Patents

Literature

332results about "Software algorithm control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

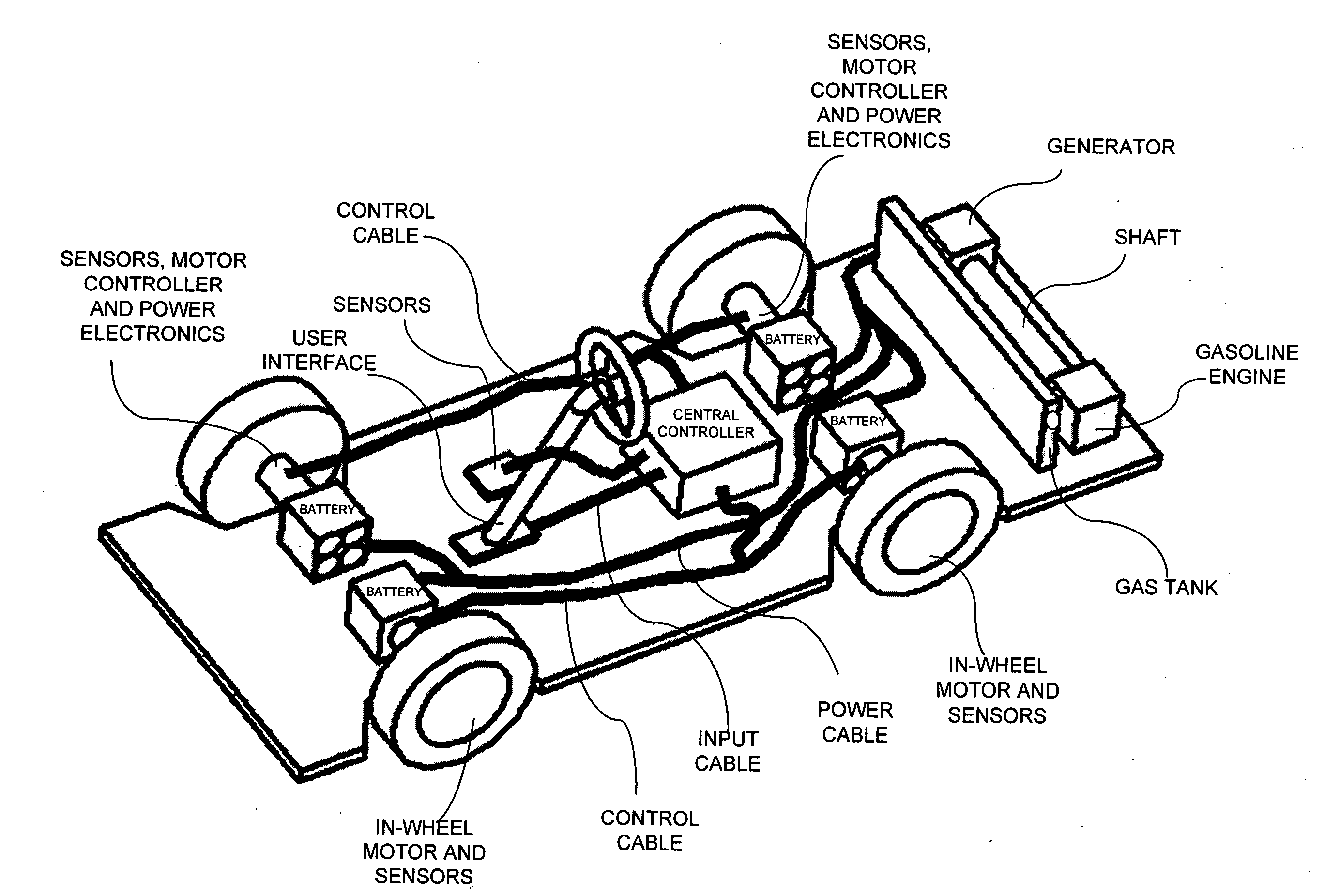

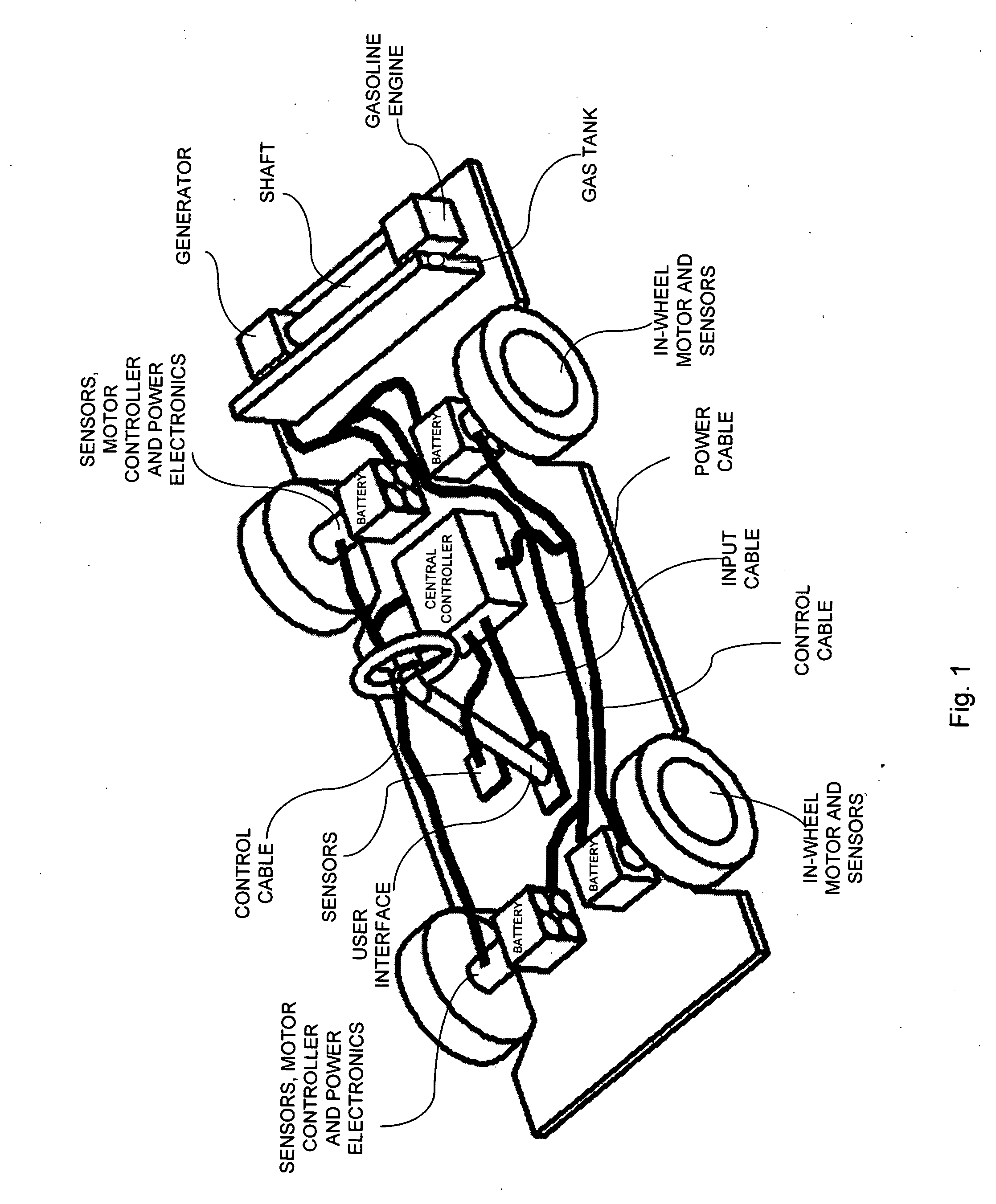

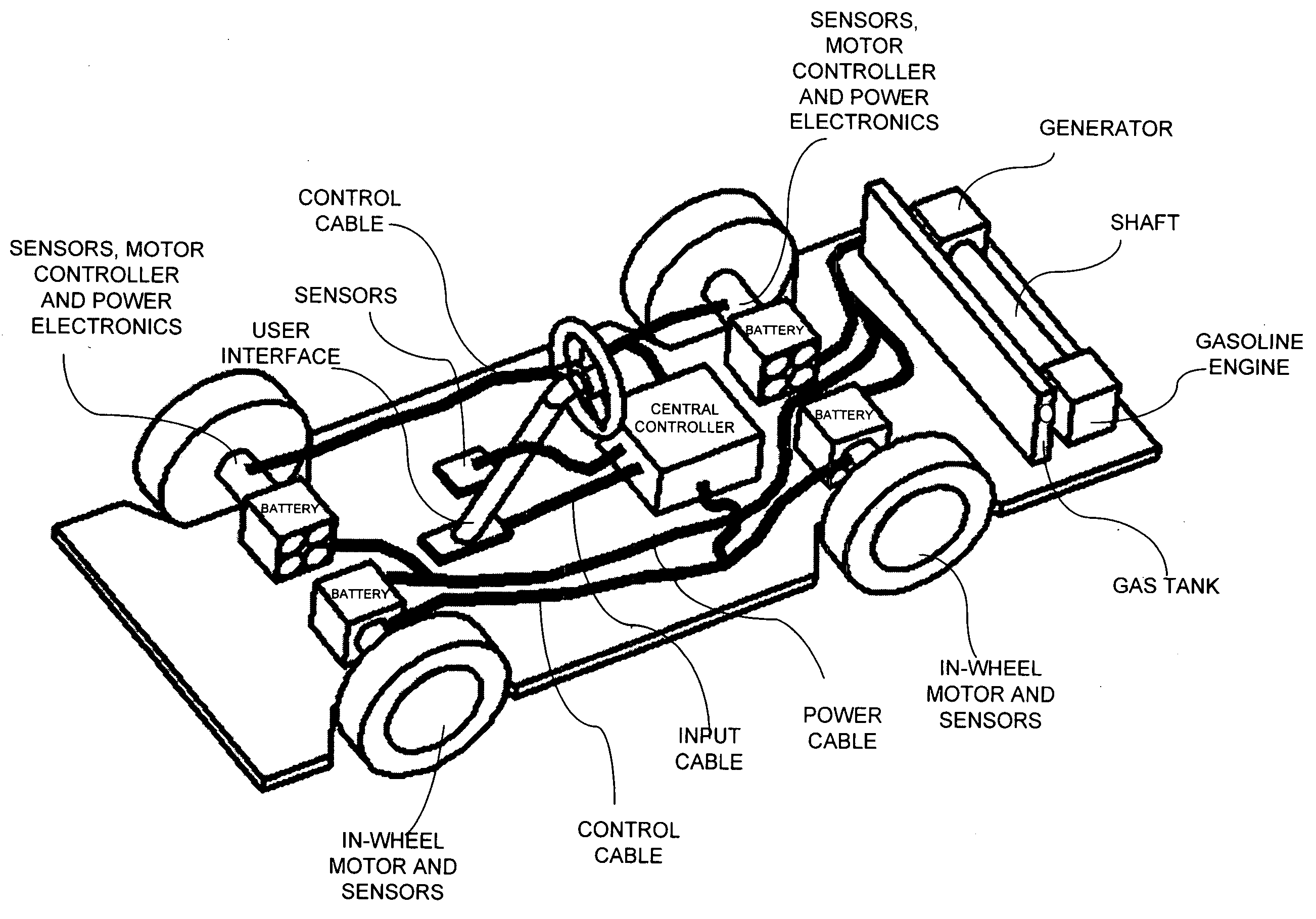

Adaptive electric car

InactiveUS20050052080A1Eliminate electromagneticEliminate electrical interferenceRailway vehiclesAc-dc conversionGasolineMotor control

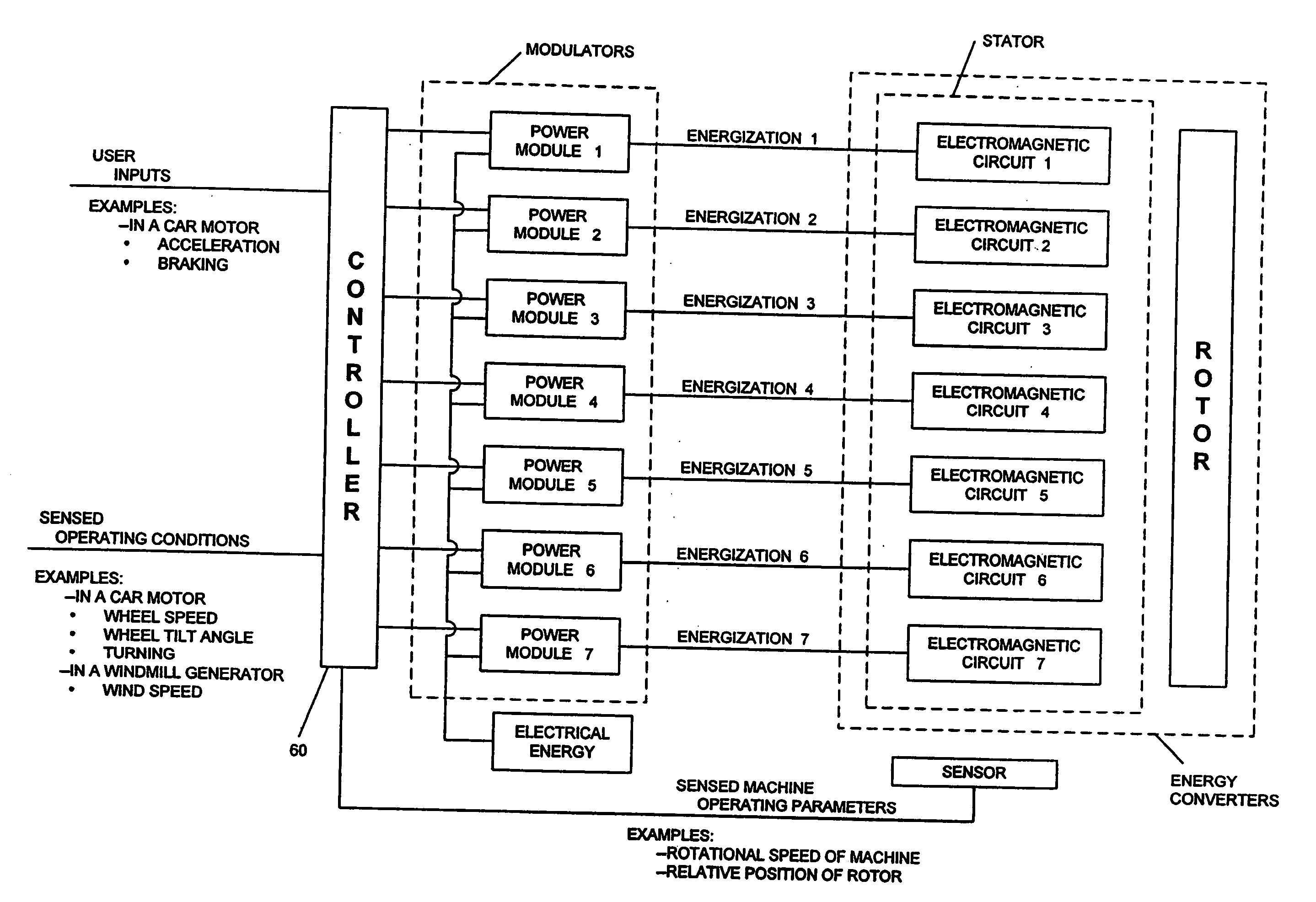

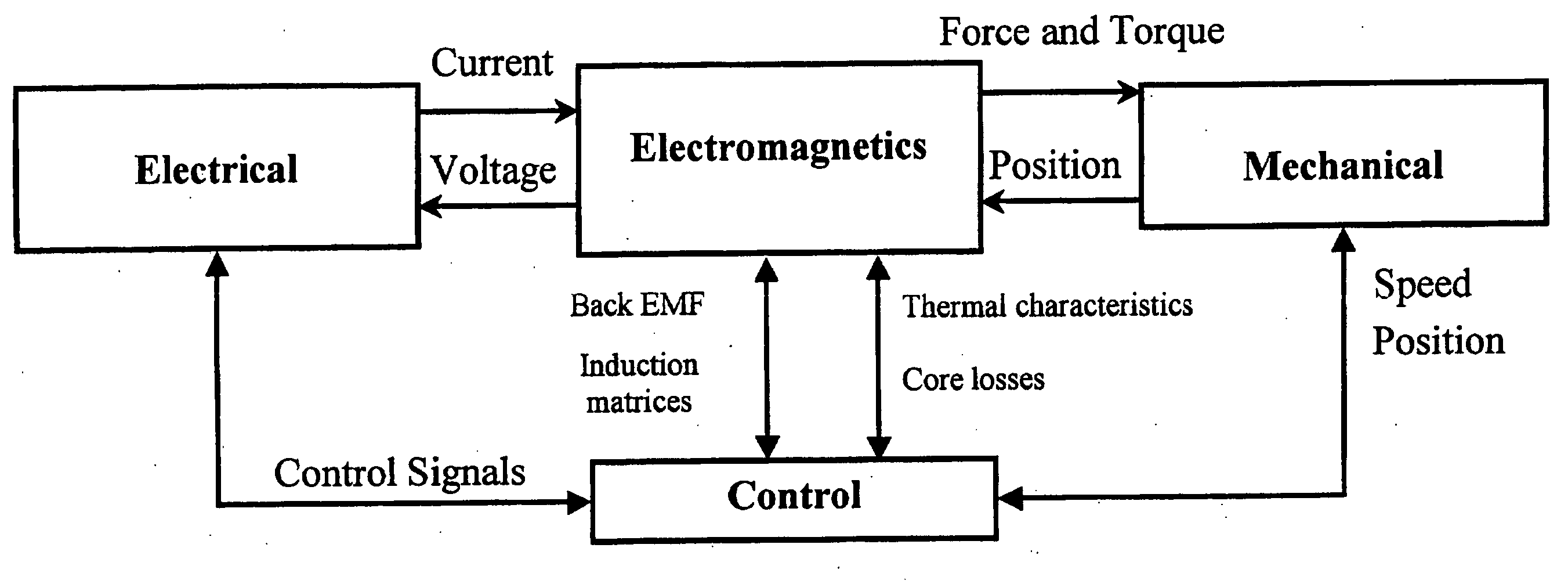

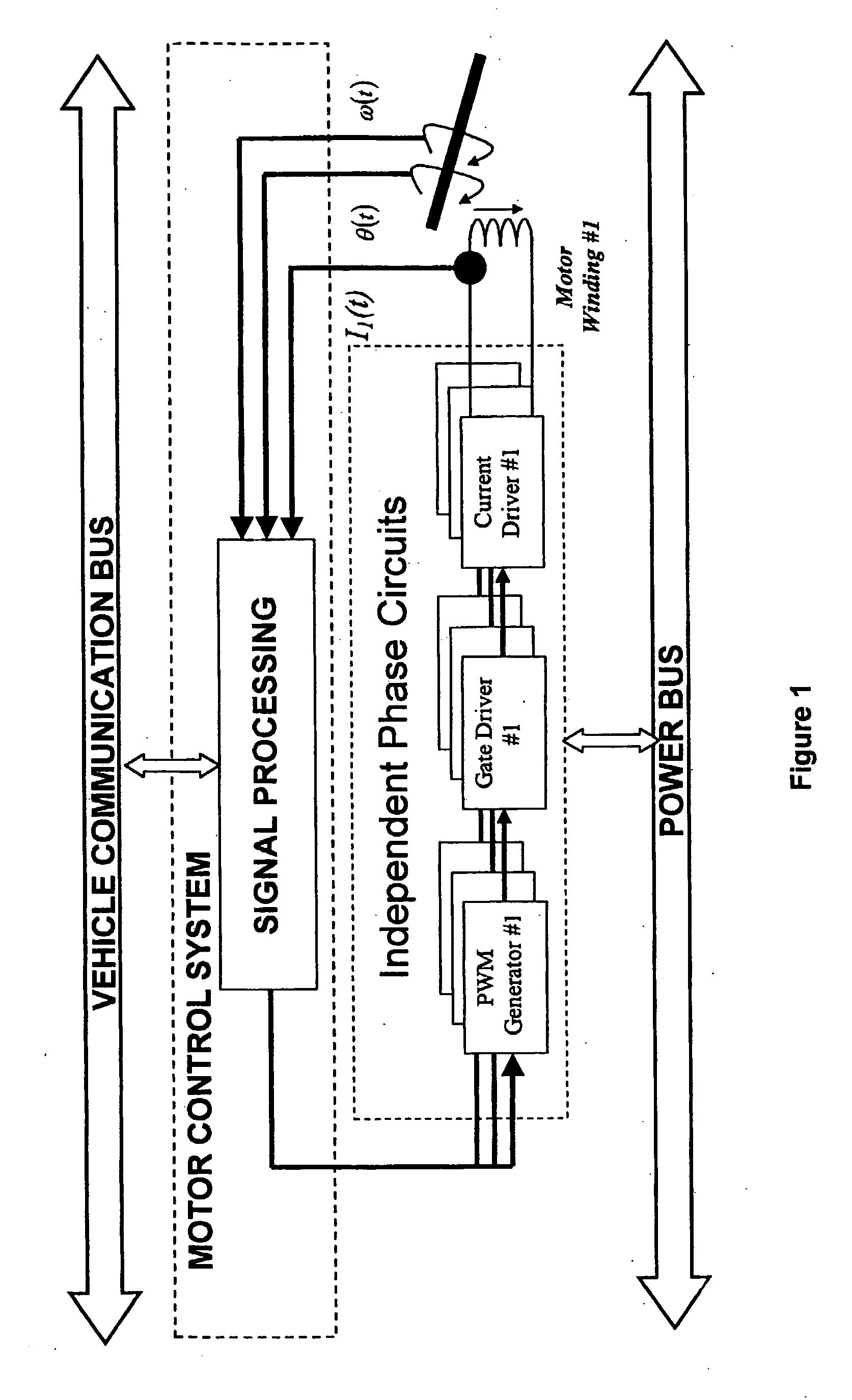

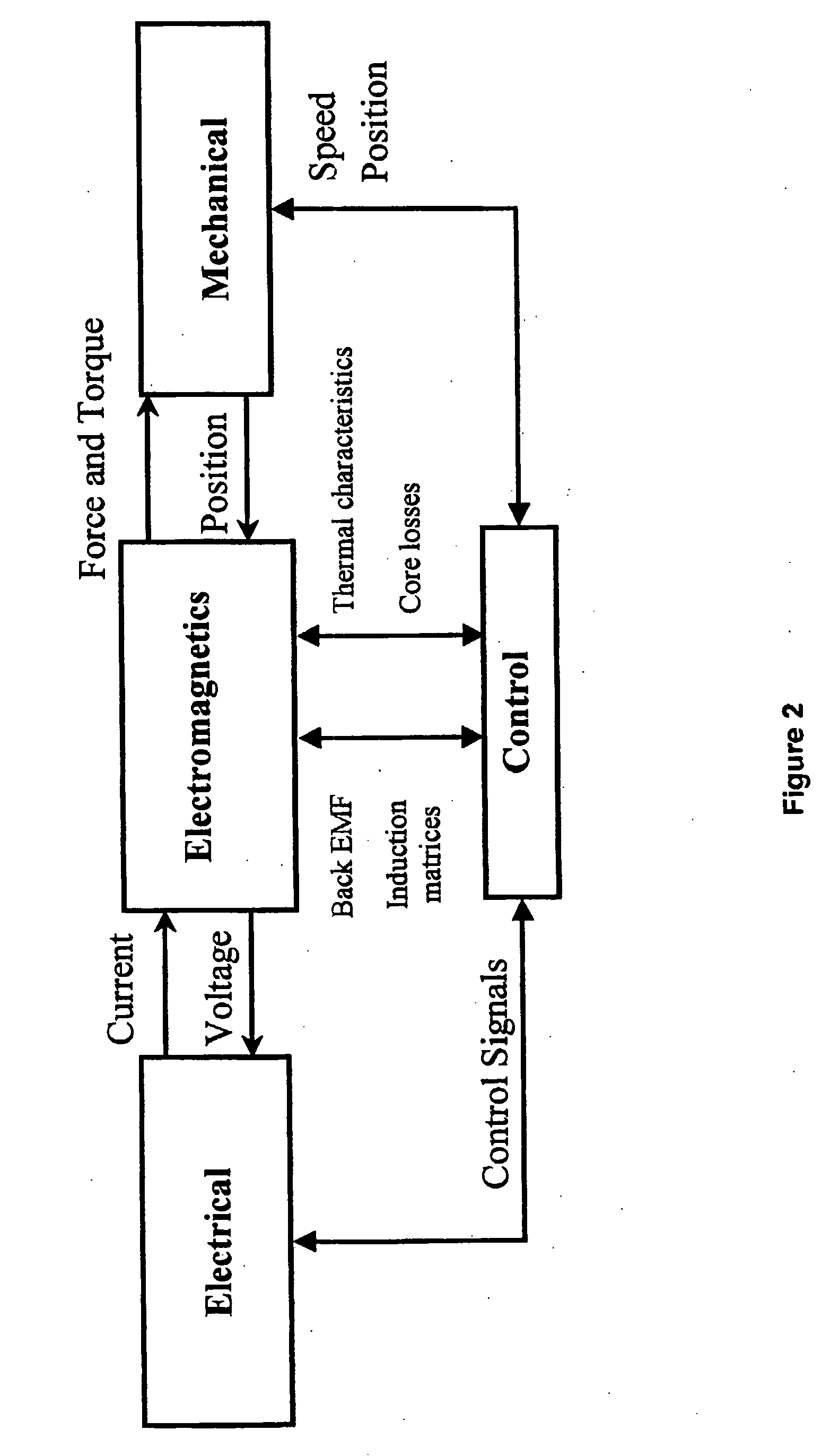

An adaptive electric car or other vehicle with potentially better performance—power, efficiency, range—than a gasoline vehicle, at a competitive cost. The motor control system can dynamically adapt to the vehicle's operating conditions (starting, accelerating, turning, braking, cruising at high speeds) and other inputs and parameters. That consistently provides better performance. Isolating the vehicle's motor or generator electromagnetic circuits allows effective control of more independent parameters. That gives great freedom to optimize. Adaptive motors and generators for an electric vehicle are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors delivers high power with low unsprung mass and high torque and power-density. Total energy management of the vehicles entire electrical system allows for large-scale optimization. An adaptive architecture improves performance of a wide variety of vehicles, particularly those that need optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

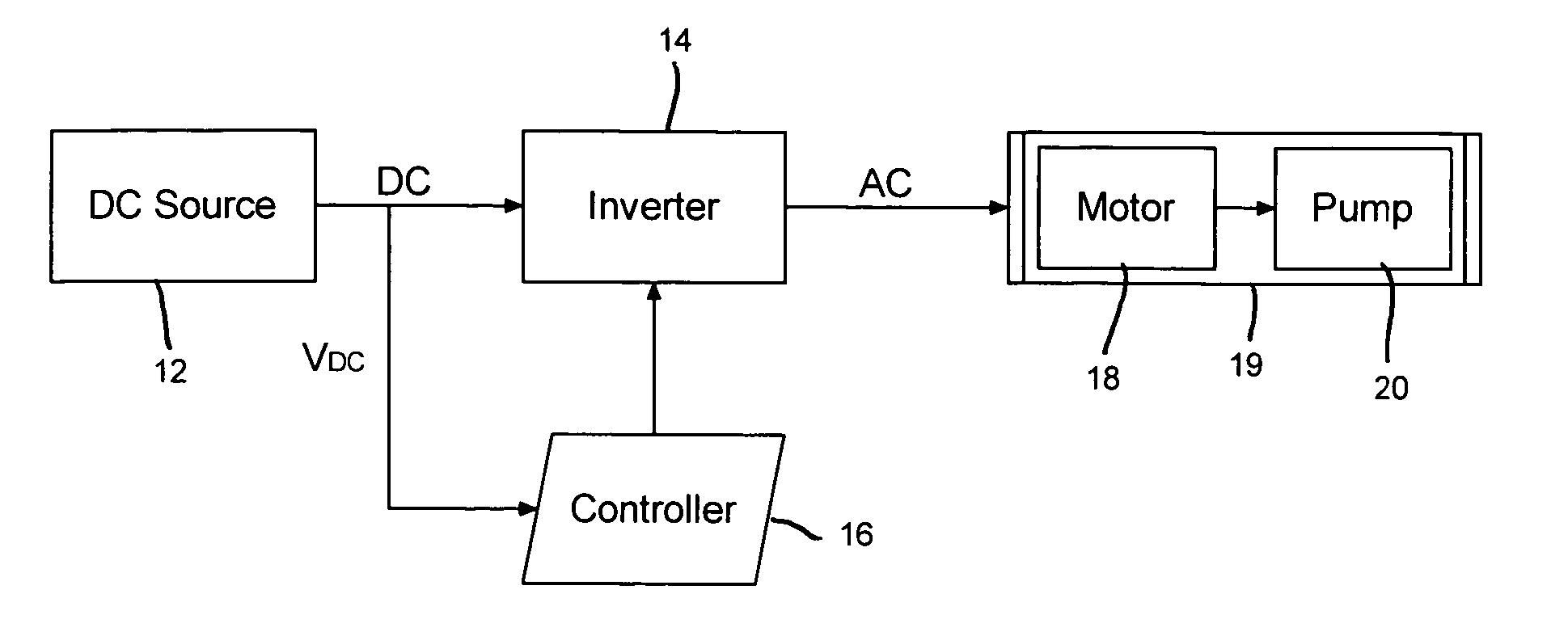

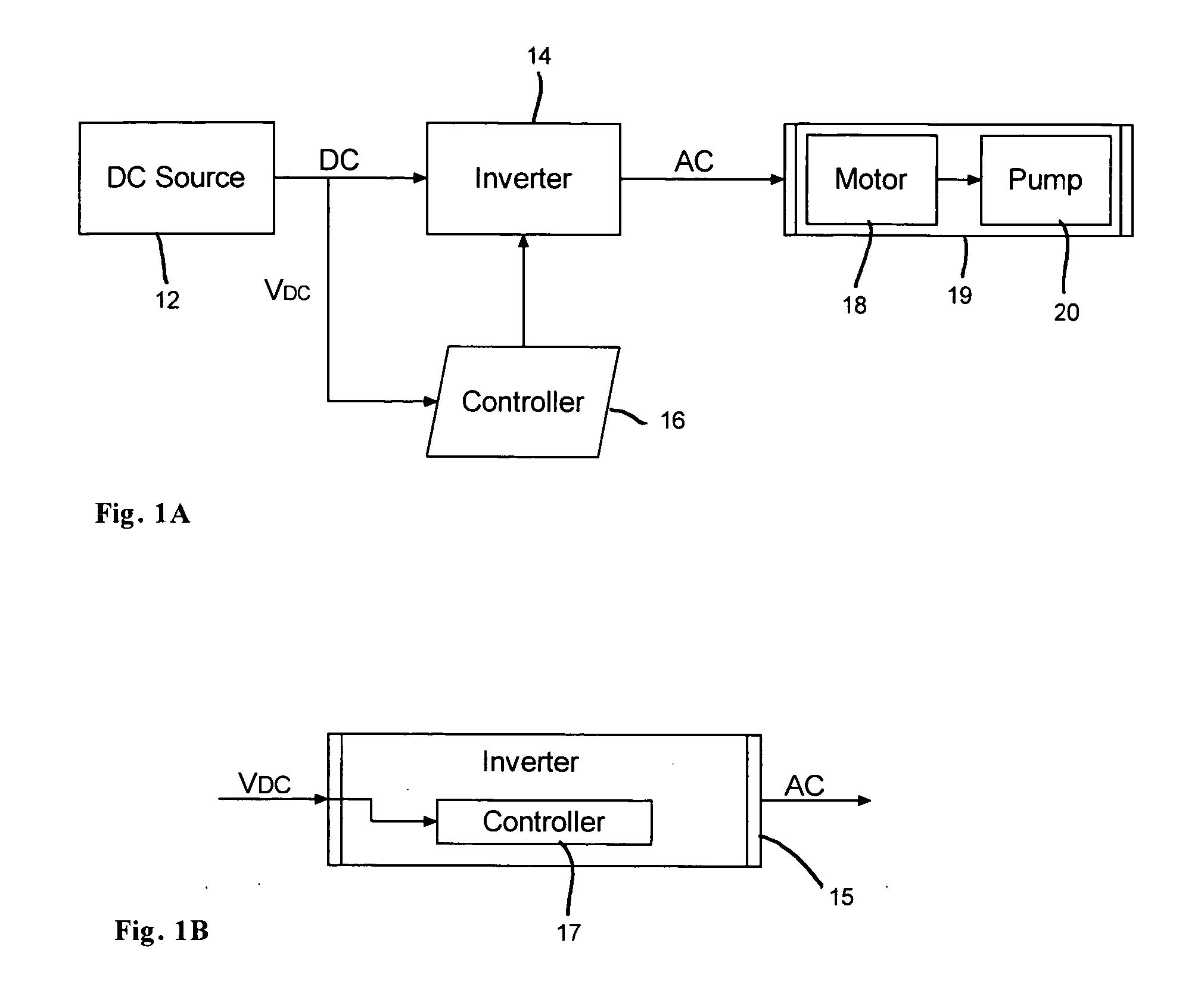

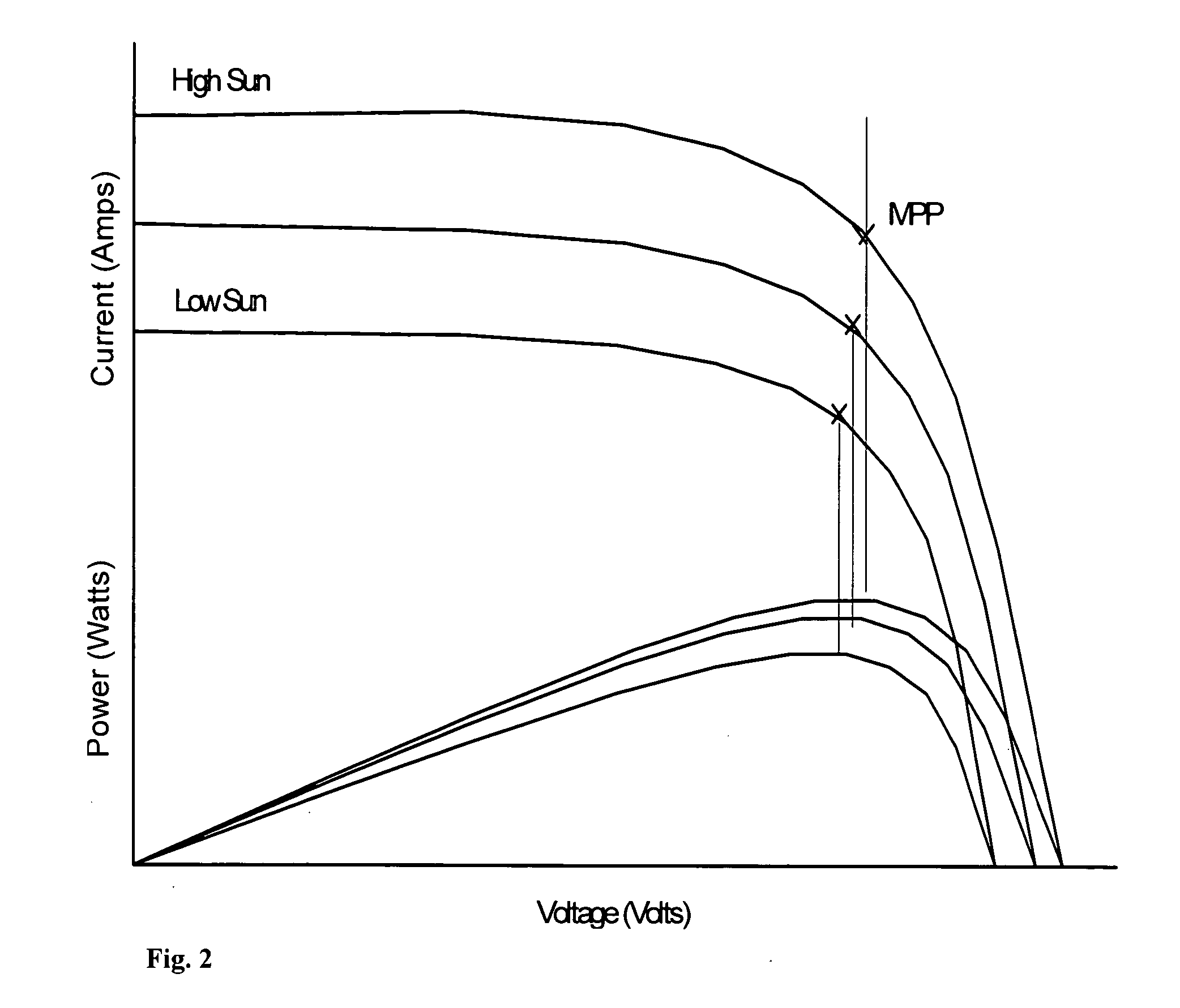

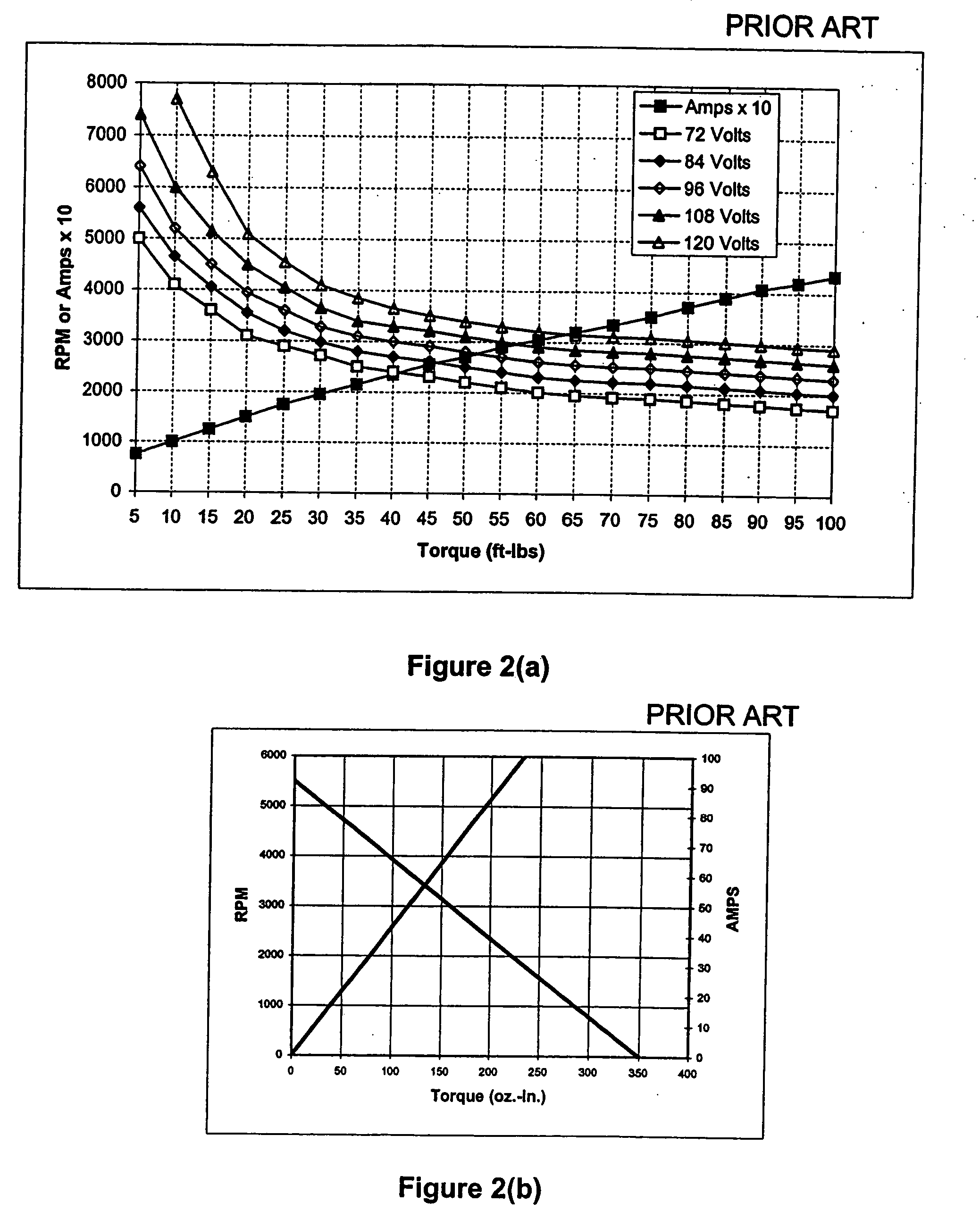

Maximum power point motor control

InactiveUS20060290317A1Batteries circuit arrangementsDC motor speed/torque controlMotor speedMotor drive

A method and apparatus are implemented in software to control motor speed as a function of available power in a DC source—inverter—AC motor system, i.e. to perform maximum power tracking of motor speed. An inverter or motor drive converts DC power from a DC source, such as a solar panel, to AC power, to power the motor. The inverter or motor drive is controlled by software, implemented either by programmable features built directly into the inverter or drive or by a separate programmable device connected to the inverter or drive, to track motor power as a function of source power. The software-controlled inverter or drive sets motor speed as a function of source power by sensing only a single parameter, the DC source voltage. The software-controlled inverter or drive samples the source voltage at preset intervals, and changes the frequency of the AC output of the inverter or drive to match or track the available power so that the motor operates at or near its optimum for any source voltage.

