Patents

Literature

526results about "Temperature measurement of moving solids" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

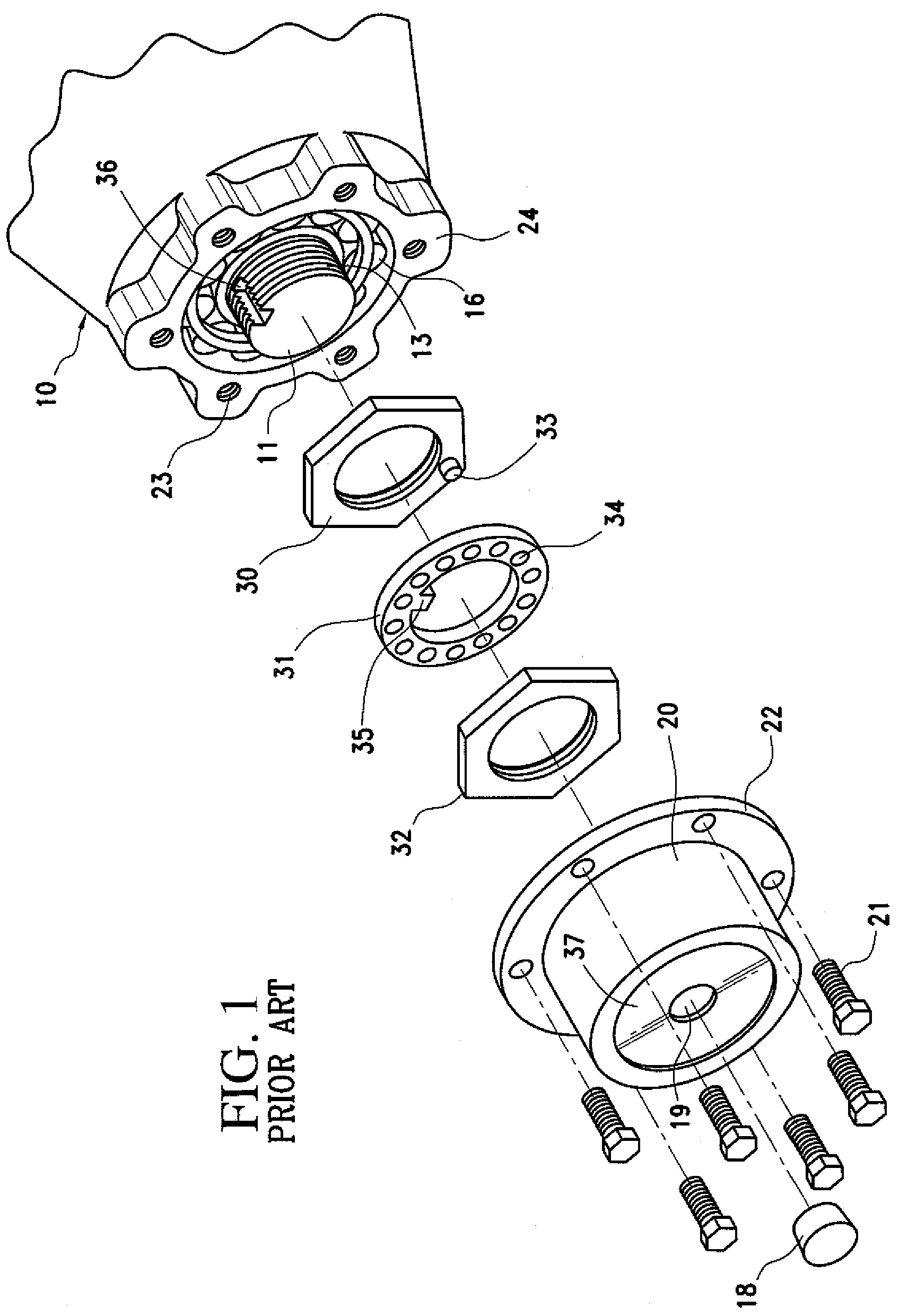

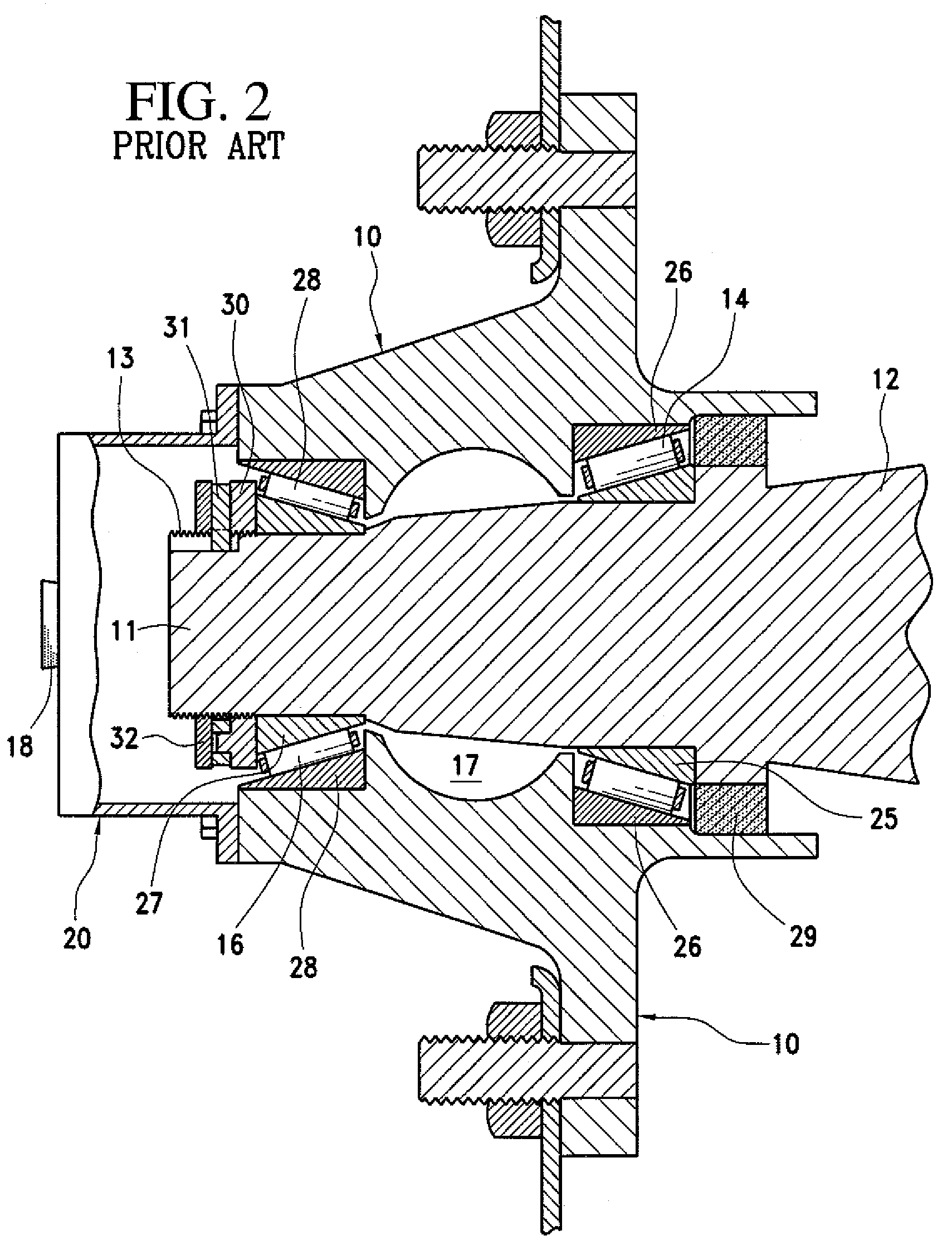

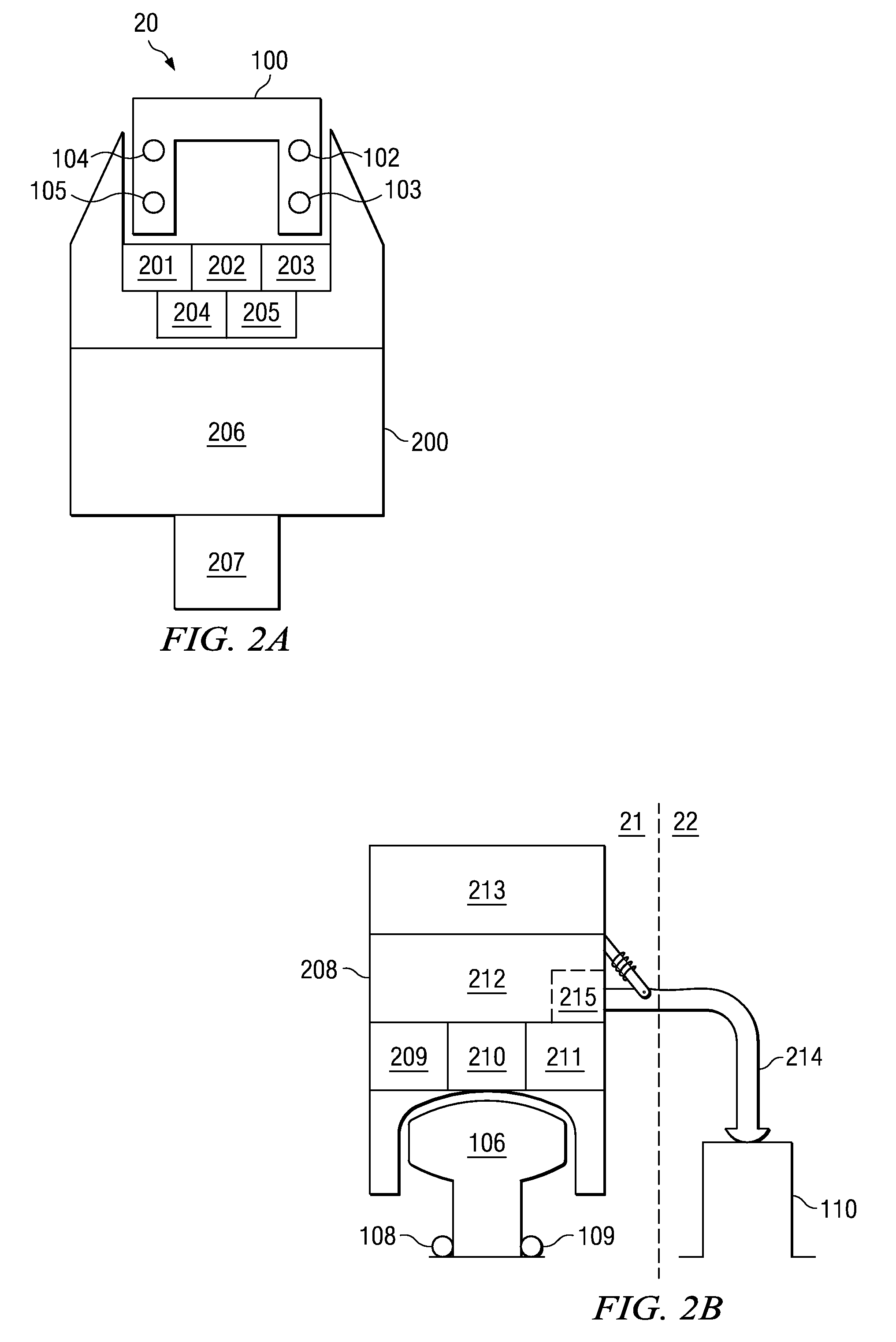

Suction roll with sensors for detecting temperature and/or pressure

InactiveUS6981935B2Promote employmentThermometer detailsLiquid surface applicatorsBiomedical engineeringPolymer

