Circuit board processing method

A processing method and circuit board technology, applied in the directions of printed circuit, printed circuit, printed circuit manufacturing, etc., can solve the problem of the difficulty of separating the reinforcement board and the circuit board from each other, so as to simplify the peeling workload, avoid deformation, and reduce the difficulty of peeling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

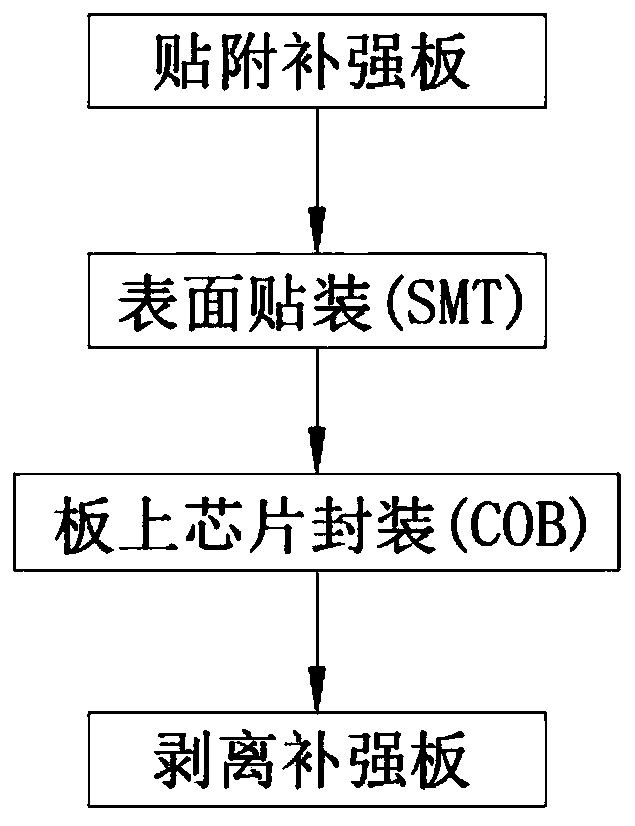

[0025] figure 1 It is a flowchart schematically showing the circuit board processing method according to the present invention. As shown in the figure, according to the circuit board processing method of the present invention, the specific steps are as follows:

[0026] a) Glue the reinforcement board 2 on the first surface 11 of the circuit board 1. The area of the reinforcement board 2 is at least 85% of the area of the first surface 11 of the circuit board 1. At 80-170°C, the first surface The peel strength between 11 and the reinforcing plate 2 is greater than 35.0gf / mm;

[0027] b) surface mount (SMT) on the second surface 12 of the circuit board 1;

[0028] c) performing chip-on-board packaging (COB) on the second surface 12 of the circuit board 1;

[0029] d) Peel off the reinforcement board 2 from the first surface 11 of the circuit board 1 .

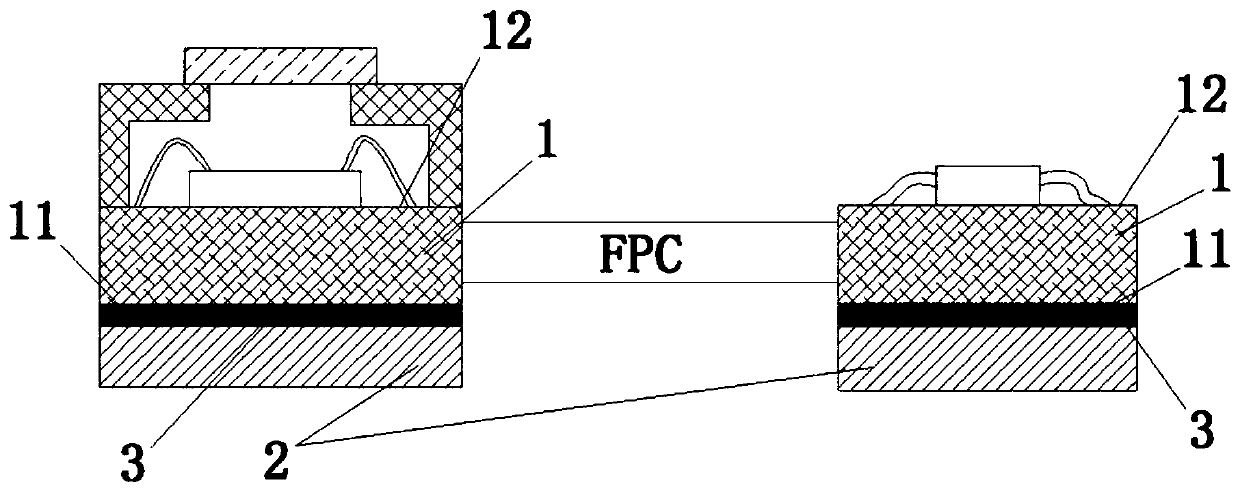

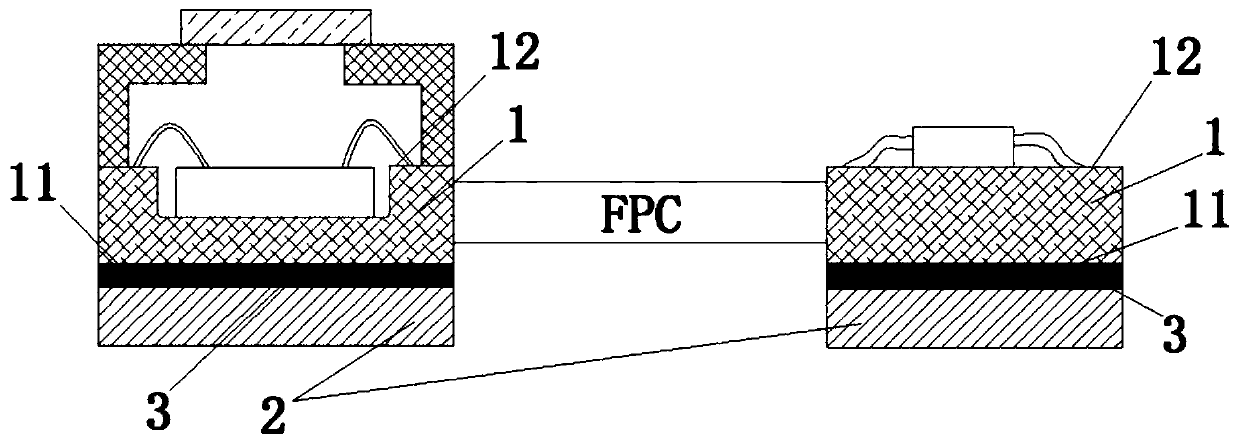

[0030] figure 2 It is a schematic diagram of an embodiment of the circuit board processing method according to the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com