Patents

Literature

36results about How to "Reduce the amount of glue applied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sound absorption and vibration reduction polyester composite cotton and preparation method of sound absorption and vibration reduction polyester composite cotton

InactiveCN103074736ATo achieve the purpose of noise reductionExtended propagation pathNon-woven fabricsMetallurgyPolyester composite

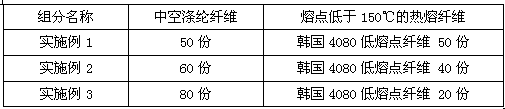

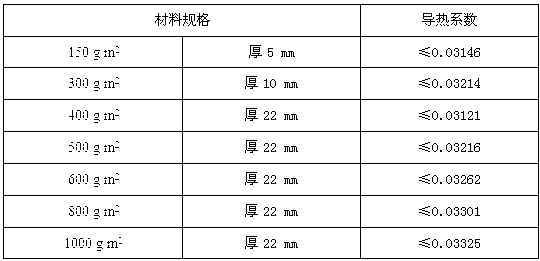

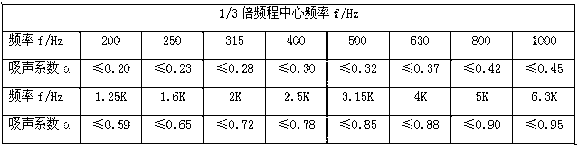

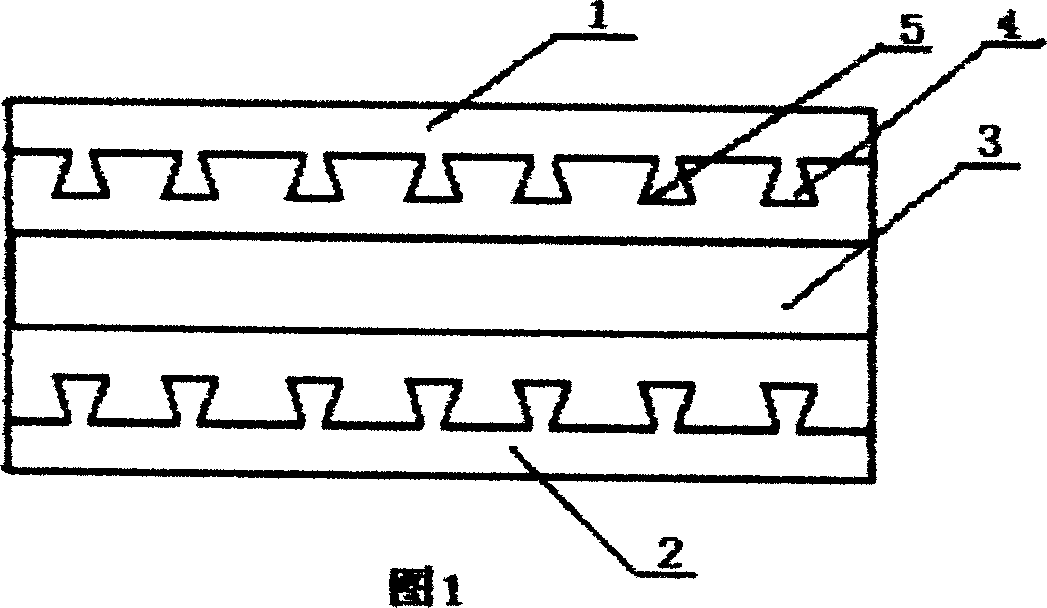

The invention discloses sound absorption and vibration reduction polyester composite cotton, which is formed by mixing 50 percent to 80 percent of hollow polyester fibers with 20 percent to 50 percent of meldable fibers with the melting point lower than 150 DEG C through being metered by the mass percent. The sound absorption and vibration reduction polyester composite cotton disclosed by the invention has the advantages that the weight is light, the environment is protected, the composite cotton is nonflammable, the heat conductivity coefficient is small, sound absorption, sound isolation, vibration reduction and water resistance are realized, the maintenance is convenient, the secondary recovery can be realized, the production quality is stable, and the likes. Meanwhile, the invention also discloses a preparation method of the sound absorption and vibration reduction polyester composite cotton.

Owner:WUHU HUANRUI AUTO INTERIOR DECORATION

Environmental-protection decorative composite board and its making method

InactiveCN1966906AHigh strengthImprove flatnessCovering/liningsBuilding componentsEngineeringSurface plate

Owner:董铁壁

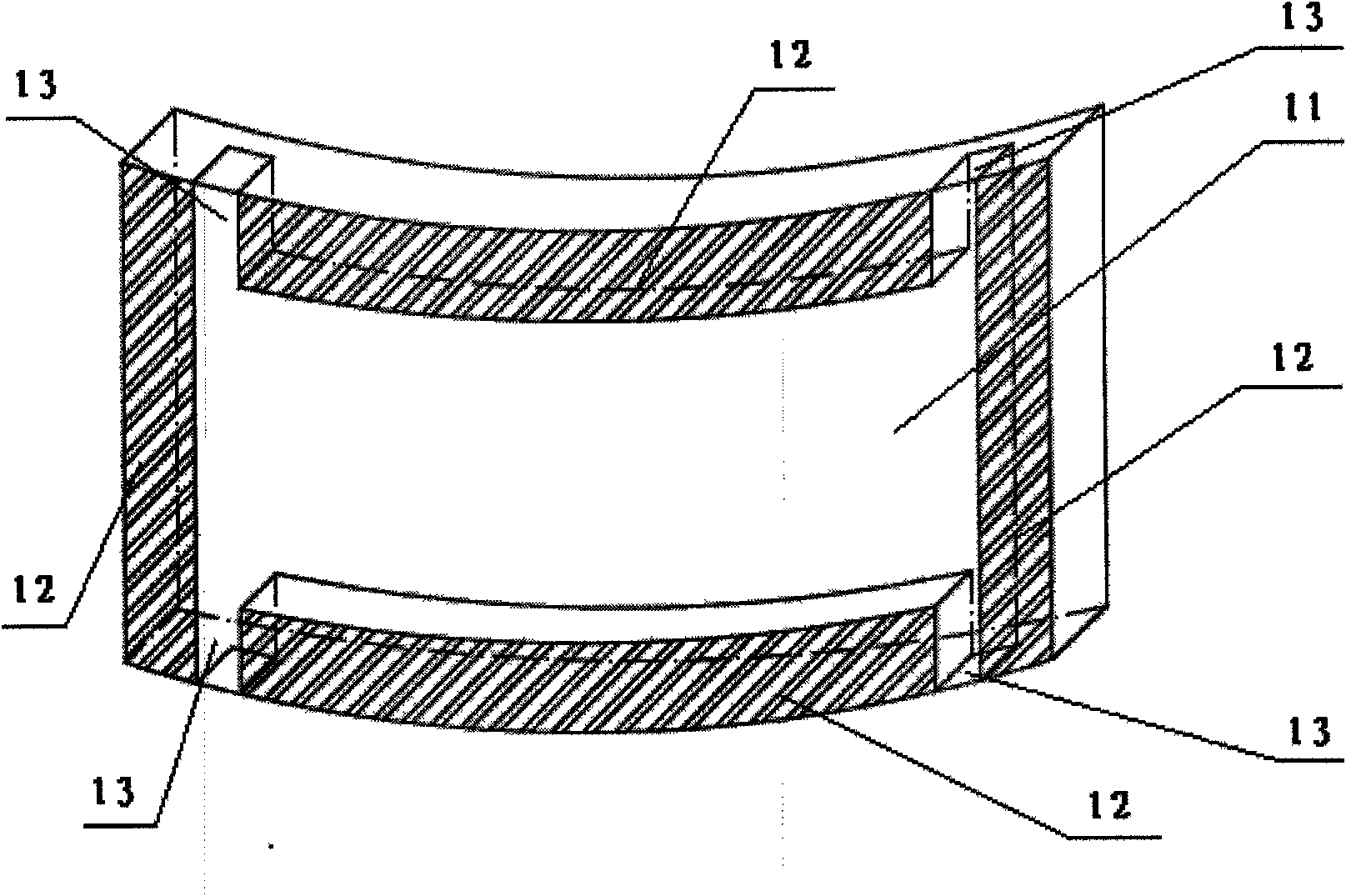

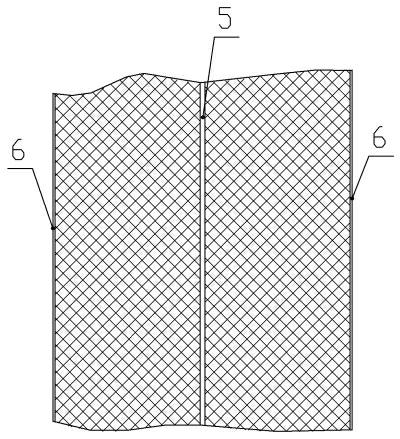

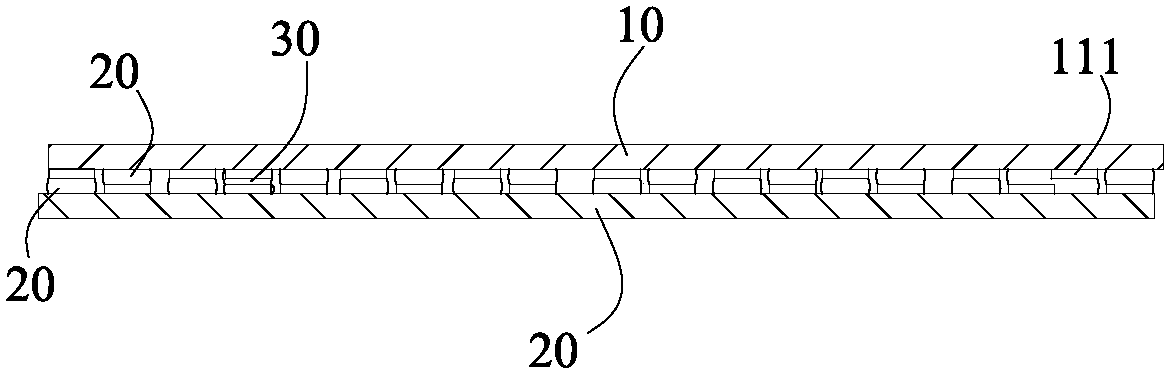

Sub-rail bamboo and wood composite heightening railroad tie plate for concrete sleeper and manufacture method thereof

ActiveCN101818468AHard woodReduce distortionRail fastenersPlant material mechanical workingSurface layerEngineering

The invention relates to a sub-rail bamboo and wood composite heightening railroad tie plate for a concrete sleeper and a manufacture method thereof, in particular to a sub-rail heightening railroad tie plate for a concrete sleeper and a manufacture method thereof, which solves the problems that the traditional heightening railroad tie plate can not simultaneously meet the requirements of planeness, rigidity, pressure resistance and wear resistance and the labor efficiency is low and the gluing amount is large in the manufacture process of the heightening railroad tie plate. The sub-rail bamboo and wood composite heightening railroad tie plate for a concrete sleeper comprises a core layer, an upper bamboo curtain surface layer and a lower bamboo curtain surface layer, wherein two sides of the core layer are respectively glued with the upper bamboo curtain surface layer and the lower bamboo curtain surface layer. The manufacture method of the heightening railroad tie plate comprises the following steps of: braiding bamboo woods on a braiding machine to form a bamboo curtain; gluing wooden materials, then assembling the wooden materials with the bamboo curtain, closing and ageing; and then hot forming a composite plate. The invention provides the heightening railroad tie plate with high planeness and rigidity as well as favorable pressure resistance and wear resistance. The adopted manufacture method improves the labor efficiency and saves the cost. The invention is used for regulating the horizontal height of the rail surface of a railroad, thereby ensuring the stable running of a train.

