Sliding guide rolling unloading device

A technology of unloading device and sliding guide rail, which is used in large fixed members, metal processing machinery parts, metal processing equipment, etc., can solve the problems of high requirements for lubrication, large contact area, large resistance, etc., and achieve high contact stiffness. , high motion sensitivity, the effect of reducing the friction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

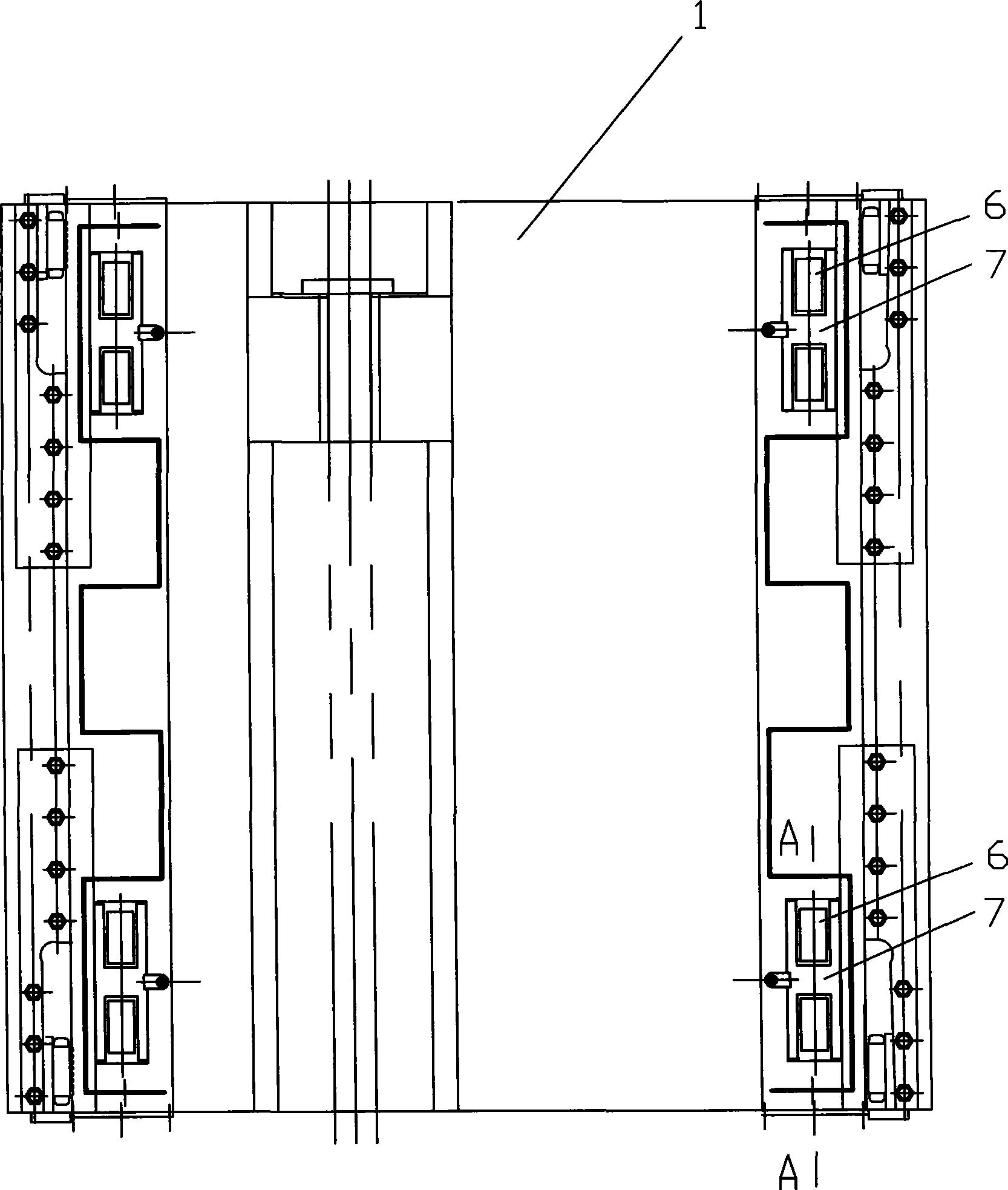

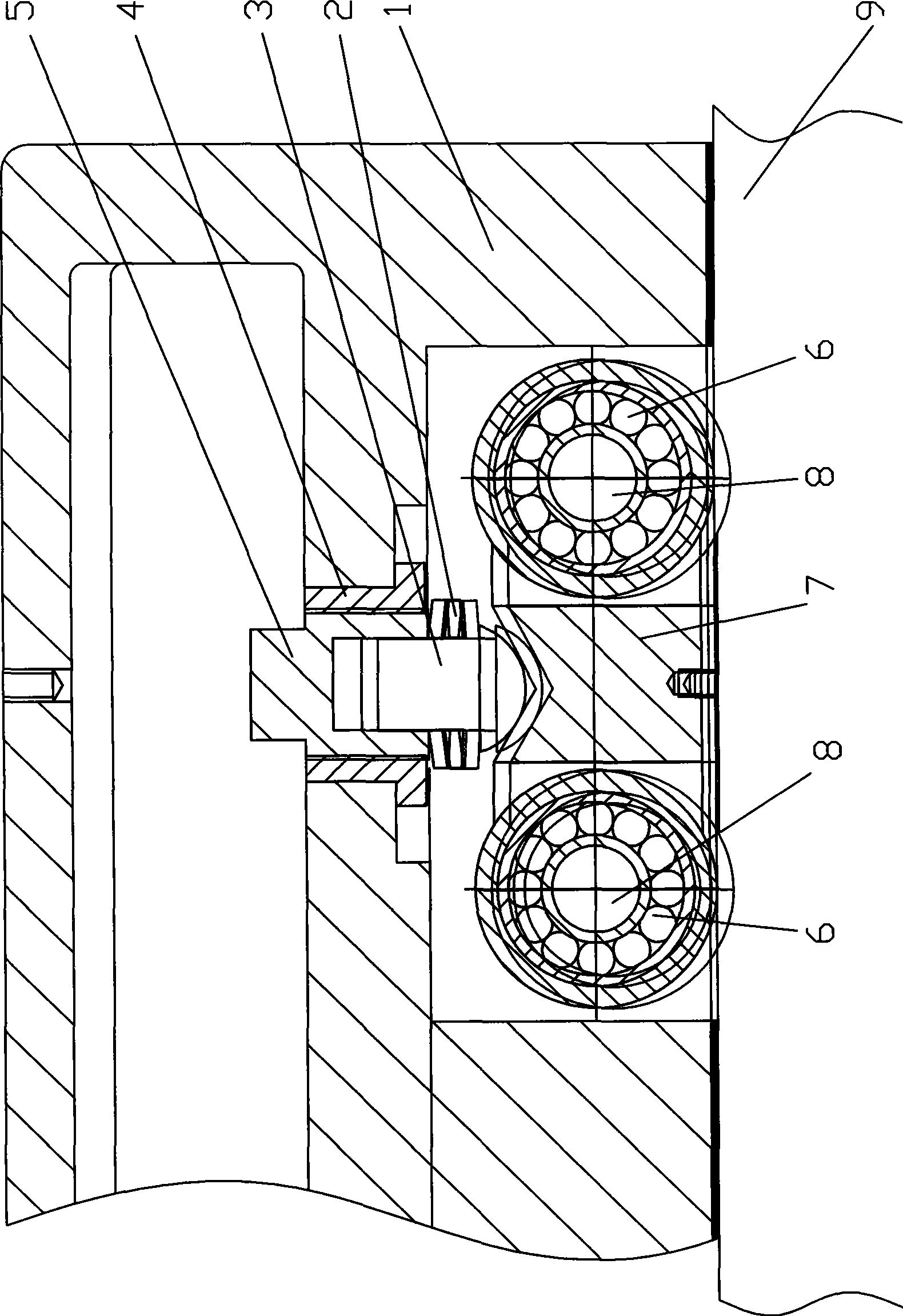

[0012] Such as figure 1 , 2 Shown: 1 is the sliding seat located above the basic guide rail 9 of the bed, on the bottom surface of the sliding seat 1 there are at least three positions that are matched with the guide rail, and rollers 6 are installed, and the outer surface of the circumference of the roller 6 is in contact with the upper surface of the guide rail below. touch. In this embodiment, rollers 6 are installed on the bottom surface of the four corners of the slide 1, and the slide 1 is supported on the guide rail by the roller 6, which unloads most of the gravity of the workbench and realizes the line contact with the guide rail. The guiding structure when the sliding seat 1 moves relative to the guide rail can be the same as the guiding structure in the prior art.

[0013] A fixed sleeve 4 is installed on the sliding seat 1, and the lower end of the fixed sleeve 4 has a boss for axial positioning. The support sleeve 5 is threadedly connected with the fixed sleeve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com