Patents

Literature

257results about How to "Reduce the impact of measurement accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Measurement system of relative altitude and relative attitude of air vehicle and measurement method thereof

InactiveCN103257348AIncrease sampling rateImprove dynamic measurement accuracyAcoustic wave reradiationFlight vehicleAtmospheric pressure

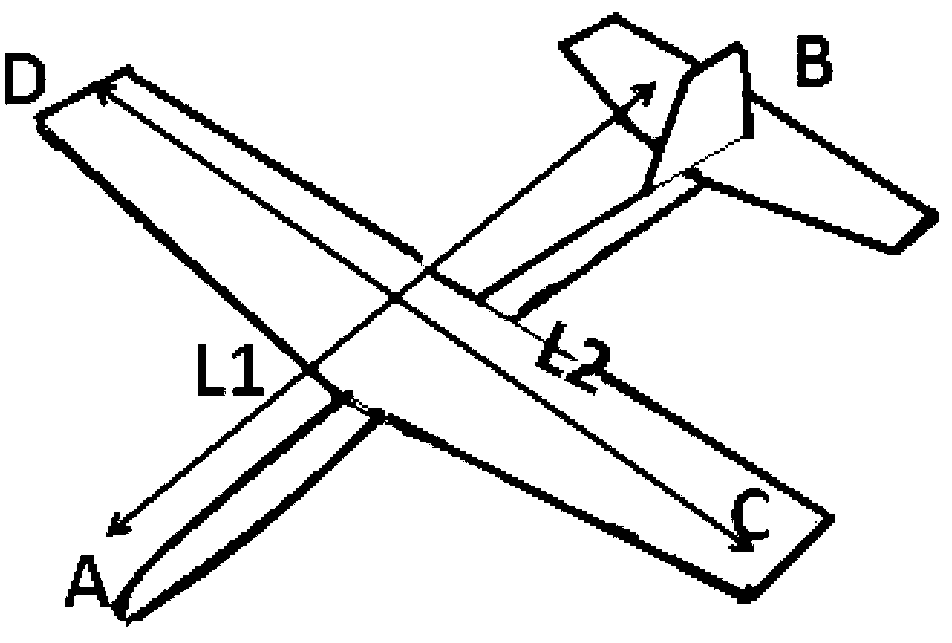

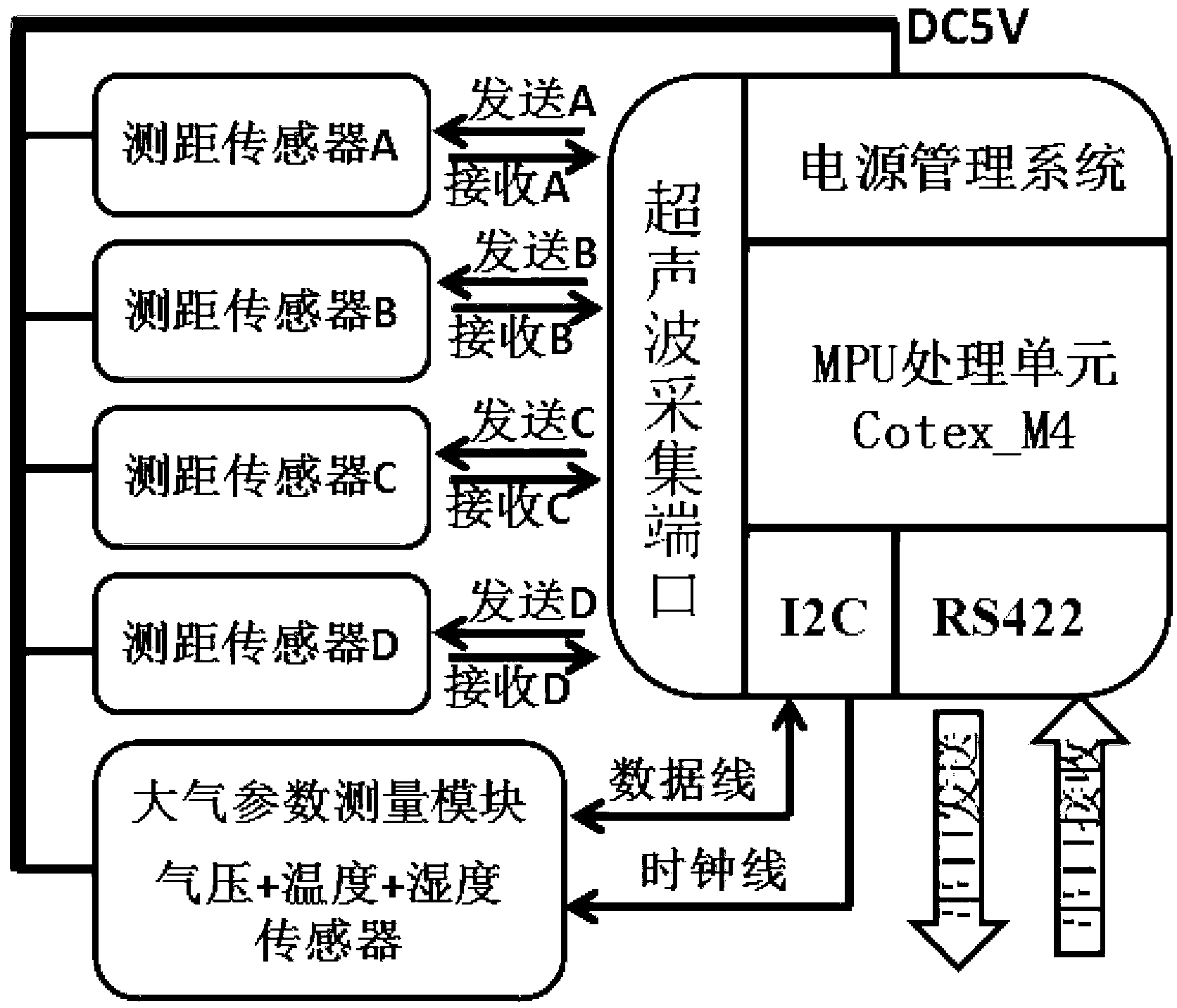

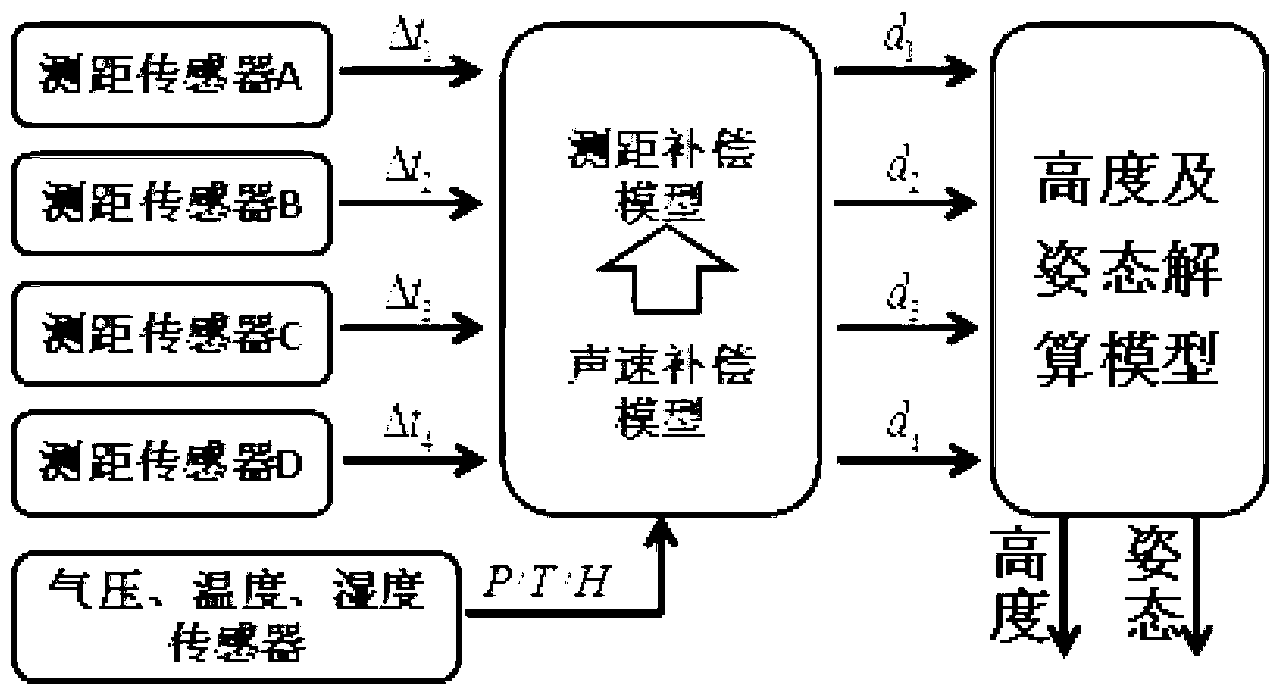

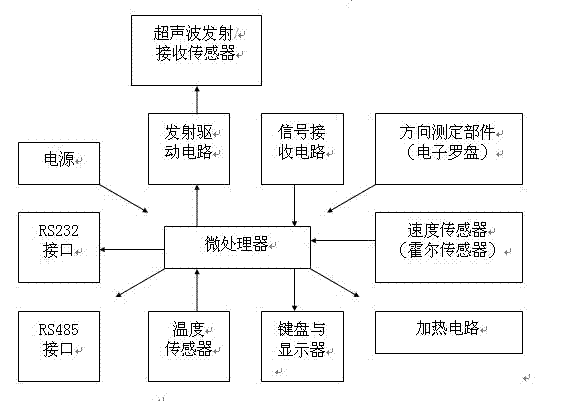

The invention discloses a measurement system of a relative altitude and a relative attitude of an air vehicle and a measurement method thereof. Four ultrasonic ranging modules are installed at different positions of the air vehicle, ultrasonic wave emitting and receiving of the ultrasonic ranging modules are controlled through an MPU, ultrasonic wave transmission time is calculated, pressure parameters, temperature parameters and humidity parameters of atmosphere are collected so that the transmission speed of the ultrasonic waves can be compensated, meanwhile by means of a range error compensation module, range errors of an ultrasonic ranging sensor are compensated, relative height data of the air vehicle and the ground are measured, a relative height calculation model and a relative attitude calculation model are built, and the precise relative height between the centers of wings of the air vehicle and a landing runway plane and attitude angle information of an ultrasonic installation plane relative to the runway plane are calculated. The measurement system and the measurement method improve precision and stability of measurement of the relative height and the relative attitude during landing of the air vehicle.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Mobile ultrasonic anemoclinograph and method for measuring wind speed and direction

InactiveCN102175887ASolve the technical problems that cannot meet the wind speed and direction measurement in mobile situationsSolve the technical problem that the position data cannot be obtained accuratelyIndication/recording movementFluid speed measurementUltrasonic sensorEngineering

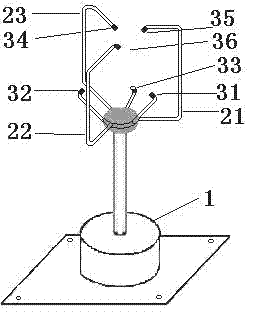

The invention provides a mobile ultrasonic anemoclinograph and a method for measuring wind speed and direction, wherein the device comprises an ultrasonic wind speed and direction measuring unit, a mobile system carrier speed measuring unit and a system direction measuring unit; the wind speed and direction measuring unit comprises a base, a control circuit board, six measuring arms and six ultrasonic transmitting / receiving sensors; the measuring arms are connected to the base and in an included angle at 60 degrees in turn; each measuring arm is provided with an ultrasonic sensor; the speed and direction measuring unit of the system carrier comprises a speed sensor and a direction measuring component; simultaneously, the invention further provides a method for measuring the wind speed anddirection in actual environment under a mobile condition by ultrasonic, wherein the method comprises the steps of: measuring the wind speed and direction parameters under the mobile condition by the ultrasonic wind speed and direction measuring unit; combining the measured moving speed and direction parameters of the system carrier; and calculating the measured wind speed and direction parametersin actual environment of the system under a mobile condition.

Owner:兴化市华伦达铸钢有限公司

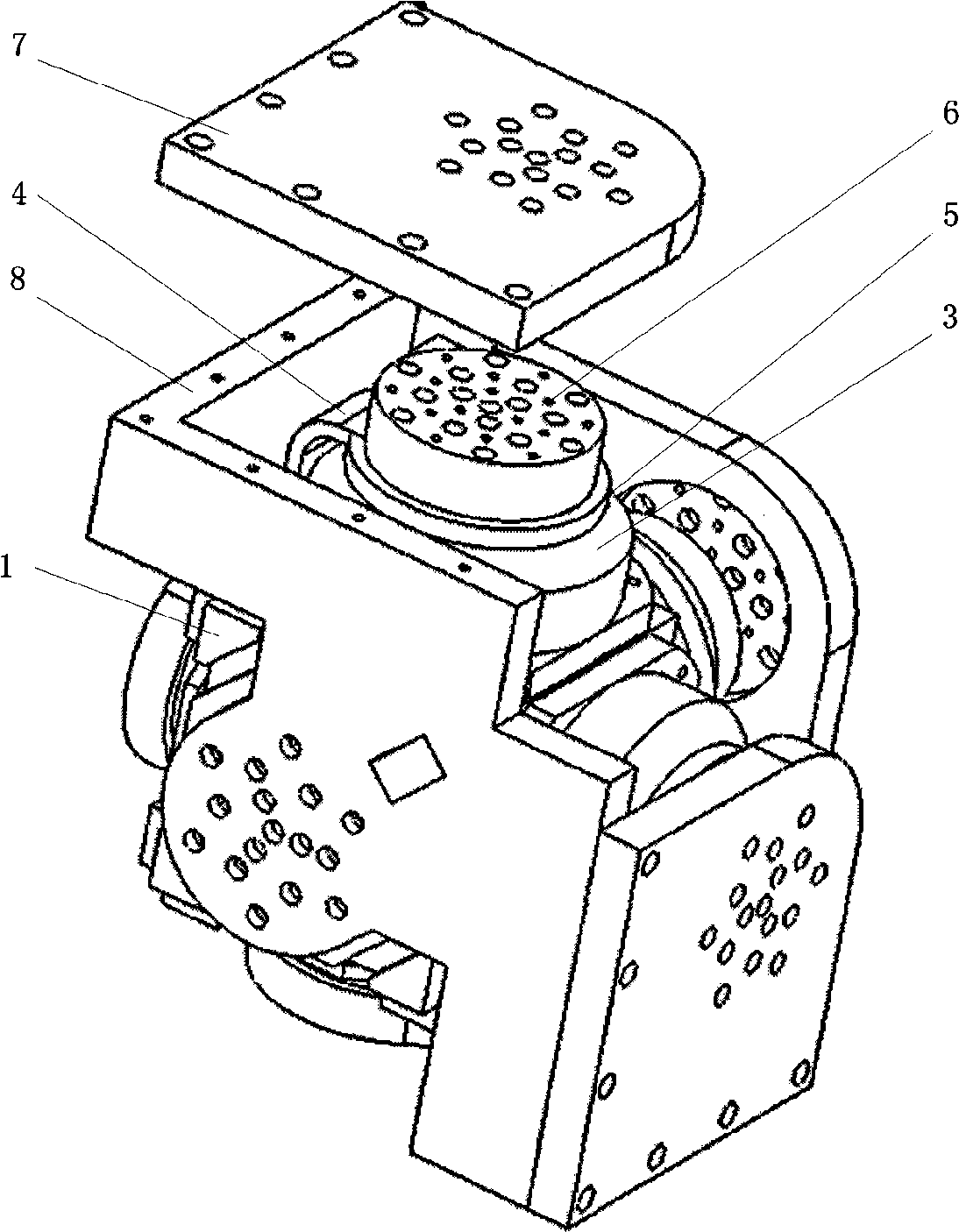

Inertia measurement device for deep-sea inertia navigation

InactiveCN101532840AHigh precisionReduce the impact of measurement accuracyNavigation by speed/acceleration measurementsAccelerometerMeasurement device

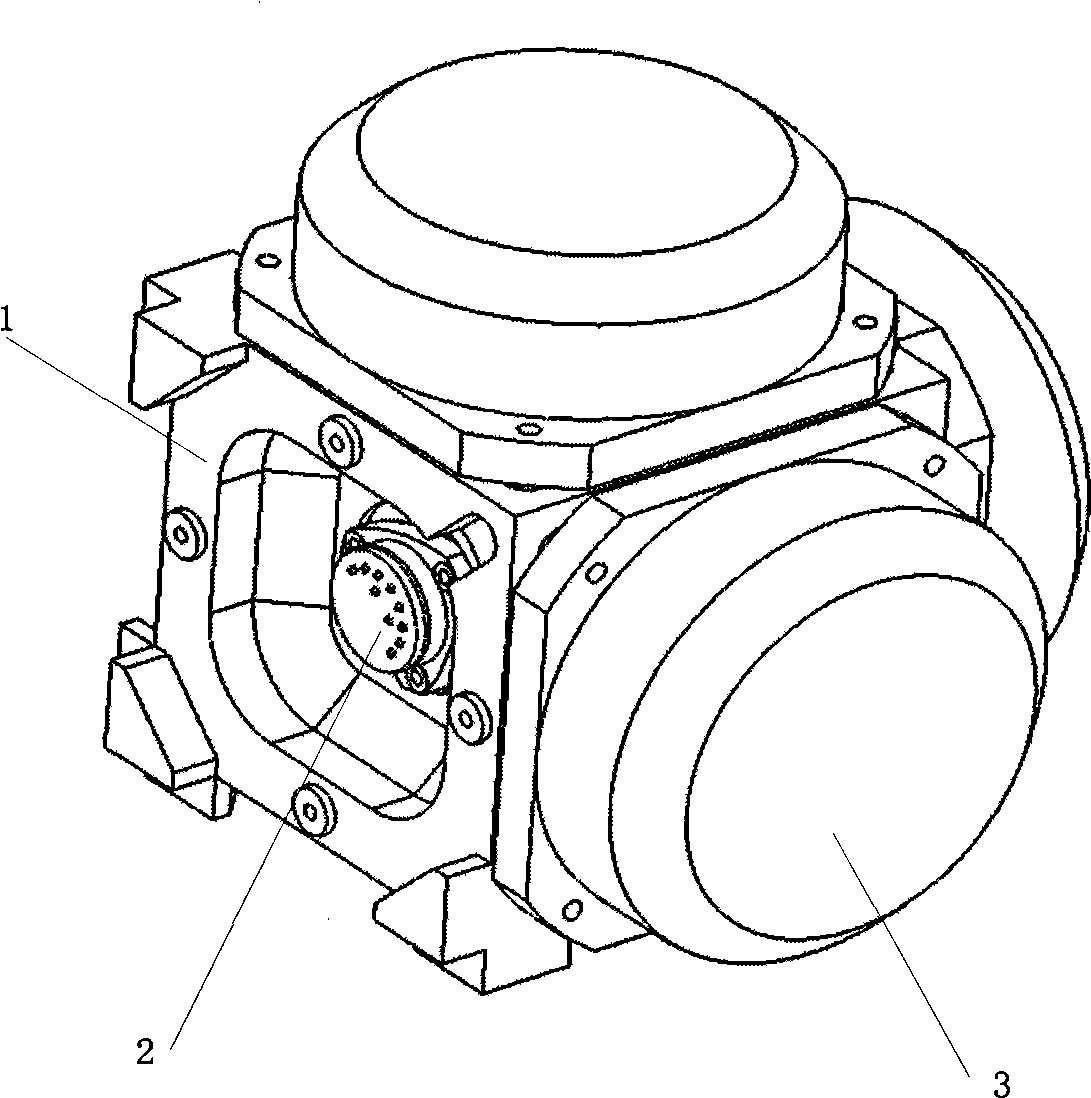

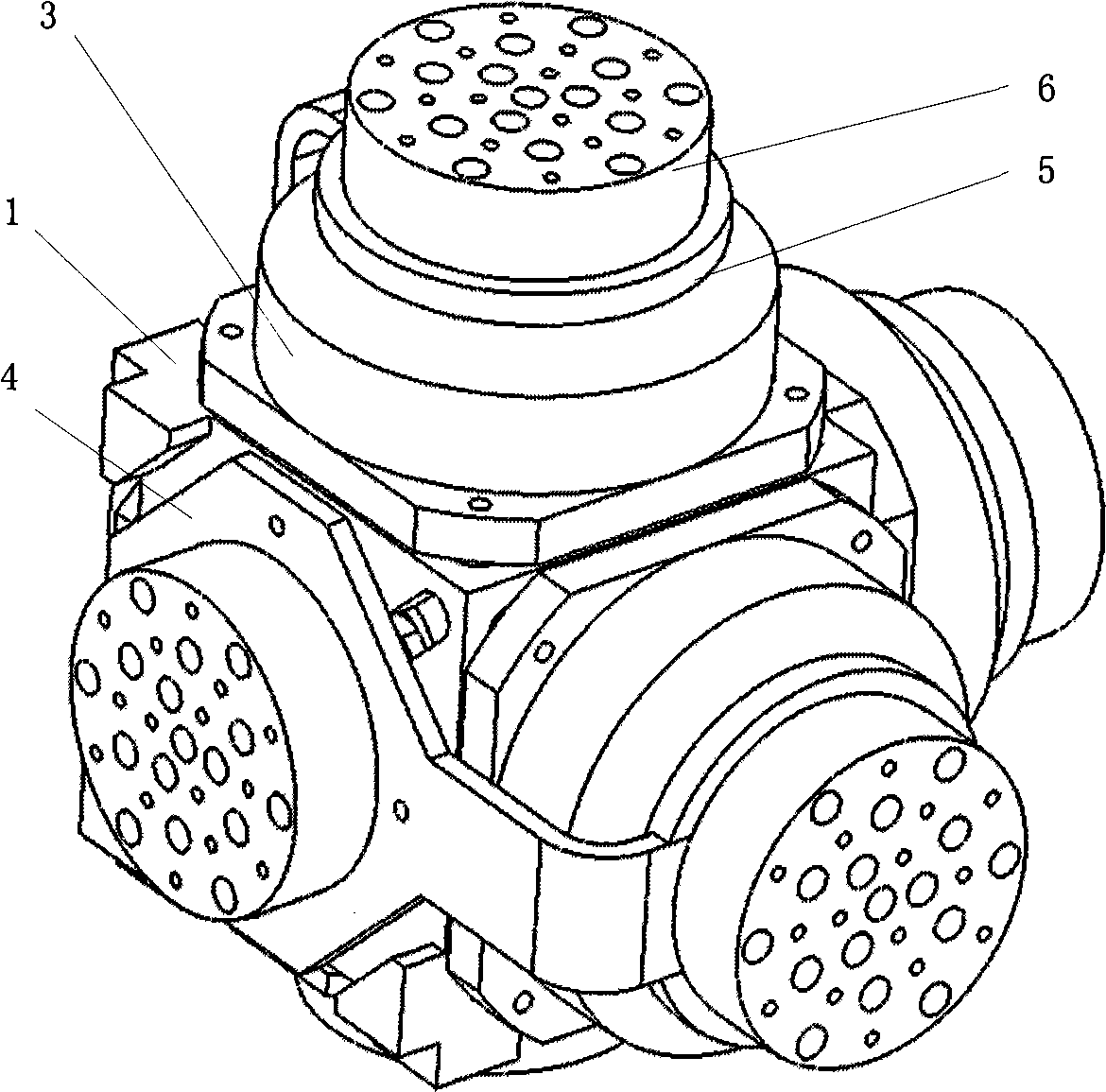

The invention relates to an inertia measurement device for deep-sea inertia navigation, which consists of six accelerometers, three gyros, a sensor bracket, a damping material, damping internal and external brackets and a mounting surface. The accelerometers and the gyros are arranged at the regular hexahedral sensor bracket. The damping internal bracket is fixed at the sensor bracket, the damping material is fixed at the damping internal bracket, the internal bracket is connected with the external bracket through the damping material and finally connected to the mounting surface, and the mounting surface is provided with a positioning surface for positioning at initial alignment. The measurement device is used for measuring the inertia of the deep-sea inertia navigation, and has the advantages of high precision and good damping property.

Owner:ZHEJIANG UNIV

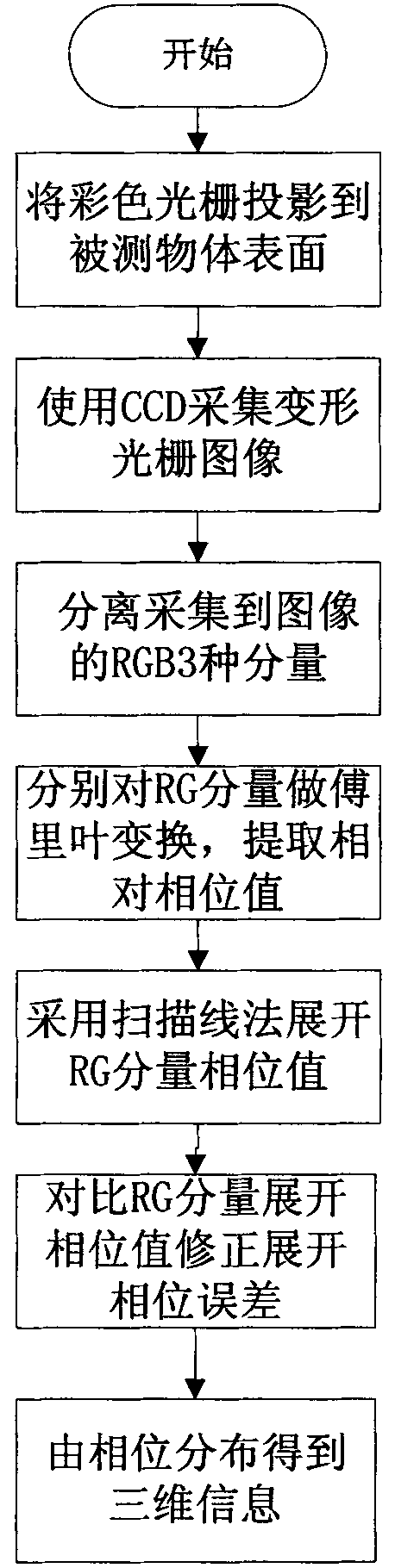

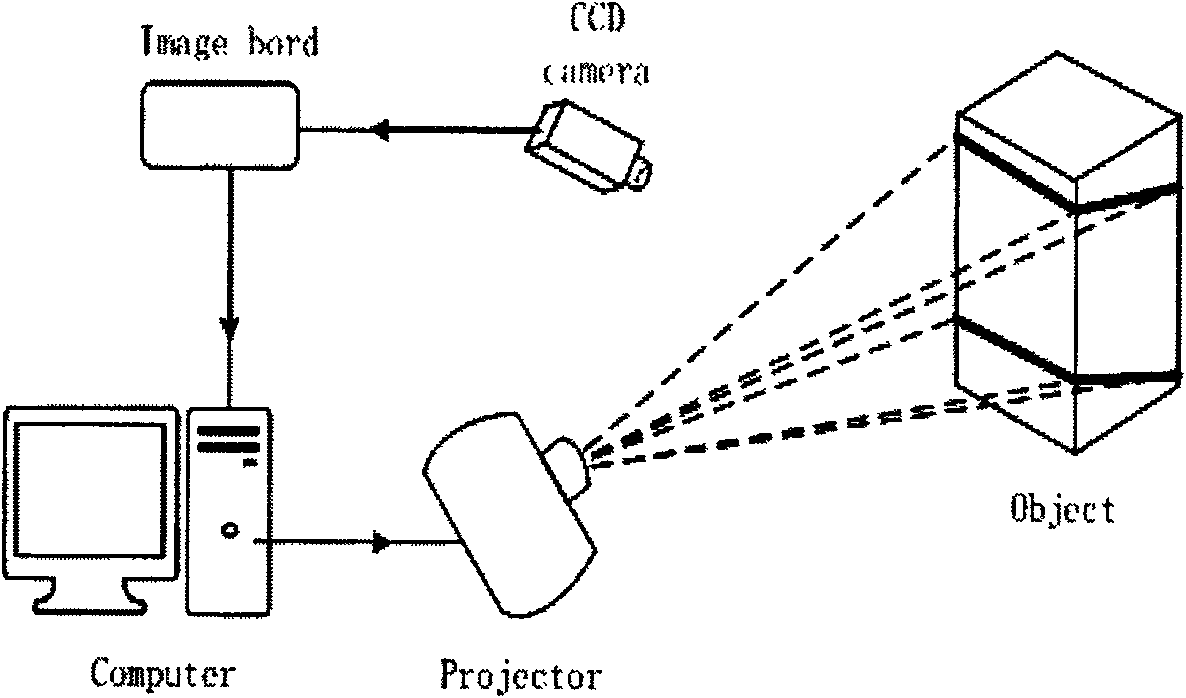

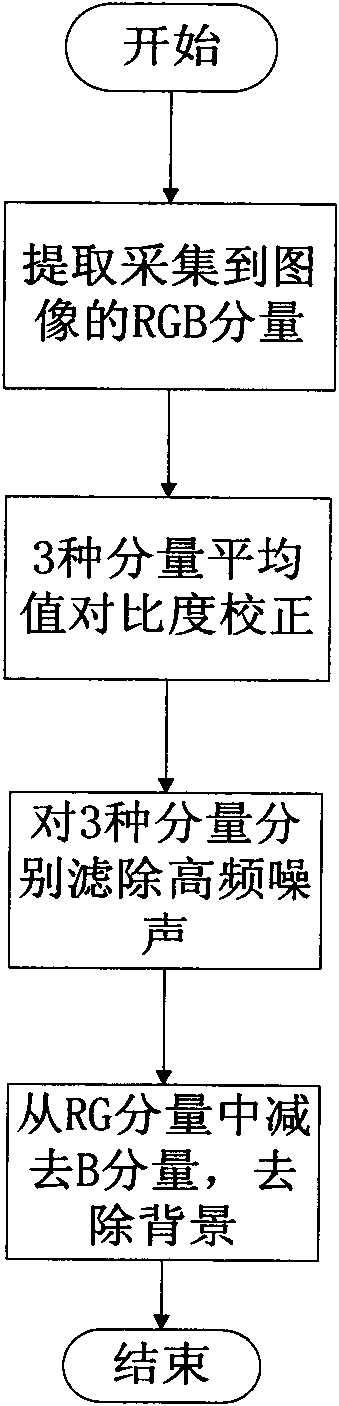

Tricolor raster projection-based Fourier transform three-dimensional measuring method

InactiveCN101986098AReduce the numberQuick measurementUsing optical meansPattern recognitionComputer graphics (images)

The invention discloses a new tricolor raster projection-based Fourier transform three-dimensional measuring method, which mainly aims to accurately work out the phase distribution of raster images, and then obtain the three-dimensional topography information of objects according to the phase distribution. The method is implemented through the steps of setting the gray values of R and G components in a projected raster to follow a sinusoidal variation regulation with two different frequencies, and setting a B component as the average value of the R component or the G component, and forming a color raster image to be projected on an object to be measured; and separating the three components of an acquired deformed color raster image, then processing the separated three gray images, meanwhile, restraining background components and high-frequency noises when the Fourier transform is used to calculate relative phases, and carrying out comparison and calibration on the three gray images with the relative phase values under the two frequencies when the phases are unwrapped so as to achieve the purpose of precisely calculating absolute phases containing height information. Only one raster image is required to be projected in the whole measuring process, therefore, the method of the invention is good in real-time.

