Patents

Literature

37results about How to "Reduce stress distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

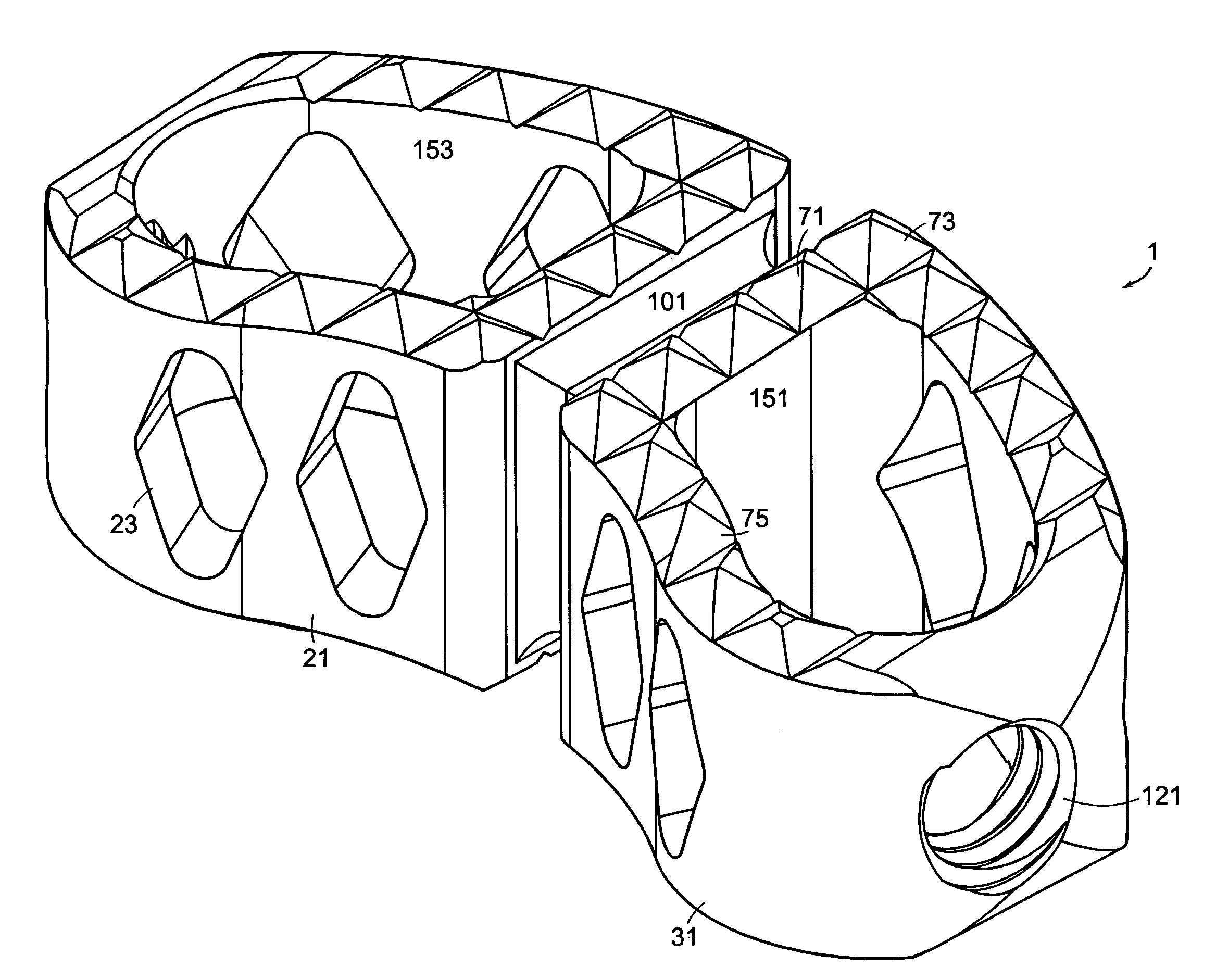

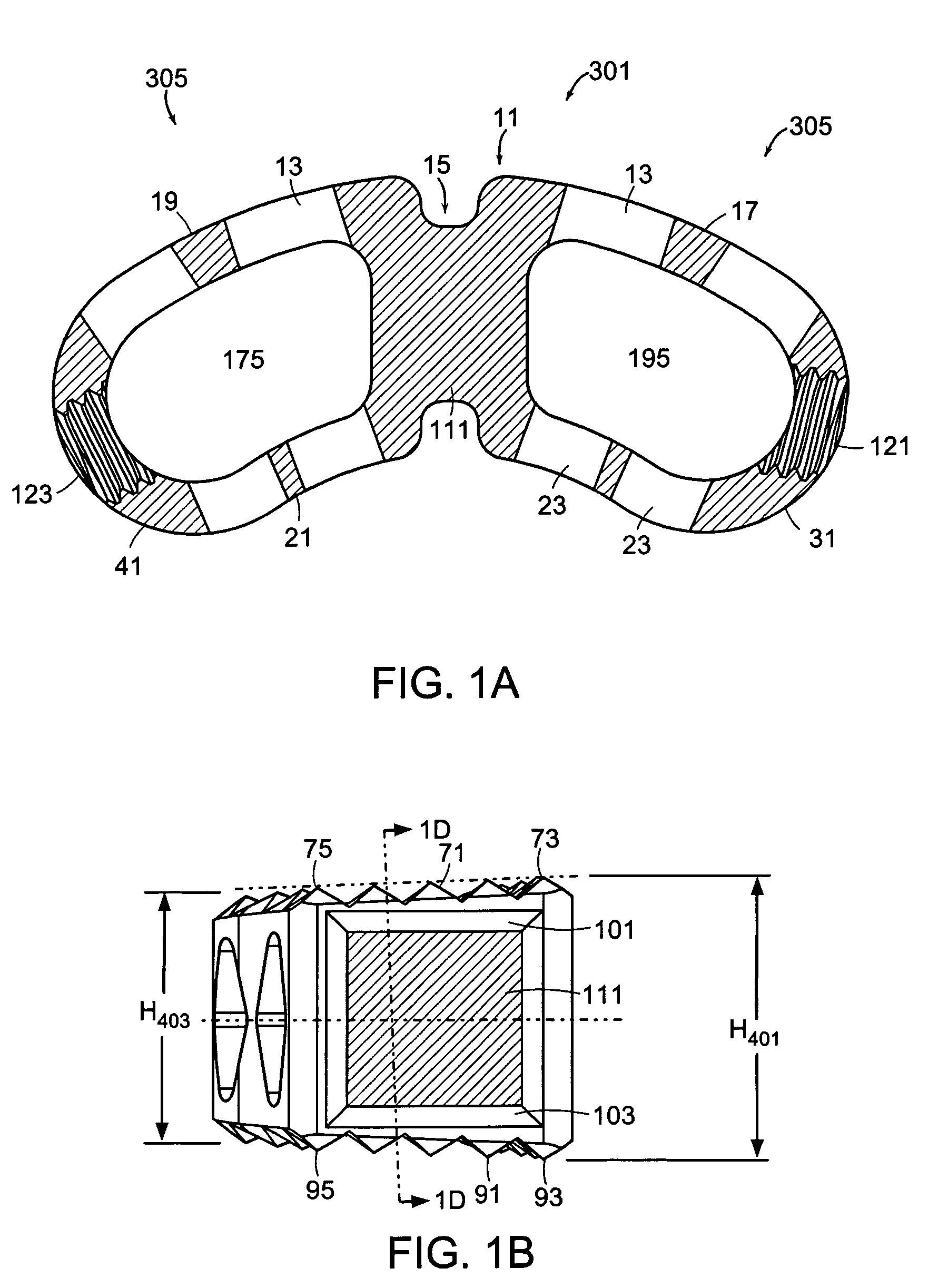

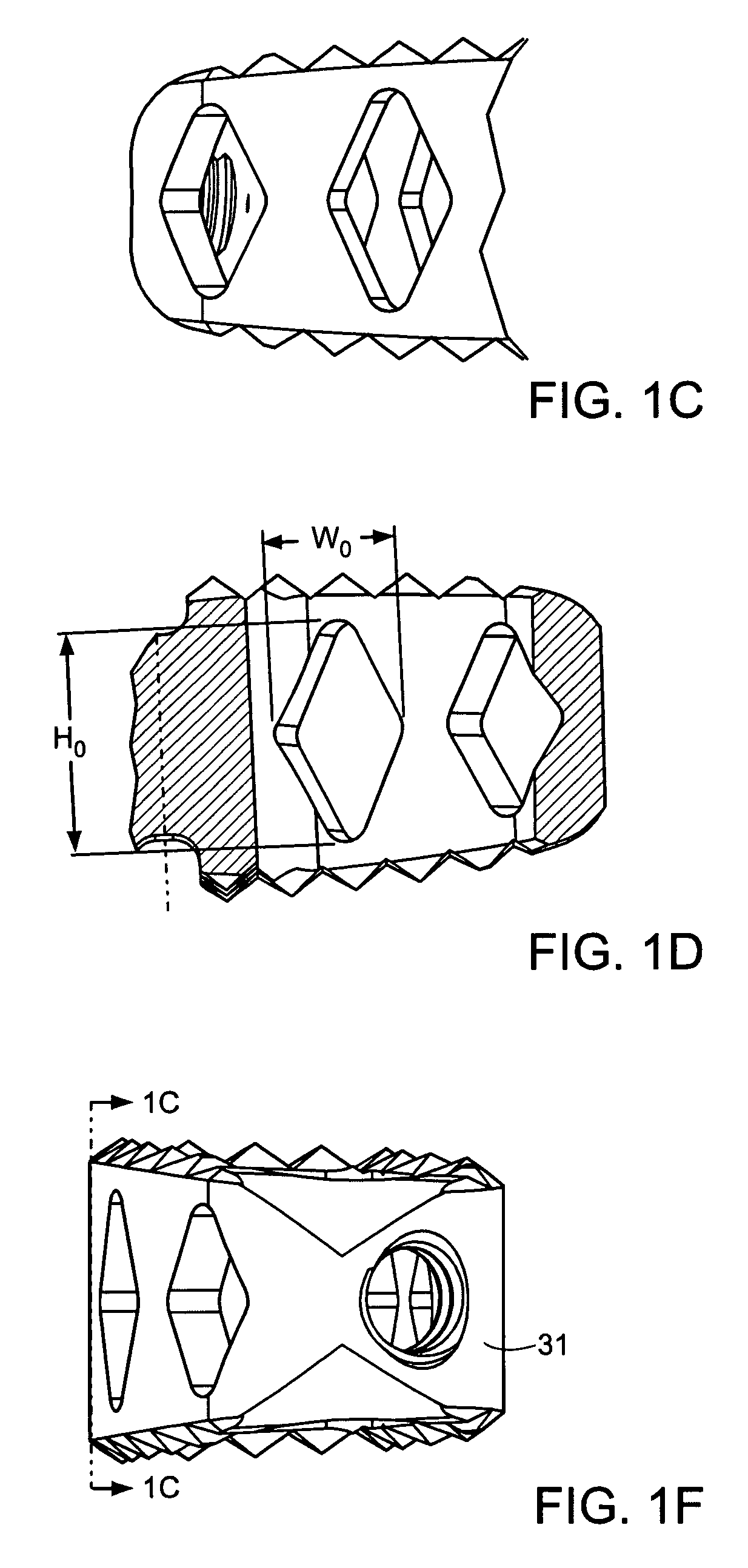

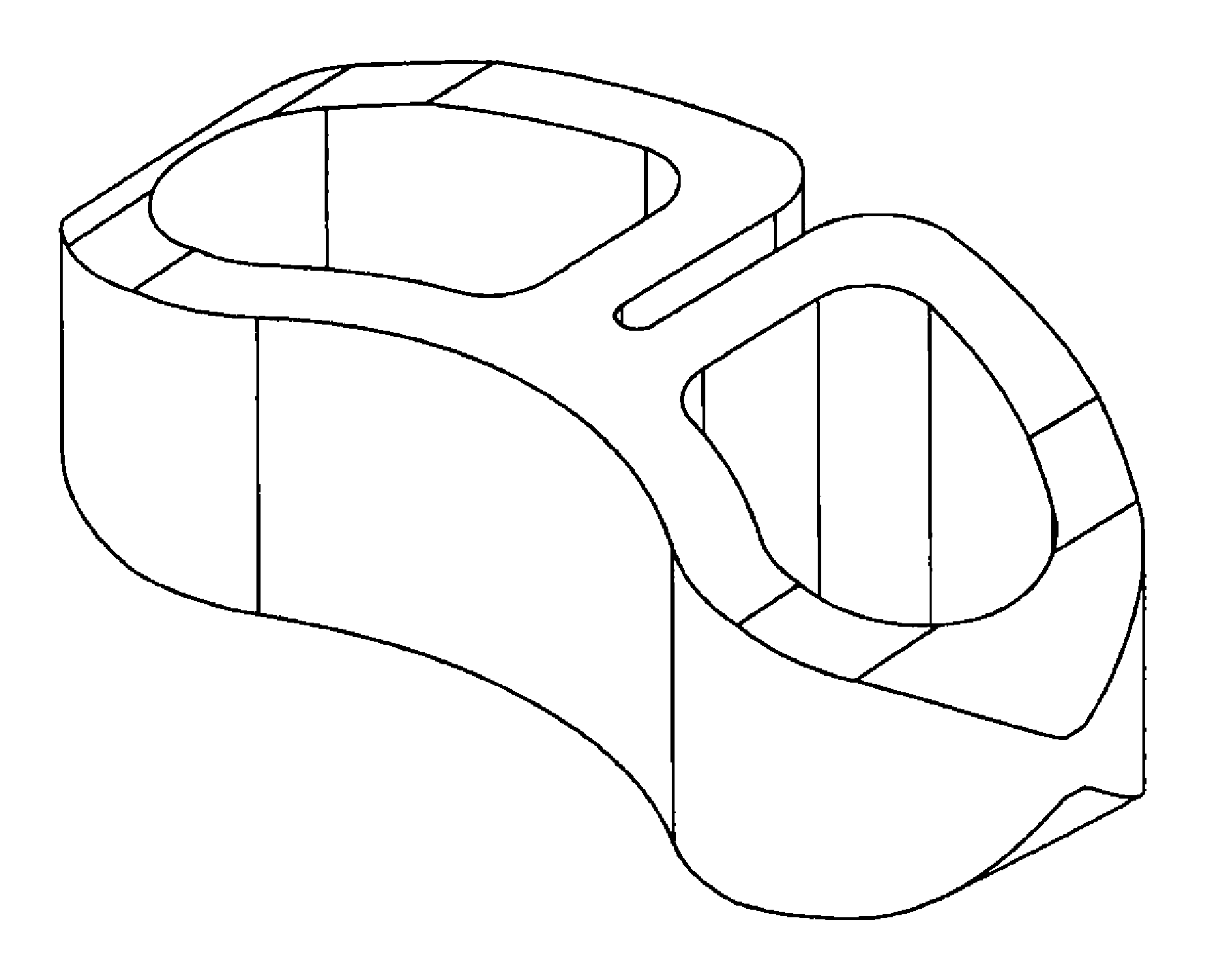

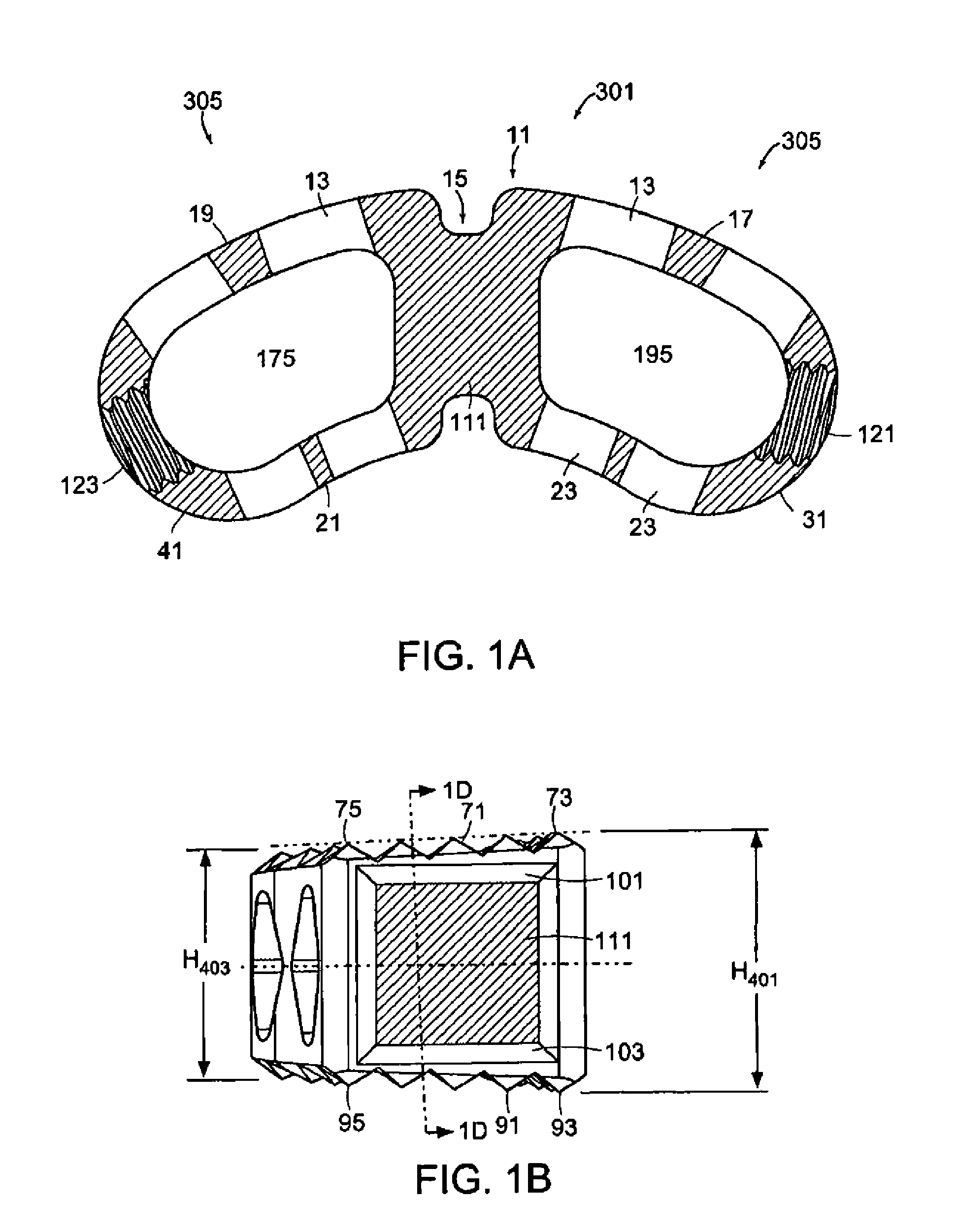

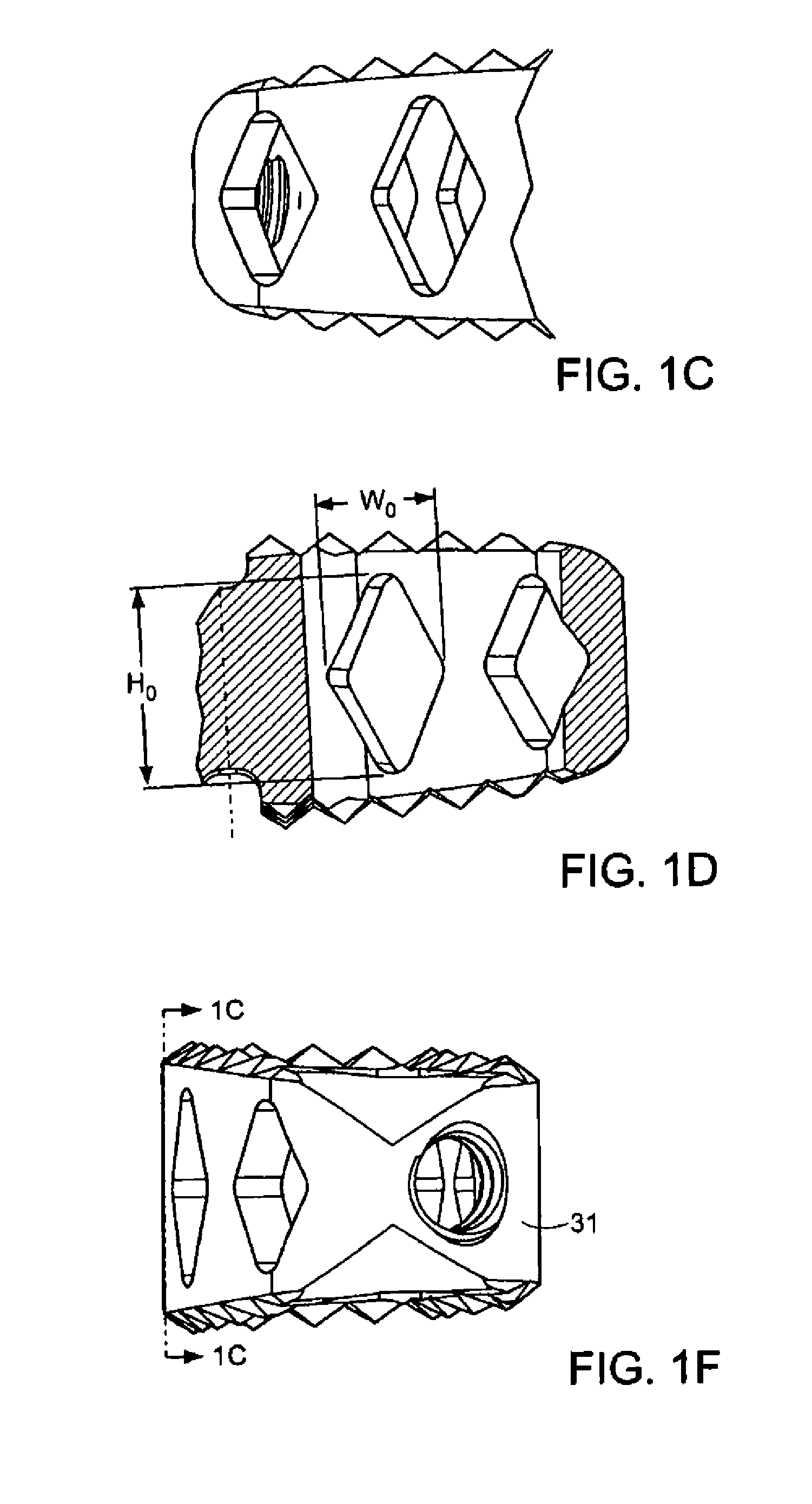

Banana cage

ActiveUS7500991B2Relieve pressureRoom for improvementBone implantJoint implantsEngineeringAnterior wall

A banana shaped intevertebral fusion cage having a domed profile, an internal planar wall defining first and second graft chambers, asymmetrically disposed leading and trailing insertion, and an anterior wall recess.