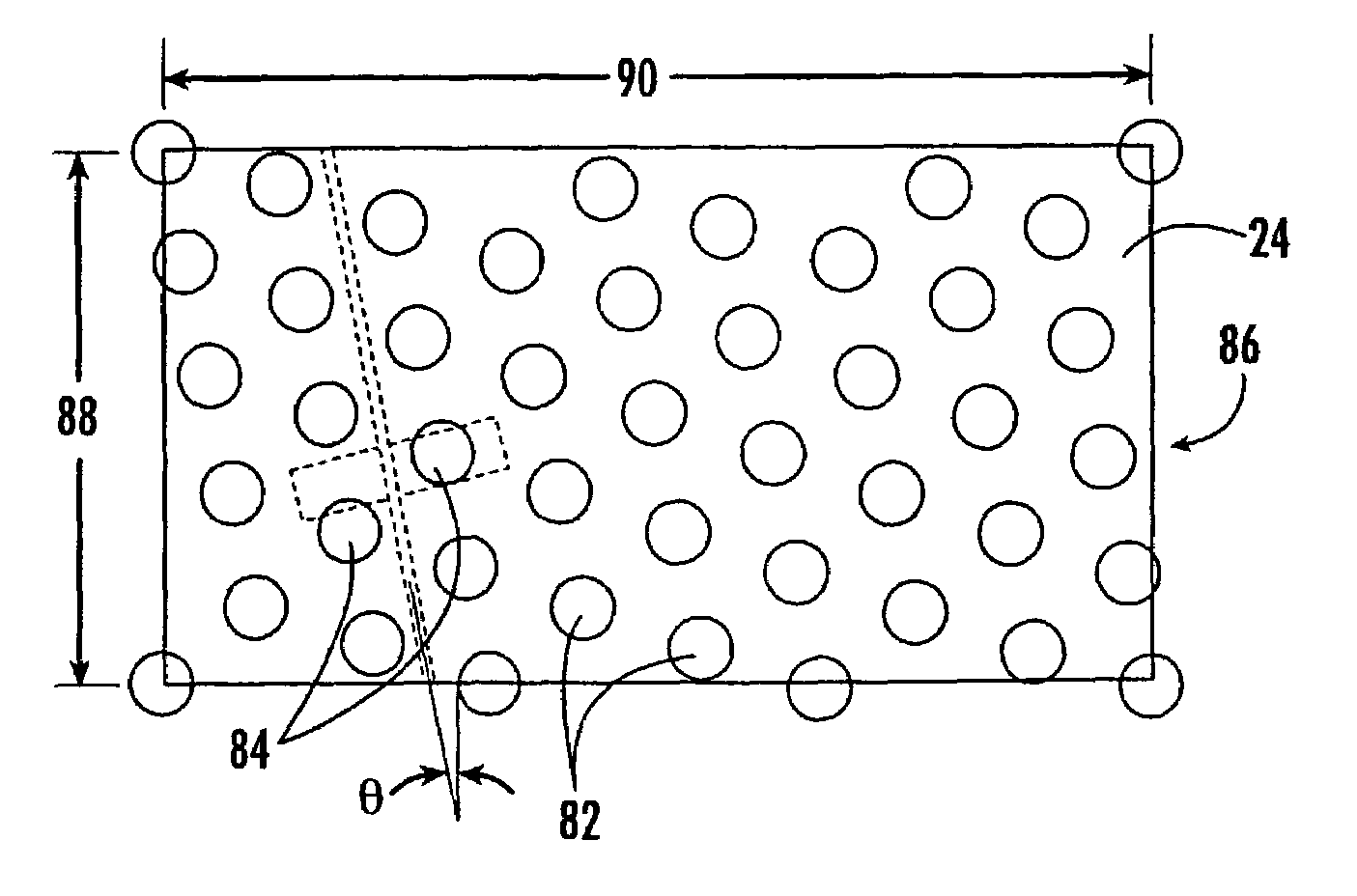

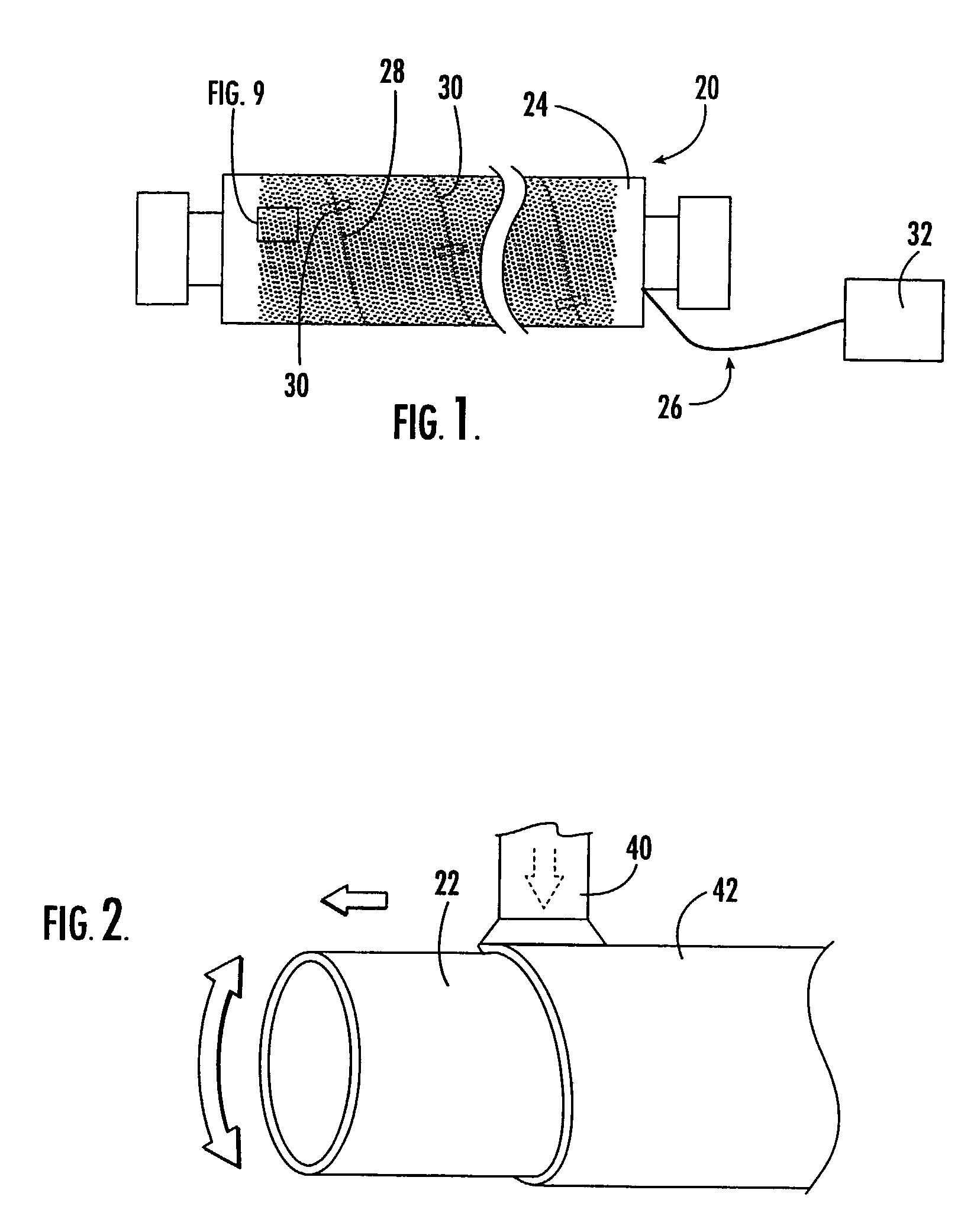

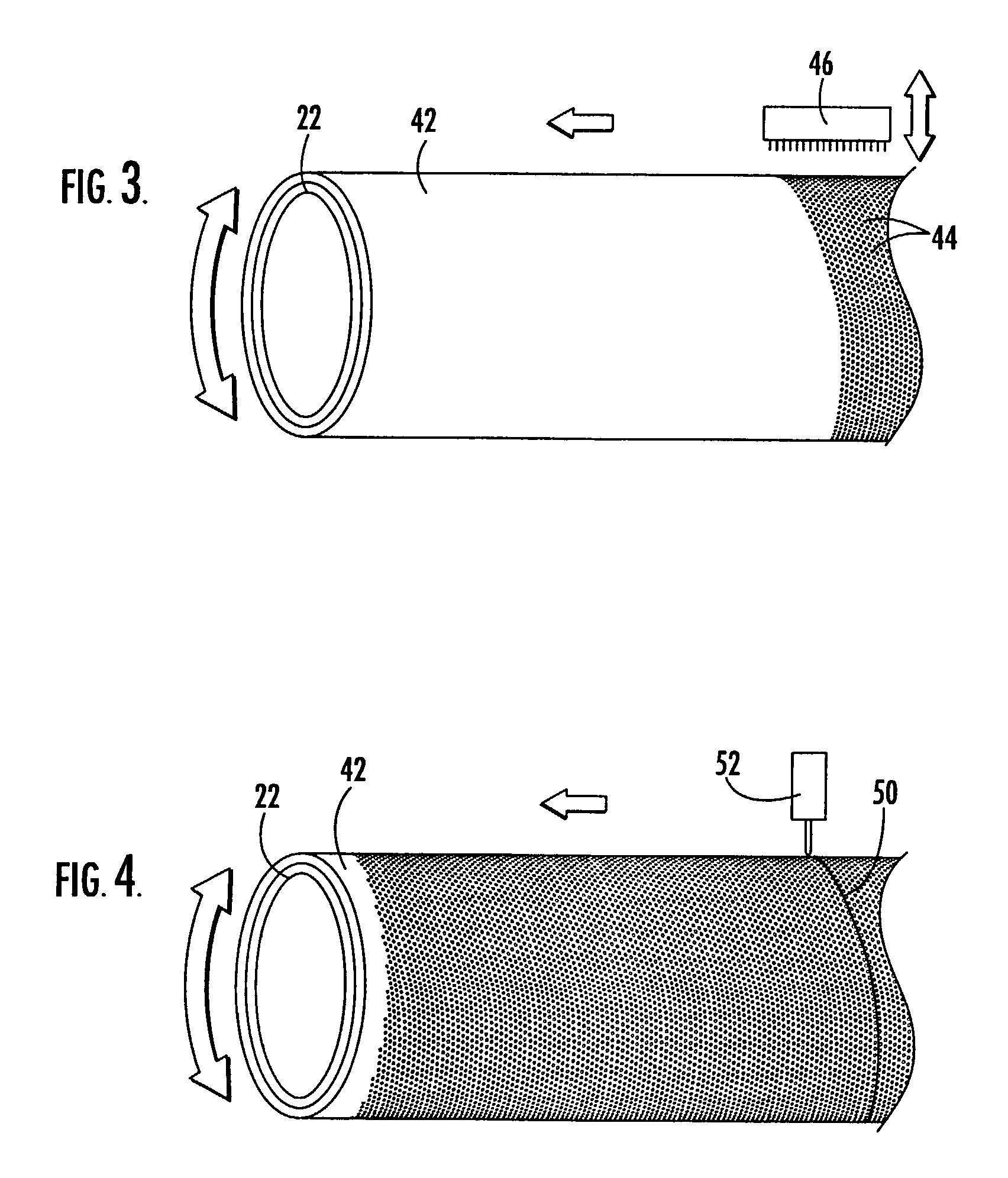

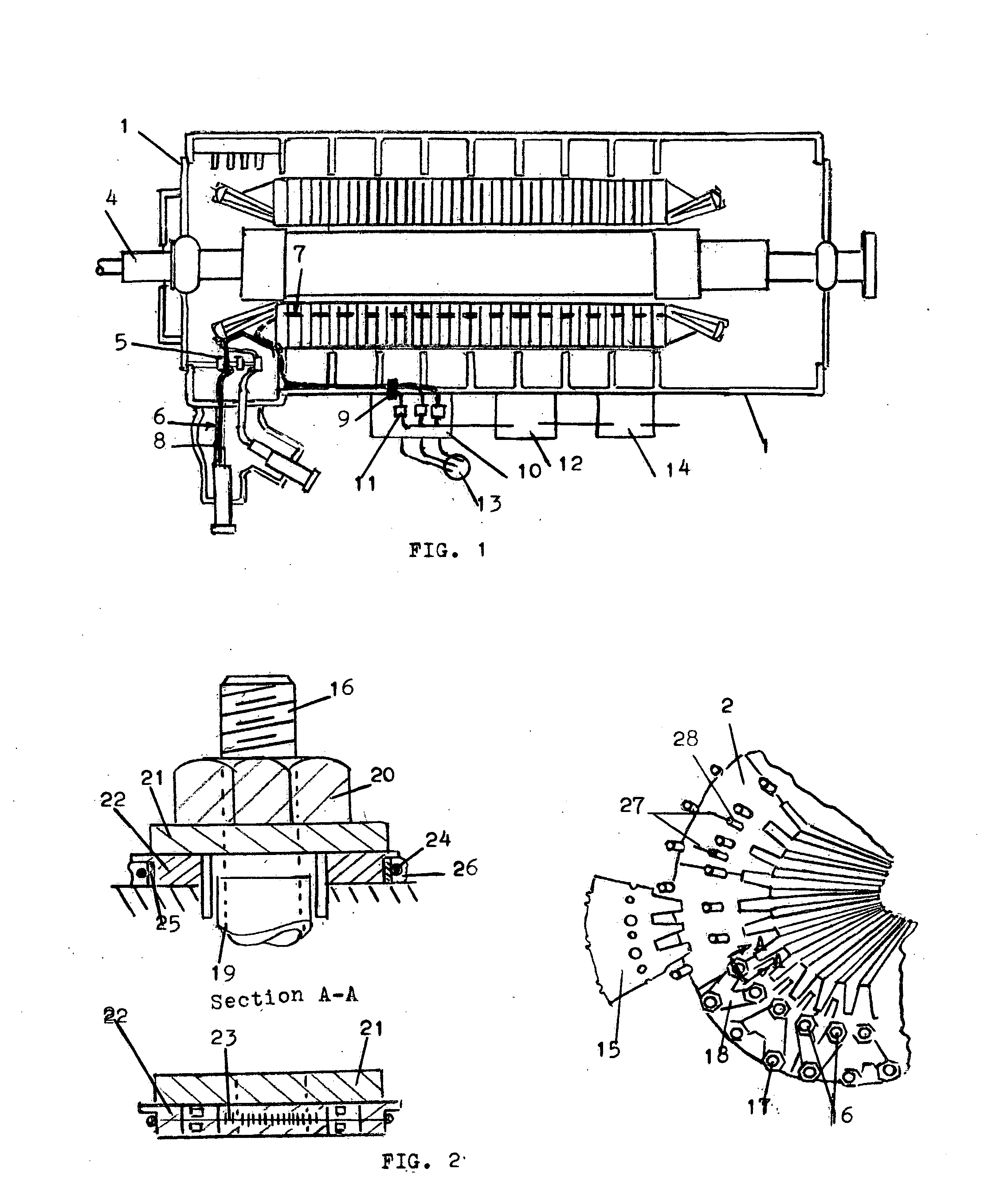

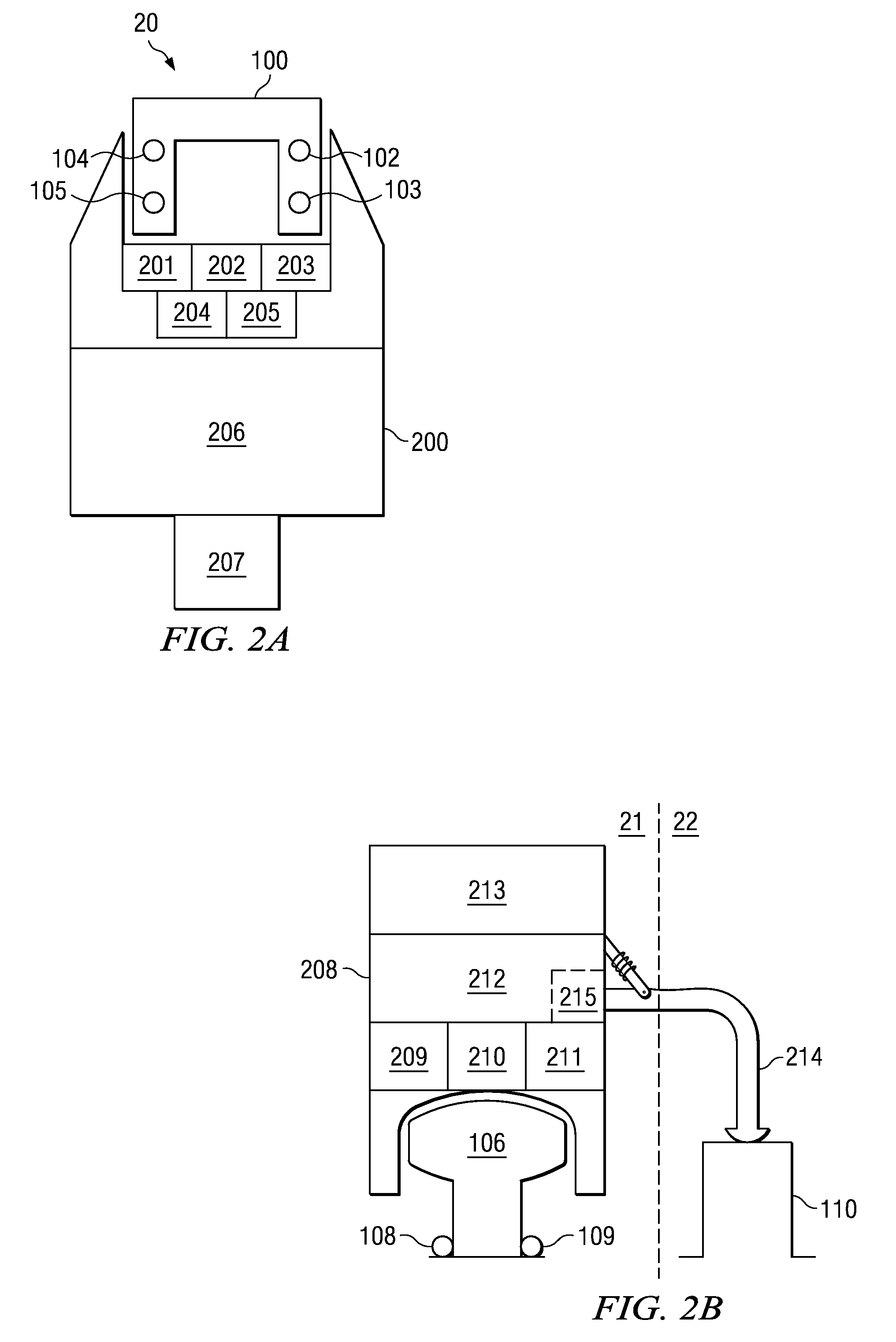

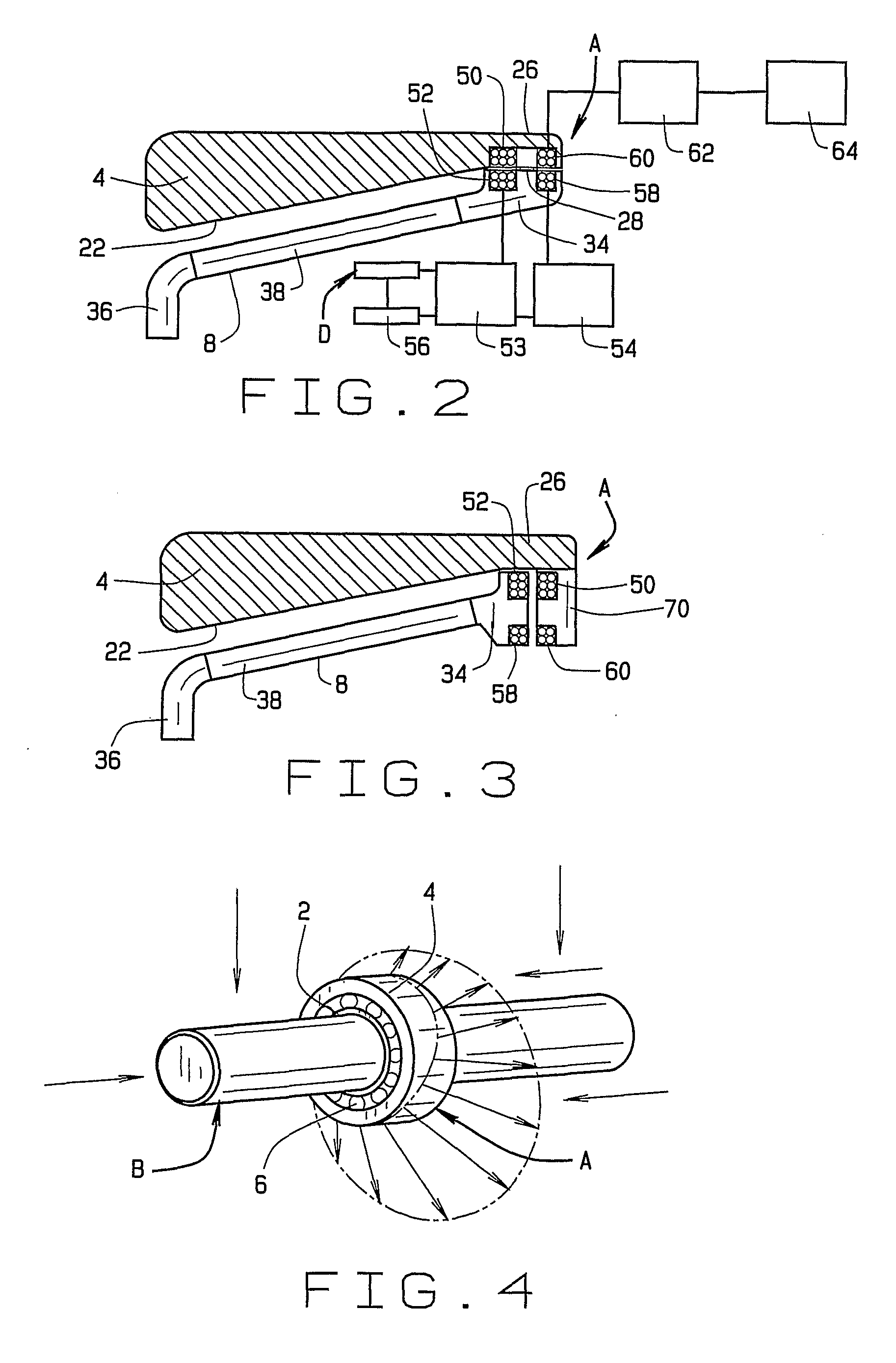

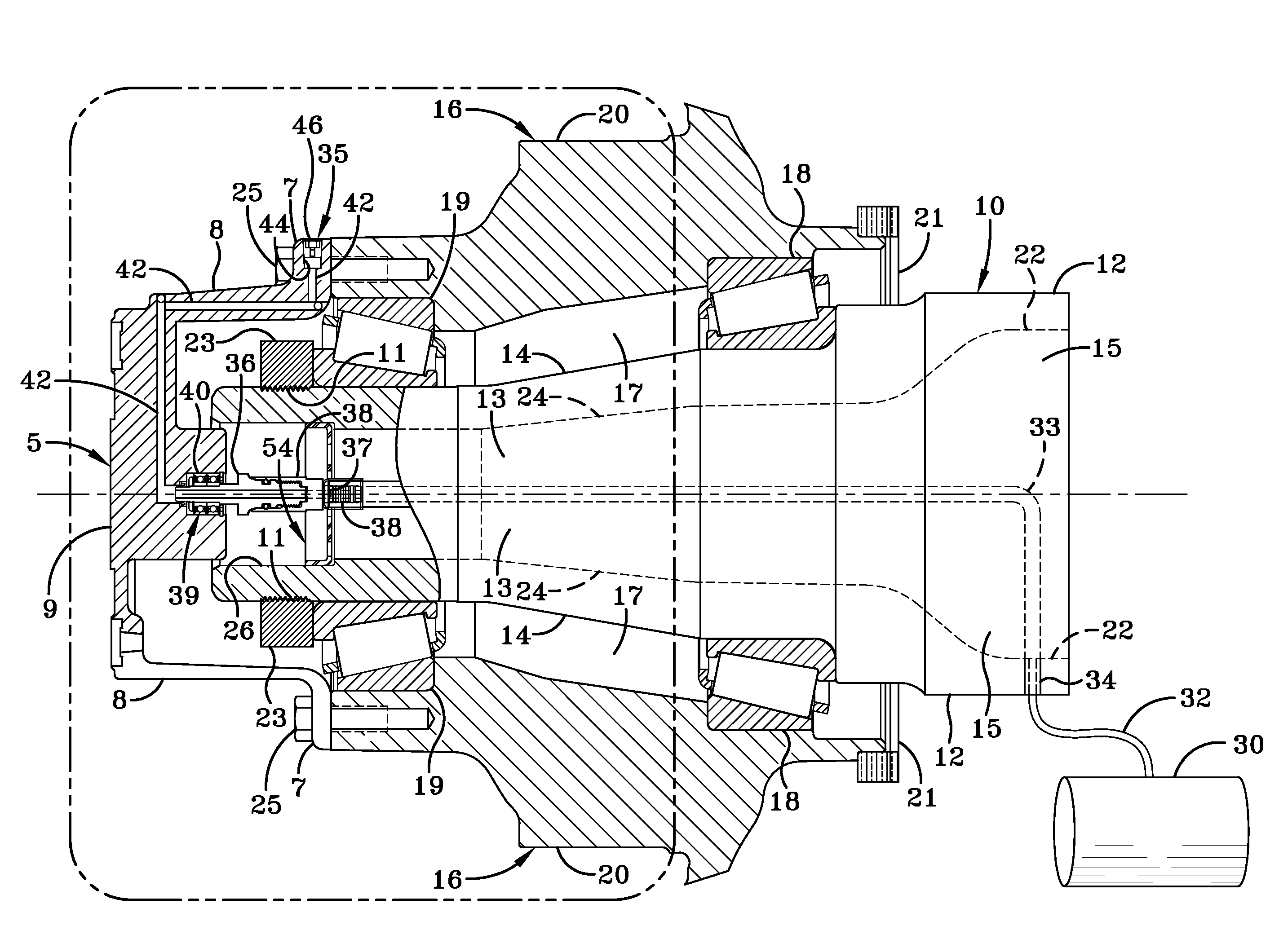

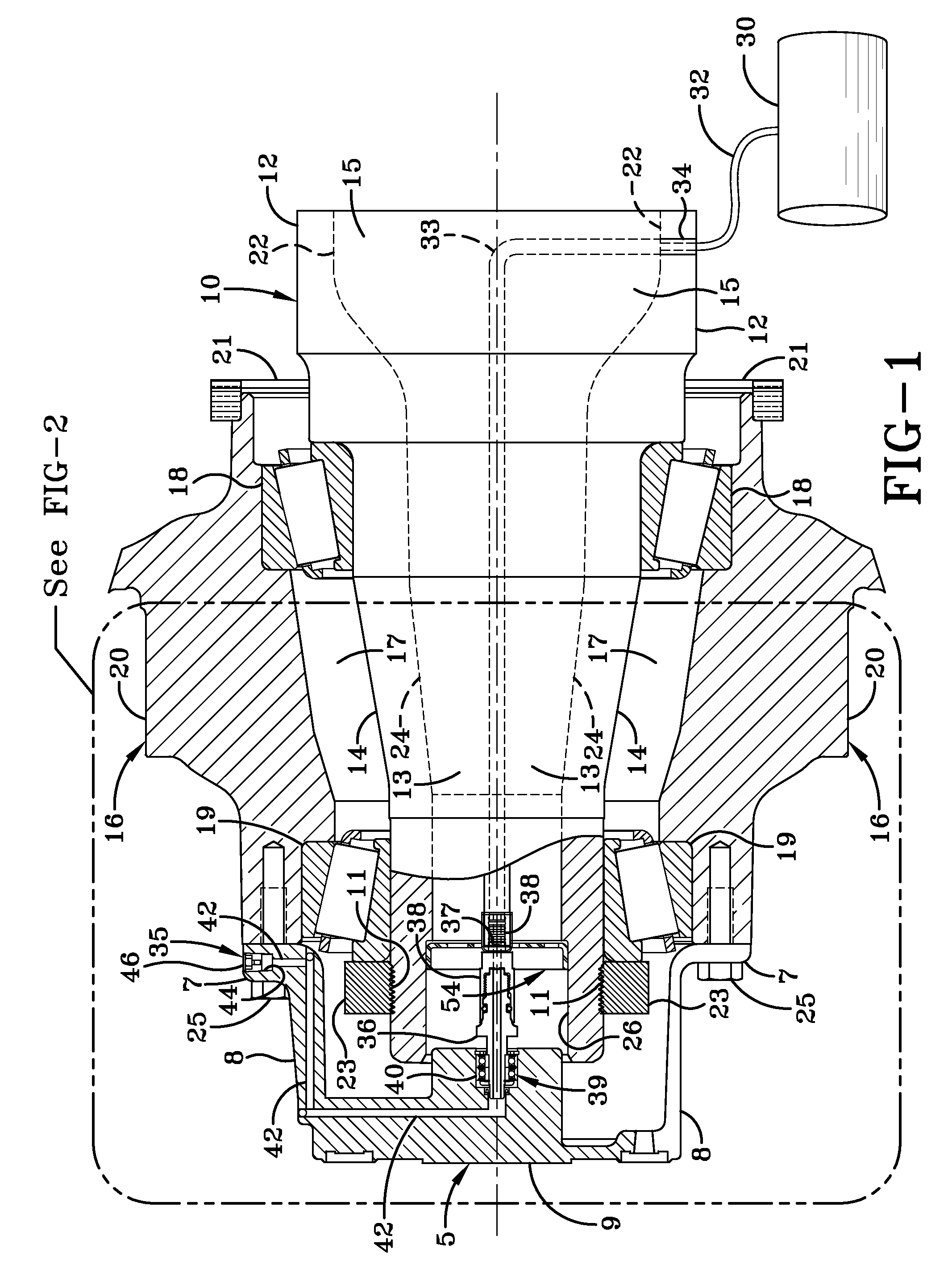

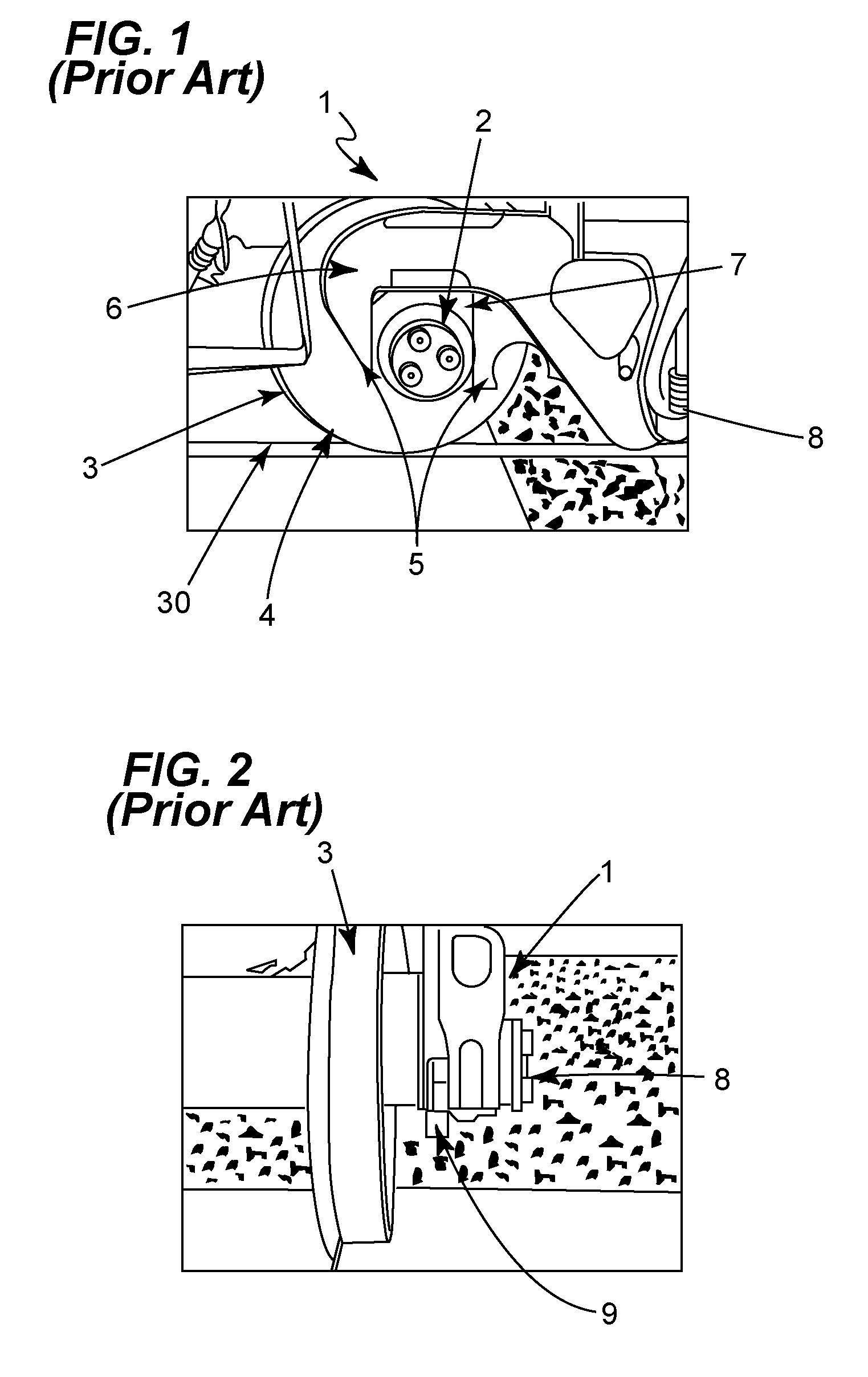

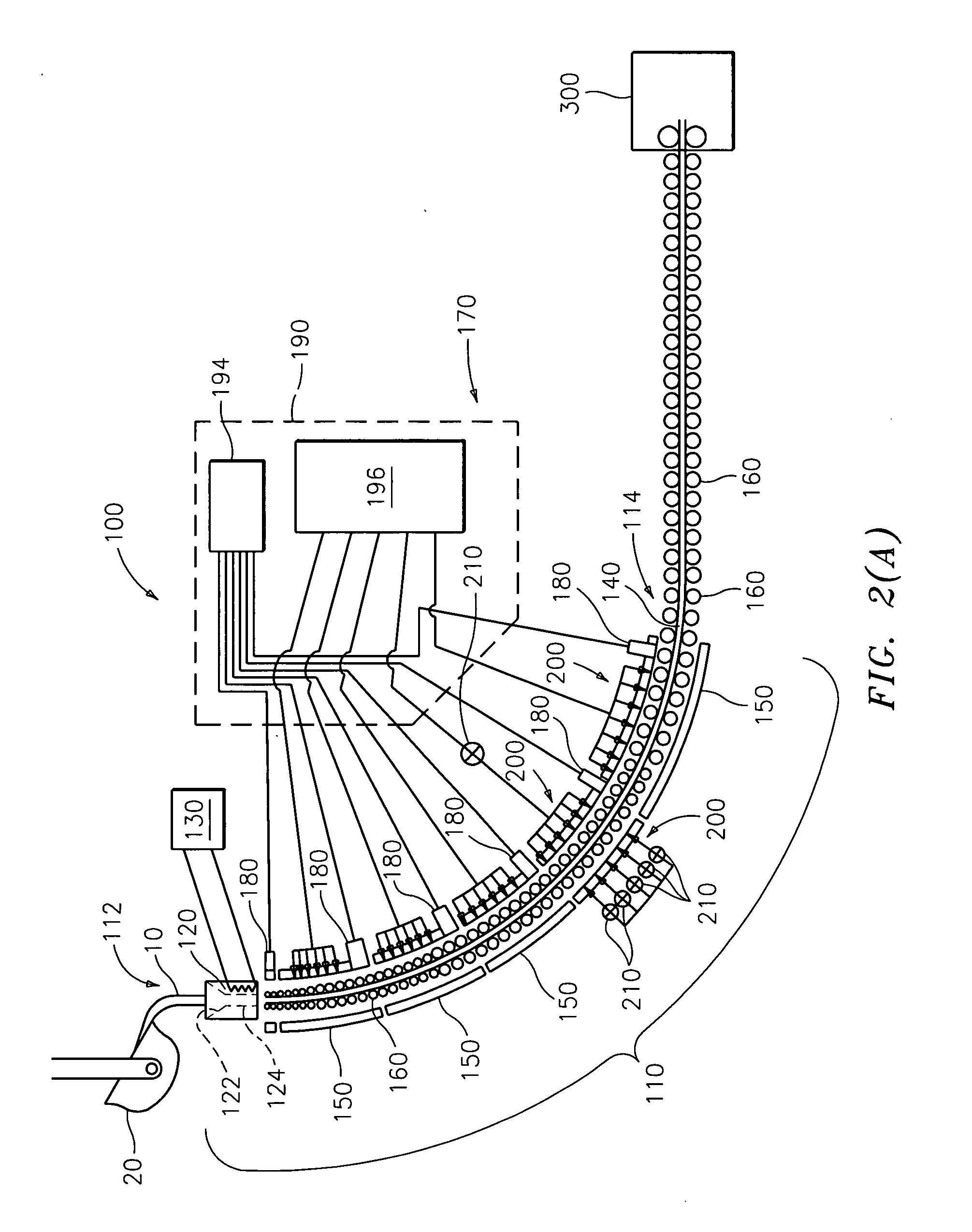

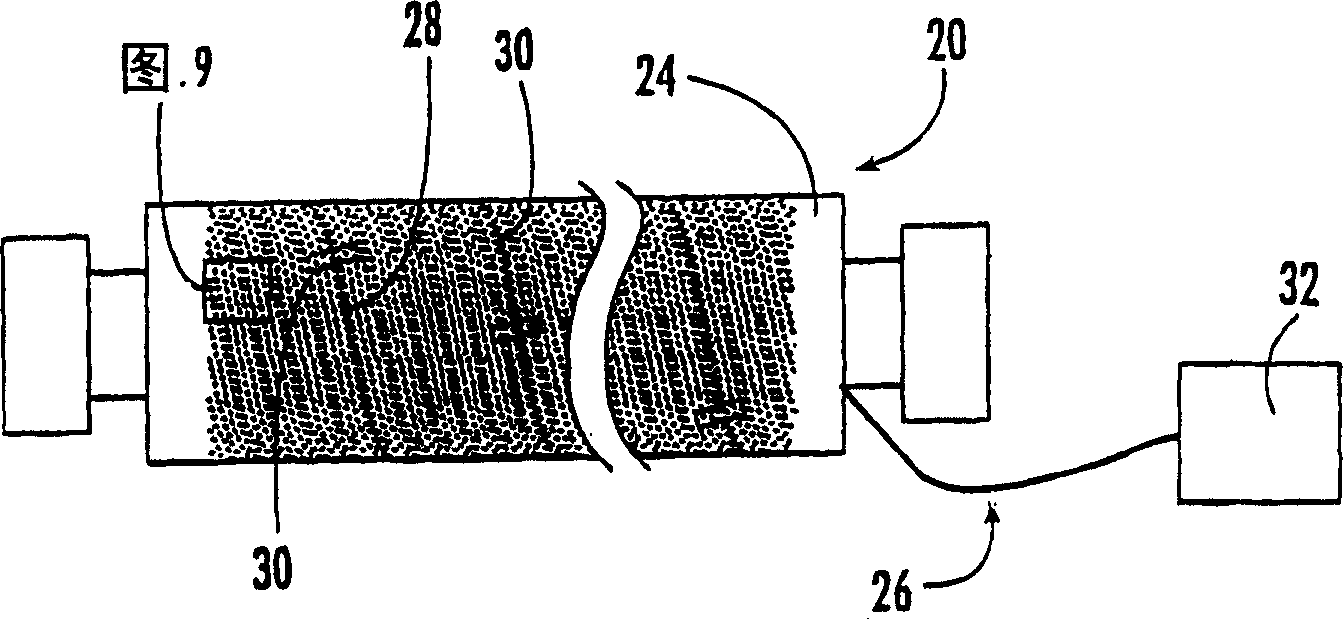

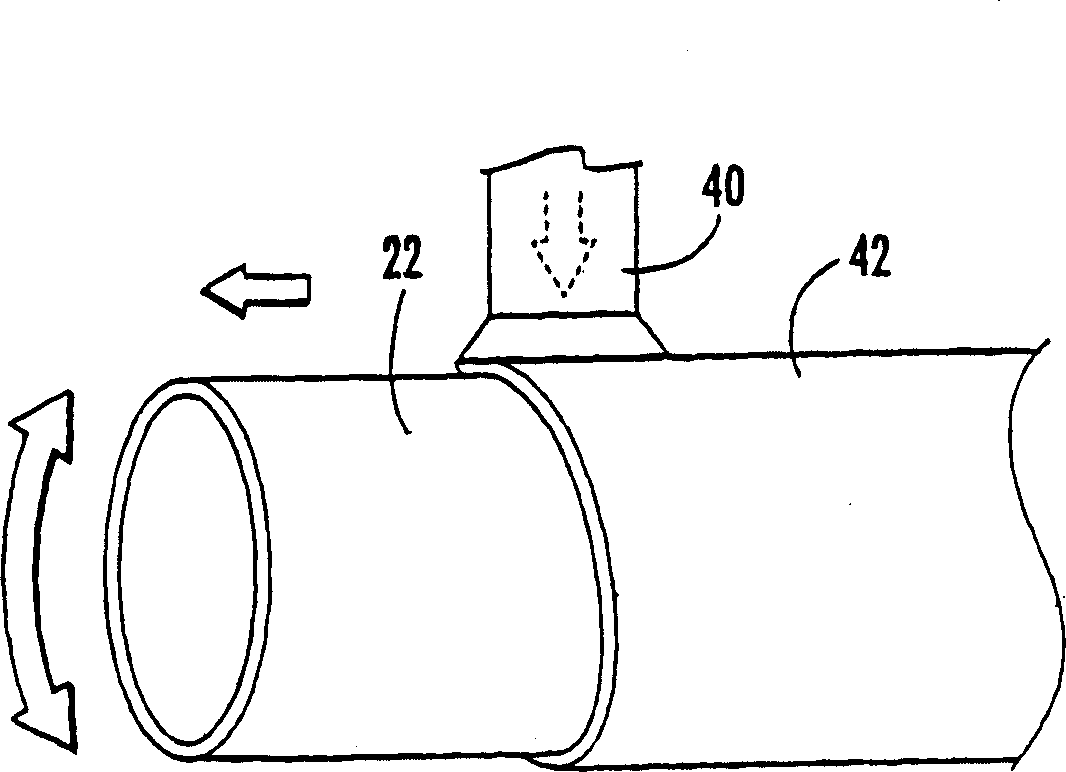

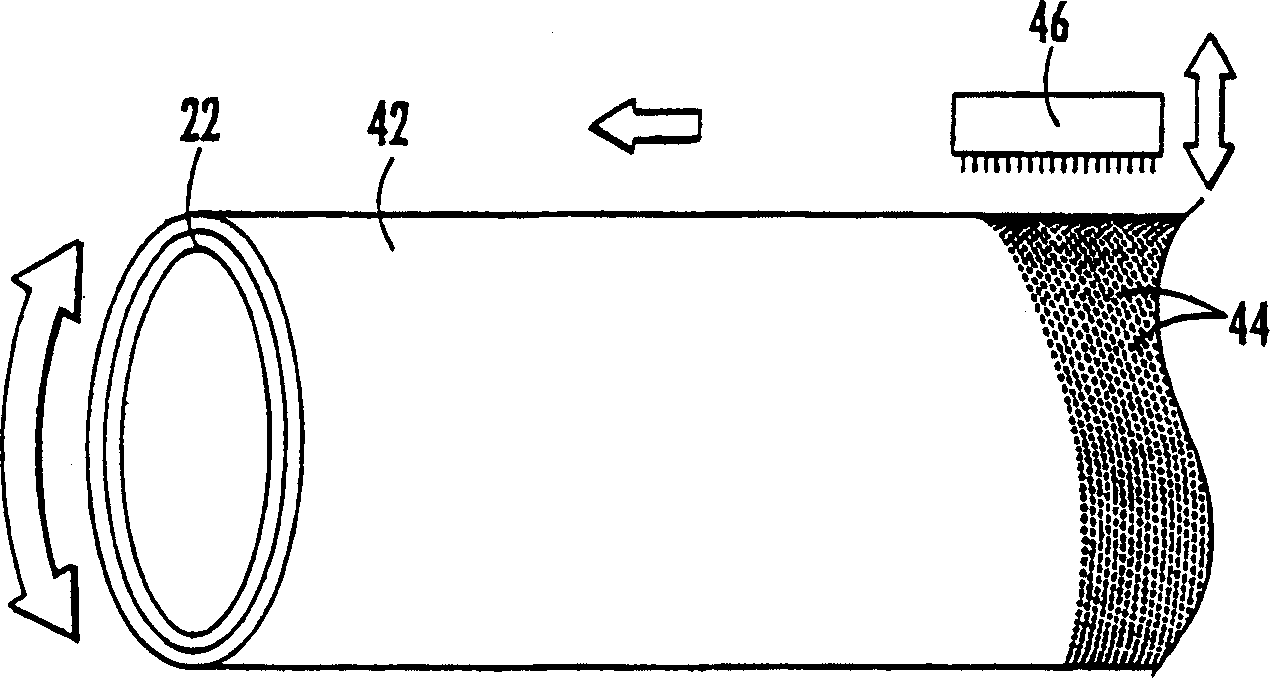

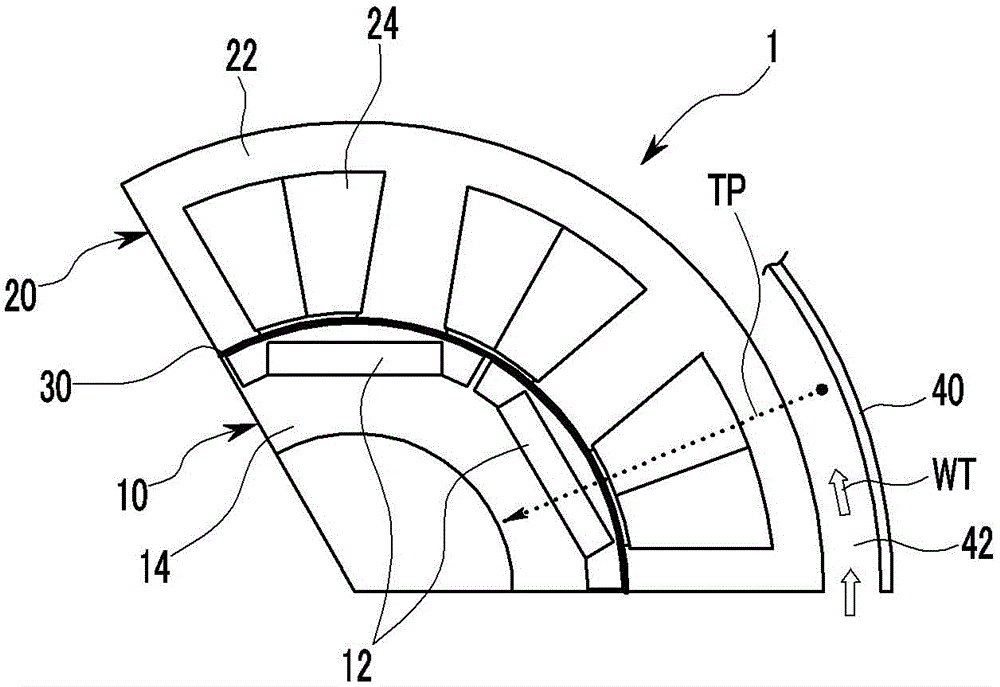

An industrial roll includes: a substantially cylindrical shell having an outer surface and an internal lumen; a polymeric cover circumferentially overlying the shell outer surface; and a sensing system. The sensing system includes: a plurality of sensors embedded in the cover, the sensors configured to sense an operating parameter of the roll; and a signal-carrying member serially connected with and extending between the plurality of sensors. The signal-carrying member follows a helical path over the outer surface of the shell, wherein the signal-carrying member extends between adjacent sensors and extends over more than one complete revolution of the shell outer surface (and, preferably, an intermediate segment of the signal-carrying member extends over more than a full revolution of the roll between adjacent sensors).

Owner:STOWE WOODWARD

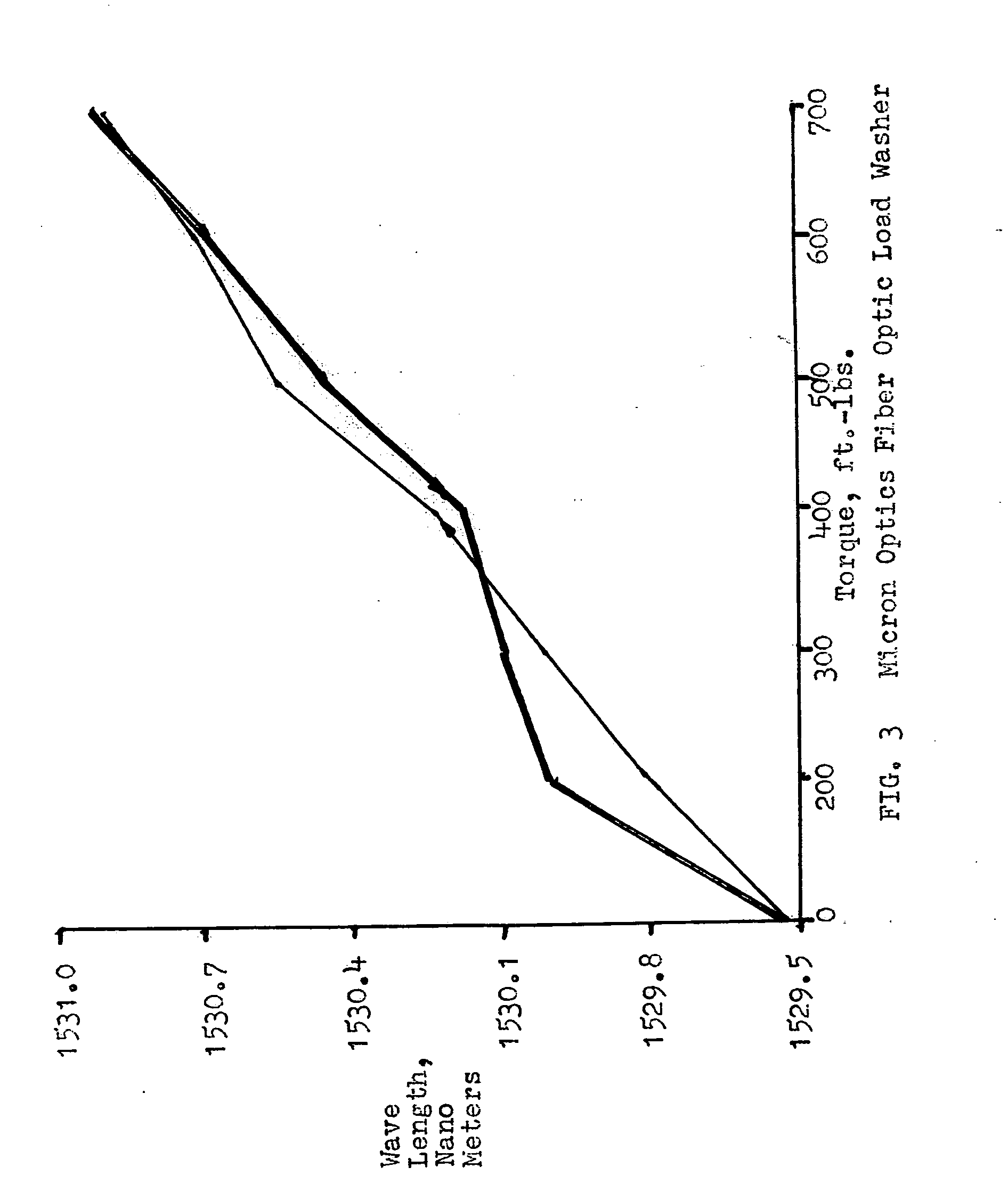

Use of fiber optic sensor techniques for monitoring and diagnostics of large AC generators

ActiveUS20120026482A1Avoid insufficient lengthForce measurementMaterial analysis by optical meansGratingEngineering

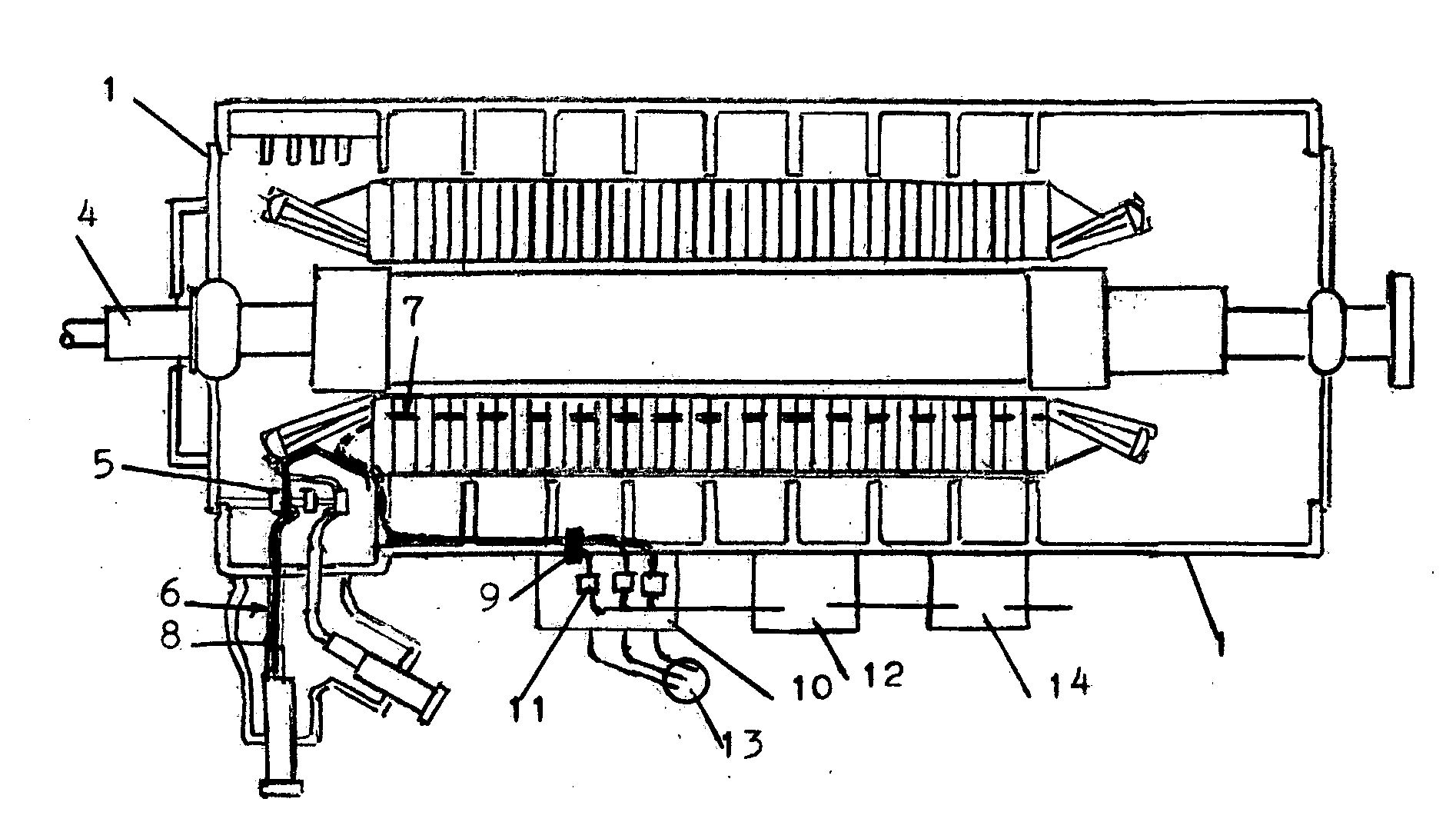

A method for monitoring the operating conditions of an electric generator including the entire stator core and all winding components for conditions of mechanical strain and temperature throughout the machine by means of distributive fiber optic sensors based on both Rayleigh back scattering techniques and Brillouin frequency shift fiber optic sensor analysis both of which do not have the gaps and limitations associated with standard fiber Bragg grating fiber optic point sensors, by virtue of the fact that both Rayleigh and Brillouin scans and allow accurate strain and temperature determinations at all points along standard fiber optic cables of considerable length, approximately two kilometers in the case of the Brillouin, which effectively yields many tens of thousands of sensors throughout the entire standard fiber optic cable. Raman distributive temperature sensing also has a limited application. Single mode and polarizing maintaining fibers can both be analyzed and read with any Rayleigh or Brillouin distributive fiber optic sensor laser system allowing great flexibility in sensor spatial resolution, total sensed length, resolution and other factors not possible with conventional fiber Bragg gratings. A sealed fiber collection box located outside the electric generator permits enhanced reliability and reconfiguration into any number of desirable fiber layouts necessary for specific static and dynamic measurements in an optimal manner.

Owner:INNOVATIVE DIAGNOSTIC SYST

Enhanced Rail Inspection

Owner:TAIWAN SEMICON MFG CO LTD

Automatically measuring the temperature of food

InactiveUS6866417B2VariationReduce variationThermometer detailsRadiation pyrometryTemperature controlEngineering

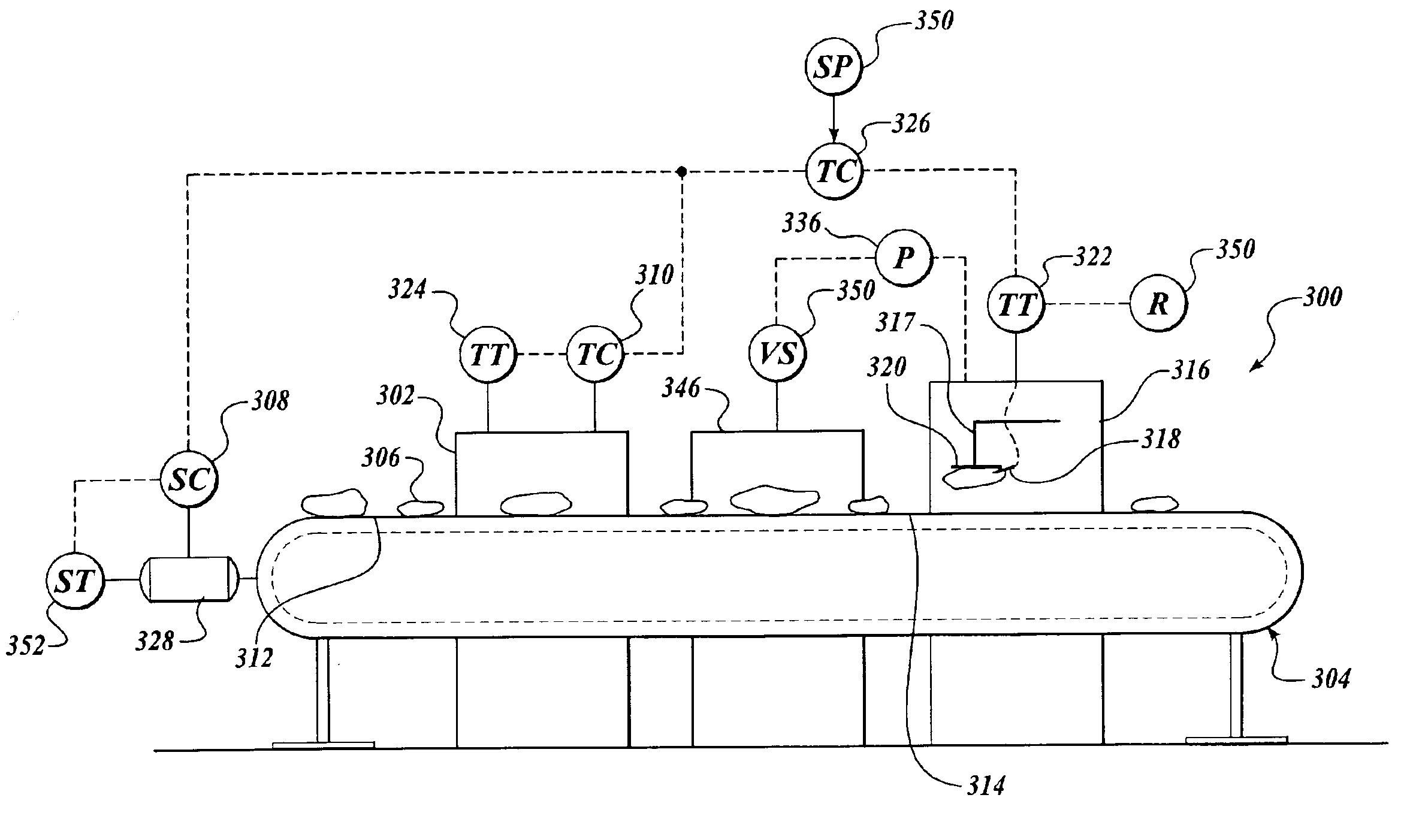

An apparatus for measuring the temperature of workpieces transported on a conveyor is disclosed. In one broad aspect of the invention, the apparatus includes a translatable assembly which has a pick-up tool for picking up workpieces and a temperature-sensing device which is in proximity to the pick-up tool for measuring the temperature of the workpiece. Other embodiments are disclosed, including eliminating the pick-up tool, provided the temperature sensing device travels with the workpiece. Scanners can be utilized to designate the largest of the workpieces to be measured or for detecting overlapping workpieces. Feedback temperature control is achieved by varying a parameter, such as conveyor speed or a heat engine temperature. Also, a modeling module can be incorporated to assist with temperature control of the workpieces.

Owner:JOHN BEAN TECH CORP

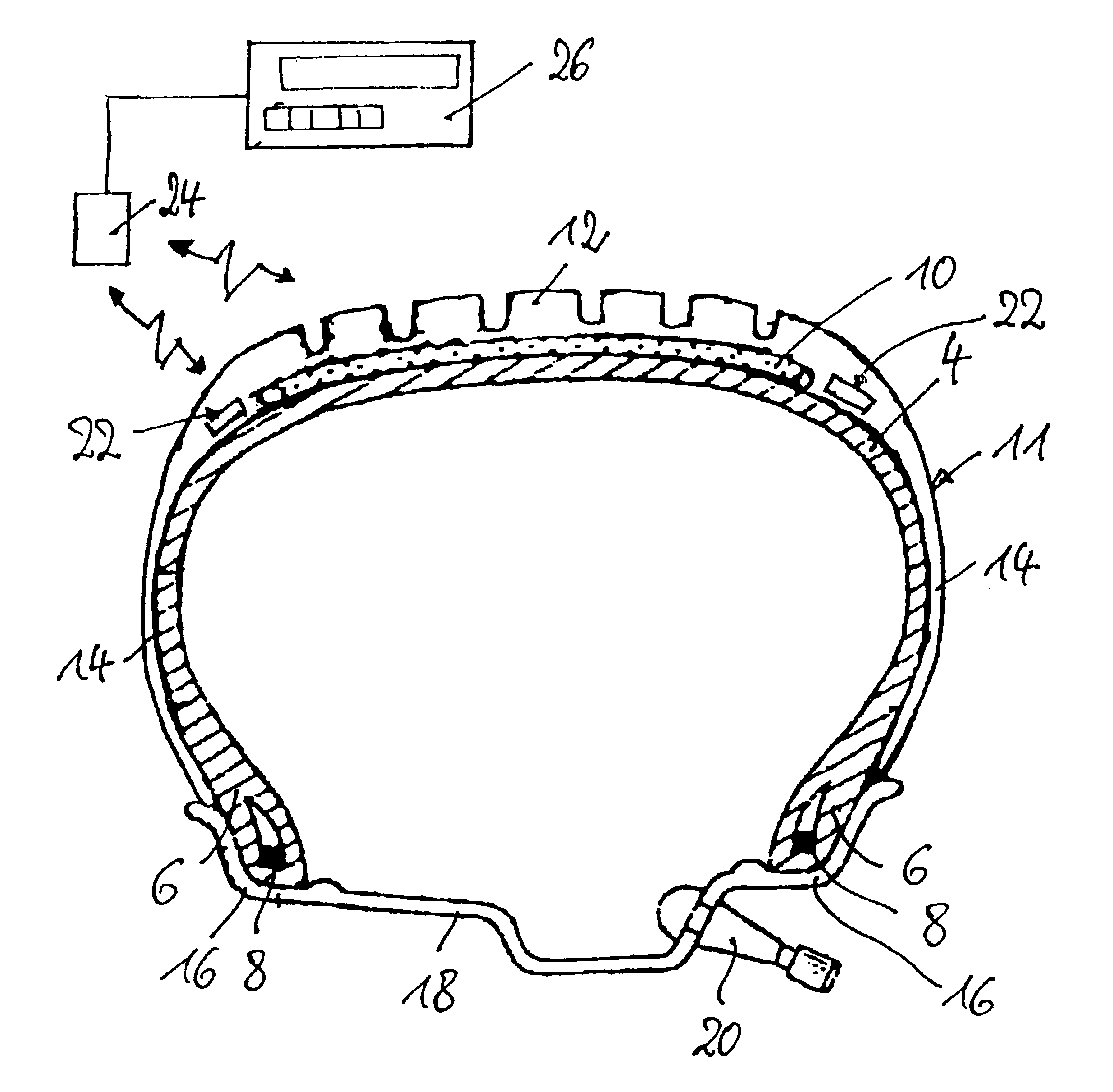

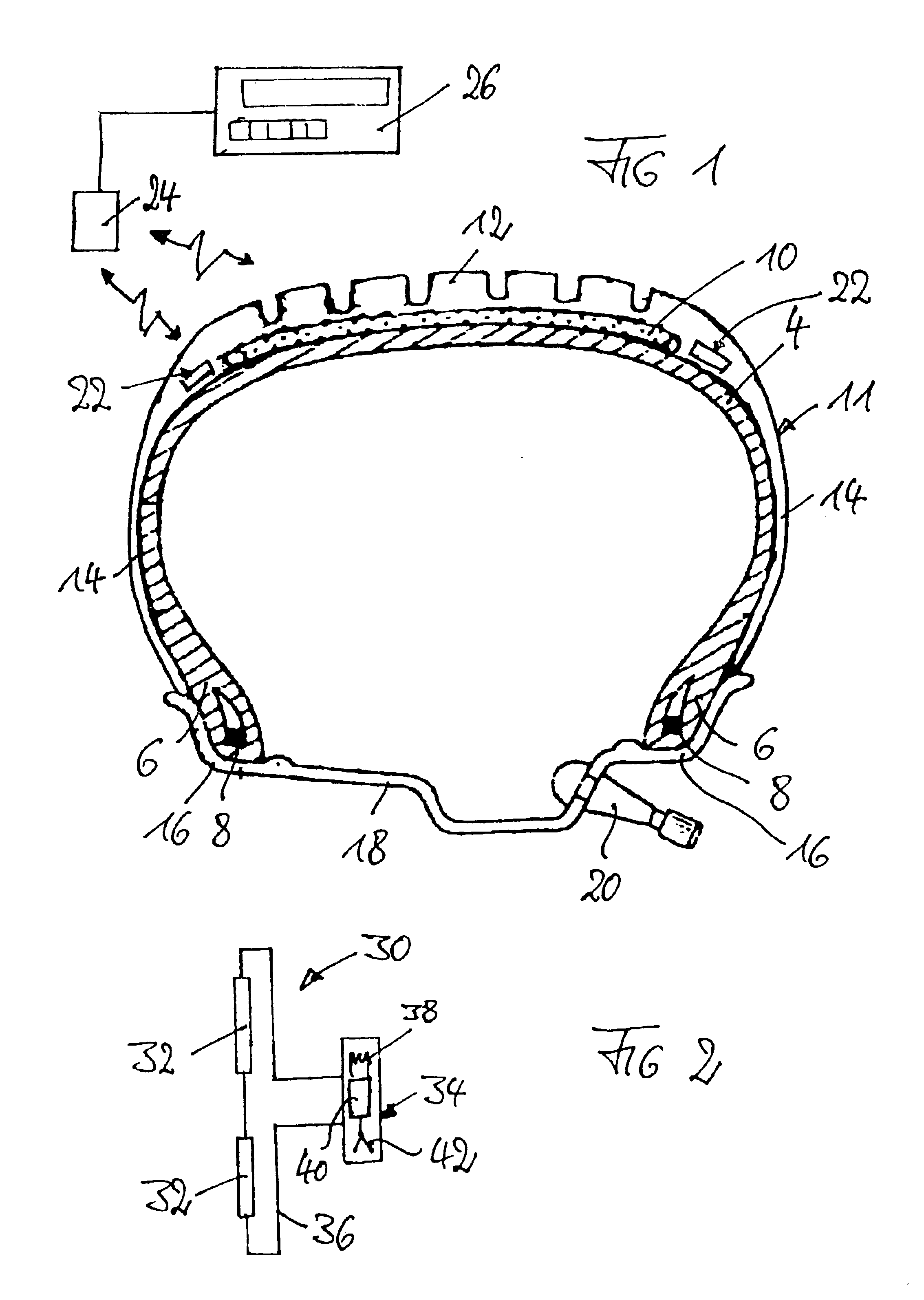

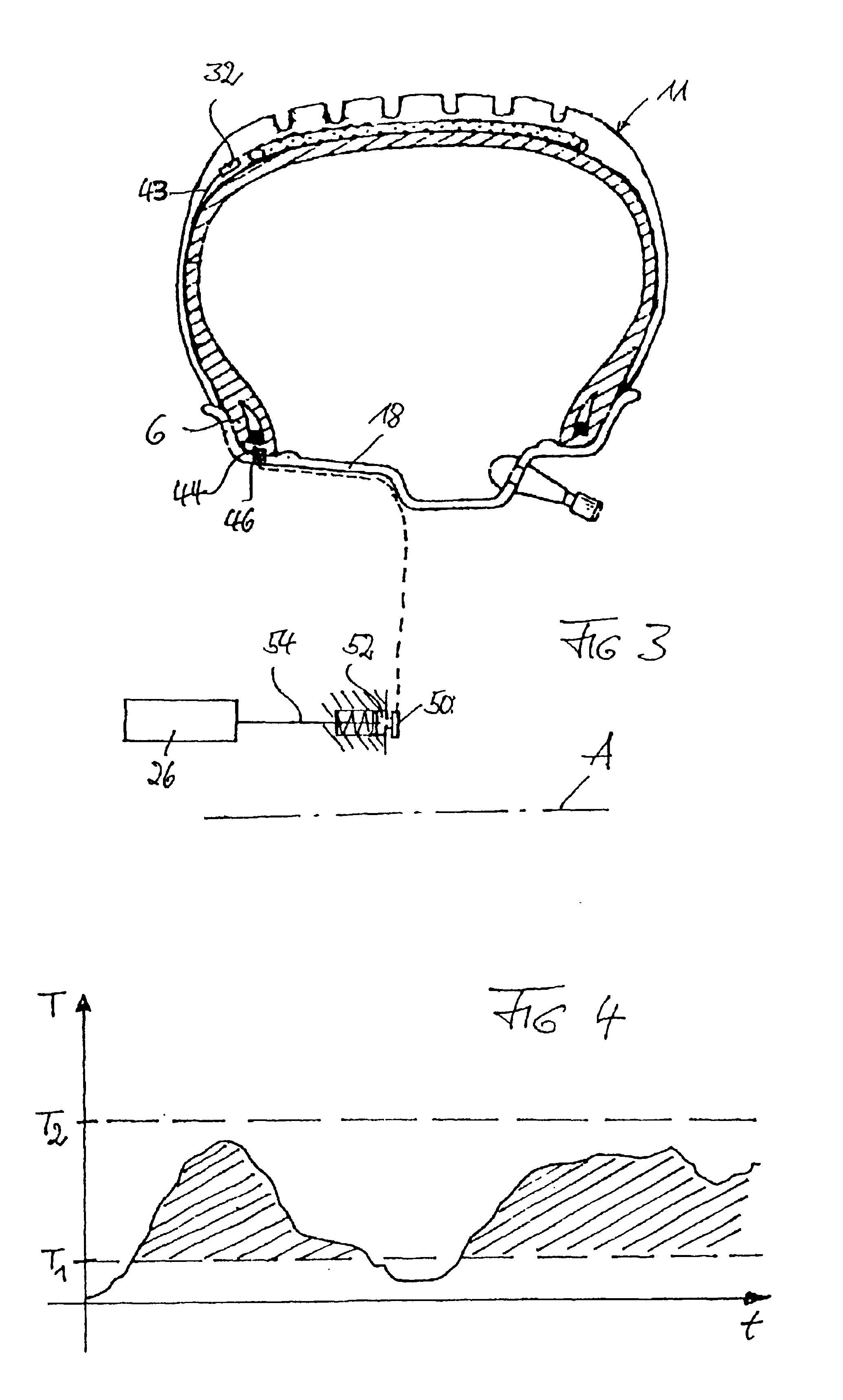

Method and system for measuring temperature and monitoring vehicle tire operation, and vehicle tire and method for introducing a temperature sensor into a vehicle tire

InactiveUS6921197B2Increasing inflation pressureThermometer detailsElectric signal transmission systemsCritical locationAutomotive engineering

A vehicle tire is provided that contains at least one temperature sensor embedded in the tire in a critical location, and a transmission unit for transferring the output signal of the temperature sensor to a location externally of the vehicle tire. A method is also provided for precisely measuring the temperature of a vehicle tire with such a temperature sensor. A method is also provided for monitoring the operation of the vehicle tire.