Owner:WORLDWATER & SOLAR TECH

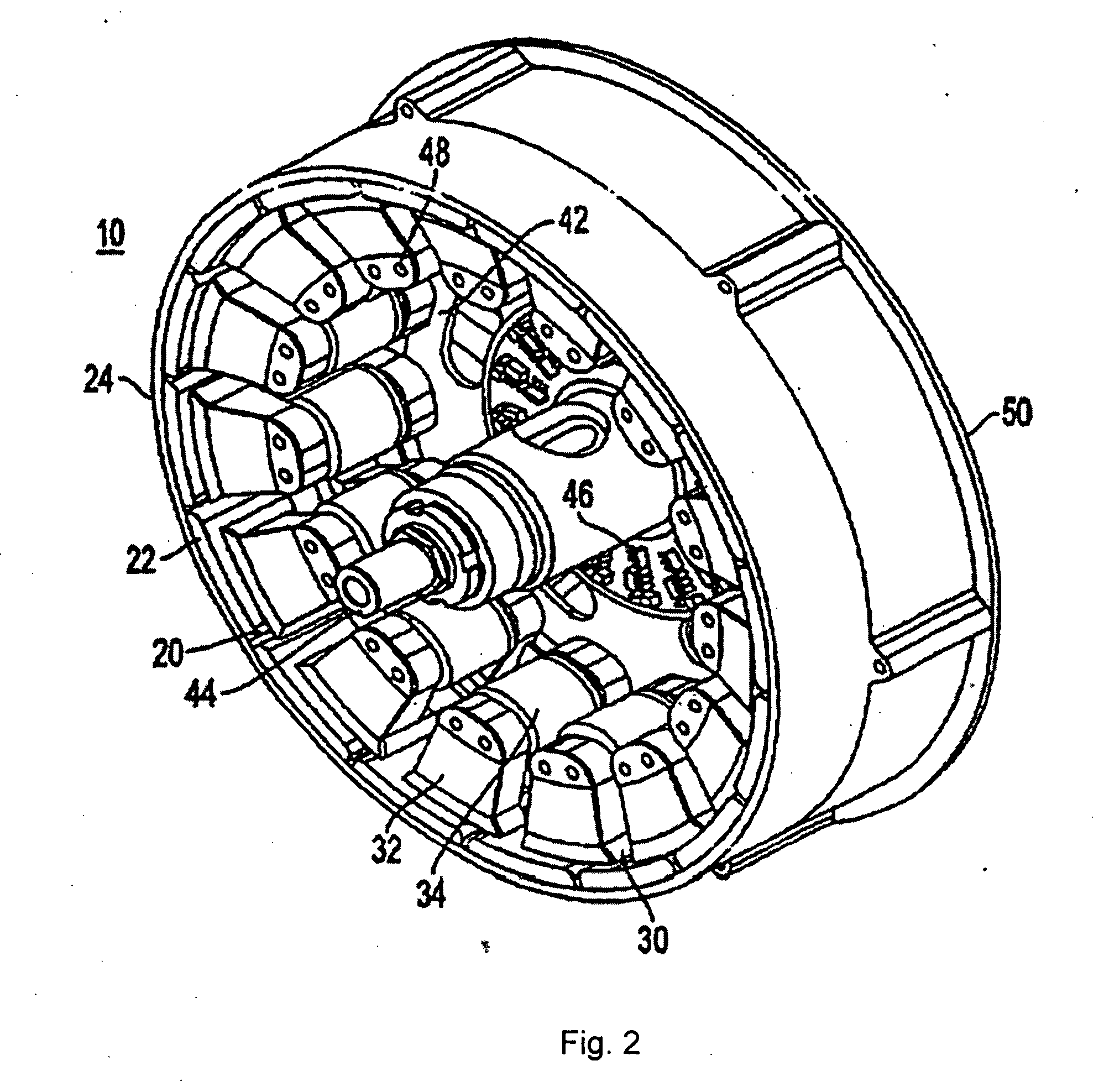

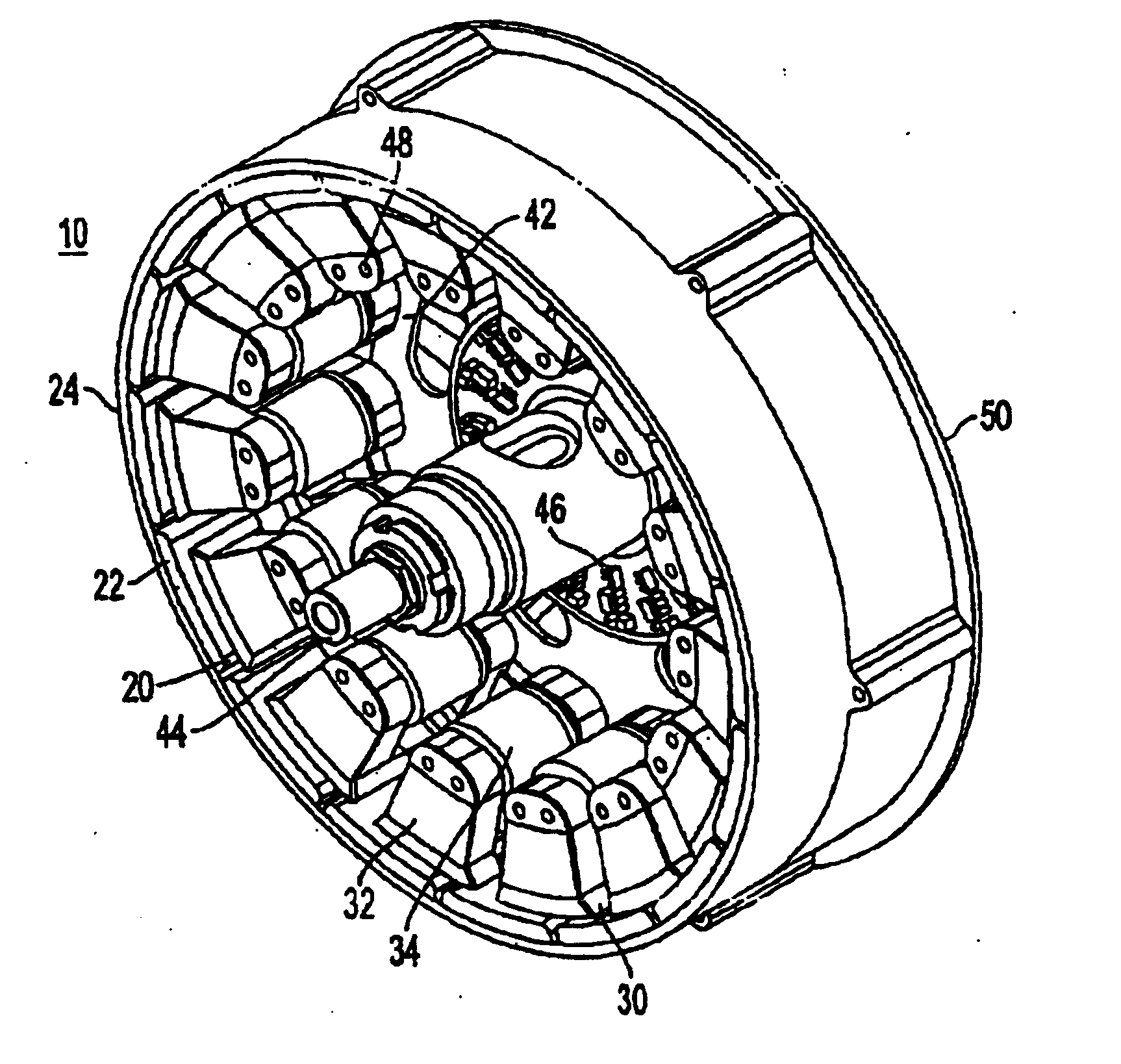

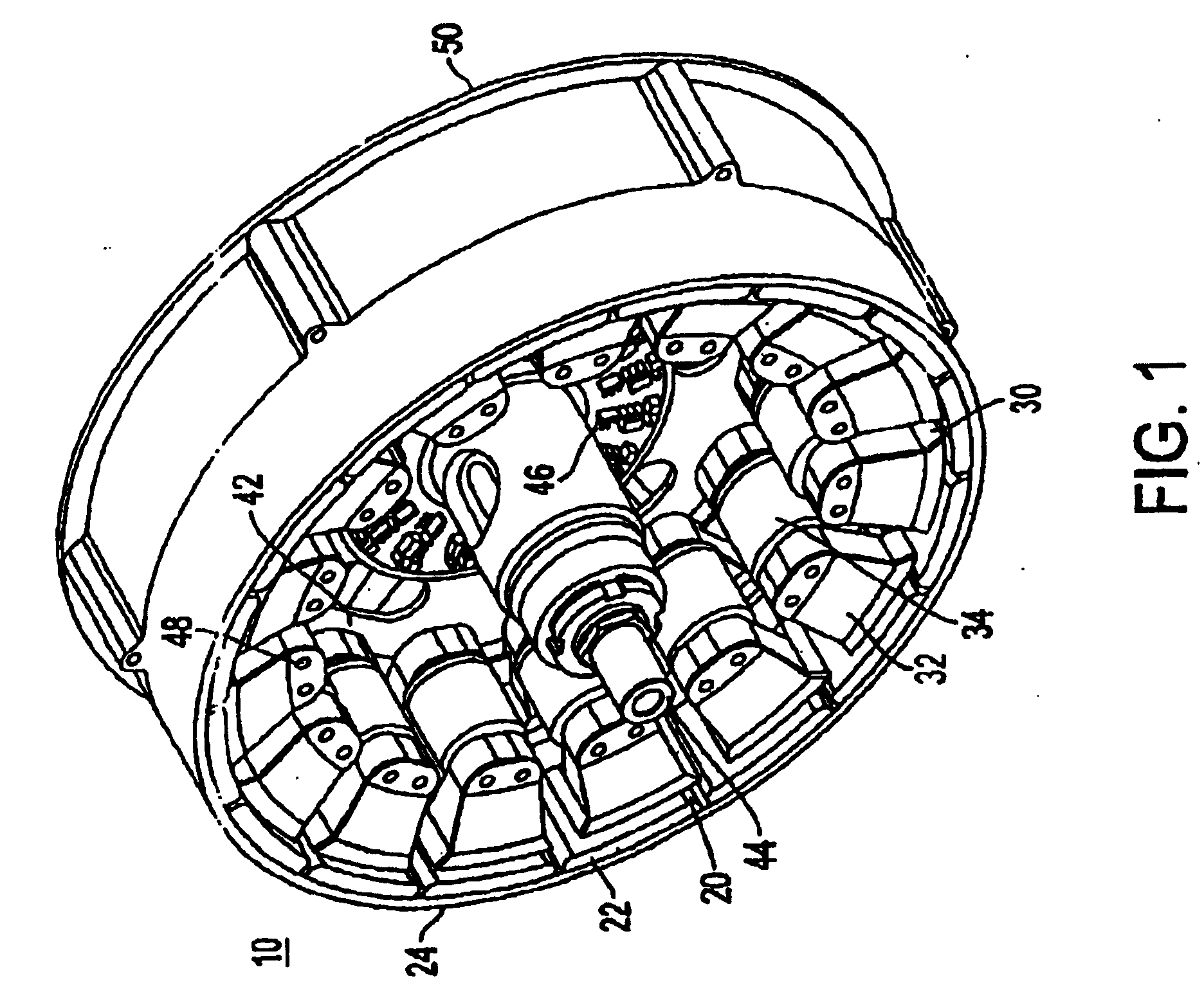

In-wheel electric motors

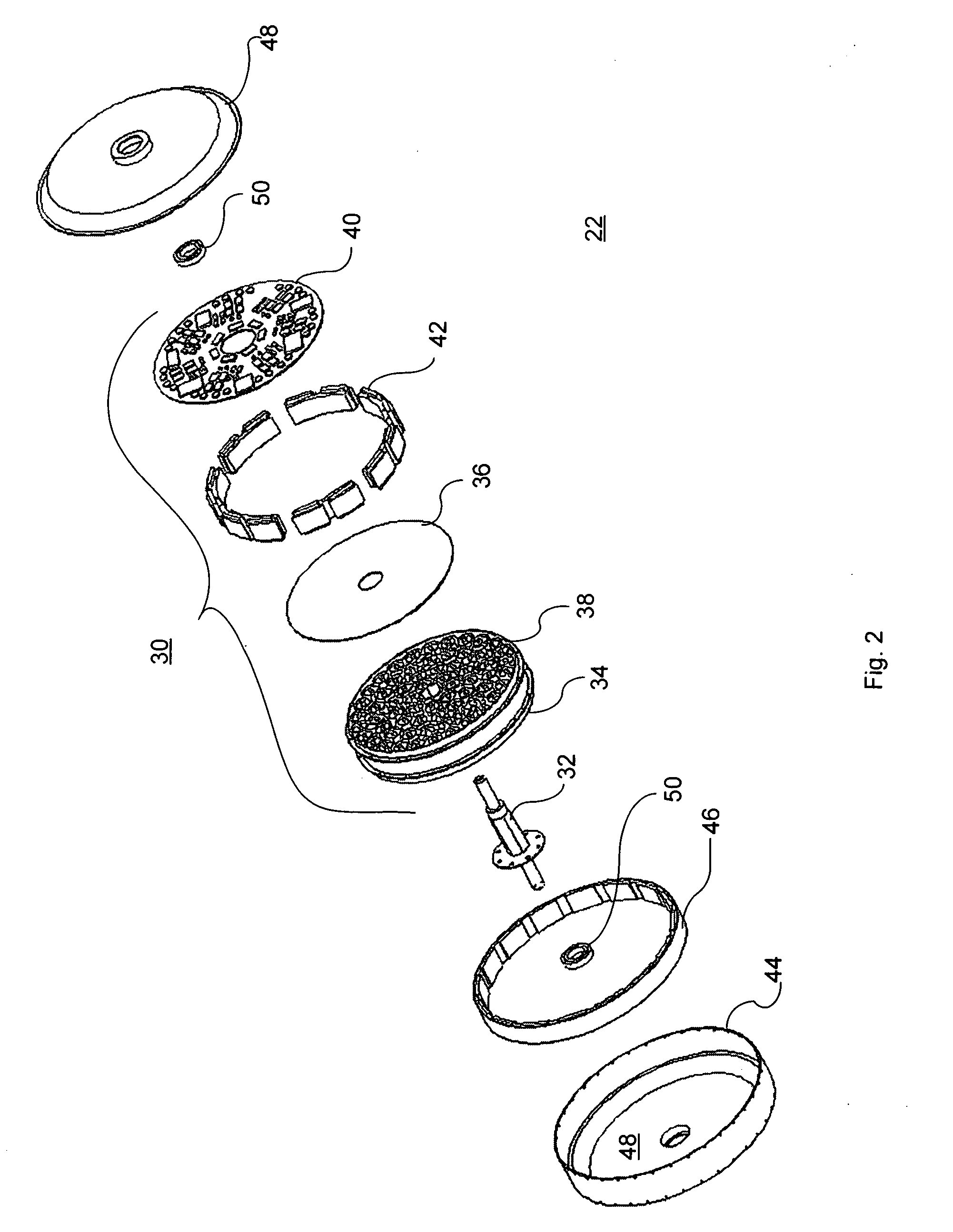

InactiveUS20050045392A1Simple eleganceImprove efficiencyVehicular energy storageMechanical energy handlingLow voltageControl system

Improved in-wheel, near-wheel and direct-drive electric motors for cars and other vehicles. This motor can be cheaper, lighter, more powerful, more efficient, and more reliable than other direct-drive motors. Its high torque-density and high performance allow it to produce the same peak power as heavier, bigger motors. That helps greatly with the handling issues caused by too much unsprung mass. The motor control system can adapt to the vehicle's operating conditions (like starting, accelerating, turning, braking, and cruising at high speeds). That provides better performance. The motor's low-voltage, low-current design helps reduce heat and weight and leads to lower motor cost. The motor can still operate with some faults, offering “get home” capability. It offers all the benefits of in-wheel motors: efficiency, compactness, direct traction control, quiet, simple driveline. And it adds to those benefits, while reducing or eliminating the drawbacks other in-wheel motors.

Owner:BLUWAV SYST LLC

Adaptive electric motors and generators providing improved performance and efficiency

InactiveUS20050184689A1Induced currentLow reliabilityMagnetic circuitVehicular energy storageElectric vehicleHigher Power

An adaptive architecture for electric motors, generators and other electric machines. An adaptive electric machine provides optimal performance by dynamically adapting its controls to changes in user inputs, machine operating conditions and machine operating parameters. Isolating the machine's electromagnetic circuits allows effective control of more independent machine parameters, enabling greater freedom to optimize and providing adaptive motors and generators that are cheaper, smaller, lighter, more powerful, and more efficient than conventional designs. An electric vehicle with in-wheel adaptive motors enables delivery of higher power with lower unsprung mass, giving better torque-density. The motor control system can adapt to the vehicle's operating conditions, including starting, accelerating, turning, braking, and cruising at high speeds, thereby consistently providing higher efficiency. A wind powered adaptive generator can adapt to changing wind conditions, consistently providing optimal performance. An adaptive architecture may improve performance in a wide variety of electric machine applications, particularly those requiring optimal efficiency over a range of operating conditions.

Owner:BLUWAV SYST LLC

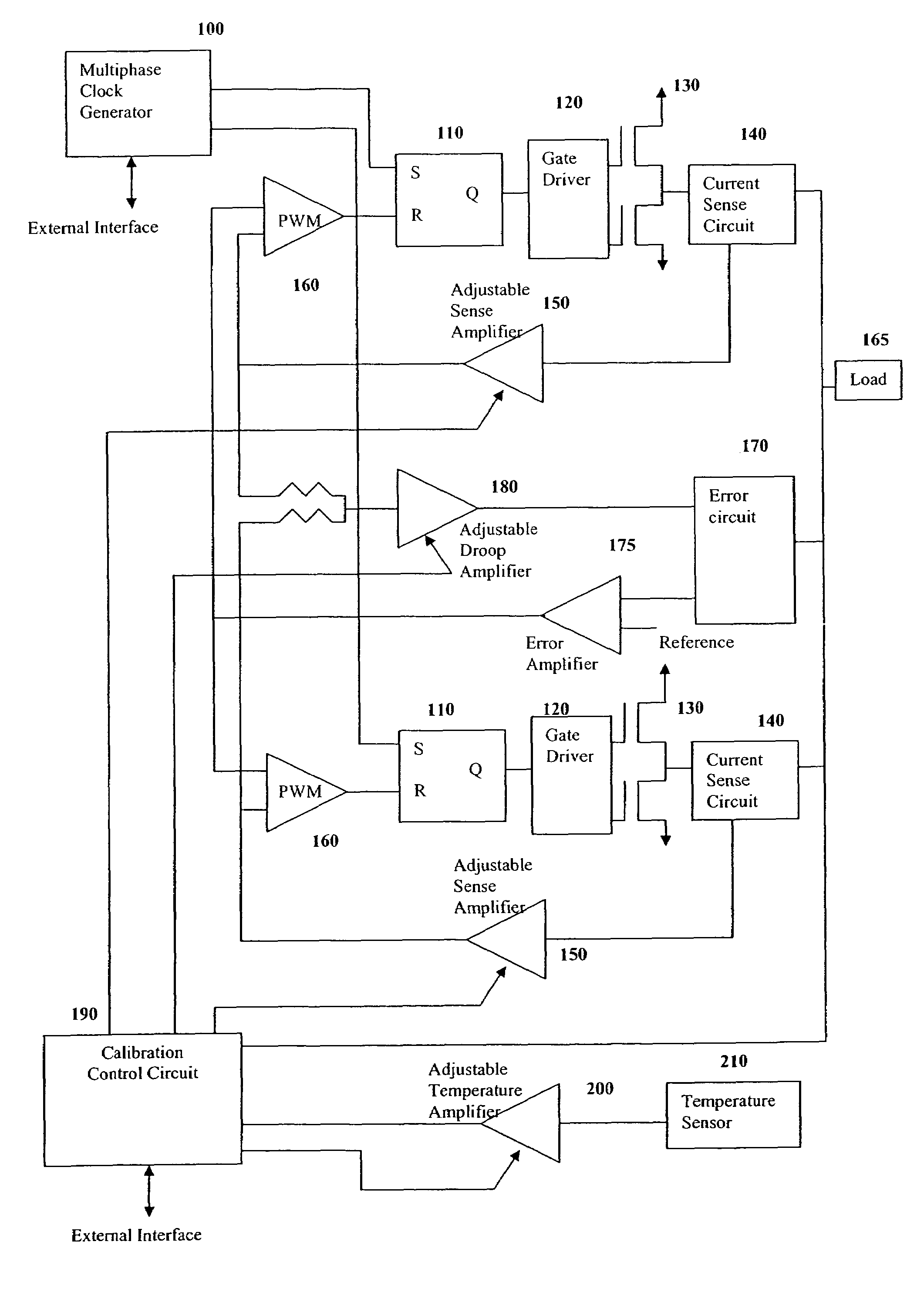

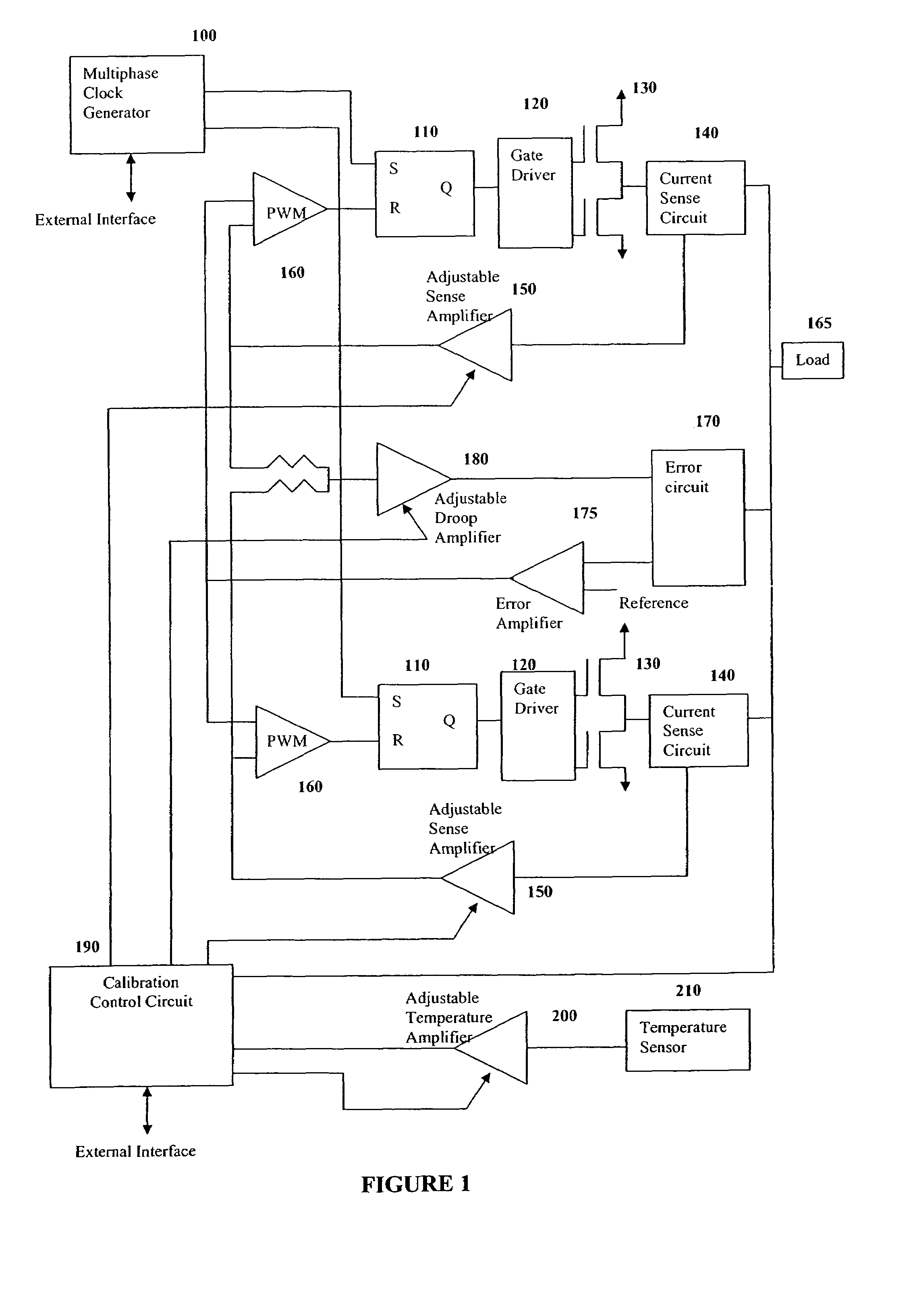

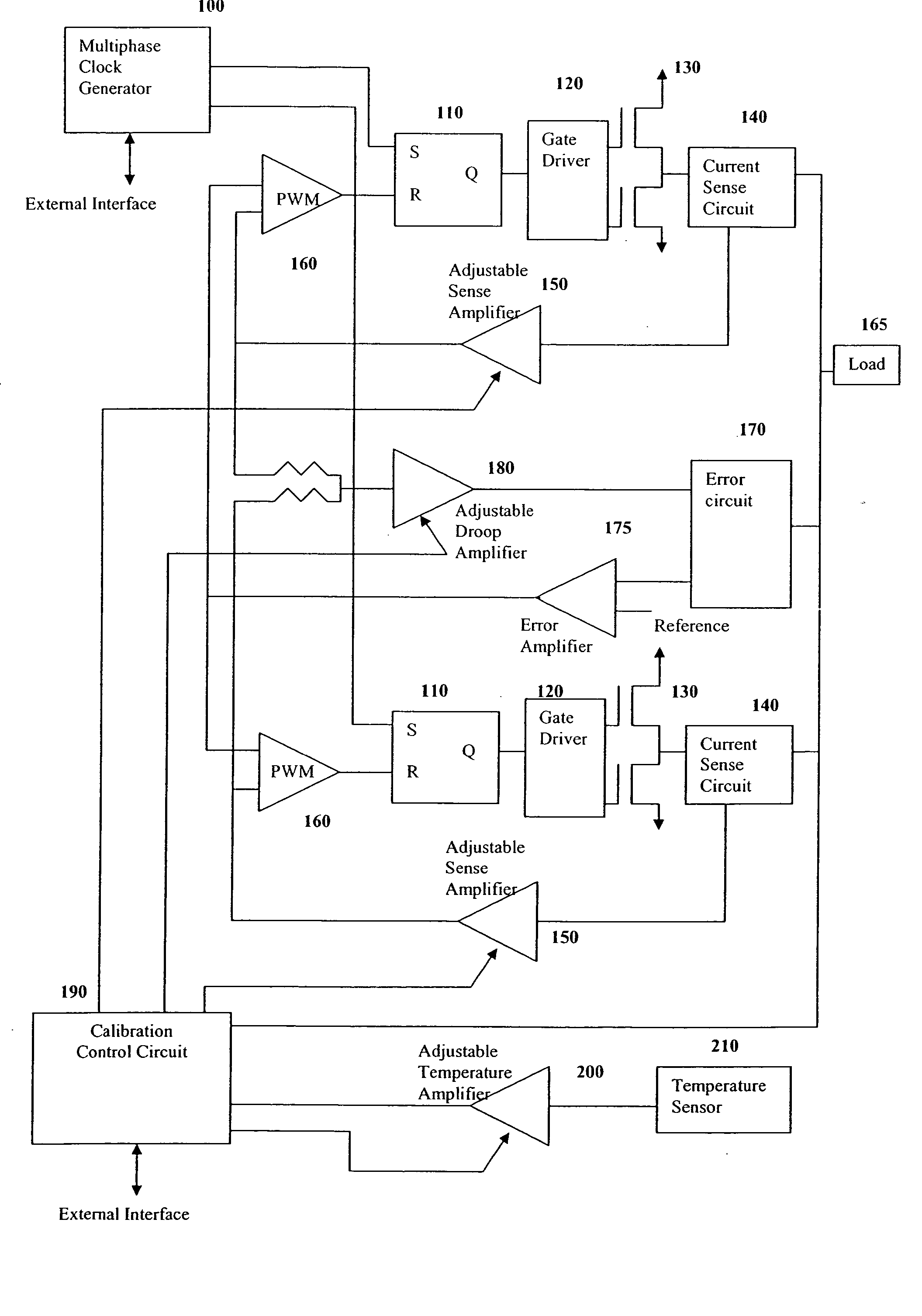

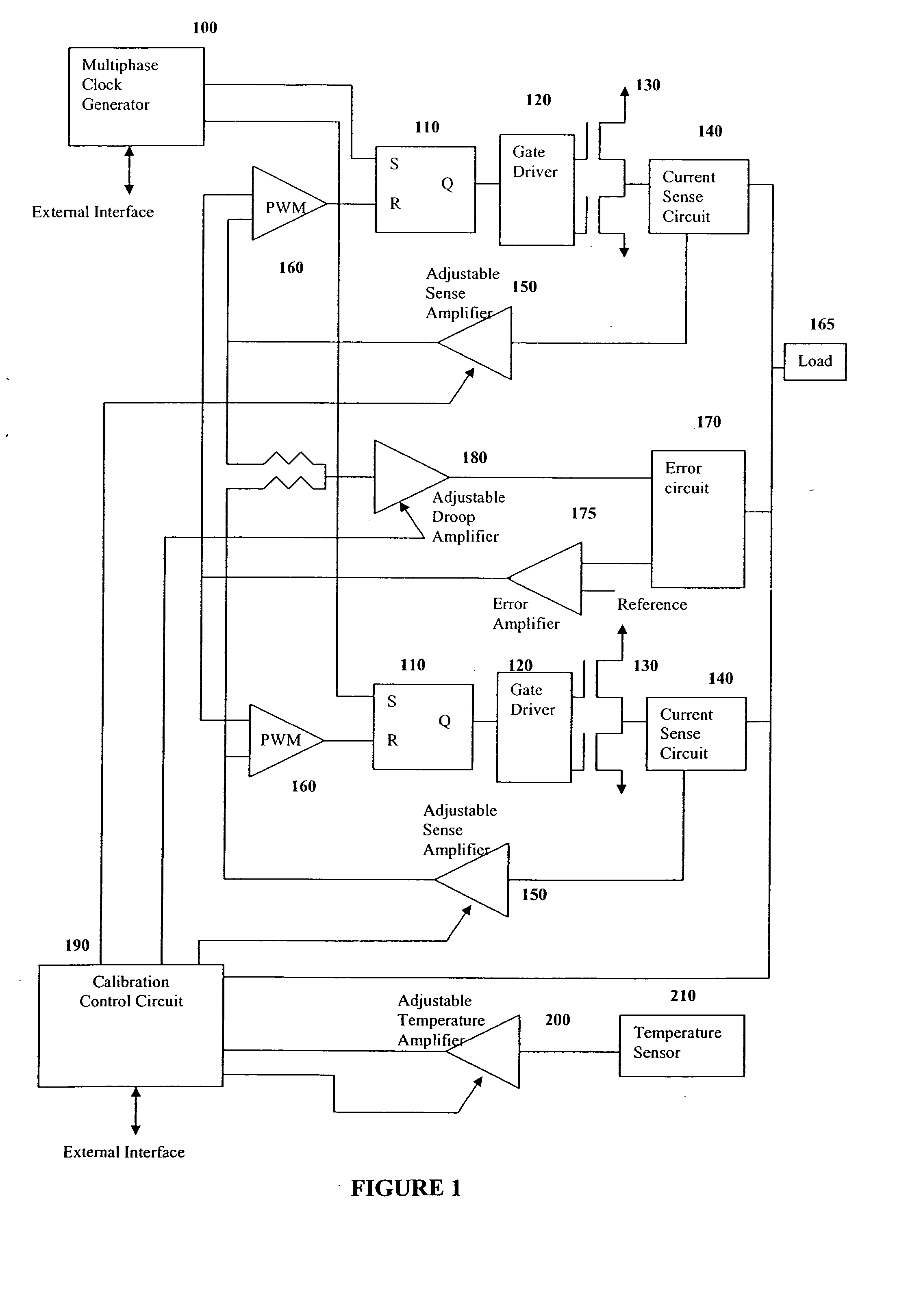

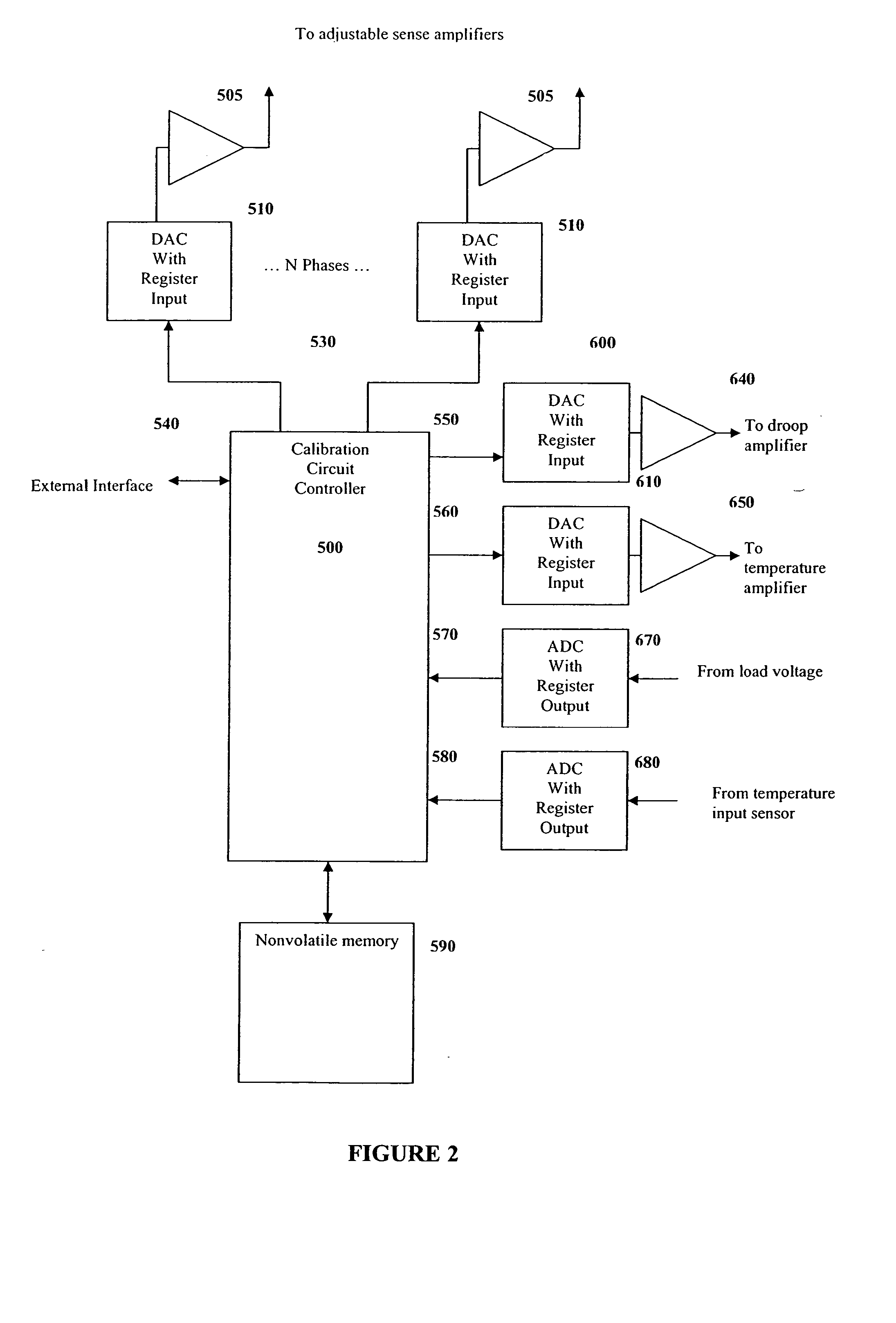

Programmable calibration circuit for power supply current sensing and droop loss compensation

ActiveUS7027944B2Reduce wasteLevel controlEmergency protective circuit arrangementsEngineeringElectrical current

A circuit for regulating power is disclosed. The present invention provides circuits and methods for current sensing variations, static droop settings, mismatched phase outputs, and temperature variations in a multiphase power regulator. The circuits may include a calibration controller that senses and regulates both a current sensing circuit and the droop in a power regulator over a range of temperatures thus equalizing phase outputs. The present invention includes the schematic organization and implementation of the circuit, the circuit's calibration, its use, and implementation. This invention advantageously provides circuits and methods to properly power a processor or IC chip according to the unique power specifications of the processor or chip.

