Patents

Literature

64results about How to "Improve the firmness of the bond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Planar silver nanowire transparent conductive thin film and preparation method thereof

InactiveCN102087885AImprove the firmness of the bondImprove bindingConductive layers on insulating-supportsIndividual molecule manipulationPolyethylene terephthalate glycolPolyethylene terephthalate

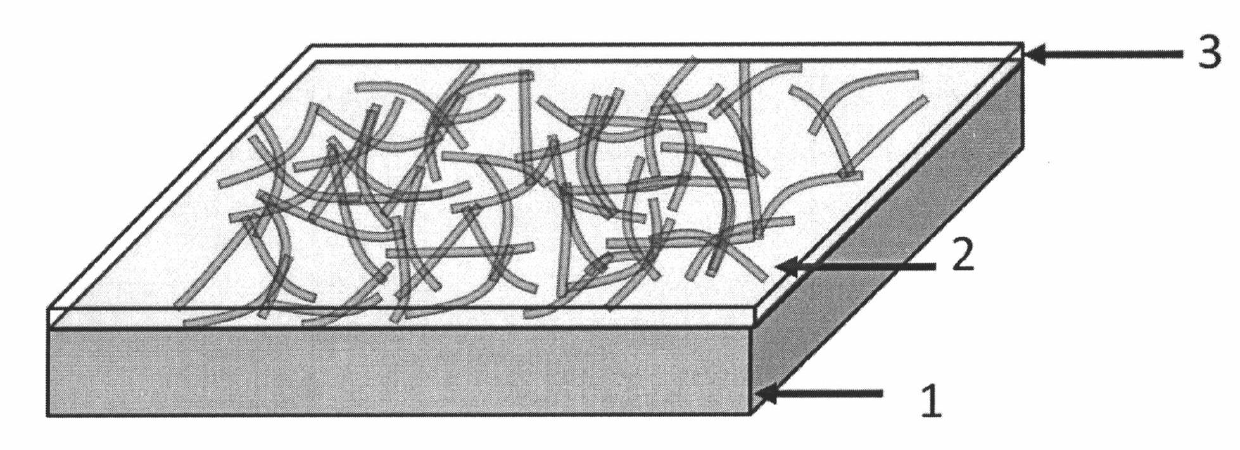

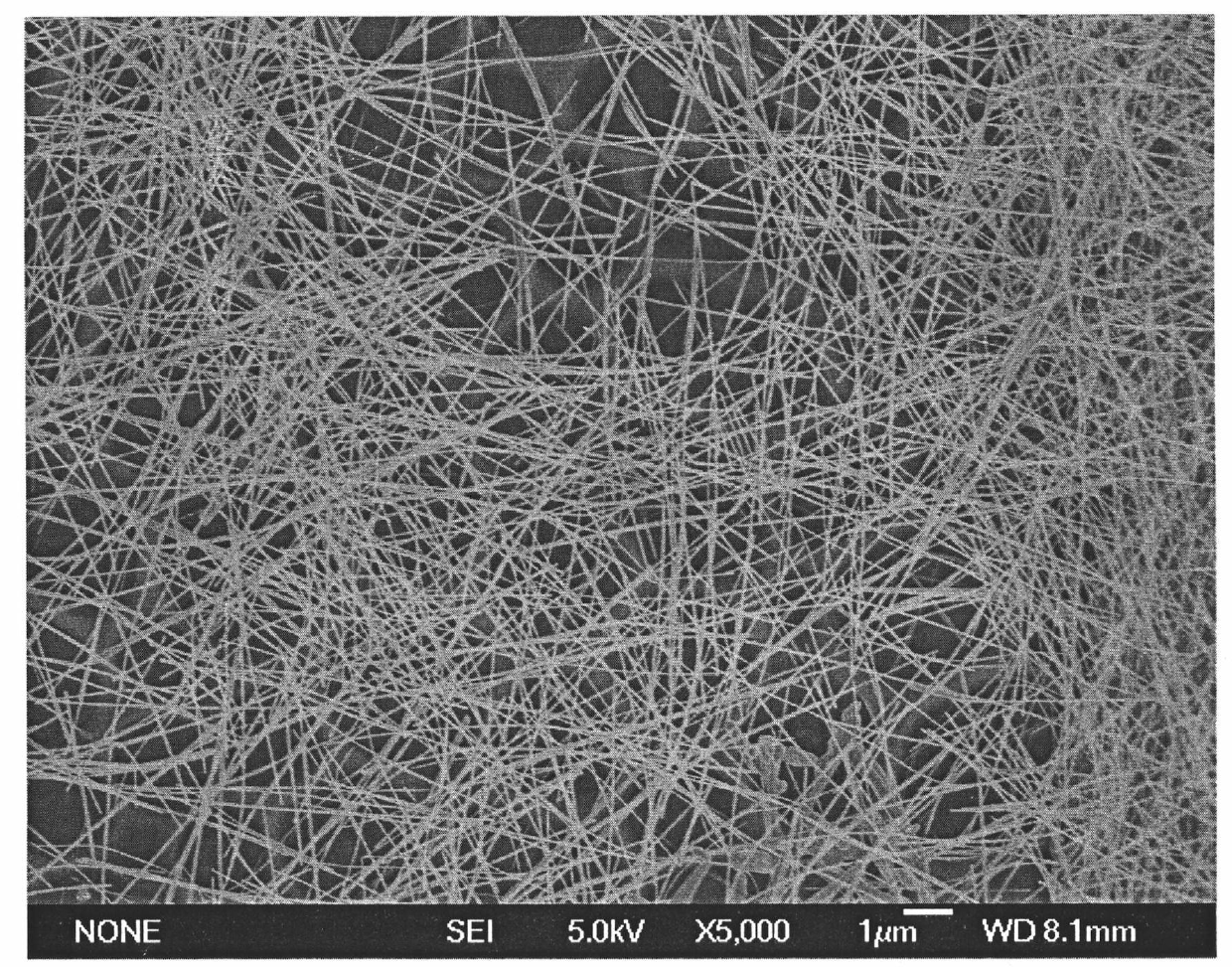

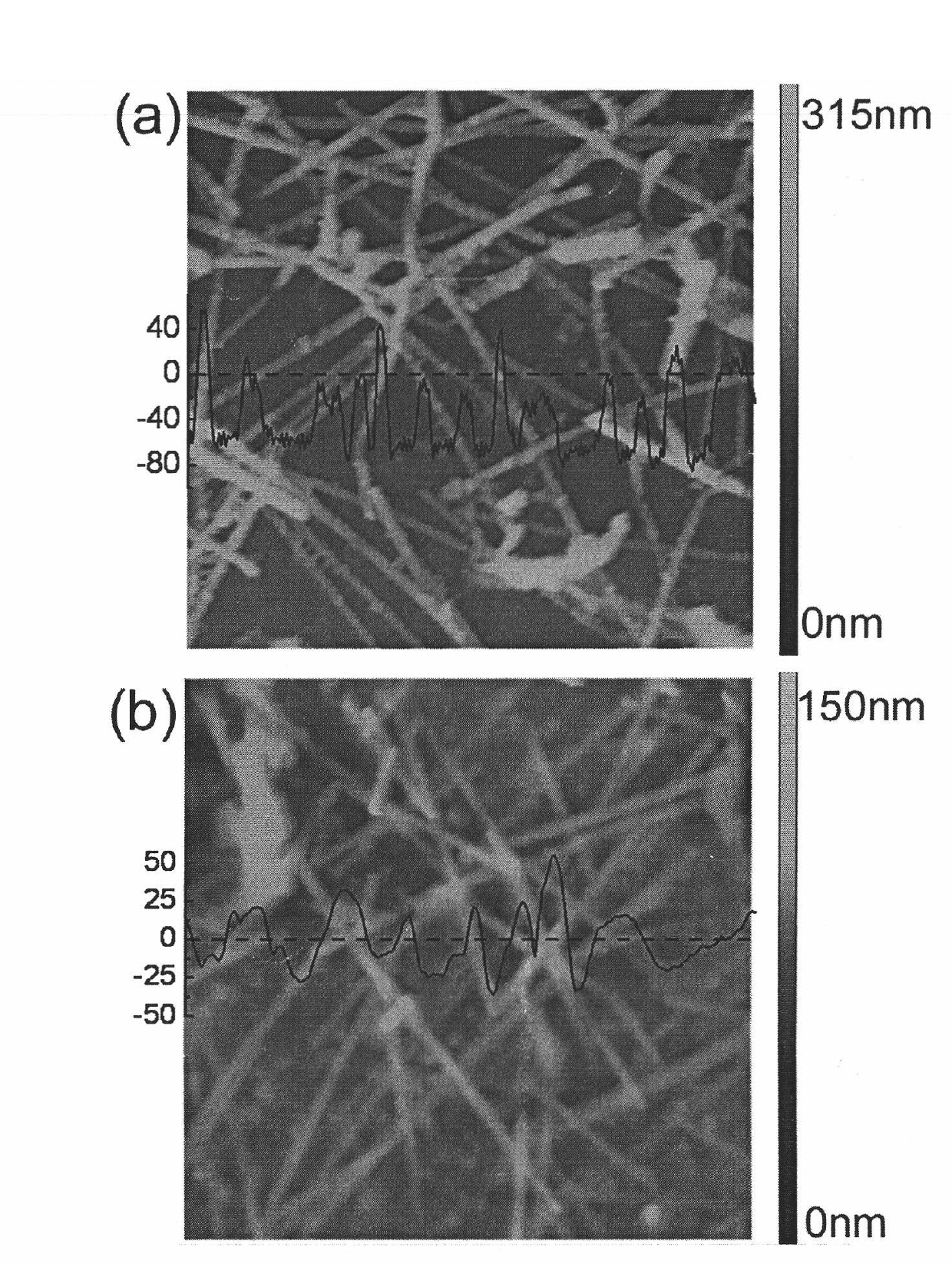

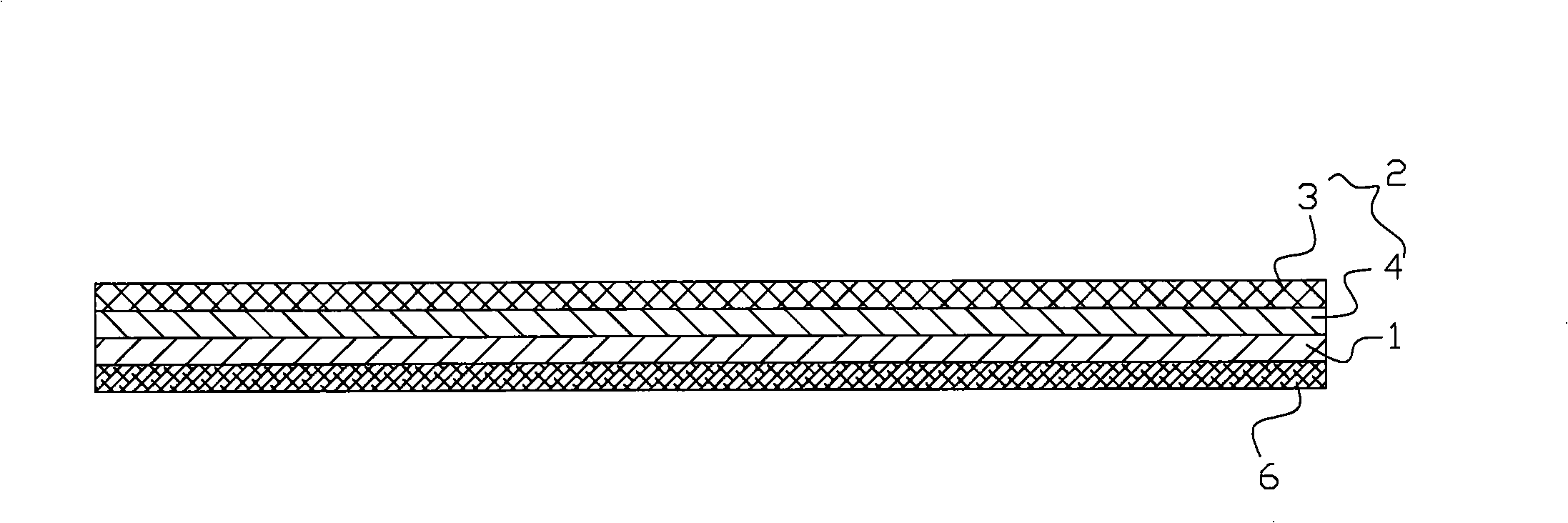

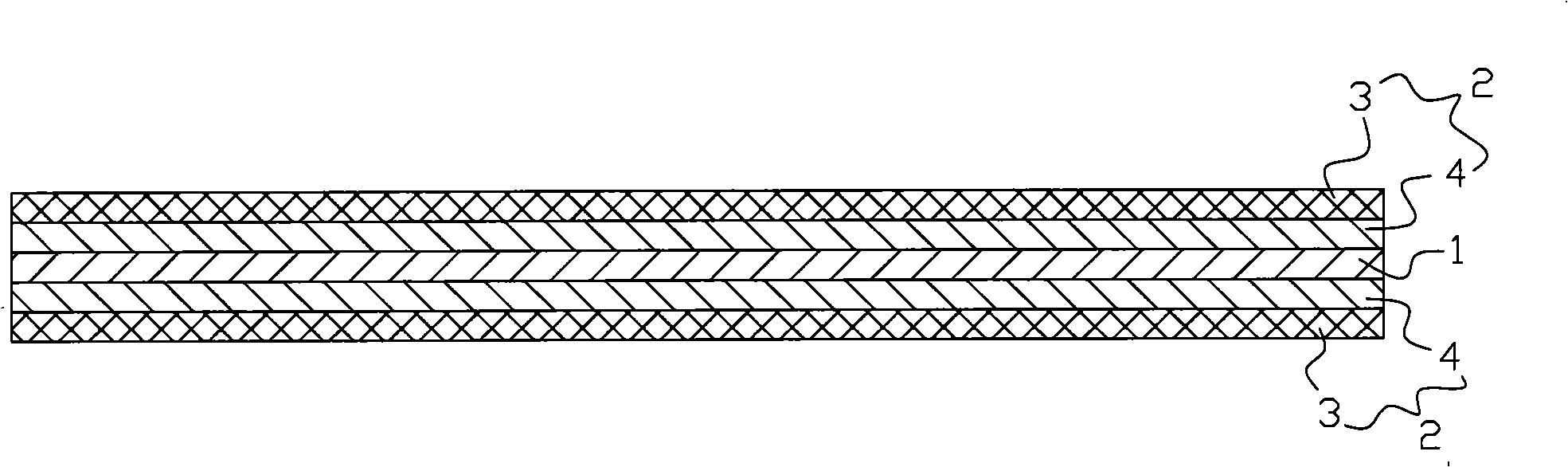

The invention provides a planar silver nanowire transparent conductive thin film and a preparation method thereof. The transparent conductive thin film is characterized in that: a silver nanowire conductive layer which is arranged on a substrate is covered by a planar conductive polymer layer; the silver nanowire conductive layer realizes a conduction function; and the planar polymer layer fills holes in the silver nanowire conductive layer, so that the surface roughness is reduced and the firmness of the bonding of the silver nanowires and the substrate is improved. For example, the roughness of the silver nanowire transparent conductive thin film on the polyethylene terephthalate (PET) substrate is reduced to 25nm from 67nm when the conductive layer is not covered by using a poly(3,4-dioxy ethyl thiophene) / poly(styrene sulfonic acid) planar layer, the visible light transmittance reaches 77 percent when square resistance is 158, and good bonding force is guaranteed.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

Solar cell backboard

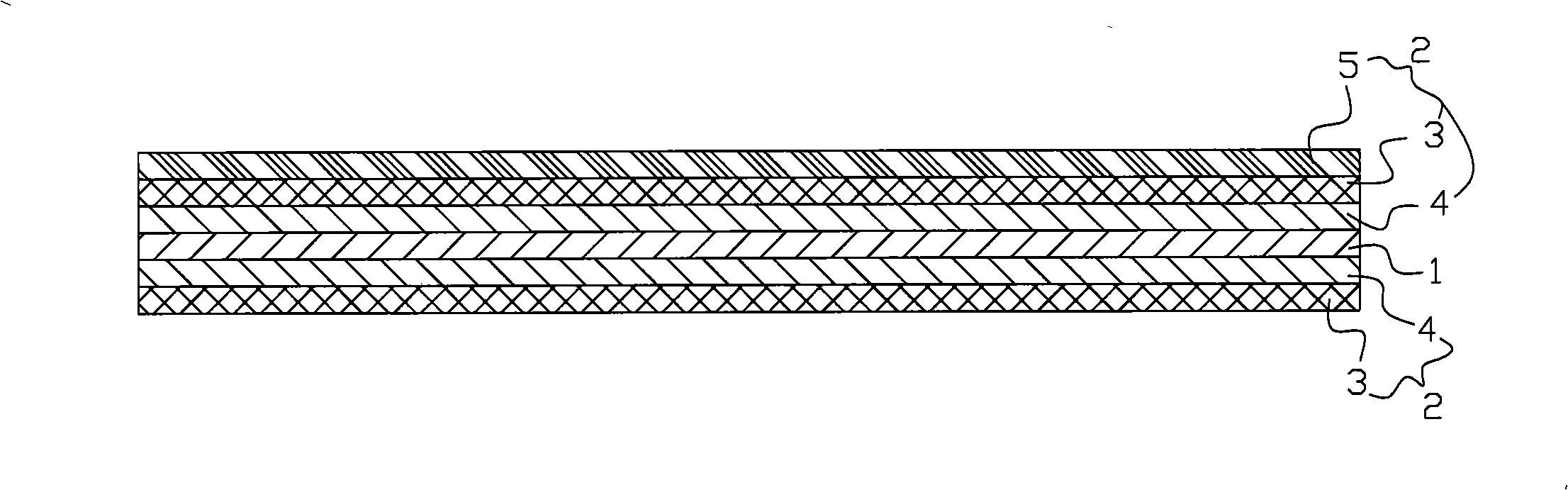

InactiveCN101515603AImprove adhesionEasy to useLayered productsPhotovoltaic energy generationResin matrixSolar cell

The invention discloses a solar cell backboard, which comprises a base layer of an unpermeability sheet and a membranelike protective layer formed on at least one surface of the base layer. The protective layer comprises a fluorine-containing coat formed by fluorine-containing polymer paint and also comprises a bonding layer coated on the surface of the fluorine-containing coat which is opposite to the base layer. The bonding layer is formed by curing bi-component high temperature setting glue series and comprises resin matrix containing solidifiability functional group and a curing agent. The bonding layer is added between the base layer and the fluorine-containing coat for strengthening the bonding and firm degree between the base layer and the protective layer; therefore, the protective layer is difficult to be peeled off when in sealing and use, and the bonding is very reliable. Meanwhile, the fluorine-containing coat does not need to copolymerize a great of other monomers containing solidifiability functional group, thus ensuring the use effect of the protective layer.

