Patents

Literature

42results about How to "Improve contact stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

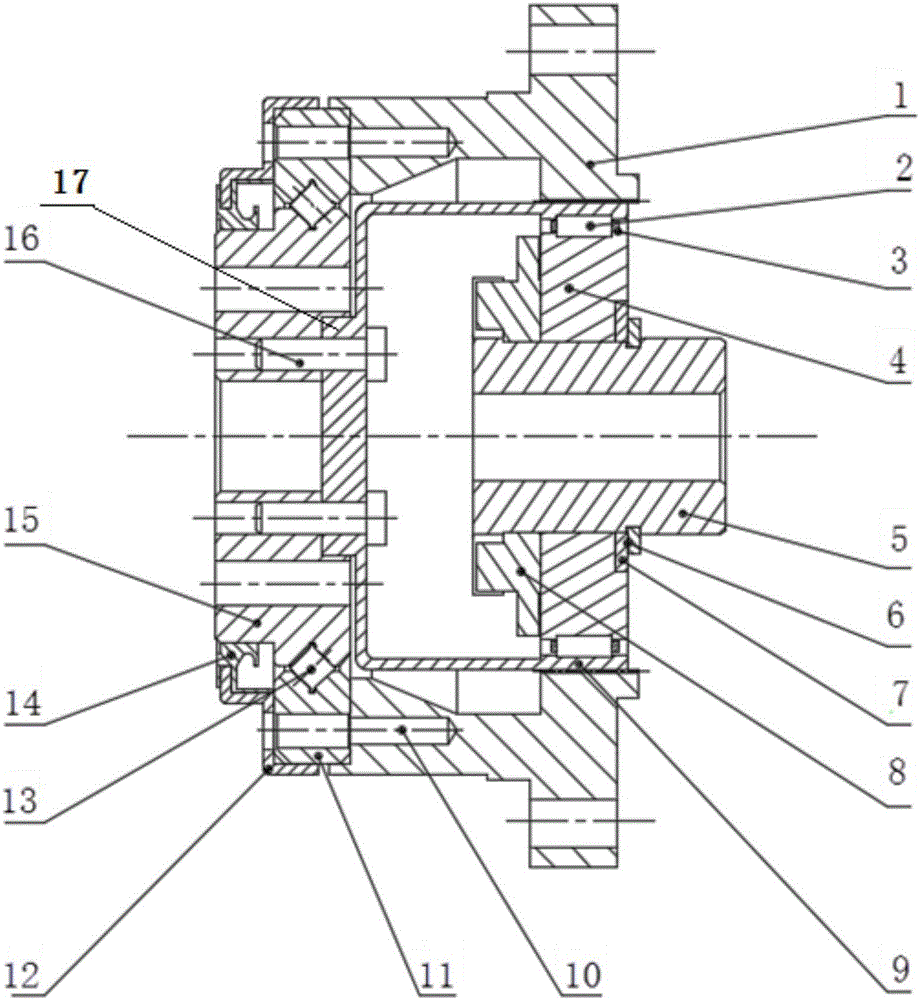

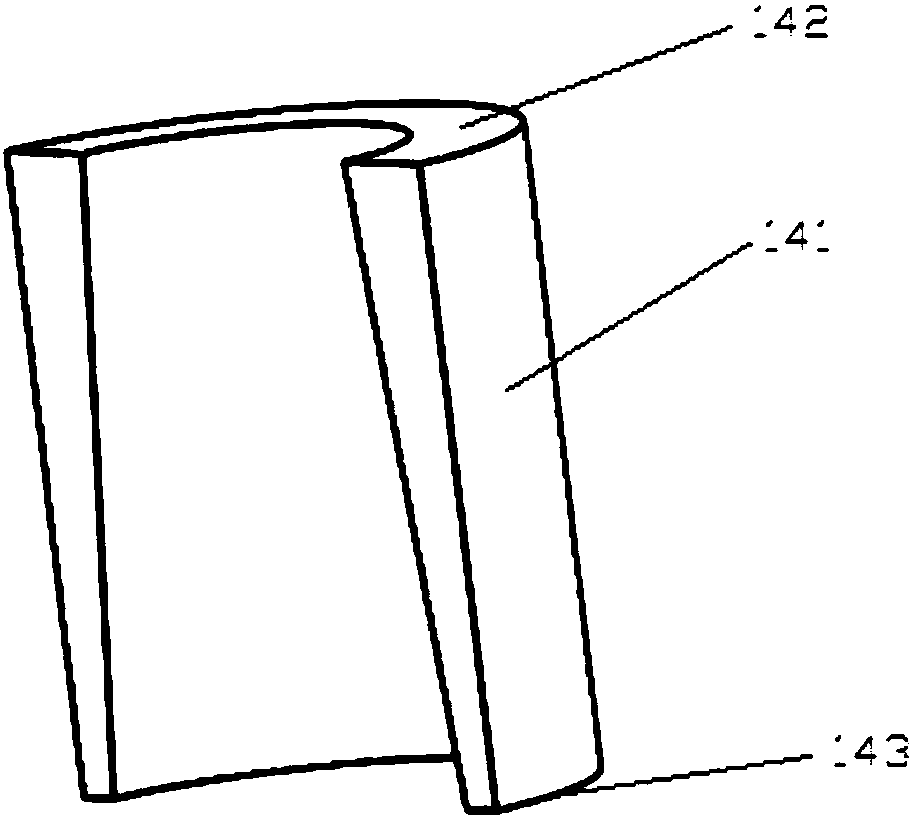

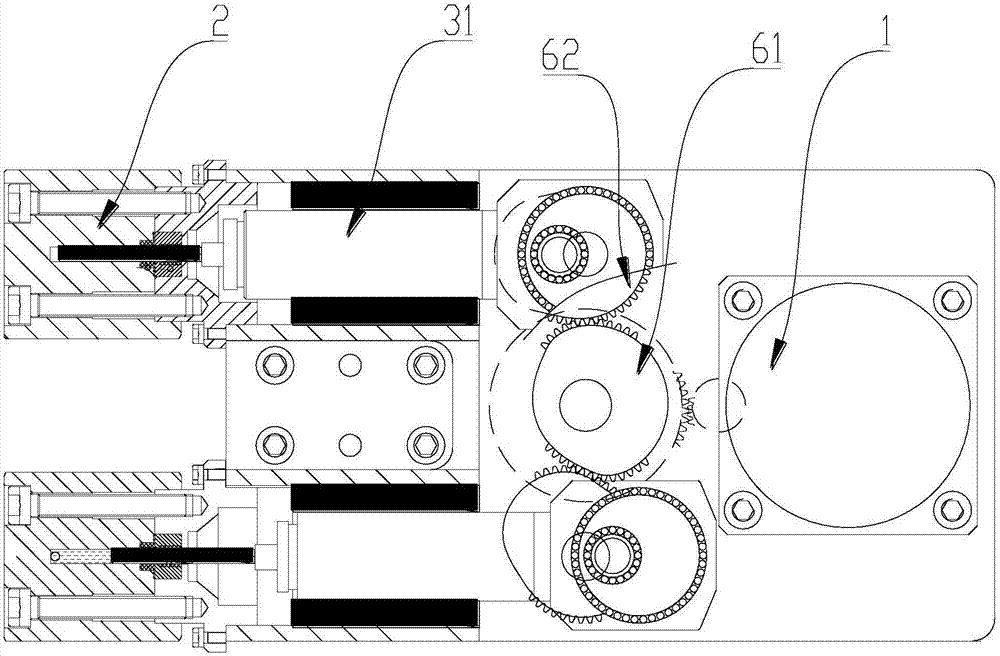

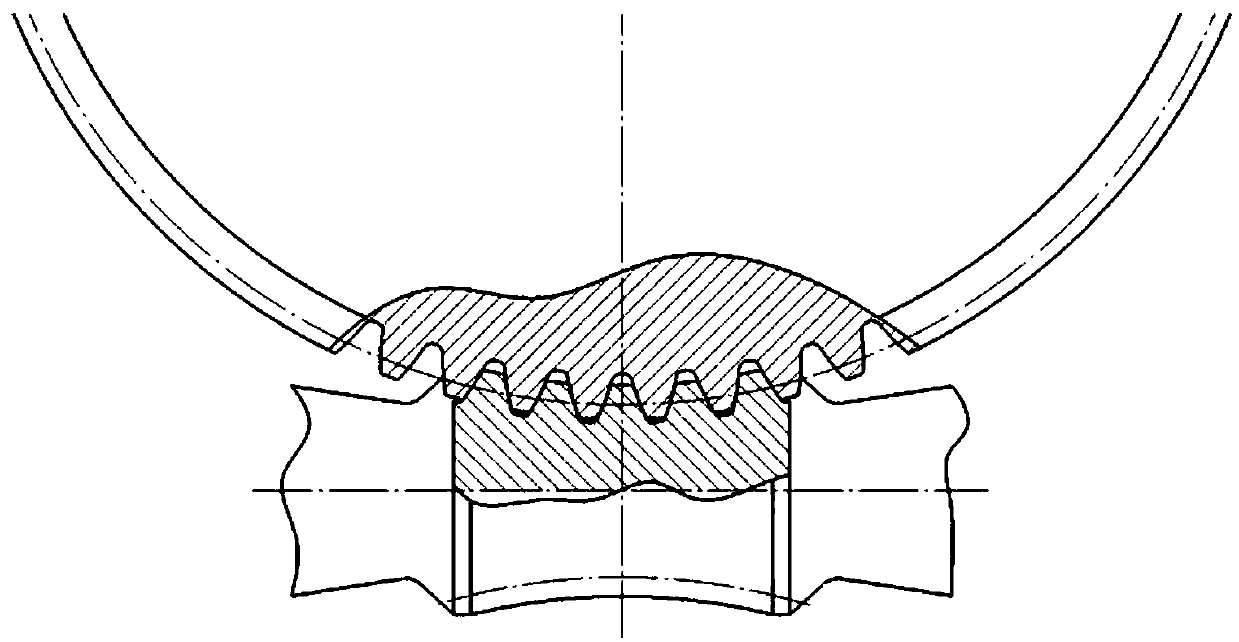

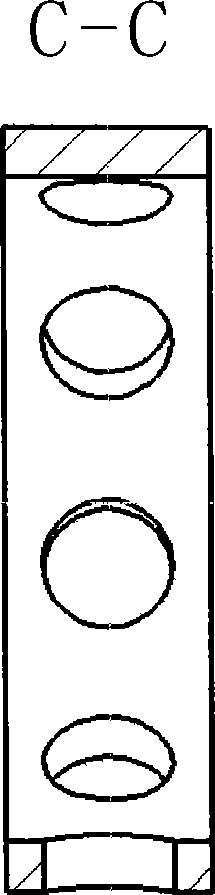

Novel harmonic reducer and input transmission structure thereof

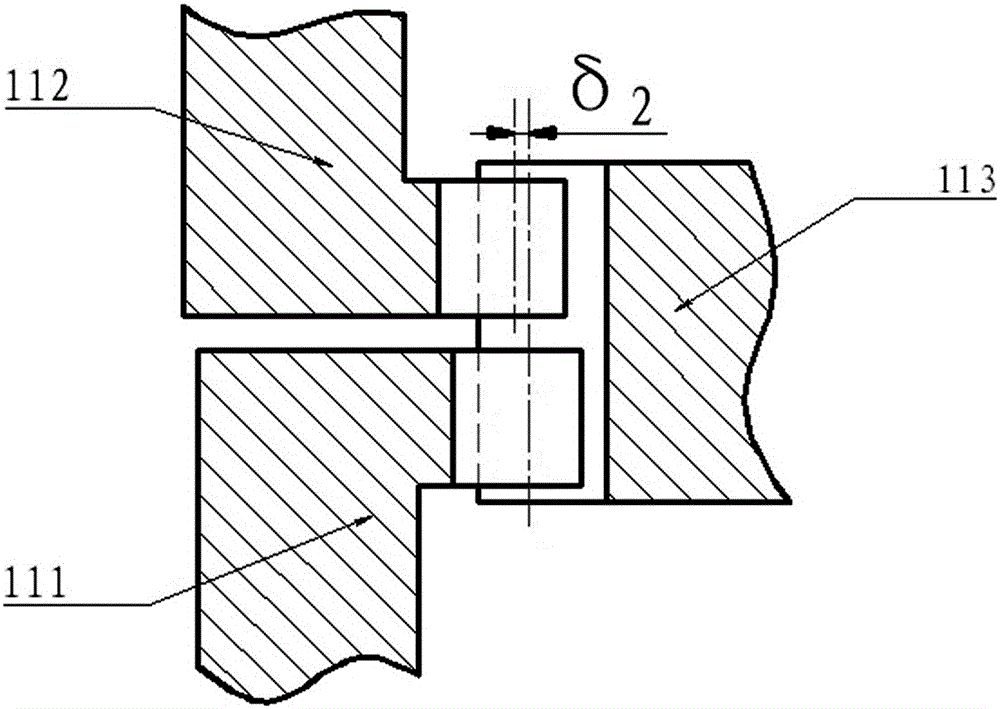

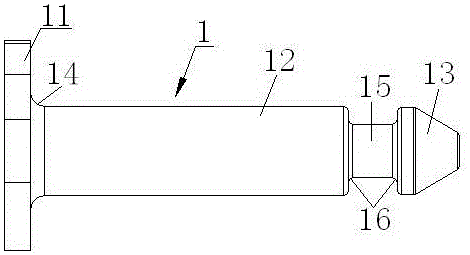

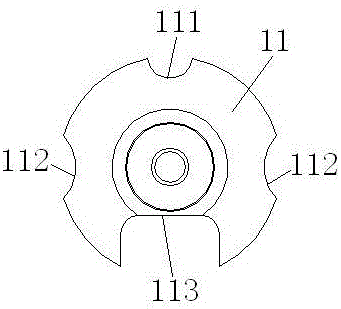

The invention discloses a novel harmonic-reducer input transmission structure. The novel harmonic-reducer input transmission structure comprises a cam connected with an input shaft, and the cam is sleeved with a flexible gear; a steel gear is engaged with the flexible gear, outer teeth are arranged on the flexible gear, inner teeth are arranged on the steel gear, and the flexible gear is engaged with the steel gear through the outer teeth and the inner teeth; a keeping frame is arranged between the flexible gear and the cam, and a cylinder roller is installed in the keeping frame; annular flanges are formed inside the flexible gear and outside the cam in an outward-protruding mode, and C-shaped grooves matched with the cylinder roller are formed in the annular flanges; the annular flanges are located on the outer-tooth side of the flexible gear. By means of the novel harmonic-reducer input transmission structure, the assembly stress of a key part of a harmonic reducer is reduced or eliminated, the engaging stress of the steel gear and the flexible gear in the movement process is reduced, the input structure and the output structure of the harmonic reducer are newly designed, the movement of the harmonic reducer is more stable during working, and the service life is prolonged.

