Patents

Literature

151results about How to "Not easy to bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

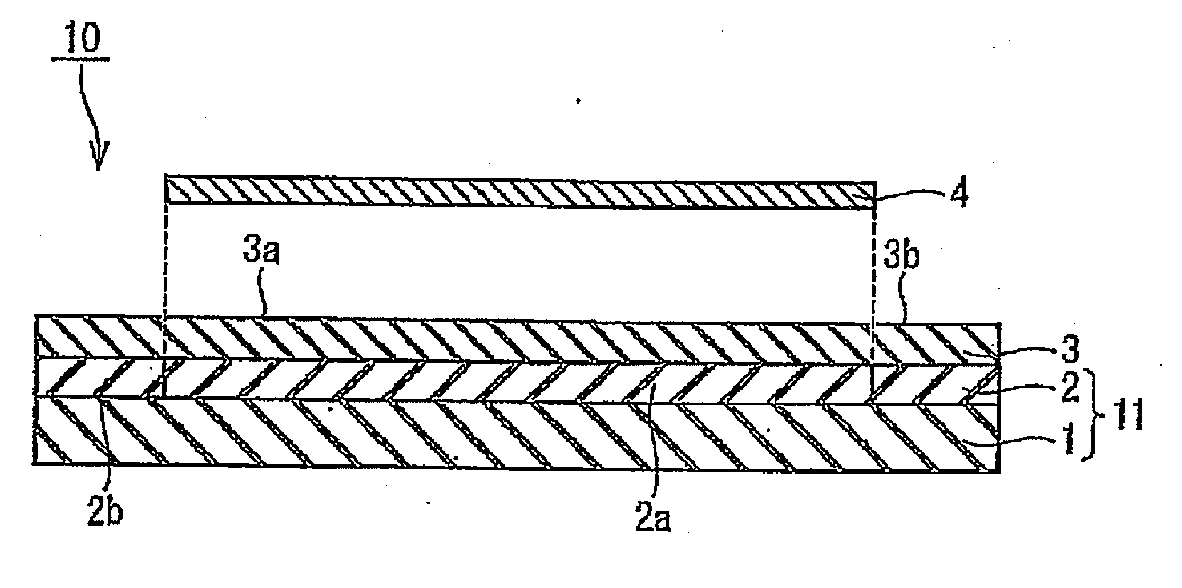

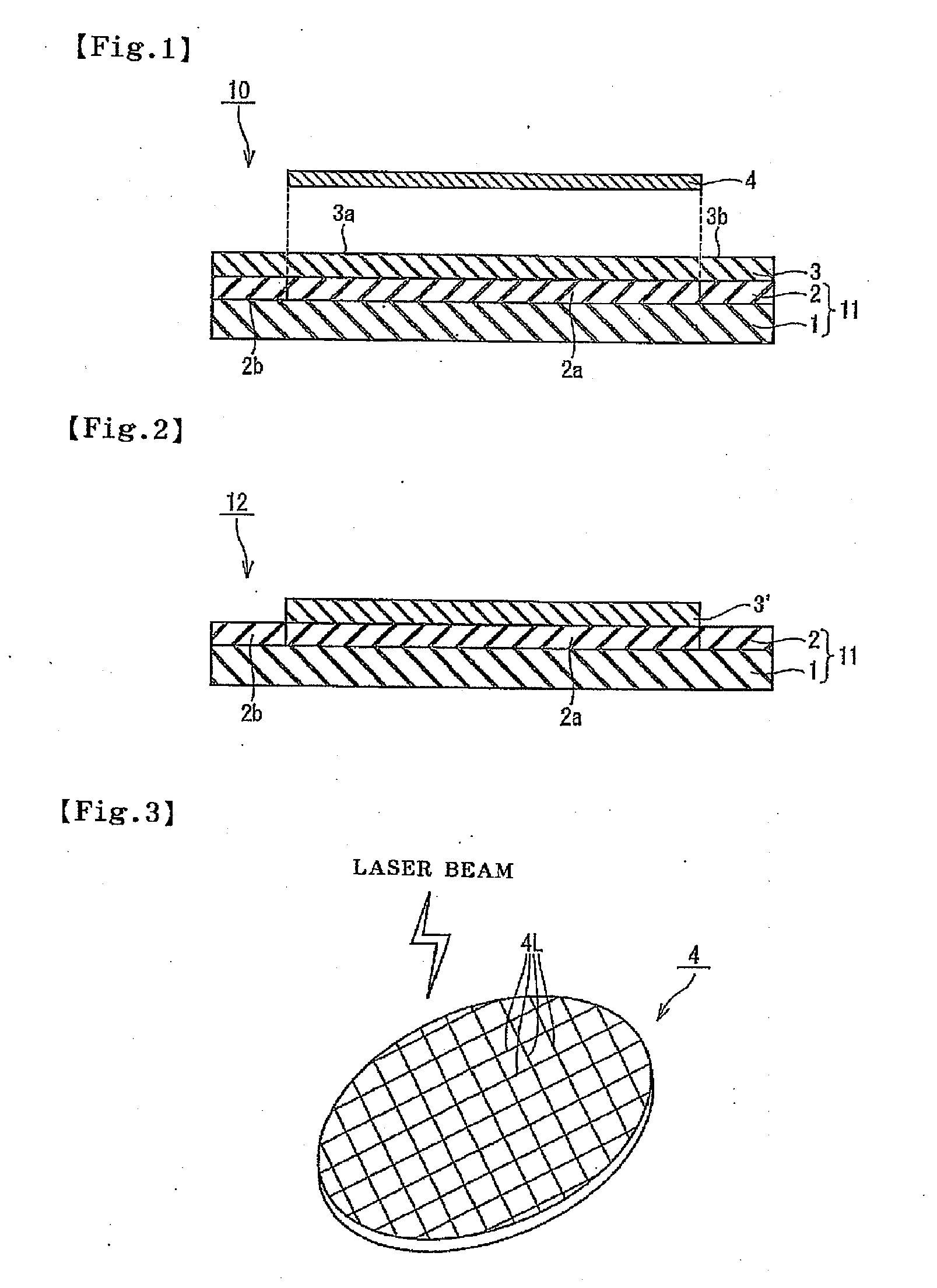

Thermosetting die bonding film, dicing die bonding film and semiconductor device

InactiveUS20110057331A1Avoid crackingImprove workabilitySemiconductor/solid-state device detailsSolid-state devicesRoom temperatureSemiconductor chip

An object of the present invention is to provide a thermosetting die-bonding film with which a die-bonding film is suitably broken with a tensile force. The object is achieved by a thermosetting die-bonding, film at least having an adhesive layer that is used to fix a semiconductor chip to an adherend, in which the breaking energy per unit area is 1 J / mm2 or less and the elongation at break is 40% or more to 500% or less at room temperature before thermal setting.

Owner:NITTO DENKO CORP

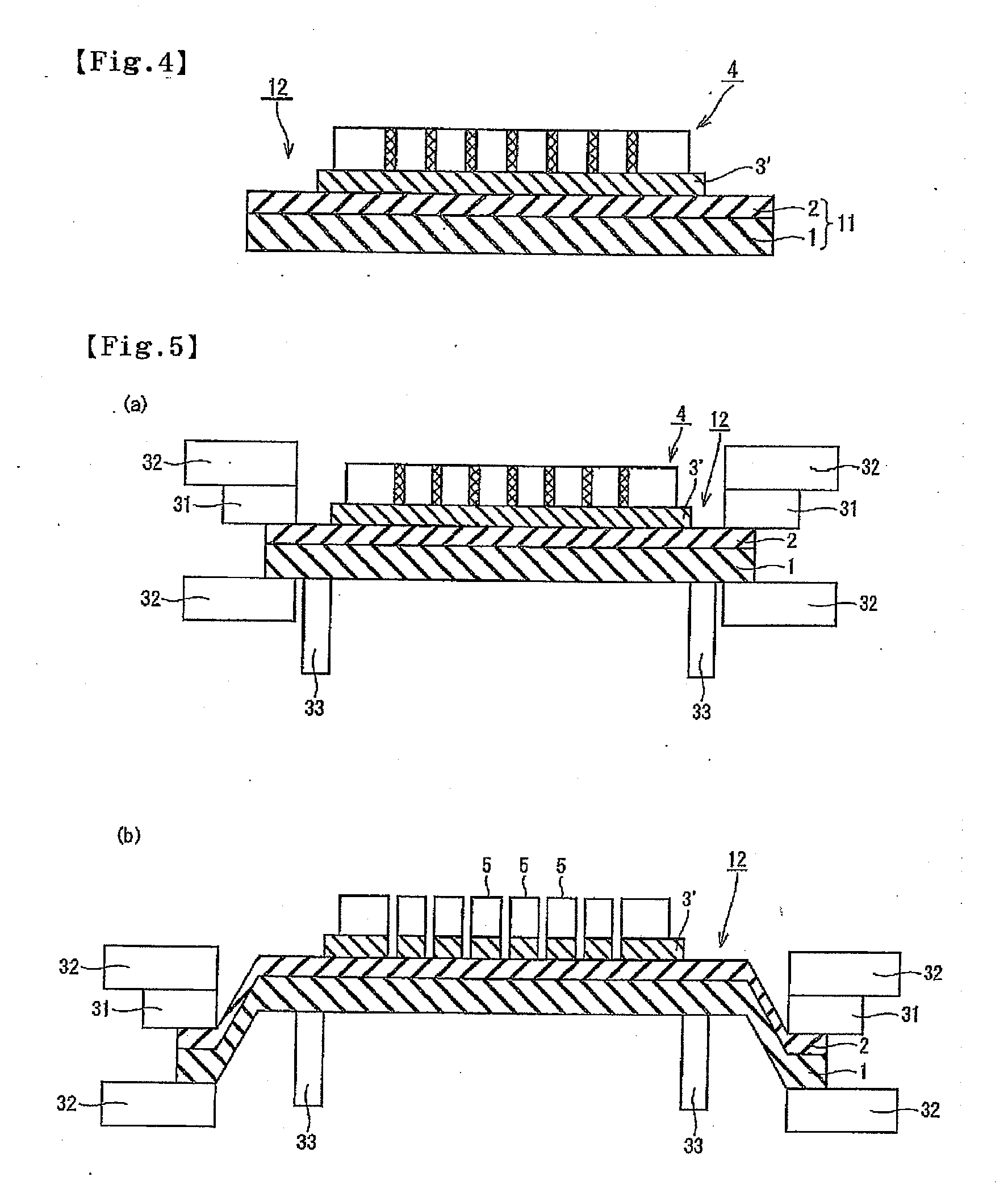

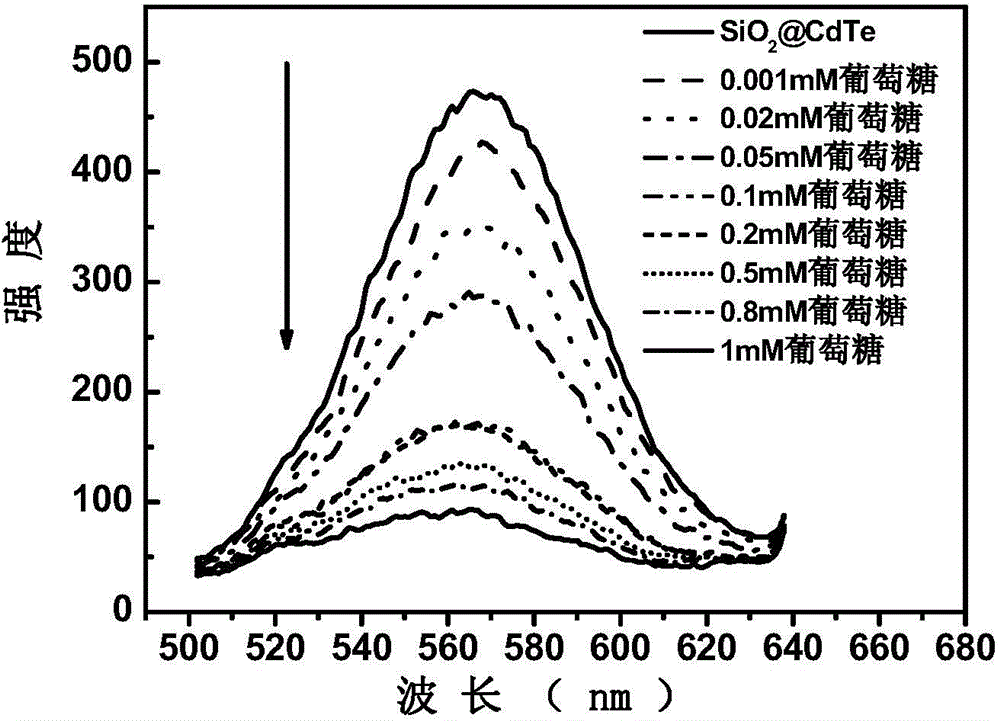

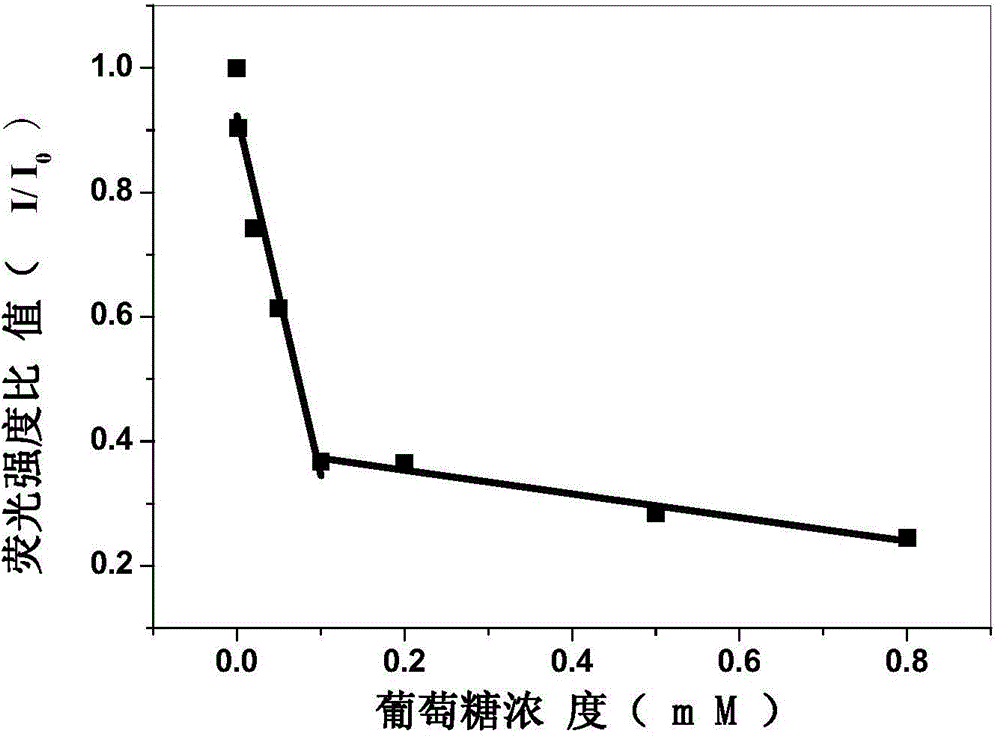

Preparation method of silicon dioxide@ quantum dot composite nanoparticles

ActiveCN104804743AIncrease productionImprove efficiencyMaterial nanotechnologyNanoopticsFluorescenceQuantum dot

The invention discloses a preparation method of silicon dioxide@ quantum dot composite nanoparticles. The method comprises steps as follows: thiolation silicon dioxide nanoparticles are prepared firstly, and the silicon dioxide@ quantum dot composite nanoparticles are prepared with a hydrothermal method. The preparation method is simple and easy to implement, high in yield and efficiency and beneficial to large-scale production. The prepared silicon dioxide@ quantum dot composite nanoparticles comprise silicon dioxide balls with particle sizes of 50-800 nm and quantum dot particles loaded on the silicon dioxide balls. The excellent fluorescence property of quantum dots is preserved, centrifugal separation of the particles is facilitated due to the fact that the quantum dots are loaded on silicon dioxide, the aftertreatment steps during use of the quantum dots are greatly optimized and simplified, and the preparation method has a broad application prospect.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

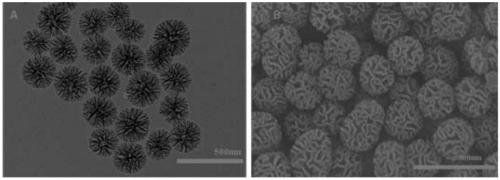

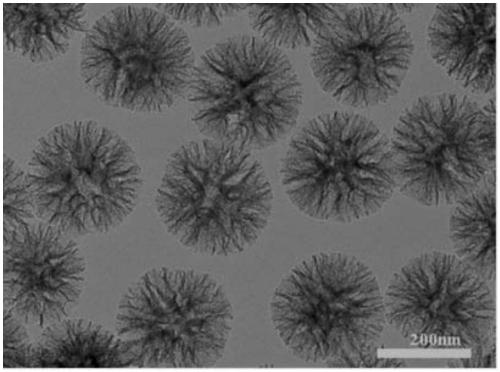

Dendritic silicon dioxide@carbon dot compound nano-particle and preparation method thereof

InactiveCN109266324ASimple methodIncrease productionMaterial nanotechnologyFluorescence/phosphorescenceNanometreSilane coupling

The invention discloses a dendritic silicon dioxide@carbon dot compound nano-particle and a preparation method thereof. According to the preparation method, the dendritic silicon dioxide@carbon dot compound nano-particle can be successfully prepared; CDs capacity is high; the preparation method is simple in operation, high in yield and easy for large-scale production. The preparation method comprises the following steps: adding carbon dot into an aqueous dispersion of dendritic silicon dioxide nano-particle; regulating pH to 7.5-14, and then adding a silane coupling agent with an amino functional group, thereby acquiring a reaction mixture; reacting for 3-24 hours at 25-40 DEG C, thereby acquiring the dendritic silicon dioxide@carbon dot compound nano-particle. In the reaction mixture, theconcentration of dendritic silicon dioxide nano-particle is 3.0*10<-4>-5.5mol / L, the concentration of carbon dot is 1.0*10<-3>-10mol / L and the concentration of 3-amino propyl trimethoxy silane is 8.0*10<-7>-2.0*10<-4>mol / L.

Owner:南京纳科伟业纳米技术有限公司

Process of making PVC mosaic floor

InactiveCN101020363ARich variety of color changesGood decorative effectDomestic articlesMetal working apparatusEngineeringPost treatment

The technological process of making PVC mosaic floor includes the following steps: preparing PVC curled filament layer, punching to cut, exchanging mosaics, configuring bottom layer, ultrasonic pressure welding, hot molting to adhere, and post-treatment. The present invention makes it possible to obtain beautiful and firm PVC mosaic floor with rich and colorful pattern.