Owner:HAIAN COUNTY SHENLING ELECTRICAL APPLIANCE MFG +1

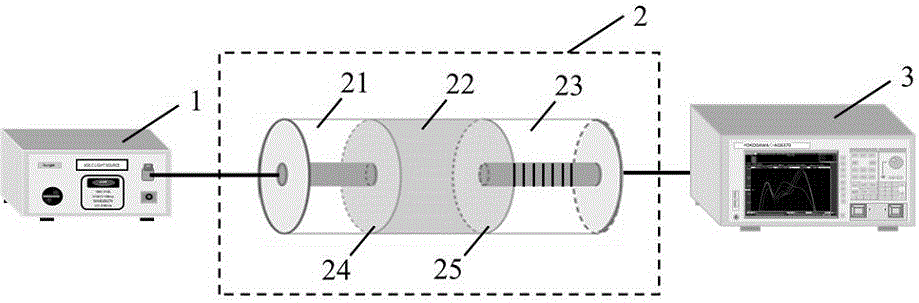

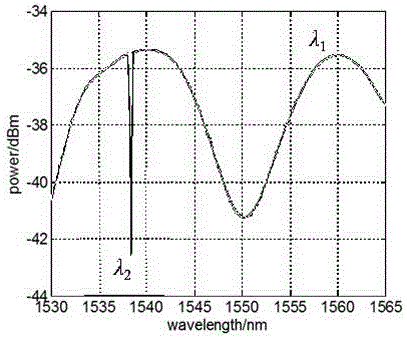

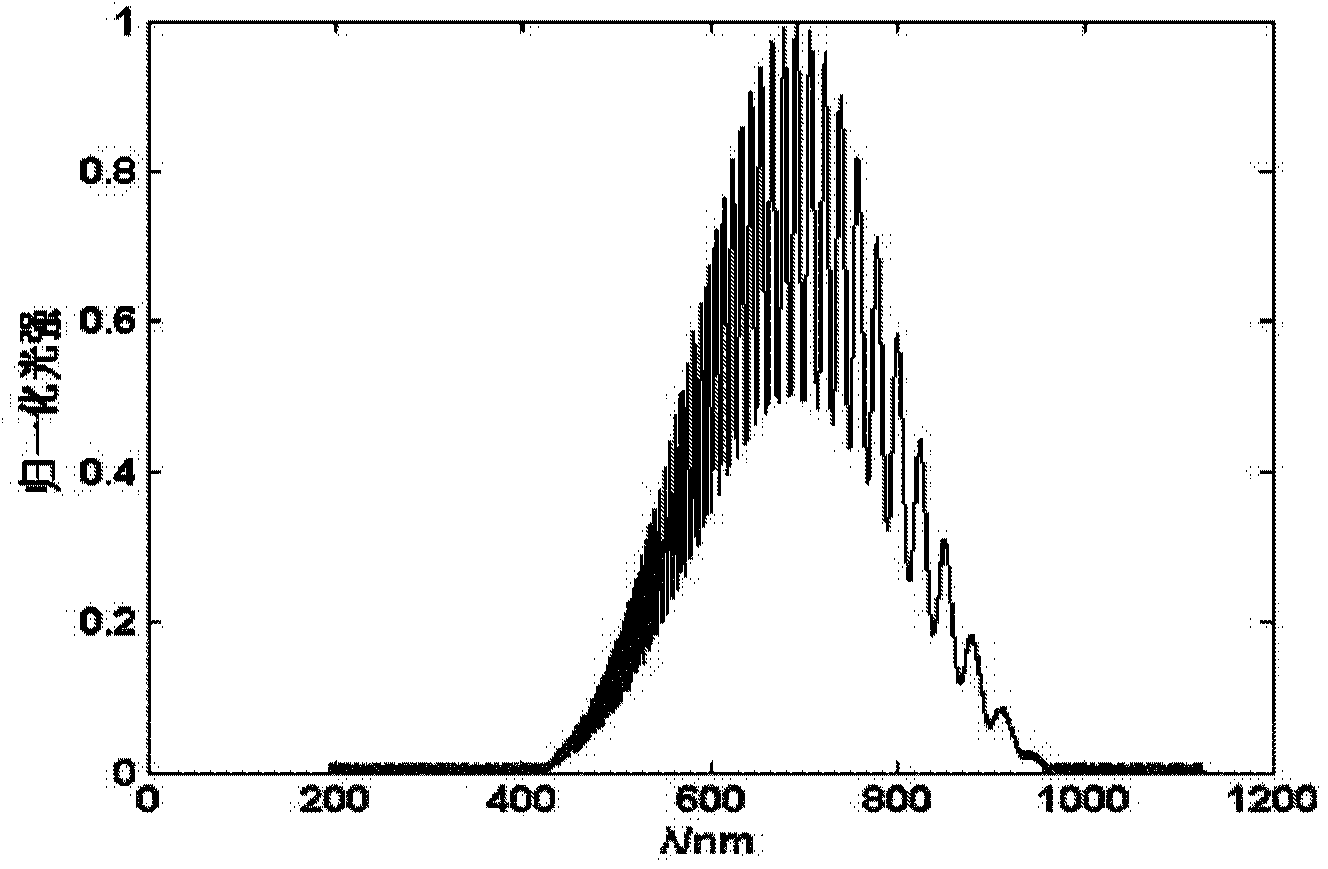

Optical fiber sensor capable of simultaneously measuring hydrogen concentration and temperature

ActiveCN105841840ASimple preparation processLow costPhase-affecting property measurementsThermometers using physical/chemical changesGratingFiber gratings

The invention provides an optical fiber sensor capable of simultaneously measuring the hydrogen concentration and the temperature. The optical fiber sensor comprises a wide-spectrum light source 1, a sensing unit 2 and a spectrometer 3. The sensing unit 2 is composed of a single-mode optical fiber 21, a coreless optical fiber 22 and a single-mode fiber grating 23. The outside of the coreless optical fiber 22 is plated with a palladium-based hydrogen sensitive film. The light emitted from the wide-spectrum light source 1 passes through the single-mode optical fiber 21 to enter the coreless optical fiber 22, and is excited at a plurality of higher order modes within a fusion area 24. In the above modes, the lights are propagated inside the coreless optical fiber at different propagation constants and interfere with each other. An interference light signal enters the single-mode fiber grating 23, and will be reflected when meeting the Bragg reflection condition of the single-mode fiber grating 23. When the external hydrogen concentration changes, the interference spectrum will move. When the ambient temperature changes, both the interference spectrum and the Bragg reflection wavelength will move. Therefore, the hydrogen concentration and the temperature can be deduced through observing the movement amount of the interference spectrum and the movement amount of the Bragg wavelength. As a result, the high-precision measurement of the hydrogen concentration can be realized.

Owner:NORTHEASTERN UNIV

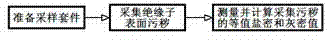

A method for on-site sampling and pollution degree measurement of insulator pollution

InactiveCN102288515ALess heavy workAvoid contamination lossWeighing by removing componentWithdrawing sample devicesEngineeringInsulator contamination

The invention discloses a method for on-site sampling and pollution degree measurement of insulator pollution. The method adopts a sampling cloth to directly wipe the pollution on the surface of the insulator to be tested without taking off the insulator, and completes the collection of pollution on the surface of the insulator to be tested. According to GB / T16434 or Q / GDW152-2006 measure the salt density and ash density value of the dirt on the sampling cloth, that is to get the salt density and ash density value of the surface of the insulator to be tested. The method of the invention does not need to take off the insulator, and has the advantages of convenient on-site measurement, small sampling workload, accurate measurement data and the like.

Owner:WUHAN UNIV +1

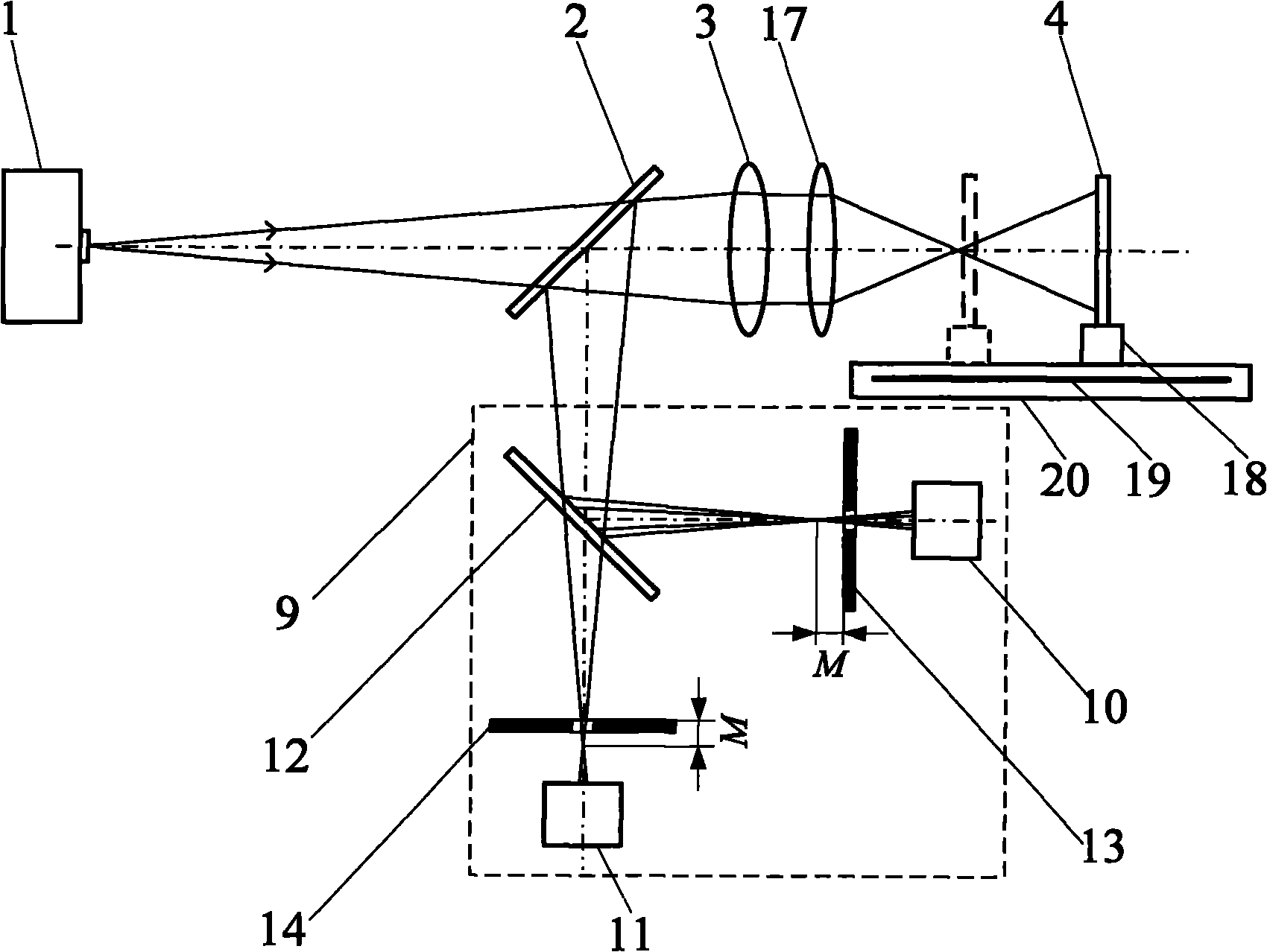

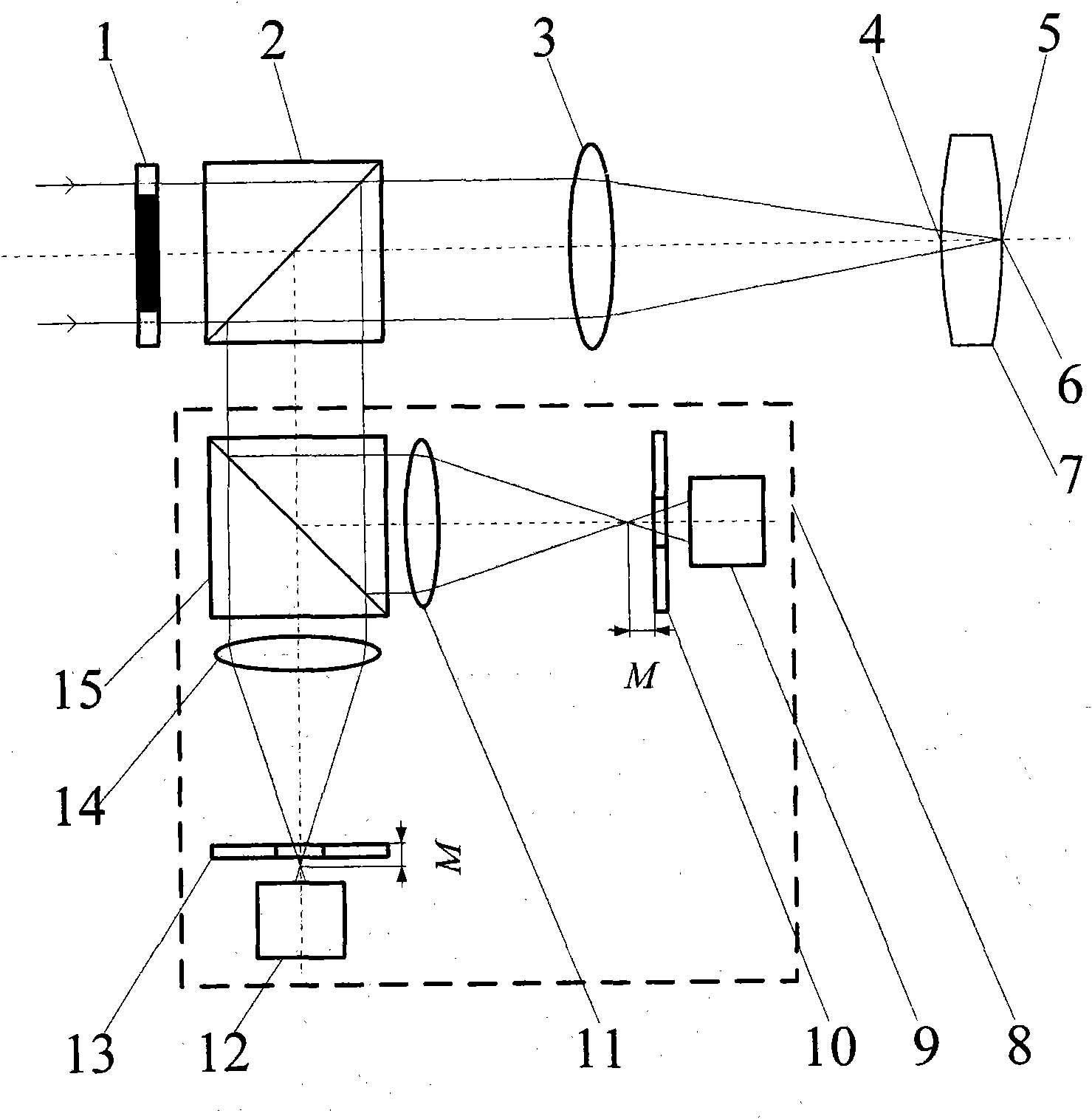

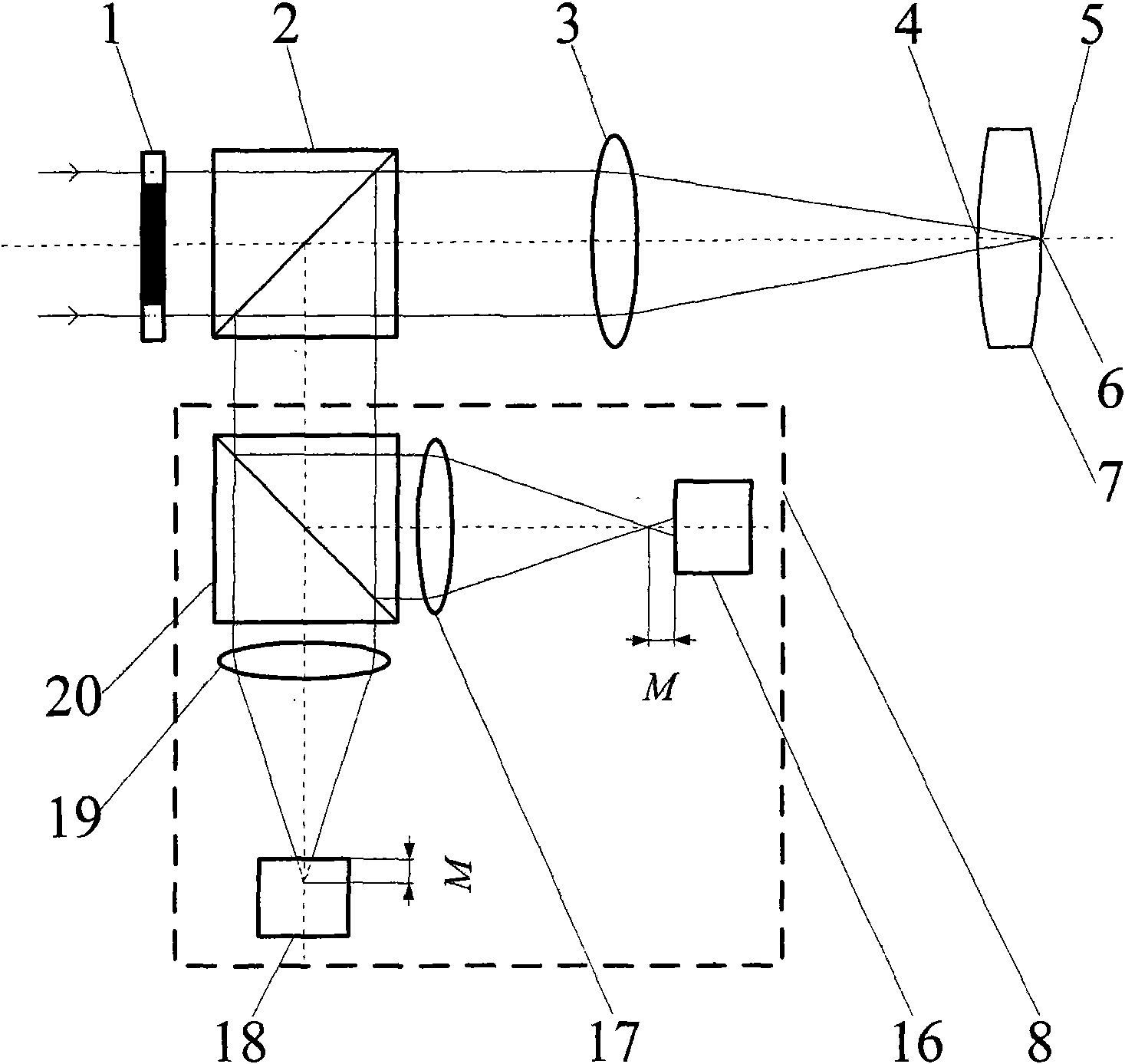

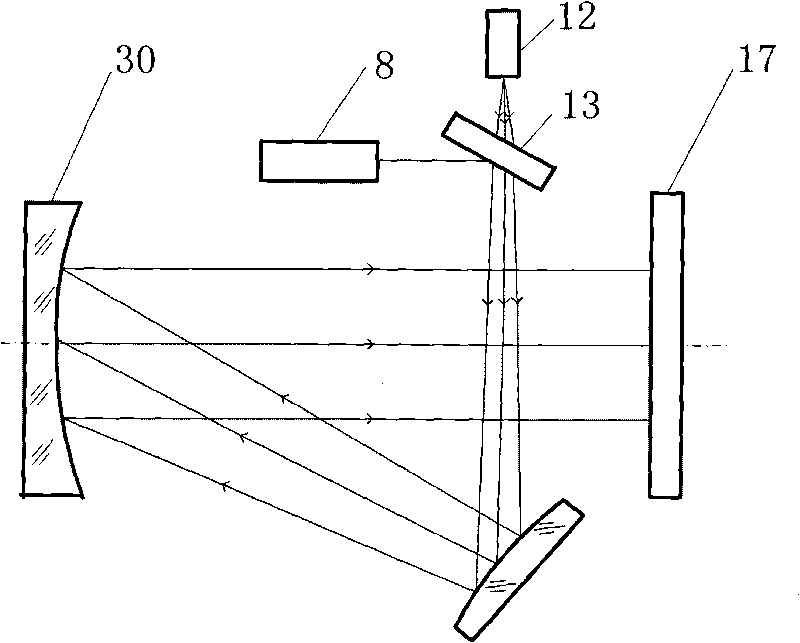

Multifocal holographic differential confocal super-large curvature radius measuring method and device

InactiveCN101858736AReduce mistakesReduce movement distanceUsing optical meansContact highInterference resistance

The invention relates to multifocal holographic differential confocal super-large curvature radius measuring method and device, belonging to the technical field of optical precision measurement. The method comprises the following steps of: firstly, calibrating the long-focus value of a multifocal holographic lens by utilizing a differential confocal system so as to reduce the system error of measurement; realizing non-contact high-precision positioning at the cat eye position and the cofocal position of a measured piece by utilizing a differential confocal fixed-focus principle; and subsequently, realizing the high-precision measurement of a super-large curvature radius by utilizing a geometrical optics principle. The device comprises a point light source, a first spectroscope, a collimator objective, the multifocal holographic lens, the differential confocal system, an adjusting frame, a length measuring system and a moving track. The invention integrates the differential confocal high-precision fixed-focus principle and a multifocal holographic lens compression optical path principle for the first time, has the advantages of small displacement distance of the measured piece, high measurement precision, high measurement speed, strong ambient interference resistance, no damage to the measured surface and the like and can be used for the high-precision non-contact measurement of the super-large curvature radius.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

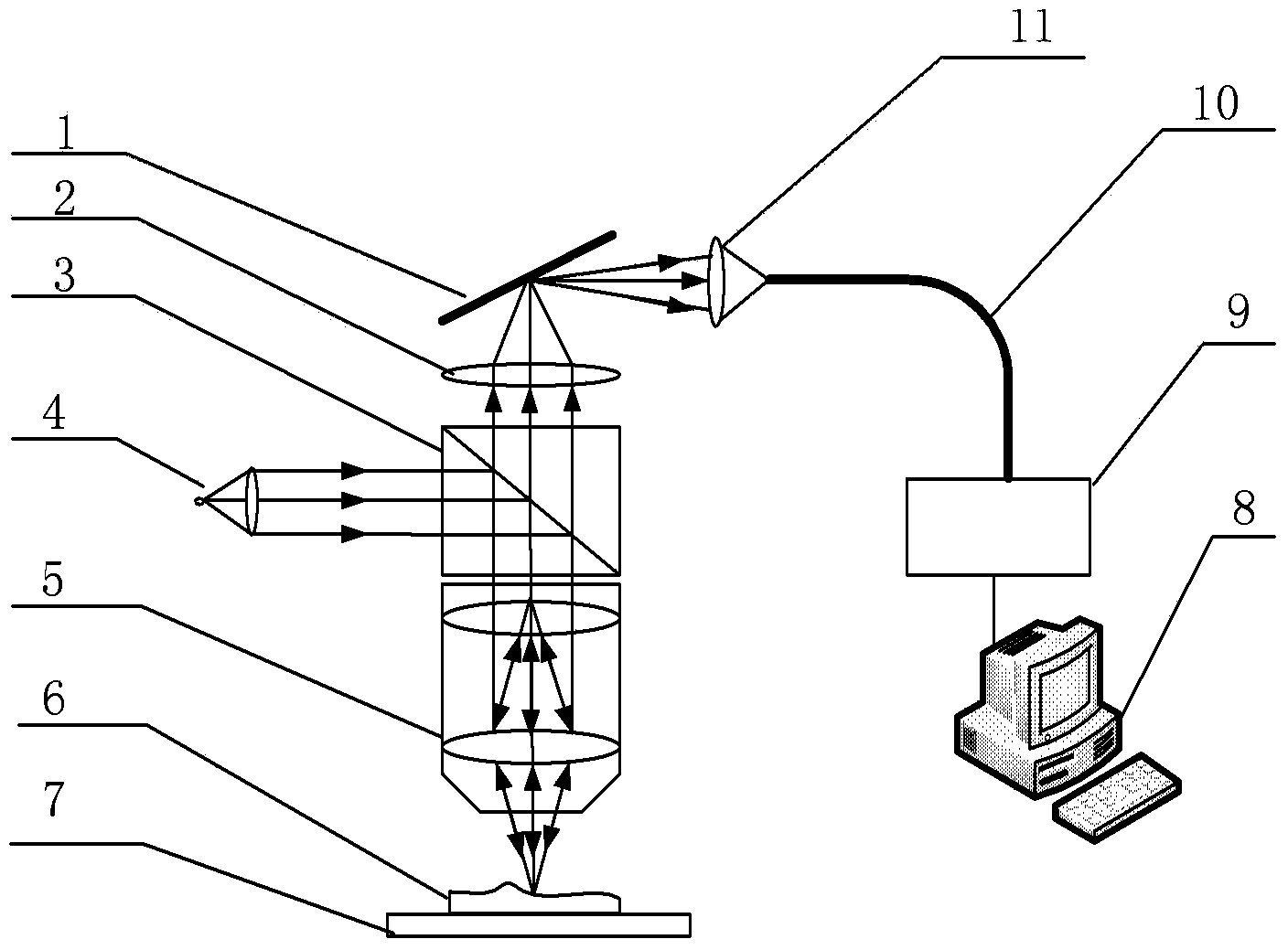

Micro-nano structure and morphology measurement device and method based on digital scanning and white light interference

ActiveCN103900493AEliminate the effects ofImprove anti-interference abilityUsing optical meansMicro nanoMeasurement device

The invention provides a micro-nano structure and morphology measurement device and method based on digital scanning and white light interference. The method includes the steps of projecting white light processed through beam expanding and collimation to the surface of an object to the measured and the surface of a reference mirror inside an interference microscope through semi-transparent and semi-reflective mirrors by means of a device composed of a digital micro mirror array, an imaging unit, the semi-transparent and semi-reflective mirrors, a white light source, an interference microscope objective, the object to be measured, a working table, a control unit, a spectrograph, optical fibers and an optical fiber coupling unit, enabling the white light to interfere with reflected light, obtaining the interference light intensities through the semi-transparent and semi-reflective mirrors, obtaining the surface of the digital micro mirror array through the imaging unit, controlling the micro mirror defection angles corresponding to pixels of the digital micro mirror array one by one so that the light intensities corresponding to different pixels can enter the optical fiber coupling unit one by one, transmitting spectral information obtained by a spectrograph and corresponding to the interference light intensities to the control unit, and conducting phase analysis on distribution of the spectrums corresponding to the interference light intensities to obtain the relative height of the surface of the object to be measured. The micro-nano structure and morphology measurement device and method have the advantages that the structure is simplified, the measurement accuracy is high, and the anti-interference capacity is high.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

