Procesing equipment capable of improving plate part formation limitation and method therefor

A technology of forming limit and processing device, used in forming tools, metal processing equipment, manufacturing tools, etc., can solve the problems of processing cost, long processing cycle, accumulation of multiple forming errors, and inability to realize part forming, so as to avoid cracking defects. , The effect of improving the uniformity of the wall thickness of the parts and not easy to scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

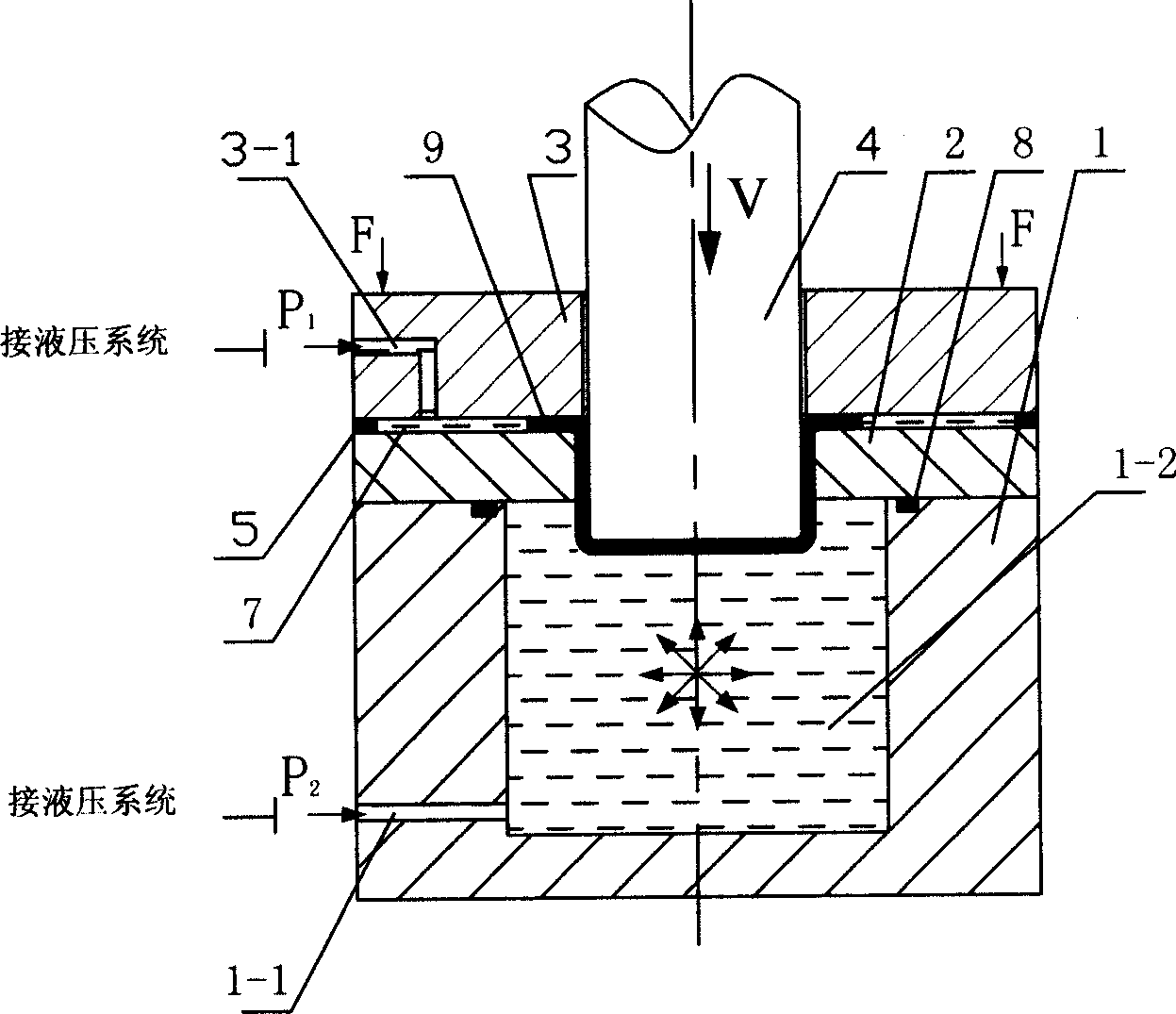

[0022] Specific implementation mode 1: This implementation mode is a processing device that can improve the forming limit of plate parts, refer to figure 1 , which includes a fluid medium cavity 1, the cavity 1 is provided with a liquid injection hole 1-1 communicating with the cavity 1-2, and the fluid medium is injected into the cavity 1 through the liquid injection hole 1-1 during operation; The upper end of the cavity 1 is open, and a lower die 2 is fixed above the cavity 1, and a sealing ring 8 is provided between the cavity 1 and the lower die 2 to prevent leakage of the fluid medium; The upper blankholder 3 and the punch 4, the blank 9 is sandwiched between the blankholder 3 and the lower die 2, the blankholder 3 is provided with a liquid injection hole 3-1, and the lower die 2 and the blankholder There is a gap 7 suitable for the thickness of the plate to be formed between the rings 3, and the liquid injection hole 3-1 communicates with the gap 7, so that the injected ...

