Rotor temperature monitoring method for permanent magnet synchronous motor and system therefor

A permanent magnet synchronous motor, rotor temperature technology, applied in the temperature measurement of moving solids, synchronous machines, thermometers with directly sensitive electrical/magnetic components, etc., can solve problems such as low system reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

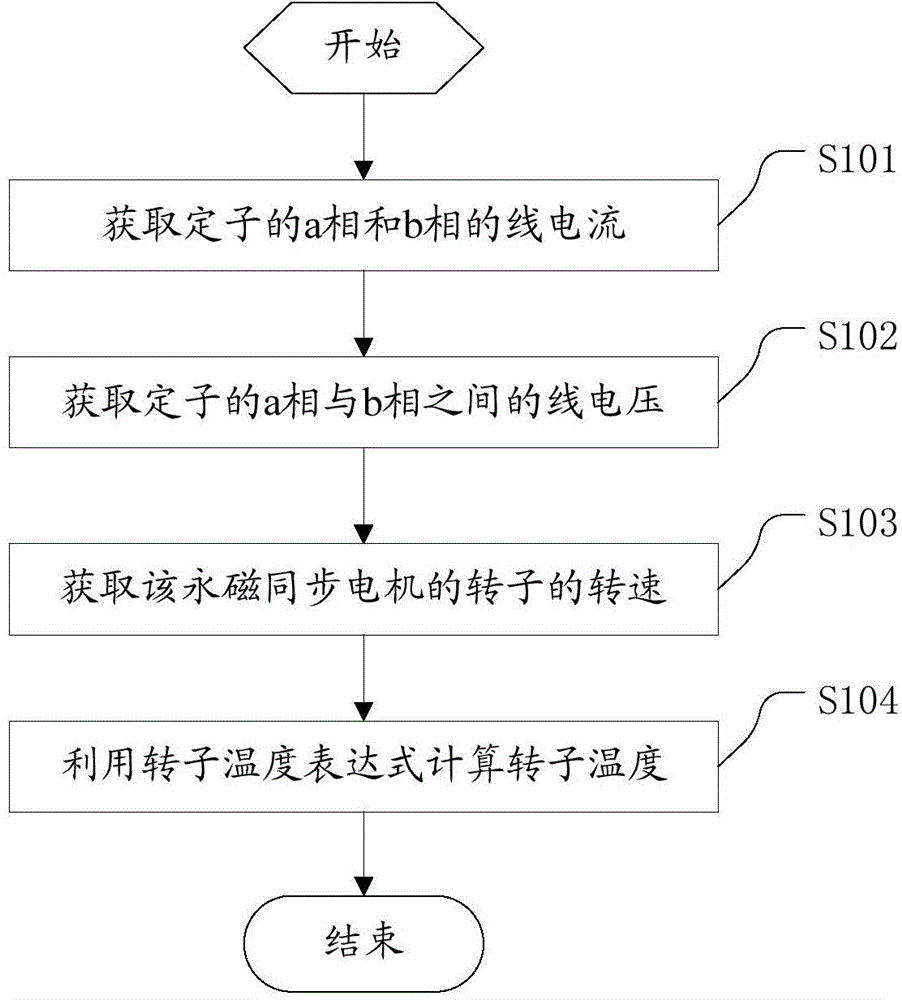

[0061] figure 1 It is a flow chart of a rotor temperature monitoring method for a permanent magnet synchronous motor provided in an embodiment of the present application.

[0062] Firstly, the steady-state mathematical model of permanent magnet synchronous motor is established:

[0063] Current coordinate transformation formula

[0064] i α i β = 1 0 1 / 3 2 / 3 i a ...

Embodiment 2

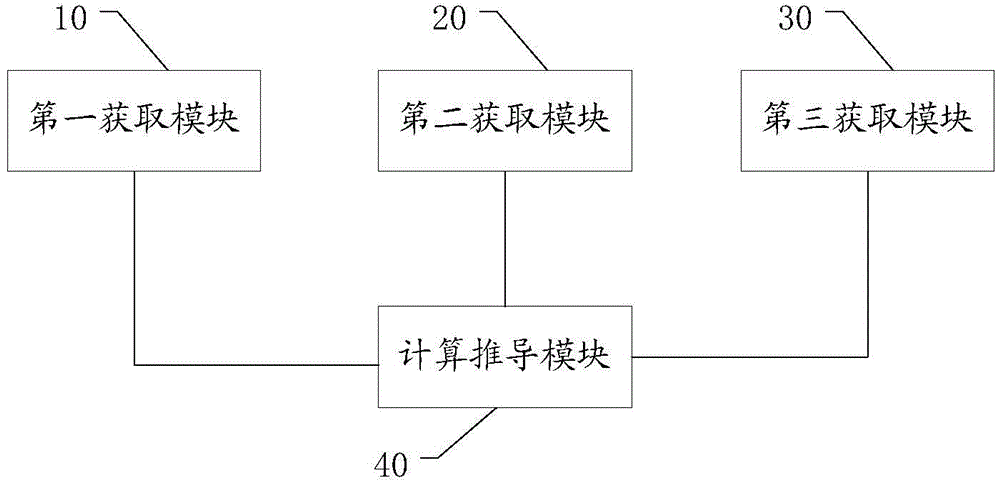

[0123] image 3 A structural diagram of a rotor temperature monitoring system for a permanent magnet synchronous motor provided in another embodiment of the present application.

[0124] like image 3 As shown, the permanent magnet synchronous motor provided in this embodiment includes a first acquisition module 10 , a second acquisition module 20 , a third acquisition module 30 and a calculation and derivation module 40 .

[0125] The first obtaining module 10 is used to obtain the line currents of phase a and phase b of the stator.

[0126] First, the line current of phase a of the stator of the permanent magnet synchronous motor is obtained, and the line current is used as the first line current; the line current of phase b of the stator is obtained, and it is used as the second line current.

[0127] The second obtaining module 20 is used to obtain the line voltage between phase a and phase b of the stator.

[0128] The third obtaining module 30 is used for obtaining th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com