Owner:DEPUY SYNTHES PROD INC

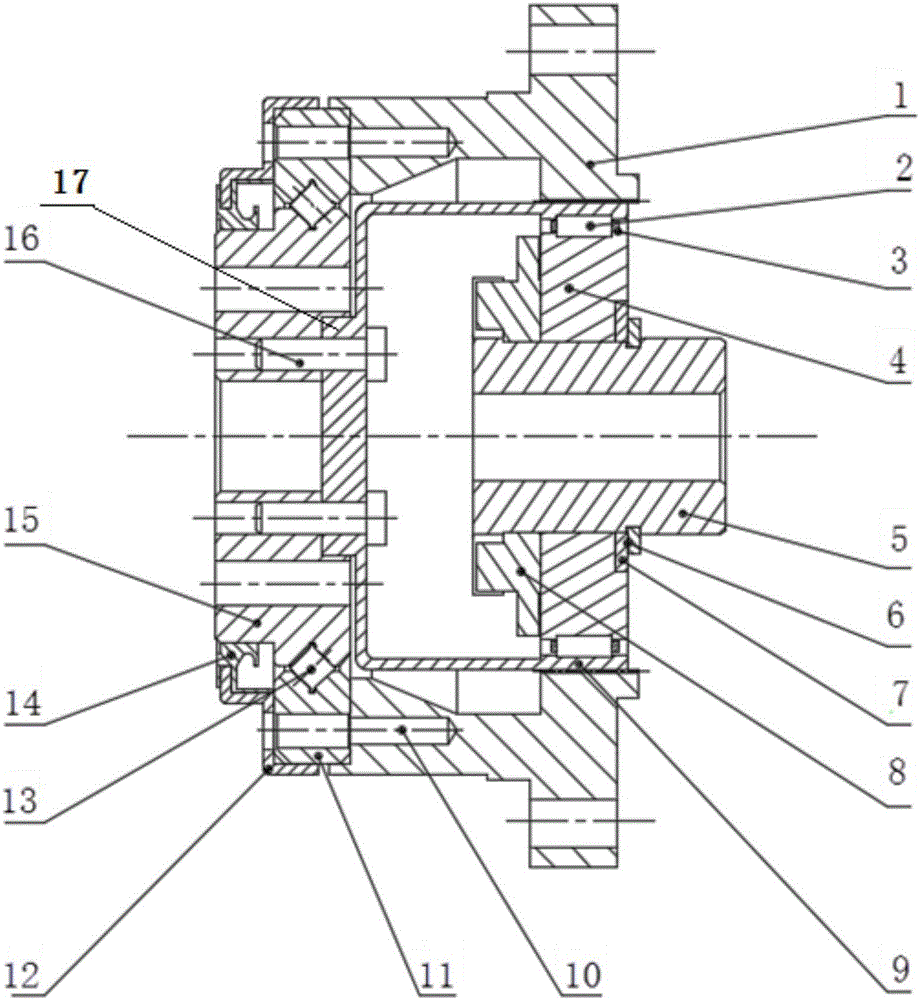

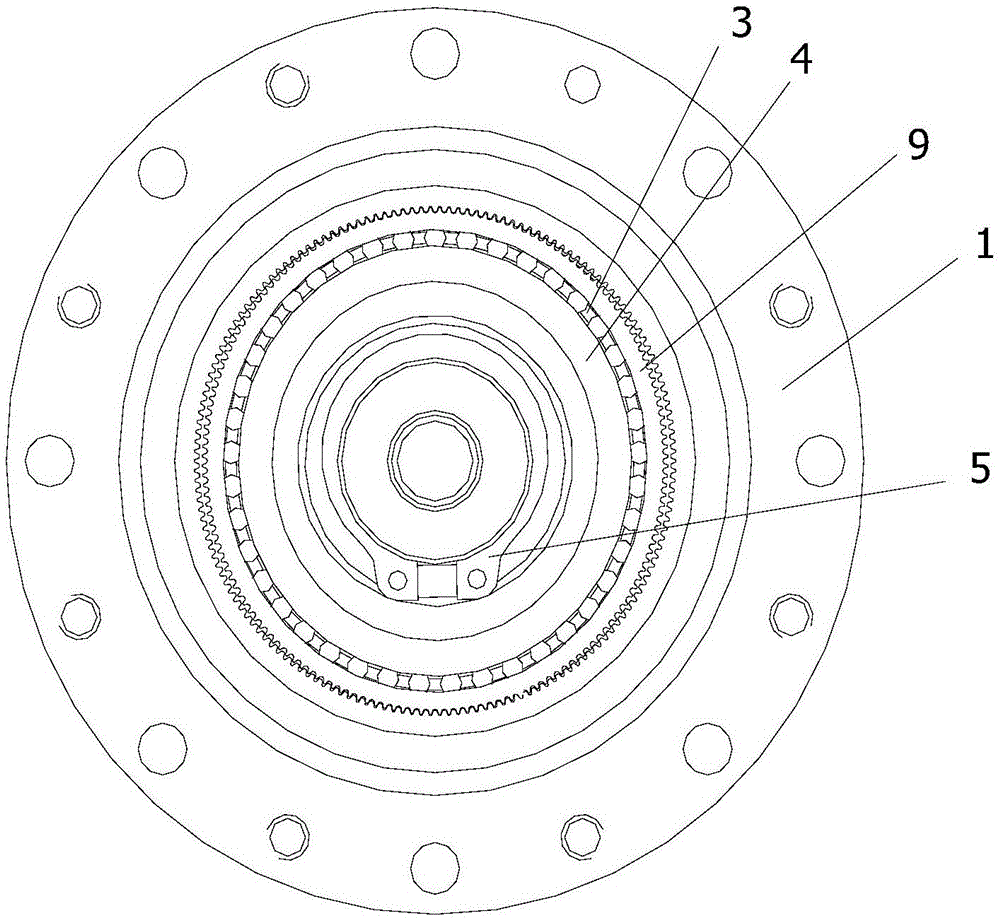

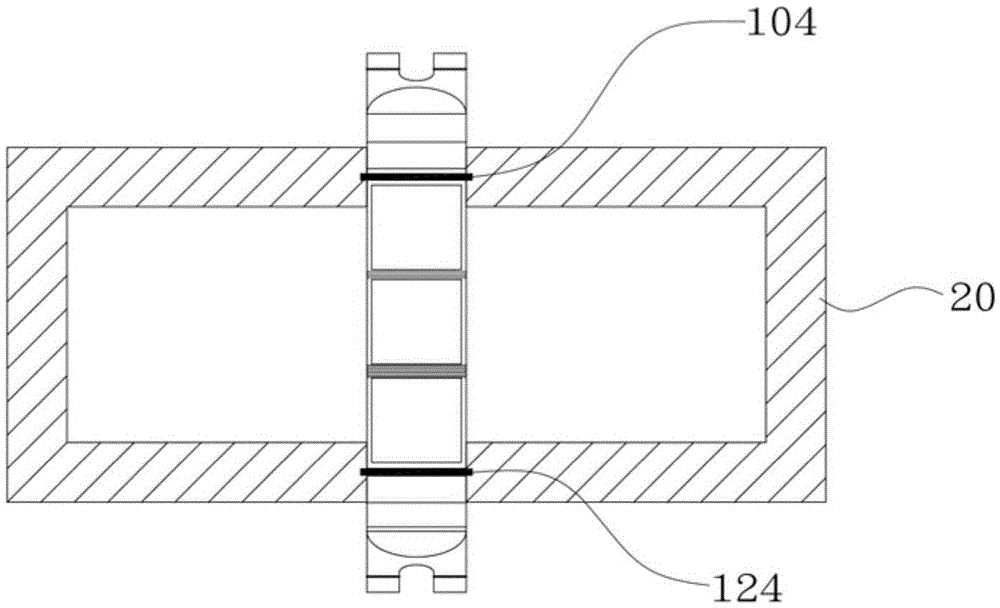

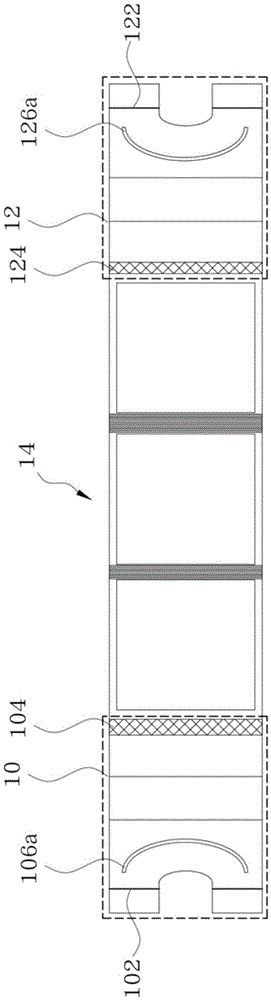

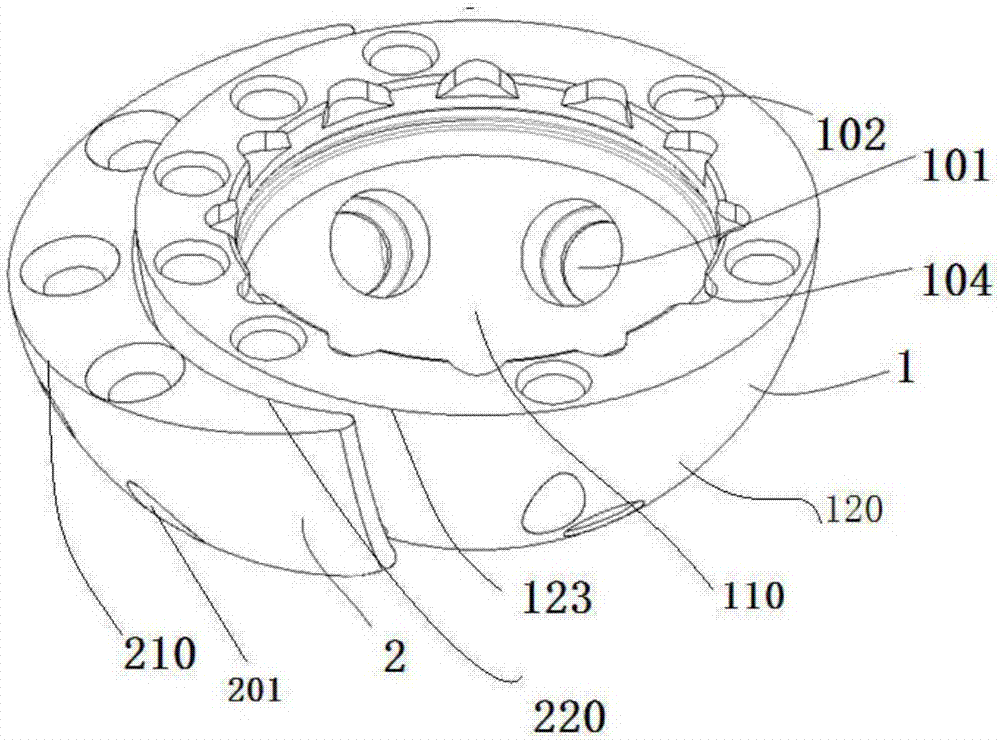

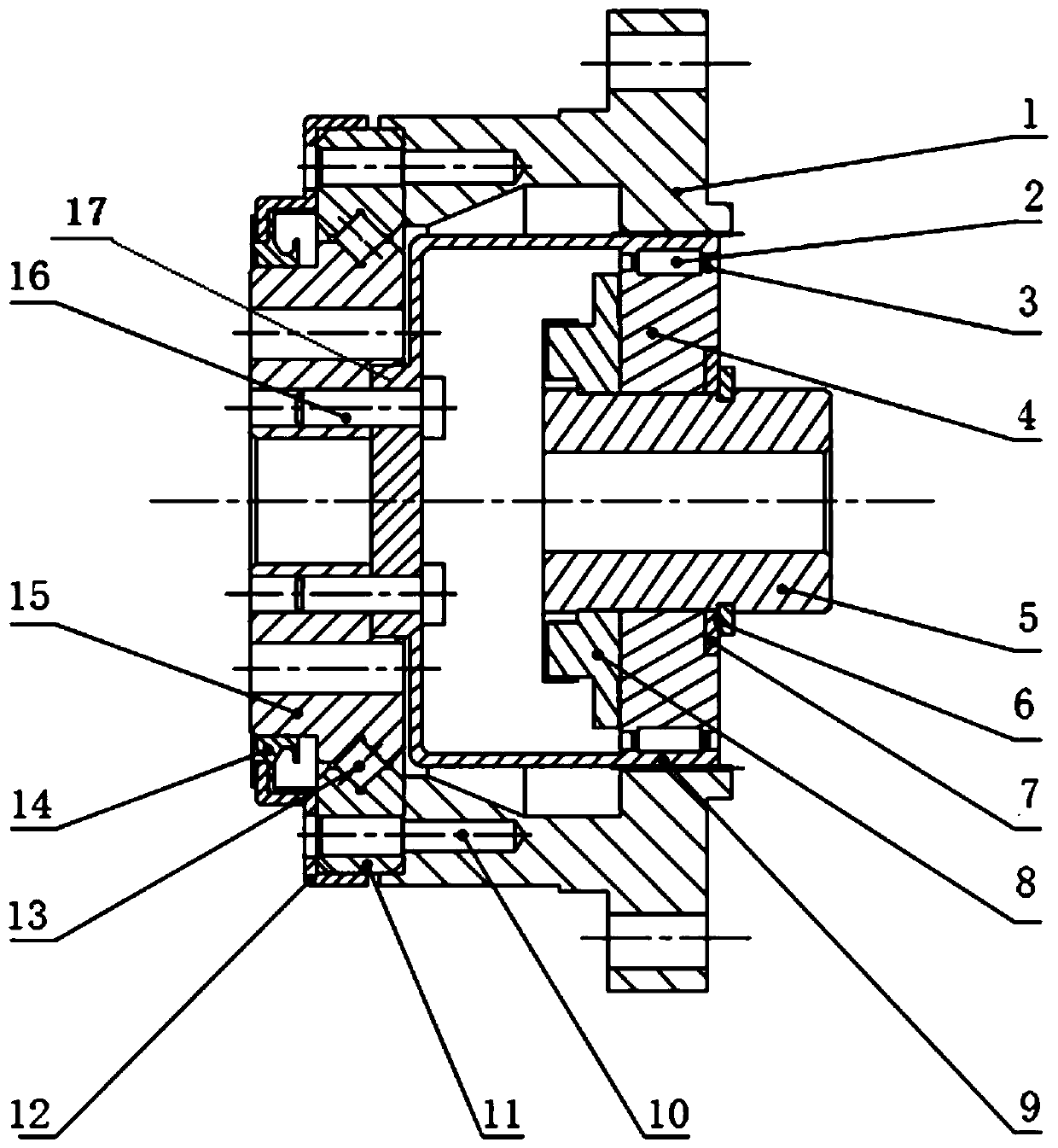

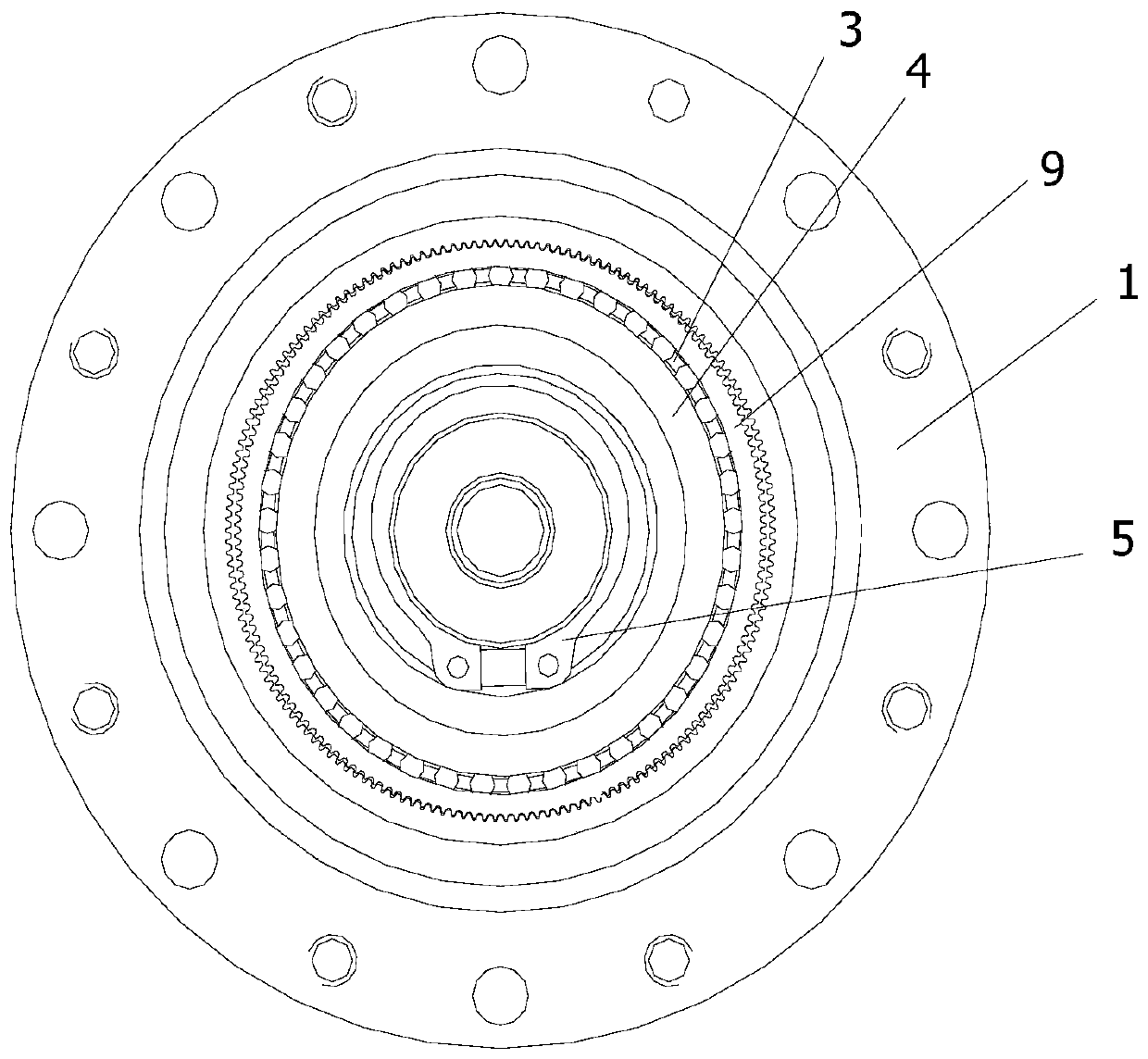

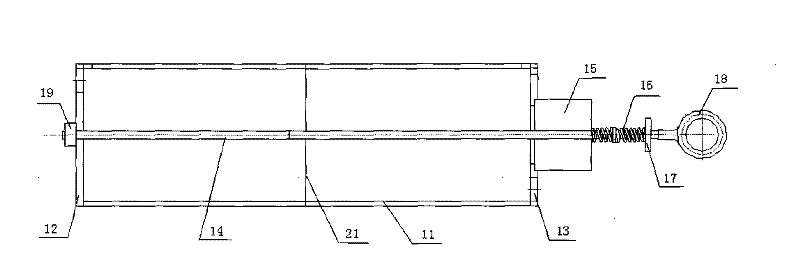

Novel harmonic reducer and input transmission structure thereof

The invention discloses a novel harmonic-reducer input transmission structure. The novel harmonic-reducer input transmission structure comprises a cam connected with an input shaft, and the cam is sleeved with a flexible gear; a steel gear is engaged with the flexible gear, outer teeth are arranged on the flexible gear, inner teeth are arranged on the steel gear, and the flexible gear is engaged with the steel gear through the outer teeth and the inner teeth; a keeping frame is arranged between the flexible gear and the cam, and a cylinder roller is installed in the keeping frame; annular flanges are formed inside the flexible gear and outside the cam in an outward-protruding mode, and C-shaped grooves matched with the cylinder roller are formed in the annular flanges; the annular flanges are located on the outer-tooth side of the flexible gear. By means of the novel harmonic-reducer input transmission structure, the assembly stress of a key part of a harmonic reducer is reduced or eliminated, the engaging stress of the steel gear and the flexible gear in the movement process is reduced, the input structure and the output structure of the harmonic reducer are newly designed, the movement of the harmonic reducer is more stable during working, and the service life is prolonged.

Owner:HUNAN UNIV

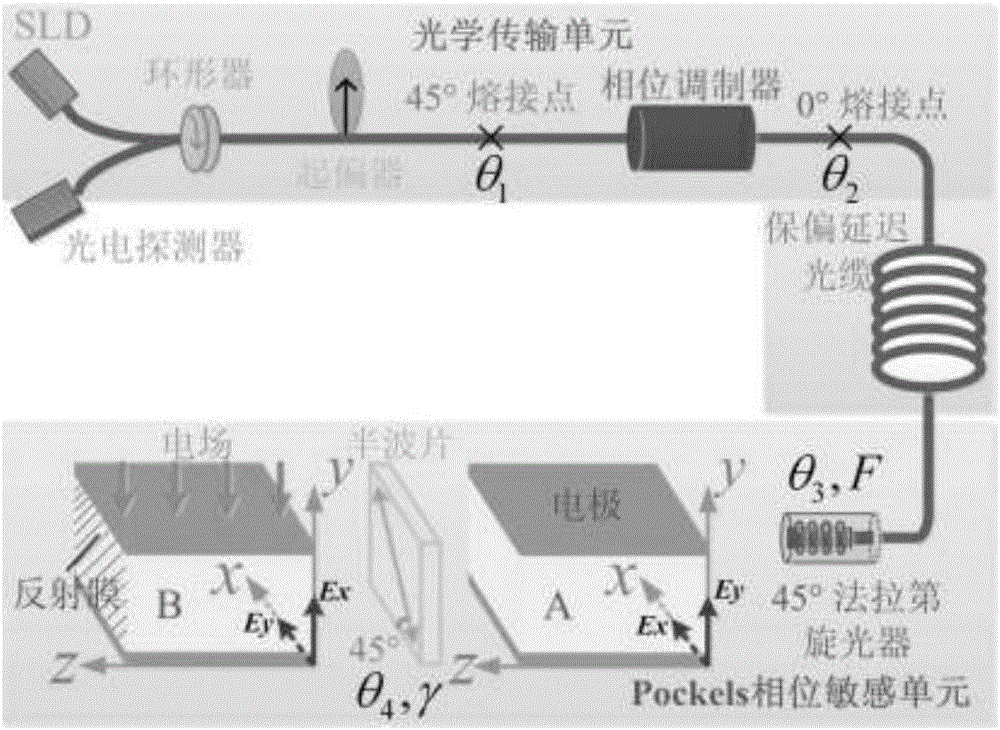

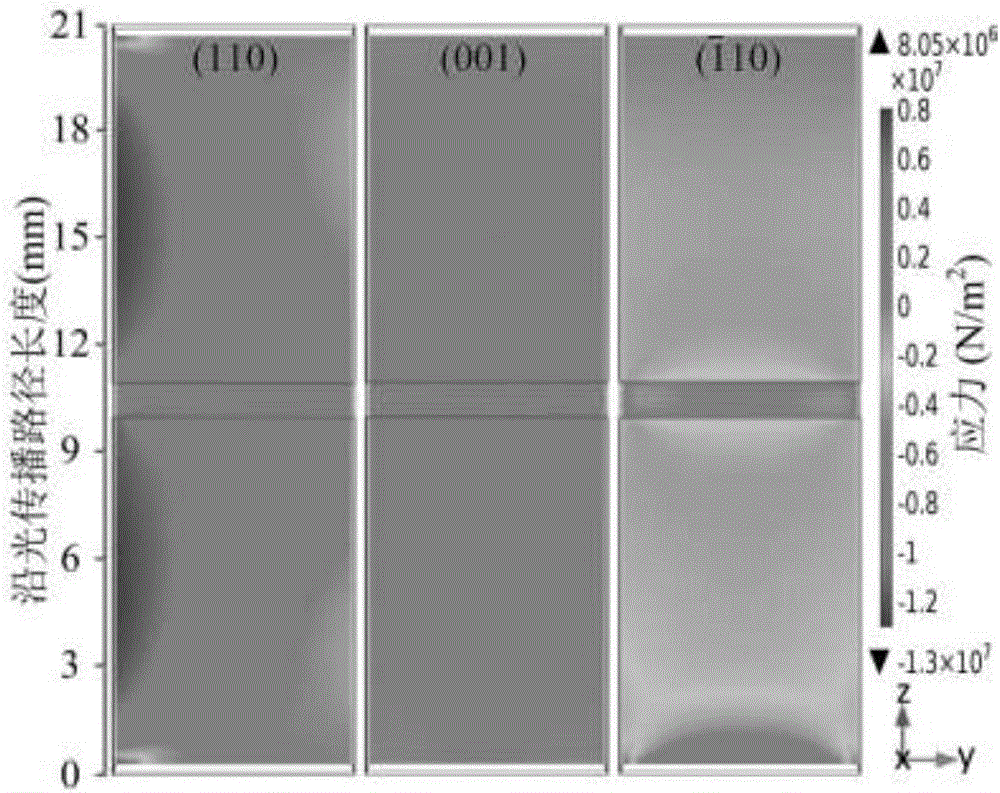

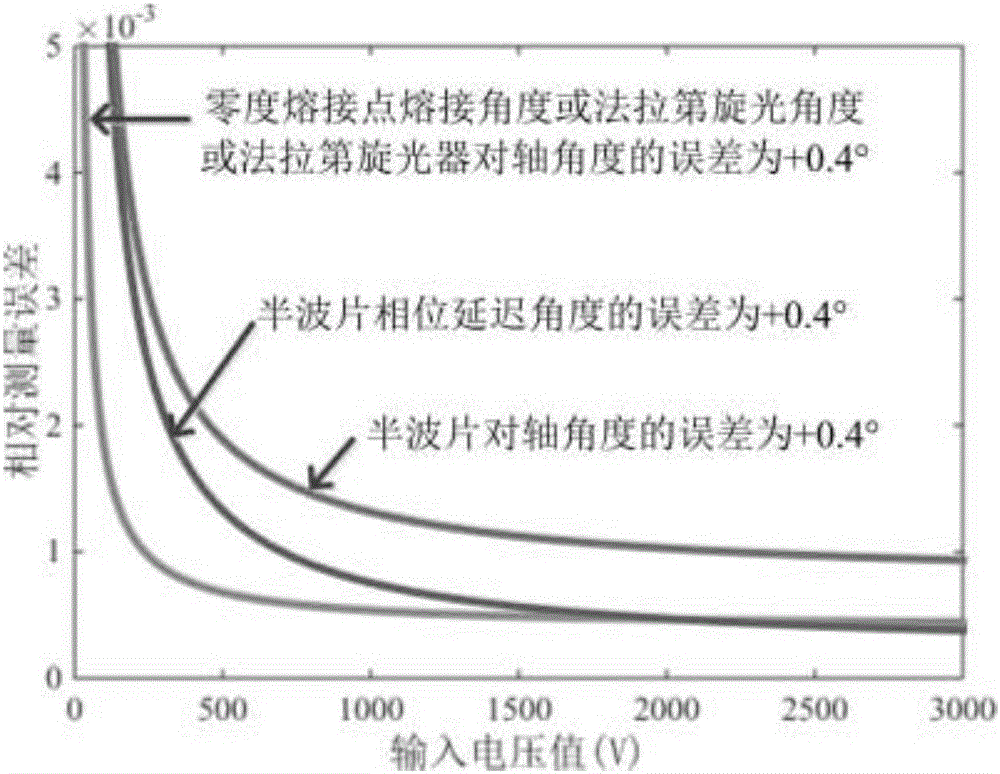

Optical sensing device for restraining voltage sensor temperature error

ActiveCN105911324AImprove temperature stabilityReduce stress distributionVoltage/current isolationSpecial purpose recording/indication apparatusOptical sensingOptical transport unit

The invention discloses an optical sensing device for restraining a voltage sensor temperature error and belongs to the field of an optical voltage sensor. The optical sensing device comprises an optical transmission unit and a Pockels phase sensing unit. The reciprocity degeneration of the Pockels phase sensing unit is caused by the inconsistency of the temperature fields and stress fields of two crystals; and the generation of a measuring error of the optical voltage sensor is caused by the influence of the non-ideal welding angle and counter shaft angle of the optical transmission unit on the magnitude of interference light intensity and feedback phase. By establishing a temperature error model of the optical transmission unit and the Pockels phase sensing unit, a novel optical base structure for counteracting additional stress birefringence in the two crystals is designed, and an angle error compensating method is provided, so that the measuring precision and temperature stability of the optical voltage sensor are increased.

