride pellet

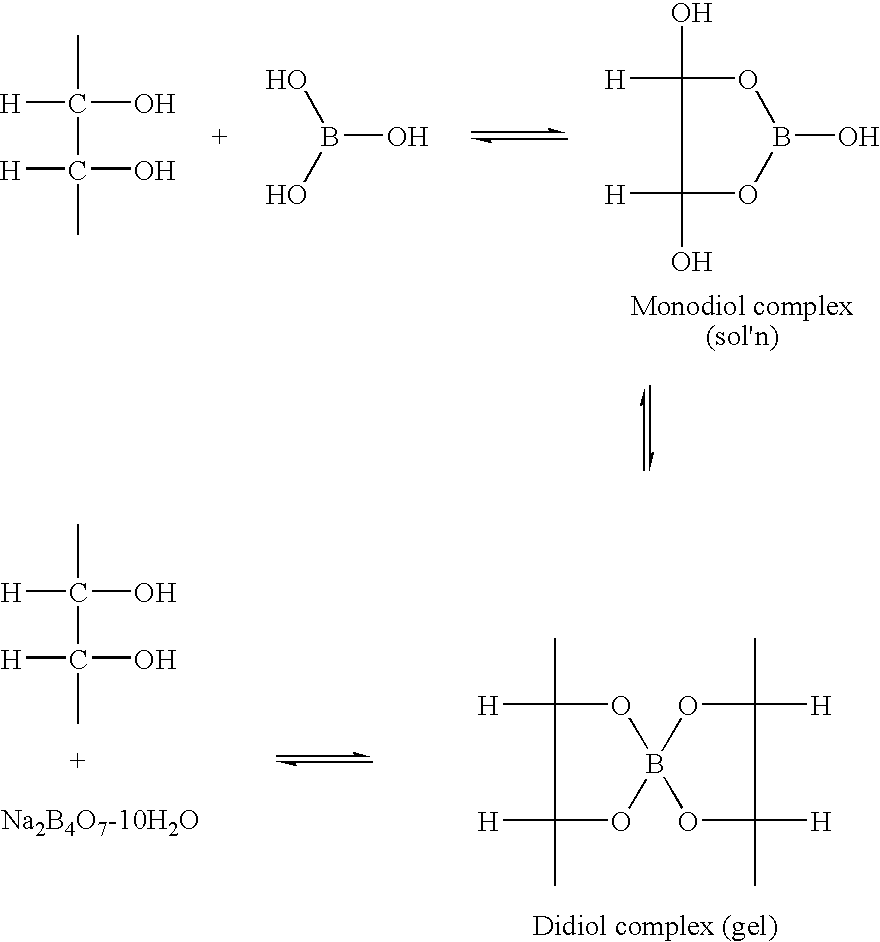

The invention discloses a production method of high-concentration potassium chloride pellets. The production method is characterized by comprising the following steps: uniformly mixing and crushing potassium chloride serving as a raw material and a pelleting agent, then enabling the mixture to enter agglomeration granulation equipment, carrying out agglomeration granulation according to a conventional agglomeration granulation technology, drying, cooling and sieving particles to obtain the high-concentration potassium chloride pellets, wherein the pelleting agent is a mixture of polyacrylamide, sodium silicate and borax, the weight of the pelleting agent accounts for 0.5%-5% of the weight of the potassium chloride raw material. The production method has the advantages that the strength of wet particles is improved by adding few pelleting agent under the condition of having no influence the nutrient content, so that the agglomeration granulation technology can be used for pelleting, and the defect that the prior art cannot be used for producing the high-nutrient potassium chloride pellets is overcome.

Owner:HUBEI FORBON TECH

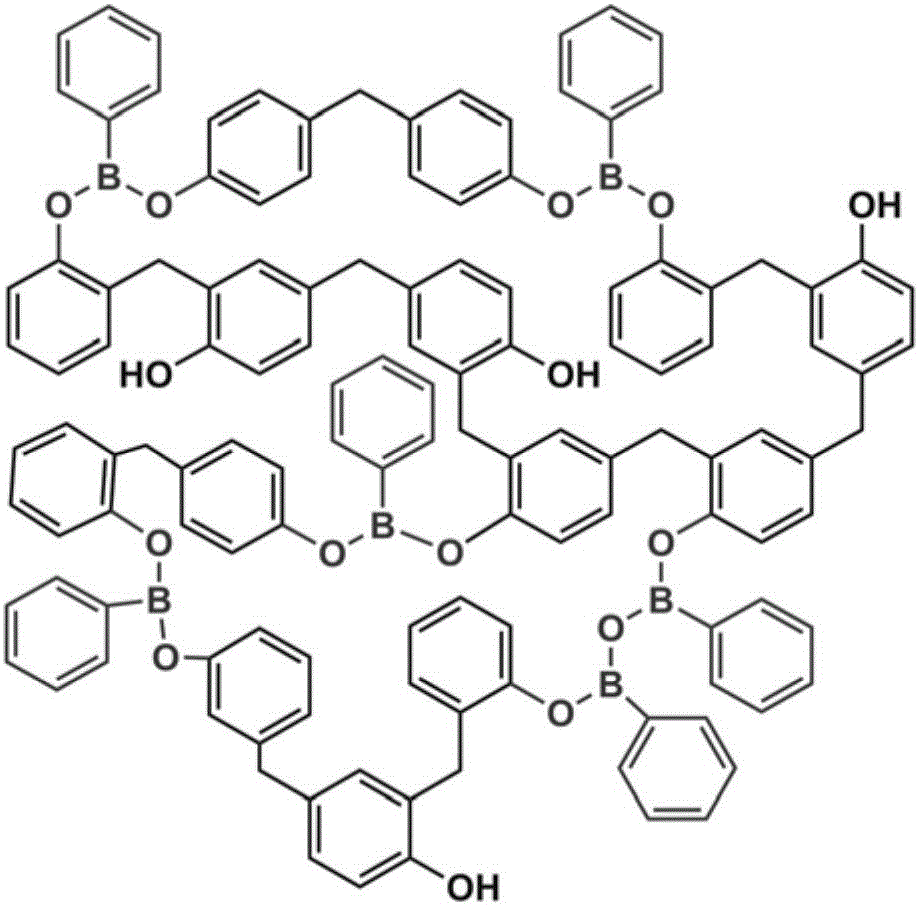

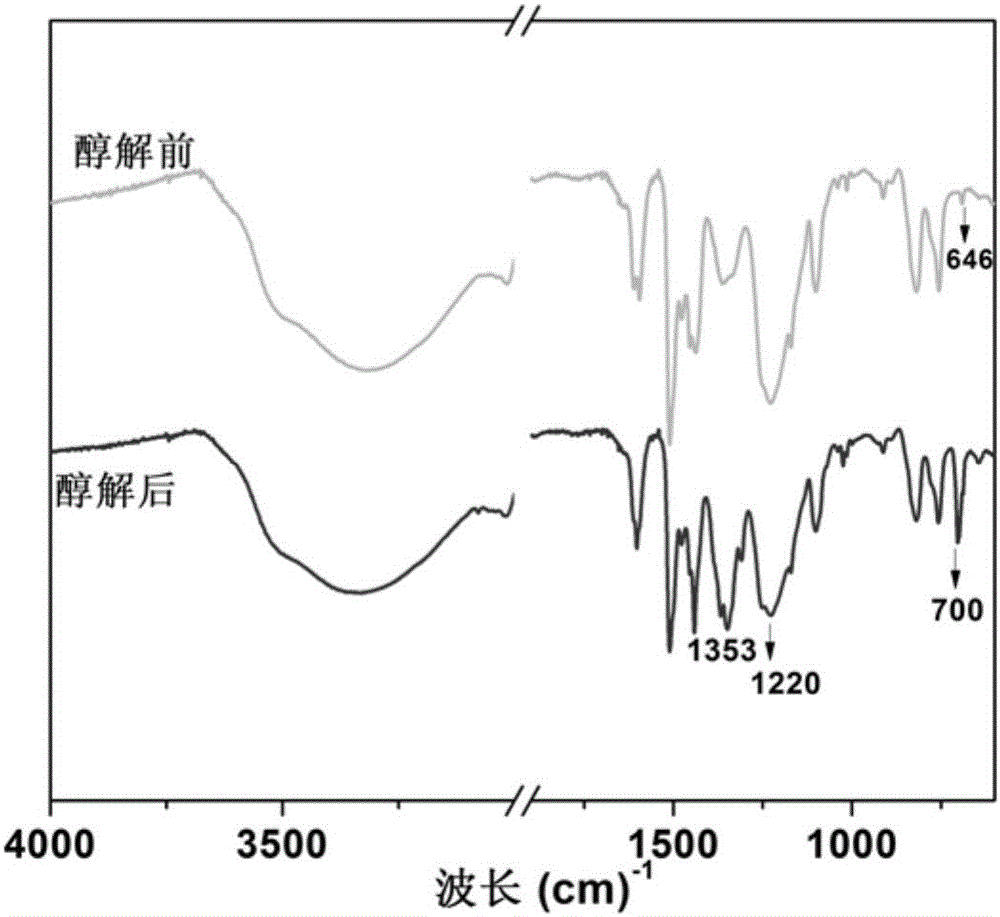

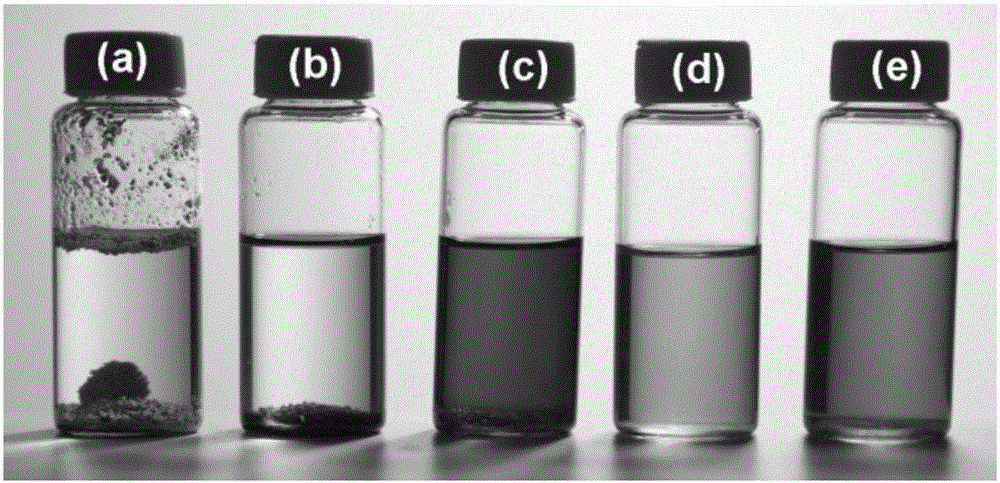

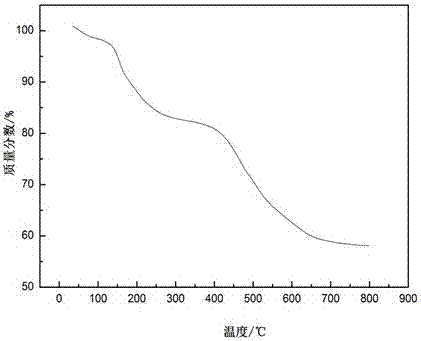

Preparation method of room-temperature regenerated phenolic resin and recycling technology and application thereof

ActiveCN106750064ALow softening temperatureReduce melt viscosityPlastic recyclingOrganic solventAlcohol

The invention relates to a preparation method of room-temperature regenerated phenolic resin and a recycling technology and application thereof. The preparation method comprises the following steps of according to parts by mass, melting and blending 100 parts of thermoplastic phenolic resin and 18.4 to 55 parts of boric acid compound at the temperature of 60 to 100 DEG C, so as to obtain boron-containing thermoplastic phenolic resin; or, dissolving 100 parts of thermoplastic phenolic resin and 20 to 50 parts of boric acid compound into an organic solvent with low boiling point at the temperature of 40 to 60 DEG C, so as to obtain the boron-containing thermoplastic phenolic resin; curing, so as to obtain the room-temperature regenerated phenolic resin. The preparation method has the advantages that the preparation technology of the resin is simple; the resin is dissolved into the mixing solvent of ethyl alcohol and water at room temperature, so that the resin can be recycled; the resin can be used for preparing the recyclable fiber reinforced boron-containing thermoplastic phenolic resin-based composite material. The prepared boron-containing thermoplastic phenolic resin has the advantages that the function of arylboronic acid ester structure promoting the heat-resistant property of the thermoplastic phenolic resin is fully realized, and the technology of the resin and the mechanical property of the composite material can be simultaneously realized.

Owner:XI AN JIAOTONG UNIV +1

Diamond-coated electrode and method for producing same

InactiveUS7314540B2Lower resistanceImprove adhesionPhysical/chemical process catalystsUltra-high pressure processesElectrical resistance and conductanceDiamond electrodes

A diamond electrode having a sufficiently low resistance is disclosed which is realized by increasing the amount of boron added thereto. A method for producing a high-performance, high-durability electrode is also disclosed by which adhesiveness between a diamond coating and a substrate and separation resistance during electrolysis are sufficiently increased. An electrode composed of a substrate and a diamond layer coating the substrate is characterized in that the electrode is composed of a base coated with diamond and the diamond contains boron in such an amount that the boron concentration is not less than 10,000 ppm but not more than 100,000 ppm. The base is preferably made of an insulating material.

Owner:SUMITOMO ELECTRIC IND LTD

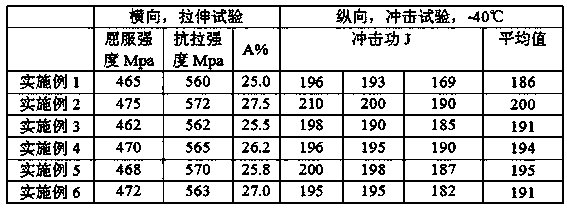

Smelting technology of ultralow boron steel

ActiveCN107841687AMeet the needs of smeltingLower boron contentManufacturing convertersProcess efficiency improvementMolten steelBoron

The invention discloses a smelting technology of ultralow boron steel, and belongs to the technical field of steel smelting. The smelting technology specifically comprises the stages of KR molten ironpretreatment, converter smelting, LF refining, pouring, cast blank stack cooling and cleaning, heating and rolling and steel plate stack cooling. According to the smelting technology, the boron content in molten steel can be controlled to be 0.0005% or below, the smelting requirements of the ultralow boron steel can be completely met, according to a prepared steel plate, the yield strength is higher than or equal to 462 MPa, the tensile strength is higher than or equal to 560 MPa, the ductility is higher than or equal to 25%, the impact strength at the temperature of minus 40 DEG C can reach186 J or above, and the overall performance is excellent.

Owner:NANYANG HANYE SPECIAL STEEL CO LTD

Process for Drying Boron-Containing Minerals and Products Thereof

InactiveUS20090082229A1Carry-outRapid and efficient dehydrationPeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesFlushingTime rangeMetallurgy

Processes for the rapid and efficient drying of boron-containing compounds, in particular boron-containing minerals and ores, are described, as well as the products which result from such processes. The process comprises the steps of providing a boron-containing material; introducing the boron-containing material into a pre-heated furnace; heating the boron-containing material in the furnace at a temperature between about 800° F. and 1000° F.; retaining the boron-containing material within the furnace for a time ranging from about 5 minutes to about 120 minutes; and removing the boron-containing material from the furnace and allowing it to cool to ambient temperature. Optionally, the process may also comprise one or more steps of grinding and / or sizing the boron-containing material to a specific particle size prior to the introduction of the material to a furnace. The boron-containing compounds that can be processed in this manner include both naturally-occurring and / or synthetic boron-containing materials, in particular boron-containing minerals and ores such as colemanite, ulexite, probertite, kernite, and mixtures thereof.