Owner:TABAIAN FEREYDUN

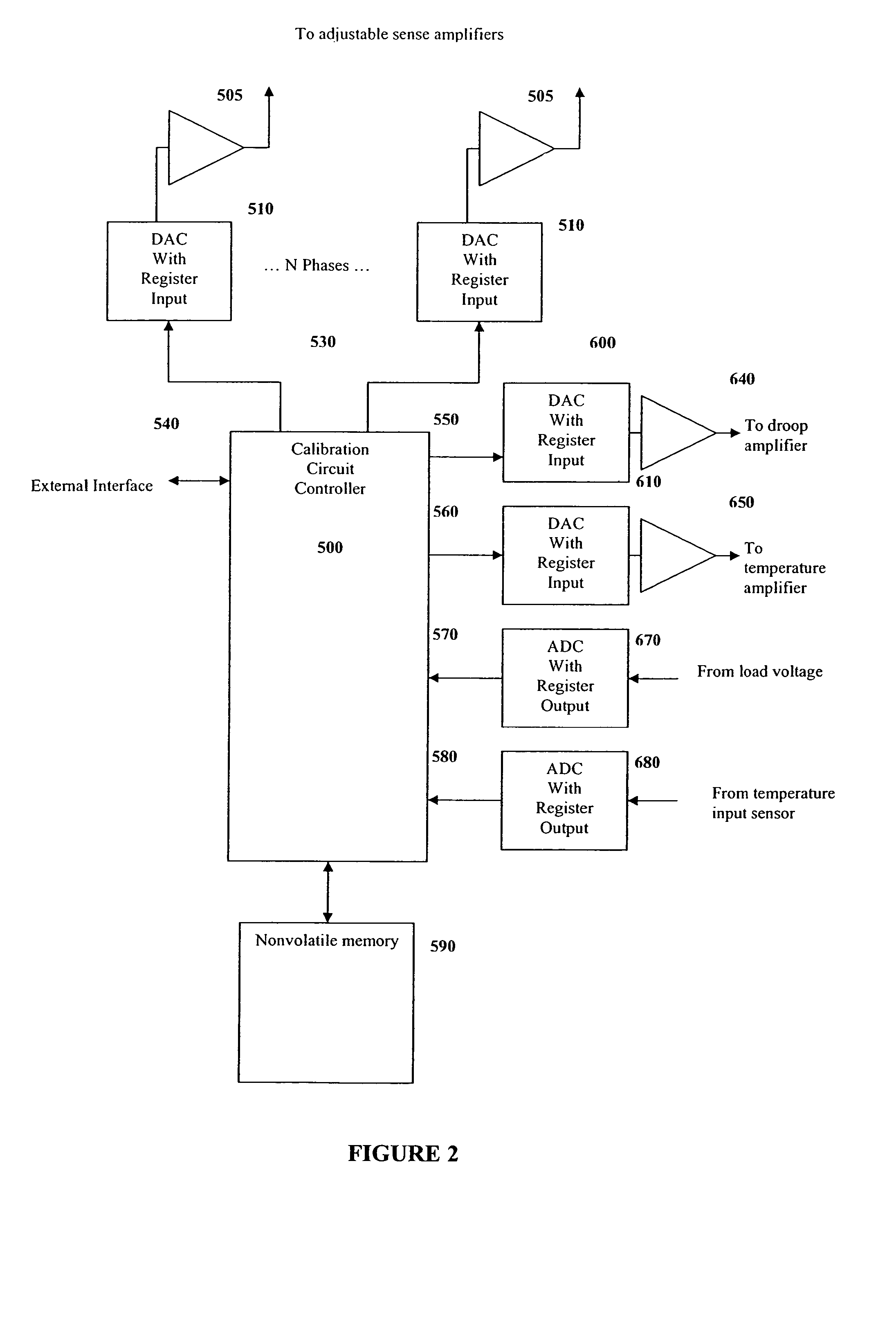

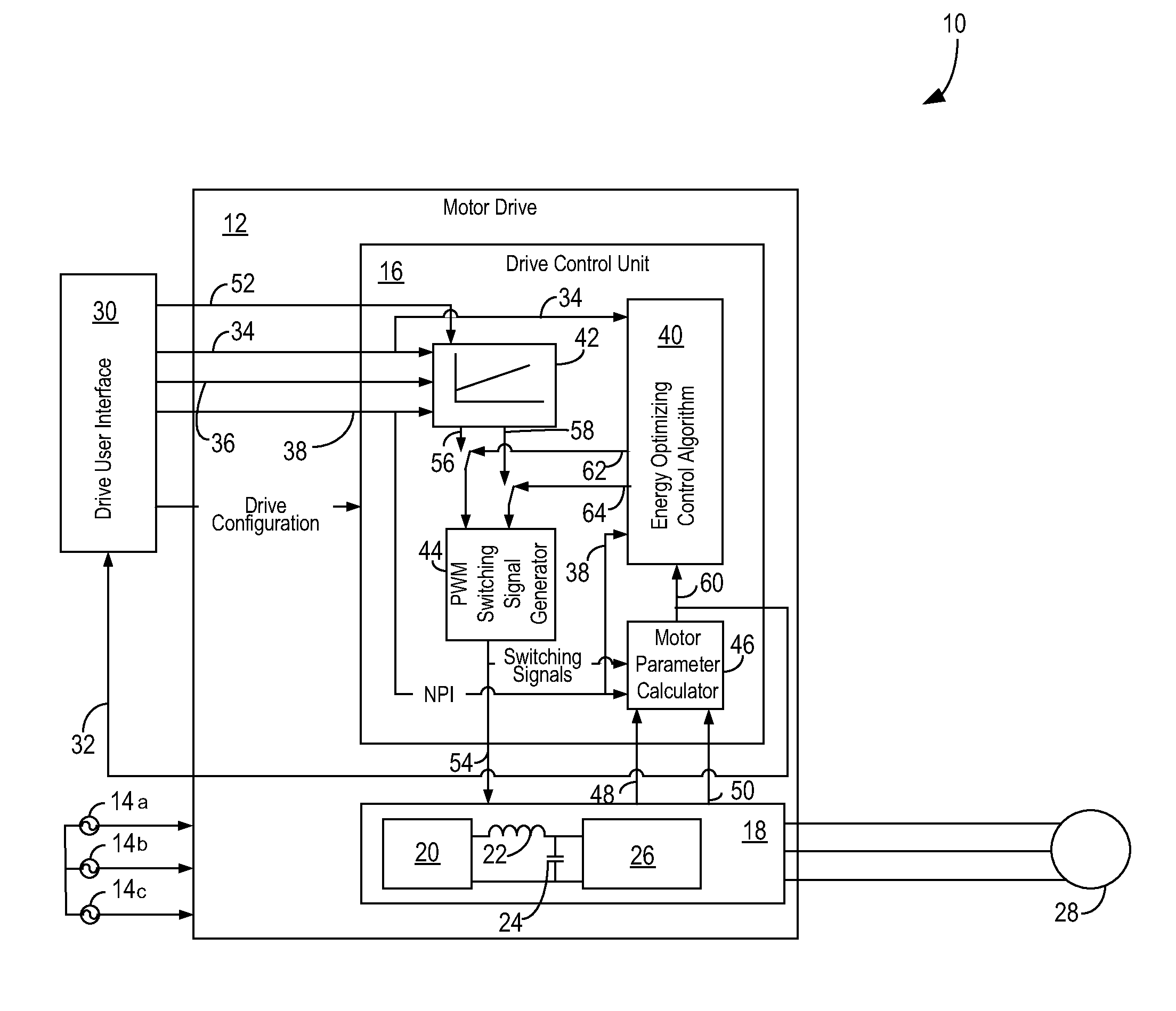

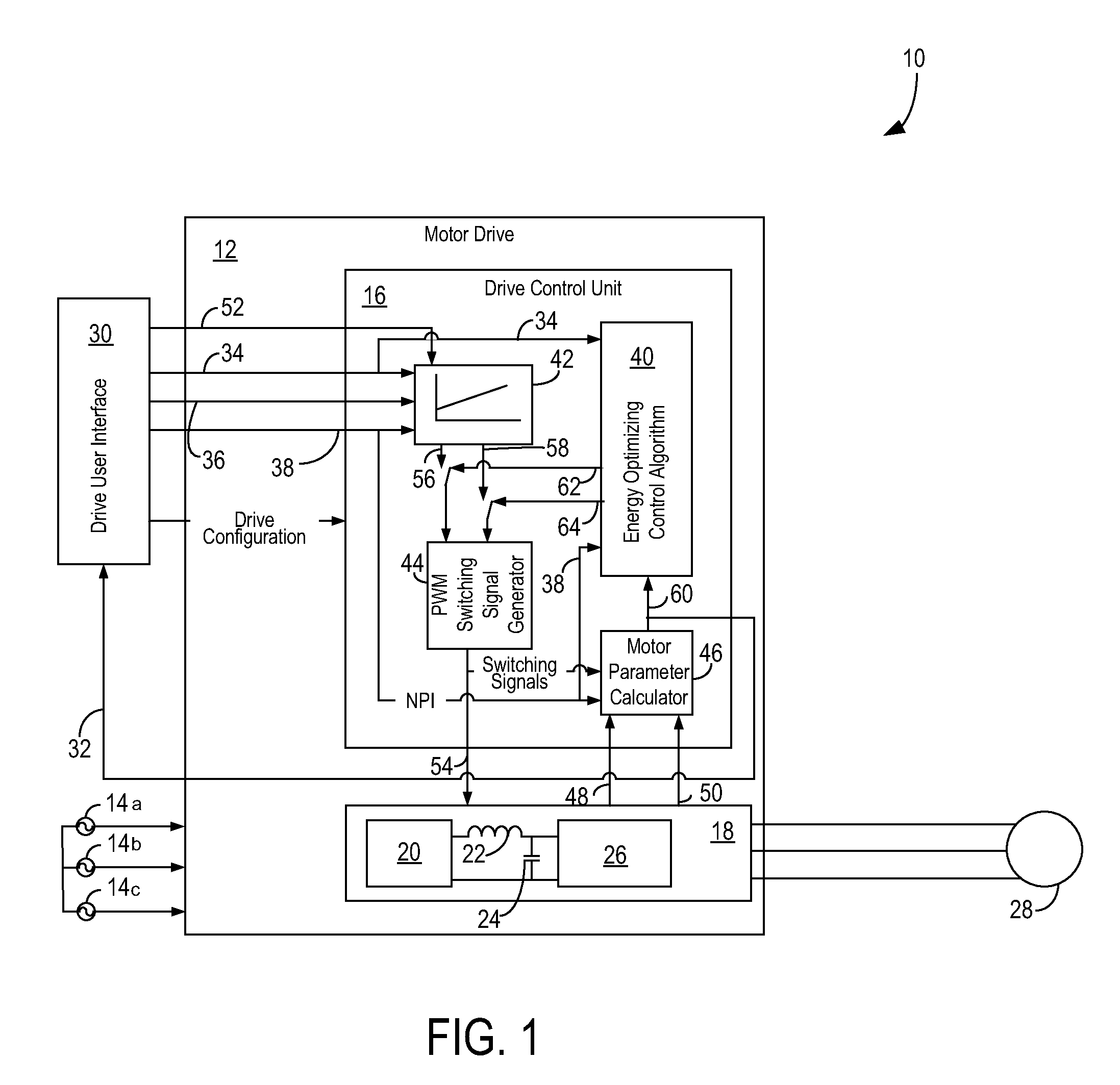

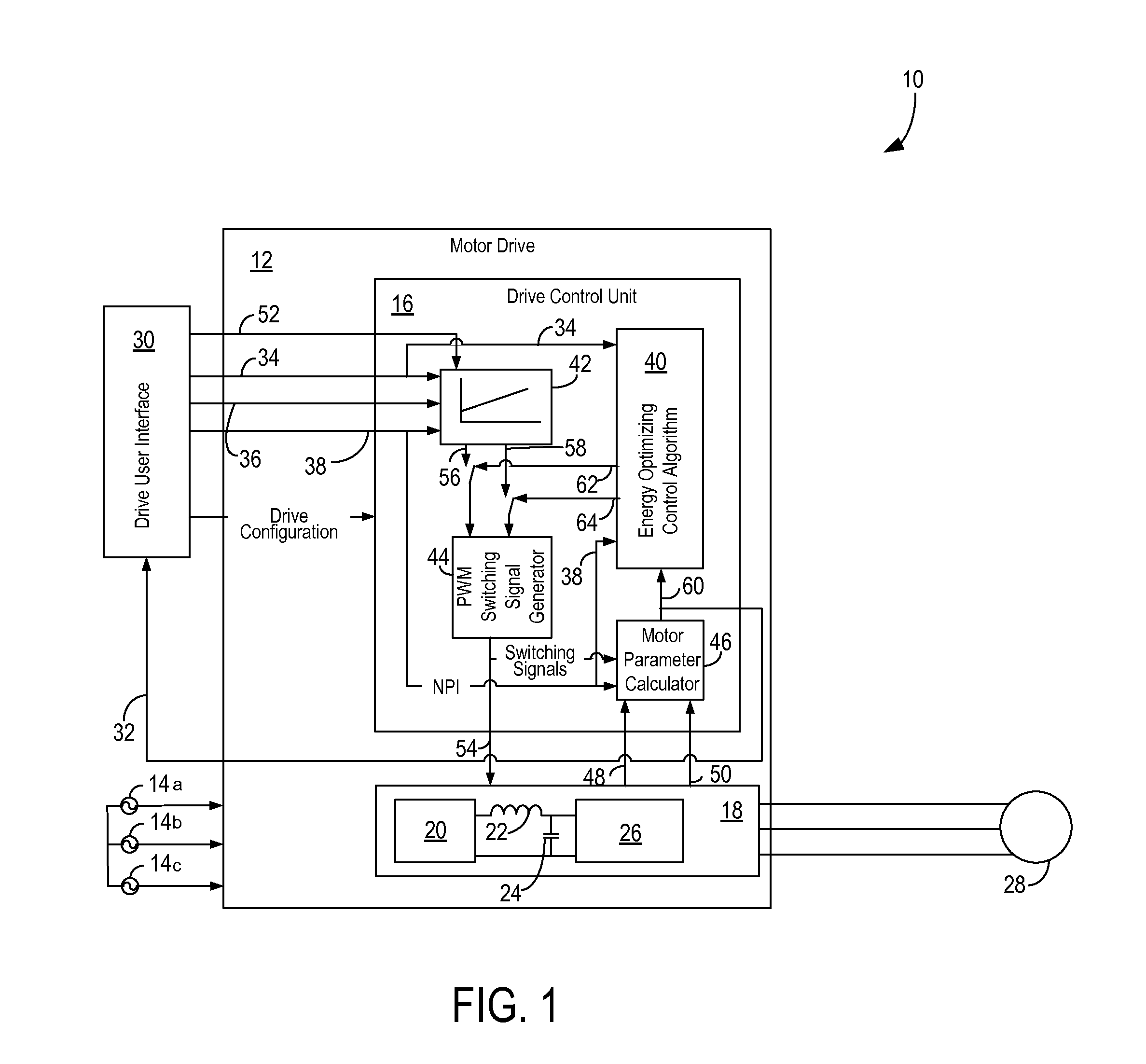

System and method of dynamic regulation of real power to a load

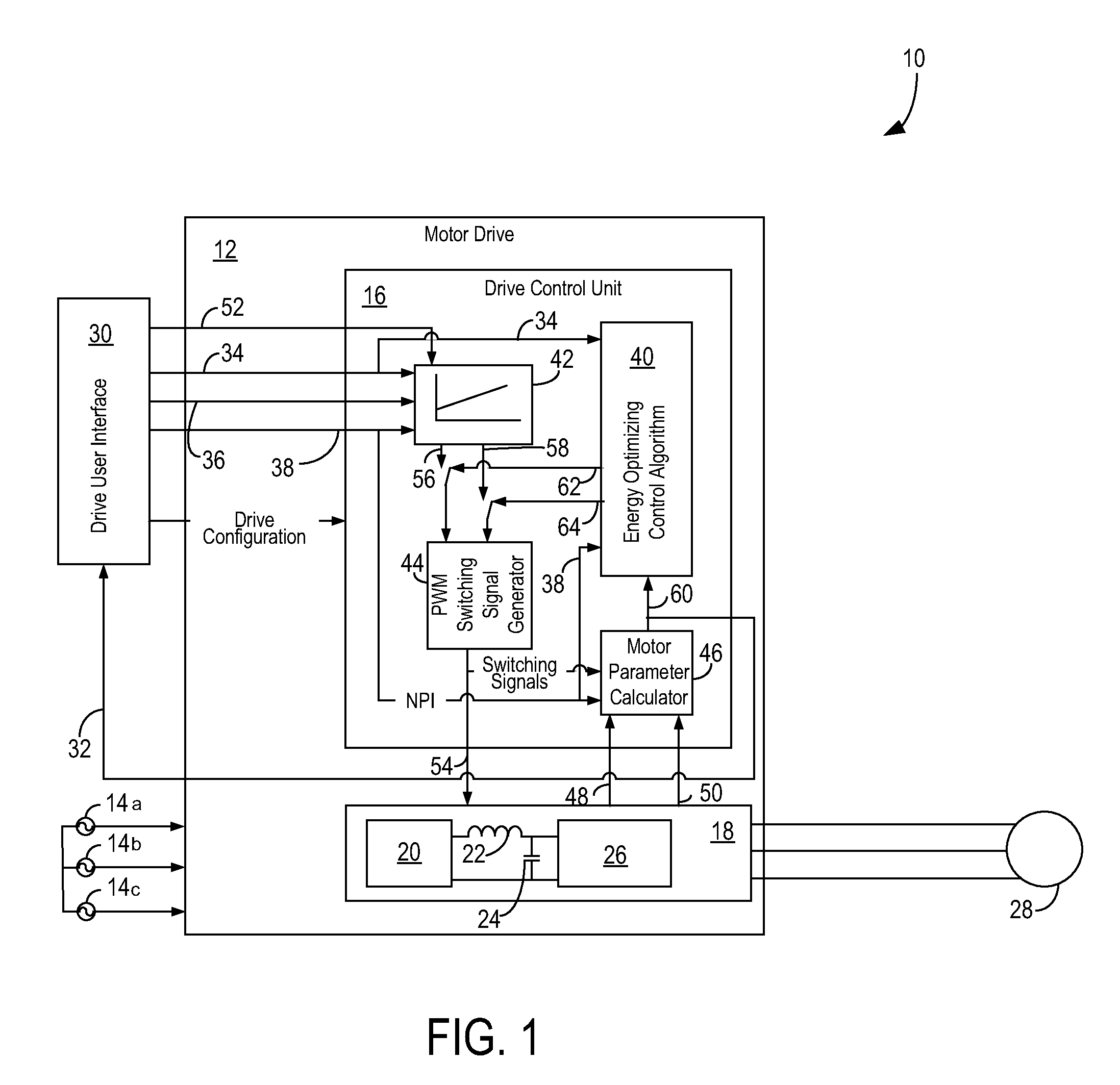

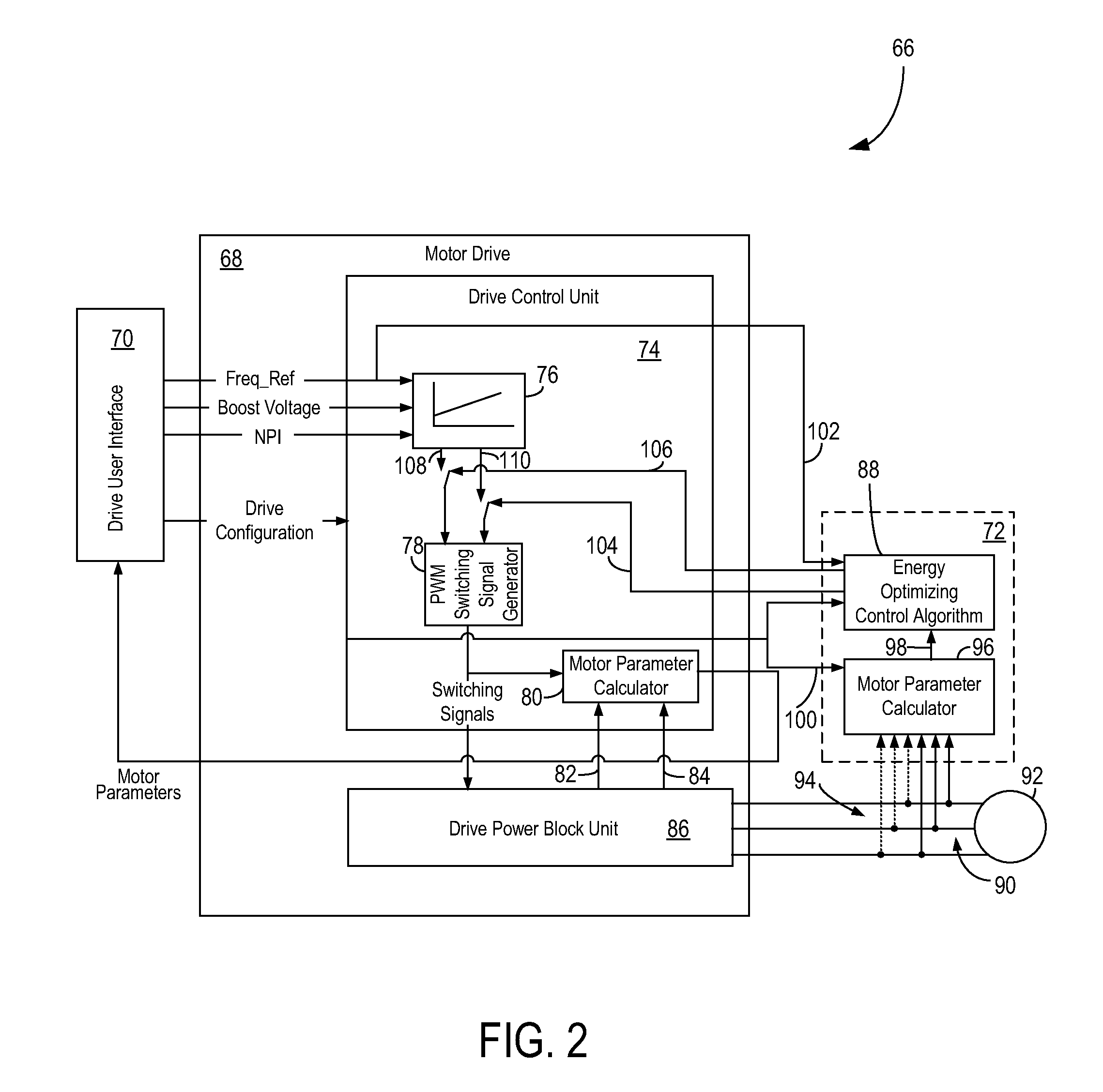

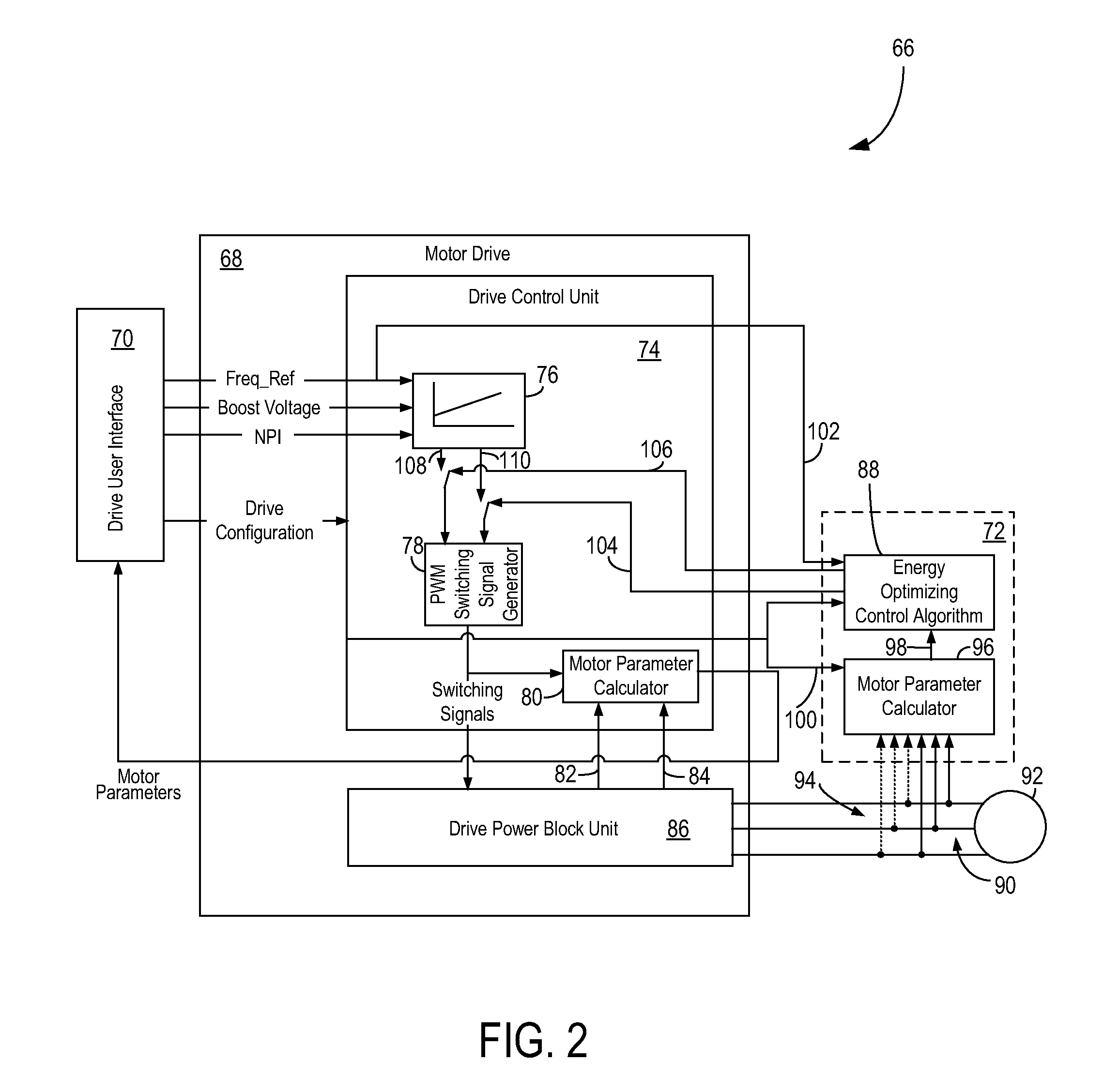

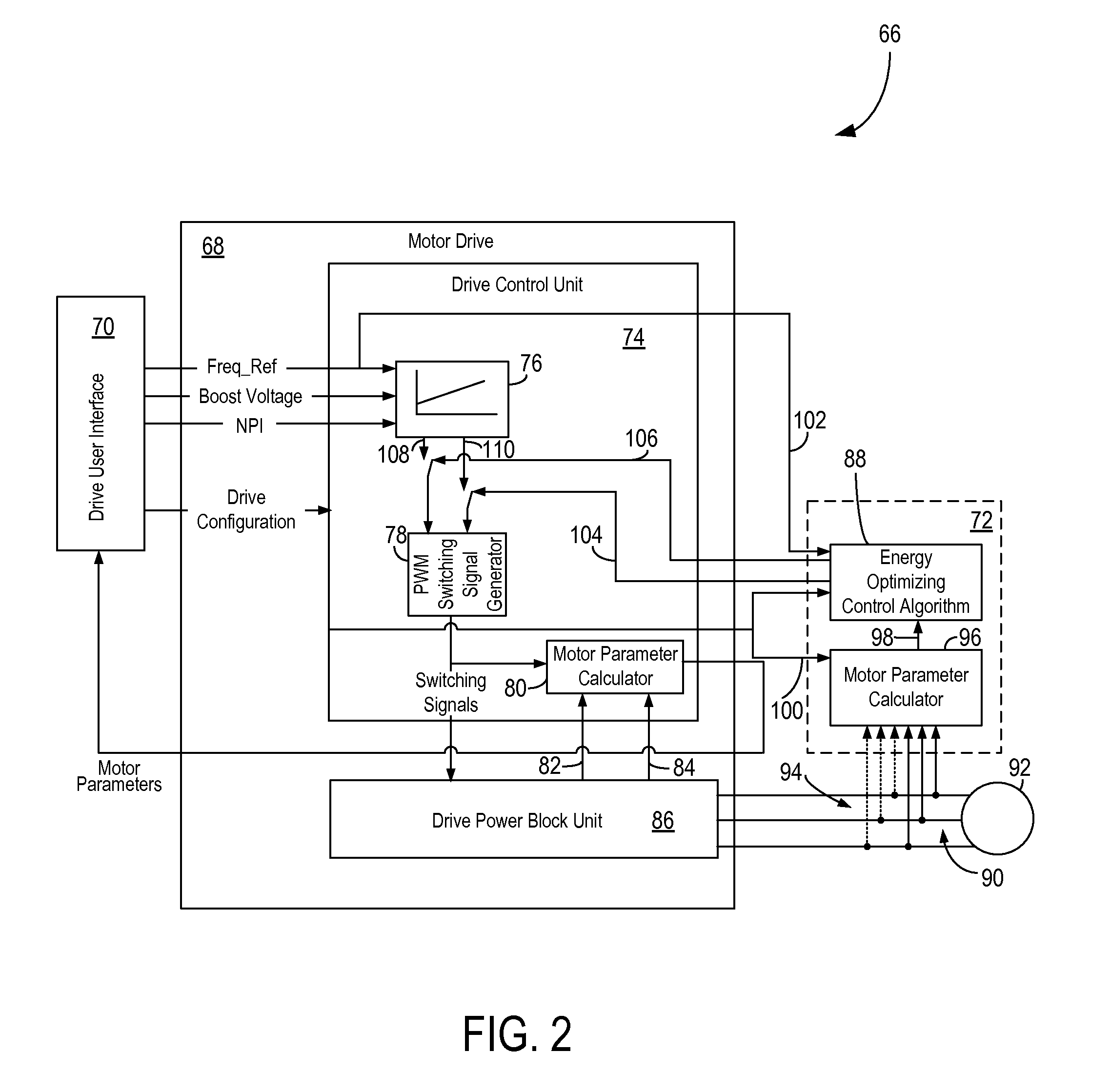

ActiveUS20100315034A1Electronic commutation motor controlMotor control for low load efficiencyMotor driveControl system

A system and method for controlling an AC motor drive includes a control system programmed with an energy algorithm configured to optimize operation of the motor drive. Specifically, the control system input an initial voltage-frequency command to the AC motor drive based on an initial voltage / frequency (V / Hz) curve, receives a real-time output of the AC motor drive generated according to the initial voltage-frequency command, and feedback a plurality of modified voltage-frequency commands to the AC motor drive, each of the plurality of modified voltage-frequency commands comprising a deviation from the initial V / Hz curve. The control system also determines a real-time value of the motor parameter corresponding to each of the plurality of modified voltage-frequency commands, and feeds back a modified voltage-frequency command to the AC motor drive so that the real-time value of the motor parameter is within a motor parameter tolerance range.

Owner:EATON INTELLIGENT POWER LIMITED

Programmable calibration circuit for power supply current sensing and droop loss compensation

ActiveUS20050024035A1Reduce wasteReduces chip wasteLevel controlEmergency protective circuit arrangementsEngineeringSupply current

A circuit for regulating power is disclosed. The present invention provides circuits and methods for current sensing variations, static droop settings, mismatched phase outputs, and temperature variations in a multiphase power regulator. The circuits may include a calibration controller that senses and regulates both a current sensing circuit and the droop in a power regulator over a range of temperatures thus equalizing phase outputs. The present invention includes the schematic organization and implementation of the circuit, the circuit's calibration, its use, and implementation. This invention advantageously provides circuits and methods to properly power a processor or IC chip according to the unique power specifications of the processor or chip.