Owner:TUV SUD AUTOMOTIVE

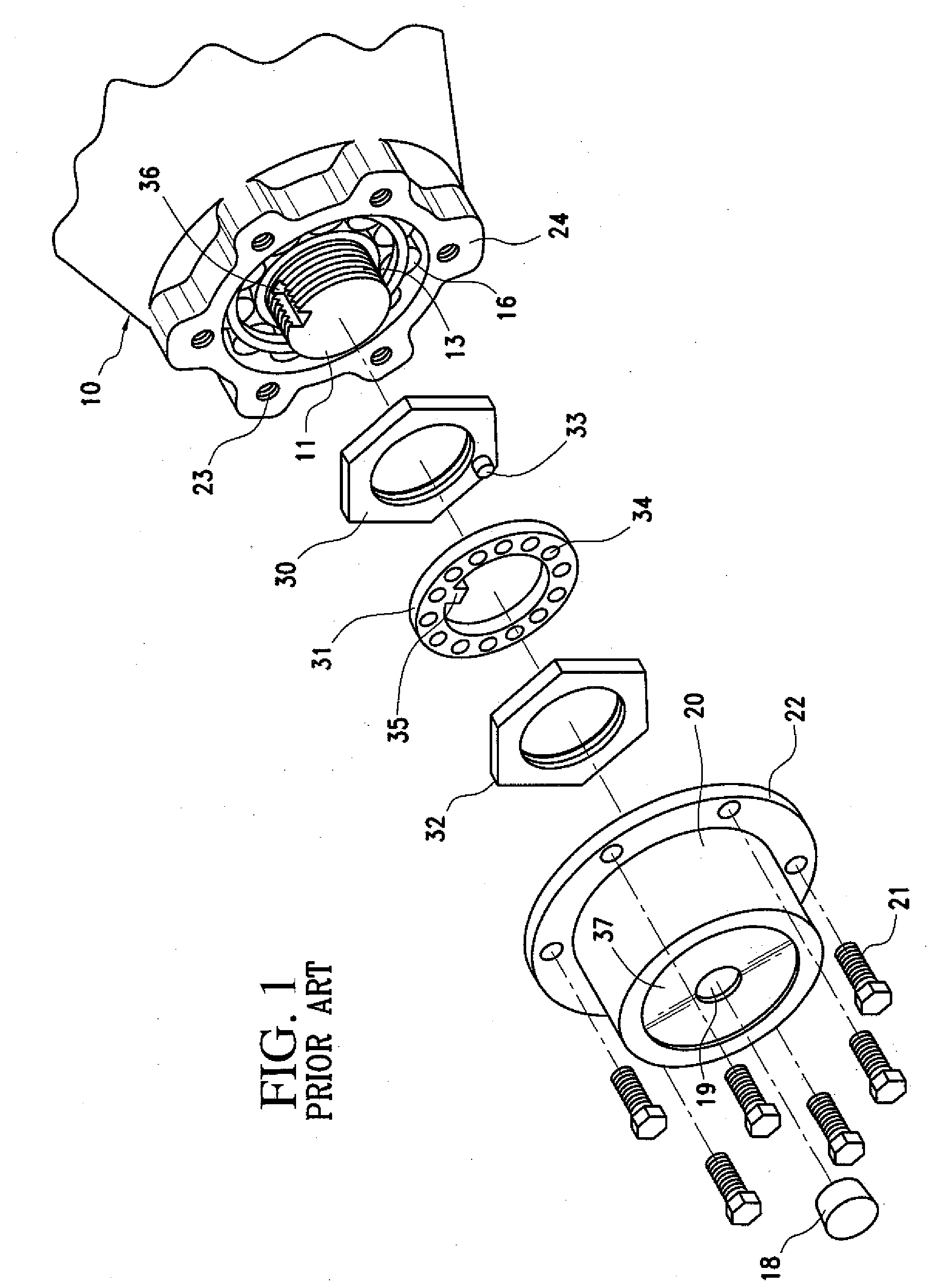

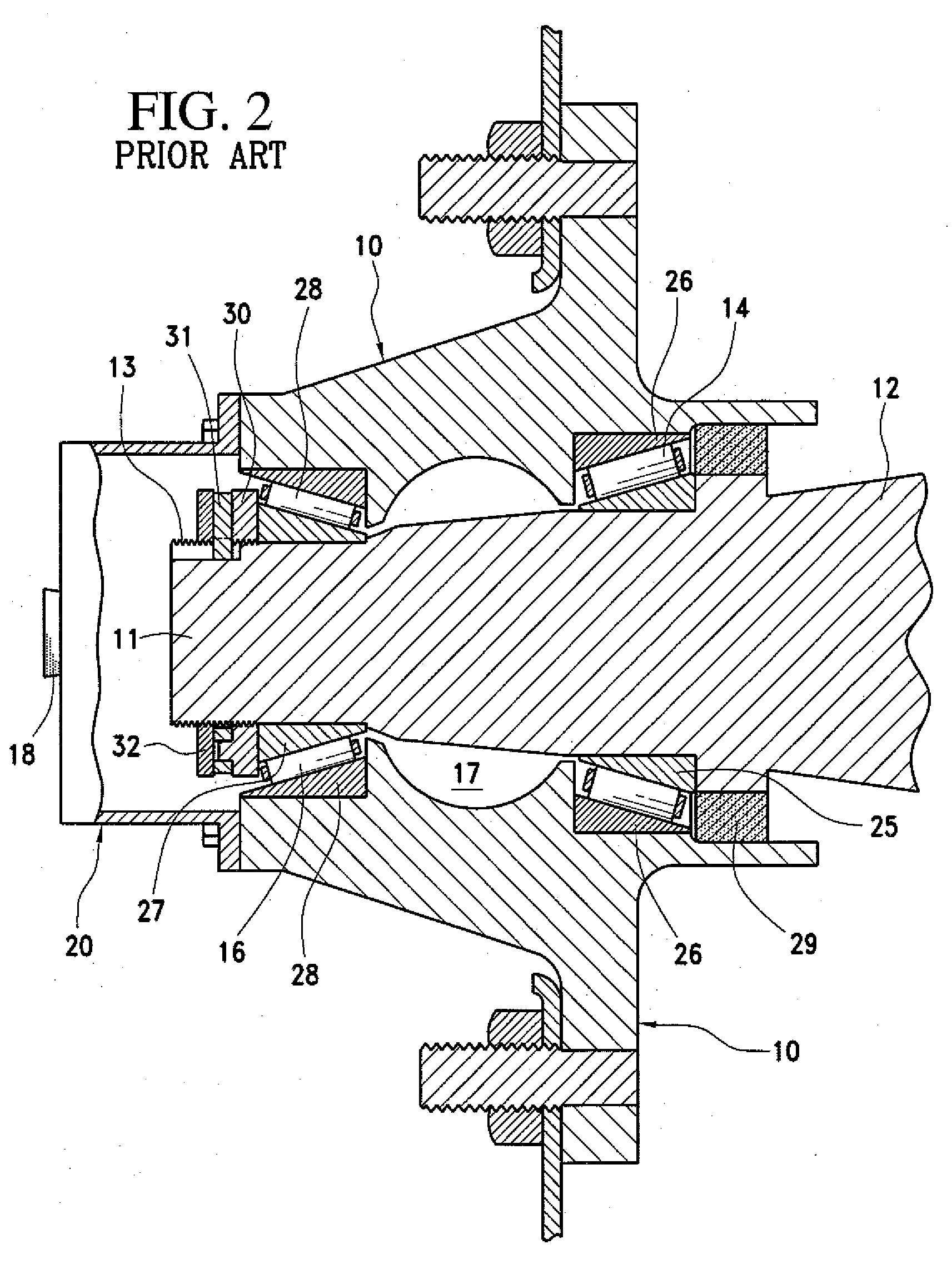

Wheel and other bearing hubs safety restraint devices, locks and visual warning indicators

InactiveUS7547077B2Prevent sudden and possible catastrophic lossLoss and damageThermometer detailsRolling contact bearingsDrive wheelEngineering