Owner:TUCC TECH LLC

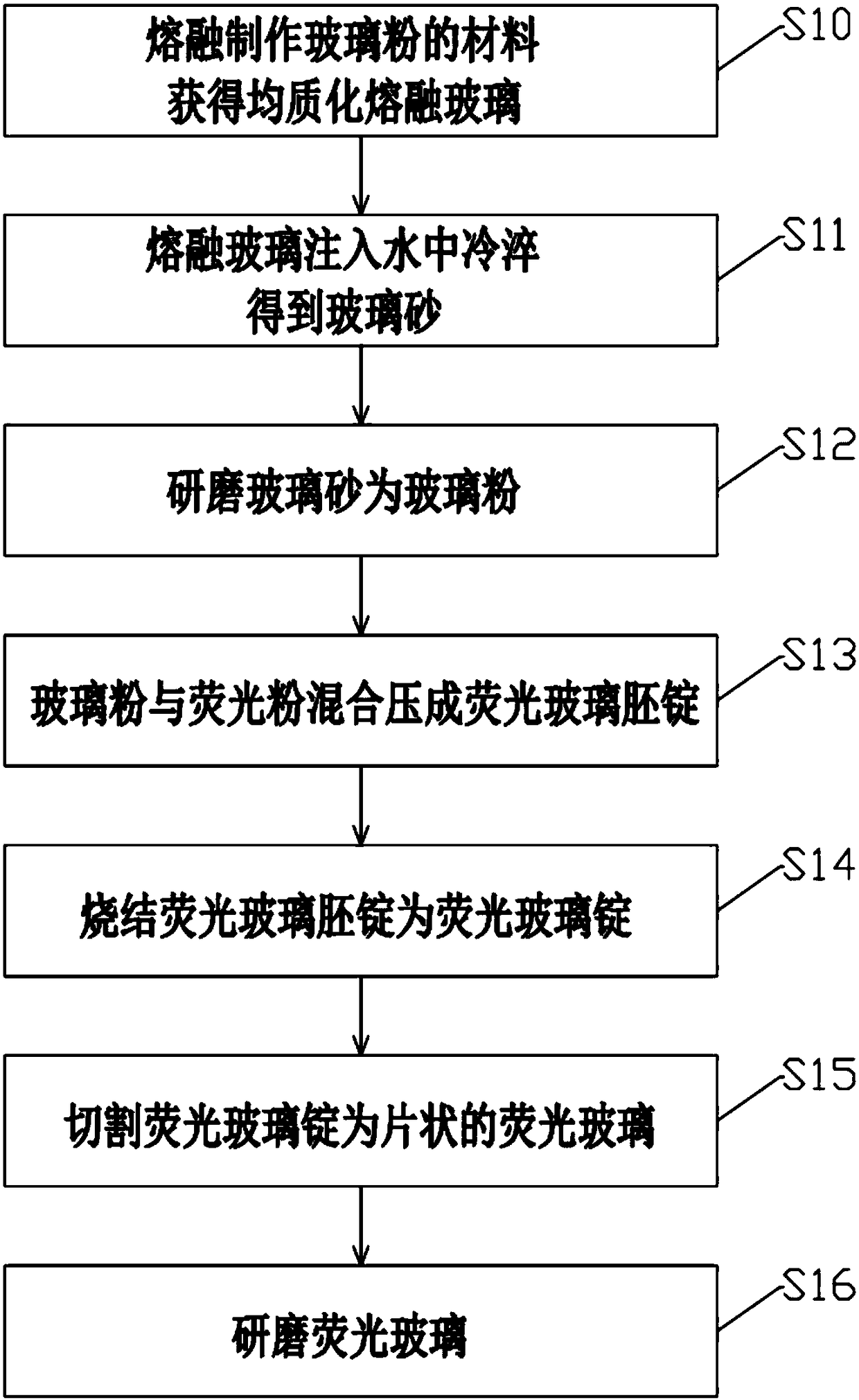

Fluorescent glass for light-emitting diodes and preparation technology thereof

InactiveCN109206009AImprove luminous efficiencyAvoid wear and tearGlass shaping apparatusLuminescent compositionsNitrogen oxidesFluorescence

The invention relates to a fluorescent glass for light-emitting diodes and a preparation method thereof. The fluorescent glass for light-emitting diodes includes glass powder and fluorescent powder. The glass powder and fluorescent powder are mixed with to form fluorescent glass. The materials for making the glass powder include 20wt%-37wt% of silicon dioxide, 31wt%-47wt% of boron trioxide and 16wt%-35wt% of calcium oxide. The material of the fluorescent powder is selected from one of Ce-YAG, LuAG, silicate and nitride / nitrogen oxide fluorescent powder. The fluorescent glass provided by the invention is obtained by mixing and sintering of glass powder and fluorescent powder. The sintering temperature is low, and deterioration and discoloration of the fluorescent powder caused by high temperature can be avoided. Therefore, the fluorescent glass provided by the invention has good light transmittance, and the light-emitting diodes using the fluorescent glass have good luminous efficiency.