Owner:TABAIAN FEREYDUN

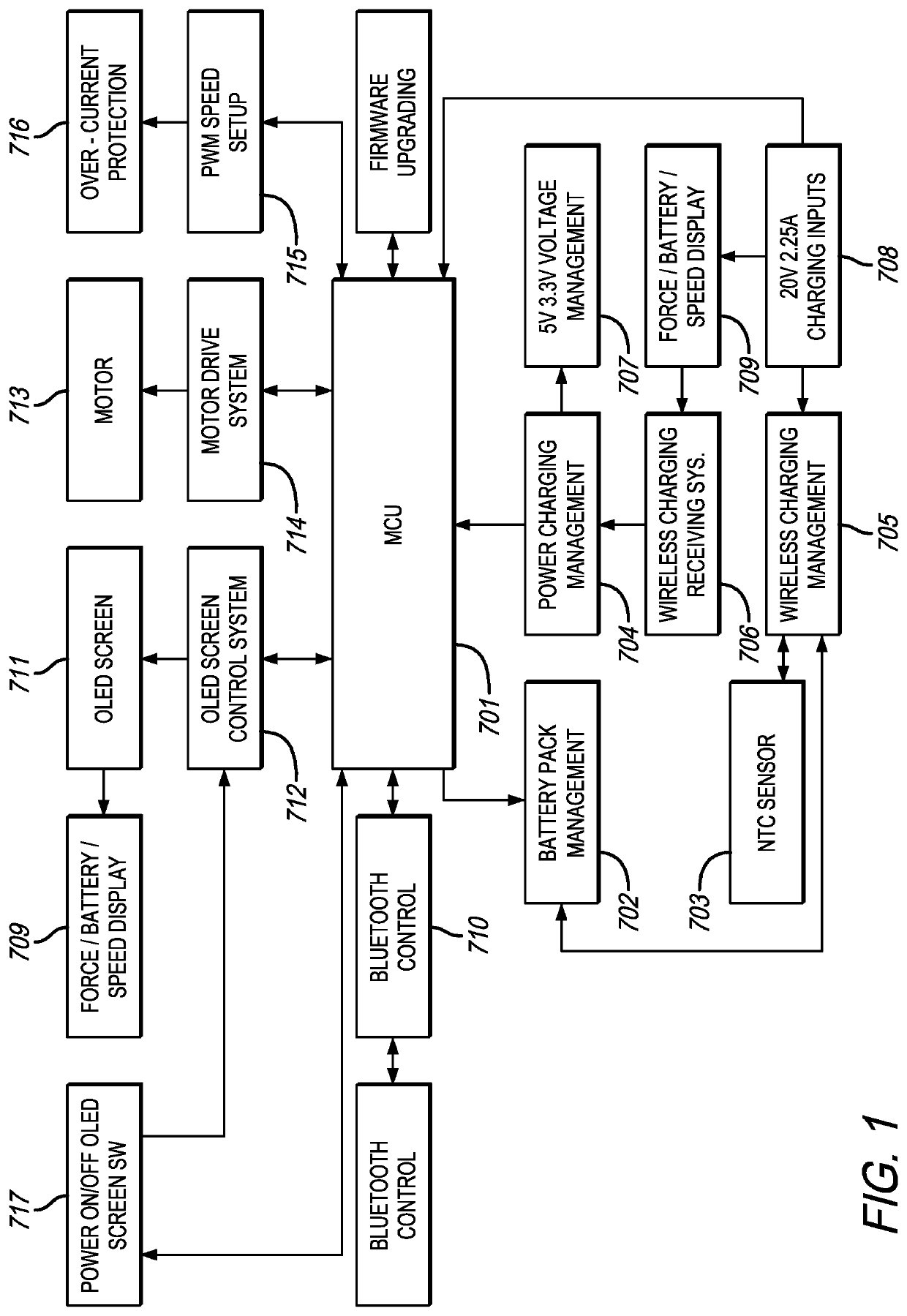

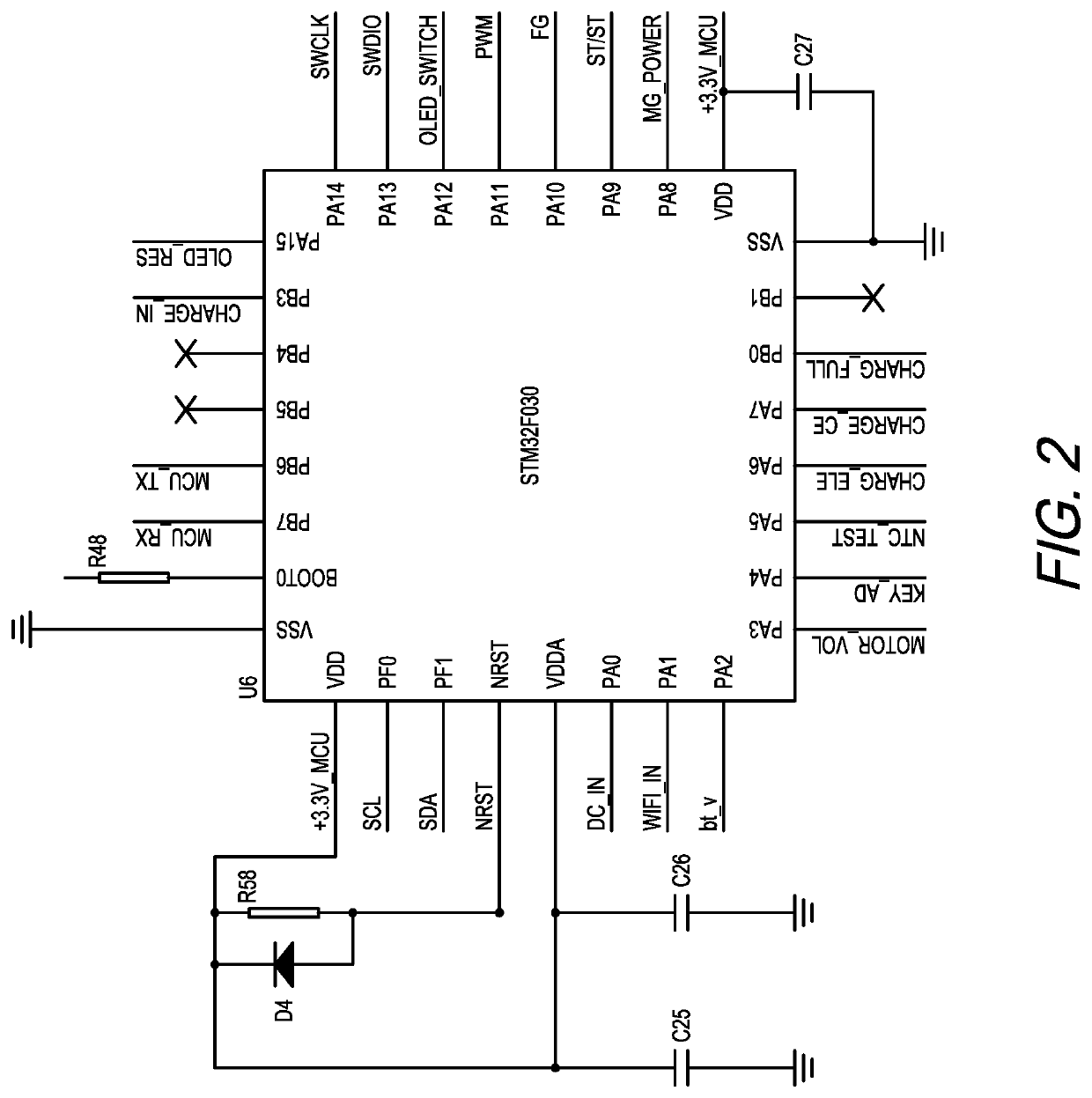

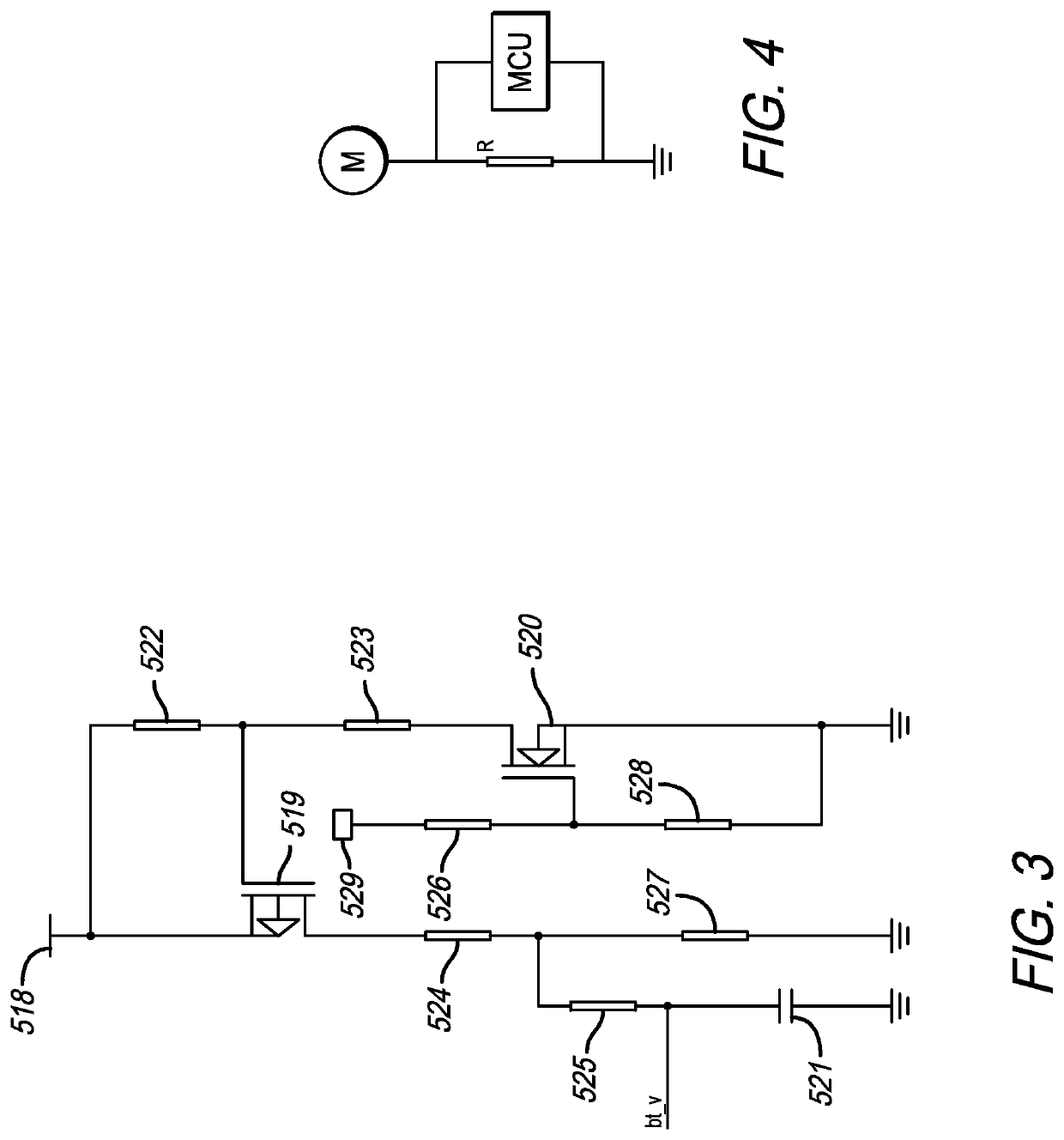

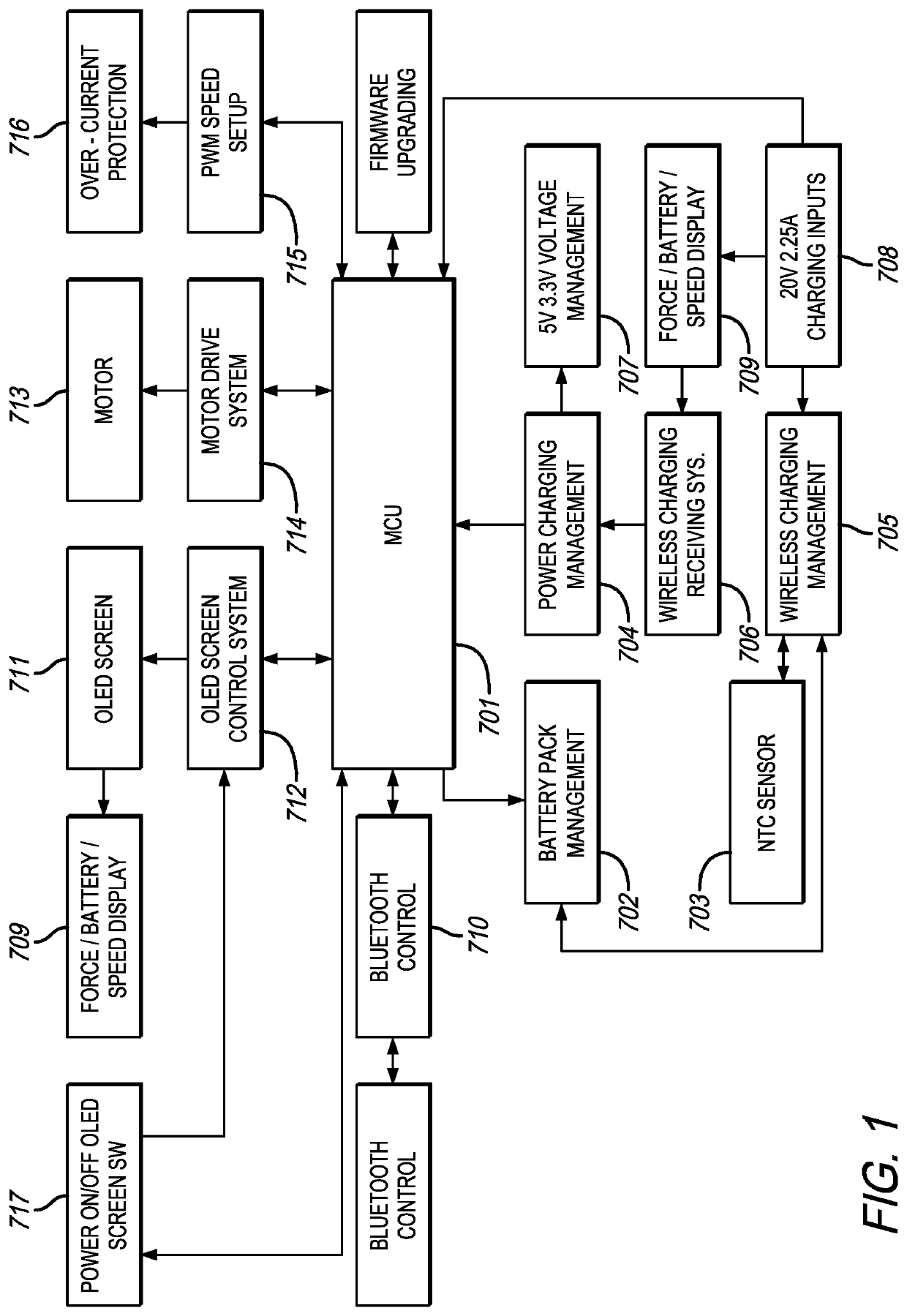

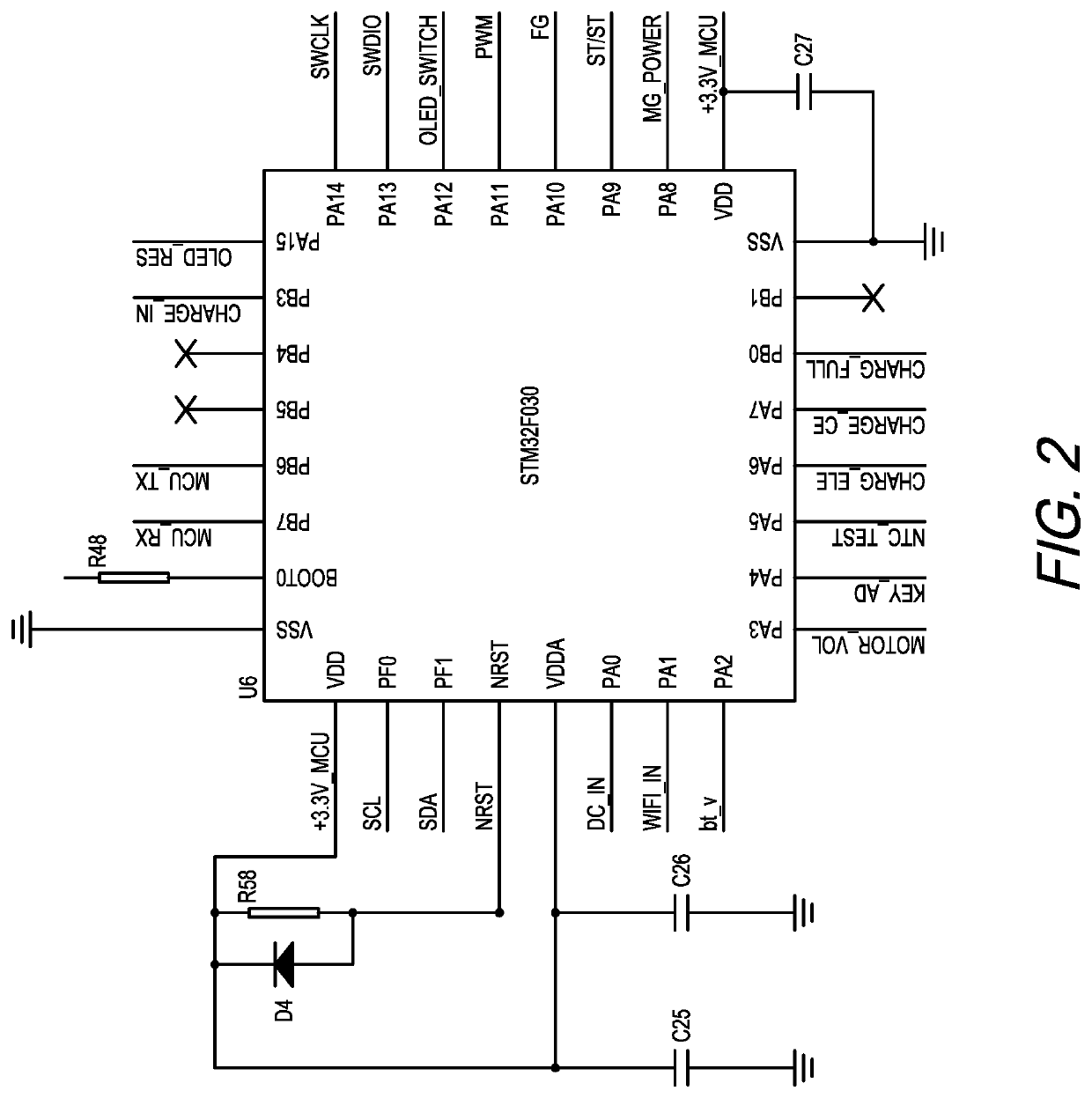

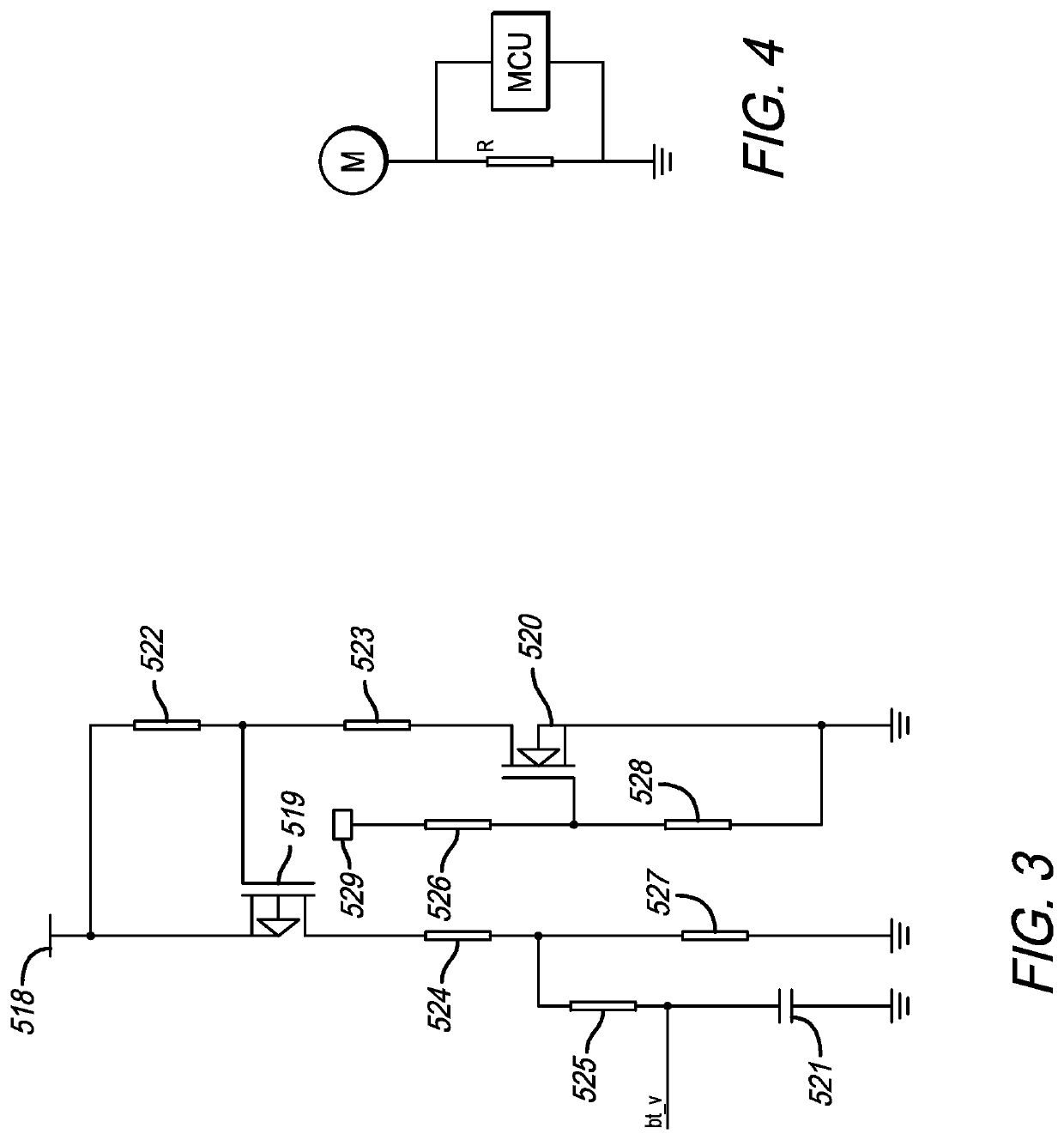

Percussive massage device with force meter

ActiveUS10940081B2Low profilePrecision therapyElectric motor controlSoftware algorithm controlPhysical medicine and rehabilitationElectric machinery

A percussive massage device with a force meter that includes a housing, an electrical source, a motor positioned in the housing, a switch for activating the motor, and a controller configured to obtain a voltage of the motor, generate a lookup table correlating voltage to force applied by the percussive massage device, and display a force magnitude corresponding to the obtained voltage using the lookup table.

Owner:THERABODY INC

Software-based adaptive control system for electric motors and generators

InactiveUS20050046375A1Increase torqueImprove efficiencyElectric motor speed/torque regulationVehicular energy storageElectric machineUser input

A control system for motors, generators and other electric machines that improves machine performance by dynamically adapting to changes. These changes may be in user inputs, machine operating conditions and / or machine operating parameters. The control system can take advantage of more independent machine parameters. That gives greater freedom to optimize and allows motors and generators to perform better than bigger, heavier machines, particularly more efficiently. The control system is software-based. So standard interfaces allow the control system to be improved and updated without changing hardware. This adaptive control system improves performance in a wide variety of motor and generator applications, particularly those that need high efficiency over varying conditions.

Owner:BLUWAV SYST LLC

Percussive massage device with force meter

ActiveUS20200352820A1Low profilePrecision therapyElectric motor controlSoftware algorithm controlPhysical medicine and rehabilitationElectric machinery

A percussive massage device with a force meter that includes a housing, an electrical source, a motor positioned in the housing, a switch for activating the motor, and a controller configured to obtain a voltage of the motor, generate a lookup table correlating voltage to force applied by the percussive massage device, and display a force magnitude corresponding to the obtained voltage using the lookup table.

Owner:THERABODY INC

System and method of dynamic regulation of real power to a load

ActiveUS8232760B2Electronic commutation motor controlMotor control for low load efficiencyMotor driveControl system

A system and method for controlling an AC motor drive includes a control system programmed with an energy algorithm configured to optimize operation of the motor drive. Specifically, the control system input an initial voltage-frequency command to the AC motor drive based on an initial voltage / frequency (V / Hz) curve, receives a real-time output of the AC motor drive generated according to the initial voltage-frequency command, and feedback a plurality of modified voltage-frequency commands to the AC motor drive, each of the plurality of modified voltage-frequency commands comprising a deviation from the initial V / Hz curve. The control system also determines a real-time value of the motor parameter corresponding to each of the plurality of modified voltage-frequency commands, and feeds back a modified voltage-frequency command to the AC motor drive so that the real-time value of the motor parameter is within a motor parameter tolerance range.

Owner:EATON INTELLIGENT POWER LTD

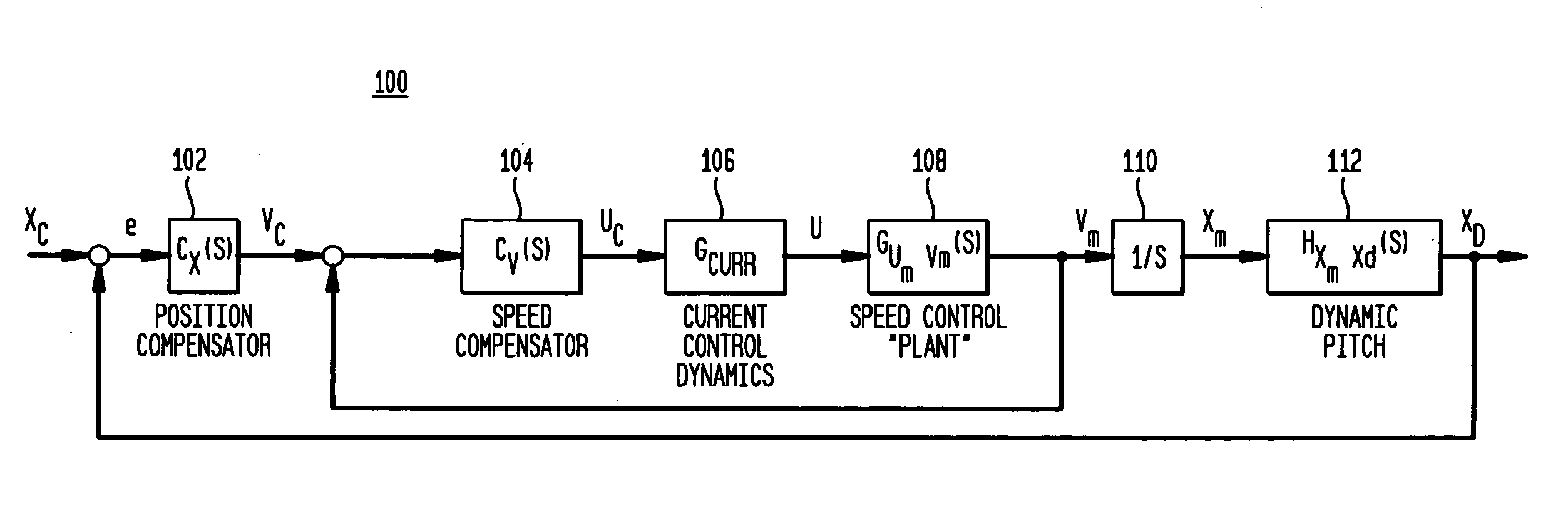

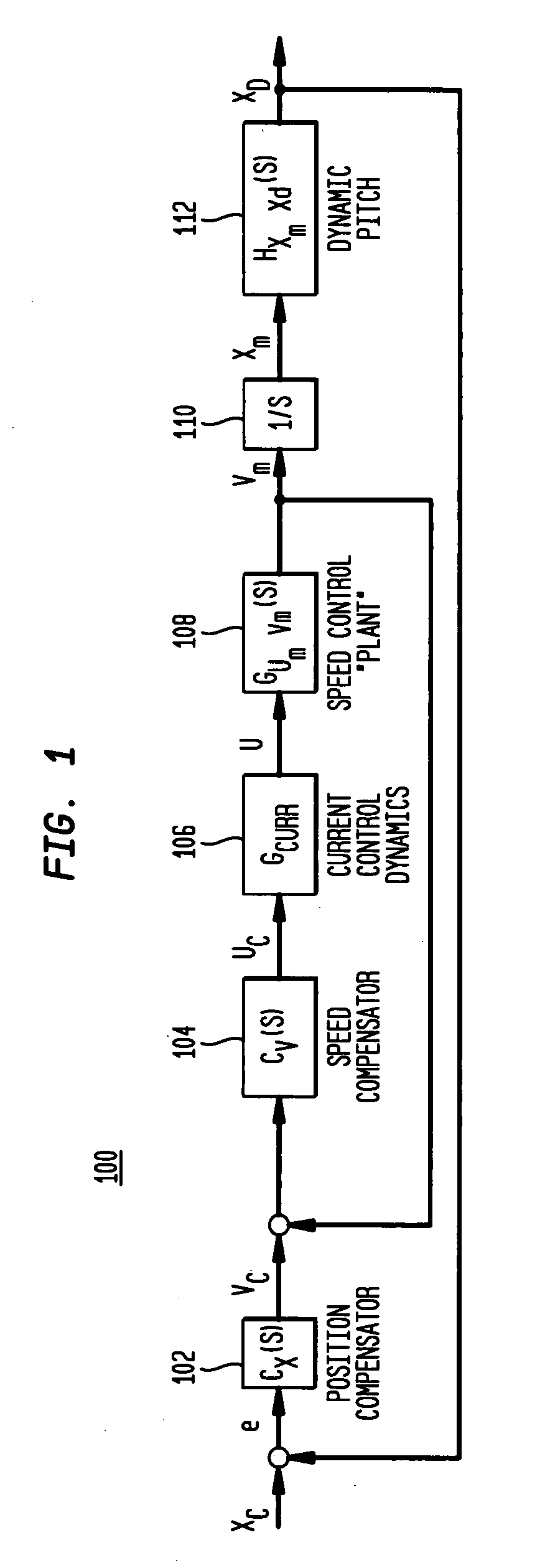

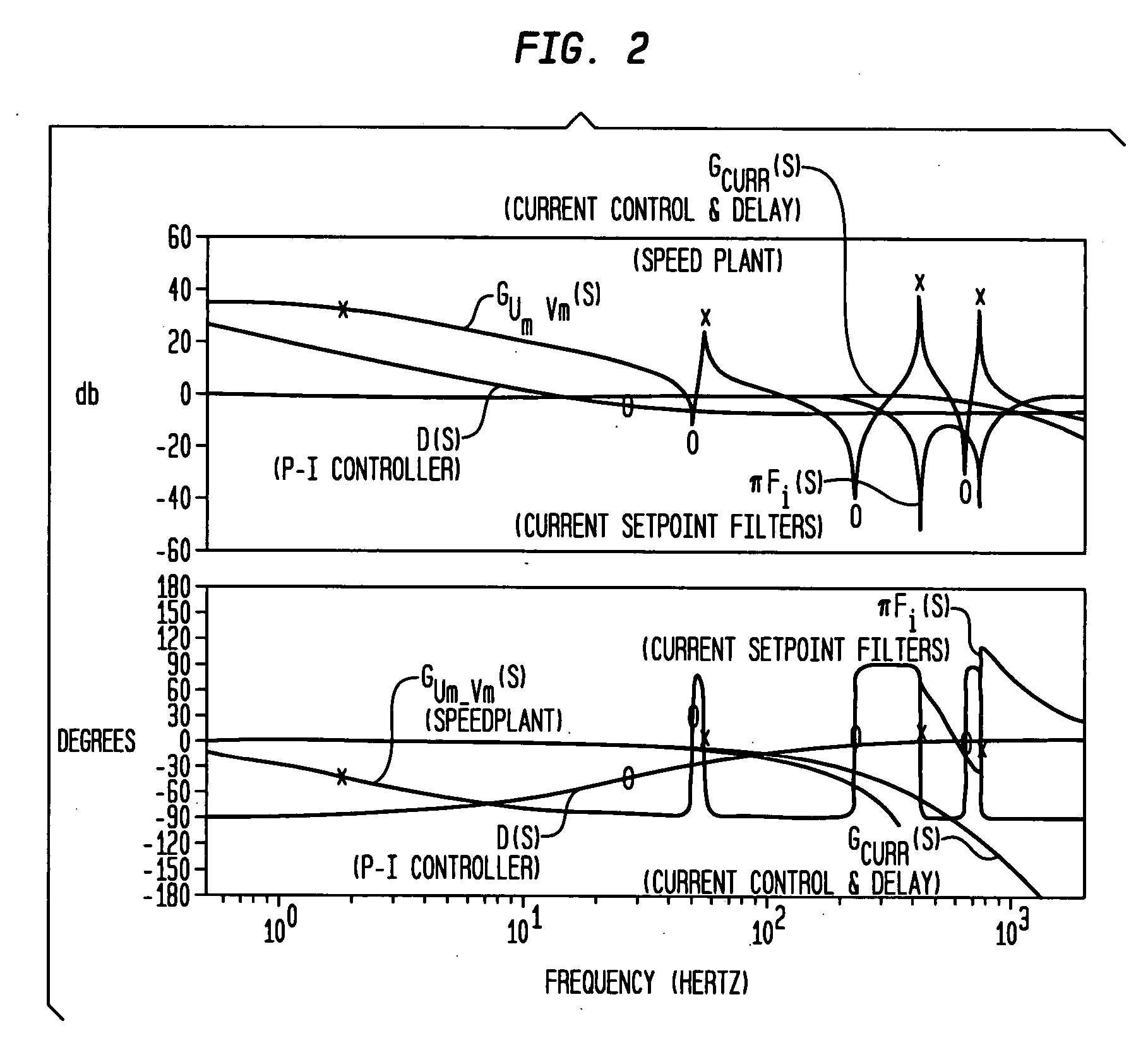

Automating tuning of a closed loop controller

ActiveUS20070268068A1Inhibition rangeMeet the restrictionsProgramme controlSoftware algorithm controlReference modelClosed loop

The present invention is a novel device, system, and method for simultaneous selection of filters and loop proportional gain for a closed loop system. According to an exemplary embodiment of the present invention, a method provides an automated selection of the portion of the controller known as the speed loop compensator. The method may operate on a frequency response function that represents the dynamic response from an actuation force (e.g. motor torque) to the sensor used for feedback of speed control (e.g. motor encoder angle). The frequency response function may be represented as a series of complex numbers each with a corresponding frequency value. The tuning method determines the combination of filter parameters that allows the loop proportional loop gain (Kp) to be maximized while meeting a specified set of criteria for stability margins. Methods for selecting integral gain and reference model are also presented.

Owner:SIEMENS IND INC

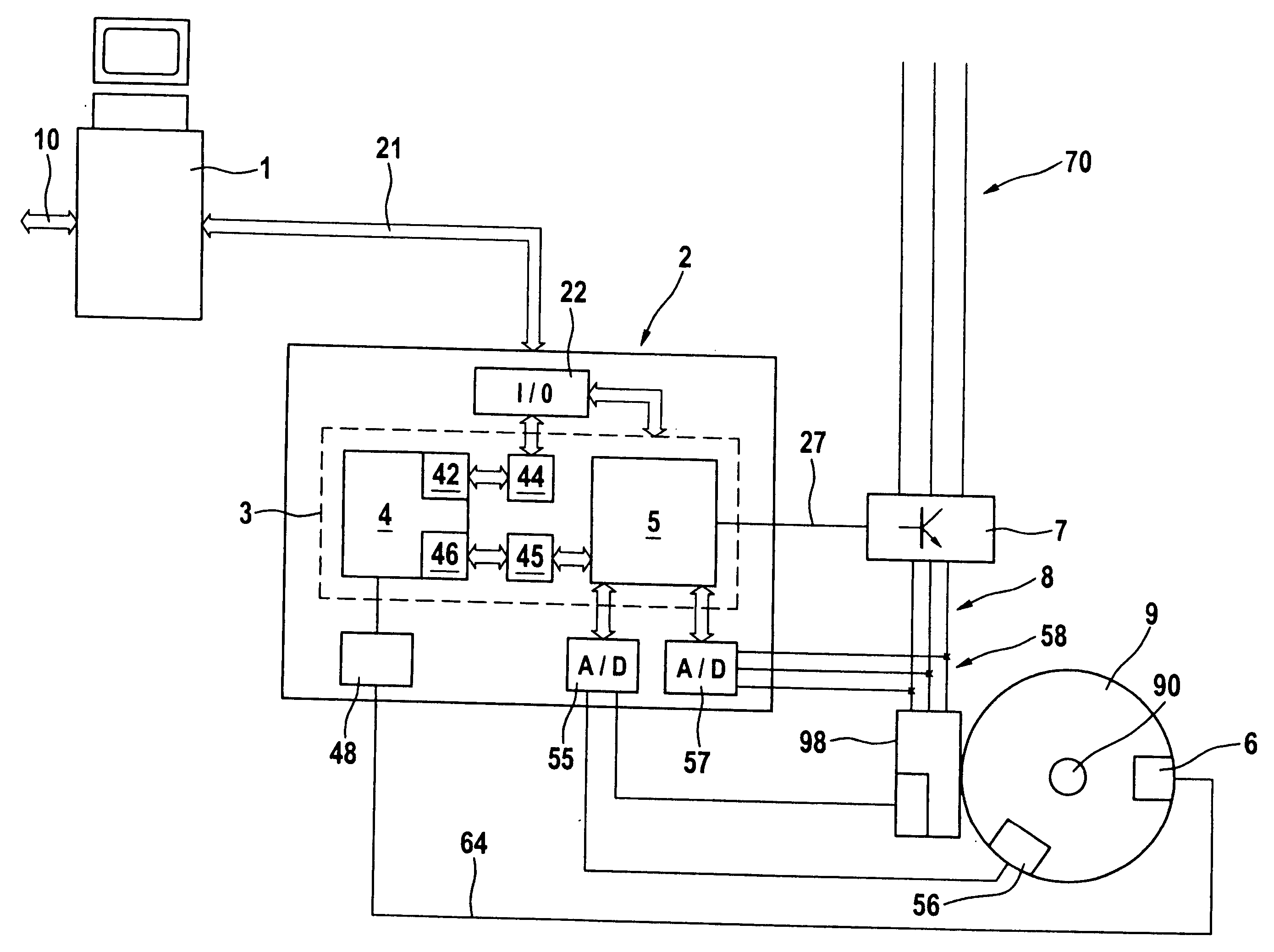

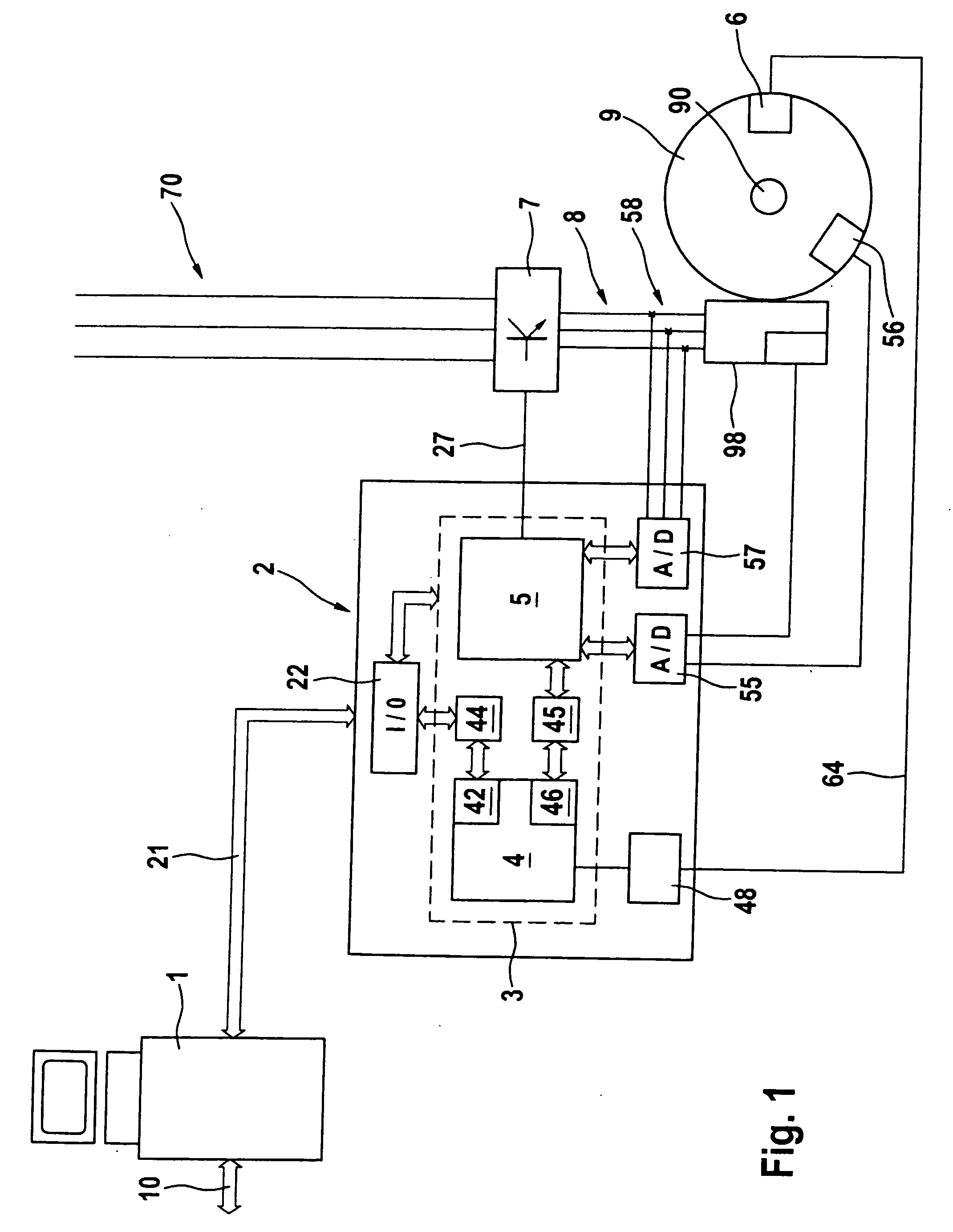

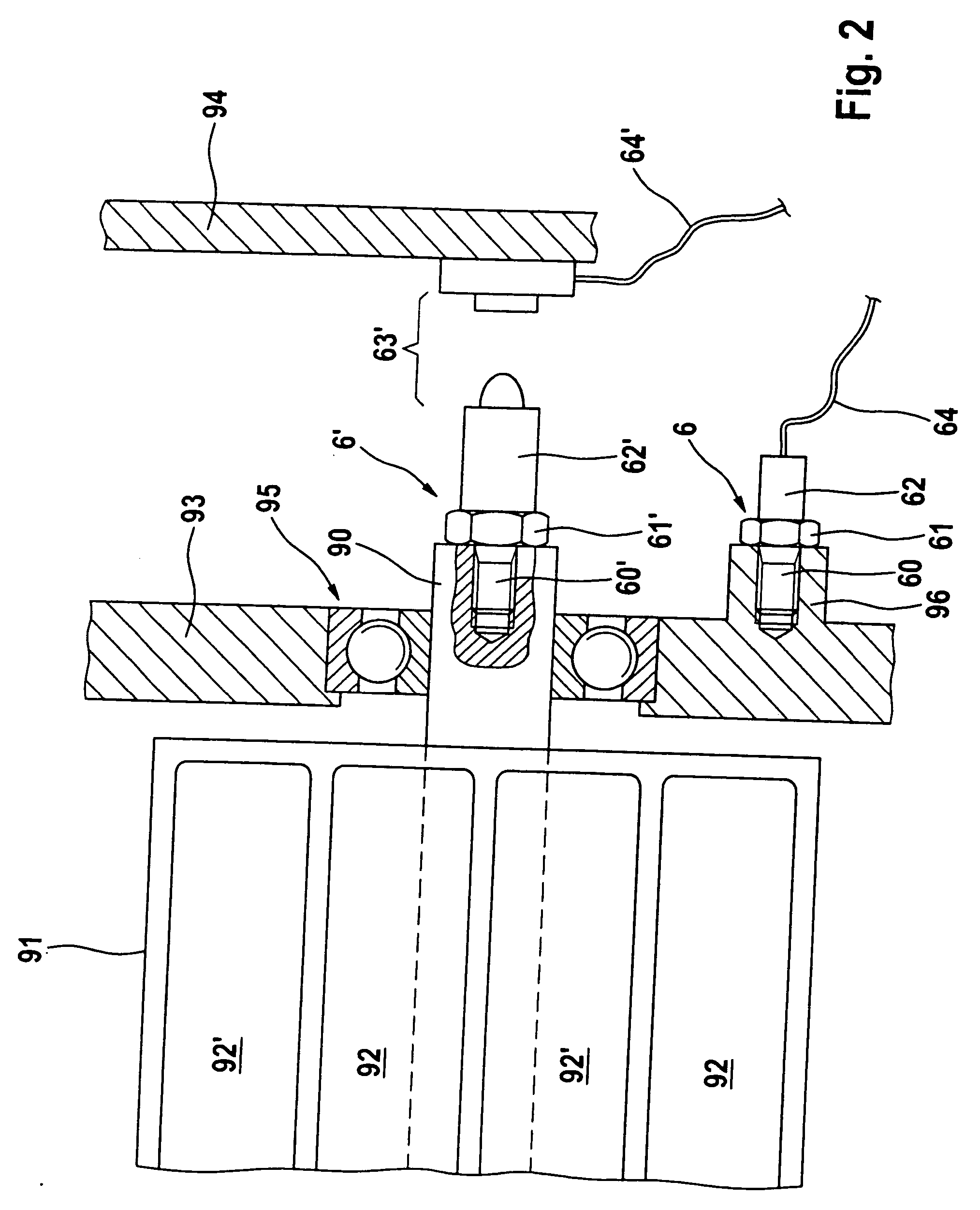

Electrical drive apparatus having a structure-borne noise sensor

InactiveUS20060192508A1Accurate operationThe production process is complicatedAssociation with control/drive circuitsMotor/generator/converter stoppersMotor controlEngineering

A drive apparatus includes an electric motor (9), a control device (2) having a microprocessor (3) and a motor control module (5), which interacts with a power module (7) for the purpose of adjusting desired electrical parameters for the electric motor (9), a connecting line (8), which connects an output of the control device (2) to the electric motor (9), and a self-diagnostics device having a structure-borne noise sensor (6), which is connected to the electric motor, and an assessment module (4) for the signals from said structure-borne noise sensor (6). The invention assessment module is integrated in the control device, to be precise such that the microprocessor (3) of the control device (2) assesses the signals from the structure-borne noise sensor (6). The computational power of the microprocessor used in the operation of the power module (7) is used for directly assessing and interpreting the structure-borne noise signal.