Owner:哈尔滨新星铁路垫板制造有限责任公司

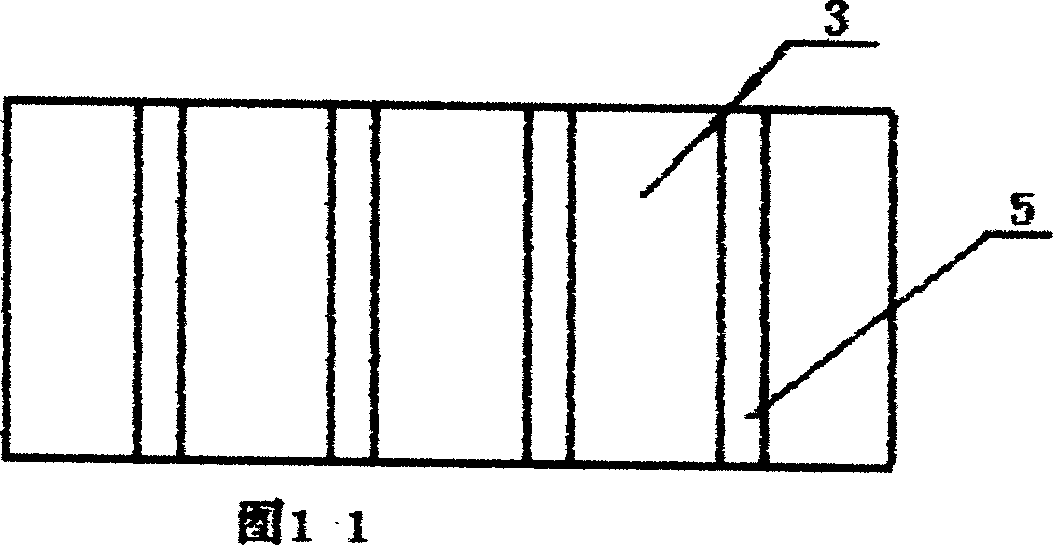

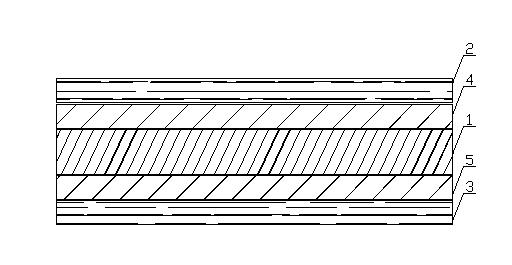

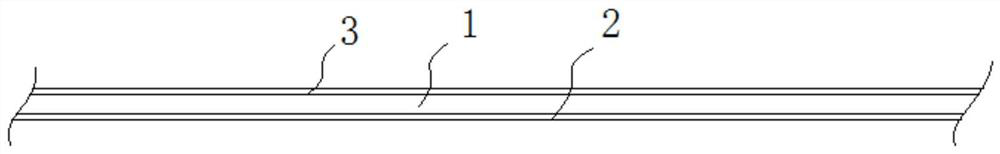

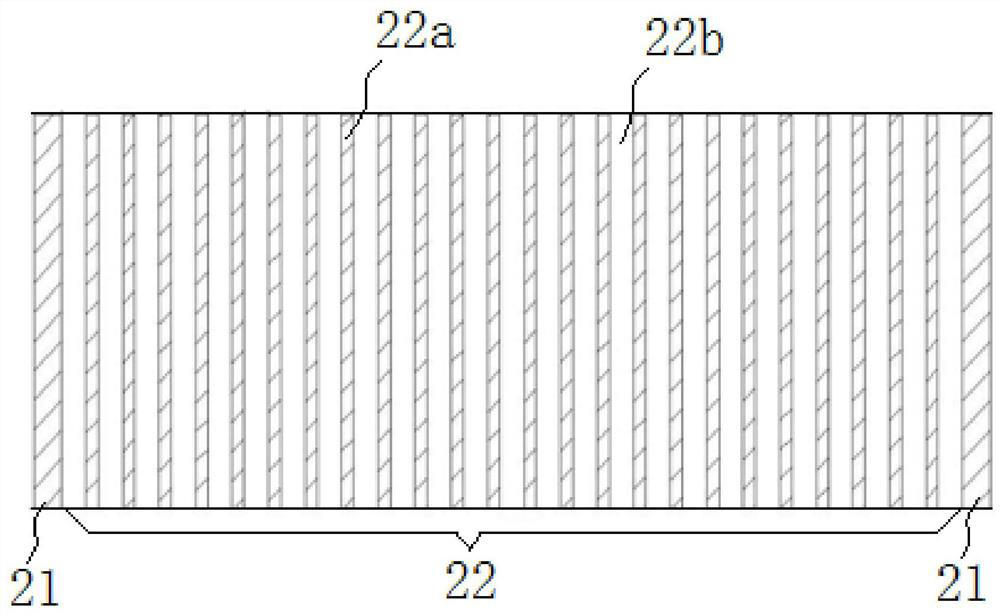

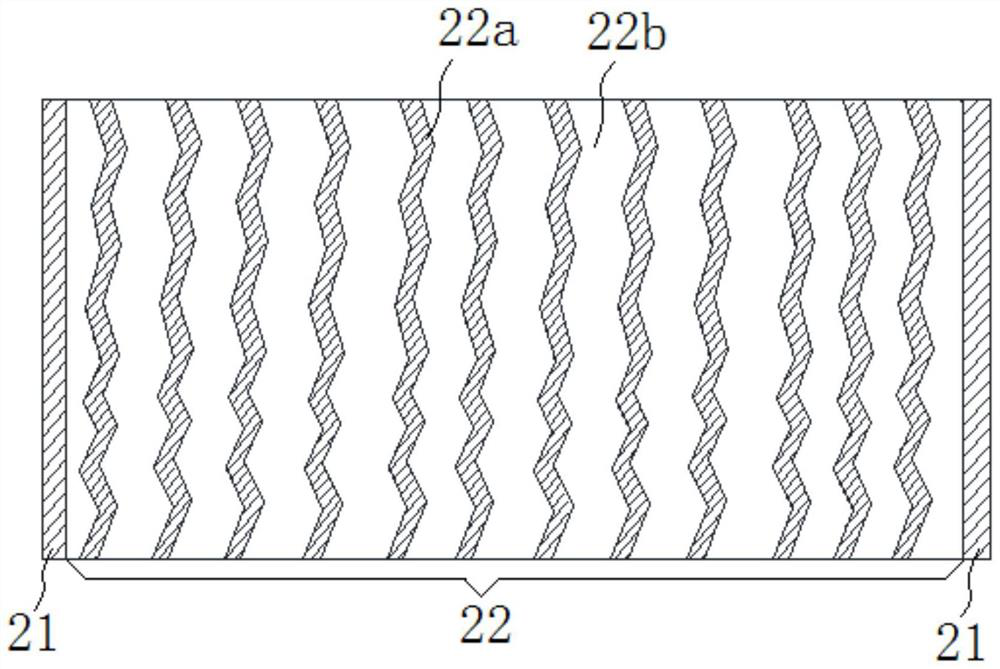

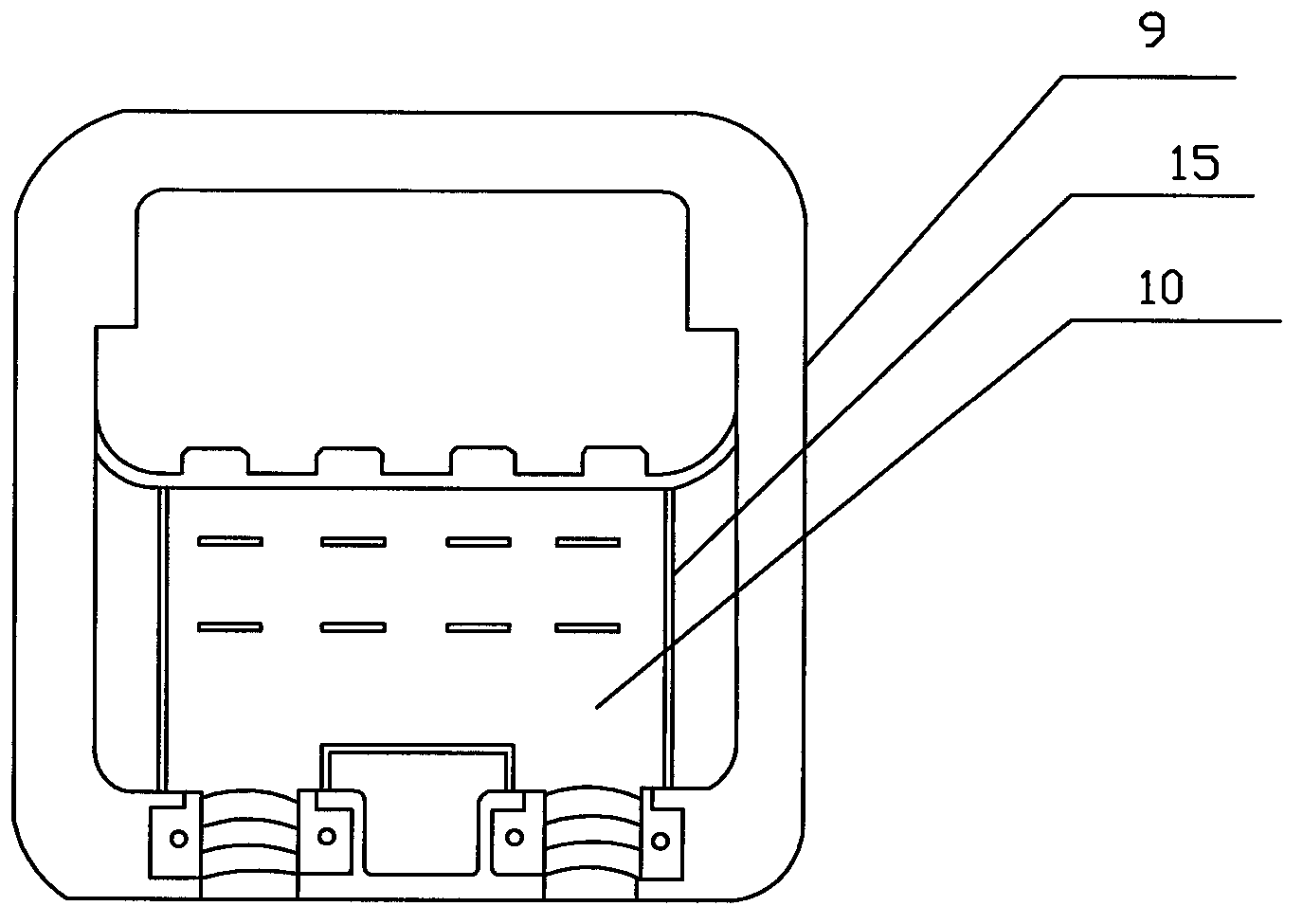

Label and package

InactiveCN111986555AImprove stiffnessReduce the amount of glue appliedStampsAdhesivesEngineeringMechanical engineering

The invention relates to a label and a package. The label comprises a substrate (1) and an adhesive layer (2) arranged on the first surface of the substrate (1); the adhesive layer (2) comprises a first adhesive part (21) which is arranged at the transverse first end of the substrate (1) and is used for connecting the transverse second end of the substrate (1), and a second adhesive part (22) which extends from the transverse first end of the substrate (1) to the transverse second end; the amount of glue applied per unit area of the second adhesive part (22) is smaller than the amount of glueapplied per unit area of the first adhesive part (21). According to the technical scheme, the gluing amount of the second gluing part (22) in the unit area is smaller than that of the first gluing part (21) in the unit area, and therefore the stiffness of a labeled object and the bonding firmness degree of the labeled object can be improved on the premise that the low gluing amount is guaranteed.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

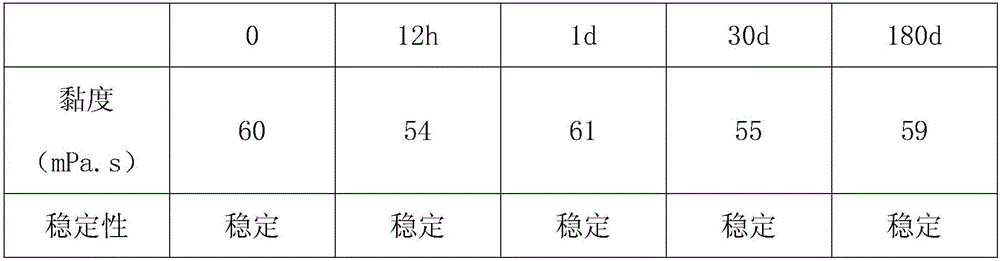

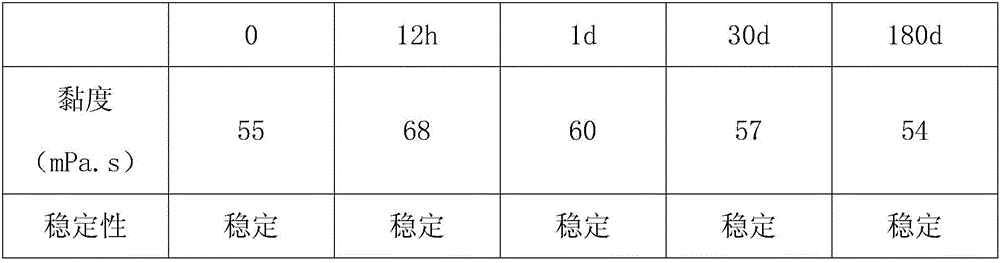

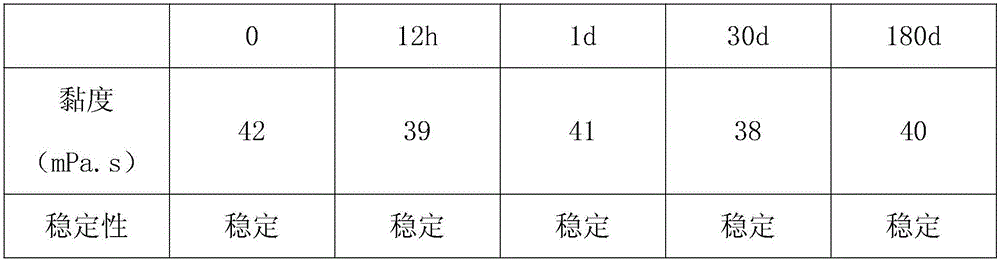

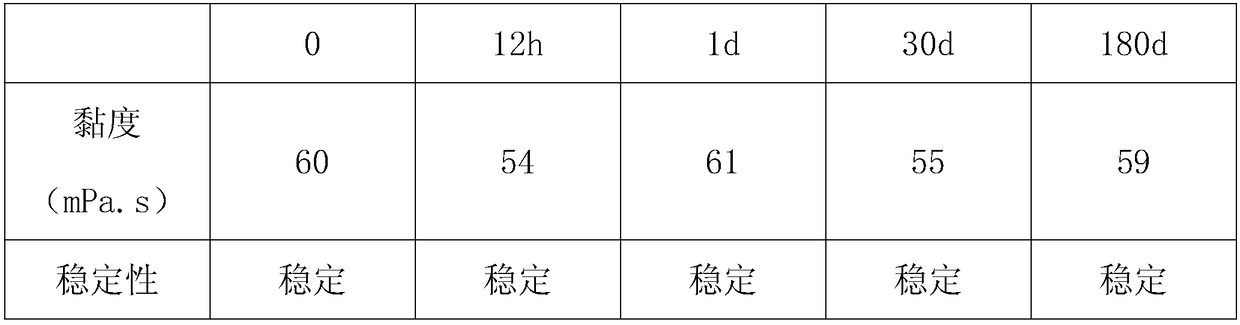

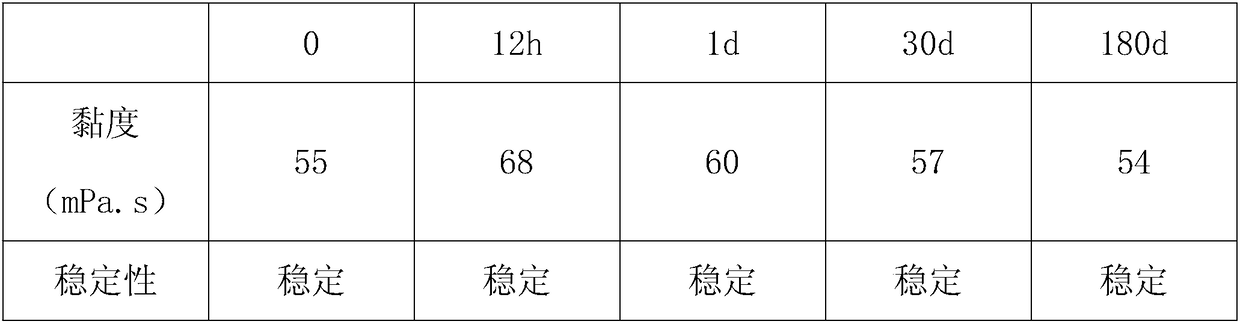

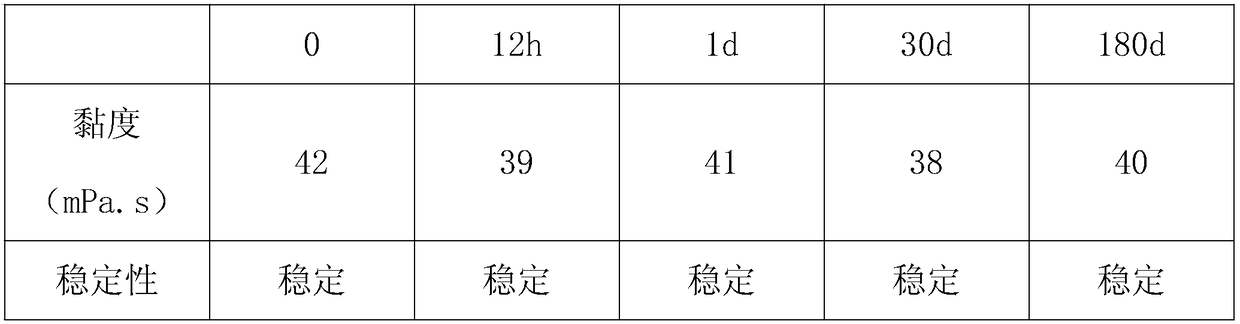

Tremella composite flocking adhesive

ActiveCN106085300ALow viscosityImprove stabilityMonocarboxylic acid ester polymer adhesivesPolysaccharide adhesivesAdhesiveFiltration

The invention discloses a tremella composite flocking adhesive. A preparation method of the adhesive includes the steps: preparing acrylic composite solution for standby application; weighing 500g of dry tremella, placing the dry tremella in 10L of 0.3% mycose solution, standing for 18-20 hours, taking out the thoroughly soaked tremella, uniformly grinding the tremella, weighing 100g of the grinded soaked tremella, treating the grinded soaked tremella in 1L of calcium chloride boiling solution with mass concentration 60% for about 50-80 minutes until dissolving most of the grinded soaked tremella, stirring the grinded soaked tremella by a glass rod during treatment, and coarsely extracting the mixed solution by wick filtration to obtain tremella extracting solution; mixing the acrylic composite solution and the tremella extracting solution well, and finally discharging and packaging a finished product.

Owner:蚌埠行时知识产权运营有限公司

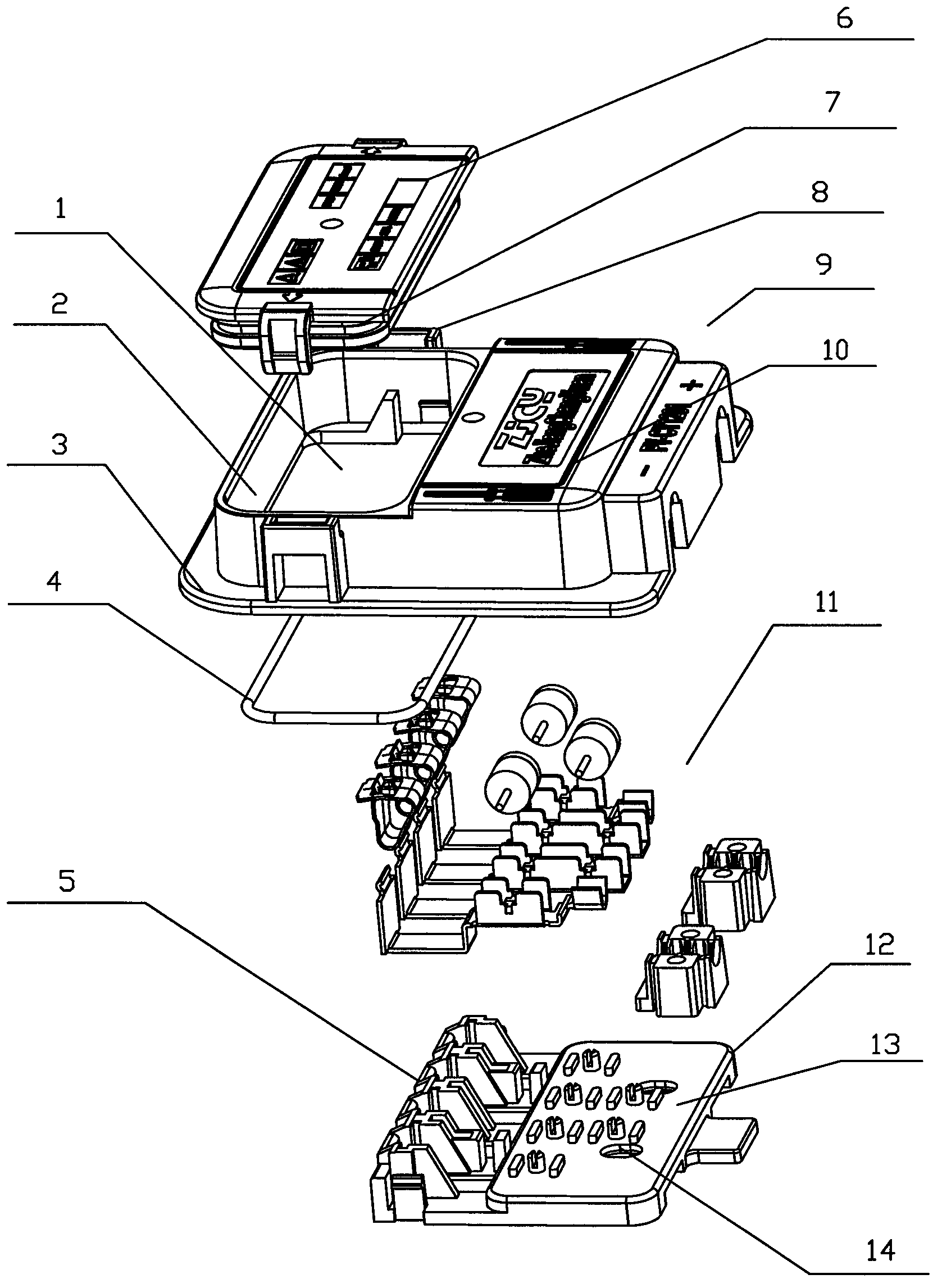

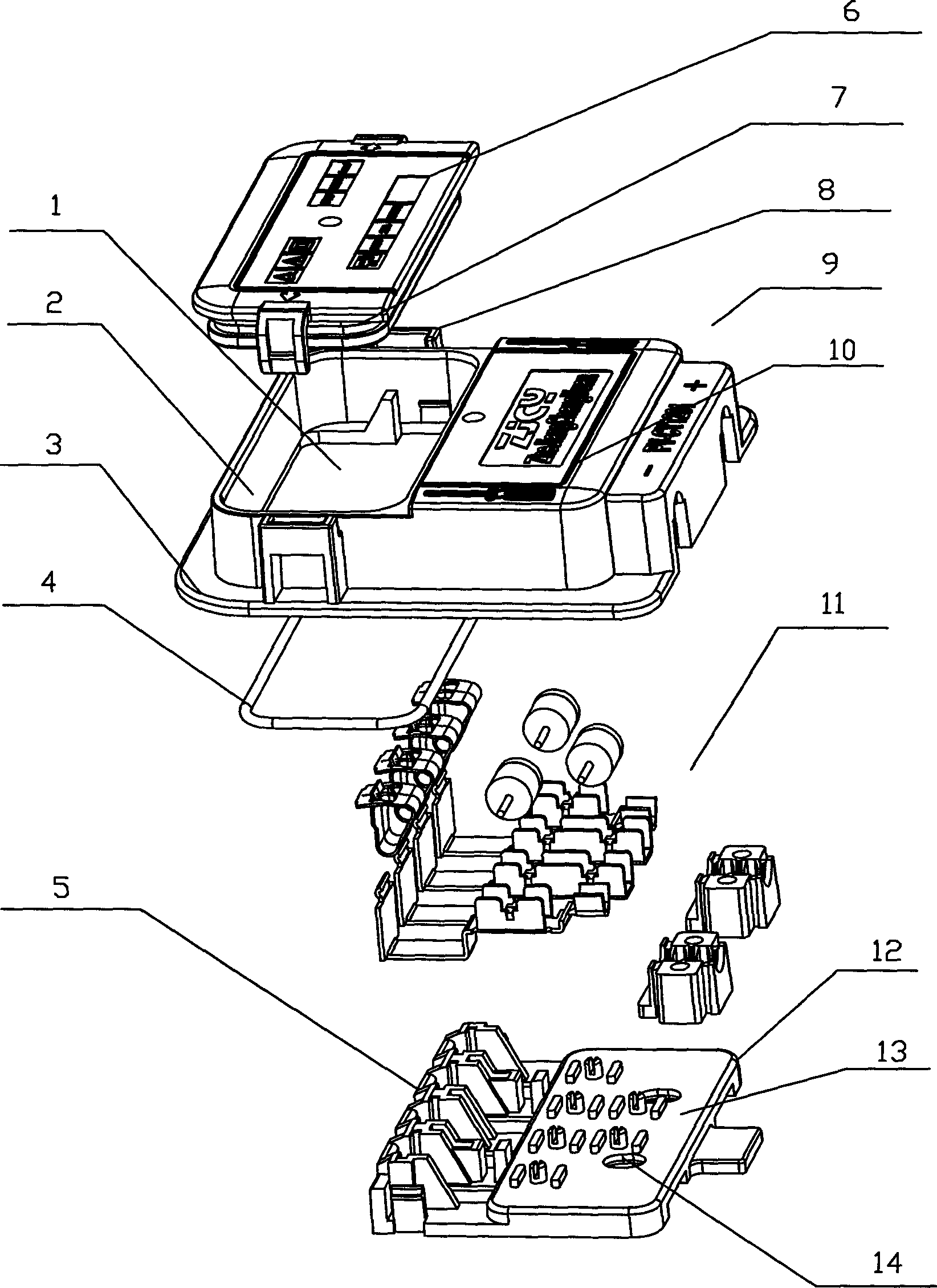

Novel solar photovoltaic junction box

InactiveCN102694045AImprove securityImprove cooling effectPhotovoltaicsPhotovoltaic energy generationClosed loopEngineering

The invention relates to a novel solar photovoltaic junction box which comprises a box base and a box cover covered on the box base, wherein the box base is provided with a photovoltaic assembly; the box cover comprises an enclosure frame which is enclosed into a closed loop; the enclosure frame is provided with a skirt edge for smearing glue; the upper end of the enclosure frame is hollow and is a hollow end; the lower end of the enclosure frame is provided with a containing groove with a downward opening; the containing groove and the box base form a containing cavity together; the box base is clamped with one end of a bus bar so as to form a clamping end; the box base is connected with one end of a cable so as to form a cable end; the clamping end extends out of the containing groove; a second box cover is covered on the upper end of the hollow end; the box base is provided with an injection hole; and the injection hole is communicated with the outer part and the inner part of the containing cavity. According to the invention, glue can be poured through the injection hole, the junction box after glue pouring is beneficial to the heat radiation of a bypass diode, the power of the junction box and the circulated current are increased, and also the structure arrangement is reasonable, and the glue pouring amount is reasonable; and additionally, an insulation wall also greatly increases the safety of the junction box.

