Novel harmonic reducer and input transmission structure thereof

A technology of harmonic reducer and transmission structure, which is applied in the direction of transmission device, gear transmission device, belt/chain/gear, etc., which can solve the problem of the working life of the easily damaged harmonic reducer, the unstable operation of the reducer, and the large stress of bearing assembly and other problems to achieve the effect of eliminating stress in the working process, compact structure, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

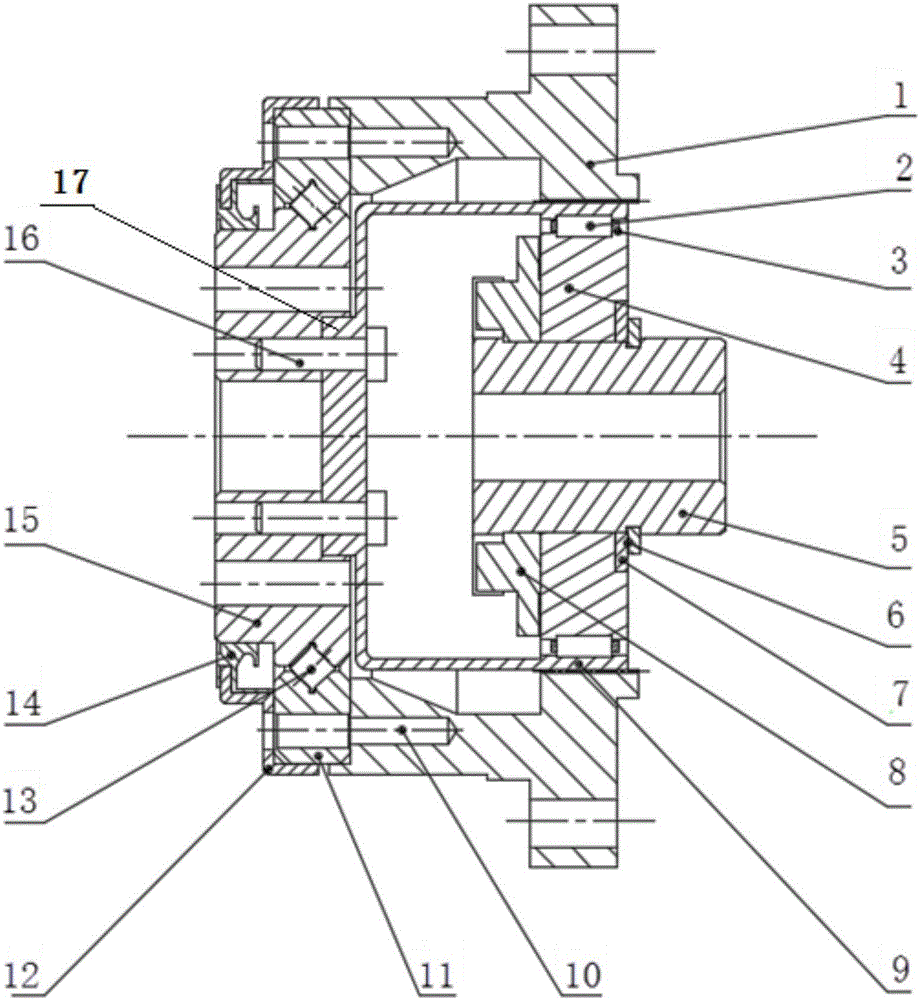

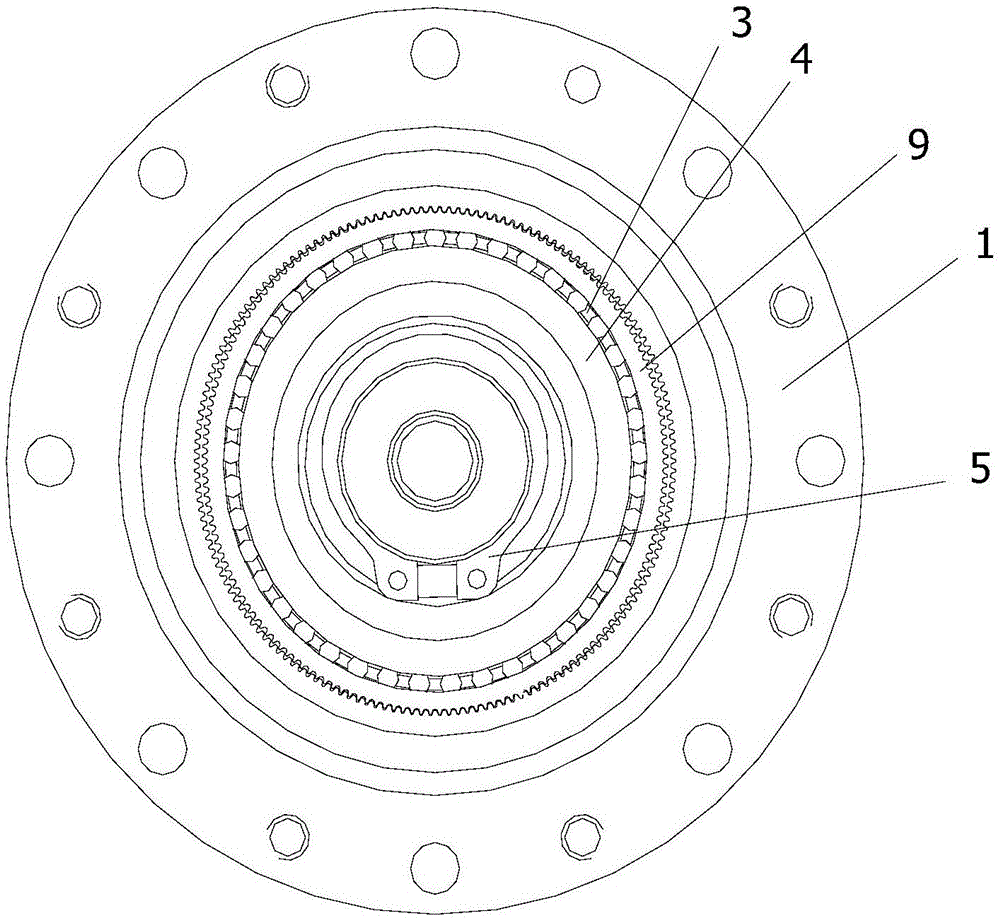

[0043] like figure 1 and figure 2 As shown, a new type of harmonic reducer input transmission structure, including the cam 4 connected to the input shaft, the cam 4 is covered with a flex spline 9; the flex spline 9 is externally meshed with a steel wheel 1; the flex spline 9 is provided with external teeth, The steel wheel 1 is provided with internal teeth, and the flex spline 9 and the steel wheel 1 are meshed through the external teeth and the internal teeth; a cage 3 is provided between the flex spline 9 and the cam 4, and cylindrical rollers 2 are installed in the cage 3; The inside of the wheel 9 and the outside of the cam 4 are both convexly formed with an annular convex circle 19, and a C-shaped groove 20 matching with the cylindrical roller 2 is formed on the annular convex circle 19; the annular convex circle 19 is located on the outer tooth side of the flexwheel 9 .

[0044] The present invention cancels the setting of the bearing by changing the structure of the...

Embodiment 2