Owner:HUNAN UNIV

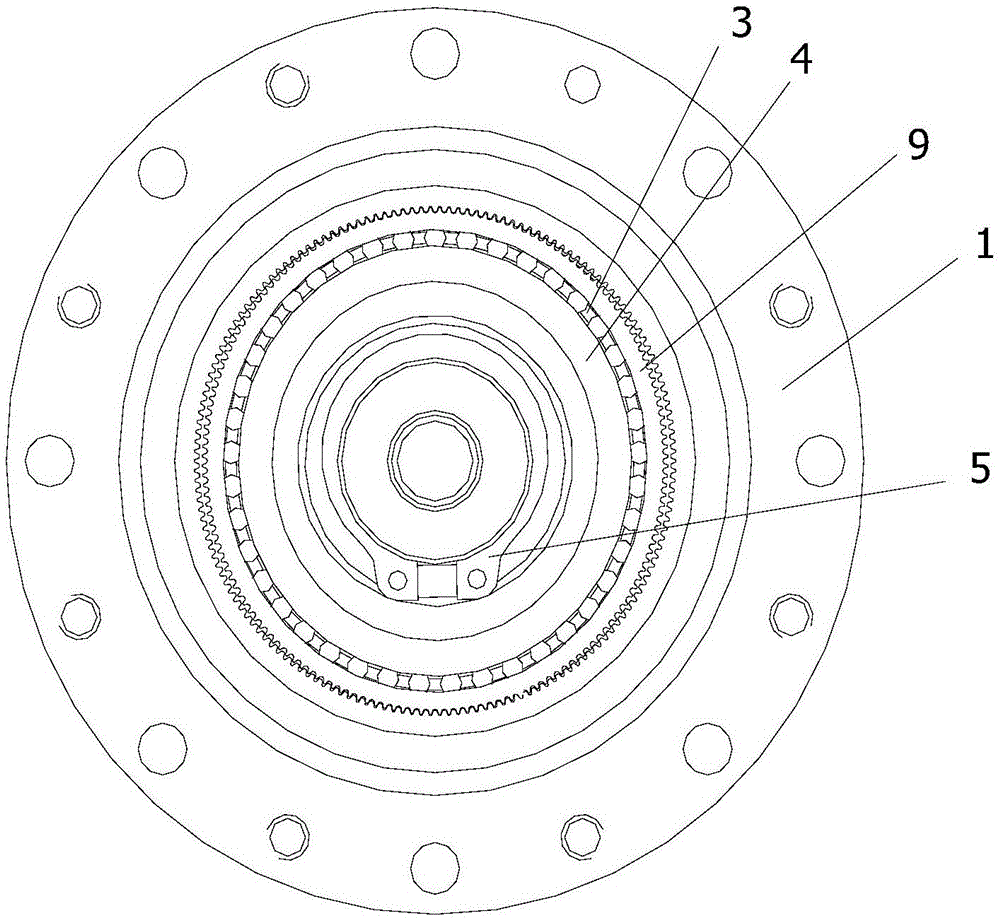

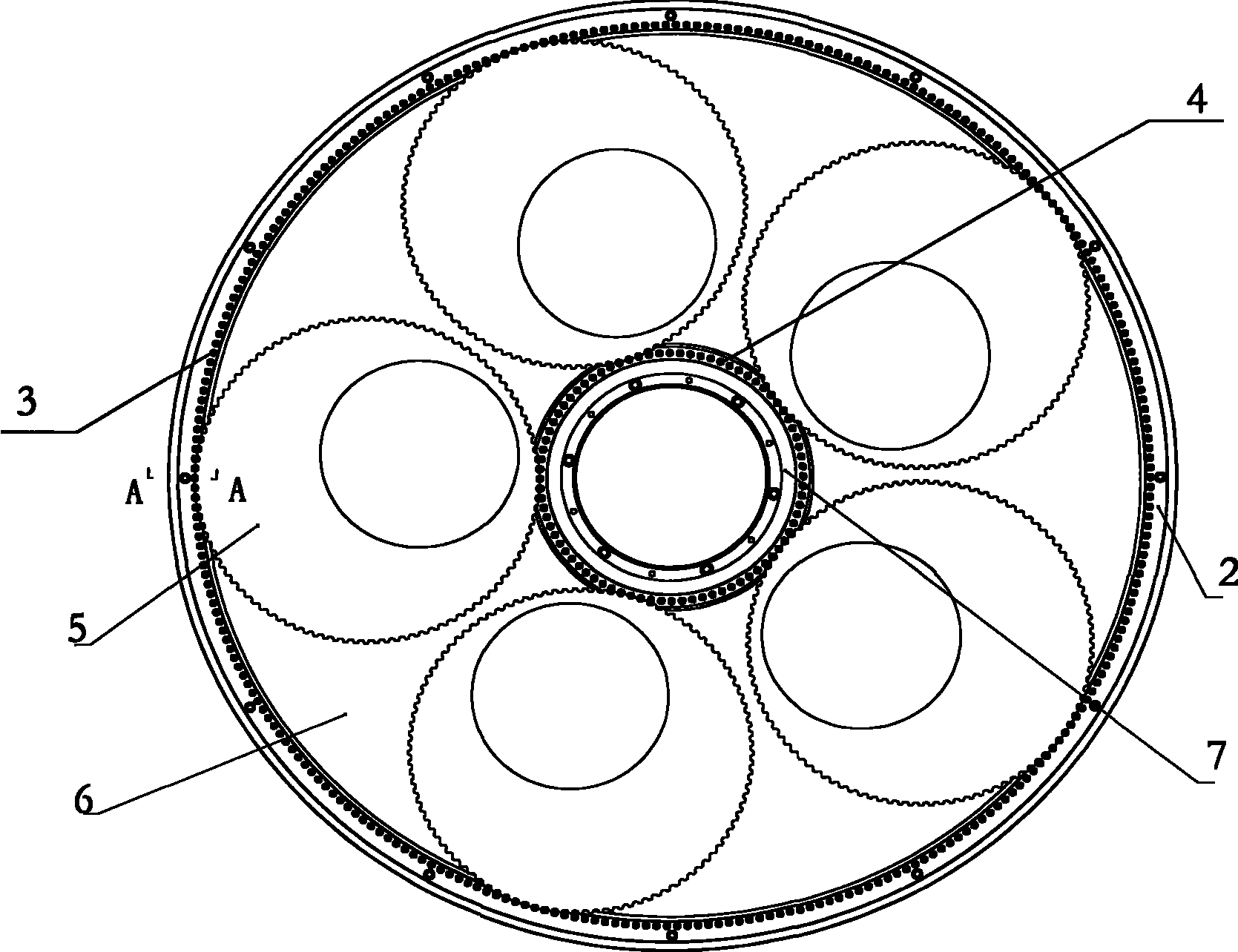

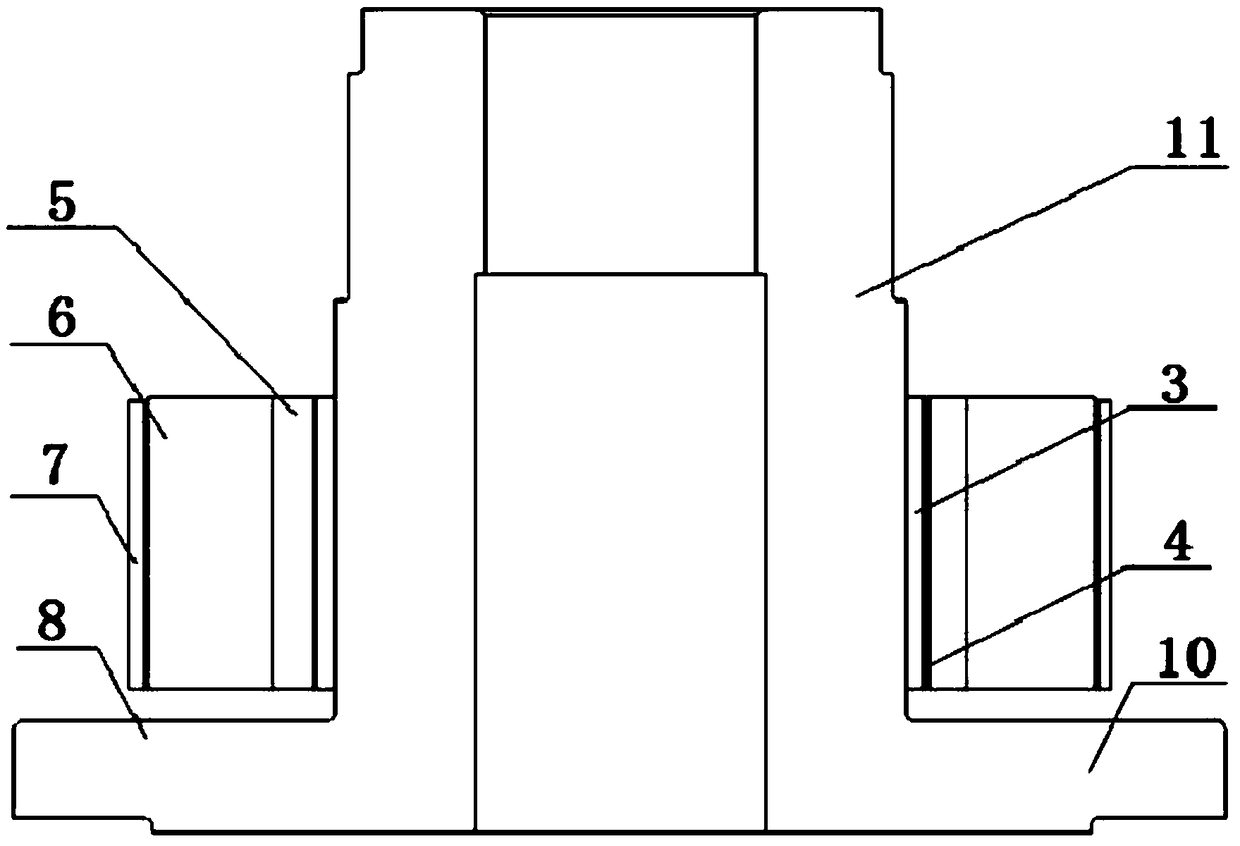

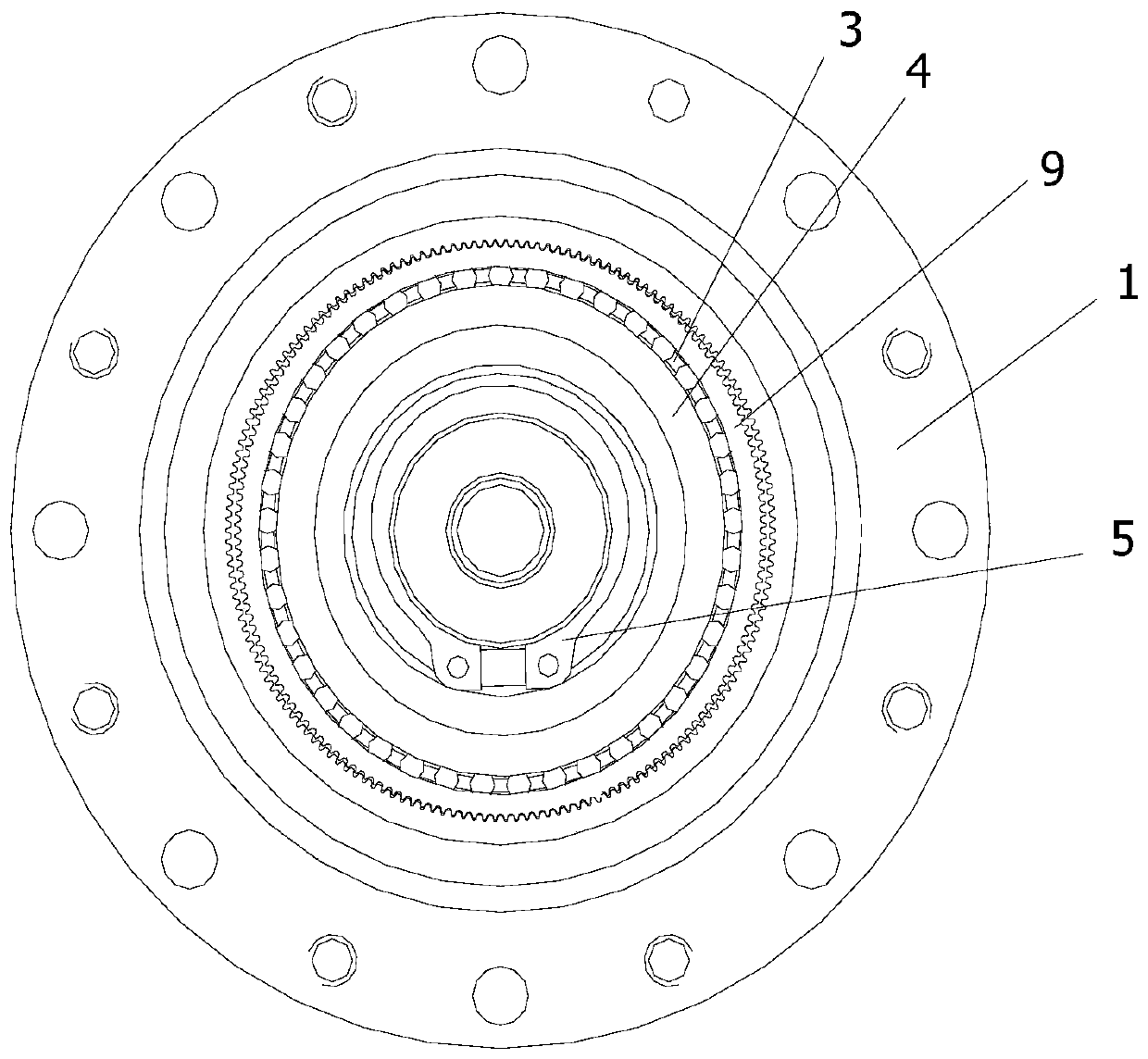

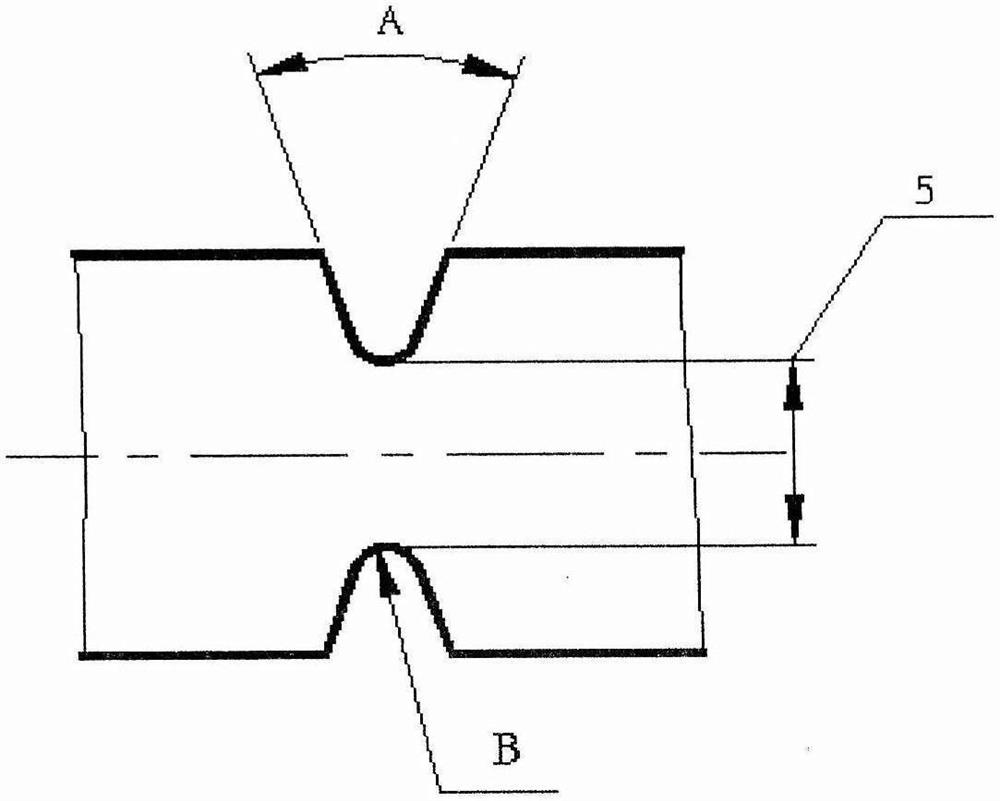

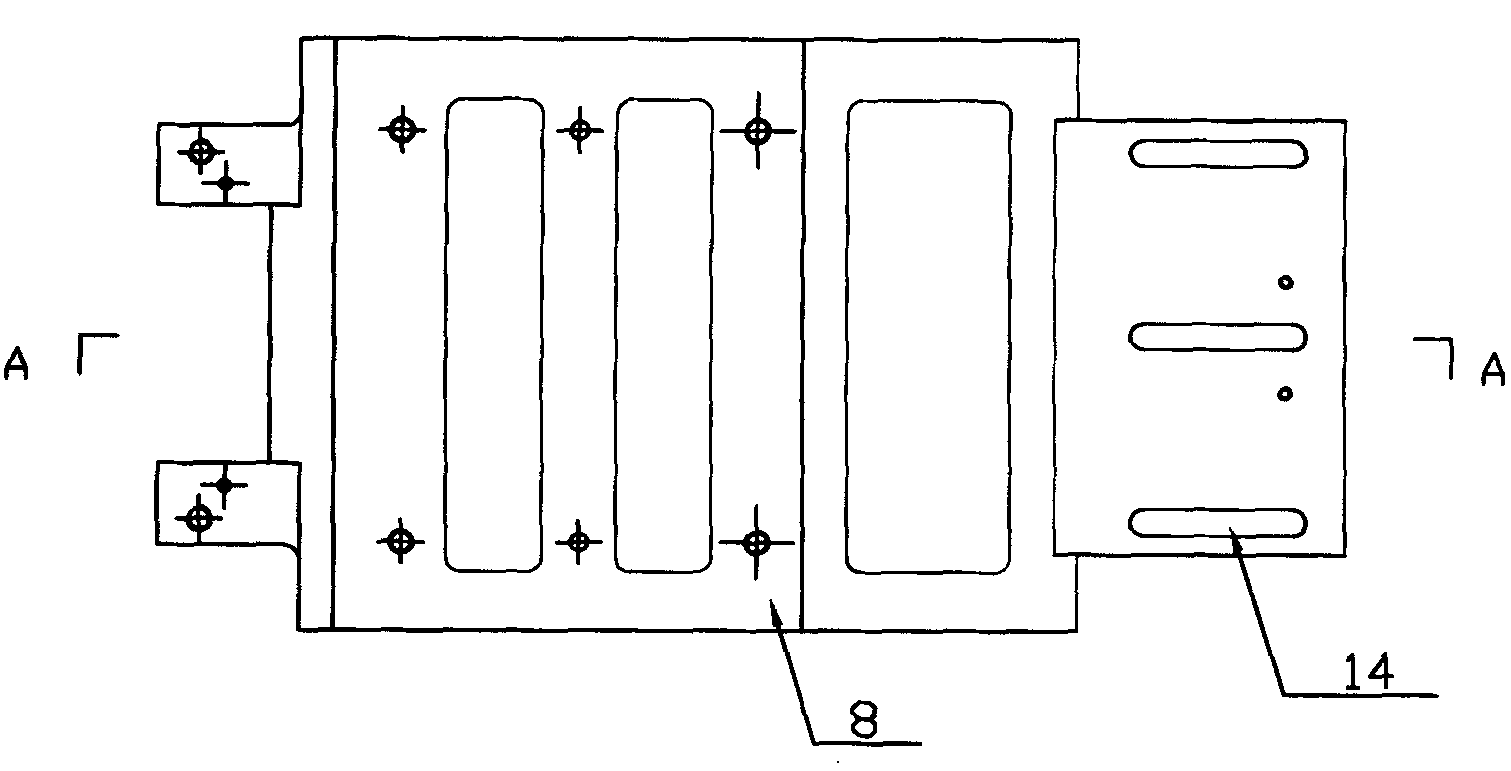

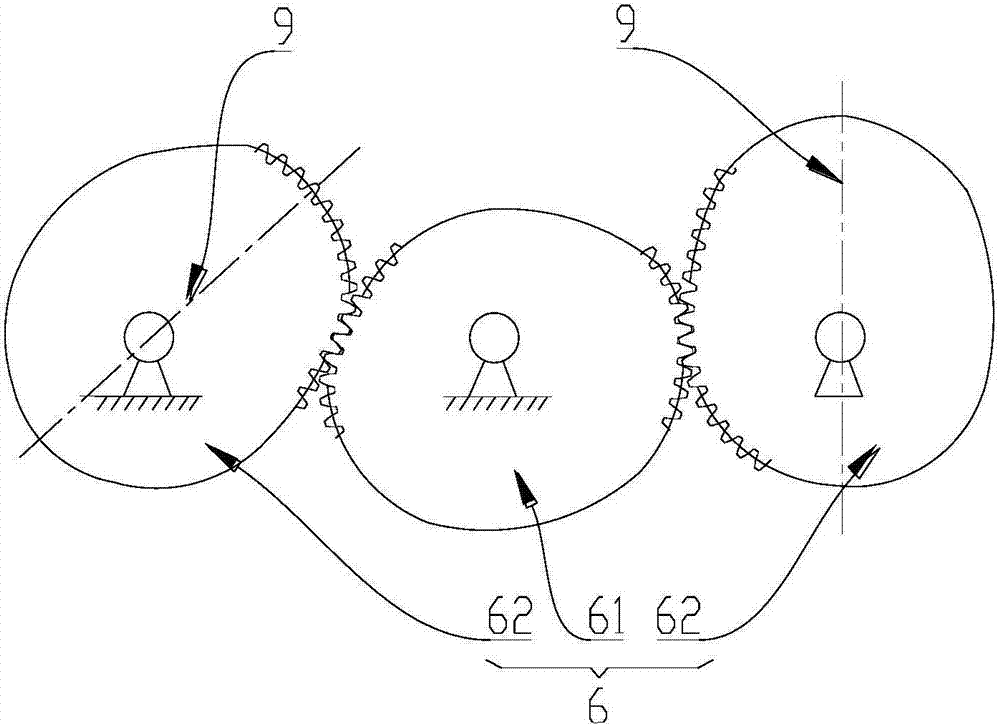

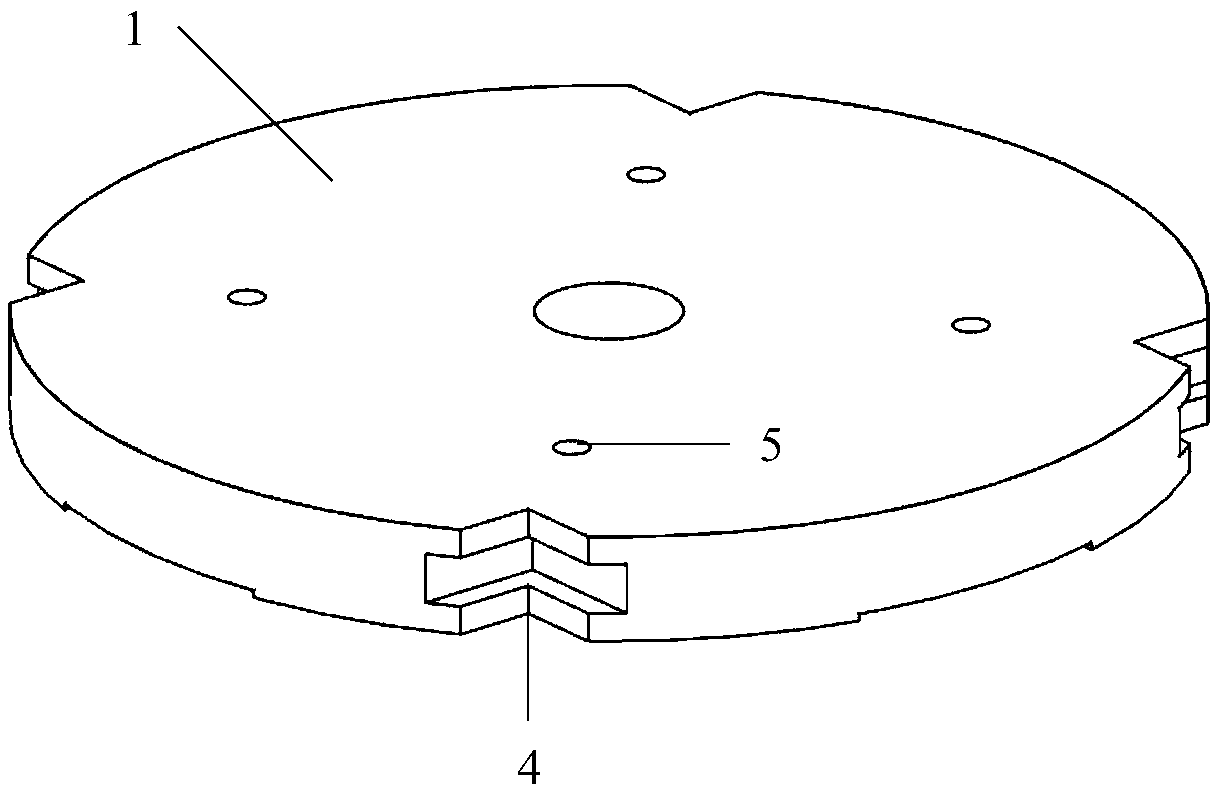

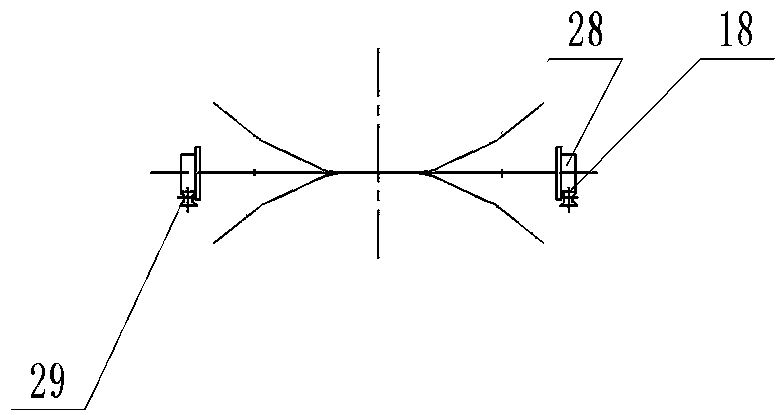

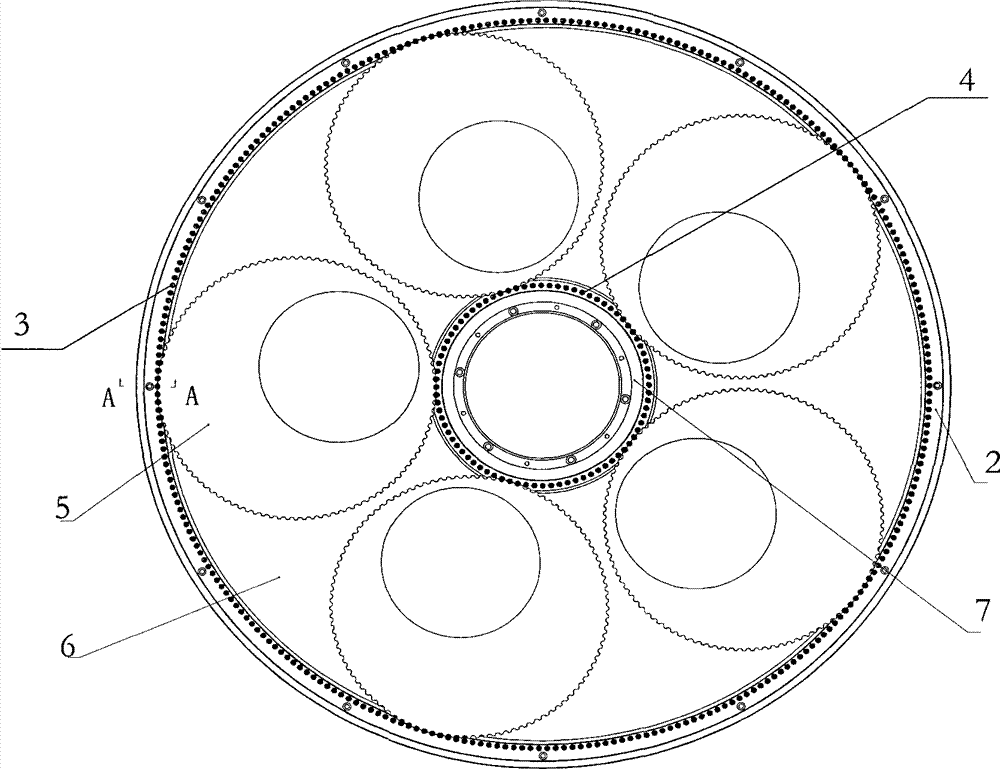

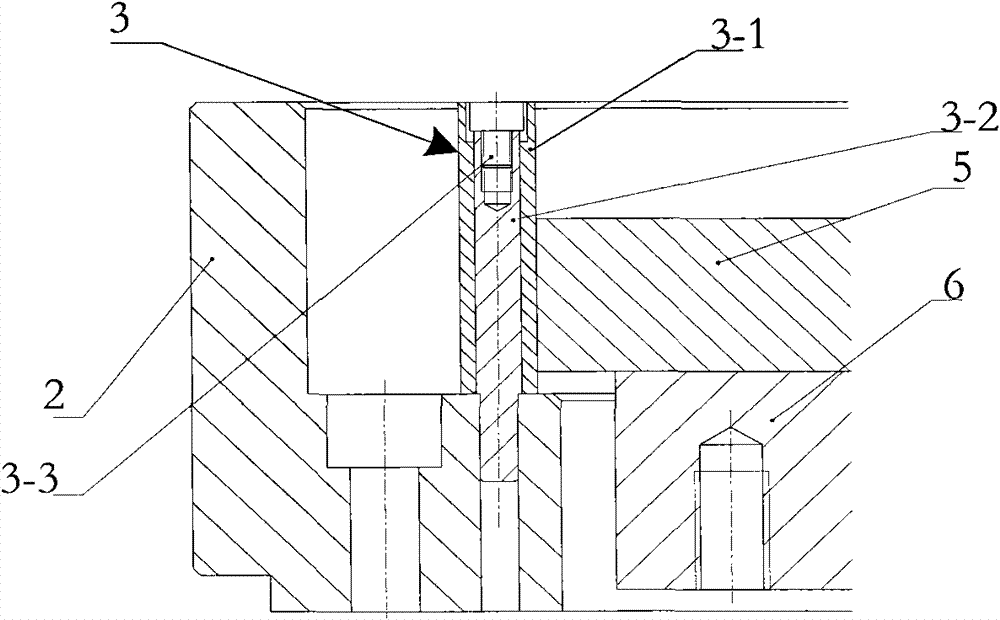

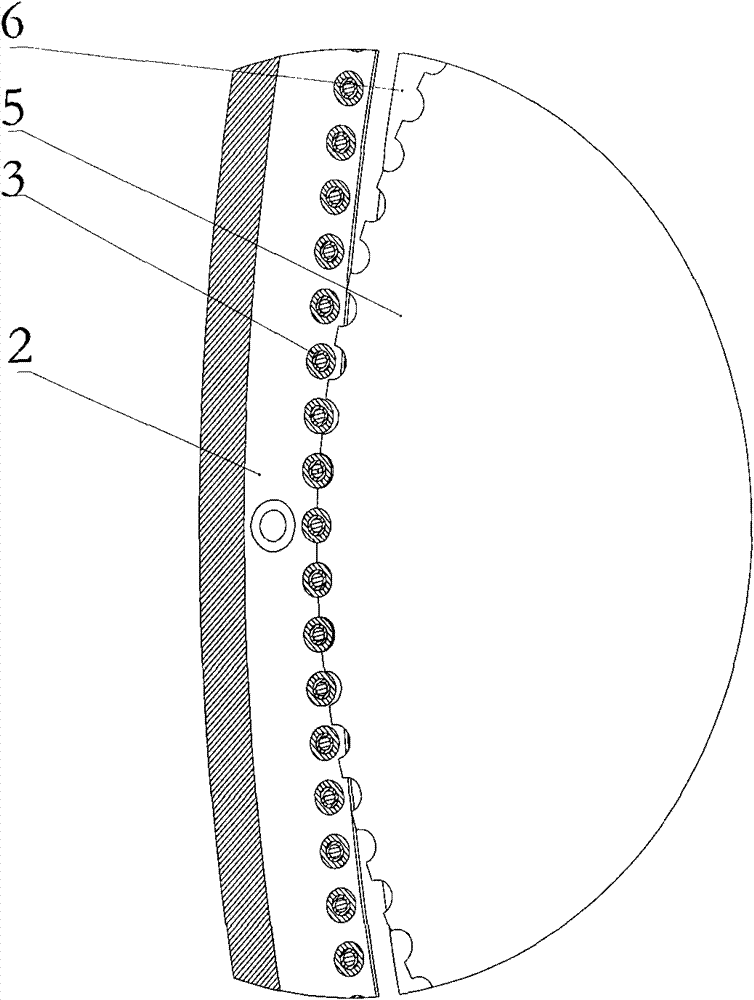

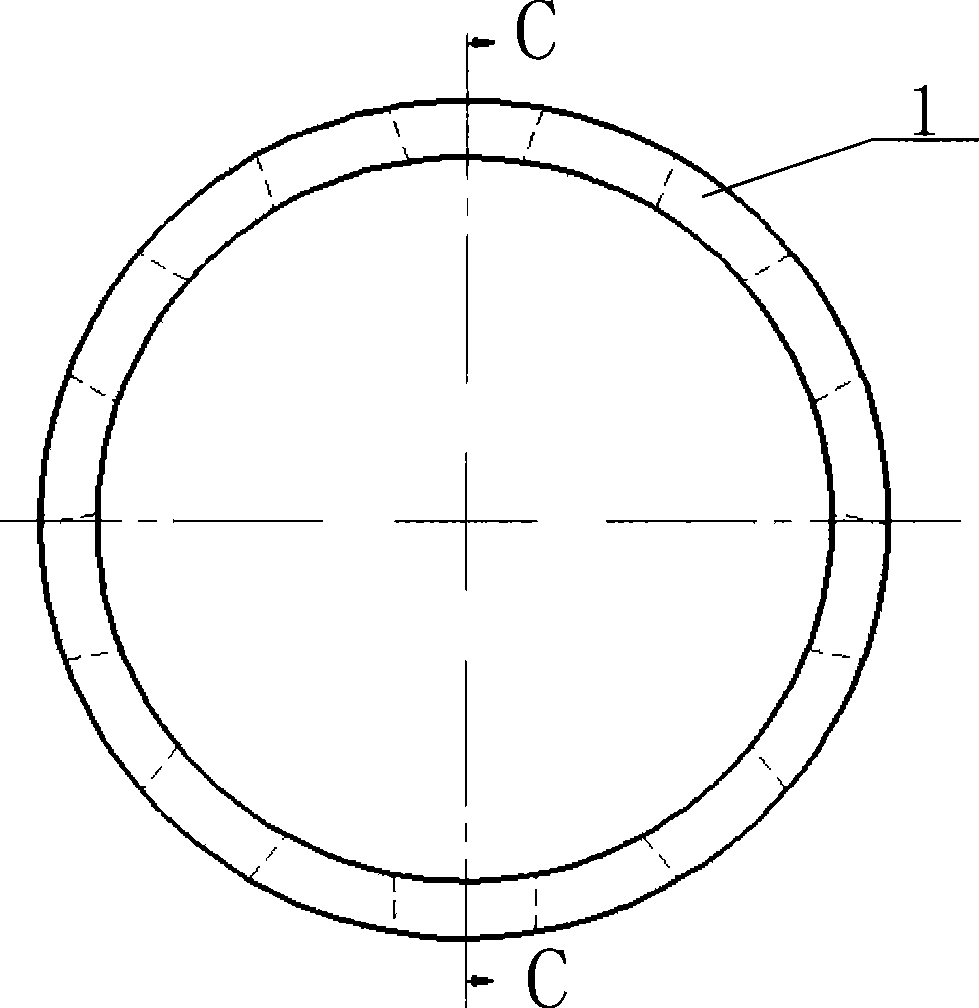

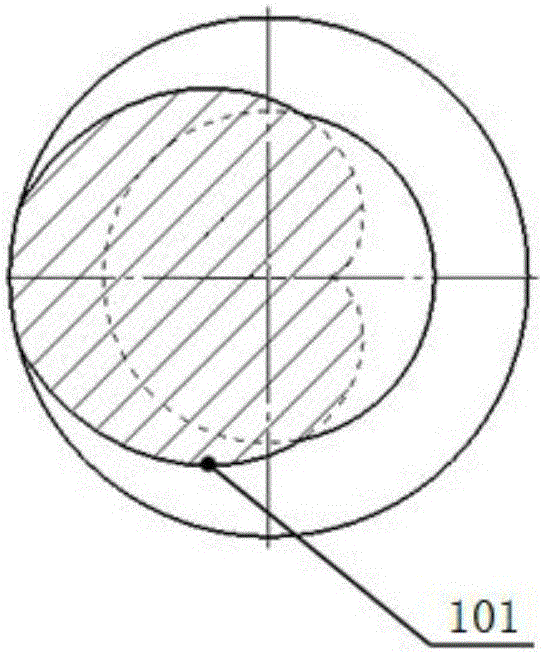

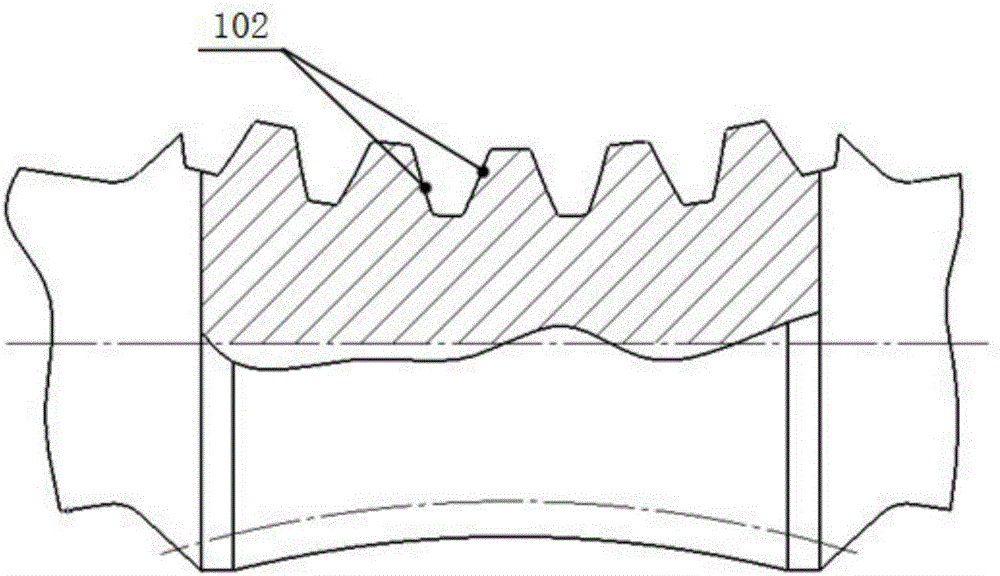

Planetary transmission mechanism for double-faced grinding/polishing machine

InactiveCN101982302ASolve the problem of inconvenient maintenance and high cost of useLow costGrinding drivesProcessing costEngineering

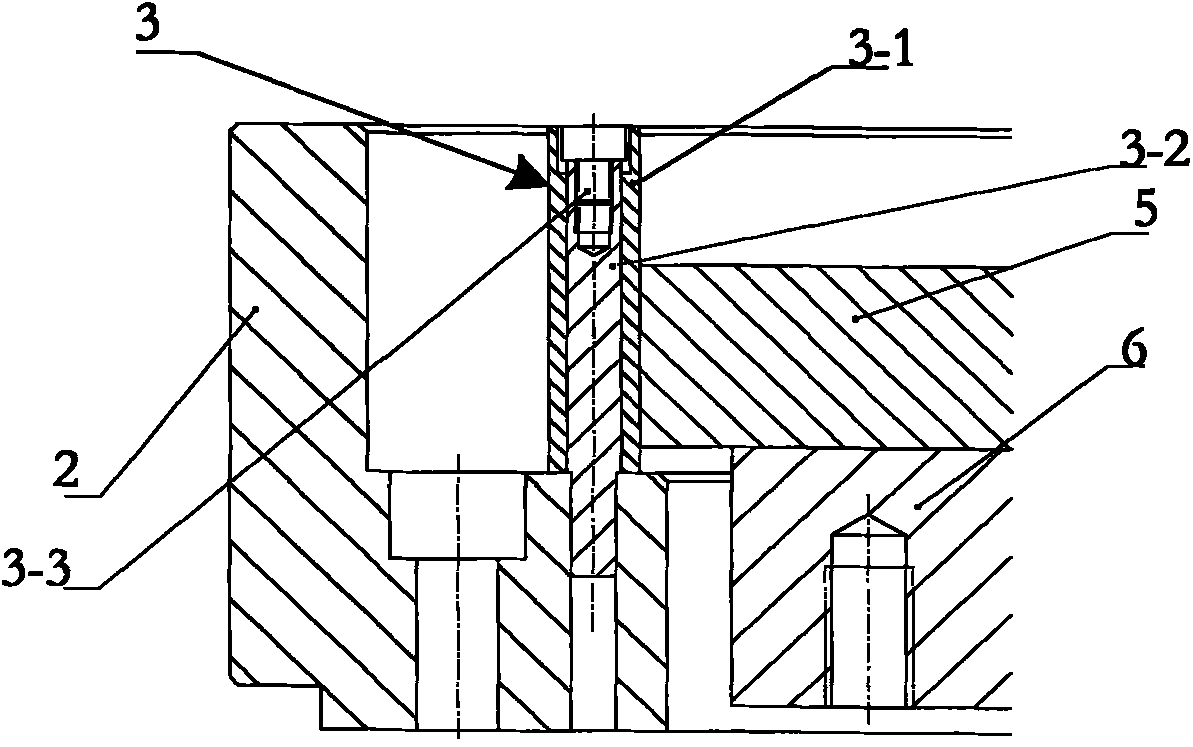

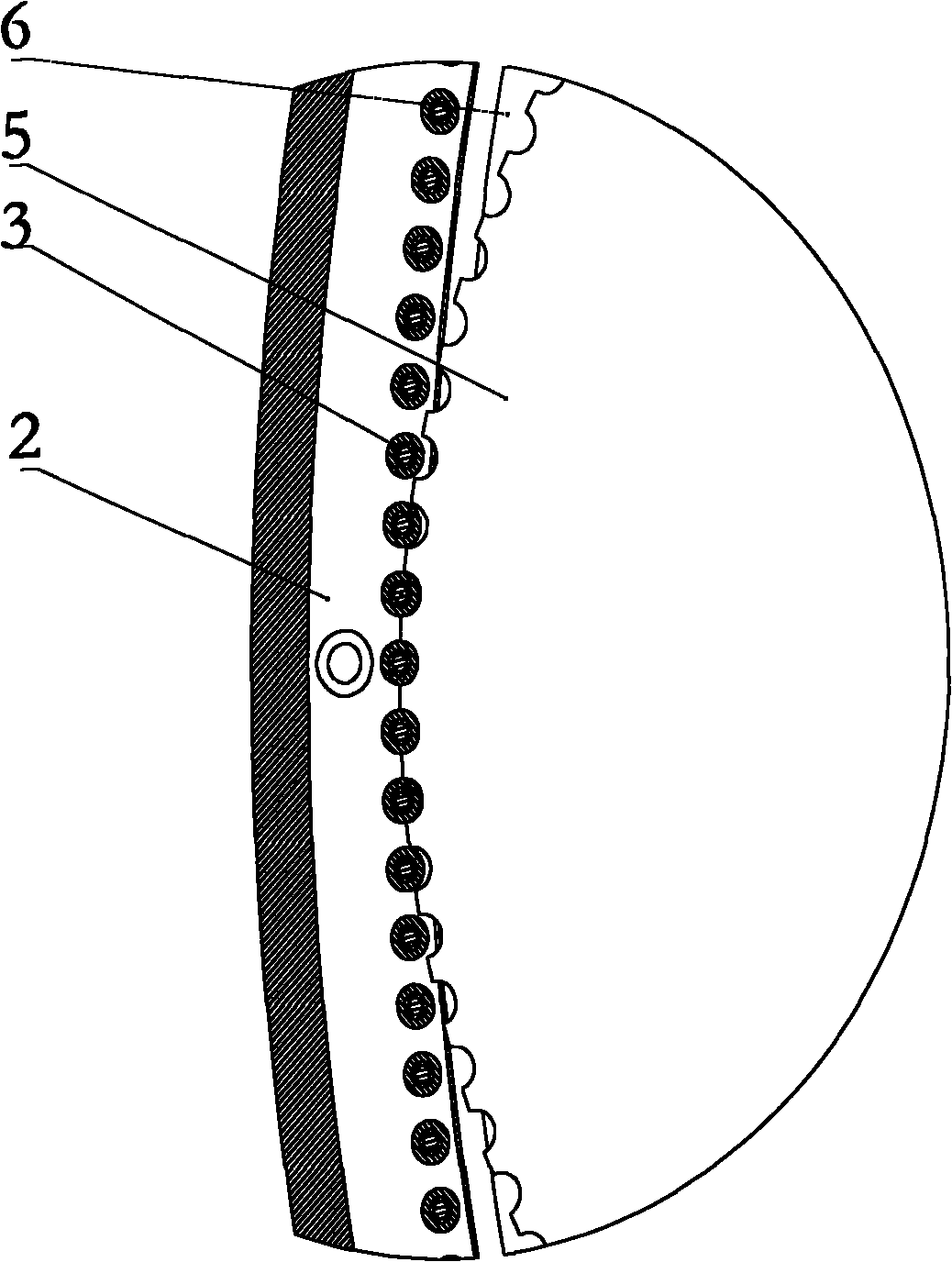

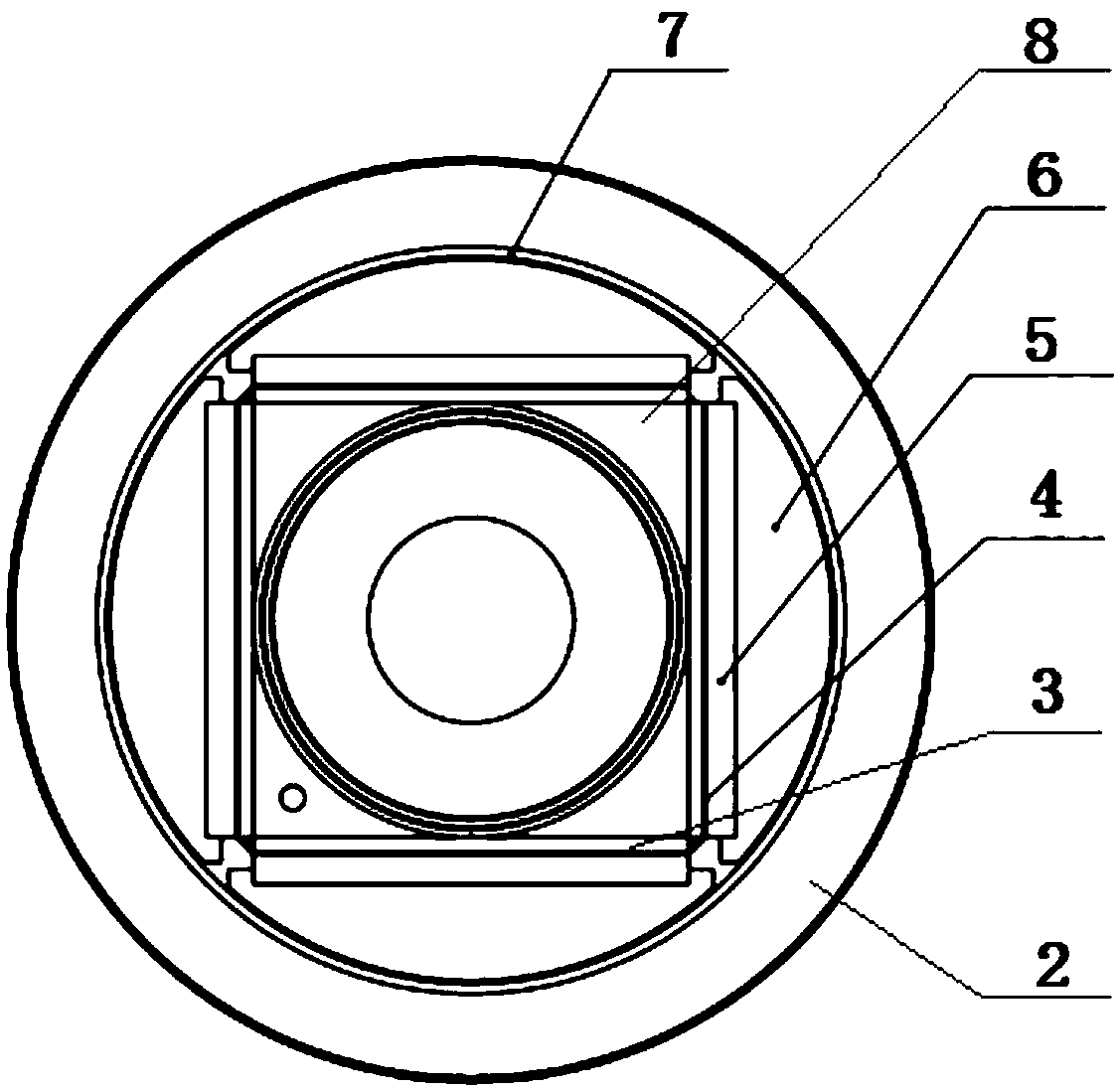

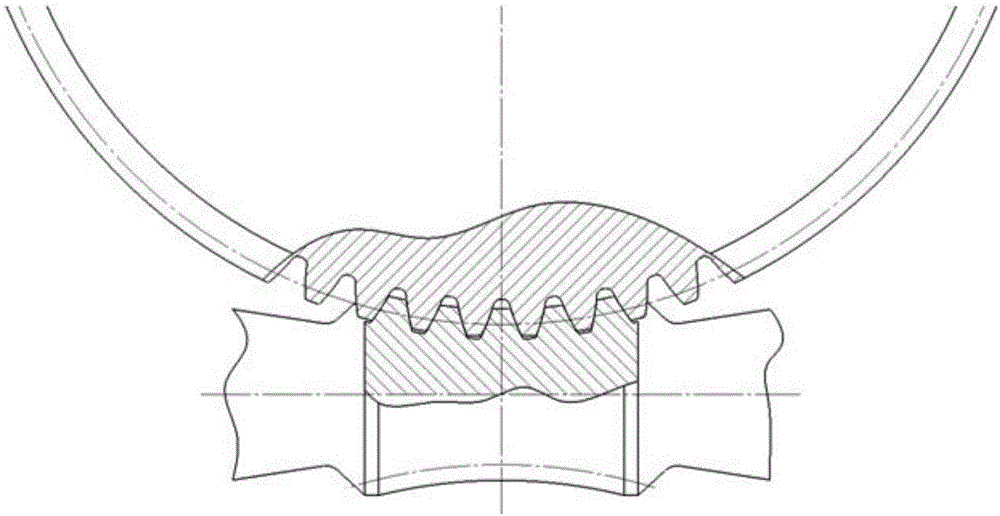

The invention relates to the field of a double-faced grinding / polishing machine, in particular to a planetary transmission structure of a double-faced grinding / polishing machine. The planetary transmission mechanism for the double-faced grinding / polishing machine comprises a planetary wheel (5) meshed with a gear ring (2), wherein the planetary wheel (5) is meshed with a sun wheel (7) and is arranged on a lower plate (6); a circle of gear ring pin teeth (3) are uniformly arranged on the inside surface of the gear ring (2); a tooth pitch is formed between two gear ring pin teeth (3); and the gear ring (2) is meshed with the planetary wheel (5) through the gear ring pin teeth (3). The invention has the advantages that because the pin tooth transmission is adopted, the cost of materials and the processing cost of an inner gear ring are reduced; the problem that the processing difficulty is increased because the size of the gear ring is increased is solved, and the problems of inconvenient maintenance and high using cost after the teeth are worn in the using process are solved; and simultaneously, because each pin tooth is in the shape of a circular arc and the meshing line is long, the contact rigidity of a part is improved, and the service life of the part is prolonged.

