Patents

Literature

126results about How to "High clamping reliability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

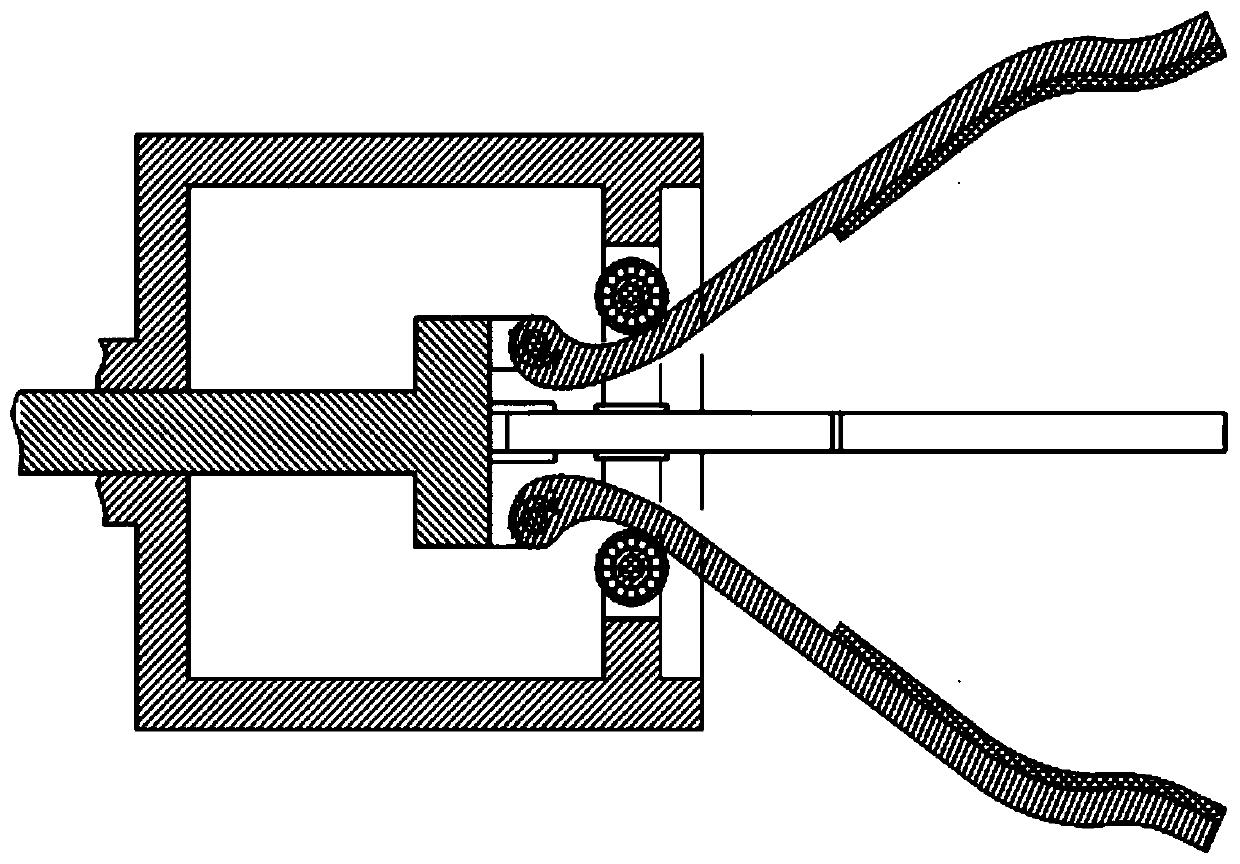

Connecting terminal for printed circuit boards

InactiveUS20100173531A1Simple functional designSmall installation sizeElectrically conductive connectionsCoupling contact membersSpring forcePrinted circuit board

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

Connecting terminal for printed circuit boards

InactiveUS7993156B2Simple functional designSmall installation sizeCoupling contact membersContact members penetrating/cutting insulation/cable strandsSpring forceEngineering