Owner:NINGBO CHUANGYUAN PHOTOVOLTAIC TECH

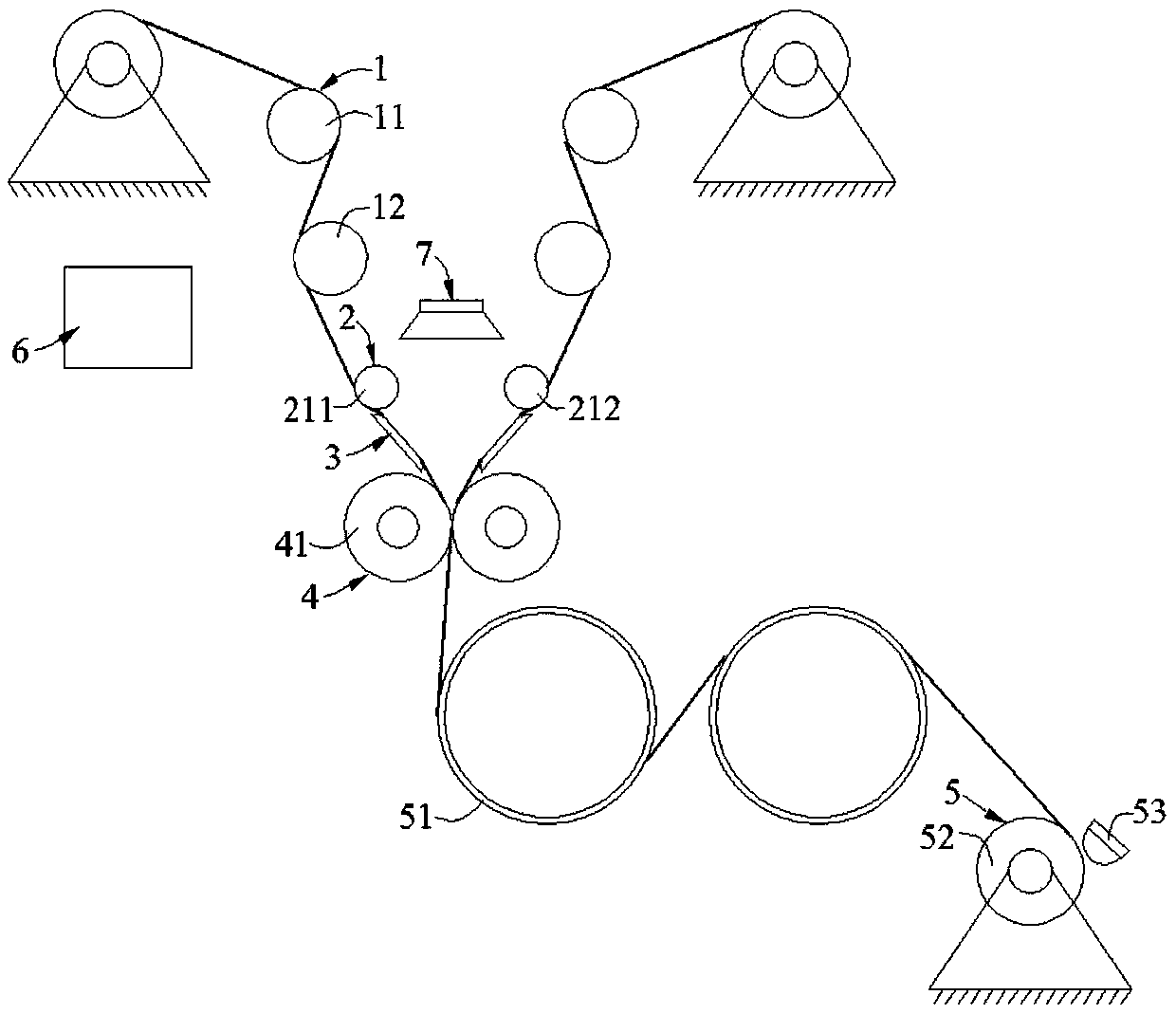

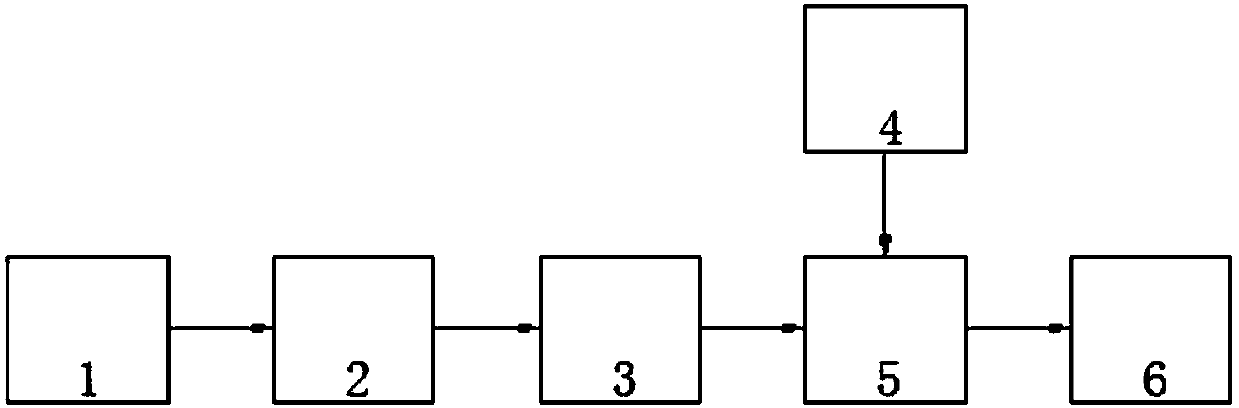

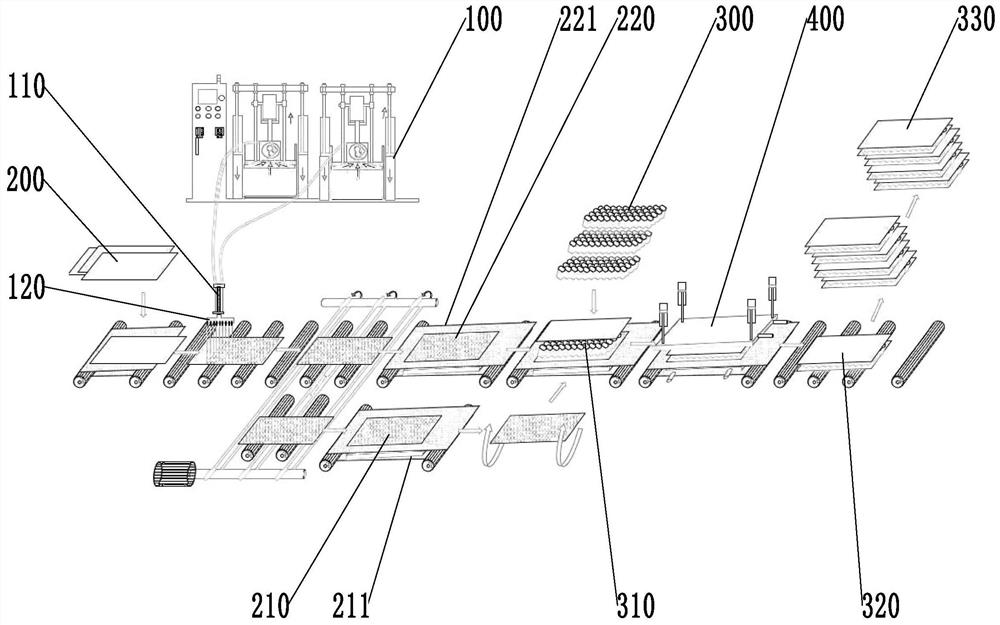

Garment cloth gluing and compounding device

InactiveCN109591433AAdhesive smoothPrecise positioningLiquid surface applicatorsLamination ancillary operationsUltimate tensile strengthMechanical engineering

The invention discloses a garment cloth gluing and compounding device. The garment cloth gluing and compounding device comprises cloth conveying devices, gluing devices, cloth neatening devices, compounding devices, a receiving device and a control device, wherein each cloth conveying device comprises a cloth conveying roller and an adjusting roller; each gluing device comprises a gluing roller and a glue tank; each gluing roller is hollow; a cylindrical glue feeding cylinder is arranged in each gluing roller; a plurality of glue inlets are formed in the surface of each glue feeding cylinder;the circumference surface of each gluing roller is coated with a coating layer; a plurality of arc protrusions which are arranged at equal intervals; a glue outlet is formed in the top end of each protrusion; the positions of the glue inlets are consistent with the positions of the protrusions; each cloth neatening device comprises an elastic sliding rod; positioning blocks are arranged on two sides of each elastic sliding rod; each compounding device comprises a pressing wheel; the receiving device comprises drying cylinders, a coiling roller and a static electricity removing rod; an ion fanis arranged in each drying cylinder. The garment cloth gluing and compounding device is capable of flatly bonding garment cloths, reducing the labor intensity, improving the garment cloth processing efficiency and ensuring that the garment cloths are beautiful and flat.

Owner:吴江市丝科服饰有限公司

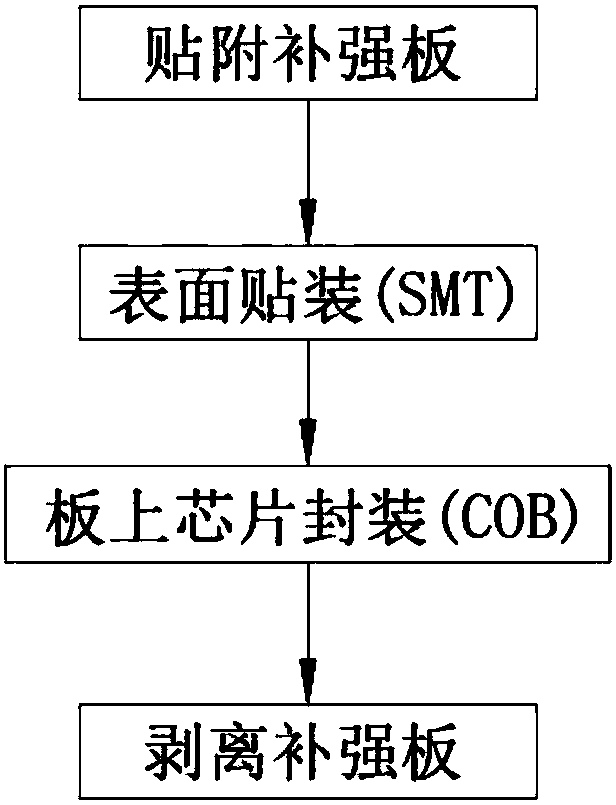

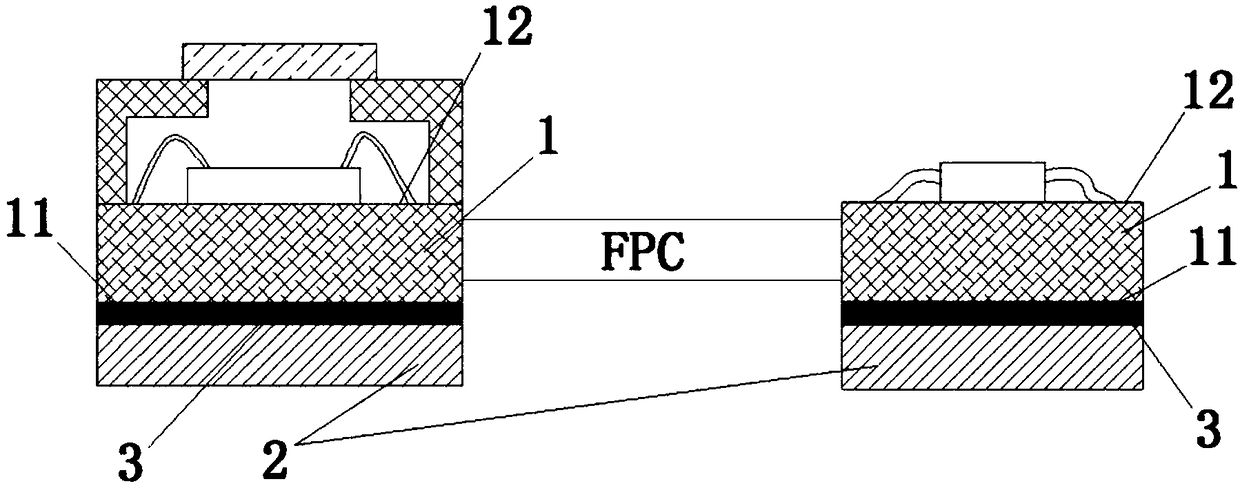

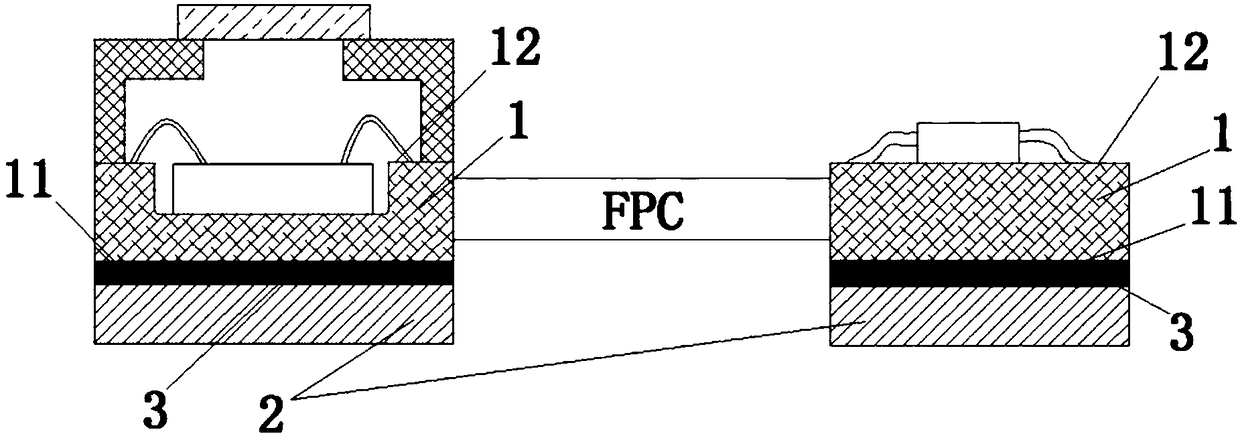

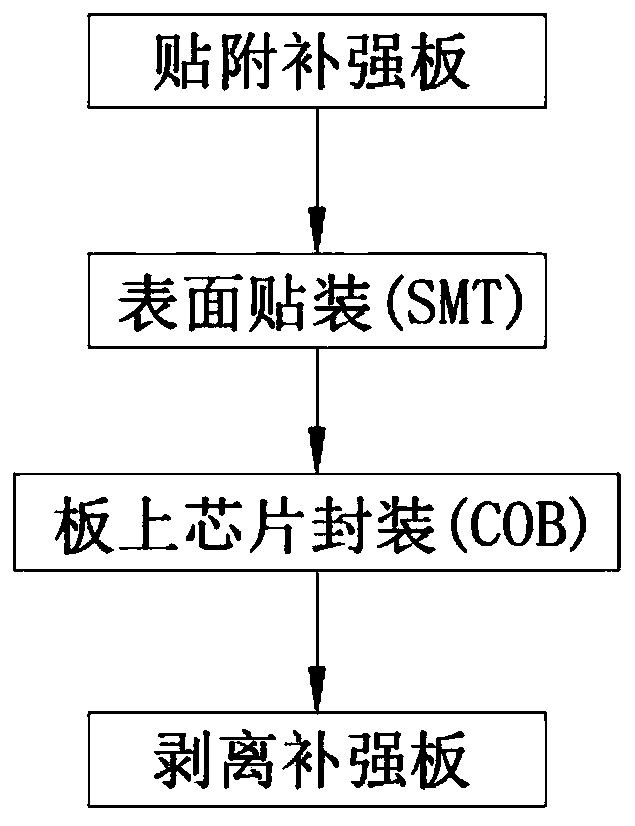

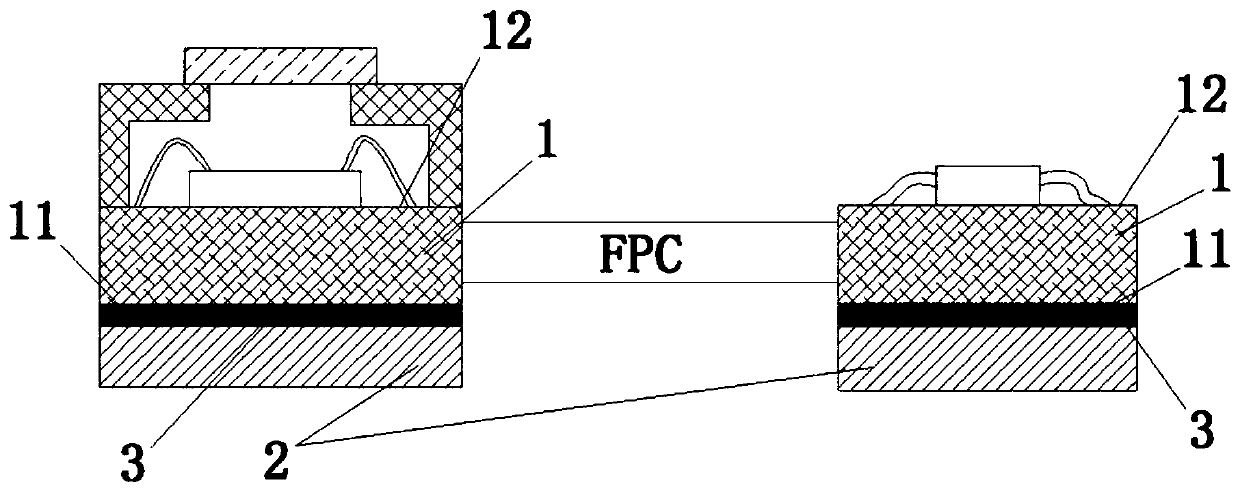

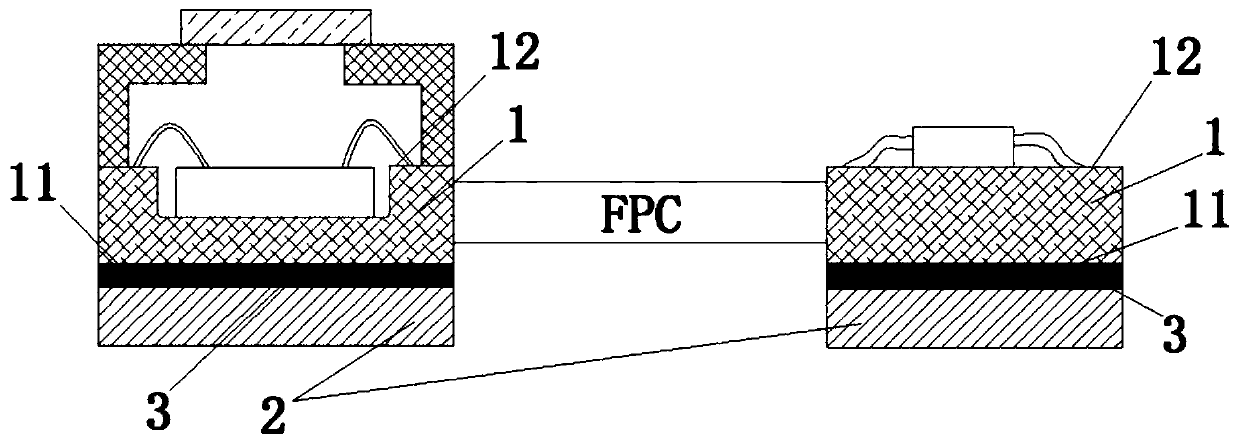

Circuit board procesing method

ActiveCN109041444AReduce the difficulty of strippingReduce workloadPrinted circuit assemblingPrinted circuit aspectsOn boardSurface mounting

The invention relates to a circuit board processing method, comprising: a) bonding a reinforcing plate on a first surface of the circuit board, wherein the area of the reinforcing plate is at least 85% of the area of the first surface of the circuit board, and in the range of 80 to 170 DEG C, the peeling strength between the first surface and the reinforcement plate is greater than 35.0 gf / mm; b)performing surface mounting (SMT) on the second surface of the circuit board; c) performing chip-on-board (COB) packaging on the second surface of the circuit board; and d) peeling the reinforcementplate from the first surface of the circuit board. According to the method of the invention, the deformation of the circuit board in the processing process can be effectively controlled. By effectively controlling the area ratio of the reinforcing board to the circuit board to be processed, the deformation of the circuit board can be avoided in the reflow soldering process, the area of the reinforcing board can be reduced, and the peeling workload and the peeling difficulty of the reinforcing board can be simplified and reduced.