Owner:安徽华驰动能科技有限公司

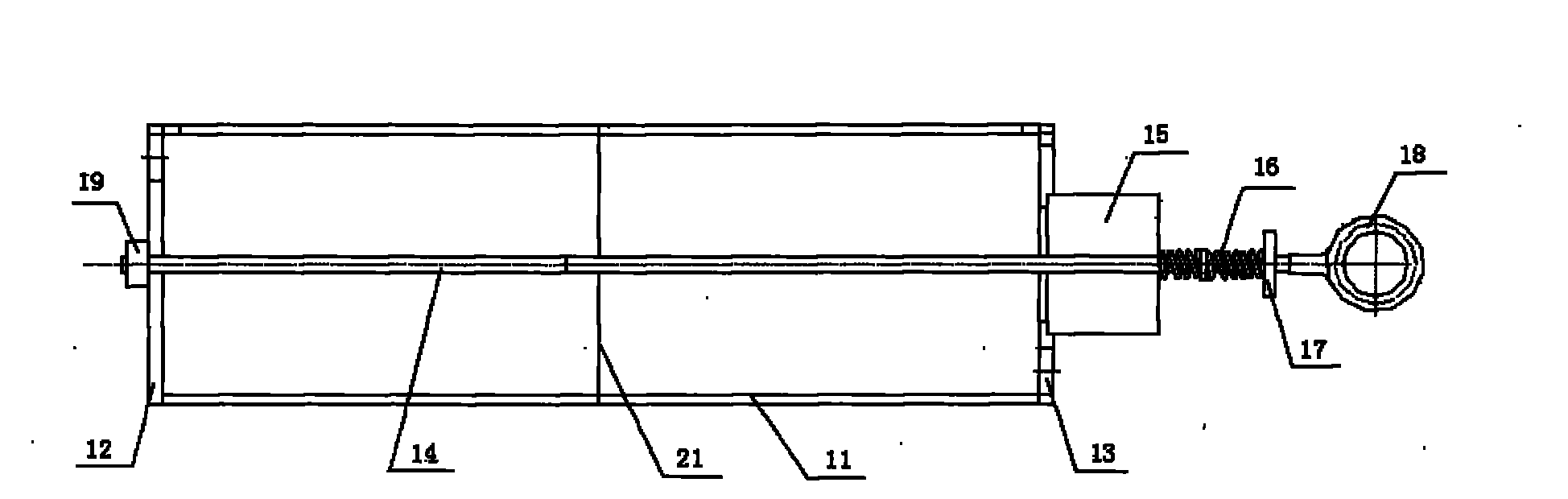

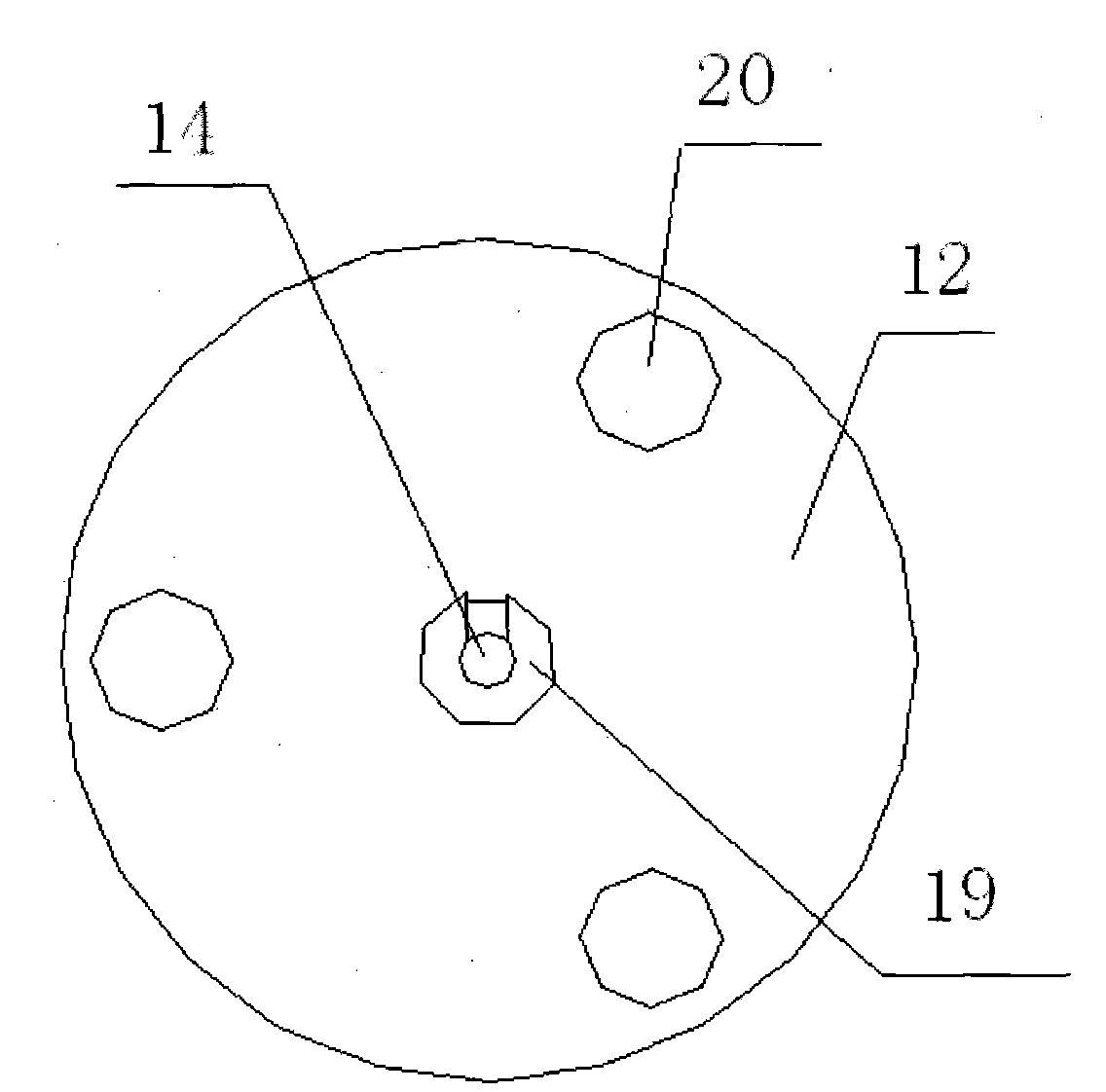

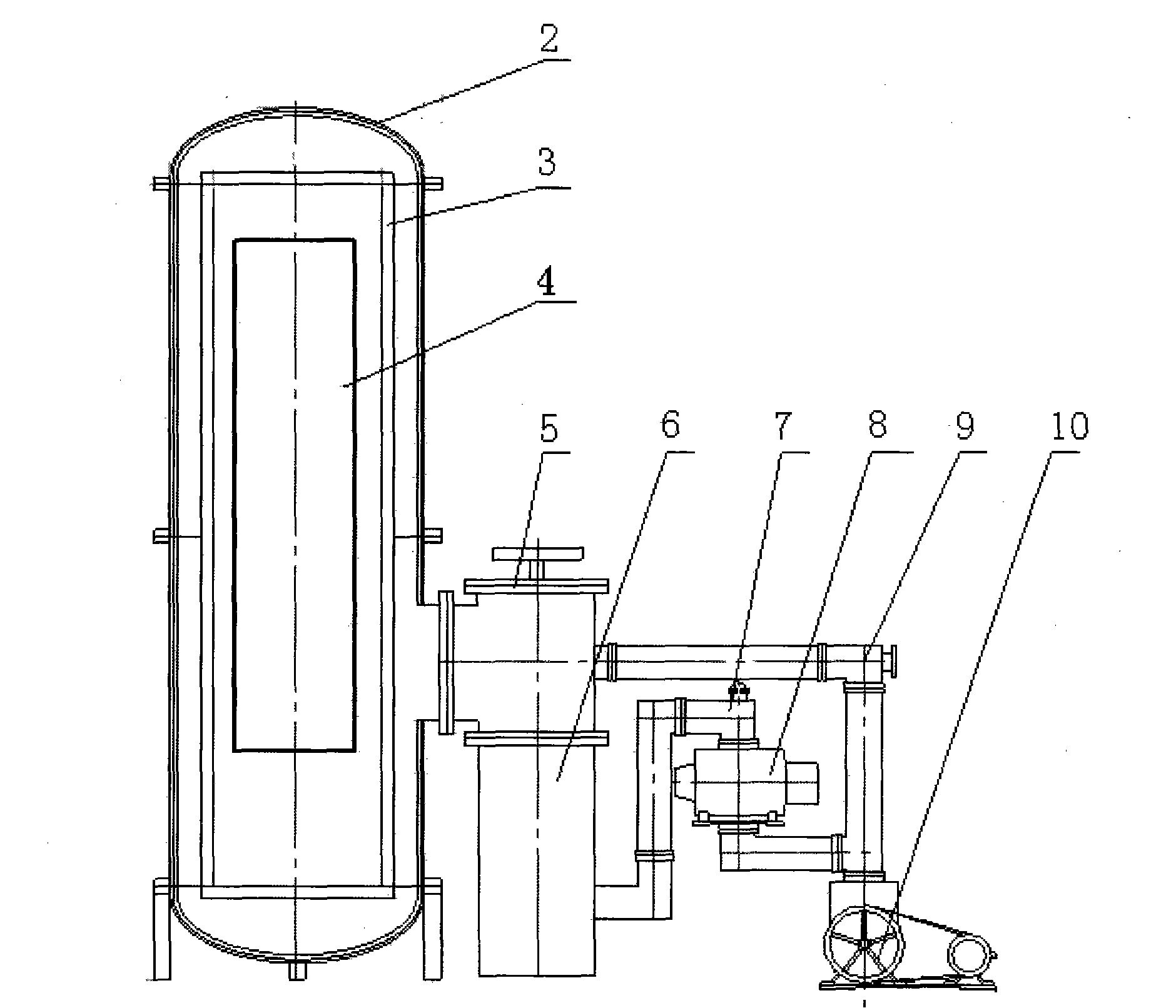

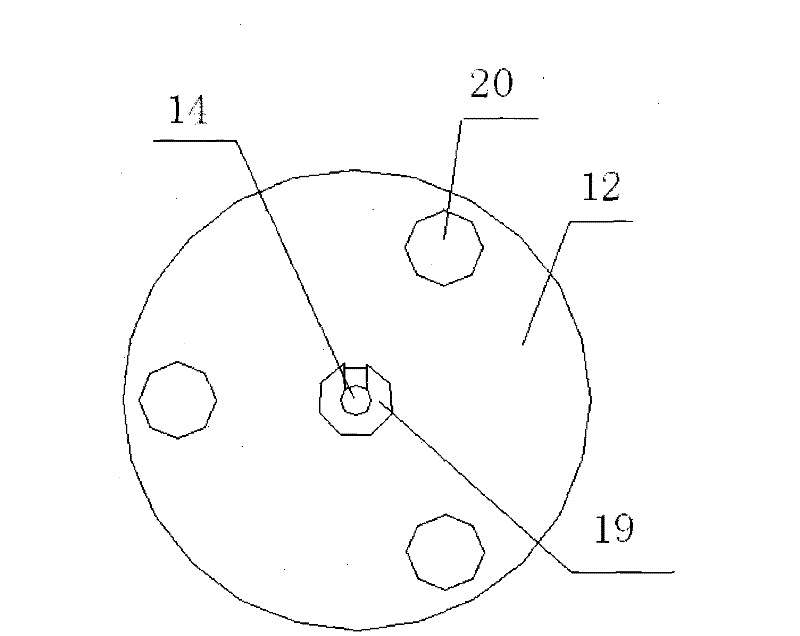

Brazing process of ceramic vacuum pipe with diameter greater than 300mm and device

ActiveCN101767236AEnsuring natural capillarityEvenly distributedSoldering apparatusTubular articlesShielding gasNitrogen gas

The invention provides a brazing process of a ceramic vacuum pipe with diameter greater than 300mm and a device, comprising the following steps: firstly, cleaning the ceramic pipe and a titanium ring, then putting them into a vacuum furnace, conducting temperature-rising weld under vacuum condition, providing shielding gas after welding, taking the ceramic pipe out from the furnace, and completing the butt-weld of two ceramic vacuum pipes. The device provided by the invention comprises a first-class mechanical rotary vane pump, a second-class Roots pump, and a third-class oil diffusion pump; the pumps are arranged in serial, meanwhile, the device is provided with a pipeline for transmitting high-purity inert gas (such as nitrogen and argon) into the furnace. The advantages of the invention are as follows: the brazing process of the ceramic vacuum pipe with diameter greater than 300mm and the device is provided, the vacuum leak rate at welded joint of the welded ceramic pipes is less than 5 * 10-12Pa. M3 / s, and no crack exists on the ceramic pipe.

Owner:上海克林技术开发有限公司

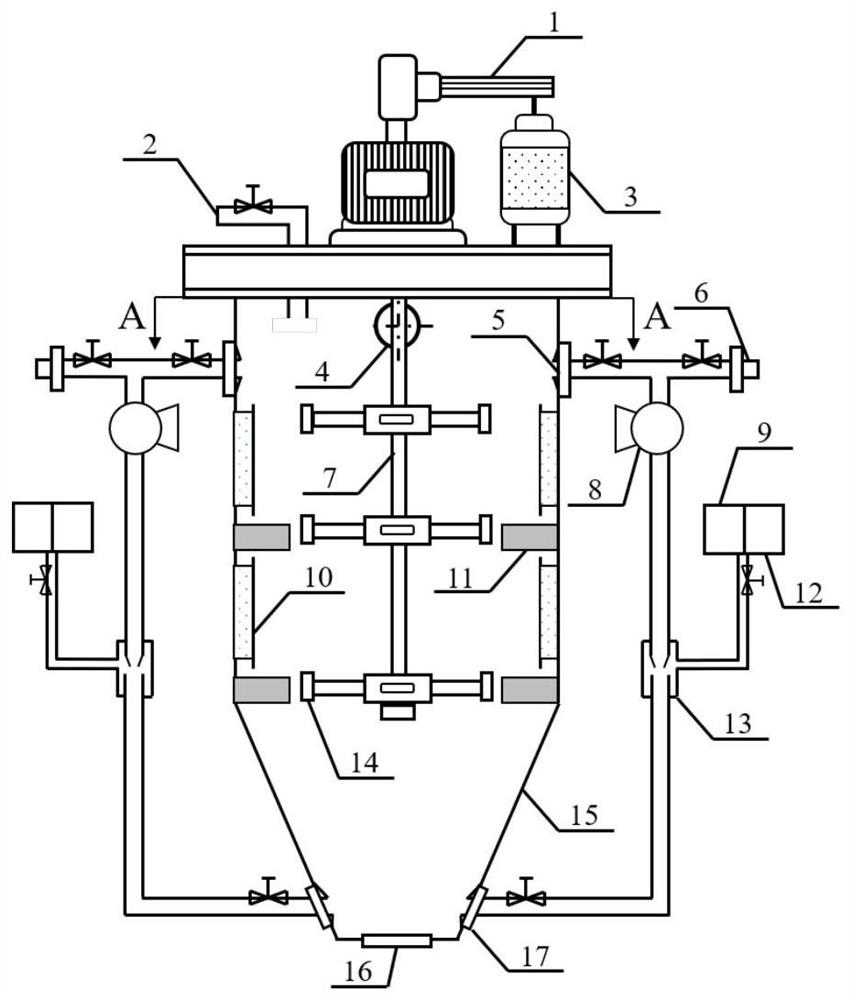

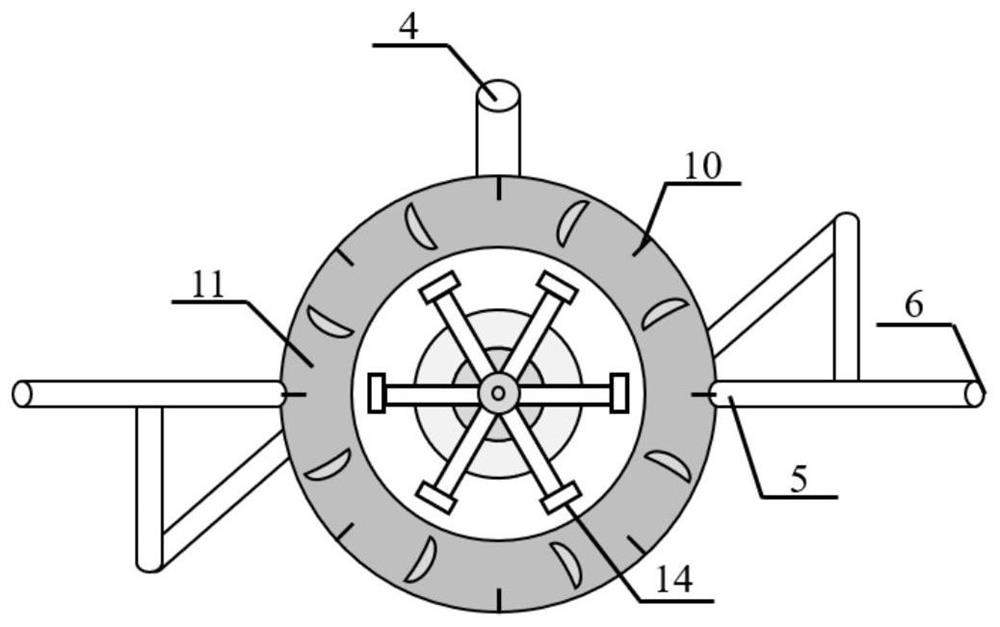

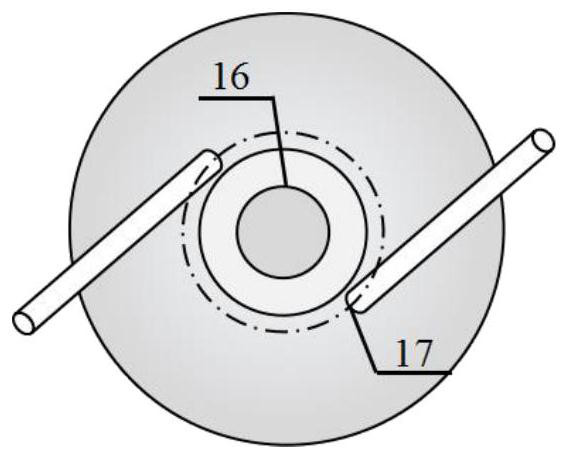

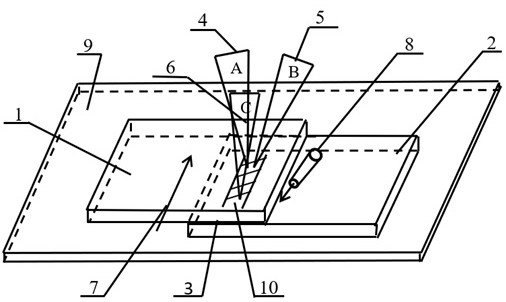

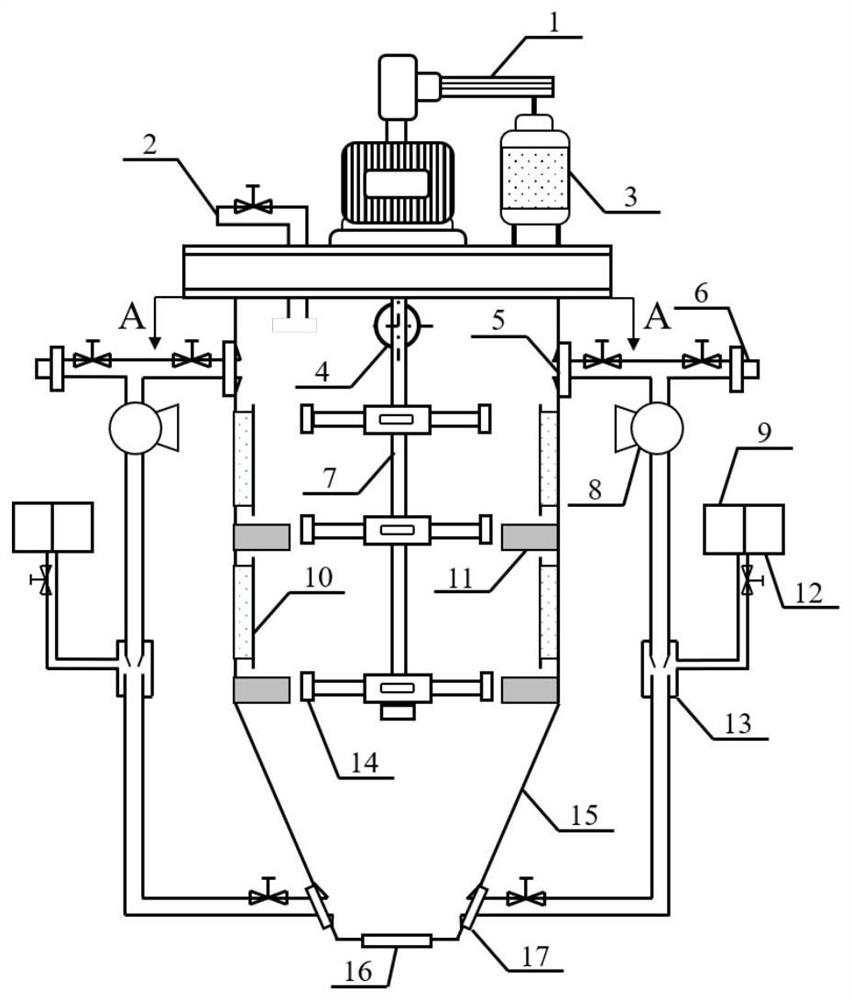

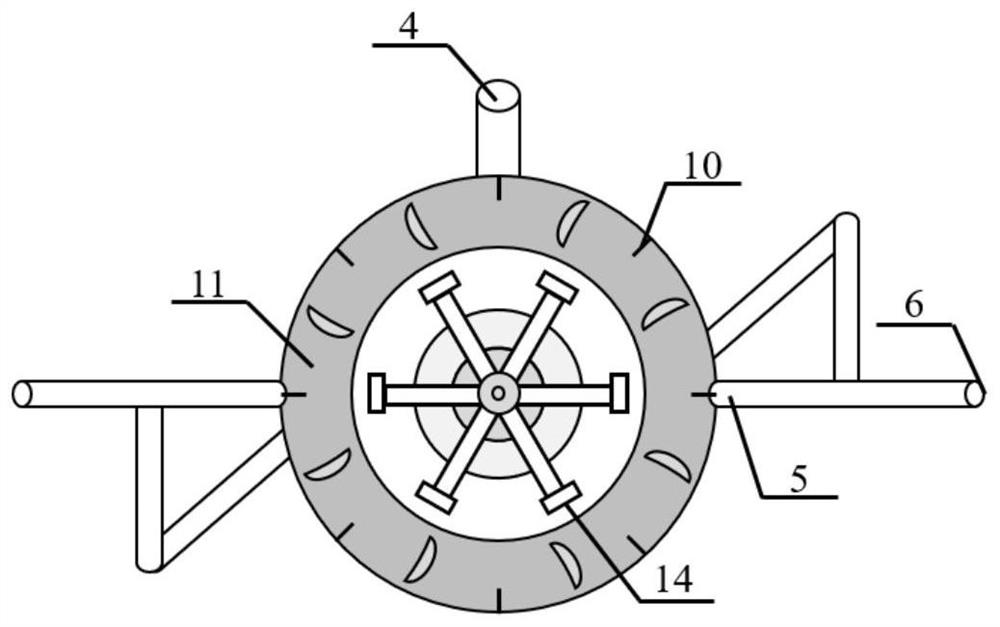

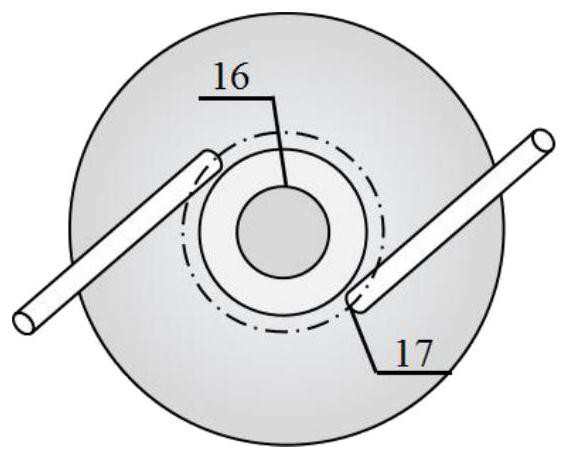

Pre-selection efficient size mixing method suitable for wide-size-fraction flotation

ActiveCN111871620AAssist in shearingIncreased turbulent energy dissipation rateRotary stirring mixersTransportation and packagingFoaming agentPulp and paper industry

The invention discloses a pre-selection efficient size mixing method suitable for wide-size-fraction flotation. The pre-selection efficient size mixing method is suitable for peat check. The method includes following steps: firstly, wide-size-fraction ore pulp is fed through ore pulp feeding ports in the two sides of a pulp mixing barrel to form high-speed jet flow, wherein the high-speed jet flowenters from the inlet end of a dosing pipe of a Venturi tube structure to form negative-pressure area ore pulp, a collecting agent and a foaming agent are self-sucked into the negative-pressure areaore pulp in a Venturi vertical pipe structure to be emulsified, and the cavitation phenomenon occurs in the ore pulp; then, ore pulp jet flow openings in the two sides of the ore pulp inverted halfpace structure are tangentially jetted and fed into the bottom of the pulp mixing barrel to form upward strong rotational flow, and the rotating direction of a rotating impeller on a stirring shaft in the pulp mixing barrel is controlled to be always opposite to the strong rotational flow direction to guarantee ore pulp reverse flow; upward strong rotational flow ore pulp and the rotary impeller formcountercurrent pulp mixing in the forced stirring area, stress distribution is reduced through the annular shearing partition plate and the flow guide plate, equipment stability is improved, meanwhile, the auxiliary shearing effect on the strong rotational flow ore pulp moving upwards is achieved, so that the pulp mixing effect is improved. The method is simple, and the size mixing effect is good.

