Preparation method of boronized silicon nitride fiber

A technology of silicon nitride fiber and fiber, which is applied in the direction of artificial filament of inorganic raw materials, can solve the problems of damage to the fibril structure, adverse effects on the spinnability of the precursor, and low content of B element, and achieve low cost and low equipment requirements , highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Preparation of highly active Si-N fibers. Put polycarbosilane non-melting fibers in the decarburization-nitriding system, vacuumize, and then replace the gas in the system with nitrogen to normal pressure, repeat at least three times; feed high-purity ammonia, heating system: 2 hours to 500 ℃, 0.50°C / min to 600°C, keep warm for 0.5h, 100°C / h to 1200°C, keep warm for 1h. Cool to room temperature with nitrogen gas to obtain highly active Si-N fibers; (2) Boronation of highly active Si-N fibers. In a nitrogen atmosphere, place the highly active Si-N fiber and sodium borohydride in a decarburization-nitridation system, program the temperature to 450°C, react for 20 hours, and cool to room temperature with nitrogen; (3) Nitrogen of the borated fiber change. Introduce high-purity ammonia gas, heat up to 1300°C for 6 hours, and keep warm for 2 hours. Cool to room temperature with nitrogen, Serve.

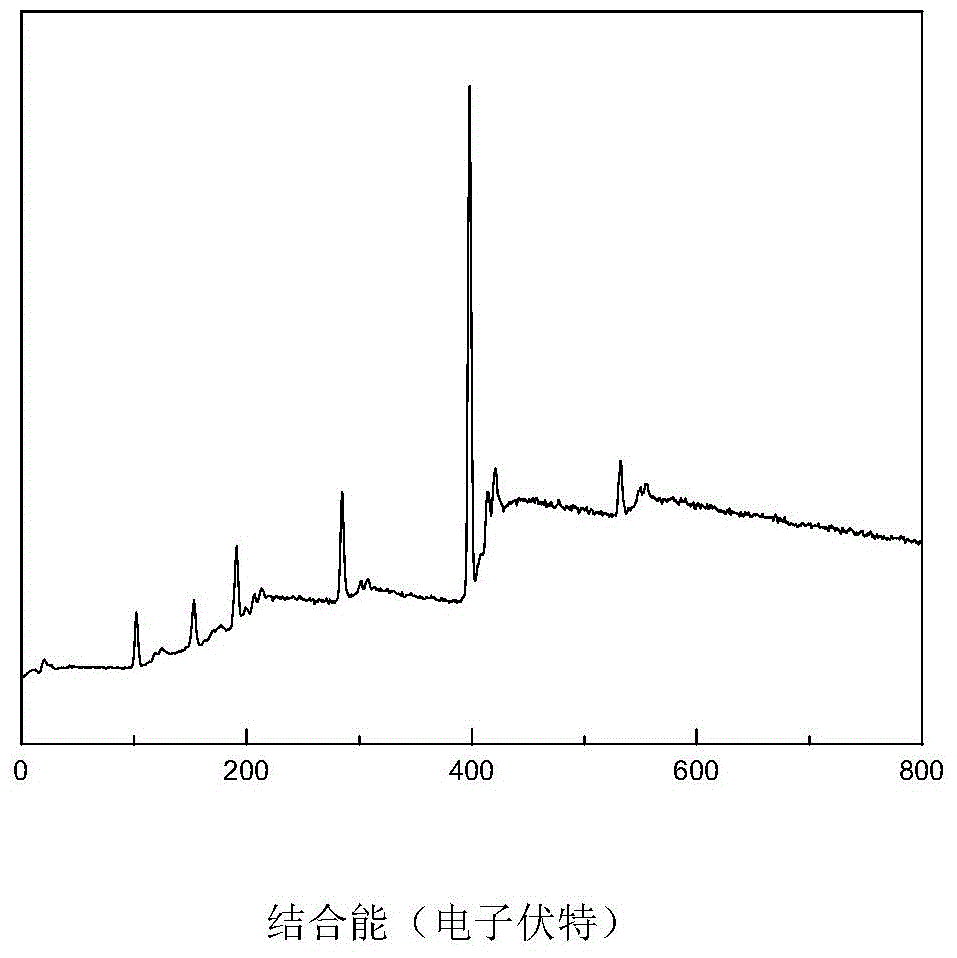

[0039] figure 1 X-ray photoelectron energy map (XPS) of the prepared b...