Owner:CYBRID TECHNOLOGIES INC

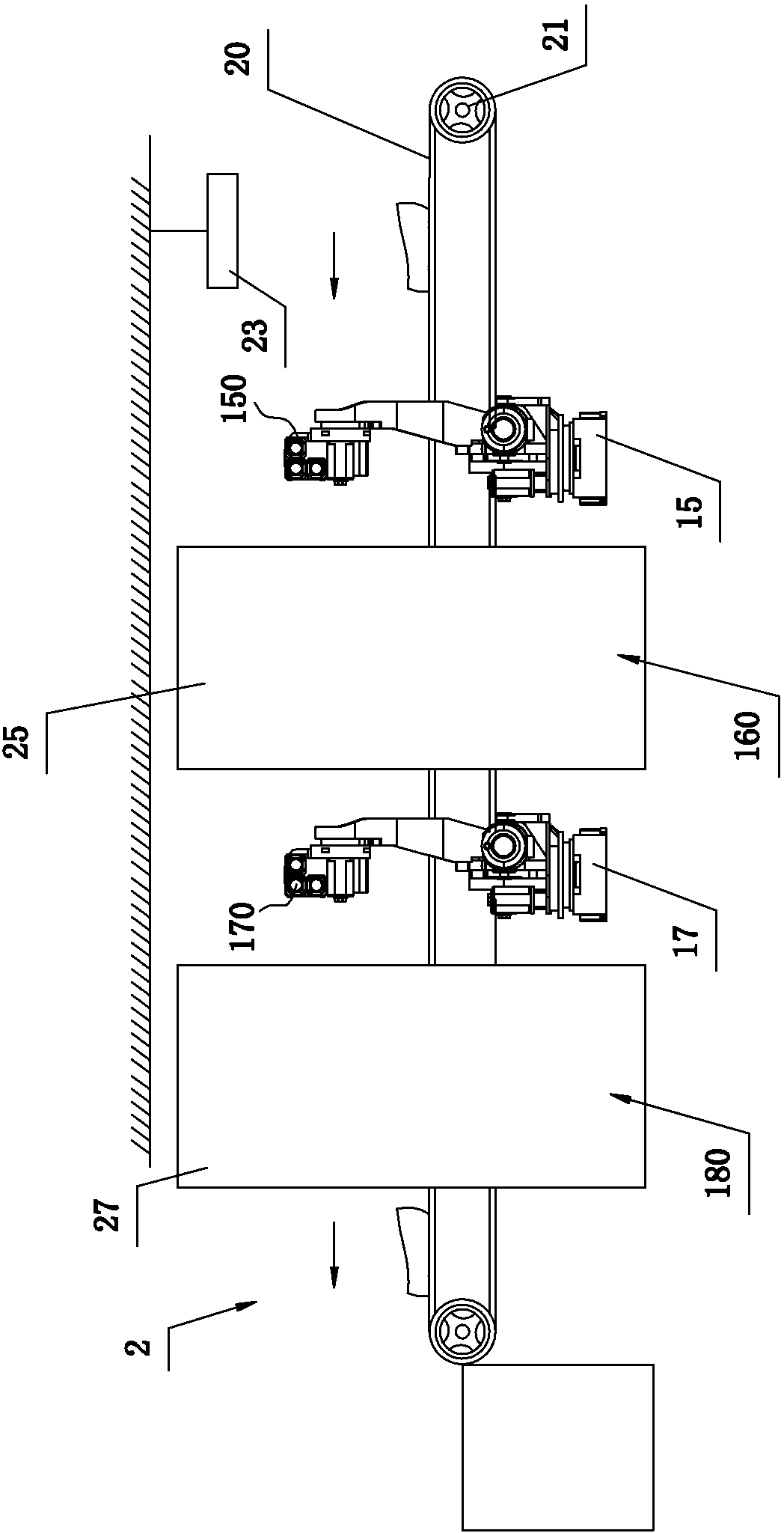

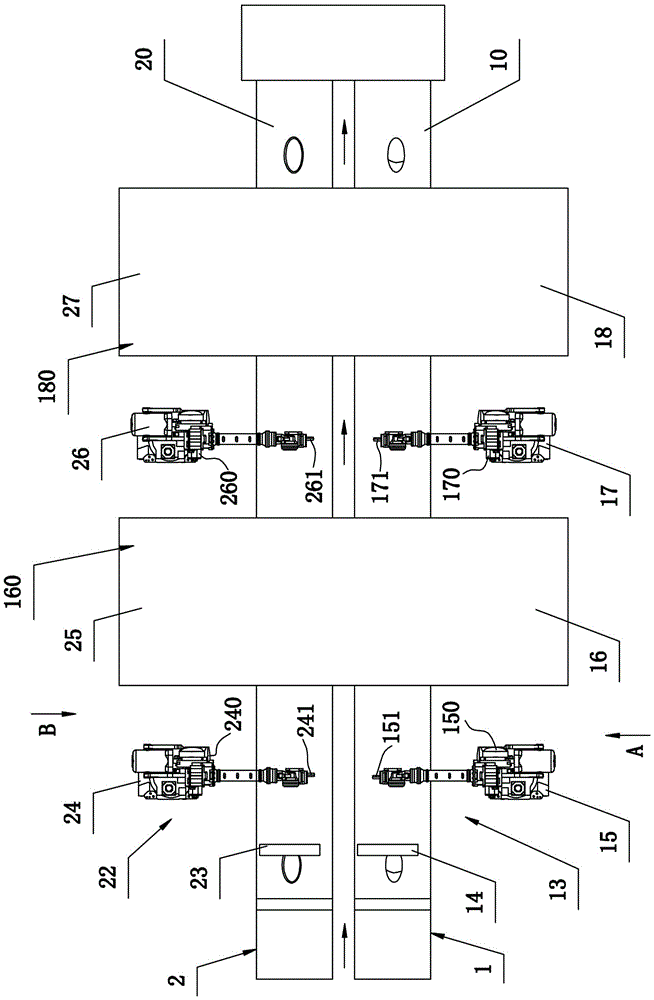

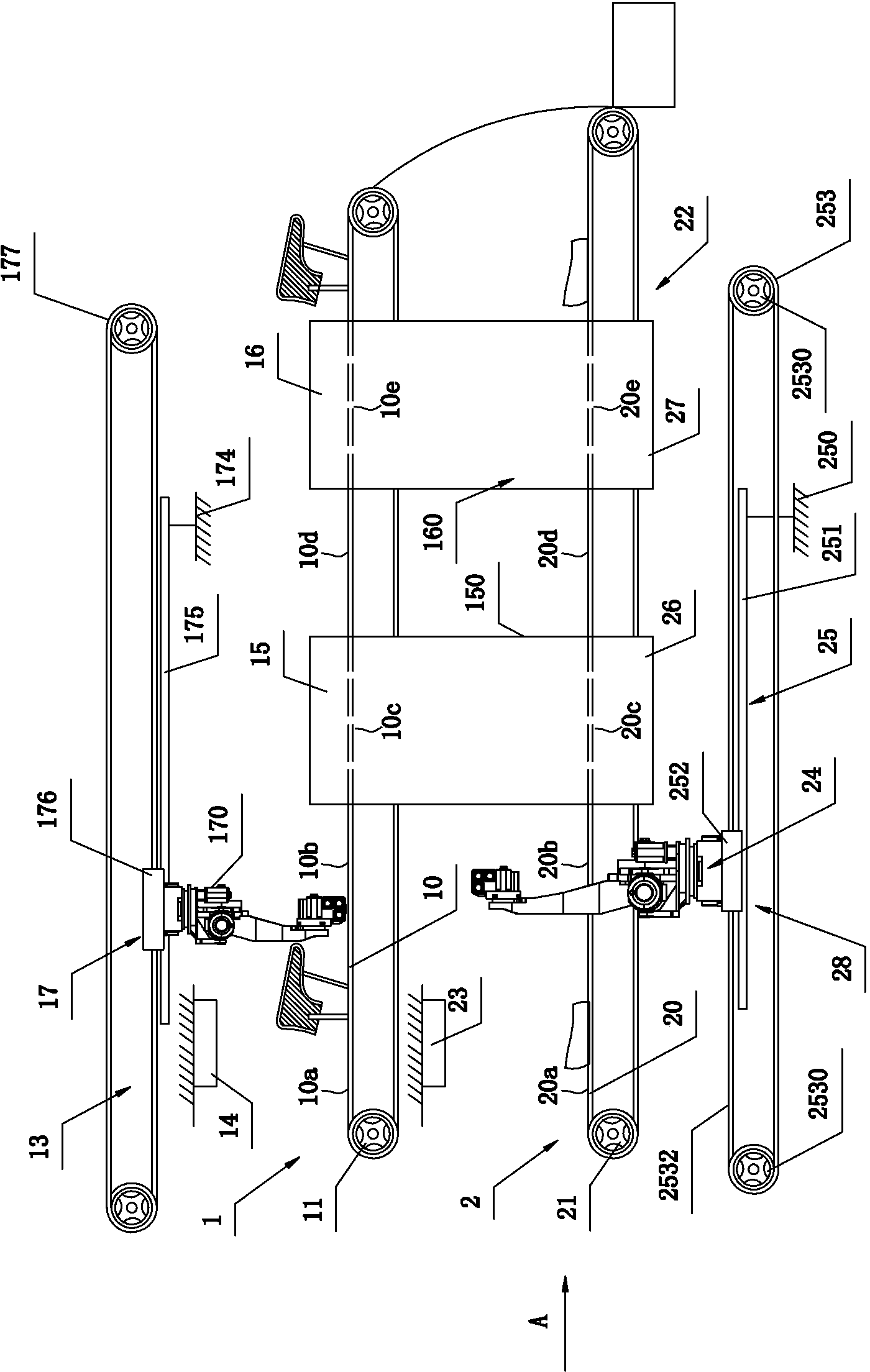

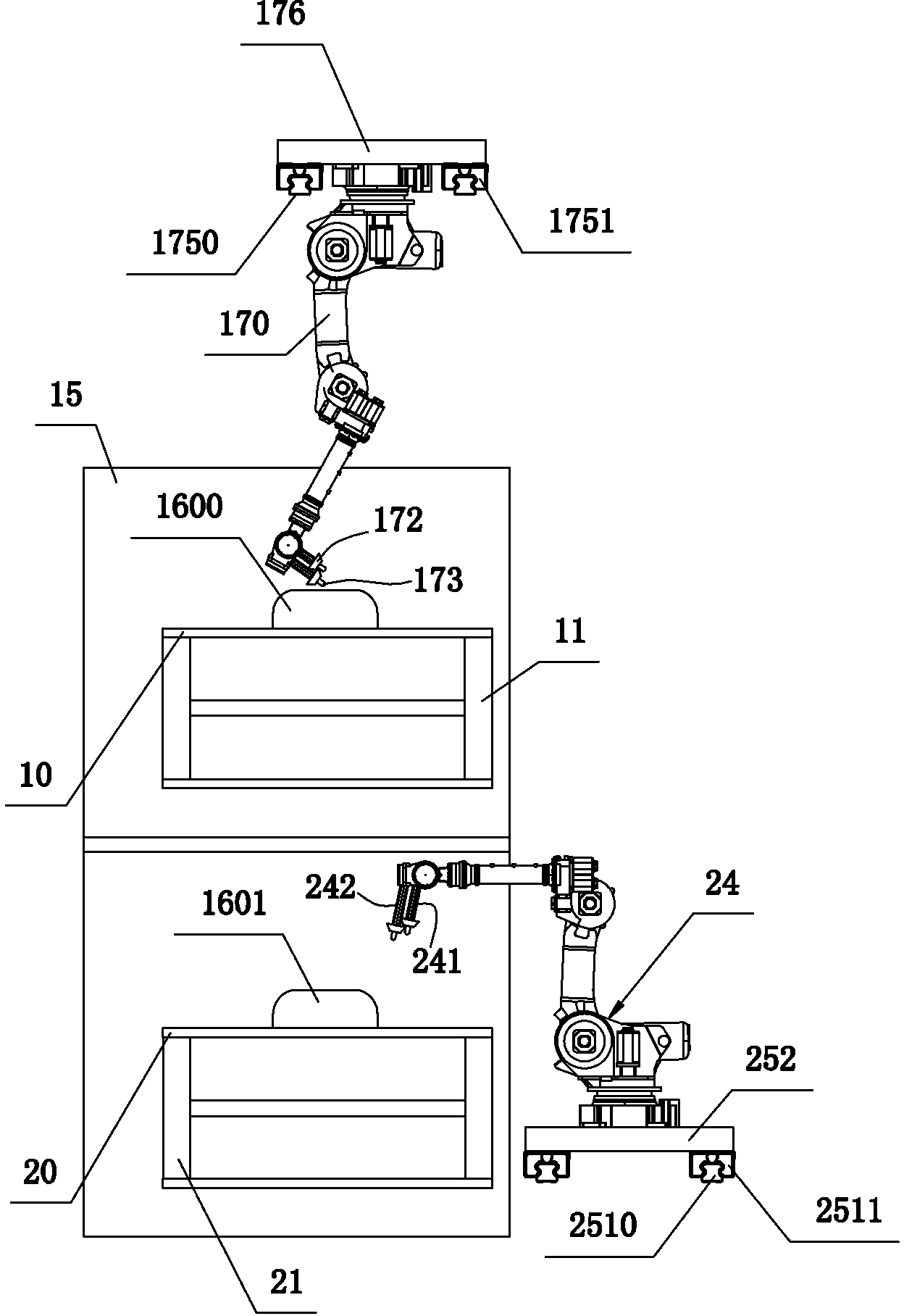

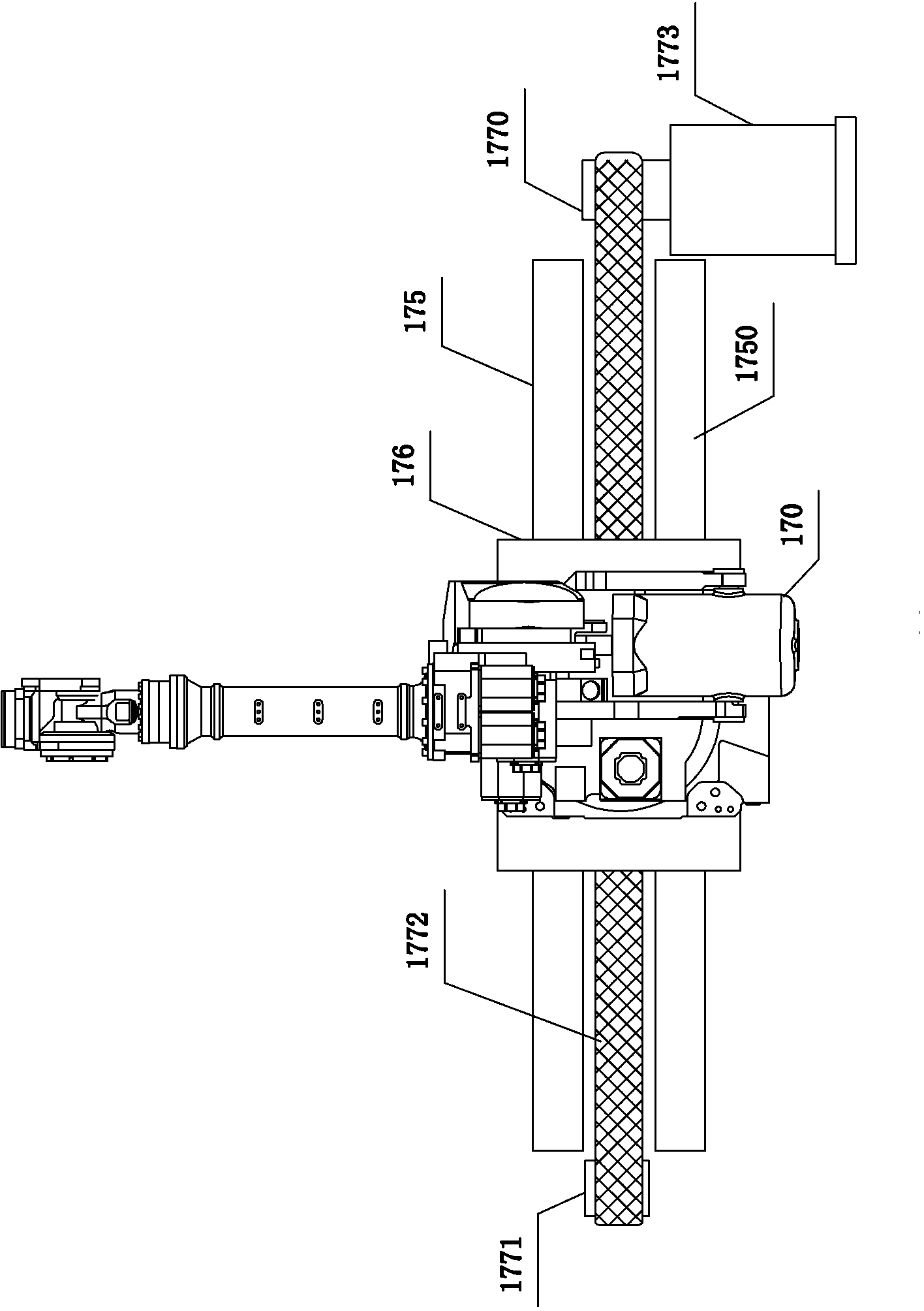

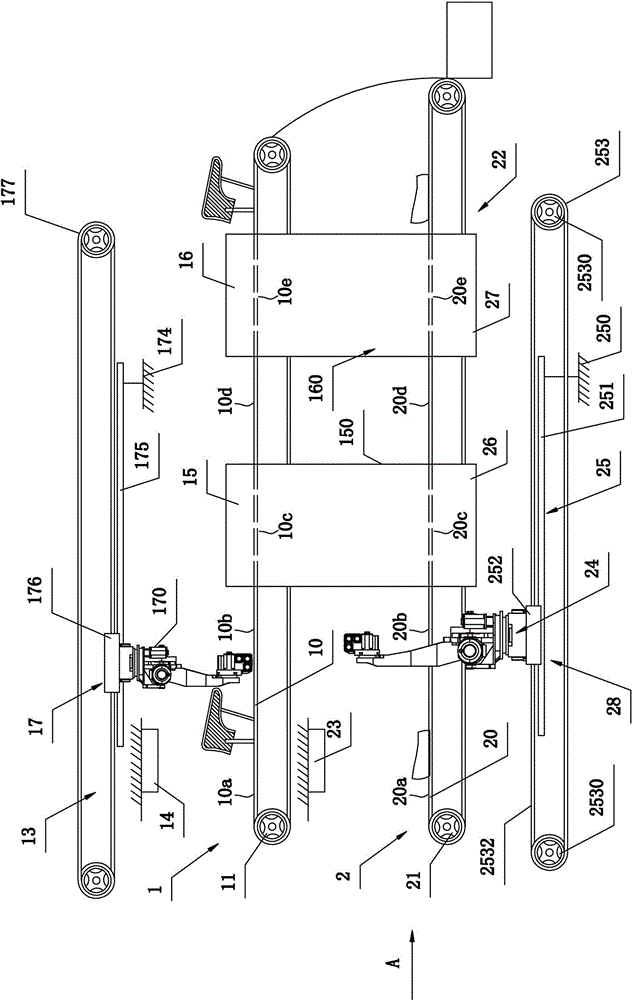

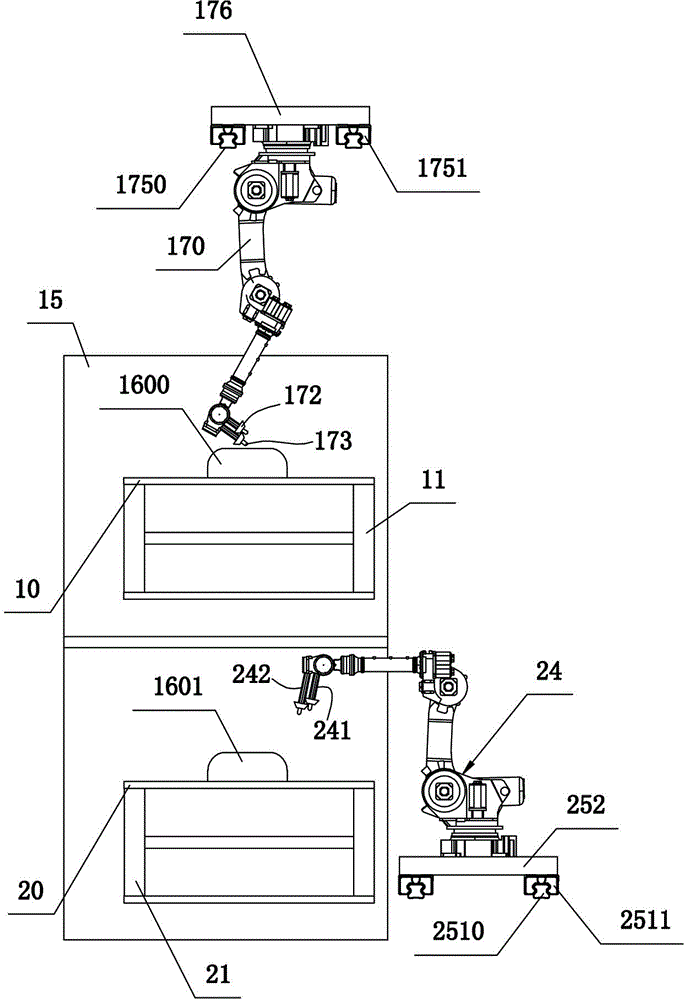

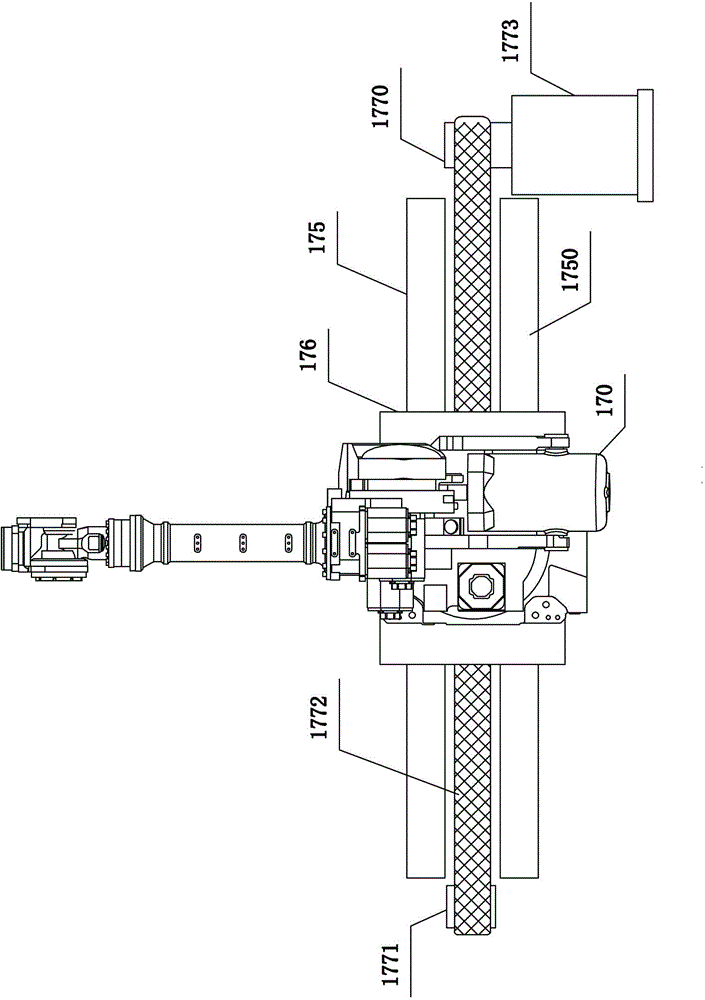

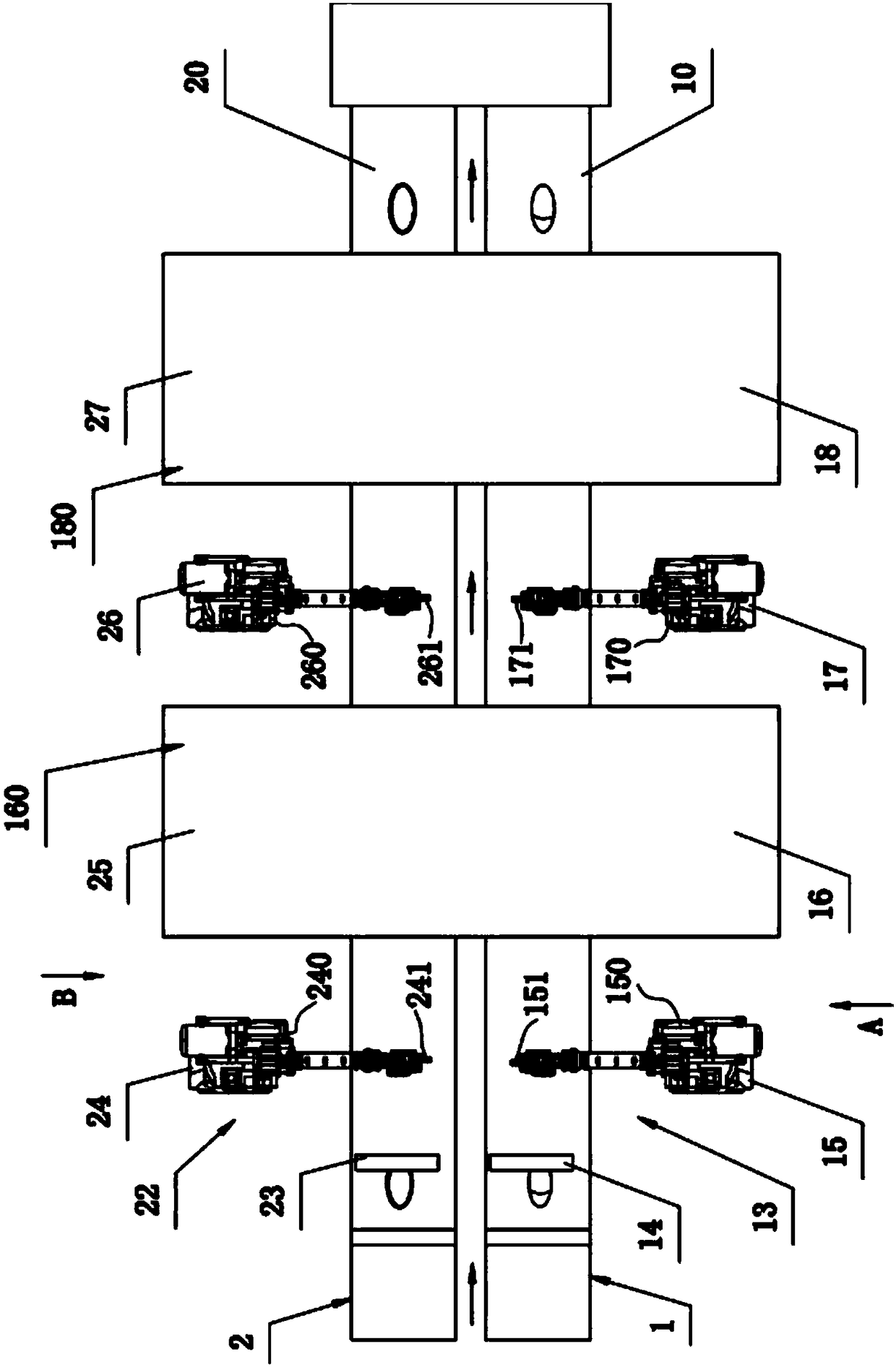

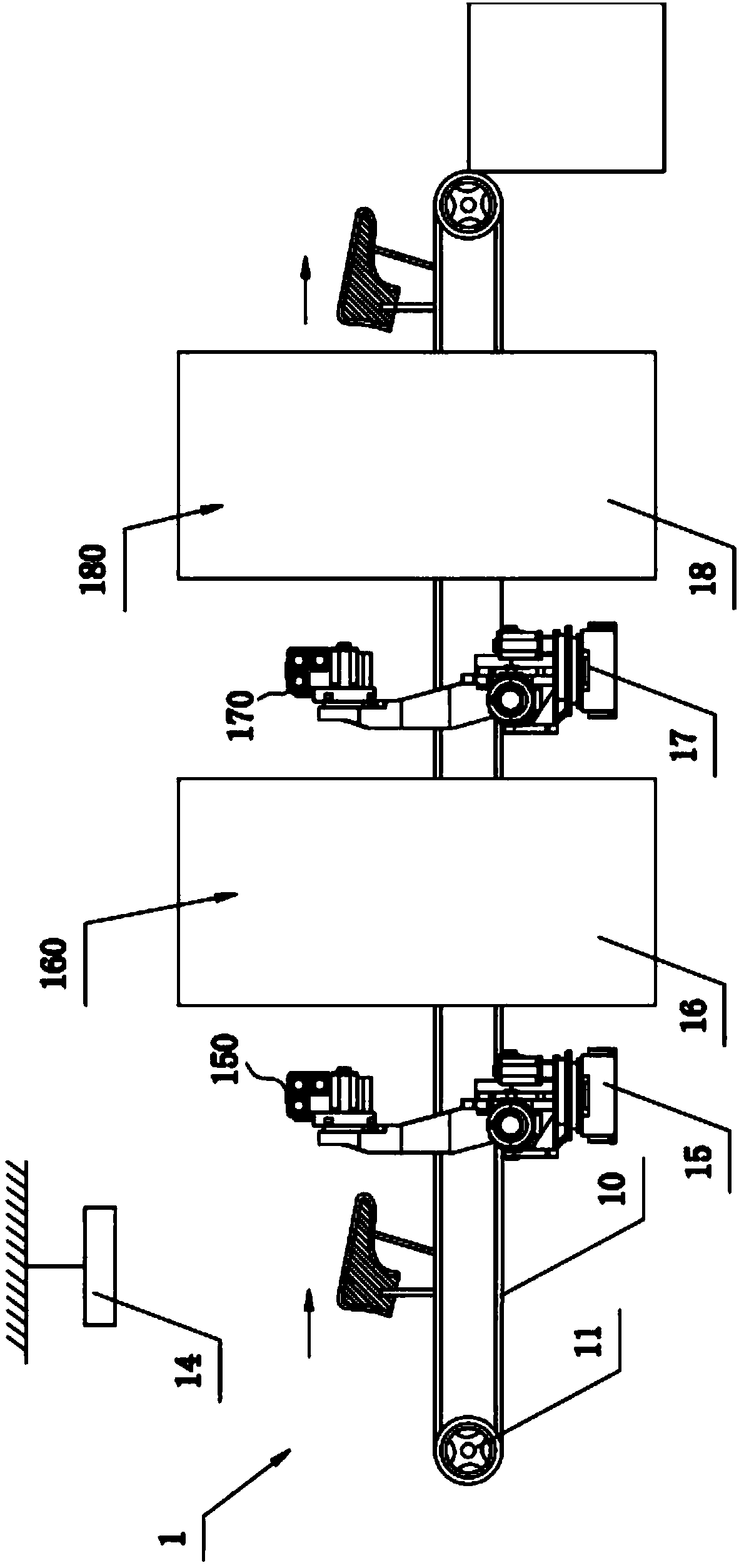

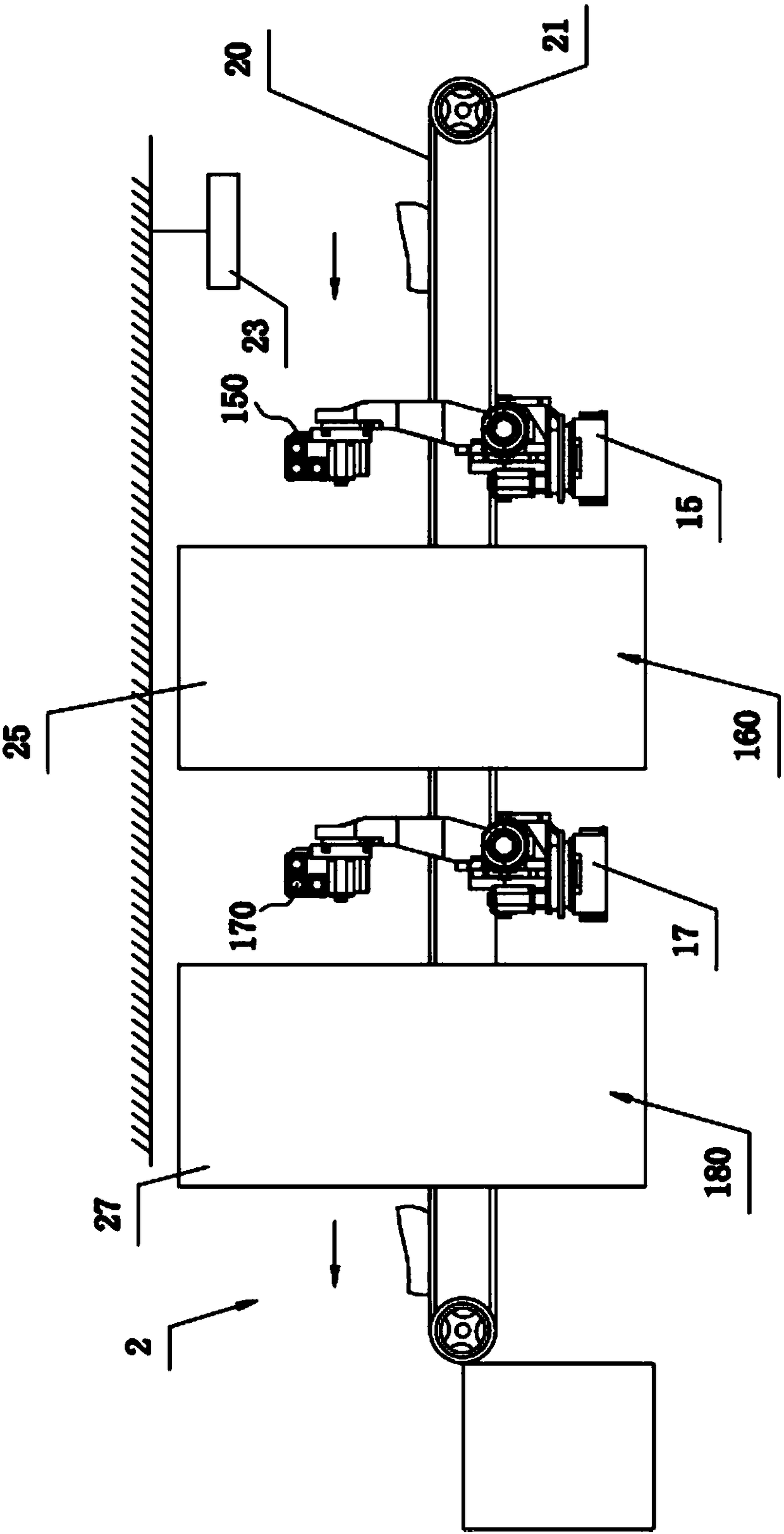

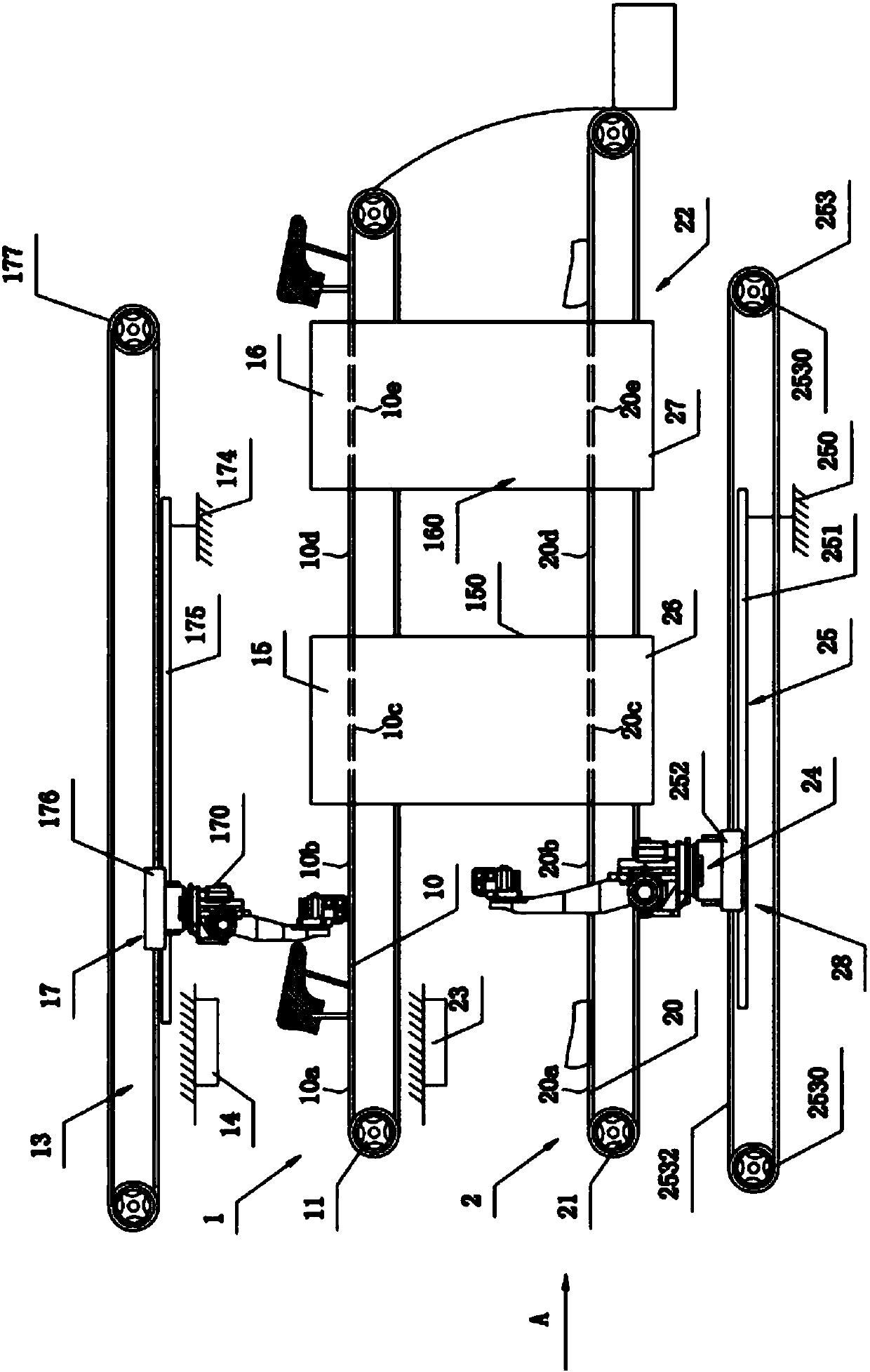

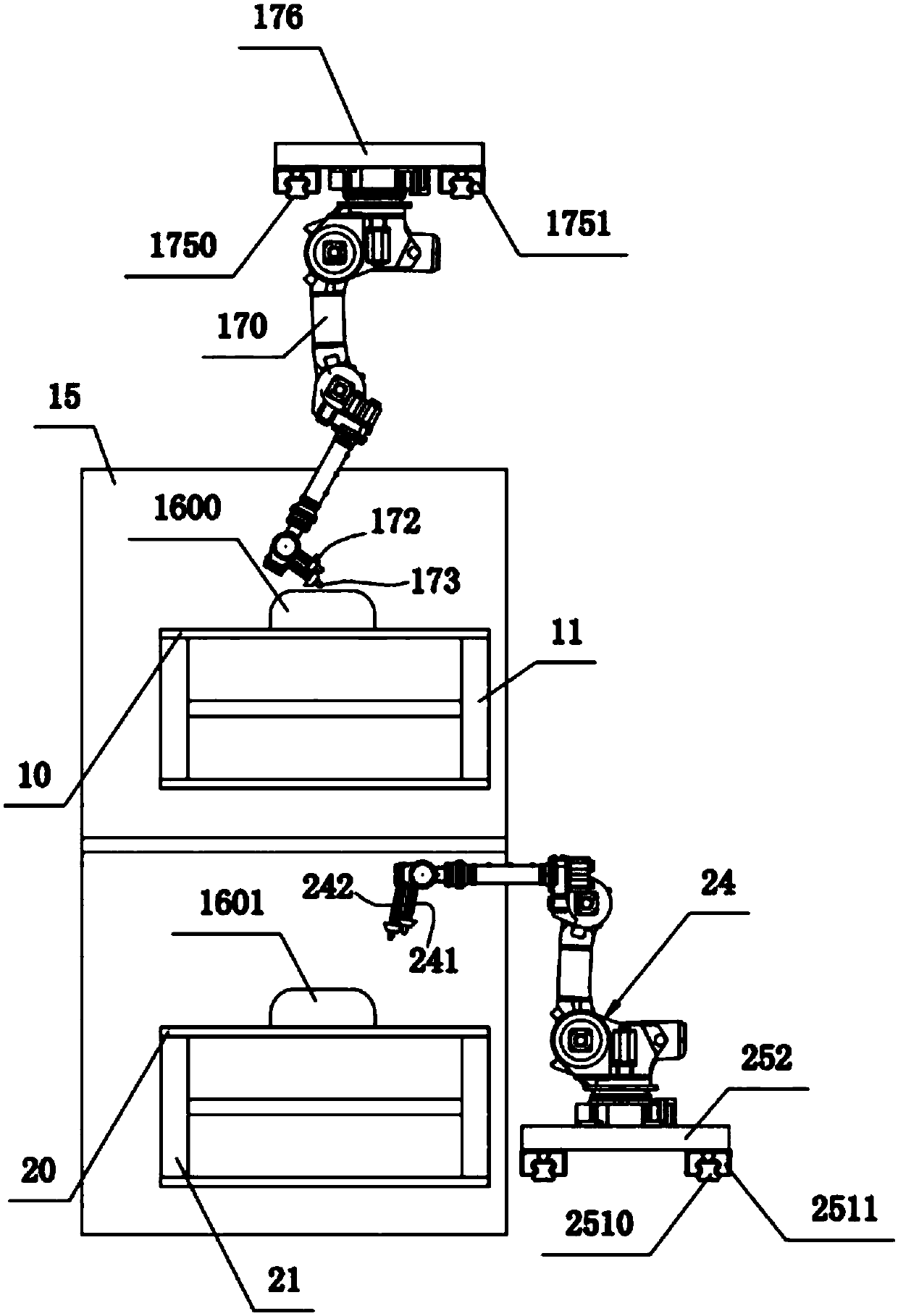

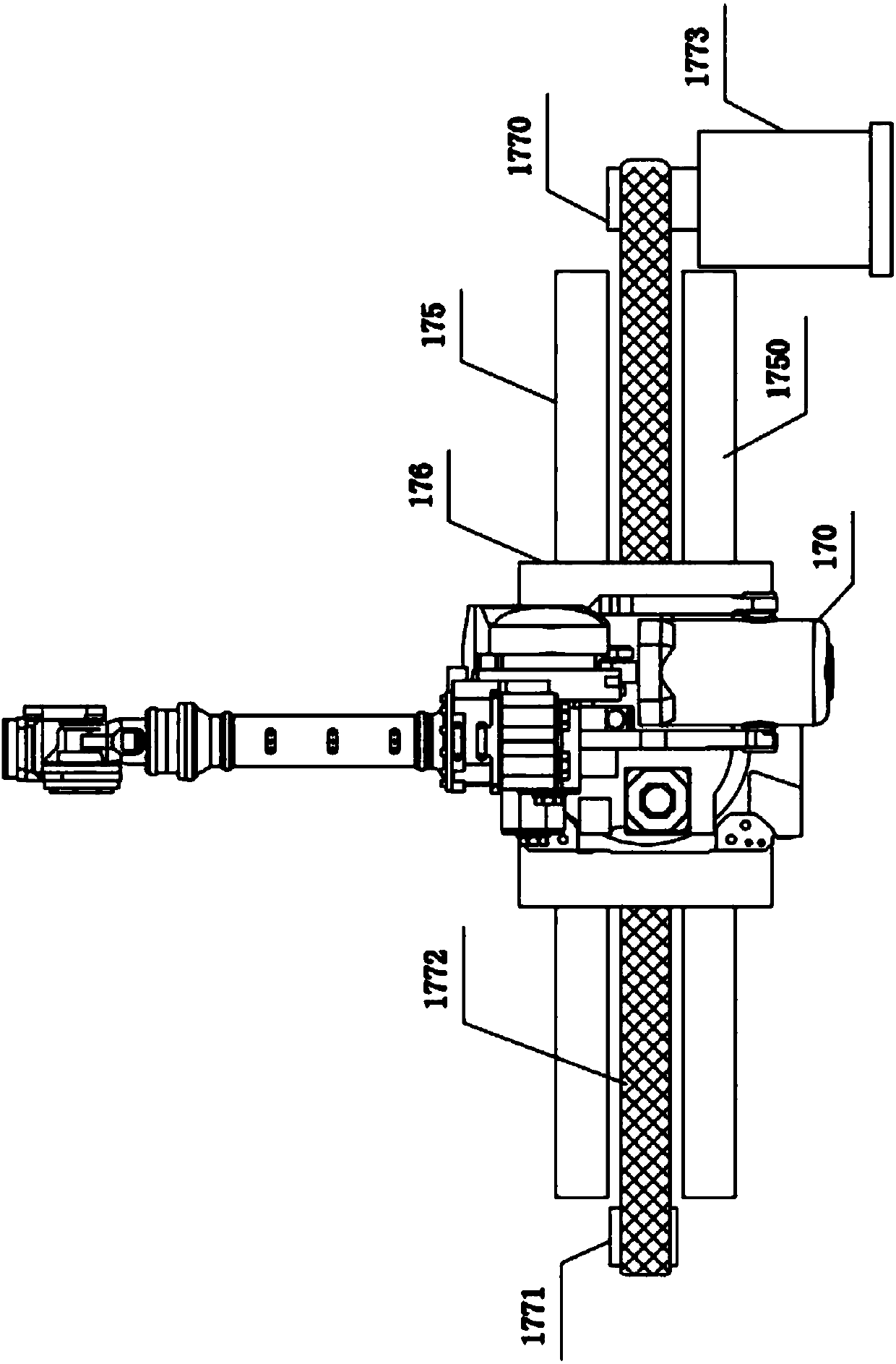

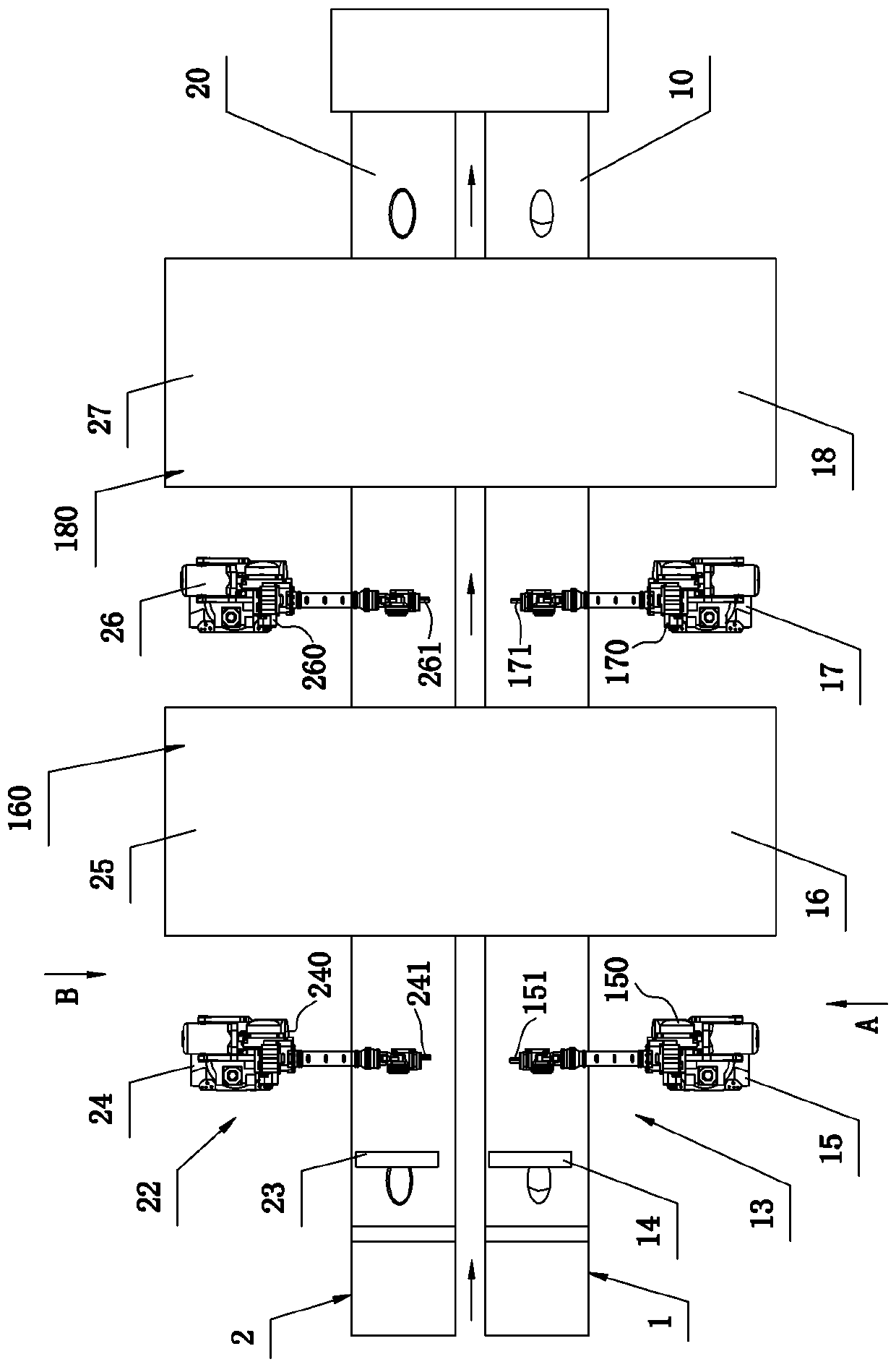

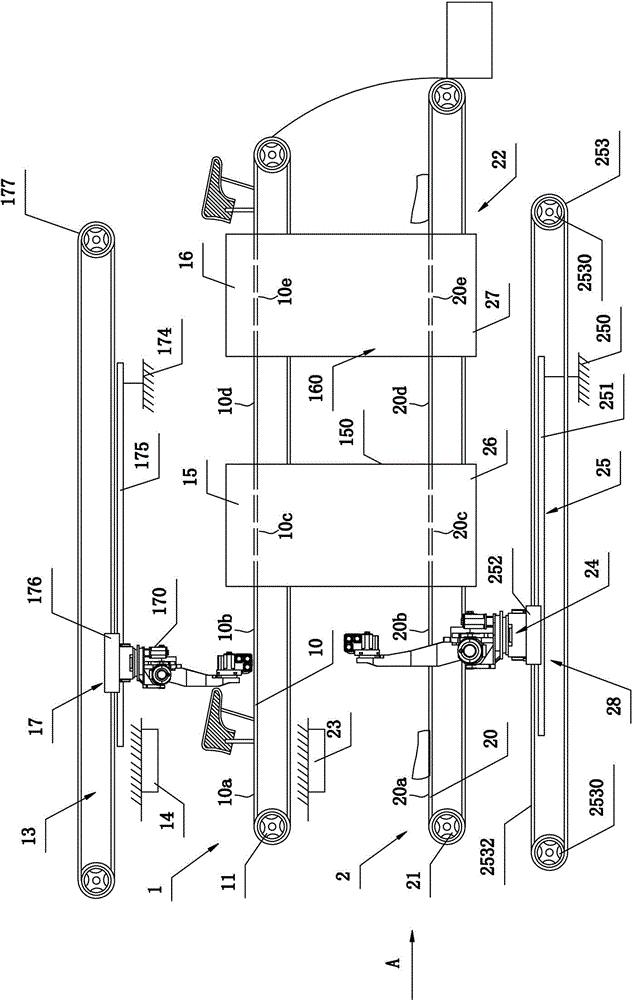

Automatic manufacturing method and automatic production line for shoes

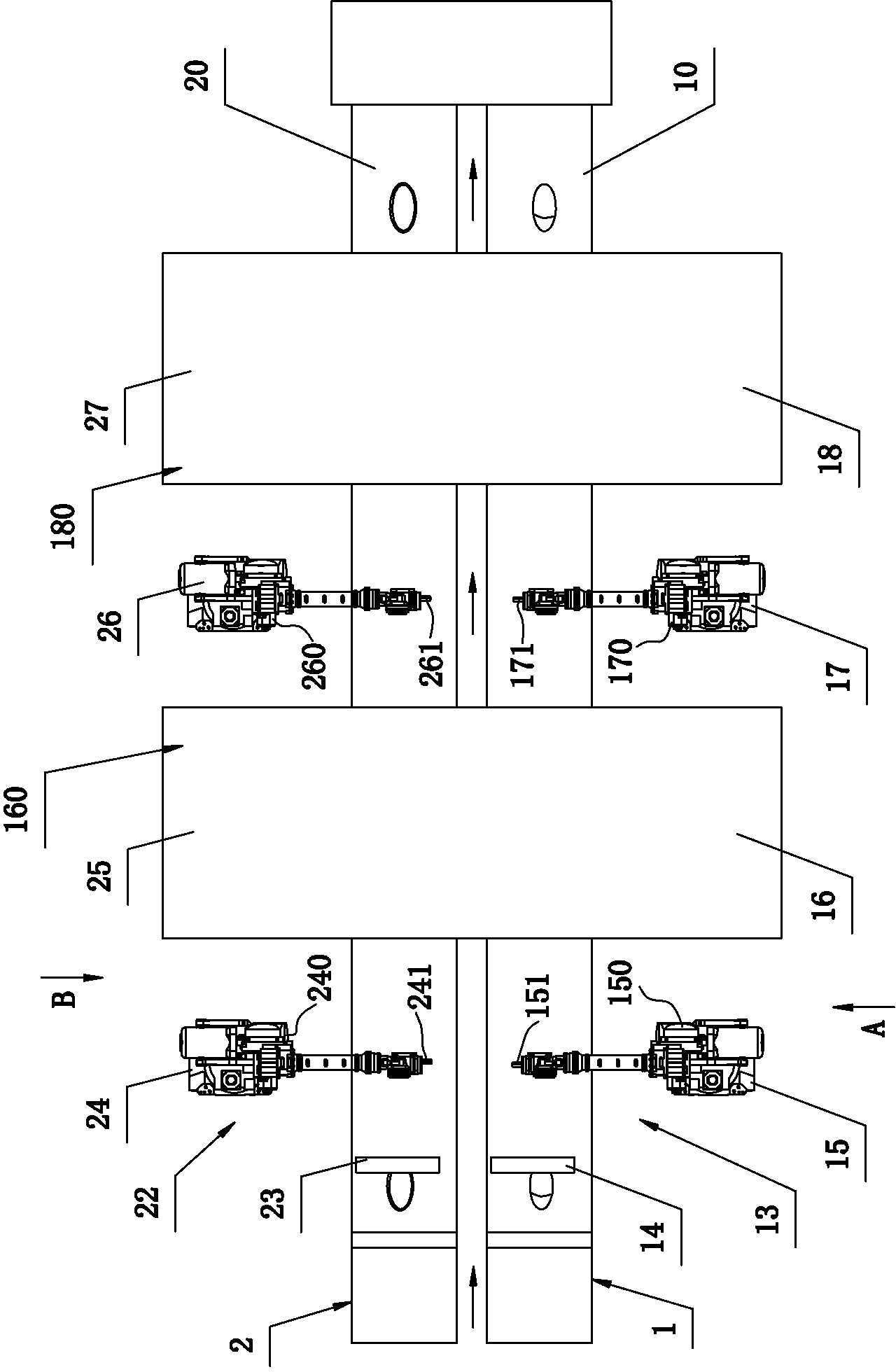

InactiveCN104161355AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingProduction lineManipulator

The invention relates to an automatic production line for shoes. The automatic production line comprises an automatic vamp gluing device and an automatic sole gluing device. The automatic vamp gluing device comprises a first conveying belt, a first driving assembly and a first automatic glue spraying control assembly. The first automatic glue spraying control assembly comprises a three-dimensional scanning mechanism, a first processing water spraying mechanism, a first processing water drying mechanism, a first glue spraying executing mechanism and a first glue drying