Owner:CHINA UNIV OF MINING & TECH

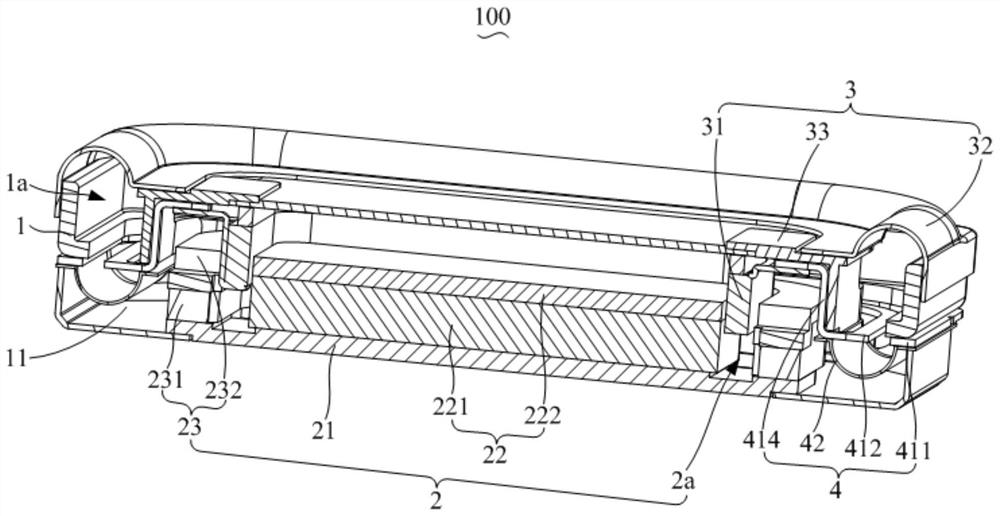

Shielding cover assembly

InactiveCN105568218AImprove accuracyImprove stress distributionVacuum evaporation coatingSputtering coatingStress distributionEngineering

The invention provides a shielding cover assembly. The shielding cover assembly comprises a fine metal shielding cover and a metal frame, wherein the fine metal shielding cover is fixed on the metal frame, and provided with two stretching areas and a pattern area; and the stretching areas are located at the two opposite sides of the pattern area respectively, wherein each stretching area comprises a semi-arc-shaped hollow part, and stress distribution during a stretching process is improved by virtue of the hollow parts. Compared with the prior art, according to the invention, one semi-arc-shaped hollow part is formed through cutting on each stretching area of the fine metal shielding cover, and stress can be reduced by virtue of the hollow parts, so that tension during a stretching process is much uniformly distributed on the surface of the fine metal shielding cover. In addition, according to the invention, wrinkles during a netting process can be reduced or eliminated, thus the accuracy of alignment measurement is improved, and the possibility of welding spot failure during a welding process is reduced.

Owner:AU OPTRONICS CORP

Banana cage

InactiveUSRE44417E1Reduce stress distributionRoom for improvementBone implantJoint implantsEngineeringAnterior wall

Owner:DEPUY SPINE INC (US) +1

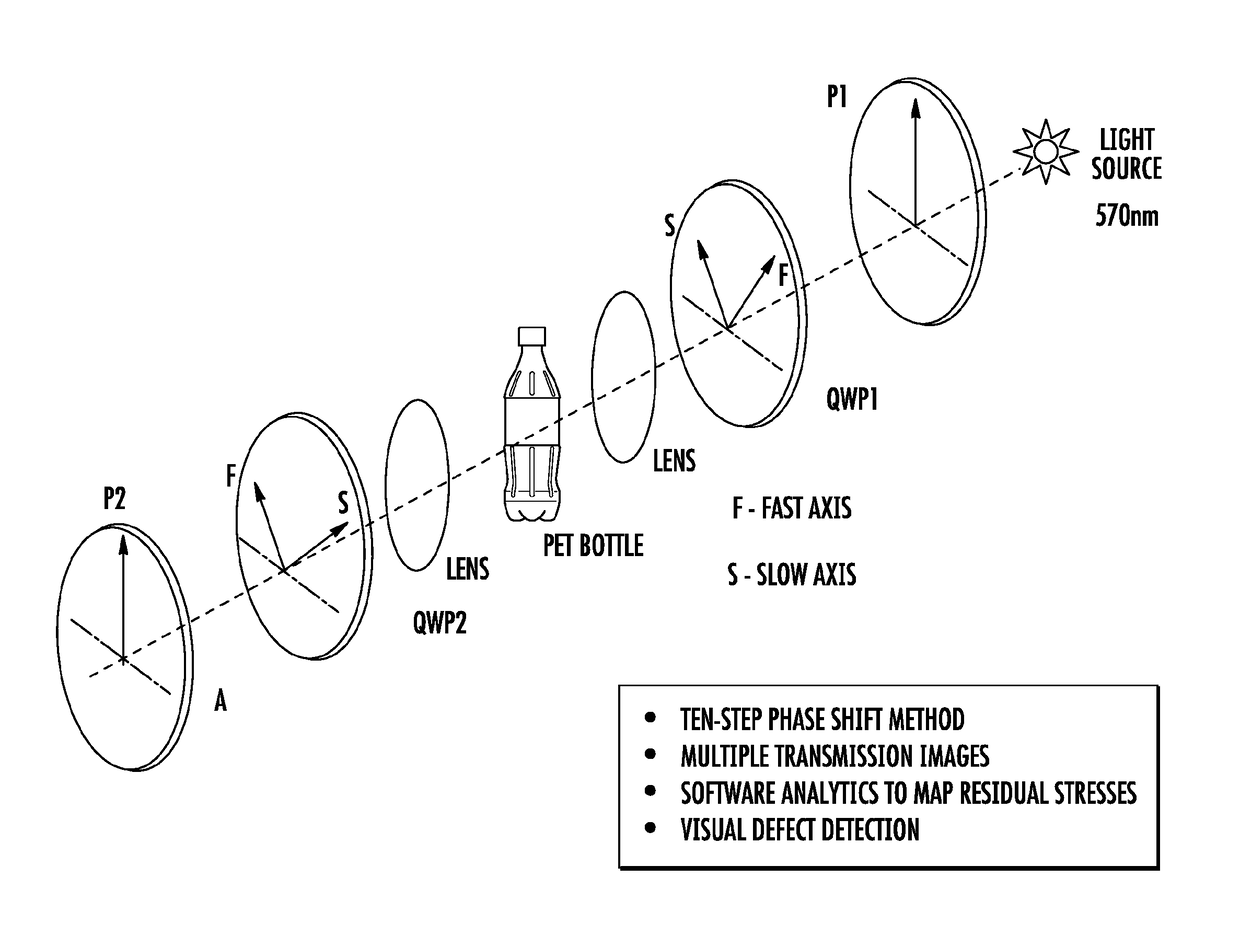

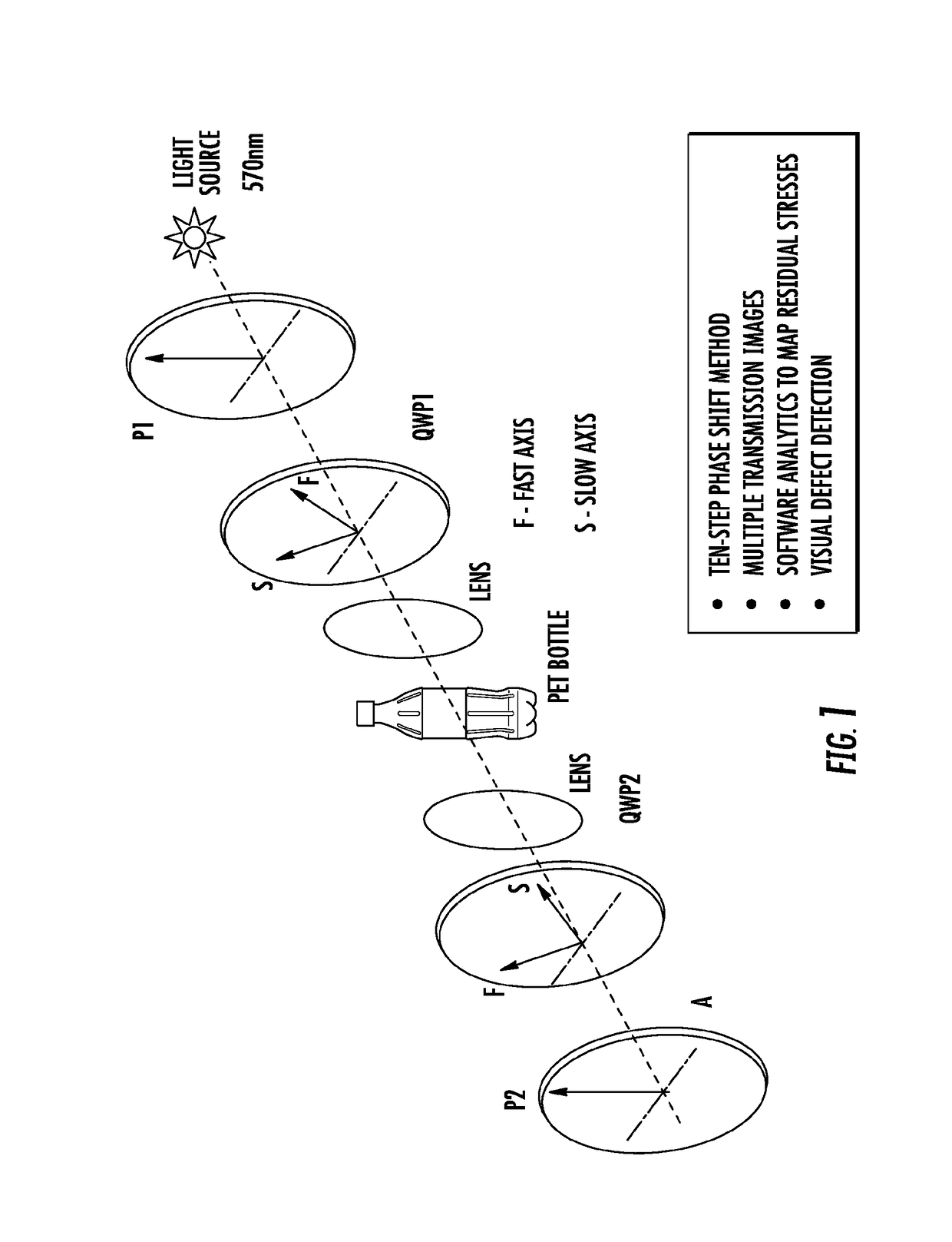

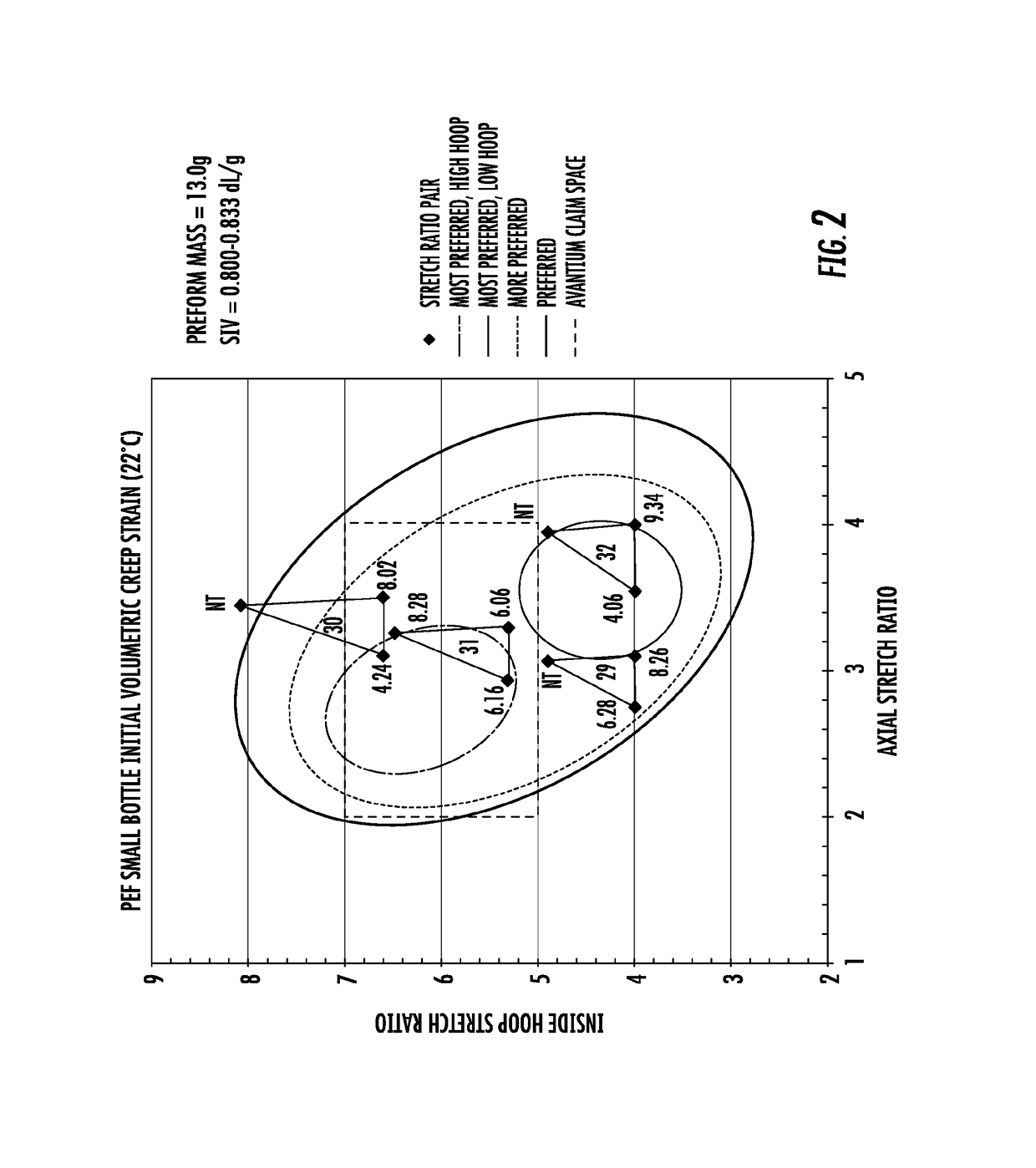

Photoelastic characterization of residual stresses and stress distributions in injection molded preforms and stretch blow-molded bottle

ActiveUS20180311883A1Reduce and minimize expected stress distributionReduce stress distributionDomestic articlesBlow moldingStress distribution

This disclosure provides new methods to characterize and relate residual stress and orientation imparted to the injection molded polymeric preform with orientation and residual stress in the resulting blow molded bottle. The method developed allows one to define and map the coupled thermal stress histories of both processes to define applicable preferred mutual processing windows for both preform and bottle molding processes. Stretch blow-molding parameters are developed using the disclosed method.

Owner:THE COCA-COLA CO

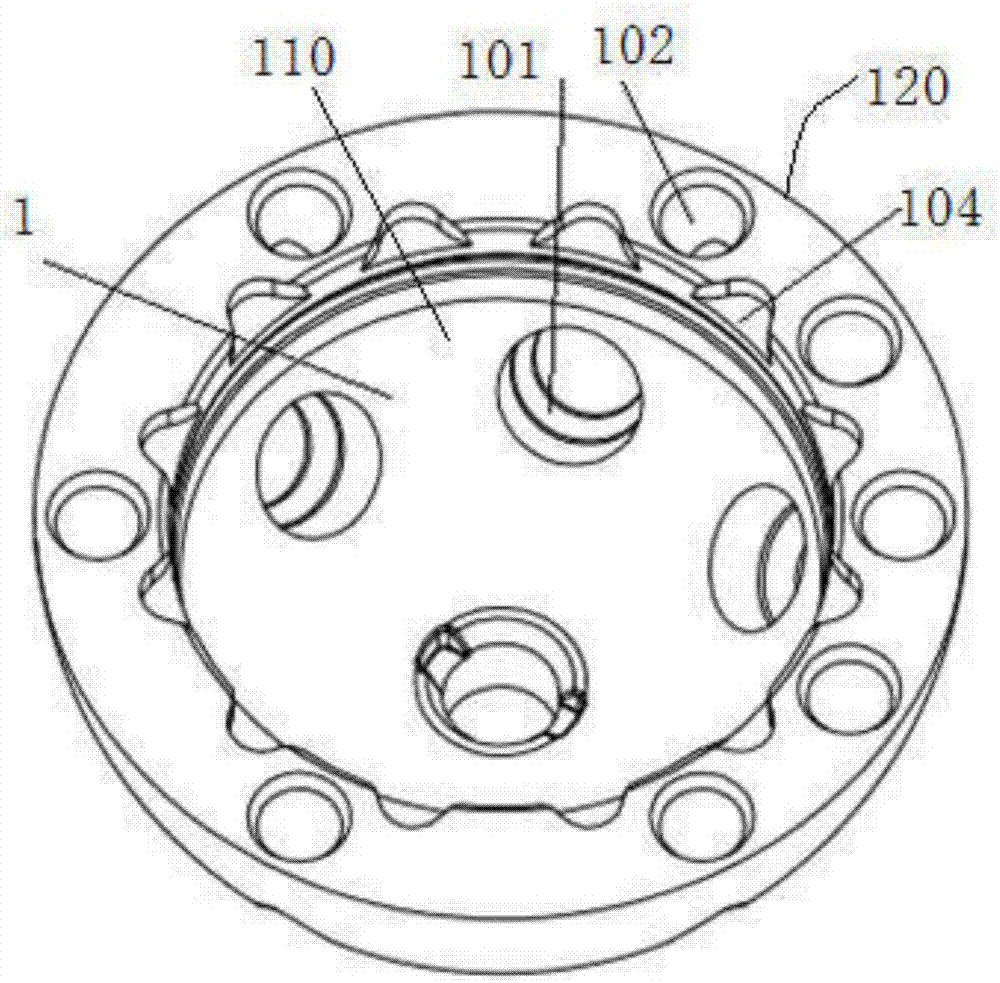

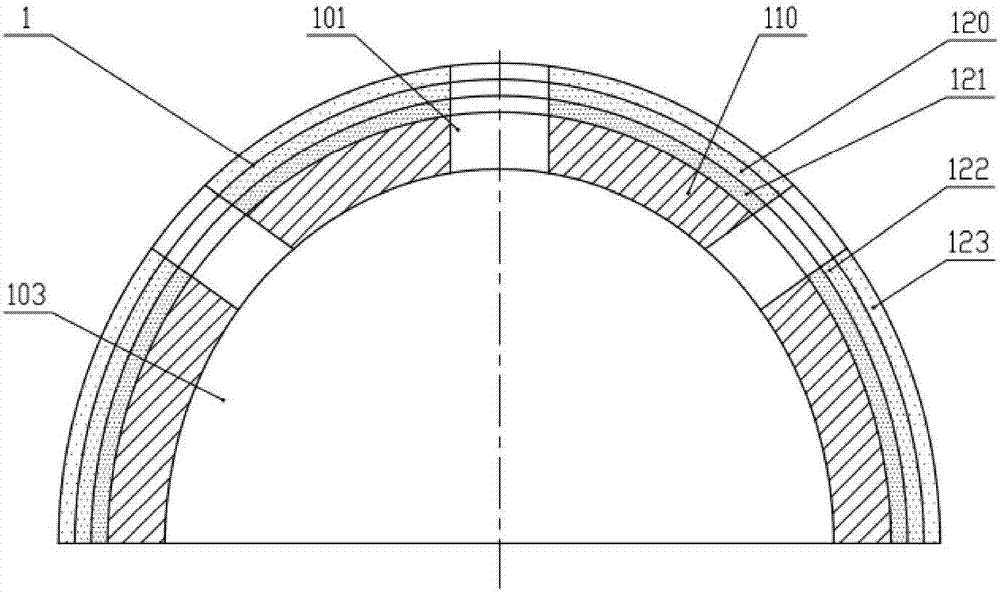

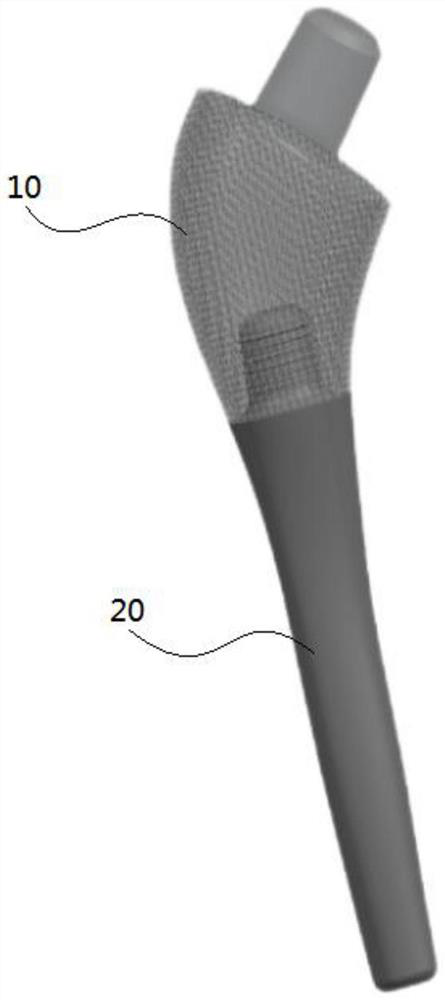

Acetabular component prosthesis

InactiveCN107280813AGuaranteed bonding strengthGuaranteed StrengthJoint implantsAcetabular cupsPorosityAcetabular component

The invention discloses an acetabular component prosthesis which comprises an acetabula cup. The acetabula cup is formed with metal powder through 3D printing and comprises a first compact part and a first microporous part. The first microporous part wraps the outer side of the first compact part. A first microporous layer, a second microporous layer and a third microporous layer which have gradually increased porosity are sequentially formed in the first microporous part from inside to outside. The acetabula cup is of a hemispherical structure. A cavity is formed in the first compact part. First through holes are formed in the hemispherical surface of the acetabula cup. Second through holes are formed in one end face of the first compact part. Second through holes are circumferentially distributed in the end face of the first compact part. The acetabular component prosthesis has the advantages that good bone engagement and ingrowth are kept, the strength of a combination part is high, cleaning and disinfection are convenient, and human bodies have no anaphylaxis.