Owner:LANZHOU RAPID INDGRPCO +1

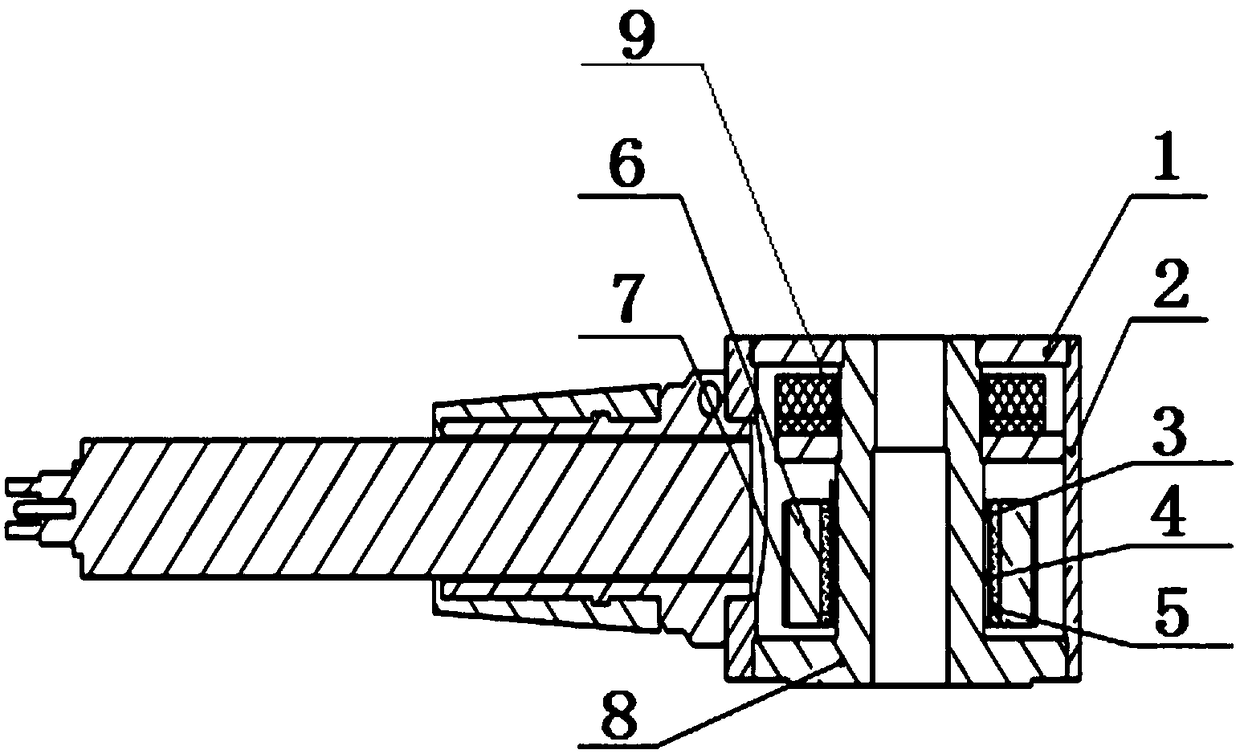

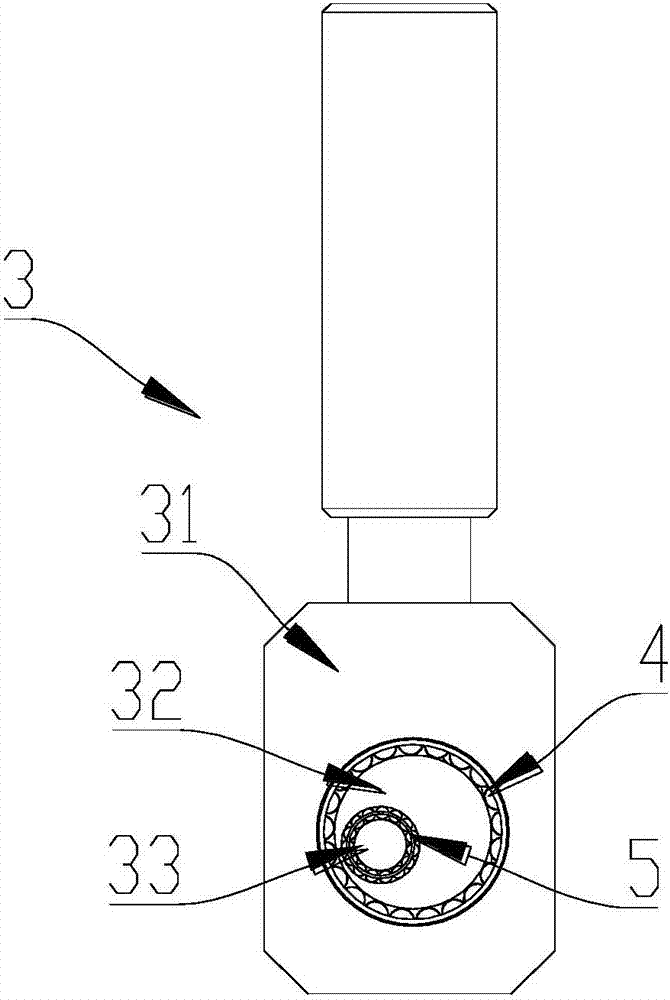

Charge output element and ring-shaped shearing type piezoelectric acceleration sensor

PendingCN107688102AAvoid expansionShorten the installation cycleAcceleration measurement using interia forcesElectricityEngineering

The embodiment of the invention provides a charge output element and a ring-shaped shearing type piezoelectric acceleration sensor which comprises a base, a piezoelectric element, a mass block, a pre-tightening part and a locking part, wherein the base comprises a supporting part, a connecting part and an installing hole; the piezoelectric element is sheathed outside the connecting part, and a ring-shaped gap is formed between the piezoelectric element and the connecting part; the mass block is sheathed outside the piezoelectric element; the pre-tightening part is inserted into the ring-shapedgap; the locking part is provided with a columnar part and a blocking part which are connected; all the elements are locked by matching of the columnar part and the installing hole; and the blockingpart abuts against a first end so as to lead the pre-tightening part to provide a radial pre-tightening force for fastening the piezoelectric element, the mass block and the base. The charge output element and the ring-shaped shearing type piezoelectric acceleration sensor provided by the embodiment of the invention have the advantages that due to rigid contact between the charge output elements,the contact rigidity of the whole structure can be greatly improved, and adhesion is not needed, so that the installation period of the charge output elements is effectively shortened.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