mechanism, wherein the three-dimensional scanning mechanism, the first processing water spraying mechanism, the first processing water drying mechanism, the first glue spraying executing mechanism and the first glue drying mechanism are located above the first conveying belt and adjacently connected in sequence. The first glue spraying executing mechanism comprises a controller, a first six-degree-of-freedom mechanical hand and a first spray gun, wherein the enable end of the controller is connected with the three-dimensional scanning mechanism, and the first spray gun is installed on the arm of the first six-degree-of-freedom mechanical hand. The invention further relates to an automatic manufacturing method for the shoes. According to the automatic production line and the automatic manufacturing method for the shoes, glue wastage can be greatly reduced, the vamp glue spraying effect consistency is improved, then the follow-up vamp and sole gluing firmness degree is improved, the service life of the shoes is prolonged, and the quality of the shoes is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

Automatic shoe manufacturing method based on point cloud identification technology

InactiveCN105595536AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingAdhesive glueProcess engineering

The invention provides an automatic shoe manufacturing method based on a point cloud identification technology. An automatic shoe production line comprises the following steps: a, pairing soles and vamps and preparing to load materials; b, scanning gluing regions of the soles and the vamps; c, spraying treatment water on the gluing regions of the soles and the vamps; d, drying the treatment water on the soles and the vamps; e, spraying glue on the gluing regions of the soles and the vamps; f, drying the glue on the soles and the vamps; and g, manually pressing the soles and the vamps. By virtue of the point cloud identification technology, requirements on rapid glue spraying processing of the vamps can be met; data processing is rapid and movement judgment and control are accurate; the efficiency of the automatic manufacturing method in shoe production is further improved; meanwhile, the waste amount of the glue can be greatly reduced, and the consistency of the glue spraying effect of the vamps is improved, and furthermore, the subsequent sticking firmness degree of the vamps and the soles is further improved, the service lives of the shoes are prolonged and the shoe quality is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

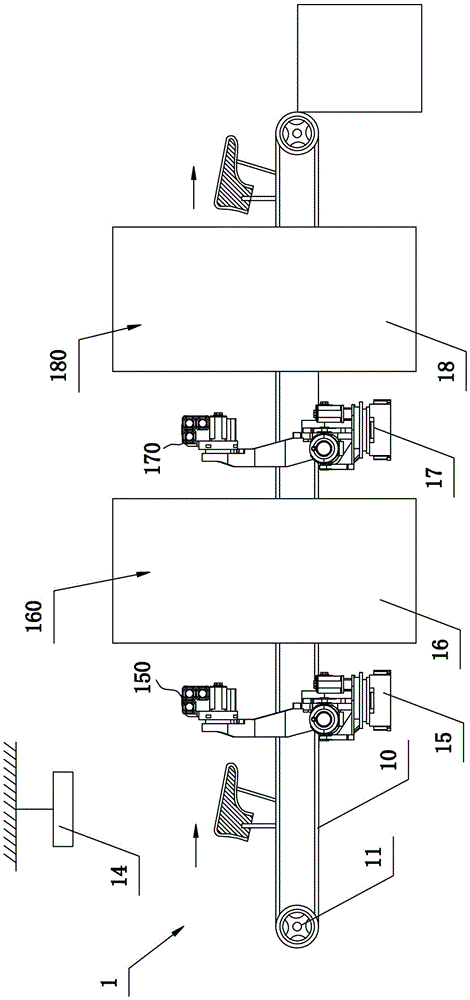

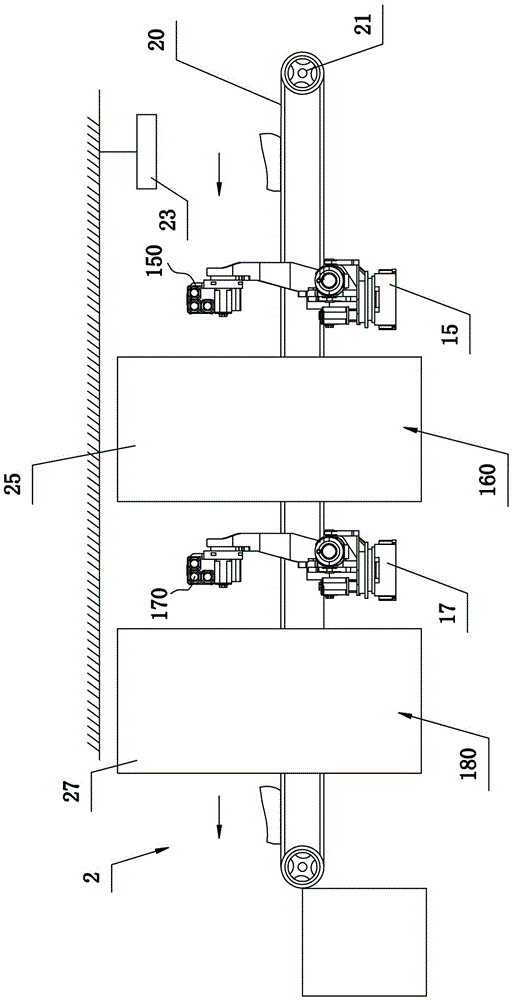

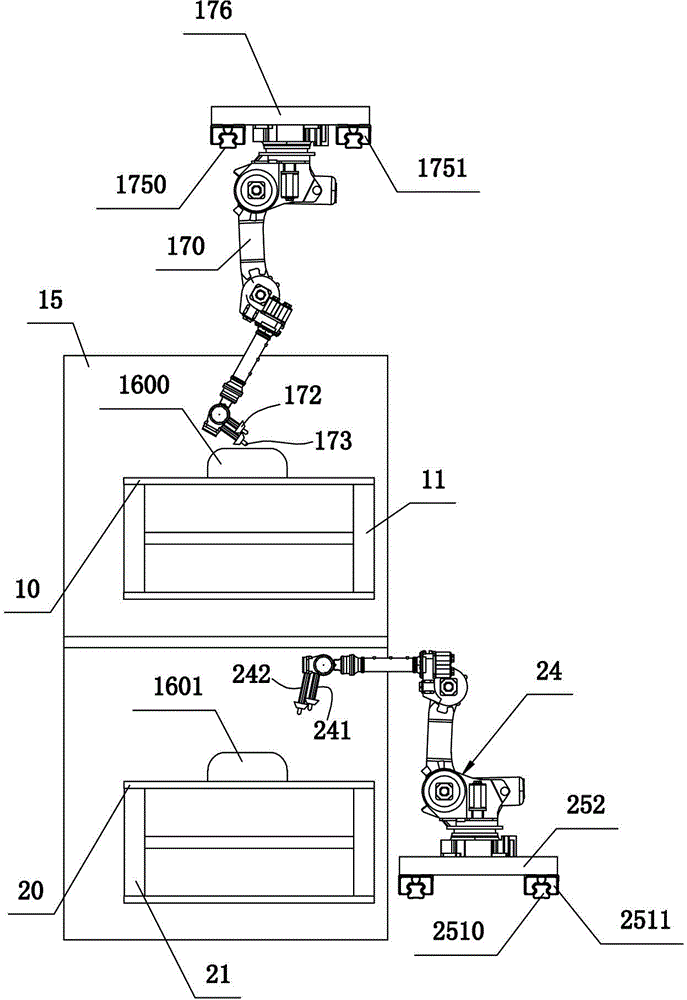

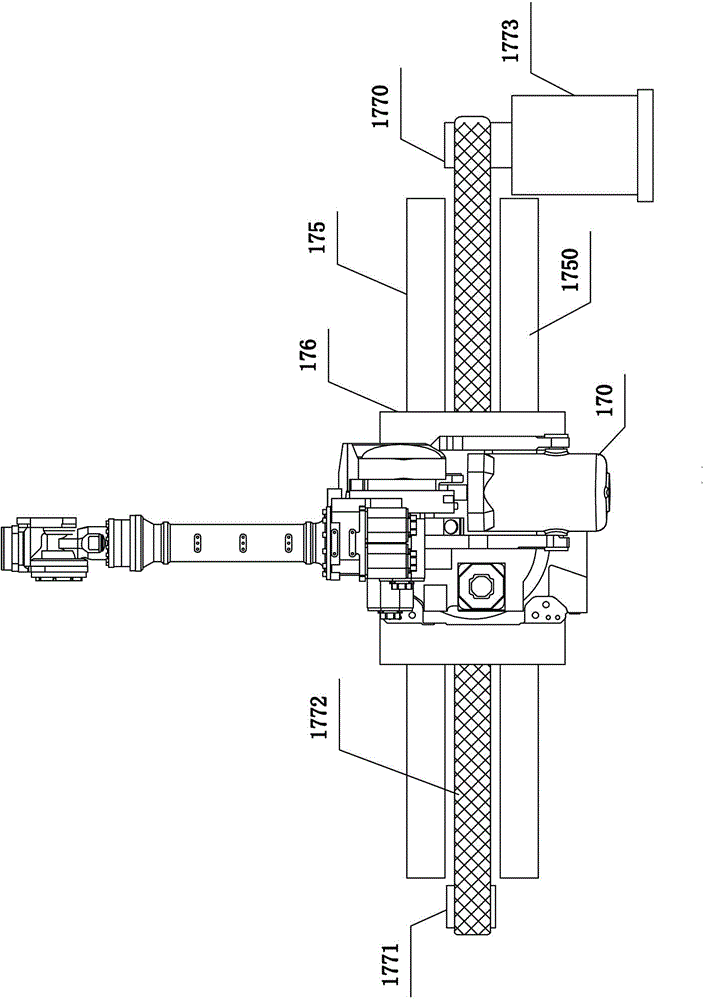

Automatic footwear production line with using space saved and automatic footwear making method

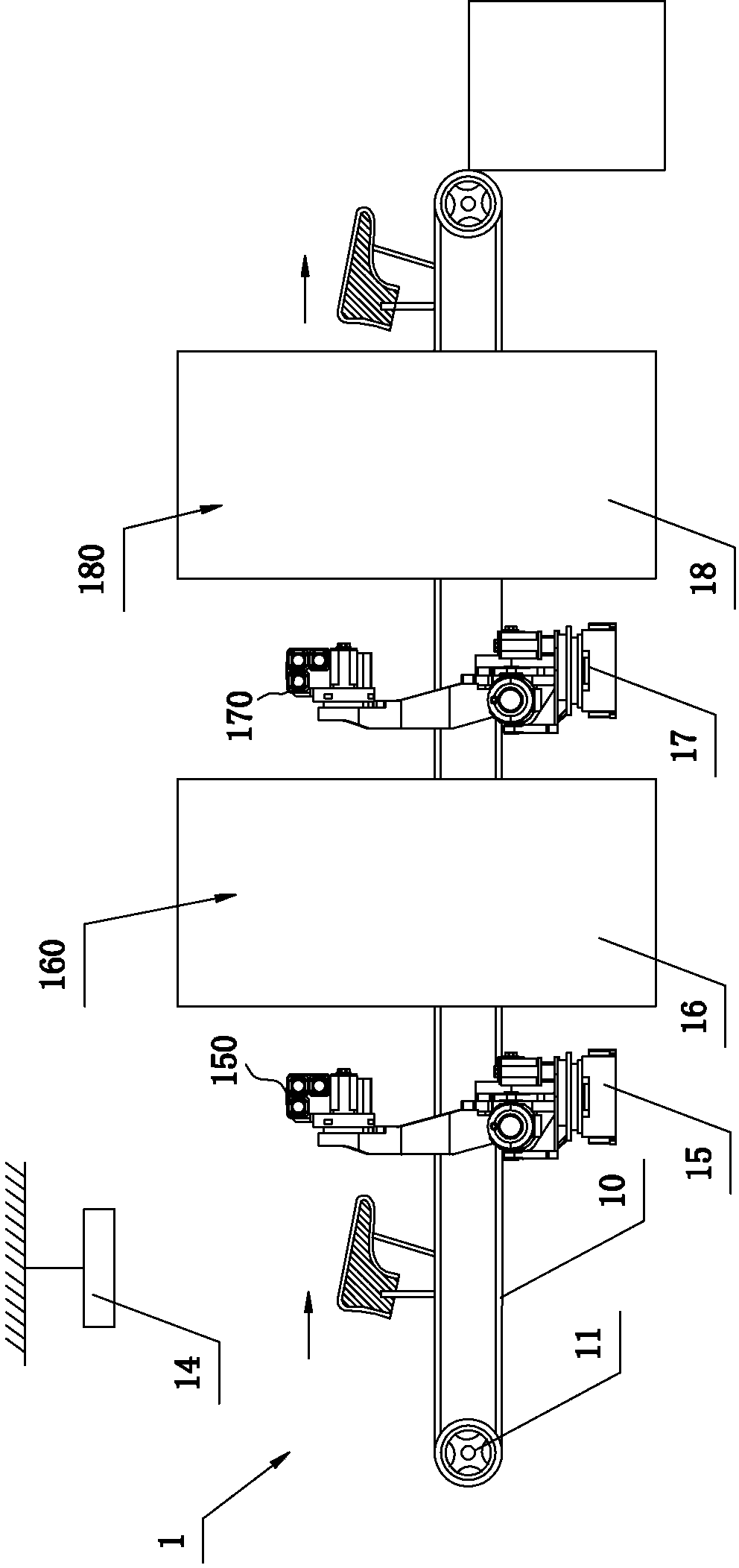

InactiveCN104161354AConsistent glue volumeImprove the consistency of spray glue effectShoemaking devicesMovement controlManipulator