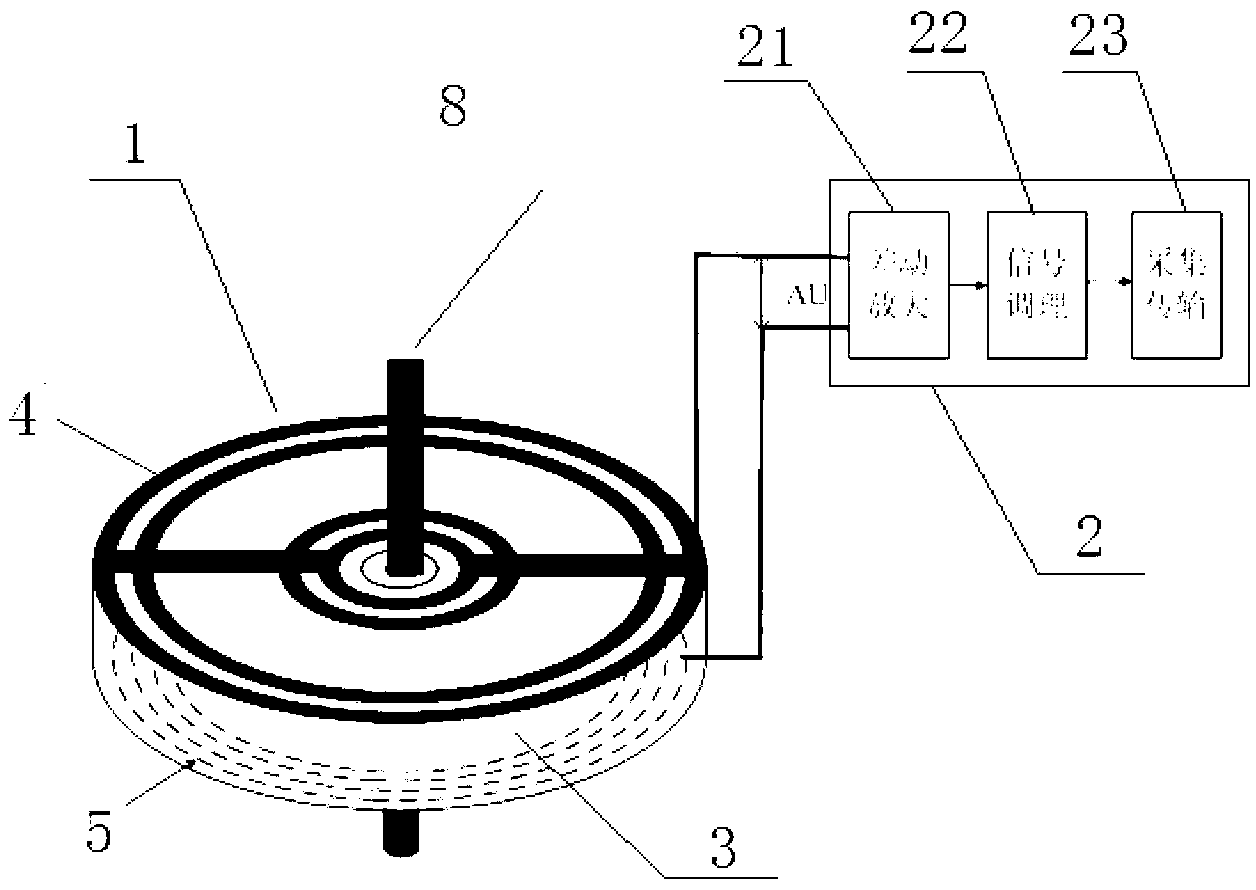

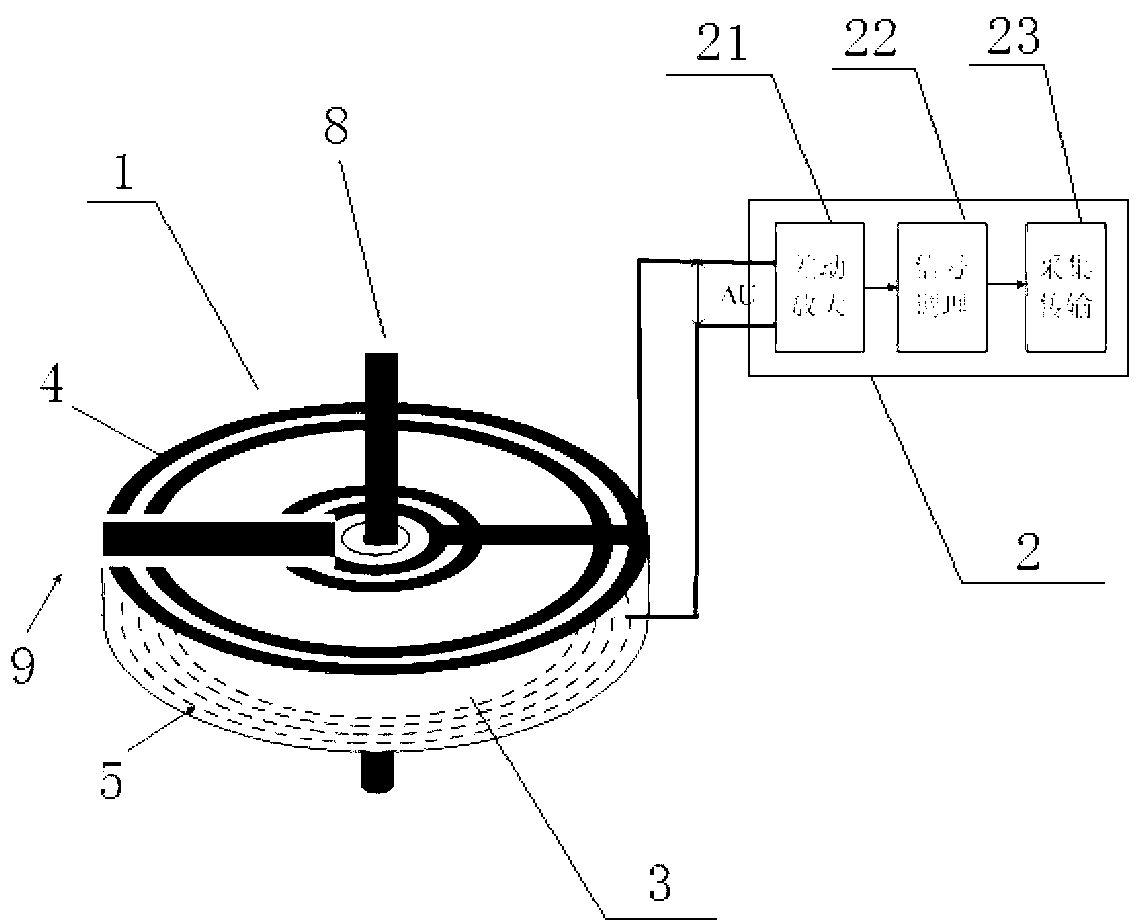

Non-contact D-dot voltage transformer and voltage detection self-correcting method thereof

ActiveCN103245824AReduce the impact of measurement accuracyAccurate measurementCurrent/voltage measurementSignal conditioningTransformer

The invention discloses a non-contact D-dot voltage transformer, which comprises a high-voltage electricity taking device, a differential amplifier unit, a signal conditioning unit and a collection and transmission unit. The high-voltage electricity taking device is used for obtaining an induction voltage signal on a wire to be tested and transmitting the induction voltage signal to the differential amplifier unit, the signal conditioning unit and the collection and transmission unit sequentially. The high-voltage electricity taking device is provided with a clamp groove, which is in a clamp opening structure and is used for allowing the wire to be inserted in and containing the wire; and after the wire is placed into the clamp groove, the broken part of the clamp groove is combined and fixed. With the adoption of the non-contact D-dot voltage transformer provided by the invention and a correction factor measuring circuit, errors of a detection circuit caused by the influence of geographical environments can be corrected, the non-contact D-dot voltage transformer can be conveniently connected to a voltage wire to be tested, the clamp opening type D-dot voltage transformer is enabled to conveniently measure correction factors in different work environments, and actual voltage in the work environments can be measured accurately, so the influence of the change of the geographical environments on the measurement accuracy of the D-dot voltage transformer is reduced to the maximum extent.

Owner:重庆灿泽科技有限公司

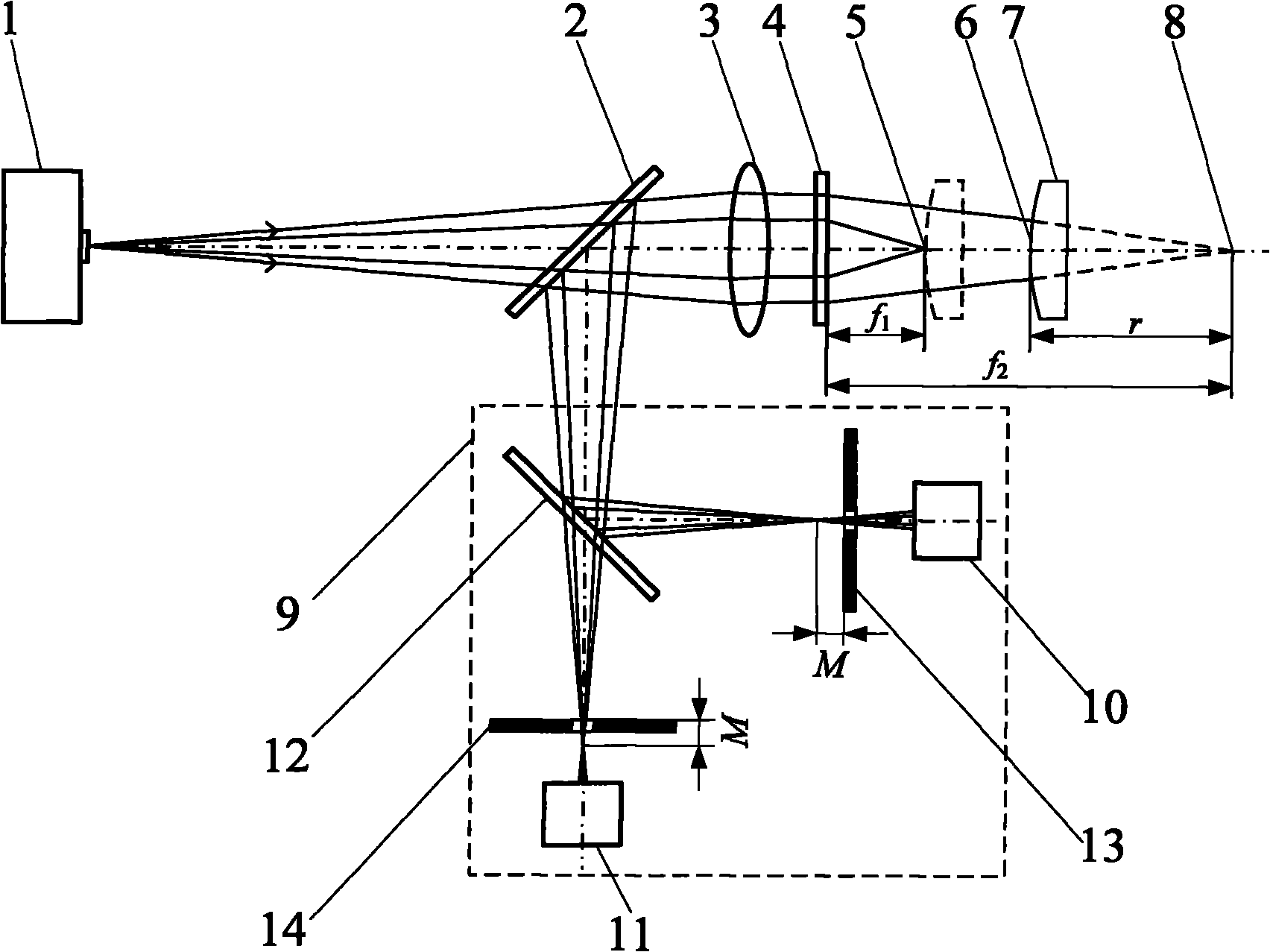

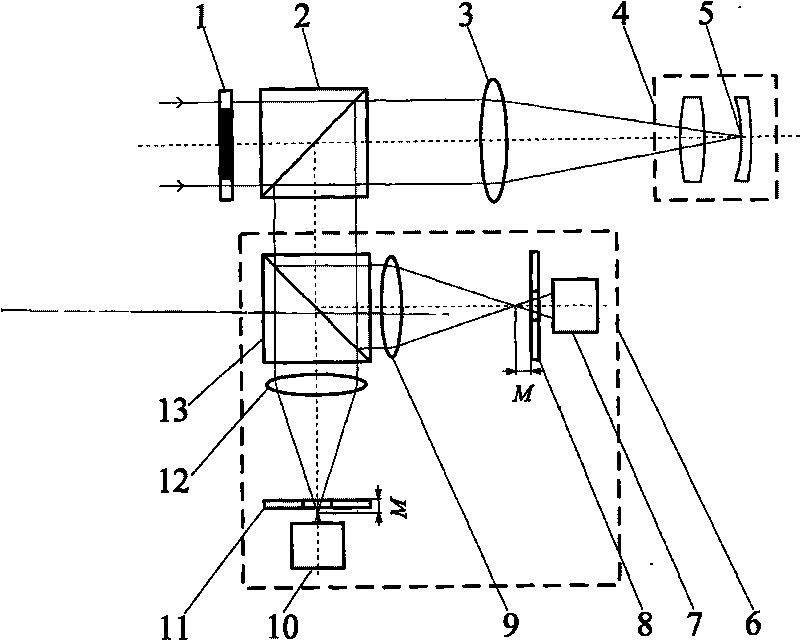

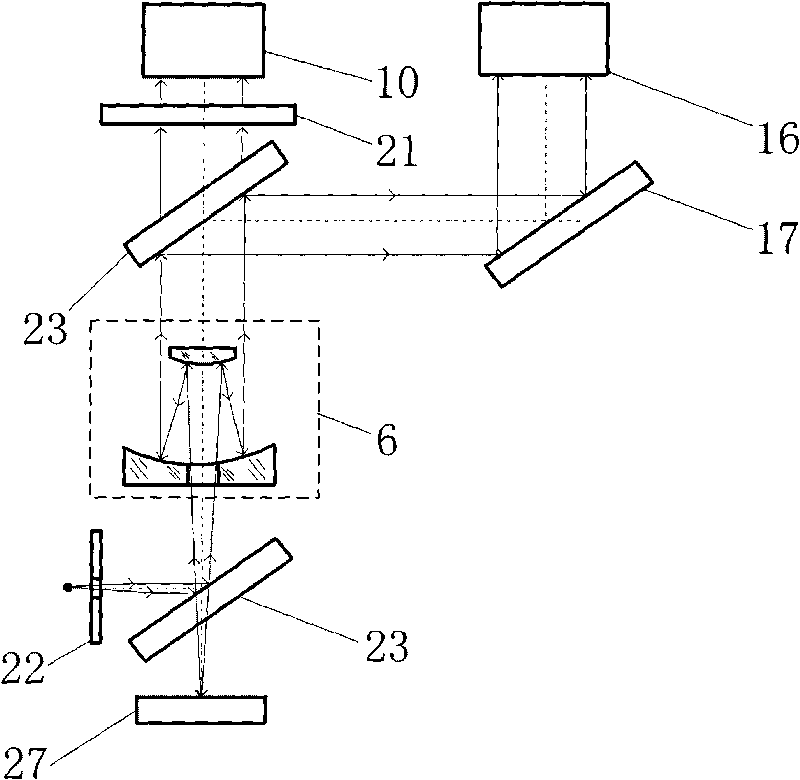

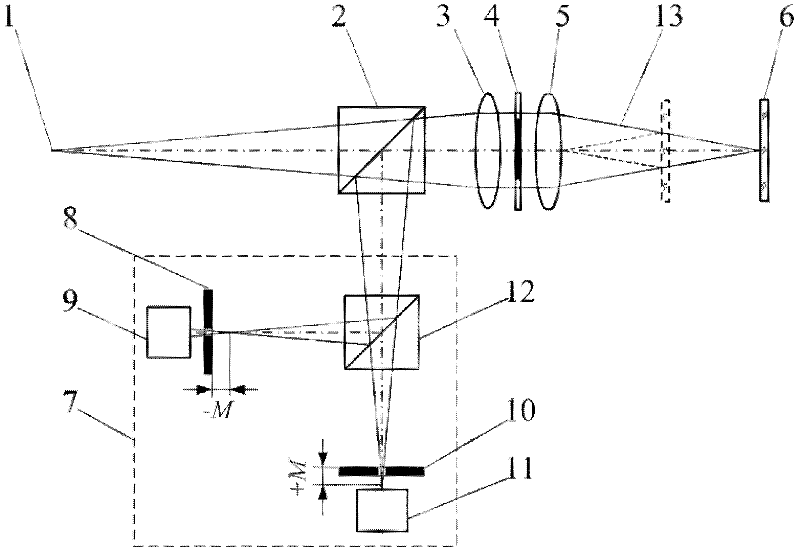

Method and device for measuring axial gaps of differential confocal lens set

The invention belongs to the technical field of optical precise measurement, in particular to a method and a device for measuring the axial gaps of a differential confocal lens set. The method comprises the following steps of: firstly, positioning the surfaces of various lens in the lens set with high precision by a differential confocal focusing principle to acquire position coordinates of a differential confocal measuring head in various positioning points; and then, sequentially calculating various axial gaps in the lens set by utilizing a beam track recurrence formula. Meanwhile, a circular pupil is introduced in a measuring light path to shield paraxial beams a hollow measuring light cone is formed so as to eliminate the influence of image difference on the measuring result. The invention realizes the non-contact high-precision positioning of the surfaces of the lens in the lens set by using the differential confocal light cone, has the advantages of long working distance, high measuring speed without dismounting the tested lens set in the measuring process, and the like, and can be used for the non-contact high-precision measurement of the axial gaps in the lens set.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

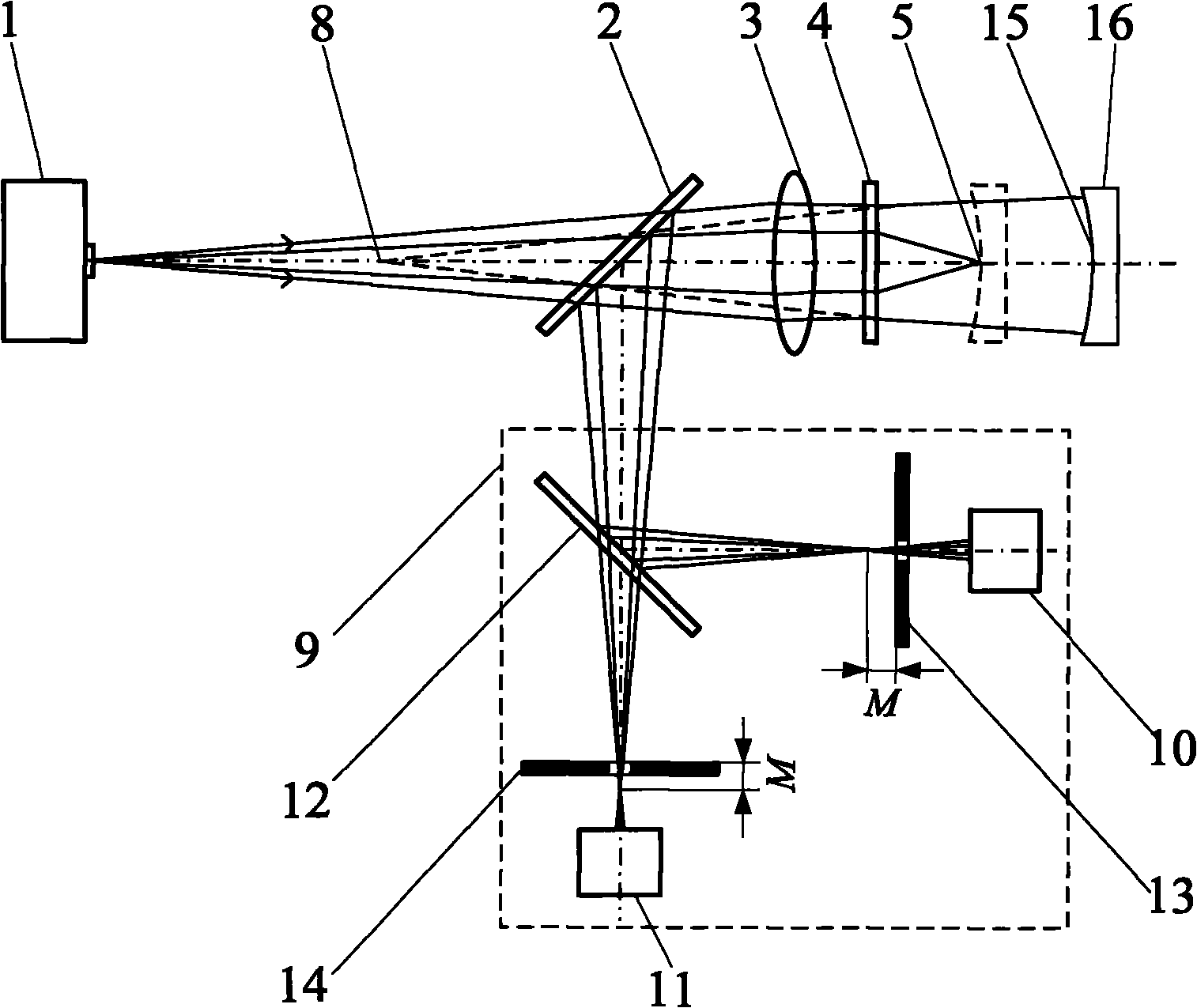

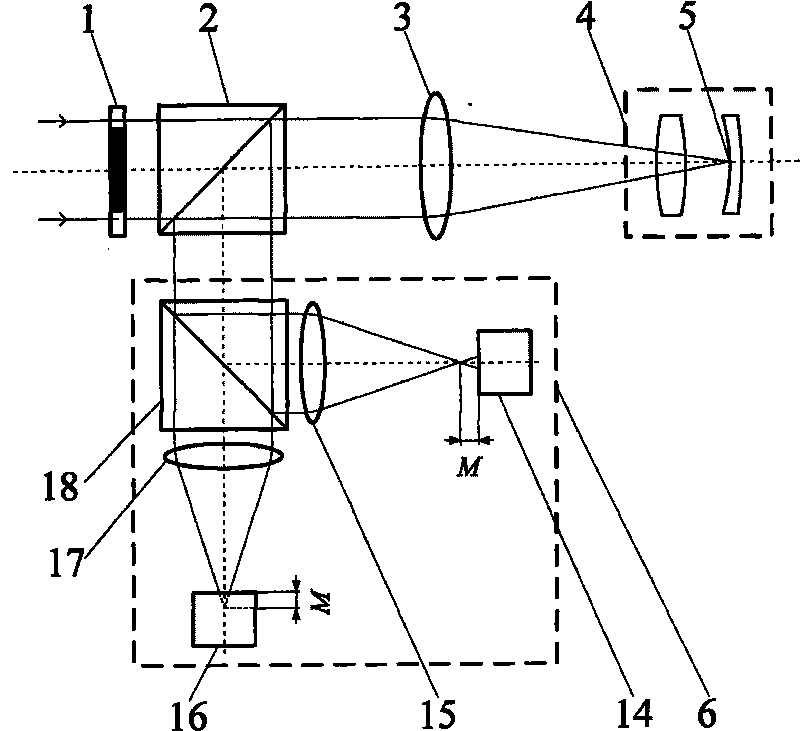

Method and device for measuring central thickness of differential confocal lens

ActiveCN101793500ANo damageFast measurementUsing optical meansOptical elementsContact highBeam splitting

The invention belongs to the technical field of optical precision measurement, relating to a method and a device for measuring the central thickness of a differential confocal lens. The method comprises the steps of: firstly, respectively determining the positions of a vertex at the front surface and a vertex at the rear surface of a lens to be measured through a differential confocal and fixed-focal principle and obtaining position coordinates positioned two times by a differential confocal measuring head; and then calculating the central thickness of the lens by utilizing a ray tracing formula. Meanwhile, an annular pupil is introduced into a measuring optical path to shade a paraxial ray and form a hollow measuring light cone, which lightens the influence of aberration on a measuring result. The device comprises a beam splitting system, an objective lens, a differential confocal system, a length measuring system and a mobile guide rail; wherein the beam splitting system, the objective lens and the lens to be measured are sequentially placed in an emergent ray direction of a collimation light source and the differential confocal system is placed in the reflecting direction of the beam splitting system. By utilizing the differential confocal light cone to accurately position the surface of the lens, the invention realizes the non-contact high precision measurement of the central thickness of the lens.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Co-graduation surface full-spectrum target

InactiveCN101726358AGood effectEliminate dissonanceRadiation pyrometrySpectrometry/spectrophotometry/monochromatorsSplit linesOptical axis

The invention belongs to the technical field of photoelectronic imaging and testing and relates to a co-graduation surface full-spectrum target. The invention comprises a substrate, a multi-quadrant detector, an asterion hole and a graduation line, wherein the multi-quadrant detector is arranged in the region outside the graduation line of the substrate, the graduation line is the region dividing line of the multi-quadrant detector, the asterion hole is a through hole and arranged in the centre of the substrate, and the substrate is made of full-spectrum transmission materials, the gradation line is any graph with identification characteristics. The invention applies the materials capable of transmitting full-spectrum waveband to the substrate of a gradation plate, greatly reduces the influence of manual or mechanical regulation control conversion on measurement precision. The graduation plate is capable of realizing the integrated functions of visual, infrared and laser graduation targets, has the advantages of high precision, small volume and light weight, is free from imbalance, and can be applied to a full-spectrum multi-optical axis consistency detection system for realizing graduation collimation with high precision and without imbalance.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

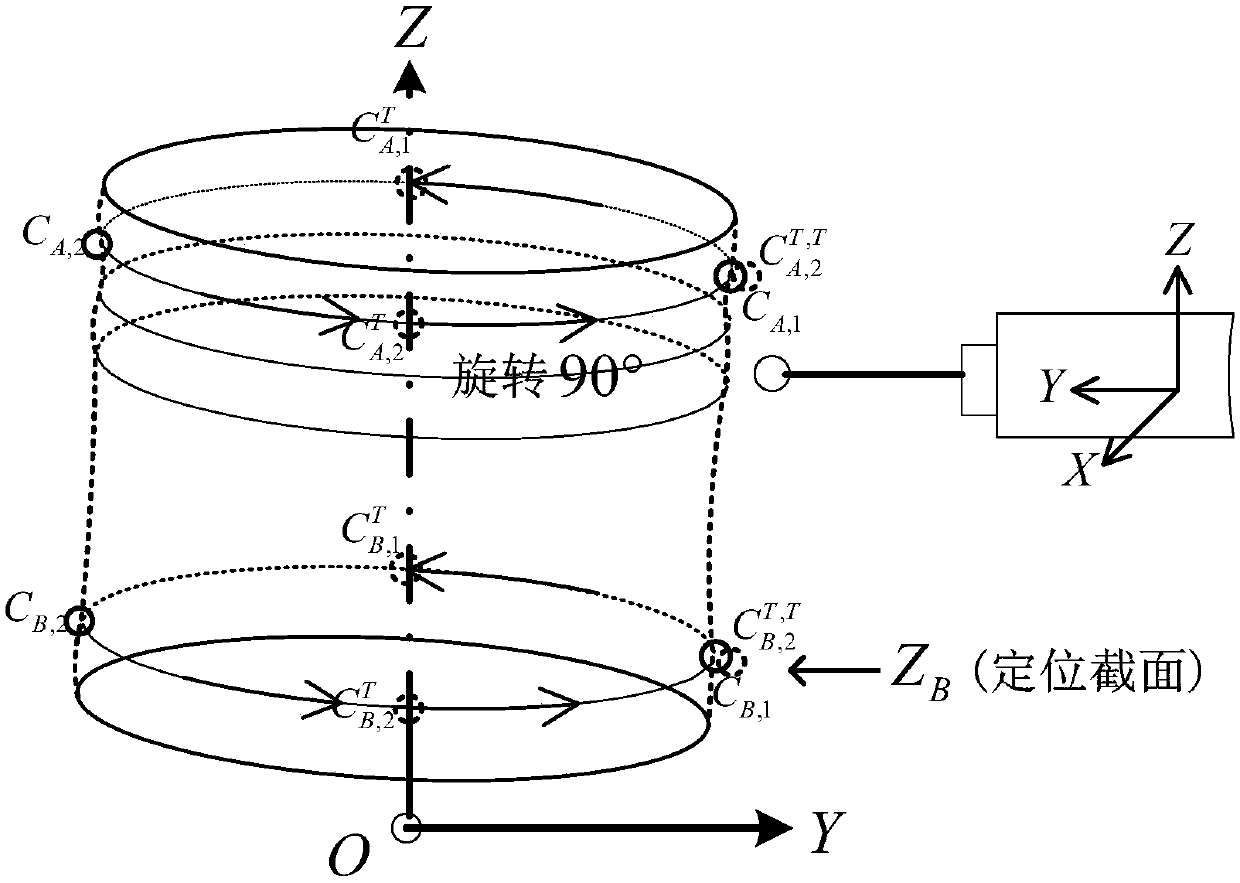

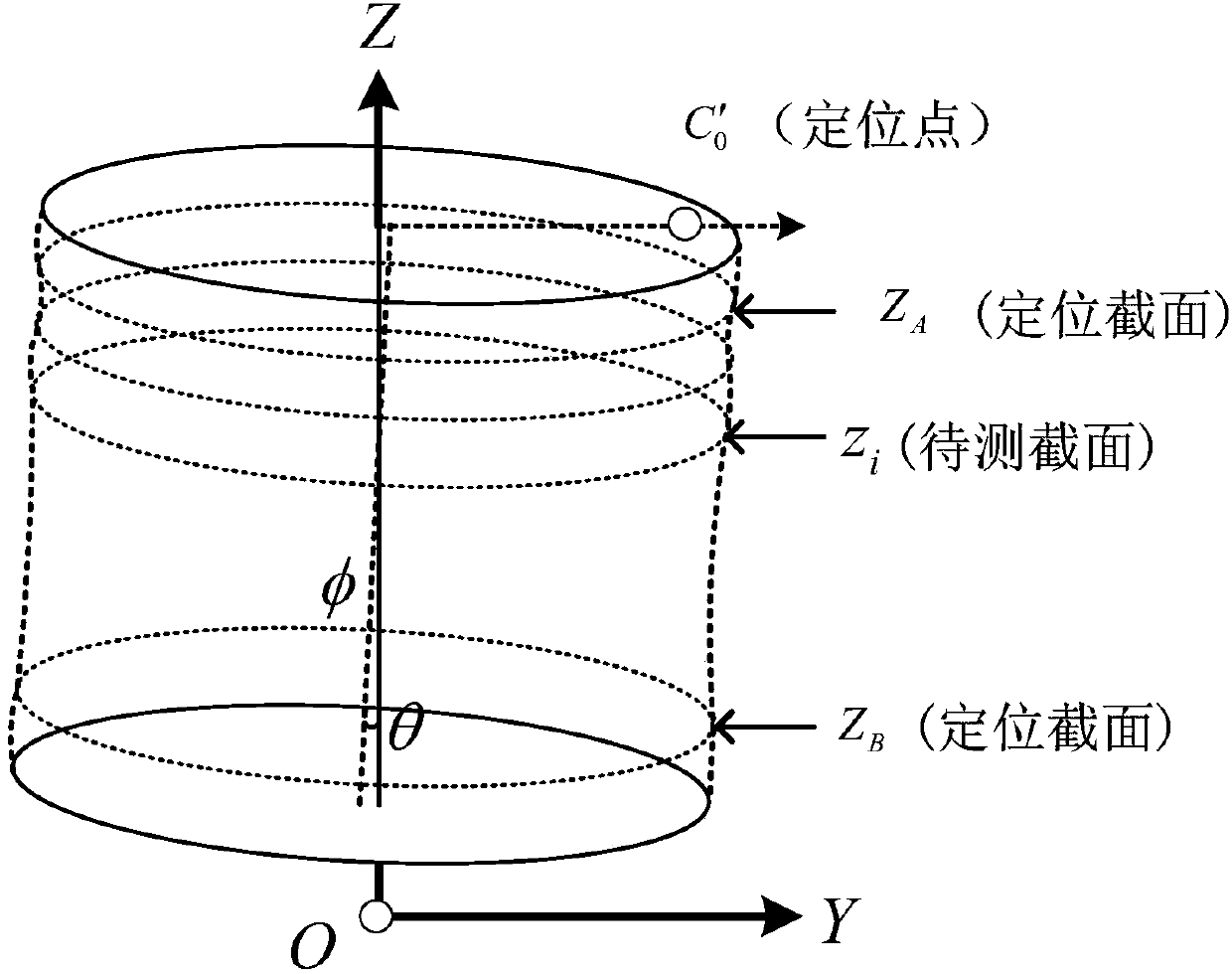

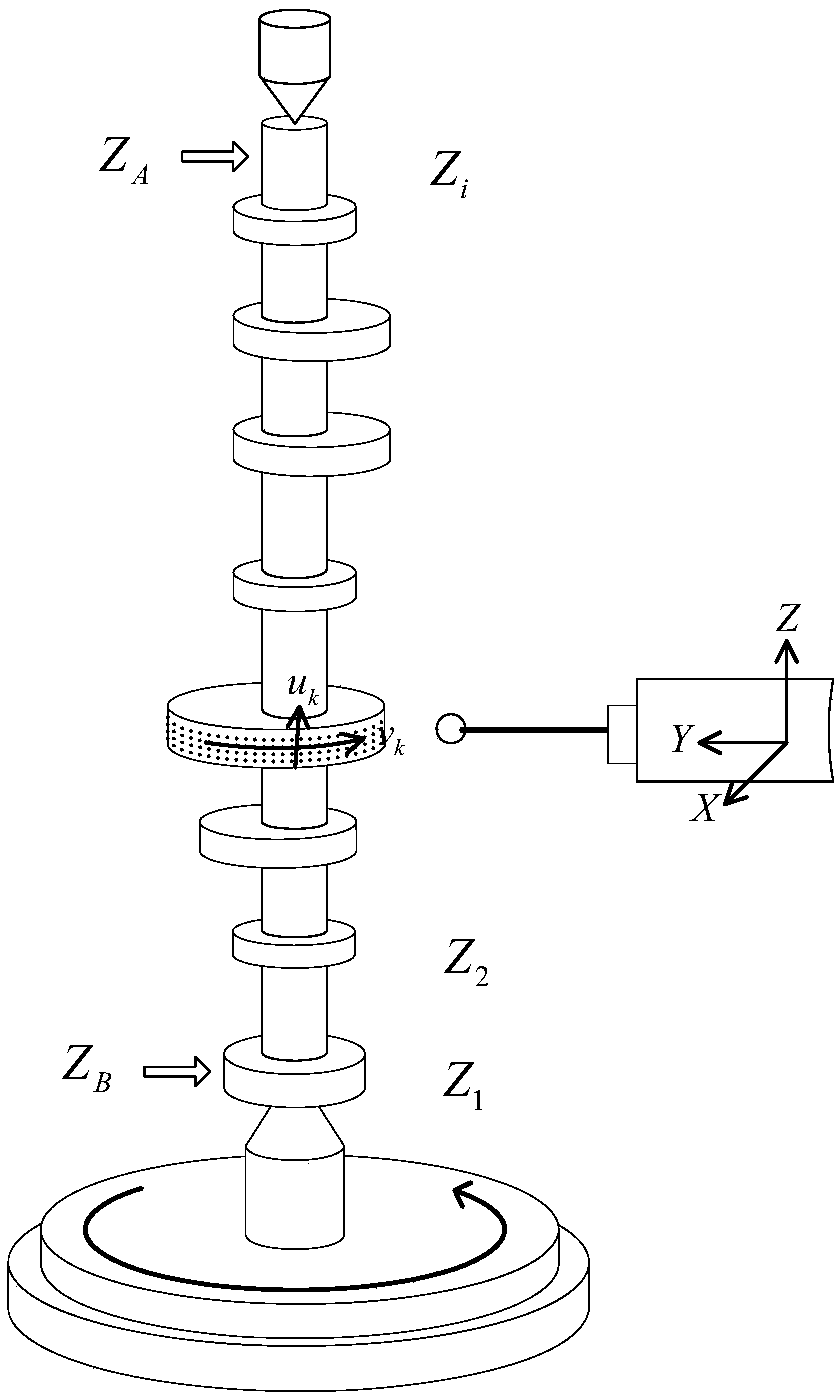

Axial line correction method of cylindrical workpiece and diameter measurement method of sectioned section of cylindrical workpiece