Owner:PLATINUM OPTICS TECH SUZHOU INC +1

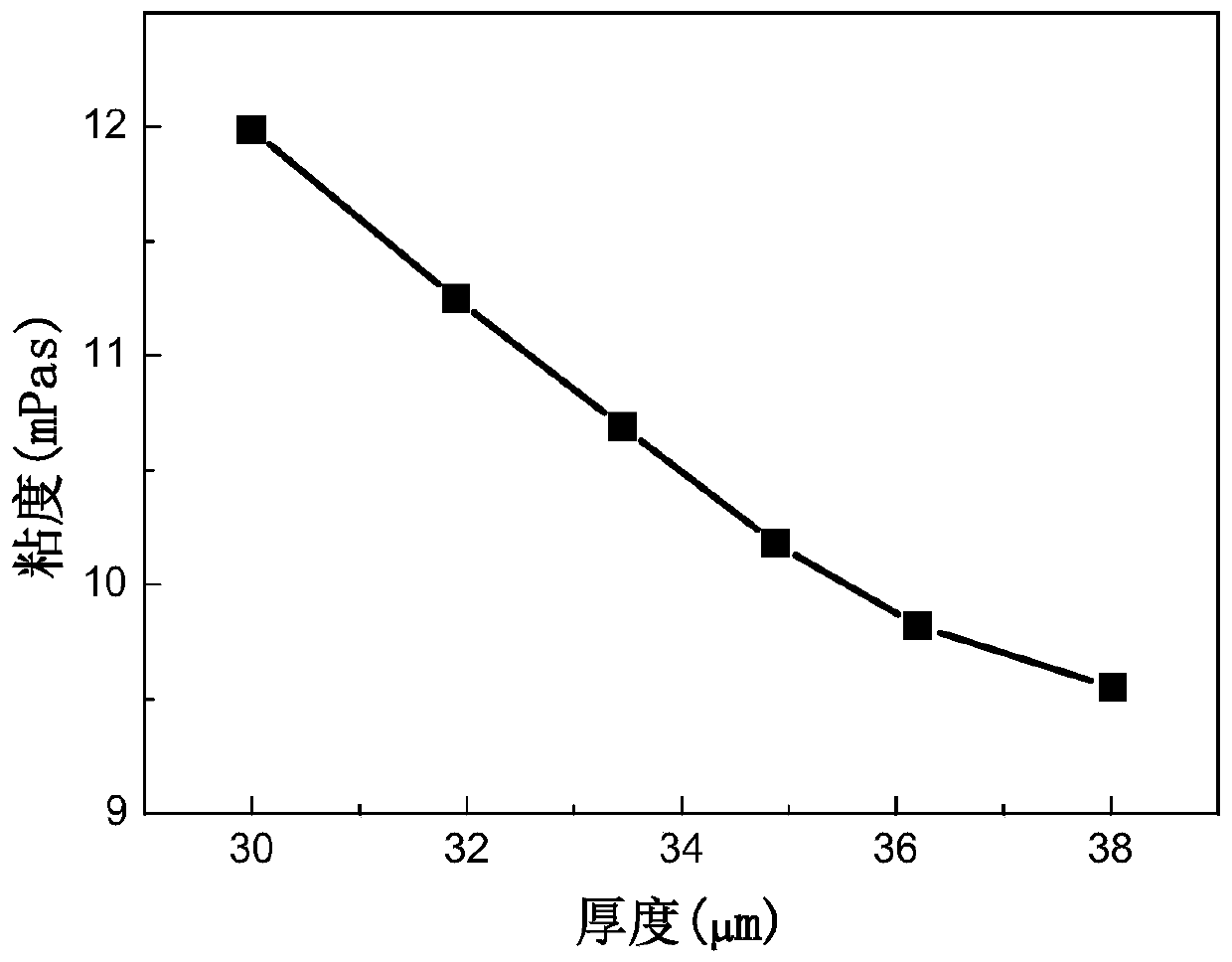

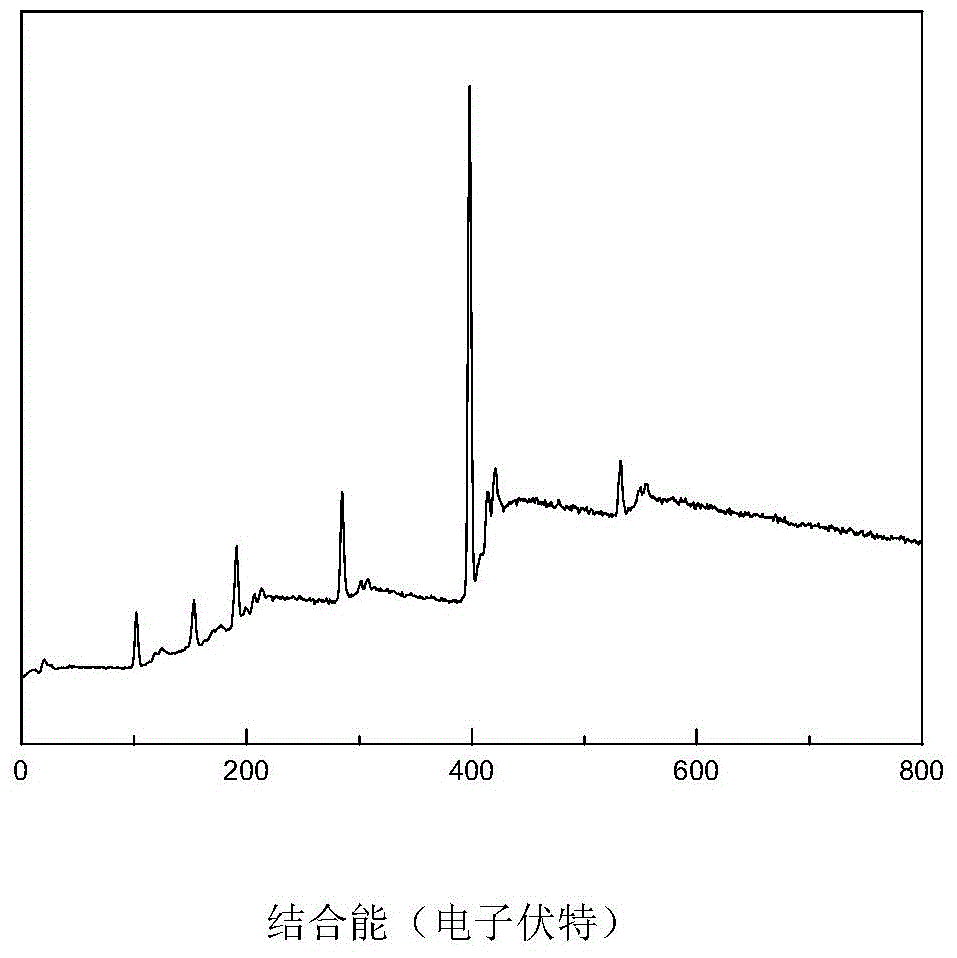

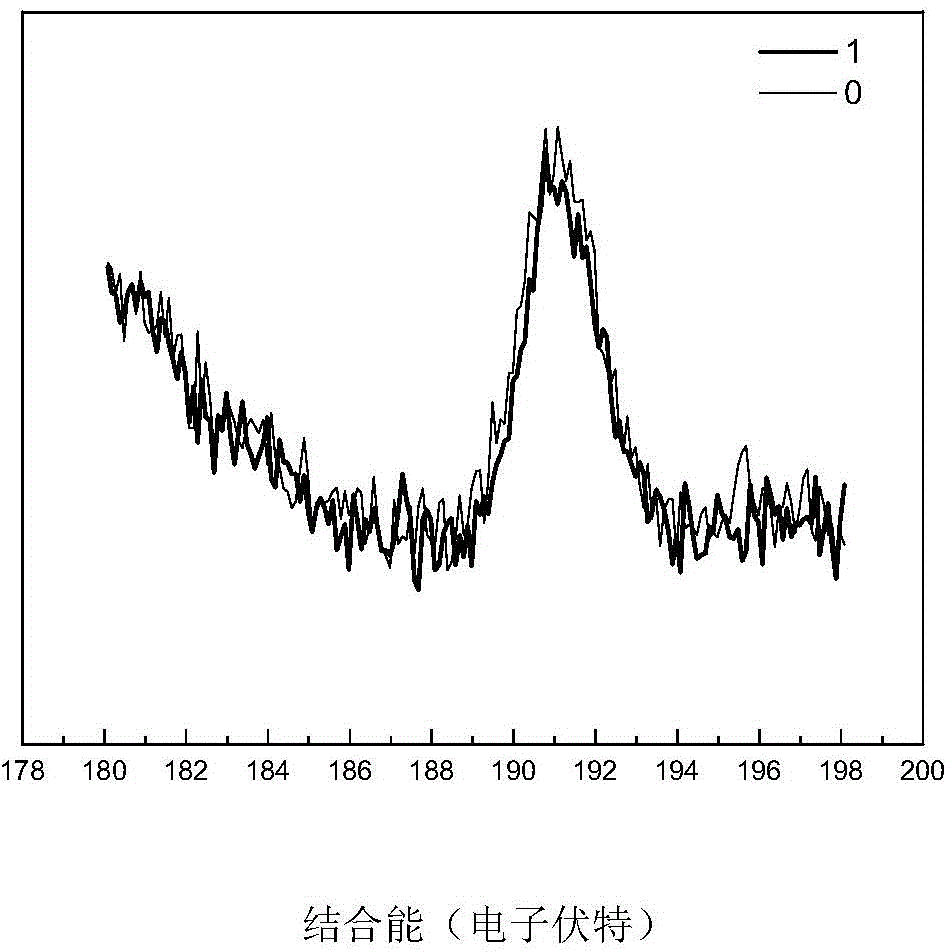

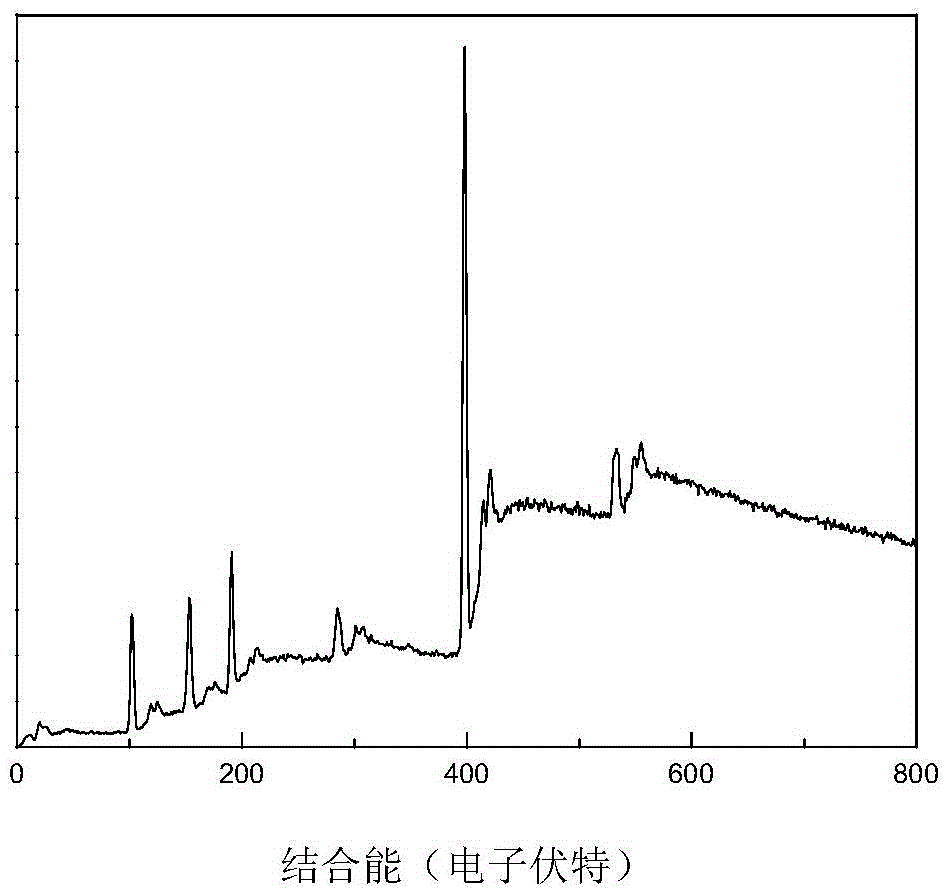

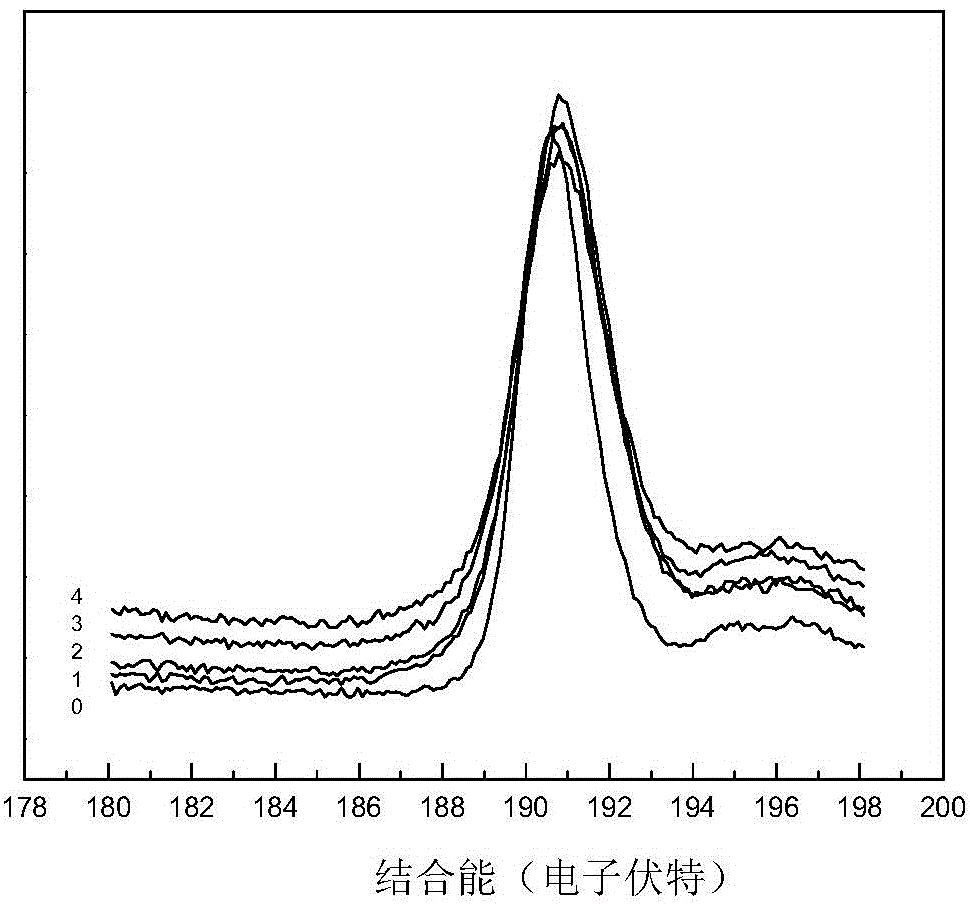

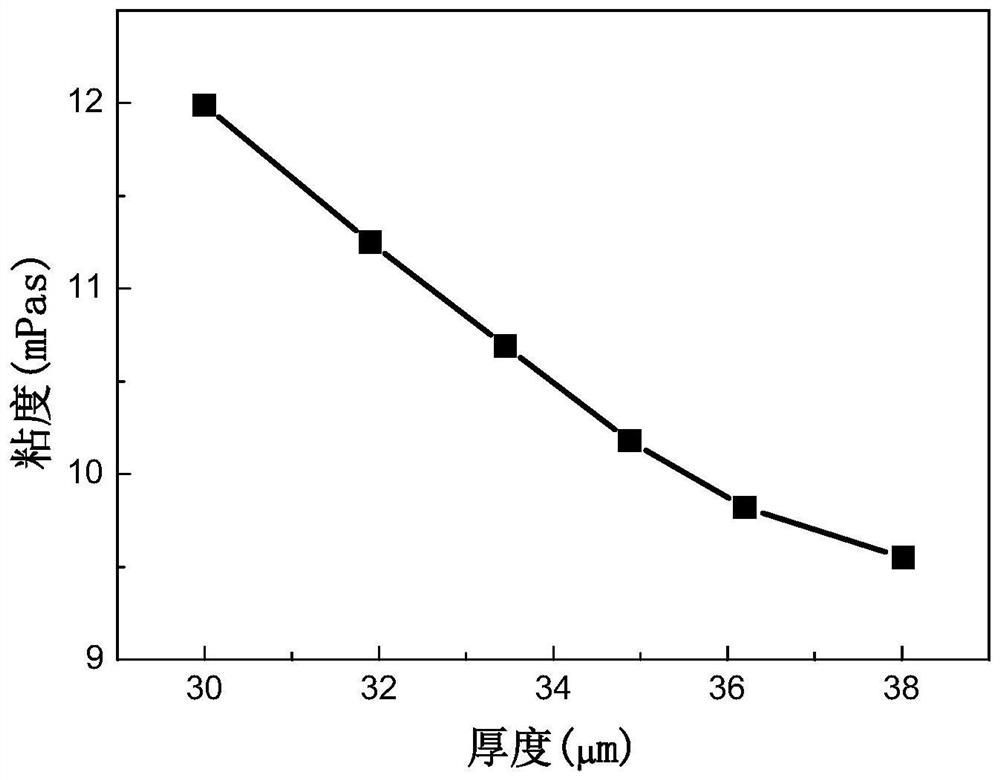

Method for regulating and controlling thickness of iron-based amorphous alloy strip

The invention relates to a method for regulating and controlling thickness of an iron-based amorphous alloy strip. According to the method, the thickness of the iron-based amorphous alloy strip is regulated and controlled by utilizing a method of iron-based alloy melt composition and heat treatment temperature under the condition of not changing rapid solidification process conditions so as to reduce the preparation difficulty of the thick iron-based amorphous alloy strip. The method has the characteristics of low implementation cost, high efficiency, high controllability and repeatability, high technical reliability and the like, and is suitable for wide application in the technical field of metal functional material preparation.

Owner:江苏中科启航新材料工业研究院有限公司 +3

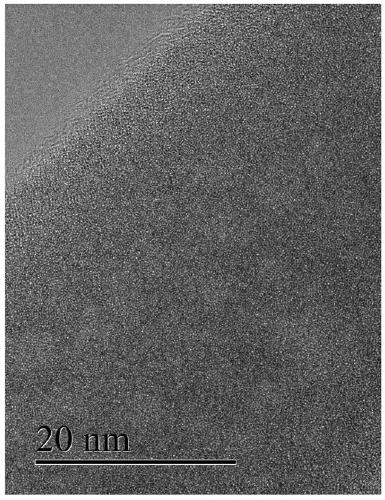

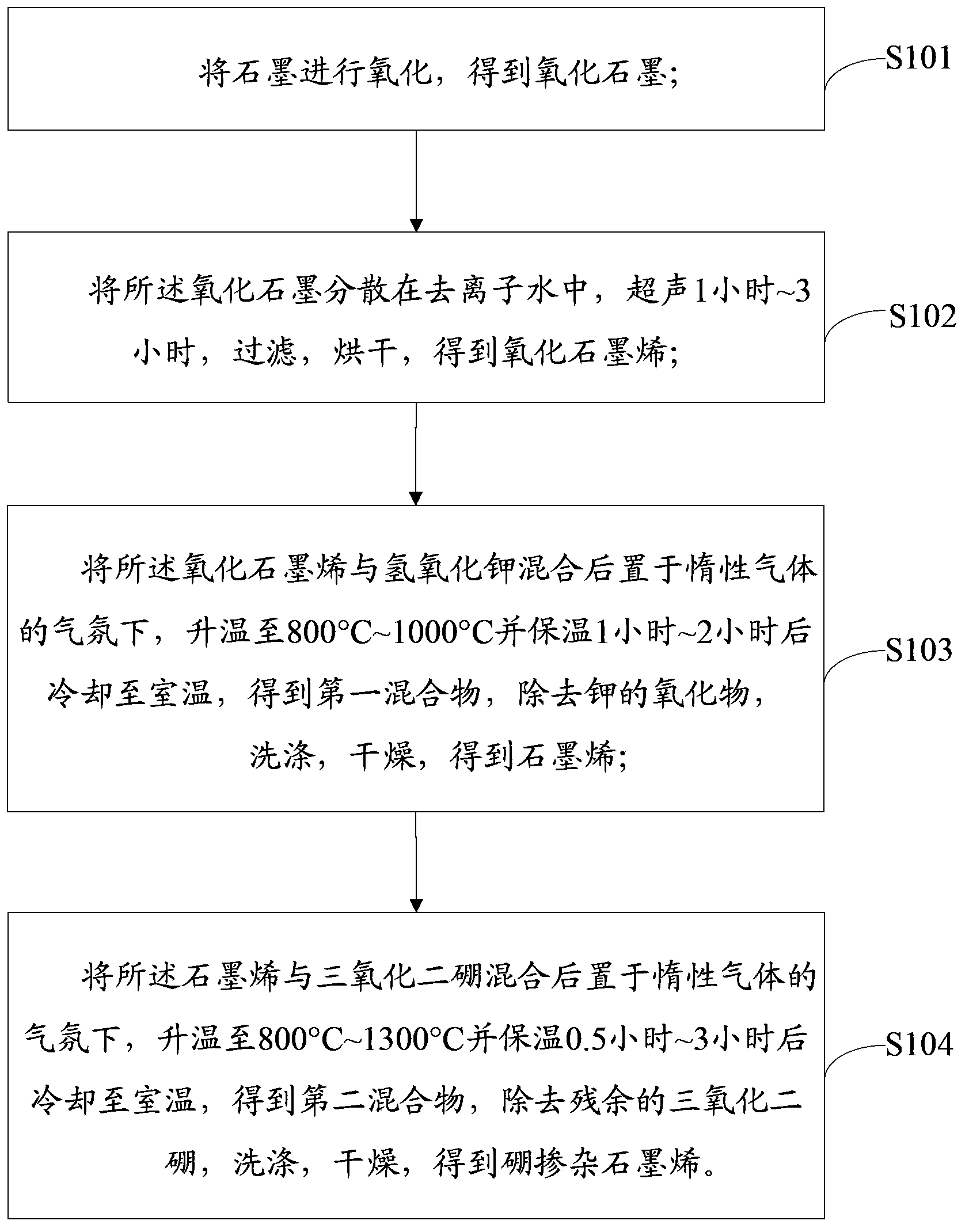

Preparation method of boron doped graphene

A preparation method of boron doped graphene comprises the steps of: oxidizing graphite to obtain the graphite oxide; dispersing the graphite oxide in deionized water, conducting ultrasonic treatment for 1-3 h, filtering and drying to obtain the graphene oxide; mixing the graphene oxide with potassium hydroxide, placing the mixture in an inert gas atmosphere, heating to 800-1000 DEG C, insulating for 1-2 h, and cooling to room temperature to obtain a first mixture; removing oxides of potassium, washing and drying to obtain graphene; mixing the graphene with boron trioxide, placing the mixture in an inert gas atmosphere, heating to 800-1300 DEG C, insulating for 0.5-3 h and cooling to room temperature to obtain a second mixture; and removing residual boron trioxide, washing and drying to obtain boron doped graphene. By adopting the preparation method, boron doped graphene with high boron content can be obtained.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

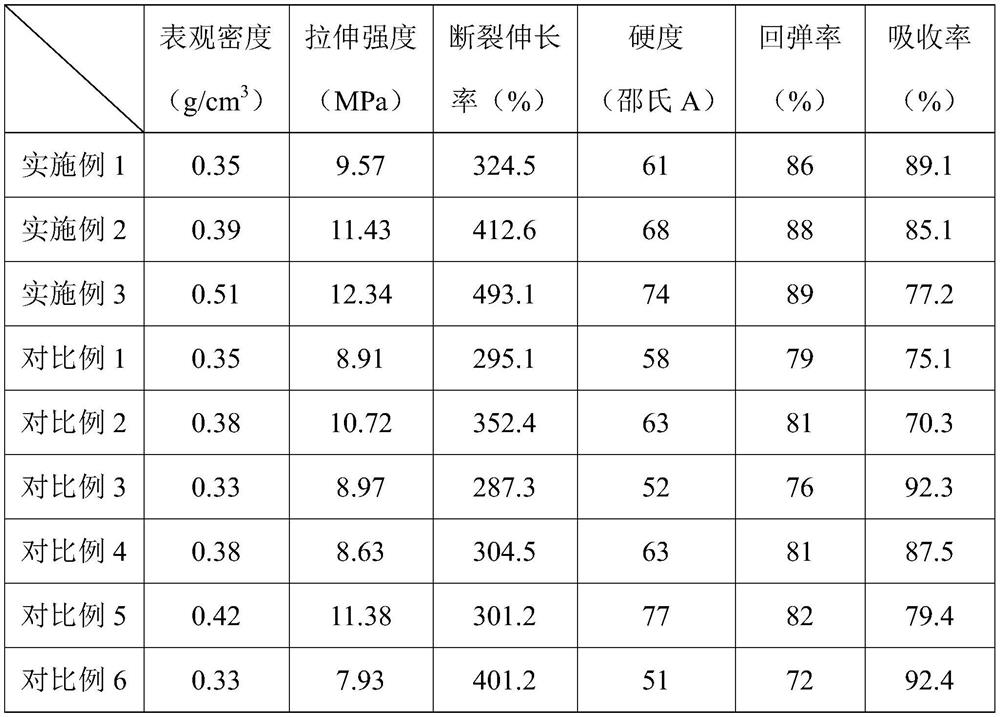

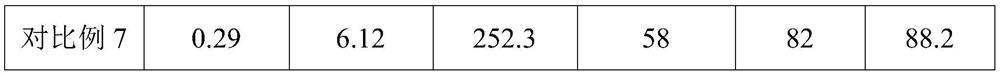

Silicone rubber foam material and preparation method thereof

The invention relates to a silicone rubber foam material and a preparation method thereof. The preparation method comprises the following steps: preparing polydimethylsiloxane, boric acid, a derivative thereof and an organic solvent into a polydimethylsiloxane solution, carrying out condensation polymerization, and then removing unreacted boric acid, the derivative thereof and the organic solvent to obtain shear thickening gel; mixing 1-10 parts by mass of the shear thickening gel with 100 parts by mass of vinyl-containing silicone rubber to obtain a silicone rubber base material; mixing the silicone rubber base material with 1-20 parts by mass of nanocellulose, 1-10 parts by mass of expanded microspheres and 0.01-0.5 part by mass of an organic peroxide cross-linking agent, so as to obtain silicone rubber compound; and performing pre-forming and cross-linking foaming on the silicone rubber compound to obtain the silicone rubber foaming material. The silicone rubber foam material obtained by the preparation method has the advantages of high resilience, low compression deformation and the like, and can be better applied to the fields of shock absorption and impact resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Preparation method of boronized silicon nitride fiber