An automatic footwear production line with using space saved comprises an automatic vamp glue applying device and an automatic sole glue applying device, wherein the automatic vamp glue applying device and the automatic sole glue applying device are vertically arranged and adjacent to each other, the automatic vamp glue applying device comprises a first conveying belt, a first driving assembly and a first automatic glue spraying control assembly, the first automatic glue spraying control assembly comprises a three-dimensional scanning mechanism, a first treating water drying mechanism, a first glue drying mechanism and a first multi-station hoisting manipulator device, the first multi-station hoisting manipulator device comprises a controller, a first six-freedom-degree manipulator, a first transverse-movement control mechanism, a first spraying gun and a second spraying gun, and the first transverse movement control mechanism comprises a first fixing frame, a first guiding assembly, a first moving table and a first transmission assembly. Due to the automatic footwear production line, it can be guaranteed that the amount of glue sprayed to all the portions of a vamp tends to be consistent, waste of glue is greatly reduced, consistency of the glue spraying effect of vamps is improved, then, it is guaranteed that firmness degree of subsequent adhering between vamps and soles is improved, the service life of footwear is prolonged, and quality of footwear is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

Space-saving vamp glue spraying device and automatic vamp glue spraying method

InactiveCN104146442AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingTreatments waterEngineering

A space-saving vamp glue spraying device comprises a first conveying belt, a first driving component and a first automatic glue spraying control component. The first automatic glue spraying control component comprises a three-dimensional scanning mechanism, a first treatment water drying mechanism, a first glue drying mechanism and a first multistation lifting manipulator device, wherein the first multistation lifting manipulator device comprises a controller, a first six-degree-of-freedom manipulator, a first sidesway control mechanism, a first spraying gun and a second spraying gun. The first sidesway control mechanism comprises a first fixing mount, a first guide assembly, a first moving platform and a first drive assembly. The invention further provides an automatic vamp glue spraying method adopting the space-saving vamp glue spraying device. By the space-saving vamp glue spraying device and the automatic vamp glue spraying method, glue sprayed to various parts of vamps tends to be uniform, waste of the glue is greatly reduced, uniformity in glue spraying is improved, follow-up bonding fastness of the vamps and shoe soles is improved, service lives of shoes are prolonged and quality of the same is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

High colorfastness transfer printing method

ActiveCN102797174AHigh color fastnessHigh glossTransfer printing processDyeing processIsobutanolDisperse dye

The invention provides a high colorfastness transfer printing method. An prepared transfer printing ink comprises the following components in percentage by mass: 50-70% of disperse dye, 14-42% of methanol and / or isobutanol, 5-15% of polyvinyl butyral and 1-3% of stabilizing agent double-hydroxy composite metal oxide; and the transfer printing method comprises the following steps of: first, wetting a fabric to be printed by using a polyoxyethylene or polypropylene oxide aqueous solution; and then carrying out transfer printing on the fabric to be printed. The high colorfastness transfer printing method provided by the invention has the advantages of simple process, low cost, strong cohesiveness between a pattern and a fabric after printing and durability; and high colorfastness can be kept under conditions of water washing, Illumination, heating and so on.

Owner:WUXI SAILITE TEXTILE TECH

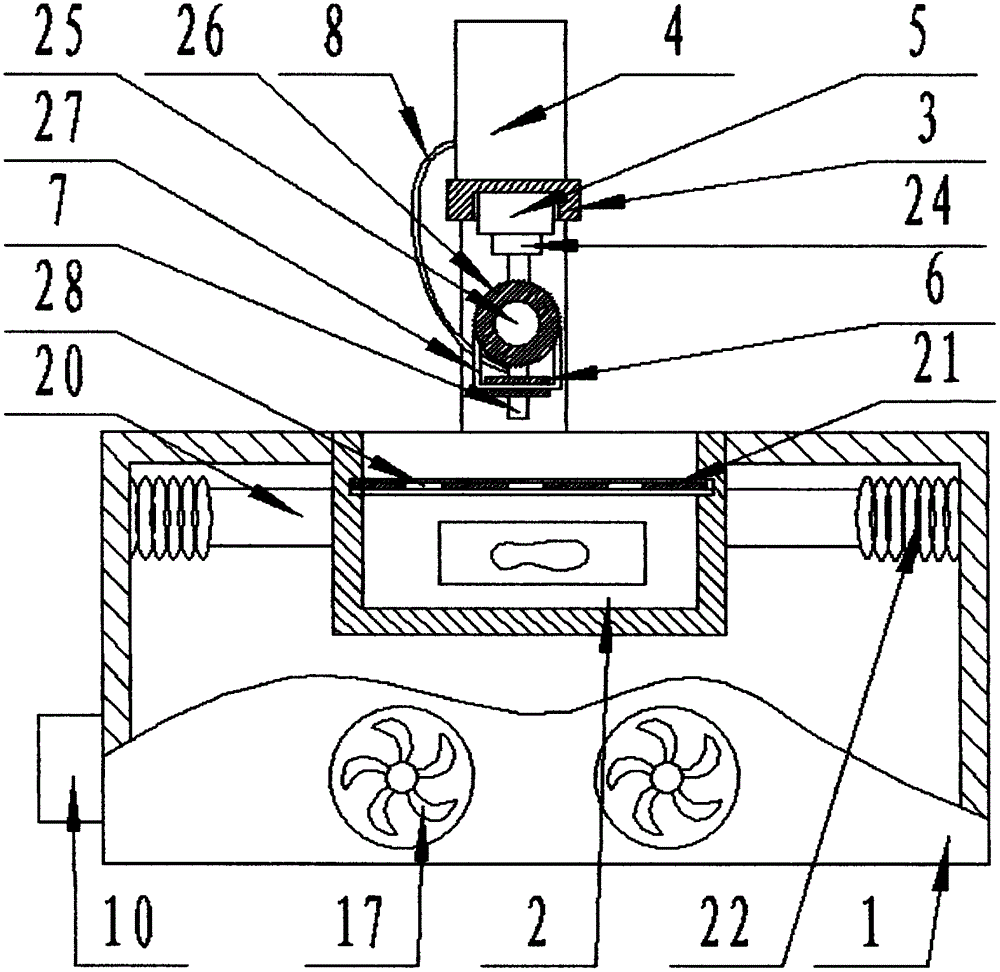

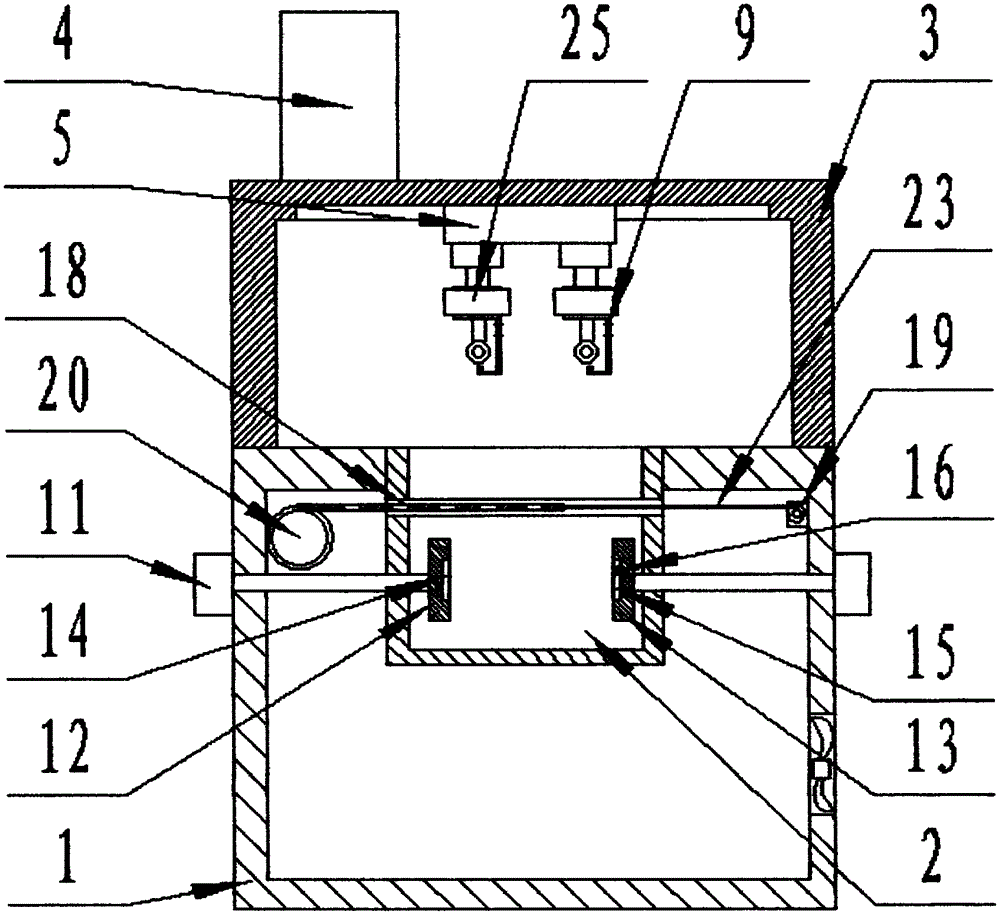

Glue application and drying production line for soles

ActiveCN105411108AImprove the consistency of spray glue effectReduce wasteShoe gluingHydraulic cylinderProduction line

The invention discloses a glue application and drying production line for soles. The production line comprises a work bench, wherein the inside of the work bench adopts a cavity structure, a rectangular work groove is formed in the work bench, and a drying unit communicated with the inside of the rectangular work groove is arranged in the cavity structure; a supporting beam is arranged on the work bench, a glue storage barrel is arranged at one end of the supporting beam, a sliding channel is formed in the supporting beam, a hydraulic cylinder capable of moving in the length direction is arranged on the sliding channel, and a glue applying unit is arranged on the hydraulic cylinder; multiple gluing units are arranged in the rectangular work groove; a controller is arranged on the work bench and is electrically connected with the drying unit, the hydraulic cylinder, a pair of telescopic arms, electromagnetic valves and the gluing units. The glue application and drying production line for the soles has the benefits of simple structure and high practicability.

Owner:阳信利鑫清真肉类有限公司

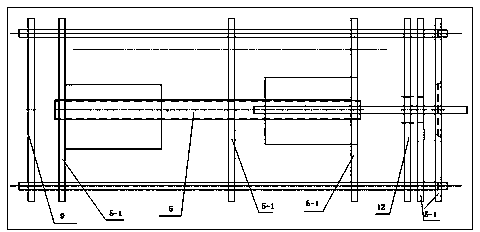

Method for manufacturing embedded bolt sleeve at root of fan blade by pultrusion process

The invention discloses a method for manufacturing an embedded bolt sleeve at the root of a fan blade by a pultrusion process. The method comprises preparation of an embedded bolt sleeve precast block, and molding of the embedded bolt sleeve precast block and a fan blade. The embedded bolt sleeve precast block is fabricated by the pultrusion process, the pultrusion process has the advantages of continuity, high industrial degree and high production efficiency, and the fabricated embedded bolt sleeve has the advantages of stable quality, high size precision, large strength and the like, and is suitable for the fan blade with large load at the root and with connection to a large quantity of bolts. The problems of incontinuity in laying, interlayer asymmetry, high probability of wrinkles and air bubbles and the like caused by manual laying and pasting can be overcome.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Automatic shoe production line

InactiveCN108078077AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingProduction lineEngineering

Disclosed is an automatic shoe production line. The automatic shoe production line comprises an automatic shoe upper sizing device and an automatic shoe sole sizing device. The automatic shoe upper sizing device comprises a first conveyor belt, a first driving assembly and a first automatic glue spraying control assembly; the first automatic glue spraying control assembly comprises a three-dimensional scanning mechanism, a first treatment water spraying mechanism, a first treatment water drying mechanism, a first glue spraying execution mechanism and a first glue drying mechanism which are located above the first conveyor belt and sequentially adjacent; the first glue spraying execution mechanism comprises a controller with the enabled end connected with the three-dimensional scanning mechanism, a first six-degree-of-freedom mechanical hand and a first spraying gun installed on the arm of the first six-degree-of-freedom mechanical hand. The invention further relates to an automatic shoe manufacturing method. The glue waste amount can be greatly lowered, the shoe upper glue spraying effect consistency is improved, then, it is ensured that follow-up shoe upper and shoe sole bonding firmness is improved, the service life of shoes is prolonged, and the quality of the shoes is improved.

Owner:PIONEDA INTELLIGENT AUTOMATION TECH NINGBO

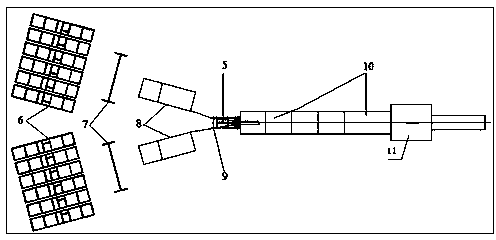

Packaging method of flat solar reflectors with metallic gasket connecting pieces

The invention relates to a packaging method of flat solar reflectors with metallic gasket connecting pieces, which comprises the following steps: (1) transferring; (2) carrying out plasma activation on a painted surface; (3) gluing the preset position of the painted surface; (4) installing metallic gaskets, and grabbing the metallic gaskets by manipulators so as to arrange the metallic gaskets in the preset gluing position; (5) detecting flatness, namely detecting the height difference of the left and right sides of the metallic gaskets; and (6) packaging, namely sequentially packaging flat reflectors of which the flatness is detected to be qualified. The method provided by the invention has the beneficial effects that pollutants on the painted surface subjected to plasma activation can be effectively eliminated, so that the bonding fastness between a flat reflector and a metallic gasket is improved; a plurality of manipulators are used for simultaneously grabbing and arranging a plurality of metallic gaskets, so that the time of the gasket arranging step is greatly shortened; and finished products are easy to assemble and disassemble, high in connection strength and better in cost benefit.

Owner:浙江大明玻璃有限公司

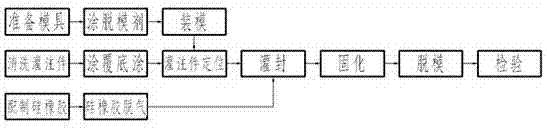

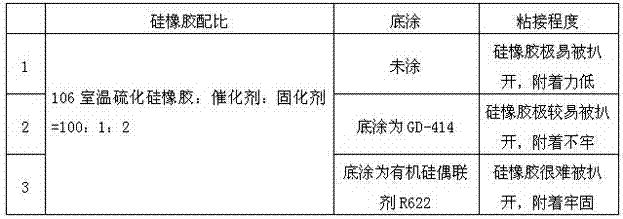

Silicon rubber for encapsulating electronic tube and encapsulating method

InactiveCN102964839AImprove the firmness of the bondGood sealing and airtightnessElectric discharge tubesTube/lamp vessels closingPolymer scienceVulcanization

The invention discloses silicon rubber for encapsulating an electronic tube. The silicon rubber is prepared from the following raw materials in parts by weight: 100-110 parts of 106 room temperature vulcanized silicone rubber, 1-1.5 parts of catalyst and 1.5-2 parts of curing agent. Through a large quantity of tests, the silicon rubber specially used for encapsulating the electronic tube is screened out, all components are scientifically proportioned, and the electronic tube obtained through encapsulation is good in electric insulation property, has good arc and corona resistance, water resistance, ozone resistance, weathering aging resistance and high-low temperature resistance, can be used within a temperature range from -60 DEG C to 200 DEG C, and is wide in application range. The method for encapsulating the electronic tube, provided by the invention, has the advantages of strong maneuverability and high process stability and reliability; and the prepared silicon rubber is high in adhesion firmness and good in encapsulation airtightness.

Owner:NANJING SANLE ELECTRONICS INFORMATION IND GRP

Flexible conductive fiber based on silver nanowires and preparation method of flexible conductive fiber

ActiveCN109338717AImprove conductivity stabilityIncreased durabilityFibre typesHydrofluoric acidMiniaturization

The invention discloses a flexible conductive fiber based on silver nanowires. The conductive fiber is characterized in that the surface of a polyurethane fiber is wrapped with a plurality of layers of silver nanowires. The invention further discloses a preparation method of the conductive fiber. The preparation method comprises the steps of transferring a silver nanowire conductive network absorbed on an inner wall of a capillary glass tube to the surface of polyurethane, and then dissolving the capillary glass tube through hydrofluoric acid to form the conductive fiber. The conductive fiberuses the silver nanowires as a material of a conductive functional layer and transparent polyurethane as a fiber matrix material; the prepared conductive fiber has excellent conductivity and good acid-base corrosion resistance; the material of conductive layer is only retained on the surface of a fiber matrix; the fiber matrix is not damaged; and compared with a conductive fiber prepared by a mixed conductive filling method, the prepared conductive fiber has better flexibility and elasticity and can be bent, wound, stretched and cut. The conductive fiber meets miniaturization, flexibility andwearability development requirements of electronic equipment in the future.