Owner:苏州元艺家庭用品有限公司

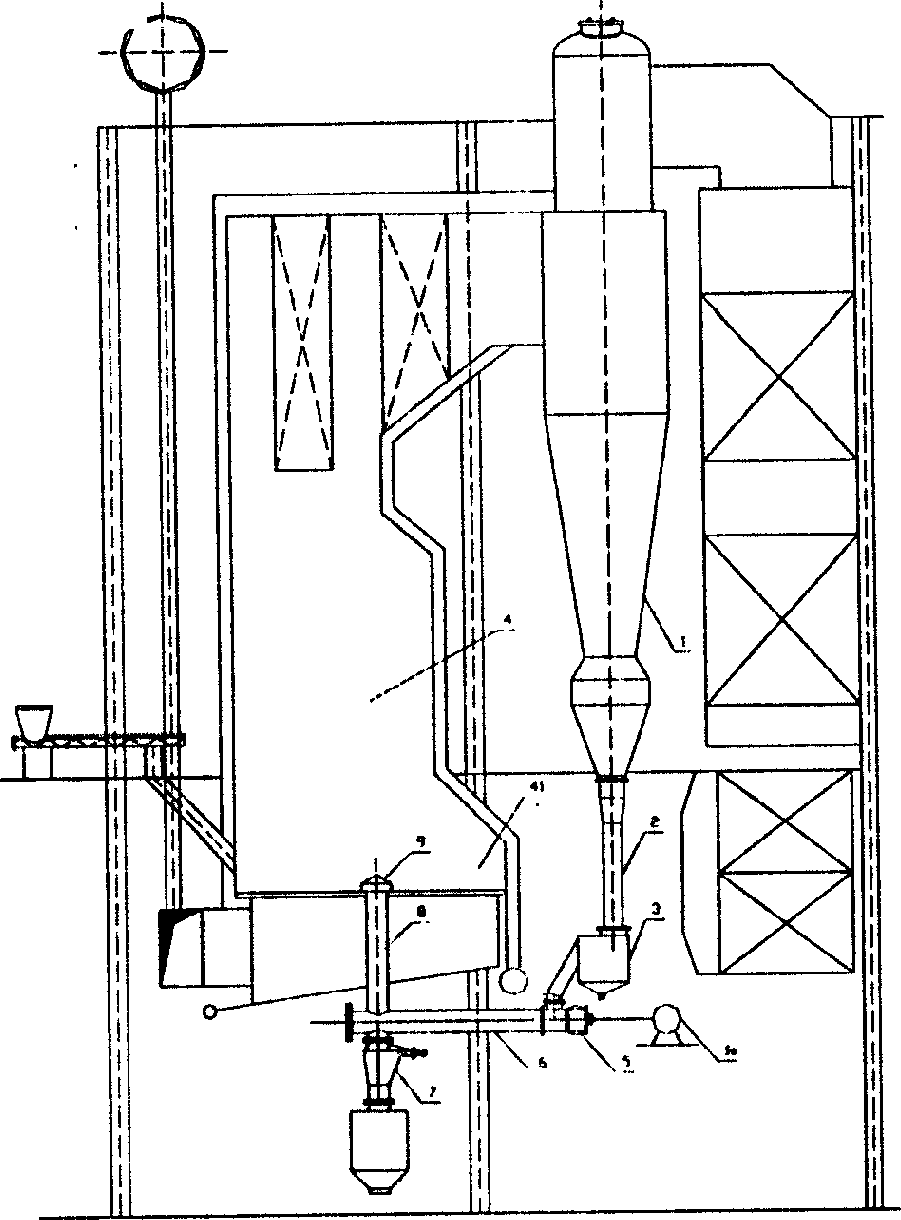

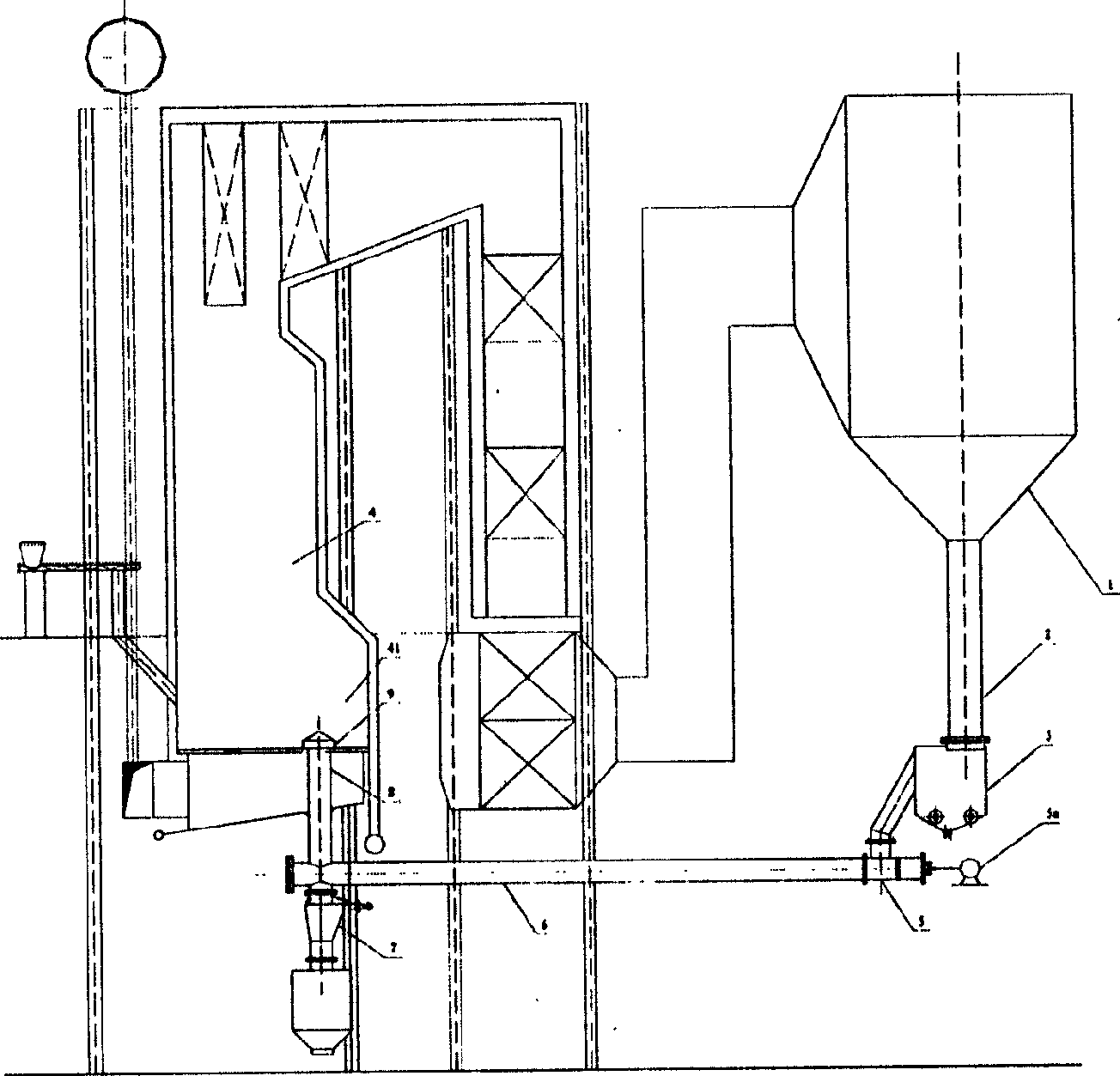

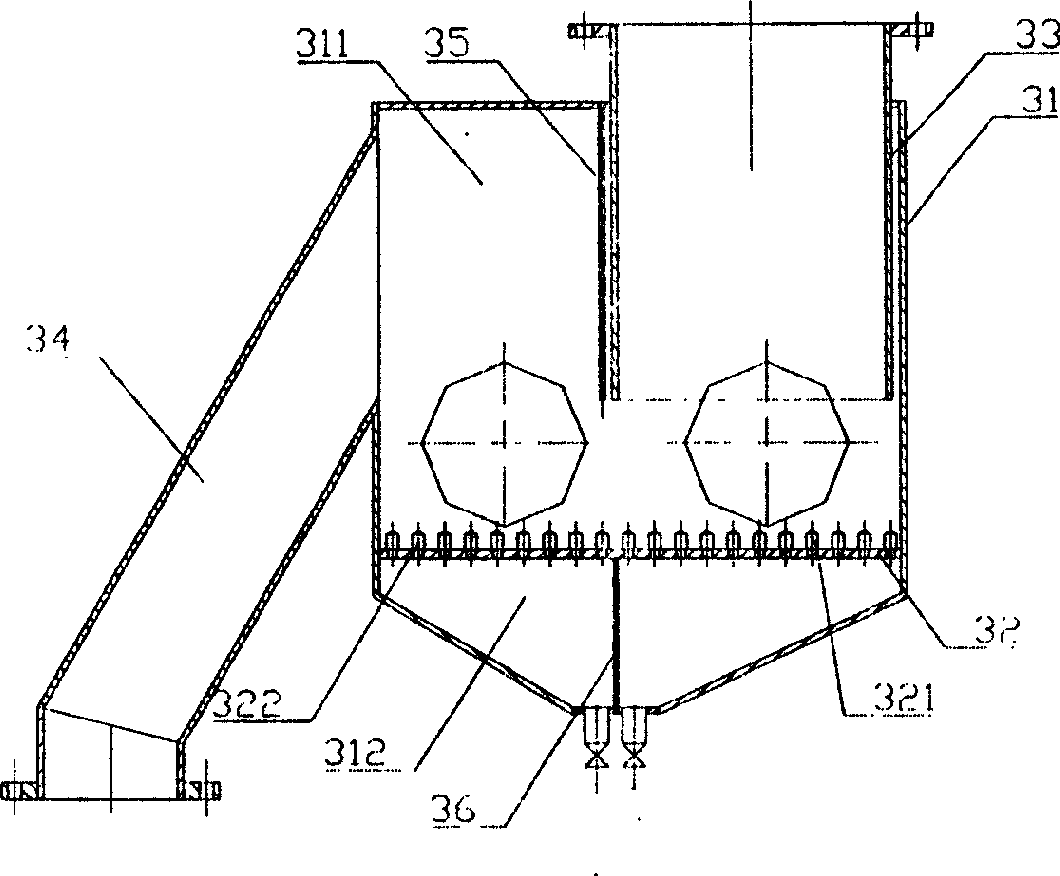

Method and apparatus for flyash bottom-feeding circulating fluidized bed for fire-resistance fuel

ActiveCN1529088AReduce leakageImprove sealing performanceFluidized bed combustionApparatus for fluidised bed combustionInjectorCorrosion

The invention provides a kind of fly ash bottom feeding circular fluidized-bed combustion method and the device, the method is: uses fly ash collector to collect the fly ash with high content in smoke, the fly ash are put into the back material controller through vertical pipe, then and they are carried to the return pipe through transmitting and ejector, and they are returned to the thick phase area of bed through bottom feeding spraying muzzle which is high temperature resisting and corrosion resisting. The device is: it is made up of fly ash collector, back material controller, gas transmitting ejector and the combustion furnace. The top of the combustion furnace connects with the inlet of fly ash collector, the fly ash through the fly ash collector outlet, are carried to the thick phase area of combustion furnace through the bottom feeding sprayer with gas transmitting ejector. The invention can enhance the combustion effect of the fly ash; it can save energy and protect the environment.

Owner:SOUTHEAST UNIV

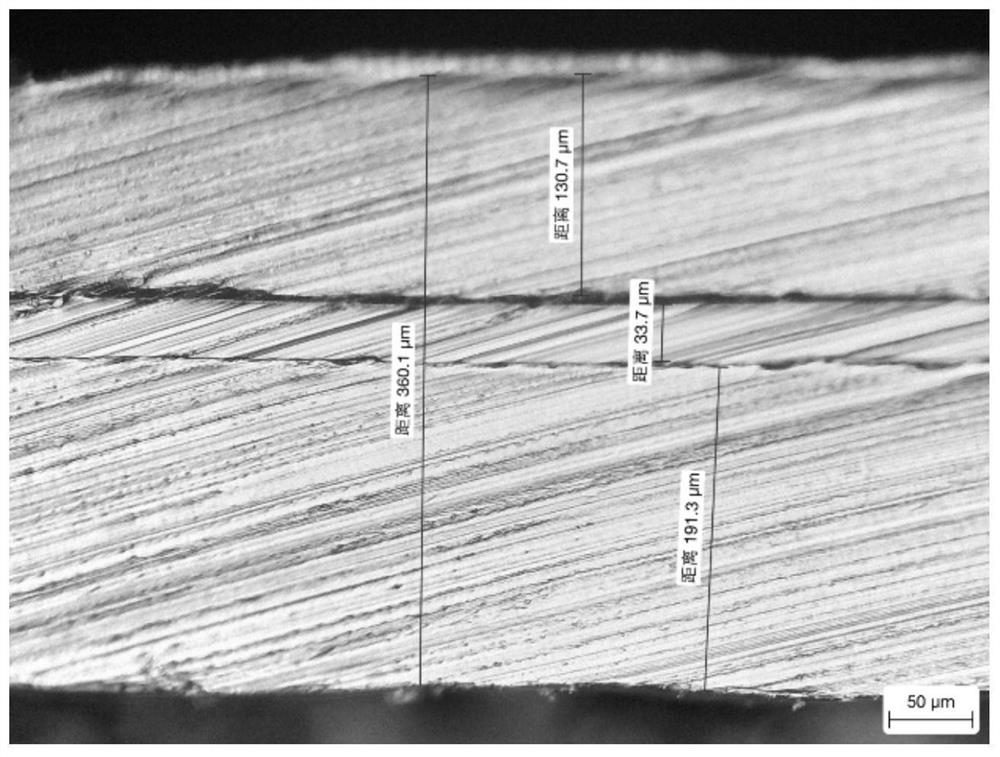

Preparation method of fluororesin-containing modified polyimide film

The invention discloses a preparation method of a fluororesin-containing modified polyimide film. The preparation method specifically comprises the following steps of firstly, adding ultrafine fluororesin powder into a precursor polyamide acid solution of polyamide; then, adding and stirring a mixed solvent of N-methyl pyrrolidone and 3,5,5-trimethyl-2-cyclohexenone to form a sizing agent; mixing the sizing agent with the polyamide acid solution in an appropriate amount, and simultaneously adding a chemical imidization additive to form a polyamide acid blended solution after high-speed stirring; coating, drying and imidizing the blended solution to obtain a modified polyimide film material. The modified polyimide film prepared by the invention has excellent corona resistance while the characteristics of high strength, high heat resistance and the like of polyimide are maintained, the stability and the durability of the polyimide film in an electric field can be increased, and the polyimide film can be well applied to the fields of a high-speed motor and the like.

Owner:NANJING UNIV OF SCI & TECH

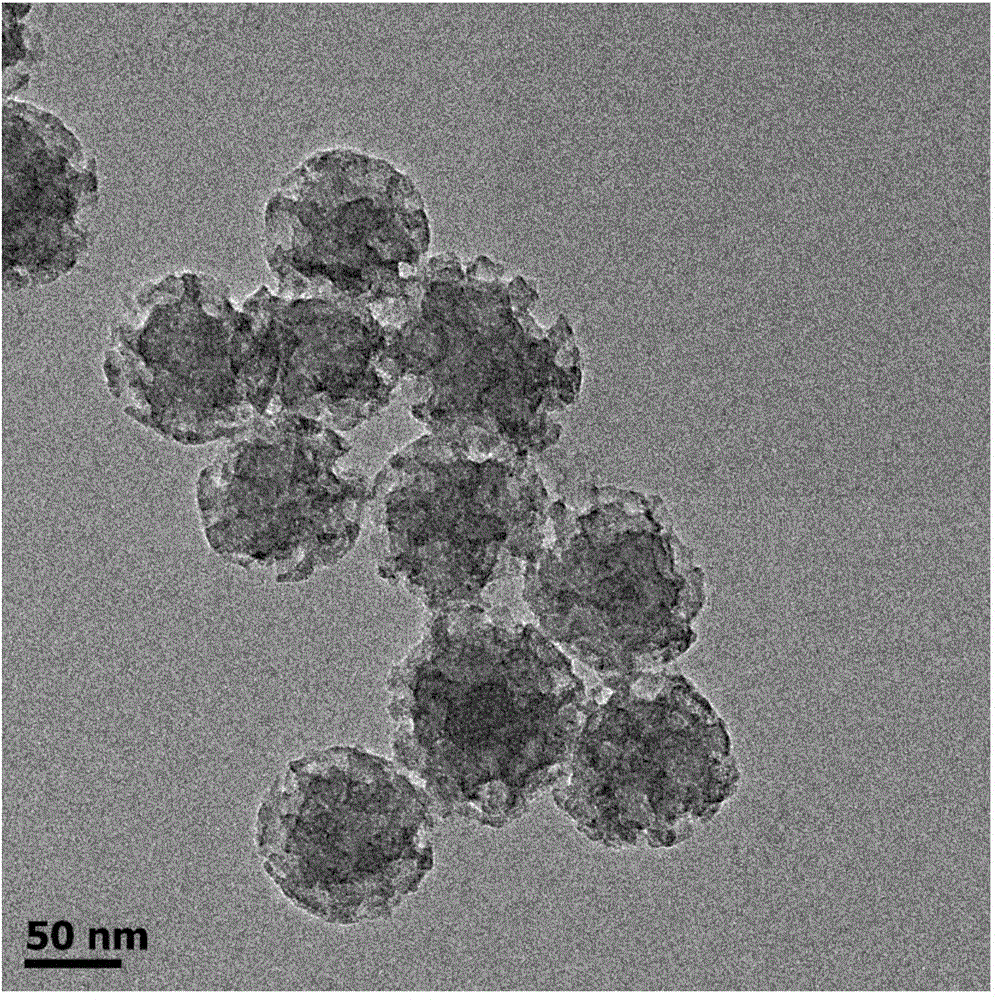

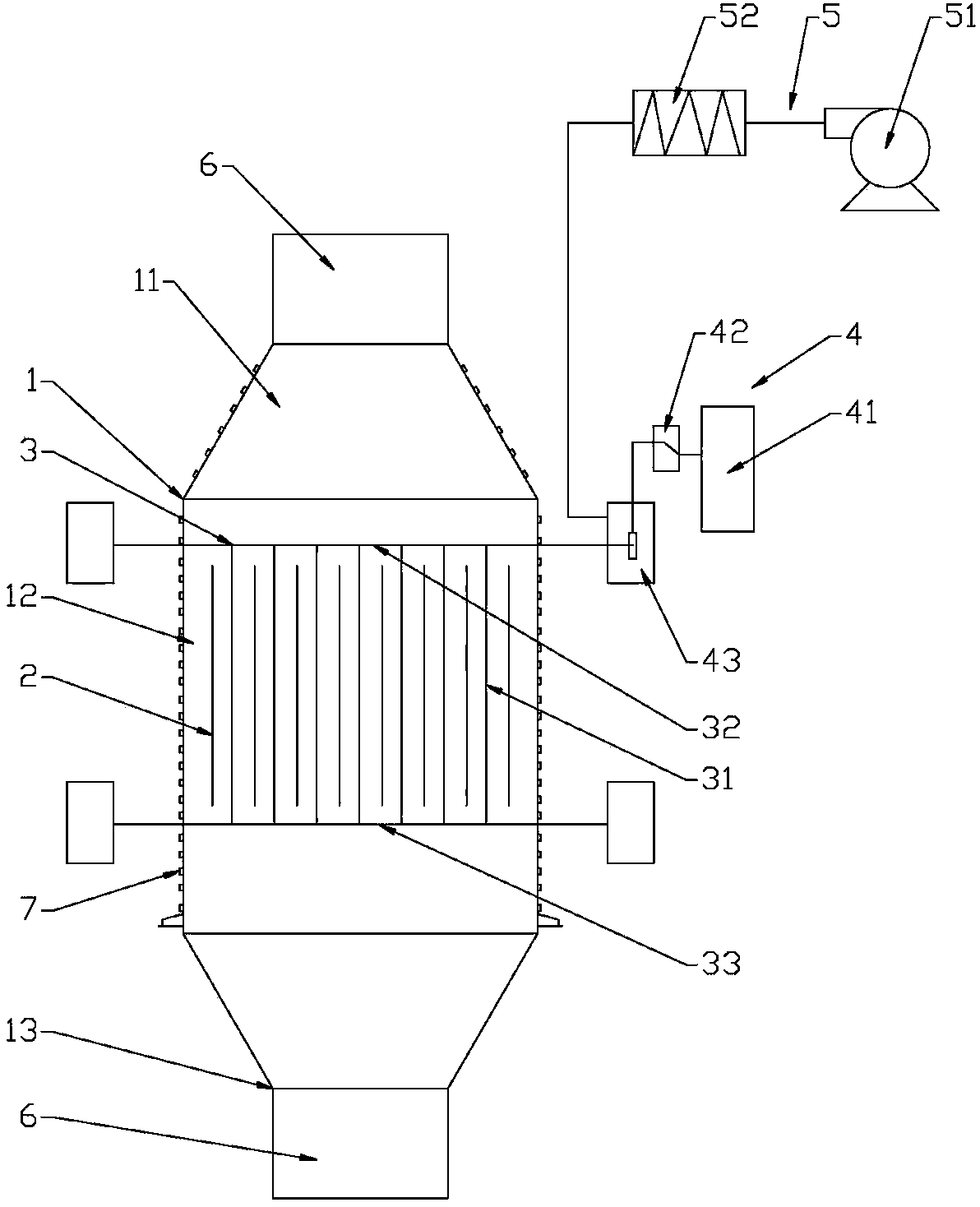

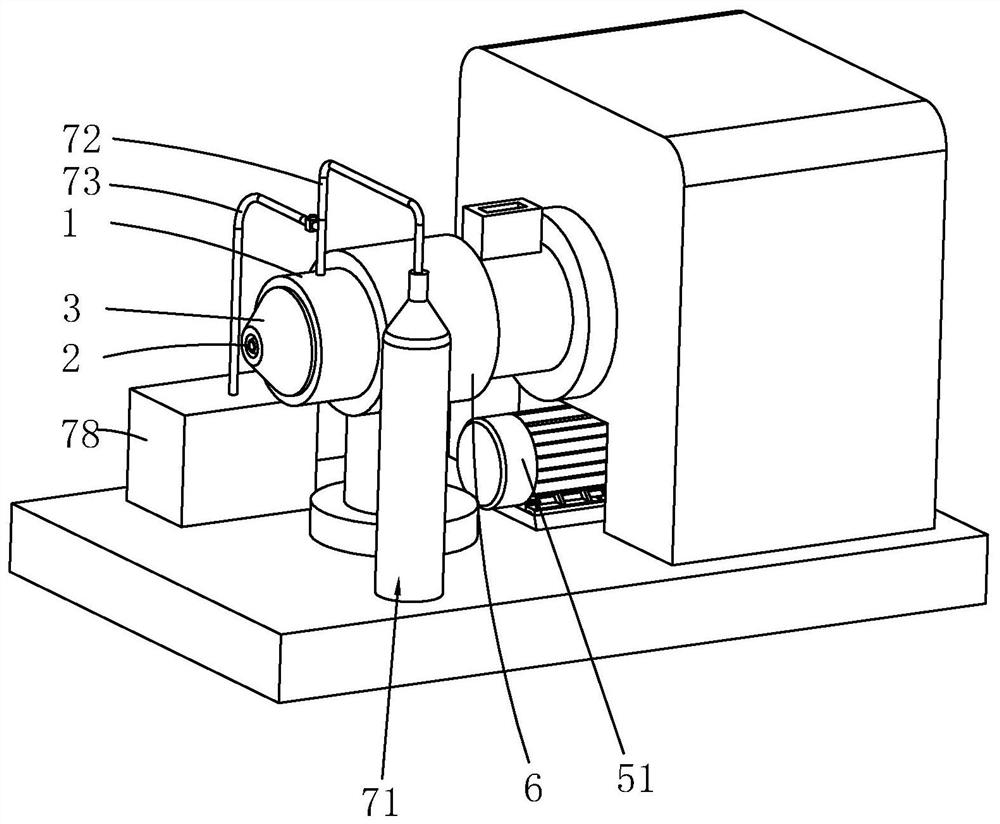

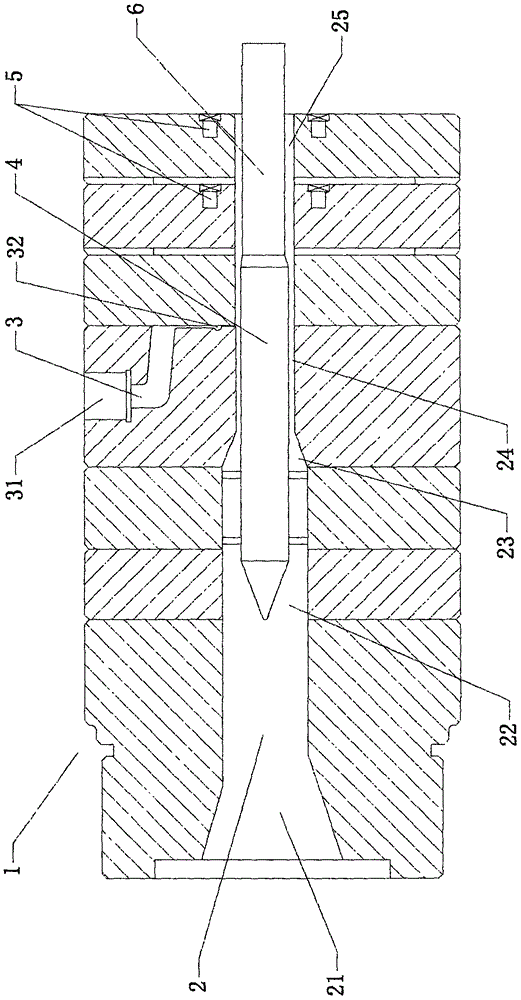

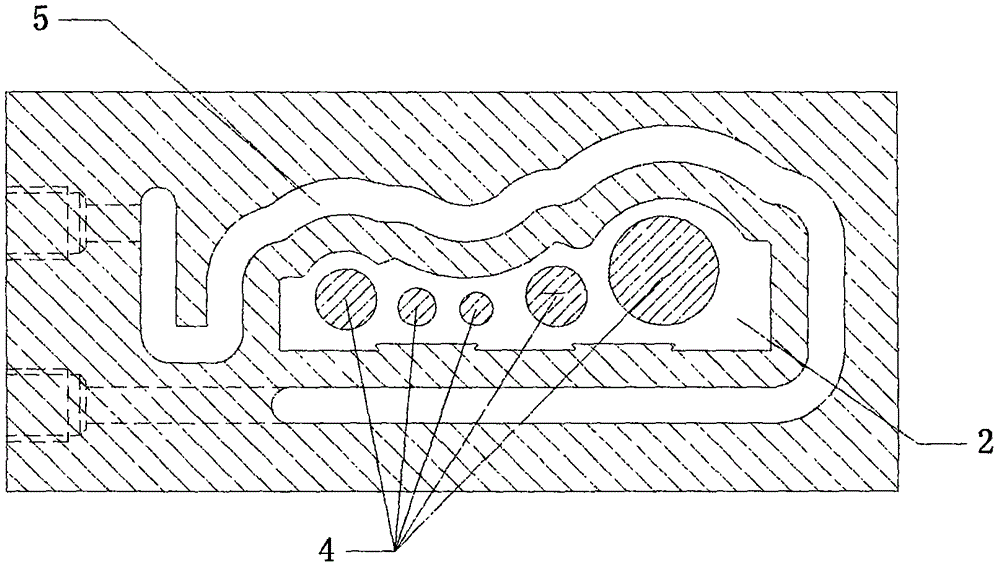

Efficient tubular plate vertical current wet-type electrostatic dust collector

InactiveCN103817005AEasy to driveImprove dust removal efficiencyExternal electric electrostatic seperatorElectric supply techniquesEngineeringHigh pressure