Owner:MELBERG NELS +1

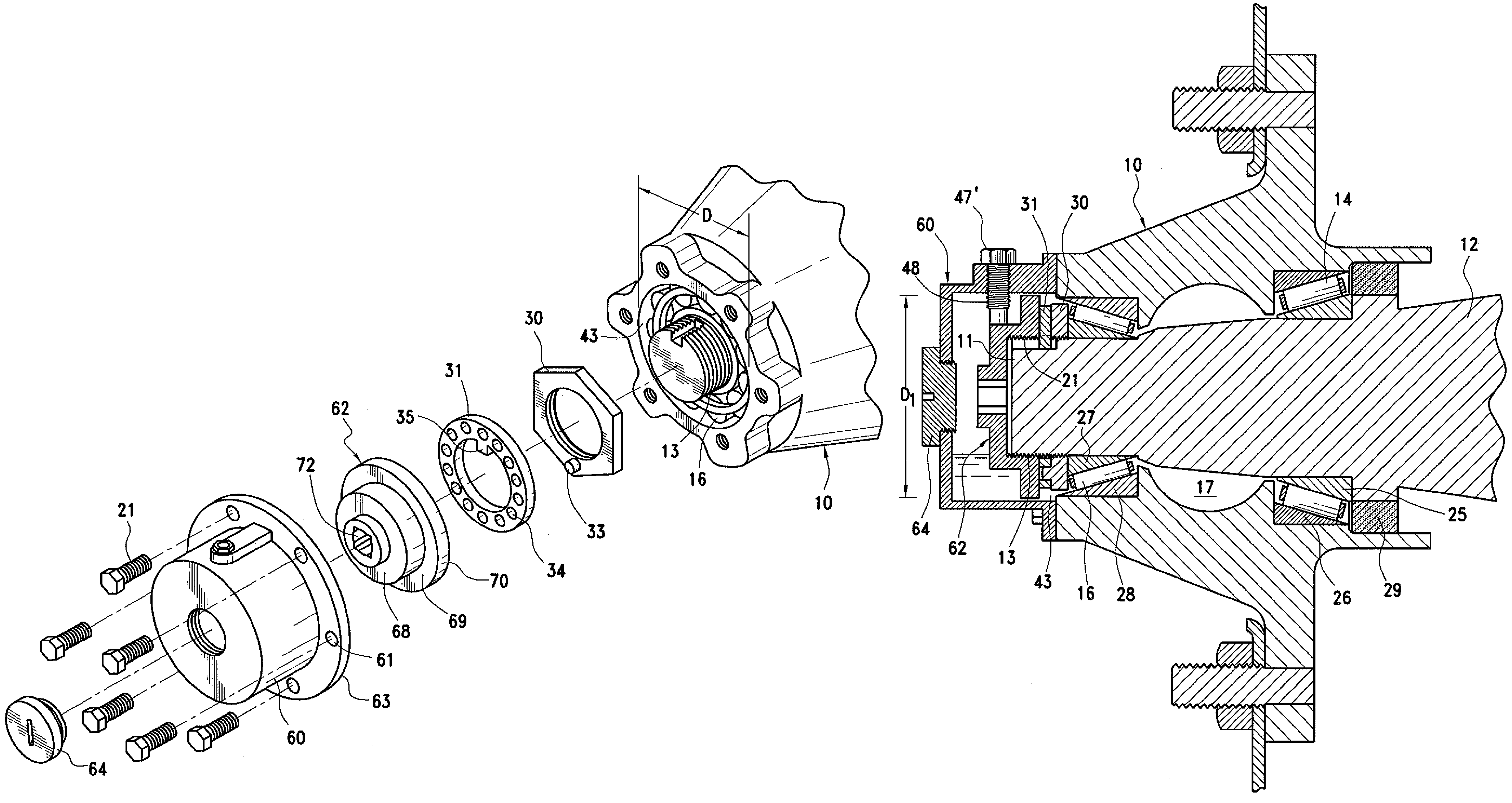

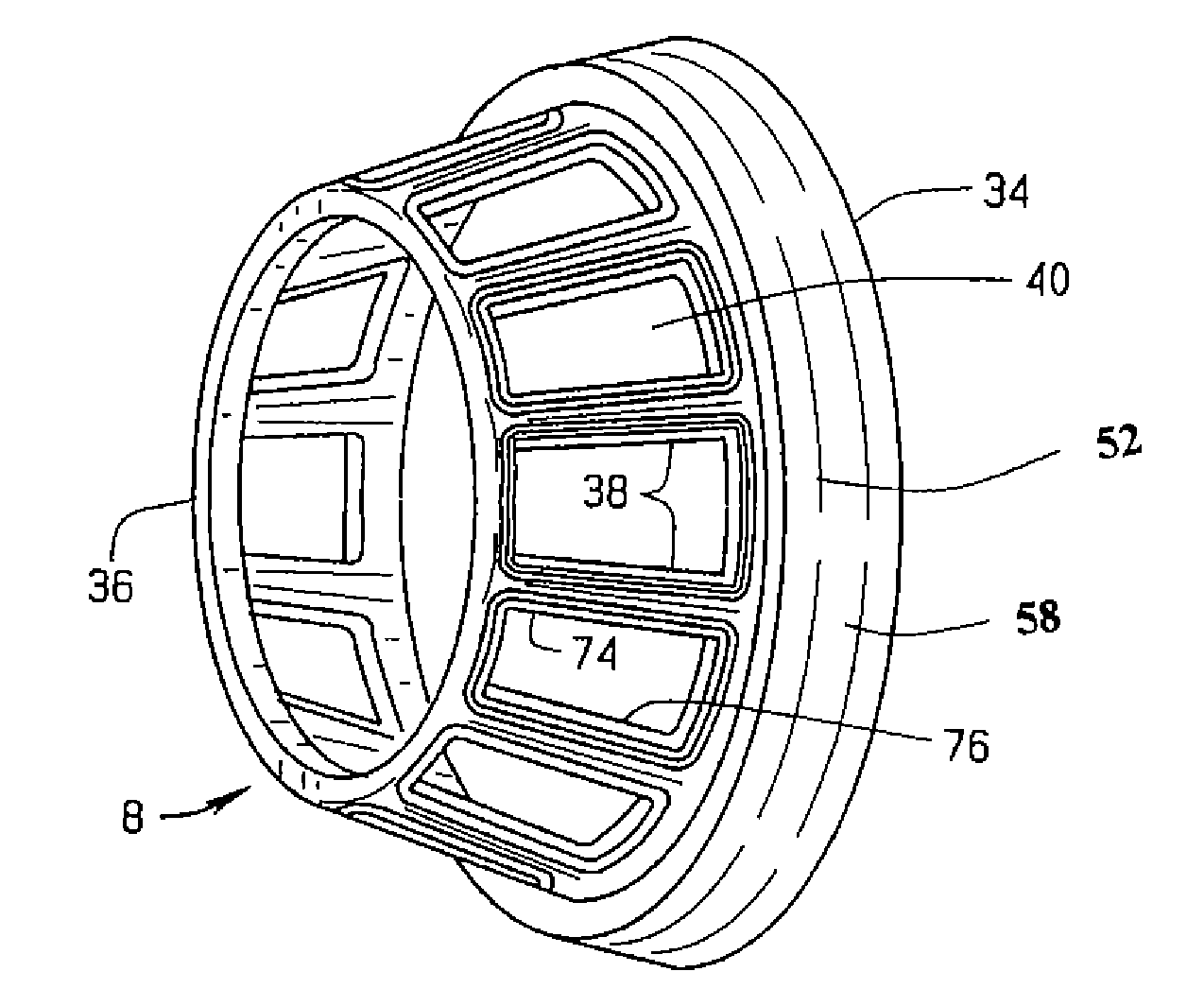

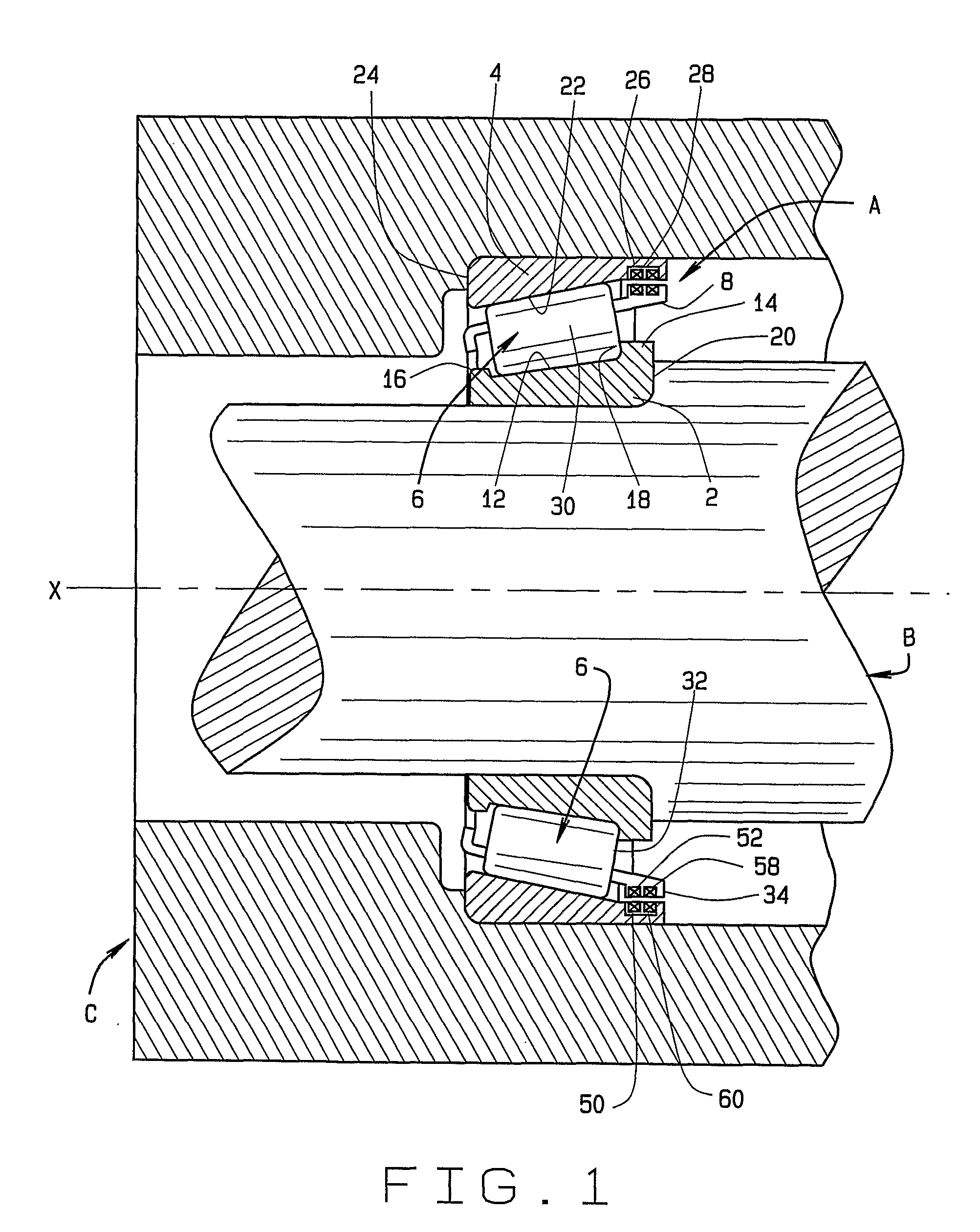

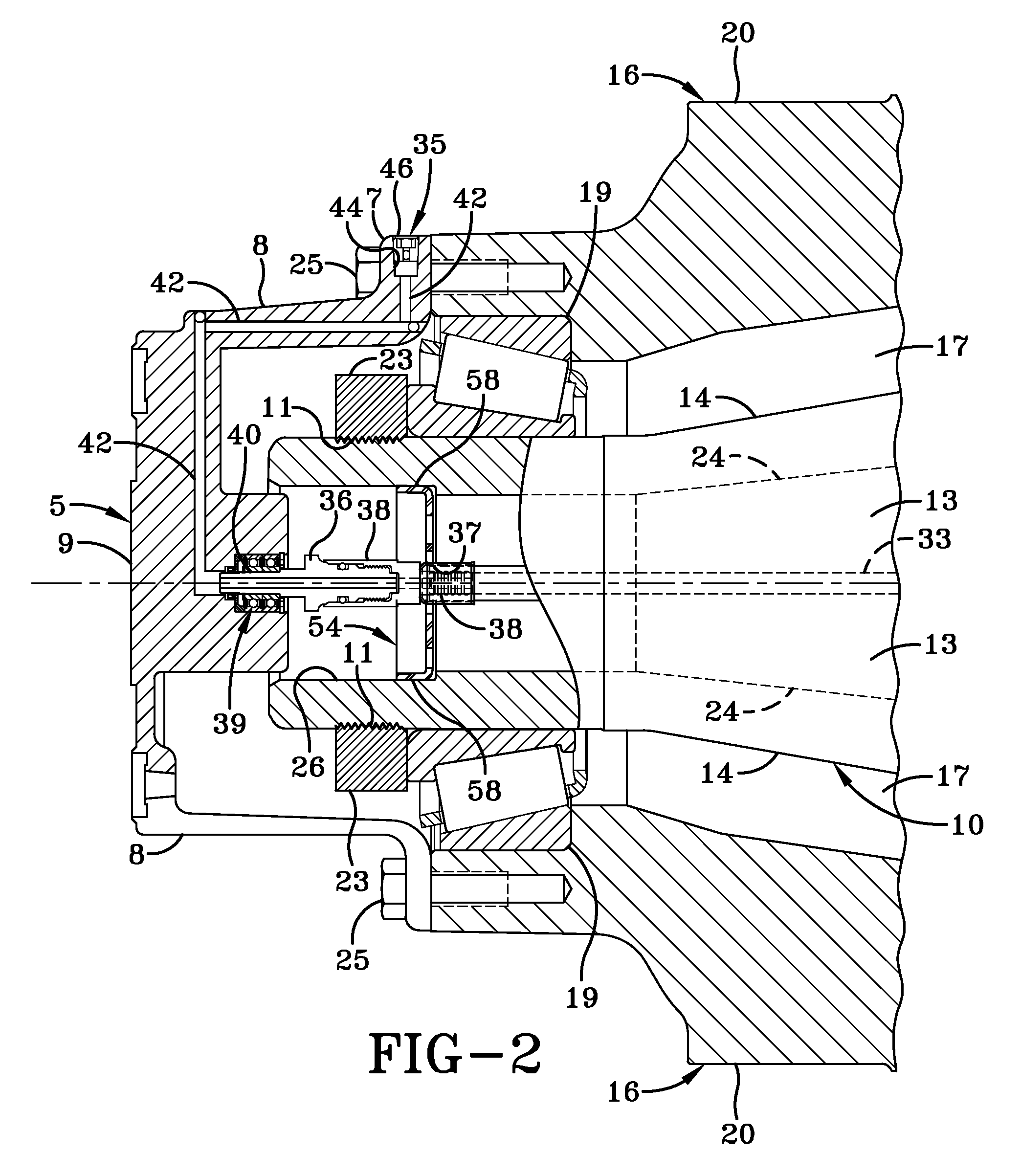

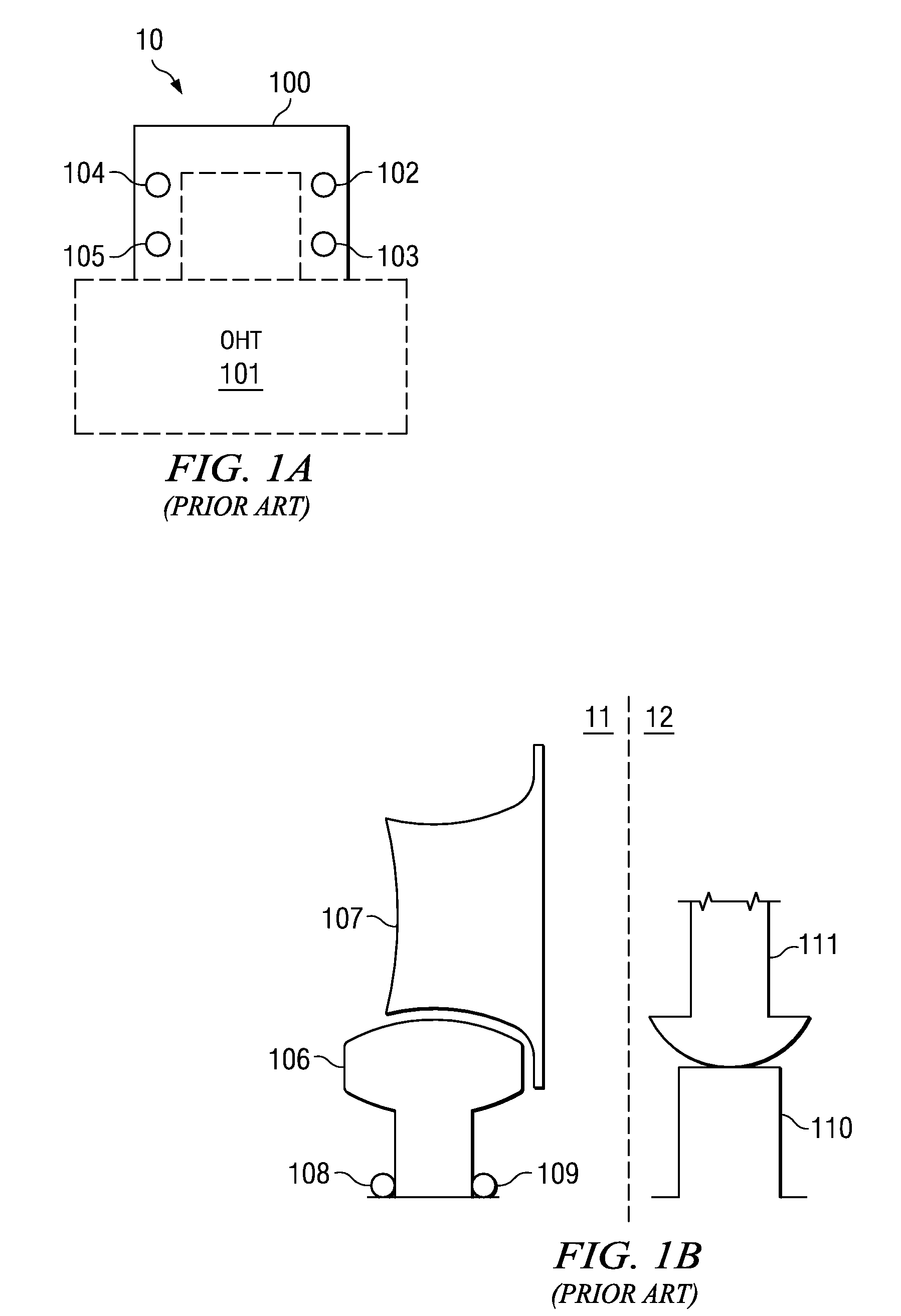

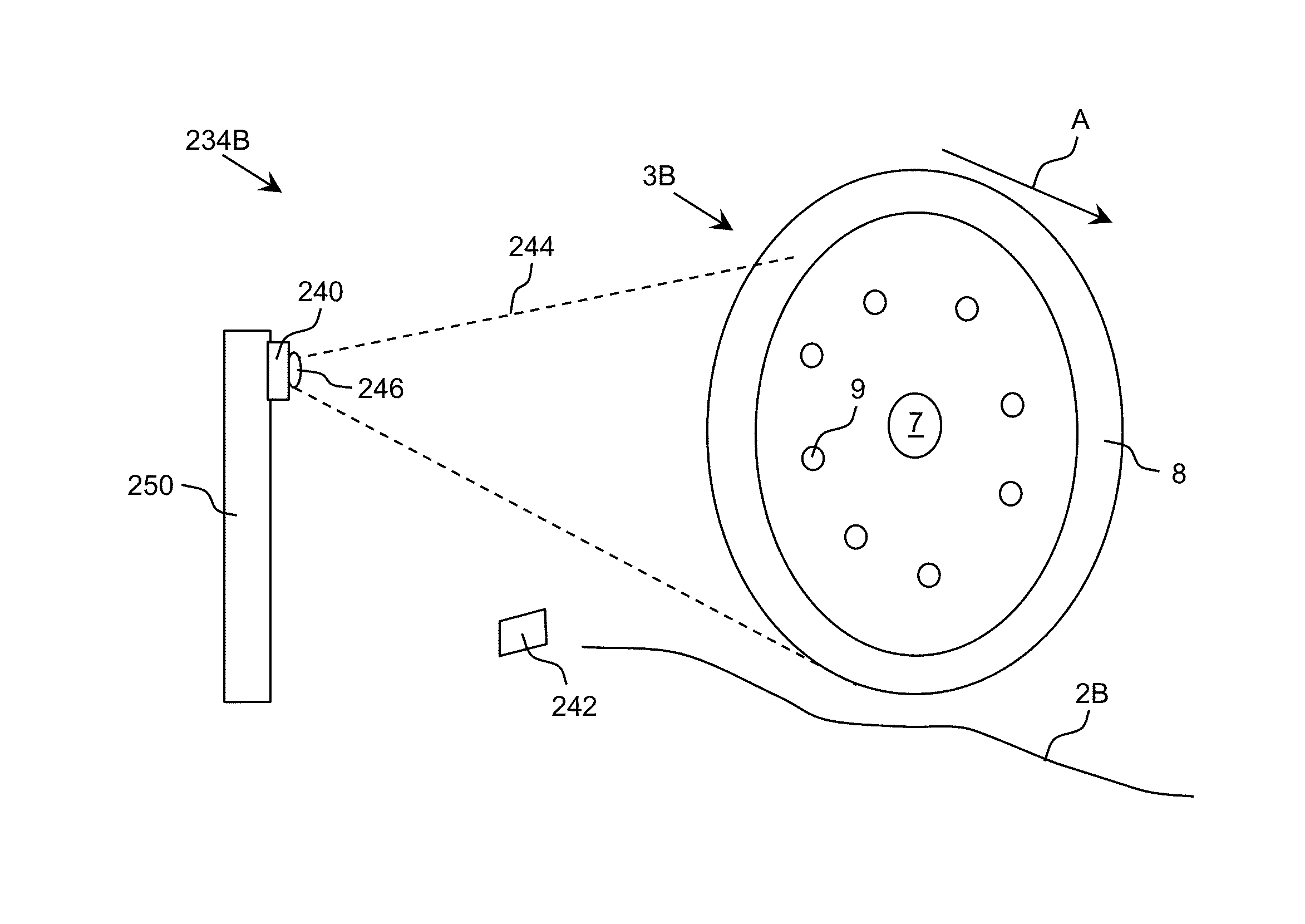

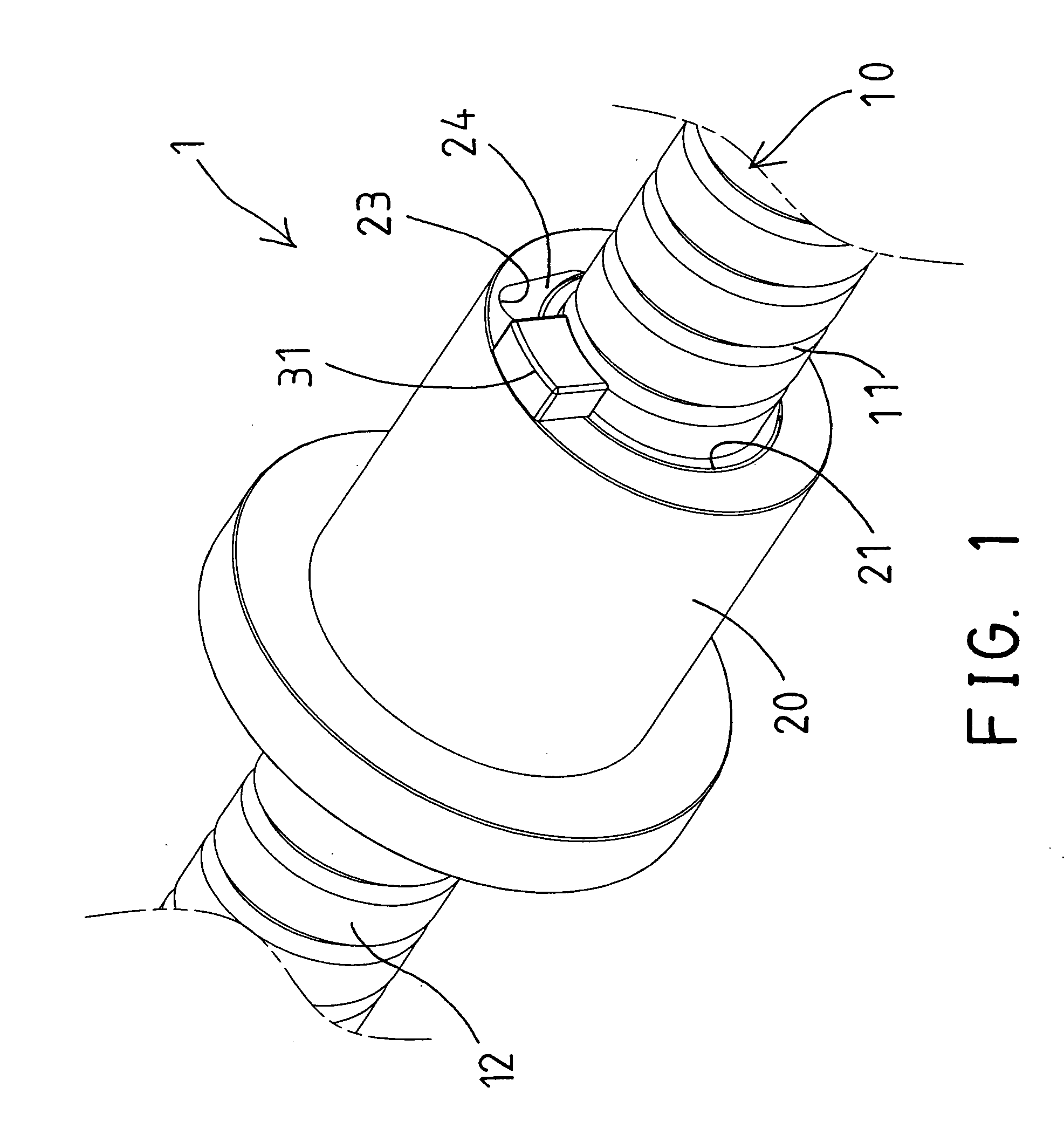

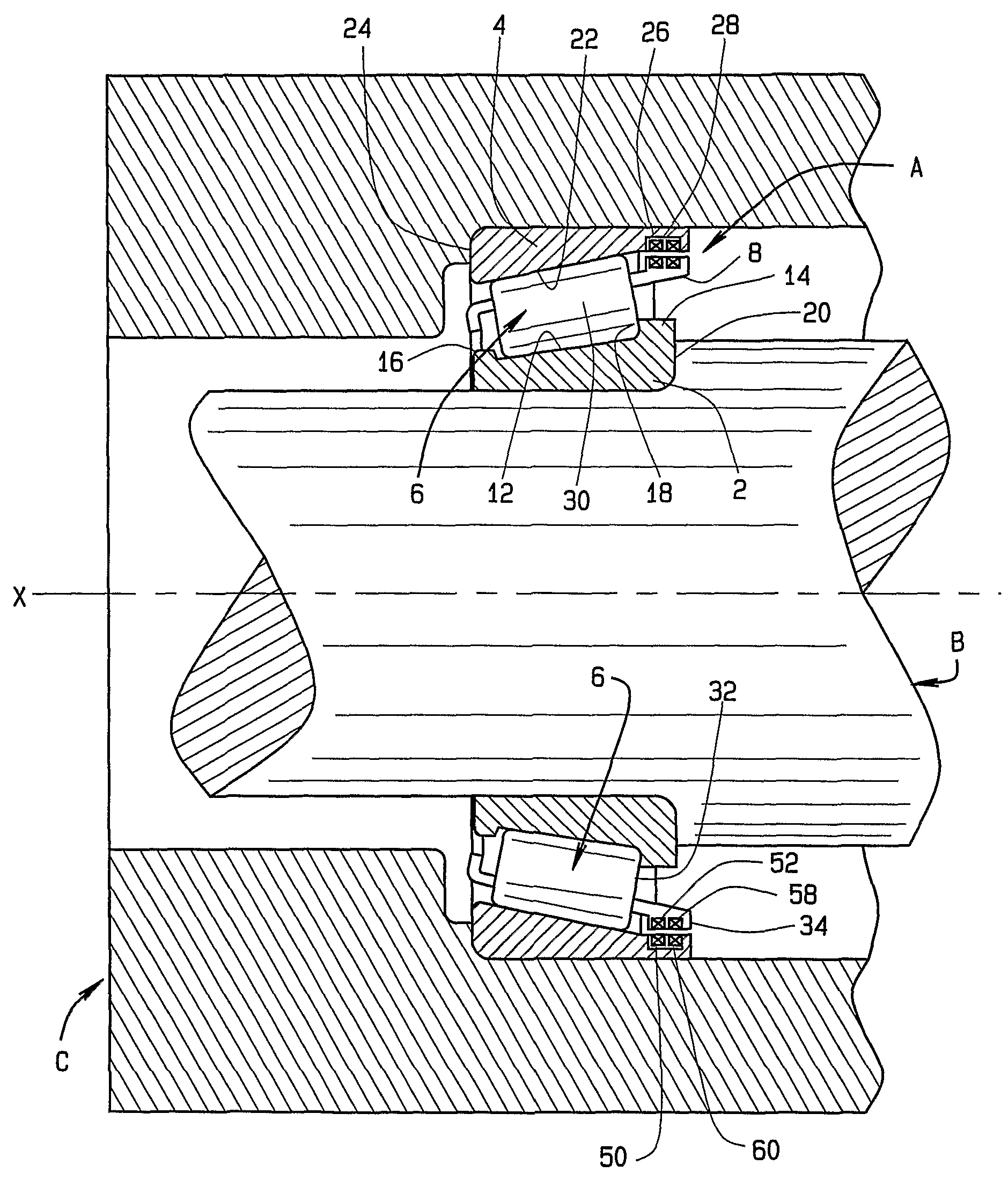

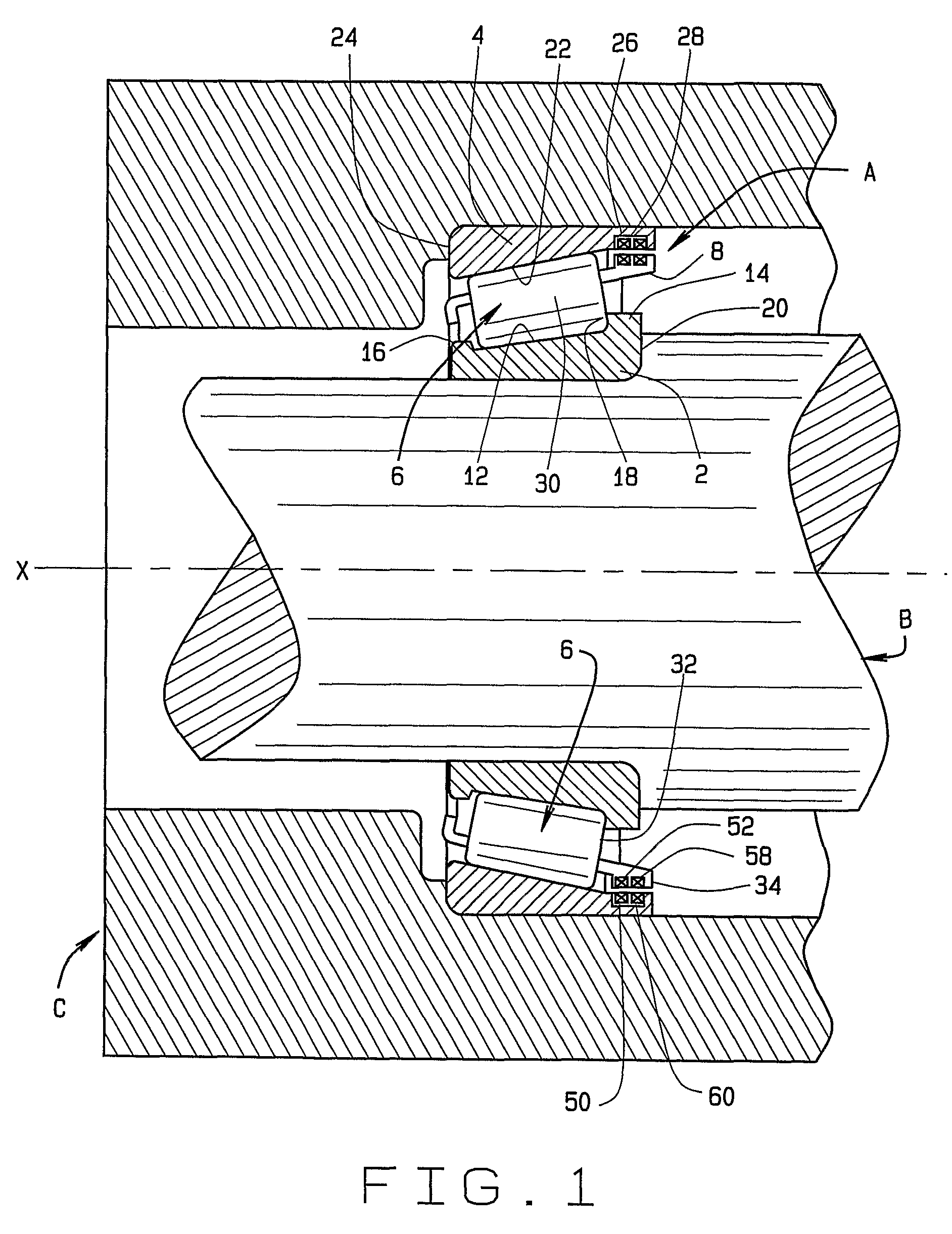

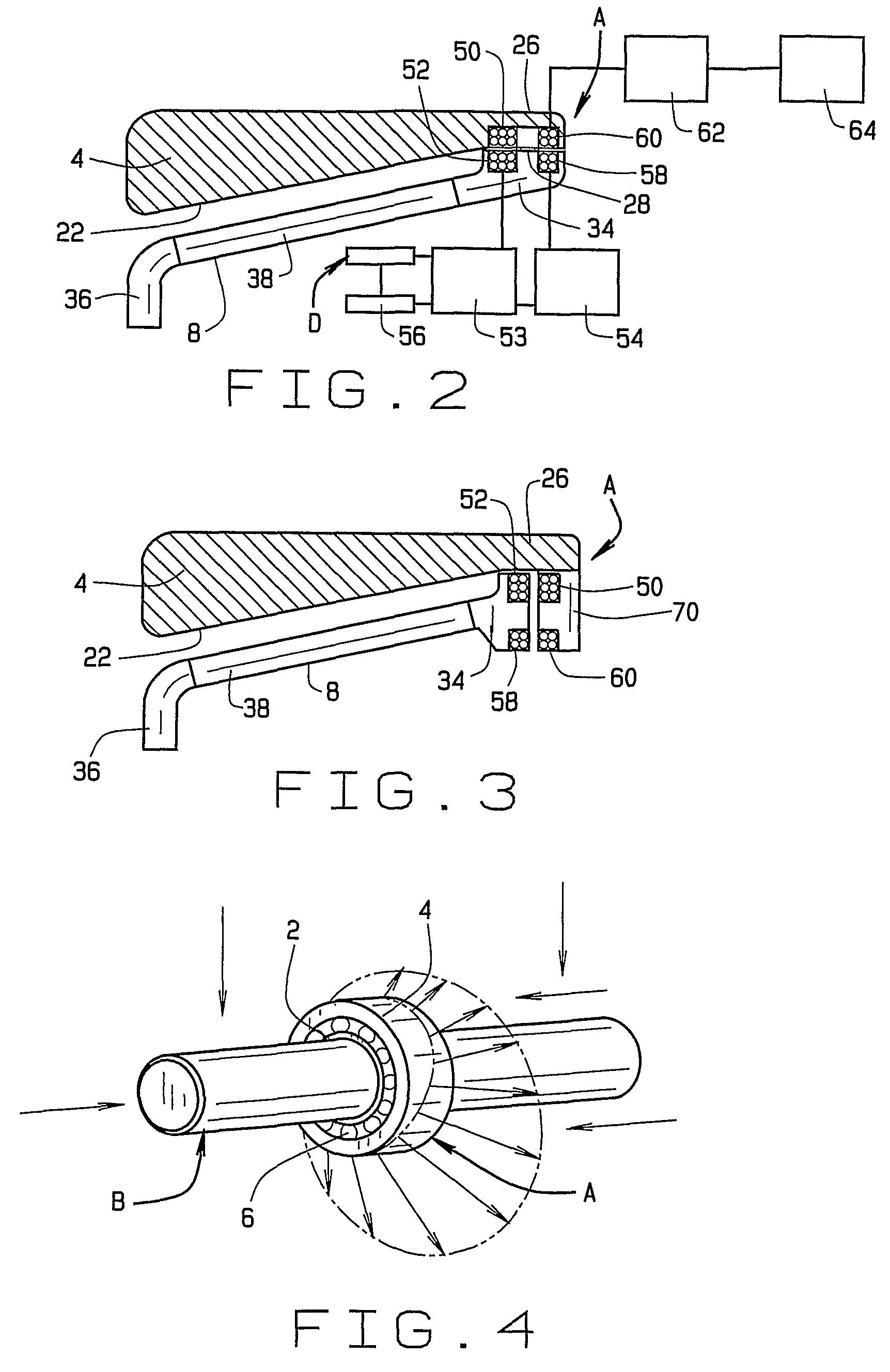

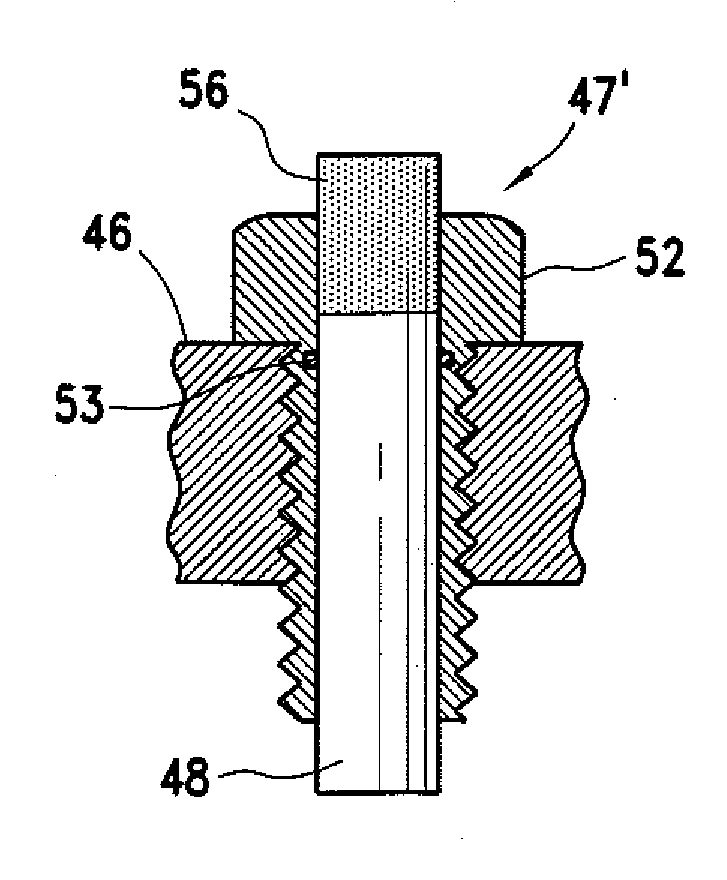

Bearing With Cage-Mounted Sensors

An antifriction bearing (A) for accommodating rotation about an axis (X) comprises an inner race (2) having a raceway (12), an outer race (4) having a raceway (22), rolling elements (6) positioned between the inner and outer races (2, 4) and contacting the raceways (12, 22) of those races (2, 4) so that when relative rotation occurs between the races (2, 4) the rolling elements (6) roll along the raceways (12, 22), a cage (8) positioned between the inner and outer races (2, 4) and having pockets (40) in which the rolling (8) being rotatable between the races (2, 4) as the rolling elements (6) roll along the raceways (12, 22), the outer race (4) having a power transmitting coil (50) and a receiver (60), the cage (8) having a power receiving coil (52), a sensing unit (D) for sensing a condition of the bearing (A), and a transmitter (54) for sending a signal indicative of the sensed condition of the bearing (A) to the receiver (60).

Owner:THE TIMKEN CO

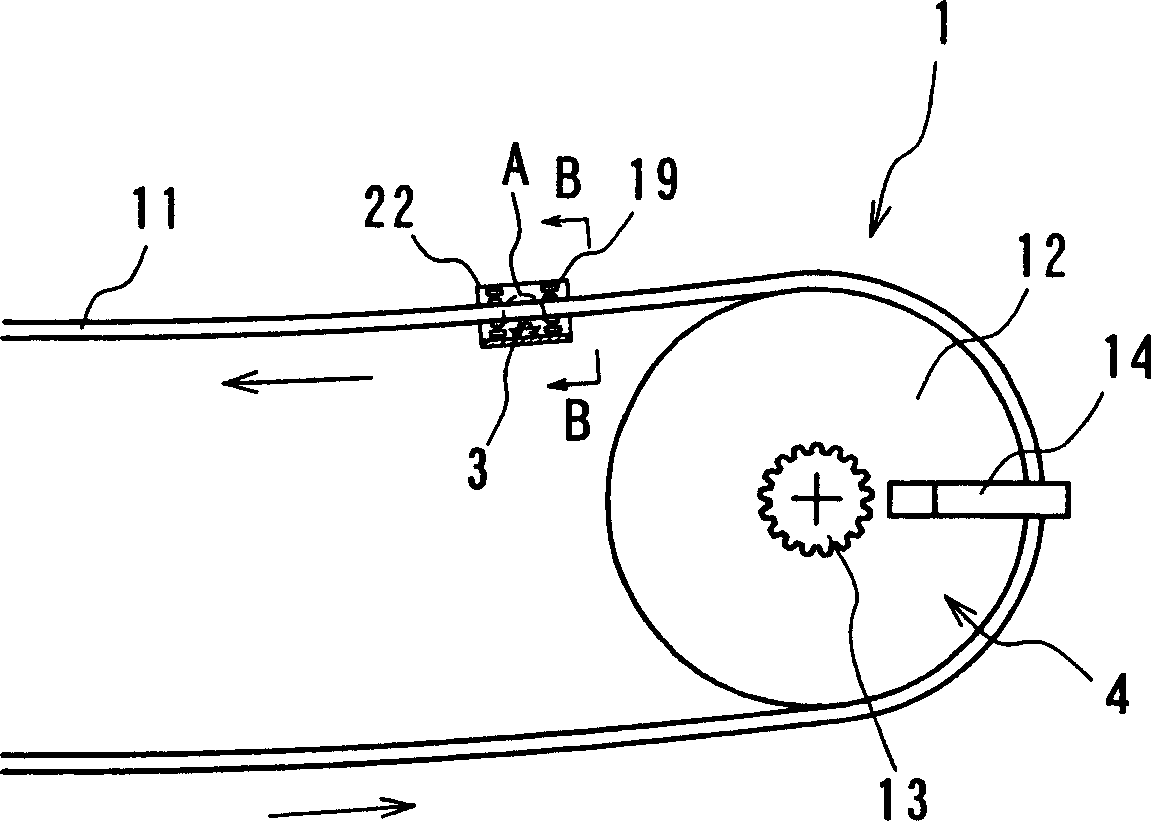

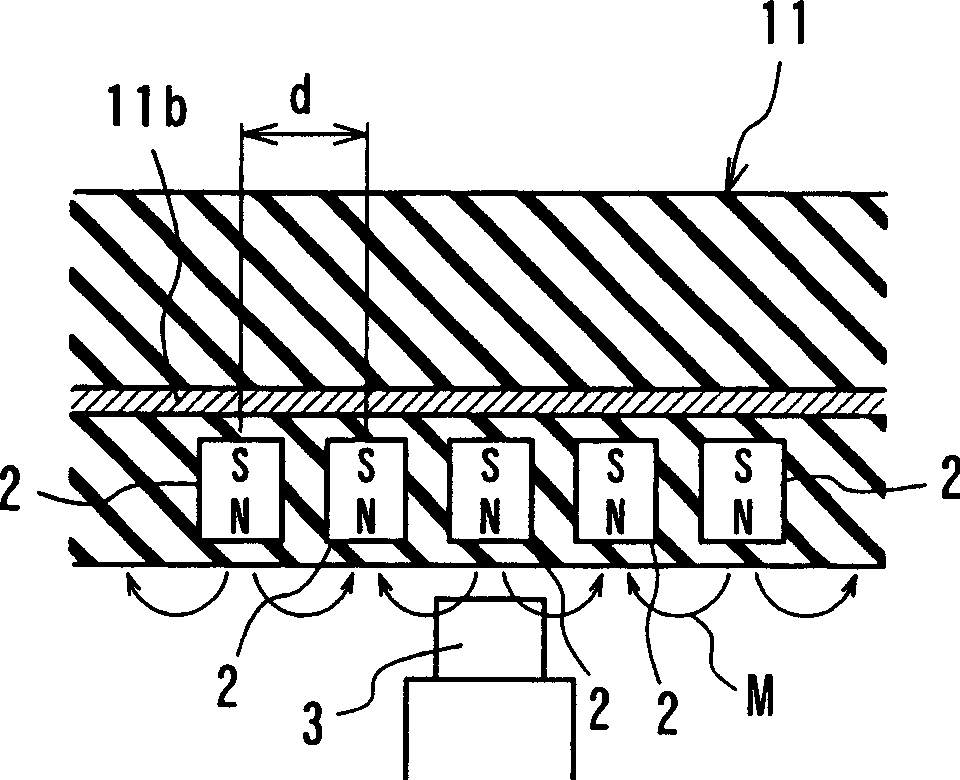

Method and device for measuring conveyor belt elongation, method and device for measuring conveyor belt wear extent, method and device for measuring conveyor belt temperature, rubber magnet sheet, and

InactiveCN1835881AShort lifeAccurate elongationConveyorsThermometers using electric/magnetic elementsConveyor beltInternal temperature

Methods and devices for measuring elongation, wear, and internal temperature of a conveyor belt to catch signs of conveyor belt failure such as breakage by detecting a magnetic field from a magnetic body by using a magnesium sensor, as well as a rubber magnet sheet as a magnetic body and a method of producing the sheet, the rubber magnet sheet being able to be used while it is embedded in the conveyor belt. To measure elongation of a running conveyor belt ( 11 ), a magnetic field of a magnetic body ( 2 ) embedded in the belt ( 11 ) is detected by a magnetism sensor ( 3 ) fixed to the earth, and elongation of the belt ( 11 ) is calculated from temporal variation of the detected magnetic field.

Owner:BRIDGESTONE CORP

Vehicle temperature warning system

ActiveUS20090284362A1Easy to detectEasy accessBraking discsTemperature measurement of moving solidsWarning systemTraffic volume

A temperature warning system for a vehicle includes a thermal plug disposed on the wheel end assembly of the vehicle. The thermal plug is in fluid communication with an air supply and with a flow sensor. The flow sensor is operatively connected to a warning light or indicator. Excessive heat in the axle spindle end and / or the wheel end assembly causes a fusible material in the thermal plug to melt allowing air to flow from the air supply through the thermal plug thus activating the flow sensor. The flow sensor in turn activates the warning light or indicator alerting the driver of the vehicle of a problem condition at the wheel end assembly and / or axle spindle.

Owner:HENDRICKSON USA L L C

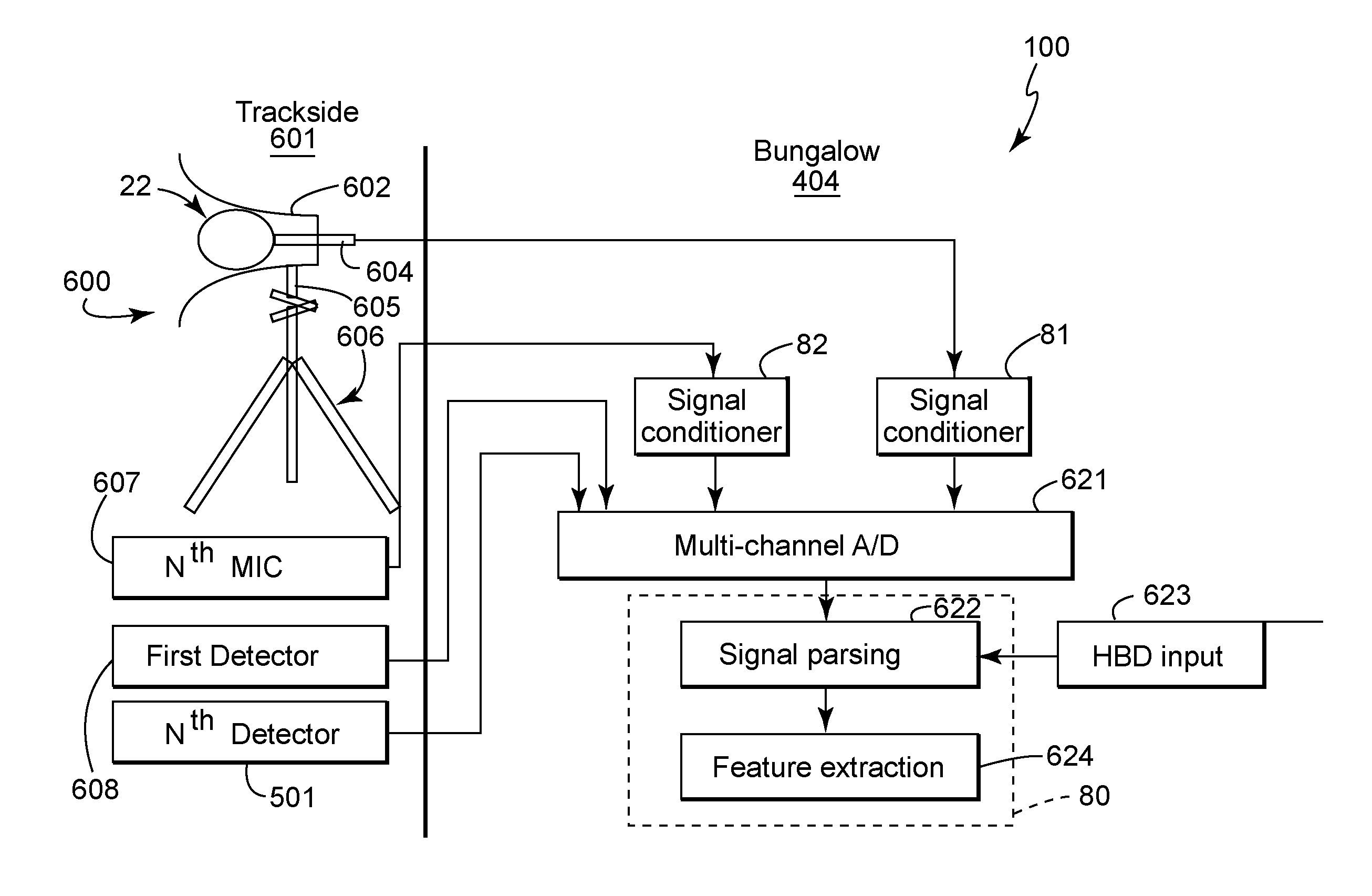

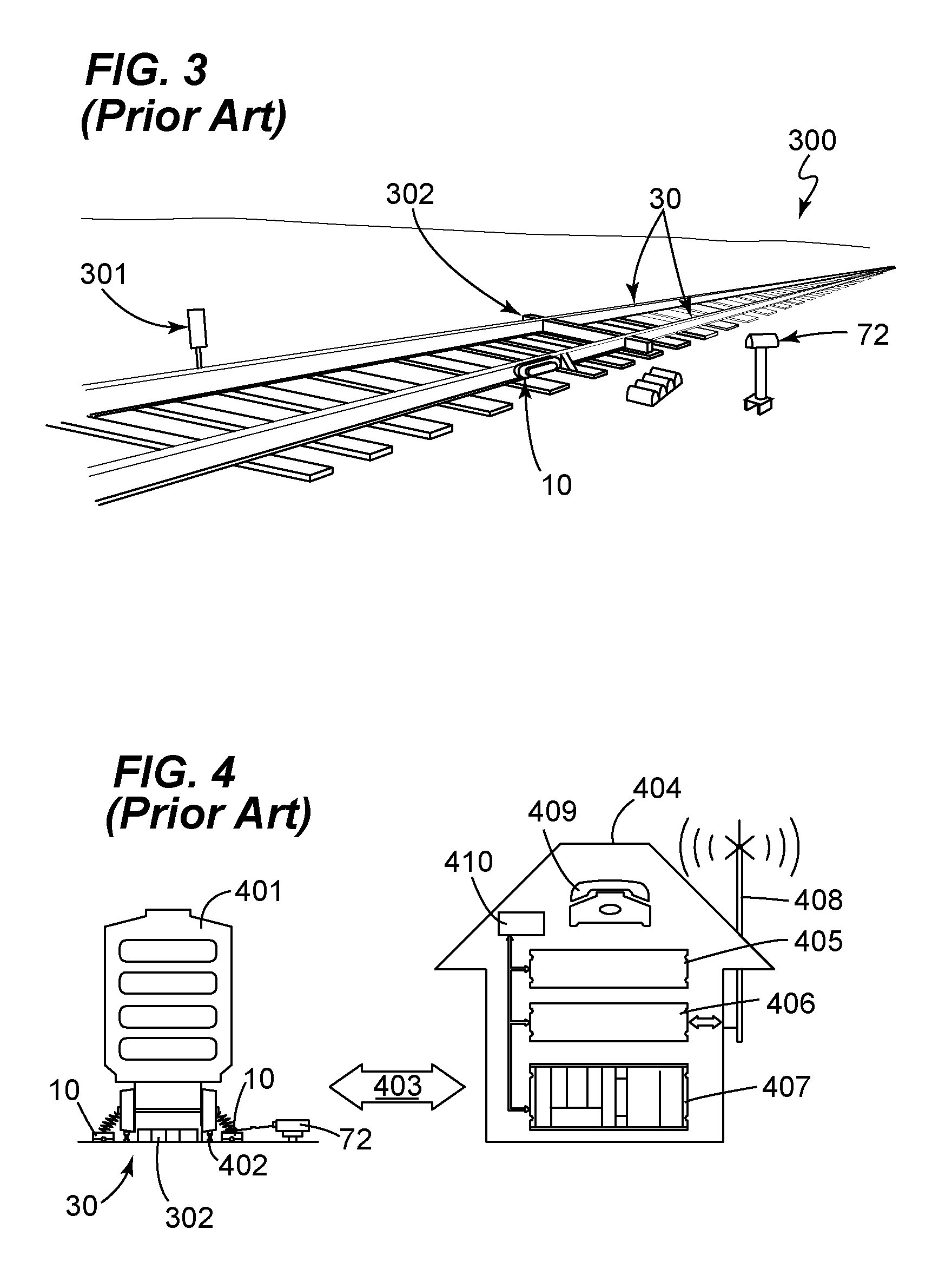

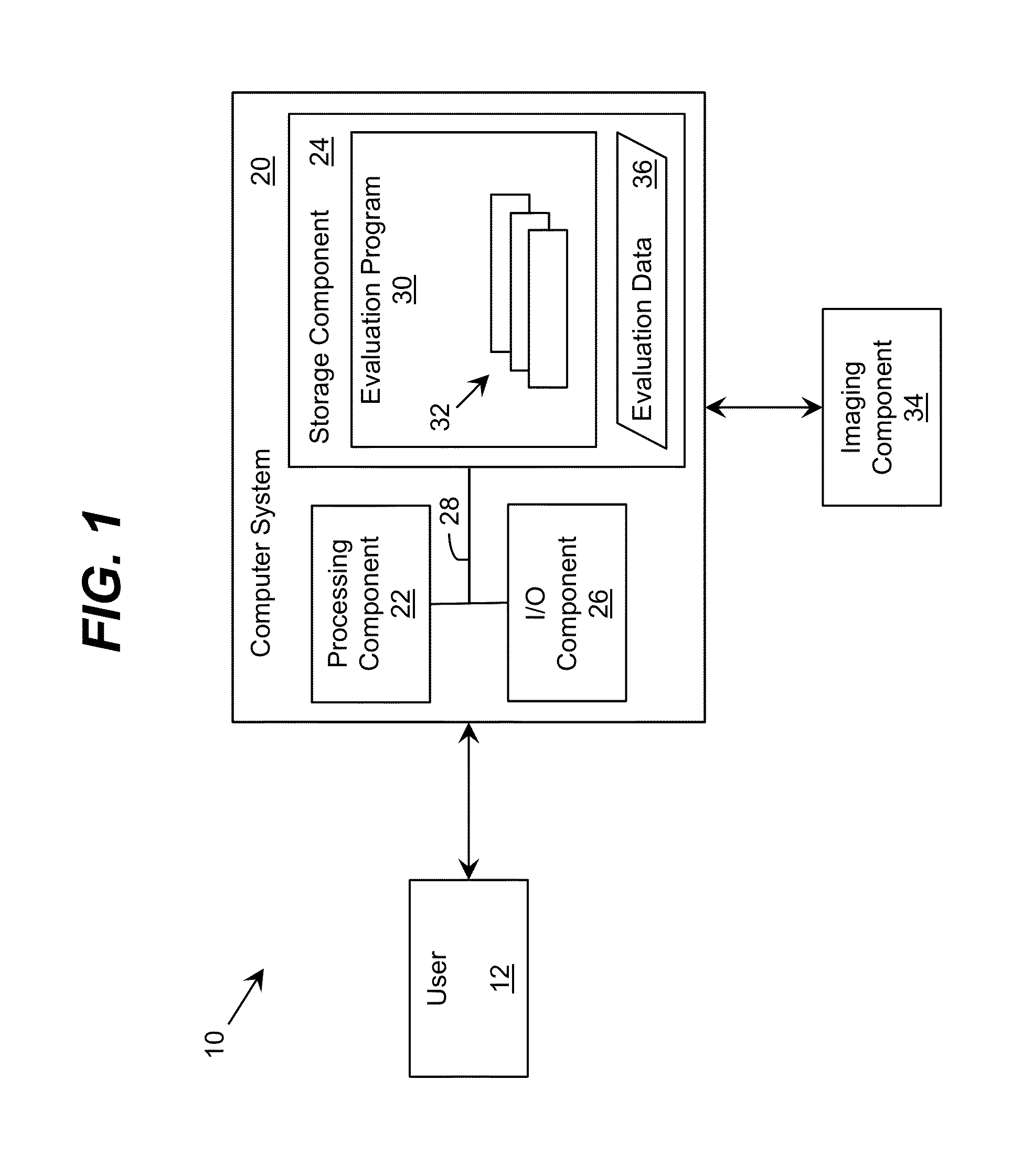

Apparatus and method for identifying a defect and/or operating characteristic of a system

ActiveUS20080306705A1Reduce probabilityImprove accuracyTemperature measurement of moving solidsThermometers using physical/chemical changesMonitoring systemComputer science

An apparatus and methods for identifying a defect and / or an operating characteristic of a system being monitored (and / or one or more of the system's components) are described. In an embodiment, orthogonally related data monitored by two or more detectors may be fused to determine whether a component of a system is defective and / or malfunctioning. Additionally or alternatively, data from a first detector may be determined to be accurate using non-orthogonally related data outputted by a second detector. Both types of determinations may be made with minimal or no false indications, which lowers the cost of operating the system being monitored. Embodiments of the invention may also be configured to forecast and / or prevent accidents and / or damage to the system being monitored by predicting whether a defect and / or a malfunction will occur

Owner:PROGRESS RAIL SERVICES

Enhanced rail inspection

Rail inspection is discussed that employs a monitor vehicle running on one or more tracks of a rail system that performs physical rail inspection in combination with monitoring and analysis of other system parameters that accompany the physical rail.

Owner:TAIWAN SEMICON MFG CO LTD

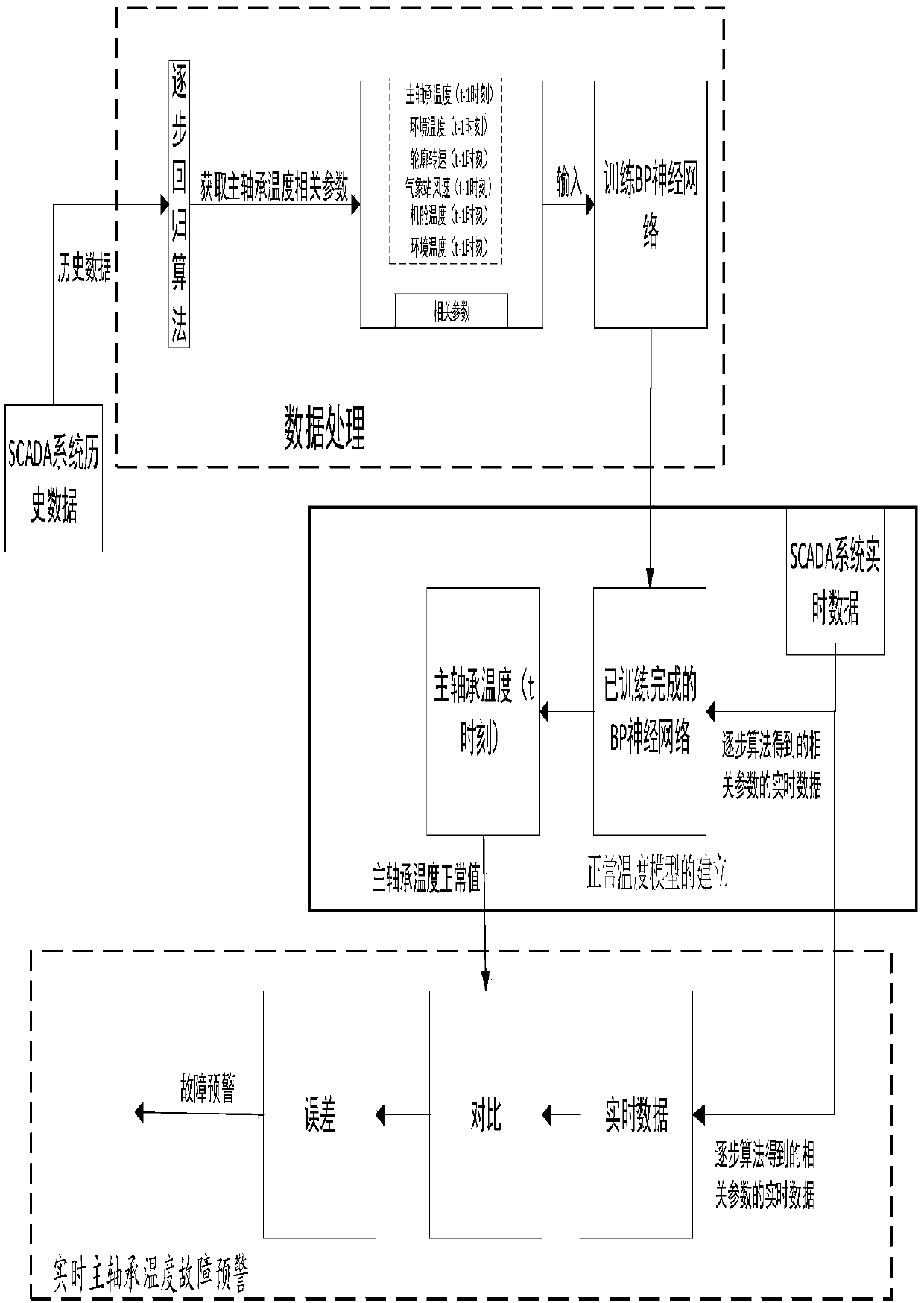

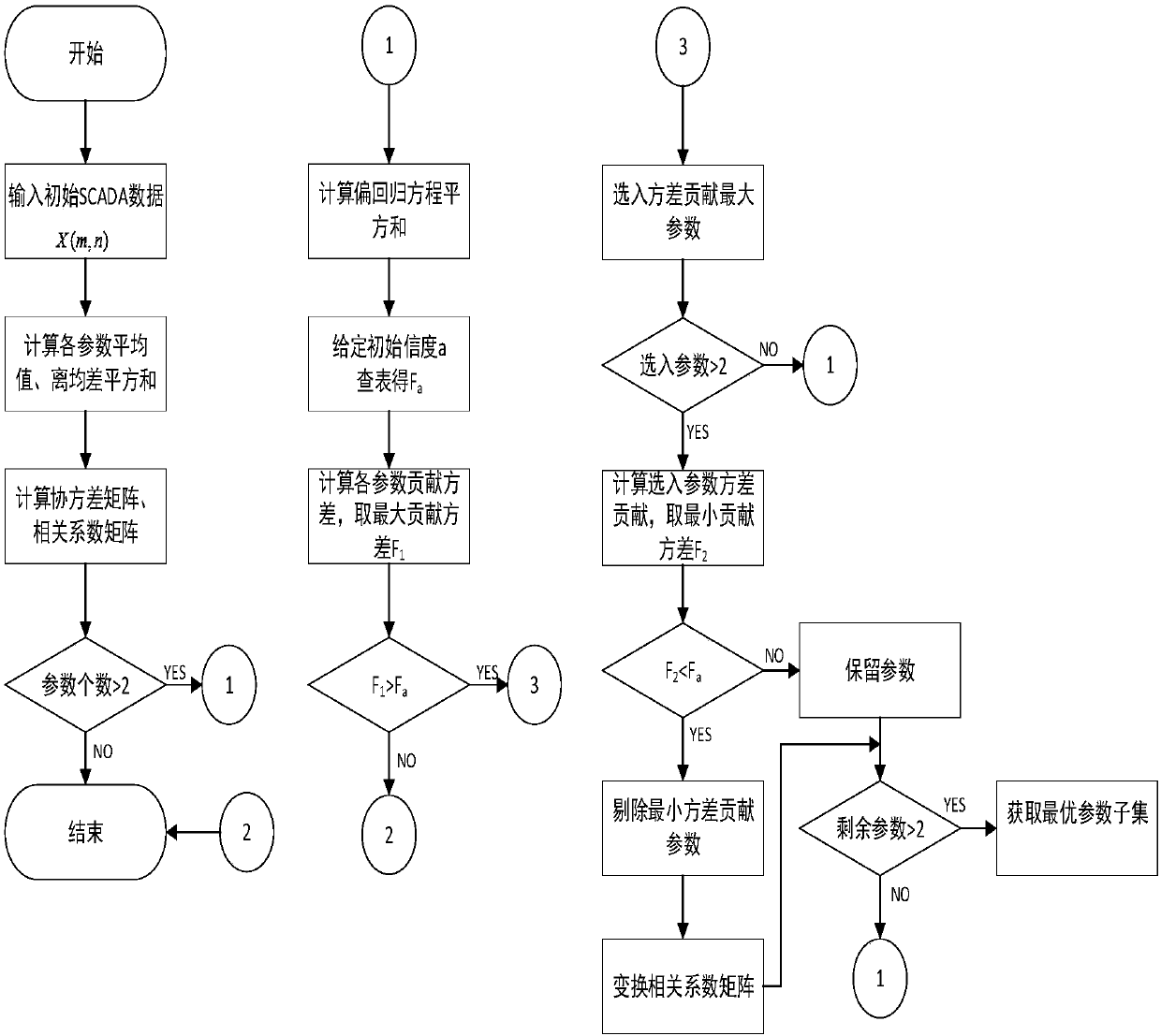

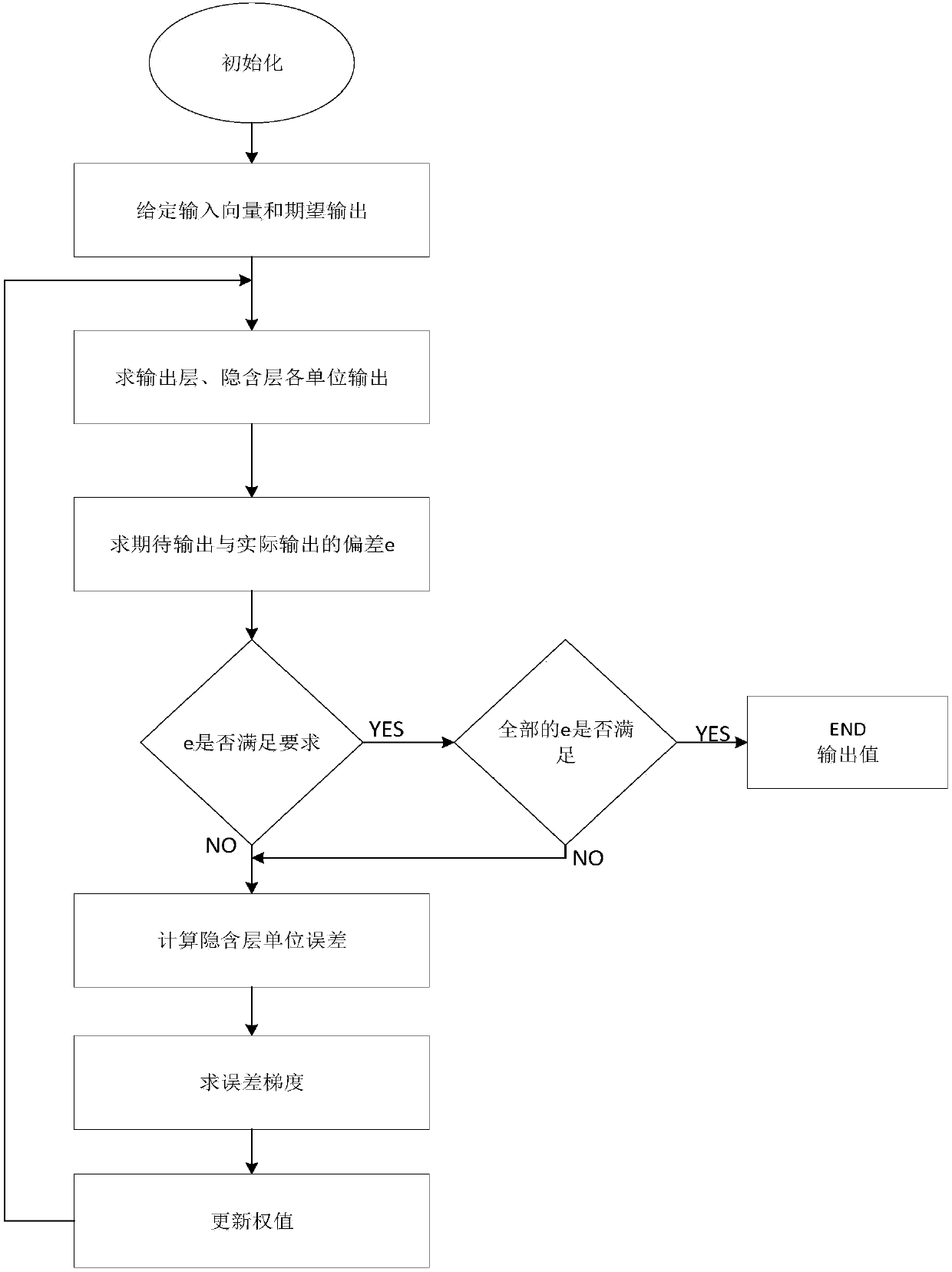

Method for early warning and diagnosis of temperature of main bearing of wind turbine generator

ActiveCN108051211AFailure predictionImprove diagnostic accuracyMachine bearings testingTemperature measurement of moving solidsReal-time dataMain bearing

The invention relates to the field of new energy wind power generation systems, in particular to a method for early warning and diagnosis of the temperature of a main bearing of a wind turbine generator. The method comprises the following steps that firstly, wind power plant monitoring data is acquired; secondly, parameters related to the temperature of the main bearing of the wind turbine generator are obtained; thirdly, a normal temperature model of the main bearing of the wind turbine generator is established; fourthly, the theoretical value of the real-time normal temperature of the main bearing of the wind turbine generator is calculated, wherein the real-time values of the parameters related to the temperature of the main bearing of the wind turbine generator in the second step are selected from the real-time data collected in the first step, the real-time values of the related parameters are input into a neural network trained in the third step, and the normal temperature valueof the main bearing of the wind turbine generator is generated; fifthly, whether the real-time temperature of the main bearing of the wind turbine generator is normal or not is judged. By means of themethod, faults of the main bearing of the wind turbine generator are effectively judged in advance, an extra sensor does not need to be installed, and the diagnosis precision and the diagnosis time advance are remarkably improved.

