Epoxy-resin-based neutron shielding material and method for preparing same

A technology of epoxy resin and shielding materials, which is applied in the field of epoxy resin-based neutron shielding materials and its preparation, can solve problems such as health hazards, unfavorable mixing operations, and environmental pollution, and achieve good heat resistance, easy promotion, and The effect of high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

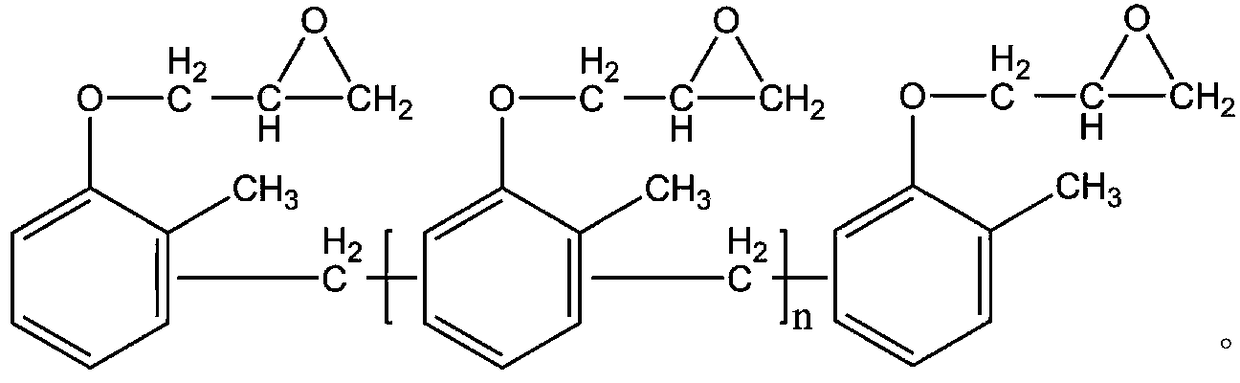

Image

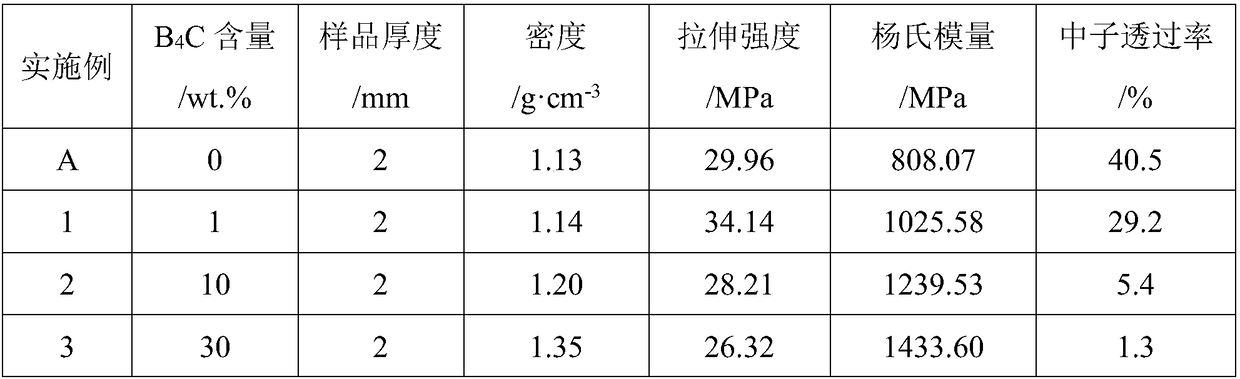

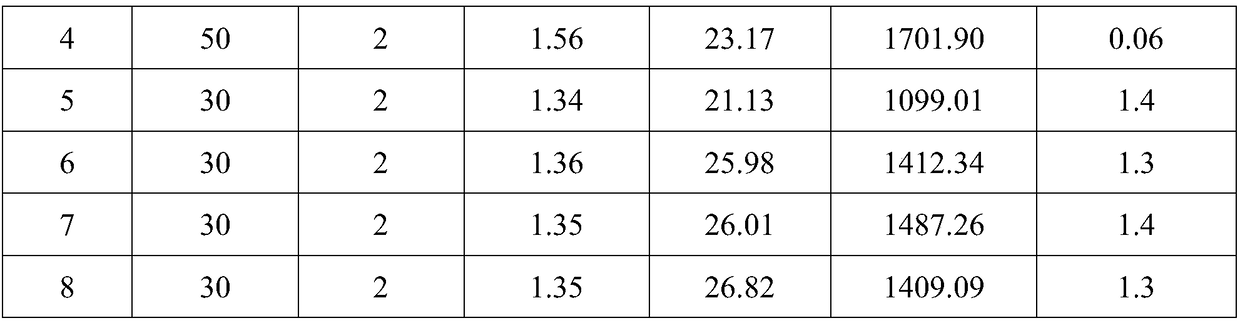

Examples

Embodiment 1

[0030] First grind and mix 6.8g of o-cresol novolac epoxy resin, 3.2g of phenolic resin, 0.1g of 2-methylimidazole and 0.101g of boron carbide, heat the mixture to 120°C and melt it, then heat-press the melted material, and finally It was heated to 180° C. for 15 minutes and then demolded.

Embodiment 2

[0032] First, crush and mix 6.8g of o-cresol novolac epoxy resin, 3.2g of phenolic resin, 0.1g of 2-methylimidazole and 1.1g of boron carbide, heat the mixture to 120°C and melt it, then heat-press the melted material, and finally It was heated to 180° C. for 15 minutes and then demolded.

Embodiment 3

[0034] First grind and mix 6.8g of o-cresol novolac epoxy resin, 3.2g of phenolic resin, 0.1g of 2-methylimidazole and 4.3g of boron carbide, heat the mixture to 120°C and melt it, then heat-press the molten material, and finally It was heated to 180° C. for 15 minutes and then demolded.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com