Doping and coating method, method for modifying ternary positive electrode material by adopting same and application

A positive electrode material and coating technology, which is applied in the field of material preparation and modification, can solve the problems of high temperature of doping and coating, defects of uniformity and adhesion of coating, and weakening of doping and coating effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

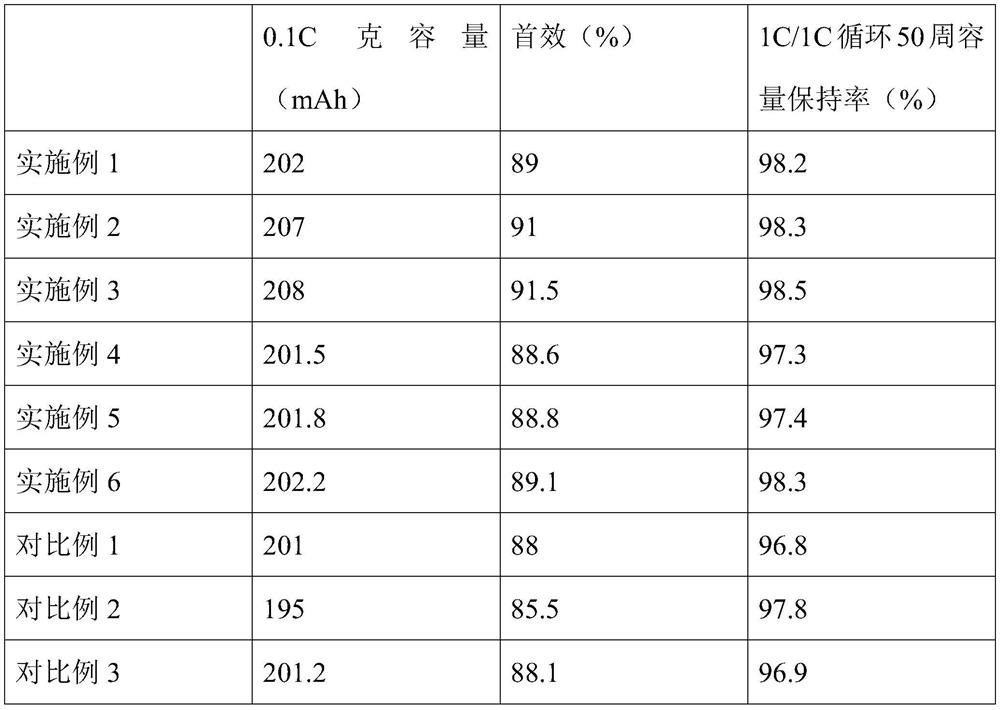

Examples

Embodiment 1

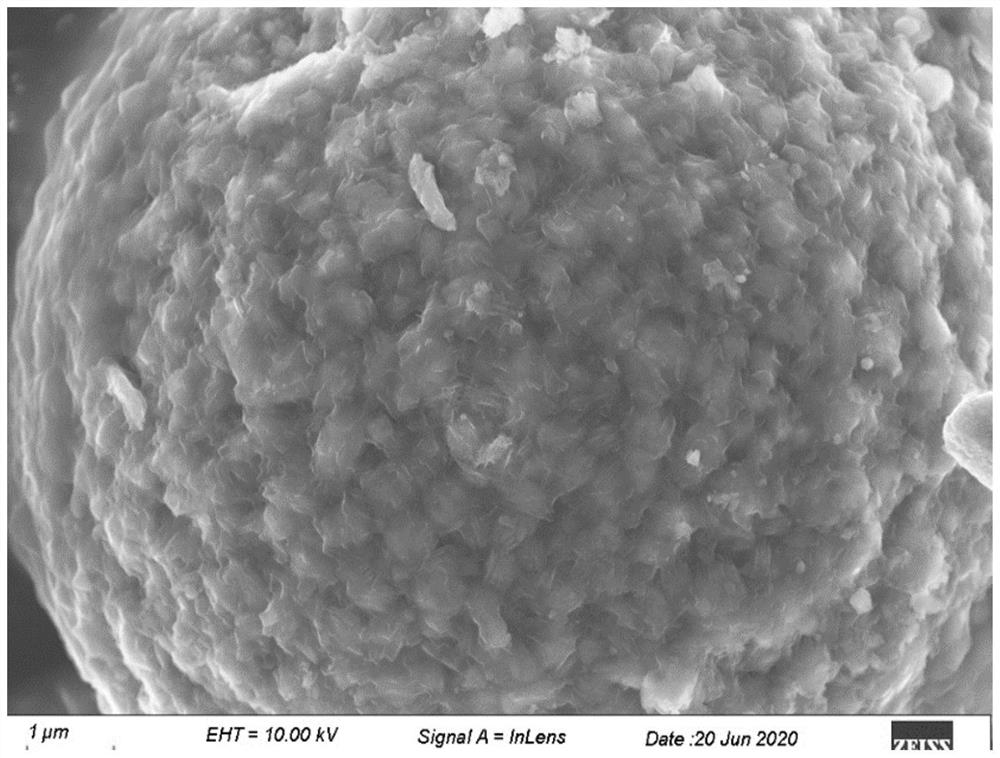

[0064] This embodiment provides a modified ternary positive electrode material, the modified ternary positive electrode material includes an Al-doped nickel-cobalt-manganese inner core, and a cladding layer coated on the surface of the inner core, in the cladding layer Contains the coating element Al.

[0065] This embodiment also provides a method for preparing the above-mentioned modified ternary positive electrode material, comprising the following steps:

[0066] ① Premixing: Premixing is carried out according to the weight ratio of additive and co-solvent 1:2, and premixing is carried out in a high-speed mixer for 10 minutes.

[0067] In this embodiment, the additive is aluminum oxide, and the cosolvent is a mixture of sodium hydroxide, lithium carbonate, and potassium chloride in a molar ratio of 1:1:1. Mixing molten salt can optimize the melting temperature, reduce the content of impurity elements, and optimize the cost structure of molten salt.

[0068] ②Pre-sinterin...

Embodiment 2

[0074] This embodiment provides a modified ternary positive electrode material, the modified ternary positive electrode material includes a Ti-doped nickel-cobalt-manganese inner core, and a coating layer coated on the surface of the inner core, in the coating layer Contains the covering element Ti.