Owner:NINGBO SUNNY OPOTECH CO LTD

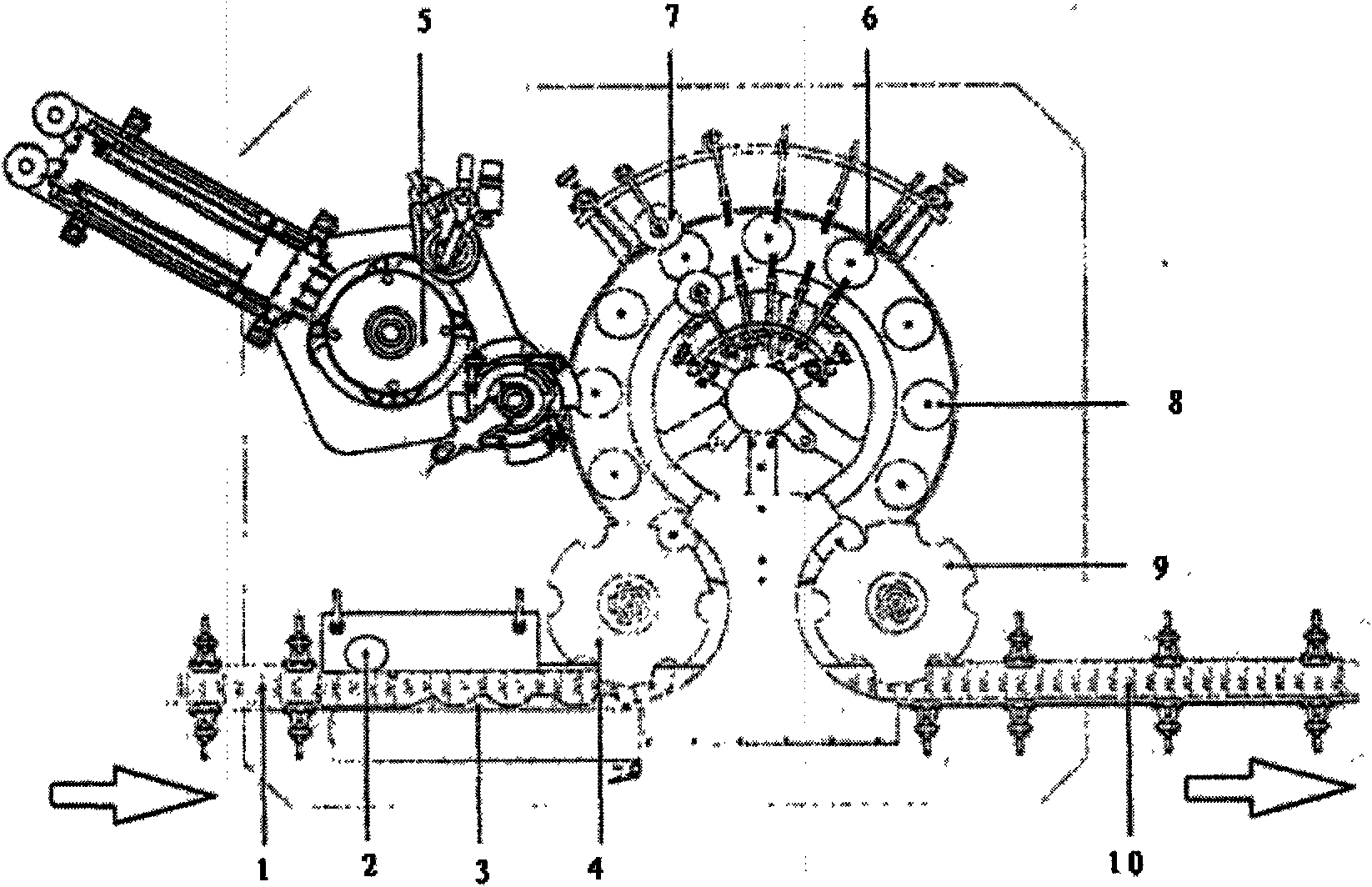

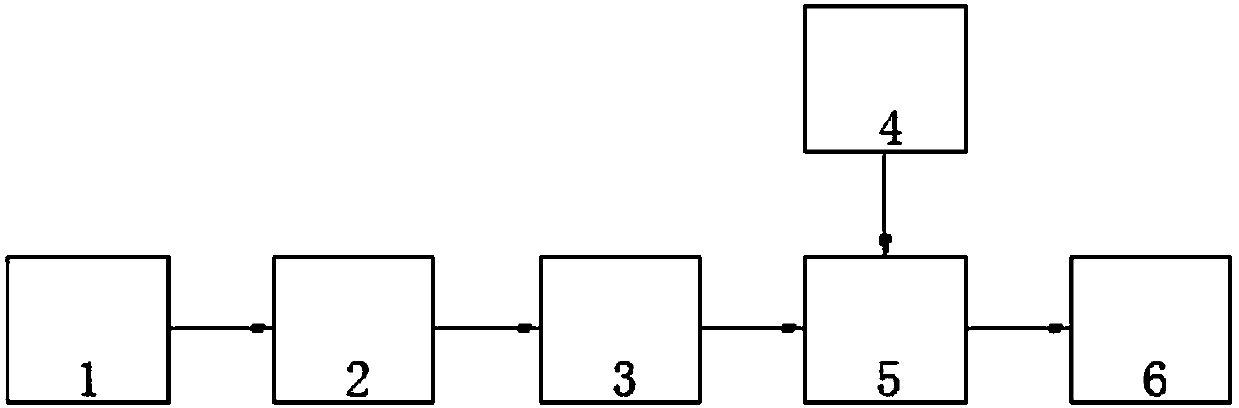

Environment-friendly handbag production line

ActiveCN108032554AHigh degree of automationQuality improvementBag making operationsPaper-makingProduction lineEngineering

The invention discloses an environment-friendly handbag production line. The environment-friendly handbag production line comprises a flexible printing device, a tailoring device, a bag body cylinder-forming device, a handlebar machine, a gluing forming device and a press. According to the manufacturing process of a handbag, the flexible printing device is located at the upper portion of the tailoring device, the tailoring device is located at the upper portion of the bag body cylinder-forming device, the bag body cylinder-forming device and the handlebar machine are located at the upper portion of the gluing forming device, and the gluing forming device is located at the upper portion of the press; the flexible printing device comprises a discharging mechanism, several printing mechanismsand a rolling mechanism, the discharging mechanism is located at the upper portions of the printing mechanisms, and the printing mechanisms are located at the upper portion of the rolling mechanism.The environment-friendly handbag production line is high in automated degree, glue and printing ink are saved, the production cost is lowered, two layers of handlebar bands are firmly pasted to handlebars and the bag body, and the quality of the handbag is guaranteed.

Owner:昆山金红凯包装制品有限公司

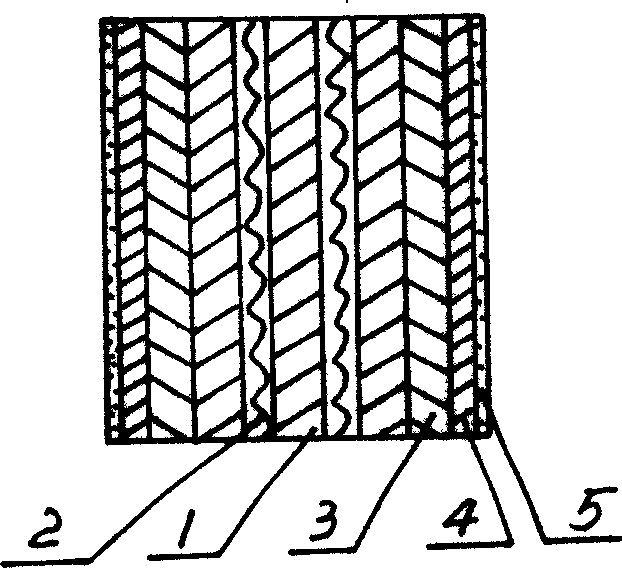

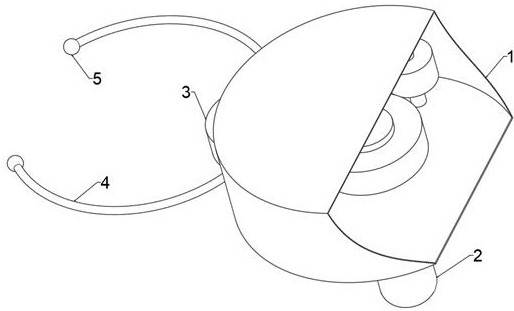

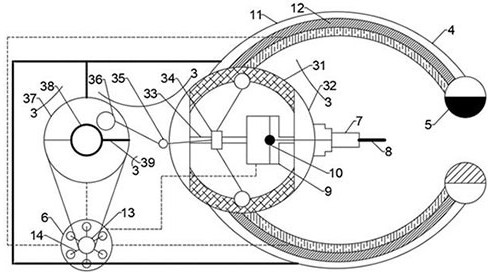

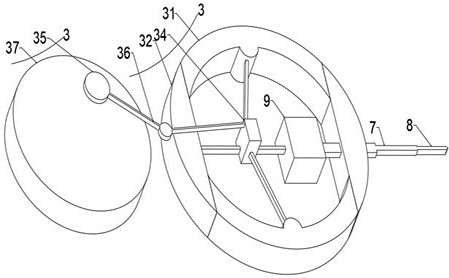

Toothed belt bottom cloth based on electromagnetic principle

InactiveCN108895076AReduce the amount of applicationFit tightlyLiquid surface applicatorsMaterial gluingEngineeringConveyor belt

The invention discloses a toothed belt bottom cloth based on an electromagnetic principle. The toothed belt bottom cloth based on the electromagnetic principle is characterized in that the toothed belt bottom cloth comprises a base; a conveyor belt is fixedly connected to the upper end surface of the base; two first support columns are in front-back symmetrical fixed connection on the upper end surface of the base with the conveyor belt as the center; a first glue block is fixedly connected between upper ends of the two first support columns; a drive space is disposed in the glue block; mobilespaces with the upper end wall communicated with the drive space are in left-right symmetrical arrangement in the lower end wall of the drive space with a transmission space as the center; the transmission space is communicated with the left and right mobile spaces; a support ring groove with the inner wall communicated with the mobile spaces is disposed in the column wall of the mobile spaces; adrive mechanism is disposed in the drive space. The toothed belt bottom cloth based on the electromagnetic principle has the advantages of having a simple structure and convenient operation, saving costs through cross-coating and saving the amount of glue while the glue is evenly glued, ensuring a close fit between the cloth and teeth through the cooperation of a pressing mechanism, and improvingprocessing quality.

Owner:程日鸿

Labeling device of labeler and working method thereof

ActiveCN101565110AReduce intensityReduce the amount of glue appliedLabelling machinesWrinkle skinWater based

A labeling device of a labeler is characterized in that a label palm of the labeling device is cut with a groove smaller than the outer edge of a label and the outer edge of the groove of the label palm is a lug boss edge as a gluing surface. The working method includes the steps of: (1) starting the label palm of the labeling device of the labeler; (2) gluing the label palm: coating a glue line only on the lug boss edge as the gluing surface and leaving no glue line in the groove of the label palm smaller than the outer edge of the label; and (3) cutting an open slot beneficial to flattening the label on the lug boss edge of the label palm, wherein the open slot has no glue line, serves as the adjusted quantity for flattening the adherence of the label, and leads the label to be neat and wrinkleless. The invention has the advantages that: 1. when the vacant depth of the label palm is less than 60 percent, water-based adhesive is easy to be deposited at the place; and the depth is more than 75 percent, the overall intensity of the label palm is reduced and the service life of the label palm does not exceed 2 months; 2. after slotted, the surface of the whole label is divided and in the drying process of the label, the internal stress of the paper is released, thus avoiding the phenomenon that a label wrinkles or foams; and (3) with the label palm of the invention being adopted, glue spread can be saved by over 50 percent for each label.

