Patents

Literature

463results about How to "Save design space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

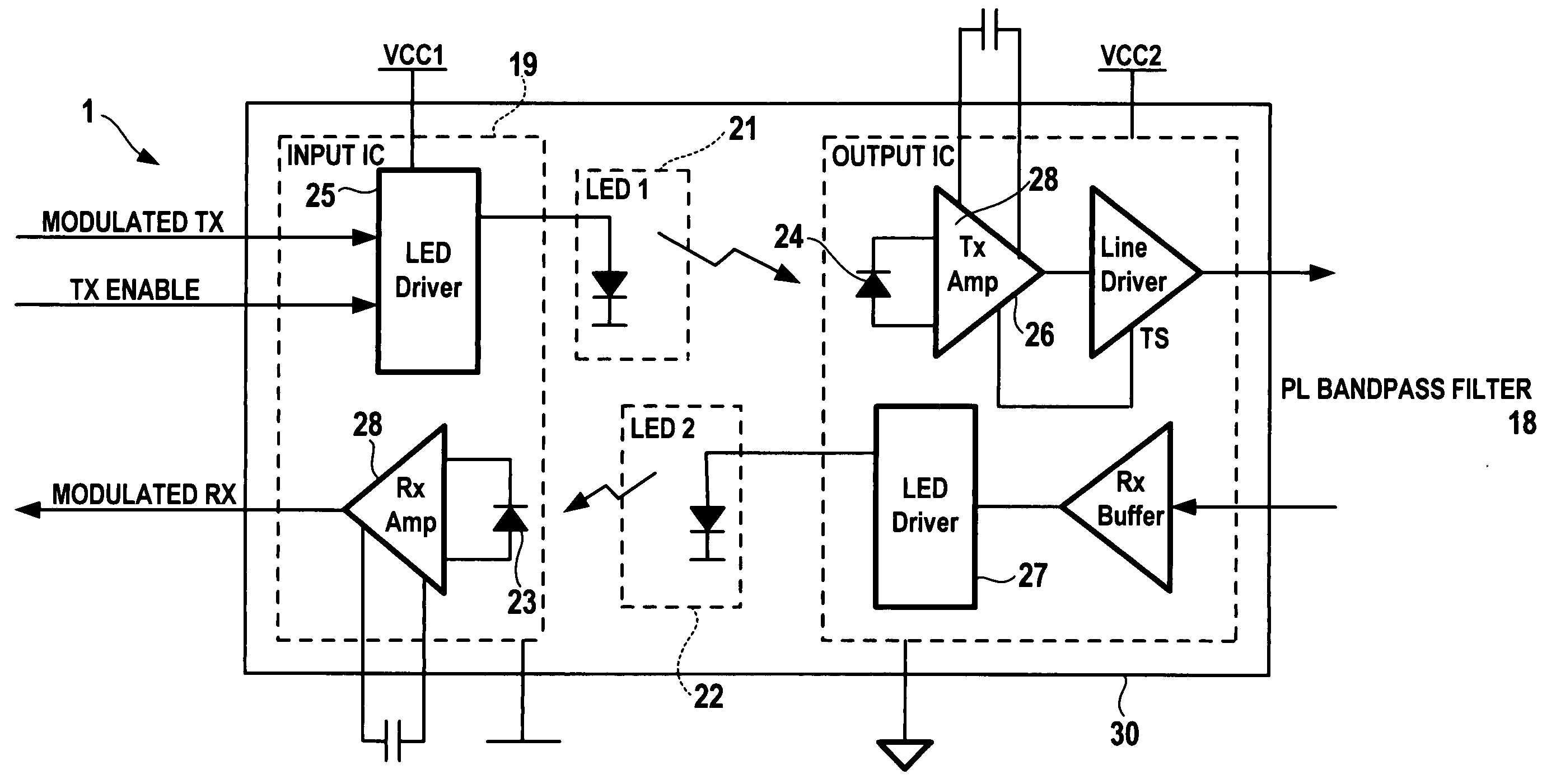

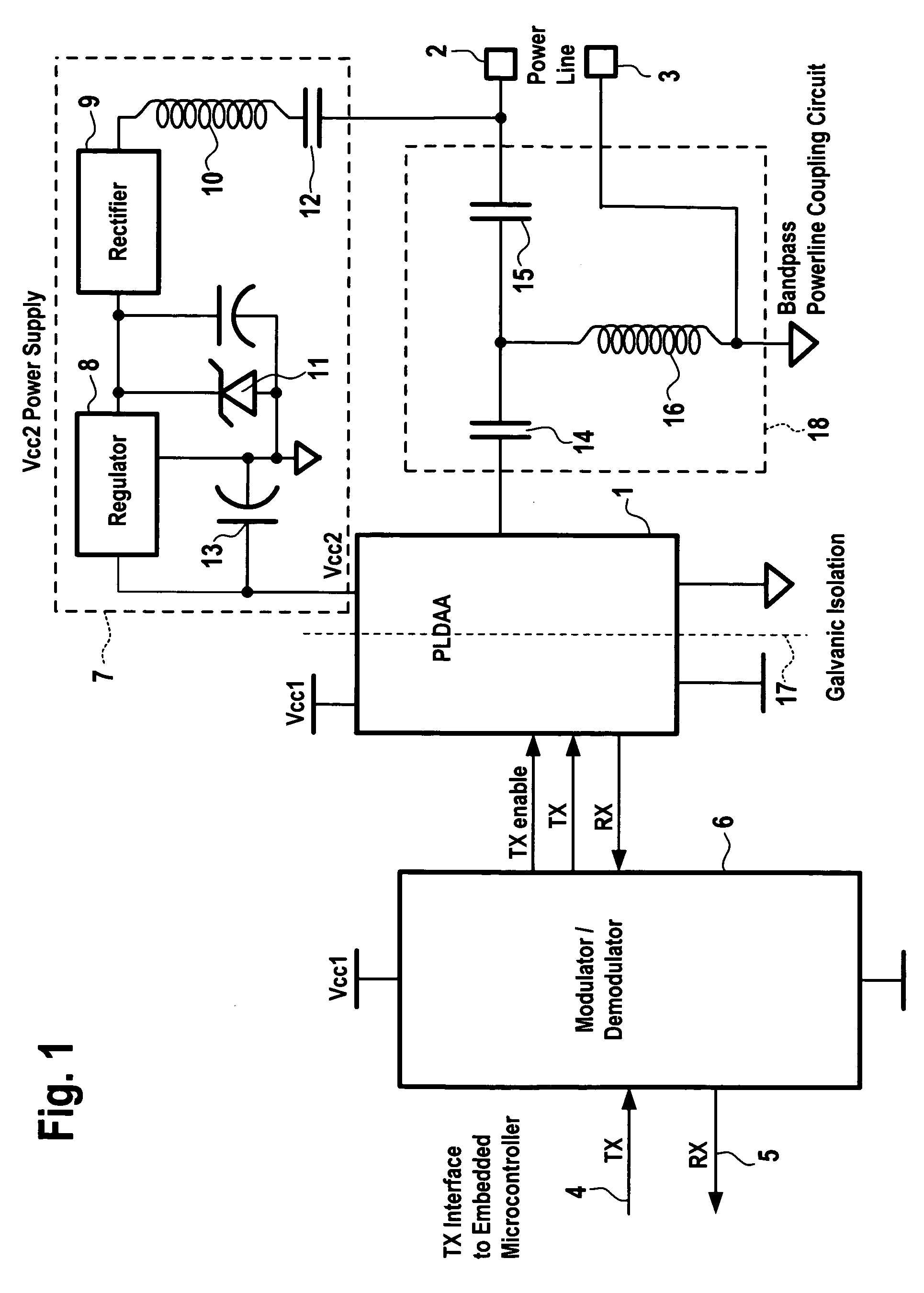

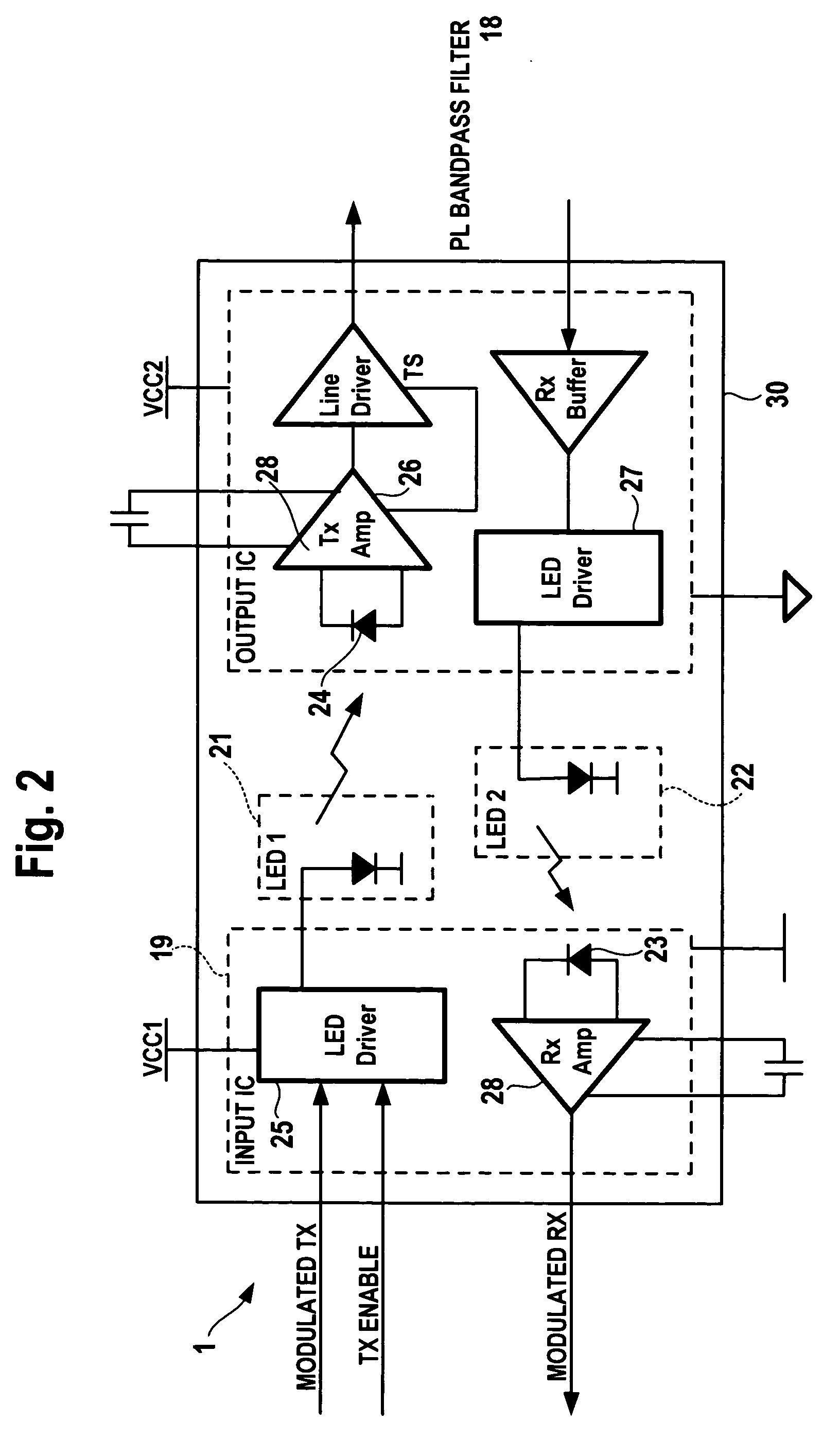

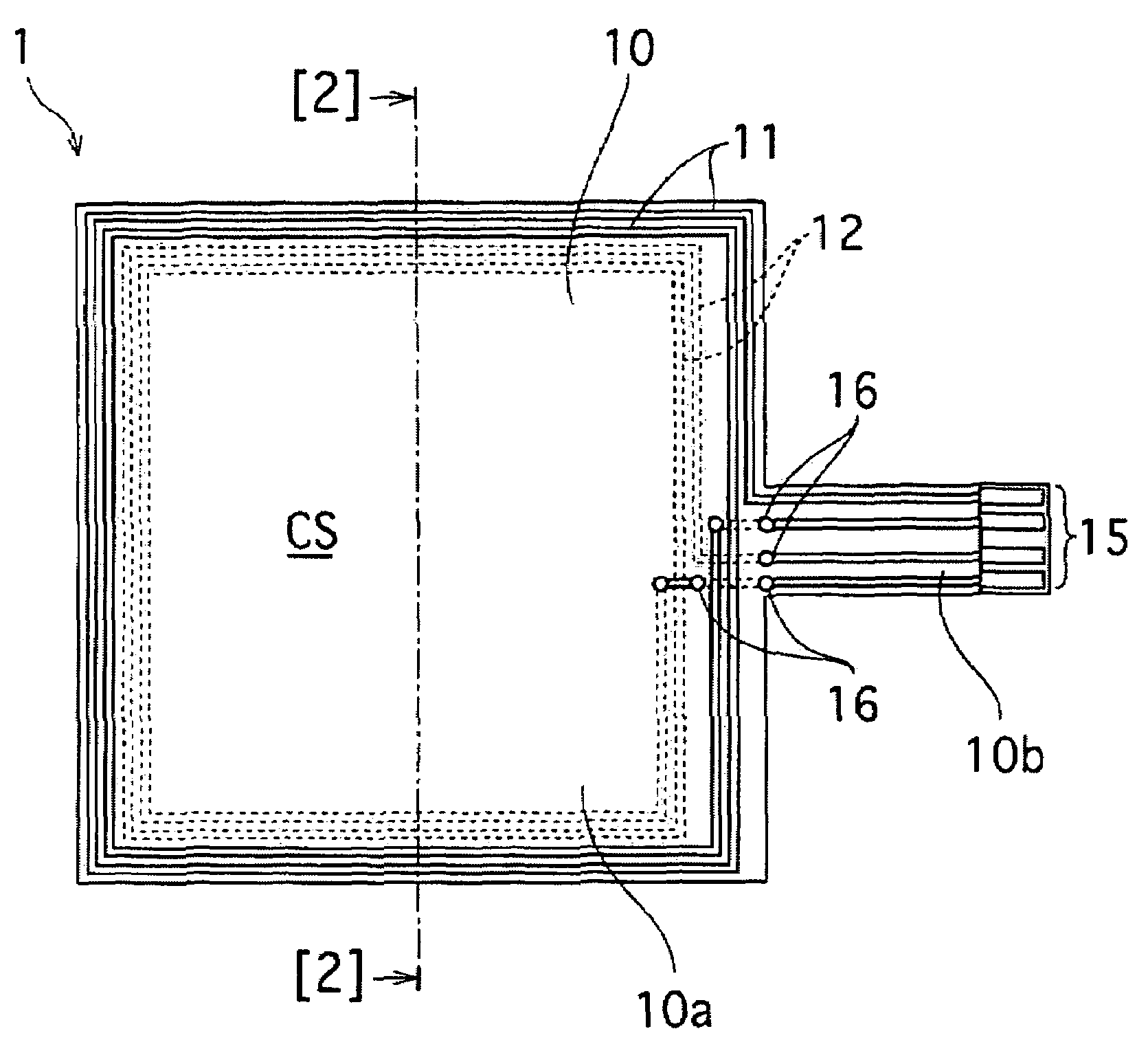

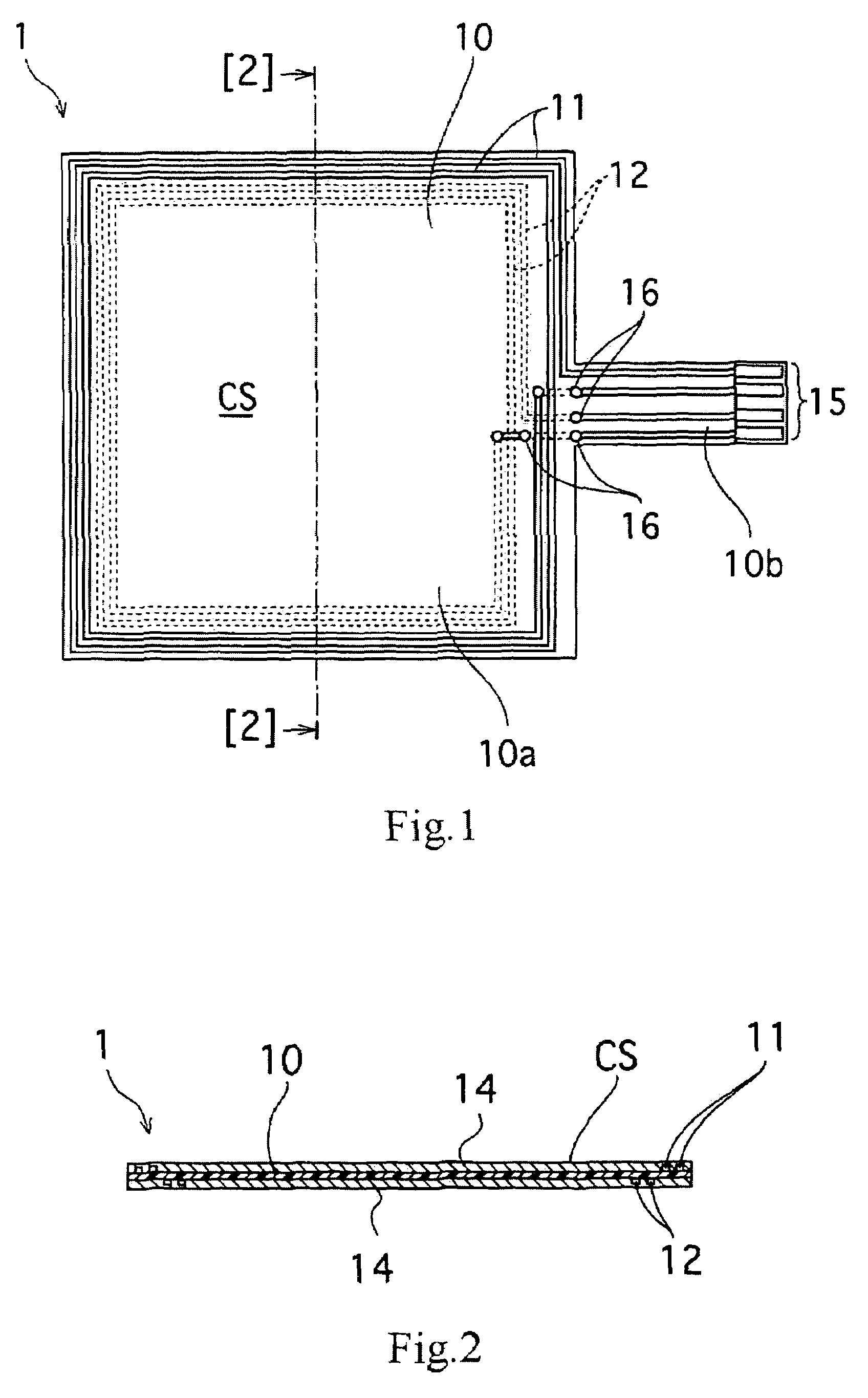

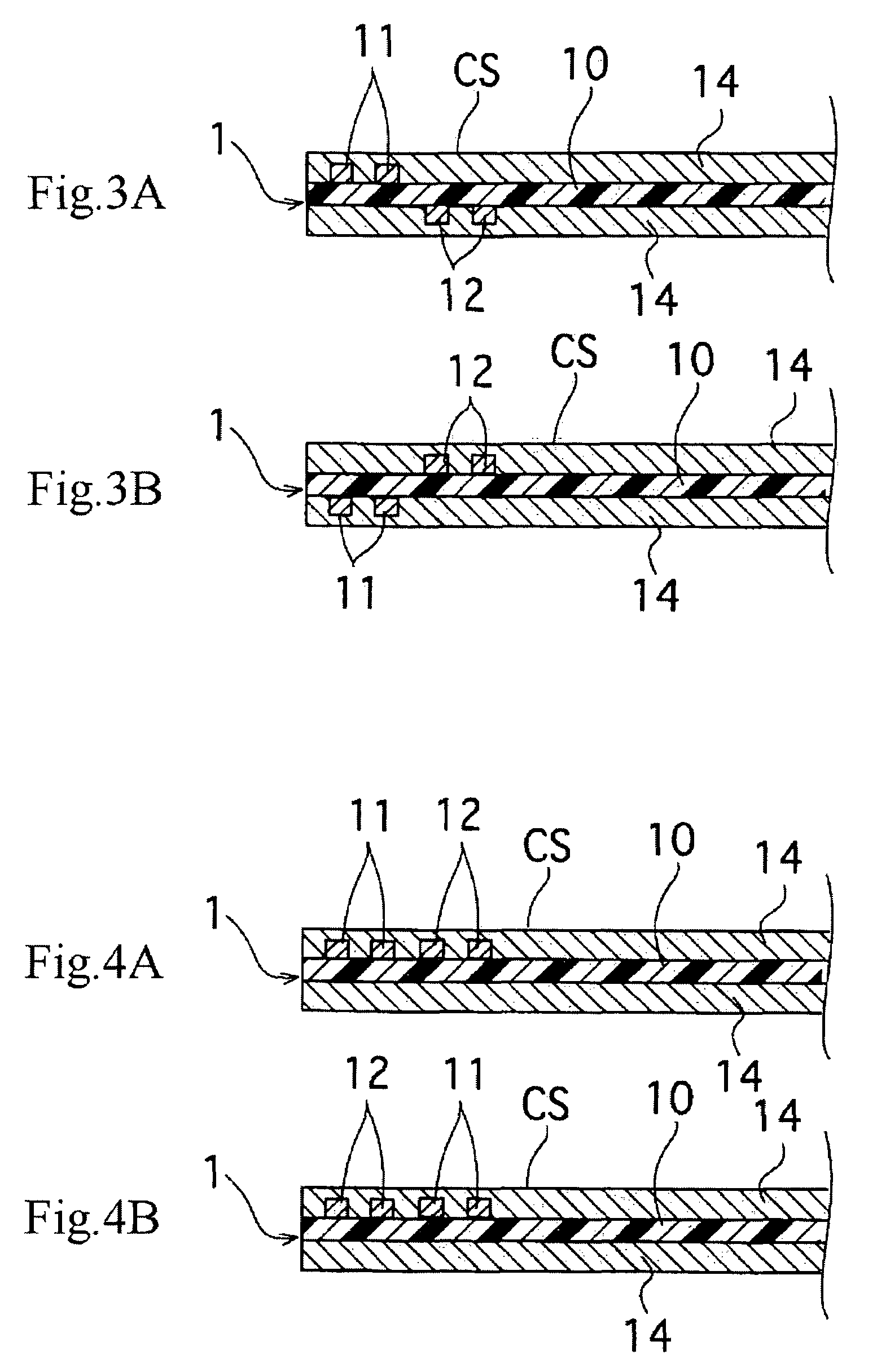

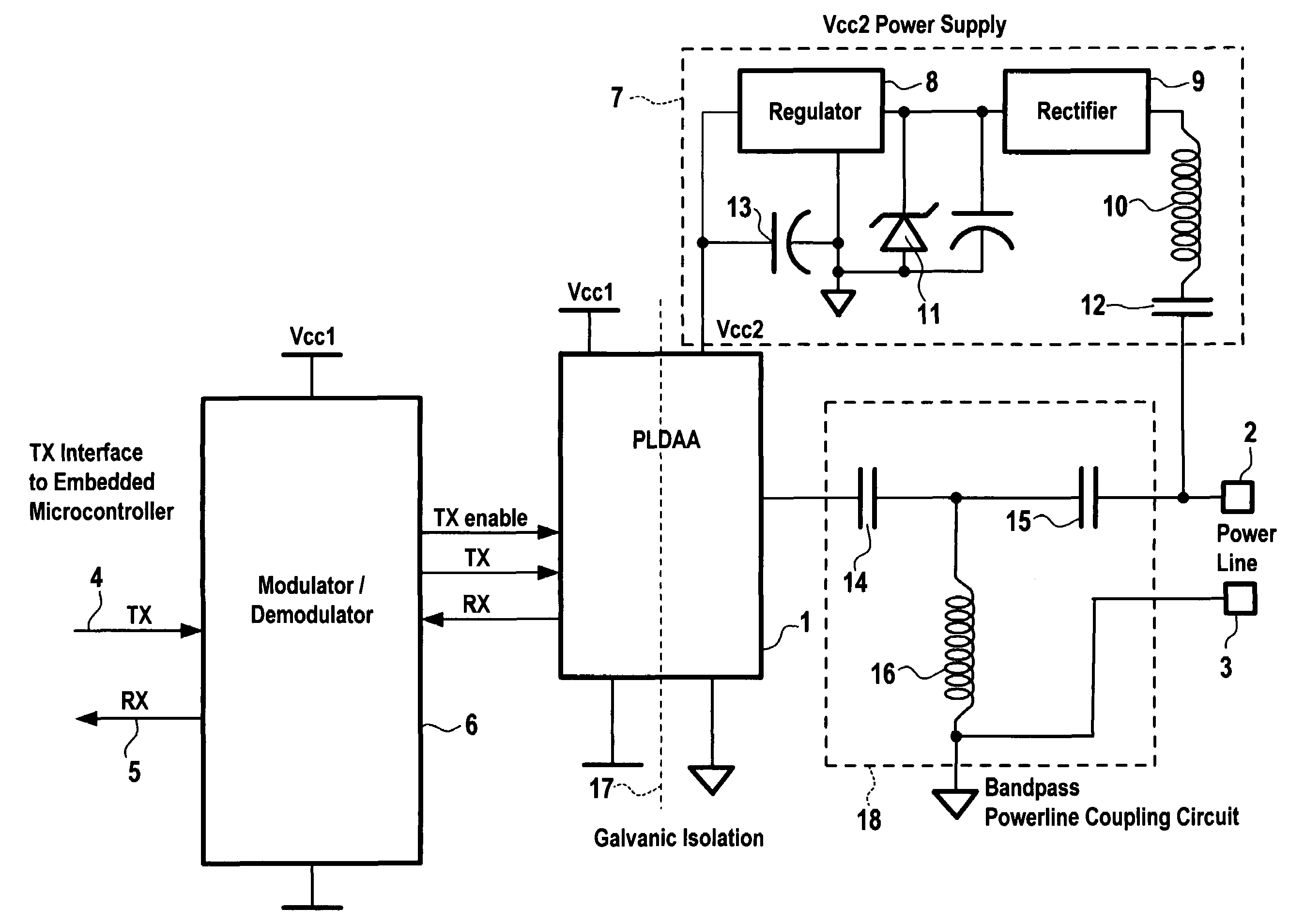

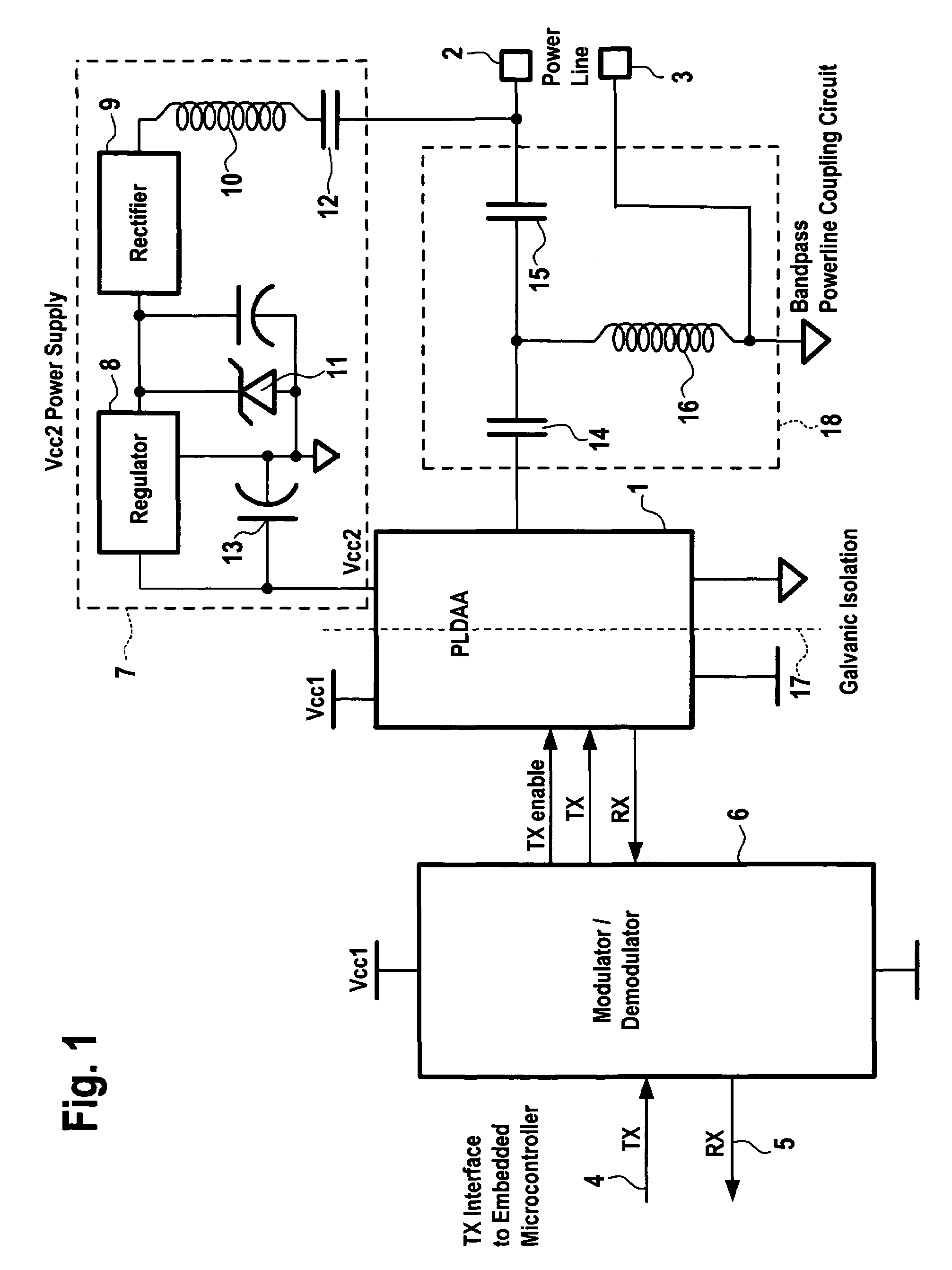

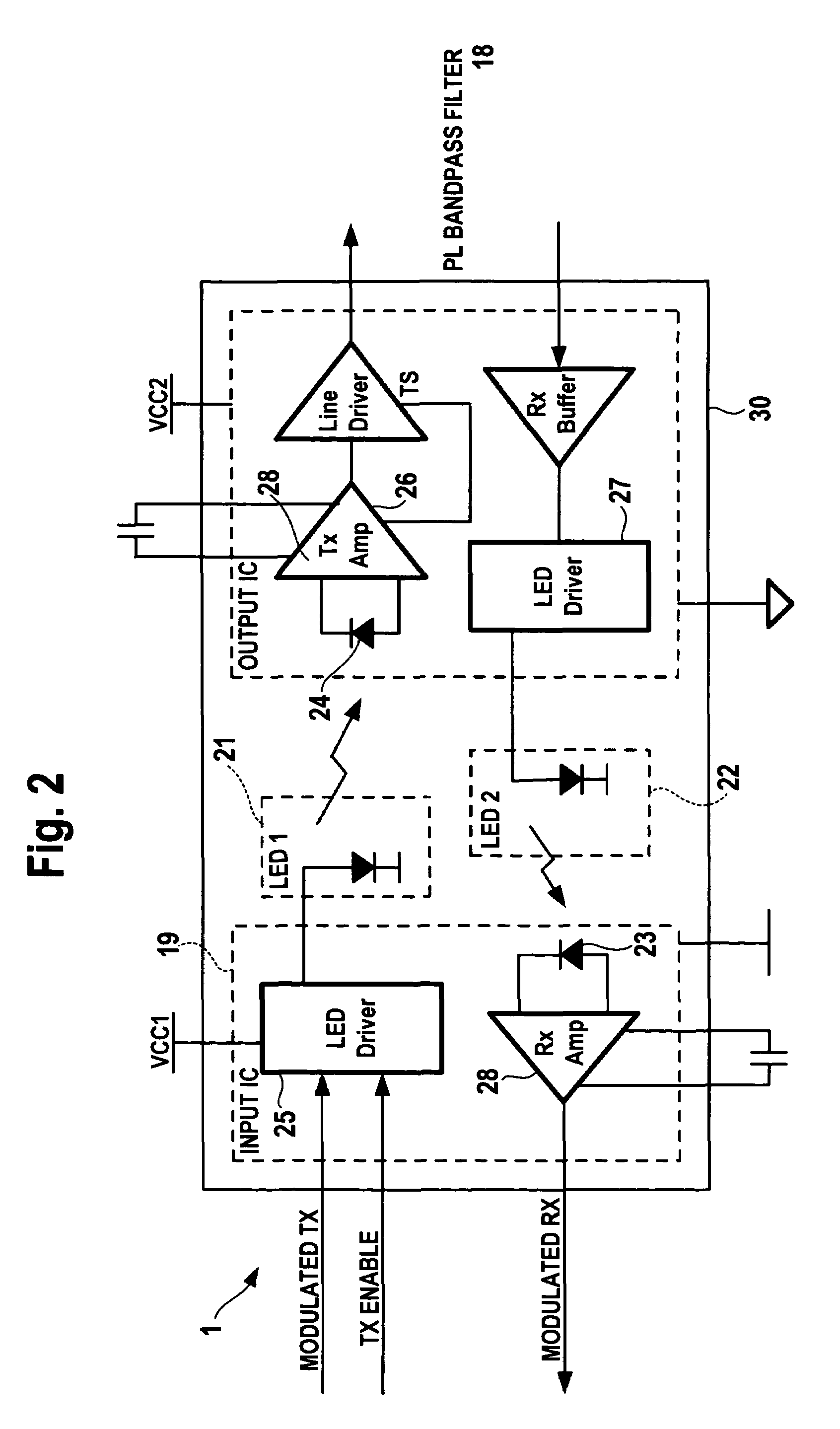

Coupling circuit arrangement for data communication over power lines

InactiveUS20050069321A1Effective preventionSave design spaceElectric signal transmission systemsFrequency-division multiplex detailsControl signalData signal

A coupling circuit arrangement for data communication over a power line comprises a modulator / demodulator circuit for modulating data signals for transmission over the power line, and for demodulating signals which have been transmitted over the power line into data signals, a power supply circuit, and isolation means for providing galvanic isolation from the power line. The isolation means comprises light emitting elements and light detecting elements, which are arranged between the modulator / demodulator circuit and the power line. The isolation means may also be used to transmit a digital control signal which indicates the status of the power supply circuit or an over-temperature condition, or which is a transmit enable signal. The digital control signal may be encoded in the analog data signal by a digital shift in the DC bias level or by a complete removal of the DC biasing signal.

