Silicone rubber foam material and preparation method thereof

A foaming material and silicone rubber technology, applied in the field of foaming materials, can solve problems such as deformation and cell wall adhesion, achieve excellent comprehensive performance, reduce cell compression deformation, and improve mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

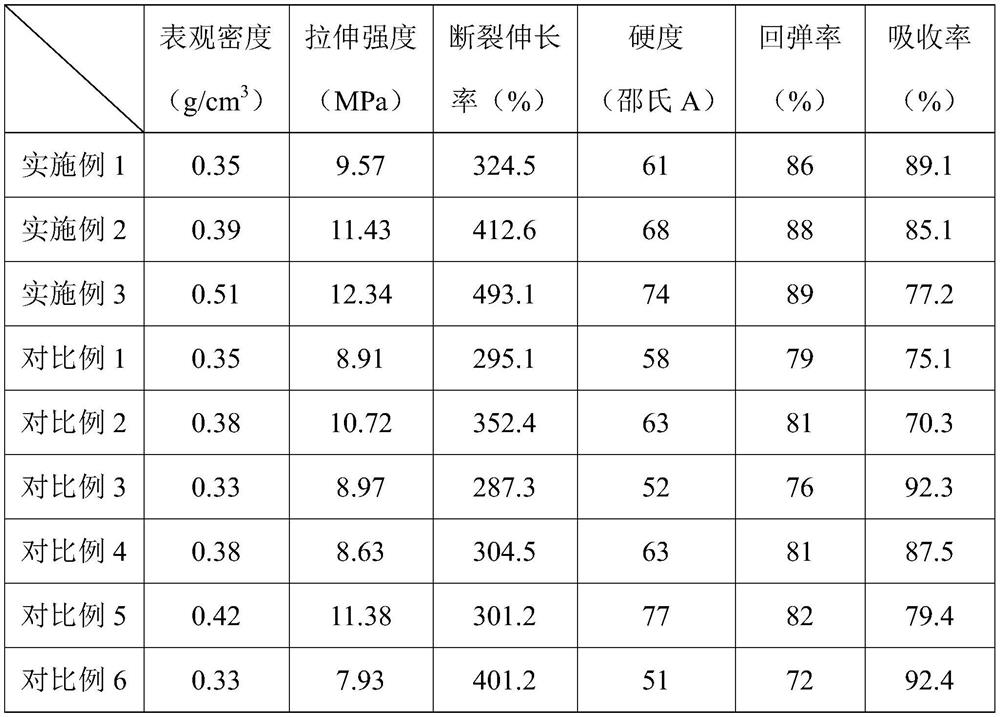

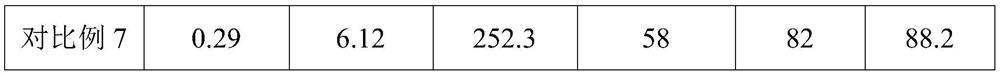

Examples

preparation example Construction

[0023] The preparation method of the silicone rubber foam material provided in the present invention comprises the following steps:

[0024] S1, the polydimethylsiloxane, boric acid and its derivatives and organic solvents are formulated into a polydimethylsiloxane solution, and polycondensation reaction is carried out, and then the unreacted boric acid and its derivatives and the organic solvent are removed to give a shear thickening gel;

[0025] S2, the shear thickening gel of 1 mass part -10 mass parts is mixed with 100 mass parts of silicone rubber containing vinyl to obtain a silicone rubber binder;

[0026] S3, the silicone rubber binder with 1 mass part -20 mass nanocellulose, 1 mass part -10 mass parts of the expanded microspheres, 0.01 mass part -0.5 mass part of the organic peroxide crosslinker for mixing, to obtain silicone rubber compound; and

[0027] S4, the silicone rubber compound is pre-formed and cross-linked foamed to obtain a silicone rubber foam material.

[...

Embodiment 1

[0049] 10 mass parts of hydroxyl-terminated dimethicone (kinematic viscosity of 65cSt), 0.5 parts of dried boric acid, 89.5 parts of mass toluene were added to the sealed container in turn, stirred at a speed of 120 rpm at 60 °C for 120 min, to obtain a uniform hydroxyl end polydimethylsiloxane solution, and the hydroxyl end polydimethylsiloxane solution was heated to 120 °C for condensation reaction, and the reaction was 12h at a stirring speed of 120 rpm. Polyborosiloxane solution is obtained. Then, the polyborosiloxane solution was filtered out of the unreacted boric acid particles with a pore size of 0.44 μm, the filtrate was poured into a glass dish, and placed in a vacuum oven at 80 °C, -3 MPa to dry for 24 h, the toluene was removed, and the shear thickening gel was obtained.

[0050] 100 parts of methyl vinyl silicone rubber (hardness 40A, molecular weight of 50×10 4g / mol, the molar fraction of vinyl is 0.55%), 10 mass shear thickening gel was added to the vacuum kneadin...

Embodiment 2

[0054] 10 mass parts of hydroxyl-terminated dimethicone (kinematic viscosity of 75cSt), 0.5 parts of dried boric acid, 89.5 parts of mass toluene were added to the sealed container in turn, stirred at a speed of 120 rpm at 60 ° C for 120 min, to obtain a uniform hydroxyl-terminated dimethicone solution, and the hydroxyl end polydimethylsiloxane solution was heated to 120 ° C for condensation reaction, and reacted at a stirring speed of 120 rpm for 12 h. Polyborosiloxane solution is obtained. Then, the polyborosiloxane solution was filtered out of the unreacted boric acid particles with a pore size of 0.44 μm, the filtrate was poured into a glass dish, and placed in a vacuum oven at 80 °C, -3 MPa to dry for 24 h, the toluene was removed, and the shear thickening gel was obtained.

[0055] 100 parts of methyl vinyl silicone rubber (hardness 40A, molecular weight of 50×10 4 g / mol, the molar fraction of vinyl is 0.55%), 10 mass shear thickening gel was added to the vacuum kneading m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| kinematic viscosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com