ActiveCN107560583AShorten positioning timeHigh measurement accuracyMeasurement devicesGeometric relationsEngineering

The present invention relates to an axial line correction method of a cylindrical workpiece. According to the method, the spatial relative position of the workpiece under a measurement coordinate system is determined based on the design of the reference point C0 of the end surface of the workpiece; the first correction deltax and deltay of the deviation of a positioning section ZA and a positioning section ZB of the workpiece on an X axis and a Y axis are realized through using two groups of symmetrically-correlated compensation points on the positioning section ZA and the positioning sectionZB of the workpiece; the outlines of the positioning section ZA and the positioning section ZB are resampled, so that sampling points are obtained, a center point O'A and a center point O'B are obtained through fitting calculation; with a straight line determined by the center point O'A and the center point O'B adopted as a reference axis phi of the cylindrical workpiece, a geometric relationshipwith the reference point C0 is built and is solved; and the calibration and correction of a relative deviation angle theta between the reference axis phi and the Z axis of the measurement coordinate system are realized. The present invention also provides a diameter measurement method of the sectioned section of a cylindrical workpiece. According to the diameter measurement method, a geometric relationship between the correction values deltax and deltay of positioning sections and a measured section is built; linear compensation values deltaxi and deltayi are obtained; the coordinates of a probe relative to a sampling point are calculated; integrated and automatic sampling on the outline of the measured section is realized; and a spatial projection and fitting algorithm is adopted to process sampling data to obtain the quantity value of the measured section.

Owner:CHONGQING ACAD OF METROLOGY & QUALITY INST

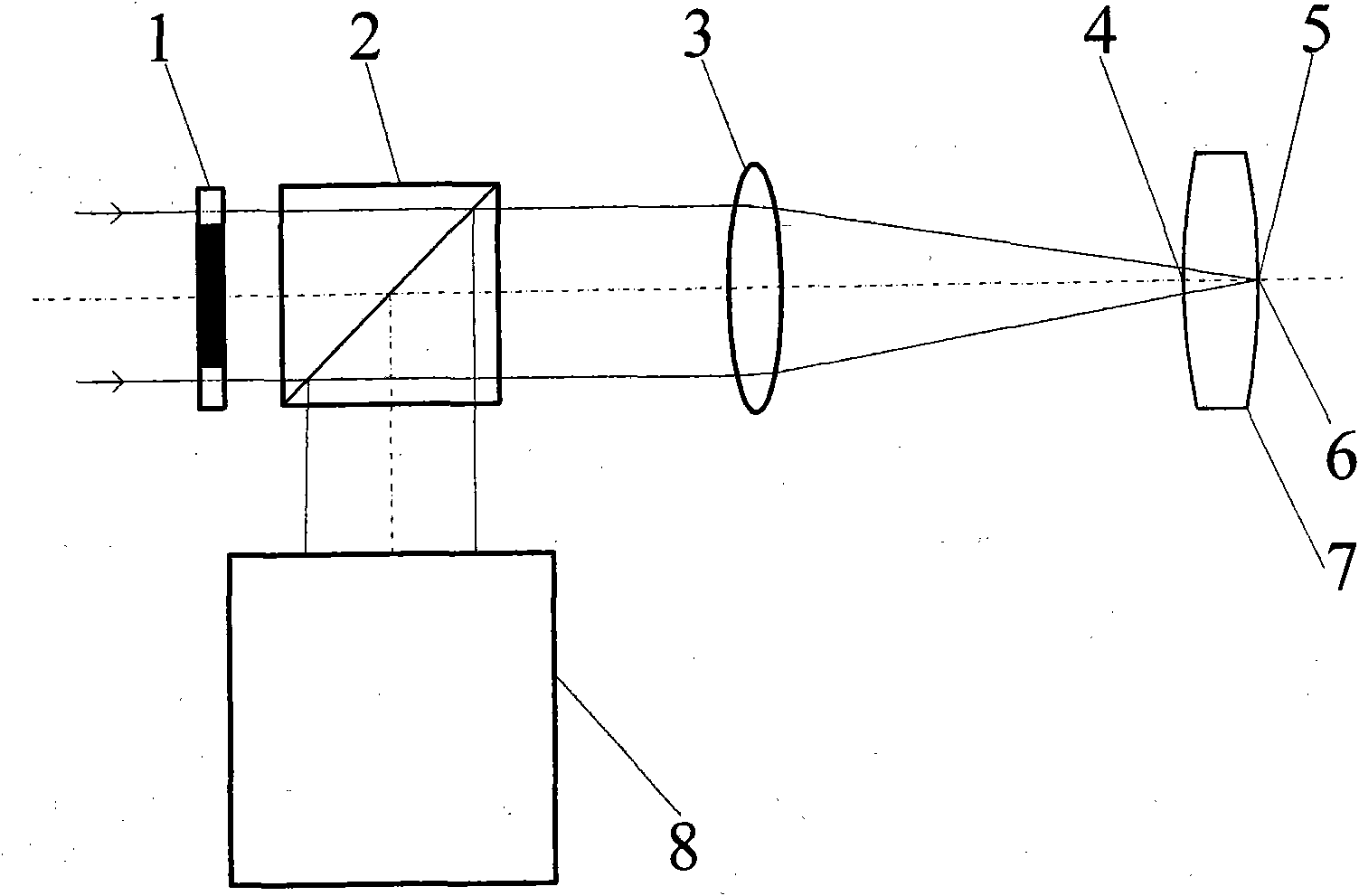

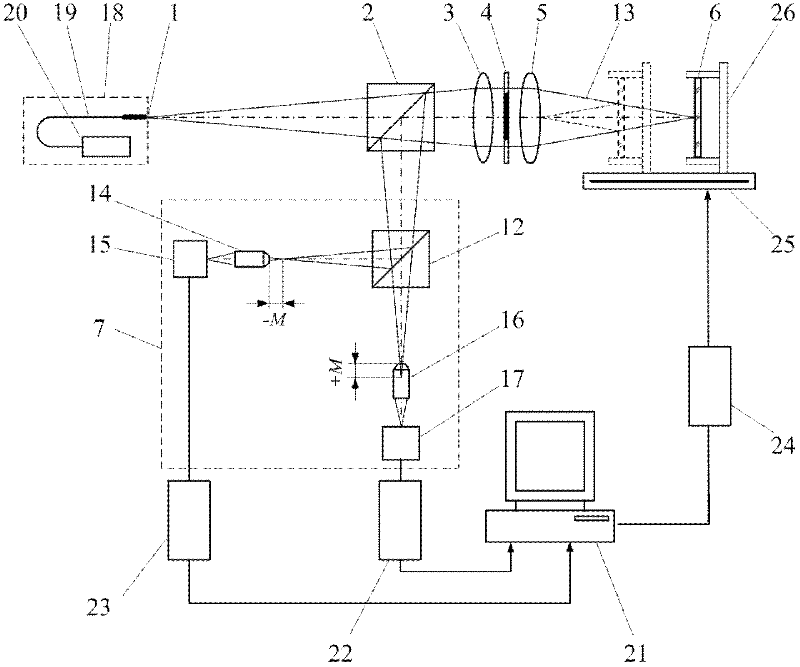

Method for measuring focal length of reflection type differential confocal lens

ActiveCN102589854AHigh measurement accuracyReduce the impact of measurement accuracyTesting optical propertiesInterference resistanceFocal position

The invention belongs to the technical field of optical precision measurement and relates to a method for measuring the focal length of a reflection type differential confocal lens. The method comprises the following steps of: precisely positioning the positions of the surface vertex and the focal point of the lens by being matched with a planar reflecting mirror through a differential confocal measuring method, and further measuring the vertex focal length and the focal length of the lens. The invention firstly provides a method for realizing precise positioning of the focal length by virtue of a characteristic that a differential confocal response curve corresponds to the focal point and the surface vertex of the tested lens when passing the zero point, and expands the differential confocal measuring technology into the field of measurement on the focal length of the lens; and the method has the advantages of high measuring precision and strong ambient interference resistance, and can be used for high-precision detection of the local length of the lens.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

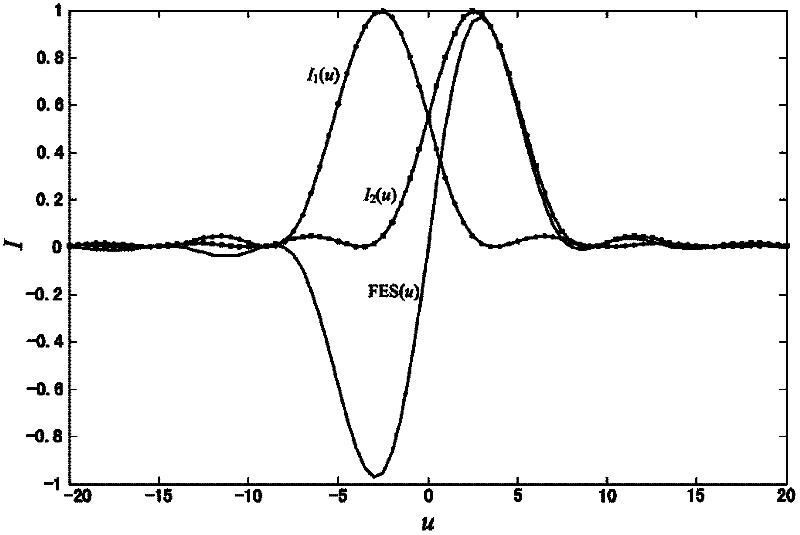

Automatic blood pressure measurement device

ActiveCN104434073AWell scaled featuresHigh measurement accuracyEvaluation of blood vesselsSensorsMeasurement deviceDrive shaft

The invention discloses an automatic blood pressure measurement device. The automatic blood pressure measurement device comprises a supporting shell, a sleeve, an air bag cuff, a tightening mechanism and a tightening motor. The automatic blood pressure measurement device is characterized in that the tightening mechanism comprises a supporting frame, a driving shaft and a driven shaft, the driving shaft is located on one side of the air bag cuff and is installed in the supporting frame in the mode that the driving shaft stretches across the air bag cuff, one end of the driving shaft is connected with the tightening motor, the driven shaft is located on the other side of the air bag cuff and is installed in the supporting frame in the mode that the driven shaft stretches across the air bag cuff and is opposite to the driving shaft, the driving shaft and the driven shaft can move relatively so as to clamp the air bag cuff, and in this way, the air bag cuff can be tightened or move in the relaxing and returning direction through rotation of the driving shaft. According to the automatic blood pressure measurement device, unidirectional pressure exerted on a measured limb can be greatly reduced, and the measurement precision of the automatic blood pressure measurement device is improved; in addition, the structure of the device is optimized, and production and maintenance of the device are facilitated.

Owner:SHENZHEN RAYCOME HEALTH TECH

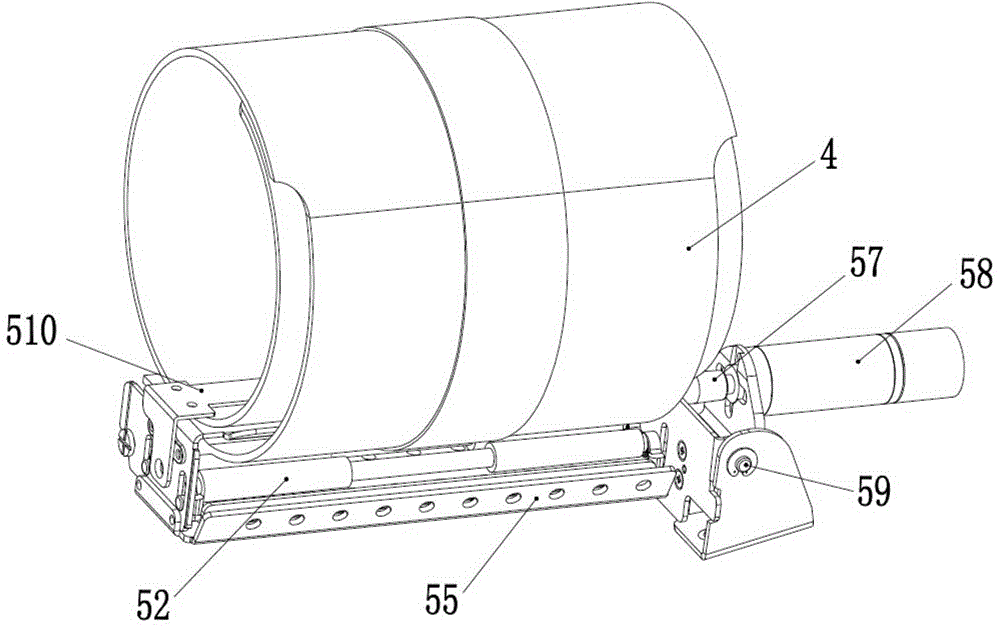

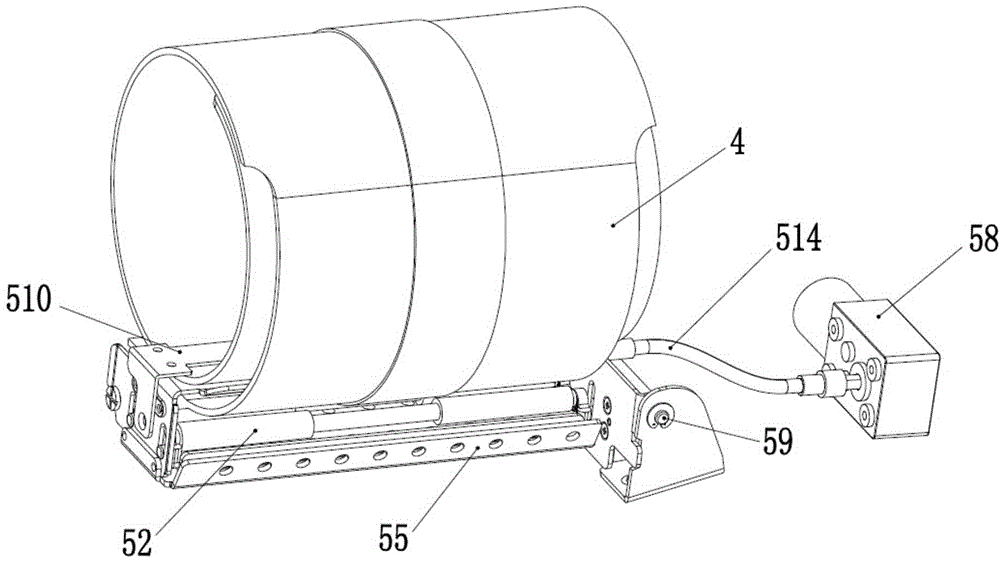

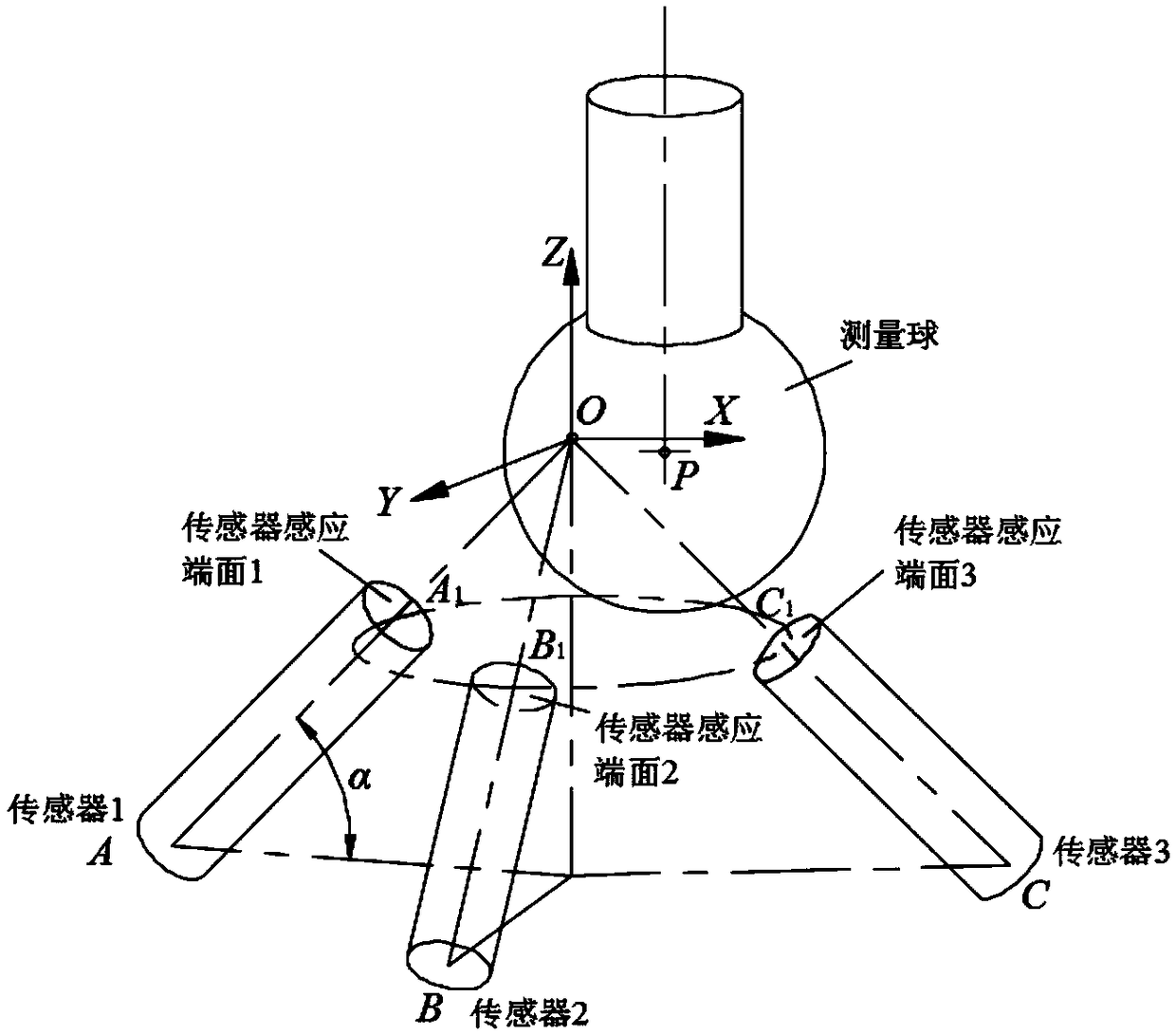

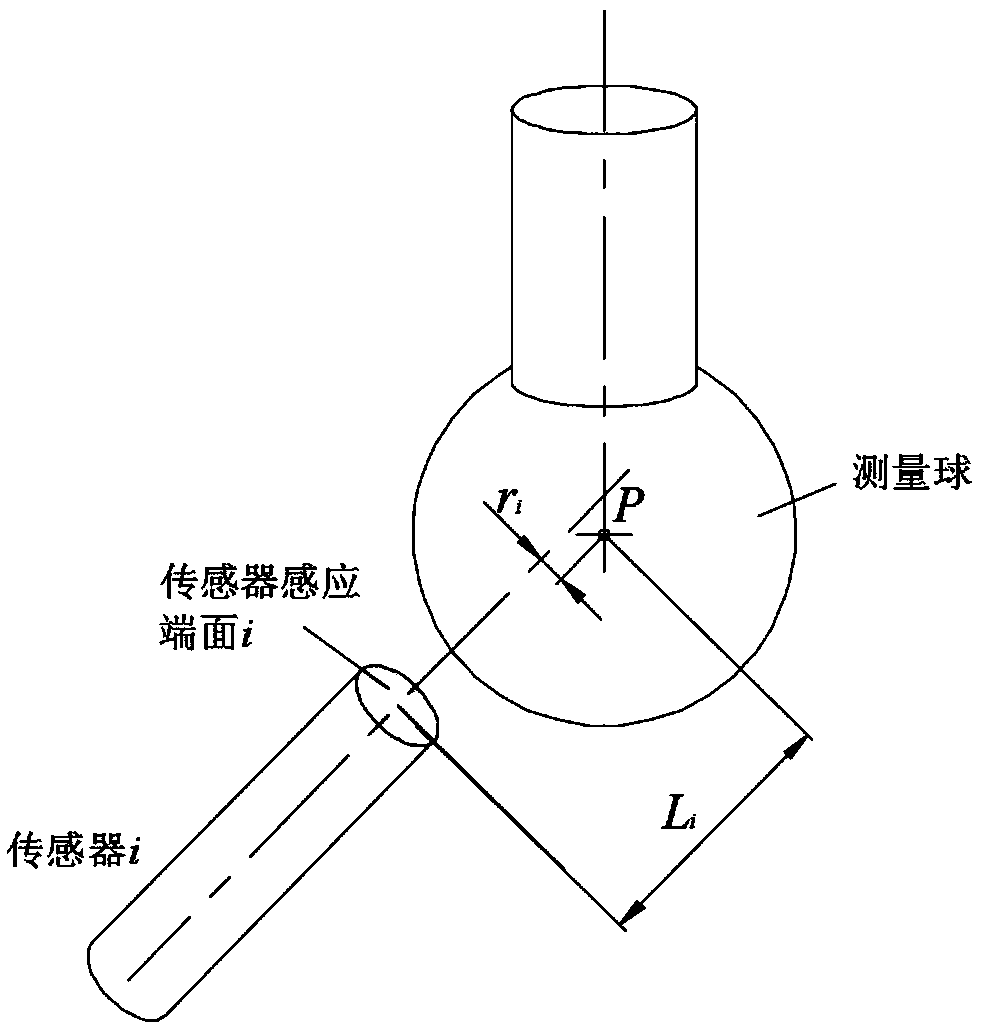

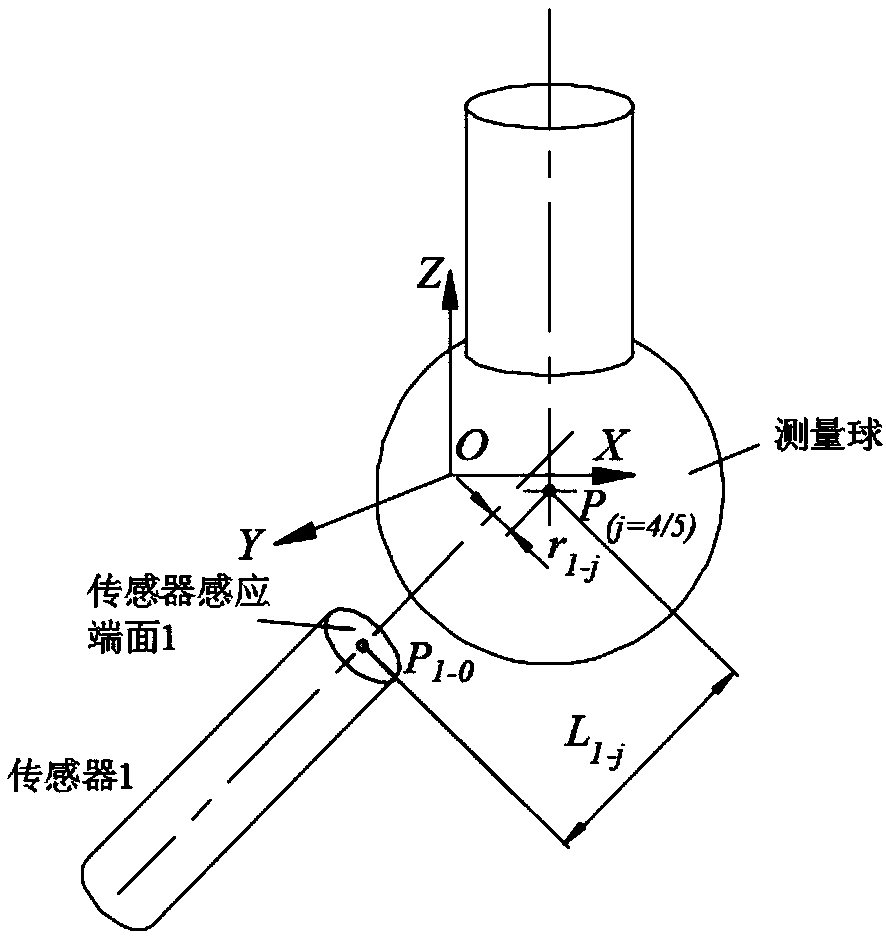

Calibration method for non-contact R-test measuring instrument using eddy current displacement sensor

ActiveCN109032070ALow cost to manufacture and useImprove measurement efficiencyProgramme controlComputer controlSensor planeInstallation Error

The invention discloses a calibration method for a non-contact R-test measuring instrument using an eddy current displacement sensor. Calibration of a measuring coordinate system and calibration of adisplacement sensor plane are included. A measuring ball is installed on a machine tool spindle, the bottom face of a measuring instrument is placed on a machine tool working table, the spindle is moved so that the measuring ball center is roughly located at the intersection point of the axes of three displacement sensors, a measuring coordinate system origin of the R-test measuring instrument iscalibrated, and the direction of a machine tool coordinate system is taken as the direction of the measuring coordinate system; the spindle is moved to make a ball head move to different coordinate points. Calibration of the non-contact R-test measuring instrument sensor reaction plane is completed according to the distances from the coordinate points to a sensor reaction plane. According to the calibration method for the non-contact R-test measuring instrument using the eddy current displacement sensor, the influence of installation errors of the non-contact R-test measuring instrument in processing and assembling and on the machine tool on the measuring accuracy can be greatly reduced, so that the manufacturing and using costs of the instrument are lowered, and the measuring accuracy andefficiency are improved.