Owner:AVAGO TECH INT SALES PTE LTD

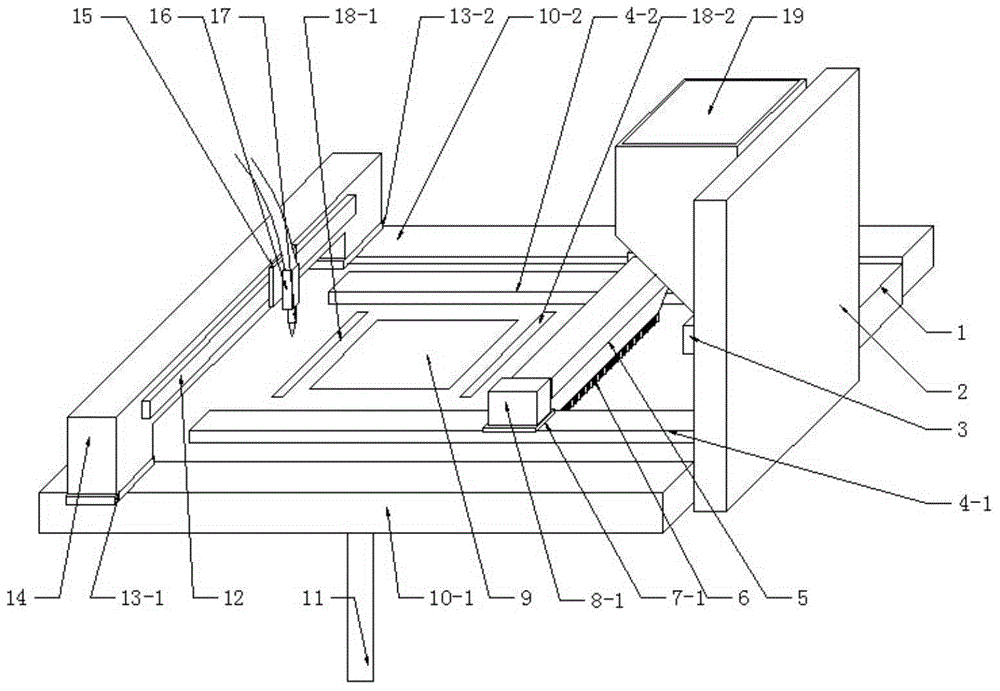

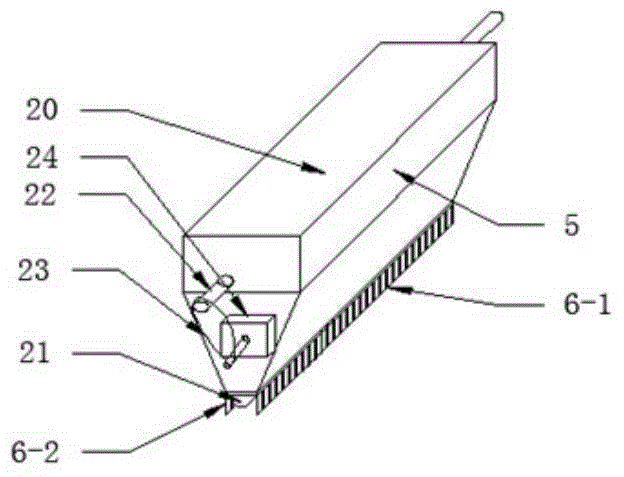

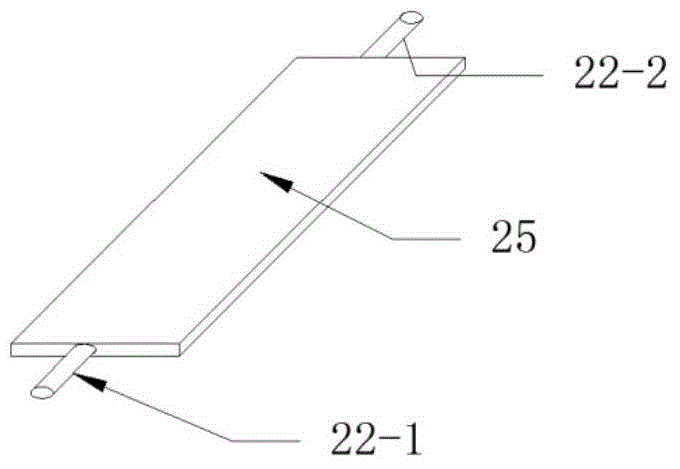

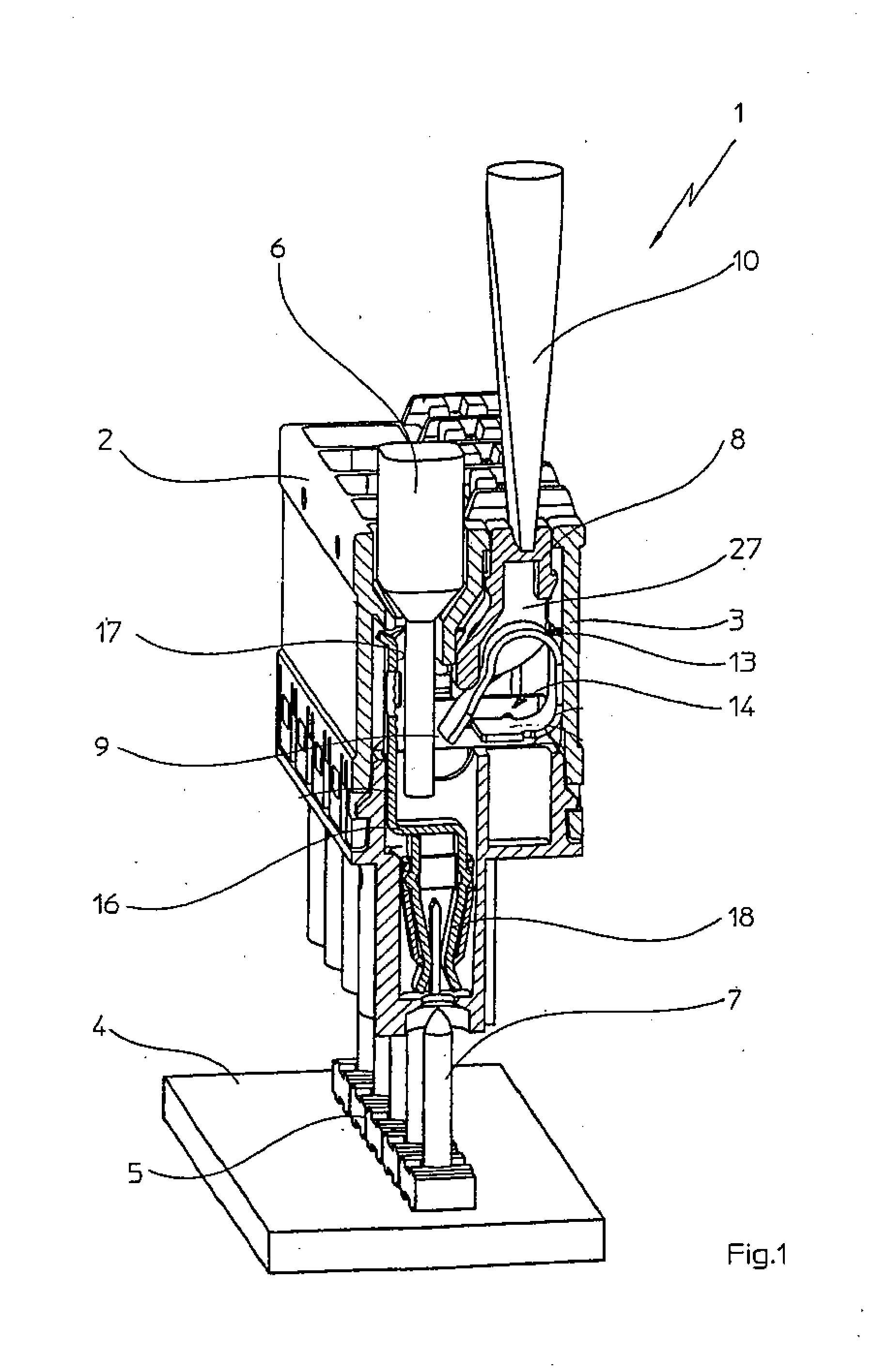

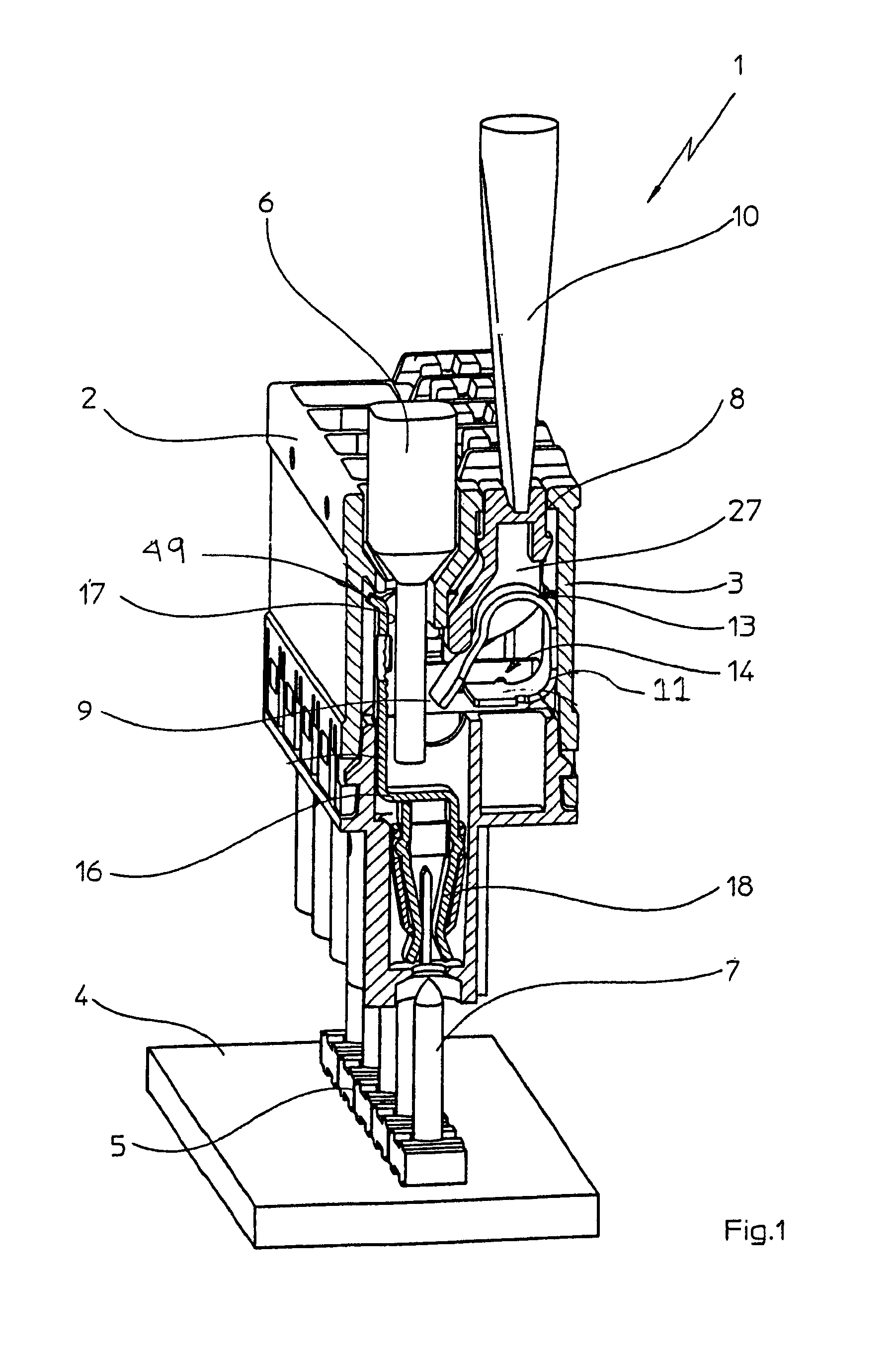

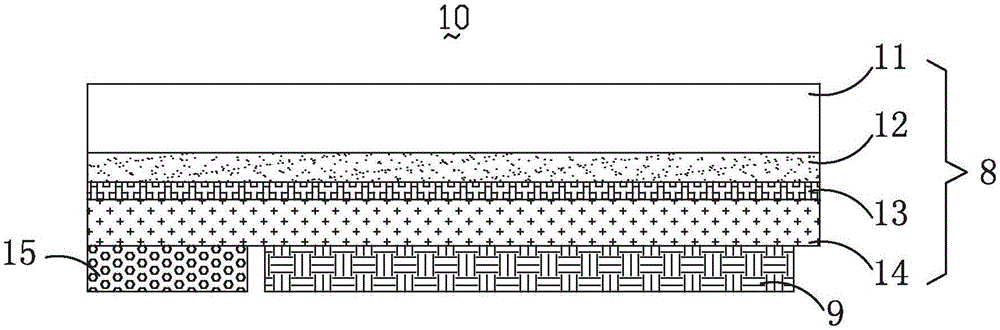

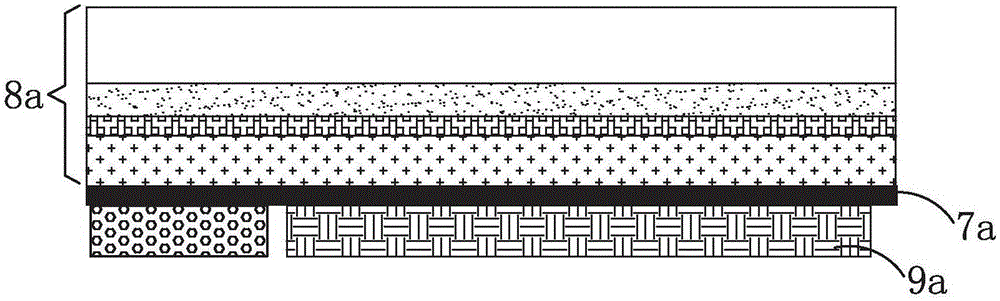

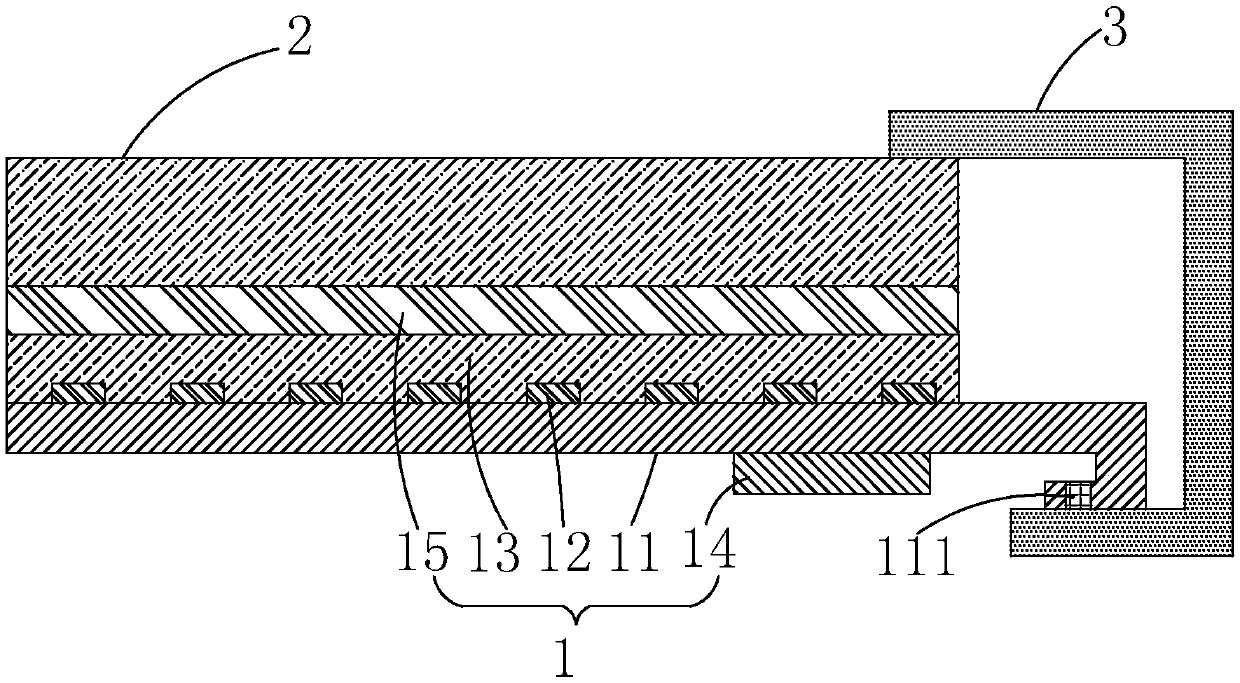

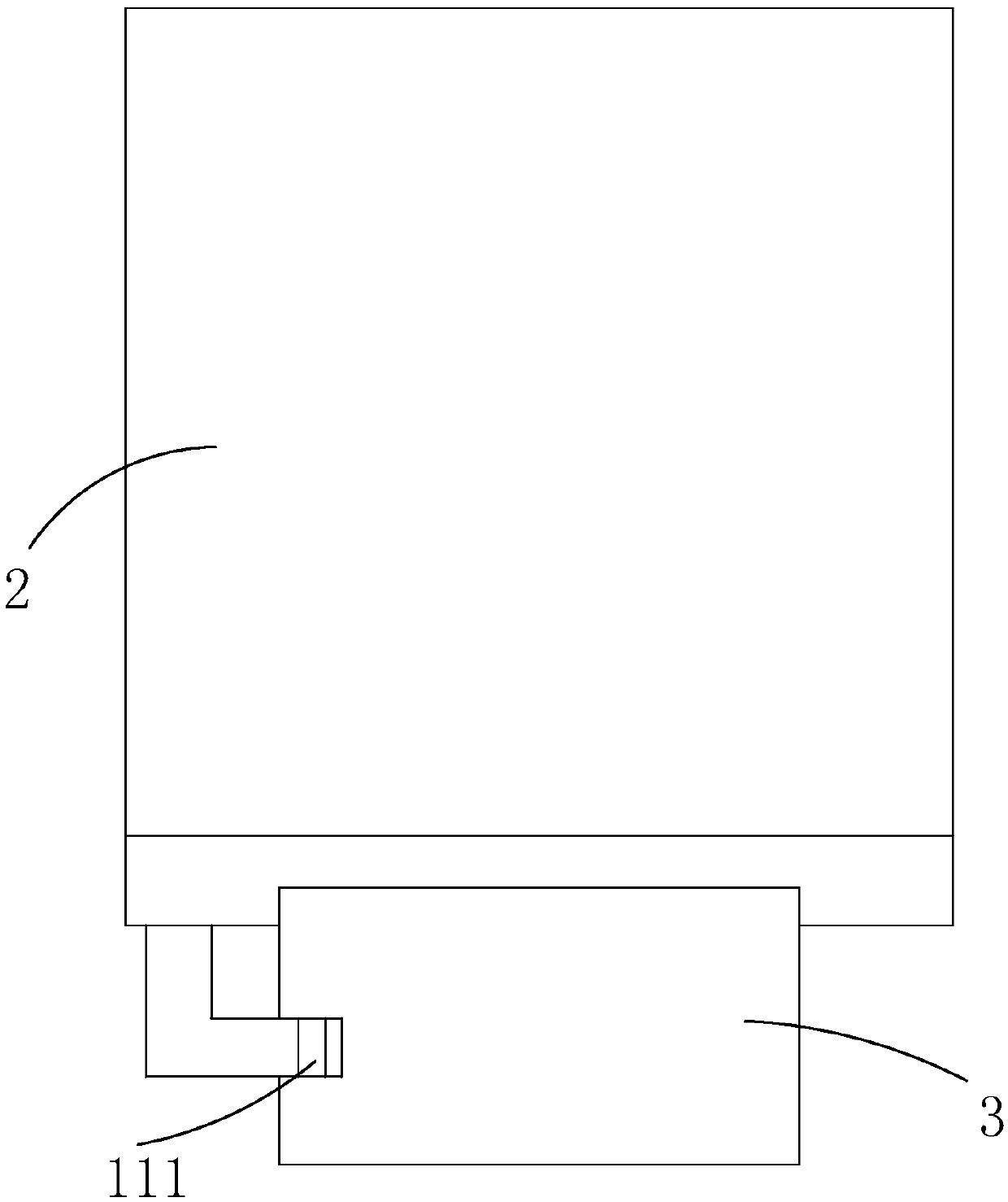

Selective laser melting powder sending and laying device used for compounding of different types of powder

ActiveCN105562687ASolve recycling difficultiesReduce consumptionIncreasing energy efficiencySelective laser meltingMetallurgy

The invention discloses a selective laser melting powder sending and laying device used for compounding of different types of powder. The selective laser melting powder sending and laying device comprises a worktable, a forming cylinder, a powder spraying device and a powder laying device. The upper surface of the forming cylinder is arranged on the worktable. The powder spraying device and the powder laying device are arranged on the two sides of the forming cylinder. The powder spraying device is characterized in that powder spraying electric guide rails, a support, a nozzle electric guide rail and a nozzle are included; the nozzle is arranged on the nozzle electric guide rail; the nozzle electric guide rail is arranged on the powder spraying electric guide rails through the support; and the powder spraying electric guide rails are fixed to the worktable. The powder laying device comprises a powder hopper, a powder scraping electric guide rail and a supporting frame; the powder hopper is arranged on the powder scraping electric guide rail through the supporting frame; and the powder scraping electric guide rail is fixed to the worktable. According to the selective laser melting powder sending and laying device used for compounding of different types of powder, the selective laser melting technology and the laser cladding coaxial powder sending technology are combined, and the purposes of effectively recovering powder during compound additive manufacturing of gradient materials and forming parts with complex gradients in any direction are achieved.

Owner:NANJING UNIV OF SCI & TECH

Antenna module and portable communication terminal equipped with the antenna module

InactiveUS7712672B2Long communication distanceSimple designLoop antennas with ferromagnetic coreOther printing matterComputer moduleComputer terminal

Owner:SONY CORP

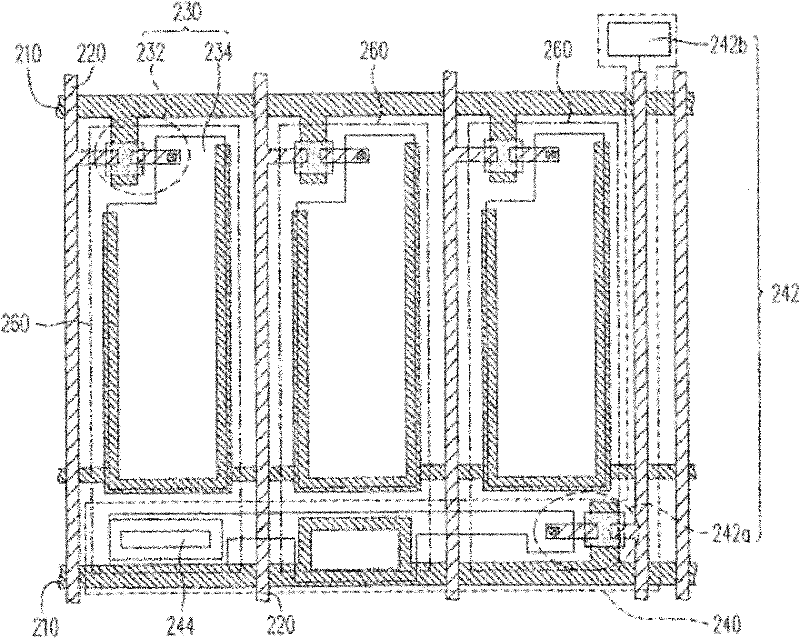

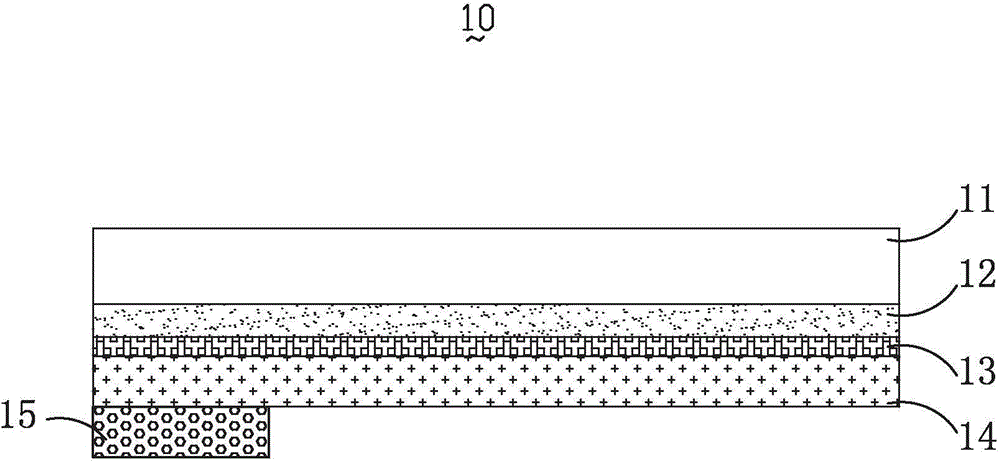

Detection device and detection method

ActiveCN102455960ASimple structureSave design spaceDetecting faulty computer hardwareControl switchControl line

The invention discloses a detection device used for detecting short circuit of touch detection lines of a touch display panel. The touch display panel comprises a substrate and a scan line, a data line and multiple touch detection lines formed on the substrate. The detection device comprises a shorting bar, a switch control line and multiple control switches respectively corresponding to the multiple touch detection lines, wherein the shorting bar is connected with the data line and the scan line; the control switches are controlled by the switch control line; and when the control switches are turned on, the control switches connect the corresponding touch detection lines with the data line. The detection device disclosed by the invention has a simple structure and occupies a smaller design space. The detection method for detecting short circuit by using the detection device disclosed by the invention is simple and can accurately judge the short circuit position, thereby repairing the touch display panel and improving the yield of products.

