Selective laser melting powder sending and laying device used for compounding of different types of powder

A selective laser melting and powder spreading device technology, which is applied in the field of additive manufacturing, can solve problems such as gradient complex parts, achieve the effects of saving powder materials, reducing design space and energy consumption, and avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

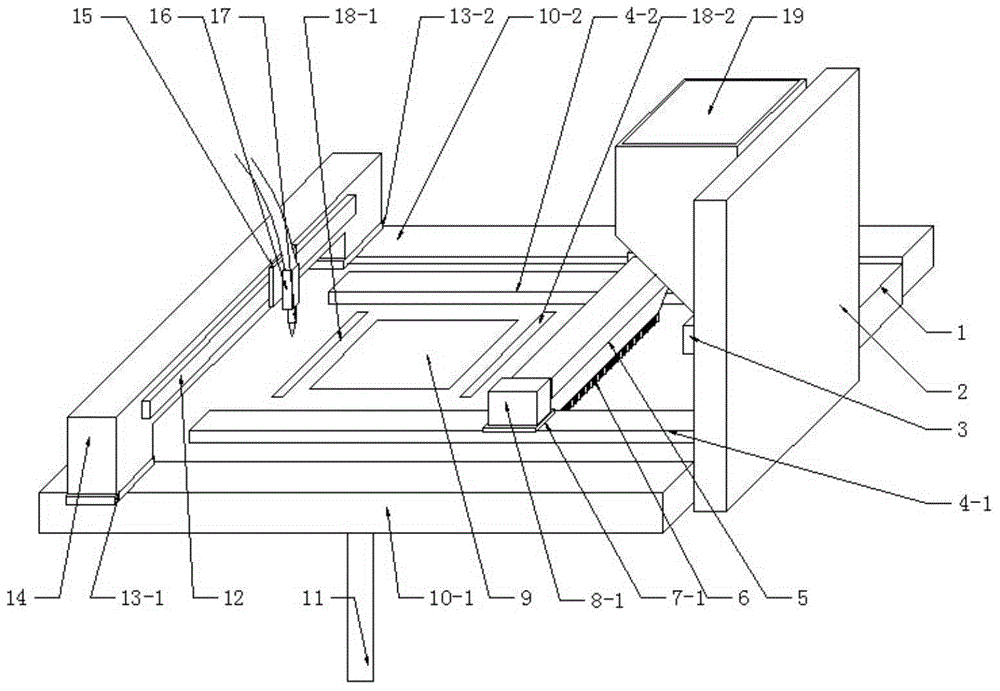

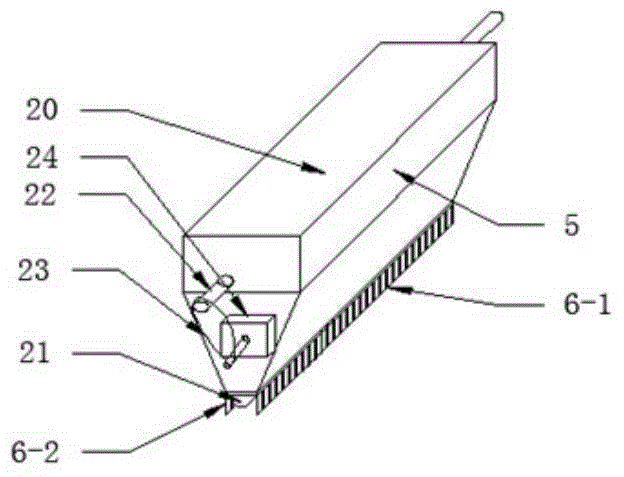

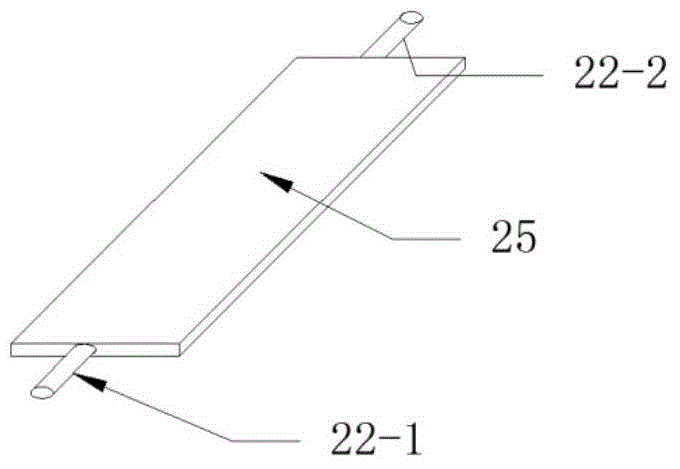

[0021] The present invention provides a selective laser melting powder feeding and spreading device for compound use of different powders, which specifically includes: a workbench 1, a fixed plate 2, a first rotating motor 3, a powder scraping electric guide rail 4, a powder funnel 5, a scraper 6, The first slider 7, the bracket 8, the forming cylinder 9, the powder spraying electric guide 10, the ball screw 11, the nozzle electric guide 12, the second slide 13, the support 14, the nozzle slide 15, the nozzle 16, the nozzle 17 , recovery cylinder 18, powder storage box 19, funnel mouth 20, powder outlet 21, rotating shaft 22, transmission belt 23, second rotating motor 24, rotating sheet 25, rotating shaft 26, sleeve 27, long groove 28, powder leakage Port 29, the first connection hole 30, the second connection hole 31.

[0022] to combine figure 1 , the forming cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com