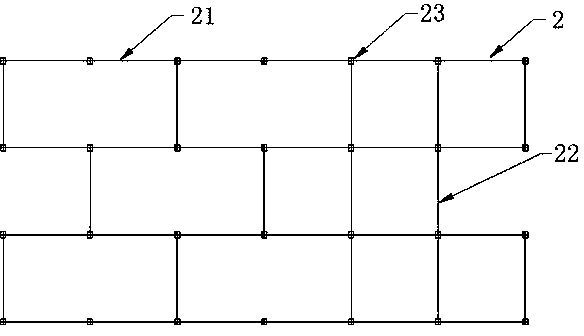

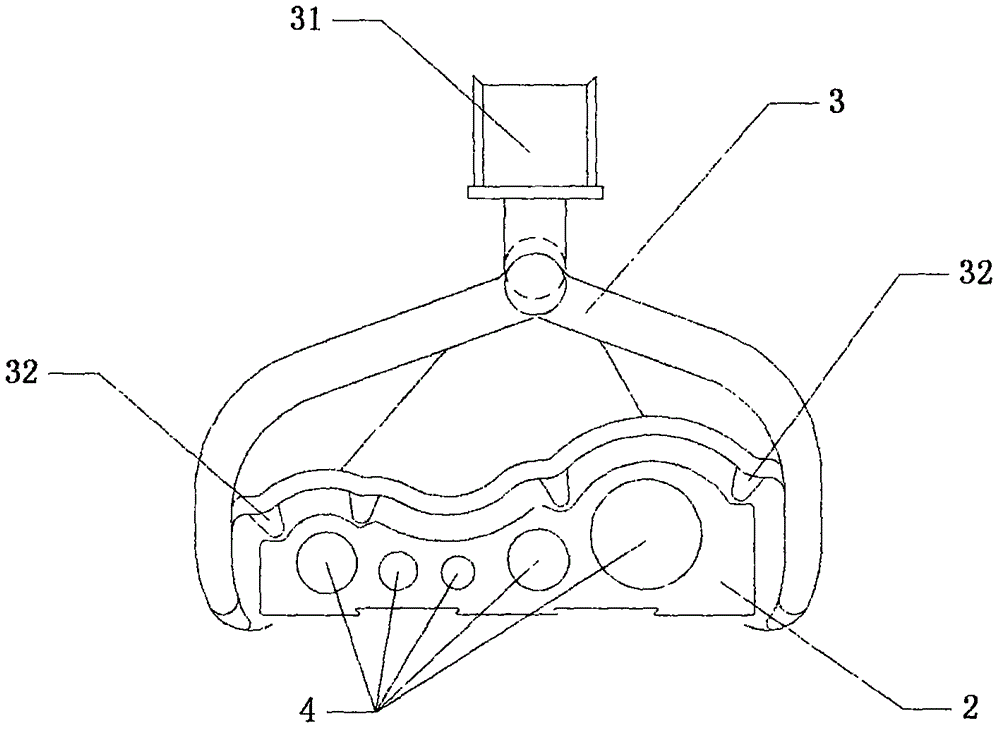

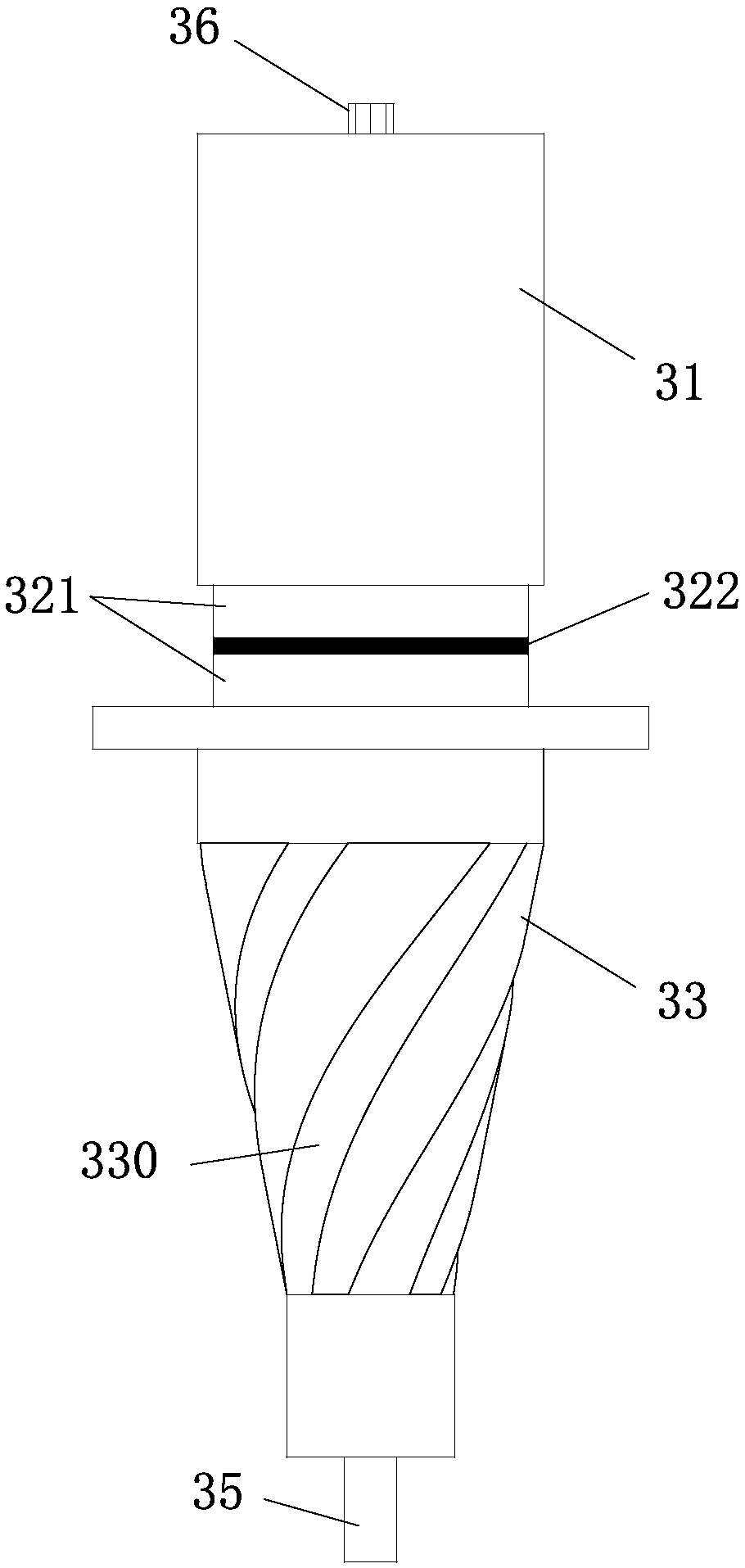

The invention discloses an efficient tubular plate vertical current wet-type electrostatic dust collector. The efficient tubular plate vertical current wet-type electrostatic dust collector comprises a shell (1), wherein an anode dust collecting mechanism (2) arranged vertically is arranged in the shell (1) and adopts a tubular plate structure formed by dust collecting boards; a vertically arranged cathode wire (31) with discharge points is arranged between the tubular plates of the anode dust collecting mechanism (2); the upper end of the cathode wire (31) is fixed on a cathode girder (32) above the cathode wire (31); the lower end of the cathode wire (31) is fixed on a tension frame (33) blow the cathode wire (31); the cathode girder (32) is connected with a high voltage power supply system (4) through conductive wires; a cathode system is formed by the cathode girder (32), the cathode wire (31) and the tension frame (33). As an electrostatic field formed by the tubular plate anode dust collecting mechanism and the cathode wires, effectively solves the problem of difficult removing of PM2.5 tiny particles, acid mist, liquid drops, aerosol, heavy metals and the like from the smoke, and the efficient tubular plate vertical current wet-type electrostatic dust collector is widely used.

Owner:双盾环境科技有限公司

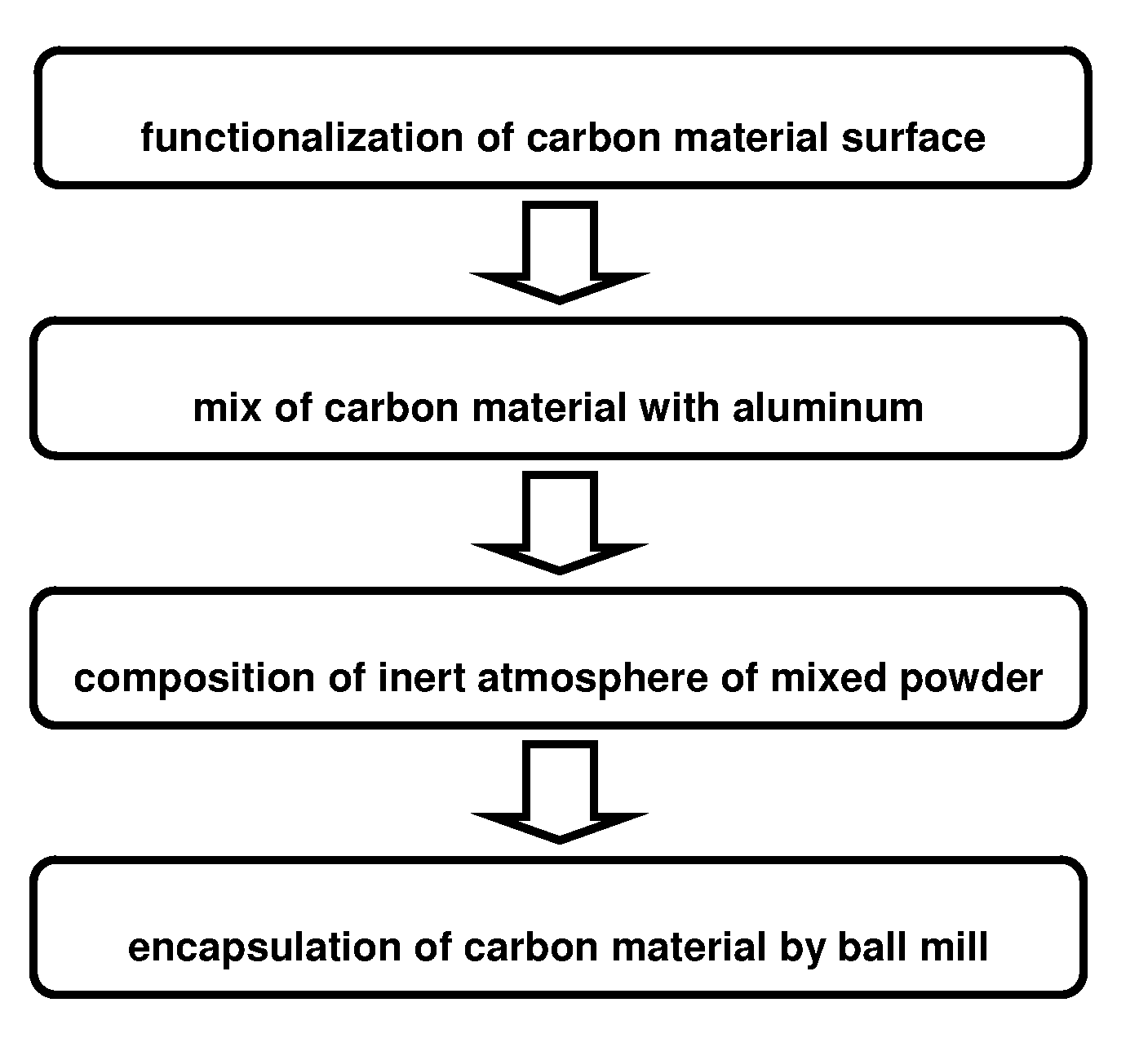

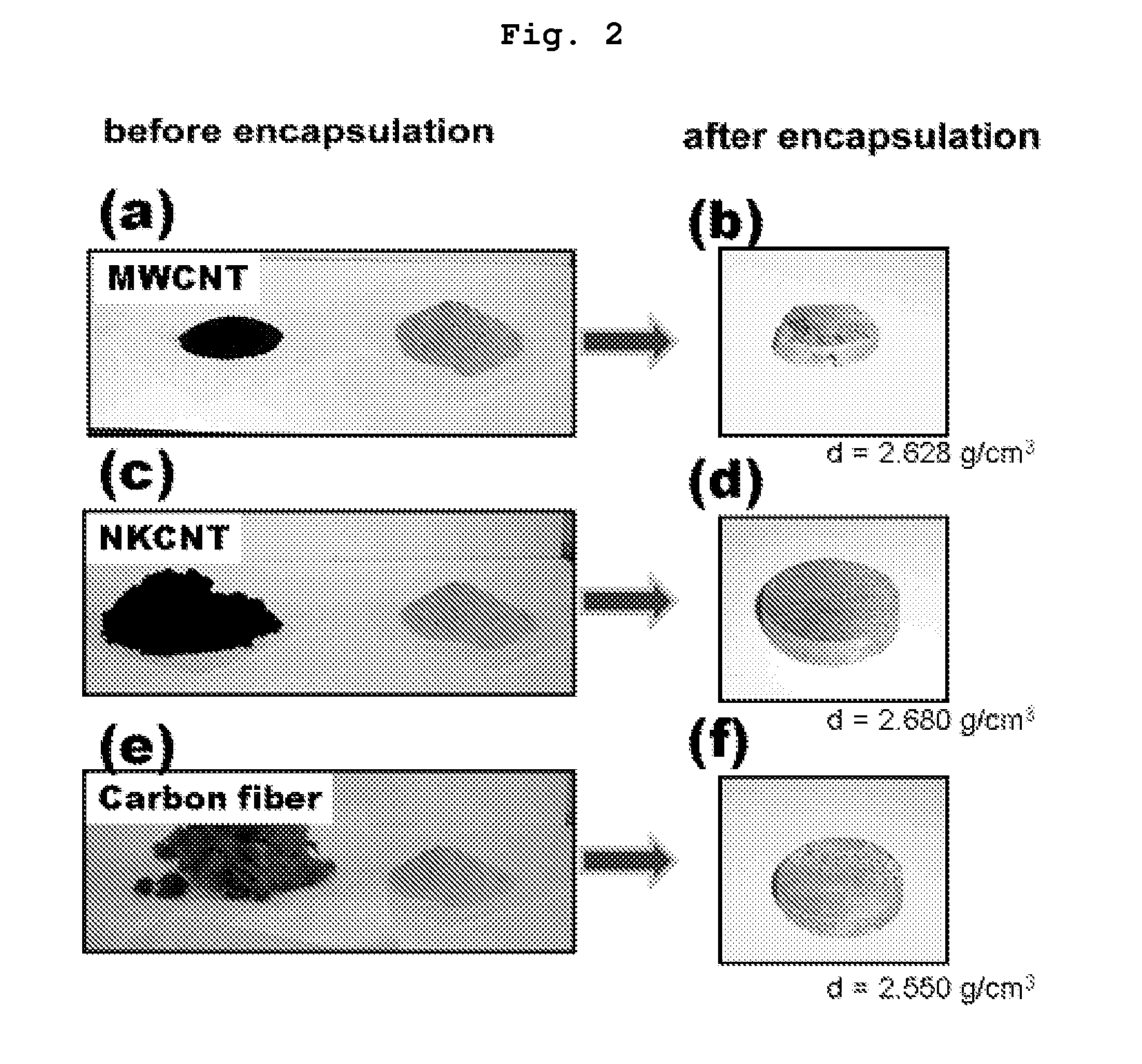

Encapsulation of carbon material within aluminum

InactiveUS20090162654A1Maintain crystallinityHigh strengthMaterial nanotechnologyPretreated surfacesBall millMaterials science

Disclosed is a method of encapsulating a carbon material within aluminum, the method including the steps of: (i) functionalizing a carbon material by introducing a defect therein; (ii) mixing the functionalized carbon material with aluminum; and (iii) ball milling the mixture under an inert gas atmosphere. In addition, the present invention discloses a method of fabricating an aluminum-carbon material composite, the method comprising the steps of: (i) functionalizing the carbon material by introducing a defect therein; (ii) mixing the functionalized carbon material with aluminum; and (iii) ball milling the mixture under an inert gas atmosphere, thereby encapsulating a carbon material within aluminum. Furthermore, the present invention discloses an aluminum-carbon material composite fabricated according to the method.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

Wear-resisting and low-temperature-resisting cable material

InactiveCN105968821AImprove wear resistanceImprove impact resistanceRubber insulatorsFiberDi-tert-butyl peroxide

The invention discloses a wear-resisting and low-temperature-resisting cable material. The wear-resisting and low-temperature-resisting cable material is prepared from, by weight, 20-30 parts of hydrogenated butadiene-acrylonitrile rubber, 50-70 parts of silicone rubber, 30-40 parts of solution polymerized styrene-butadiene rubber, 60-80 parts of a composite filler, 4-6 parts of epoxidized soybean oil, 20-30 parts of magnesium hydroxide, 10-20 parts of microencapsulation red phosphorus, 1-2 parts of Si69, 1-2 parts of sulphur, 0.3-0.5 part of di-tert-butyl peroxide, 0.1-0.3 part of an accelerant, 1-3 parts of a rear earth stabilizer, 1-3 parts of a Ca / Zn compound stabilizer, 0.3-0.5 part of anti-oxidant and 2-4 parts of paroline. The composite filler is prepared from nanosilicon dioxide, modified carbon fiber and modified kieselguhr. The wear-resisting and low-temperature-resisting cable material is good in low temperature resistance, high in wear resistance and good in mechanical performance.