Owner:WAGO VERW GMBH

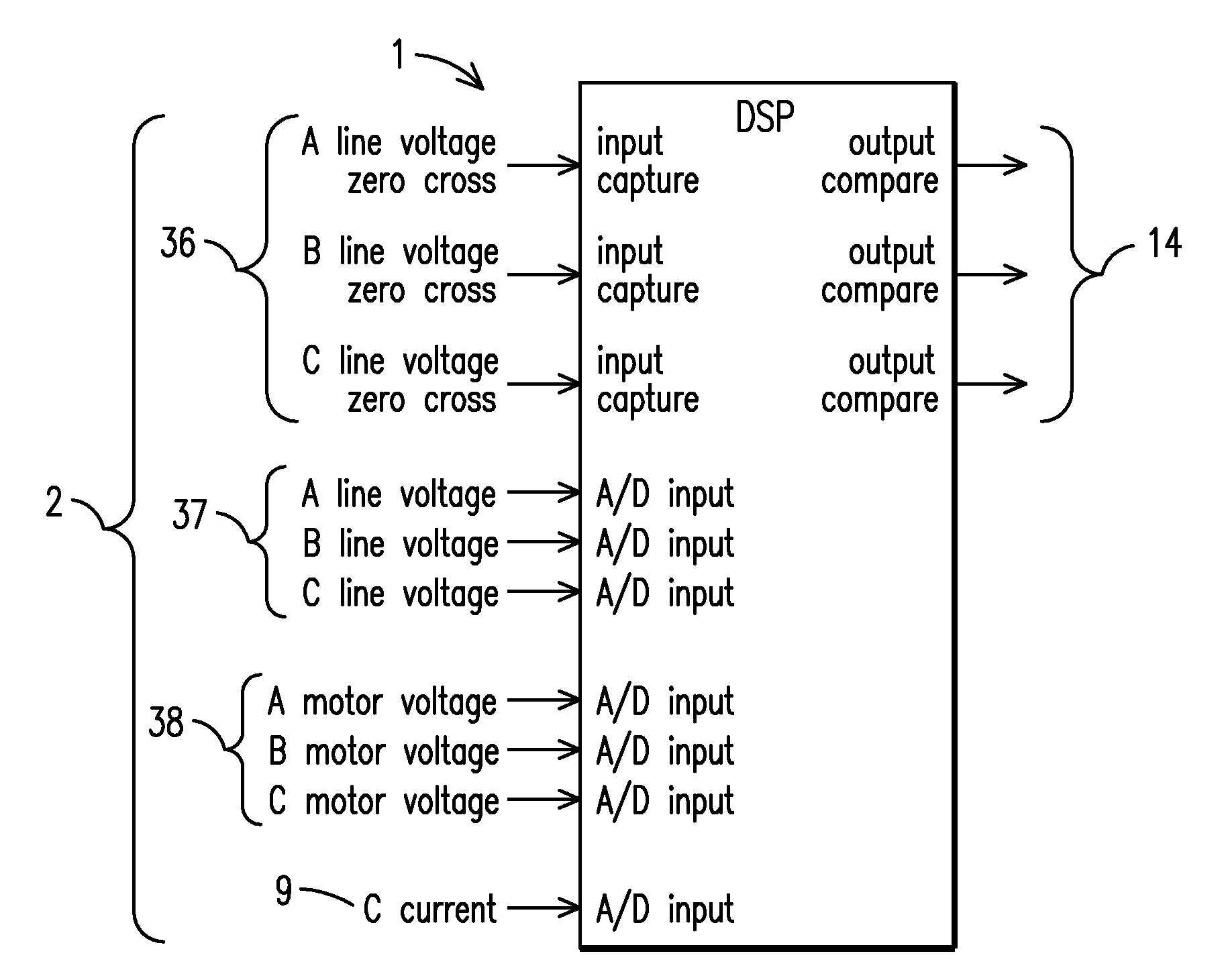

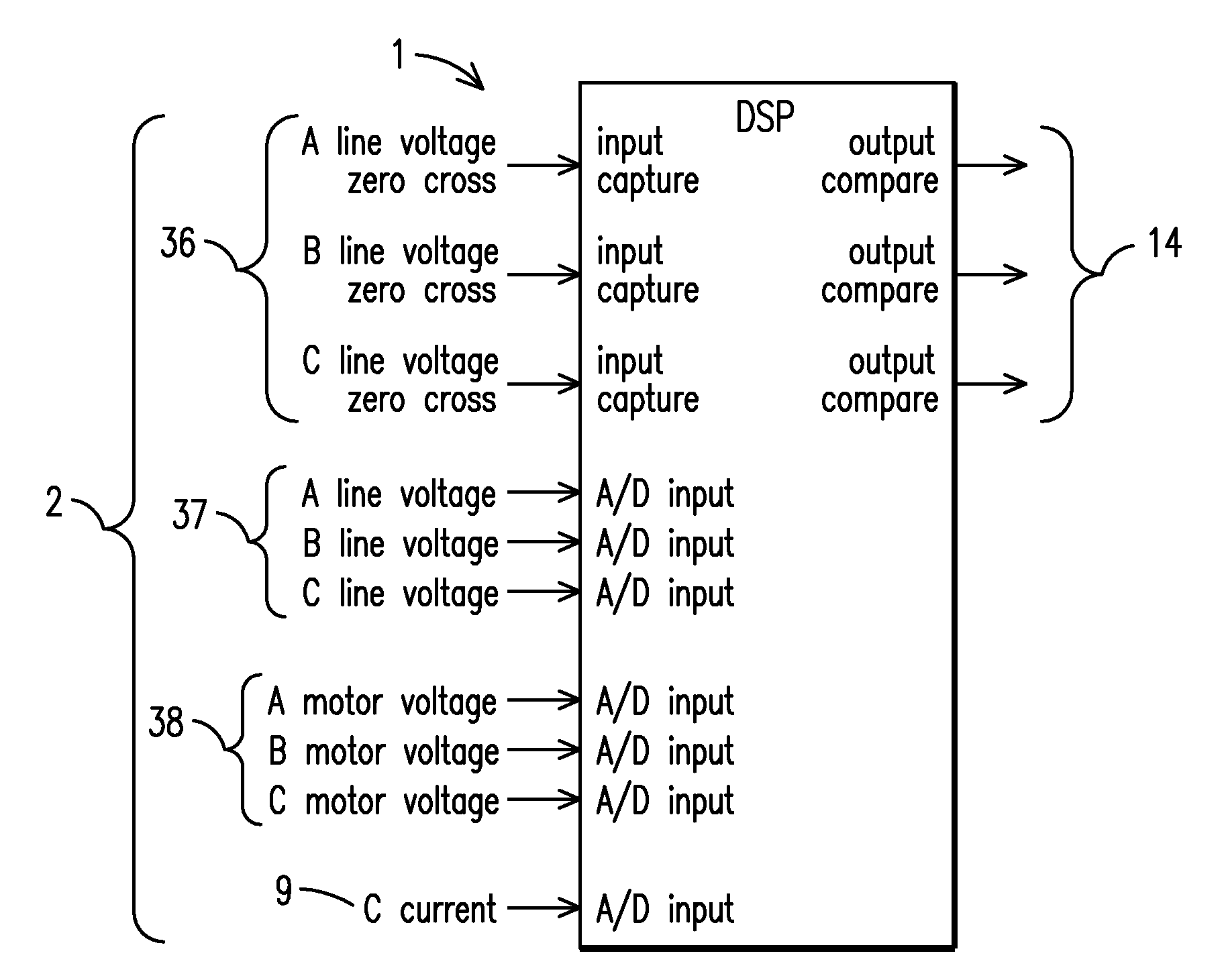

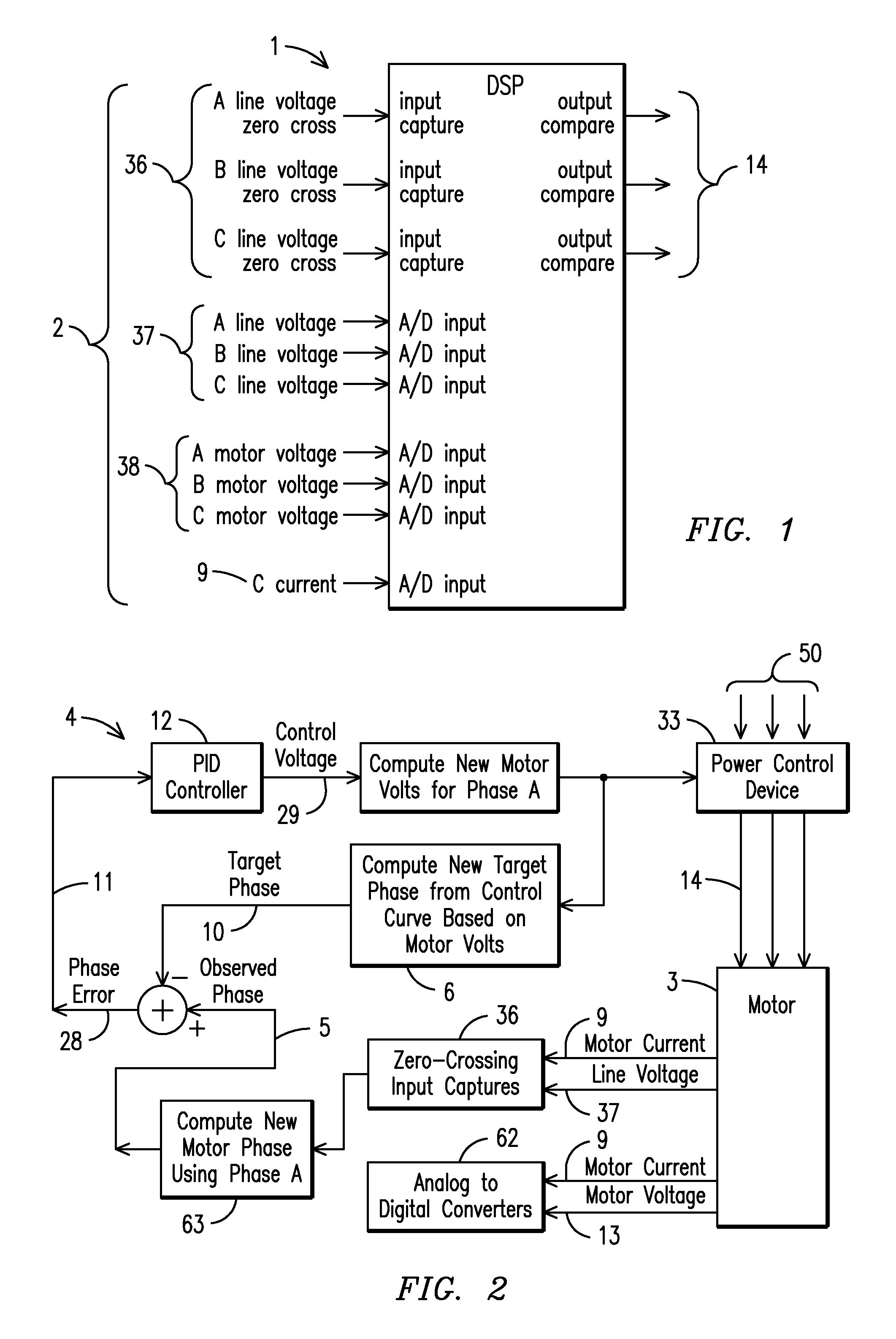

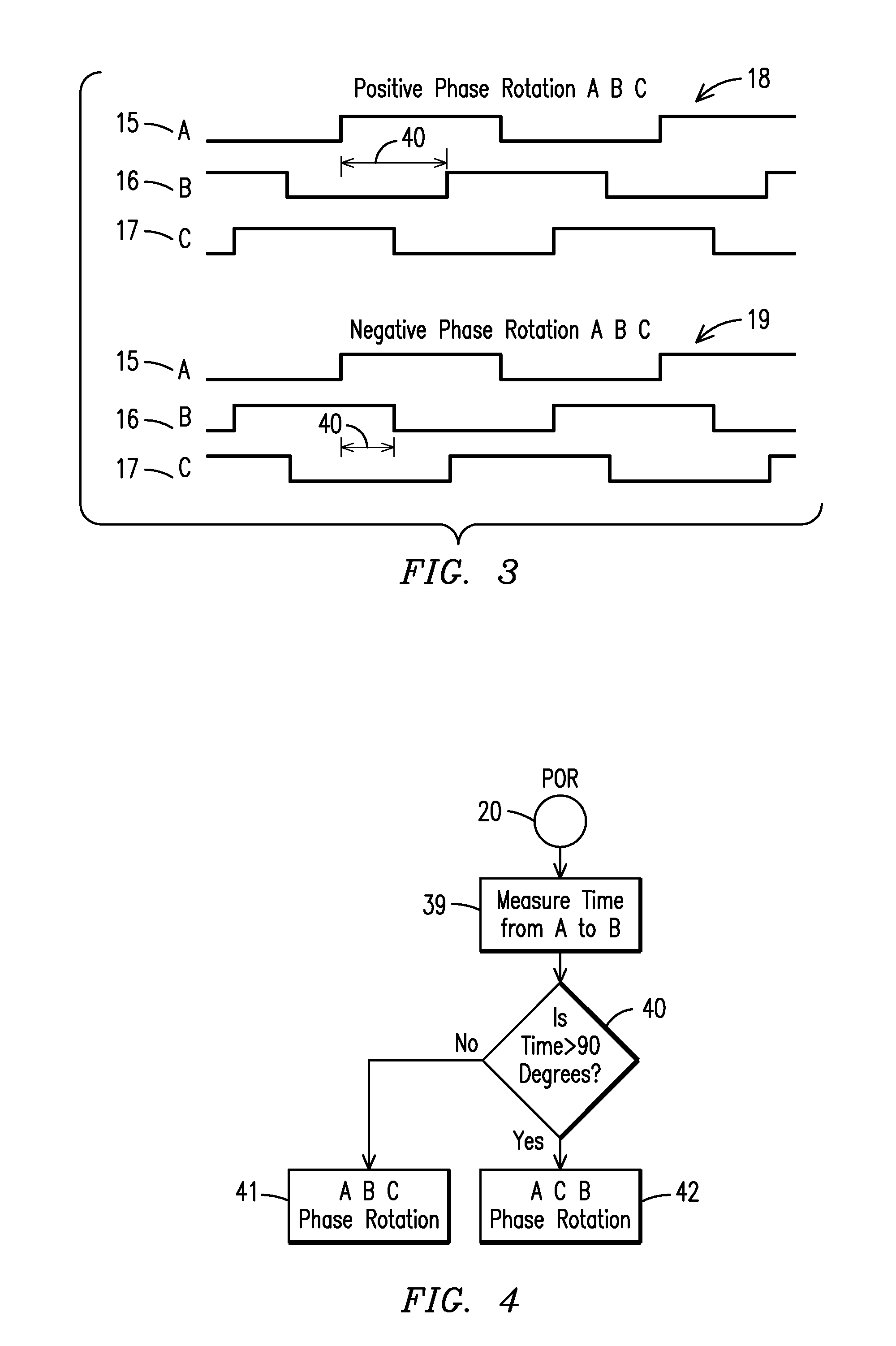

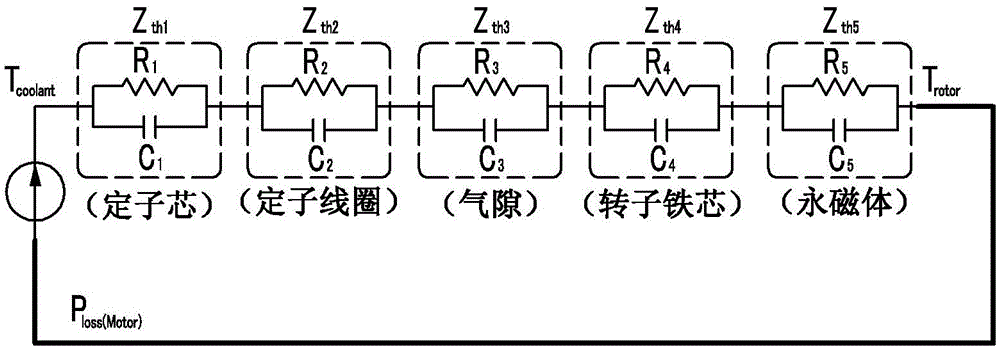

Motor controller system and method for maximizing energy savings

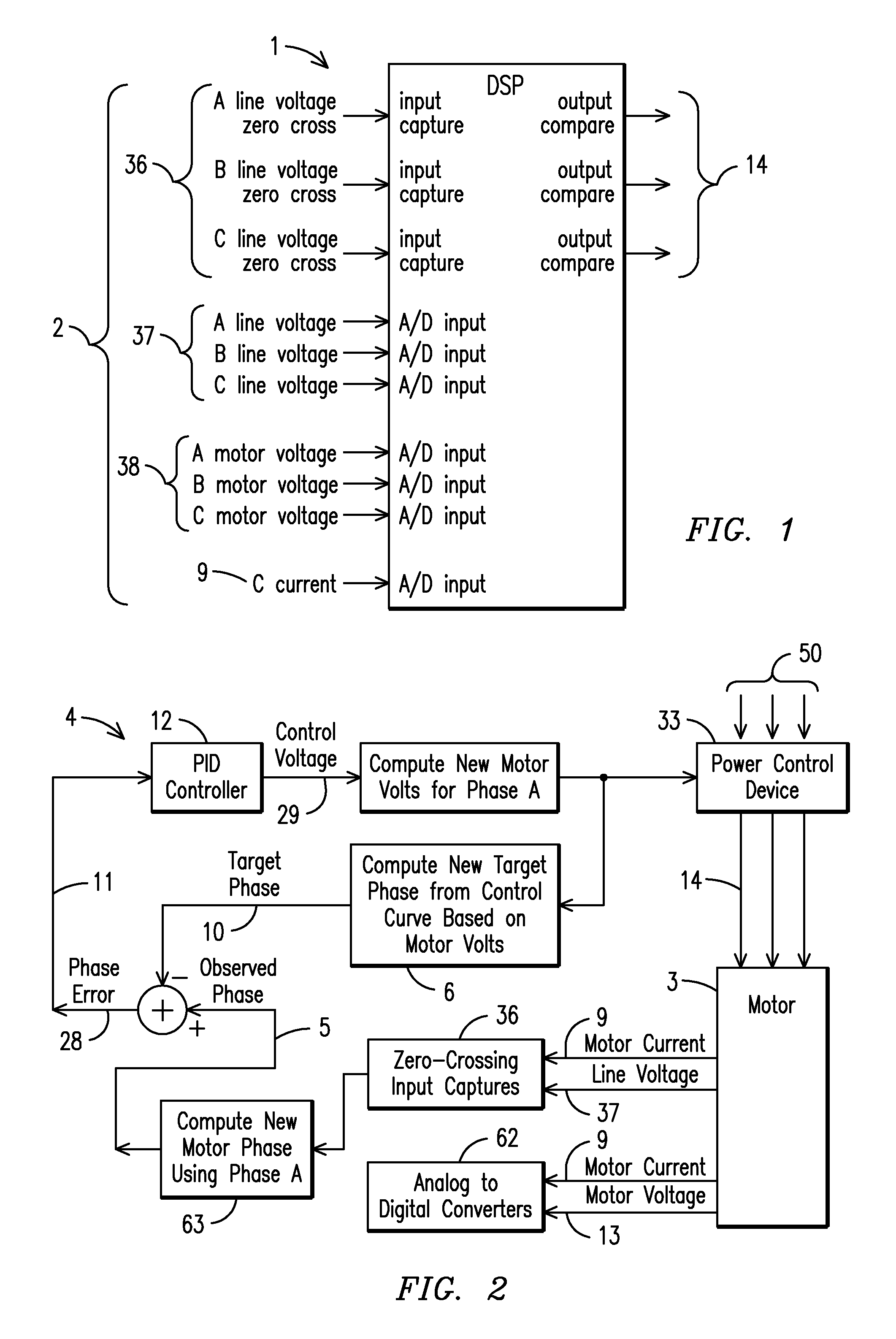

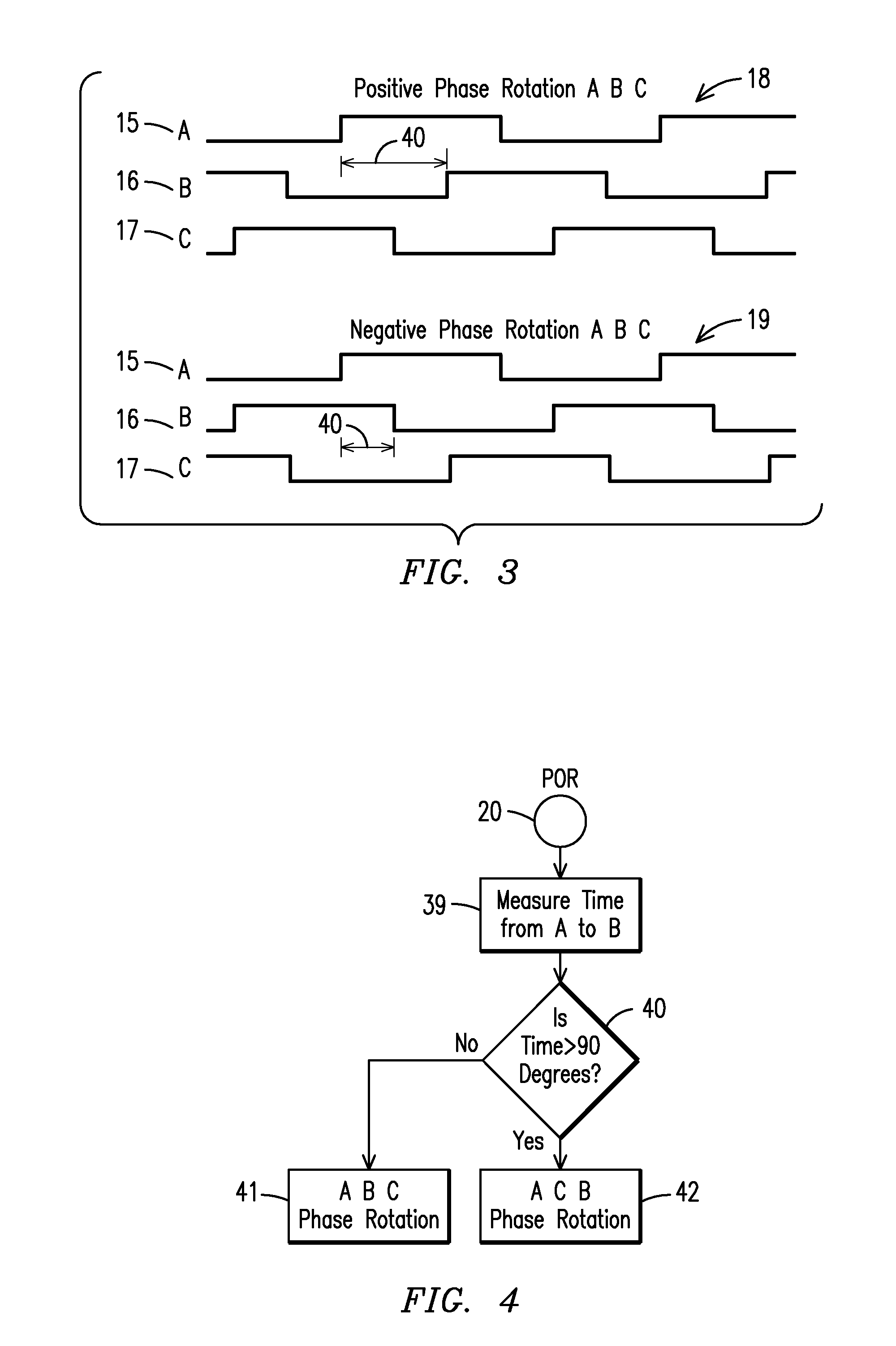

ActiveUS20100013427A1Maximize energy savingSave energyMotor control for low load efficiencyMotor/generator/converter stoppersTarget controlInduction motor

A motor controller (4) and method for maximizing the energy savings in an AC induction motor (3) at every load wherein the motor is calibrated at two or more load points to establish a control line (6), which is then programmed into a non-volatile memory (30) of the motor controller. A DSP-based closed-loop motor controller observes the motor parameters of the motor such as firing angle / duty cycles (23), voltage (37), current (9) and phase angles to arrive at a minimum voltage necessary to operate the motor at any load along the control line. The motor controller performs closed-loop control to keep the motor running at a computed target control point, such that maximum energy savings are realized by reducing voltage through pulse width modulation.

Owner:THE POWERWISE GRP

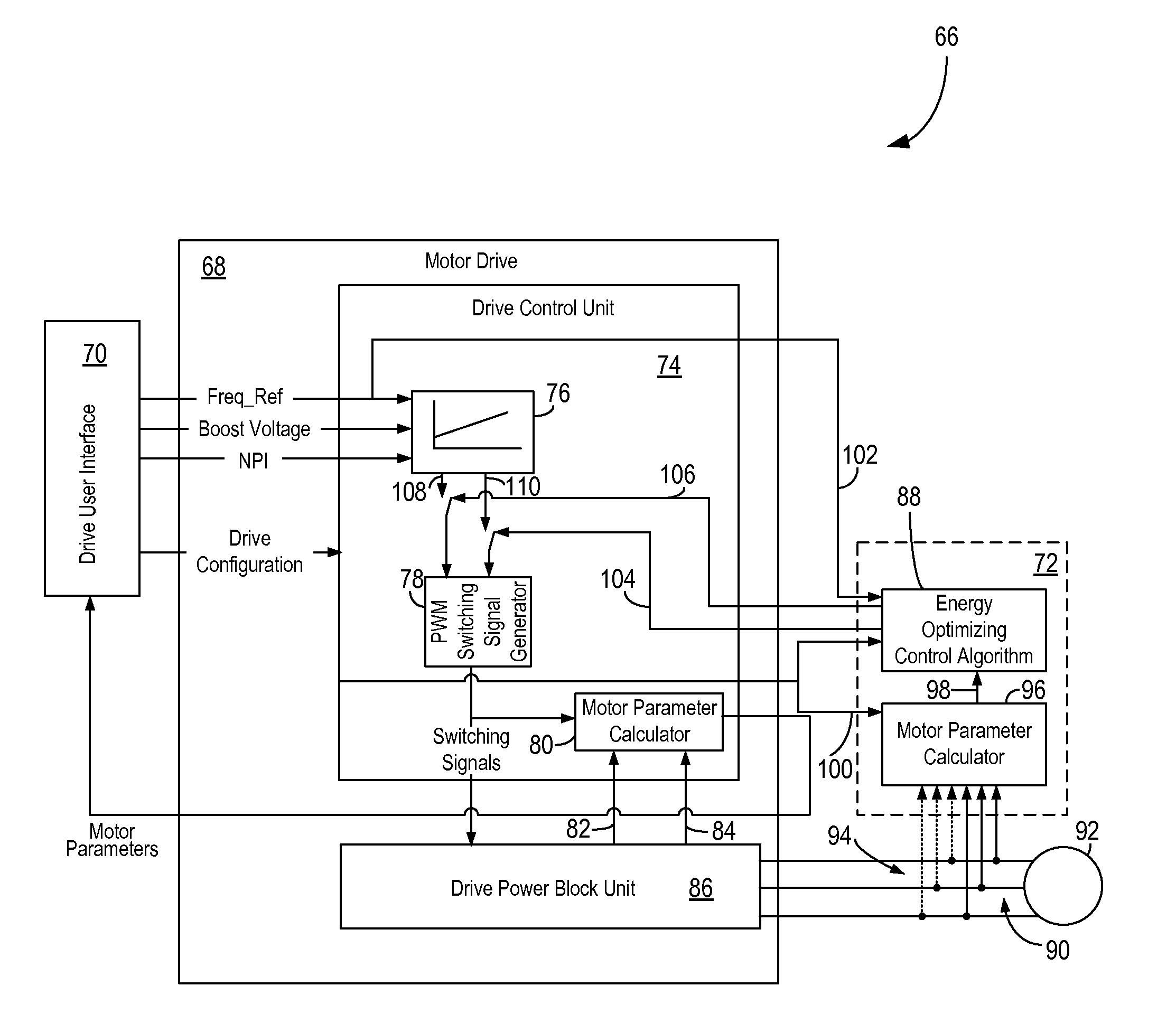

System and method of dynamic regulation of real power to a load

ActiveUS20120280645A1Additional energy savingStable motor operating conditionMotor control for low load efficiencySoftware algorithm controlOperating pointControl system

A system and method for controlling an AC motor drive includes a control system programmed with an algorithm configured to optimize operation of the motor drive. Specifically, the control system is programmed to input an initial voltage-frequency command to the drive. The initial voltage-frequency command includes a voltage reference and a frequency reference corresponding to an operating point of an initial voltage / frequency (V / Hz) curve. The control system monitors a real-time output of the drive, modifies the voltage reference based on the real-time output of the drive, and transmits a modified voltage-frequency command to the drive. The modified voltage-frequency command corresponds to an operating point of a modified V / Hz curve defined by the modified voltage reference and the initial V / Hz curve.

Owner:EATON INTELLIGENT POWER LIMITED

Motor controller system and method for maximizing energy savings

ActiveUS20100117588A9Maximize energy savingSave energyMotor control for low load efficiencyMotor/generator/converter stoppersLoop controlInduction motor

A motor controller (4) and method for maximizing the energy savings in an AC induction motor (3) at every load wherein the motor is calibrated at two or more load points to establish a control line (6), which is then programmed into a non-volatile memory (30) of the motor controller. A DSP-based closed-loop motor controller observes the motor parameters of the motor such as firing angle / duty cycles (23), voltage (37), current (9) and phase angles to arrive at a minimum voltage necessary to operate the motor at any load along the control line. The motor controller performs closed-loop control to keep the motor running at a computed target control point, such that maximum energy savings are realized by reducing voltage through pulse width modulation.

Owner:THE POWERWISE GRP INC

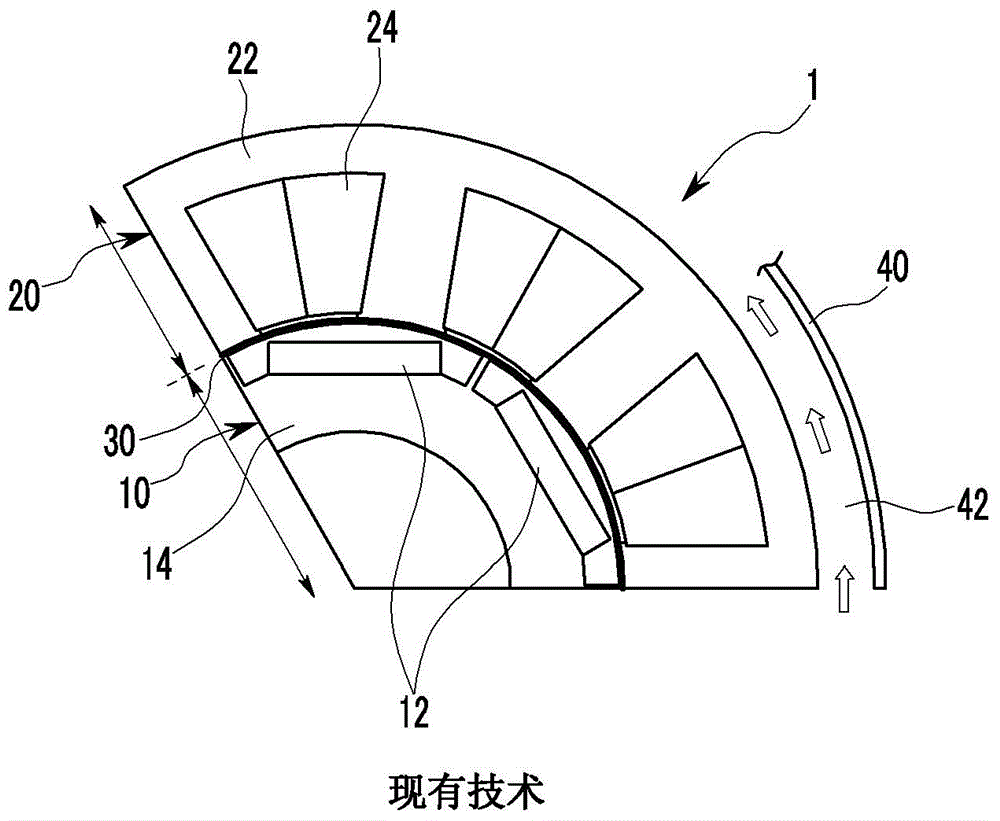

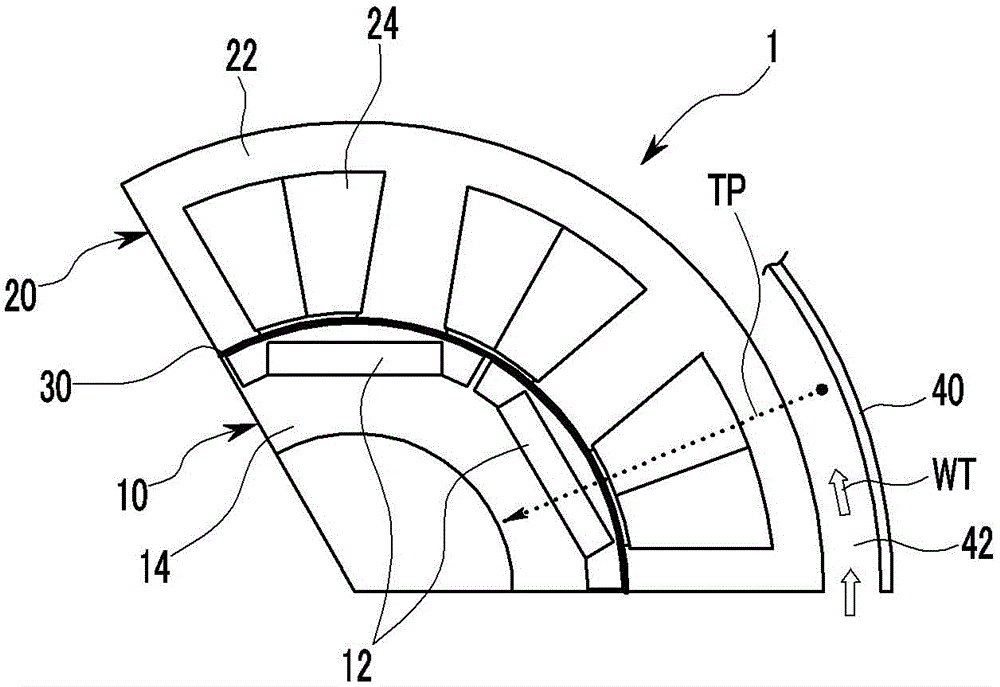

System and method for estimating temperature of rotor of motor

InactiveCN104978477AImprove performanceImprove efficiencySoftware algorithm controlTemperature measurement of moving solidsEngineeringEnergy loss

A system and method are provided for estimating temperature of a rotor of a motor configured to calculate temperature of the rotor using an actual measured data-based thermal model (thermal impedance model) and an energy loss model, and to estimate temperature of the rotor using the calculated temperature variation of the rotor. The method includes calculating, by a controller, an energy loss of the motor using driving conditions of the motor. The controller is also configured to calculate a temperature variation of the rotor in a predetermined reference temperature using the calculated energy loss and thermal resistances of the rotor and a stator of the motor. Further, the controller is configured to estimate a rotor temperature in the predetermined reference temperature using the temperature variation of the rotor.

Owner:HYUNDAI MOTOR CO LTD

System and Method for Collecting Characteristic Information of a Motor, Neural Network and Method for Estimating Regions of Motor Operation from Information Characterizing the Motor, and System and Method for Controlling Motor

ActiveUS20080315811A1Programme-controlled manipulatorSynchronous motors startersOperating pointConductor Coil

A method for collecting operational parameters of a motor may include controlling the energization of a phase winding of the motor to establish an operating point, monitoring operational parameters of the motor that characterize a relationship between the energization control applied to the motor's phase winding and the motor's response to this control, and collecting information of the operational parameters for the operating point that characterizes the relationship between the applied energization control and the motor's response. The collected information characterizing the relationship between the applied energization control and the motor's response may be employed by a neural network to estimate the regions of operation of the motor. And a system for controlling the operation of motor may employ this information, the neural network, or both to regulate the energization of a motor's phase winding di-ring a phase cycle.

Owner:VIRGINIA TECH INTPROP INC +1

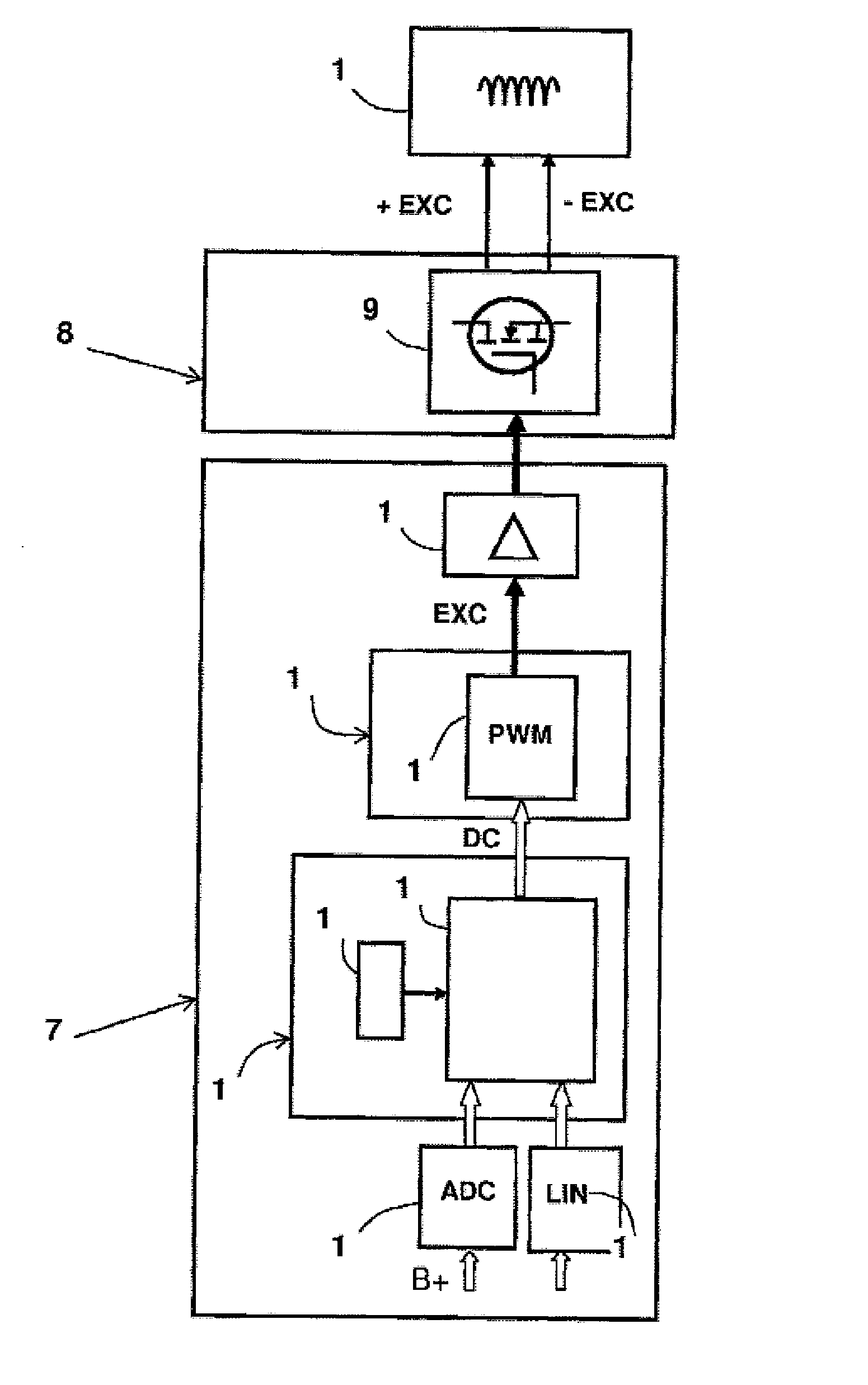

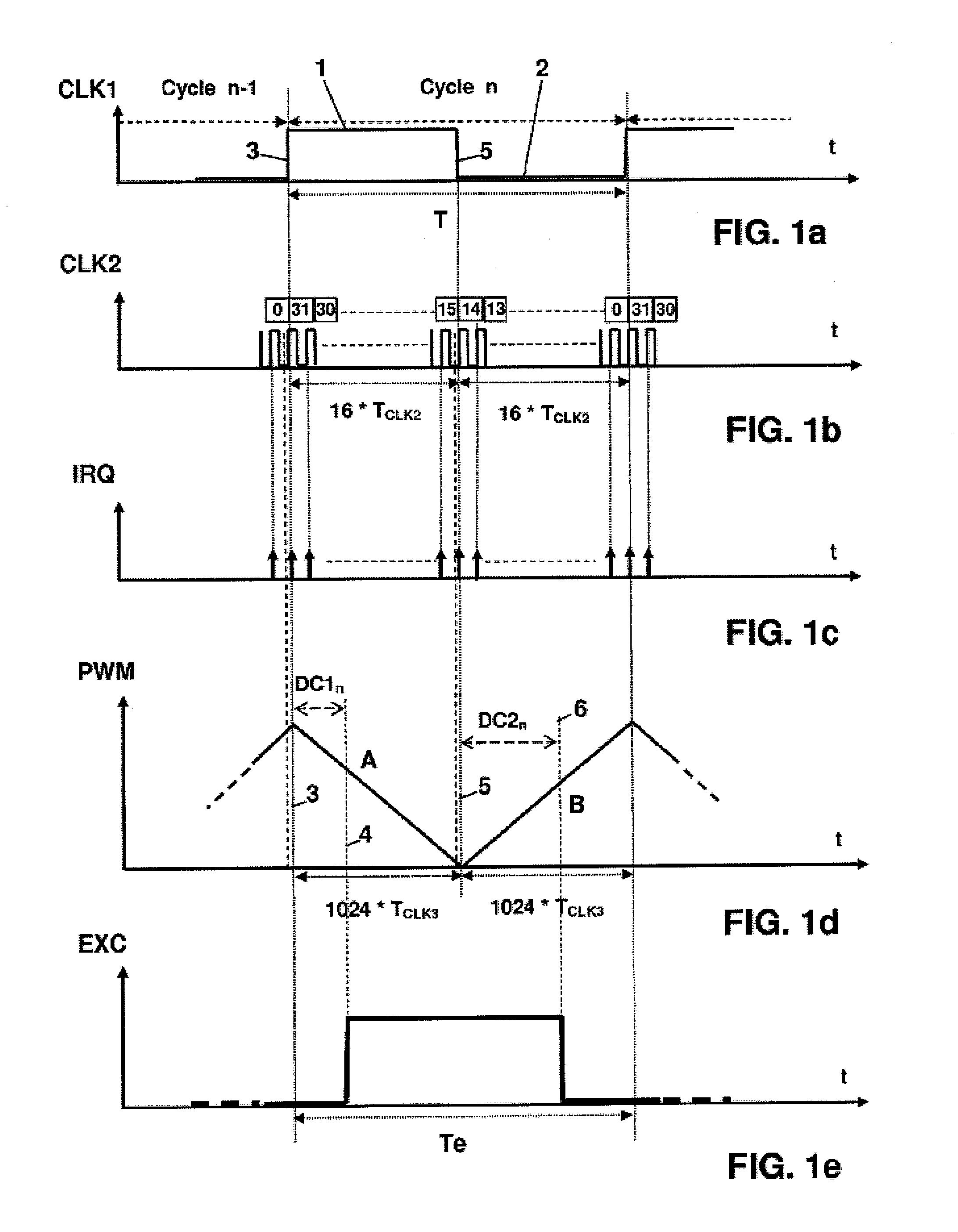

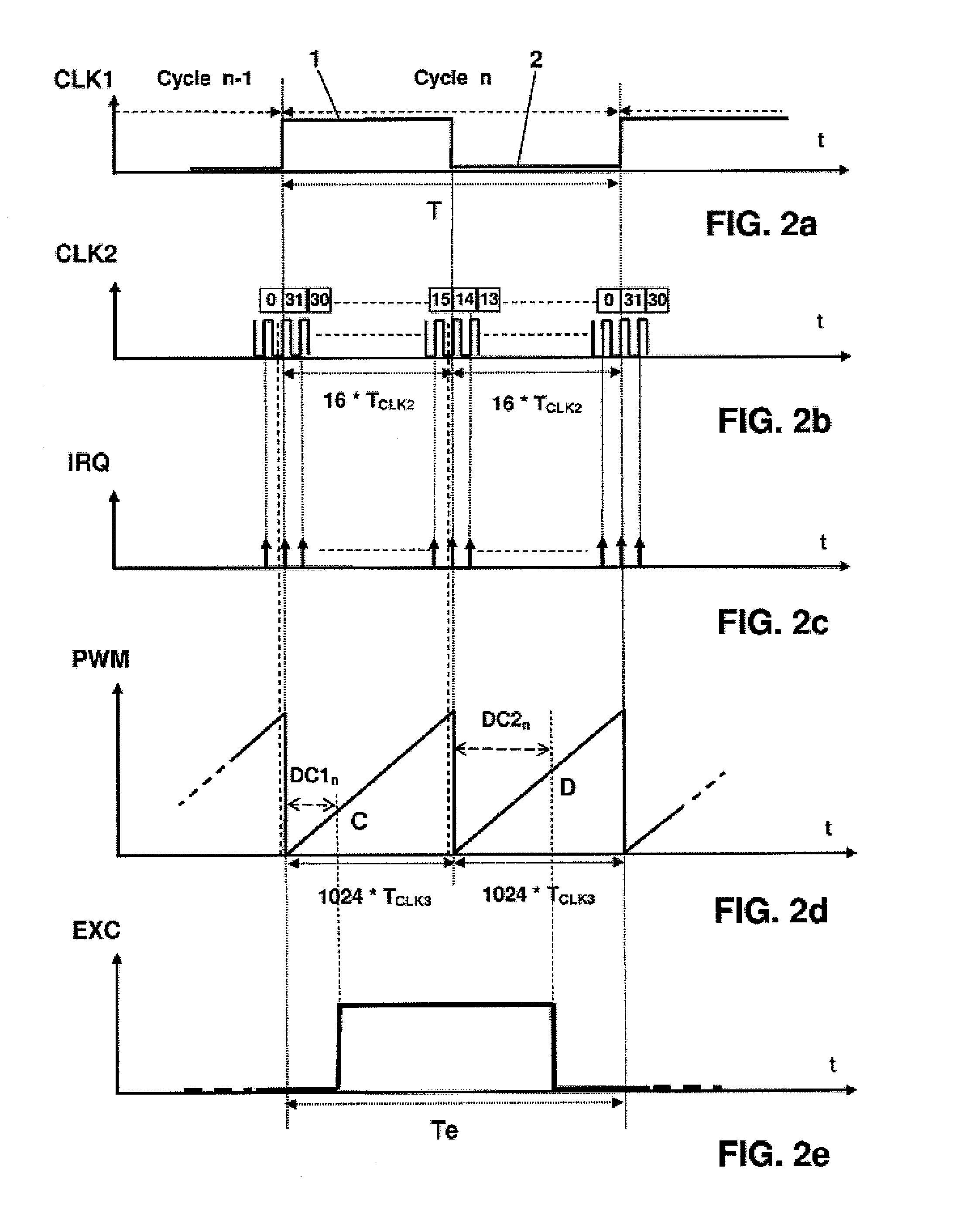

Method and device for regulating a polyphase rotating electrical machine operating as a generator, and polyphase rotating electrical machine using them

ActiveUS20100295516A1Software algorithm controlEmergency protective circuit arrangementsPeriodic excitationMicrocontroller

The regulating method is employed in a polyphase rotating electrical machine operating as a generator and having an excitation coil (10). The method is of the type in which a DC voltage (B+) is slaved to a predetermined setpoint, the voltage being produced by rectifying an AC voltage generated by the machine by controlling the duty cycle of a periodic excitation current (+EXC,−EXC) by means of a microcontroller (11), or the like, as a function of sampled values of the DC voltage (B+). The duty cycle is determined by the microcontroller (11) twice during an excitation current cycle (+EXC, −EXC).

