A heat-proof layer forming tool for the outsole of a returnable spaceship

A returnable airship and forming tooling technology, which is applied to household appliances, other household appliances, household components, etc., can solve the problem that the heat-proof bottom layer of the returnable airship cannot be directly implemented with vacuum impregnation, drying, and curing processes, so as to prevent Floating deformation, uniform heating, avoiding the effect of excessive force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

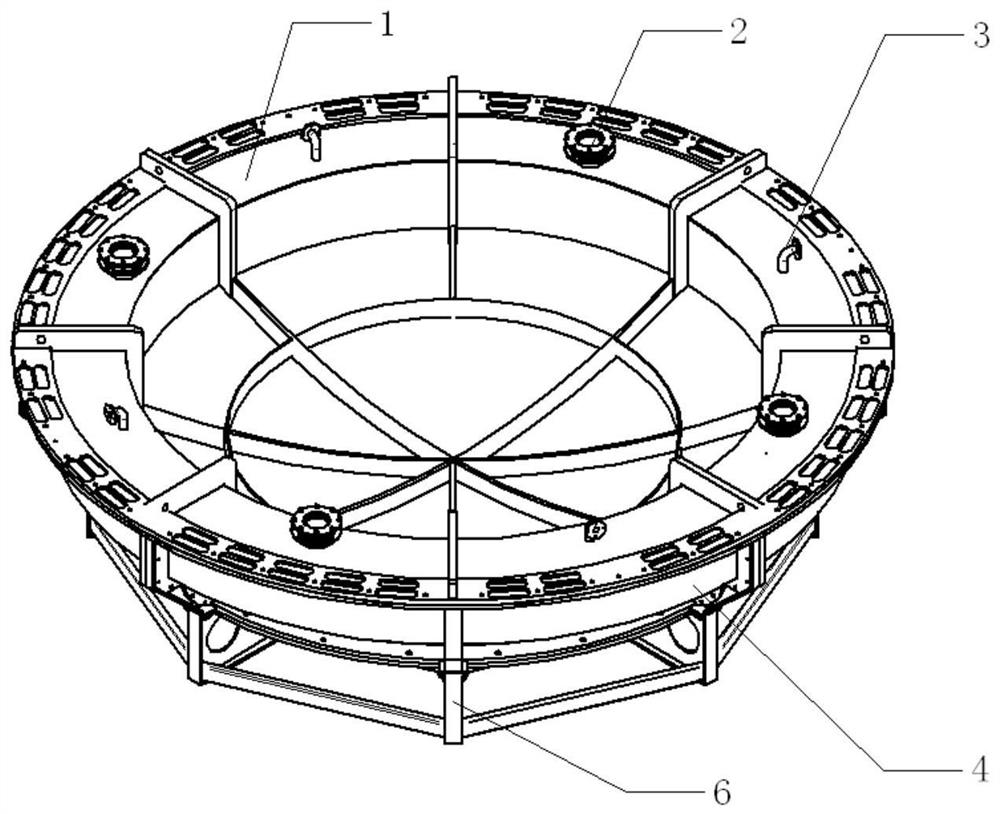

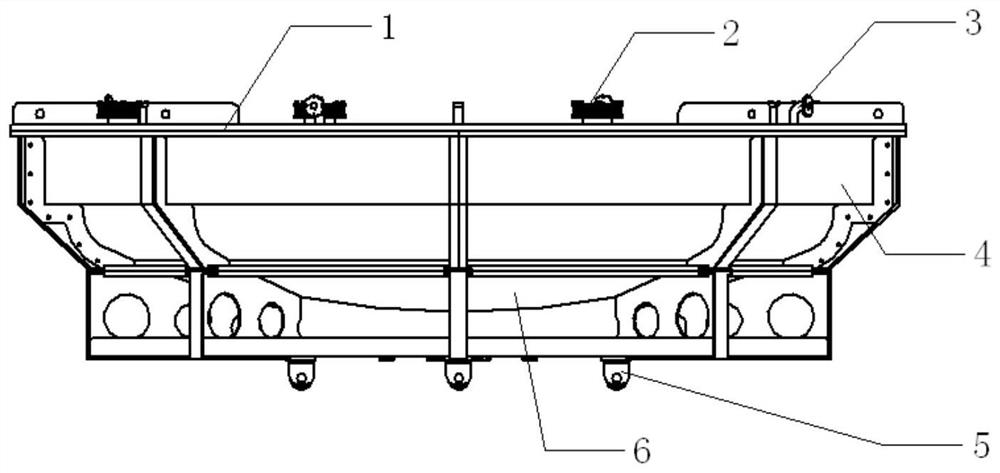

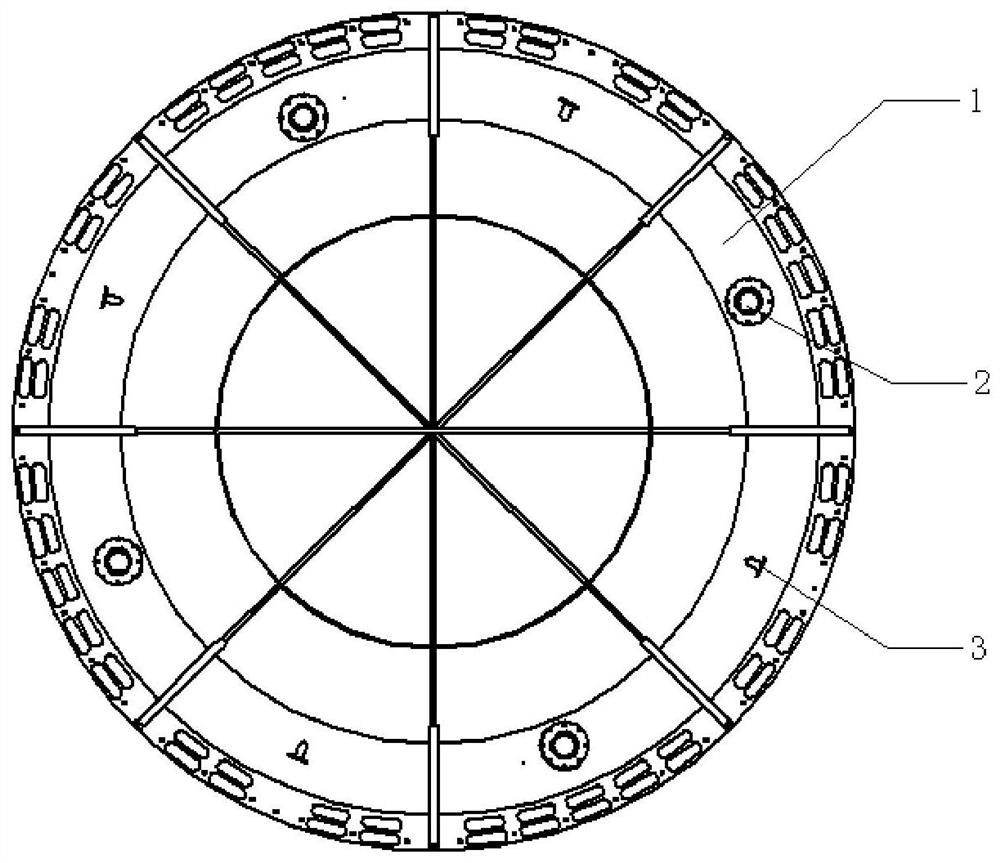

[0050] Such as Figure 1 to Figure 6 As shown, a heat-proof layer forming tool for the outsole of a returnable spaceship includes an upper mold 1, a middle mold 4, a lower mold 6, a guide wheel 5, a tray 10, a lifting ring 9, an observation window 2, a temperature sensor, and a glue injection pipeline 7. Vacuum pipeline 3, compression frame 12, compression plate 8.

[0051] Along the height direction, the tooling is divided into three layers, the upper mold 1, the middle mold 4, and the lower mold 6; The installation surface is in the middle of the height direction of the inner tray 10; the upper mold 1 is used as an upper cover, and after assembly, forms a closed cavity together with the middle mold 4 and the lower mold 6.

[0052] The lower mold 6 is located at the bottom of the tooling and has a concave mold structure. The distance between the inner wall and the heat-proof layer 11 of the outsole of the spacecraft is 20mm; the lowest part of the inner cavity of the lower m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com