Owner:ANHUI HAIRONG CABLE

Boron-sodium double-doped nano-layered graphite-like carbon nitride, and preparation method and application thererof

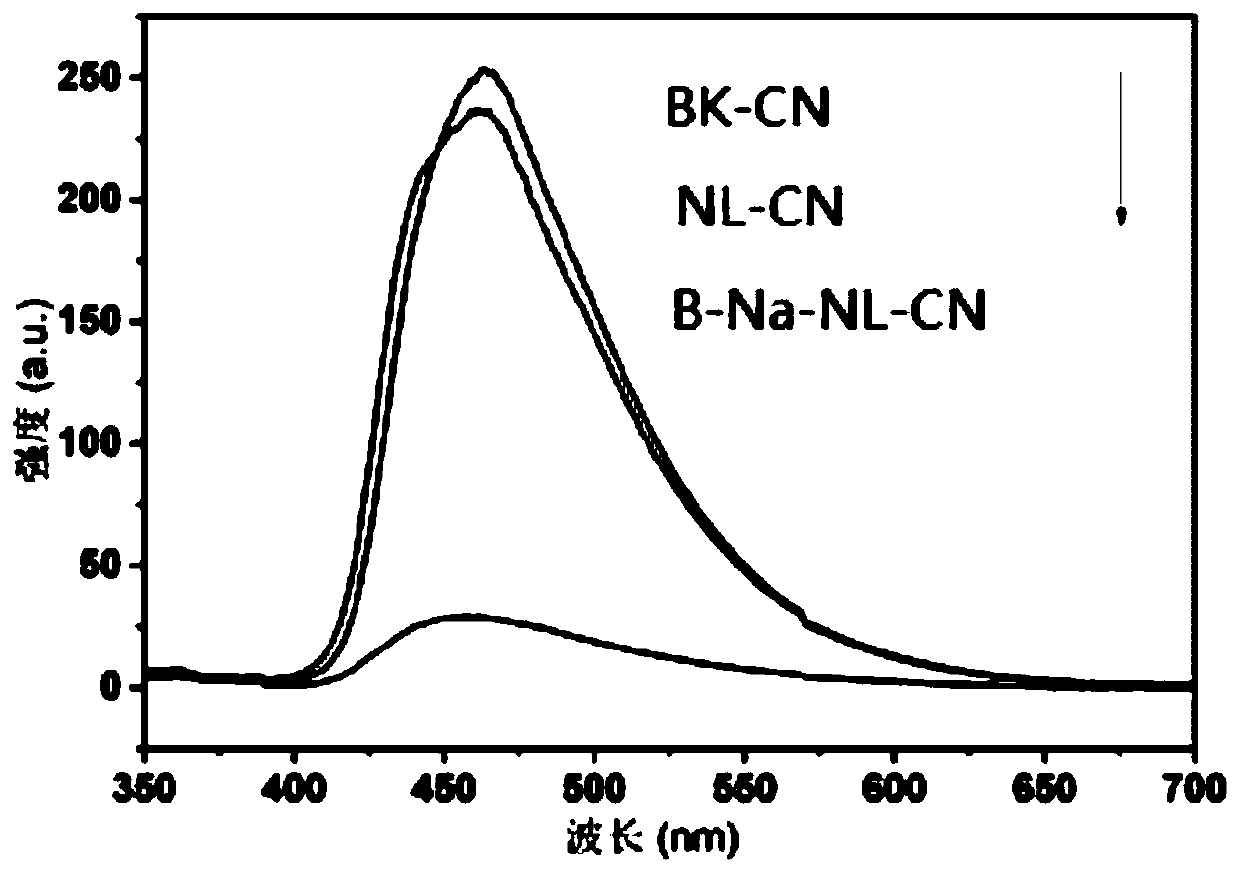

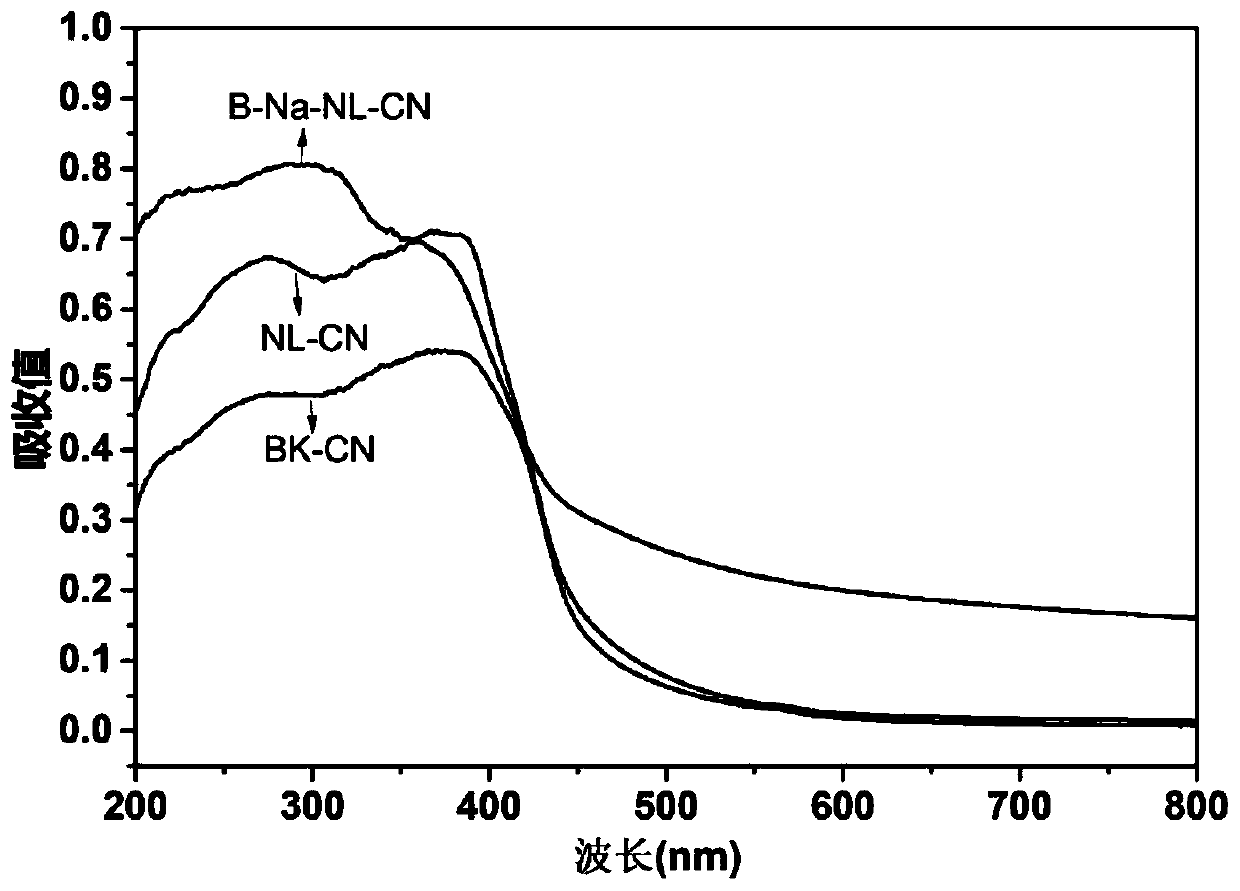

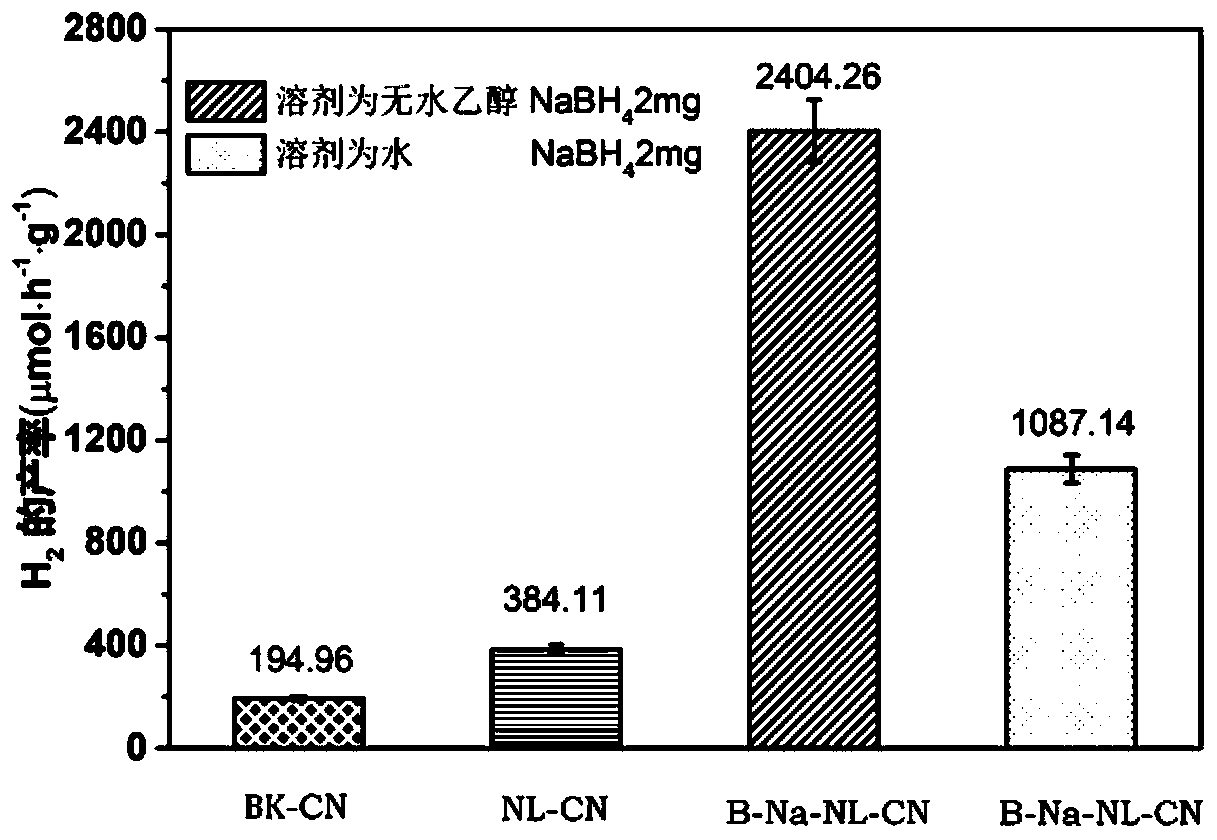

ActiveCN111215118AReduce recombination rateImprove photocatalytic activityPhysical/chemical process catalystsHydrogen productionPhysical chemistryCarbon nitride

The invention belongs to the technical field of inorganic photocatalyst materials, and concretely relates to a preparation method of boron-sodium double-doped nano-layered graphite-like carbon nitride. The preparation method comprises the following steps: S1, dissolving melamine in water to obtain a melamine solution, adding ammonium nitrate into the melamine solution, and calcining an obtained solid product after the reaction is completed so as to obtain g-C3N4 with a nano-layered structure; and S2, mixing the nano-layered structure g-C3N4 with NaBH4, and then carrying out calcining and cooling so as to obtain the boron-sodium double-doped nano-layered structure g-C3N4. The boron-sodium double-doped nano-layered graphite-like carbon nitride obtained by the preparation method has a good photocatalytic performance and has a relatively good application prospect.

Owner:YANCHENG INST OF TECH

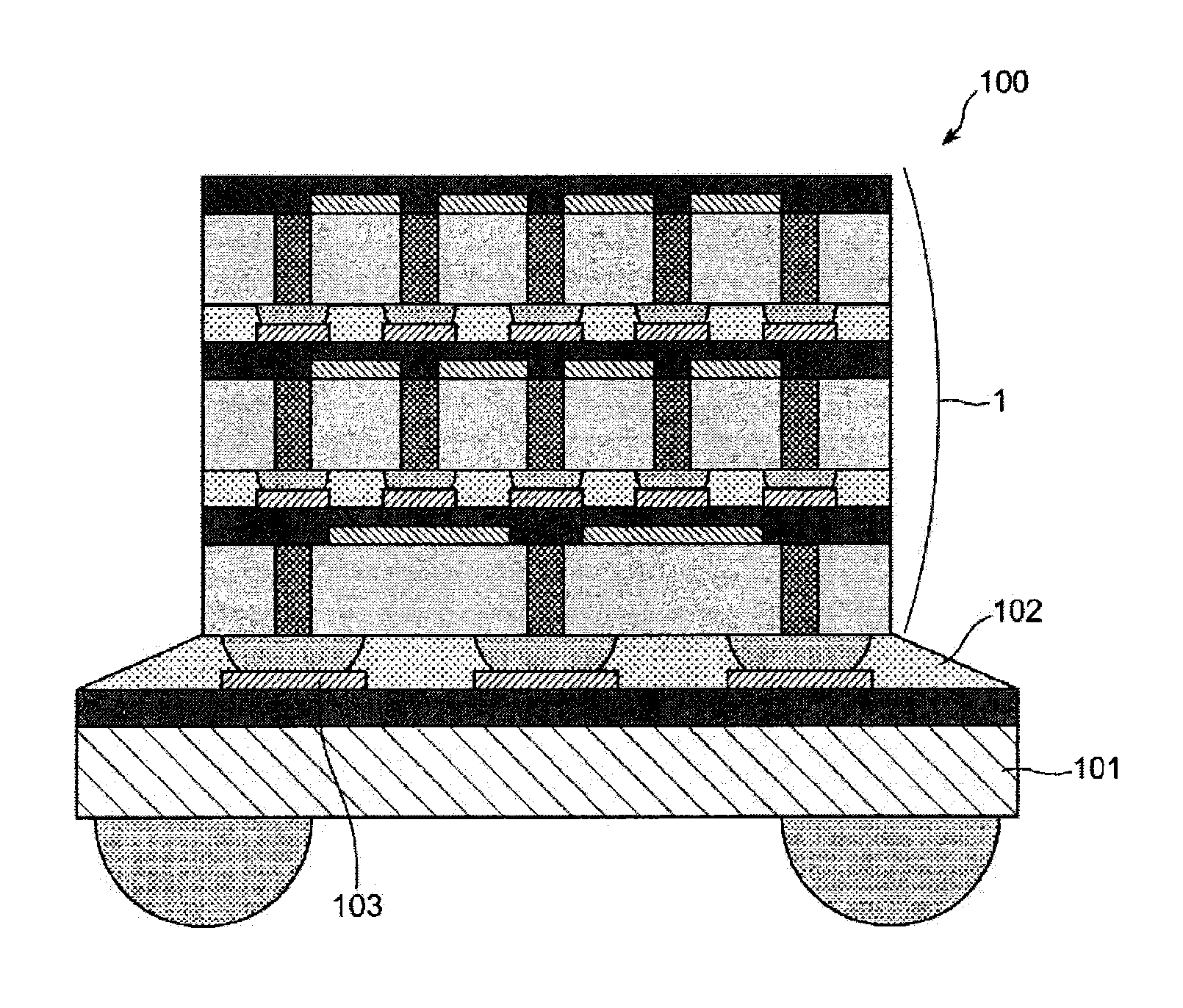

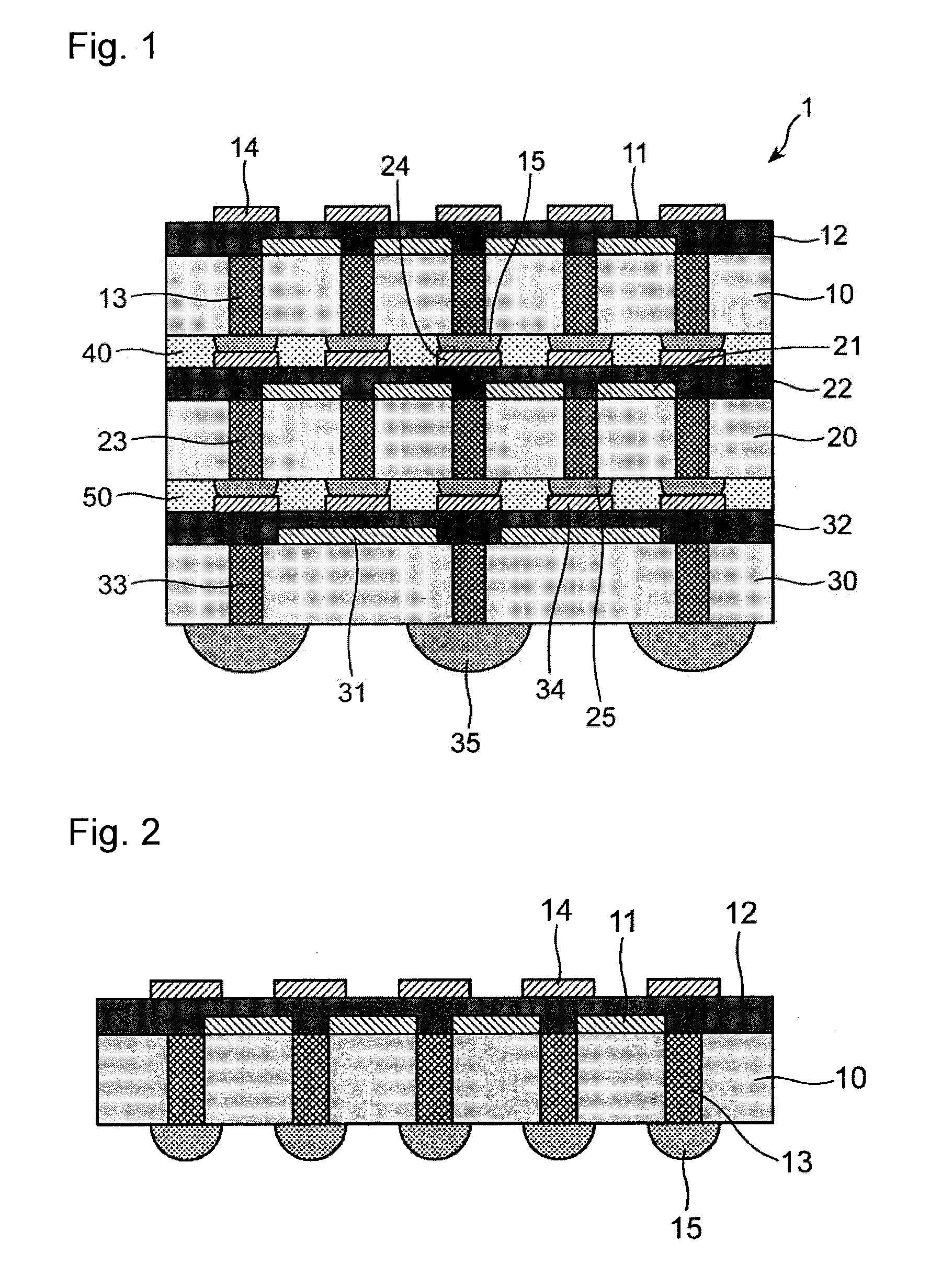

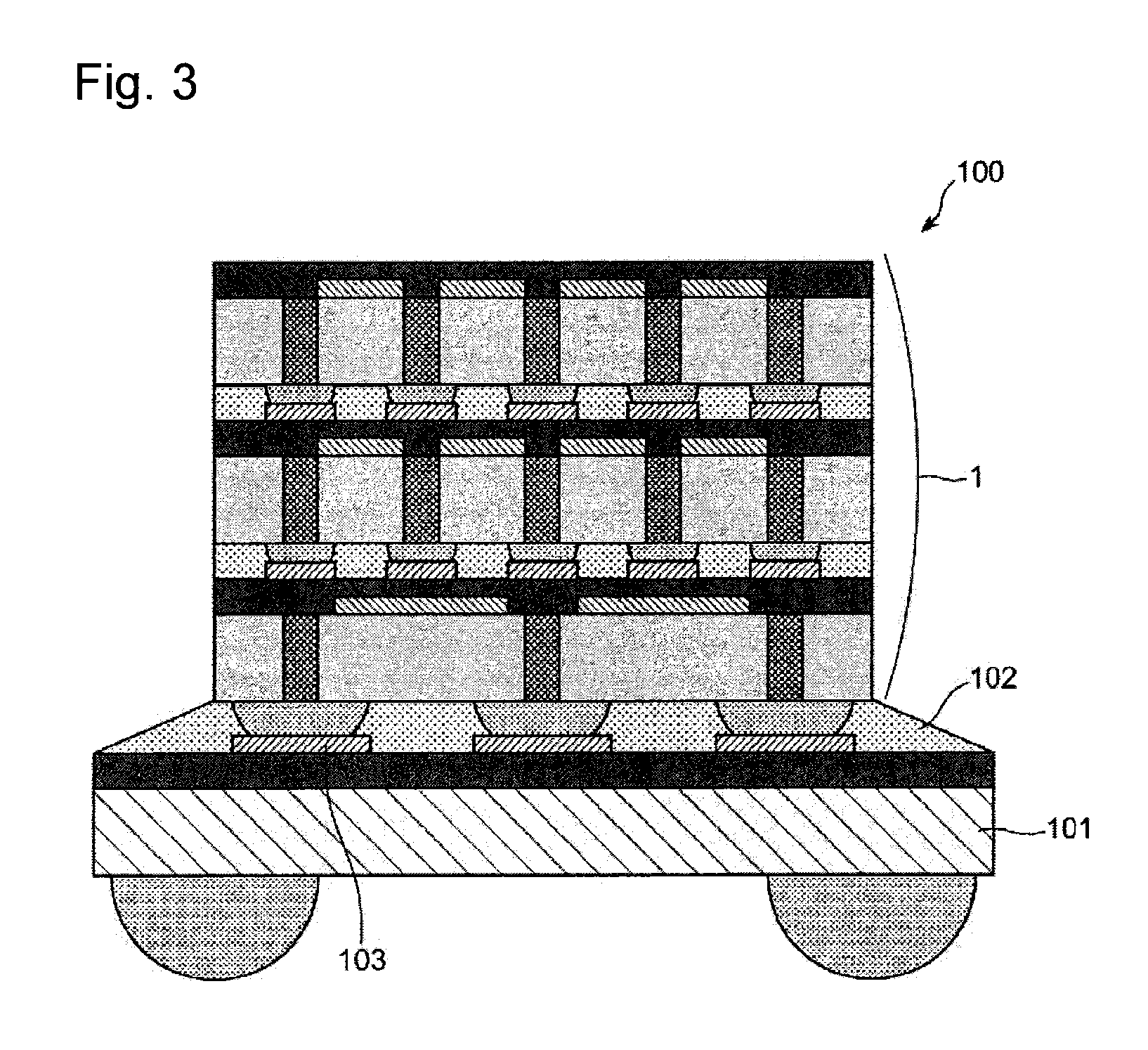

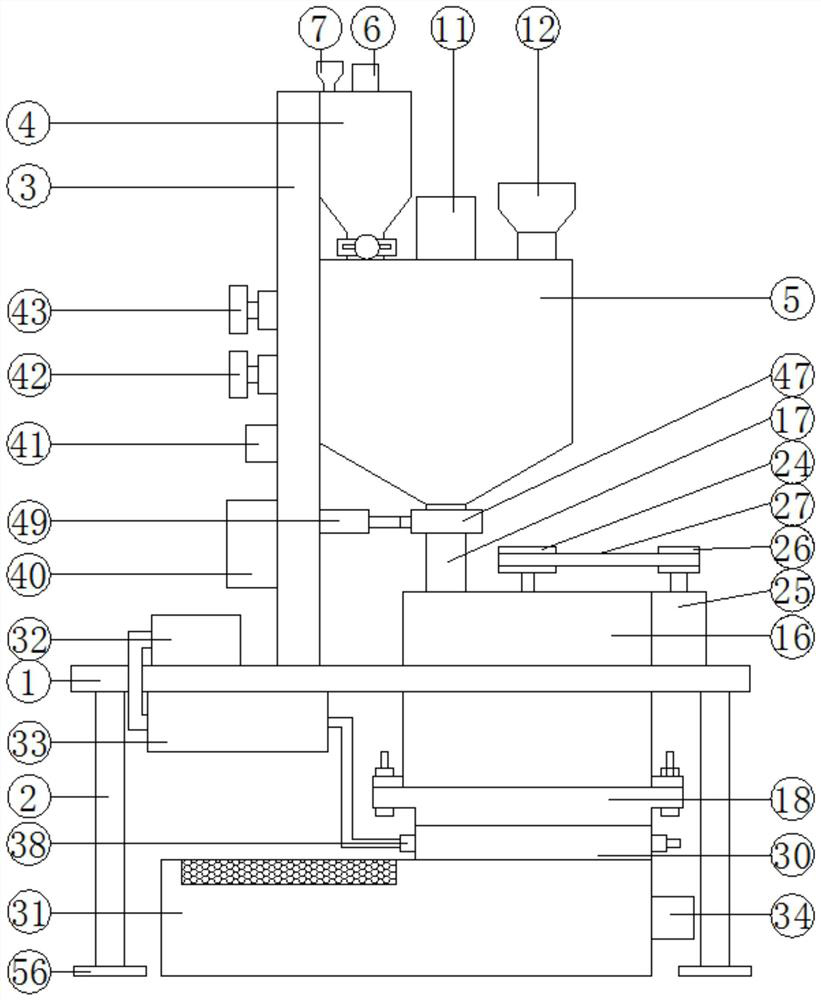

Three-dimensional integrated circuit laminate, and interlayer filler for three-dimensional integrated circuit laminate

ActiveUS9508648B2Improve reliabilityImprove thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesDevice materialPhysical chemistry

To provide a three-dimensional integrated circuit laminate filled in with an interlayer filler composition having both high thermal conductivity and low linear expansion property, a three-dimensional integrated circuit laminate, which comprises a semiconductor substrate laminate having at least two semiconductor substrates each having a semiconductor device layer formed thereon laminated, and has a first interlayer filler layer containing a resin (A) and an organic filler (B) and having a thermal conductivity of at least 0.8 W / (rrrK) between the semiconductor substrate.