Owner:深圳市海云通信有限公司

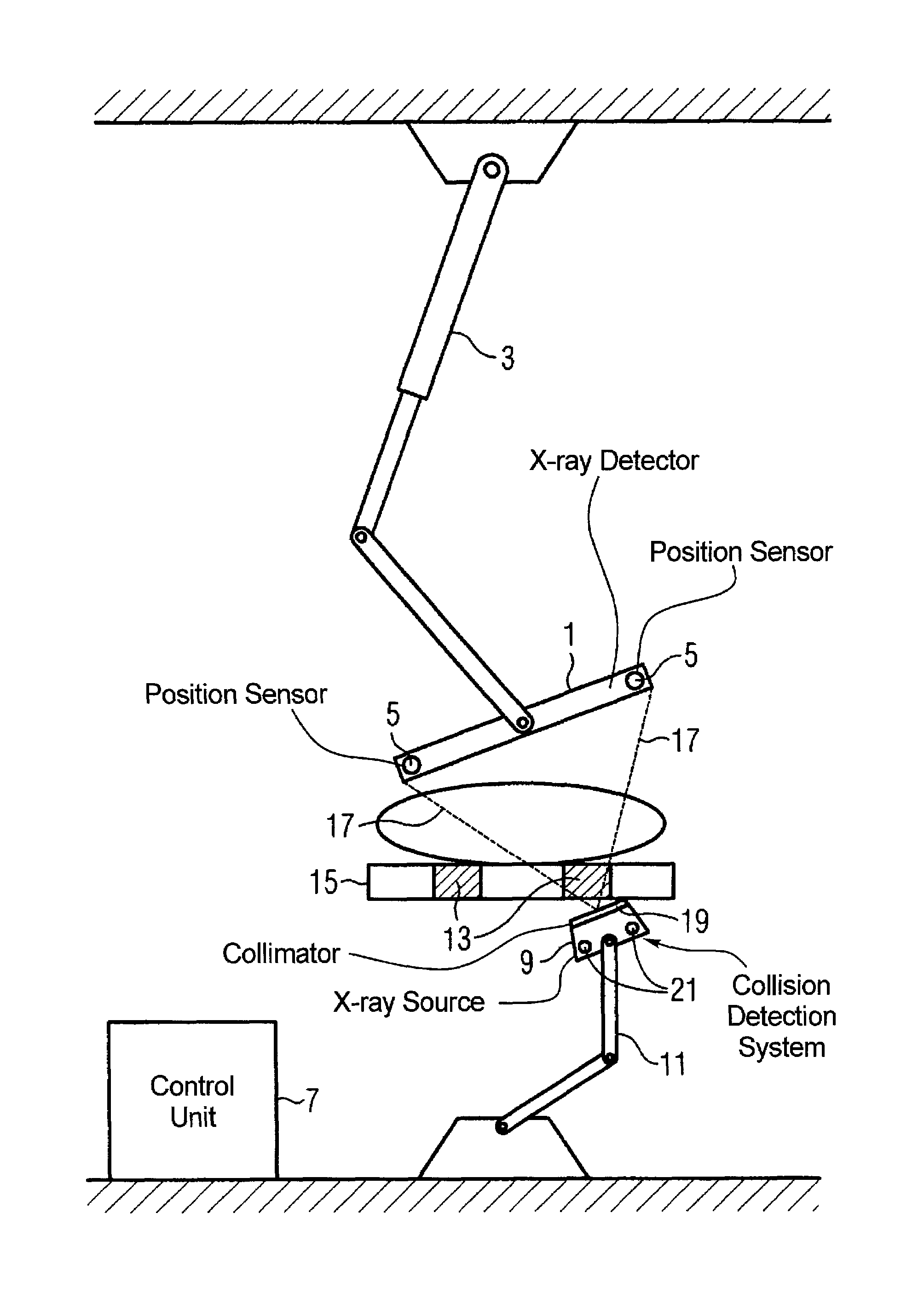

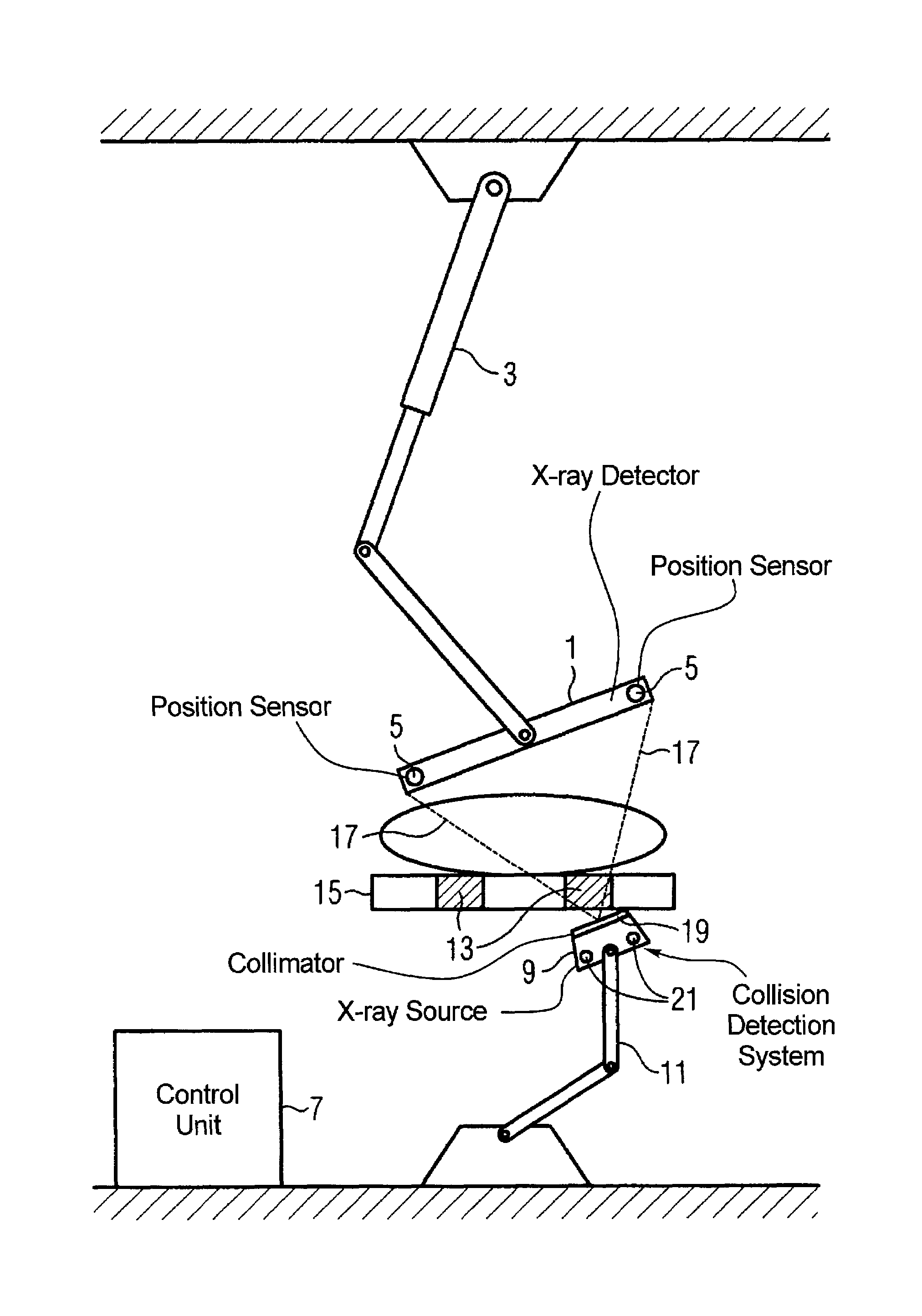

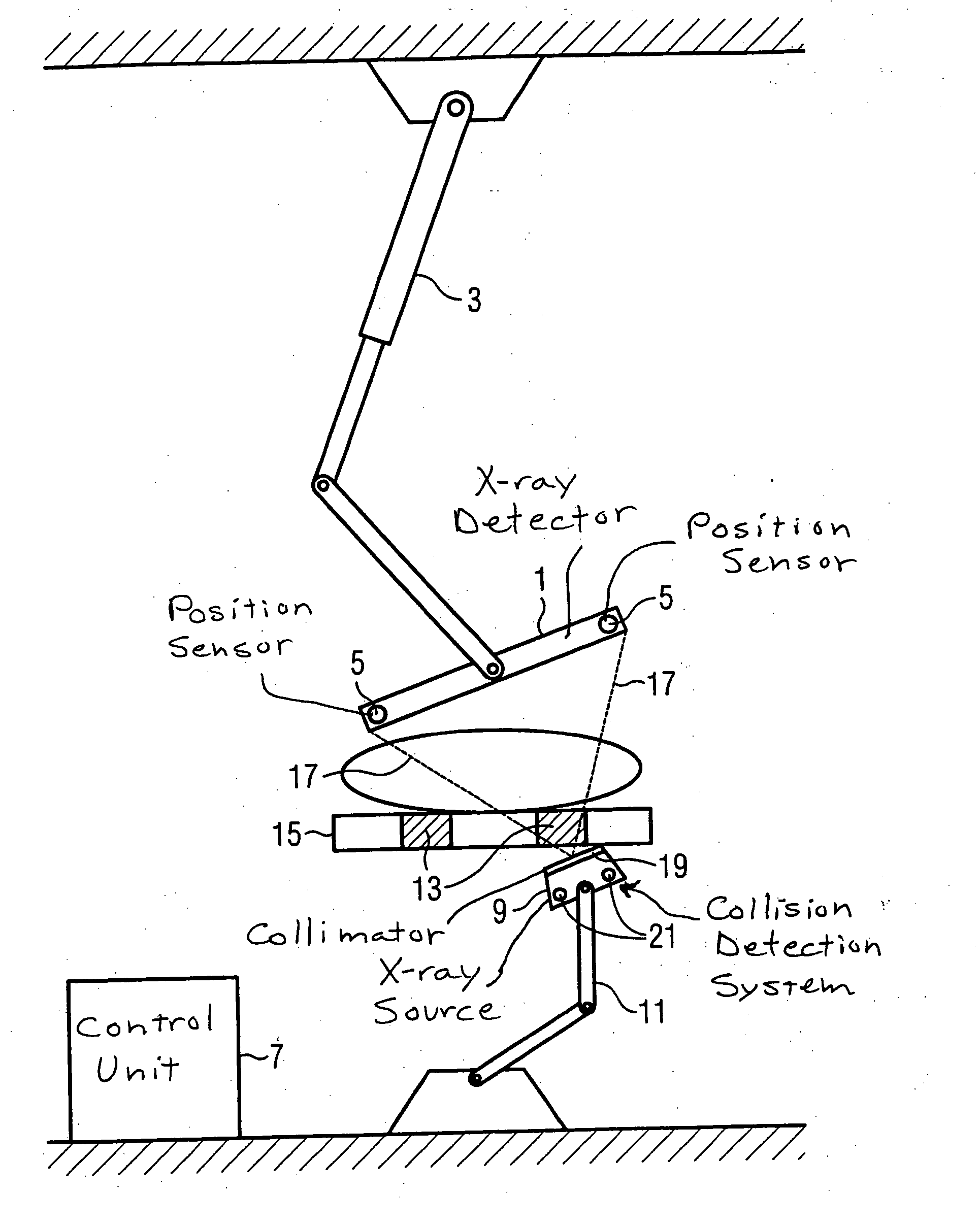

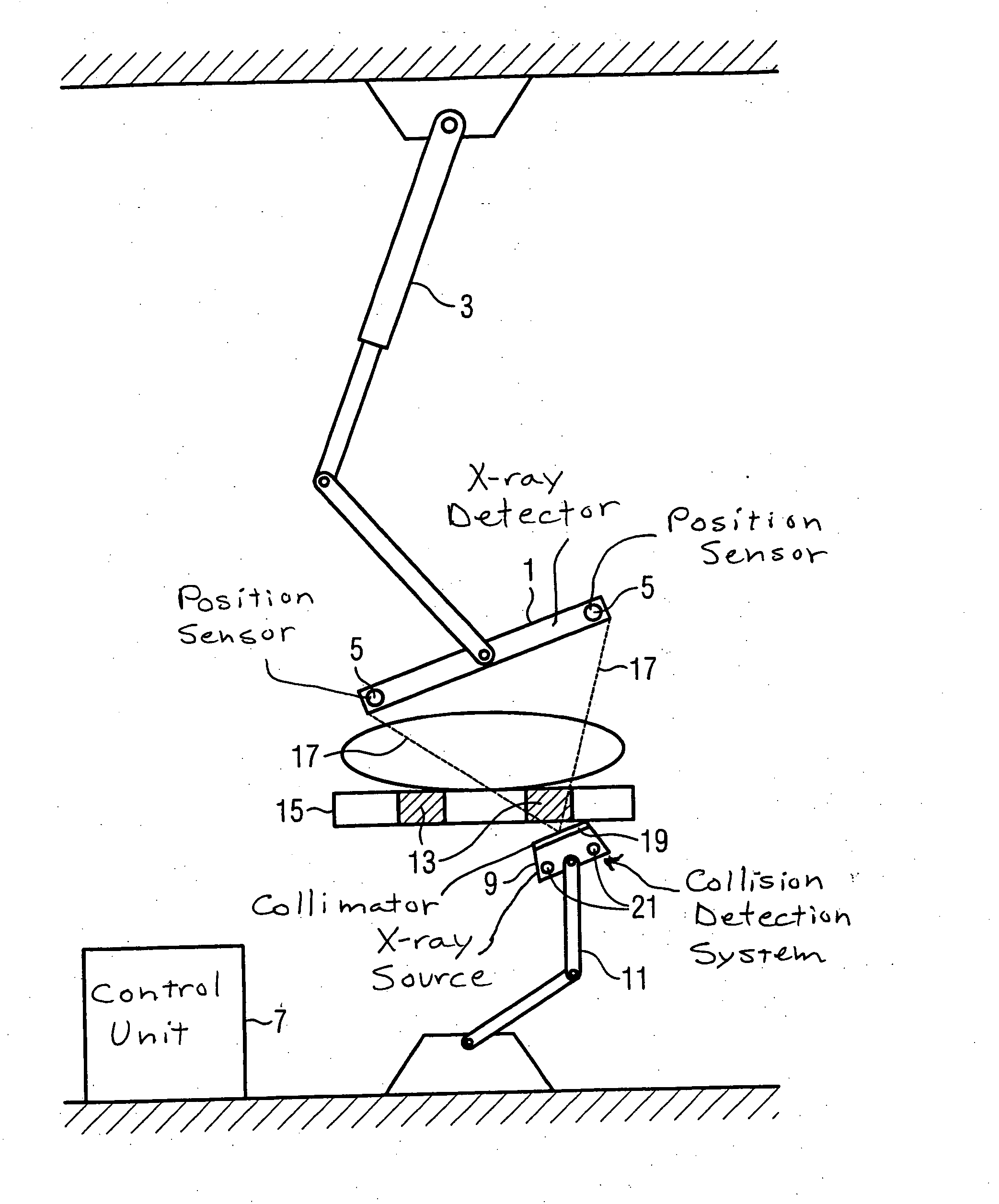

X-ray apparatus with component positioning coordinated with radio-opaque objects in examination room

InactiveUS7401977B2Short amount of timeEasy to useMaterial analysis using wave/particle radiationRadiation/particle handlingSoft x rayAcquisition apparatus

An x-ray acquisition apparatus has a spatially adjustable x-ray detector, a spatially adjustable x-ray source, and a control unit with which the x-ray source can be aligned relative to the x-ray detector. The control unit accounts for the position of radio-opaque objects in the examination room and, before an x-ray acquisition, outputs a signal is a radio-opaque object is located in the beam path of the x-ray source.

Owner:SIEMENS HEALTHCARE GMBH

Illuminated vanity mirror unit

InactiveUS20060181893A1Save design spaceExpensive stepLighting circuitsAntiglare equipmentEngineeringMotorized vehicle

Owner:IND TECHNO MATIC

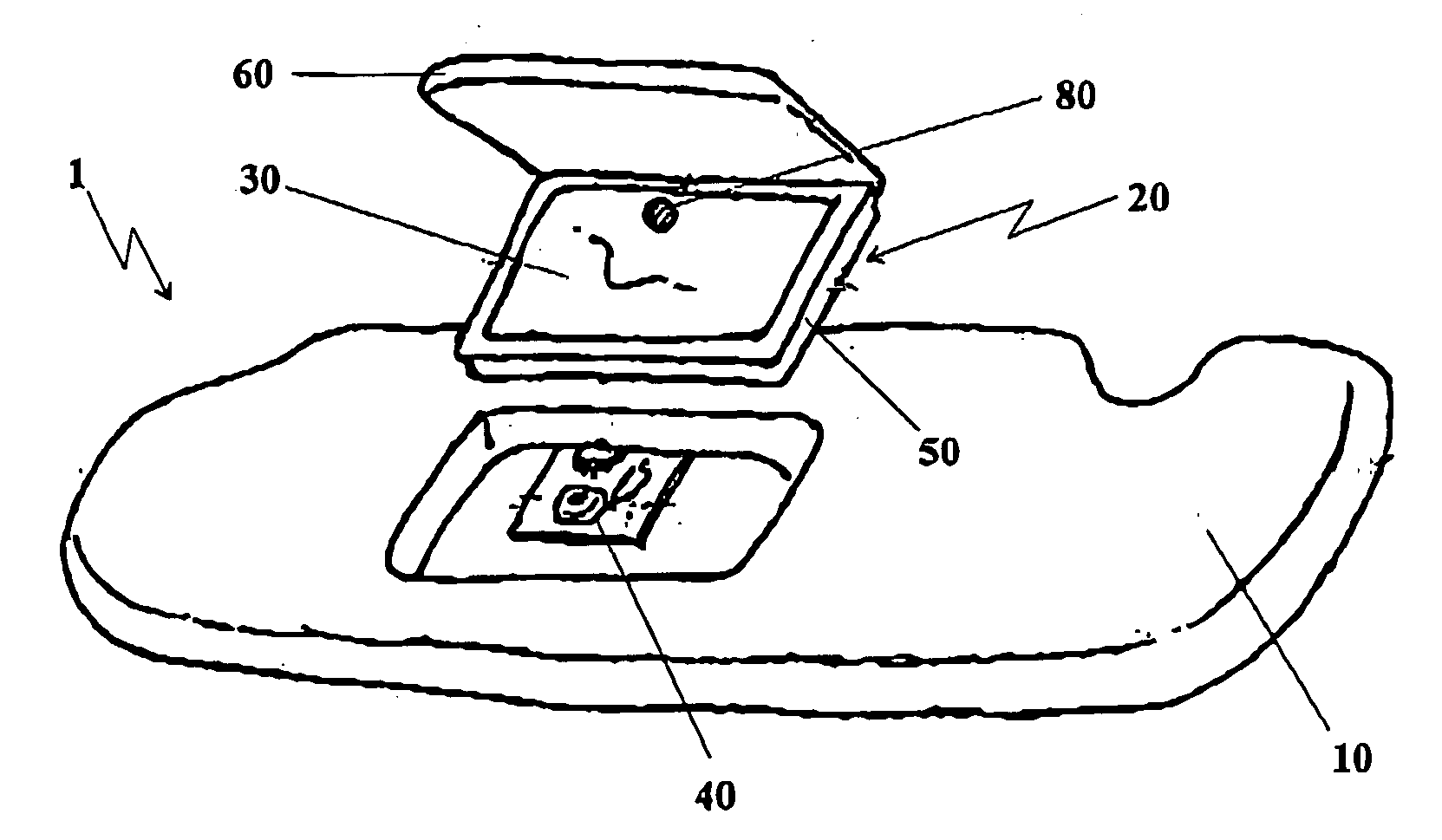

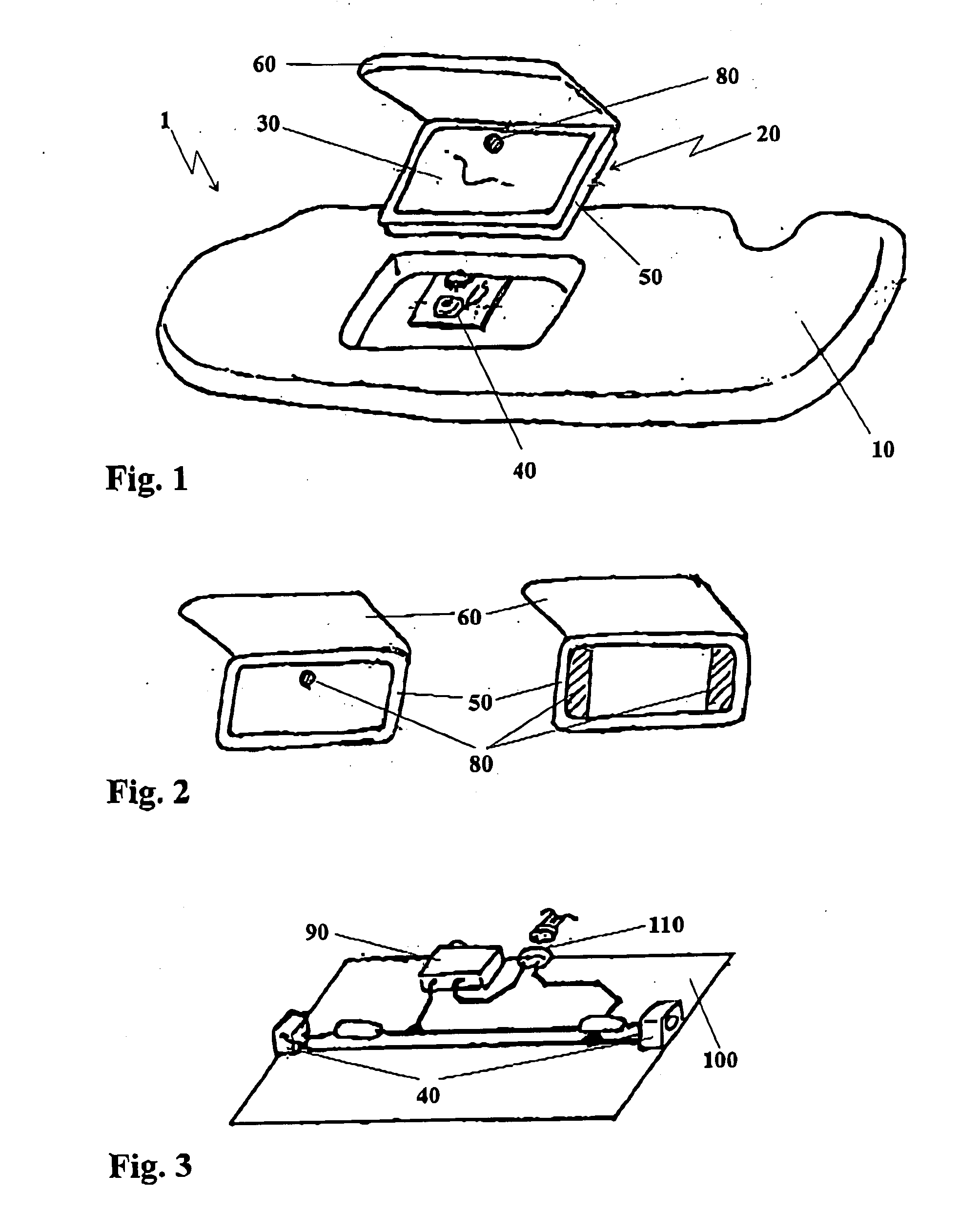

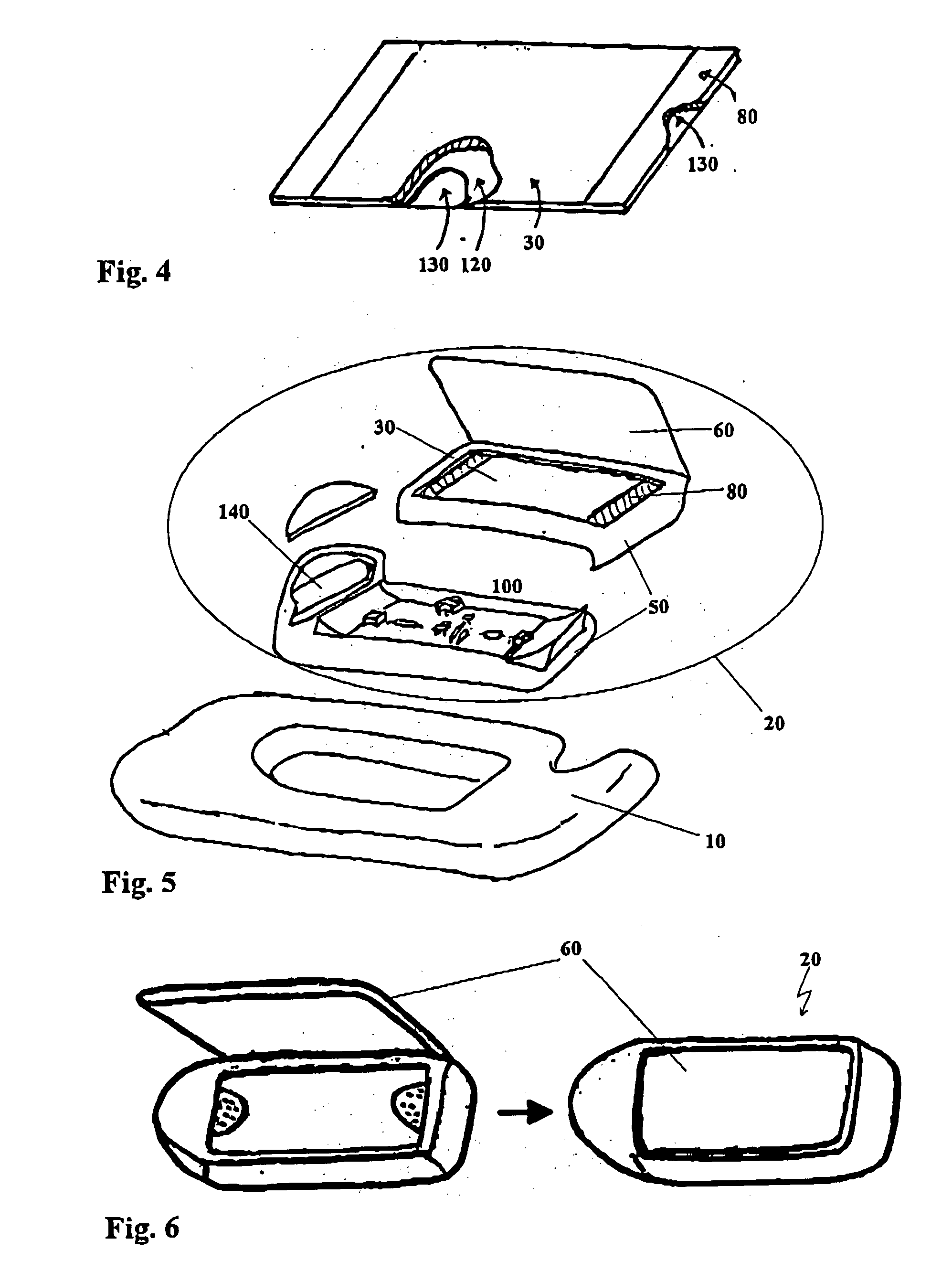

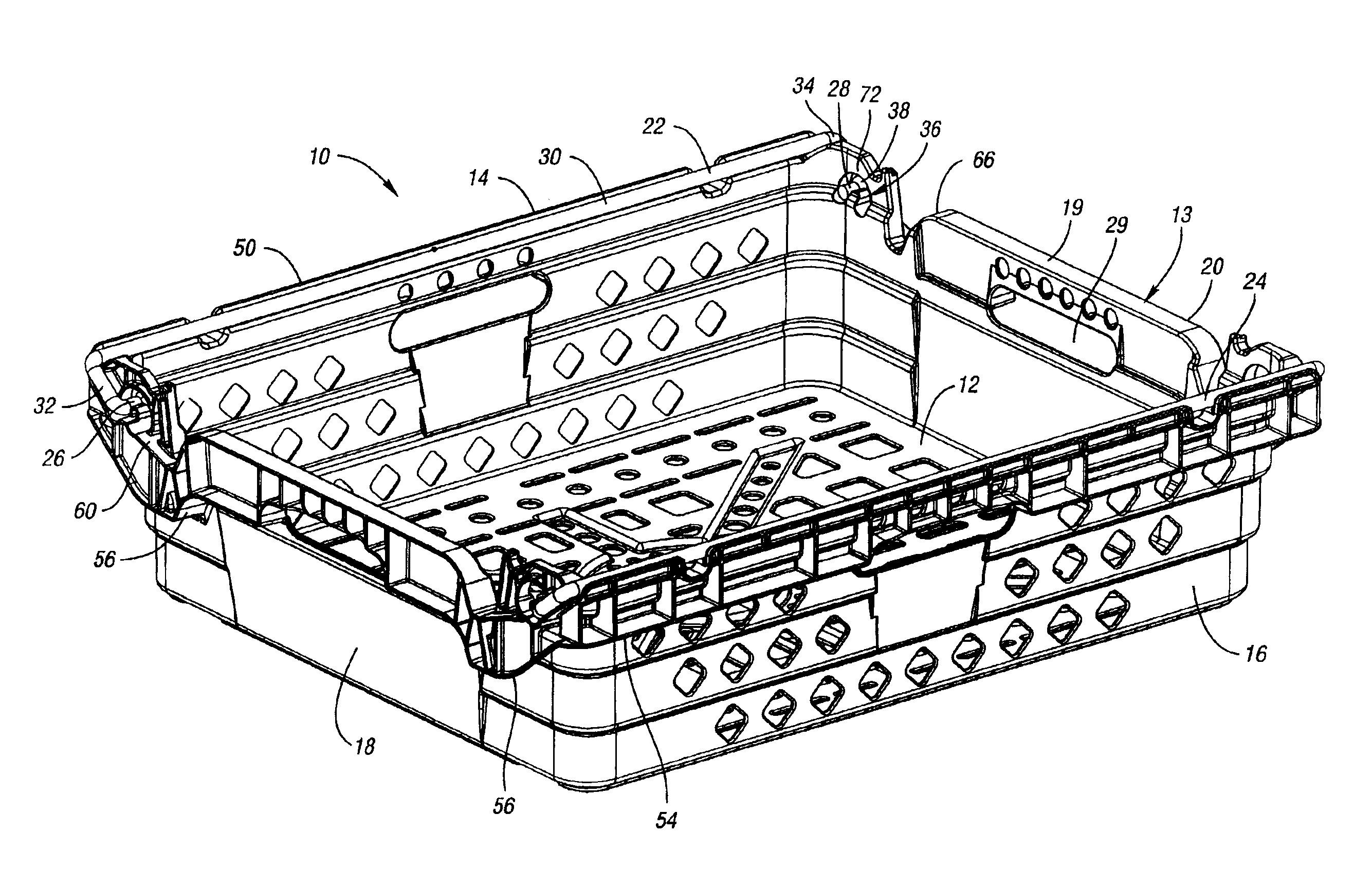

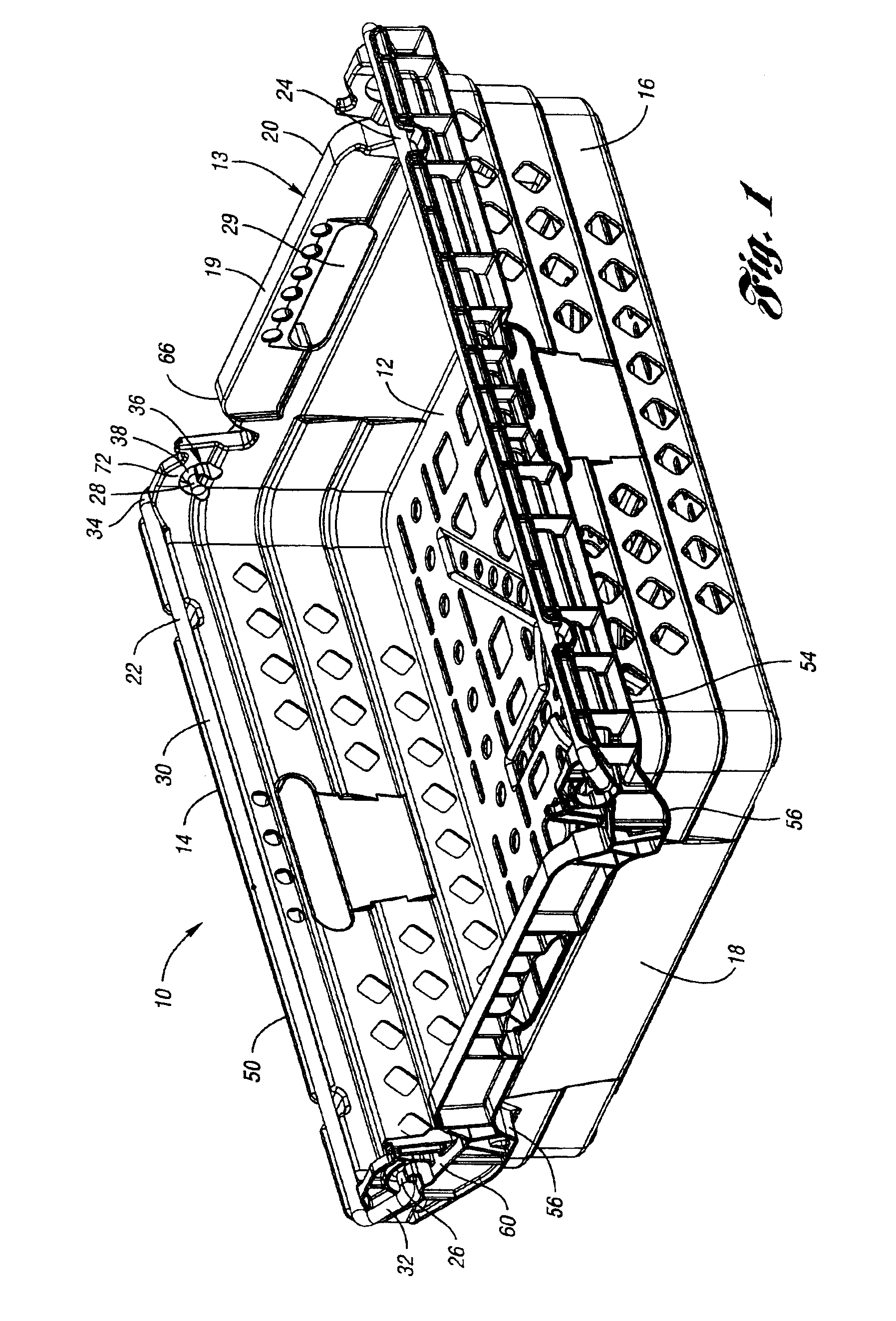

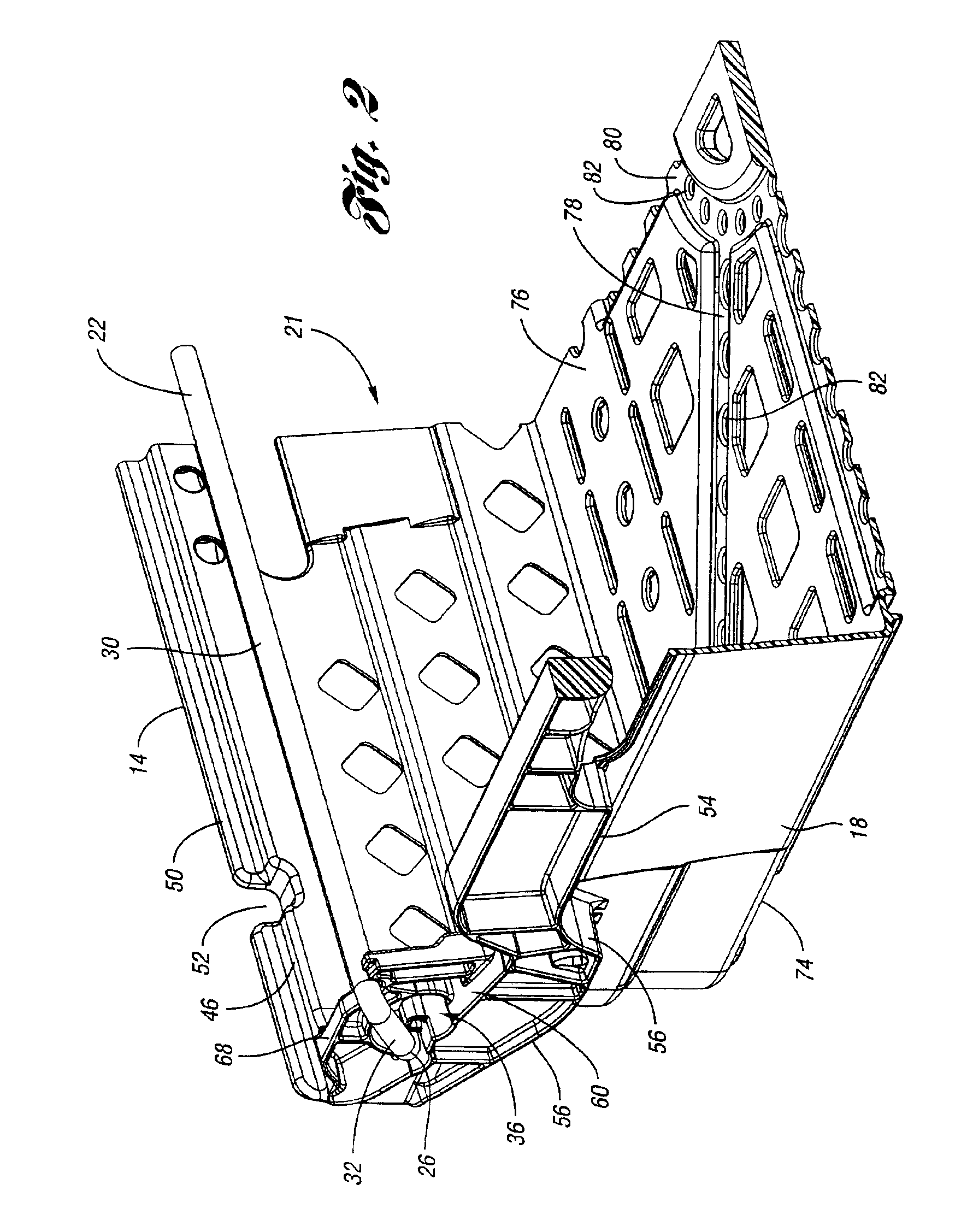

Portable storage container

InactiveUS6938772B2Provide strengthEffective supportTray containersEngineeringMechanical engineering

A storage container has a floor and two pairs of opposed walls extending upwardly from the floor. Included is a bail member having bail ends mountable to one of the pairs of walls, and movable among nest and stack positions. Also included are mounting portions on one of the pairs of walls for receiving the bail ends. Mounting portions include an opening defining a plurality of pivot axes about which the bail member pivots, each axis oriented at substantially similar heights above the floor. When bail ends are positioned at one pivot axis, bail member is movable between the nested and a first stack positions. When bail ends are positioned at an other pivot axis, bail member is oriented in the second stack position. To move the bail member between first and second pivot axes, the bail member is raised upwardly within the opening and moved around an interference portion.