Owner:中粮粮油工业(荆州)有限公司

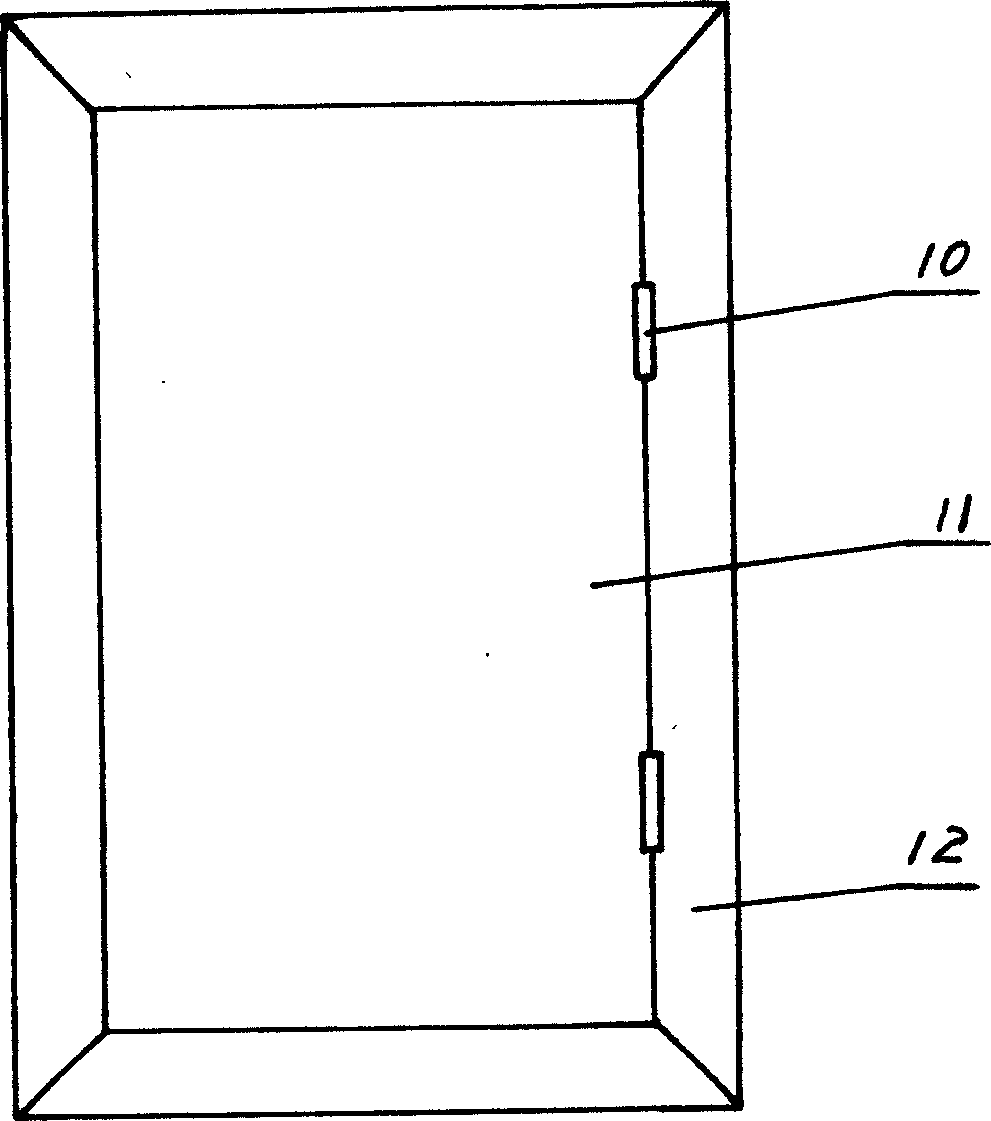

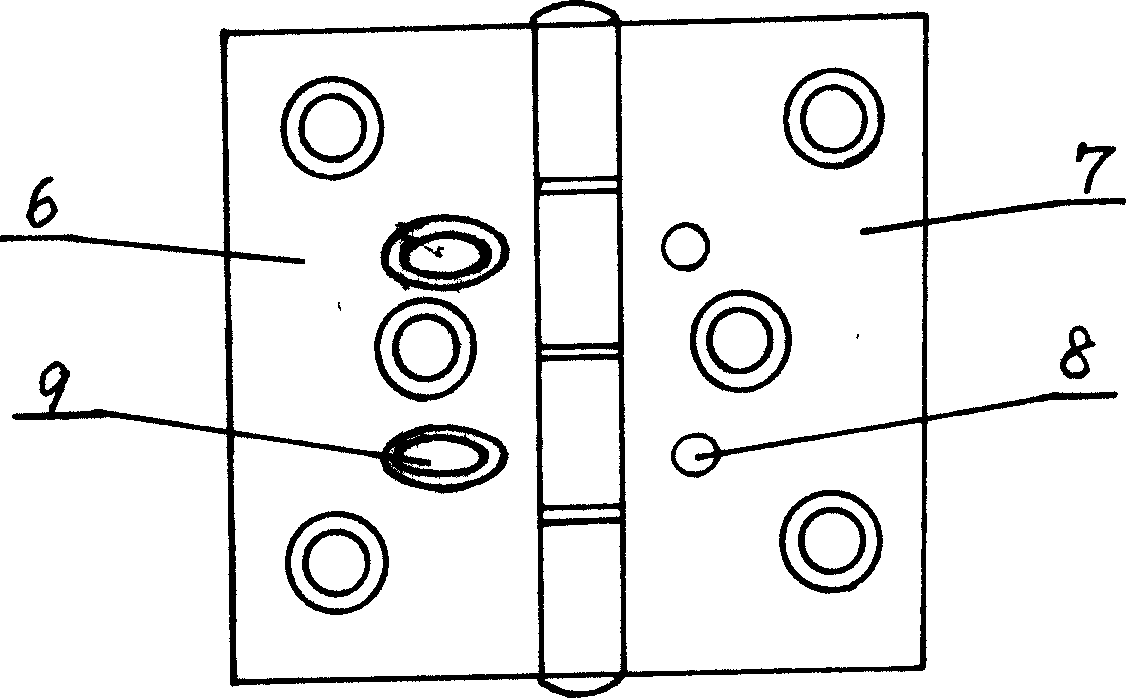

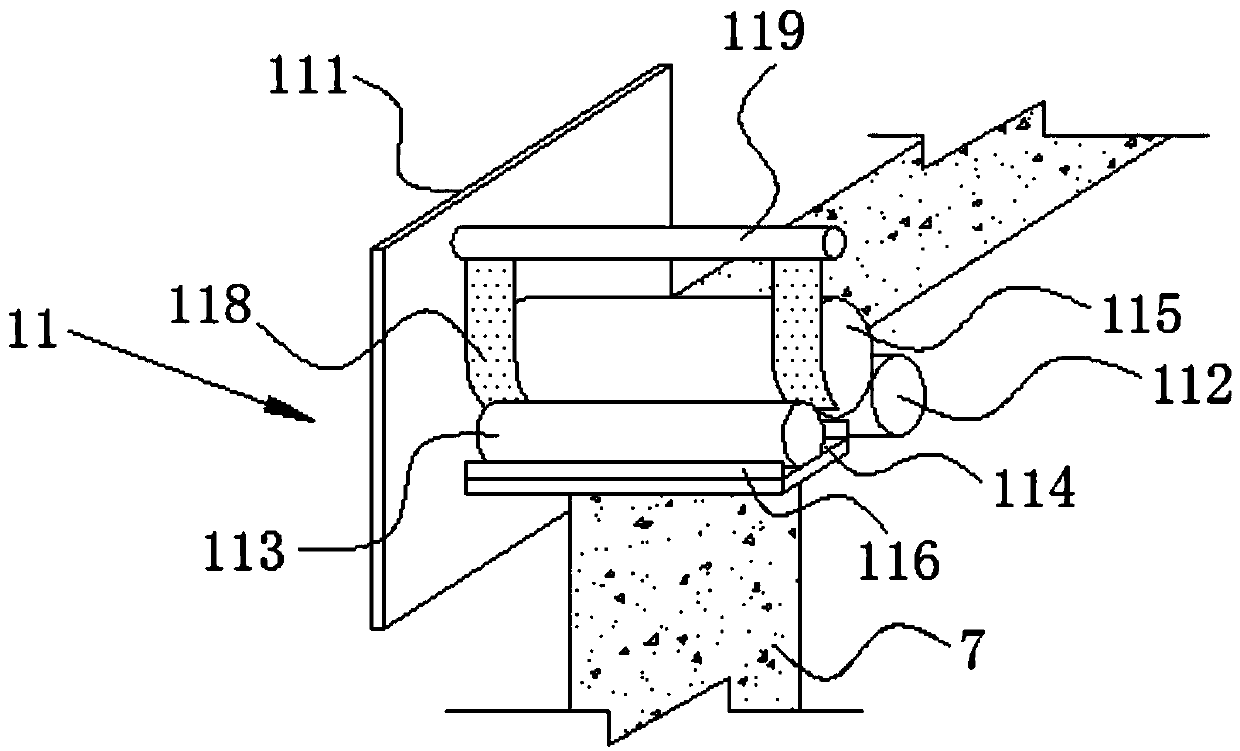

Laminated wood (laminated material) artistic wood door

InactiveCN1624286AEmission reductionAnti-pry functionWing arrangementsDoor leavesEngineeringMetal mesh

This invention is about building appurtenances involving a door framework. This is a process wooddoor made from the laminated wood, and its improvement is the door which consists of core boards, process faceplate and metal net or cotton thread net set between the core boards. The door11 is linked with the door covering by door hinge. The door appears a common one but the metal net (cotton thread net) and fireproof plate are added in the boards, so it is light in weight and easy to close and open, also it solid and durable with a good and quality of burglarproofing and fireproofing. The door hinges are pryingproof, even when they are damaged by prying tools, the door covering will still be attached to the door.

Owner:ANLITUN COLD DRAWN STEEL MILL WENAN COUNTY HEBEI PROV

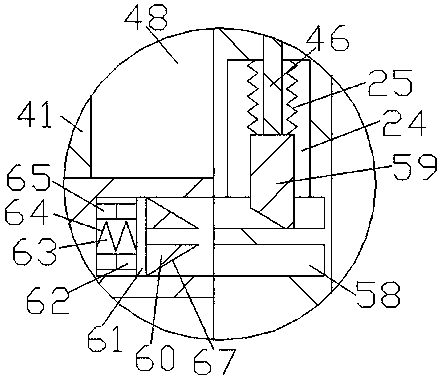

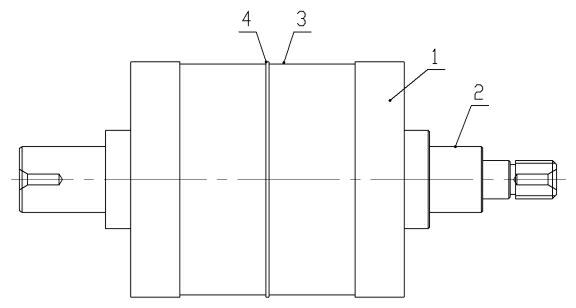

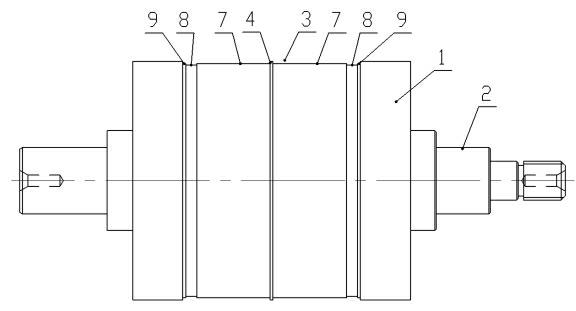

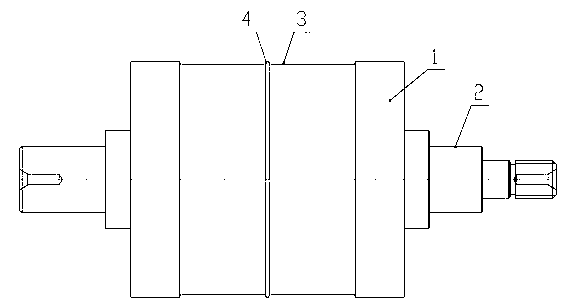

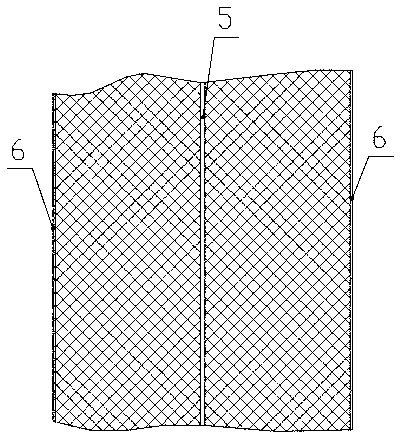

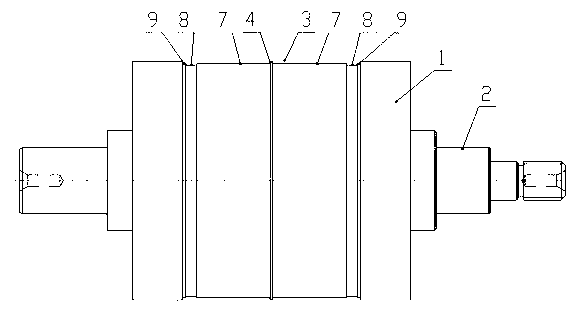

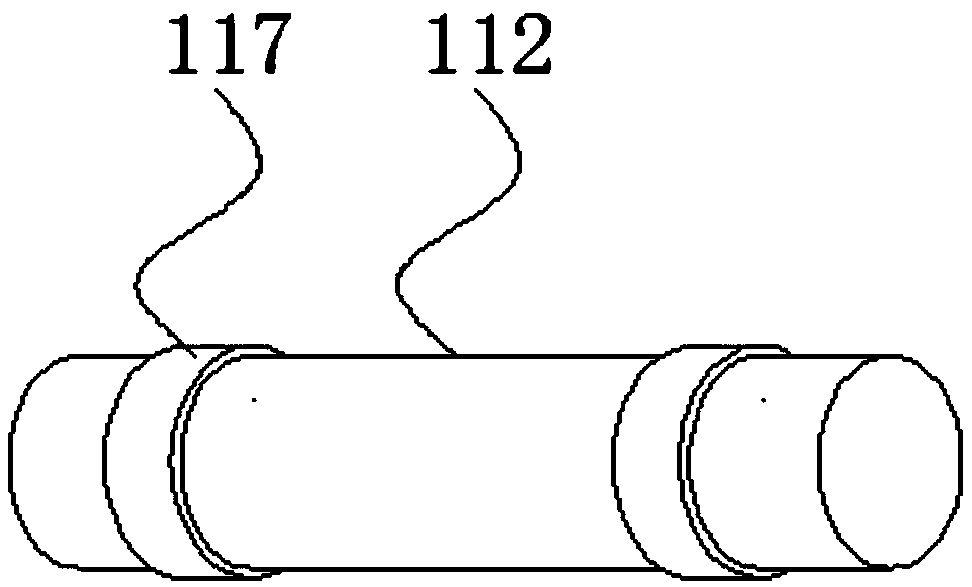

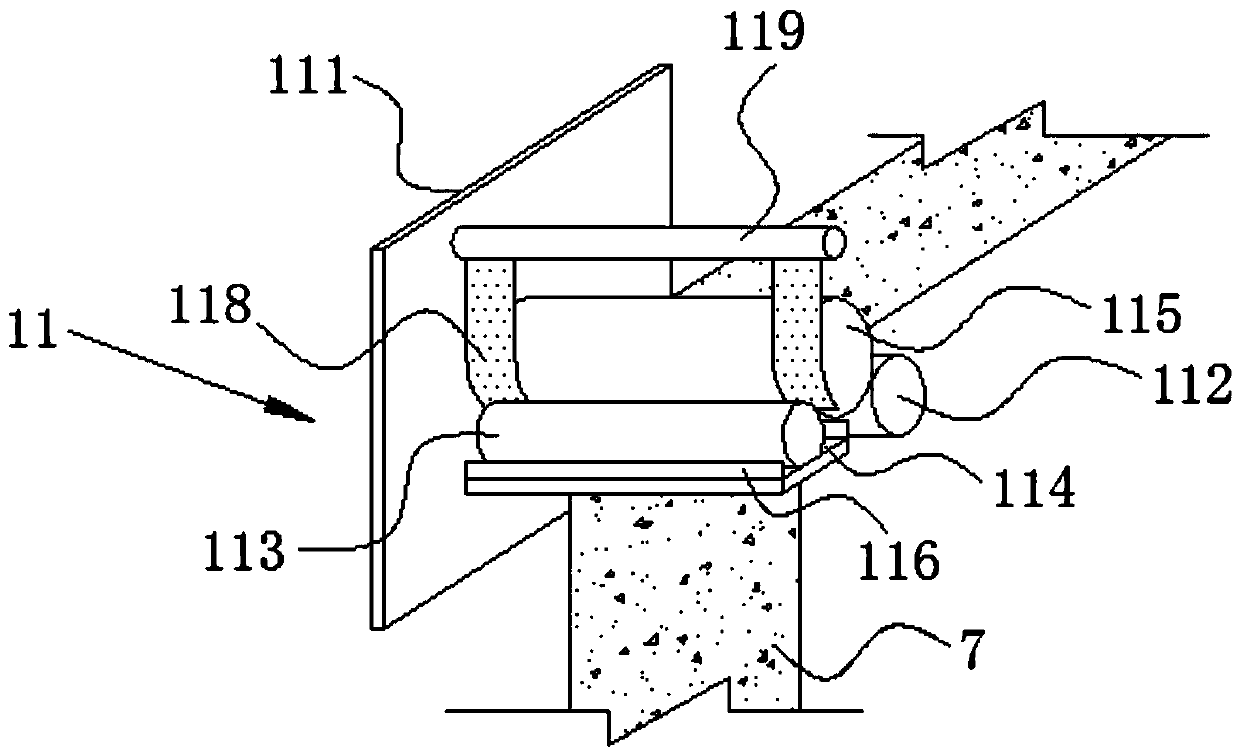

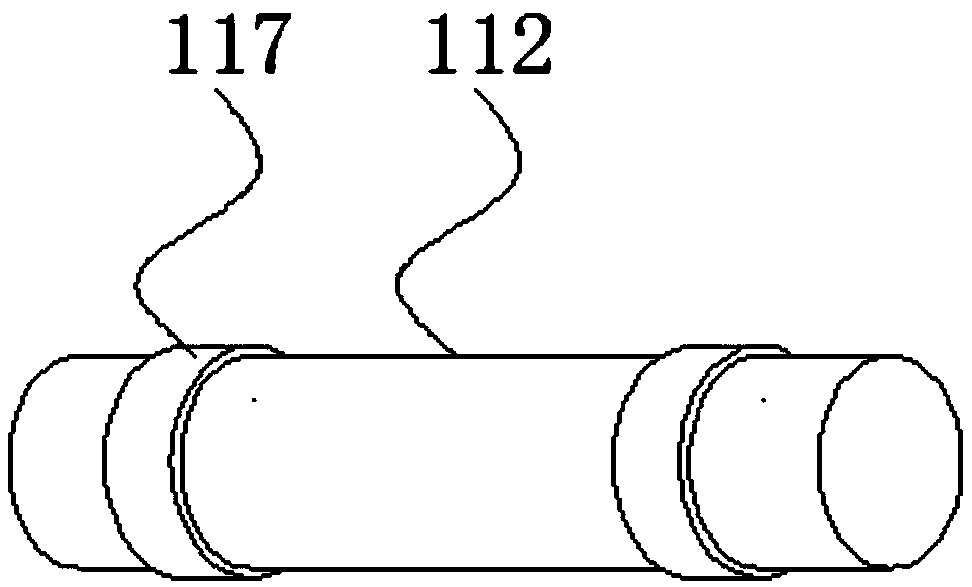

Gum control roller of cigarette making and tipping machine combination

ActiveCN102429321APrevent air leakageHigh bonding strengthCigarette manufactureEngineeringUltimate tensile strength

The invention discloses a gum control roller of a cigarette making and tipping machine combination, comprising a roller and a rotary shaft which is arranged on the centre of the roller, wherein the circumferential surface of the roller is provided with a groove, and the centre of the groove is provided with an annular convex edge. The surface of the groove is respectively provided with a first annular gum coating strap, a second annular gum coating strap and a third annular gum coating strap in turn from the convex edge to the two sides. The gum control roller designs the gum coating quantityof the tipping paper which meets the twisting requirements according to the twisting technology, and coats a thin gum on the middle part to reduce the gum scale of cutters; the gum control roller increases the gum coating quantity in the joint area of the cigarette and the filter tip and improves the bonding strength, so the cigarette cannot leak the air; and the edge of the tipping paper is coated with little gum coating quantity, so that the curling sides of the tipping paper caused by the shortage gum quantity of the part can be compensated.

Owner:CHINA TOBACCO HENAN IND

Gum control roller of cigarette making and tipping machine combination

ActiveCN102429321BPrevent air leakageHigh bonding strengthCigarette manufactureUltimate tensile strengthPaper sheet

The invention discloses a gum control roller of a cigarette making and tipping machine combination, comprising a roller and a rotary shaft which is arranged on the centre of the roller, wherein the circumferential surface of the roller is provided with a groove, and the centre of the groove is provided with an annular convex edge. The surface of the groove is respectively provided with a first annular gum coating strap, a second annular gum coating strap and a third annular gum coating strap in turn from the convex edge to the two sides. The gum control roller designs the gum coating quantityof the tipping paper which meets the twisting requirements according to the twisting technology, and coats a thin gum on the middle part to reduce the gum scale of cutters; the gum control roller increases the gum coating quantity in the joint area of the cigarette and the filter tip and improves the bonding strength, so the cigarette cannot leak the air; and the edge of the tipping paper is coated with little gum coating quantity, so that the curling sides of the tipping paper caused by the shortage gum quantity of the part can be compensated.

Owner:CHINA TOBACCO HENAN IND

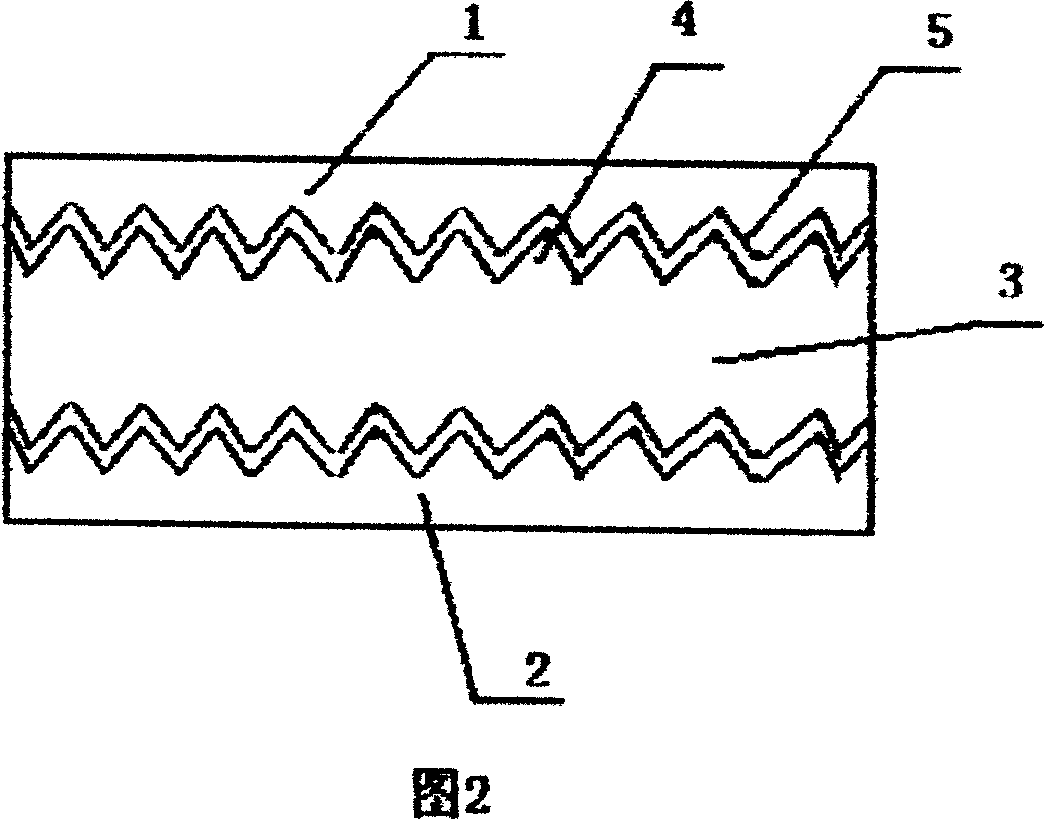

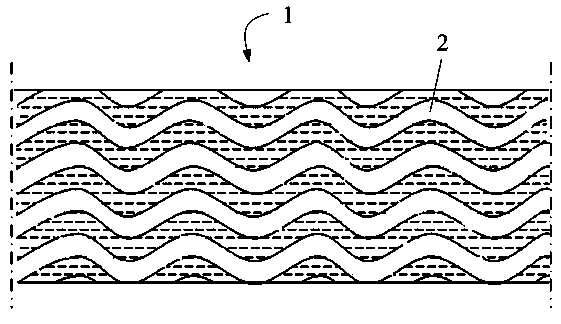

Water corrugate gluing kinesio adhesive tape and preparation method thereof

ActiveCN103436196BIncrease stickinessReduce the amount of glue appliedFilm/foil adhesivesAdhesiveViscosity

The invention relates to a water corrugate gluing kinesio adhesive tape and a preparation method thereof. The water corrugate gluing kinesio adhesive tape is characterized in that an adhesive layer is formed on release paper, a water corrugate strip structure is formed in the adhesive layer, and the adhesive layer with the water corrugate strip structure is compounded with an adhesive tape base material. The preparation method comprises the following steps of: firstly coating an adhesive on the release paper; drying the adhesive on the release paper by using a drying oven; cooling, and then scraping out the water corrugate strip structure on the adhesive layer coated on the release paper; laminating the adhesive layer with the water corrugate strip structure and the adhesive tape base material. The water corrugate gluing kinesio adhesive tape has good viscosity and good air permeability; the gluing amount of the adhesive tape is reduced, and raw materials are saved; the air permeability of the product is enhanced, and the comfort sensation of the skin is improved.