Owner:MITSUBISHI CHEM CORP

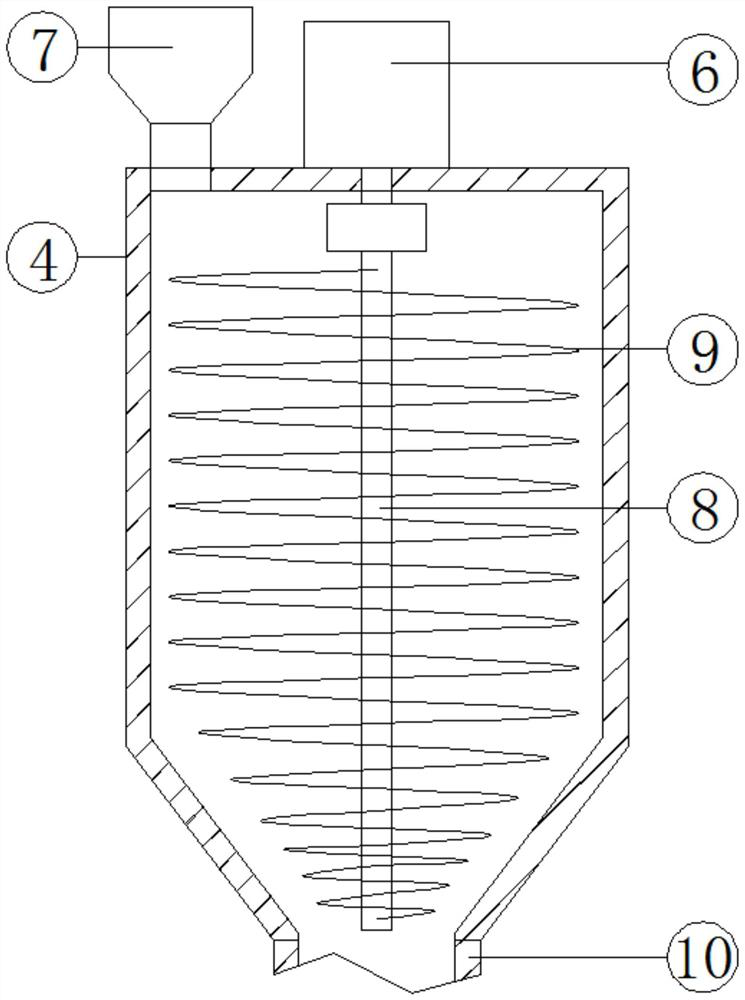

Aquatic feed mixing, processing and granulating device for micropterus salmoides

ActiveCN111743179AImprove adhesionNutritional balanceDispersed particle filtrationFeeding-stuffAnimal scienceNutrition

The invention discloses an aquatic feed mixing, processing and granulating device for micropterus salmoides. A workbench is provided, and supporting columns are fixedly arranged on the lower portionsof the four corners of the workbench correspondingly. A supporting plate is fixedly arranged on the workbench. A crushing cylinder and a mixing cylinder are sequentially and fixedly arranged on one side of the upper end of the supporting plate from top to bottom, a first motor and a first feeding opening are fixedly formed in the crushing cylinder, a rotating shaft of the first motor extends intothe crushing cylinder and is fixedly provided with a first transmission shaft, and a spiral crushing blade is fixedly arranged on the outer wall of the first transmission shaft. The invention has thebeneficial effects that granulated granules can be dried, so that the granules are not easy to adhere together, the quality of the granulated granules can be guaranteed, the micropterus salmoides is balanced in nutrition after being eaten by the micropterus salmoides due to uniform mixing of the raw materials, the growth of the micropterus salmoides is facilitated, the operation is simple, the automation degree is high, and the workload of workers is greatly reduced.

Owner:福建大昌盛饲料有限公司

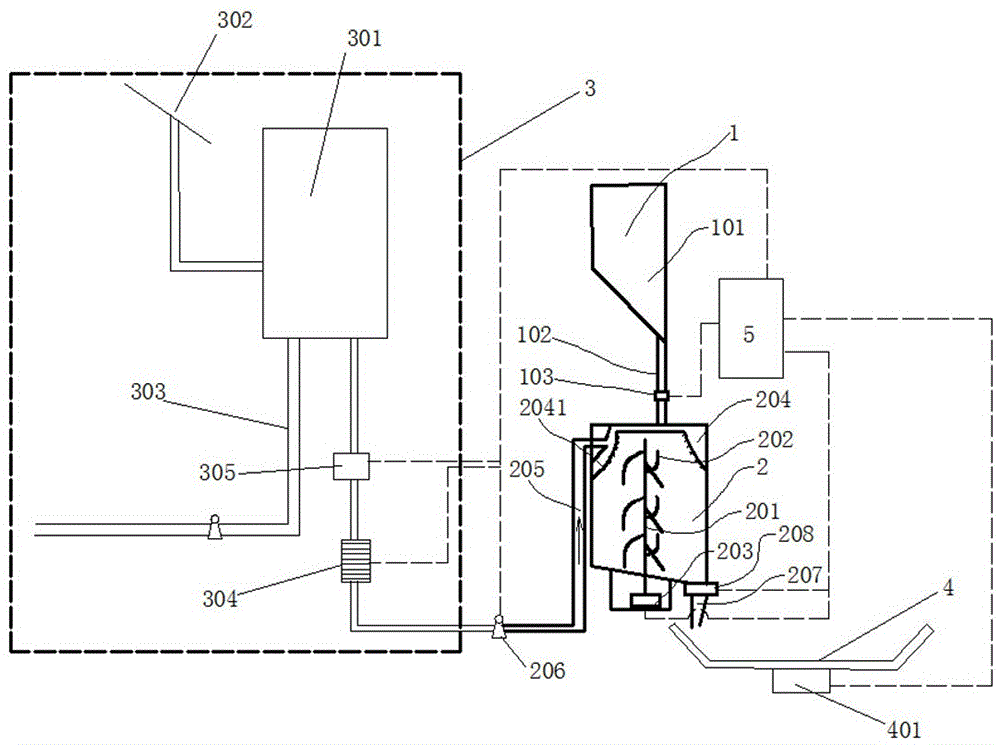

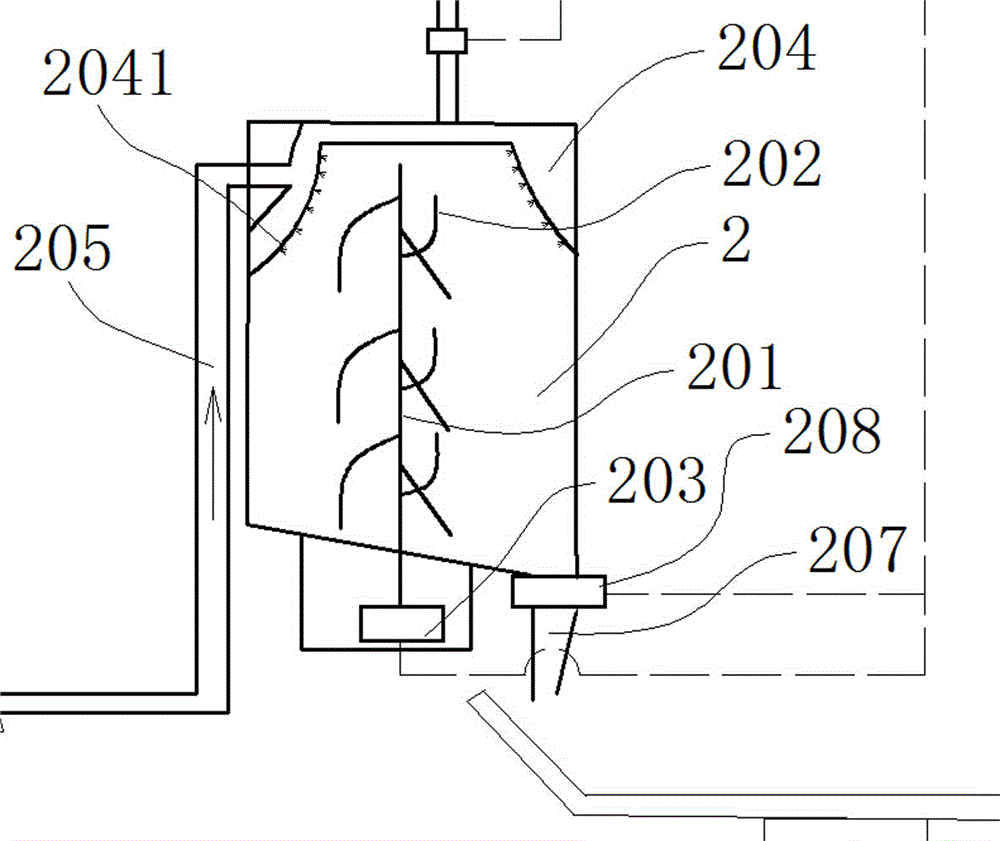

Energy-saving and automatic poultry and livestock breeding device

InactiveCN106342710AAvoid wastingWell mixedAnimal watering devicesAnimal feeding devicesAnimal scienceLivestock breeding

The invention discloses an energy-saving and automatic poultry and livestock breeding device and belongs to the breeding field. The device comprises a feeding device (1), a stirrer (2), a water supply system (3) and a trough (4), wherein the feeding device is connected with the stirrer (2), the water supply system is connected with the stirrer (2) located in the trough (4), and the stirrer is in contact connection or is in non-contact connection with the trough when located above the trough; a stirring shaft (201) is arranged in the stirrer, stirring blades (202) are arranged on the stirring shaft, and a motor (203) is arranged at the bottom end of the stirring shaft and connected with a power supply.

Owner:成都测迪森生物科技有限公司

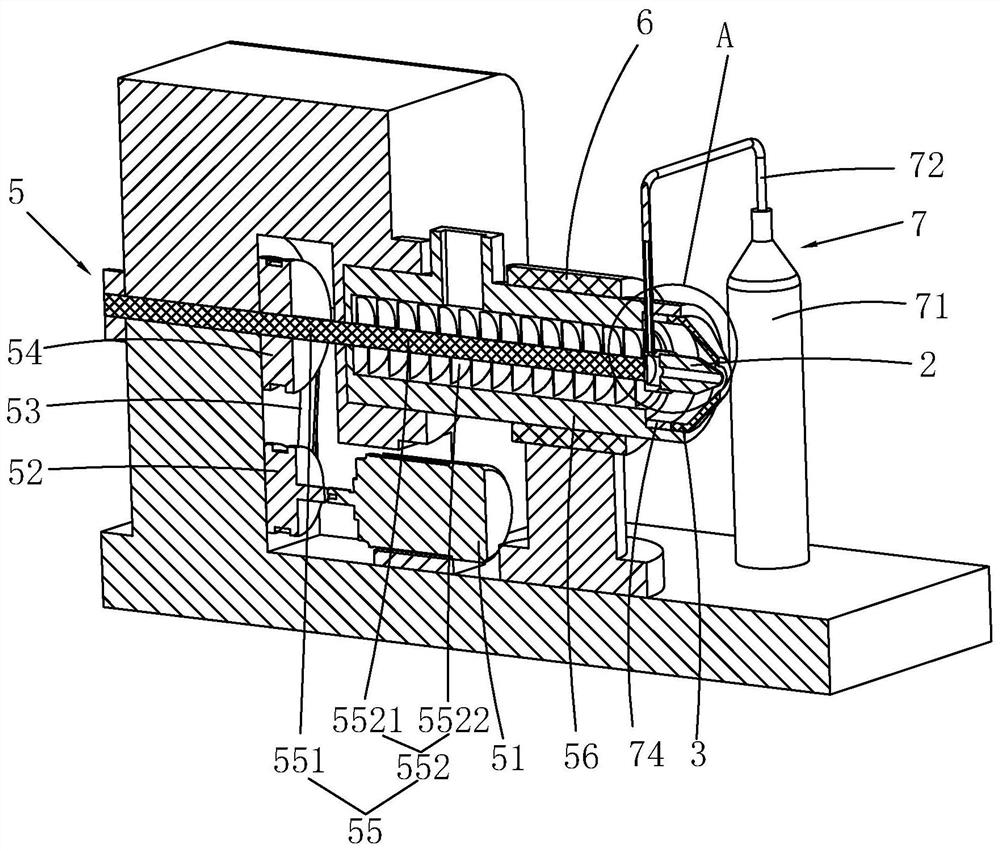

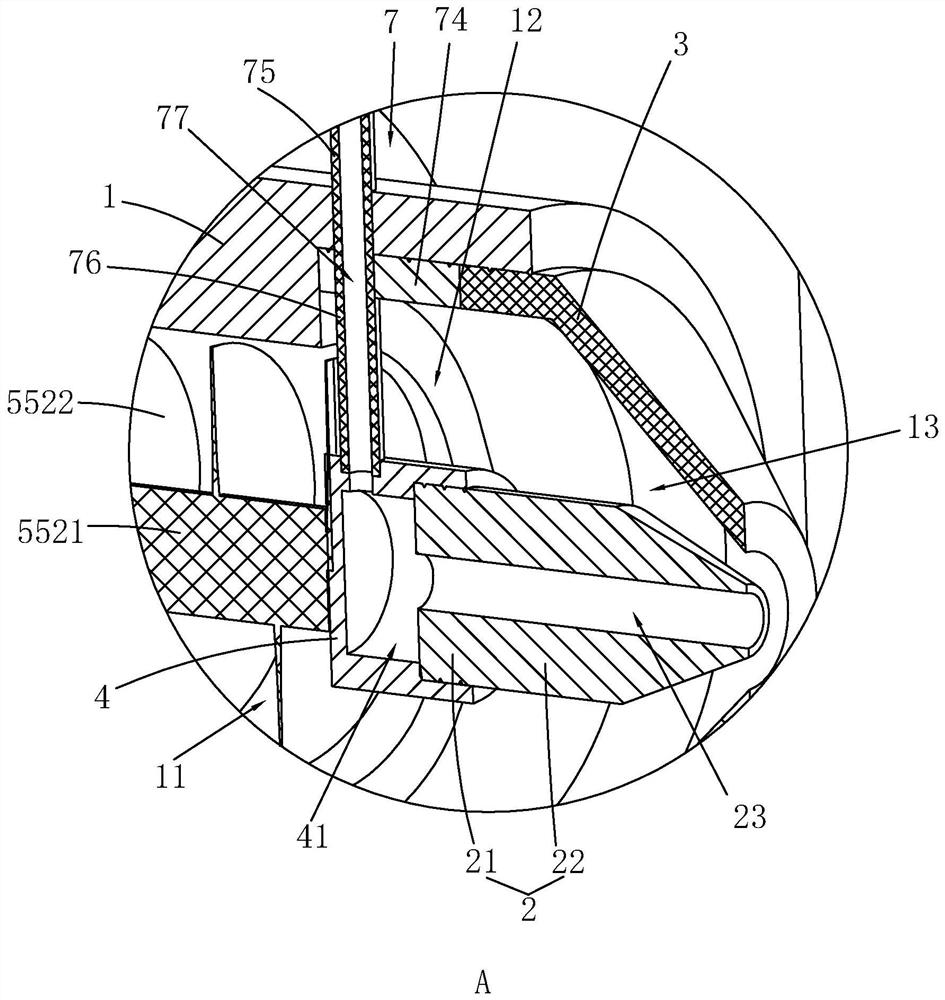

Rubber tube extrusion device and method

InactiveCN112848197AFacilitate subsequent processingImprove processing efficiencyEngineeringMechanical engineering

The invention relates to a rubber tube extrusion device and method. The rubber tube extrusion device comprises a machine body, a mold core, a mouth mold and a mounting lantern ring, wherein the mold core, the mouth mold and the mounting lantern ring are arranged close to one end of a discharge port of the machine body, a transition cavity is formed between the mold core and the mounting lantern ring, and a forming cavity is formed between the mold core and the mouth mold. The rubber tube extrusion device further comprises a connecting mechanism, wherein the connecting mechanism comprises a hollow screw rod, an air pipe, a powder pipe, a connecting piece and an air blowing piece; the connecting piece is connected with the inner side wall of a mounting column; one side, far away from the mounting column, of the connecting piece is connected with the mold core; a through hole is formed in the connecting piece; the hollow screw rod penetrates through the mounting lantern ring and communicates with the through hole; a discharge hole is formed in the mold core; one end, far away from the mounting lantern ring, of the hollow screw rod is connected with the air pipe; the powder pipe is arranged on the air pipe; and one end of the air pipe is connected with the air blowing piece. According to the rubber tube extrusion device and method, powder is blown to the inner wall of a rubber tube, so that the adhesive force between the inner walls of the rubber tube is reduced, the inner walls of the rubber tube are inconvenient to bond, then the rubber tube is convenient to carry out subsequent processing, and the processing efficiency of the rubber tube is improved.

Owner:陕西金迪橡胶制品有限公司

Production process method for producing rice by using paddy rice

InactiveCN103521286AReduce processing costsAdditional cooking stepsGrain treatmentsCookerElectricity

The invention discloses a production process method for producing rice by using paddy rice. The production process method comprises: step 1, cleaning unprocessed grains, specifically adopting a cylindrical pre-cleaning screen, a vibrating screen and a stoning machine device to perform paddy rice cleaning; step 2, performing cooking, specifically adding an appropriate amount of water into the paddy rice and using a heating device to cook and heat the paddy rice till paddy rice hulls open; step 3, performing dehydration, specifically setting a dehydrator to be at the low temperature of 38-42 DEG C and enabling the dehydrator to perform spin-drying type dehydration; step 4, performing drying, specifically setting the dehydrator to be at the low temperature of 48-52 DEG C, drying the paddy rice and controlling the moisture content of the paddy rice to be 16-17%; step 5, performing hull removal; step 6, performing screening and grading; step 7, performing package. The production process method can enable processed rice to be mellow and large in size. In addition, the rice is easily cooked thoroughly and electricity is saved during cooking, and cooked rice does not easily stick onto a cooker, is not sticky together and has granular sensation.

Owner:江振福

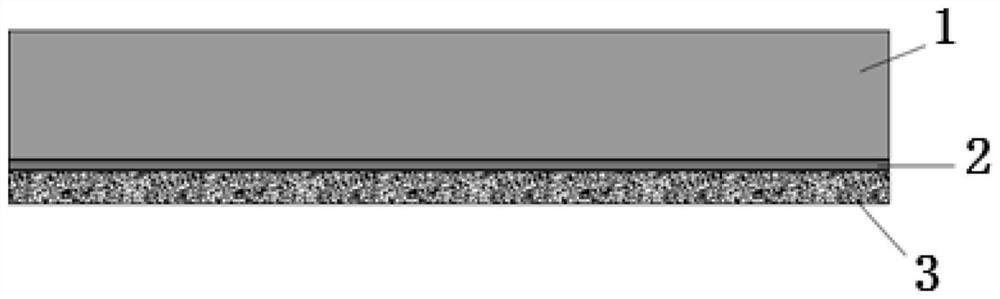

Easy-to-unwind self-adhesive protection film and preparation method thereof

ActiveCN111925738AStrong pressure sensitive self-adhesiveReduce usageFilm/foil adhesivesUnsaturated alcohol polymer adhesivesPolymer sciencePolyolefin

The invention provides an easy-to-unwind co-extrusion self-adhesive protection film which is of a three-layer structure and sequentially comprises a self-adhesive layer, a connecting layer and a supporting layer, and the thickness ratio of the self-adhesive layer to the connecting layer to the supporting layer is 8-35: 5-15: 50-87. The self-adhesive layer is made of a thermoplastic modified polyvinyl alcohol material; the connecting layer comprises a maleic anhydride modified polyolefin bonding resin material; and the supporting layer is made of a modified polyolefin material. According to theinvention, a strong intermolecular force is formed between polar functional groups on thermoplastic modified polyvinyl alcohol and the surface of the connecting layer material, so that the protectionfilm has strong pressure-sensitive self-adhesion and stable viscosity, tackifying resin does not need to be added, and a release agent or a separant does not need to be used or an independent releaselayer does not need to be arranged. The problems that the protection film is not easy to unwind or the unwinding force is too high after being wound, the film is easy to stretch and deform or inconvenient to use when the protection film is used, the tackifying resin is easy to migrate to the surface along with time extension or temperature rise, and the surface of a protected object is polluted or remained are generally solved.

Owner:佛山(华南)新材料研究院

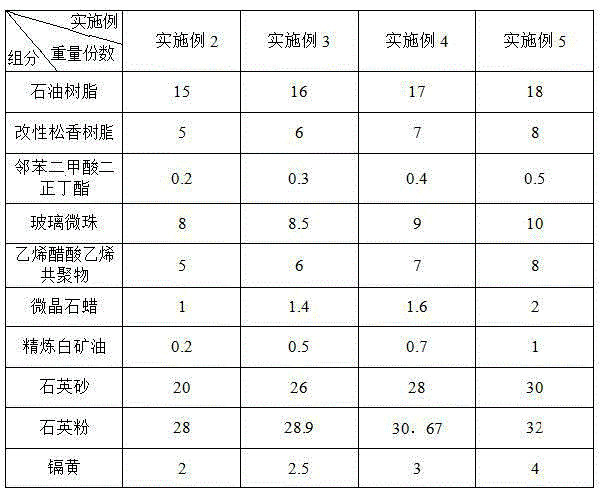

Heat melting high-wear-resistant anti-pollution yellow traffic marking material and preparation method thereof

The invention discloses a heat melting high-wear-resistant anti-pollution yellow traffic marking material and a preparation method thereof. The preparation method is used for preparing the traffic marking material in the technical field of traffics. The heat melting high-wear-resistant anti-pollution yellow traffic marking material comprises the following components: petroleum resin, modified rosin resin, di-n-butyl phthalate, glass beads, an ethylene vinyl acetate copolymer, microcrystalline wax, refined white mineral oil, quartz sand, quartz powder and cadmium yellow. The traffic marking material prepared by using the preparation method not only can be used for improving the wear resistance and anti-pollution capacity of a traffic marking, but also can be used for increasing the adhesive force of the traffic marking.

