Clamp for testing elevator traction machine and clamping method thereof

A technology of elevator traction machine and fixture, which is applied in elevators, elevators, transportation and packaging in buildings, etc., to achieve the effects of ensuring reliability, large transmission ratio, and improving clamping efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

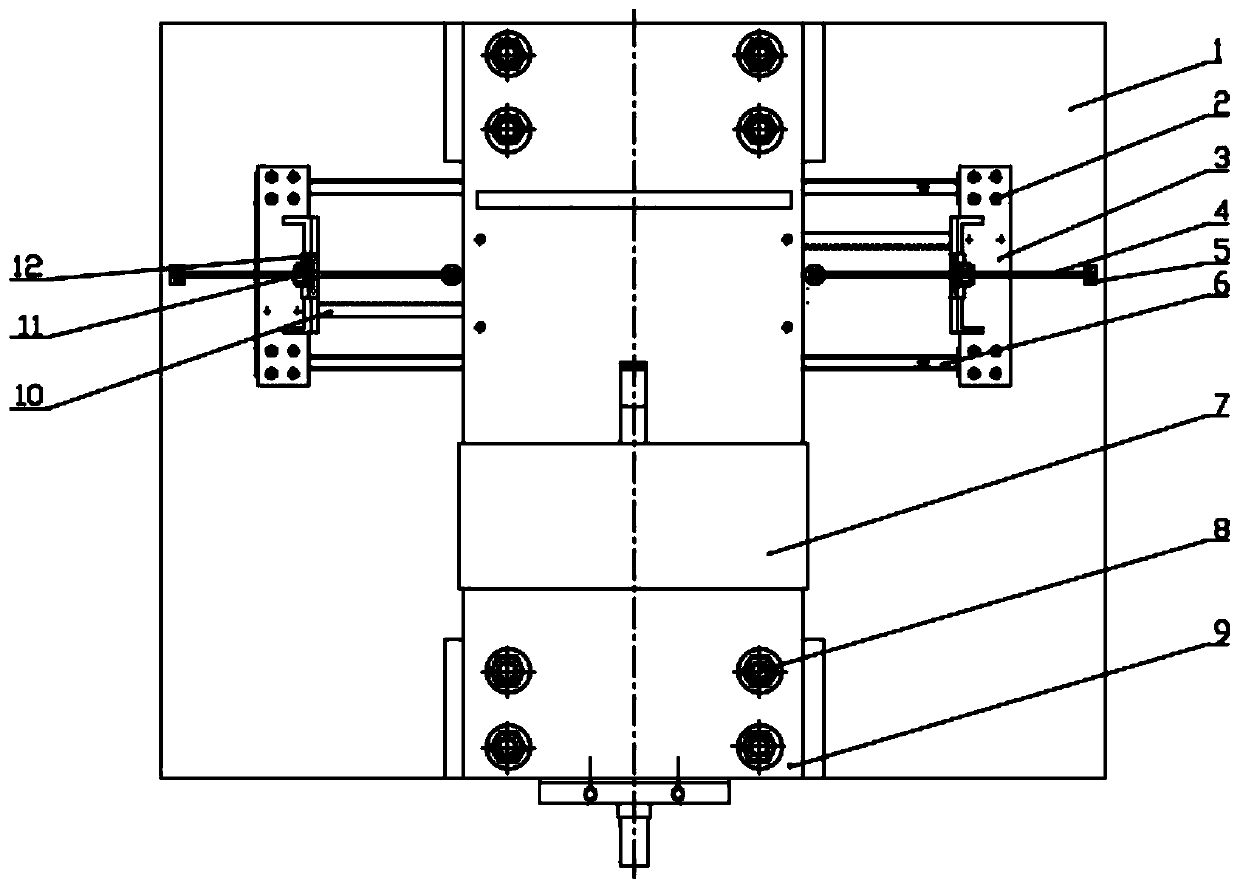

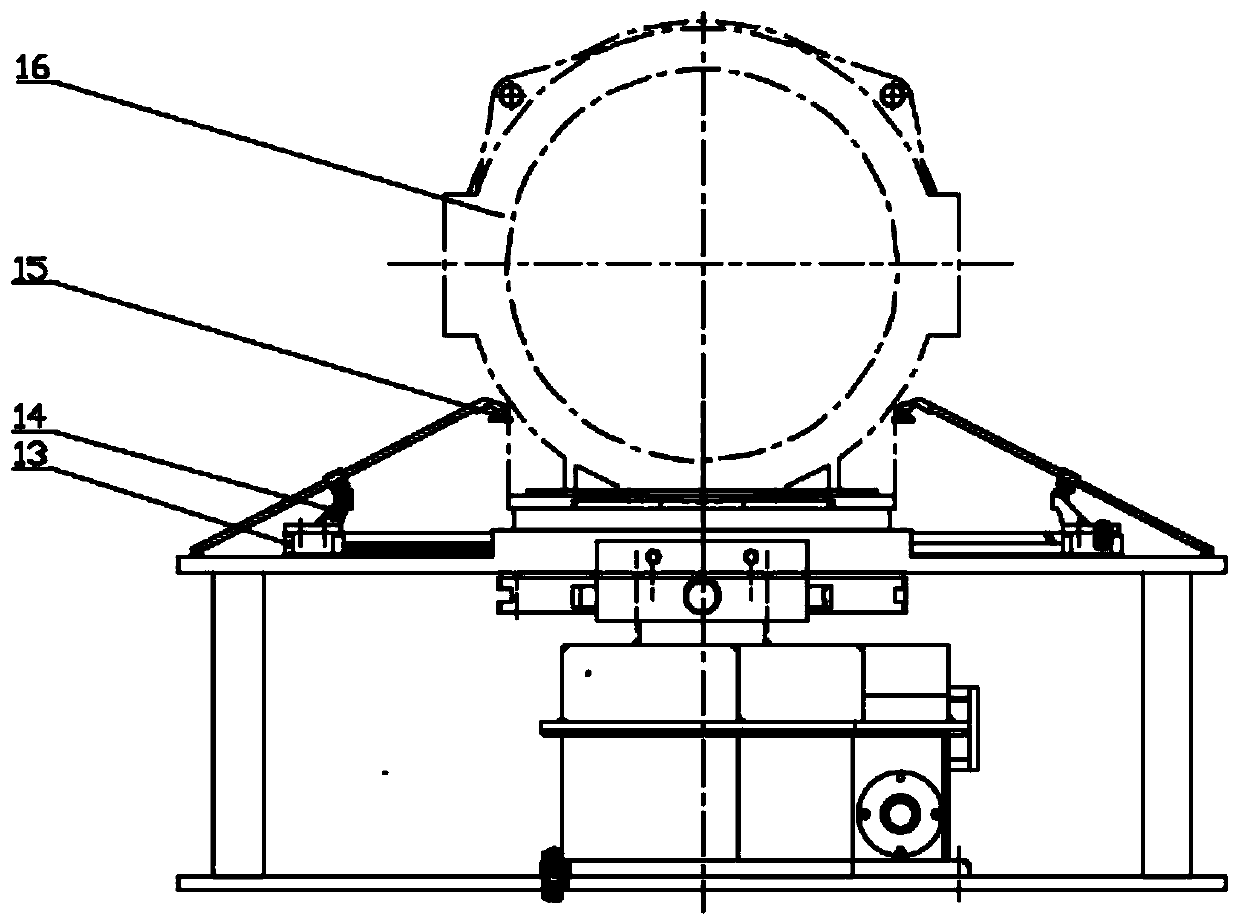

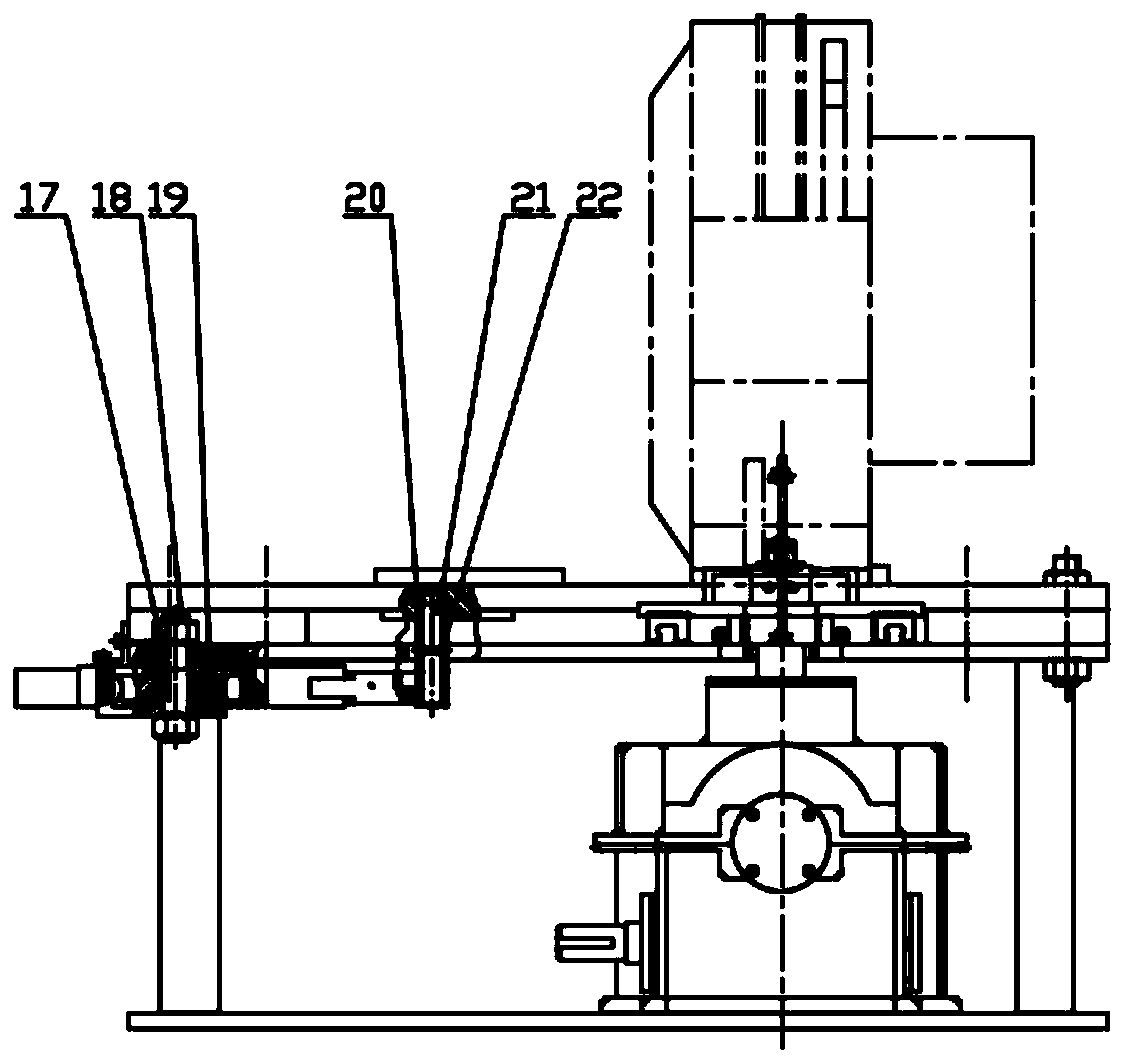

[0026] Such as figure 1 , 2 As shown in and 3, the test fixture for the elevator traction machine includes a centering mechanism, a top pressing mechanism, a side positioning clamping mechanism and a base platform 1. Such as figure 1 , 2, 3, 4, 5 and 8, the centering mechanism includes motor one, worm one 38, worm gear installation shaft 39, worm gear one 40, small bevel gear 42, large bevel gear 33, gear installation shaft 43, spur gear 44. Rack 10, connecting plate 3, sliding block 13, slide rail 6 and fixed plate 12; the output shaft of motor one is connected with worm one 38 through a coupling, and worm one 38 is supported in the box by tapered roller bearing one (the box body is made up of box cover 32 and box seat 36 fixed together); worm gear one 40 is connected with worm gear installation shaft 39 through a key, and meshes with worm screw one 38; the two ends of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com