Owner:VALEO EQUIP ELECTRIC MOTEUR

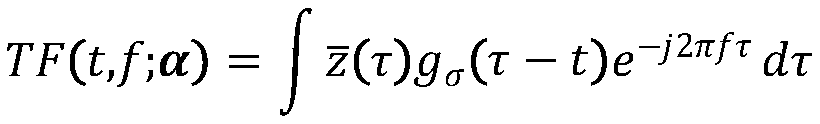

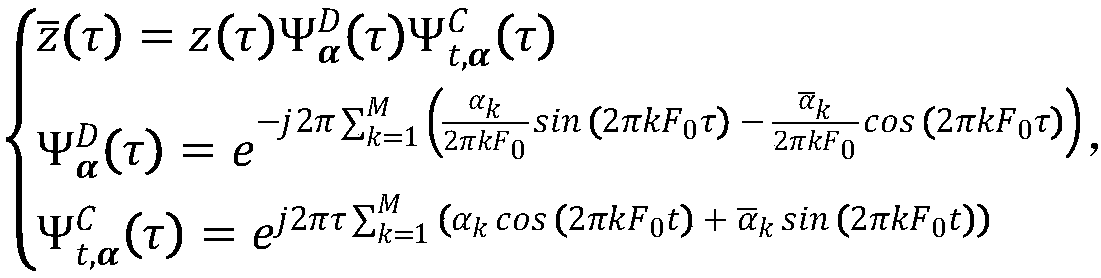

Instantaneous rotation speed estimation method for rotation equipment

ActiveCN107783938AComplex instantaneous speed changesOvercome the shortcoming that the estimation accuracy is limited by the time-frequency resolutionSoftware algorithm controlMotor parameters estimation/adaptationFrequency conversionClassical mechanics

The invention provides an instantaneous rotation speed estimation method for rotation equipment. According to the method, the instantaneous frequency of rotor vibration signals is precisely estimated,and thus rotation speed estimation of the equipment is achieved. The method comprises the steps that firstly, a parameterization time frequency analysis method is used for roughly estimating the instantaneous frequency of the vibration signals, then, a novel envelope tracking filter is used for precisely correcting an initial estimation result, and the finally obtained signal instantaneous frequency directly reflects the instantaneous rotation speed of the equipment; the envelope tracking filter uses a Fourier series model to depict the signal envelope, and a least square method is adopted for optimizing and solving an envelope parameter. According to the method, the instantaneous rotation speed estimation method which combines parameterization time frequency conversion with the envelopetracking filter is adopted, the defect can be overcome that the estimation precision is limited by the time frequency resolution ratio in the prior art, and the method has the advantages of high estimation precision and easy operation.

Owner:SHANGHAI JIAO TONG UNIV

Control electronics for brushless motors

InactiveUS7715698B2Improve electricity efficiencyEliminate needMotor/generator/converter stoppersSynchronous motors startersMicrocontrollerBrushless motors

An electronic control circuit controls a brushless DC motor. It includes an input power supply control circuit. A microcontroller integrated circuit has control functions to control a brushless DC motor. Additional control functions are provided by software program instructions, which when executed, cause the microcontroller integrated circuit to perform additional control functions for the brushless DC motor.

Owner:THOR POWER

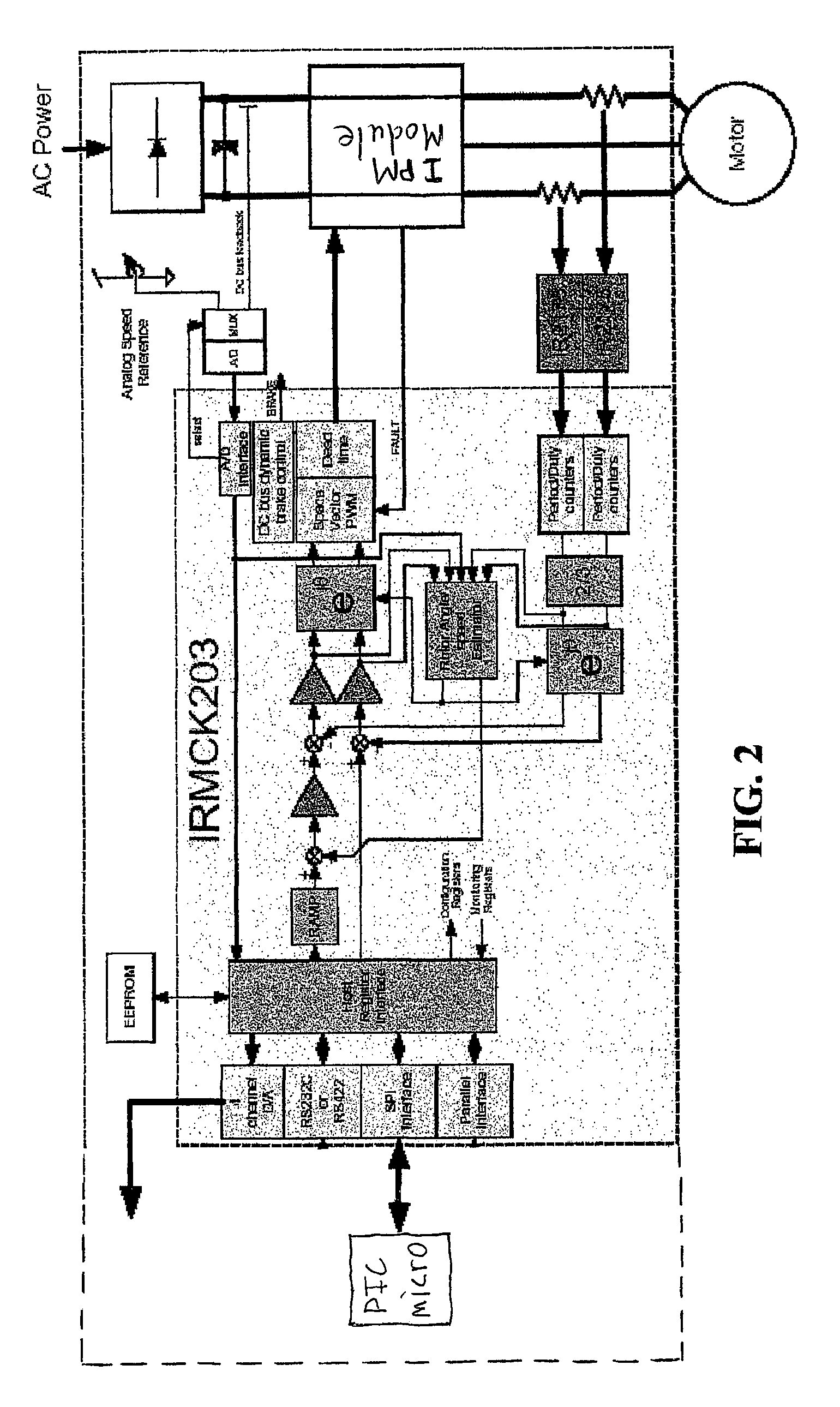

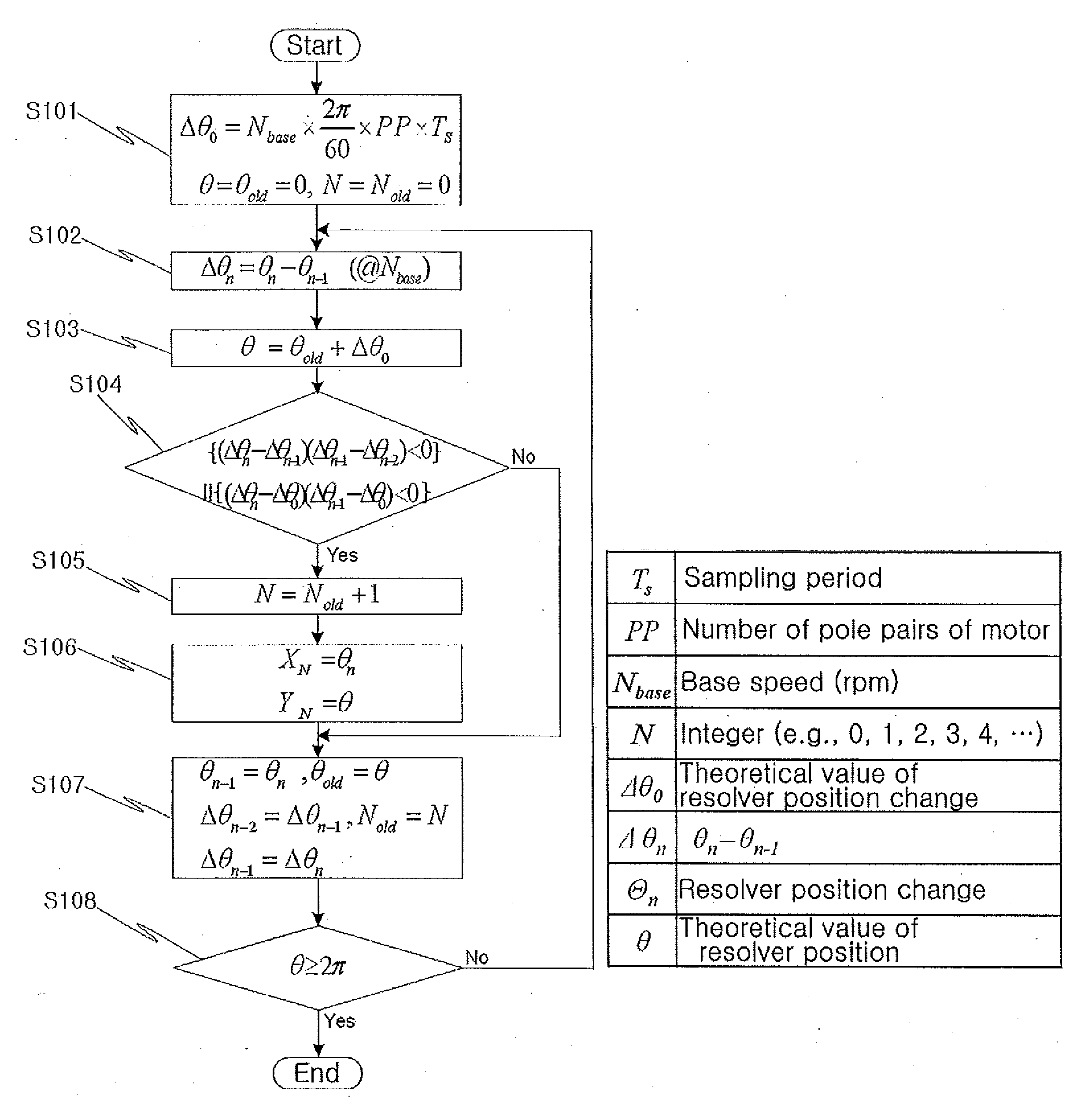

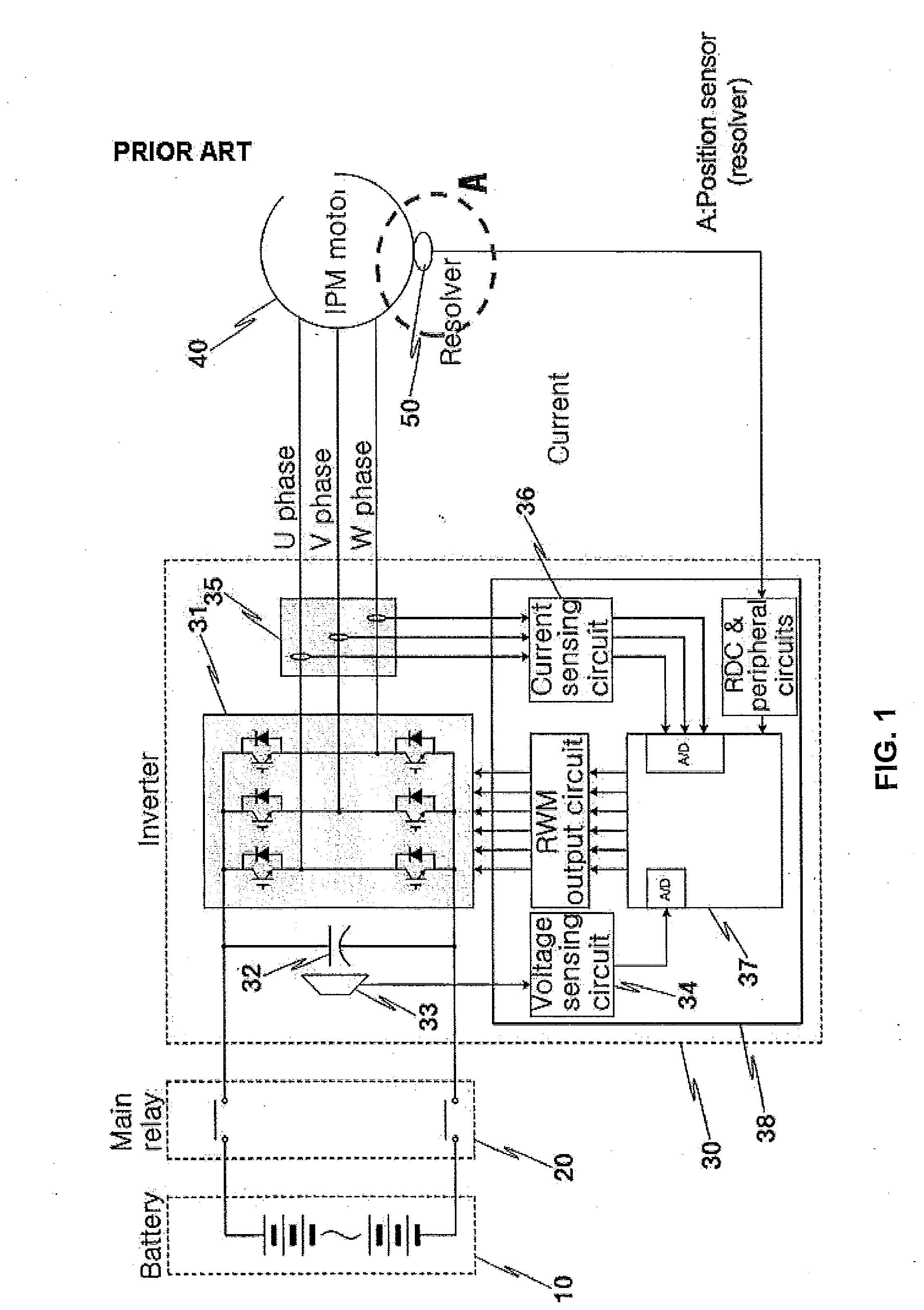

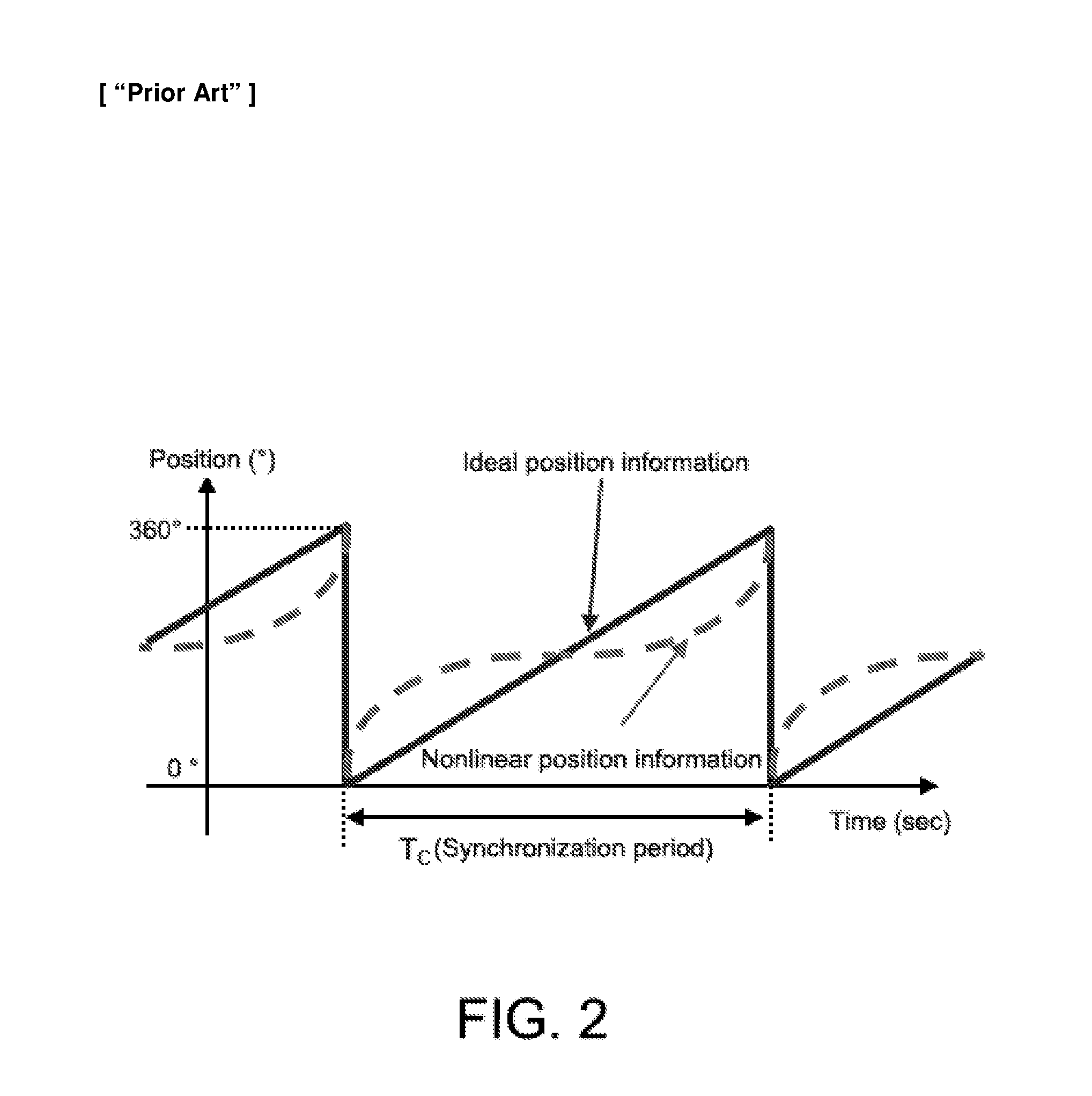

Method for compensating nonlinearity of resolver for hybrid and fuel cell vehicles

ActiveUS20110260663A1Motor/generator/converter stoppersSynchronous motors startersFuel cellsHigh torque

The present invention provides a method for compensating nonlinearity of a resolver to control a motor in hybrid and fuel cell vehicles, thereby stably controlling the motor current during high-torque and high-speed operation. In preferred aspects, the present invention provides a method for compensating nonlinearity of a resolver to control a motor in hybrid and fuel cell vehicles, the method including collecting resolver position data; determining whether to perform resolver position correction in the corresponding vehicle; and compensating nonlinearity of the resolver based on the collected resolver position data, if it is determined that the resolver position correction is not performed.

Owner:HYUNDAI MOTOR CO LTD +1

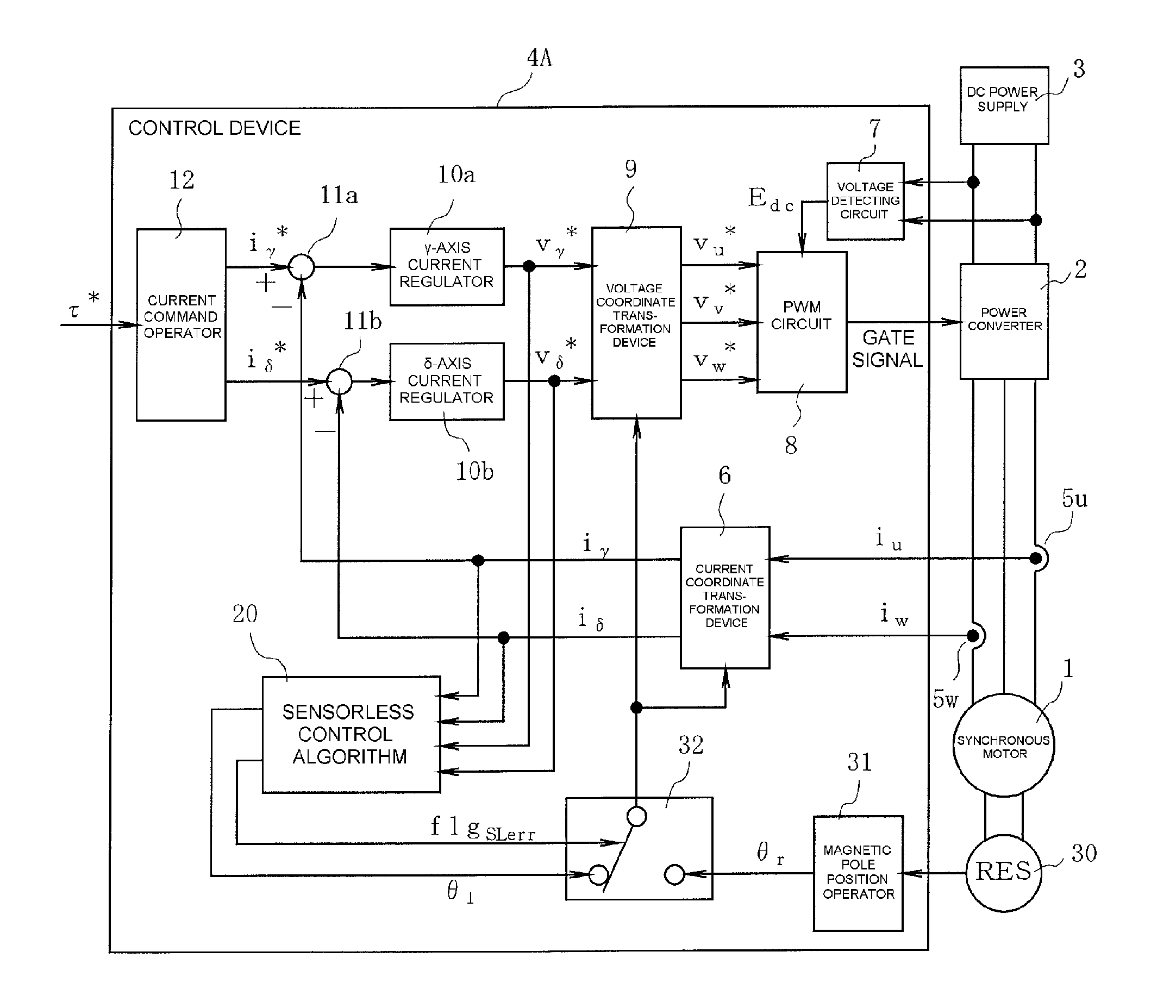

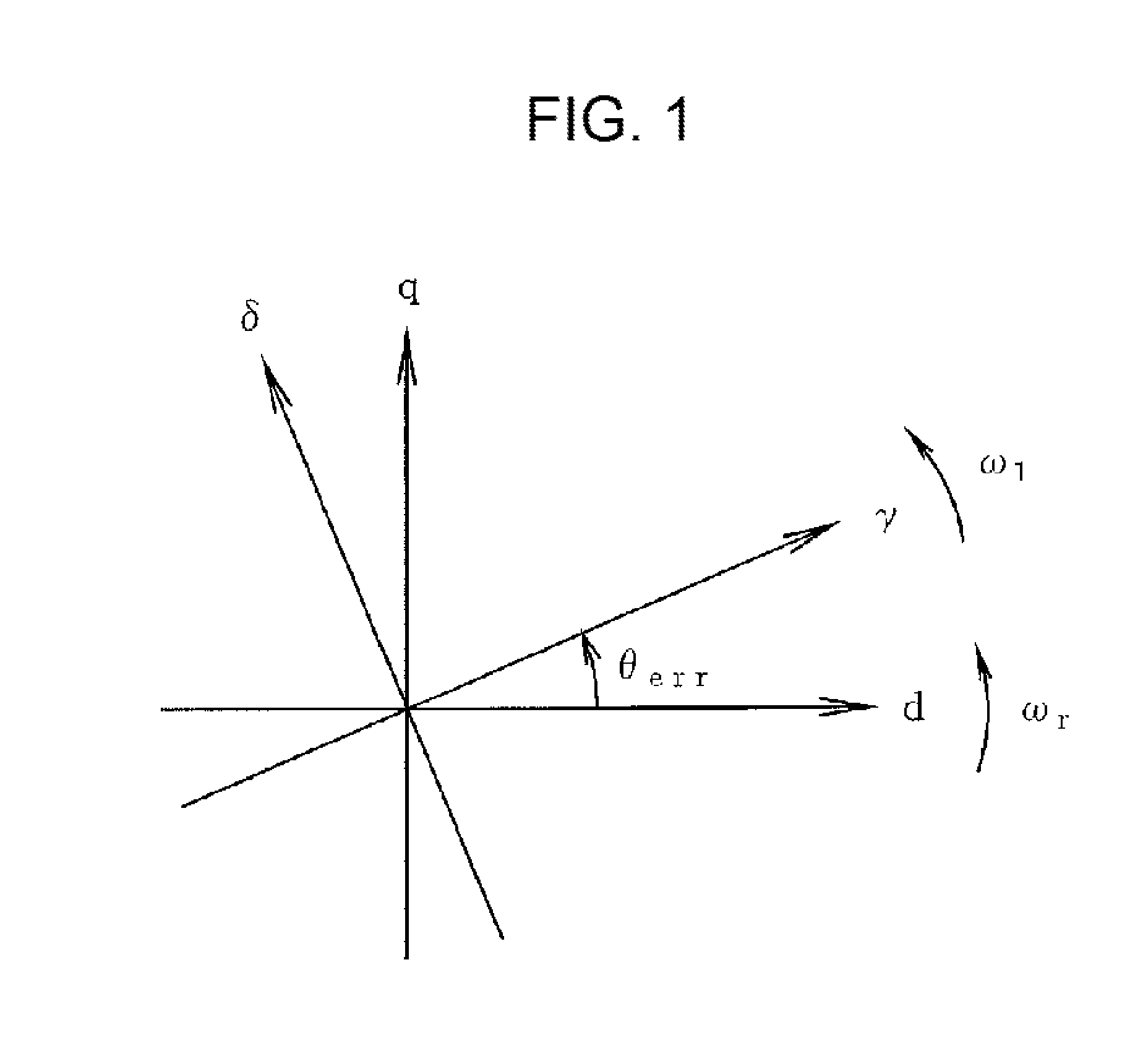

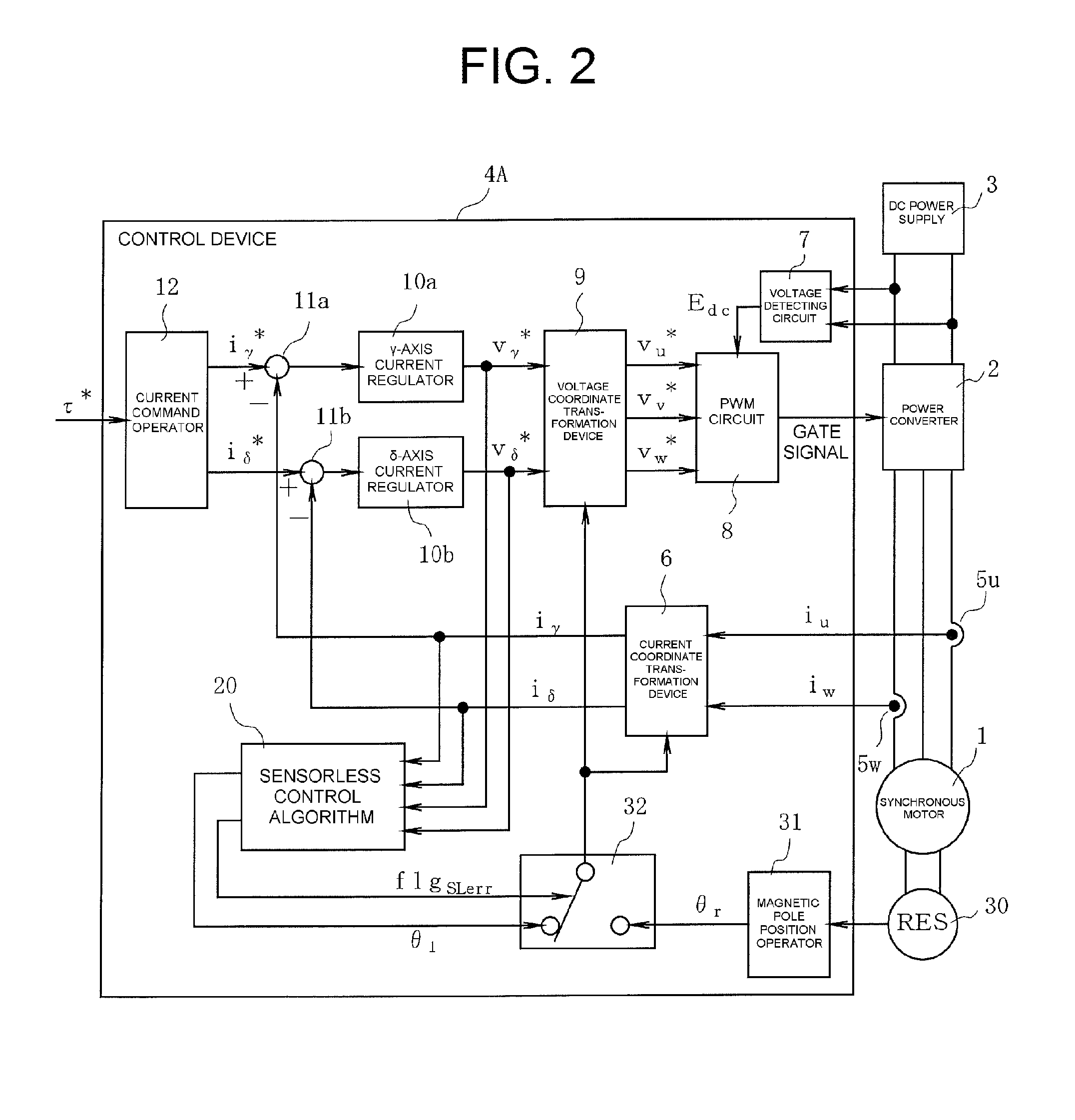

Motor driving system

ActiveUS20140055067A1Small sizeReduce manufacturing costCommutation monitoringMotor/generator/converter stoppersMotor driveSynchronous motor

A motor driving system is disclosed having a control device 4A for controlling a synchronous motor 1, the control device 4A comprising a sensorless control algorithm device 20 that includes an abnormality determining device 25 for determining abnormality of the algorithm based on a magnetic pole position error estimated value of the motor 1. When the abnormality determining device 25 has determined abnormality of the algorithm, the control device 4A controls a power converter 2 using a magnetic pole position detected value detected by a magnetic pole position detector 30 attached to the motor, in place of using a magnetic pole position estimated value. This motor driving system can guarantee reliability of the sensorless control algorithm device 20 while assuring safety. Safety of electric vehicles is enhanced by installing the motor driving system that has been guaranteed reliable.

Owner:FUJI ELECTRIC CO LTD

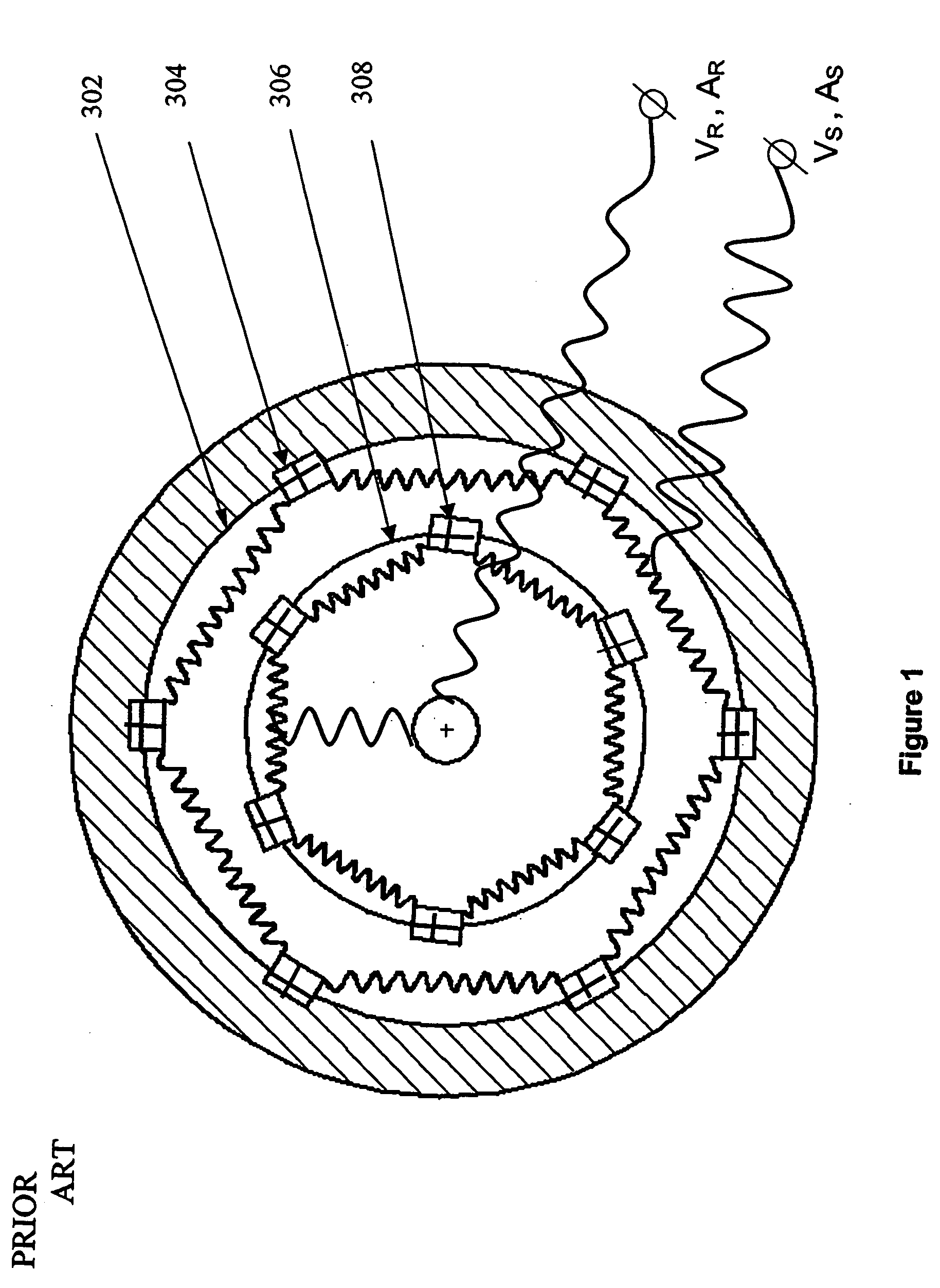

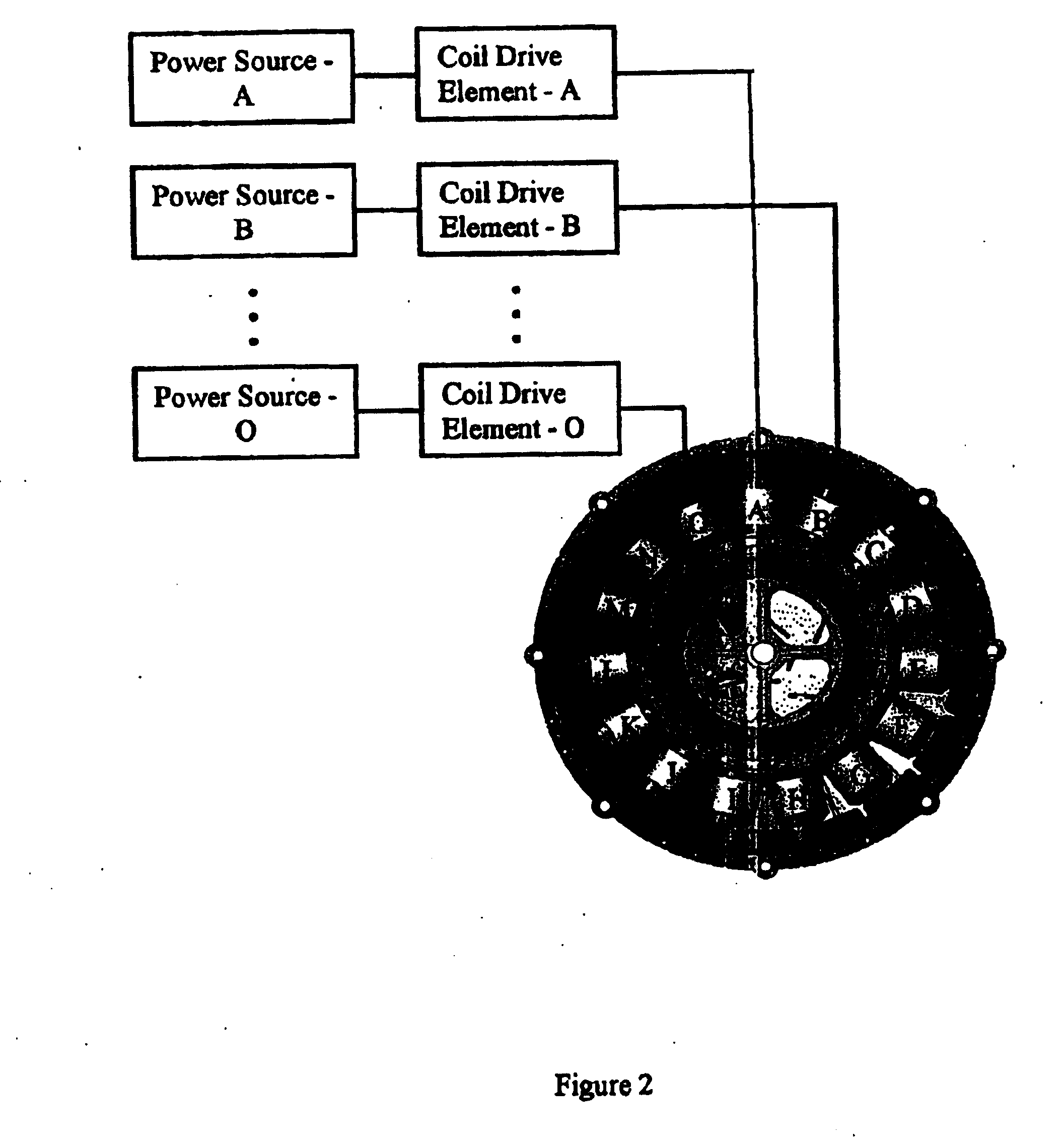

Low-voltage electric motors

InactiveUS20050127856A1Synchronous motors startersEmergency protective circuit arrangementsPhase currentsLow voltage

A distributed architecture for electric motors and generators. This distributed architecture motor can deliver high power at low voltage and low phase current. It works by distributing total current across several “phases,” or electromagnetic circuits of the motor. That creates several advantages. These motors can deliver the high power needed by an electric car at 50 volts or less, which is safer for humans. They improve safety by allowing a motor to operate in an emergency even when one or more phases has a fault. Low voltage motors in electric vehicles allow batteries and fuel cells to have fewer cells. The low voltage and distributed current makes heat easier to handle. The distributed architecture lowers cost by allowing cheaper power electronics to be used. The distributed architecture allows smaller, lighter motors to be made with light wiring, switches and connectors. In addition, it opens the path to lower cost battery and fuel cell technologies, simplified battery and fuel cell management, and wider packaging options.