Owner:REHRIG PACIFIC CO INC

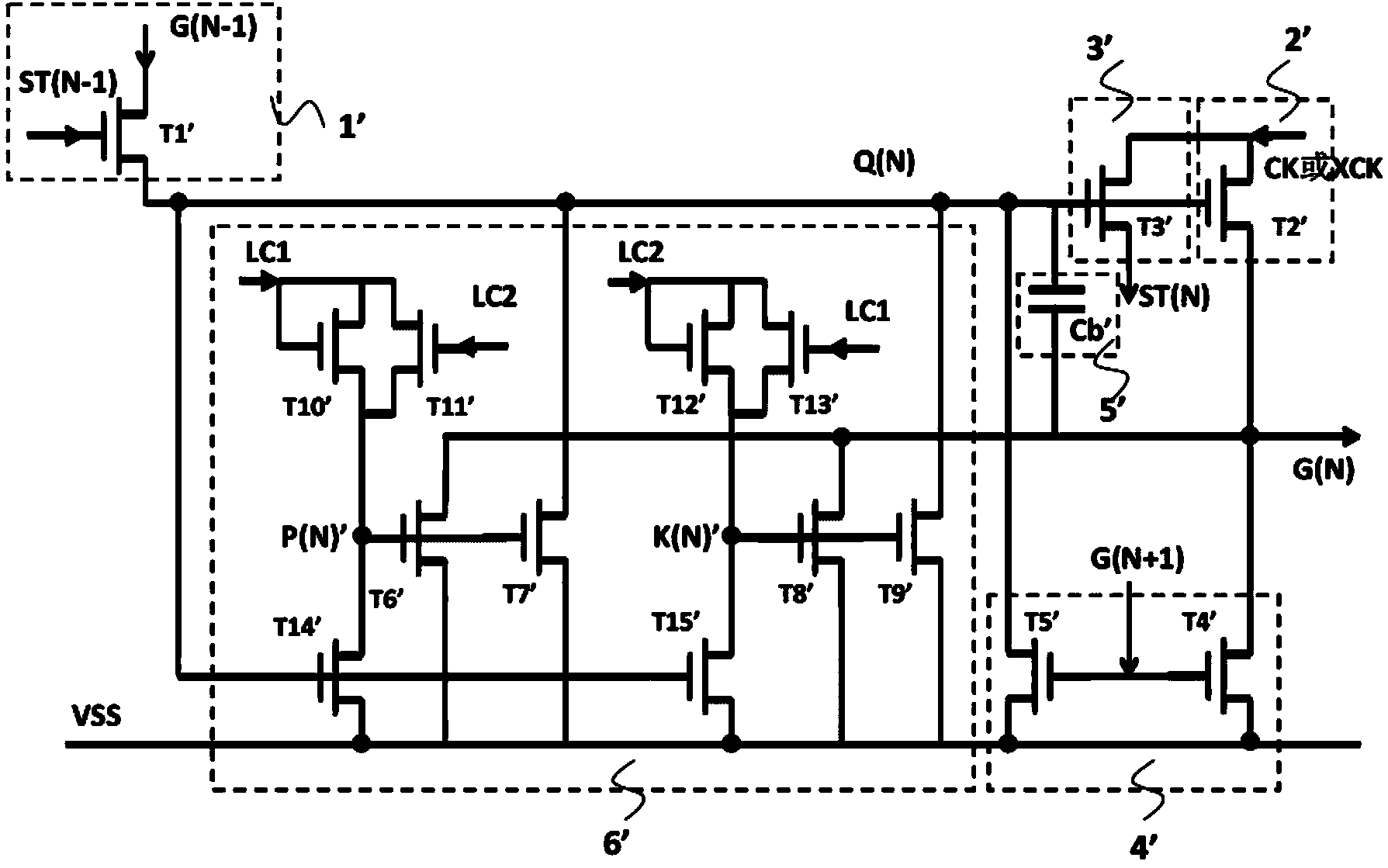

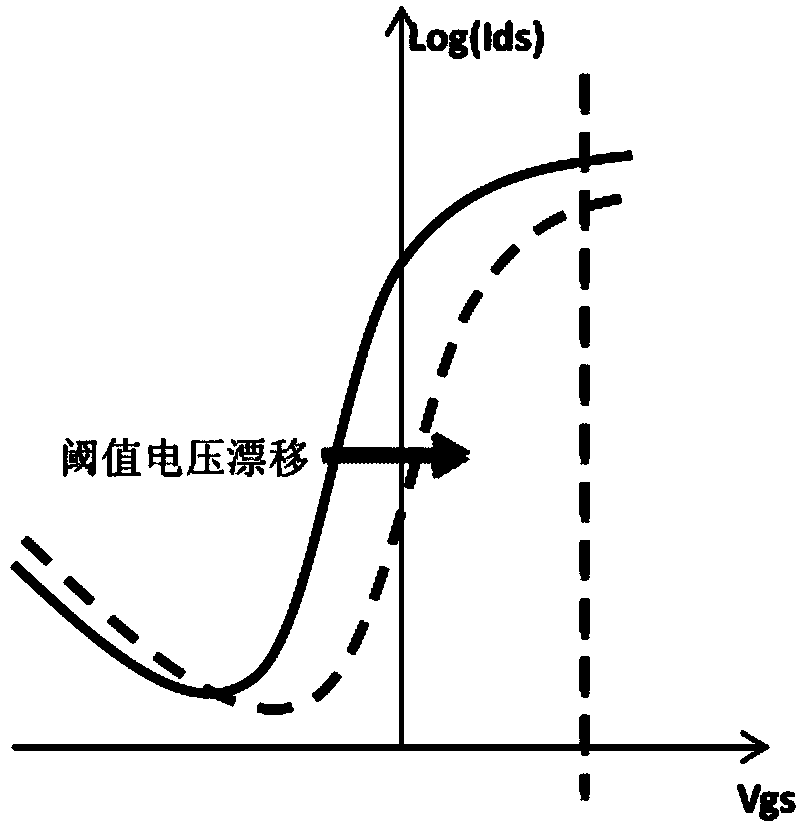

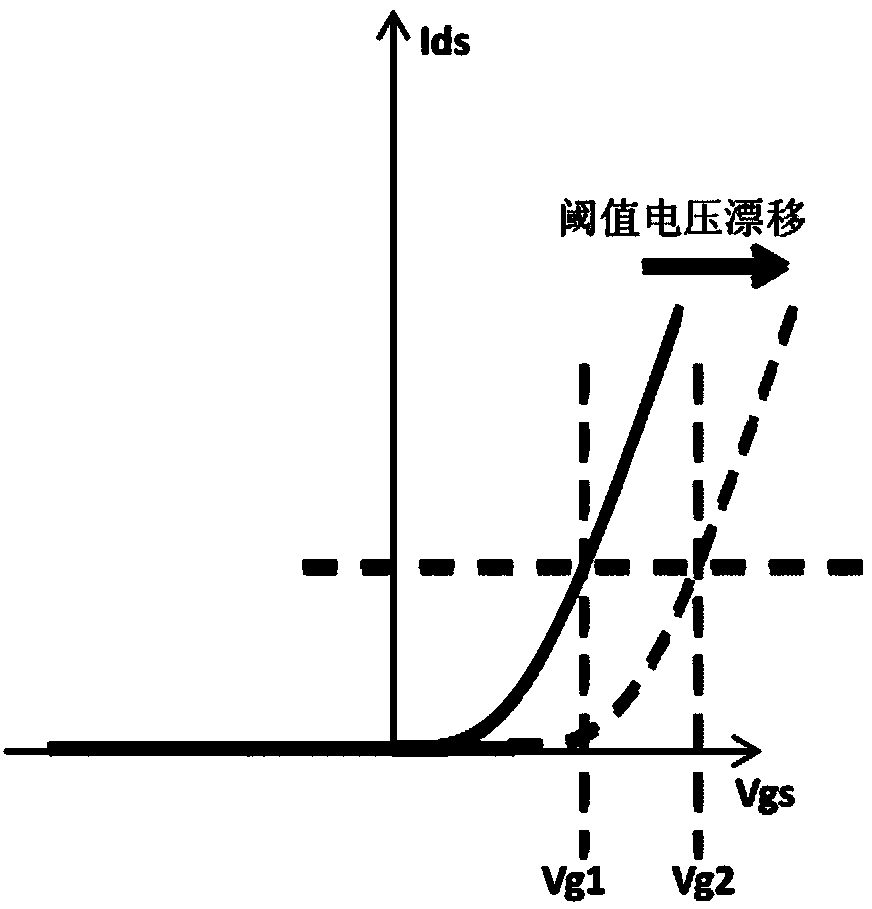

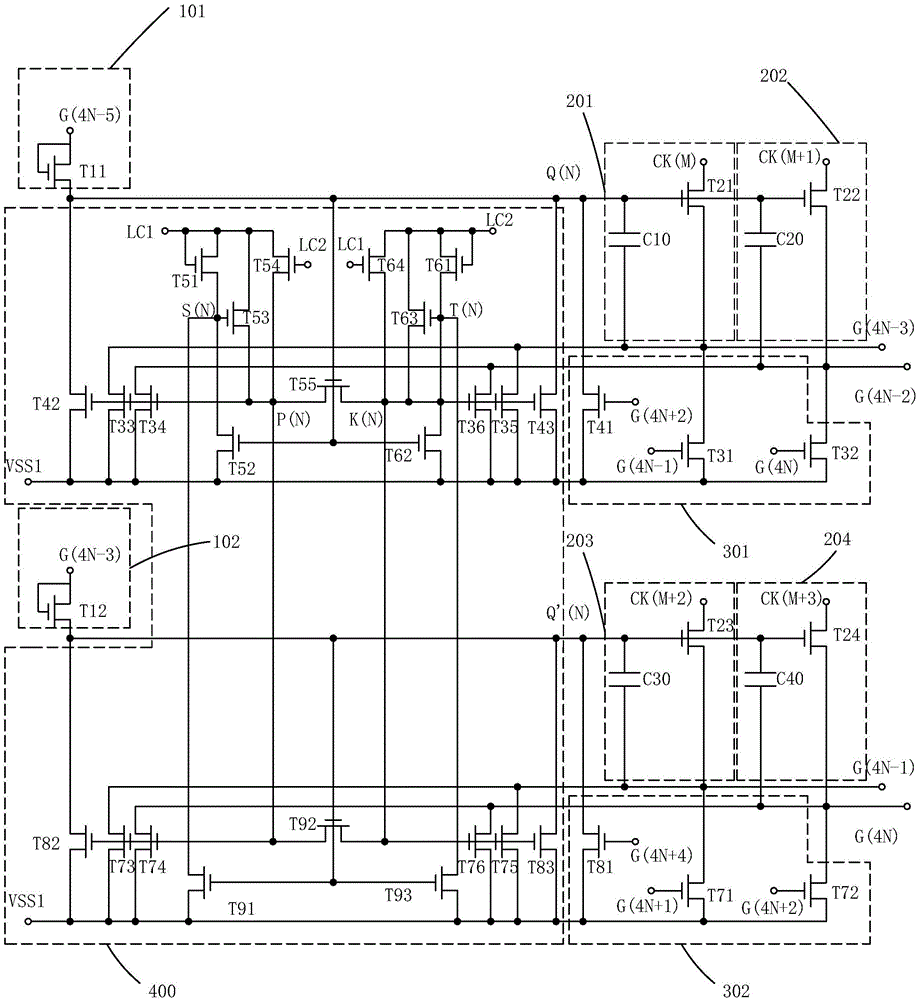

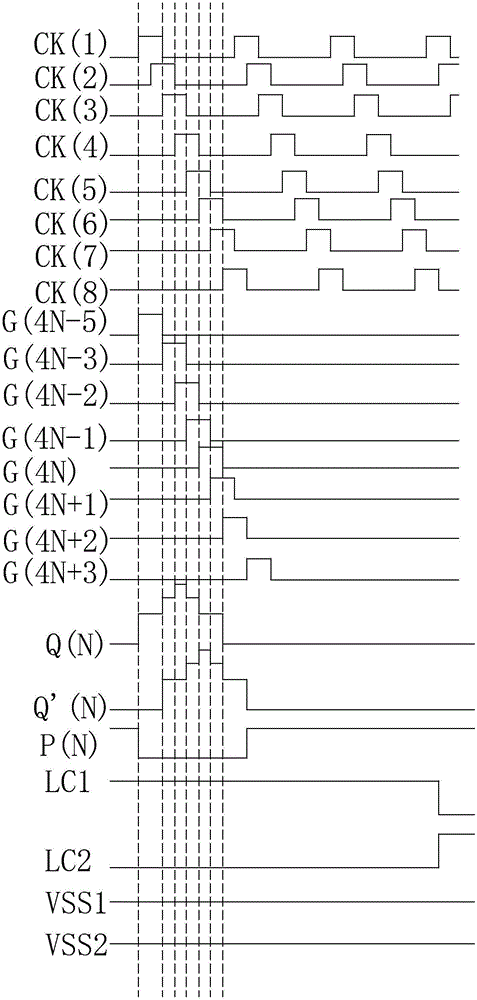

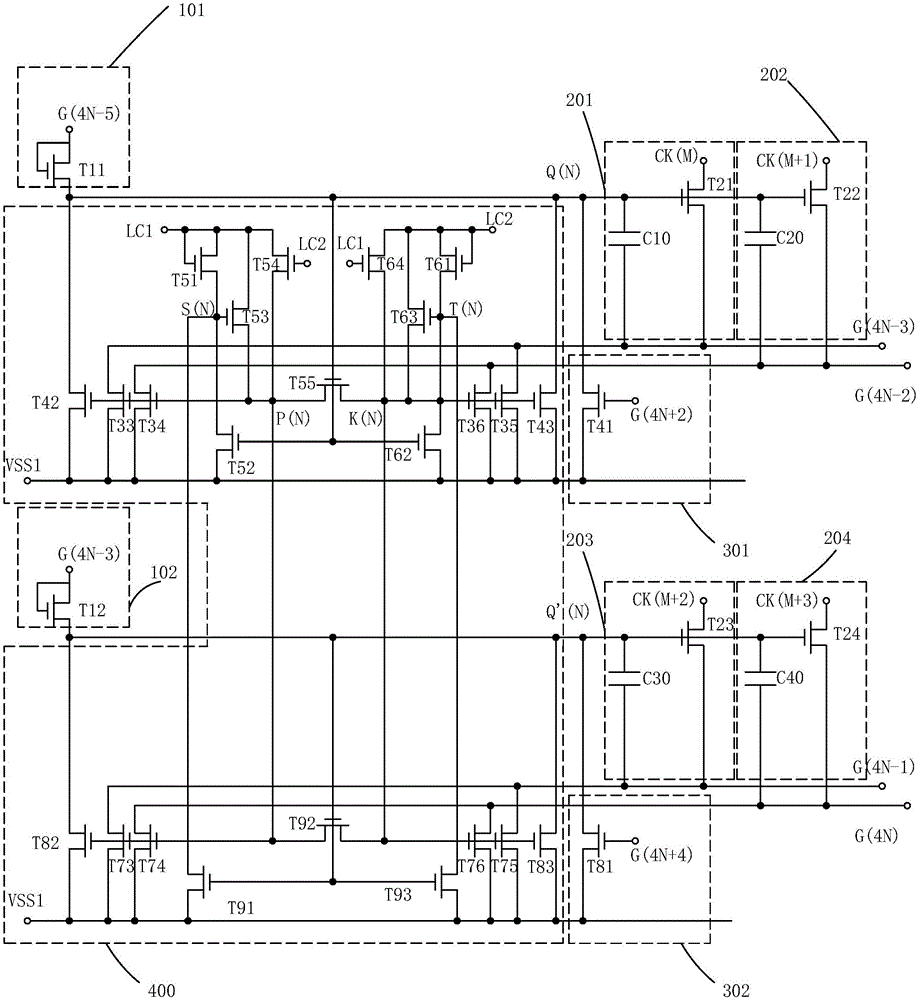

Grid drive circuit with self-compensation function

ActiveCN104064159AImprove reliabilityReduce power consumptionStatic indicating devicesDigital storageCapacitanceLow voltage

The invention provides a grid drive circuit with the self-compensation function. The grid drive circuit comprises a plurality of cascaded grid driver on array (GOA) units. The Nth grade of GOA unit comprises an upward-pull control module, an upward-pull module, a downward-transfer module, a first downward-pull module, a bootstrap capacitor module and a downward-pull maintaining module; the upward-pull module, the first downward-pull module, the bootstrap capacitor module and the downward-pull maintaining module are electrically connected with the Nth grade grid signal point Q(N) and the Nth grade horizontal scanning line G(N), the upward-pull control module and the downward-transfer module are electrically connected with the Nth grade grid signal point Q(N), and the first direct-current low voltage VSS1 and the second direct-current low voltage VSS2 are input into the downward-pull maintaining module. Due to the design of the downward-pull maintaining module with the self-compensation function, reliability of long-term operation of the grid drive circuit is improved; moreover, the design of the downward-pull maintaining module directly controlled by a set of direct-current signal source DC can be adopted for the grid drive circuit with the self-compensation function, and therefore not only can circuit layout design space be saved, but also the overall power consumption of the circuit can be reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

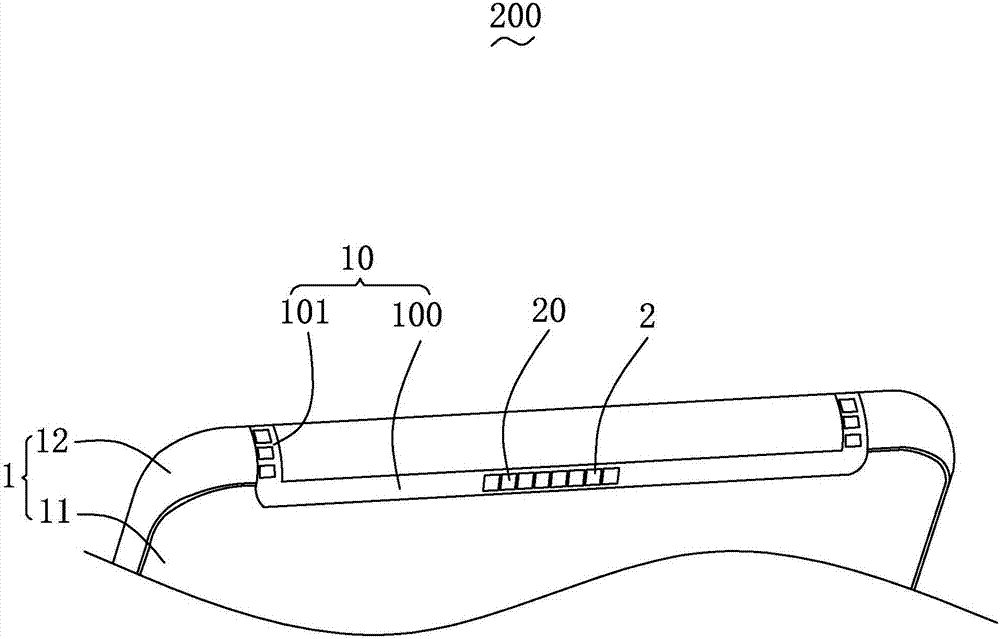

Antenna device

InactiveCN106921023AImprove radiation efficiencyAvoid individual slitsAntenna supports/mountingsAntenna equipments with additional functionsRadiation bandwidthRadio frequency signal

The invention provides an antenna device. The antenna device comprises a millimeter wave microstrip antenna, wherein the millimeter wave microstrip antenna is assembled on a shell of electronic equipment, the electronic equipment comprises a main antenna, the main antenna is arranged in the shell, an antenna gap is formed in the shell and is used for radiation / receiving of a radio frequency signal by the main antenna, the millimeter wave microstrip antenna comprises a plurality of unit antennas, the plurality of the unit antennas are arranged at intervals, and the plurality of the unit antennas and the shell are arranged at an interval and are arranged in the antenna gap in an array way. Compared with prior art, the antenna device provided by the invention has the advantages that the millimeter wave microstrip antenna is arranged in the antenna gap for radiation / receiving of the radio frequency by the main antenna, so that independent gap opening on the millimeter wave microstrip antenna is prevented, the same antenna clearance region can be shared with the main antenna, the design space of the millimeter wave microstrip antenna is saved, and the space utilization ratio is improved; and meanwhile, the radiation bandwidths of the unit antennas can also be effectively expanded, the gain is improved, the side lobe is suppressed, and the radiation efficiency of the antenna device is further improved.

Owner:AAC TECH PTE LTD

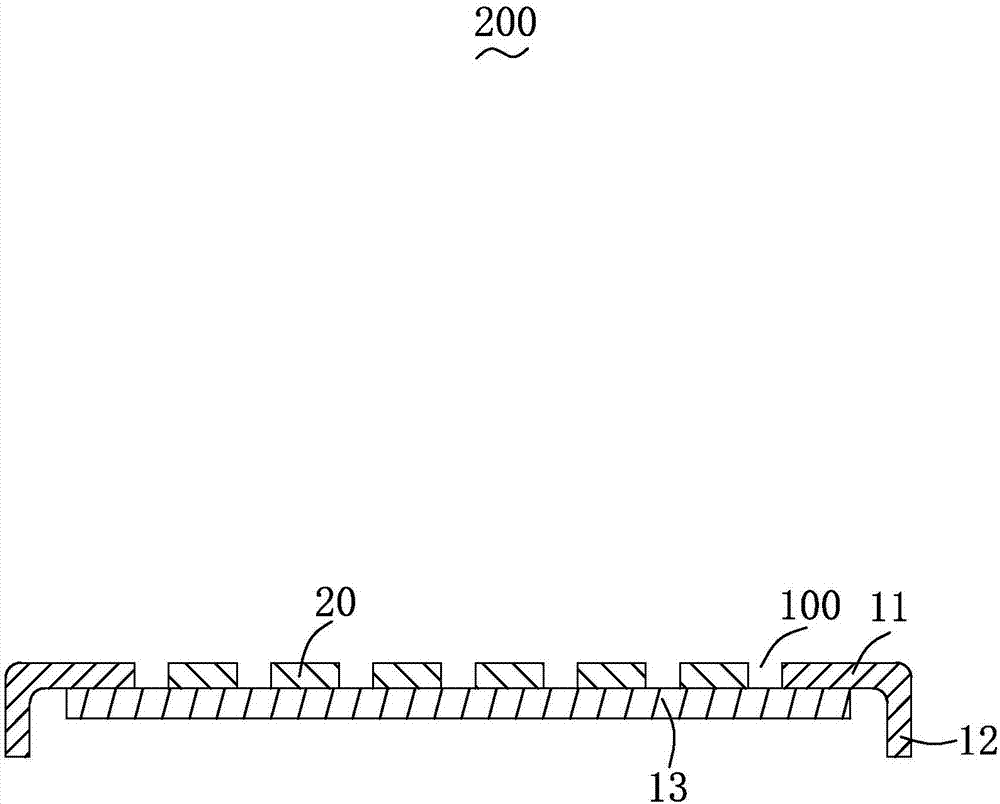

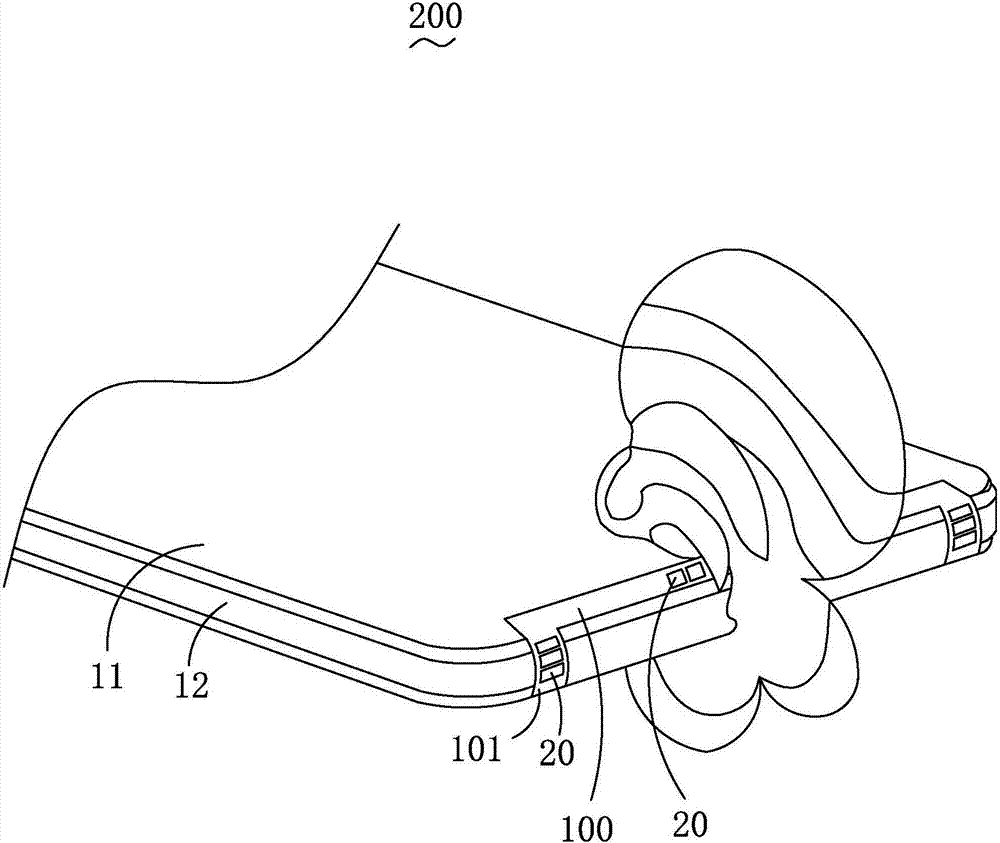

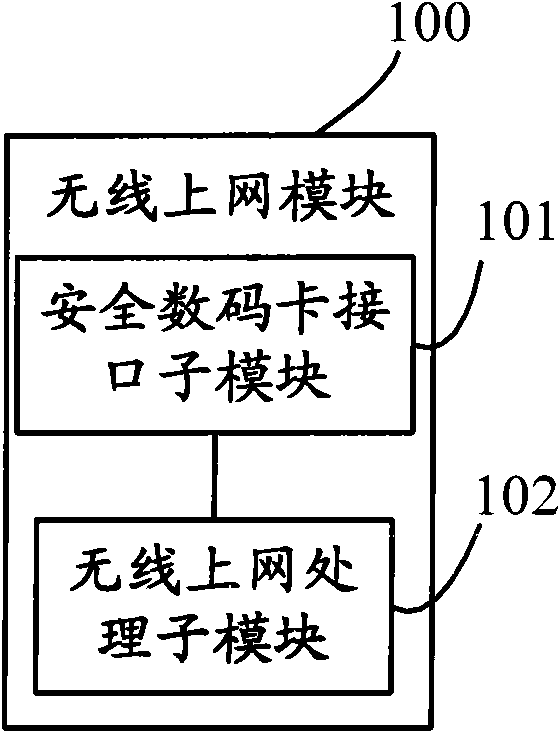

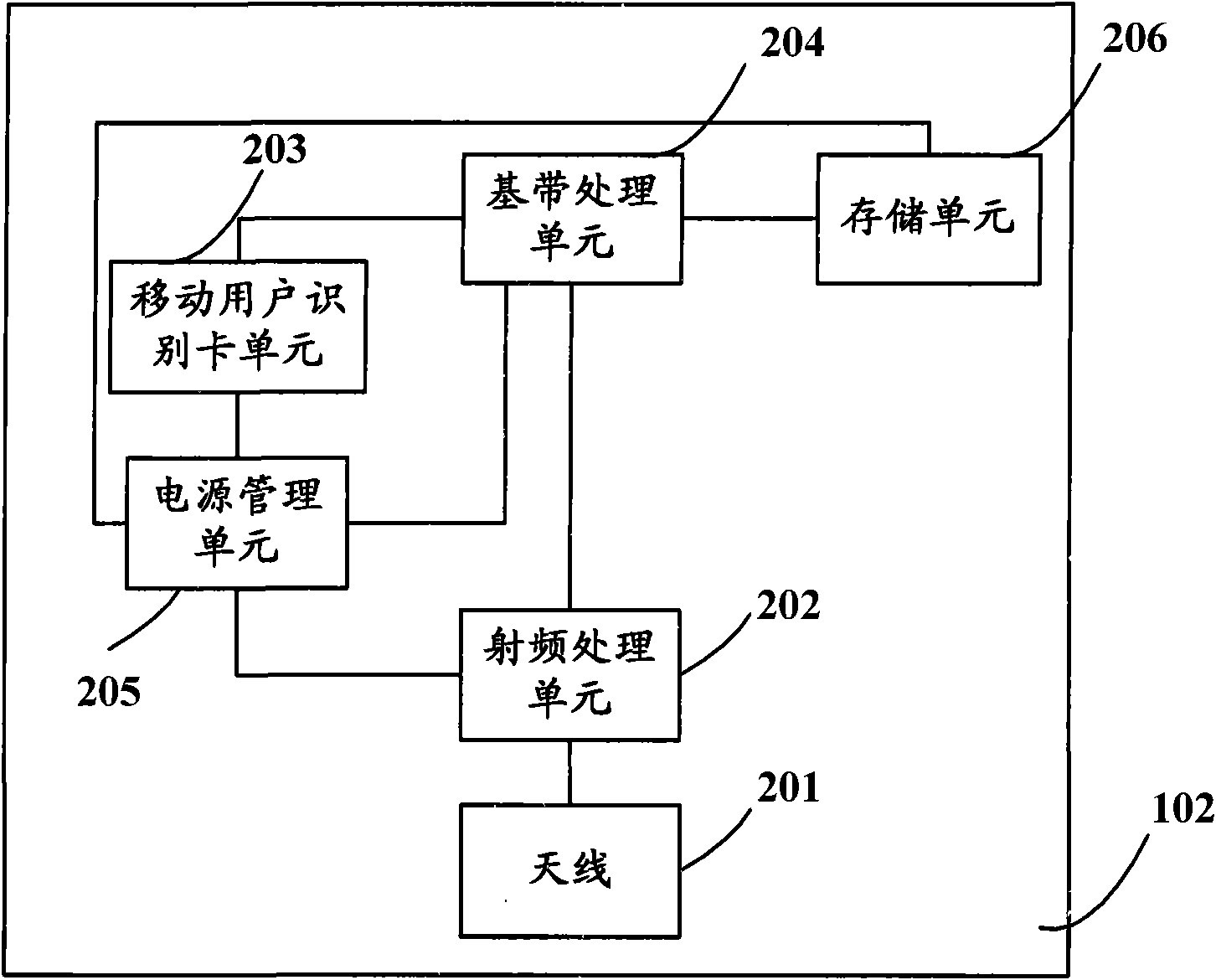

Wireless Internet access module, user terminal, secure digital card and wireless communication method

ActiveCN101835282ASmall footprintSave design spaceDevices with card reading facilitySubstation equipmentComputer hardwareCable Internet access

The embodiment of the invention discloses a wireless Internet access module, a user terminal, a secure digital card and a wireless communication method, relates to the technical field of wireless communication and aims to solve the problem that the wireless Internet access module in the prior art cannot be built into a miniature ultrathin user terminal due to a large volume. The wireless Internet access module provided by the embodiment of the invention comprises a secure digital card interface sub-module and a wireless Internet access processing sub-module, wherein the wireless Internet access processing sub-module performs information interaction with the user terminal through the secure digital card interface sub-module. Due to the adoption of the embodiment of the invention, the reduction of space occupation of the wireless Internet access module is realized, the types of Internet access equipment can be enriched and user experience is improved.