Owner:SOUTHWEST JIAOTONG UNIV

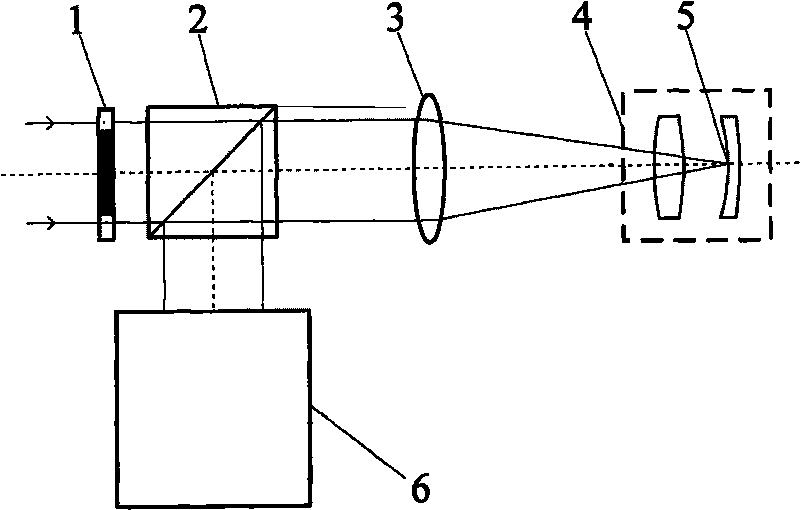

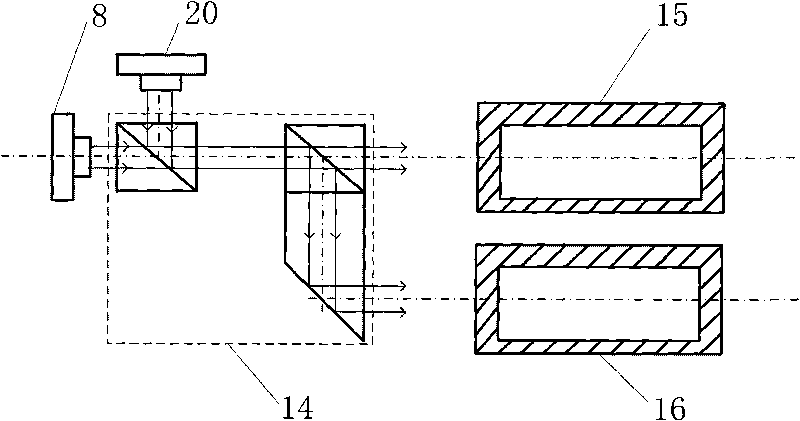

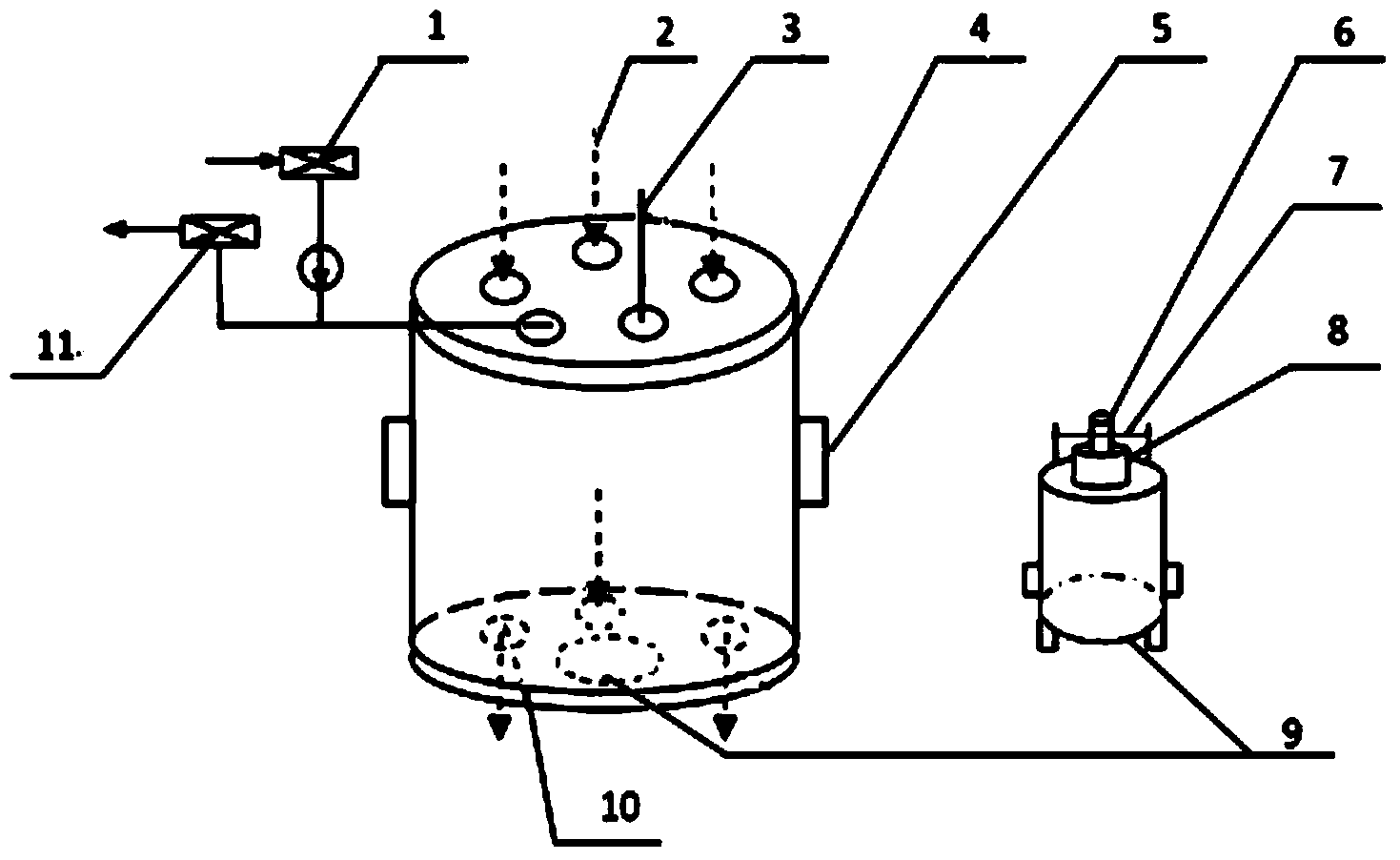

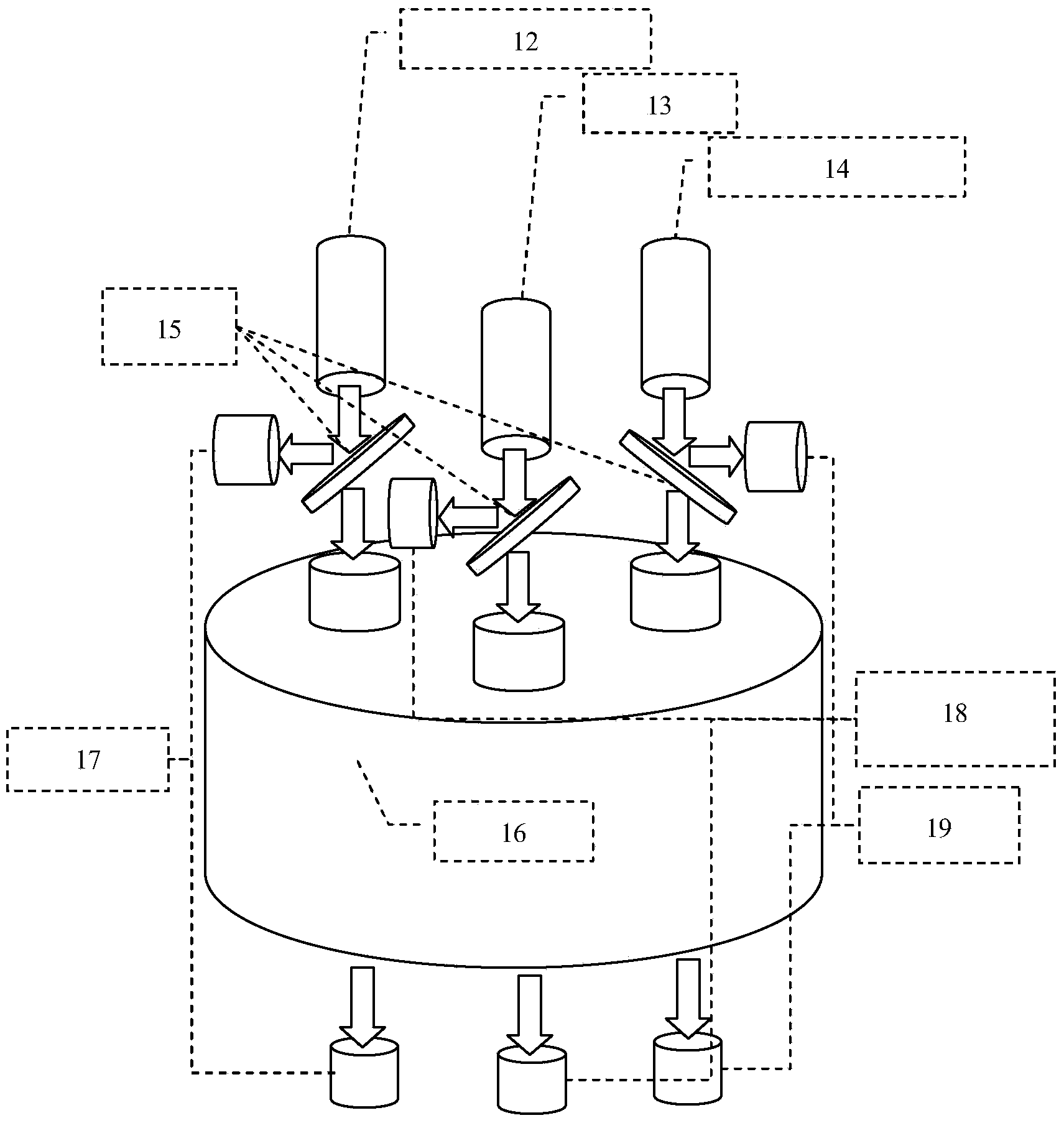

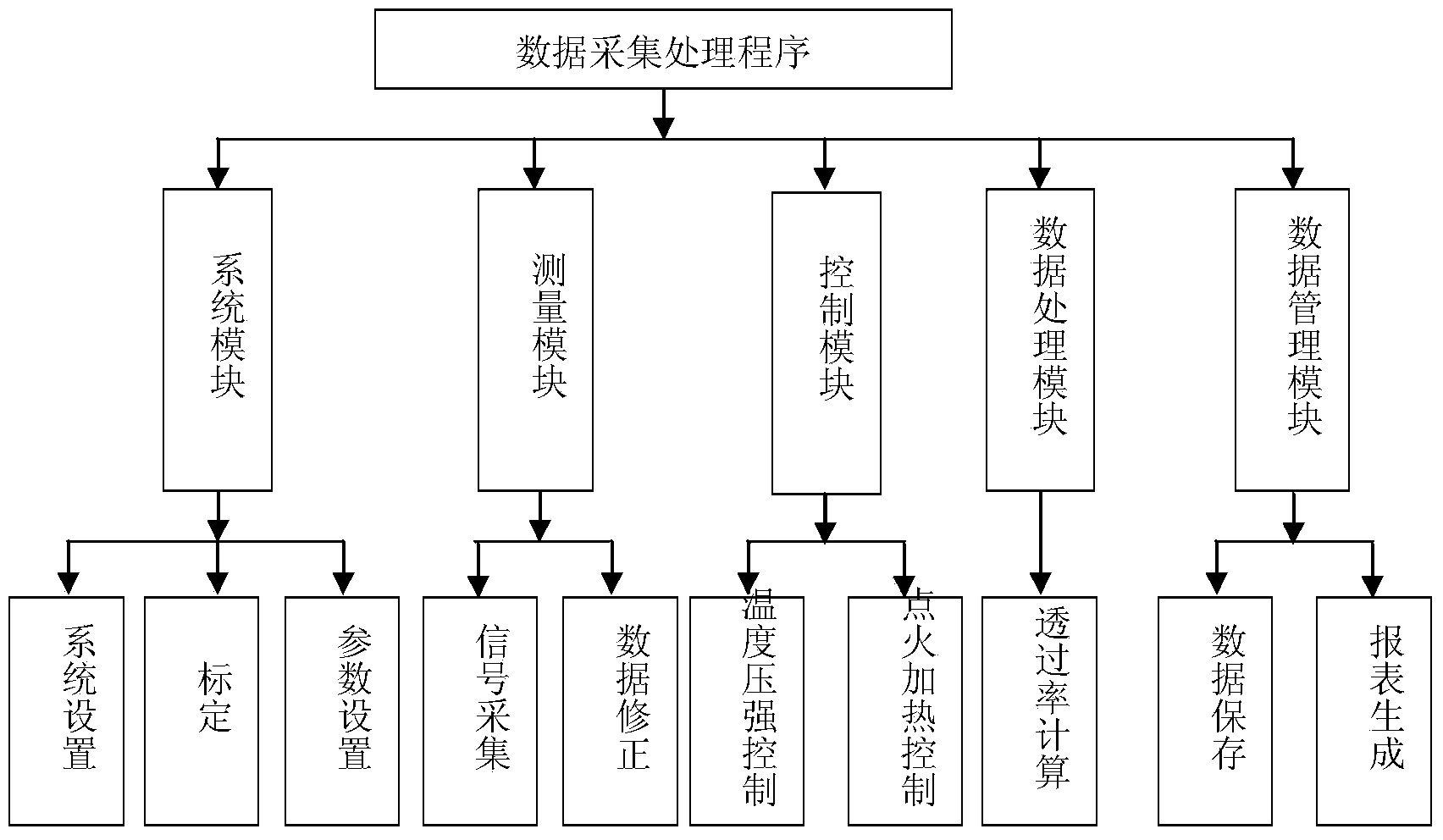

Longitudinal multi-optical-path multi-waveband measuring device for optical transmittance of solid propellant smog

ActiveCN104181129AHigh measurement accuracyReduce the impact of measurement accuracyTransmissivity measurementsCombustion chamberBeam splitting

The invention discloses a longitudinal multi-optical-path multi-waveband measuring device for optical transmittance of solid propellant smog, and is used for solving the problem of a smoke box method that the measure precision of the smog optical transmittance is poor. The longitudinal multi-optical-path multi-waveband measuring device comprises a light source unit, a beam splitting unit, a medium unit, a signal receiving unit, a signal processing unit and a measure and control software unit. Incidence light is split by the beam splitting unit into reference light and measure light, the measure light perpendicularly enters a smog area from a light incidence window on the upper part of a combustion chamber, two beams of light are respectively received by a sensor, and an output signal can be processed to acquire the smog optical transmittance. By designing the longitudinal optical path, the unfavorable influence of the sedimentation effect of the smog on the measure precision can be eliminated. By designing three optical paths, the synchronous measurement of infrared, visible light and laser transmittance of the smog can be realized. The longitudinal multi-optical-path multi-waveband measuring device is suitable for measuring the optical transmittance of the smog which is produced by materials such as a solid propellant, propellant powder and a cladding layer under a given condition and has an important significance on the research of low-characteristic-signal propellants.

Owner:XIAN MODERN CHEM RES INST

Detecting device and detecting method for measuring outer diameter and the inner diameter of wheel of motor train

InactiveCN107084673AMeasurement position does not occurPrecise control of measurement positionUsing optical meansEngineeringLaser

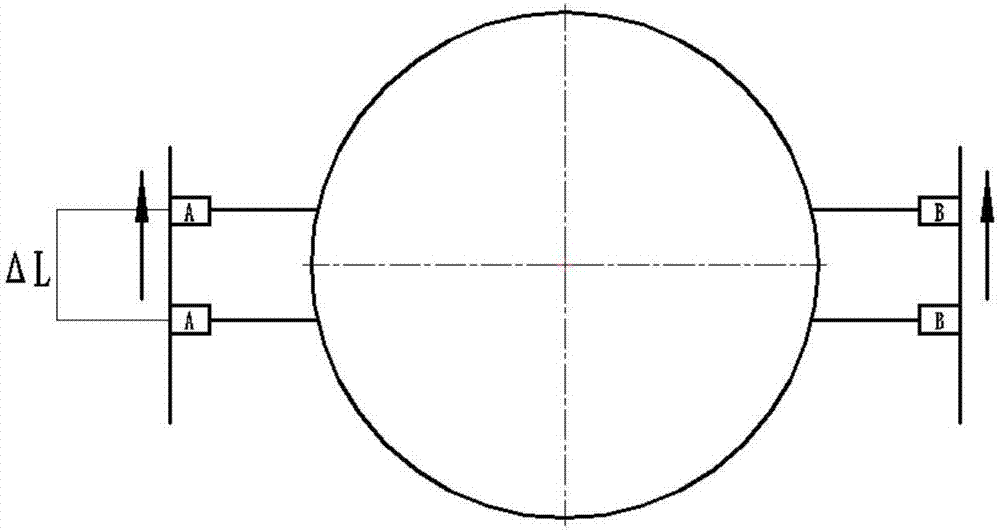

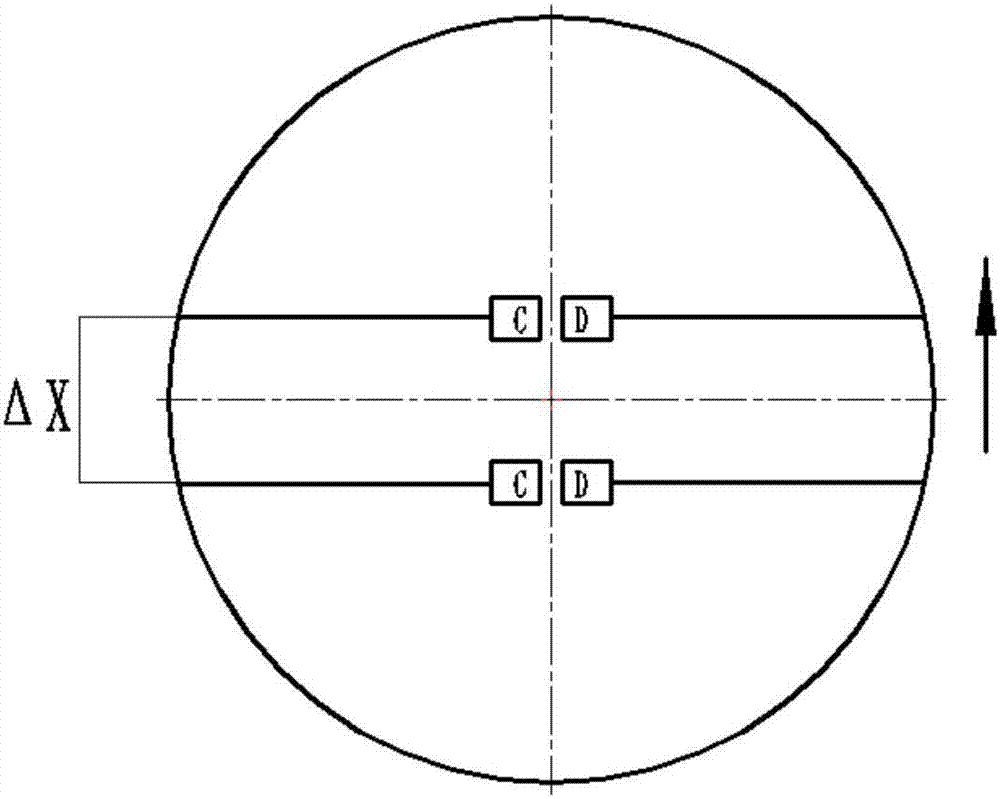

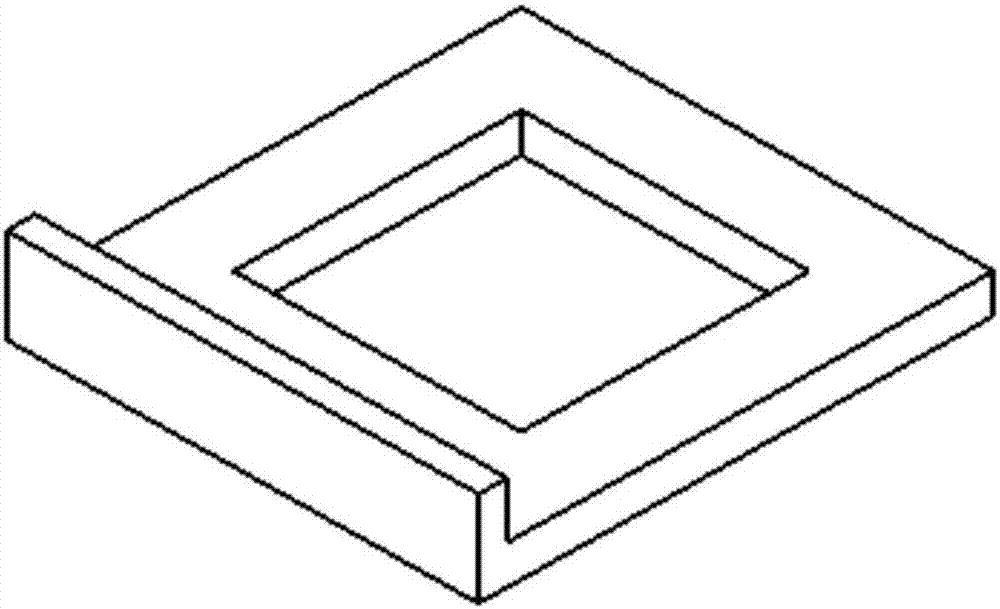

The invention discloses a detecting device and detecting method for measuring the outer diameter and the inner diameter of the wheel of a motor train. The device mainly comprises a wheel vertical detection platform, a horizontal detection platform, a fine reference support device, a coarse reference support device, a transportation platform, a rotary driving device. Four laser displacement sensors, including laser displacement sensors A and B installed on a crescent board tail end IV and laser displacement sensors C and D installed on the wheel vertical detection platform III, horizontally move a [delta]L and a [delta]X in the radial direction of the wheel of the motor train respectively. The scanning measured values in each length unit of the four laser displacement sensors are stored in an acquisition card. Then the maximum value of the measured data of each laser displacement sensor is selected to be compared with standard data to calculate the outer diameter and the inner diameter of the wheel. Then, the above operation is performed after a wheel rotary driving device is rotated by a certain angle. After measurement is performed three times, average values are acquired to be used as the measured values of the outer diameter and the inner diameter of the wheel.

Owner:CHANGCHUN INST OF TECH

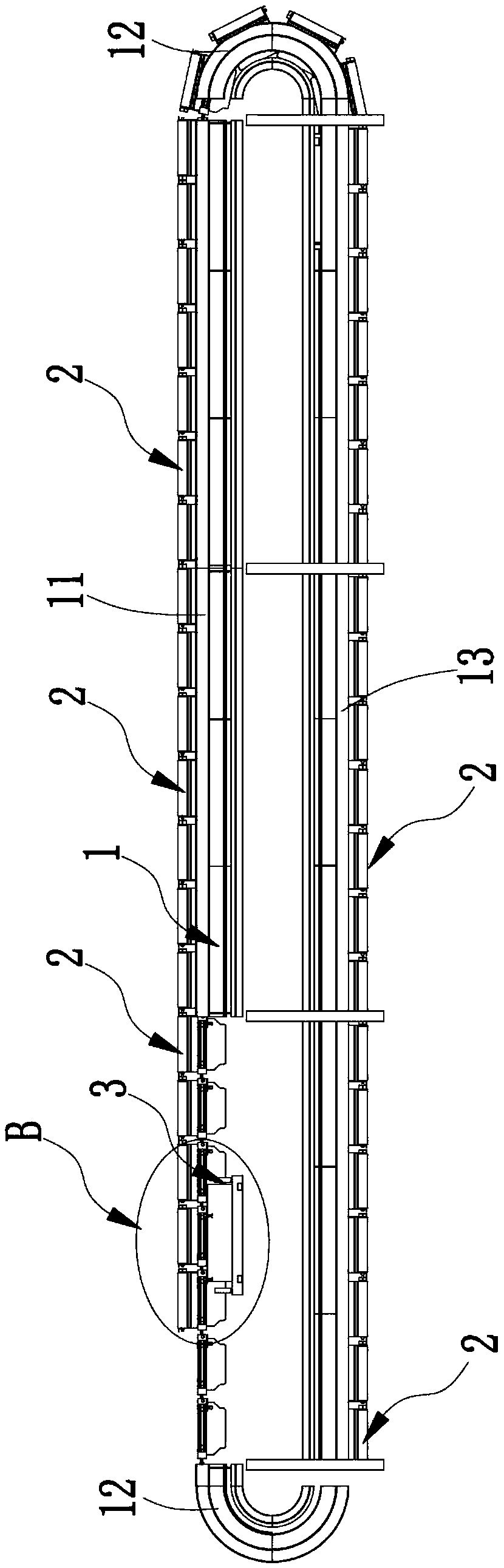

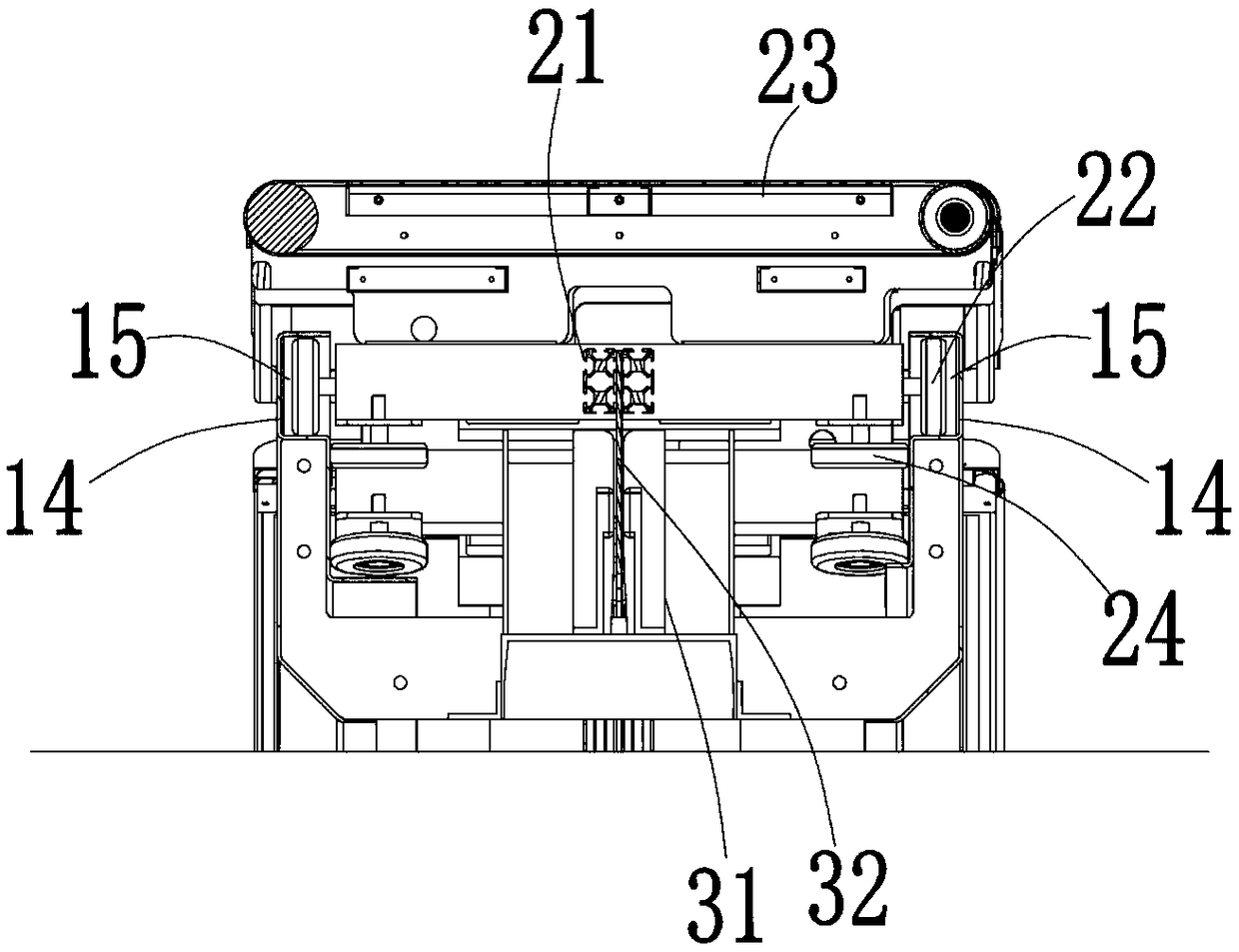

Double-loop-line intersected belt sorting machine, intersected belt sorting system and sorting method thereof

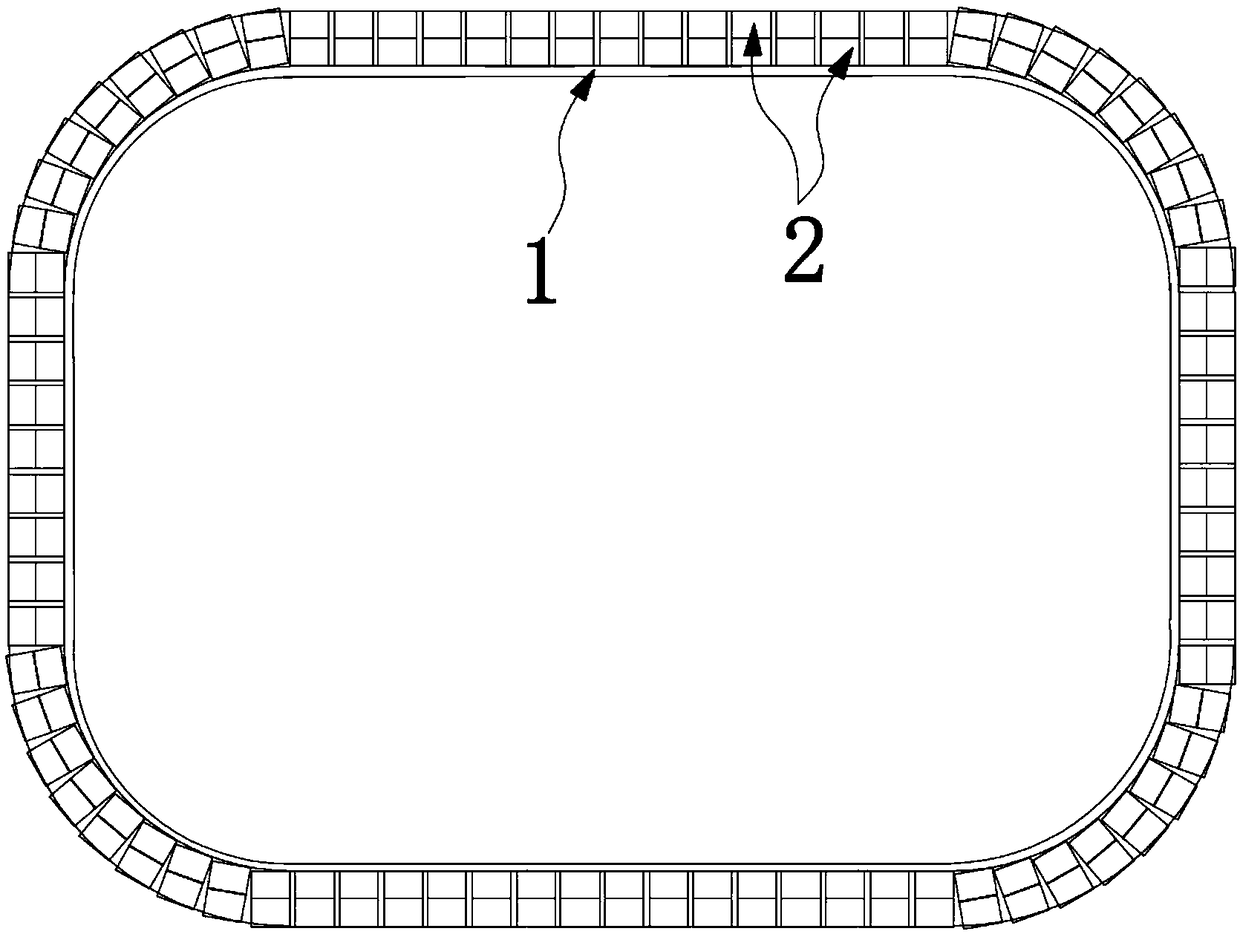

PendingCN109335538AReduce vacancy rateIncrease the number ofPackagingConveyor partsEngineeringMechanical engineering

The invention discloses a double-loop-line intersected belt sorting machine, an intersected belt sorting system and a sorting method thereof. The double-loop-line intersected belt sorting machine comprises at least one annular rail, two sets of intersected belt cars for forming two conveying loop lines circularly rotated on the annular rails side by side, and a power device for driving the two sets of intersected belt cars to move along the annular rails. The double-loop-line intersected belt sorting machine is delicate in design and simple in structure; as two sets of cars are used in one annular rail, the number of the intersected belt cars is increased by using internal space of the loop lines under the precondition of not increasing the floor area to multiply the sorting capacity, theuse efficiency of the sorting machine is improved, and the equipment cost is reduced; and meanwhile, parcels can be transferred between two conveying annular intersected belt cars, so that the idlingrate of the cars can be reduced, meanwhile, the parcel loading flexibility is improved, and the arrangement requirements and the occupied space of a particle loading line are reduced.