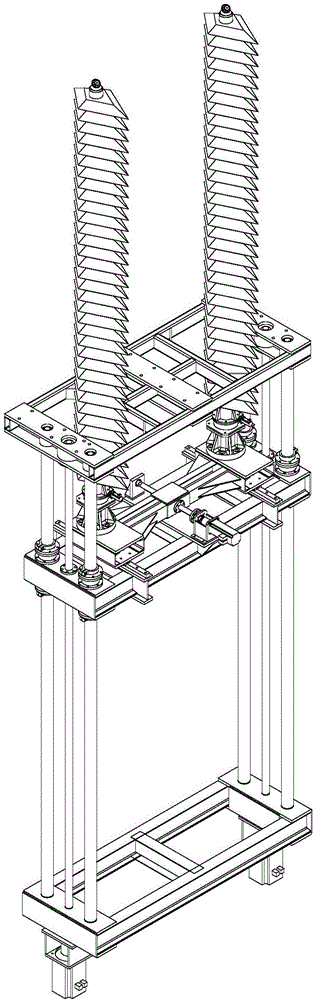

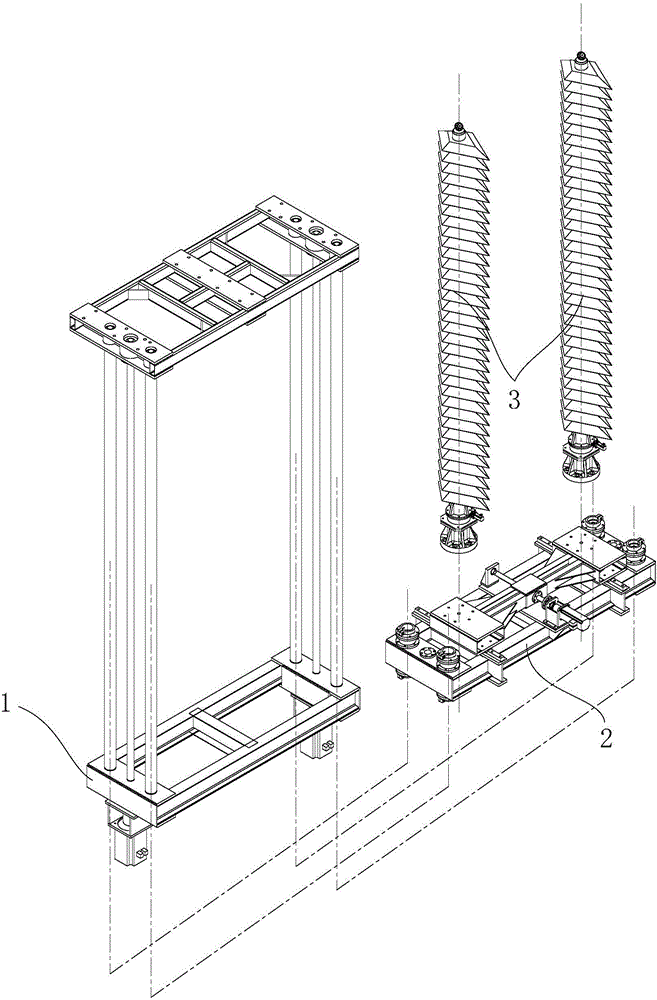

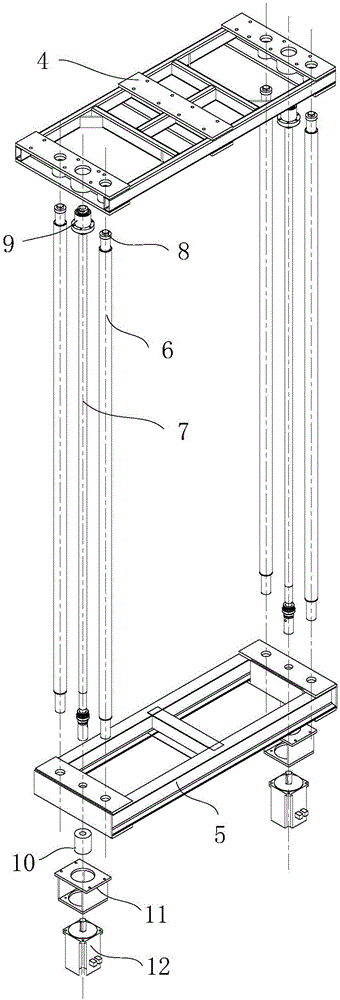

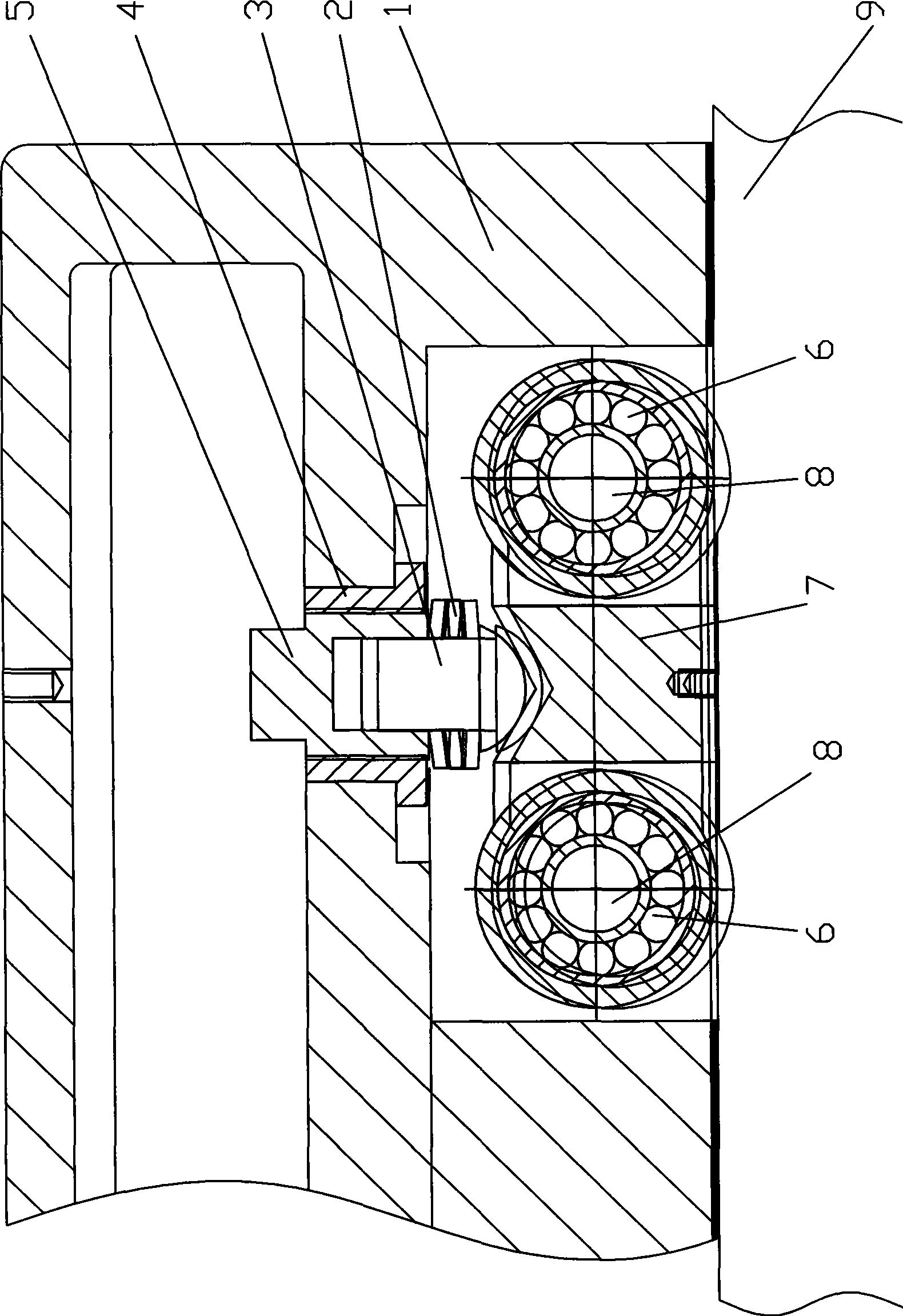

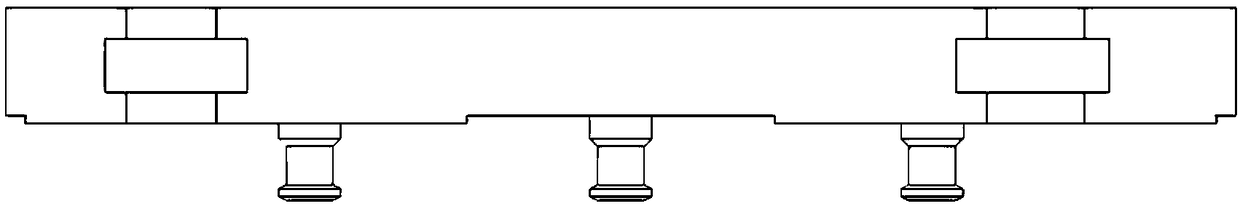

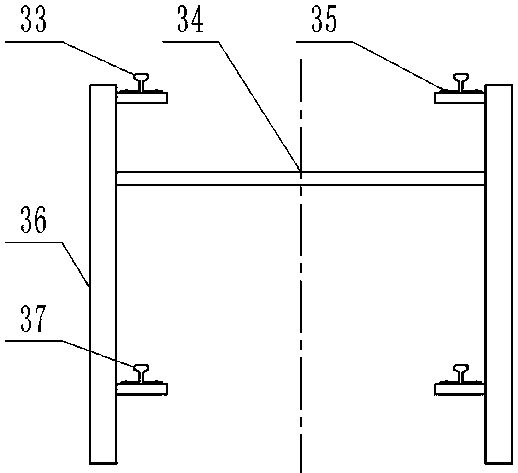

Support unit of two-support and one-lifting target support rotary table

The invention relates to a support unit of a two-support and one-lifting target support rotary table. The support unit mainly consists of a vertical driving guide assembly, a horizontal driving guide assembly, and a support rod and wave absorbing material sleeve cylinder assembly. The support unit is characterized in that the support function of the two-support and one-lifting target support rotary table is mainly realized, and the high-precision movement of the support unit along two directions is realized, namely the vertical movement along the direction of a revolving shaft of the target support rotary table, and the horizontal movement along the radial direction of the target support rotary table; the high-precision movement and positioning along the vertical direction can be realized by the matching of two servo driving motors, two groups of high-precision ball screws and four groups of high-precision guide columns, and the high-precision movement and positioning along the horizontal direction can be realized by the matching of one servo driving motor, one group of high-precision ball screw and two linear guide rails; a support rod is connected with a to-be-tested target through a ball hinge movement pair. The support unit has the advantages that the movement is flexible, the stability is high, the contact area is small, and the like; the support unit is matched with a traction unit, so that the building height and pitch attitude of the to-be-tested target can be adjusted.

Owner:BEIHANG UNIV

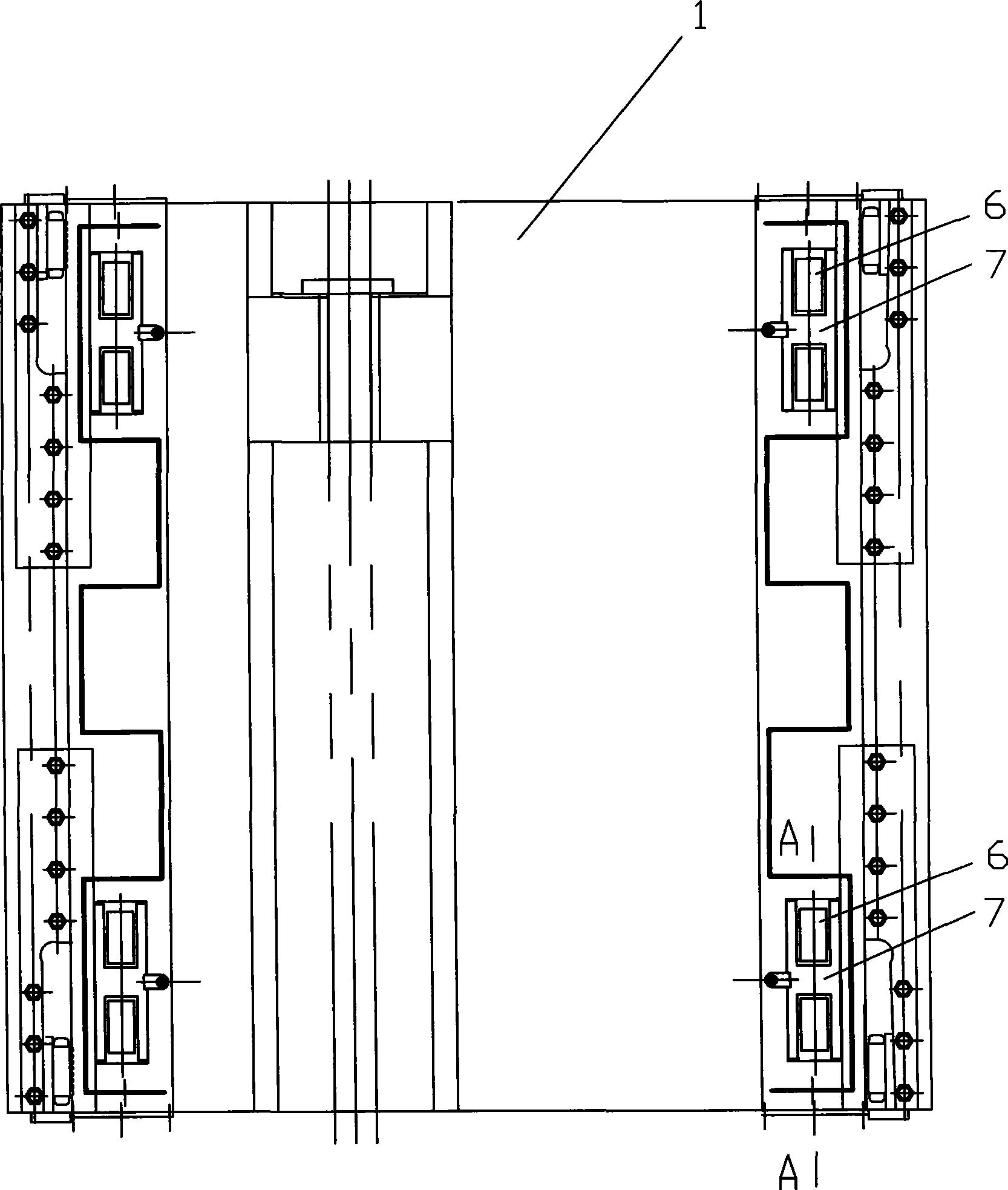

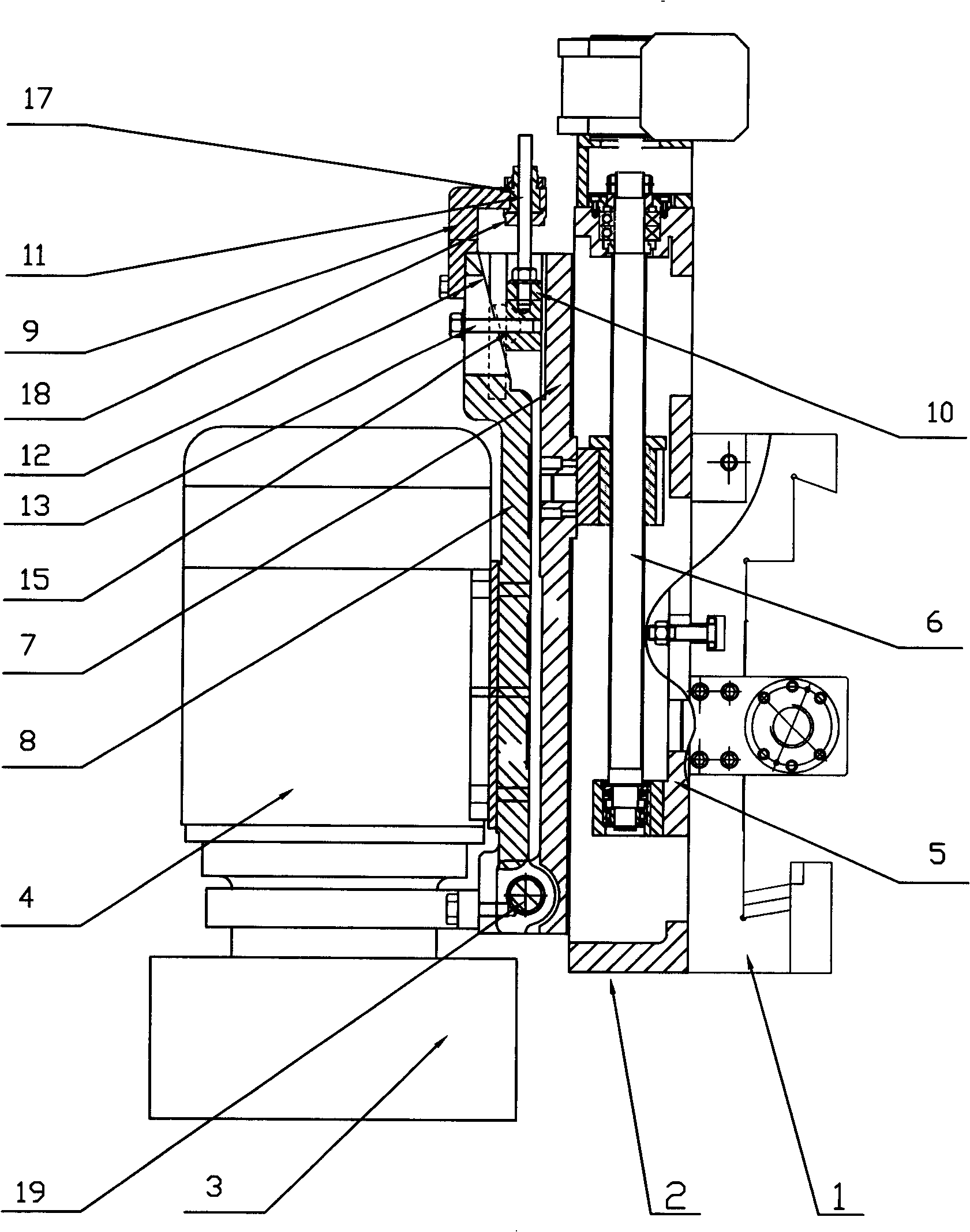

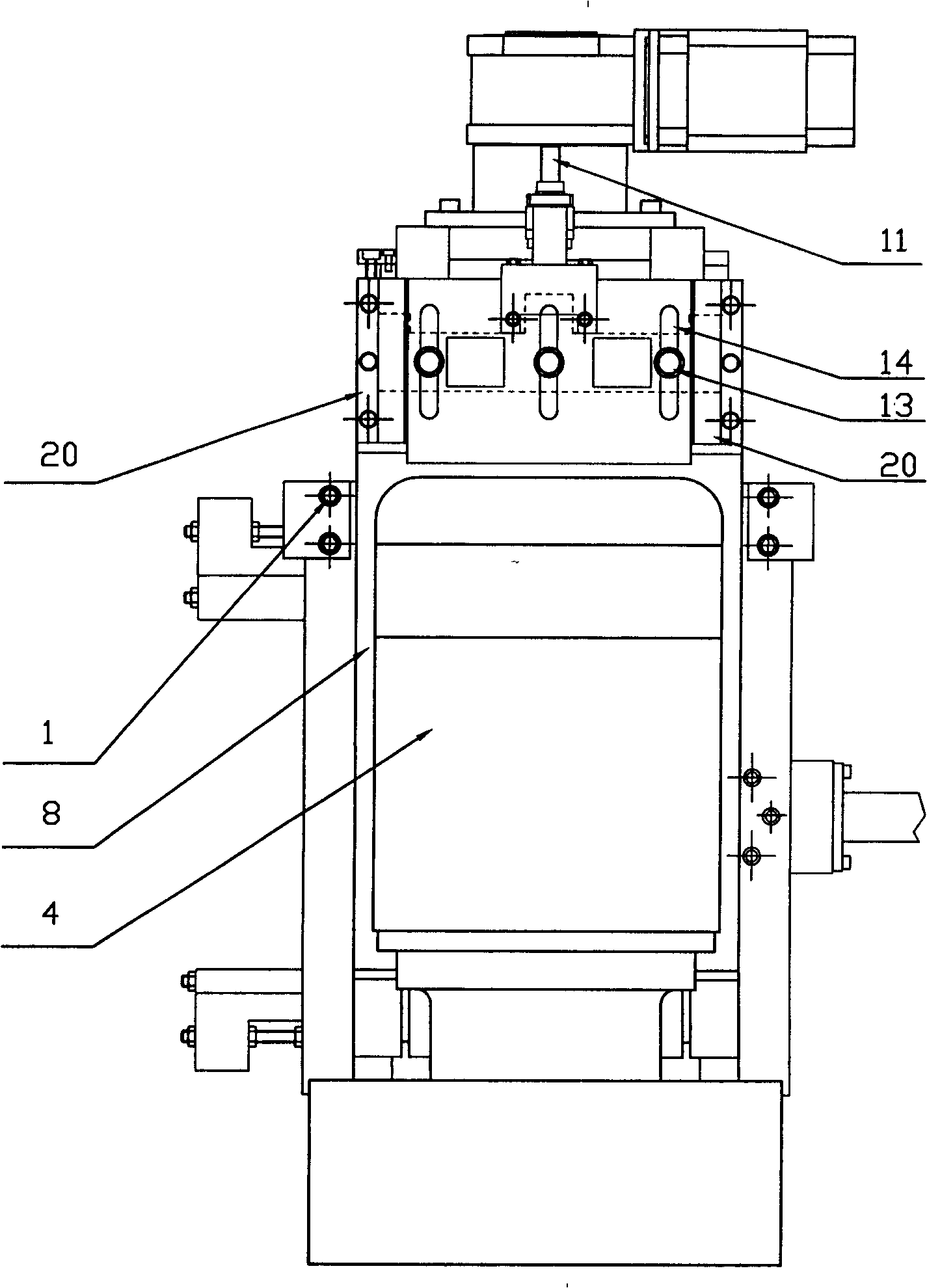

Sliding guide rolling unloading device

InactiveCN101508076AImprove contact stiffnessReduce friction areaLarge fixed membersEngineeringLubrication

The invention discloses a sliding device, in particular a slide guide rail rolling and unloading device for machine tool equipment. The device comprises a guide rail and a slide seat (1) which is positioned on the guide rail and can slide relative to the guide rail, and is characterized in that: at least three positions matched with the guide rail on the bottom surface of the slide seat (1) are provided with roller wheels (6), and the circumferential lateral surfaces of the roller wheels (6) are contacted with the upper surface of the guide rail positioned under the slide seat (1). In the device, as the slide seat and the guide rail do not directly contact, are supported by the roller wheel, and slide, the device realizes line contact of the roller wheel and the guide rail, greatly reduces the mutual friction area, reduces moving resistance, saves energy and lowers the requirement on lubrication compared with a sliding mode of surface contact.

Owner:DALIAN MACHINE TOOL GROUP CO LTD

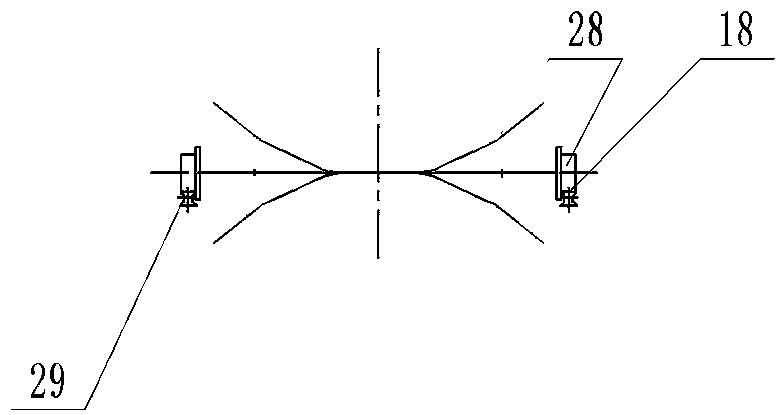

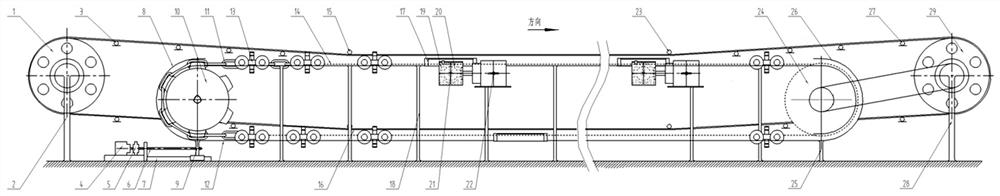

Trolley group towed type adhesive tape conveyor

ActiveCN109230261AImprove contact stiffnessLow coefficient of rolling frictionConveyorsSprocketAdhesive

The invention belongs to the technical field of bulk material transport equipment and particularly relates to a trolley group towed type adhesive tape conveyor. The problems are solved that existing adhesive tape conveyors have a large difference in tension of adhesive tapes, the running adhesive tapes deviate and are unsafe, the running resistance is large, and the energy consumption is high. Theadhesive tape conveyor comprises a fixed bearing rack, a driving device, a traction mechanism and a guiding mechanism, wherein the driving device, the traction mechanism and the guiding mechanism aredisposed on the fixed bearing rack; the traction mechanism pulls a trolley group sprocket chain to move horizontally on the rack when a machine head guide rail sprocket wheel rotates so that trolleygroup sprocket trolleys can move along a guide rail, and the adhesive tapes are moved forward simultaneously, so that transport of materials is achieved. The adhesive tapes are in fraction with trolley supports to transmit a traction force, and the adhesive tapes run along with a belt conveyor body under the action of the traction force of the trolleys; since the trolleys are distributed at intervals, segmental traction is achieved, and the difference in the tension of the adhesive tapes is small. The low-strength adhesive tapes can be selected, and the investment cost of the adhesive tapes isreduced.