Owner:湖南优利泰克自动化系统有限公司 +1

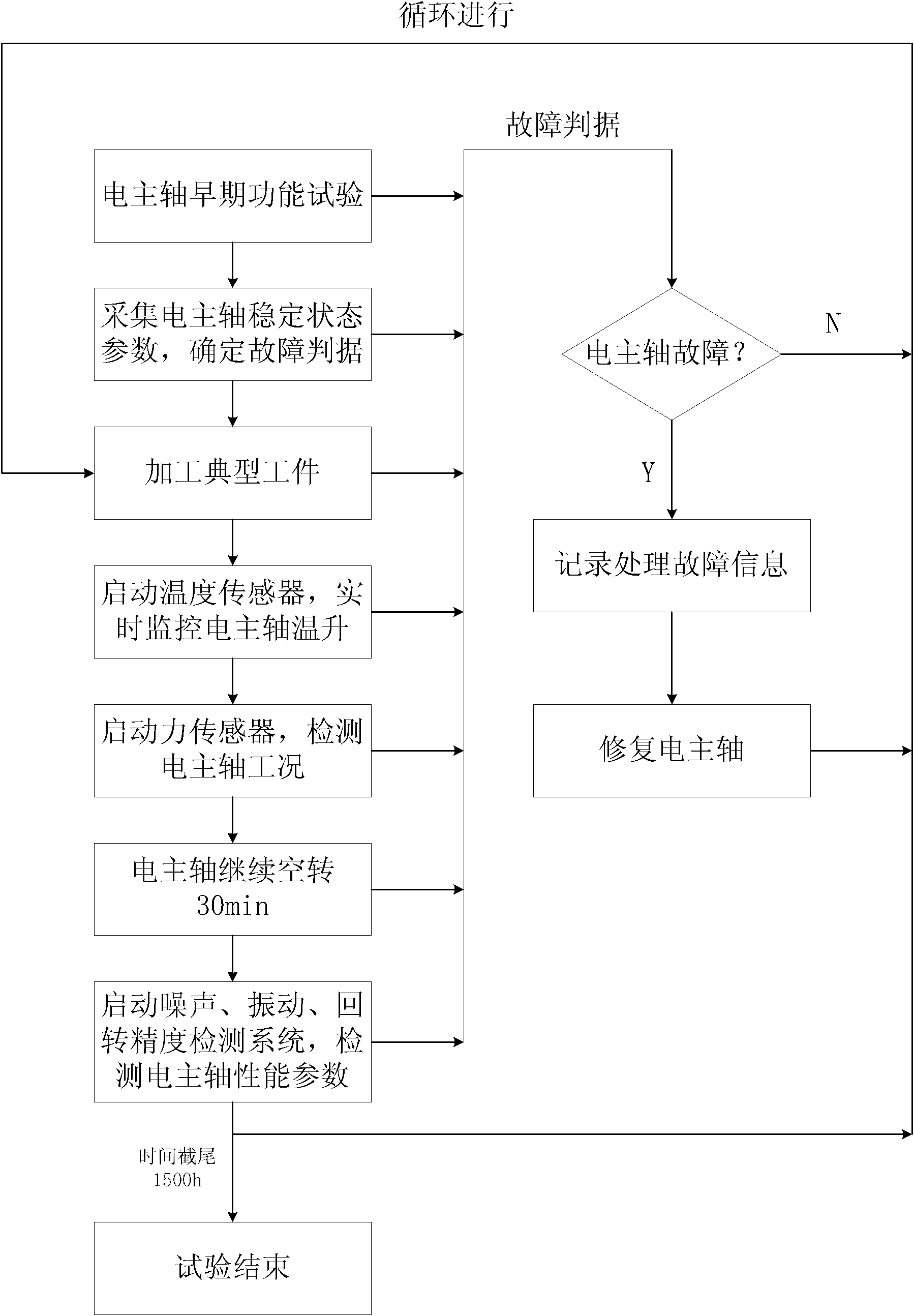

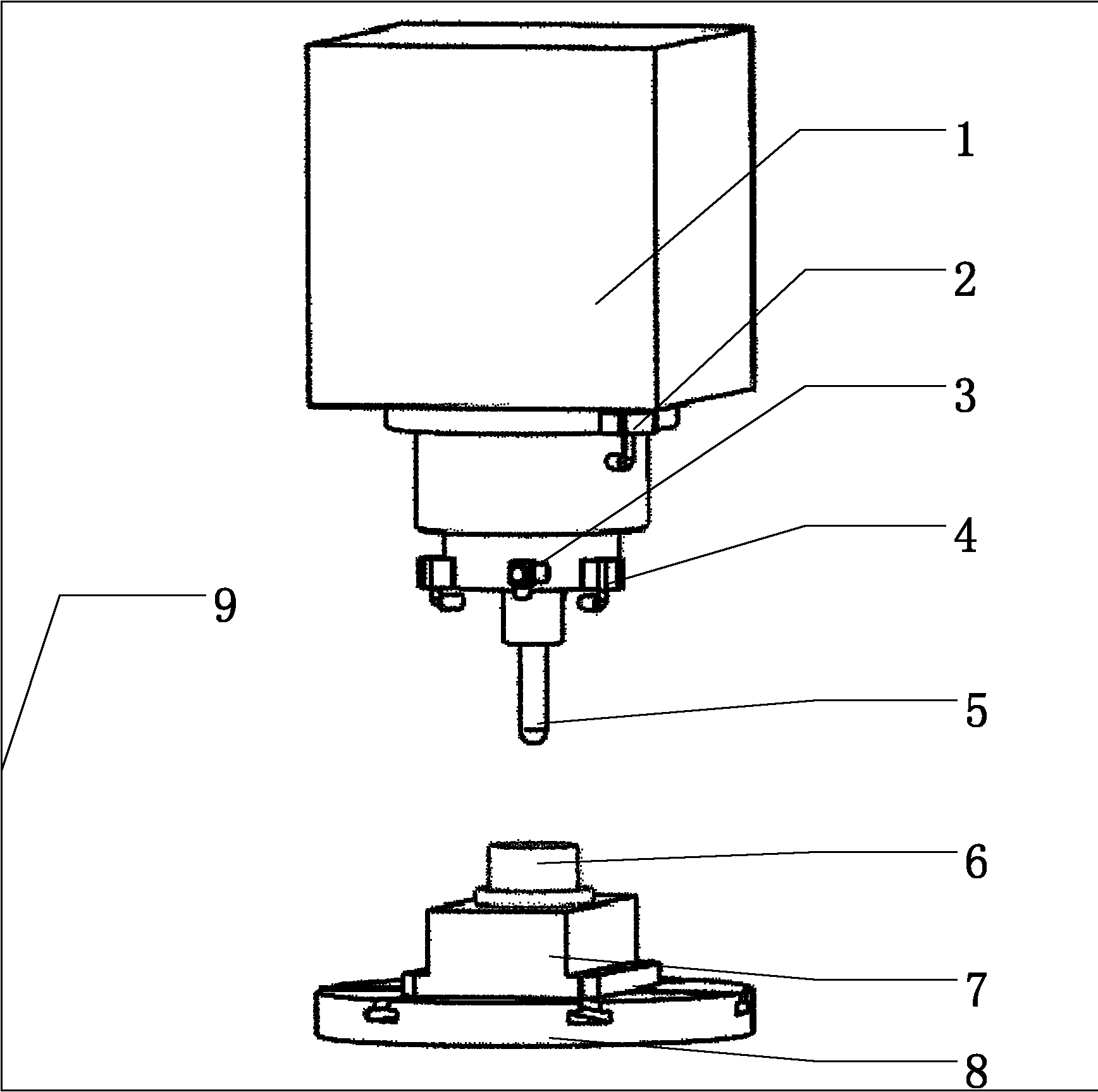

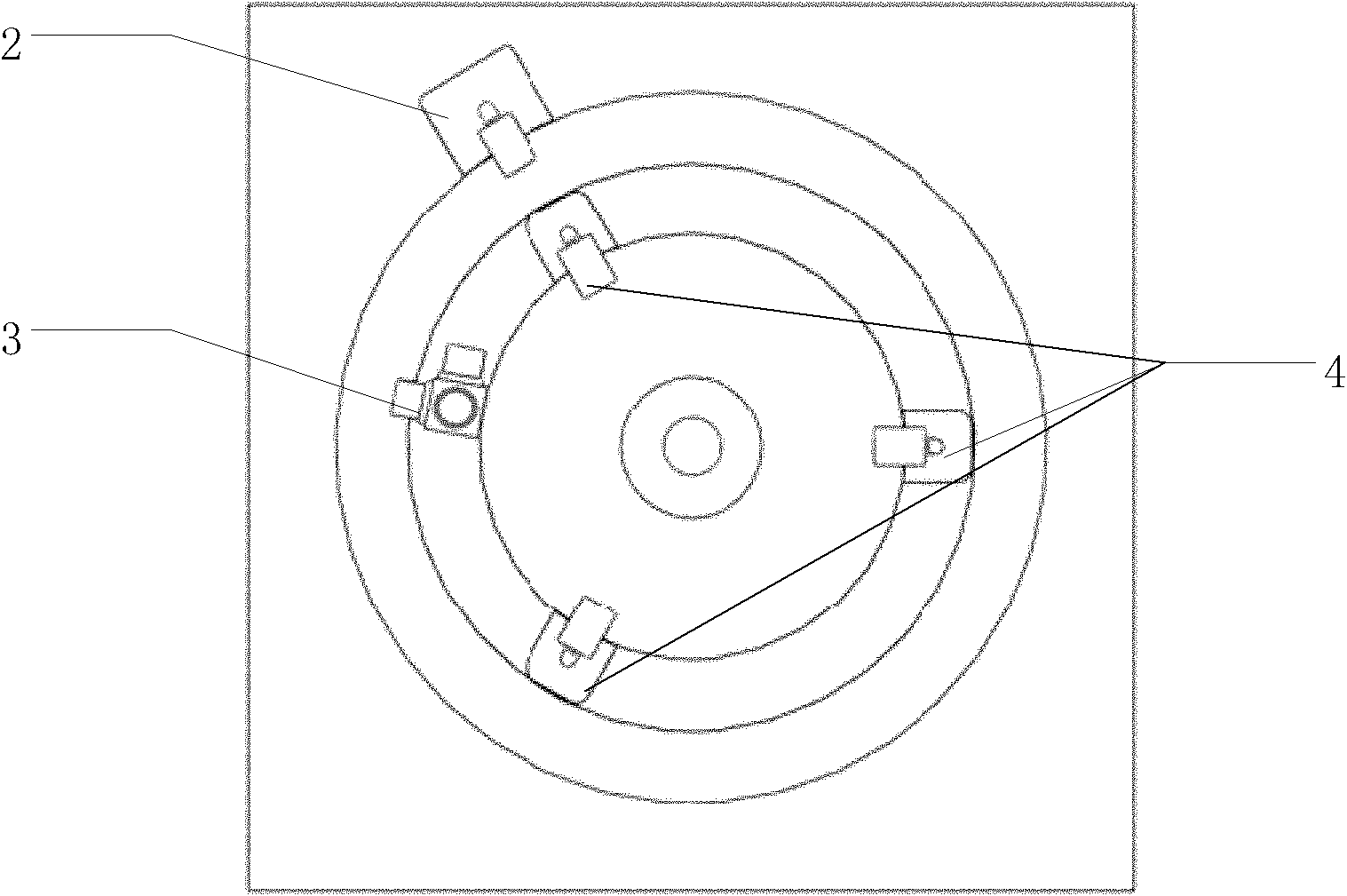

Method and system for testing reliability of electric spindle in machining center

InactiveCN102012286ALow costShort build timeSubsonic/sonic/ultrasonic wave measurementForce measurementStable stateTested time

The invention discloses a system and a method for testing the reliability of an electric spindle in a machining center. The method comprises the following steps of: 1, establishing the system for testing the reliability of the electric spindle in the machining center; 2, determining test environment and test time; 3, performing a function test on the electric spindle to remove early failures; 4, acquiring the performance parameter of the electric spindle in a stable state and determining a failure criterion; and 5, circularly machining a typical workpiece, monitoring the state and performance parameter of the electric spindle and judging the failures. The system comprises a temperature sensor, a noise sensor, a force sensor, an eddy current displacement sensor, a vibration sensor, and a control unit connected with the parts. The system has the advantages of simple and compact structure, low cost, simple principle, convenience of operation, high test accuracy and the like.

Owner:NAT UNIV OF DEFENSE TECH

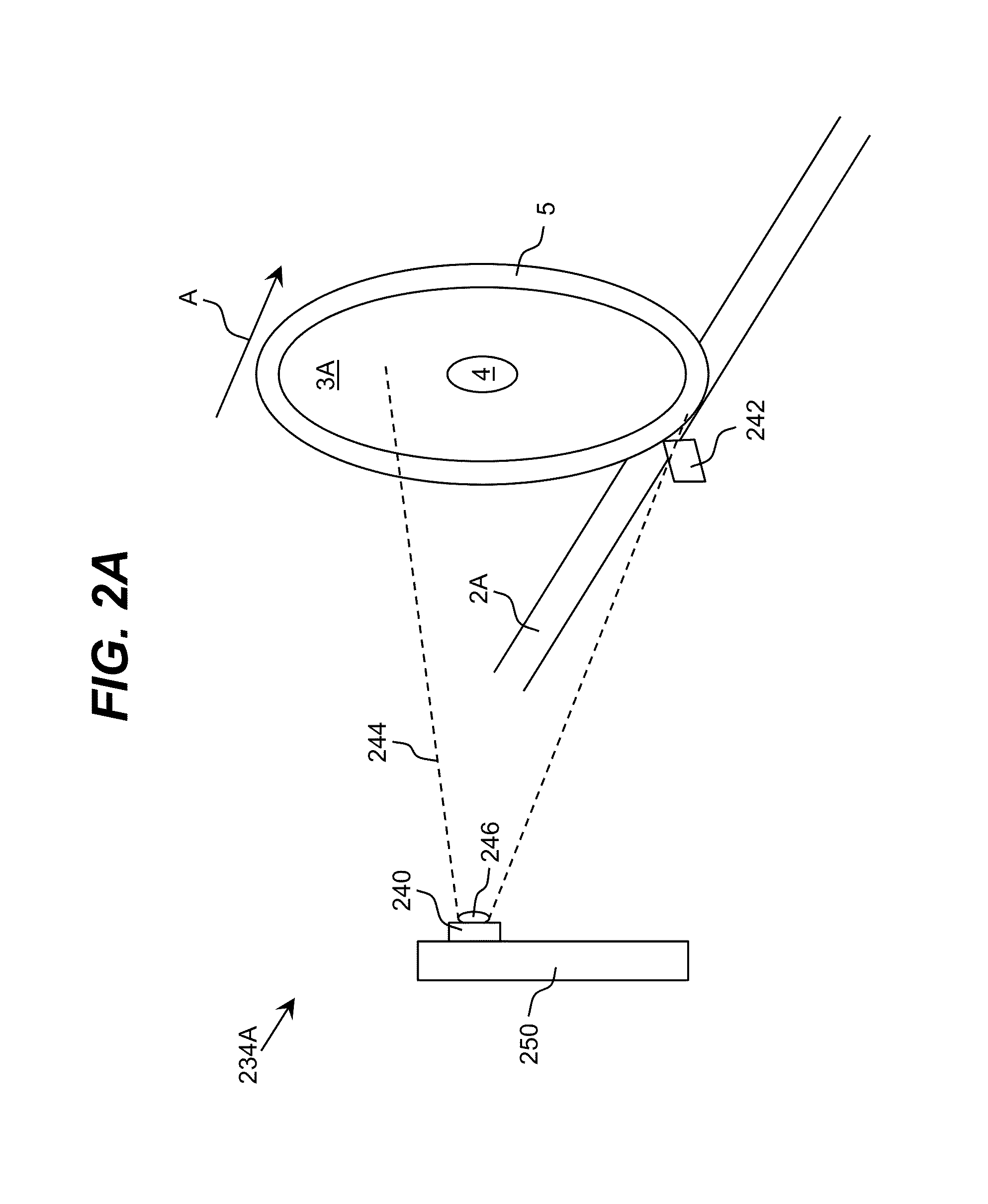

Infrared-based vehicle component imaging and analysis

ActiveUS9134185B2High sensitivitySimple systemTemperature measurement of moving solidsSensing radiation from moving bodiesThermoelectric coolingElectrical conductor

An improved system for evaluating one or more components of a vehicle is provided. The system includes a set of imaging devices configured to acquire image data based on infrared emissions of at least one vehicle component of the vehicle as it moves through a field of view of at least one of the set of imaging devices. An imaging device in the set of imaging devices can include a linear array of photoconductor infrared detectors and a thermoelectric cooler for maintaining an operating temperature of the linear array of detectors at a target operating temperature. The infrared emissions can be within at least one of: the mid-wavelength infrared (MWIR) radiation spectrum or the long wavelength infrared (LWIR) radiation spectrum.

Owner:INT ELECTRONICS MACHINES

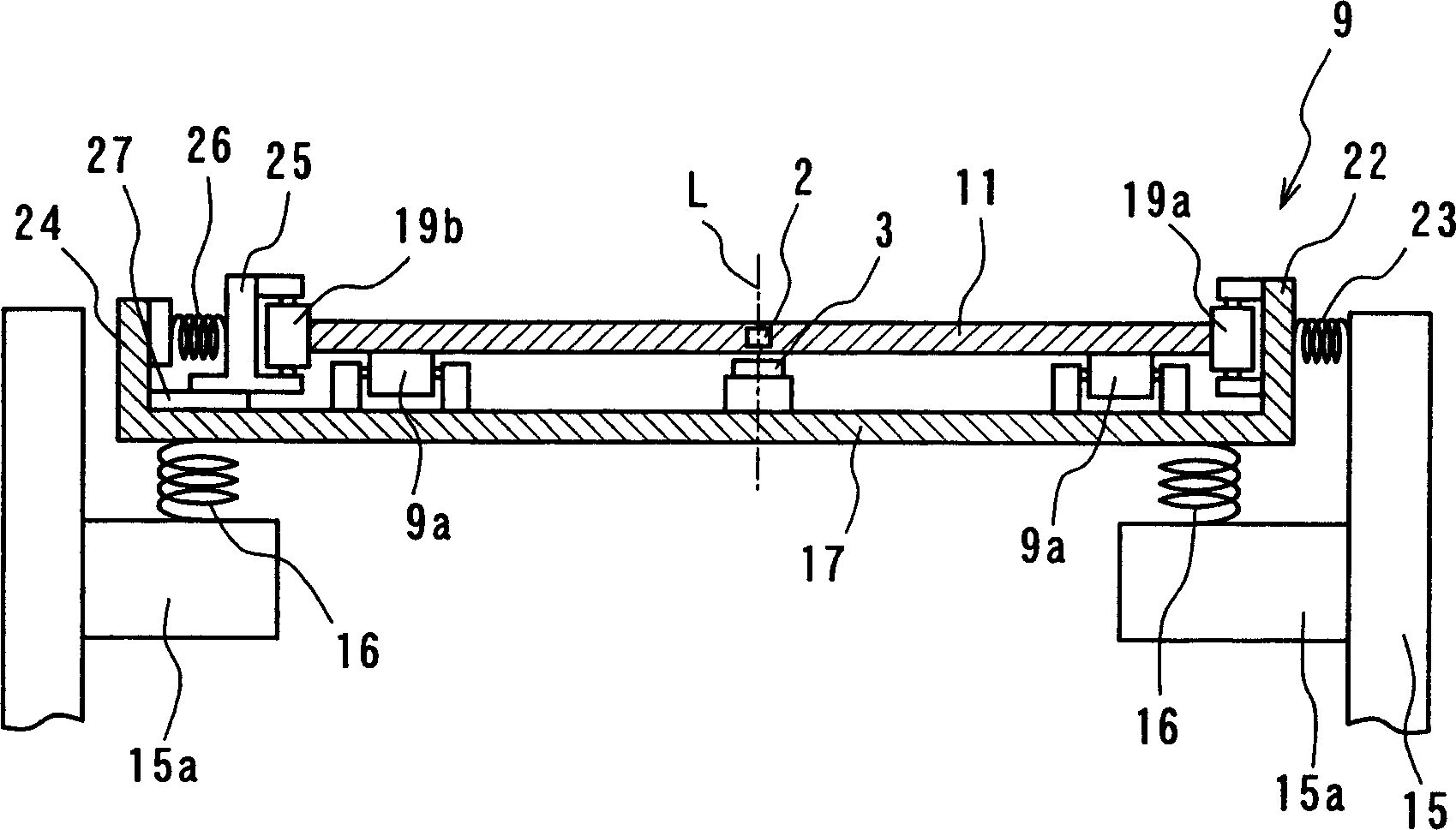

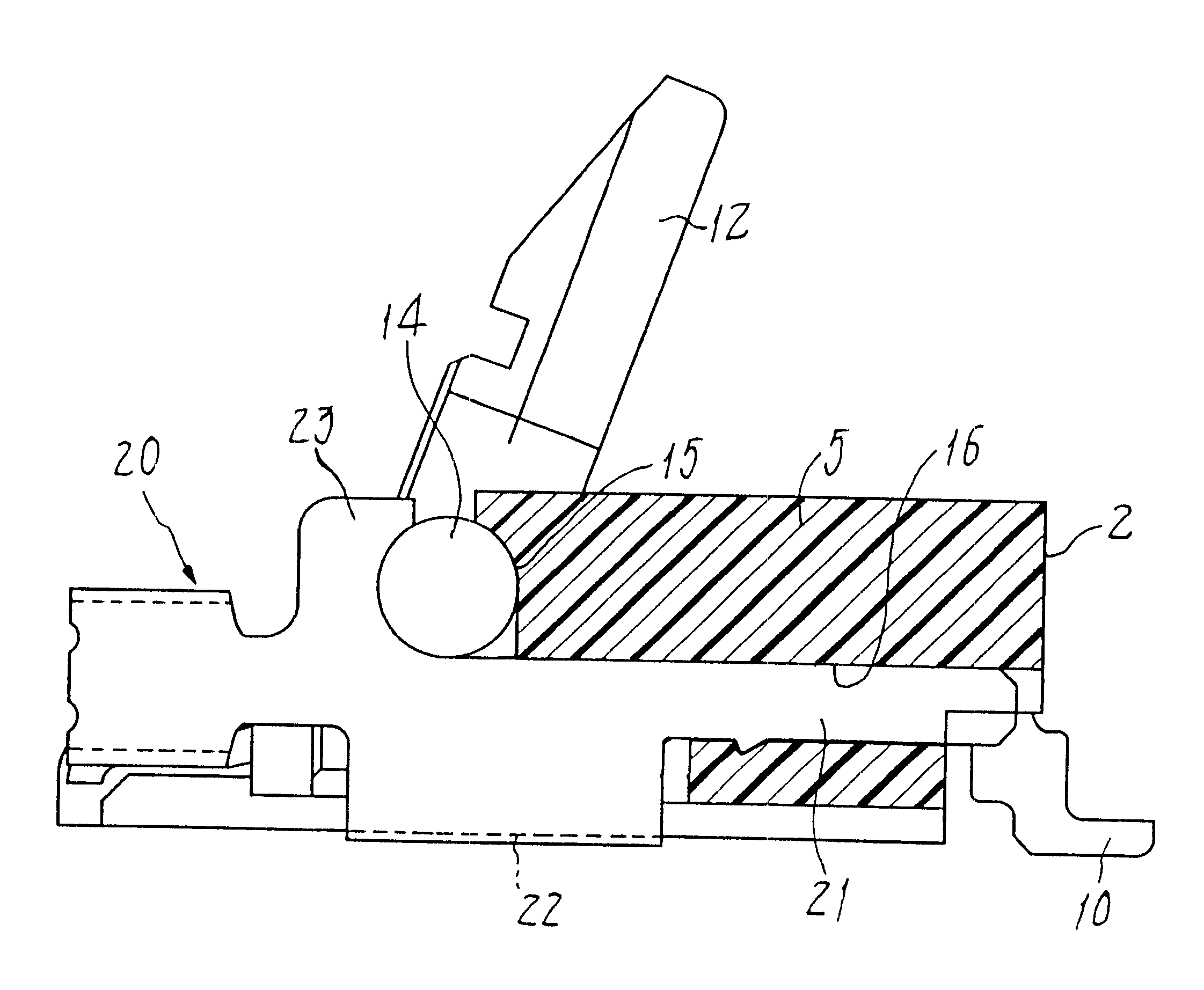

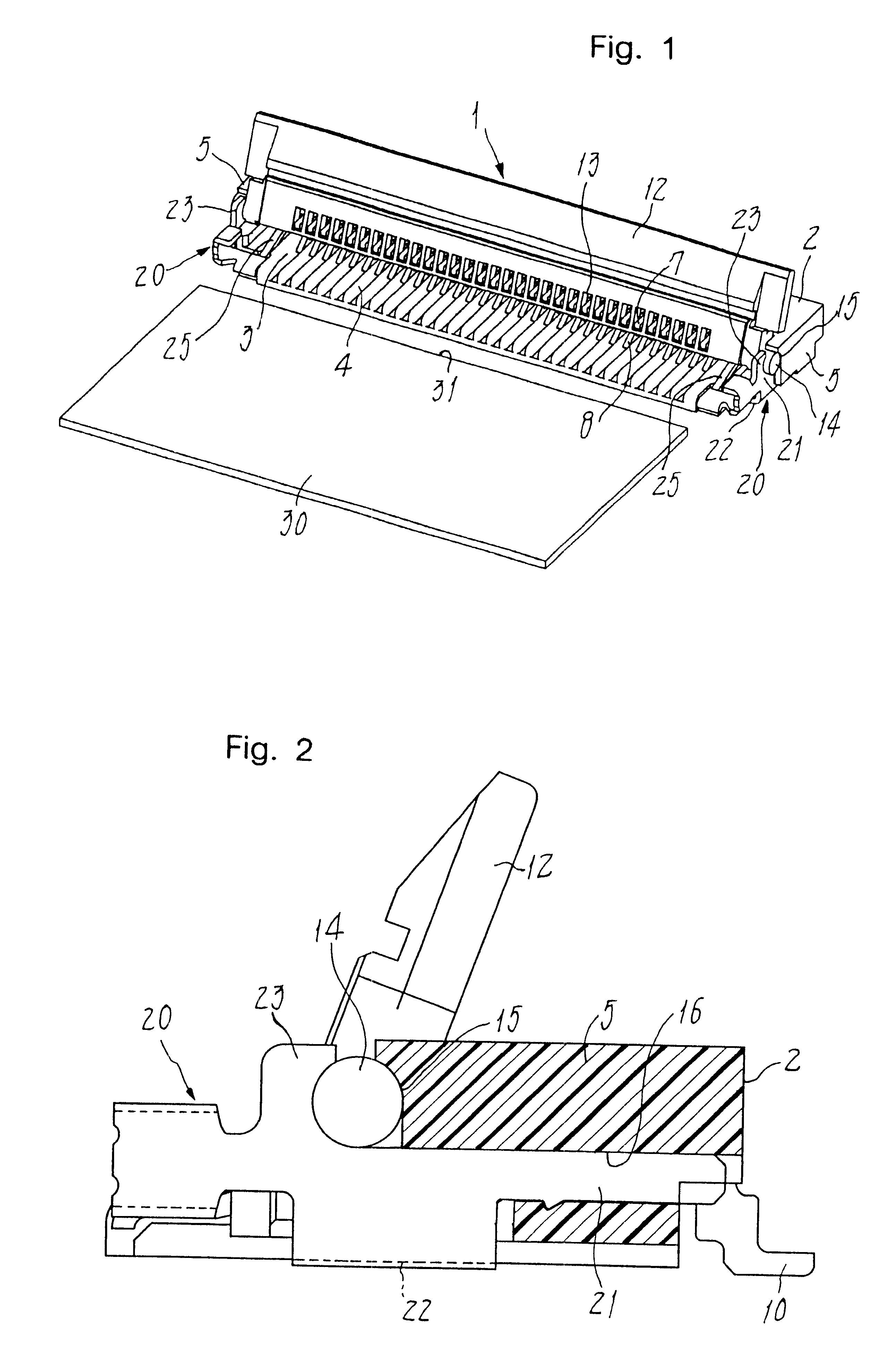

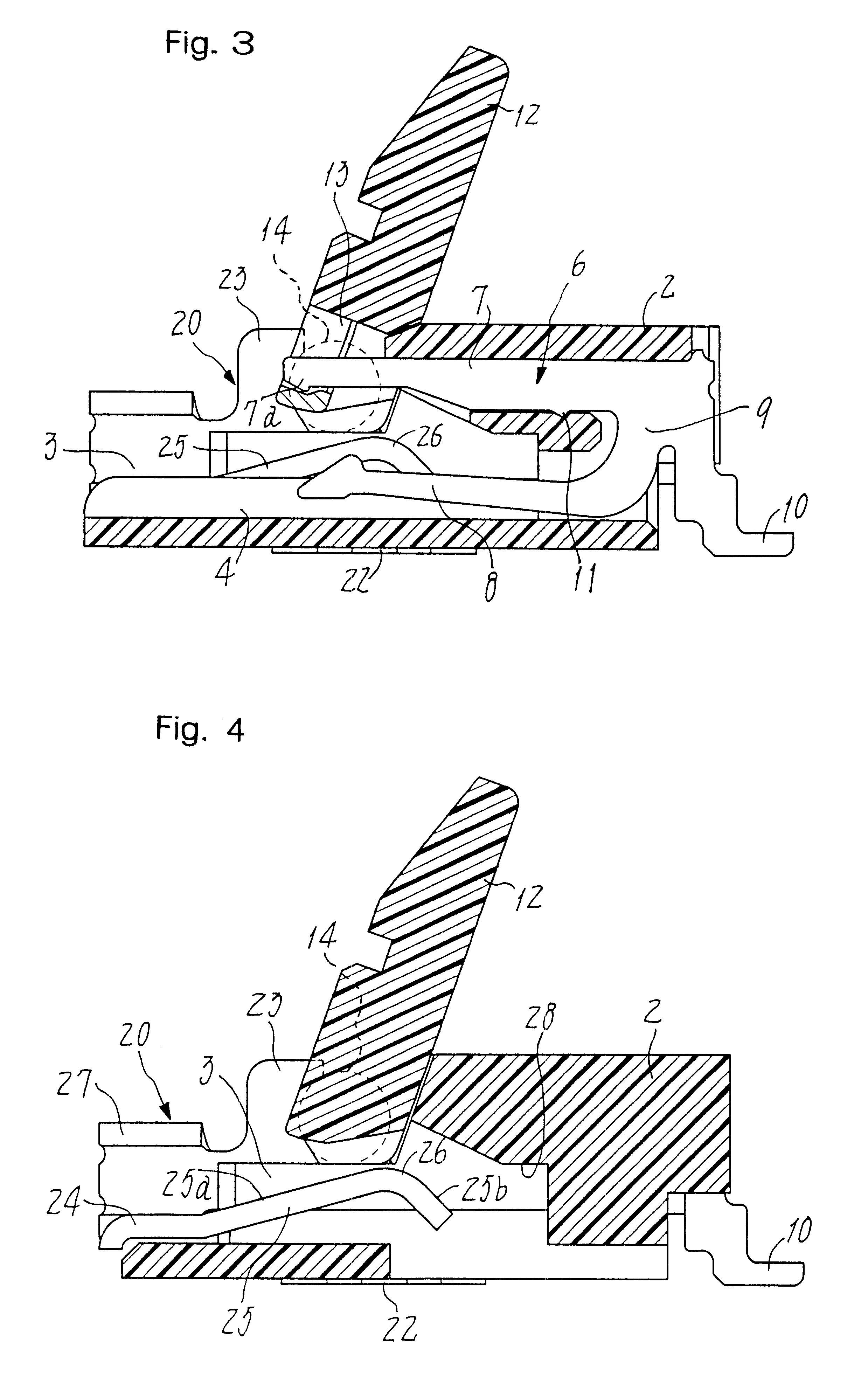

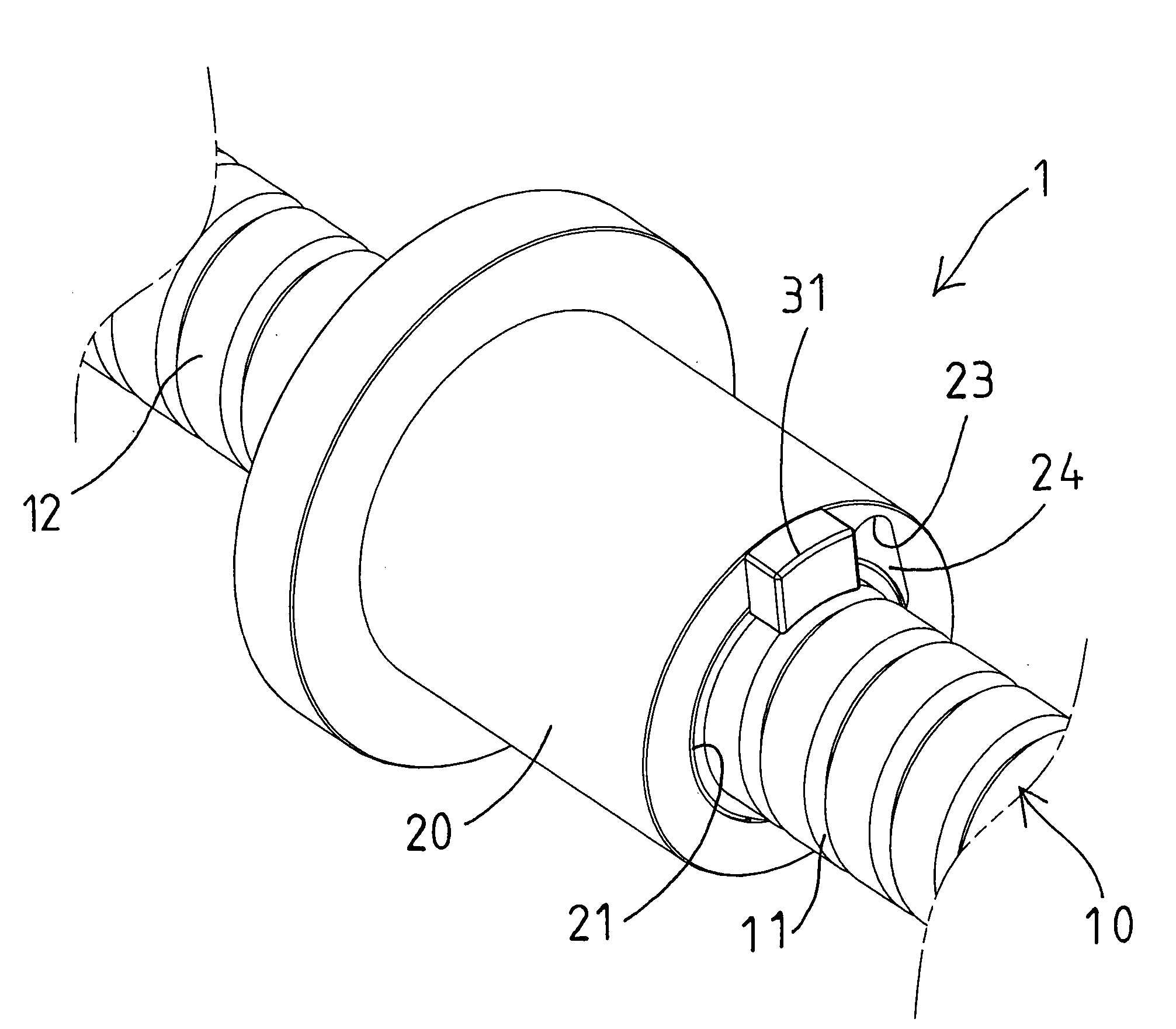

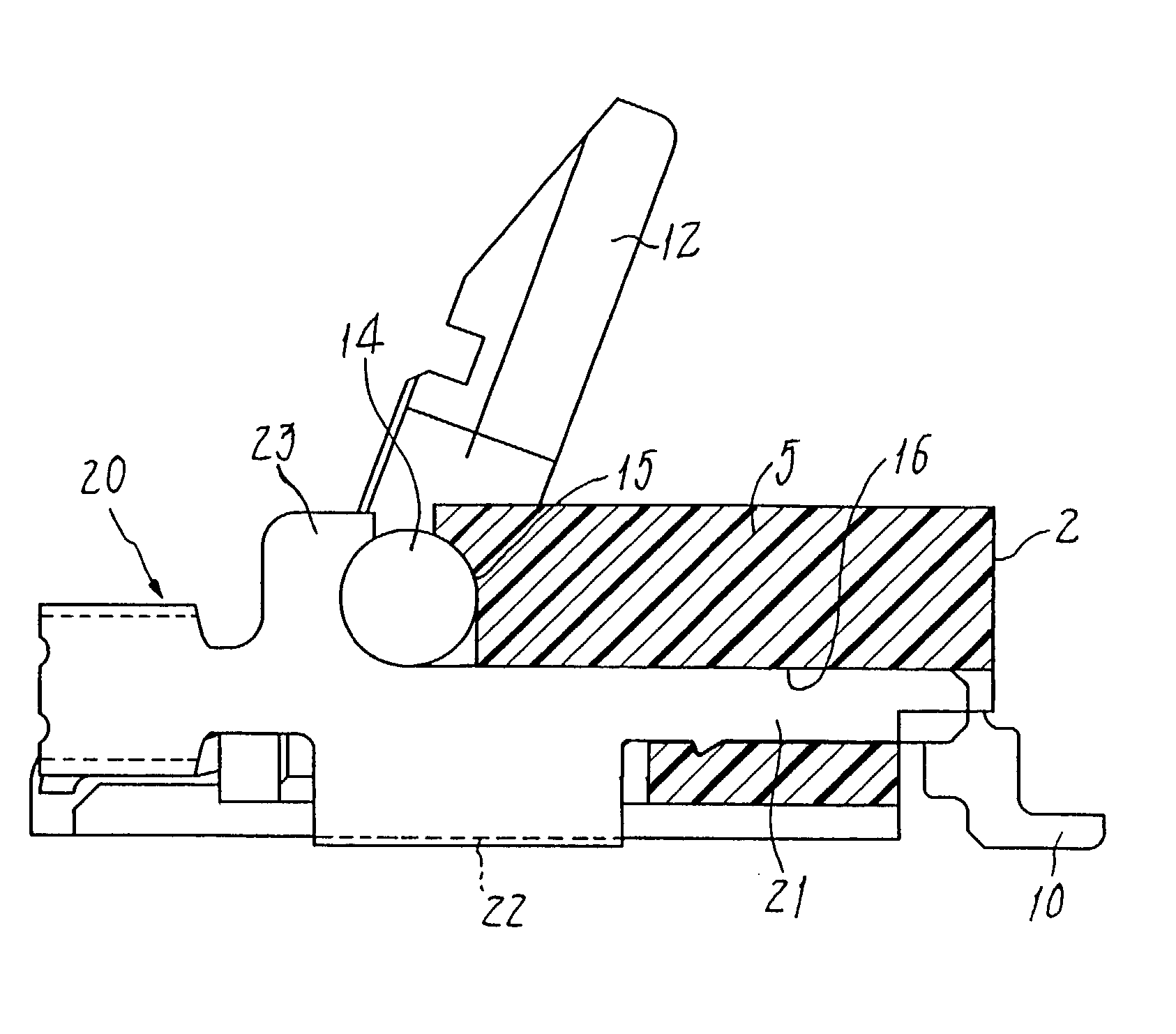

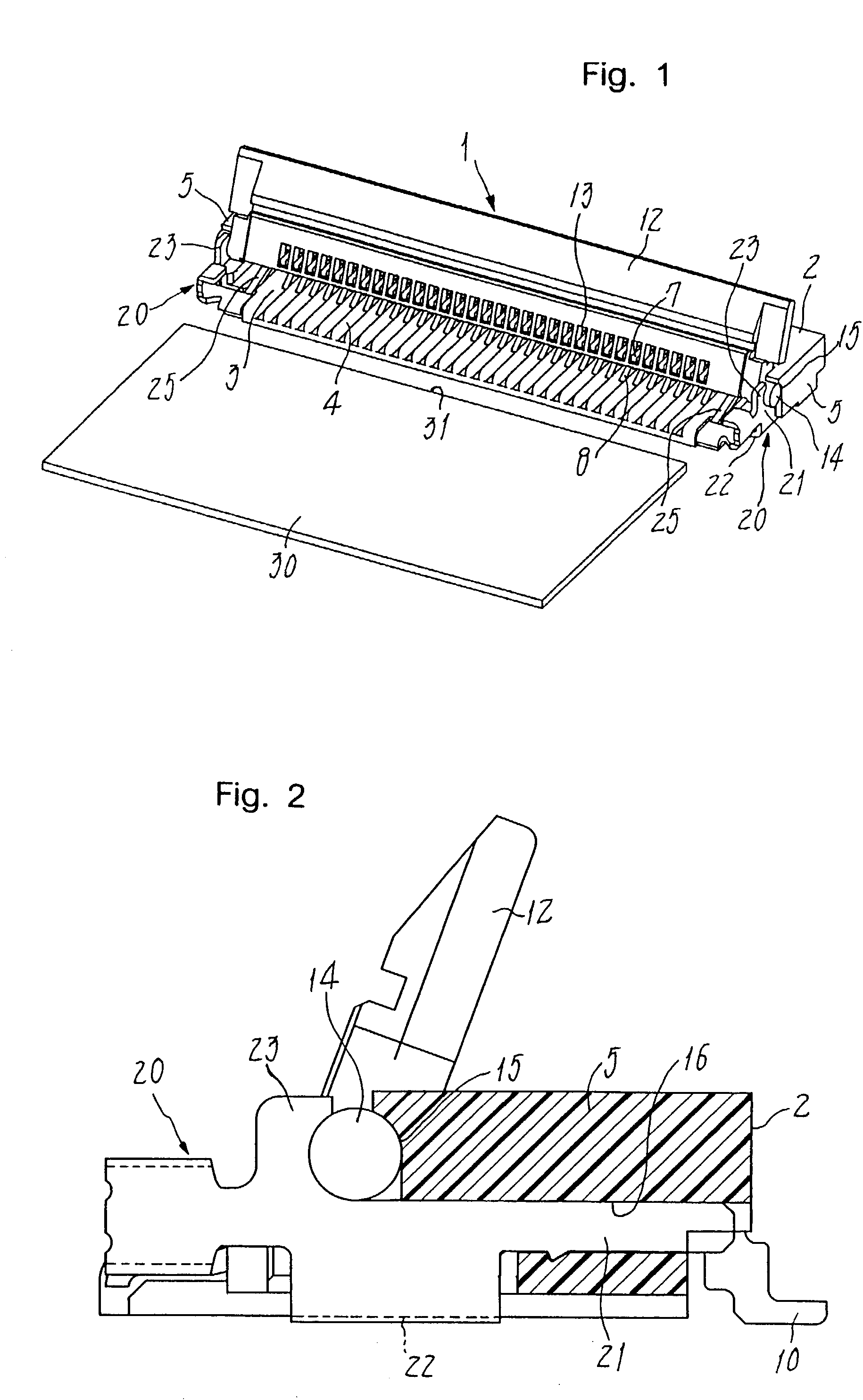

Connector for a flexible circuit board

InactiveUS6679713B2Protection from damageEngagement/disengagement of coupling partsRimsFlexible circuitsEngineering