Owner:SUZHOU JINFENG INTERNET OF THINGS TECH CO LTD

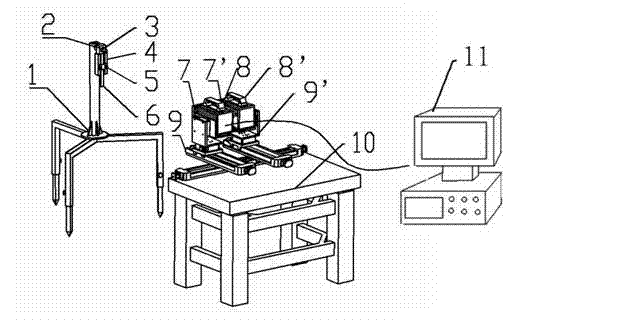

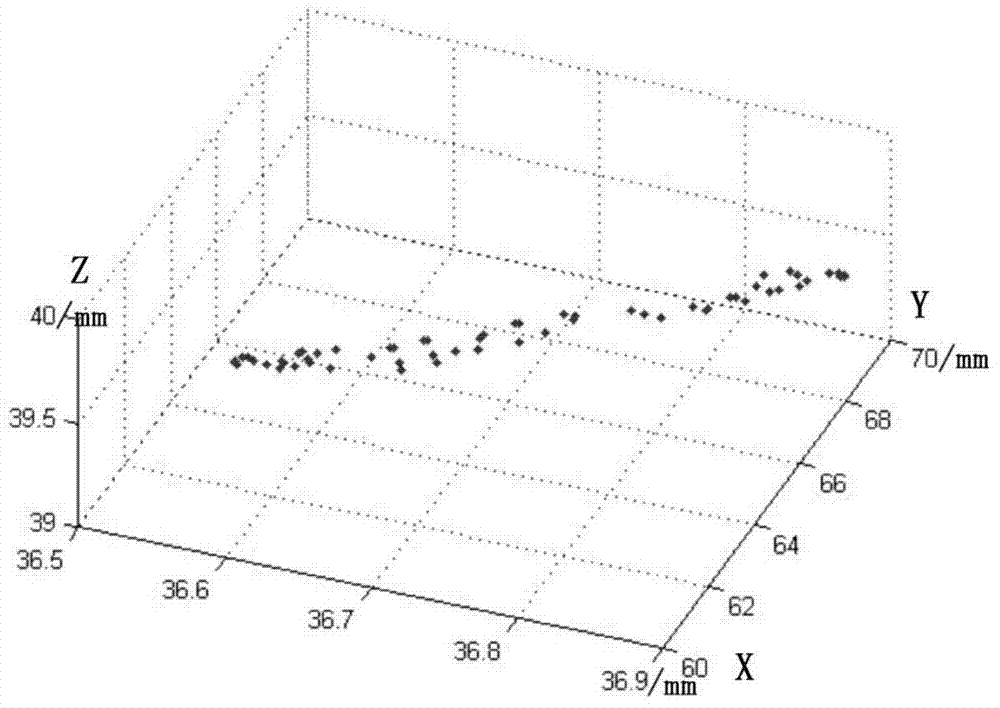

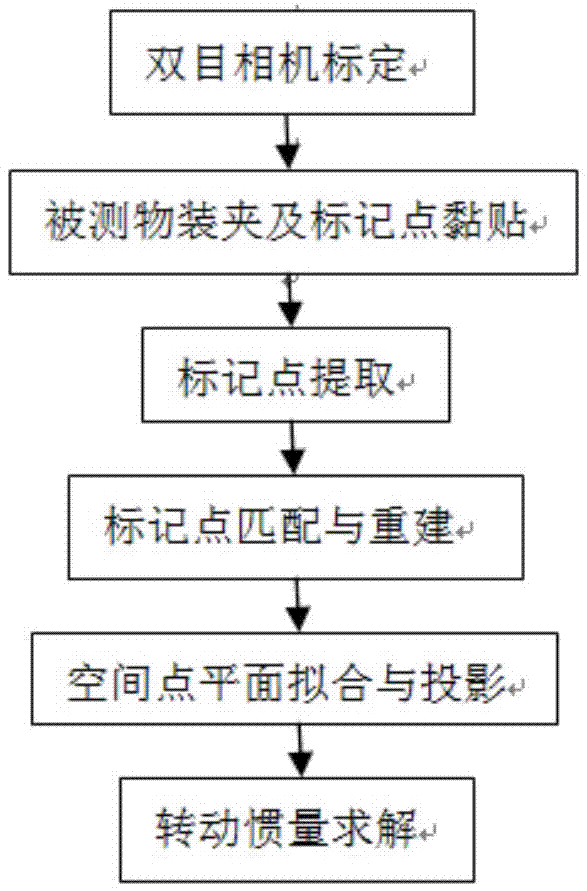

Method for measuring rotary inertia through binocular vision

ActiveCN103542981AReduce the impact of measurement accuracyHigh measurement accuracyStatic/dynamic balance measurementDamping factorCurve fitting

The invention belongs to the technical field of computer vision measurement and relates to a binocular-vision-based method for quickly and accurately measuring rotary inertia. The method includes that a binocular vision system is adopted, two ultra-high-speed cameras are utilized to collect moving images of surface mark points of a measured object in real time, a graphic workstation processes image information transmitted by the two ultra-high-speed cameras to acquire moving tracks of the mark points in space, and the rotary inertia of the measured object is calculated through fitting of the tracks. Plane fitting and projection are performed on space position of the measured object at each moment by utilizing the binocular vision system, space moving coordinates of the measured object are enabled to be in a same plane, and influences, on measuring accuracy, caused by the fact that swinging motion is not in a plane are reduced; by real-time space moving coordinate curve fitting taking damping coefficients into consideration, influences, of air resistance and mechanism resistance, on accuracy of a measuring system are reduced, and measuring accuracy of the rotary inertia is improved.

Owner:DALIAN UNIV OF TECH

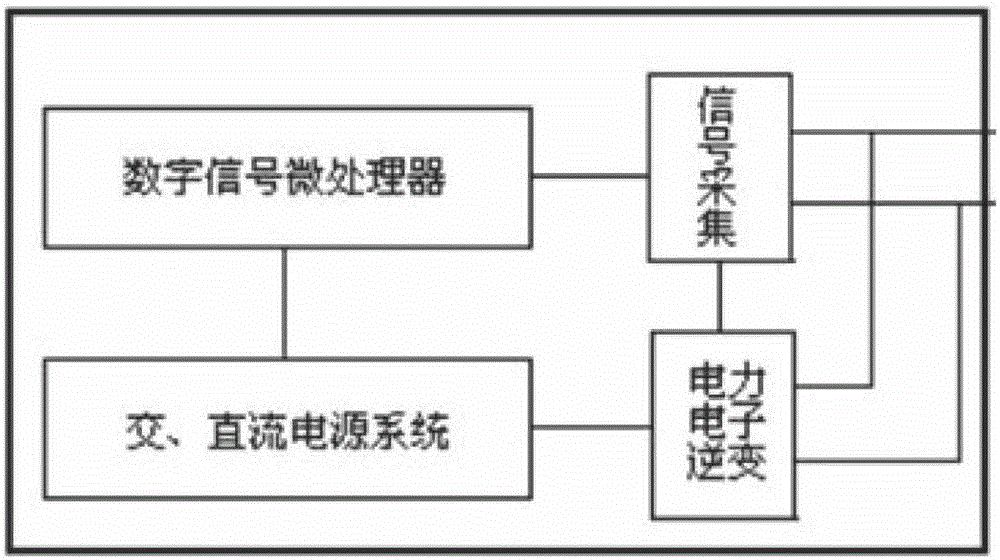

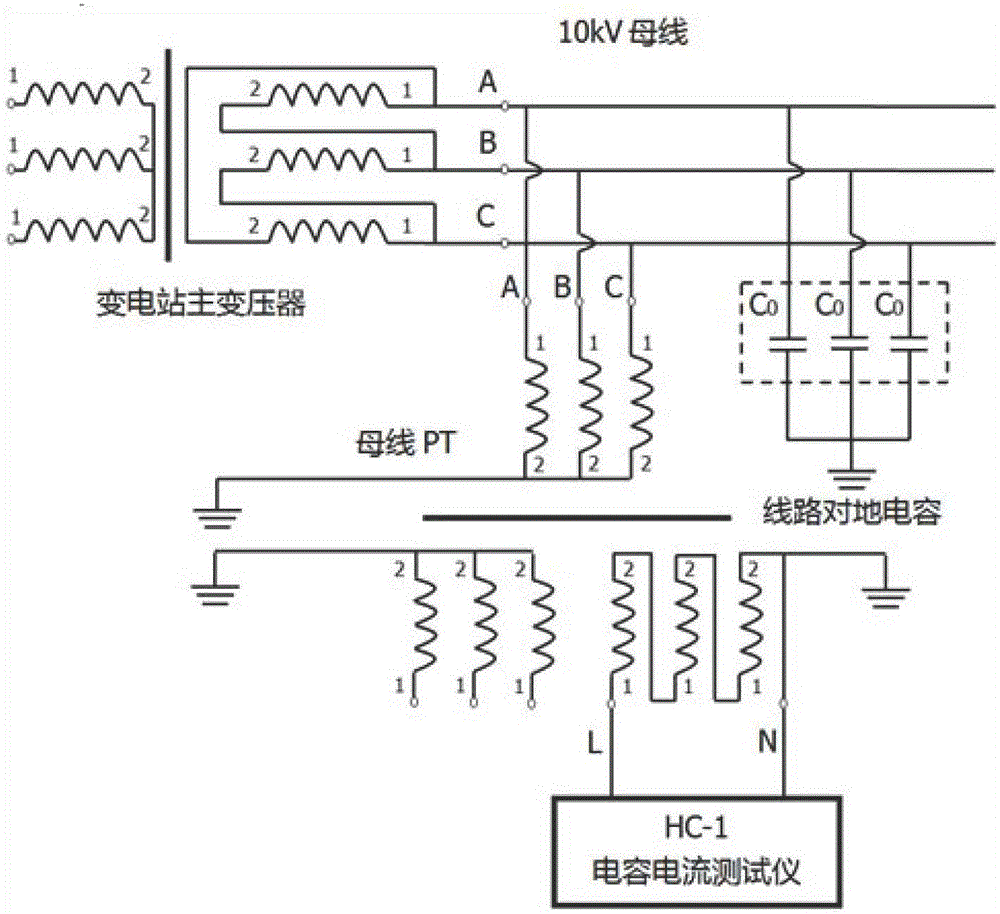

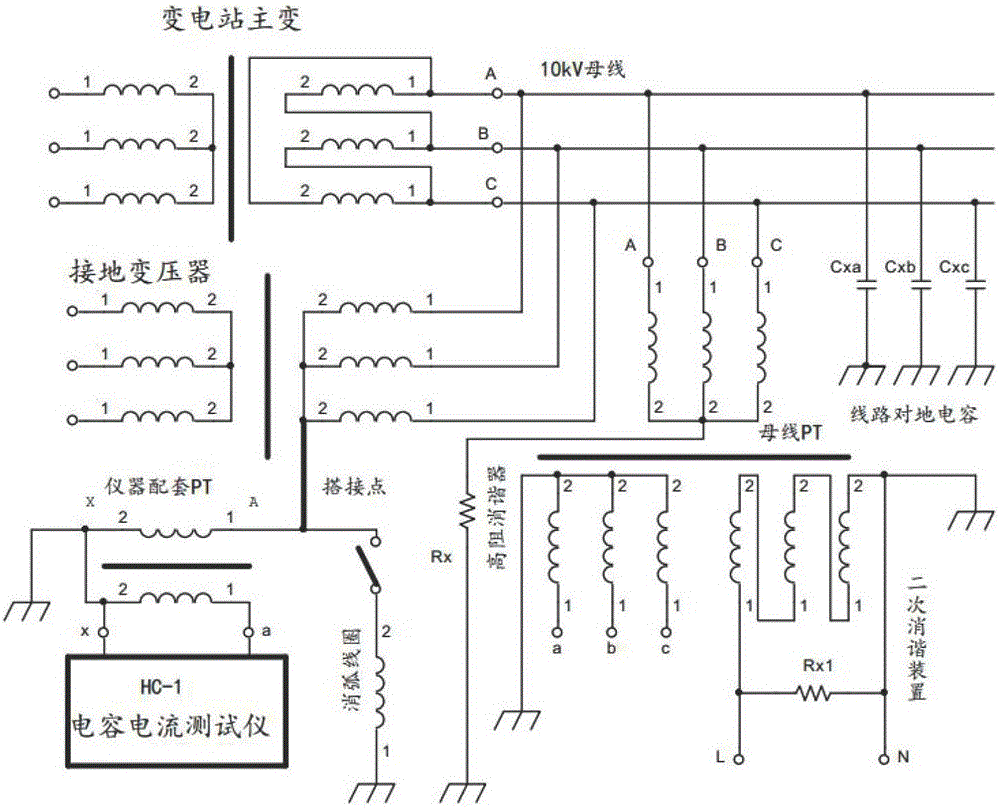

Method for measuring capacitive current of low-current grounding power grid

InactiveCN106771647AReduce the impact of measurement accuracyMeasure securityCapacitance measurementsMeasurement using digital techniquesDigital signal processingCapacitance

The invention relates to a method for measuring capacitive current of a low-current grounding power grid. The method comprises an HC-1 capacitive current tester and a measurement device, wherein the HC-1 capacitive current tester injects a 5Hz constant-current square wave signal into a zero-sequence circuit of a power distribution network, carries out charging and discharging on a grounding capacitor of a line to measure the grounding capacitive current of the power distribution network; the measurement device comprises an AC / DC power supply system, a digital signal microprocessor, a signal collection unit and a power electronic inverter circuit; the digital signal microprocessor controls the power electronic inverter circuit to generate the 5Hz constant-current square wave signal, and injects the 5Hz constant-current square wave signal into the zero-sequence circuit of the system through a bus open delta of the system, a grounded variable neutral point or a neutral point of a capacitor bank; and a high-performance A / D sampling circuit and digital signal processing are adopted by a signal collection system.

Owner:STATE GRID TIANJIN ELECTRIC POWER +1

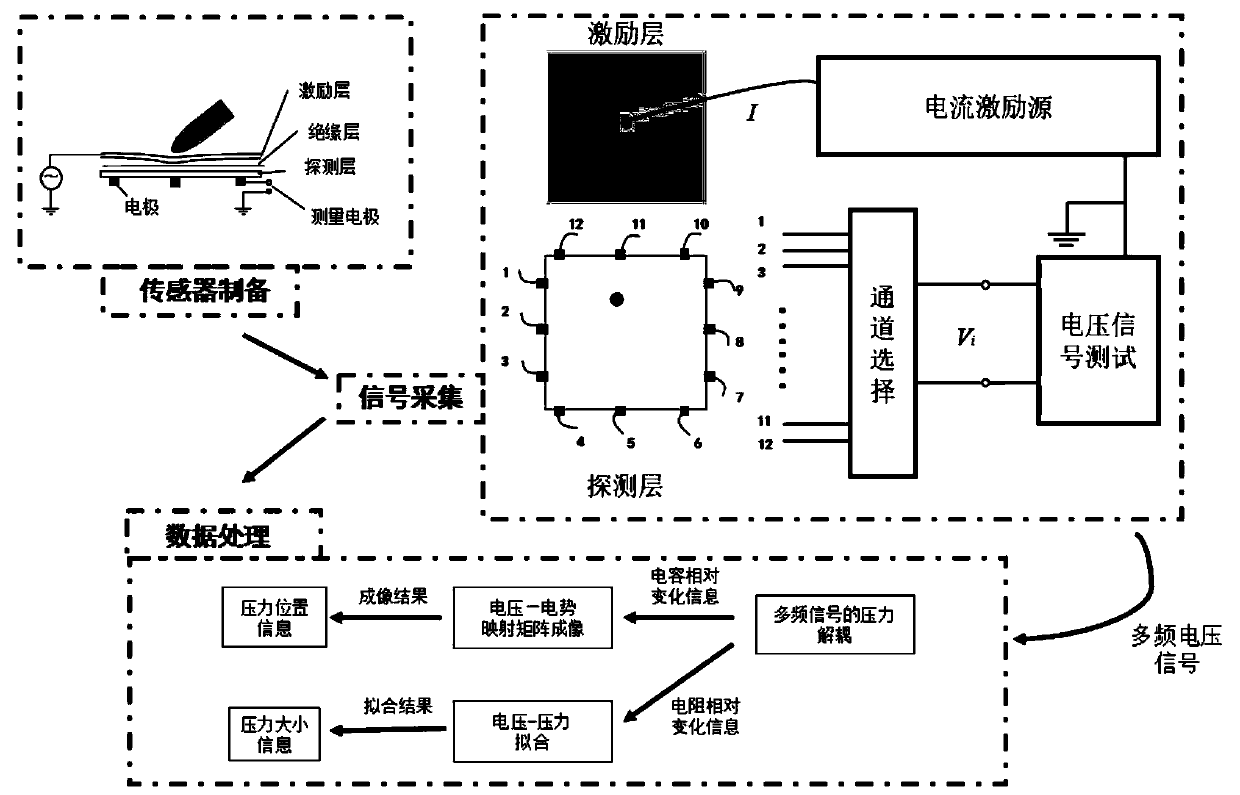

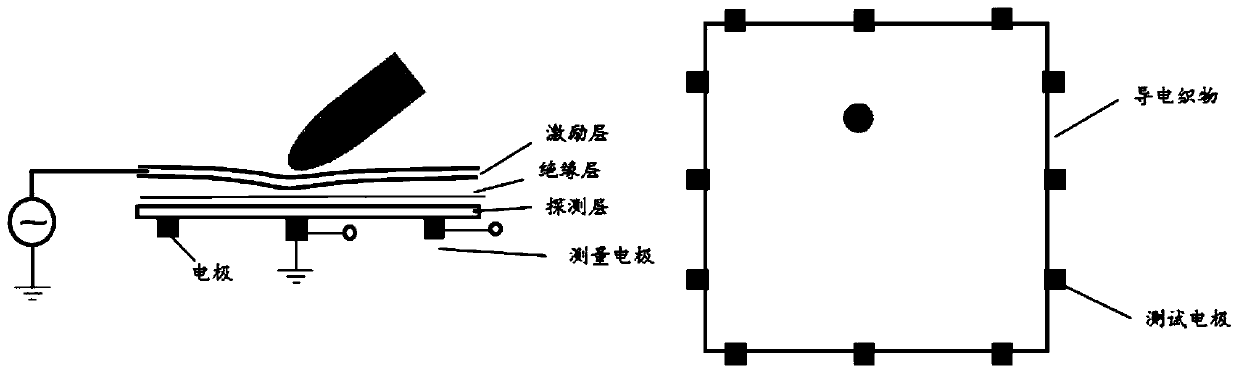

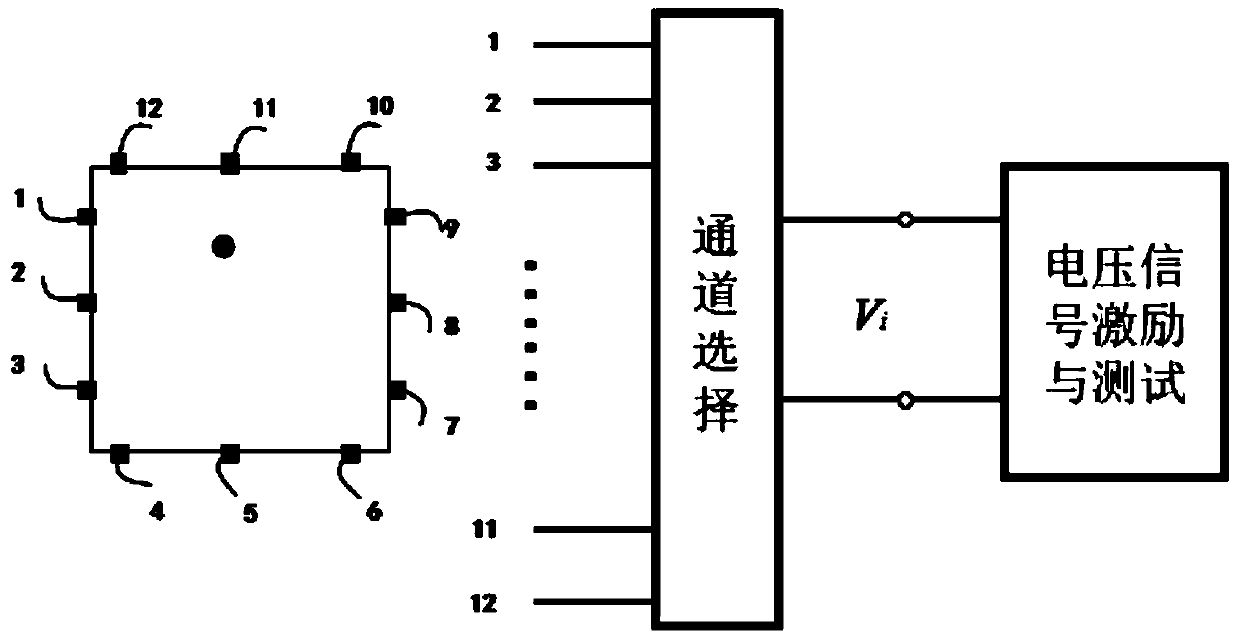

Tactile pressure sensor based on electrical impedance tomography and signal acquisition method

ActiveCN110207862AReduce power consumptionHigh sensitivityForce measurement using piezo-resistive materialsMeasurement pointElectrical impedance tomography

The invention provides a tactile pressure sensor based on electrical impedance tomography and a signal acquisition method, and belongs to the field of sensor design and testing. An excitation layer ofthe sensor is prepared by using a highly conductive fabric coated with a non-polar polymer, a detection layer is prepared by using a low-conductivity fabric coated with a weakly polar polymer, and anelectrode array is arranged at the edge of the detection layer; during measuring, two electrodes are adopted, one of the two electrodes is used as a grounding point and the other is used as a measuring point. The magnitude of the applied pressure is calculated and position measuring is carried out based on electrical impedance tomography by gating the different two electrodes for measuring. The high-precision distributed sensing o tactile skin characteristics and tactile morphology of a robot can be realized, the tactile pressure sensor based on the electrical impedance tomography is simple in structure, high in reliability, low in power consumption, good in flexibility and low in price, and simplicity and accuracy of pressure magnitude and position measuring are improved.

Owner:BEIHANG UNIV

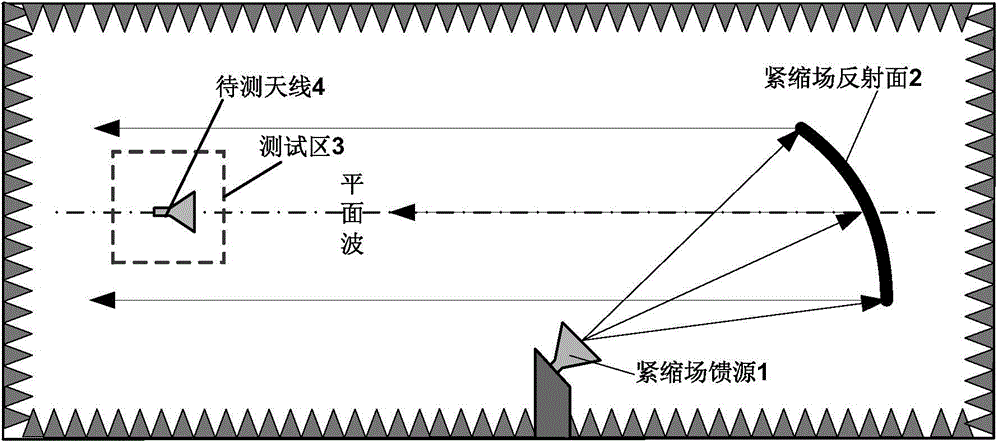

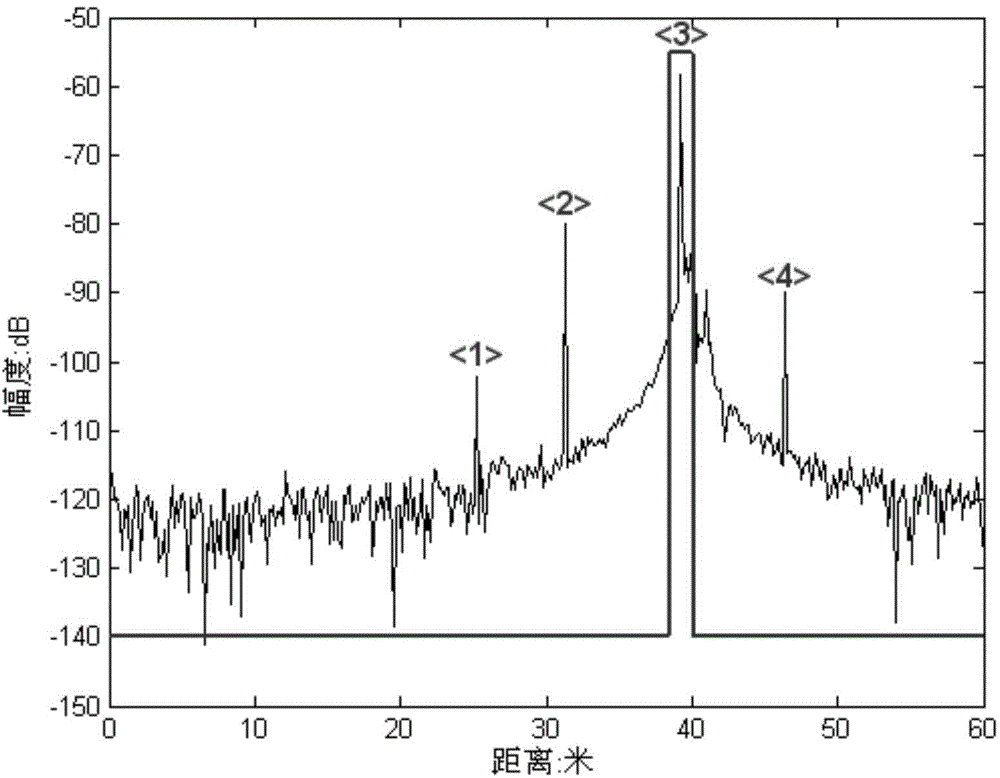

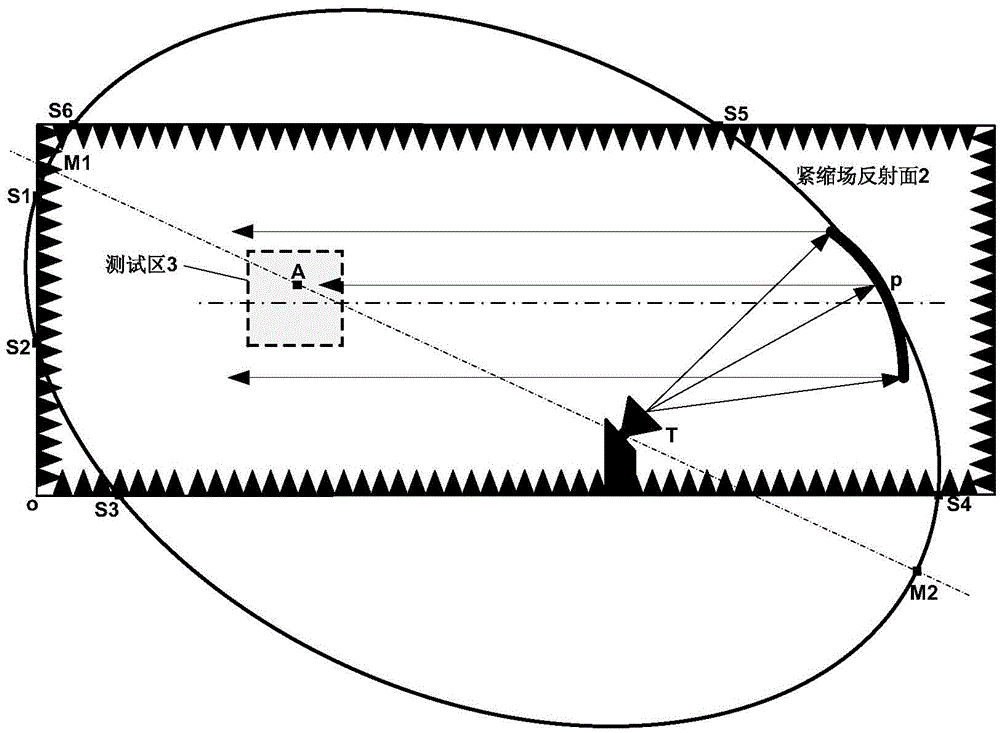

Method for recognizing synchronous reflection point position in compact field antenna measurement

InactiveCN104597331AReduce the impact of measurement accuracyReduce intensitySpecial data processing applicationsAntenna radiation diagramsRectangular coordinatesSpace object

The invention discloses a method for recognizing a synchronous reflection point position in the compact field antenna measurement. The method comprises the steps of building a three-dimensional rectangular coordinate system in a dark chamber of a compact field; determining the position of a compact field feed source in the three-dimensional rectangular coordinate system; determining the position of the compact field reflecting surface according to the position of the compact field feed source and the position of a testing area; building an ellipsoidal surface in the compact field dark chamber by using the position of the compact field feed source and the position of an antenna to be measured, in the testing area as the focuses and the length of the transmission path of the compact field feed source from the reflecting surface to the antenna to be measured, at any position in the testing area, wherein the part in which the ellipsoidal surface is intersected with each surface of the compact field dark chamber and an object in an inner space of the compact field dark chamber is the position of a synchronous reflecting point. With the adoption of the method, the position of the synchronous reflecting point that a reflecting signal and a direct wave signal in a compact field synchronously reaches a receiving antenna.