Owner:XIAN UNIV OF TECH

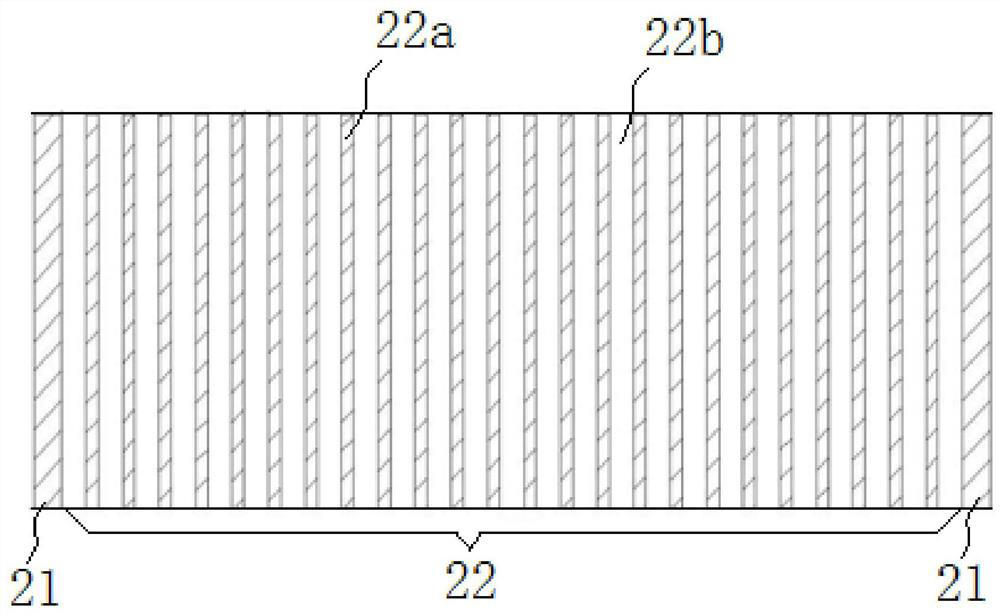

Label and package

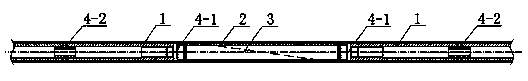

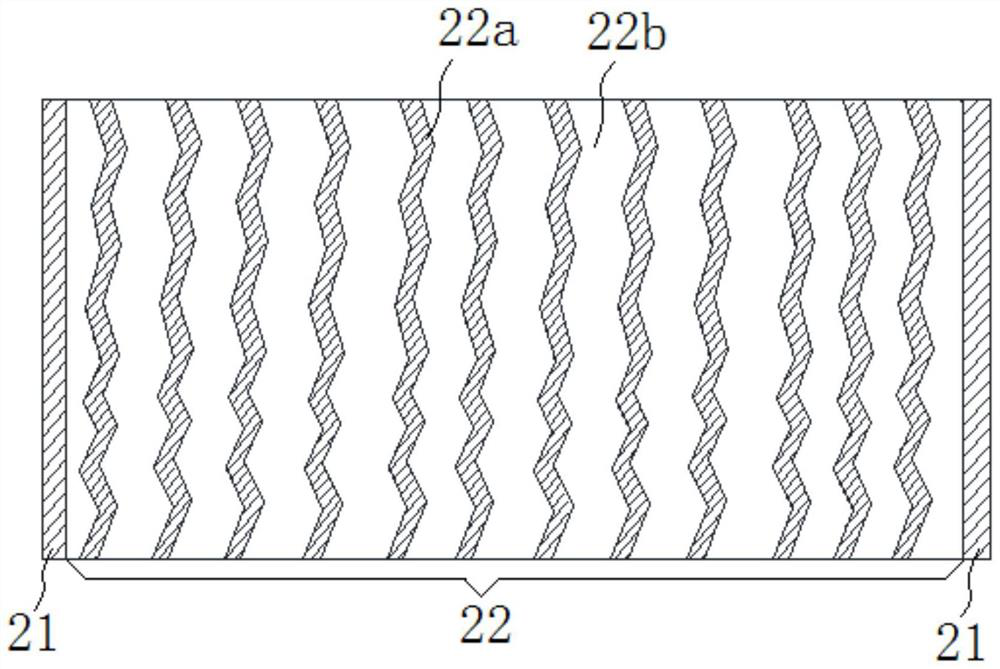

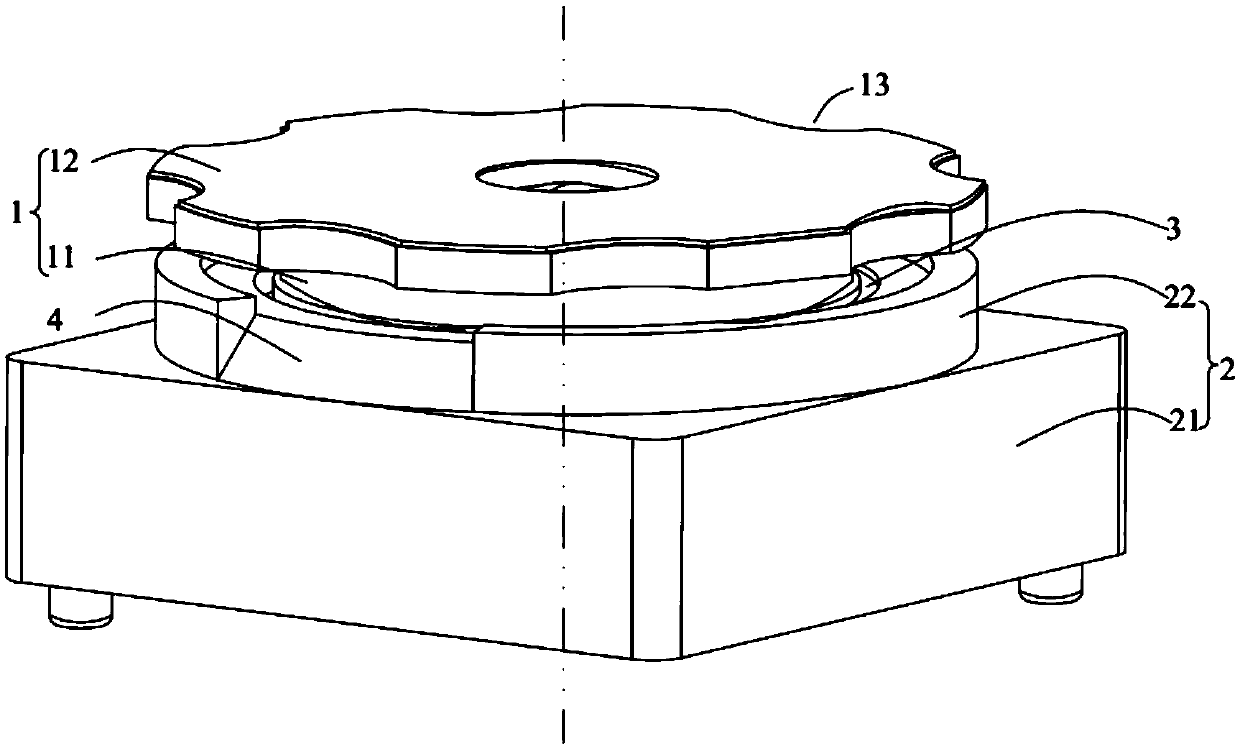

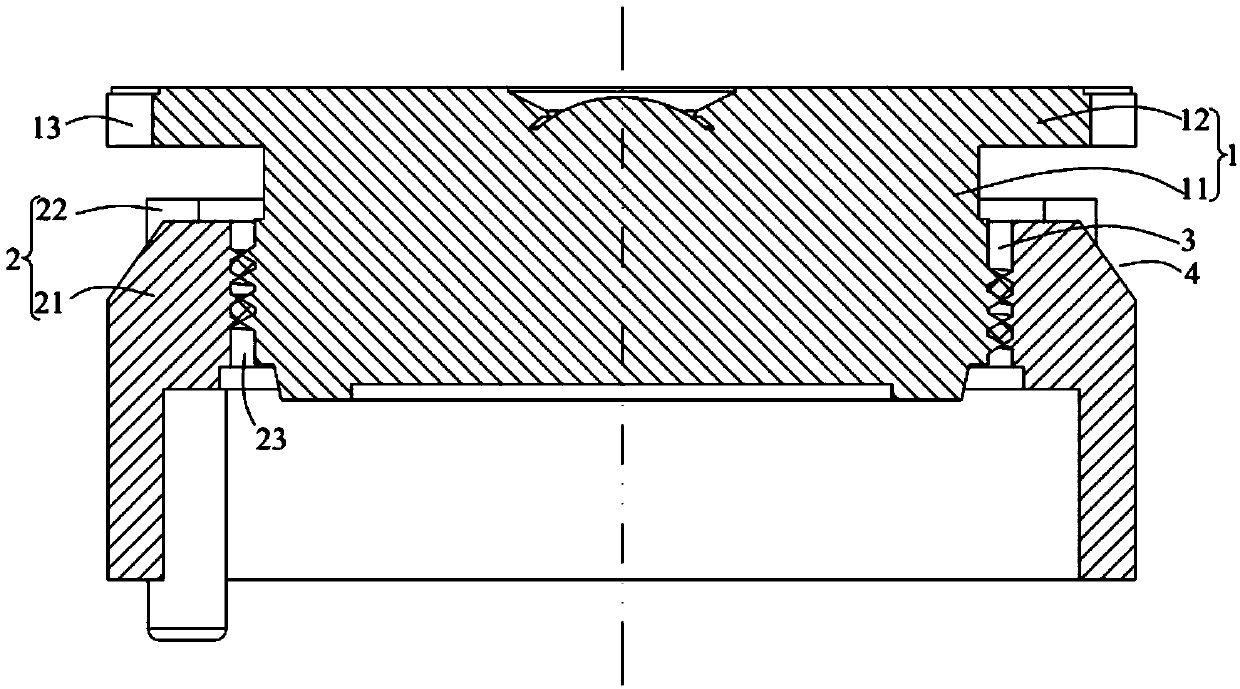

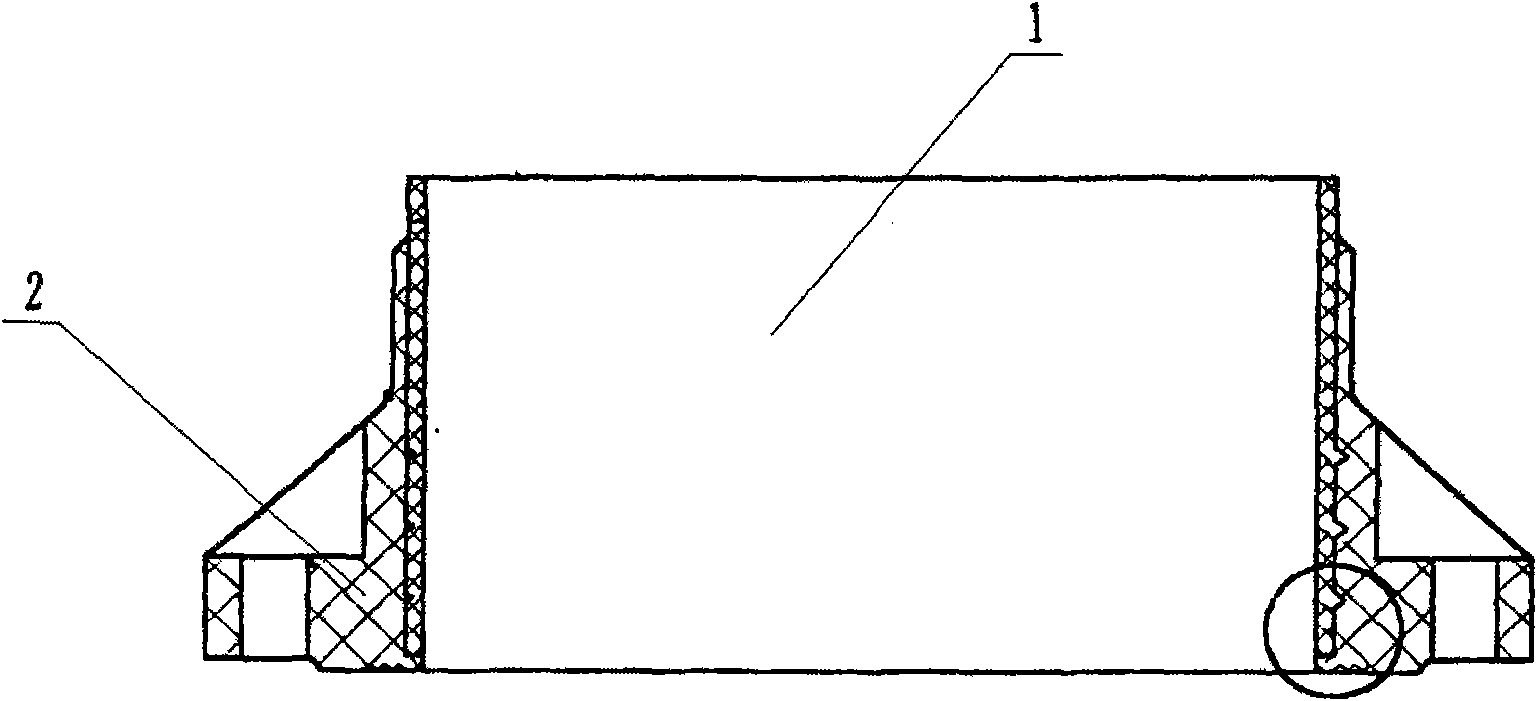

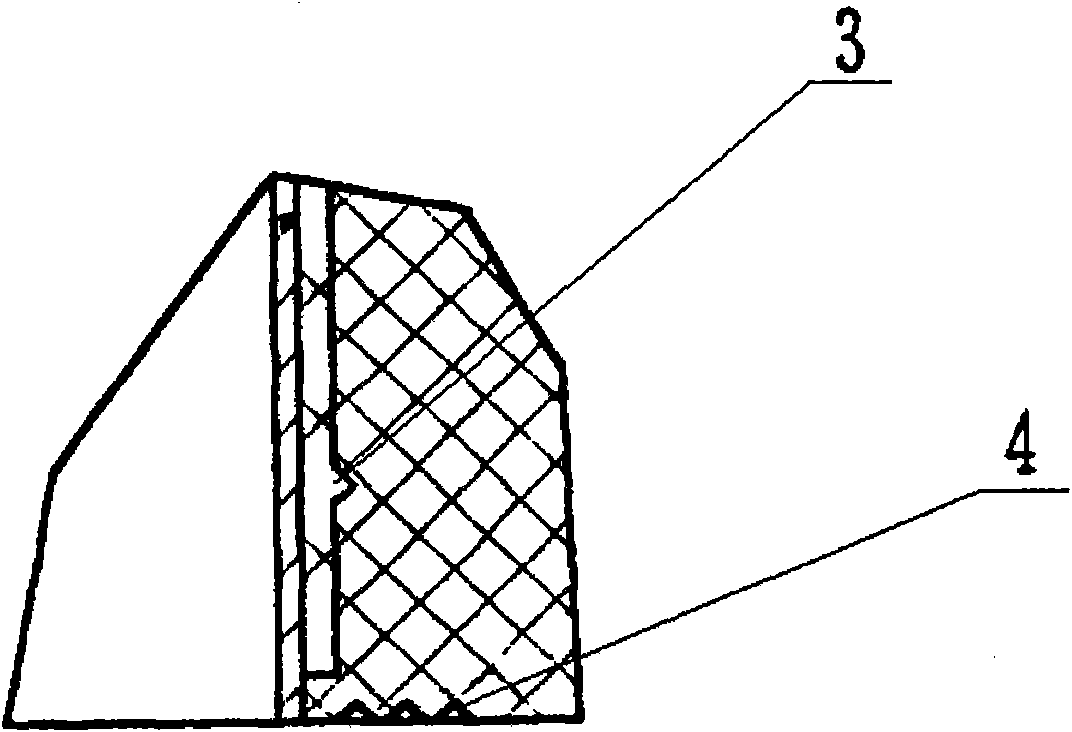

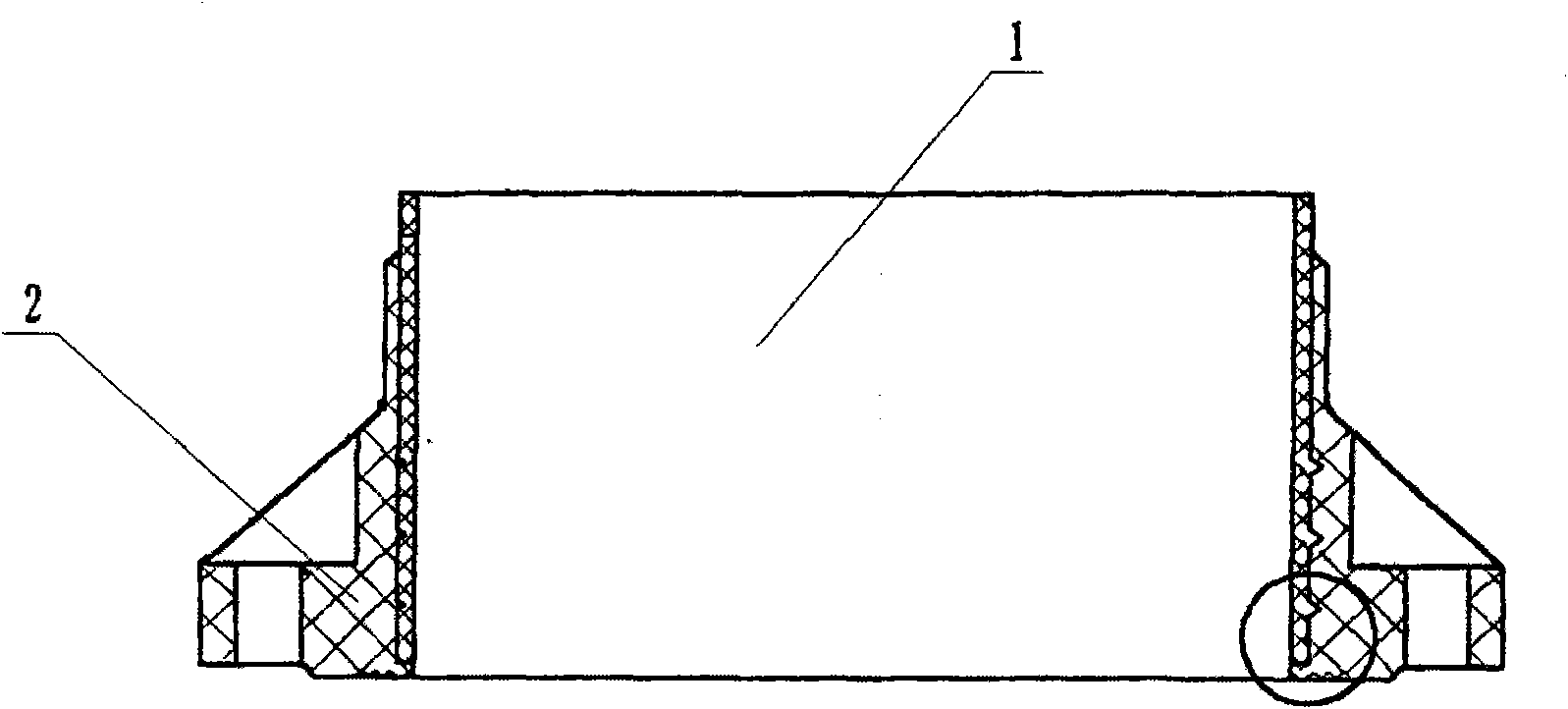

InactiveCN111986555AImprove stiffnessReduce the amount of glue appliedStampsAdhesivesEngineeringMechanical engineering

The invention relates to a label and a package. The label comprises a substrate (1) and an adhesive layer (2) arranged on the first surface of the substrate (1); the adhesive layer (2) comprises a first adhesive part (21) which is arranged at the transverse first end of the substrate (1) and is used for connecting the transverse second end of the substrate (1), and a second adhesive part (22) which extends from the transverse first end of the substrate (1) to the transverse second end; the amount of glue applied per unit area of the second adhesive part (22) is smaller than the amount of glueapplied per unit area of the first adhesive part (21). According to the technical scheme, the gluing amount of the second gluing part (22) in the unit area is smaller than that of the first gluing part (21) in the unit area, and therefore the stiffness of a labeled object and the bonding firmness degree of the labeled object can be improved on the premise that the low gluing amount is guaranteed.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Lens module

The invention belongs to the technical field of optics, and discloses a lens module. The lens module includes a lens and a barrel which are connected with each other, a glue groove is formed between the lens and the barrel, a collision avoidance groove is formed in the side wall of the barrel, the bottom of the collision avoidance groove is angled with the central axis of the barrel, and the distance between the bottom of the collision avoidance groove and the central axis of the barrel decreases gradually in the direction close to the lens. According to the lens module, the collision avoidance groove is formed in the side wall of the barrel, which makes it easy for a rubber needle to extend into the glue groove and inject a glue, and the case that the glue overflows on the surfaces of thelens and the barrel is reduced, thereby improving the cleanliness and aesthetics of the lens module; the glue can enter the glue groove completely for the bonding between the lens and the barrel, theglue is sufficient, which enhances the bonding firmness effect, and the torsion of the lens after glued is large, which reduces the deviation and defocusing of the lens in the actual use process, thereby improving the imaging quality.

Owner:GUANGZHOU LUXVISIONS INNOVATION TECH LTD

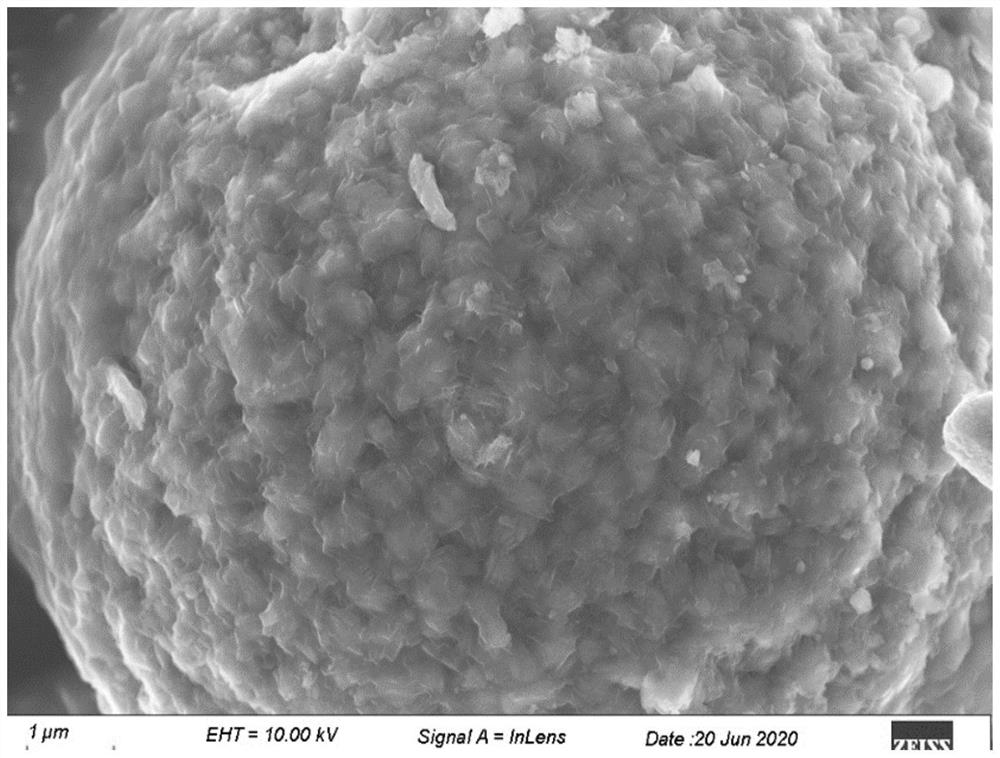

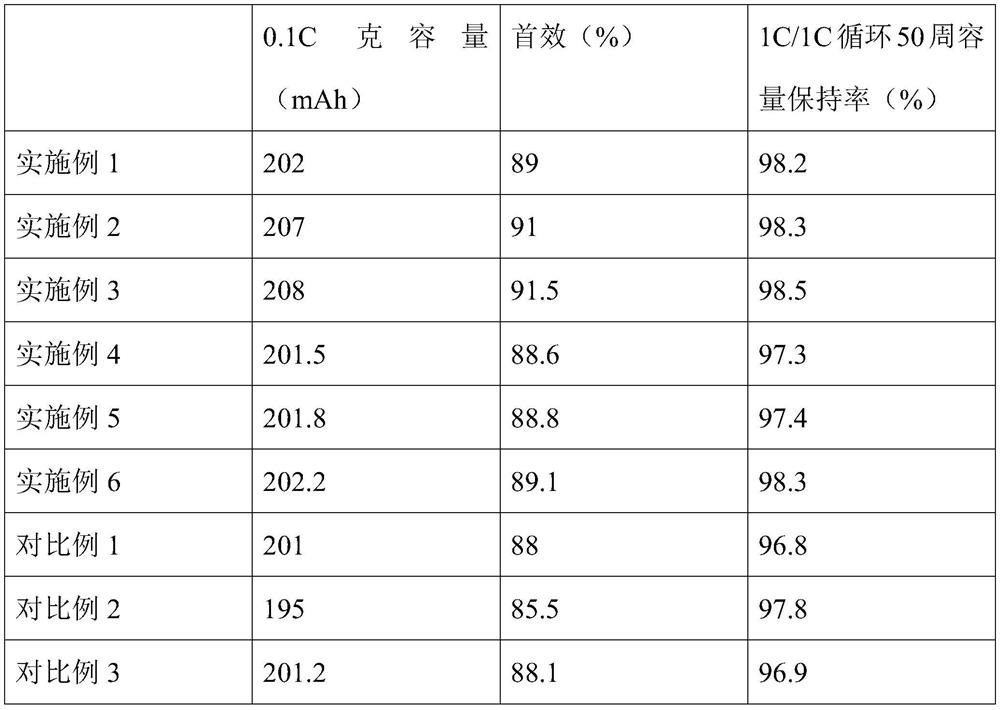

Doping and coating method, method for modifying ternary positive electrode material by adopting same and application

ActiveCN113603155ALower sintering temperatureShorten the sintering timeSecondary cellsPositive electrodesMetallurgyPhysical chemistry

The invention discloses a doping and coating method, a method for modifying a ternary positive electrode material by adopting the method and an application. The doping and coating method comprises the following steps: 1) mixing a doping and coating additive and a cosolvent, pre-sintering, washing and drying to obtain a low-melting-point additive; and 2) adopting the low-melting-point additive, and performing doping treatment and / or coating treatment on a to-be-modified material by using a sintering method. According to the method, the sintering temperature and time of doping and coating can be properly reduced, the uniformity of doping and the firmness of coating combination can be properly improved, the process requirements can be reduced, and the method has a wide application prospect.