Owner:优适医疗科技(苏州)有限公司

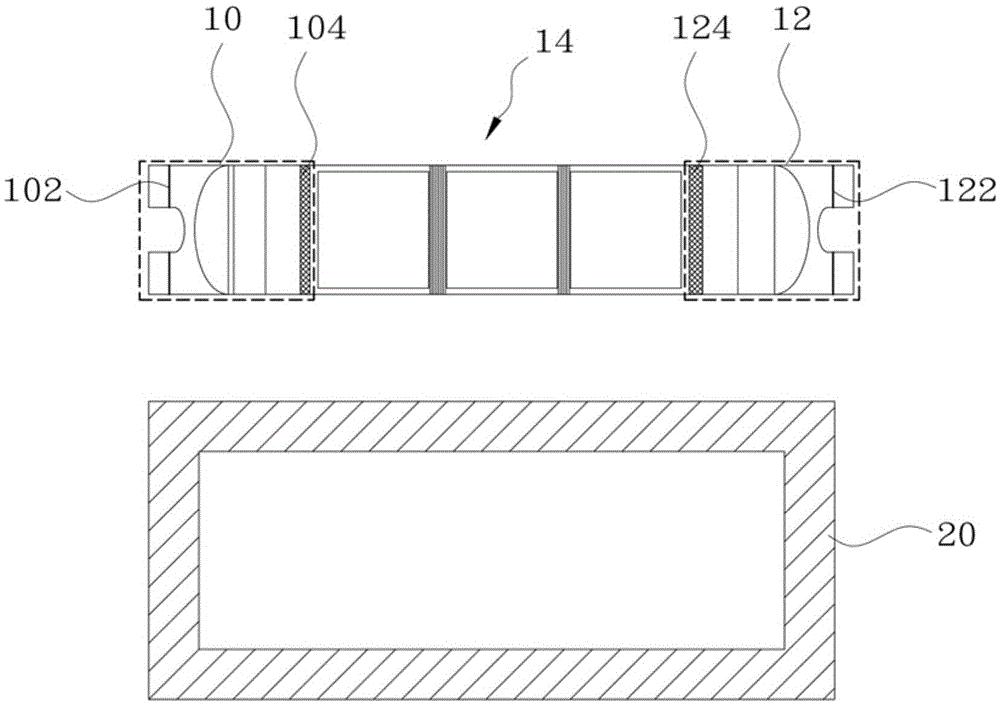

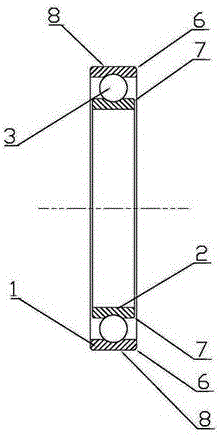

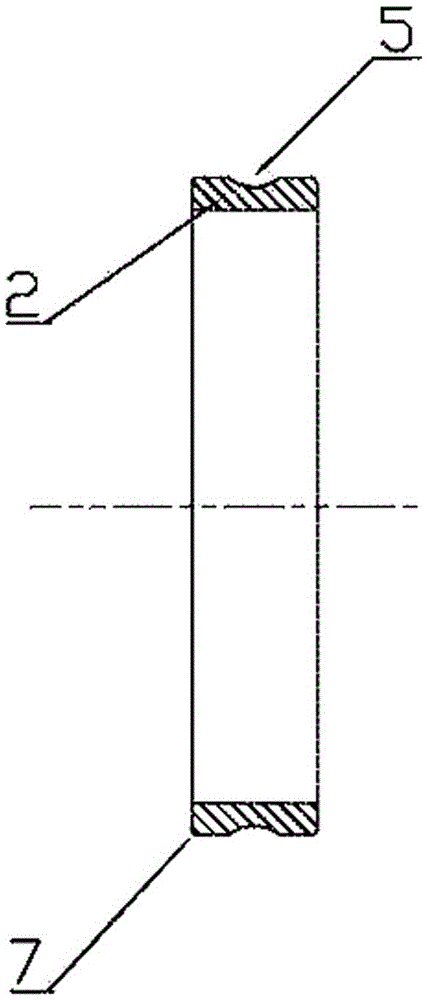

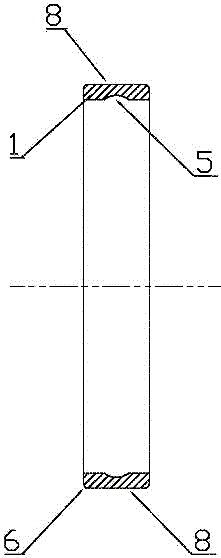

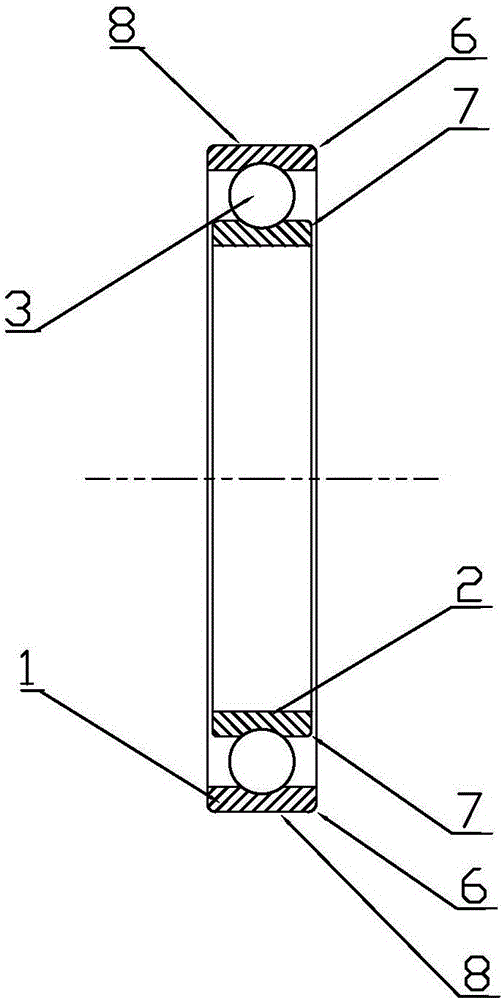

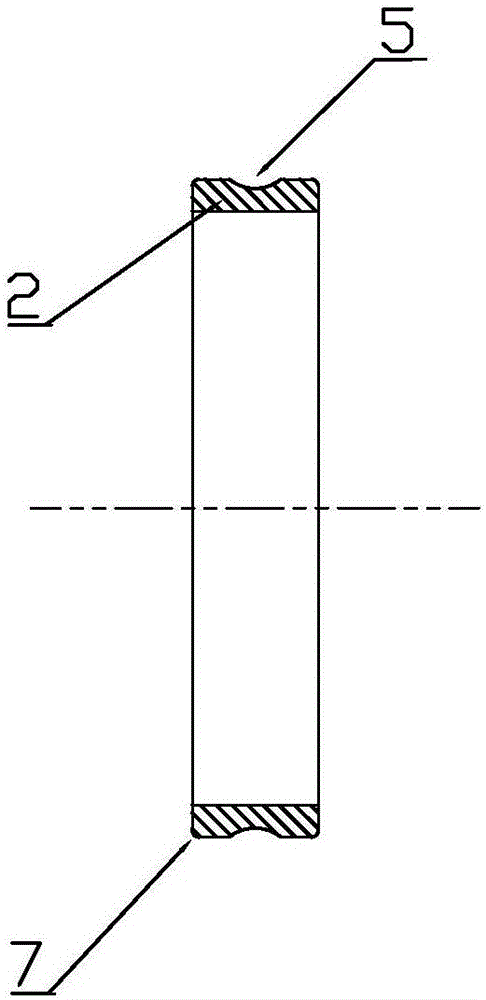

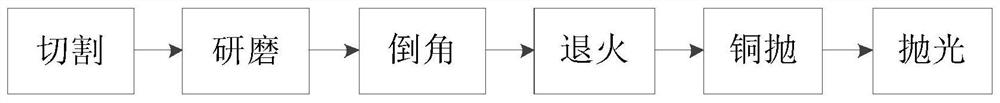

Processing method of thin-wall bearing for industrial robot

InactiveCN106801706AReduce production and processing requirementsLow unit manufacturing costBall bearingsBearing componentsIndustrial roboticsSteel ball

The invention relates to a processing method of a thin-wall bearing for an industrial robot. Through technical innovation, deep research of the thin-wall bearing comprises a dynamic quality high-precision detection technology of the thin-wall bearing, a ferrule micro-deformation thermal treatment step, a grinding metamorphic layer-controlled bearing ring fine grinding process, a negative play precise control technology, a precise assembly technology, a ferrule inner and outer diameter non-contact measuring technology and a bearing comprehensive property test technology, so that the thin-wall bearing meets the production demand of think-wall bearing design. The processing method provided by the invention has the beneficial effects that a steel ball is assembled by way of pulling the outer ring and jacking the inner ring by virtue of an assembling tool, the quality and reliability of the thin-wall bearing and a whole harmonic speed reducer are greatly improved, and the deformation residual stress of the outer ring is reduced to the maximum due to the pulling and jacking process during assembly. The minimum deformation of the outer ring needed is formed when the steel ball is assembled and placed due to the process of puling the outer ring and jacking up the inner ring, so that the residual stress caused by assembly is greatly reduced, and the service life of a product is also effectively ensured.

Owner:JIANGSU WANDA SPECIAL BEARING CO LTD

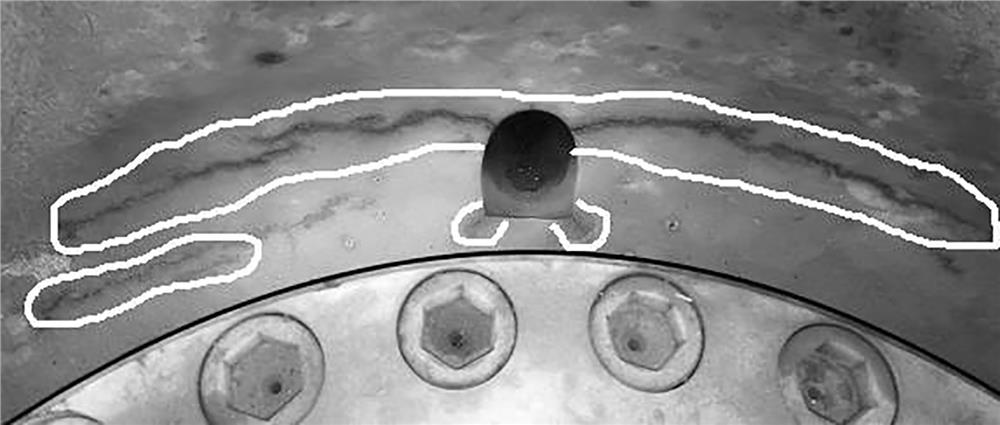

Thin-walled flexible bearing machining technology

InactiveCN106041435AReduce production and processing requirementsLow unit manufacturing costSteel ballEngineering

The invention discloses a thin-walled flexible bearing machining technology. The thin-walled flexible bearing machining technology includes the thin-walled inner ring machining procedure, the thin-walled outer ring machining procedure, the pulling and jacking assembly procedure and the examination procedure. An outer ring chamber of a thin-walled outer ring and an inner ring chamber of a thin-walled inner ring are subjected to turning machining before heat treatment; an outer ring R angle on the outer circumferential face of the thin-walled outer ring is machined and formed through a grinding process; and an assembling tool guarantees that the deformation amount of the thin-walled outer ring and the deformation amount of the thin-walled inner ring are the minimum at the same orientation through the outer ring tensile force and the inner ring jacking force. According to the thin-walled flexible bearing machining technology, a steel ball is assembled in the manner that the assembling tool pulls the outer ring and jacks the inner ring, the pulling and jacking process during assembling makes the deformation residual stress of the outer ring reduced to the minimum, the essential minimum deformation amount of the outer ring is formed when the steel ball is placed in for assembly, and therefore the residual stress caused by assembly is greatly reduced, and the service life of a product is also effectively guaranteed.

Owner:顾建祖

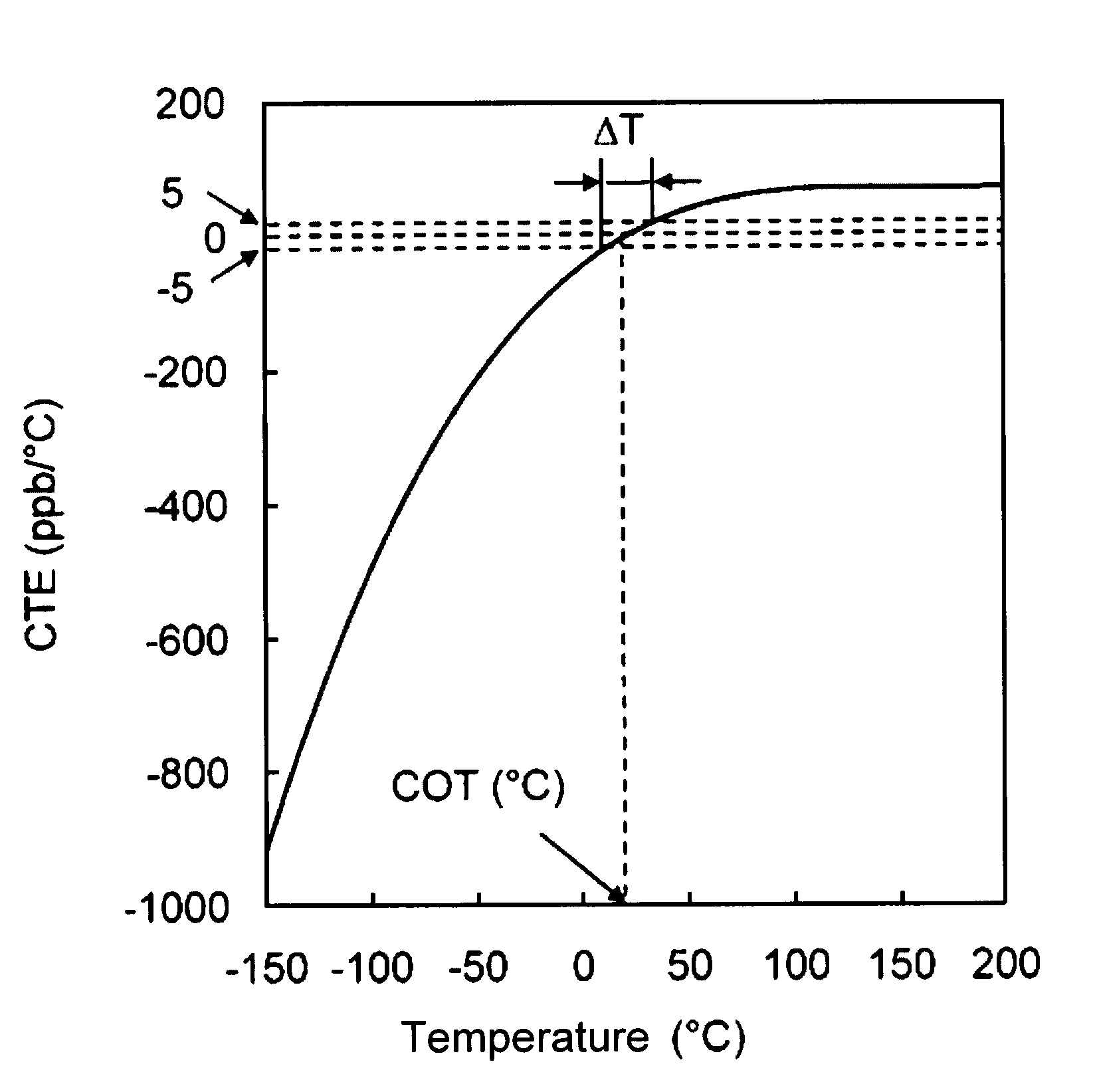

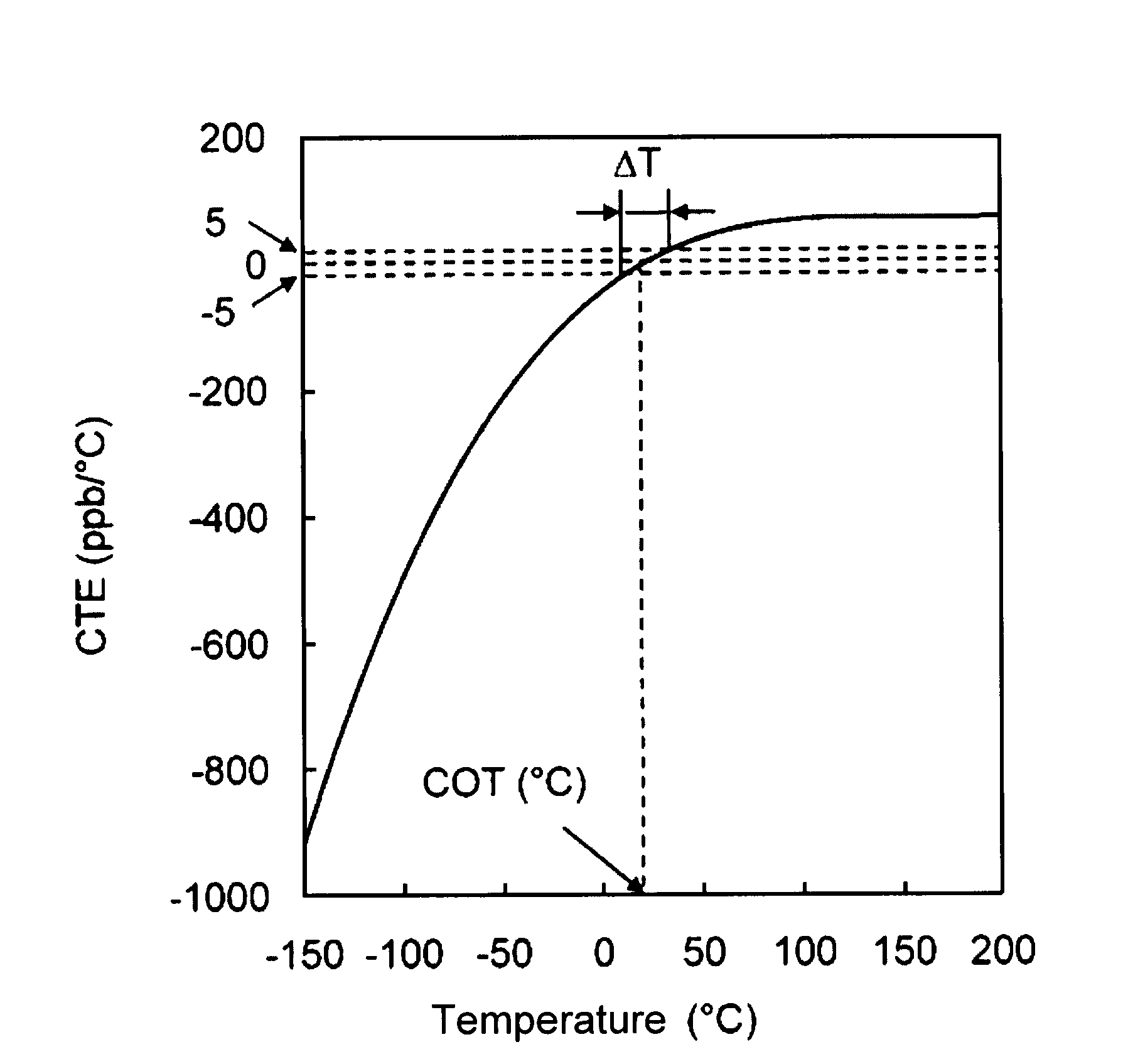

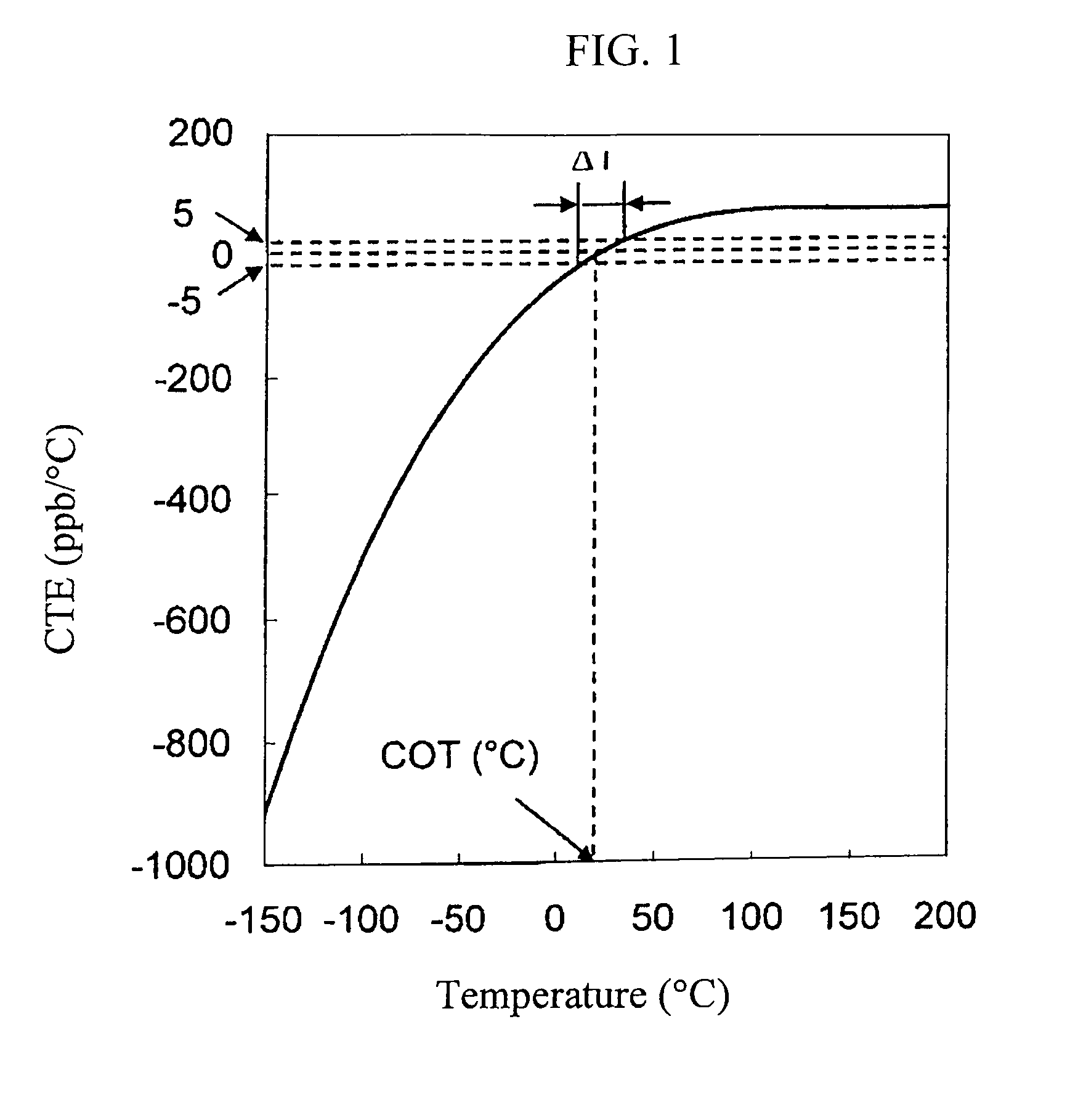

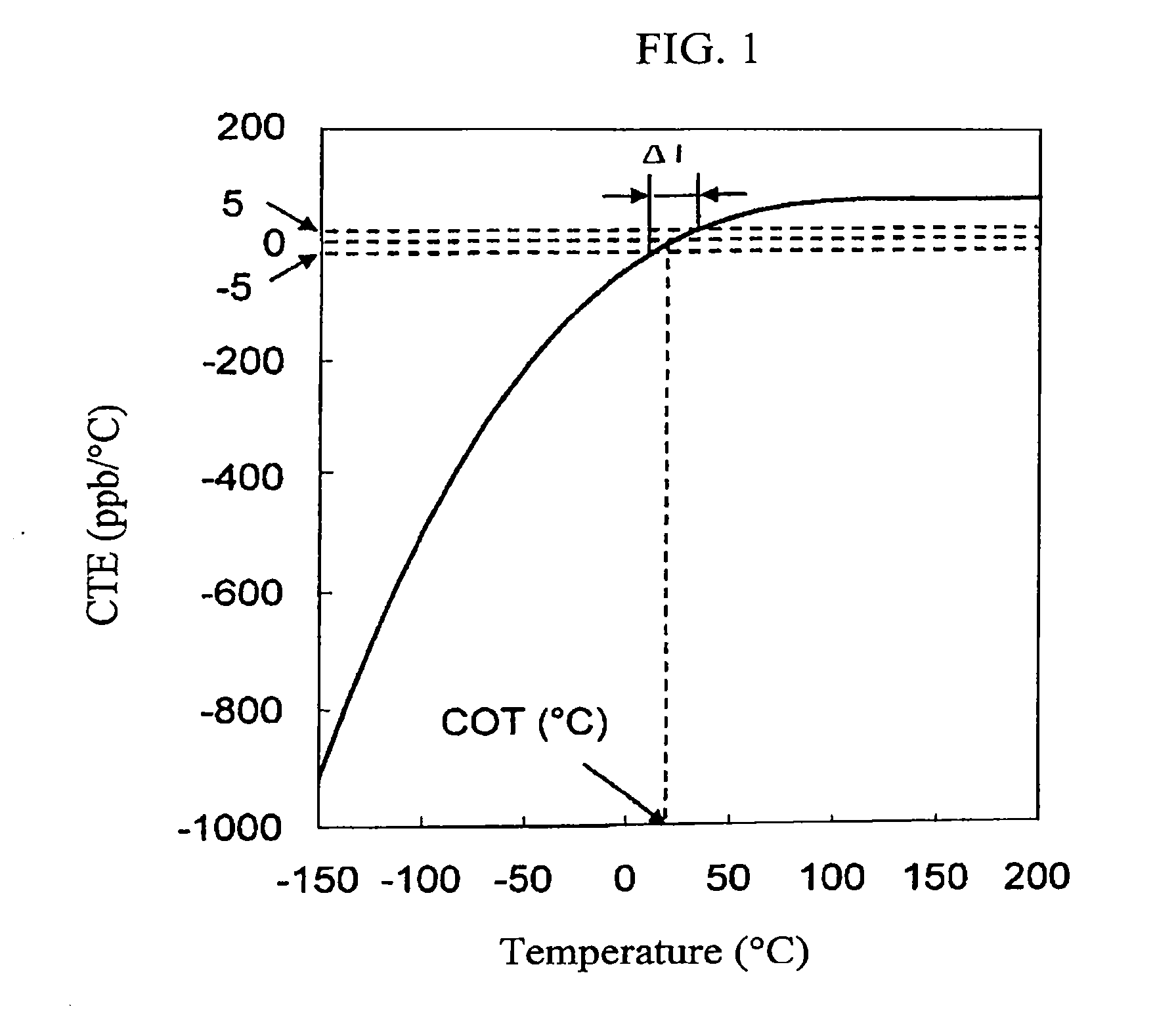

Method for producing TiO2-SiO2 glass body, method for heat-treating TiO2-SiO2 glass body, TiO2-SiO2 glass body, and optical base for EUVL

ActiveUS8590342B2Decrease productivityReduce allocationNanoinformaticsGlass shaping apparatusVitrificationVitreous Bodies

The present invention relates to a process for production of a TiO2—SiO2 glass body, comprising a step of, when an annealing point of a TiO2—SiO2 glass body after transparent vitrification is taken as T1(° C.), holding the glass body after transparent vitrification in a temperature region of from T1−90(° C.) to T1−220(° C.) for 120 hours or more.