Owner:BEIJING INST OF RADIO METROLOGY & MEASUREMENT

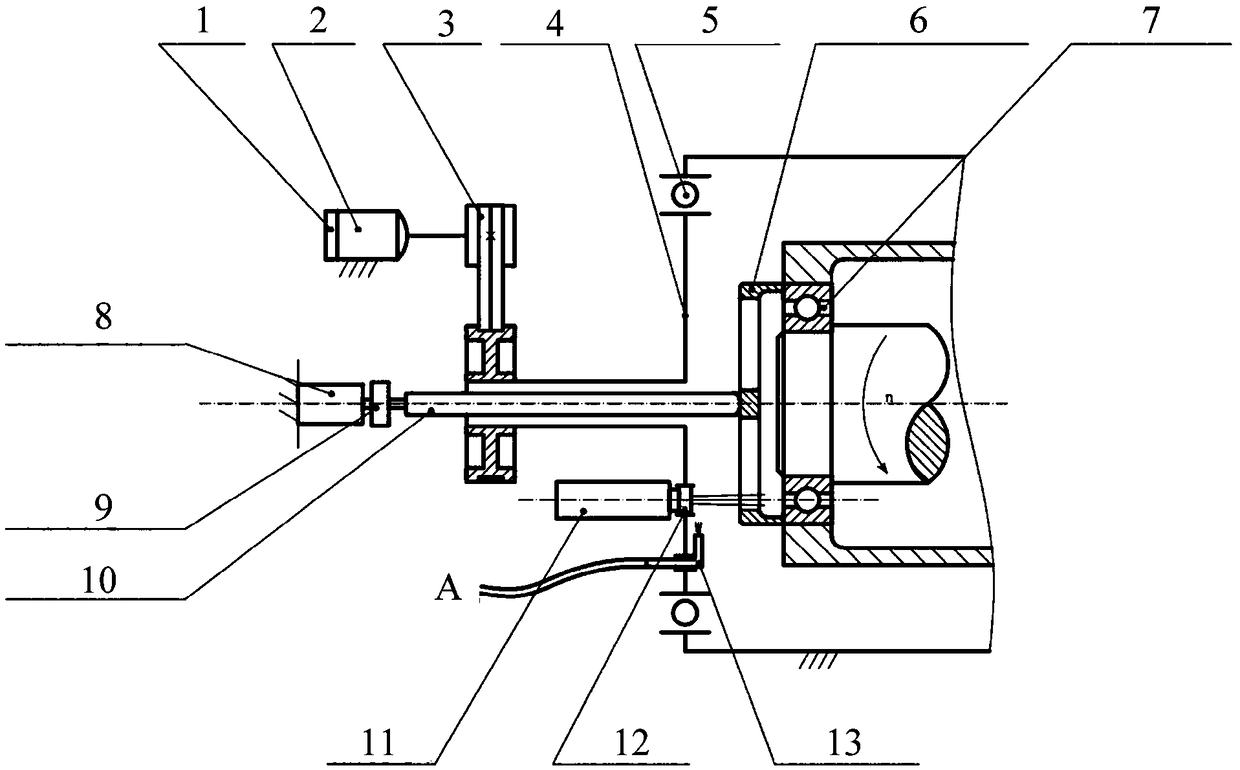

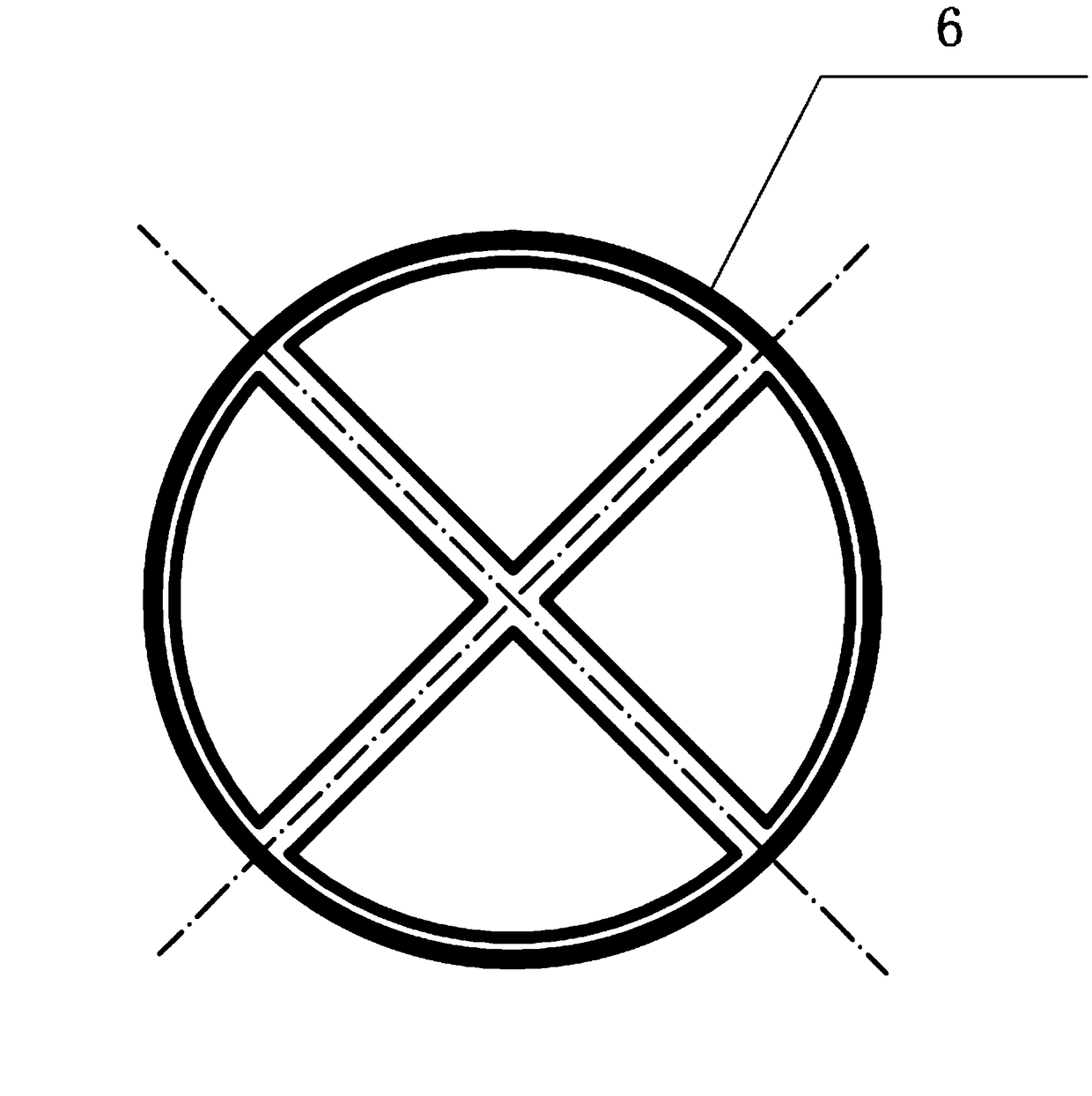

Temperature field measuring apparatus and method of antifriction bearing test

ActiveCN108168889ADoes not affect the lubrication effectAvoid accumulationMachine bearings testingTemperature measurement of moving solidsMeasurement deviceEngineering

The invention provides a temperature field measuring apparatus and method of an antifriction bearing test, and belongs to the bearing temperature measuring field. The temperature field measuring method of an antifriction bearing test includes the steps: after a motor and a thermal imaging system are started so as to start preheating and become stable, a test bearing starts working and gradually improves the rotating speed and the axial load to approach to the practical condition; a servo motor is controlled to rotate at slow speed so as to drive the thermal imaging system to rotate around an axle, so as to obtain the temperature of a test bearing retainer or rolling body and the outer ring of the test bearing; a code disc is used to read the positional information of the test bearing, andthen the real time position of the thermal imaging system can be obtained through calculation, and then the temperature information measured by the thermal imaging system and the positional information of the thermal imaging system are corresponding to each other, so that the temperature field distribution situation of the surface of the test bearing can be obtained. The temperature field measuring method of an antifriction bearing test sets germanium glass on the accessories of the bearing temperature measurement region to reduce the influence of lubricating oil on the measurement precision,and designs a blowing and sweeping module to blow away the randomly splashed oil mist on the premise of not influencing the lubrication effect of the lubricating oil, thus improving precision of a non-contact test.

Owner:HARBIN INST OF TECH

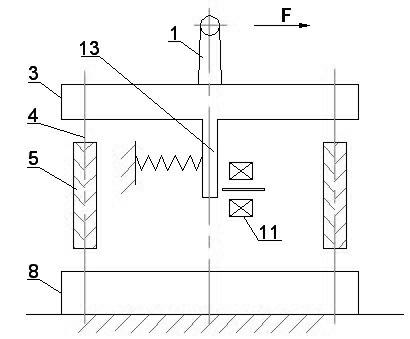

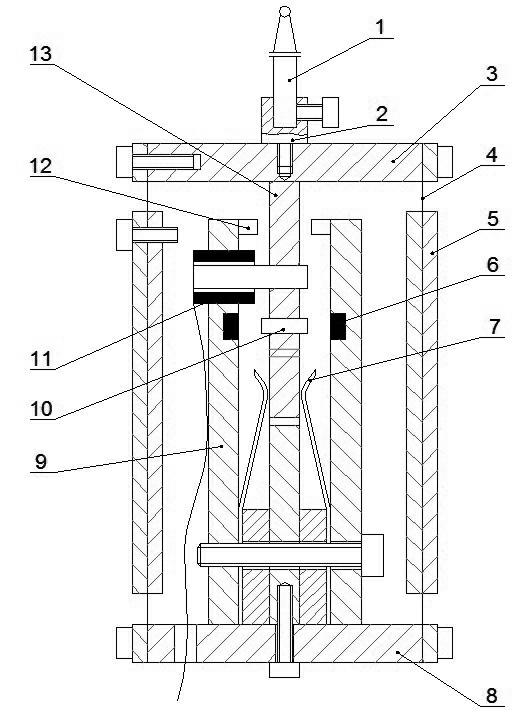

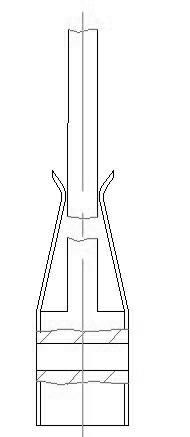

One-dimensional scanning measurement head mechanism with constant measurement force

InactiveCN102155902AConstant measuring forceAccurate measurement indicationPoint coordinate measurementsEngineeringSensor holder

The invention relates to a one-dimensional scanning measurement head mechanism with constant measurement force. The mechanism comprises a movable plate and a fixed plate; the upper part of the fixed plate is provided with a limiting seat; the middle part of the limiting seat is provided with a limiting swing rod; the lower end of a movable rod is arranged opposite to the upper end of the limiting swing rod; a pair of reset reeds and a pair of sensor brackets symmetrical to the movable rod are arranged on the limiting seat, the upper ends of the reset reeds are pressed on two sides of the lower end of the movable rod, one of the pair of sensor brackets is provided with a fixing part for a sensor, and the movable part of the sensor is arranged on the movable rod; an armature is arranged on the movable rod positioned between the upper end of the reset reed and the sensor, and the pair of sensor brackets corresponding to the armature is provided with a permanent magnet respectively; and the inner sides of the upper ends of the pair of sensor brackets are oppositely provided with limiting blocks. By designing a negative rigidity elastic supporting mechanism, the continuously increased reacting force, increased together with displacement, of the parallel reed and the pre-pressing reed is balanced by using magnetic force so as to realize basically constant measurement force.

Owner:XIAN TECH UNIV +1

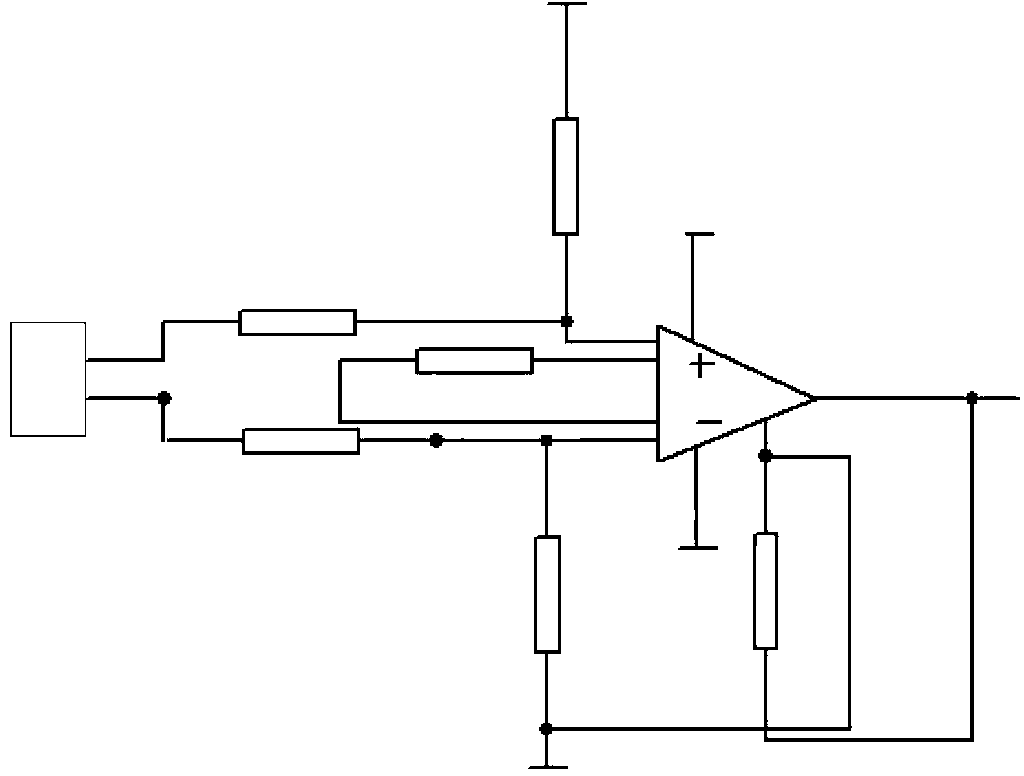

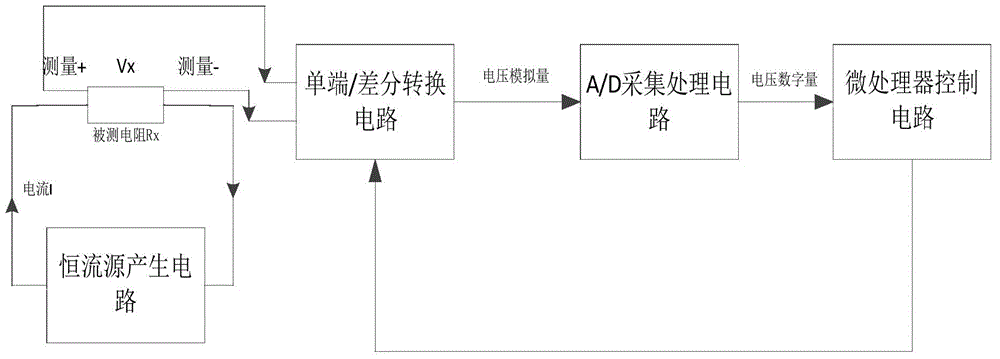

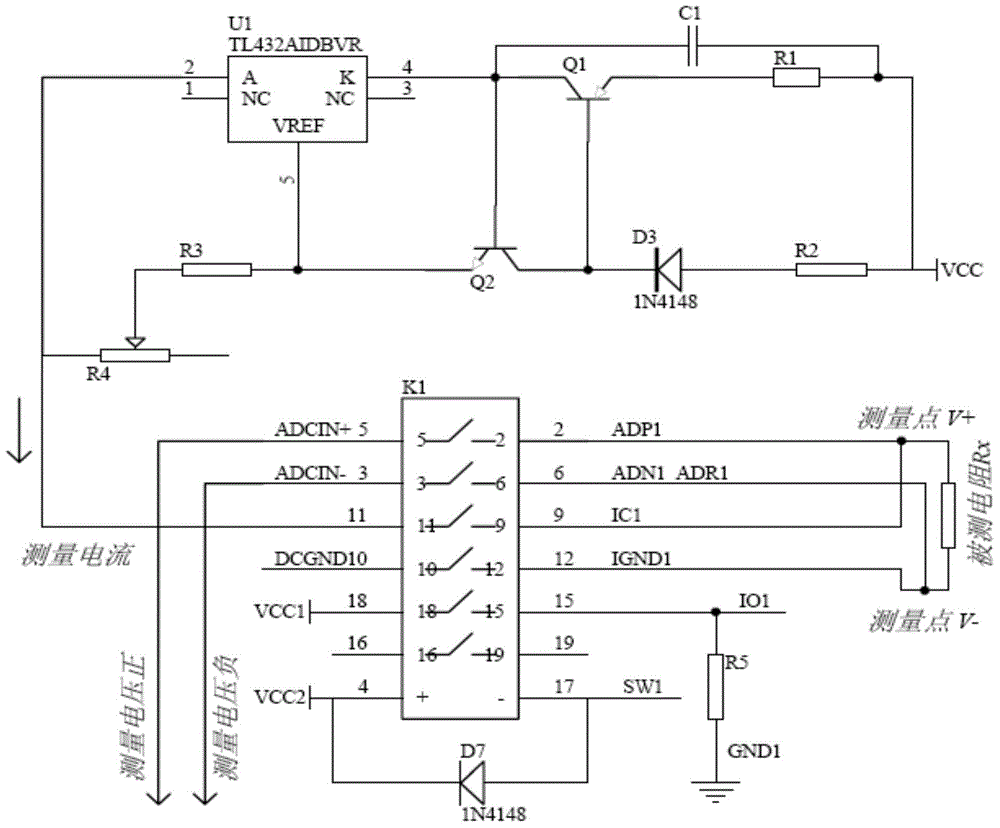

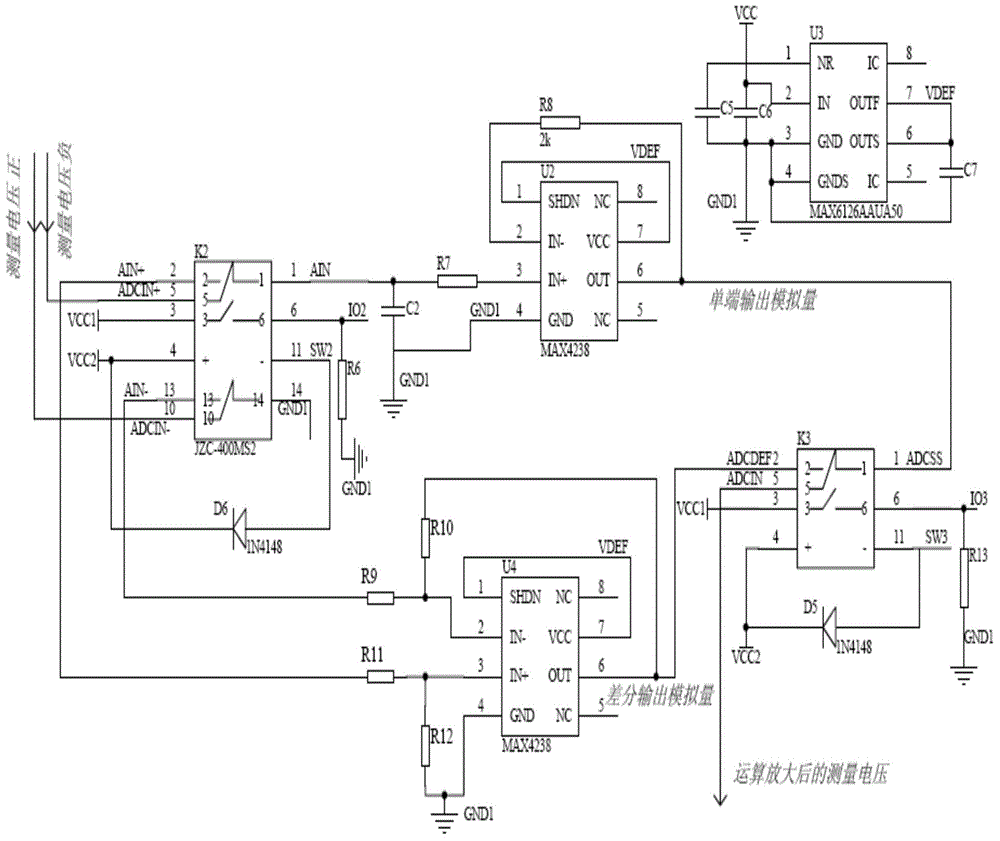

High-precision small resistor resistance measurement circuit

ActiveCN106383272AEliminate measurement errorsHigh measurement accuracyResistance/reactance/impedenceElectrical resistance and conductanceControl circuit

The invention discloses a high-precision small resistor resistance measurement circuit. The circuit comprises a constant current source circuit, a single-terminal / difference operation amplification circuit, an A / D conversion processing circuit and a microprocessor control circuit. The constant current source circuit provides a constant micro current for a measured resistor and generates a millivolt-level measured voltage on the measured resistor. The single-terminal / difference operation amplification circuit amplifies the millivolt-level voltage to acquire the measured voltage after operation amplification. The A / D conversion processing circuit converts the measured voltage after operation amplification into a digital waveform so as to acquire the measured voltage of the digital waveform. The microprocessor control circuit carries out filtering processing on the measured voltage of the digital waveform, calculates and acquires a resistance of the measured resistor. In the technical scheme, measurement precision of the small resistor is increased.

Owner:BEIJING INST OF ELECTRONICS SYST ENG

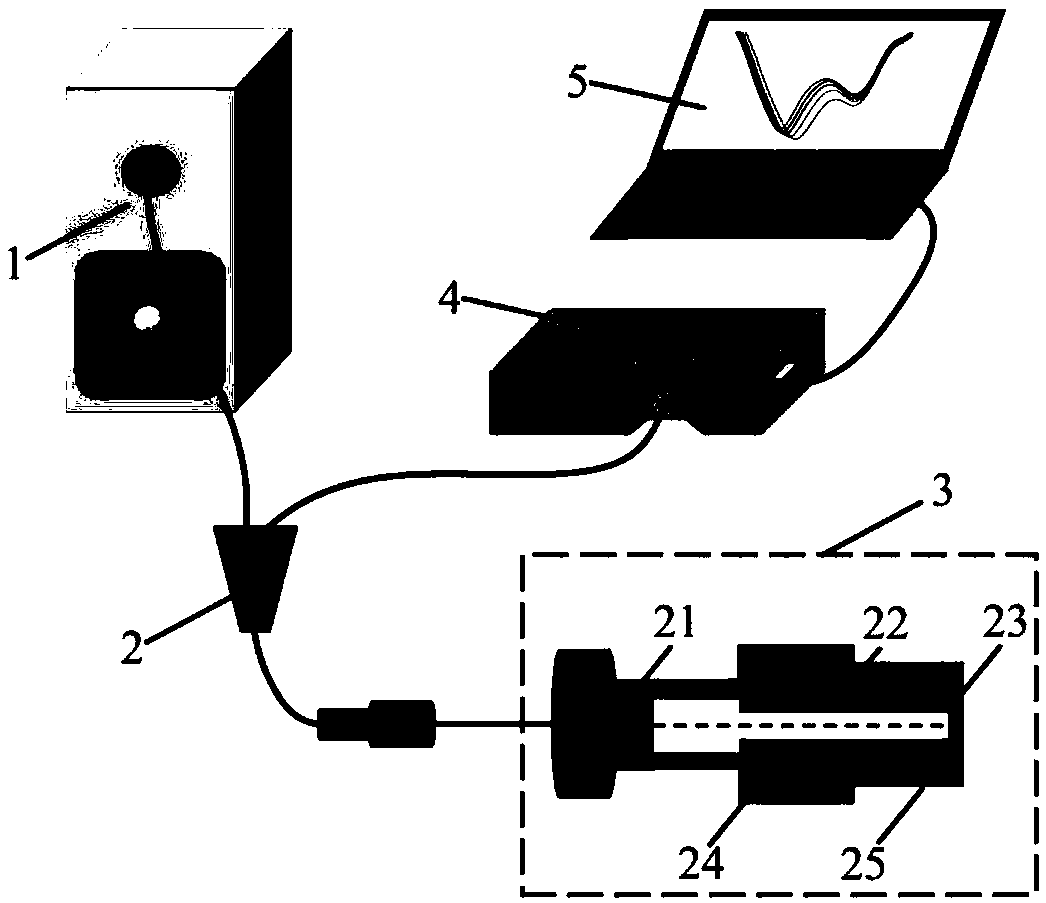

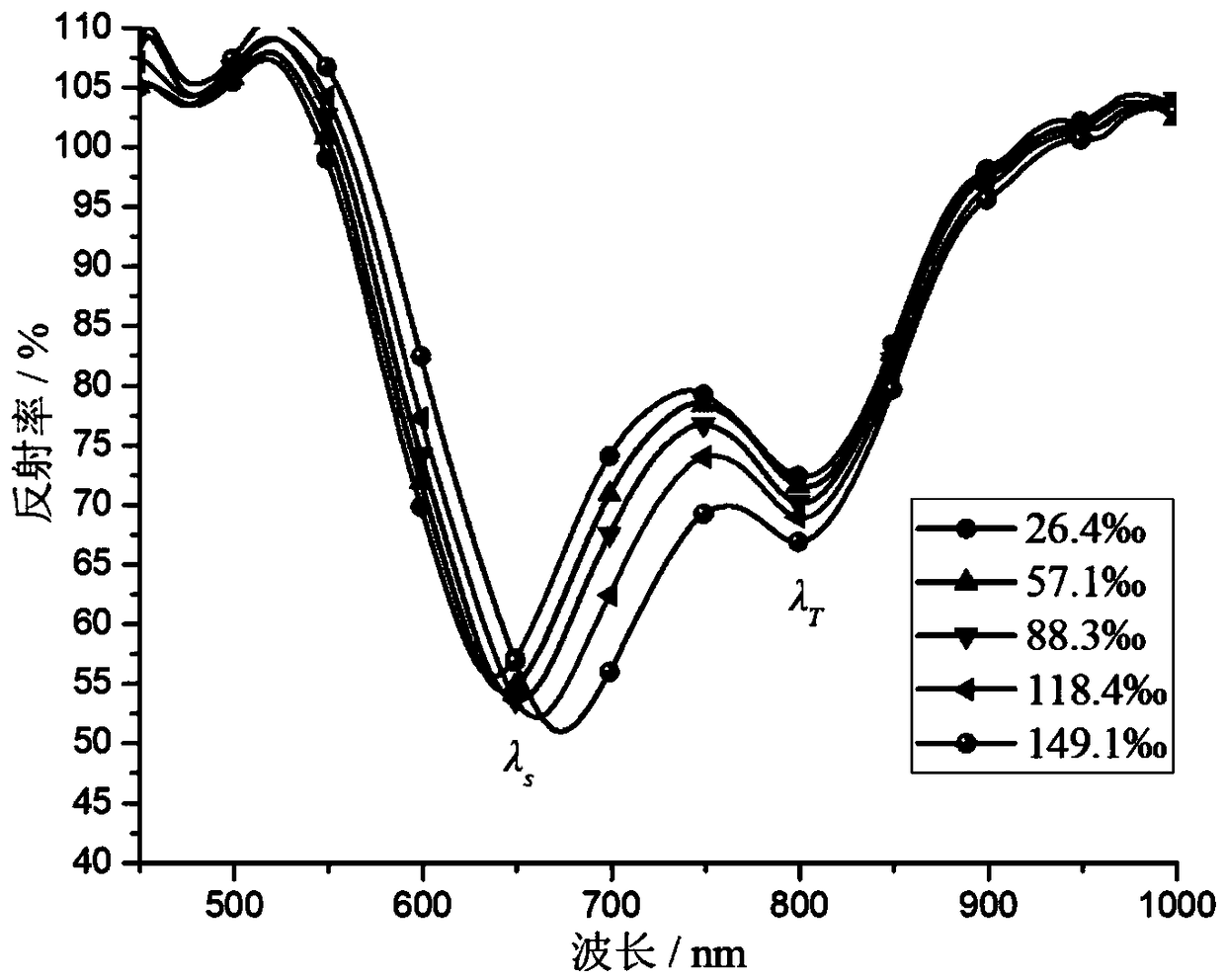

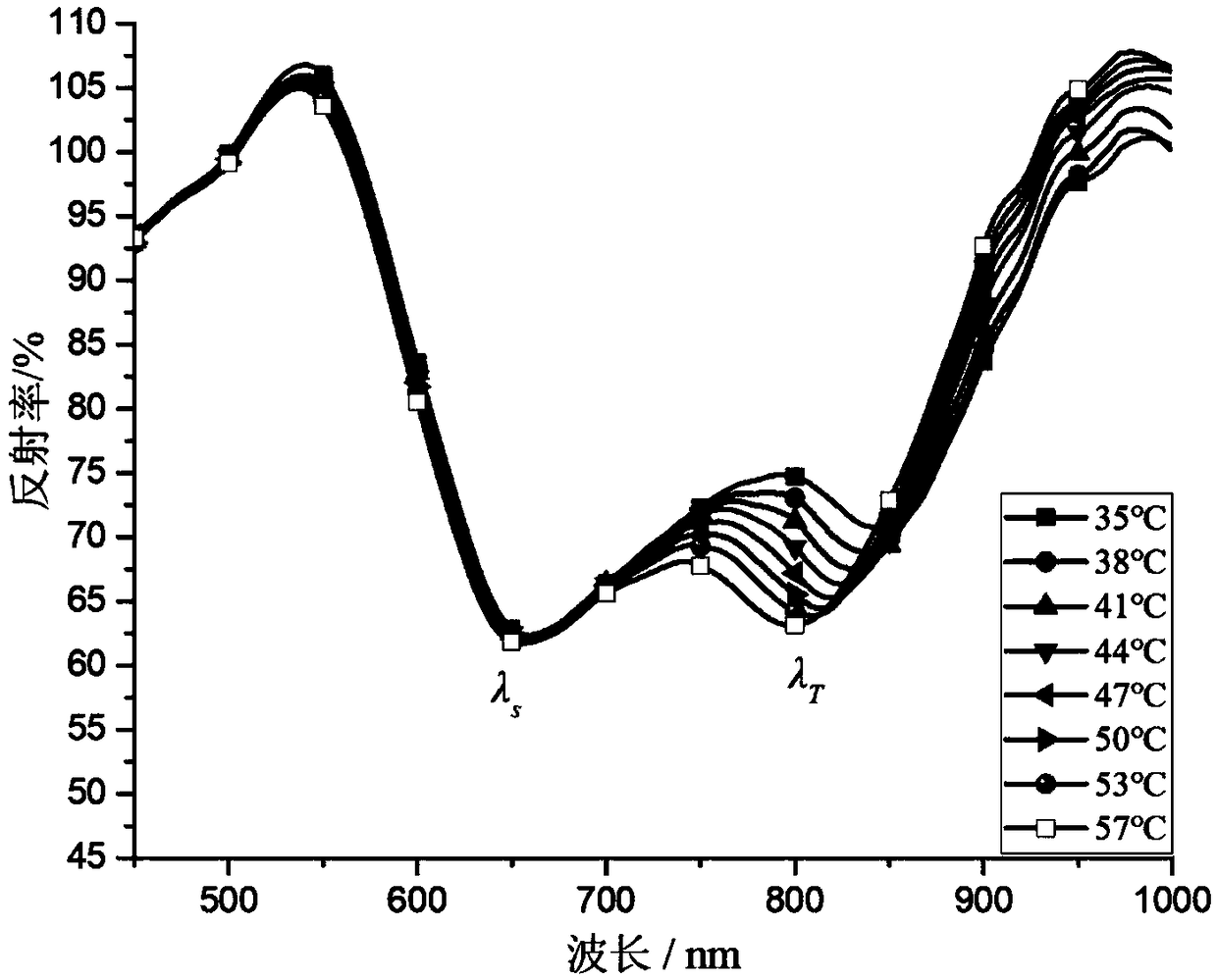

Reflective fiber sensor for simultaneous measurement of seawater salinity and temperature

InactiveCN108955774AReduce the impact of measurement accuracySimple preparation processThermometers using physical/chemical changesColor/spectral properties measurementsHalogenGold film

The invention belongs to the technical field of fiber sensing and discloses a reflective fiber sensor for simultaneous measurement of seawater salinity and the temperature. The sensor comprises a halogen light source, a Y-type fiber, a sensing unit, a spectrometer and a host computer, wherein the halogen light source is connected with the sensing unit through a branch of the Y-type fiber, the sensing unit is connected with the spectrometer through another branch of the Y-type fiber, the spectrometer is connected with the host computer, the sensing unit is formed by a multi-mode fiber and a single-mode fiber which are cascaded, the multi-mode fiber and the single-mode fiber are coaxially welded, an outer surface and an end surface of the single-mode fiber are plated with a gold film, and outer periphery of the gold film is plated with a temperature sensitive film from a welding end of the single-mode fiber to the half-length position of the single-mode fiber. The sensor is advantaged inthat not only can simple manufacturing process, low cost and stable structure be achieved, but also, through simultaneous measurement of seawater salinity and the temperature, influence of the temperature on seawater salinity measurement accuracy can be effectively reduced.