Owner:SVOLT ENERGY TECHNOLOGY CO LTD

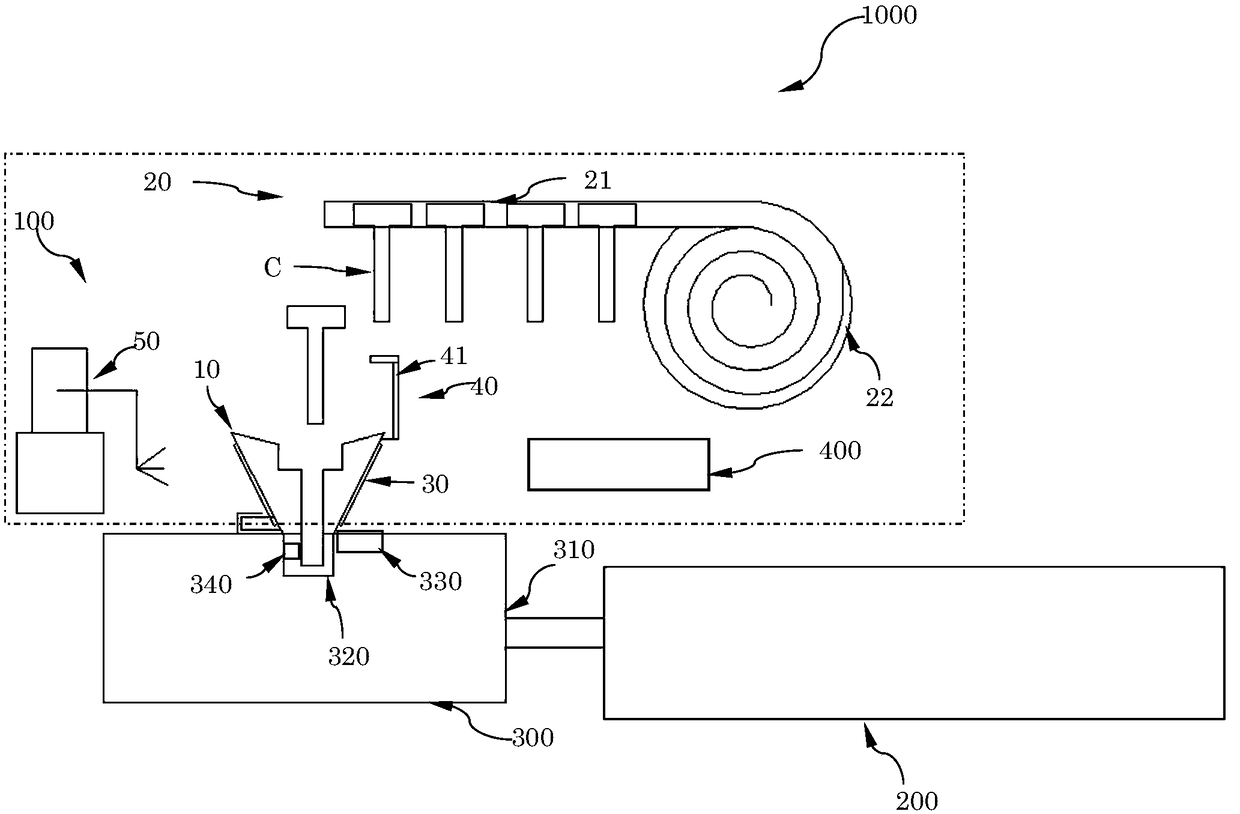

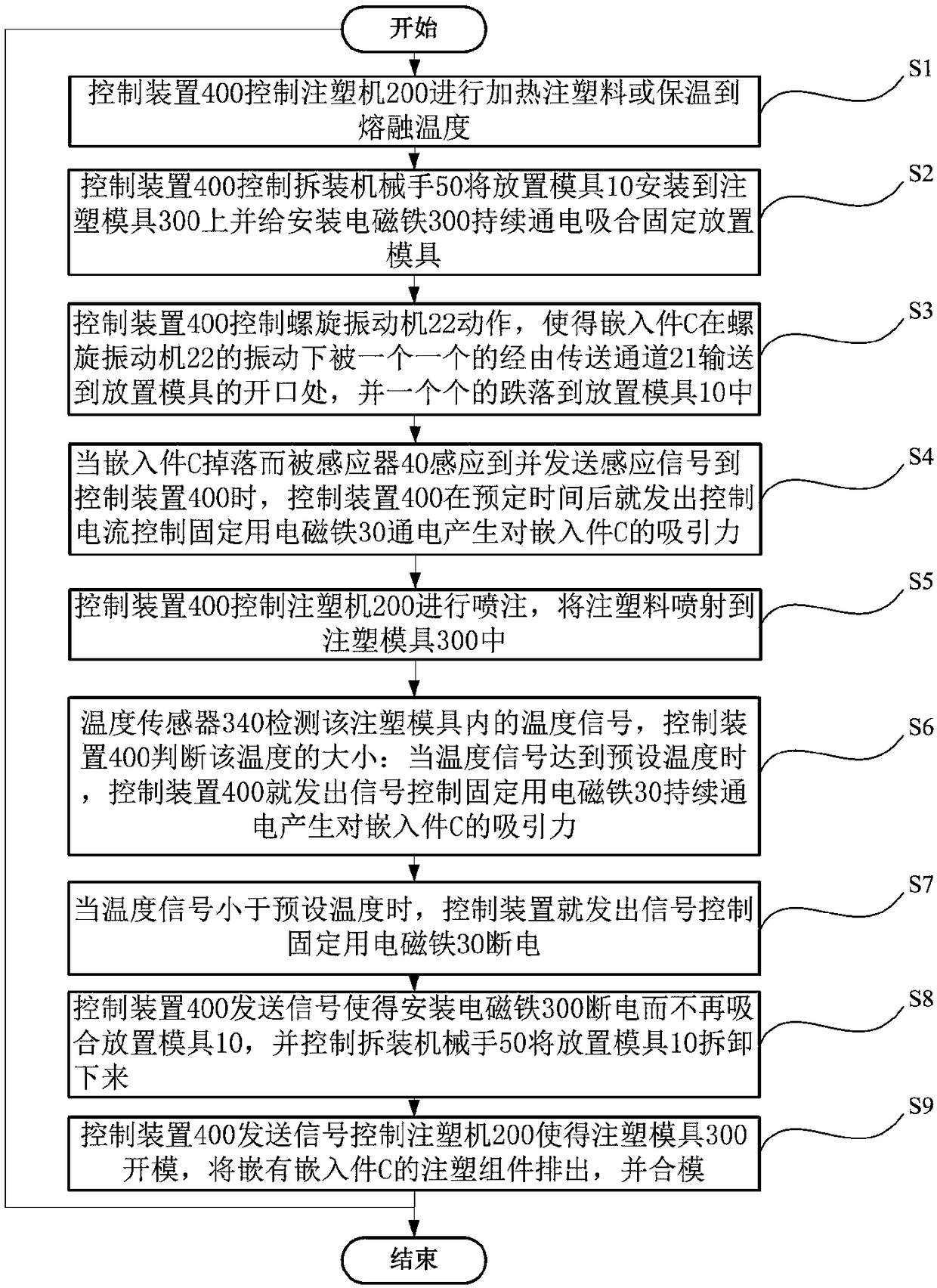

Injection-molded component manufacturing method

The invention provides an injection-molded component manufacturing method for inserting an iron insert part into an injection-molded blank which is injection-molded in an injection mold of an injection molding machine so as to obtain an injection-molded component by means of integral formation. The injection-molded component manufacturing method is characterized by adopting the injection molding machine, the injection mold connected with the injection molding machine, an insert part placing device for inserting an iron metal insert part, and an injection-molded component manufacturing system of a control device for manufacturing, and the specific manufacturing method is shown in the abstract and attached drawings. By designing a set of injection-molded component manufacturing system and manufacturing method, the insert part is placed at a preset position of the mold in an injection molding process of the injection molding machine so that the metal insert part can be inserted by just preforming or designing one connecting opening in the existing injection mold, and thus the cost is lowered, the design is simplified, and an existing mold can be used just after being simply modified.

Owner:宿州大地网络科技有限公司

Moth proofing technology for China fir board

InactiveCN108501151AGood insect resistancePromote absorptionWood treatment detailsWood heatingChinWater content

The invention discloses a moth proofing technology for a China fir board. The technology comprises the following steps: A, soaking and washing a raw Chin fir board into 91 to 93 DEG C water, so as toobtain a product a; B, putting the product a into 8 to 12 DEG C bug repellent to perform diffusion treatment, and ensuring the soaking time is 30 to 35min, so as to obtain a product b; C, drying the product b, so as to obtain a product c with the water content being 19 to 21 percent; D, putting the product c into a pressure impregnating tank, injecting bug repellent into the pressure impregnatingtank, and performing pressure treatment on the product c, so as to obtain a product d; E, performing high-temperature qualitative treatment on the product d, so as to obtain a product e; F, performingairing treatment on the product e, so as to obtain a finished China fir board. The technology has the characteristic that the moth proofing effect of the China fir board can be improved.

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Automatic footwear production line with saved use space

InactiveCN109907430AConsistent glue volumeImprove the consistency of spray glue effectShoe gluingSix degrees of freedomManipulator

The invention relates to an automatic footwear production line with a saved use space. The automatic footwear production line comprises an automatic upper sizing device and an automatic sole sizing device which are arranged up and down in an abutted manner, wherein the automatic upper sizing device comprises a first conveying belt, a first driving assembly and a first automated glue spraying control assembly, the first automated glue spraying control assembly comprises a three-dimensional scanning mechanism, a first treating water baking mechanism, a first glue baking mechanism and first multi-station hoisting manipulator equipment, the first multi-station hoisting manipulator equipment comprises a controller, a first manipulator with six degrees of freedom, a first lateral movement control mechanism, a first spray lance and a second spray lance, and the first lateral movement control mechanism comprises a first fixing frame, a first guiding assembly, a first mobile table and a first transmission assembly. According to the automatic footwear production line with the saved use space, the volume of glue sprayed to each part of an upper can tend to consistency, the wastage of the glueis greatly lowered, the consistency of glue spraying effect of the upper is improved, then, the degree of firmness of subsequent bonding between uppers and soles is increased, service lives of footwear are prolonged, and the quality of the footwear is improved.

Owner:淮安金盟机械有限公司

Imitation marble water-based paint

The invention discloses imitation marble water-based paint, and belongs to the technical field of building materials. The imitation marble water-based paint is prepared from, by weight, 40-45 parts ofdeionized water, 40-45 parts of transparent emulsion, 40-45 parts of solution of 5% protection glue powder, 6-8 parts of roll-coated diatom ooze, 4-6 parts of barium sulfate, 0.8-1.0 part of coalescing agent, 1.0-1.2 parts of cellulose, 0.1-0.2 part of defoaming agent and 0.05-0.1 part of wetting agent. The roll-coated diatom ooze is prepared from, by weight, 30-40 parts of deionized water, 20-30parts of kieselguhr dry powder, 10-20 parts of rubber powder, 1-2 parts of valencianite powder and 1-2 parts of decoration pattern additive. Kieselguhr ores are precipitated and separated after beingscrubbed to obtain fine kieselguhr, and the fine kieselguhr is dryed through a vacuum freeze-drying method to prepare the kieselguhr dry powder. Through the coordinative effect of the kieselguhr drypowder and the valencianite powder, pigments and micro-pores are firmly combined, and the problems that the imitation marble water-based paint is instable in color chip, unclear in color chip boundaryand prone to photolysis are solved.

Owner:马鞍山市银洁建材科技有限公司

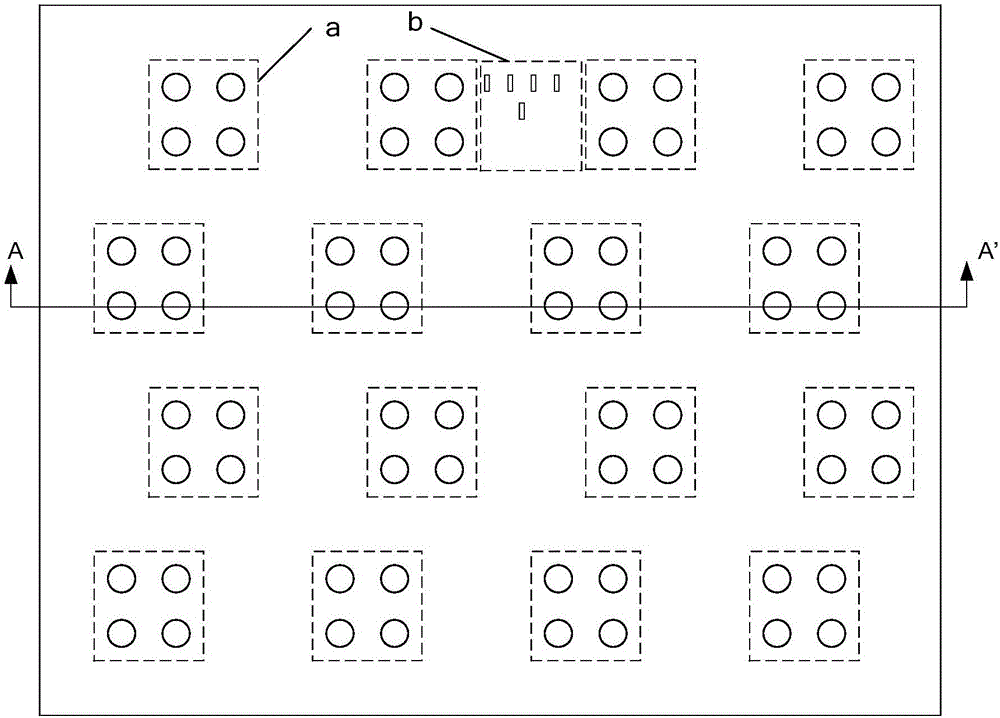

Display substrate, production method and display equipment

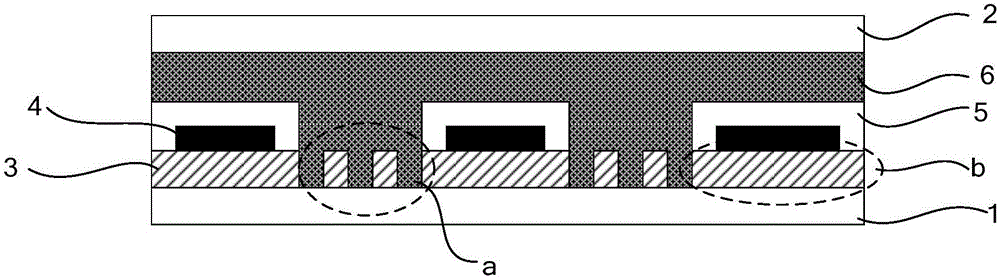

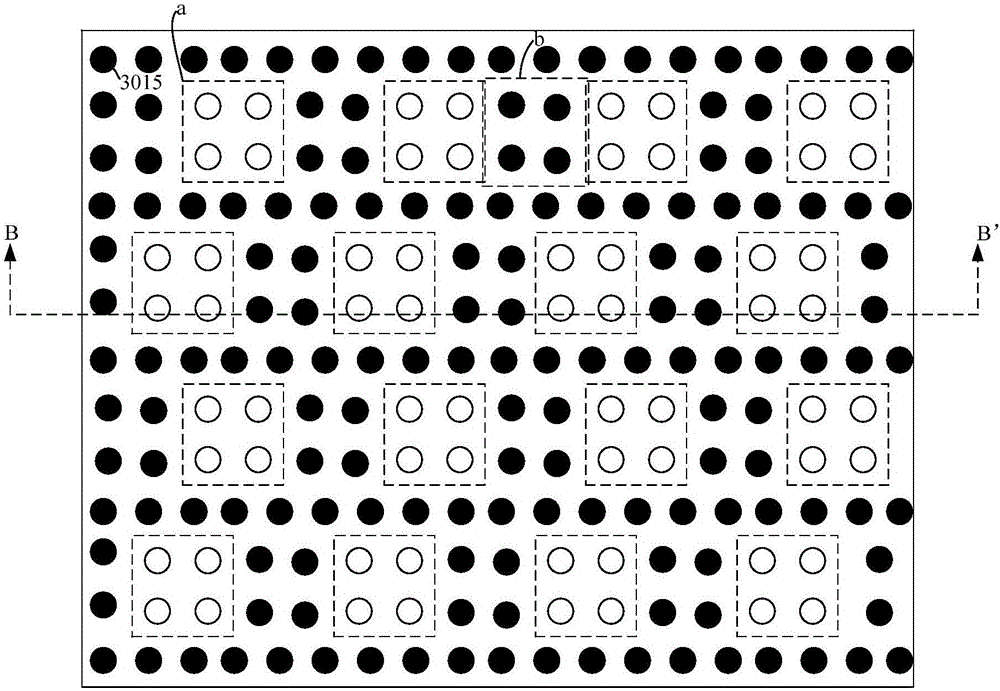

ActiveCN106356392AReduce the probability of falling off and breakingImprove the firmness of the bondSolid-state devicesSemiconductor/solid-state device manufacturingButt jointDisplay device

The invention provides a display substrate, a production method and display equipment and relates to the technical field of display. The display substrate is characterized in that the display substrate is provided with functional film layers, and one side, away from the display substrate, of at least one functional film layer is provided with protruding arrays; when the display substrate is in butt joint with another display substrate, the corresponding protrusions of the protruding arrays are embedded into the sealing glue between the two display substrates. The display substrate used for producing display devices has the advantages that the falling off and breaking probability of the sealing glue can be lowered, and the problem that a display device is eroded by water and oxygen due to the falling off and breaking of the sealing glue is solved.

Owner:BOE TECH GRP CO LTD +1

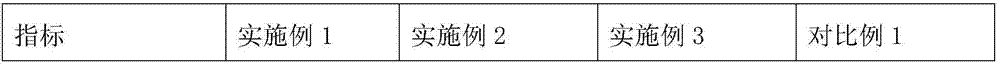

Building material and preparation method thereof

The invention provides a building material and a preparation method thereof and relates to the field of construction. The building material comprises, by weight, 25 to 40 parts of yellow sand soil, 20 to 30 parts of expanded perlite, 25 to 30 parts of polyphenyl particles, 24 to 28 parts of polyurethane foam plastic, 20 to 30 parts of ash-calcium powder, 15 to 20 parts of quartz sand, 13 to 21 parts of bentonite, 15 to 25 parts of aluminum silicate, 11 to 15 parts of stearic acid, 5 to 9 parts of sodium formate, 8 to 14 parts of synthetic fibers, 5 to 7 parts of cement, 18 to 22 parts of electric furnace slag powder, 10 to 15 parts of a filler, 0.2 to 0.6 parts of a retarder, 0.3 to 0.5 parts of a water reducer and 4 to 6 parts of water. The preparation method comprises (1) raw material weighing, (2) polyurethane foamed plastic crushing, (3) stirring, and (4) molding, drying, cooling and storage. The building material solves the problem that the existing thermal insulation material has defects in buildings having high environmental protection, energy saving, sound insulation, tensile strength, compressive strength and heat preservation performance requirements.

Owner:合肥市晨雷思建筑材料科技有限公司

Environment-friendly type white glass wool product

InactiveCN102491634ASolve the difficulty of degradationSolving Corrosion ProblemsGlass making apparatusPolymer sciencePtru catalyst

The invention belongs to the field of glass wool production, and especially relates to an environment-friendly type white glass wool product. The glass wool product does not contain free phenol and formaldehyde. The glass wool product is composed of glass wool fiber and a total regulating liquid. A preparation method comprises specific steps that: A, glass wool fiber is obtained with a centrifugal blowing method; B, prepared total regulating liquid is uniformly ejected onto the glass wool fiber; curing is carried out, such that the glass wool product is formed. The total regulating liquid comprises components of, by weight: 18-26 parts of an environment-friendly type formaldehyde-free glass wool fiber bonding agent, 3-6 parts of a coupling agent, 0.3-1 part of an auxiliary cross-linking agent, 1-3 parts of a curing catalyst, 1-3 parts of a surfactant, and 70-80 parts of a solvent.