A connector (1) for a flexible circuit board (30) has a housing (2), a pressing means (12), and parallel contacts (6) each having a conductive arm (8) and arranged at a pitch to form a row in the recess (3) of the housing. The pressing means (12) can be swung to close the recess so that an inner end portion of the flexible board (30) overlying the conductive arms (8) will be pressed down onto these arms. Reinforcement metals (20) face one another over the row of the contacts (6) and are attached to opposite sides (5) of the housing (2), so as to be soldered to a rigid printed circuit board. Each reinforcement metal (20) has a resilient support (25) for urging upwards the flexible board (30) in a direction away from the conductive arms (8) so as to keep the board in place.

Owner:JST MFG CO LTD

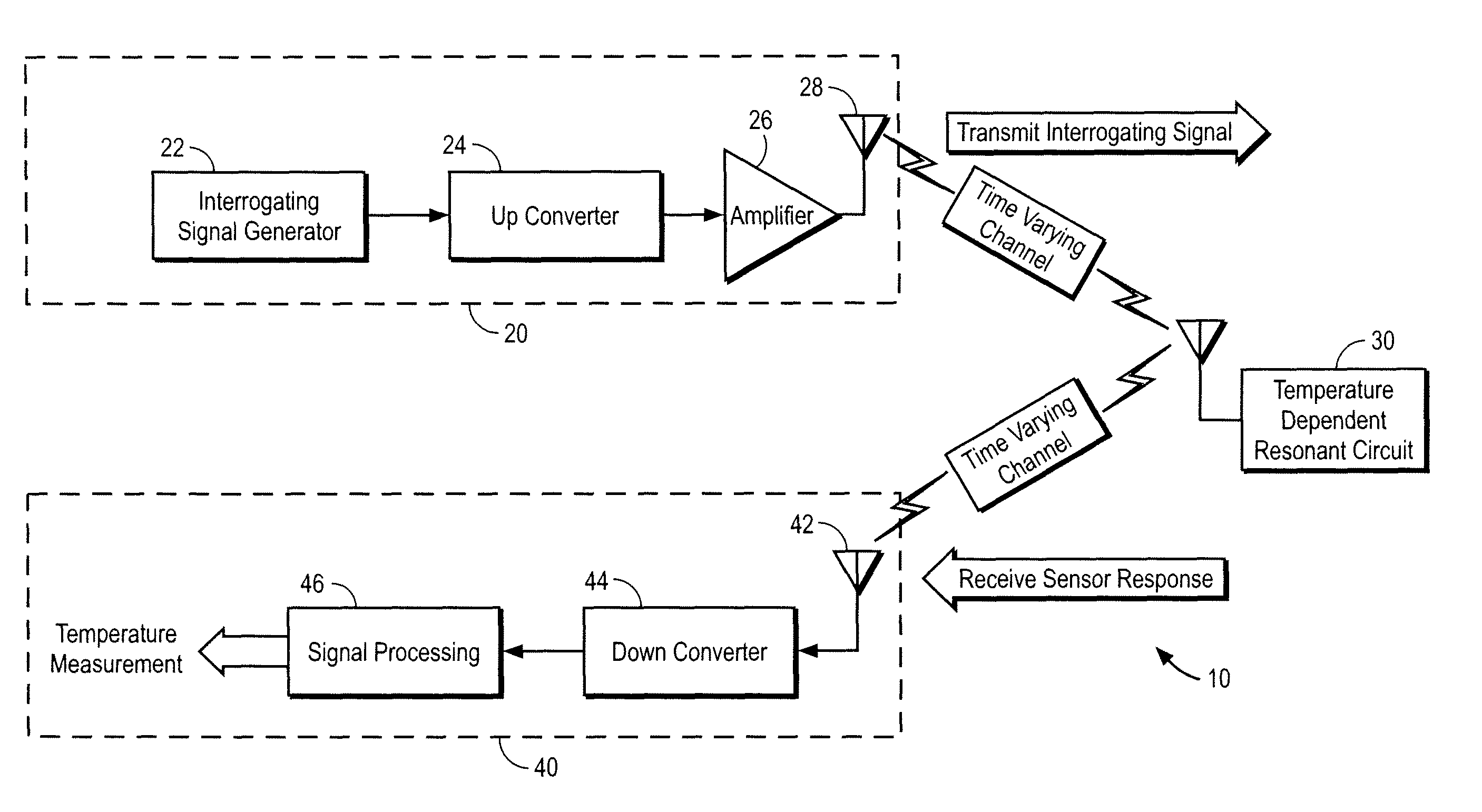

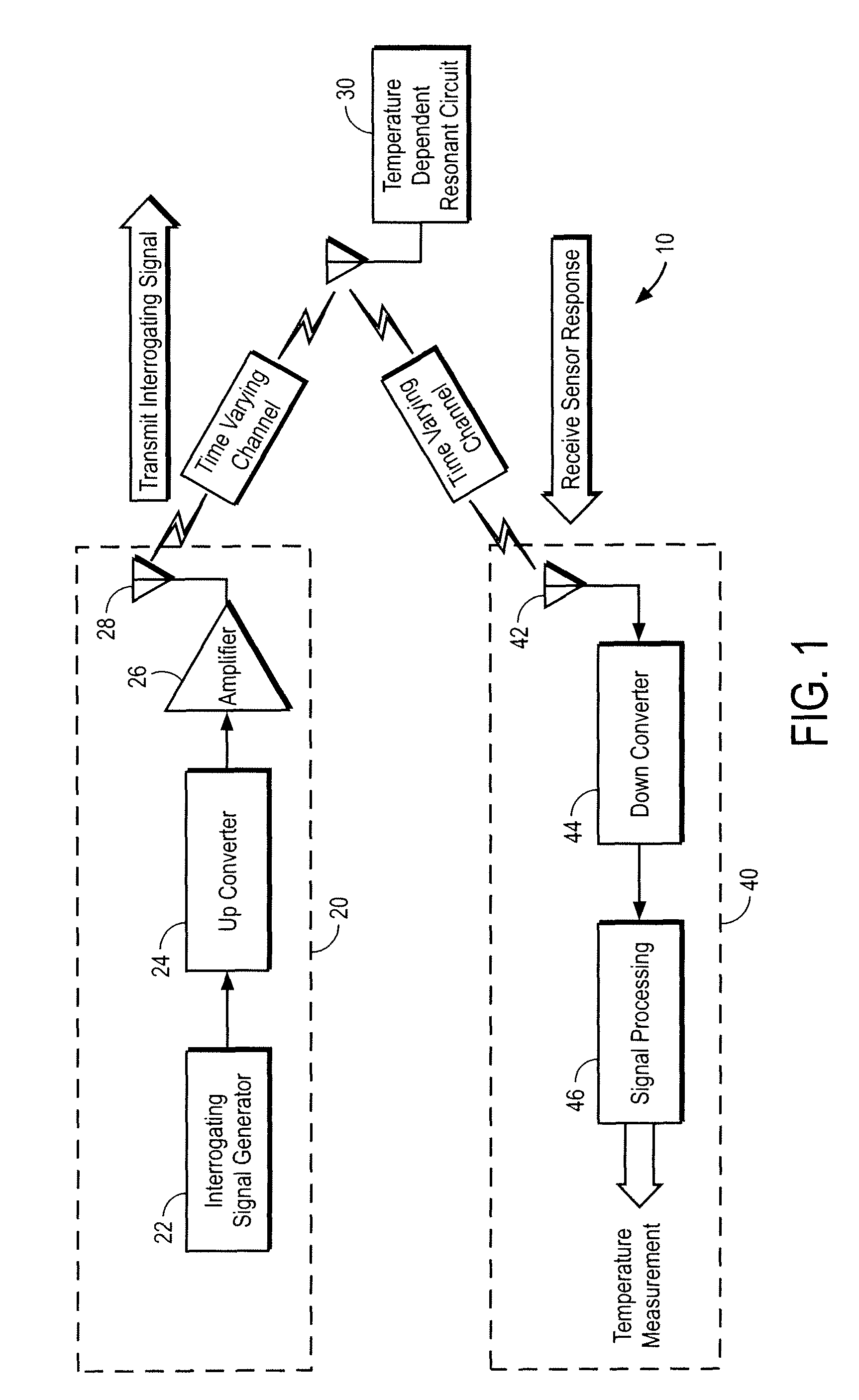

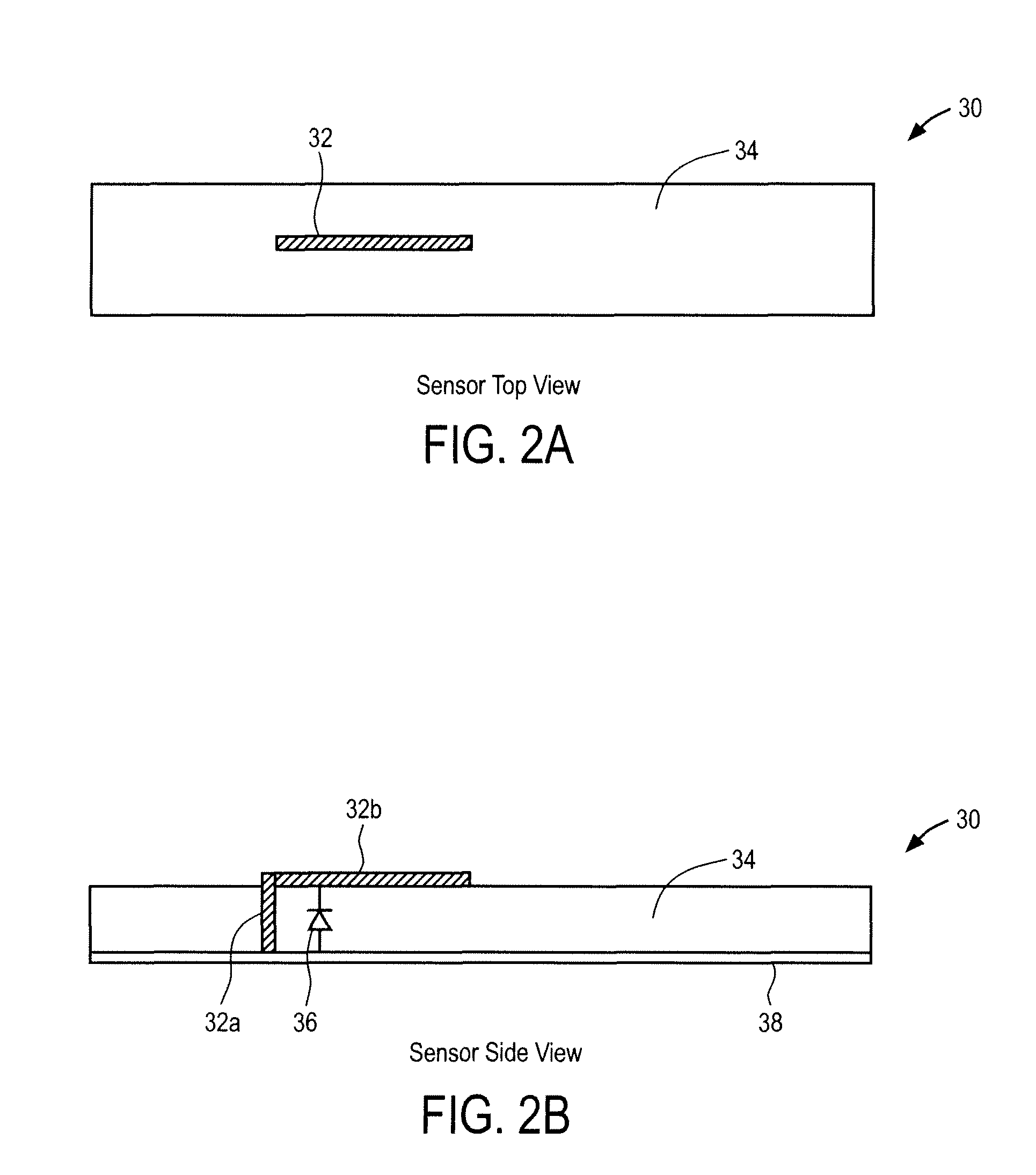

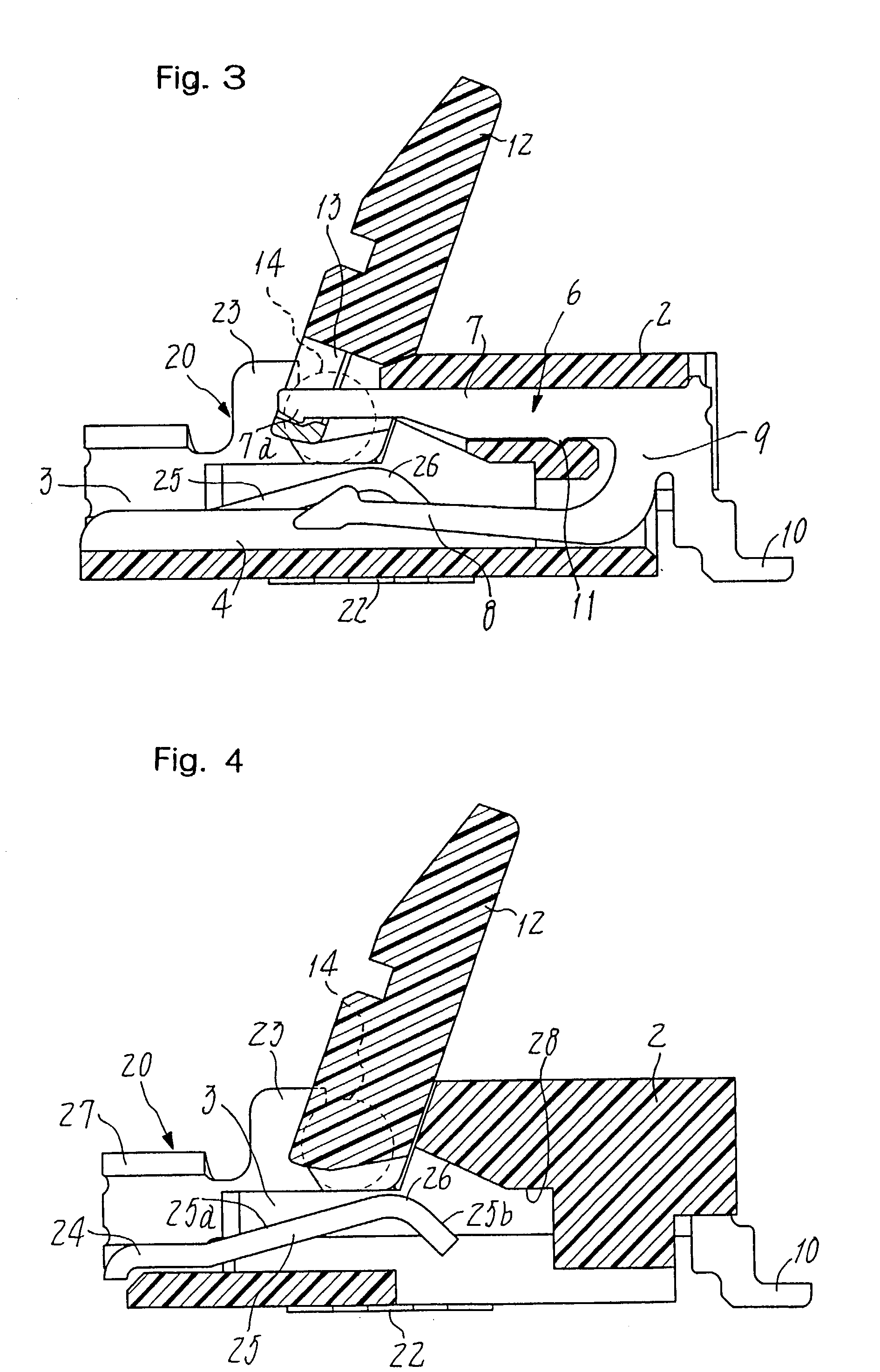

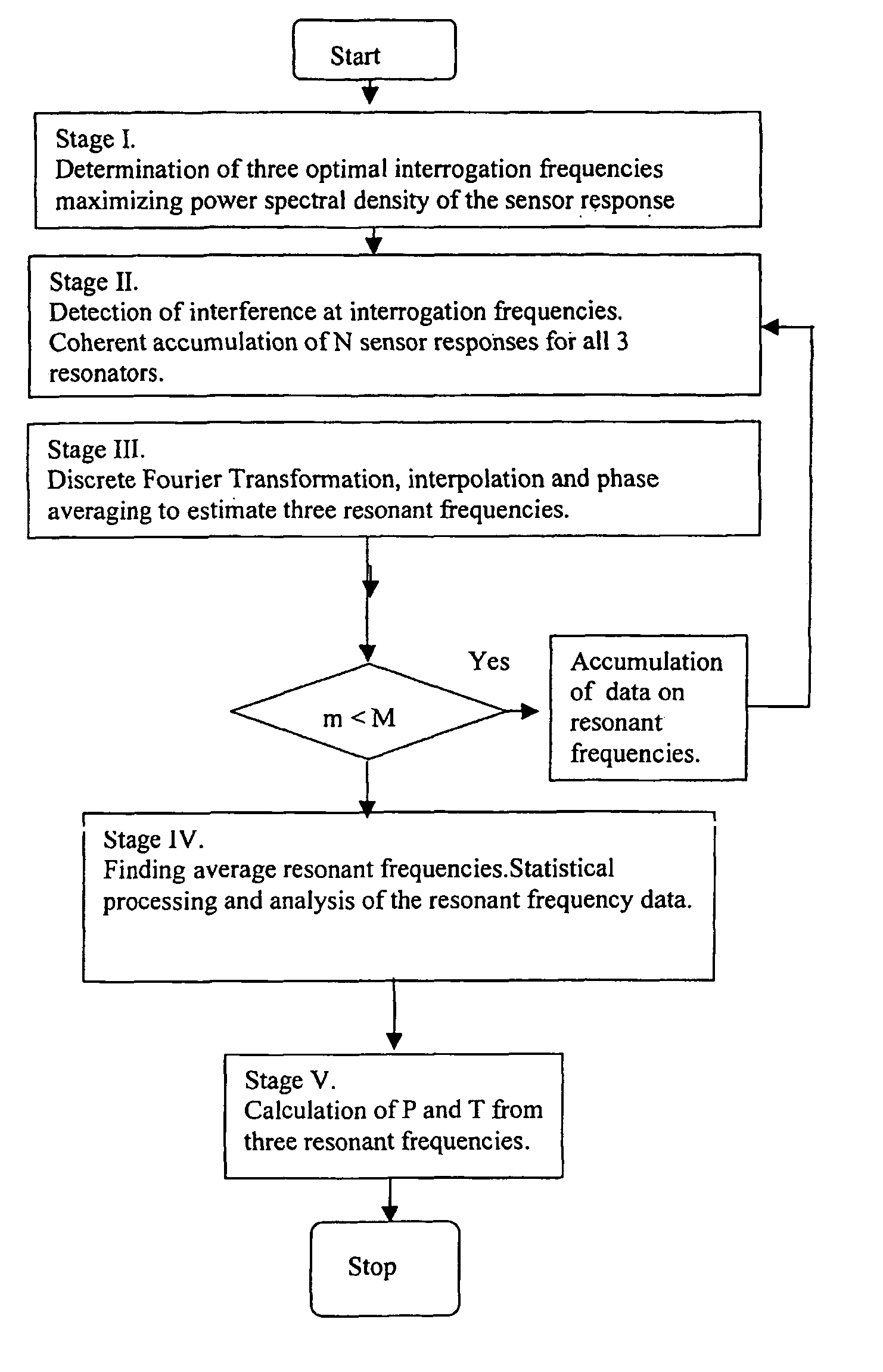

Wireless temperature measurement system and methods of making and using same

ActiveUS8348504B2Improve performanceSmall footprintThermometer detailsEngine fuctionsElectricityTemperature response

A temperature measurement system capable of operating in harsh environments including a temperature sensor having an antenna, diode, and dielectric layer disposed on the object of interest is provided, wherein the antenna includes a buried portion that extends through and is electrically coupled to the object of interest, and an exposed portion disposed upon an outer surface of the dielectric layer and the diode is coupled between the object of interest and the exposed portion of the antenna. The antenna is configured to receive interrogating signals from a transmitter, and to transmit response signals corresponding to the resonant frequency of the temperature sensor and its harmonics, which are indicative of the measured temperature of the object of interest. A receiver detects the response signals and correlates the frequency to a known temperature response of the dielectric material. Methods of making and using the temperature measurement system are also provided.

Owner:WIRELESS SENSOR TECH

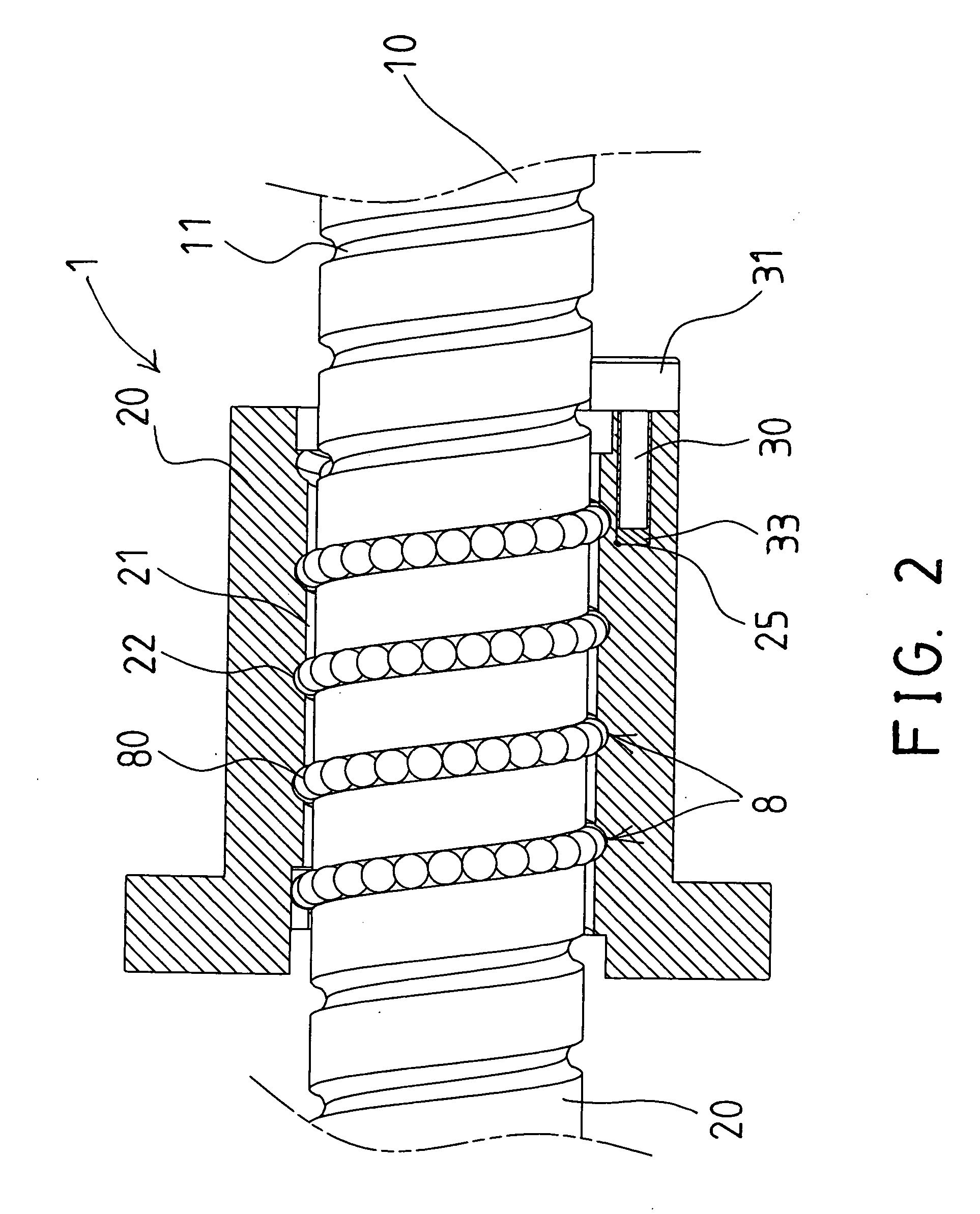

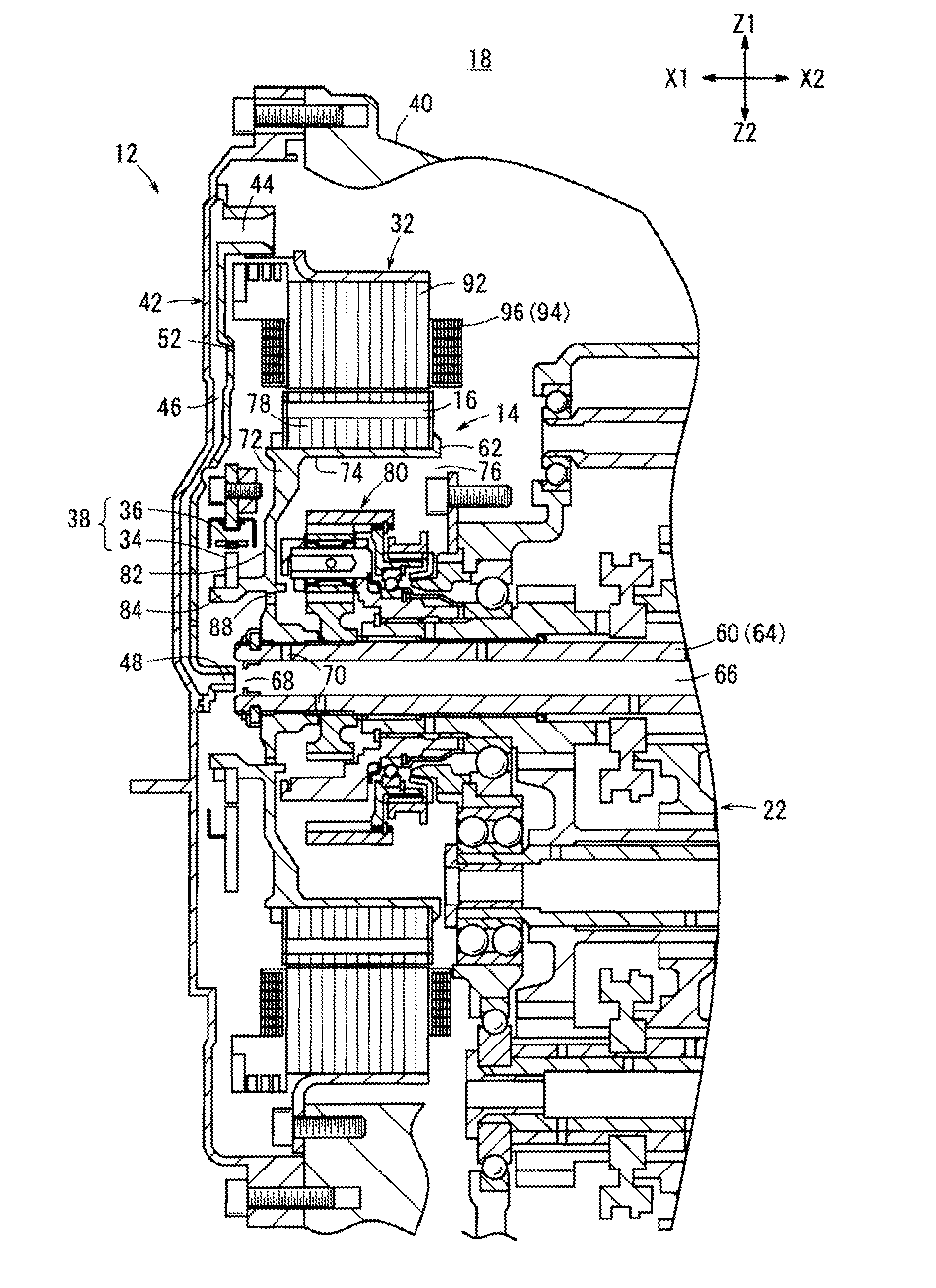

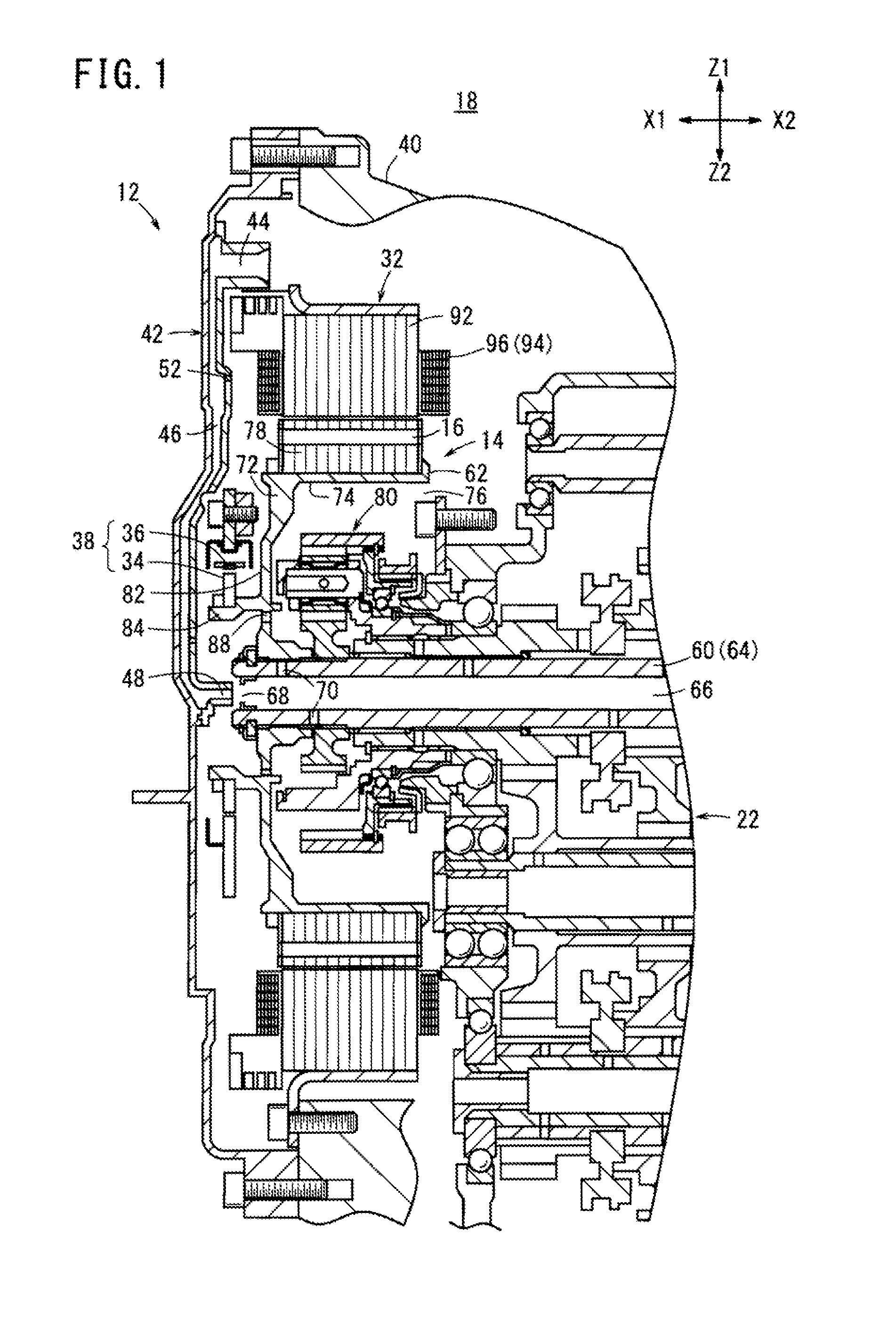

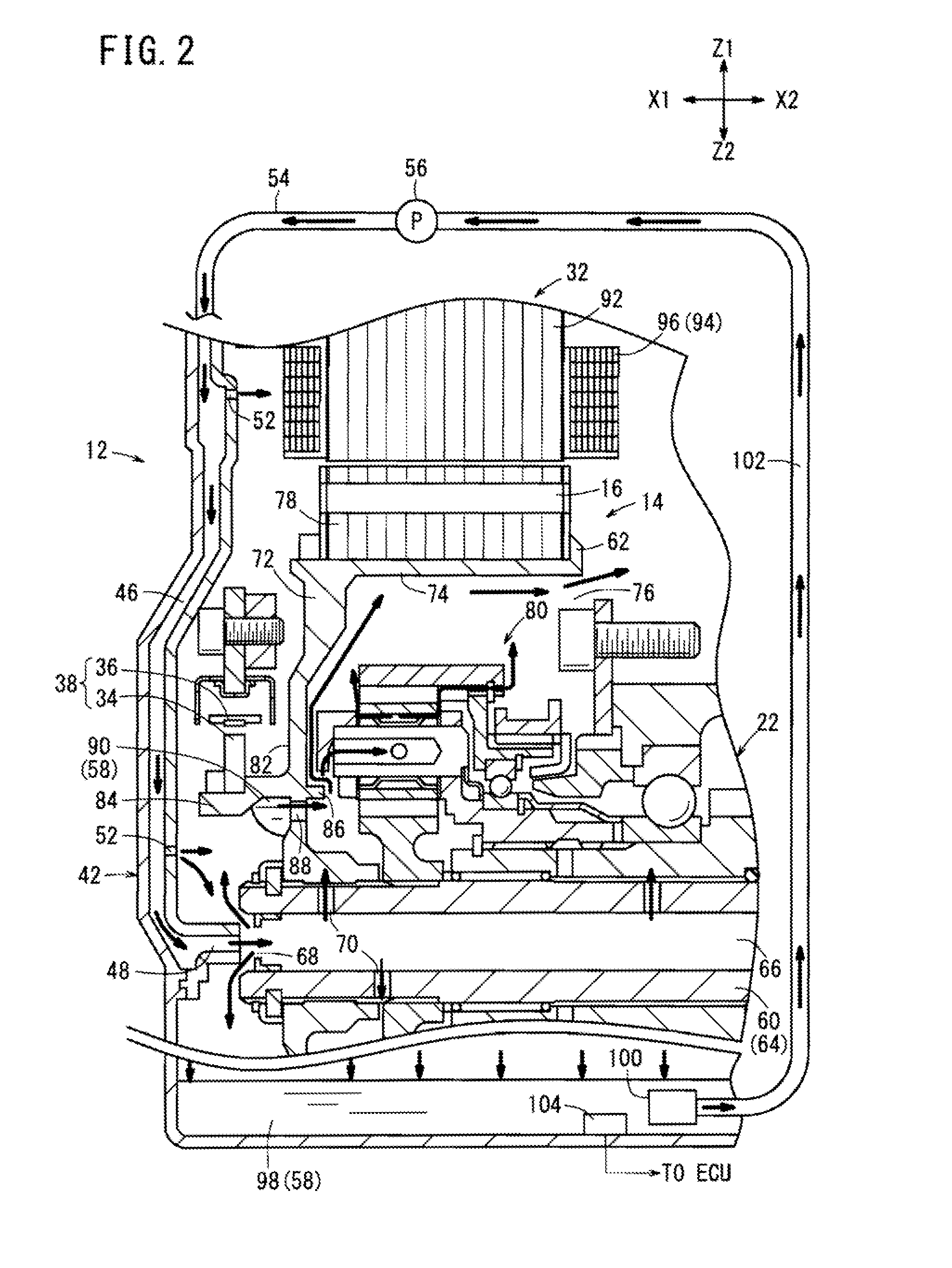

Temperature detecting device for motion guide apparatus

InactiveUS20110096808A1Avoid relative motionAvoid overall overheatingThermometer detailsThermometers using electric/magnetic elementsStopped workBall bearing

A motion guide device includes a ball nut attached onto a shaft and having helical grooves for receiving a number of ball bearing elements, and having a compartment form receiving a temperature detecting device which detects a temperature of the ball nut for preventing the ball nut from overheating, an indicating device is coupled to the temperature detecting device for generating an indicating signal when the temperature detecting device has sensed or detected that the temperature of the ball nut or the screw shaft is higher than the predetermined temperature or value, and the user may then stop working to find out what problems have been happened and thus to prevent the motion guide device from overheating.