Owner:SUZHOU MEDSPORT PROD

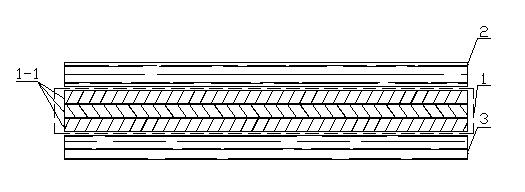

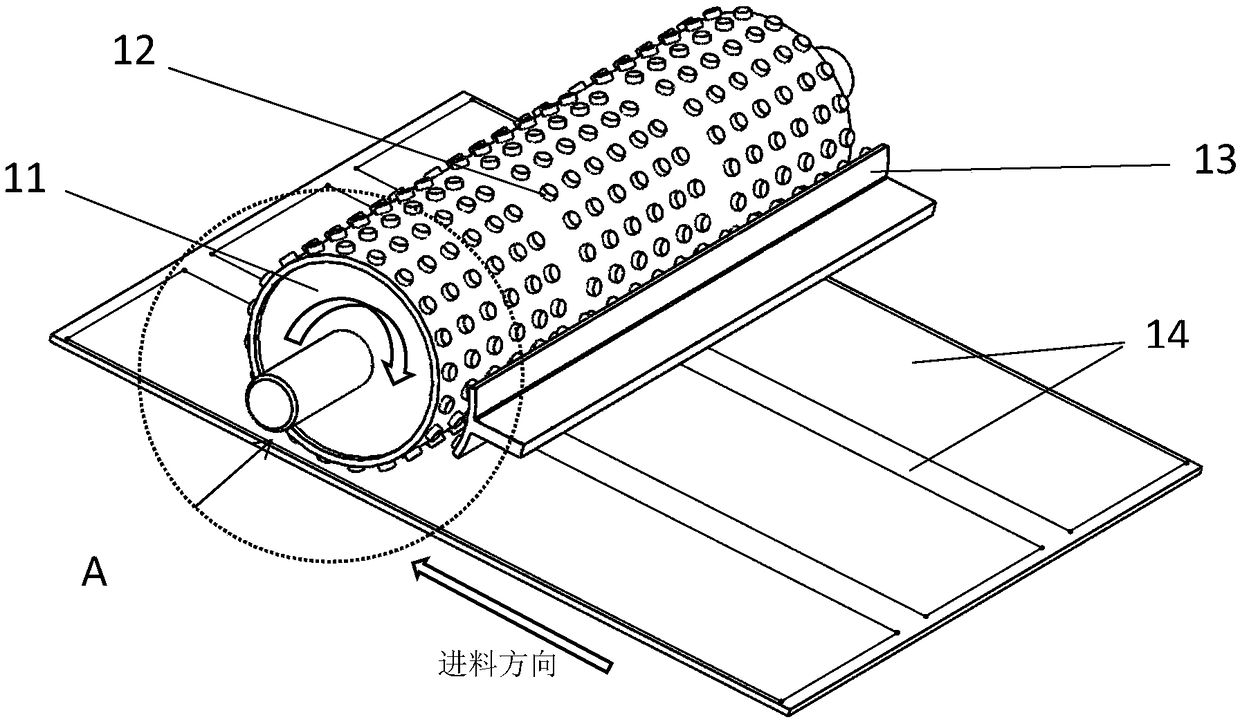

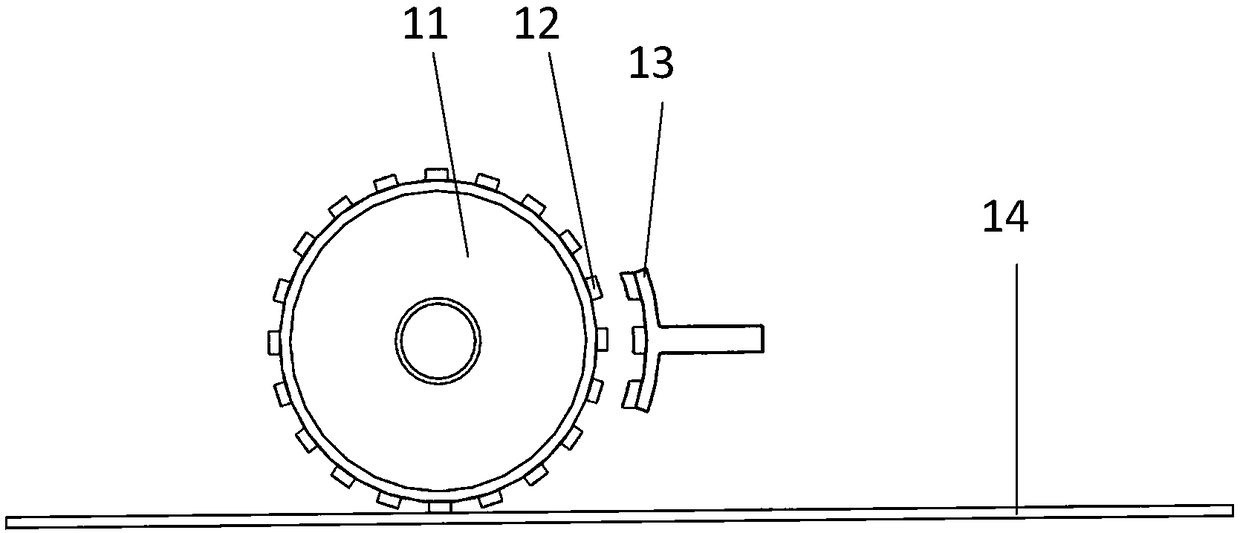

A kind of continuous lamination method of composite floor

ActiveCN106827115BDoes not affect the gluing processIncrease productivityOther plywood/veneer working apparatusLaminationEngineeringUltimate tensile strength

The invention provides a continuous laminating method for a composite floor. The method comprises the steps that a base material, a surface plate and a bottom plate are selected and prepared; secondly, point type gluing is conducted on the base material through moisture curing reaction type polyurethane hot melt adhesive; thirdly, blank assembling is conducted, and the surface plate, the base material and the bottom plate are automatically and continuously assembled through accurate surface plate, base material and bottom plate positioning equipment, and are directly and automatically conveyed to enter a continuous press to be subjected to cold pressing; fourthly, continuous normal-temperature pressure applying is conducted; and fifthly, splitting is conducted, a floor blank obtained after cold pressing enters a multiple blade saw unit and is split into floor blank bodies equal in width, wherein a multiple blade saw is a composition unit of the continuous cold press and is arranged after the laminating procedure. The composite floor manufactured through the method has many beneficial effects that the glue spreading amount is small, glue spreading is uniform, the gluing strength is uniform, the inner stress of the floor is small, the size stability is high, free formaldehyde release is avoided, the product quality is high, and the cold pressing period is short; and the production technology is simple, energy consumption is low, the production efficiency is high, and continuous and automatic production can be achieved.

Owner:菲林格尔家居科技股份有限公司

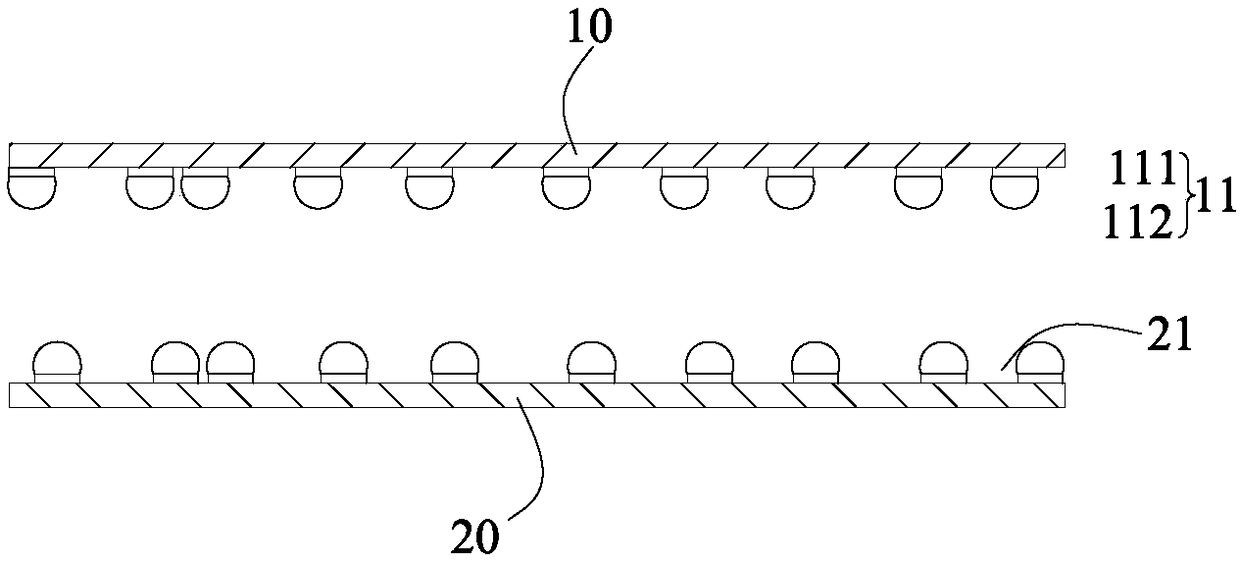

Process for improving bonding strength of aluminum honeycomb plates

ActiveCN110789184AHigh bonding strengthIncrease contact areaLayered product treatmentLaminationAluminum honeycombAdhesive glue

The invention discloses a process for increasing the bonding strength of aluminum honeycomb plates. The aluminum honeycomb plate comprises an upper plate, an aluminum honeycomb core and a lower platewhich are sequentially overlapped from top to bottom, the overlapped surfaces of the upper plate and the aluminum honeycomb core, and the overlapped surfaces of the lower plate and the aluminum honeycomb core are coated with a glue. The process comprises the following steps: (1) fixing the upper plate and the lower plate of the assembled aluminum honeycomb plate; and (2) moving the aluminum honeycomb core for a distance a, so that the glue is gathered on the outer edge of the hole grids of the aluminum honeycomb core. According to the process, glue is gathered on the outer edges of the hole grids of the aluminum honeycomb core, so that the contact area between the hole grids of the aluminum honeycomb core and the glue can be greatly increased, the bonding strength between the aluminum honeycomb core and the upper and lower plates is improved, the bonding strength of the aluminum honeycomb plate is improved, the gluing amount can be reduced on the premise of meeting the bonding strengthrequirement, and the cost is saved.

Owner:广东华粘新材料研究有限公司

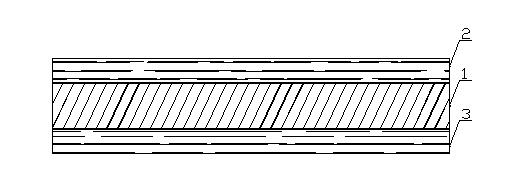

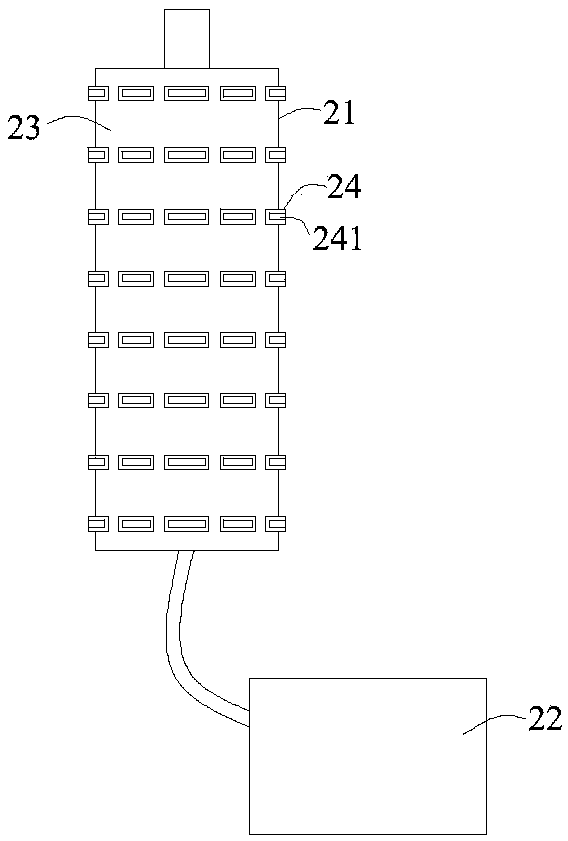

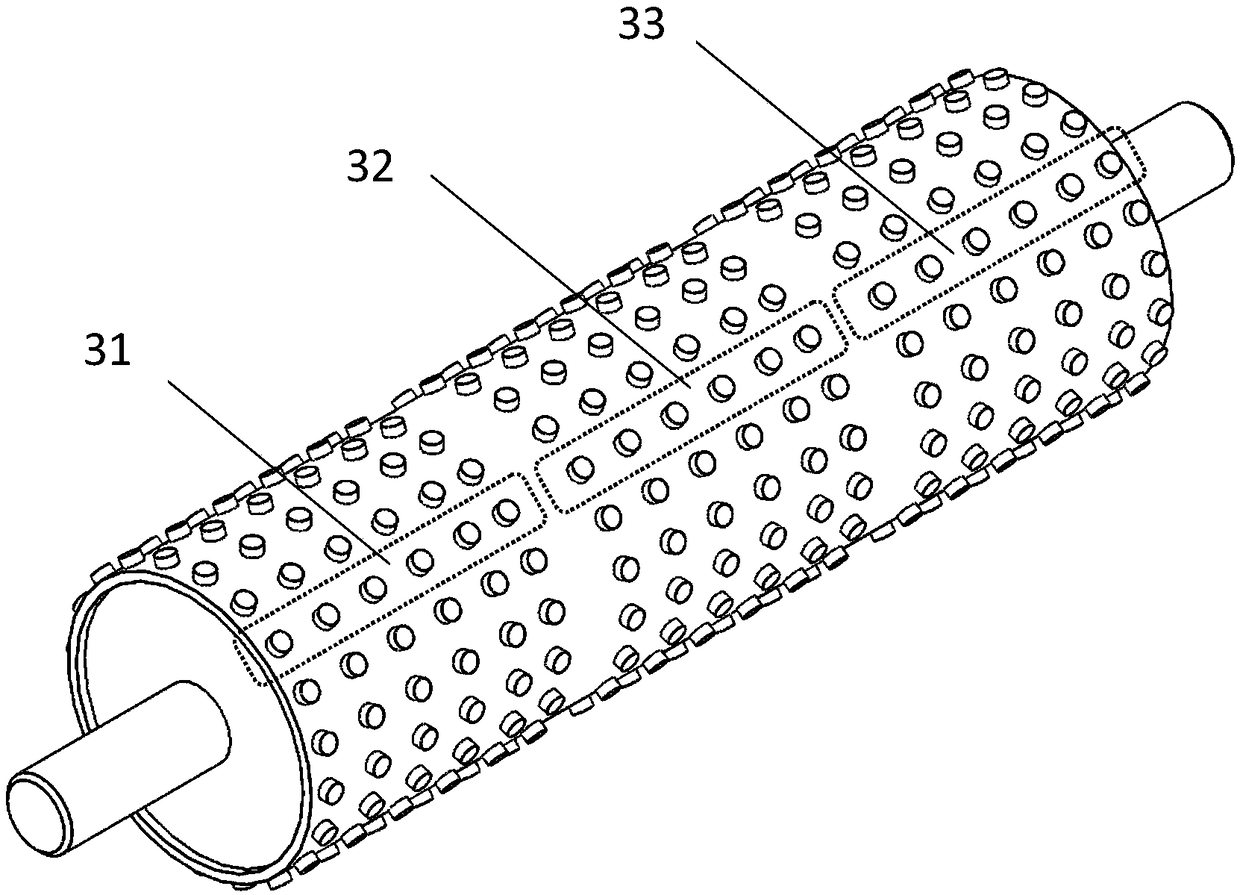

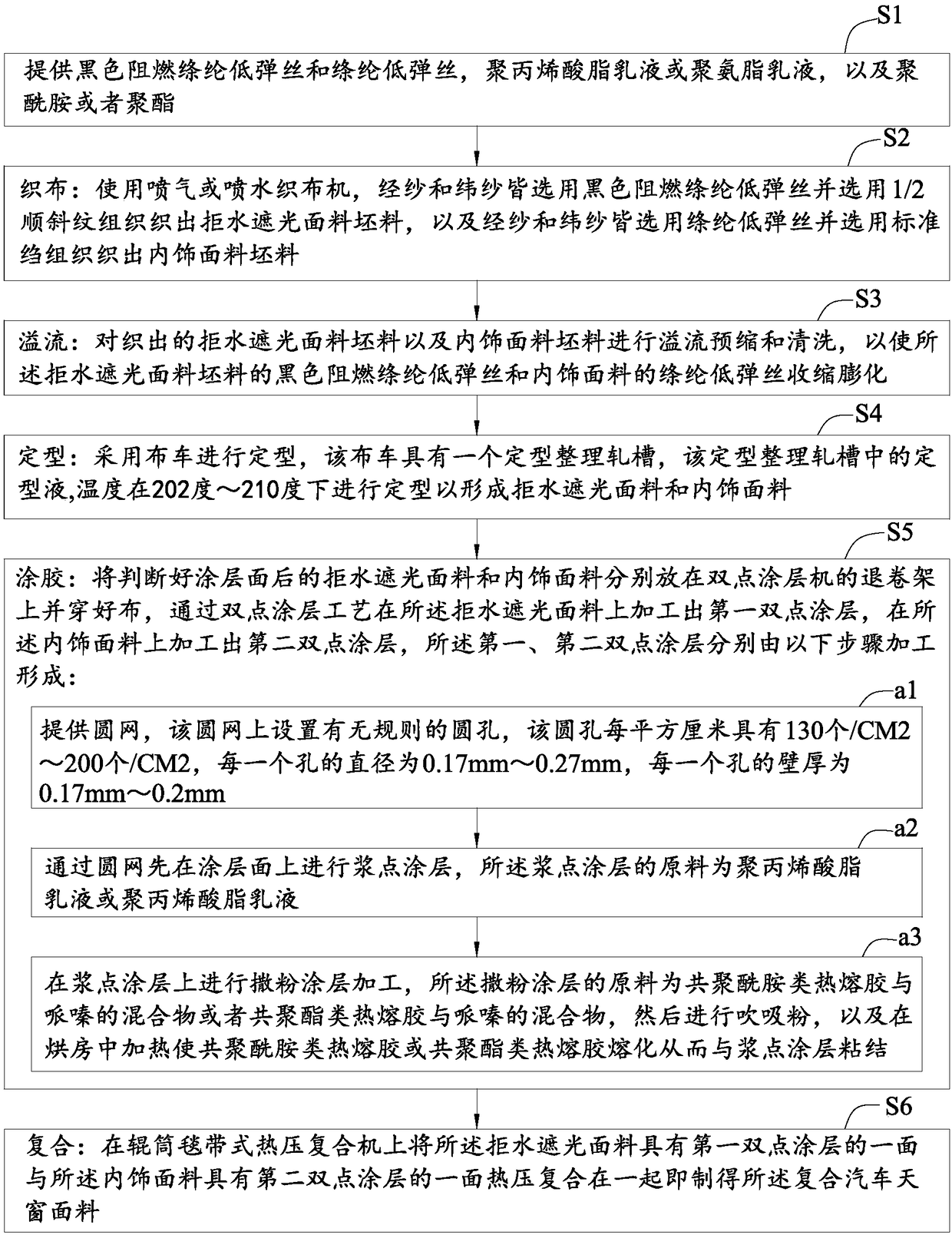

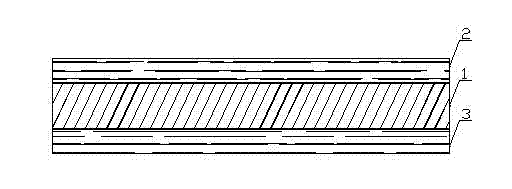

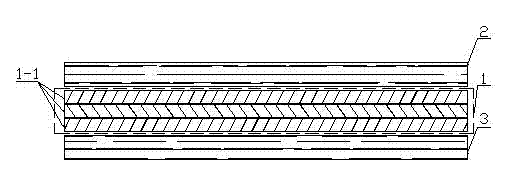

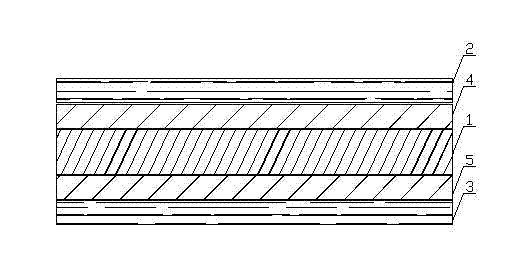

Composite blank, composite fabric for power sunroof and production process of composite fabric