Owner:HUAWEI DEVICE CO LTD

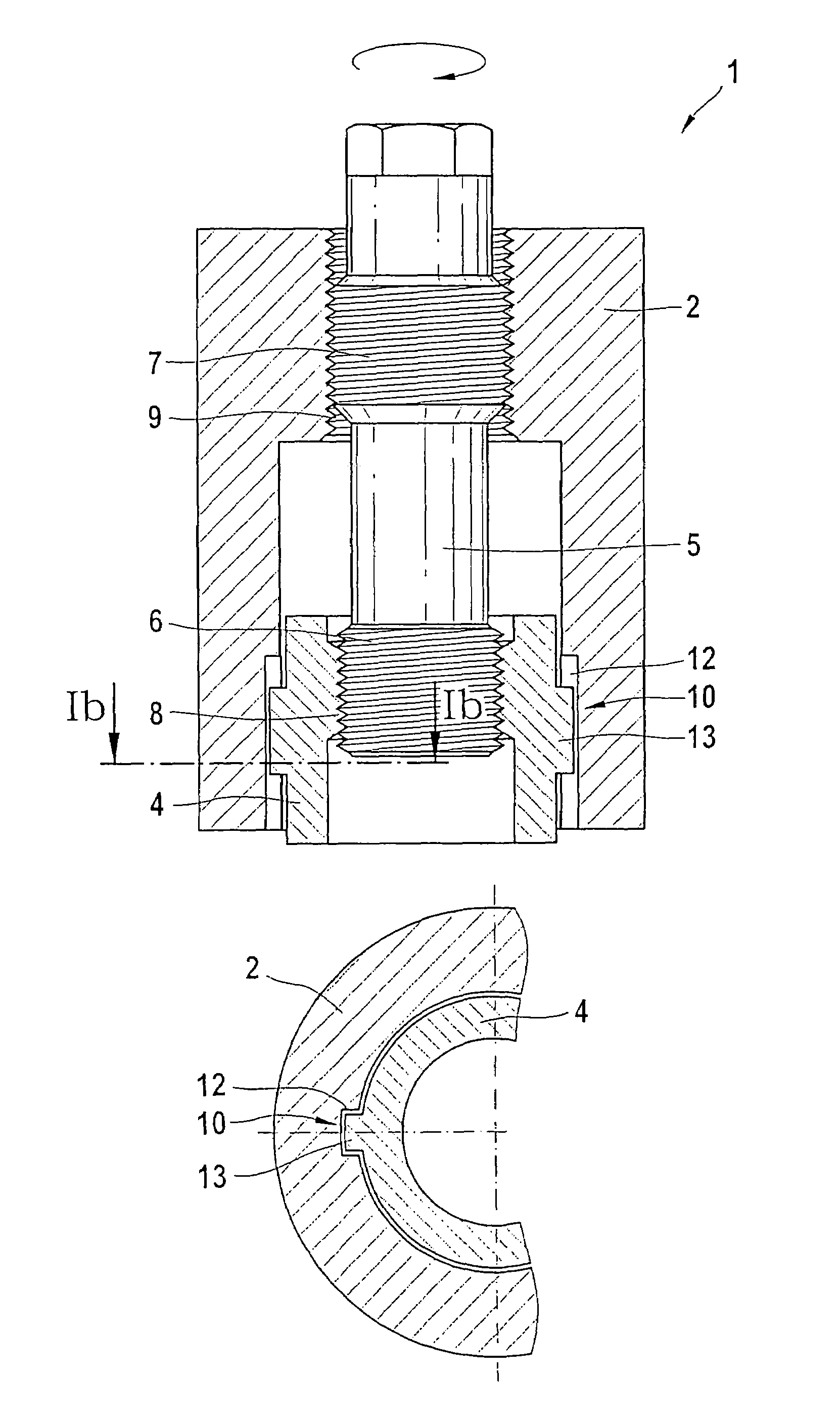

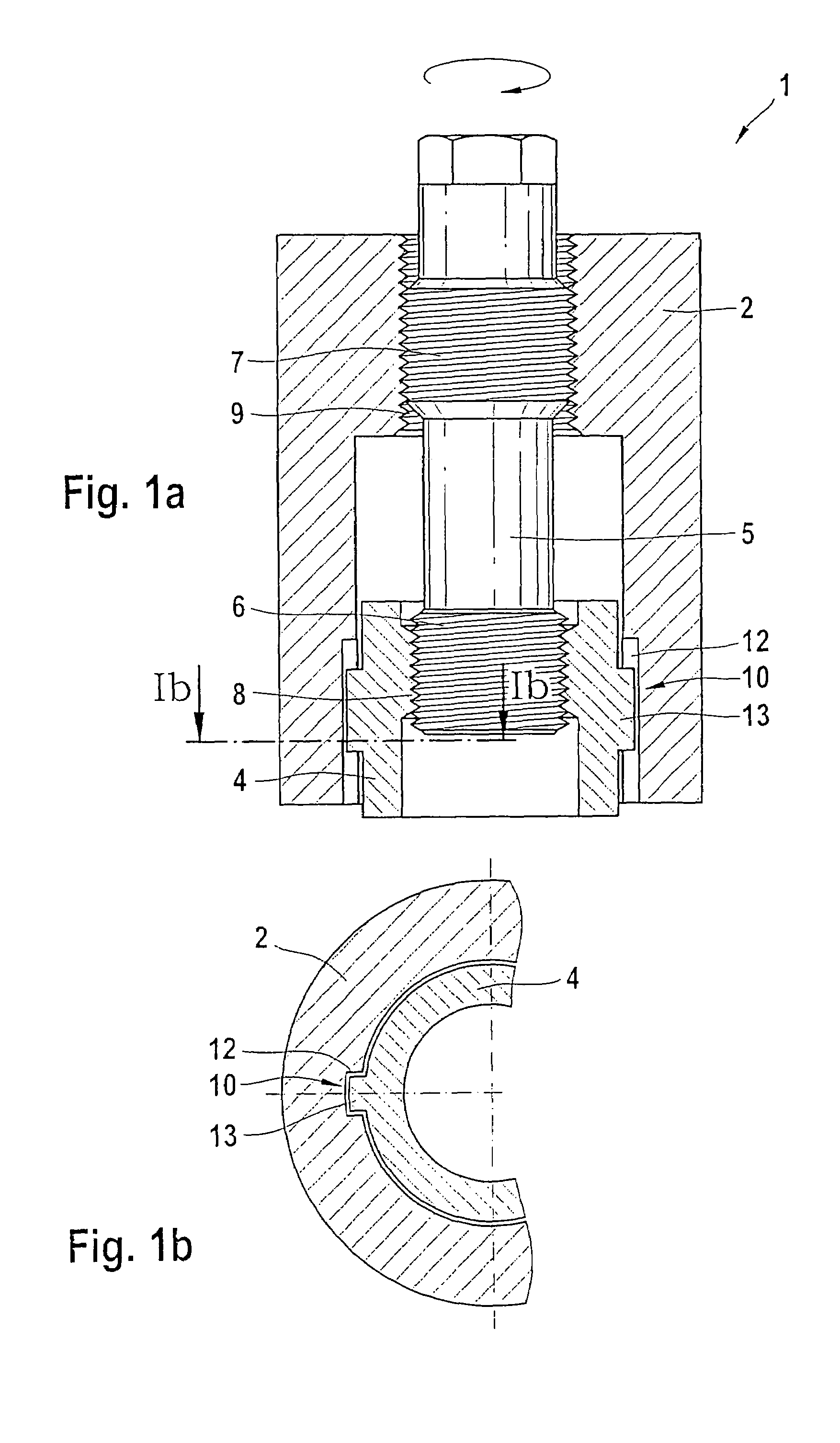

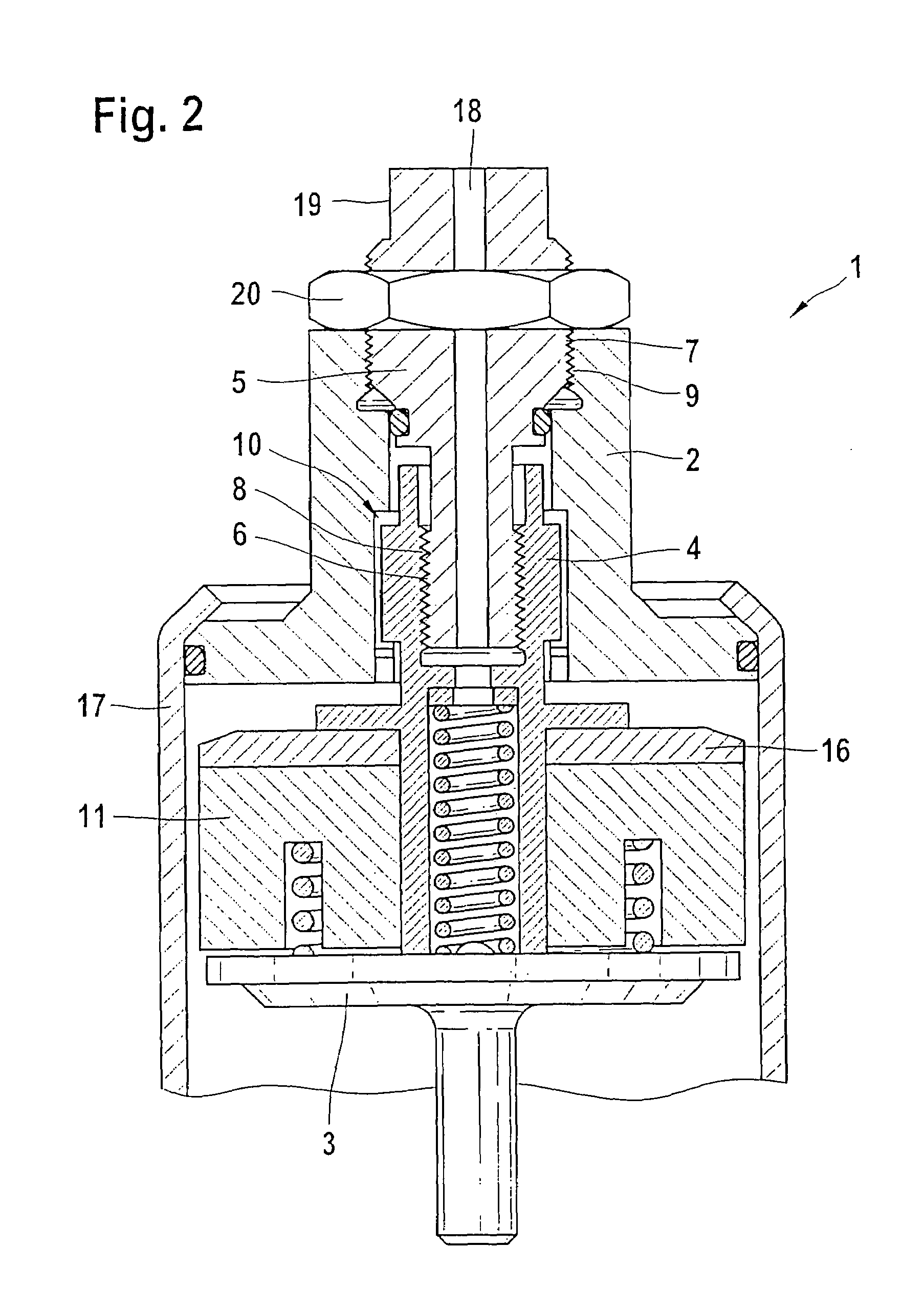

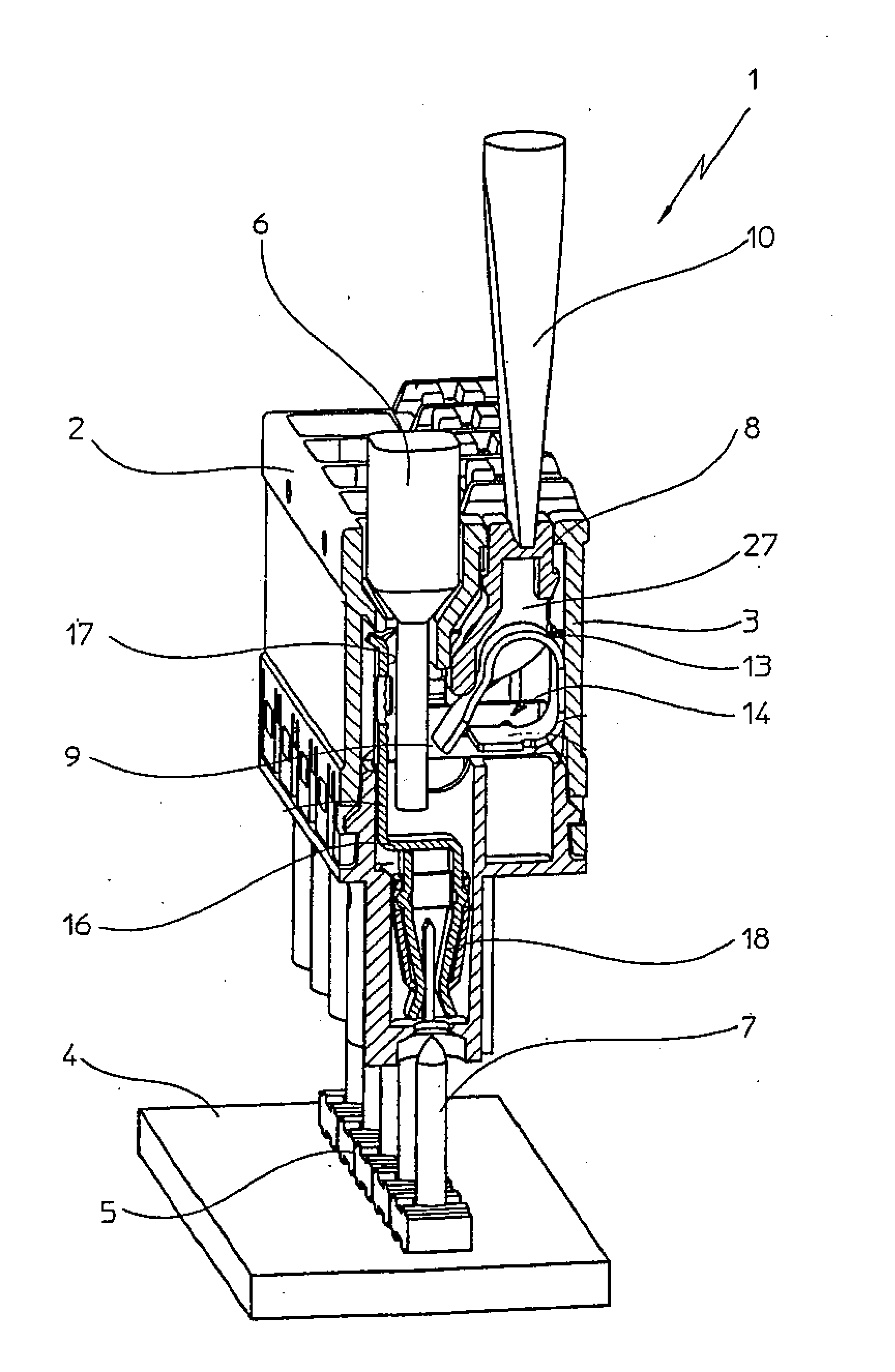

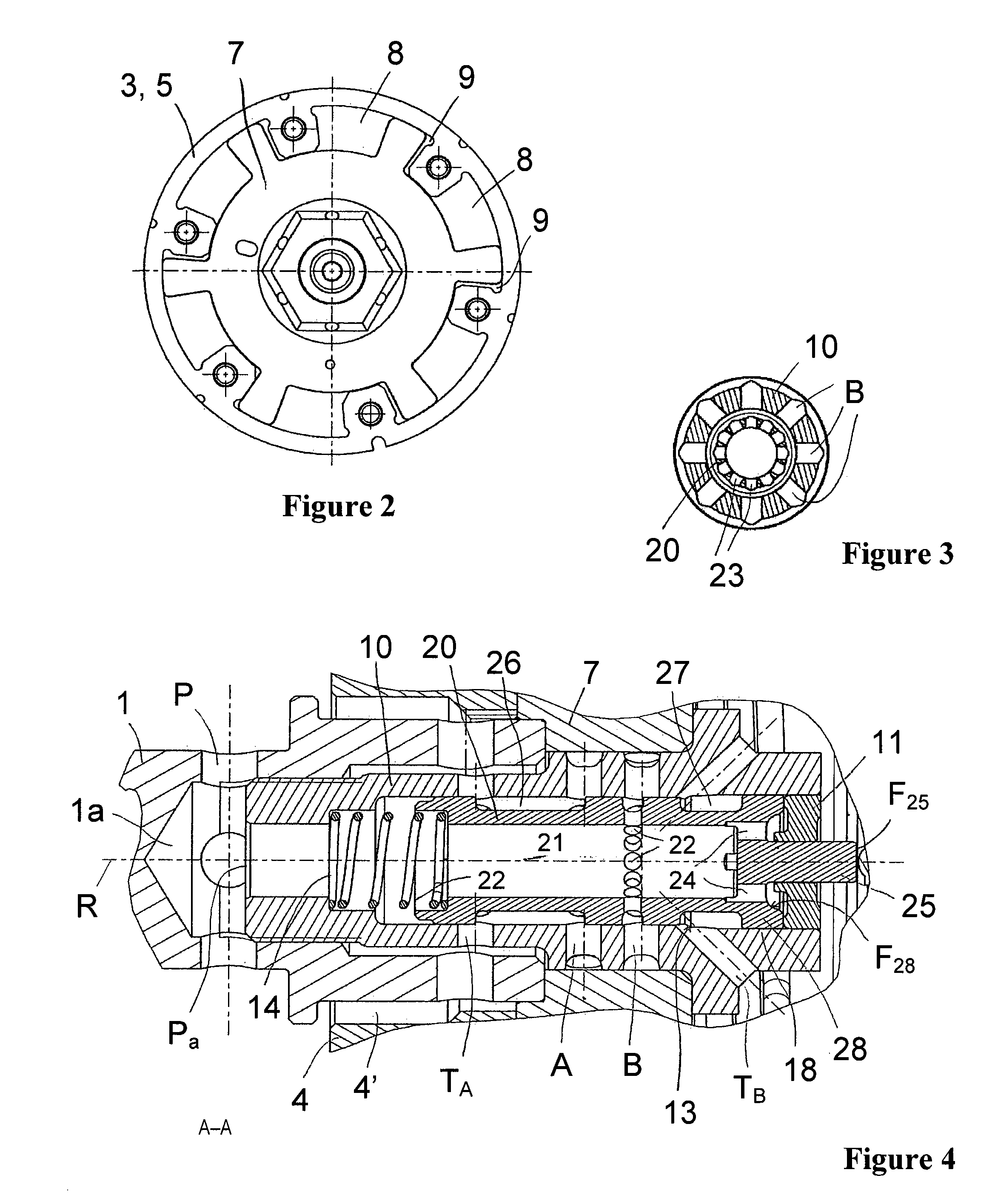

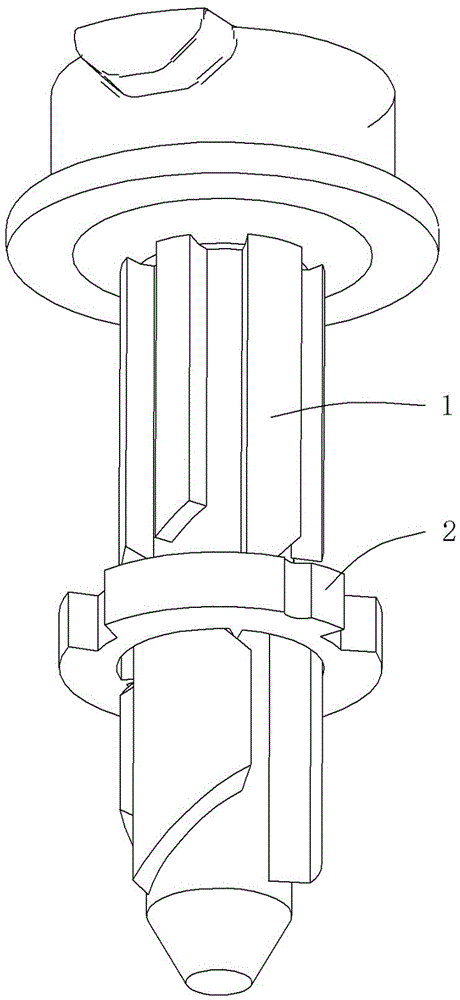

Device for adjusting the armature stroke of a solenoid valve

InactiveUS6994312B2Save materialLow production costOperating means/releasing devices for valvesMachines/enginesSolenoid valveScrew thread

A device for adjusting an armature stroke of an armature upon actuation of a magnet of an electromagnetic valve having a stop bush disposed in an axial guide relative to a main body of the electromagnetic valve and adjustable in its axial position relative to the main body of the electromagnetic valve, which stop bush forms a stop for limiting the armature stroke in an axial direction. A variable adjusting element with two threaded portions providing a variable thread pitch (P) and the same thread direction by which the position of the stop bush is adjustable. The first threaded portion engages a corresponding first threaded portion of the stop bush, and the second threaded portion engages a corresponding second threaded portion of the main body, and to an electromagnetic valve having a corresponding device, in particular for use in a fuel injector.

Owner:ROBERT BOSCH GMBH

Damping valve assembly with a progressive damping force characteristic

InactiveUS20050115786A1No sacrifice of comfortIncrease damping forceSpringsMultiple way valvesEngineeringThrottle

Damping valve assembly includes a first damping valve, which, in a first operating range, opens as the flow velocity of the damping medium increases, where a second operating range with a progressive damping force characteristic is influenced by a throttle in conjunction with a control slide, which can be moved into a closed position. The control slide has a pressure-actuated surface, which, as a function of the flow velocity of the damping medium, acts in the closing direction on the control slide.

Owner:ZF FRIEDRICHSHAFEN AG

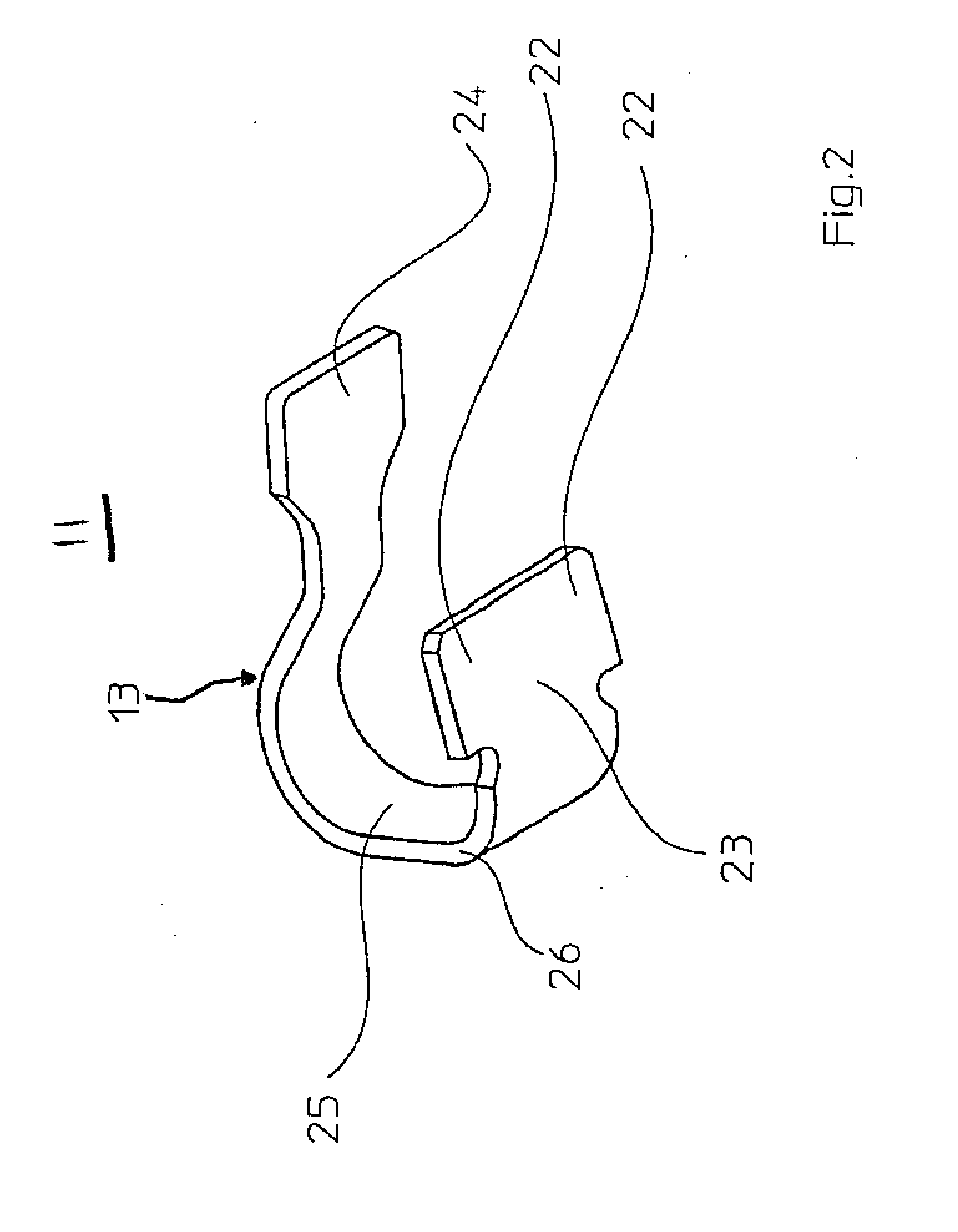

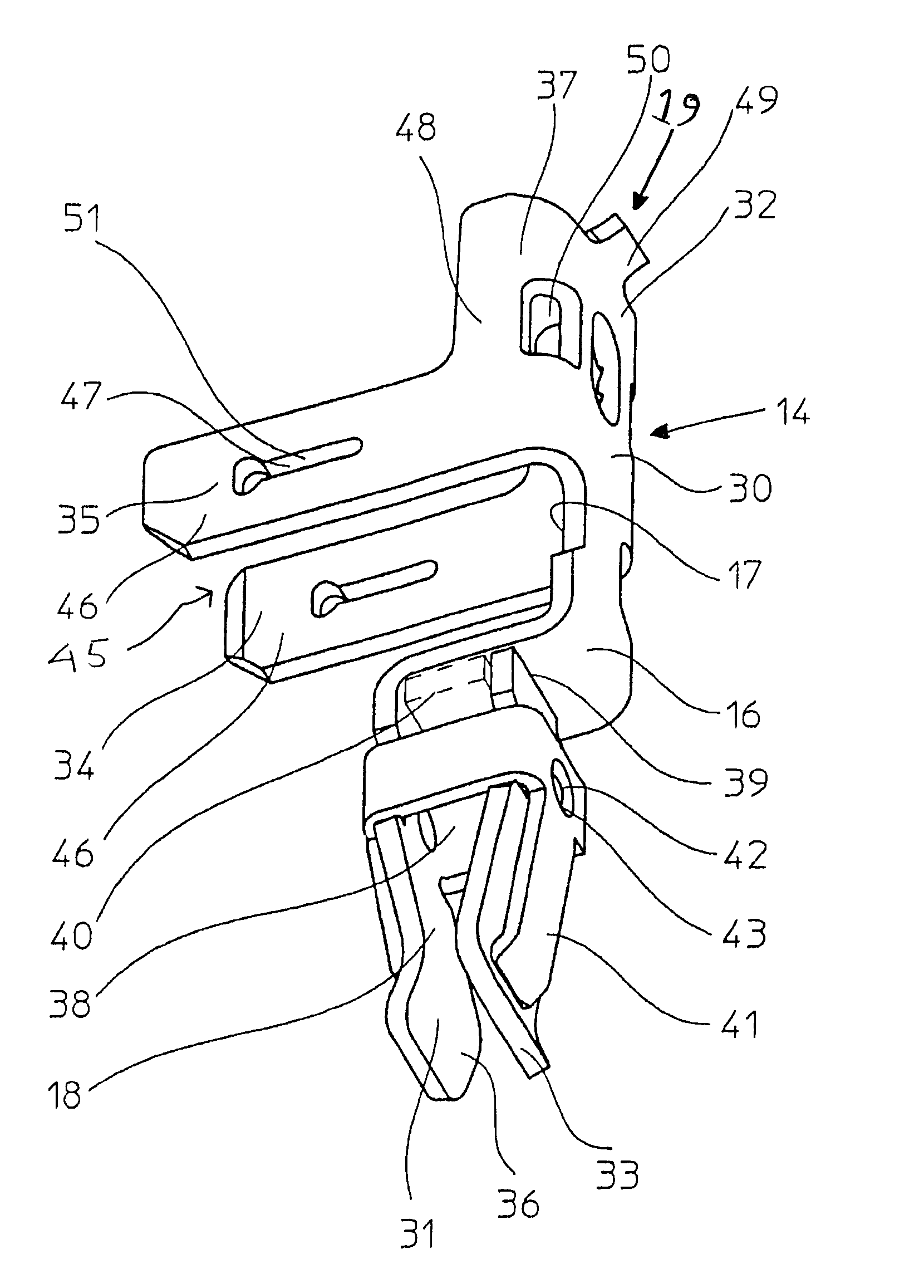

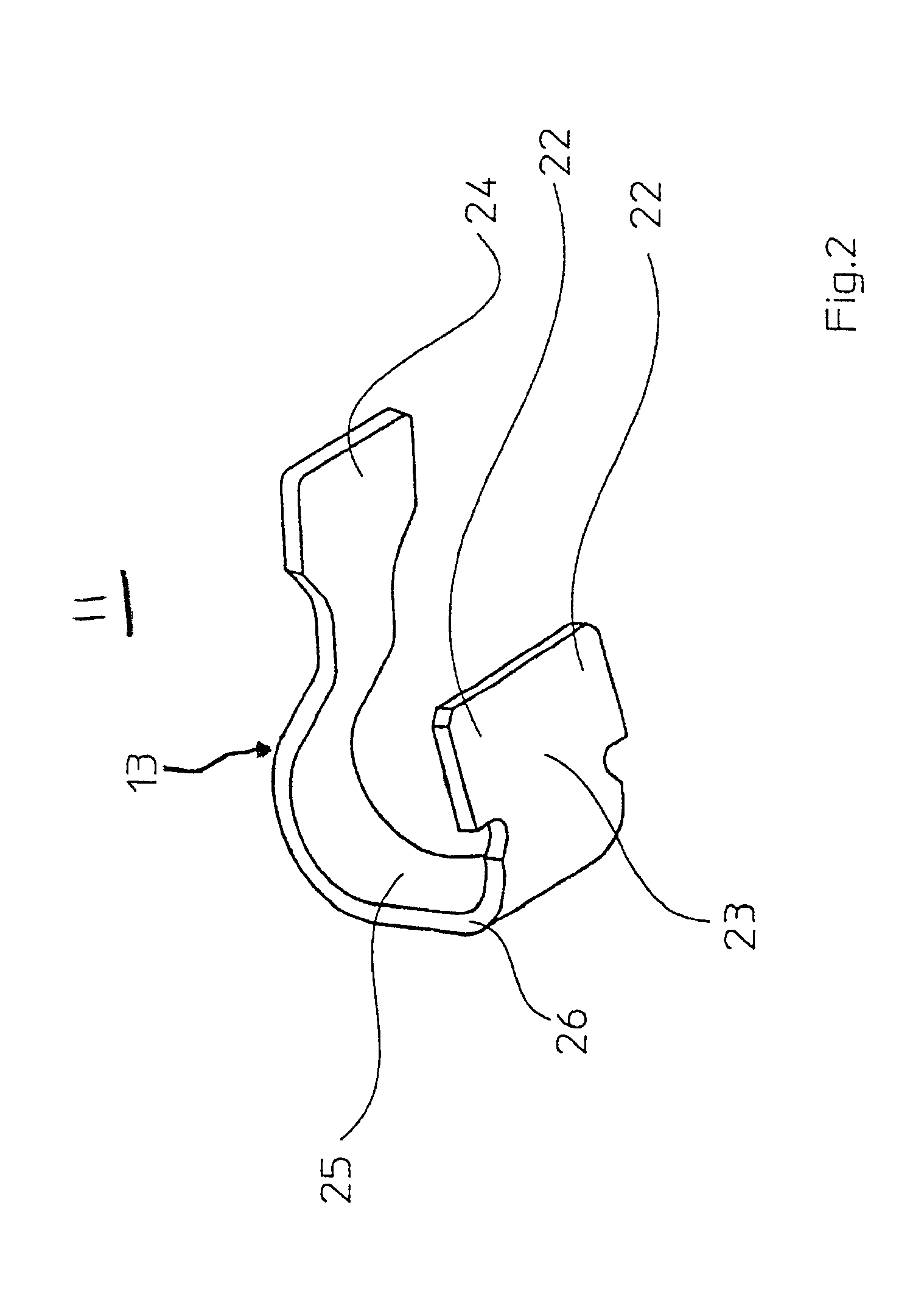

Connecting terminal for printed circuit boards

InactiveUS20100173531A1Simple functional designSmall installation sizeElectrically conductive connectionsCoupling contact membersSpring forcePrinted circuit board