Owner:BAODING VICTORY TRAFFIC FACILITIES ENG CO LTD

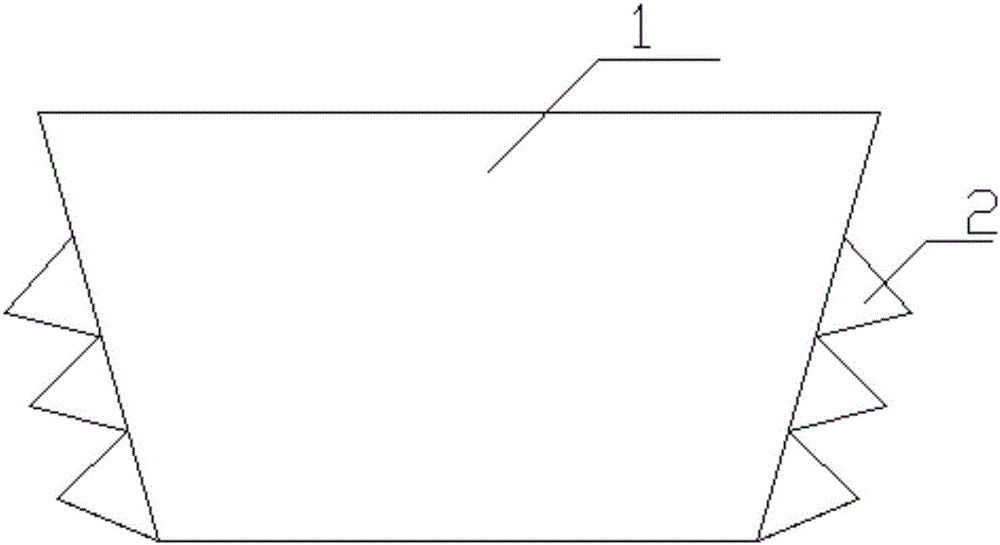

Rapid compounding repair method of pavement

The invention discloses a rapid compounding repair method of pavement. The method includes: conducting crushing treatment on concrete pavement cracks or pit slots to form a quadrangular frustum structure seam pit with big top and small bottom, wherein one group of opposite sides at the seam pit bottom are consistent with the travelling direction, and the included angles between any side of the seam pit and the seam pit bottom are all 110DEG-130DEG, at least 3 successively connected grooves are digged on two sides of the beam pit parallel to the travelling direction from the bottom up, the grooves are in a regular triangular prism structure, and the triangular sides of the grooves are perpendicular to the travelling direction; mixing a grouting material, then injecting the grouting material into the seam pit and performing inserting pounding, wherein the grouting material includes the following raw materials: cement, purified diatomite, first rock sand, a molasses retarder, a water reducer, lithium chloride and a coagulant. The method provided by the invention has short construction time, can significantly improve the bonding strength between to-be-repaired concrete pavement and a newly poured material layer, so that the repaired concrete pavement can become a whole, and has the advantages of good deformation ability and difficult shedding.

Owner:曹立强 +7

Production method and processing mold of PVC co-extrusion stone plastic profiled material

The invention provides a production method and a processing mold of a PVC co-extrusion stone plastic profiled material. The production method comprises the technical steps of (1) adding PVC stone plastic materials into a mixer according to the formula proportion, increasing the temperature to be 110 to 130 DEG C through self friction of the materials, then cooling till the temperature reaches 40 to 50 DEG C through a condenser, and adding the cooled materials into a main hopper; (2) adding PVC materials into the mixer according to the formula proportion, increasing the temperature to be 110 to 130 DEG C through self friction of the materials, then cooling till the temperature reaches 40 to 50 DEG C through the condenser, and adding the cooled materials into an auxiliary hopper; and (3) extruding the PVC stone plastic materials through an extruder, pressing the extruded PVC stone plastic materials into a PVC stone plastic material feed inlet of the processing mold, carrying out compaction, fusion and mixing homogenization, molding a core in the processing mold, at the same time, squeezing the PVC materials into a PVC material feed inlet of the processing mold through the extruder, and coating the outer surface of the molded core, wherein the temperature of a screw of the extruder is 85 to 95 DEG C; and the extrusion pressure is 8 to 16 Mpa. According to a product produced through the production method, the waterproofness, bending resistance, toughness, surface ageing resistance and adhesion firmness degree for hot rolling printing are higher than those of a stone plastic material, the weight is lower than that of the stone plastic material, the hardness is higher than that of PVC, and the construction cost is lower than that of PVC.

Owner:黄石市鸿达塑料模具有限责任公司

Silica gel pad, and preparation method thereof

The invention belongs to the field of silica gel product processing, and especially relates to a silica gel pad, and a preparation method thereof. According to the preparation method, liquid state silica gel is prepared from vinyl polysiloxane, white carbon black, and hydrogen-containing polysiloxane; certain amounts of the liquid state silica gel, dimethicone, a platinum catalyst, and a silica gel color paste are stirred at vacuum conditions, wherein stirring time is controlled to be 60min or shorter, stirring speed is controlled to be 30 to 70rpm, temperature is controlled to be 25 DEG C or lower, vacuum degree is controlled to be -0.09MPa or lower, and vacuum treatment time is controlled to be 20 to 40min; after uniform stirring, a silica gel precoating product is prepared, a reinforcing substrate taken as a supporting material is selected, the reinforcing substrate is coated with the silica gel precoating product so as to obtain a silica gel composite material; and the silica gel composite material is subjected to high temperature baking for 3 to 10min at 80 to 160 DEG C; after baking, the reinforcing substrate is removed so as to obtain the silica gel pad finished product. The silica gel pad is prepared based on scientific formula via advanced technology, is suitable to be used in different food steaming boxes and baking boxes, and is promising in market prospect.

Owner:KUNSHAN SHUOHONG ELECTRONICS MATERIAL CO LTD

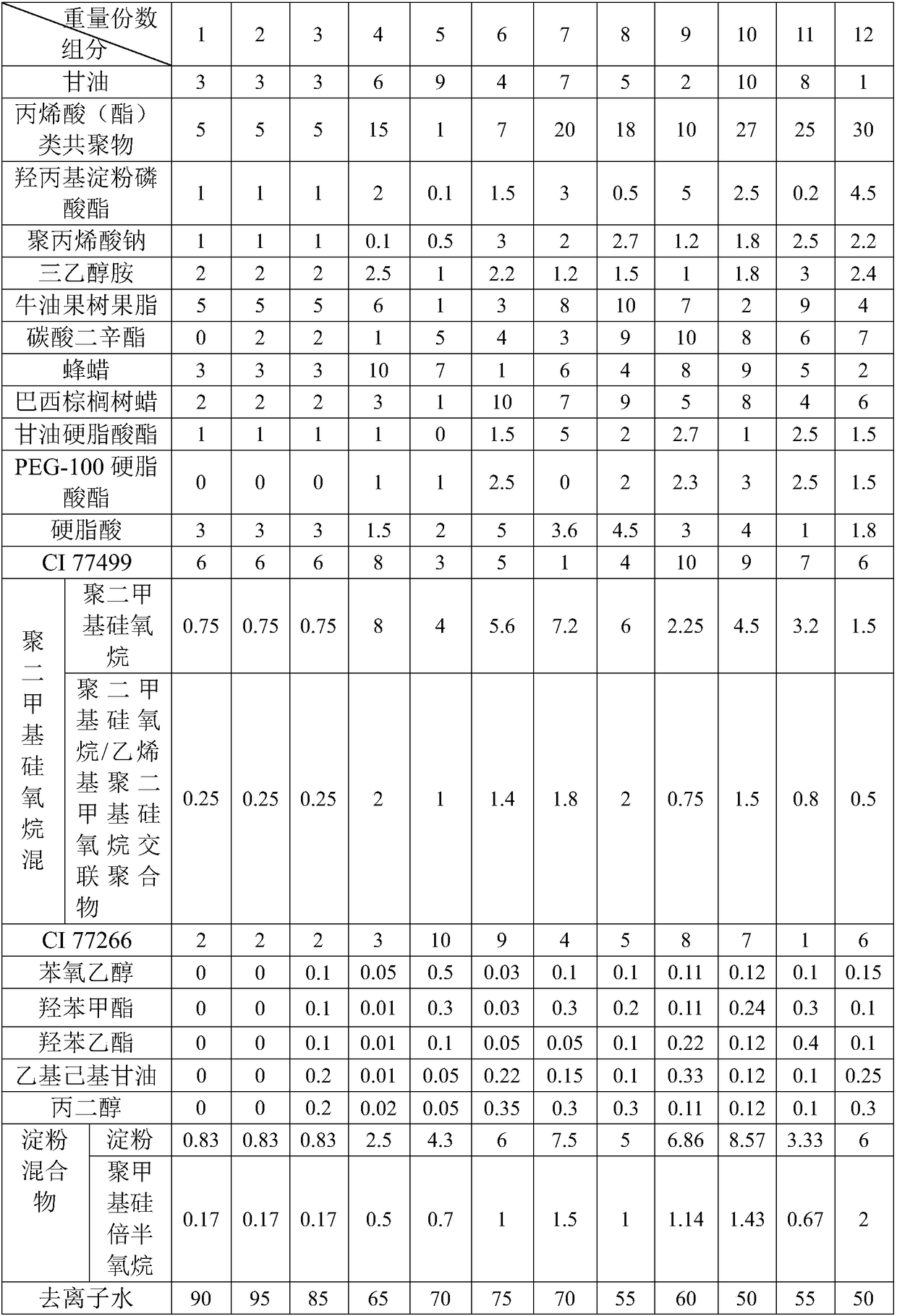

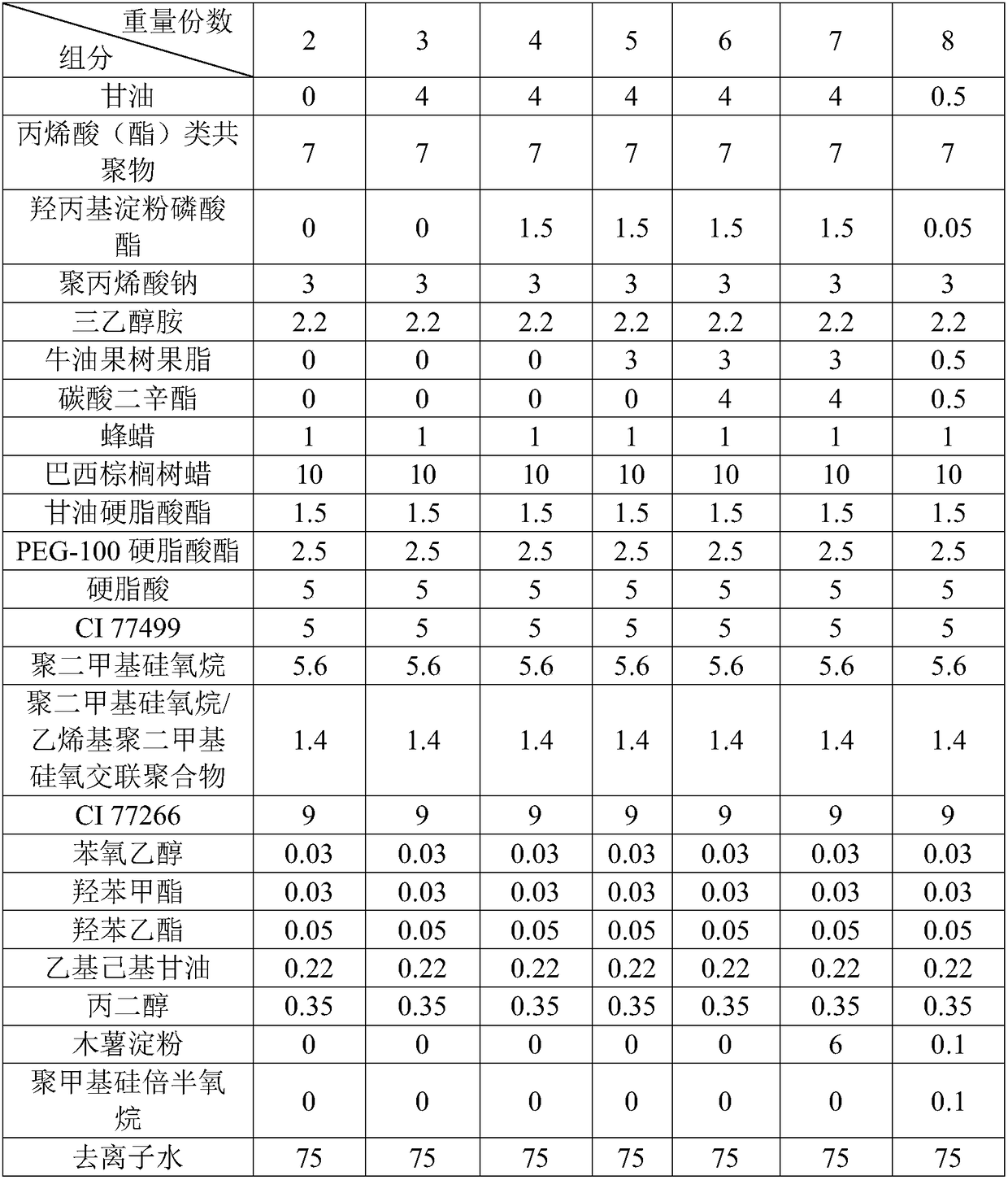

Starch mascara cream and preparation method thereof

The invention discloses a starch mascara cream and a preparation method thereof. The starch mascara cream comprises, by weight, 1 to 30 parts of an acrylic acid (acylate) copolymer, 0.1 to 3.0 parts of sodium polyacrylate, 1 to 10 parts of beeswax, 1 to 10 parts of Brazilian palm wax, 1 to 10 parts of glycerol, 1 to 10 parts of shea butter, 1 to 10 parts of CI 77499, 1 to 10 parts of CI 77266, 1 to 10 parts of a polydimethylsiloxane mixture, 1 to 5 parts of a surfactant, 1 to 5 parts of stearic acid, 1 to 3 parts of triethanolamine, 0.1 to 5.0 parts of hydroxypropyl starch phosphate, 1 to 10 parts of a starch mixture and 50 to 95 parts of deionized water, wherein the surfactant comprises at least one selected from a group consisting of glyceryl stearate and PEG-100 stearate. The mascara cream of the invention has the advantages that the mascara cream can be uniformly made up and be quickly and gently removed.

Owner:上海明轩化妆品科技有限公司

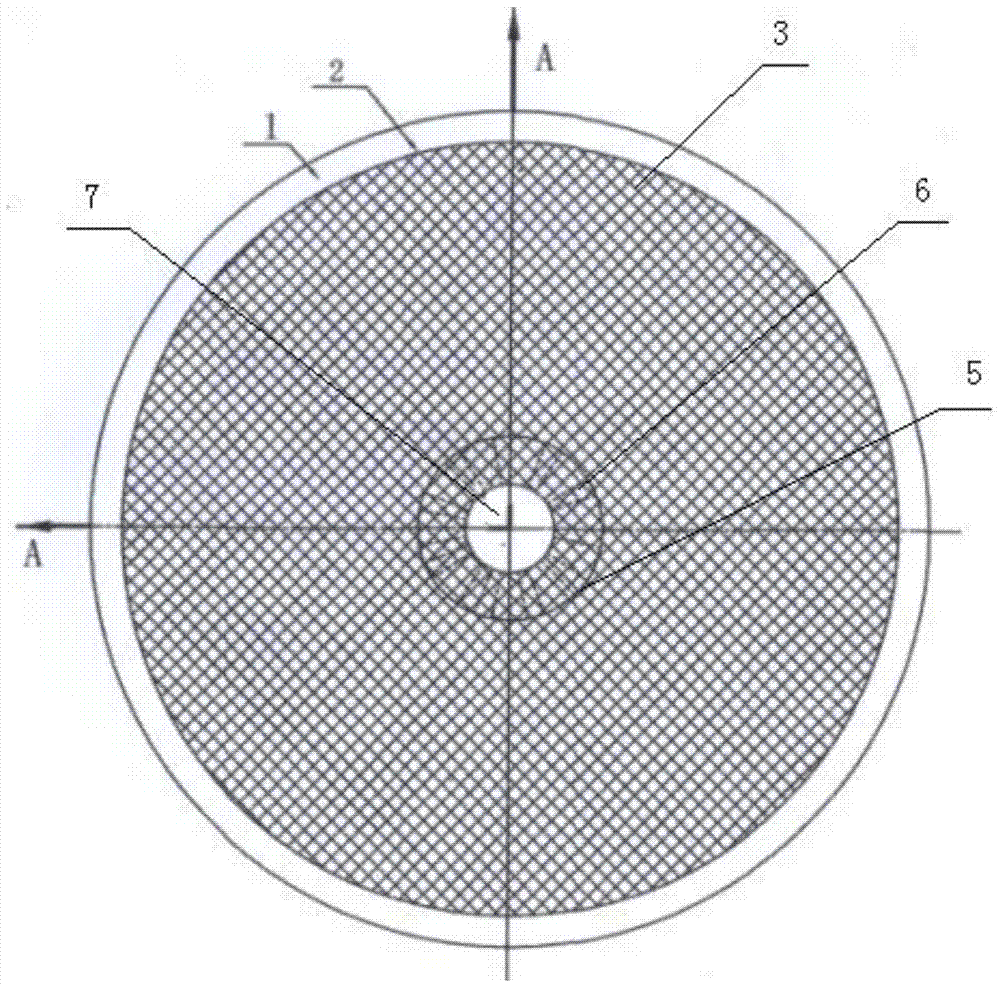

Single-sided hollow stainless steel welded filter plate

ActiveCN104941322BWon't tearQuality assuranceStationary filtering element filtersWire gauzeMetallurgy

A single-sided hollow stainless steel welded filter plate, the support layer is fixed between the stainless steel forming base plate and the stainless steel wire mesh; the outer edges of the stainless steel forming base plate and the stainless steel wire mesh are welded and fixed; the support ring is provided with diversion grooves at intervals, and is installed on the stainless steel forming base plate and the stainless steel wire mesh The stainless steel wire mesh is located in the inner ring of the support layer, and a through liquid outlet hole is provided in the middle of the stainless steel forming bottom plate, the stainless steel wire mesh and the support ring. The advantages of the present invention are: the stainless steel forming bottom plate is integrally welded with the outer edge of the stainless steel wire mesh to form a single-sided filter unit, and the edge is welded firmly during reverse flushing, and the outer edge of the filter plate will not be torn, ensuring the quality of the filtered liquid. The stainless steel wire mesh is not easy to stick to impurities, not easy to clog, and easy to wash. The gap of the stainless steel wire mesh on the upper surface is uniform, and the stainless steel formed bottom plate ensures that the liquid does not leak. It has the characteristics of high strength and high strength.

Owner:天津市宝钜净化设备工程有限公司

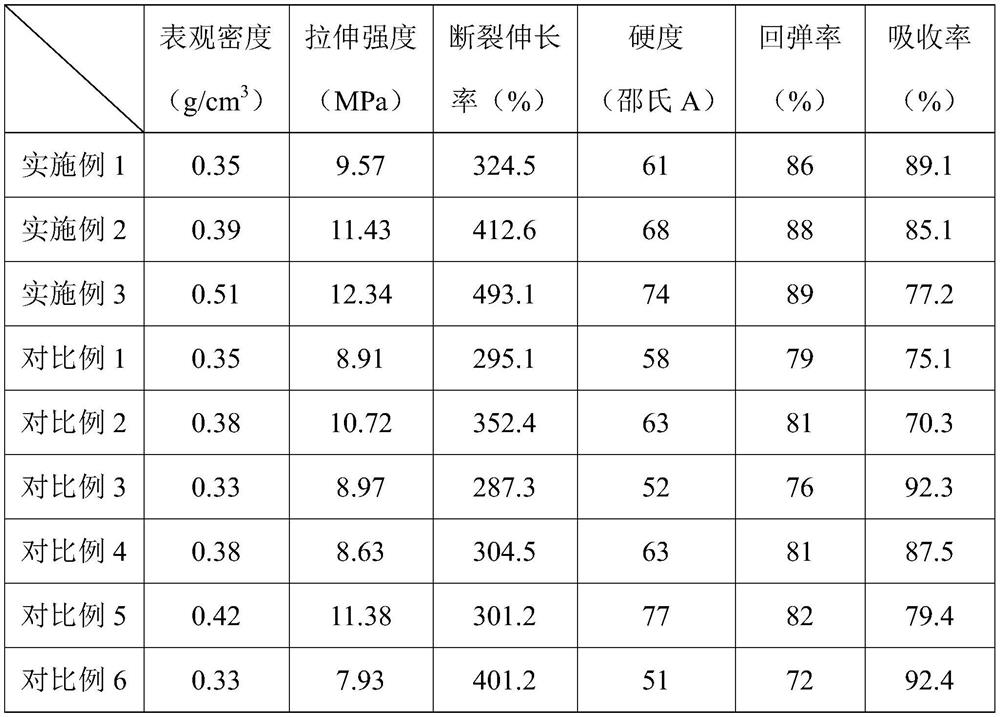

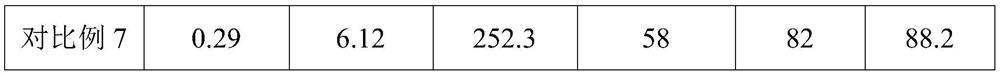

Silicone rubber foam material and preparation method thereof

The invention relates to a silicone rubber foam material and a preparation method thereof. The preparation method comprises the following steps: preparing polydimethylsiloxane, boric acid, a derivative thereof and an organic solvent into a polydimethylsiloxane solution, carrying out condensation polymerization, and then removing unreacted boric acid, the derivative thereof and the organic solvent to obtain shear thickening gel; mixing 1-10 parts by mass of the shear thickening gel with 100 parts by mass of vinyl-containing silicone rubber to obtain a silicone rubber base material; mixing the silicone rubber base material with 1-20 parts by mass of nanocellulose, 1-10 parts by mass of expanded microspheres and 0.01-0.5 part by mass of an organic peroxide cross-linking agent, so as to obtain silicone rubber compound; and performing pre-forming and cross-linking foaming on the silicone rubber compound to obtain the silicone rubber foaming material. The silicone rubber foam material obtained by the preparation method has the advantages of high resilience, low compression deformation and the like, and can be better applied to the fields of shock absorption and impact resistance.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

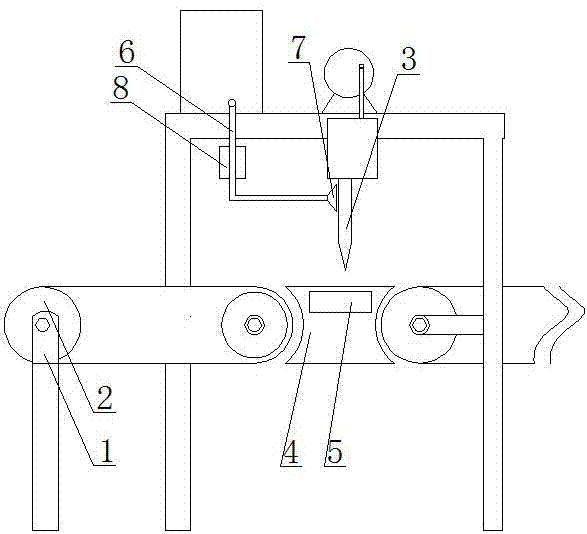

Device for slitting waterproof material and method for slitting waterproof material

The invention relates to equipment and a method in the technical field of waterproof materials, and provides a device for slitting a waterproof material and a method for slitting the waterproof material. The device for slitting the waterproof material comprises a machine frame, wherein a conveyor is arranged on the machine frame; a slitting knife driven by a power device is further arranged on the machine frame; the slitting knife operates downwards under the action of the power device to slit the waterproof material; slitting backing plates are arranged under and behind the slitting knife; and a first refrigeration part is arranged in each slitting backing plate. The method for slitting a waterproof material comprises the step of slitting the waterproof material at a low temperature of 0-5 DEG C. The device for slitting the waterproof material and the method for slitting the waterproof material have the advantages that the waterproof material is easy to slit, and the coating in the waterproof material is not likely to be adhered to the slitting knife.

