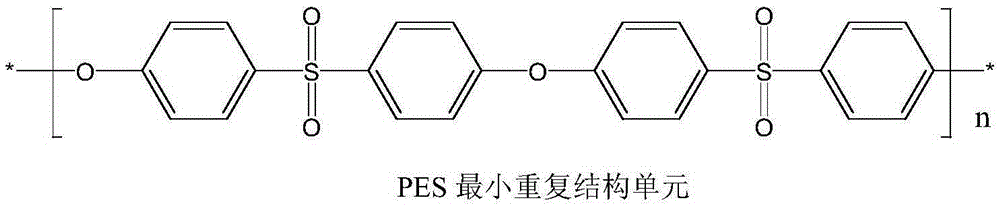

Preparation method of polyethersulfone resin

A technology of polyethersulfone resin and sulfolane, which is applied in the field of polyethersulfone resin synthesis, can solve problems such as difficult automatic operation, wide molecular weight distribution of products, and large on-site pollution, so as to overcome discontinuous process flow, ensure purity and performance, Overcome the effect of unclean cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

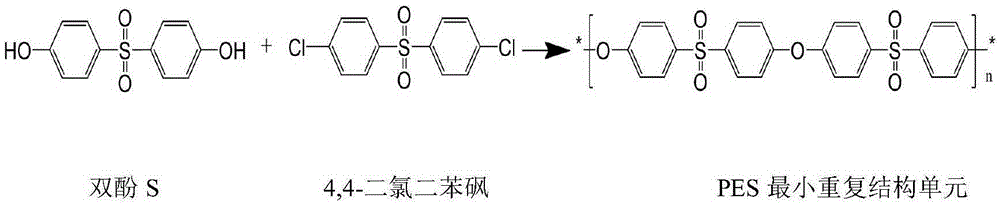

[0023] Taking a 100L polymerization kettle as an example, prepare raw materials according to the following quality: 4,4-dichlorodiphenyl sulfone (13.04Kg), bisphenol S (5.22Kg), potassium carbonate (4.3Kg), sulfolane (20Kg), trimethylbenzene (4Kg).

[0024] Accurately weigh the above formula components respectively, add sulfolane, 4,4-dichlorodiphenyl sulfone, bis Phenol S, trimethylbenzene, inert gas and nitrogen protection, start stirring, frame stirring 30r / min, paddle stirring 60r / min, heat the reactor jacket to 120°C, stir for 40 minutes until all raw materials are dissolved, then add potassium carbonate , the temperature of the jacket of the polymerization kettle was raised to 200° C. for reflux reaction for 2.5 hours, and trimethylbenzene and generated water were released from the water separator, and the jacket temperature of the polymerization kettle was raised to 230° C. and the polymerization reaction was completed for 3 hours.

[0025] After the polymerization rea...

Embodiment 2

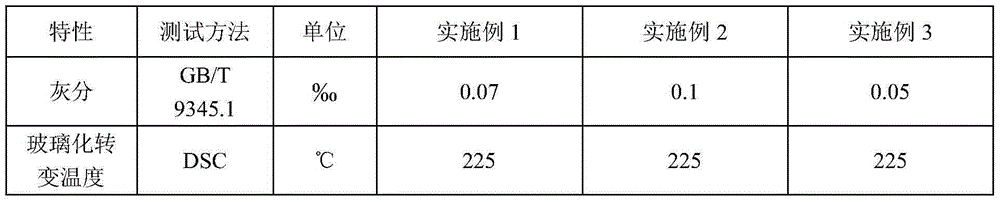

[0030] Referring to Example 1 for the specific method, the difference from Example 1 is only that the reflux reaction time is extended for 30 minutes, and the polymerization reaction time is extended for 30 minutes; the properties of the obtained polyphenylsulfone resin are shown in Table 1.

Embodiment 3

[0032] Referring to Example 1 for the specific method, the difference from Example 1 is only that the reflux reaction time is shortened by 30 minutes, and the polymerization reaction time is shortened by 30 minutes; the properties of the obtained polyphenylsulfone resin are shown in Table 1.

[0033] Table 1 Polyethersulfone resin properties

[0034]

[0035]

[0036] It can be seen from the above examples that with the appropriate extension of the reflux reaction and polymerization reaction time, the molecular weight of the polyphenylsulfone resin increases, which increases its mechanical properties, and the purification effect of the same post-treatment method decreases slightly. Reaction time and polymerization reaction time, although the mechanical properties are slightly reduced, but the precipitation effect is better and the purification effect is increased.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com