specific Embodiment approach 2

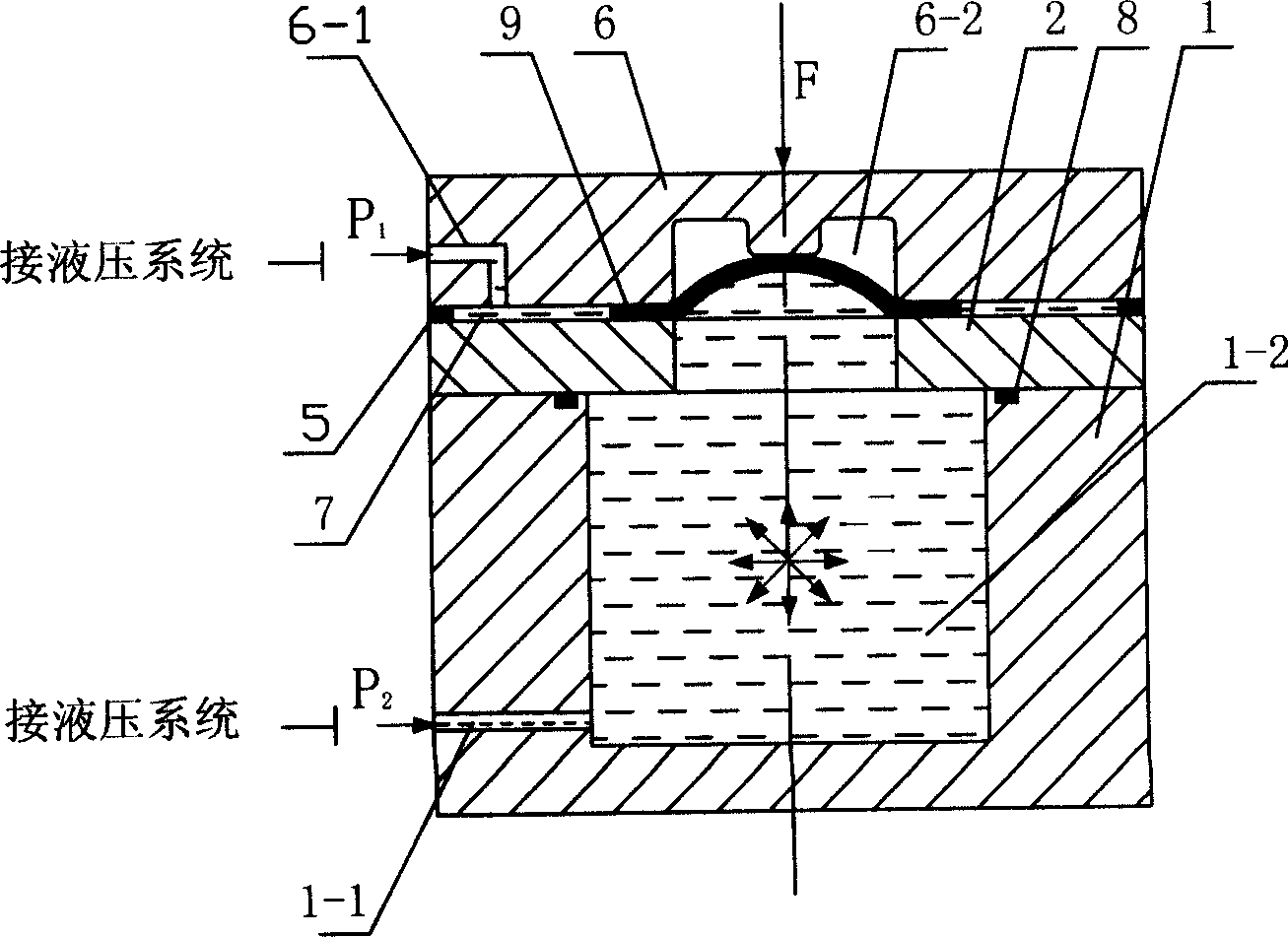

[0031] Specific implementation mode two: refer to figure 2 , this embodiment includes a fluid medium chamber 1, the chamber 1 is provided with a liquid injection hole 1-1 communicating with the chamber body 1-2, through which the liquid injection hole 1-1 is connected to the hydraulic system, the chamber can be 1 is injected with a fluid medium; the upper end of the cavity 1 is open, and a lower die 2 is fixed above the cavity 1, an inner hole is provided on the lower die 2, and a sealing ring is provided between the cavity 1 and the lower die 2 8, to prevent fluid medium leakage; it also includes a forming die 6 arranged above the lower die 2, a groove 6-2 is provided at a position where the lower bottom surface of the forming die 6 is adapted to the inner hole of the lower die 2, When working, the blank 9 is placed between the forming die 6 and the lower die 2, and the blank 9 is gradually deformed under the action of the fluid medium in the cavity 1 and abuts against the g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| plasticity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com