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

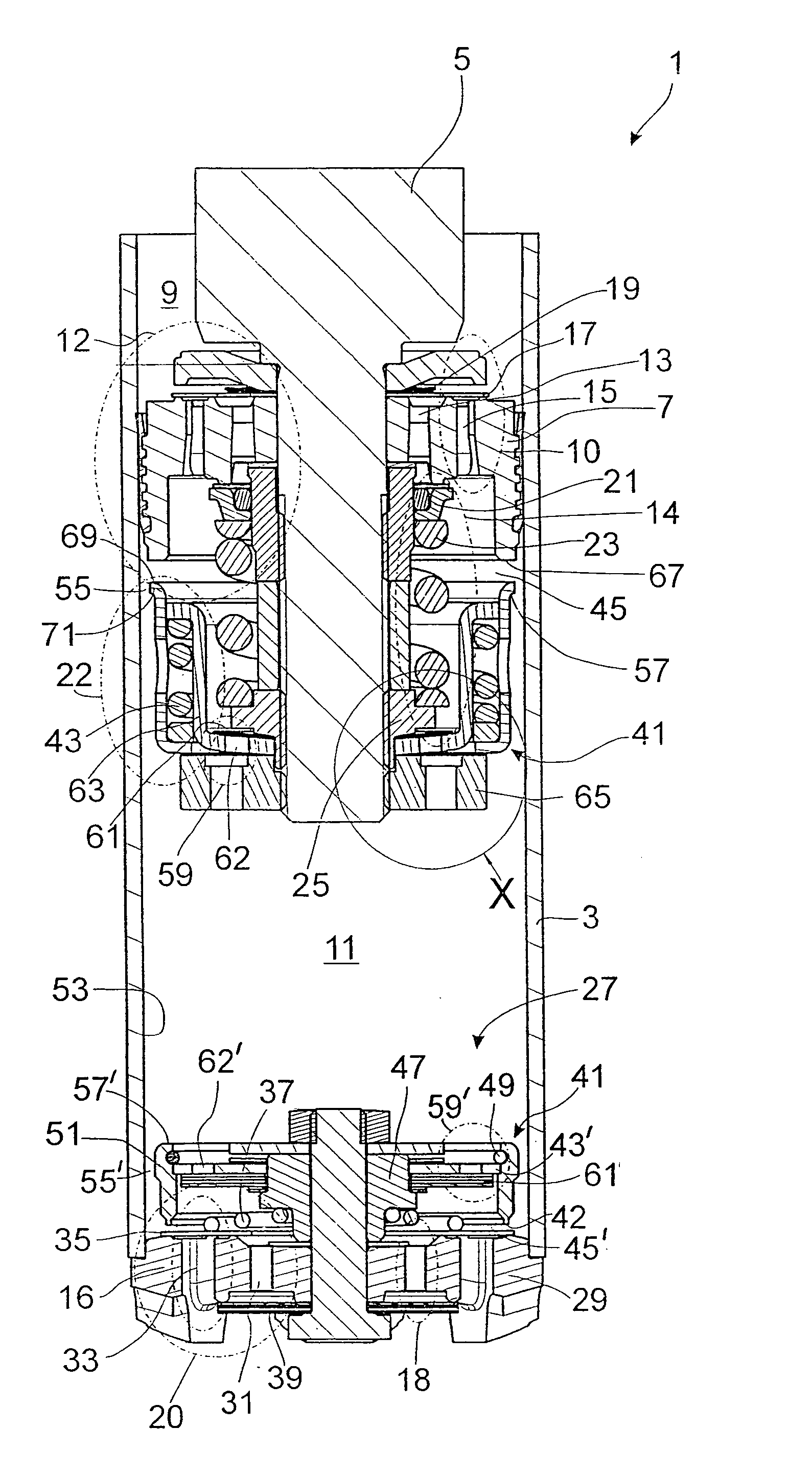

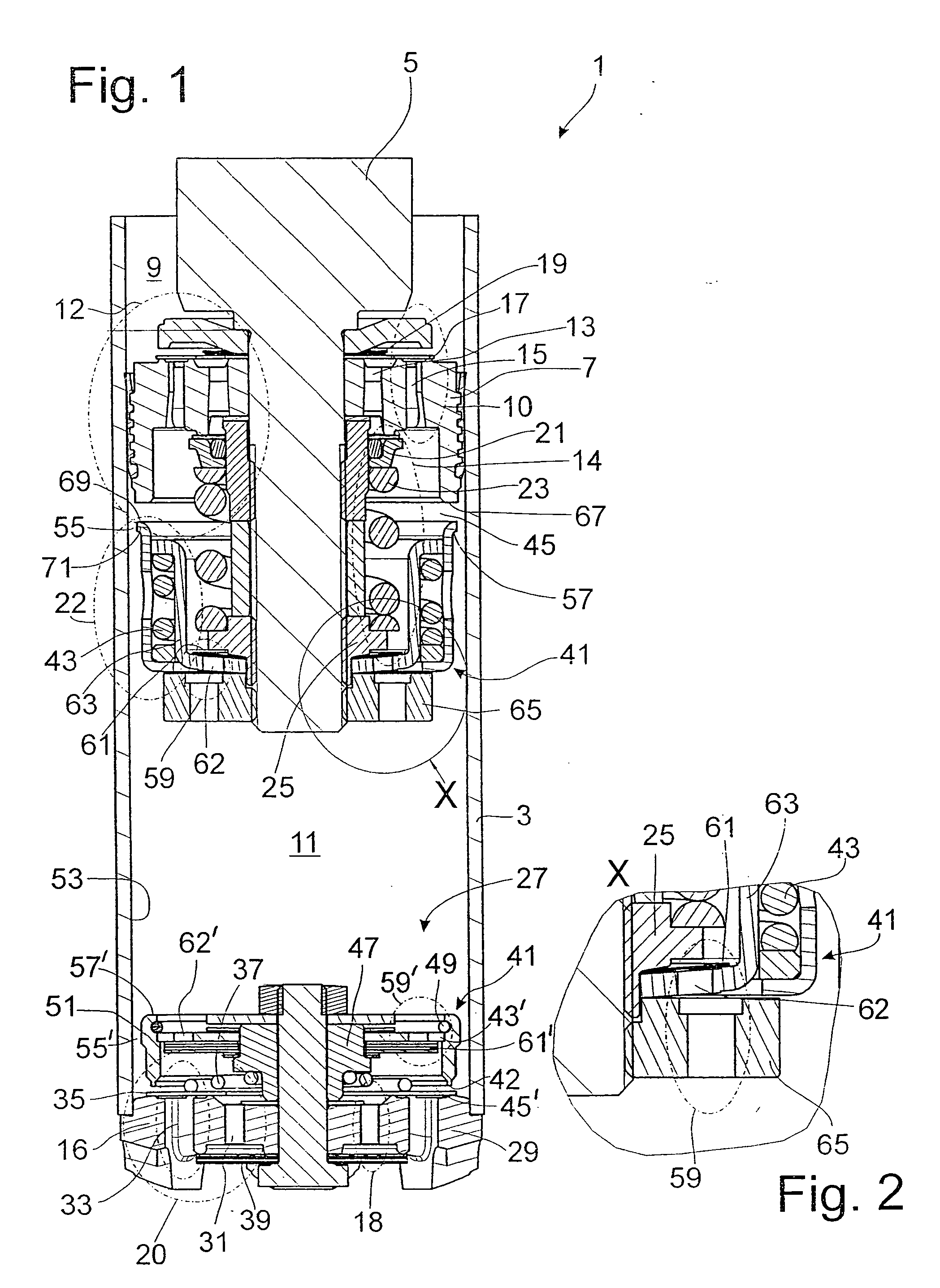

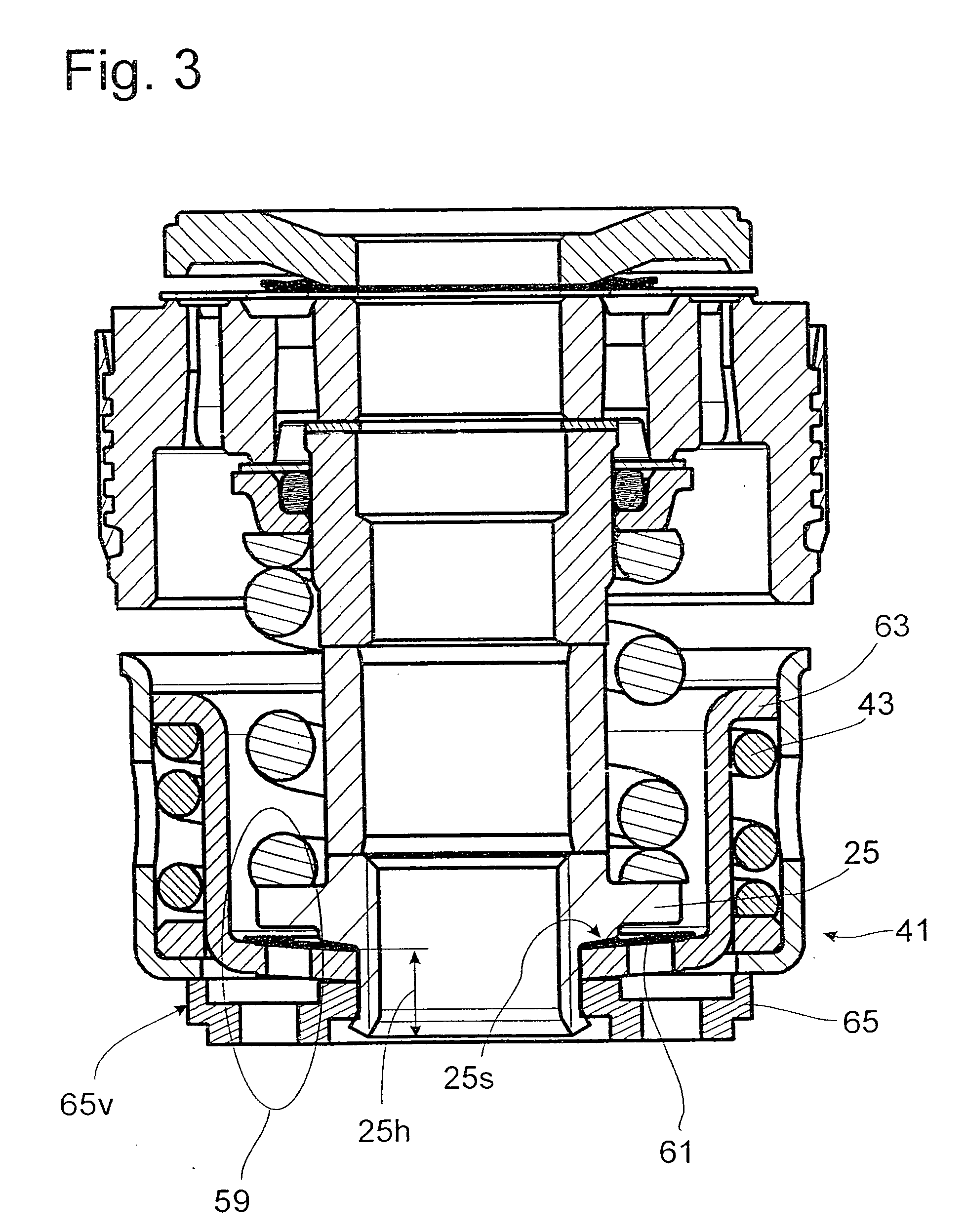

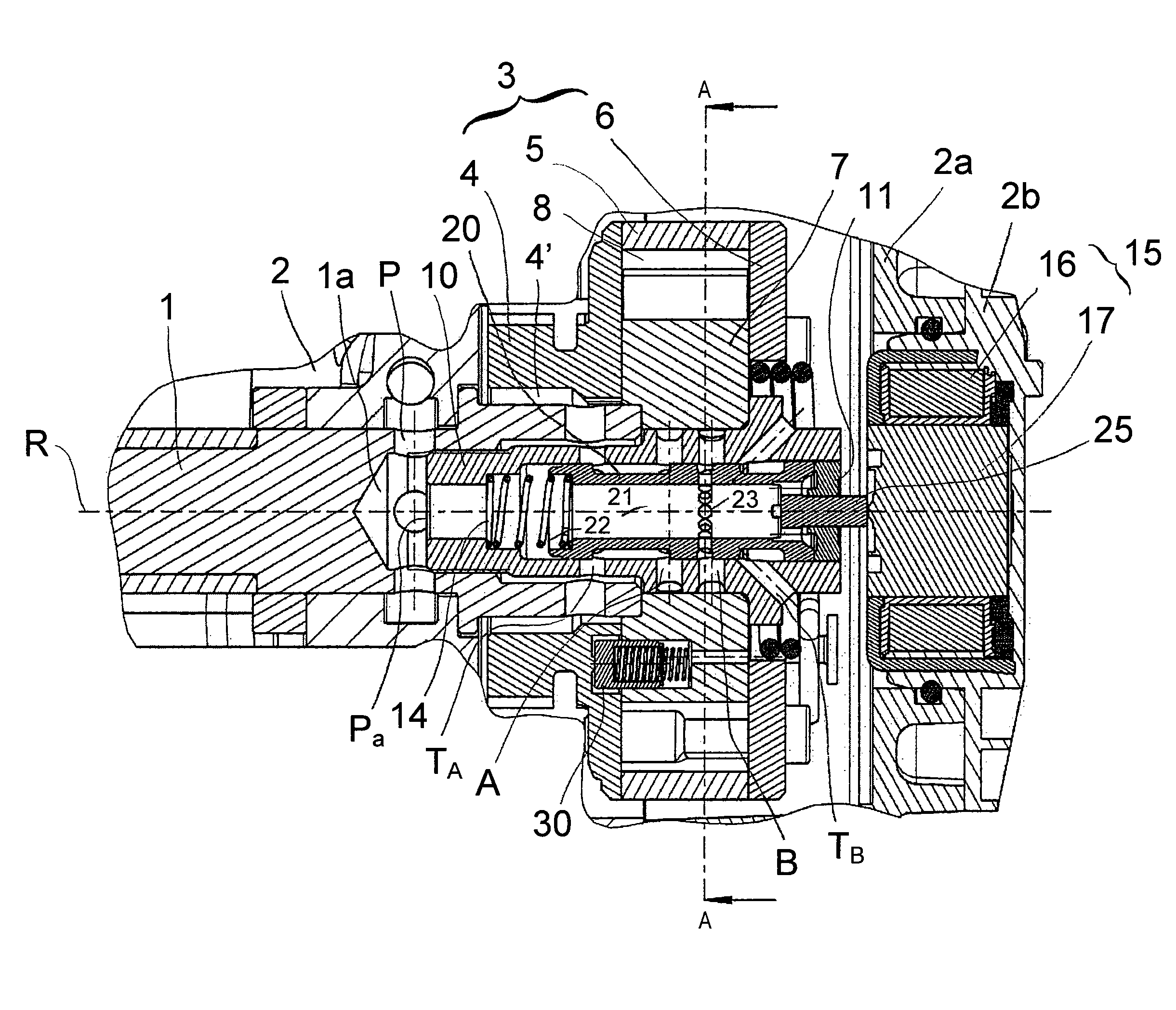

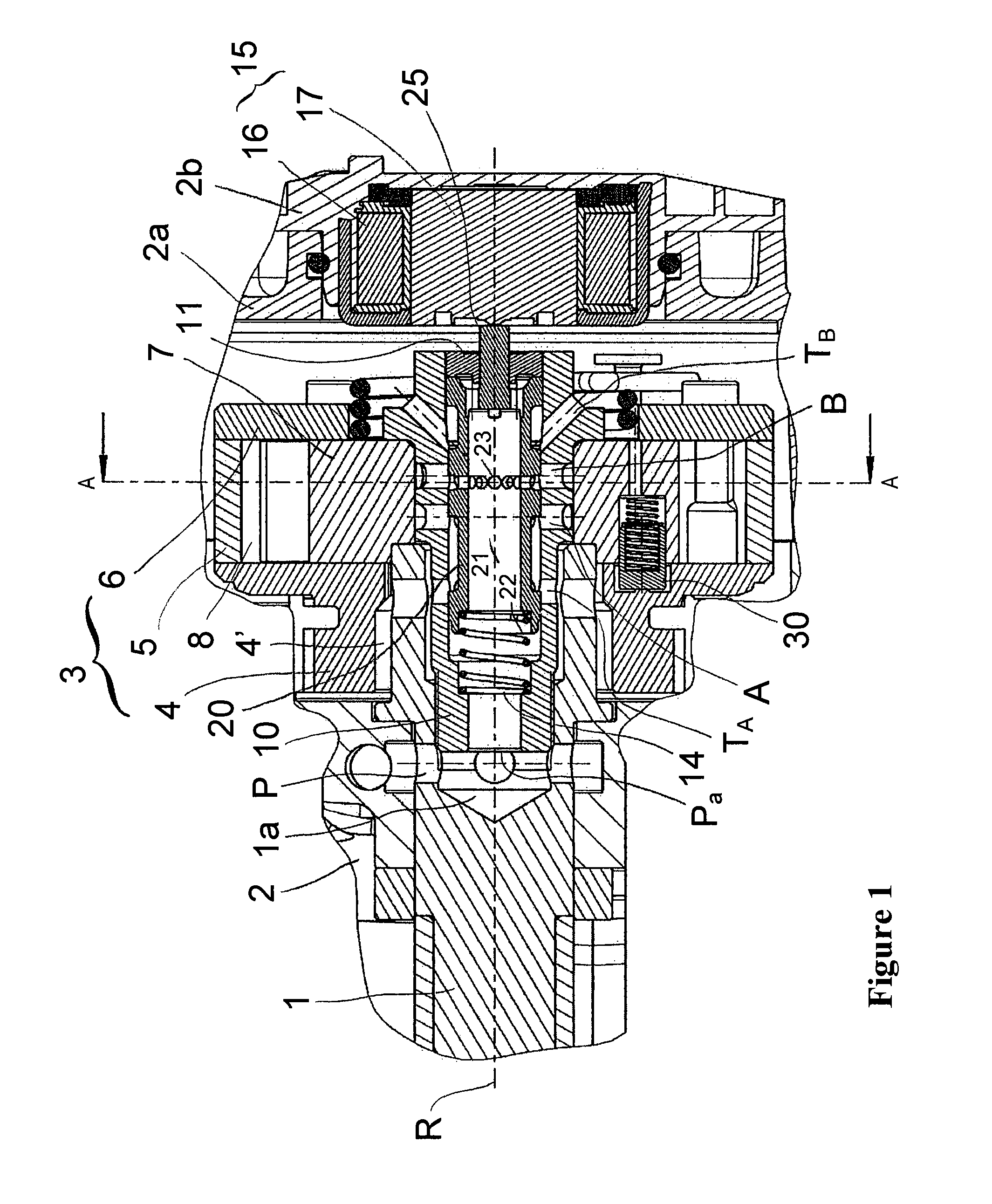

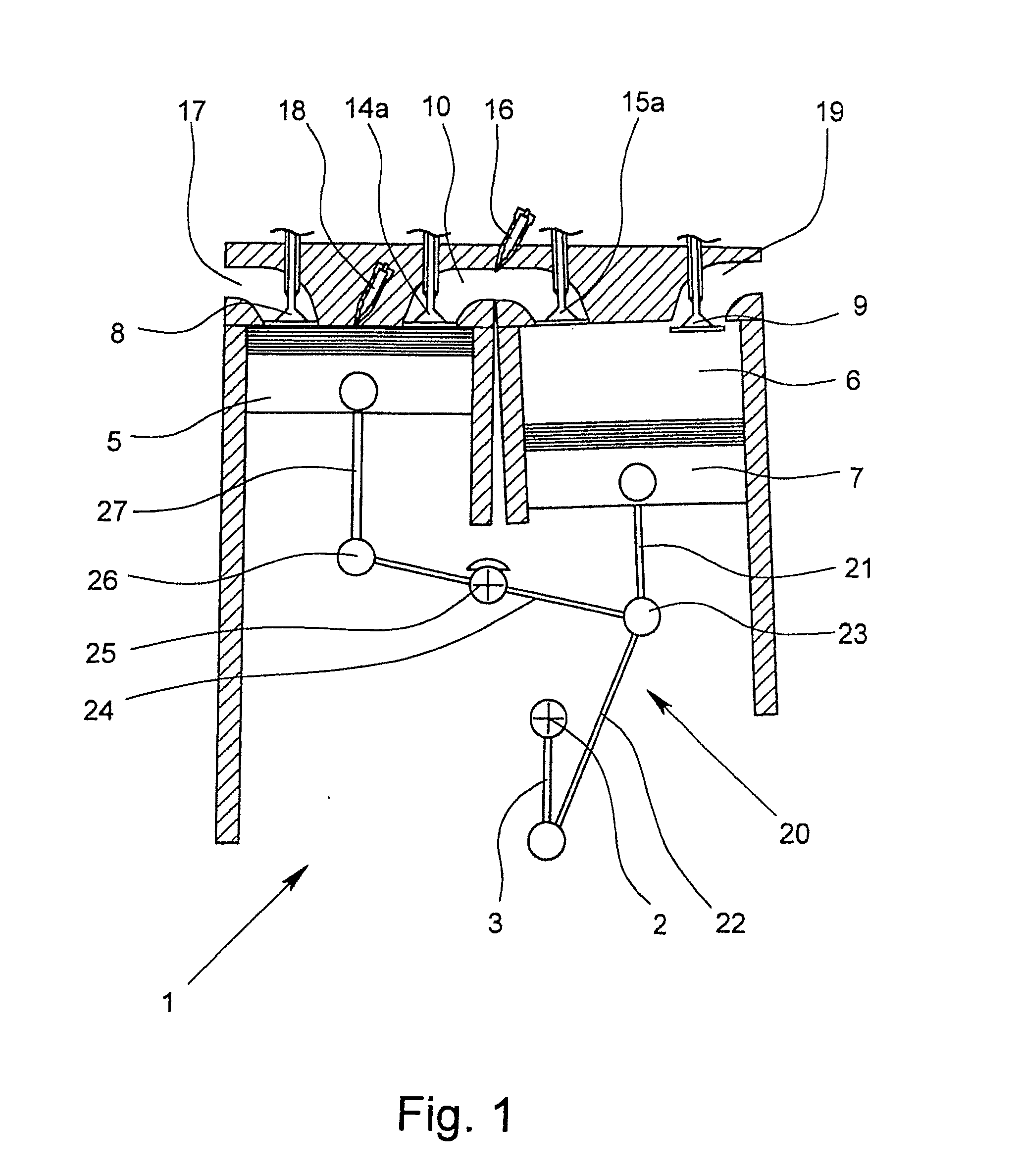

Cam shaft phase setter comprising a control valve for hydraulically adjusting the phase position of a cam shaft

InactiveUS20110220046A1Suitable for mass productionSimple geometryValve arrangementsMachines/enginesAxial pressureSetter

A cam shaft phase setter including a control valve for controlling the feeding and draining of a hydraulic fluid into and out of a pressure chamber which serves to adjust the rotational angular position of a cam shaft relative to a crankshaft of an internal combustion engine. The control valve includes a valve housing with an operating port to the pressure chamber and a reservoir port to a reservoir for the fluid. A valve piston is axially adjustable back and forth in the valve housing between a first position and a second position and includes an axial hollow space, a piston inlet for introducing the fluid into the hollow space, and a piston outlet which leads out of the hollow space and is connected to the operating port in the first position of the valve piston and separated from the operating port in the second position of the valve piston. An actuating unit is coupled to the valve piston for axially adjusting the valve piston. A coupling member protrudes through an axially facing closure wall which closes off the valve housing and couples the actuating unit to the valve piston. The valve piston includes a radial widening which is surrounded by a complementarily widened housing portion of the valve housing and to which the fluid can be applied in an axial direction pointing away from the axially facing closure wall in order to generate an axial pressure force. The widening is dimensioned such that the fluid acts on the valve piston with a pressure force of at least substantially equal size in both axial directions, despite the coupling member.

Owner:SCHWABISCHE HUTTENWERKE AUTOMOTIVE CMBH

GOA circuit

ActiveCN106128380ASave design spaceReduce power consumptionStatic indicating devicesCircuit designTransistor

The invention provides a GOA circuit wherein neighboring four stage GOA units in a conventional GOA circuit are restructured into a GOA circuit shared unit via circuit structure design; in the GOA circuit shared unit, a first stage GOA unit and a second stage GOA unit share one control node, a third grade GOA unit and a fourth stage GOA unit share another control node, the neighboring four stage GOA units are enabled to share a pull-down maintaining module, the pull-down maintaining module of one stage is kept, pull-down maintaining modules of the other three grades can be removed, the number of thin film transistors in the GOA circuit can be reduced, wire distribution design can be lessened, reduction of GOA circuit design space can be facilitated so as to realize narrow bezel design, and power consumption of the GOA circuit can be lowered due to simplification of the GOA circuit.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

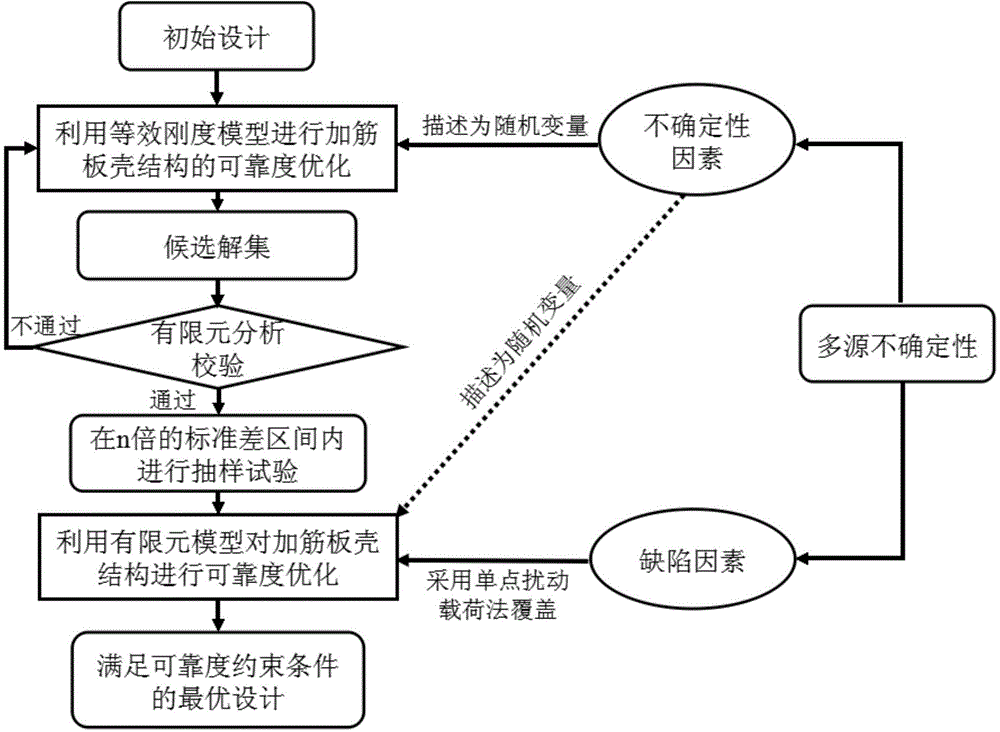

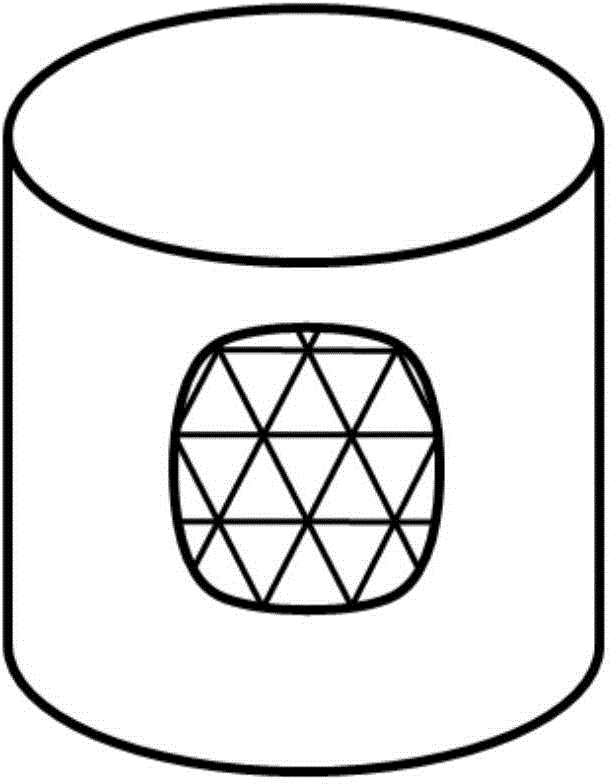

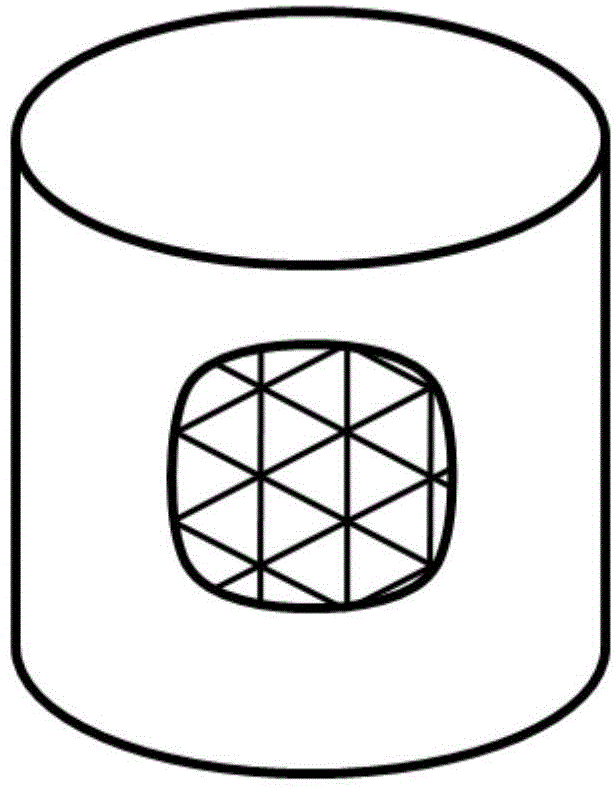

Stiffened plate shell structure reliability optimization method with multisource uncertainty being considered

ActiveCN104484531AImprove reliabilityMake up for the disadvantages of not being able to consider the impact of defectsSpecial data processing applicationsElement modelElement analysis

The invention relates to the technical field of optimization design and provides a stiffened plate shell structure reliability optimization method with the multisource uncertainty being considered. The stiffened plate shell structure reliability optimization method with the multisource uncertainty being considered comprises the following steps of performing reliability optimization on a stiffened plate shell structure by utilizing an equivalent stiffness model; performing finite element analysis validation on every elite individual in a candidate solution set, wherein the finite element analysis validation comprises performing nonlinear post-buckling analysis on the stiffened plate shell structure comprising defects by utilizing a single-point disturbing load method with defect factors being considered to screen out the elite individuals satisfying a reliability constraint condition; performing the reliability optimization on the stiffened plate shell structure by utilizing a finite element model. The stiffened plate shell structure reliability optimization method with the multisource uncertainty being considered can improve the reliability optimization efficiency of the stiffened plate shell structure and reduce calculation costs.

Owner:DALIAN UNIV OF TECH

Connecting terminal for printed circuit boards

InactiveUS7993156B2Simple functional designSmall installation sizeCoupling contact membersContact members penetrating/cutting insulation/cable strandsSpring forceEngineering

A contact insert for a connecting terminal of a multiplicity of mutually isolated connection elements, designed in particular for printed circuit boards, with a spring force element being mounted symmetrically, with the spring force element designed with a simple section geometry and its simple mounting together with the advantageous connection to the contact insert, results in a closed terminal cage which makes it possible to reduce the physical height of the dielectric housing to a major The connecting terminal is used as a linking element in printed circuit board connection technology for providing a reliable supply to industrial electronics and economic individual wiring on printed circuits.

Owner:PHOENIX CONTACT GMBH & CO KG

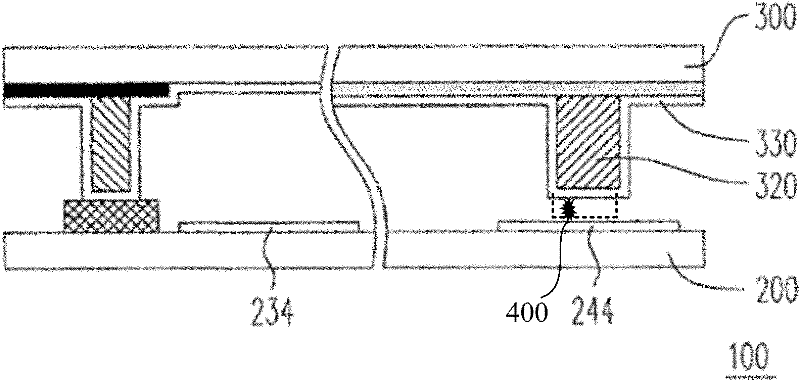

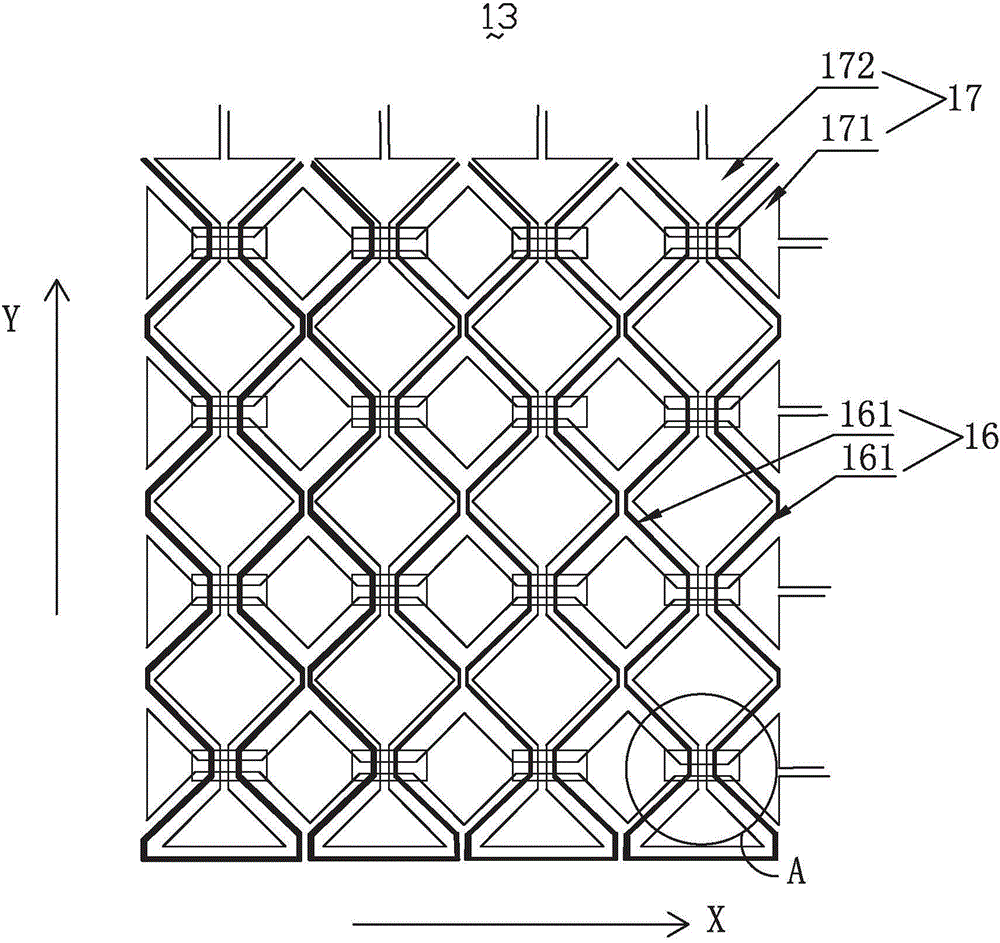

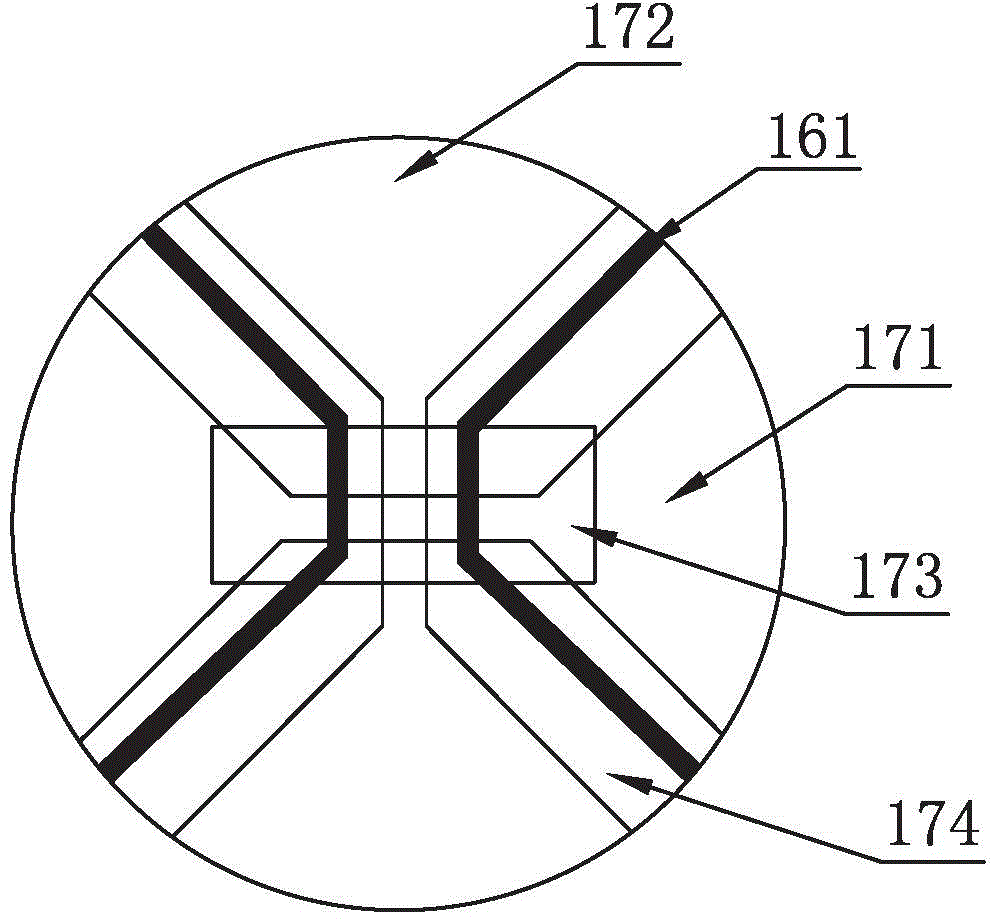

Touch display module with pressure detection and driving method of touch display module

ActiveCN106325631AReduce distractionsQuick responseNon-linear opticsInput/output processes for data processingHuman–computer interactionPressure sensitive

The invention provides a touch display module with pressure detection. The touch display module comprises a plurality of pixel units arrange in an array manner and a three-dimensional sensor, wherein the three-dimensional sensor comprises a plurality of touch units and at least one pressure sensitive unit; the multiple pixel units receive a grid driving scanning pulse to control the grid driving scanning pulse to display a color updating time sequence; the multiple touch units receive a touch scanning pulse to control and detect a time sequence of touch points; the at least one pressure sensitive unit receives a pressure scanning pulse to control and detect a time sequence of pressure; potential switching points among the grid driving pulse, the touch scanning pulse and the pressure scanning pulse are staggered. The invention further provides a driving method of the touch display module with pressure detection. According to the method, the potential switching points among the grid driving pulse, the touch scanning pulse and the pressure scanning pulse are staggered. The touch display module with pressure detection and the driving method of the touch display module have the advantages of high anti-noise property and the like.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