InactiveCN104831420AEasy to operateImprove stabilityInorganic material artificial filamentsDecarburizationSilicon nitride

The invention relates to a preparation method of a boronized silicon nitride fiber. The preparation method comprises the steps of firstly preparing a high-activity Si-N fiber by transforming an infusible polycarbosilane fiber, carrying out dehydrogenation coupling reaction on excessive N-H in the high-activity Si-N fiber and B-H compounds generated by virtue of pyrolysis of boron hydrides so as to chemically introduce an element B, and carrying out boron hydrides in ammonia gas, so as to prepare the boronized silicon nitride fiber. Compared with the prior art, the boronized silicon nitride fiber prepared by virtue of the preparation method is relatively high in boron content, nitrogen content and fiber strength and relatively uniform in boron distribution. The preparation method has the advantages that the process is simple and convenient, and the cost is low. Compared with SiBN fiber prepared by virtue of a polyborosilazane precursor route, the preparation method has relatively great cost advantage and is applicable to large-scale production, and existing decarburization-nitridation systems do not need to be changed.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of SiBN fiber

InactiveCN104831419AHigh activityPerfect synthesis technologyInorganic material artificial filamentsArtificial filament chemical after-treatmentFiberNitrogen

The invention relates to a preparation method of SiBN fiber. The preparation method comprises the following steps: (1) preparing a high-activity Si-N fiber, namely adding an infusible polycarbosilane fiber into a decarburization-nitridation system, carrying out vacuumizing, replacing gas in the decarburization-nitridation system by virtue of nitrogen or argon until reaching an atmospheric pressure state, and repeating for at least three times; introducing high-purity ammonia gas, heating to 500 DEG C within 2 hours, after the temperature is increased to 700 DEG C at the speed of 0.90 DEG C / min-0.95DEG C / min, maintaining the temperature for 0.5 hour, heating until the temperature is 800-1200 DEG C at the speed of 100 DEG C / h, and maintaining the temeprature for 1-2 hours; introducing nitrogen / argon to cool to the room temperature, so as to obtain the high-activity Si-N fiber; (2) boronizing the high-activity Si-N fiber, namely heating until the temperature is 400-450 DEG C within 2 hours, introducing borane compound gas at least containing one B-H bond into the system, reacting for 24-36 hours, and introducing nitrogen / argon to cool to the room temperature; and (3) nitriding a boronized fiber, namely introducing high-purity ammonia gas, heating until the temperature is 1300-1400 DEG C within 6 hours, and maintaining the temperature for 1-2 hours; introducing nitrogen / argon to cool to the room temperature, so as to obtain the SiBN fiber. The preparation method is simple and convenient in process, low in cost and applicable to large-scale production, and existing decarburization-nitridation systems do not need to be changed.

Owner:NAT UNIV OF DEFENSE TECH

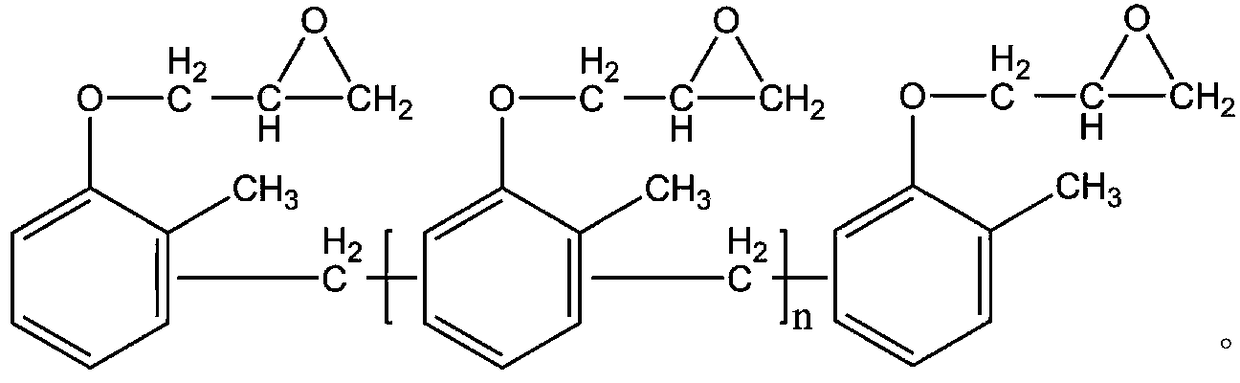

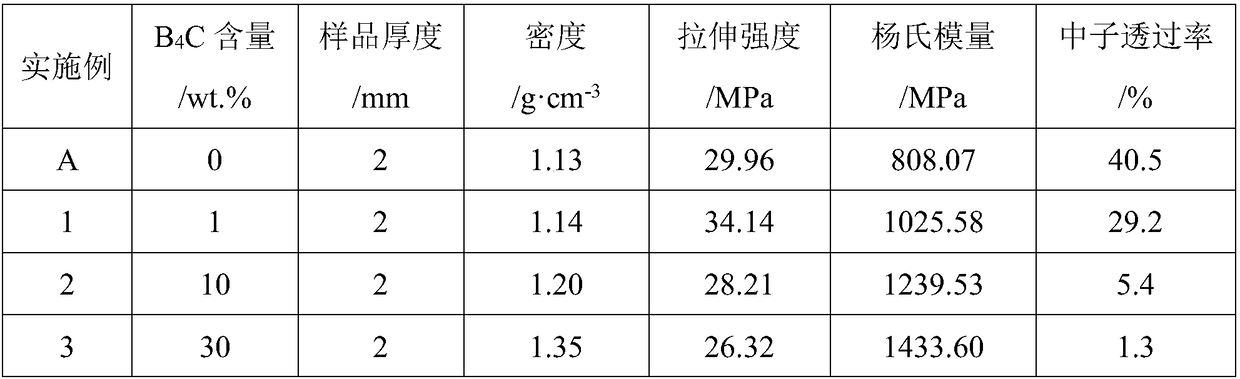

Epoxy-resin-based neutron shielding material and method for preparing same

The invention discloses an epoxy-resin-based neutron shielding material and a method for preparing the same. The epoxy-resin-based neutron shielding material is prepared from epoxy resin matrix composite boron carbide fillers. Epoxy resin for the epoxy-resin-based neutron shielding material is o-cresol-formaldehyde epoxy resin, a curing agent is phenolic resin, and a curing accelerator is imidazole or an imidazole compound. The epoxy-resin-based neutron shielding material and the method have the advantages that the epoxy-resin-based neutron shielding material which is an epoxy resin / boron carbide composite material prepared by the aid of the method is excellent in neutron shielding performance; processes are easy to operate and popularize and low in cost.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Ultraviolet-transmitting high-boron glass tube and preparation method thereof

PendingCN111825334AHigh in boronImprove purple transmittanceGlass furnace apparatusGlass forming apparatusAluminium hydroxideTitanium oxide

The invention discloses an ultraviolet-transmitting high-boron glass tube, which is prepared from the following raw materials by weight: 20-25 parts of boric acid, 12-18 parts of borax pentahydrate, 8-18 parts of anhydrous borax, 1-4 parts of aluminum hydroxide, 60-65 parts of quartz sand, 0.4-0.7 part of tartaric acid and 0.2-0.5 part of titanium oxide. The ultraviolet-transmitting high-boron glass tube provided by the invention has the characteristics of uniform outer diameter and wall thickness, good lamp working performance, high ultraviolet transmittance and the like; the preparation method comprises the following steps of: (1) uniformly mixing boric acid, borax pentahydrate, anhydrous borax, aluminum hydroxide, quartz sand, tartaric acid and titanium oxide, adding the mixture into anelectric melting furnace, completely melting the mixture into molten glass at 1480-1520DEG C, cooling the molten glass to 1000-1100DEG C, and enabling the molten glass to flow into a rotating pipe ofa forming machine; and (2) enabling the molten glass in the rotating pipe in the step (1) to enter a heat preservation box for homogenizing forming, then enabling the molten glass to flow into a cooling runway of 400-600DEG C, and enabling the molten glass to enter a dragger for drawing and cutting, thus obtaining the ultraviolet-transmitting high-boron glass tube. Standardized production of continuous feeding and continuous drawing is achieved through a Danla method (parallel drawing method).

Owner:驻马店市辉源照明器材有限公司

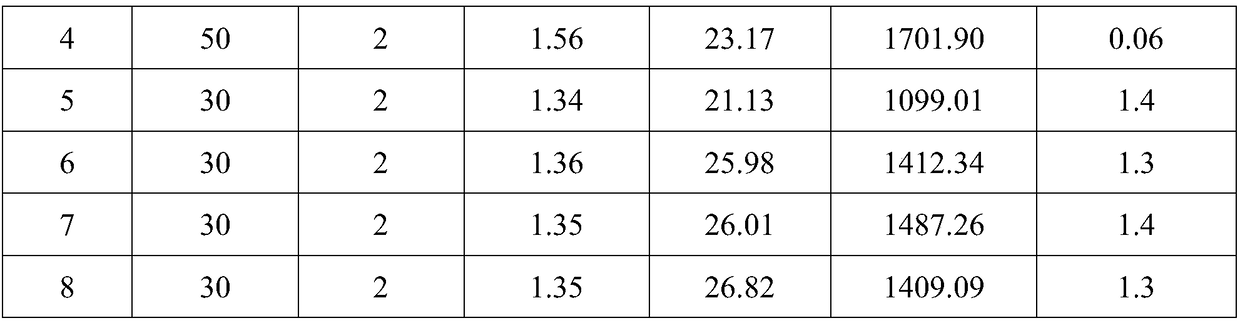

Preparation method of boronized ashless dispersant

The invention relates to a preparation method of a boronized ashless dispersant. The method comprises the following steps that firstly, an amine compound and epoxy glycidol are subjected to a ring-opening reaction to prepare an intermediate product amine; then, polyisobutene maleix anhydride, basic oil and the intermediate product amine are subjected to a reaction, and polyisobutene succinimide is prepared; finally, the polyisobutene succinimide, a boron compound and a solvent are subjected to a reaction to prepare the boronized ashless dispersant. According to the preparation method, the boron content, the hydrolytic stability and the low-temperature oil sludge dispersion performance of the boronized ashless dispersant are improved, and the product can be used for internal combustion engine oil, gear oil, transmission fluid and other lubricating oil.