Owner:长葛市长润钢结构有限公司

Method for recycling beech waste wood chips

The invention discloses a method for recycling beech waste wood chips. The method comprises the following steps that the beech waste wood chips are produced into a decorative board after being collected; (1), the following raw materials of the beech waste wood chips, epoxy resin, 2,000-mesh quartz powder, 800-mesh quartz powder, 40-mesh quartz sand, salicylate, nano zinc oxide, a coupling agent and a curing agent are weighed; (2), the raw materials are evenly mixed; (3), the mixture is loaded into a mold, and vibrating and pressing forming are carried out; (4), curing is carried out; and (5),grinding and polishing are carried out. By the adoption of the method, the beech waste wood chips can be recycled, resources are fully used, and the produced decorative board has the beneficial effects of being high in practicability, durable in use, high in anti-aging capability, good in toughness, good in sound insulation effect and the like and has the natural feeling of logs and good appearance.

Owner:贵港市万升木业有限公司

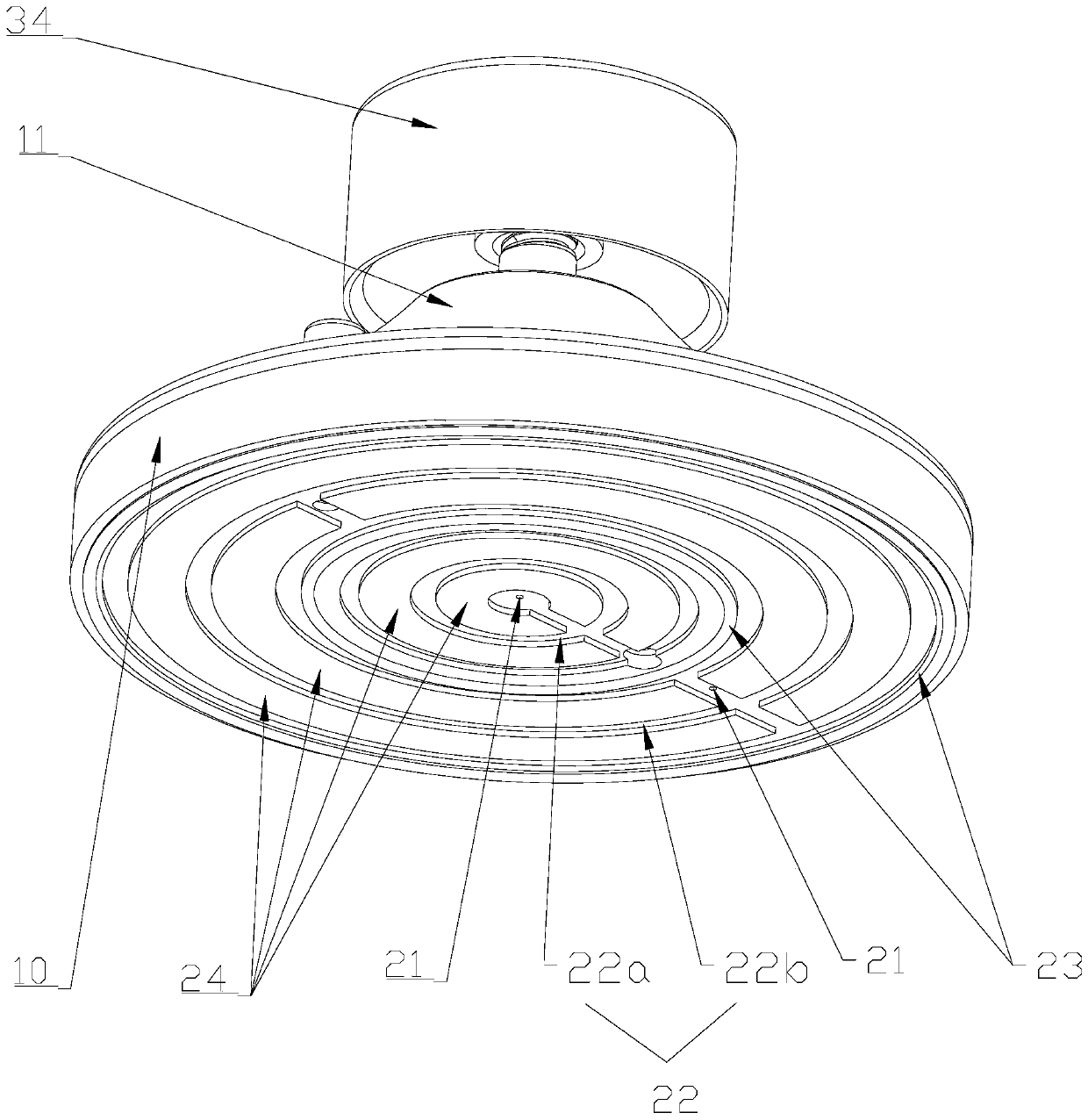

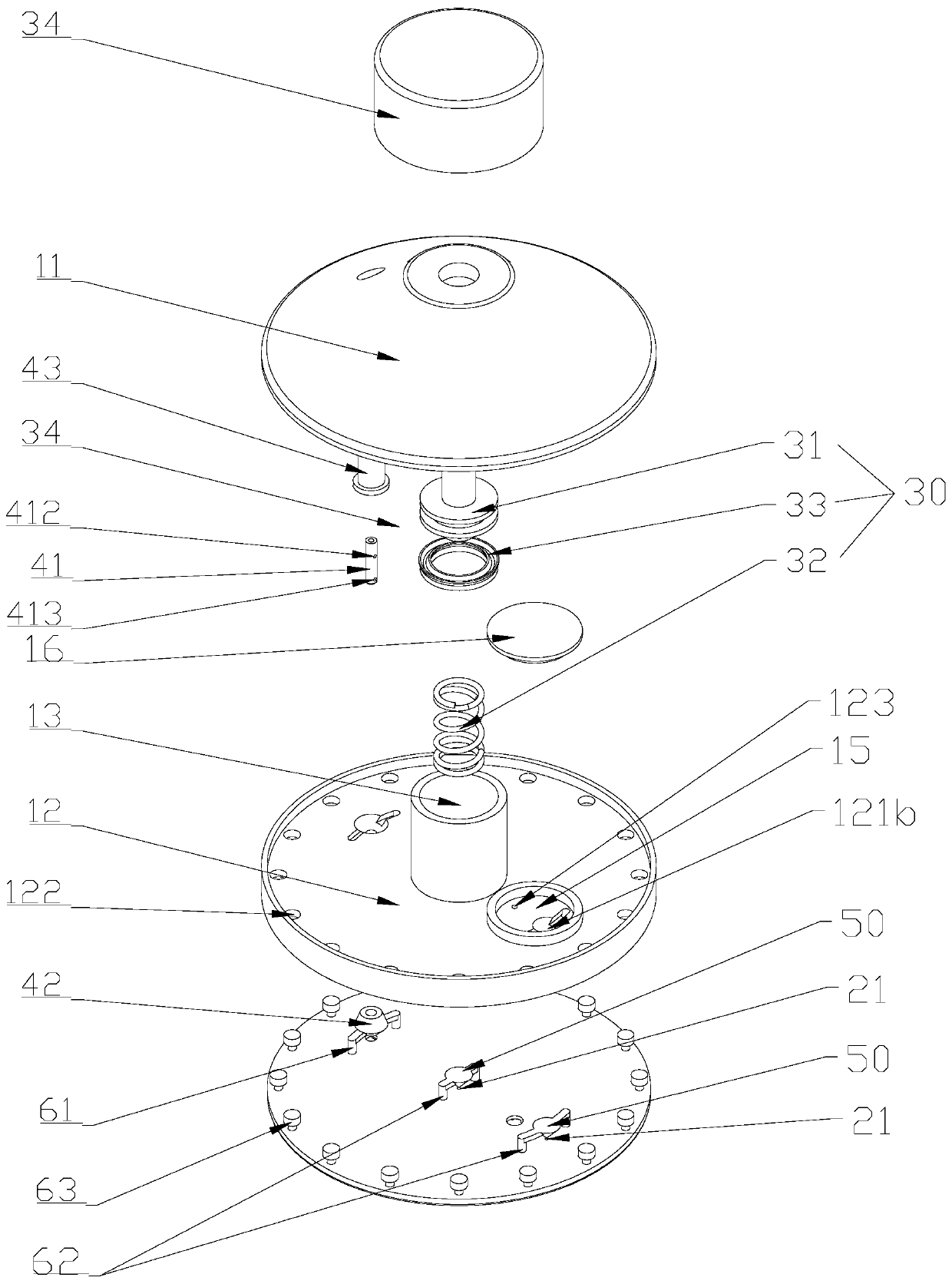

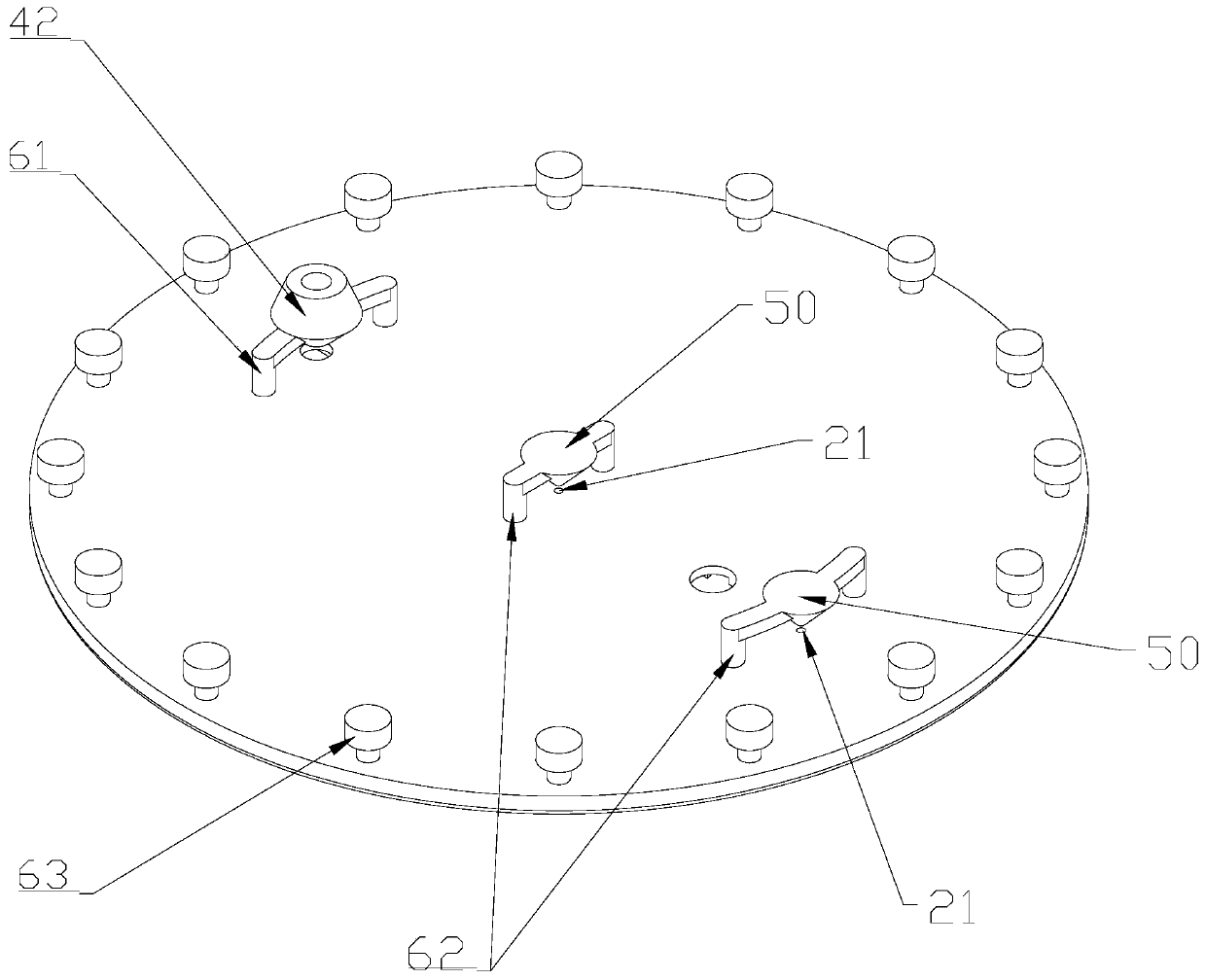

Vacuum absorption device

InactiveCN111486167AGuaranteed adsorption functionReliable functionCheck valvesKitchen equipmentSilica gelCheck valve

The invention discloses a vacuum absorption device comprising a body, an air extracting mechanism, a check valve, a sealing silica gel gasket and a pressure relief mechanism, wherein the body is provided with an air extracting cavity and a first adsorption wall, the adsorption wall is provided with a first through hole communicating with the air extracting cavity, the air extracting mechanism is used for extracting air in the air extracting cavity into the external environment, the check valve is matched with the first through hole so as to allow air to flow into the air extracting cavity fromthe first through hole in a single direction, the sealing silica gel gasket is provided with a second through hole corresponding to and communicating with the first through hole, one side of the sealing silica gel gasket is attached to the bottom face of the adsorption wall, the other side of the sealing silica gel gasket is provided with at least two sealing concave cavities, each sealing concave cavity communicates with the air extracting cavity through the second through hole and the first through hole which are corresponding, when the sealing silica gel gasket is adsorbed on the adsorption face, the sealing concave cavities do not communicate, the pressure relief mechanism is provided with a pressure relief channel enabling the sealing concave cavities to communicate with the outside,and the pressure relief channel can move between a sealing position and a pressure relief position so as to be opened or closed. The vacuum absorption device enables the adsorption function to be more reliable, adsorption can be easily relieved, the use effect is better, and the structure is simple.