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

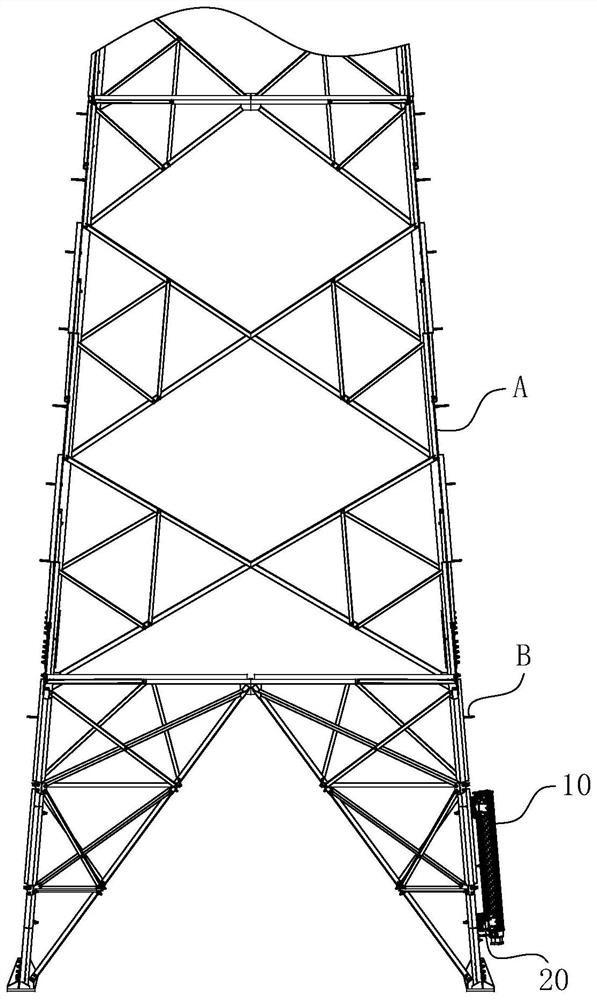

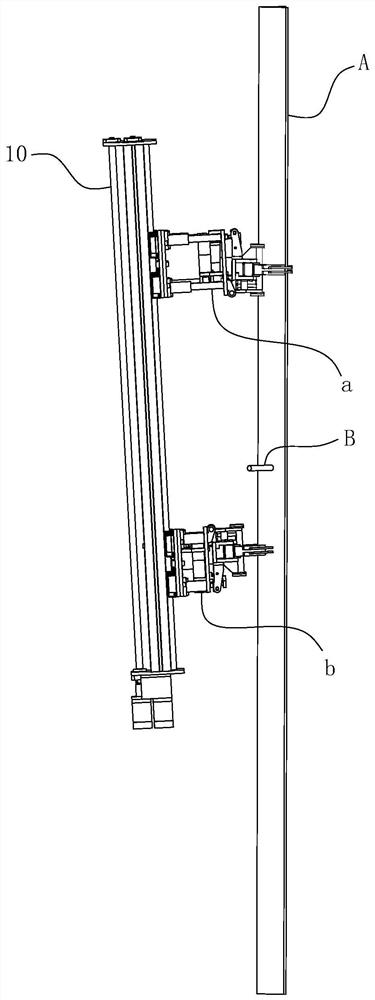

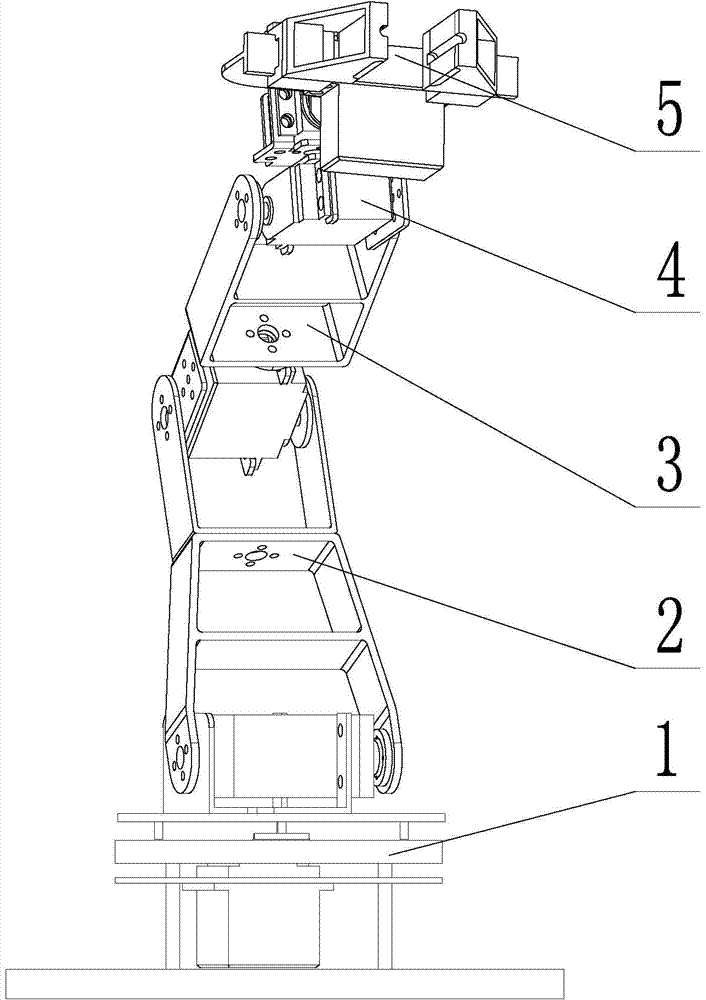

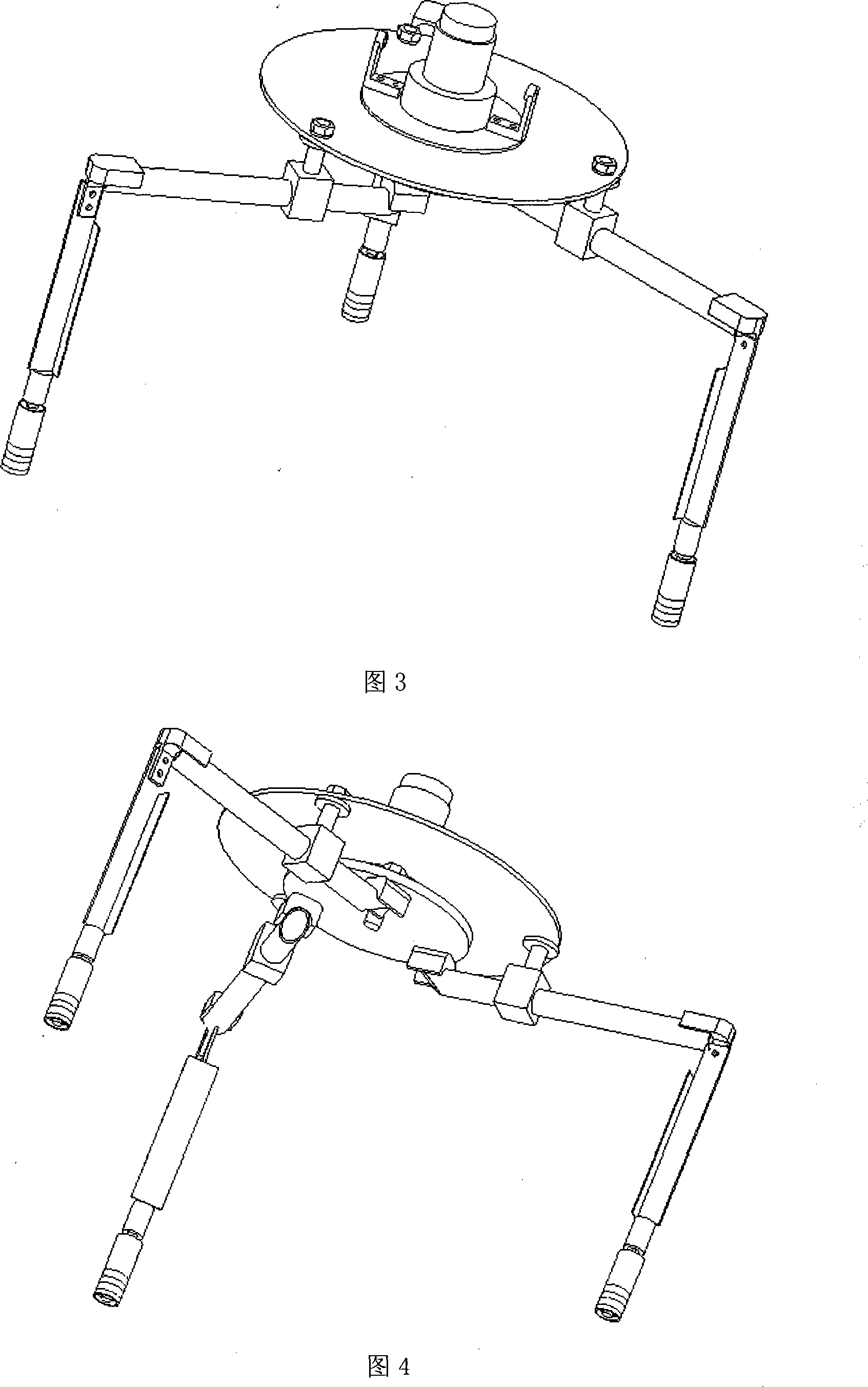

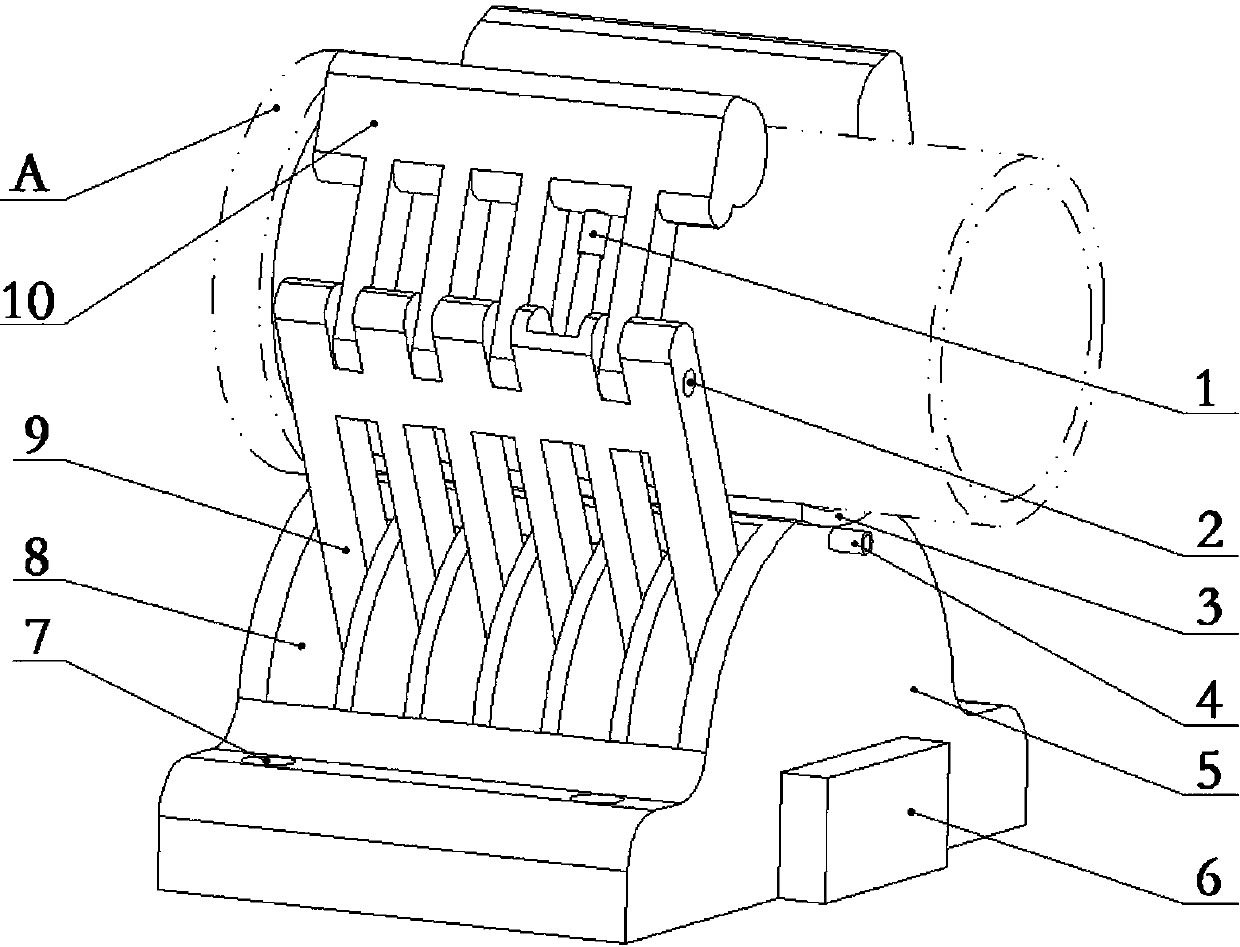

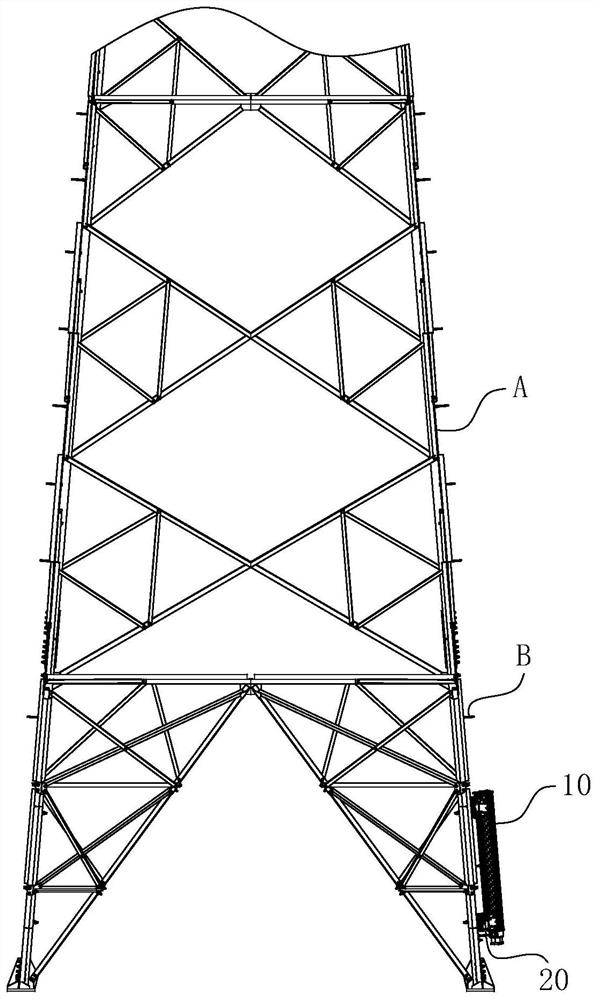

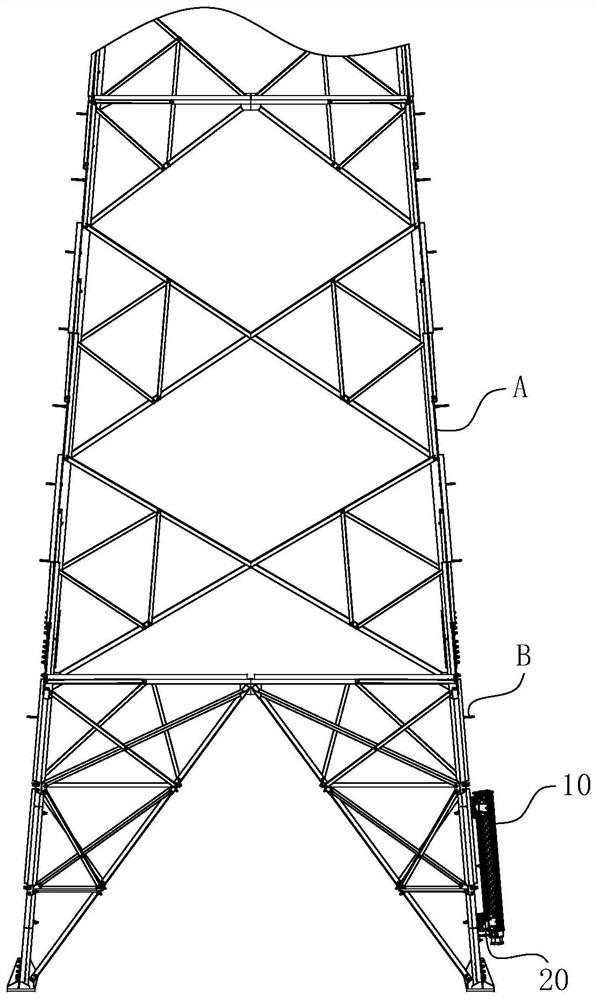

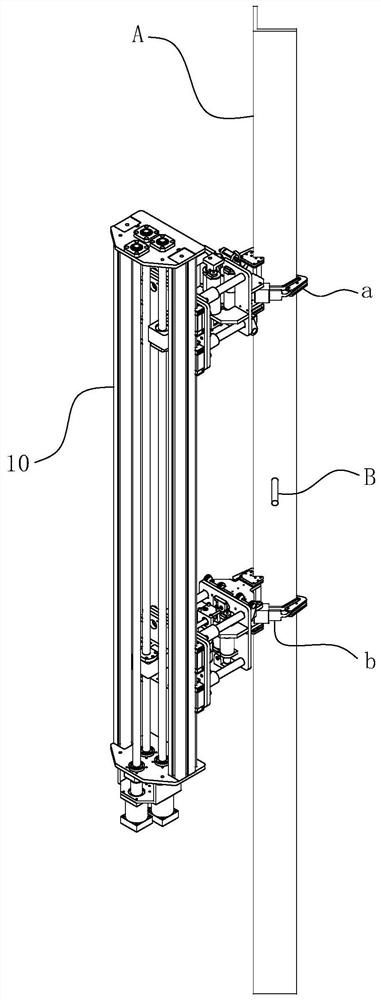

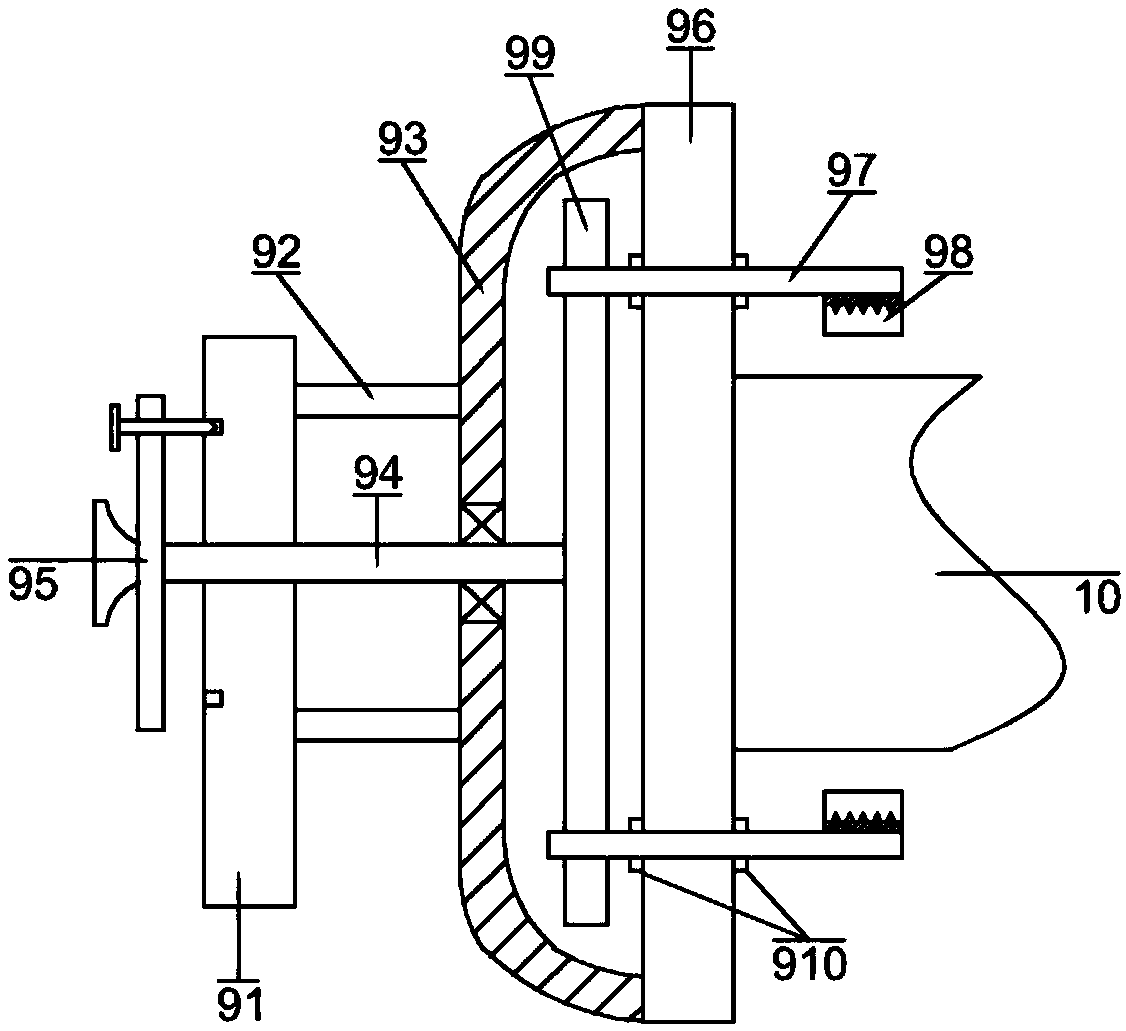

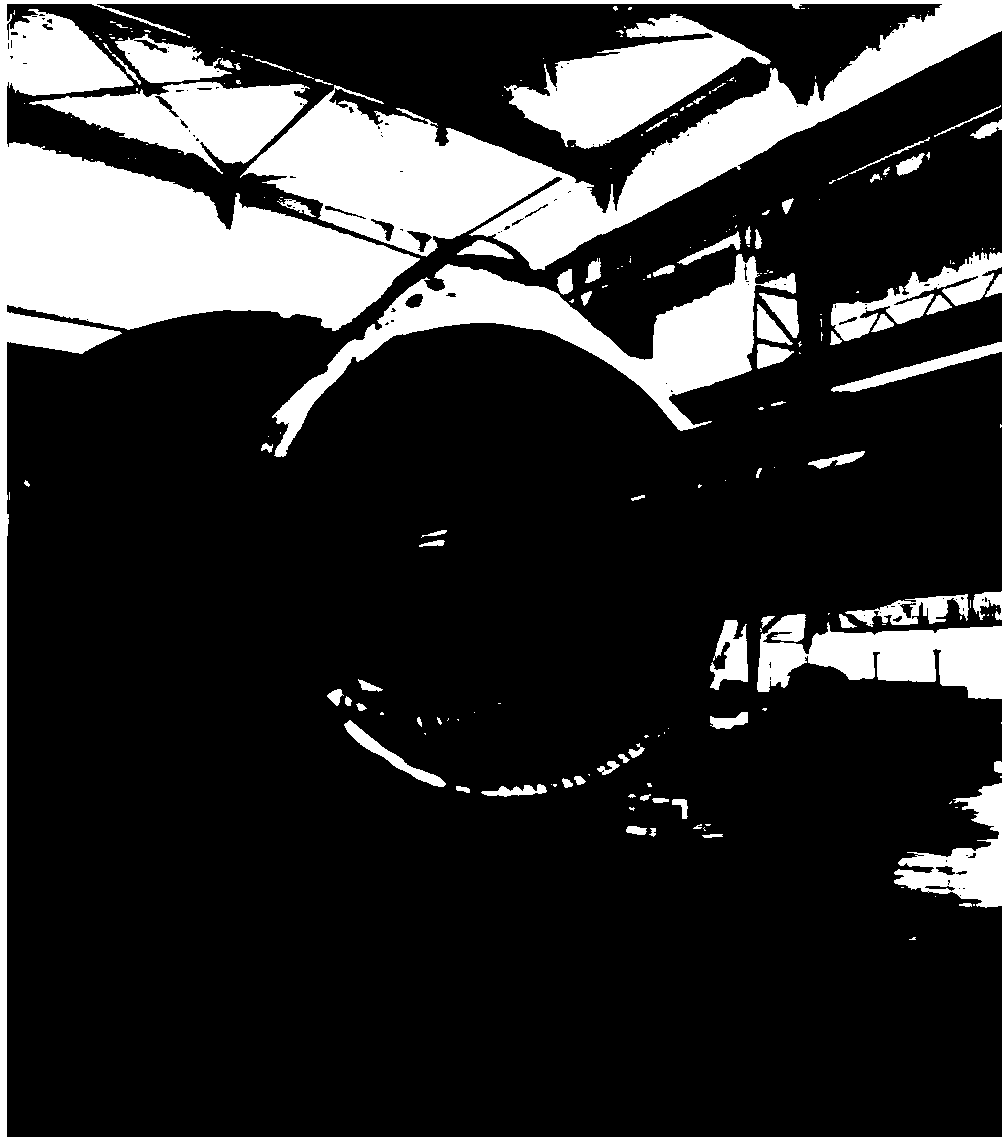

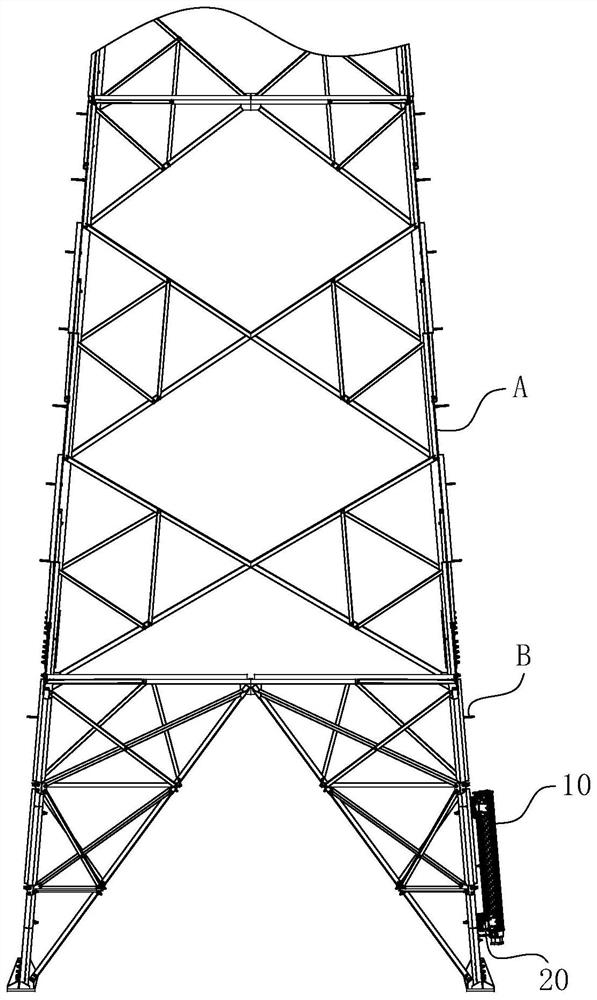

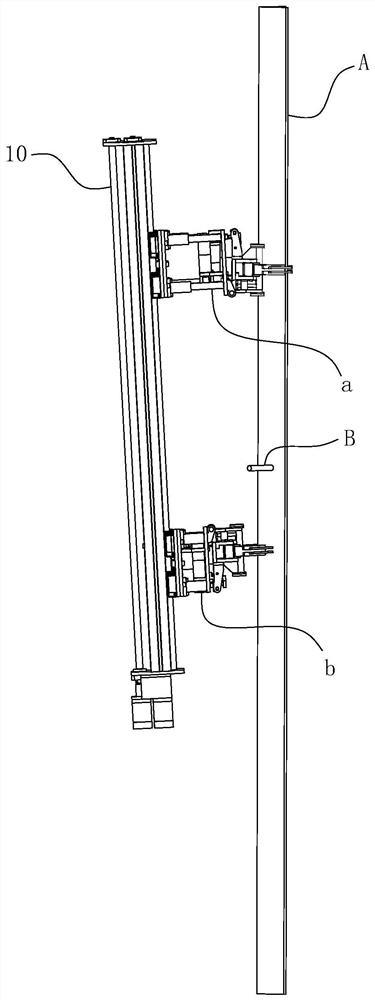

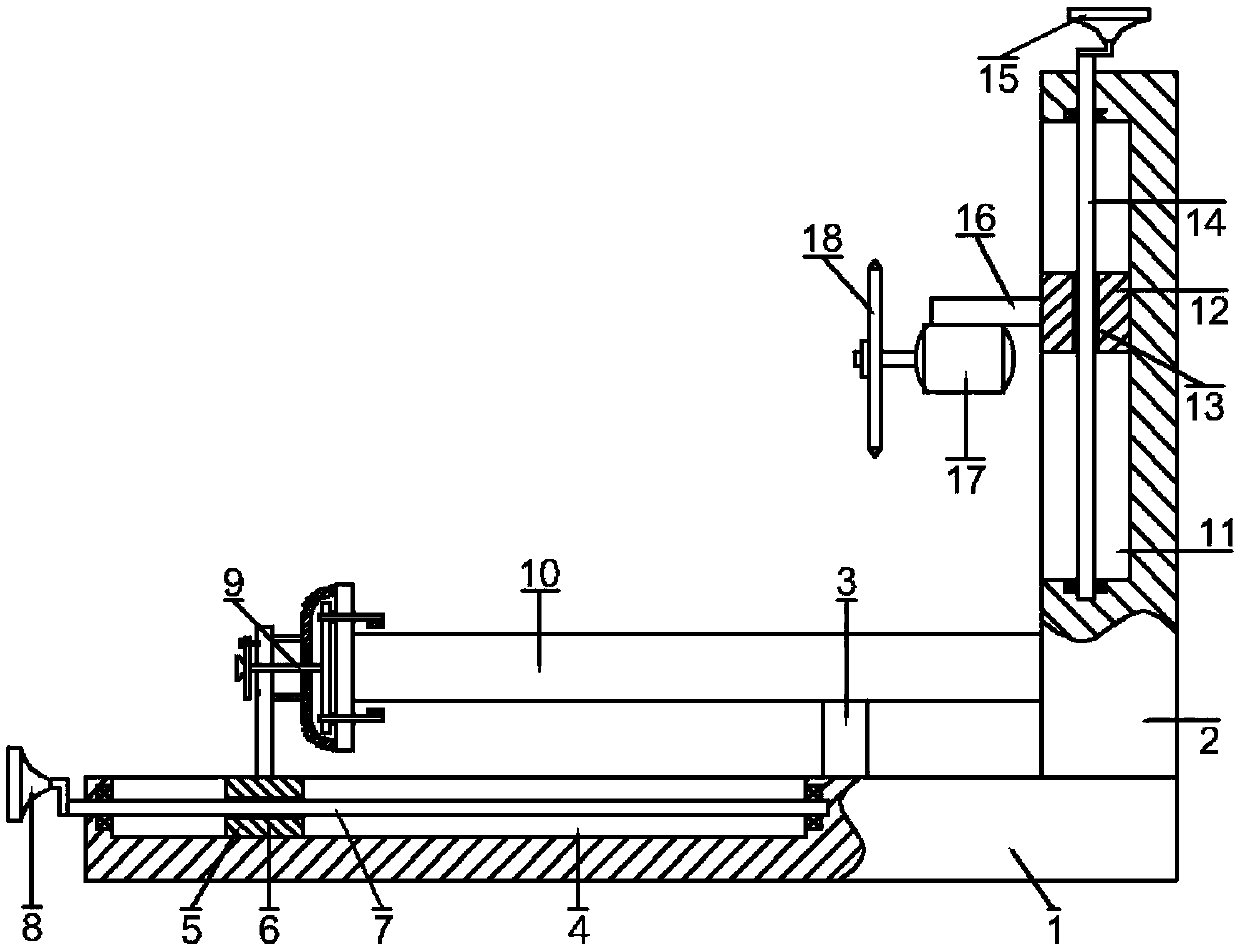

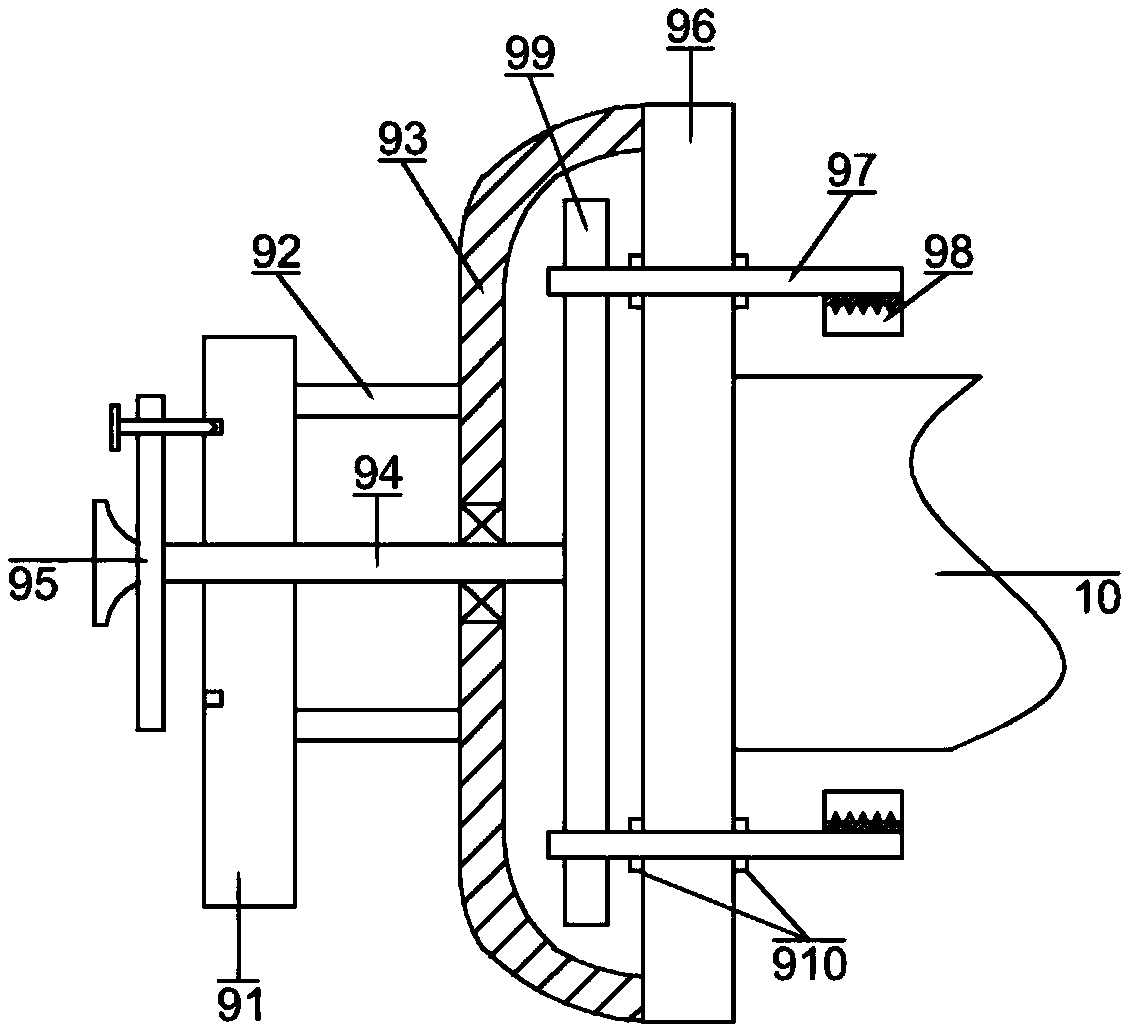

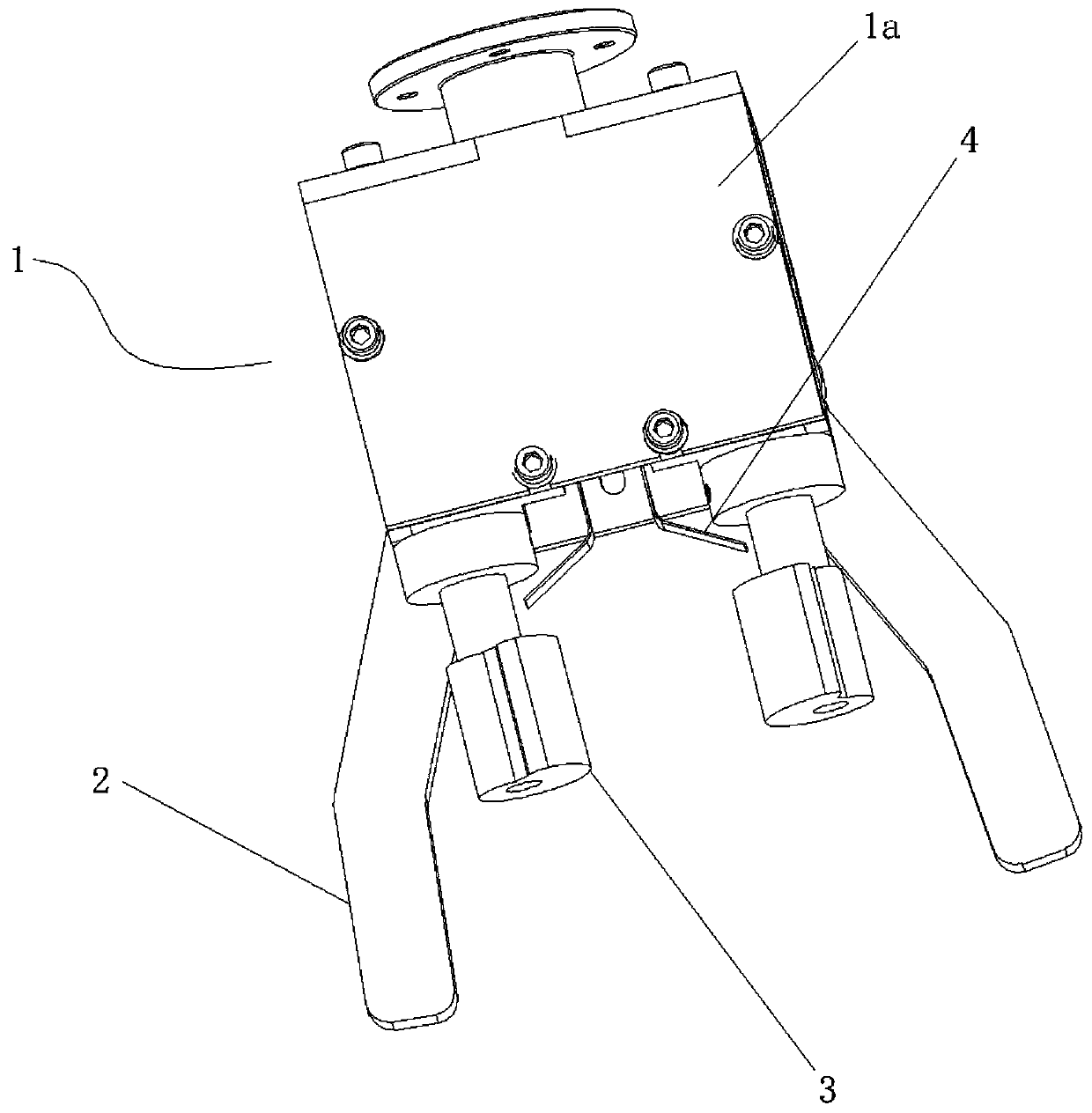

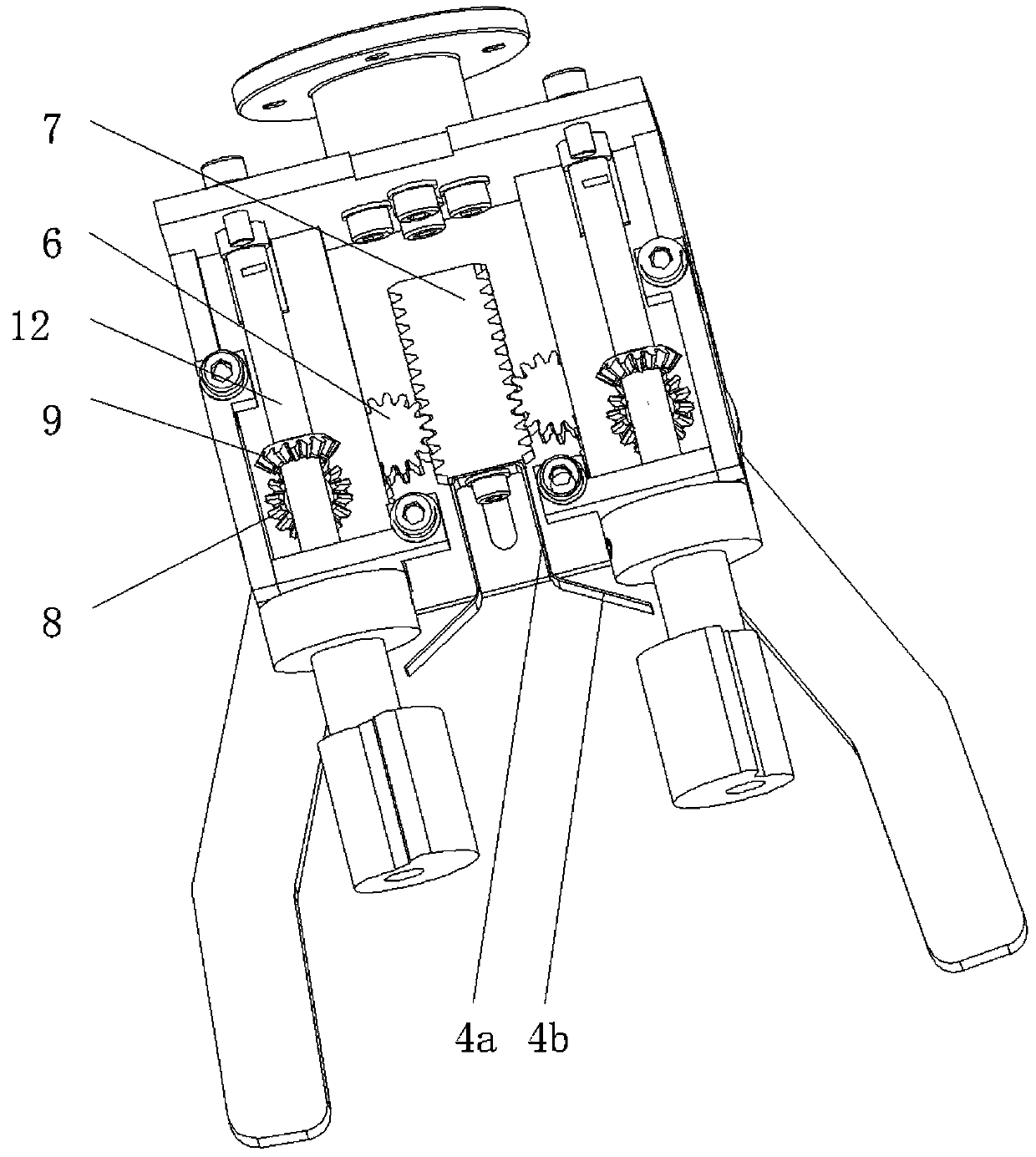

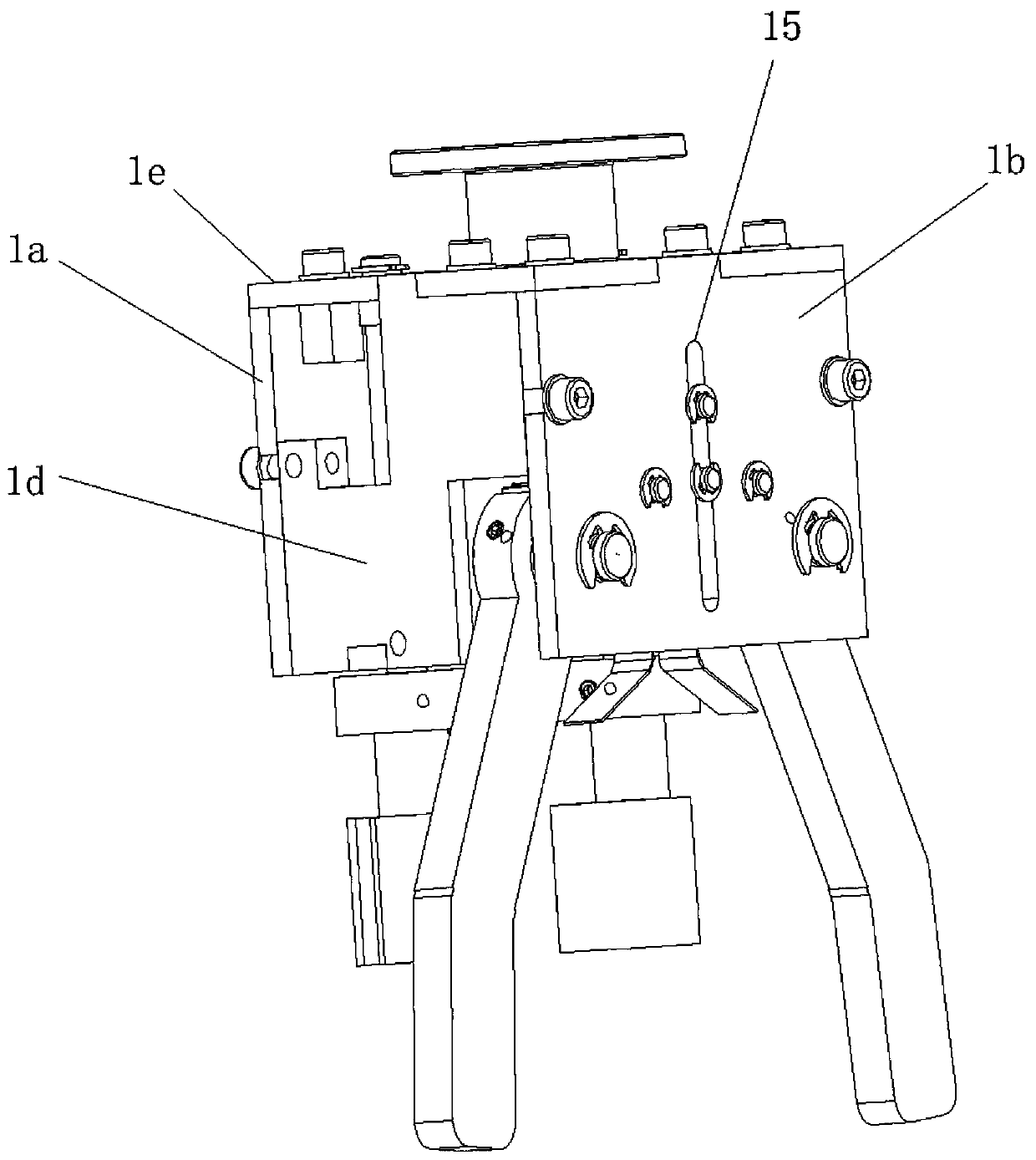

Climbing robot for angle steel tower

ActiveCN112356940AGuaranteed efficient obstacle clearanceGuaranteed clamping effectManipulatorVehiclesControl engineeringMachine

The invention belongs to the technical field of climbing robots for electric power operation, and particularly relates to a climbing robot for an angle steel tower. The robot comprises a main machineand clamping assemblies, the clamping assemblies comprise the upper clamping assembly and the lower clamping assembly, and at least one set of clamping assemblies can do reciprocating displacement motion parallel to the advancing path of the main machine relative to the main machine; each clamping assembly comprises a clamping jaw, an angle adjusting assembly and a lifting assembly, wherein the angle adjusting assembly is installed on the clamping jaw and can enable the main machine to generate pitching angle adjustment relative to the angle steel, and the lifting assembly can enable the clamping jaw to generate approaching and departing actions relative to the angle steel. The hinge axis of the angle adjusting assembly is horizontally arranged and is perpendicular to the length directionof the angle steel. The robot has high obstacle crossing capability and high climbing efficiency, and can synchronously guarantee the action stability and action reliability of climbing operation, sothat the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and the safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