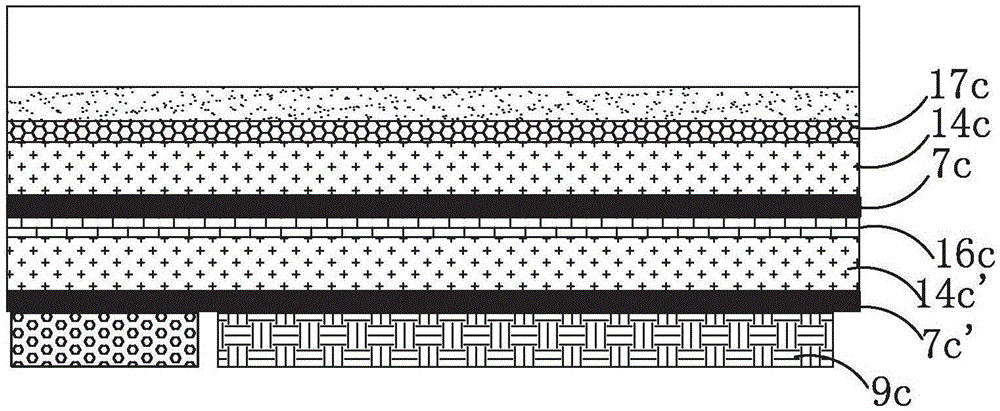

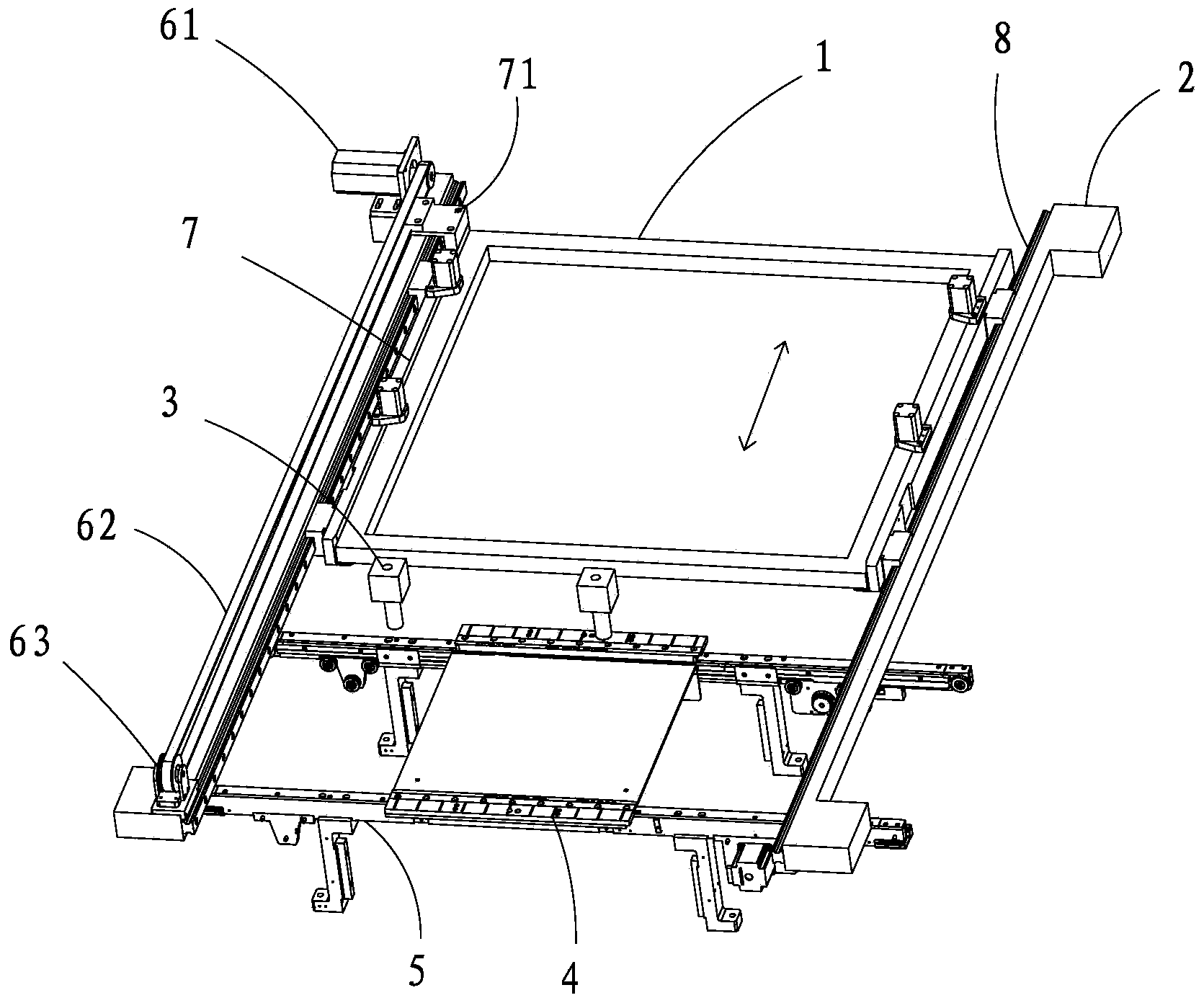

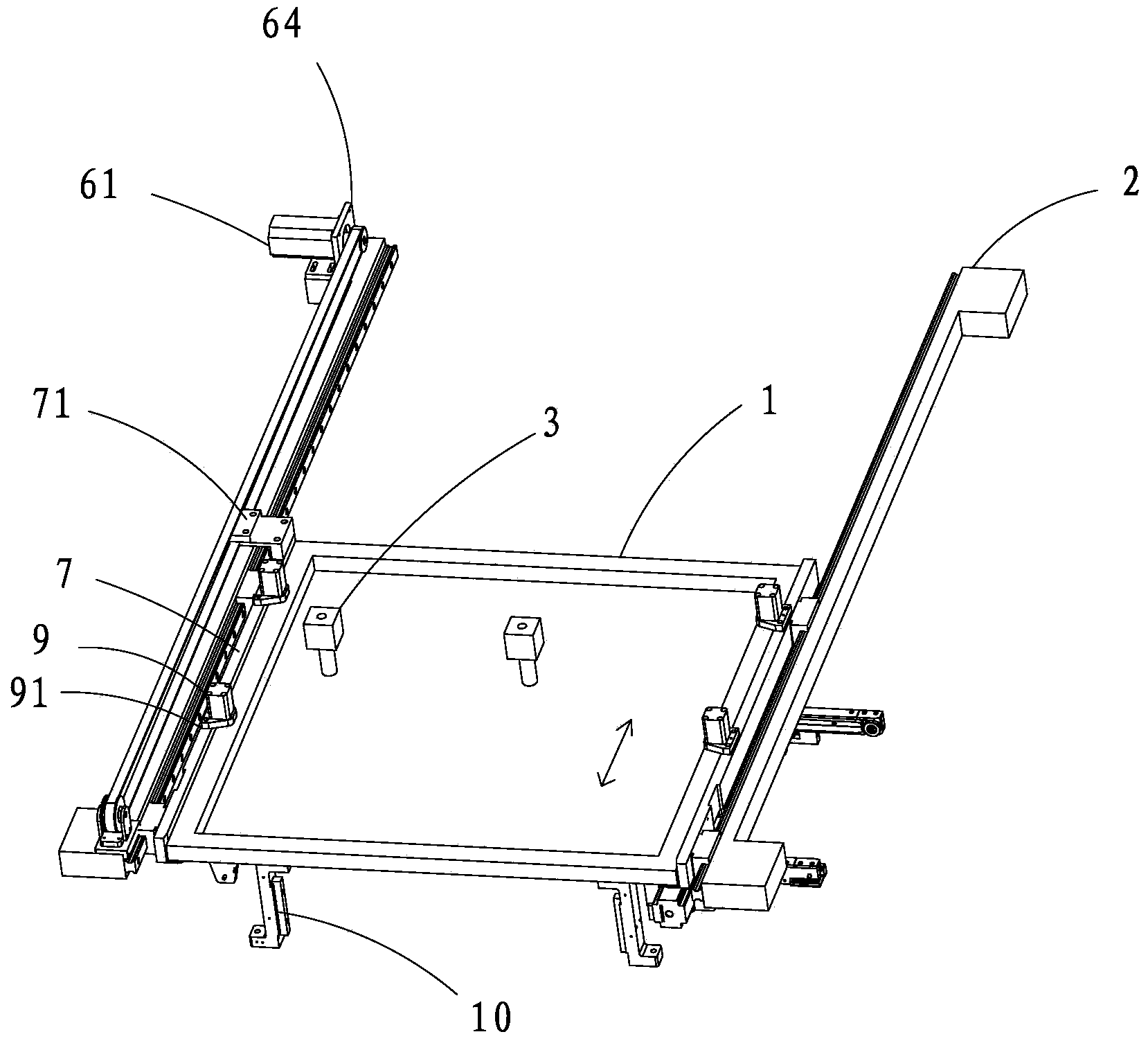

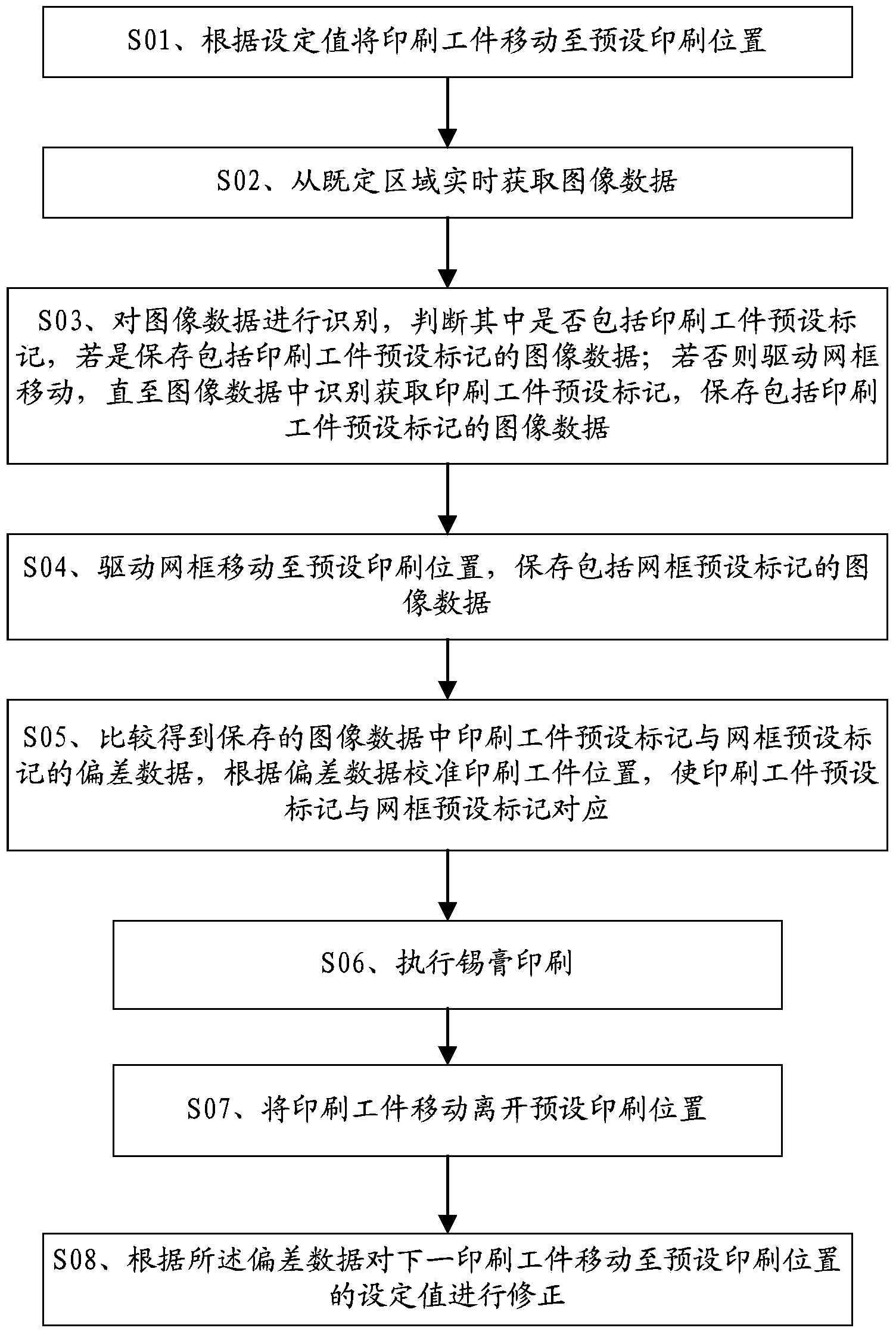

Automatic solder paste printing press and printing method thereof

ActiveCN103522740AIncrease productivityShorten the printing cycleScreen printersOther printing apparatusPrinting pressSolder paste

The invention discloses an automatic solder paste printing press and a printing method thereof. The automatic solder paste printing press comprises an image collecting mechanism, a printed workpiece conveying mechanism and a net frame moving mechanism. The net frame moving mechanism comprises a net frame, a net frame movable frame, a net frame fixed frame, a linear guide rail and a moving device, wherein the net frame movable frame is connected with the net frame fixed frame in a sliding mode through the linear guide rail, the net frame movable frame is connected with the moving device, and the net frame is arranged on the net frame movable frame and correspondingly arranged on the upper portion of the printing position of a printed workpiece. An image collector of the image collecting mechanism is located above the printing position of the net frame, a moving controller controls the moving device to drive the net frame to move according to electric signals of the image collector, and therefore the image collector above the net frame can capture images of the characteristics of a net plate on the net frame and the characteristics of the printed workpiece. By means of the automatic solder paste printing press, the solder paste printing cycle can be greatly shortened, and production efficiency of the printed workpiece can be improved.

Owner:SUNEAST ELECTRONICS TECH SHENZHEN

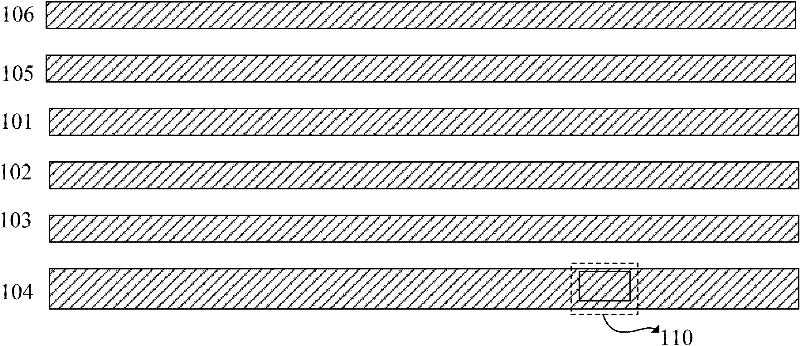

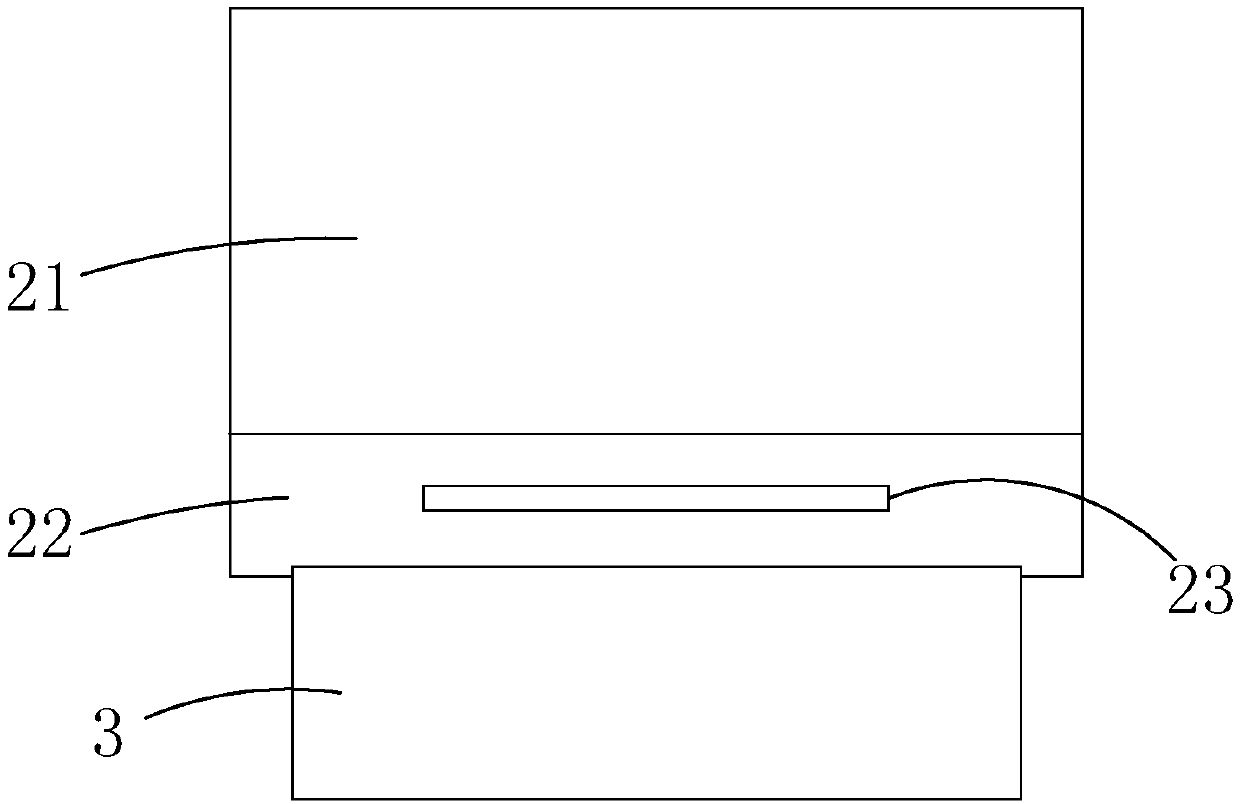

Liquid crystal display

ActiveCN108681118ASave design spaceReduce the difficulty of routingStatic indicating devicesNon-linear opticsLiquid-crystal displayFlexible circuits

The invention provides a liquid crystal display, which comprises a MINI LED substrate, a plurality of MINI LED chips arranged on one side surface of the MINI LED substrate, a MINI LED driving IC arranged on the other side surface of the MINI LED substrate and a fluorescent film covering the plurality of MINI LED chips, wherein the MINI LED driving IC drives the plurality of MINI LED chips to emitlight, compared with the prior art, the MINI LED driving IC is not required to be arranged on a flexible circuit board assembly, a connector is saved, the design space for compressing the flexible circuit board assembly is avoided, the difficulty of electrically wiring the MINI LED driving IC and the plurality of MINI LED chips is reduced, so that the manufacturing cost is reduced.

Owner:WUHAN CHINA STAR OPTOELECTRONICS TECH CO LTD

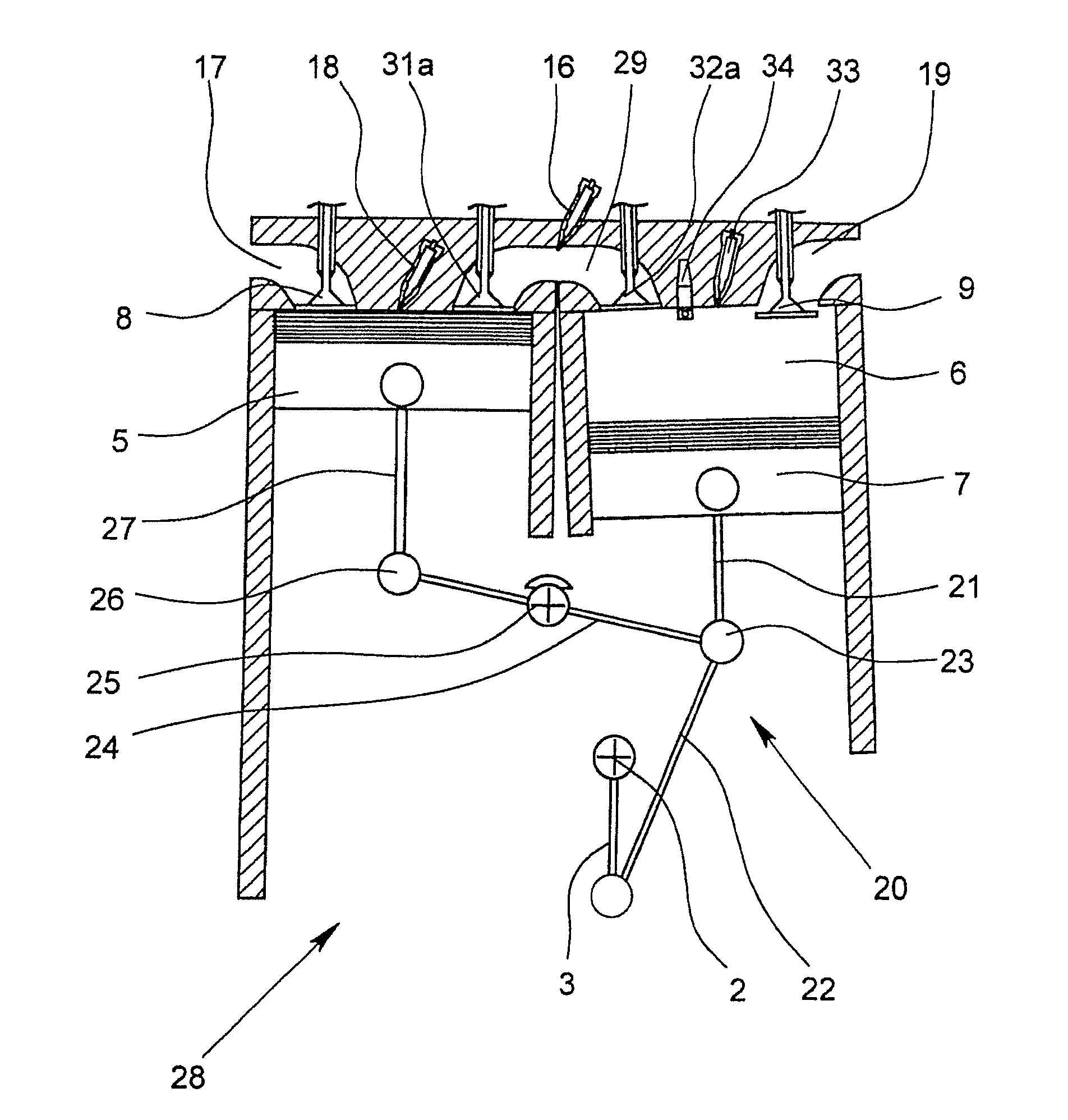

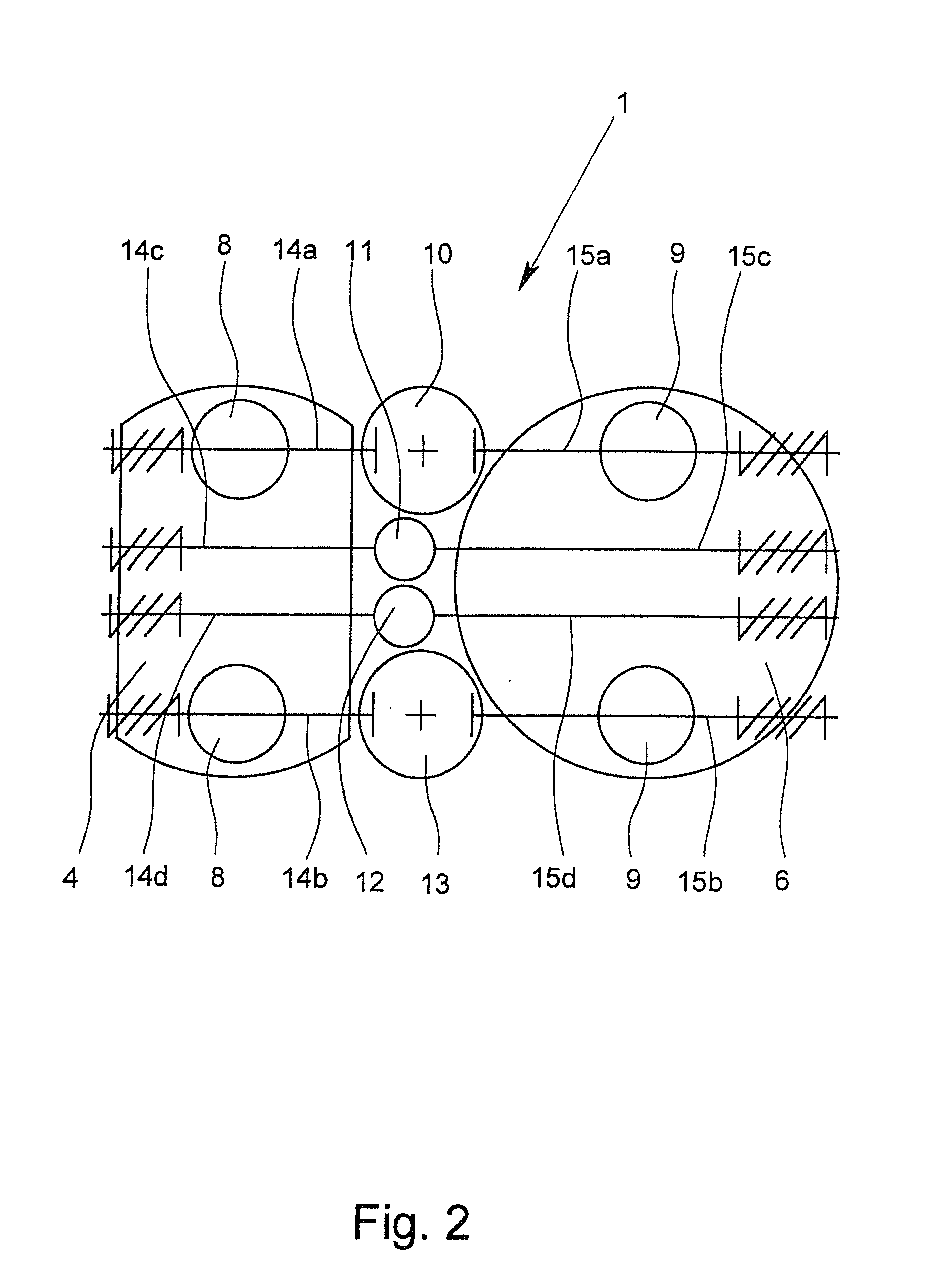

Internal combustion engine

InactiveUS20120031383A1Improve efficiencyImproved torque responseInternal combustion piston enginesGaseous engine fuelsCombustionExternal combustion engine

An internal combustion engine with a crankshaft, at least one compression piston which is housed in a compression cylinder, and at least one working piston which is housed in a working cylinder. Movement of the compression piston and of the working piston are coupled kinematically to movement of the crankshaft, so that the compression piston moves back and forth during a single revolution of the crankshaft in an intake stroke and a compression stroke and that the working piston moves back and forth during a single revolution of the crankshaft by a working stroke and an exhaust stroke. The compression cylinder has at least one inlet valve for drawing-in air into the compression cylinder during downward movement of the compression piston, and the working cylinder has at least one outlet valve for discharging combustion gases from the working cylinder during upward movement of the working piston.

Owner:WILLI FECHNER

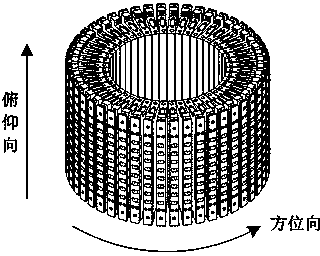

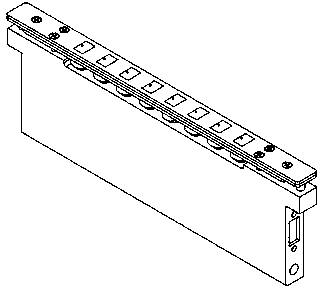

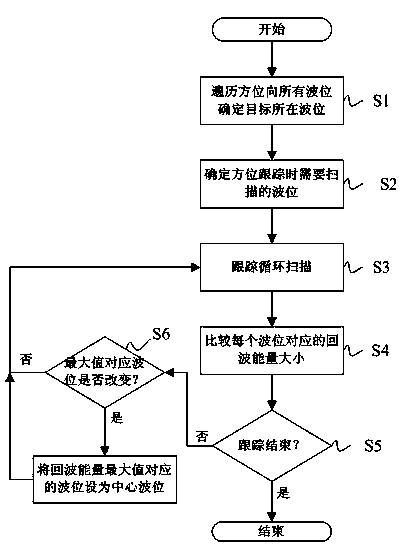

Phased array beam tracking method

ActiveCN104297747ARealize beam tracking functionSimple designRadio wave reradiation/reflectionClassical mechanicsMiniaturization

The invention discloses a phased array beam tracking method. The method includes the steps that an annular syntype phased array traverses all wave potentials on an azimuth by controlling beams on the azimuth, and a wave potential of the azimuth where a tracking target is located is determined; the wave potential on the azimuth is controlled to point to the wave potential where the tracking target is located, and the wave potential serves as a center wave potential of tracking loop scanning; the center wave potential serves as the center of the annular syntype phased array, tracking loop scanning is carried out on three wave potentials in adjacent airspaces of the tracking target, and target echo energy is recorded; the annular syntype phased array compares the magnitudes of the target echo energy of the three wave potentials in the adjacent airspace of the tracking target, and the wave potential where the target echo energy is largest is determined to be a center wave potential of next tracking circulating scanning. The direction of the target is determined according to the magnitudes of the target echo energy, the phased array achieves a beam tracking function on the azimuth, complexity of phased array design is effectively reduced, design space is reduced and miniaturization design of the phased array is facilitated.

Owner:SHANGHAI RADIO EQUIP RES INST

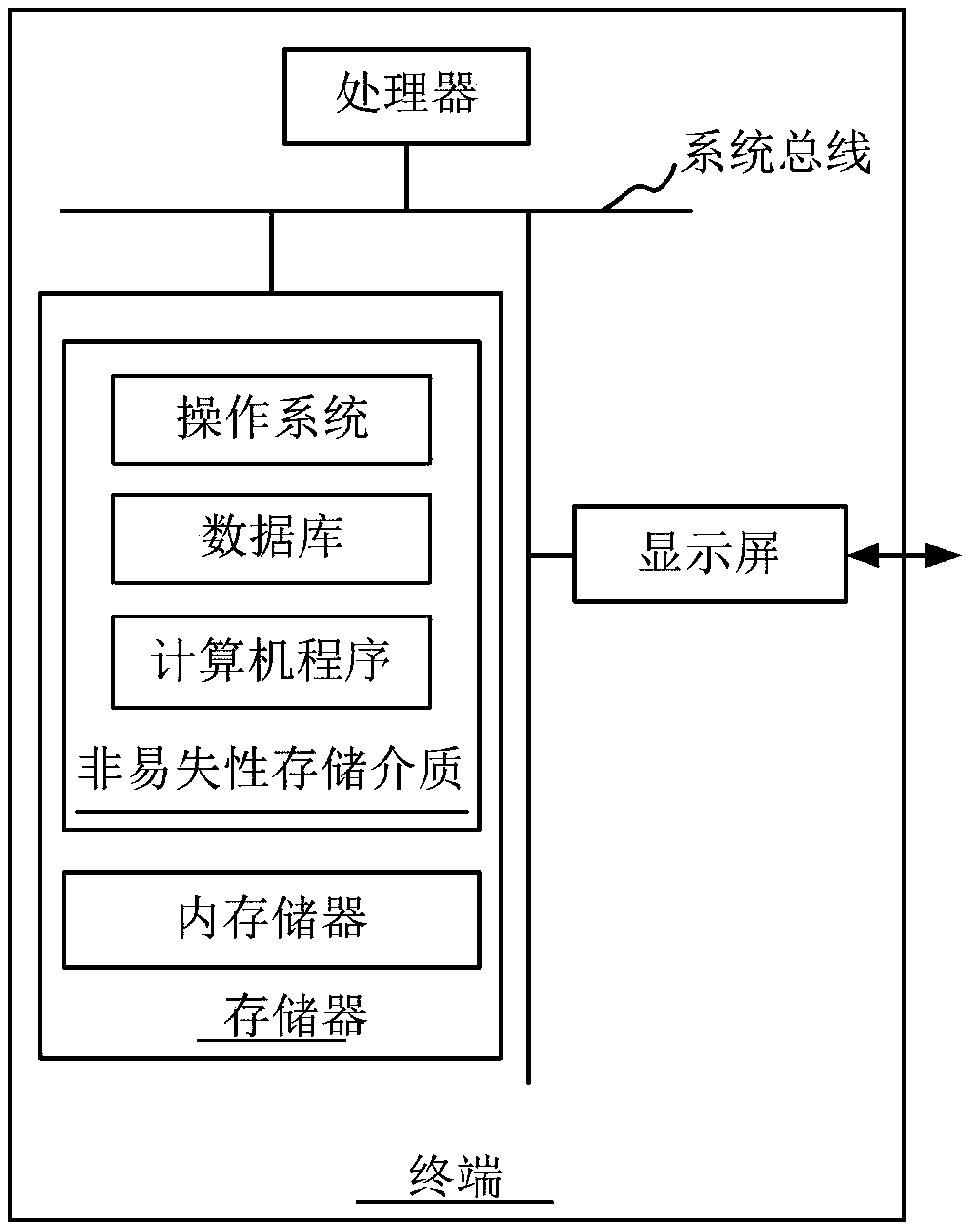

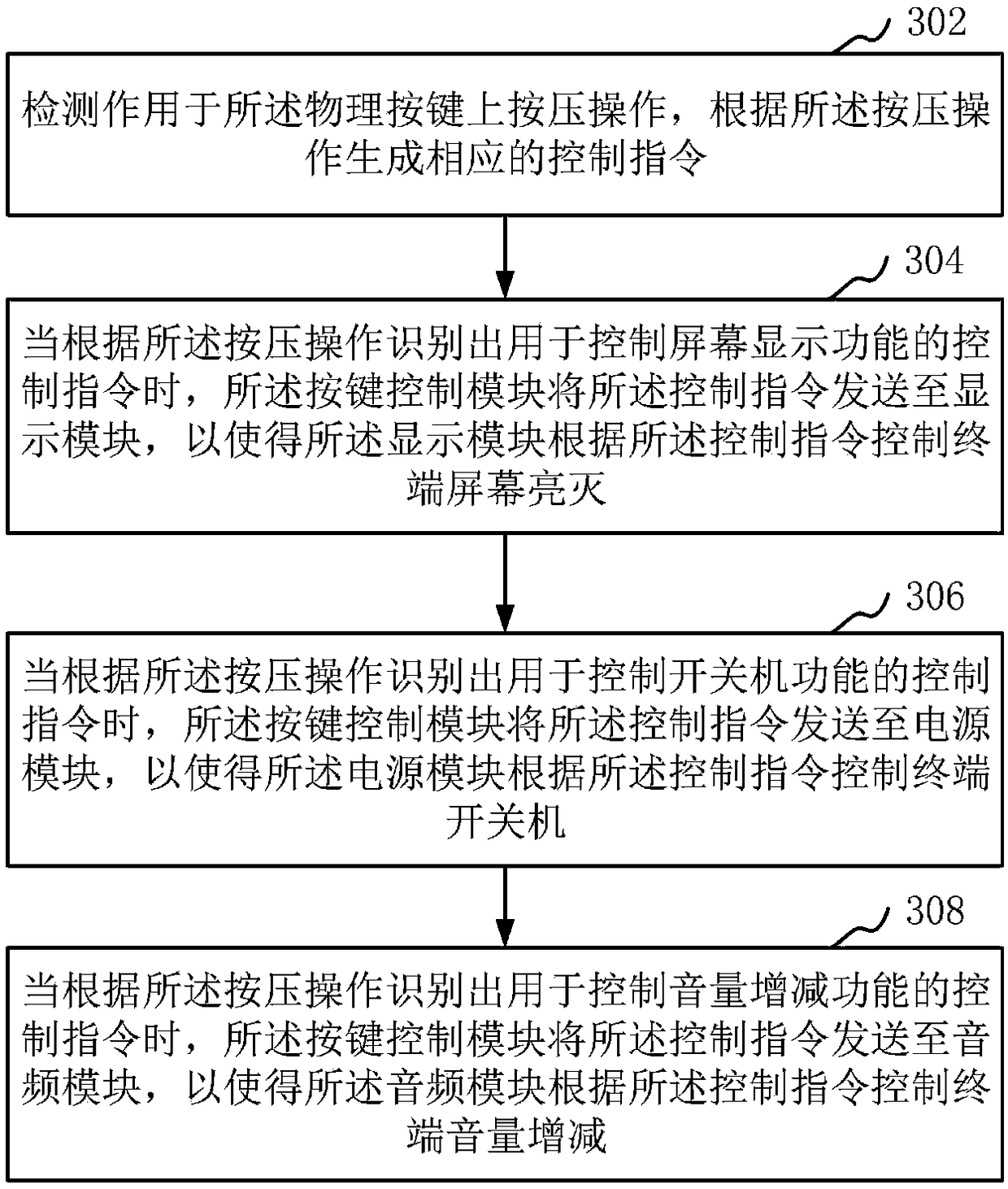

Key control method and device, terminal and computer readable storage medium

InactiveCN108769390AControl on and offControl switchSubstation equipmentSound input/outputKey pressingComputer terminal

The invention relates to a key control method and device, a terminal and a computer readable storage medium. The method comprises the following steps: detecting pressing operation on a physical key, and generating a corresponding control instruction according to the pressing operation; and realizing functions of turning on and turning off a terminal screen, switching on and switching off the terminal, increasing and decreasing the volume and the like according to different control instructions. By the method, the number of the physical keys on the terminal is reduced; control of the functionsof terminal displaying, volume, switching on and the switching off and the like can be realized through the single physical key; the design space in the terminal is saved, so that the terminal tends to be light in weight from the appearance; and furthermore, control of various functions can be realized without adding extra devices under the condition of reducing the number of keys, so that the design cost is reduced.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Coupling circuit arrangement for data communication over power lines

InactiveUS7183900B2Easy to integrateInsulation safetyElectric signal transmission systemsFrequency-division multiplex detailsControl signalData signal

Owner:AVAGO TECH INT SALES PTE LTD

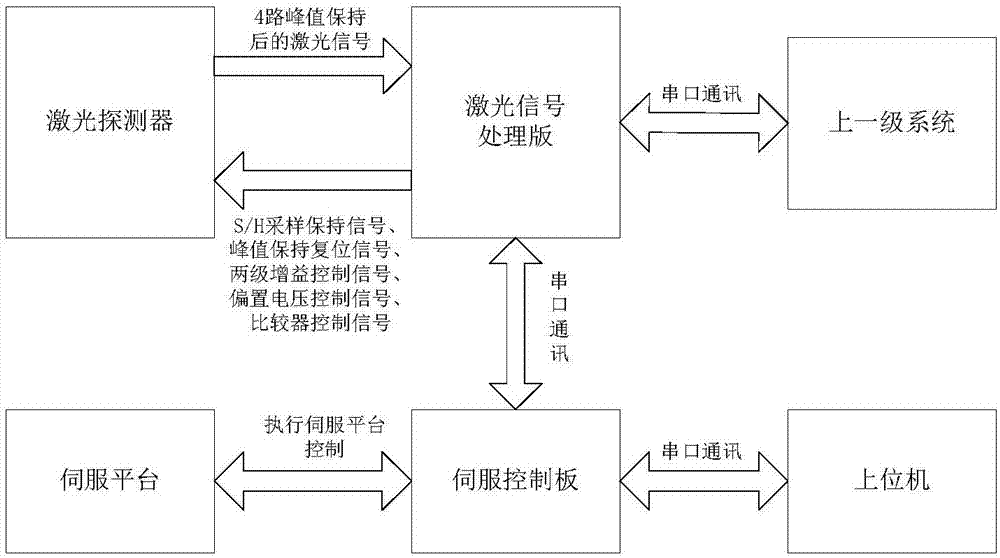

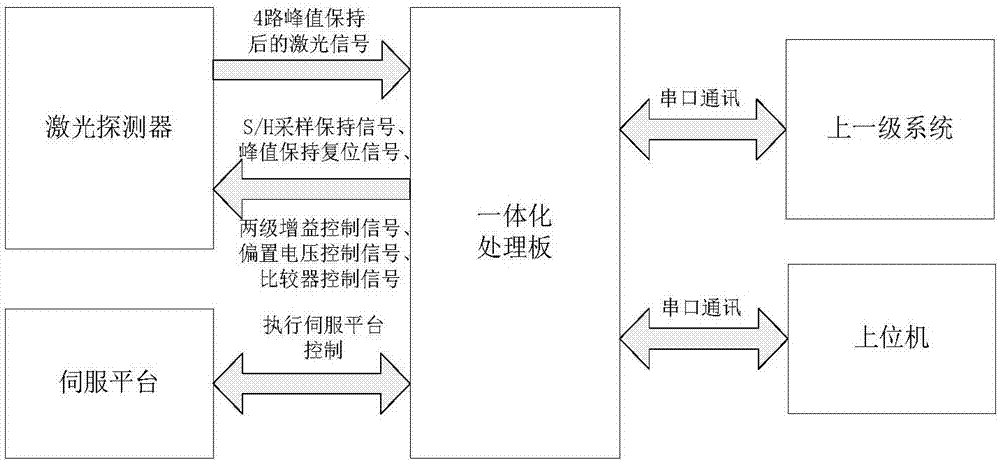

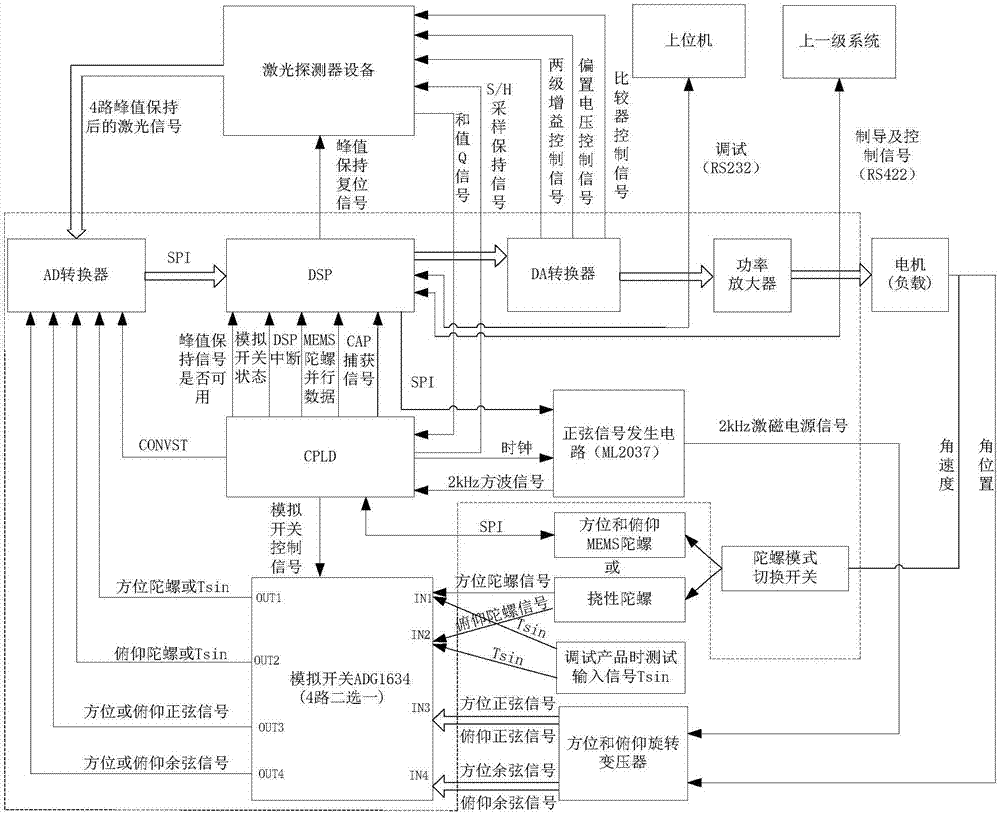

Laser signal solution and servo control integrated processing system

ActiveCN107388904ARealize time-sharing switchingAchieving processing powerSelf-propelled projectilesResource utilizationMiniaturization

The invention discloses a laser signal solution and servo control integrated processing system. The system comprises an AD converter, a DSP, a DA converter, a power amplifier, a CPLD, a sine signal generation circuit, a gyro mode switching switch and four ways of alternative analog switches; the DSP is responsible for data solution; the CPLD is responsible for working coordination and time sequence control of each module; and the system realizes timing switching and processing of multiple data through the switching switch and the alternative analog switches, so that laser signal solution and servo control work are organically combined to realize a double-function processing system on one board. The system finishes laser signal processing and servo control based on one set of DSP main controllers, so that the system cost is reduced, the hardware resource utilization rate is increased, and the system miniaturization, lightness and reliability are improved.