[0075] This embodiment also provides a method for preparing the above-mentioned modified ternary positive electrode material, comprising the following steps:

[0076] ① Premixing: Premixing is carried out according to the weight ratio of additive and co-solvent 1:5, and premixing is carried out in a high-speed mixer for 10 minutes.

[0077] In this embodiment, the additive is titanium dioxide, and the cosolvent is a mixture of sodium chloride, lithium hydroxide, and potassium fluoride in a molar ratio of 2:1:0.2. Mixing molten salt can optimize the melting temperature, reduce the content of impurity elements, and optimize the cost structure of molten salt.

[0078] ②Pre-sinteri...

Embodiment 3

[0084] This embodiment provides a modified ternary positive electrode material, the modified ternary positive electrode material includes an NCM811 core, and a cladding layer coated on the surface of the NCM811 core, and the cladding layer contains the cladding element Ti , Al and P.

[0085] This embodiment also provides a method for preparing the above-mentioned modified ternary positive electrode material, comprising the following steps:

[0086] ① Pre-mixing: Pre-mixing is carried out according to the weight ratio of additives and co-solvents of 1:10, and pre-mixing is carried out in a high-speed mixer for 10 minutes.

[0087] In this embodiment, the additive is titanium dioxide, aluminum oxide, ammonium dihydrogen phosphate (molar ratio 1.7:0.15:3.0), and the cosolvent is sodium chloride, lithium hydroxide, and potassium bromide according to the molar ratio of 1:2:0.1. mixture. Mixing molten salt can optimize the melting temperature, reduce the content of impurity element...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com