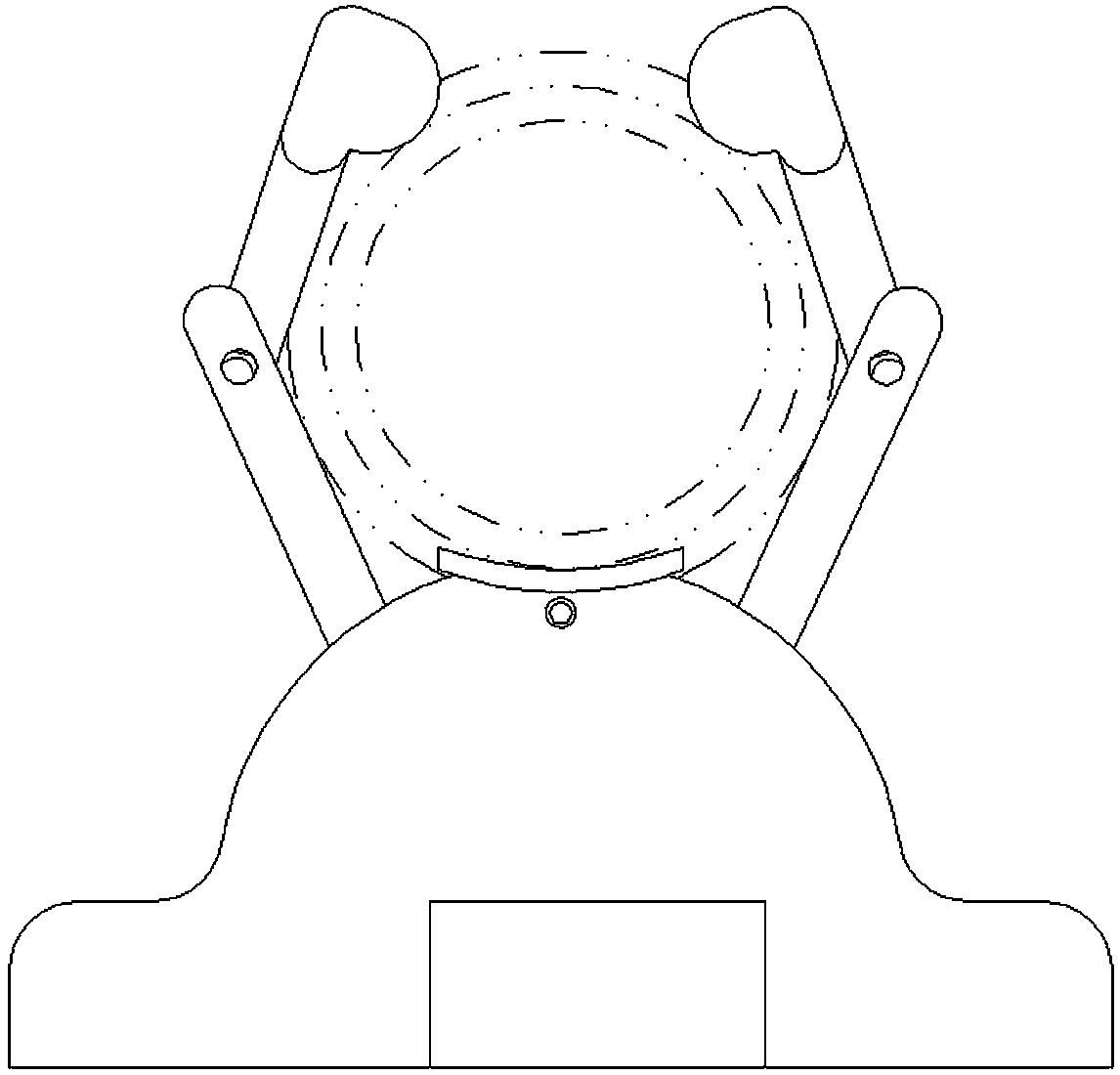

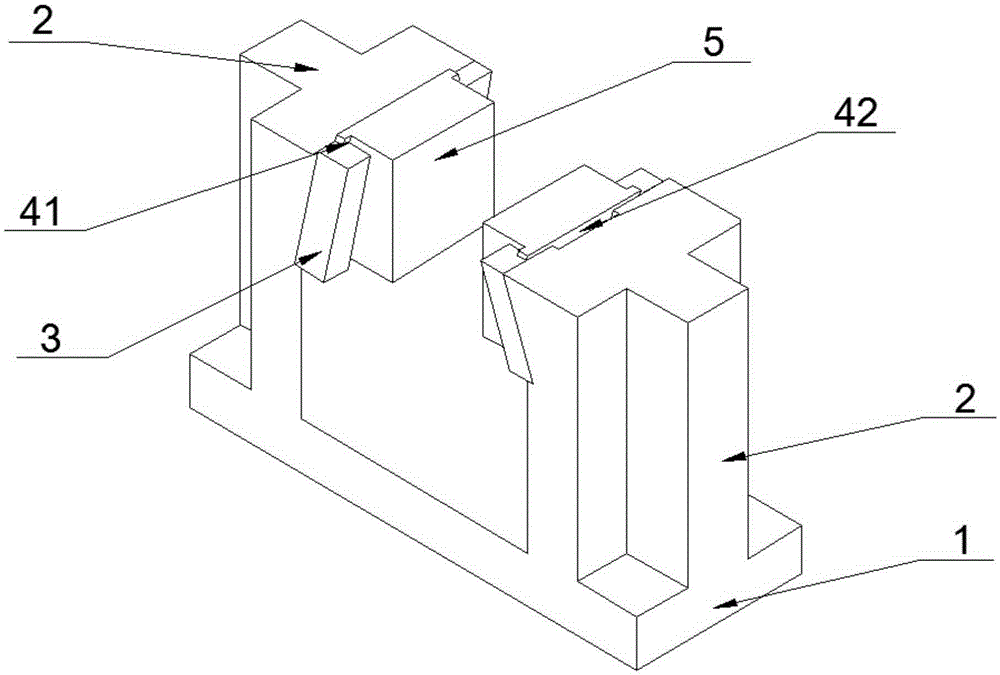

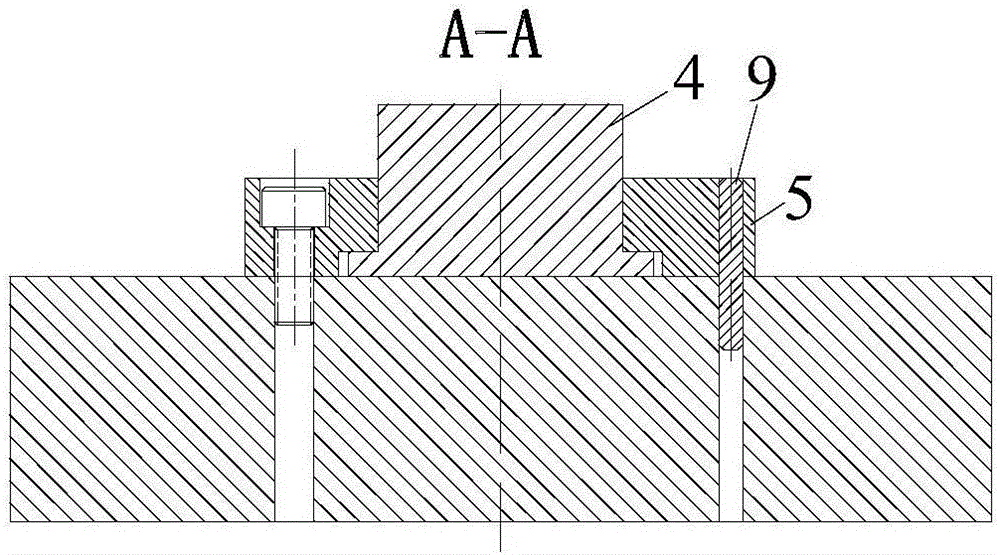

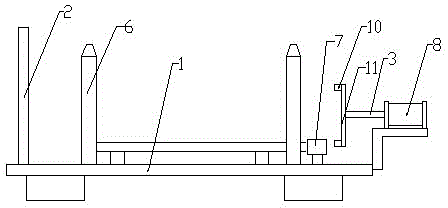

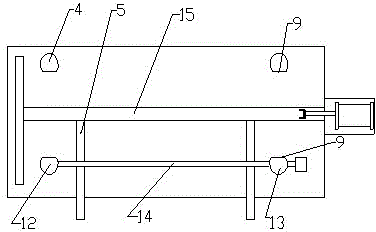

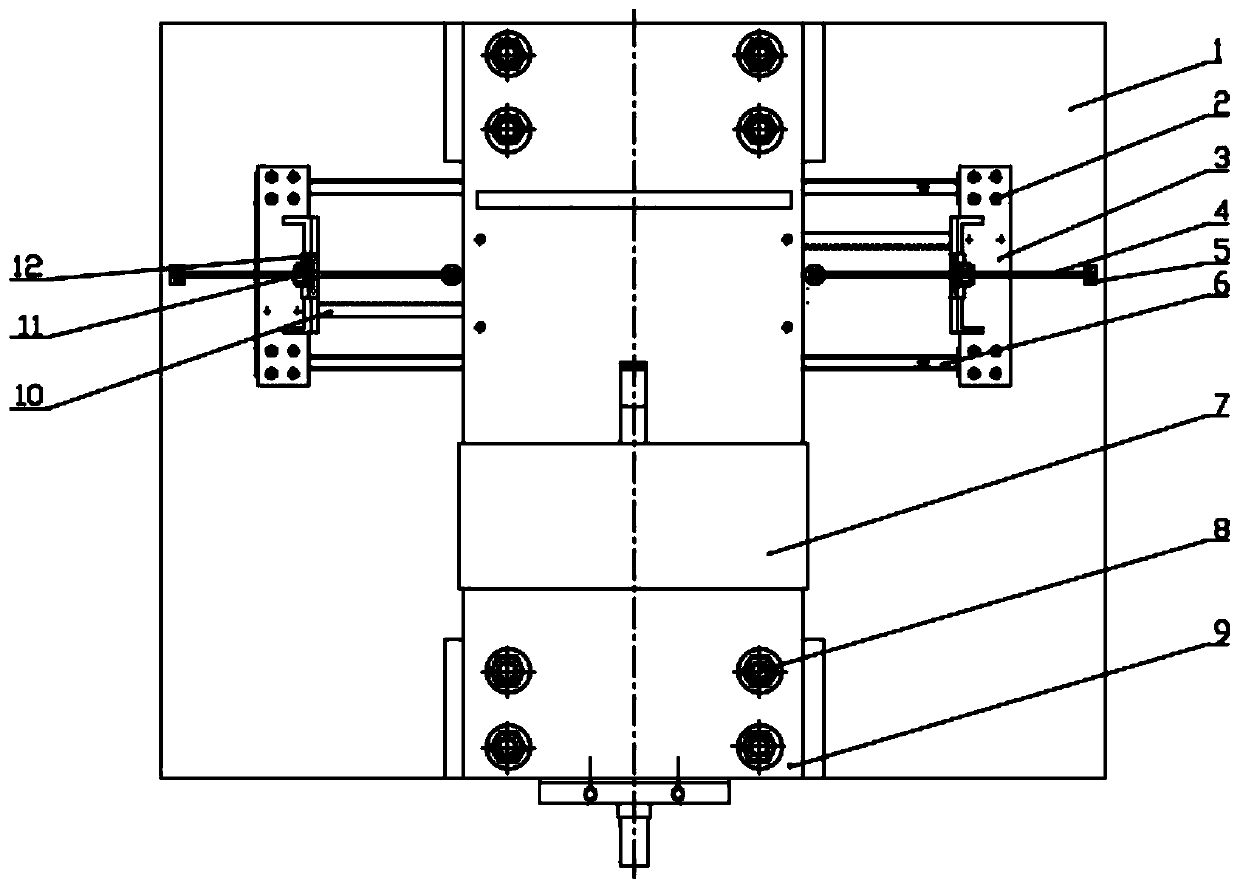

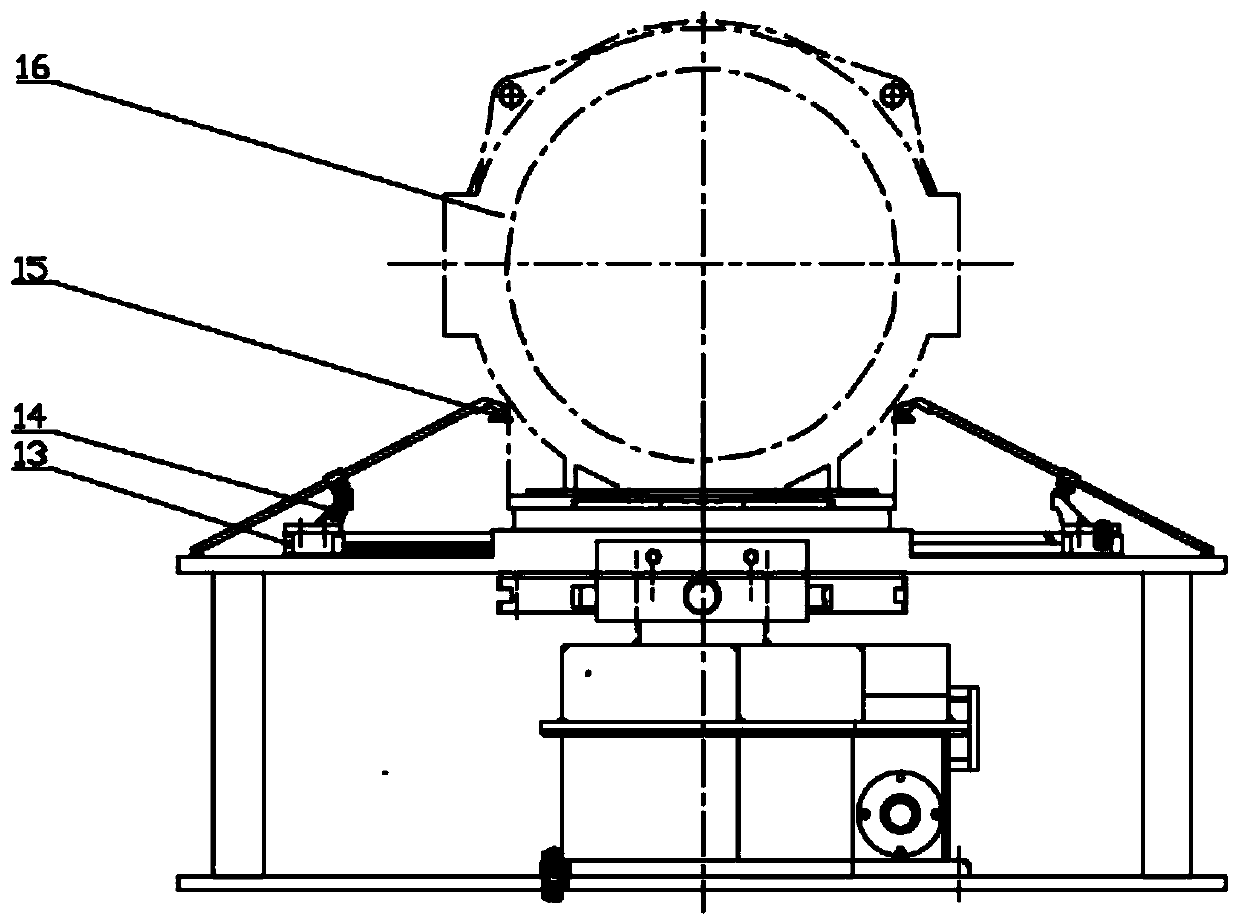

Horizontal rotating device for conical barrel body

ActiveCN106624576ASmooth horizontal rotationReduce manufacturing costWelding/cutting auxillary devicesAuxillary welding devicesCircular coneEngineering

The invention discloses a horizontal rotating device for a conical barrel body. The horizontal rotating device comprises support rings and hinged supports installed on the support rings, each support ring is a disc-shaped member, through holes are evenly distributed at the periphery of each support ring, and each group of through holes comprises a plurality of pairs of equidistant through holes distributed radially along the support ring. The support surfaces of lower hinged supports are uniformly in contact with the periphery of the outer circular conical surface of the conical barrel body at the same time, the horizontal rotating device is guaranteed to clamp the conical barrel body coaxially, the connection positions of upper hinged supports and the radial through holes of the support rings are adjusted, and then the distances from the lower hinged supports to the axes of the support rings are changed to adapt to clamping of the conical barrel bodies of different diameters. The horizontal rotating device is novel and simple in structure, and when the rotating device clamps the conical barrel body to roll on an idler wheel, the various operations like automatic welding for the butted joint of the long conical barrel body, multi-directional mounting on a cone body, and welding parts inside and outside the cone body are completed.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

Multifunctional mechanical arm for helping physically-challenged people

InactiveCN103932828AThe shape has a wide range of applicationsSatisfy gripping workWheelchairs/patient conveyanceInvalid friendly devicesManipulatorBellcrank

The invention belongs to the technical field of mechanical arms, and relates to a multifunctional mechanical arm for helping physically-challenged people. The mechanical arm comprises a base plate, a steering machine and clamping fingers. A sliding way is arranged on the base plate, the lower portions of the clamping fingers are connected with sliding blocks, the clamping fingers are matched with the base plate through the sliding blocks and the sliding way in a sliding mode, the steering machine is installed on the base plate, and the steering machine and the sliding blocks are connected through a crank link mechanism. The crank link mechanism comprises a crank and a connecting rod, the center of a rod body of the crank is connected with a power output shaft of the steering machine, one end of the crank and one end of the connecting rod are hinged, and the other end of the connecting rod is hinged to the sliding blocks. The sliding blocks are provided with sliding ways, the lower portions of the clamping fingers are provided with sliding grooves, and the clamping fingers are connected with the sliding blocks through the sliding grooves and the sliding ways. Springs are arranged between the sliding blocks and the clamping fingers, and the clamping planes of the clamping fingers are provided with elastic rubber pads. The mechanical arm is provided with a tool connecting handle, the tool connecting handle is matched with the mechanical arm, and the end of the tool connecting handle is connected with a tool. The clamping planes of the clamping fingers are provided with grooves, and the grooves correspond to the tool connecting handle.