Owner:PETROCHINA CO LTD

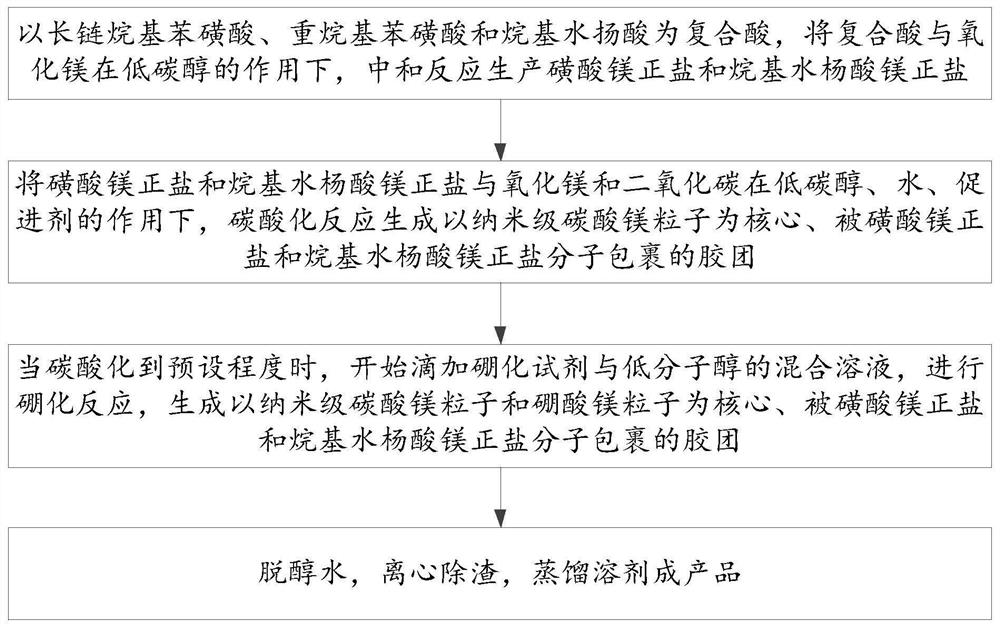

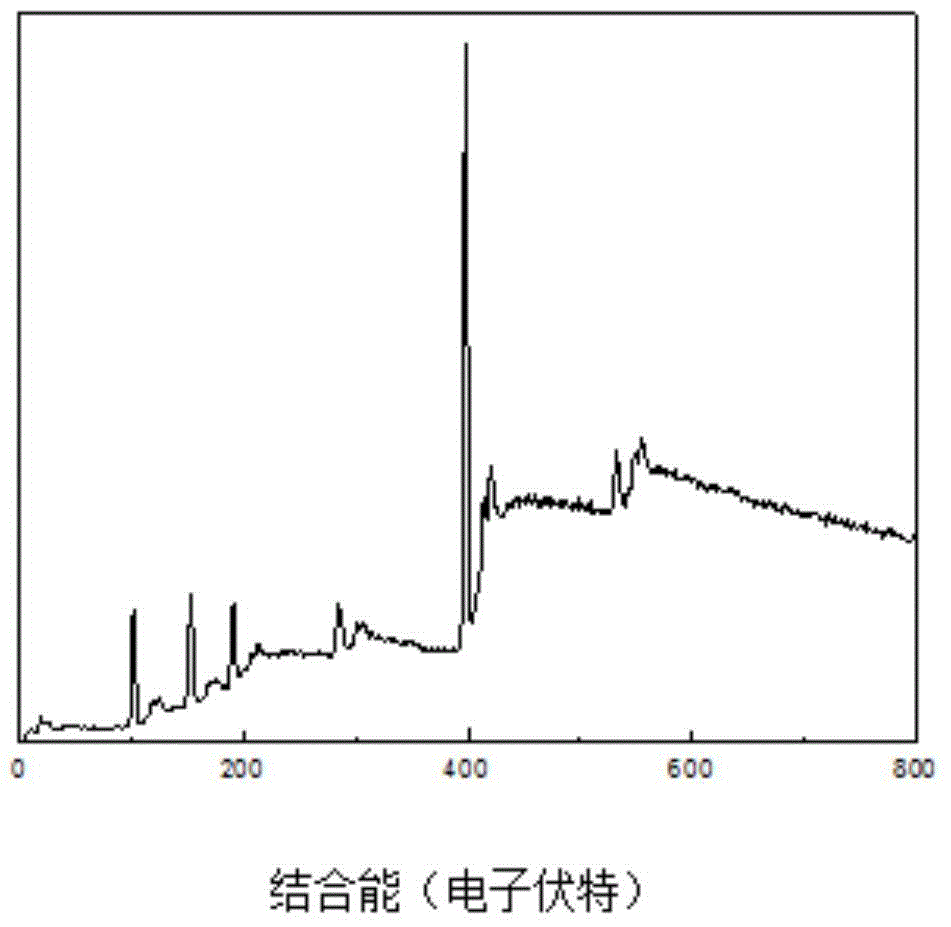

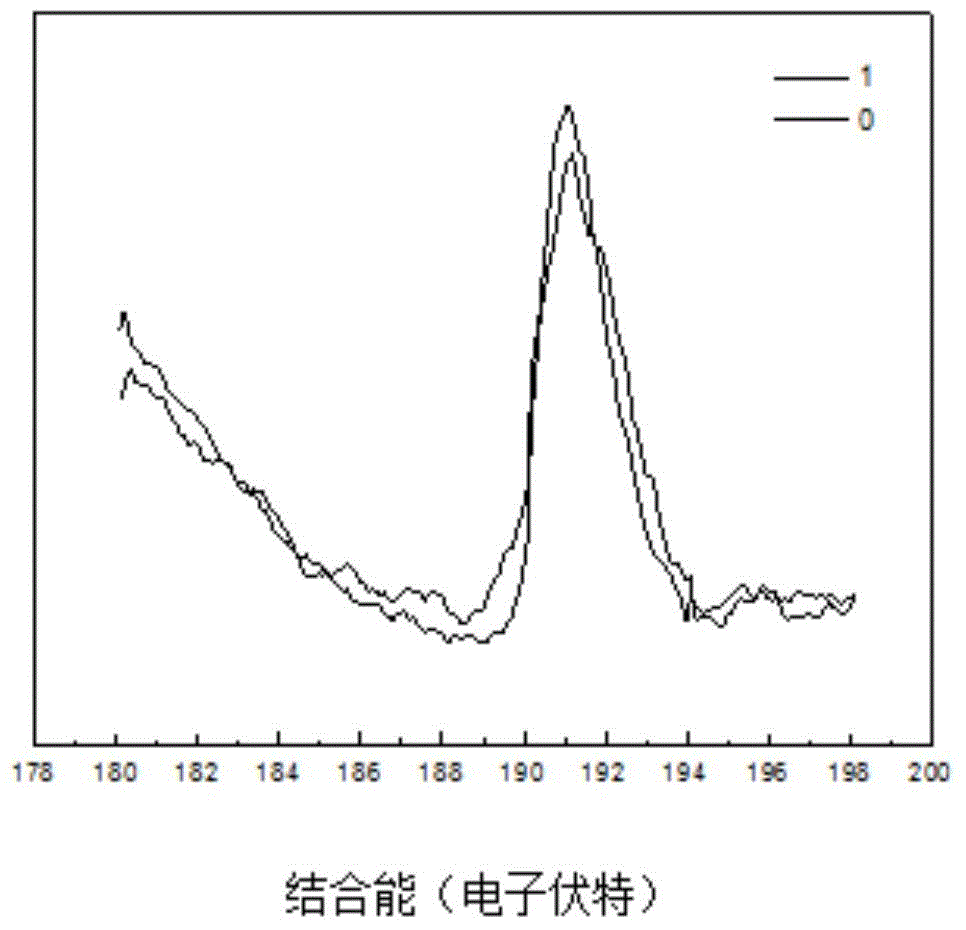

Preparation method of nanoscale high-boron-content composite acid magnesium detergent

The invention discloses a preparation method of a nanoscale high-boron-content composite acid magnesium detergent, and the method comprises the following steps: carrying out neutralization reaction on composite acid (long-chain alkyl benzene sulfonic acid, heavy alkyl benzene sulfonic acid and alkyl salicylic acid) and magnesium oxide to produce magnesium sulfonate normal salt and alkyl magnesium salicylate normal salt; carrying out carbonation reaction on magnesium sulfonate normal salt, alkyl magnesium salicylate normal salt, magnesium oxide and carbon dioxide to generate micelles which take nanoscale magnesium carbonate particles as cores and are wrapped by magnesium sulfonate normal salt and alkyl magnesium salicylate normal salt molecules; continuously dropwise adding a mixed solution of a boronizing reagent and low-molecular alcohol, and carrying out boronizing reaction to generate micelles which take nanoscale magnesium carbonate particles and magnesium borate particles as cores and are wrapped by magnesium sulfonate normal salt and alkyl magnesium salicylate normal salt molecules; ad removing alcohol water, centrifugally removing slag, and distilling the solvent to obtain the product. The prepared composite acid magnesium detergent has excellent detergency, oxidation resistance and wear resistance, and meanwhile, the product is low in viscosity and good in colloidal stability.

Owner:XINXIANG RICHFUL LUBE ADDITIVE CO LTD

Preparation method of boron-doped silicon nitride fiber

InactiveCN104894690AHigh activityPerfect synthesis technologyInorganic material artificial filamentsArtificial filament chemical after-treatmentNitrogenOptoelectronics

Disclosed is a preparation method of a boron-doped silicon nitride fiber. The preparation method comprises: preparing a high-activity Si-N fiber by adopting conversion of a dis-molten polycarbosilane fiber; realizing chemical introduction of the B element by utilizing HX elimination reaction between spare N-H in the high-activity Si-N fiber and borazine containing a B-X (X=H, Cl, Br, and I) bond; and performing nitridation in ammonia gas to prepare the boron-doped silicon nitride fiber. Compared with the prior art, the boron-doped silicon nitride fiber prepared through the method in the invention is relatively high in boron content, nitrogen content, and fiber strength, and is uniform in dispersion. According to the invention, the technology is simple; the cost is low; and no change is needed in a current decarburization-nitridation system, so that the preparation method is suitable for mass production.

Owner:NAT UNIV OF DEFENSE TECH

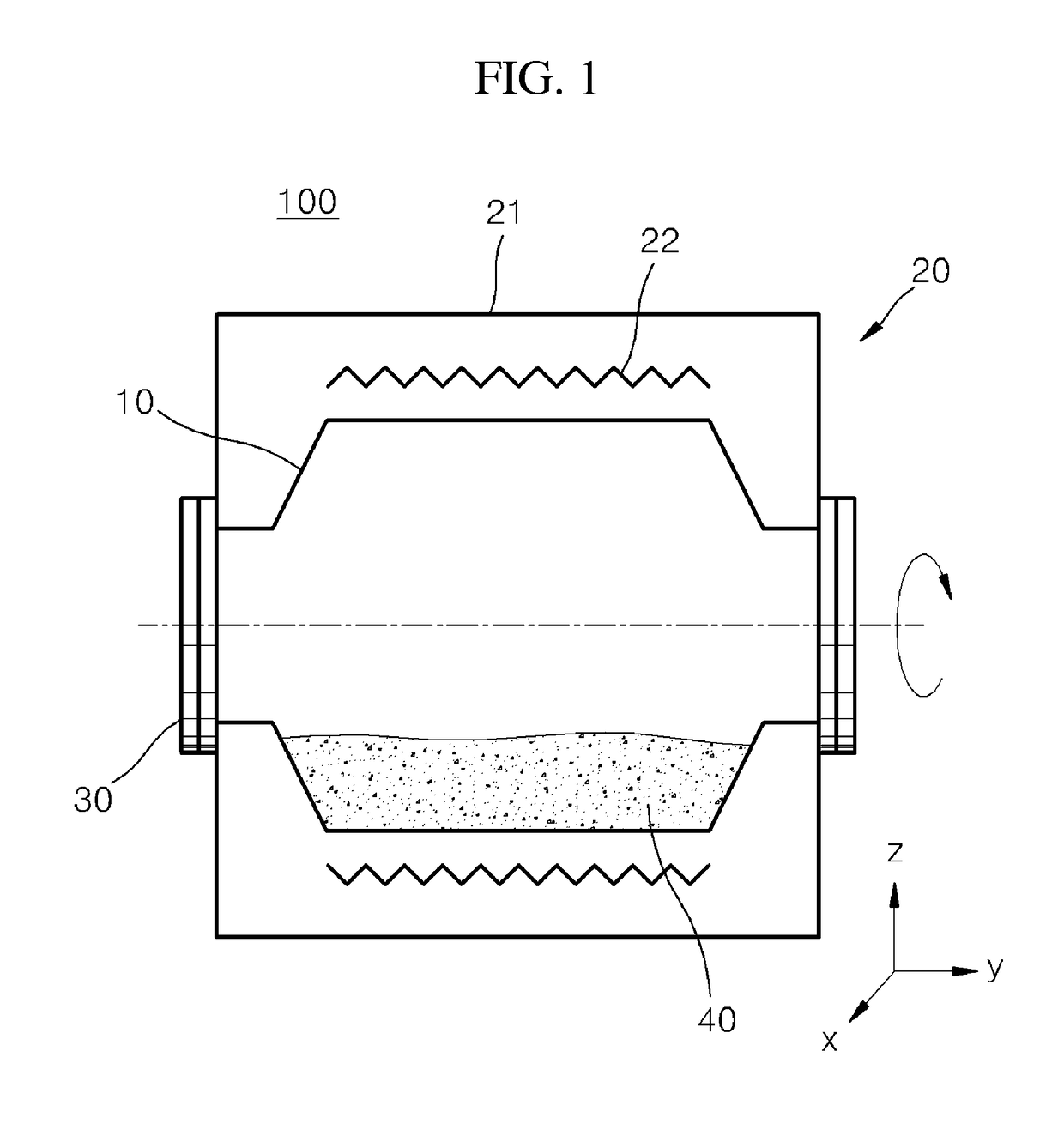

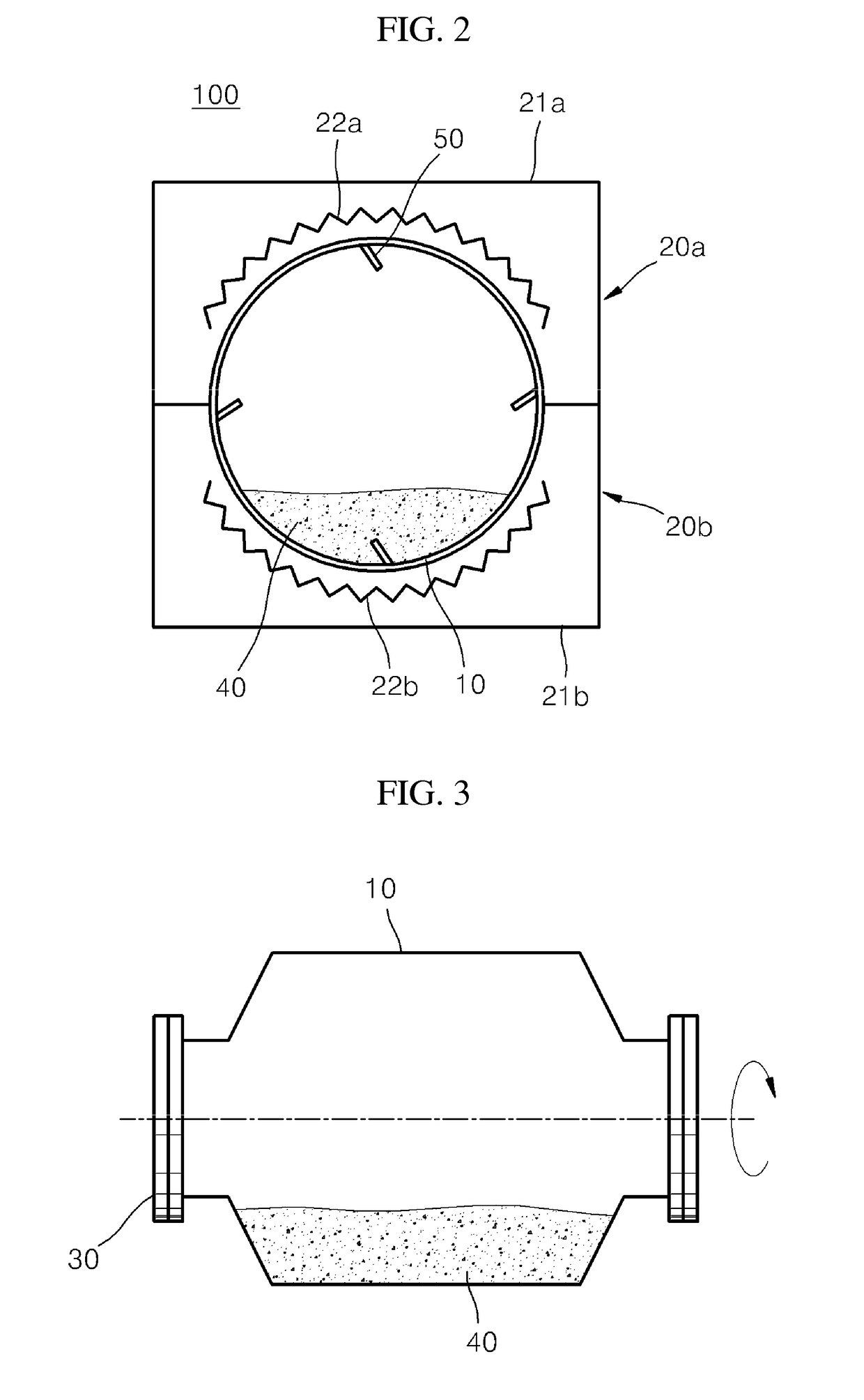

Apparatus for manufacturing compound powder, method of manufacturing iron-boron compound powder by using the apparatus, boron alloy powder mixture, method of manufacturing the boron alloy powder mixture, combined powder structure, method of manufacturing the combined powder structure, steel pipe, and method of manufacturing the steel pipe

ActiveUS9725789B2High hardnessExcellent self-fluxingHeat treatmentsTransportation and packagingPowder mixtureAlloy

Owner:KMT CO LTD

Three-dimensional continuous network hydrophilic boron-doped diamond radiator and preparation method and application thereof

ActiveCN111647873AImprove wettabilityMaintain thermal conductivityChemical vapor deposition coatingPhysicsChemistry

The invention discloses a three-dimensional continuous network hydrophilic boron-doped diamond radiator and a preparation method and application thereof. The hydrophilic boron-doped diamond radiator comprises a three-dimensional continuous network metal framework, a diamond layer and a boron-doped diamond layer, the diamond layer is arranged on the surface of the three-dimensional continuous network metal framework, the boron-doped diamond layer is arranged on the surface of the diamond layer, the boron content in the boron-doped diamond layer is gradually increased from bottom to top, and micropores and / or pointed cones are distributed on the surface of the boron-doped diamond layer. According to the three-dimensional continuous network hydrophilic boron-doped diamond radiator and the preparation method and application thereof, the diamond film layer with excellent heat conduction performance is prepared on the surface of the three-dimensional continuous network metal framework firstly, then the boron-doped diamond layer with function modification performance is arranged on the surface of the diamond film layer, gradient setting is carried out during boron doping, trace boron doping is adopted for the bottom layer making contact with the diamond layer, purity is kept, and heat conductivity is guaranteed, then the boron doping concentration is gradually increased, so that the top layer adopts the relatively high boron content, and high-temperature heat treatment is used in combination to obtain excellent hydrophilicity.

Owner:CENT SOUTH UNIV

Surface treatment method for nuclear reactor waste container

ActiveCN110643920AMeet structural strength requirementsExtended service lifeMolten spray coatingPortable shielded containersNuclear reactorComposite pellet

The invention discloses a surface treatment method for a nuclear reactor waste container. The method includes the following steps of S1, mixing Al alloy and B<4>C powder in the mass ratio of 5-7% to 30-95% for 60-240 min by using a high-speed mixer to obtain mixed powder; S2, carrying out ultrasonic screening on the surface of the mixed powder obtained in the S1 by using ultrasonic waves to obtainB<4>C / Al composite particles; S3, directly spraying the B<4>C / Al composite powder in the S2 onto the surface of the nuclear reactor waste container through a spray gun by adopting a hypersonic flamespraying method to obtain a layer of B<4>C / Al composite coating, and then repeatedly spraying the B<4>C / Al composite powder back and forth on the surface of the nuclear reactor waste container throughthe spray gun to stack the B<4>C / Al composite coatings layer by layer, wherein the thickness of each layer of the B<4>C / Al composite coating is 10-20 micrometers. The structural strength requirementof the container is met, the aim of radioactive shielding is achieved, the bonding force of the B<4>C / Al composite coatings to the nuclear reactor waste container and the density of the B<4>C / Al composite coatings are improved, the porosity of the B<4>C / Al composite coatings is reduced, and it is ensured that B<4>C is uniformly dispersed.

