Built-in cooling assembly type height sensor device for laser processing head

A technology of height sensor and laser processing head, which is applied in the direction of electromagnetic measuring devices, laser welding equipment, metal processing equipment, etc., can solve the problems of insufficient sensitivity of the heat removal method, increased product cost, and inability to guarantee the height sensor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

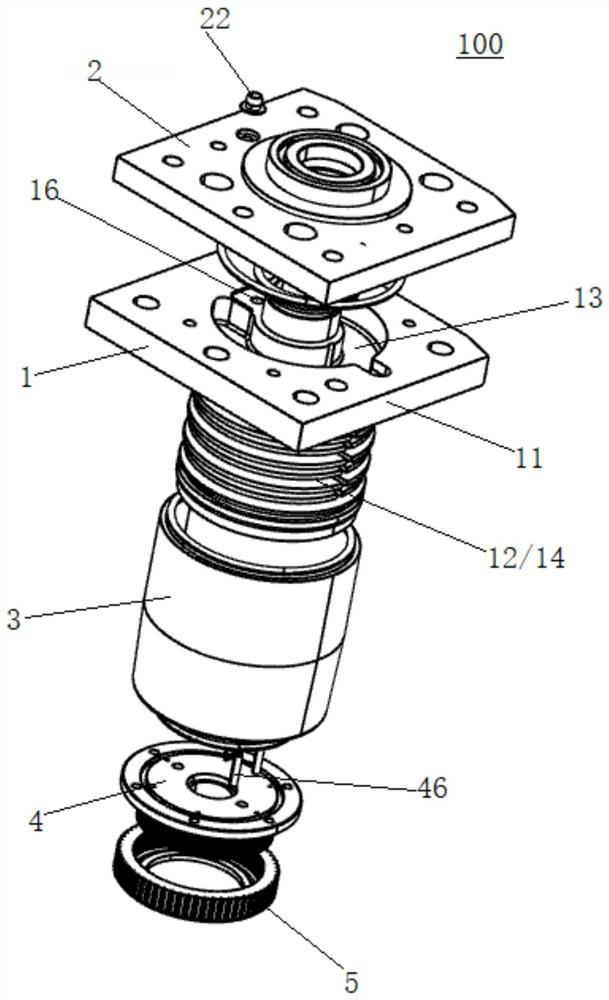

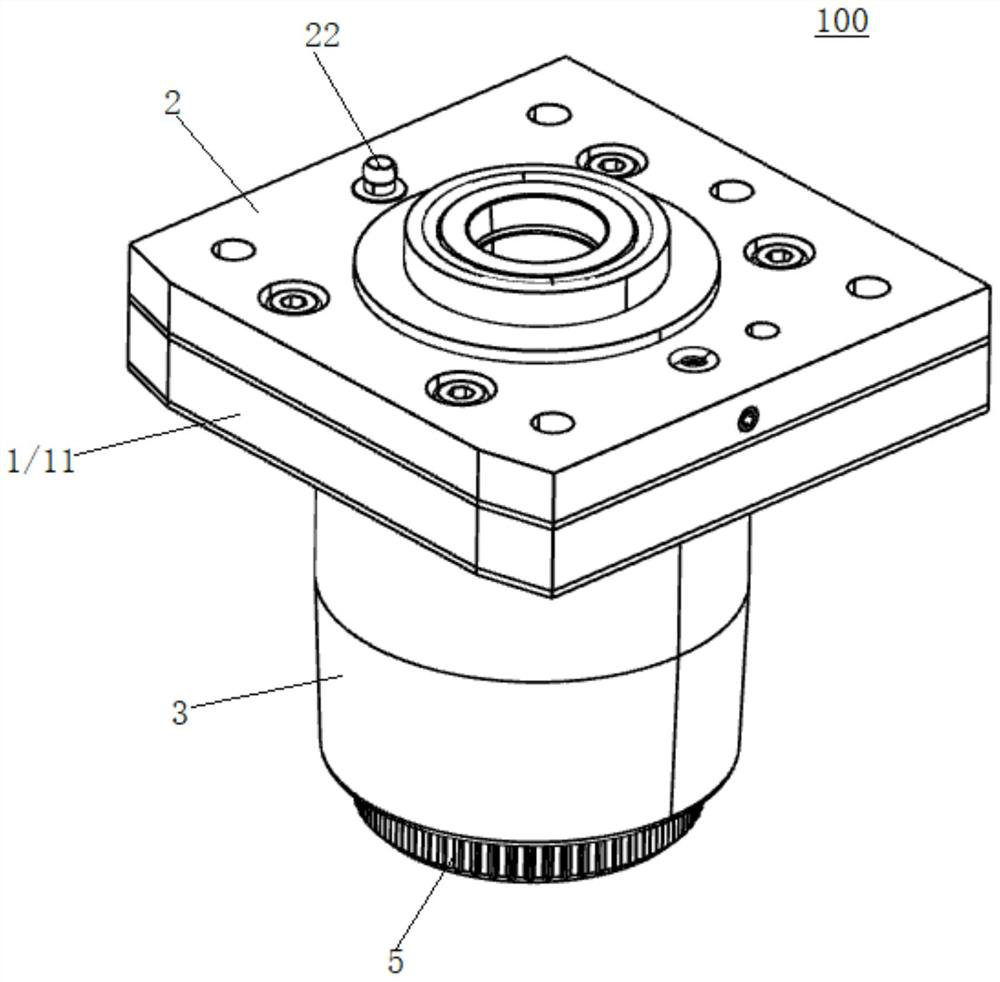

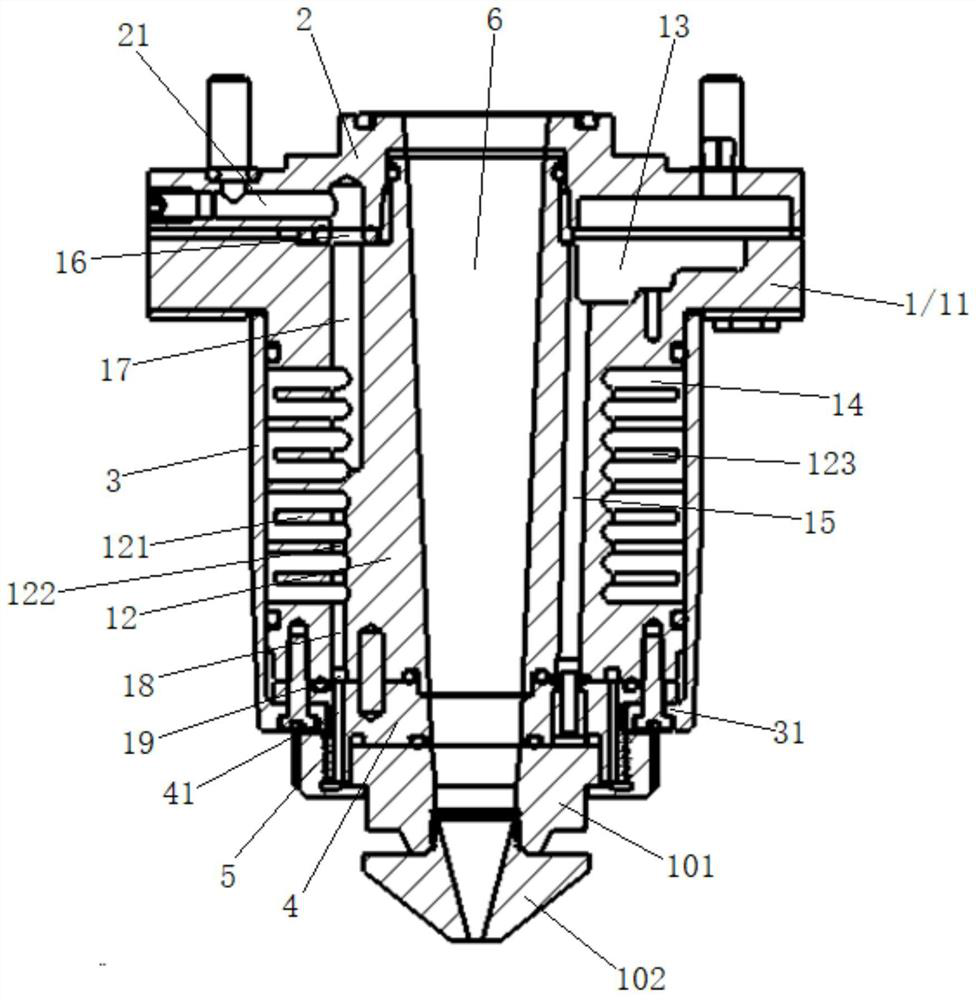

[0026] Please refer to Figure 1-Figure 6 , the present embodiment is a built-in cooling component type height sensor device 100 for a laser processing head, which includes a cooling main body 1, an upper cover plate 2 sealed and arranged on the cooling main body 1, and a casing wrapped around the outer circumference of the cooling main body 1 cylinder. 3. The ceramic body mounting seat 4 arranged at the bottom of the cooling body 1, the ceramic body locking sleeve 5 that locks the ceramic body nozzle assembly on the ceramic body mounting seat 4 as a whole, and the vertically penetrating laser channel 6, the cooling body 1 It includes a connection cover 11 that is covered with the upper cover 2, and a cooling cylinder 12 located below the connection cover 11. The upper surface of the connection cover 11 is concavely formed with a first receiving groove 13, and the inside of the first receiving groove 13 A sensor circuit board (not shown in the figure) is provided, and the oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com