Owner:NORTHEASTERN UNIV

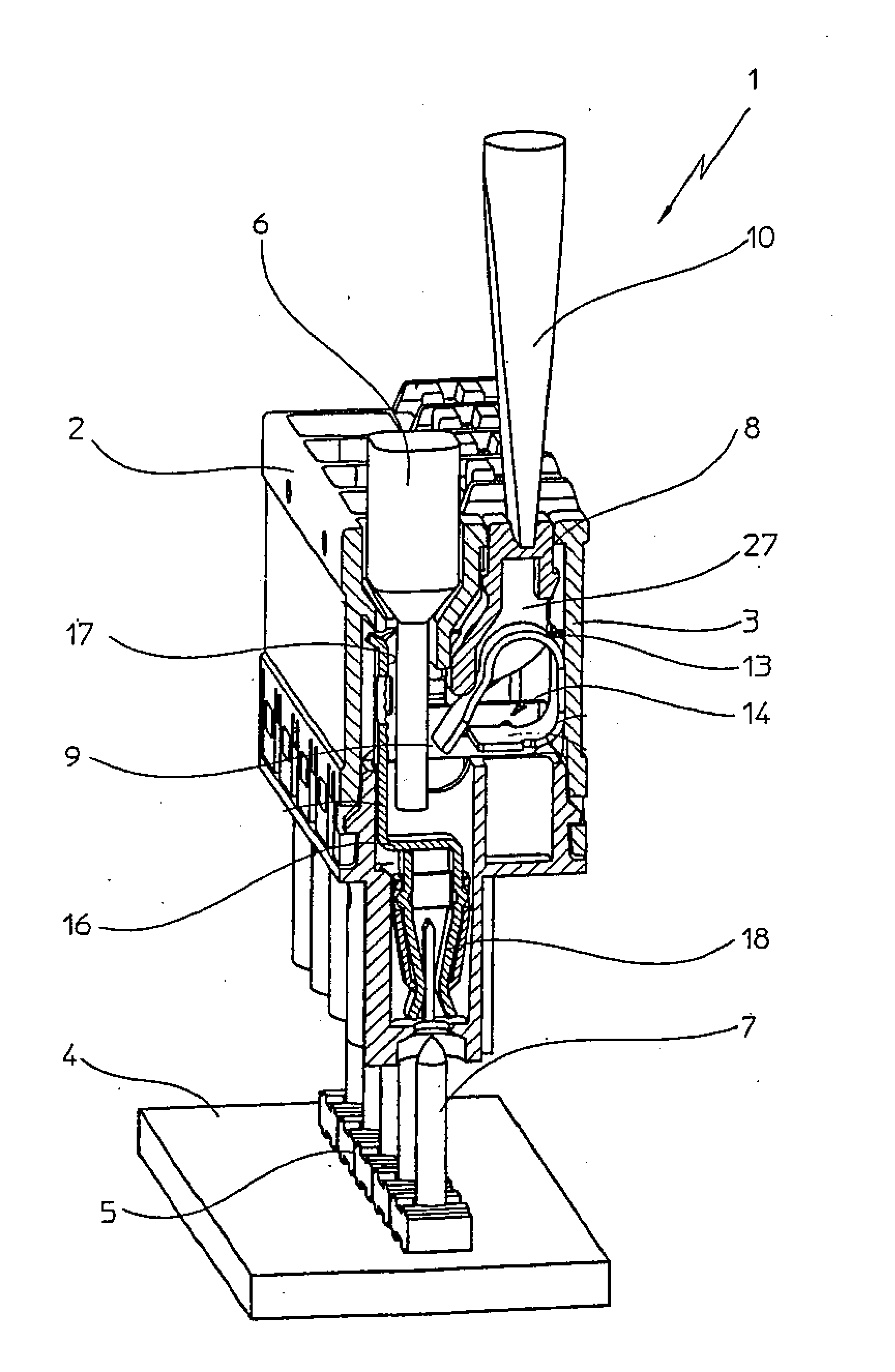

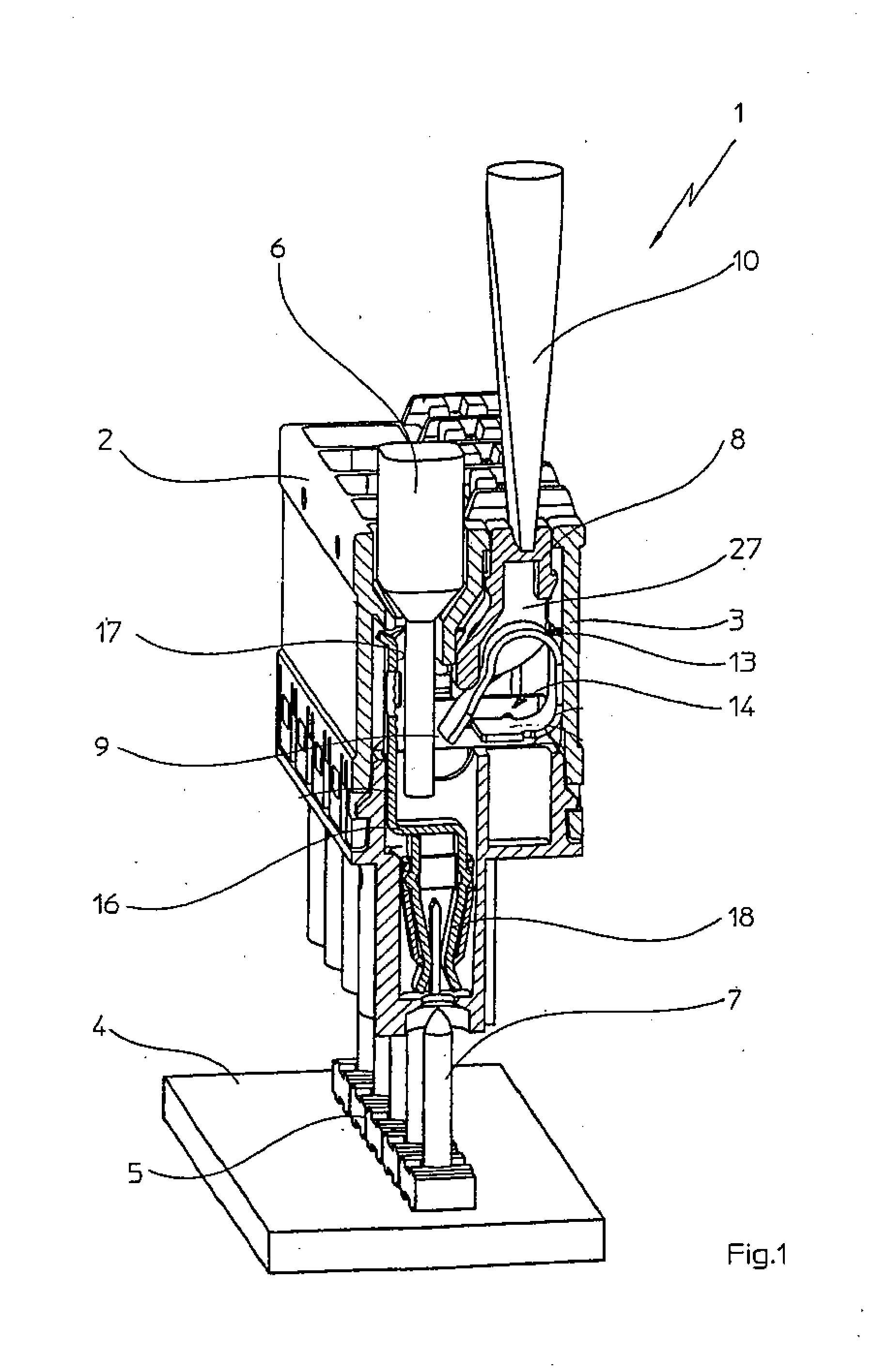

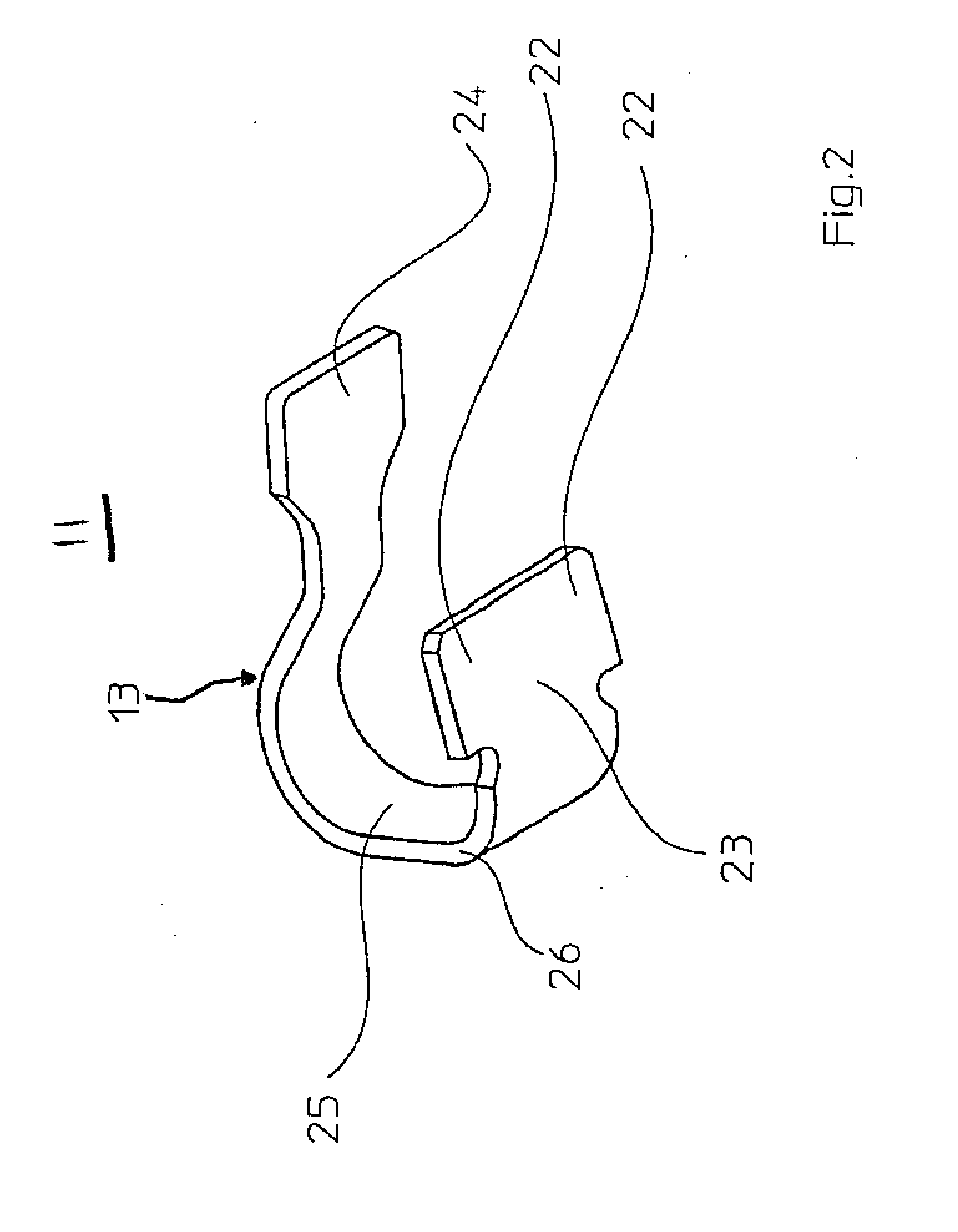

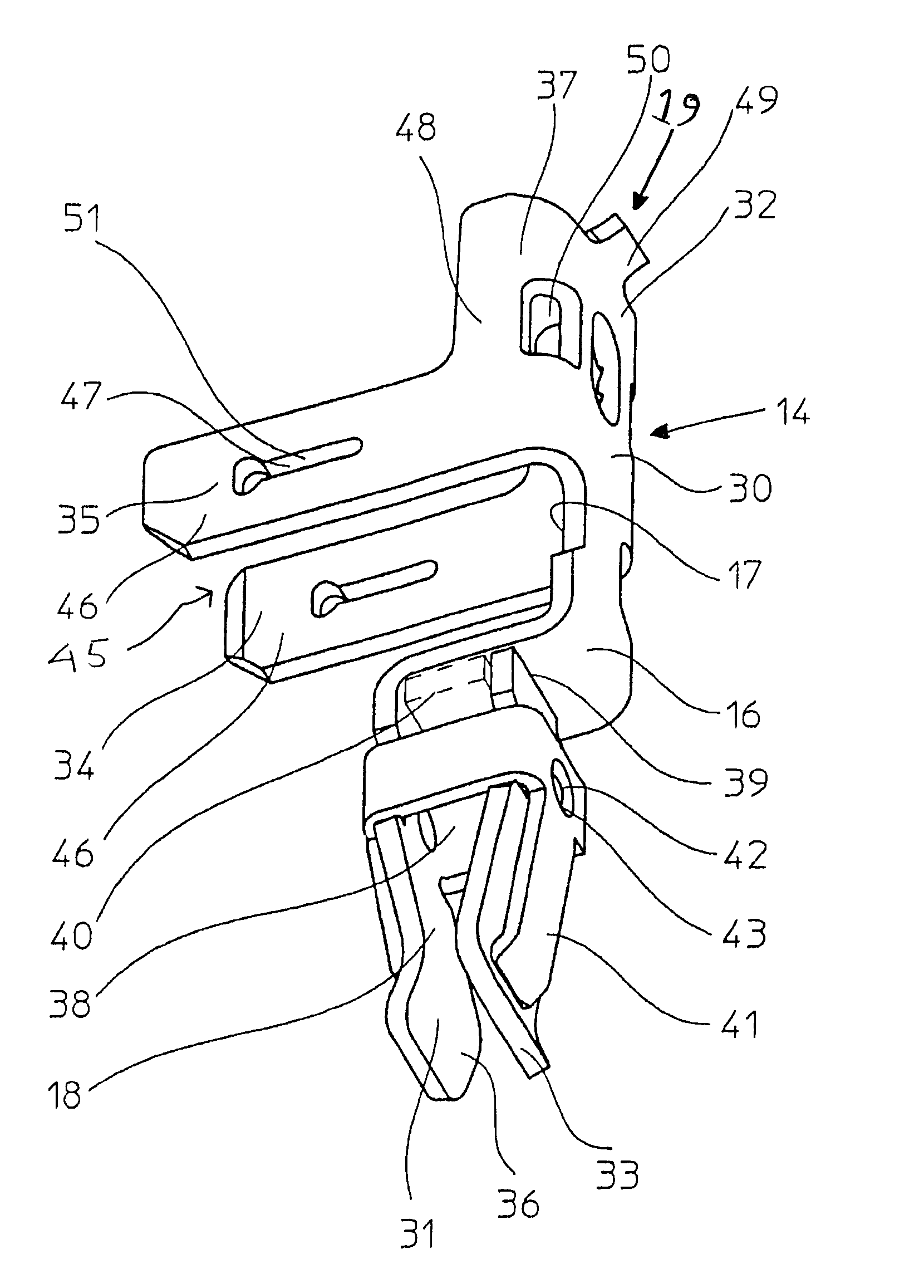

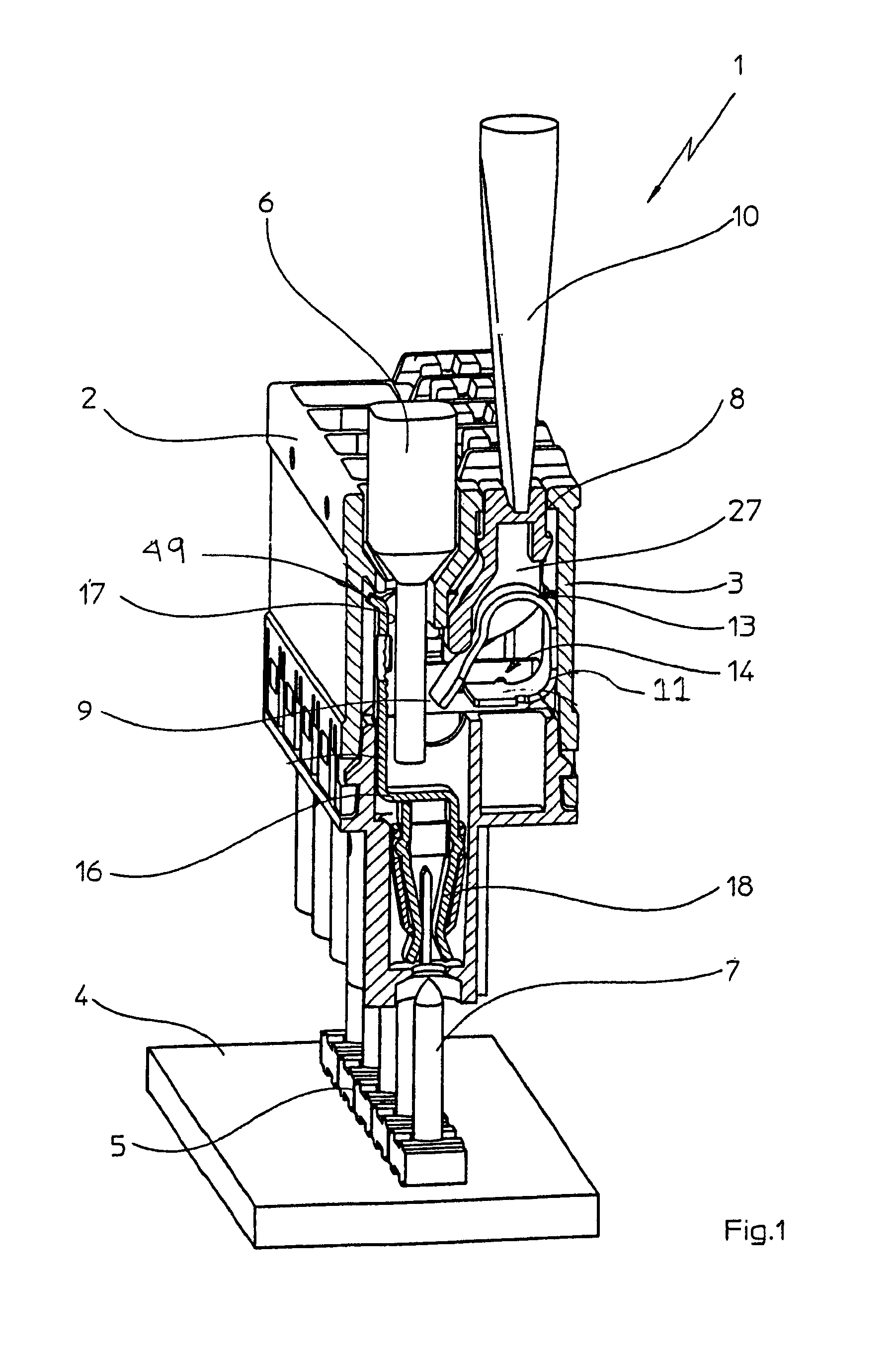

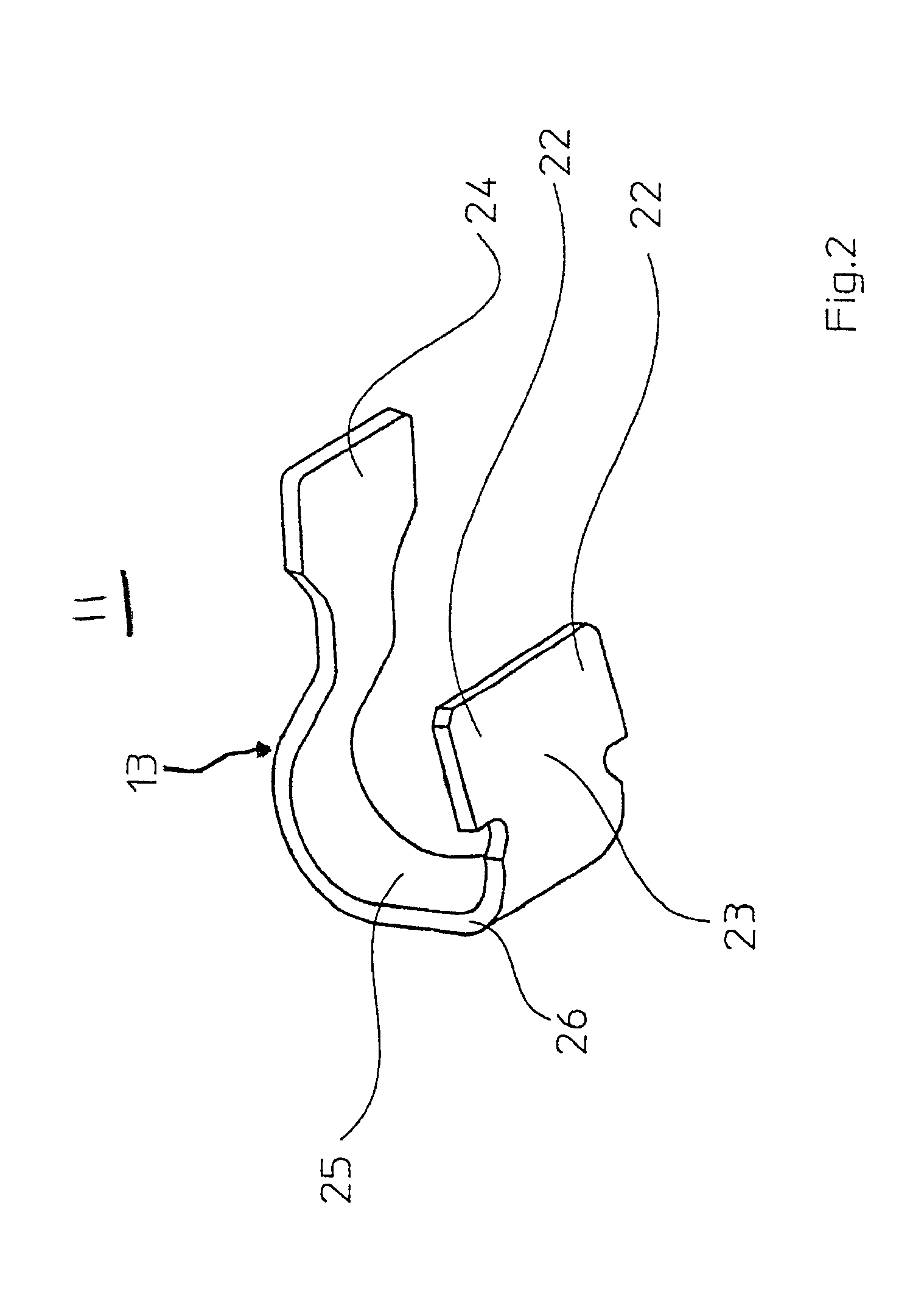

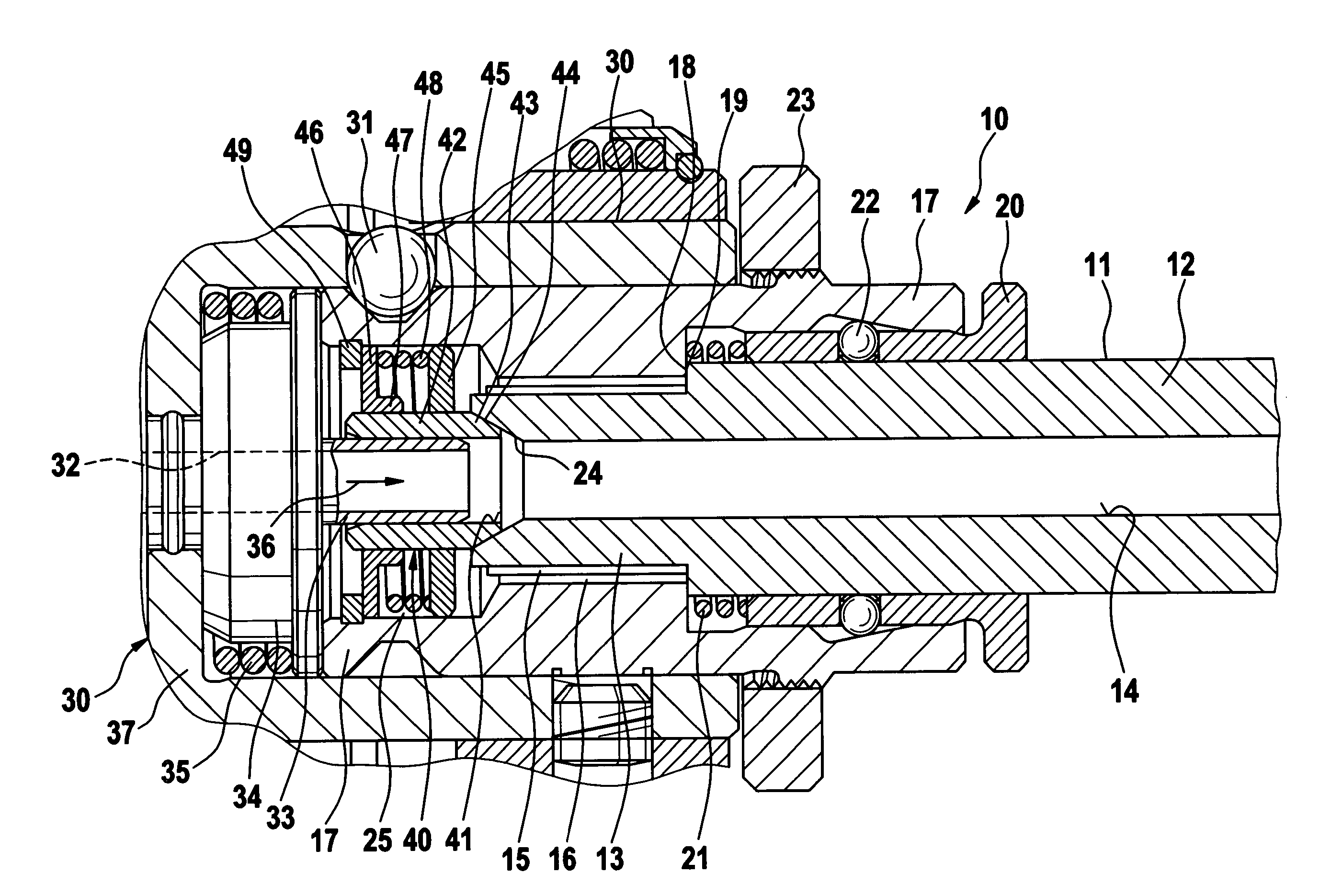

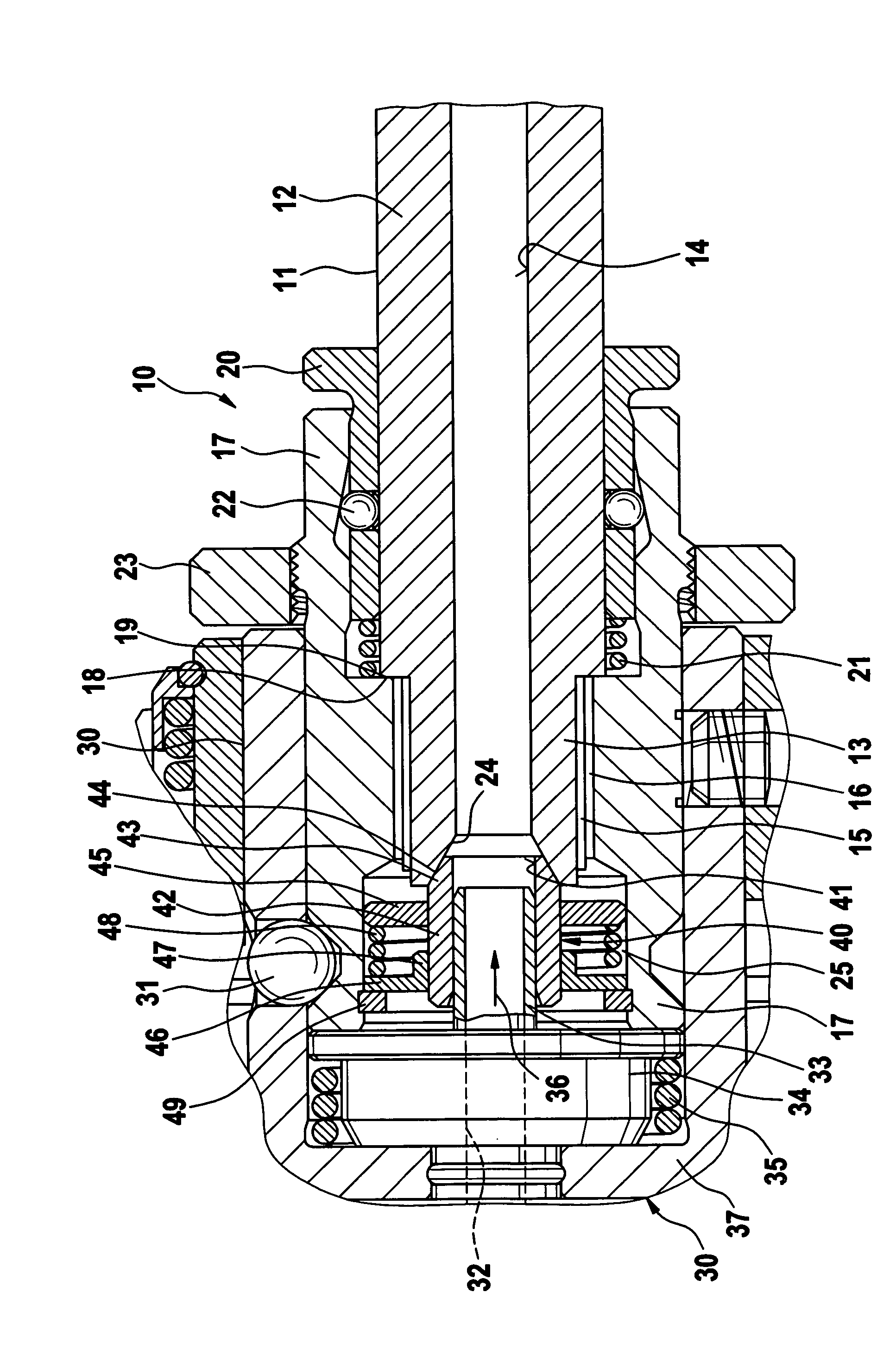

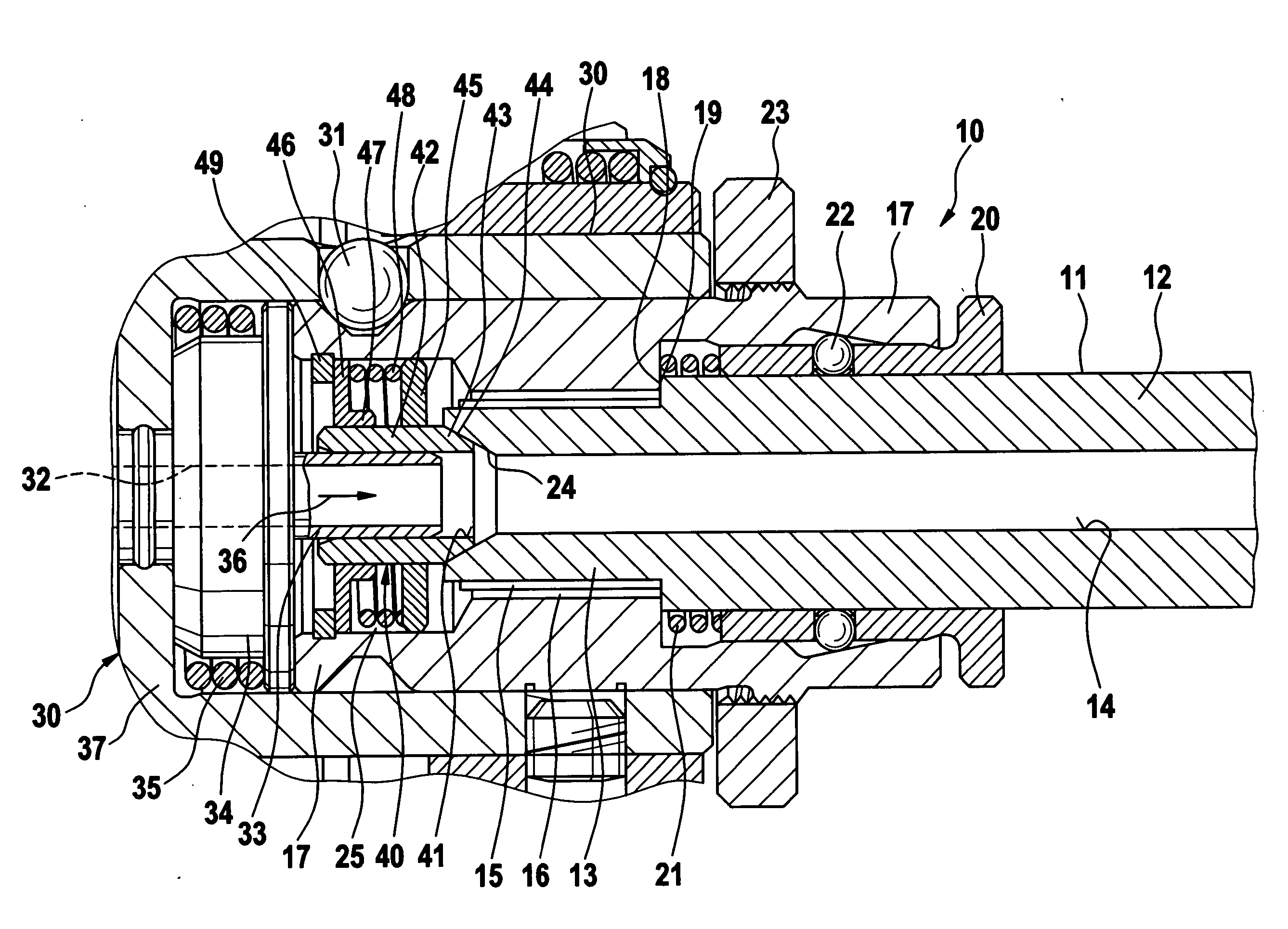

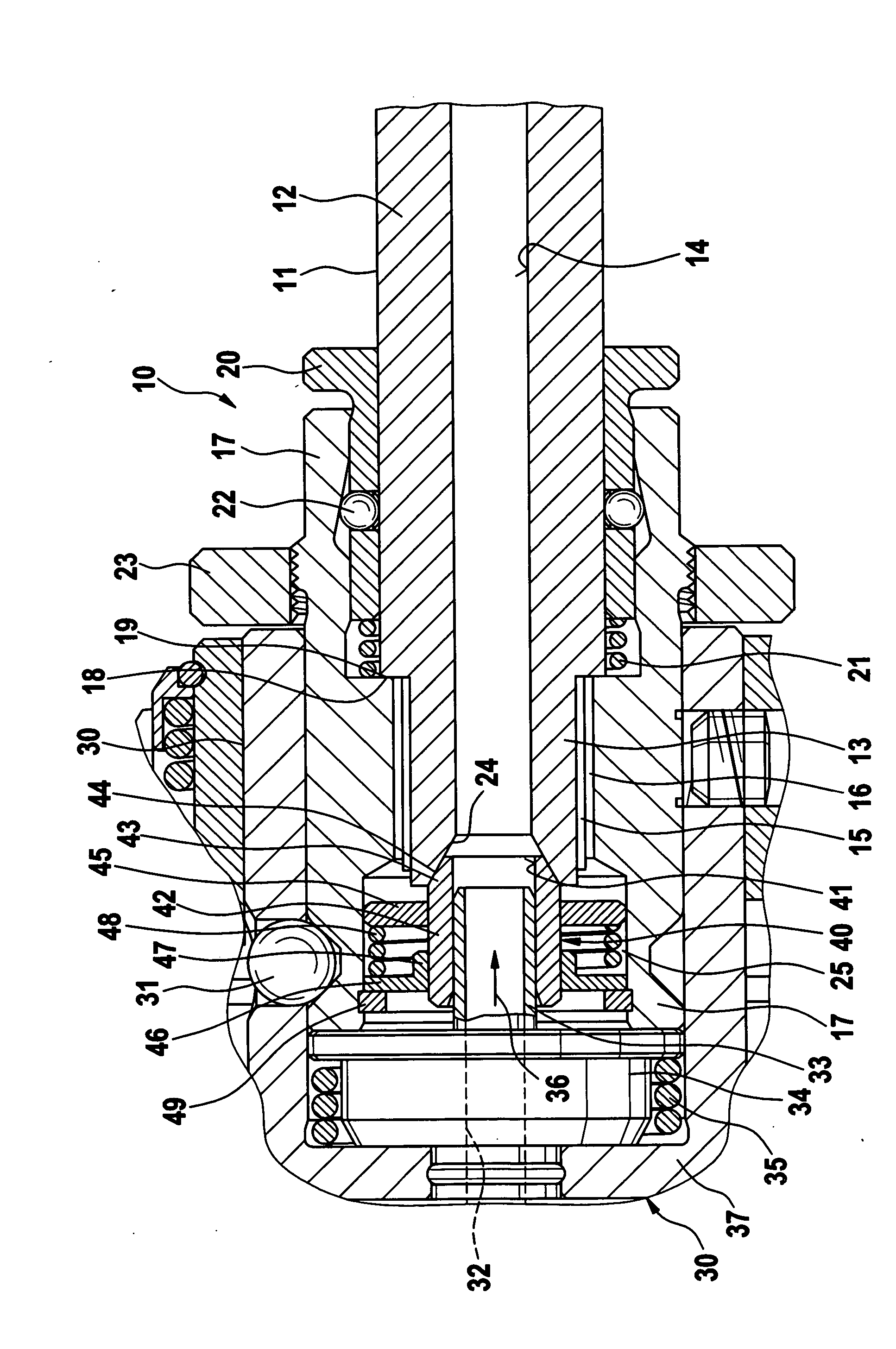

Quick-change insert for tools, especially for thread drills

InactiveUS7244080B2High clamping reliabilityMinimal lubricationThread cutting machinesTransportation and packagingEngineeringKnife blades

The present invention relates to a quick-change insert (10) for tools (11), in particular thread drills (12), for minimal lubrication, that is designed for detachable installation in a chuck (30) provided with a central lubricant channel (32) and for introducing the lubricant as an aerosol from the lubricant channel (32) into the rear end of a longitudinal bore (14) of an inserted tool (11). A sealing body (40) provided with a central passage (41) is located in a rear receptacle (25) of the insert body (17) such that, when the tool (11) is inserted and installed in the chuck (30), it connects the lubricant channel (32) and the longitudinal bore (14) of the tool (11) with each other in an at least substantially leakproof manner.

Owner:OTTO BILZ WERKZEUGFAB

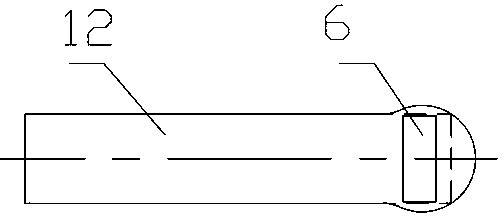

Parallel crank guide rod self-rotating positioning mechanical arm

InactiveCN101234487APrecise pick and place functionLow positioning dependenceProgramme-controlled manipulatorGripping headsManipulatorBellcrank

The invention provides an autorotation location manipulator of a parallel crank guide, which comprises an interface frame, driving location, a parallel crank guide clamping mechanism and autorotation location fingers, wherein, the interface frame comprises a fixed disc 13 and a manipulator interface mechanism 8 arranged on the fixed disc; the driving location part comprises a motor 11 arranged on the fixed disc, a motor code disc 10 arranged at the back of the motor and a travel switch 5 at the terminal end of the guide 6; the parallel crank guide clamping mechanism comprises a guide 6, an autorotation revolute joint 7, a crank revolute joint 9 and a crank disc 12 connected with the motor output shaft. The guide 6 is articulated with the crank disc 12 by the crank revolute joint 9 and the autorotation revolute joint 7 is arranged between the fixed disc 13 and the guide 6. The autorotation location manipulator has the advantages of autorotation location and low dependence on the noumenon location of robots. The clamping gesture of objects in the manipulator is adjusted by autorotation location fingers. The manipulator is reliable in clamping and simple in structure.

Owner:HARBIN ENG UNIV

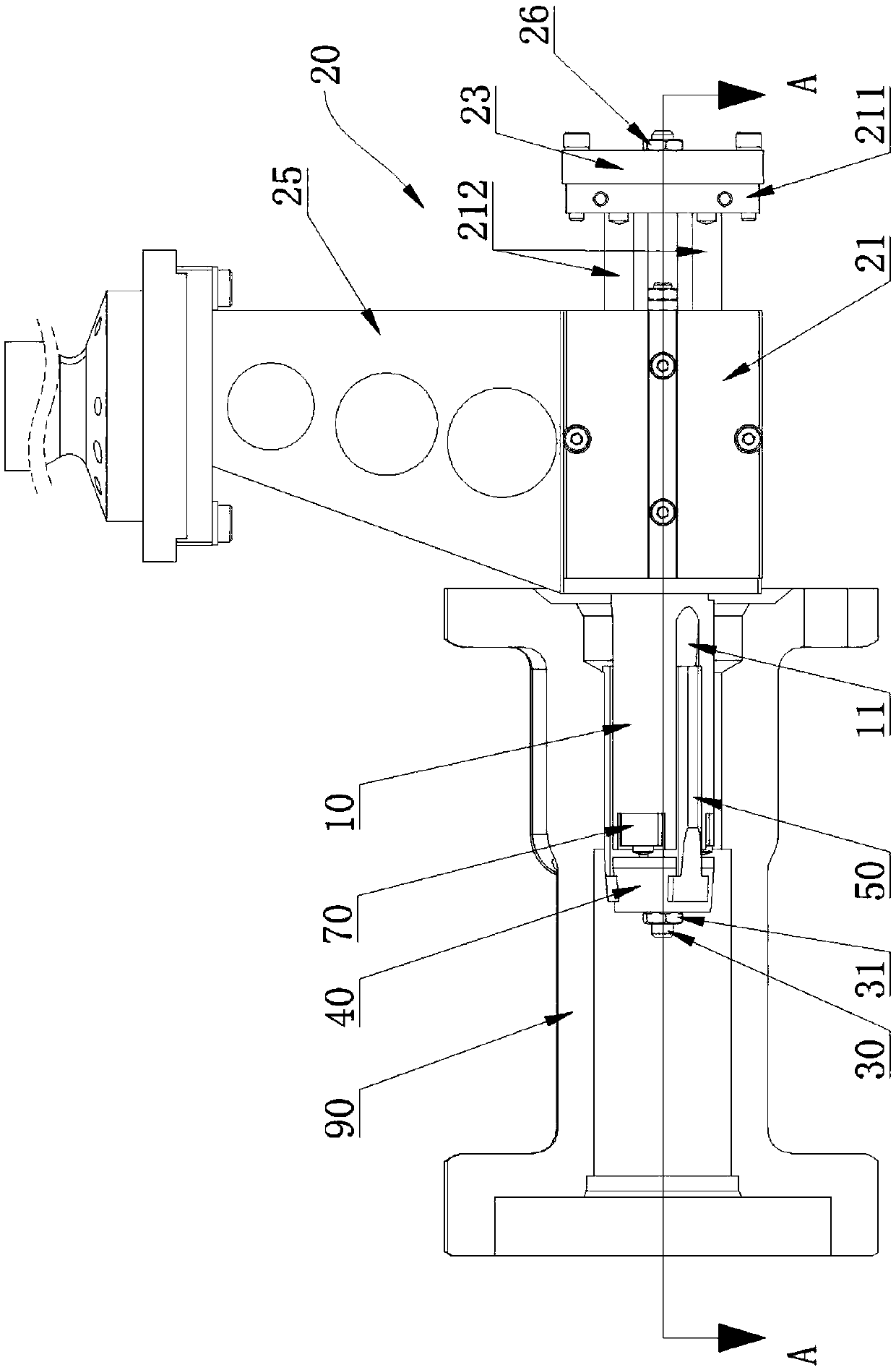

Inner hole clamping device

PendingCN107650138ARealize automatic alignmentRealize automatic centeringGripping headsConveyor partsEngineeringSmall hole

The invention provides an inner hole clamping device. The inner hole clamping device can solve the problem that a traditional spring sleeve cannot conduct reliable clamping or picking on small-inner-hole, large-dead-load and long-inner-hole workpieces, and accordingly the industrial machine automatic production requirement can be met. The inner hole clamping device comprises a core bar and a drivemechanism, the core bar is provided with an axial center through hole, the axial center through hole is internally provided with a pull rod in a penetrating manner, the pull rod can move in the axialdirection, the front end of the pull rod is connected with a pulling block, and the rear end of the pull rod is connected with the drive mechanism. Three sliding grooves which horizontally extend inthe axial direction and are parallel are evenly distributed in the peripheral face of the front end of the core bar in the circumferential direction. The groove bottom faces of the sliding grooves arewedge-shaped groove faces with the radial groove depths gradually increased from back to front. Each of the three sliding grooves internally contains a sliding claw, each sliding claw is provided with a wedge-shaped inclined face which is in sliding fit with the corresponding wedge-shaped groove, and the front end of each sliding claw is fixedly connected with the pulling block.

Owner:昆山巨林科教实业有限公司

Air cylinder sleeve clamp

ActiveCN107900746AAvoid damageSmall clamping deformationWork holdersPositioning apparatusEngineeringMechanical engineering