Owner:上海离原环境科技有限公司

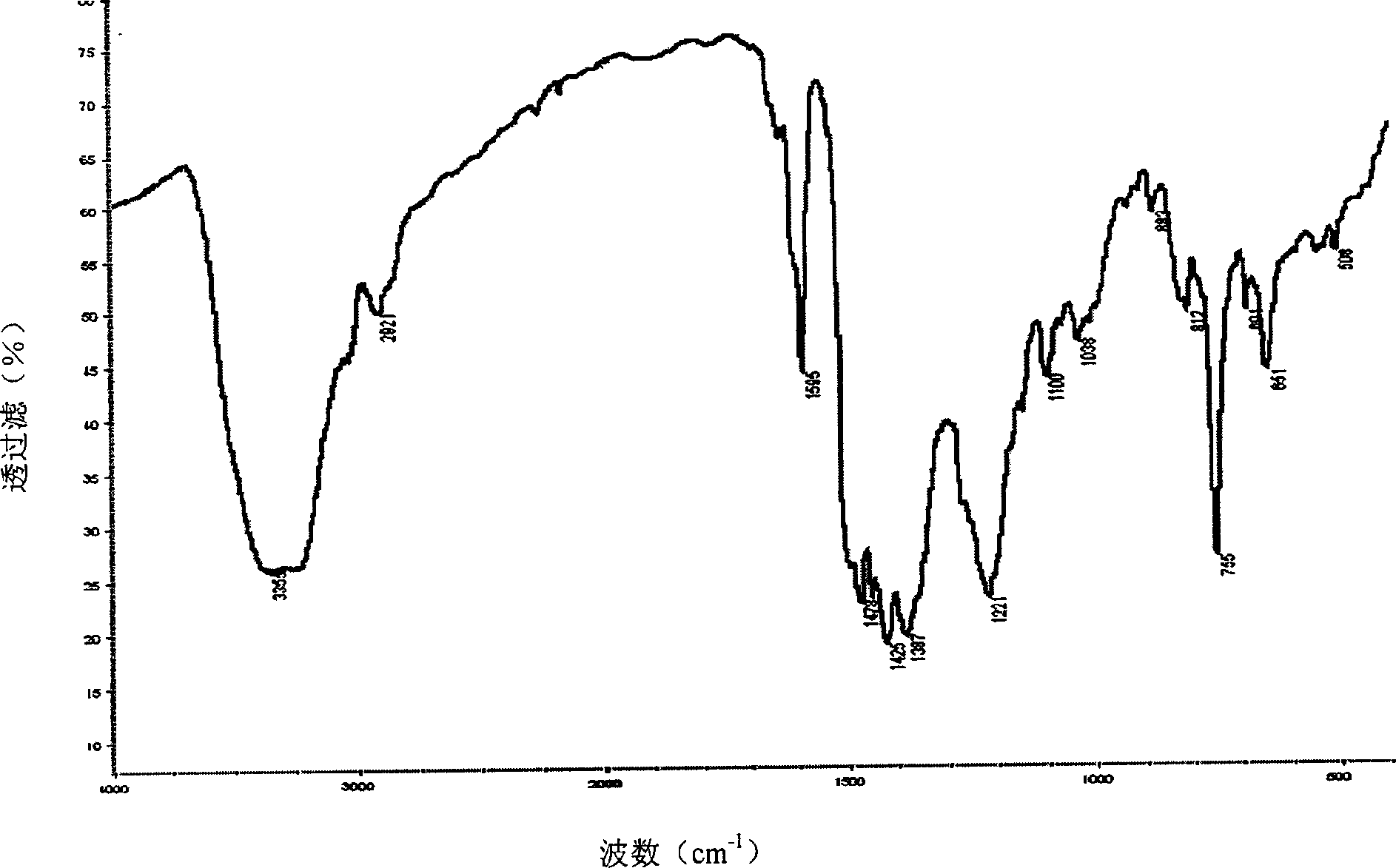

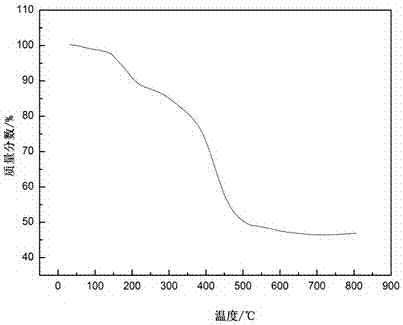

Modified phenolic resin for friction material and preparation method thereof

InactiveCN105294963BImprove heat resistanceImprove toughnessOther chemical processesPolymer scienceBoric acid

The invention discloses a modified phenolic resin for friction materials and a preparation method thereof, belonging to the technical field of modified phenolic resins. The preparation method comprises the following steps: (1) cardanol-formaldehyde reaction: mixing cardanol, catalyst A and formaldehyde , react at a temperature of 50-80°C for 0.5-5h, then add phenol in batches, after reacting for 1-5h, under a vacuum of 0.02-0.04MPa and a temperature of 60-90°C, dehydration under reduced pressure for 0.5-2h; (2) Polymerization reaction: add boric acid, nano ZrO2 and catalyst B to the product obtained in step (1), at a temperature of 100-110°C, a vacuum of 0.05-0.08MPa, dehydration reaction under reduced pressure for 1-5h, and heat up After reaching 120-160°C, the material is discharged to obtain the finished product. The modified phenolic resin prepared by this method is applied to friction materials, which can make the friction materials have excellent thermal properties, mechanical properties and friction properties.

Owner:WUHAN YOUFIN FRICTION MATERIAL +2

Smelting method for stably increasing content of boron in boron-containing steel

The invention relates to a smelting method for stably increasing the content of boron in boron-containing steel. The smelting method is characterized in that high-carbon ferromanganese, high-carbon ferrochromium and iron-core aluminum are subjected to the deoxidation alloying in the steel tapping process of a converter, and a whole-course bottom argon blowing and wash heat technology is adopted for reducing oxygen content and nitrogen content in the steel; after steel tapping is completed, molten steel is lifted to an argon station, and the molten steel is converted to an LF (Ladle Furnace) after ferroaluminium is added for adjusting the activity of oxygen in the steel to a required control range; and submerged arc operation, soft argon blowing control, a deep deoxidation technology and a titanium alloy technology are adopted for refining in the LF, then boron alloying is carried out, and later the long-time soft argon blowing is carried out, thus the recovery rate of boron in the steel reaches 82%-86%, the problems of low and instable recovery rate of boron are solved, the fluctuation quantity between the furnaces is less than 0.0005%, the ideal control level is achieved, the dependence of boron alloying on vacuum refining is eliminated, and the requirement of subsequent process for the quality of the boron-containing steel is ensured.

Owner:WUKUN STEEL

Special fertilizer for open-field muskmelons and application method

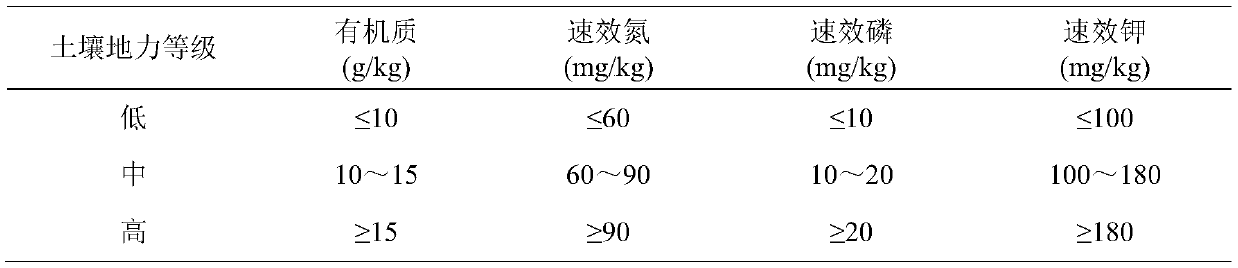

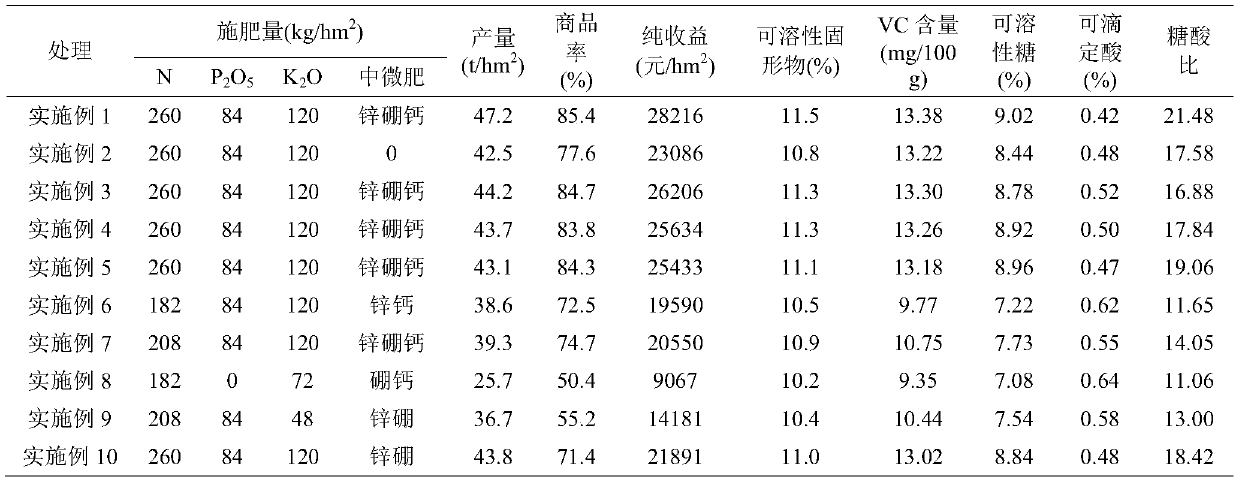

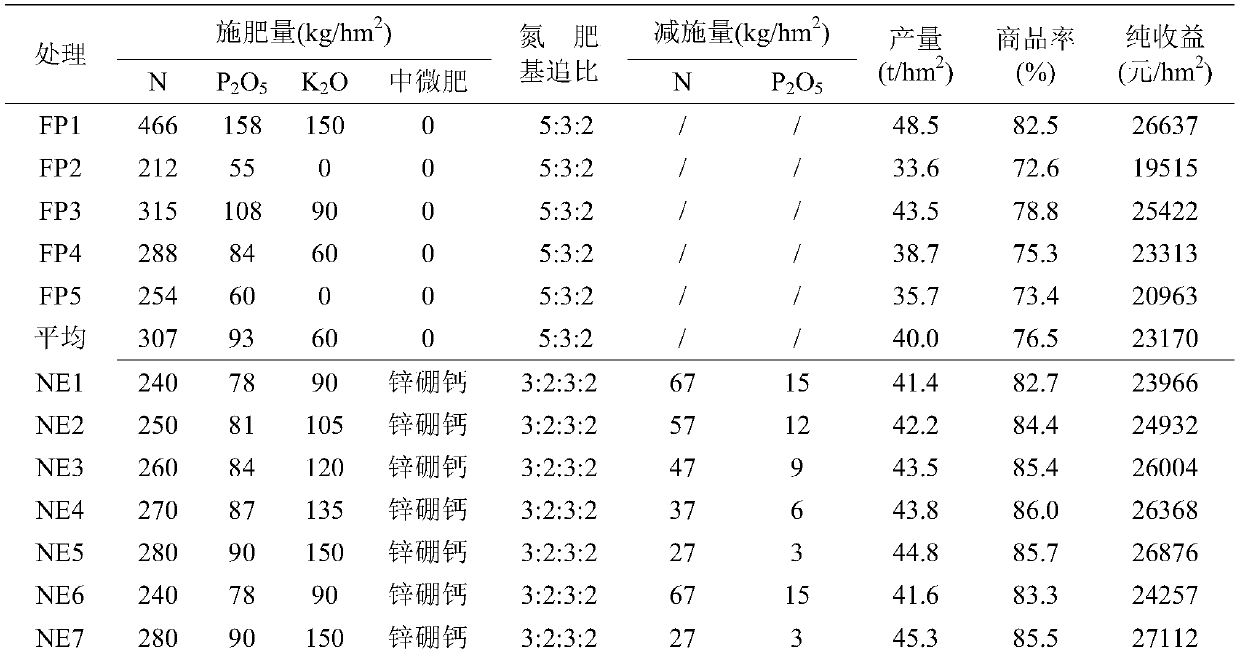

PendingCN111454090AAvoid wastingAvoid luxury absorptionFertilising methodsFertilizer mixturesBiotechnologyPhosphorus fertilizer

The invention provides a special fertilizer for open-field muskmelons. The special fertilizer consists of four groups of fertilizers A, B, C and D, wherein the group A fertilizer is prepared from 72.0to 84.0 kg / hm2 of N, 78.0 to 90.0 kg / hm2 of P2O5 and 36.0 to 60.0 kg / hm2 of K2O; the fertilizer in the group B comprises 48.0-56.0 kg / hm2 of N; the fertilizer in the group C comprises 72.0-84.0 kg / hm2 of N; the fertilizer of the group D comprises 48.0 to 56.0 kg / hm2 of N and 54.0 to 90.0 kg / hm2 of K2O; wherein the application amounts of N, P2O5 and K2O are based on pure nutrient amounts. Methodsof application are also provided. When the special fertilizer is applied, compared with habitual fertilization of farmers, the nitrogen fertilizer consumption is reduced by 15.2% on average, the phosphate fertilizer consumption is reduced by 9.7%, the muskmelon yield is increased by 8.4%, and the pure income is increased by 11.3%.

Owner:INST OF SOIL FERTILIZER & WATER SAVING AGRI GANSU ACAD OF AGRI SCI

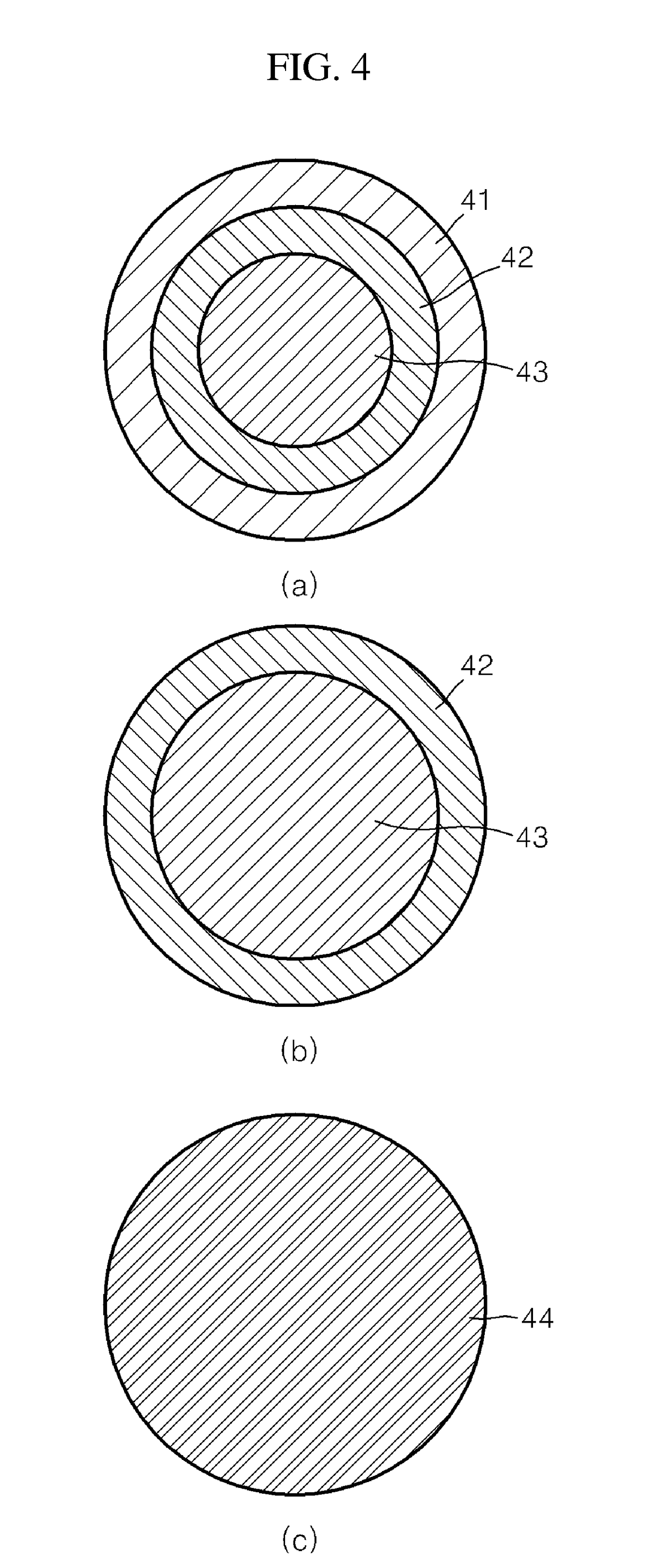

A kind of anti-radiation stainless steel plate and its preparation method and application