Owner:BLUWAV SYST LLC

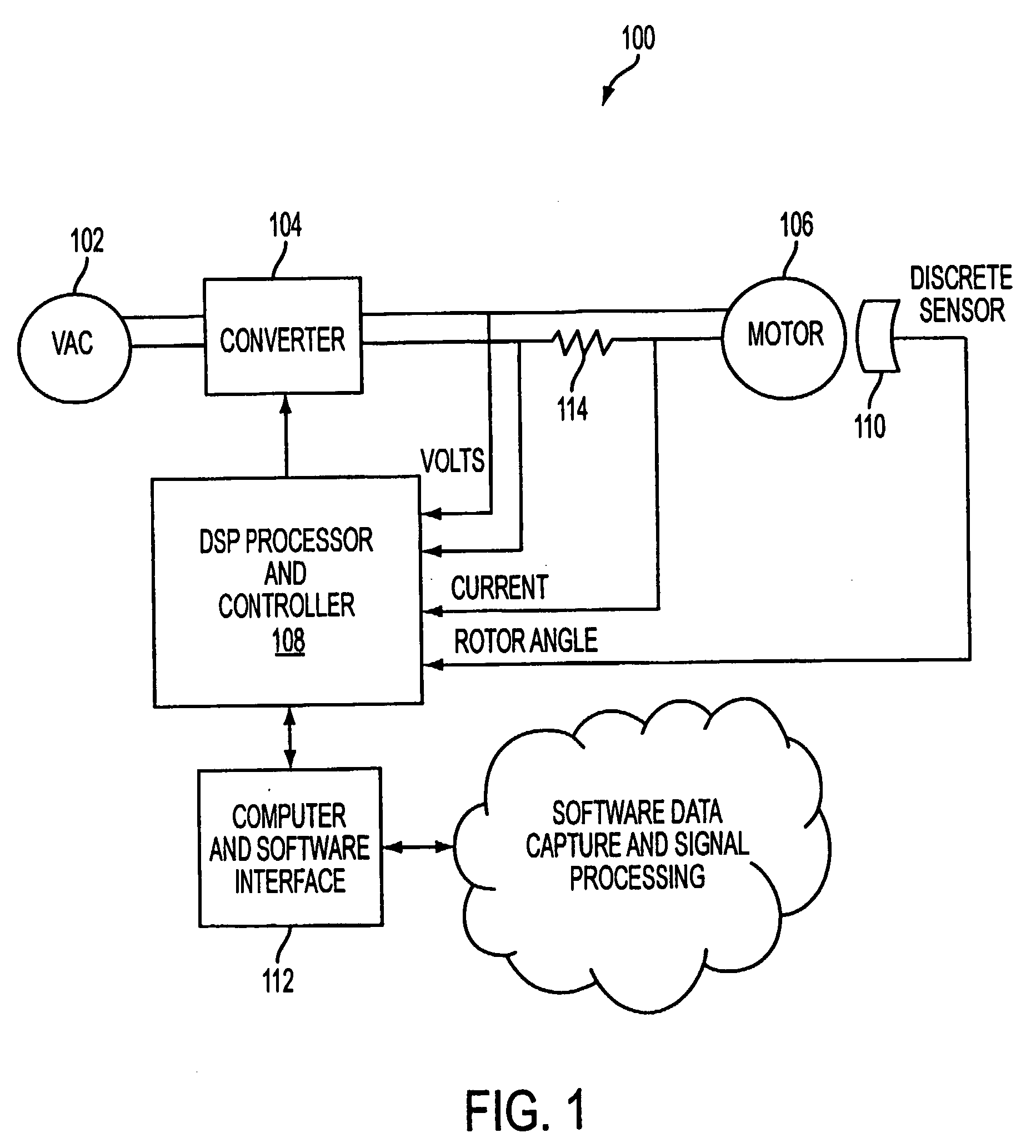

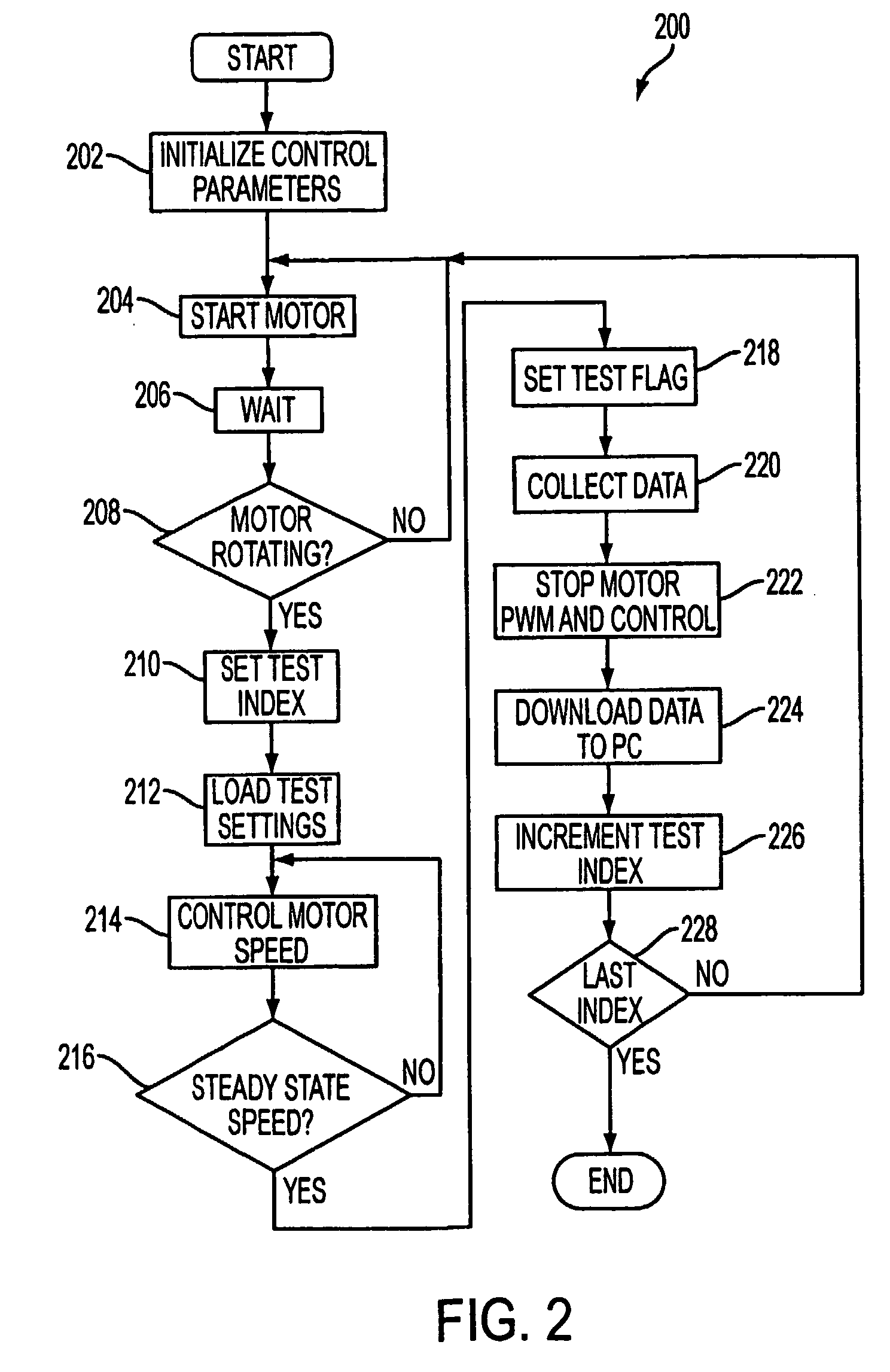

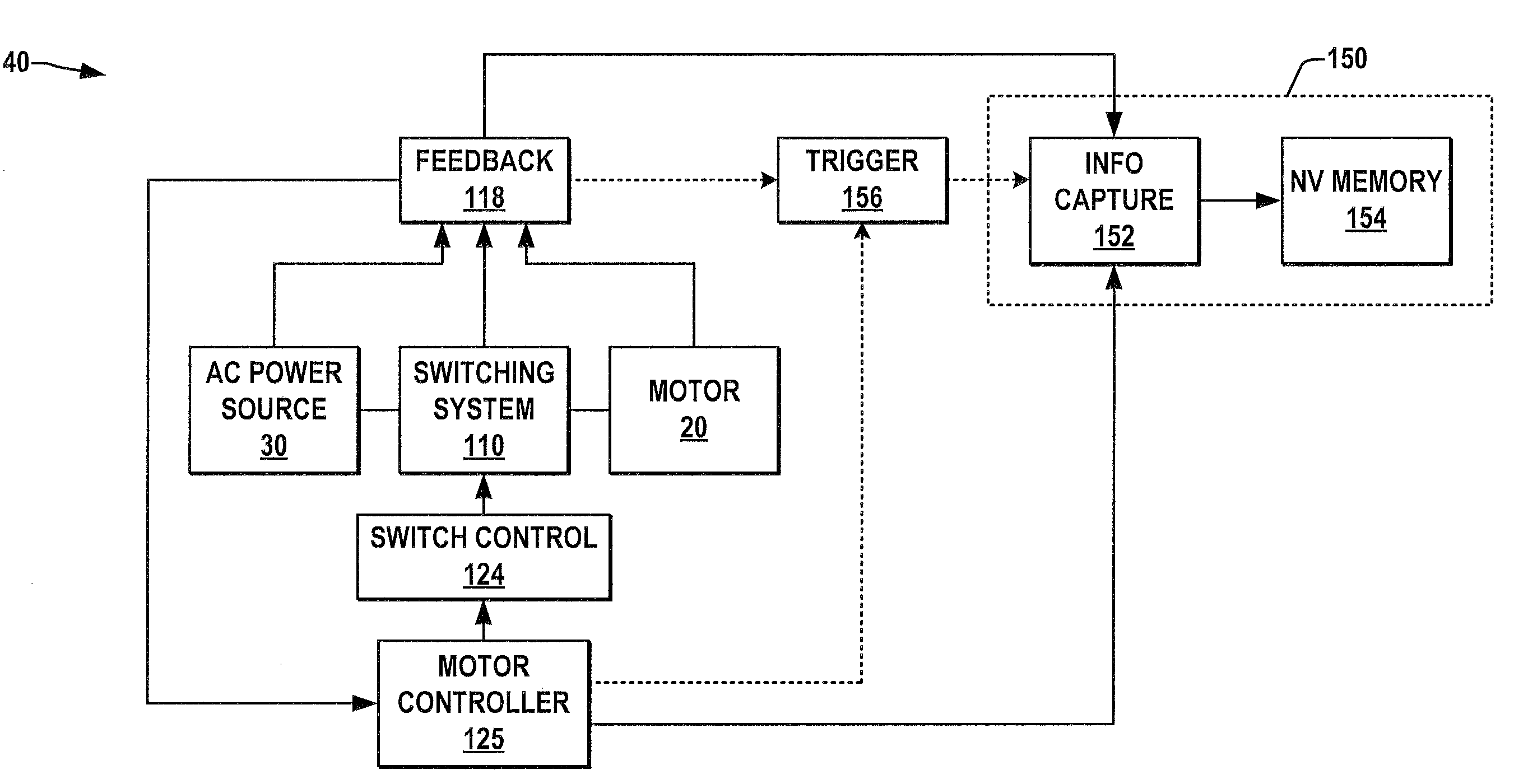

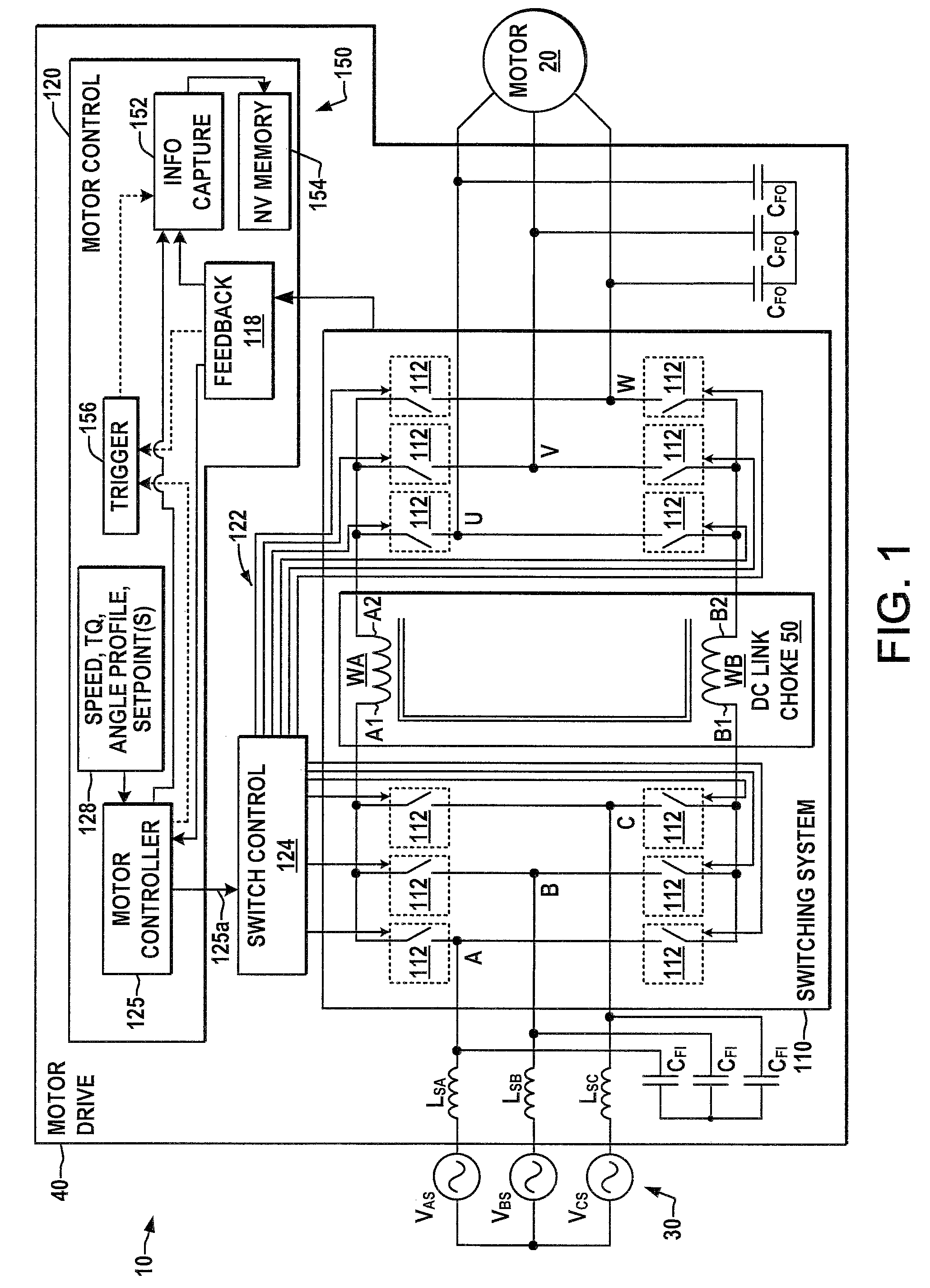

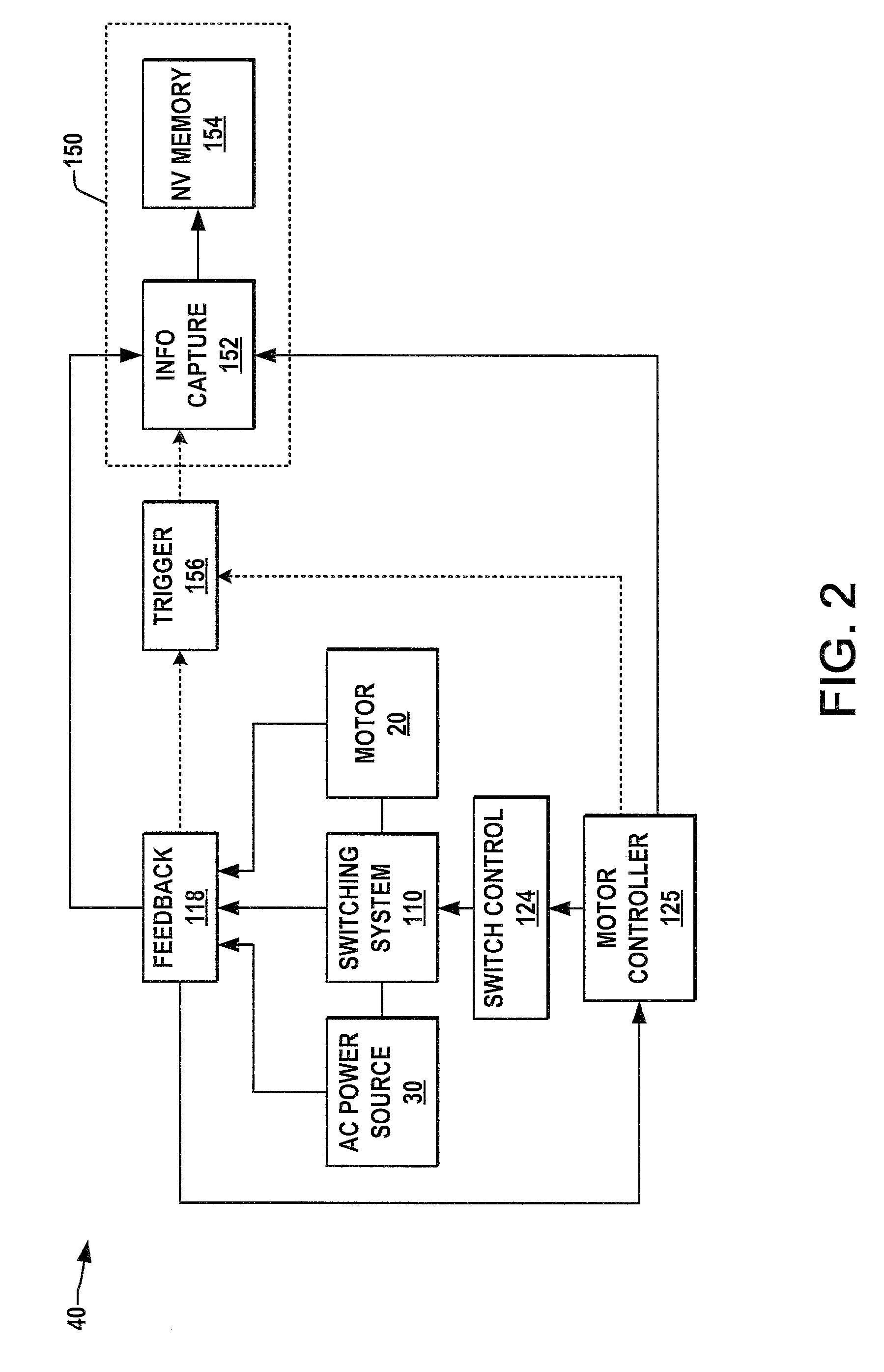

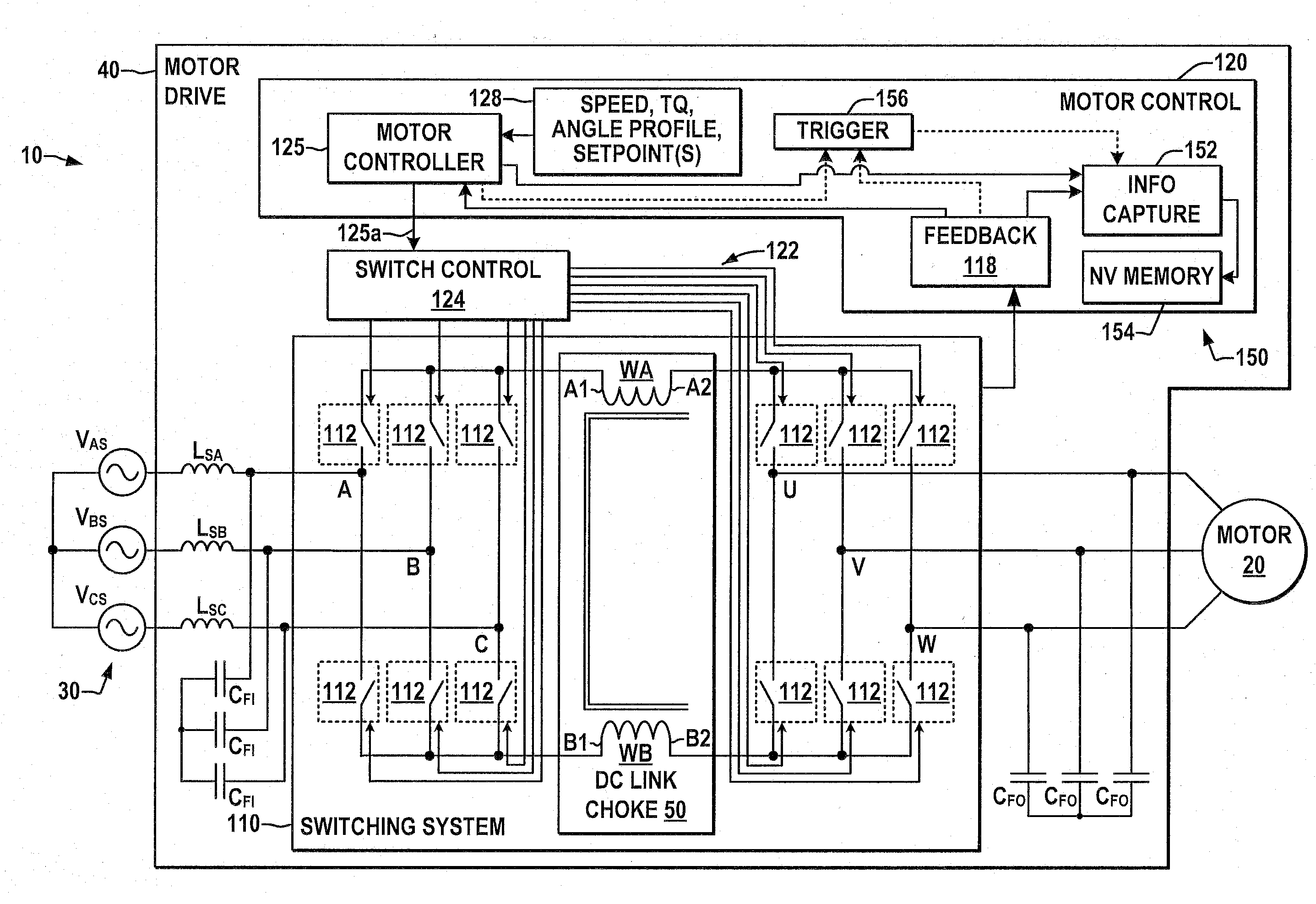

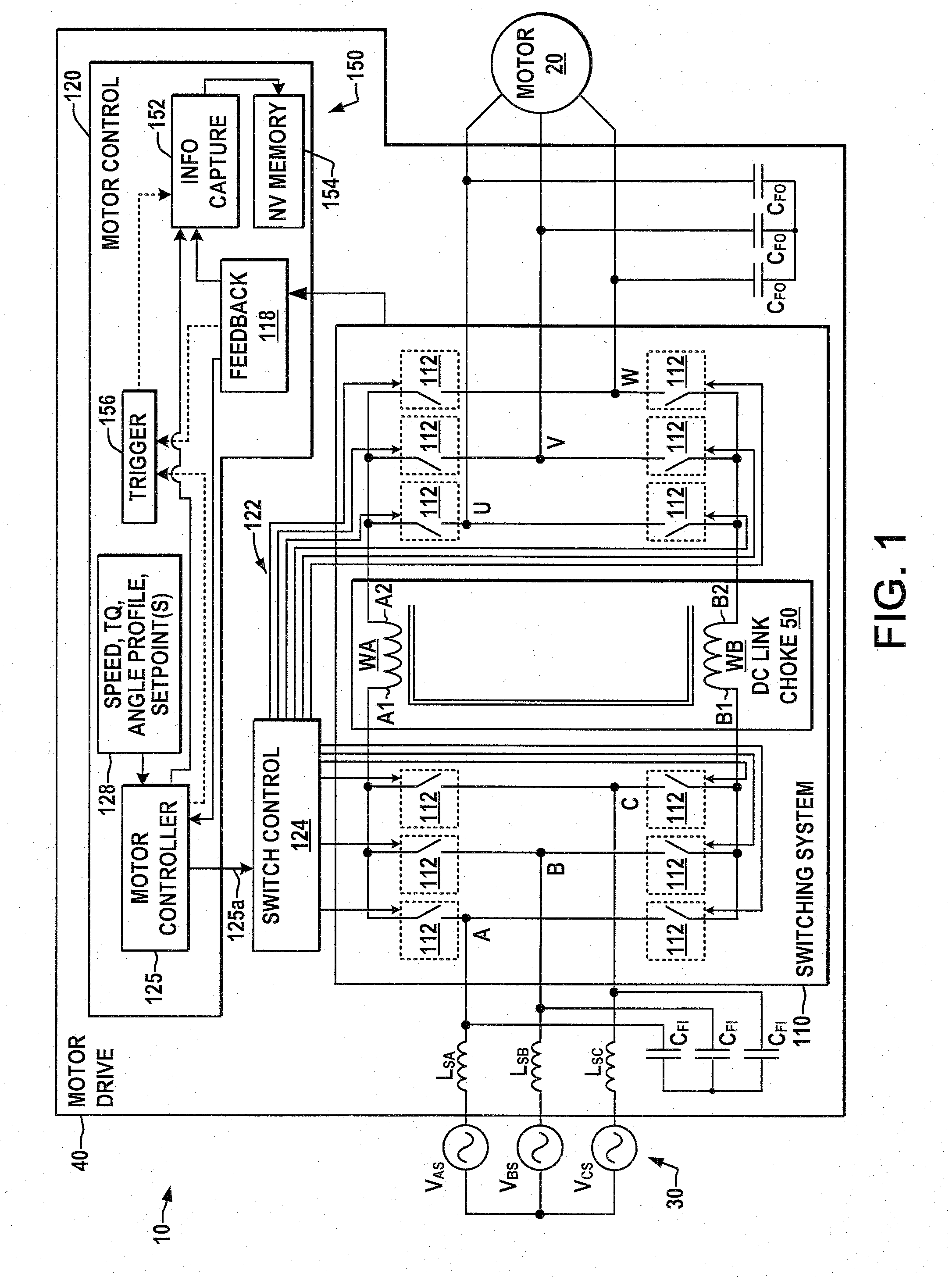

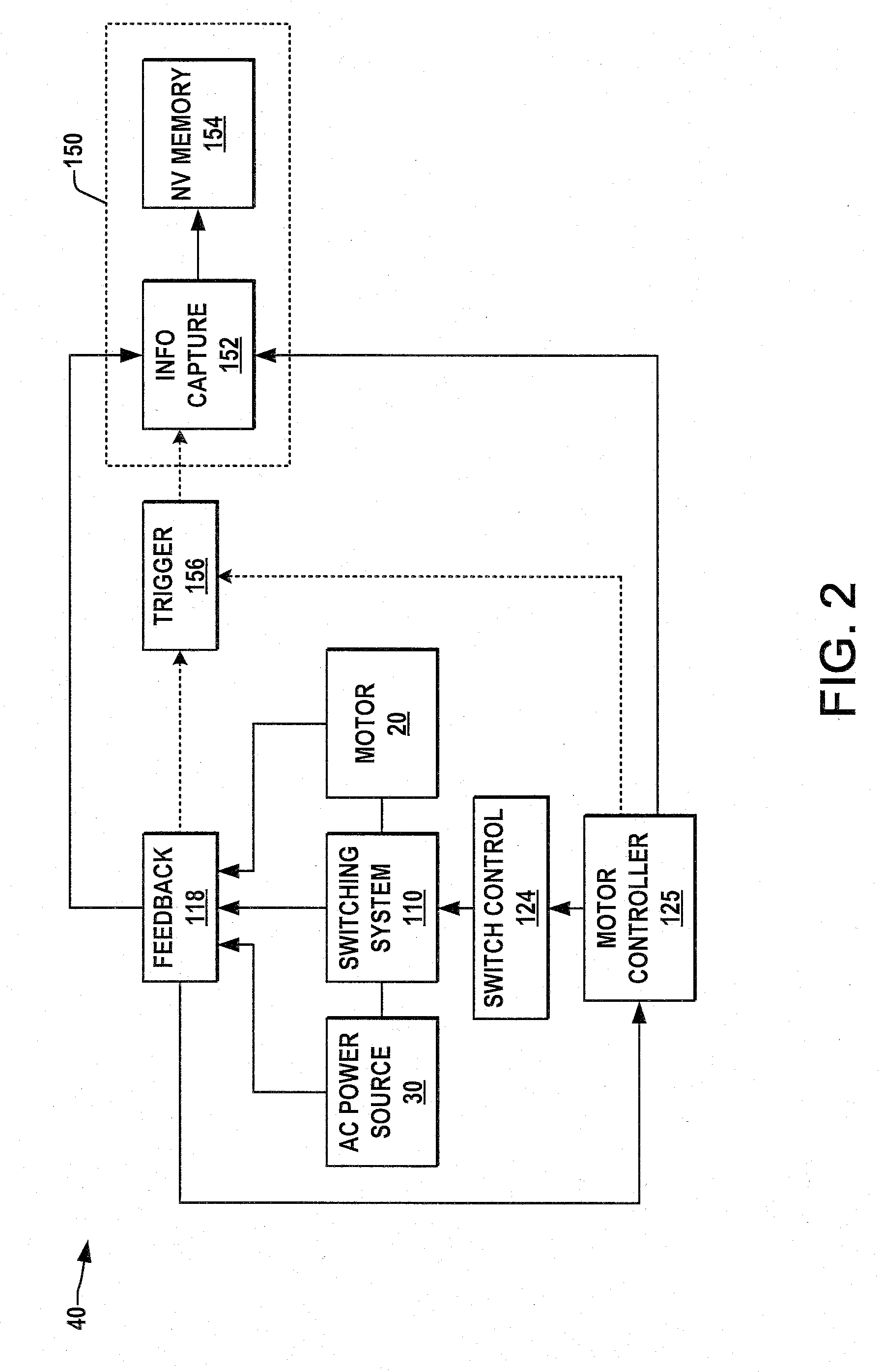

Methods and system for motor drive information capture

ActiveUS7602132B2Motor/generator/converter stoppersDC motor speed/torque controlMotor driveControl system

Methods and systems are provided for capturing and saving motor drive information in a non-volatile memory to facilitate troubleshooting and motor fault analysis. The motor drive includes a power conversion system that provides electrical power to an electric motor and a control system providing a control input to the power conversion system, and an information capture system is provided with an information capture component to capture motor drive information and a non-volatile memory component to store the captured information.

Owner:ROCKWELL AUTOMATION TECH

Methods and system for motor drive information capture

ActiveUS20080074075A1Easy to identifyPromote reconstructionMotor/generator/converter stoppersDC motor speed/torque controlMotor driveControl system

Methods and systems are provided for capturing and saving motor drive information in a non-volatile memory to facilitate troubleshooting and motor fault analysis. The motor drive includes a power conversion system that provides electrical power to an electric motor and a control system providing a control input to the power conversion system, and an information capture system is provided with an information capture component to capture motor drive information and a non-volatile memory component to store the captured information.

Owner:ROCKWELL AUTOMATION TECH

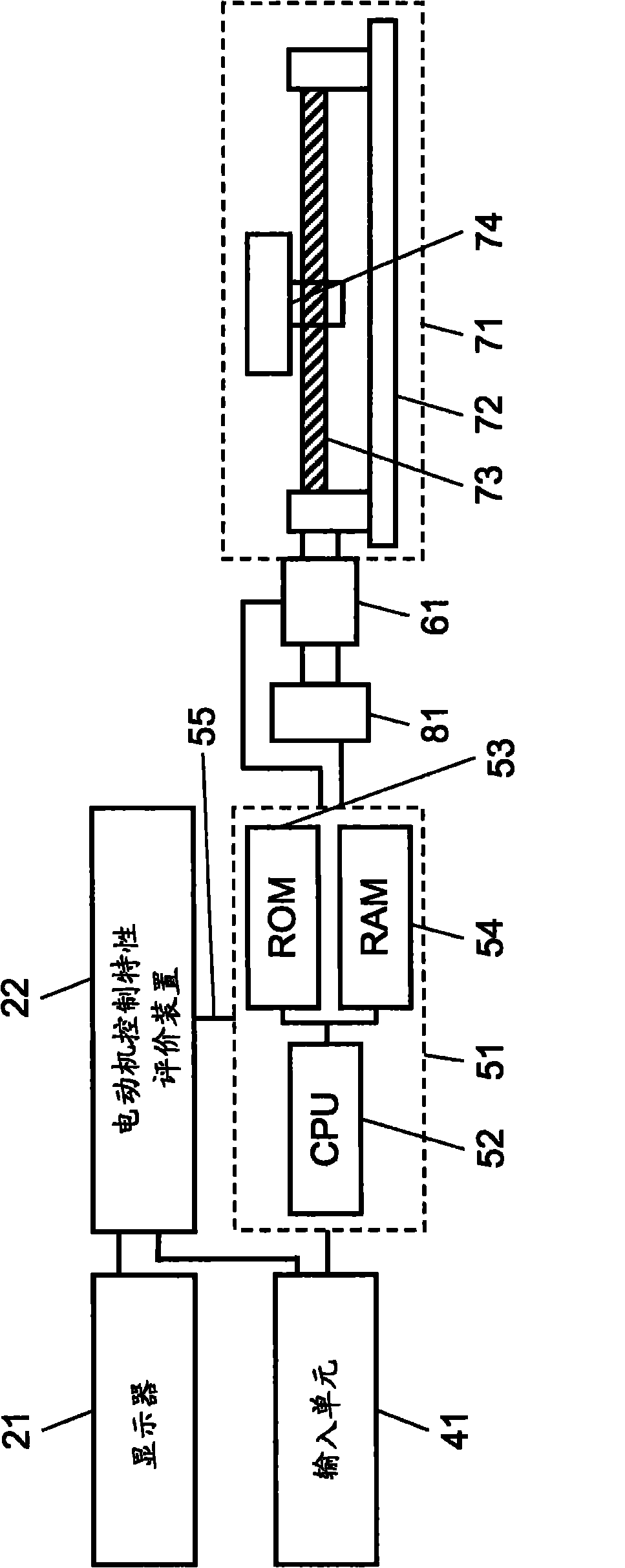

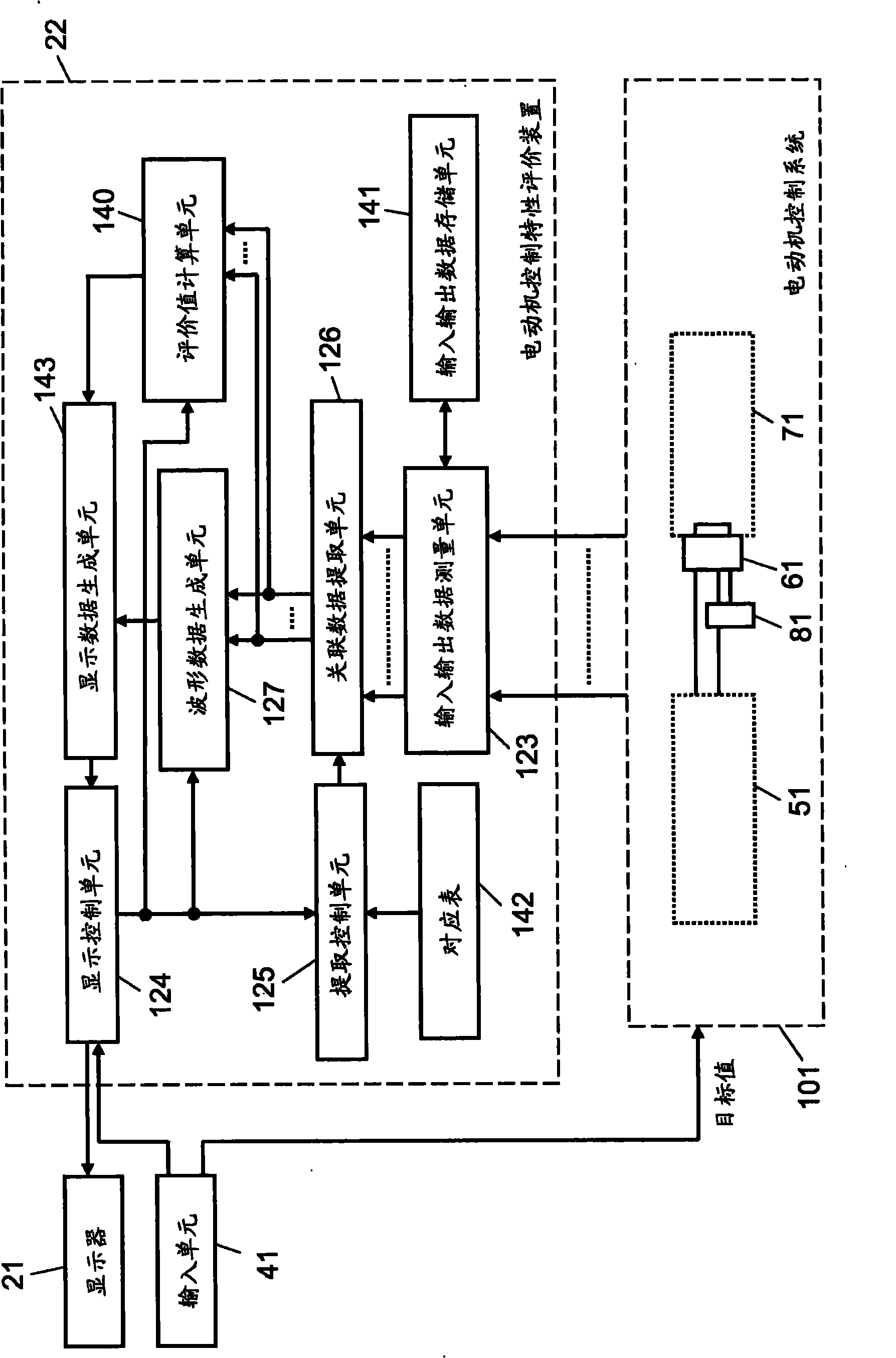

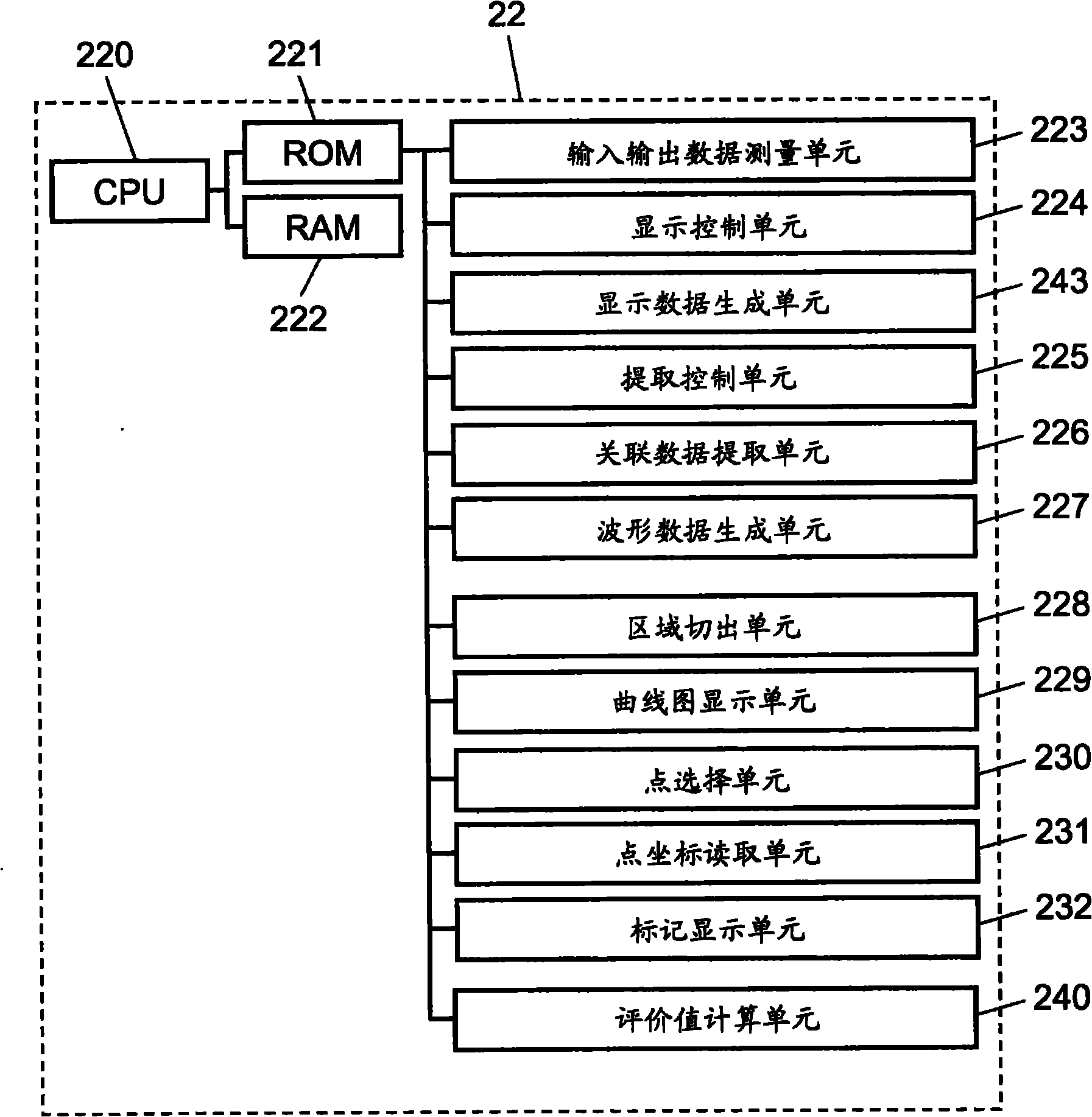

Motor control characteristic evaluation device and motor control characteristic presentation method

InactiveCN101932982ASimplify the evaluation processTips are simpleElectric motor controlSoftware algorithm controlIndex selectionDisplay device

A motor control characteristic evaluation device includes: an evaluation index selection unit which selects any one of evaluation indexes in a motor control system control characteristics and outputs selection information indicating the selected evaluation index; a correlated data extraction unit which extracts data correlated with the selected evaluation index from the motor control system data group according to the selected information; an evaluation value calculation unit which calculates an evaluation value of the evaluation index according to the extracted data; and a display control unit which displays the calculated evaluation value on a display.