Owner:UNIV OF JINAN

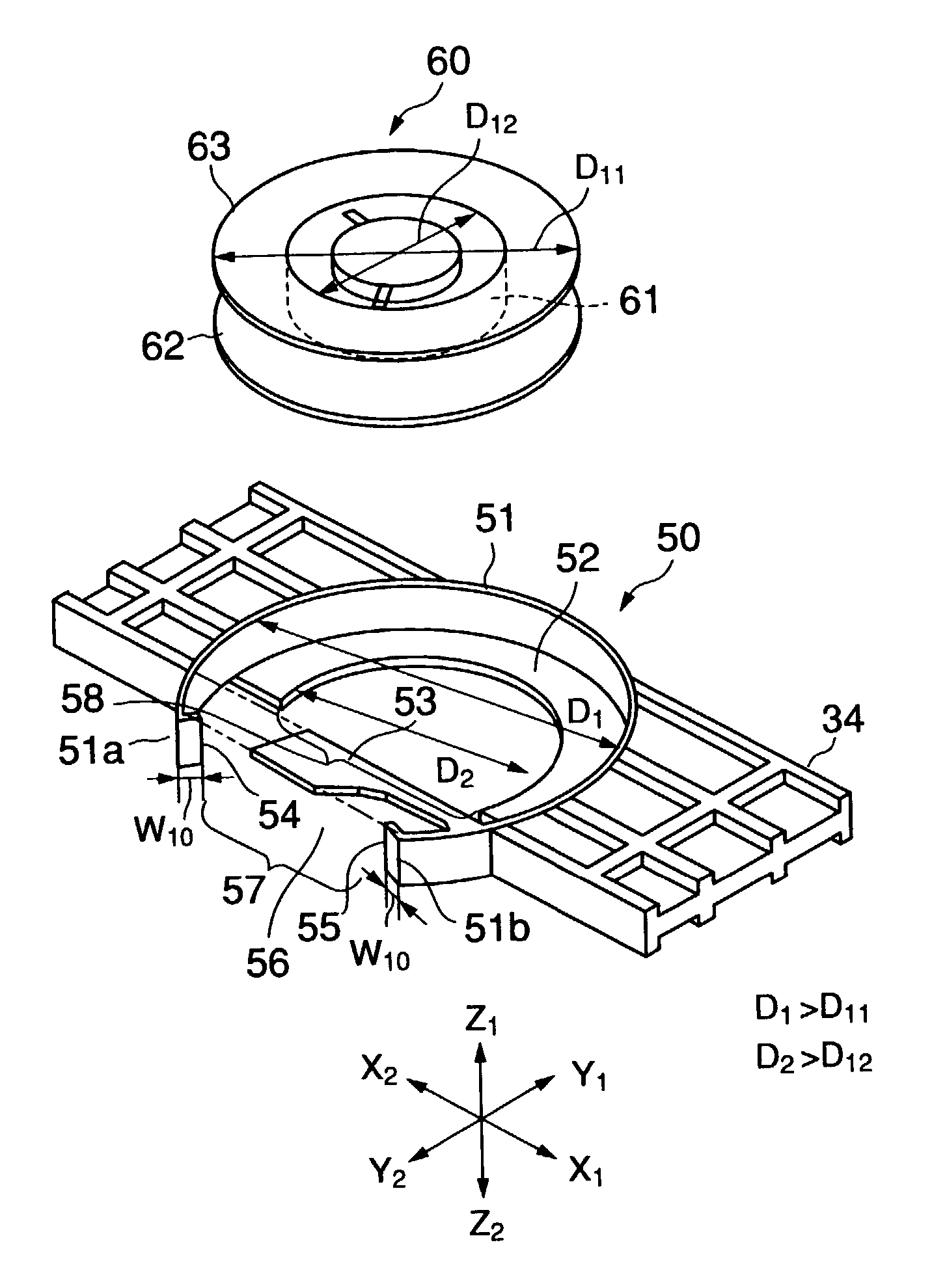

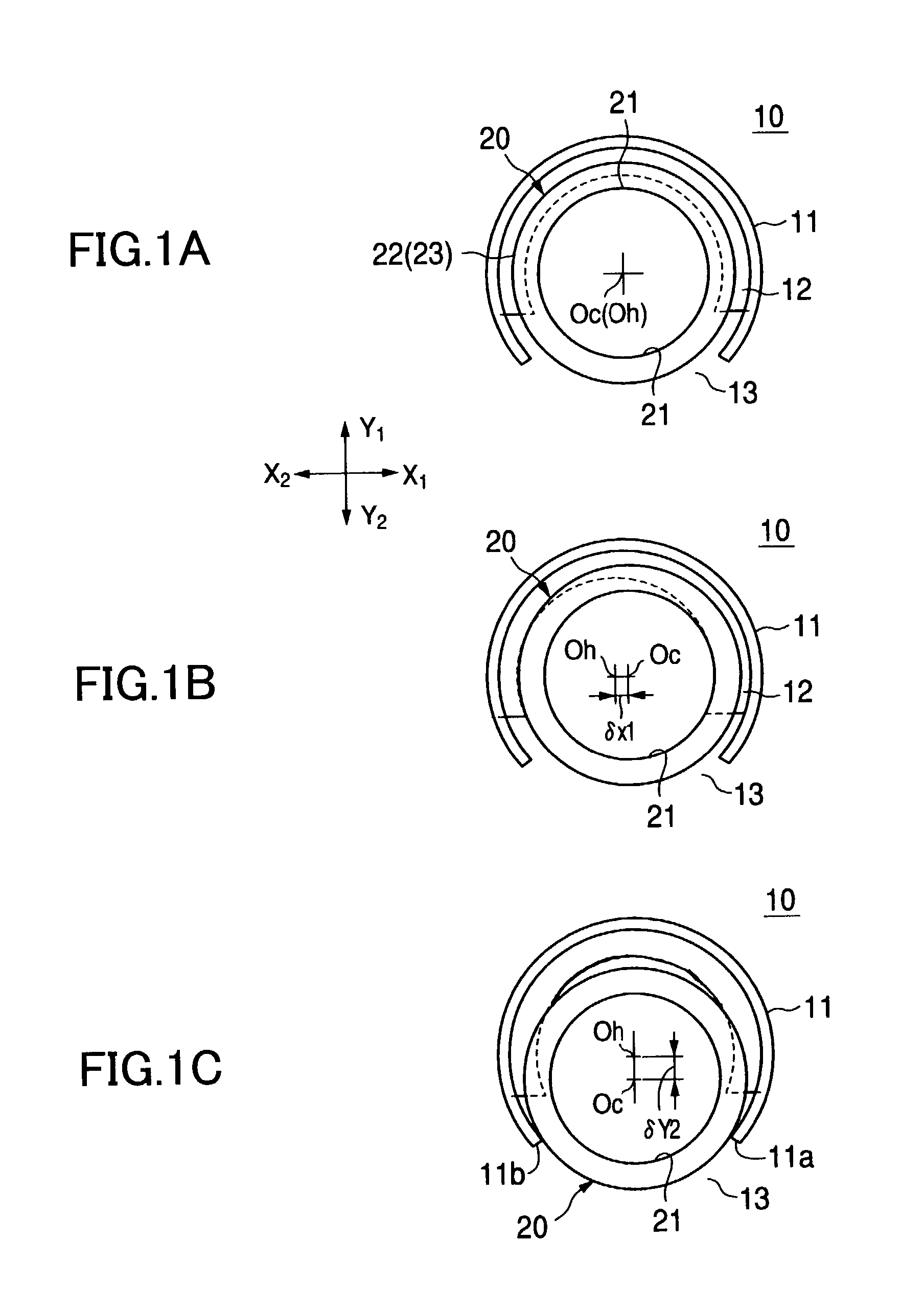

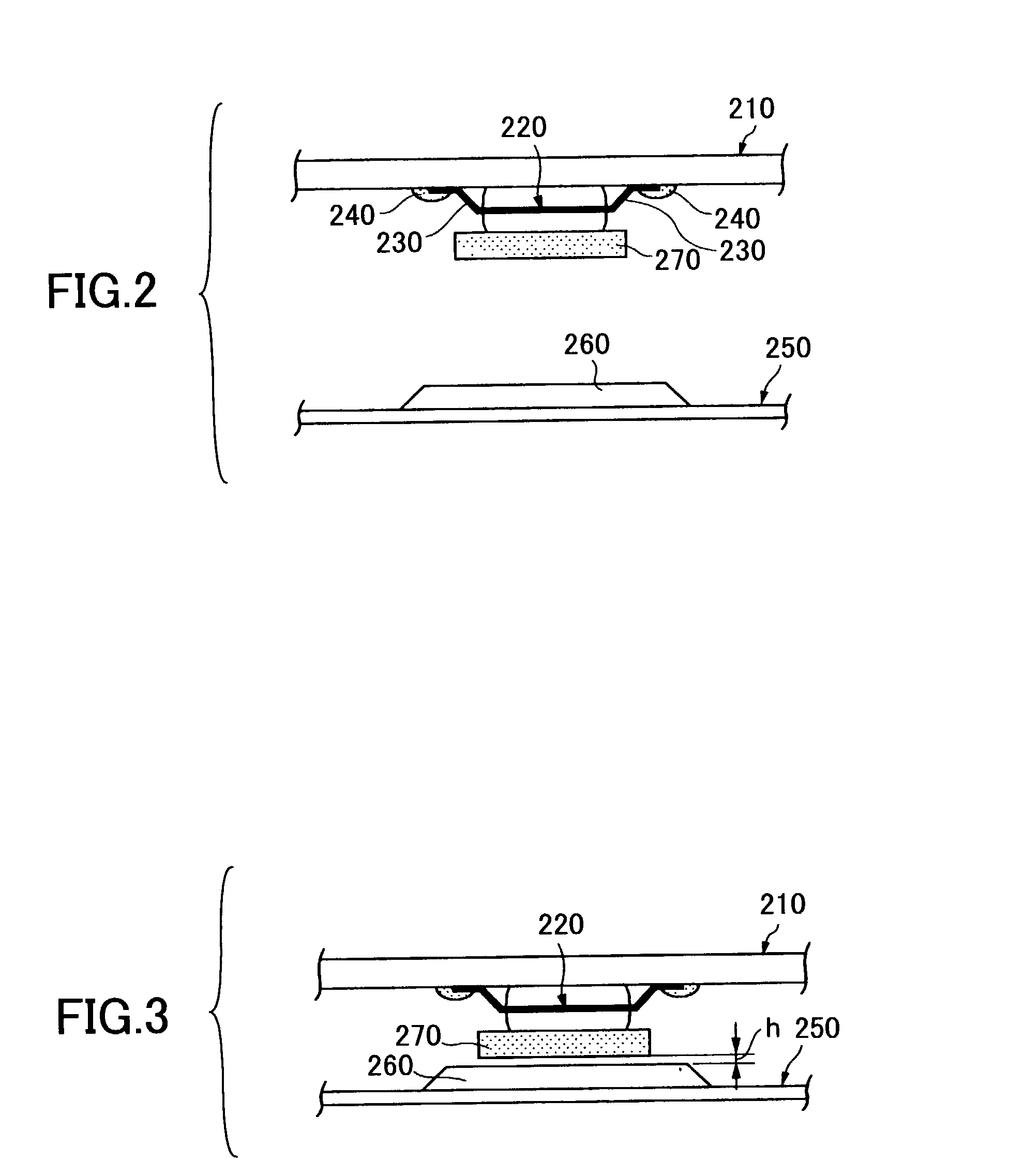

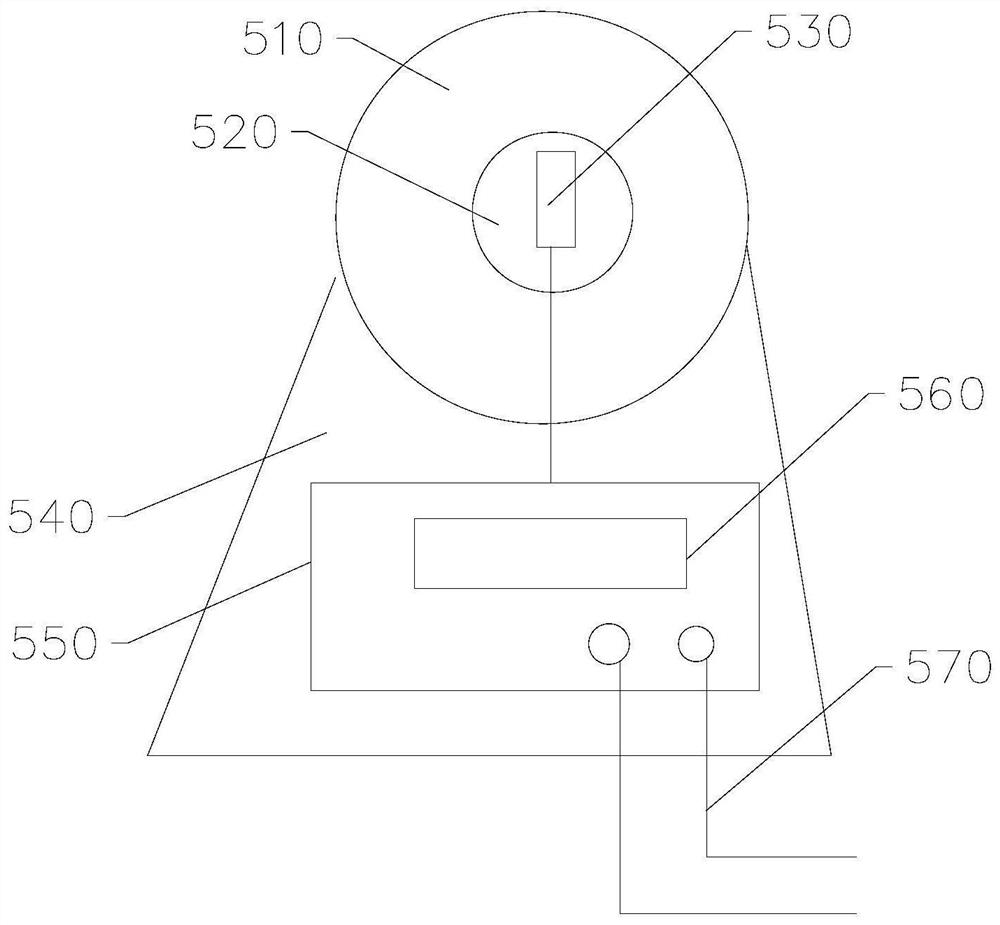

Holding mechanism of an optical disk clamper and an optical disk drive using the same

InactiveUS7194745B2Eliminate the problemHigh clamping reliabilityRecord information storageReducing physical parameters of carriersEngineeringOptical disc drive

An optical disk clamper holding mechanism that holds an optical disk clamper includes a surrounding unit, a flange unit, a rib that touches, when the optical disk clamper moves in the direction of the flange opening, a rim portion of an upper flange unit of the optical disk clamper, the rib protruding inwardly at a position opposite to the flange opening. Since the range of clearance in which the optical disk clamper can move in the optical disk clamper holding mechanism is restricted, the optical disk clamper always fits in the turntable normally and consequently, always clamps the optical disk normally.

Owner:MITSUMI ELECTRIC CO LTD

Quick-change insert for tools, especially for thread drills

InactiveUS20050244234A1High clamping reliabilityEffort has been simplified and reducedSleeve/socket jointsTransportation and packagingEngineeringKnife blades

The present invention relates to a quick-change insert (10) for tools (11), in particular thread drills (12), for minimal lubrication, that is designed for detachable installation in a chuck (30) provided with a central lubricant channel (32) and for introducing the lubricant as an aerosol from the lubricant channel (32) into the rear end of a longitudinal bore (14) of an inserted tool (11). A sealing body (40) provided with a central passage (41) is located in a rear receptacle (25) of the insert body (17) such that, when the tool (11) is inserted and installed in the chuck (30), it connects the lubricant channel (32) and the longitudinal bore (14) of the tool (11) with each other in an at least substantially leakproof manner.

Owner:OTTO BILZ WERKZEUGFAB

Under-actuated space capturing device with self-adaptability

ActiveCN110104228AGood self-centering clamping effectSmall and convenient structural designToolsReciprocating motionOrbit insertion

The invention provides an under-actuated space capturing device with self-adaptability. One ends of a plurality of clamping heads are positioned outside a shell; the other ends of the plurality of clamping heads extend into the shell through a shell end surface opening and are hinged to one end of a telescopic rod; torsion springs are mounted at the hinging positions; the telescopic rod is drivento move in a reciprocating manner in the axial direction of the shell so as to drive the clamping heads to extend out or retract into the shell; when the clamping heads extend out of the shell, the clamping heads are opened outwards in the radial direction of the shell under the effect of the torsion springs; the clamping heads are extruded by the shell end surface opening when retracting into theshell, and the clamping heads are closed to capture a target; pressure sensors are mounted at the contacting parts of the clamping heads and the target to feed back and control motion of the telescopic rod. The under-actuated space capturing device with self-adaptability has the advantages that the structure is small, simple and convenient, the cost is low, the labor is saved, the service life islong, automatic centering is realized, the clamping is reliable, continuous capturing and releasing of multiple targets can be realized, clamping head components possess self-adaptability and wide interface applicability; and greater application values in space operation tasks such as repairing, auxiliary orbit insertion and deorbiting of a failed satellite are realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