Owner:TAIYUAN UNIV OF TECH

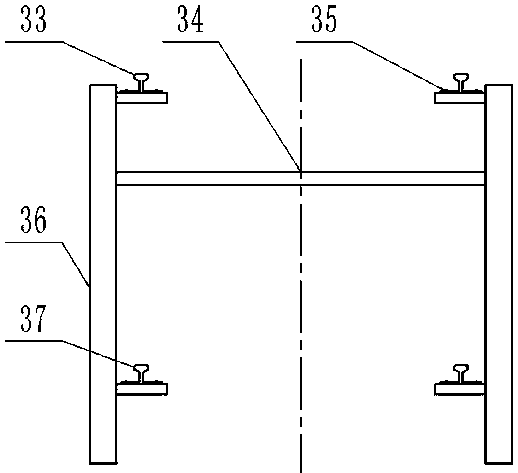

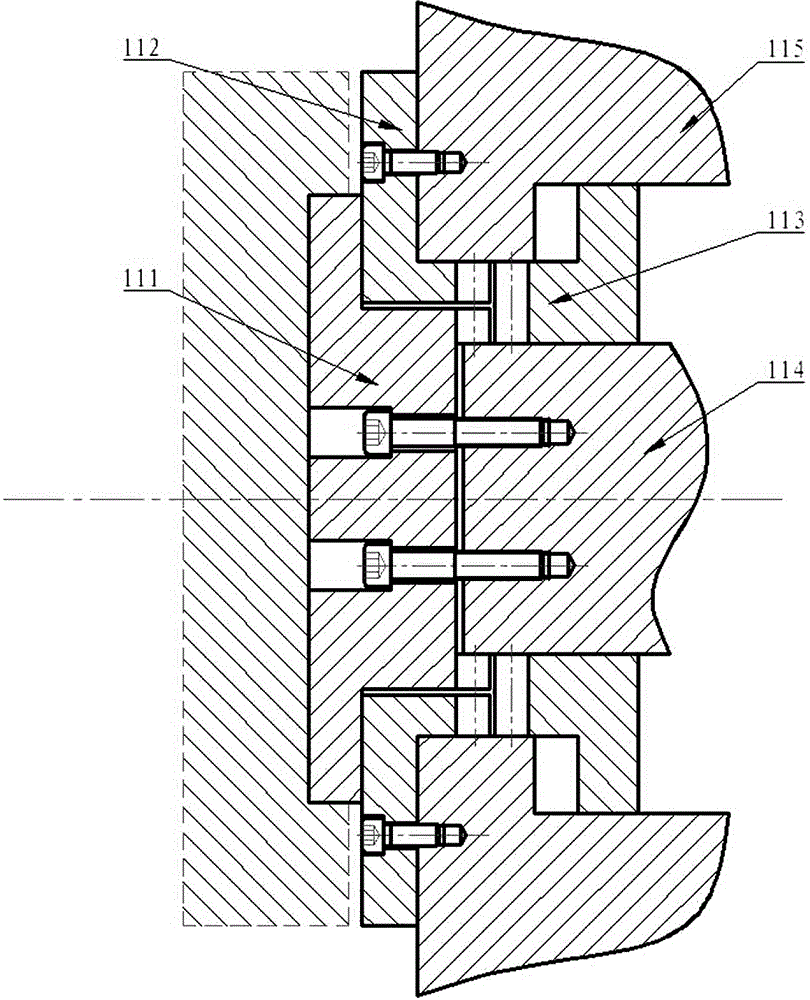

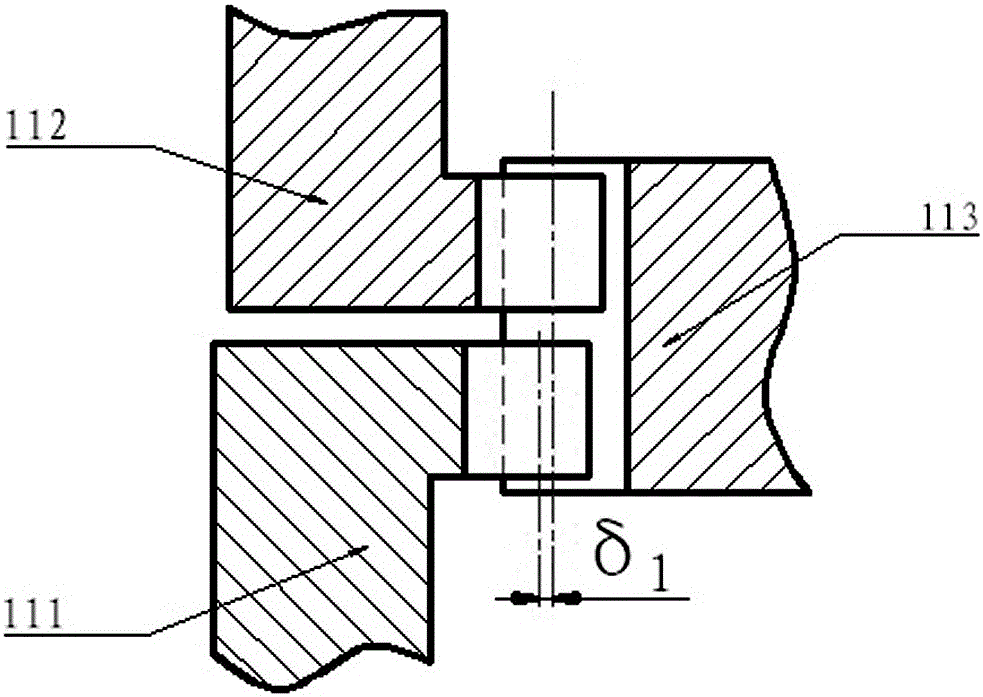

Indexing and positioning mechanism of rotary-tower knifetool rest

InactiveCN102975081AEliminate incomplete engagementHigh positioning accuracyPrecision positioning equipmentTool holdersEngineeringKnife holder

The invention provides an indexing and positioning mechanism of a rotary-tower knifetool rest, comprising a main shaft and a box body, wherein the box body is arranged at the periphery of the main shaft. The indexing and positioning mechanism is characterized by also comprising a locking tooth disc, a positioning disc and a movable tooth disc, wherein the movable tooth disc is arranged at the front end of the main shaft; the movable tooth disc is provided with a knifetool disc; the positioning disc is arranged on the box body; the locking tooth disc is arranged on a shaft body of the main shaft and can move on the shaft body of the main shaft along the axial direction of the main shaft; the locking tooth disc is meshed with the movable tooth disc by conical teeth arranged at the front end; and the locking tooth disc is connected with the positioning disc by a guiding and positioning pin. The indexing and positioning mechanism provided by the invention ahs the advantages of reasonable structure and obvious effect.

Owner:SHENYANG POLYTECHNIC UNIV

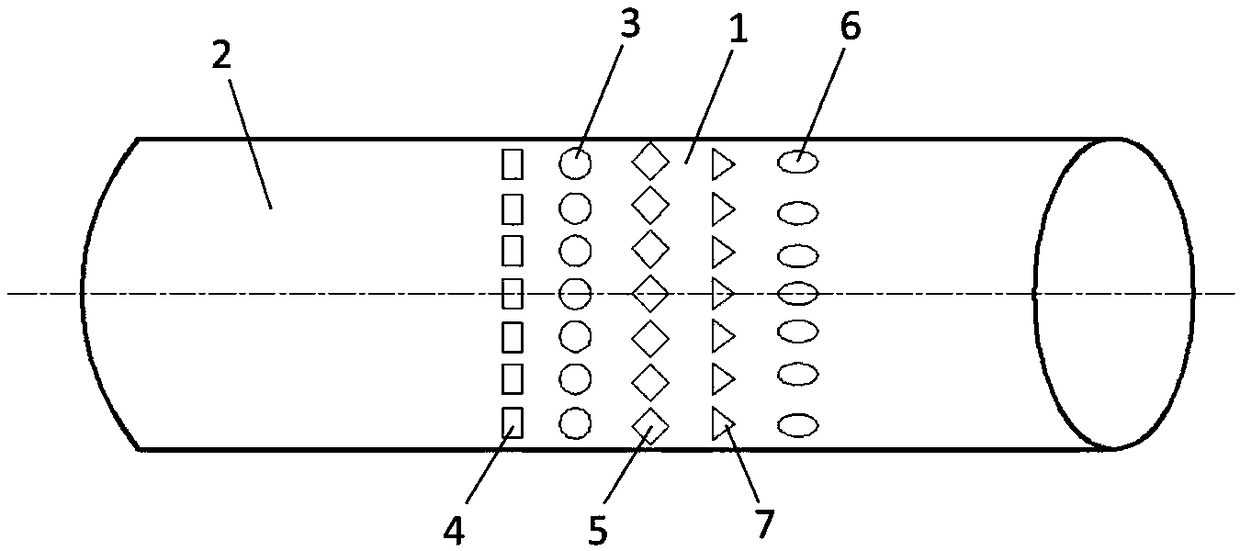

Design method for textured interference connecting surface group

ActiveCN108869473AImprove performanceImprove contact stiffnessNon-rotating vibration suppressionShrinkage connectionsEngineeringBinding force

The invention discloses a design method for a textured interference connecting surface group. A connecting matching surface comprises a texture area and a non-texture area. The texture area is only designed on the outer circle matching surface of the connecting surface group, or is only designed on the inner circle matching surface of the connecting surface group, or is designed on the outer circle matching surface and the inner circle matching surface of the connecting surface group simultaneously. The texture area is designed with circular pits, square pits, diamond pits, elliptical pits, triangular pits or arbitrary combination of several pits. Pit textures are arranged parallel to the axial direction of the connecting face group or at a certain angle with the axial direction of the connecting face group in a row and column mode. According to the design method for the textured interference connecting surface group, the concave textures are designed on the matching surface of interference connection, the contact characteristic of the matching surface is changed, the binding force of the interference connection can be improved, and the comprehensive performance of the interferenceconnection is effectively improved.

Owner:XI AN JIAOTONG UNIV

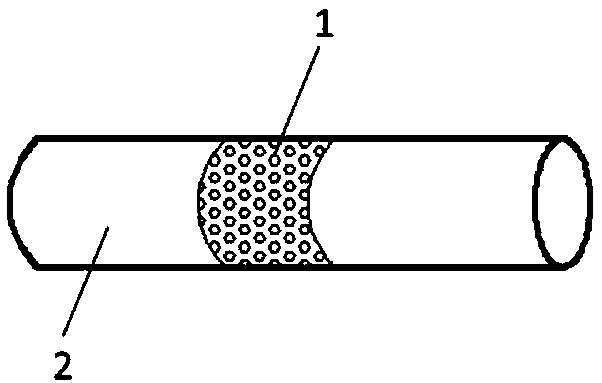

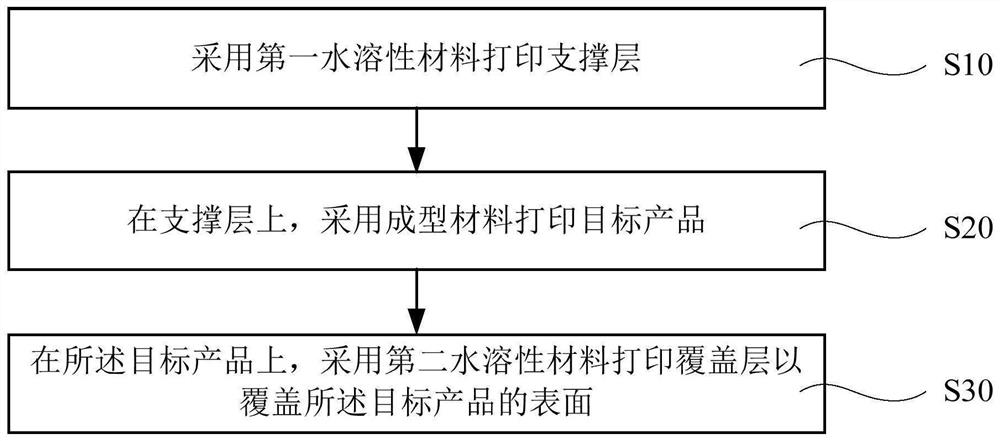

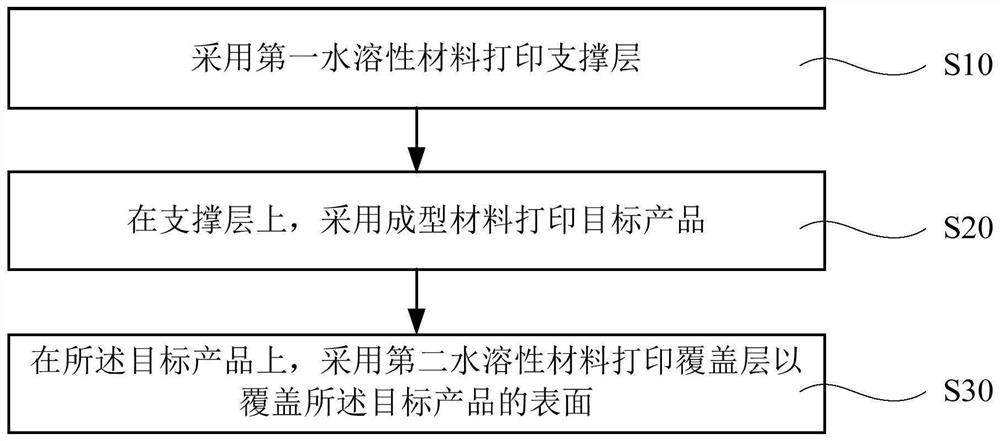

Three-dimensional printing forming product, manufacturing method of three-dimensional printing forming product and supporting jig

ActiveCN112277308AReduce overheadReduce processing timeAdditive manufacturing apparatusAdditive manufacturing with liquidsSurface roughnessProcess engineering

The invention relates to a three-dimensional printing forming product, a manufacturing method of the three-dimensional printing forming product and a supporting jig. The manufacturing method of the three-dimensional printing forming product comprises the steps that a first water-soluble material is adopted for printing a supporting layer; a target product is printed on the supporting layer by adopting a forming material; and a covering layer is printed on the target product by adopting a second water-soluble material so as to cover the surface of the target product. According to the manufacturing method of the three-dimensional printing forming product, on the premise of not additionally increasing the subsequent processing procedure, the surface roughness is reduced, the surface smoothness is improved, and the manufacturing method is particularly suitable for products with small thicknesses; on one hand, the product indexes such as wear resistance, clearance fit connection strength, fatigue strength and contact rigidity are improved; on the other hand, stacking matching is facilitated, the tight position relation is achieved, and the stability of the final product structure is improved; and on the other hand, the model cost expenditure is reduced, the processing time is shortened, and the high cost caused by product design change, mold repairing and mold opening in the new product development stage is reduced.

Owner:INTERFACE TECH CHENGDU CO LTD +2

Charge output structure and piezoelectric acceleration sensor with same

PendingCN109239398AImprove contact stiffnessEliminate the effects ofAcceleration measurement using interia forcesSpeed/acceleration/shock instrument detailsElectricityEngineering

The invention relates to the field of sensor technology, and particularly to a charge output structure. The structure includes a base; and a pre-tensioning member, which is arranged on outer circumference of a mass block in a sleeving manner, and has an annular structure of which volume is contracted with temperature increasing for applying radial-direction pre-tensioning force to an insulating member, a piezoelectric element and the mass block. The insulating member, the piezoelectric element and the mass block are sequentially arranged in a sleeving manner from an inside to an outside alonga radial direction of the base. The invention also provides a piezoelectric acceleration sensor with the above-described charge output structure. The structure and the sensor greatly increase contactstiffness of the overall structure, and thus improve the overall frequency response characteristics and resonance.

Owner:FATRI UNITED TESTING & CONTROL QUANZHOU TECH CO LTD

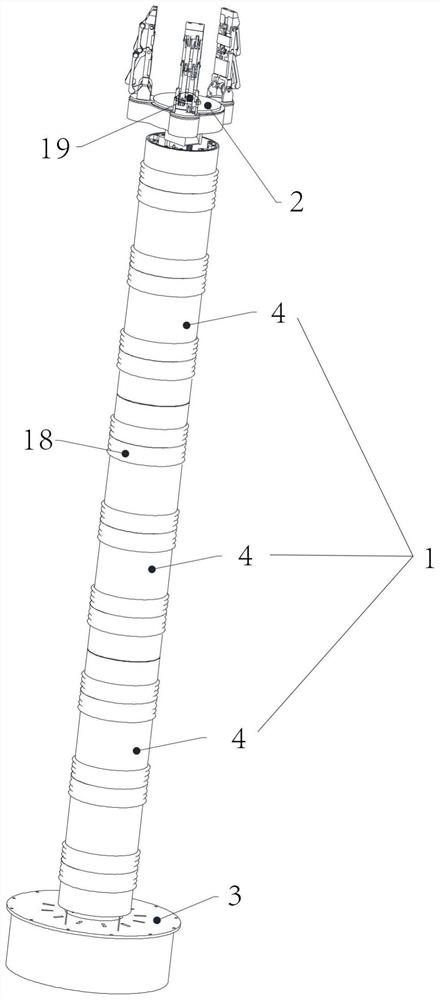

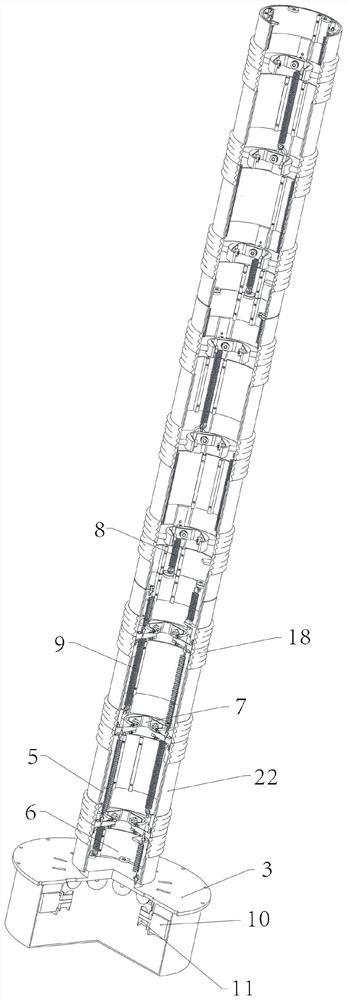

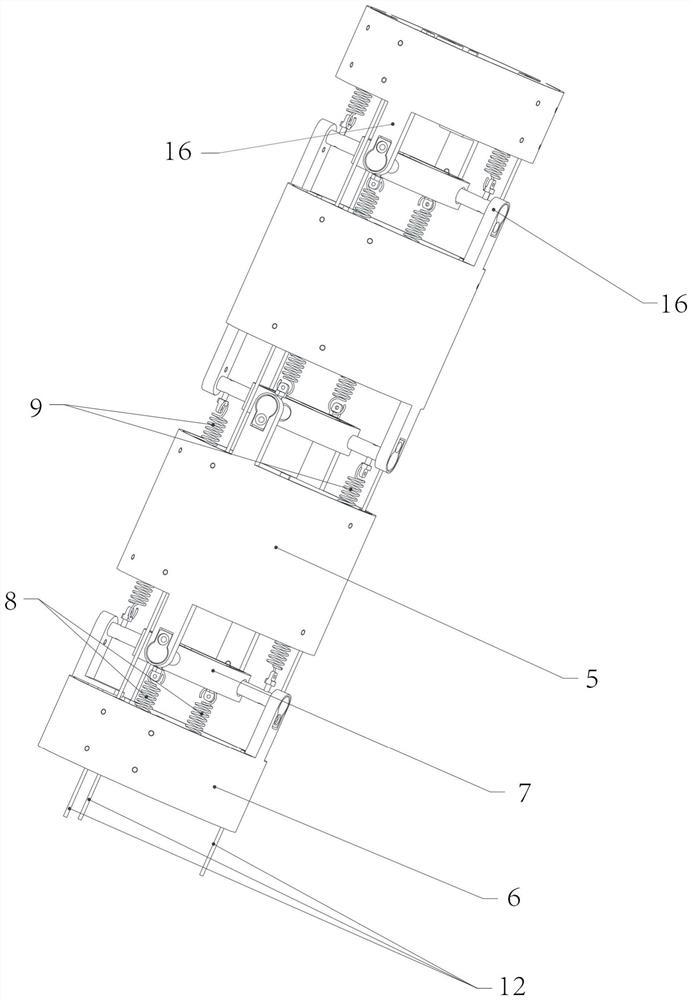

Rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm and using method thereof

PendingCN114227660AModularity hasStrong adaptability to space environmentProgramme-controlled manipulatorJointsControl engineeringElectric machinery

The rigid-flexible coupling hyper-redundant intelligent sensing mechanical arm comprises a mechanical arm body, an operation device and a driving mechanism are arranged at the front end and the rear end of the mechanical arm body respectively, and the mechanical arm body is formed by sequentially connecting a plurality of bending units; each bending unit comprises a plurality of middle sections connected in sequence, base sections are arranged at the two ends of each middle section, the base sections and the middle sections are of hollow cylindrical structures, the base sections and the middle sections are movably connected through cross hinges, and every two adjacent middle sections are movably connected through cross hinges; the driving mechanism comprises a plurality of driving motors, reels are arranged on rotating shafts of the driving motors, a plurality of tendon ropes are arranged in the bending unit, one ends of the tendon ropes are fixed to the front end of the bending unit, and the other ends of the tendon ropes are connected with the reels respectively. The mechanical arm has the advantages of modularization, super-redundancy self-adaption, high space environment adaptability, measurable tail end pose, perceptible external contact and the like, and can be used for capturing and grabbing non-cooperative and cooperative targets and internal investigation of complex cavities.