Owner:HIWIN TECH

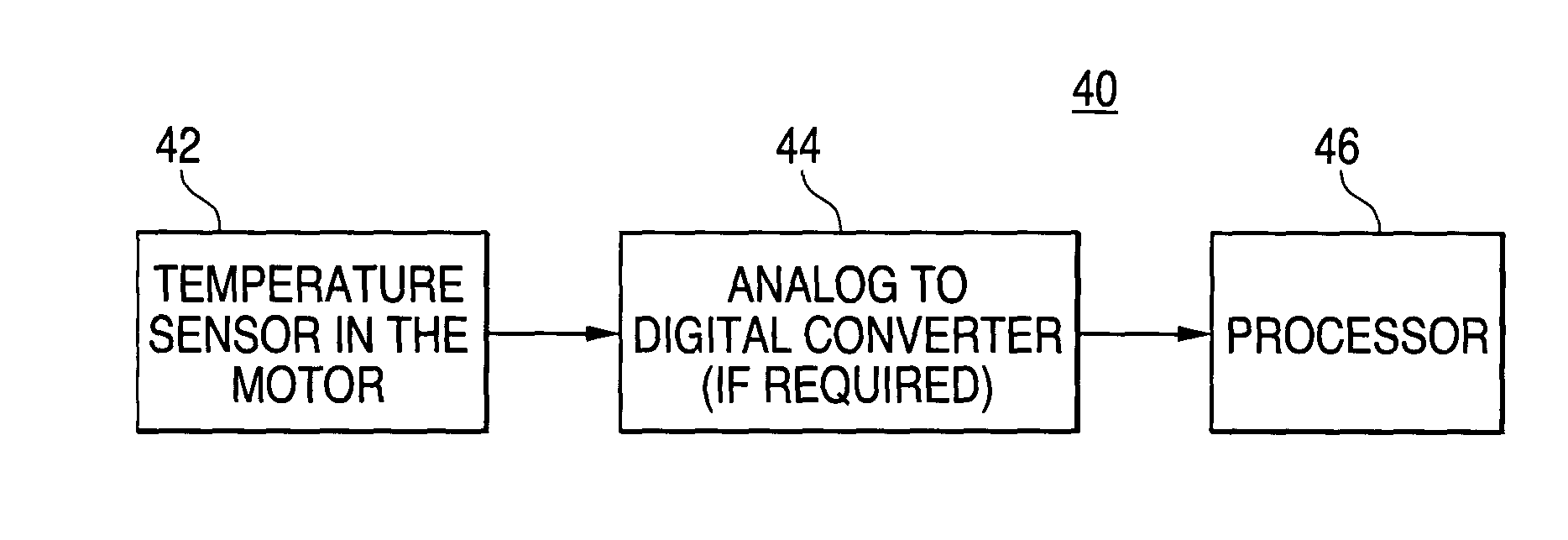

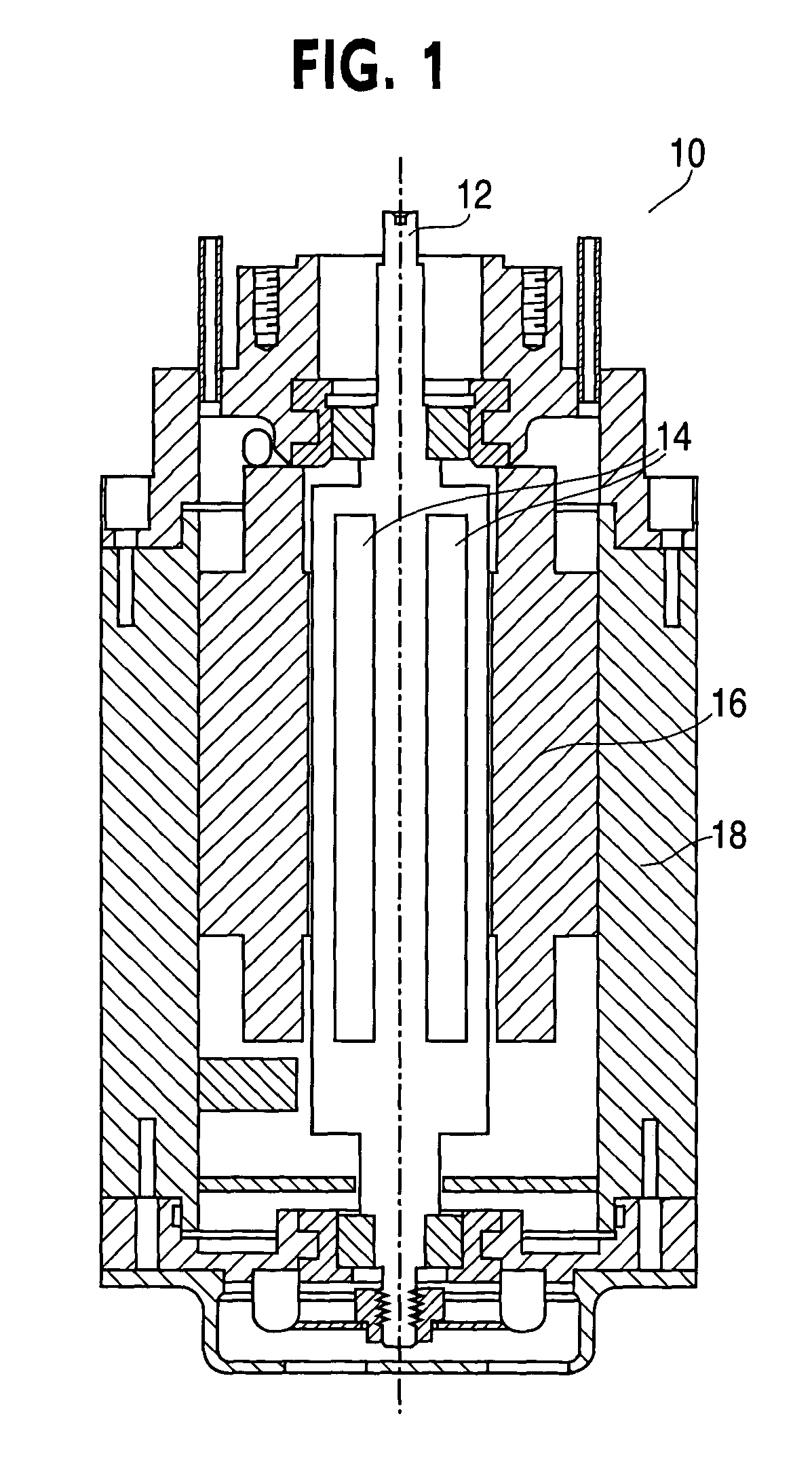

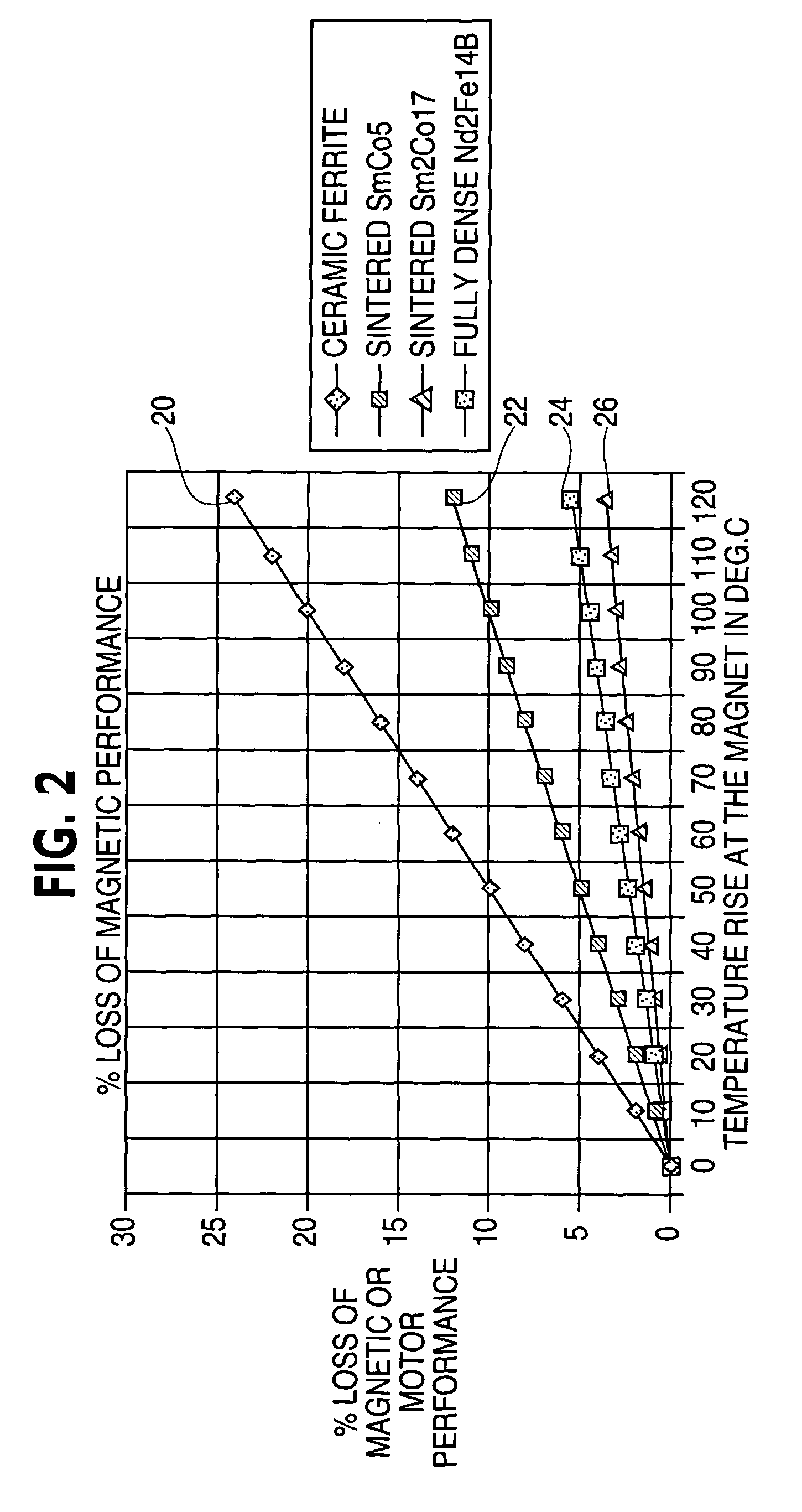

Motor temperature sensor system and method to determine motor performance

InactiveUS20050029975A1Motor/generator/converter stoppersDC motor speed/torque controlRotor magnetsControl theory

Systems and methods for sensing the temperature of the rotor magnets of an electric motor are provided to facilitate the determination of motor performance characteristics such as the torque of the rotor.

Owner:KENDRO LAB PRODS

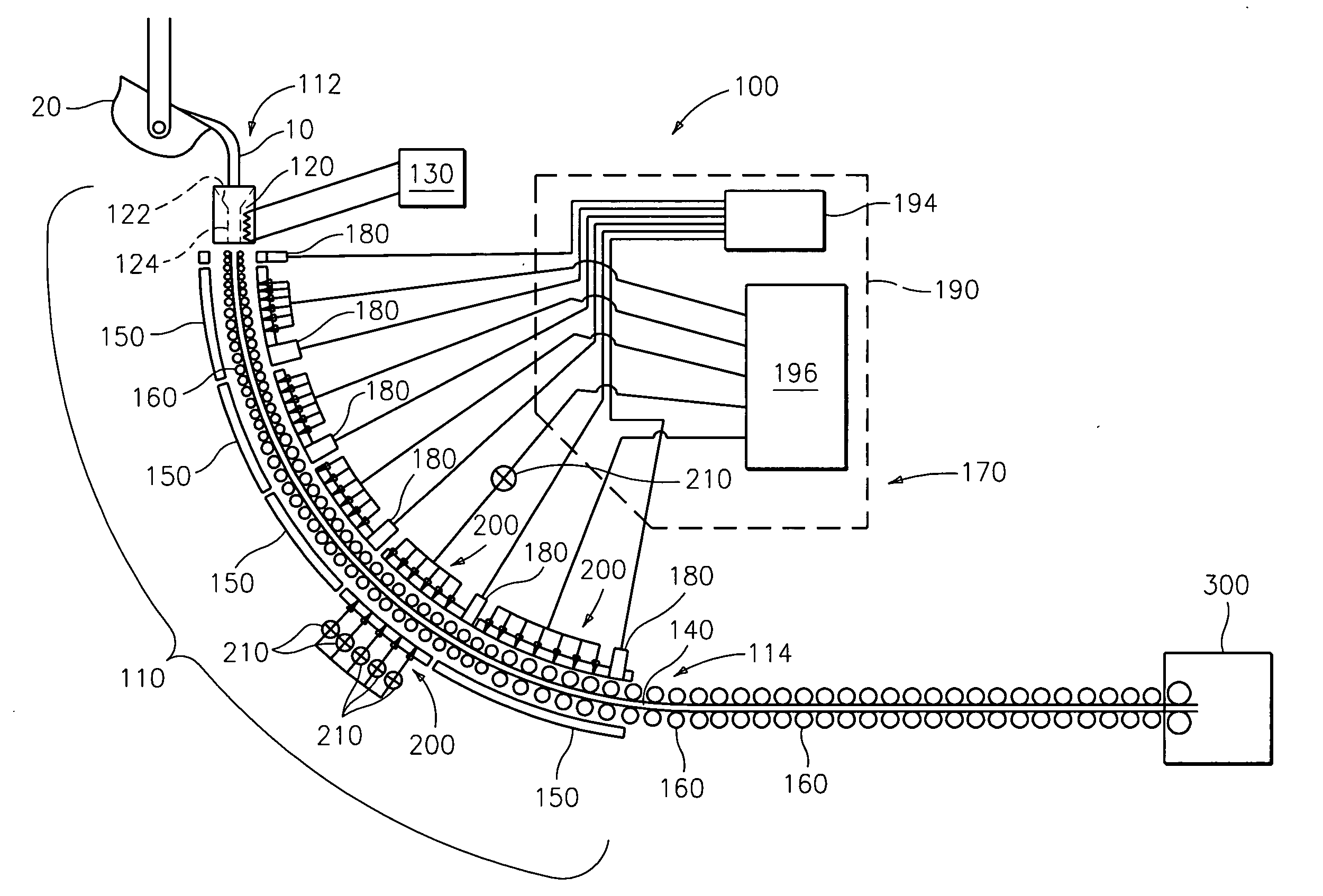

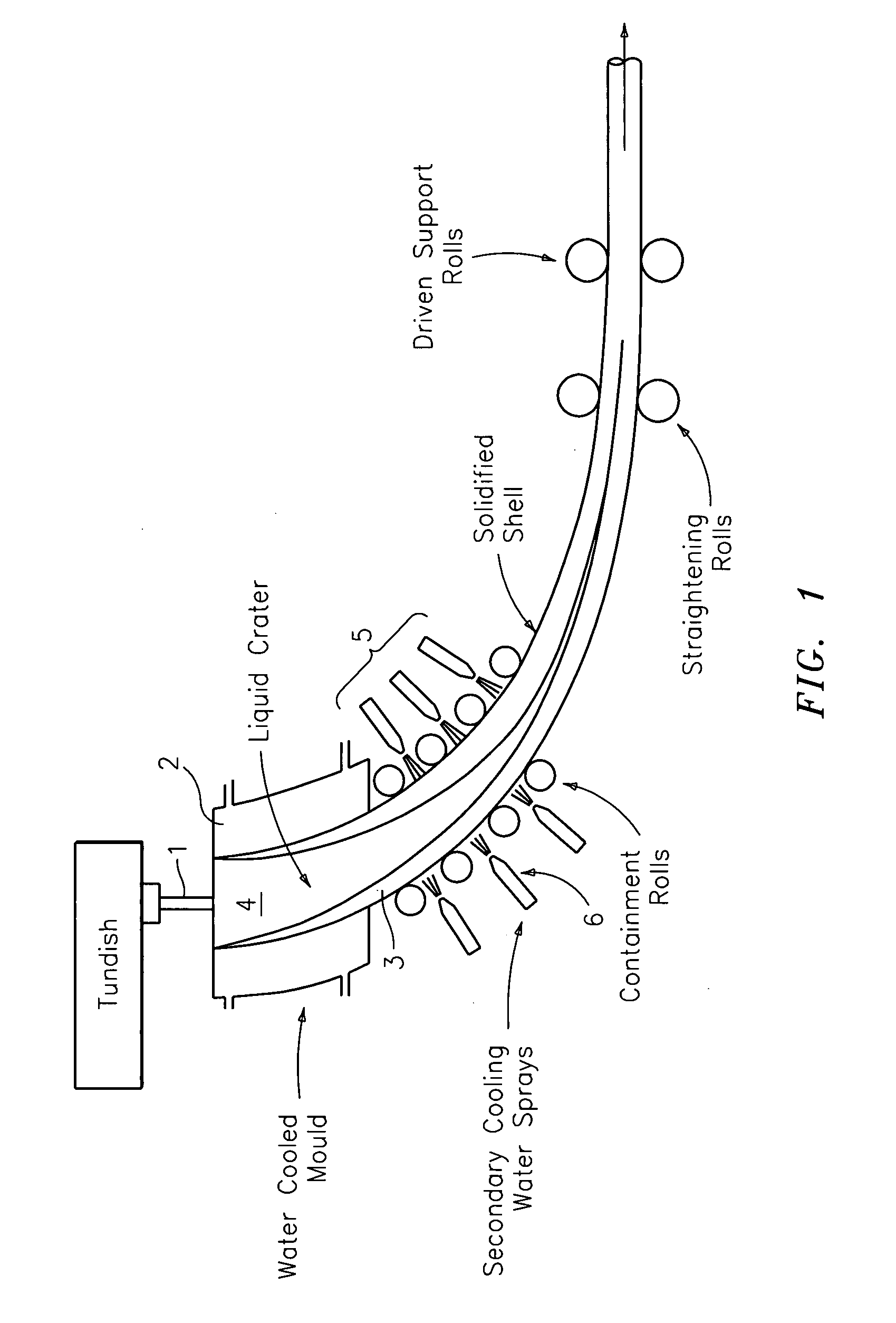

Active temperature feedback control of continuous casting

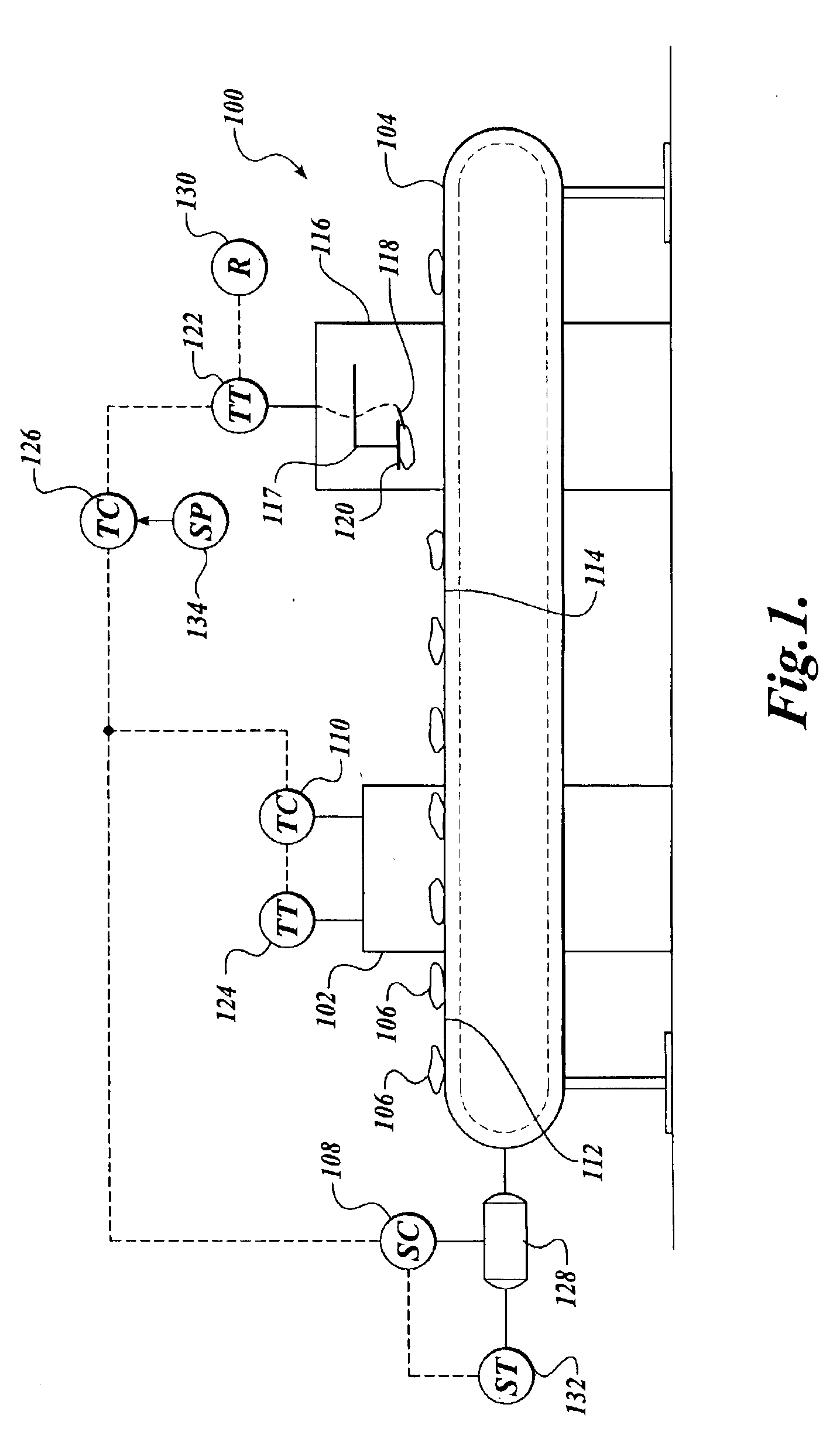

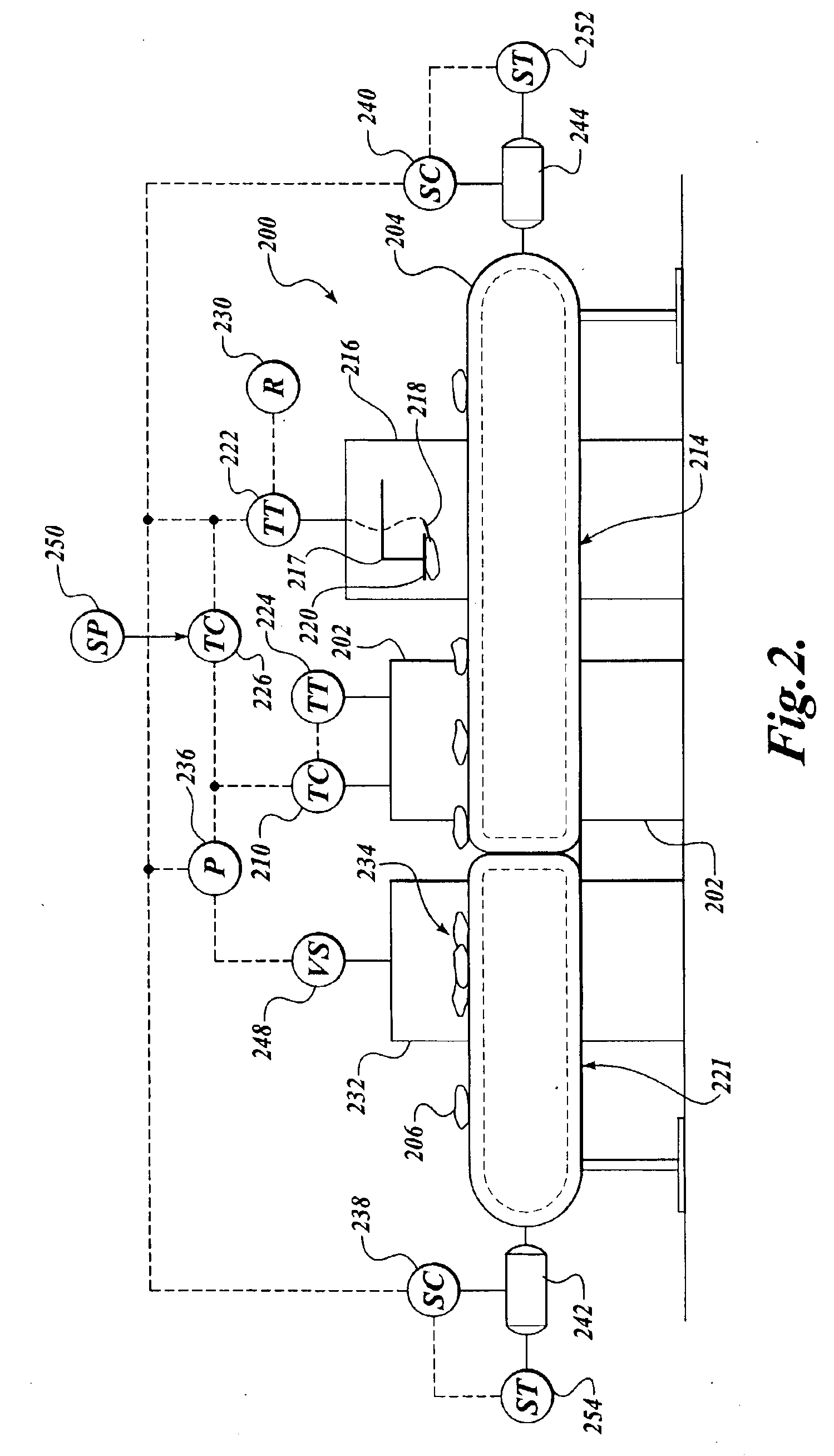

InactiveUS20070251663A1Uniform surface temperatureImprove efficiencyTemperature control using plurality of sensorsCasting safety devicesEngineeringFeedback control

The invention includes a system, method and machine readable program for dynamically controlling the casting of a material. Generally, the systems and methods described herein include an active control feedback system or aspects thereof including a temperature sensing device that is well-suited for the harsh environment of the interior of a caster such as a caster for casting metal. Temperature measurement can be accomplished either directly or indirectly. The system is configured to compare the measured temperature with an ideal casting temperature. The temperature sensing device is operably coupled to a cooling device that modulates a flow of coolant to dynamically cool the material being cast. In accordance with one embodiment of the invention, the cooling device includes a plurality of nozzles for delivering one or more cooling fluids to the material being cast.

Owner:ROSEMOUNT AEROSPACE +1

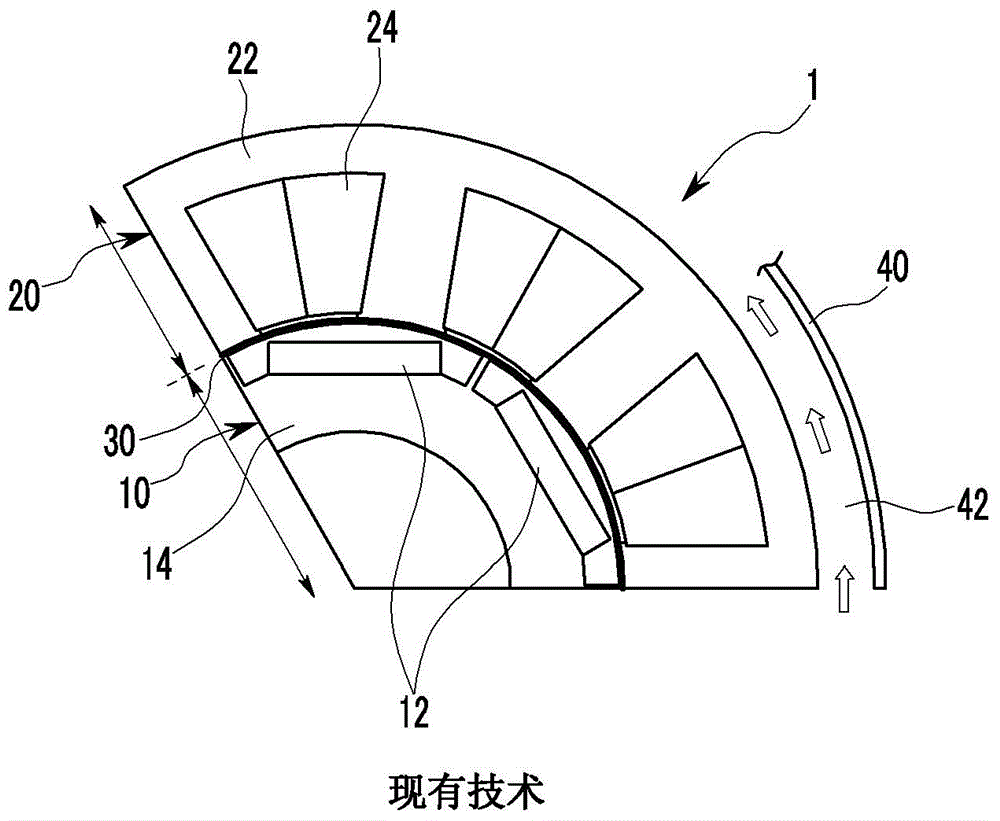

Suction roll with sensors for detecting temperature and/or pressure

InactiveCN1681993AAvoid difficultiesThermometer detailsNon-electrical signal transmission systemsEngineeringBiomedical engineering

a substantially cylindrical shell (22) having an outer surface and an internal lumen; a polymeric cover (24) circumferentially overlying the shell outer surface; and a sensing system (26). The sensing system includes: a plurality of sensors (30) embedded in the cover (24), the sensors (30) configured to sense an operating parameter of the roll (20); and a signal-carrying member (28) serially connected with and extending between the plurality of sensors (30). The signal-carrying member (28) follows a helical path over the outer surface of the shell (22), wherein the signal-carrying member (28) extends over more than one complete revolution of the shell outer surface (and, preferably, an intermediate segment of the signal-carrying member (28) extends over more than a full revolution of the roll (20) between adjacent sensors (30)).