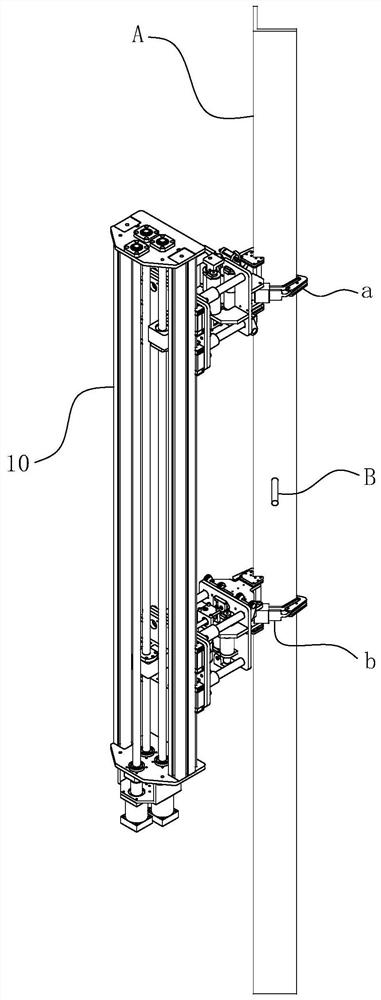

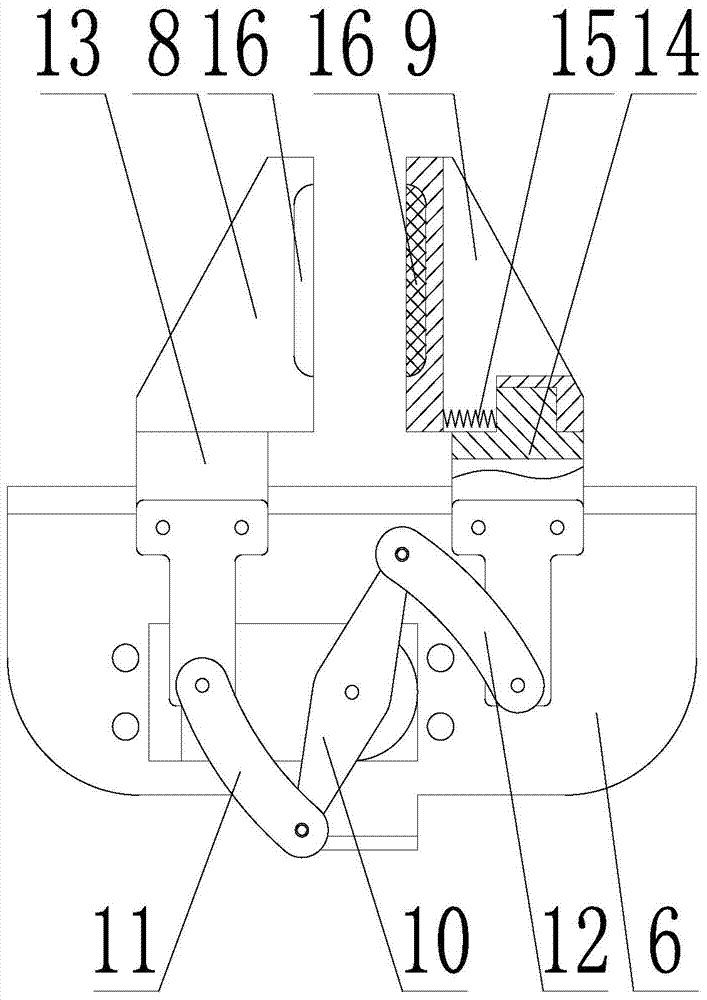

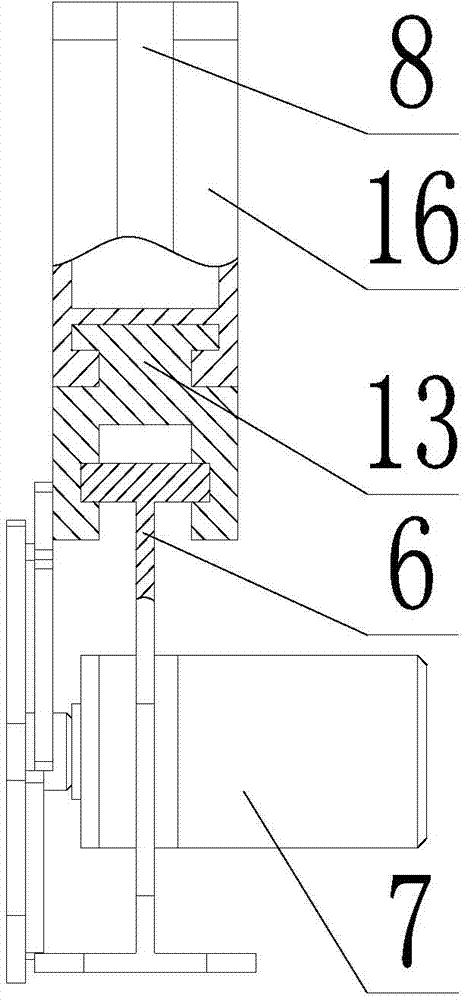

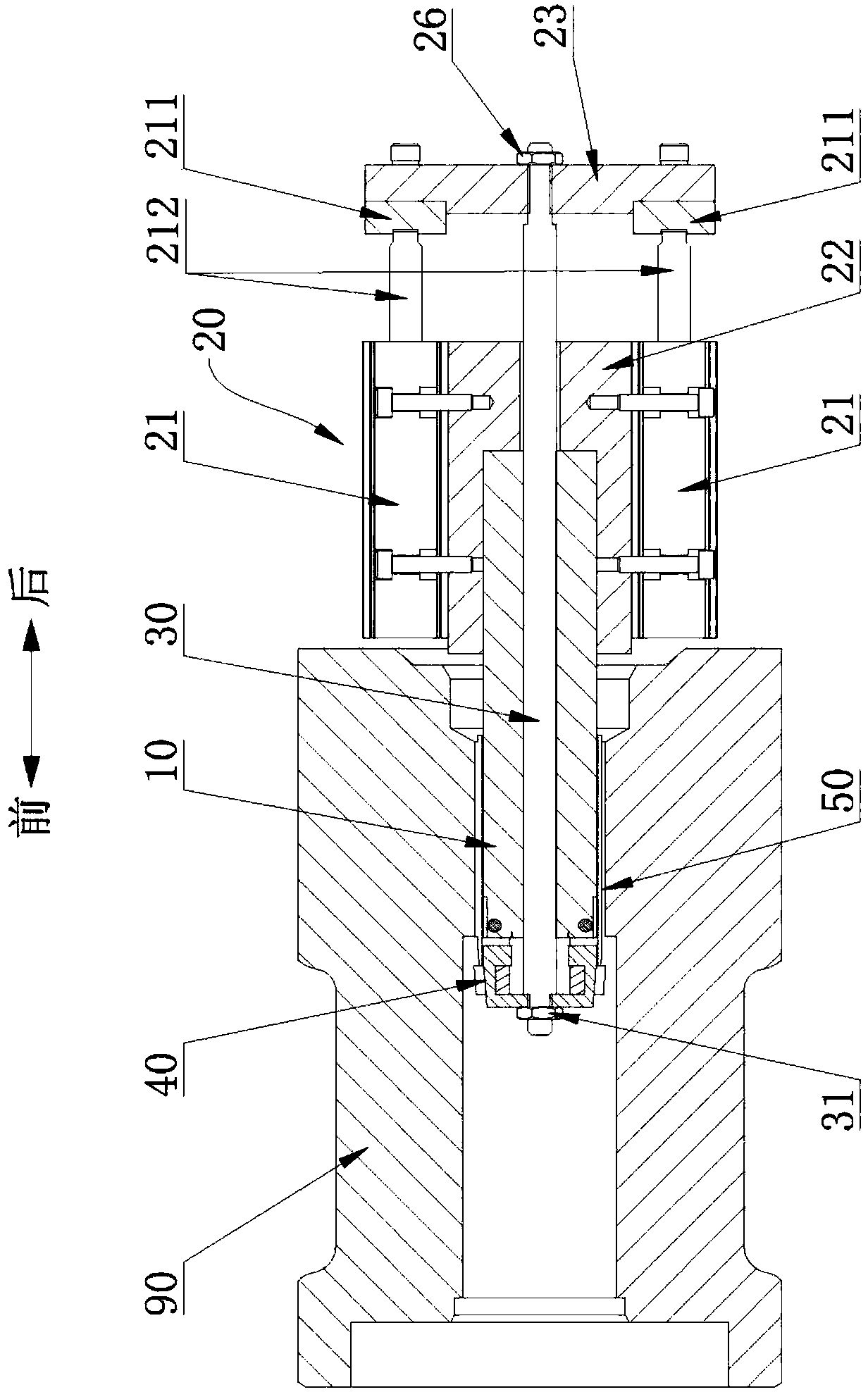

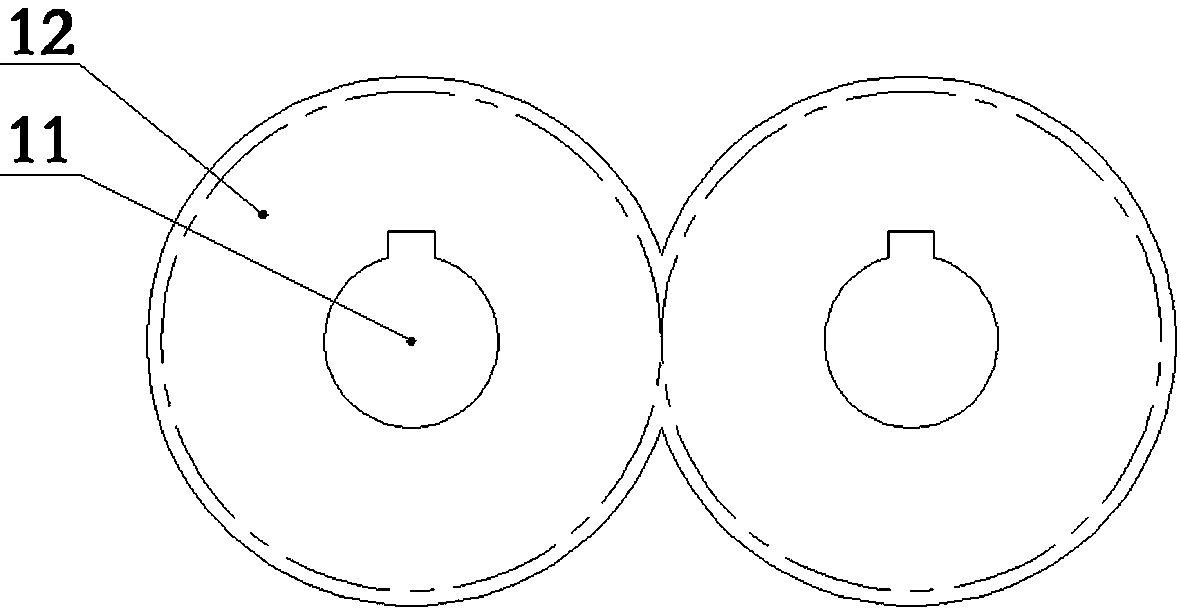

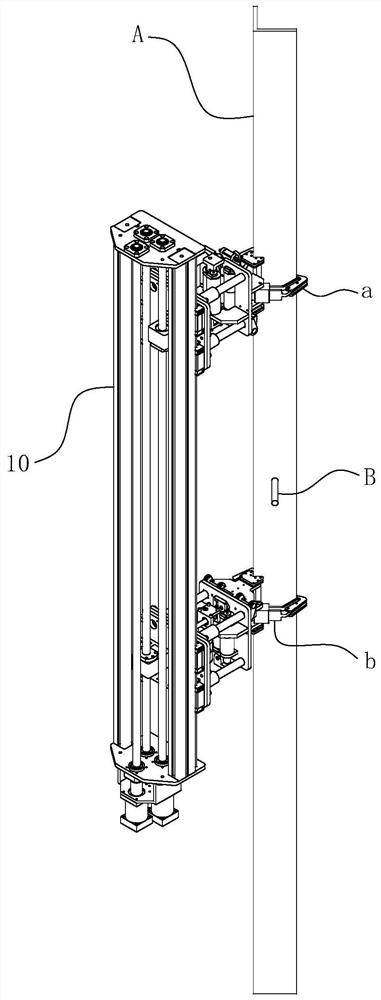

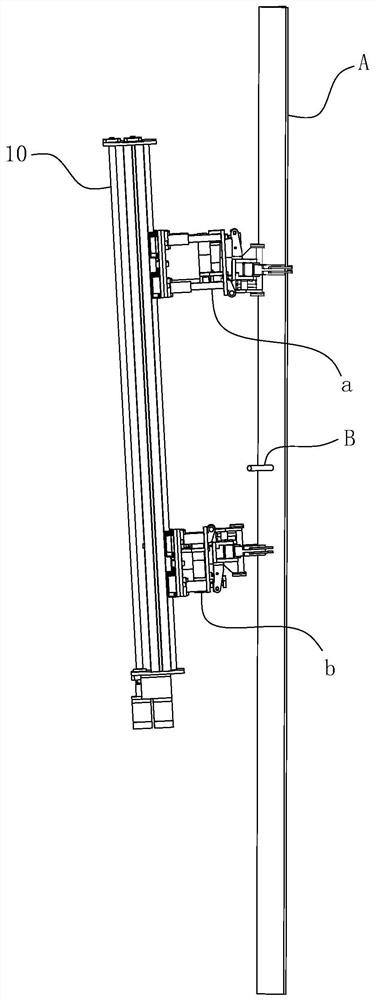

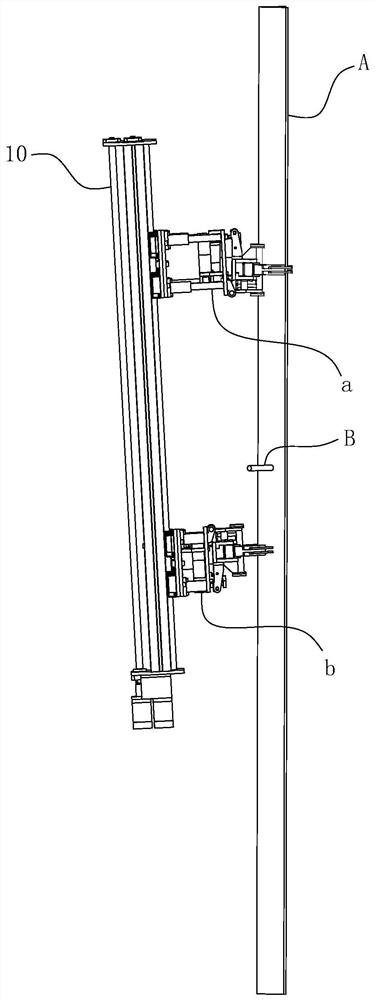

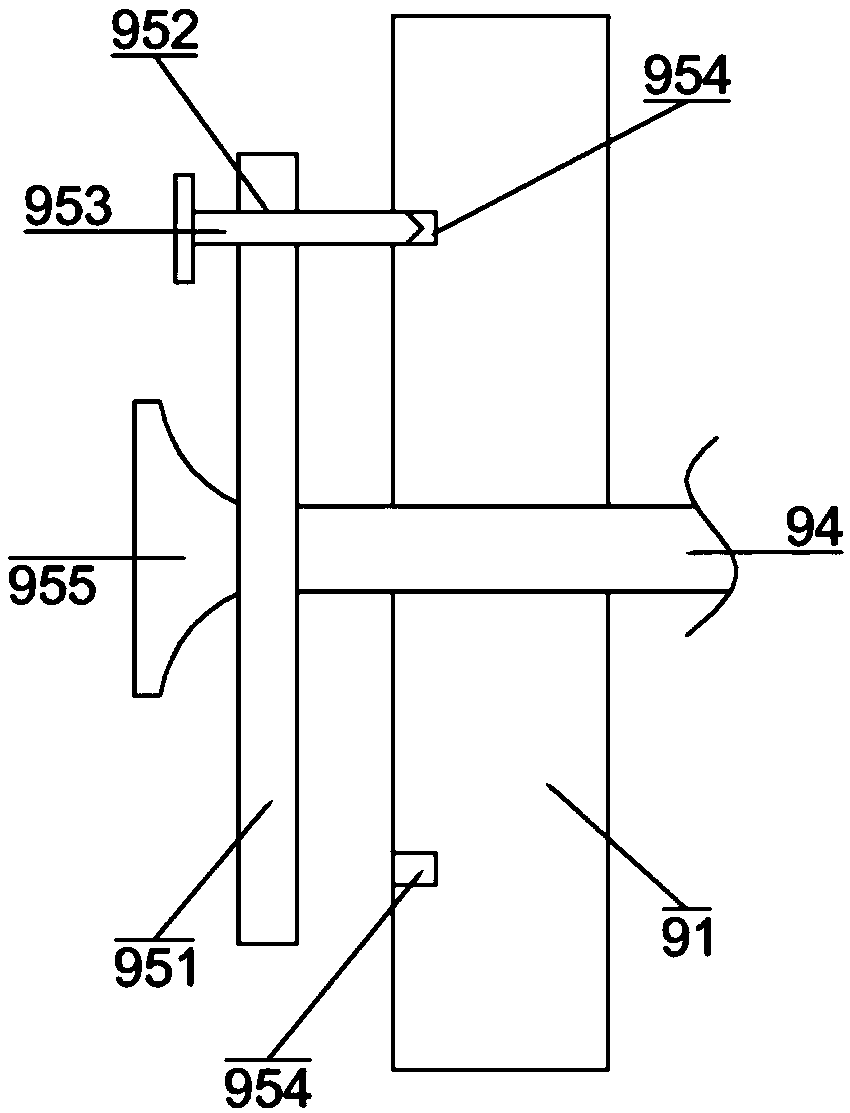

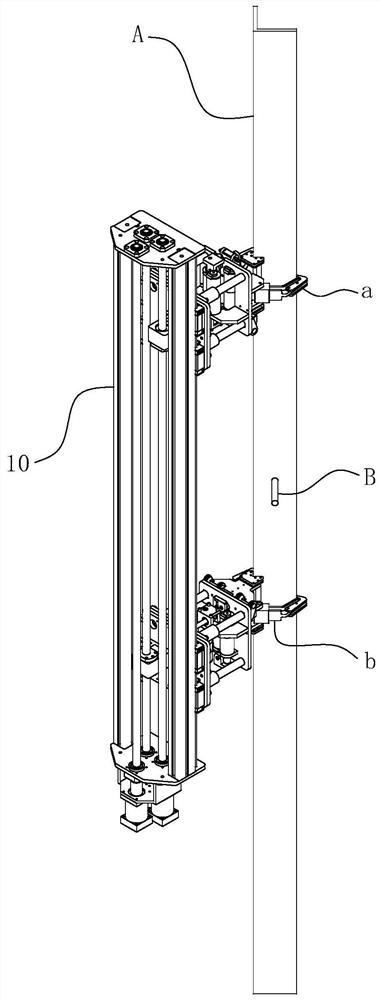

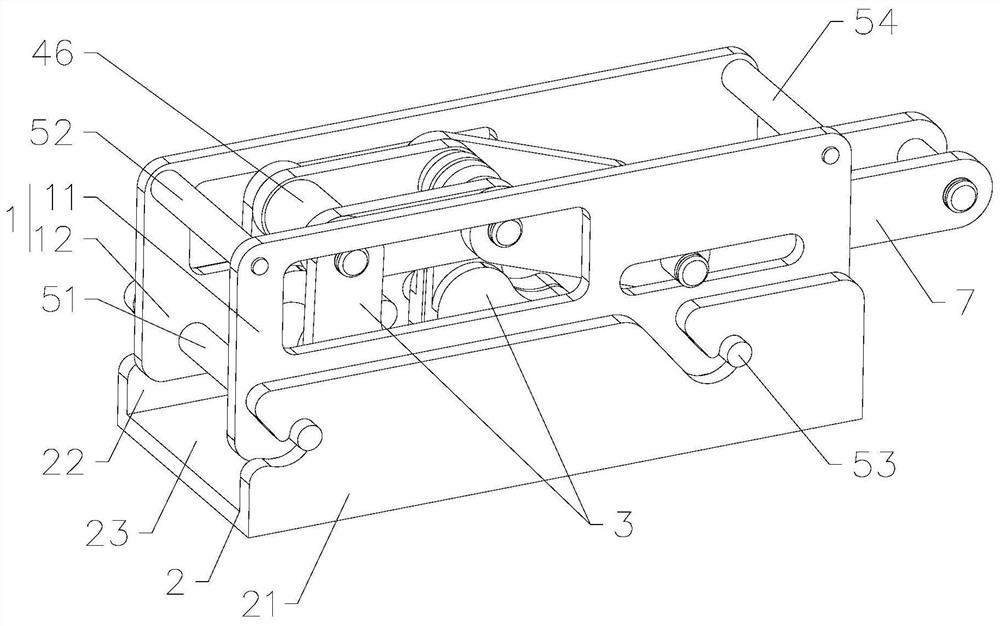

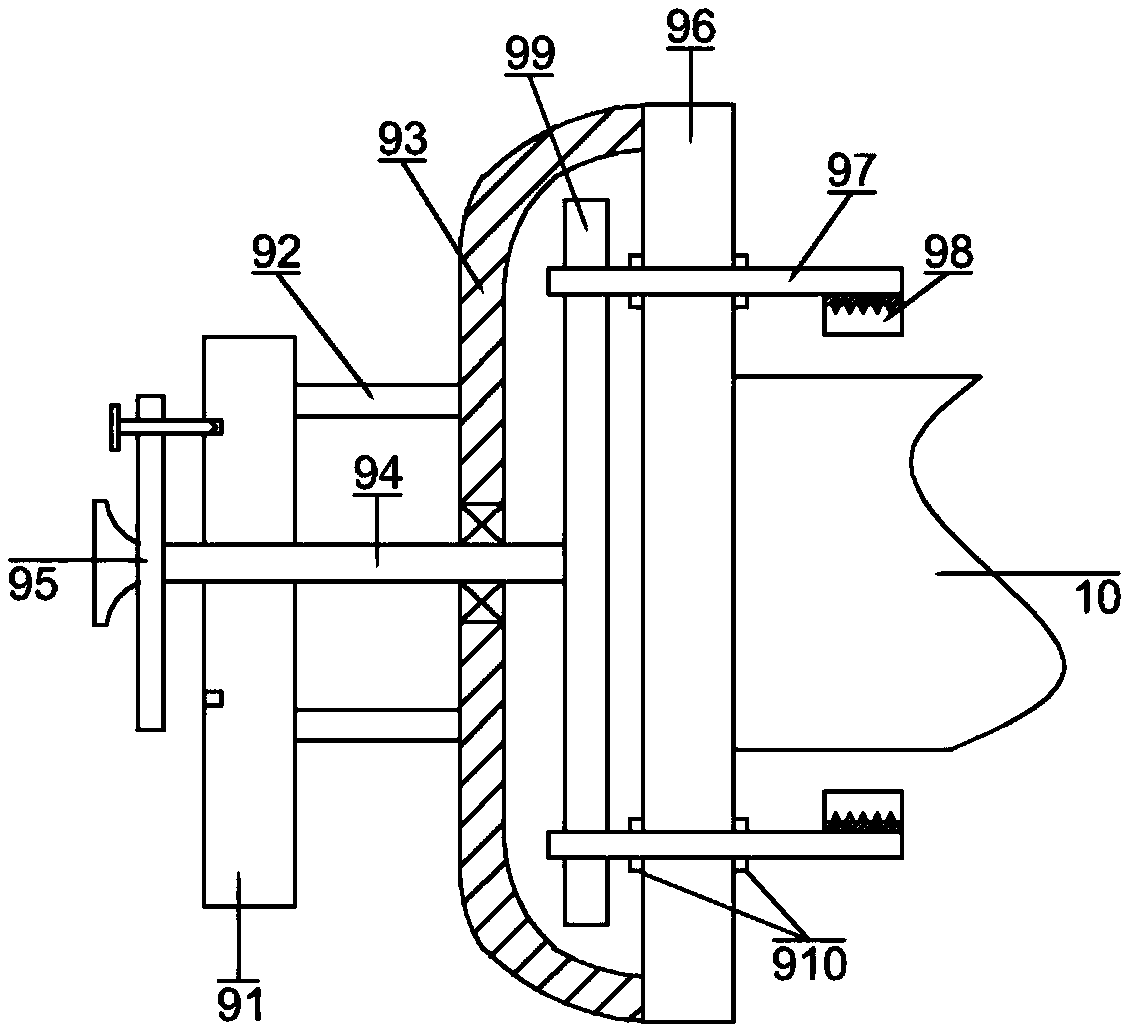

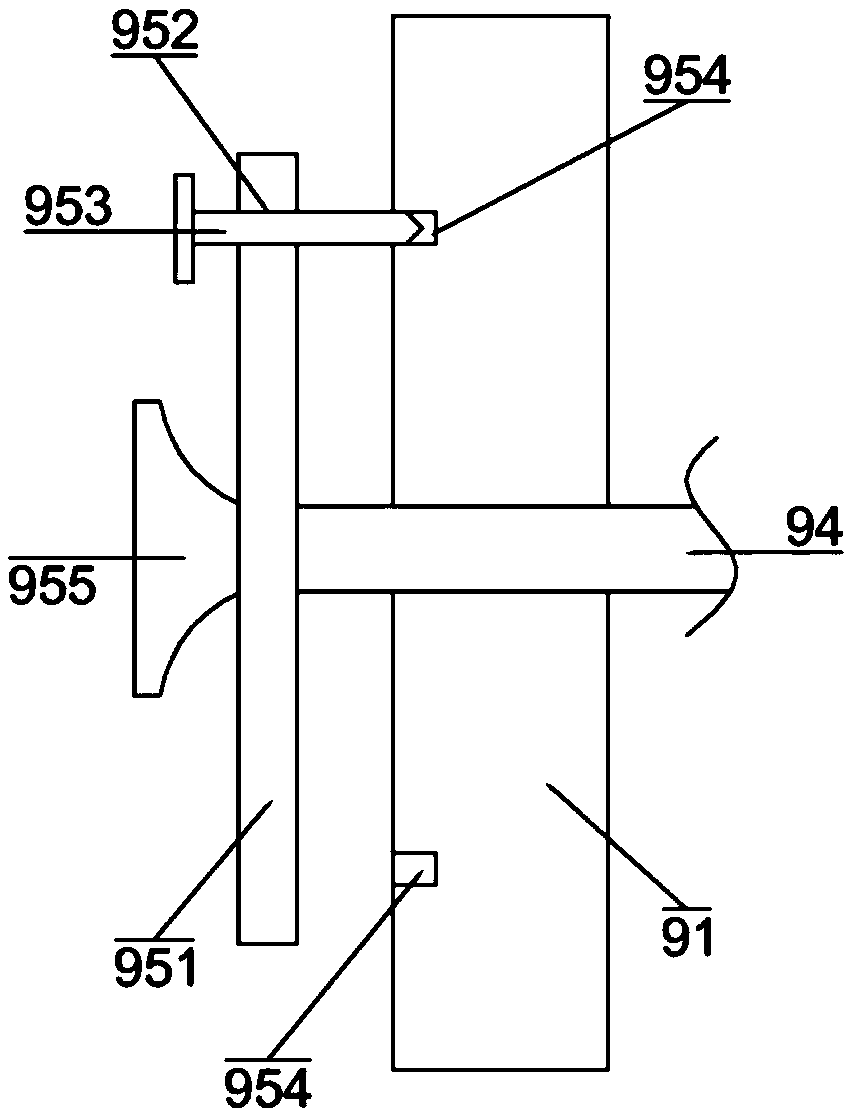

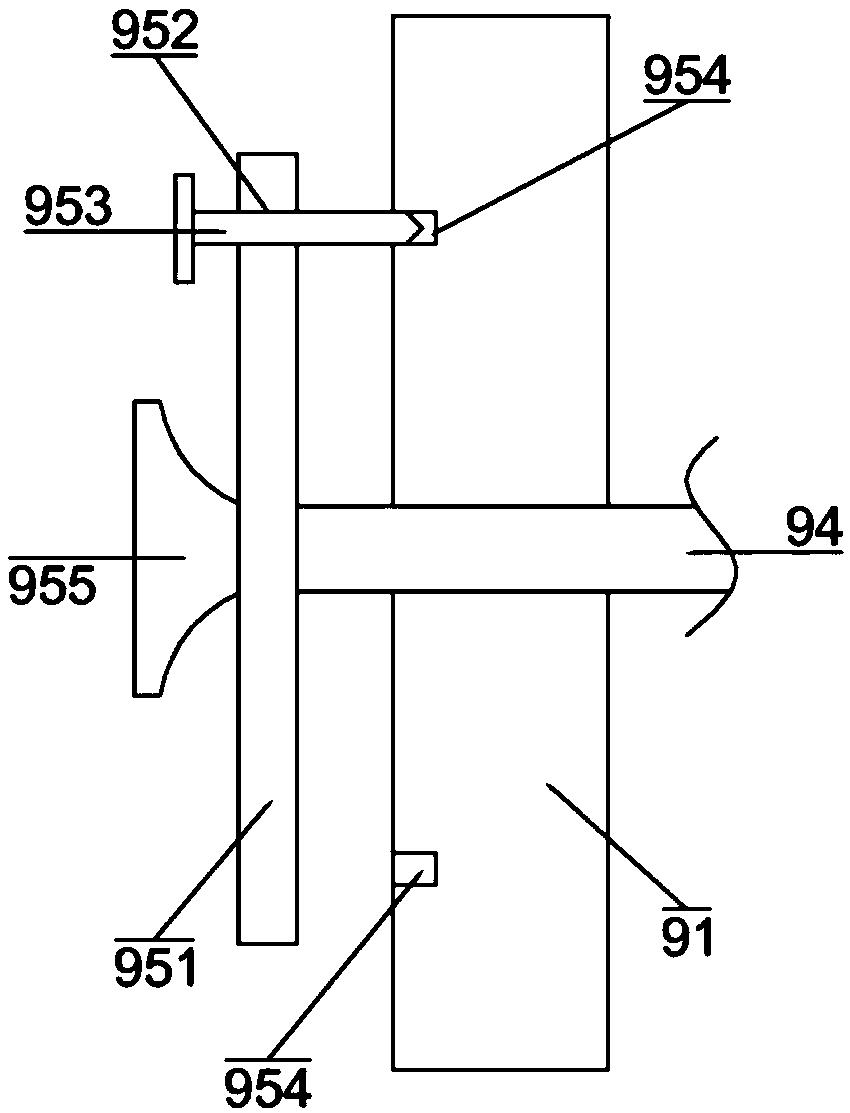

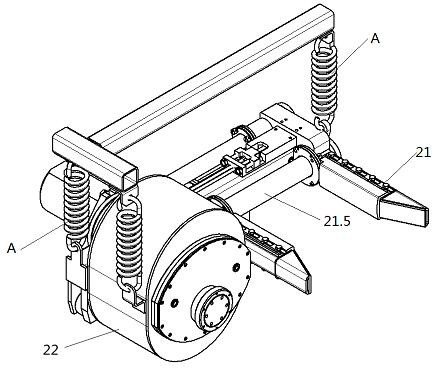

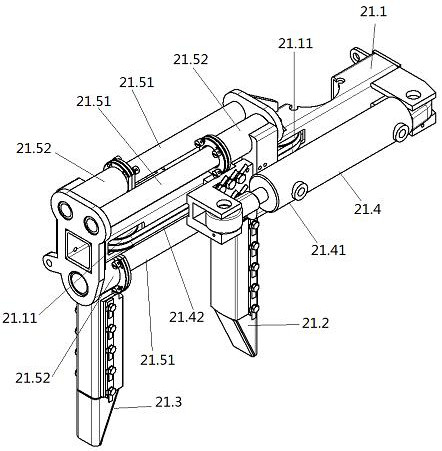

Clamping jaw for climbing robot

PendingCN112278107AEnsure movement stabilityEnsure operation reliabilityVehiclesReciprocating motionControl engineering

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a clamping jaw for a climbing robot. The clamping jaw comprises a fixing base anda clamping end, the clamping end is formed by matching two symmetrical claw rods, the claw rods can do linear reciprocating motion in the axial direction of a matched rotary sliding sleeve, and the rotary sliding sleeve is hinged to a fixed seat through a vertical hinge base; the fixed seat comprises a lower mounting plate, a push-pull plate is arranged right above the lower mounting plate, and two shaft ends of a vertical push-pull shaft at the tail end of each claw rod are respectively matched with an orientation groove at the lower mounting plate and a guide groove at the push-pull plate; the push-pull plate can generate a horizontal reciprocating action vertical to the direction of the vertical push-pull shaft; the fixing seat further comprises a V-shaped block. Force closure and shapeclosure in the climbing process along the angle steel tower can be achieved, so that the action stability and the action reliability of climbing operation of the climbing robot are effectively guaranteed, the manpower inspection cost can be greatly saved, the maintenance efficiency is improved, and safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

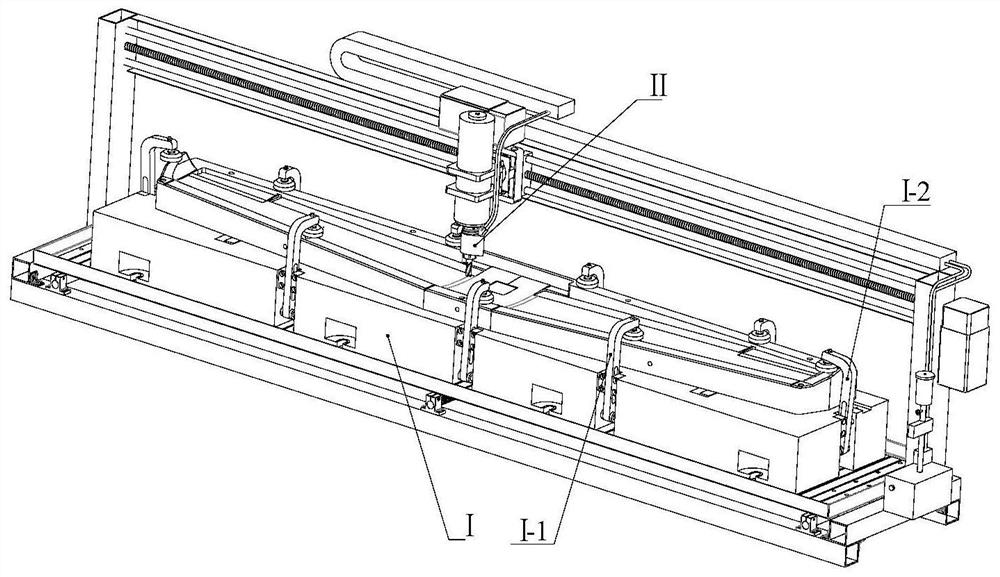

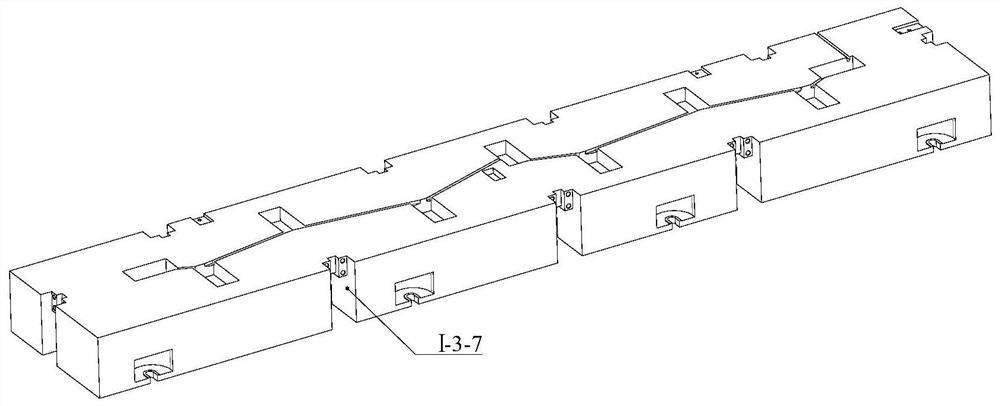

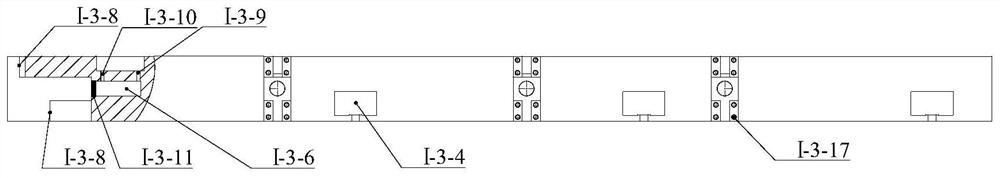

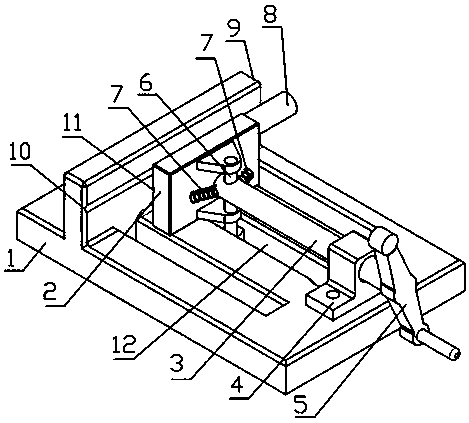

Aviation aluminum alloy minimal quantity lubrication milling device

ActiveCN112605709AEvasive trajectoryRealize linkage workWorkpiecesMeasurement/indication equipmentsEngineeringMachine tool

The invention relates to an aviation aluminum alloy minimal quantity lubrication milling device. The aviation aluminum alloy minimal quantity lubrication milling device comprises a machine tool workbench and a main shaft connected with a machine tool power system, wherein the main shaft is connected with a tool handle; the tool handle is fixed to a tool; the machine tool workbench is provided with a machine tool clamp; the tool handle is connected with a minimal quantity lubrication mechanism; the machine tool clamp comprises a clamp body; a limiting block is fixed to the clamp body and used for making contact with the two adjacent side faces of a workpiece; the clamp body is further provided with a plurality of clamping elements capable of pressing the workpiece to the upper surface of the clamp body; and a detection piece is arranged on the top of each clamping element and used for detecting the relative position of the clamping element and the main shaft. According to the device, interference touch of a nozzle and the clamping elements can be avoided.

Owner:QINGDAO TECHNOLOGICAL UNIVERSITY +1

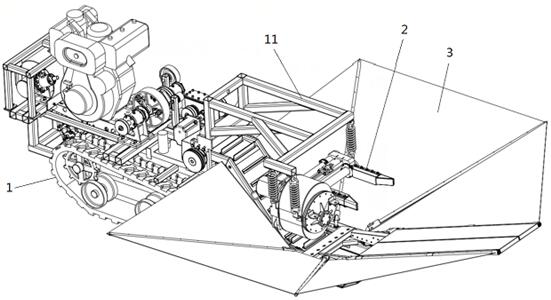

Climbing robot

PendingCN112278108AEnsure movement stabilityEnsure operation reliabilityVehiclesReciprocating motionEngineering

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a climbing robot. The climbing robot comprises a main machine and a clamping jaw;the clamping jaw comprises a fixed seat and a clamping end, the clamping end is formed by two symmetrical jaw rods in a matched mode, the jaw rods can do linear reciprocating motion in the axial direction of a matched rotary sliding sleeve, and the rotary sliding sleeve is hinged to a fixed seat through a vertical hinge seat; the fixed seat comprises a horizontally-arranged lower mounting plate, apush-pull plate is arranged over the lower mounting plate, and the two shaft ends of a vertical push-pull shaft at the tail end of each claw rod are matched with a directional groove in the lower mounting plate and a guide groove in the push-pull plate respectively. The push-pull plate is driven by a horizontal driving assembly to generate a horizontal reciprocating action vertical to the direction of the vertical push-pull shaft; the fixed seat further comprises a V-shaped block. Force closure and shape closure in the climbing process along the angle steel tower can be achieved, so that theaction stability and the action reliability of climbing operation are effectively guaranteed, and safe and reliable operation of a power transmission system is guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER +1

Clamping tool

InactiveCN105312926AEasy to switchHigh clamping reliabilityPositioning apparatusMetal-working holdersSlide plateMachining

The invention discloses a clamping tool which comprises a base. Two clamping blocks are arranged on the base and arranged in a direct facing mode, and clamping sliding plate mounting seats are fixed to the opposite side faces of the two clamping blocks respectively. The clamping sliding plate mounting seats are provided with a first guide sliding groove and a second guide sliding groove respectively, clamping sliding plates are arranged in the first guide sliding groove and the second guide sliding groove respectively, and the first guide sliding groove and the second guide sliding groove are both chutes with the upper ends inclined inwards. The clamping tool has the beneficial effects that when the clamping sliding plates move upwards in the guide sliding grooves, a rotor can be clamped, and machining is facilitated; when the clamping sliding plates move downwards in the guide sliding grooves, the rotor can be loosened, and machining faces can be conveniently switched; therefore, the action that when the machining faces are repeatedly switched due to machining needs, a whole clamping device is removed repeatedly, and after the machining faces are adjusted, mounting and clamping are repeated is avoided; machining efficiency can be improved, the labor intensity of workers can be lowered, and meanwhile the clamping reliability of the whole clamping tool is improved.

Owner:CHONGQING JINCHEN MACHINERY MFG

Reinforced clamping type high-efficiency tree pipe cutting and cutting-off equipment

InactiveCN109015921APrevent rotationHigh clamping reliabilityProfiling/shaping machinesEngineeringScrew thread

The invention provides reinforced clamping type high-efficiency tree pipe cutting and cutting-off equipment. The equipment comprises a bottom plate, a vertical plate is fixedly connected to the upperside of the right part of the bottom plate, a first moving groove with an upward opening is formed in the bottom plate, and a first moving block is arranged in the first moving groove. A first threaded through hole is formed in the first moving block, the first threaded through hole is in threaded connection with a first threaded rod, and the two ends of the first threaded rod are rotationally connected with the bottom plate. The left end of the first threaded rod is fixedly connected with a first handle, and the upper side of the first moving block is fixedly connected with a rotary synchronous positioning and clamping device. The equipment has the beneficial effects that the circle center of an arc-shaped through groove does not coincide with the circle center of a driving disc, in the rotating process of the driving disc, moving rods can be gradually close to the circle center of the driving disc, and then the moving rods are driven to move in linear through grooves, so that the three moving rods are close to one another at the same time, and a cylindrical object is clamped and positioned through three clamping bodies.

Owner:合肥晶诺知识产权信息服务有限责任公司

First process fixture for processing engine water pipe and first process processing method adopting first process fixture

InactiveCN105855968AIncrease productivityEasy to operatePositioning apparatusMetal-working holdersWater pipeIndustrial engineering

The invention discloses a first process fixture for processing an engine water pipe. The first process fixture comprises a baseplate, a positioning block arranged on the baseplate, and a pressing block which is movably arranged, is matched with the positioning block and used for clamping a workpiece to be processed. According to the first process fixture for processing the engine water pipe, through the match of the pressing block and the positioning block which are arranged on the baseplate, a water pipe blank can be clamped, the clamping operation is convenient and simple, the clamping reliability and the clamping precision are high, the production efficiency of the engine water pipe can be improved, and the production cost can be saved. The invention further discloses a first process processing method adopting the first process fixture for processing the engine water pipe.

Owner:芜湖县富力机械科技有限公司

Dedicated fixture for drilling hole on steel plate side face

InactiveCN104786081AEasy accessEasy to removePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:TAICANG SIPUNING PRECISION MACHINERY

Large-sized high-strength alloy steel lifting hook forge piece and machining method

The invention relates to a large-sized high-strength alloy steel lifting hook forge piece and a manufacturing machining method, and the large-sized high-strength alloy steel lifting hook forge piece adopts a three-dimensional model to analyze and numerical control machine the working allowance of a four-claw hook with the overall height being 2840 mm, the hook body being 2030 mm, the net weight being 7.7 t, the unit lifting tonnage being 4500 t; and the upper end of a hook neck of the four-claw hook is a thread and the thread portion is rotatably connected with a hook beam, and bending portionof the lower portion of the four-claw hook is the hook body and the section of a fishing body is in a circular arc shape. The large-sized high-strength alloy steel lifting hook forge piece has the advantages that 1, the surface quality of the forge piece and ultrasonic flaw detection are required to meet a CCS classification society requirement; 2, accurate and effective residuals removing and measurement are easily achieved during machining, and defect that clamping and positioning deviation cannot meet drawing related requirements is avoided; and 3, the quality of hook surface profile machining is ensured.

Owner:宝鼎重工有限公司

Clamping assembly with angle and height adjusting function

PendingCN112339878AGuaranteed efficient obstacle clearanceGuaranteed clamping effectVehiclesClassical mechanicsControl theory

The invention belongs to the technical field of electric power operation climbing robots, and particularly relates to a clamping assembly with an angle and height adjusting function. The clamping assembly comprises a clamping jaw, an angle adjusting assembly and a lifting assembly, wherein the angle adjusting assembly is mounted on the clamping jaw and can adjust the pitch angle of relative anglesteel, and the lifting assembly can enable the clamping jaw to move close to or away from the angle steel. The hinge axis of the angle adjusting assembly is horizontally arranged and is perpendicularto the length direction of angle steel. The clamping assembly enables a climbing robot to have extremely high obstacle crossing capacity and climbing efficiency, the action stability and the action reliability of climbing operation of the climbing robot can be synchronously guaranteed, and therefore the manpower inspection cost can be greatly reduced, the maintenance efficiency can be improved, and safe and reliable operation of a power transmission system can be guaranteed.