Owner:BEIJING INST OF SPACECRAFT SYST ENG +1

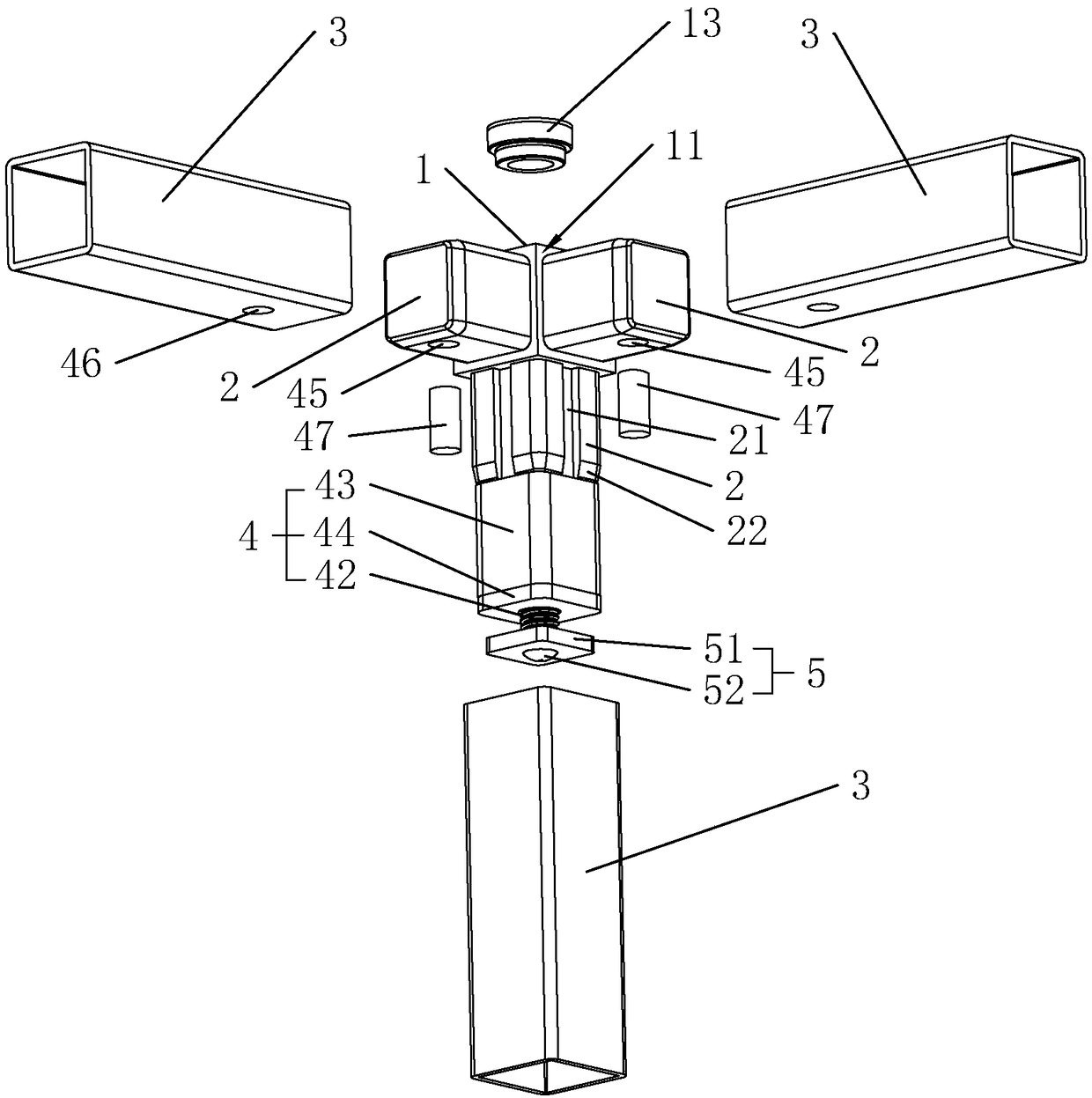

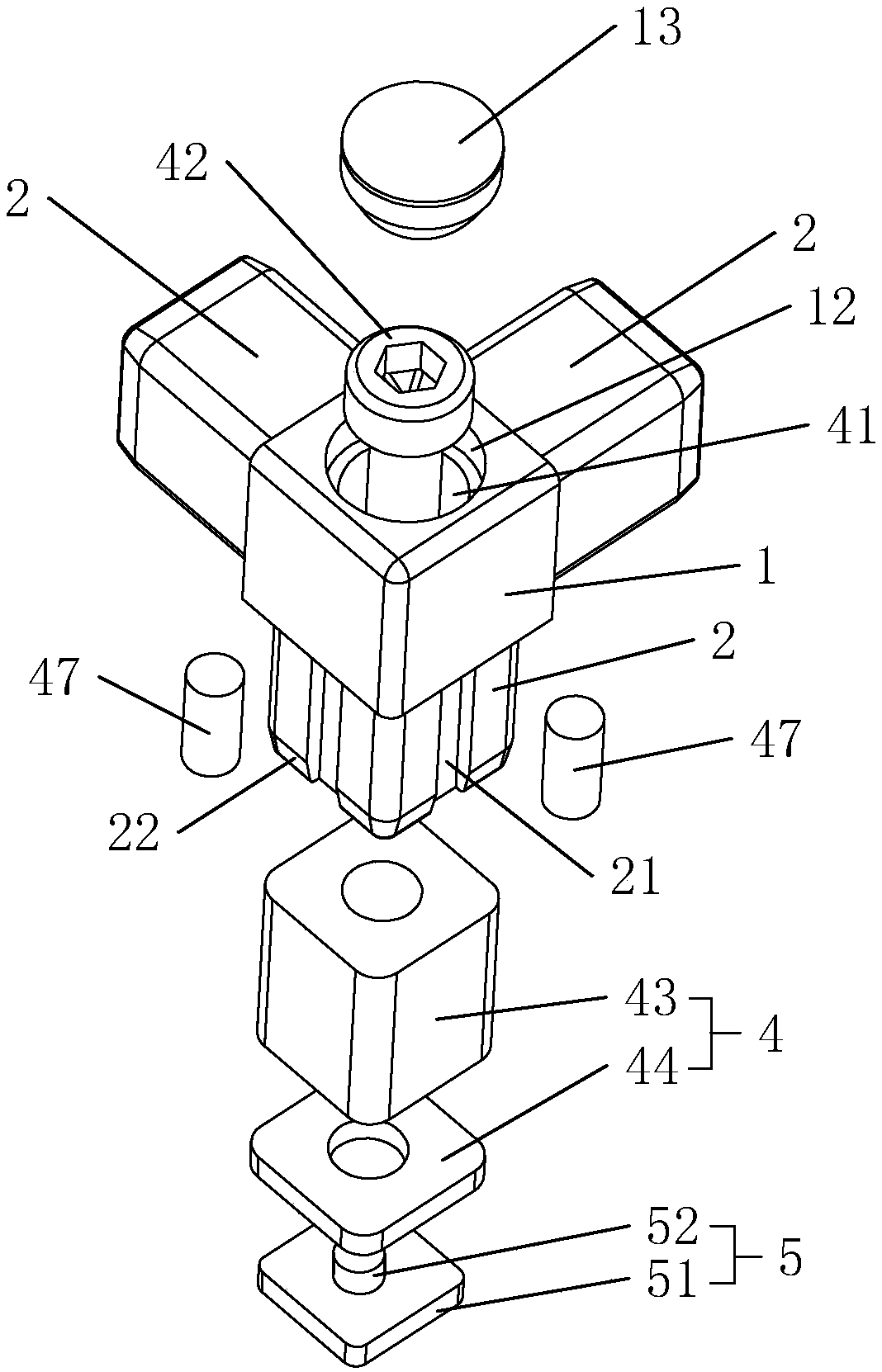

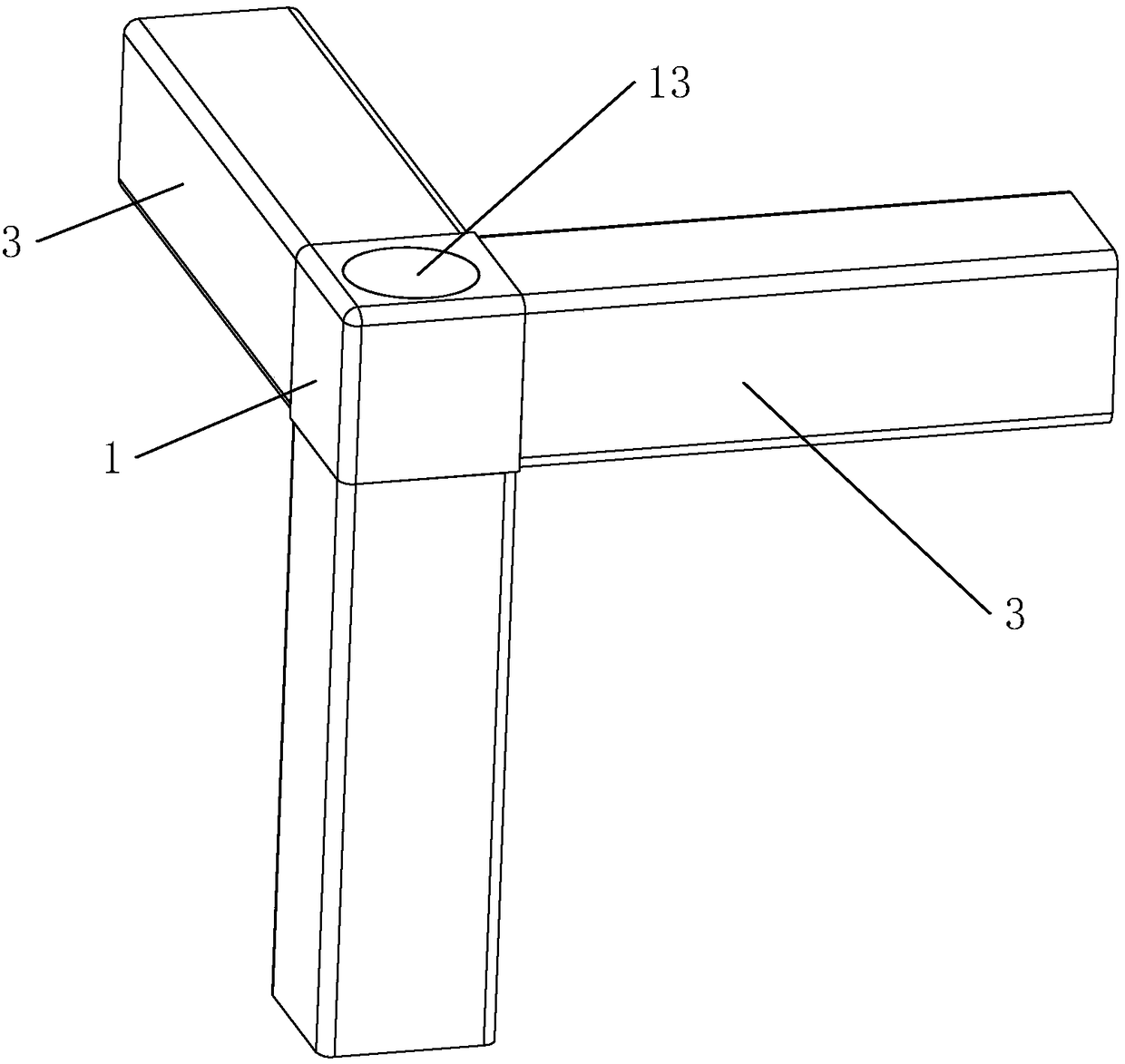

Corner three-way connector and mounting method thereof

InactiveCN108252990ANot easy to moveImprove the stability of the connection structureRod connectionsEngineeringMechanical engineering

Owner:SHANGYU MEISI CRAFTS

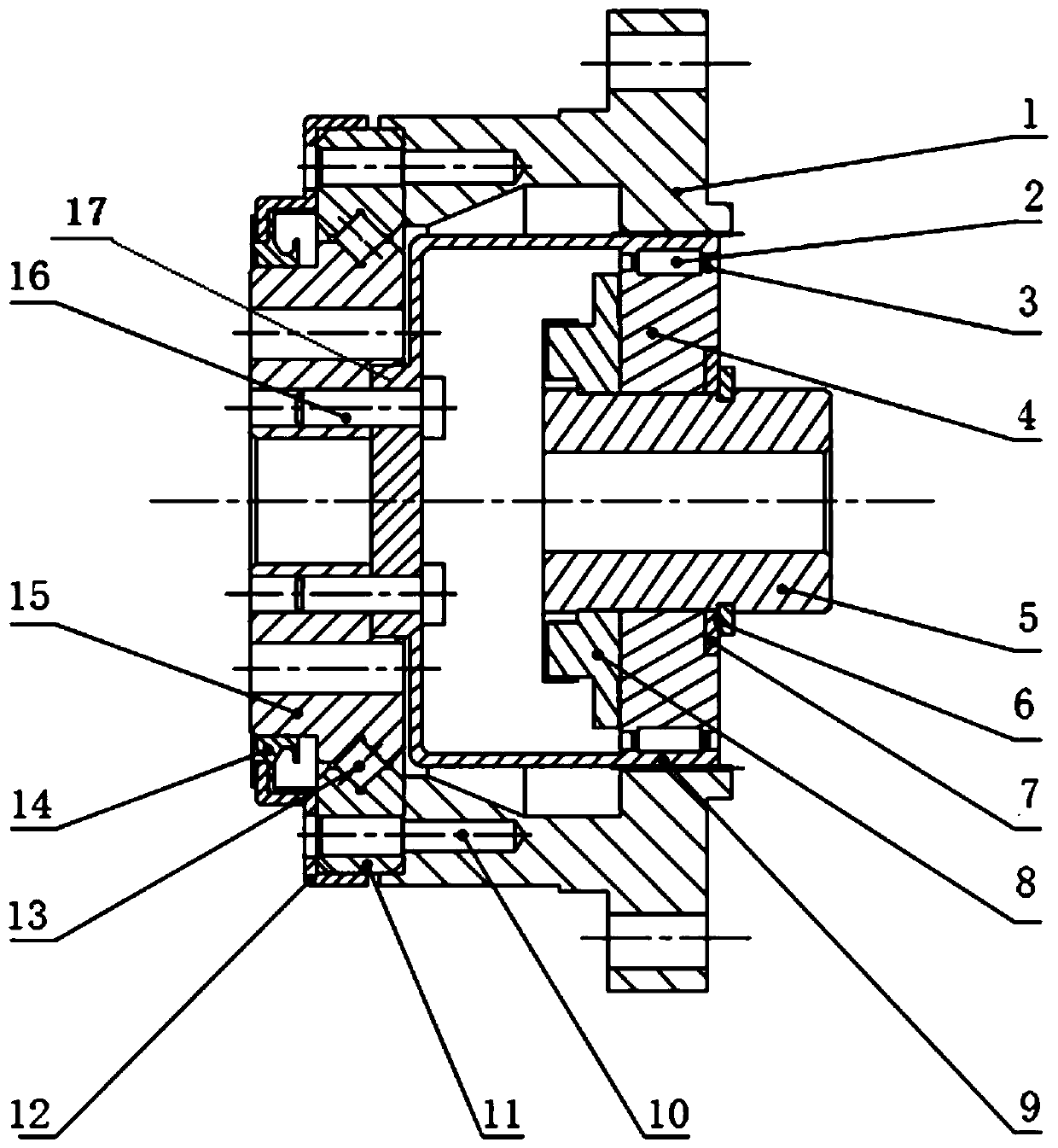

A harmonic reducer and its input drive structure

The invention discloses a novel harmonic-reducer input transmission structure. The novel harmonic-reducer input transmission structure comprises a cam connected with an input shaft, and the cam is sleeved with a flexible gear; a steel gear is engaged with the flexible gear, outer teeth are arranged on the flexible gear, inner teeth are arranged on the steel gear, and the flexible gear is engaged with the steel gear through the outer teeth and the inner teeth; a keeping frame is arranged between the flexible gear and the cam, and a cylinder roller is installed in the keeping frame; annular flanges are formed inside the flexible gear and outside the cam in an outward-protruding mode, and C-shaped grooves matched with the cylinder roller are formed in the annular flanges; the annular flanges are located on the outer-tooth side of the flexible gear. By means of the novel harmonic-reducer input transmission structure, the assembly stress of a key part of a harmonic reducer is reduced or eliminated, the engaging stress of the steel gear and the flexible gear in the movement process is reduced, the input structure and the output structure of the harmonic reducer are newly designed, the movement of the harmonic reducer is more stable during working, and the service life is prolonged.

Owner:HUNAN UNIV

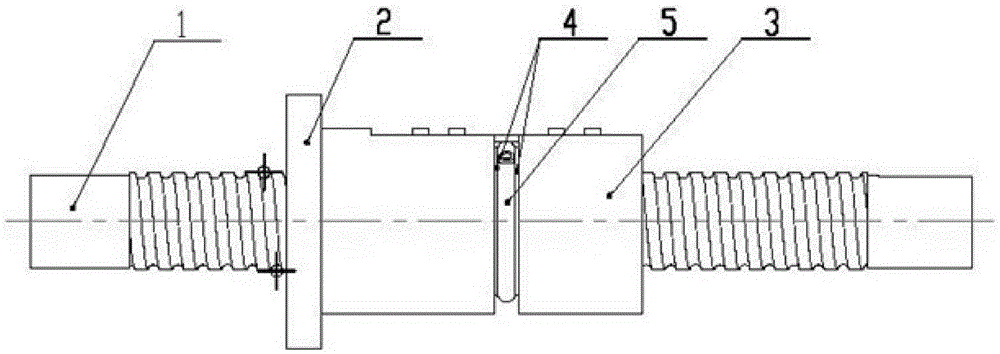

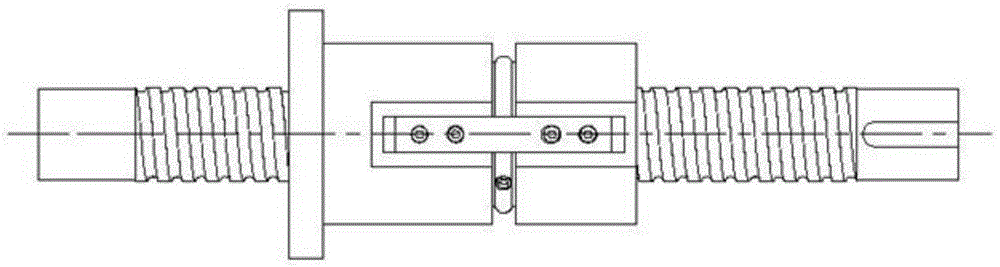

A self-adjusting pretightening force ball screw pair

The invention discloses a ball screw pair capable of automatically adjusting pretightening force and belongs to the technical field of pretightening force control of ball screw pairs. By the adoption of the structure, the pretightening force can be adjusted according to the types of screws and it is guaranteed that the value of the pretightening force is constant in the operation process of a ball screw. A pretightening force adjusting device is an inflated rubber air bag or a hydraulic oil rubber air bag. The pretightening force adjusting device is simple and compact in structure, high in reliability and high in operability. In addition, the pressure intensity of compressed air or oil pressure can be adjusted to adapt to ball screw pairs of different types and the contact rigidity between the ball screw and a roller path is improved; according to the automatic pretightening force adjusting device (the rubber air bag), impact on the screw by nuts can be relieved when the ball screw pair is suddenly stopped or started, and vibration and abrasion of the ball screw pair are reduced.

Owner:江苏启尖丝杠制造有限公司

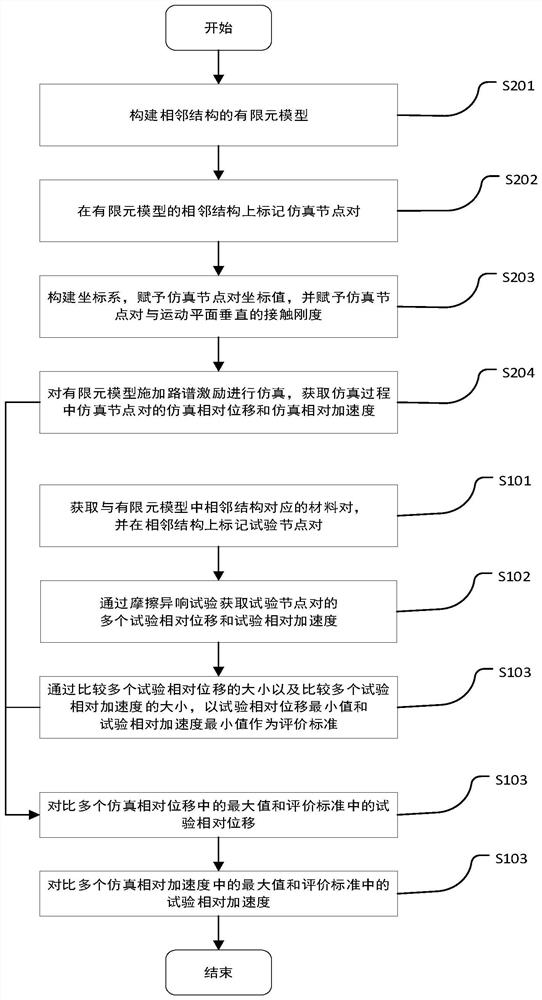

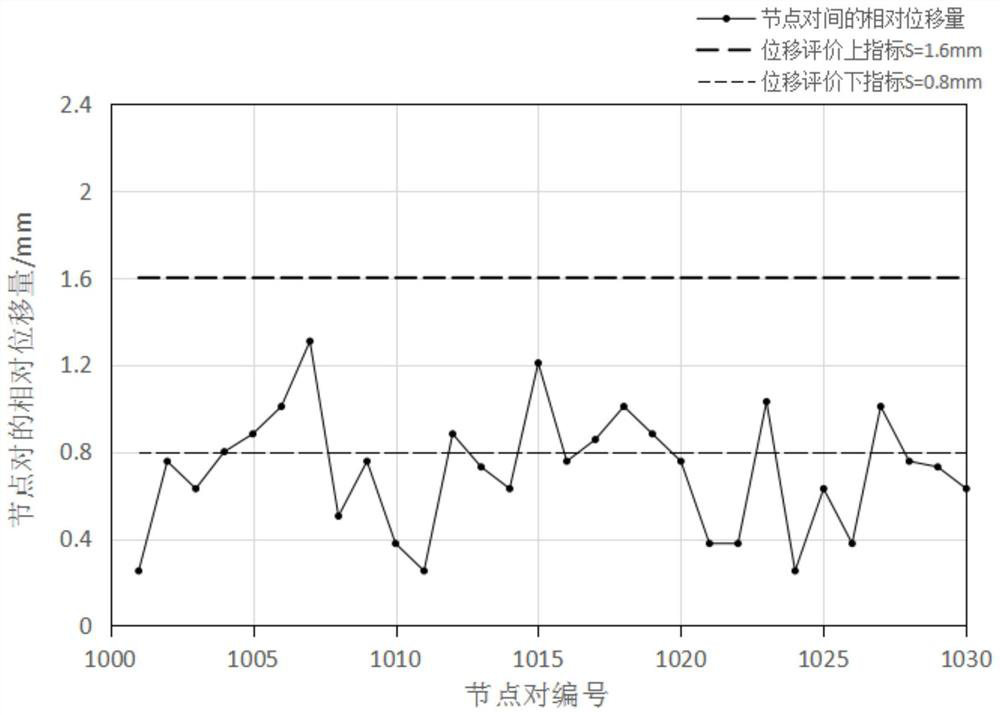

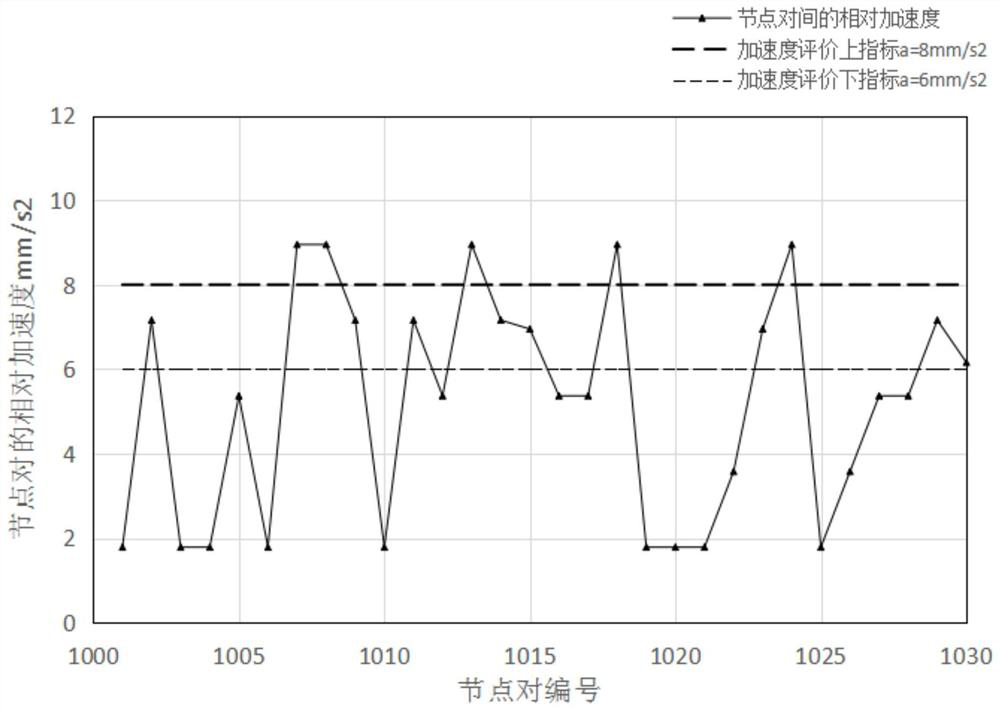

Automobile friction abnormal sound risk prediction method and device

PendingCN113626936AEnsure consistencyImprove contact stiffnessGeometric CADDesign optimisation/simulationAcousticsSimulation

The invention relates to the technical field of vehicle friction abnormal sound prediction, in particular to an automobile friction abnormal sound risk prediction method and device, and the method comprises the following steps: S200, obtaining simulation relative displacement and simulation relative acceleration of a simulation node pair in a simulation process; S100, obtaining the test relative displacement and the test relative acceleration of the simulation node pairs through the friction abnormal sound test to serve as evaluation standards, wherein the test node pairs and the simulation node pairs are in one-to-one correspondence; S200, S200 and S100 being used only for distinguishing and not representing the sequence of the steps, and executing S300 after the S100 and S200 are executed; S300, judging the simulation relative displacement and the simulation relative acceleration according to the evaluation standard to generate a prediction result. By adopting the scheme, the technical problems that in the prior art, whether the position is redesigned, optimized and tested or not cannot be judged according to the sensing condition of the passenger in the vehicle on the friction abnormal sound, so that the development cost is wasted, and the development period is prolonged can be solved.

Owner:CHINA AUTOMOTIVE ENG RES INST

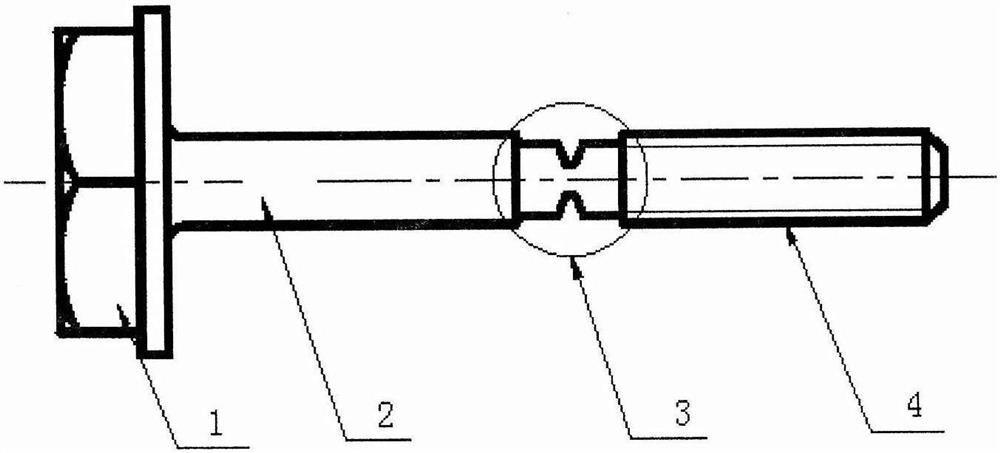

Titanium Alloy Notched Bolts

The invention discloses a titanium alloy notch bolt, which comprises a bolt head (1) and a screw rod (2); the upper part of the bolt head (1) is hexagonal, and the lower part of the bolt head (1) is a cylinder; the cylinder The diameter is larger than the diameter of the hexagonal outer circle, and when the bolt head is in contact with the loaded surface, the cylinder acts as a gasket; the screw rod (2) has a notch (3) in the middle. In the notch bolt of the present invention, a notch (3) is designed in the middle of the screw rod (2). While satisfying the static connection performance, the separation power provided by the pyrotechnic device to the notch at the moment of separation realizes reliable and efficient separate. Simultaneously, the notch bolt of the present invention adopts an integrated design, and the cylinder at the lower part of the bolt head (1) plays the role of a gasket, which reduces the loading surface of the bolt head and the contact surface of the gasket, increases the surface contact stiffness, and makes the concave Port bolts improve separation performance by increasing the stiffness of the contact surface under high dynamic shock loads.

