Worm provided with double-involute-arc tooth profile

A double involute and involute technology, applied to components with teeth, belts/chains/gears, portable lifting devices, etc., can solve problems such as poor lubrication, large wear, and low efficiency of worm gear transmission. Achieve the effects of improving power and lubricating performance, increasing contact area, and reasonable oil-holding space distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

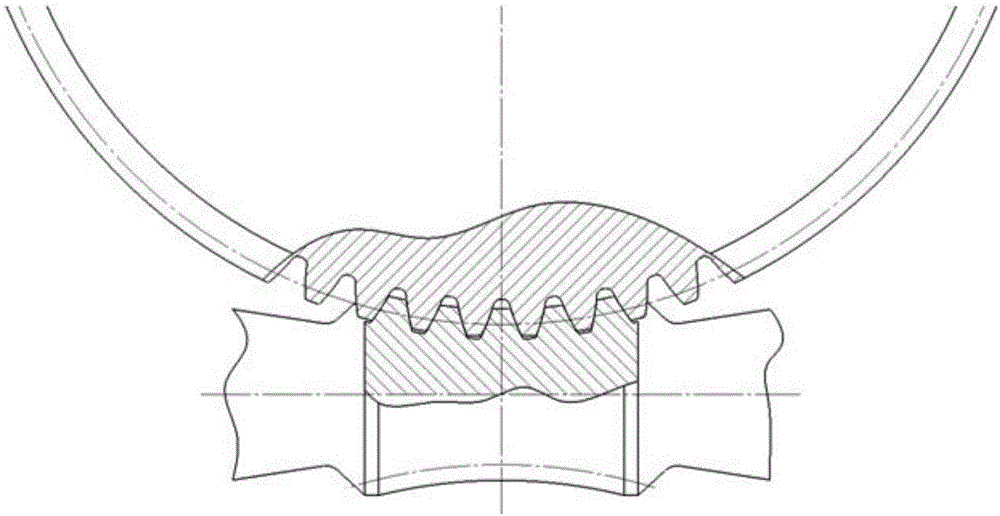

[0025] Through in-depth research and experiments on worm gear transmission, the applicant proposes to directly design the tooth profile of the worm as a double involute compound arc, taking into account the contact form of the tooth surface and the improvement of the oil storage space, so as to eliminate the poor lubrication of the worm gear drive. The shortcomings of low efficiency and large wear caused by excessive contact stress can be applied to various toroidal and cylindrical worms.

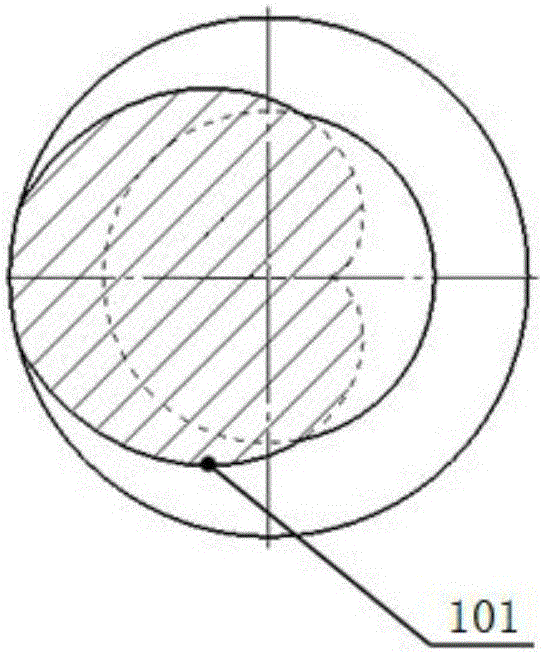

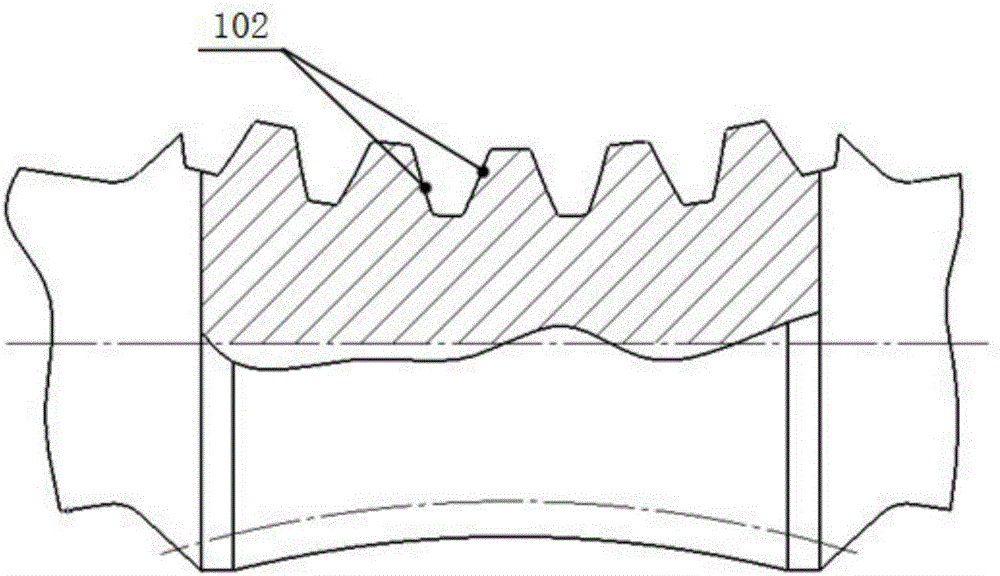

[0026] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a worm with a double involute arc-shaped tooth profile in this embodiment includes a worm body and a worm tooth. The worm tooth is arranged in the middle of the worm body. The cross-sectional tooth profile 101 The shape is an involute arc, and the shape of the axial section tooth profile 102 of the worm gear is also an involute arc, thereby forming a compound arc tooth profile 1 of the worm. The compound arc tooth pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com