PendingCN108407416AFeel goodReduce the amount of glue appliedLamination ancillary operationsSynthetic resin layered productsHot-melt adhesivePollution

The invention provides a composite blank, a composite fabric for power sunroofs and a production process of the composite fabric. The composite fabric for power sunroofs comprises a layer of water-repellent shading fabric, a layer of interior fabric, a layer of disordered first and second double dot coatings located between the water-repellent shading fabric and the interior fabric, and a layer ofhot melt adhesive located between paste dot coatings or between the paste dot coating and the water-repellent shading fabric, and the paste dot coating and the interior fabric; the first and second double dot coatings are respectively arranged on the water-repellent shading fabric and the interior fabric, and the first and second double dot coatings are partially bonded to the interior fabric andthe water-repellent shading fabric respectively through the hot melt adhesive, and the first and second double dot coatings are partially bonded to each other through the hot melt adhesive. Since thecomposite fabric for power sunroofs provided by the invention has the advantage of small adhesive applying amount, so that the resulted pollution is small; and when compounding, the first and seconddouble dot coatings are arranged face to face and bonded, so that the double dot coatings can be firmly bonded with each other through adhesive after adhesive applying.

Owner:CPL NEW MATERIAL TECH CO LTD

Sub-rail bamboo and wood composite heightening railroad tie plate for concrete sleeper

ActiveCN101818468BHard woodReduce distortionRail fastenersPlant material mechanical workingSurface layerEngineering

Owner:哈尔滨新星铁路垫板制造有限责任公司

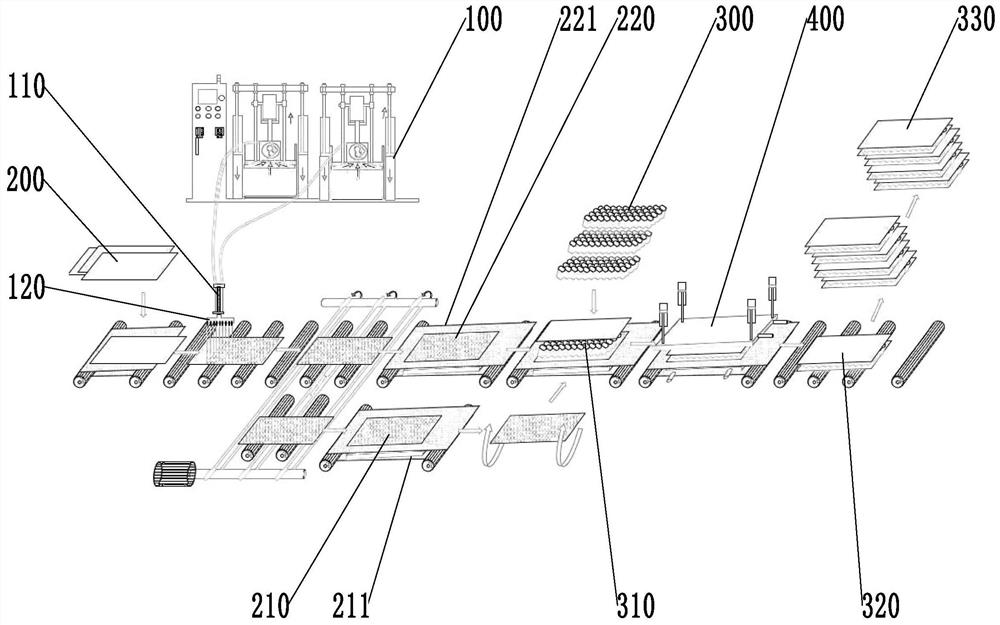

An automatic bag making production line

ActiveCN108032553BHigh degree of automationQuality improvementBag making operationsPaper-makingProduction lineEngineering

The invention discloses an automatic bag manufacturing production line which comprises a flexible printing device, a part cutting device, a bag body cylinder forming device, a handle machine, a coating forming device and a press. According to the processes of a hand bag, the flexible printing device is located at the upstream of the part cutting device, the part cutting device is located at the upstream of the bag body cylinder forming device, the bag body cylinder forming device and the handle machine are located at the upstream of the coating forming device, and the coating forming device islocated at the upstream of the press; the flexible printing device comprises a discharging mechanism, a plurality of printing mechanisms and a furling mechanism, the discharging mechanism is locatedat the upstream of the printing mechanism, and the printing mechanisms are located at the upstream of the furling mechanism. The automatic bag manufacturing production line is high in automatic degree, the amount of glue and ink is lowered, the production cost is lowered, two layers of handle belts are firmly stuck, handles and a bag body are firmly stuck, and the quality of the hand bag is ensured.

Owner:昆山金红凯包装制品有限公司

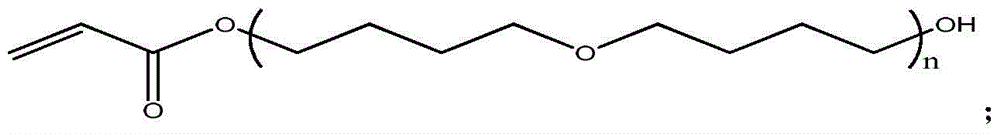

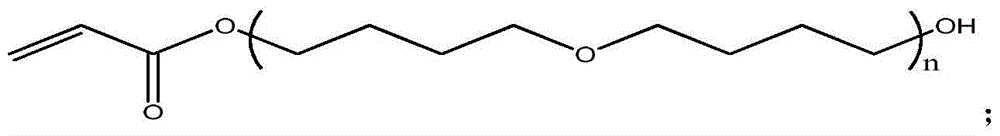

A kind of anti-broken pressure-sensitive adhesive and preparation method thereof

ActiveCN104694054BEasy to operateSimple production processEster polymer adhesivesFunctional monomerPolymer science

The invention relates to an anti-fracture pressure sensitive adhesive and a preparation method of the pressure sensitive adhesive. The preparation method of the anti-fracture pressure sensitive adhesive comprises the following steps: synthesizing a polytetrahydrofurfuryl acrylate monomer which comprises a long carbon chain of an ether bond and is high in flexibility; and synthesizing the polytetrahydrofurfuryl acrylate monomer which serves as a functional monomer with a soft monomer and a hard monomer to prepare an acrylic acid pressure-sensitive adhesive. The tensile elongation of the prepared acrylic acid pressure-sensitive adhesive is obviously improved; the problem of tensile fracture in the using process of the acrylic acid pressure-sensitive adhesive can be solved; the acrylic acid pressure-sensitive adhesive can be widely used in various fields.

Owner:滁州云林数码影像耗材有限公司

A kind of Tremella composite flocking adhesive

ActiveCN106085300BLow viscosityImprove stabilityMonocarboxylic acid ester polymer adhesivesPolysaccharide adhesivesAdhesiveFiltration

The invention discloses a tremella composite flocking adhesive. A preparation method of the adhesive includes the steps: preparing acrylic composite solution for standby application; weighing 500g of dry tremella, placing the dry tremella in 10L of 0.3% mycose solution, standing for 18-20 hours, taking out the thoroughly soaked tremella, uniformly grinding the tremella, weighing 100g of the grinded soaked tremella, treating the grinded soaked tremella in 1L of calcium chloride boiling solution with mass concentration 60% for about 50-80 minutes until dissolving most of the grinded soaked tremella, stirring the grinded soaked tremella by a glass rod during treatment, and coarsely extracting the mixed solution by wick filtration to obtain tremella extracting solution; mixing the acrylic composite solution and the tremella extracting solution well, and finally discharging and packaging a finished product.

Owner:蚌埠行时知识产权运营有限公司

Nonformaldehyde nonpoisonous adhesive and preparation method thereof

ActiveCN101709211BFormula stableWide adaptabilityPolyureas/polyurethane adhesivesNon toxicityAdhesive

The invention discloses a nonformaldehyde nonpoisonous adhesive and a preparation method thereof. The method comprises the following steps: firstly, adding proper water in a reactor which is provided with a stirring device; secondly, slowly adding polyvinyl alcohol into the reactor when the water is heated to 40 DEG C, heating the mixture to over 90 DEG C to ensure that the polyvinyl alcohol is completed dissolved, and preserving the heat for 1 hour; thirdly, cooling the materials to 70 DEG C, and adding polyalcohol, dispersant, emulsifier and aqueous solution of plasticizer into the reactor respectively, adding filler into the reactor, keeping stirring for 15 to 20 minutes to ensure that the raw materials are uniformly mixed, and filtering and discharging; and finally, uniformly mixing the raw materials with isocyanate in the proportion when the adhesive is used. The adhesive has simple production technology, can be subjected to both cold pressing and hot pressing, has low cost, and can completely realize non toxicity, harmlessness, greenness and environmental protection.

Owner:东营市盛基环保工程有限公司

Glue applicator intelligent control device for fast and precise glue application

ActiveCN113245155BFully protectedAvoid necrosisLiquid surface applicatorsCoatingsAutomatic controlCrank

The invention discloses a fast and precise intelligent control device for the glue application amount of a gluing machine, which comprises a housing, a handle is fixed below the housing, an adjustment assembly is arranged inside the housing, and the upper and lower ends of the housing are slidably connected with Pressing rods, rolling balls are fixed on the outer ends of the two pressing rods, the pressing rods are fixedly connected to the adjustment assembly, the adjustment assembly includes pressing cotton, the pressing cotton is fixedly connected to the pressing rod, and the pressing cotton Fixed blocks are fixed on the left and right sides, a slide bar is fixed in the middle of the two fixed blocks, and a slide block is sleeved on the outside of the slide bar. The upper and lower ends of the slide block are respectively fixedly connected with the pressing cotton. The left side is fixedly connected with a crank connecting rod, the left end of the crank connecting rod is fixed with an eccentric column, the outside of the eccentric column is fixed with a rolling wheel, and the middle bearing of the rolling wheel is connected with a rolling shaft. The characteristics of quantity and automatic control of insecticide dosage.

Owner:南通市通州区同博机械制造有限公司

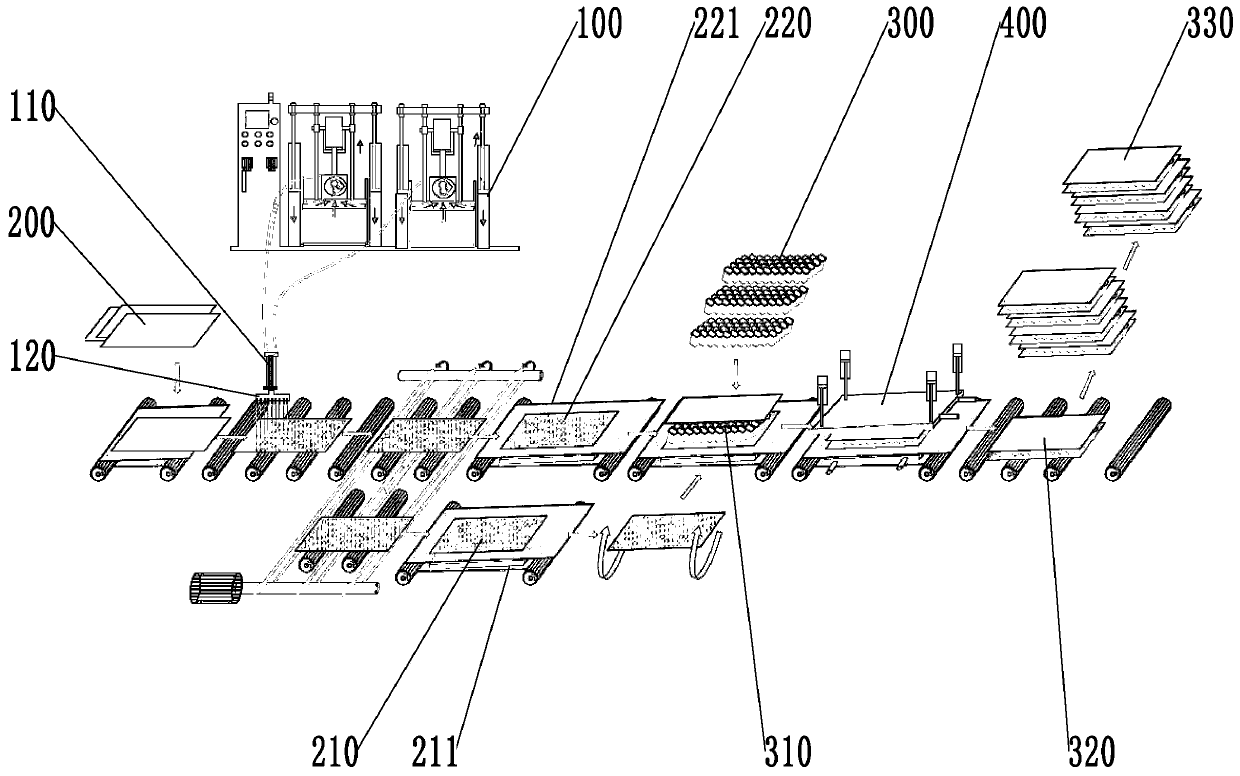

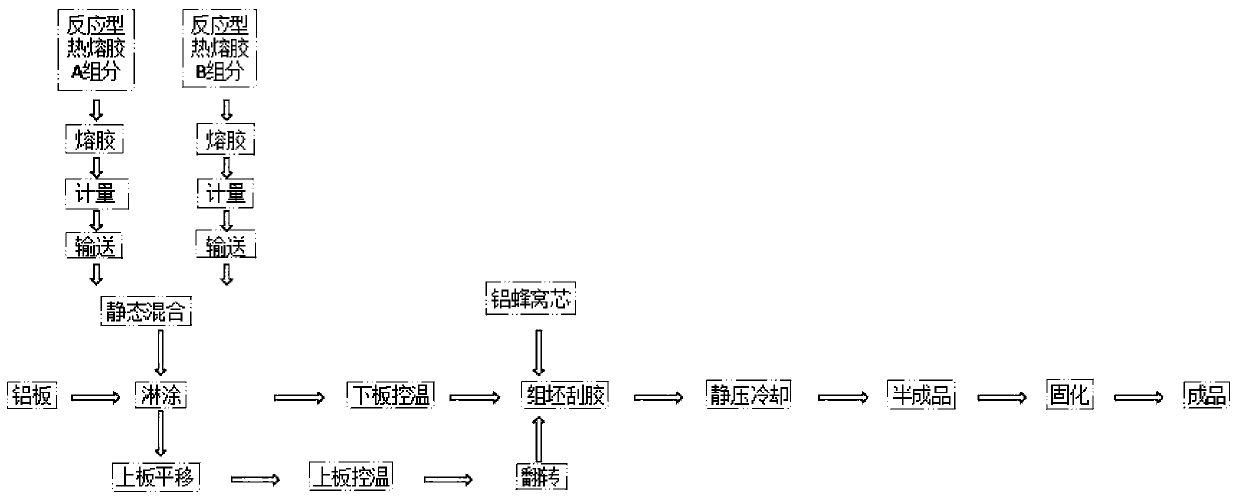

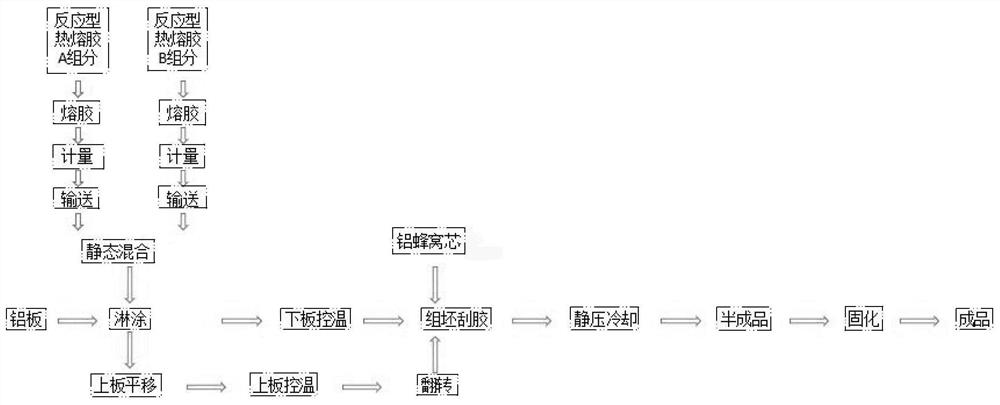

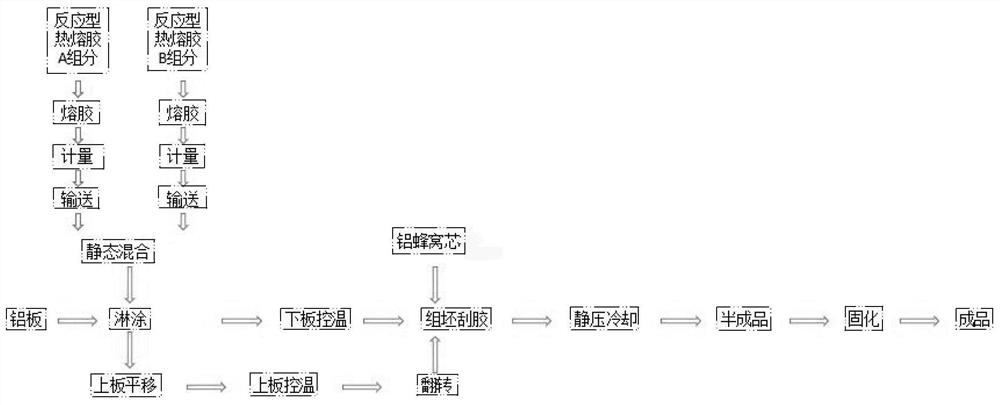

A continuous production process of aluminum honeycomb panel

ActiveCN110789185BReduce weightGood adhesionLayered product treatmentLaminationAluminum honeycombAdhesive glue

The invention discloses a continuous production process of aluminum honeycomb panels, which mainly includes the steps of mixing, gluing, billet formation, squeegeeing, static pressure cooling and solidification, using polyurethane two-component reactive hot melt adhesive as the aluminum plate and aluminum honeycomb The adhesive between the cores allows the glue to obtain a higher initial adhesion with less static pressure cooling time, which greatly reduces the waiting time, thereby realizing continuous production, greatly improving production efficiency, and can reduce The amount of glue applied can reduce the weight of the aluminum honeycomb panel, increase the specific strength, and reduce the production cost. At the same time, the polyurethane two-component reactive hot melt adhesive has good and stable bonding performance, including excellent bonding strength, and can withstand high Low temperature cycle impact improves the quality of the product.