Owner:ASAHI GLASS CO LTD

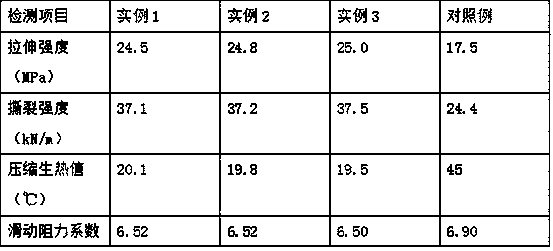

Preparation method for modified white carbon black tread rubber

The invention relates to a preparation method for a modified white carbon black tread rubber and belongs to the technical field of preparation of tire materials. The preparation method comprises the following steps: taking bagasse as a raw material; treating bagasse in the manner of steam explosion, thereby acquiring exploded fibers; mixing the exploded fibers with a sodium silicate solution, andthen adding hydrochloric acid for reaction; dehydrating under high temperature after reaction, thereby acquiring filter residue; modifying the filter residue with acetic anhydride, thereby acquiring amodified white carbon black filler; blending the white carbon black filler with other auxiliary materials, thereby acquiring the modified white carbon black tread rubber. The modified white carbon black tread rubber prepared according to the invention has the advantages of low sliding resistance, high cracking resistance and wide application prospect.

Owner:CONTINENTAL TIRES (CHINA) CO LTD

A harmonic reducer and its input drive structure

The invention discloses a novel harmonic-reducer input transmission structure. The novel harmonic-reducer input transmission structure comprises a cam connected with an input shaft, and the cam is sleeved with a flexible gear; a steel gear is engaged with the flexible gear, outer teeth are arranged on the flexible gear, inner teeth are arranged on the steel gear, and the flexible gear is engaged with the steel gear through the outer teeth and the inner teeth; a keeping frame is arranged between the flexible gear and the cam, and a cylinder roller is installed in the keeping frame; annular flanges are formed inside the flexible gear and outside the cam in an outward-protruding mode, and C-shaped grooves matched with the cylinder roller are formed in the annular flanges; the annular flanges are located on the outer-tooth side of the flexible gear. By means of the novel harmonic-reducer input transmission structure, the assembly stress of a key part of a harmonic reducer is reduced or eliminated, the engaging stress of the steel gear and the flexible gear in the movement process is reduced, the input structure and the output structure of the harmonic reducer are newly designed, the movement of the harmonic reducer is more stable during working, and the service life is prolonged.

Owner:HUNAN UNIV

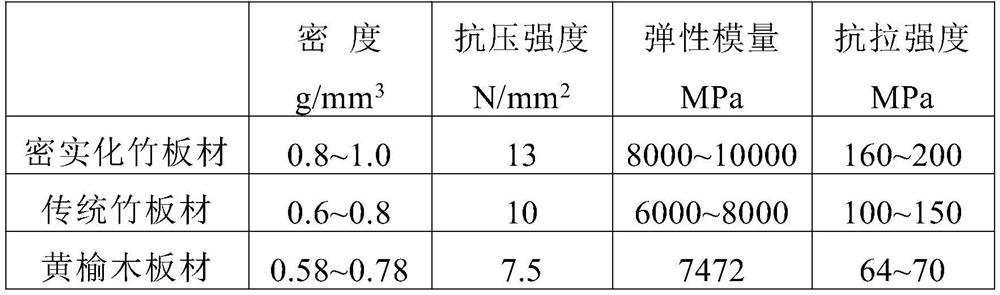

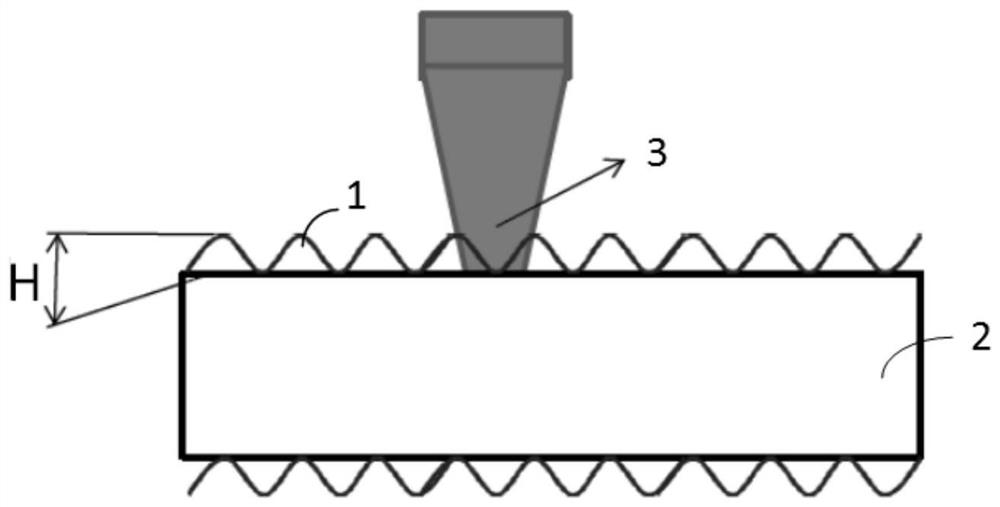

Production method of densified bamboo board

InactiveCN112959447AFacilitate redistributionReduce stress distributionWood treatment detailsCane mechanical workingProcess engineeringVacuum drying

The invention discloses a production method of a densified bamboo board. The method comprises the following steps: cutting bamboo into sections, slicing, polishing a bamboo partition protruding part on a green surface, and milling a yellow surface in a fixed thickness manner to manufacture bamboo chips; placing the bamboo chips in a water pool, soaking for 1-2 h, air-drying the surfaces of the bamboo chips, pushing the bamboo chips into a steam treatment tank, and keeping the bamboo chips for 7-10 min in the environment with the pressure being 1.2-1.5 MPa and the temperature being 190-200 DEG C; performing longitudinal flattening: extruding and flattening the bamboo chips through a bamboo chip unfolding machine; fixing width and fixing thickness: planing the flattened bamboo chips to the standard thickness in a finish planer, and performing fixed-width saw cutting on the planed bamboo chips; carrying out mould compacting: placing the bamboo chips with the fixed width and the fixed thickness in a steam mould pressing machine, performing mould pressing in the environment with the temperature ranging from 190 DEG C to 220 DEG C and the unit pressure ranging from 2 MPa to 4 MPa, cooling, and taking out the bamboo chips; performing vacuum drying: placing the bamboo chips obtained after mould pressing and compacting in a high-frequency vacuum drying tank, and in the environment with the vacuum degree ranging from -0.090 Mpa to -0.075 Mpa, heating the bamboo chips to 40-55 DEG C, and keeping for 18-23 hours; and performing board forming: placing the dried board at the room temperature, aging for 7-10 days, and then machining and forming the board into the needed shape.

Owner:ZHEJIANG FORESTRY UNIVERSITY

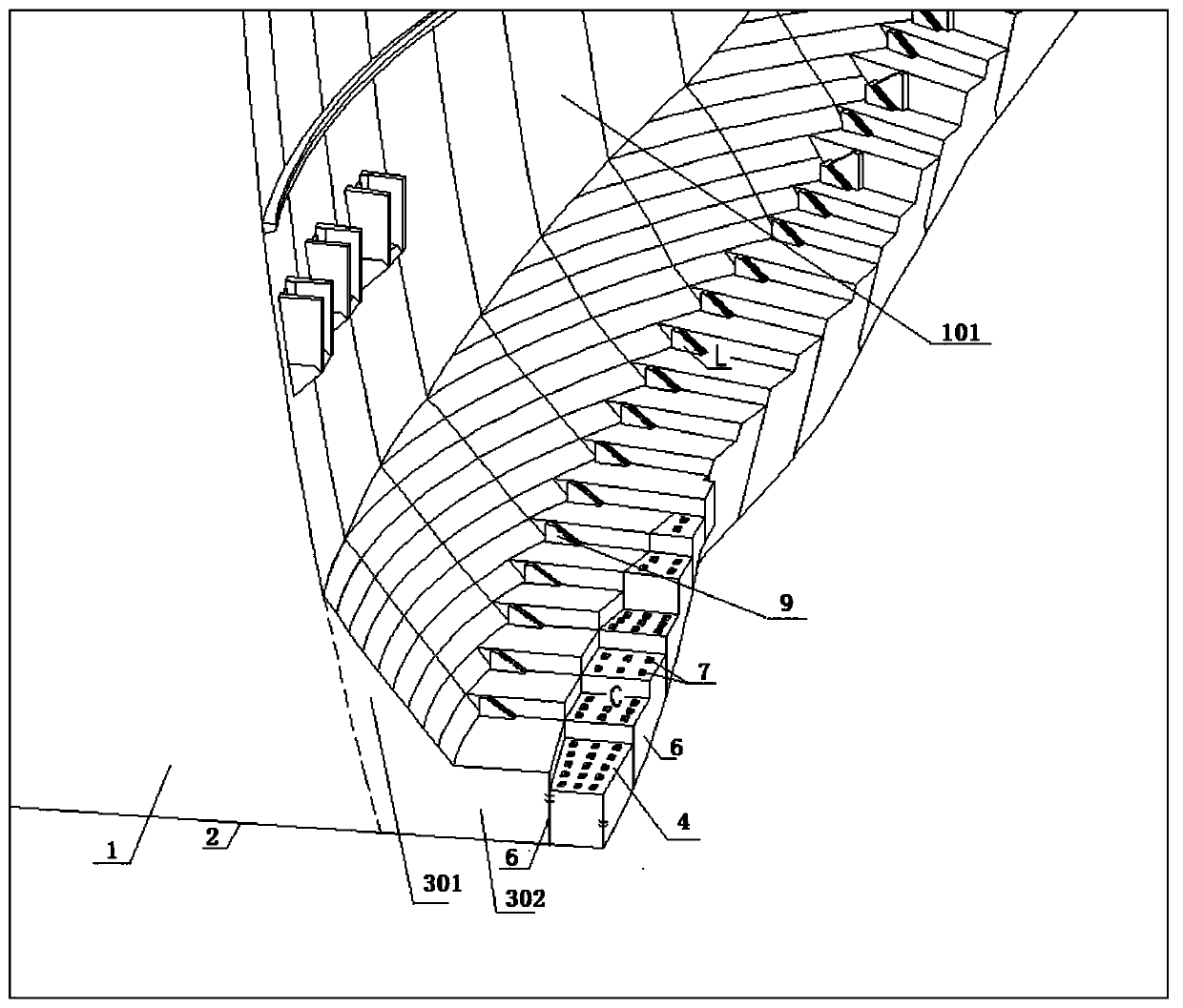

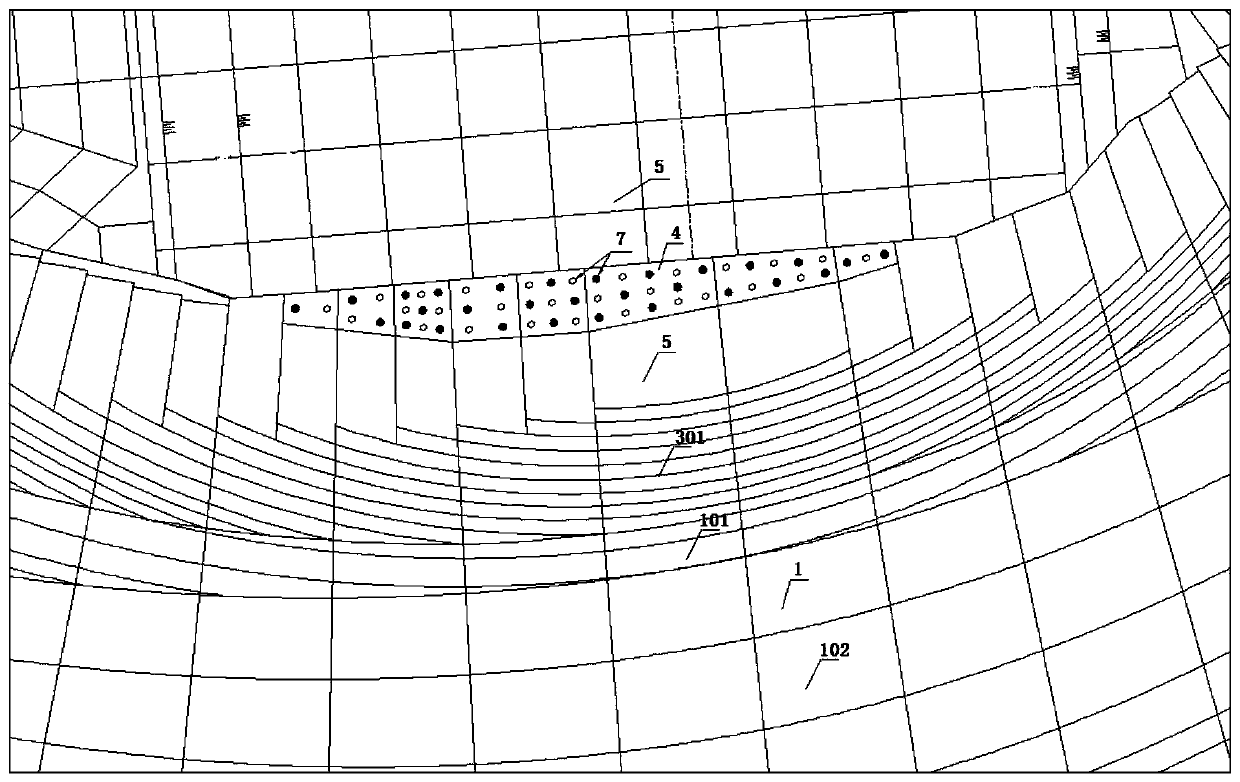

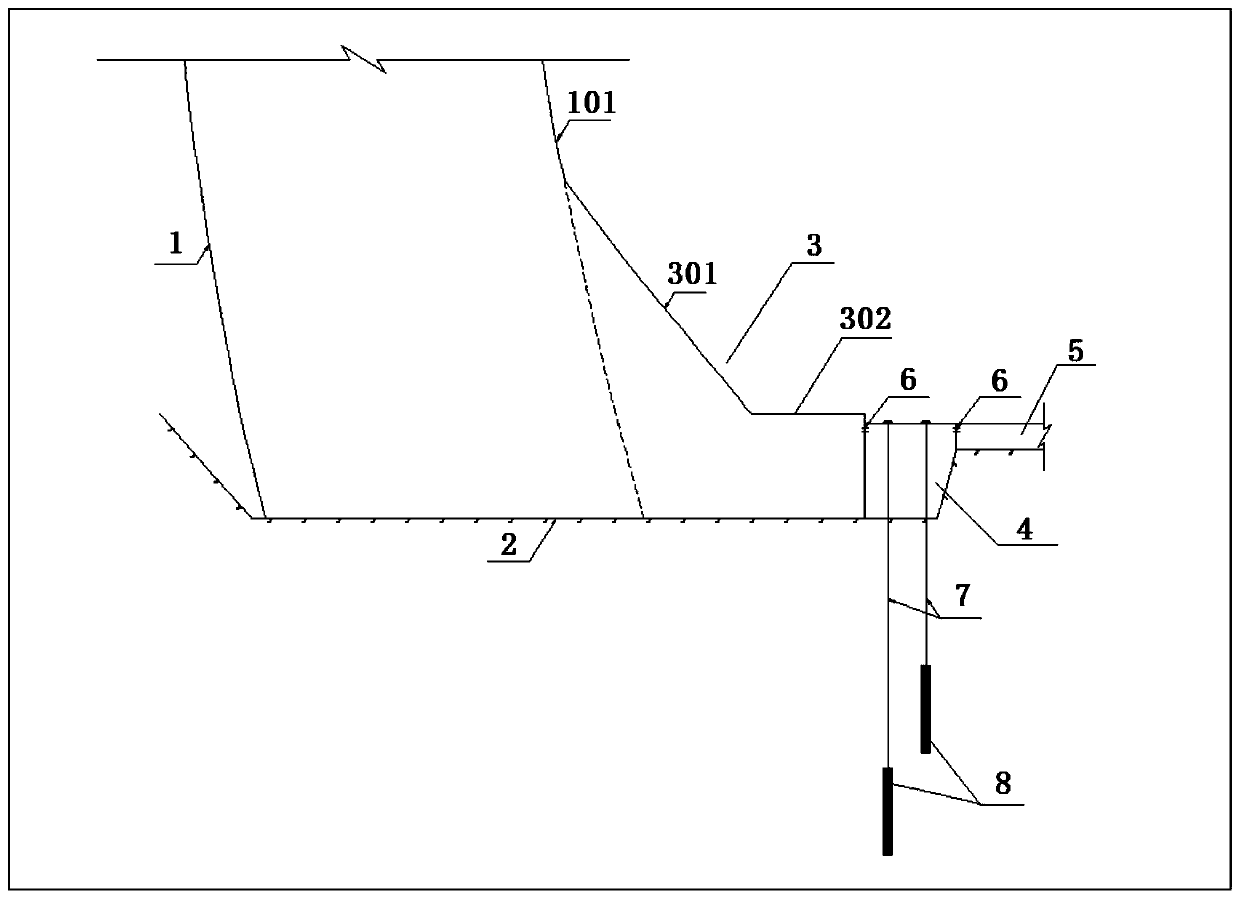

Dam toe transition structure suitable for arch dam on complex rock stratum

PendingCN110344376AIncrease stressMorph coordinationBarrages/weirsWater-power plantsBedrockEngineering

The invention provides a dam toe transition structure suitable for an arch dam on a complex rock stratum. The dam toe transition structure is arranged between the dam toe and an apron at the downstream of the arch dam and includes a multi-circular center foundation and dam toe transition blocks. The multi-circular center foundation is arranged along the downstream dam toe of the arch dam. The damtoe transition blocks are arranged between the multi-circular center foundation and the downstream apron. The multi-circular center foundation includes an inclined part and a horizontal part. The surface of the inclined part is smoothly and closely connected to a downstream face of the arch dam. The surface of the inclined part is provided with a multi-circle center arc combination structure. Themulti-circle center foundation can be smoothly and closely combined with the arch dam, which can fully spread thrust of the arch dam to bedrock of a dam foundation and improve the stress distributionof the arch dam foundation. The dam toe transition blocks can reduce a stress gradient between the arch dam and the downstream apron, homogenize stress transfer in the bedrock and coordinate deformation between the arch dam and the downstream apron.

Owner:POWERCHINA HUADONG ENG COPORATION LTD

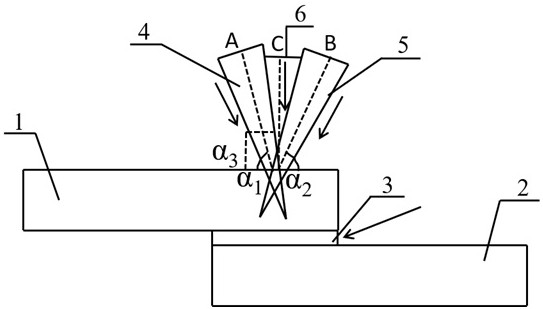

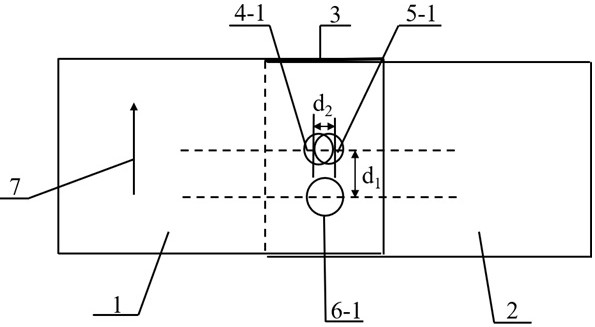

Steel-aluminum alloy laser welding method adopting nickel-based high-entropy alloy intermediate layer

PendingCN114406469AReduce thicknessReduce interdiffusionWelding/soldering/cutting articlesLaser beam welding apparatusMolten stateMetal foil

The invention relates to a steel-aluminum alloy laser welding method adopting a nickel-based high-entropy alloy intermediate layer, and belongs to the technical field of dissimilar material welding. And a nickel-based high-entropy alloy metal foil is used as a middle layer material. The high entropy effect and the high thermal resistance effect of the nickel-based high-entropy alloy metal foil control that no intermetallic compound is generated in a weld fusion area, and the intermetallic compound is only generated at the interface of the fusion area and the aluminum alloy. And by adding the nickel element and the silicon element, generation of Fe-Al intermetallic compounds at the interface is reduced, a Ni-Al-Si phase with better toughness is generated, the metallurgical reaction at the interface is improved, and then the mechanical property of the joint is improved. Laser beams A, B and C are adopted for simultaneous welding, the connecting area of the interface of the steel plate and the aluminum alloy plate is increased, and it is ensured that aluminum in the molten state fully wets and spreads the interface. The anti-shearing strength of a lap joint is improved; and meanwhile, the defects such as cracks and air holes are avoided.