Owner:HEBEI HANGUANG HEAVY IND

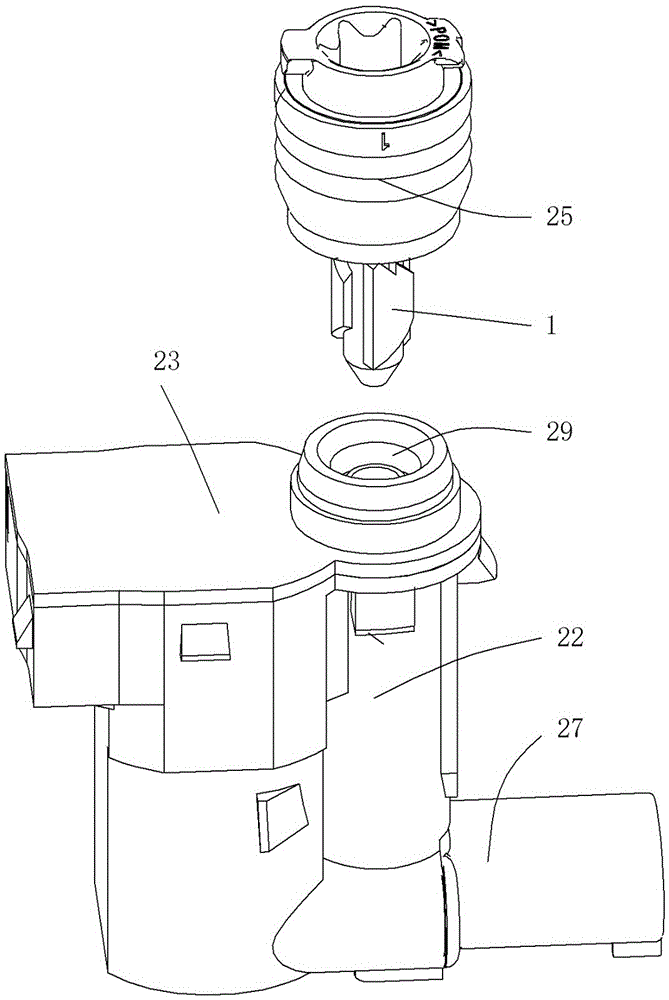

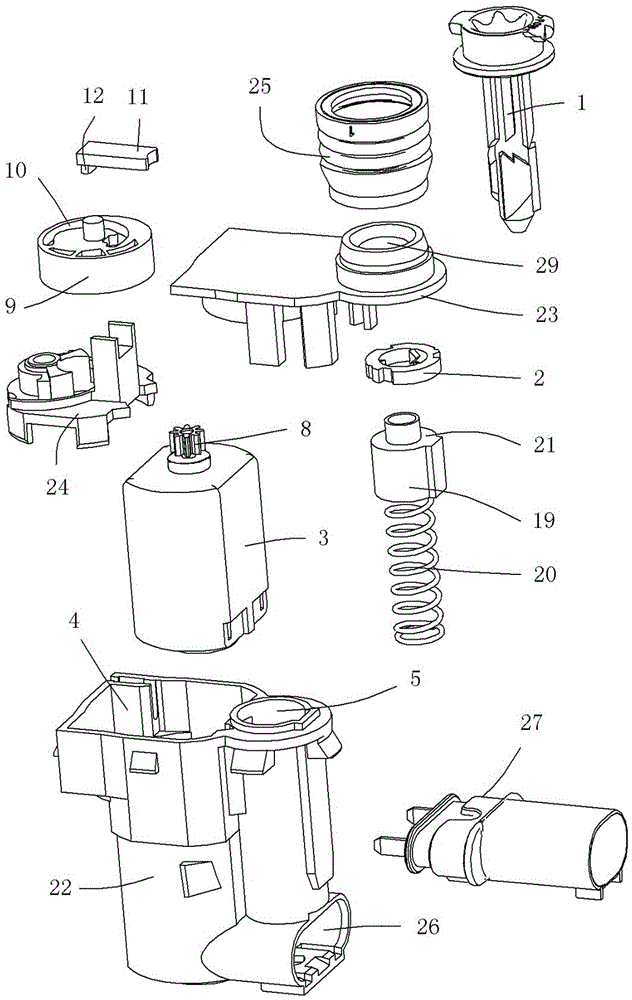

Micro actuator for oil filler cap and charging cap

ActiveCN106150230ACompact structureReduce volumeElectrical locking actuatorsMotor driveMicro actuator

The invention provides a micro actuator for an oil filler cap and a charging cap. The micro actuator comprises a lock bracket assembly and a lock rod. The lock bracket assembly comprises a base, a locking plate and a motor. A motor cavity and a locking cavity are formed in the base. The motor cavity is sealed. One end of the locking cavity is opened. The locking plate and a resetting piece are mounted in the locking cavity. A lock hole and lock lugs are arranged at the center of the locking plate. The motor, a gear, a gear sleeve and a positioning pin are mounted in the motor cavity. A slide block at one end of the positioning pin is arranged in an arc-shaped groove in the end surface of the gear sleeve. The other end of the positioning pin extends into the locking cavity. The resetting piece is locked at the other end of the positioning pin. A first slope, a second slope, a first guiding groove, a second guiding groove, a yielding groove and a locking groove are formed in the outer wall of the lock rod. When the lock rod is inserted in the lock hole, the lock lugs enter a part between the first slope and the second slope along the second guiding groove and are locked in the locking groove under the resetting action of the resetting piece. The motor drive way and the pressing drive way are integrated, the micro actuator is simple and compact in structure, and small in size, the design space is saved, operation is convenient, and locking is reliable.

Owner:NINGBO HUADE AUTOMOBILE PARTS

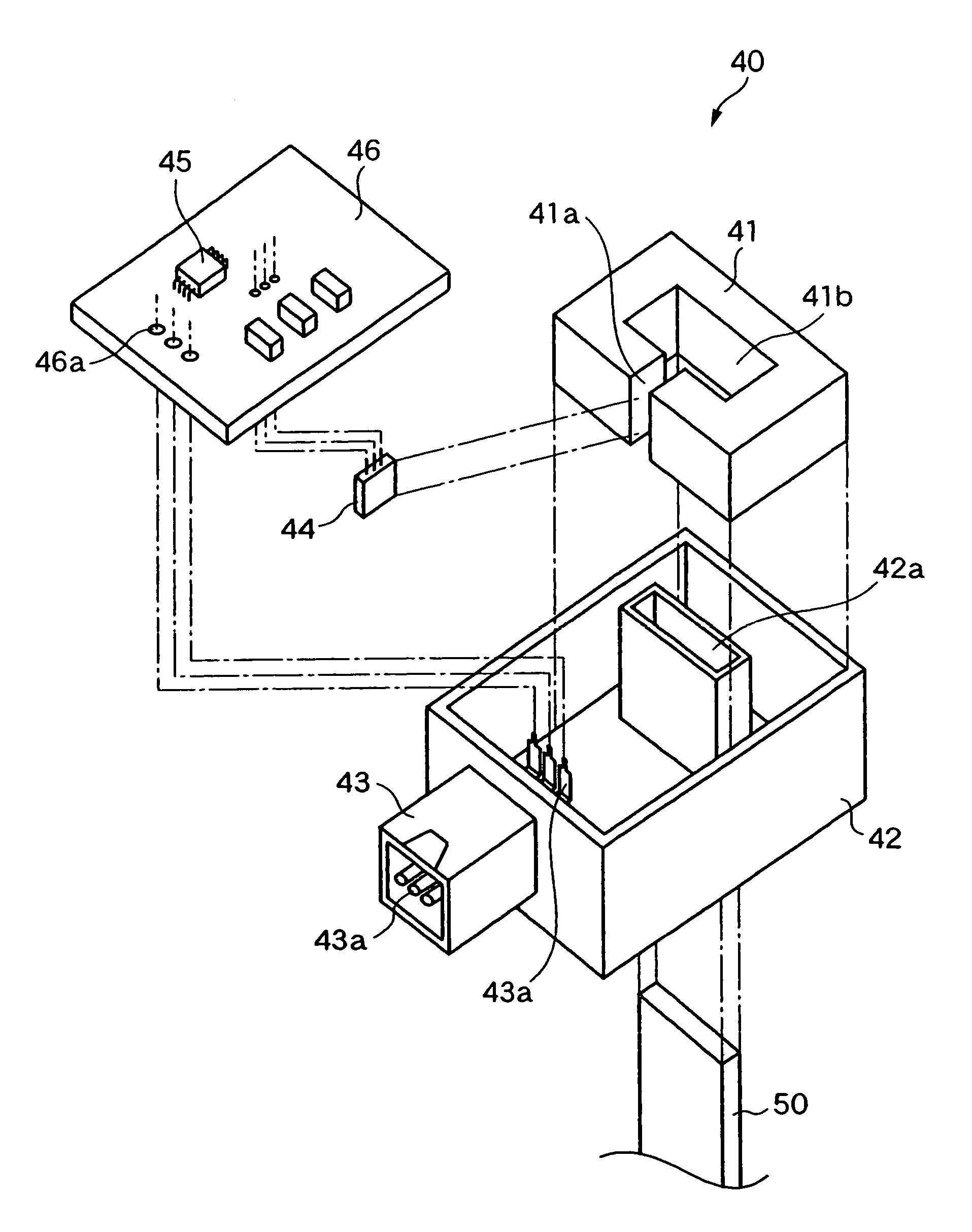

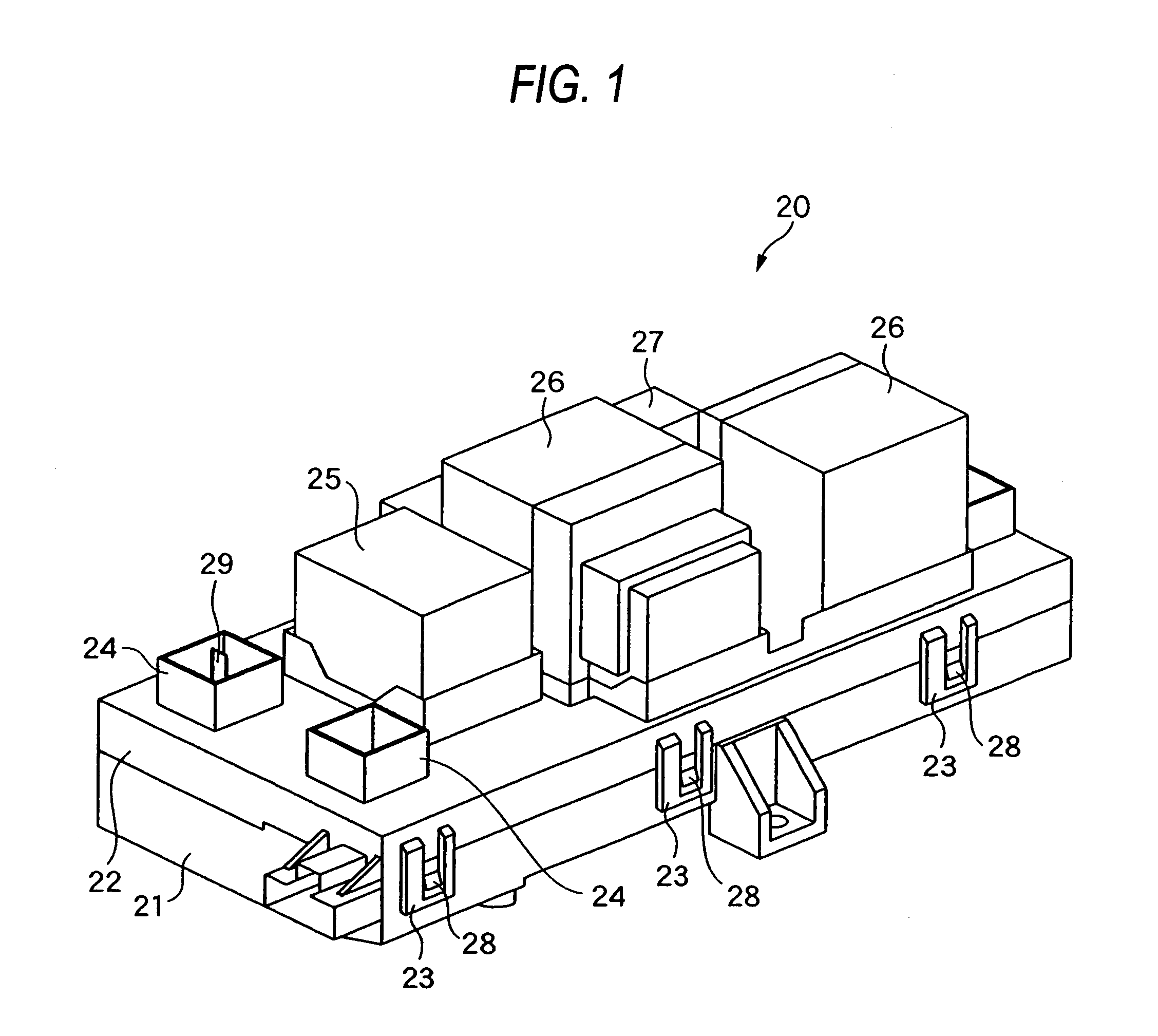

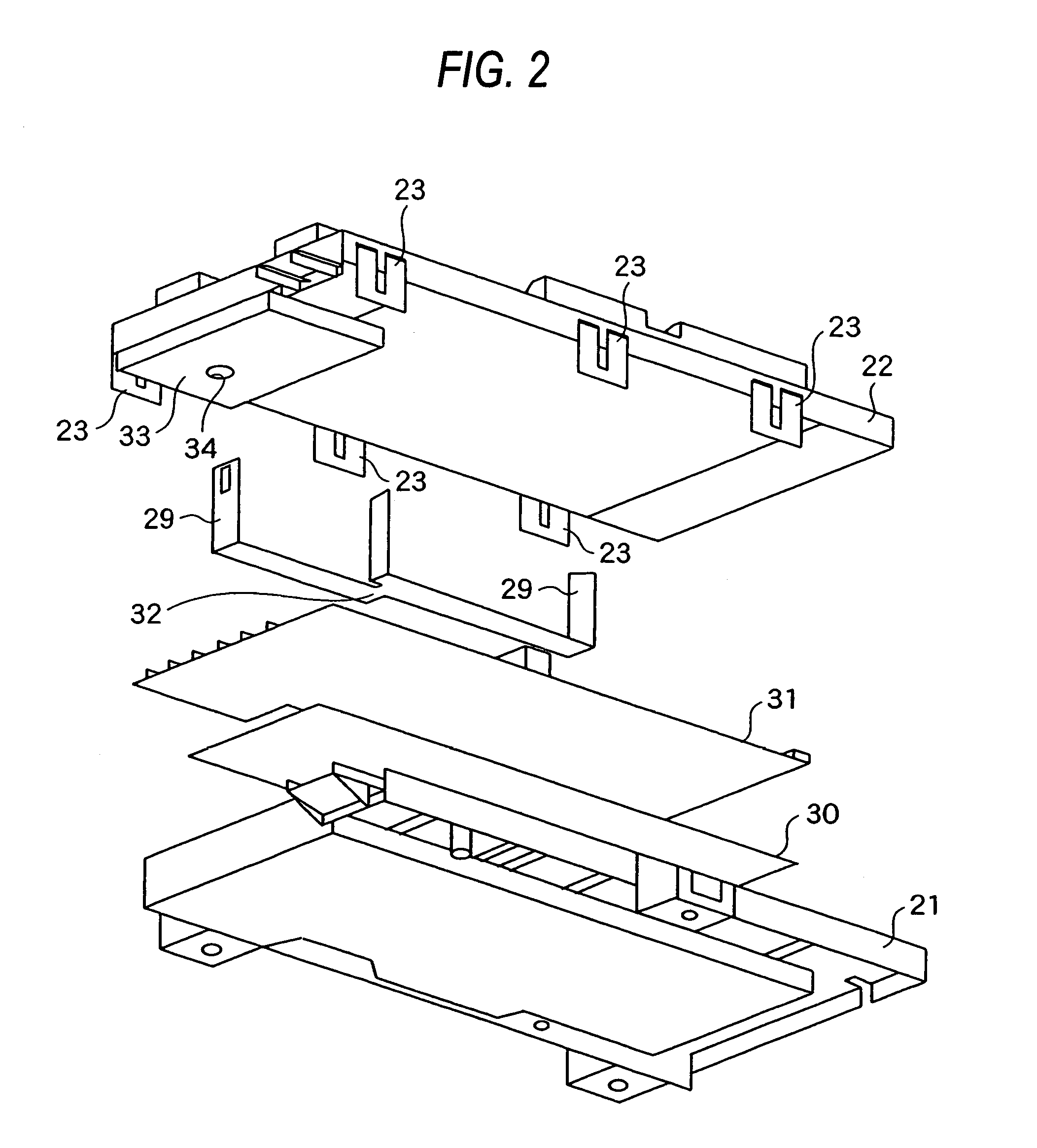

Electric connection box

InactiveUS7316576B2Save design spaceAvoid complex structuresMagnetic field measurement using galvano-magnetic devicesElectric/fluid circuitElectricityCurrent sensor

An electric connection box is mounted within an engine room of a vehicle. A bus bar and a current sensor are sequentially mounted on a lower cover, and an upper cover is joined to the lower cover to cover the bus bar and the current sensor. The current sensor is molded integrally with the upper cover. With this construction, the current sensor and the bus bar are less liable to be displaced relative to each other, and the number of the component parts, as well as time and labor required for an assembling operation, is reduced.

Owner:YAZAKI CORP

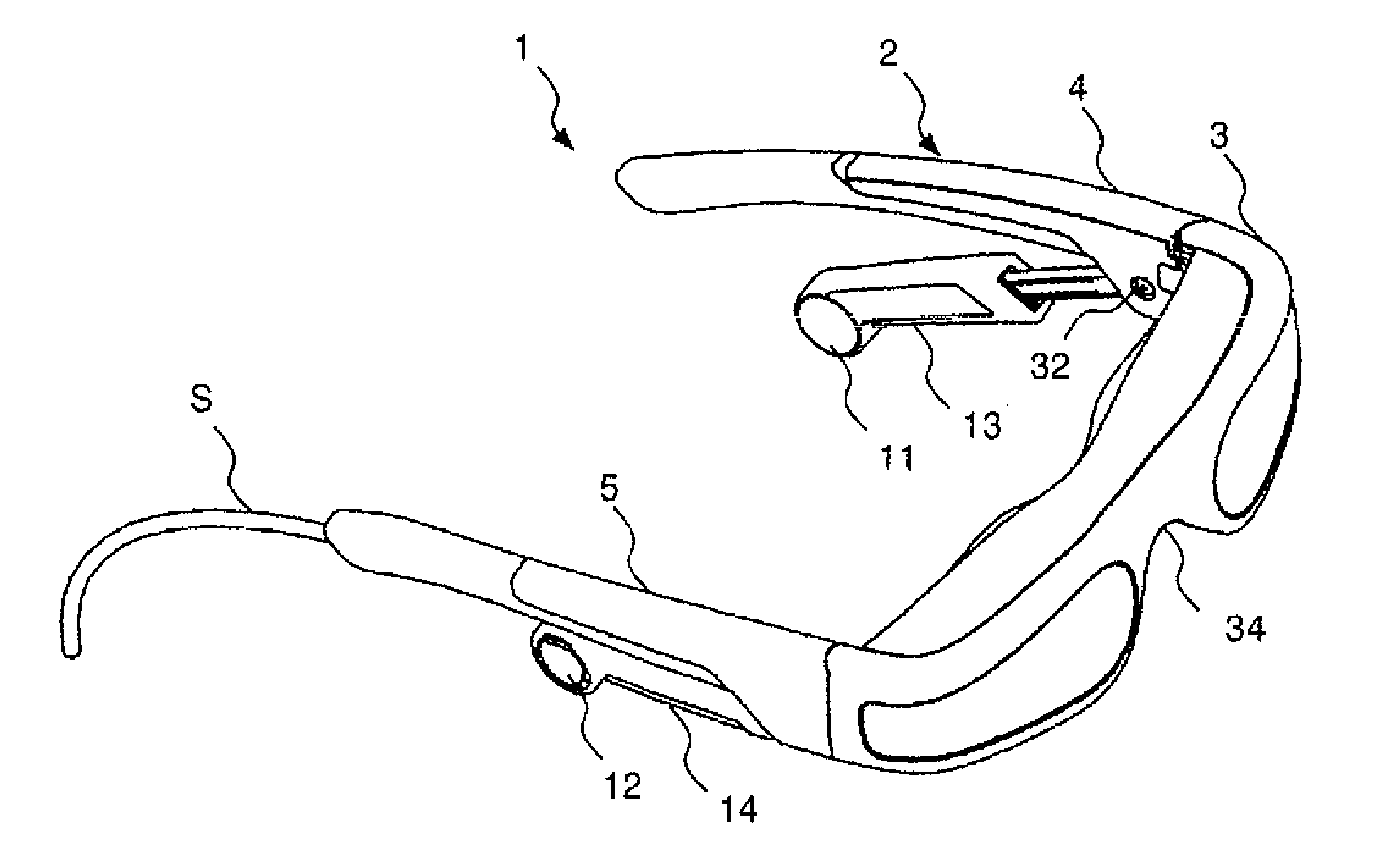

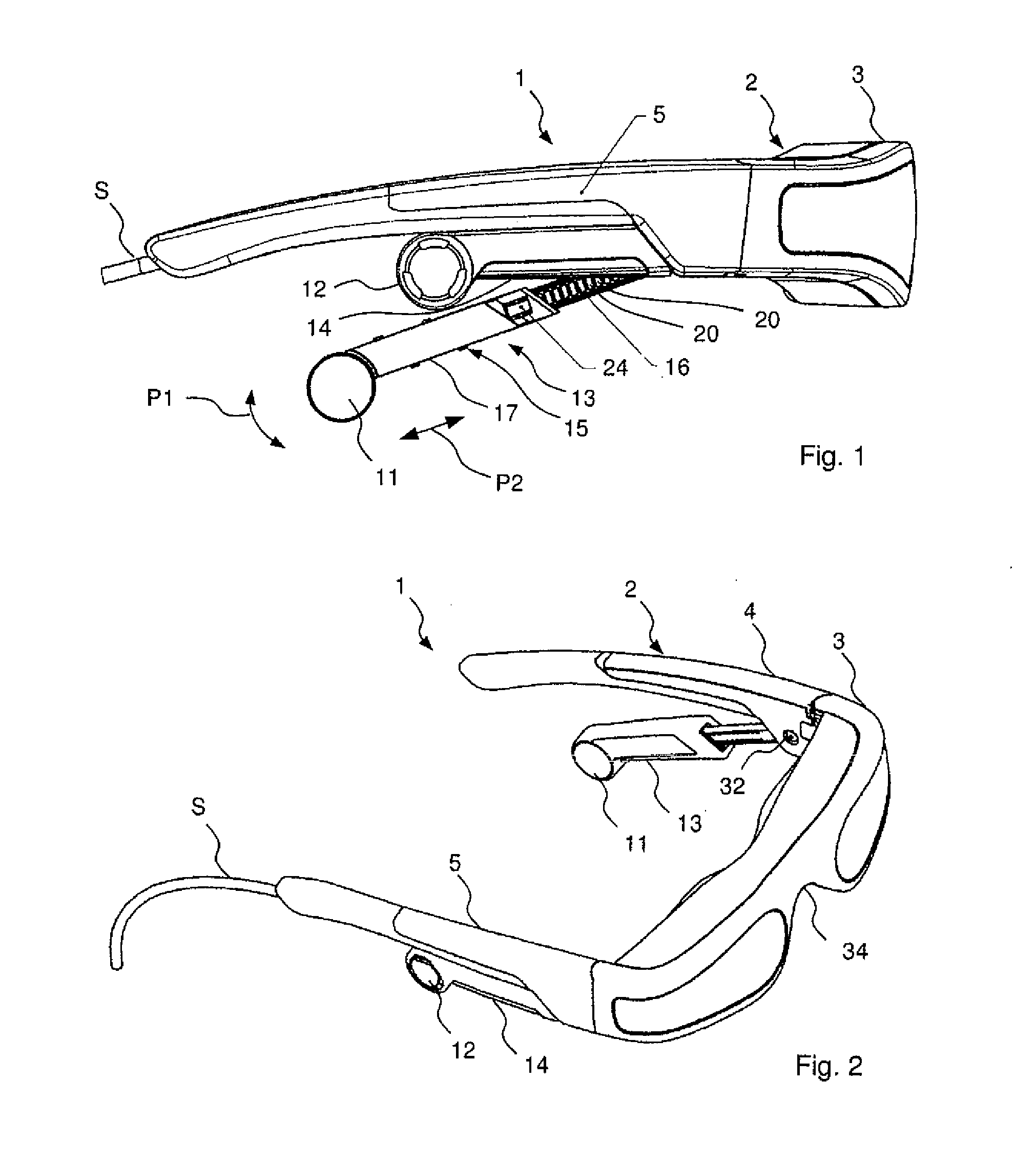

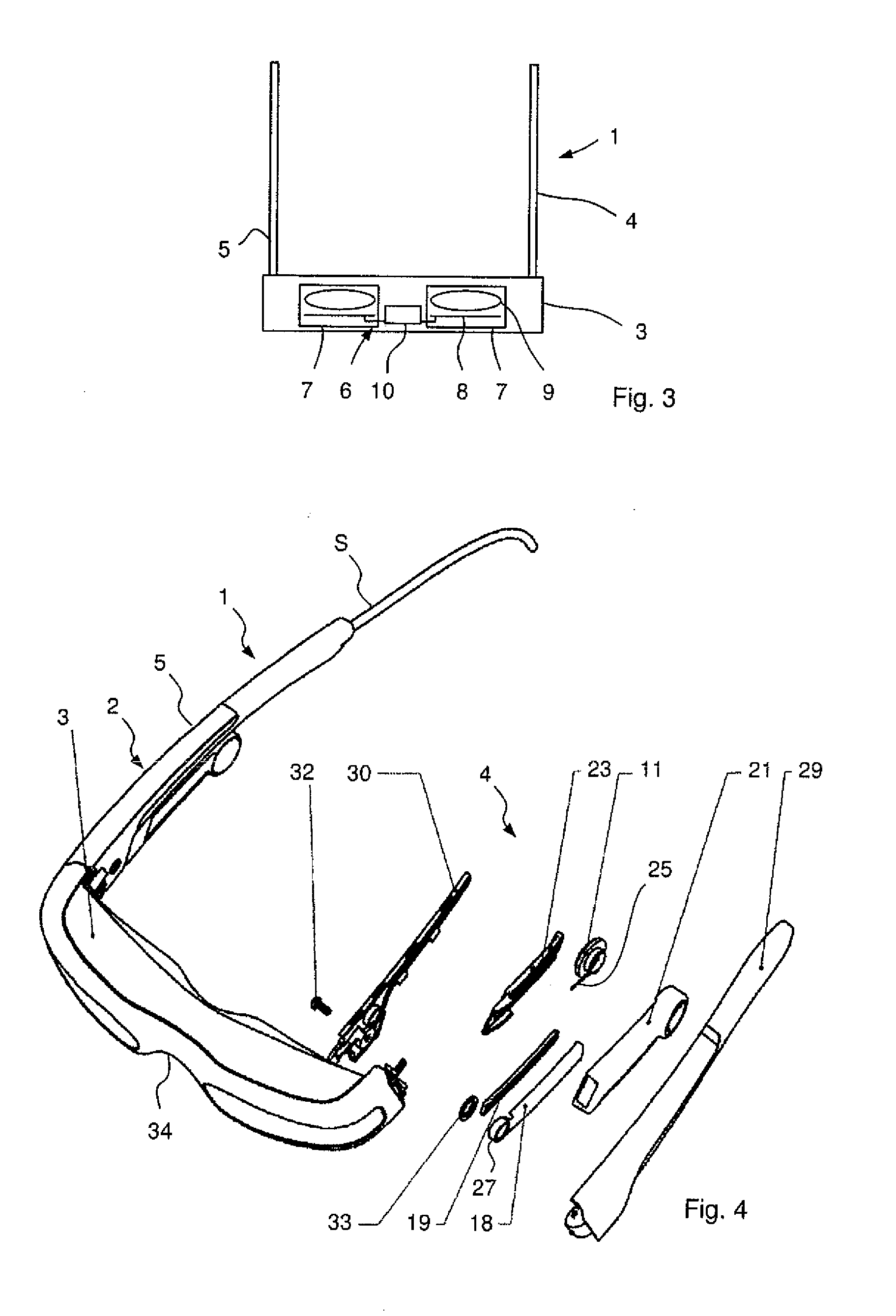

Display apparatus

InactiveUS20090243964A1Compact designComfortable to wearNon-optical adjunctsCathode-ray tube indicatorsHeadphonesComputer science

A display apparatus which comprises an image module for generating an image, a spectacle-like frame which carries the image module, and wherein the spectacle-like frame comprises a front portion with a nose support, as well as two side arms mounted to the front portion. At least one earphone is mounted to the frame via a positioning mechanism. The earphone can be positioned in front of an ear of a user by means of the positioning mechanism, when the display apparatus is mounted on the user's head. The positioning mechanism comprises a linear guide which is mounted to the frame via a hinge joint and the earphone is positioned at the end of the linear guide, turned away from the hinge joint.

Owner:CARL ZEISS SMT GMBH

X-ray apparatus with component positioning coordinated with radio-opaque objects in examination room

InactiveUS20070165775A1Short amount of timeEasy to useMaterial analysis using wave/particle radiationRadiation/particle handlingAcquisition apparatusX-ray

An x-ray acquisition apparatus has a spatially adjustable x-ray detector, a spatially adjustable x-ray source, and a control unit with which the x-ray source can be aligned relative to the x-ray detector. The control unit accounts for the position of radio-opaque objects in the examination room and, before an x-ray acquisition, outputs a signal is a radio-opaque object is located in the beam path of the x-ray source.

Owner:SIEMENS HEALTHCARE GMBH

Touch assembly with pressure detection and driving method of touch assembly

ActiveCN106325582AHighly integratedReduce thicknessInput/output processes for data processingEngineeringPressure detection

The invention provides a touch assembly with pressure detection. The touch assembly with pressure detection comprises a three-dimensional sensor and a three-dimensional controller, wherein the three-dimensional sensor comprises a plurality of touch electrodes and at least one pressure detection electrode; the three-dimensional controller comprises a driver and a driving pulse processor; the driver supplies a pressure scanning pulse to the at least one pressure detection electrode and supplies a touch scanning pulse to the multiple touch electrodes under the cooperation of the driving pulse processor. The invention further provides a driving method of the touch assembly with pressure detection. The method comprises the following steps: the driver supplies the pressure scanning pulse to the at least one pressure detection electrode under the cooperation of the driving pulse processor; the driver supplies the touch scanning pulse to the multiple touch electrodes. The touch assembly with pressure detection has the advantages of simple hardware design, high integration degree, high anti-noise property, simple driving method and the like.

Owner:TPK TOUCH SOLUTIONS (XIAMEN) INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com