Owner:STATE GRID ANHUI ELECTRIC POWER CO LTD +1

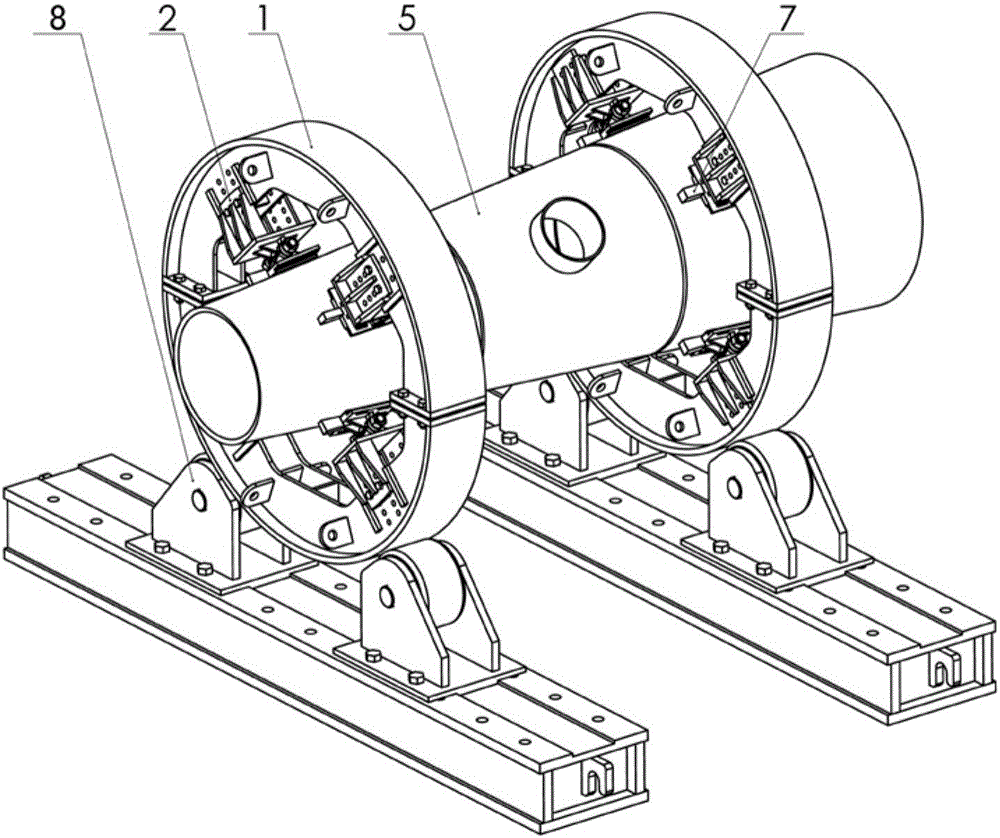

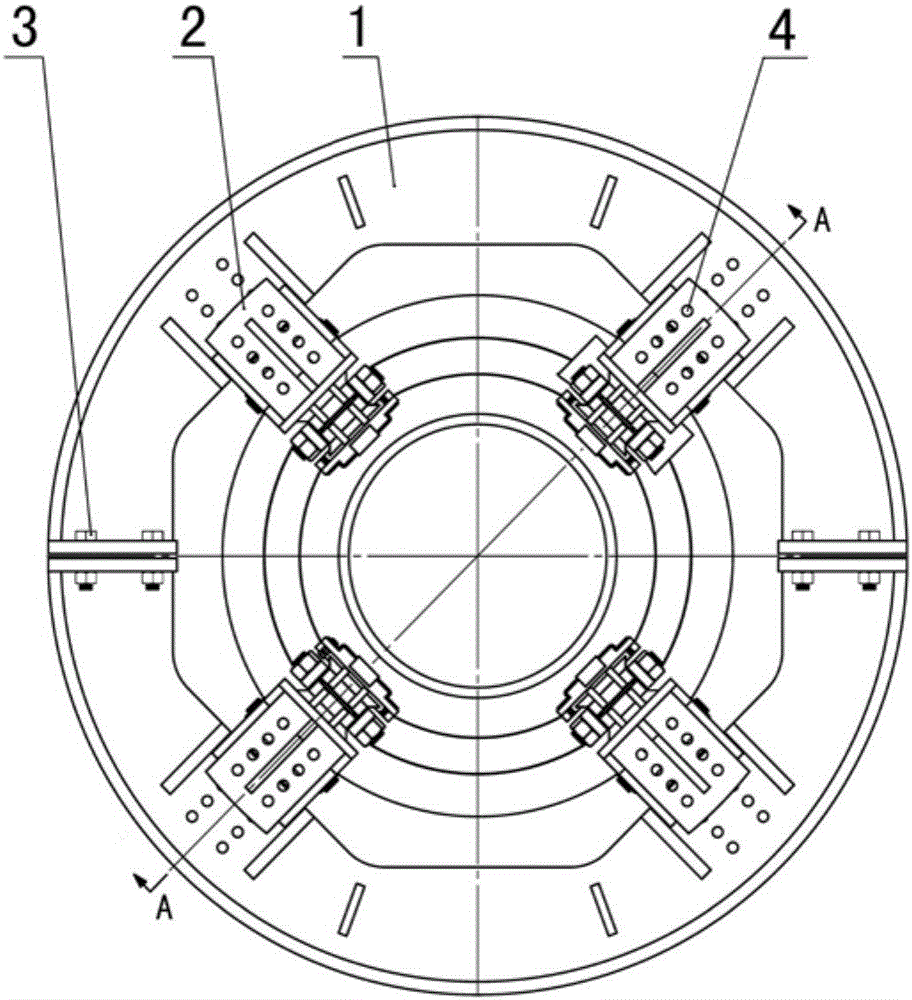

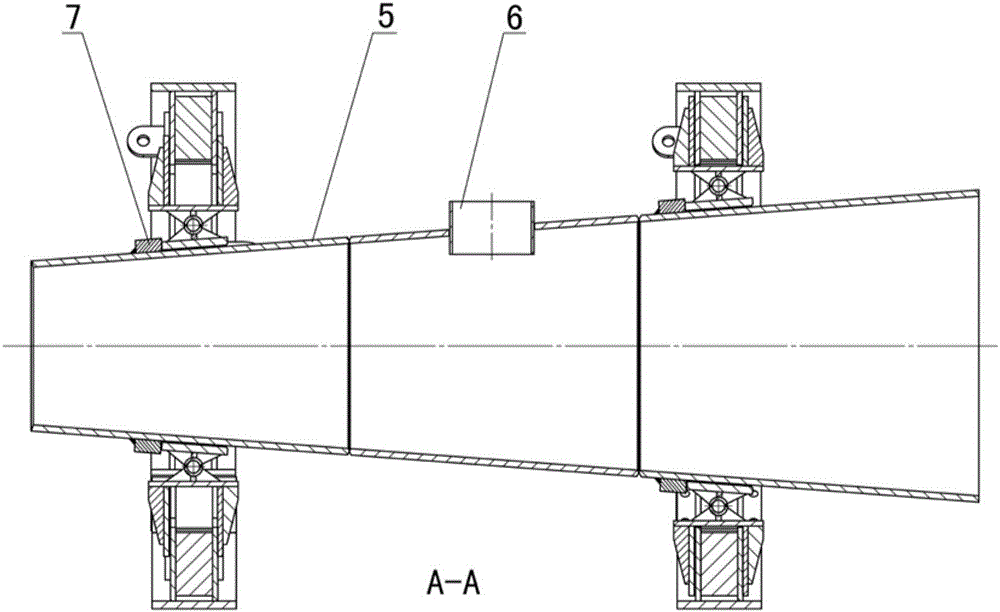

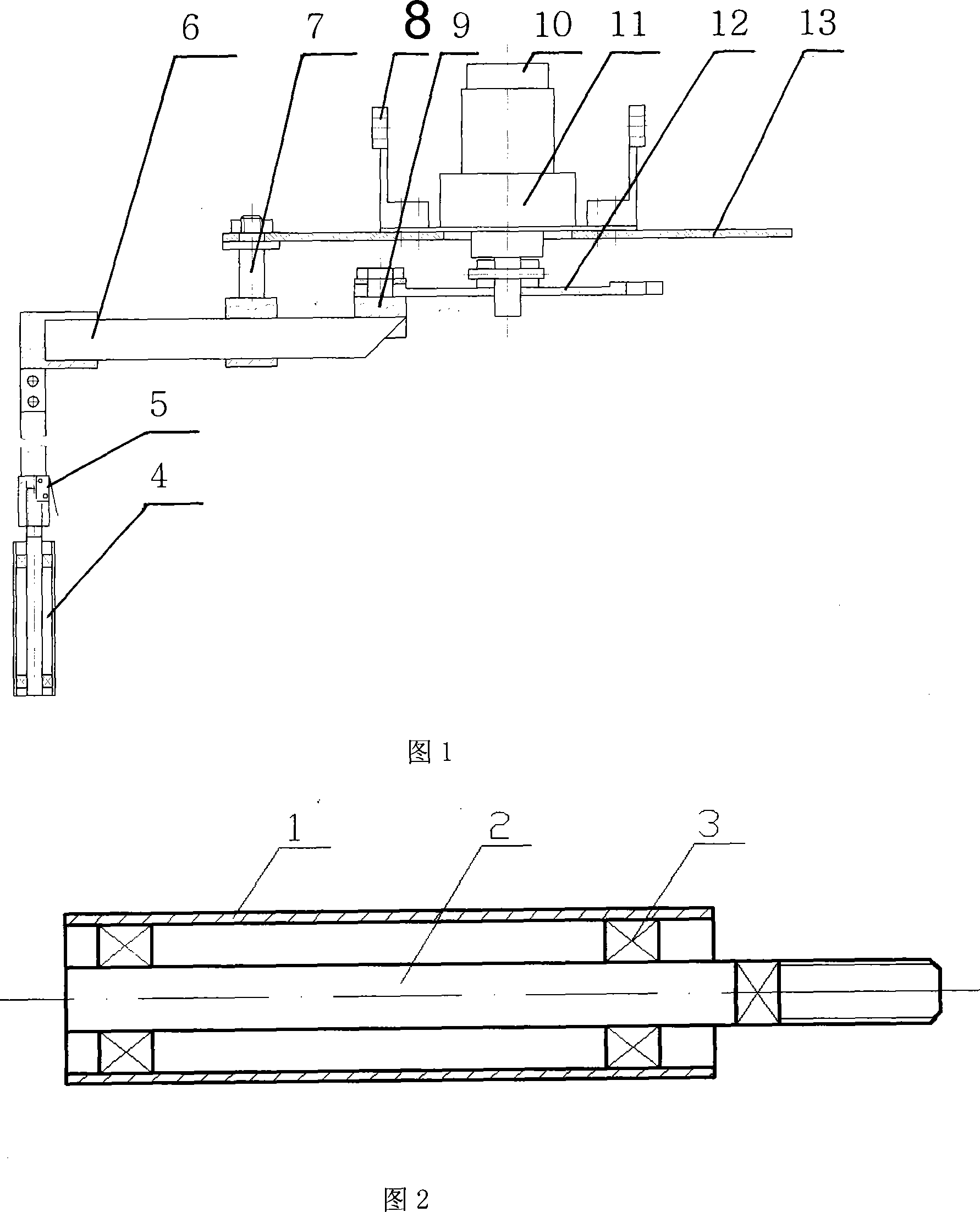

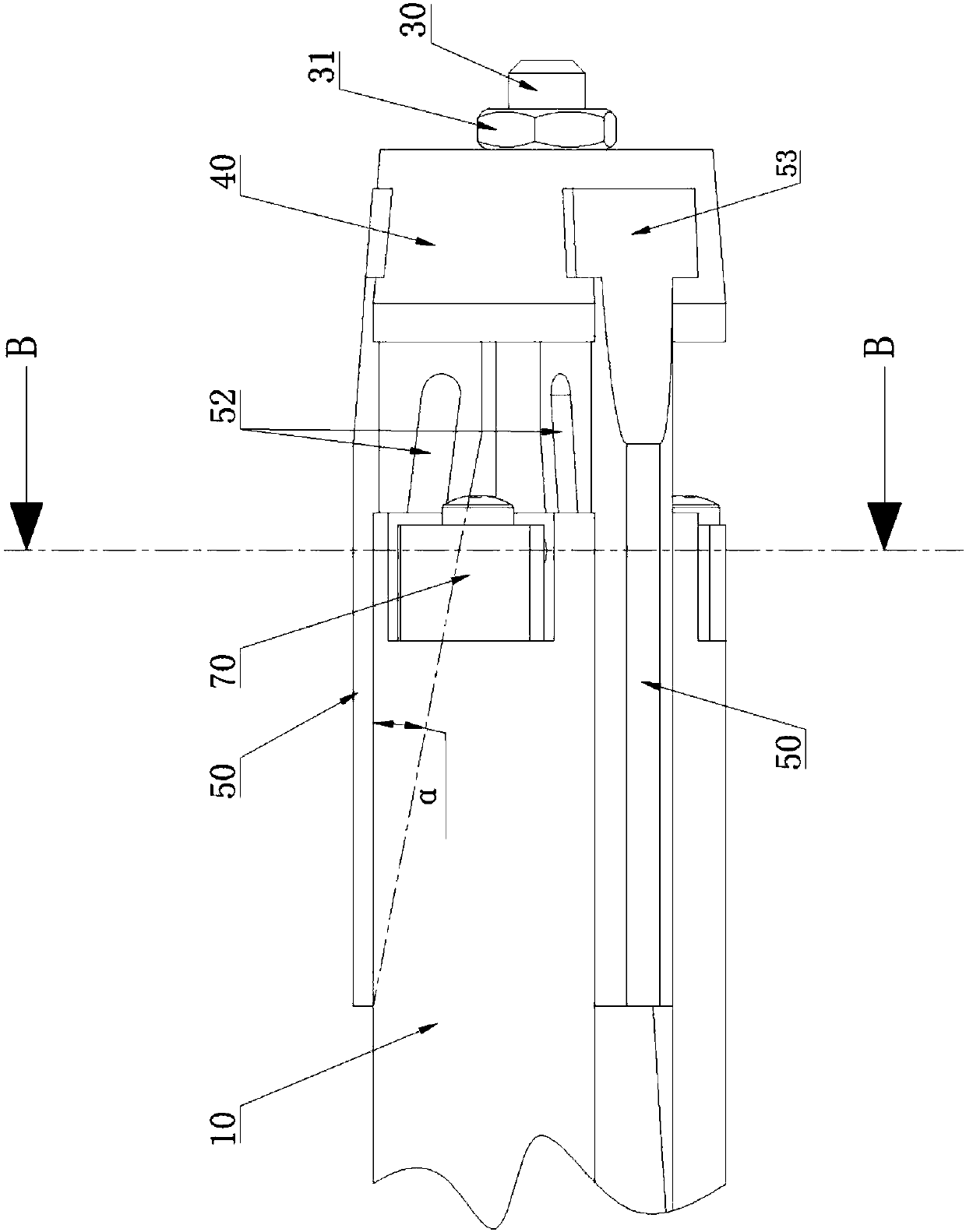

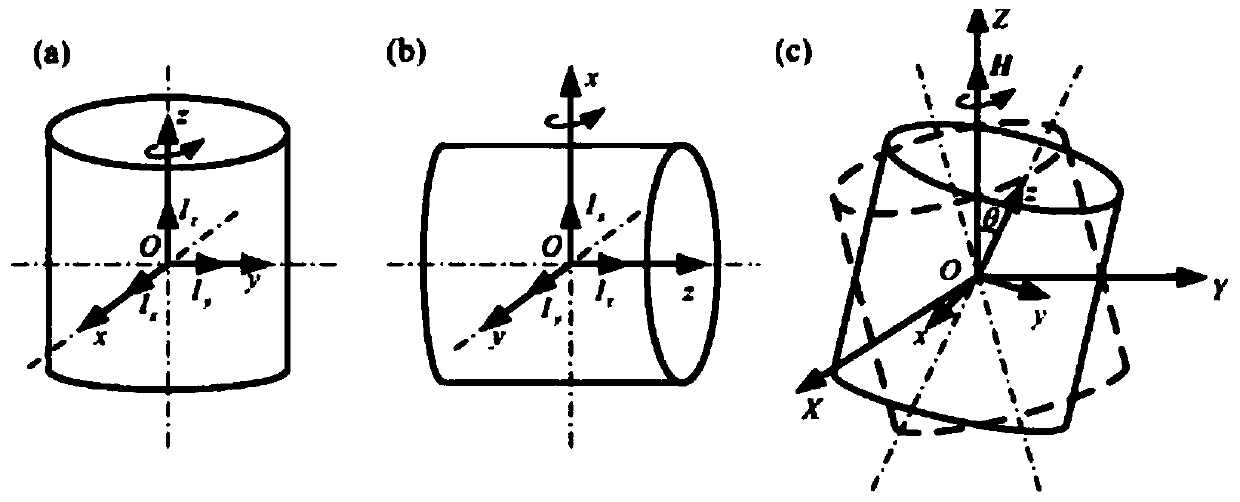

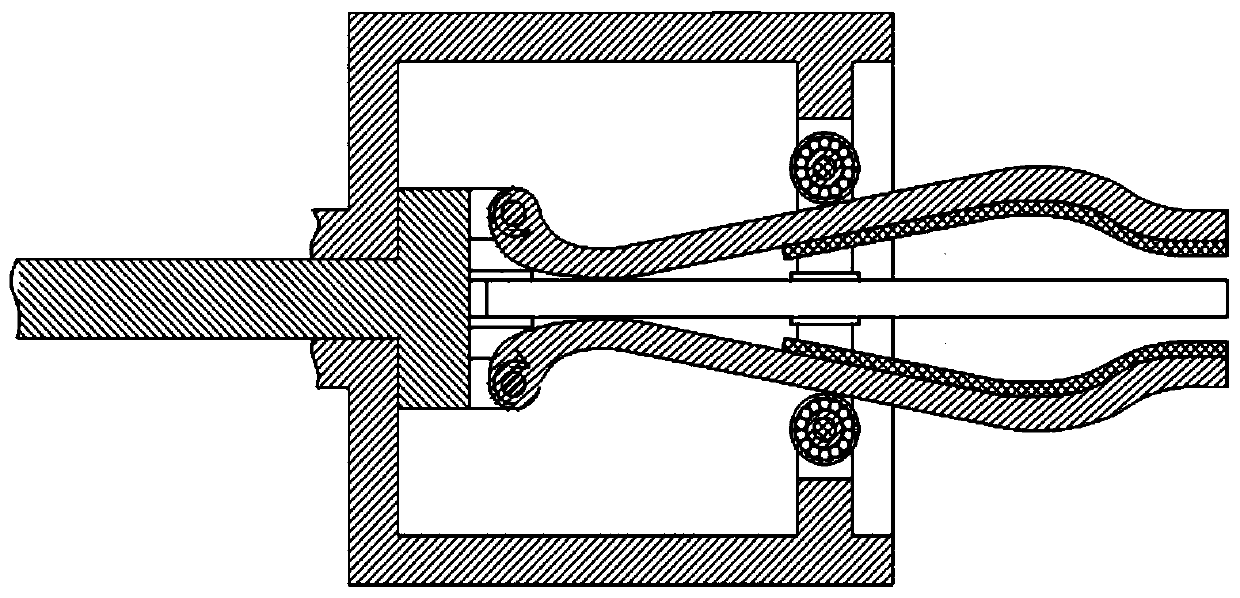

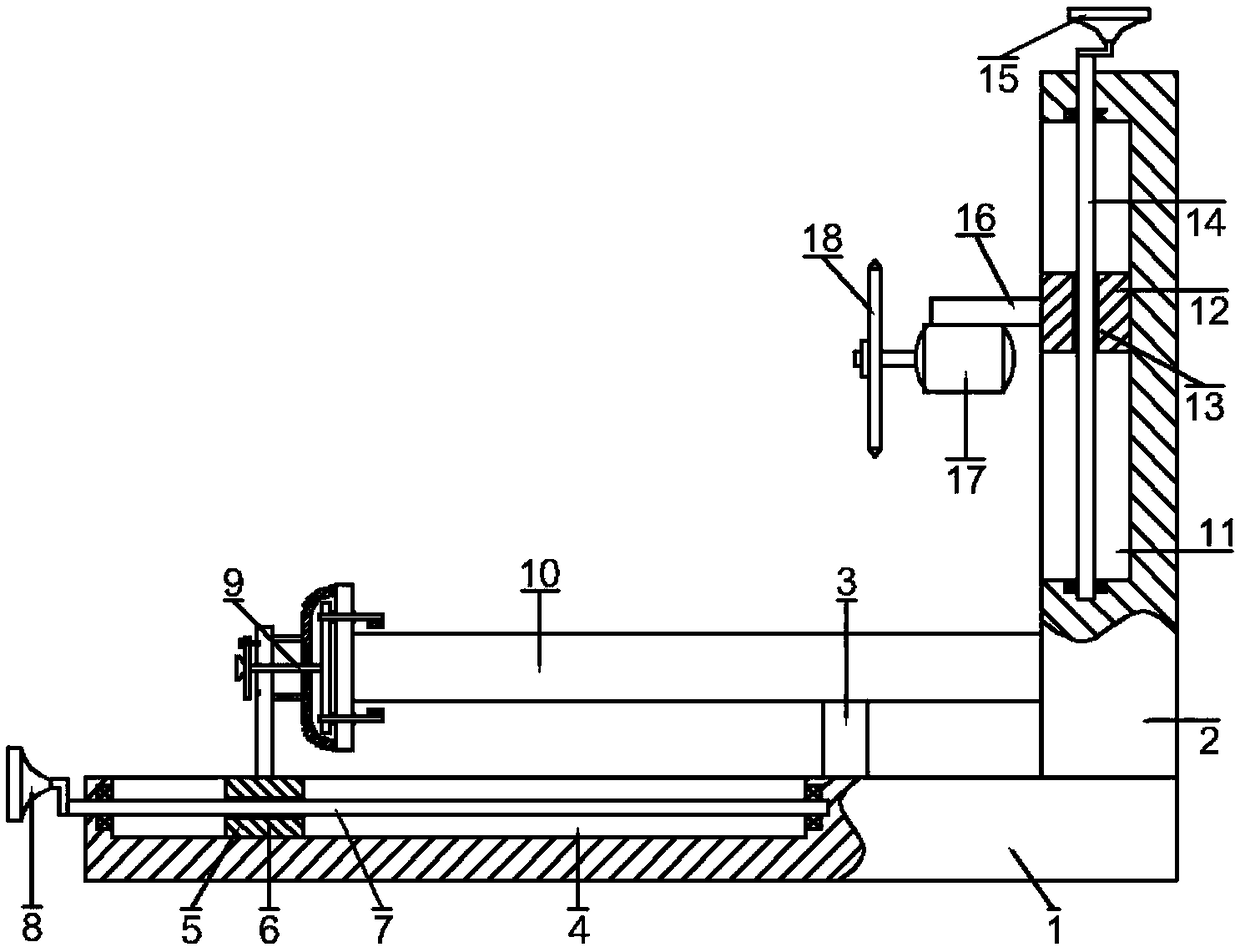

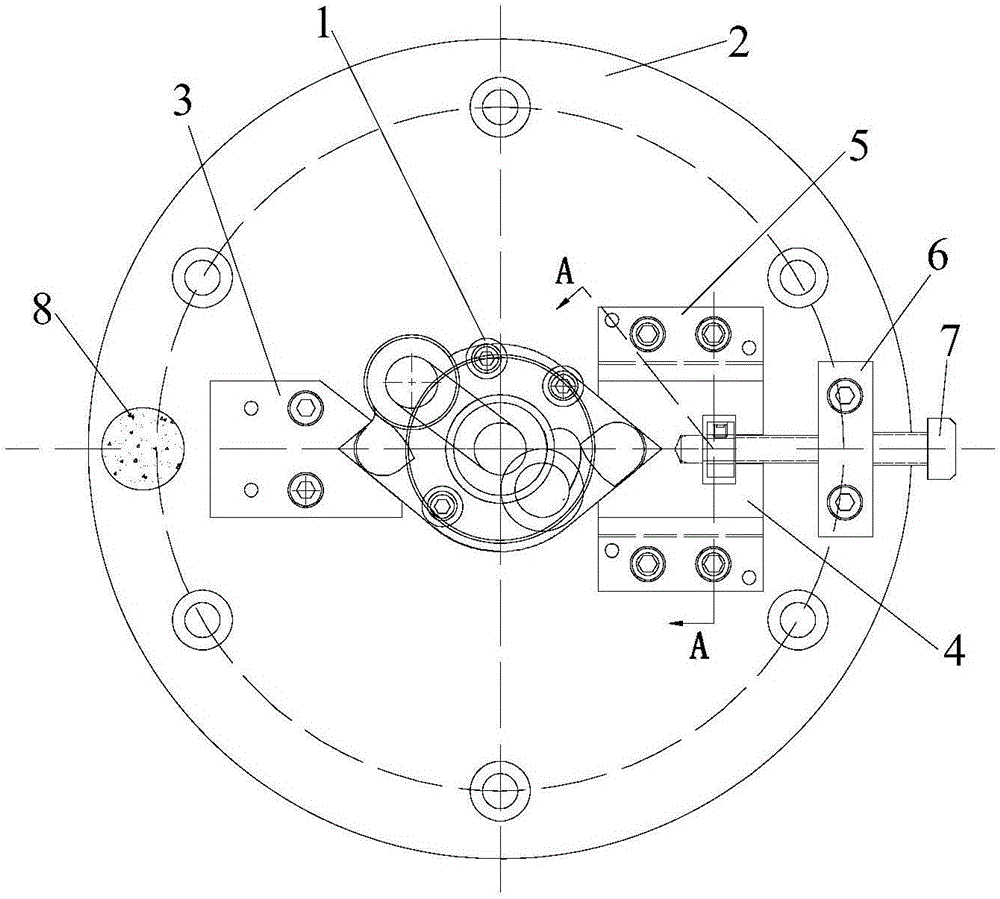

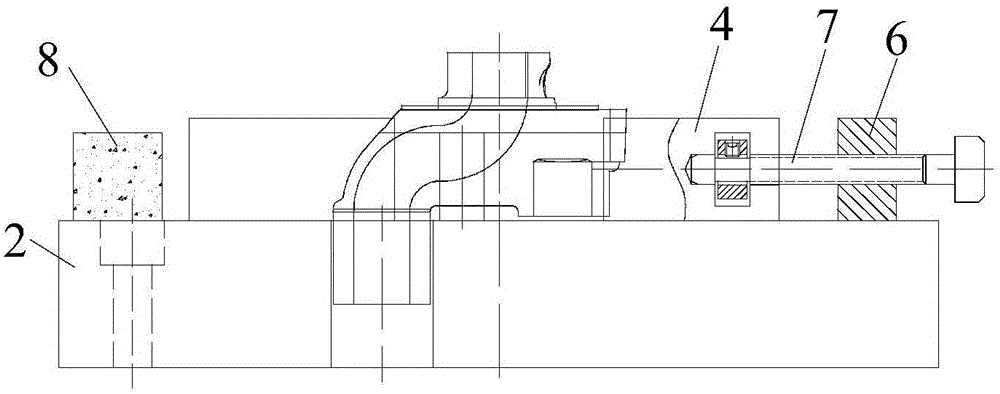

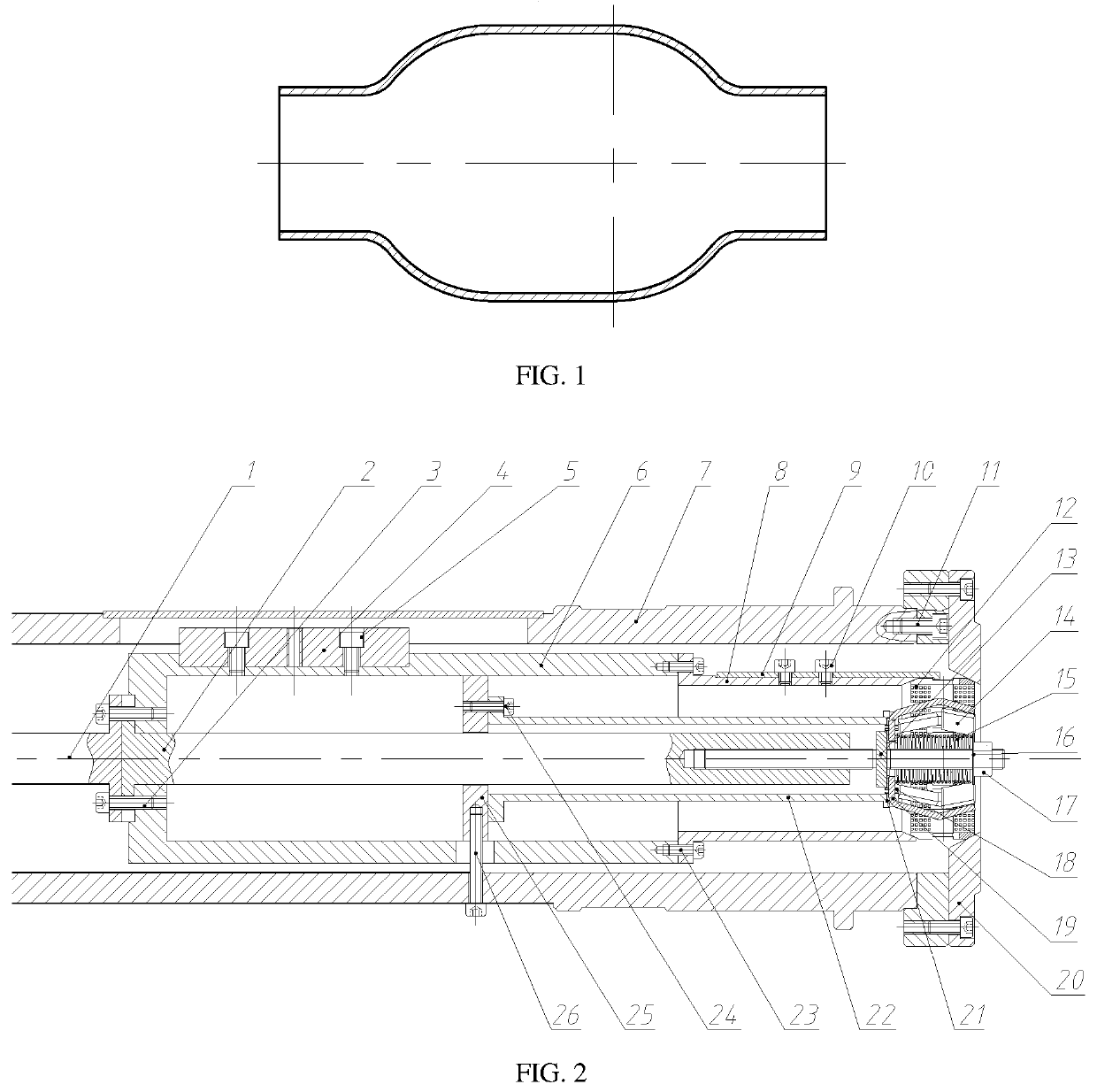

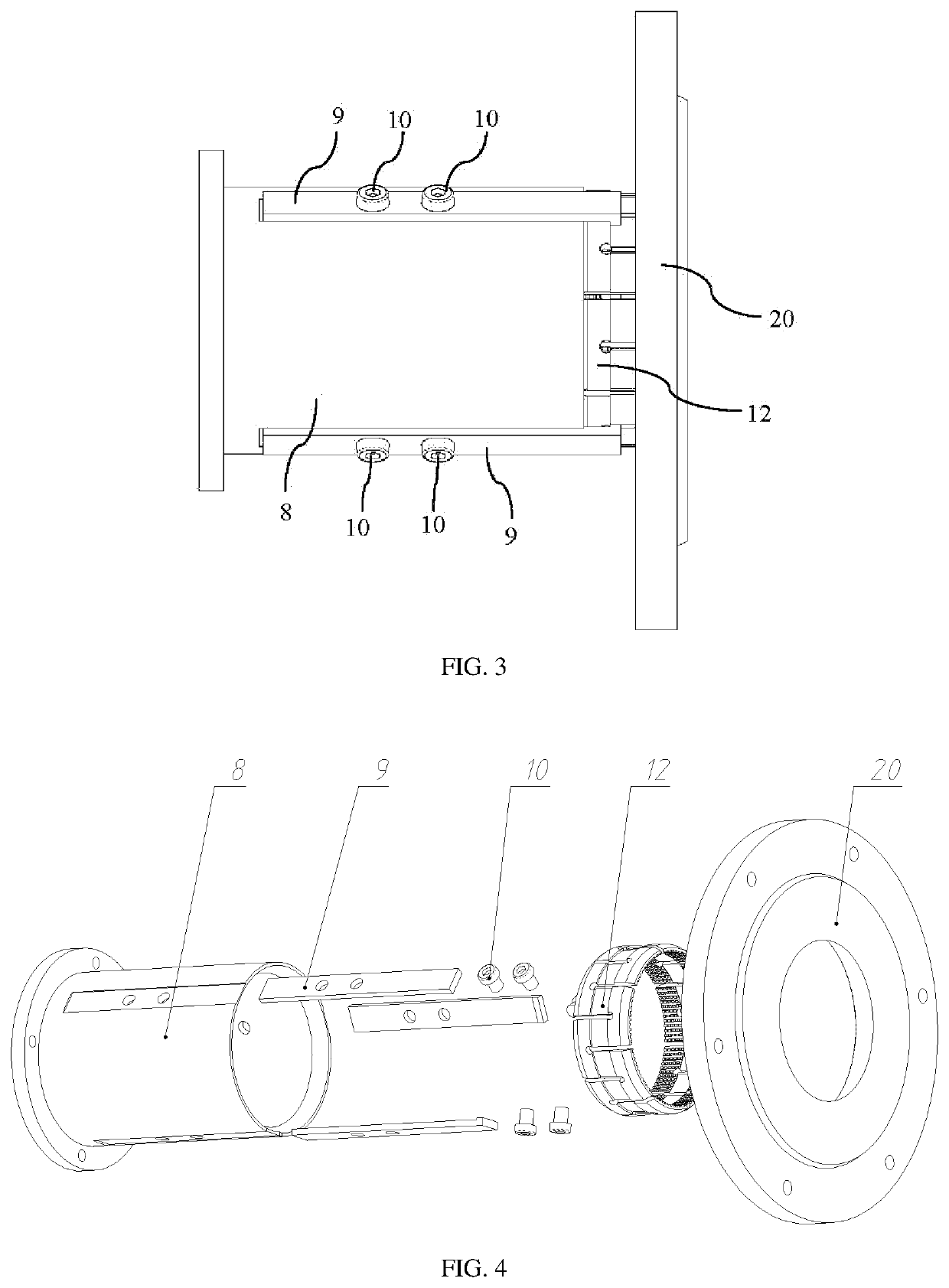

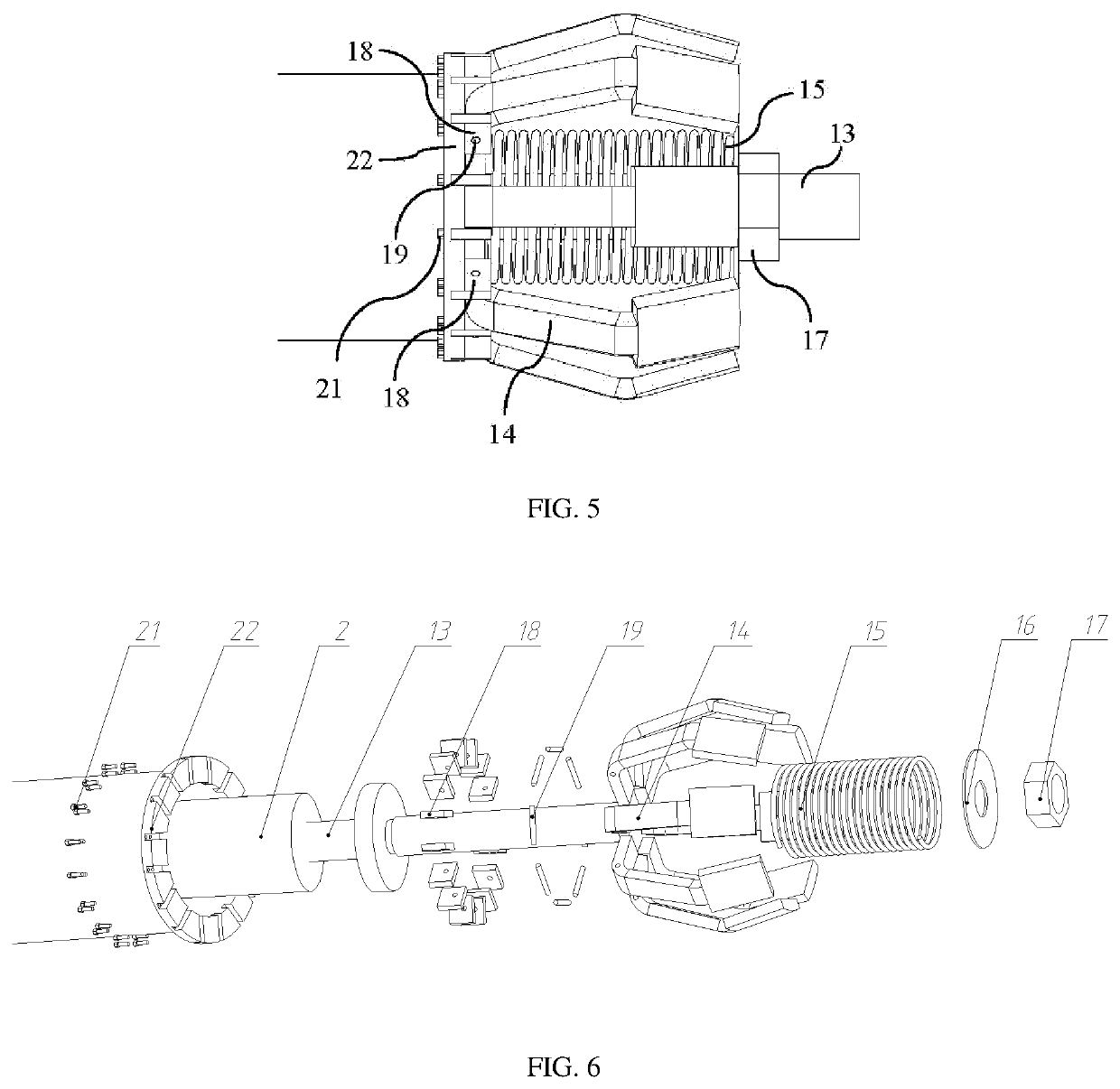

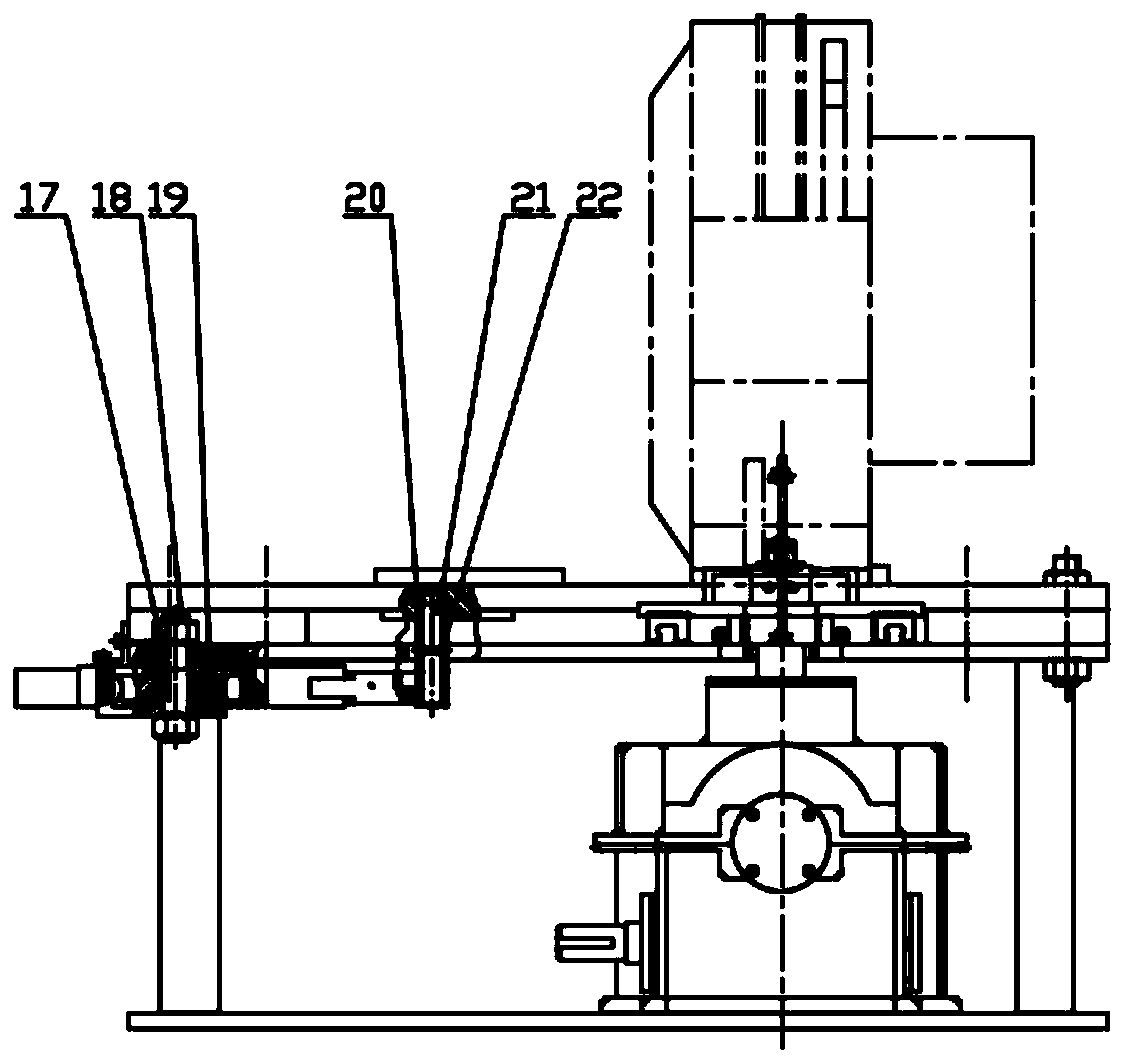

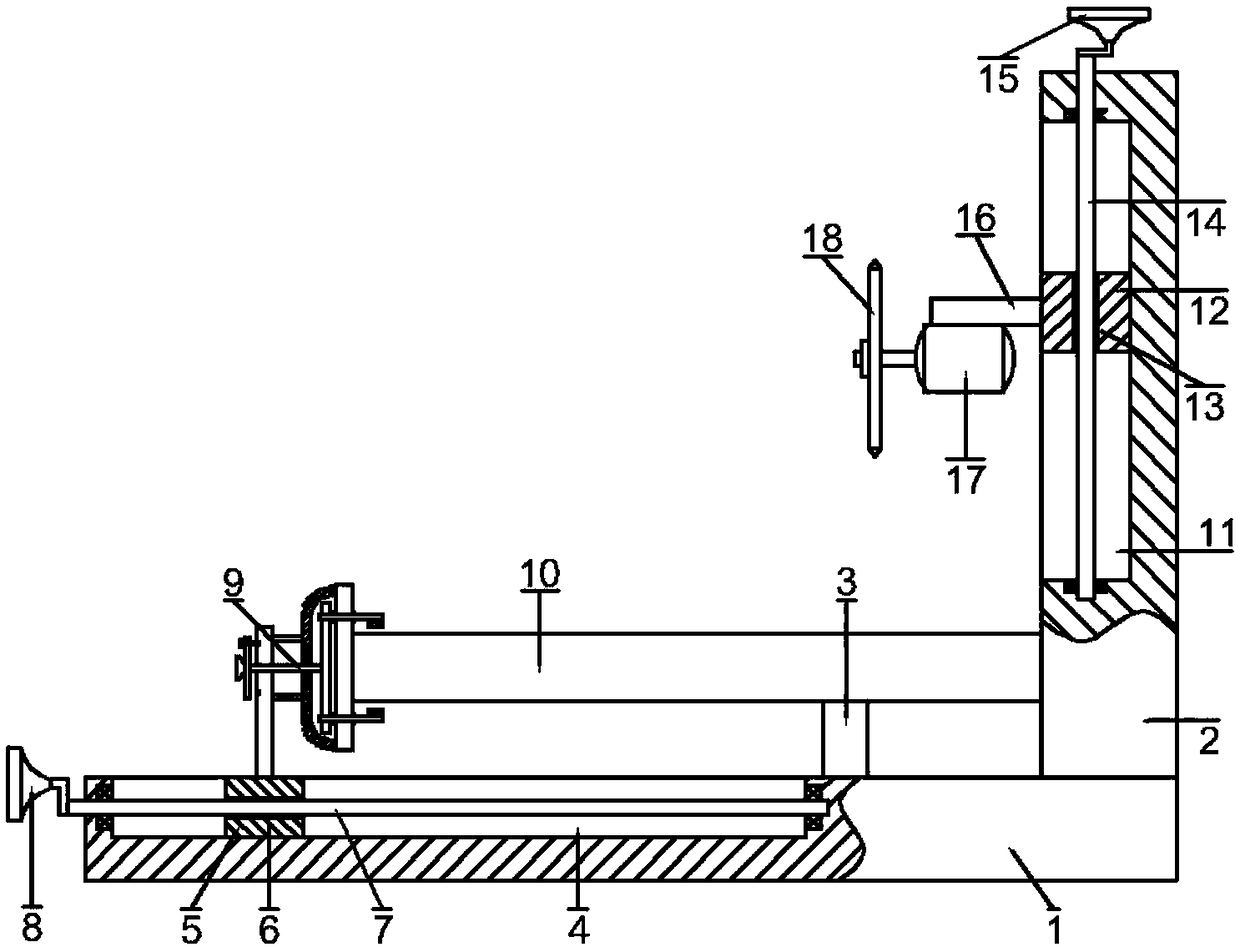

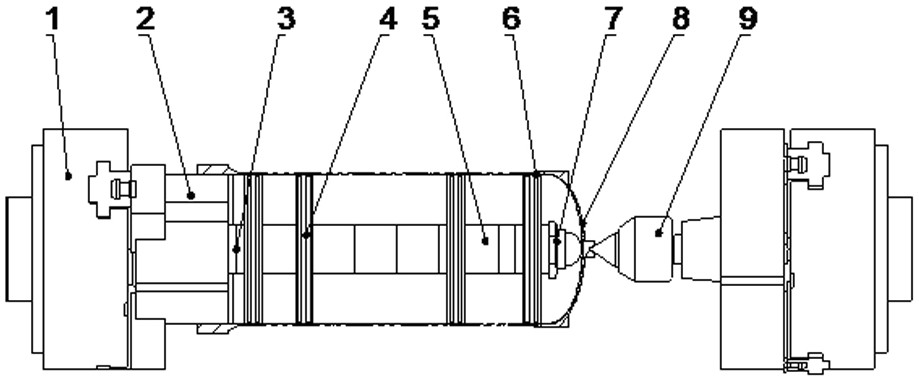

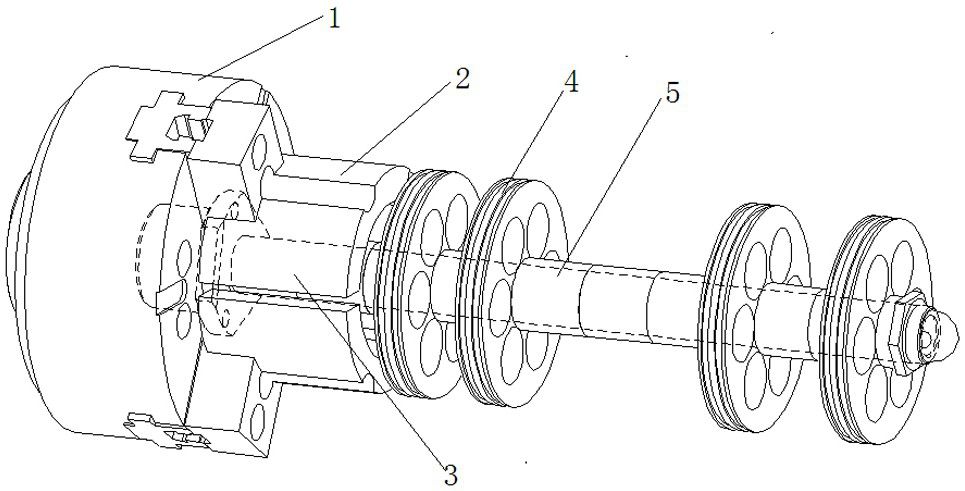

Internal and external clamping method and device of thin-wall tubular part during rotary processing

ActiveUS20200331122A1High clamping reliabilityExpansion mandrelsClampsMechanical engineeringIndustrial engineering

The present disclosure discloses an internal and external clamping method and device of a thin-wall tubular part during rotary processing. A plurality of support blocks of this device are spaced to form an annular structure around the flange bush; the middle portion of each support block is provided with a through hole; a support claw is provided between every two support blocks, and the side surface of the support claw is provided with the through hole; a rotary shaft penetrates through the through holes in the support claws and the support blocks; the plurality of support claws are spaced to form a support claw ring having the annular structure, and each support claw is formed by connecting the front end, the rear end, and the bottom; the support claw ring is provided in a clamping cylinder, and the thin-wall tubular part is provided between the outside surface of the support claw ring and the inside surface of the clamping cylinder. The clamping cylinder of the present disclosure is contracted under the combined action of a wedge-shaped sleeve and a jacket, and is used for pressing the outer wall of the part, so that the external clamping of the thin-wall tubular part is realized; the support claw ring is turned over and expanded around the rotary shaft between the two support blocks separately, so that the internal clamping of the thin-wall tubular part is realized.

Owner:SOUTH CHINA UNIV OF TECH

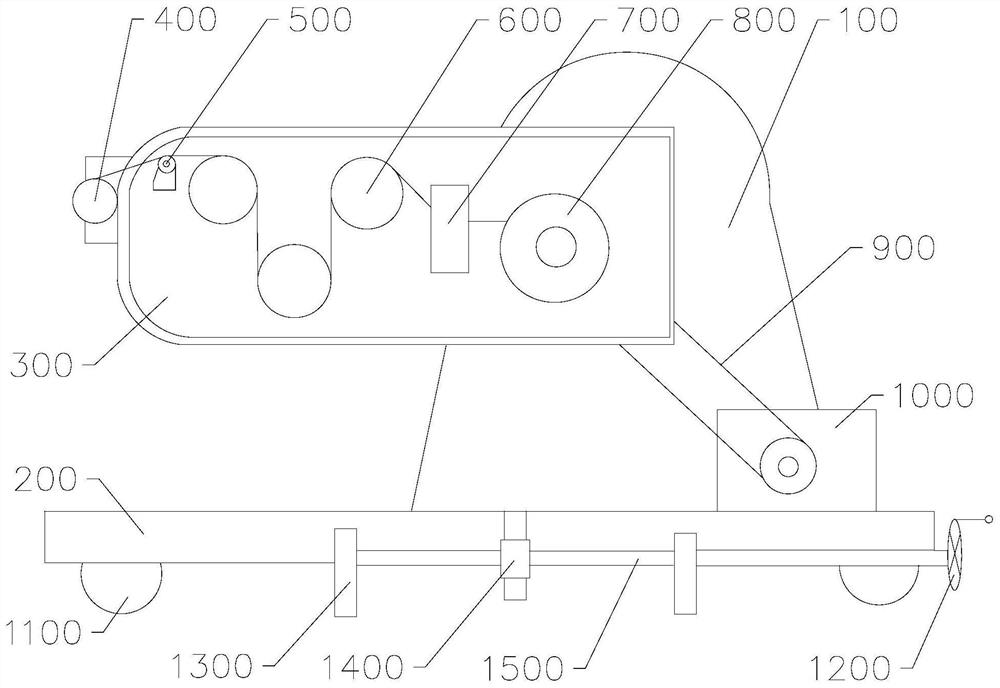

Wire tightening device for low-voltage bundled wire installation

ActiveCN112909829APrevent fallingHigh clamping reliabilityElectronic waste recyclingApparatus for overhead lines/cablesElectric machineDrive motor

The invention provides a wire tightening device for low-voltage bundled wire installation, which comprises a bracket, a base, a tensioning frame, a wire clamping device, a tension detection device, a pulley block, a non-return device, a winding wheel, a synchronous belt, a driving motor, a moving wheel, a fixed hand wheel, a moving clamping jaw, a fixed clamping jaw and a lead screw, and is characterized in that the wire clamping device comprises a frame plate and a wire pressing assembly; the wire pressing assembly comprises four wire pressing cams, a connecting plate and a pressing handle, every two of the four wire pressing cams are divided into two sets of wire pressing cams, the two sets of wire pressing cams comprise the first set of wire pressing cams and the second set of wire pressing cams, the first set of wire pressing cams and the second set of wire pressing cams are arranged in a front-back spaced mode and the frame plate comprises a bottom frame plate and a side frame plate; the wire pressing assembly is arranged on the side frame plate, and after the side frame plate and the bottom frame plate are installed in place, the four wire pressing cams press and fix the bundled wires placed on the bottom frame plate, so that the wire tightening effect and the operation efficiency of the wire tightening device can be greatly improved, the operation time of operators is shortened, and the labor intensity of the operators is reduced.

Owner:STATE GRID ZHEJIANG TONGLU POWER SUPPLY +1

Cutting clamp applicable to clamping workpiece at multiple angles

PendingCN107639441AGuaranteed automatic recoveryImprove continuous work efficiencyPositioning apparatusMetal-working holdersMechanical engineeringEngineering

The invention discloses a cutting clamp applicable to clamping a workpiece at multiple angles. The cutting clamp comprises a base, a movable block, a screw rod, a plug pin, a supporting base and a fixed block, the supporting base and the fixed block are fixedly connected to the two ends of the base respectively, the screw rod is perpendicular to the clamping working surface of the fixed block andis matched with an inner thread arranged in the supporting base, the head end of the screw rod is hinged to the movable block through the upper end of the plug pin, the movable block is in clearance fit with the plug pin, is located between the supporting base and the fixed block and further comprises two elastic parts, the elastic parts are symmetrically arranged at the two sides of the head endof the screw rod, and the two ends of each elastic parts are connected with the movable block and the screw rod respectively. By arranging the elastic parts, after the movable block rotates for some angle to clamp the workpiece, the movable block can automatically return to the position parallel to the fixed block, and the efficiency of continuous work is improved; meanwhile, by arranging cross net patterns and an arc groove, the clamping force among the clamping surfaces is improved, and the reliability is high.

Owner:彭州市和顺电器有限公司

Material cutting equipment improving cross section smoothness

InactiveCN109093178APrevent rotationHigh clamping reliabilityShearing machinesShearing machine accessoriesProviding materialEngineering

The invention provides material cutting equipment improving cross section smoothness. The material cutting equipment comprises a base plate. A vertical plate is fixedly connected with the upper side of the right portion of the base plate. A first moving groove with an opening facing upwards is formed in the base plate. The first moving groove is internally provided with a first moving block. A first threaded through hole is formed in the first moving block. A first threaded rod is connected into the first threaded through hole in a threaded mode. Two ends of the first threaded rod are rotatably connected with the base plate. The left end of the first threaded rod is fixedly connected with a first handle. The upper side of the first moving block is fixedly connected with a rotary synchronization positioning clamping device. The material cutting equipment has the beneficial effects that the center of an arc through groove is not coincide with that of a driving disc, and therefore duringthe rotating process of the driving disc, moving rods can gradually move close to the center of the driving disc to drive the moving rods to move in a linear through groove, and therefore the three moving rods get closer simultaneously, and a cylindrical object can be clamped and positioned by three clamping bodies.

Owner:泾县瑞旺农业科技服务有限公司

Clamp for testing elevator traction machine and clamping method thereof

ActiveCN111017685AImprove clamping efficiencyHigh clamping reliabilityElevatorsBuilding liftsControl engineeringProcess engineering