Owner:STOWE WOODWARD

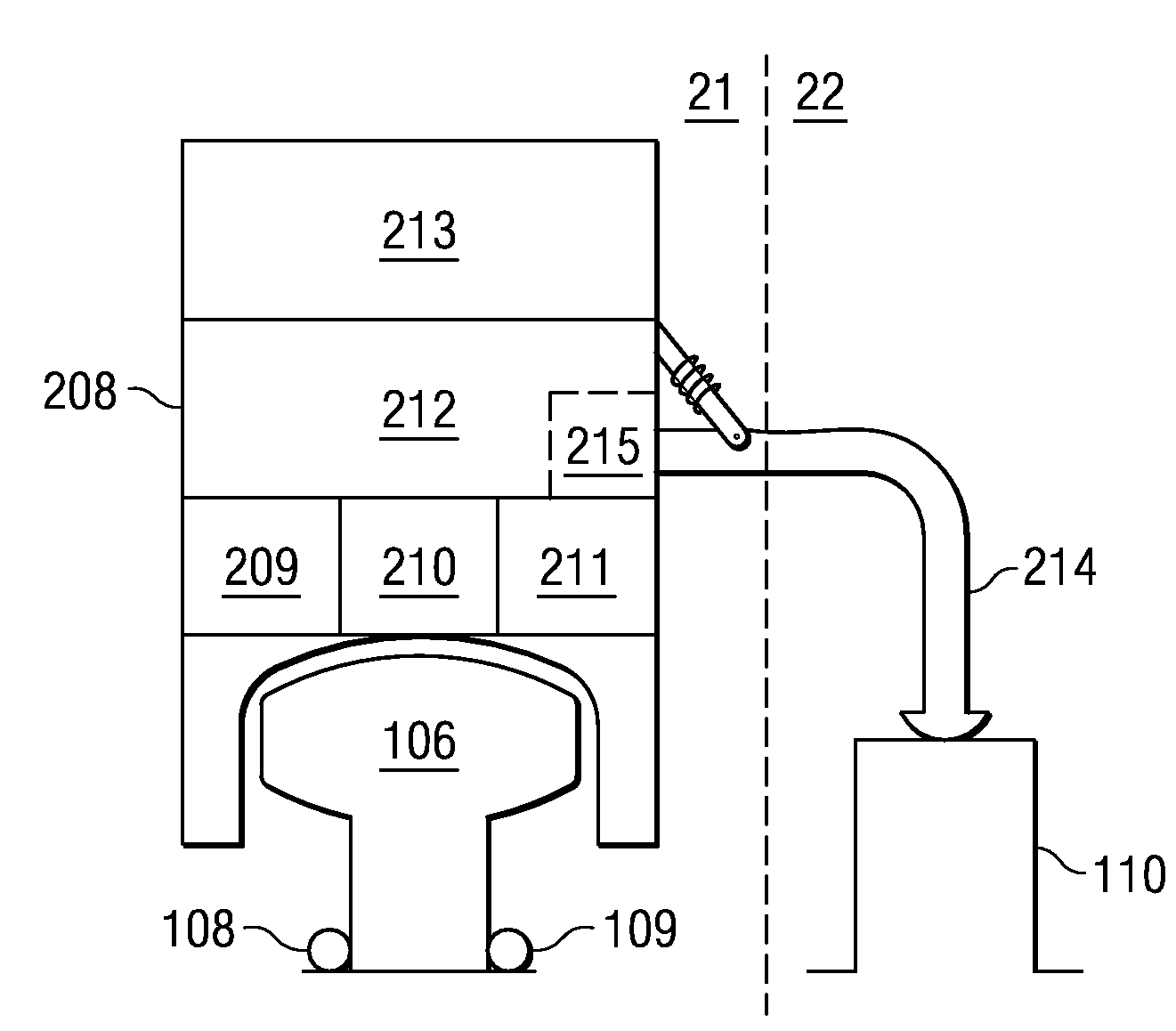

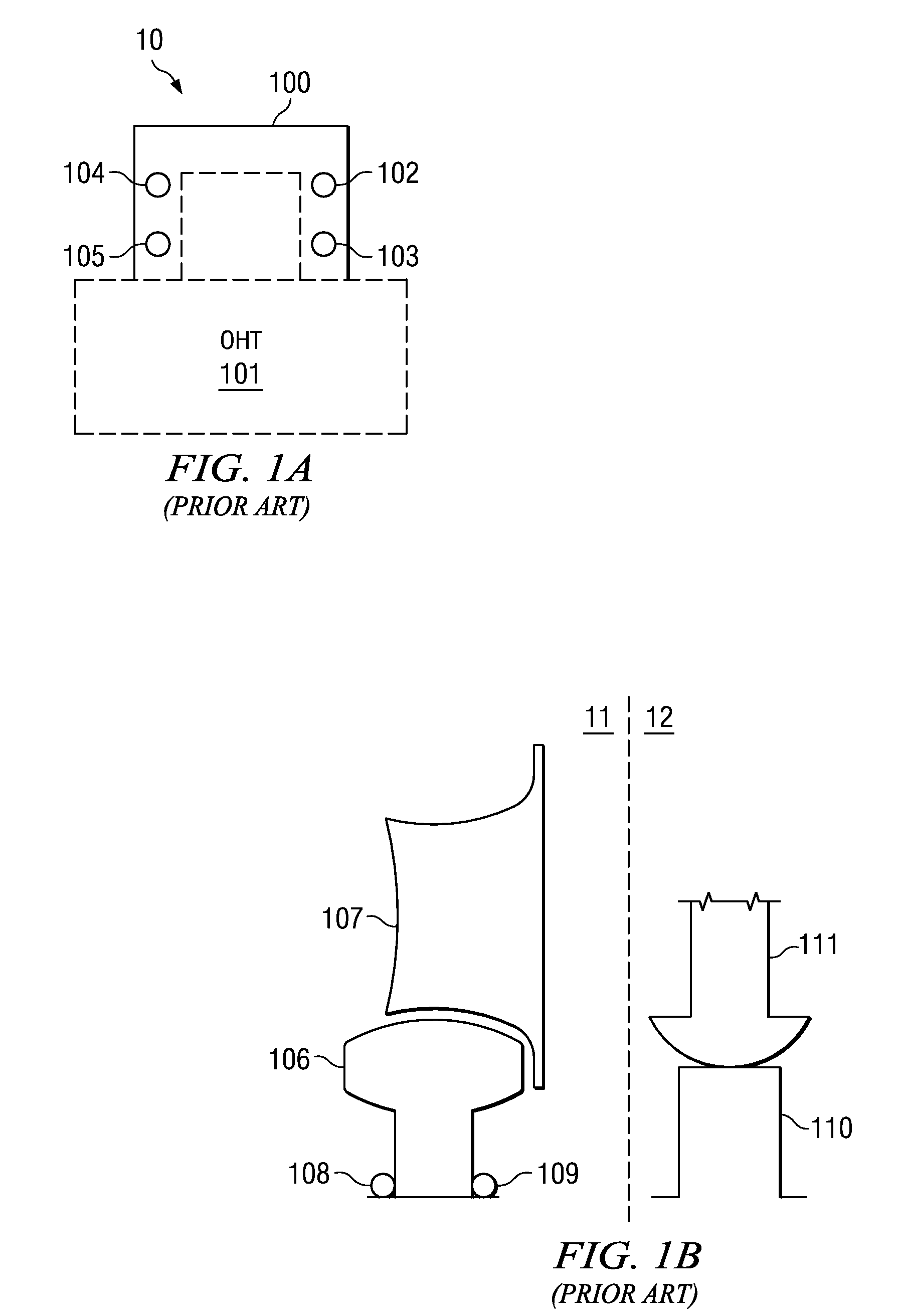

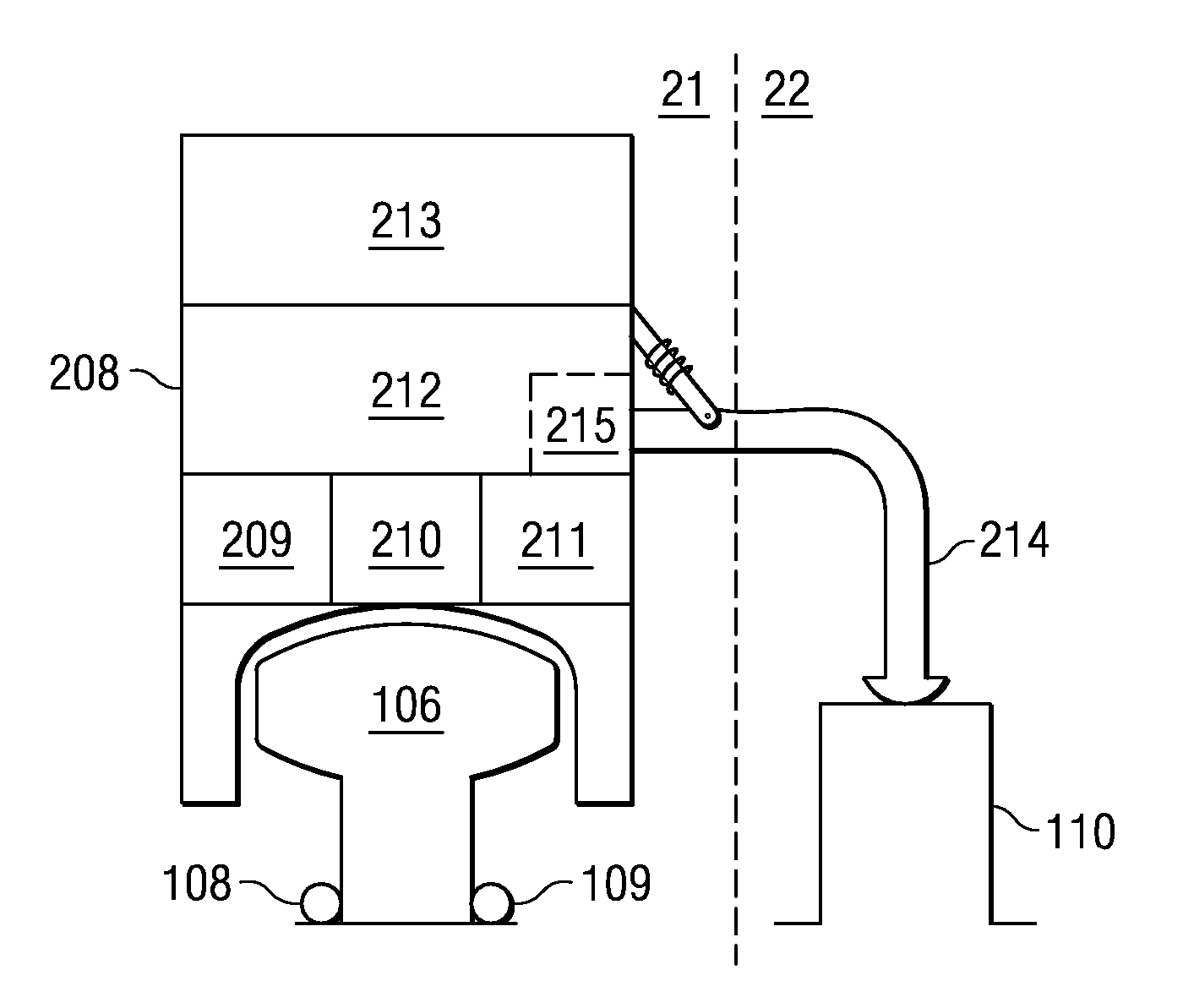

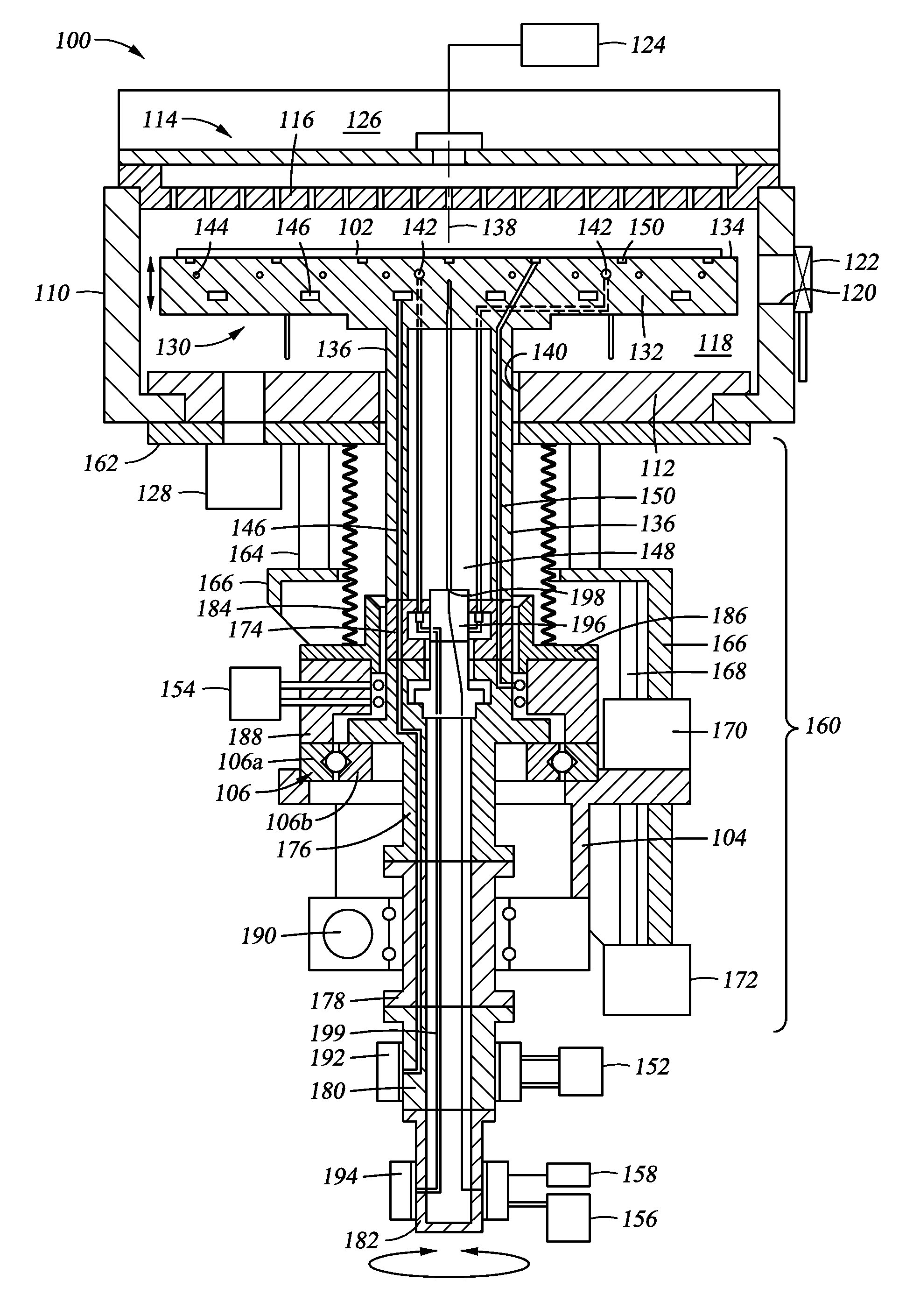

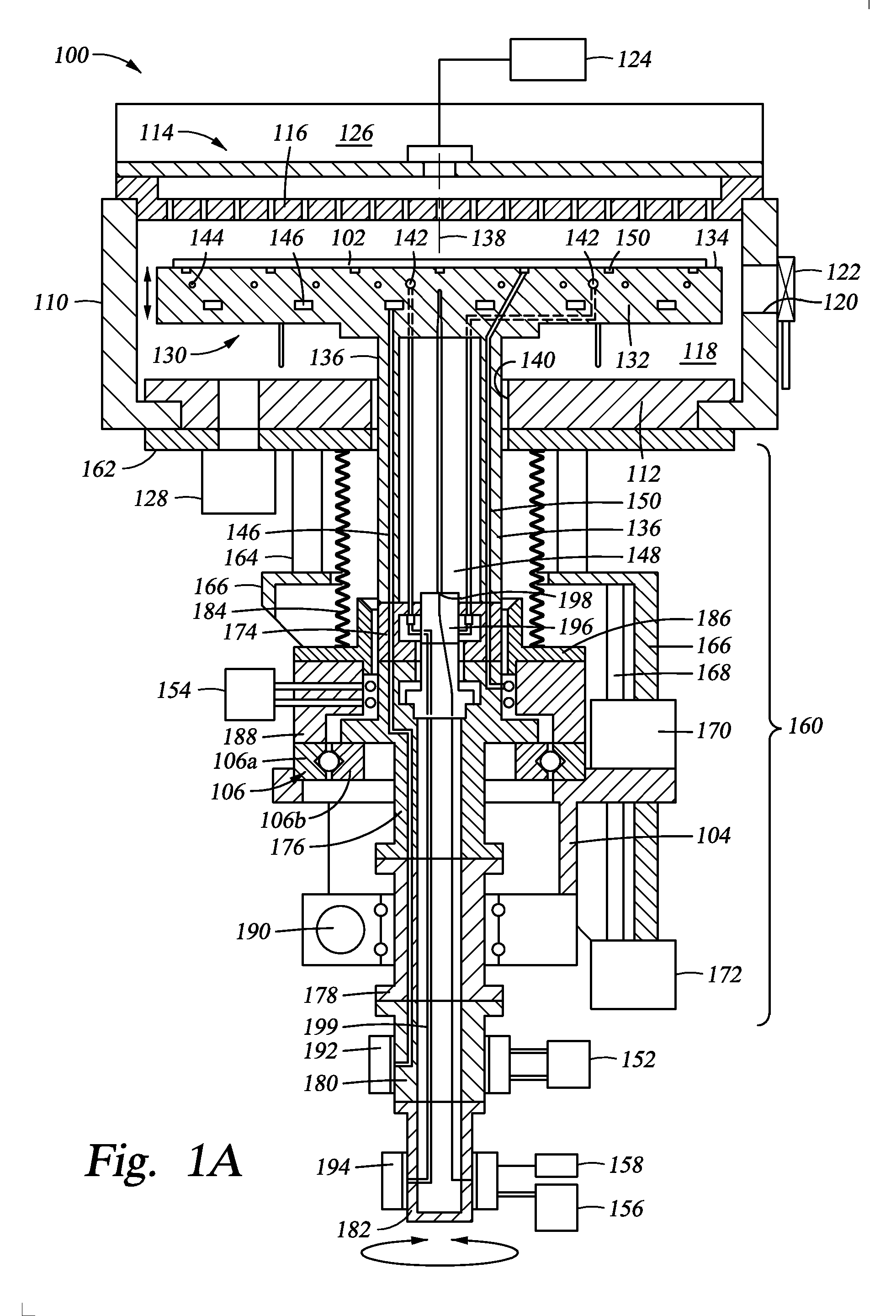

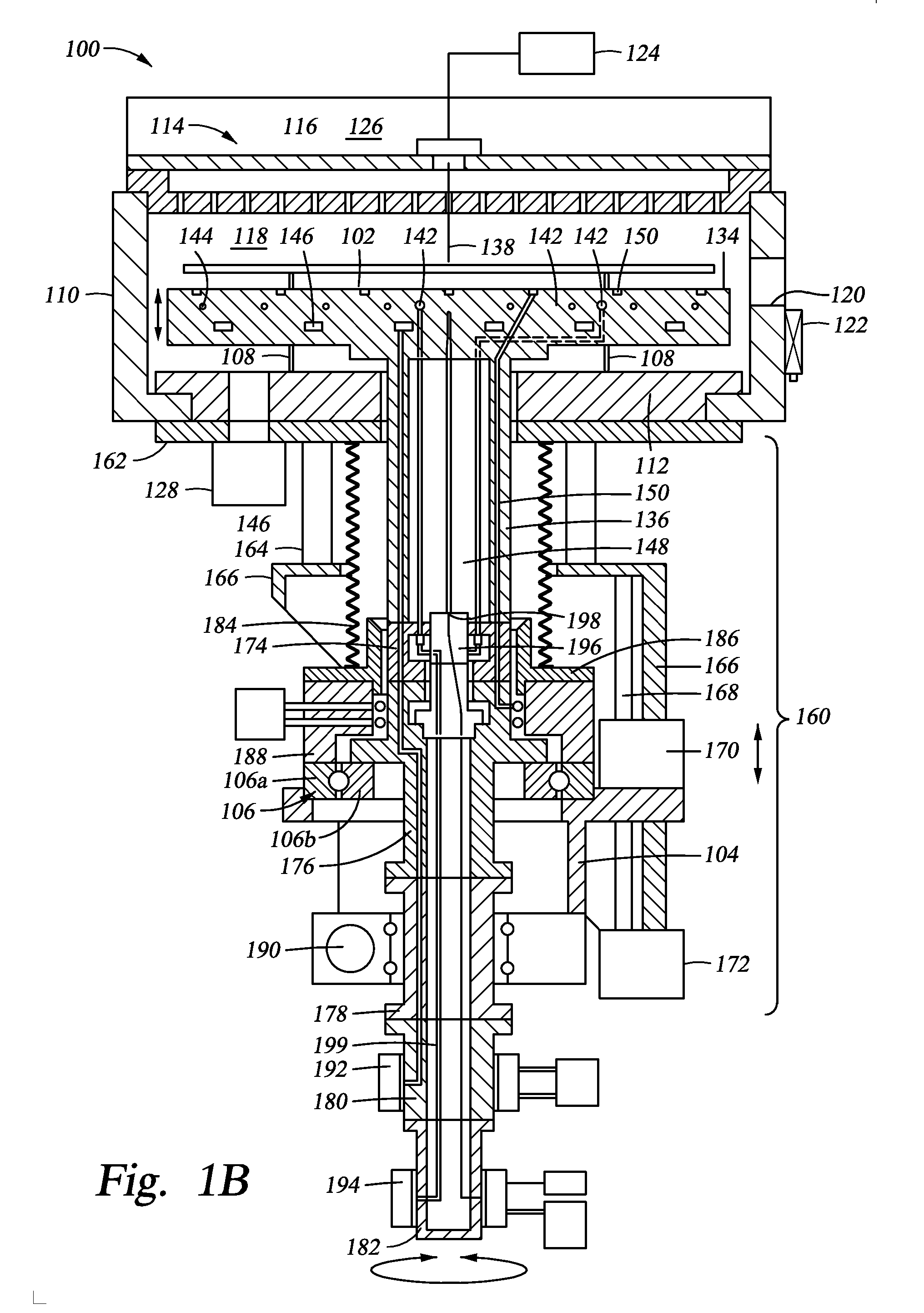

Rotation enabled multifunctional heater-chiller pedestal

InactiveUS20140263275A1Improve uniformityThermometers using electric/magnetic elementsSemiconductor/solid-state device manufacturingTemperature controlEngineering

Embodiments of the present disclosure provide apparatus and methods for improving process uniformity. Particularly, embodiments of the present disclosure provide a rotatable temperature controlled substrate support for a semiconductor processing chamber. The rotatable temperature controlled substrate support includes one or more heating elements, one or more temperature sensors and cooling channels for circulating a cooling / heating fluid in the rotatable temperature controlled substrate support. One embodiment of the present disclosure includes a thermocouple extension assembly for extending cold junctions of the thermocouple in the substrate support away from the substrate support. The thermocouple extension assembly includes extension cords formed from materials matching with the materials of thermocouple.

Owner:APPLIED MATERIALS INC

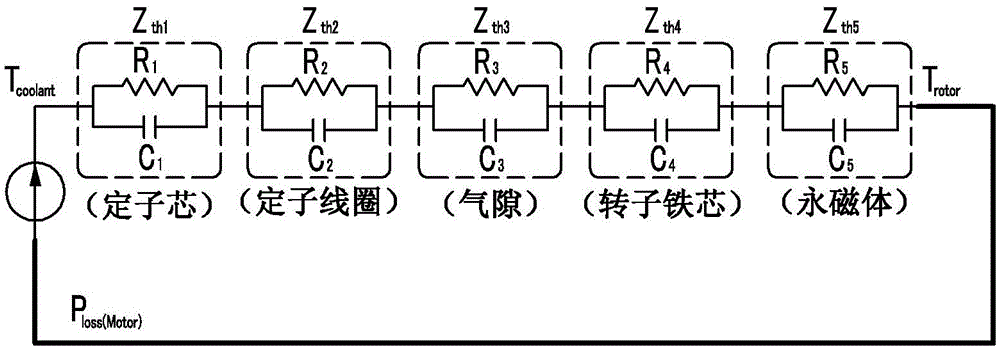

System and method for estimating temperature of rotor of motor

InactiveCN104978477AImprove performanceImprove efficiencySoftware algorithm controlTemperature measurement of moving solidsEngineeringEnergy loss

A system and method are provided for estimating temperature of a rotor of a motor configured to calculate temperature of the rotor using an actual measured data-based thermal model (thermal impedance model) and an energy loss model, and to estimate temperature of the rotor using the calculated temperature variation of the rotor. The method includes calculating, by a controller, an energy loss of the motor using driving conditions of the motor. The controller is also configured to calculate a temperature variation of the rotor in a predetermined reference temperature using the calculated energy loss and thermal resistances of the rotor and a stator of the motor. Further, the controller is configured to estimate a rotor temperature in the predetermined reference temperature using the temperature variation of the rotor.

Owner:HYUNDAI MOTOR CO LTD

Bearing with cage-mounted sensors

An antifriction bearing (A) for accommodating rotation about an axis (X) comprises an inner race (2) having a raceway (12), an outer race (4) having a raceway (22), rolling elements (6) positioned between the inner and outer races (2, 4) and contacting the raceways (12, 22) of those races (2, 4) so that when relative rotation occurs between the races (2, 4) the rolling elements (6) roll along the raceways (12, 22), a cage (8) positioned between the inner and outer races (2, 4) and having pockets (40) in which the rolling elements (6) are received with the cage (8) being rotatable between the races (2, 4) as the rolling elements (6) roll along the raceways (12, 22), the outer race (4) having a power transmitting coil (50) and a receiver (60), the cage (8) having a power receiving coil (52), a sensing unit (D) for sensing a condition of the bearing (A), and a transmitter (54) for sending a signal indicative of the sensed condition of the bearing (A) to the receiver (60).

Owner:THE TIMKEN CO

Wheel and other bearing hubs safety restraint devices, locks and visual warning indicators

InactiveUS20070215032A1Avoid harmAvoid injuryThermometer detailsRolling contact bearingsDrive wheelLocknut

Owner:MELBERG NELS +1

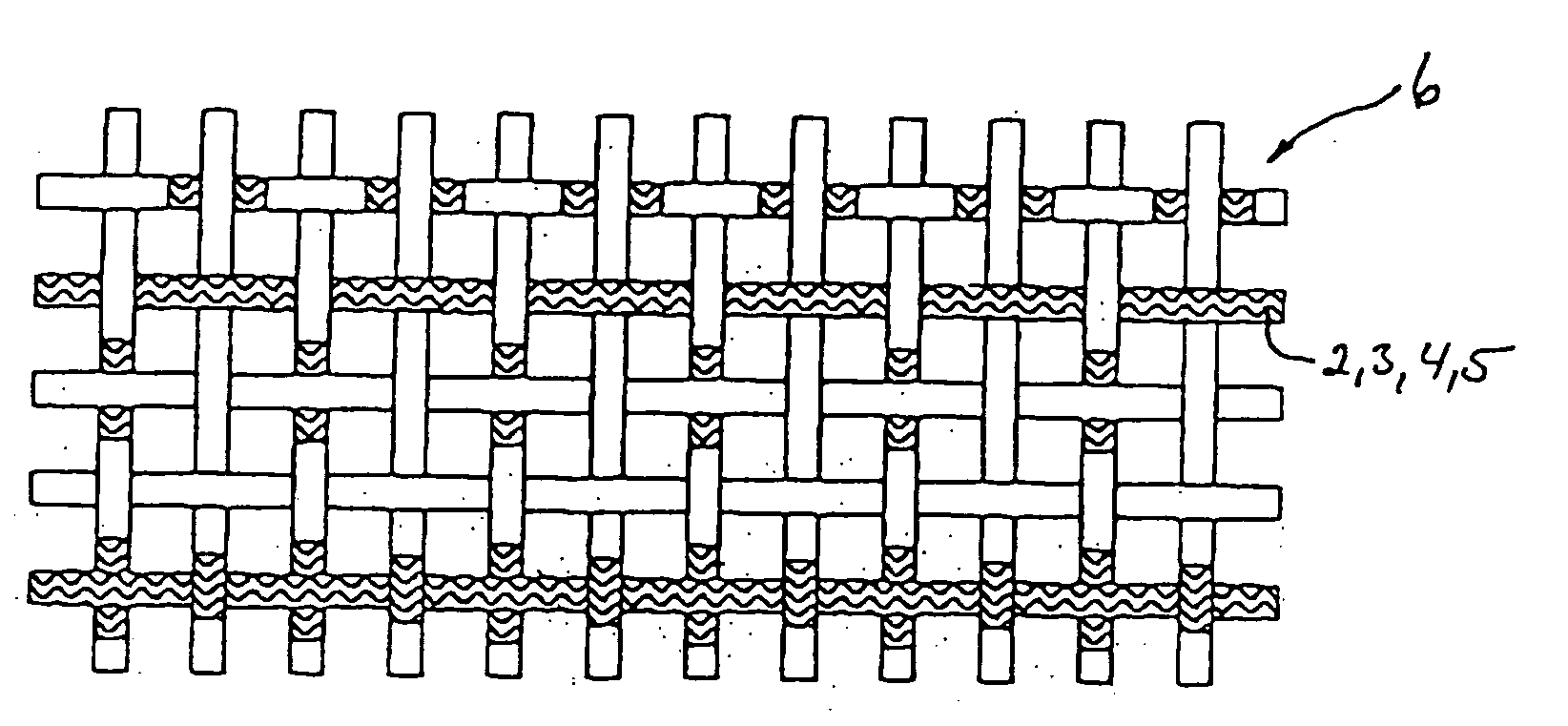

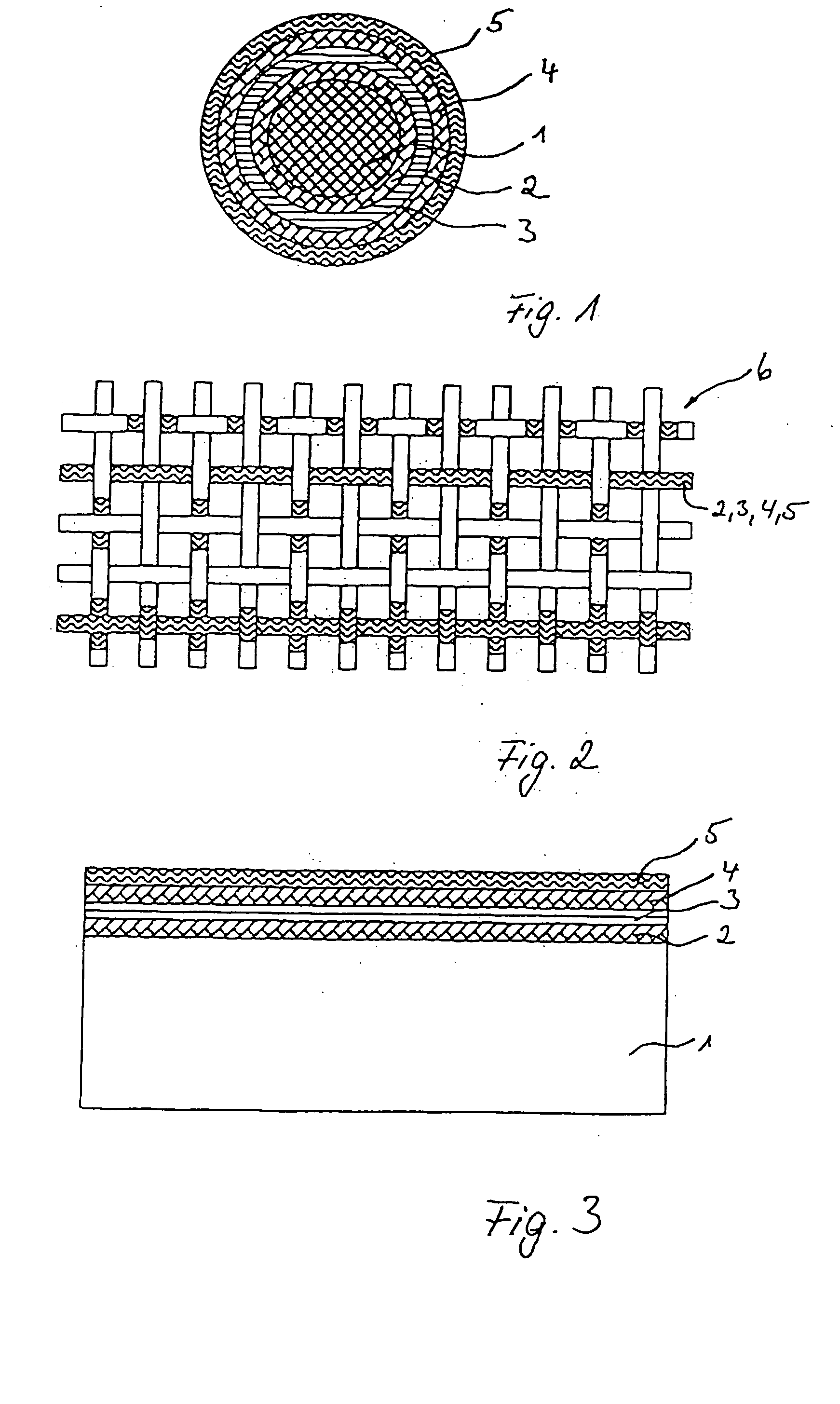

Textile product having an integrated sensor for measuring pressure and temperature

InactiveUS20050109587A1Flexible configurationReduced space required for installationControl devices for conveyorsTemperature measurement of moving solidsElectricityEngineering

The invention concerns a textile product (6) for use in a paper machine, having a monofilament or a profiled structure as support element (1) on which is arranged a layered sensor for measuring pressure and / or temperature, and is characterized in that the sensor is constituted from at least three layers (2, 3, 4), the second layer (3) having piezoelectric properties and the layers (2, 4) in contact against the second layer (3) forming electrodes that are couplable or coupled to an analysis device. The invention further concerns a method for producing such a textile product.

Owner:HEIMBACH GMBH & CO KG

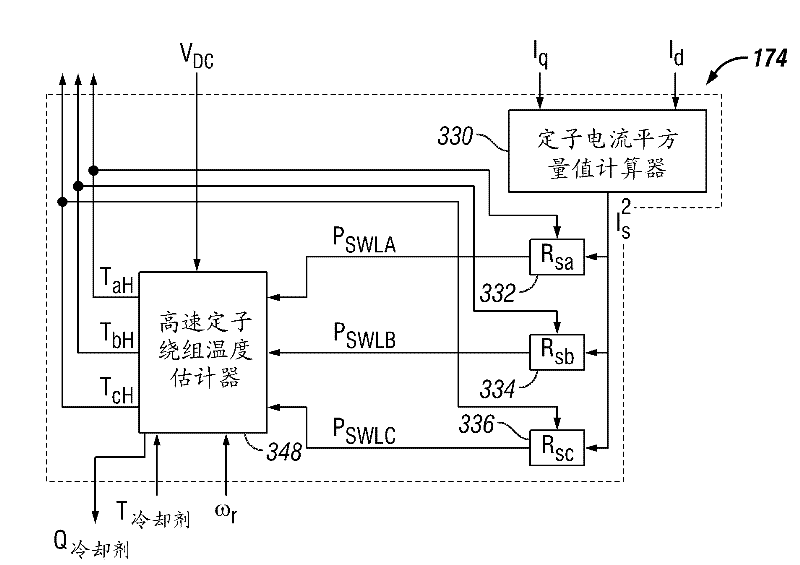

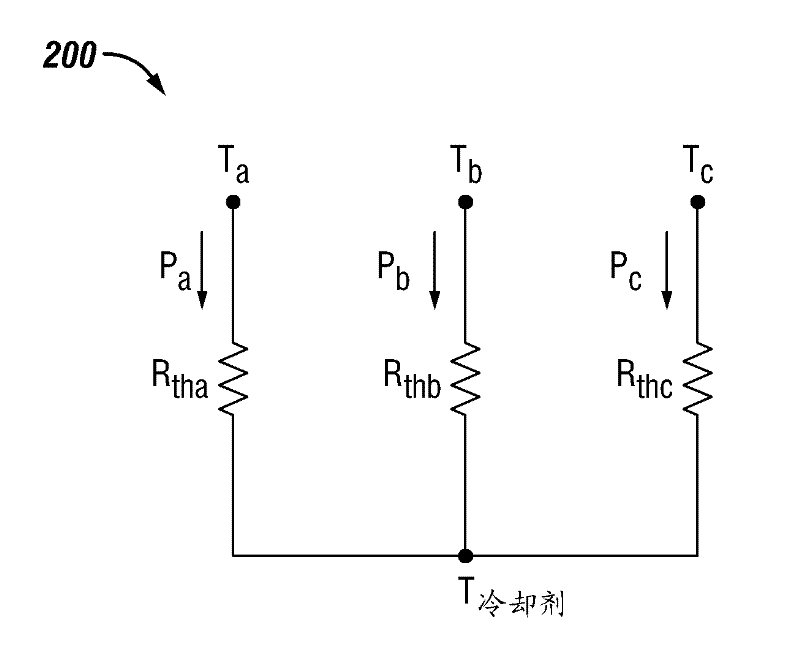

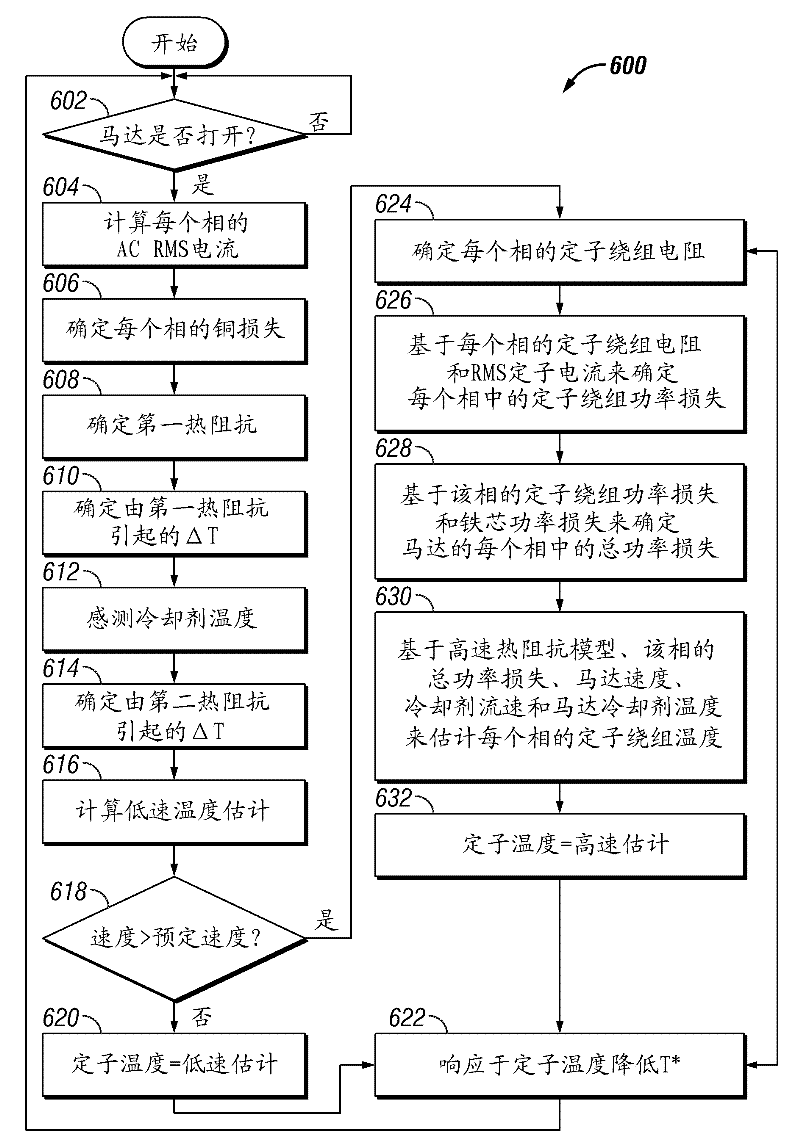

Electric motor stator winding temperature estimation systems and methods

InactiveCN102255435AElectric motor controlThermometers using electric/magnetic elementsMotor speedControl signal

Owner:GM GLOBAL TECH OPERATIONS LLC

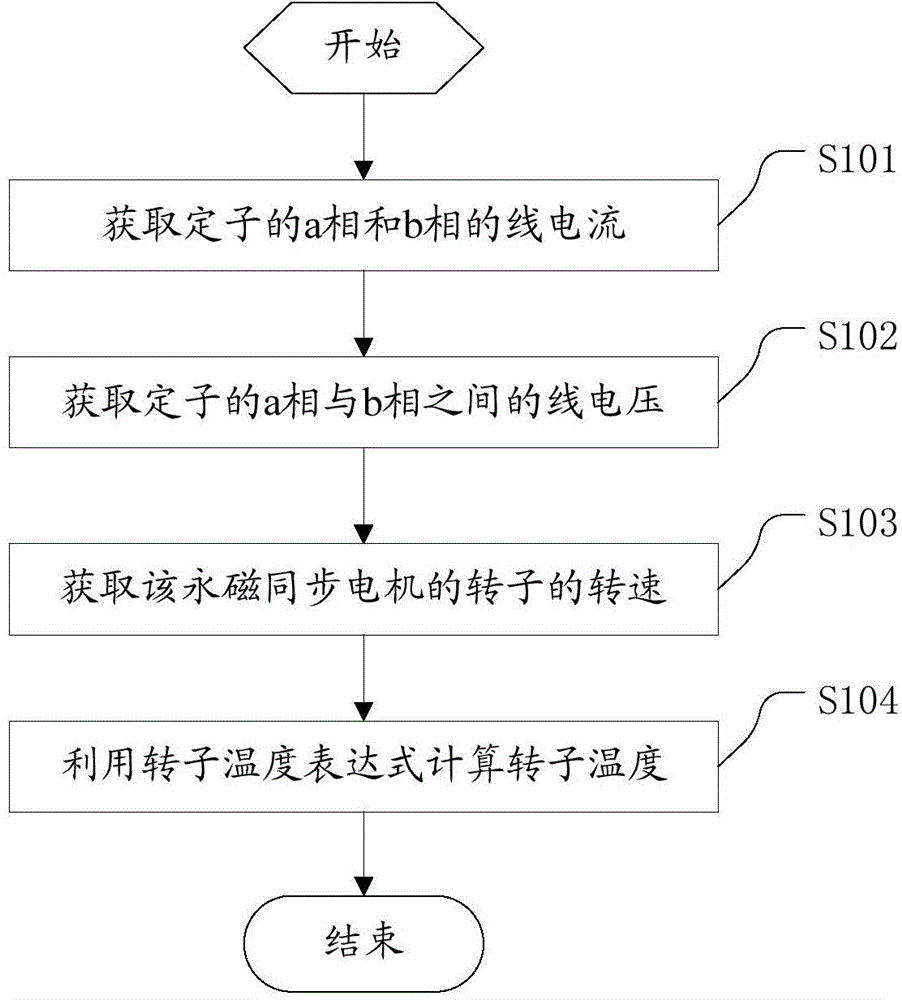

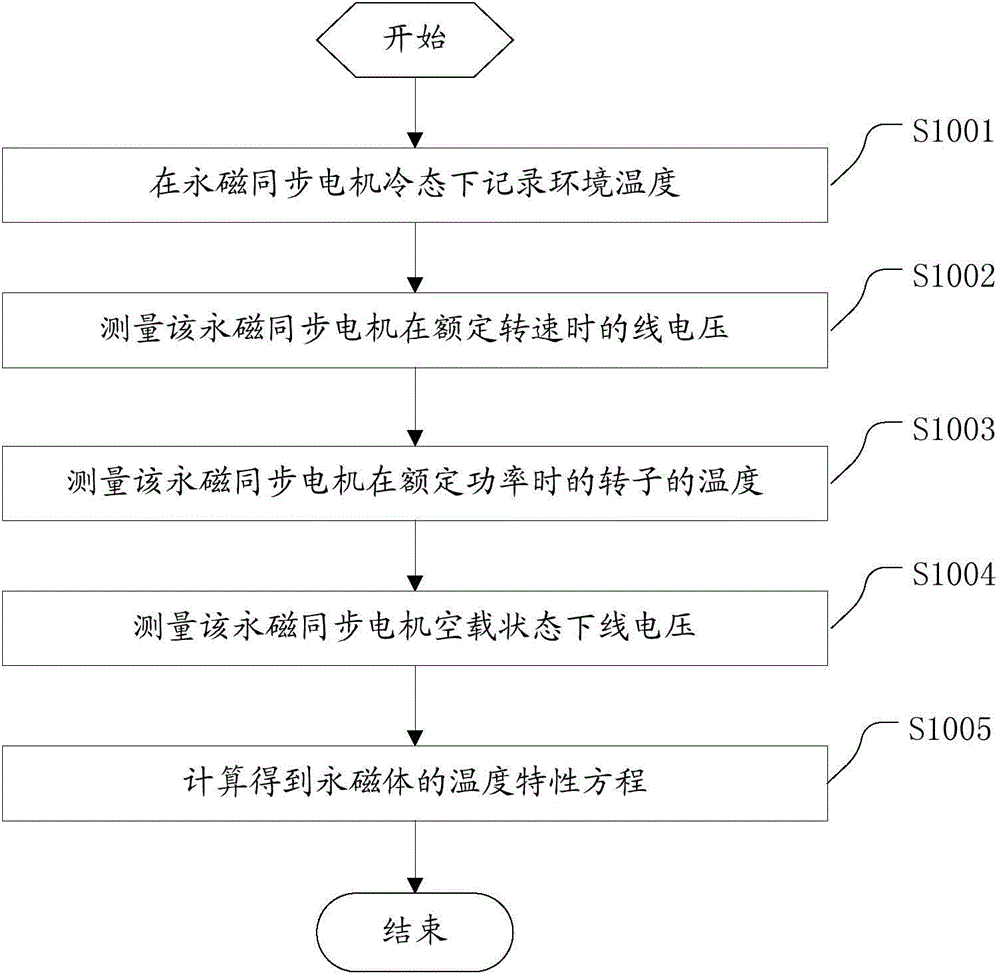

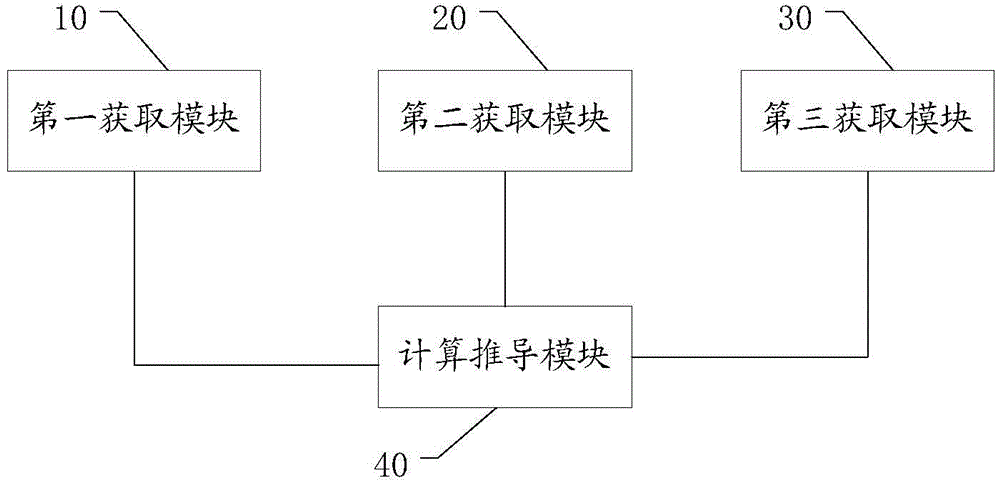

Rotor temperature monitoring method for permanent magnet synchronous motor and system therefor

ActiveCN104158463AImprove reliabilityGet the temperature in timeElectric motor controlVector control systemsPermanent magnet synchronous motorTemperature monitoring

The application discloses a rotor temperature monitoring method for a permanent magnet synchronous motor and a system therefor. The rotor temperature monitoring method includes the following steps: an a-phase line current and a b-phase line current of a permanent magnet synchronous motor stator are firstly obtained as a first line current and a second line current, and meanwhile a line voltage between the a phase and the b phase of the stator is obtained; the first line current, the second line current, the line voltage, the inductance parameter of the permanent magnet synchronous motor and the temperature characteristic equation of the permanent magnet of the rotor are put into a preset rotor permanent magnet temperature expression to calculate and obtain a rotor temperature. The rotor temperature monitoring method and the system therefor do not need to embed a temperature sensor in the rotor to monitor the temperature of the rotor permanent magnet, thereby avoiding the problem of low system reliability due to the configuration of the temperature sensor to monitor the temperature of the rotor permanent magnet.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

Method of estimating magnet temperature for rotary electric machinery

ActiveUS20140126606A1Improve estimation accuracyAccurate calculationThermometers using electric/magnetic elementsElectric machinesElectric machineryCalculator

In a magnet temperature estimating method, in the event that a rotor of a rotary electric machine is cooled by a cooling oil, a magnet temperature calculator estimates the magnet temperature of magnets provided on the rotor, based on losses of the rotary electric machine including a loss of the rotor and the temperature of the cooling oil.

Owner:HONDA MOTOR CO LTD

Connector for a flexible circuit board

InactiveUS20030060072A1Protection from damageEngagement/disengagement of coupling partsRimsFlexible circuitsEngineering

A connector (1) for a flexible circuit board (30) has a housing (2), a pressing means (12), and parallel contacts (6) each having a conductive arm (8) and arranged at a pitch to form a row in the recess (3) of the housing. The pressing means (12) can be swung to close the recess so that an inner end portion of the flexible board (30) overlying the conductive arms (8) will be pressed down onto these arms. Reinforcement metals (20) face one another over the row of the contacts (6) and are attached to opposite sides (5) of the housing (2), so as to be soldered to a rigid printed circuit board. Each reinforcement metal (20) has a resilient support (25) for urging upwards the flexible board (30) in a direction away from the conductive arms (8) so as to keep the board in place.

Owner:JST MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com