Owner:BEIJING INST OF ASTRONAUTICAL SYST ENG

Vertical axis type grinding head

InactiveCN1927542BRealize the adjustment of parallelismAdjust parallelismGrinding machine componentsVertical axisMachining

Owner:GUANGDONG SHENGDU MOLD

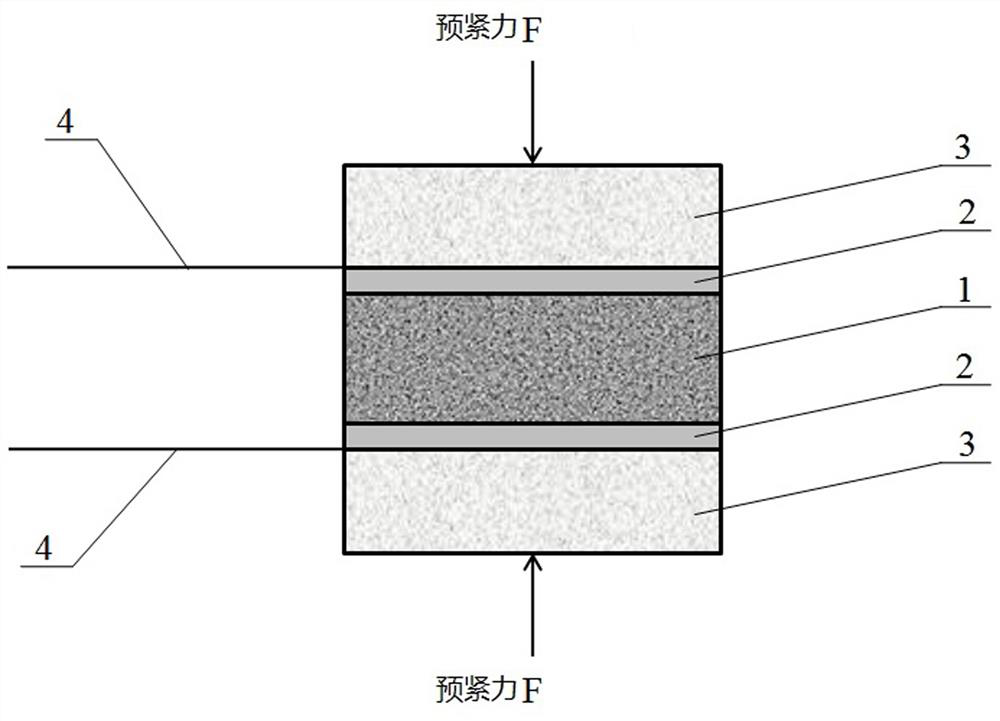

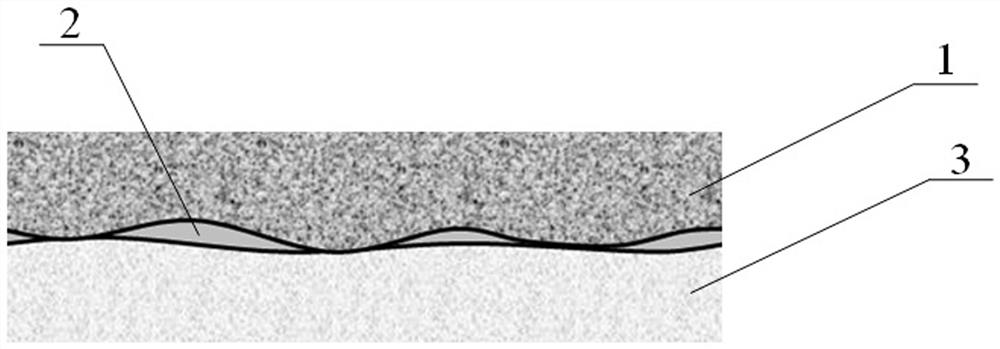

Installation method for improving contact rigidity between piezoelectric element and conducting strips

PendingCN113945267AImprove contact stiffnessHigh hardnessSubsonic/sonic/ultrasonic wave measurementUsing electrical meansMetal foilMechanical engineering

The invention discloses an installation method for improving the contact rigidity between a piezoelectric element and conducting strips. The installation method comprises the following steps that (1) the conducting strips are installed on the surfaces of two electrodes of the piezoelectric element respectively; 2) a metal foil is arranged between the piezoelectric element and the conducting strips; and (3) uniform pre-tightening force is applied to the conducting strips on the two sides so that the metal foil between the piezoelectric element and the conducting strips extends and deforms, and the microscopic contact gaps between the piezoelectric element and the conducting strips are filled. According to the invention, the metal foil is arranged between the piezoelectric element and the conducting strips so that the metal foil fills the microscopic contact gaps between the piezoelectric element and the conducting strips to improve the contact rigidity between the piezoelectric element and the conducting strips; by using the conducting strips with the glass as the base material, the surface of the conducting strips has high hardness and tiny roughness so as to improve the contact rigidity between the piezoelectric element and the conducting strips, and the manufacturing process is simple, the manufacturing cost is low and wide popularization and application are facilitated.

Owner:CHENGDU KAITIAN ELECTRONICS

Plunger pump transmission device

InactiveCN107327554AReduce axial sizeEquipment is smallPositive displacement pump componentsGearingPlunger pumpEngineering

The invention relates to a plunger pump transmission device. The plunger pump transmission device comprises a driving device and pump bodies, and further comprises power executing assemblies, wherein the power executing assemblies comprise guide rod shafts which move in the pump bodies in a reciprocating mode, eccentric discs and eccentric shafts; round swinging holes are formed in the ends, extending the pump bodies, of the guide rod shafts; the eccentric discs are round, the eccentric discs are arranged in the swinging holes and are rotationally connected with the swinging holes, round eccentric holes are formed in the eccentric discs, and the rotation axes of the eccentric holes are parallel to the rotation axes of the eccentric discs; and the eccentric shafts comprise power output ends and power input ends, the power output ends are arranged in the eccentric holes and are rotationally connected with the eccentric holes, and the power input ends are connected with the driving device. The plunger pump transmission device cannot only be applied to a small-flow region for a long time, but also can be applied to a large-flow area; and the plunger pump transmission device is long in service life, compact in structure and small in size.

Owner:殷图源

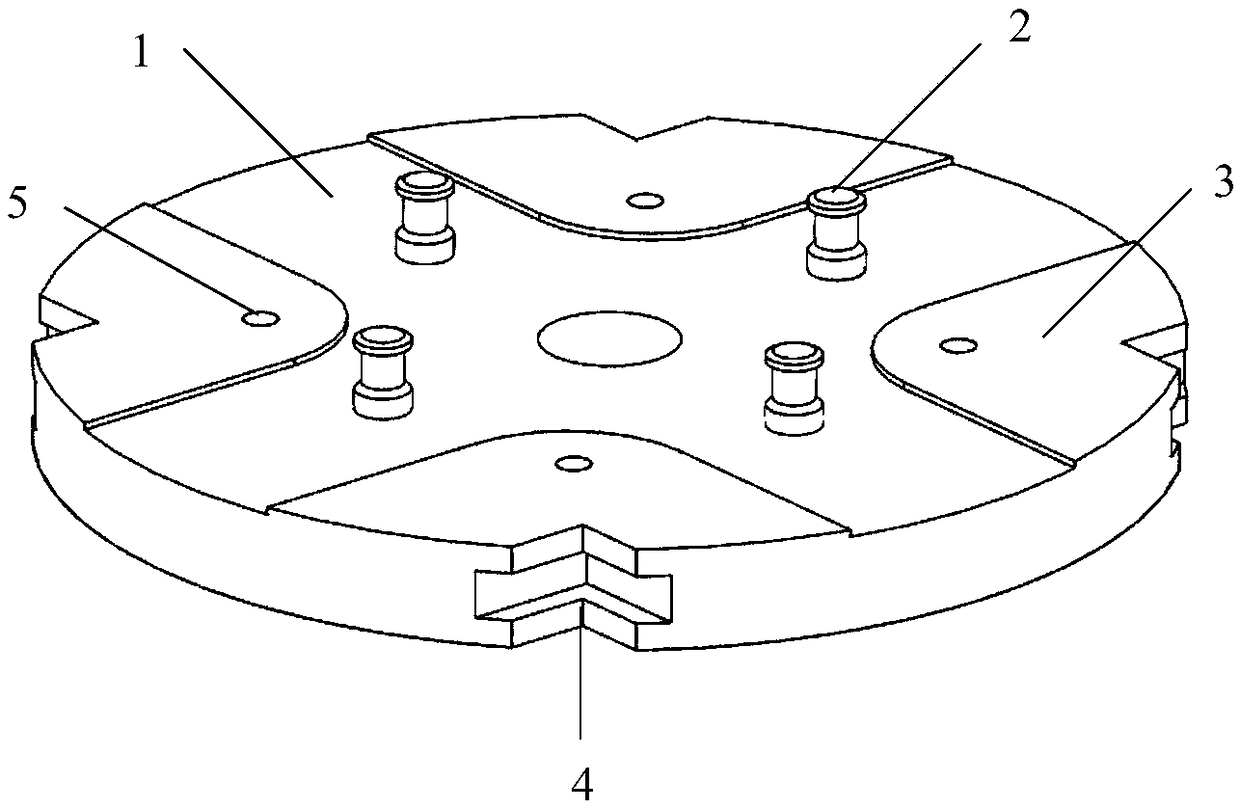

Quick replacement sub-board for impeller part

InactiveCN108907768AImprove contact stiffnessHigh positioning accuracyPositioning apparatusMetal-working holdersImpellerEngineering

The invention discloses a quick replacement sub-board for an impeller part. A concave surface is processed in the middle portion of the sub-board to form a mounting surface matched with a mother board. Pop-rivets mounted with the mother board in a matched mode are fixed on the concave surface, the pop-rivets are evenly distributed along the circumference, the center of the circumference which thepop-rivets are along and the center of the sub-board coincide, and the outer circumference of the sub-board is provided with a clamping groove for an external mechanical hand to capture. The quick replacement sub-board can improve the contact rigidity and the positioning precision of the sub-board and the mother board in the process of quick replacement of the impeller part, and the repeated positioning precision of quick replacement of the impeller part is ensured.

Owner:BEIJING POWER MACHINERY INST

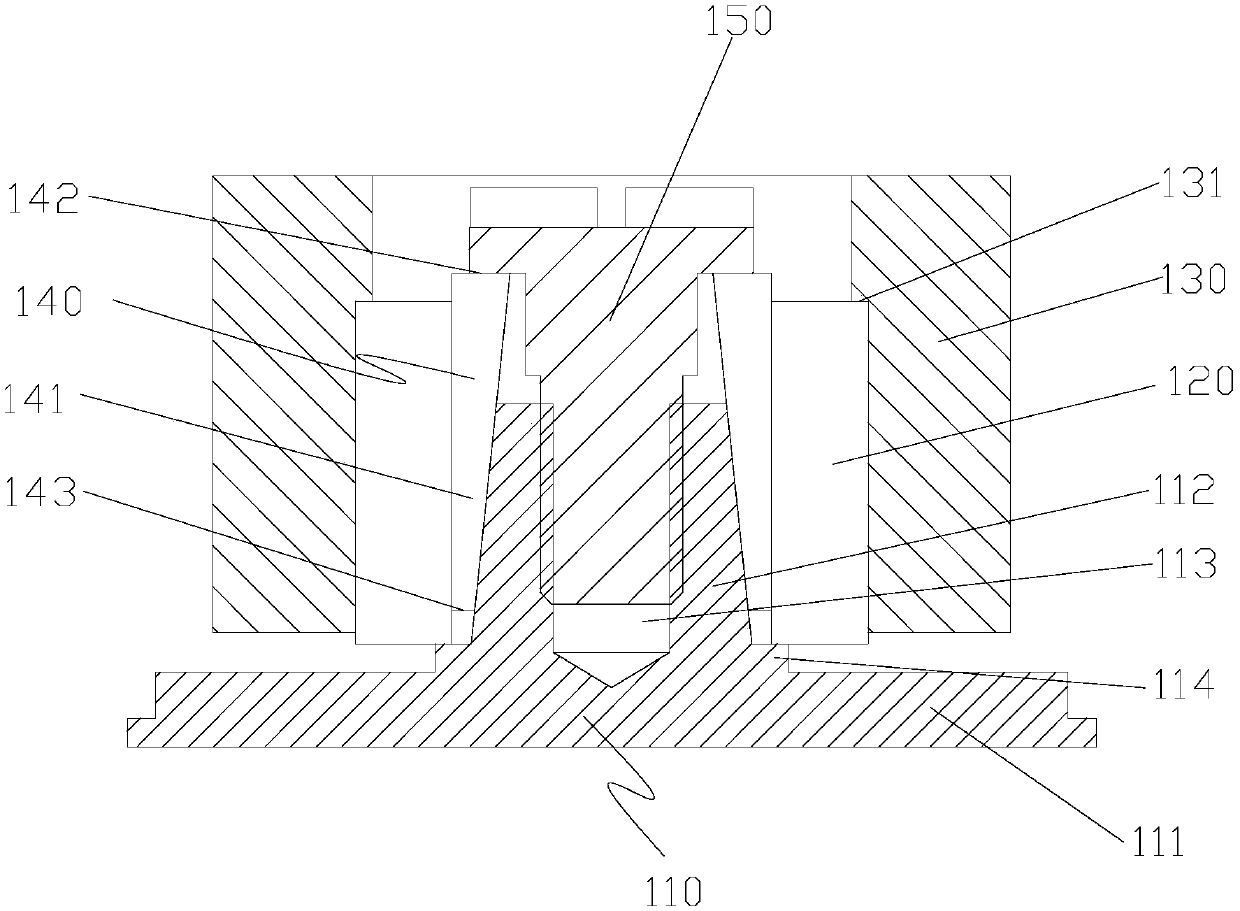

Turret tool post indexing and positioning mechanism

InactiveCN102975081BEliminate incomplete engagementHigh positioning accuracyPrecision positioning equipmentTool holdersEngineeringTower

The invention provides an indexing and positioning mechanism for a turret tool holder, which includes a main shaft and a box body, and the box body is arranged around the main shaft. Set on the front end of the main shaft, the cutter head is installed on the movable toothed plate, the positioning plate is set on the box body, the locking toothed plate is set on the main shaft body and can move along the axial direction of the main shaft on the main shaft body, and the locking toothed plate passes through The conical teeth arranged at the front end mesh with the movable toothed plate, and the locking toothed plate is connected with the positioning plate through the guide positioning pin. The invention has reasonable structure and obvious effect.

Owner:SHENYANG POLYTECHNIC UNIV

Central spindle for baby carriage

InactiveCN106672053AHigh strengthNo breakageCarriage/perambulator accessoriesShaftsSurface layerSurface roughness

The invention provides a central spindle for a baby carriage. The central spindle comprises a central spindle body, which is characterized by comprising a limiting board and a bearing shaft segment, a first circle arc shape transitional surface is formed on the place between the limiting board and the bearing shaft segment, a cone shape clip head is formed on the edge of the other side of the bearing shaft segment, a limit shaft segment is formed on the inner side of the cone shape clip head, and the surface roughness of the bearing shaft segment and the limit shaft segment is Ra=0.8. The central spindle for the baby carriage adopts a warm forging technology processing, after the forge forming, the inner tissues of the blank take a fiber flow distribution, the cracking situation of the central spindle body is guaranteed not to appear, then the central spindle body adopts the technology of heat processing, so that the tensile strength, the hardness, the plasticity and the tenacity of the central spindle body obtain relatively good mechanical property on the whole, meanwhile, the surface roughness of the bearing shaft segment and the limit shaft segment is Ra=0.8, and the abrasive resistance, fatigue resistance, contact stiffness, and oscillations of the surface layer of the central spindle body are further improved, and the service life of the central spindle body is prolonged.

Owner:SUZHOU YINTAO PRECISION FORGING CO LTD

A car group pull type belt conveyor

ActiveCN109230261BReduce energy consumptionLow coefficient of rolling frictionConveyorsFixed bearingAdhesive belt

Owner:TAIYUAN UNIV OF TECH

A kind of worm with double involute arc tooth profile

ActiveCN106151458BIncrease contact areaImprove contact stiffnessPortable liftingGearing elementsEngineeringTooth part

Owner:马鞍山大一智能机械科技有限公司

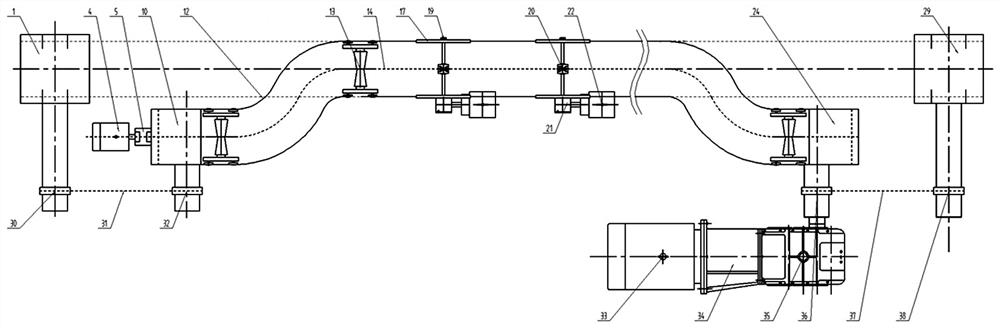

Multi-point drive belt conveyor and chain tensioning method for infinite car group chain

The invention discloses an electrodeless car unit chain multi-point driving belt type conveyor and a chain tensioning method. The conveyor comprises a bearing machine frame, a machine head driving device, a multi-point driving transmission mechanism and a bearing rail used for bearing the operation of the multi-point driving transmission mechanism; the bearing rail, the machine head driving device and the multi-point driving transmission mechanism are arranged on the bearing machine frame; a conveyor belt of the conveyor is driven by an electrodeless closed annular car unit chain; and the car unit chain is driven by a multi-point chain wheel, so that the maximum tension of the chain is reduced, and the tension of each chain segment of the car unit chain is ensured by adopting a segmented tensioning mode. The maximum tension of the chain is effectively reduced by the drive of the multi-point chain wheel, so that the stress of the machine frame during turning is improved, the carrying capacity of the chain and the conveying distance of the conveyor are improved, and the method is suitable for the development direction of large transport capacity and long transport distance of the conveyor; and the segmented tensioning method is adopted, so that the required tension of the car unit chain can be obtained, the tensioning adjusting amount of a machine tail is small, and the method is suitable for installing, adjusting and testing and maintaining of the long-distance conveyor.

Owner:TAIYUAN UNIV OF TECH

Planetary transmission mechanism for double-faced grinding/polishing machine

The invention relates to the field of a double-faced grinding / polishing machine, in particular to a planetary transmission structure of a double-faced grinding / polishing machine. The planetary transmission mechanism for the double-faced grinding / polishing machine comprises a planetary wheel (5) meshed with a gear ring (2), wherein the planetary wheel (5) is meshed with a sun wheel (7) and is arranged on a lower plate (6); a circle of gear ring pin teeth (3) are uniformly arranged on the inside surface of the gear ring (2); a tooth pitch is formed between two gear ring pin teeth (3); and the gear ring (2) is meshed with the planetary wheel (5) through the gear ring pin teeth (3). The invention has the advantages that because the pin tooth transmission is adopted, the cost of materials and the processing cost of an inner gear ring are reduced; the problem that the processing difficulty is increased because the size of the gear ring is increased is solved, and the problems of inconvenient maintenance and high using cost after the teeth are worn in the using process are solved; and simultaneously, because each pin tooth is in the shape of a circular arc and the meshing line is long, the contact rigidity of a part is improved, and the service life of the part is prolonged.

Owner:LANZHOU RAPID INDGRPCO +1

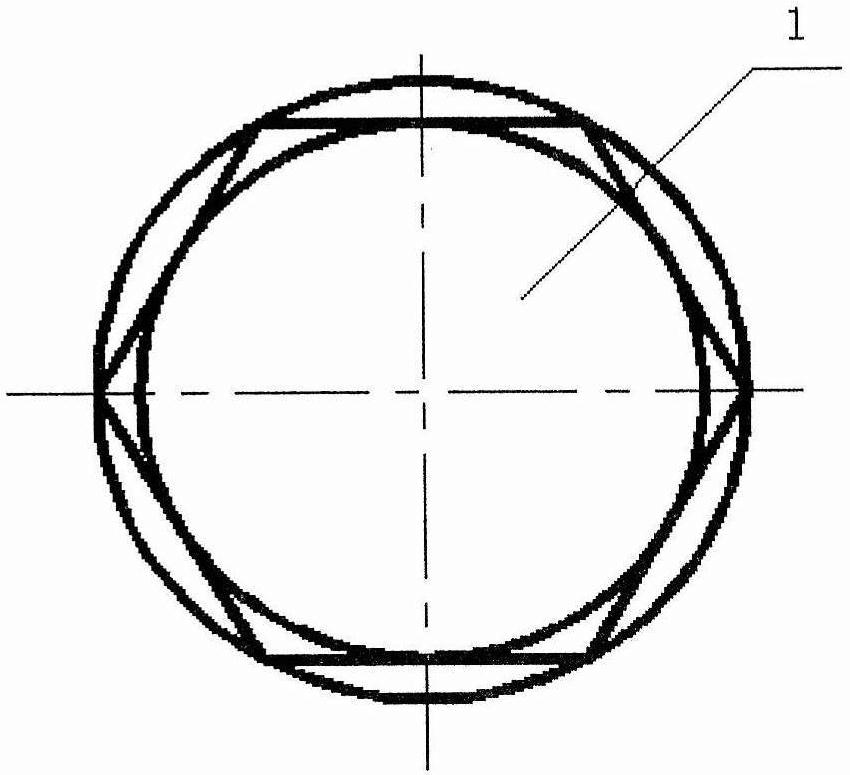

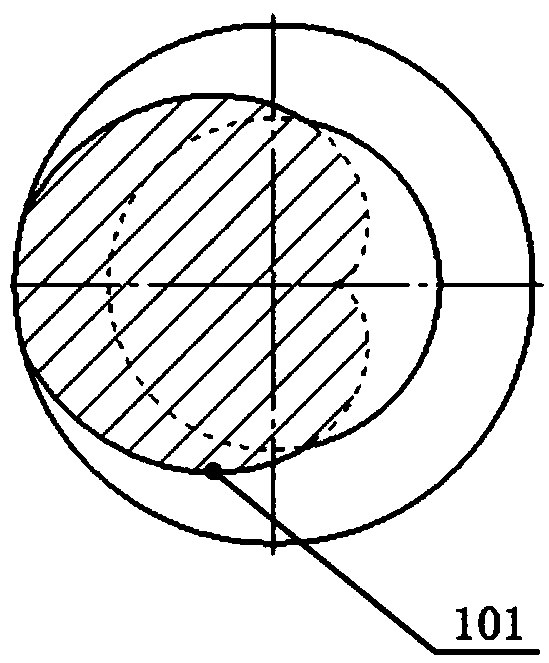

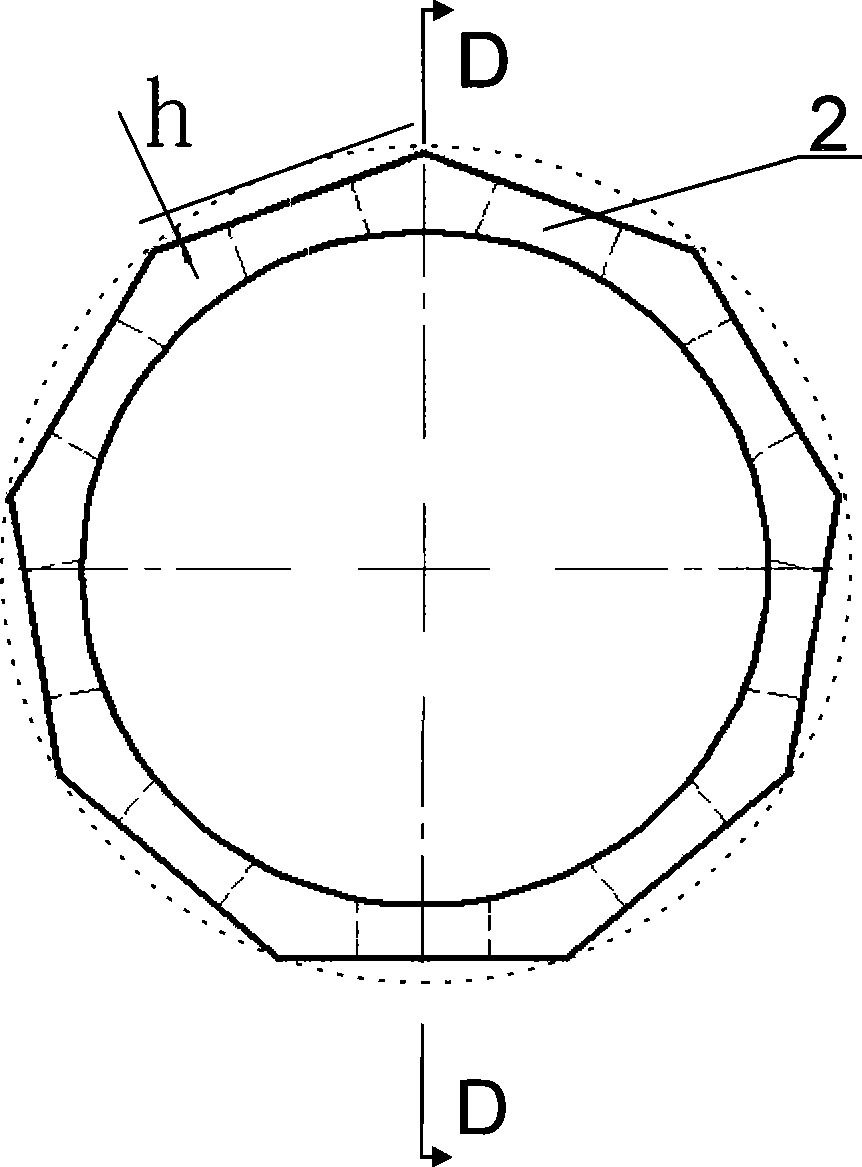

Multiple-prismatic high speed entity ball bearing retainer

ActiveCN101413545AImprove contact stiffnessReduce contact deformationBearing componentsContact conditionLubrication

The invention discloses a multi-prismatic high-speed solid ball bearing retainer. In the retainer, an external radial tangent perpendicular to the center line of each pocket of the retainer is drawn, all intersection points of the external radial tangents are connected to form a multi-prismatic shape and cause the thickness at the tangent intersection point to be thickened, and cause the contact stiffness of the tangent intersection point to be increased, which ensures the overall stiffness thereof; the multi-prismatic structure of the retainer causes the contact between the multi-prismatic structure and a circular bearing ring guide rib to be a two-point contact under the stable contact condition; on the one hand, the two-point contact can obviously enhance supporting stability of the retainer, and improve high-speed running stability of the retainer; on the other hand, the two-point contact reduces contact stress at the contact point of the retainer, and reduces frication and wear of the retainer; meanwhile, a tangential straight edge can seal part of lubricant in a contact state, which is beneficial to improving the lubrication status of the contact point of the multi-prismatic retainer 2; the external radial tangent height h of the multi-prismatic retainer is controlled between 0.1mm and 0.3mm, and the running smoothness of the multi-prismatic retainer is effectively ensured as the h numerical value is very small.