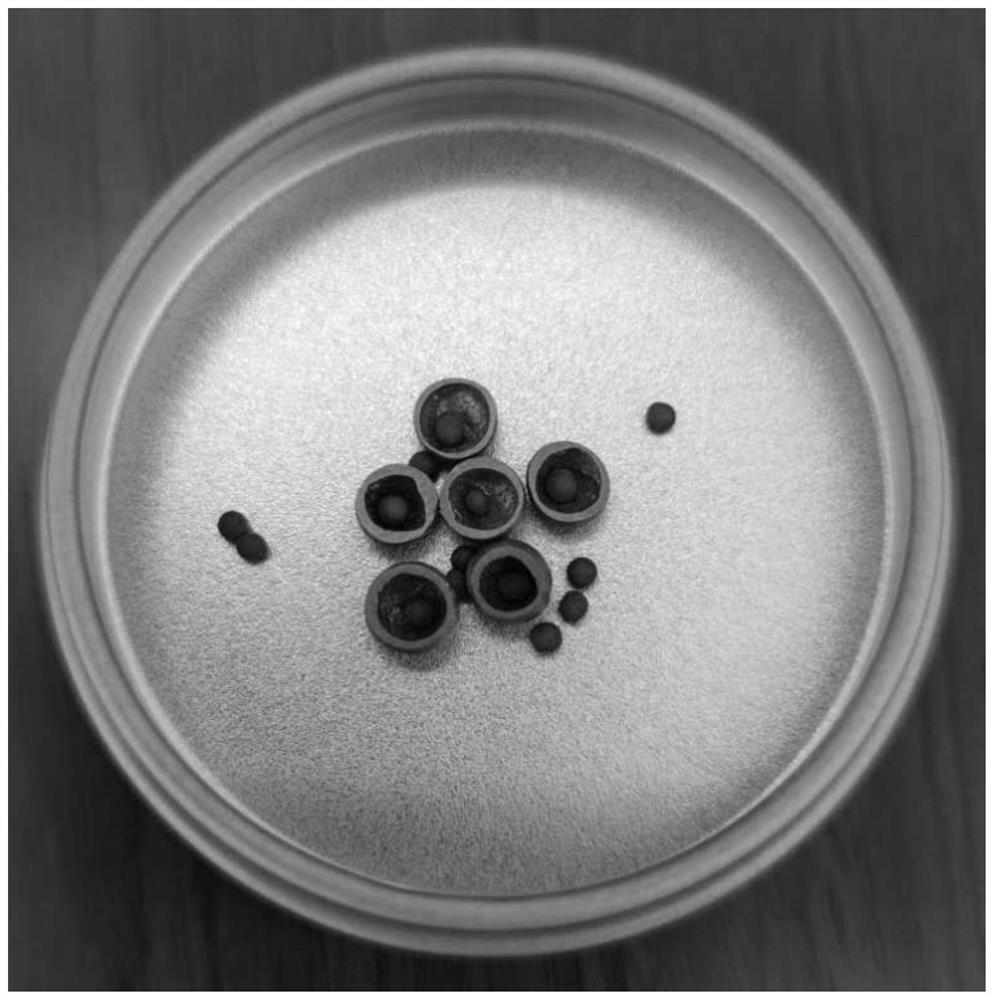

ActiveCN112045184BLow densityHigh in boronTransportation and packagingMetal-working apparatusCompression moldingSS - Stainless steel

The invention provides a radiation-resistant stainless steel plate, which is prepared by injection molding or compression molding after mixing several composite balls and stainless steel powder, wherein the structure of the composite ball includes a hollow spherical shell and a core, and the inner wall of the hollow spherical shell There is a gap between the core and the inner core; the anti-radiation stainless steel plate provided by the present invention is made by mixing composite balls with the ability to shield gamma rays and neutrons with stainless steel powder, which reduces the weight of the plate on the one hand. Density, on the other hand, makes the plate have the ability to shield gamma rays and neutrons at the same time, and, because the interior of the composite ball has a gap, there is room for the helium generated when shielding and absorbing neutrons, effectively avoiding the helium Cracks occur inside the plate, which can increase the boron content of the plate, thereby improving the ability to shield and absorb neutrons.

Owner:成都邦普精密工业有限公司

A process method for adjusting the thickness of iron-based amorphous alloy strip

The invention relates to a process method for regulating the thickness of iron-based amorphous alloy strips. The invention can control the iron-based amorphous alloy strip thickness by using the process method of iron-based alloy melt composition and heat treatment temperature without changing the rapid solidification process conditions. The thickness of the crystal alloy strip is reduced, and the difficulty of preparing the iron-based amorphous alloy thick strip is reduced. The invention has the characteristics of low implementation cost, high efficiency, strong controllability and repeatability, high technical reliability, etc., and is suitable for wide application in the technical field of metal functional material preparation.

Owner:江苏中科启航新材料工业研究院有限公司 +3

A kind of preparation method of boron-containing silicon nitride fiber

InactiveCN104846484BHigh activityPerfect synthesis technologyInorganic material artificial filamentsArtificial filament chemical after-treatmentOptoelectronicsBoron nitride

The invention relates to a preparation method of silicon nitride fiber containing boron. Firstly, high-activity Si-N fiber is prepared by converting polycarbosilane non-melting fiber, then chemical introduction of a B element is realized by utilizing H2 elimination reaction between excessive N-H in the high-activity Si-N fiber and high-chemical activity boron compound gas, and then nitridation is performed in ammonia gas, so as to prepare the silicon nitride fiber containing boron. Compared with the prior art, the silicon nitride fiber containing boron, which is prepared by adopting the method, has the advantages of high boron content, uniformity in distribution, high nitrogen content and high fiber strength. The preparation method has the advantages of simple process and low cost and is suitable for large-scale production, and an existing decarburization-nitridation system does not need to be changed.