Owner:周华

Pressure flange

The invention discloses a pressure flange which comprises a pipeline and a flange plate matched with and connected to the outer periphery of the pipeline. The flange is characterized in that the inner periphery of the flange plate is provided with an annular groove. The pressure flange has the advantages of safety, long service life and good sealing performance and is suitable for being used under high working pressure.

Owner:吕增和

Anti-corrosion solution for cedar board

InactiveCN108544615AImprove anti-corrosion performanceImprove permeabilityWood treatment detailsWood impregnation detailsBromineCarbon nanotube

The invention discloses an anti-corrosion solution for a cedar board. The anti-corrosion solution is prepared from the following components in parts by weight: 5 parts to 6 parts of sodium metabisulfite, 3 parts to 4 parts of polyethylene glycol, 15 parts to 18 parts of propylene carbonate, 10 parts to 15 parts of parachlorometaxylenol, 2 parts to 3 parts of nano silicon dioxide, 1 part to 2 partsof nano titanium dioxide, 0.6 part to 1.2 parts of monodisperse colloid microsphere, 1.1 parts to 1.8 parts of carbon nano-tube, 5 parts to 8 parts of alkyl dimethyl benzyl ammonium chloride, 1 partto 3 parts of zinc sulfate, 1 part to 3 parts of copper citrate, 0.6 part to 1.1 parts of potassium bromide, 3 parts to 4 parts of bronopol, 25 parts to 30 parts of methylene bisthiocyanate, 30 partsto 40 parts of fatty alcohol polyvinyl chloride ester and 50 parts to 60 parts of water. The anti-corrosion solution for the cedar board disclosed by the invention has the characteristic that an anti-corrosion effect of the cedar board can be effectively improved.

Owner:ZHEJIANG YUEQIANG FURNITURE TECH CO LTD

Vacuum spraying treatment technology used for aluminum profile machining

InactiveCN111235530AImprove the firmness of the bondImprove dispersion uniformityVacuum evaporation coatingSputtering coatingThin metalMetal alloy

The invention discloses a vacuum spraying treatment technology used for aluminum profile machining and relates to the technical field of aluminum profile machining. The technology includes aluminum profile surface treatment, pre-spraying, pre-spraying layer heat treatment, continuous spraying and annealing treatment. By means of the vacuum spraying treatment technology used for aluminum profile machining, heat treatment is conducted on a thin metal coated layer generated on the surface of an aluminum profile, an aluminum and coated metal alloy layer is formed between the surface of the aluminum profile and a coated metal layer to serve as a transition layer, and the bonding firmness degree of aluminum and coated metal is improved; in the alloy layer generation process, ultrasonic waves areused for blowing a molten liquid aluminum layer and liquid coated metal atoms, mutual merging between the liquid aluminum layer and the coated metal atoms is promoted, and the dispersing uniformity of alloy particles is better improved; and due to heating, ultrasonic treatment and two-stage annealing in the subsequent continuous spraying process, the coated metal dispersing uniformity is better improved, the generation number of air holes and cracks is reduced, and the bonding firmness degree of the coated layer and the aluminum profile is further improved.

Owner:董翠萍

A kind of automatic manufacturing method of footwear

InactiveCN105747384BConsistent glue volumeImprove the consistency of spray glue effectShoe gluingProduction lineEngineering

An automatic manufacturing method for footwear, using an automatic footwear production line to respectively complete the following steps: a. pairing of soles and uppers and preparation for loading materials; b. scanning the gluing areas of soles and uppers; c. Spray water on the gluing area of the sole and upper; d, dry the treated water on the sole and upper; e, spray glue on the gluing area of the sole and upper; f, spray the sole and upper The glue on the shoe is dried; g, the manual pressing of the sole and the upper. The present invention takes six pictures at the same time through the cameras in all directions, and analyzes them by computer software, thus reducing the production cost of the three-dimensional scanning mechanism and ensuring a certain accuracy, especially in the area where the shoe surface is sprayed. Under the premise of the accuracy of each position parameter, the scan time can be greatly reduced.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

Package method for plane solar reflector provided with strip metal connector

The invention relates to a package method for a plane solar reflector provided with a strip metal connector. The package method comprises the following steps: (1) conveying; (2) plasma excitation for a paint coat; (3) gluing in a preset position on an adhesion surface of the strip metal connector or a paint coat of the plane reflector; (4) installation of the strip metal connector, that is, the strip metal connector is tightly clamped by a clamp to place the strip metal connector, with the adhesion surface downwards, in the preset position on the paint coat of the plane reflector; (5) flatness detection, that is, the height difference of left and right sides of the strip metal connector is detected; (6) package, that is, plane solar reflectors qualified in the flatness detection are sequentially packaged. The package method has the benefits that pollutants on the paint coat can be effectively removed, and the adhesion firmness degree of the plane solar reflector and the strip metal connector is improved; the package process is full-automatic, the efficiency is high, and the labor is saved; the strip metal connector is provided with a bolt hole for the connection with a bracket, is convenient to mount with the bracket, and is easy to dismount and maintain.

Owner:浙江大明玻璃有限公司

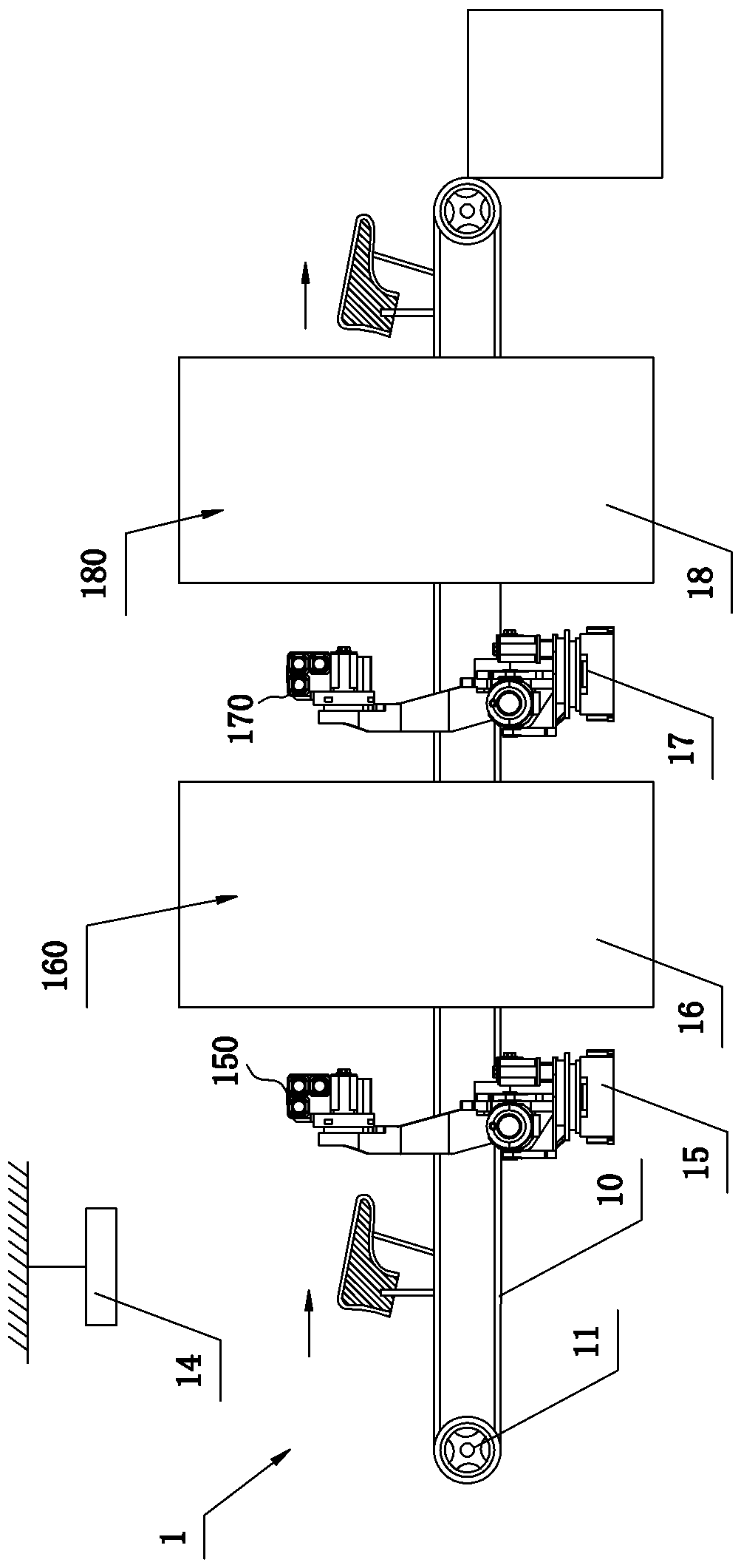

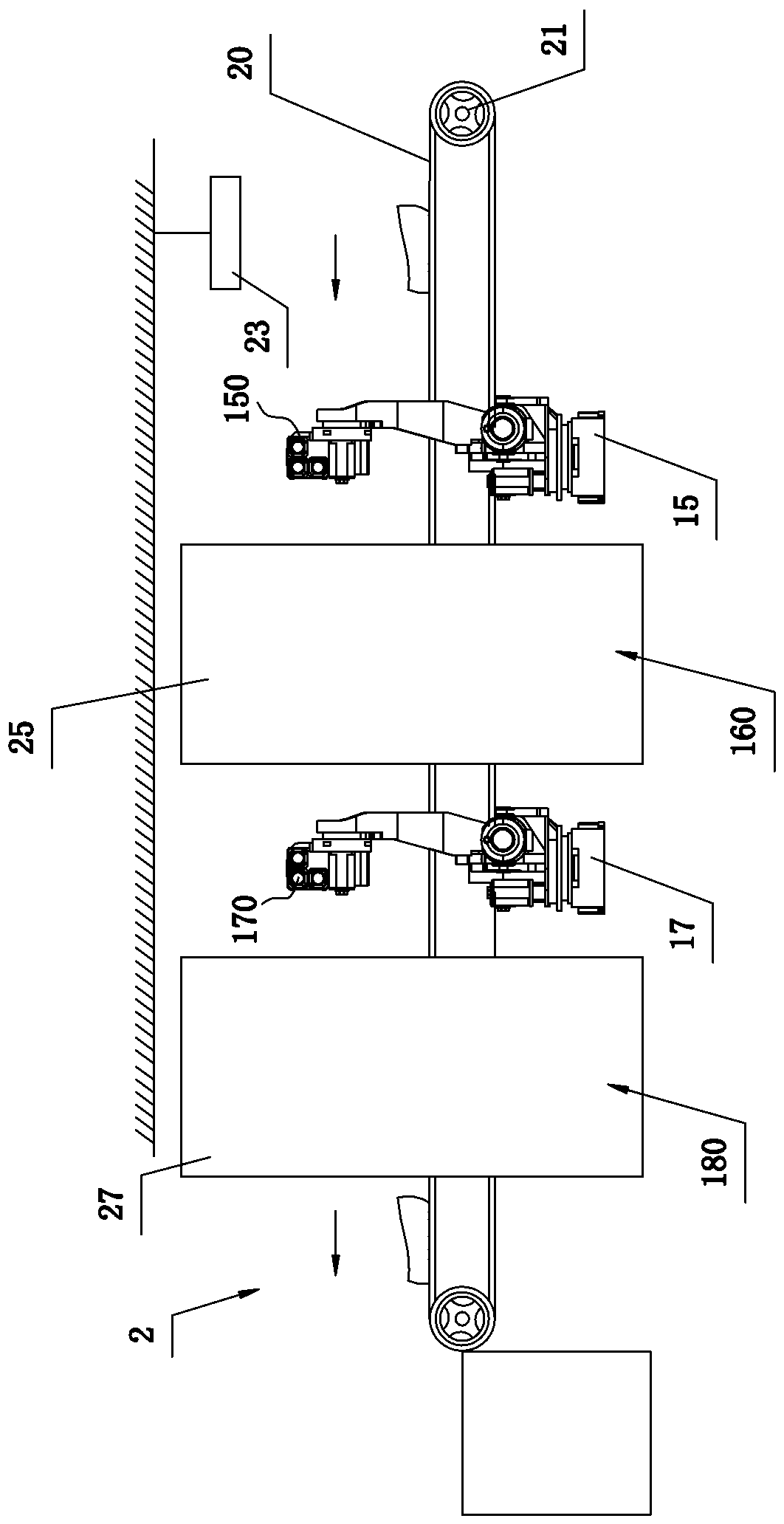

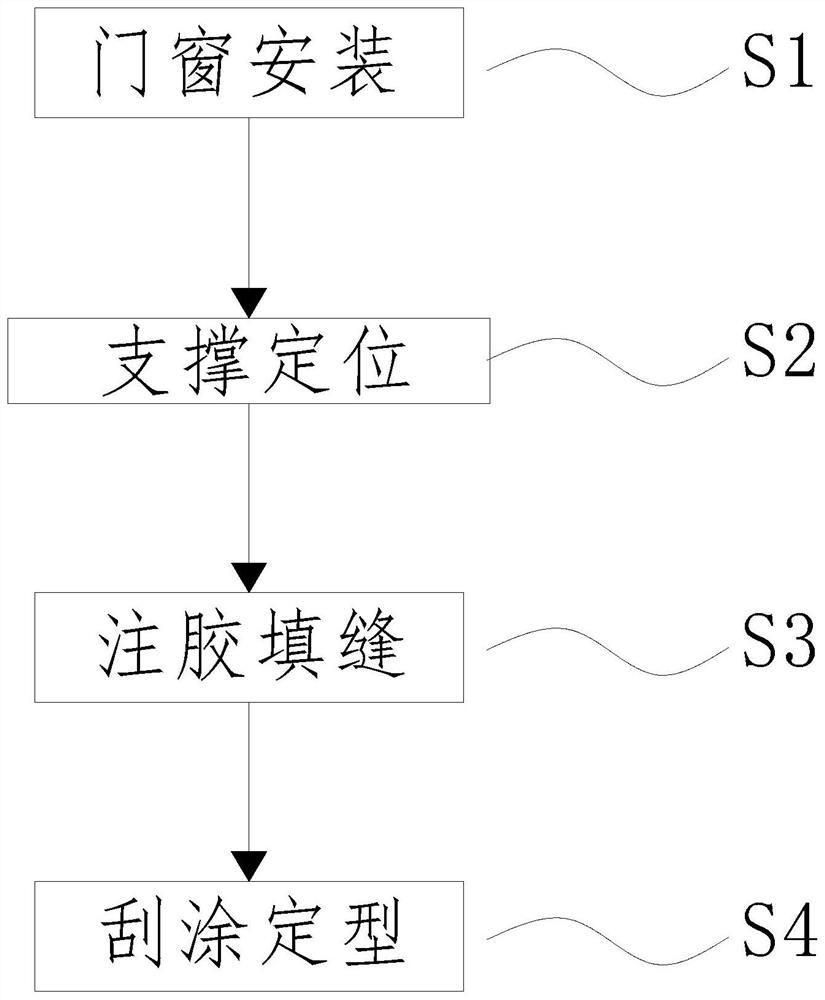

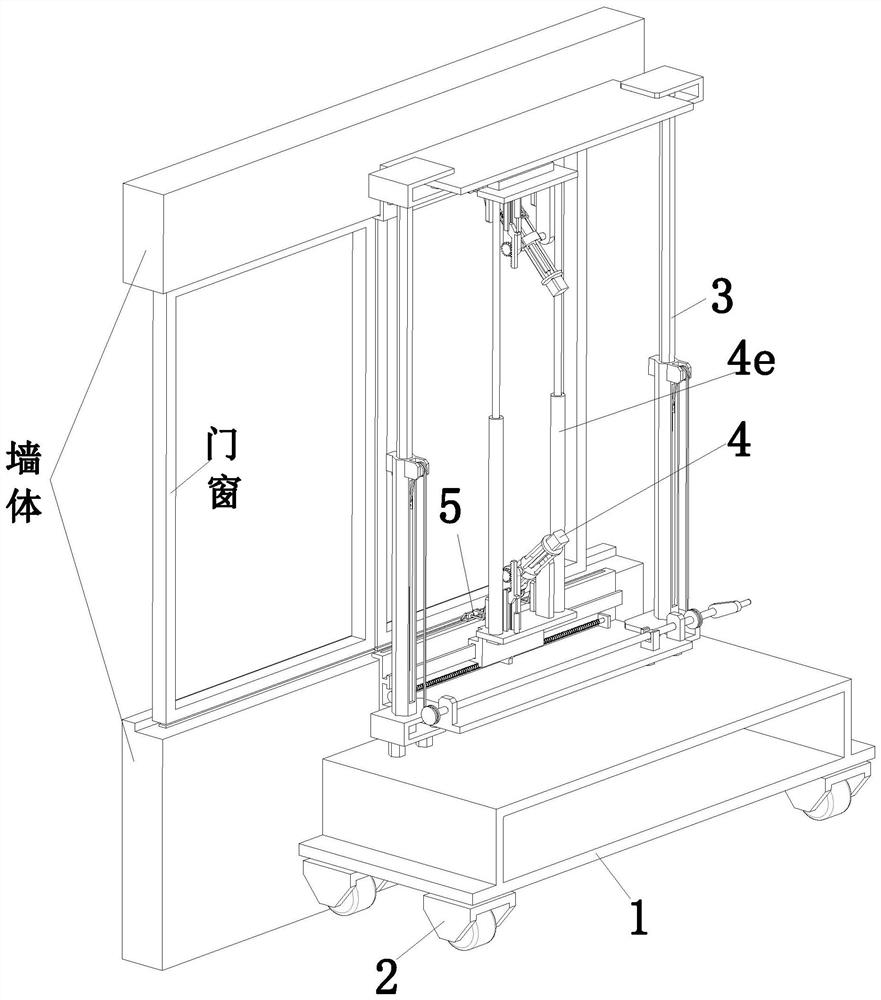

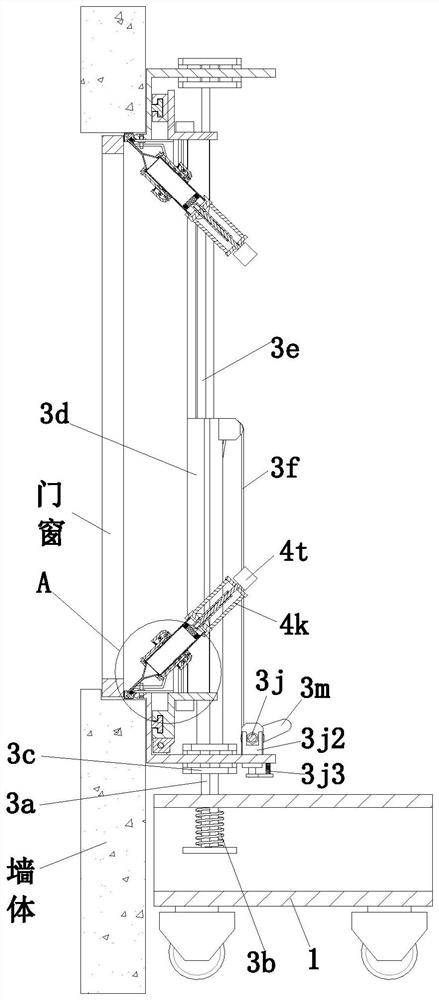

Method for filling and repairing building door and window mounting gaps by using gap filling glue

InactiveCN113250418AEasy to moveReduces the likelihood of a hard crashFrame fasteningAdhesive glueStructural engineering

The invention relates to a method for filling and repairing building door and window mounting gaps by using gap filling glue. A device for filling and repairing the building door and window mounting gaps by using the gap filling glue is used and comprises a moving frame, universal wheels, a positioning mechanism, a gap filling mechanism and a blade coating mechanism. The method for filling and repairing the building door and window mounting gaps by using the gap filling glue can solve the problems that in the process of filling and repairing building door and window mounting gaps with the gap filling glue, different height changes of the upper side and the lower side of the door and window mounting position are difficult to adapt, the included angle between the glue outlet position of glue and the door and window mounting gaps is difficult to keep consistent, the extrusion uniformity of the glue at the door and window gap positions is difficult to control, secondary pollution to surrounding wall surfaces is caused by excessive extrusion of the glue, dust removal treatment is more difficult to carry out on the mounting gaps before the glue is filled, and the filled glue is scraped, spread, dried and cooled quickly and the like are solved.

Owner:席灵军

Space-saving footwear automation production line and footwear automation manufacturing method

InactiveCN104161354BConsistent glue volumeImprove the consistency of spray glue effectShoemaking devicesProduction lineFixed frame

An automatic footwear production line with using space saved comprises an automatic vamp glue applying device and an automatic sole glue applying device, wherein the automatic vamp glue applying device and the automatic sole glue applying device are vertically arranged and adjacent to each other, the automatic vamp glue applying device comprises a first conveying belt, a first driving assembly and a first automatic glue spraying control assembly, the first automatic glue spraying control assembly comprises a three-dimensional scanning mechanism, a first treating water drying mechanism, a first glue drying mechanism and a first multi-station hoisting manipulator device, the first multi-station hoisting manipulator device comprises a controller, a first six-freedom-degree manipulator, a first transverse-movement control mechanism, a first spraying gun and a second spraying gun, and the first transverse movement control mechanism comprises a first fixing frame, a first guiding assembly, a first moving table and a first transmission assembly. Due to the automatic footwear production line, it can be guaranteed that the amount of glue sprayed to all the portions of a vamp tends to be consistent, waste of glue is greatly reduced, consistency of the glue spraying effect of vamps is improved, then, it is guaranteed that firmness degree of subsequent adhering between vamps and soles is improved, the service life of footwear is prolonged, and quality of footwear is improved.

Owner:BLACK GOLD STEEL AUTOMATION TECH FUJIAN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com