Owner:晋江一岂科技有限公司

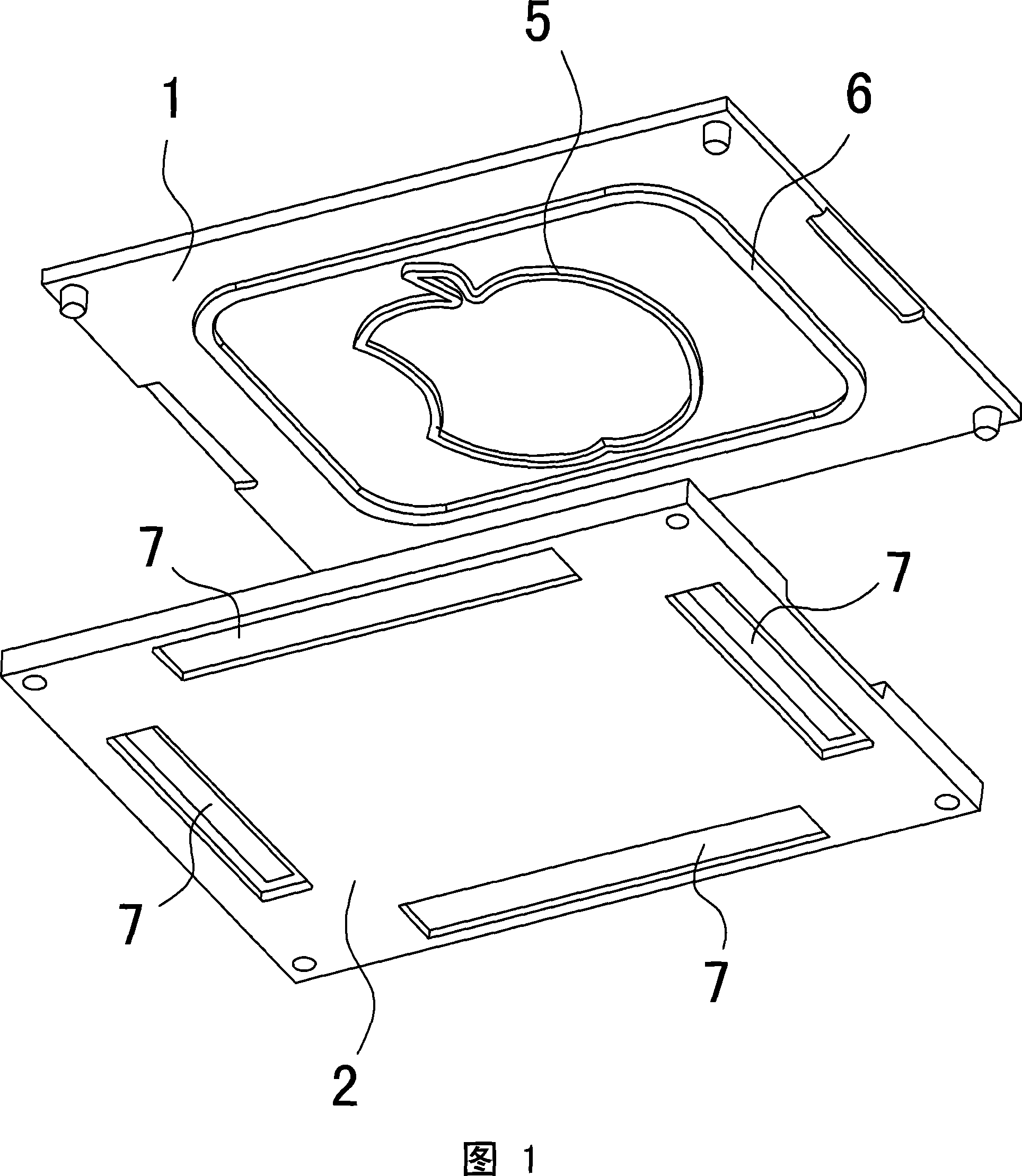

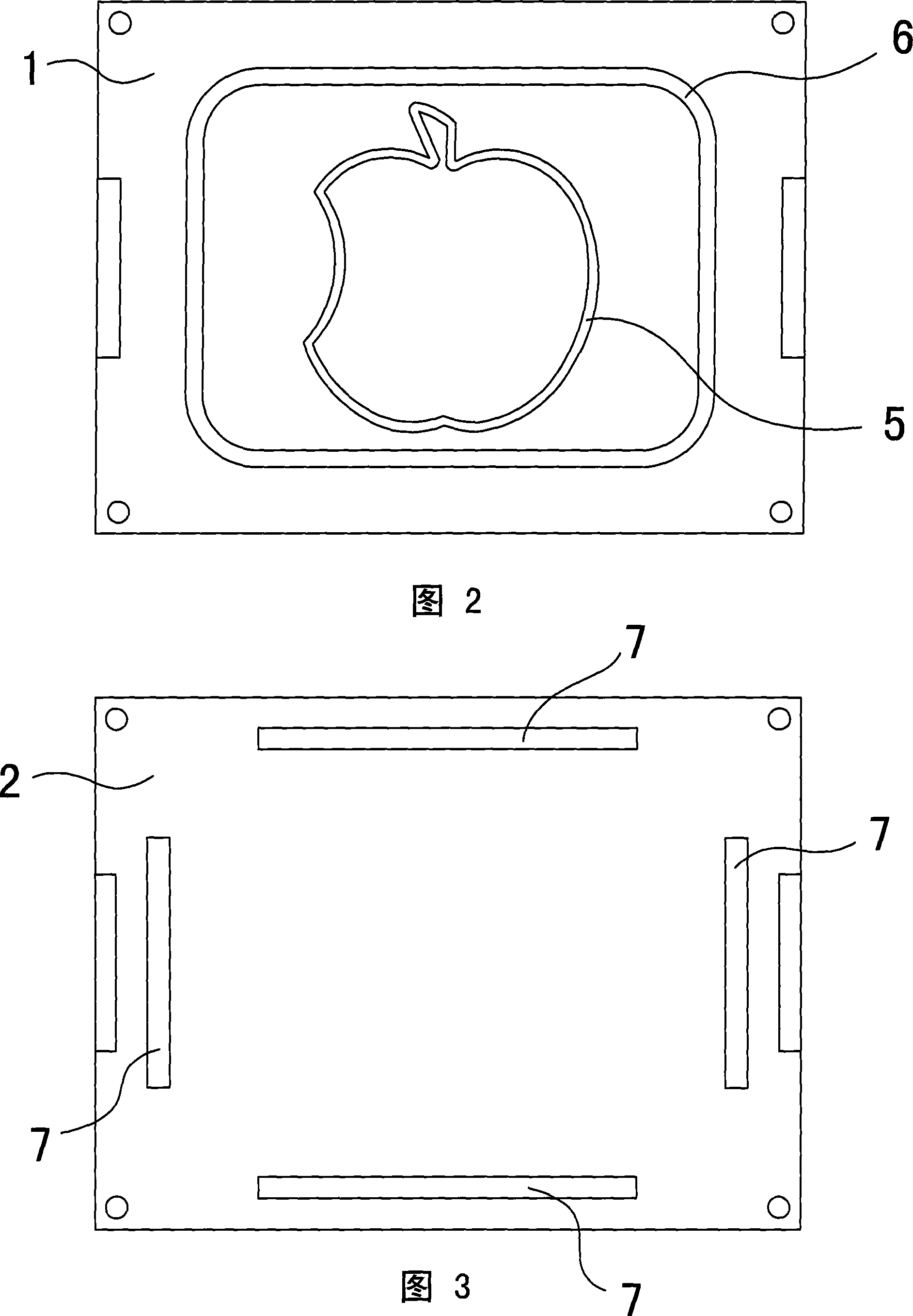

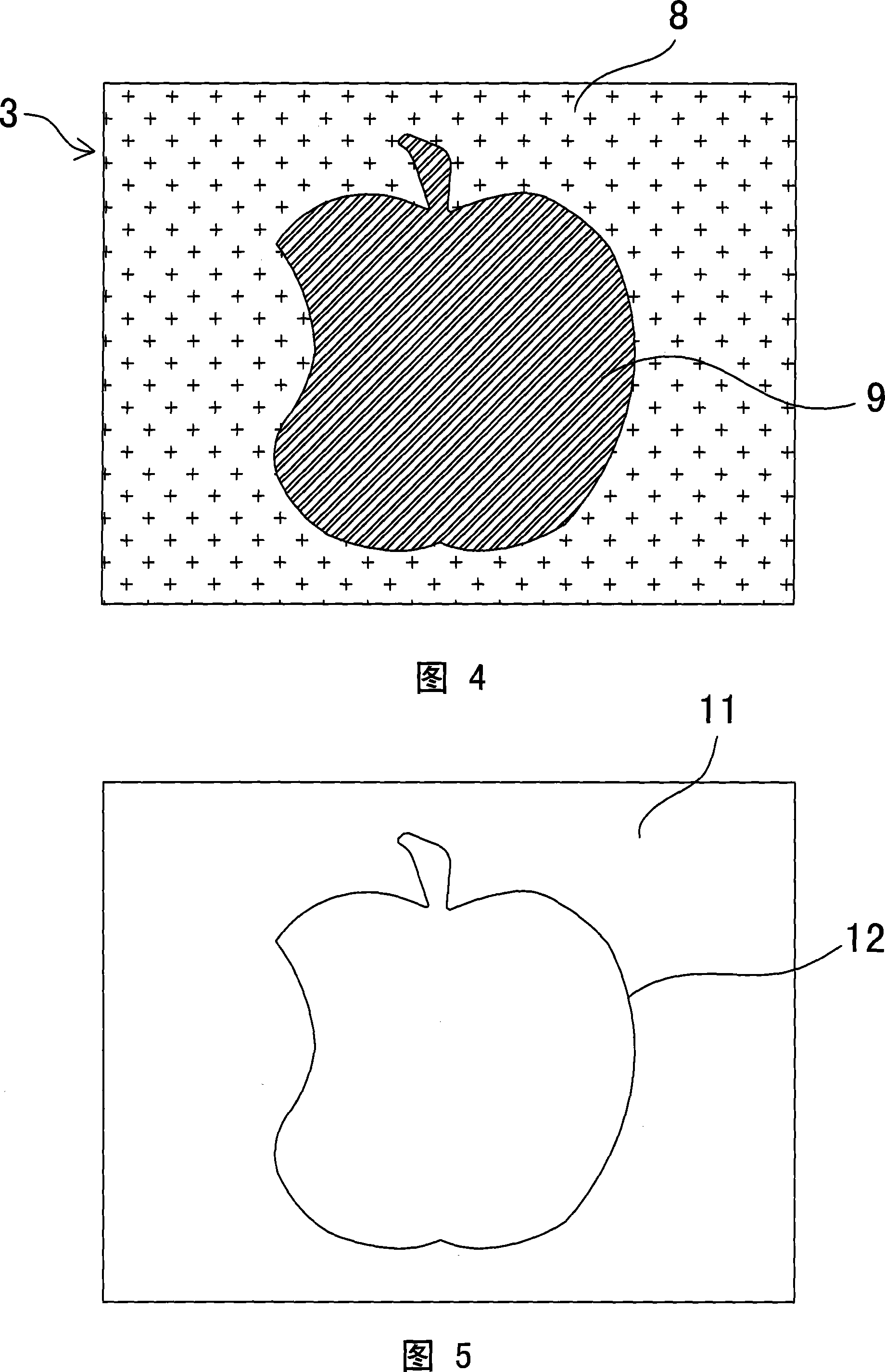

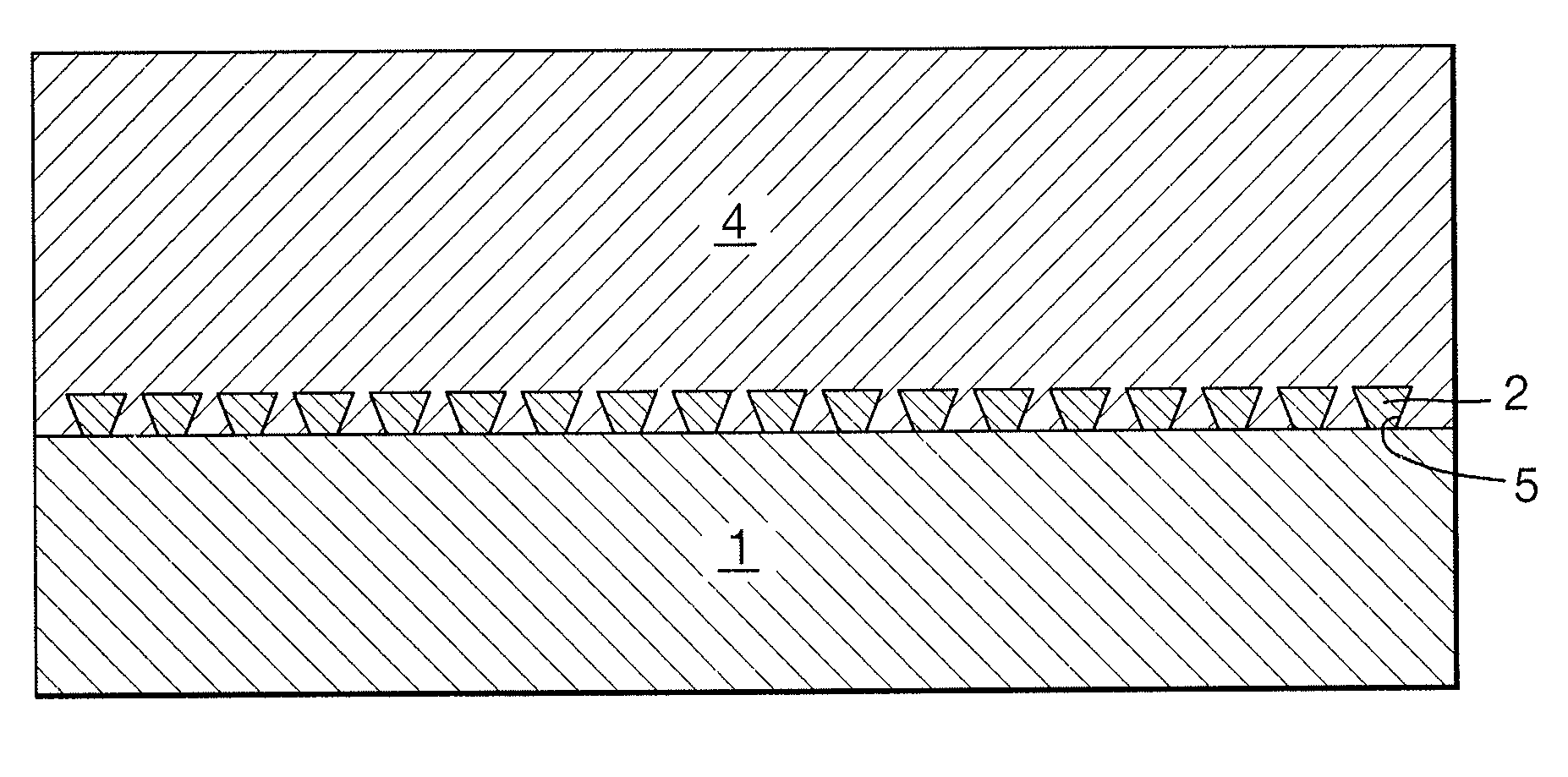

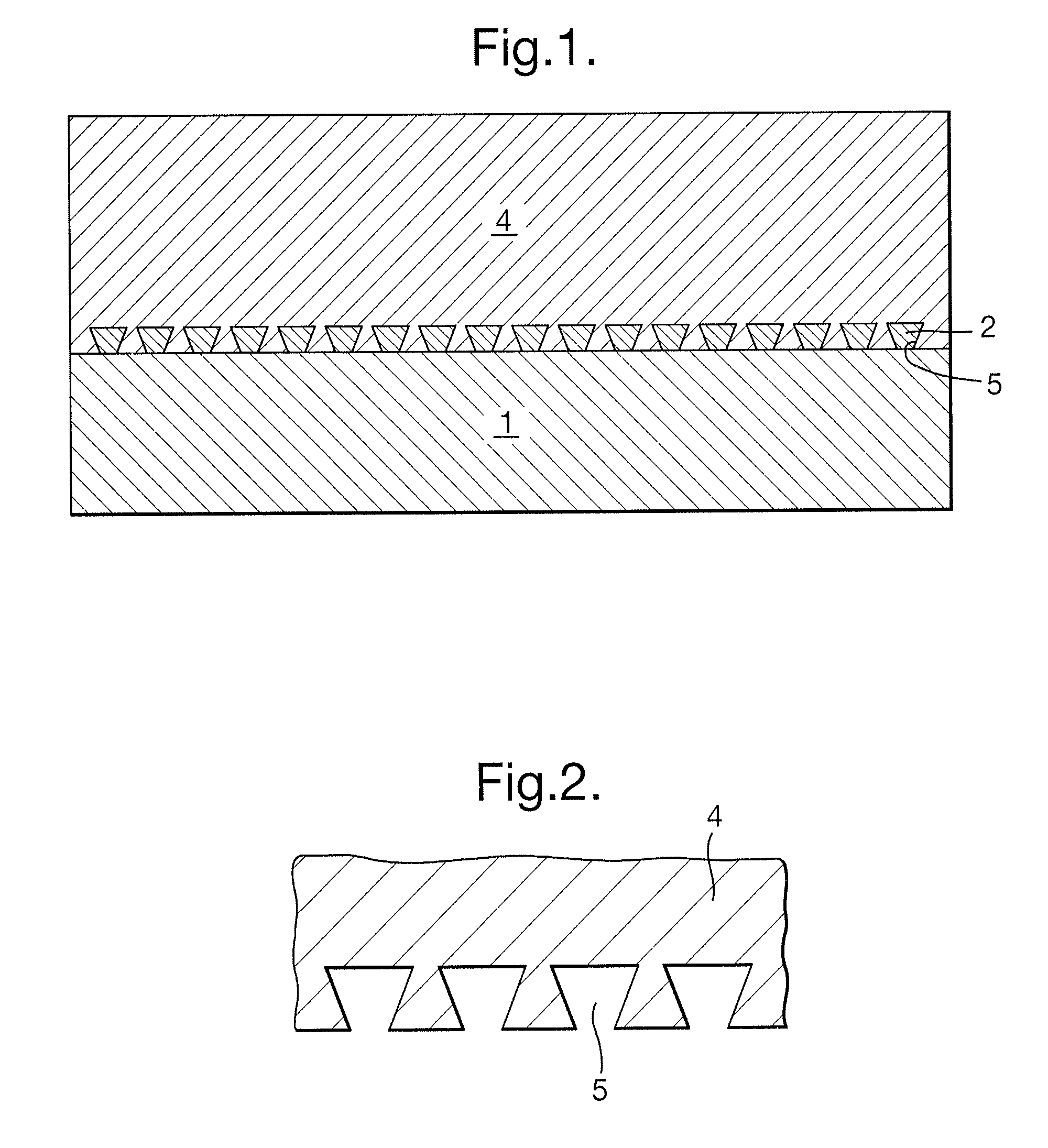

Mould lining

InactiveUS20080203612A1Not easy to bondEasy to produceConfectionerySweetmeatsReciprocating motionAdhesive

Powder metallurgy techniques are utilised to form components and in particular titanium components in moulds. By the nature of the powder forming process, closed surfaces are created in the powder formed component, particularly when hot iso-static pressing techniques are utilised. In order to create surface texturing, and in particular entrant features, a mould lining is associated such that it reciprocates the shape of an underlying mould. The mould lining incorporates surface discontinuities such as holes, slots, spots or folds which result, once the moulded material is formed, in entrant features which can be utilised to enhance bonding through adhesives or other surface features beneficial to a component.

Owner:ROLLS ROYCE PLC

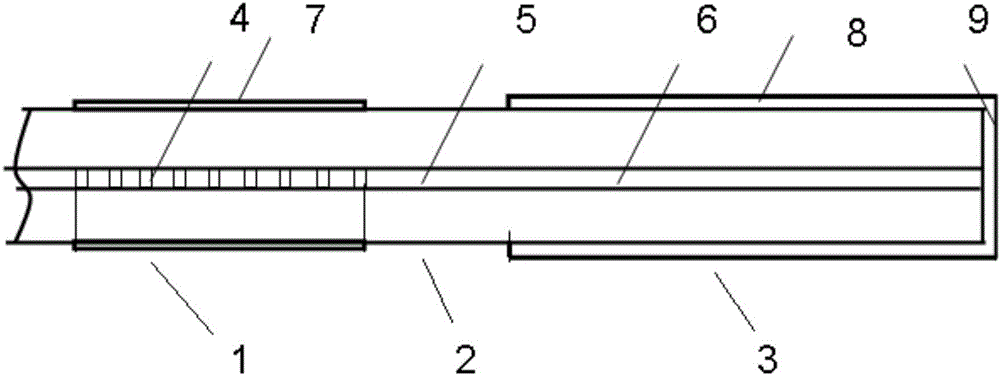

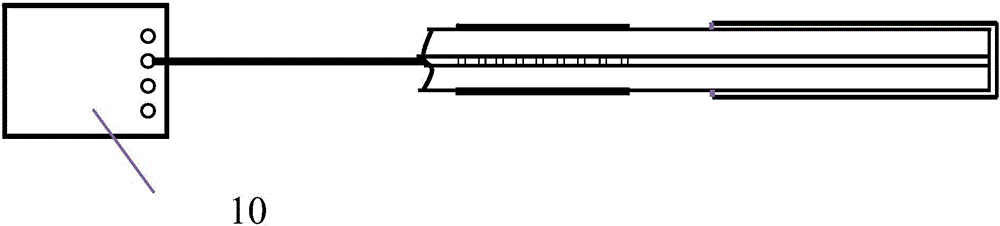

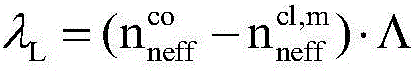

Single-end reflective long-period fiber grating sensor and manufacture process thereof

ActiveCN105973279AAvoid the effects of reflectance spectrumIncrease flexibilityConverting sensor output opticallyFiberLong-period fiber grating

The invention discloses a single-end reflective long-period fiber grating sensor and a manufacture process thereof, wherein the single-end reflective long-period fiber grating sensor and the manufacture process thereof belong to the field of fiber grating sensing technology. The single-end reflective long-period fiber grating sensor comprises a long-period fiber grating segment, a fiber segment and a tail segment. The long-period fiber grating segment, the fiber segment and the tail segment are successively arranged from left to right. The surface of the long-period fiber grating segment is provided with a fiber grating segment metal film. The surface of the tail segment is provided with a tail segment metal film. The end surface of the tail segment is provided with a tail segment end surface metal film. In the fiber grating segment, a fiber grating segment core and the fiber grating segment metal film are successively arranged from inside to outside. The fiber grating segment metal film, the tail segment metal film and the tail segment end surface metal film are palladium films. The single-end reflective long-period fiber grating sensor has a probe type structure and has advantages of simple structure, small size and high sensitivity. Furthermore the single-end reflective long-period fiber grating sensor is sensitive to external physical quantities such as temperature, refractivity and liquid level. Furthermore the single-end reflective long-period fiber grating sensor can be widely used in the fields of biology, chemistry, physics, civil engineering, medical treatment, etc.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

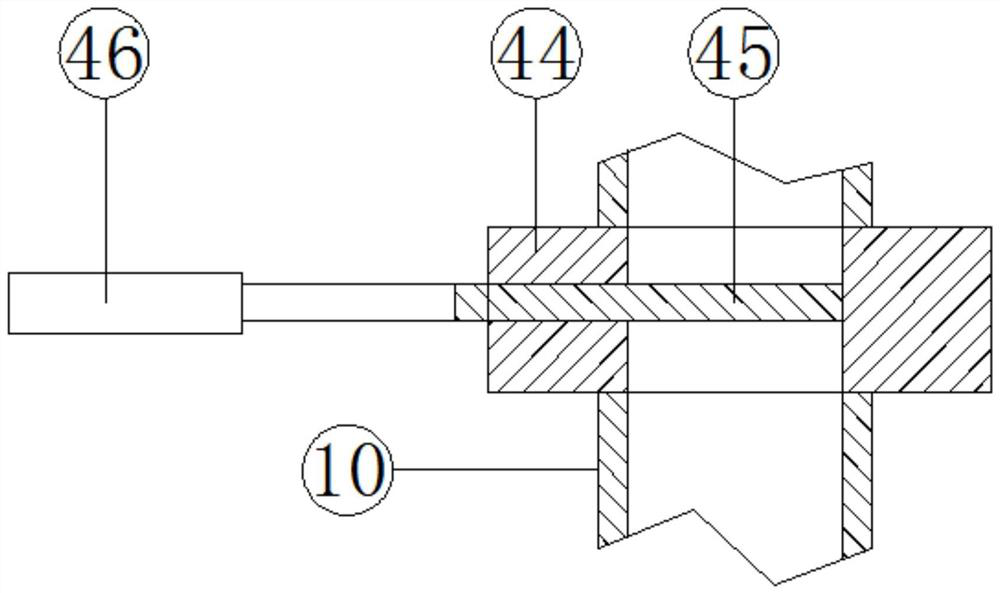

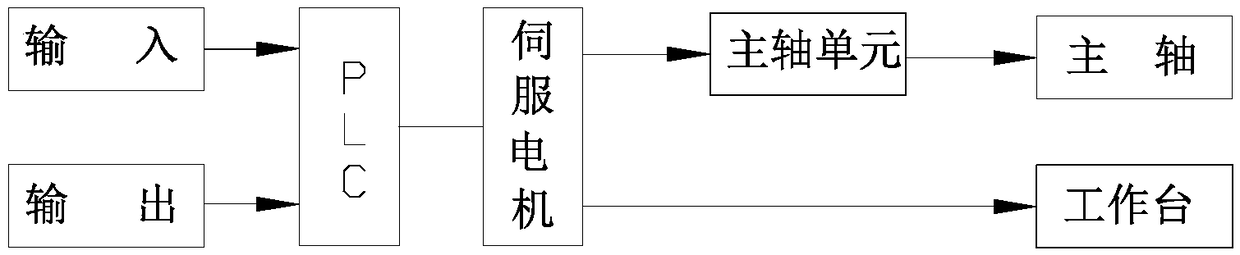

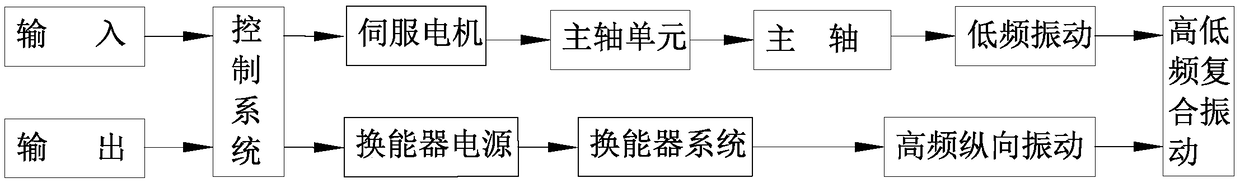

Ultrasonic transduction equipment for tapping processing and torsional tapping machine

InactiveCN109290642AFast processingEfficient processingThread cutting machinesMechanical vibrations separationEnergy transferLow load

The invention discloses ultrasonic transduction equipment for tapping processing and a torsional tapping machine. The ultrasonic transduction equipment comprises an upper load block which weakens thelongitudinal vibration energy transfer and has a heat-dissipating function and a lower load block which enhances transfer of the longitudinal vibration energy to a screw tap and generates torsional vibration transformation. A transduction component capable of achieving converting to generate longitudinal vibration mechanical energy is mounted between the upper load block and the lower load block.When the longitudinal vibration generated by the transduction component is diffused to the outer surface of the lower load block, the lower load block where a spiral groove is machined converts part of longitudinal vibration into torsional vibration, and vibration and torsion are coupled to from a torsional vibration effect which is diffused to the screw tap mounted on the bottom surface of the lower load block, so that the screw tap generates a torsional vibration action force for tapping processing of a workpiece. The ultrasonic transduction equipment provided by the invention can generate acompound vibration mode combining torsion and vibration to drive the screw tap to generate the torsional vibration effect for a tapping processing course well.

Owner:常晓旺 +2

Polylactic acid film material for small packaging of traditional Chinese medicine decoction pieces and preparation method of polylactic acid film material

The invention relates to a polylactic acid film material for small packaging of traditional Chinese medicine decoction pieces and a preparation method of the polylactic acid film material. The polylactic acid film material is mainly prepared from the following raw materials in parts by weight: 80 parts of polylactic acid, 4.0-5.0 parts of poly succinic acid-butanediol ester, 10-12 parts of polycaprolactone, 4.0-5.0 parts of epoxidized soybean oil, 0.40-0.50 part of nano SiO2, 0.45-0.55 part of nano ZnO, 0.45-0.55 part of nano kaolin, 0.40-0.50 part of nano TiO2, 1.0-1.2 parts of an amino silane coupling agent, 0.30-0.40 part of stearate, and 0.40-0.45 part of an antioxidant. According to the polylactic acid film material, good mechanical strength and toughness are achieved, obstructing performance on oxygen and water vapor is achieved, an addition agent is not prone to removing and dissolving out, bag making processing is easy, the polylactic acid film material is suitable for use andpopularization in the field of the small package traditional Chinese medicine decoction pieces, rapid degradation can be achieved in the environment, and the safety and reliability are achieved.

Owner:巩义市欧洁源环保技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com