Owner:NORTHEASTERN UNIV LIAONING

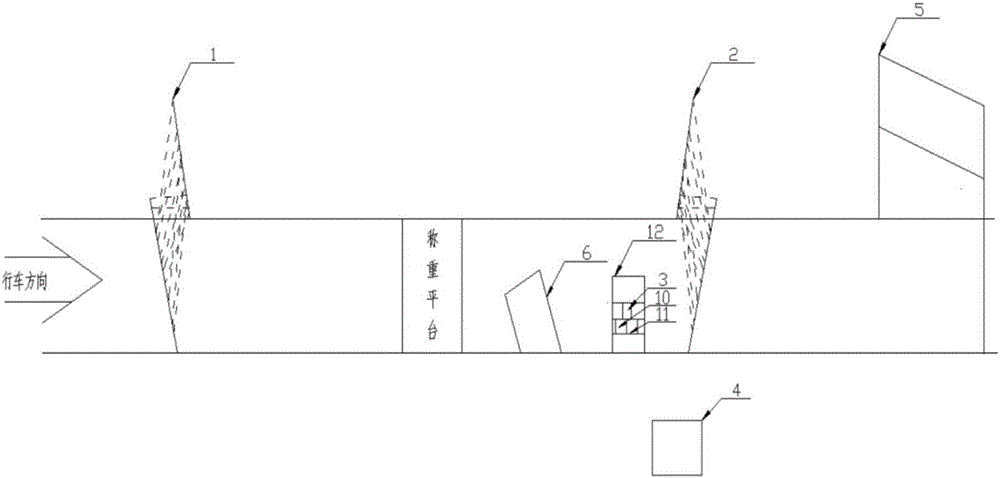

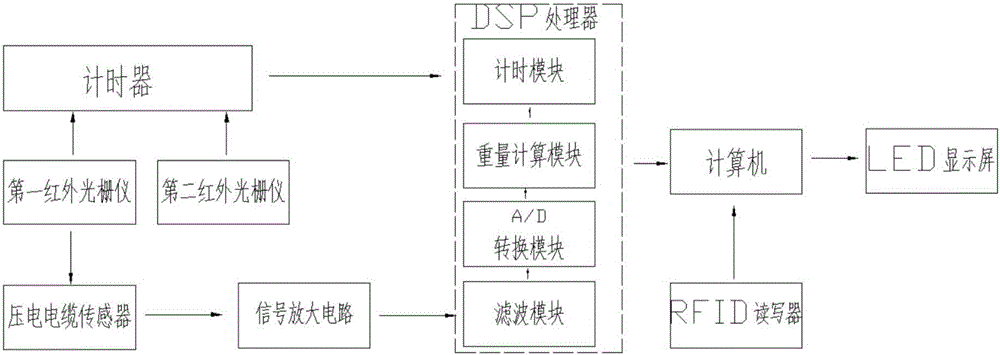

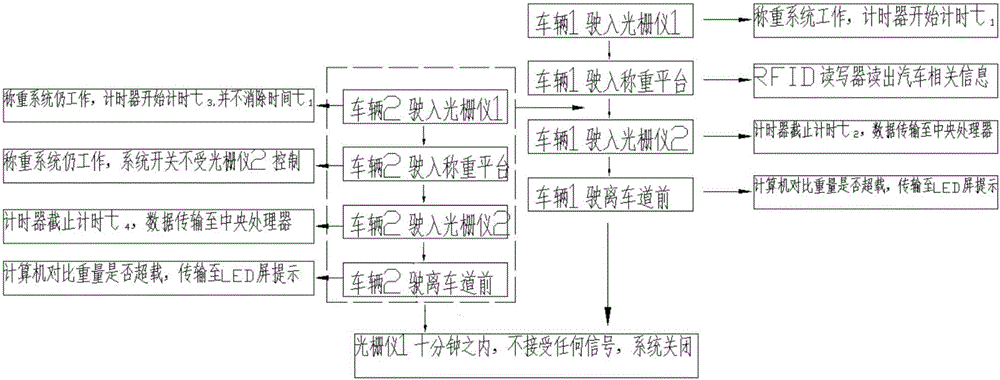

Automobile overload non-stop detection system and detection method based on RFID

ActiveCN106017621AReduce damageAccurate weightProgramme controlWeighing apparatus using elastically-deformable membersRoad surfaceTimer

The invention provides an automobile overload non-stop detection system and detection method based on RFID. The system includes a piezoelectric cable sensor, two groups of infrared grating instruments, an RFID reader, an RFID label, a computer, a DSP processor, a signal amplification circuit, a timer, and an LED display screen. A weigh-in-motion system is composed of the piezoelectric cable sensor, the signal amplification circuit, and the DSP processor, the dynamic weighing system is connected with the computer, the timer is connected with the infrared grating instruments, the infrared grating instruments are connected with the piezoelectric sensor, the RFID reader is connected with the computer, the RFID label is arranged on an automobile, and the computer is connected with the LED display screen. The weigh-in-motion system measures the weight signal during the automobile driving process and performs data processing; the timer records the automobile driving time; and the infrared grating instruments eliminate vehicle following phenomenon and are taken as the switch of the weigh-in-motion system. The system has the characteristics of high measurement precision, less damage to the pavement, and high adaptability.

Owner:江苏星火汽车部件制造有限公司

Optical fiber-based power transmission conductor aeolian vibration monitoring digital sensor and monitoring method

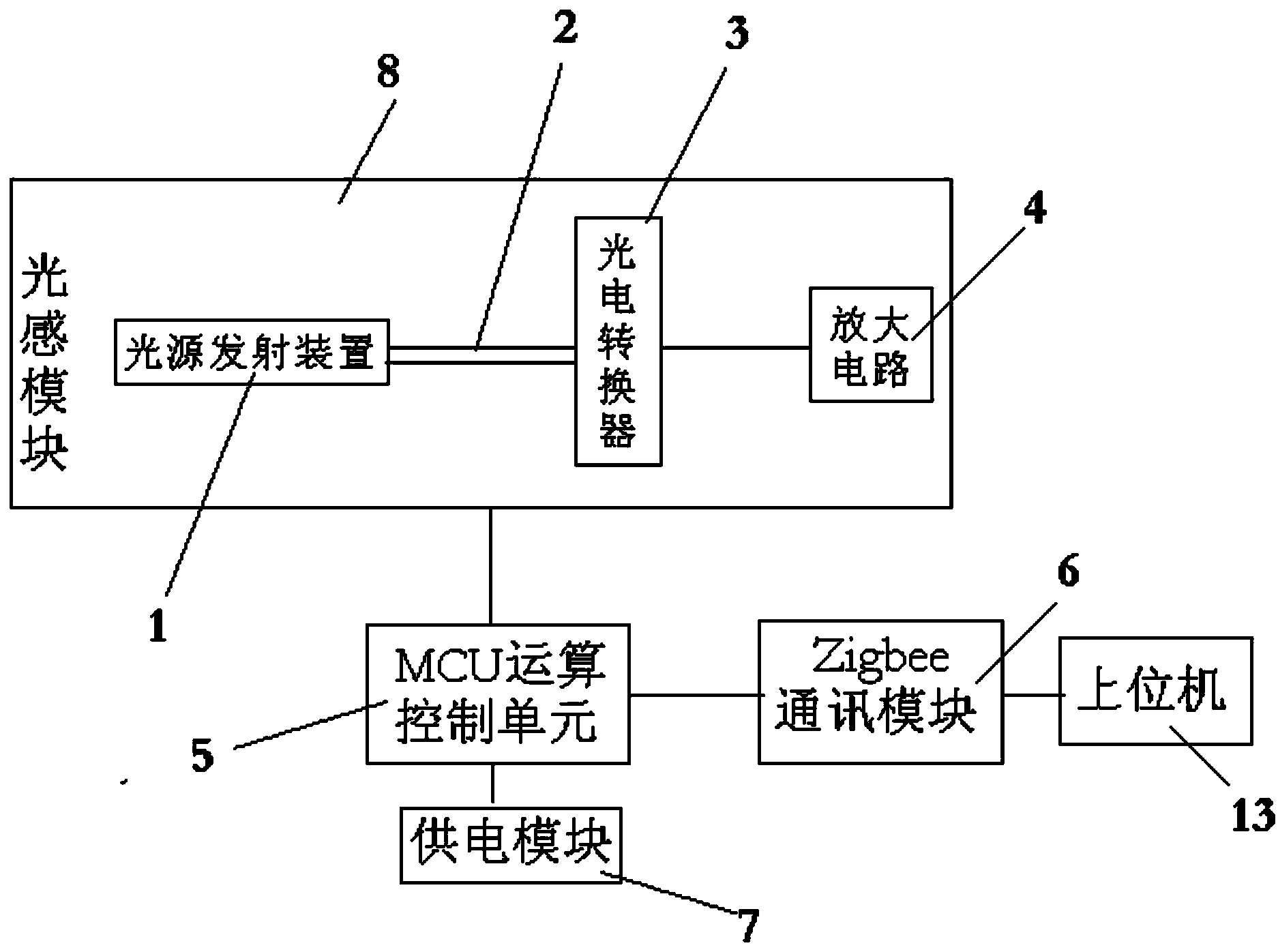

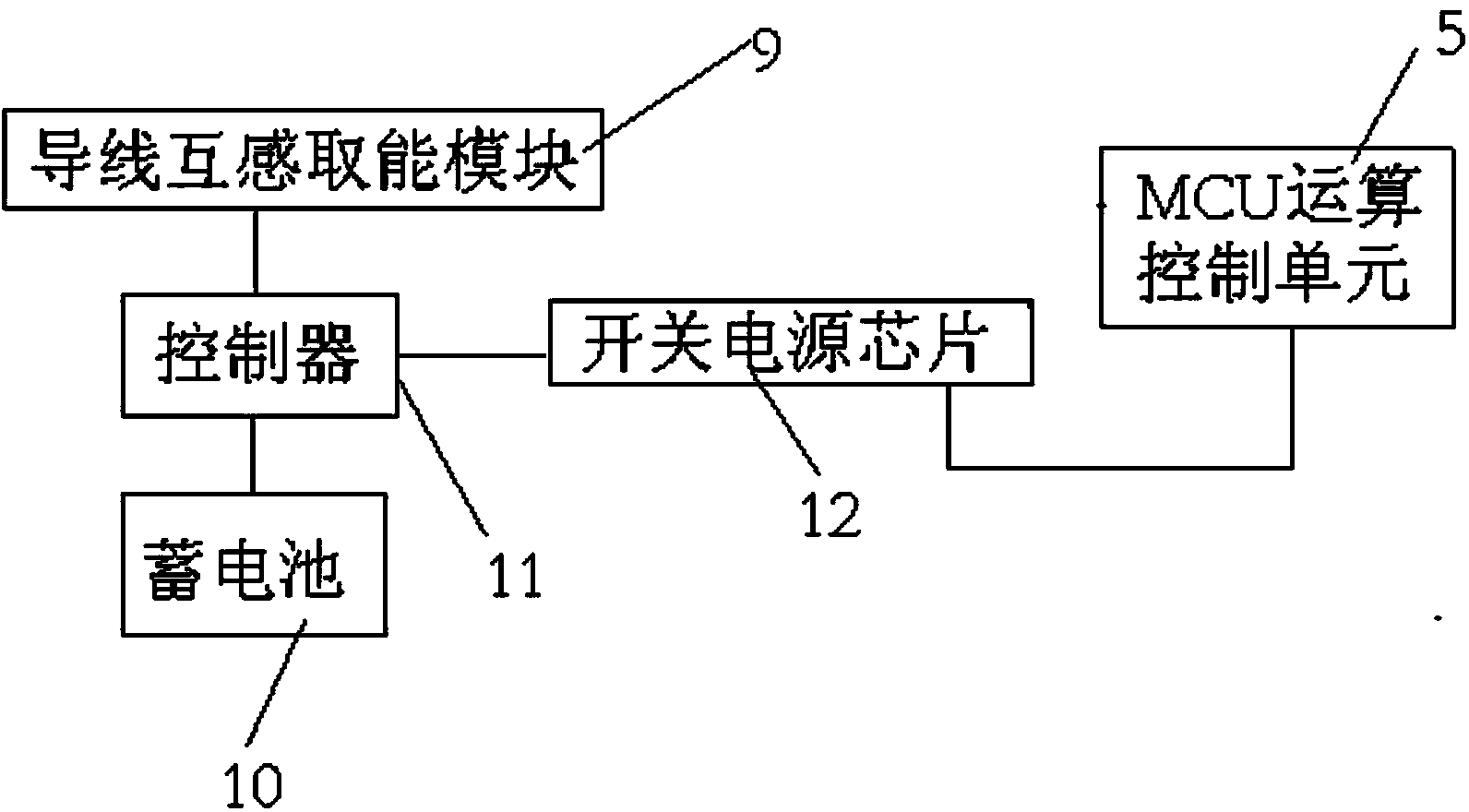

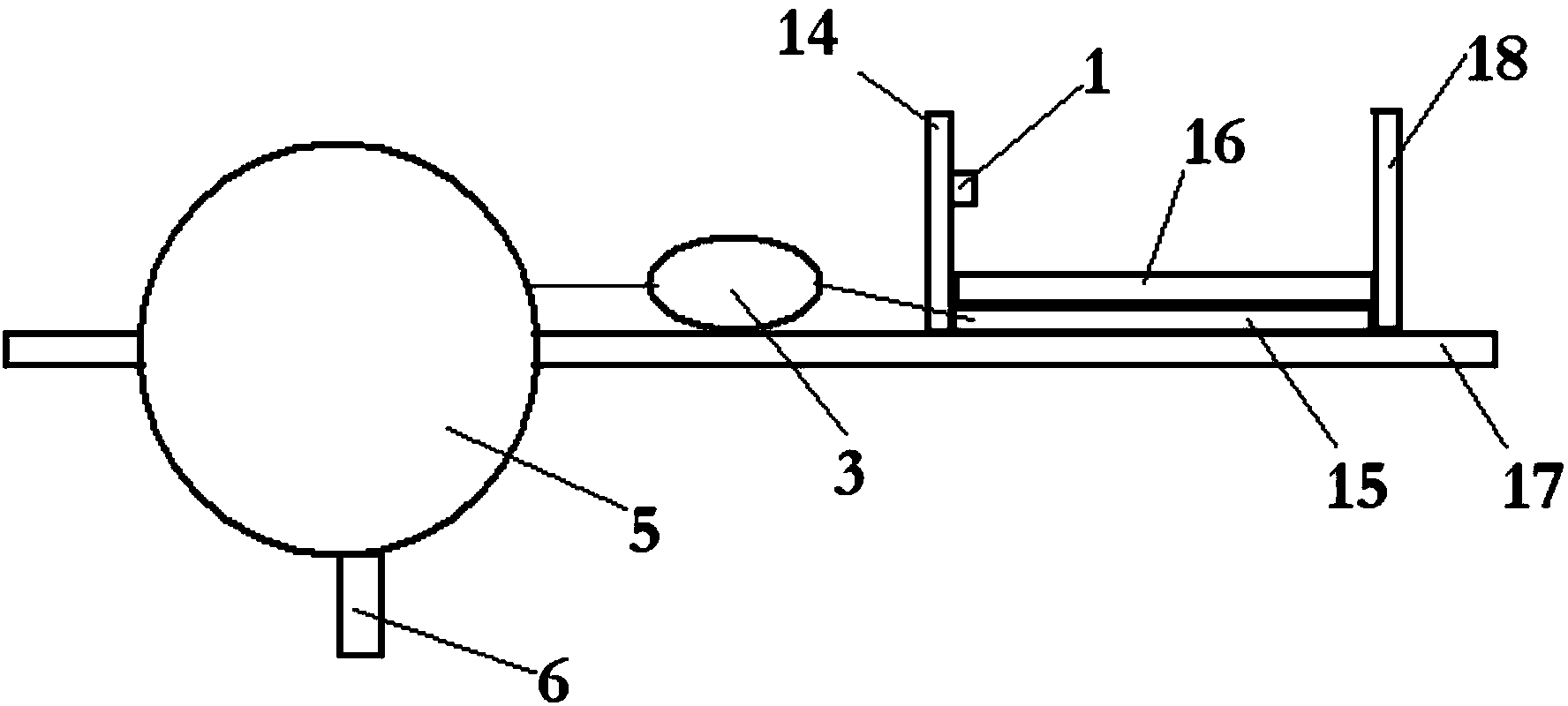

ActiveCN103868580AHigh measurement accuracyStrong anti-electromagnetic interference abilitySubsonic/sonic/ultrasonic wave measurementUsing wave/particle radiation meansData acquisitionComputer module

The invention relates to an optical fiber-based power transmission line aeolian vibration monitoring digital sensor which comprises an MCU (microprogrammed control unit) computing control unit, wherein the MCU computing control unit is respectively connected with a power supply module and a light sensation module by wires and is sequentially connected with a Zigbee communication module and an upper computer by a Zigbee network. The invention also discloses a monitoring method of the sensor; the method comprises the steps of mounting the power transmission line aeolian vibration monitoring digital sensor on a power transmission line; initializing by the MCU computing control unit, and sequentially performing data acquisition and data processing and outputting an optical fiber phase change electrical signal by the light sensation module; transmitting the optical fiber phase change electrical signal to the MCU computing control unit to obtain an amplitude value and frequency; sending the amplitude value and the frequency to the upper computer by the Zigbee wireless communication module. The sensor disclosed by the invention solves the problems that the existing cantilever beam type aeolian vibration monitoring sensor is poor in frequency response effect and is relatively sensitive to temperature.

Owner:XI'AN POLYTECHNIC UNIVERSITY

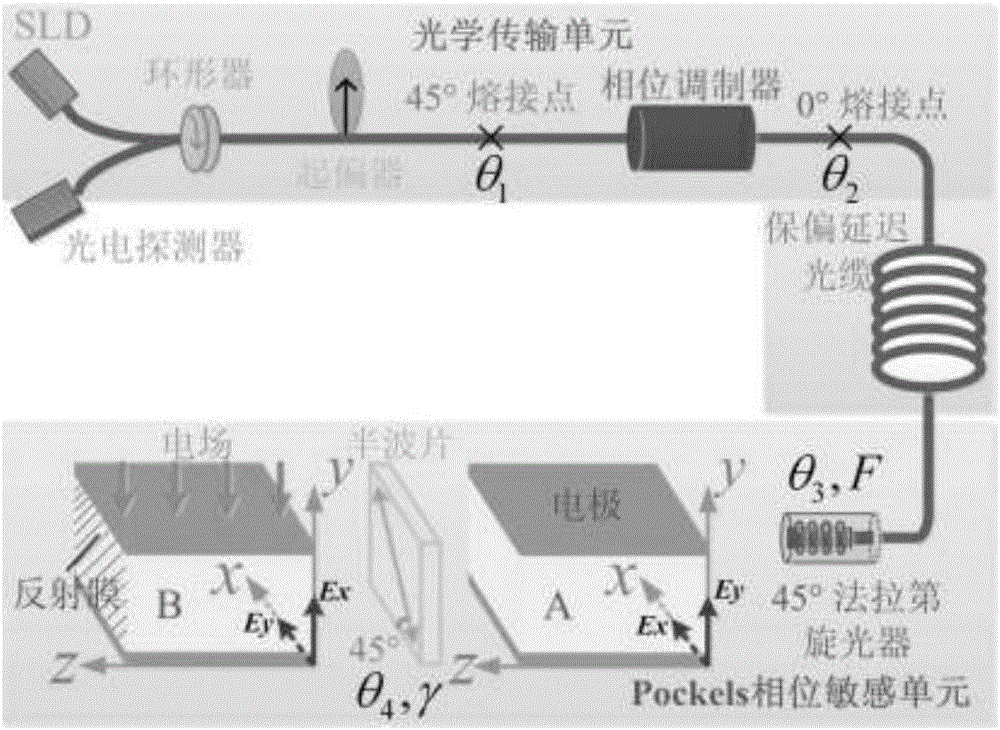

Optical sensing device for restraining voltage sensor temperature error

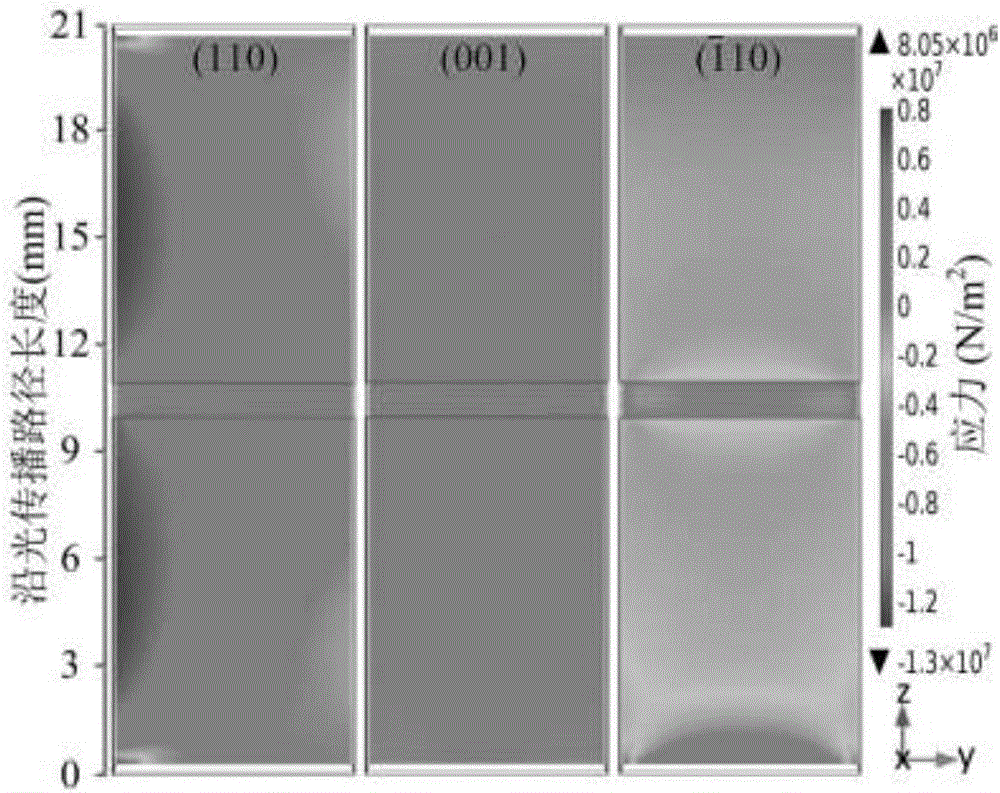

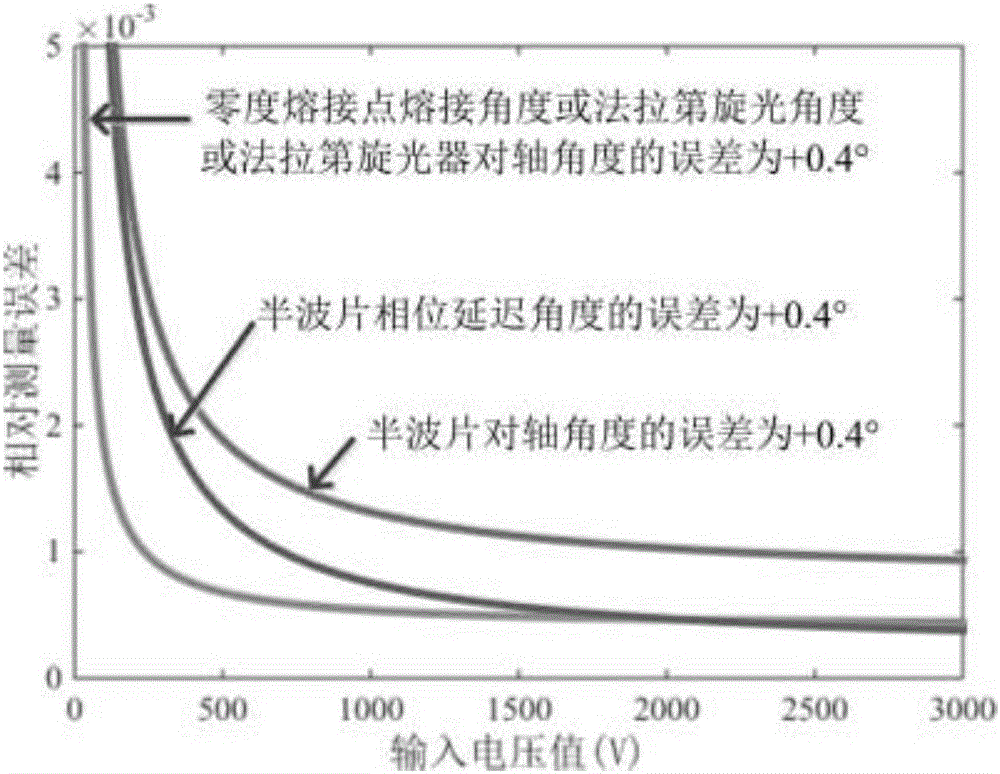

ActiveCN105911324AImprove temperature stabilityReduce stress distributionVoltage/current isolationSpecial purpose recording/indication apparatusOptical sensingOptical transport unit

The invention discloses an optical sensing device for restraining a voltage sensor temperature error and belongs to the field of an optical voltage sensor. The optical sensing device comprises an optical transmission unit and a Pockels phase sensing unit. The reciprocity degeneration of the Pockels phase sensing unit is caused by the inconsistency of the temperature fields and stress fields of two crystals; and the generation of a measuring error of the optical voltage sensor is caused by the influence of the non-ideal welding angle and counter shaft angle of the optical transmission unit on the magnitude of interference light intensity and feedback phase. By establishing a temperature error model of the optical transmission unit and the Pockels phase sensing unit, a novel optical base structure for counteracting additional stress birefringence in the two crystals is designed, and an angle error compensating method is provided, so that the measuring precision and temperature stability of the optical voltage sensor are increased.

Owner:安徽华驰动能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com