Owner:NAT UNIV OF DEFENSE TECH

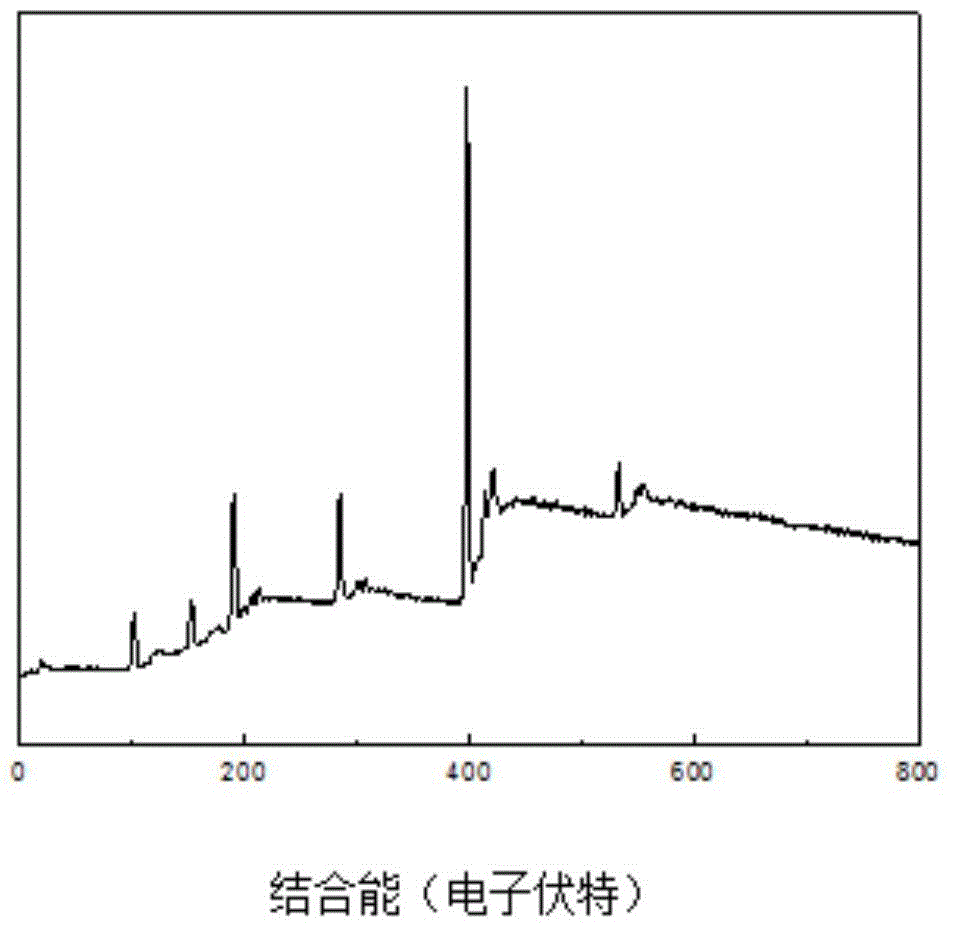

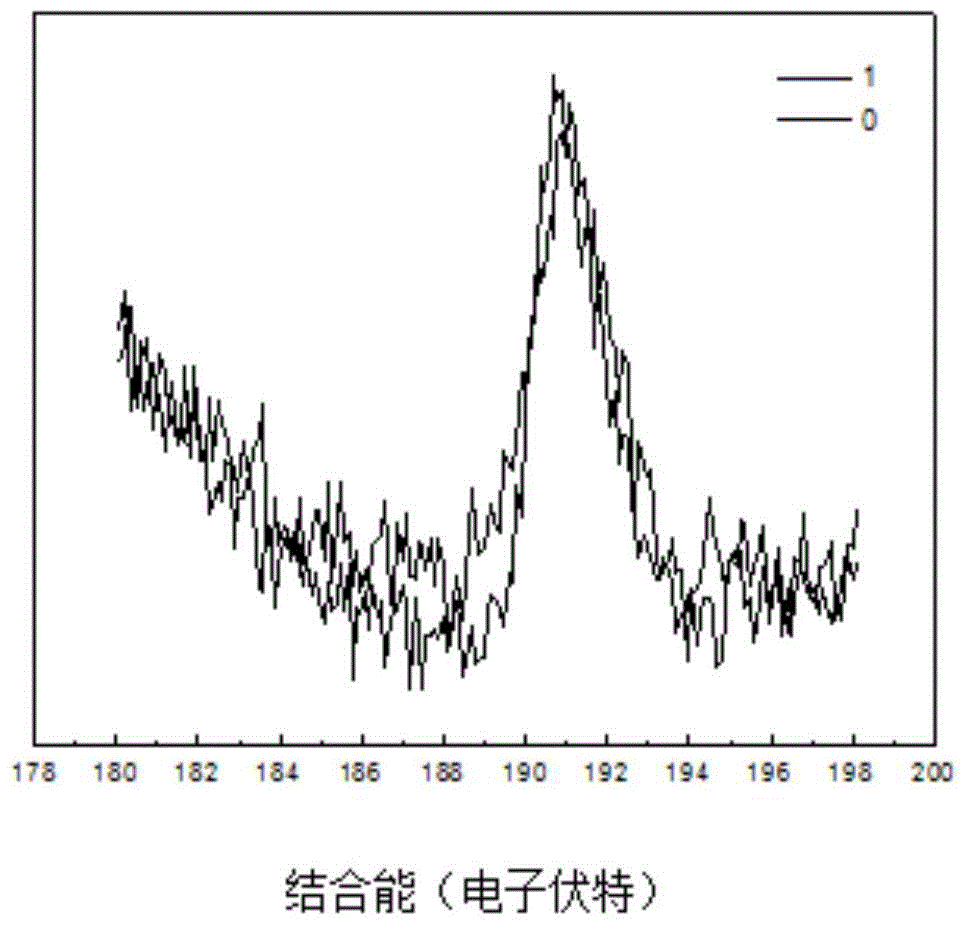

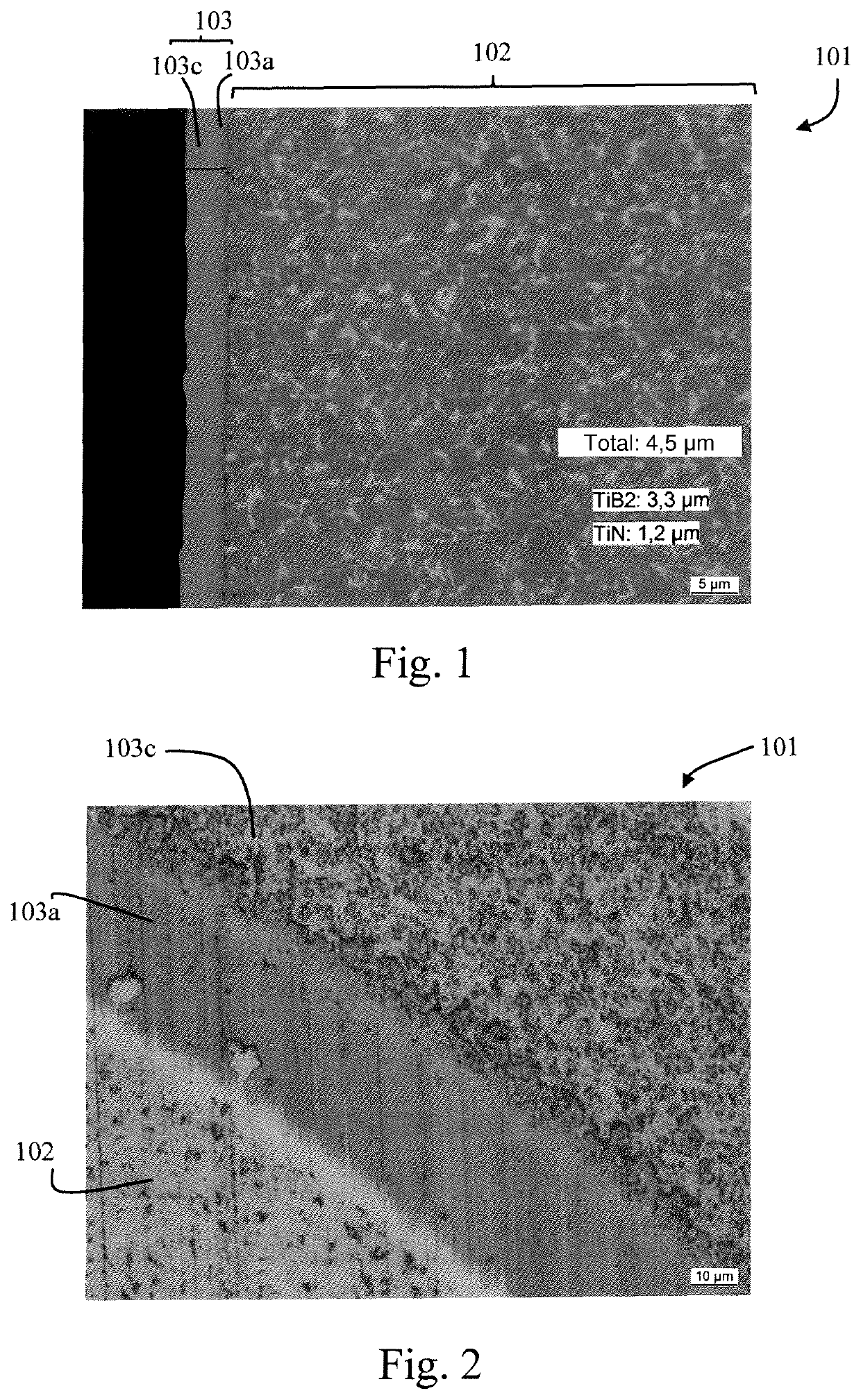

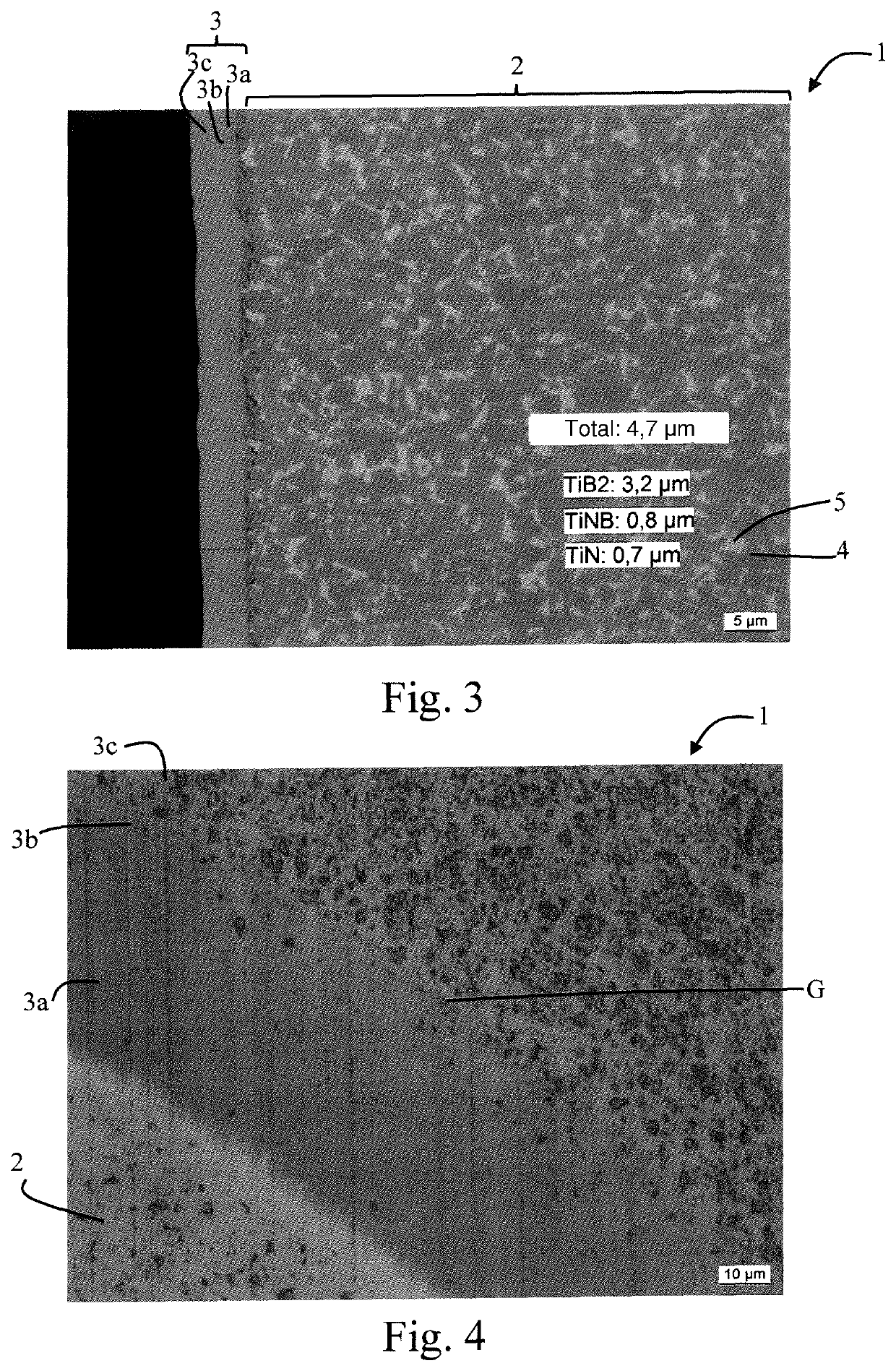

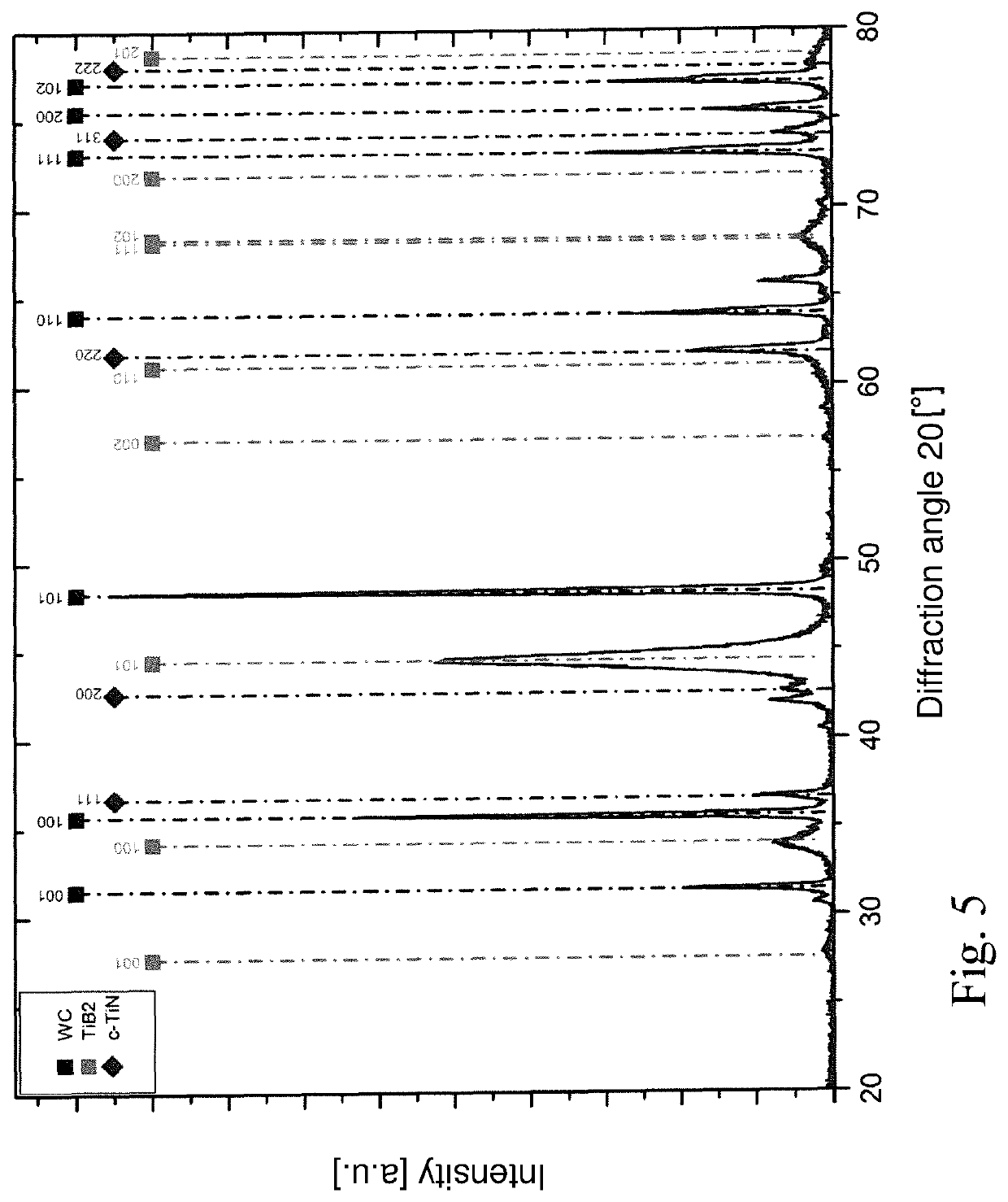

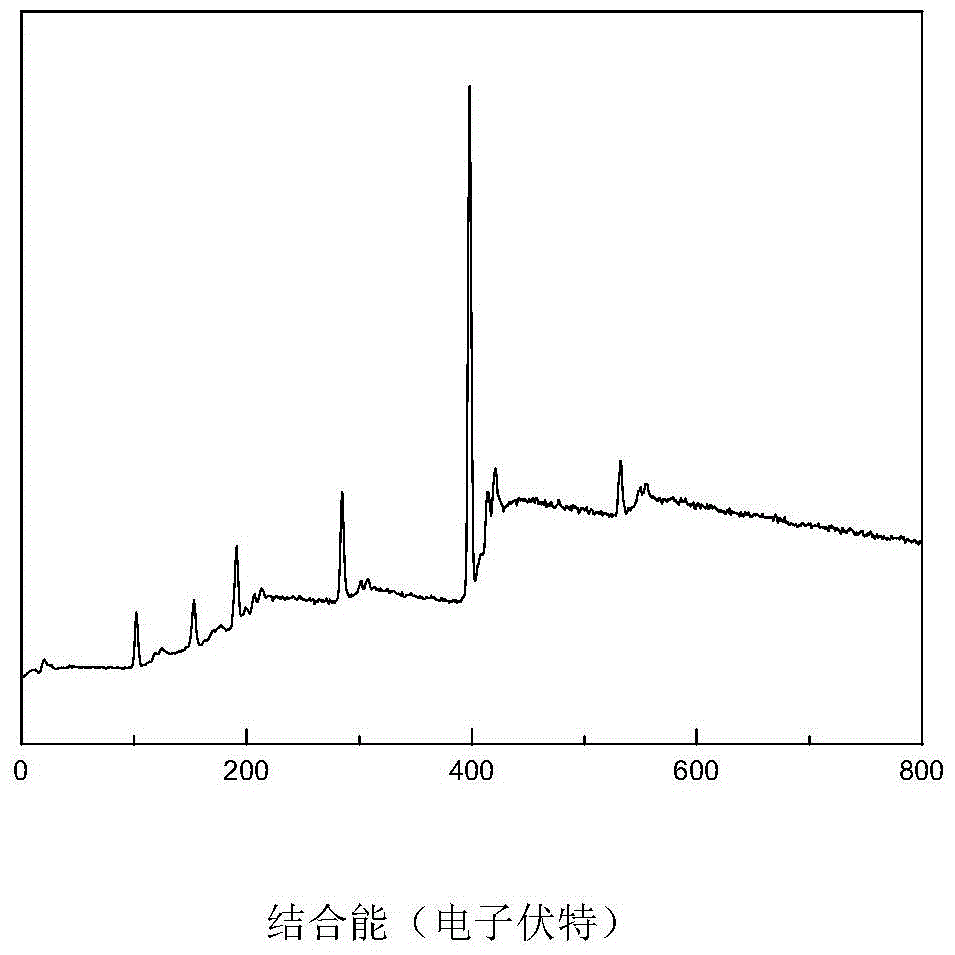

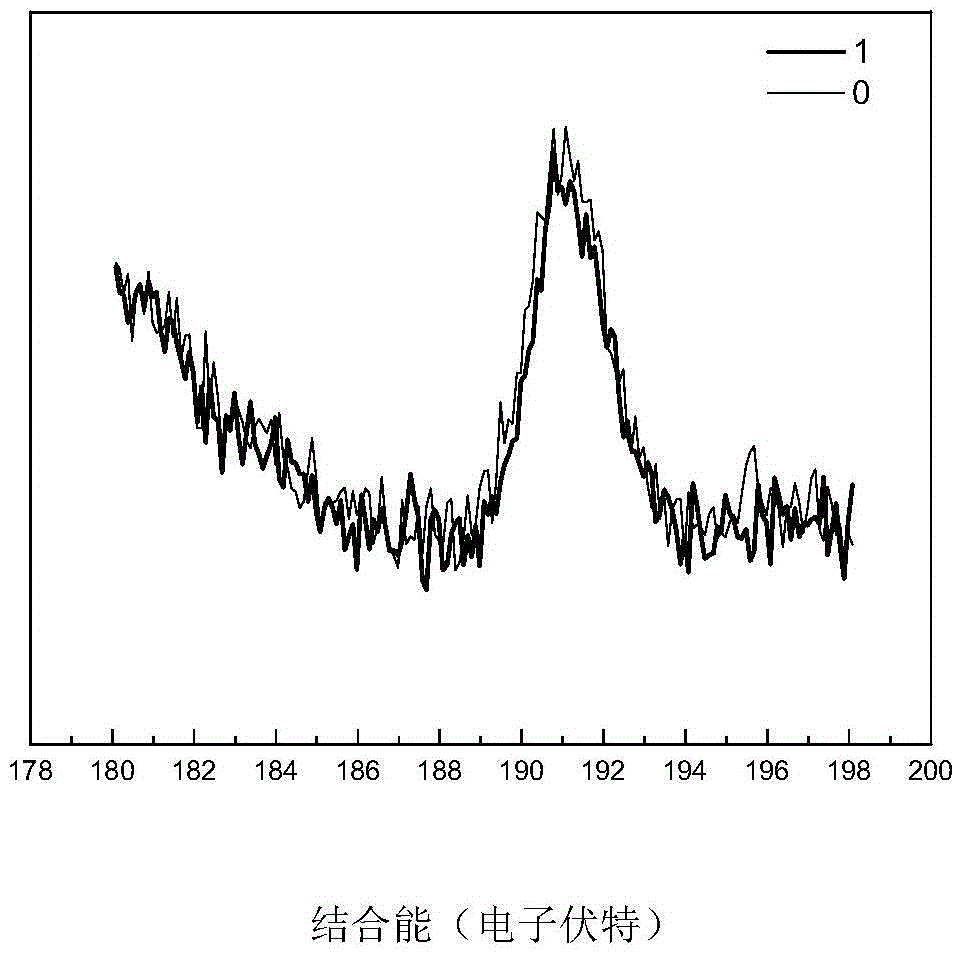

Coated tool

ActiveUS11104999B2Improved layer adhesionImprove adhesionMilling cuttersChemical vapor deposition coatingTitanium nitrideBoron nitride

A coated tool has a substrate and a hard material coating deposited on the substrate. The hard material coating has a layer structure in the following order, starting from the substrate: a titanium nitride layer, a titanium boron nitride transition layer, and a titanium diboride layer. The titanium boron nitride transition layer has a boron content that increases from the titanium nitride layer in the direction of the titanium diboride layer. The boron content does not exceed 15 at %.

Owner:CERATIZIT AUSTRIA GES

A kind of preparation method of boronizing silicon nitride fiber

InactiveCN104831420BPerfect synthesis technologyHigh activityInorganic material artificial filamentsDehydrogenationOptoelectronics

The invention relates to a preparation method of a boronized silicon nitride fiber. The preparation method comprises the steps of firstly preparing a high-activity Si-N fiber by transforming an infusible polycarbosilane fiber, carrying out dehydrogenation coupling reaction on excessive N-H in the high-activity Si-N fiber and B-H compounds generated by virtue of pyrolysis of boron hydrides so as to chemically introduce an element B, and carrying out boron hydrides in ammonia gas, so as to prepare the boronized silicon nitride fiber. Compared with the prior art, the boronized silicon nitride fiber prepared by virtue of the preparation method is relatively high in boron content, nitrogen content and fiber strength and relatively uniform in boron distribution. The preparation method has the advantages that the process is simple and convenient, and the cost is low. Compared with SiBN fiber prepared by virtue of a polyborosilazane precursor route, the preparation method has relatively great cost advantage and is applicable to large-scale production, and existing decarburization-nitridation systems do not need to be changed.

Owner:NAT UNIV OF DEFENSE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com