Owner:JILIN UNIV

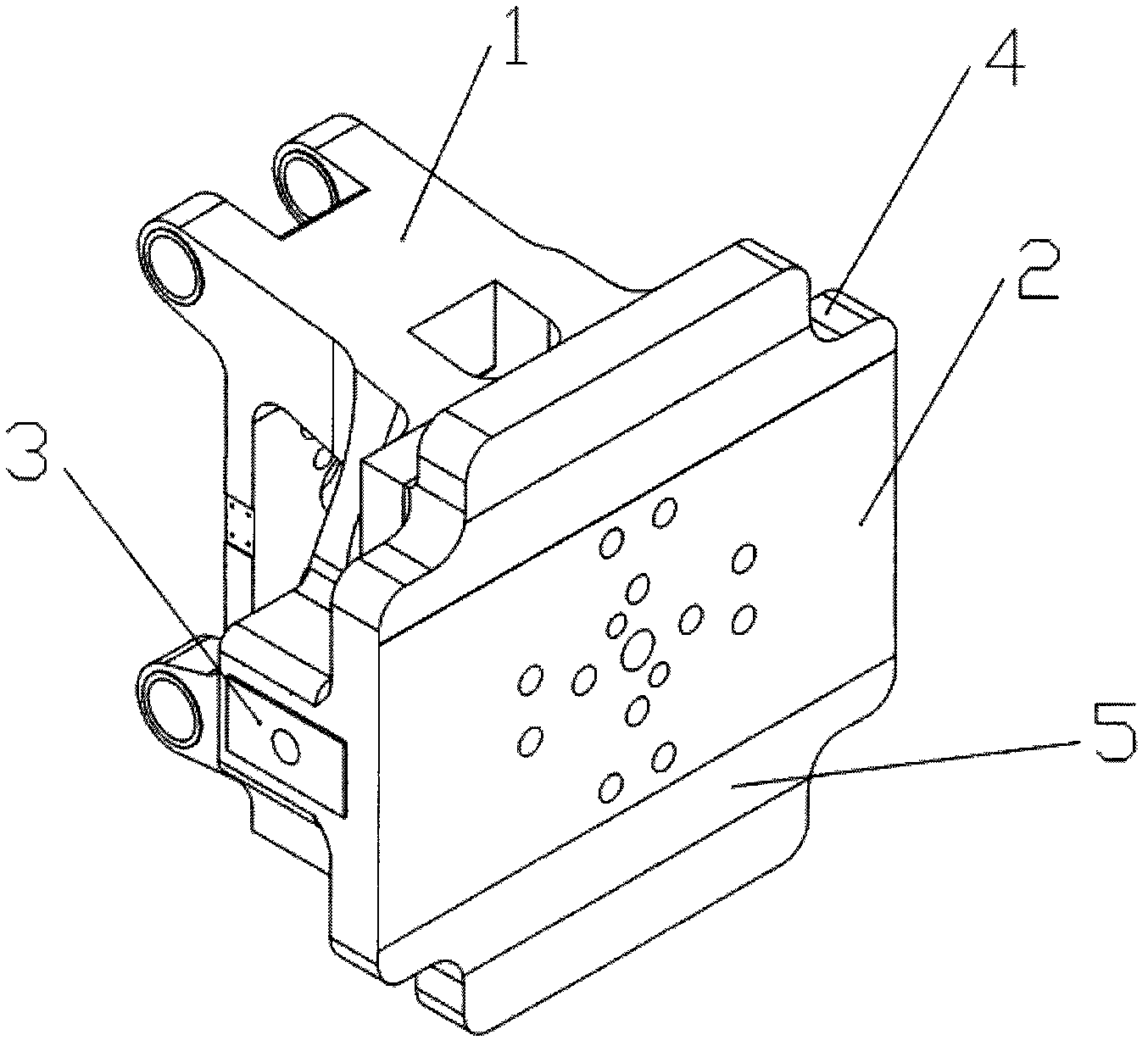

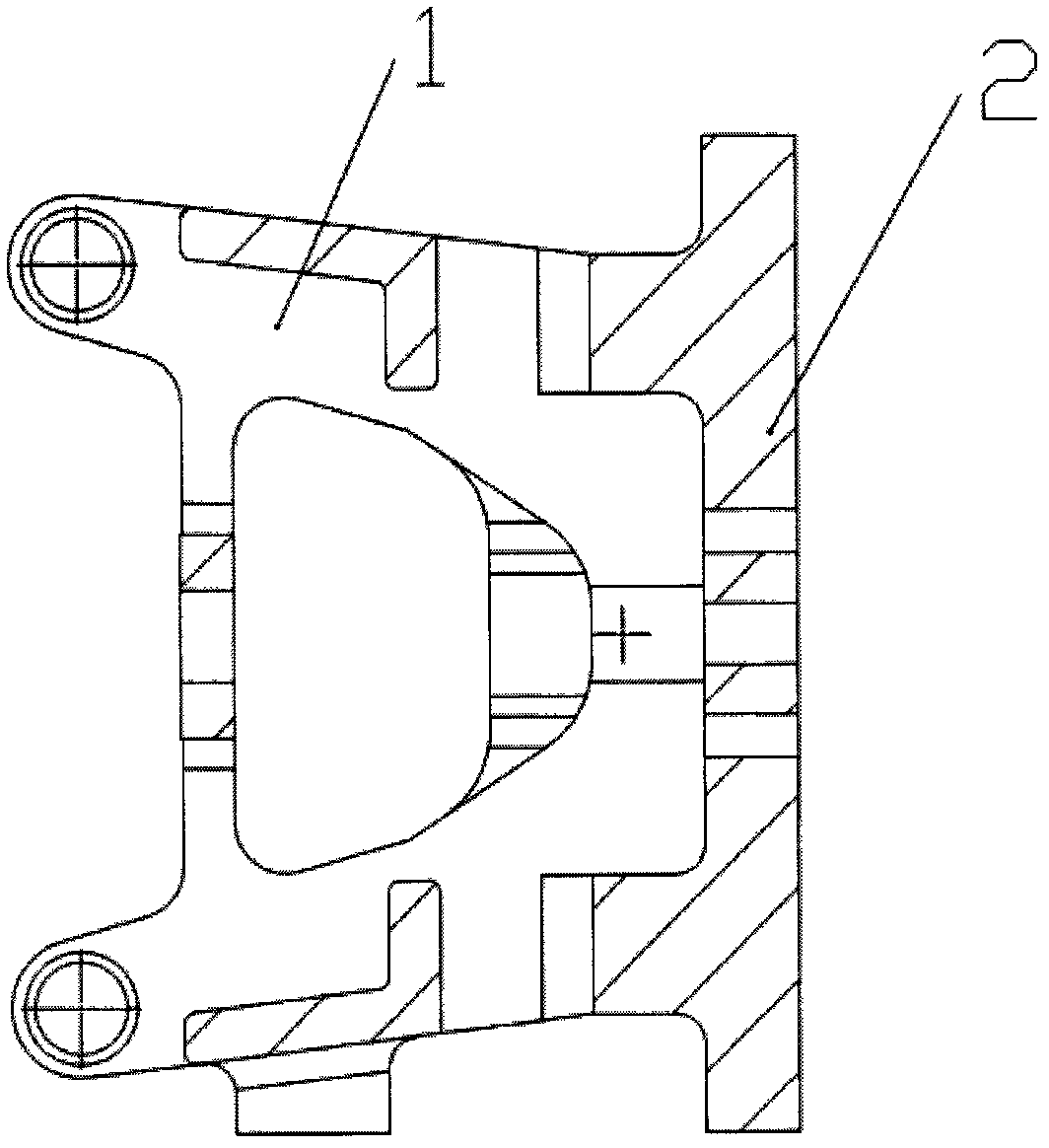

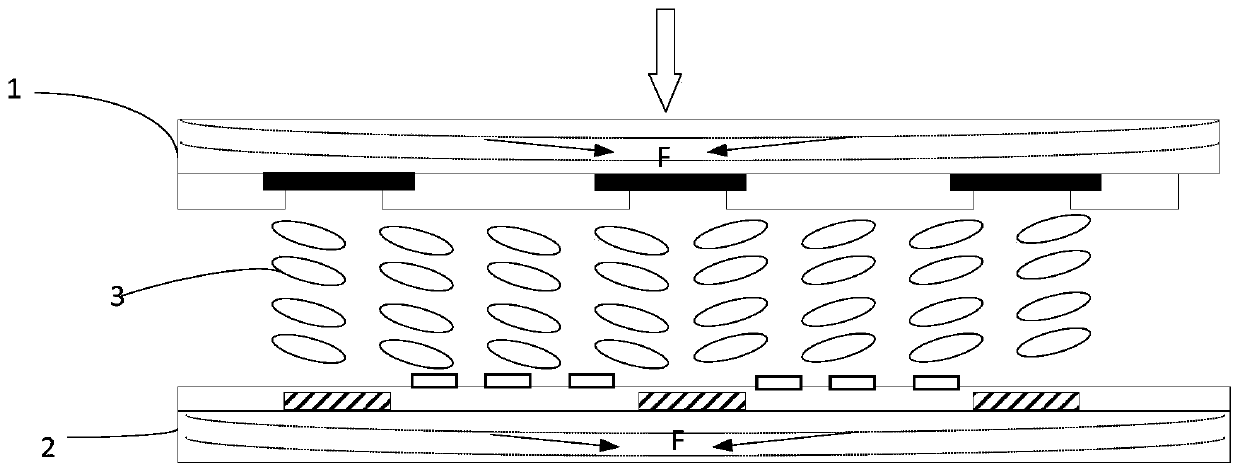

High-rigidity low-deformation movable template

InactiveCN103203849AEliminate pollutionReduce stress distributionMechanical engineeringOil pollution

The invention relates to a high-rigidity low-deformation movable template. According to the movable template, a linear guide rail support is arranged by using central boss position minimum deformation areas on left and right sides, and a linear guide rail is then arranged. The guidance of the linear guide rail is used for replacing the guidance of four draw bar holes, such that the movable template does not contact the draw bar, and the movable template is prevented from lubricating oil pollution. According to the movable template, with an A-shaped hinge ear rack structure, clamping force is transmitted from hinge ear to the area close to the center of a movable template arrangement surface, such that movable template arrangement surface bending deformation and bending stress are reduced. Small sizes are respectively milled off on the upper and lower sides of the movable template arrangement surface from the centers to the outer sides, such that tiny stepped surfaces are formed, and movable template deformation is further offset. Therefore, when the mold is under clamping force, the influence caused by movable template deformation is minimized.

Owner:BORCH MACHINERY

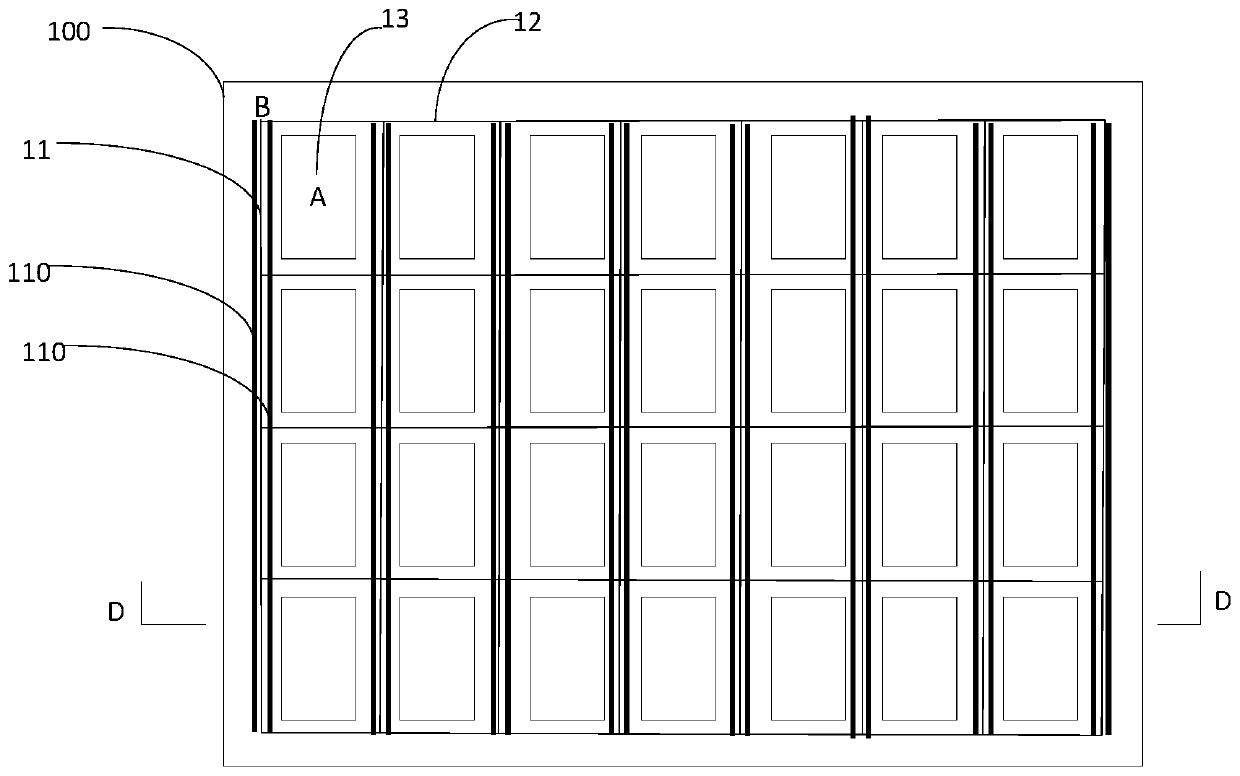

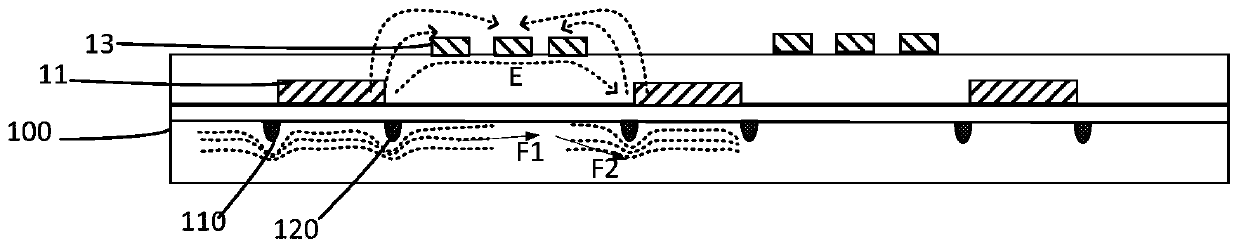

Display panel, manufacturing method thereof and display device

ActiveCN111240067AMitigate the effect of birefringenceImprove light leakageNon-linear opticsPhysicsEngineering

The invention provides a display panel, a manufacturing method thereof and a display device. A display substrate comprises a substrate body and a plurality of pixels located on the substrate body. Gaps among the pixels are first areas. The first surface of the substrate body is provided with a plurality of grooves in the first areas, and the first surface is the face, facing the other display substrate body, of the display substrate body when the display substrate body and the other display substrate body are combined. According to the display panel, the manufacturing method of the display panel and the display device, the phenomena of light leakage and uneven dark state of the panel can be improved.

Owner:BOE TECH GRP CO LTD +1

Method for producing tio2-sio2 glass body, method for heat-treating tio2-sio2 glass body, tio2-sio2 glass body, and optical base for euvl

InactiveUS20120100341A1Decrease in productivityReduce stressNanoinformaticsGlass shaping apparatusVitreous BodiesMaterials science

The present invention relates to a process for production of a TiO2—SiO2 glass body, comprising: a step of, when an annealing point of a TiO2—SiO2 glass body after transparent vitrification is taken as T1 (° C.), heating the glass body after transparent vitrification at a temperature of T1+400° C. or more for 20 hours or more; and a step of cooling the glass body after the heating step up to T1−400 (° C.) from T1 (° C.) in an average temperature decreasing rate of 10° C. / hr or less.

