Method and system for testing reliability of electric spindle in machining center

A machining center and test system technology, applied in the direction of using electric devices, electromagnetic means, measuring devices, etc., can solve the problems of not well reflecting the living environment of the electric spindle, complex environmental stress, etc., achieving easy implementation and short construction time. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

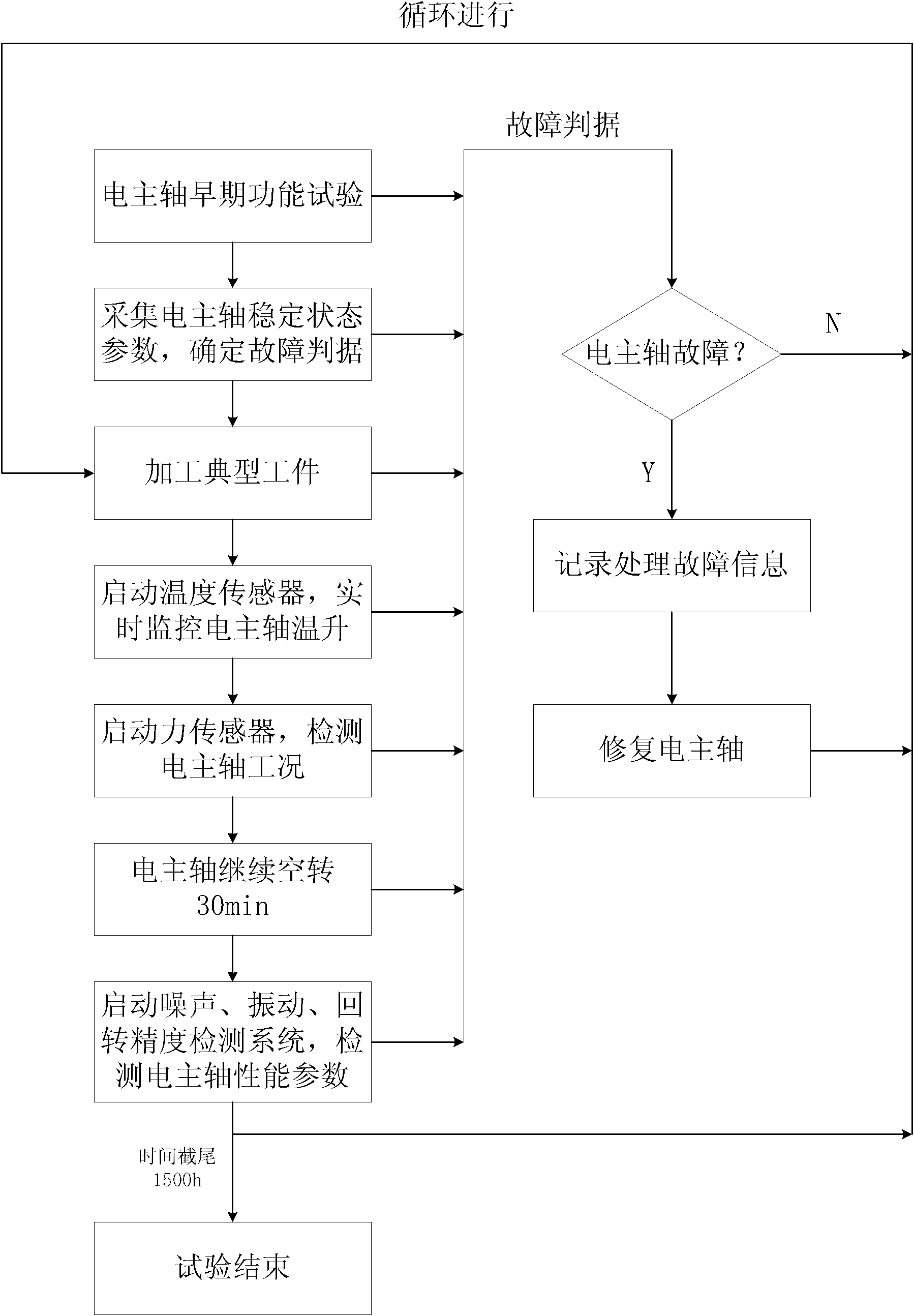

[0039] A method for testing the reliability of an electric spindle of a machining center according to the present invention, the steps of which are as follows:

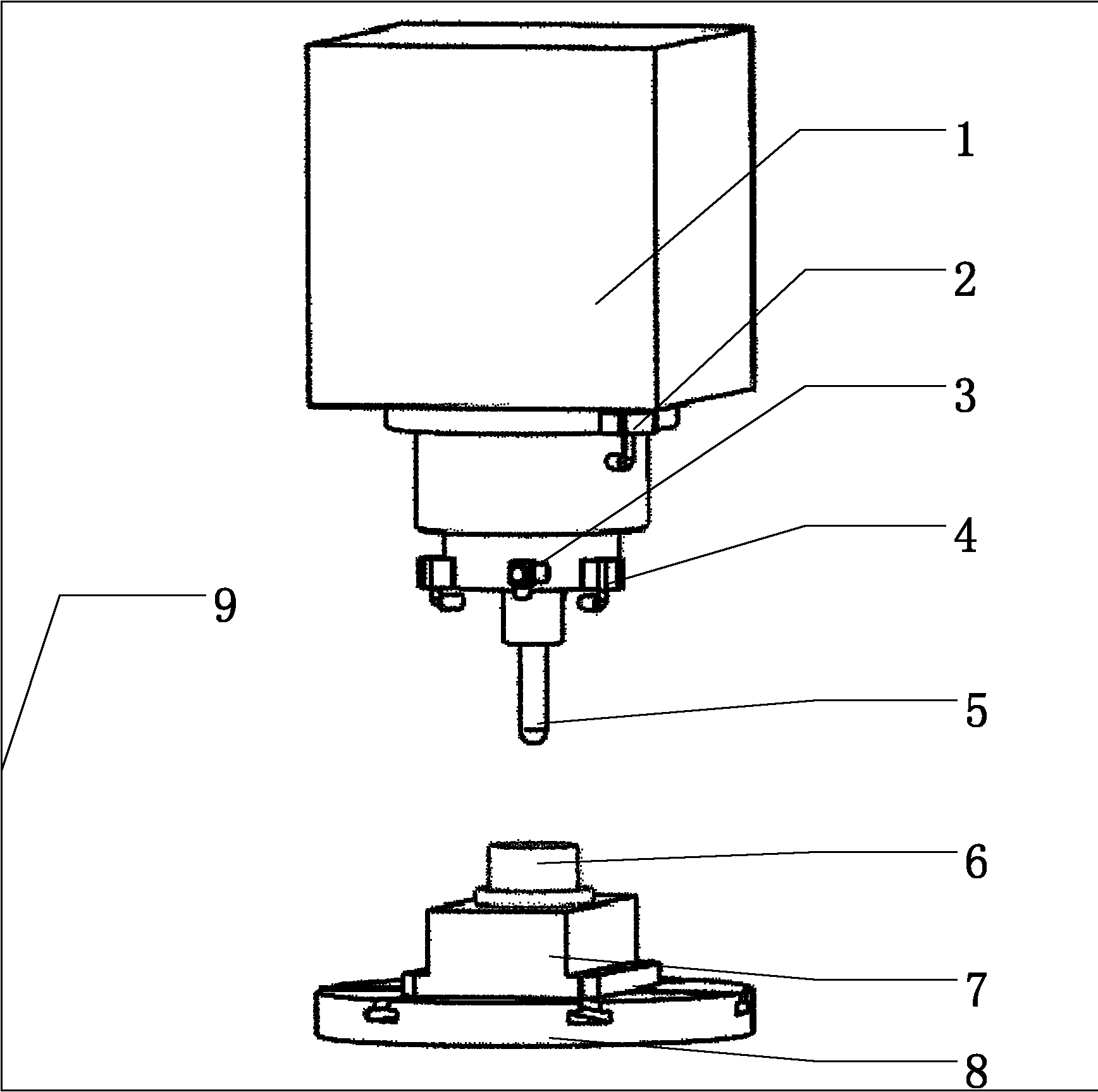

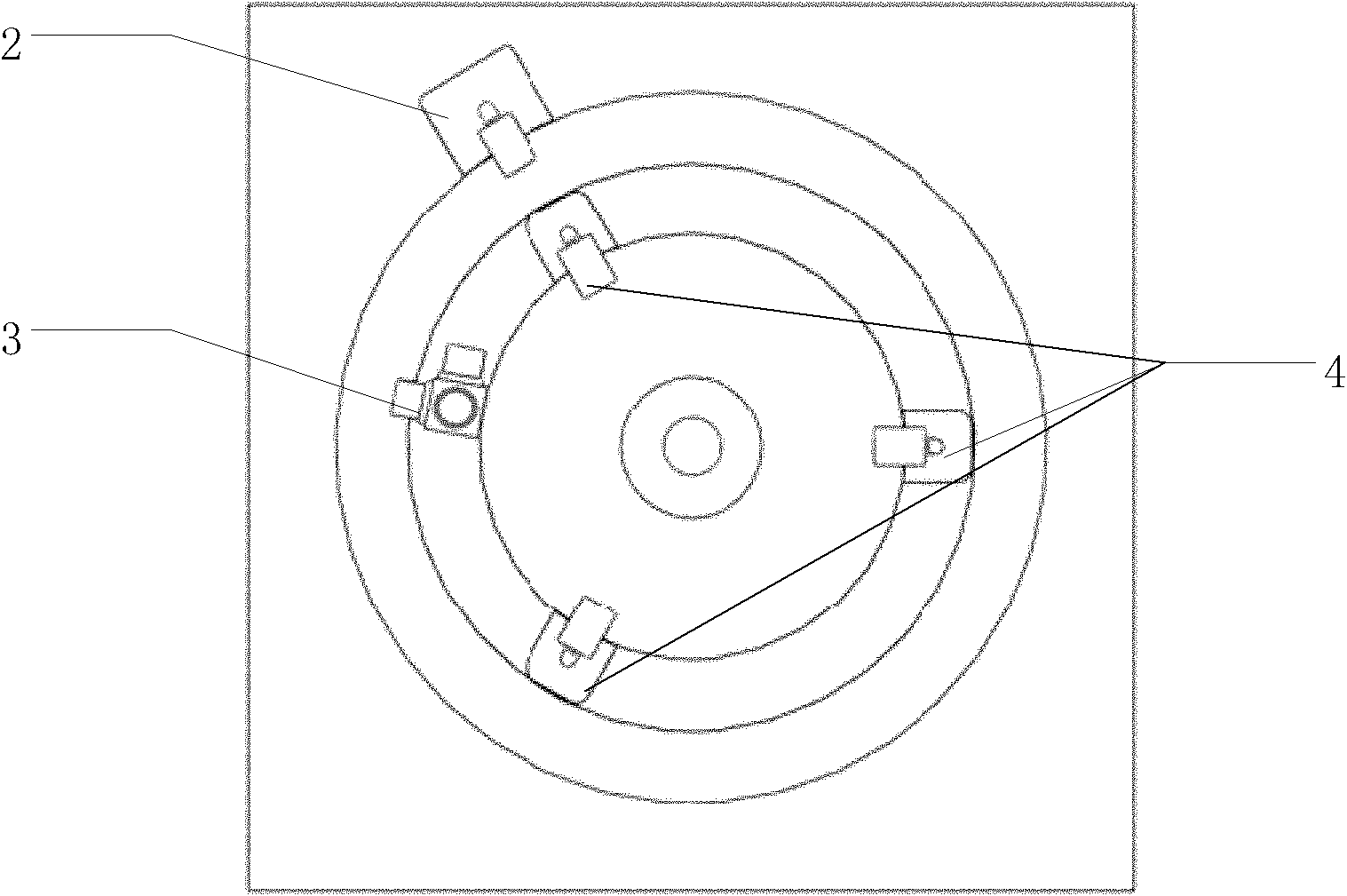

[0040] ①. The test system built: a temperature sensor for real-time measurement of the temperature of the electric spindle 1 axis, a noise sensor for real-time monitoring of the noise change during the idling period of the electric spindle 1, and a noise sensor for detecting the temperature of the electric spindle 1 in the machining center working room 9 are installed The force sensor of the machining load of the electric spindle 1, the vibration sensor used to monitor the vibration change of the electric spindle 1 during the idling period, and the eddy current displacement sensor used to detect the rotation accuracy of the electric spindle 1;

[0041] ②. Determine the test envir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com