A kind of high-speed cutting mechanism and using method of bt tool holder

A high-speed cutting and tool handle technology, which is applied in the direction of metal processing machinery parts, clamping, support, etc., can solve the problems of poor quality of machined parts, low axial positioning accuracy, and easy damage of tools, so as to reduce tool wear and improve machining Accuracy and processing efficiency, and the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

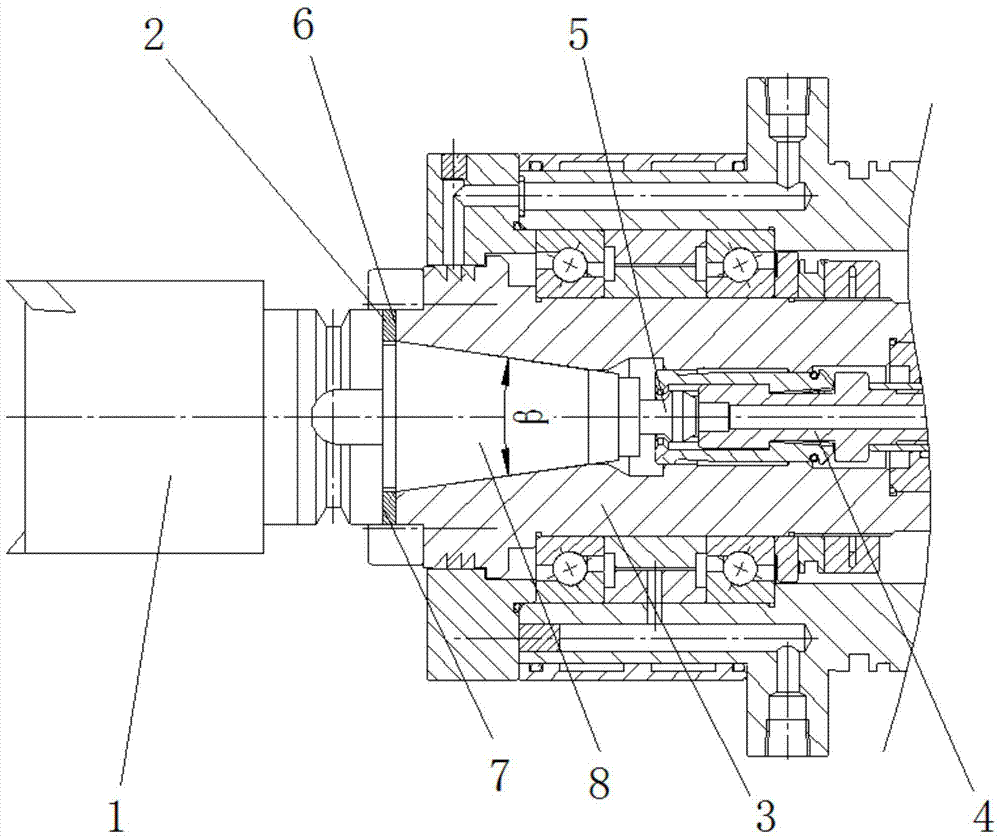

[0042] Such as figure 1 As shown, a BT handle high-speed cutting mechanism of this embodiment includes a BT handle 1, a main shaft 3, a broach mechanism 4, a pull nail 5 and a pad cover 2, and the end face of the non-tool mounting end of the BT handle 1 is a knife The rear end face 7 of the shank is provided with a cone 8 at the center of the rear end face 7 of the handle, and the pull stud 5 is connected to the center position of the end face of the truss 8 through threads; The end face is the front end face 6 of the spindle, and a taper hole is provided at the center of the front end face 6 of the spindle. The shape of the taper hole matches the truncated cone 8, which is installed in the taper hole; Between the front end faces 6 , the material of the cushion cover 2 in this embodiment is 40CrNi, the broach mechanism 4 is installed in the central cavity of the main shaft 3 , and the broach mechanism 4 is engaged with the pull rivet 5 .

[0043] In the present embodiment, th...

Embodiment 2

[0055] Basically the same as Embodiment 1, the difference is that the working tension F of the broach mechanism 4 max =10000N, the thickness of the obtained cushion sleeve 2 is L=4.007mm, that is, the thickness of the cushion sleeve 2 is greater than the distance between the rear end surface 7 of the tool holder and the front end surface 6 of the main shaft L-k=0.007mm, and the radial runout of the BT tool holder 1 is less than 0.001mm, the service life of BT toolholders is increased by 77%, and the service life of machine tools is increased by 65%.

Embodiment 3

[0057] Basically the same as Embodiment 1, the difference is that the working tension F of the broach mechanism 4 max =12000N, the thickness of the obtained cushion sleeve 2 is L=4.009mm, that is, the thickness of the cushion sleeve 2 is greater than the distance between the rear end surface 7 of the tool holder and the front end surface 6 of the spindle L-k=0.009mm, and the radial runout of the BT tool holder 1 is less than 0.001mm, the service life of BT toolholders is increased by 73%, and the service life of machine tools is increased by 72%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com