Owner:LUOYANG BEARING RES INST CO LTD

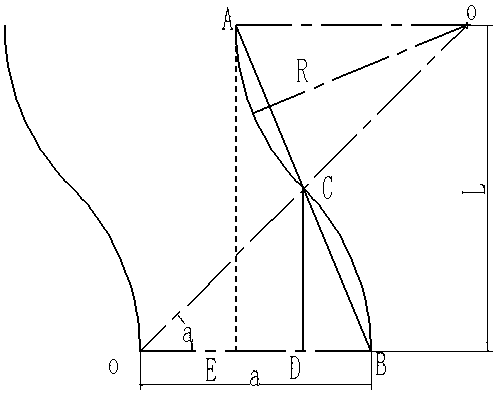

Worm provided with double-involute-arc tooth profile

ActiveCN106151458AReduce adverse factorsImprove the lubrication effectPortable liftingGearing elementsEngineeringTooth part

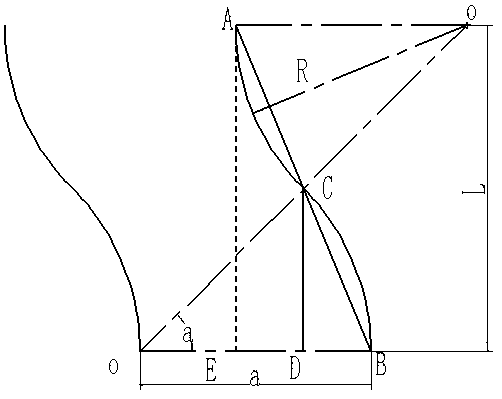

The invention discloses a worm provided with a double-involute-arc tooth profile and belongs to the technical field of worm wheel and worm transmission. The worm comprises a worm body and a worm tooth part. The worm tooth part is arranged in the middle of the worm body. The tooth profile of the cross section of the worm tooth part is in an involute arc shape. The tooth profile of the shaft cross section of the worm tooth part is also in an involute arc shape, thus, the worm composite arc tooth profile is formed and matched with a worm wheel tooth profile, the worm composite arc tooth profile is provided with an oil containing gap in the reference circle, and the portions close to the upper side and the lower side of the reference circle are in smooth coincidence contact along the worm wheel tooth profile to achieve meshing transmission. By means of selection and recombination of two involute arc segments of the cross section and the shaft cross section, the contact area can be increased, and contact stress is reduced. Meanwhile, oil containing space distribution is more reasonable, power of a transmission pair is increased, lubricating performance of the transmission pair is improved, multiple adverse factors in worm wheel and worm transmission are reduced greatly, and the application effect is improved.

Owner:马鞍山大一智能机械科技有限公司

Three-dimensional printing product, its manufacturing method, and supporting jig

ActiveCN112277308BReduce overheadReduce processing timeAdditive manufacturing apparatusAdditive manufacturing with liquidsSurface roughnessProcess engineering

The present application relates to a three-dimensional printed product, a manufacturing method thereof, and a support fixture. The three-dimensional printed product manufacturing method includes: using a first water-soluble material to print a support layer; on the support layer, using a forming material to print a target product ; On the target product, a cover layer is printed with a second water-soluble material to cover the surface of the target product. The above-mentioned manufacturing method of a three-dimensional printed product can reduce the surface roughness and improve the surface flatness without adding additional subsequent processing processes, and is especially suitable for products with thin thickness; on the one hand, it is beneficial to improve wear resistance, Product indicators such as clearance fit connection strength, fatigue strength, contact stiffness, etc.; on the other hand, it is conducive to stacking to achieve a close positional relationship and improve the stability of the final product structure; on the other hand, it is conducive to reducing model cost overhead and process time, reducing new High cost caused by product redesign, mold repair, and mold opening in the product development stage.

Owner:INTERFACE TECH CHENGDU CO LTD +2

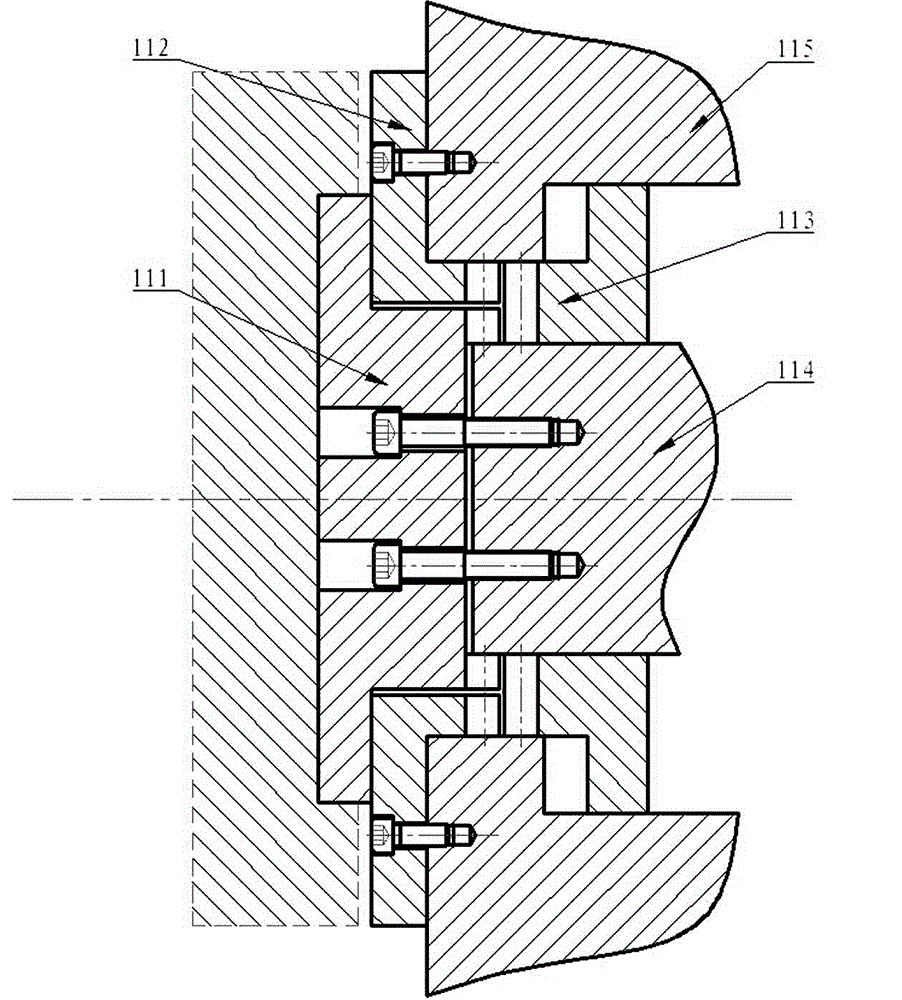

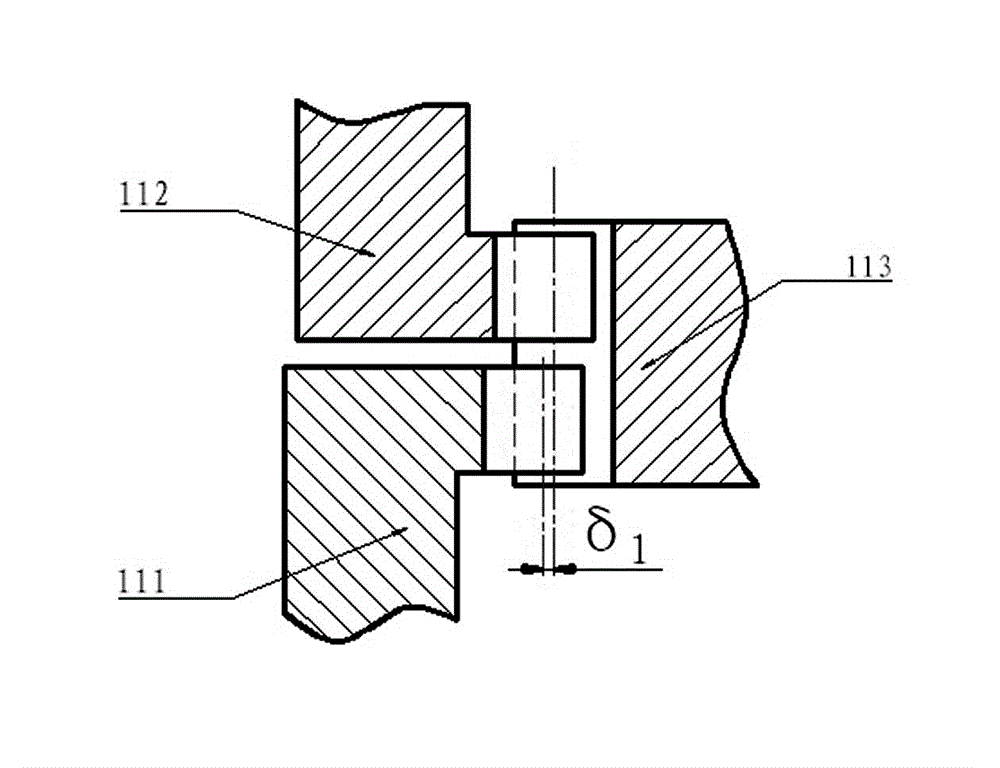

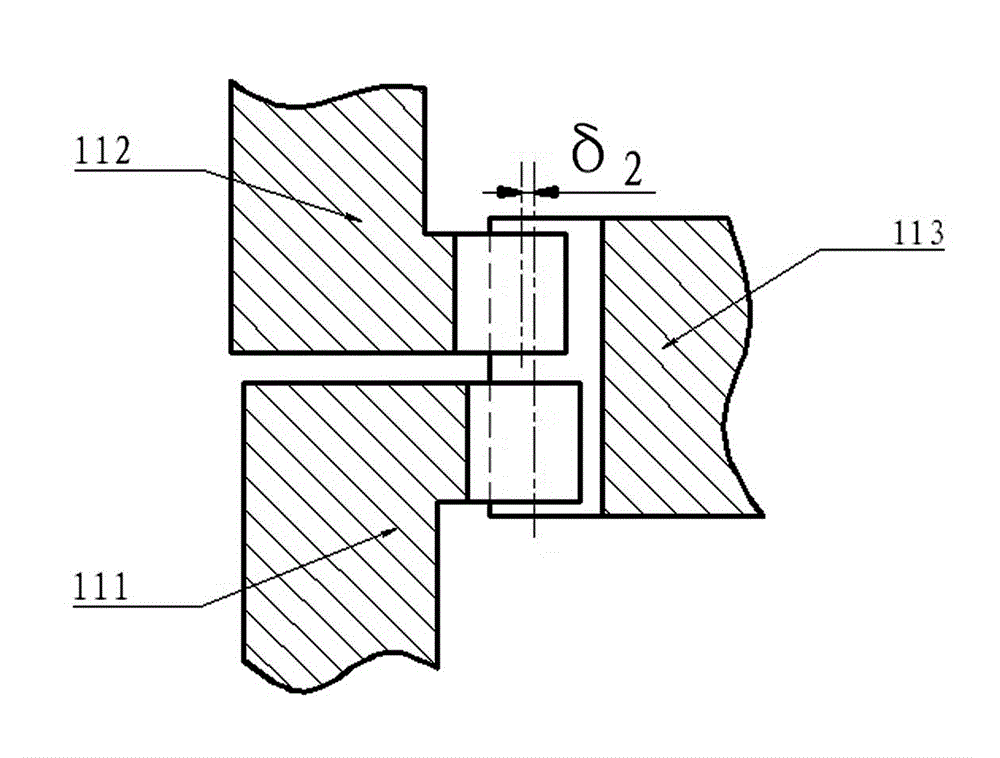

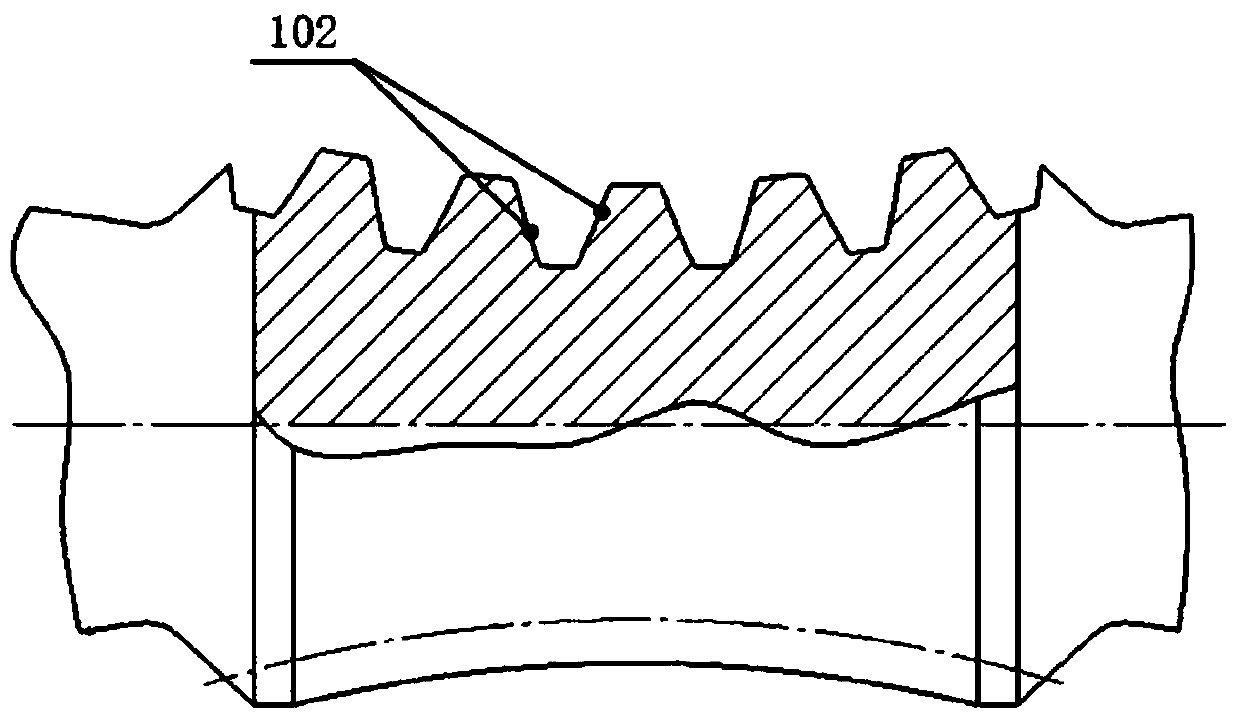

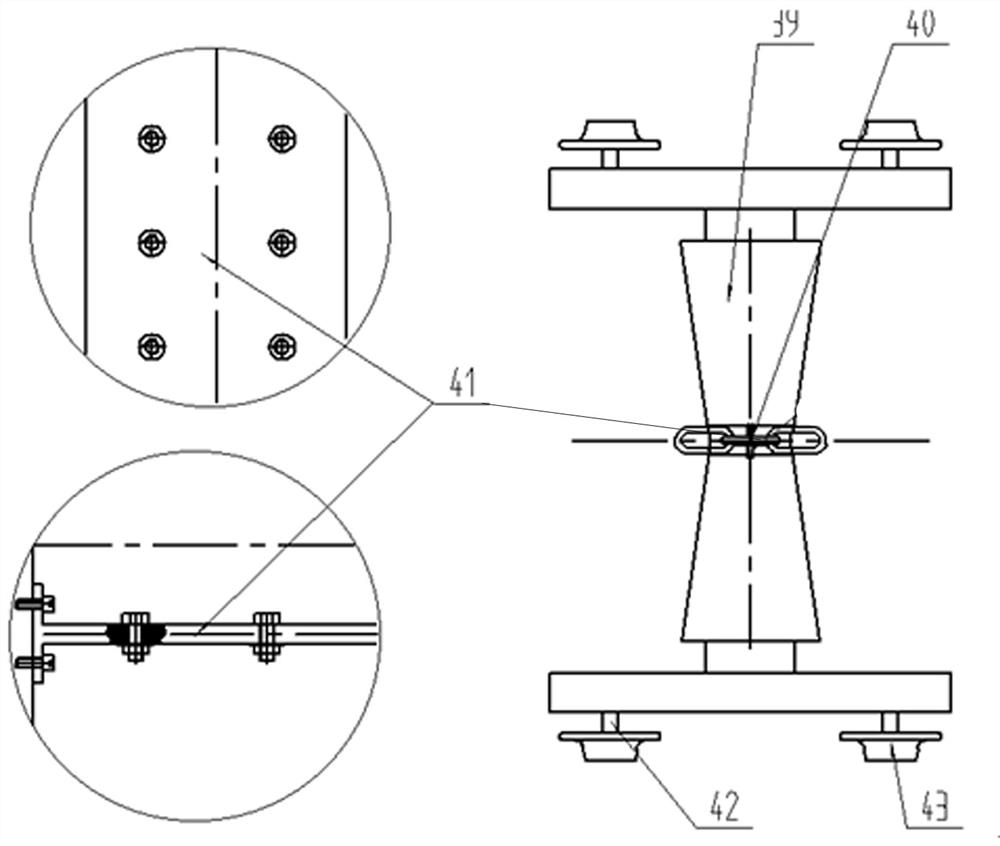

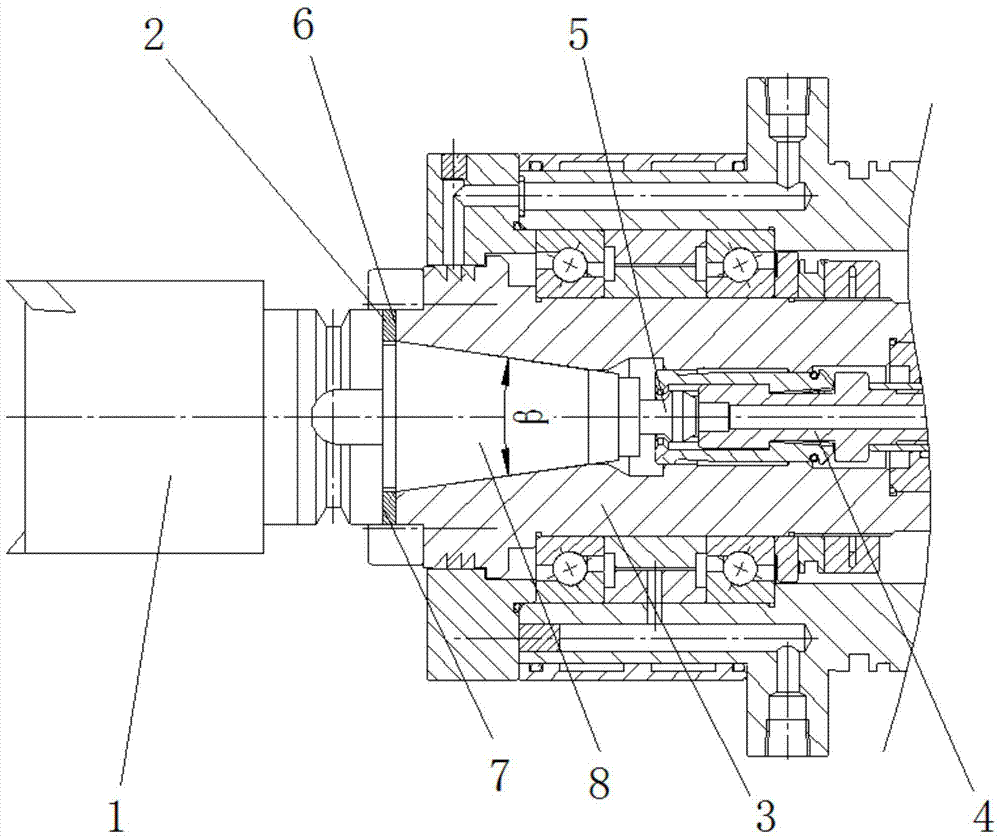

A kind of high-speed cutting mechanism and using method of bt tool holder

ActiveCN104924136BImprove contact stiffnessHigh repeat positioning accuracyPositioning apparatusMetal-working holdersNumerical controlCircular cone

The invention discloses a BT knife handle high-speed cutting mechanism and a use method and belongs to the technical field of numerically-controlled machine tool cutting machining. The BT knife handle high-speed cutting mechanism comprises a BT knife handle, a main shaft, a knife pulling mechanism, a pop-rivet and a cushion cover, wherein the end face of the non tool installation end of the BT knife handle is a knife handle rear end face, a circular cone frustum is arranged on the center position of the knife handle rear end face, the pop-rivet is installed on the center position of the end face of the circular cone frustum, the main shaft is a hollow shaft, the end face of the end, close to the rear end face of the knife handle, of the main shaft is a main shaft front end face, a taper hole is formed in the center portion of the main shaft front end face, the shape of the taper hole is matched with that of the circular cone frustum, the circular cone frustum is installed in the taper hole, the cushion cover is arranged between the knife handle rear end face and the main shaft front end face, the knife pulling mechanism is installed in a main shaft center cavity, and the knife pulling mechanism is connected with the pop-rivet in a clamped mode. By means of the BT knife handle high-speed cutting mechanism and the use method, the high-speed cutting of the BT knife handle is achieved, the contact rigidity and the repeated positioning accuracy of the BT knife handle are high, the high-speed cutting machining precision and the efficiency are high, the service lives of a tool and a machine tool are prolonged, and the BT knife handle can replace an HSK knife handle to be used.

Owner:JIANGSU YUANLI AVIA PRECISION MACHINE TOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com