Owner:广东中粘新材料科技有限公司

A kind of EVA edge-sealing hot-melt adhesive with no glue line and low glue amount and preparation method thereof

ActiveCN111944456BLight weightLow viscosityNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceHazardous substance

The invention relates to the technical field of hot-melt adhesives, in particular to an EVA edge-sealing hot-melt adhesive with no glue lines and low glue application and a preparation method thereof. In parts by weight, the preparation raw materials at least include: ethylene-vinyl acetate copolymer 25 -45 parts, 15-30 parts of petroleum resin, 2-10 parts of tackifying resin, 5-10 parts of viscosity regulator, 20-55 parts of filler, 0.01-0.05 parts of antioxidant, the hot melt adhesive provided by the invention has strength Good, thin adhesive layer, saving glue, good adhesive softness, hot melt adhesive environmental protection, no formaldehyde, toluene and other harmful substances, no phthalate, no heavy metals, etc., and the color of the board and furniture edge banding In contrast, no glue lines can be seen, and no twisted wires are achieved.

Owner:上海路嘉胶粘剂有限公司

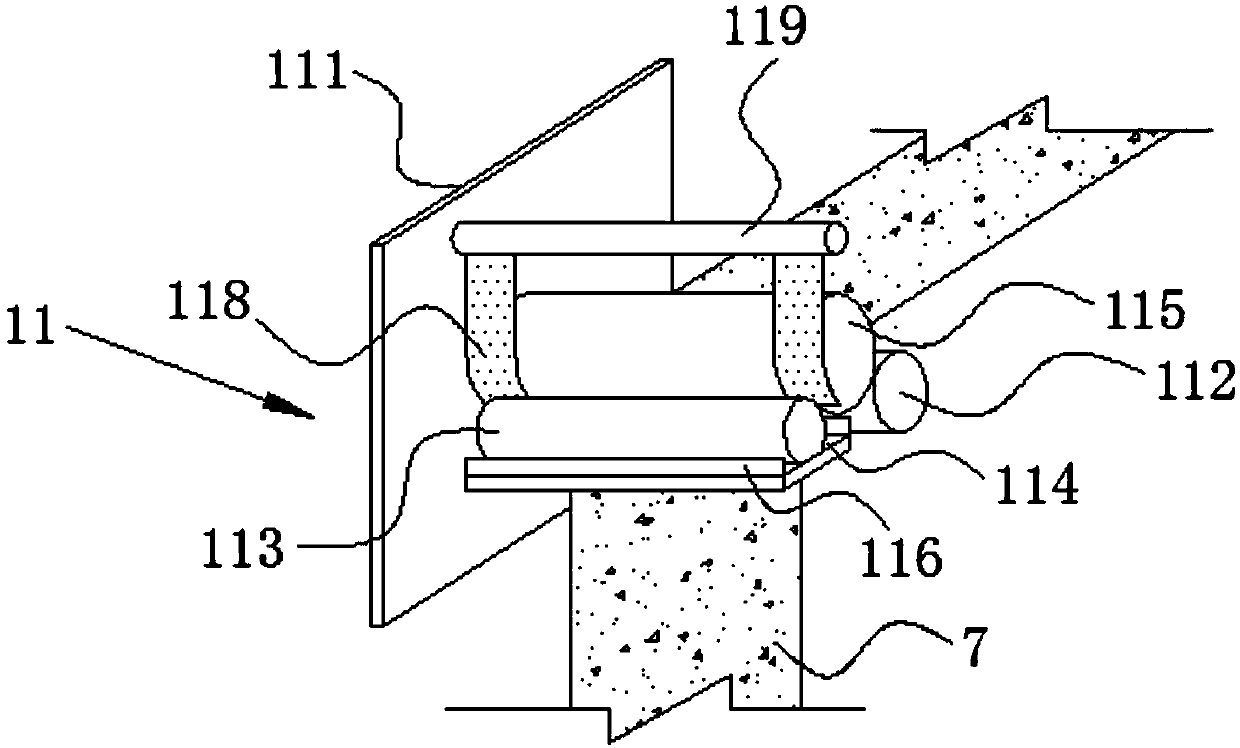

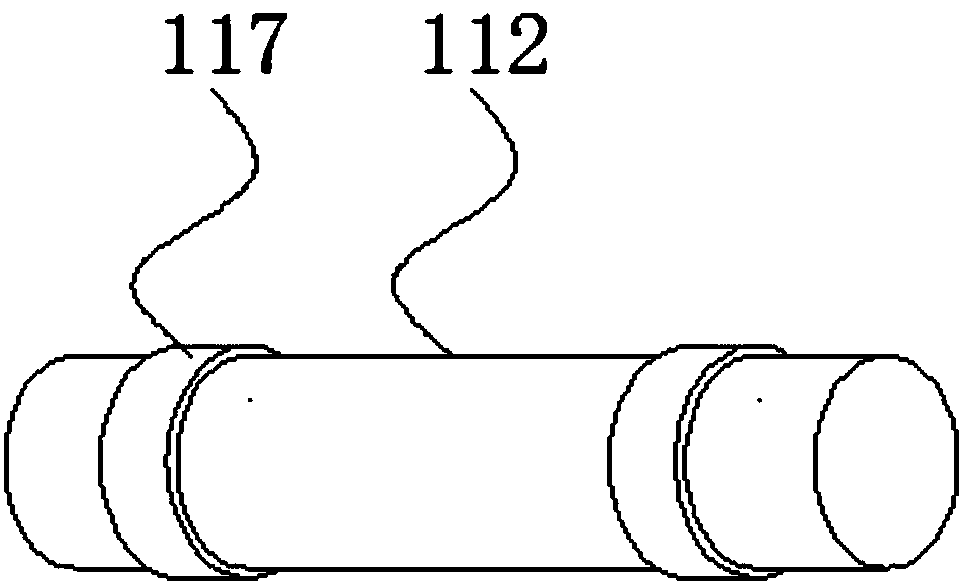

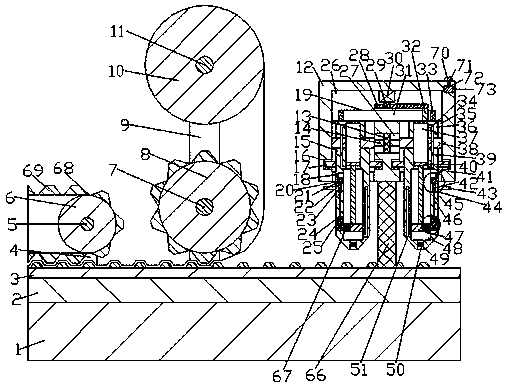

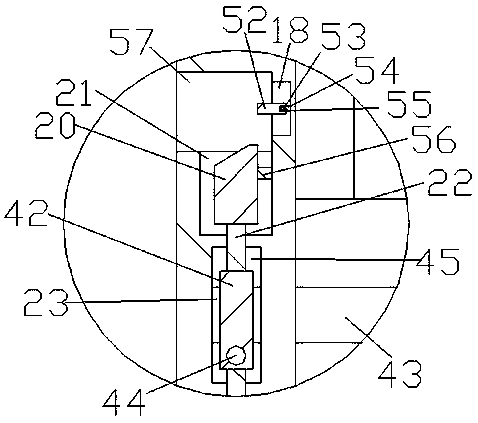

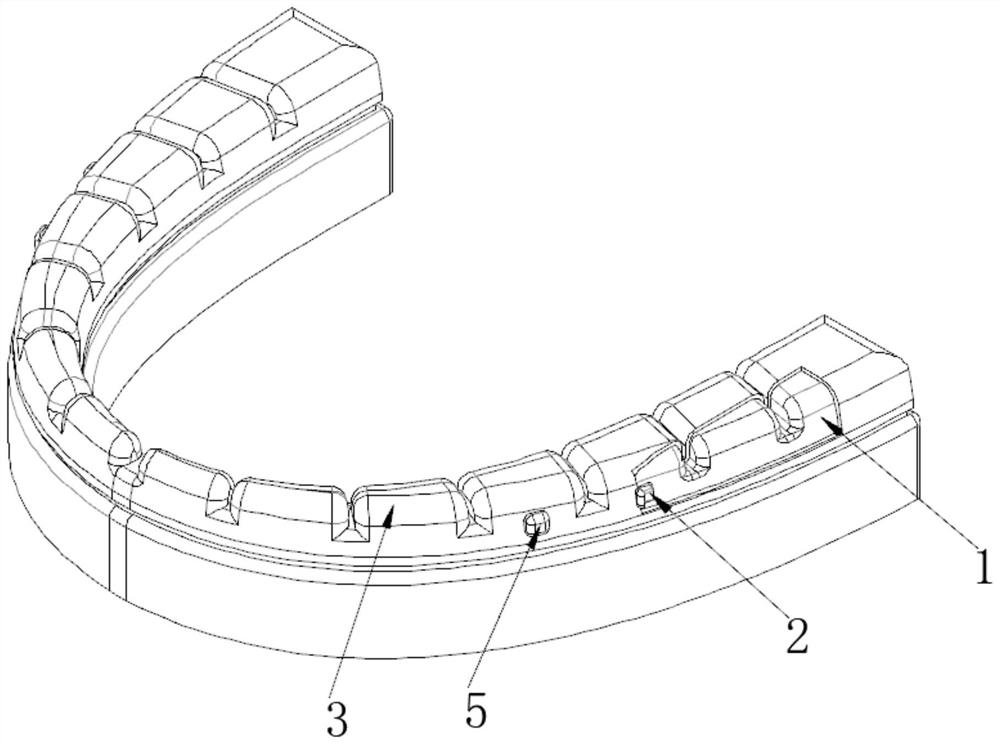

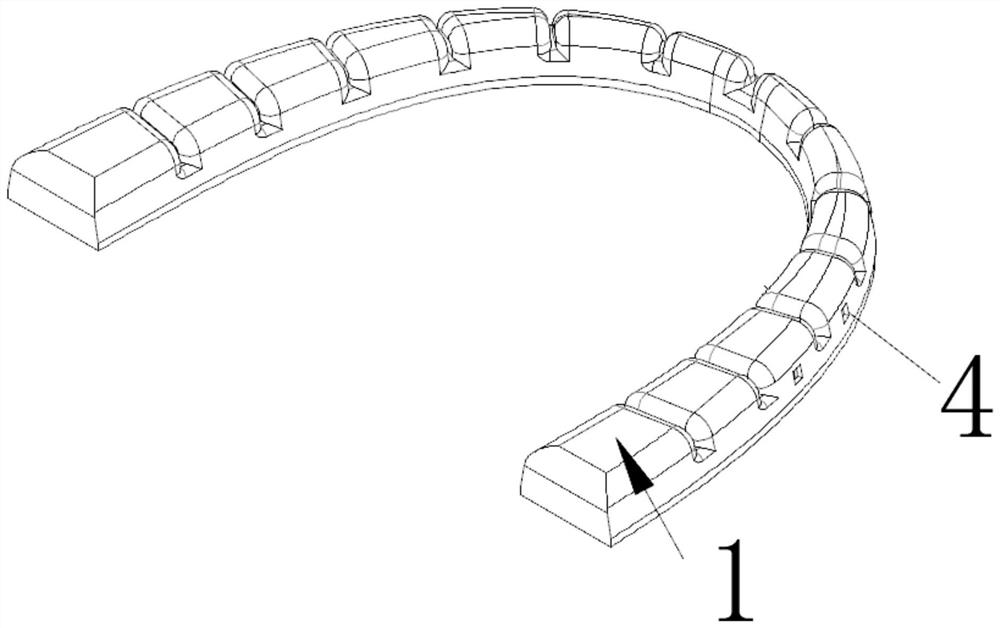

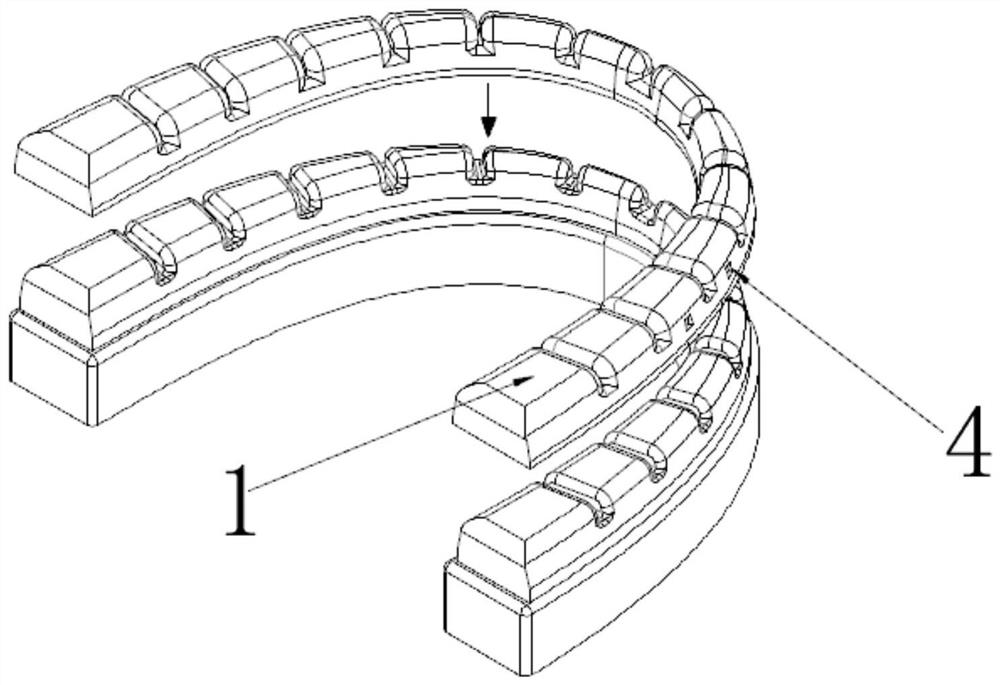

Invisible brace accessory installation device and method capable of achieving self-service precise positioning and convenient installation

The invention discloses an invisible tooth socket accessory installation device and method capable of achieving self-service precise positioning and convenient installation, the device comprises a tooth socket base, a fixing accessory, a tooth socket, a tooth socket preformed hole and an accessory groove hole, the tooth socket is placed on the tooth socket base, the accessory groove hole is formed in the tooth socket, and meanwhile the fixing accessory is placed in the accessory groove hole; the installation method comprises the following steps: step 1, digital processing; step 2, cleaning; step 3, curing; step 4, accurate fixation; according to the invention, the designed tooth socket base and the tooth socket basic part are matched for use, digital data acquisition and design are carried out on an original oral cavity model, the tooth socket base and the tooth socket basic part are designed, and the fixed accessory is mounted and fixed, so that the fixed accessory and the tooth socket can be perfectly and accurately positioned; the invisible orthodontic tooth socket is firm and does not fall off after being worn, the designed fixing accessory is used for installation, a patient can conveniently and accurately install the fixing accessory by himself, and the comfort level and convenience of the patient are greatly improved.

Owner:北京中鑫三维科技有限公司

A kind of environmental protection bag production line

ActiveCN108032554BHigh degree of automationQuality improvementBag making operationsPaper-makingEngineeringPrinting ink

The invention discloses an environment-friendly handbag production line. The environment-friendly handbag production line comprises a flexible printing device, a tailoring device, a bag body cylinder-forming device, a handlebar machine, a gluing forming device and a press. According to the manufacturing process of a handbag, the flexible printing device is located at the upper portion of the tailoring device, the tailoring device is located at the upper portion of the bag body cylinder-forming device, the bag body cylinder-forming device and the handlebar machine are located at the upper portion of the gluing forming device, and the gluing forming device is located at the upper portion of the press; the flexible printing device comprises a discharging mechanism, several printing mechanismsand a rolling mechanism, the discharging mechanism is located at the upper portions of the printing mechanisms, and the printing mechanisms are located at the upper portion of the rolling mechanism.The environment-friendly handbag production line is high in automated degree, glue and printing ink are saved, the production cost is lowered, two layers of handlebar bands are firmly pasted to handlebars and the bag body, and the quality of the handbag is guaranteed.

Owner:昆山金红凯包装制品有限公司

A process for increasing the bonding strength of aluminum honeycomb panels

ActiveCN110789184BHigh bonding strengthIncrease contact areaLayered product treatmentLaminationAluminum honeycombAdhesive glue

The invention discloses a process for increasing the bonding strength of an aluminum honeycomb panel. The aluminum honeycomb panel includes an upper panel, an aluminum honeycomb core and a lower panel sequentially laminated from top to bottom. The upper panel and the lower panel are connected with the aluminum honeycomb panel One side of the laminated core is coated with glue, including the following steps: (1) fixing the upper plate and the lower plate of the aluminum honeycomb panel after forming the billet; (2) moving the distance a of the aluminum honeycomb core to make the glue gather on the aluminum honeycomb core on the outer edge of the hole. This process makes the glue gather on the outer edge of the cells of the aluminum honeycomb core, thereby greatly increasing the contact area between the cells of the aluminum honeycomb core and the glue, thereby increasing the bonding strength between the aluminum honeycomb core and the upper and lower plates, and improving the aluminum honeycomb core. The bonding strength of the honeycomb panel can reduce the amount of glue on the premise of meeting the bonding strength requirements, thereby saving costs.

Owner:广东华粘新材料研究有限公司

Circuit board processing method

ActiveCN109041444BReduce the difficulty of strippingReduce workloadPrinted circuit assemblingPrinted circuit aspectsSurface mountingStructural engineering

The invention relates to a circuit board processing method, comprising: a) bonding a reinforcing plate on a first surface of the circuit board, wherein the area of the reinforcing plate is at least 85% of the area of the first surface of the circuit board, and in the range of 80 to 170 DEG C, the peeling strength between the first surface and the reinforcement plate is greater than 35.0 gf / mm; b)performing surface mounting (SMT) on the second surface of the circuit board; c) performing chip-on-board (COB) packaging on the second surface of the circuit board; and d) peeling the reinforcementplate from the first surface of the circuit board. According to the method of the invention, the deformation of the circuit board in the processing process can be effectively controlled. By effectively controlling the area ratio of the reinforcing board to the circuit board to be processed, the deformation of the circuit board can be avoided in the reflow soldering process, the area of the reinforcing board can be reduced, and the peeling workload and the peeling difficulty of the reinforcing board can be simplified and reduced.

Owner:NINGBO SUNNY OPOTECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com