Owner:PANASONIC CORP

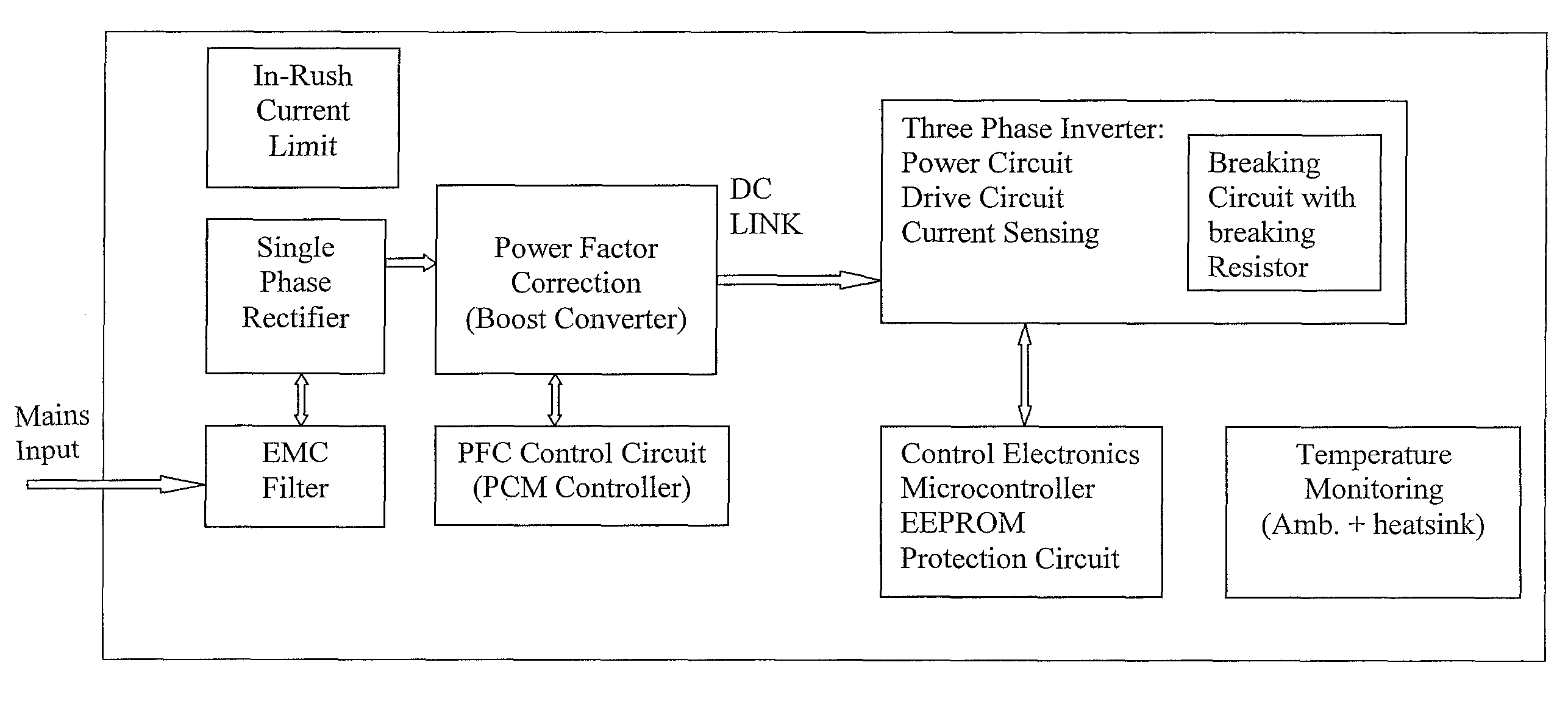

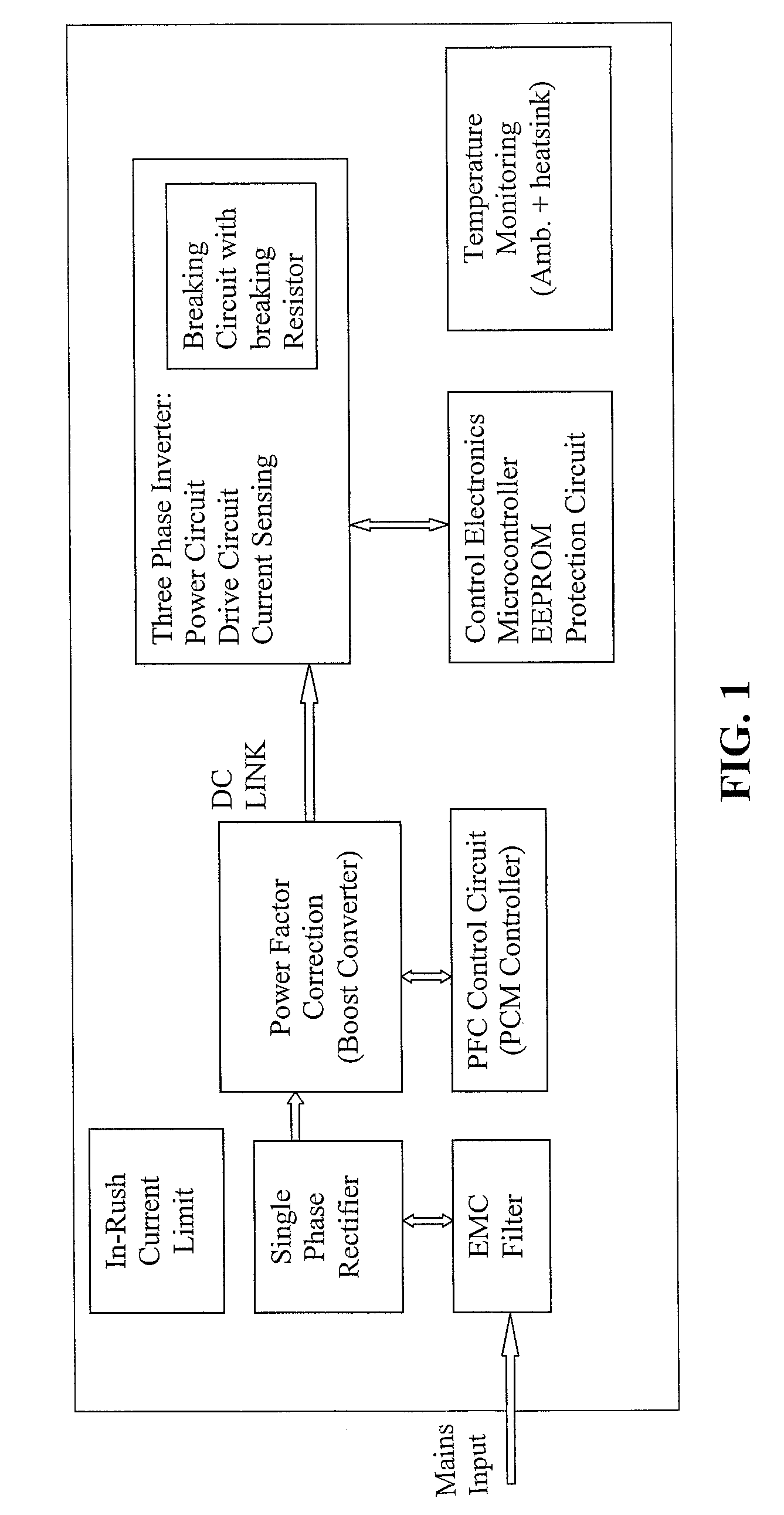

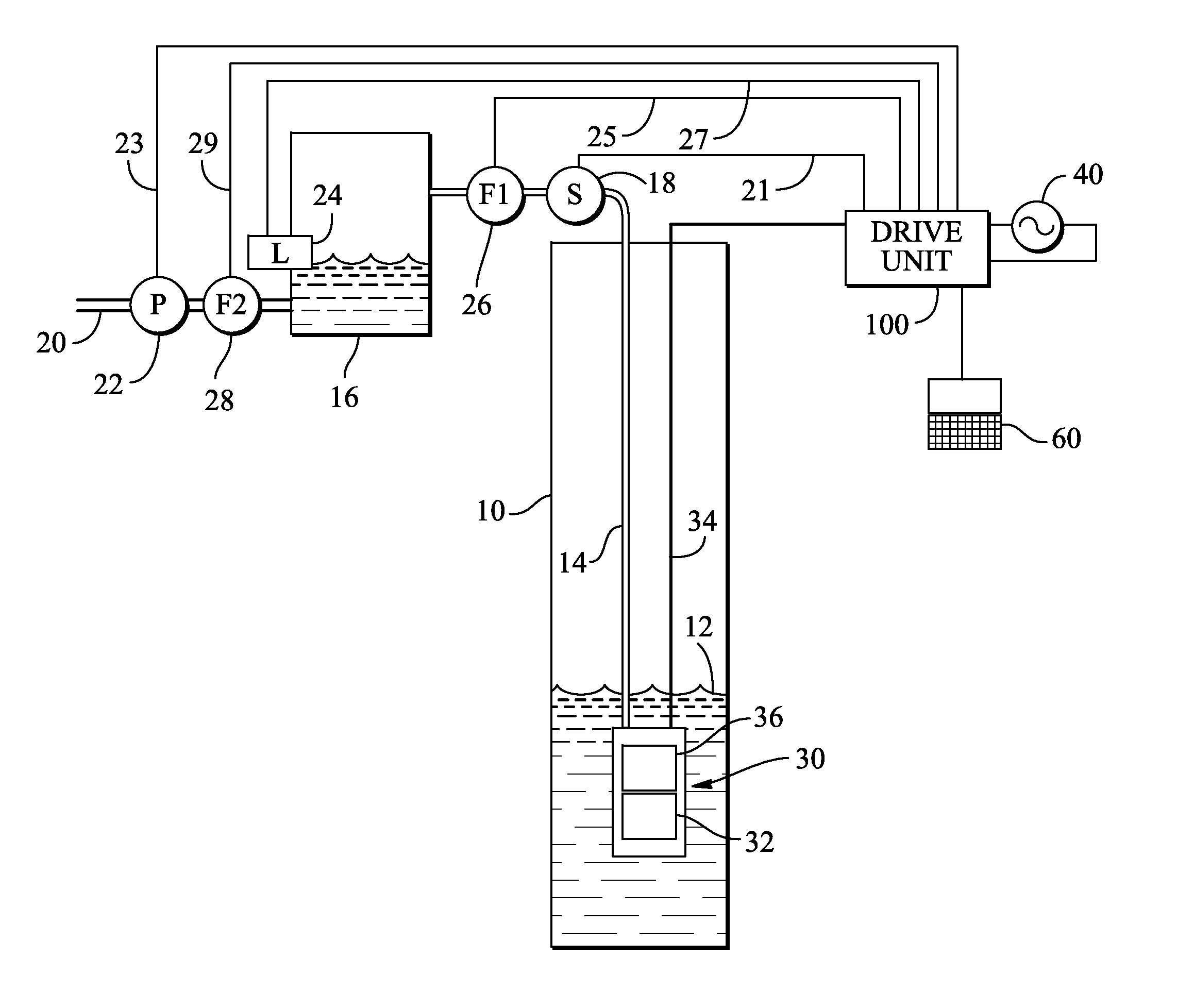

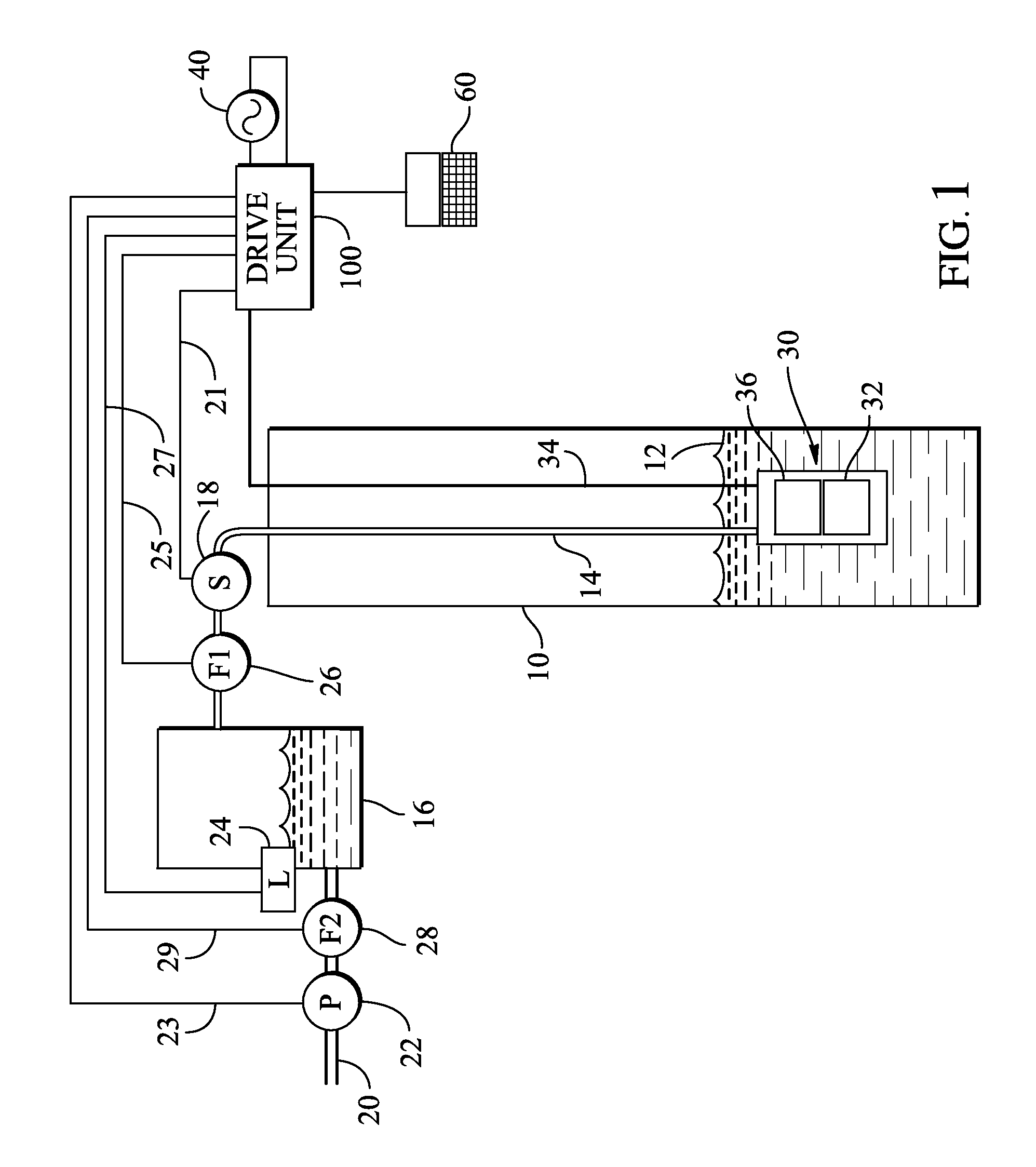

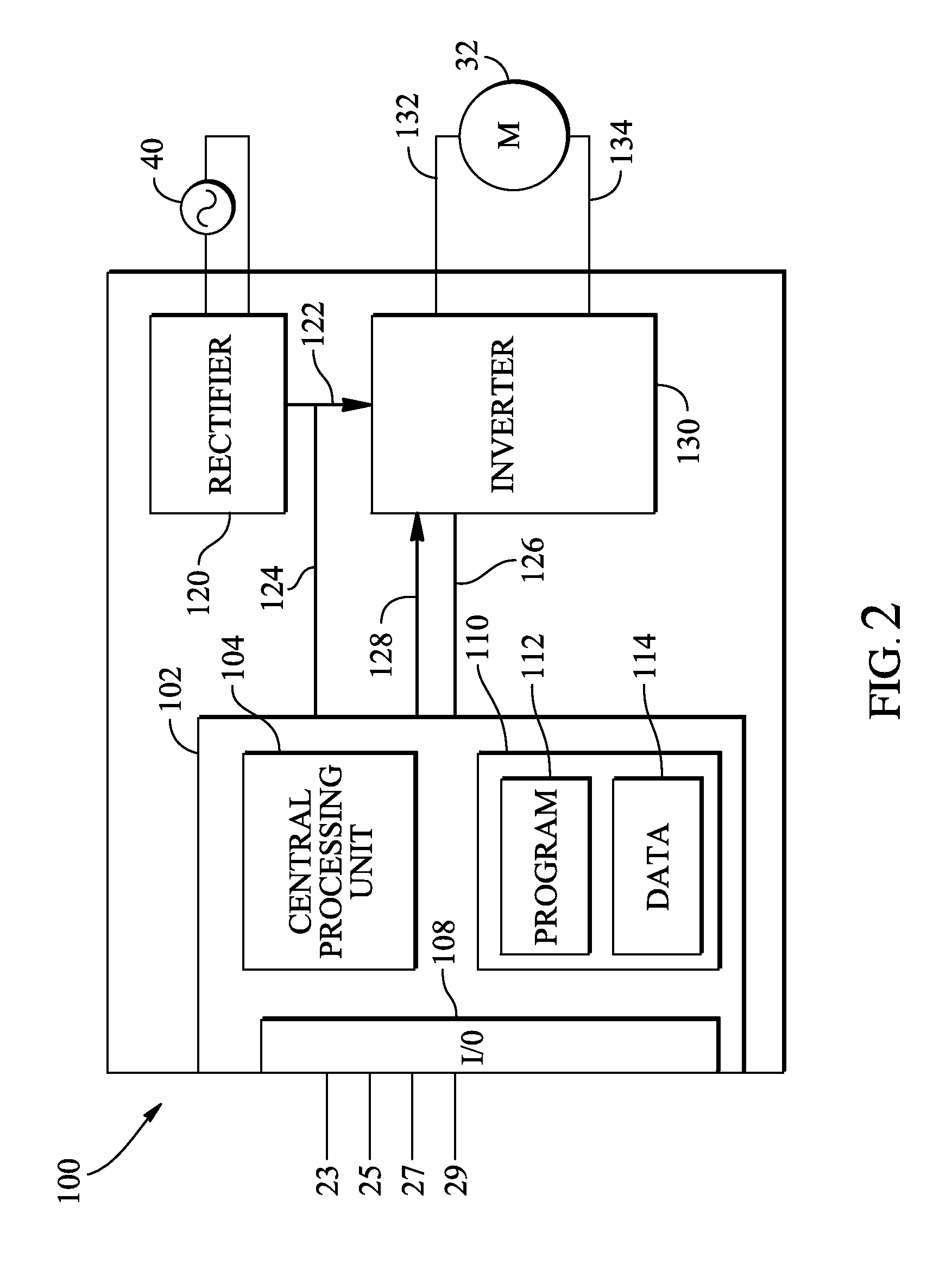

Variable speed drive system

ActiveUS20130002187A1Improved performance characteristicsLower performance requirementsSoftware algorithm controlSingle phaseVoltage

This disclosure relates to a variable speed drive for driving a single phase motor. The variable speed drive generates enhanced motor voltages including harmonic components configured to reduce torque pulsations.

Owner:FRANKLIN ELECTRIC CO INC

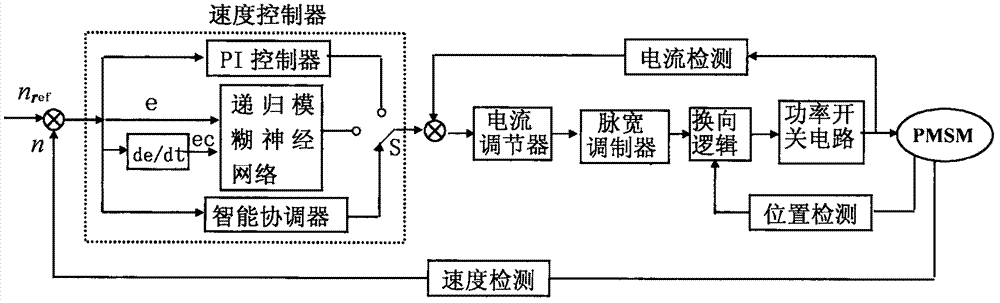

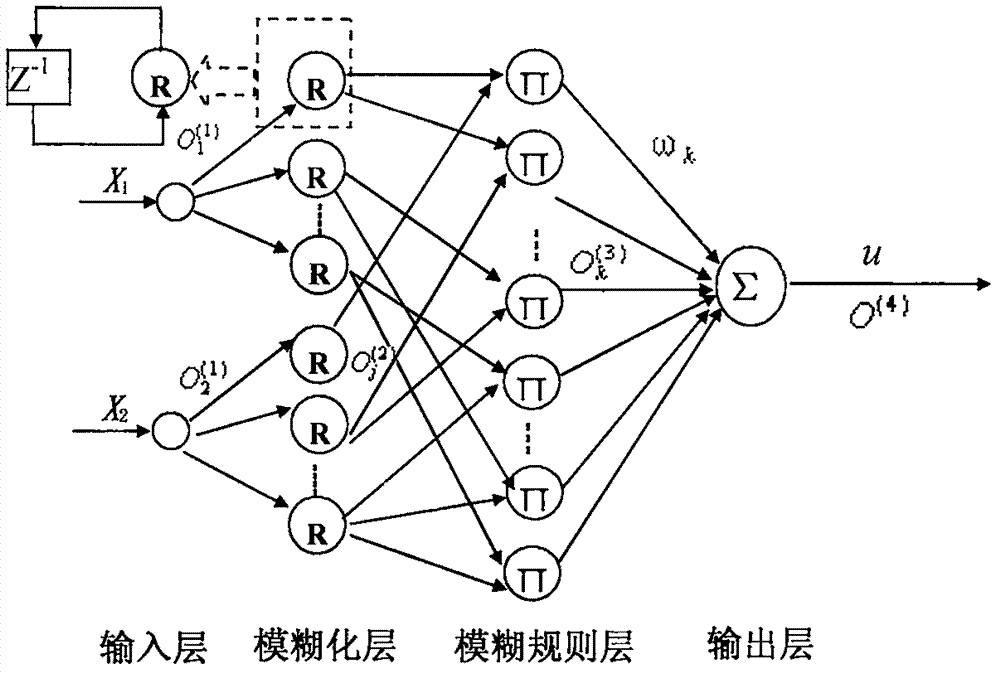

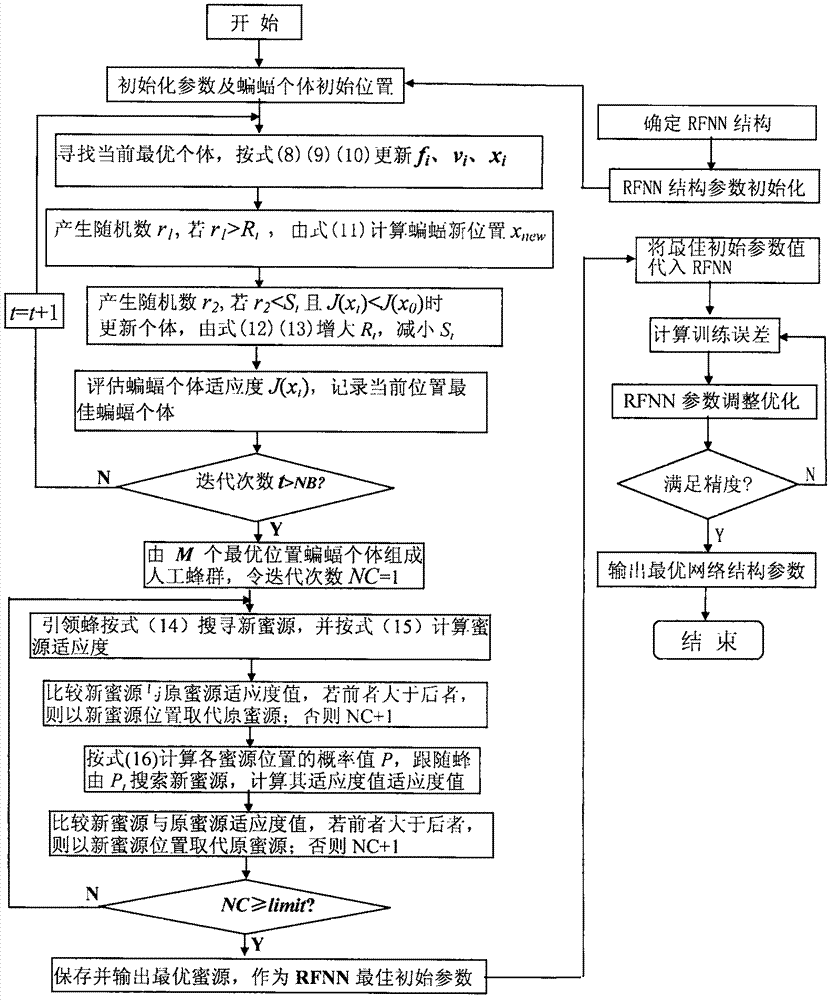

Permanent magnet synchronous motor rotation speed controller based on recursive fuzzy neural network

InactiveCN107968613AFast searchStrong global search capabilitySoftware algorithm controlArtificial lifeNeural network controllerSpeed control system

The invention discloses a permanent magnet synchronous motor rotation speed controller based on a recursive fuzzy neural network. The permanent magnet synchronous motor rotation speed controller combines a bat algorithm and an artificial bee colony algorithm to form a bat-artificial bee colony hybrid algorithm, which is used for optimizing structural parameters of a recursive fuzzy neural networkcontroller, and introducing the recursive fuzzy neural network controller into a rotation speed control system of a permanent magnet synchronous motor. A simulated and experimental analysis shows that: by adopting the recursive fuzzy neural network rotation speed controller optimized based on the bat-artificial bee colony hybrid algorithm, rapid response of a permanent magnet synchronous motor control system can be realized without overshoot, the control precision is high, the robustness is good, the anti-interference capability is high, and precise rotation speed control can be realized.

Owner:WUXI OPEN UNIV

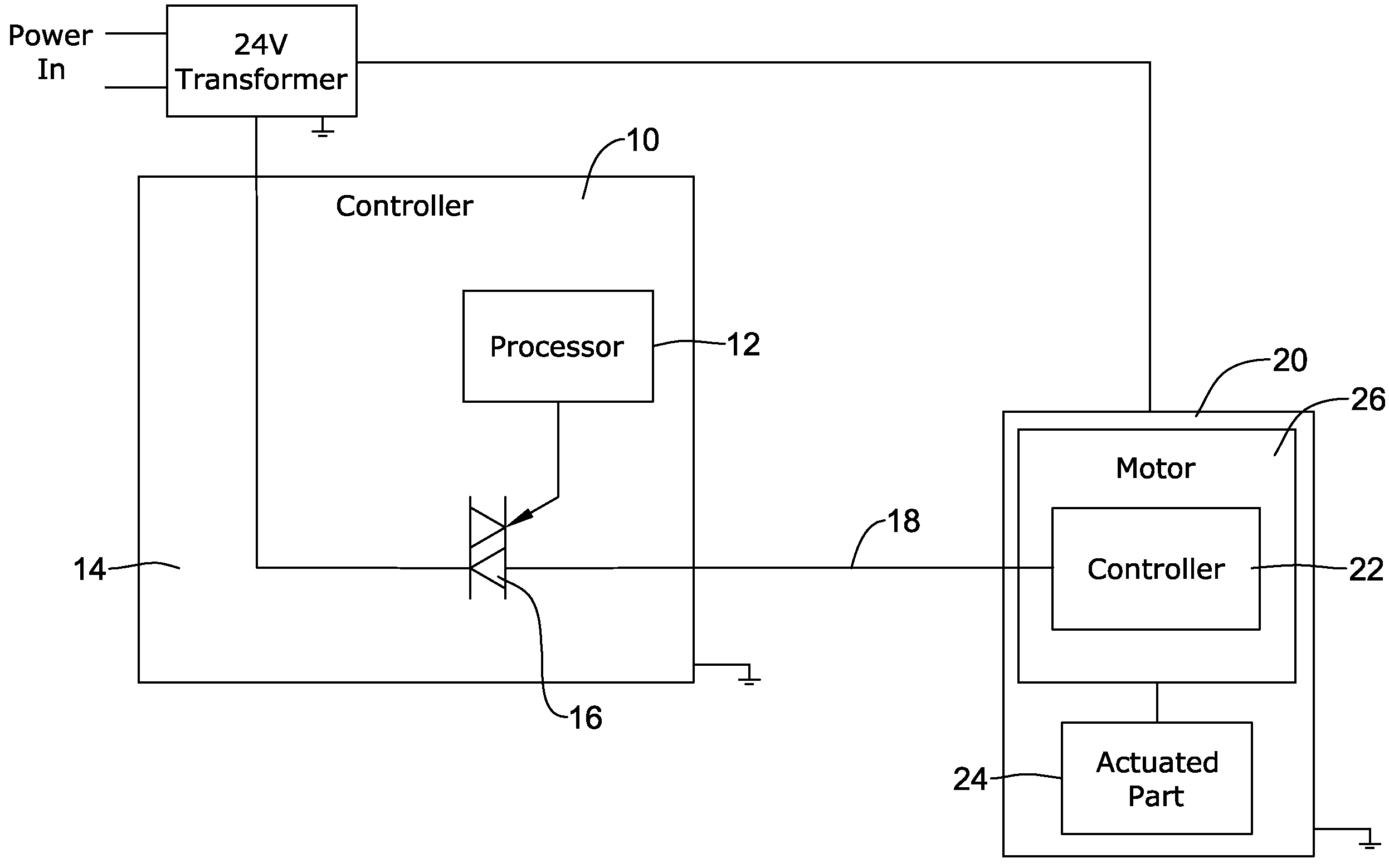

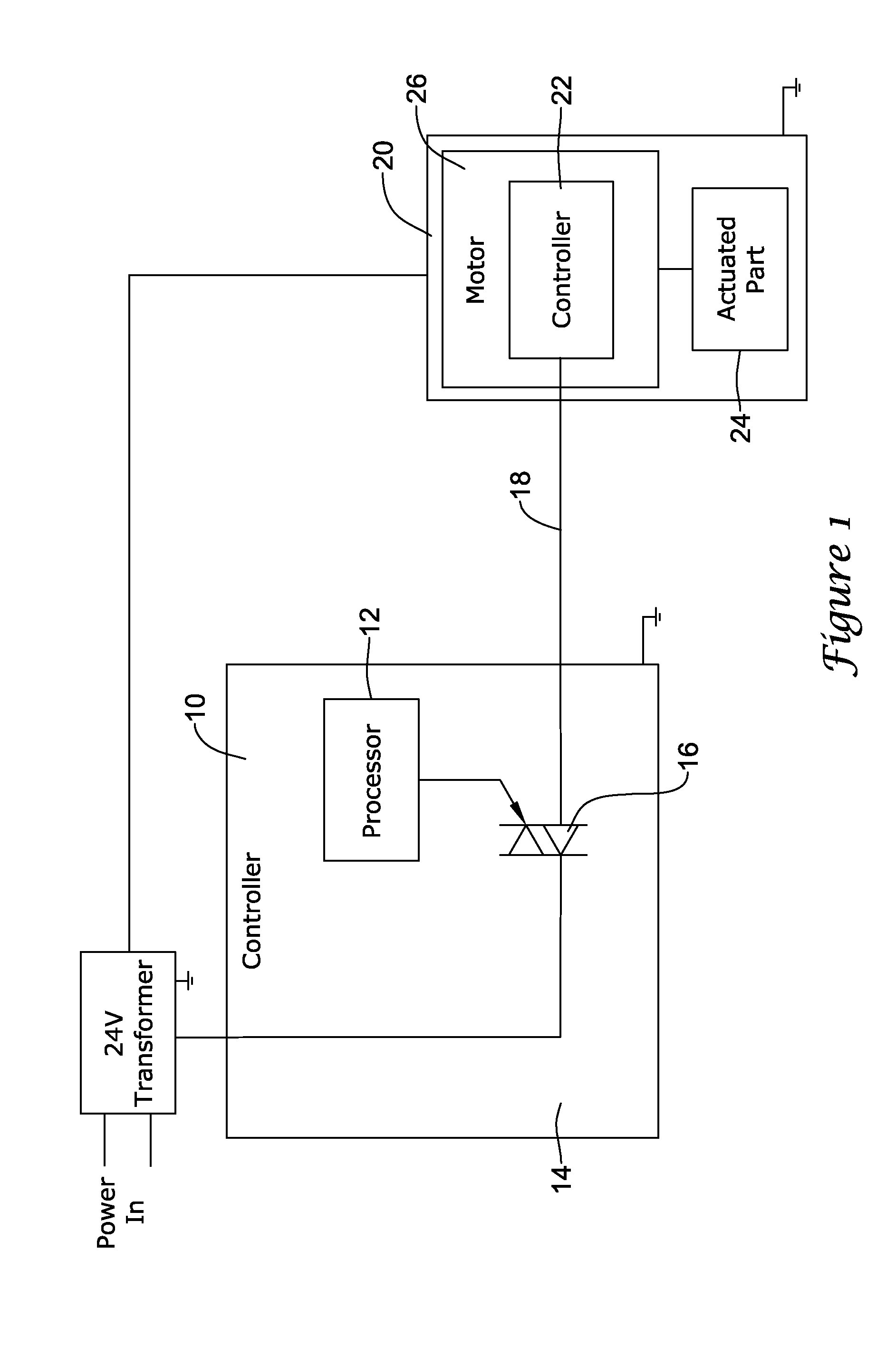

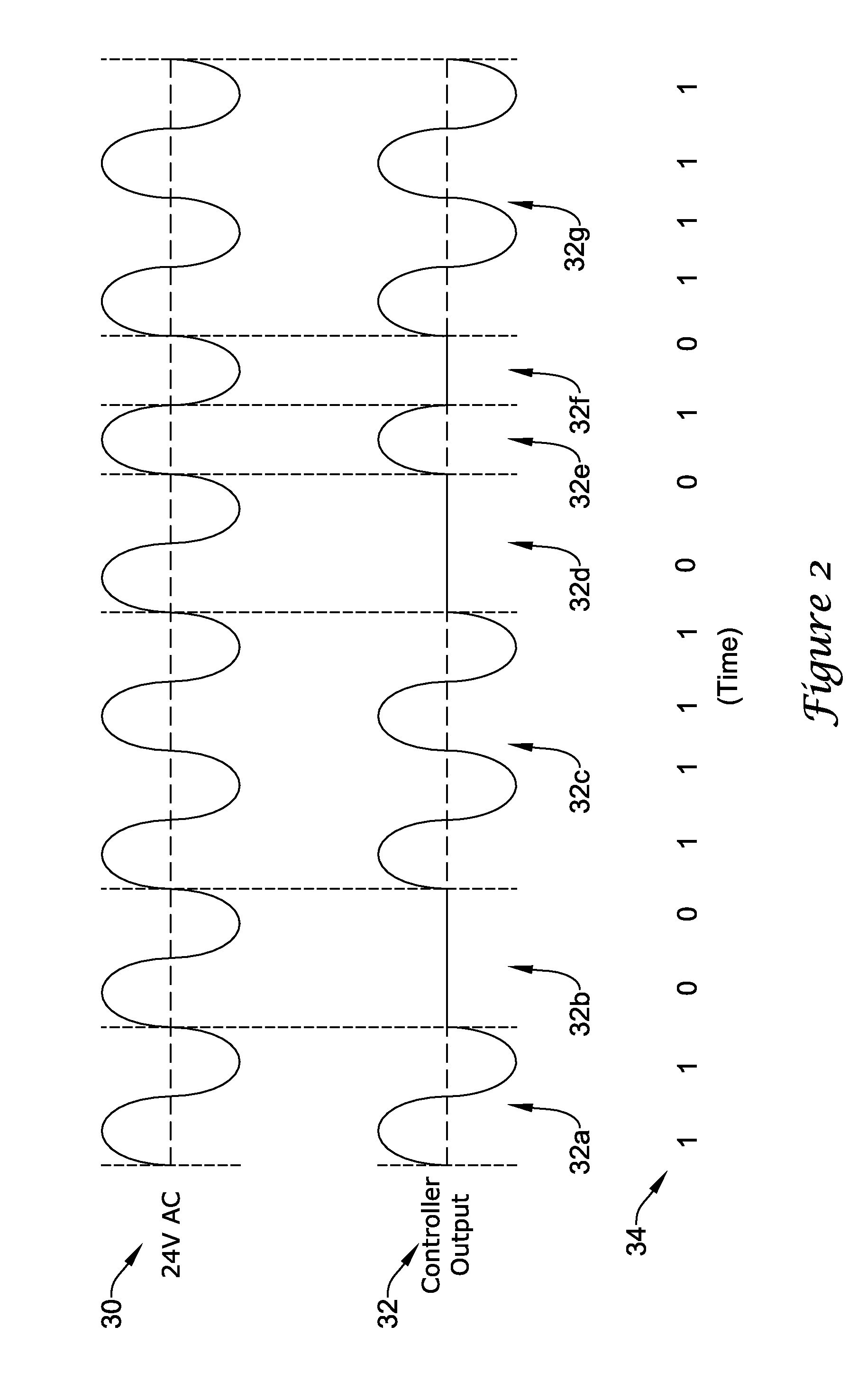

Single line control for HVAC actuator

InactiveUS7787994B2Sampled-variable control systemsElectric signal transmission systemsControl signalActuator

Owner:HONEYWELL INT INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com