Embodiment 2

[0042] (1) Preparation of highly active Si-N fibers. Put polycarbosilane non-melting fibers in the decarburization-nitriding system, vacuumize, and replace the gas in the system with argon to normal pressure, repeat at least three times; feed high-purity ammonia gas, heating system: 2 hours to 500°C, 0.6°C / min to 600°C, heat for 0.5h, 100°C / h to 1000°C, hold for 2h. Cool to room temperature with argon to obtain highly active Si-N fibers; (2) Boronation of highly active Si-N fibers. In an argon atmosphere, place the highly active Si-N fiber and potassium borohydride in a decarburization-nitridation system, program the temperature to 480°C, react for 30 hours, and cool to room temperature with argon; (3) boronized fiber Nitriding. Introduce high-purity ammonia gas, heat up to 1350°C for 6 hours, and keep warm for 1 hour. Cool to room temperature with argon, and it's done.

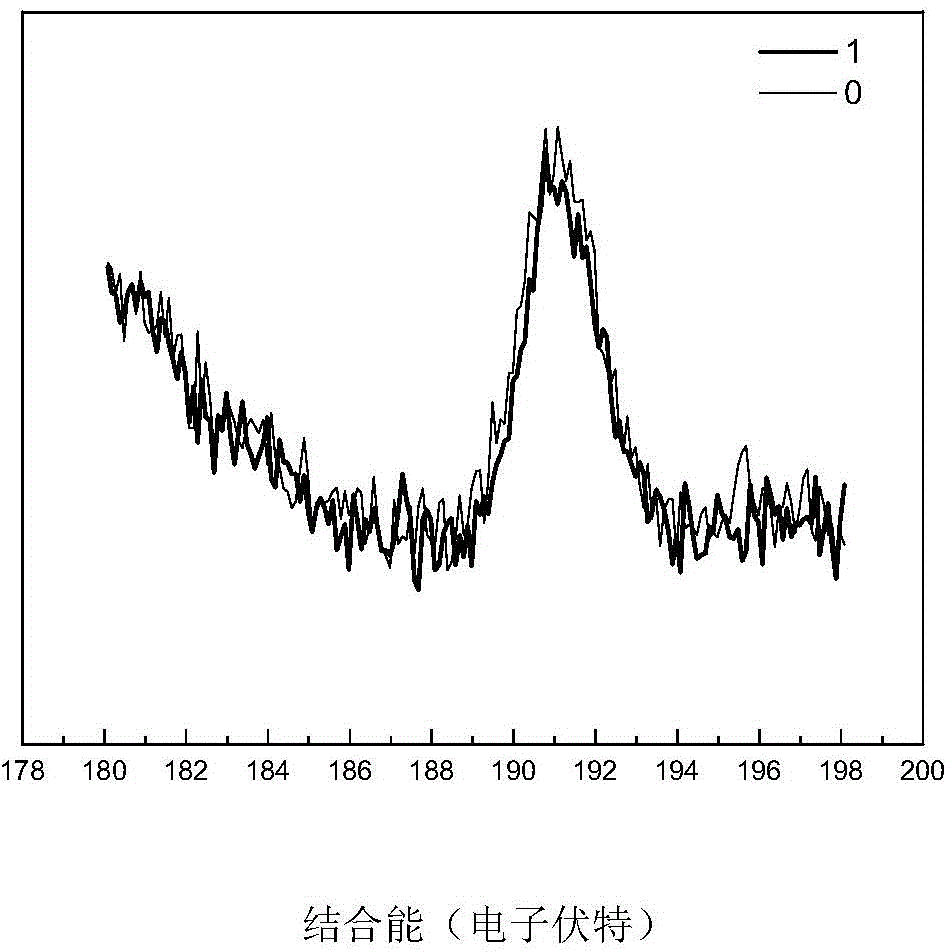

[0043] The X-photoelectron spectrum and radial B element X-ray photoelectron spectrum of the prepared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Monofilament strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Monofilament strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com