Owner:ASAHI GLASS CO LTD

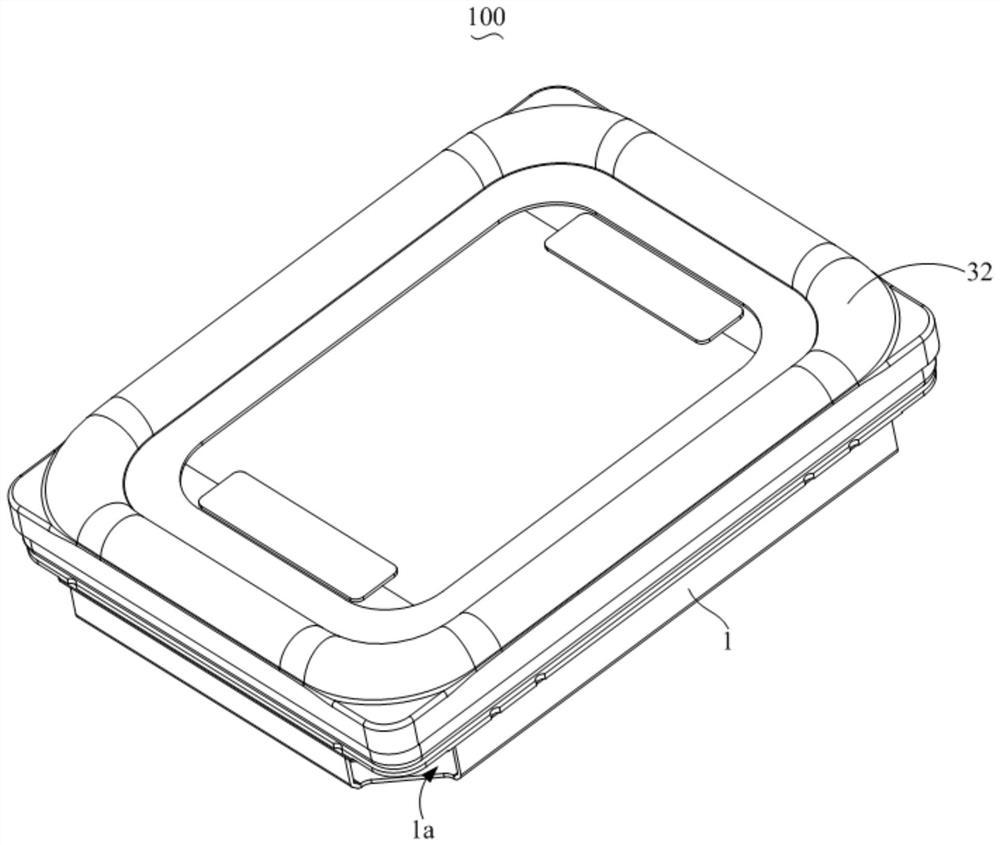

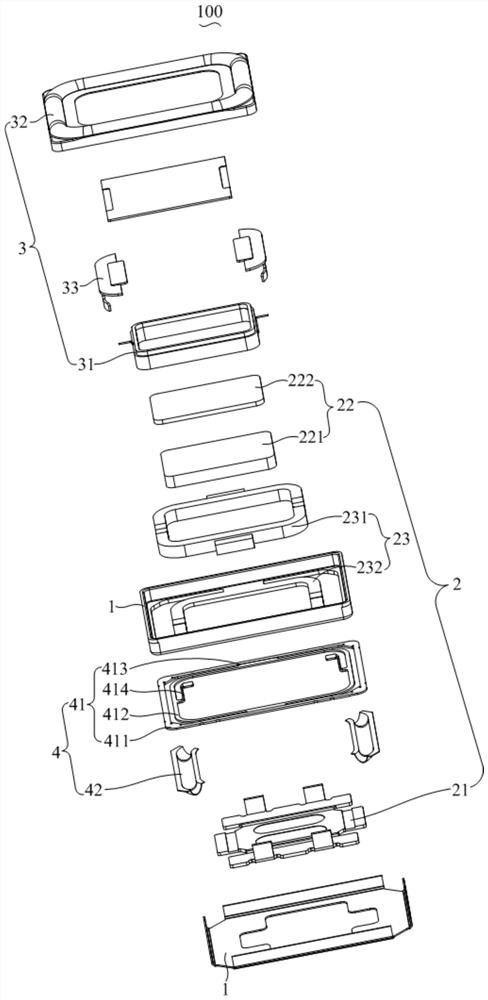

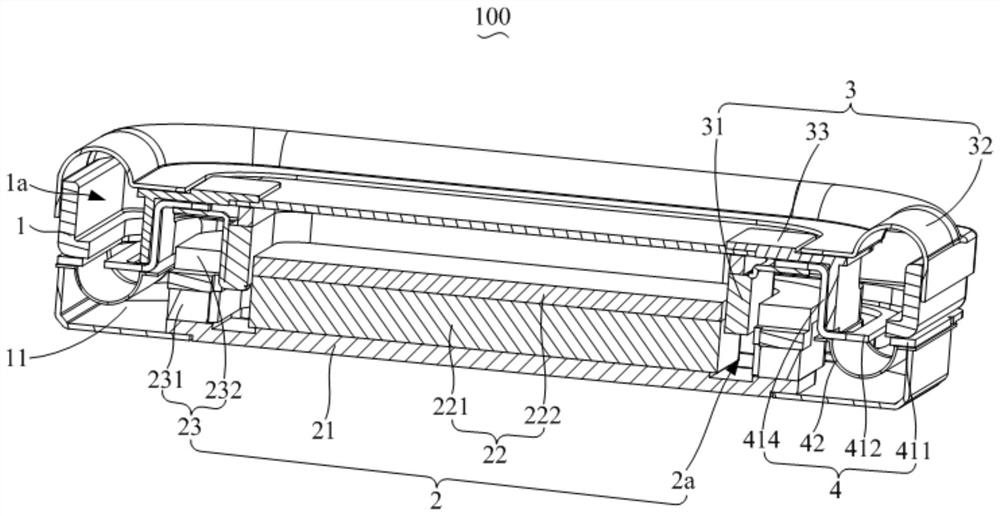

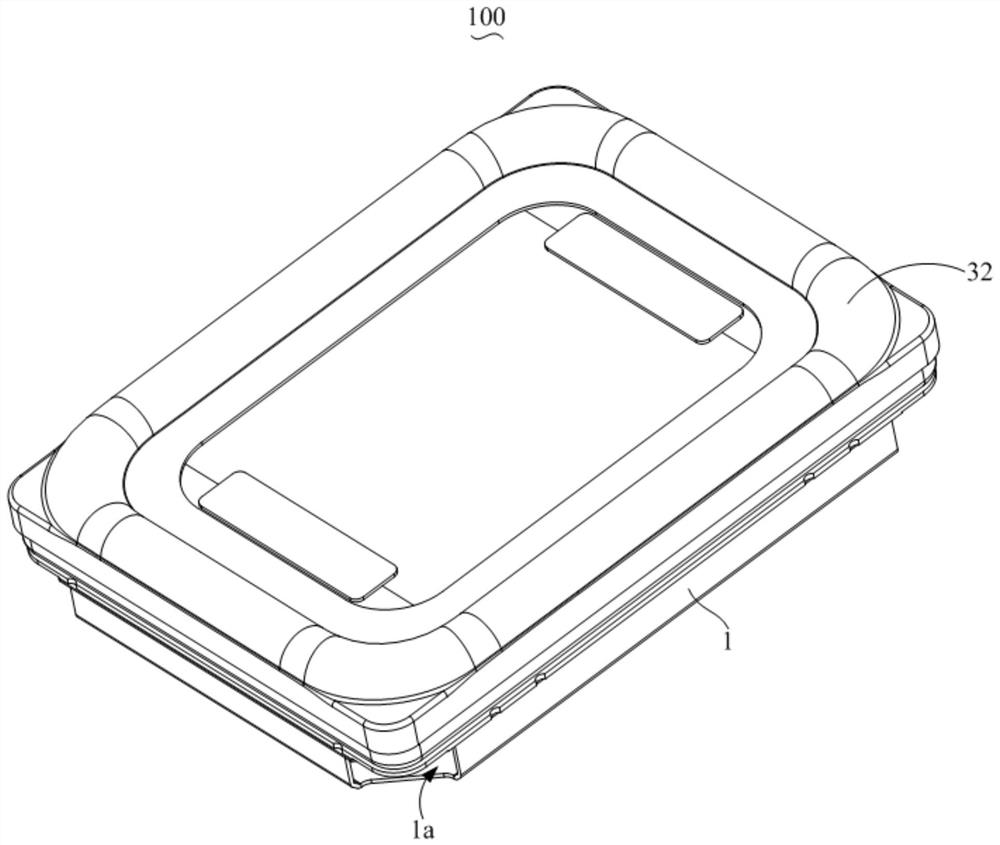

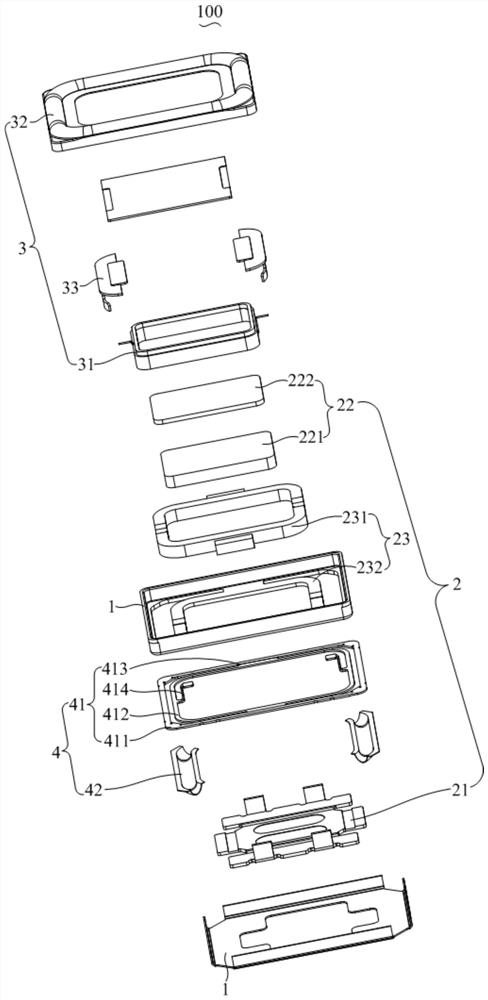

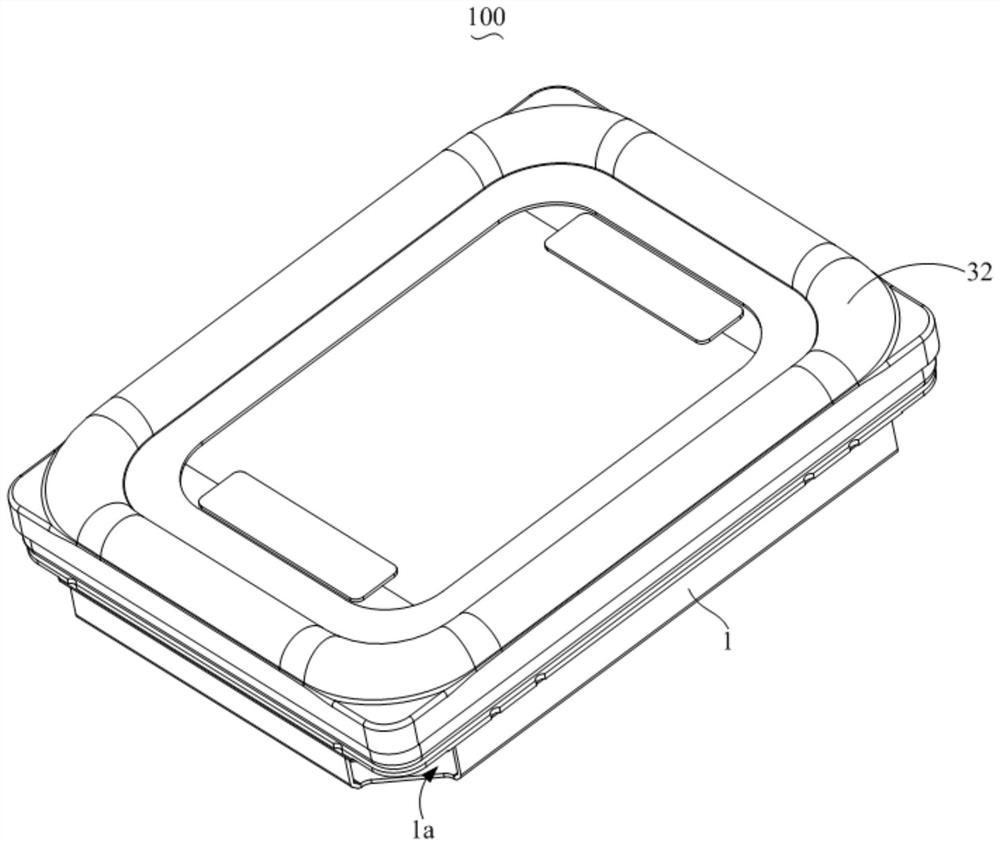

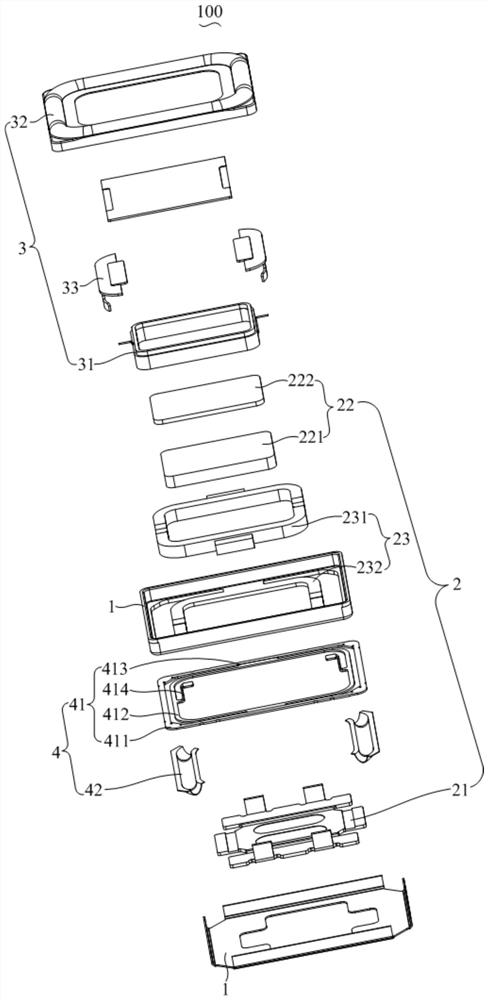

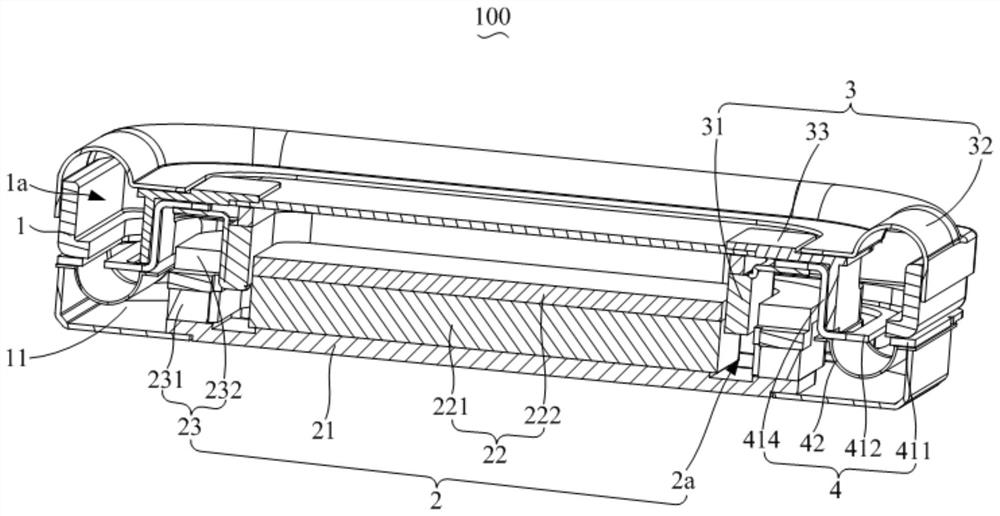

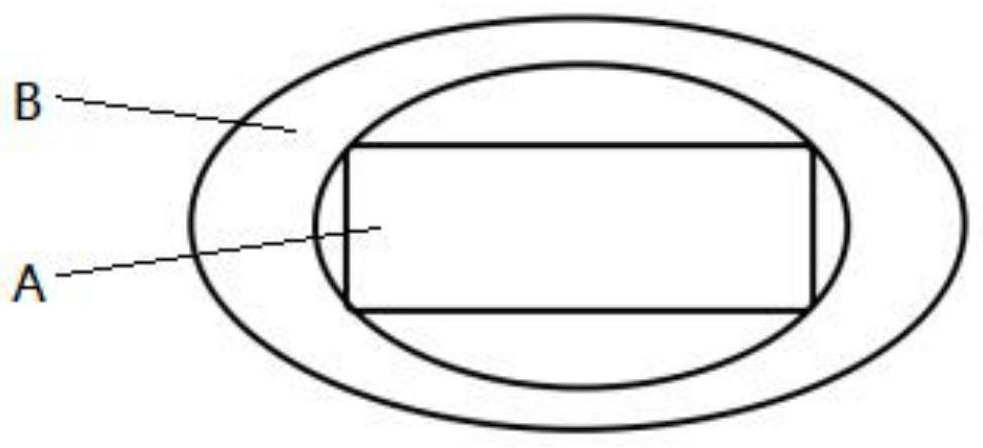

Loudspeaker unit and electronic terminal

ActiveCN111901715AImprove acoustic performanceImprove installation stabilityLoudspeaker transducer fixingLoudspeaker casing supportsEngineeringLoudspeaker

The invention discloses a loudspeaker unit and an electronic terminal. The loudspeaker unit comprises a shell assembly, a magnetic circuit system, a vibration system and a balance assembly, the balance assembly is arranged corresponding to a gap, the balance assembly comprises a centering support chip made of FPCB material, the centering support chip comprises an outer fixing part, an elastic support part and a bonding pad structure, and the outer fixing part is connected with the shell assembly; the elastic supporting part is connected with the outer fixing part, located in the gap and partially connected with a support, and the elastic supporting part elastically deforms along with vibration of the support. The bonding pad structure comprises a cantilever and a bonding pad which are arranged at an included angle, one end of the cantilever away from the bonding pad is connected with the elastic supporting part, the cantilever extends along the support, the bonding pad is fixedly connected with the diaphragm or the top wall of the support, and a lead of the voice coil is electrically connected with the bonding pad. According to the loudspeaker unit provided by the invention, the structure of a voice coil in the magnetic gap is arranged more freely, and the volume of a magnetic circuit system is effectively increased, so that the magnetic field intensity is higher, and the acoustic performance is better.

Owner:GOERTEK INC

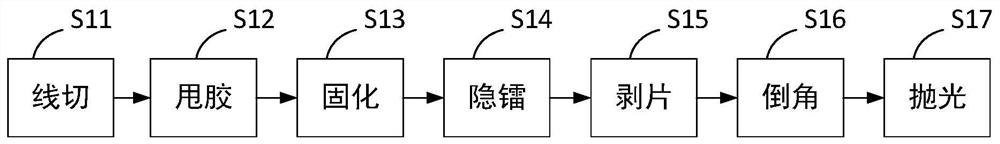

Substrate processing method and substrate processed by method

PendingCN112635309AReduce stress distributionQuality improvementSemiconductor/solid-state device manufacturingPolyurea/polyurethane coatingsMachining processElectrical and Electronics engineering

The invention provides a substrate processing method and a substrate processed by the method, and the substrate processing method comprises the following steps: carrying out linear cutting of the substrate, and obtaining a substrate with a preset thickness; carrying out whirl coating treatment on the substrate obtained by cutting to form a layer of flat film on the surface of the substrate; generating a damage layer at a predetermined depth position of the cut substrate by two-dimensionally scanning the cut substrate by a focused laser after the flat film is cured; carrying out stripping processing on the substrate based on the damage layer; and carrying out polishing treatment on the substrate subjected to stripping treatment. According to the substrate processing method and the substrate processed by the method, the machining process can be greatly reduced, so that the stress distribution of the substrate is reduced, the quality of the substrate is improved, and the processing cost of the substrate is reduced.

Owner:FUJIAN JING AN OPTOELECTRONICS CO LTD

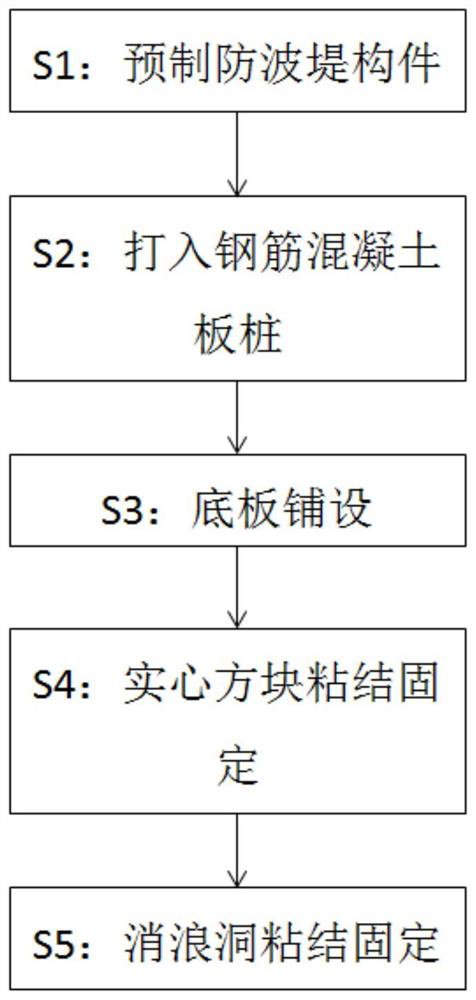

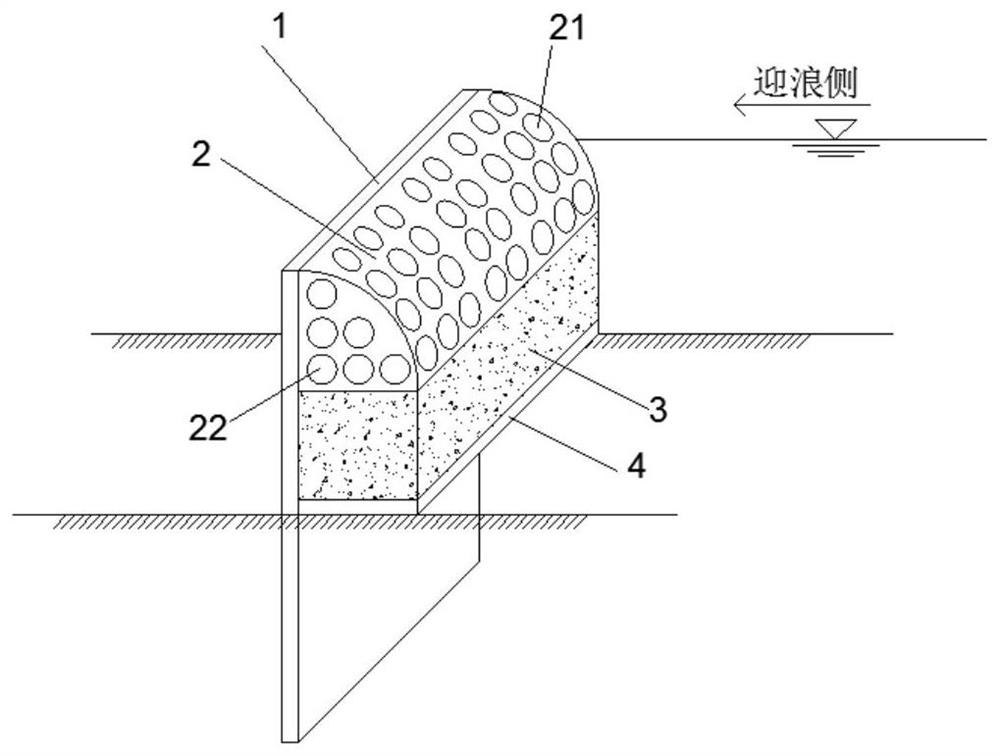

Sheet pile and gravity combined type breakwater construction method

PendingCN114182681AReduce pollutionSimple structureDamsBarrages/weirsStructural engineeringSheet pile

The invention discloses a sheet pile gravity type breakwater construction method which comprises the following construction steps: S1, prefabricating breakwater components such as a bottom plate, sheet piles, a bearing body and a wave dissipation hole, and transporting the breakwater components to a construction site; s3, laying a bottom plate; s4, mounting a bearing body; and S5, the wave dissipation holes are assembled, and the breakwater structure is obtained. The construction method is easy and convenient to construct, short in construction period, free of a large amount of riprap operation, small in environmental pollution, capable of being widely applied to muddy coast or soft soil foundations in deep water areas and good in application prospect.

Owner:CCCC FOURTH HARBOR ENG CO LTD +2

A high-efficiency pulping method before selection suitable for wide particle size flotation

ActiveCN111871620BReduce entrainmentSolve the problem of poor dispersionTransportation and packagingRotary stirring mixersFoaming agentSlurry

A pre-selection high-efficiency slurry adjustment method suitable for wide particle size flotation, suitable for use in peat re-selection. First, the wide-grained pulp is fed through the pulp inlets on both sides of the mixing tank to form a high-speed jet, and the high-speed jet enters from the inlet end of the dosing pipe of the Venturi tube structure to form a negative pressure zone. The pulp, collector and foaming agent The slurry is emulsified in the negative pressure area of the Venturi standpipe structure by self-suction, and cavitation occurs in the slurry. The tangential jets of the slurry jet ports on both sides of the slurry inversion platform structure are fed into the bottom of the mixing tank to form a strong upward swirling flow, which is controlled. The rotation direction of the rotating impeller on the stirring shaft in the mixing tank is always opposite to the direction of the strong swirling flow to ensure the counterflow of the pulp; the upward strong swirling pulp forms a countercurrent mixing with the rotating impeller in the forced stirring area, and uses the annular shear baffle And the guide plate reduces the stress distribution, improves the stability of the equipment, and at the same time plays an auxiliary shearing effect on the strong swirling slurry moving upwards, and improves the slurry mixing effect; the steps are simple and the slurry mixing effect is good.

Owner:CHINA UNIV OF MINING & TECH

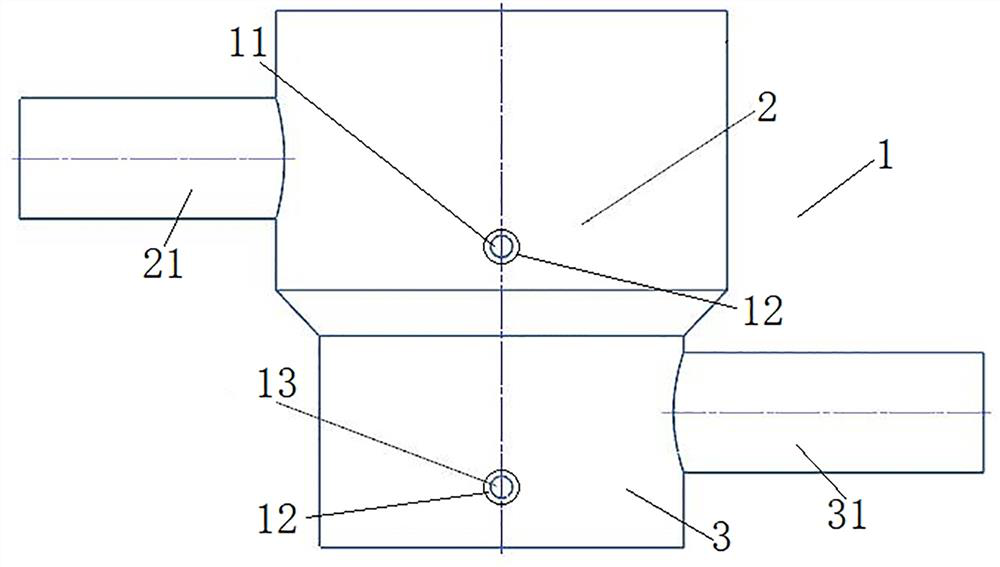

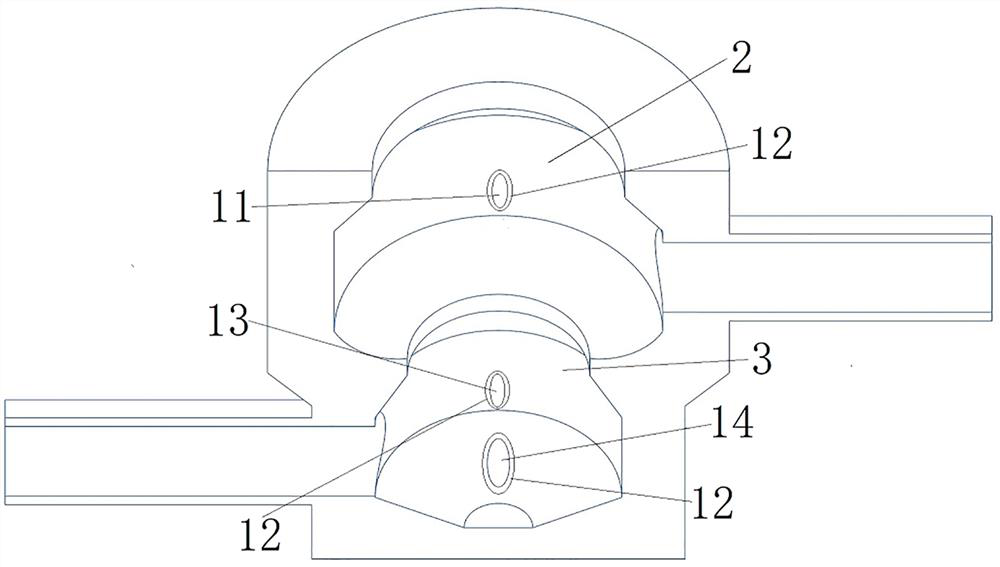

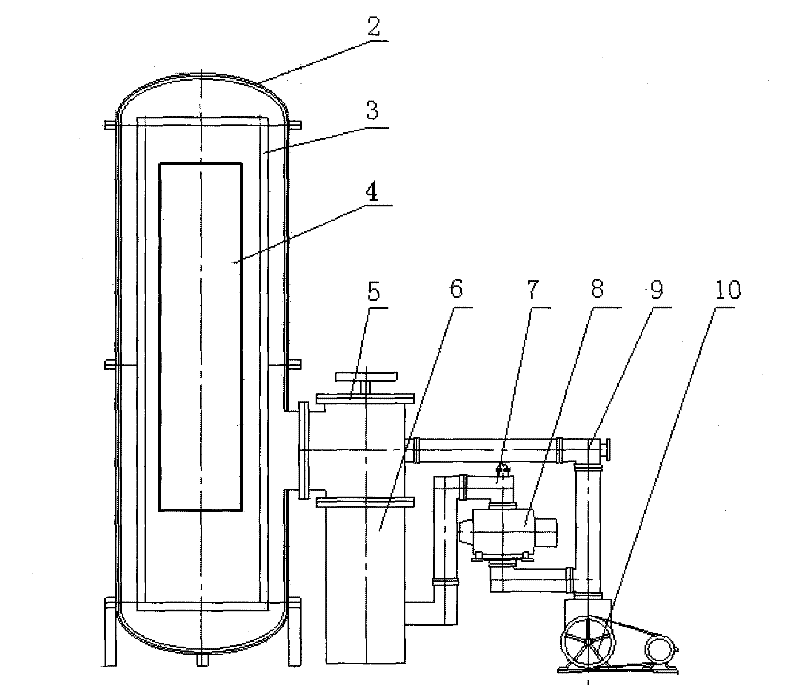

High-pressure main steam combined valve capable of locally reducing stress and stress analysis method

PendingCN113958749AReduce stress distributionReduce stress concentrationGeometric CADMachines/enginesThermodynamicsEngineering

The invention discloses a high-pressure main steam combined valve capable of locally reducing stress and a stress analysis method. The combined valve comprises a valve body (1), the valve body (1) is provided with at least one valve front drain hole (11), and the valve front drain hole (11) is connected with the valve body (1) through a transition round edge (12); the valve body (1) is of an integrally-formed structure, the valve body (1) comprises a regulating valve body (2) and a main steam valve body (3) communicating with the regulating valve body, a steam inlet pipe (21) and a steam outlet pipe (31) are fixed to the side face of the regulating valve body (2) and the side face of the main steam valve body (3) respectively, and the valve front drain hole (11) is formed in the side face wall of the regulating valve body (2); and a valve back drain hole (13) is formed in the side face wall of the main steam valve body (3), and at least one door rod steam leakage drain hole (14) is further formed in the valve body (1). The combined valve and the stress analysis method have the advantage that local stress concentration of the valve body drain hole can be reduced.

Owner:HANGZHOU HUADIAN BANSHAN POWER GENERATION +2

Loudspeaker monomer and electronic terminal

ActiveCN111901714BImprove acoustic performanceReduce stress distributionLoudspeaker transducer fixingLoudspeaker casing supportsStructural engineeringLoudspeaker

Owner:GOERTEK INC

Brazing process of ceramic vacuum pipe with diameter greater than 300mm and device

ActiveCN101767236BEnsuring natural capillarityEvenly distributedSoldering apparatusTubular articlesShielding gasCarbon Dioxide / Helium

Owner:上海克林技术开发有限公司

Loudspeaker monomer and electronic terminal

ActiveCN111901715BImprove acoustic performanceImprove installation stabilityLoudspeaker transducer fixingLoudspeaker casing supportsElectrical connectionEngineering

The invention discloses a loudspeaker unit and an electronic terminal. The loudspeaker unit includes a shell assembly, a magnetic circuit system, a vibration system, and a balance assembly. The balance assembly is arranged corresponding to a gap, and the balance assembly includes a centering support piece made of FPCB material. The centering strut includes an external fixing part, an elastic supporting part and a pad structure, wherein the external fixing part is connected with the shell assembly; the elastic supporting part is connected with the external fixing part, the elastic supporting part is located in the gap and partially connected with the bracket, and The supporting part elastically deforms with the vibration of the bracket; the pad structure includes a cantilever and a pad arranged at an angle, the end of the cantilever away from the pad is connected to the elastic supporting part, the cantilever extends along the bracket, the pad and the diaphragm or the top of the bracket The wall is fixedly connected, and the leads of the voice coil are electrically connected to the pads. The loudspeaker unit of the present invention not only makes the structural setting of the voice coil in the magnetic gap more free, but also effectively increases the volume of the magnetic circuit system, so that the magnetic field intensity is higher and the acoustic performance is better.

Owner:GOERTEK INC

Split type bionic femoral stem prosthesis

PendingCN113456311AWith anti-rotation effectThere will be no embarrassment that cannot be taken outJoint implantsFemoral headsFemoral boneProsthesis

The invention relates to a split type bionic femoral stem prosthesis comprising a near-end femoral connecting part and a far-end stem body part, wherein the near-end femoral connecting part is detachably connected to the upper end of the far-end stem body part, the upper end of the near-end femoral connecting part is used for being connected with a near-end femoral marrow cavity, and the lower end of the far-end stem body part is used for being inserted into a far-end femoral marrow cavity, so that a defective femoral section is replaced. The near-end femoral connecting part and the far-end stem body part adopt the split design of threaded connection, so that the structure not only has the anti-rotation effect of a conical connection mode, but also is firmer and more durable than a conical connection mode; and the awkward situation that the far-end stem body part is remained in the femoral far-end medullary cavity and cannot be taken out due to loosening of the conical connection in the prosthesis rebuilding process is avoided.

Owner:PEOPLES HOSPITAL PEKING UNIV

Method for producing tio2-sio2 glass body, method for heat-treating tio2-sio2 glass body, tio2-sio2 glass body, and optical base for euvl

InactiveUS20130276480A1Decrease productivityReduce allocationGlass furnace apparatusNanoinformaticsVitrificationMaterials science

The present invention relates to a process for production of a TiO2—SiO2 glass body, comprising: a step of, when an annealing point of a TiO2—SiO2 glass body after transparent vitrification is taken as T1 (° C.), heating the glass body after transparent vitrification at a temperature of T1+400° C. or more for 20 hours or more; and a step of cooling the glass body after the heating step up to T1−400 (° C.) from T1 (° C.) in an average temperature decreasing rate of 10° C. / hr or less.

Owner:AGC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com