The invention discloses a clamp for testing an elevator traction machine and a clamping method thereof. An existing clamp for testing a traction machine is low in clamping efficiency and reliability.The clamp comprises a centering mechanism, a top pressing mechanism and a side face positioning and clamping mechanism; the centering mechanism finishes centering positioning of the elevator tractionmachine on a supporting plate, drives the top pressing mechanism to press against the upper surface of an elevator traction machine base, and finishes vertical pressing positioning of the elevator traction machine; and the side face positioning and clamping mechanism finishes side face clamping and positioning of the elevator traction machine. After the elevator traction machine is conveyed to thesupporting plate, the elevator traction machine can be adjusted to the correct position in an automatic mode, then the elevator traction machine is clamped and fixed, the form of manual bolt fixing is avoided, the defect that manual operation is long in consumed time is overcome while the elevator traction machine is firmly fixed, and the clamping efficiency and reliability of the clamp are improved.

Owner:ZHEJIANG SCI-TECH UNIV

Special device for circular material with locking function and capable of improving cutting effect

InactiveCN109093690APrevent rotationHigh clamping reliabilityMetal working apparatusEngineeringScrew thread

The invention provides a special device for a circular material with a locking function and capable of improving the cutting effect, the device includes a bottom plate, an upper side of the right partof the bottom plate is fixedly connected with a vertical plate, the bottom plate is provided with a first moving groove with an opening facing upward, a first moving block is arranged in the first moving groove, the first movable block is provided with a first threaded through hole, the first threaded through hole is internally threaded with a first threaded rod, both ends of the first threaded rod are rotatably connected with the bottom plate, the left end of the first threaded rod is fixedly connected with a first handle, and the upper side of the first movable block is fixedly connected with a rotary synchronous positioning clamping device. The invention has the following beneficial effects: as the center of the arc-shaped through-groove does not coincide with the center of the drivingdisk, the driving disk can gradually make the moving rod approach the center of the driving disk in the rotating process, and then drive the moving rod to move in the straight through-groove, so thatthe three moving rods are close to one another at the same time, and the cylindrical object is clamped and positioned by three clamping bodies.

Owner:安徽致链科技有限公司

Adjustable thin-wall shell vibration-reduction clamping device and operation method

PendingCN112059674AEasy to completeEasy to processTailstocks/centresPositioning apparatusRubber ringMachine tool

The invention discloses an adjustable thin-wall shell vibration-reduction clamping device and an operation method. The clamping device comprises a mandrel and a plurality of supporting wheels; one endof the mandrel is of a cone frustum structure matched with a center hole of a three-jaw chuck; the plurality of supporting wheels are arranged on the mandrel in parallel, and the supporting wheels are coaxial with the mandrel; and annular grooves are formed in the cylindrical side faces of the supporting wheels, and rubber rings are arranged in the grooves. The clamping device is simple and compact in structure, low in cost and convenient to operate; the multiple supporting wheels on the mandrel are adopted for supporting the inner wall of a thin-wall shell, the thin-wall shell is positionedin the radial direction, and the thin-wall shell is positioned in the axial direction through a tailstock center of a machine tool; the clamping reliability is high, and finish turning and finish milling of the appearance characteristics of the thin-wall shell can be completed efficiently; and the positions of the supporting wheels can be adjusted on the mandrel, the supporting wheels can be conveniently adjusted to the appearance characteristic position to perform supporting, the supporting wheels can be replaced, and machining of thin-wall shells of different types is facilitated.

Owner:江南工业集团有限公司

Suspension clamping vibration harvester

PendingCN112075206AIncrease flexibilityImprove structural reliability and practicalityPicking devicesAgricultural engineeringStructural engineering

The invention discloses a suspension clamping vibration harvester. The harvester comprises a crawler-type walking mechanism, a fruit picking mechanism and a fruit collecting mechanism, the fruit picking mechanism is suspended on a rack, extending forwards, of the crawler-type walking mechanism through a plurality of vertically-arranged springs and located over the fruit collecting mechanism, and the fruit picking mechanism comprises a clamping assembly and a vibrator. The clamping assembly comprises a horizontally-arranged clamping support, an inner clamping plate extending forwards, an outerclamping plate aligned with the inner clamping plate, an oil cylinder power assembly used for pulling the inner clamping plate and the outer clamping plate to be close to or away from each other, anda guide assembly used for guiding movement of the inner clamping plate and the outer clamping plate, and the clamping support and the vibrator are connected with the rack through springs. The vibratoris arranged on the clamping support, the oil cylinder power assembly and the guide assembly are respectively arranged on the clamping support, and the inner clamping plate and the outer clamping plate are respectively fixed on the guide assembly and are both connected with the oil cylinder power assembly. According to the suspension clamping vibration harvester, structural reliability and practicability of the fruit picking mechanism are improved, and the terrain adaptability and practicability of the whole harvester are improved.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

End effector applicable to clamping spheroidal fruits

The invention discloses an end effector applicable to clamping spheroidal fruits. The end effector applicable to clamping the spheroidal fruits comprises an effector body, an effecting module mountedon the effector body, and a driving module for driving the effecting module to achieve gripping operation, wherein the effecting module comprises a pair of lower clamping fingers and a pair of upper clamping fingers, the pair of lower clamping fingers are matched with the effector bod, are in a swing arm structure, extend downwards and are arranged left and right, and the pair of upper clamping fingers are connected to the effector body, extend downwards and are arranged left and right; the upper clamping fingers are arranged in front of the lower clamping fingers and in a clamping area whichis formed by projection of the lower clamping fingers from back to front and enclose a space together with the lower clamping fingers for circumferentially clamping the fruits. According to the end effector applicable to clamping the spheroidal fruits, the pair of upper clamping fingers and the pair of lower clamping fingers enclose the clamping space, and the lower clamping fingers and the upperclamping fingers are matched to achieve circumferential clamping of the fruits and improve the clamping stability; by circumferentially clamping the fruits, clamping force can be uniformly diffused tothe circumference of the fruits to avoid mechanical damage to the fruits due to stress concentration.

Owner:CHONGQING UNIV OF ARTS & SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com