[0046]The fatigue failure of the harmonic reducer mostly occurs in the flex spline and the bearing, so the meshing degree and mode of the flex spline and the steel wheel have a great influence on the stability and life of the harmonic reducer. In the present invention, the flexible spline is made of PA 12 plastic. Because its elasticity is better than the elastic metal used in the original flexspline manufacturing, the external teeth on the flexible spline that are opposite to the long axis of the cam can completely mesh with the internal teeth of the steel wheel. No backlash, if attached Figure 5 shown. Among them, the tooth profile curve is composed of R1, R2, R3 three-segment curves and R1', R2', R3' three-segment curves that are symmetrical to it, and the starting or adjacent curves of the curve intersect at P 1 ,P 2 ,P 3 ,P 4 (P 4 '), P 3 ',P 2 ',P 1 '. In Cartesian coordinates, the curve equations of R1, R2, and R3 are shown below. This design method can impro...

Embodiment 3

[0061] The PA 12 used in the flexible wheel of the harmonic reducer of the present invention is an engineering plastic with low specific gravity, high tensile strength, wear resistance, good self-lubrication, excellent impact toughness, and both rigidity and flexibility, rather than metal Material. Its elastic modulus is 1.646GPa, and its shrinkage rate can reach 1% to 2%. like figure 1 As shown, the harmonic reducer of the present invention is input into a traditional structure, and the cam 4 of the transmission structure is in the shape of an ellipse, and the contour curve satisfies the equation: r=0.5r B +ωcos(2θ), there is a C-shaped groove on the outer surface of the cam. The flexible spline 9 has an annular convex circle 19 with the same width as the gear teeth inside the tooth cylinder, and the inner surface of the convex circle has a C-shaped groove 20.

[0062] 41 cylindrical rollers 2 are evenly arranged between the C-shaped rolling grooves between the cam 4 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com