Regeneration method of waste transformer oil

A technology of transformer oil and sodium hydroxide, applied in the direction of lubricating composition, etc., can solve problems such as unusable, environmental pollution, aging, etc., and achieve the effects of reducing environmental pressure, important economic benefits, ensuring purity and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

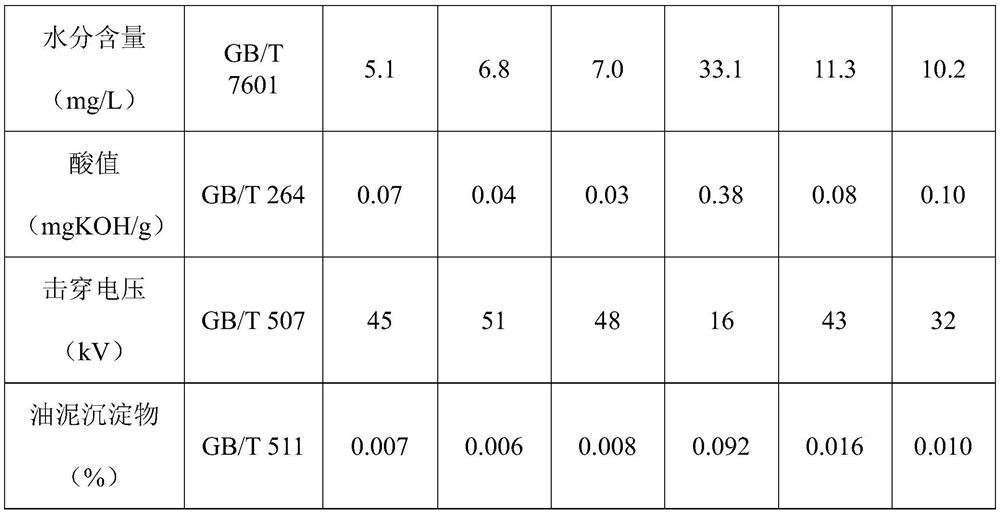

[0026] Example 1

[0027] Put 100g of waste transformer in a small reactor, heat it at 80°C for one hour, then cool it to room temperature and leave it for 24 hours, and filter it with a filter press to remove most of the mechanical impurities to obtain component oil A 1 ;to A 1 Add 1 g of concentrated sulfuric acid to the mixture and stir well to obtain B 1 ; to B 1 Add sodium hydroxide with a concentration of 3%, adjust the pH to 6.3, and obtain C 1 ;to C 1 Add 5g of desulfurizer to it, stir it evenly, filter it with a filter press, and then pass it through the acrylic resin to obtain D 1 ; finally put D 1 After passing through molecular sieves, light yellow regenerated transformer oil is obtained.

Example Embodiment

[0028] Example 2

[0029] Put 100g waste transformer in a small reactor, heat it at 90°C for one hour, then cool it to room temperature and leave it for 24 hours, filter it with a filter press, remove most of the mechanical impurities, and obtain component oil A 2 ;to A 2 Add 5g of concentrated sulfuric acid to it, stir well, get B 2 ; to B 2 Add sodium hydroxide with a concentration of 5%, adjust the pH to 7.2, and obtain C 2 ;to C 2 Add 10g of desulfurizer to it, stir it evenly, filter it with a filter press, and then pass it through the phenolic resin to obtain D 2 ; finally put D 2 After passing through molecular sieves, light yellow regenerated transformer oil is obtained.

Example Embodiment

[0030] Example 3

[0031] Put 100g waste transformer in a small reactor, heat it at 90°C for one hour, then cool it to room temperature and leave it for 24 hours, filter it with a filter press, remove most of the mechanical impurities, and obtain component oil A 3 ;to A 3 Add 3 g of concentrated sulfuric acid to the mixture, stir evenly to obtain B 3 ; to B 3 Add sodium hydroxide with a concentration of 5%, adjust the pH to 7.5, and obtain C 3 ;to C 3 Add 12g of desulfurizer to it, stir it evenly, filter it with a filter press, and then pass it through phenolic resin and acrylic resin to obtain D 3 ; finally put D 3 After passing through molecular sieves, light yellow regenerated transformer oil is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com